Patents

Literature

201results about "Auxillary electrodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma display device and driving method thereof

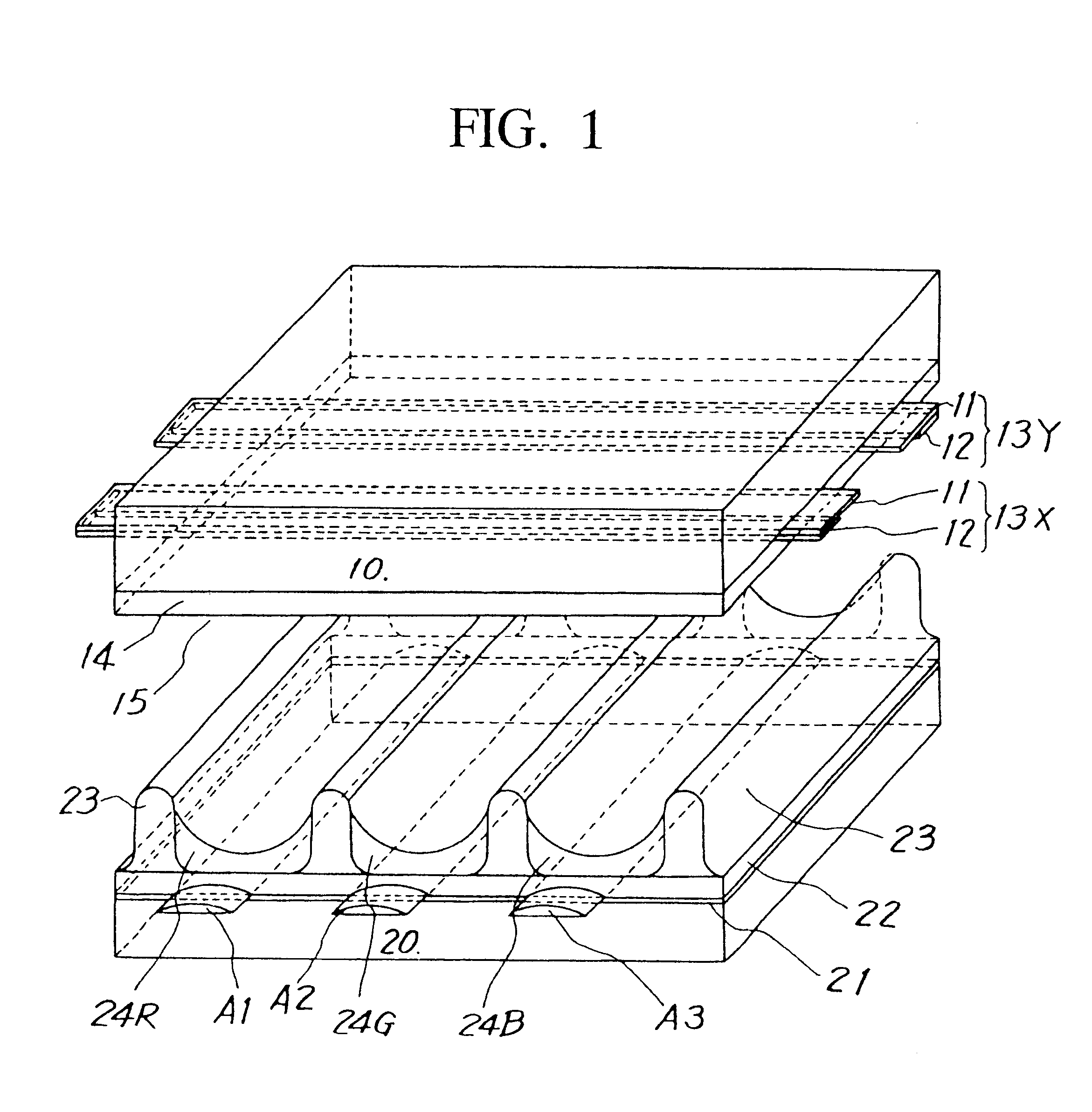

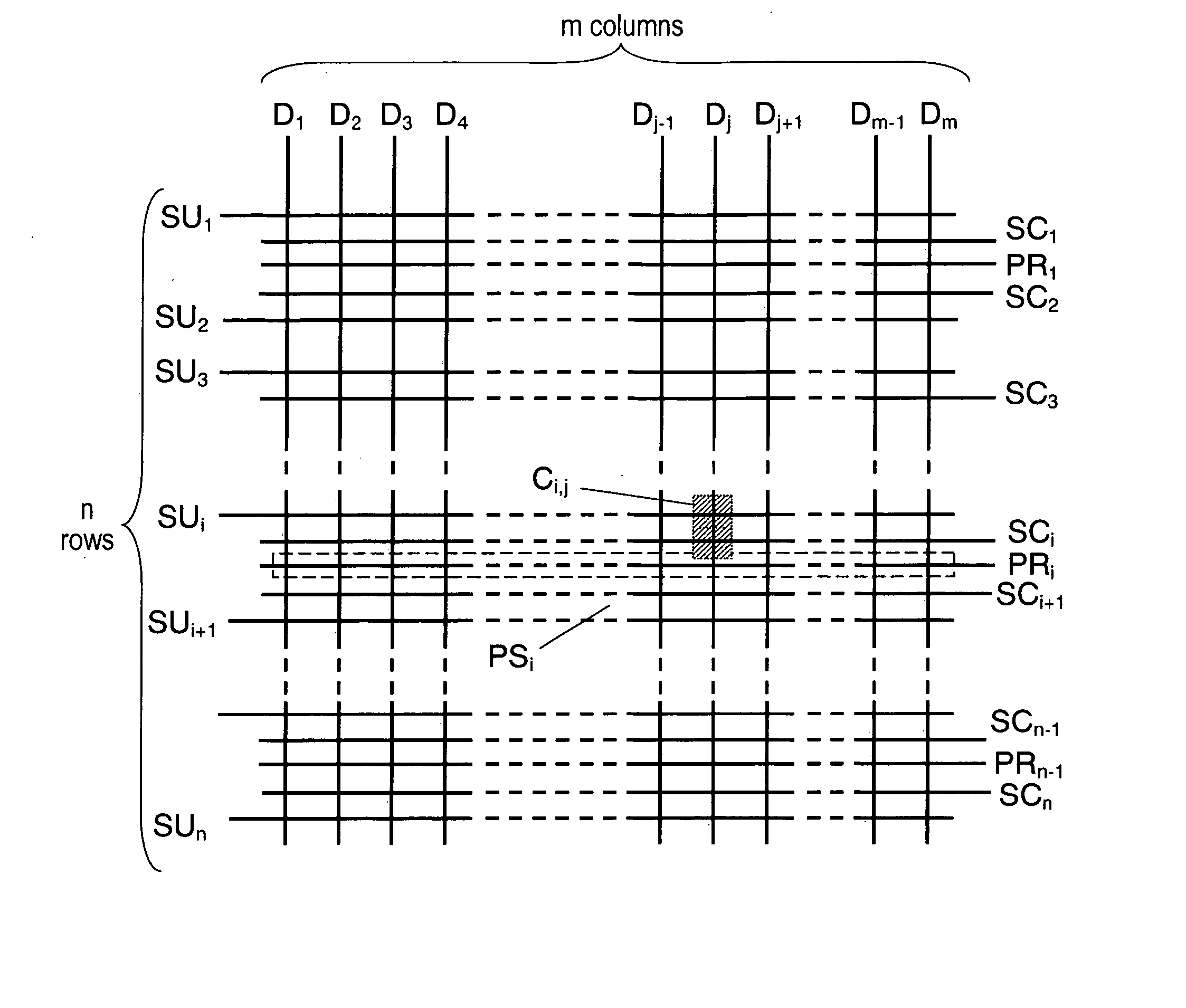

The plasma display device has pixels each formed by a plurality of sub pixels of the same color provided in an address-electrode direction, and provides gray-scale display by controlling the number of sub pixels to be turned ON. A plurality of address electrodes are provided for each sub pixels. Each sub pixel is addressed by a conductive layer which is electrically connected to one of the plurality of address electrodes.

Owner:SHARP KK

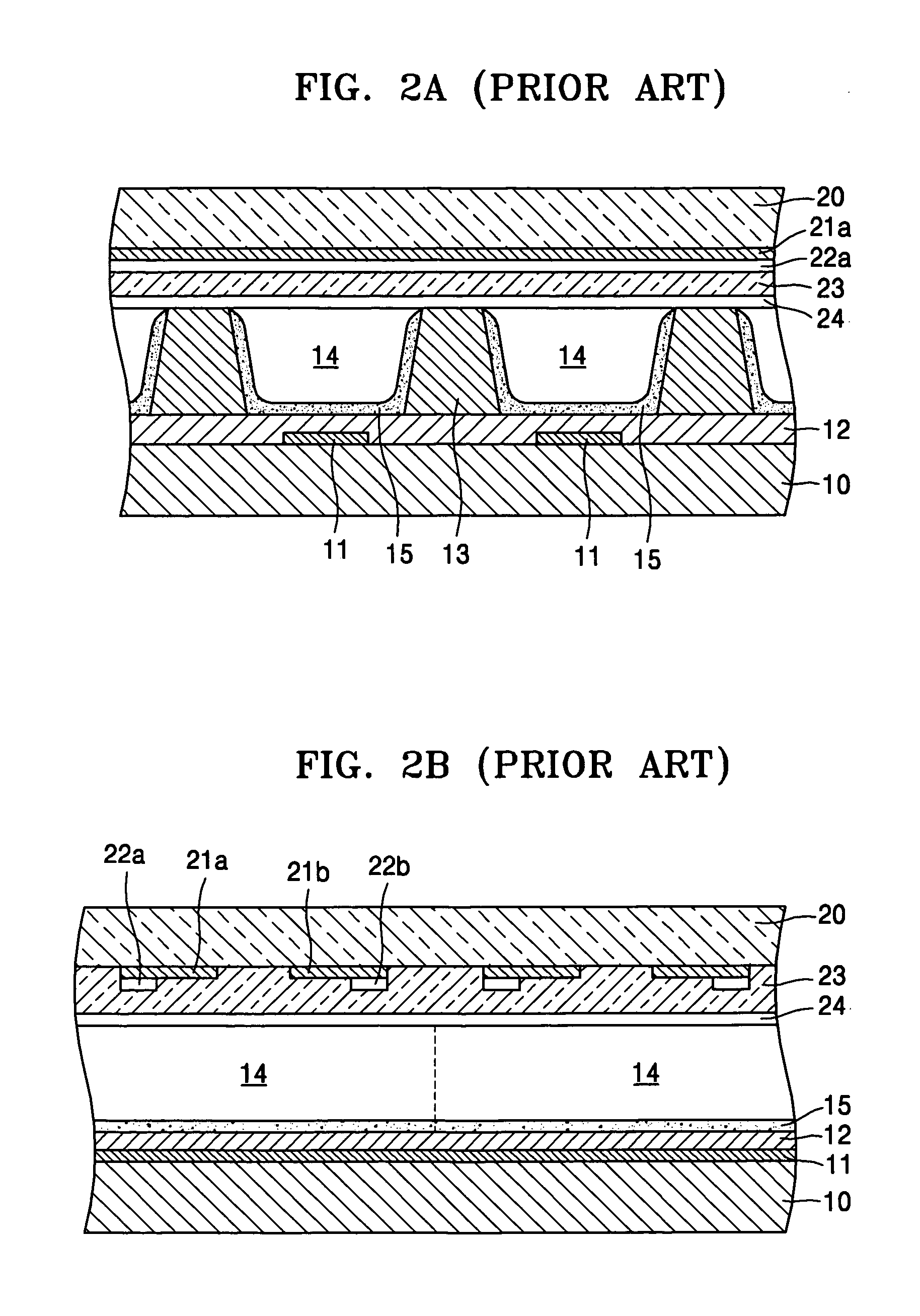

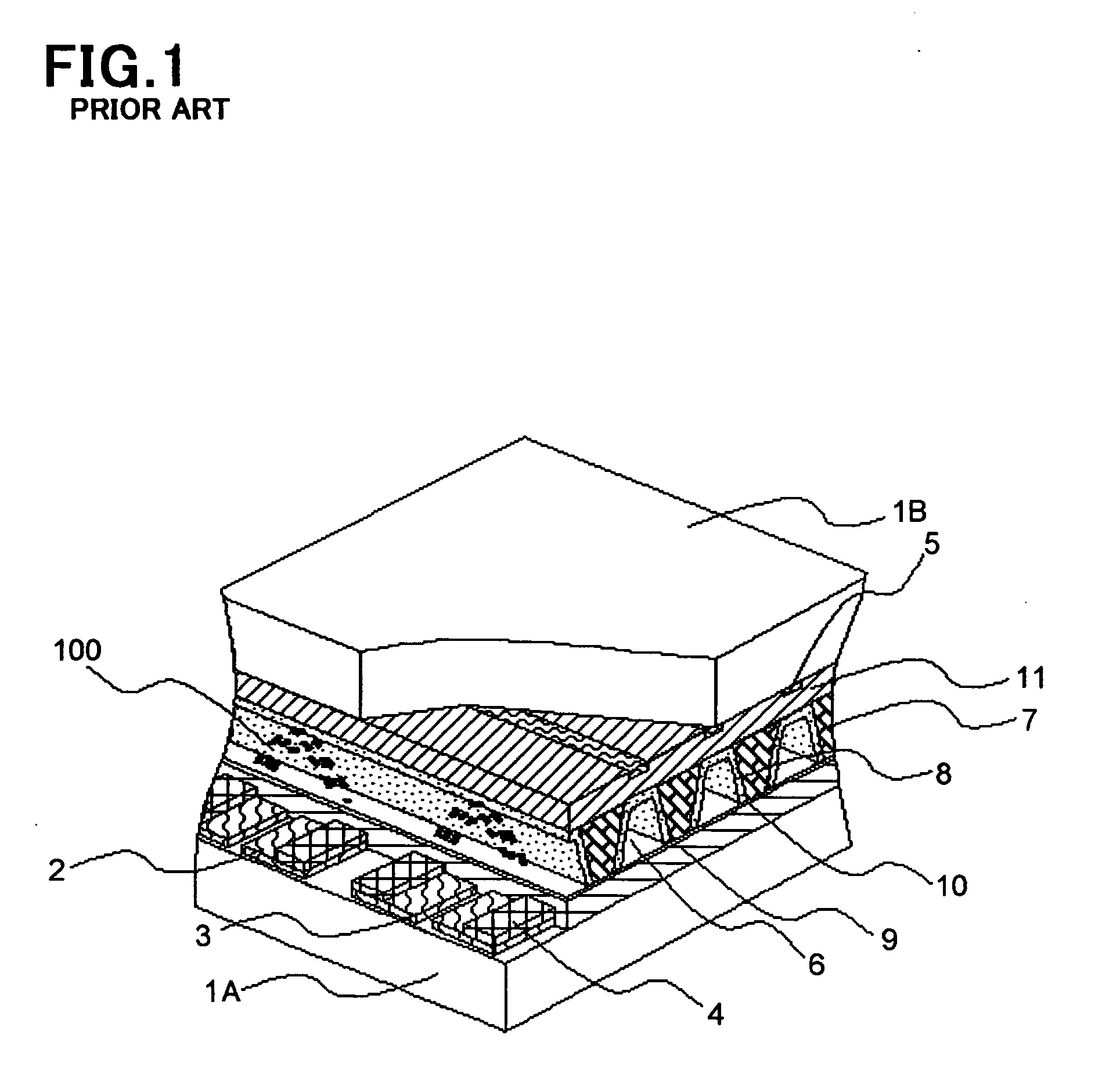

Method of making plasma display panel with dielectric layer suppressing reduced electrode conductivity

InactiveUS6296539B1Drop in conductivitySuppresses resistance riseAddress electrodesSustain/scan electrodesIndiumIndium tin oxide

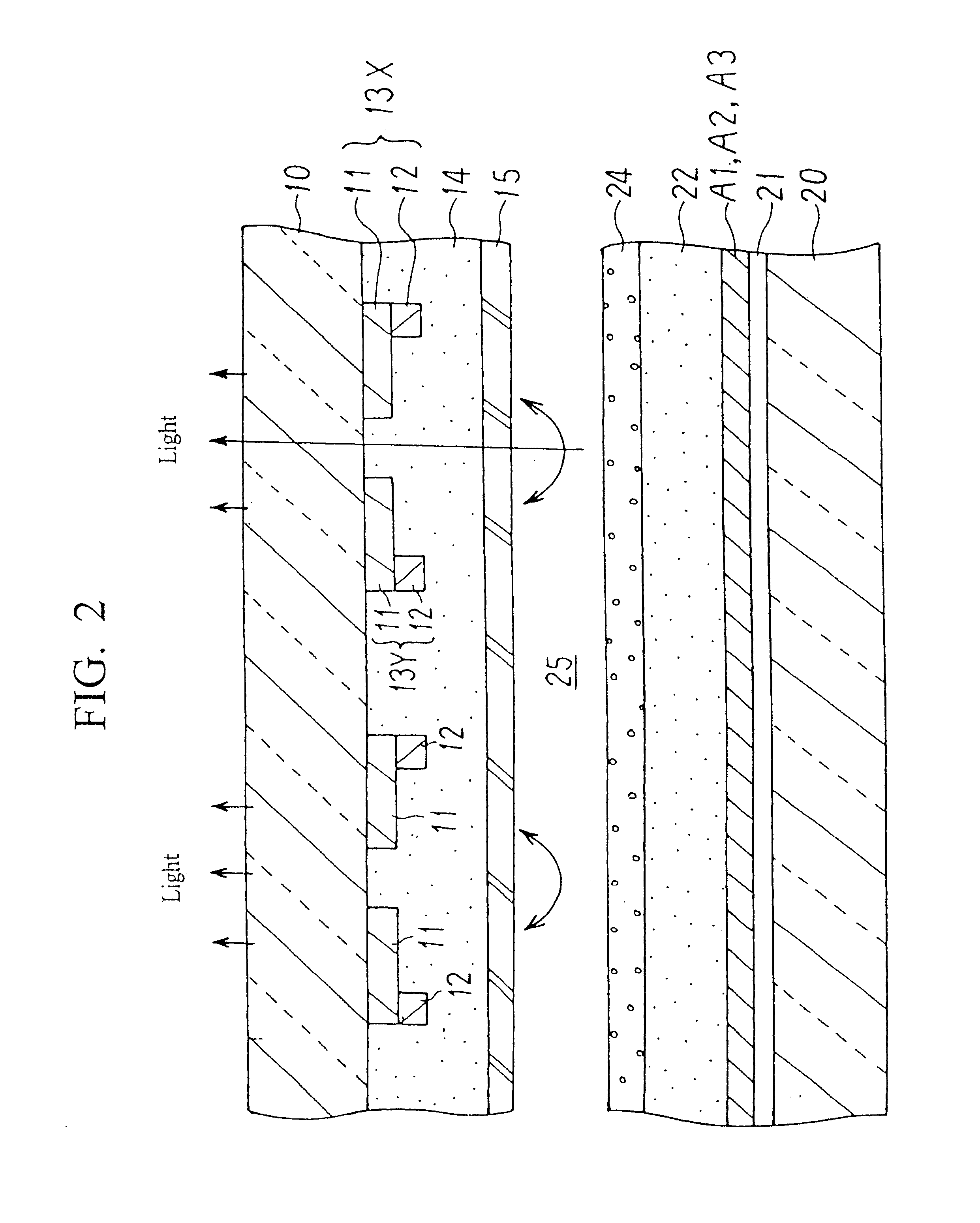

The present invention relates to a plasma display panel comprising transparent electrodes and a dielectric layer covering said transparent electrodes on at least one substrate of a pair of substrates facing each other with a discharge space therebetween, the main constituent of the transparent electrodes is included in the dielectric layer. Further, the main constituent of the transparent electrode is indium oxide and indium oxide is included in the dielectric layer. By including the main constituent of the transparent electrodes in the dielectric layer, it is believed that the drop in conductivity caused by diffusion of the dielectric substance in the transparent electrodes during high-temperature processing is prevented.

Owner:HITACHT MAXELL LTD

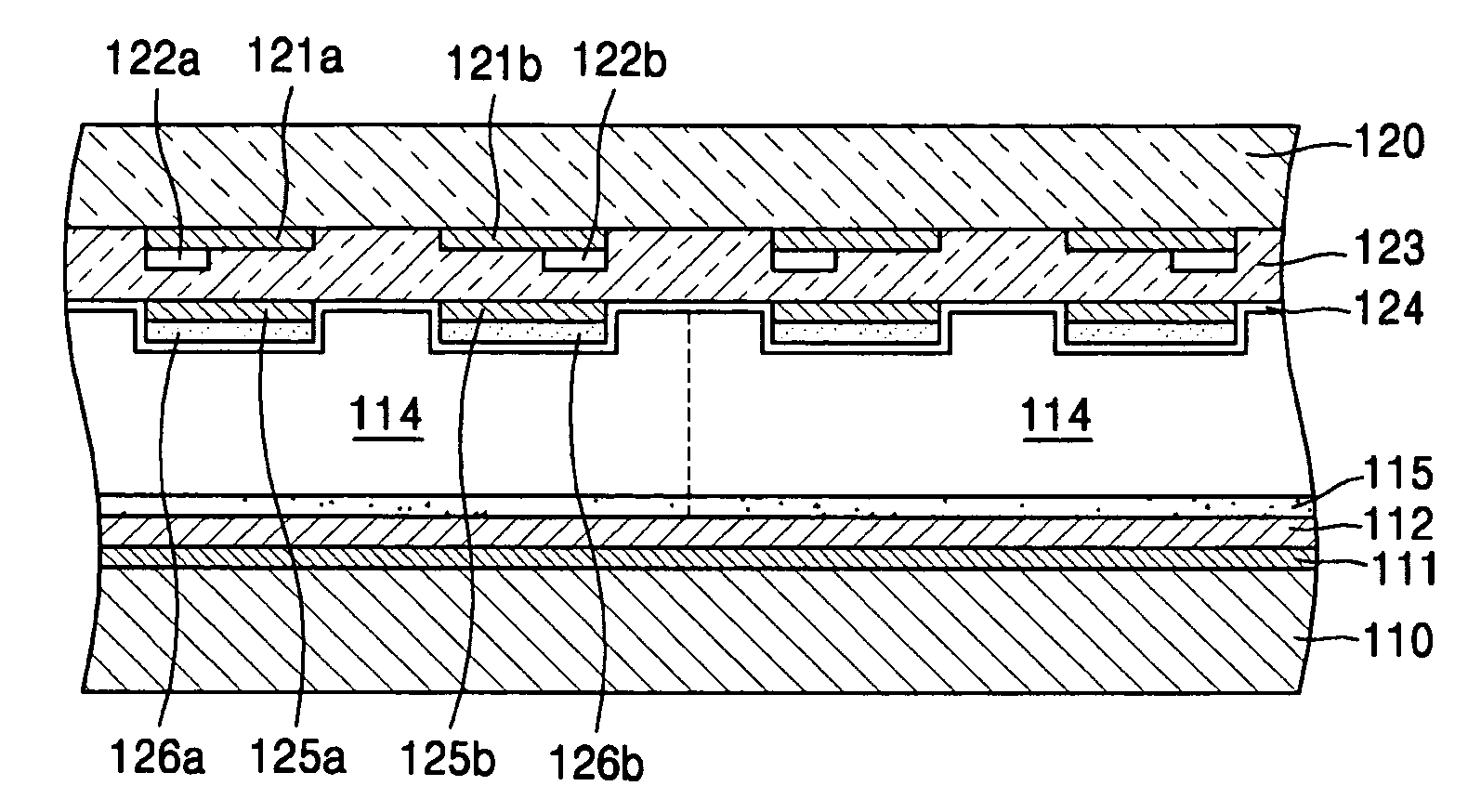

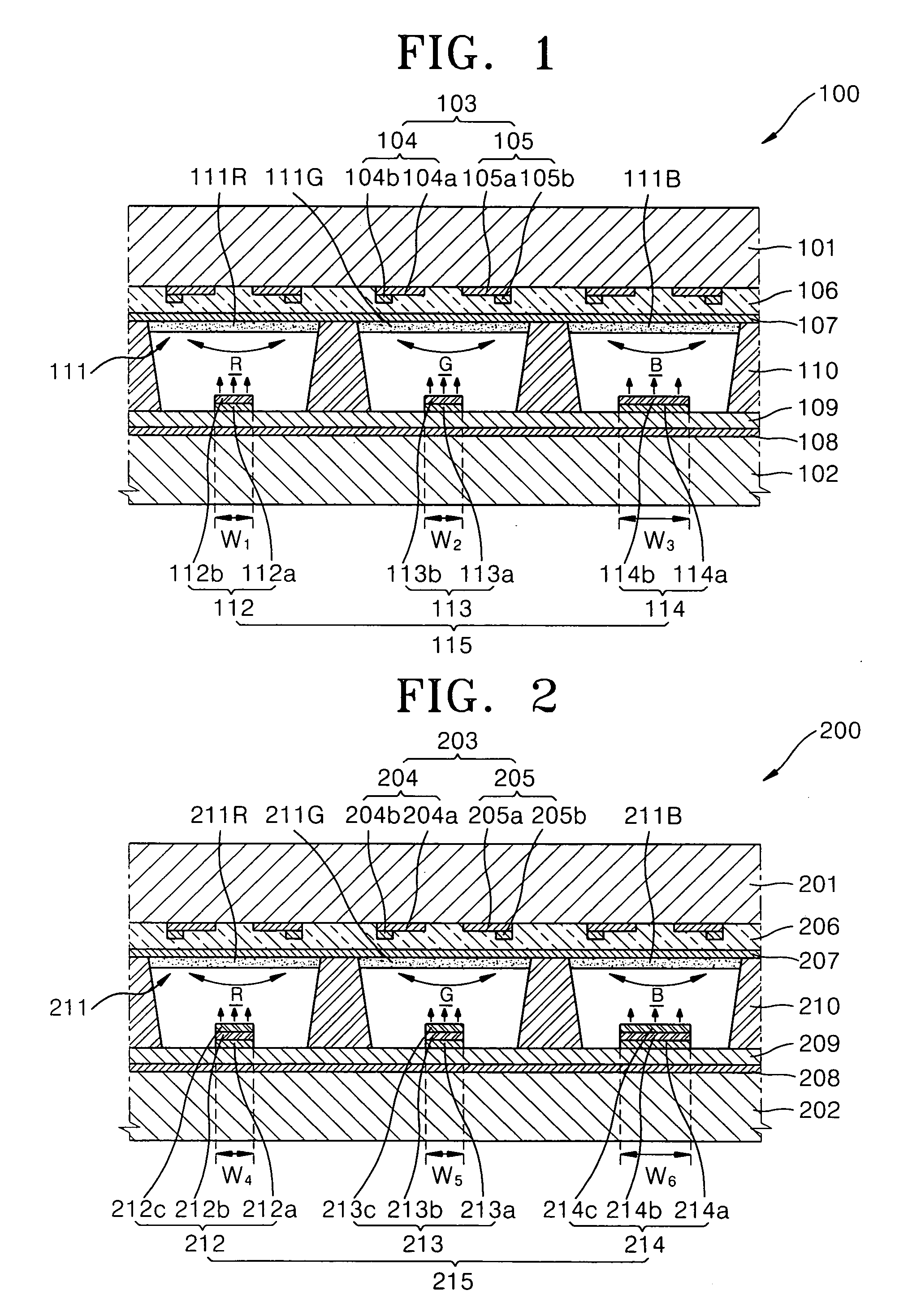

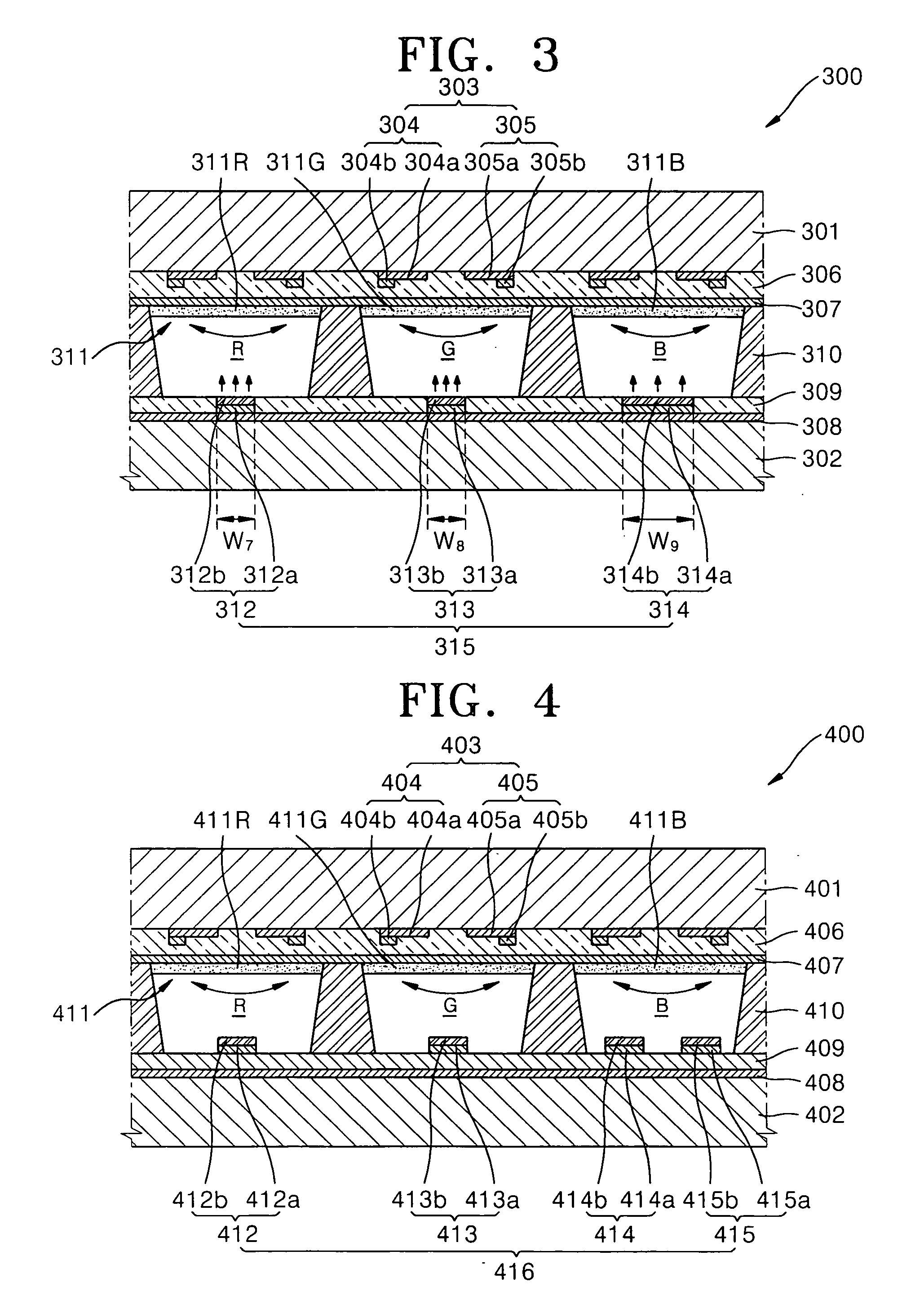

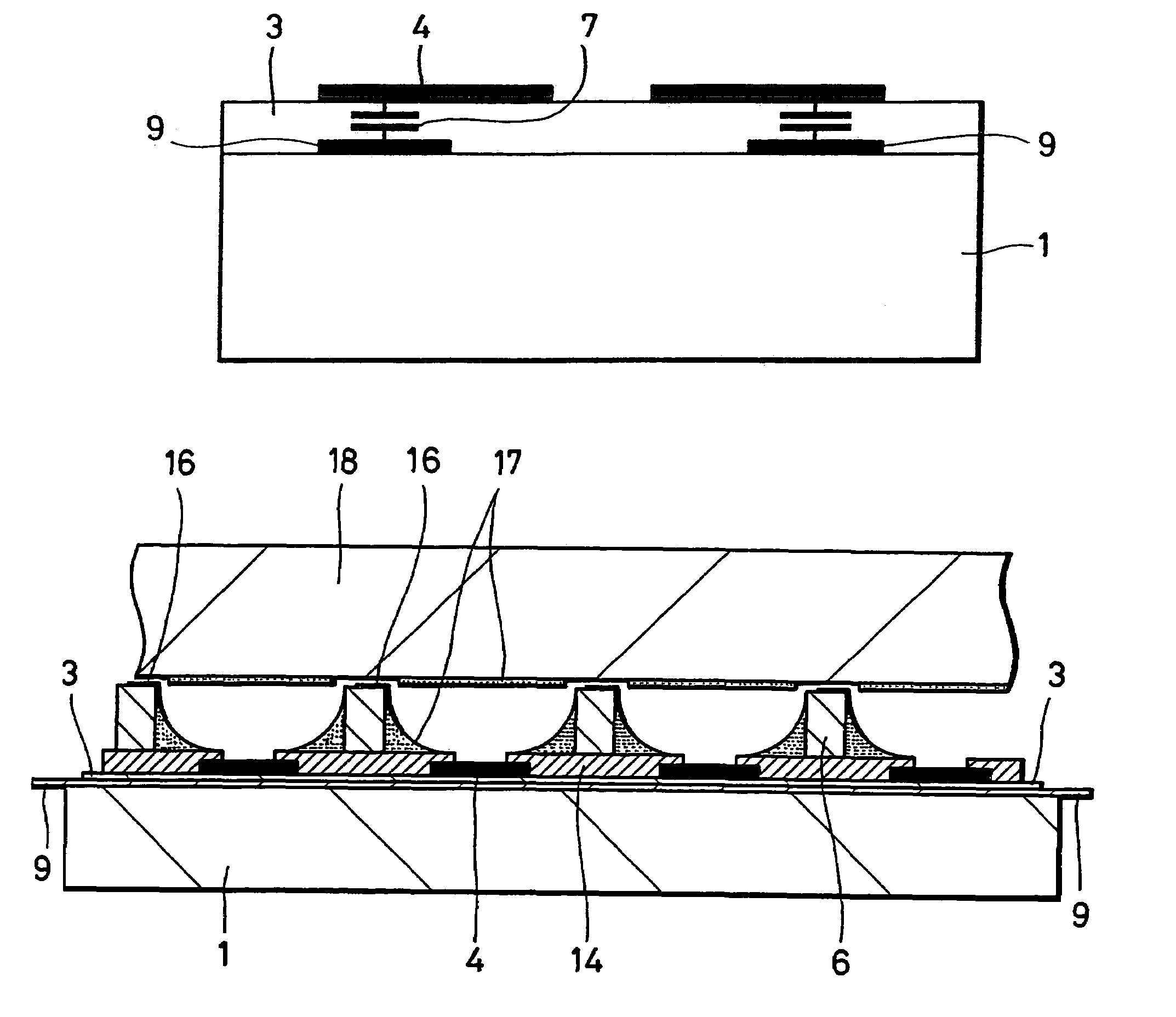

Gas discharge panel with electrodes comprising protrusions, gas discharge device, and related methods of manufacture

InactiveUS7045962B1Improve discharge performanceImproving illuminance efficiencySustain/scan electrodesAuxillary electrodesGas-discharge lampIlluminance

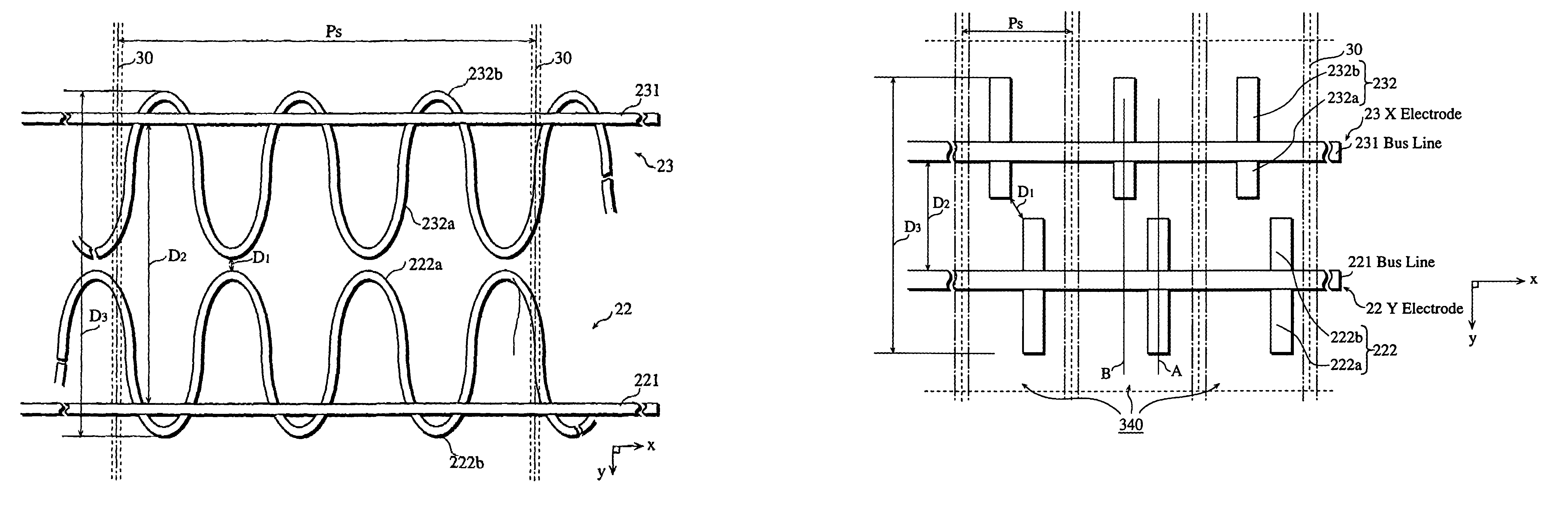

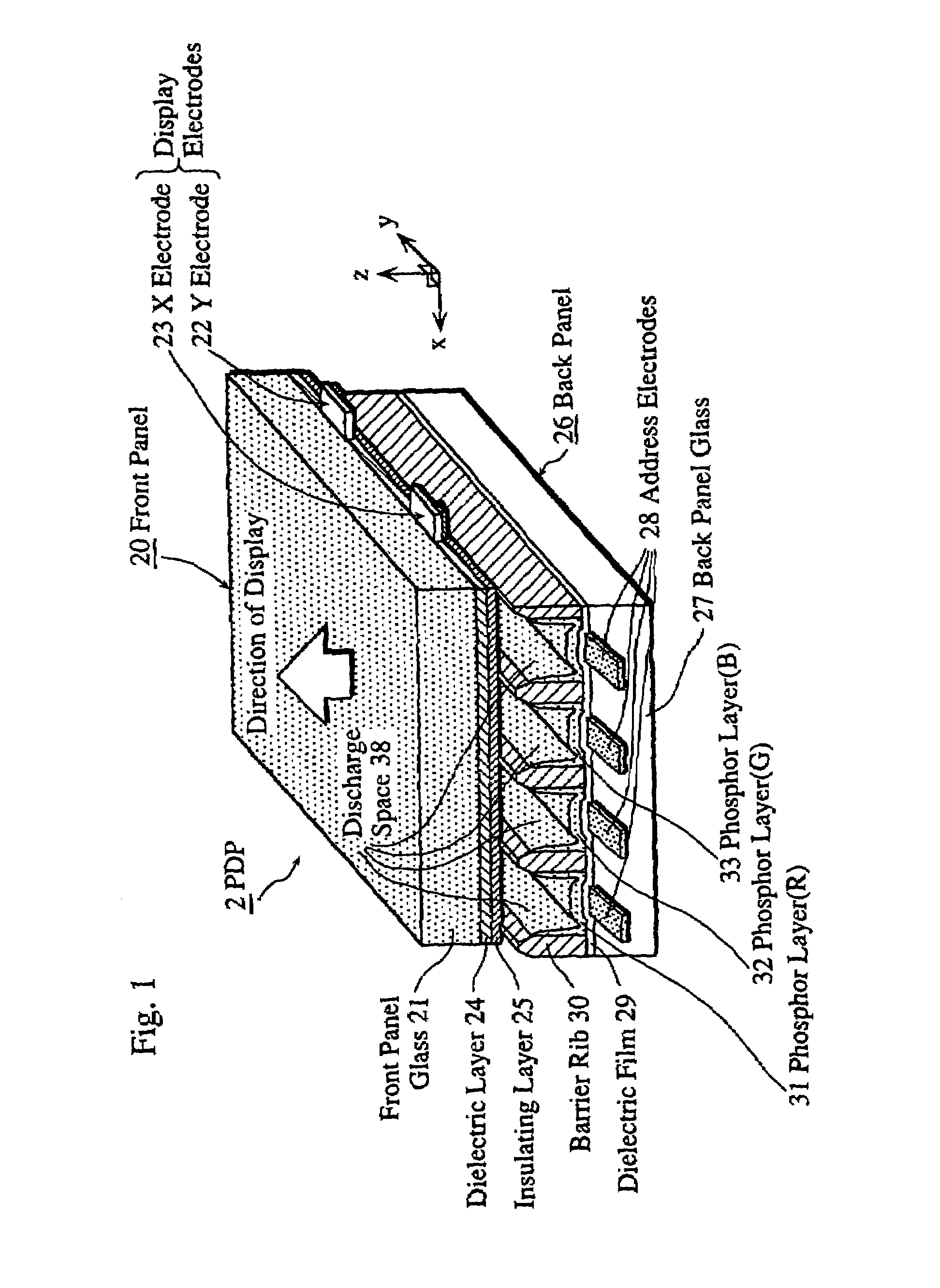

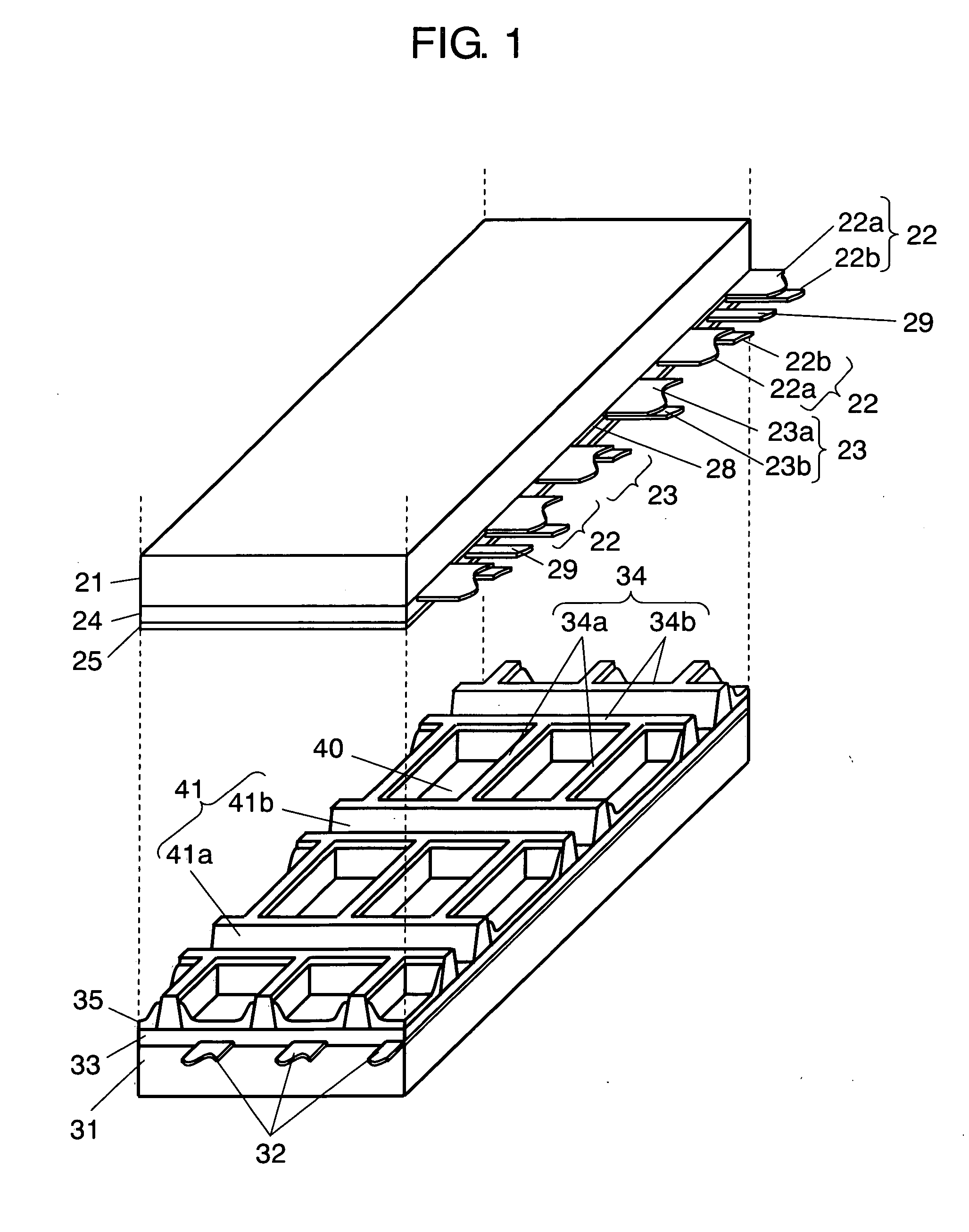

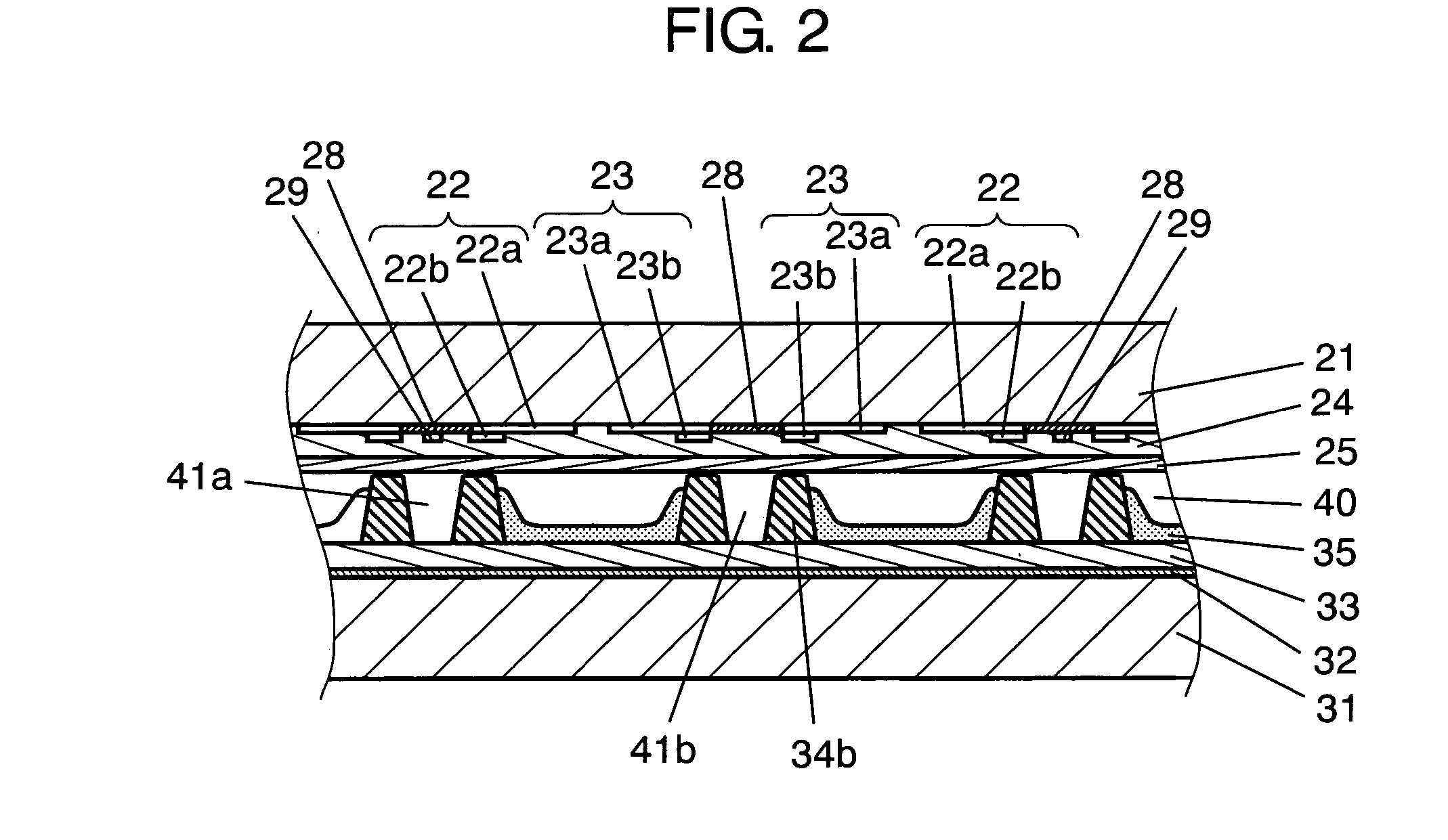

A gas discharge panel to increase the illuminance efficiency and a method of manufacturing includes providing a plurality of cells arranged in a matrix between a pair of substrates. Pairs of display electrodes are arranged on an inner surface of one of the substrates and include two bus lines lying parallel to each other with one or more inner protrusions arranged within each cell relative to the bus lines. This arrangement provides a relatively short discharge gap between the pair of display electrodes.

