Patents

Literature

778results about How to "Stable formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor device, electronic device, and method of manufacturing semiconductor device

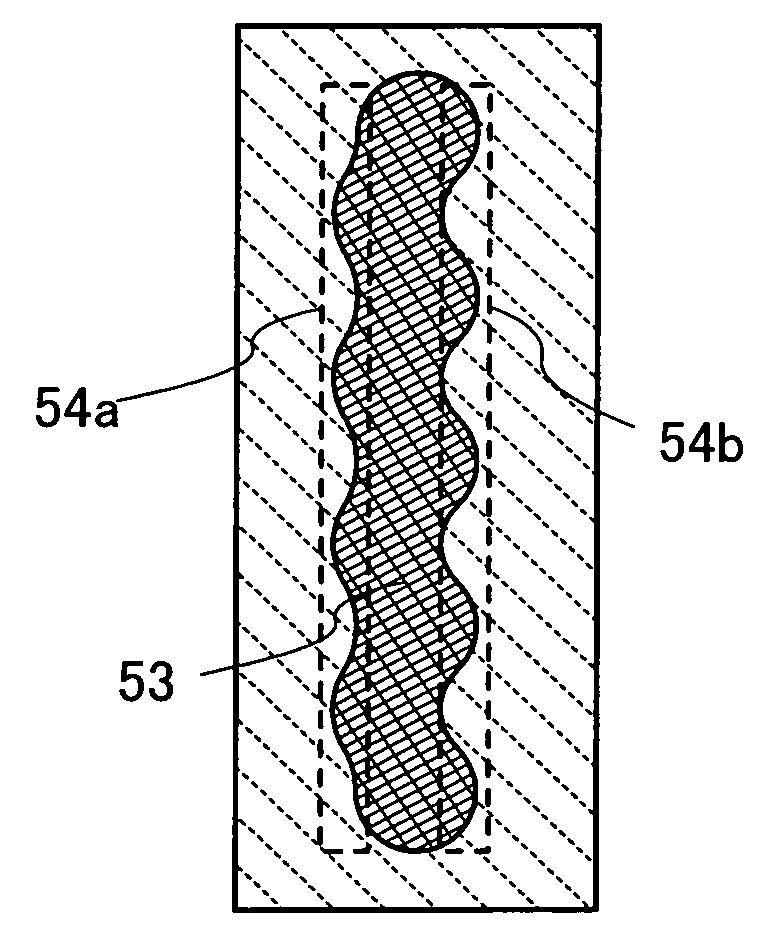

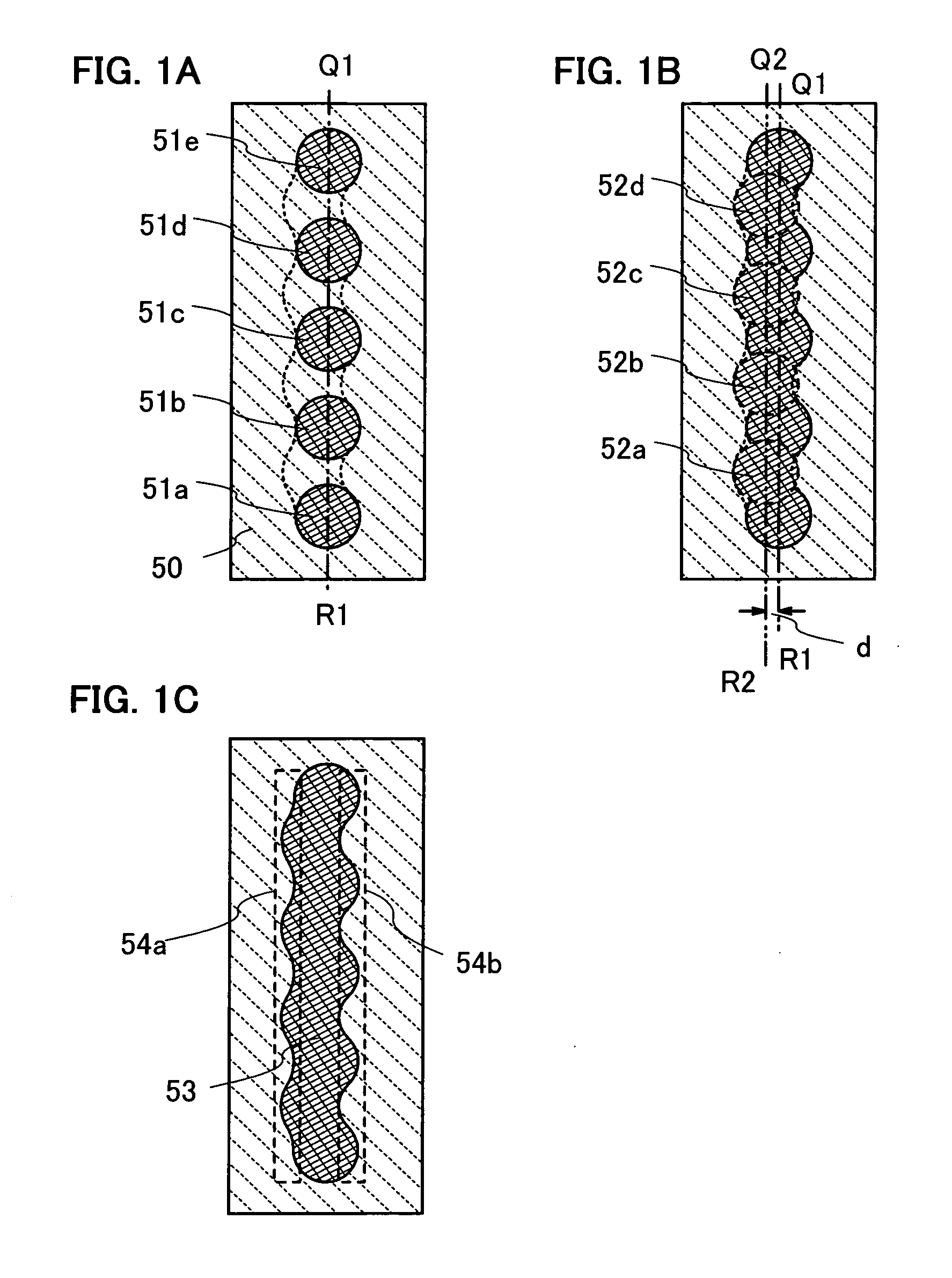

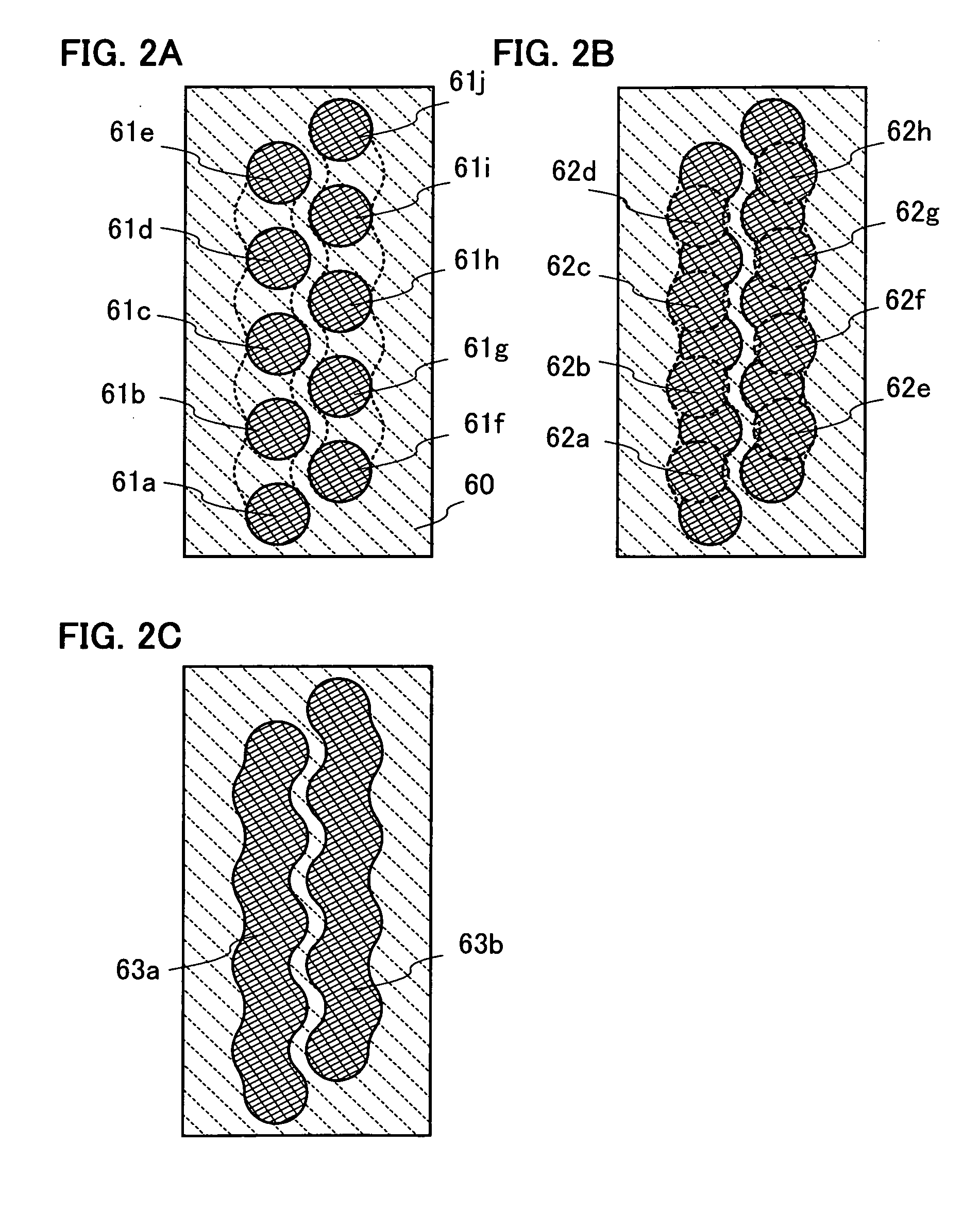

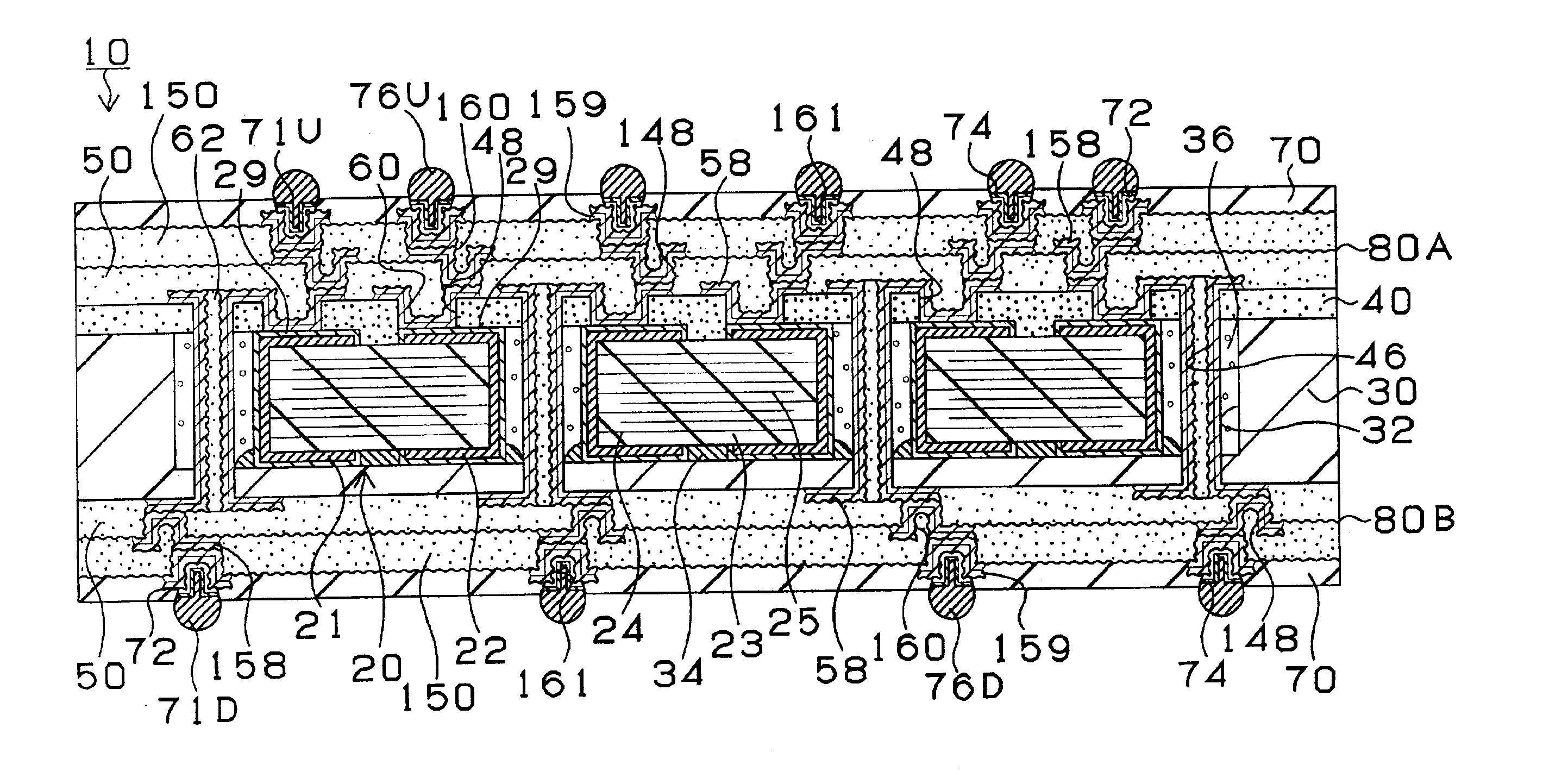

InactiveUS20060169973A1Stable formationImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialDisplay device

To provide a semiconductor device and a display device which can be manufactured through a simplified process and the manufacturing technique. Another object is to provide a technique by which a pattern of wirings or the like which is partially constitutes a semiconductor device or a display device can be formed with a desired shape with controllability.

Owner:SEMICON ENERGY LAB CO LTD

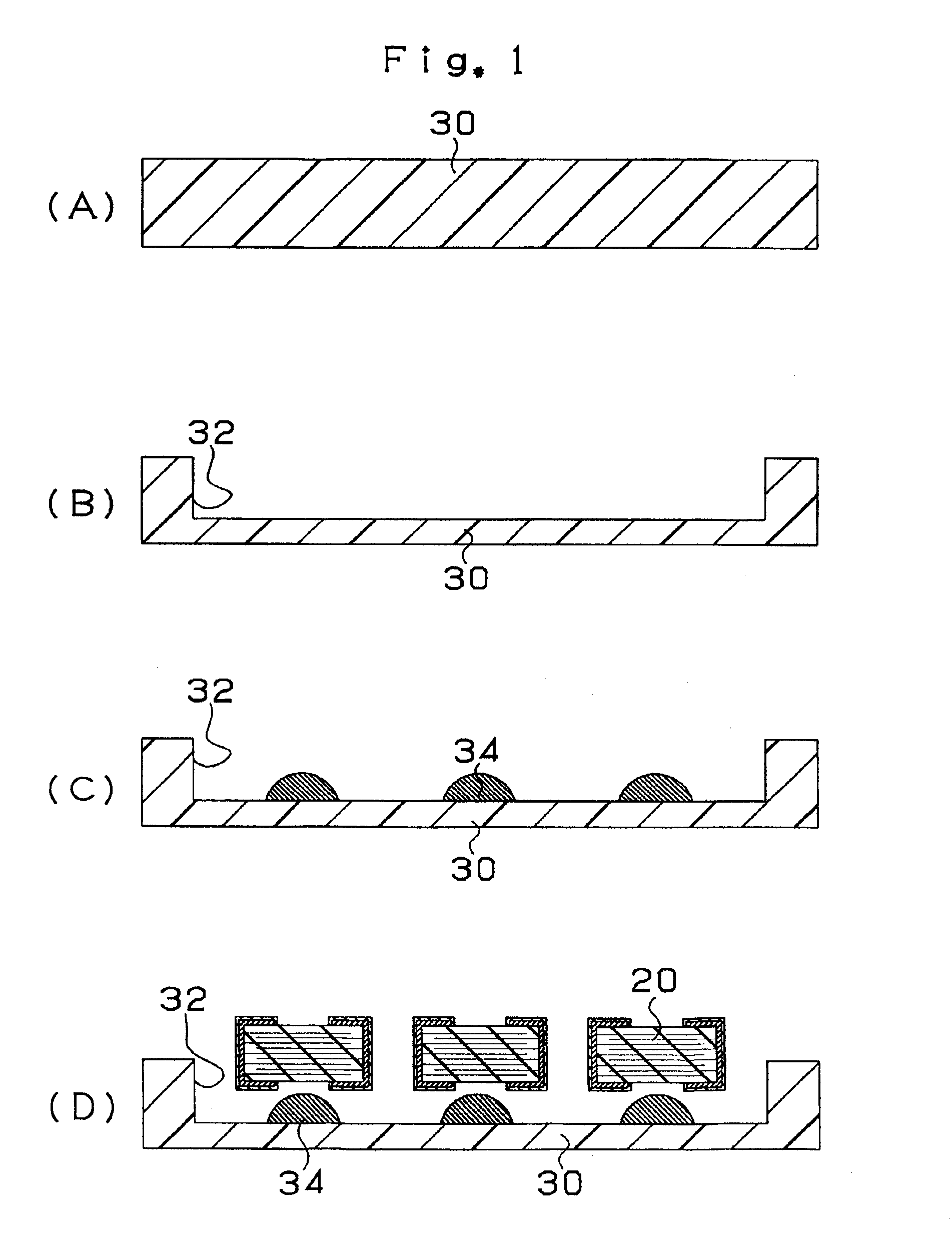

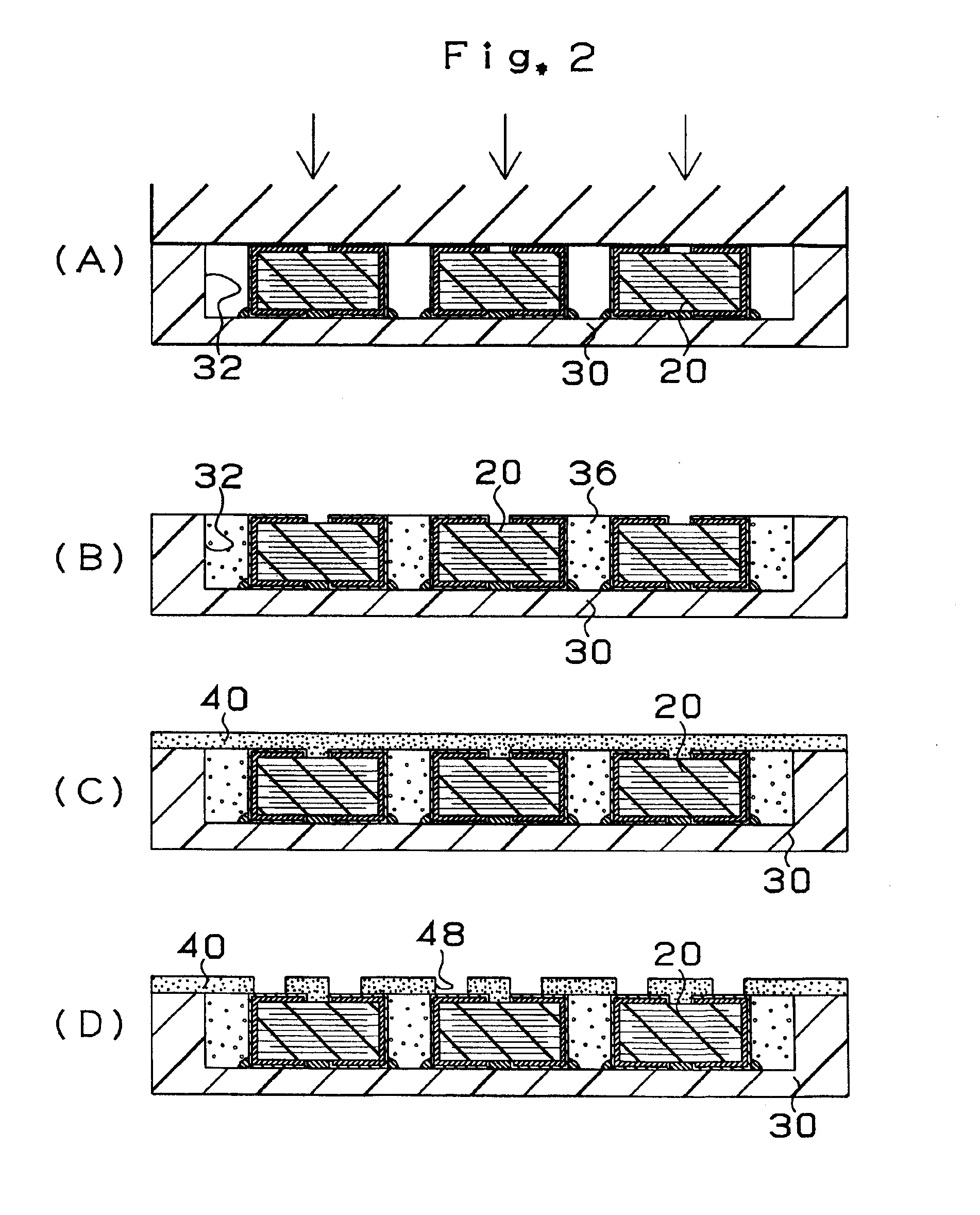

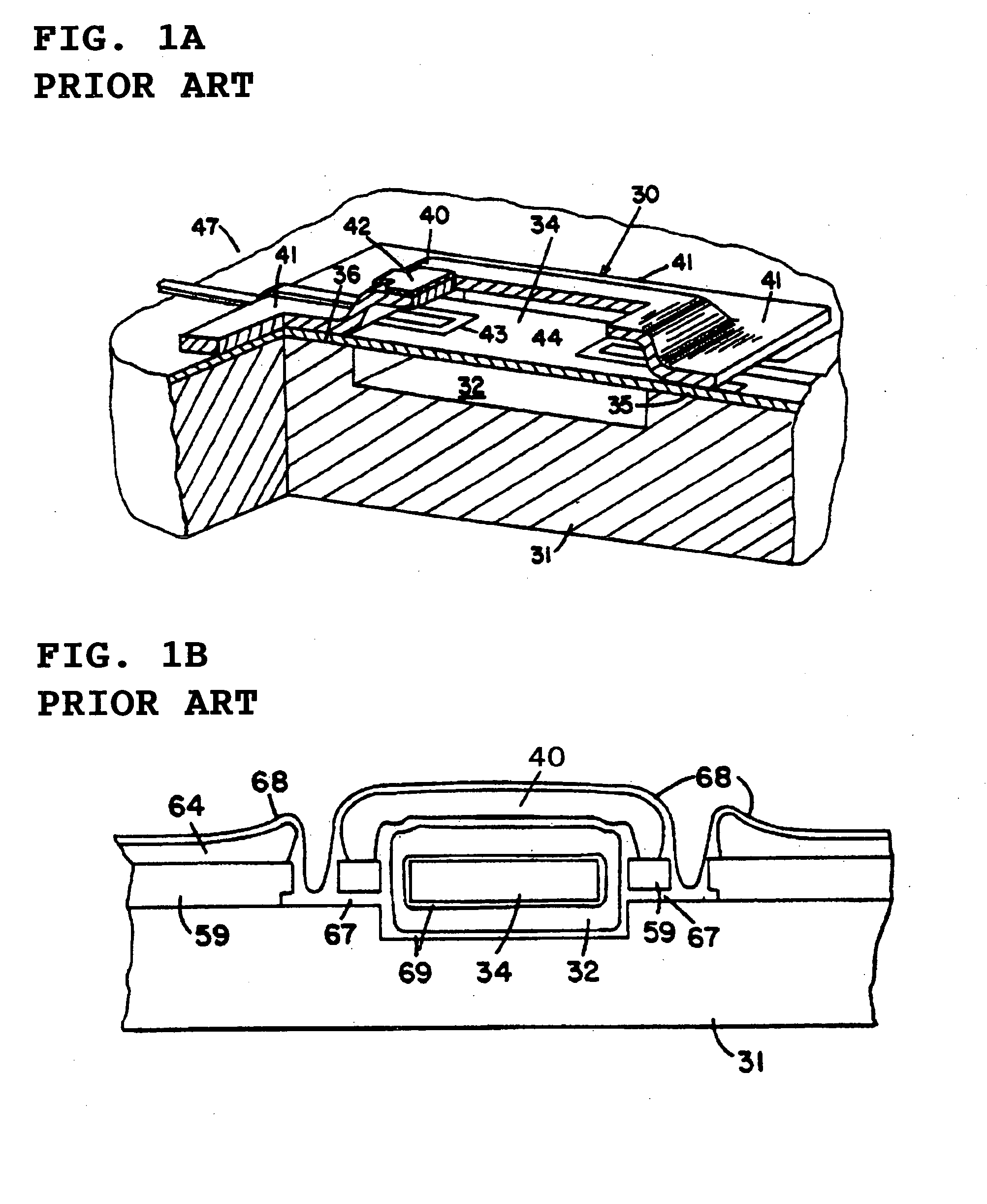

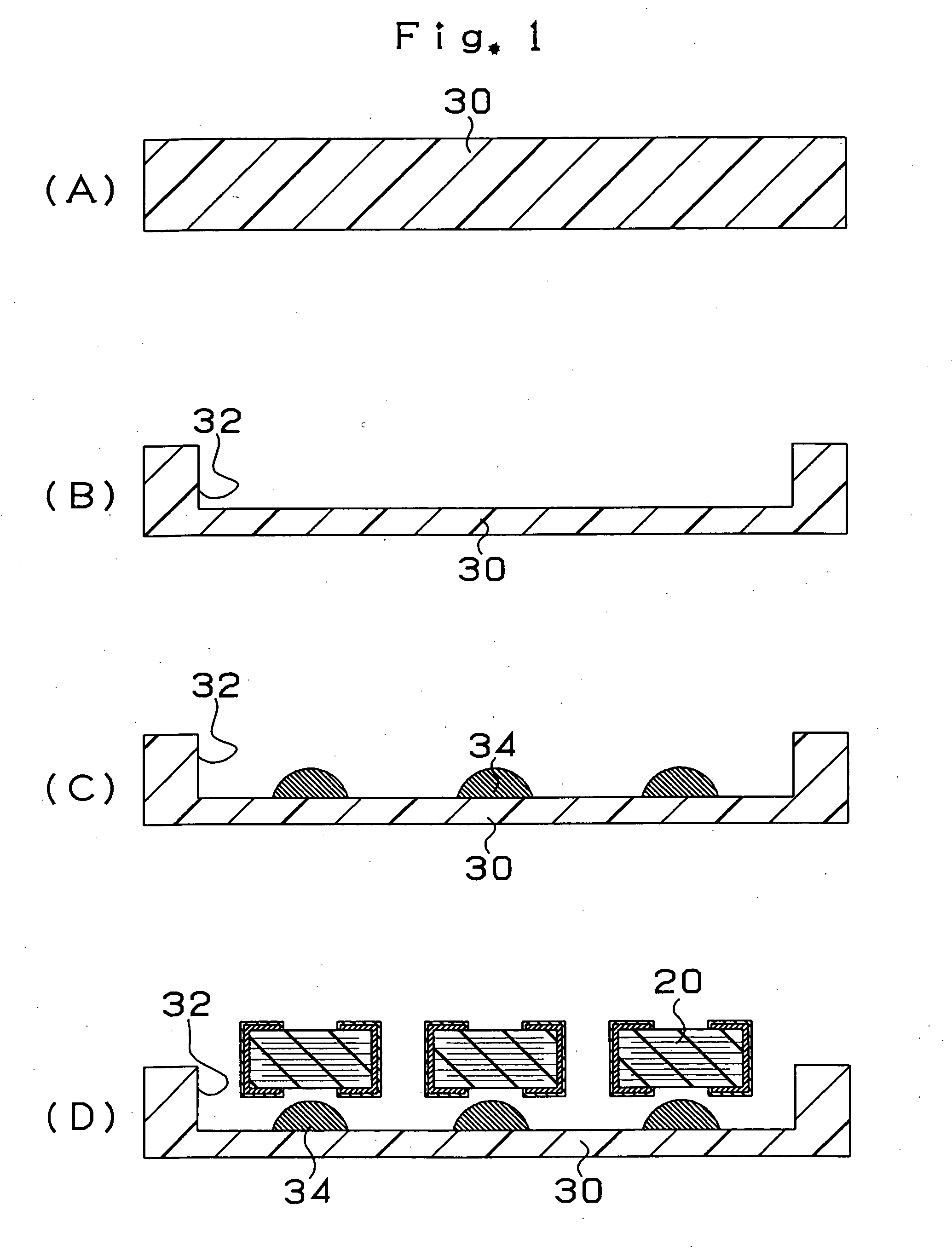

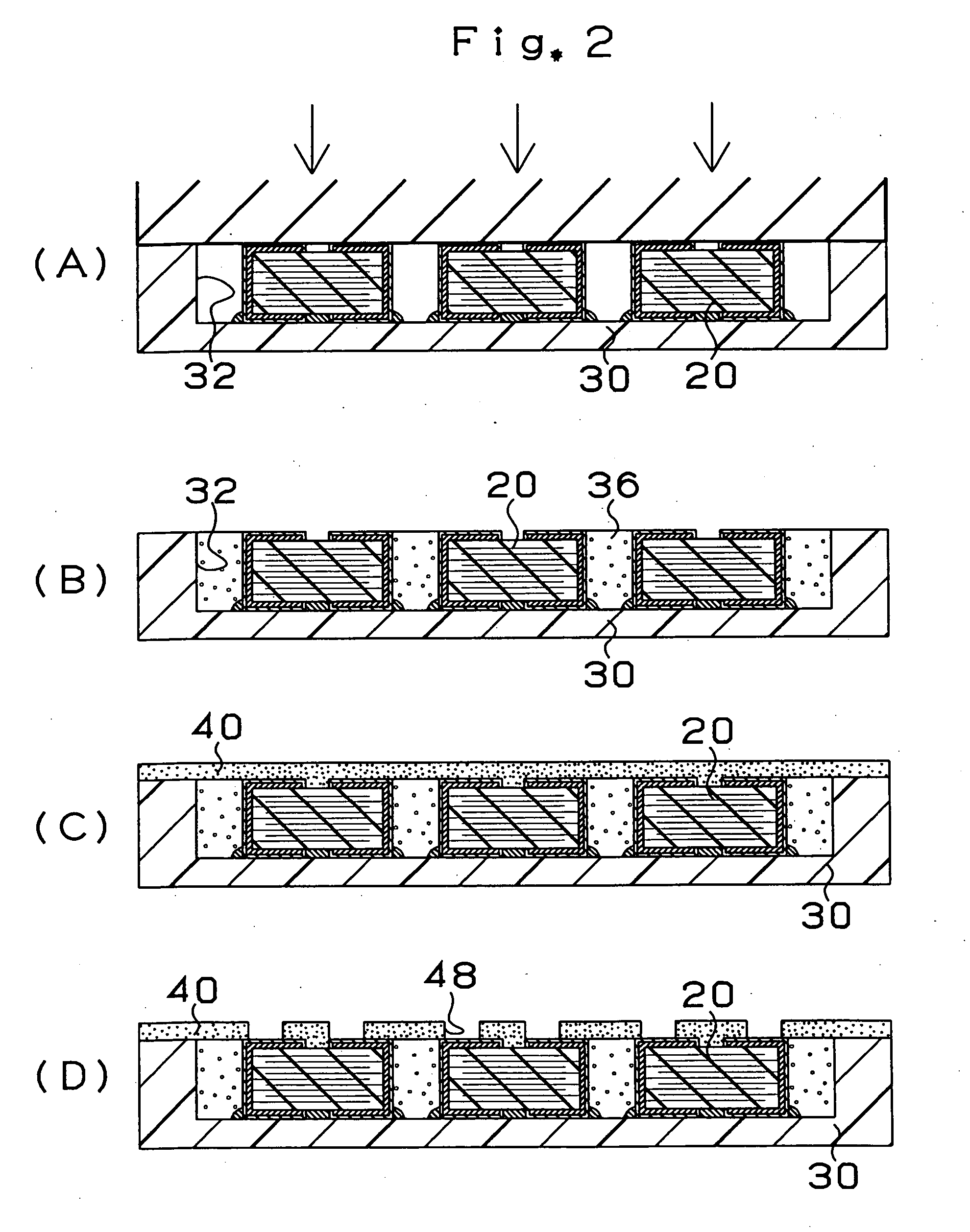

Printing wiring board and method of producing the same and capacitor to be contained in printed wiring board

InactiveUS6876554B1Improve reliabilityFlat surfaceFinal product manufactureSemiconductor/solid-state device detailsEngineeringPrinted circuit board

Chip capacitors 20 are provided in a printed circuit board 10. In this manner, the distance between an IC chip 90 and each chip capacitor 20 is shortened, and the loop inductance is reduced. In addition, the chip capacitors 20 are accommodated in a core substrate 30 having a large thickness. Therefore, the thickness of the printed circuit board does not become large.

Owner:IBIDEN CO LTD

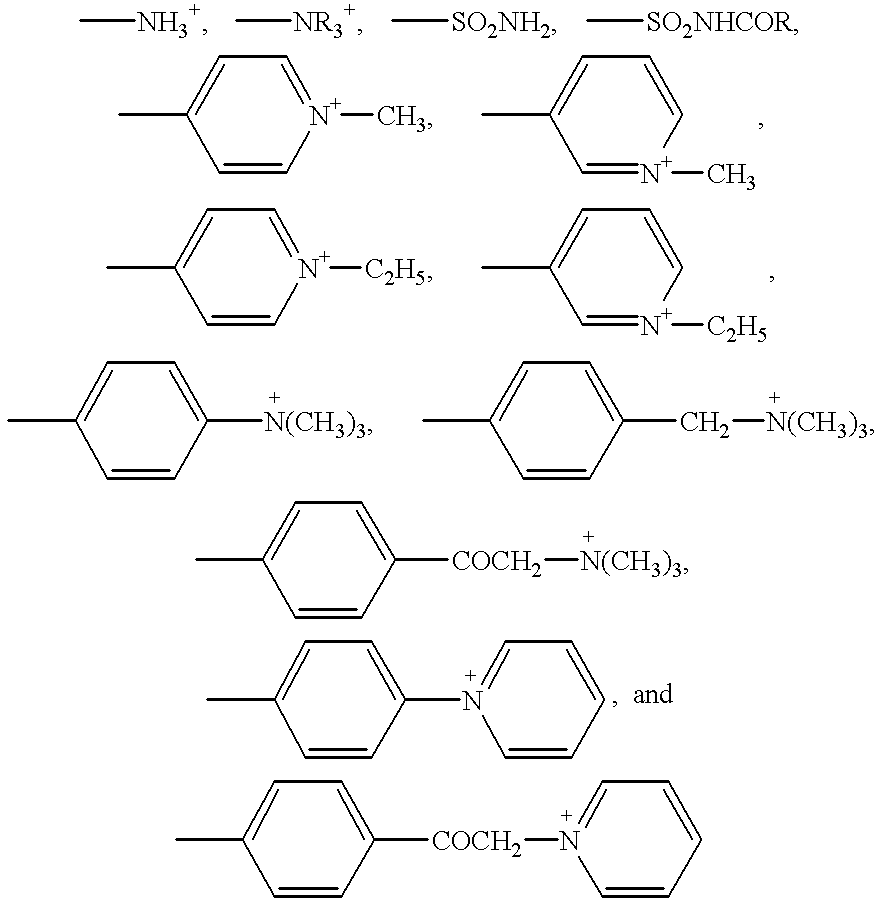

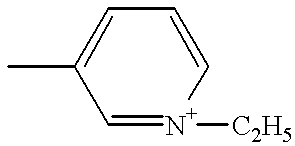

Ink, ink-jet recording process, recording unit, ink cartridge and ink-jet recording apparatus

InactiveUS6375317B1Stable formationQuality improvementMeasurement apparatus componentsInksPolymer scienceAqueous medium

An ink comprising particles of self-dispersing carbon black having at least one hydrophilic group at the surface thereof, and calcium in an aqueous medium. The ink can form images excellent in fastness properties such as water fastness and light fastness and character quality, and can be stably ejected from a recording head irrespective of printing environment.

