Patents

Literature

63results about How to "Increase linear density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

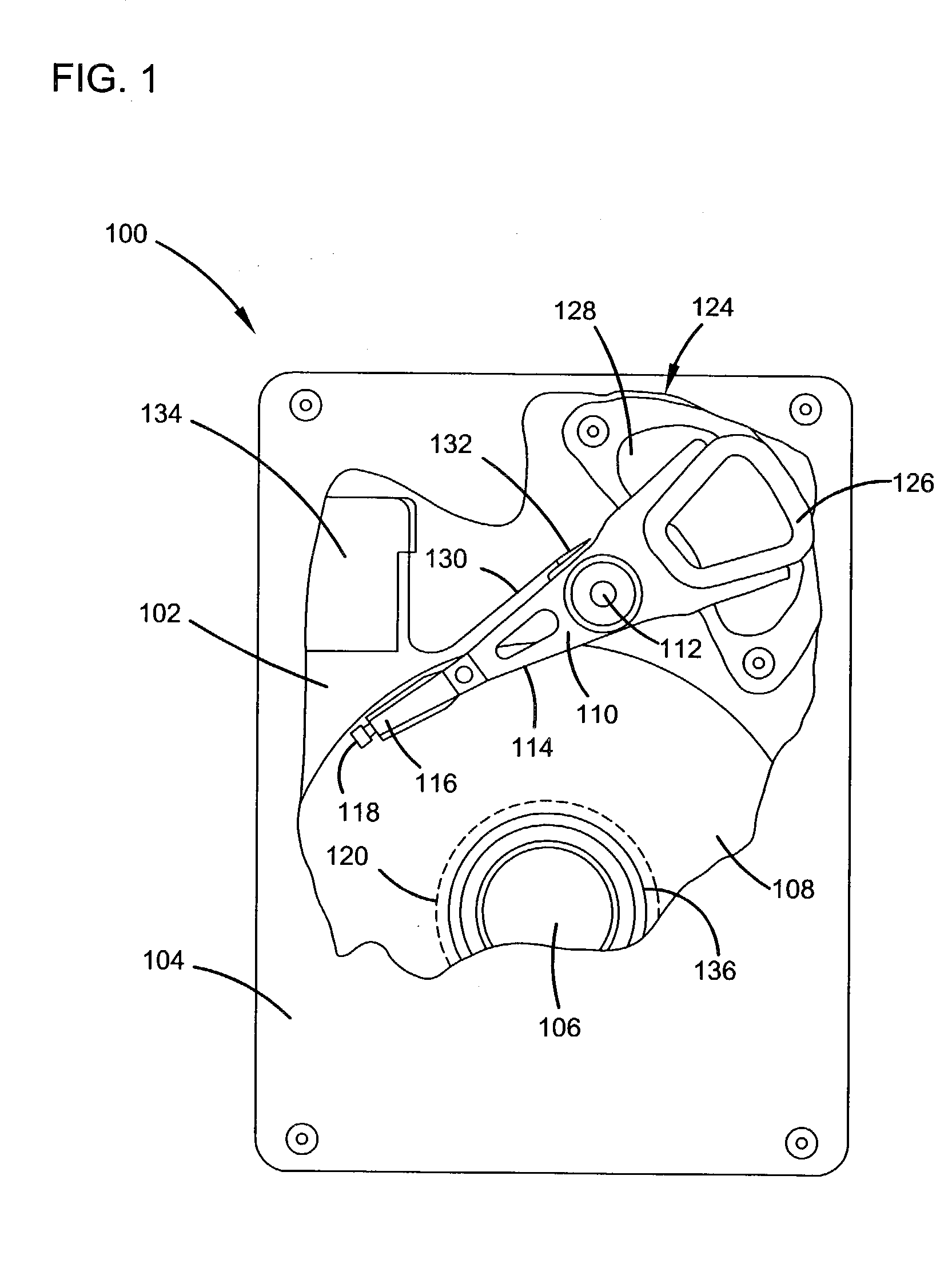

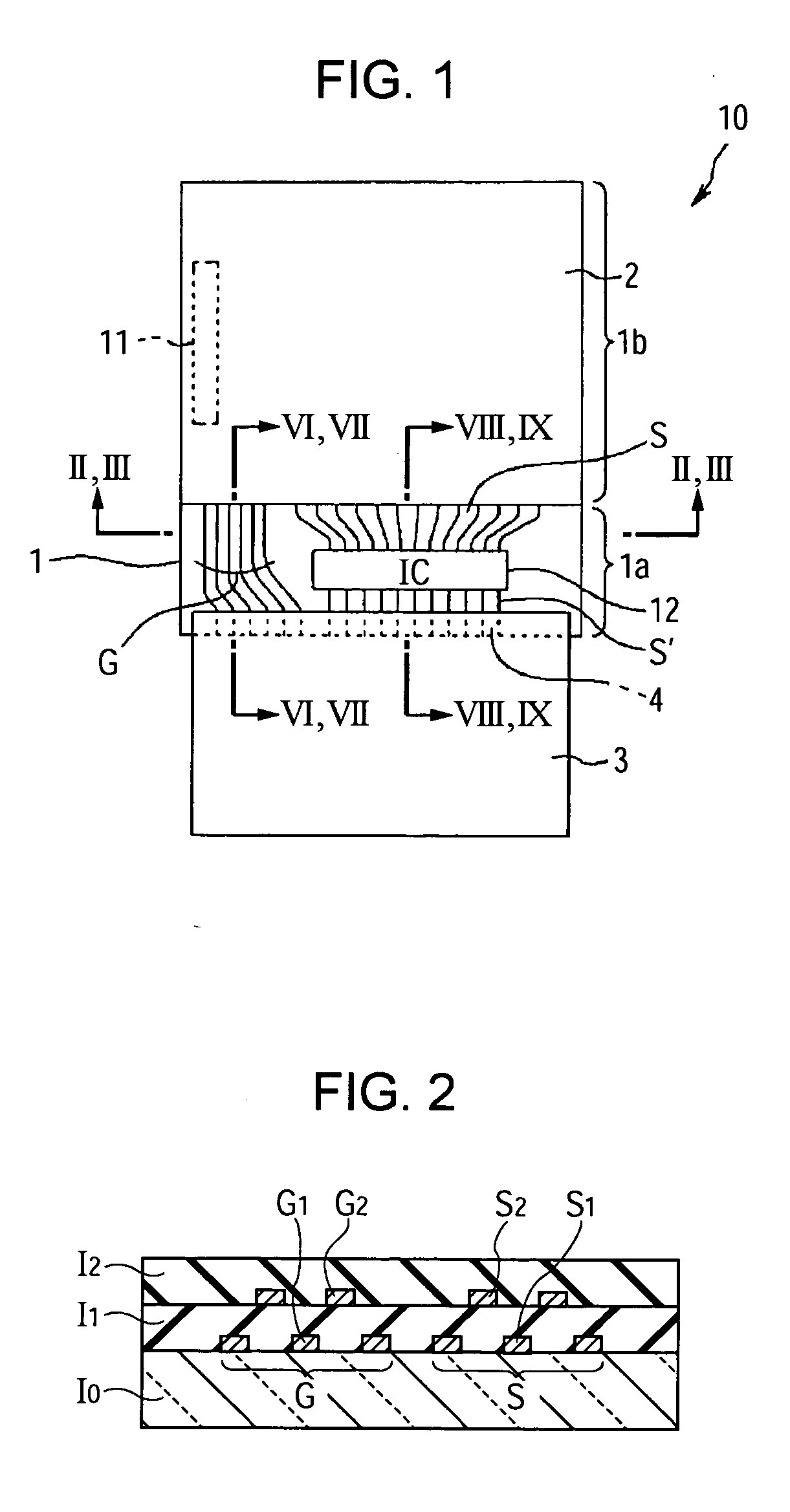

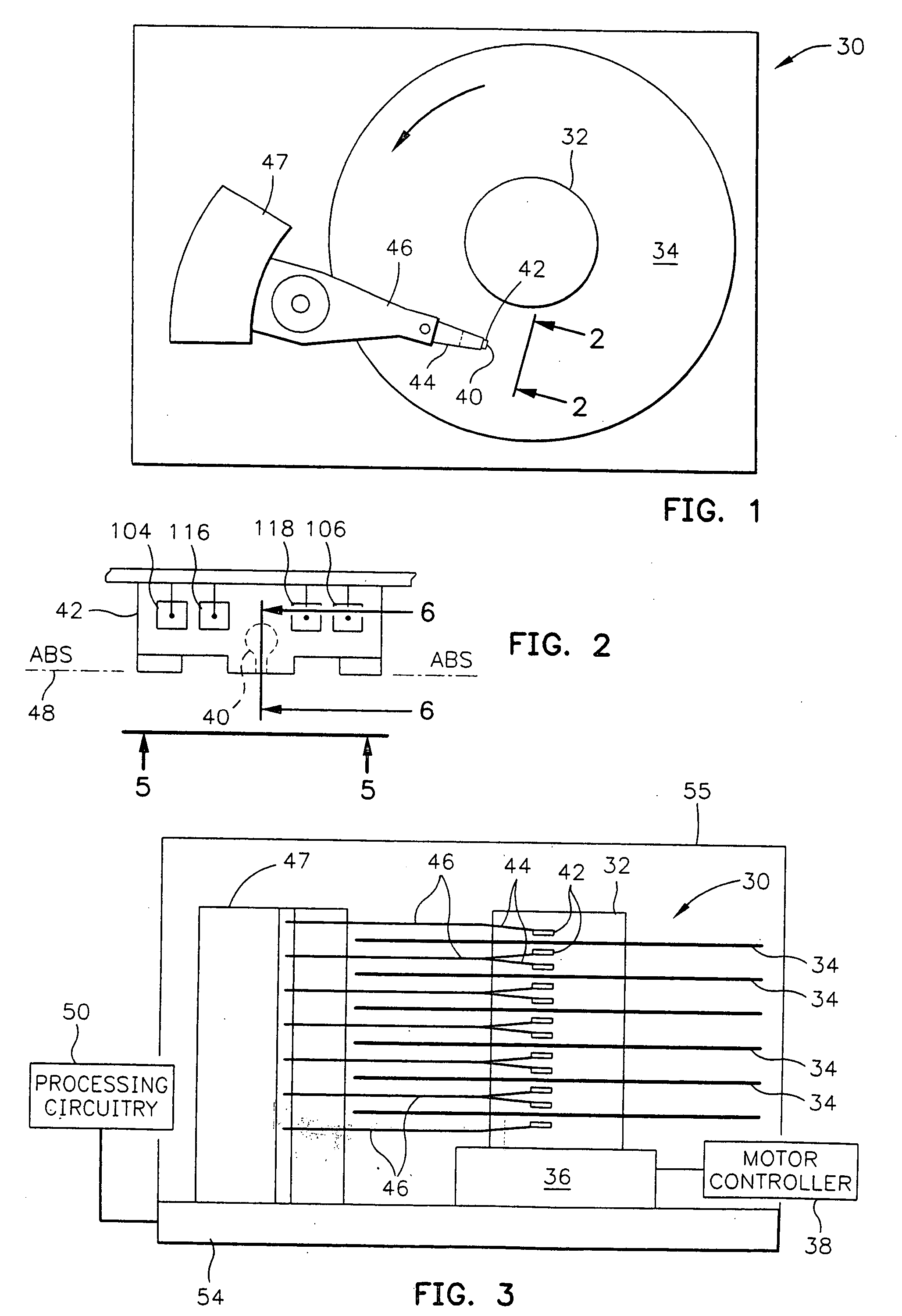

Structure to achieve sensitivity and linear density in tunneling GMR heads using orthogonal magnetic alignments

ActiveUS7035062B1Increase linear densityHigh sensitivityNanomagnetismNanoinformaticsMagnetic reluctanceMagnetization

The present invention provides a tunneling magneto-resistive read sensor structure that improves sensitivity and linear density of the sensor structure. The sensor includes first and second electrodes and a stack positioned between the electrodes. The stack includes first and second free layers with magnetization orientations that are biased relative to each other. A tunneling barrier (insulating layer) or non-magnetic metal spacer is positioned between the first and second free layers. A sense current is passed between the first and second free layers of the stack. The amount of current passing through the first and second free layer changes based upon the orientation of the first and second free layers relative to each other.