Owner:PANASONIC CORP

Plasma display panel with dielectric layer suppressing reduced electrode conductivity

InactiveUS6344713B1Suppresses resistance riseReduce discharge voltageAddress electrodesSustain/scan electrodesIndiumDielectric layer

The present invention relates to a plasma display panel comprising transparent electrodes and a dielectric layer covering said transparent electrodes on at least one substrate of a pair of substrates facing each other with a discharge space therebetween, the main constituent of the transparent electrodes is included in the dielectric layer. Further, the main constituent of the transparent electrode is indium oxide and indium oxide is included in the dielectric layer. By including the main constituent of the transparent electrodes in the dielectric layer, it is believed that the drop in conductivity caused by diffusion of the dielectric substance in the transparent electrodes during high-temperature processing is prevented.

Owner:HITACHT MAXELL LTD

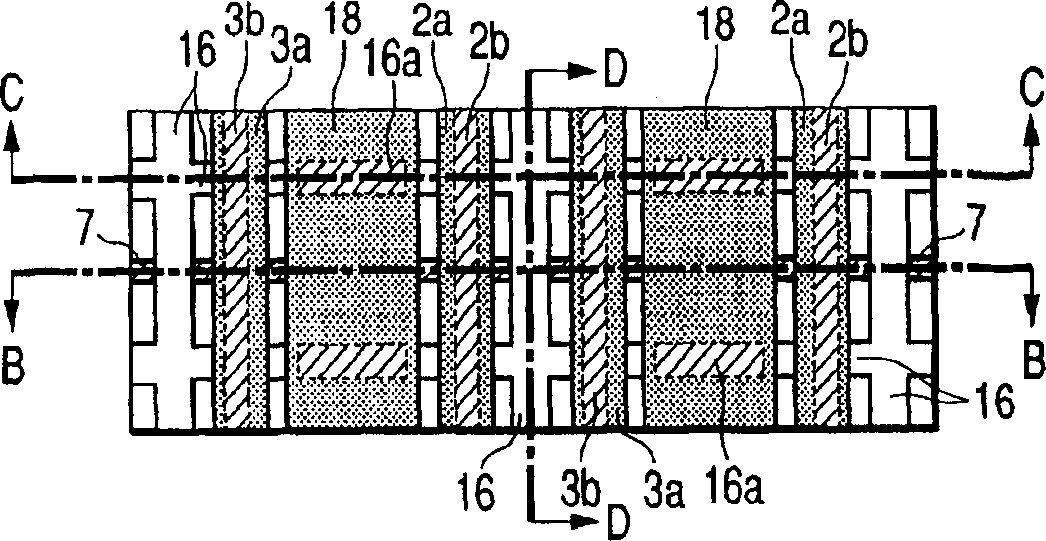

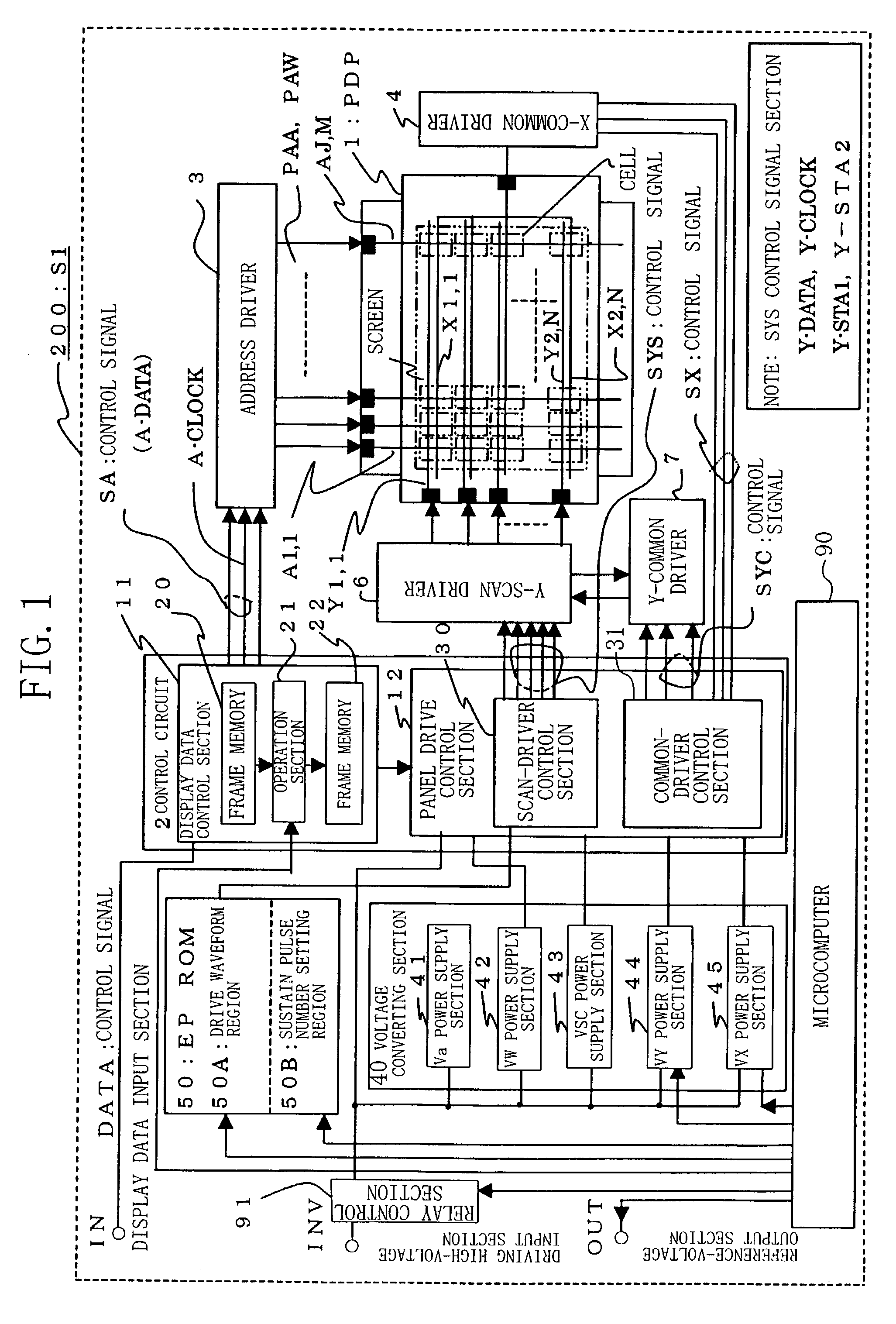

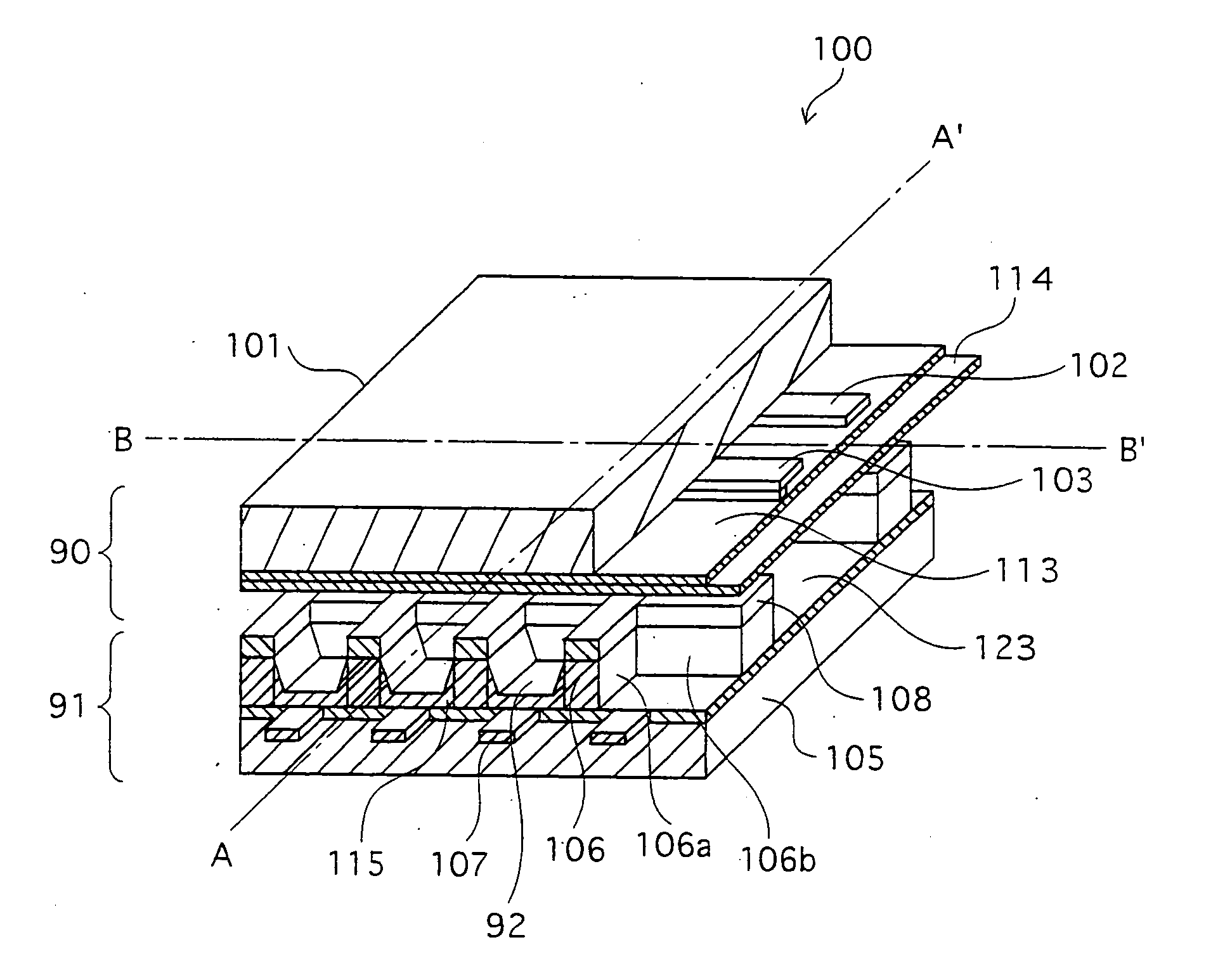

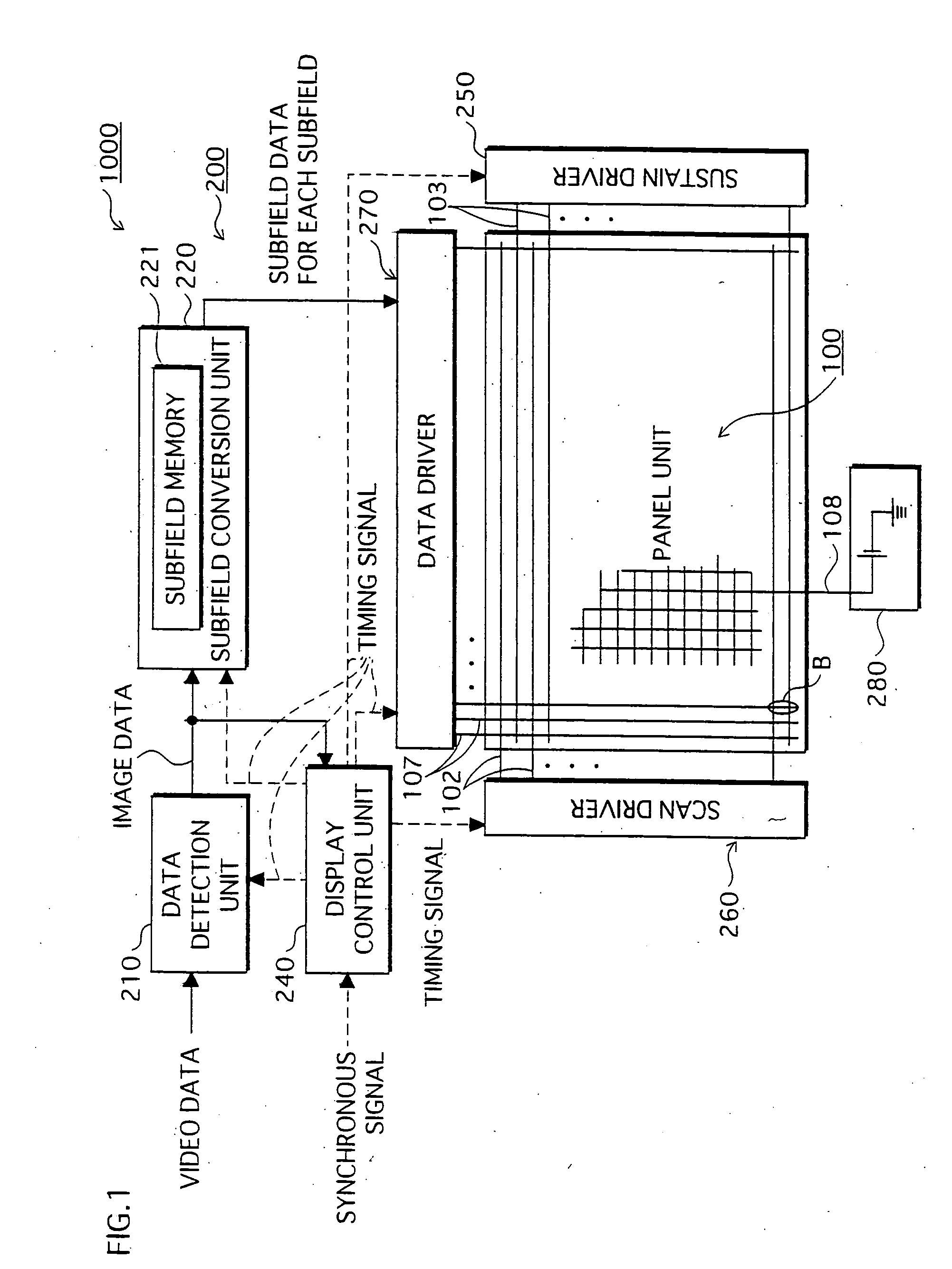

Plasma display device and method for driving same

InactiveUS20050093776A1Enhance the imageIncrease costAddress electrodesSustain/scan electrodesEngineeringPlasma display