Owner:CANON KK

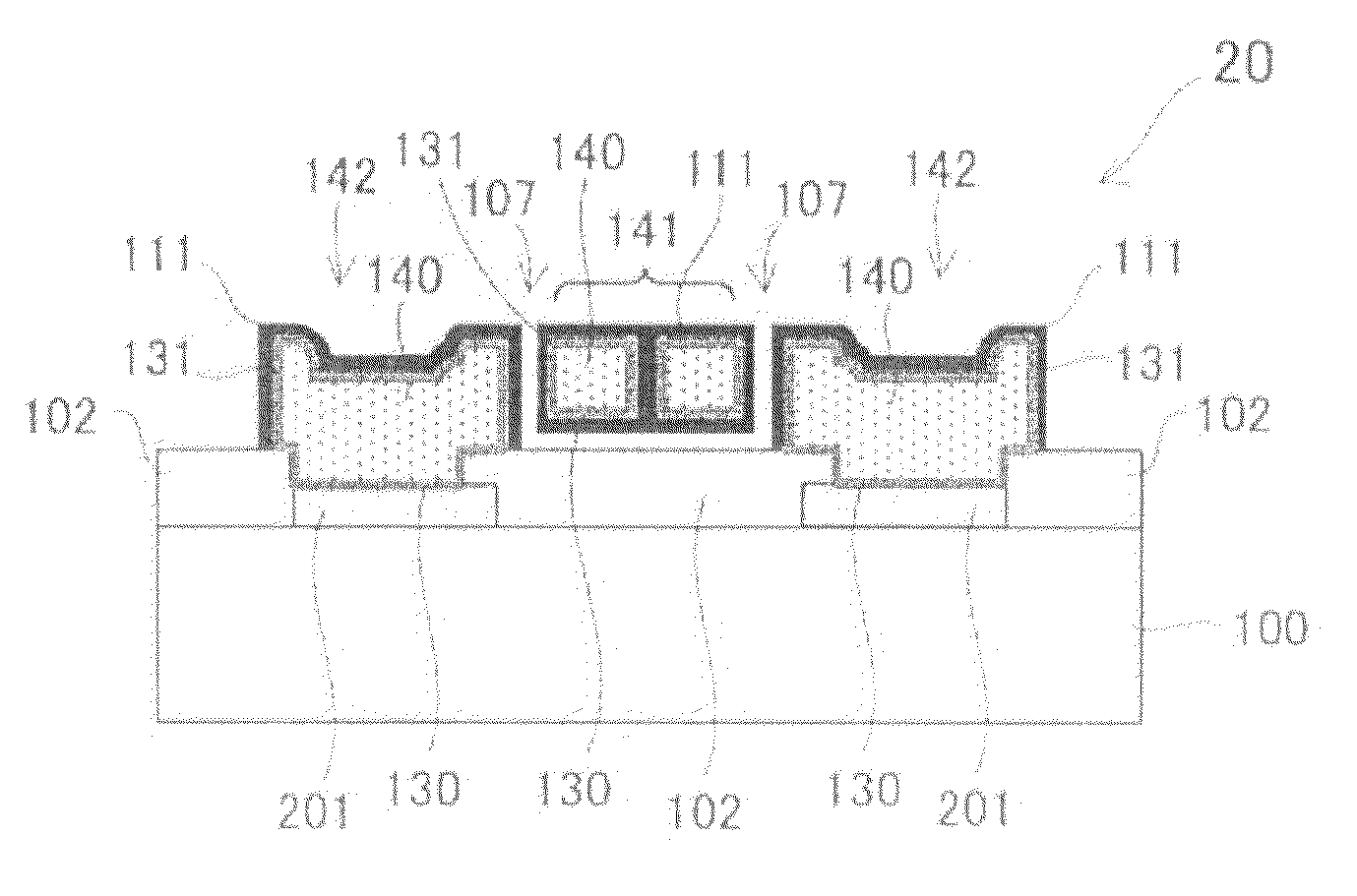

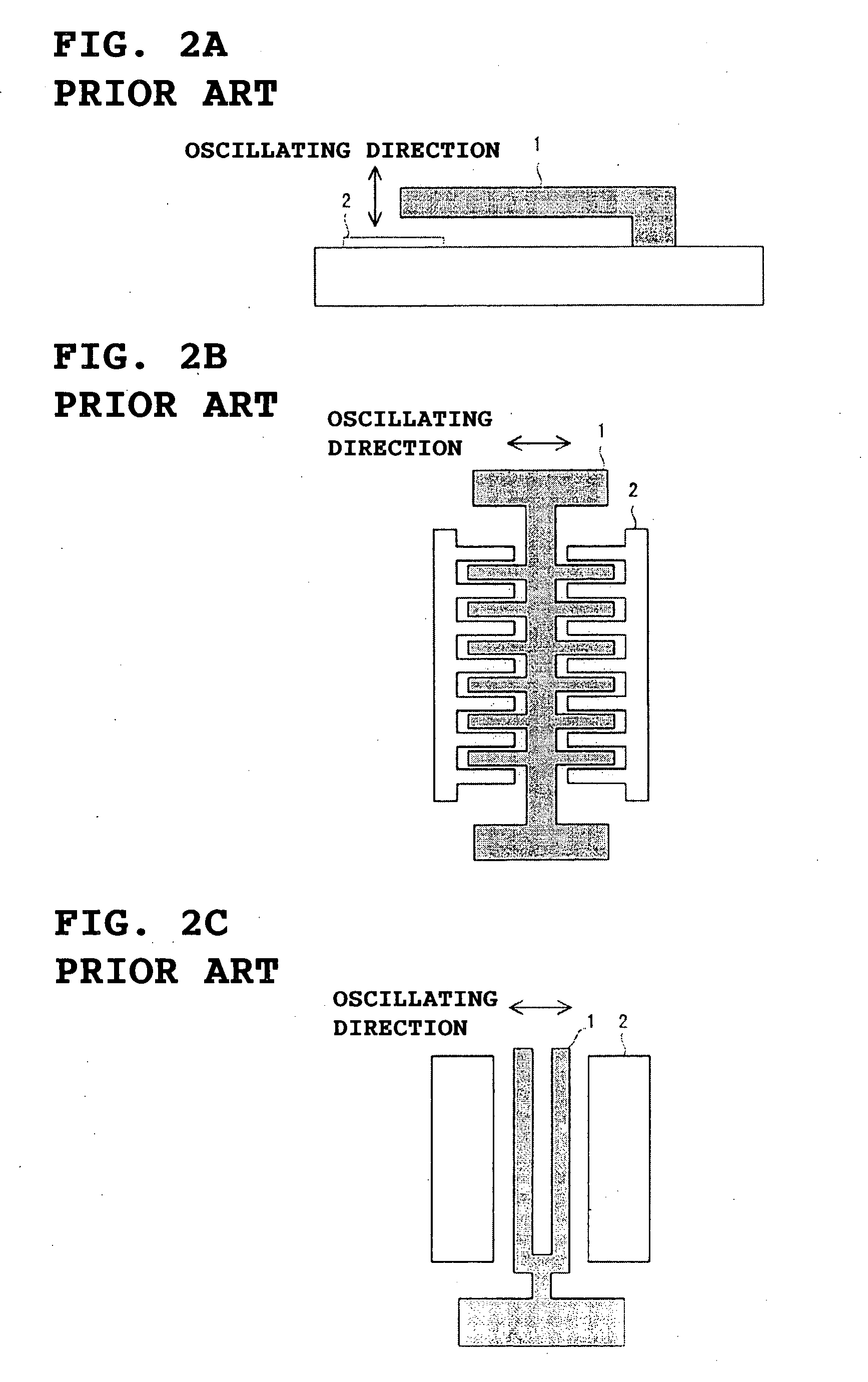

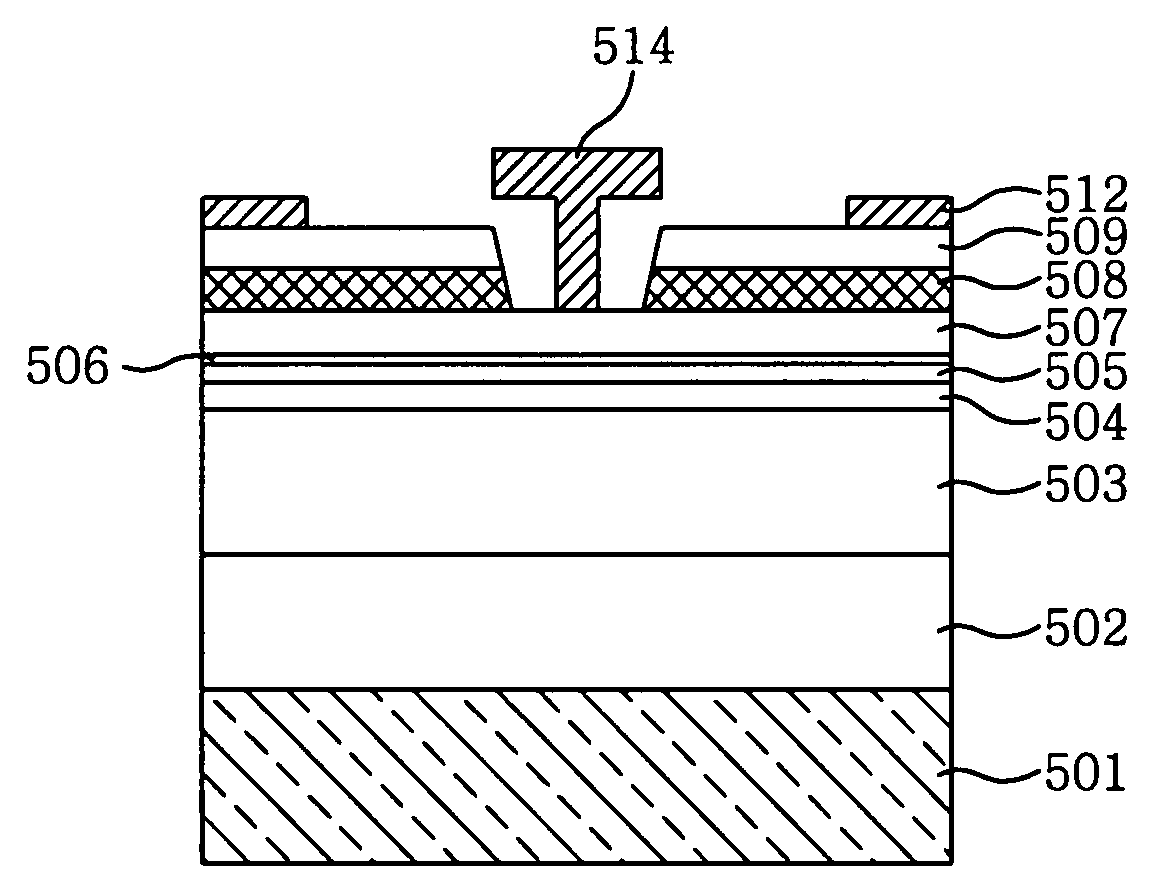

Micro electro-mechanical system and method of manufacturing the same

ActiveUS20080224319A1Avoid stickingReduce gapImpedence networksSemiconductor/solid-state device detailsMicroelectromechanical systemsEngineering

A micro electro-mechanical system, which can be stably formed so as to prevent sticking of a movable part and which has a narrow gap, and a method of manufacturing the same are provided. The micro electro-mechanical system includes at least one fixed electrode formed above a principal surface of a semiconductor substrate and at least one movable electrode formed on the principal surface. The at least one movable electrode includes the movable part separated from the principal surface and the at least one fixed electrode. The movable part is movable with respect to the principal surface and the at least one fixed electrode. The method of manufacturing the micro electromechanical system includes a sacrifical film formation step for forming a sacrifical film above the principal surface, an electrode layer formation step for forming an electrode layer above the principal surface so as to cover over the sacrifical film, an etching step for partially etching the electrode layer via a pattern so as to form the at least one electrode and the at least one fixed electrode, a sacrifical film removal step for removing the sacrifical film, and a conducting film formation step for forming a conducting film on surfaces of the at least one electrode and the at least one fixed electrode.

Owner:LAPIS SEMICON CO LTD

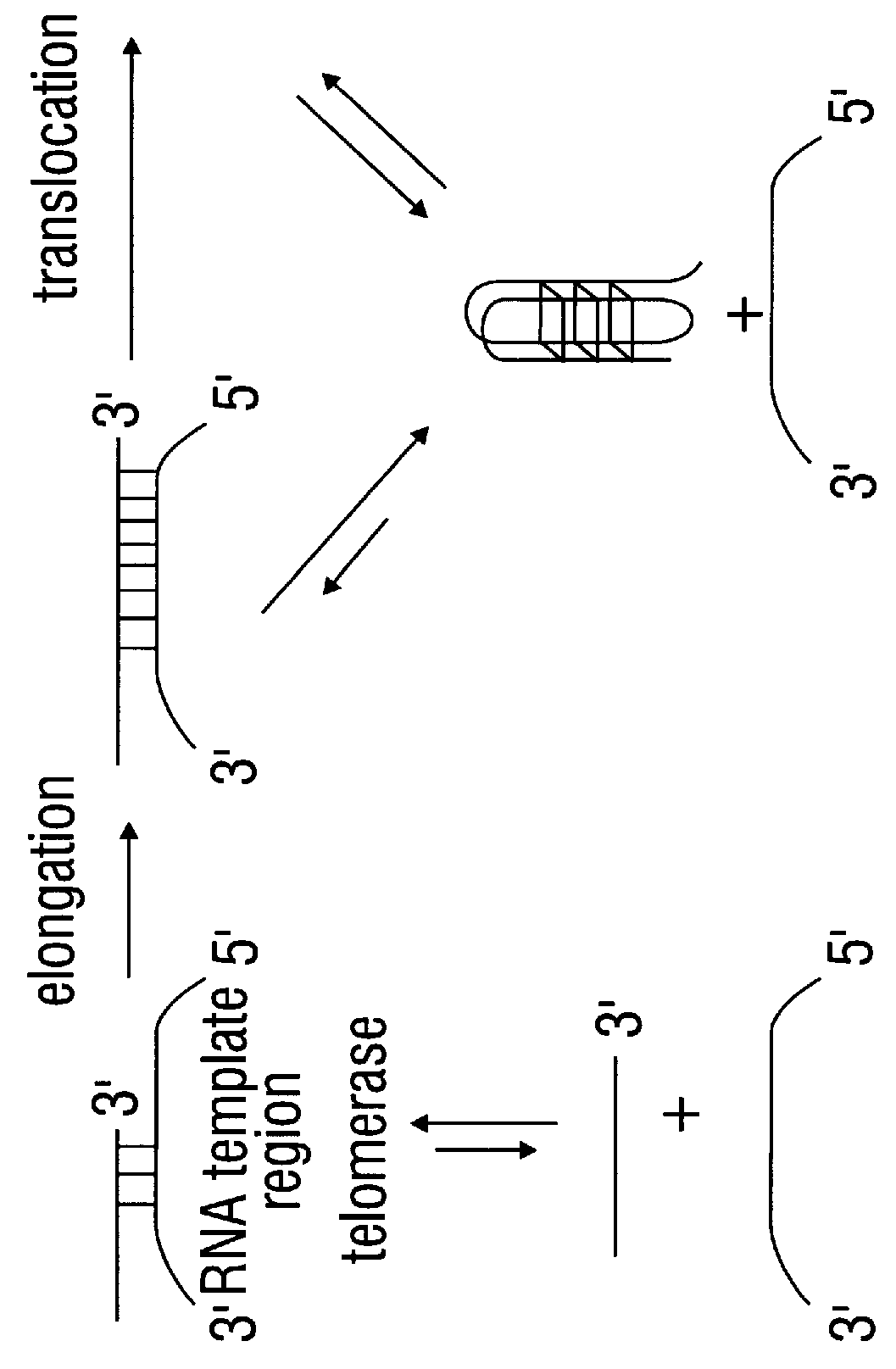

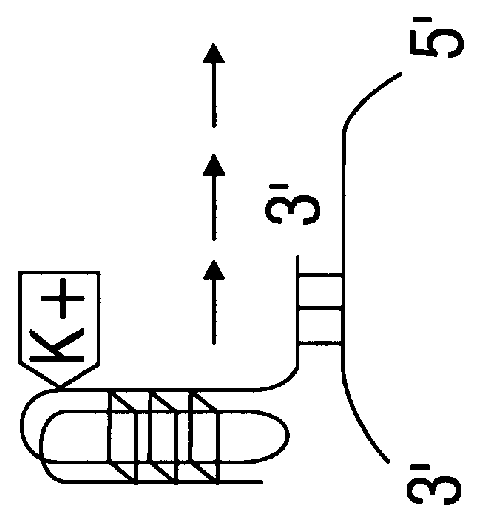

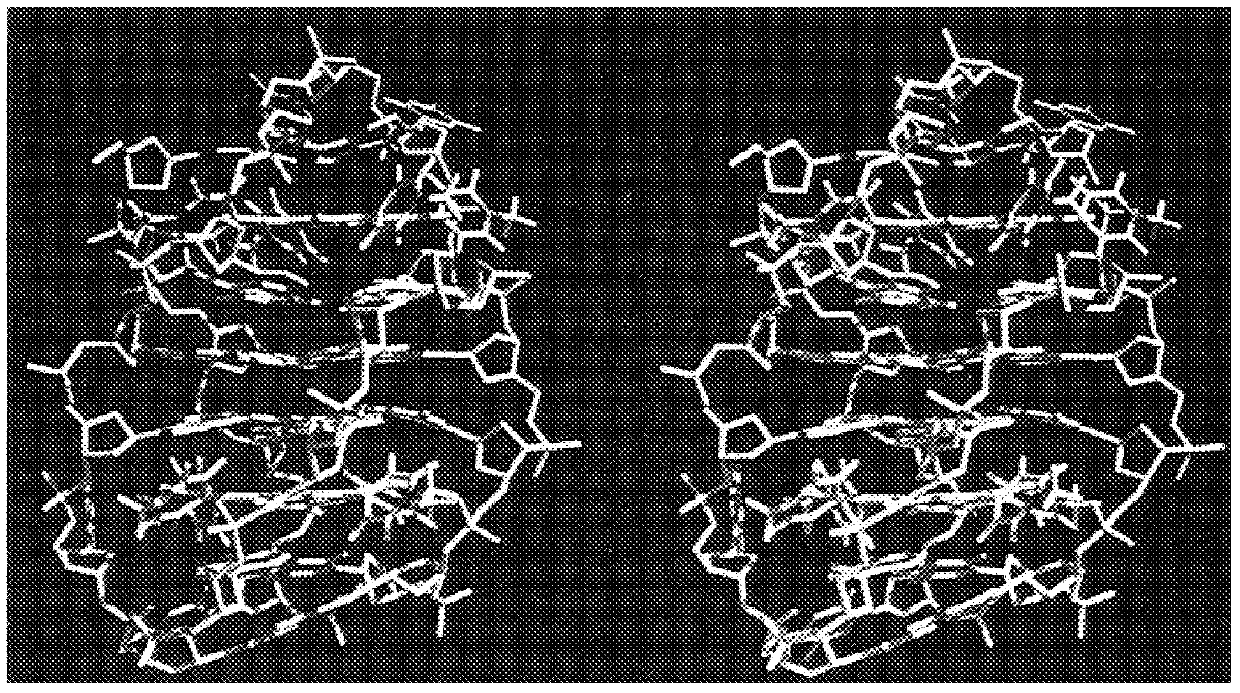

Porphyrin compounds as telomerase inhibitors

InactiveUS6087493ARegulating telomerase functionModulating tumor proliferation and mortalitySugar derivativesMicrobiological testing/measurementTelomeraseDna interaction

The present invention has identified compounds with extended aromatic chromophores that bind the G-quadruplex formed by the folding of single-stranded human telomeric DNA. These compounds have been shown to be effective telomerase inhibitors and are contemplated to be useful in developing cancer treatments. A model of cationic porphyrin interaction with quadruplex DNA by intercalation has been established and in combination with structure activity relations has provided novel porphyrin compounds that exhibit discrimination between binding duplex and quadruplex DNA and show improved activity against telomerase.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

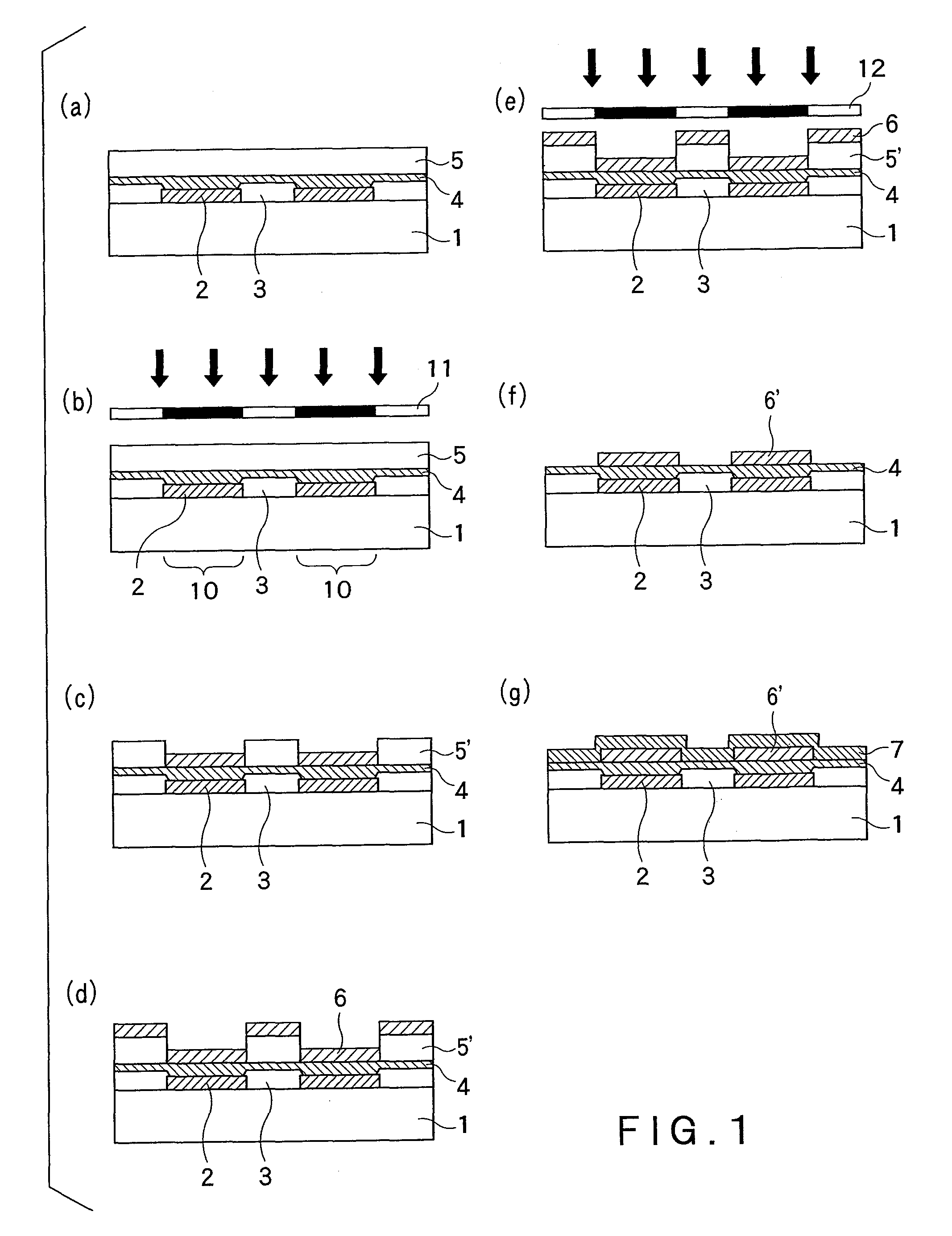

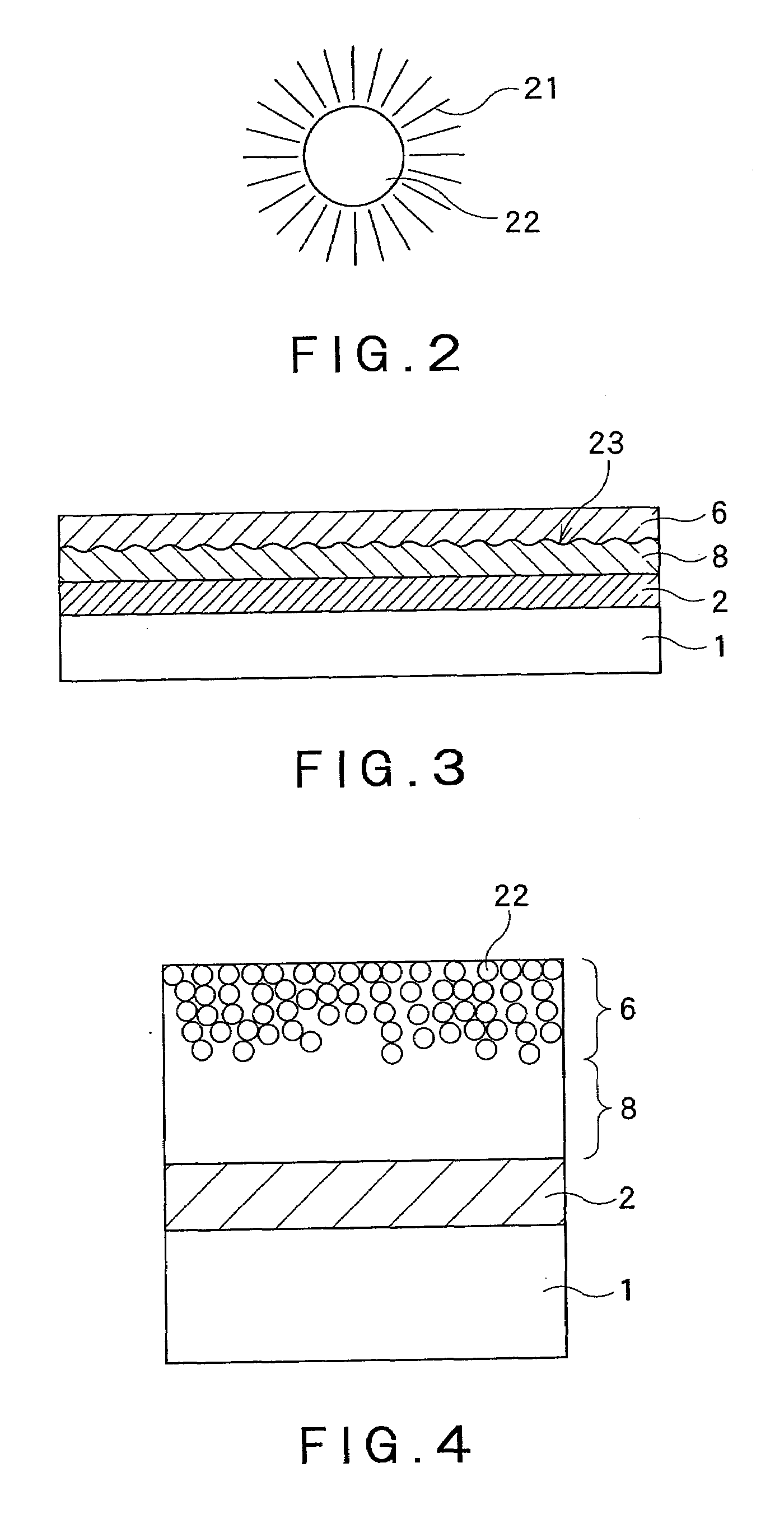

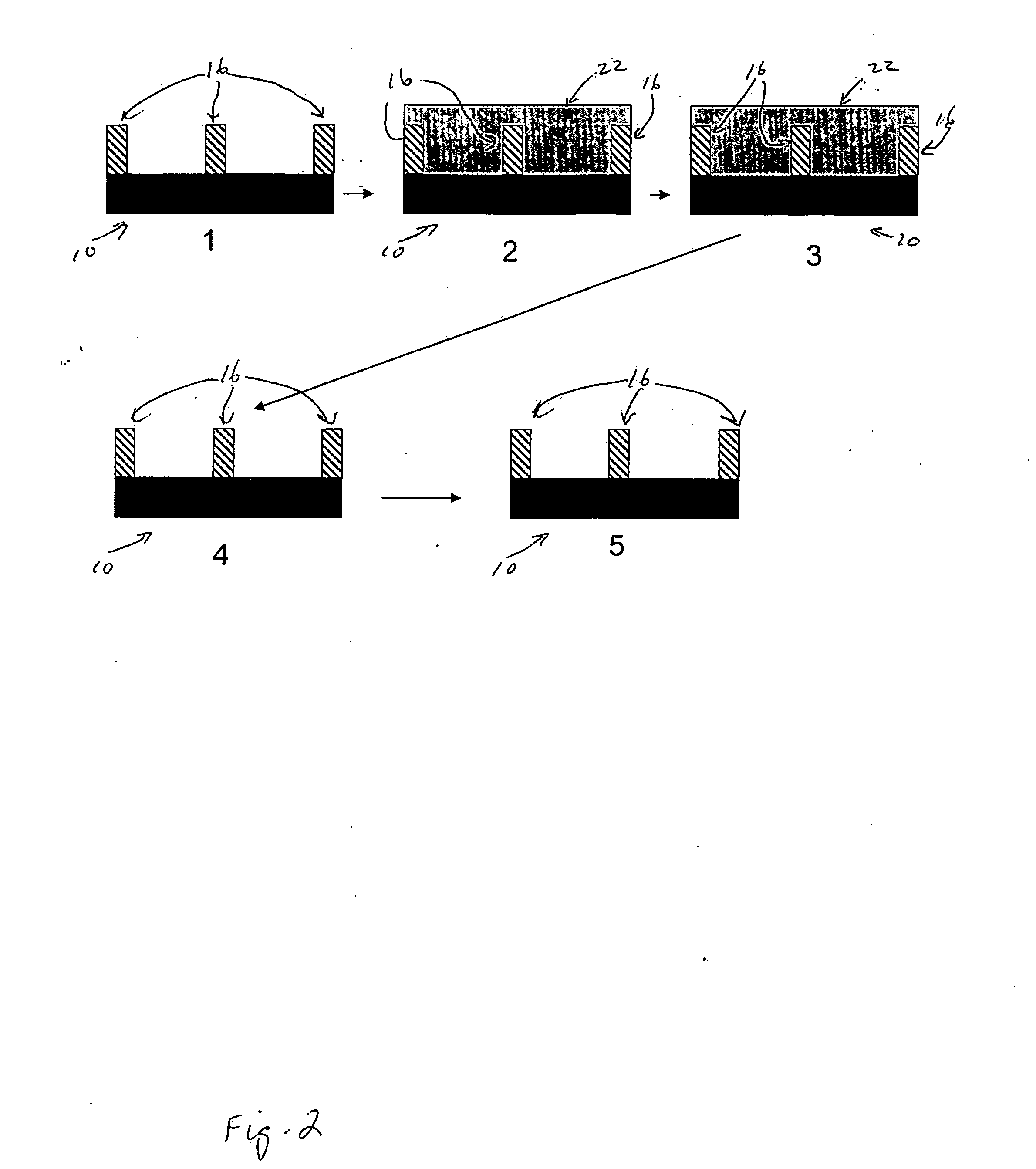

Method for manufacturing electroluminescence element

ActiveUS20090087792A1Simple processTransport charge very efficientlyElectroluminescent light sourcesSemiconductor/solid-state device manufacturingQuantum dotPhotoresist

The present invention provides a method for manufacturing an electroluminescence element that has a light emitting layer containing a quantum dot and exhibits excellent life characteristics. In the method, patterning of the light emitting layer can be stably performed by a lift-off method. A photoresist layer is formed on a substrate having a first electrode layer. The photoresist layer is then exposed, developed, and patterned to ensure that a portion of the photoresist layer, which is located in a light emission area, is removed. A coating liquid containing a quantum dot having a silane coupling agent attached to the surface thereof is coated on the resultant substrate having the patterned photoresist layer and cured to form a light emitting layer. The remaining photoresist layer is then removed to lift off a portion of the light emitting layer, which is present on the photoresist layer.