Owner:SEAGATE TECH LLC

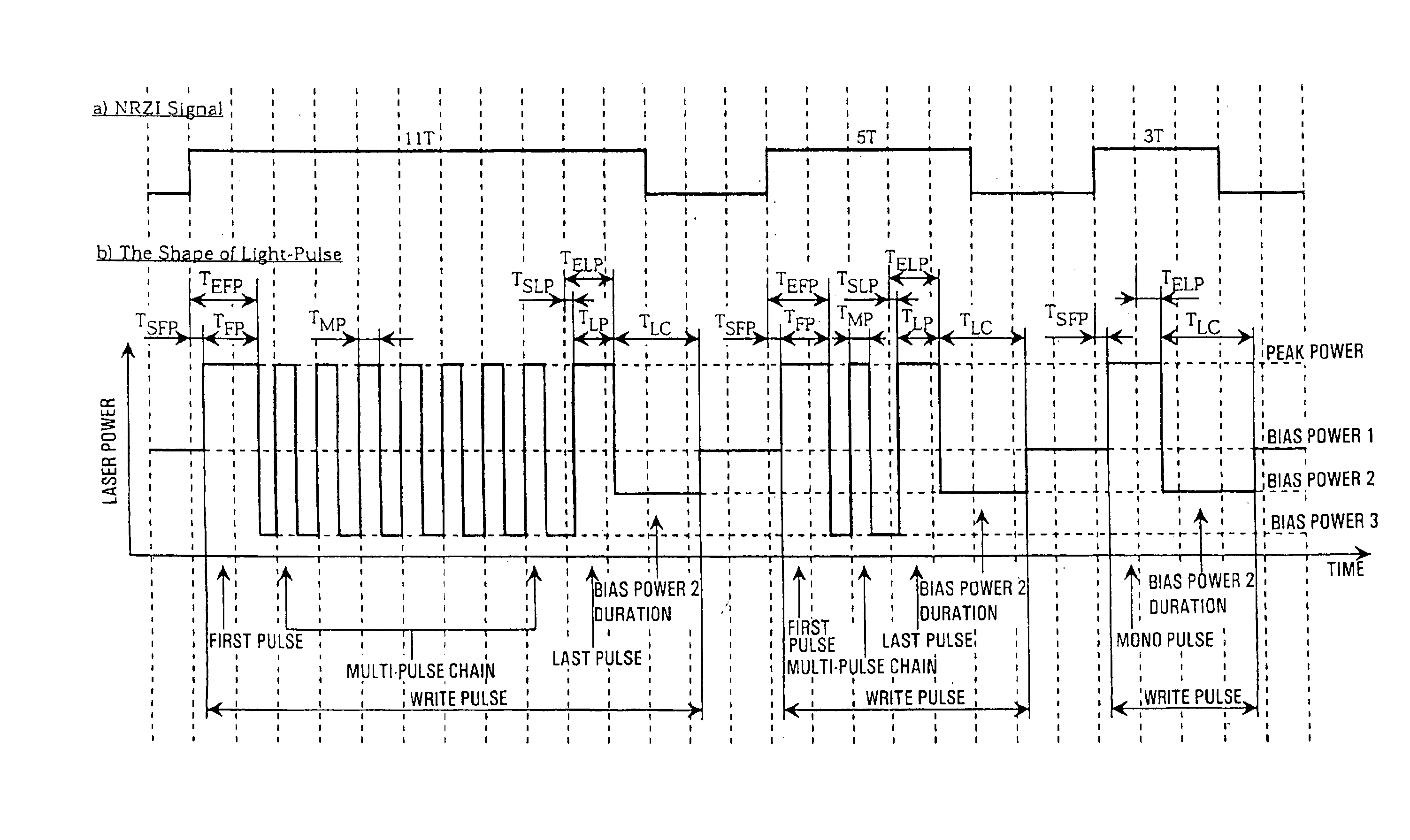

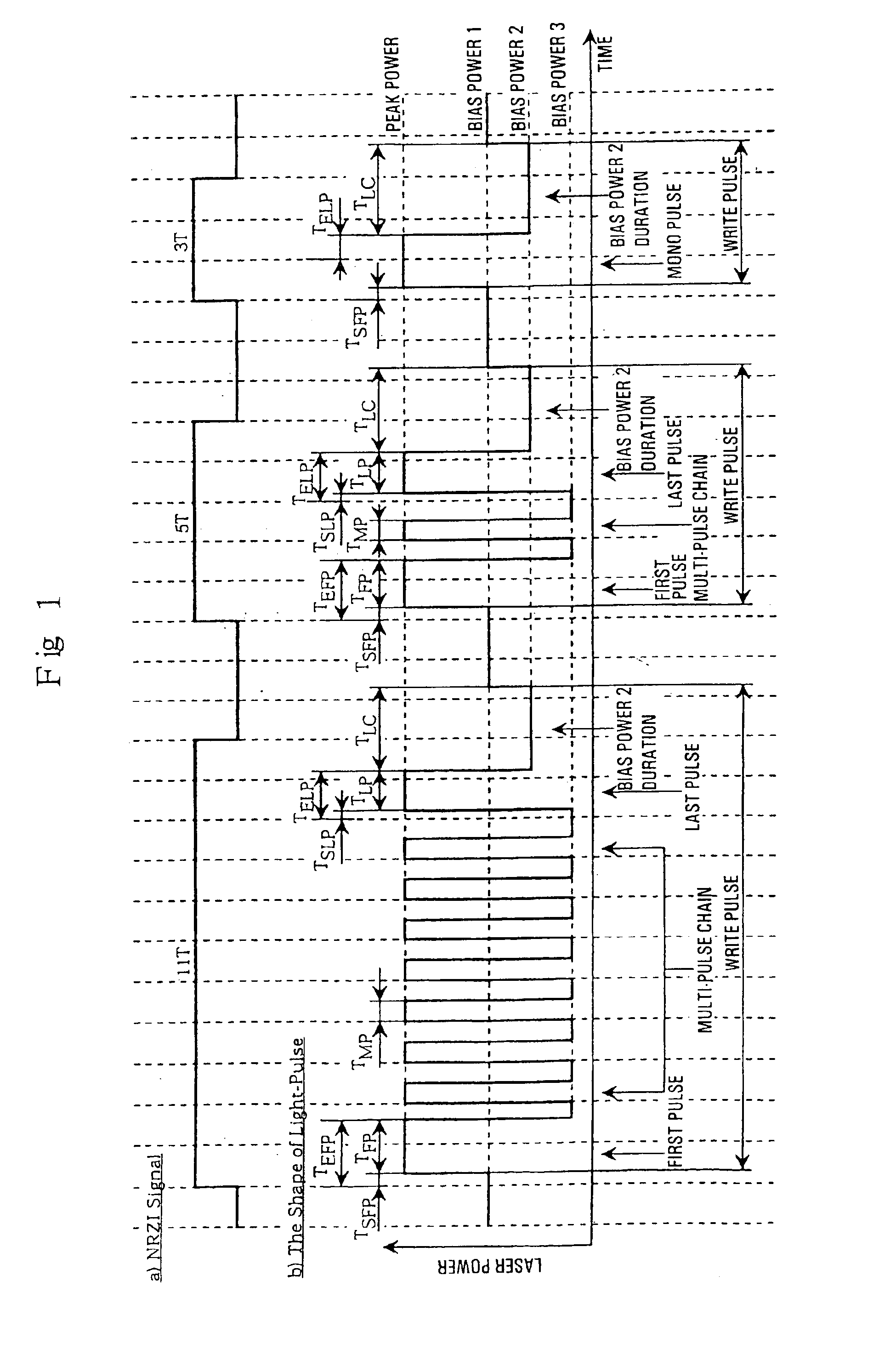

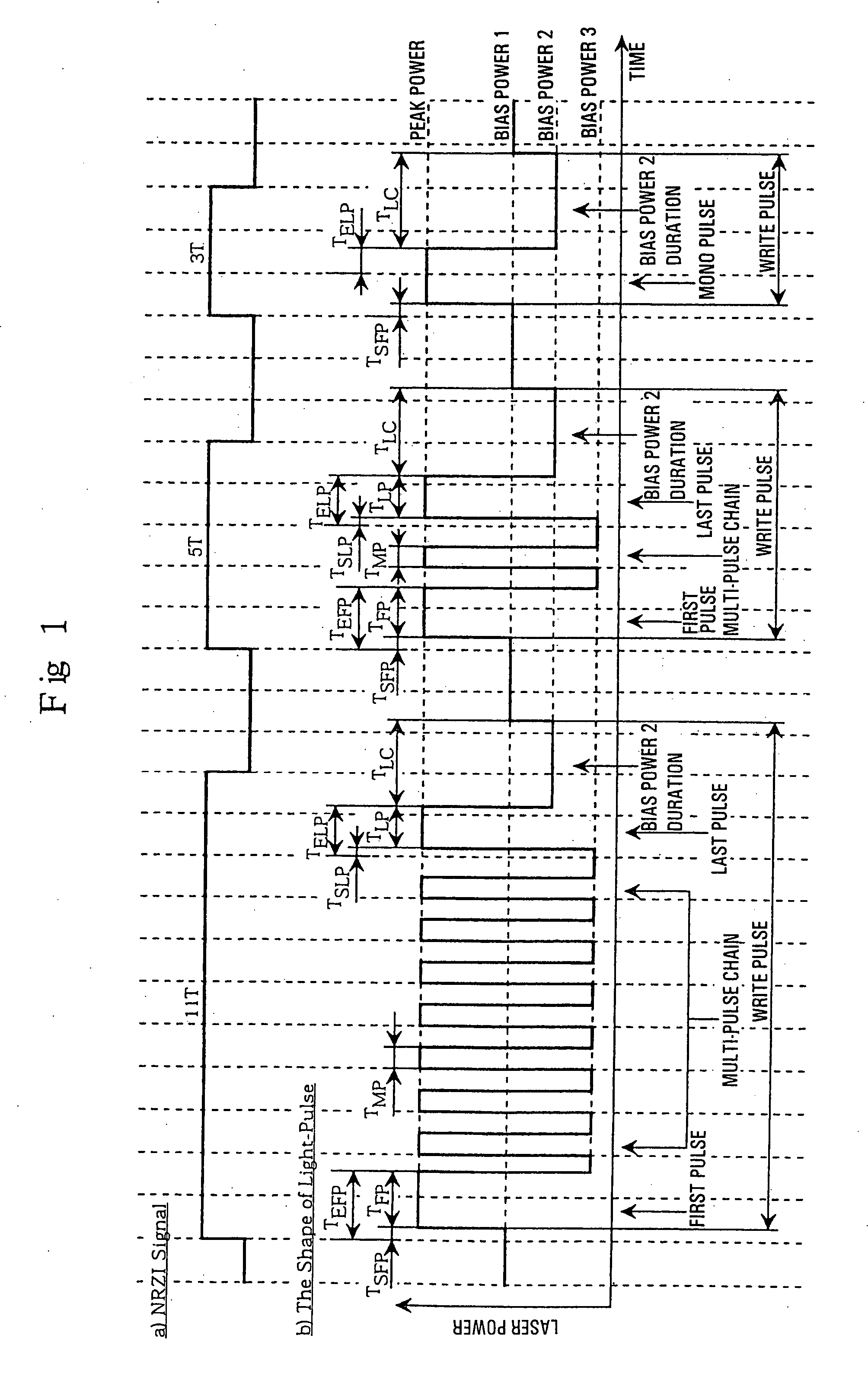

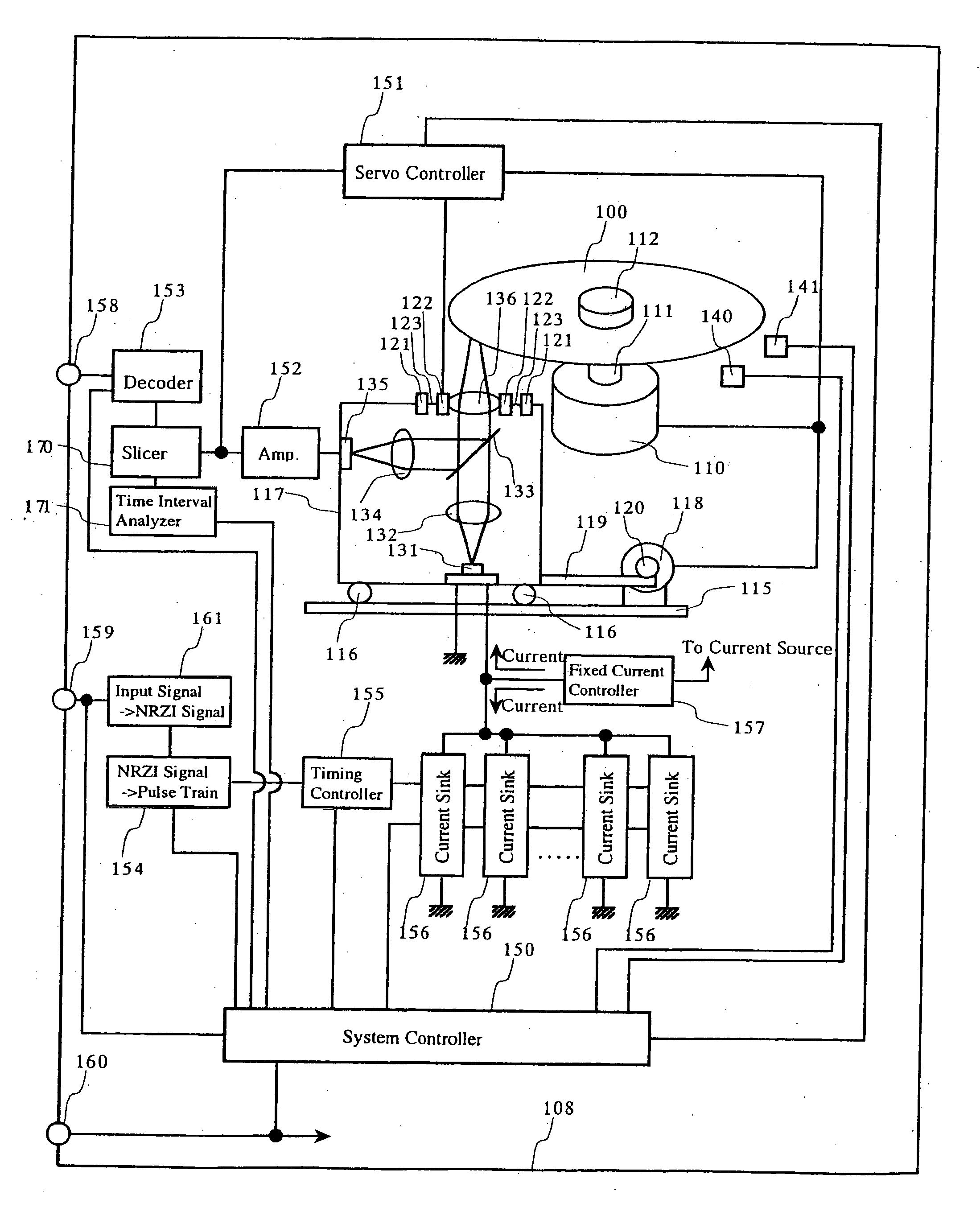

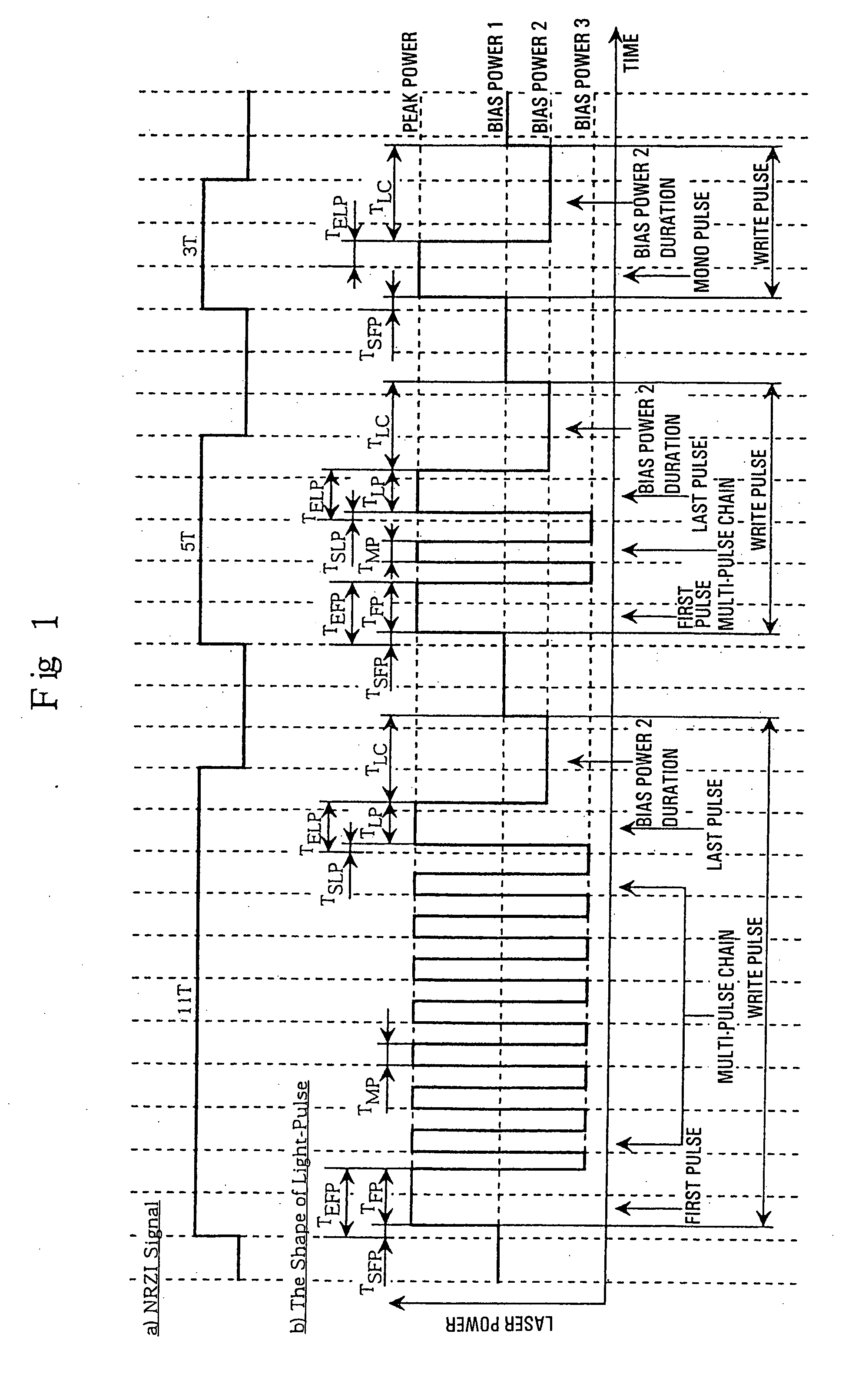

Information recording method, information recording medium and information recording apparatus

InactiveUS6925040B1Avoid distortionIncrease linear densityRecording strategiesTelevision system detailsLookup tableComputer science

Owner:HITACHI CONSUMER ELECTRONICS CORP

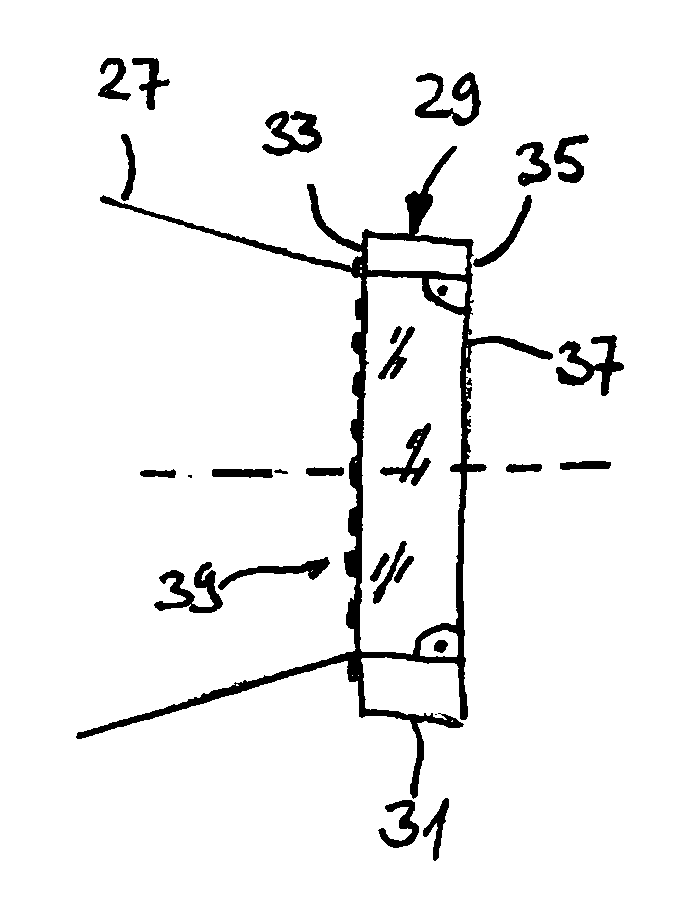

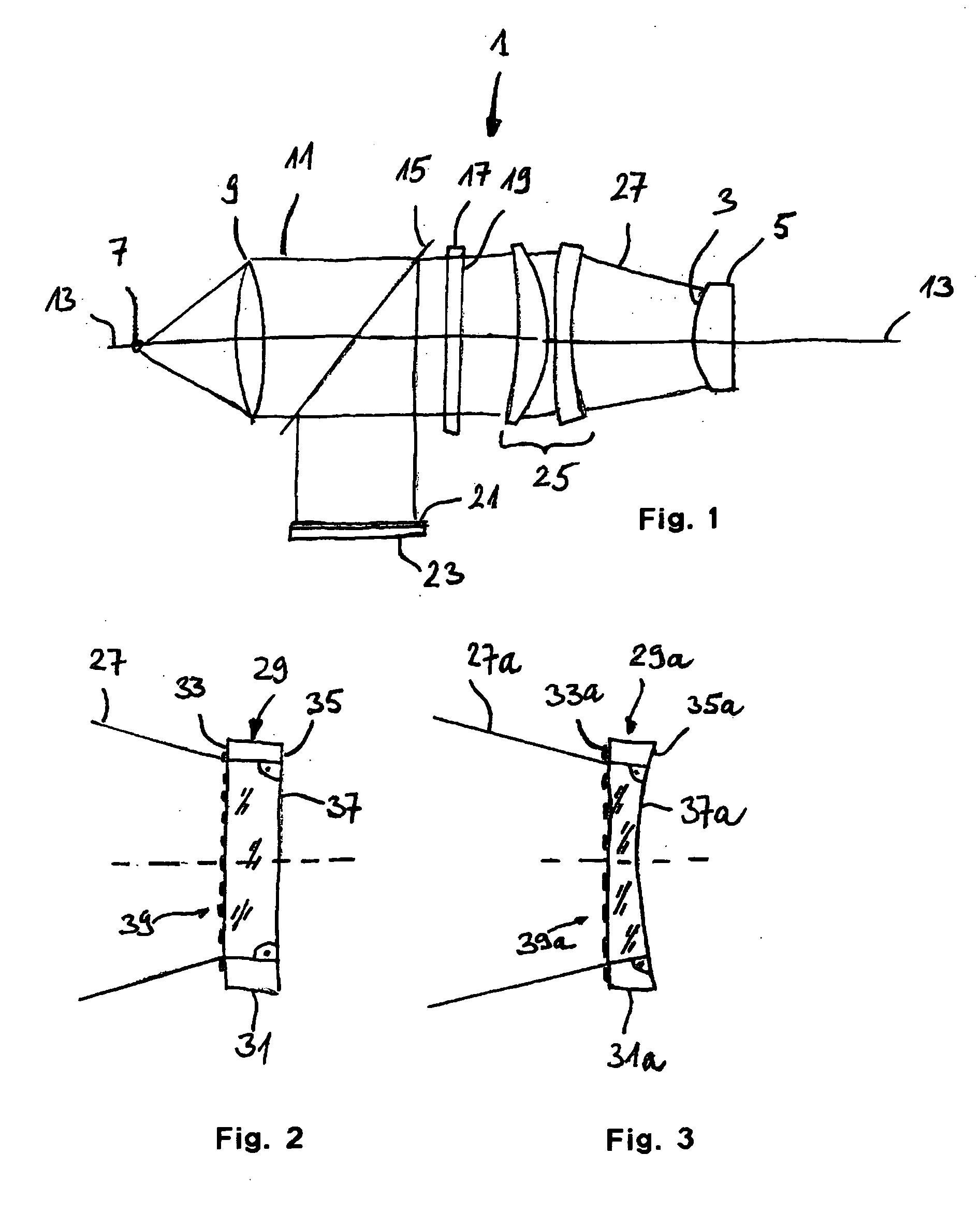

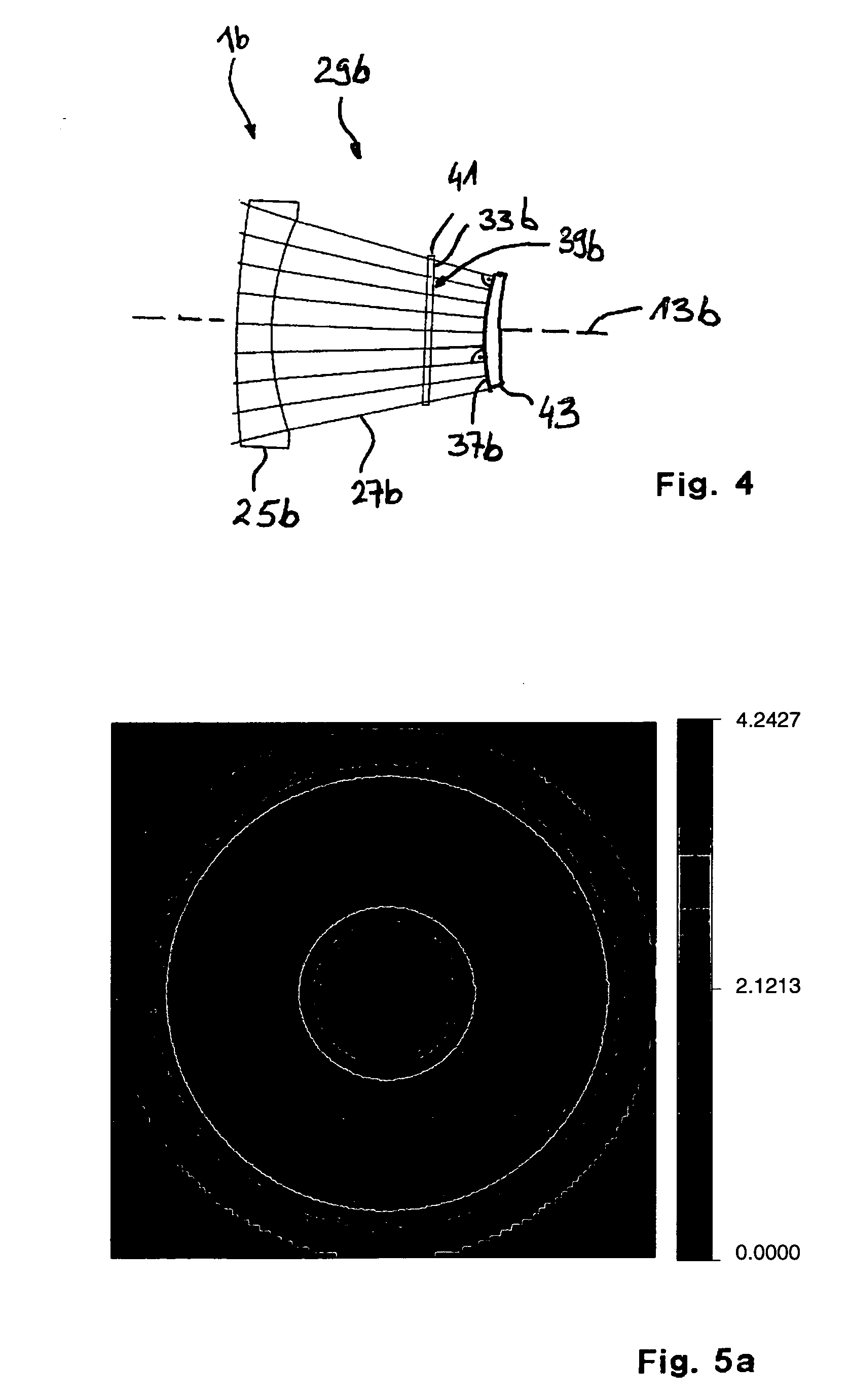

Method of calibrating an interferometer and method of manufacturing an optical element

InactiveUS20050275849A1Improve accuracyEasy to manufactureReflective surface testingUsing optical meansOptical propertyLight beam

A method of calibrating an interferometer for determining an optical property of the interferometer uses a calibrating optical arrangement. The calibrating optical arrangement comprises at least one diffractive pattern and a mirror having a reflecting surface. The diffractive pattern and the reflecting surface are disposed at a distance from each other in a beam path of measuring light emitted from an interferometer optics of the interferometer system to be calibrated.