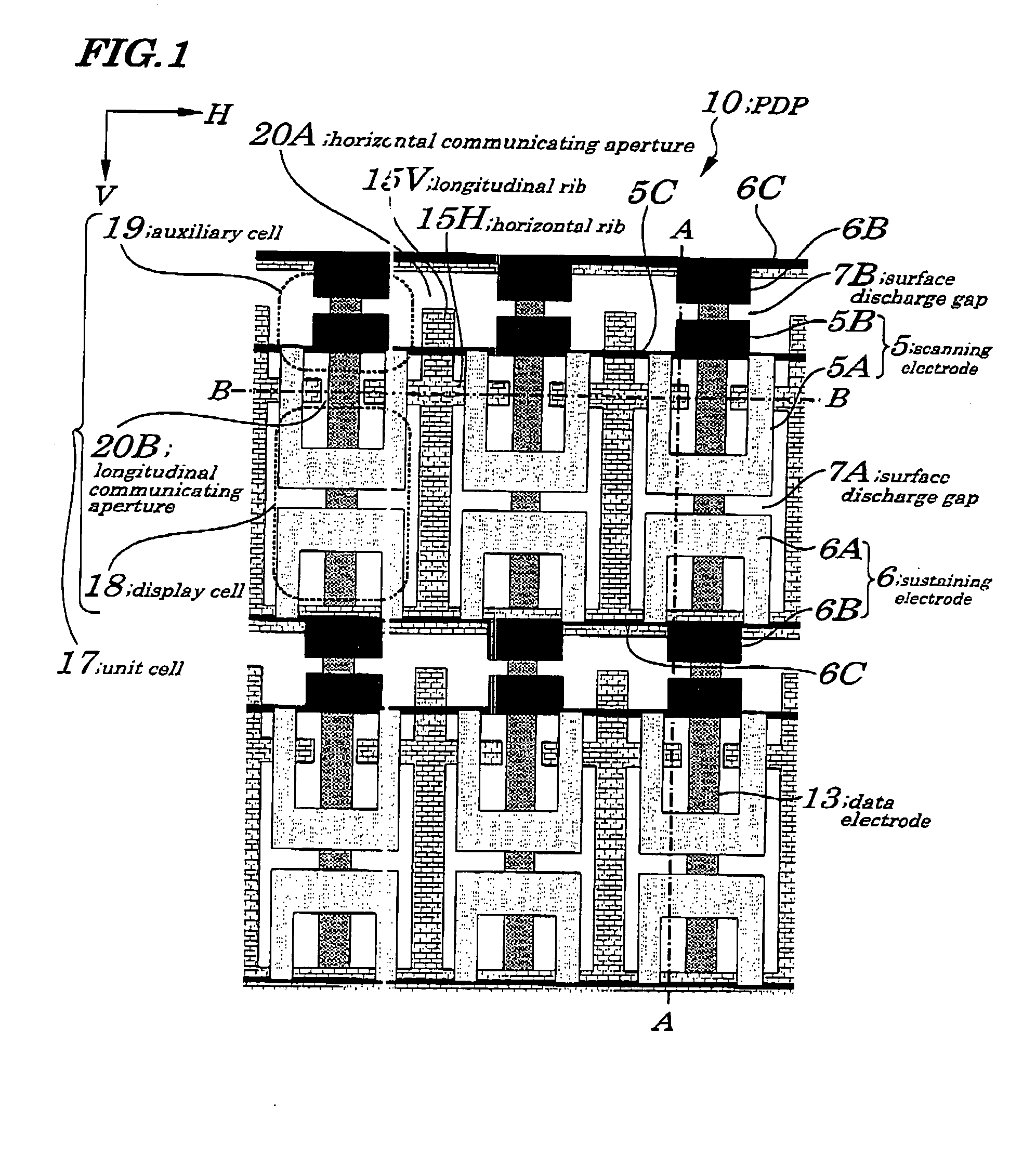

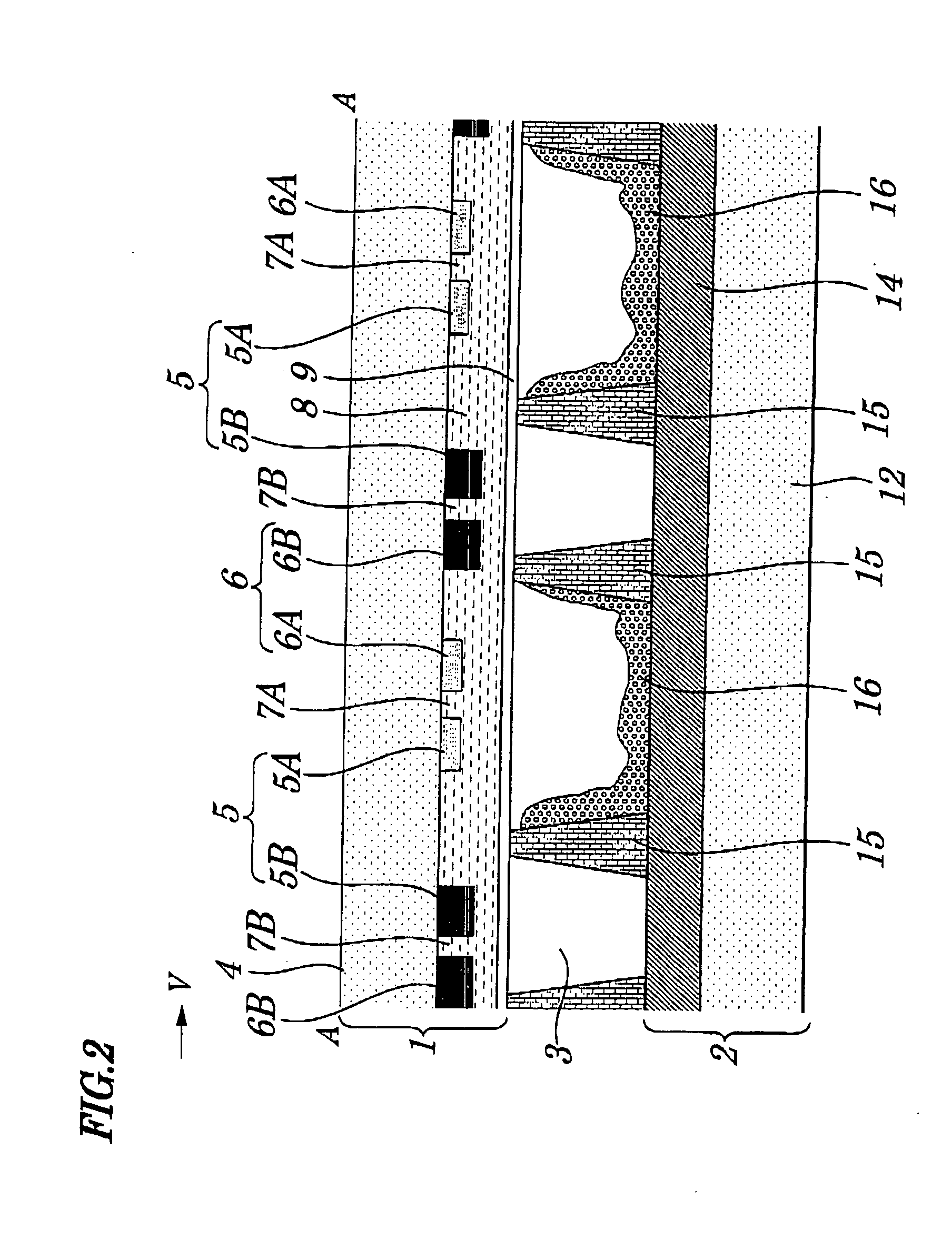

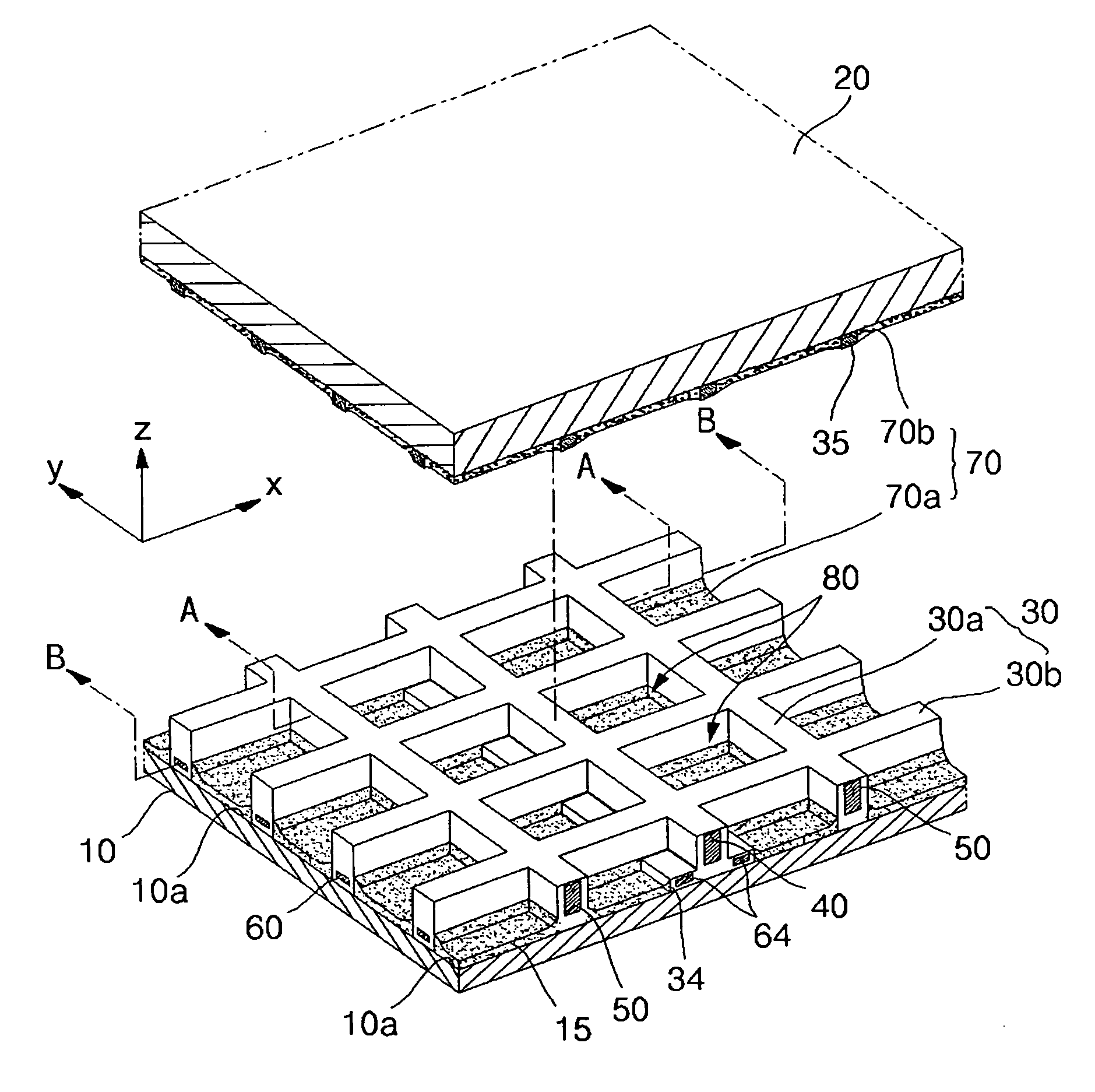

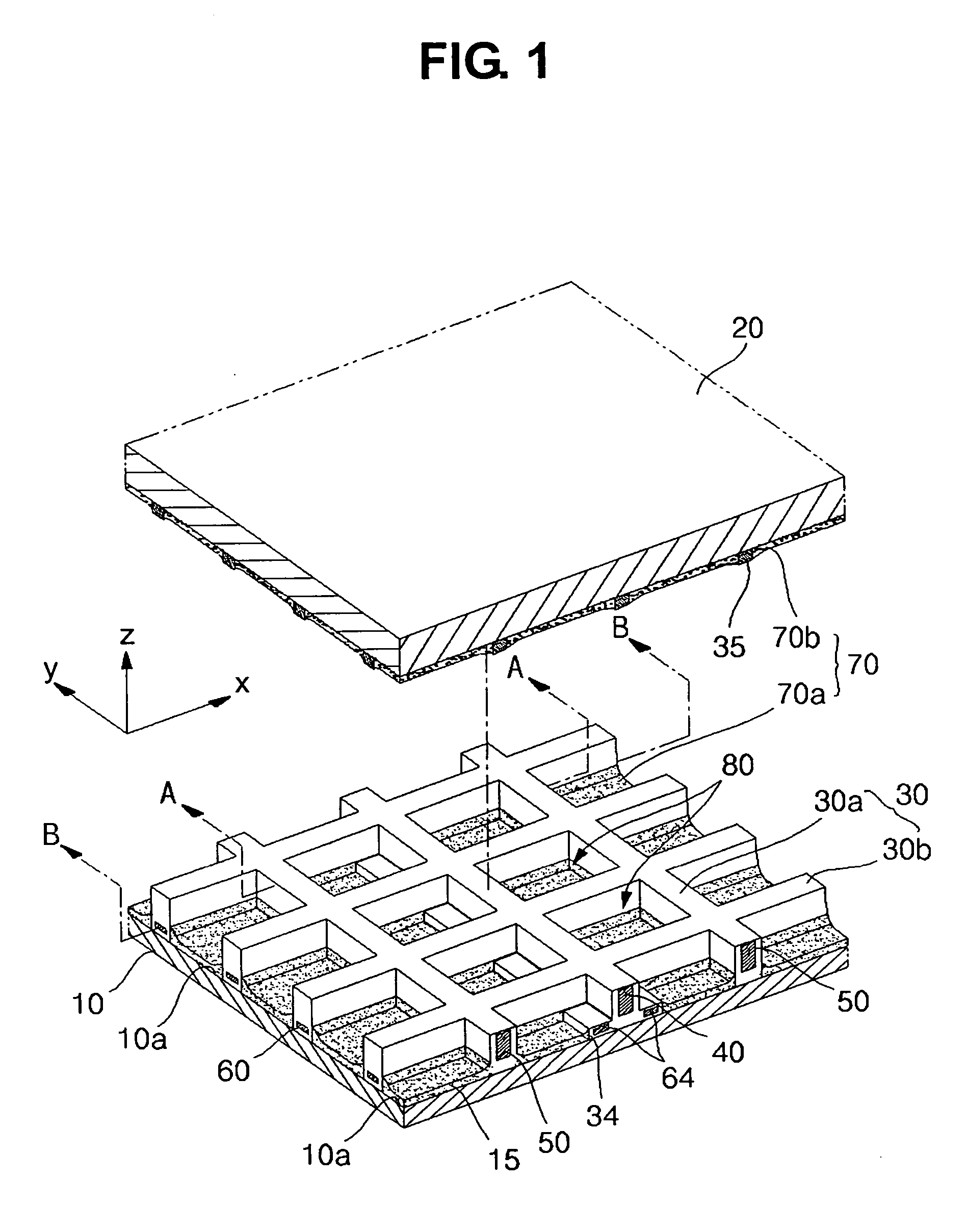

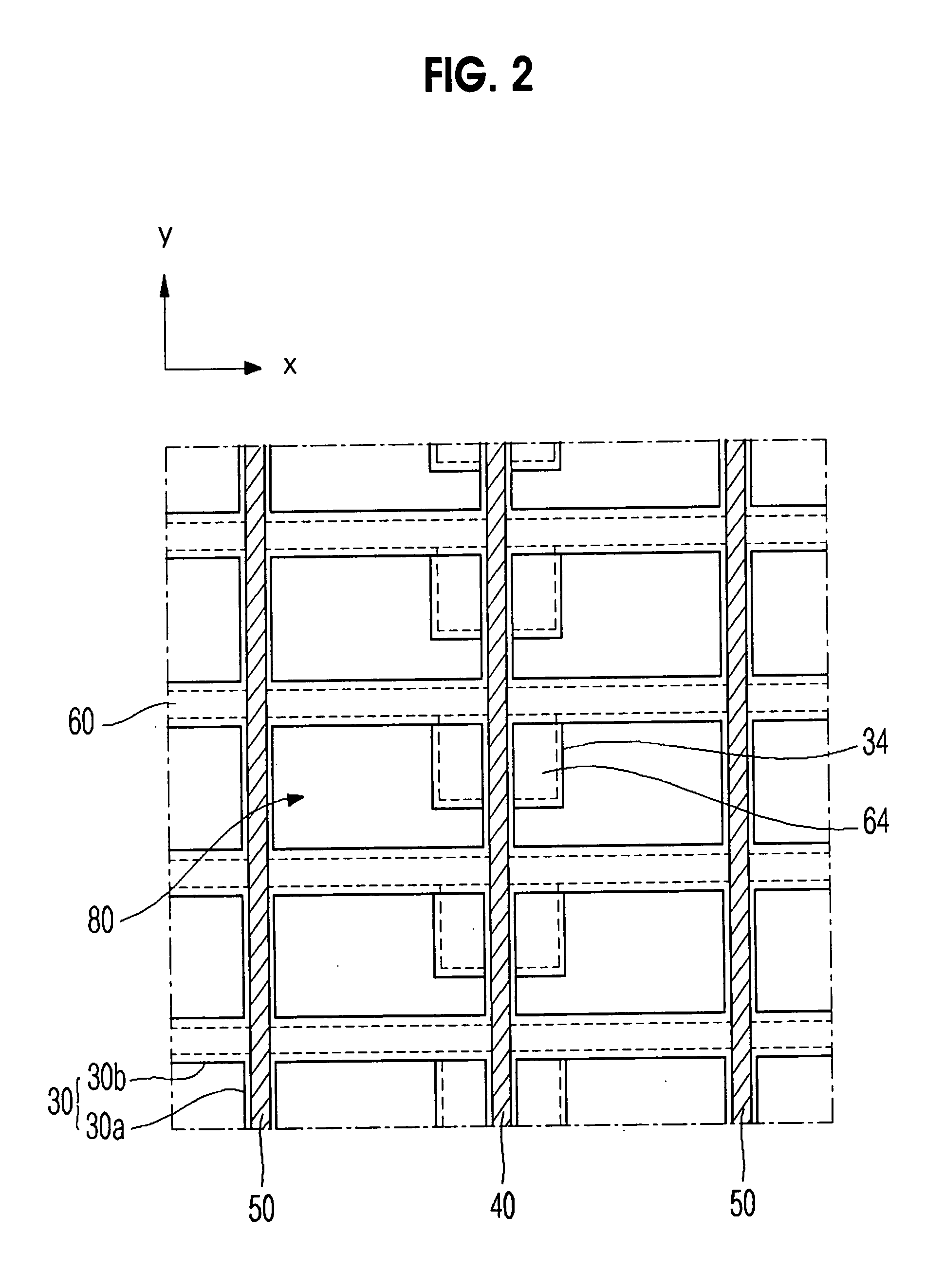

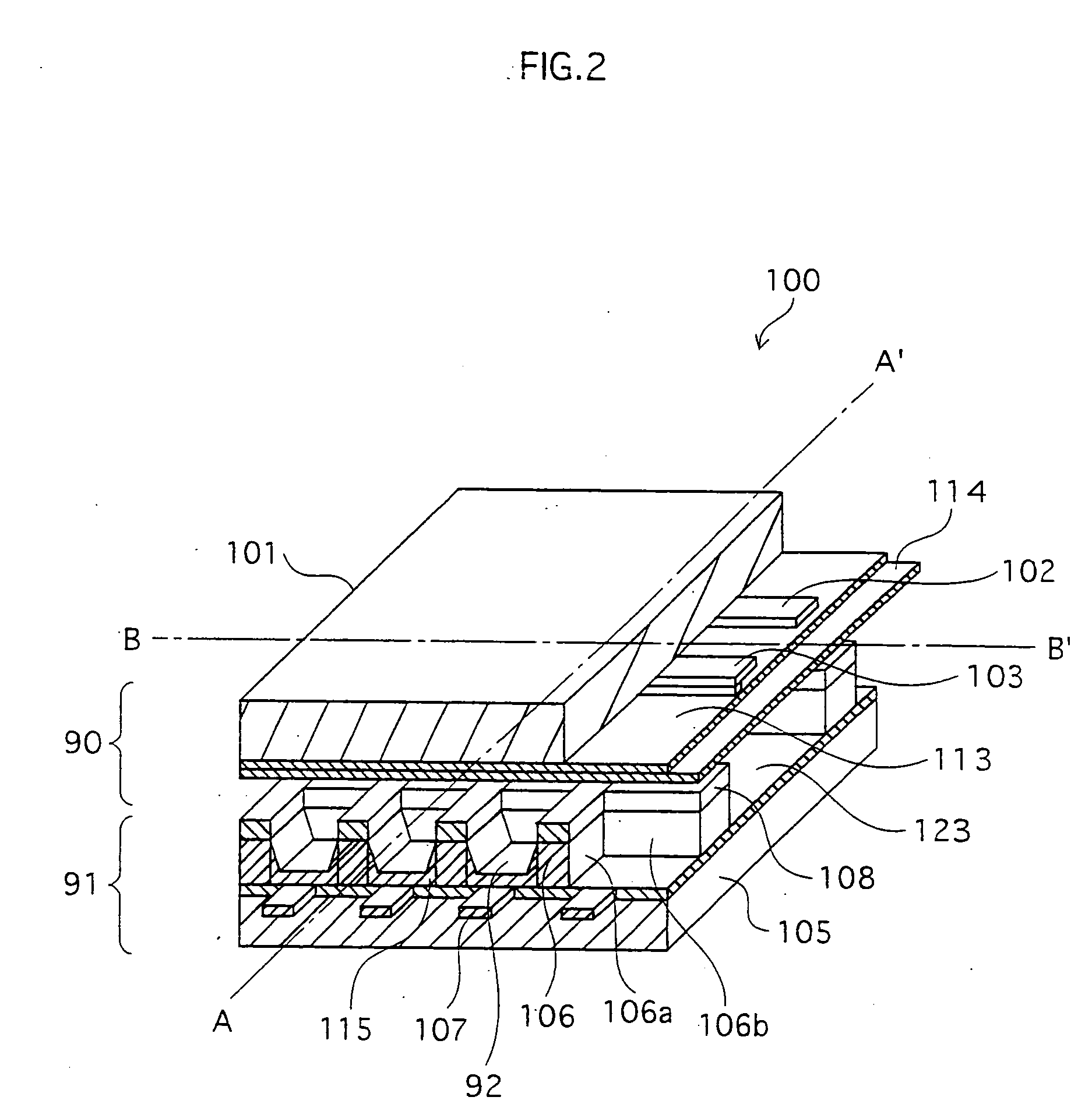

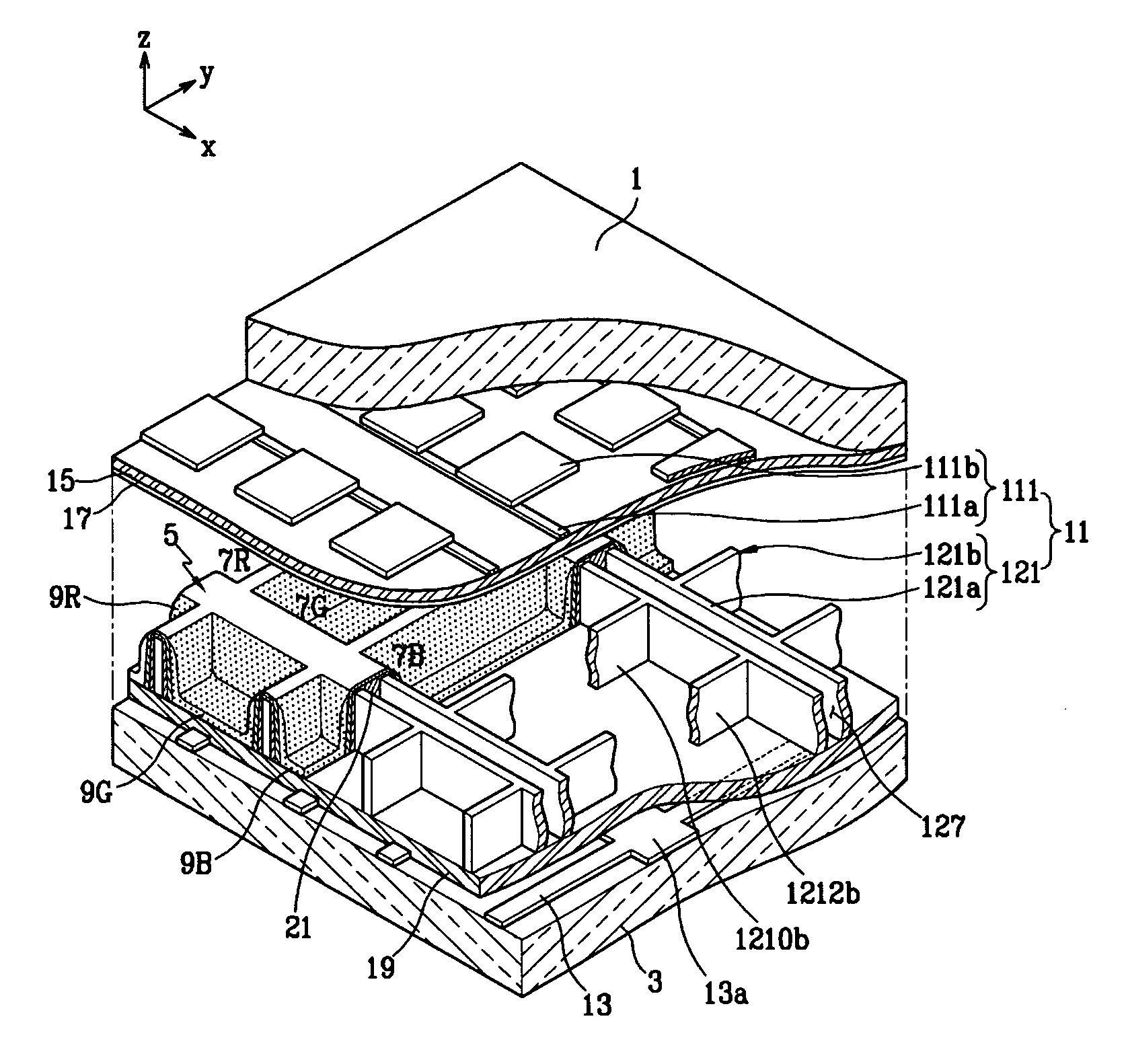

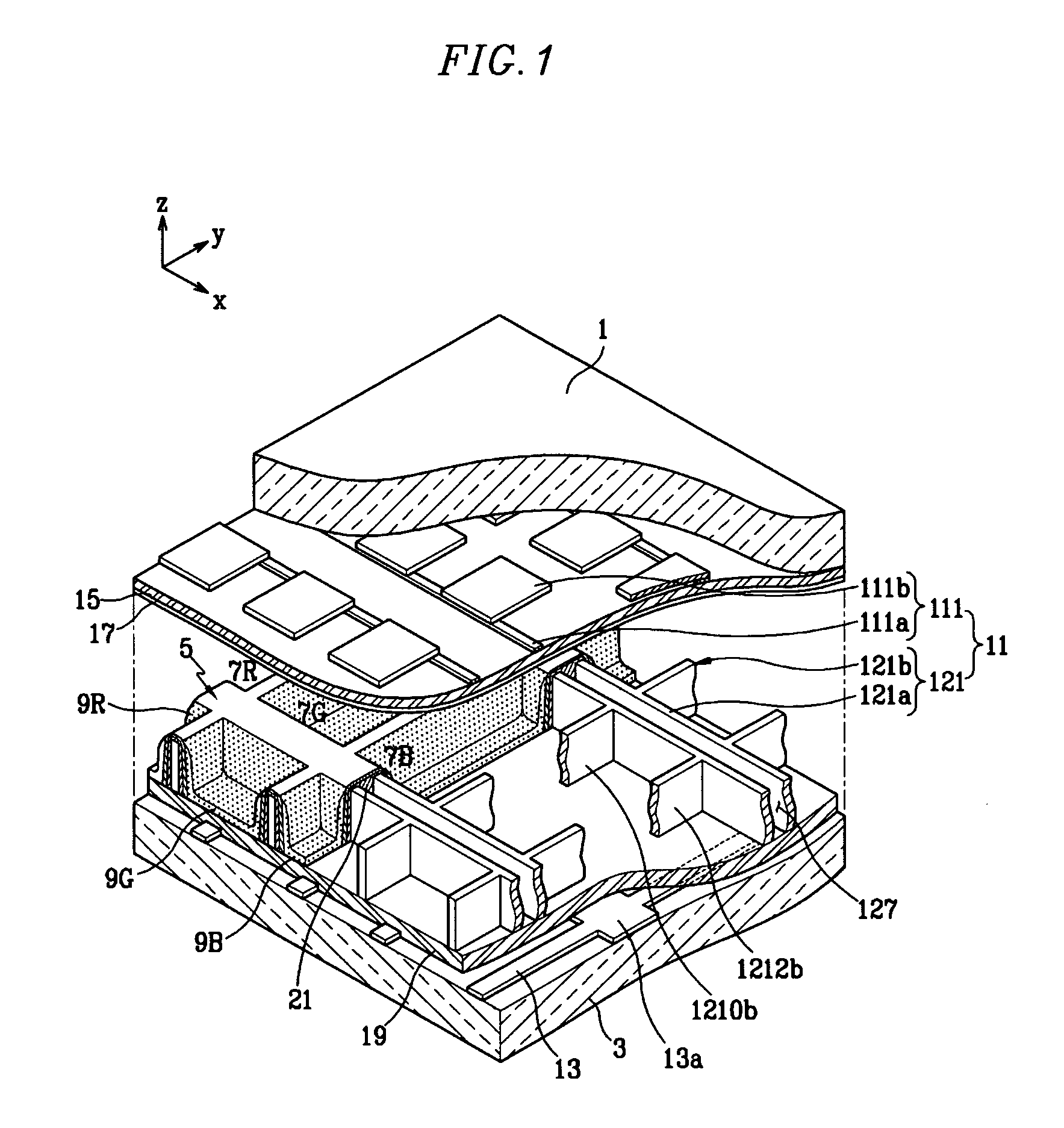

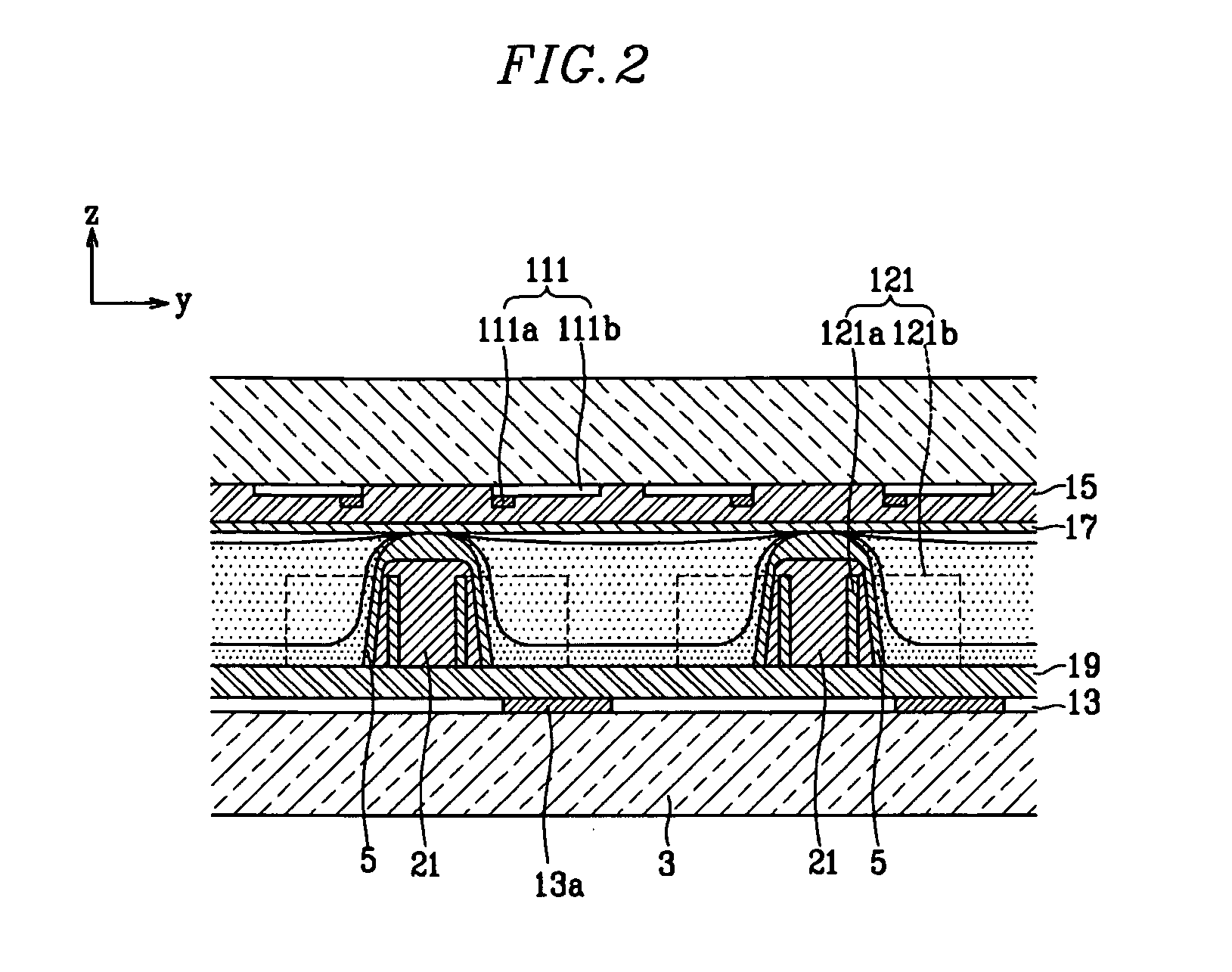

A plasma display device and its driving method are provided which are capable of displaying an excellent image, without an increase in costs caused by an increased number of driving circuits, by shortening a scanning period while writing discharge is made to occur with reliability and by improving contrast. In a plasma display panel (PDP) in the plasma display device, a group of unit cells is formed at intersecting points between each of groups of row electrodes and a group of column electrodes. Each of unit cells is made up of a display cell and auxiliary cell and is surrounded by a horizontal rib and a longitudinal rib. A horizontal communicating aperture is formed in the longitudinal rib to partition among two or more auxiliary cells and a longitudinal communicating aperture is formed in the horizontal rib to partition between the display cell and auxiliary cell both being arranged in the column direction.

Owner:PIONEER CORP

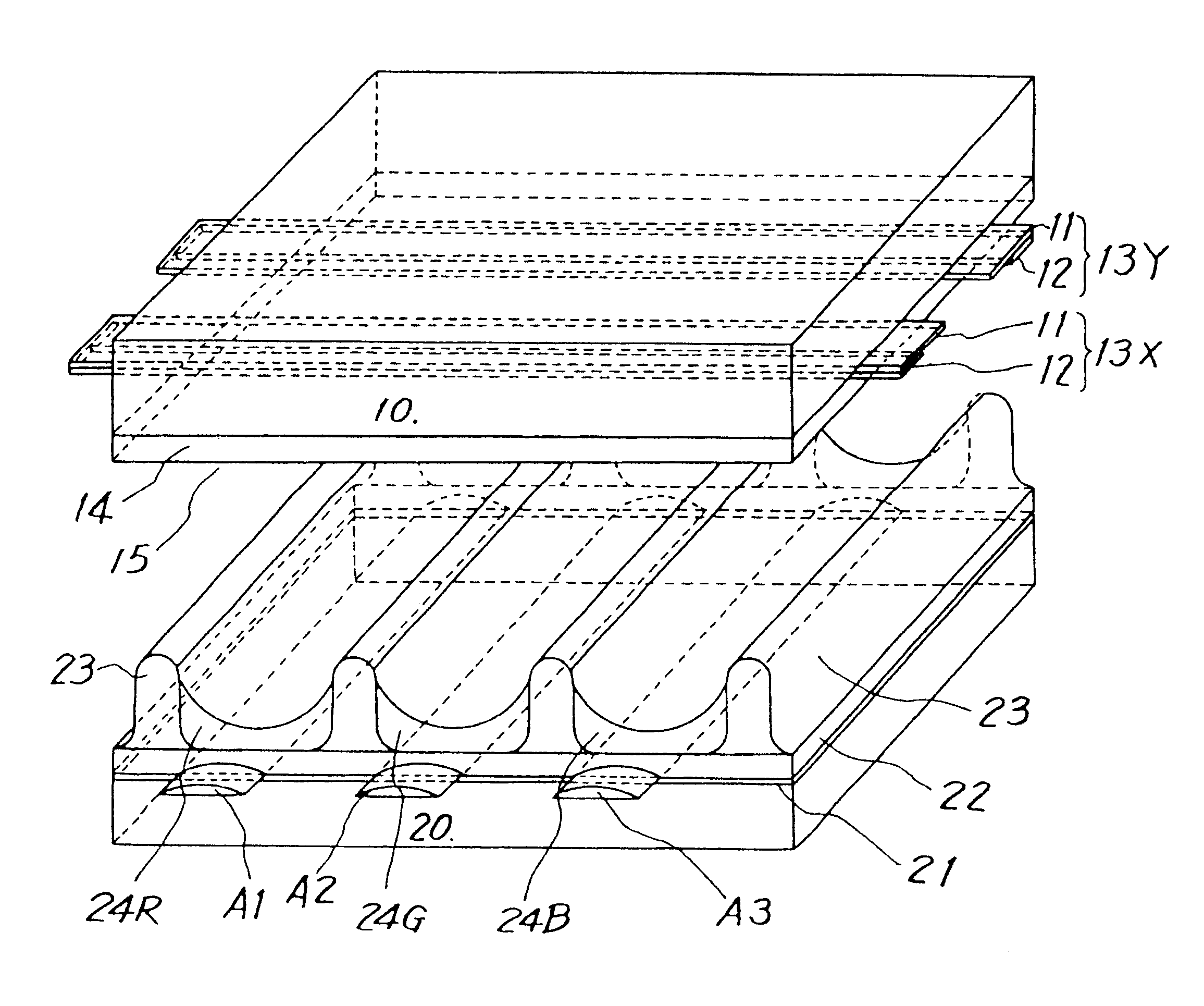

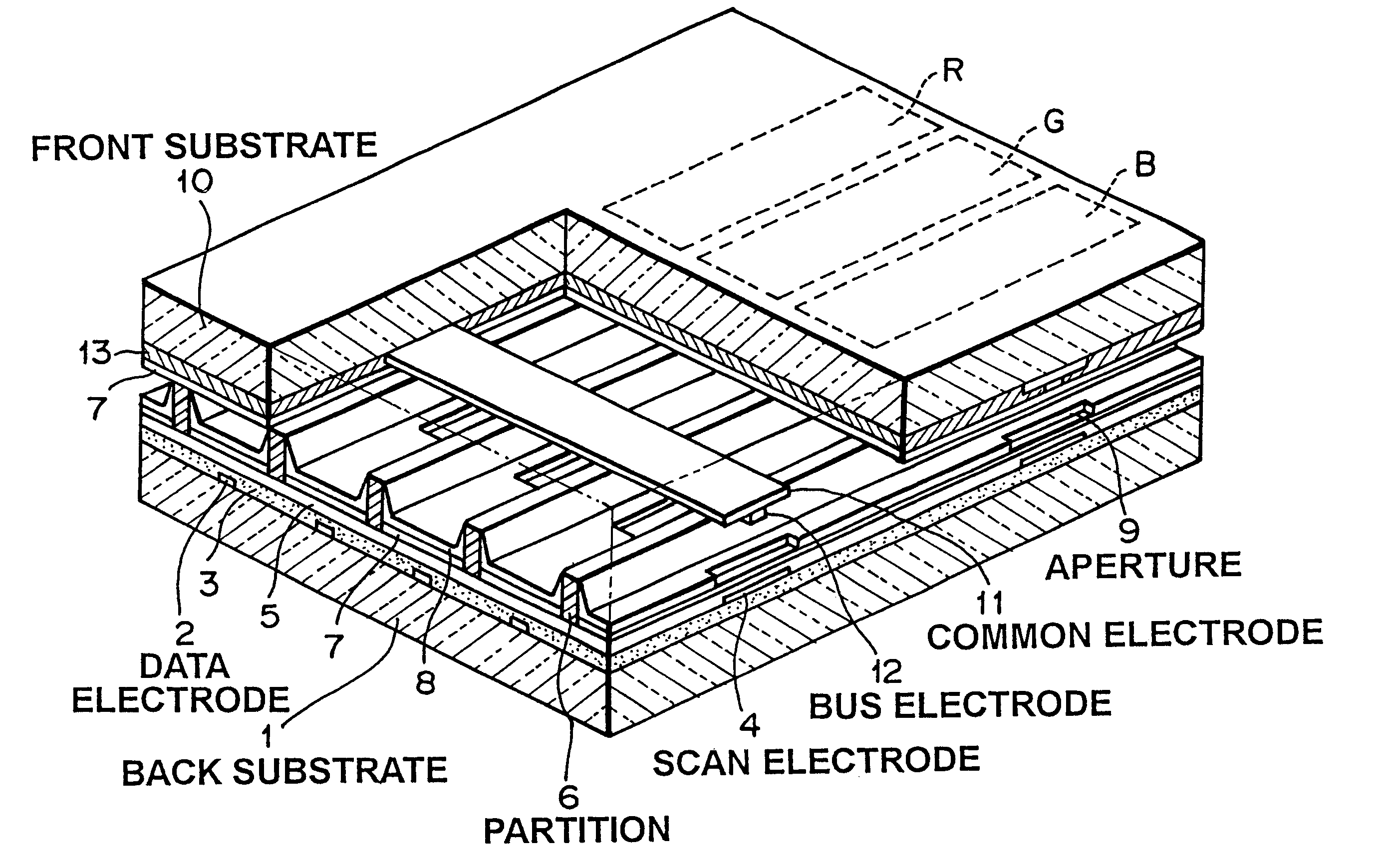

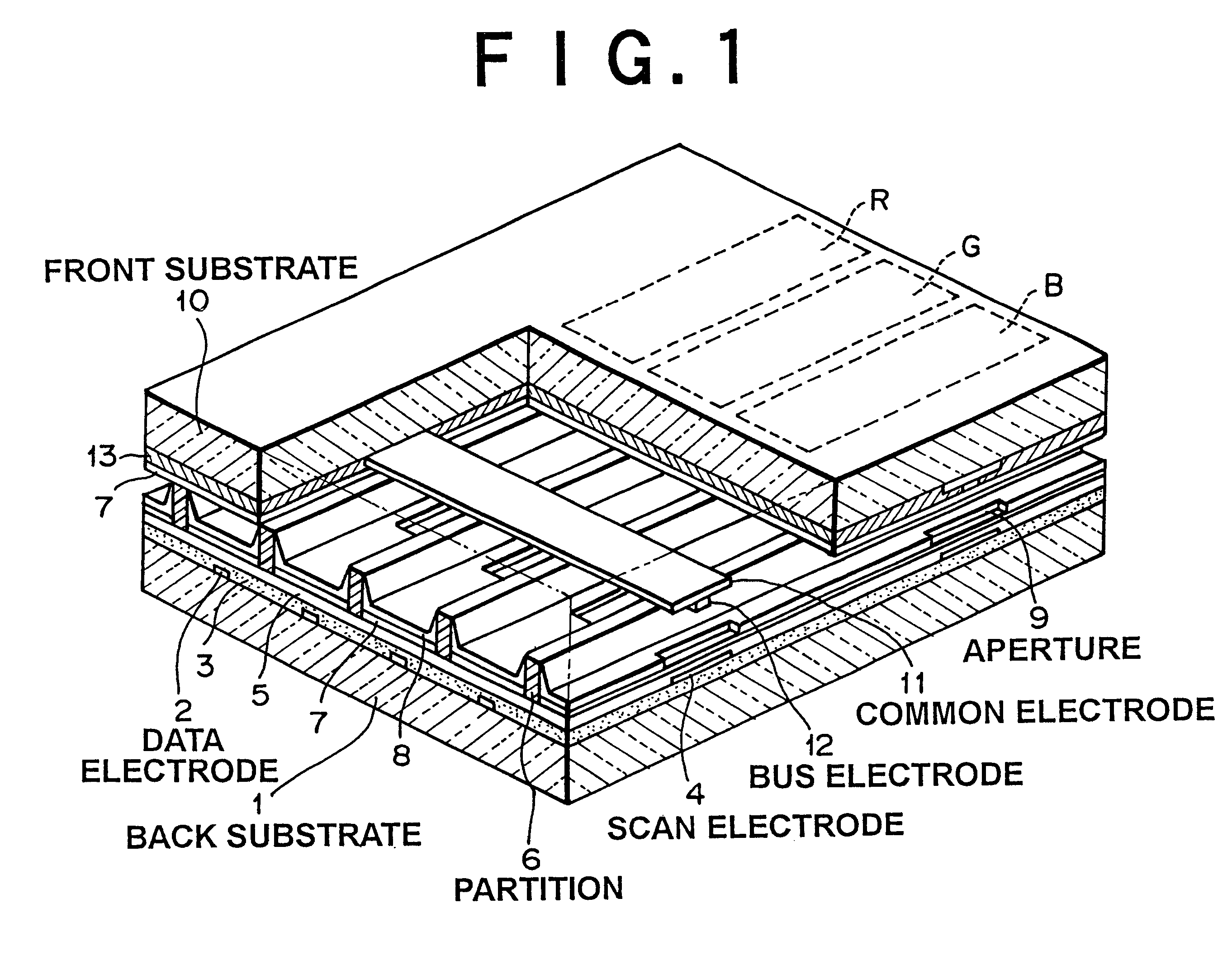

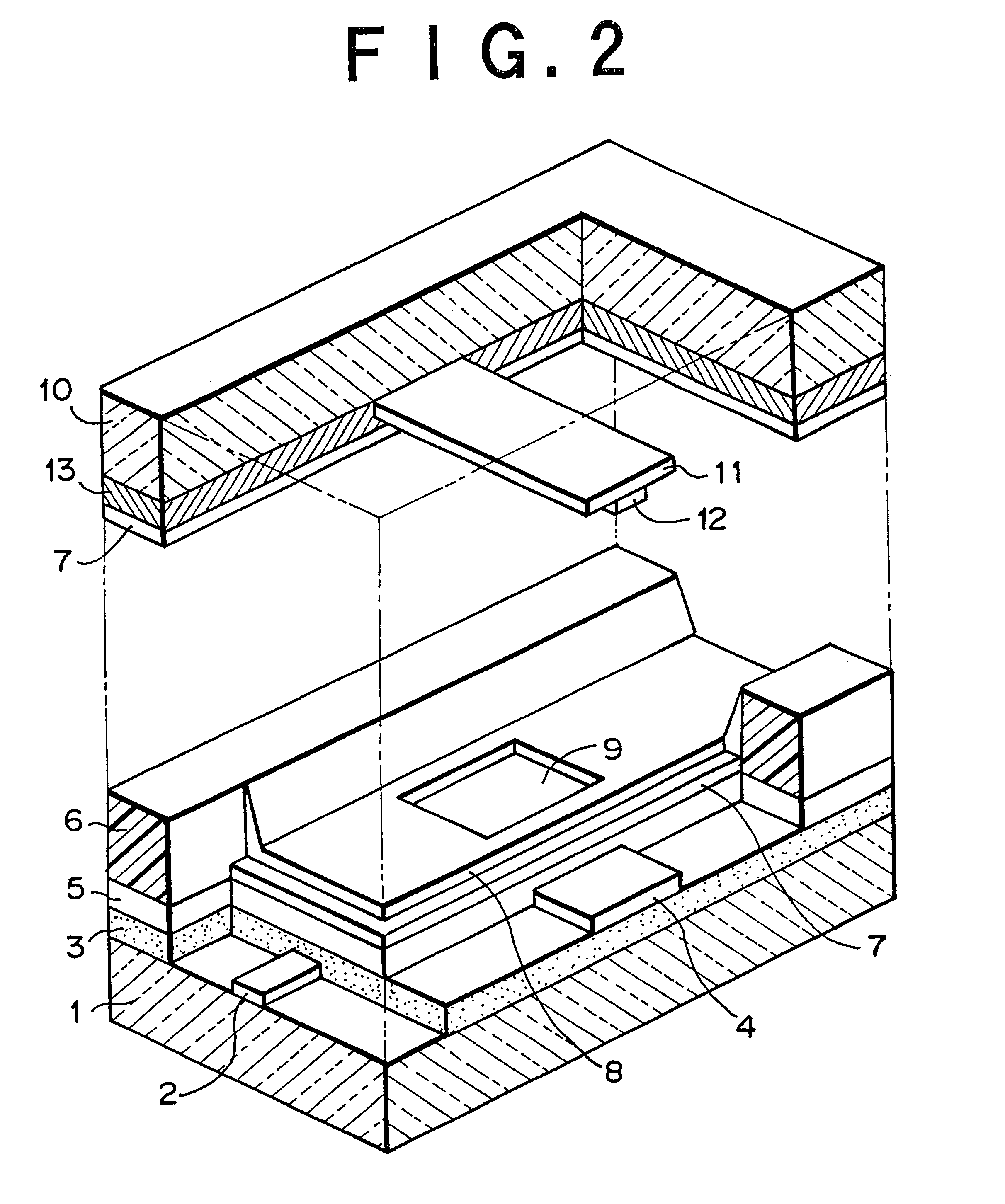

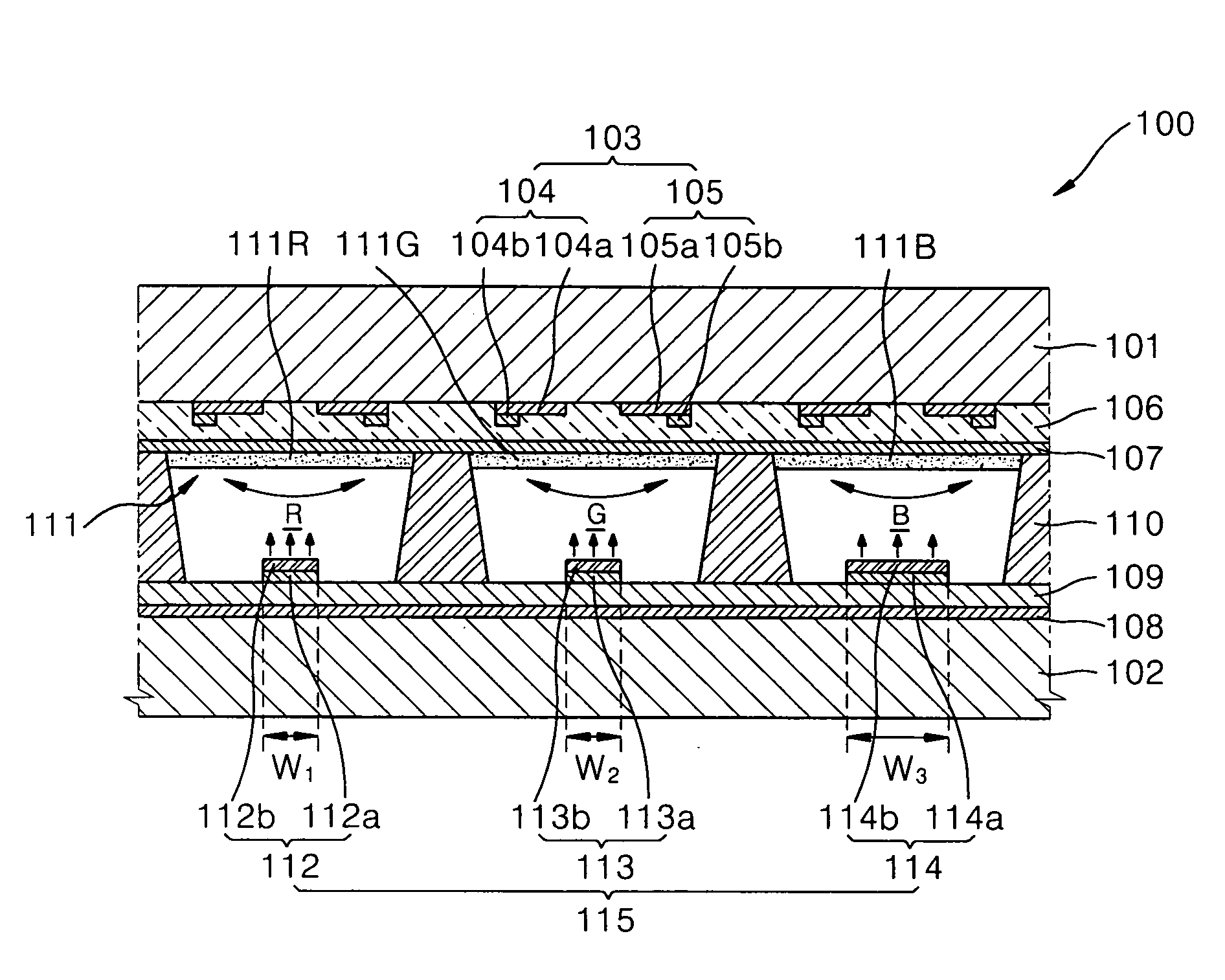

Apparatus, manufacturing method and driving method of plasma display panel

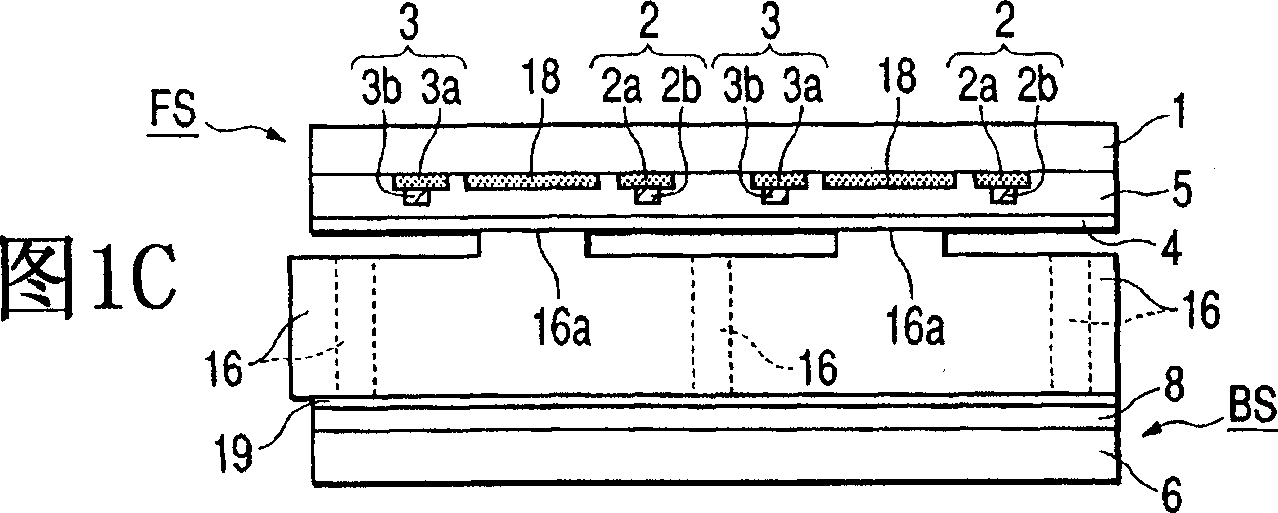

To provide a plasma display panel which improves the write characteristics, luminous luminance, and luminous efficiency and which has a longer life. On a back glass substrate, data electrodes are formed in the substrate column direction. Over the data electrodes, a dielectric layer is formed. On the dielectric layer, scan electrodes are formed in a substrate row direction. Over the scan electrodes, a dielectric layer is formed. On the dielectric layer, partitions are formed in the substrate column direction. On the dielectric layer including the partitions, a protection layer and a fluorescent material layer are formed. On the other hand, on a front glass substrate, common electrodes and bus electrodes electrically connected to the common electrodes are formed in the substrate row direction so as to be opposed to the scan electrodes. Over the common electrodes and the bus electrodes, a dielectric layer and a protection layer are formed.

Owner:PIONEER CORP

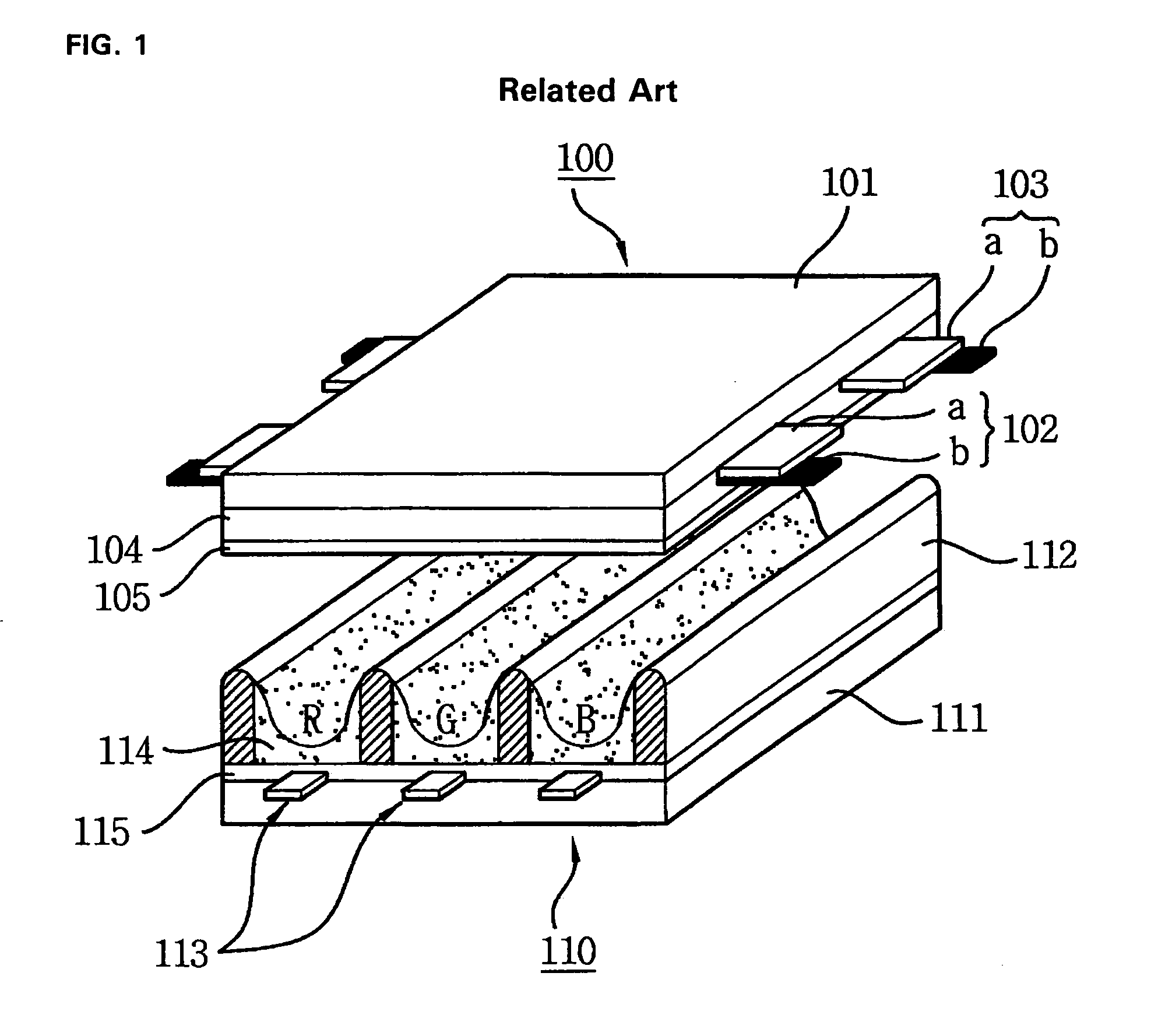

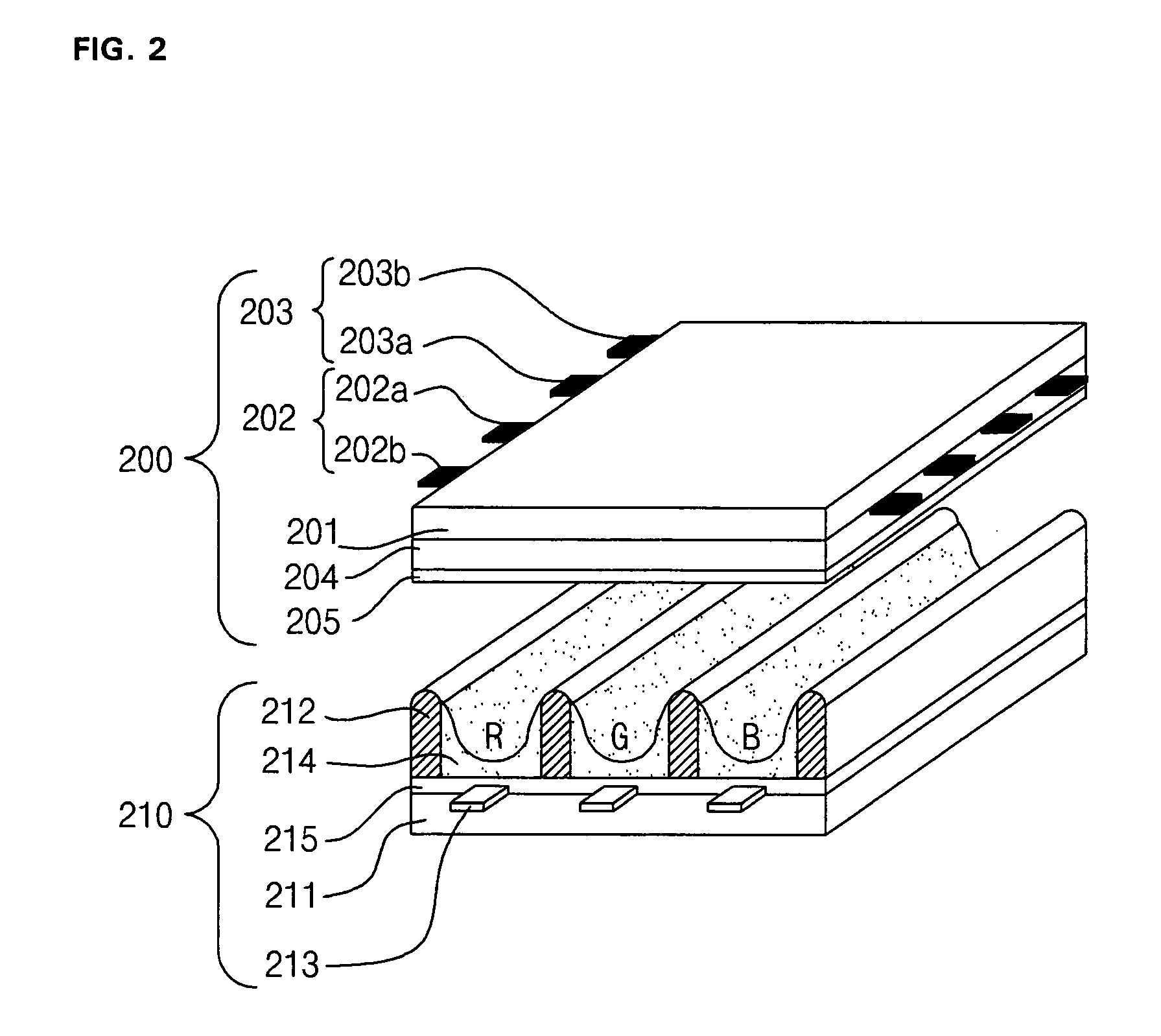

Plasma display panel and flat lamp using oxidized porous silicon

InactiveUS20060012304A1Improve propertiesAddress electrodesSustain/scan electrodesEngineeringPorous silicon

A plasma display panel (PDP) and a flat lamp. The PDP includes an upper panel and a lower panel facing each other, a plurality of address electrodes formed in the lower panel, a plurality of sustaining electrodes formed in the upper panel, and an oxidized porous silicon layer formed in the upper panel and corresponding to a sustaining electrode.