Owner:DAI NIPPON PRINTING CO LTD

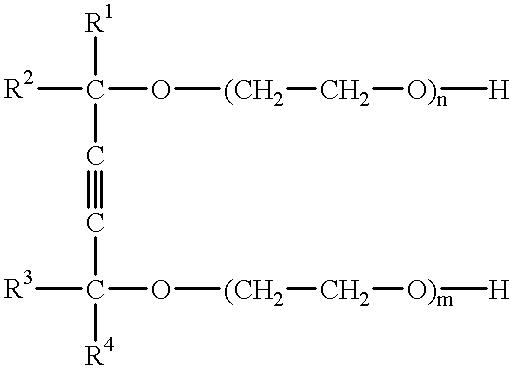

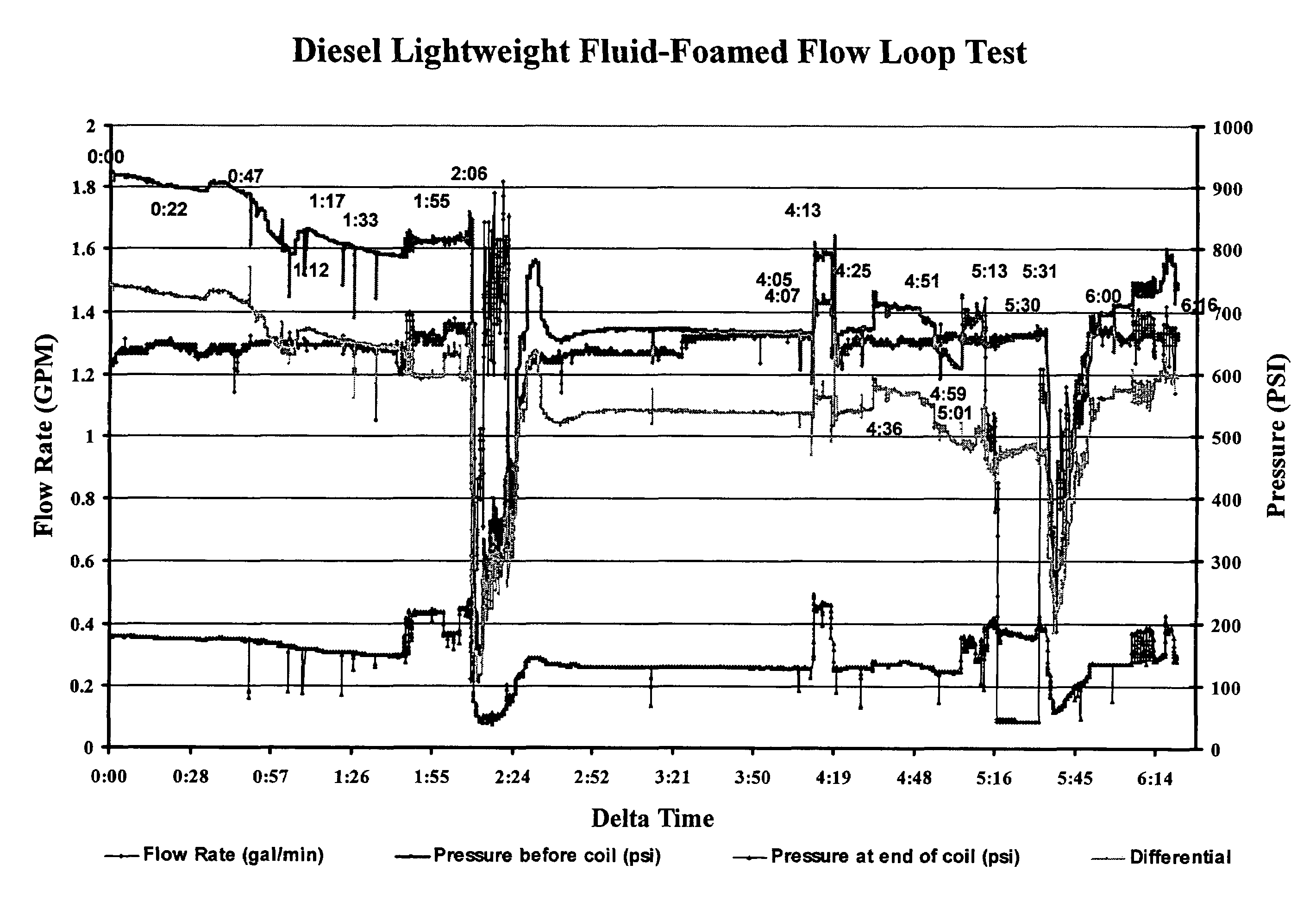

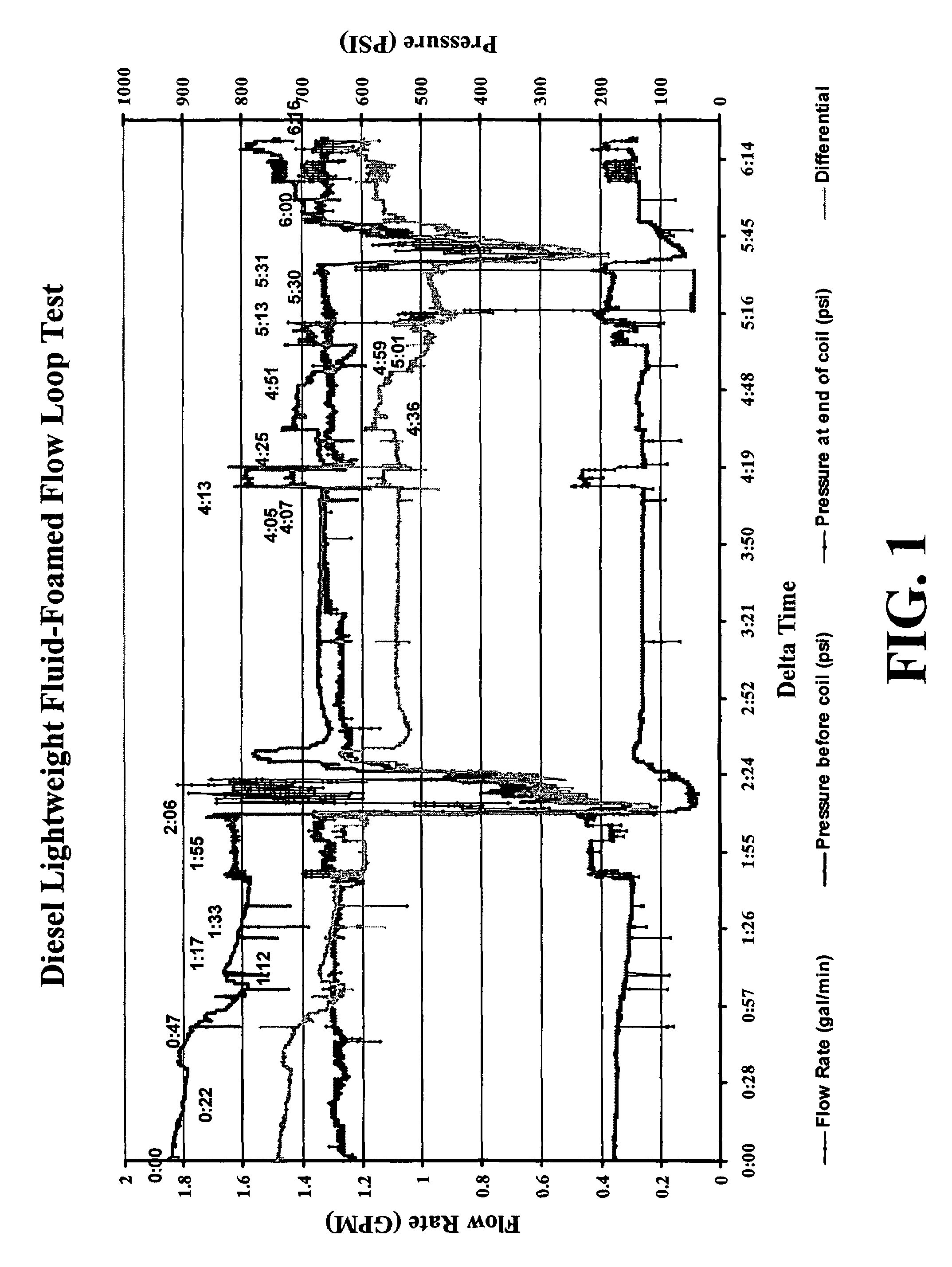

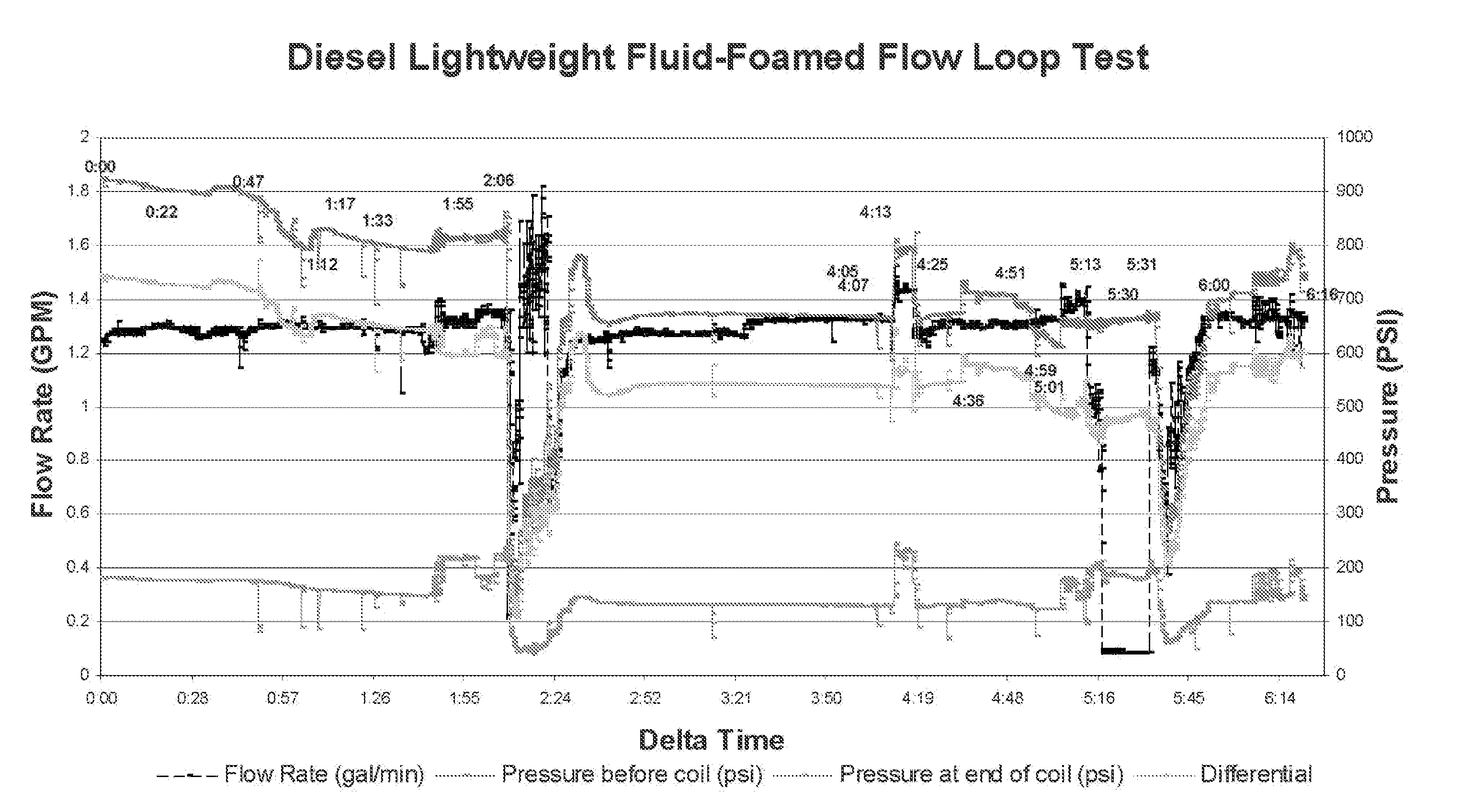

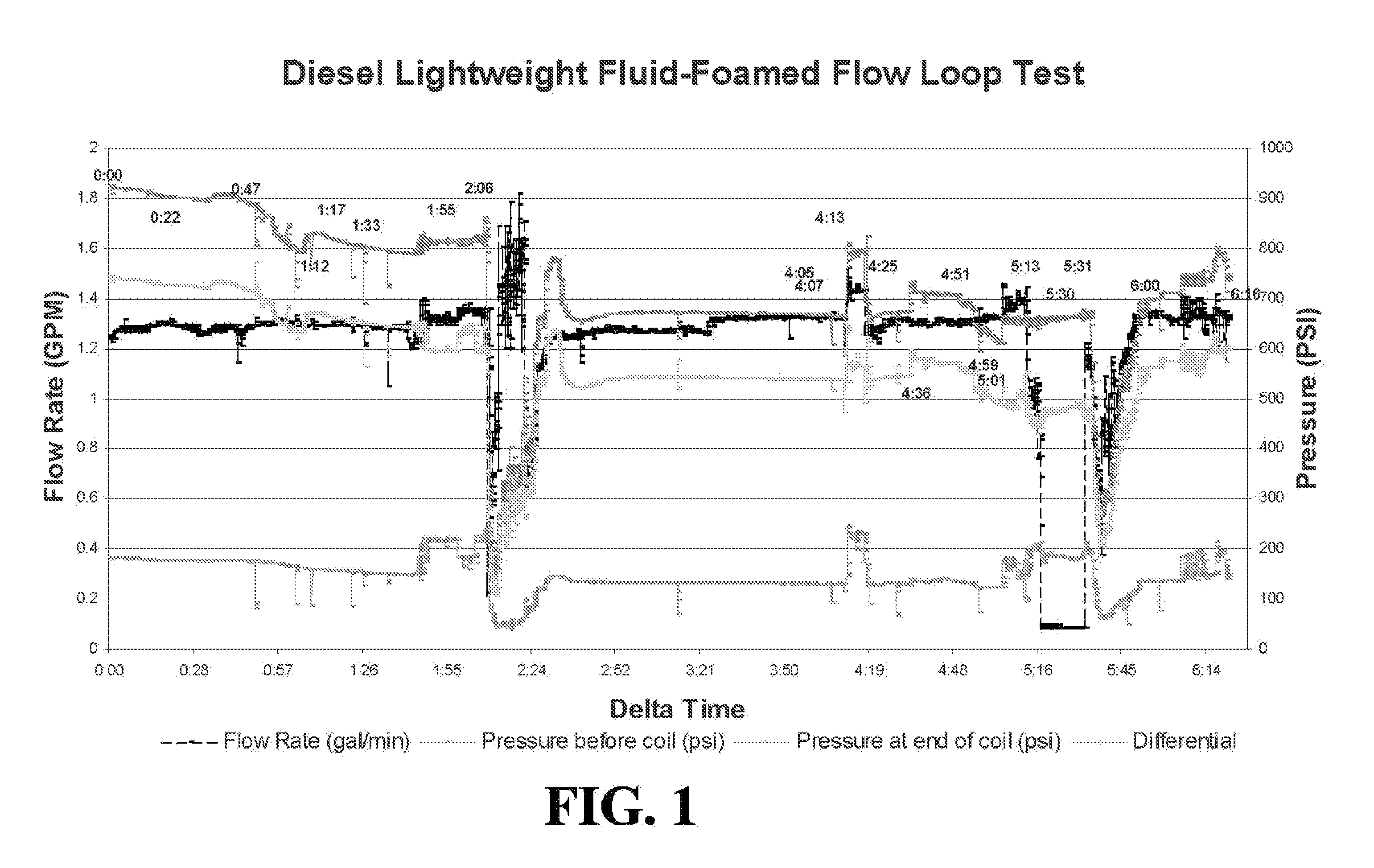

Non-aqueous foam composition for gas lift injection and methods for making and using same

InactiveUS7565933B2Reduce hydrostatic pressureHigh trafficFluid removalDrilling compositionFoaming agentGas lift

A hydrocarbon drilling fluid system is disclosed including a hydrocarbon fluid and a foaming composition, where the foaming composition includes a polymer, a gelling agent and its cross-linking agent, an optional foaming agent, or mixtures or combinations thereof. Uses of this drilling fluid system in a variety of downhole application are also disclosed.

Owner:WEATHERFORD TECH HLDG LLC

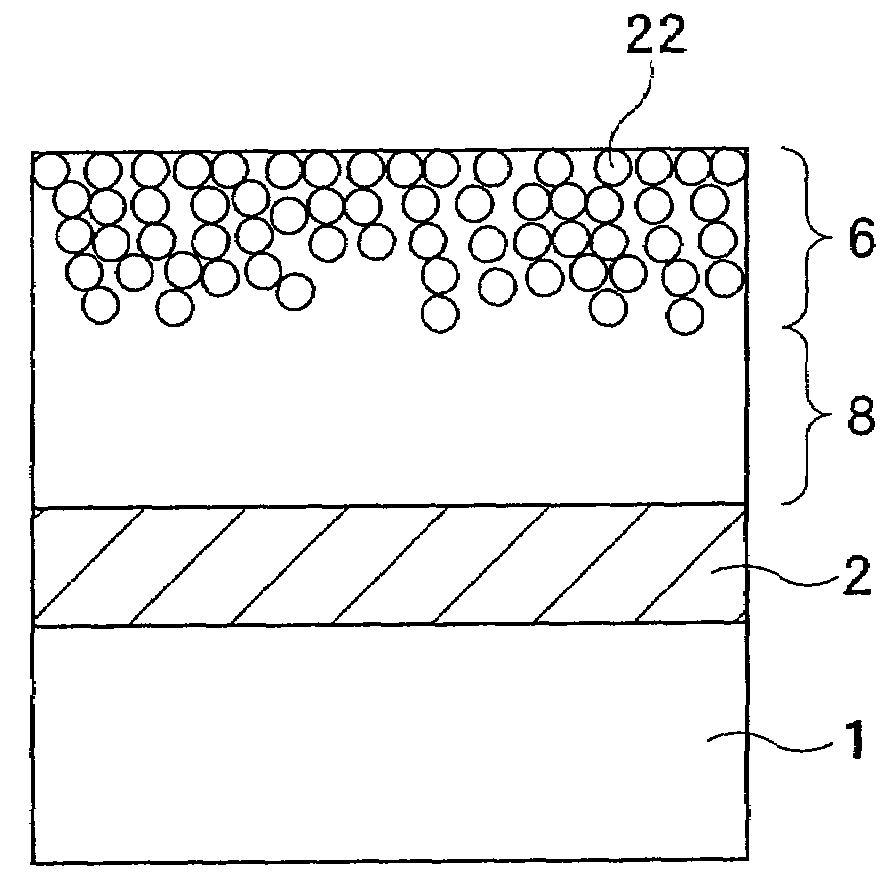

Printed circuit board and method for manufacturing printed circuit board

InactiveUS20050157478A1Lowering rate of generatingHigh bulk densityFinal product manufactureSemiconductor/solid-state device detailsCapacitanceEngineering

Chip capacitors 20 are provided in a printed circuit board 10. In this manner, the distance between an IC chip 90 and each chip capacitor 20 is shortened, and the loop inductance is reduced. In addition, the chip capacitors 20 are accommodated in a core substrate 30 having a large thickness. Therefore, the thickness of the printed circuit board does not become large.

Owner:IBIDEN CO LTD

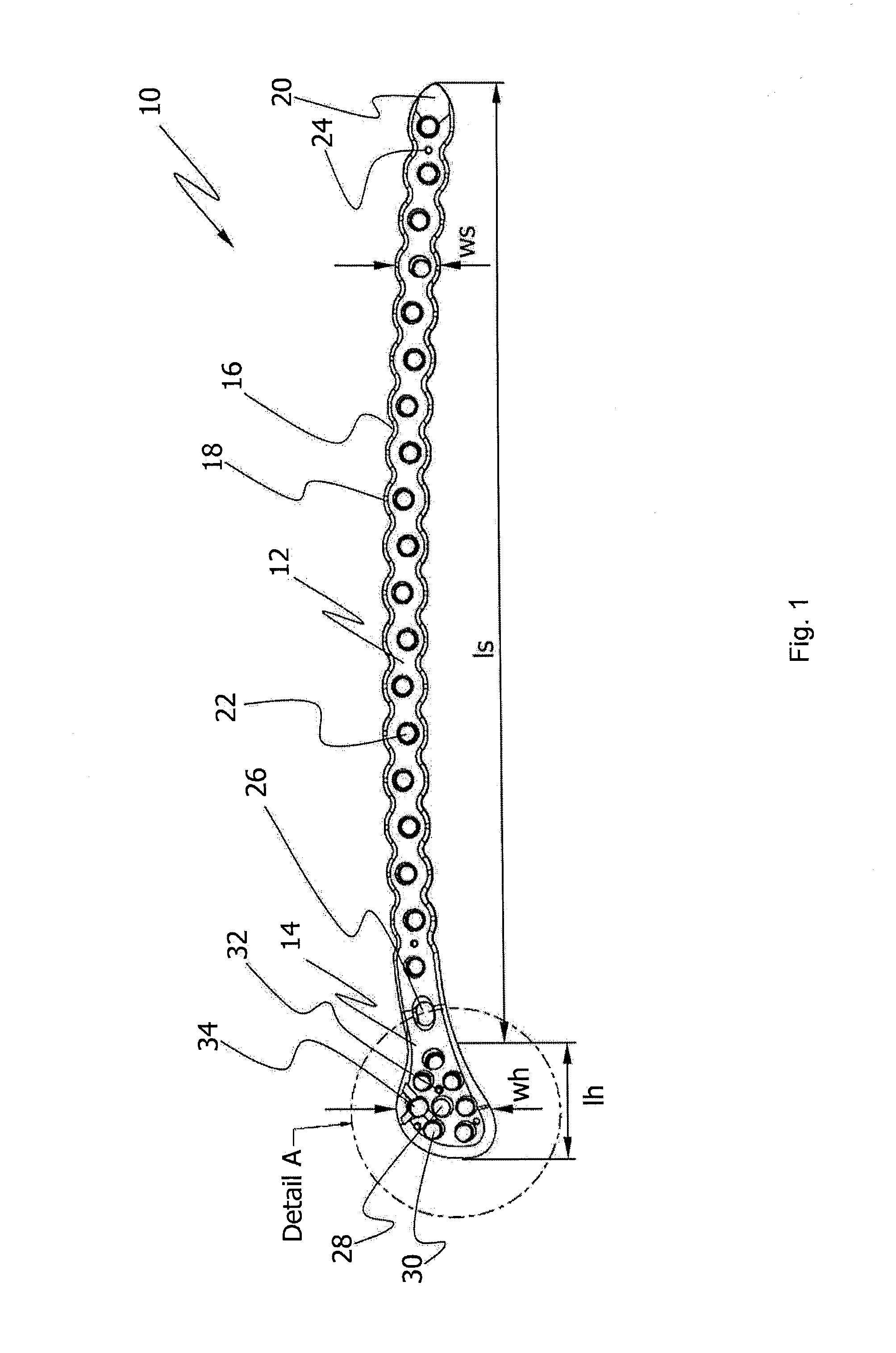

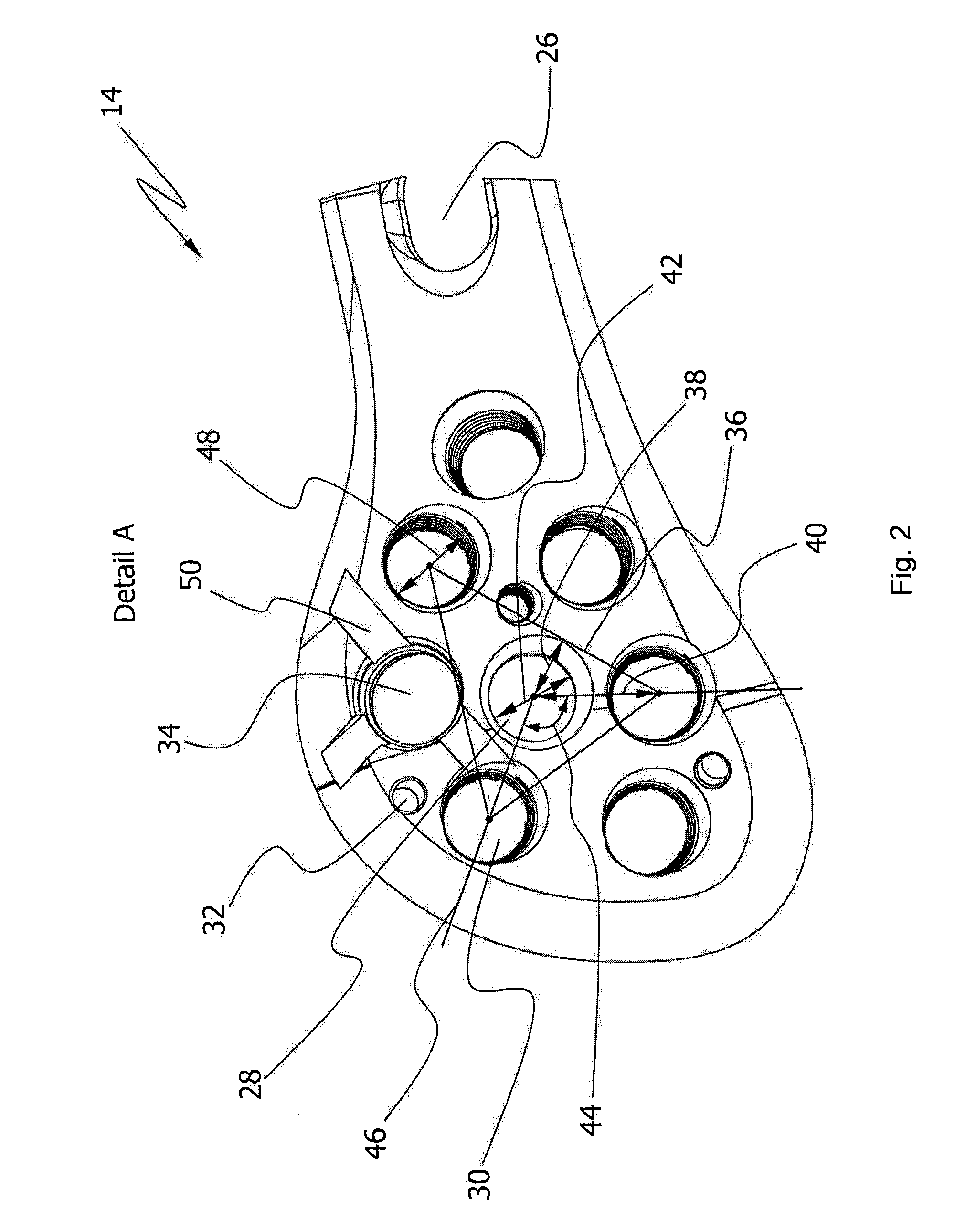

Implant for bone fixation

ActiveUS8864802B2Rapid healing of a bone fractureTall in constructionJoint implantsBone platesPlastic surgeryOrthopedic surgery

An implant for use in orthopedic surgery for fixation of bone has a shaft region and a head region, both including a plurality of holes for receiving bone fasteners. The head region of the implant has a central screw hole and threaded surrounding screw holes surrounding the central screw hole in a defined configuration.

