Forming method of anode oxidation film on chain tooth row and its forming equipment

A technology of anodic oxidation film and zipper, applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve problems such as corrosion, and achieve the effect of avoiding discharge points or corrosion and continuous formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

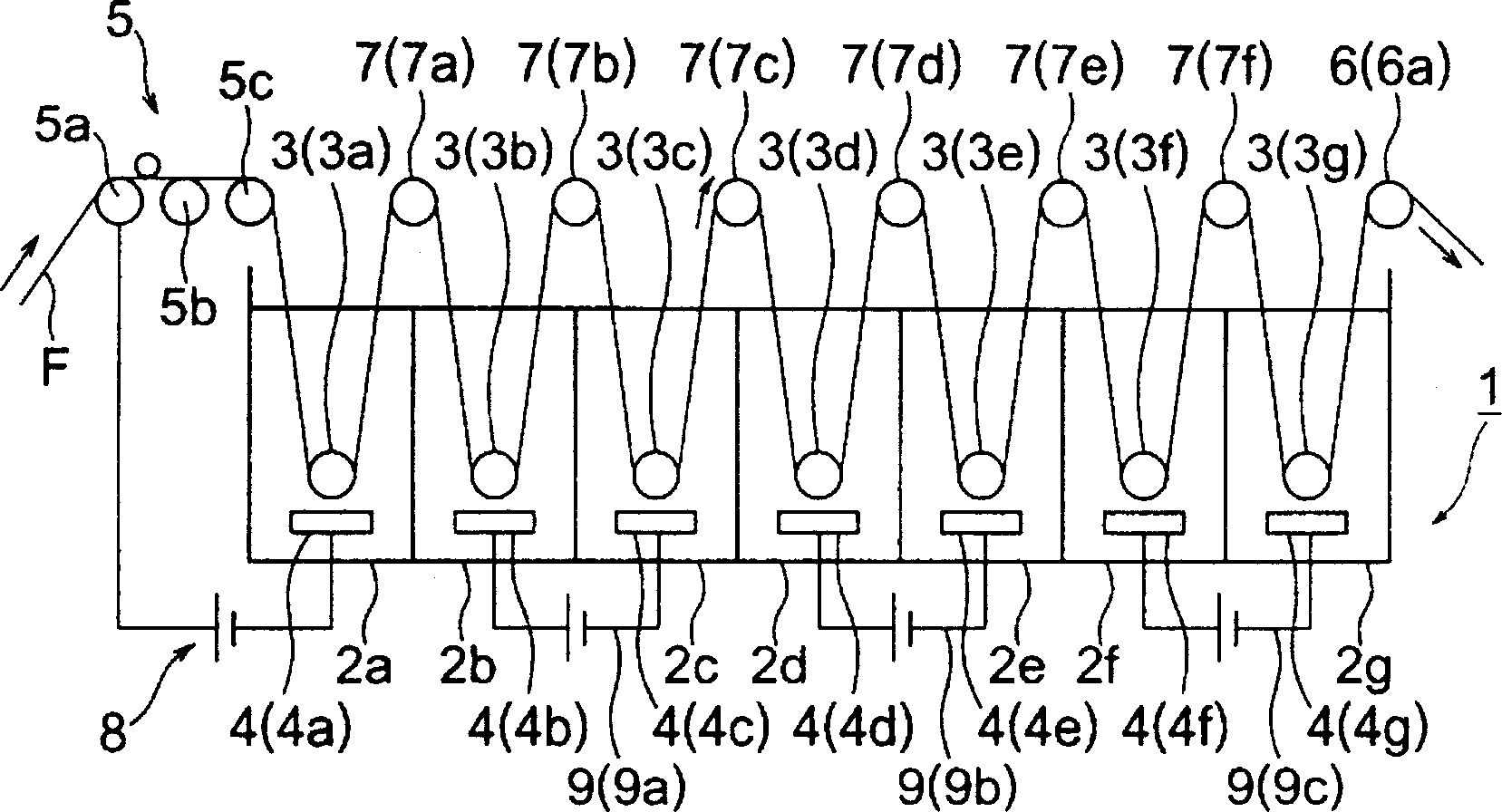

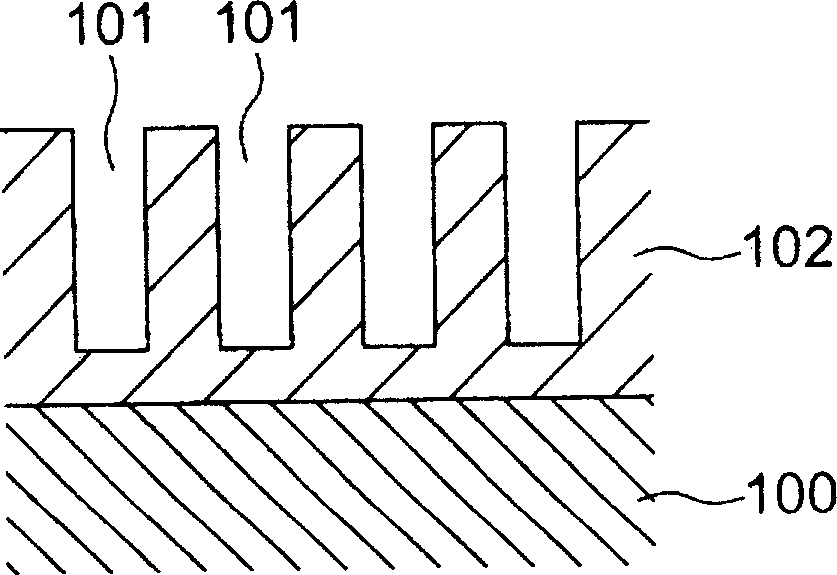

[0086] According to the embodiment of the present invention, in the slide fastener F (hereinafter referred to as slide fastener F) that is made up of elongated linear bodies, electrified thin wires wound with foil-like or wire-like materials such as aluminum or copper are sewn as the composition of the slide fastener tape. The part of the thread which keeps the energized thread in contact with a plurality of zipper teeth made of aluminum or an aluminum alloy implanted at equal intervals along the side edges of the zipper tape, as described previously by the same applicant in the Japanese Utility Model Gazette No. 2587180 as proposed. A sulfuric acid solution was used as the solution used in the electrolytic bath in this example.

[0087] Hereinafter, best modes of the present invention will be described in detail by referring to the accompanying drawings.

[0088] figure 1 According to a first embodiment of the present invention, an anodized film forming apparatus of element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com