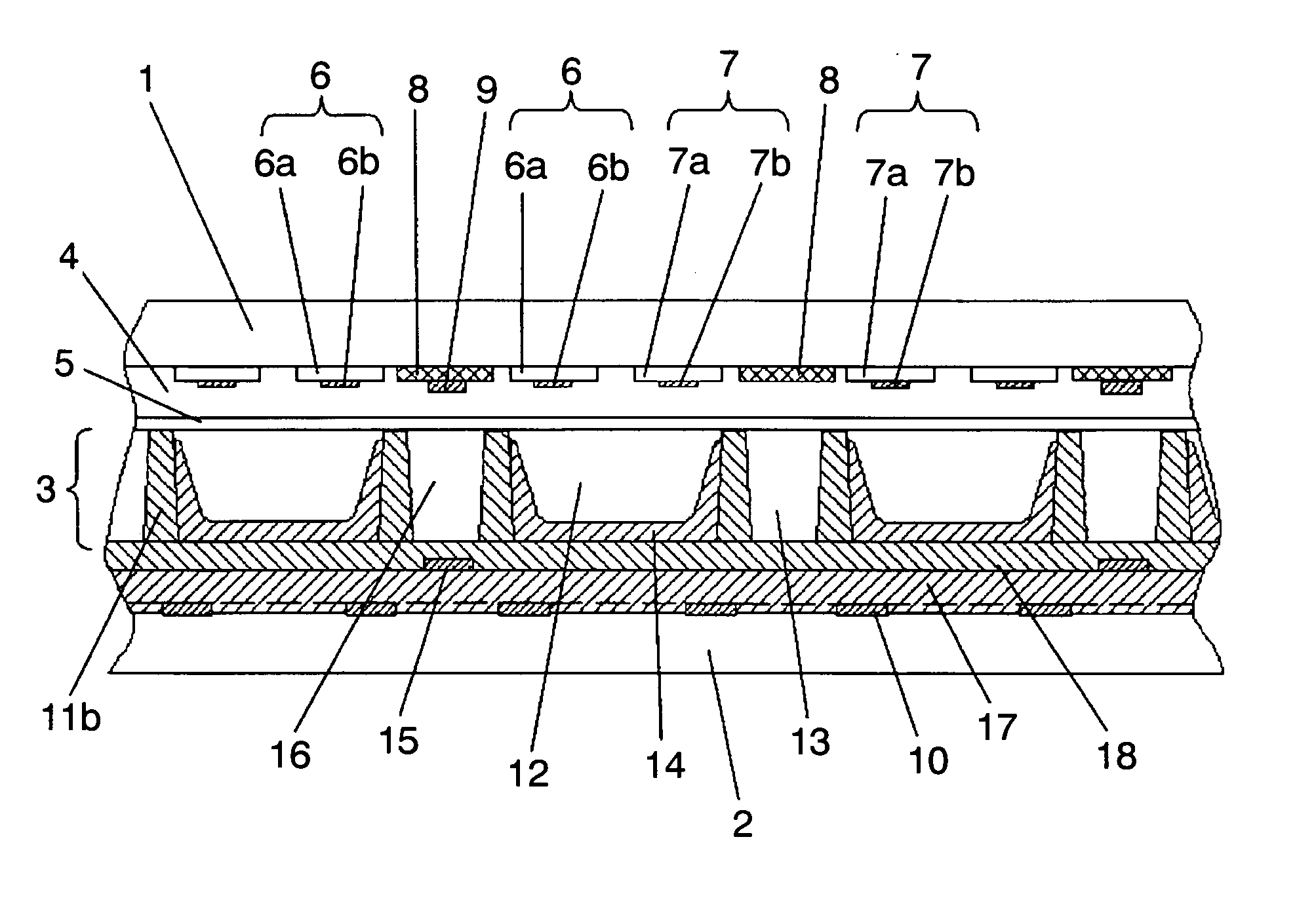

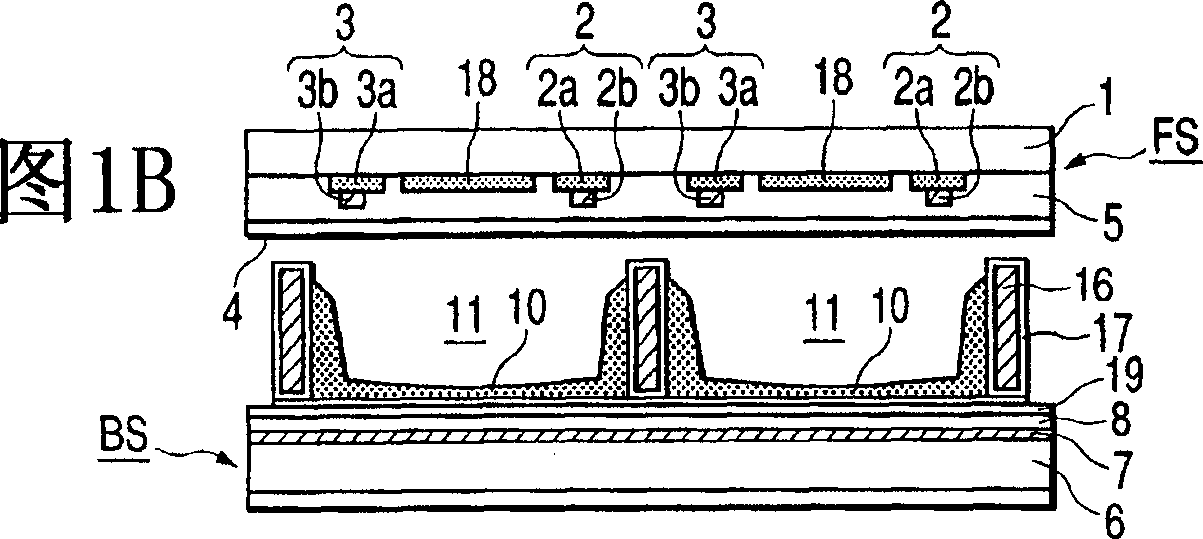

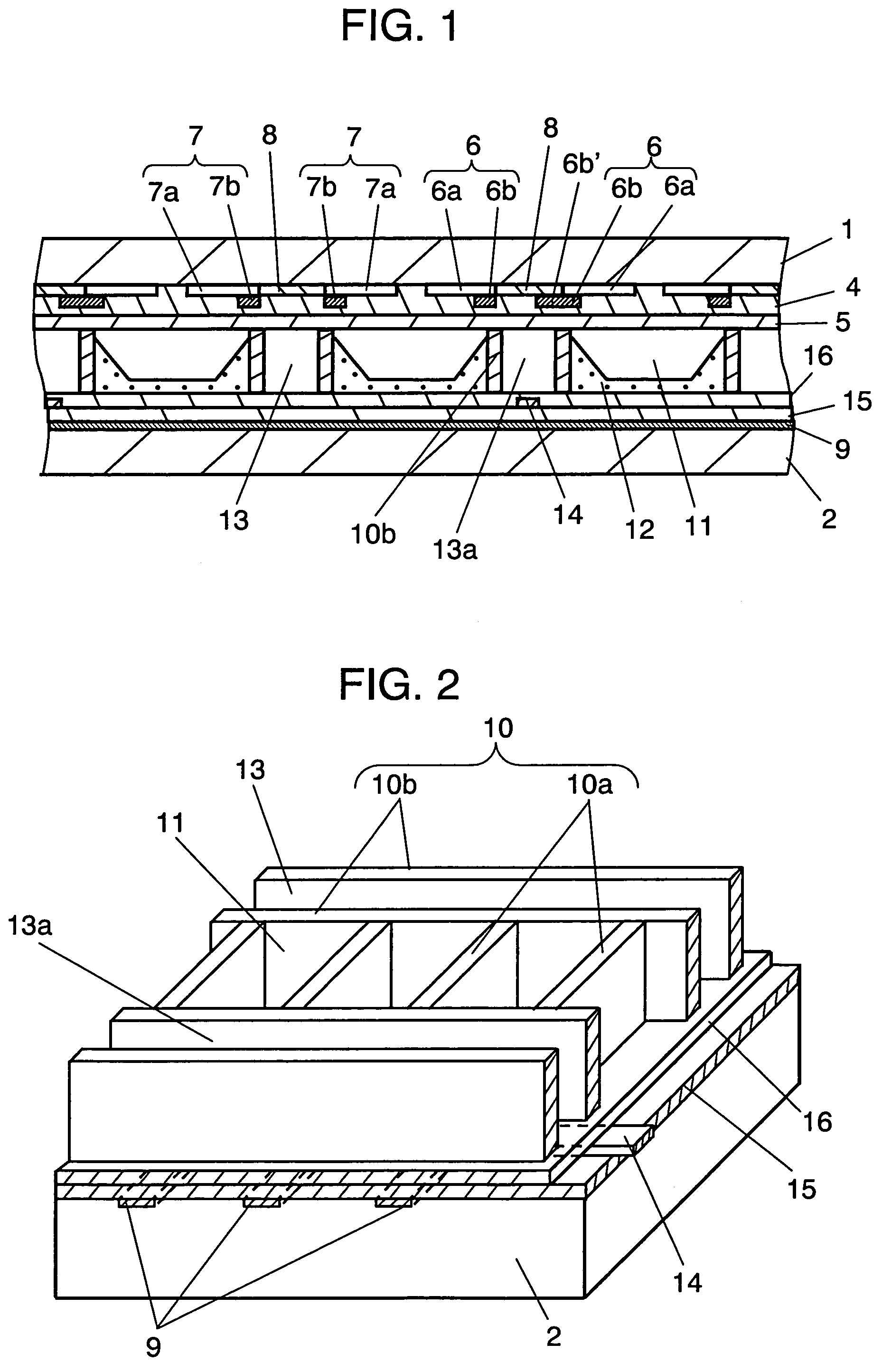

Plasma display panel

InactiveUS20060113914A1Reduce discharge delayImprove reliabilityAddress electrodesAuxillary electrodesPhysicsOptoelectronics

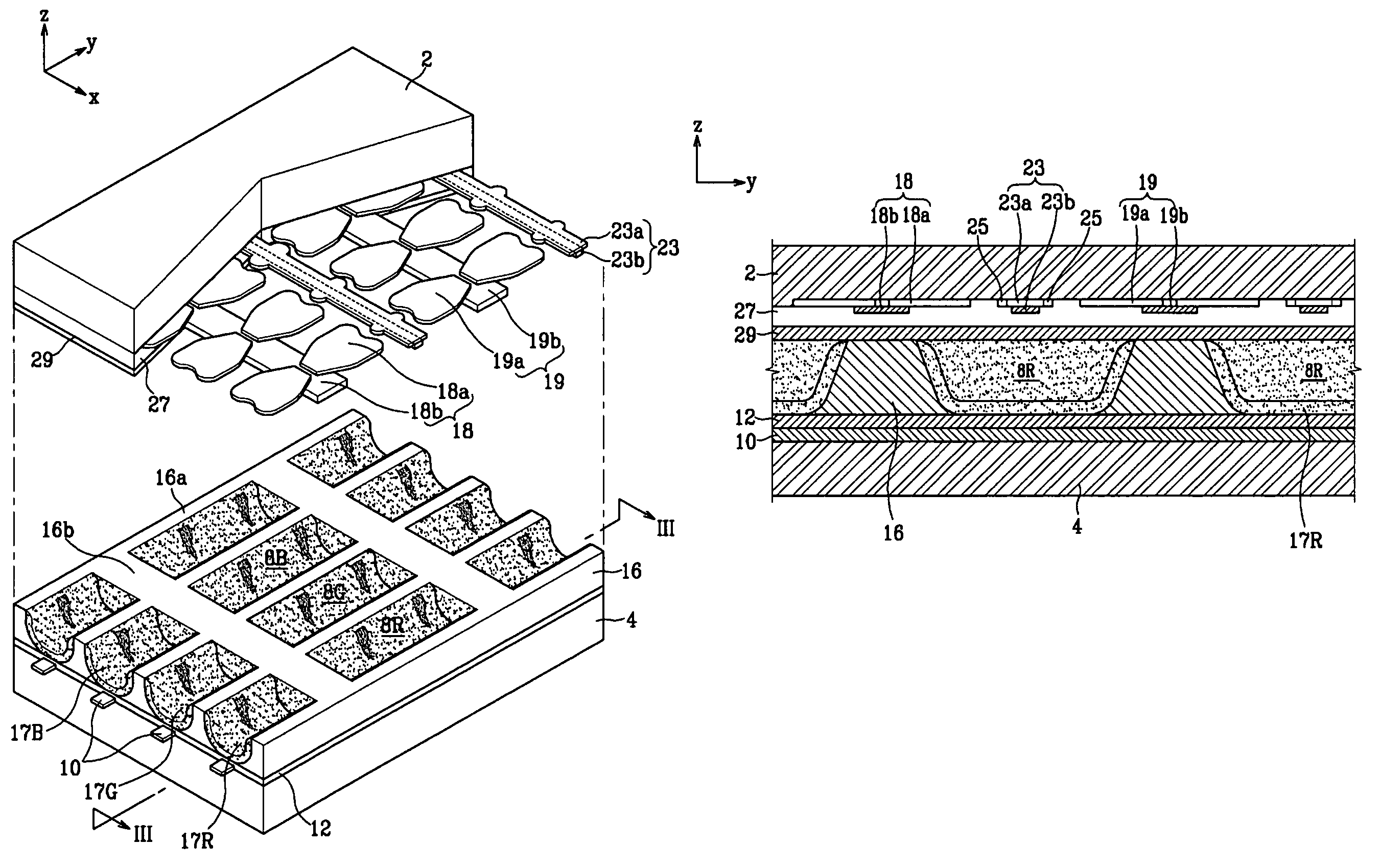

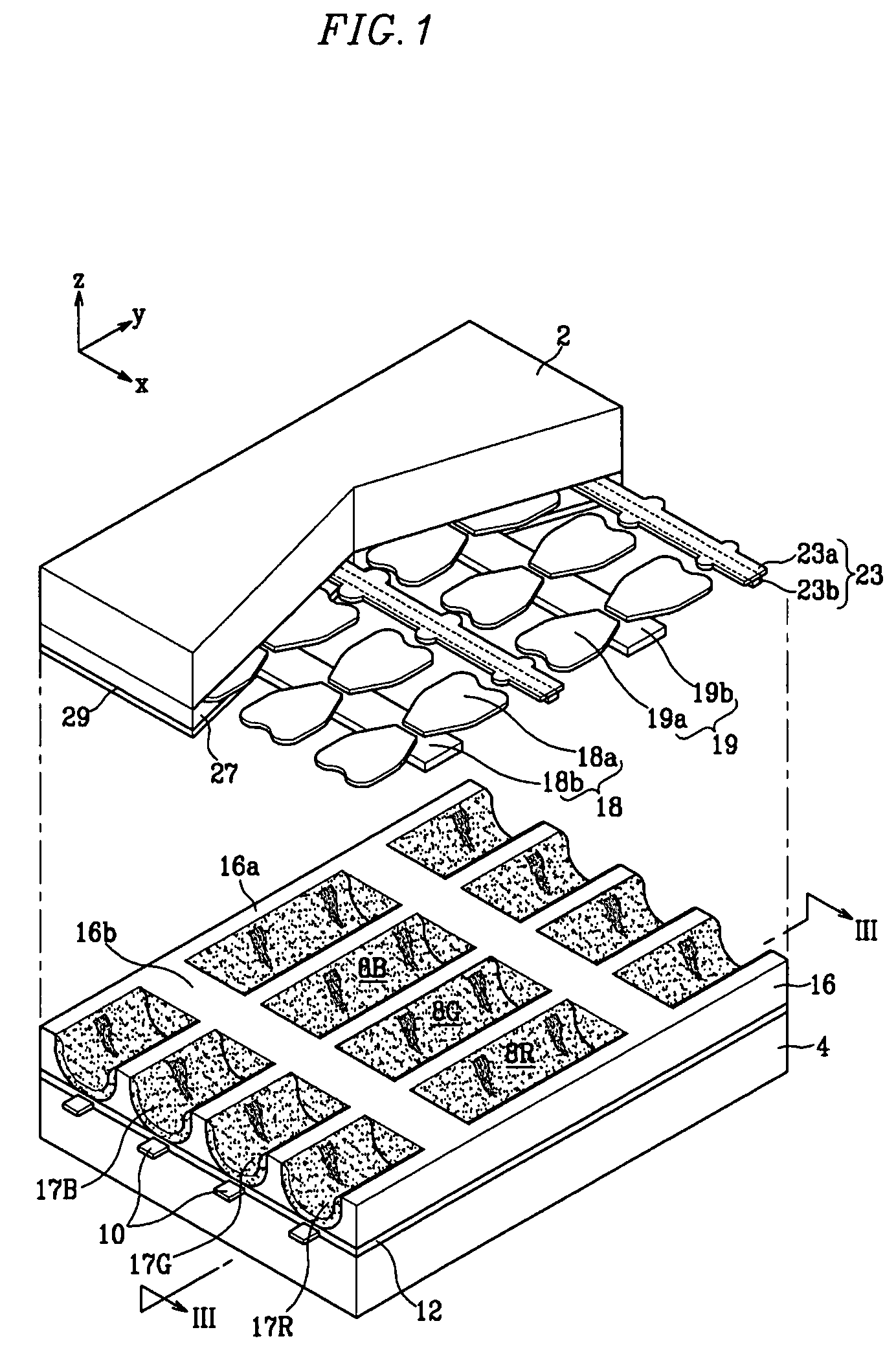

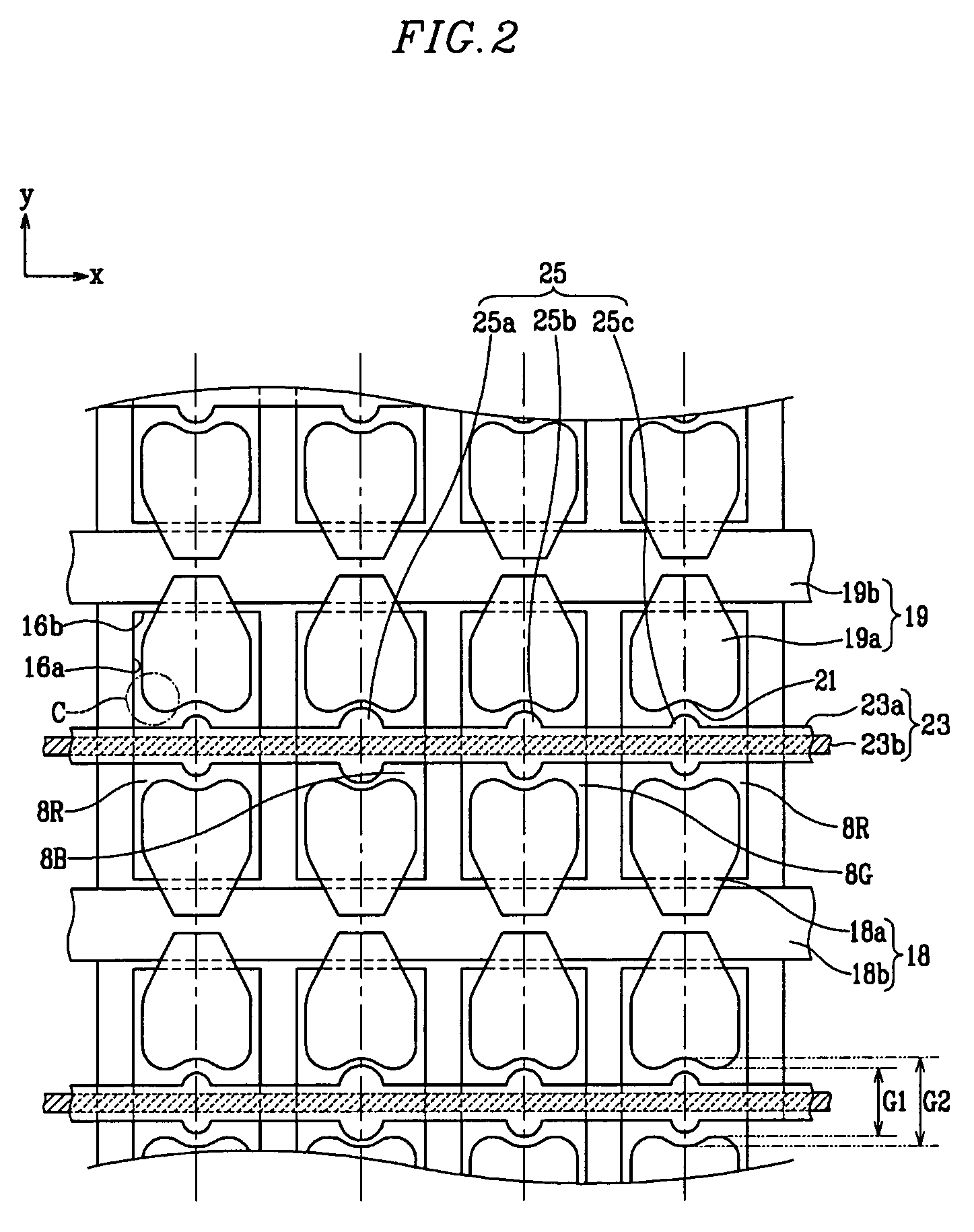

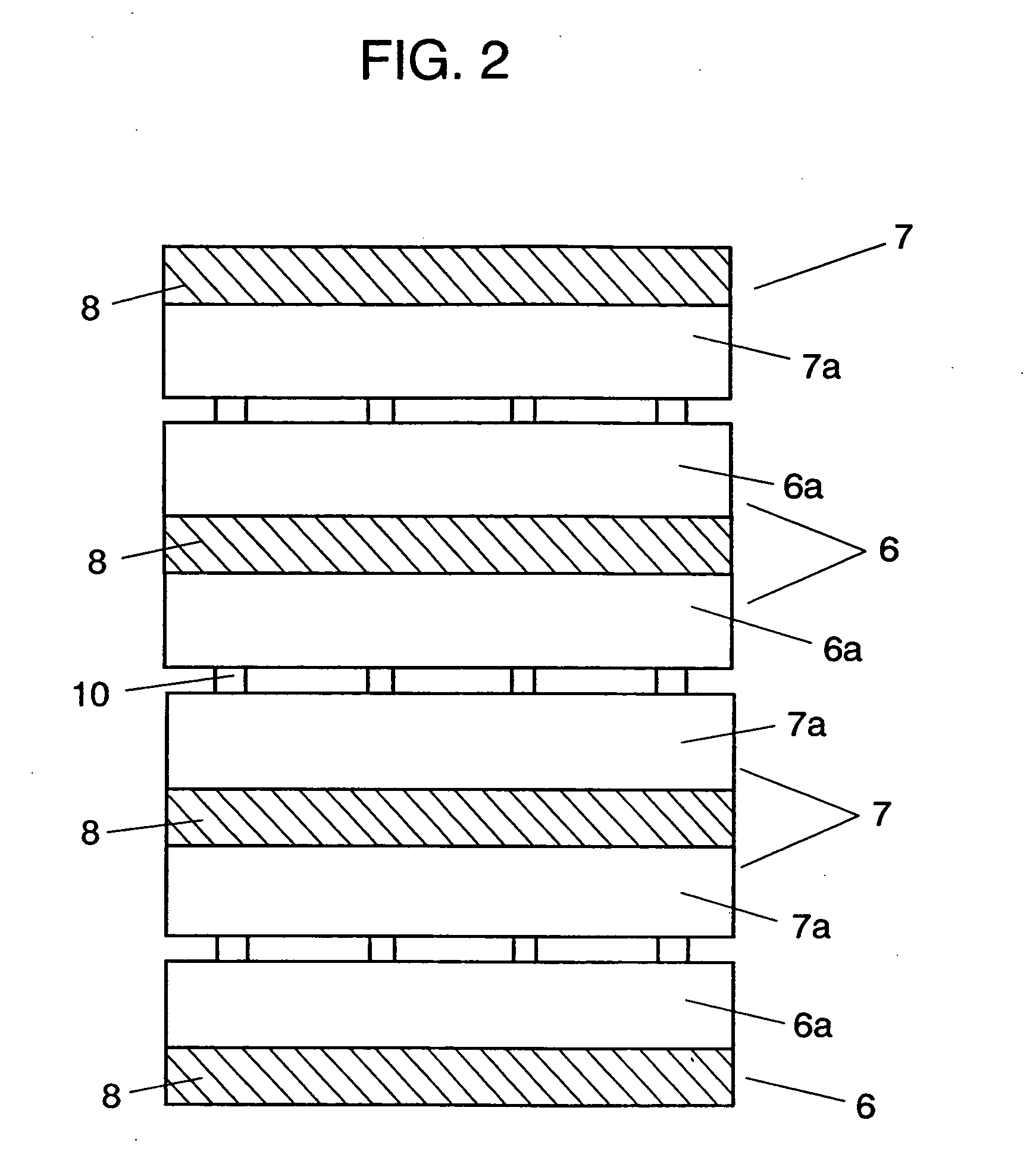

A plasma display panel has a stable addressing characteristic, no dielectric breakdown, and high reliability. Data electrodes (10), first dielectric layer (17) for covering them, priming electrodes (15), and second dielectric layer (18) for covering them are sequentially formed on back substrate (2). Slotted parts (10a) are formed in a part of each data electrode (10). Thus, data electrodes (10) are prevented from deforming during the manufacturing, and dielectric voltage between data electrodes (10) and priming electrodes (15) is improved.

Owner:PANASONIC CORP

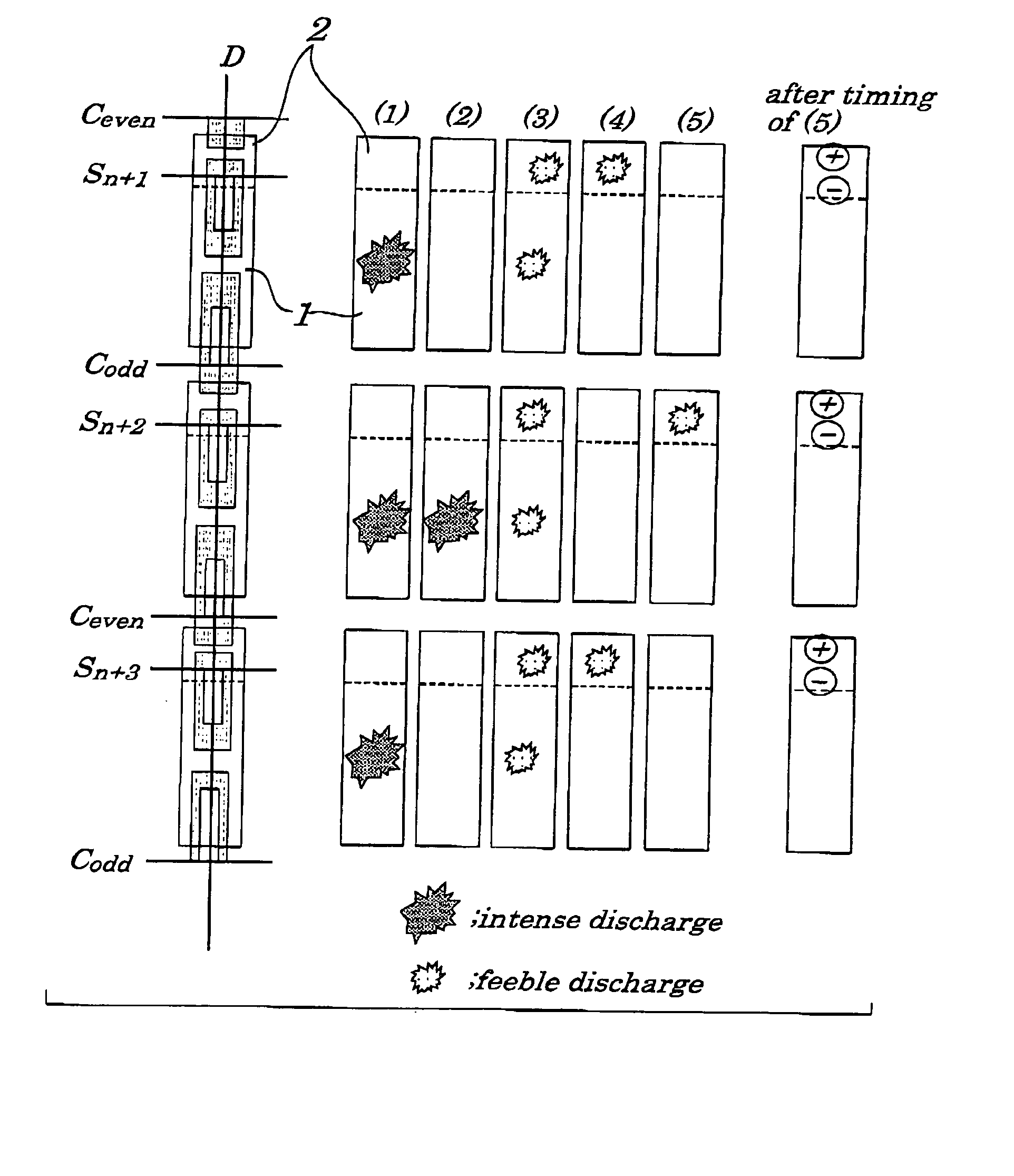

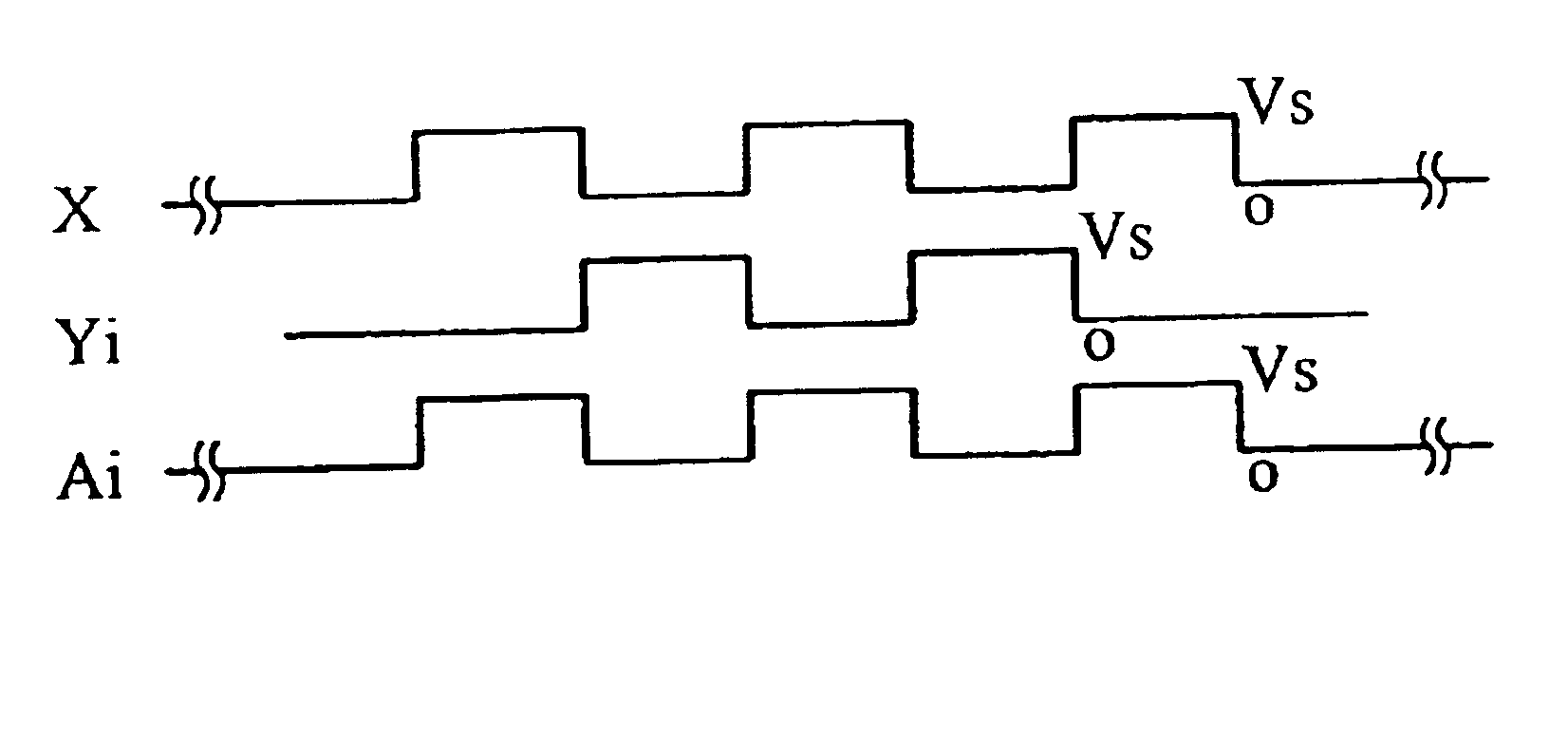

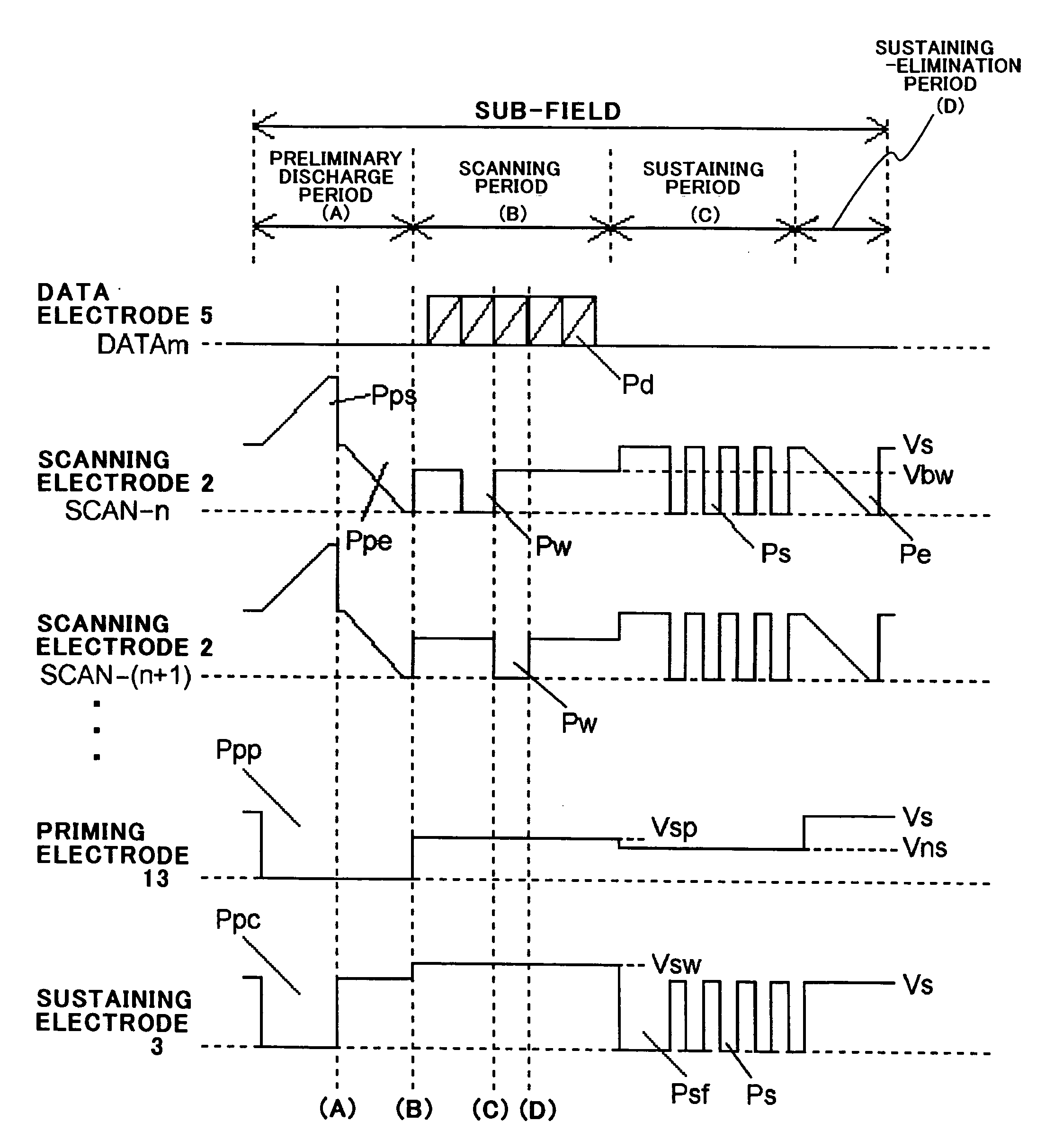

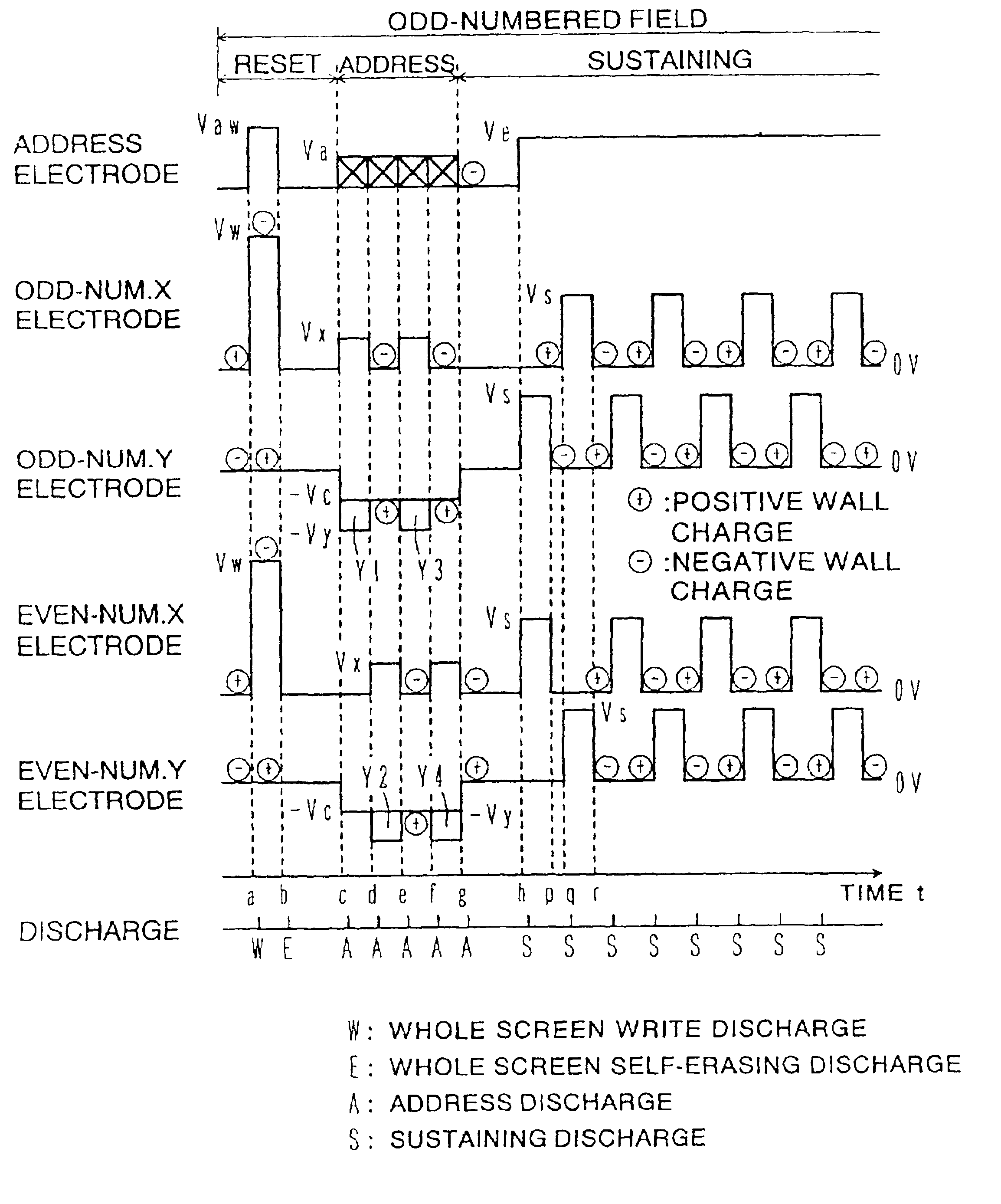

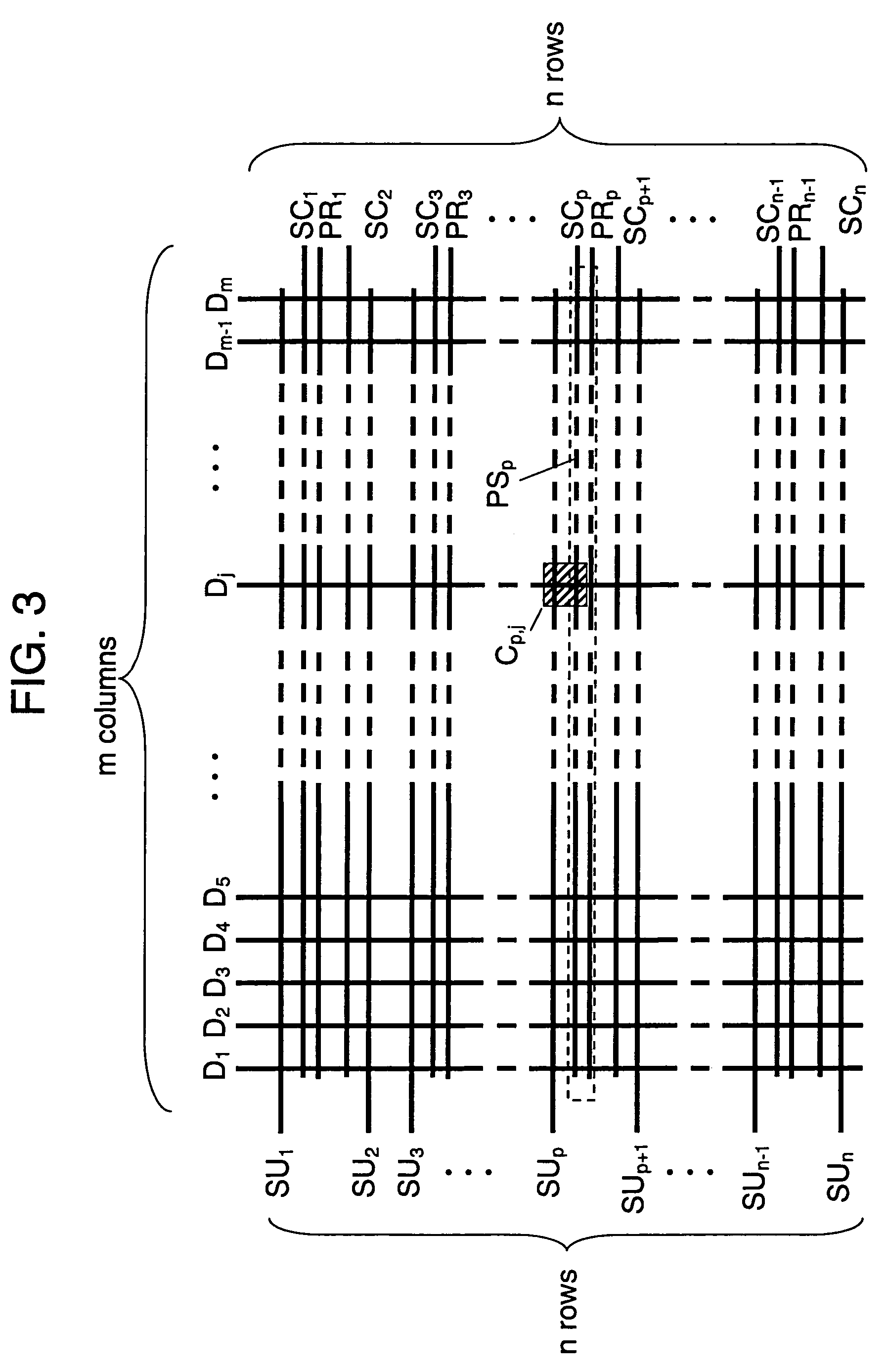

Method of Driving Plasma Display Panel

A method of driving a plasma display panel having display electrode pairs each one of which pairs is formed of a scan electrode and a sustain electrode. A priming electrode is placed in every other spaces between the display electrode pairs and in parallel with the display electrode pairs. An addressing period includes an odd-line addressing period in which an address operation is conducted to primary discharge cells having odd-number scan electrodes, an even-line addressing period in which an address operation is conducted to primary discharge cells having even-number scan electrodes. During the respective addressing periods, scan pulse voltage Va is applied to odd-number scan electrodes or even-number scan electrodes while priming pulse voltage Vp is applied, prior to the application of the scan pulse voltage, to a priming electrode adjacent to the scan electrode to which scan pulse voltage Va is to be applied, in order to generate a priming discharge between the priming electrodes and the data electrodes.