Owner:STRYKER EURO OPERATIONS HLDG LLC

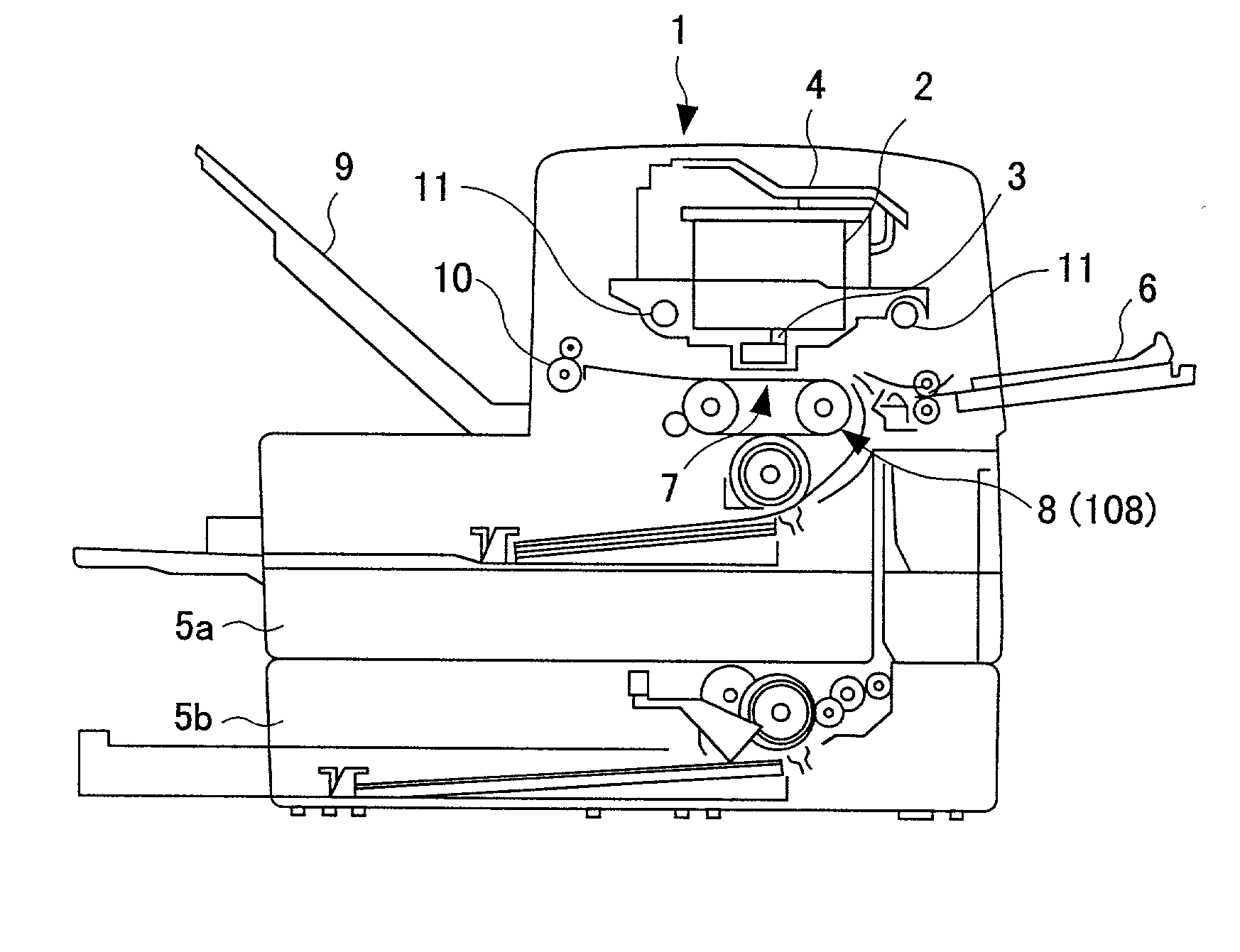

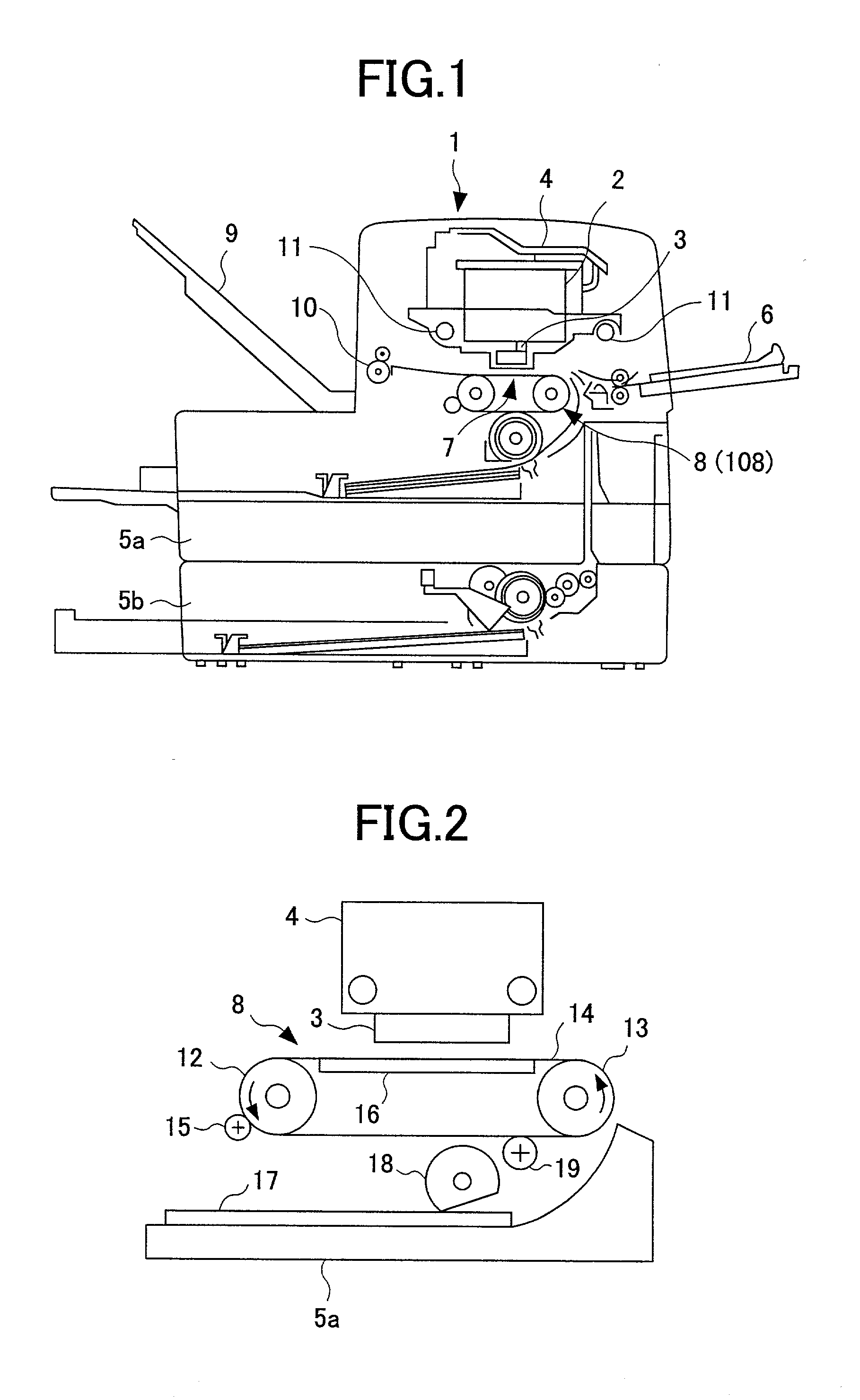

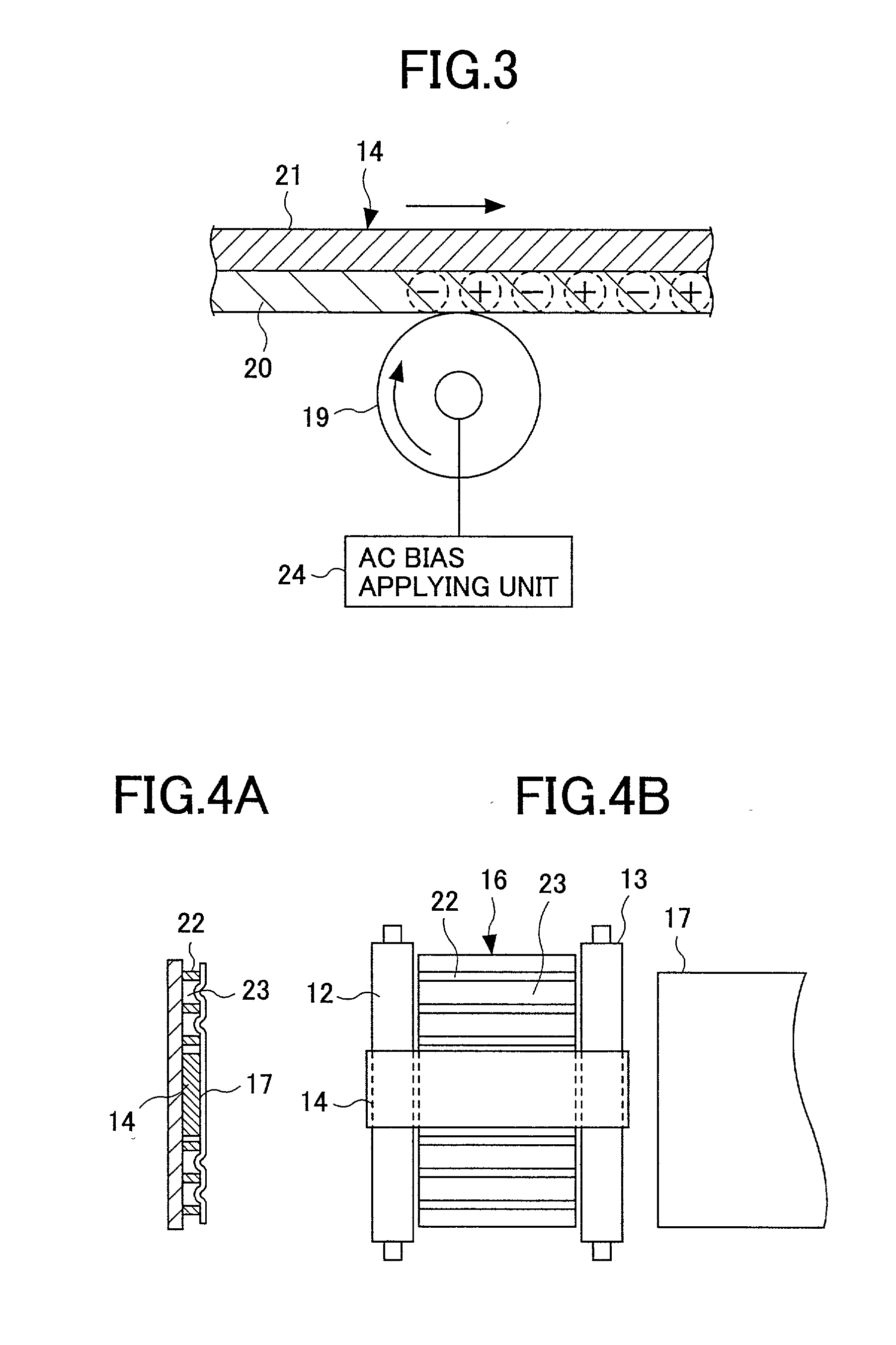

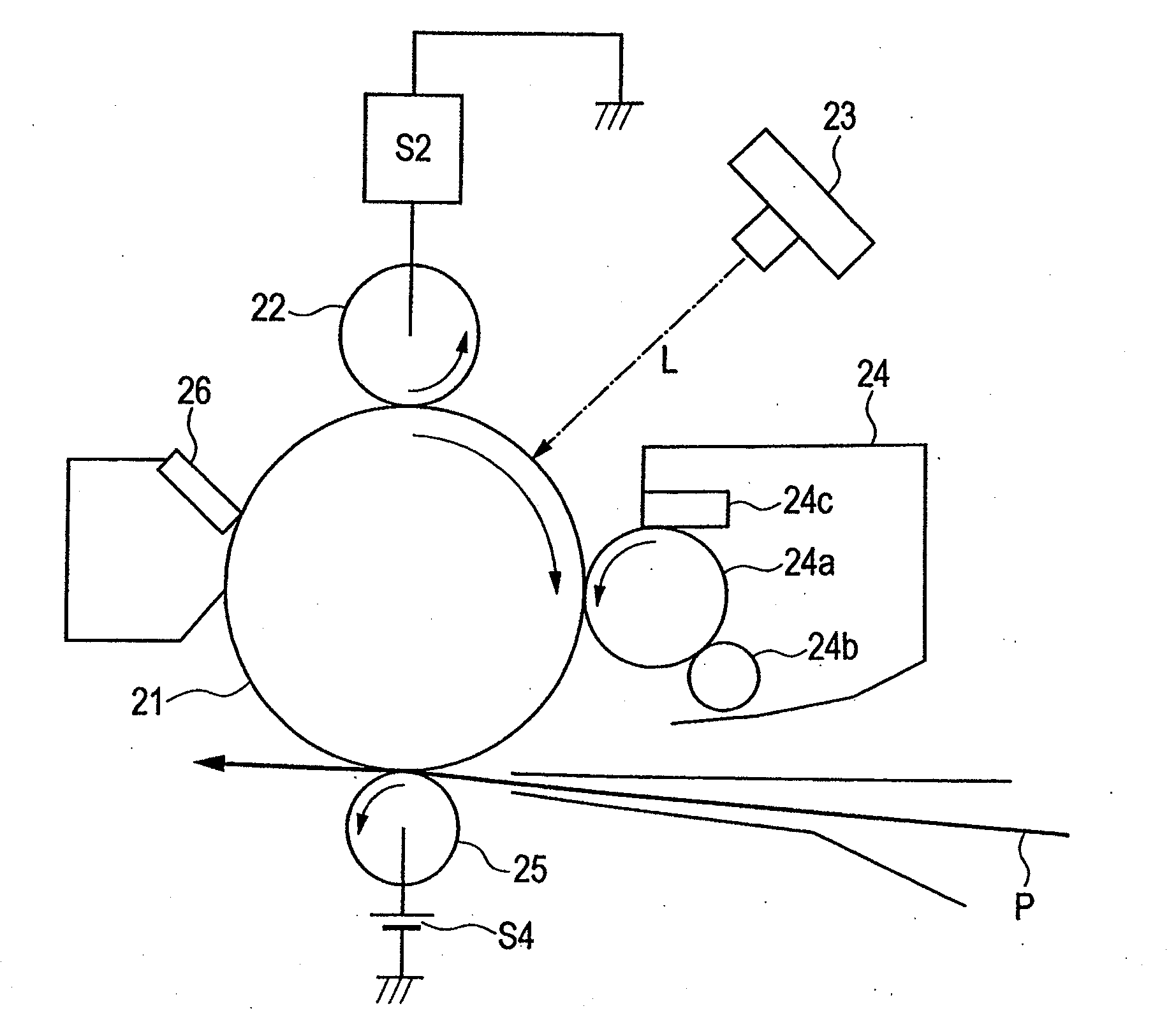

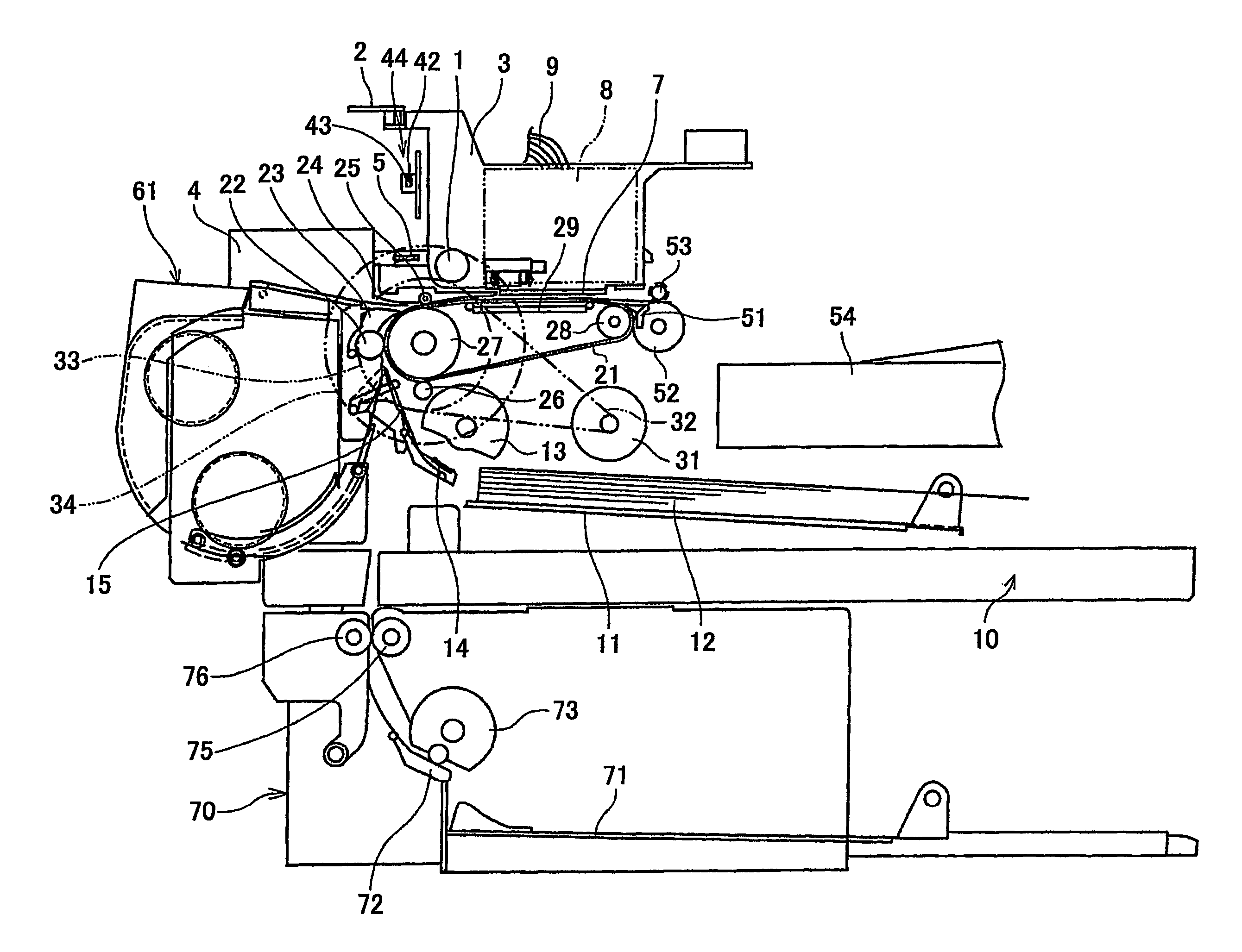

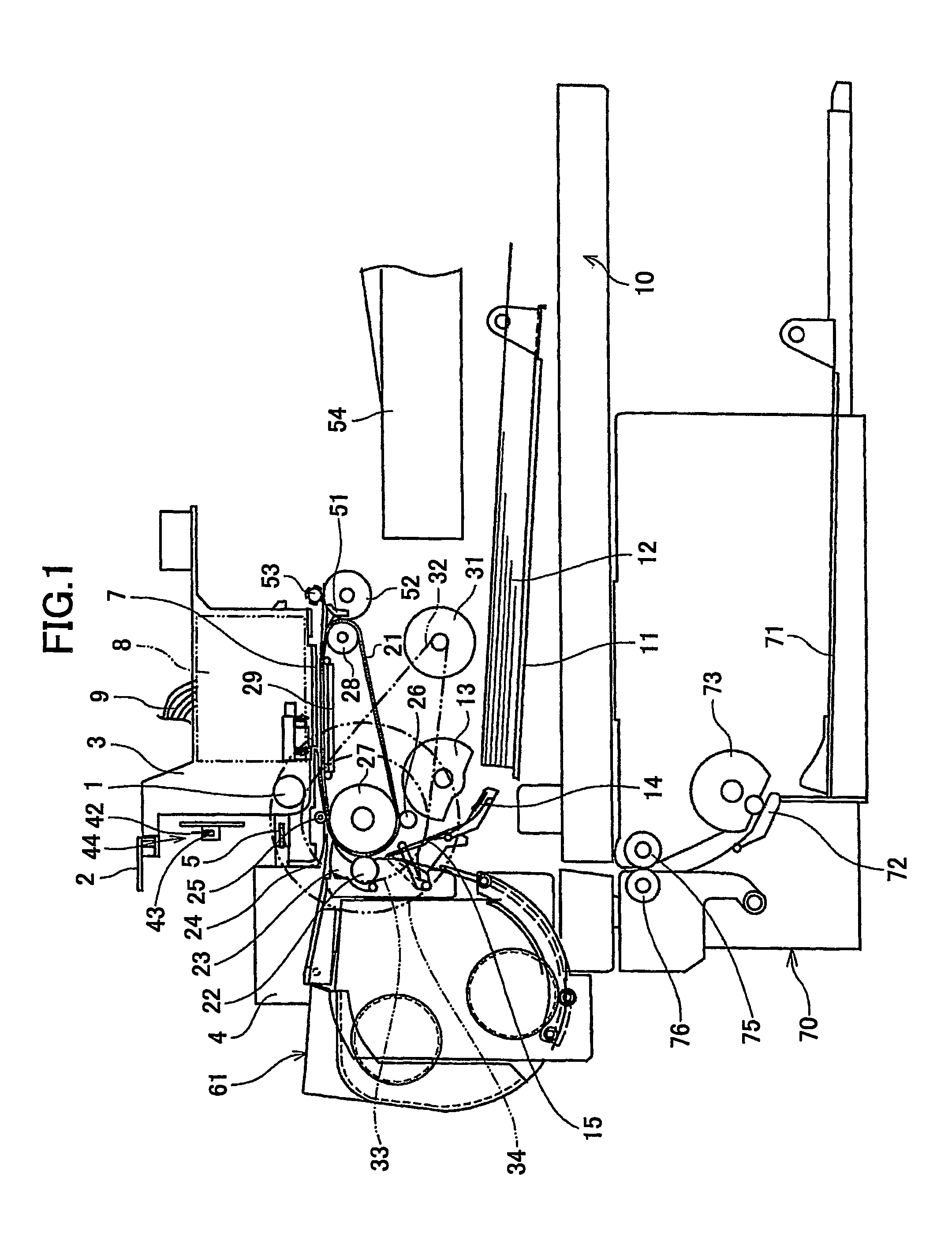

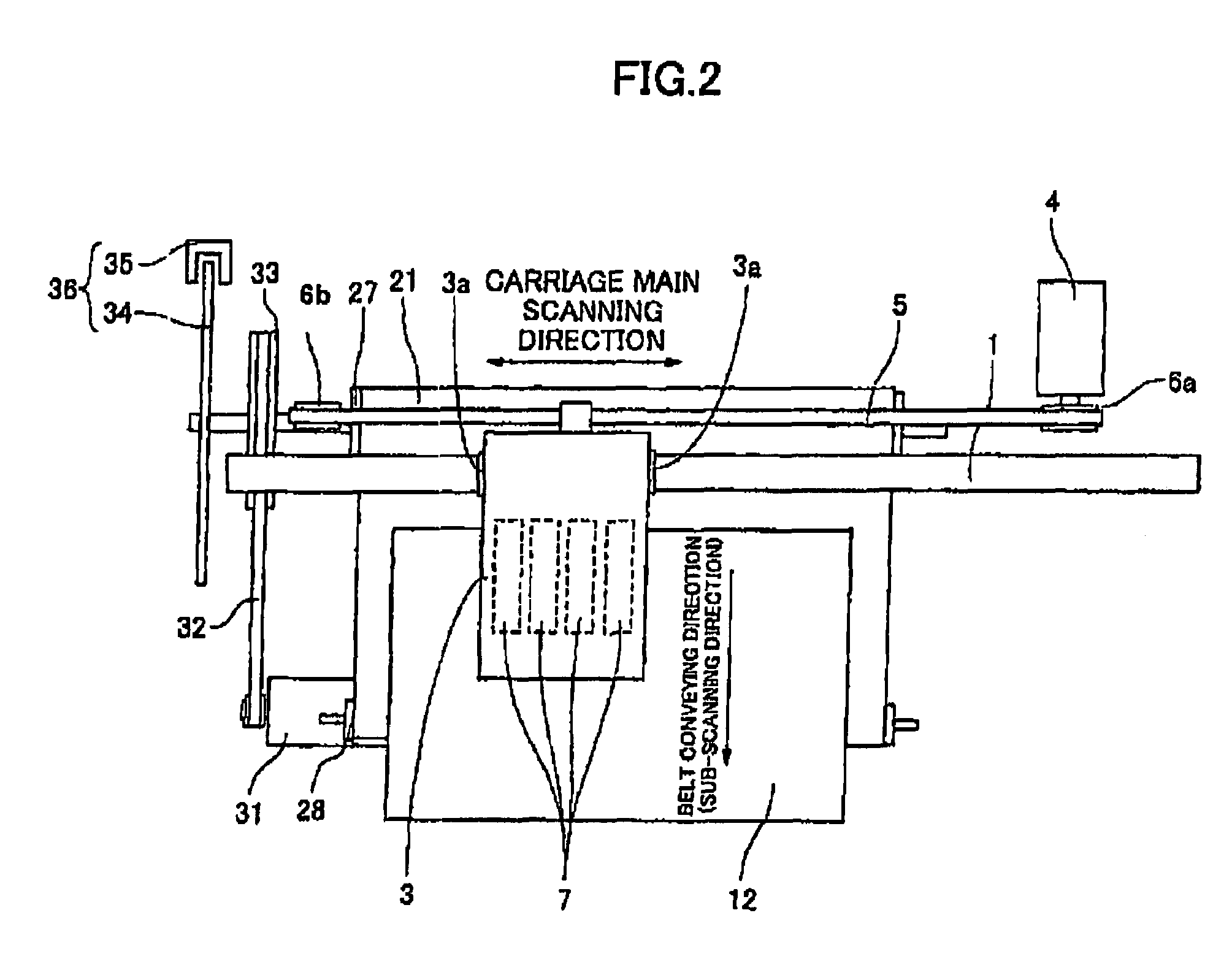

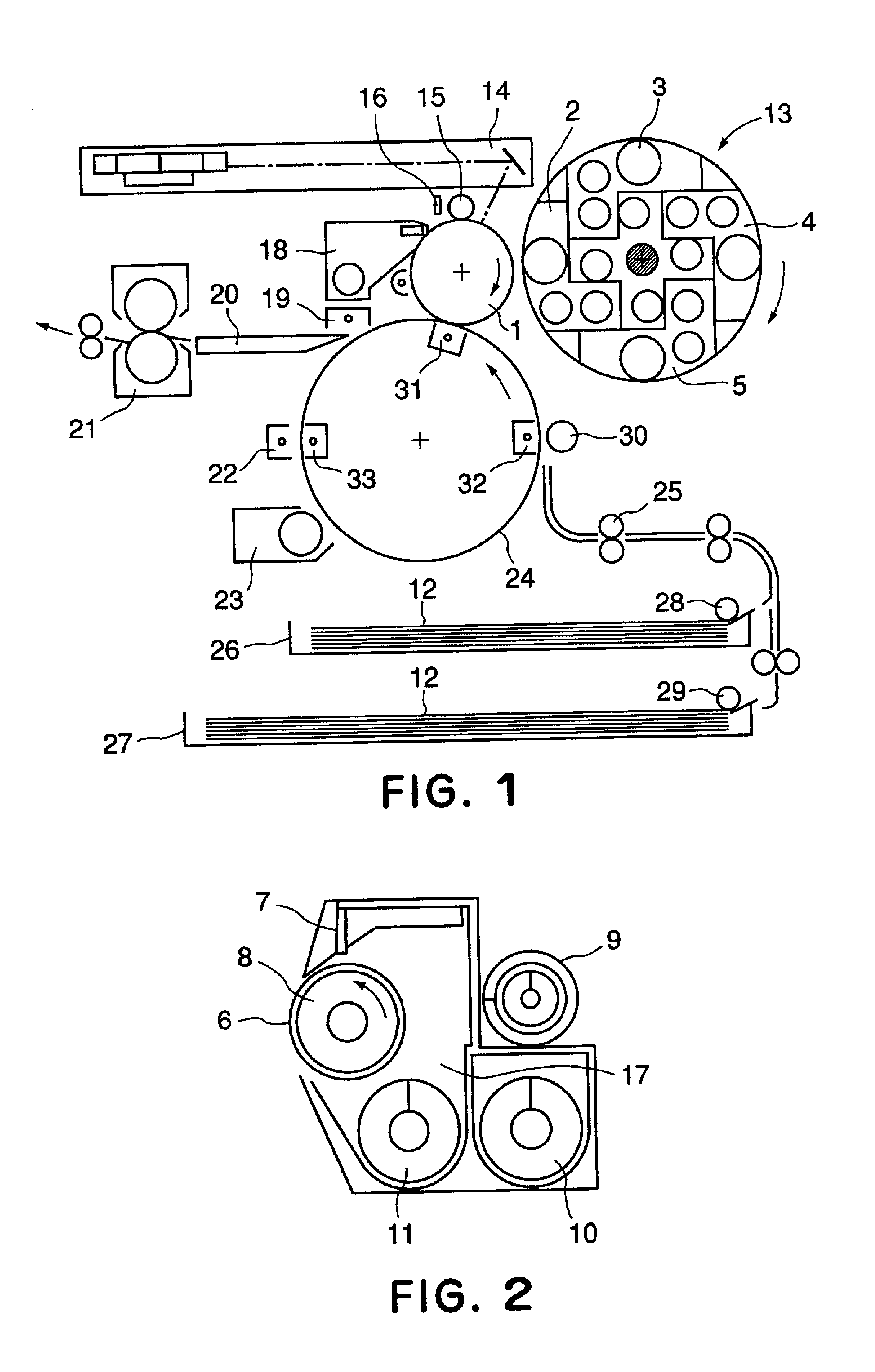

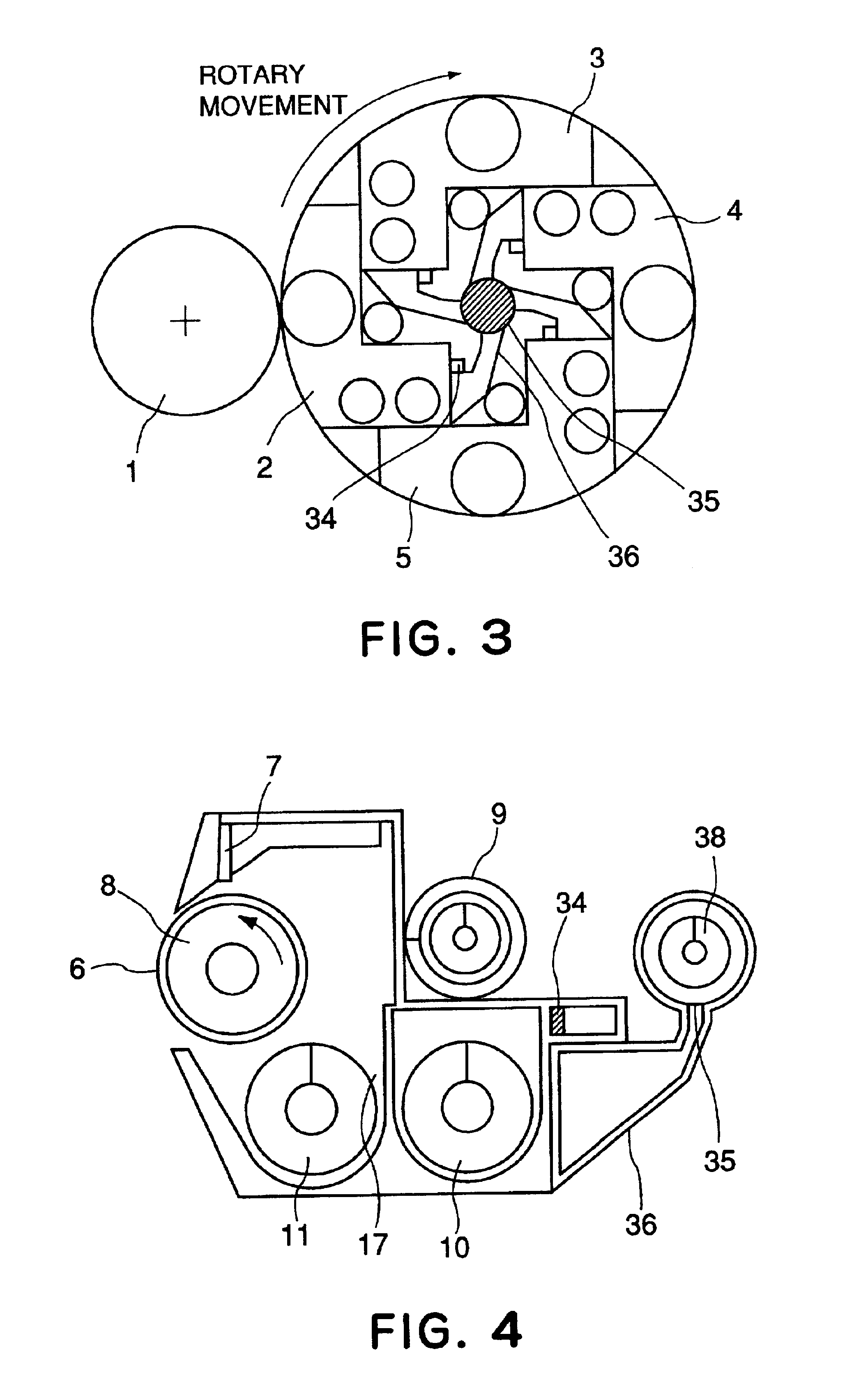

Recording-medium conveying device conveying a recording medium on a conveying belt charged with a positive charge and a negative charge alternately

InactiveUS20020126193A1Eliminate the problemHigh precisionOther printing apparatusArticle feedersImage recordingEngineering

This recording-medium conveying device comprises a conveying belt, the conveying belt, a belt charging unit, and a pressing roller. The conveying belt is wound around a driving roller and a driven roller so as to convey a recording medium to an image recording part. The conveying belt includes an insulating layer formed at one side contacting the recording medium. The belt charging unit is provided in contact with the insulating layer so as to charge the insulating layer with a positive charge and a negative charge alternately in a moving direction of the conveying belt by applying an AC bias to the conveying belt. The pressing roller presses the conveying belt against the driving roller so as to prevent the conveying belt from slipping on the driving roller.

Owner:RICOH KK

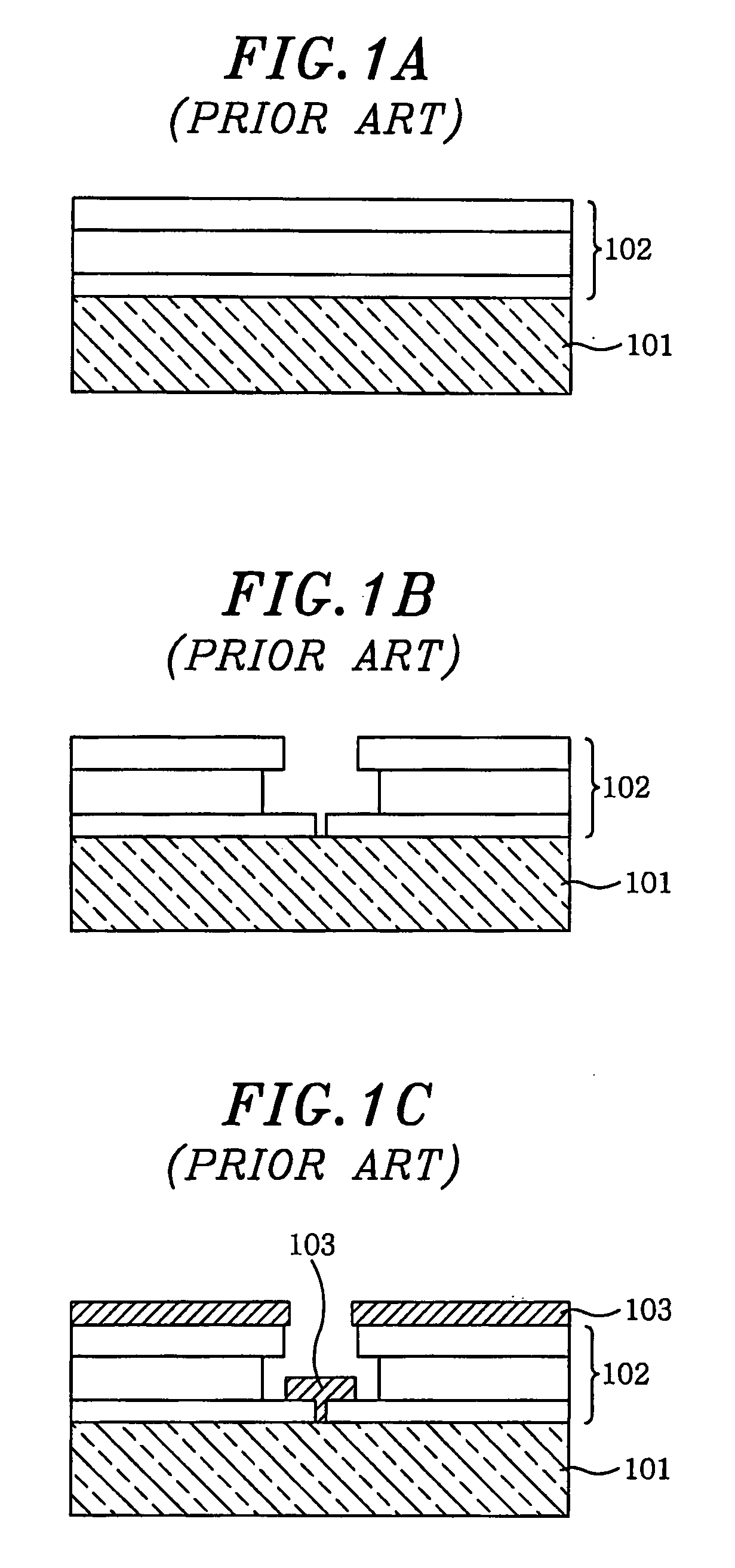

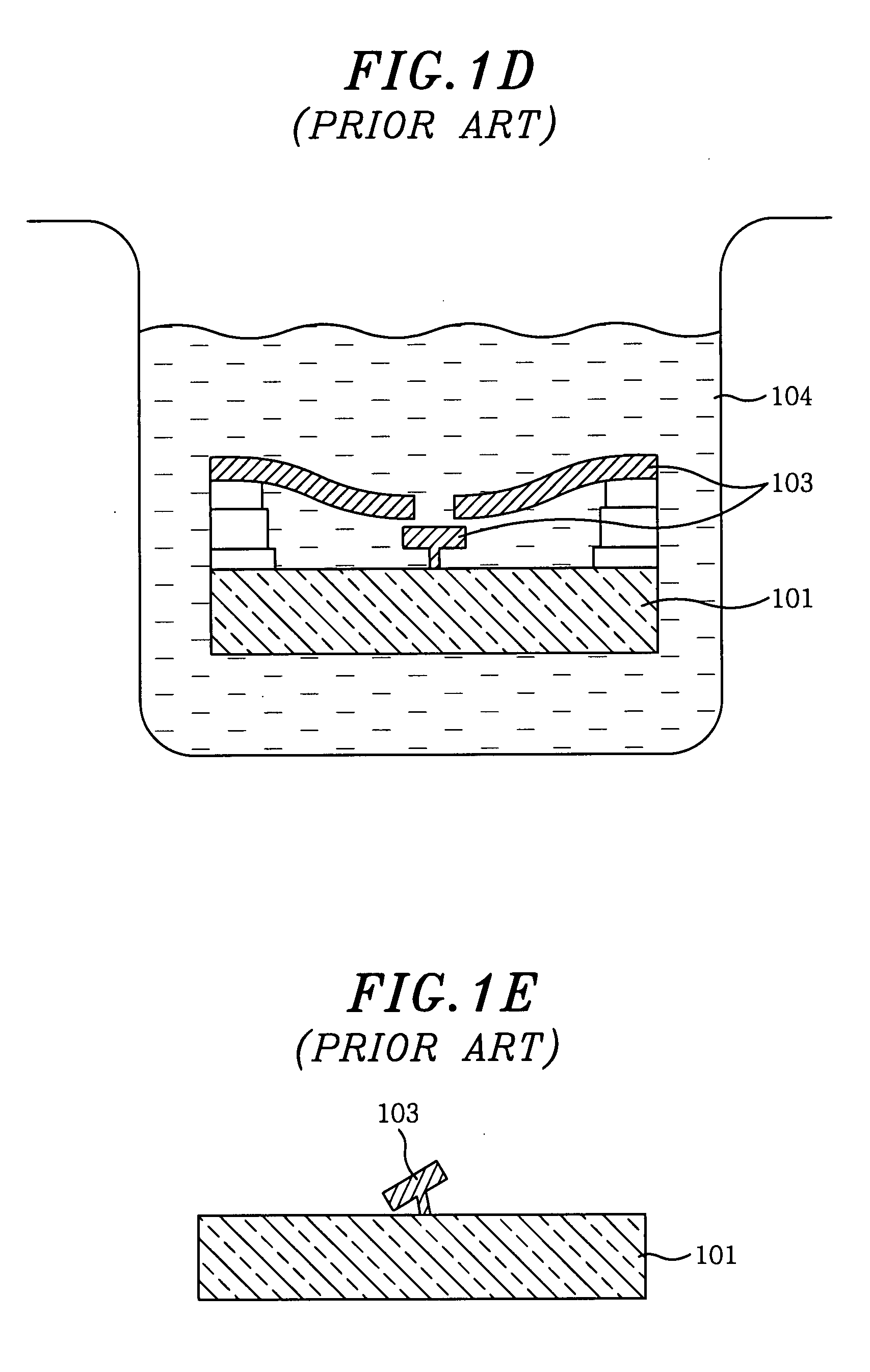

T-gate forming method and metamorphic high electron mobility transistor fabricating method using the same

InactiveUS20080182369A1Reduce physical impactImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesResistMetamorphic high electron mobility transistor

A method for forming a T-gate of a metamorphic high electron mobility transistor is provided. The method includes sequentially laminating a plurality of resist films on a substrate; forming a T-shaped pattern in the laminated resist films using electron beam lithography; forming a gate metal layer on the substrate where the T-shaped pattern has been formed; attaching an adhesion member to the gate metal layer formed on a top surface of the laminated resist films and detaching the adhesion member to thereby remove the gate metal layer; and removing the laminated resist films.