Owner:CARL ZEISS SMT GMBH

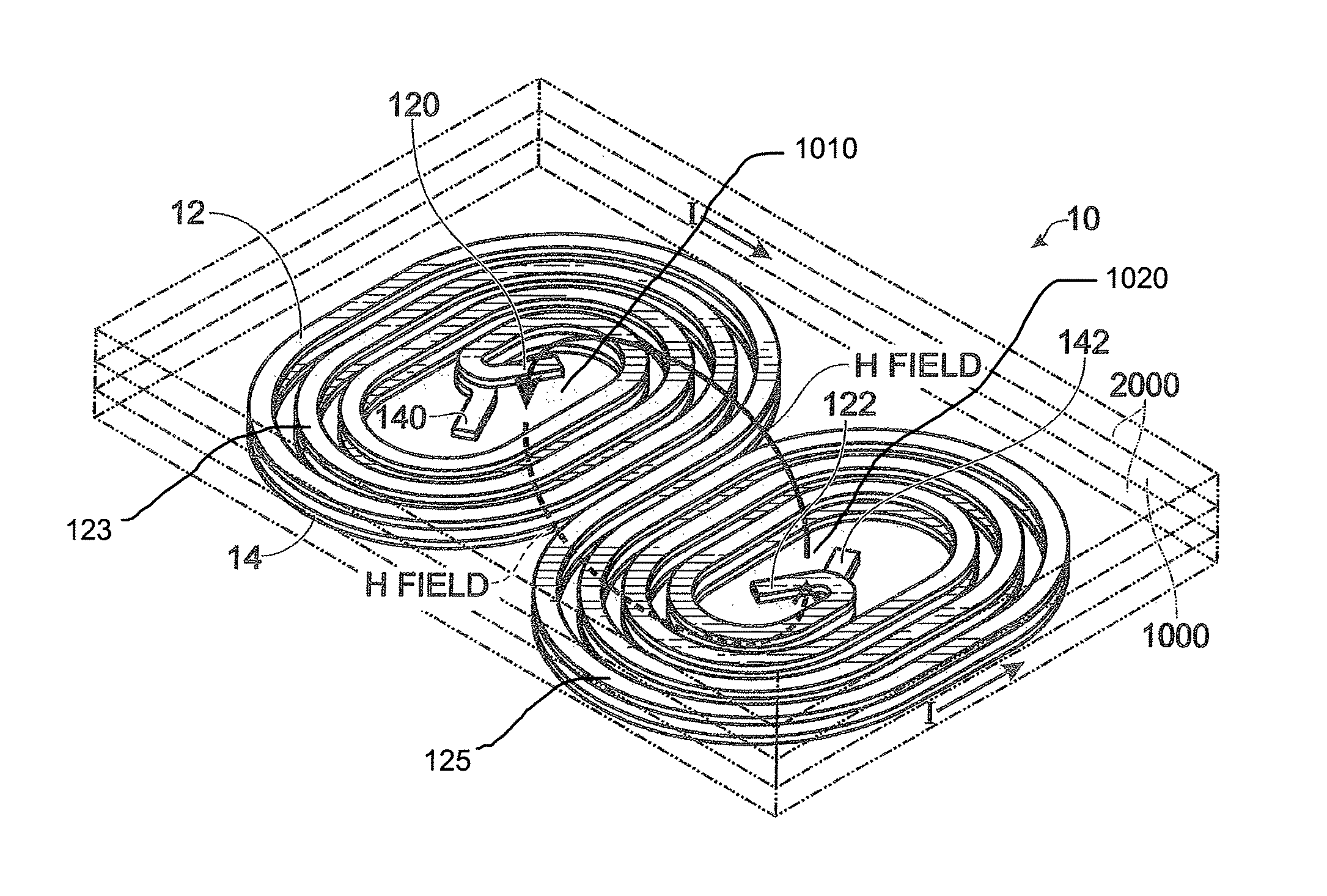

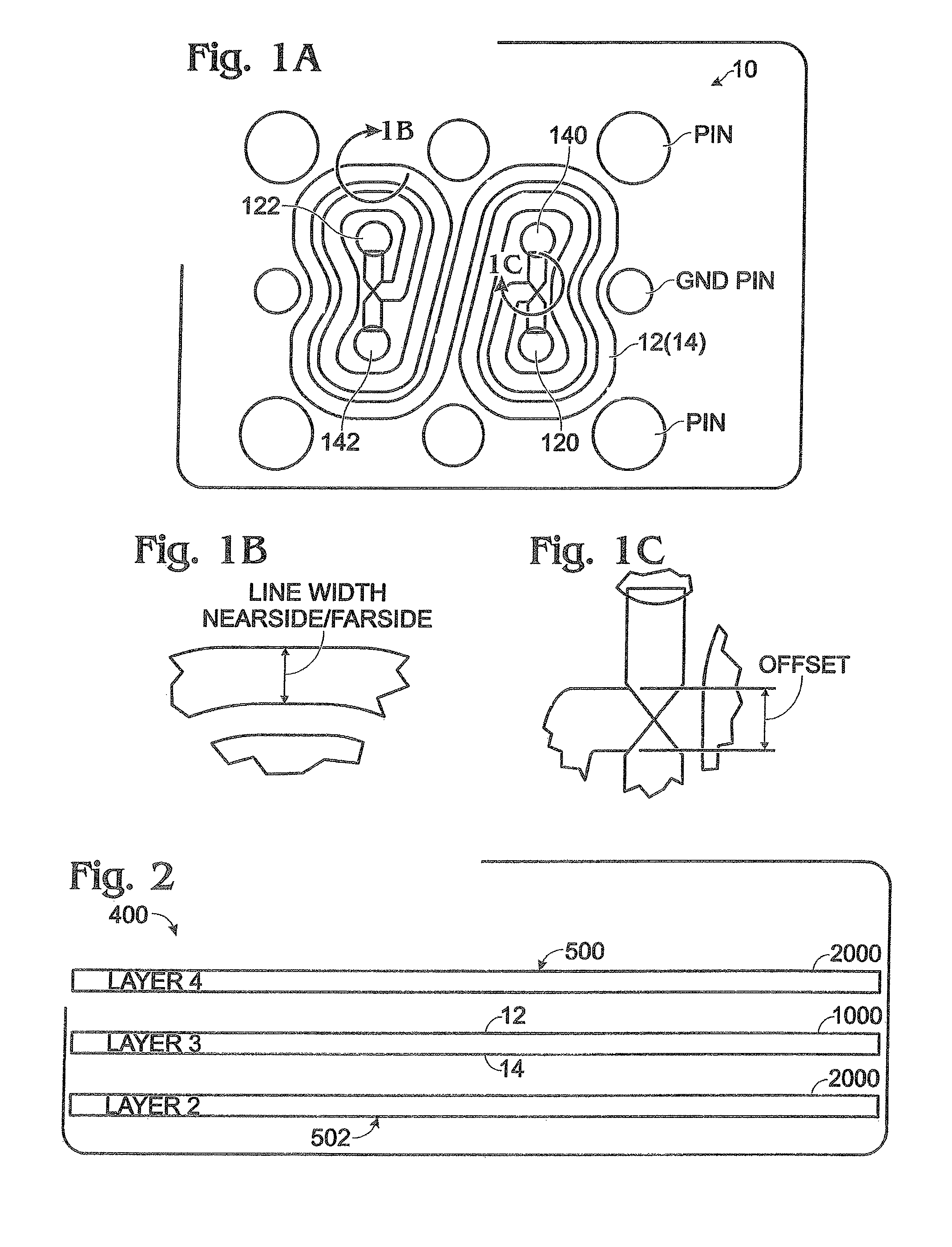

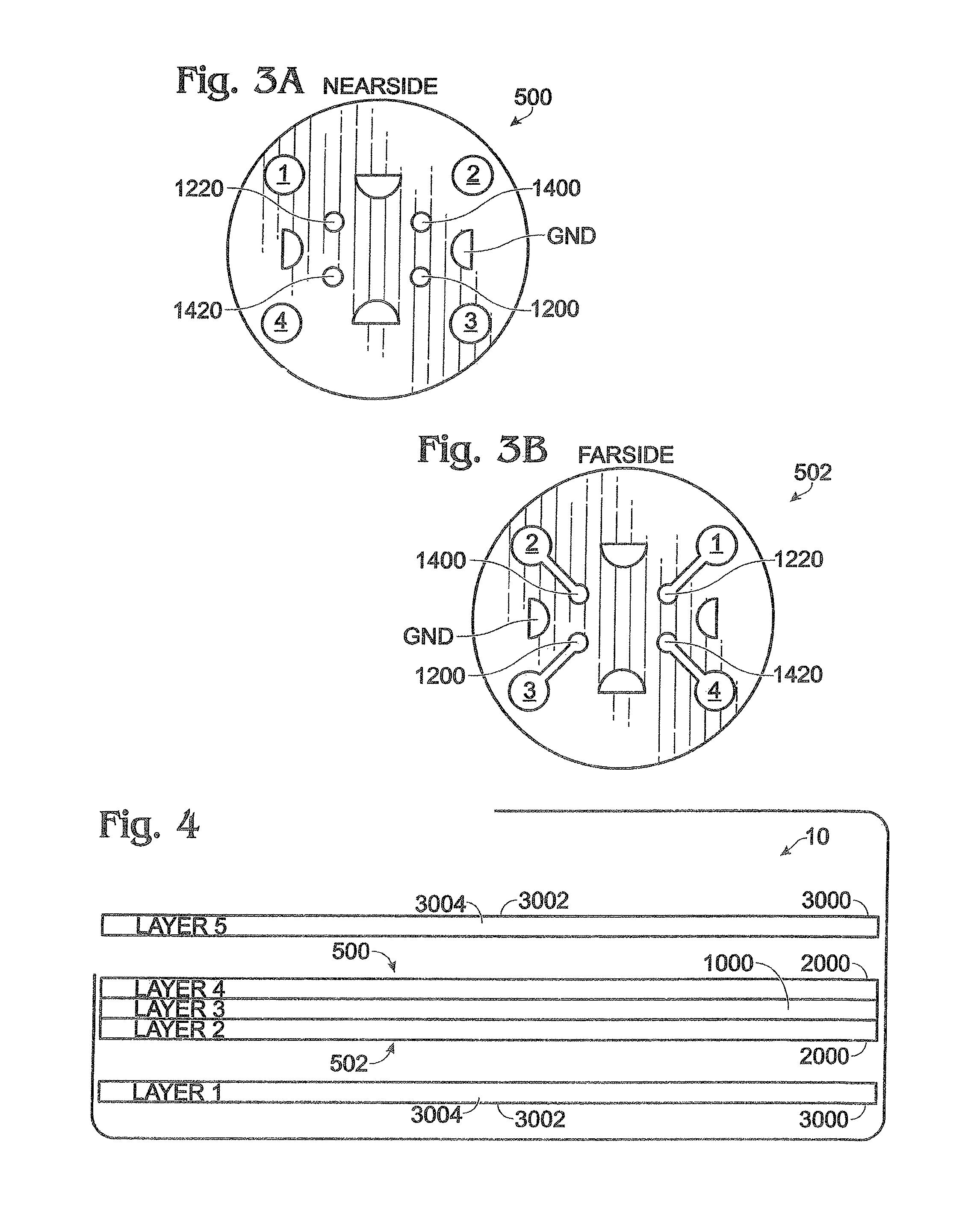

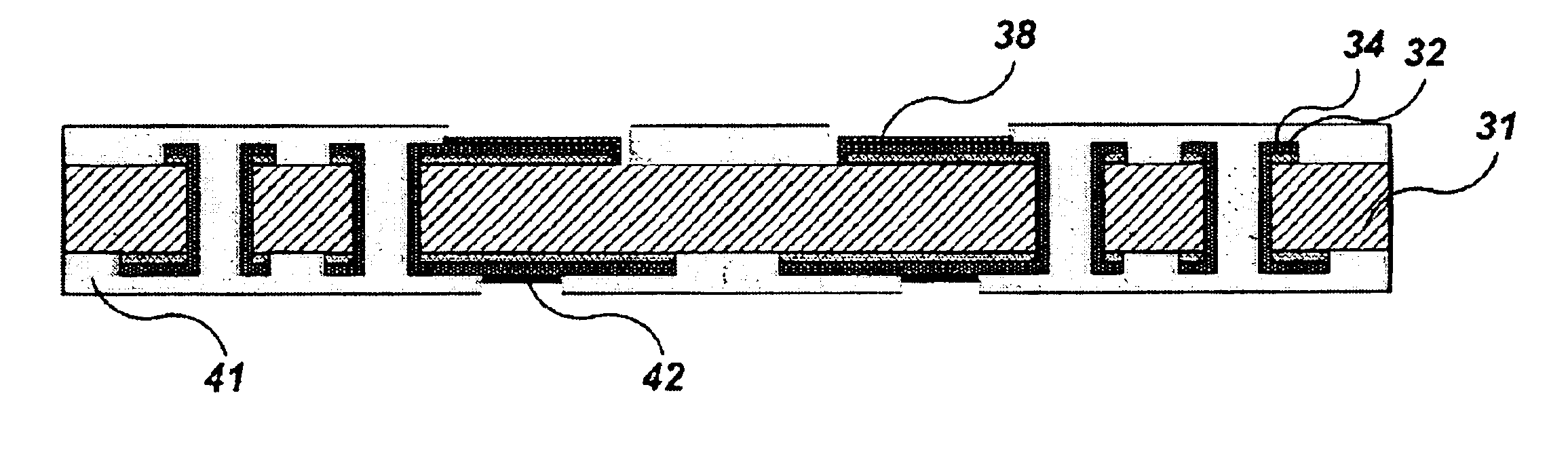

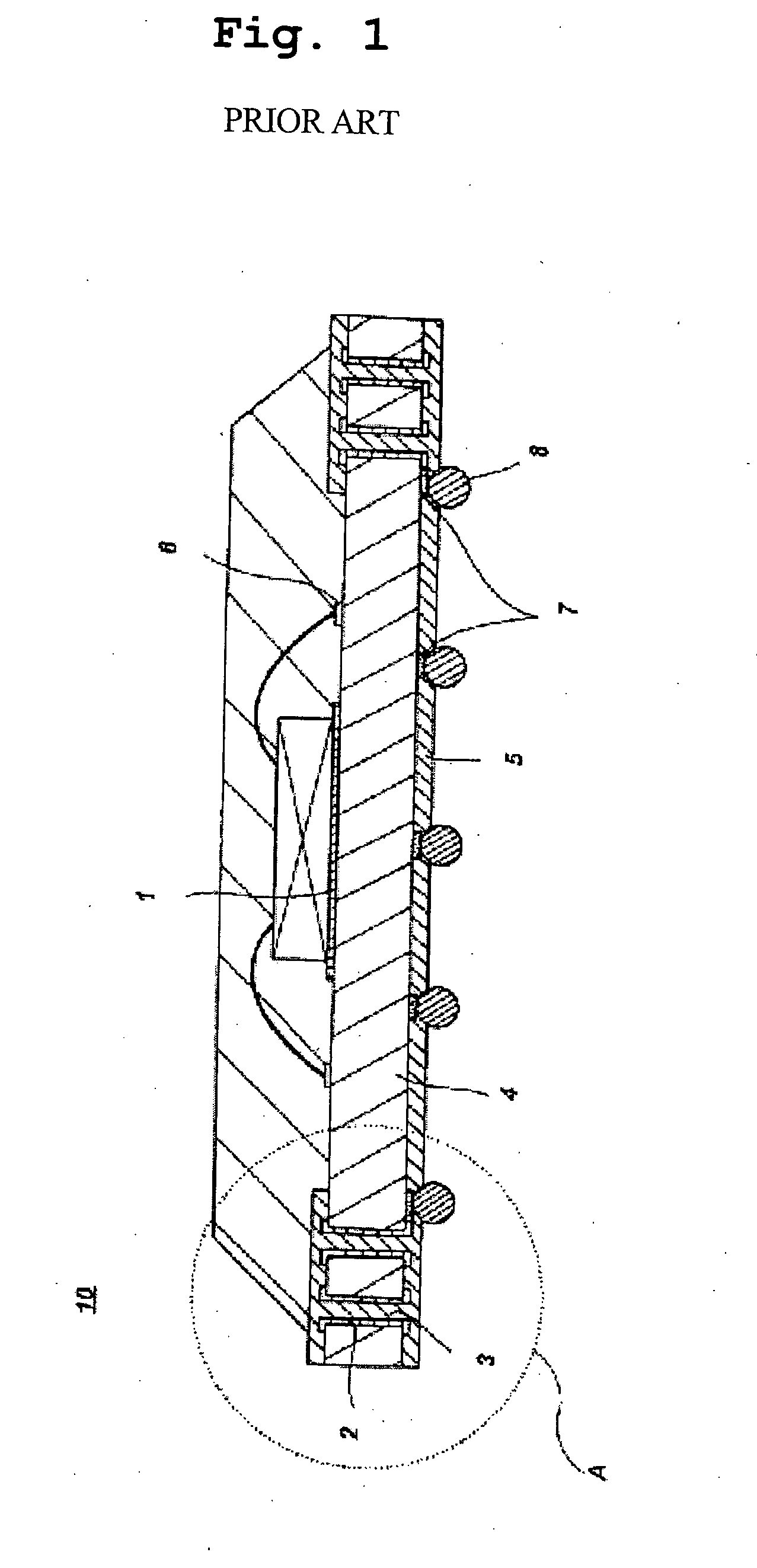

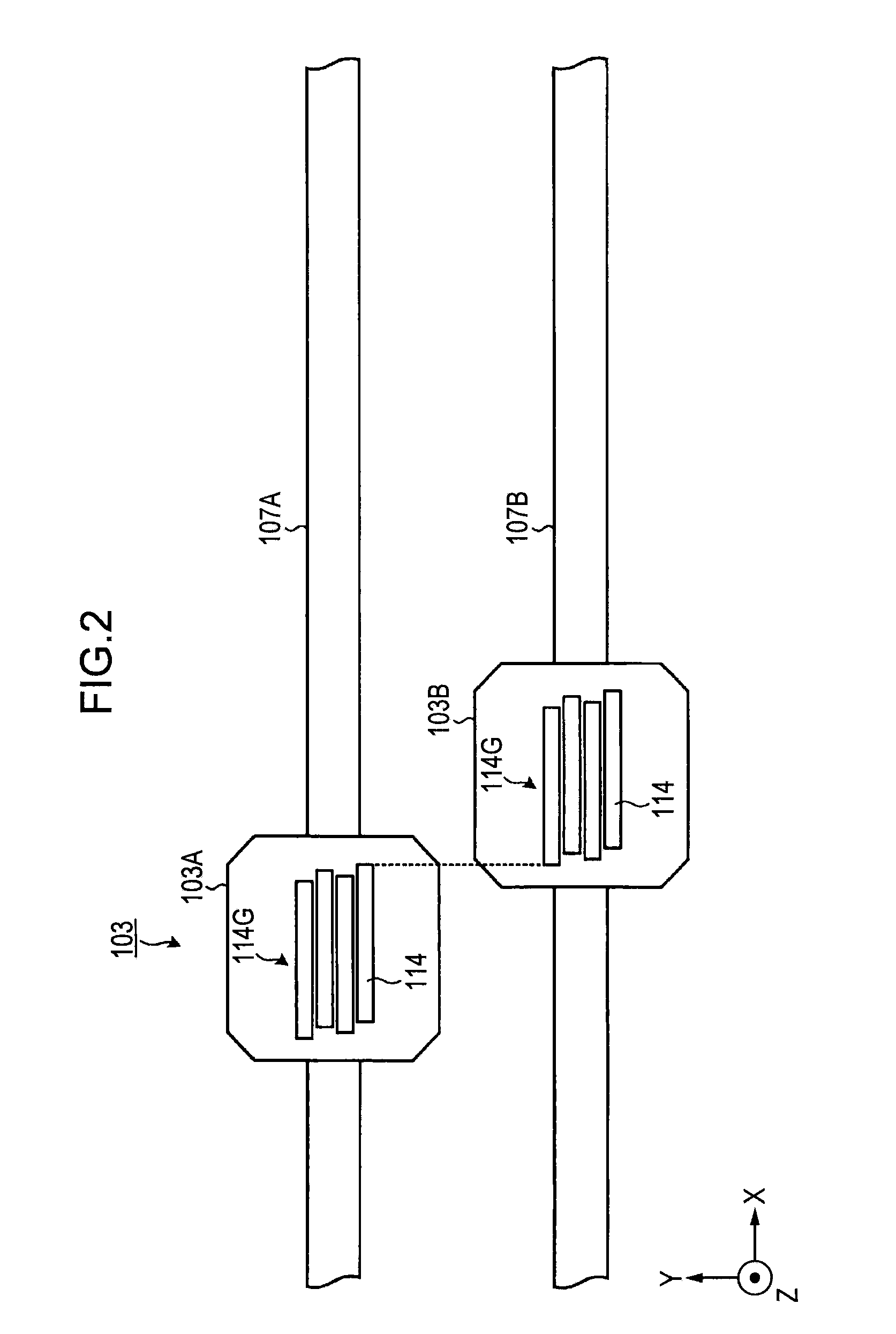

Coupler device

ActiveUS8044749B1Reduce thicknessExcellent heat resistanceMultiple-port networksWaveguidesDielectric substrateGround plane

The present invention is directed to a coupler that includes a coupler structure including at least one first transmission line disposed on a first major surface of a coupler dielectric substrate and at least one second transmission line disposed on a second major surface of the coupler dielectric substrate. The coupler structure includes four symmetric ports such that each port of the four symmetric ports is characterized by substantially identical impedance characteristics. A first ground plane structure is coupled to the coupler structure and including a first outer dielectric material and a first conductive exterior layer disposed substantially parallel to the first major surface. A second ground plane structure is coupled to the coupler structure and including a second outer dielectric material and a second conductive exterior layer disposed substantially parallel to the second major surface. A thermal path is disposed between the coupler structure and at least one of the first conductive exterior layer or second conductive exterior layer. The thermal path is characterized by a thermal resistance substantially within a range between 15 W / mK and 50 W / mK, such that the coupler has a power handling capability of more than 800 W per square inch of heat sink interface.

Owner:TTM TECH INC

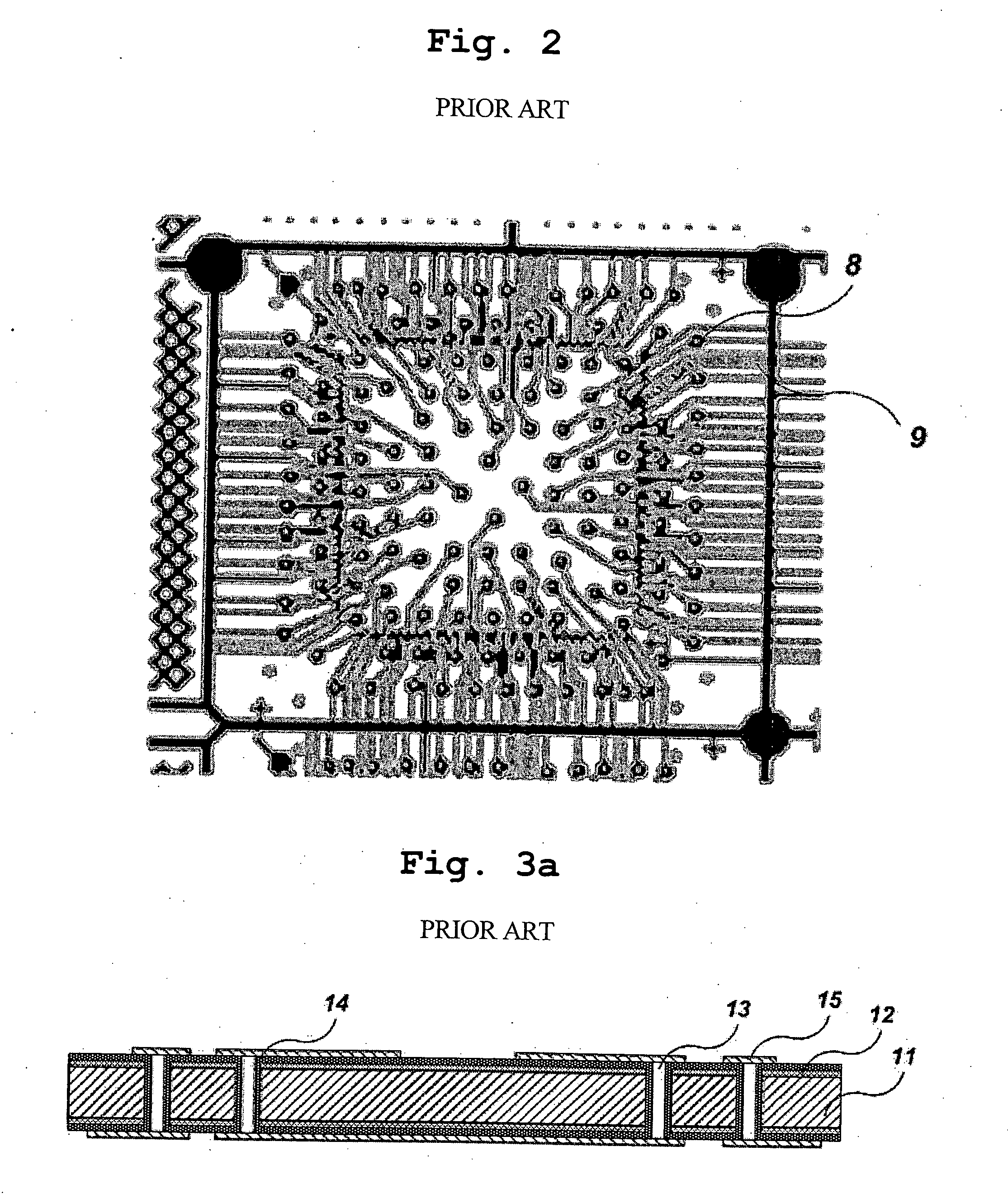

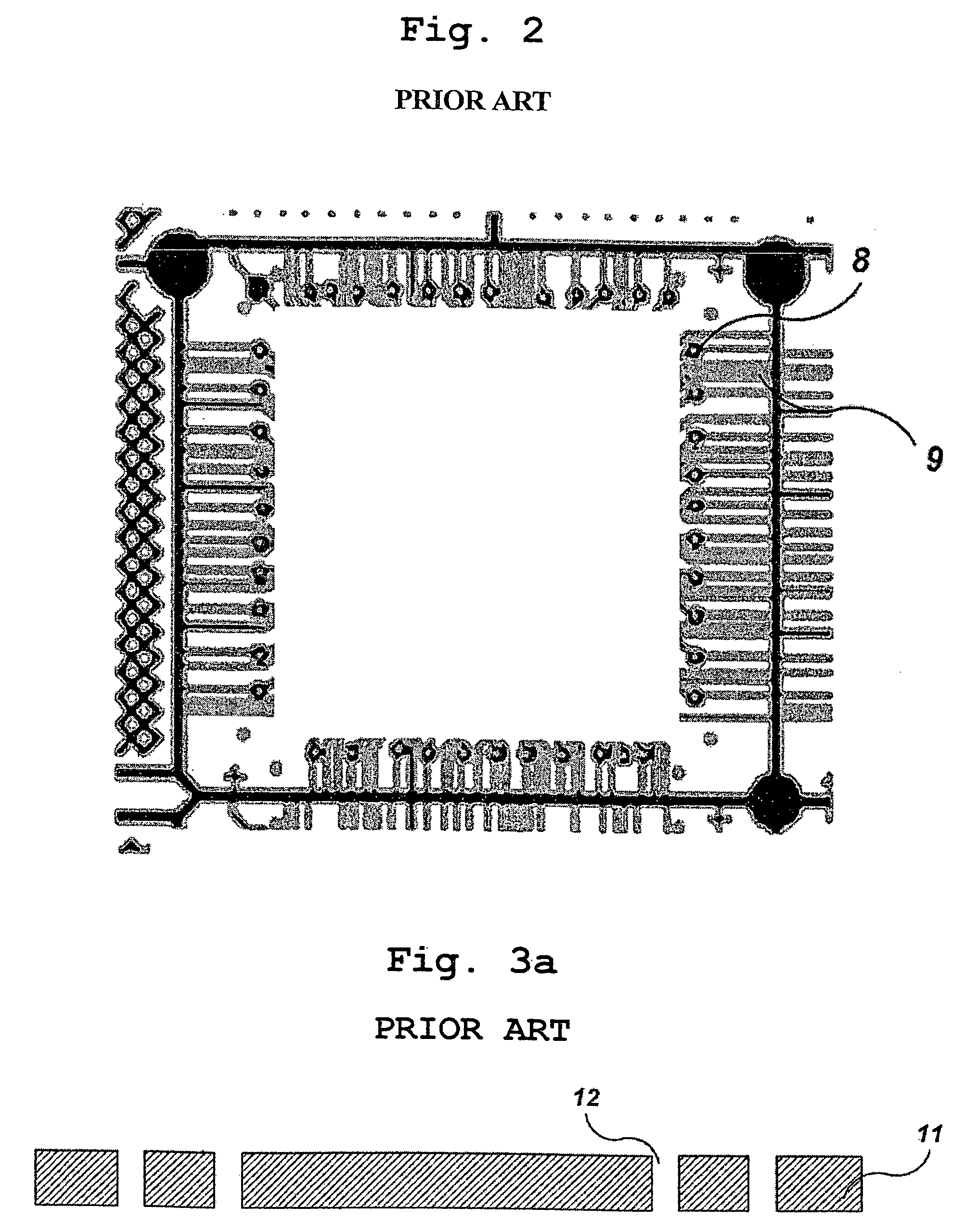

Package substrate for electrolytic leadless plating and manufacturing method thereof

InactiveUS6872590B2Increase linear densityAvoid it happening againSemiconductor/solid-state device detailsPrinted circuit aspectsResistElectrolysis

Disclosed is a package substrate for electrolytic leadless plating, characterized in that a wire bonding pad onto which a semiconductor chip is mounted is subjected to electrolytic leadless Au plating, and a solder ball pad is subjected to OSP metal finishing or electroless Au plating without use of plating lead lines, upon preparation thereof. A method of manufacturing the package substrate is also disclosed. The method includes Cu plating a whole surface of a base substrate having through-holes, developing a first dry film laminated onto the through-holes, removing a copper foil not covered with the first dry film, stripping the first dry film, exposing and developing a second dry film on the substrate so that only an upper portion to be subjected to electrolytic Au plating is exposed, grounding an electrolytic Au plating terminal to a solder ball pad, Ni—Au plating the wire bonding pad, removing the second dry film by a stripping solution, exposing and developing a third dry film, removing the exposed copper foil by an etching solution, removing the third dry film by a stripping solution, performing a series of processes of coating, exposing, developing and drying a solder resist, and subjecting the solder ball pad to OSP metal finishing.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

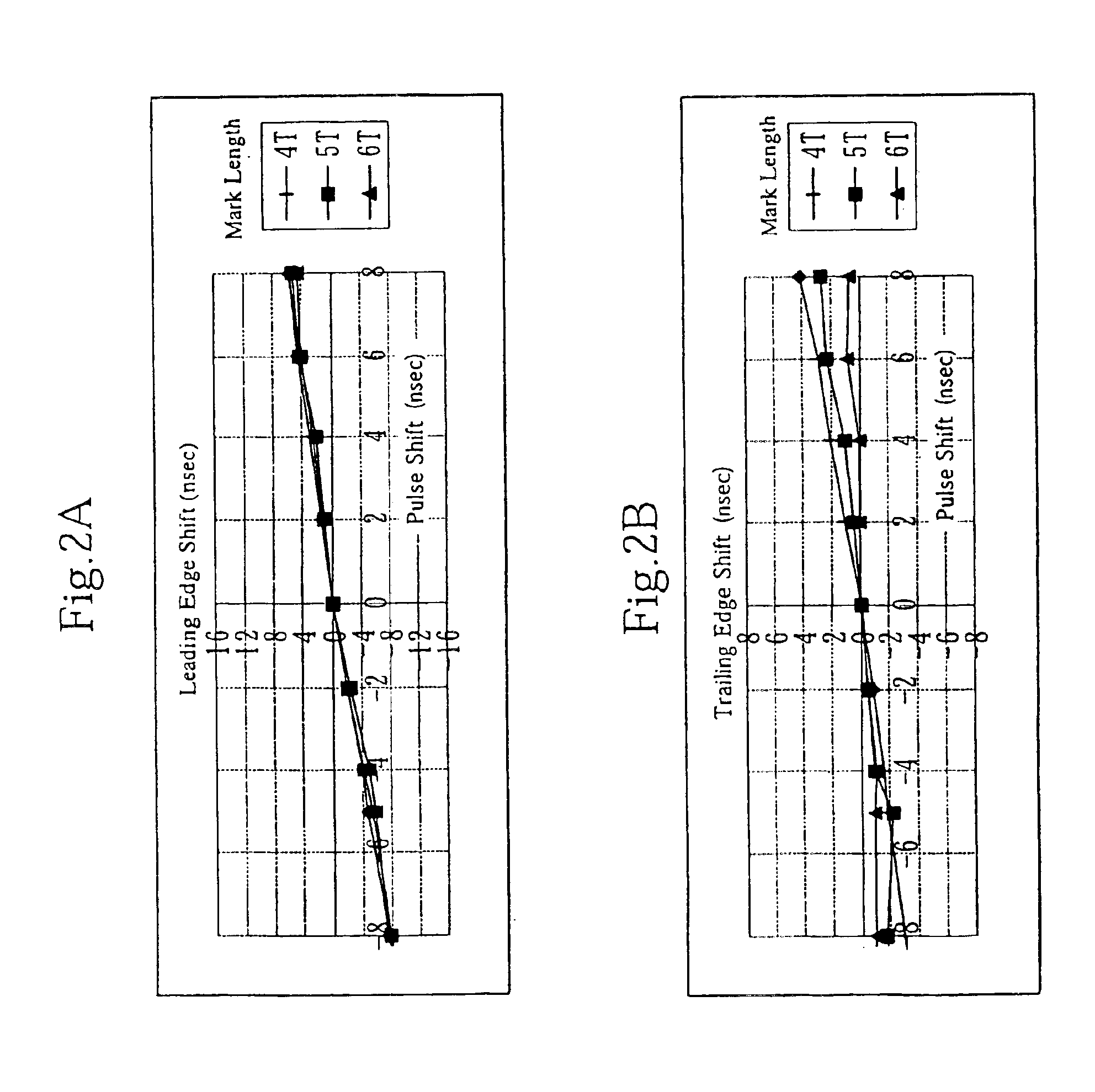

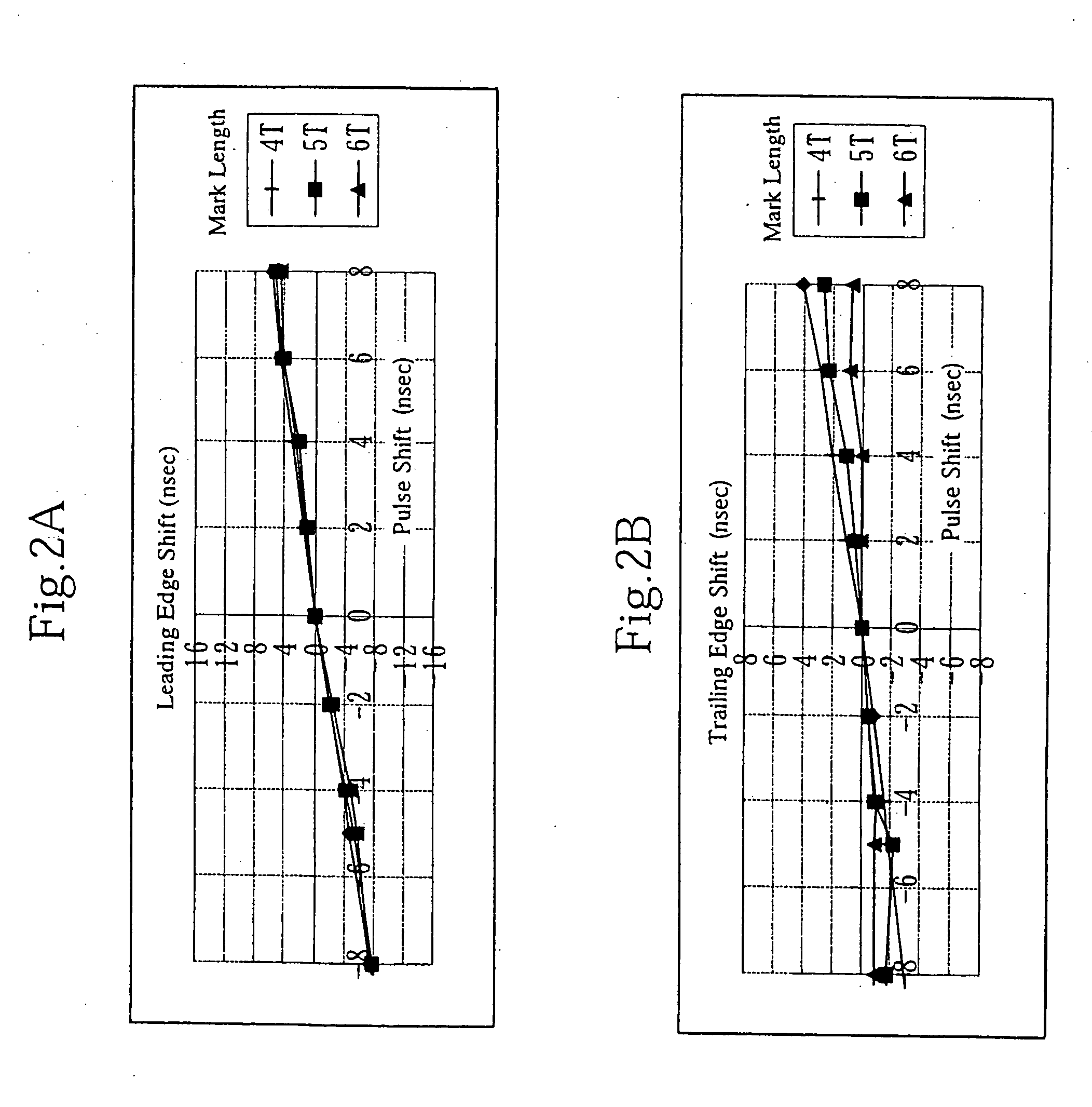

Information recording method, information recording medium and information recording apparatus