Owner:PANASONIC CORP

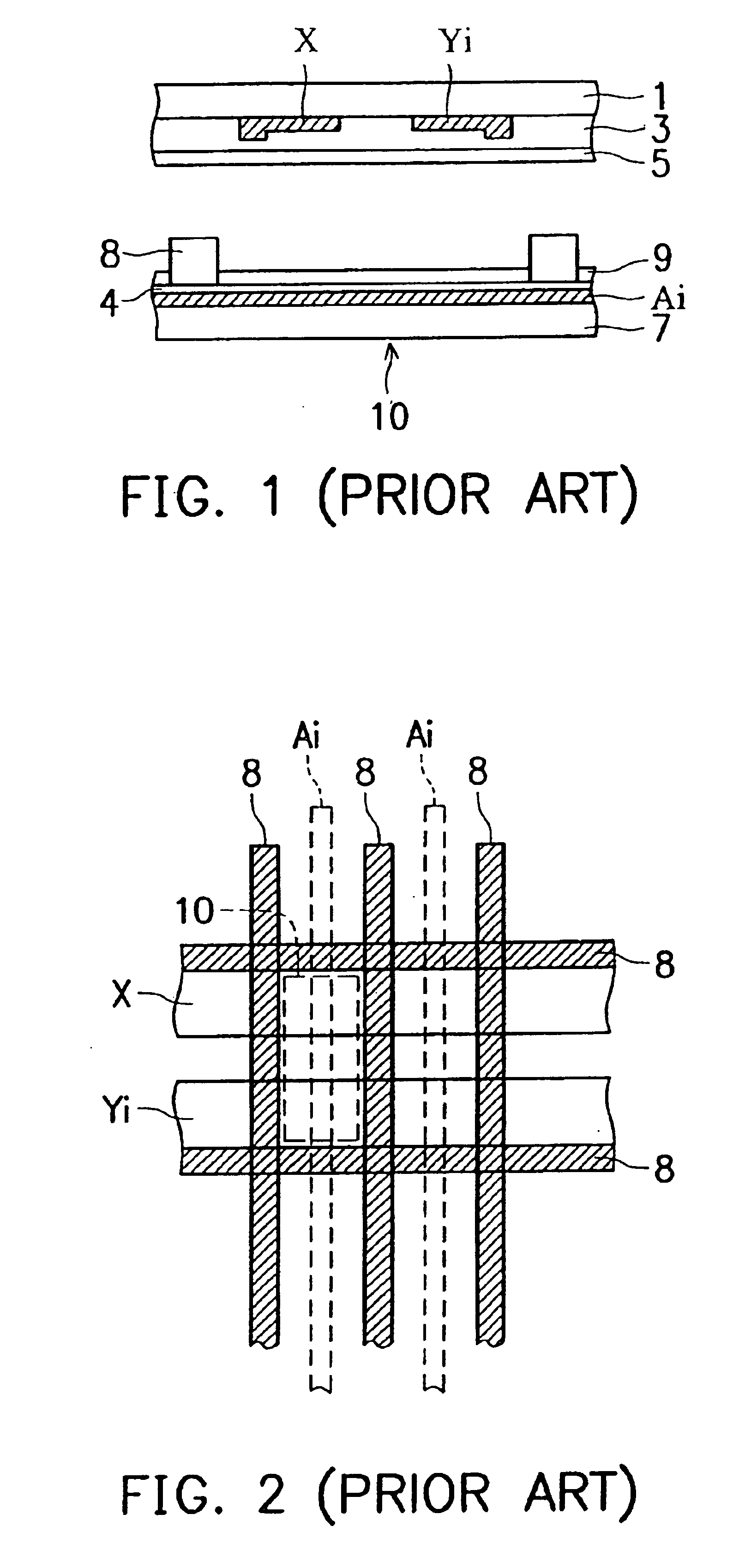

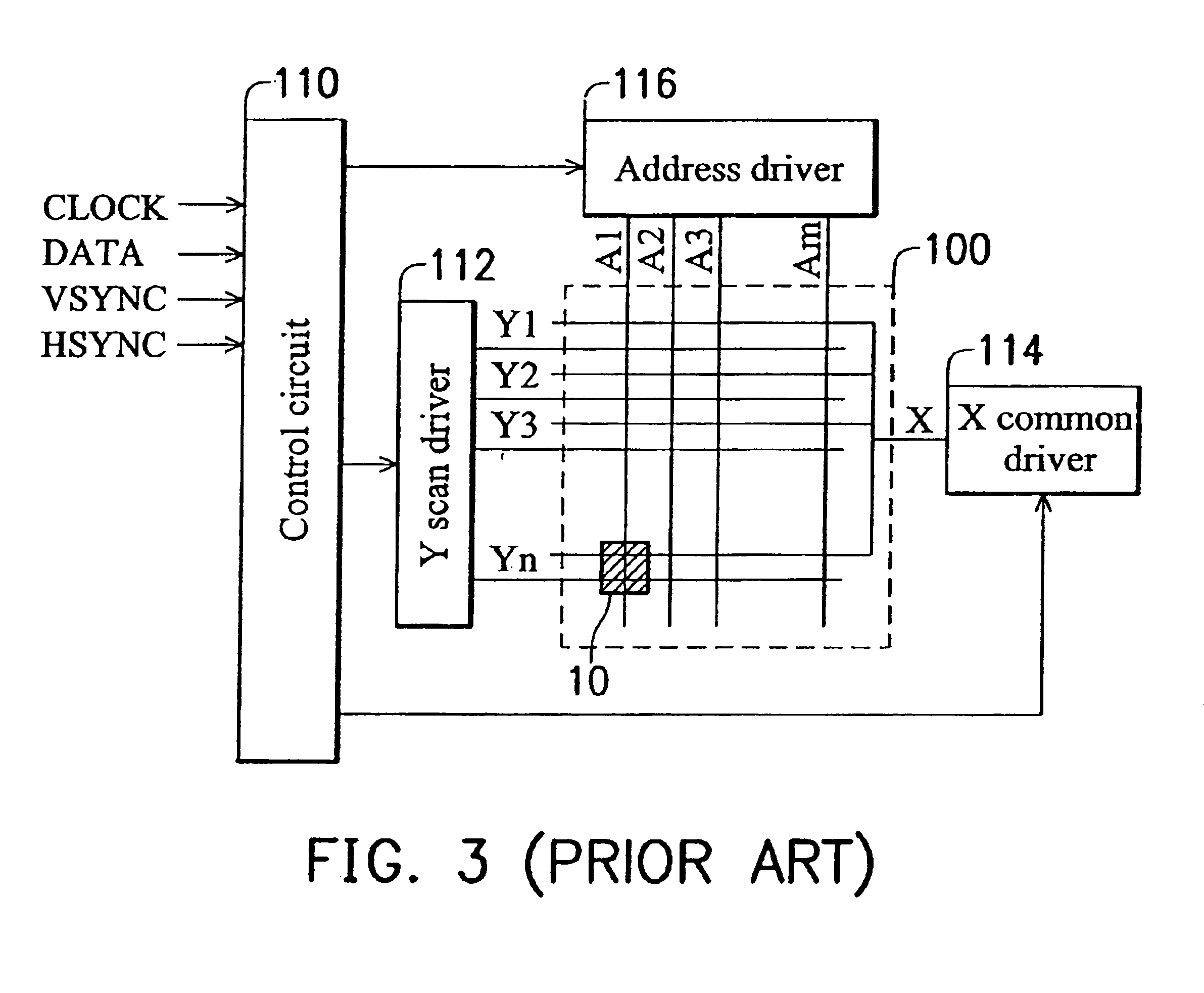

Plasma display panel and method of driving the same

InactiveUS6954035B2Avoid erasureEasy to operateAddress electrodesStatic indicating devicesEngineeringBrightness perception

A method of driving a plasma display panel to improve display brightness and luminescent efficiency. In the sustain periods, the same driving signal is sent to the sustain electrode X as well as the address electrode Ai at the same time to achieve the desired volume discharge effect. In addition, the structure of PDPs is modified to raise firing voltages between these electrodes, preventing erasure of the data written in the address periods.

Owner:AU OPTRONICS CORP

Display device and driving method thereof

An intermediate electrode is formed in a space between an X display electrode and a Y display electrode parallel thereto. A negative voltage is applied to the Y display electrode to use the Y display electrode as a cathode. A charge is stored between the Y display electrode and an intermediate electrode to create an electric field. Upon the increase of the intensity of the electric field to a sufficiently high level, an instant discharge occurs between the Y display electrode and the X display electrode and intense ultraviolet rays are produced. The fluorescent layer excited by the ultraviolet rays emits visible light. Only a narrow pulse current flows through the X display electrode and the Y display electrode, so that power consumption can be suppressed at high emission efficiency.

Owner:HITACHI LTD

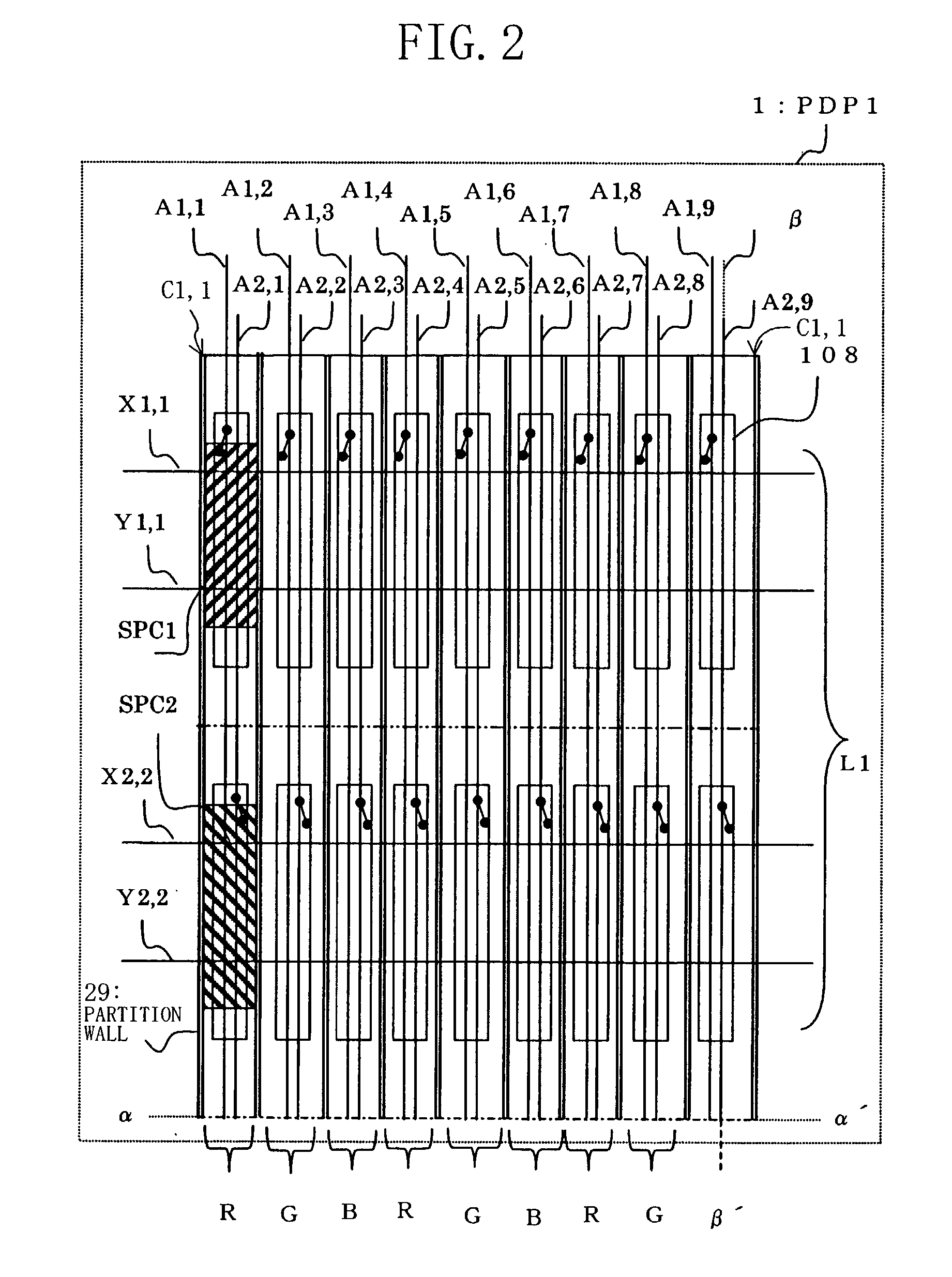

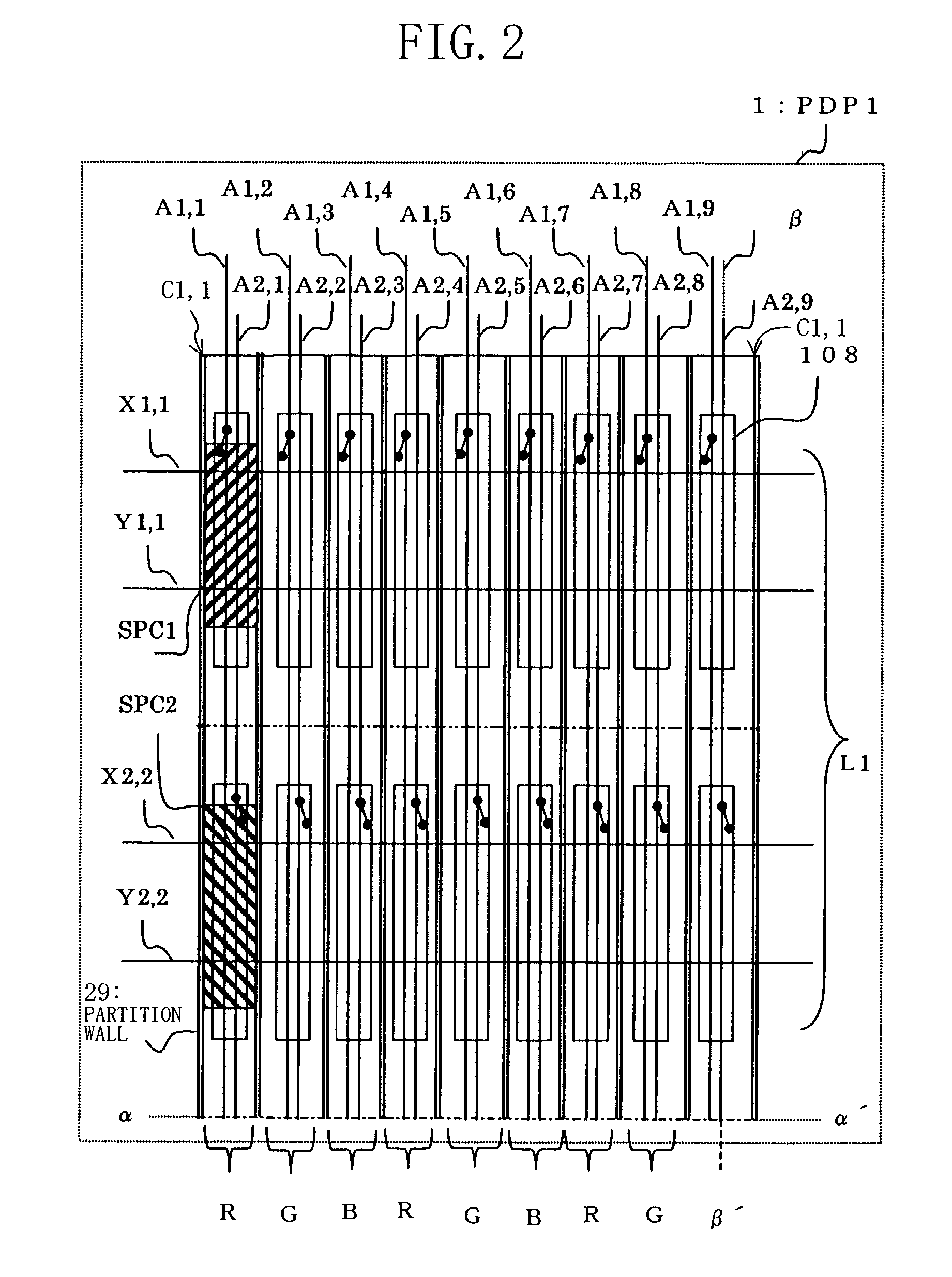

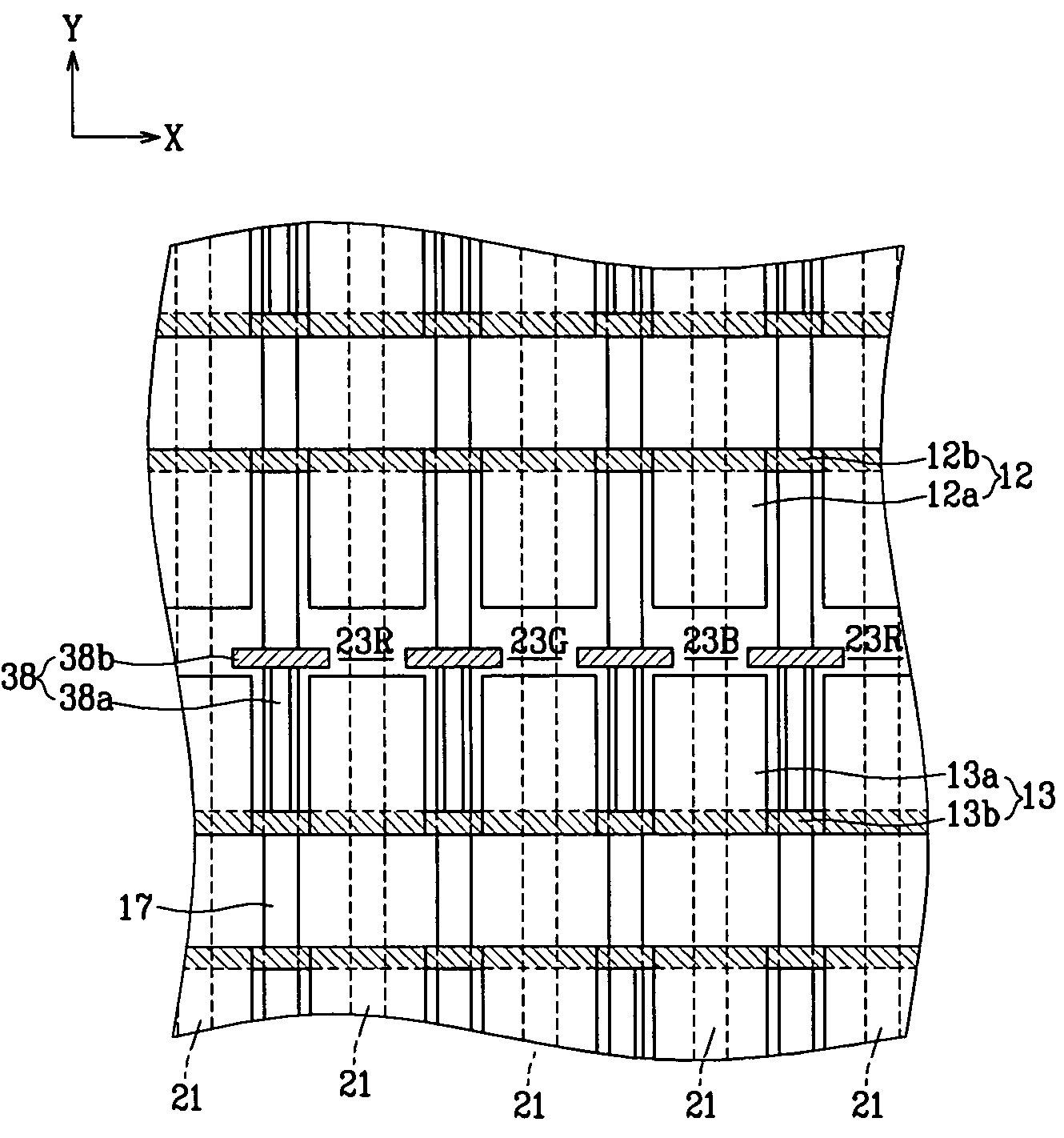

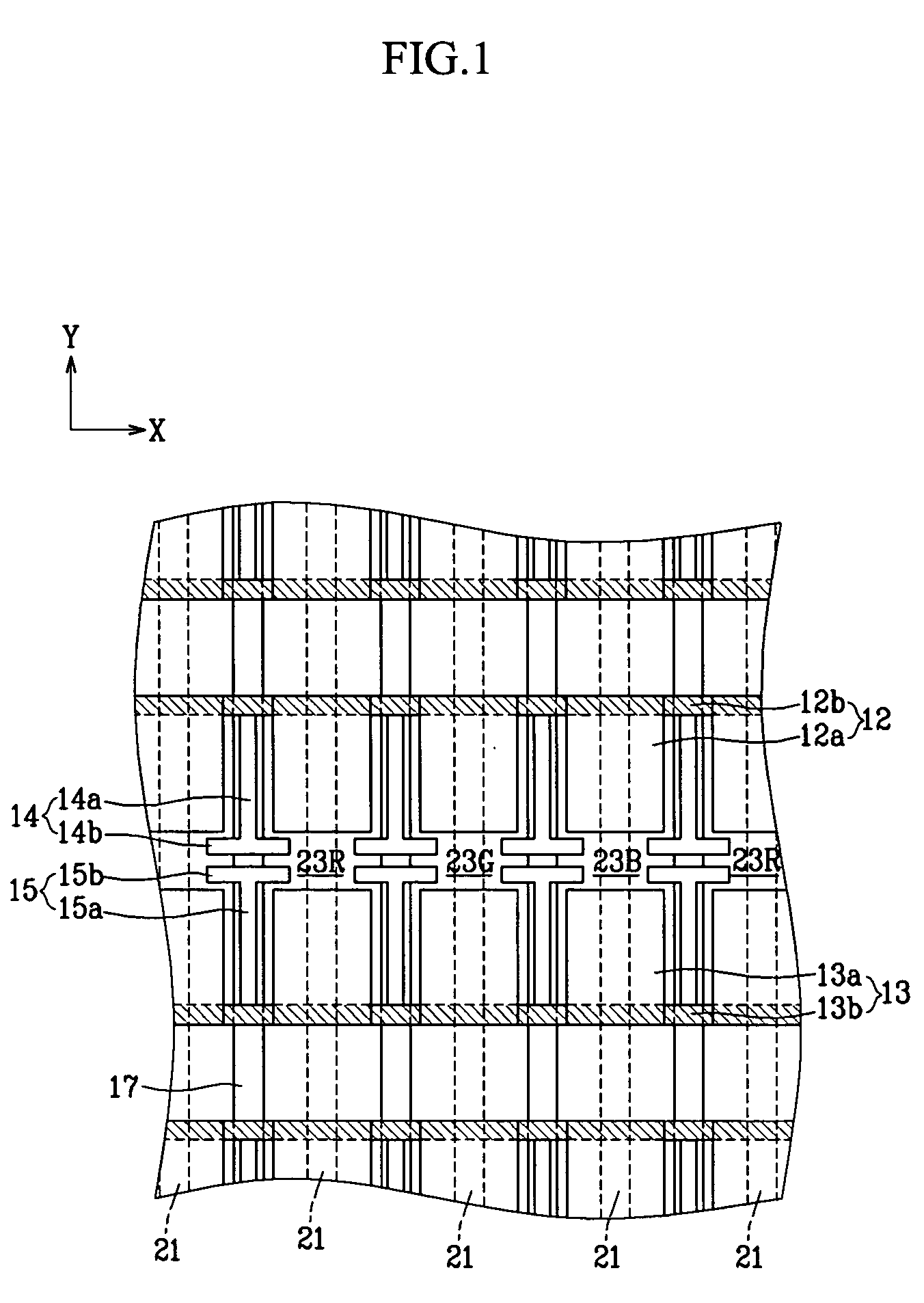

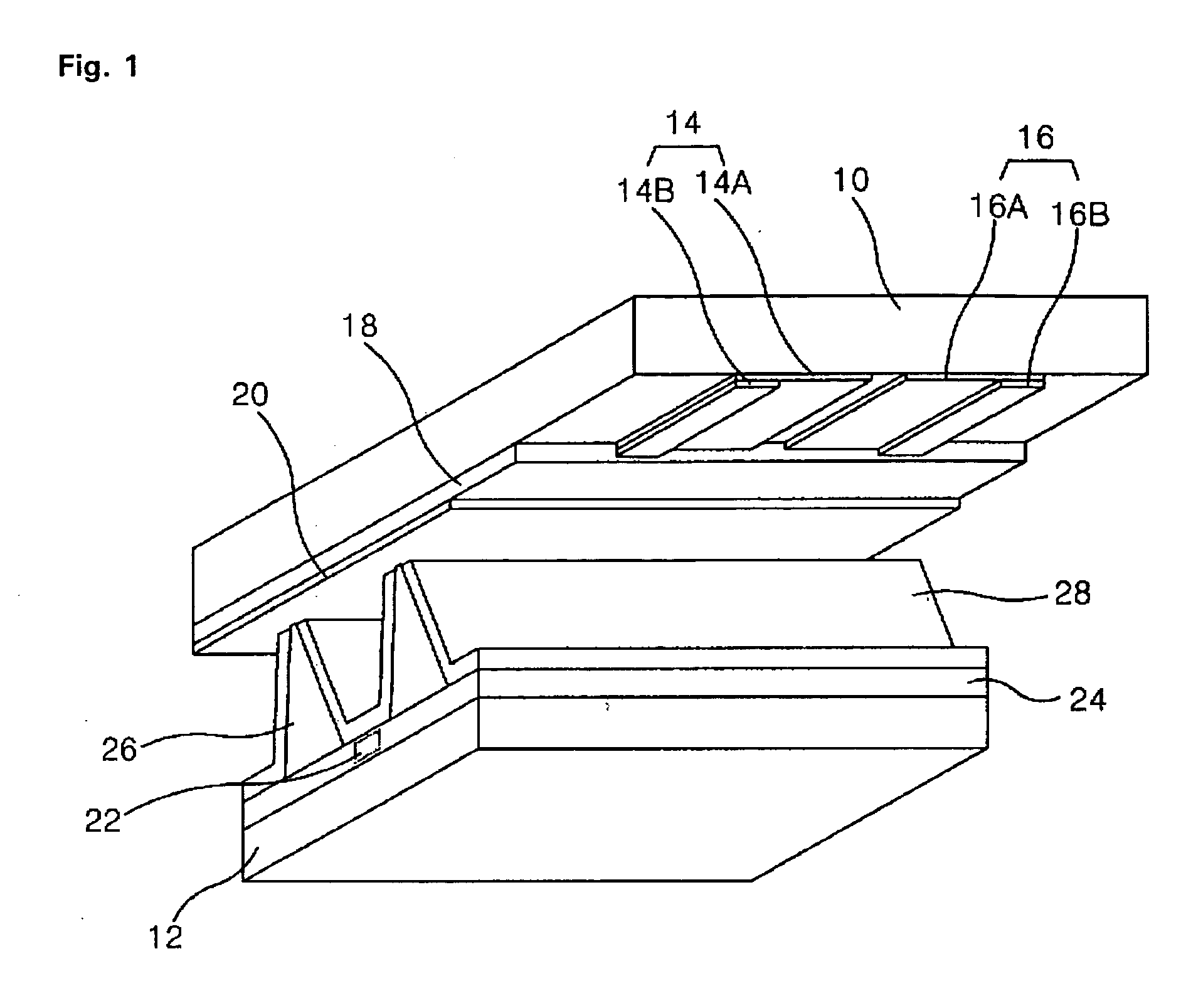

Plasma display panel, method of driving same and plasma display apparatus

InactiveUS20060050094A1High quality imagingHigh definitionAuxillary electrodesAlternating current plasma display panelsMonochromatic colorEngineering

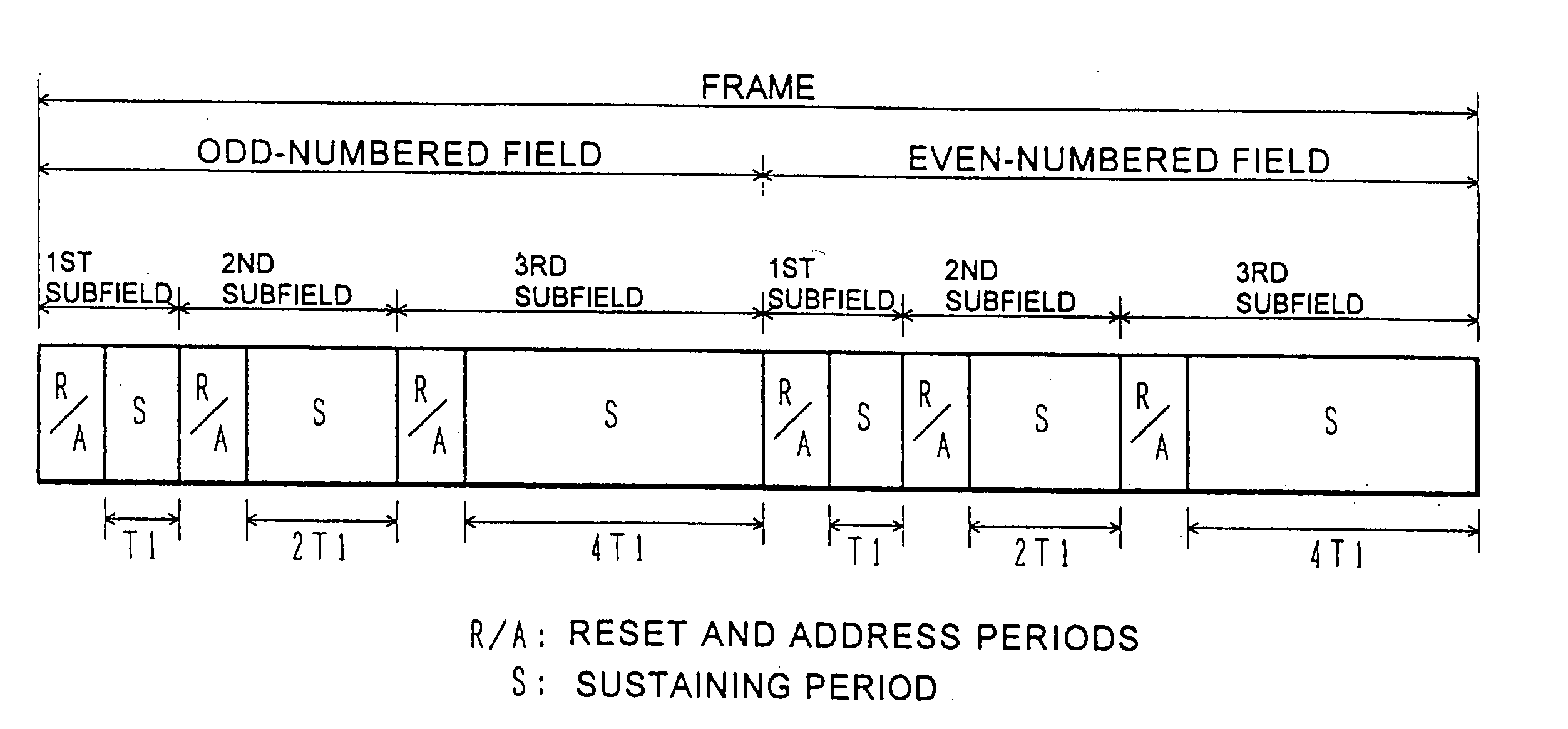

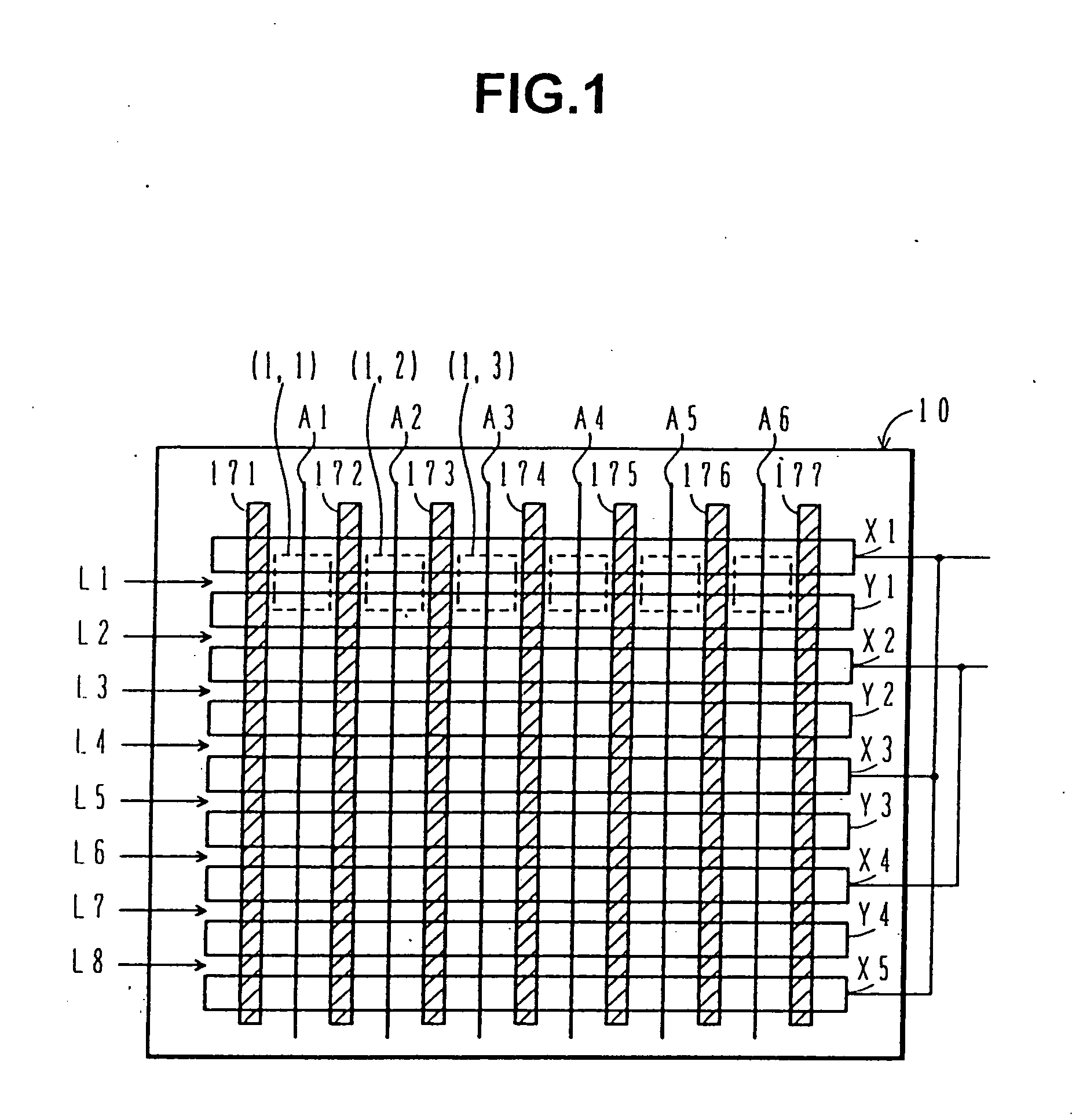

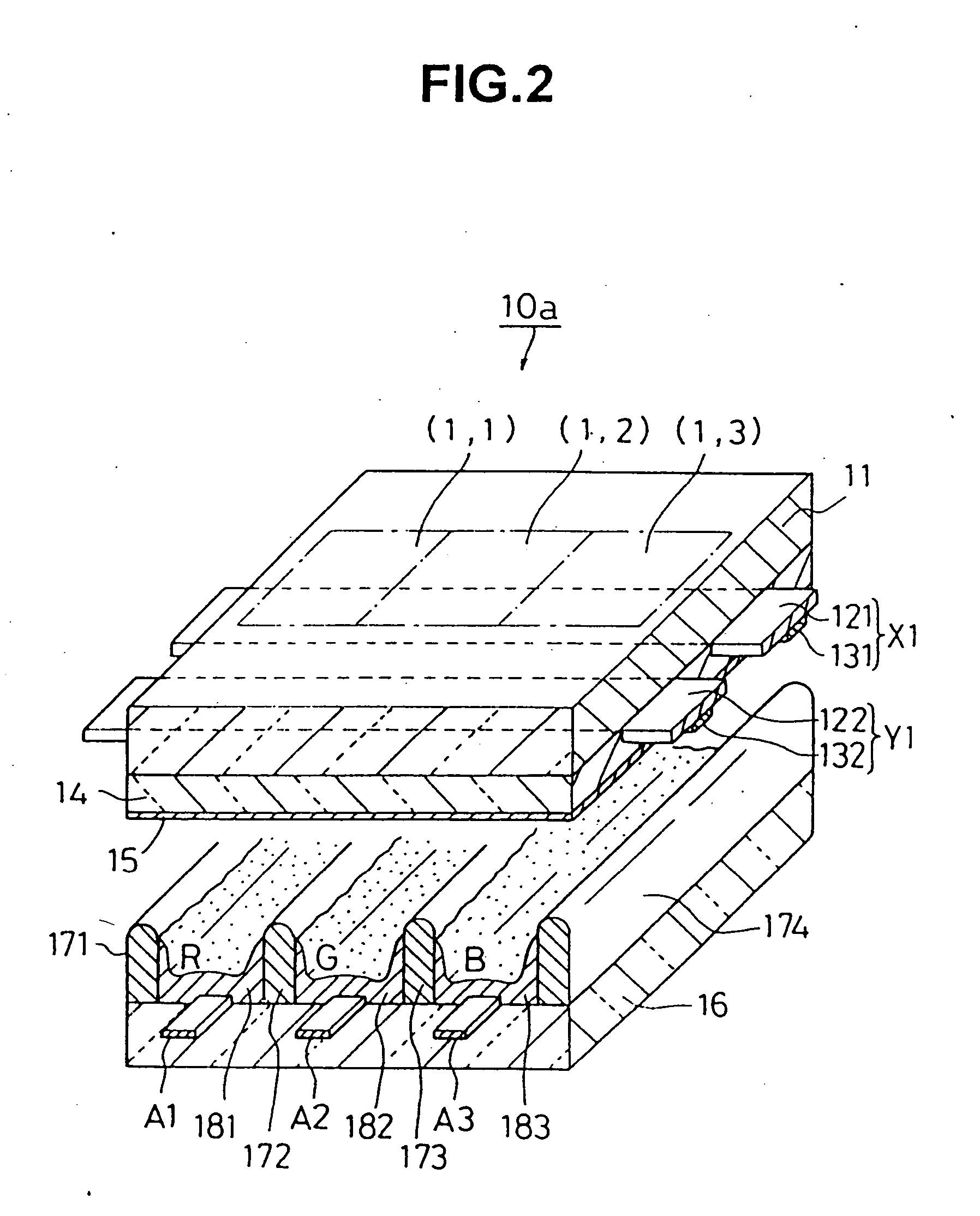

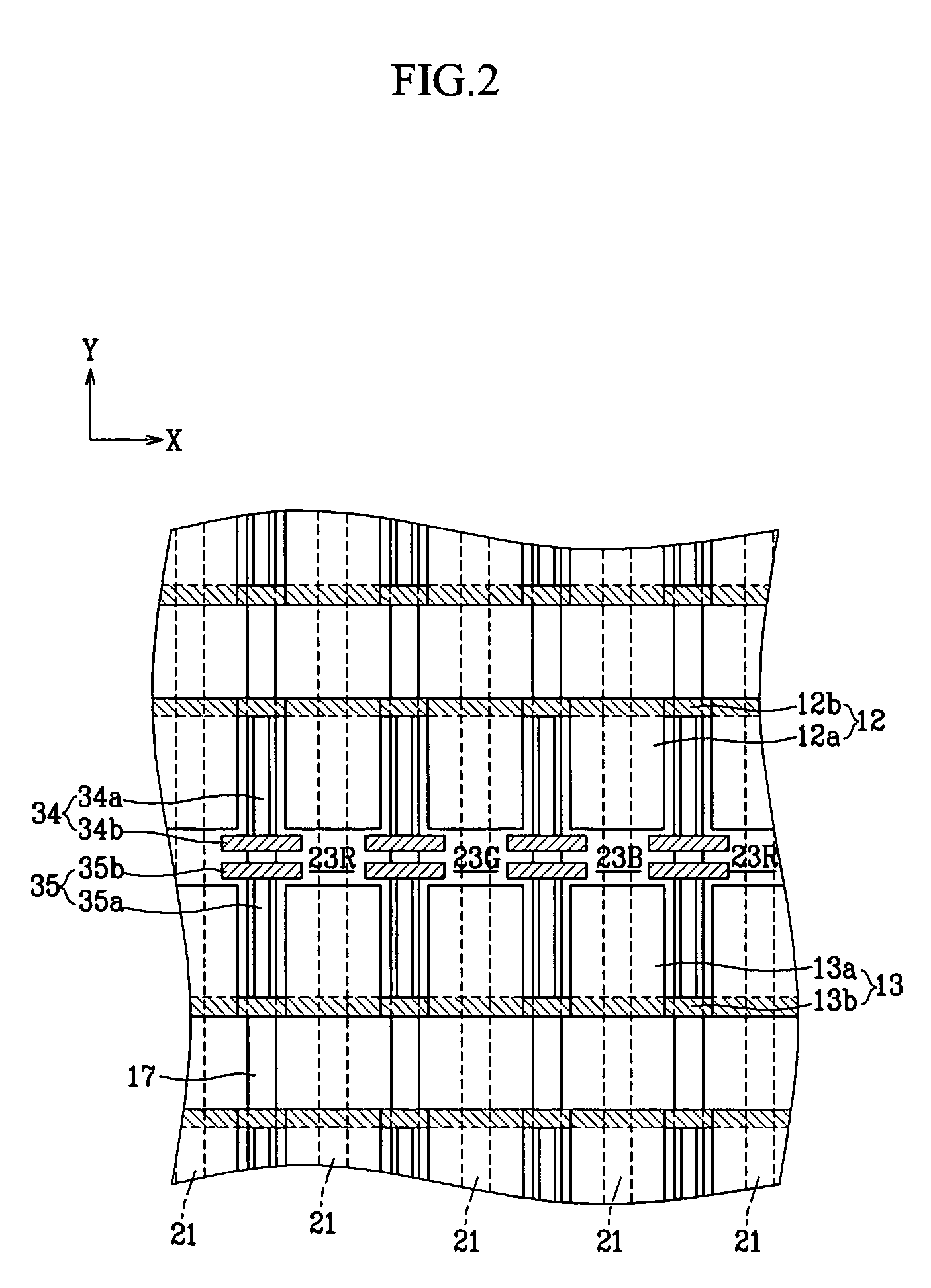

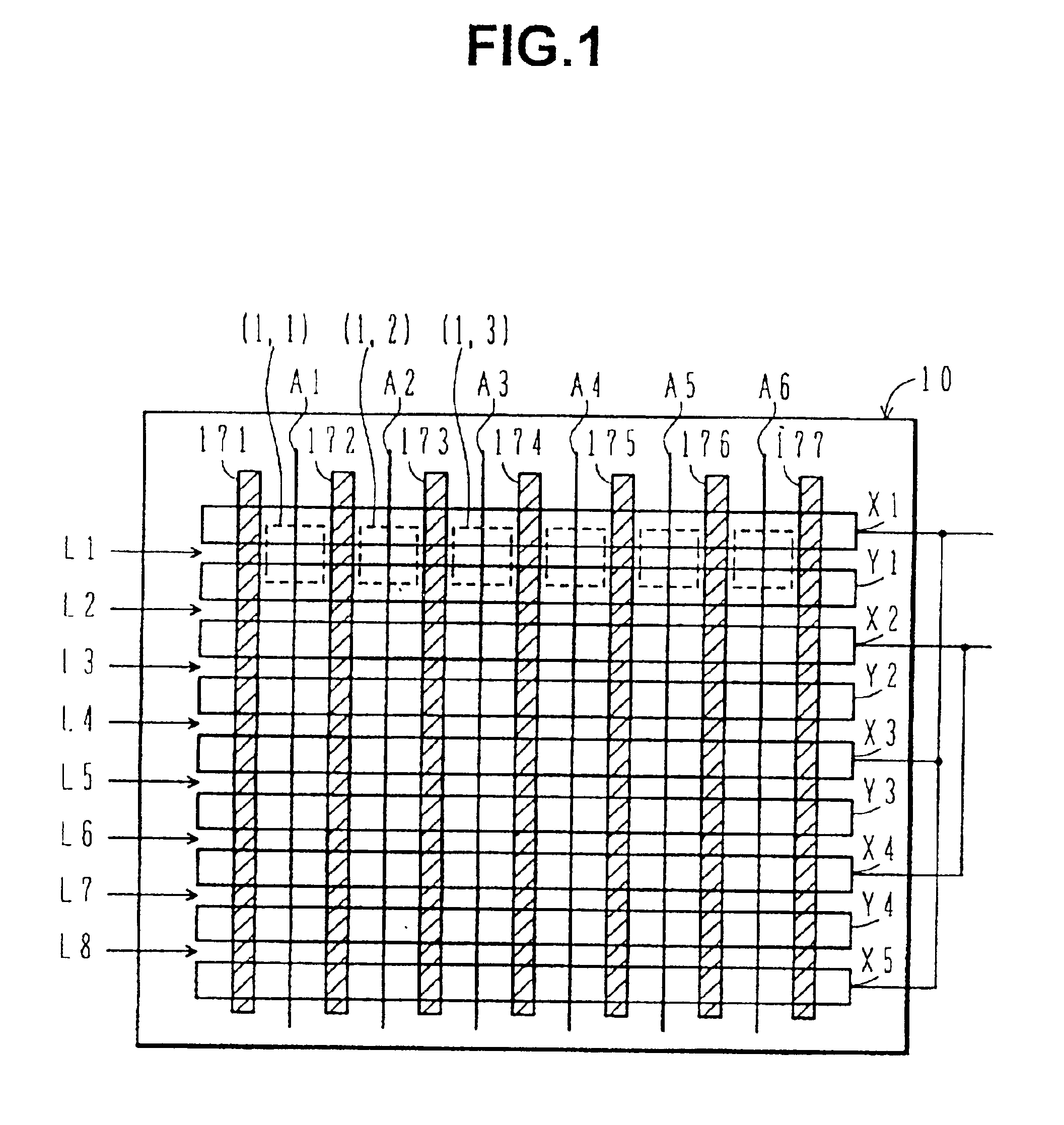

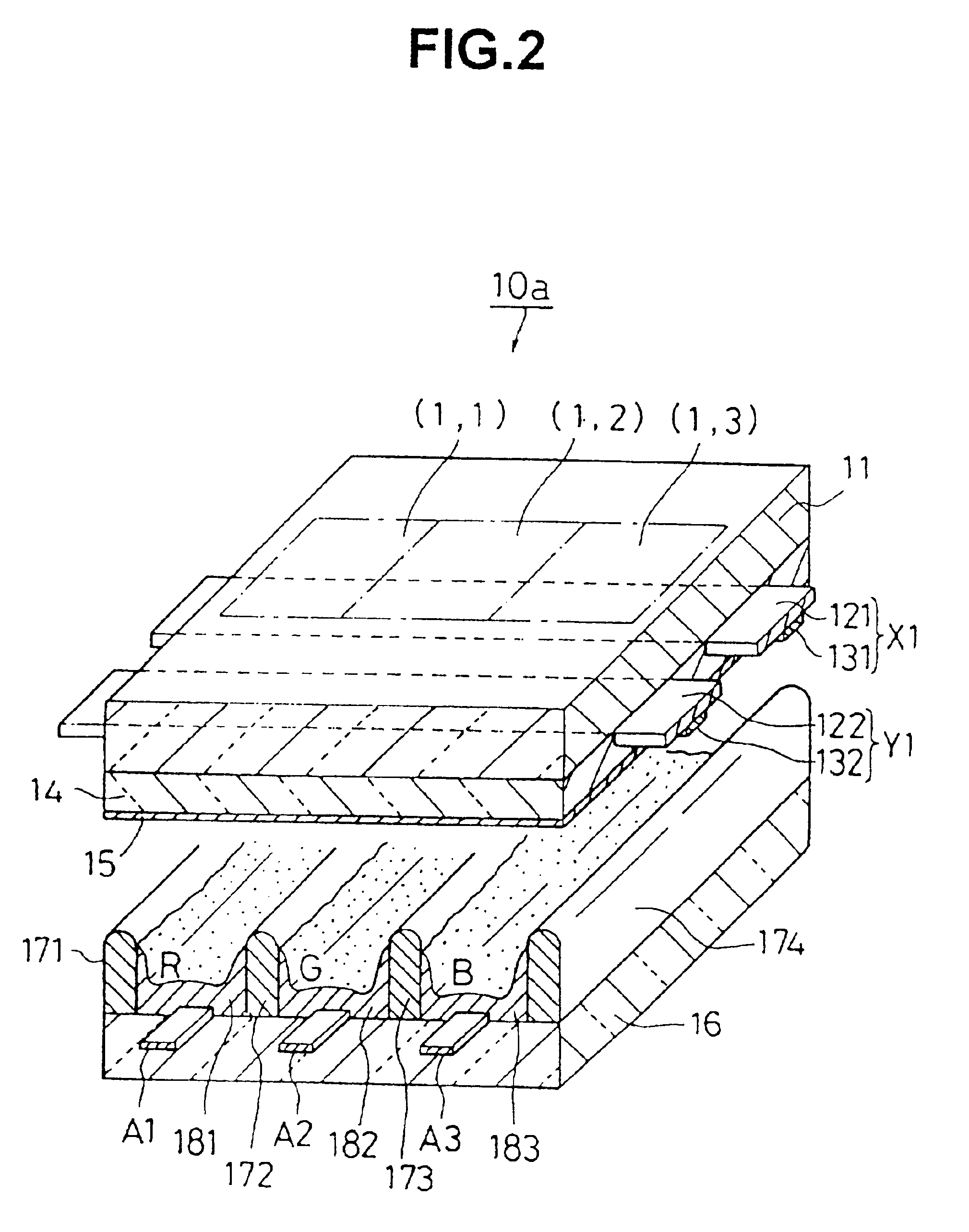

An electrode drive circuit performs interlaced scanning, ensuring that the phases of the sustaining pulse in odd-numbered lines and even-numbered lines among L1 to L8 between surface discharge electrodes are the reverse of each other. With this, when either odd-numbered lines or even-numbered lines are displayed, the voltages applied between the electrodes of the undisplayed lines are at 0, eliminating the necessity for partitioning walls on the surface discharge electrodes. In surface discharge electrodes, X electrodes are provided on the two sides of a Y electrode and the area between the Y electrode and the X electrode on one side is assigned a display line at an odd-numbered frame, and the area between the Y electrode and the X electrode on the other side is assigned a display line in an even-numbered frame. Alternate areas between the surface discharge electrodes are assigned as blind lines and a discharge light emission in the blind lines is blocked or incident light to the blind lines from the outside is absorbed. Address electrodes are provided for each monochromatic pixel column and selectively connected with the pads above them, performing simultaneous selection of lines.