Owner:POSTECH ACAD IND FOUND

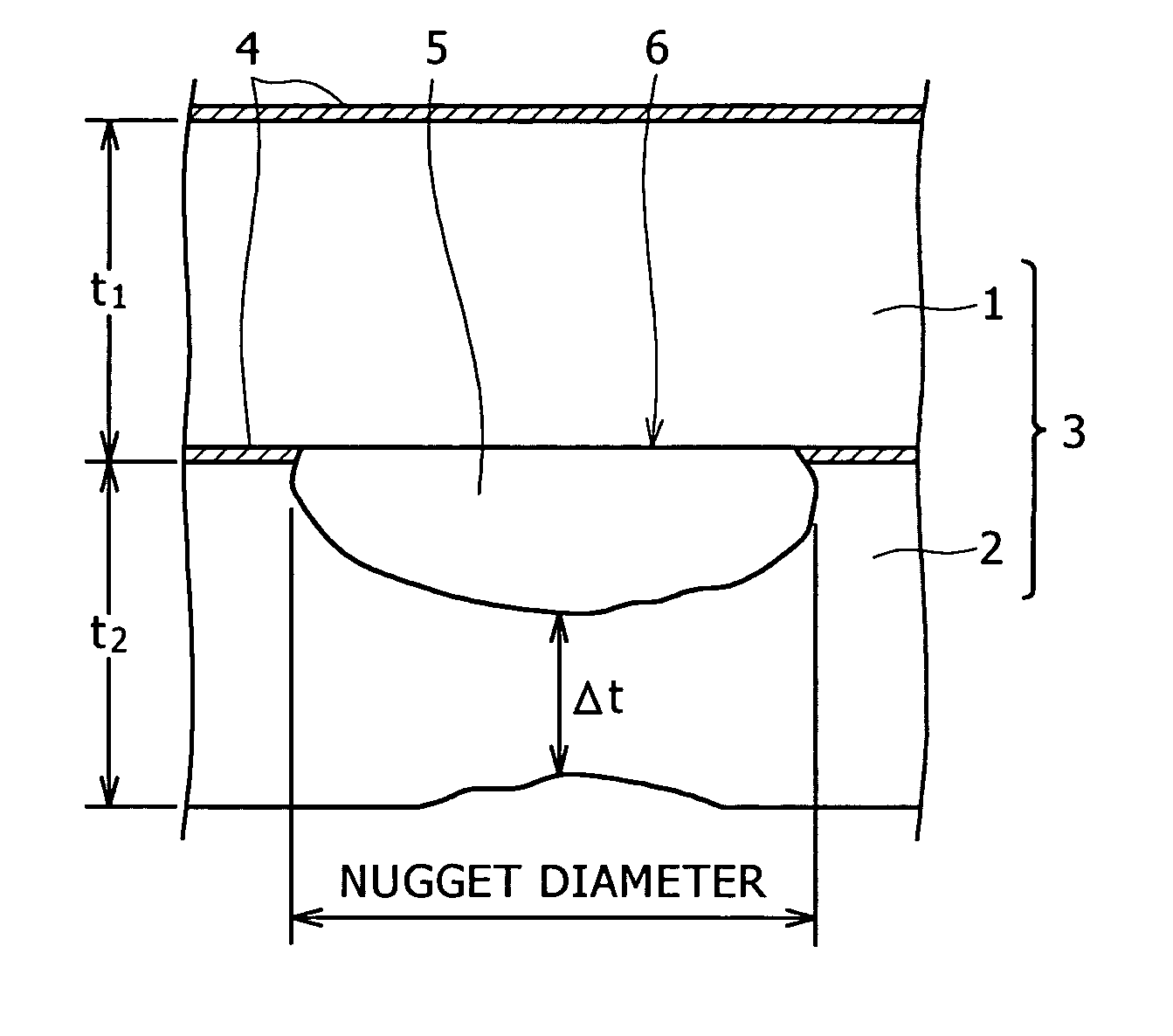

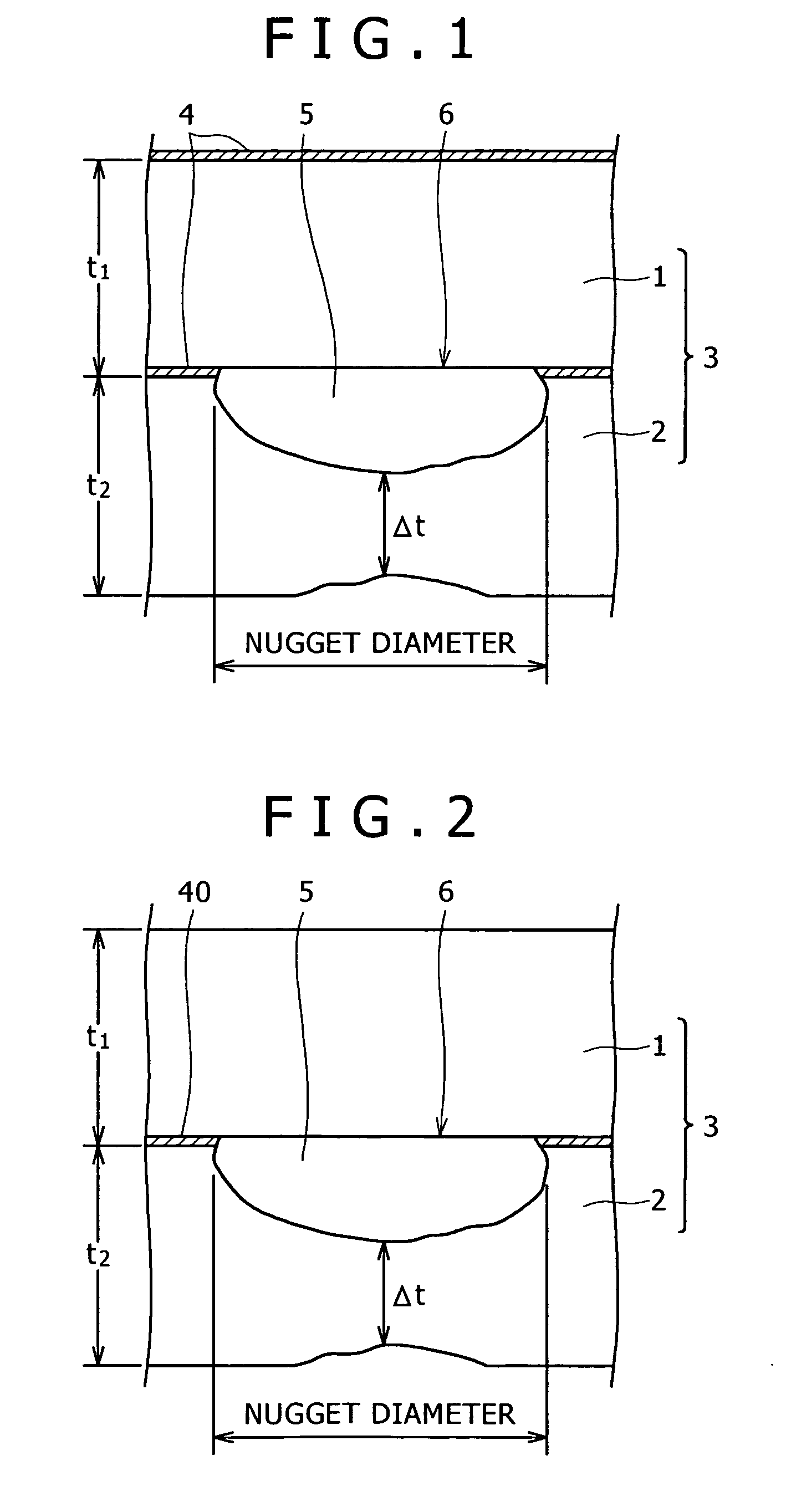

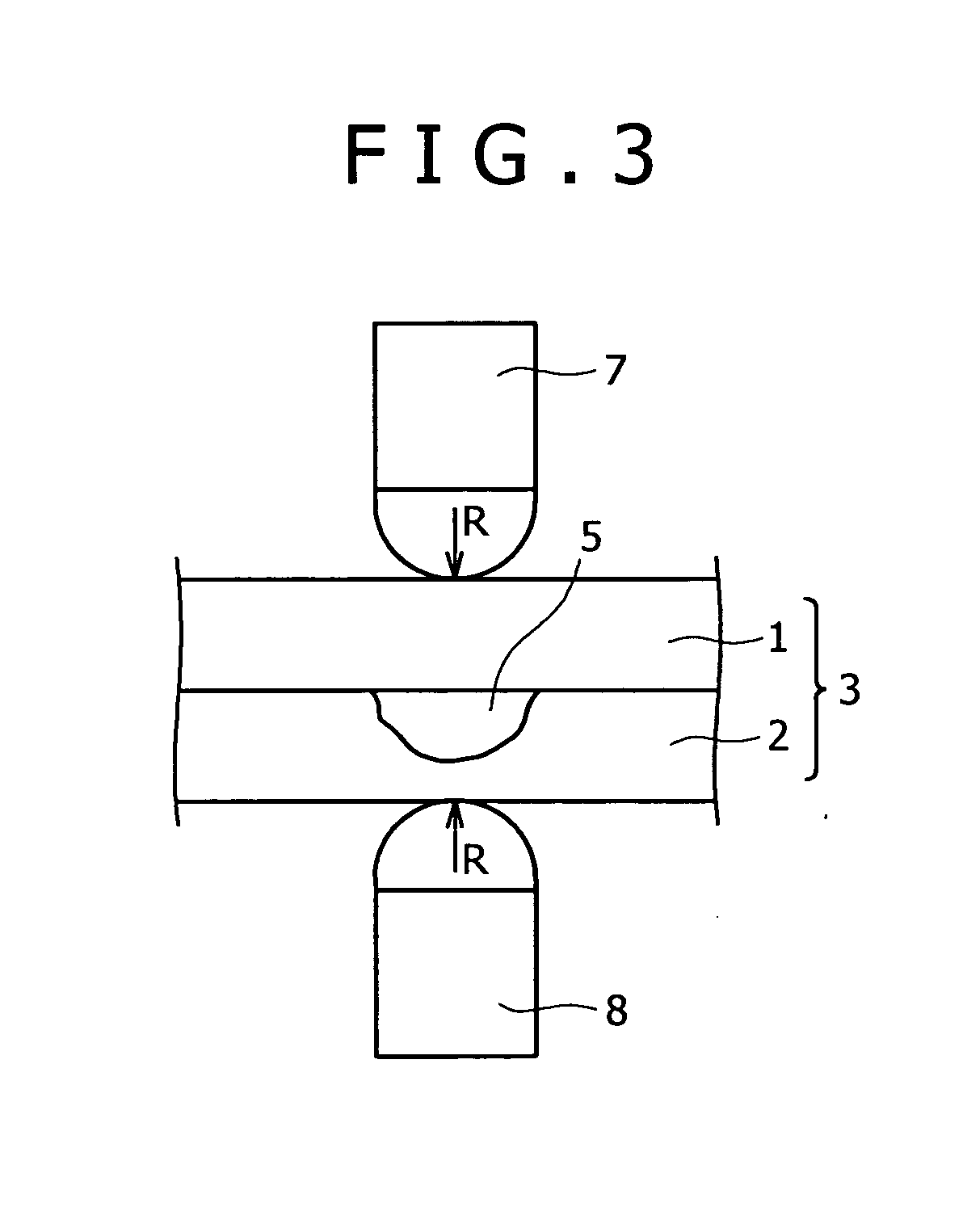

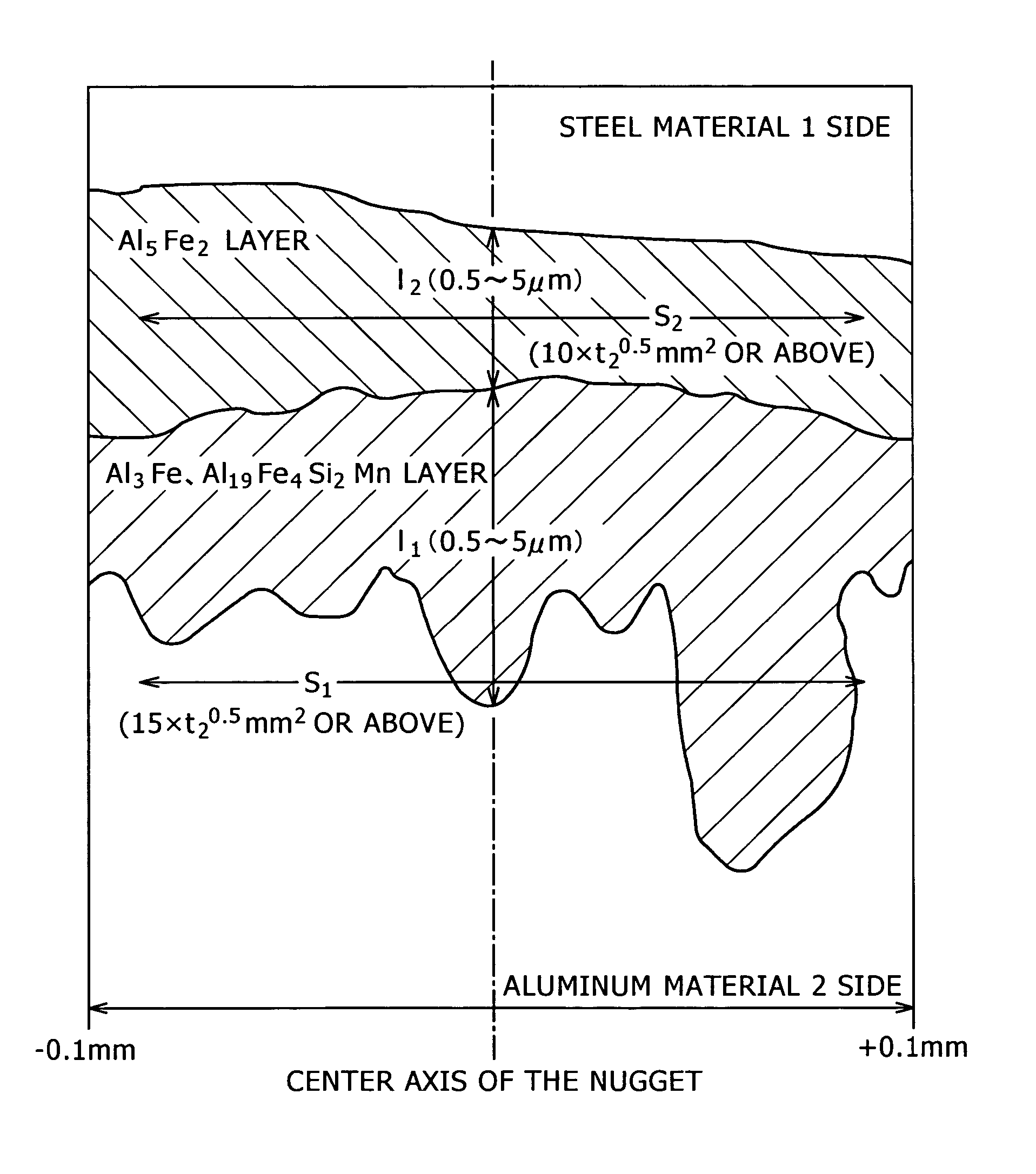

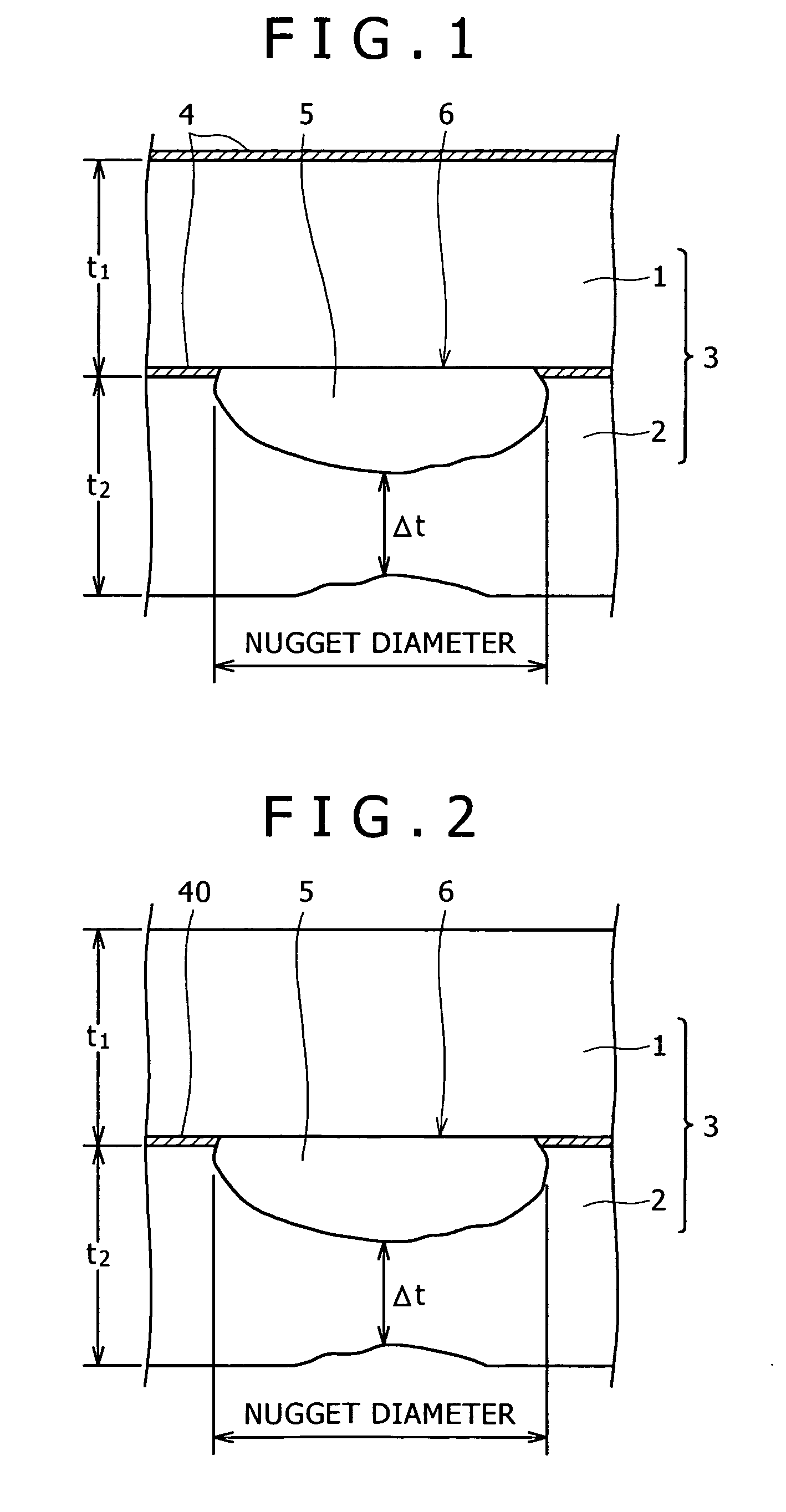

Joined Body of Dissimilar Materials Comprising Steel Material and Aluminum Material, and Joining Method Therefor

ActiveUS20070212565A1Improve welding strengthSatisfactory repeatabilityHot-dipping/immersion processesContact member assembly/disassemblyAluminiumWeld strength

To provide a steel-aluminum welded material and a spot welding method therefor having high weld strength. The steel-aluminum welded material 3 includes a steel material 1 and an aluminum material 2 having predetermined widths. The area of a nugget 5 of a spot-welded part is determined as a function of the thickness of the aluminum material 2, and the area of a part of the nugget 5 corresponding to a part having a thickness in a range between 0.5 and 10 μm of an interface reaction layer 6 is defined as a function of the thickness of the aluminum material 2.

Owner:KOBE STEEL LTD

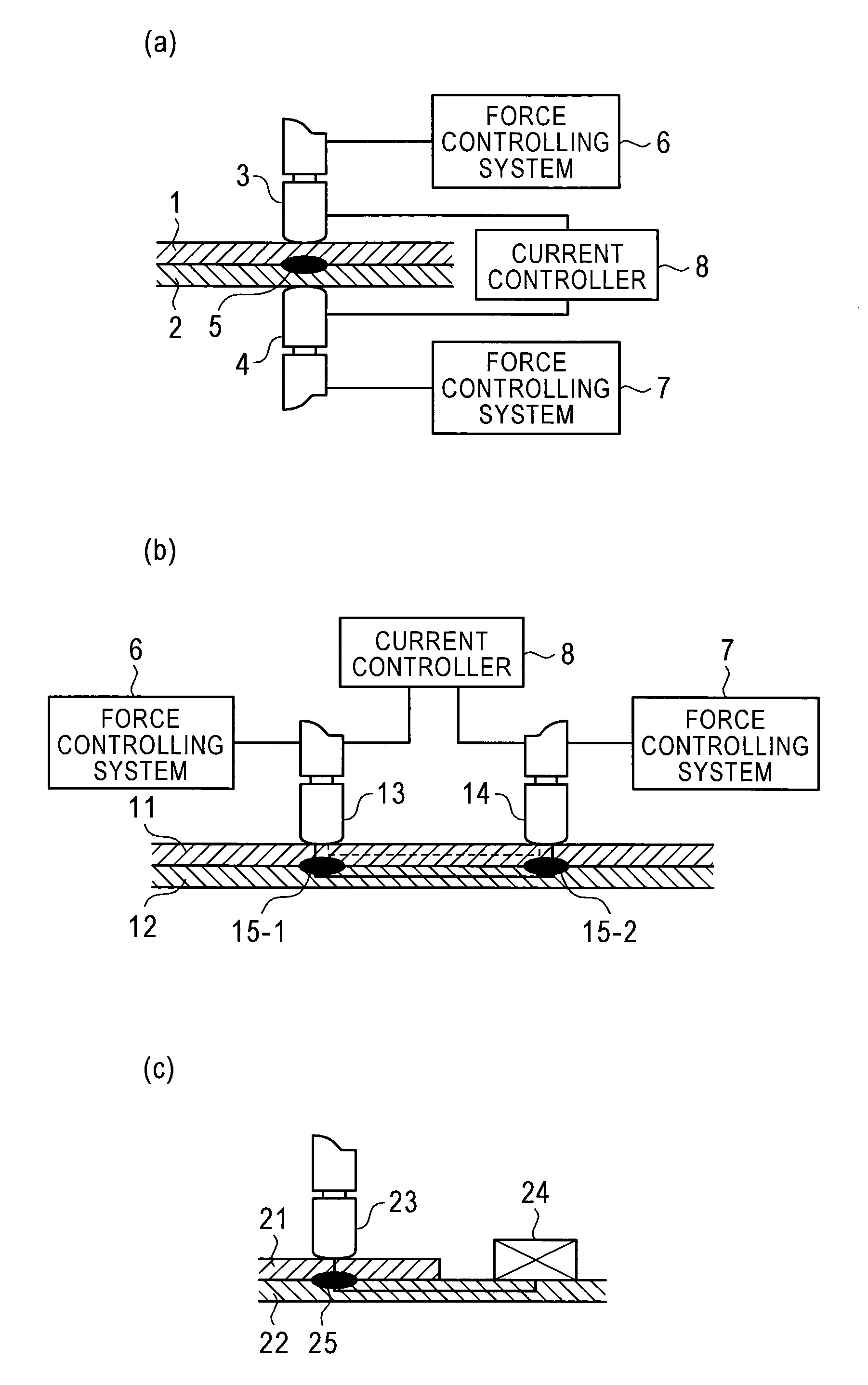

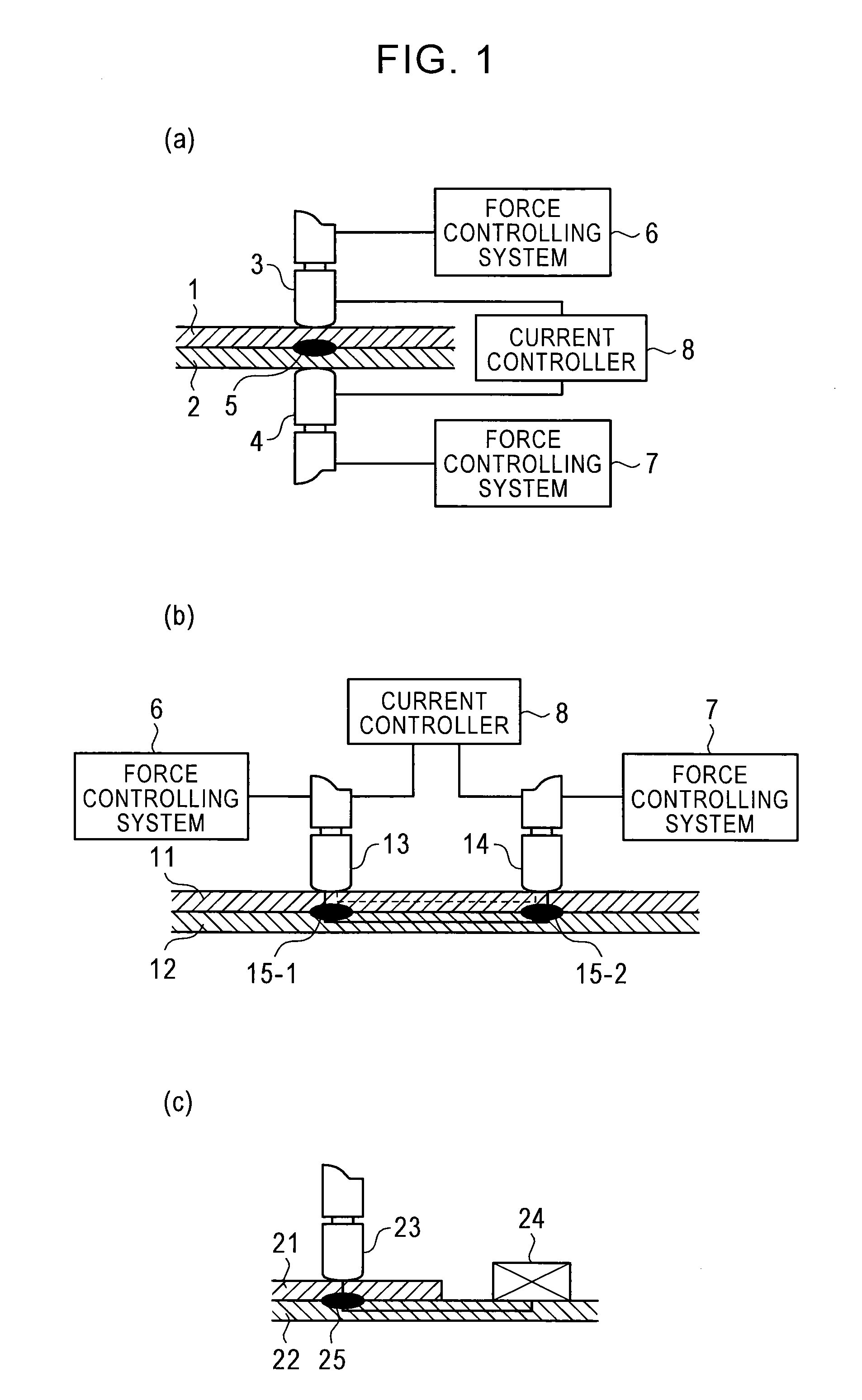

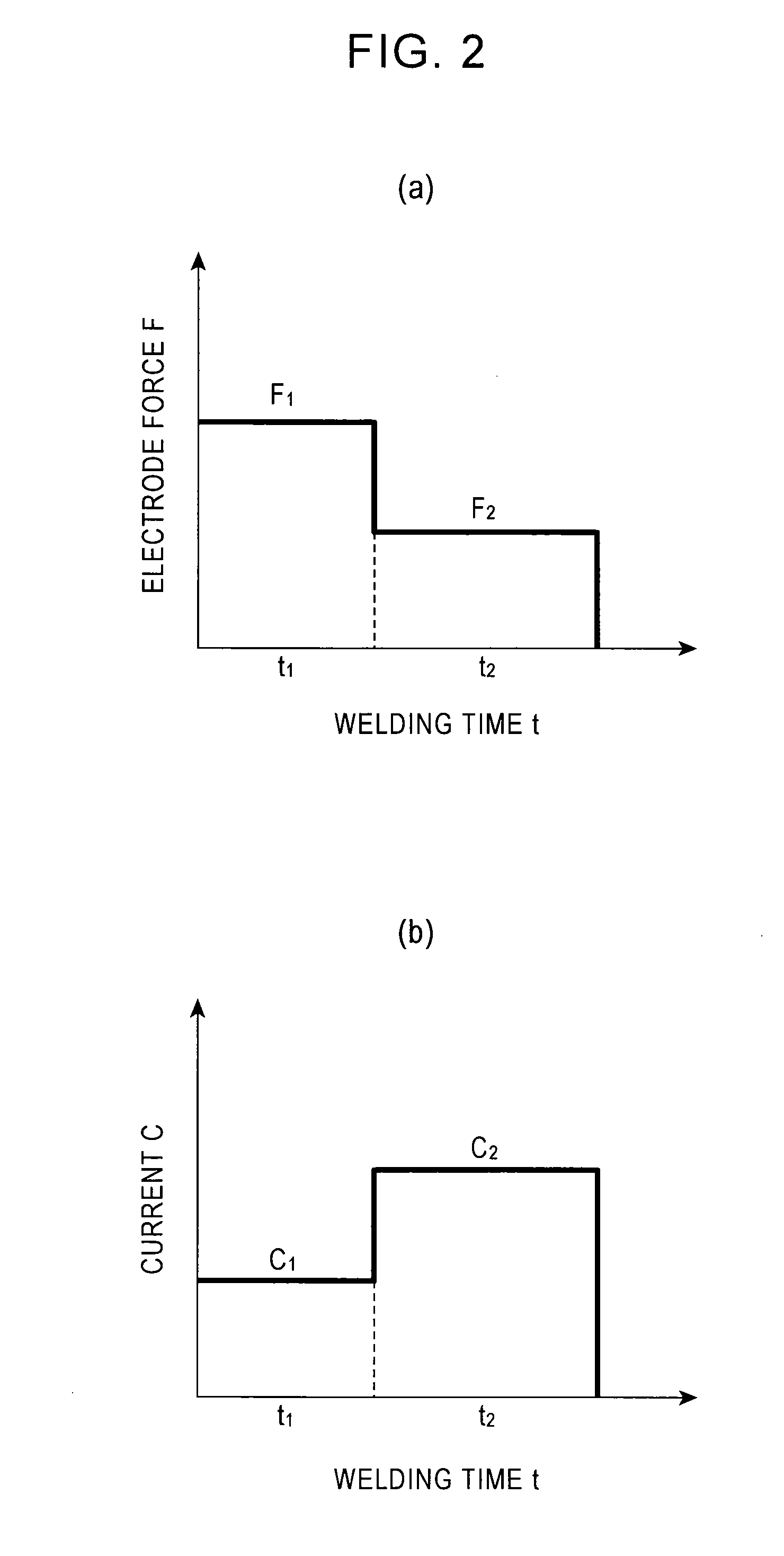

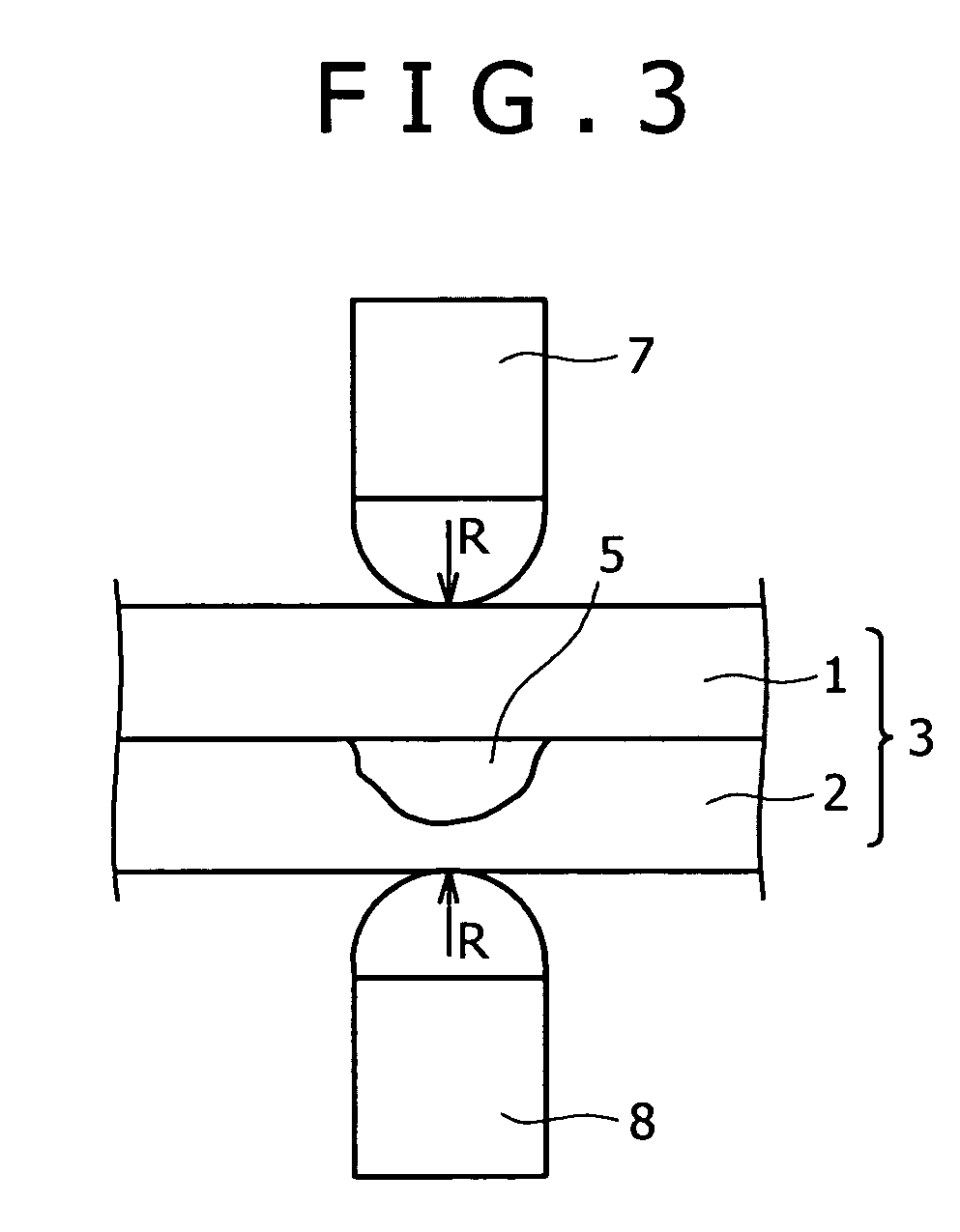

Indirect spot welding method

ActiveUS20110272384A1Get stableStable formationWelding electric supplyPressure electrodesEngineeringSpot welding

An indirect spot welding method is provided in which, in indirect spot welding, nuggets formed in a fused state can be stably obtained. In the indirect spot welding method, the welding time is divided into two time periods t1 and t2, where electrode force F1 and current C1 are applied in the first time period t1, and electrode force F2 lower than electrode force F1 and current C2 higher than current C1 are applied in the next time period t2.

Owner:JFE STEEL CORP

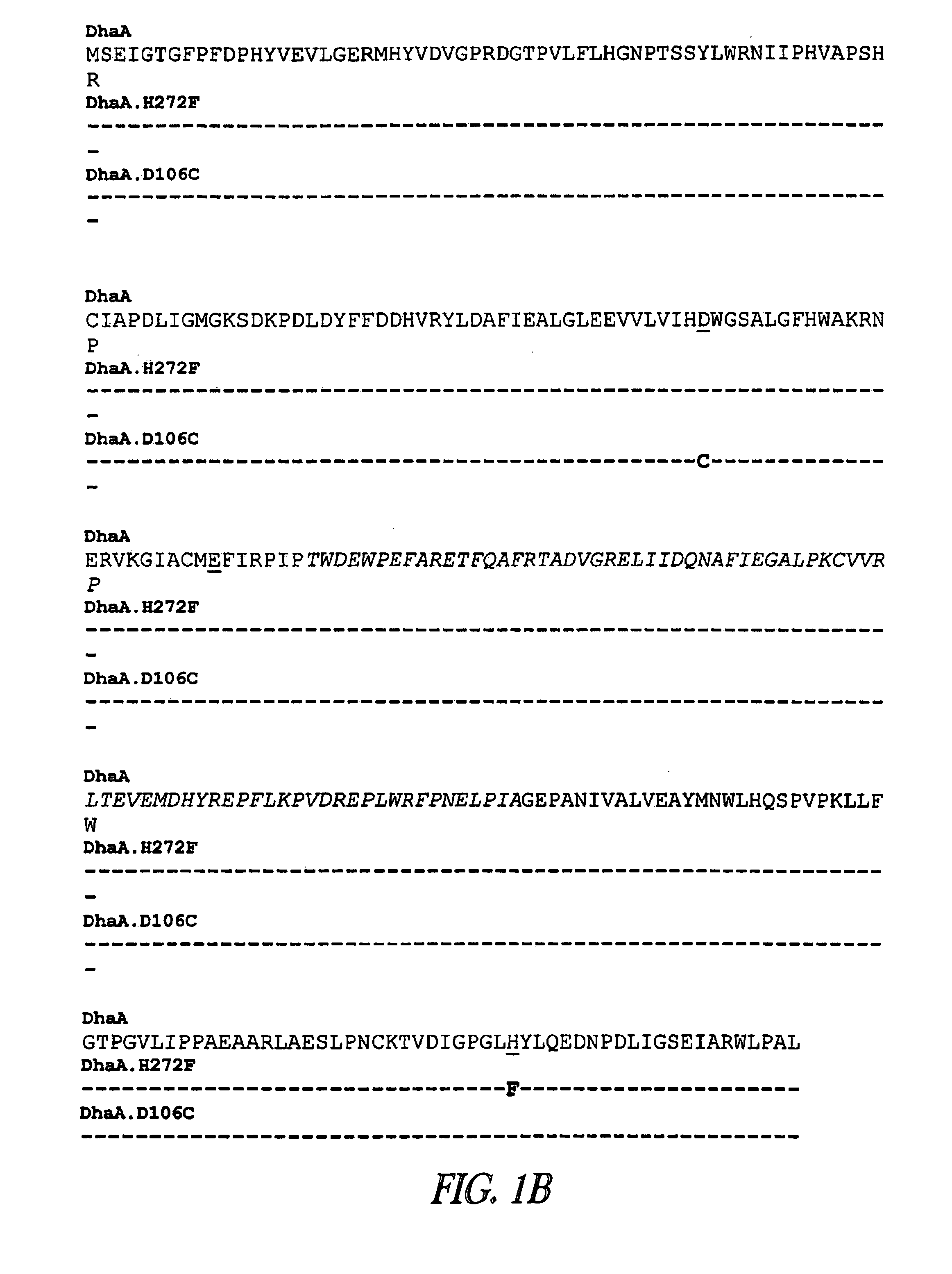

Mutant hydrolase proteins with enhanced kinetics and functional expression

ActiveUS20080145882A1Improved functional expressionHigh protein yieldBacteriaSugar derivativesMutated proteinNucleotide

Owner:PROMEGA

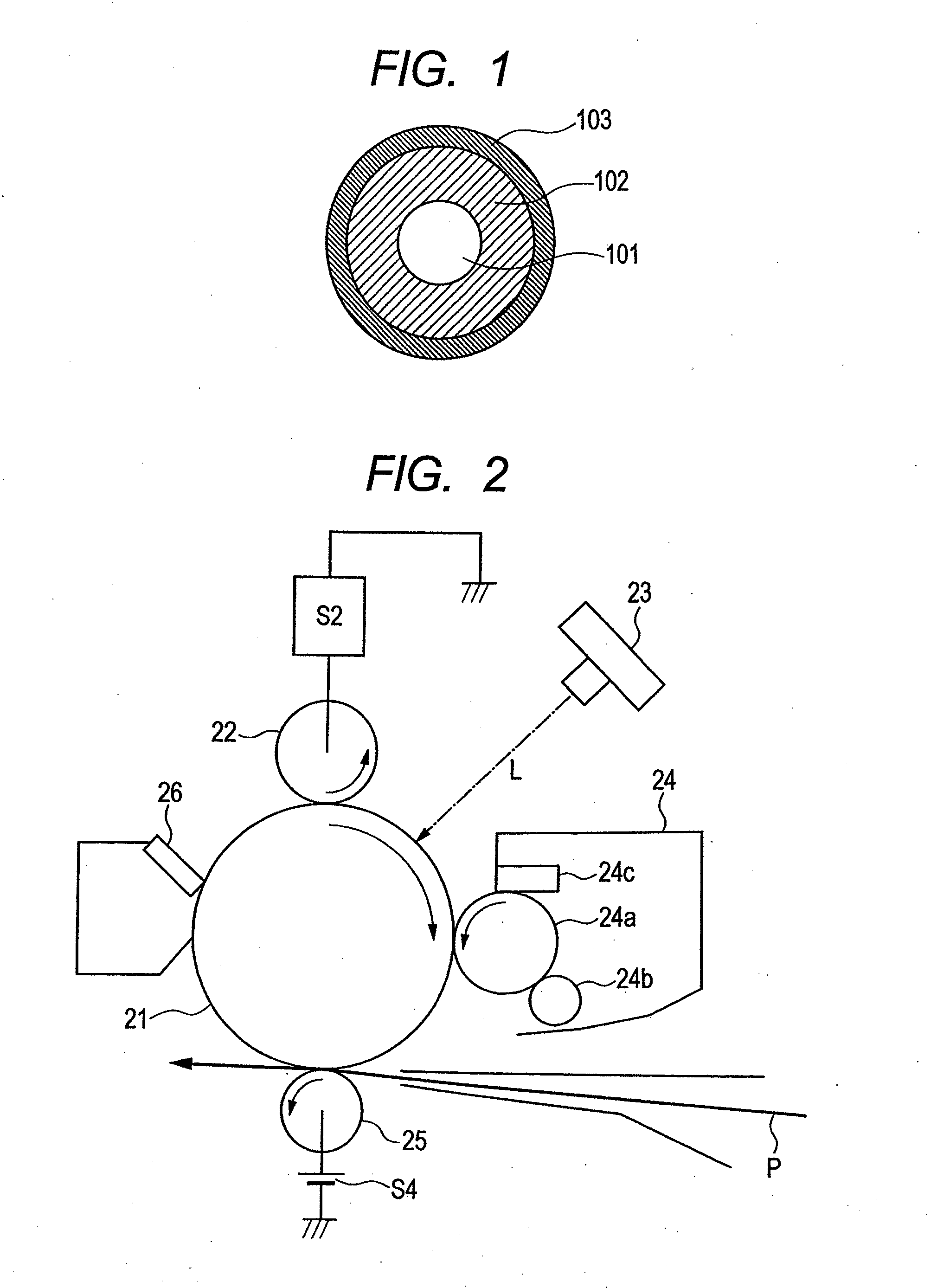

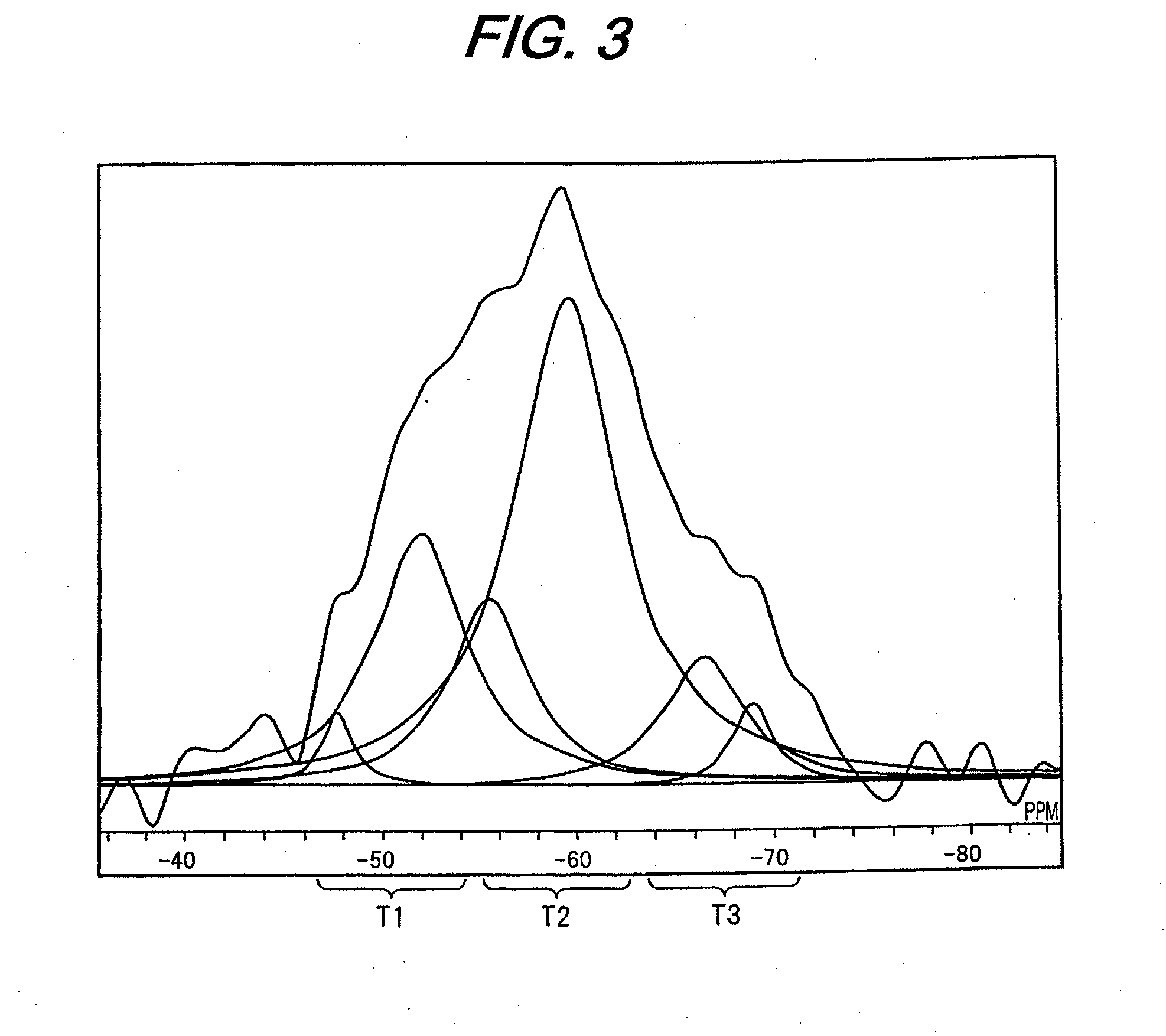

Charging member, process cartridge and electrophotographic apparatus

InactiveUS20130004206A1Improve charging effectNot easy to changeElectrographic process apparatusCorona dischargeSurface layerElectron

A charging member for electrophotographic apparatus is provided which has a superior charging performance for the electrophotographic photosensitive member and also can not easily change with time in charging performance. The charging member has a substrate, an elastic layer and a surface layer, which surface layer contains a high-molecular compound having an Si—O—Ti linkage in the molecular structure and a cyclic polysilane represented by the general formula (7) defined in the specification, and the high-molecular compound has a constituent unit represented by the general formula (1) and a constituent unit represented by the following formula (2) which are defined in the specification.