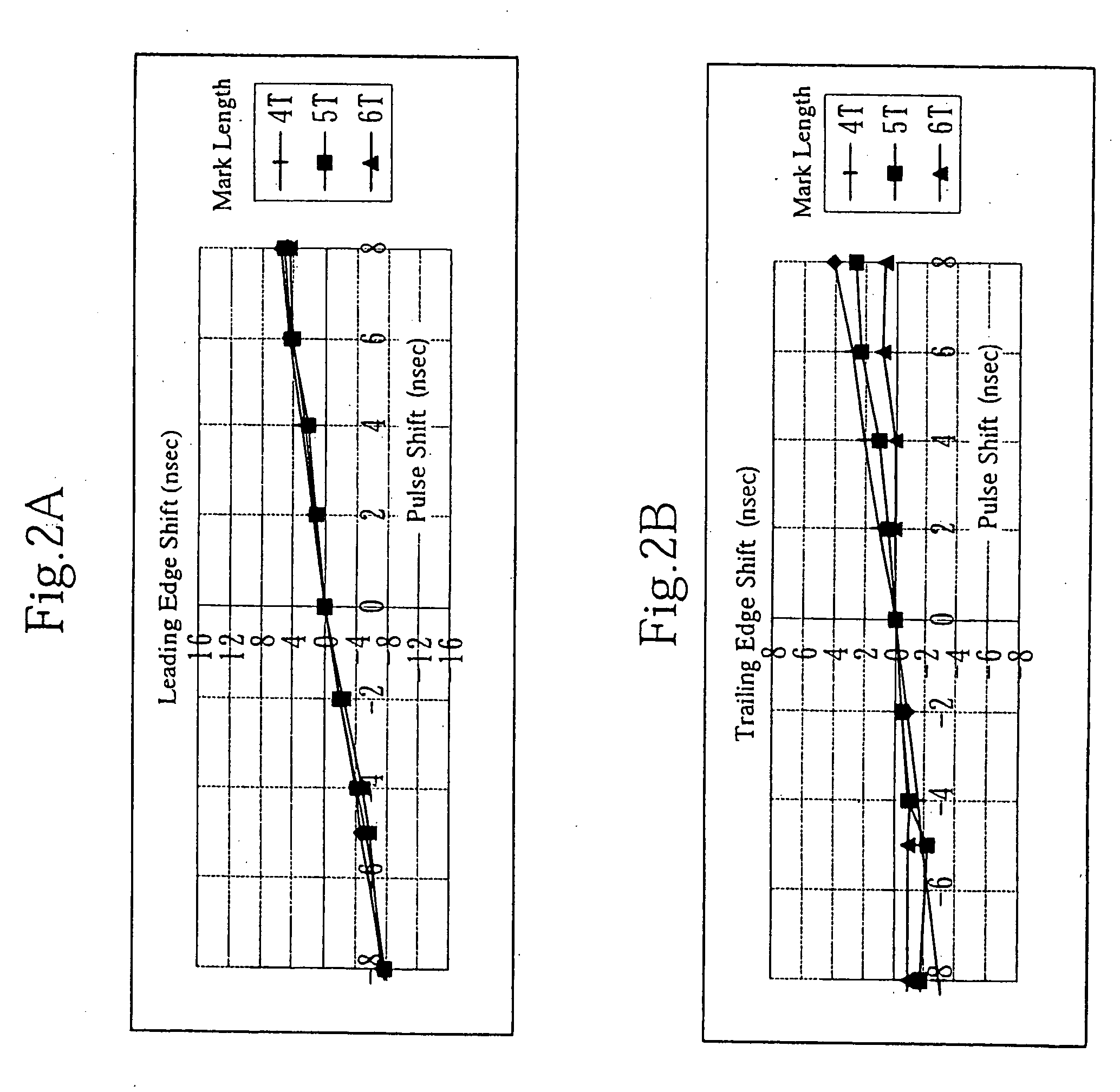

InactiveUS20050243679A1Avoid distortionIncrease linear densityTelevision system detailsRecording strategiesLeading edgeOptical recording

An information recording method using an optical recording medium includes the steps of forming a plurality of recording pulses to irradiate the optical recording medium and recording information to the optical recording medium by irradiating the recording pulses on the optical recording medium. At least a leading edge of a first recording pulse and a trailing edge of a last recording pulse of the recording pulses shift at a shifting value, wherein the shifting value is determined by combinations of a length of M(n) of a mark being currently written and at least one of a length s(n−1) of a space precedent to the mark and a length s(n+1) of a space subsequent to the mark.

Owner:HITACHI CONSUMER ELECTRONICS CORP

Information recording method, information recording medium and information recording apparatus

InactiveUS20050243680A1Avoid distortionIncrease linear densityRecording strategiesTelevision system detailsLeading edgeLight beam

Owner:HITACHI CONSUMER ELECTRONICS CORP

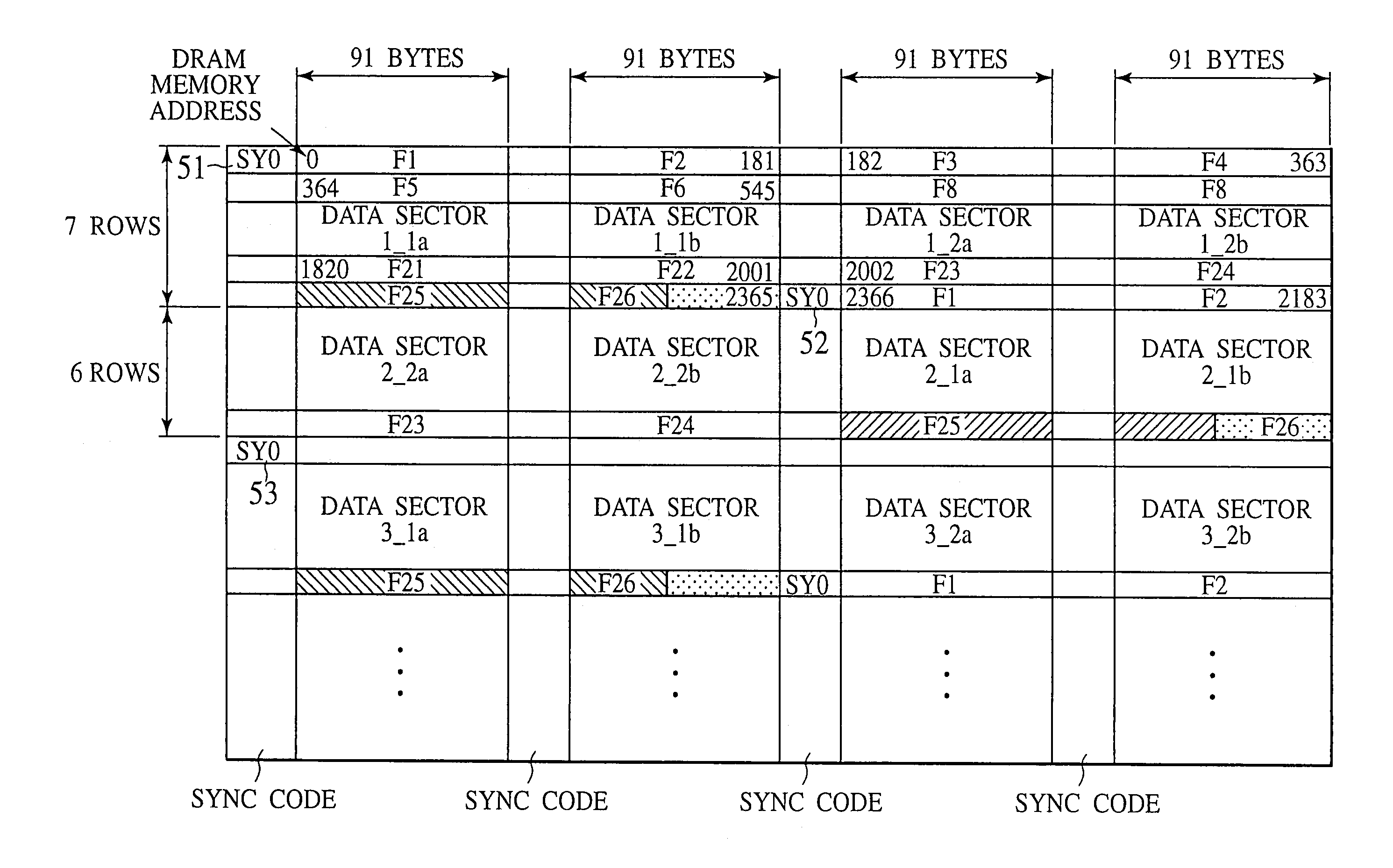

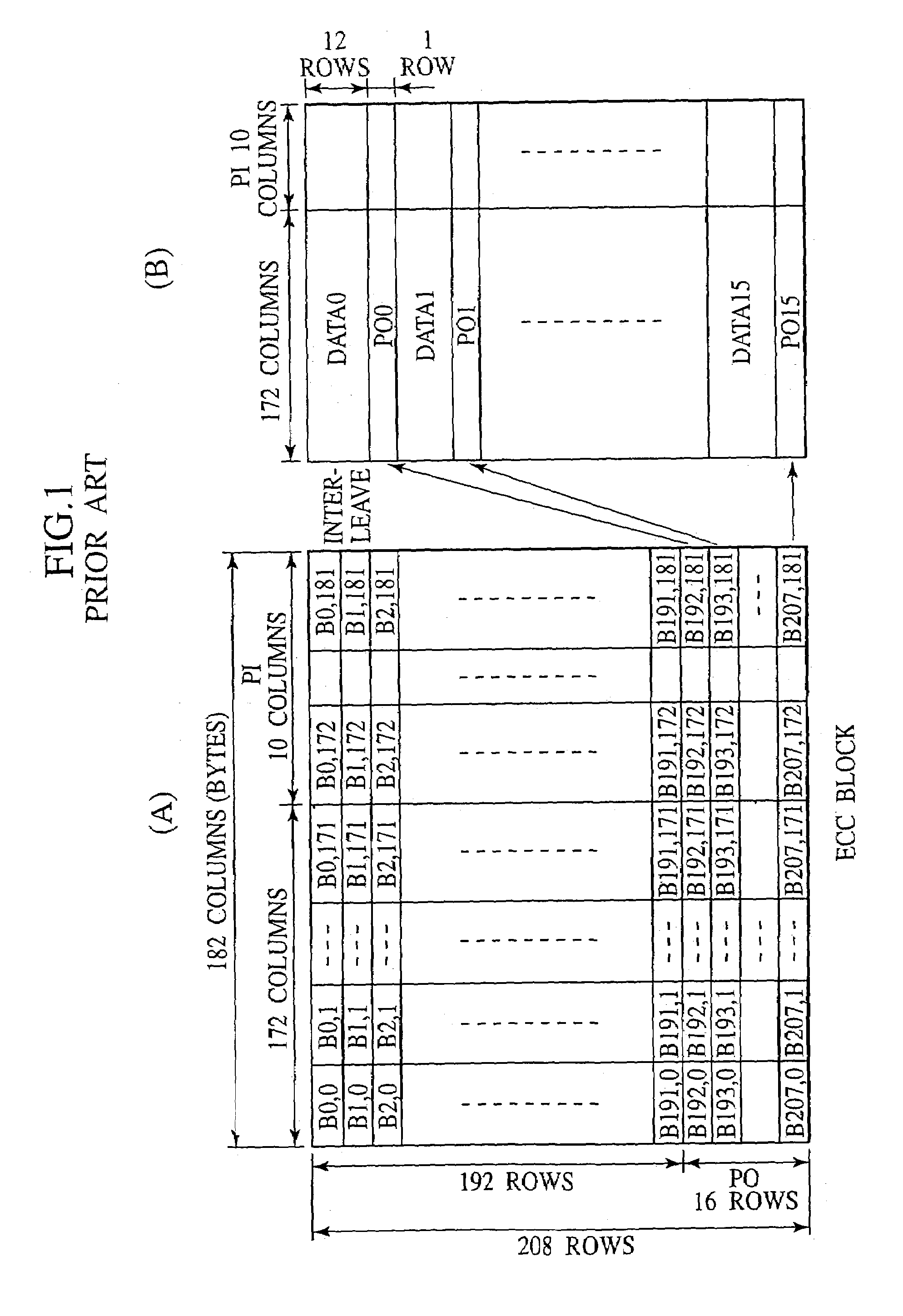

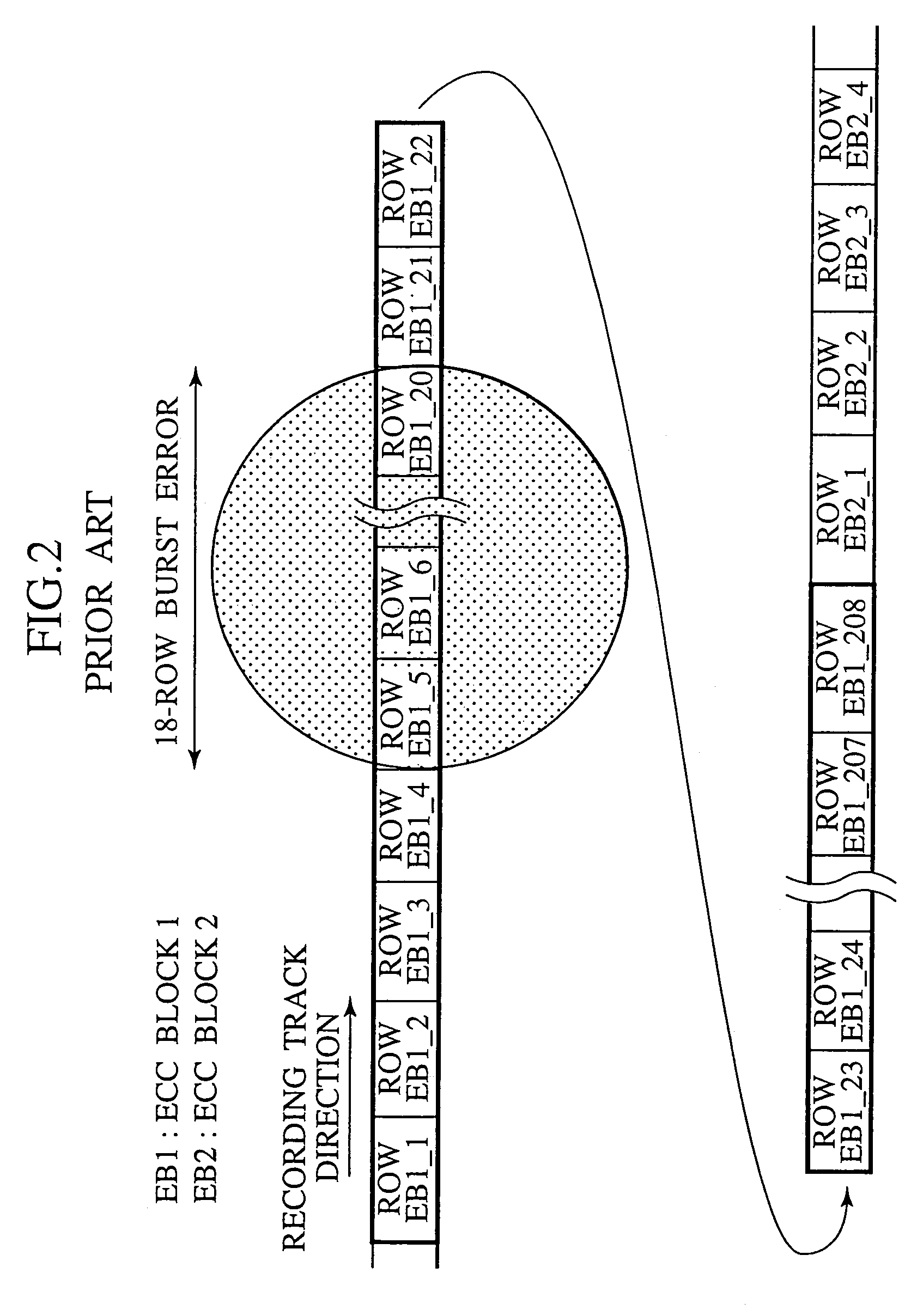

Digital signal processing method, data recording and reproducing apparatus, and data recording medium that are resistant to burst errors

InactiveUS20020038443A1Convenient lengthIncrease redundancyOptical discsError correction/detection using multiple parity bitsDigital signal processingData recording

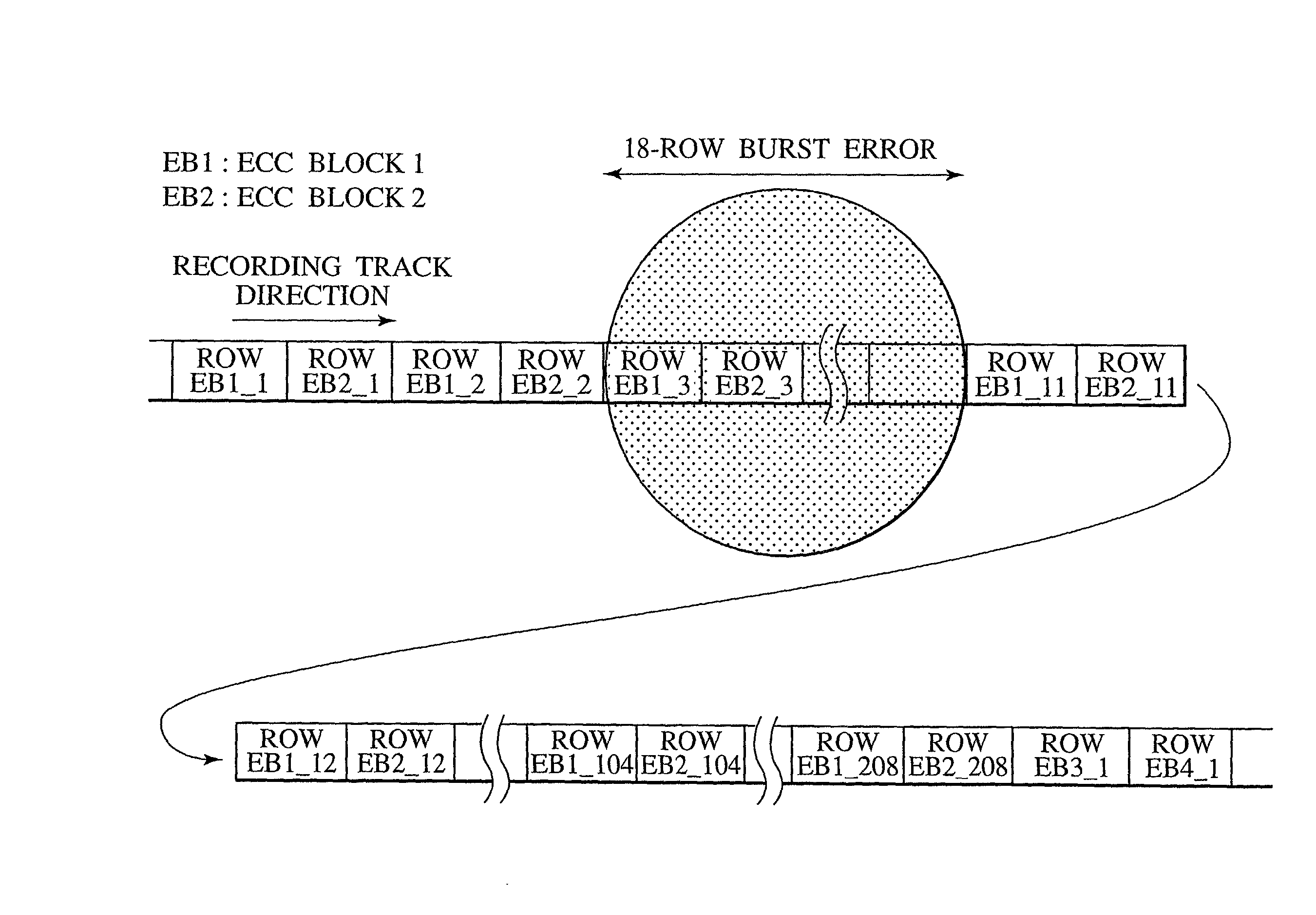

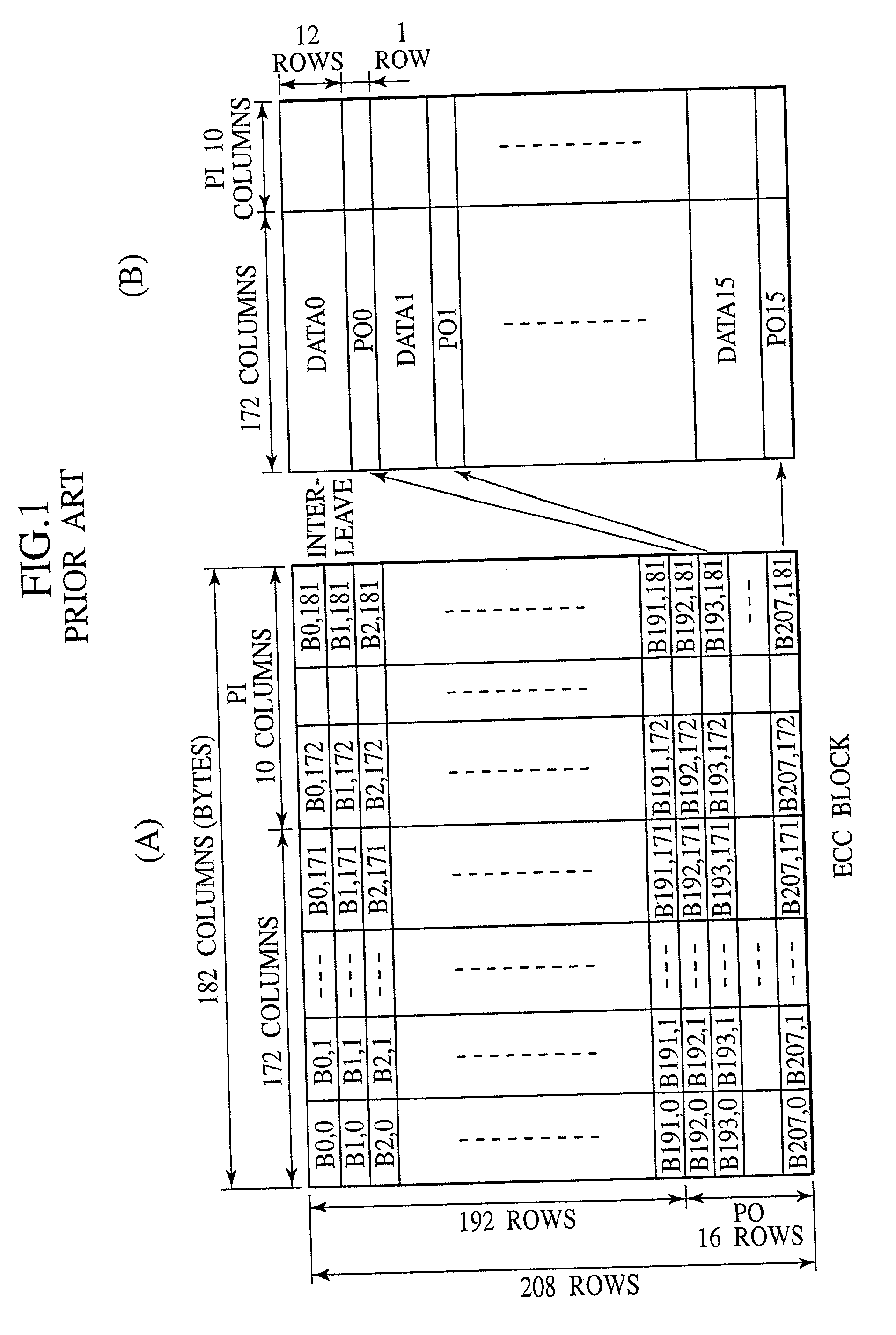

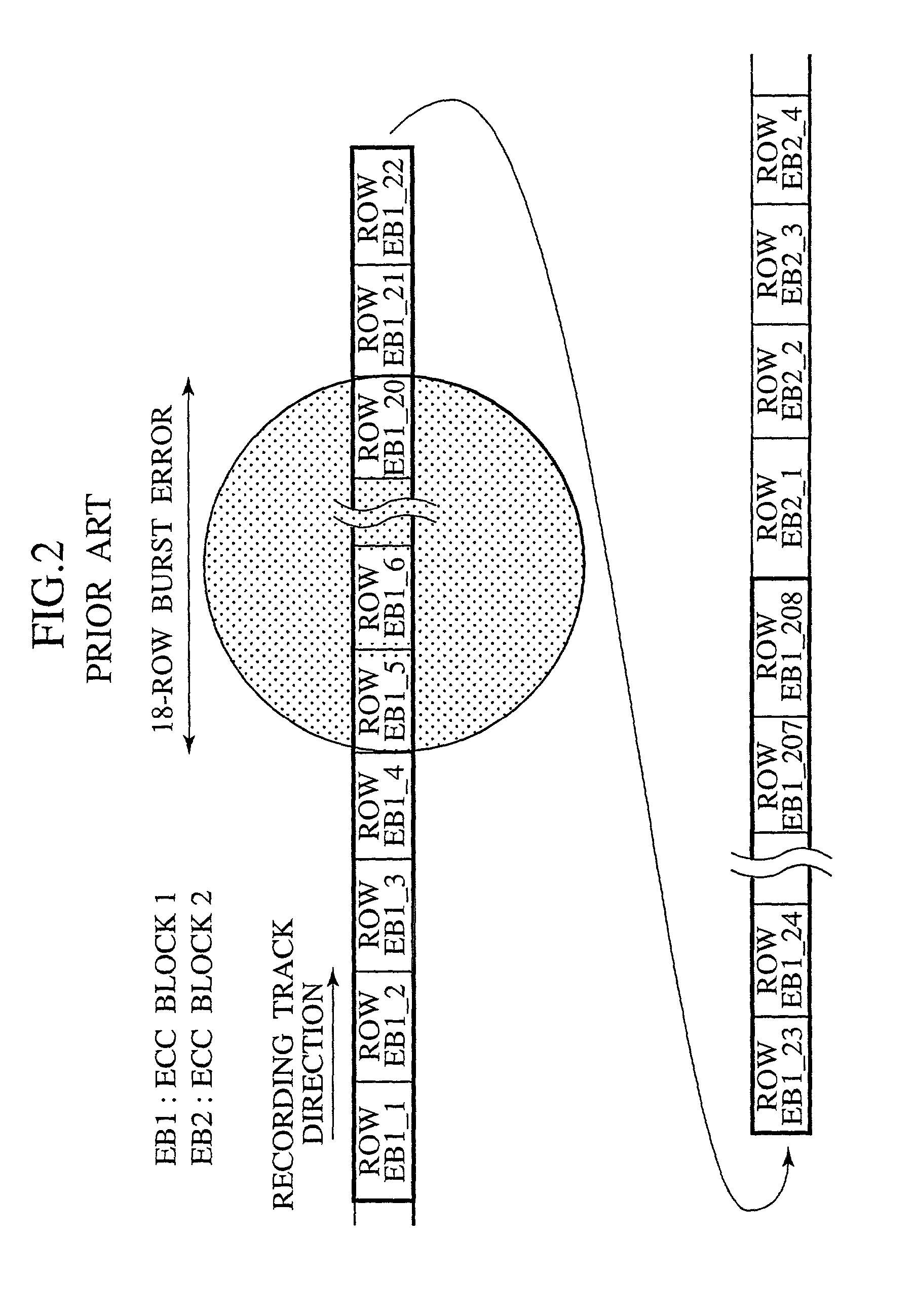

With two consecutive product-coded ECC blocks, EB1 and EB2, as a set, the rth row of first ECB block EB1 is followed by the rth row of second ECC block EB2 in such a way that the first row of first ECC block EB1 is followed by the first row of second ECB block EB2, which is followed by the second row of first ECC block ECB1, which is followed by the second row of second ECC block EB2, and so on, to interleave data on a row basis. That is, data of two ECC blocks, EB1 and EB2, is allocated alternately on a row basis. This allocation method allows an error to be distributed after reproduction even when a serious burst error extending 18 rows occurs in an ECC block.