Owner:MAXELL HLDG LTD

Plasma display panel

InactiveUS7365712B2Reduce the differenceExtended voltage rangeAddress electrodesLighting and heating apparatusEngineeringPlasma display

Owner:SAMSUNG SDI CO LTD

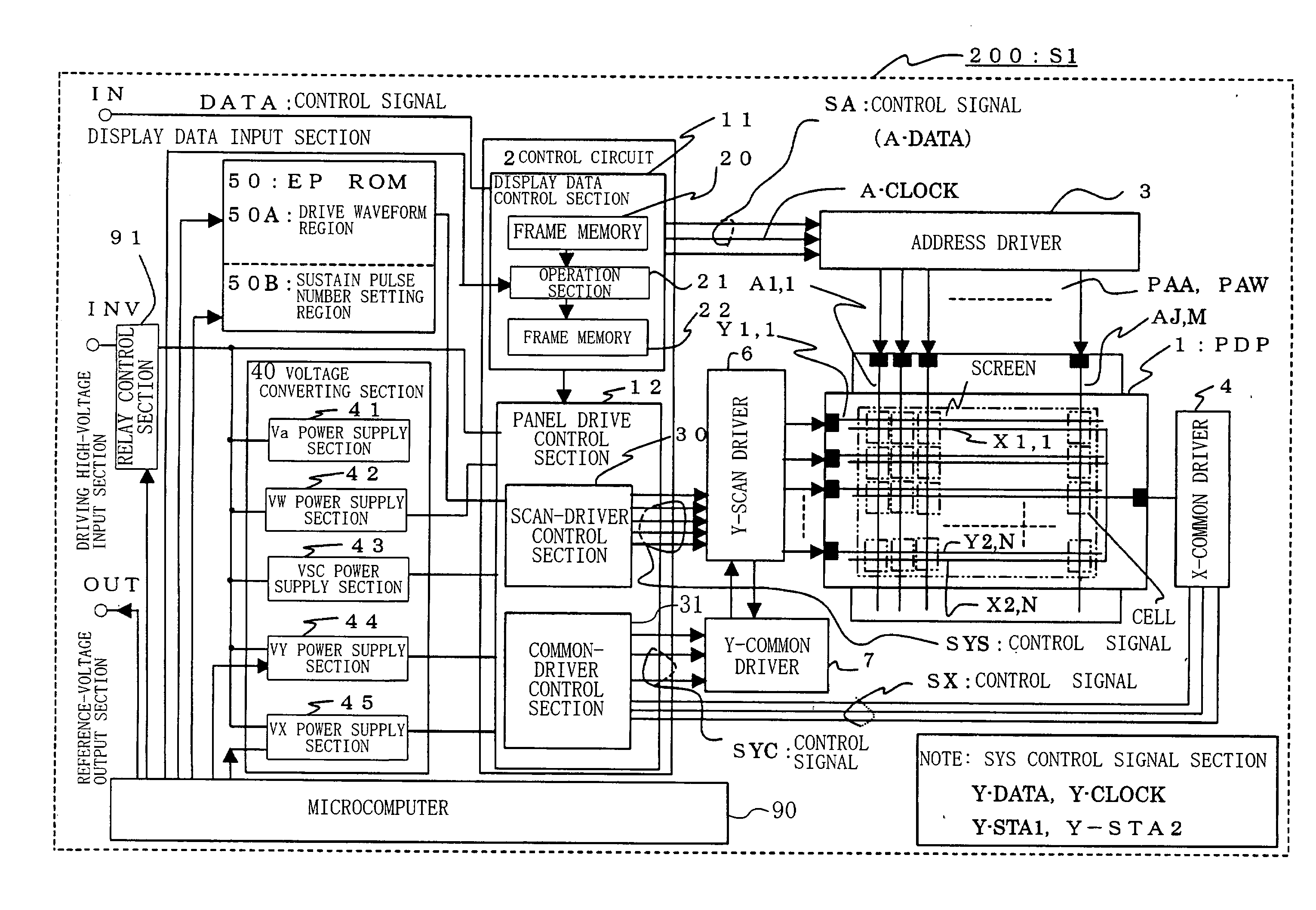

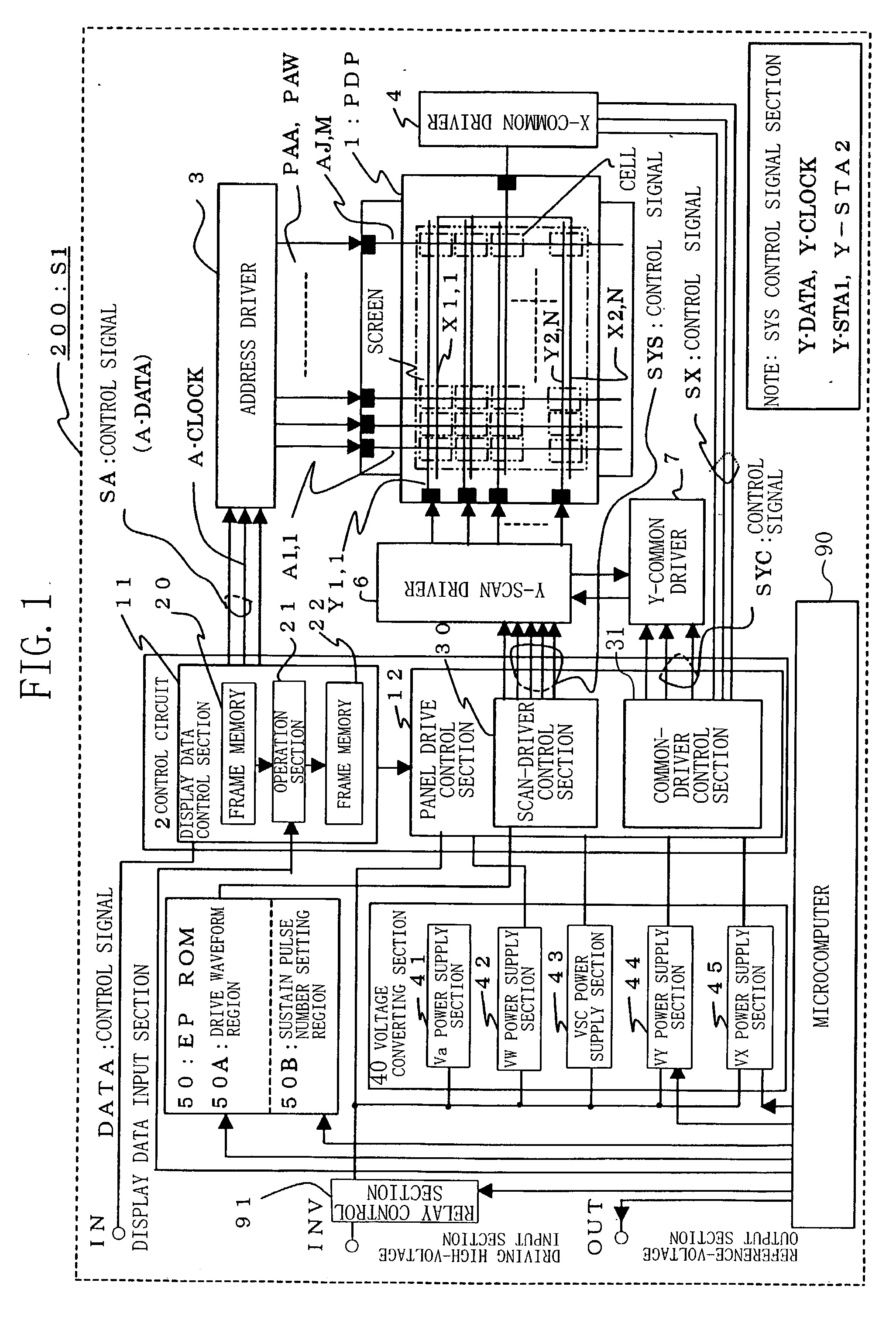

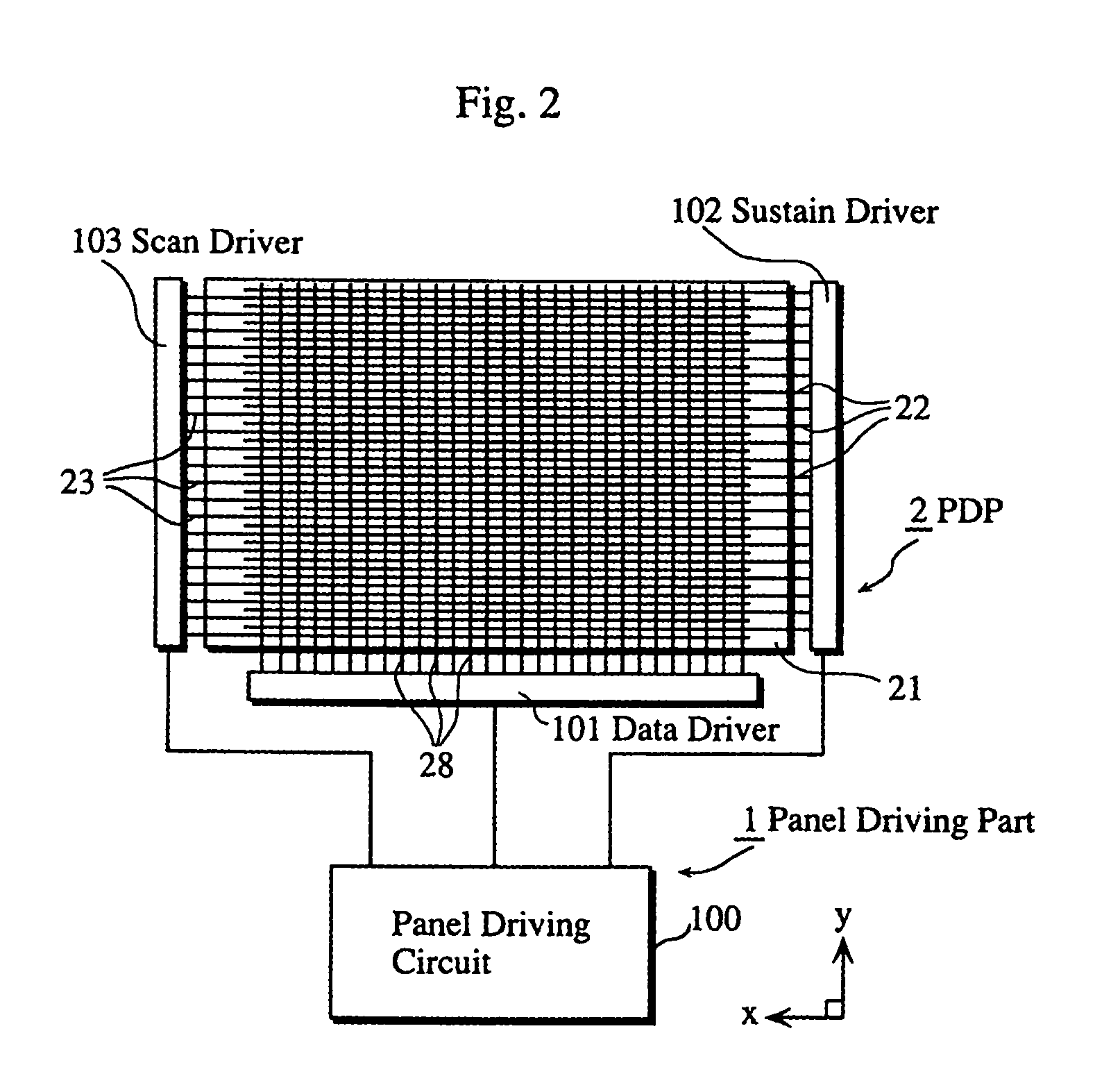

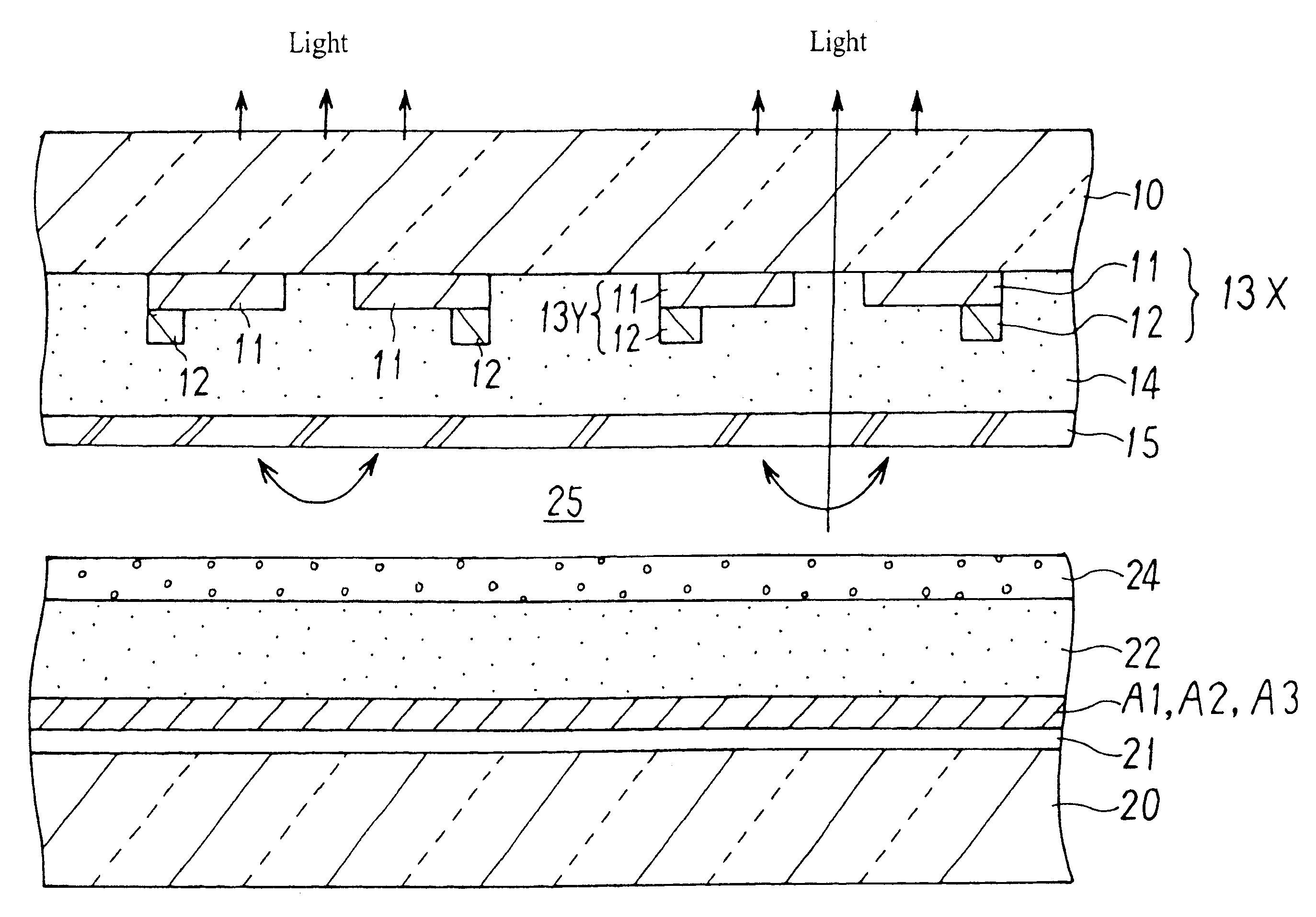

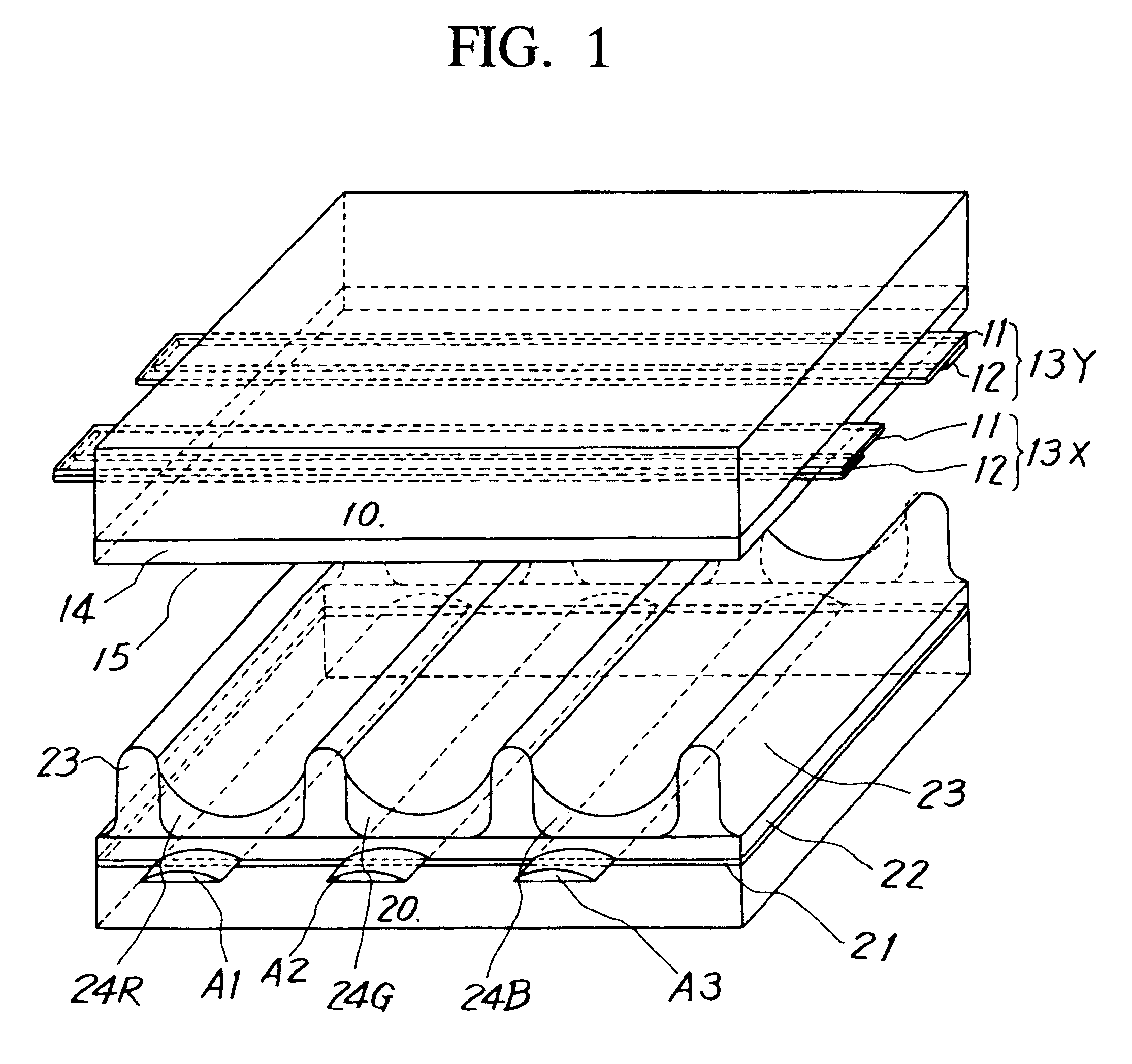

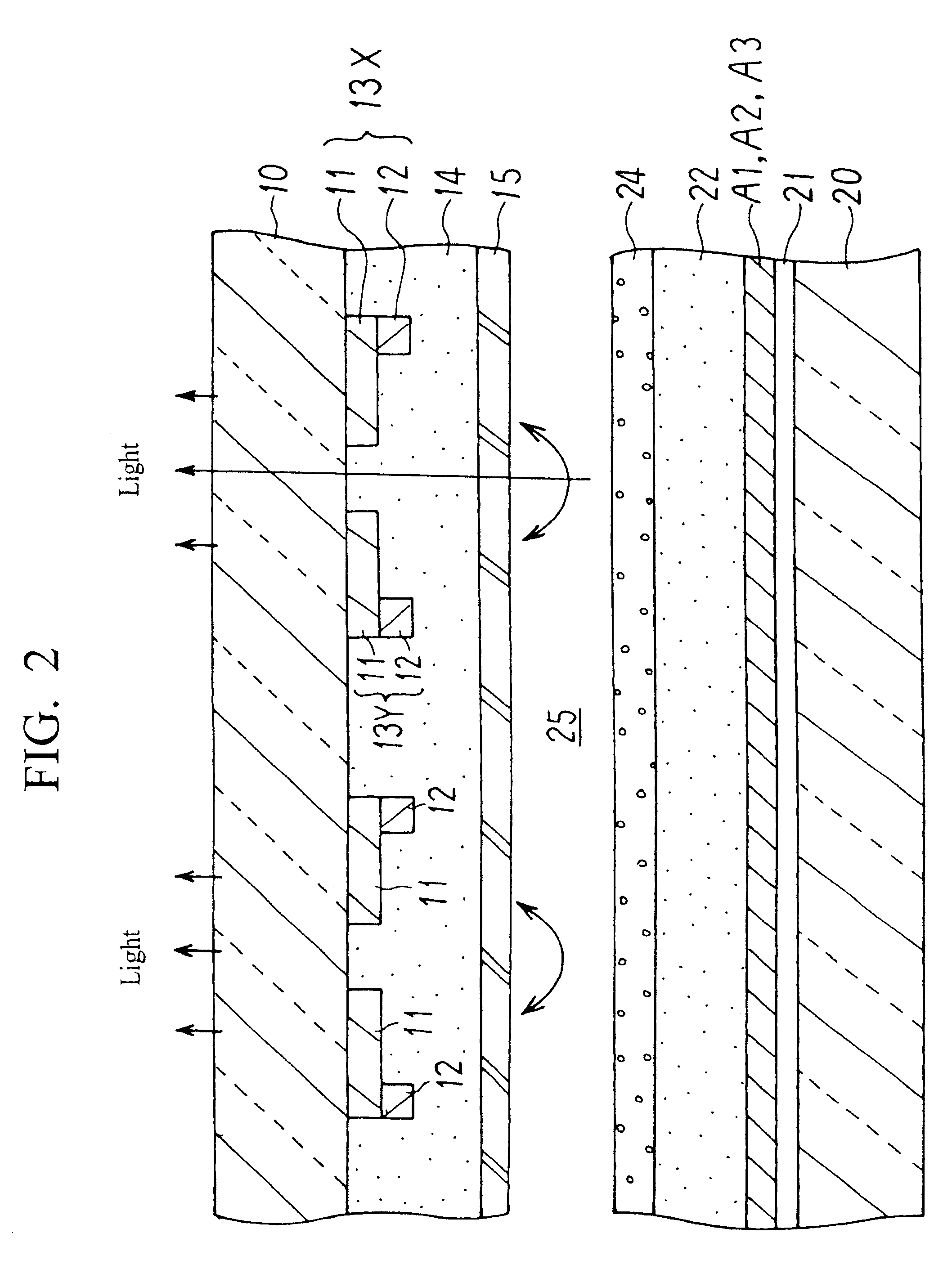

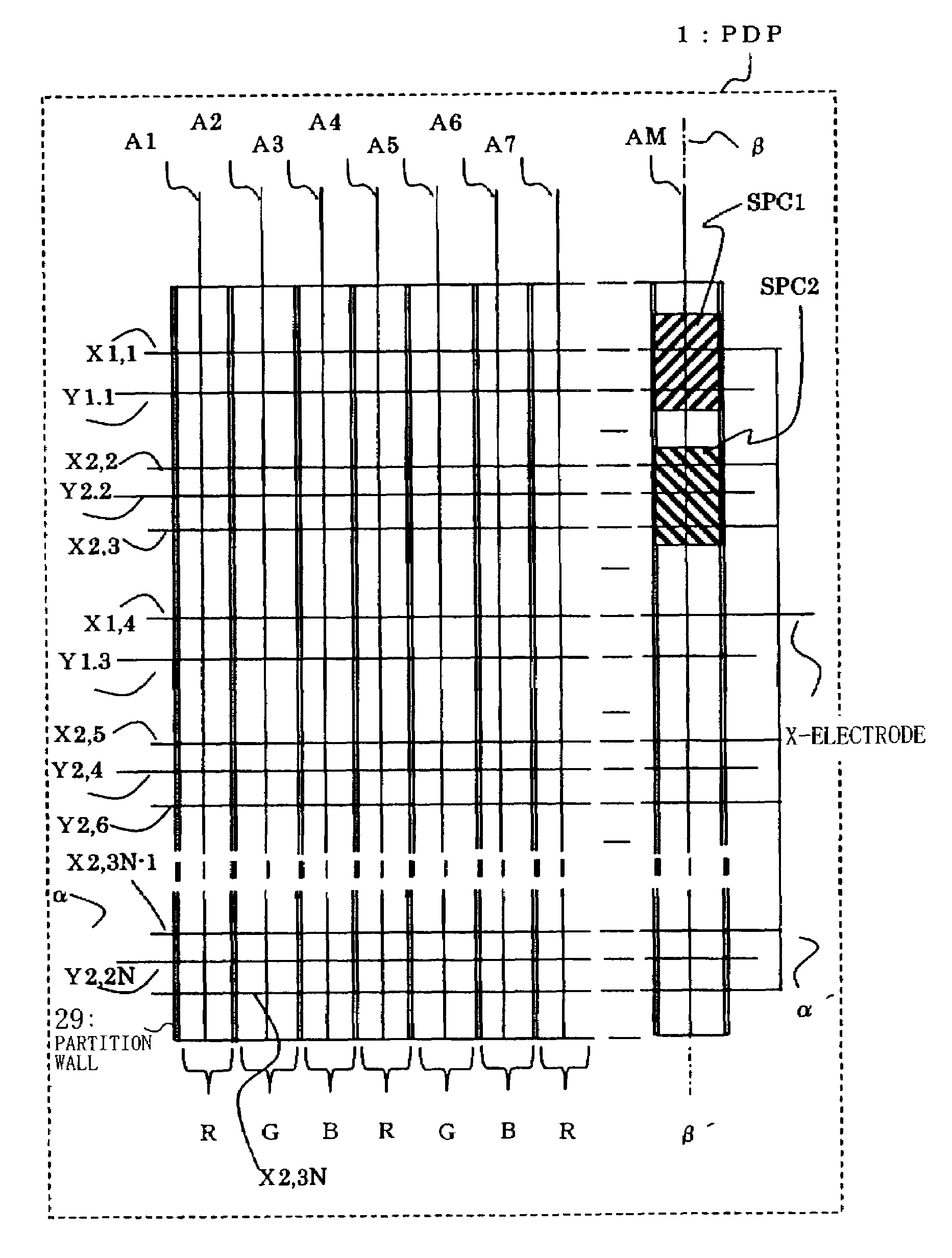

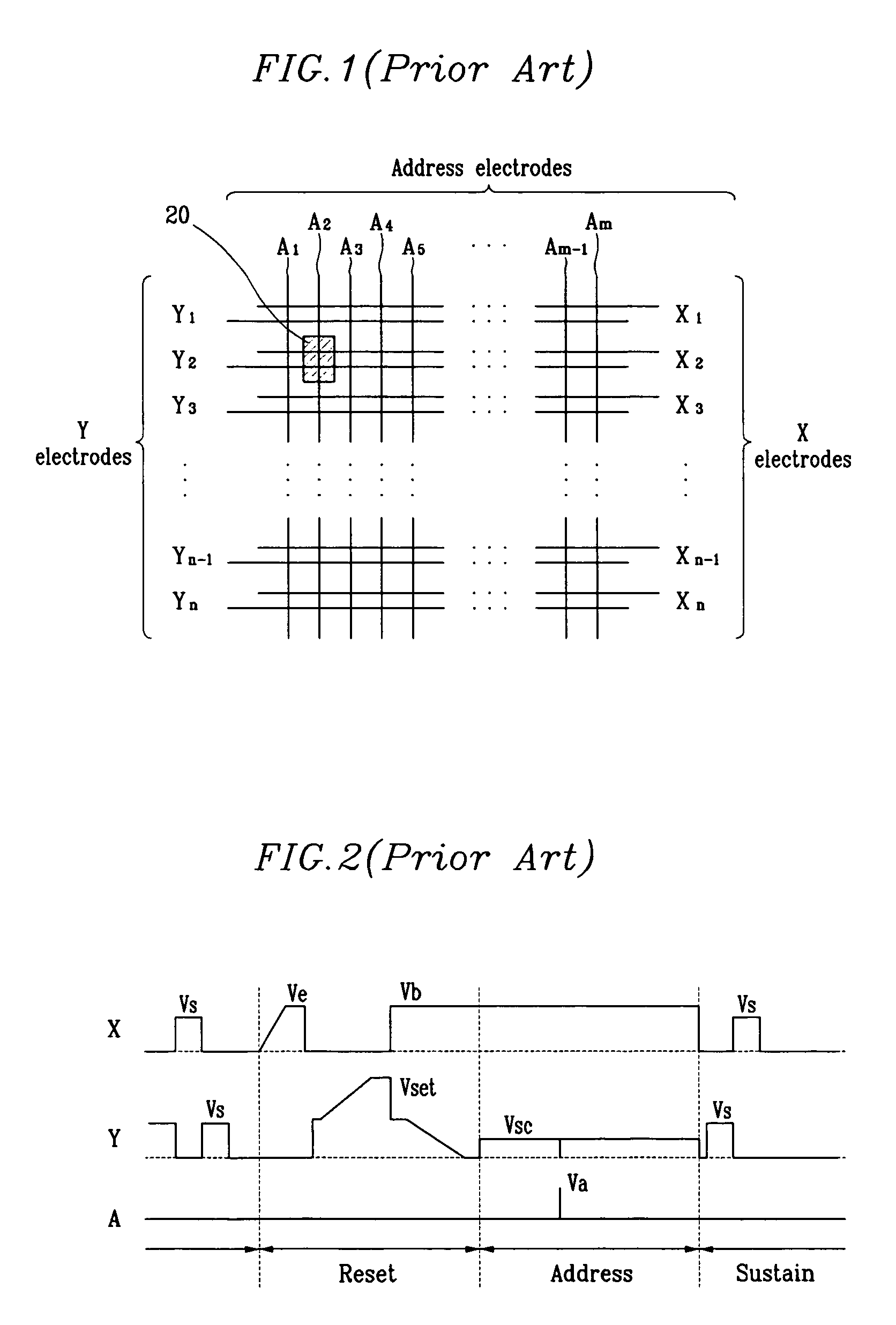

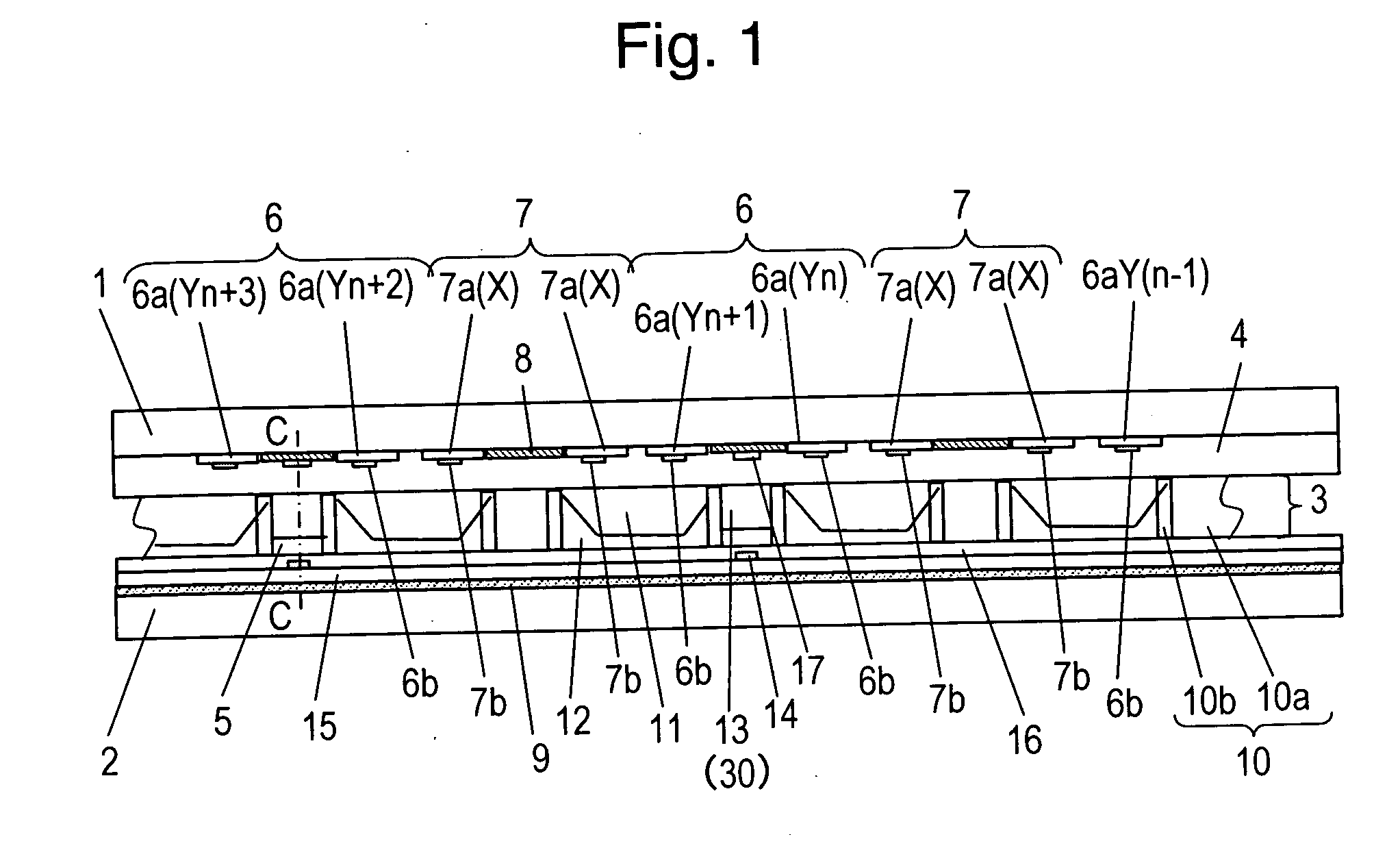

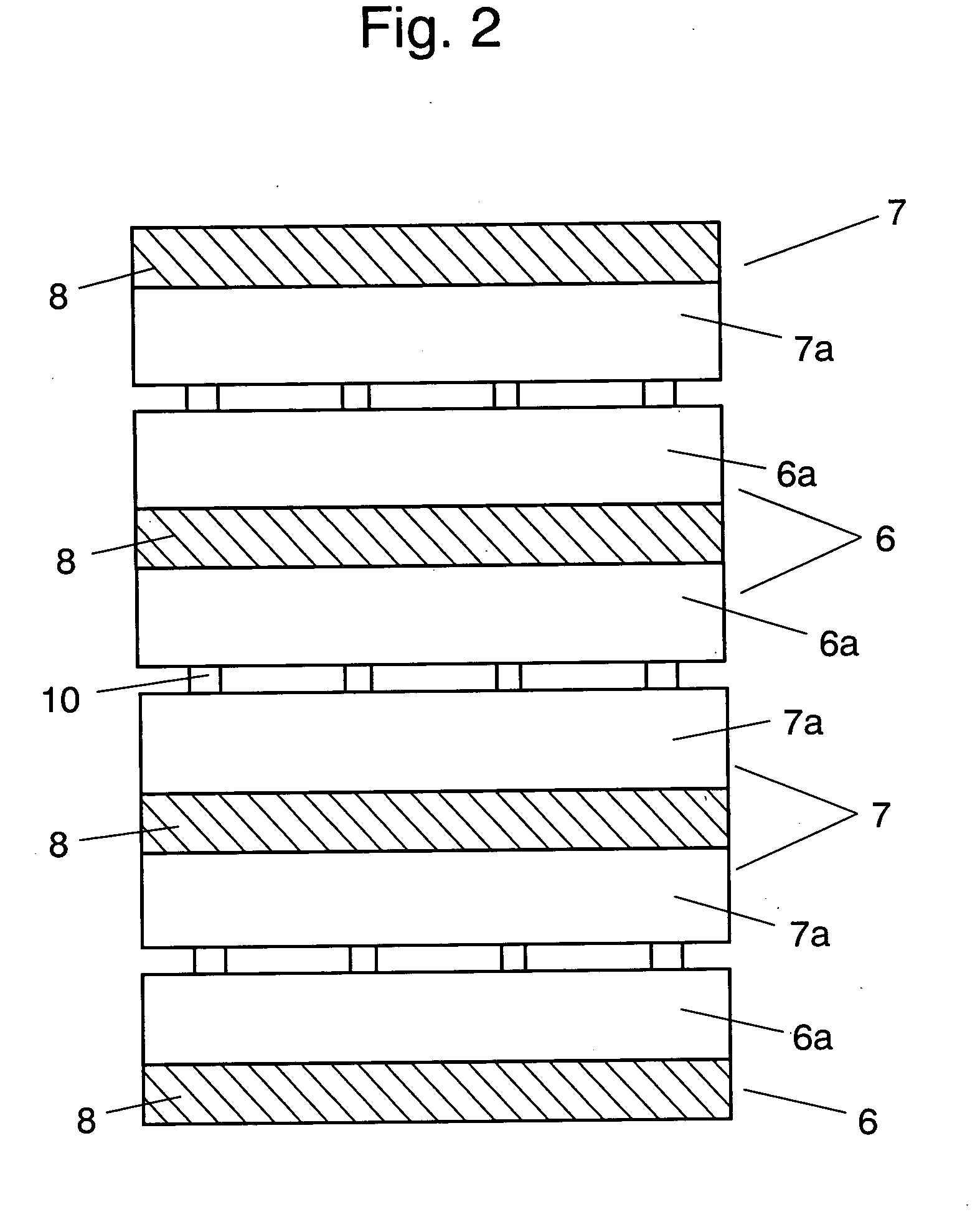

Plasma display device and driving method thereof

InactiveUS7068243B2Increase the number ofHigh definitionTelevision system detailsAddress electrodesDisplay deviceComputer science

The plasma display device has pixels each formed by a plurality of sub pixels of the same color provided in an address-electrode direction, and provides gray-scale display by controlling the number of sub pixels to be turned ON. A plurality of address electrodes are provided for each sub pixels. Each sub pixel is addressed by a conductive layer which is electrically connected to one of the plurality of address electrodes.

Owner:SHARP KK

Plasma display panel and method of driving the same

InactiveUS20050128166A1Shorten the overall cycleReduction ratio of generationAddress electrodesSustain/scan electrodesEngineeringPlasma display

A plasma display panel includes (a) first and second substrates facing each other, (b) a plurality of first electrodes formed on the first substrate and extending in parallel with one another, (c) a plurality of second electrodes formed on the second substrate and extending in parallel with one another perpendicularly to the first electrodes, and (d) a plurality of display cells arranged at intersections of the first electrodes with the second electrodes, wherein a first selection pulse is input into the first electrodes and a second selection pulse is input selectively into one or more of the second electrodes to thereby control whether light is to be emitted in each of the display cells, and at least one of the display cells has a third electrode formed on the first substrate and being electrically connected to a first electrode other than a first electrode belonging to a display cell to which the third electrode belongs.