Owner:CANON KK

Sliding component

ActiveUS20110215531A1Stable formationInhibit wearEngine sealsCHEEK DIMPLESElectrical and Electronics engineering

Owner:EAGLE INDS

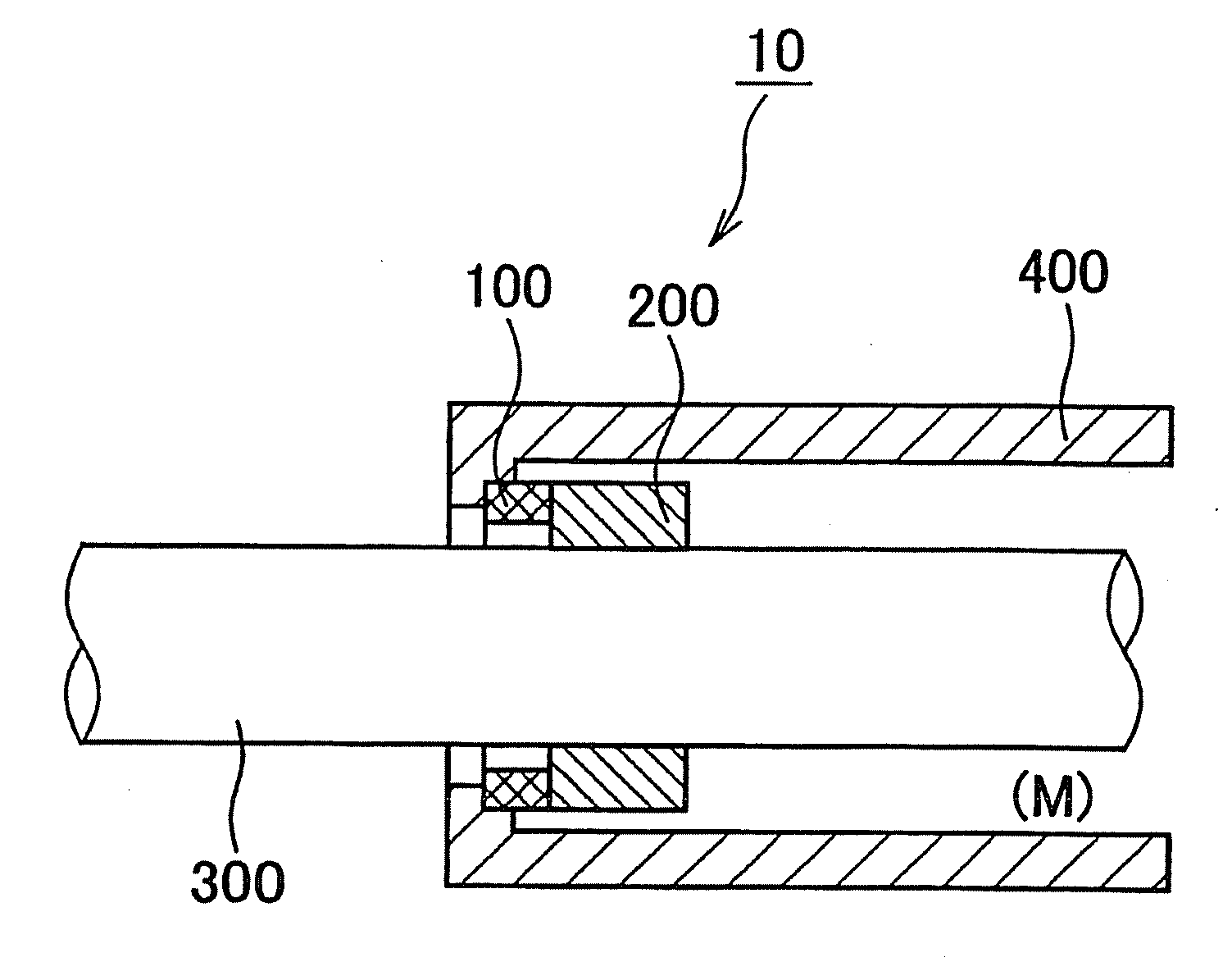

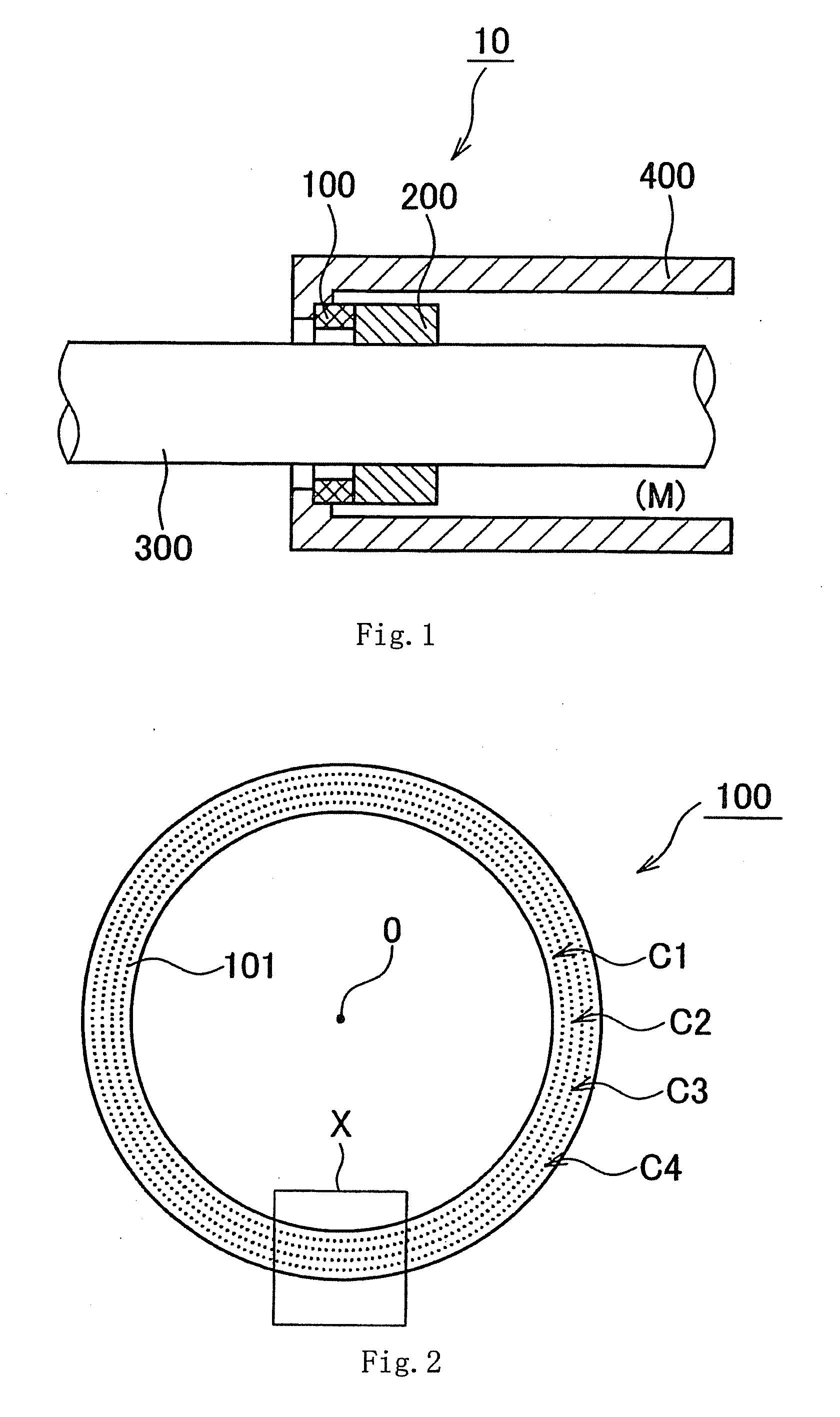

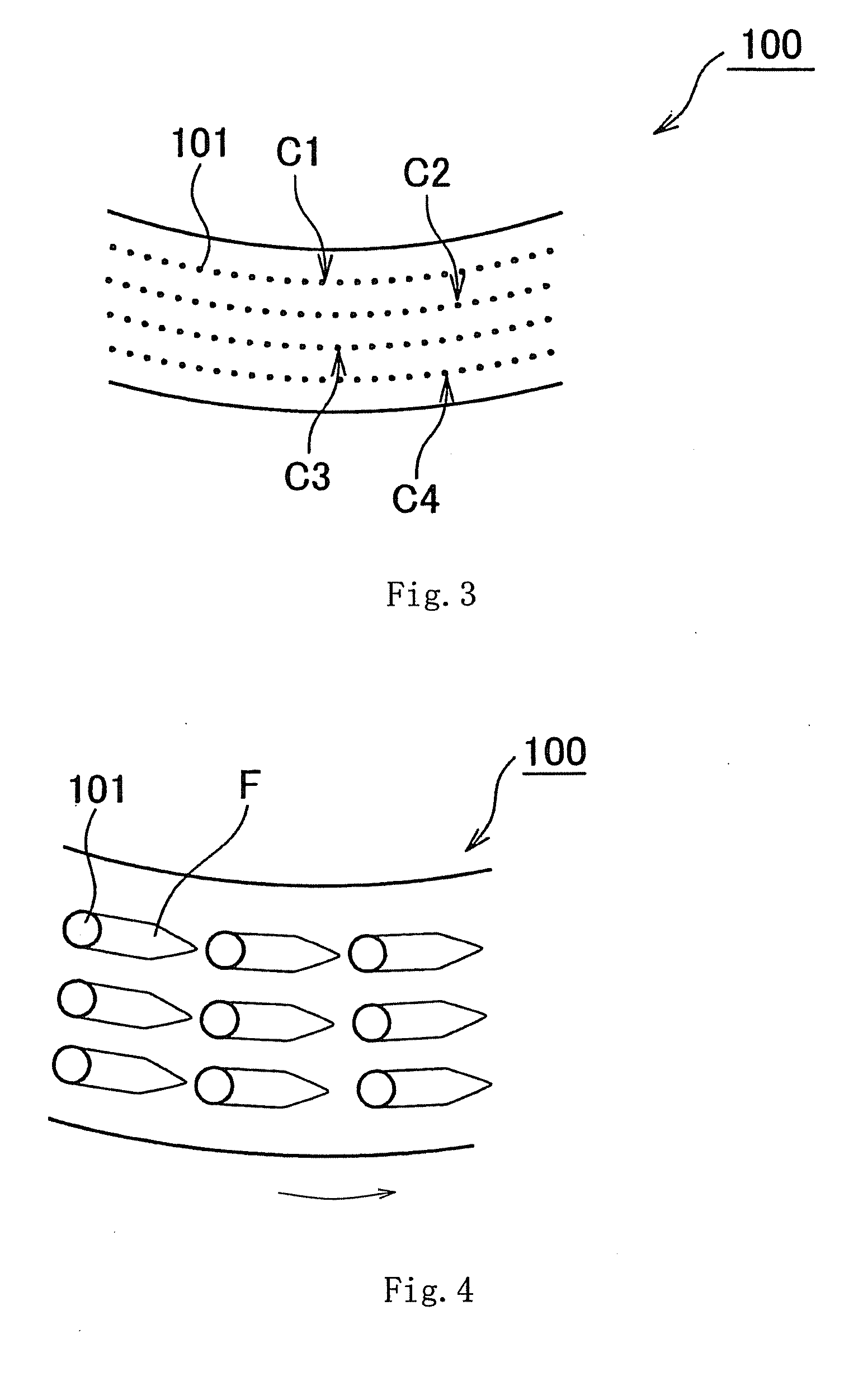

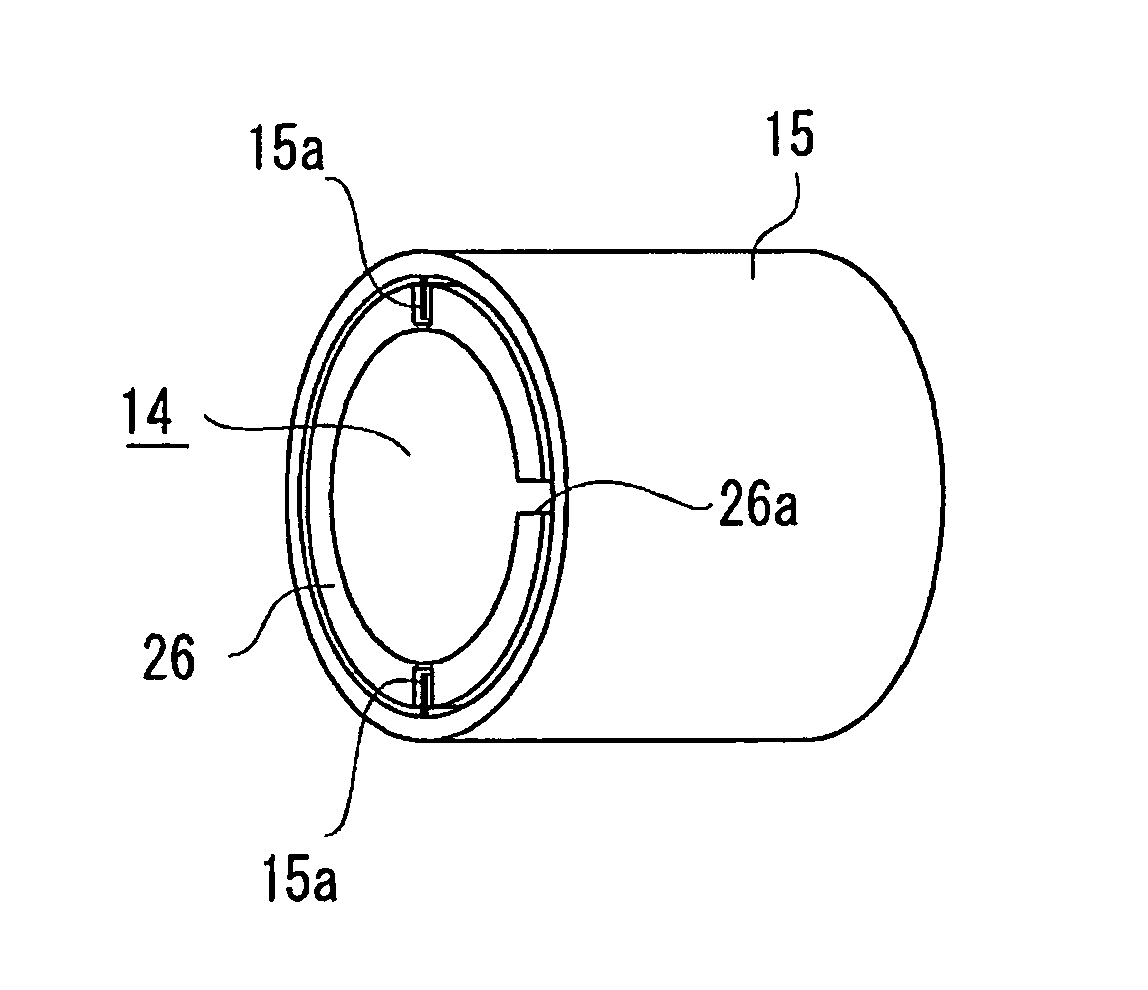

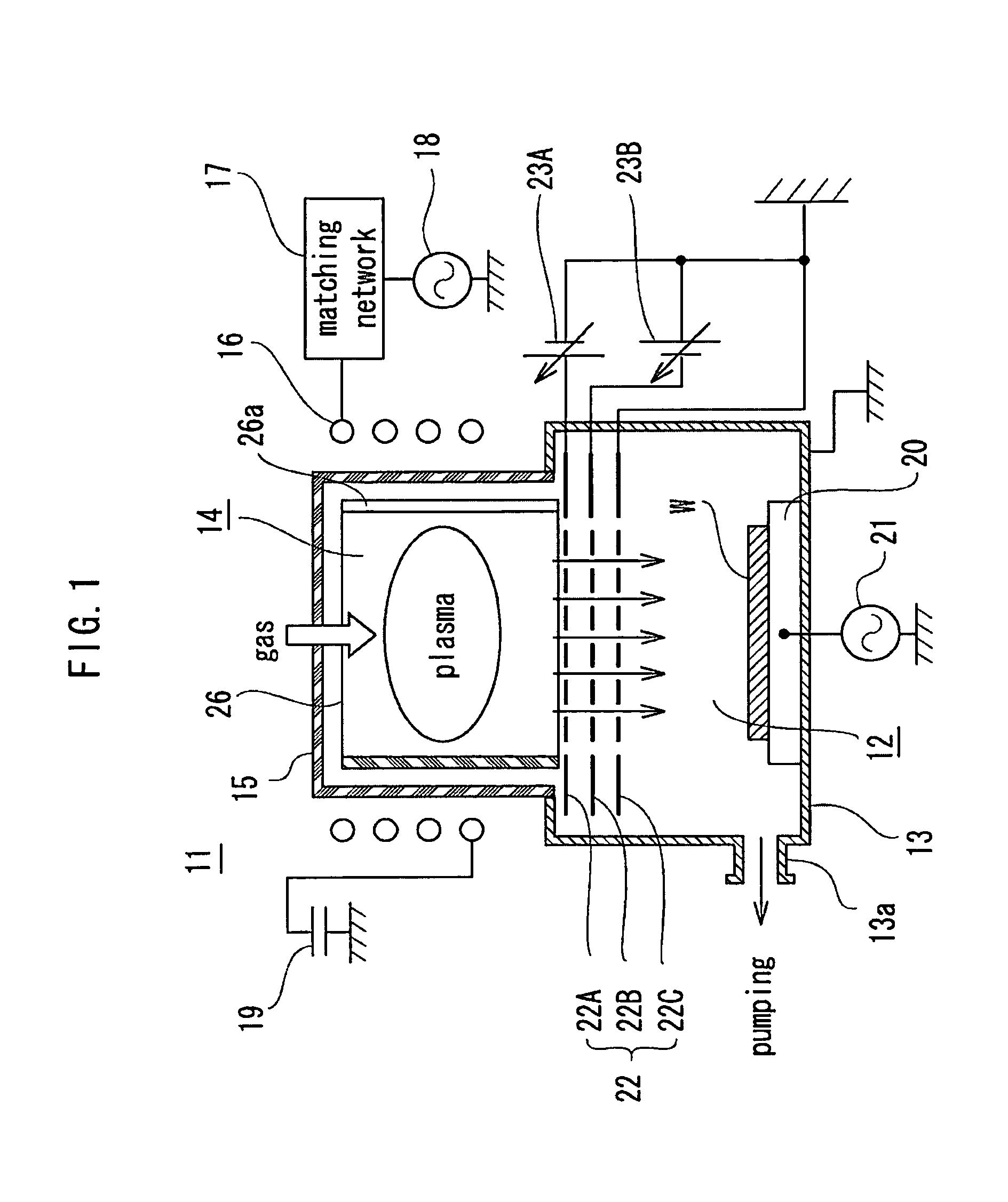

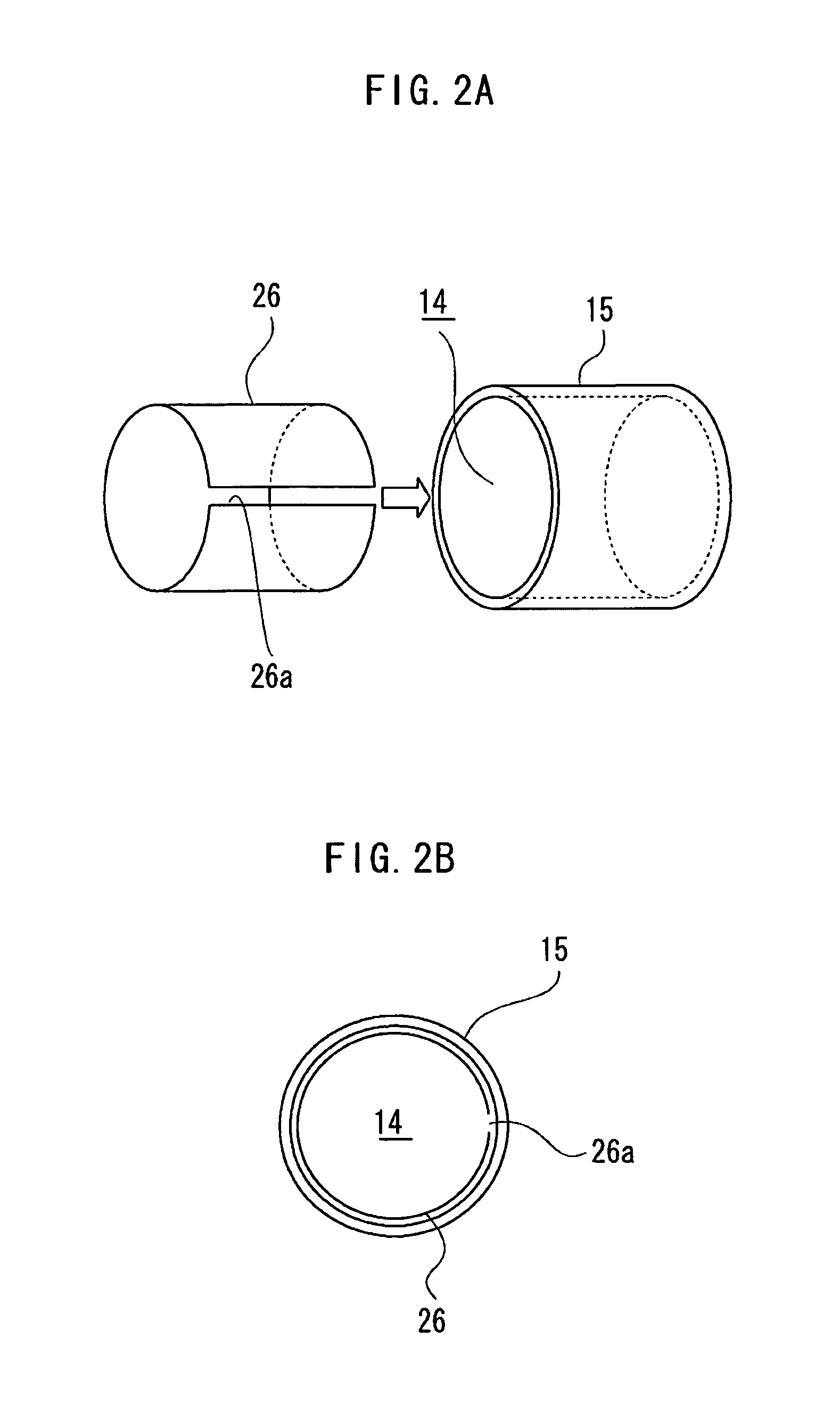

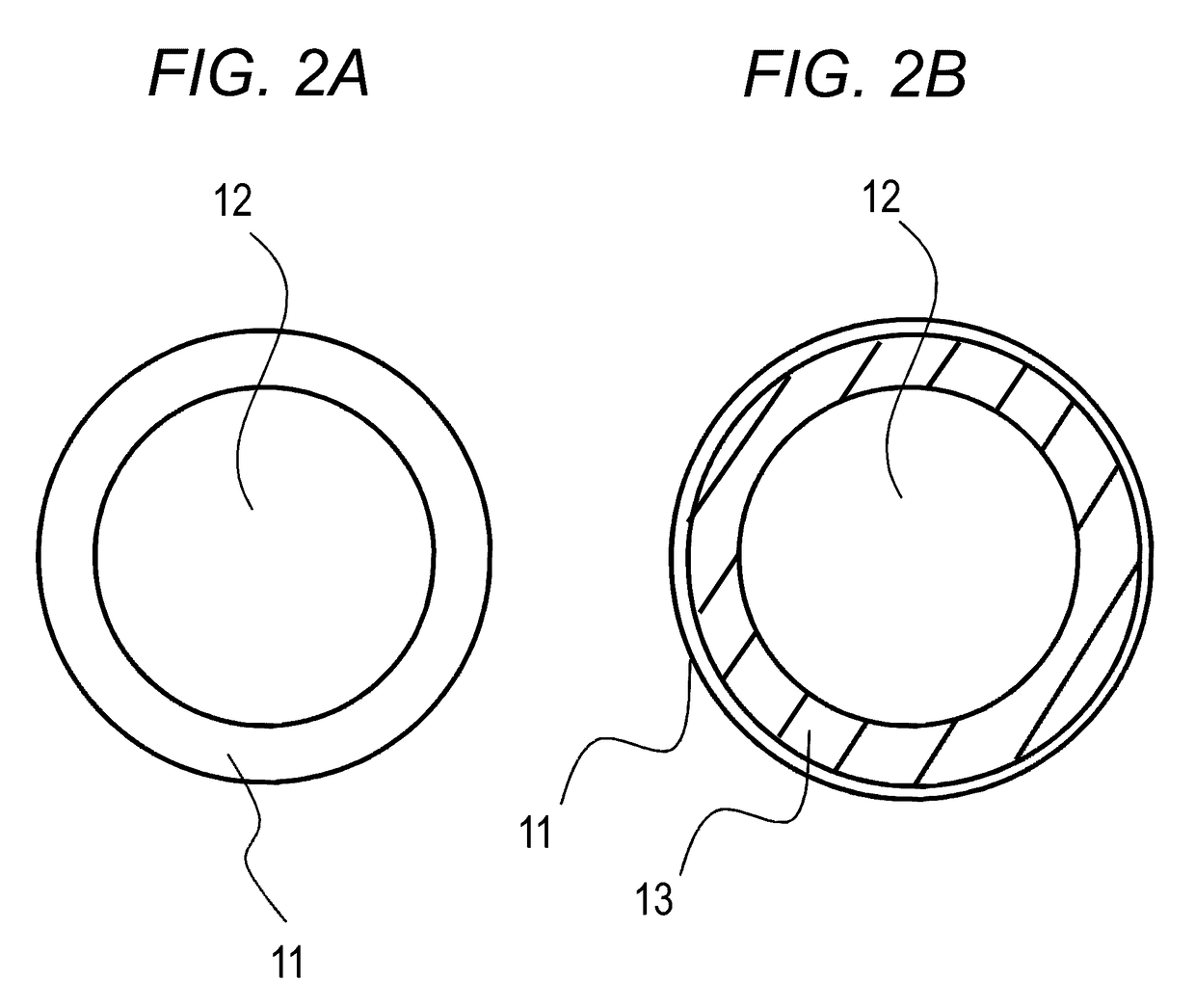

Ion source and plasma processing apparatus

ActiveUS8356575B2Stable formationCellsElectric discharge tubesHigh frequency powerConductive materials

It is an object of this invention to provide an ion source and a plasma processing apparatus capable of generating stable and long-life plasma. The ion source is provided with a high-frequency antenna (16) installed on the outer peripheral side of a partition wall (15) made of a dielectric material and partitioning a plasma generating chamber (14) and a shield body (26) made of a dielectric material and preventing deposition on the inner peripheral surface of the partition wall (15) facing the high-frequency antenna (16) inside the plasma generating chamber (14). The structure made of a dielectric material can prevent an increase in high-frequency power required for inductive coupling with plasma. The shield body (26) is formed with a slot (26a) in a direction crossing a winding direction of the high-frequency antenna (16). Since this arrangement can prevent continuous deposition on the inner surface of the partition wall in the winding direction of the high-frequency antenna, an induction loss between the high-frequency antenna and the plasma generating chamber can be effectively prevented even if the deposited film is made of a conductive material.

Owner:UI VAC

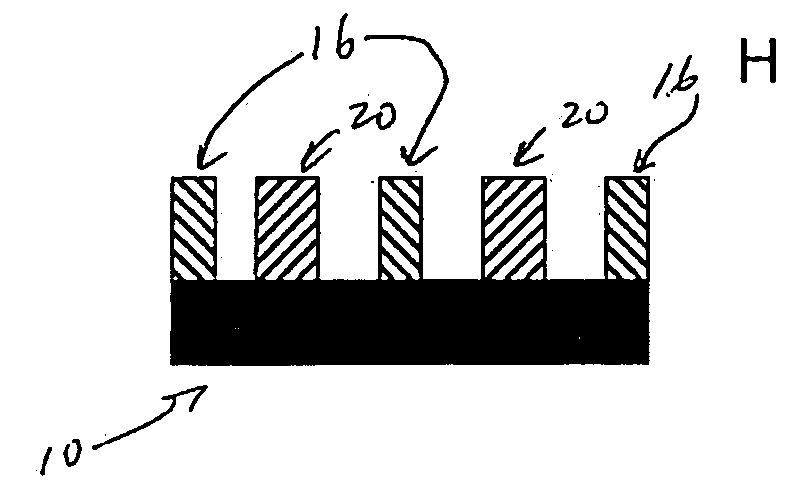

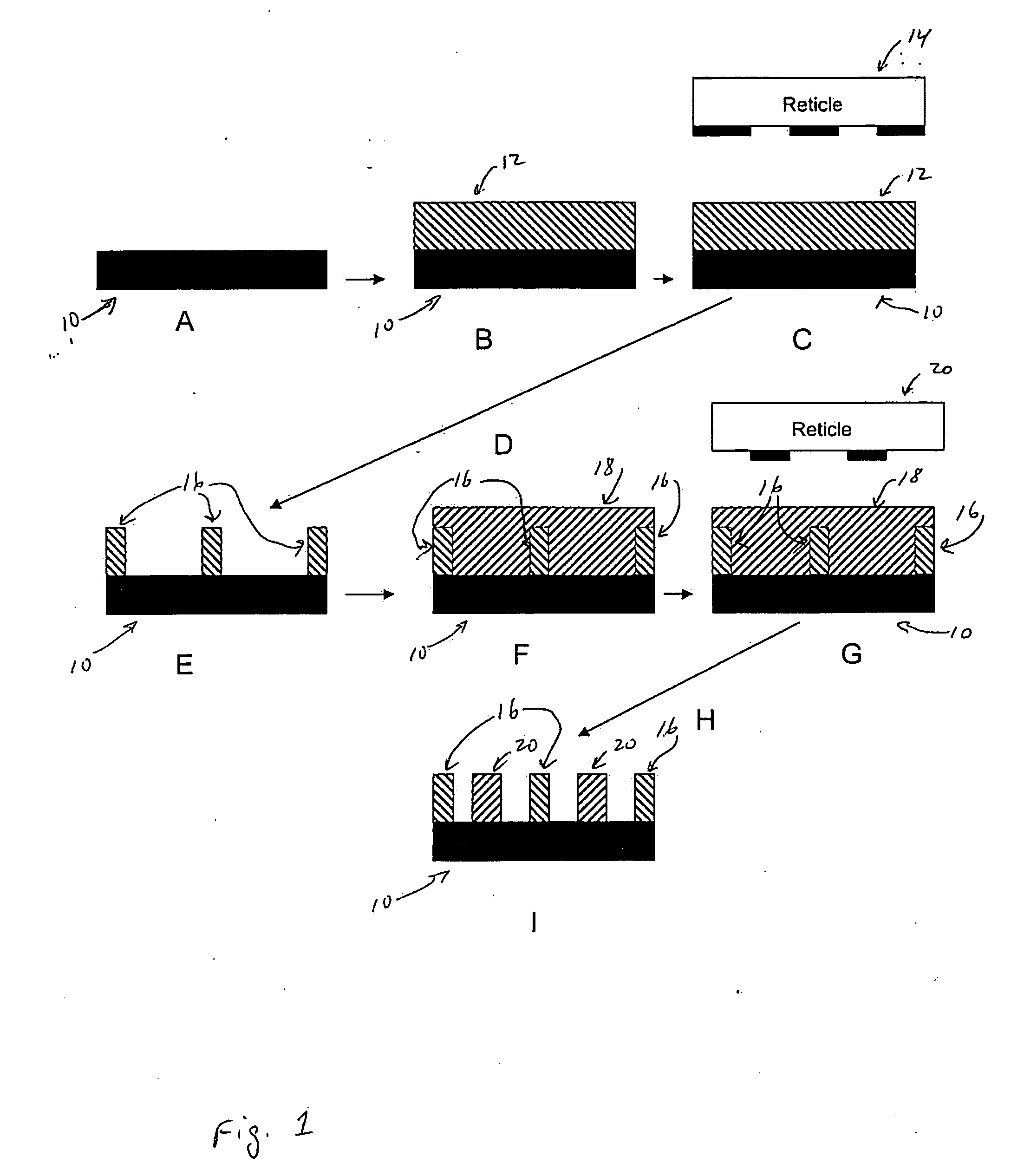

Photoresist Image-forming Process Using Double Patterning

InactiveUS20100183851A1Increase linear densityImproved pattern definitionPhotosensitive materialsDecorative surface effectsDouble patterning lithographyPhotochemistry

Owner:CAO YI +5

Image forming apparatus

InactiveUS7334858B2High quality imagingImprove conveying performanceDigitally marking record carriersDigital computer detailsImage formationPeriod length

Owner:RICOH KK

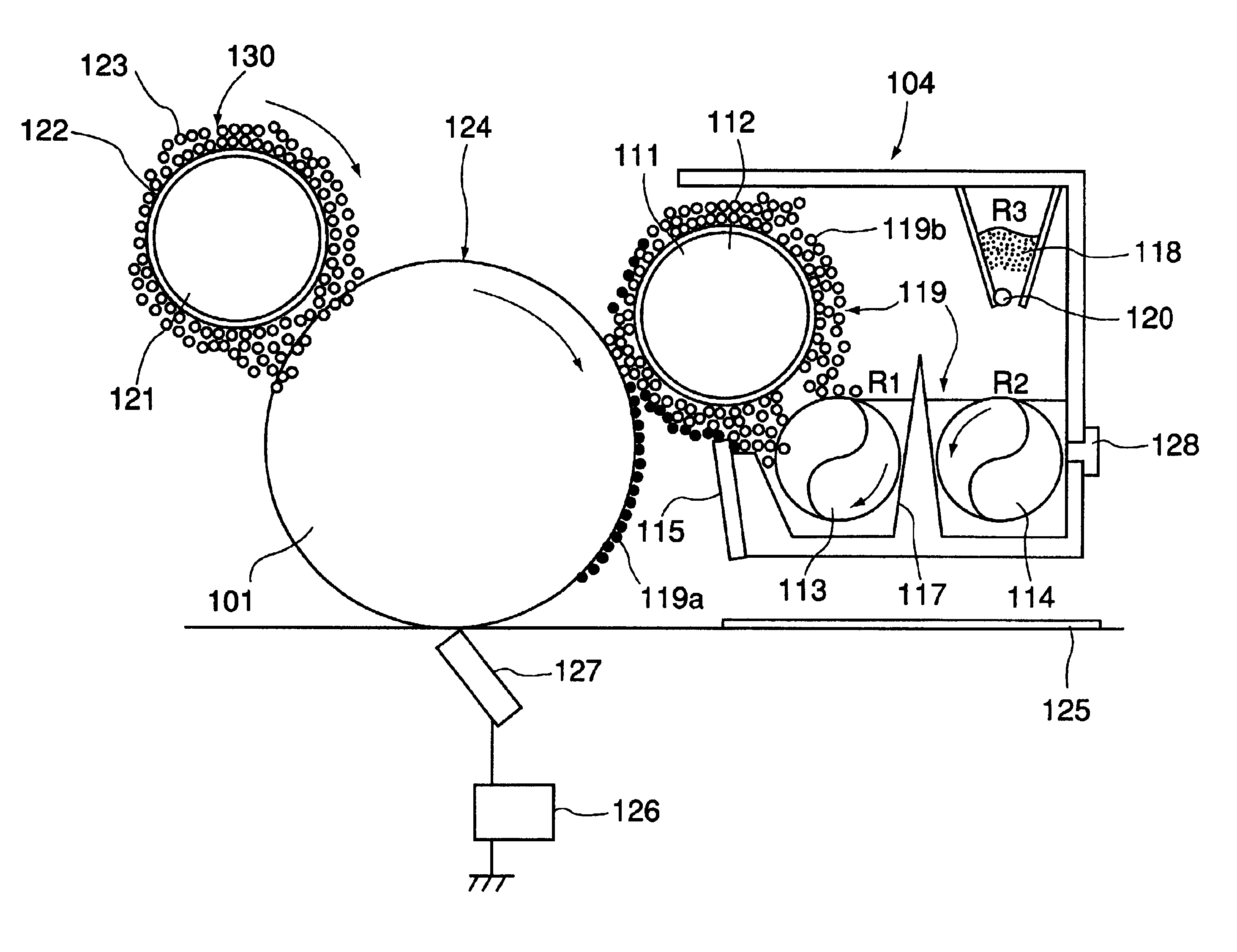

Replenishing developer and developing method

InactiveUS6936394B2Image stabilizationStable formationElectrographic process apparatusDevelopersLatent imageInorganic compound

An electrostatic latent image on an image-bearing member is developed with a two-component developer comprising a toner and a carrier stored in a developer vessel while supplying as required a replenishing developer to the developer vessel. The replenishing developer comprises 1 wt. part of a carrier and 2-50 wt. parts of a toner, wherein the carrier is a magnetic fine particle-dispersed resin carrier comprising at least inorganic compound particles and a carrier binder resin, and the toner has a weight-average particle size of 3 to 10 μm and contains 1 to 40 wt. % of solid wax.