Owner:JVC KENWOOD CORP A CORP OF JAPAN

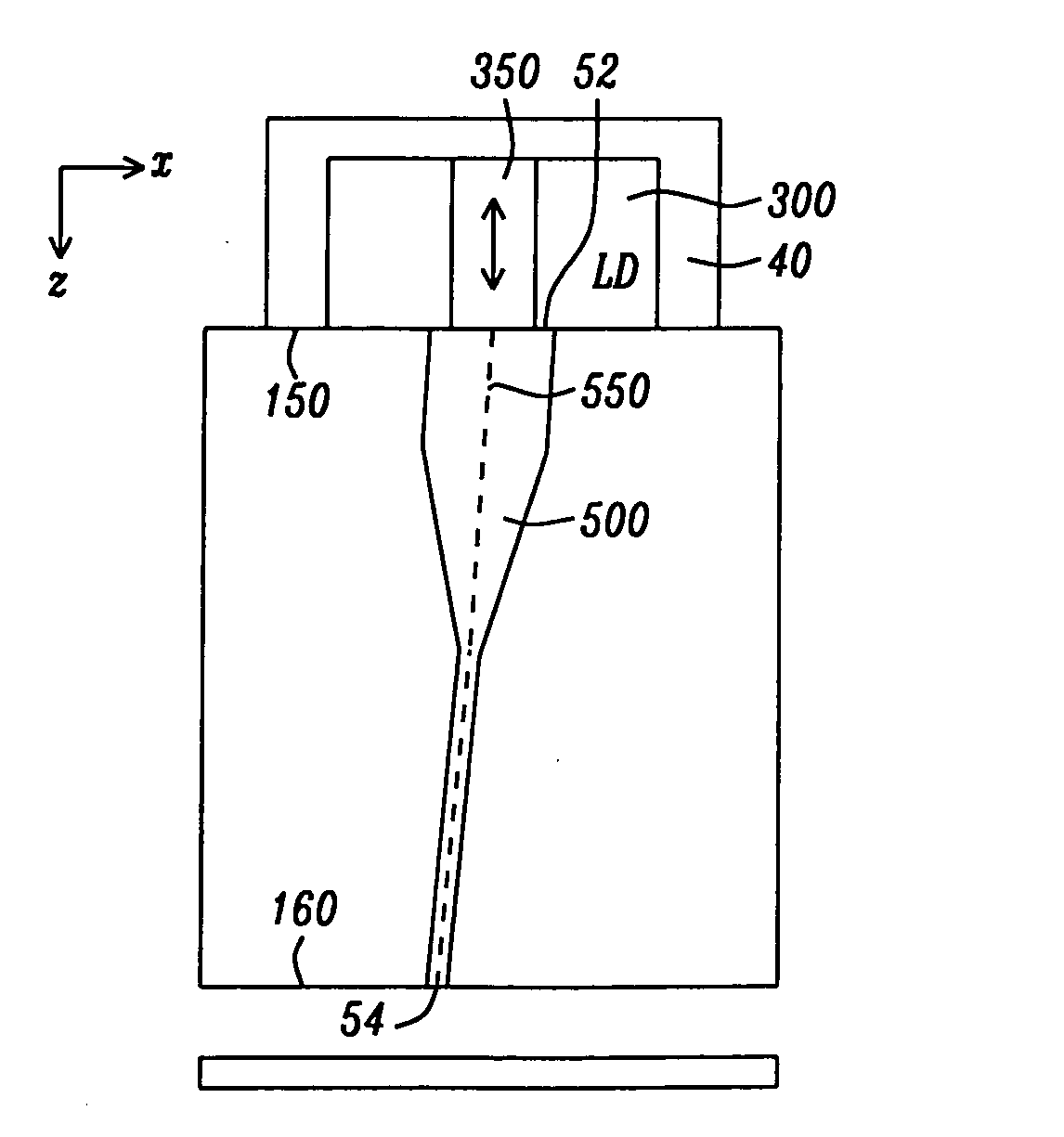

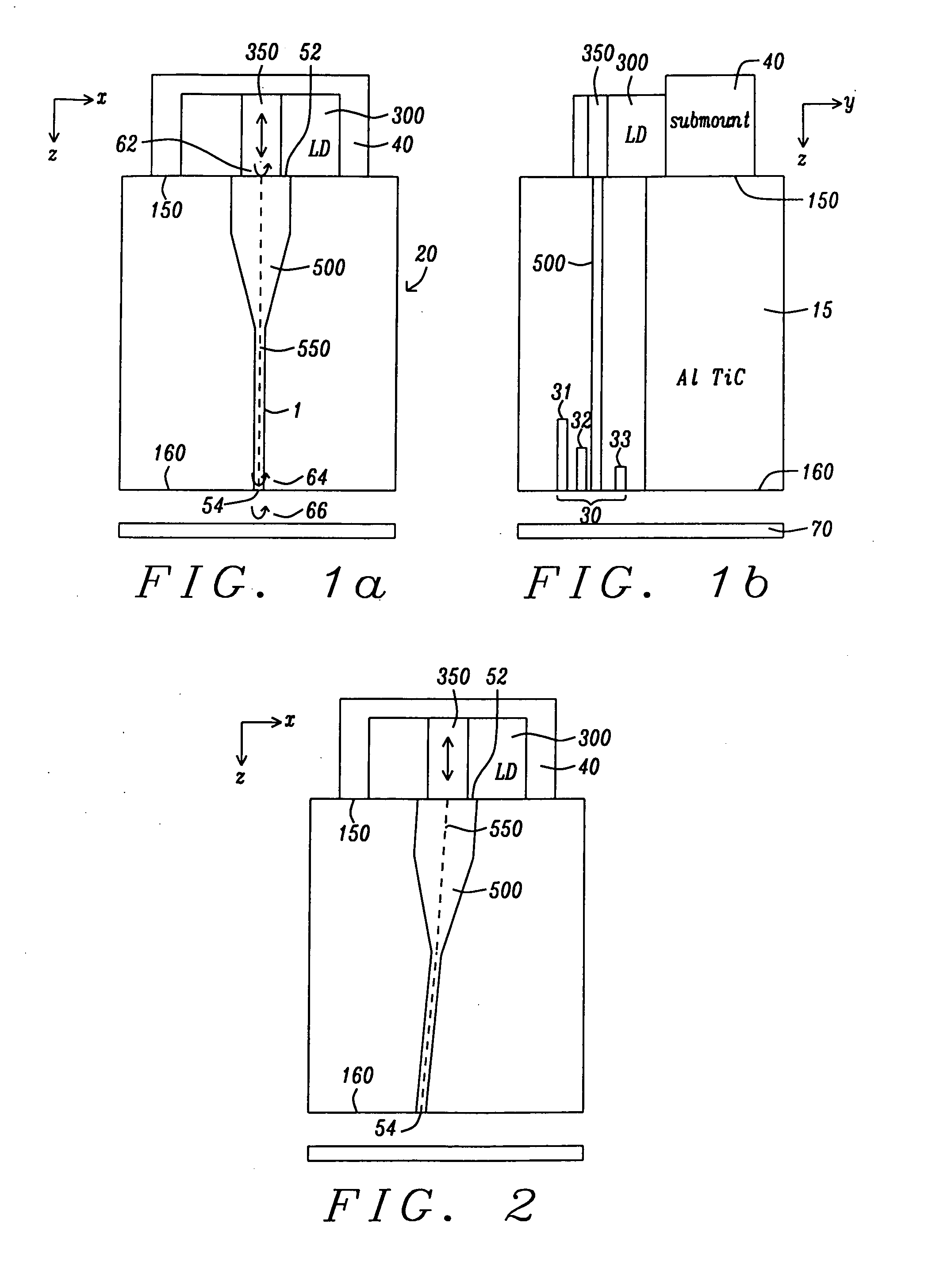

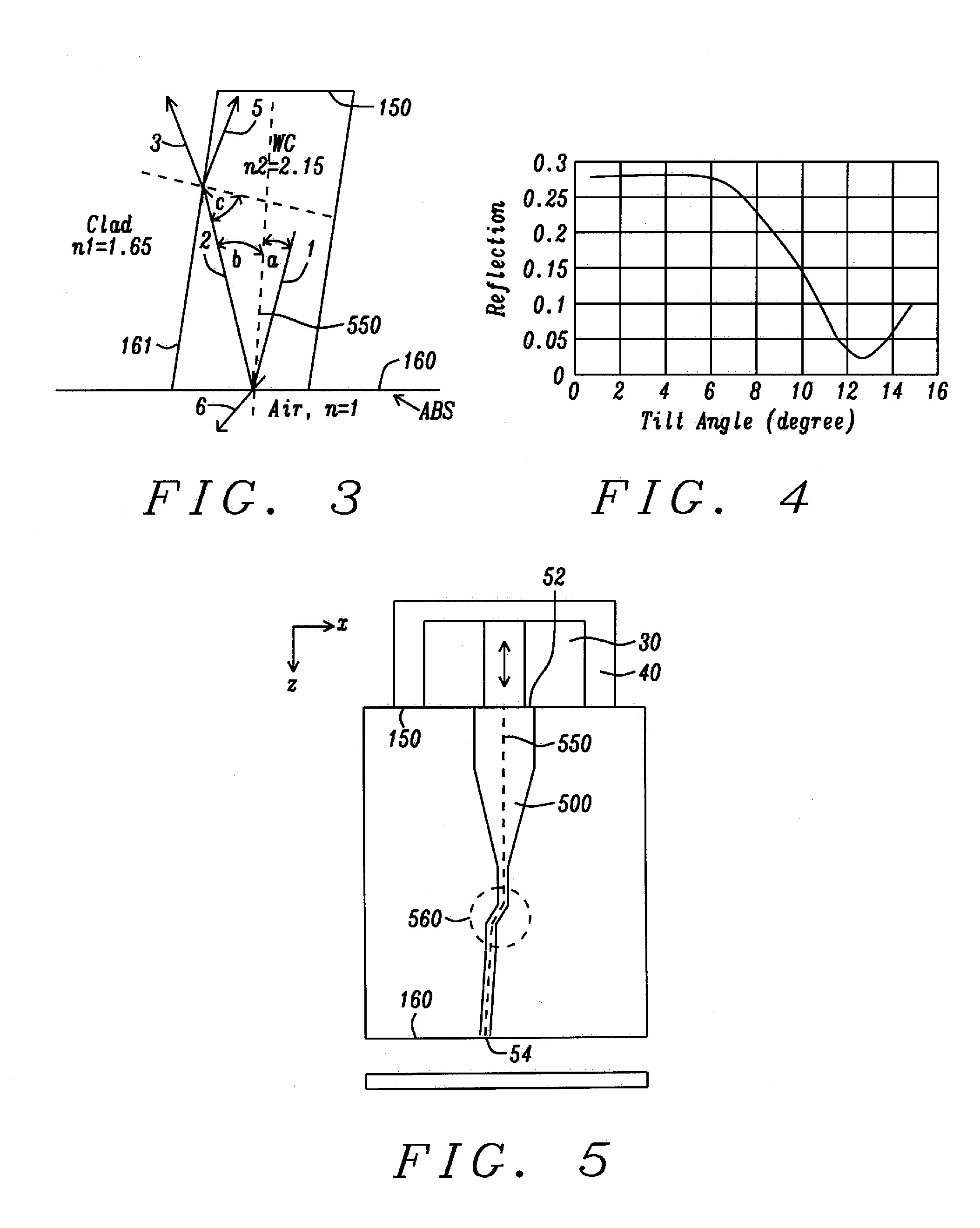

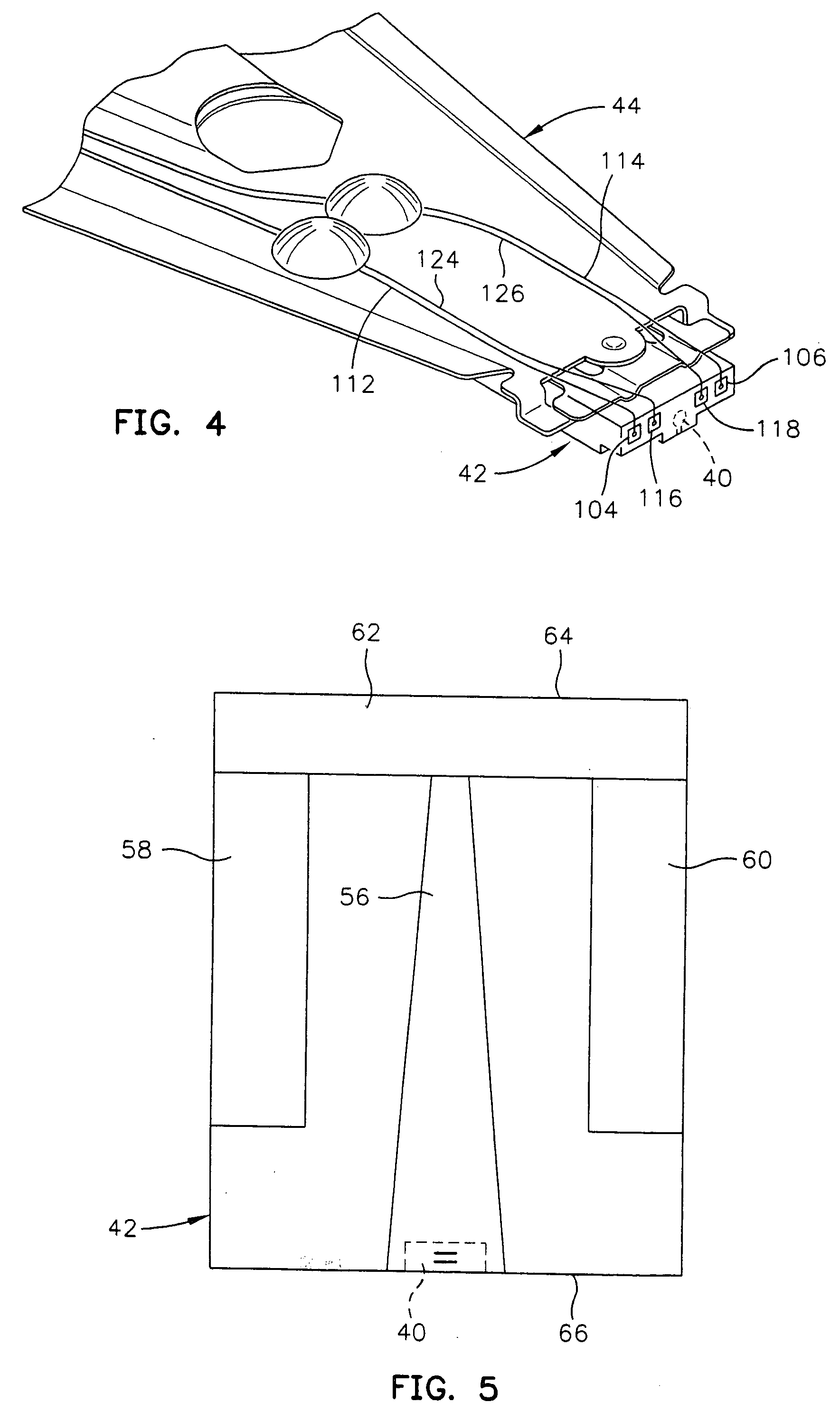

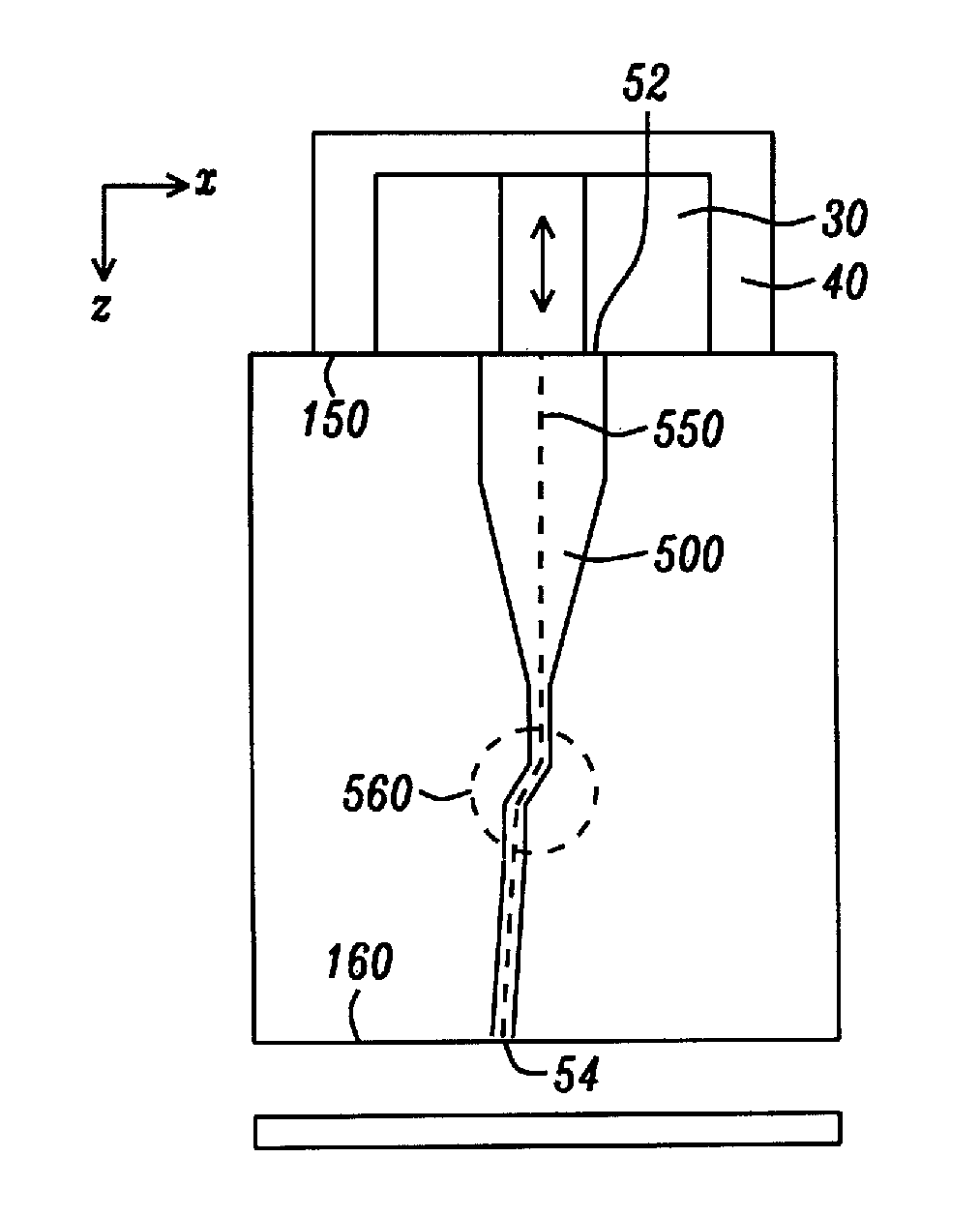

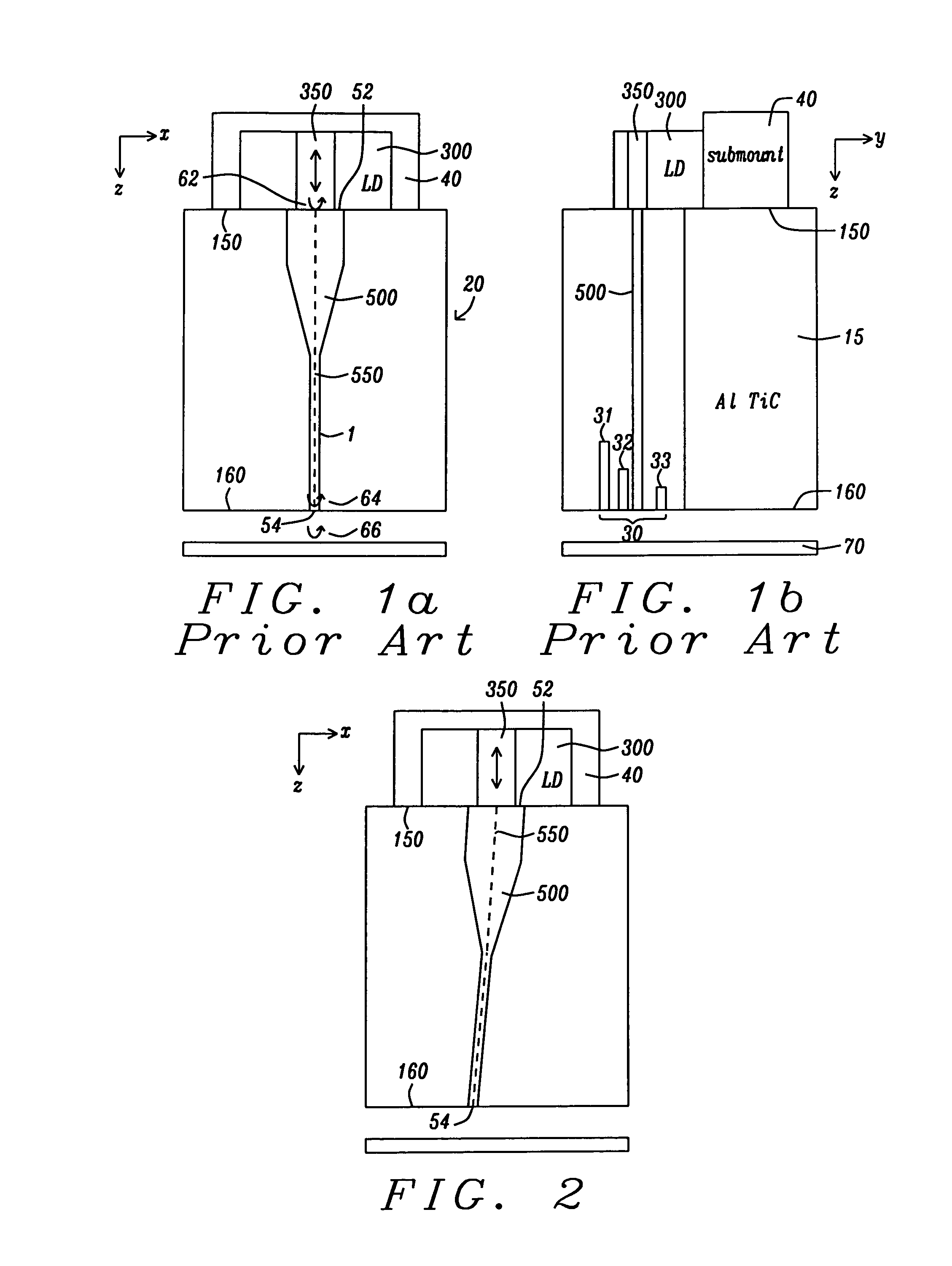

Tilted Structures to Reduce Reflection in Laser-Assisted TAMR

ActiveUS20140241137A1Eliminate the effects ofStable powerElectrical transducersArm with optical waveguideOptical radiationMagnetic anisotropy

A TAMR (Thermal Assisted Magnetic Recording) write head uses the energy of optical-laser excited surface plasmons in a plasmon generator to locally heat a magnetic recording medium and reduce its coercivity and magnetic anisotropy. The optical radiation is transmitted to the plasmon generator by means of a waveguide, whose optical axis (centerline) is tilted relative to either or both the backside surface normal and ABS surface normal in order to eliminate back reflections of the optical radiation that can adversely affect the properties and performance of the laser. Variations of the disclosure include tilting the plasmon generator, the waveguide and the laser diode.