Owner:PANASONIC CORP

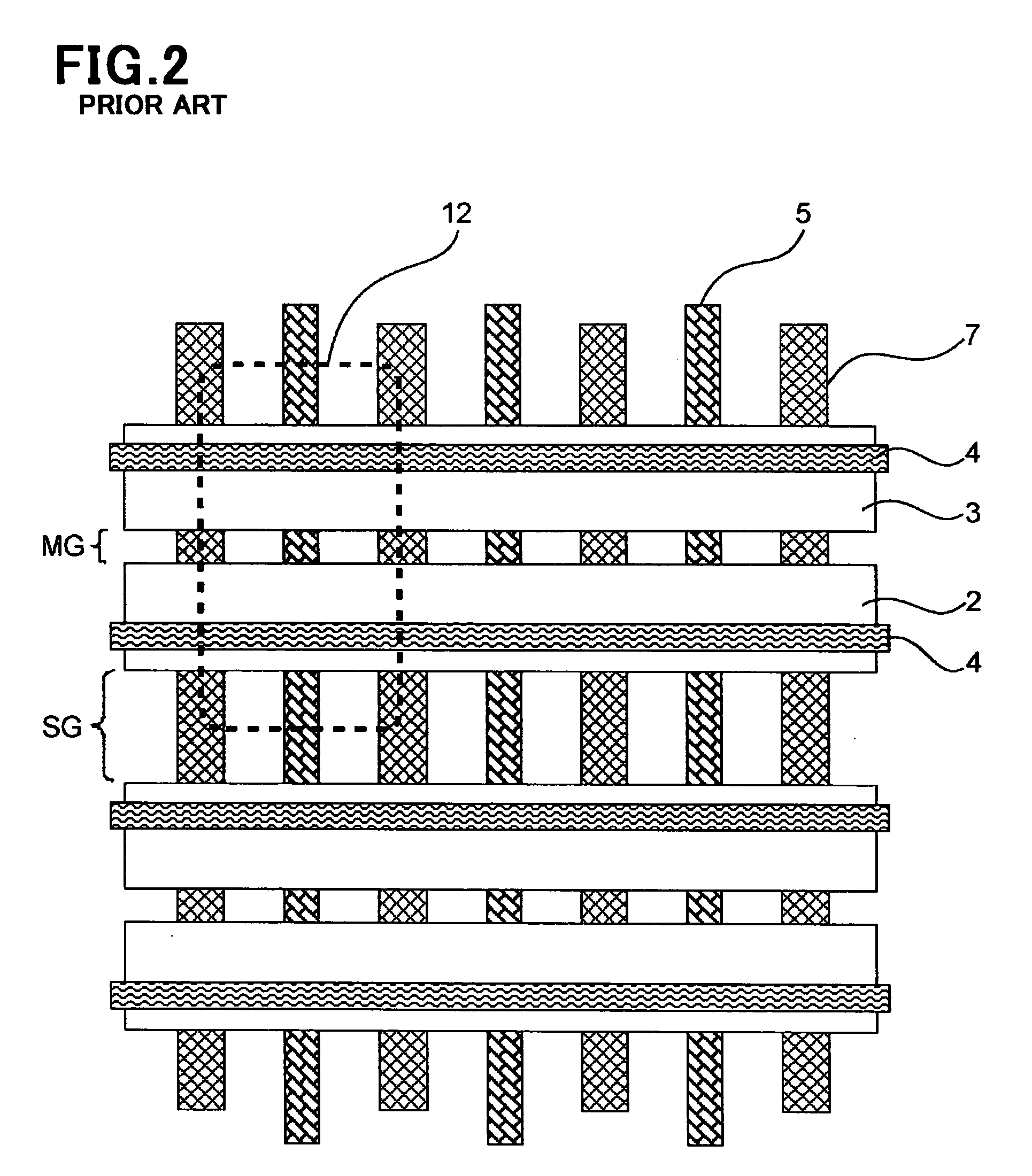

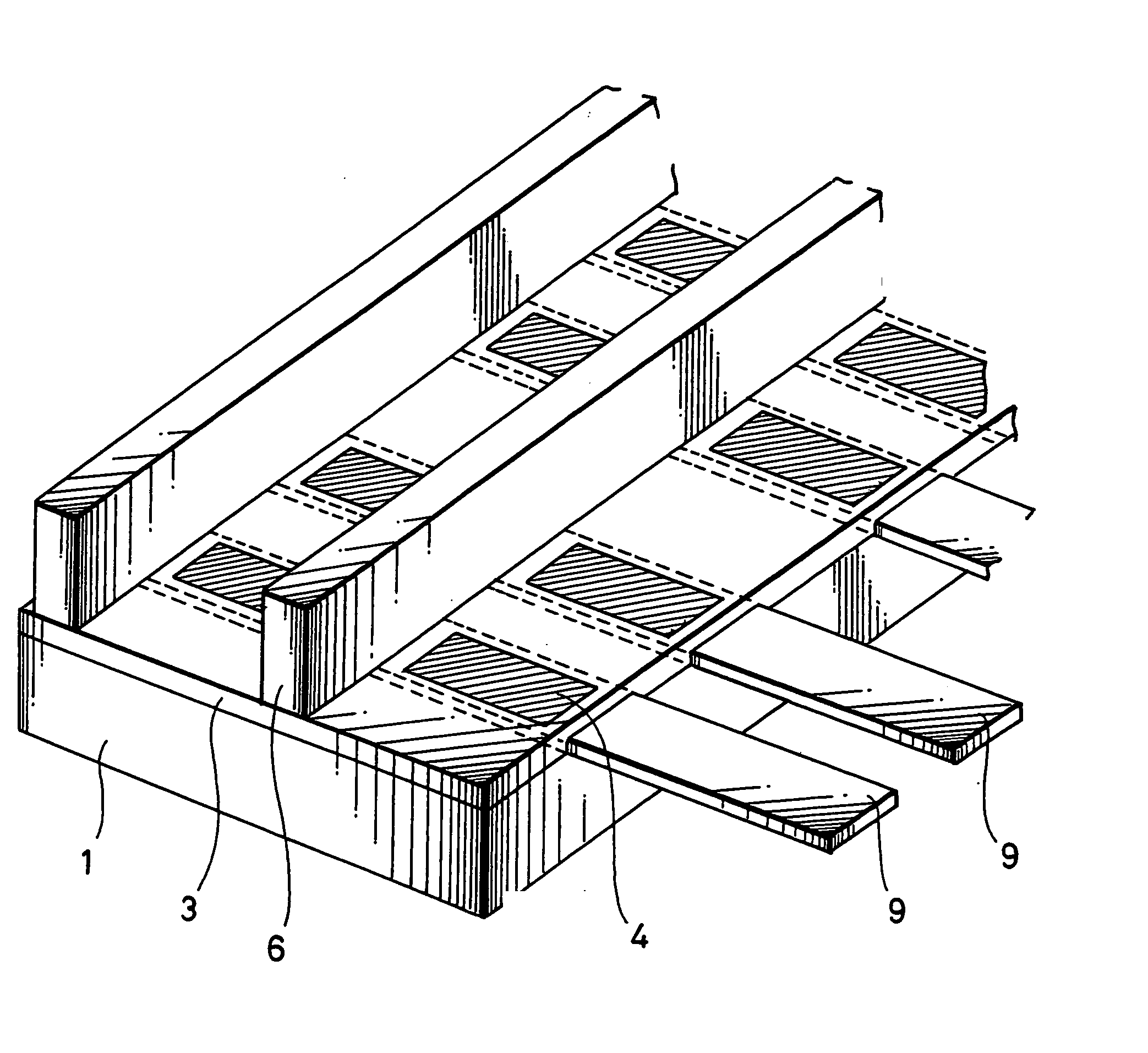

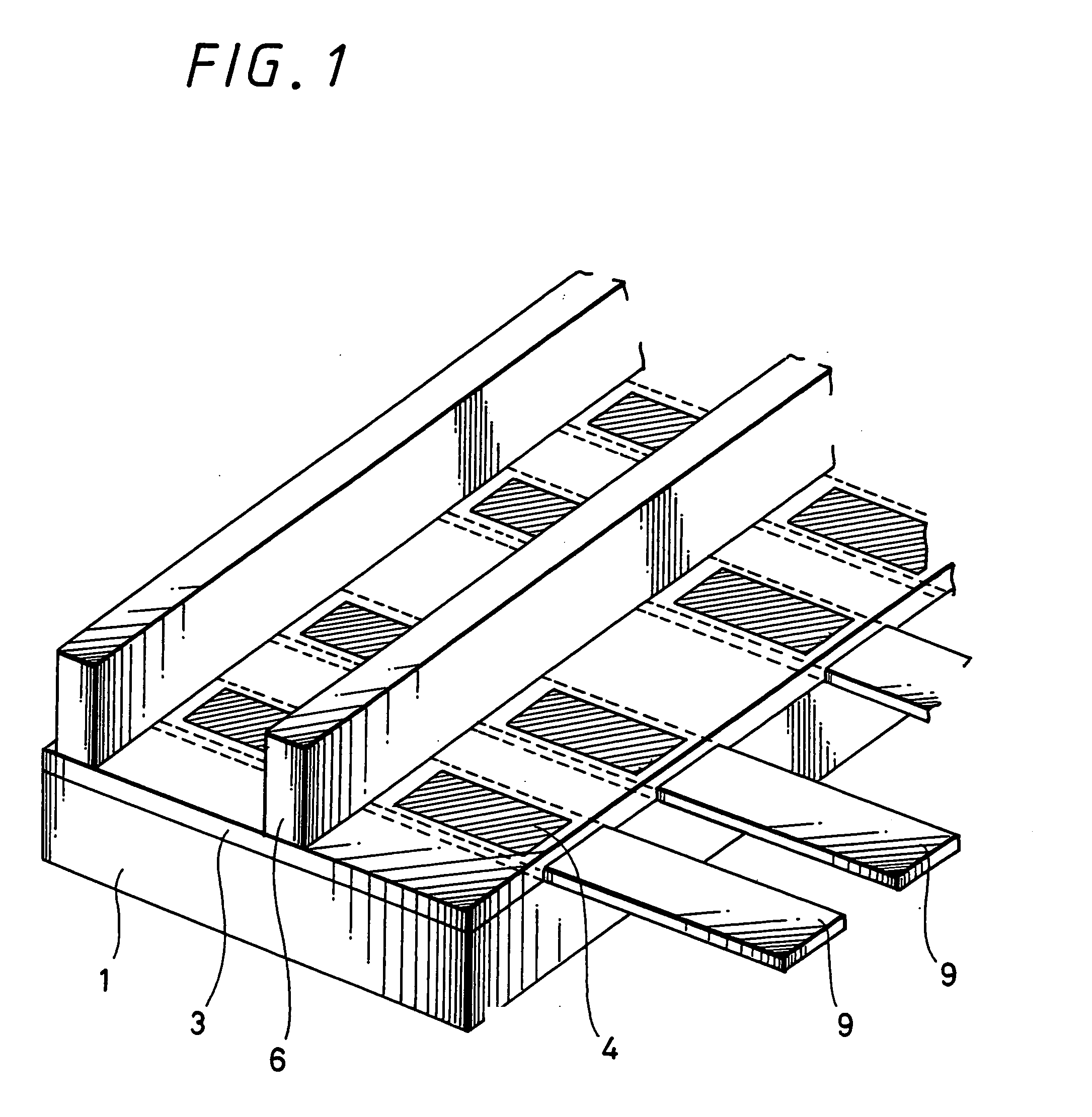

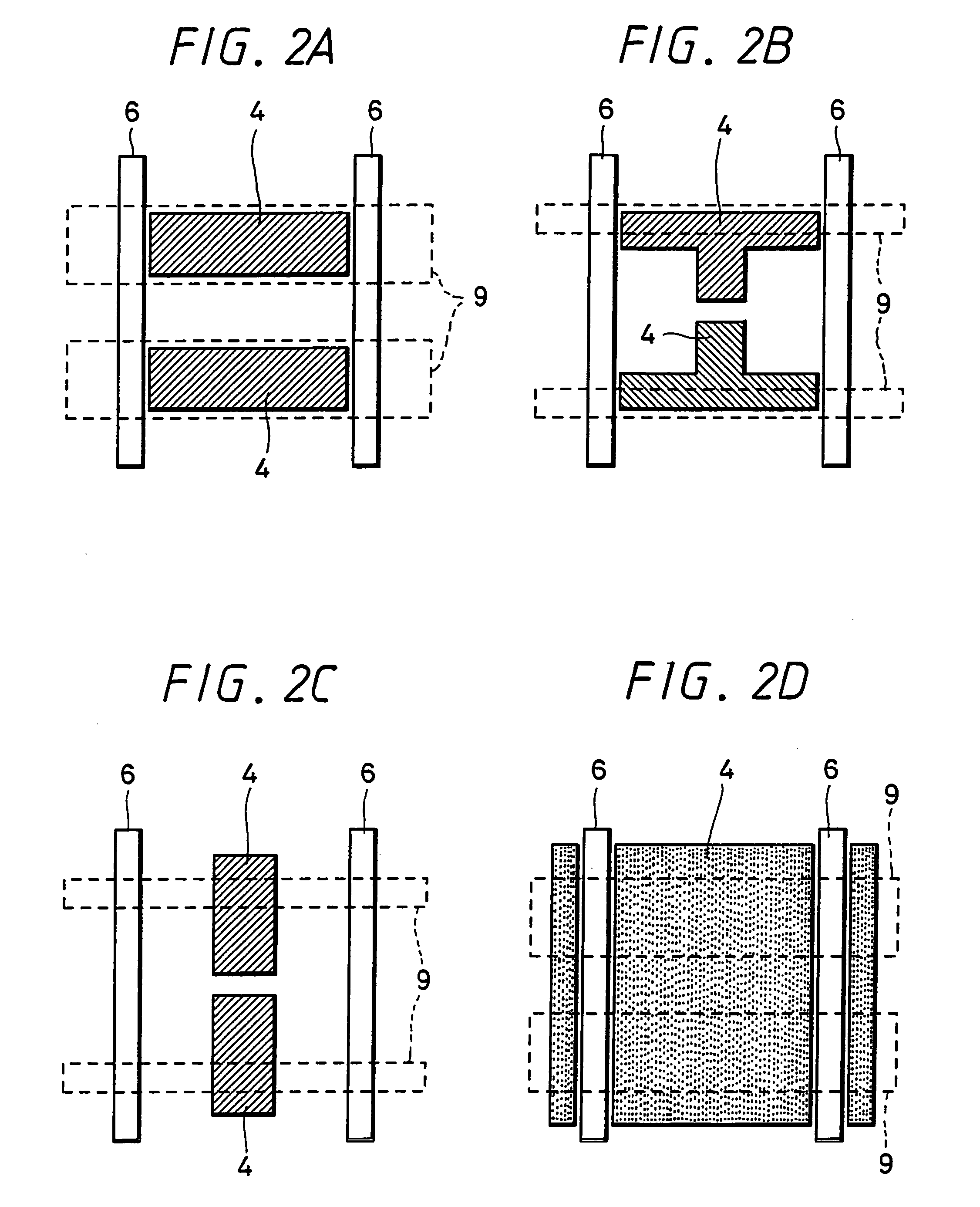

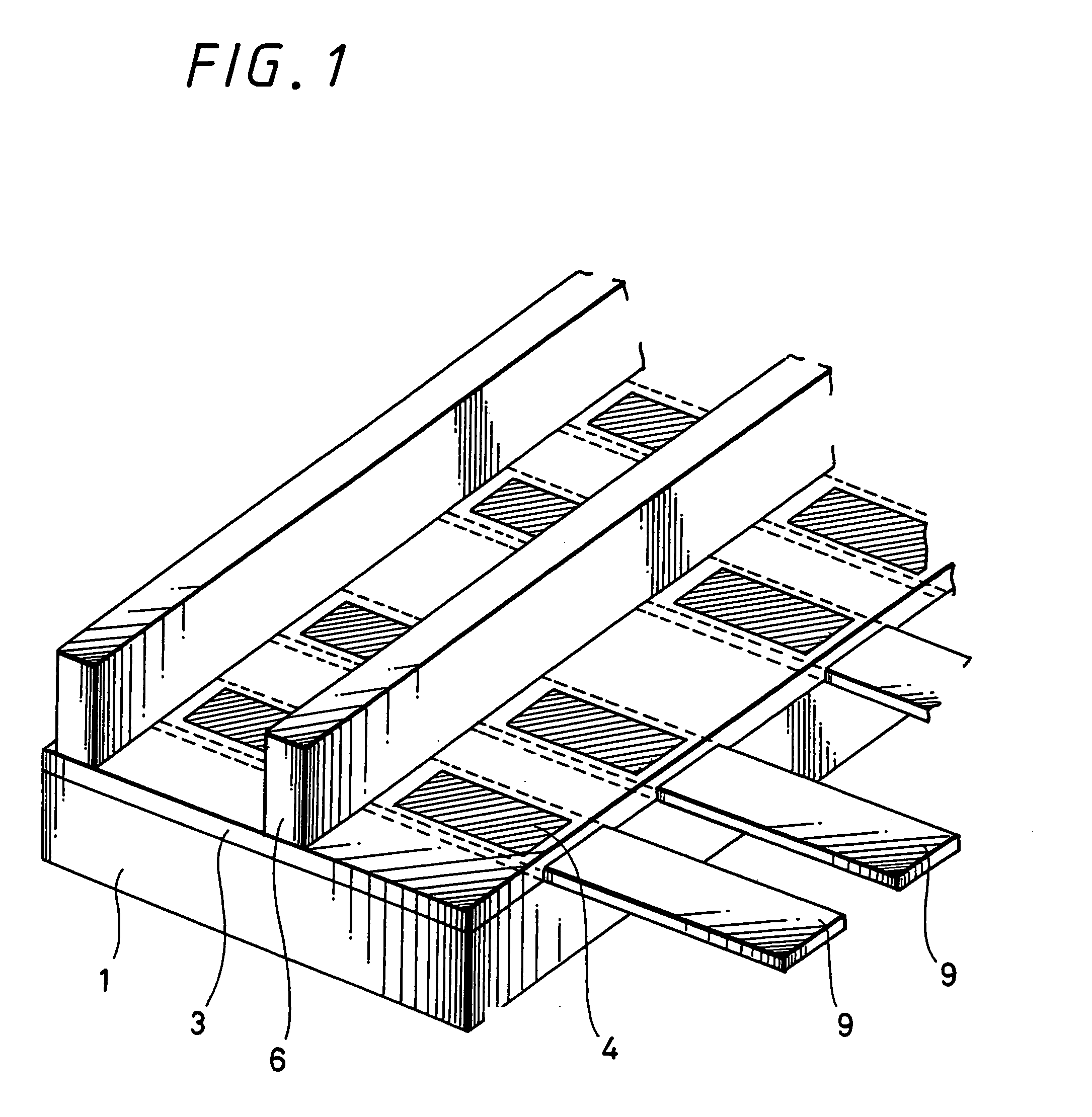

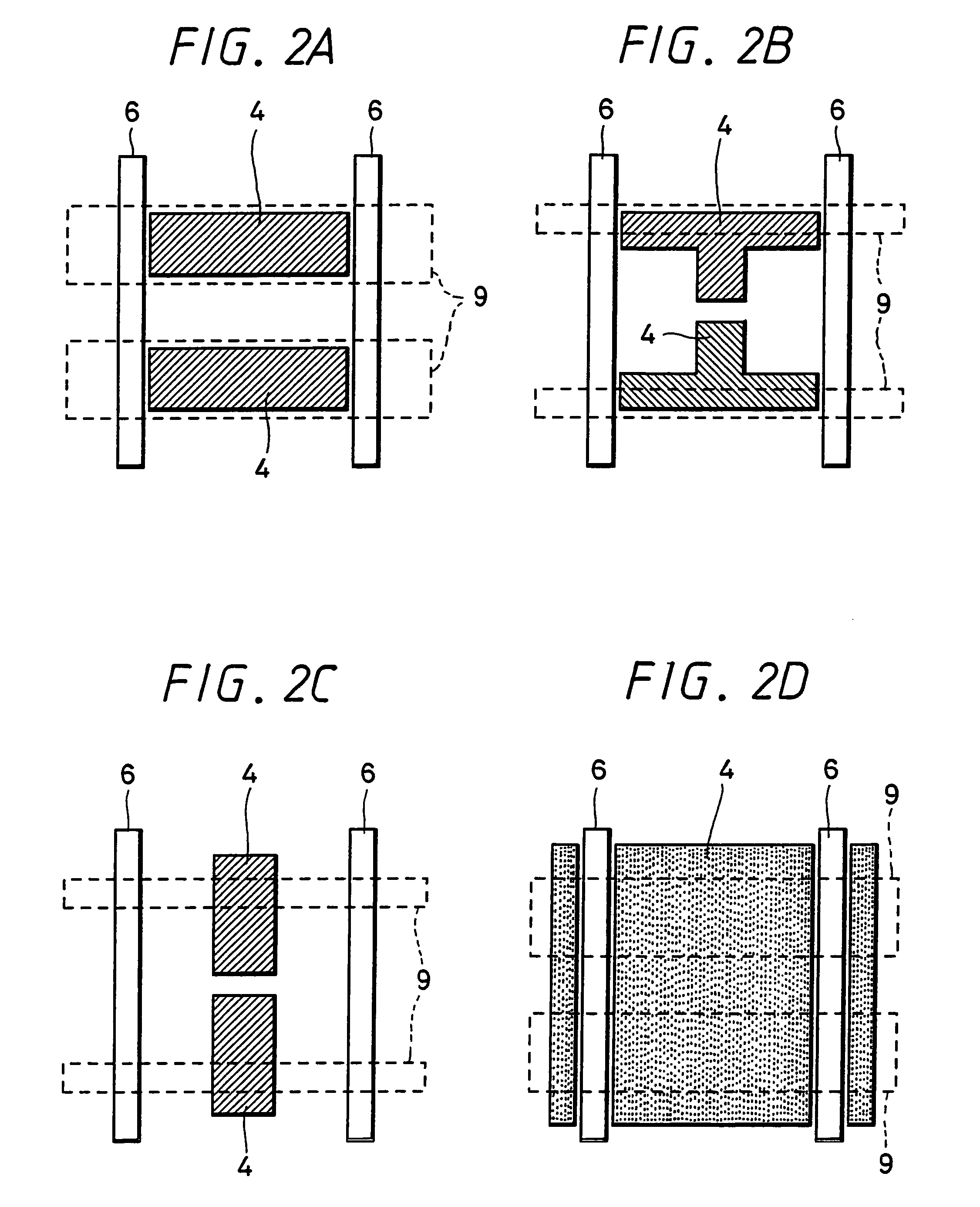

Structure of ac type pdp

InactiveUS20050127838A1Well formedEasy to processAddress electrodesSustain/scan electrodesConductive materialsSecondary electrons

Almost only choice by a secondary electron emission layer / protection layer covering the dielectric layer of an AC type PDP has been magnesium oxide (MgO) that is unstable during the production process and difficult to form, thus posing a serious production problem. An AC type PDP constructed such that, instead of covering the surface of a dielectric layer (3) with a dielectric material such as MgO, an insular electrode (4) is made by forming a conductive material such as nickel, aluminum, magnesium and lanthanum hexaboride into an insular shape, and the insular electrode (4) is allowed to capacity-couple with a lower-layer bus electrode (9) by means of an electrostatic capacity formed by a dielectric layer (3) to operate the insular electrode (4) as a sustained electrode.

Owner:TECHNOLOGY TRADE AND TRANSFER CORP

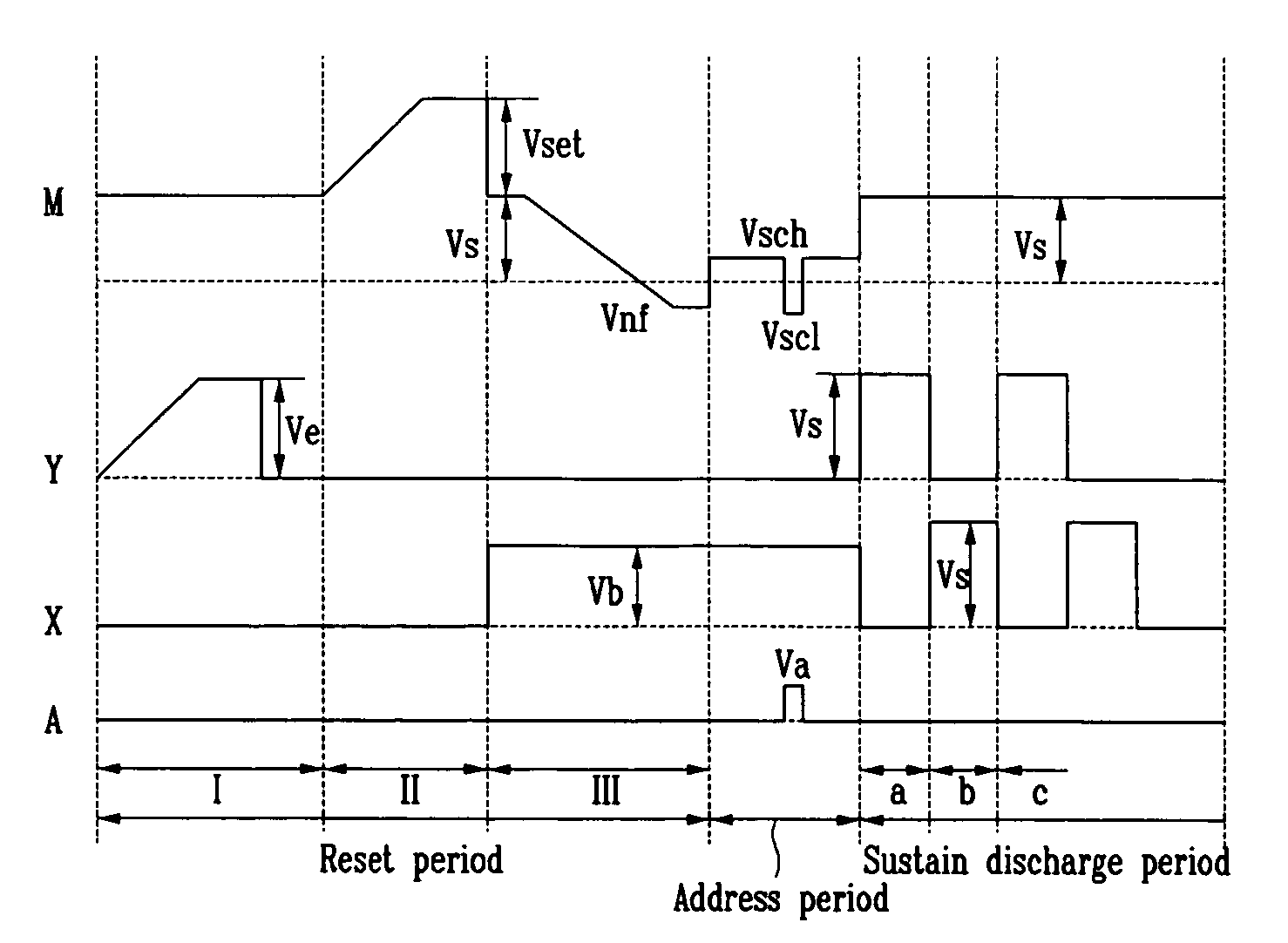

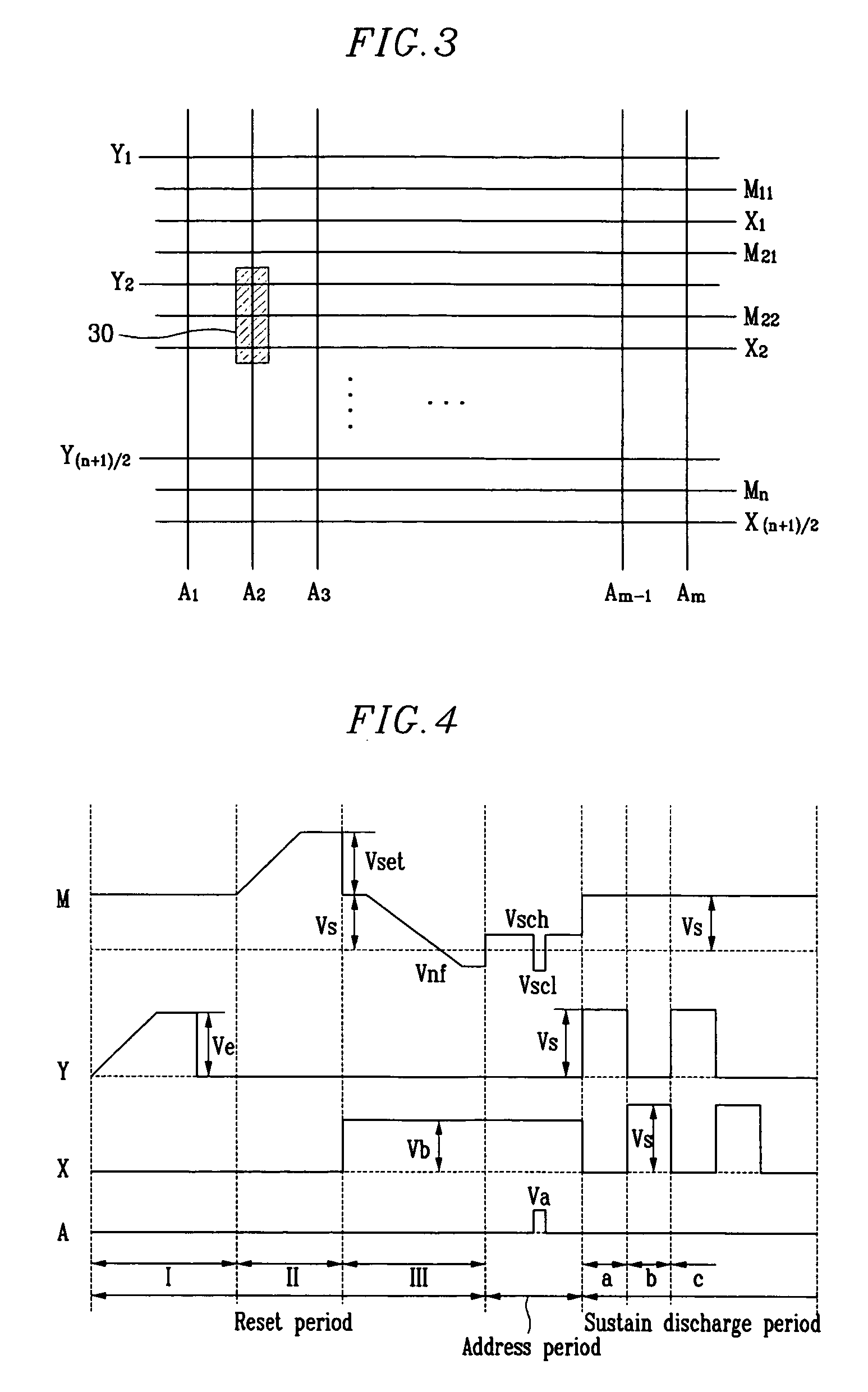

Plasma display device and driving method thereof

In a plasma display device and driving method thereof, middle electrodes are formed between X electrodes for receiving a sustain pulse voltage and Y electrodes. A reset waveform and a scan pulse voltage are applied to the middle electrodes. A short-gap discharge is performed between the X electrode and the middle electrode in the earlier stage of a sustain discharge period, and a long-gap discharge is normally performed between the X electrode and the Y electrode after the earlier stage of the sustain discharge period, thereby performing stable discharge. Further, the number of switches of the M electrode driver may be reduced by floating the M electrode and applying a rising ramp waveform to the Y electrode in the reset period, thereby increasing the voltage at the M electrode.

Owner:SAMSUNG SDI CO LTD

Plasma display panel

Provided is a plasma display panel. The plasma display panel comprises: a front substrate; a rear substrate opposing the front substrate; a plurality of discharge electrodes disposed inside the substrates; a plurality of light emitting layers formed inside discharge cells; and an electron emitting source disposed inside the discharge cells so as to supply electrons, the area of electron emitting source differing in each of the discharge cells. The electron emitting source is installed in the discharge cells such that an electron emission characteristic is improved and brightness and luminous efficiency of the plasma display panel can be improved. The area of the electron emitting source or the number of electron emitting sources in each of the discharge cells differs such that a discharge characteristic in the discharge cells having lower brightness can be improved.

Owner:SAMSUNG SDI CO LTD

Plasma display panel having igniter electrodes

InactiveUS20050029946A1Reduce discharge voltageSmooth rideSustain/scan electrodesAuxillary electrodesEngineeringPlasma display

A plasma display panel, and particularly to a surface-discharge plasma display panel that may have an electrode structure in which a pair of discharge sustain electrodes may be arranged at respective discharge cells between two substrates to make the display discharge. The plasma display panel may include igniter electrodes formed over barrier ribs extending from discharge sustain electrodes along the barrier ribs, and protruding toward the inside of discharge cells at their ends.

Owner:SAMSUNG SDI CO LTD

Method of driving plasma display panel by applying discharge sustaining pulses

InactiveUS6965359B2High quality imagingHigh definitionStatic indicating devicesAuxillary electrodesPlasma displayPhysics

Method for driving a plasma display panel. At least one first discharge sustaining pulse is applied to a first pair of display electrodes, and at least one second discharge sustaining pulse applied to an adjacent pair of display electrodes. The first and second discharge sustaining pulses are applied such that they are in the same phase as one another and / or such that a current in the first pair of display electrodes flows in the opposite direction from a current in the adjacent pair of display electrodes.

Owner:HITACHI PLASMA PATENT LICENSING

Plasma display panel

InactiveUS20050099125A1Reduce discharge delayImprove the exhaust effectAddress electrodesIncadescent body mountings/supportEngineeringPlasma display