Owner:CANON KK

Developing assembly, process cartridge and image-forming method

InactiveUS6873816B2Good developing performanceImprove development performanceShaft and bearingsElectrographic process apparatusEngineeringImaging equipment

A developing assembly is disclosed having at least a developer container, a developer-carrying member and a developer layer thickness regulation member, wherein the developer is composed mainly of toner particles containing at least a binder resin and a colorant, and conductive fine particles, and the developer-carrying member has a substrate and a surface layer formed on the substrate of a non-magnetic metal, an alloy or a metallic compound. This developing assembly causes no sleeve ghost, enables electrostatic latent images to be faithfully developed, causes no fading phenomenon, and enables high-density images to be formed in every environment. Also disclosed are a process cartridge having the developing assembly and the latent-image-bearing member integrally set as one unit detachably mountable on the main body of an image-forming apparatus, and an image-forming method making use of the features of this developing assembly.

Owner:CANON KK

Non-aqueous foam composition for gas lift injection and methods for making and using same

InactiveUS20080257556A1Reduce hydrostatic pressureHigh trafficFluid removalDrilling compositionFoaming agentGas lift

A hydrocarbon drilling fluid system is disclosed including a hydrocarbon fluid and a foaming composition, where the foaming composition includes a polymer, a gelling agent and its cross-linking agent, an optional foaming agent, or mixtures or combinations thereof. Uses of this drilling fluid system in a variety of downhole application are also disclosed.

Owner:WEATHERFORD TECH HLDG LLC

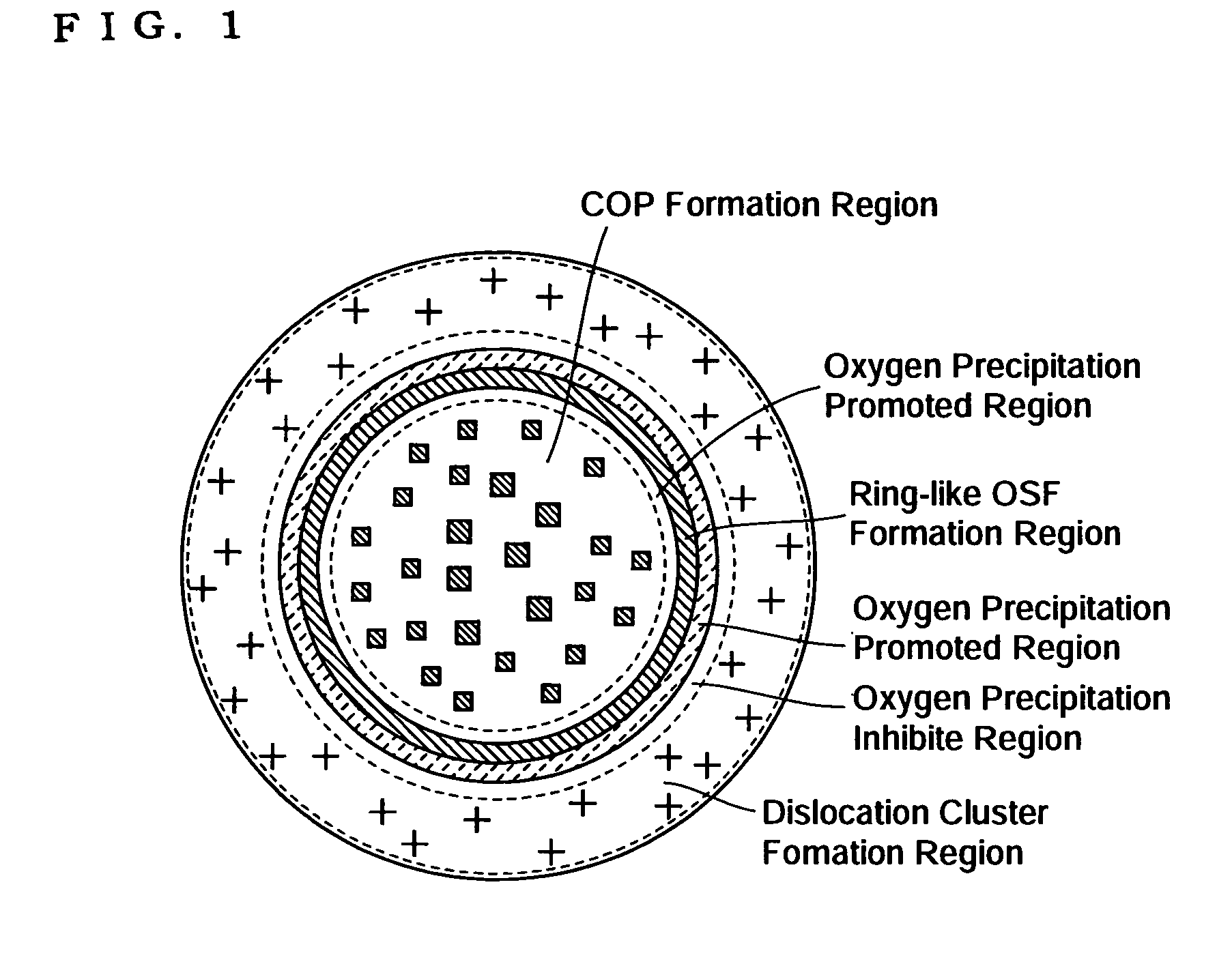

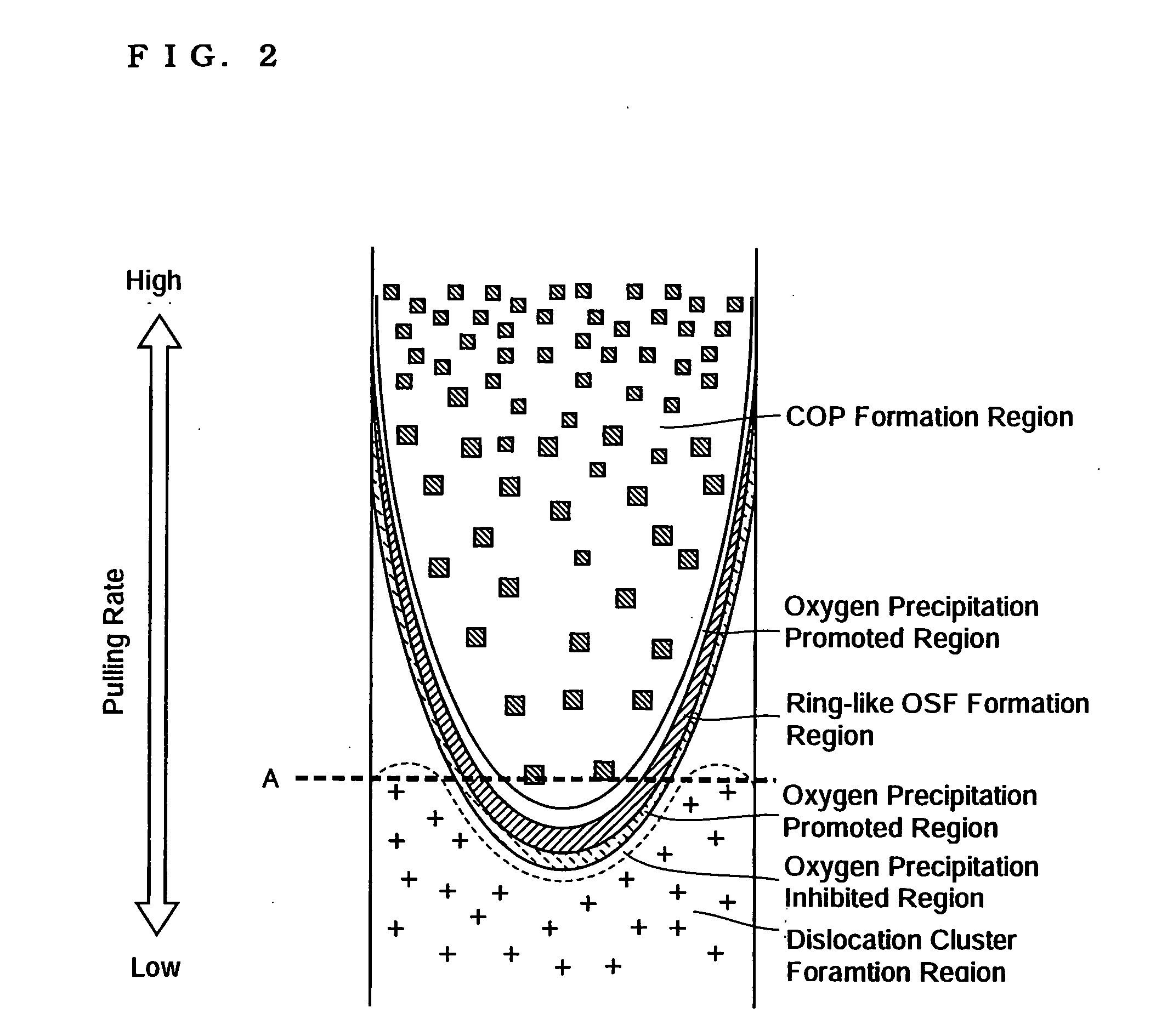

Method for heat treatment of silicon wafers

InactiveUS20060189169A1Promote formationStable formationSemiconductor/solid-state device manufacturingHigh densityOxygen ions

A method is provided for the heat treatment of low oxygen concentration silicon wafers obtained from a silicon single crystal produced by the Czochralski process. The method comprises high-temperature oxidation heat treatment for the formation of a high oxygen concentration region under the wafer surface and the subsequent oxygen precipitation heat treatment. The high-temperature oxidation heat treatment can cause inward diffusion of oxygen from the wafer surface to form a region increased in oxygen concentration under the wafer surface, and the subsequent oxygen precipitation heat treatment can form a DZ layer on the wafer surface and stably form oxygen precipitates optimal in size within the wafer at a high density, so that excellent gettering effects can be produced. Further, in case of using as SOI substrates formed by SIMOX, too, the same effects as mentioned above can be produced by carrying out the high-temperature oxidation heat treatment after oxygen ion implantation in the SIMOX process and then carrying out the oxygen precipitation heat treatment.

Owner:SUMCO CORP

Joined body of dissimilar materials comprising steel material and aluminum material, and joining method therefor

InactiveUS7951465B2Improve welding strengthSatisfactory repeatabilityHot-dipping/immersion processesContact member assembly/disassemblyReaction layerSpot welding

To provide a steel-aluminum welded material and a spot welding method therefor having high weld strength.The steel-aluminum welded material 3 includes a steel material 1 and an aluminum material 2 having predetermined widths. The area of a nugget 5 of a spot-welded part is determined as a function of the thickness of the aluminum material 2, and the area of a part of the nugget 5 corresponding to a part having a thickness in a range between 0.5 and 10 μm of an interface reaction layer 6 is defined as a function of the thickness of the aluminum material 2.

Owner:KOBE STEEL LTD

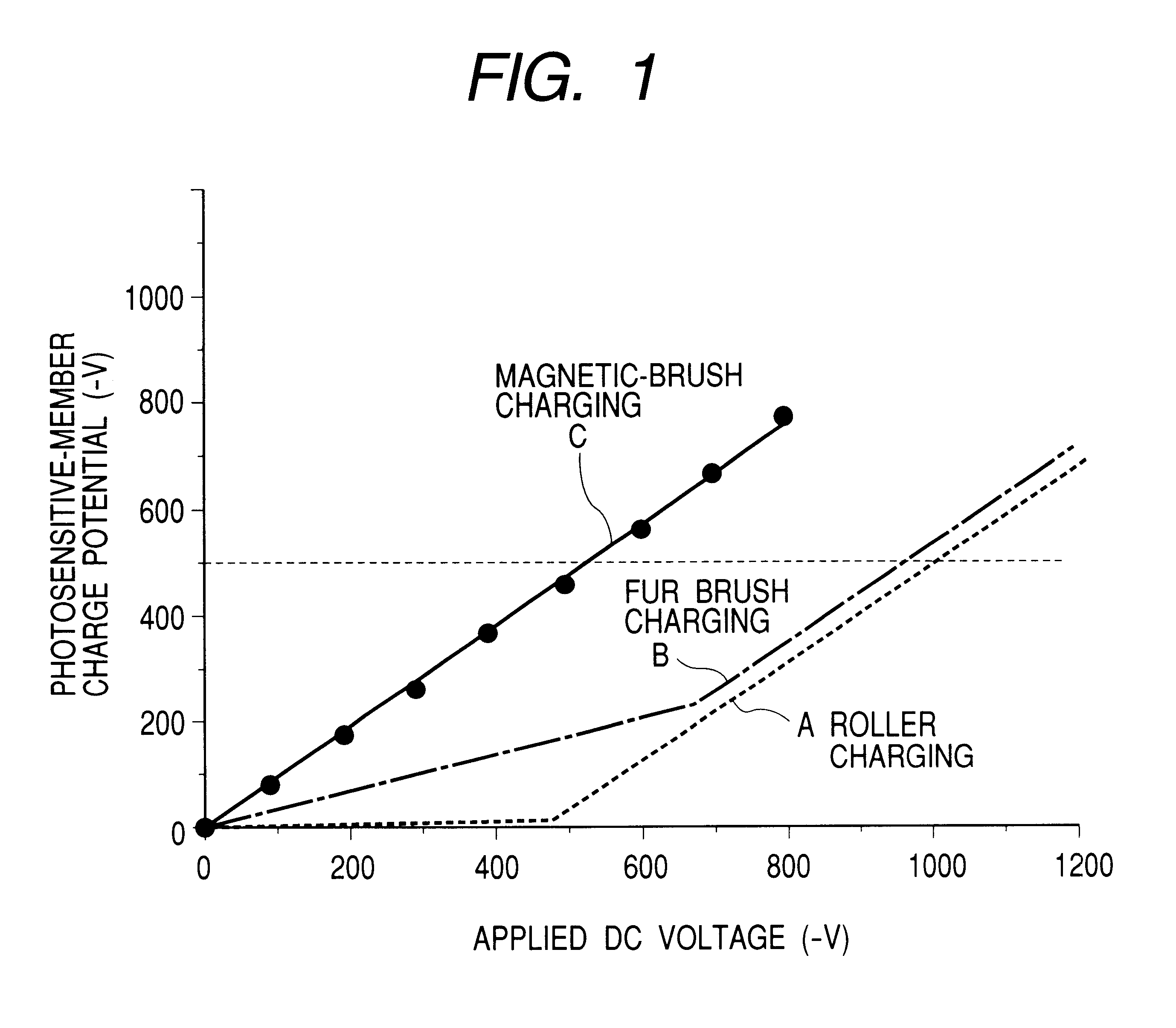

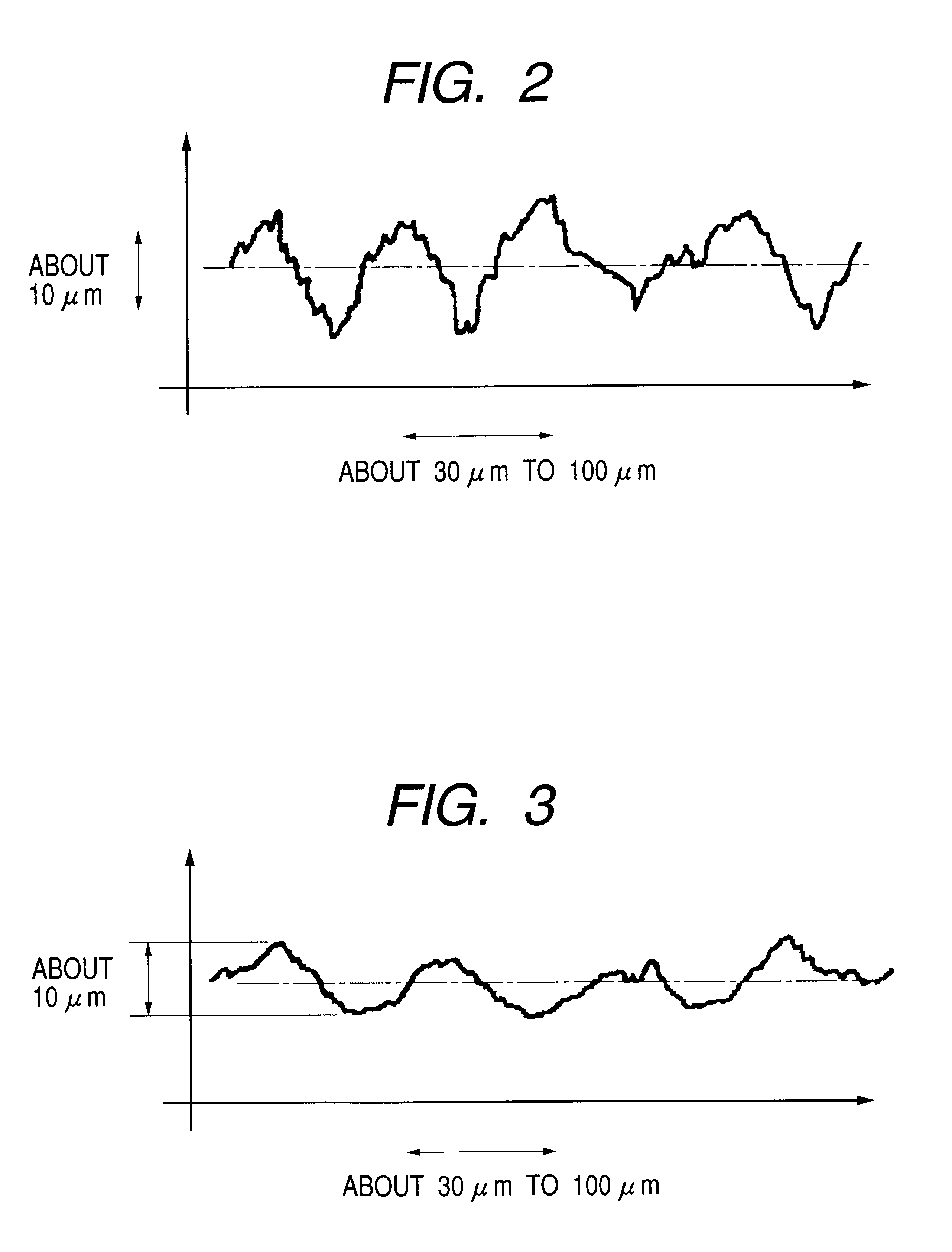

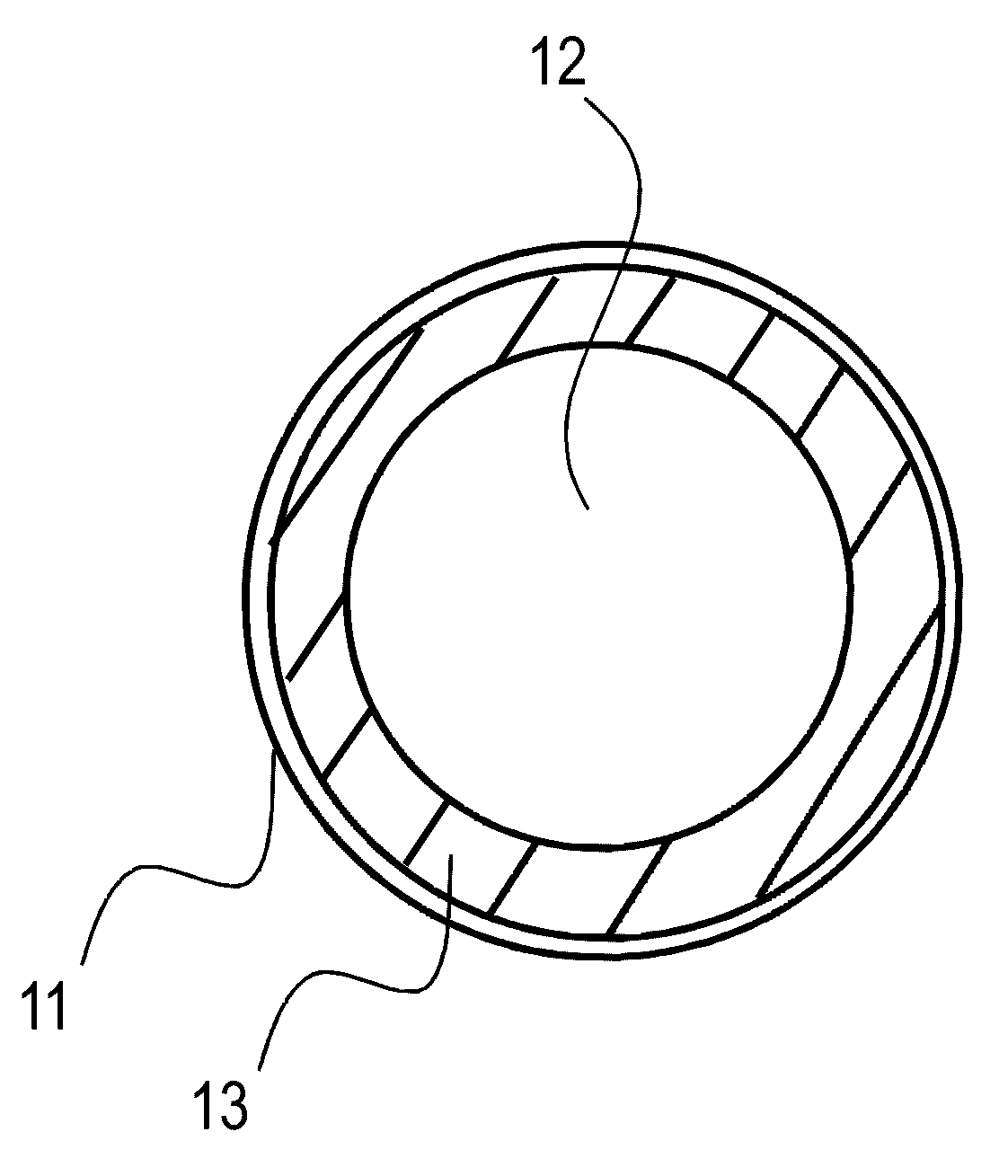

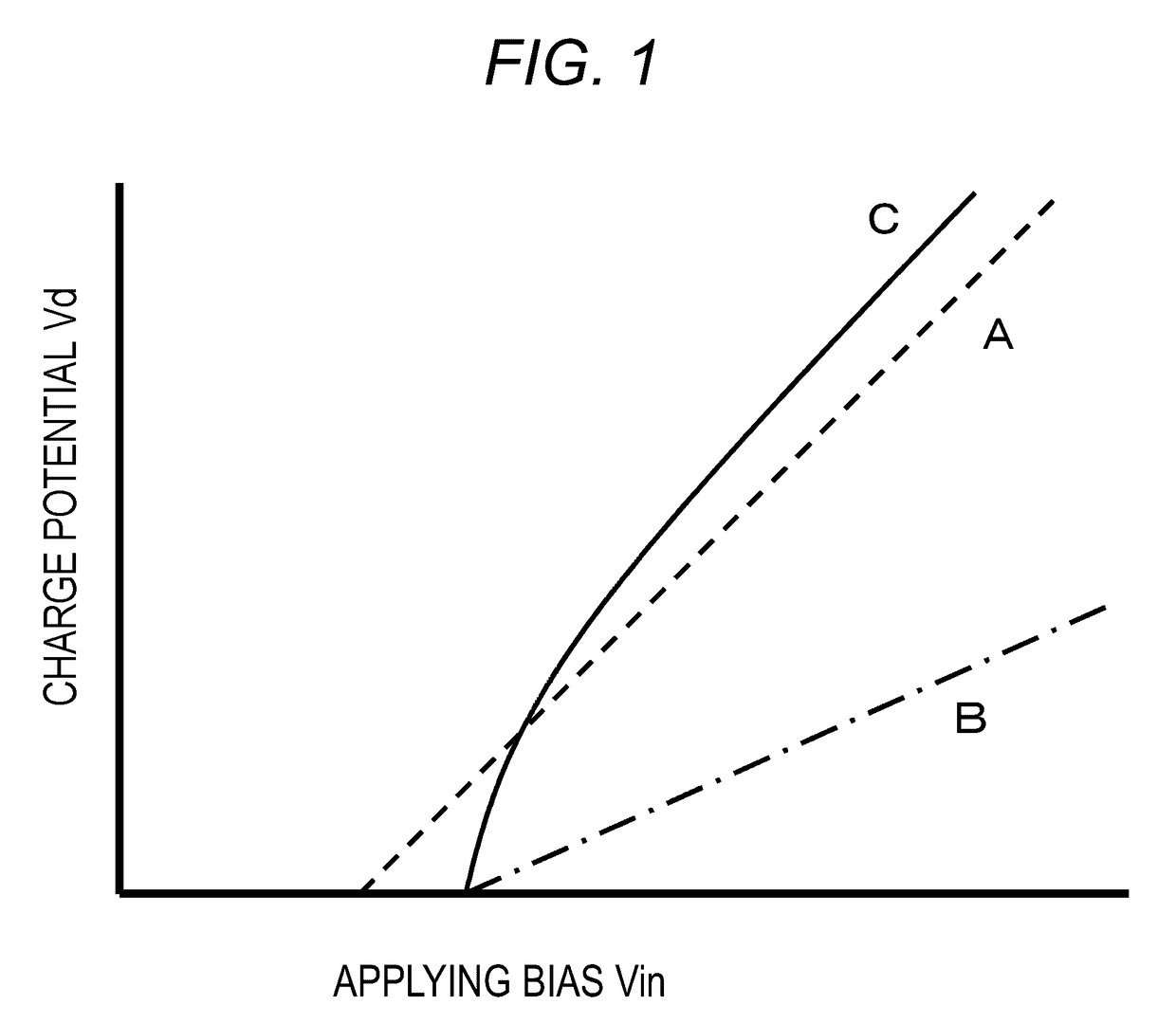

Electroconductive member with a surface layer including a porous body having a continuous open pore

ActiveUS9651888B2High-quality electrophotographicStable formationElectrographic process apparatusCorona dischargePolymer sciencePolyethylene terephthalate glycol

The electroconductive member has an electroconductive support and a surface layer formed on the electroconductive support, wherein the surface layer has a porous body having a continuous open pore, and the electroconductive member satisfies the following (1) and (2):(1) in a specific condition, a surface potential of the electroconductive member, after an elapse of 10 seconds since a completion of a discharge is 10 V or more; and(2) when applying a direct voltage between a polyethylene terephthalate film as a member to be charged and the electroconductive member, and charging the polyethylene terephthalate film, |Vd|≧|Vin|−|Vth| is satisfied within a range of |Vin|>|Vth|, wherein, Vd represents a charge potential of the polyethylene terephthalate film, Vin represents a voltage applied between the electroconductive member and the polyethylene terephthalate film, Vth represents a discharge starting voltage.

Owner:CANON KK

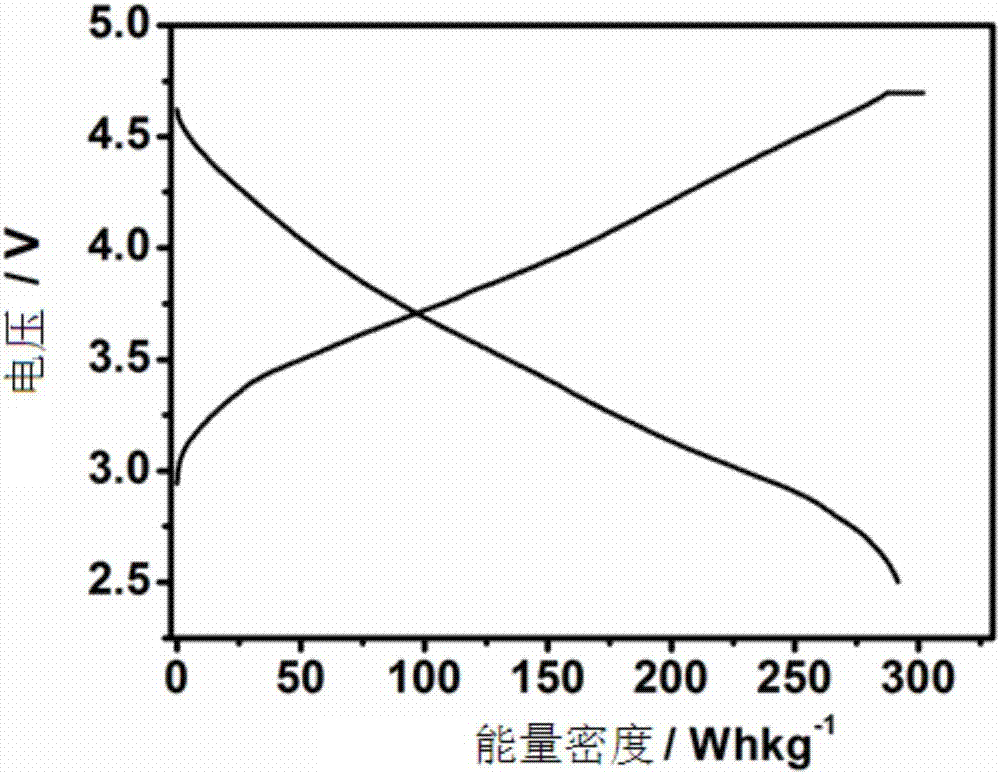

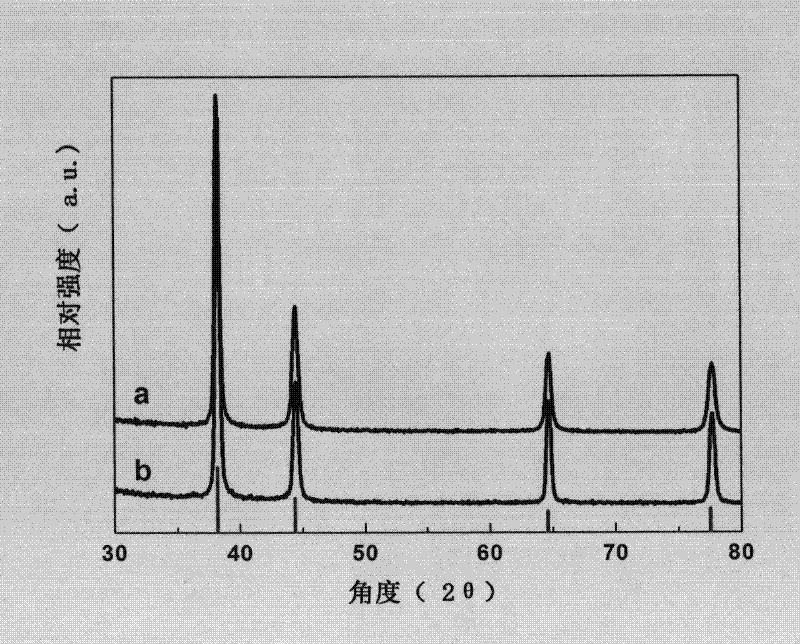

Lithium ion battery and formation method thereof

ActiveCN107959071AImprove structural stabilityImprove capacity playSecondary cells charging/dischargingLow voltageManganese

The invention discloses a lithium ion battery formation method. A negative electrode active substance of a lithium ion battery comprises a lithium-rich manganese-based positive electrode material. Theformation method includes at least three times of charge-discharge cycles; in the two former charge-discharge cycles, charge cut-off voltage is lower than 4.4V, discharge current is higher than charge current, and the second-time charge current is higher than the first-time charge current; in the last charge-discharge cycle, the charge cut-off voltage is not lower than 4.4V, and the charge current is not lower than the second-time charge current. By the step voltage charge-discharge formation method, a stable SEI film can be formed on the surface of a negative electrode in repeated low-voltage charge-discharge processes while a stable CEI film is formed on the surface of a positive electrode, side reaction between electrolyte and an electrode piece can be inhibited, gas generation is reduced, and accordingly the problem of battery swelling is solved. In addition, by the method, structural stability and capacity exertion of the lithium-rich manganese-based positive electrode material under a high voltage can be improved, and the cycle performance and the energy density of the battery are improved as well.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