Owner:HEADWAY TECH INC

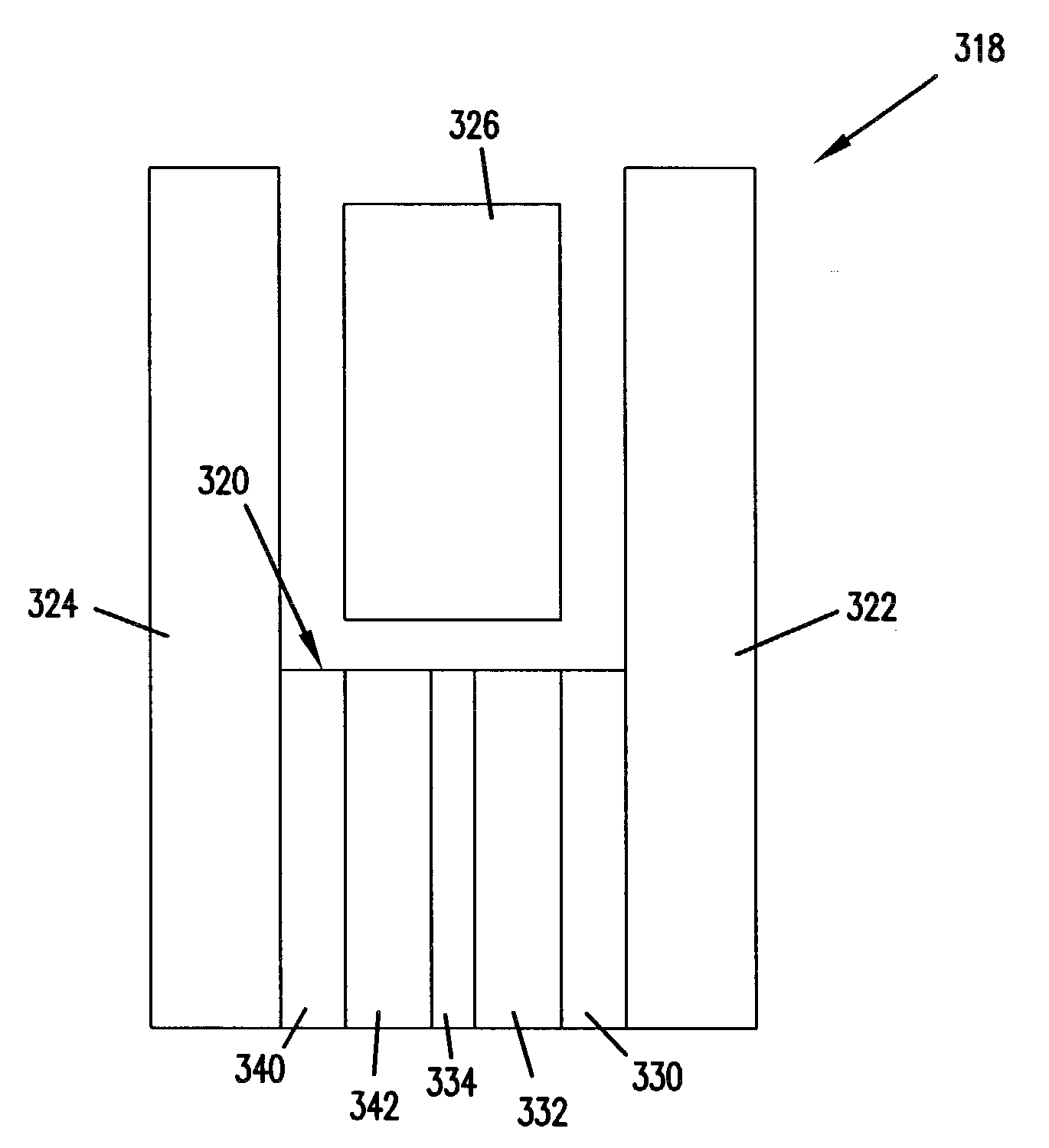

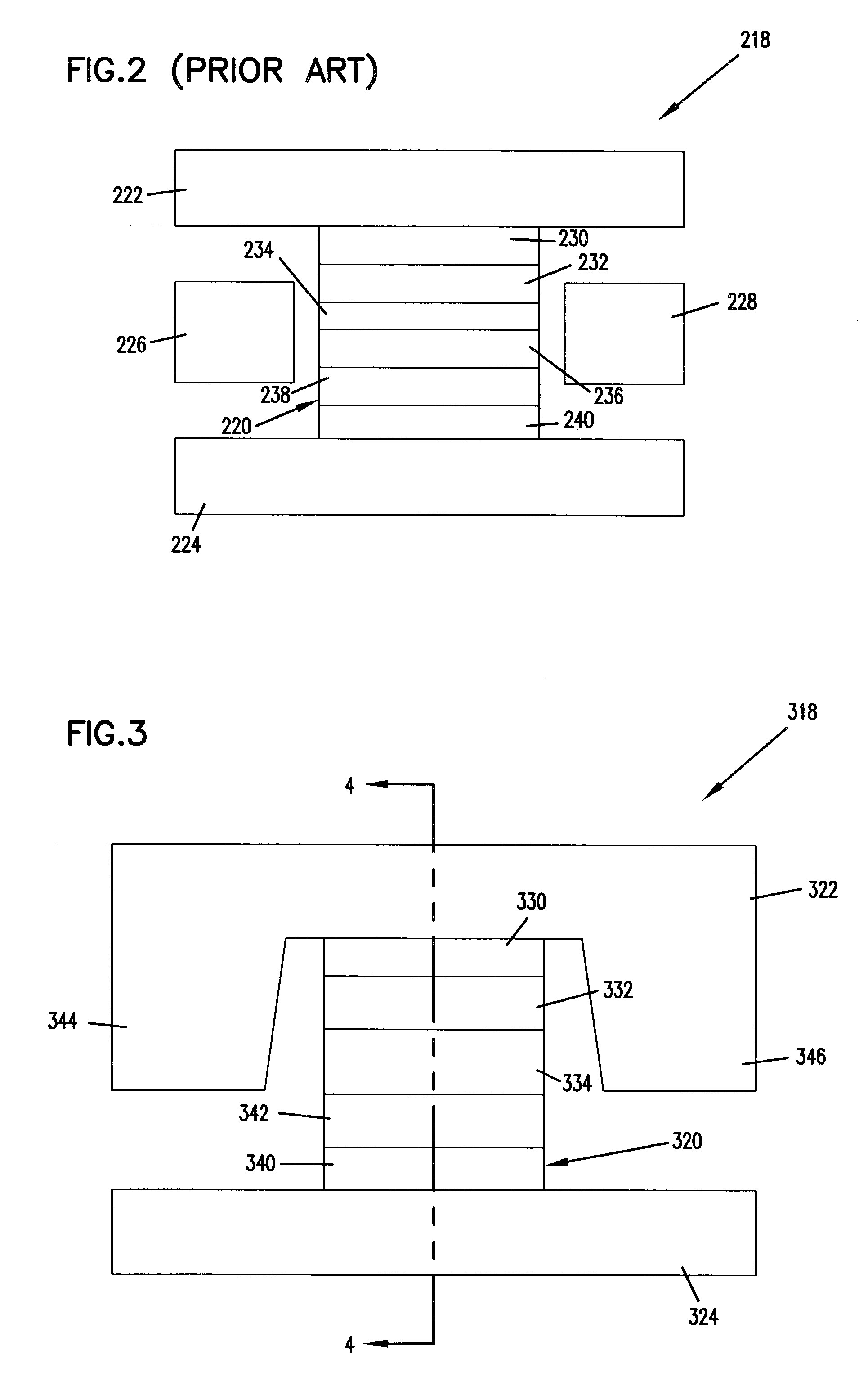

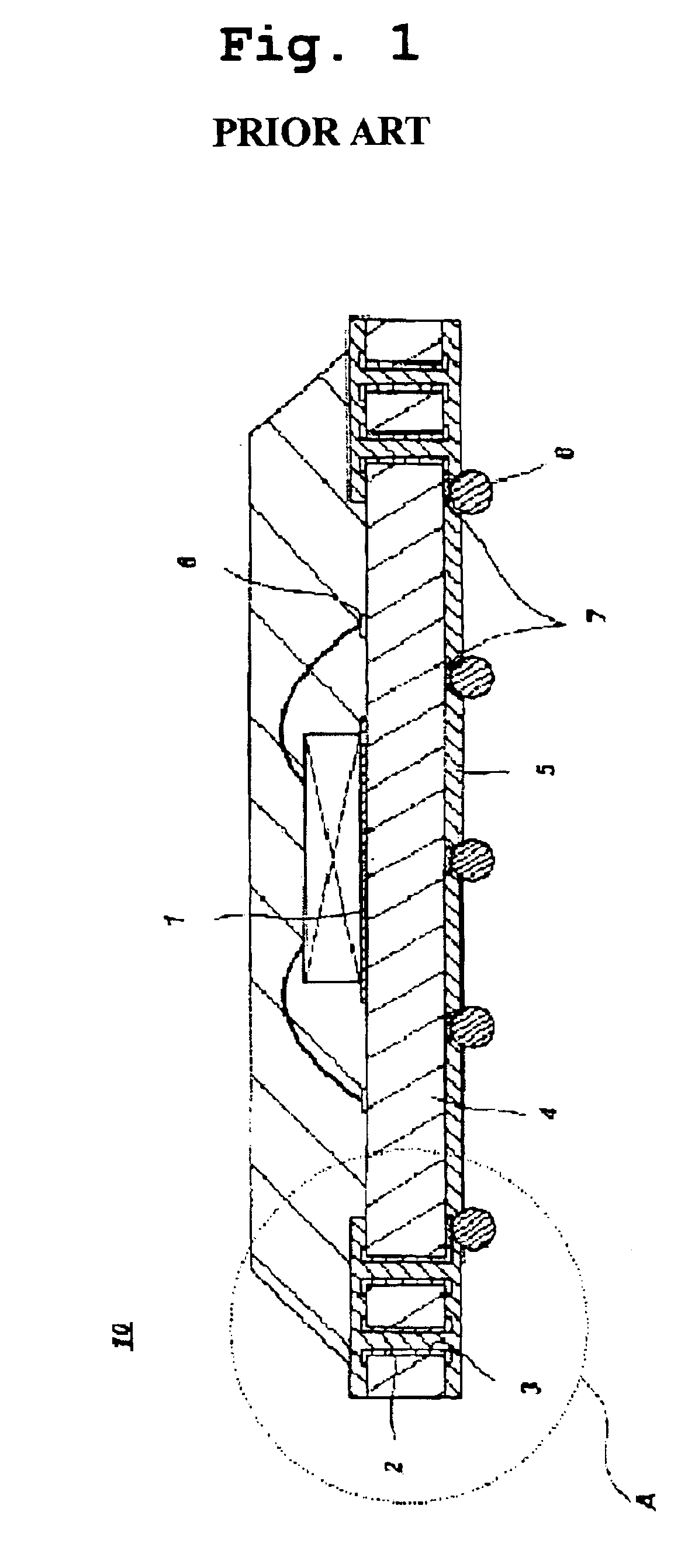

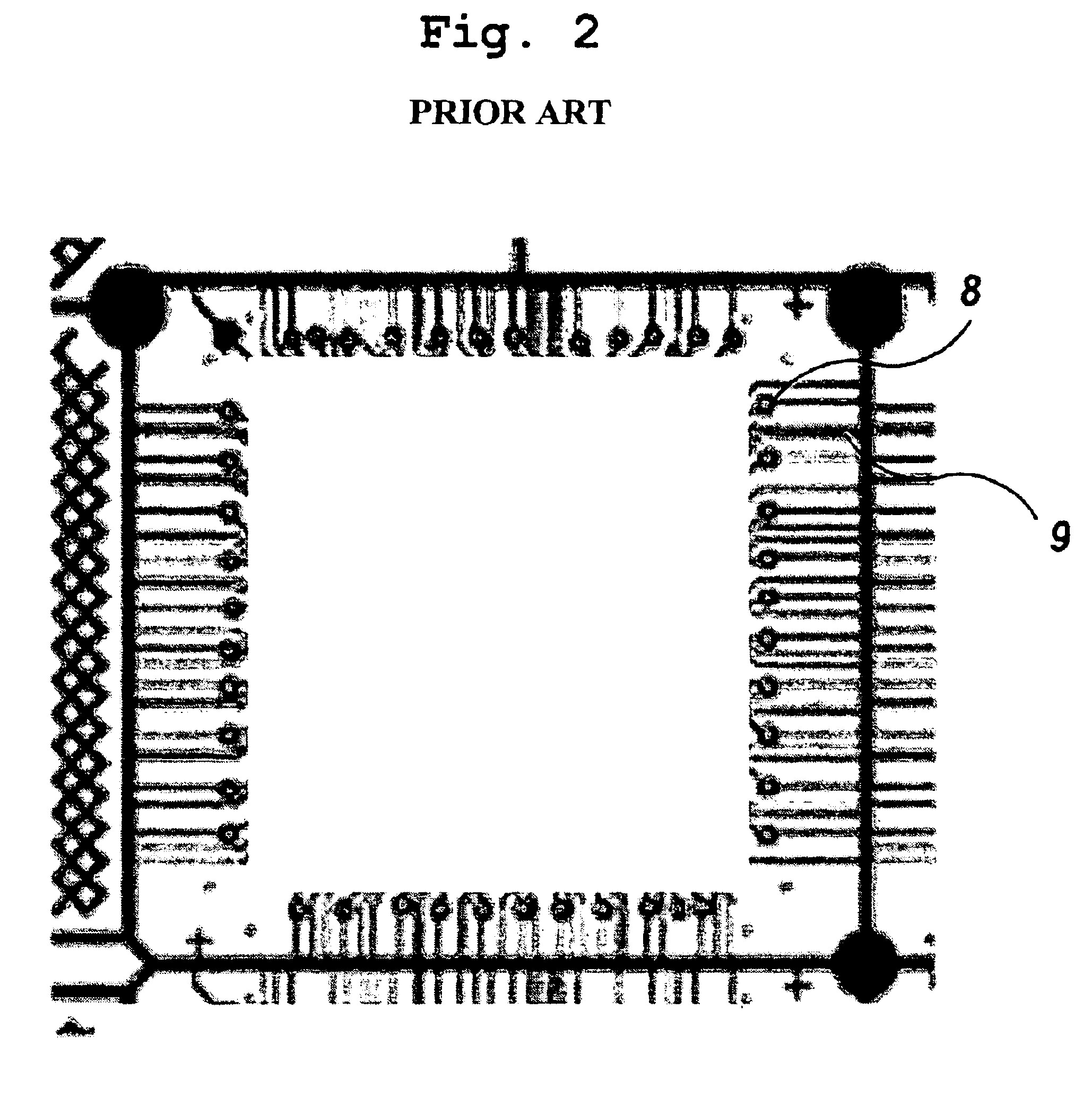

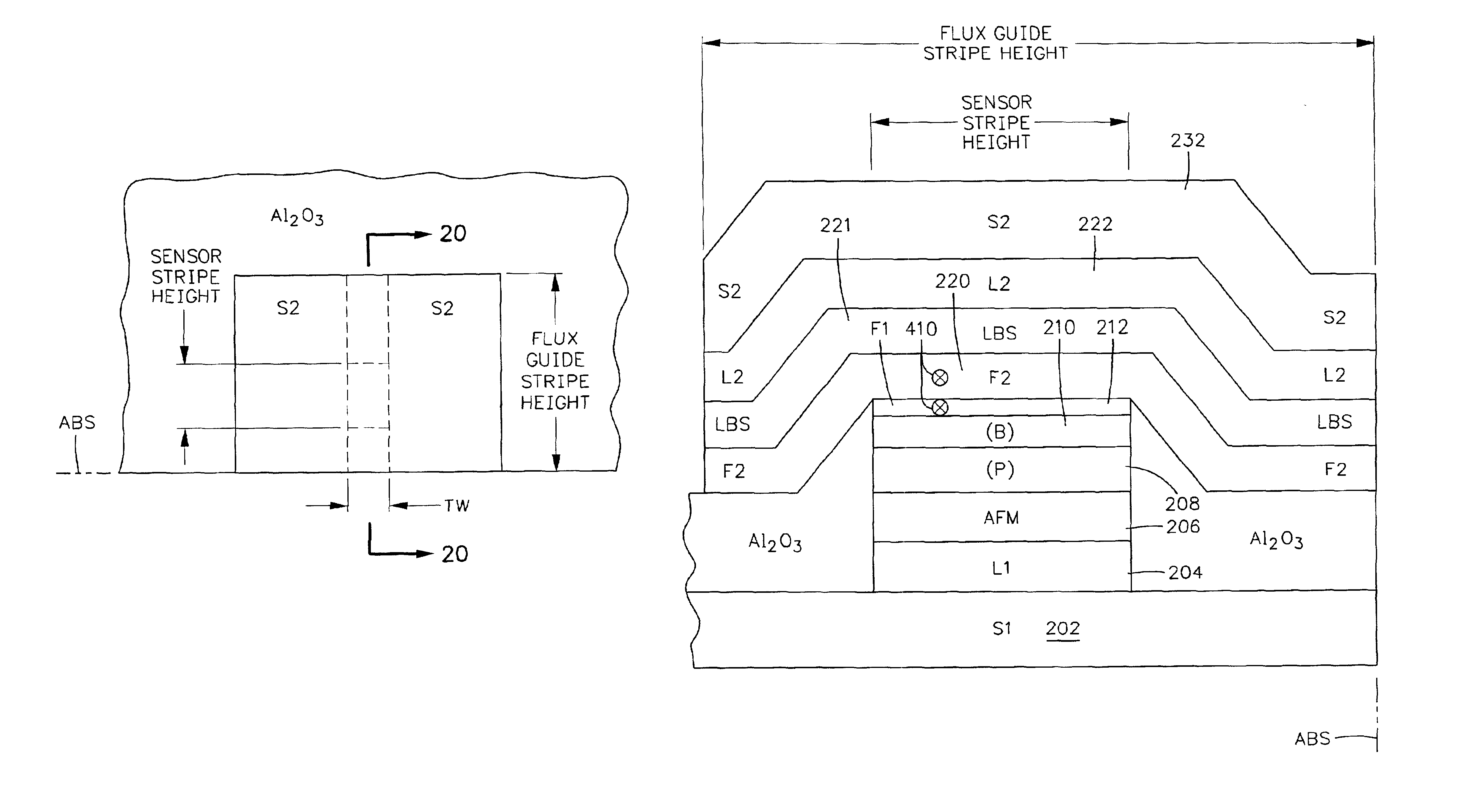

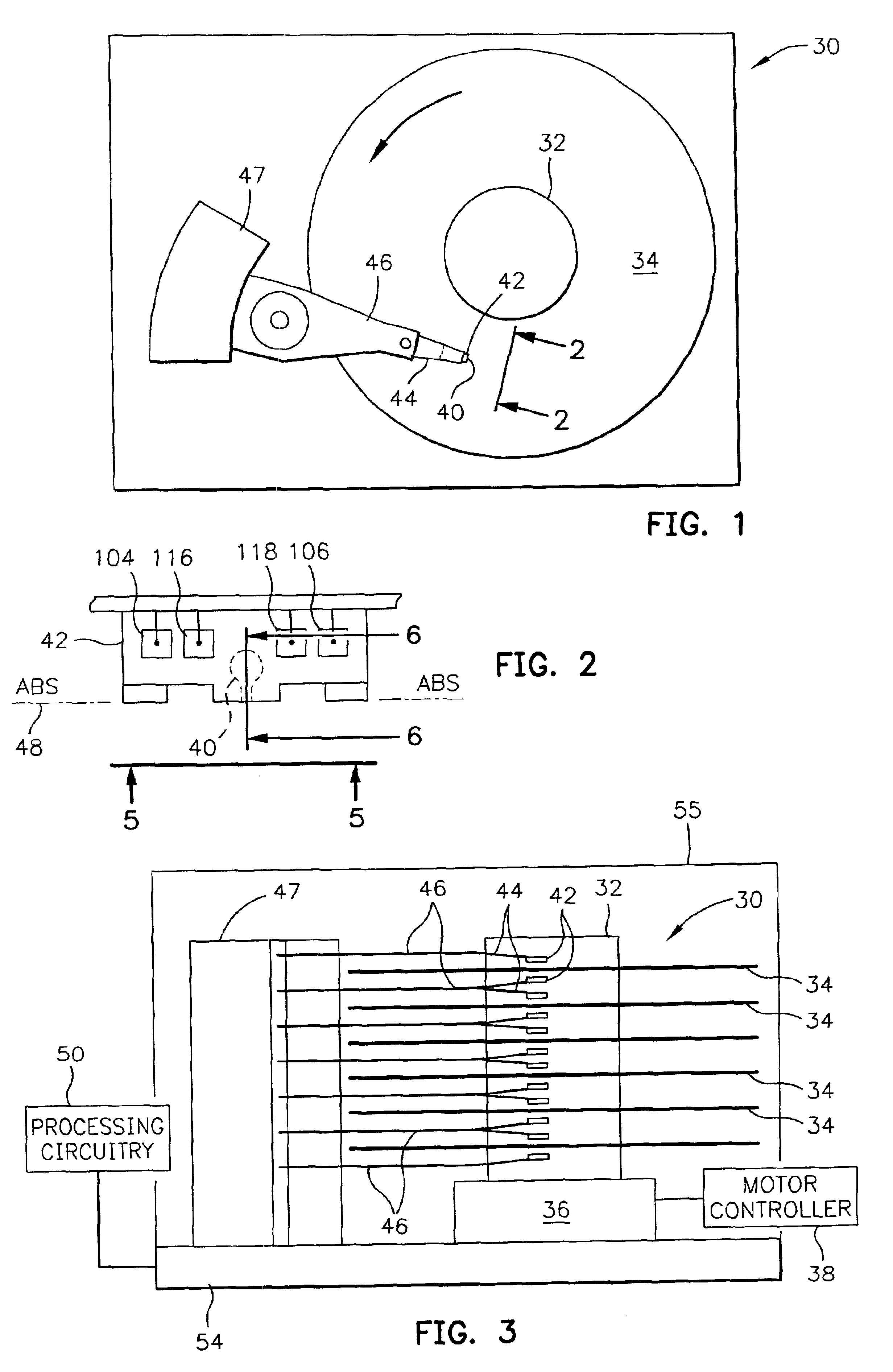

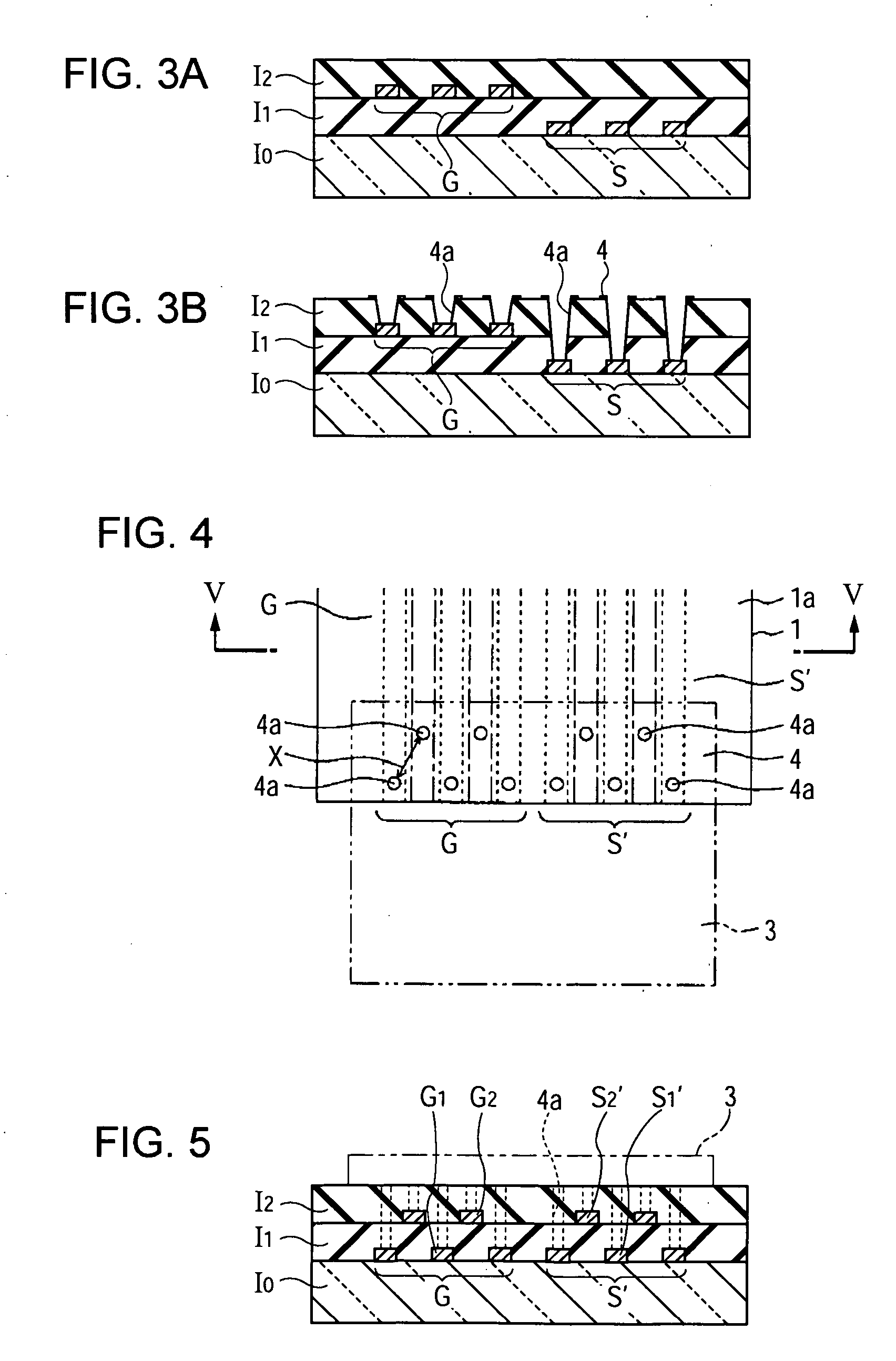

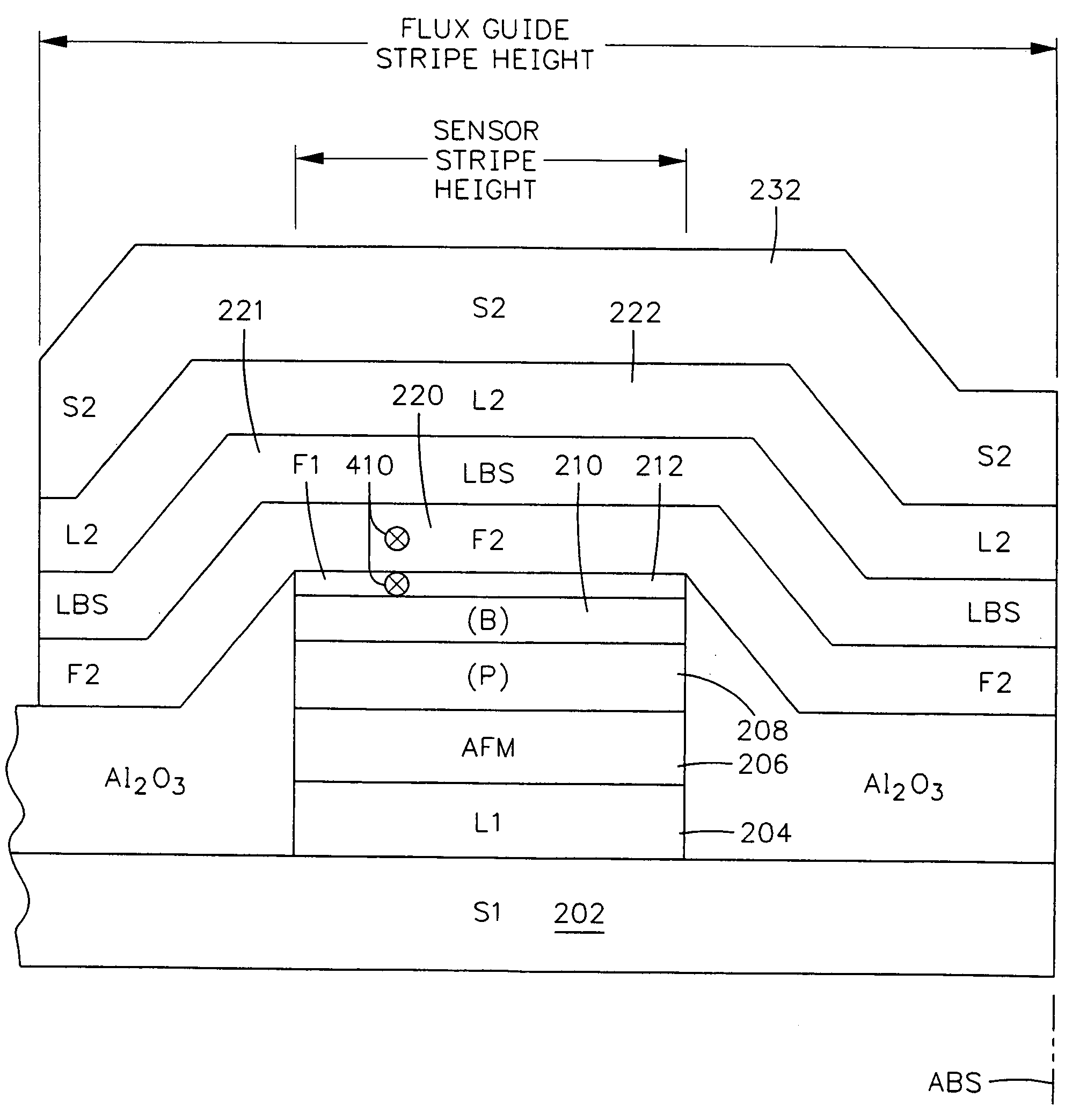

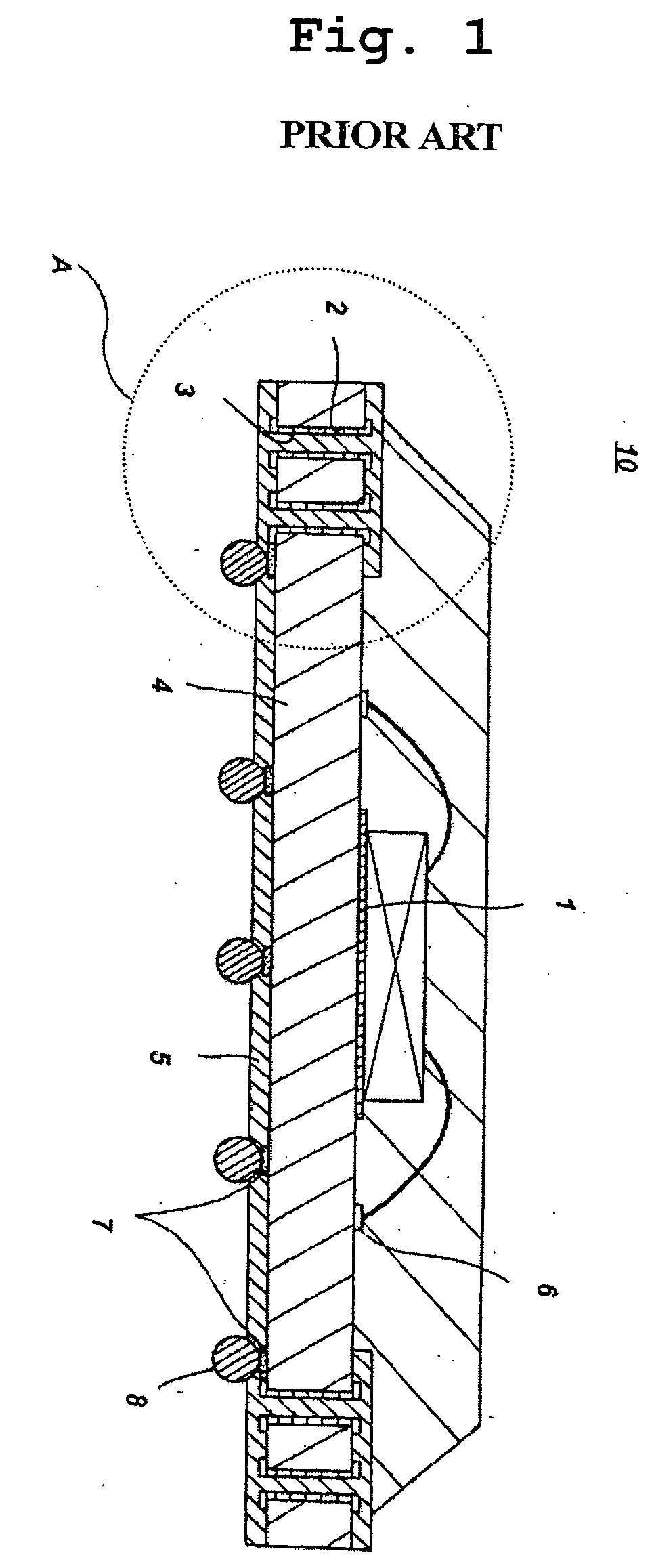

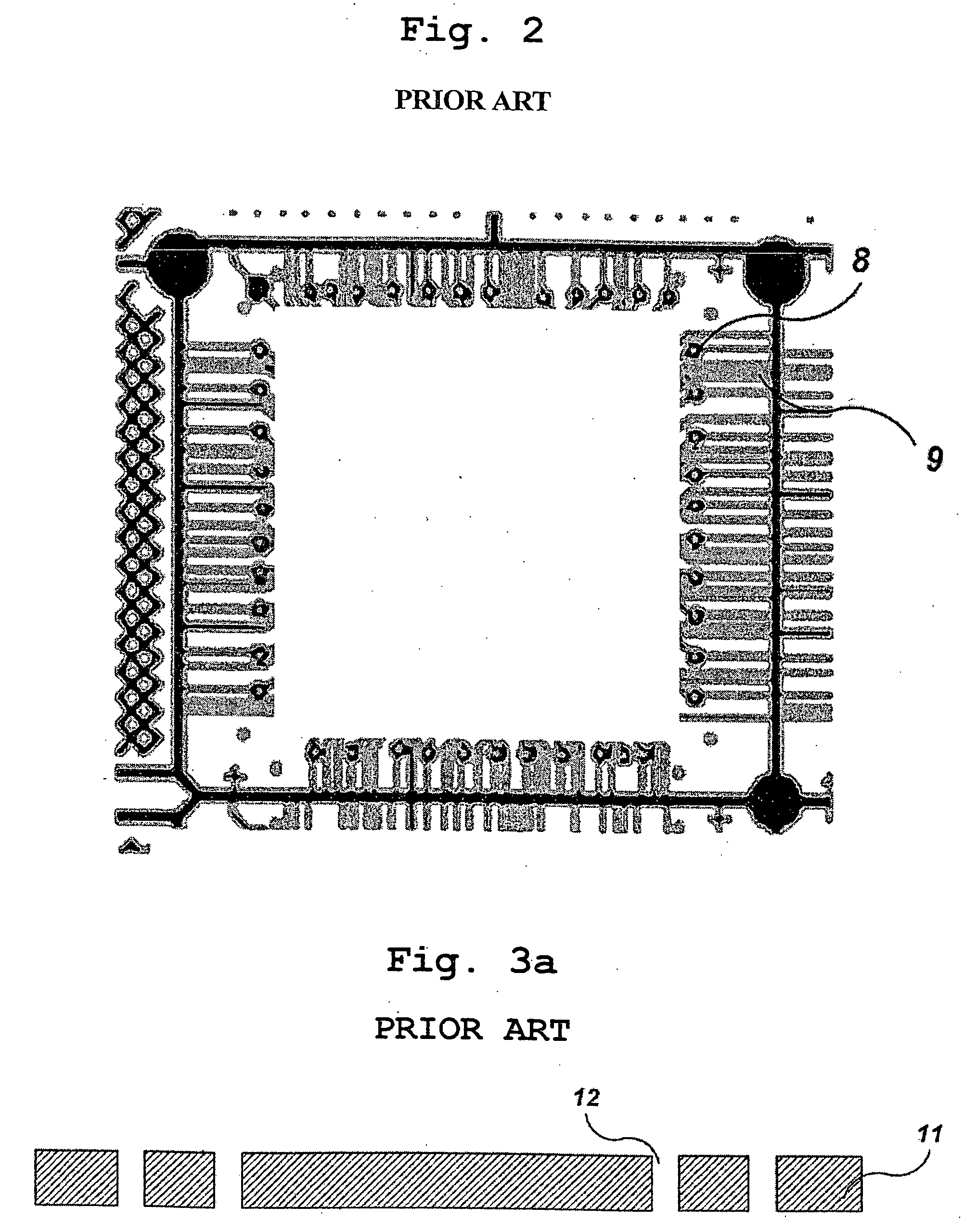

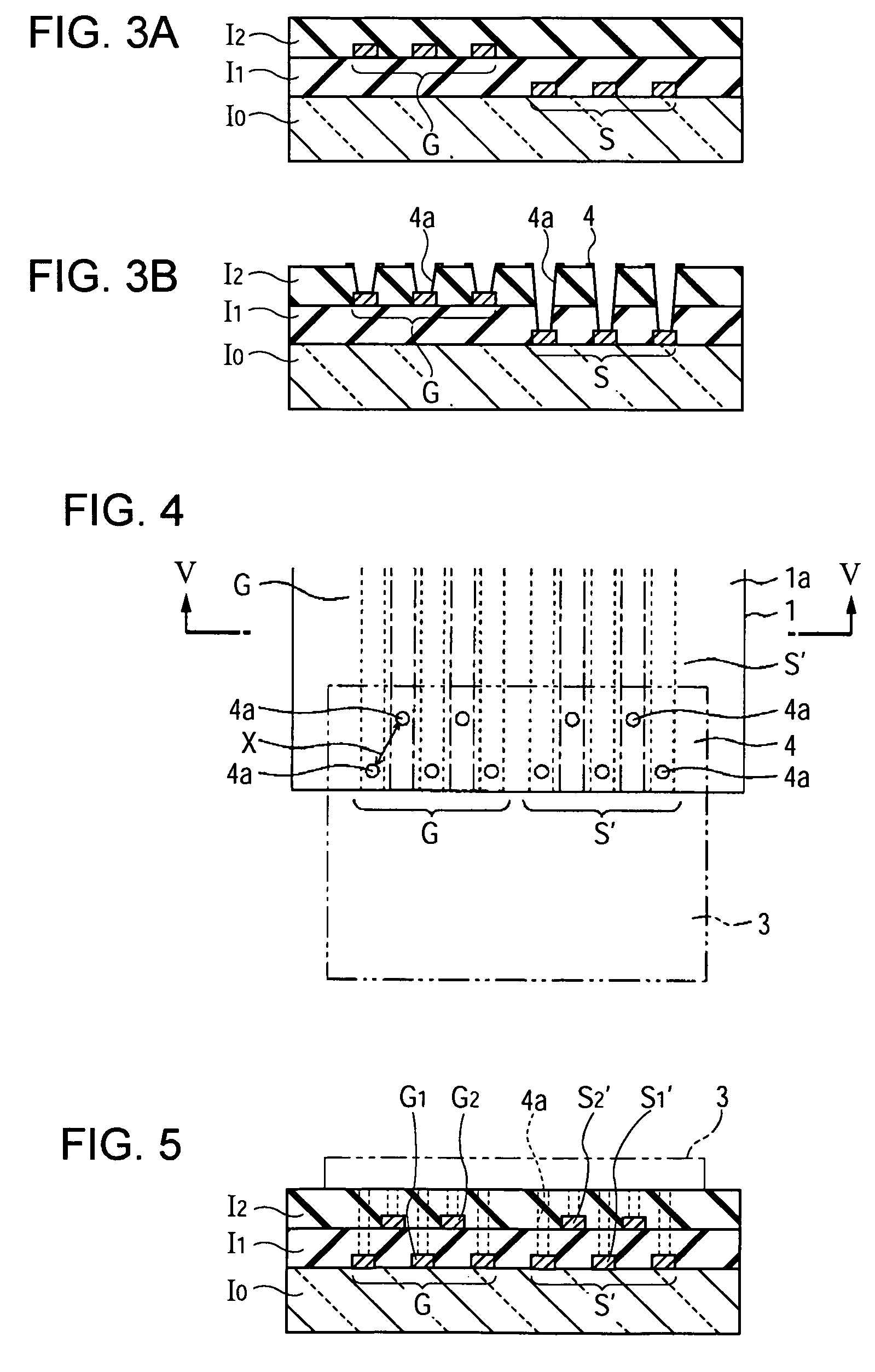

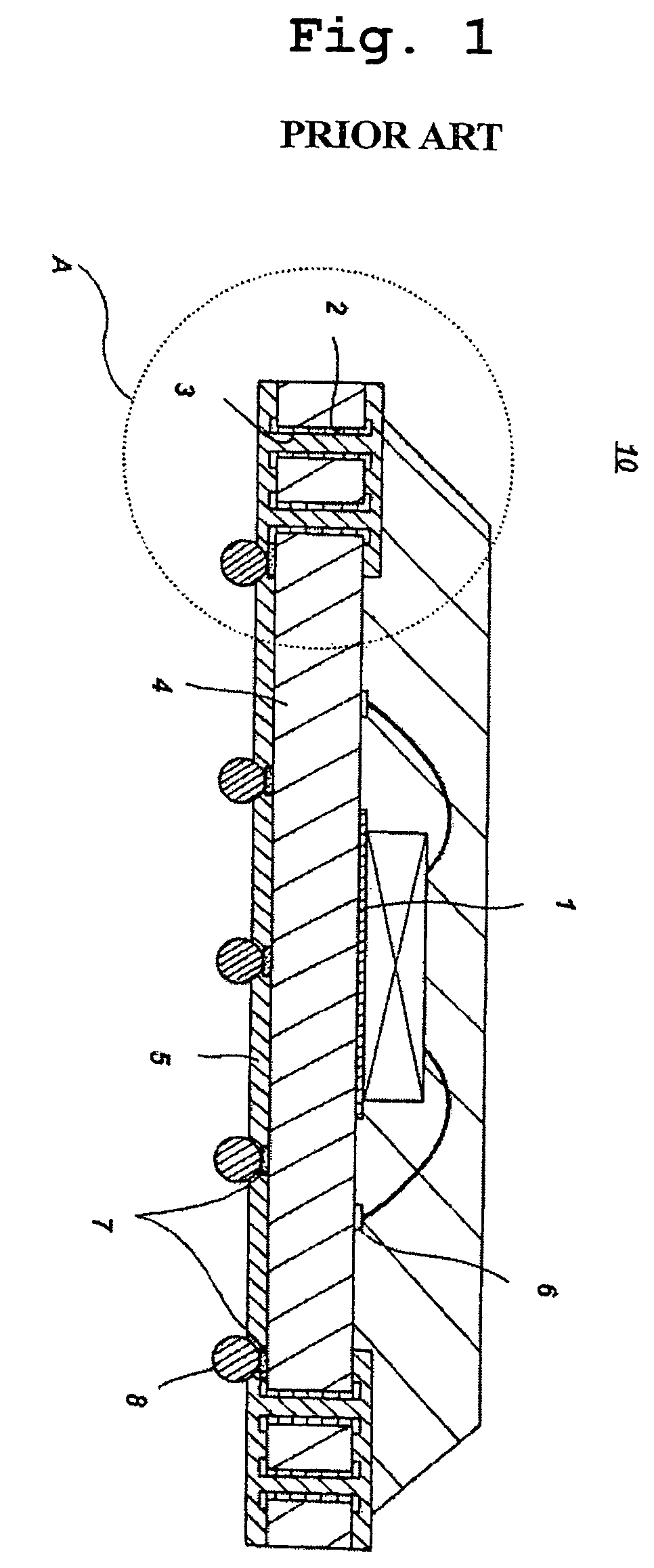

High linear density tunnel junction flux guide read head with in-stack longitudinal bias stack (LBS)

InactiveUS6888705B2Reduce gapAvoid large gapsElectrical transducersNanomagnetismSensor planeLinear density

Several embodiments of a sense current perpendicular to the planes of the sensor (CPP) and flux guide type of read head has a gap between first and second shield layers at an air bearing surface (ABS) where the flux guide is located which is less than a gap between the first and second shield layers at a recessed location where the sensor is located. This reduced gap increases the linear bit density capability of the read head. A longitudinal bias stack (LBS) is located in the sensor stack. Several unique methods of construction are described for forming the magnetic head assemblies.