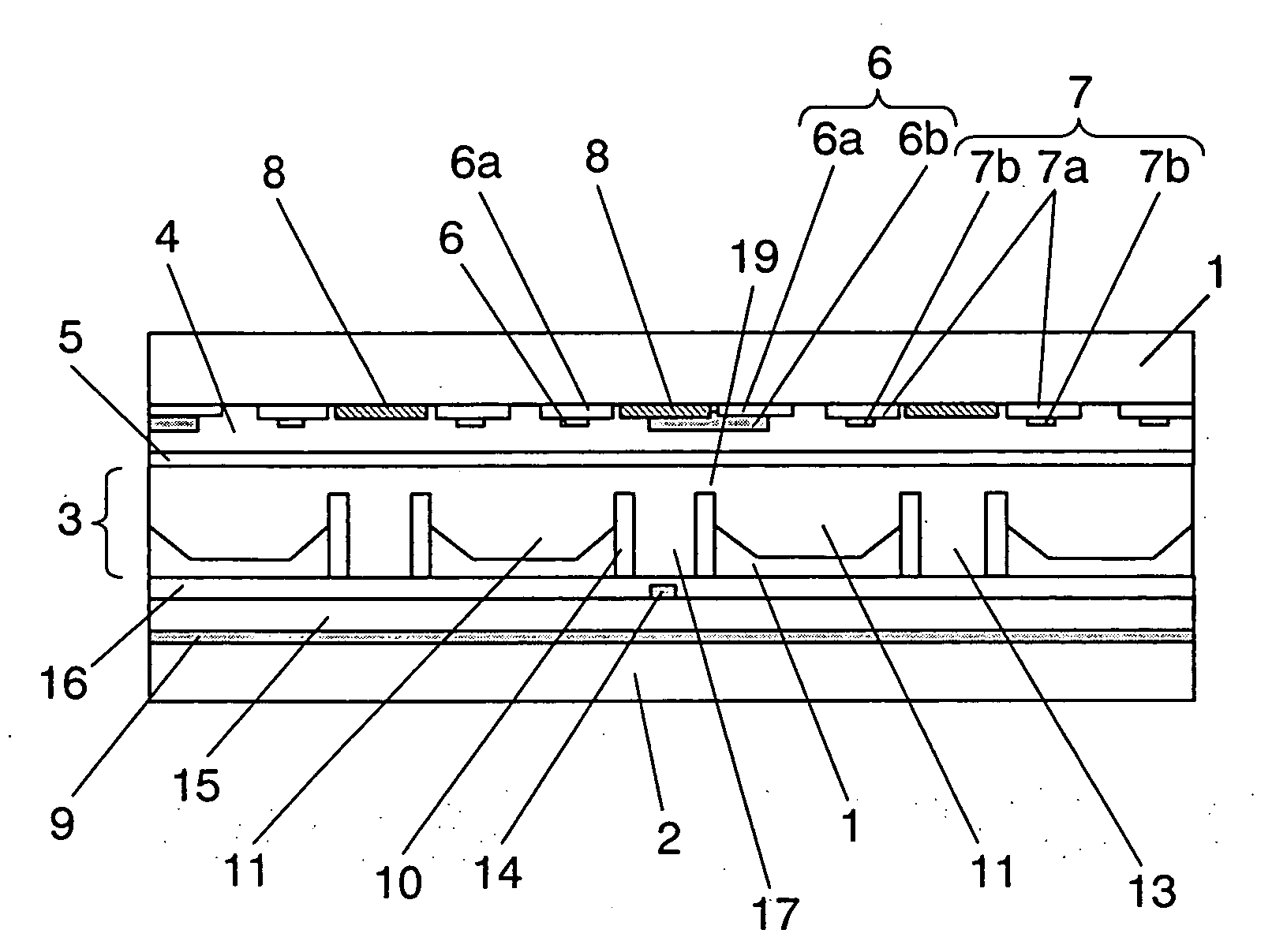

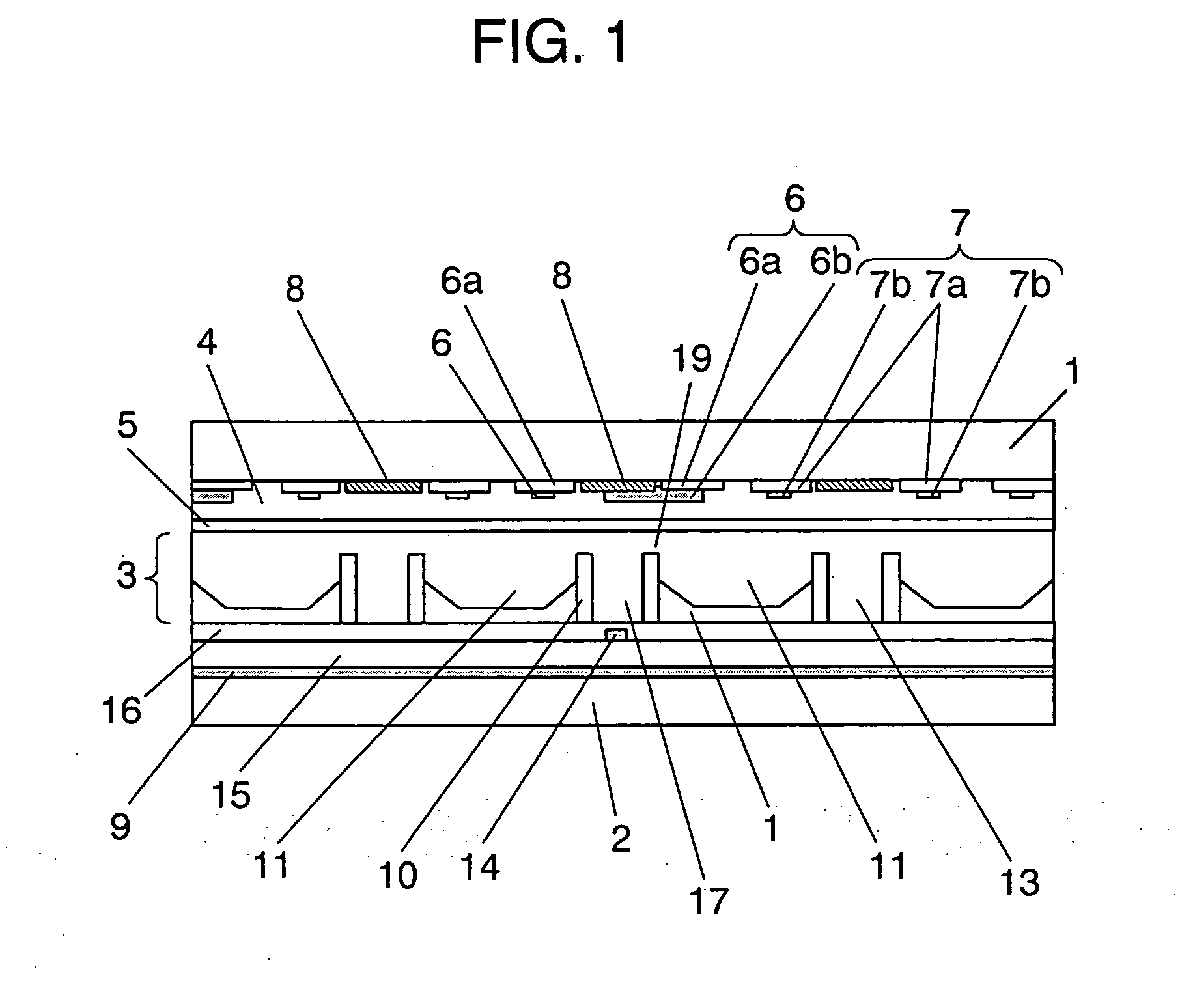

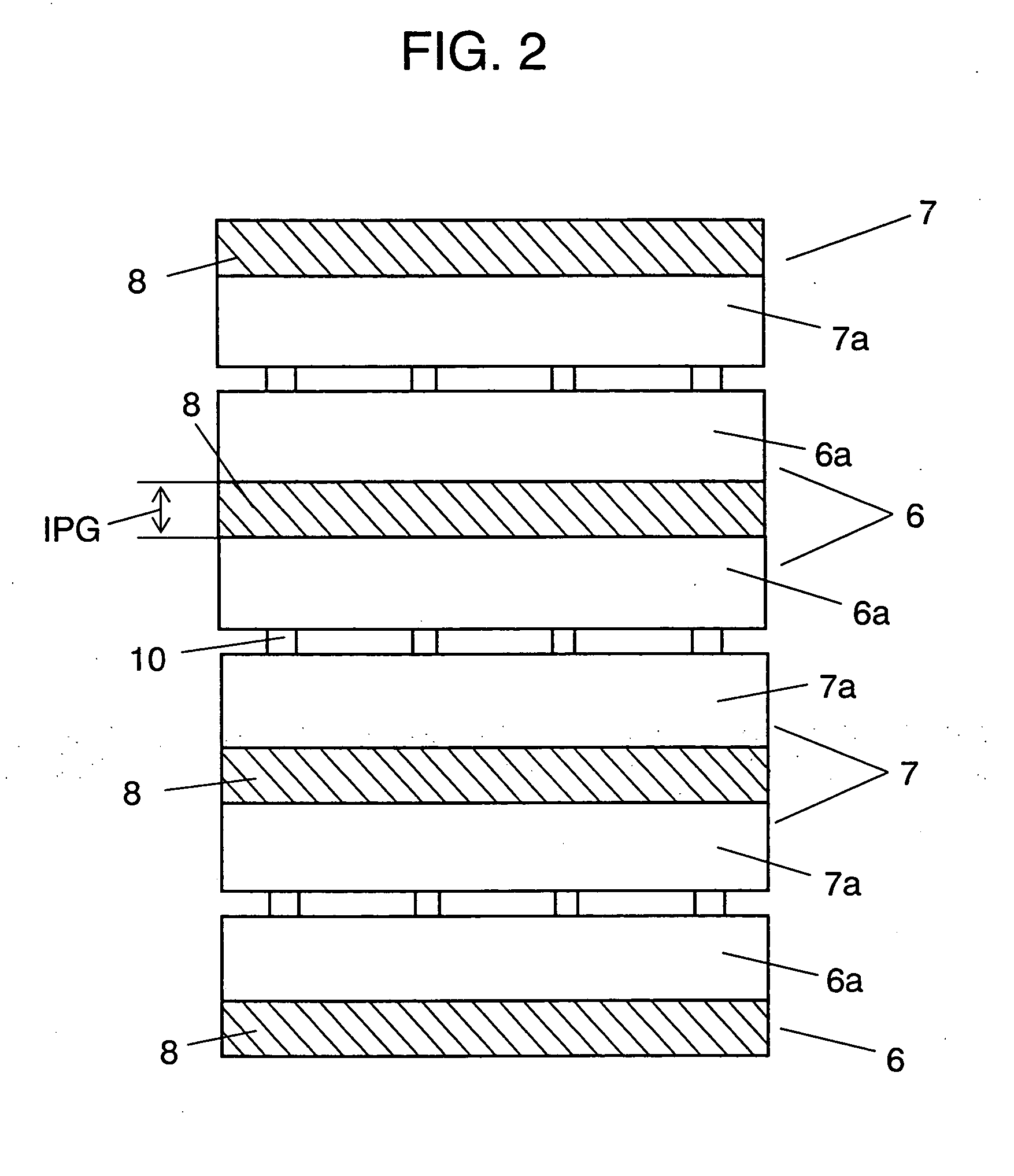

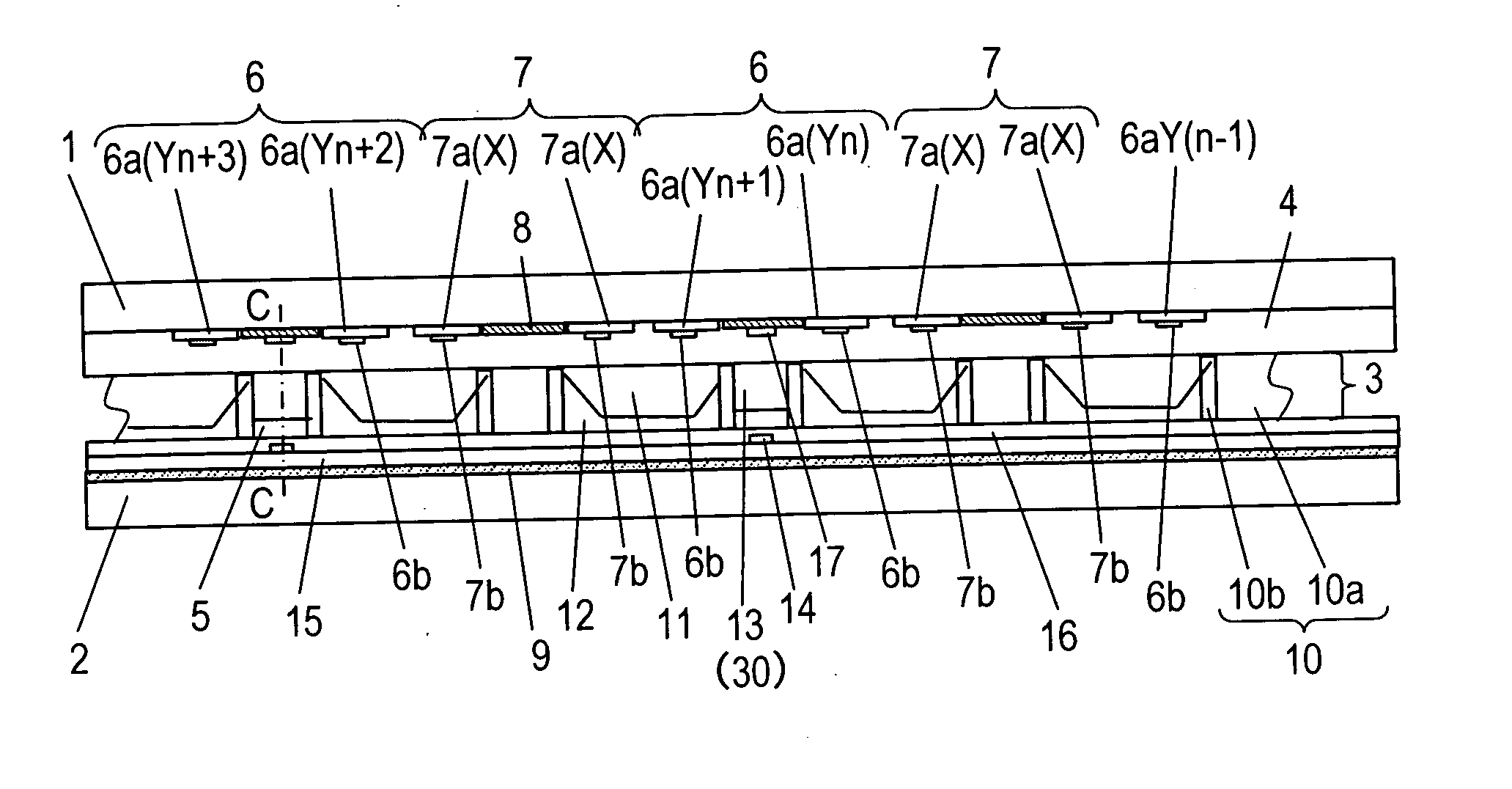

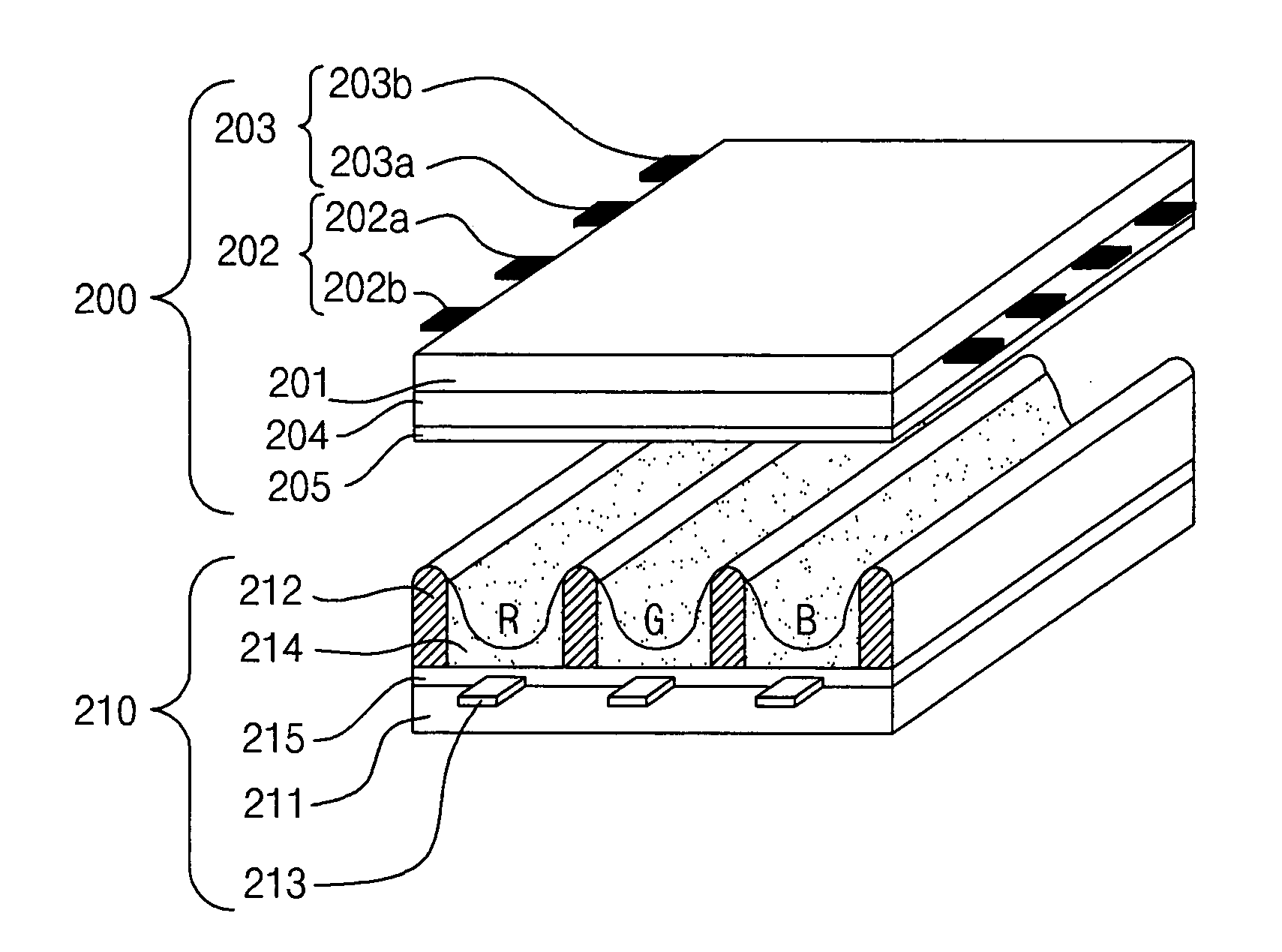

A plasma display panel can reduce a discharge delay in address discharge, thereby performing high-speed addressing in a stable manner. A front substrate (1) and a back substrate (2) are disposed to face each other, and a discharge space (3) is formed and partitioned by barrier ribs (10) so as to form priming discharge cells (17) and main discharge cells (11). A clearance (19) is provided between the barrier ribs (10) of the priming discharge cells (17) and the front substrate (1), and priming particles generated in the priming discharge cells (17) are supplied to the main discharge cells (11) through the clearance (19), whereby a PDP performing high-speed addressing is obtained.

Owner:PANASONIC CORP

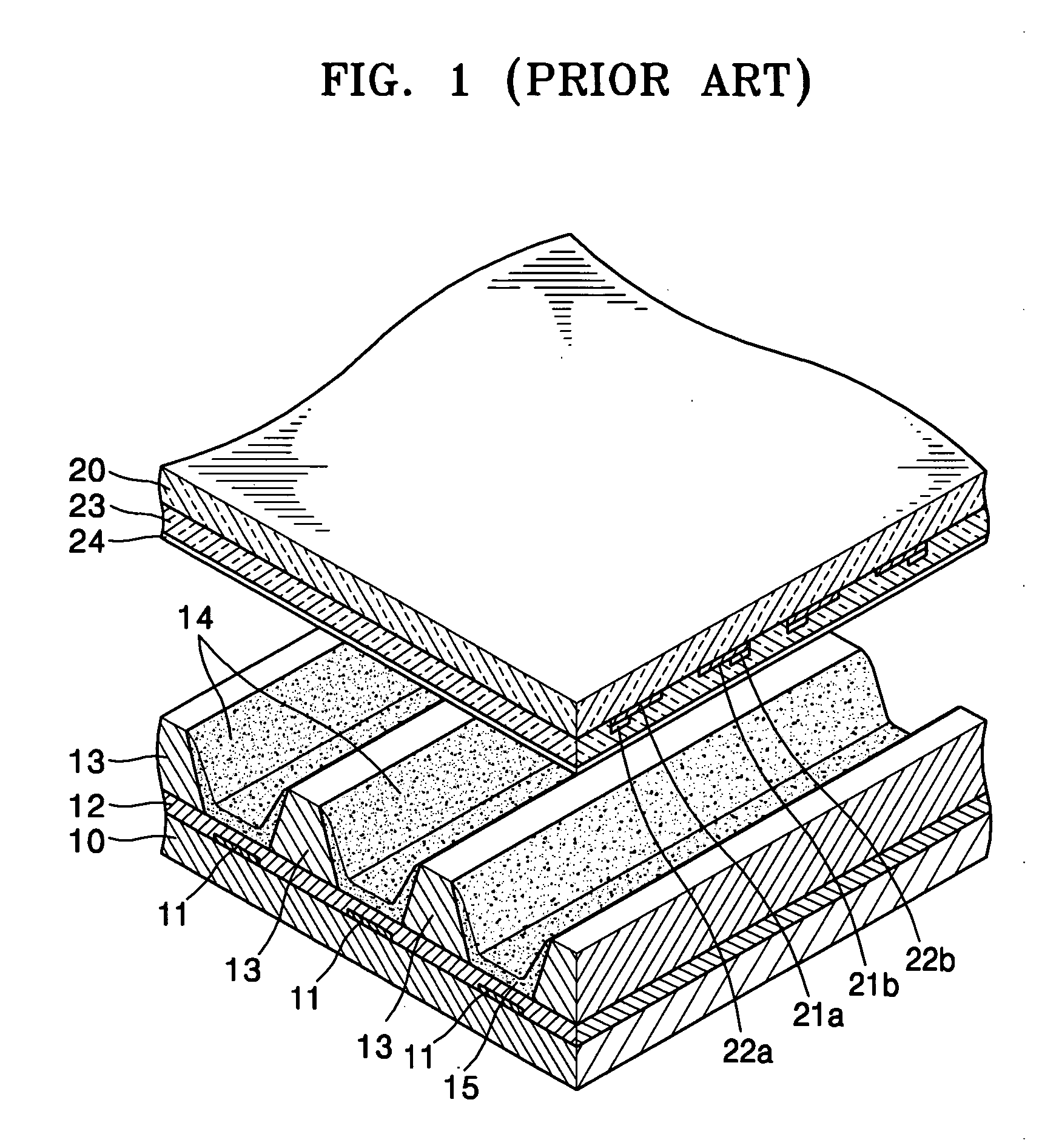

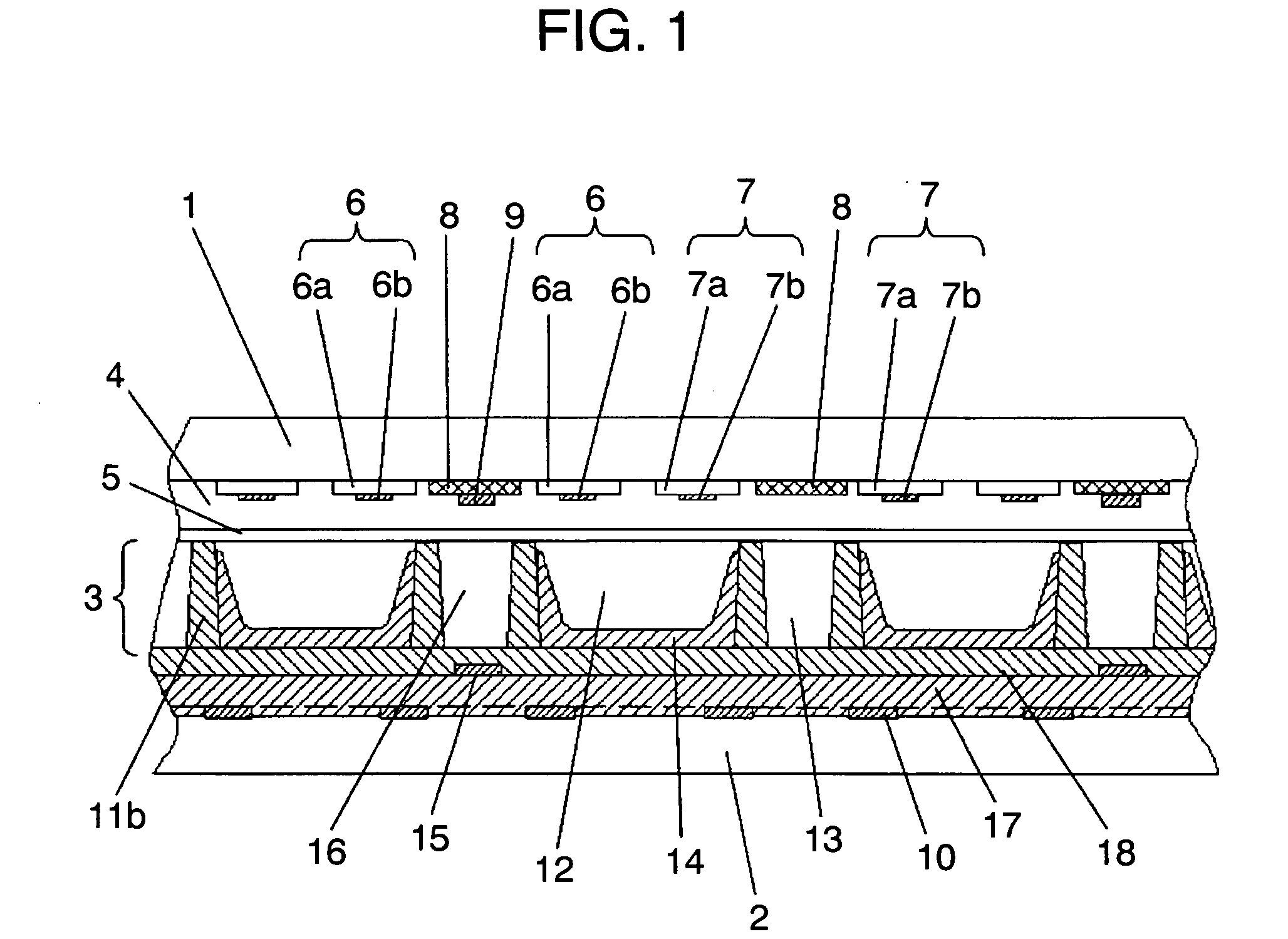

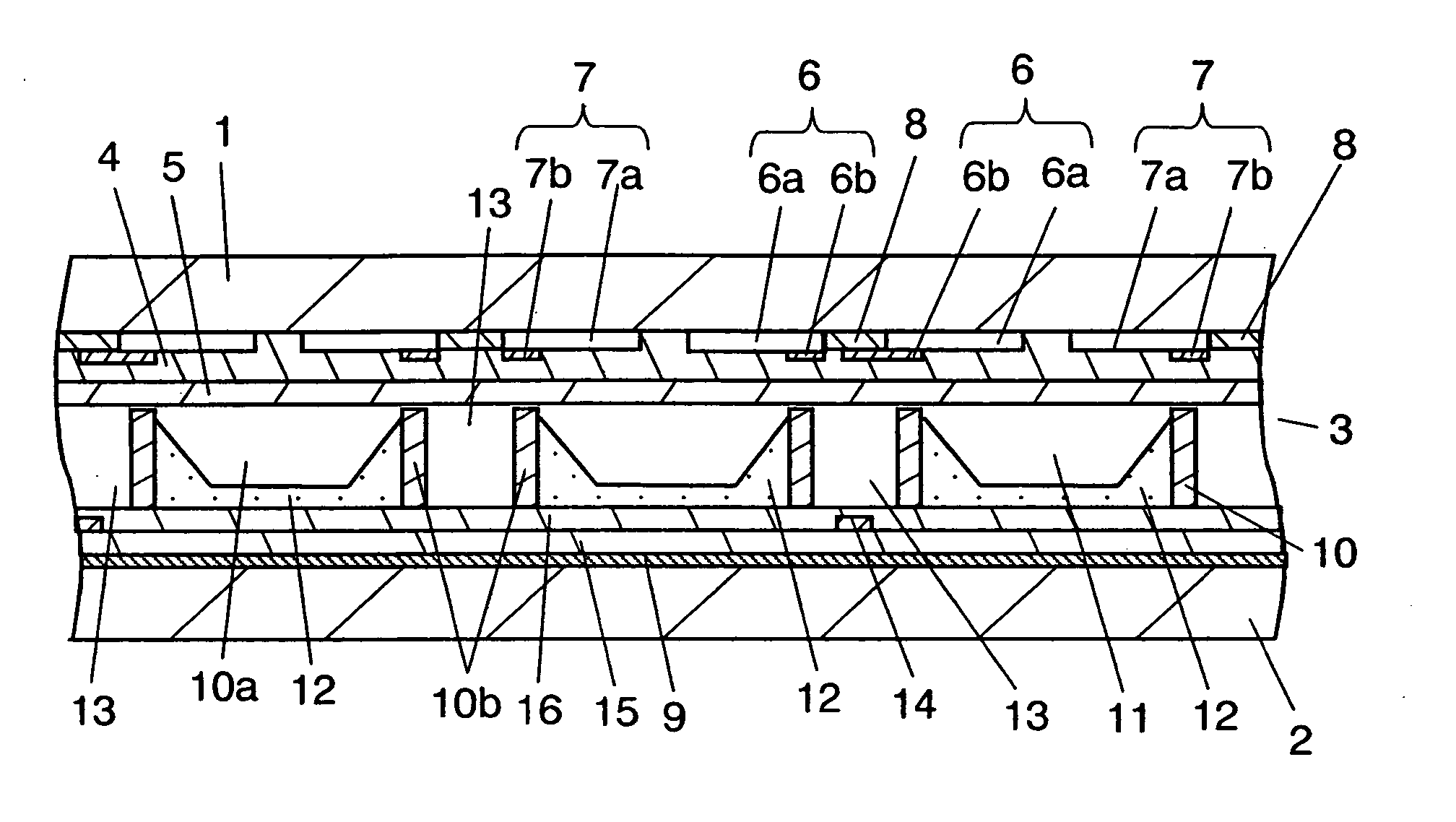

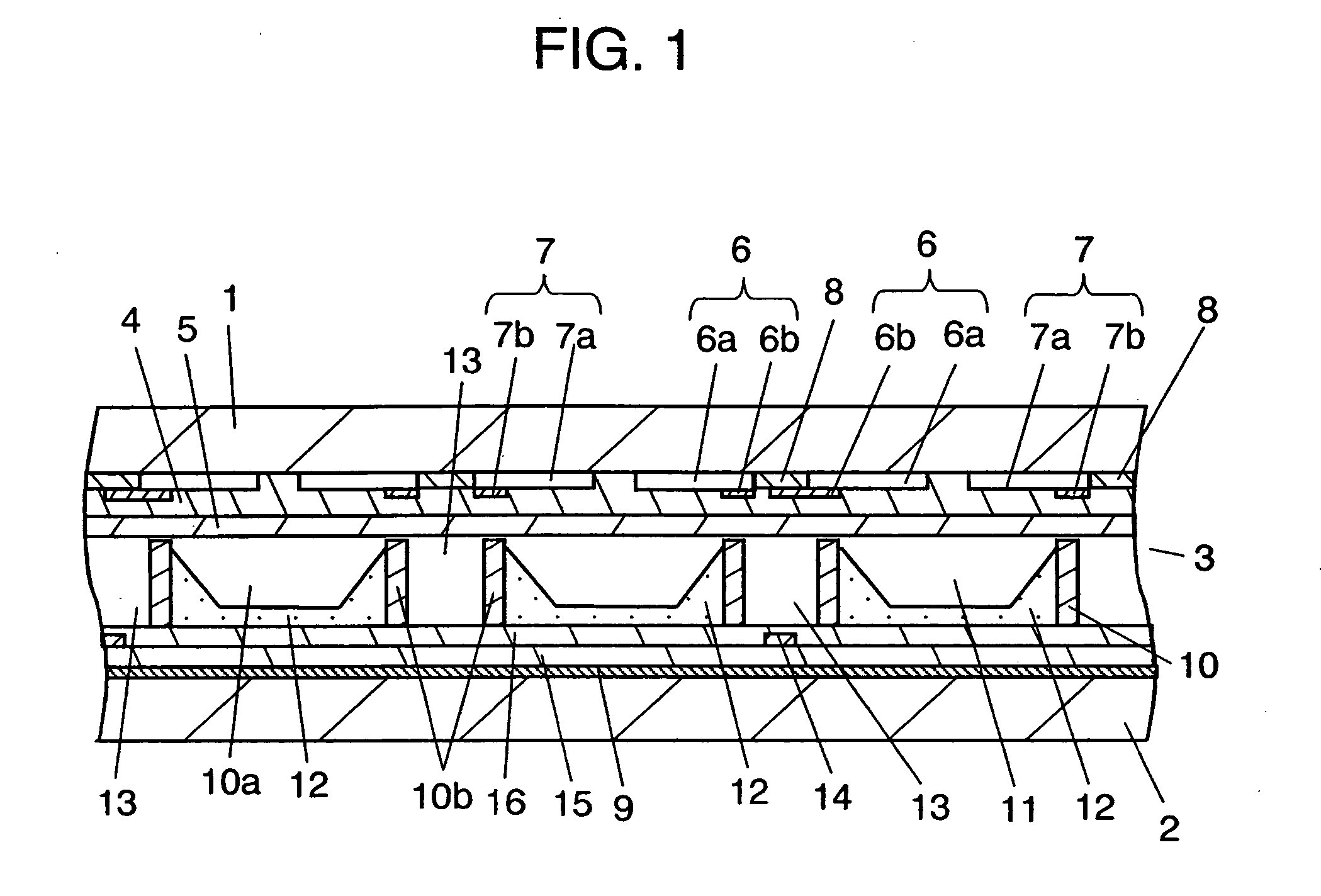

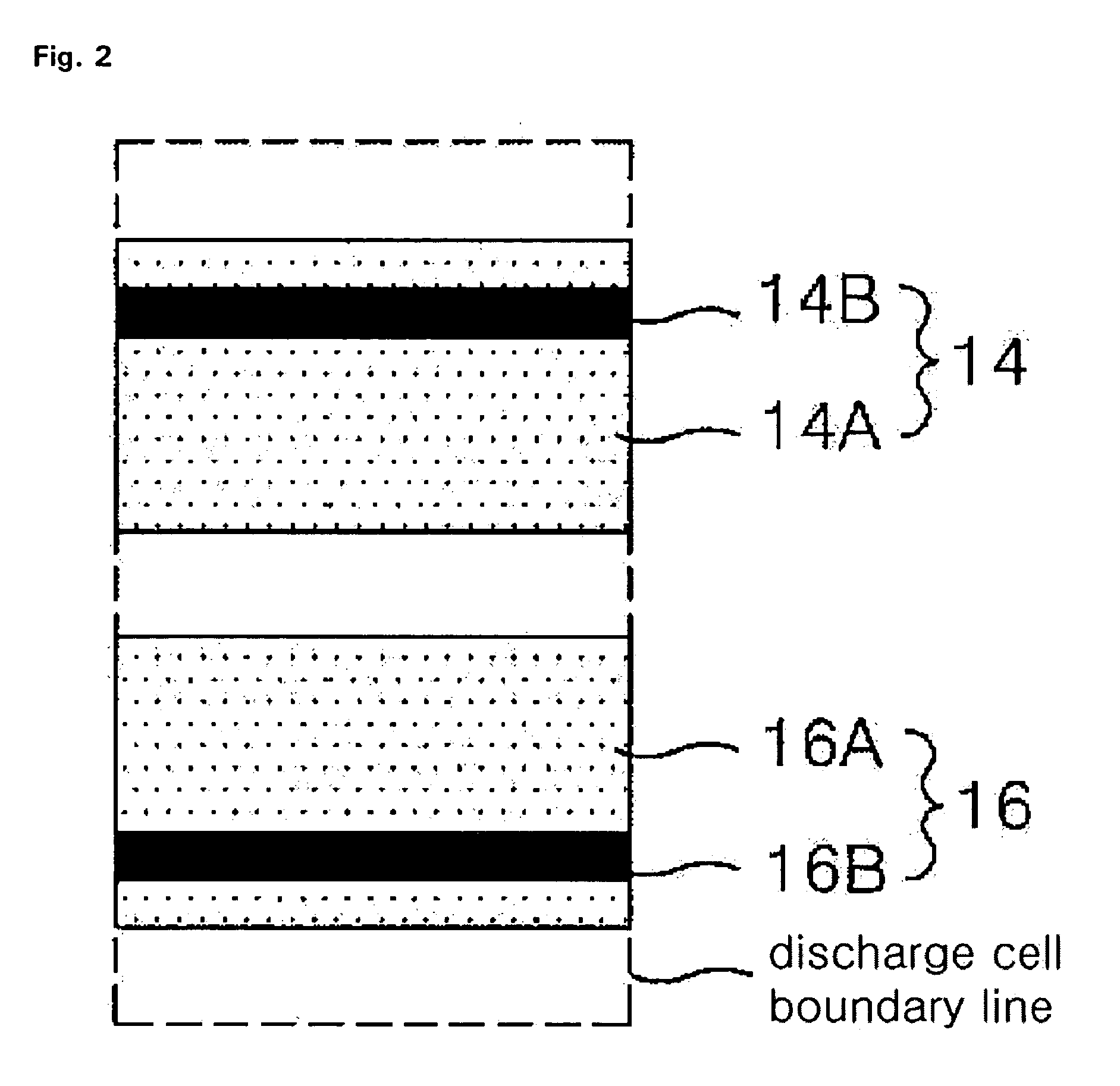

Plasma display panel

InactiveUS20050104807A1Reduce discharge voltageStable formationStatic indicating devicesAuxillary electrodesAlkaline earth metalAlkali metal oxide

A plasma display panel has address properties stabilized. A priming discharge is performed between auxiliary electrodes (17), which are formed on a front substrate (1) and coupled with scan electrodes (6) and priming electrodes (14) formed on a back substrate (2). Furthermore, a material layer (5) containing at least one of alkali metal oxide, alkaline earth metal oxide and fluoride is provided on regions corresponding to priming discharge spaces (30) (gap parts 13) on the back substrate (2). As a result, the priming discharge has a wider margin, and a supply of priming particles to the discharge cells is stabilized, whereby a discharge delay during the addressing is reduced, and the address properties are stabilized.

Owner:PANASONIC CORP

Plasma display panel

InactiveUS20050040766A1Reduce discharge voltageDecreasing discharge time lagSustain/scan electrodesAuxillary electrodesTime lagCell space

The invention is a plasma display panel capable of stabilizing the addressing characteristics. A barrier rib is formed by longitudinal barrier ribs portion orthogonal to the scan electrodes and sustain electrodes on the front substrate, and side barrier rib portions crossing with these longitudinal barrier rib portions, to form cell spaces and form interstice portions between the cell spaces, and priming electrodes for producing a discharge between the front substrate and the rear substrate within the interstice portions are formed. Stable priming discharge is produced with certainty by the scan electrode and the priming electrode, hence decreasing the discharge time lag at the time of addressing and stabilizing the addressing characteristics.

Owner:PANASONIC CORP

Plasma display panel

InactiveUS20060238125A1Improve lighting efficiencyAddress electrodesSustain/scan electrodesAtomic physicsPlasma display

Disclosed is a plasma display panel. The plasma display panel includes an electrode structure in which an address electrode and a scan electrode generating an address discharge are aligned adjacent to each other such that an address voltage is constantly maintained at a relatively low level, thereby improving the light efficiency of the plasma display panel.

Owner:SAMSUNG SDI CO LTD

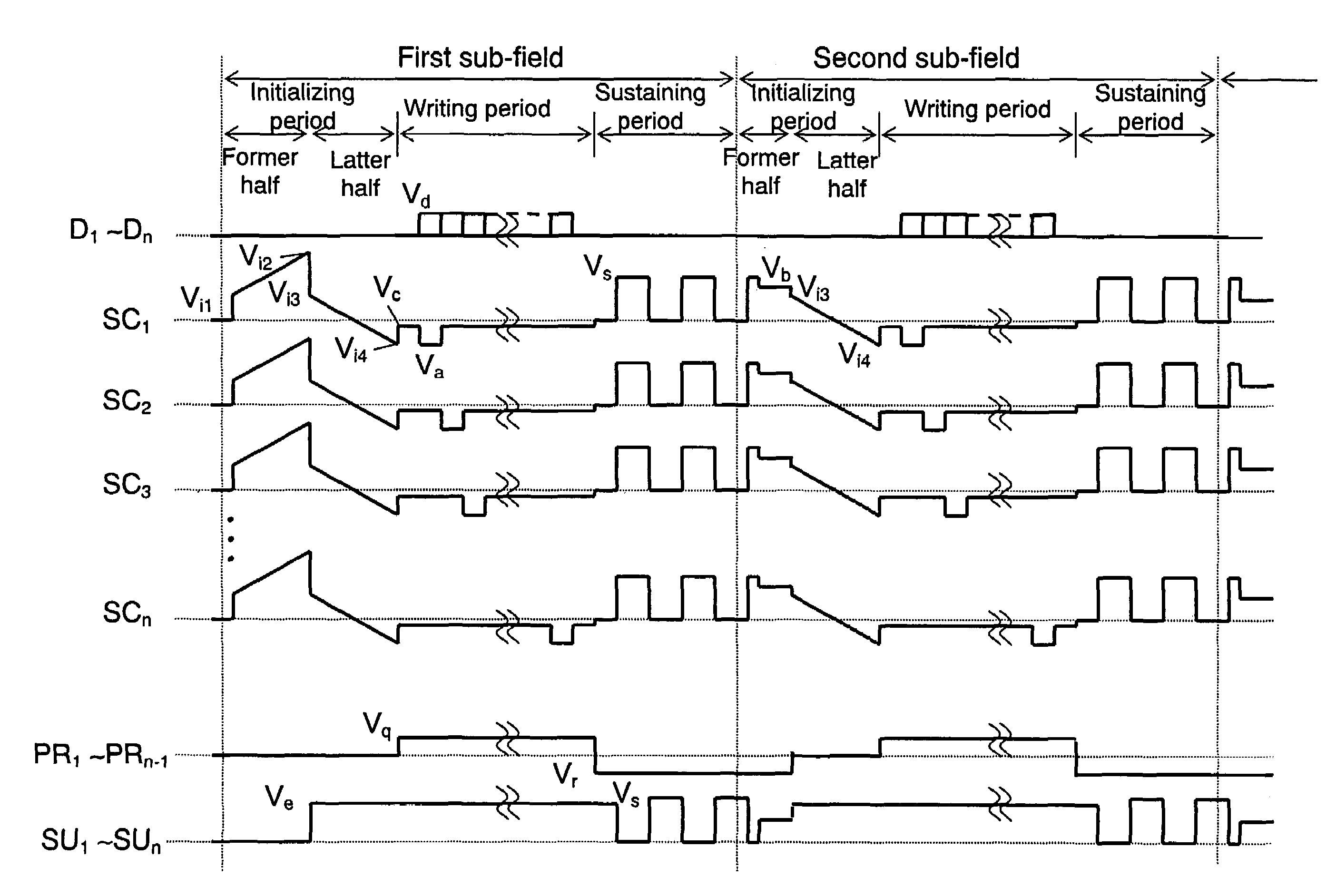

Plasma display panel drive method

The initializing period of at least one of a plurality of sub-fields constituting one field is a selective initializing period for selectively initializing discharge cells in which a sustain discharge has occurred in the sustaining period of the preceding sub-field. In the sustaining period of the sub-field prior to the sub-field including the selective initializing period, voltage Vr is applied to a priming electrode (PRi) for causing a discharge between the priming electrode (PRi) and corresponding scan electrode (SCi) using the priming electrode (PRi) as a cathode.

Owner:PANASONIC CORP

Structure of AC type PDP

InactiveUS7245077B2Well formedEasy to processAddress electrodesSustain/scan electrodesCapacitanceConductive materials

Almost only choice by a secondary electron emission layer / protection layer covering the dielectric layer of an AC type PDP has been magnesium oxide (MgO) that is unstable during the production process and difficult to form, thus posing a serious production problem. An AC type PDP constructed such that, instead of covering the surface of a dielectric layer with a dielectric material such as MgO, an insular electrode is made by forming a conductive material such as nickel, aluminum, magnesium and lanthanum hexaboride into an insular shape, and the insular electrode is allowed to capacity-couple with a lower-layer bus electrode by means of an electrostatic capacity formed by a dielectric layer to operate the insular electrode as a sustained electrode.

Owner:TECHNOLOGY TRADE AND TRANSFER CORP

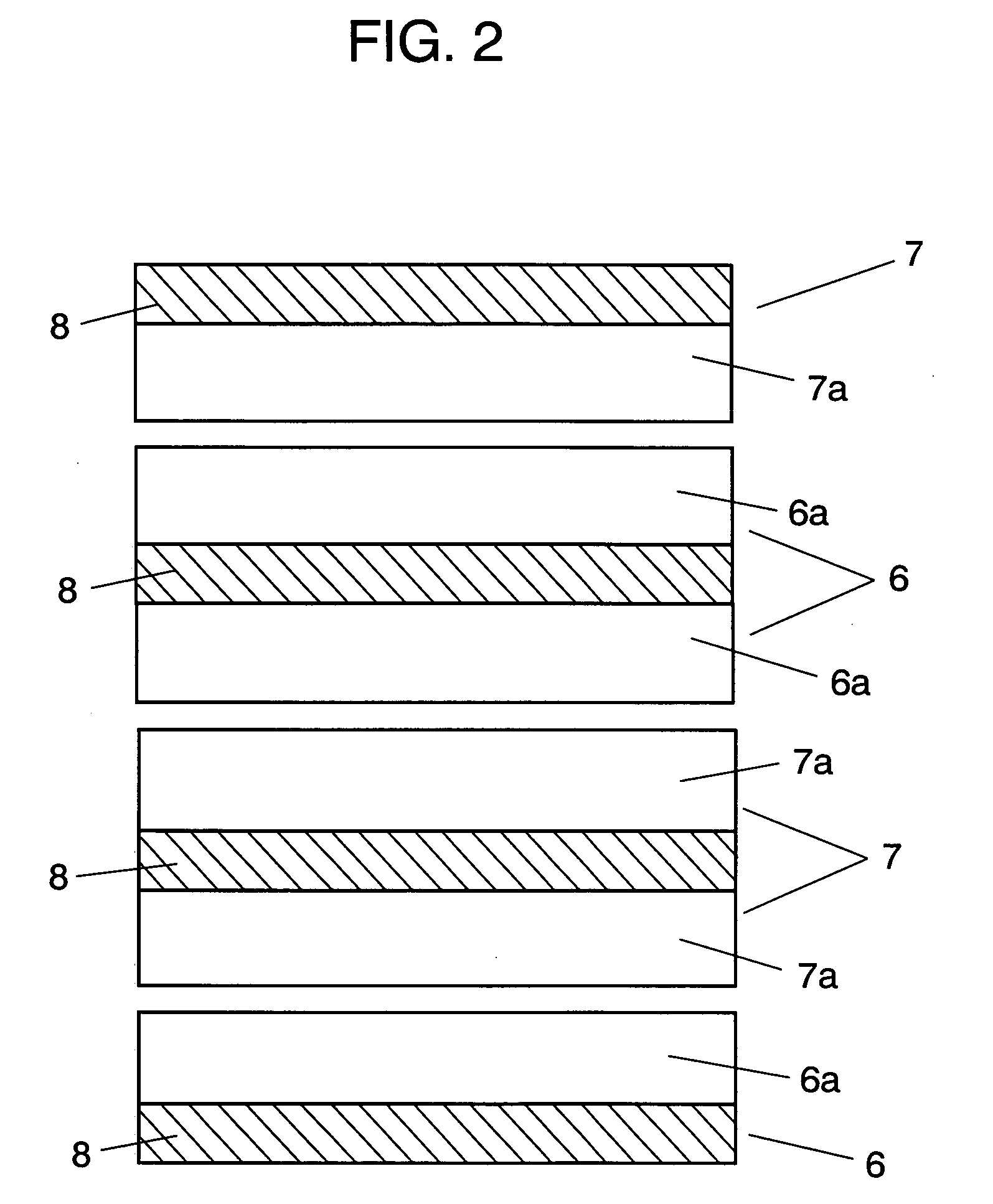

Plasma display panel and plasma display

InactiveUS20050218805A1Good conditionStatic indicating devicesAuxillary electrodesPlasma displayElectrical and Electronics engineering

A plasma display panel in which a plurality of pairs of first and second electrodes are disposed on a first substrate so as to be parallel to each other, a plurality of third electrodes are disposed on a second substrate, and main parts of a plurality of barrier ribs are disposed between adjacent third electrodes, the third electrodes being orthogonal to a longitudinal direction of display electrodes each of which consists of a pair of the first and second electrodes, wherein a plurality of fourth electrodes are fixed to the barrier ribs or areas of a surface of the first substrate facing the barrier ribs so as to be at least in vicinities of areas between adjacent display electrodes, the fourth electrodes being electrically exposed to discharge spaces which are defined by the barrier ribs.

Owner:PANASONIC CORP

Plasma display panel

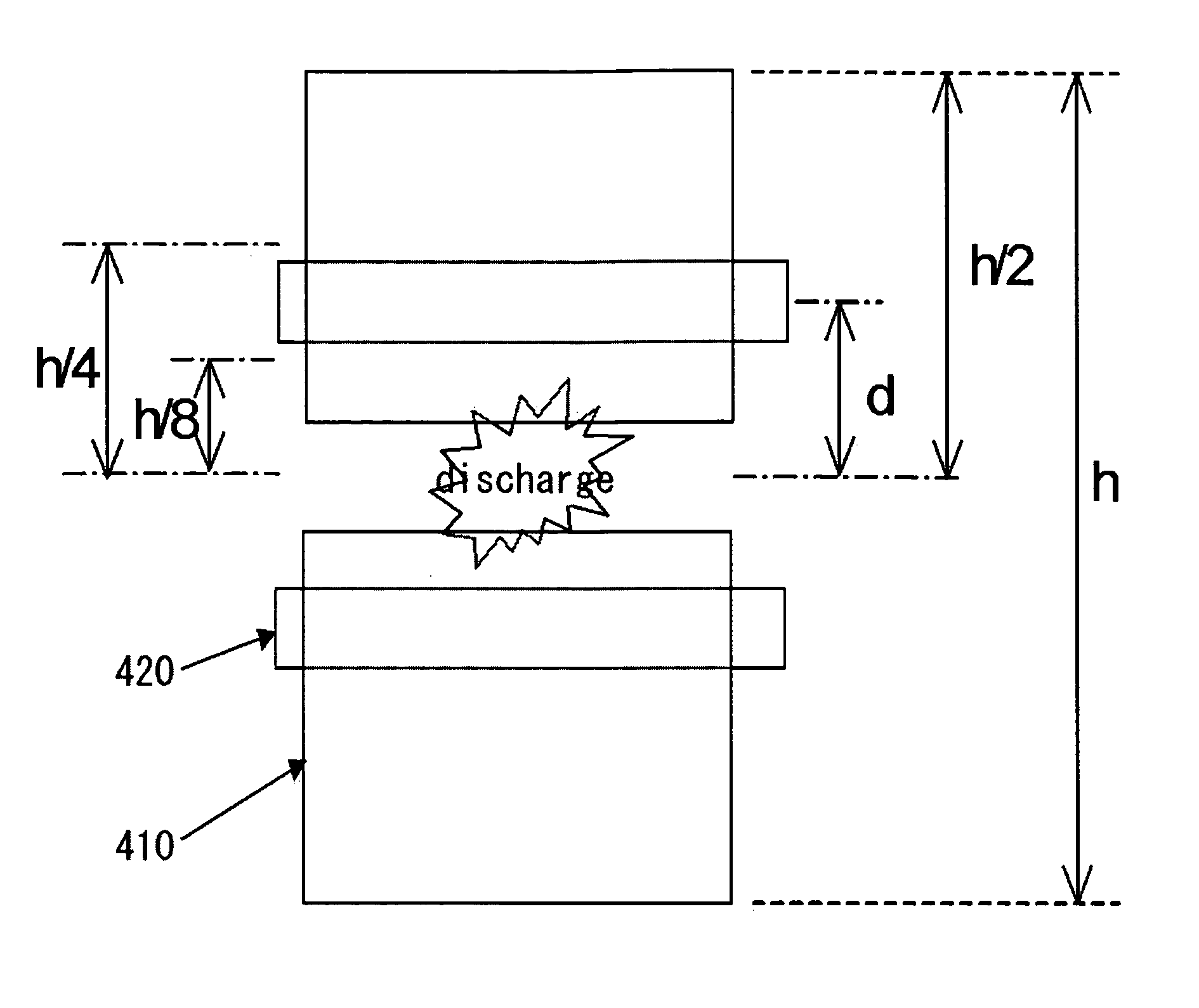

InactiveUS20050093445A1Increasing brightnessIncreasing efficiencyAddress electrodesSustain/scan electrodesDelayed timeMetal electrodes

The present invention relates to a plasma display panel, and more particularly, to an electrode structure of a plasma display panel capable of improving brightness and efficiency. According to the present invention, in the plasma display, assuming that a distance from the center of a discharge region between a pair of transparent electrodes to the center of metal electrodes is “d” and a distance between both ends of the pair of the transparent electrodes is “h”, a location on the transparent electrodes of metal electrodes satisfies d<h / 4. Therefore, brightness and efficiency can be increased without increasing the Xe content. Furthermore, it is possible to reduce power consumption since a discharge start voltage and a discharge sustain voltage are lowered. Discharge stability can be improved since a discharge delay time is shortened.

Owner:LG ELECTRONICS INC

Plasma display panel

InactiveUS20050242726A1Simple structureImprove efficiencySustain/scan electrodesAuxillary electrodesPhosphorDielectric layer

A plasma display panel is provided. A first substrate faces a second substrate. Barrier ribs positioned between the first substrate and the second substrate form a plurality of polyhedral discharge cells. A plurality of display electrodes formed substantially along a first direction of the first substrate have portions placed at positions corresponding to at least three planes of the discharge cell's composing planes. A dielectric layer for the display electrode covers the display electrodes. A plurality of address electrodes formed along a second direction of the second substrate have portions placed at positions corresponding to at least one plane of the discharge cell's composing planes. A dielectric layer for the address electrode covers the address electrodes. A phosphor layer is formed inside the discharge cells.

Owner:SAMSUNG SDI CO LTD

Plasma display panel

InactiveUS20060232210A1Improve diffusion efficiencyReducing plasma display panel manufacturing costAddress electrodesSustain/scan electrodesOptoelectronicsAperture ratio

A plasma display panel is provided. Particularly, an embodiment of the present invention suggests a sustain electrode structure comprising opaque electrodes instead of transparent electrodes to improve an aperture ratio. The number of electrode lines pertained to each sustain electrode is suggested to improve the aperture ratio, and a first projection electrode projecting to a central portion of a discharge cell from the electrode line can allows a discharge initiation voltage level to be decreased. A second projection electrode projecting in a direction away from the central portion of the discharge cell can be advantageous of increasing discharge diffusion efficiency within the discharge cell.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com