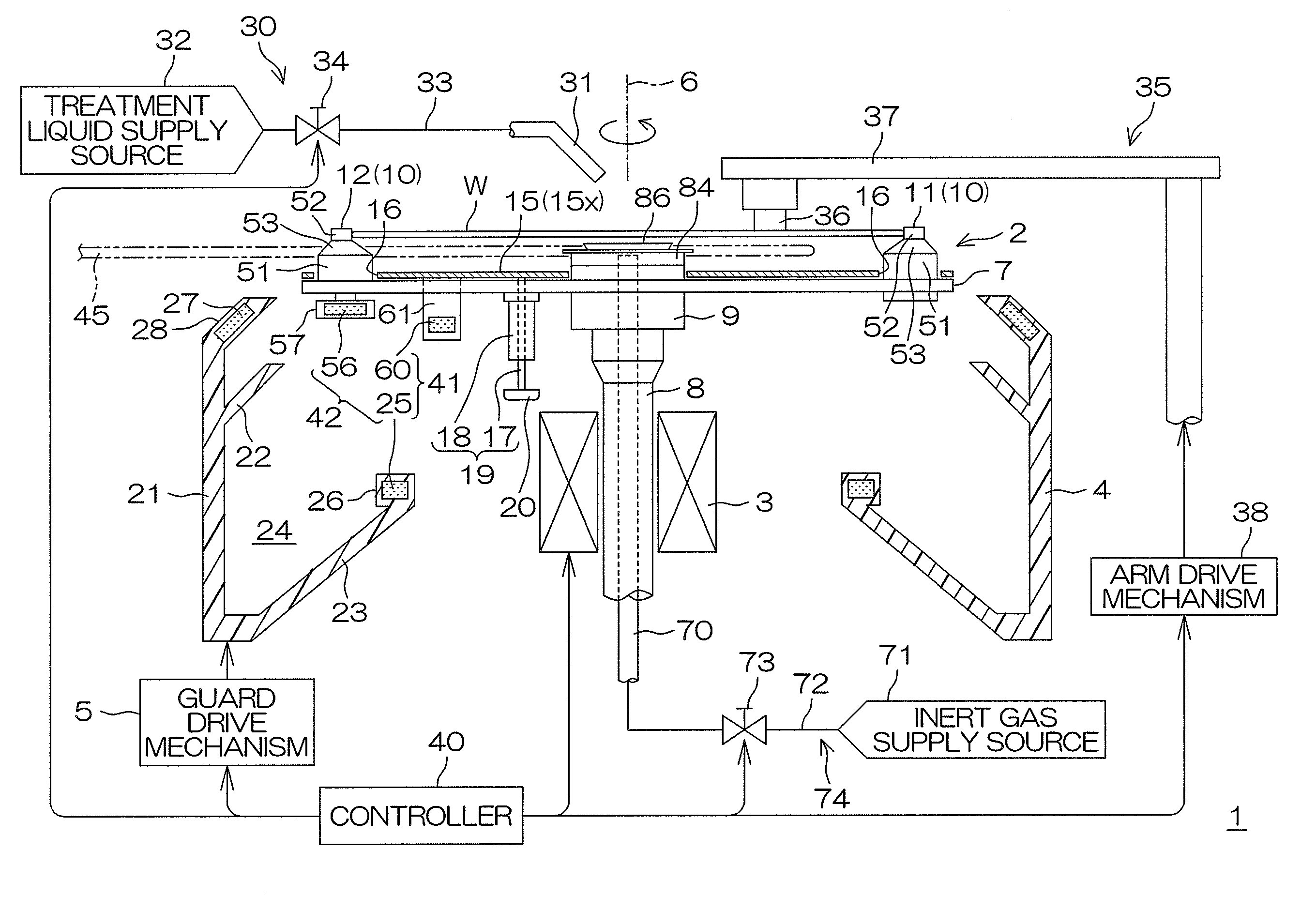

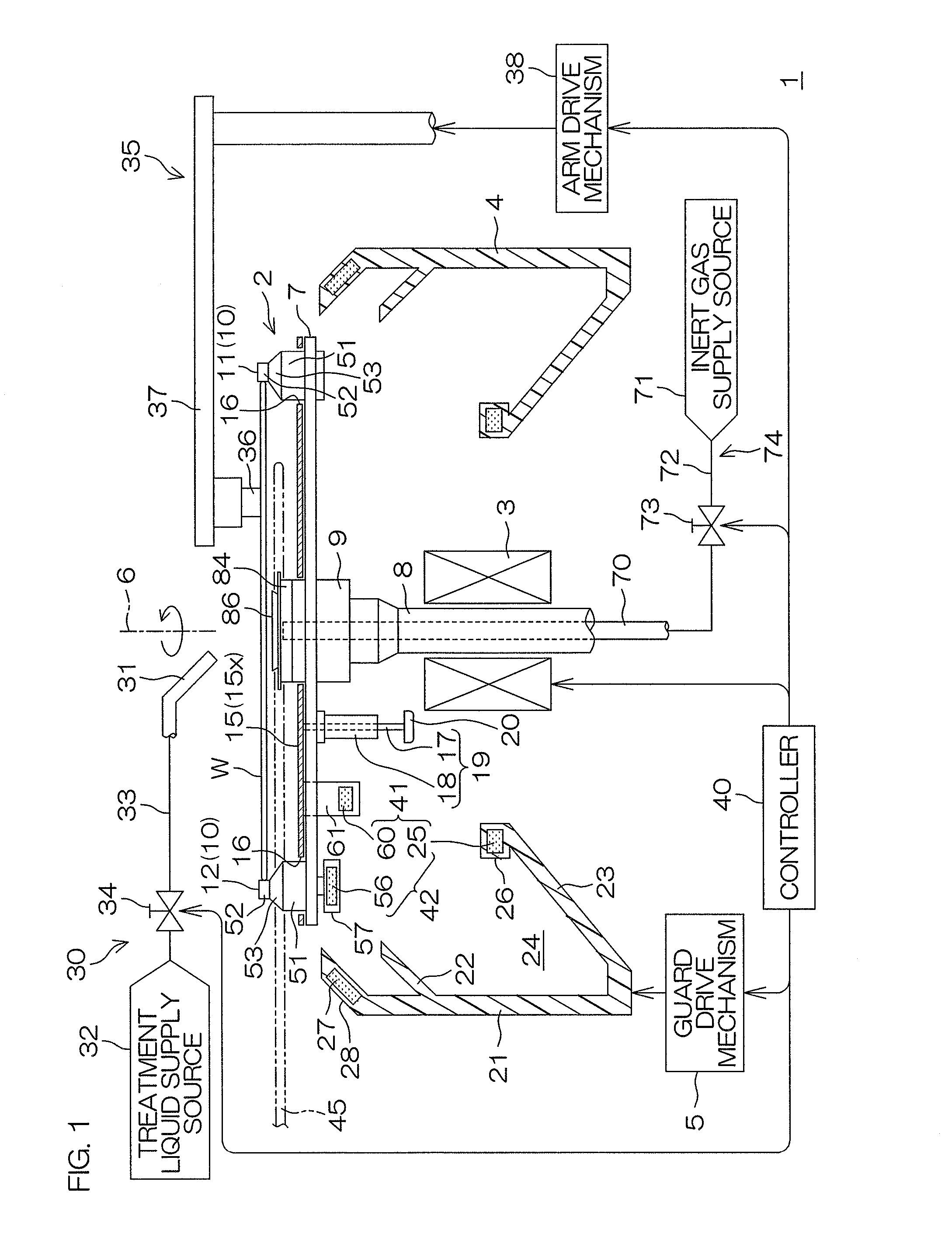

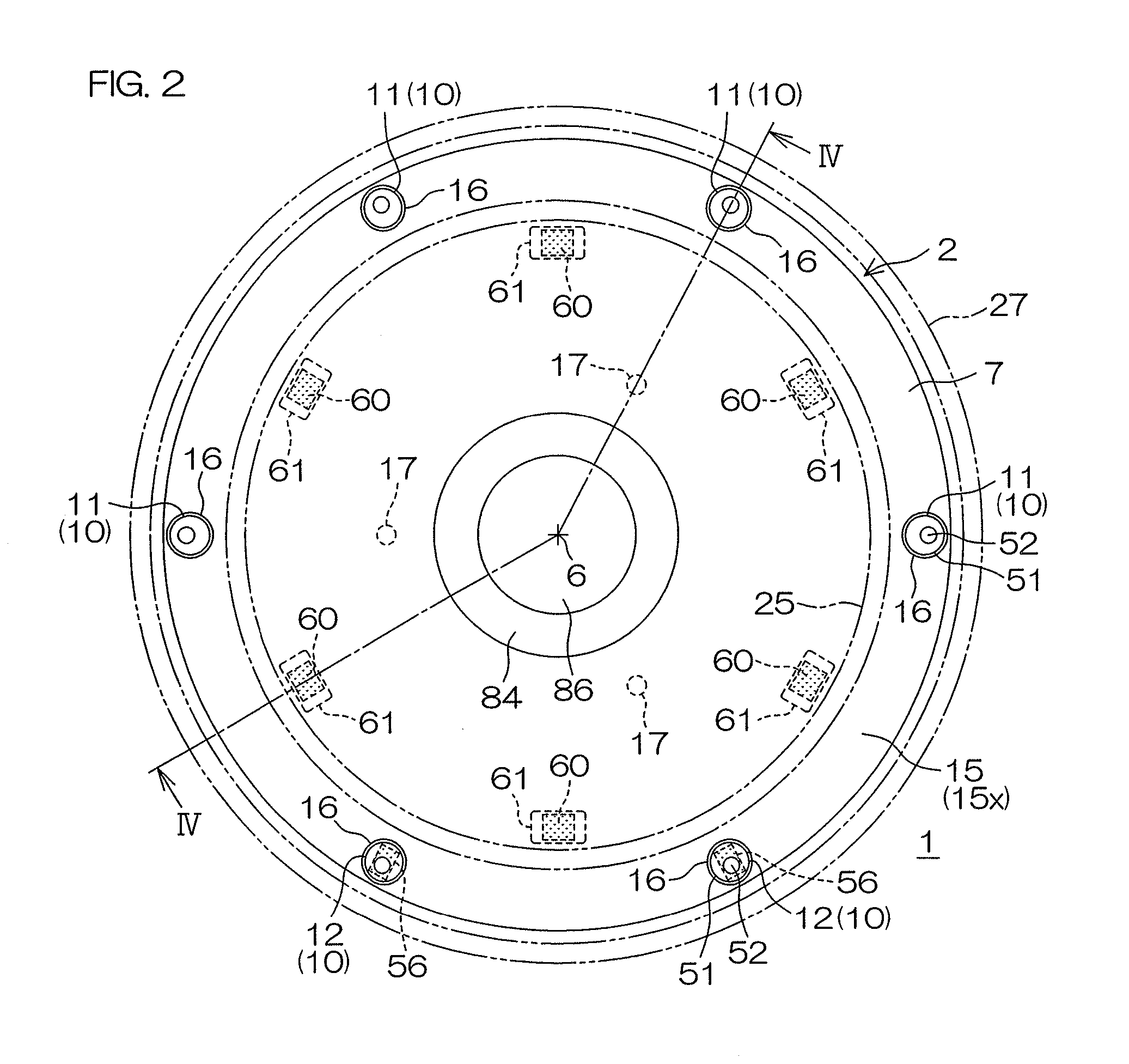

Substrate holding and rotating device, substrate processing device equipped with same, and substrate processing method

ActiveUS20160096205A1Avoid stickingInhibitionSemiconductor/solid-state device manufacturingCleaning using gasesEngineeringMagnetic levitation

A substrate treatment apparatus includes a turntable, a rotative drive unit, a holding pin provided on the turntable, a protection disk for covering a lower surface of a substrate, and a magnetic levitation mechanism that levitates the protection disk from the turntable. The protection disk is vertically movable relative to the turntable between a lower position and an adjacent position above the lower position and close to a lower surface of the substrate. The magnetic levitation mechanism includes a protection disk permanent magnet and an annual guard permanent magnet held by a splash guard. When a guard drive mechanism moves up the splash guard, the protection disk is levitated from the turntable and held at the adjacent position by a magnetic repulsive force generated between the permanent magnets.

Owner:DAINIPPON SCREEN MTG CO LTD

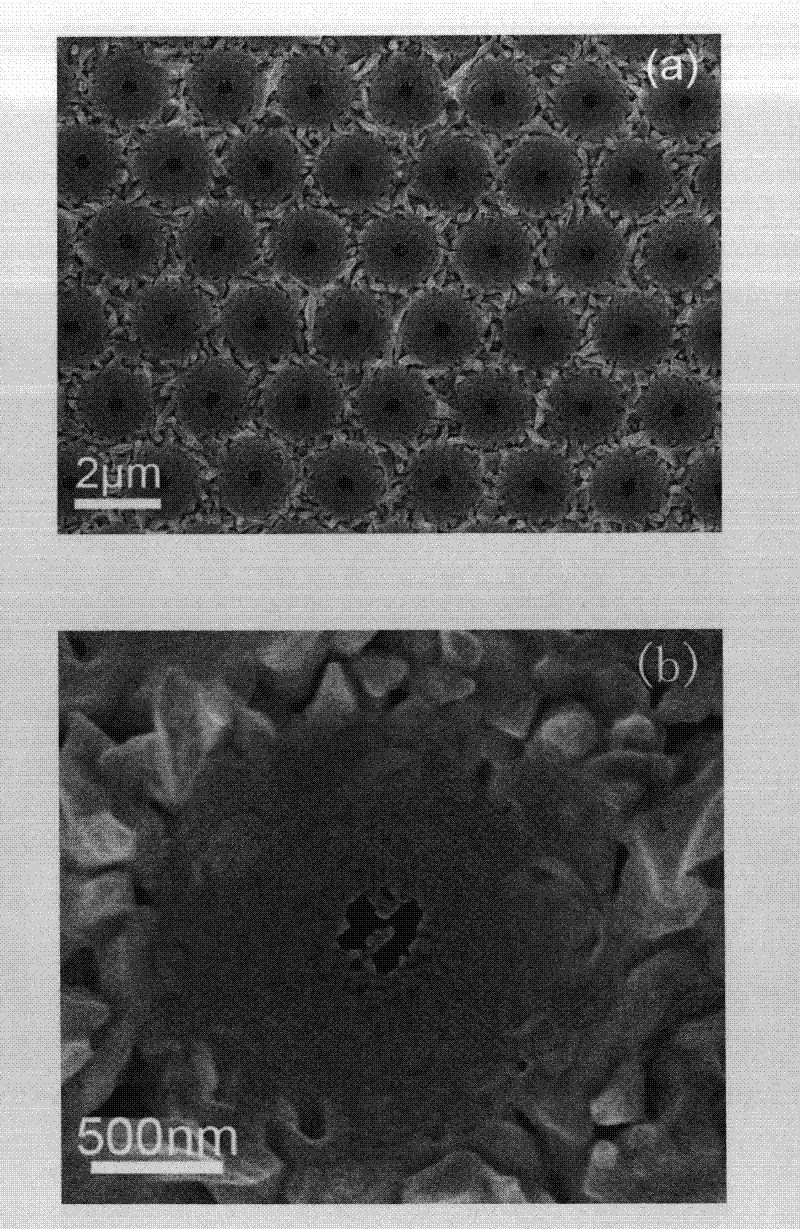

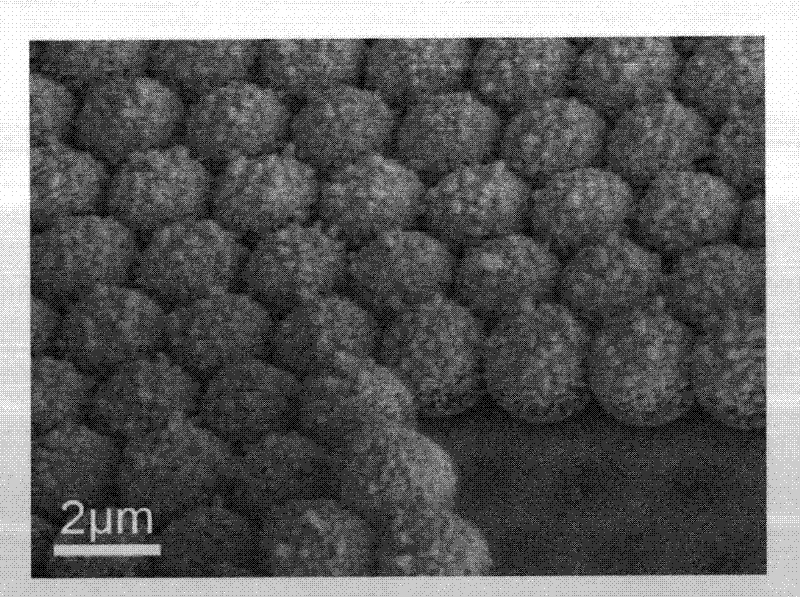

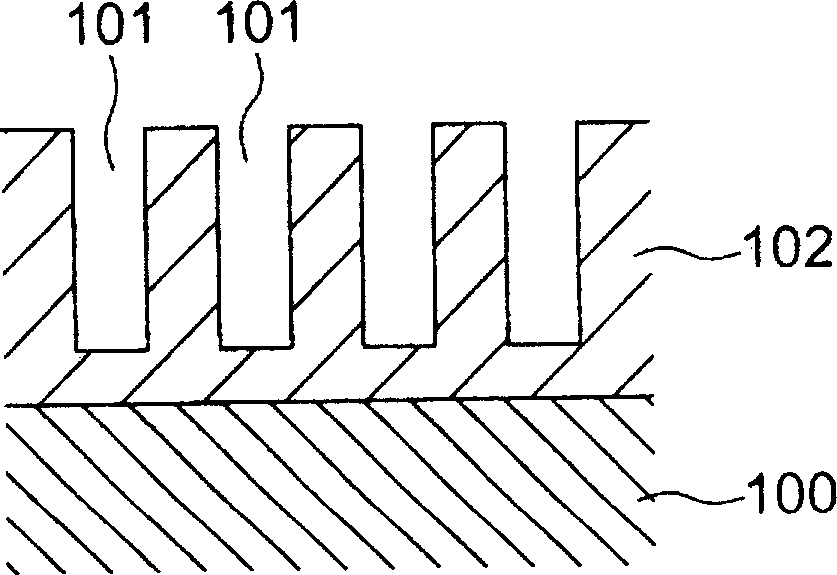

Gold micro-nano composite structure array and preparation method thereof

InactiveCN102674236AEliminate interfering peaksThe preparation process is simpleDecorative surface effectsCoupling light guidesGold filmMicrometer

The invention discloses a gold micro-nano composite structure array and a preparation method thereof. The array is a gold bowl array or a gold hollow sphere array disposed above a gold film covered on a substrate, wherein the diameter of a gold bow opening is from 500 nanometers to 10 micrometers, a bowl wall is composed of gold rods, the lengths of the gold rods are 100-1000 nanometers, the diameters of the gold rods are 50-400 nanometers, the inner diameter of a gold hollow sphere is from 500 nanometers to 10 micrometers, a sphere casing is composed of gold particles with diameters of 50-600 nanometers, and the thickness of the gold film is 5-25 nanometers. The preparation method includes sputtering a layer of the gold film on the substrate, placing a single layer colloidal crystal template which is composed of polystyrene colloidal spheres with diameters from 500 nanometers to 10 micrometers on the substrate which is covered with the gold film, then placing the substrate covered with the gold film and the colloidal crystal template into a chloroauric acid solution with concentration of 0.3-0.7g / L, using the solution with the substrate as a working electrode, subjecting the mixture to electro-deposition for 2-8 hours under the deposition electric current density of 0.03-0.05mA / cm<2> or 0.15-0.45mA / cm<2> to obtain a complex array, and placing the complex array in a dichloromethane solution for to removing the polystyrene colloidal spheres to obtain target products. The gold micro-nano composite structure array can be used as a surface enhanced raman scattering active substrate.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

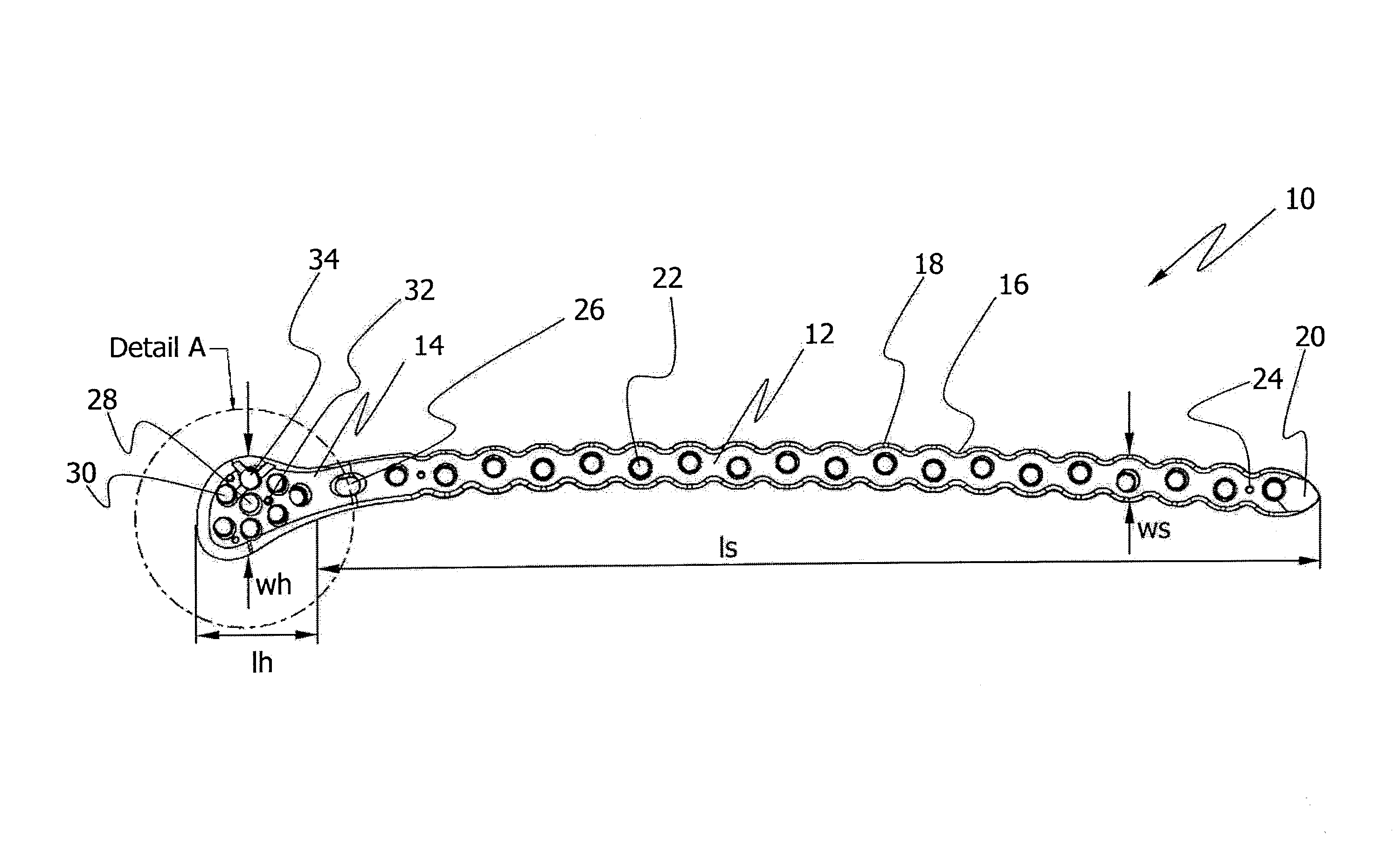

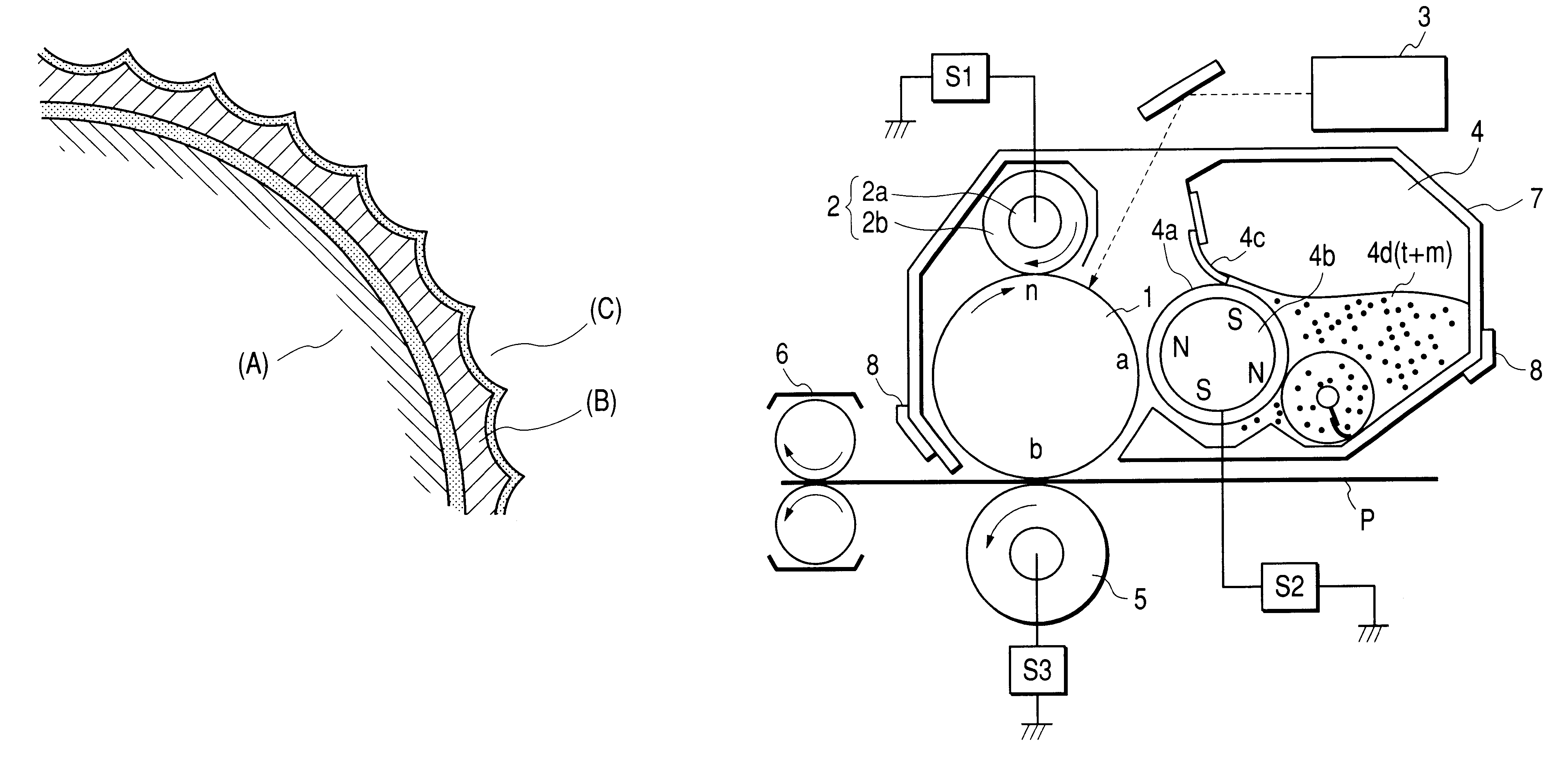

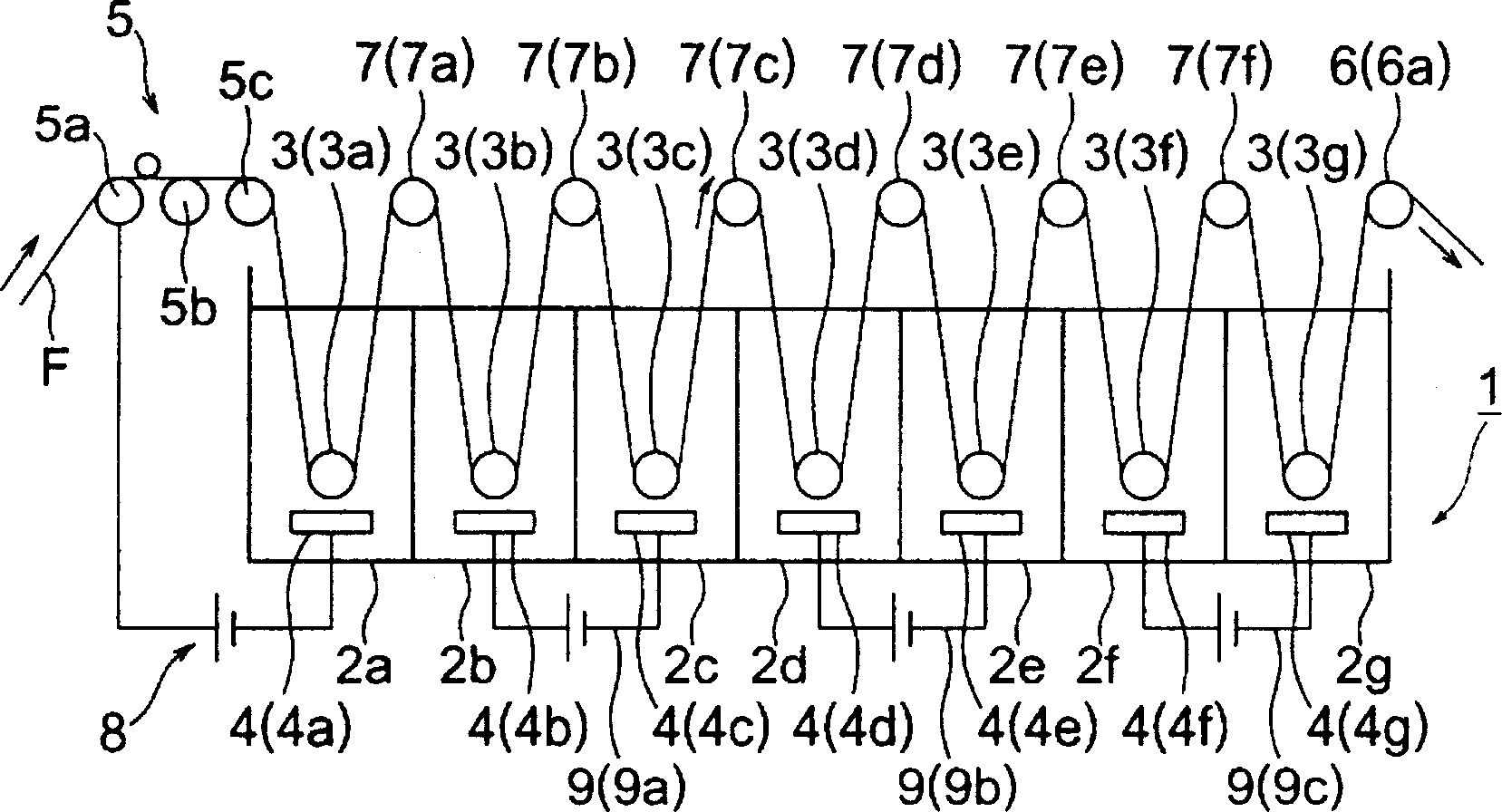

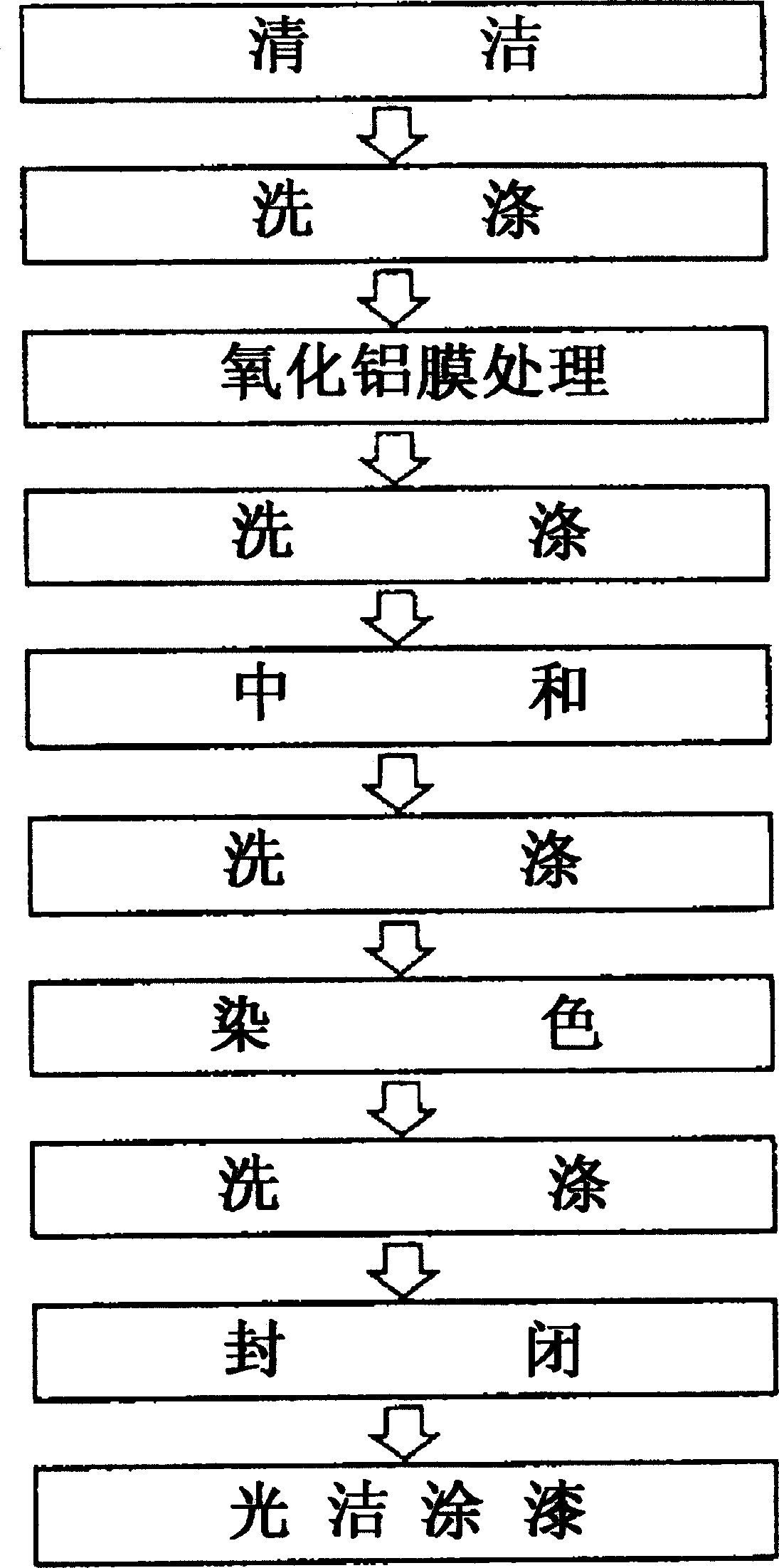

Forming method of anode oxidation film on chain tooth row and its forming equipment

PROBLEM TO BE SOLVED: To form the anodically oxidized films of the row of zip teeth of a fastener chain to arbitrary thicknesses while preventing the defects of energization and contact.SOLUTION: The forming apparatus 1 has an external energizing section 8 for electrically and directly energizing an electrode plate 4a disposed in an electrolyte of a first electrolytic cell 2a and a chain introducing section 5 to each other and a plurality of energizing sections 9 for energizing two sets a pair of adjacent electrode plates 4 within the second and subsequent electrolytic cells 2 to each other across the electrolyte and the fastener chain F. While the fastener chain is successively wrapped around a plurality of rollers 3 and 7 and is transferred zigzag, the tooth trains of the fastener chain are directly energized through the energizing yarn of the fastener chain by the external energizing section. The two sets a pair of the second and subsequent electrode plates are energized to each other in the bath by the energizing sections. The anodically oxidized films having the arbitrary film thicknesses are formed by changing the number of the passage stages to the second and subsequent electrolytic cells, the energizing quantity in the arbitrary electrolytic cells, etc.

Owner:YKK CORP

Anion responsive Pickering emulsion as well as preparation method and application thereof

ActiveCN105944581ALower pHGreat application potentialTransportation and packagingMixing methodsIon exchangePickering emulsion

The invention discloses an anion responsive Pickering emulsion. The emulsion is prepared from ionic liquid modified sheet materials which are taken as a particle emulsifier, have different front and back surface properties and are dispersed on an interface of a water phase and an oil phase; one side of the particle emulsifier is a lipophilic group, and the other side is an ionic liquid functional group. According to the emulsion, the ionic liquid functional group has an anion exchangeable characteristic and can adjust the surface wettability while being endowed with functionalization after the anion exchange, and accordingly, the sheet materials have adjustable emulsifying performance; anion control functionalization and phase inversion are performed according to the characteristic that types of the stabilized emulsion are different due to different physicochemical properties of ionic liquid base materials containing different anions in the specific oil-water proportion, and the emulsion has broader application potentiality.

Owner:LIAONING UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com