Owner:WESTERN DIGITAL TECH INC

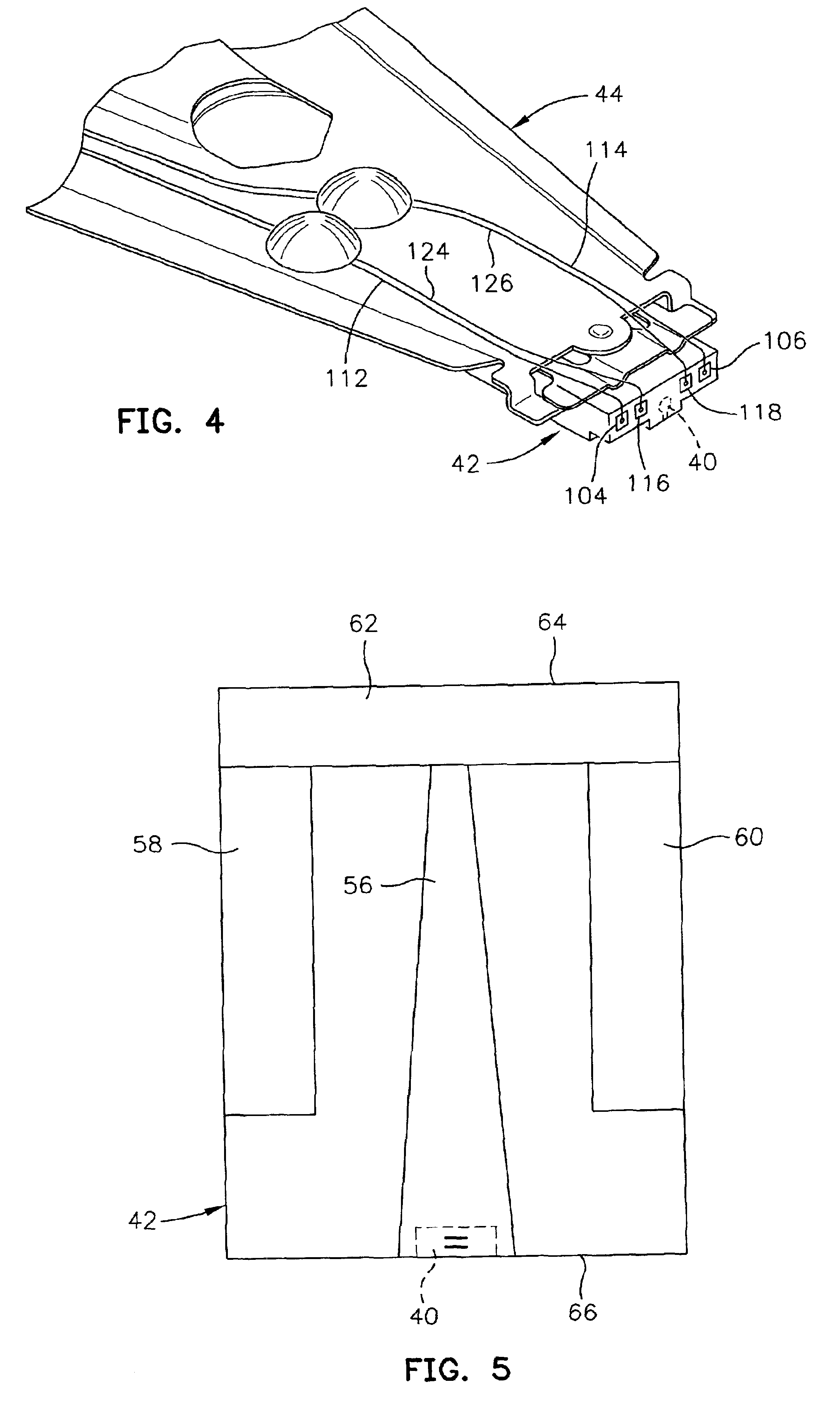

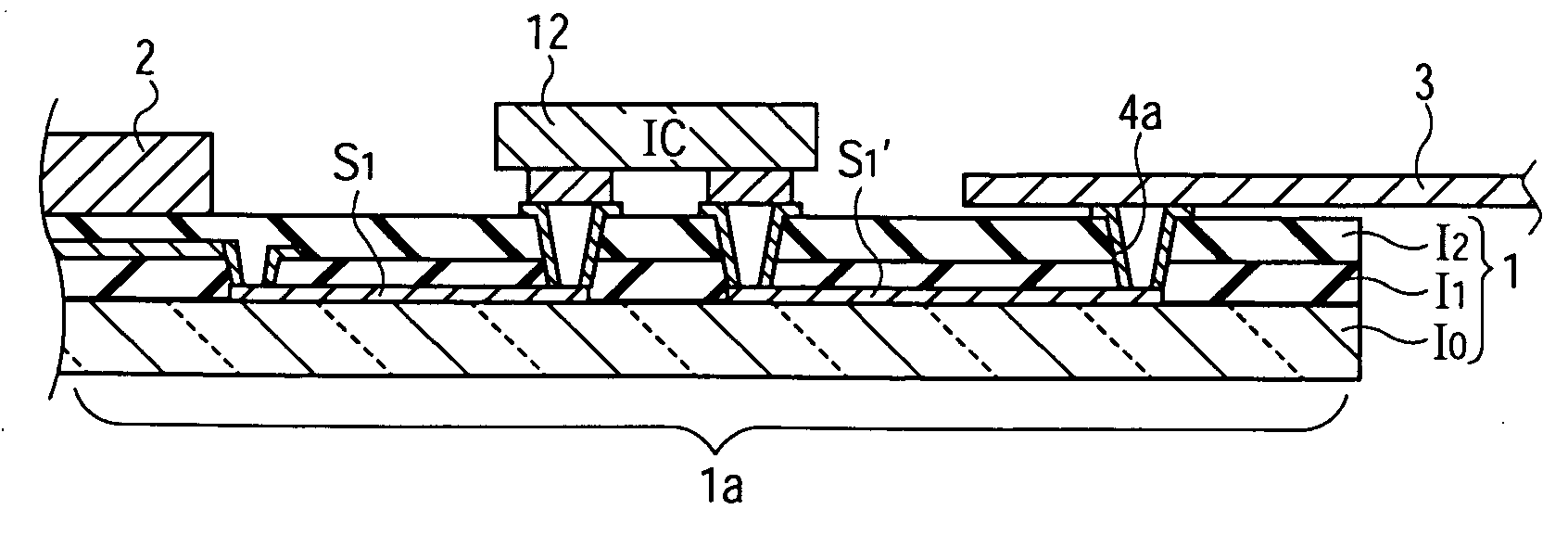

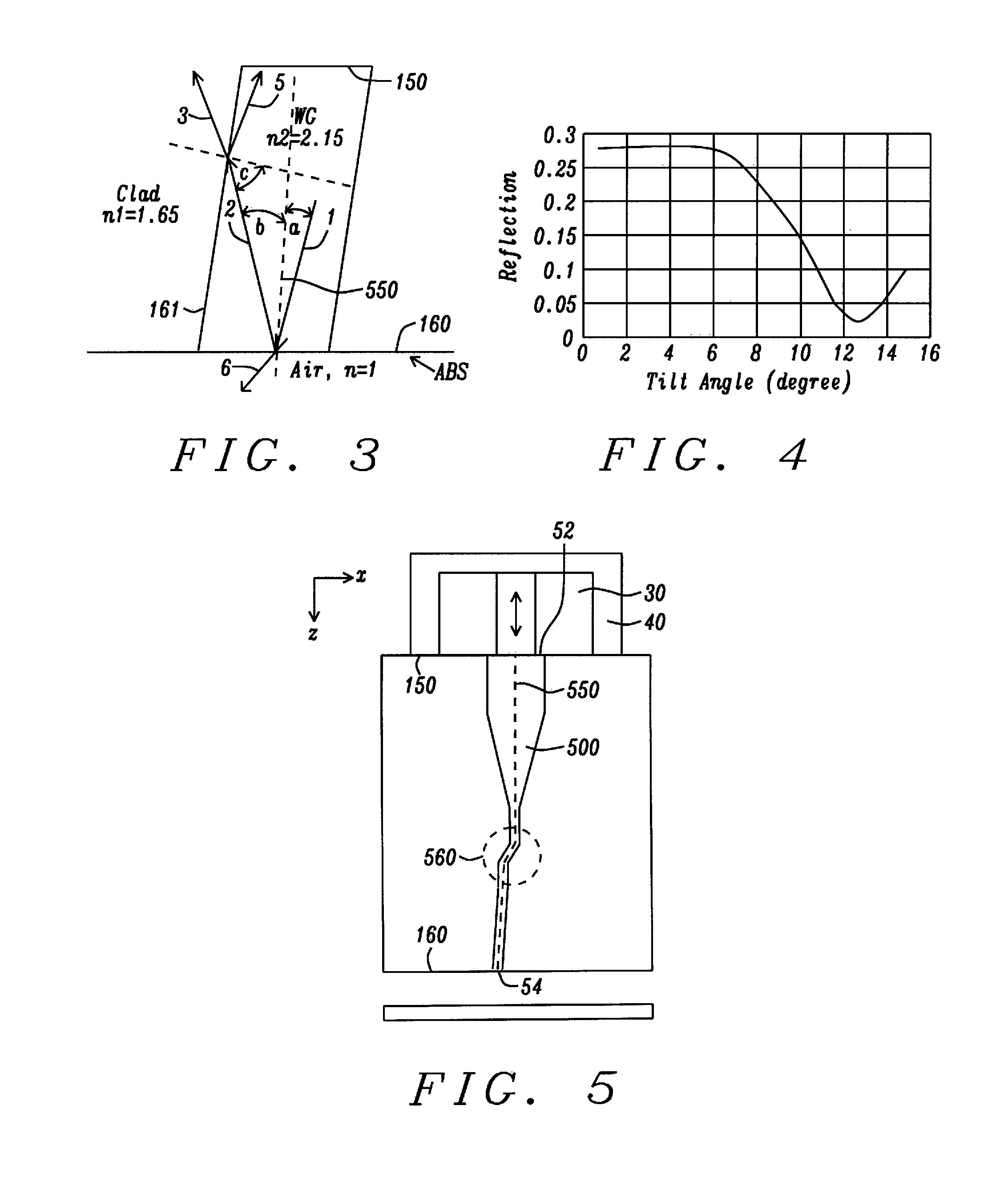

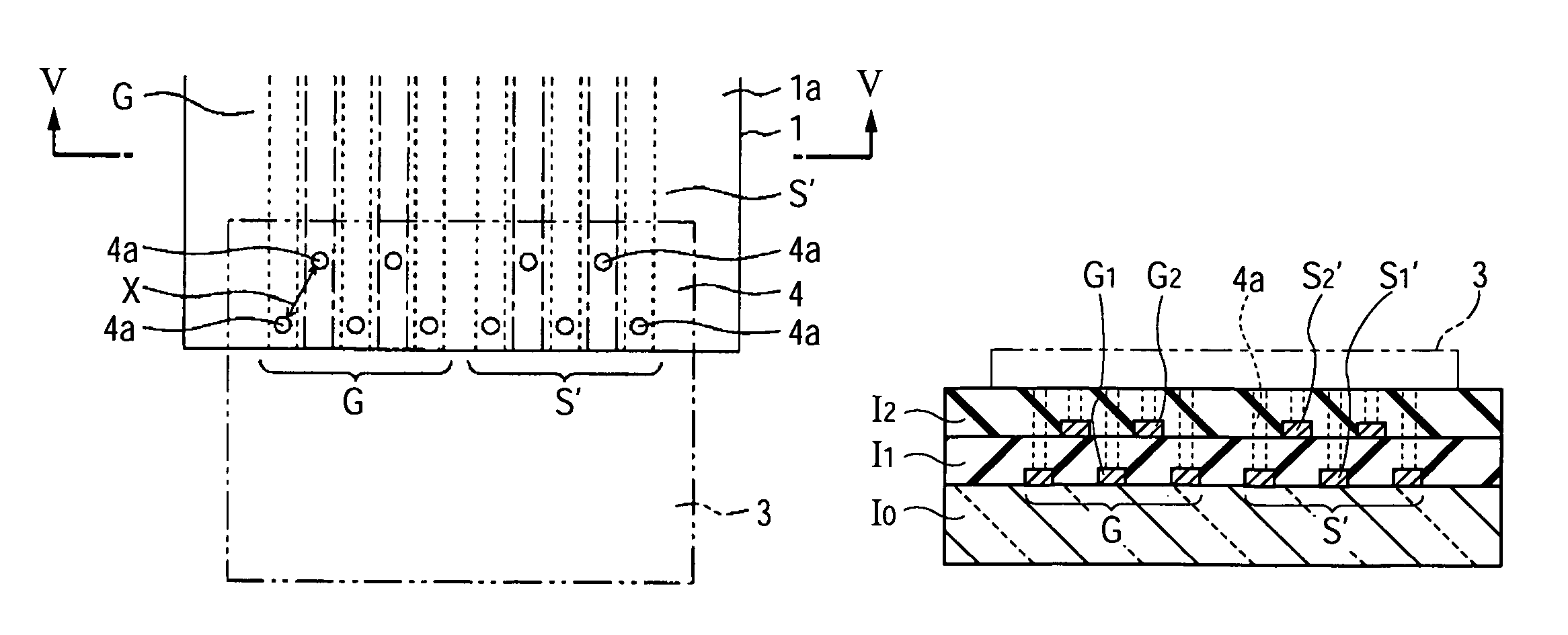

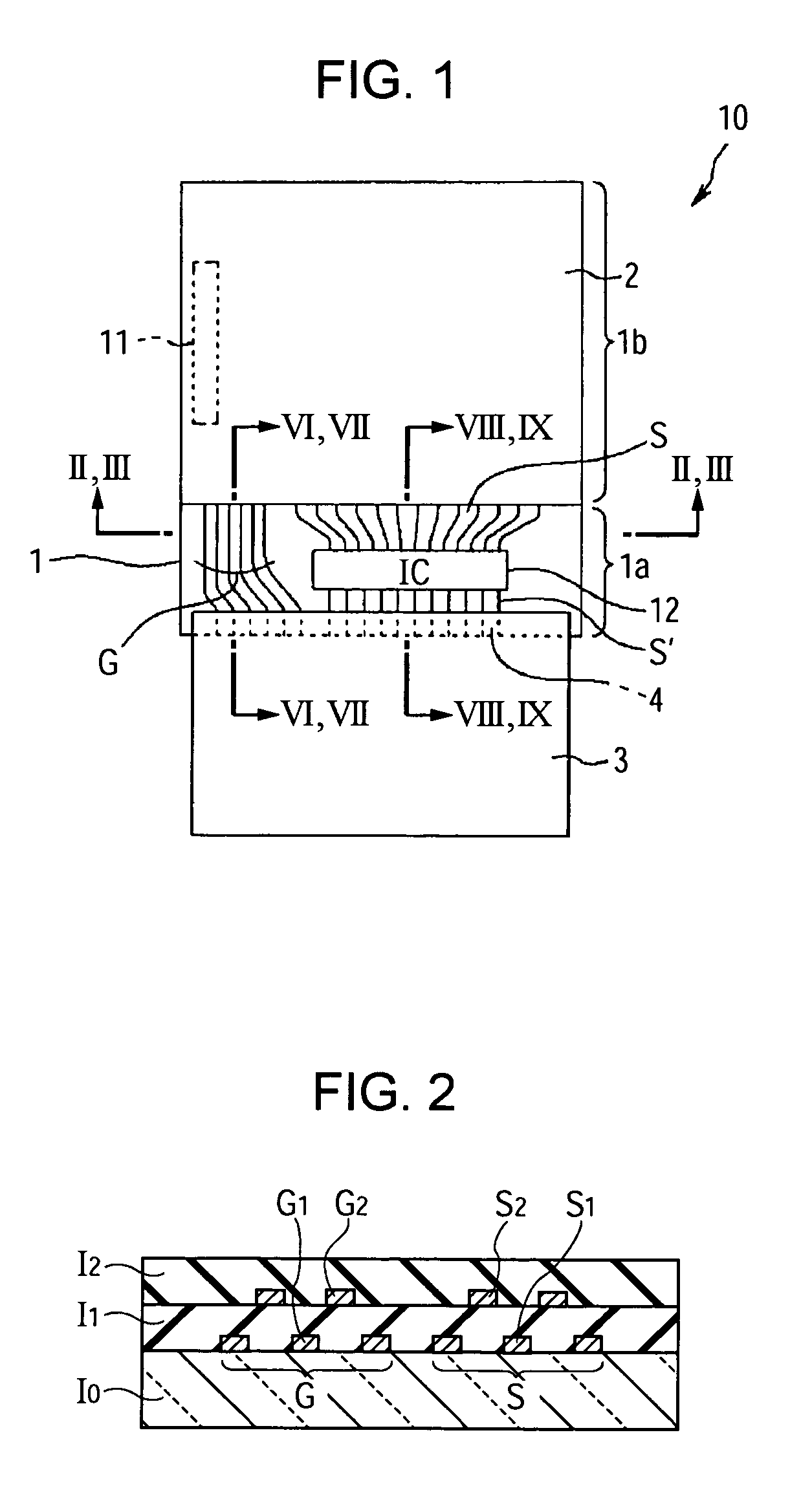

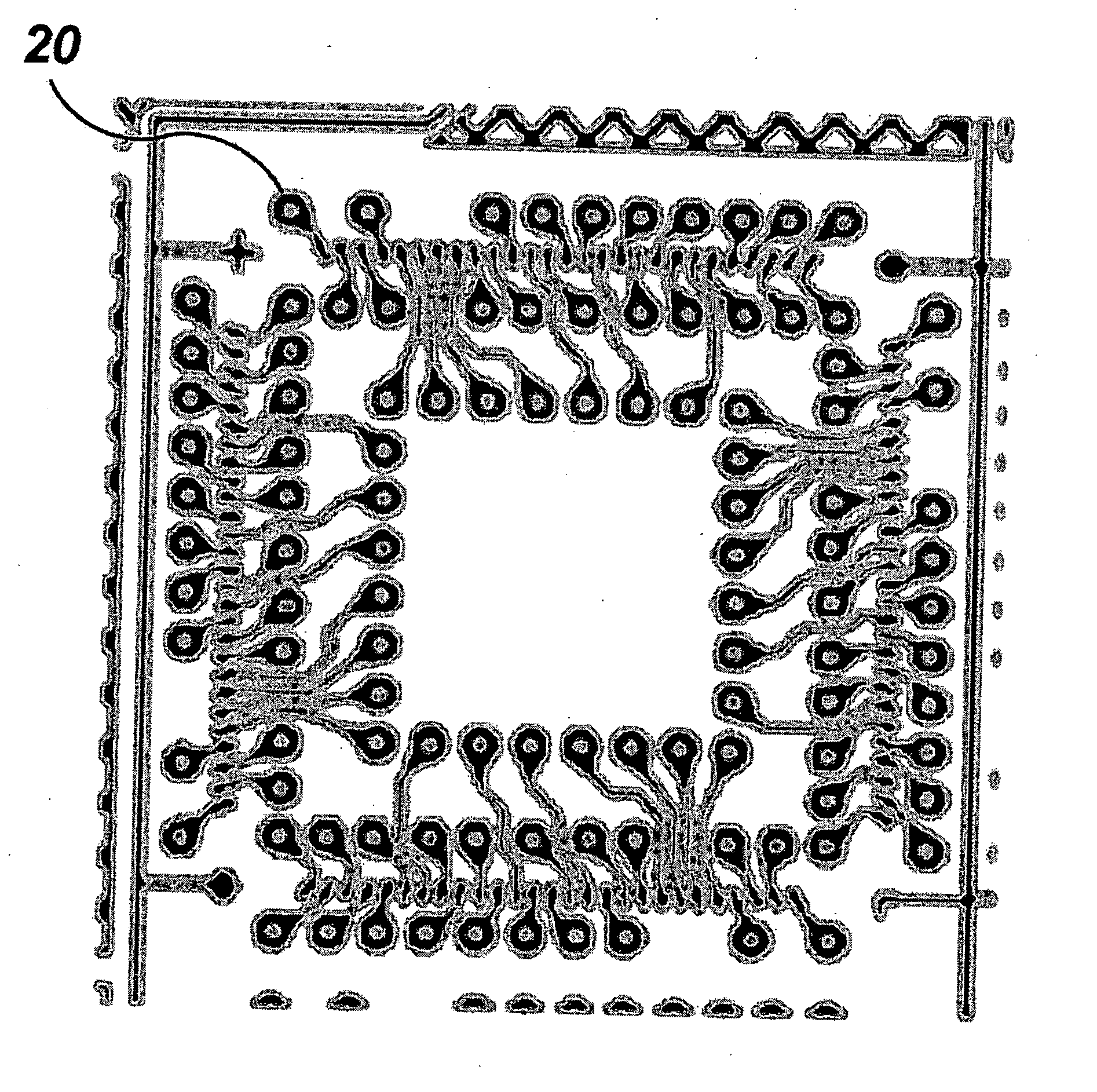

Electro-optical device and electronic apparatus

ActiveUS20060044504A1Improve insulation performanceImprove routing densityPrinted circuit aspectsSolid-state devicesElectronElectro-optics

An electro-optical device includes a substrate having a display region; and an extending region extending from the display region. The extending region is provided with wiring lines, and at least some wiring lines, which are disposed to be adjacent to each other, are correspondingly disposed in a plurality of different layers.

Owner:BOE TECH GRP CO LTD

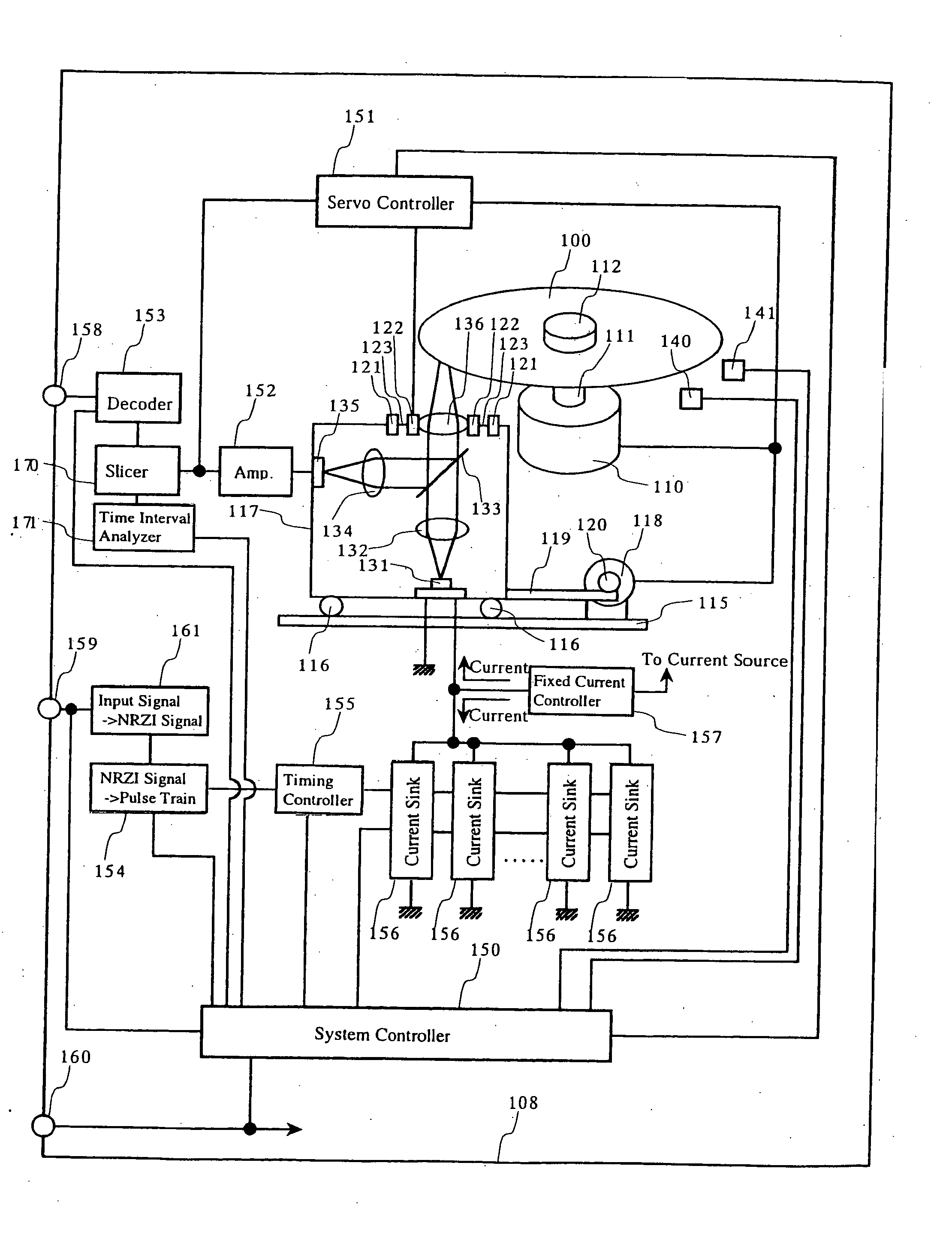

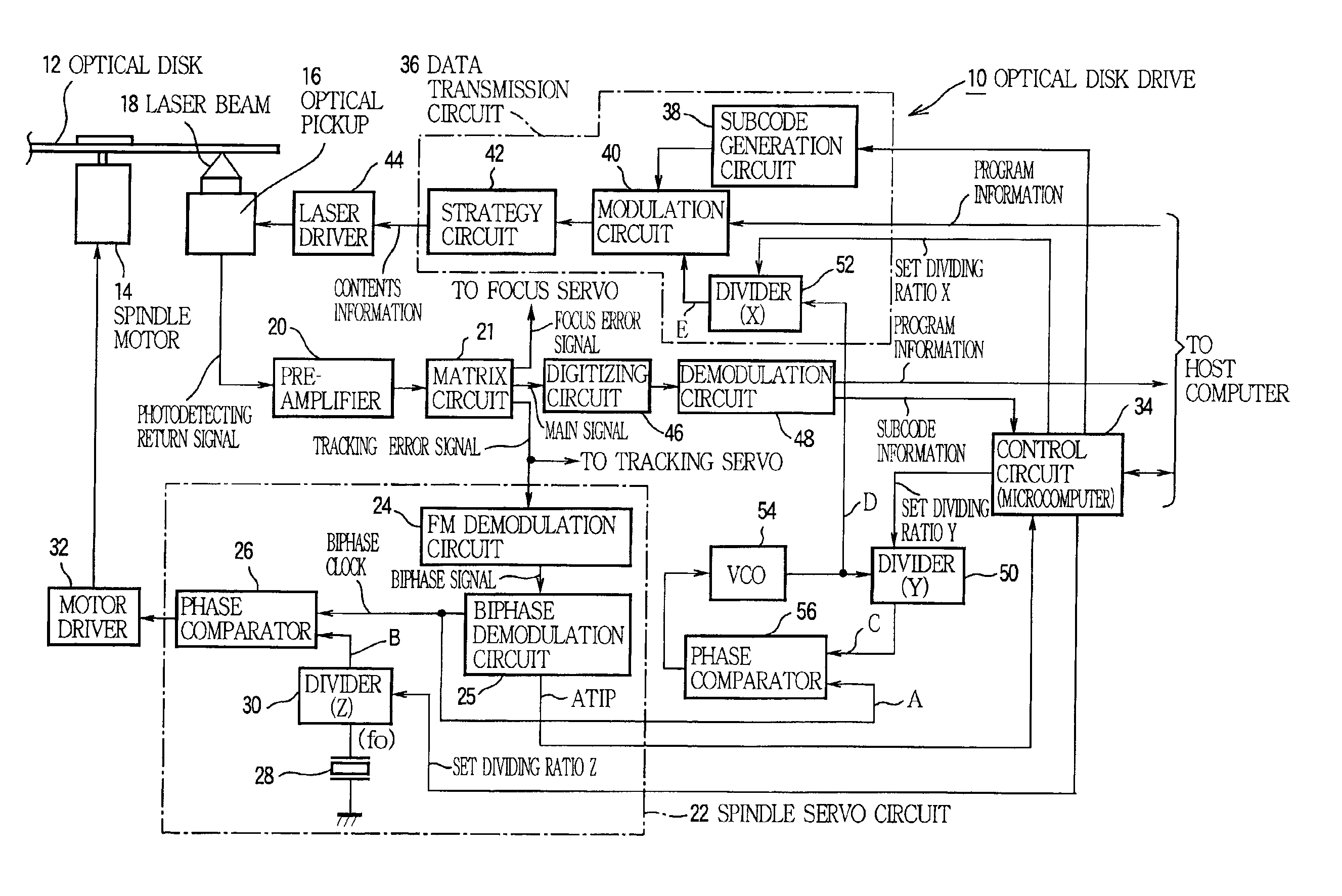

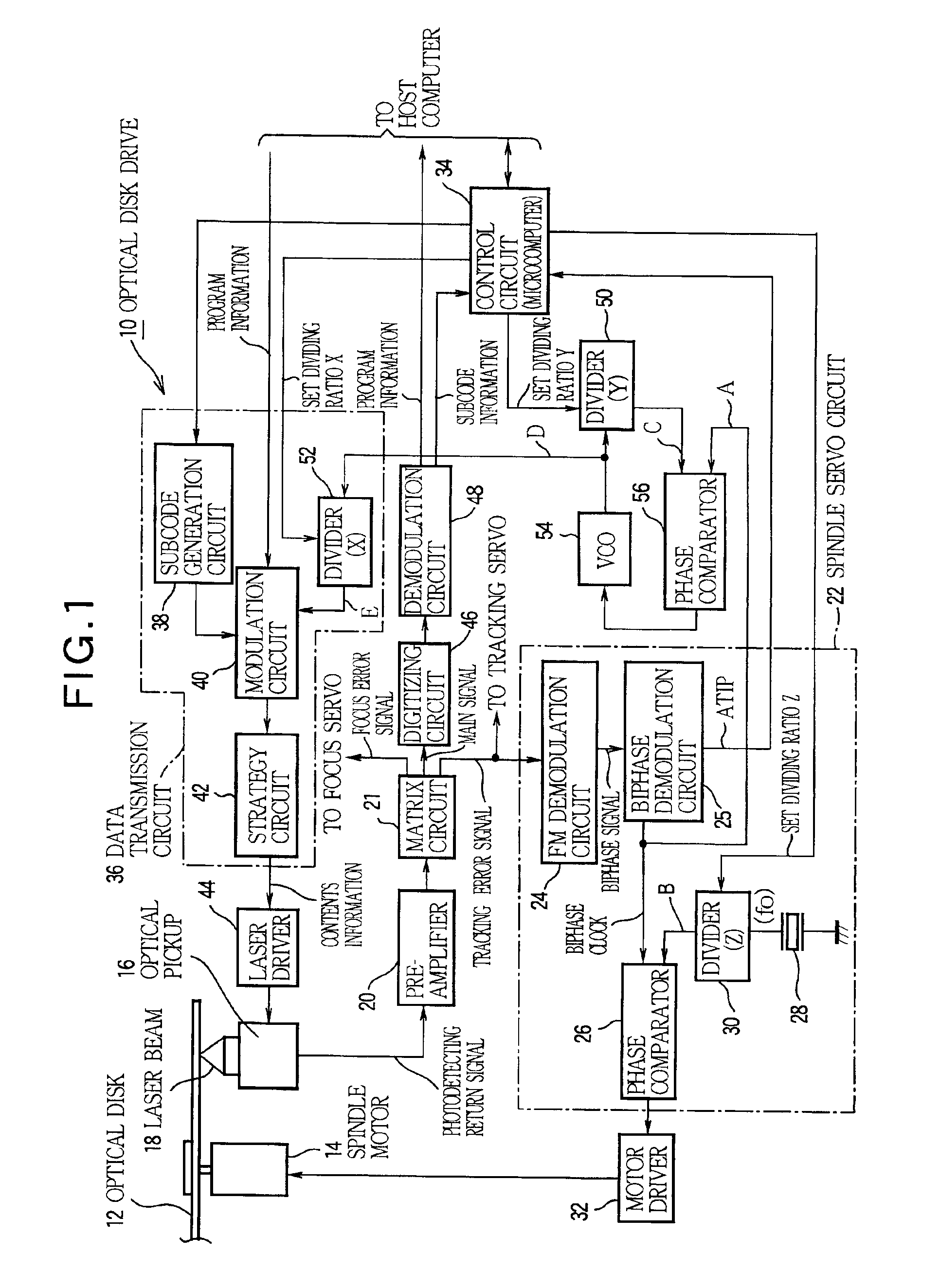

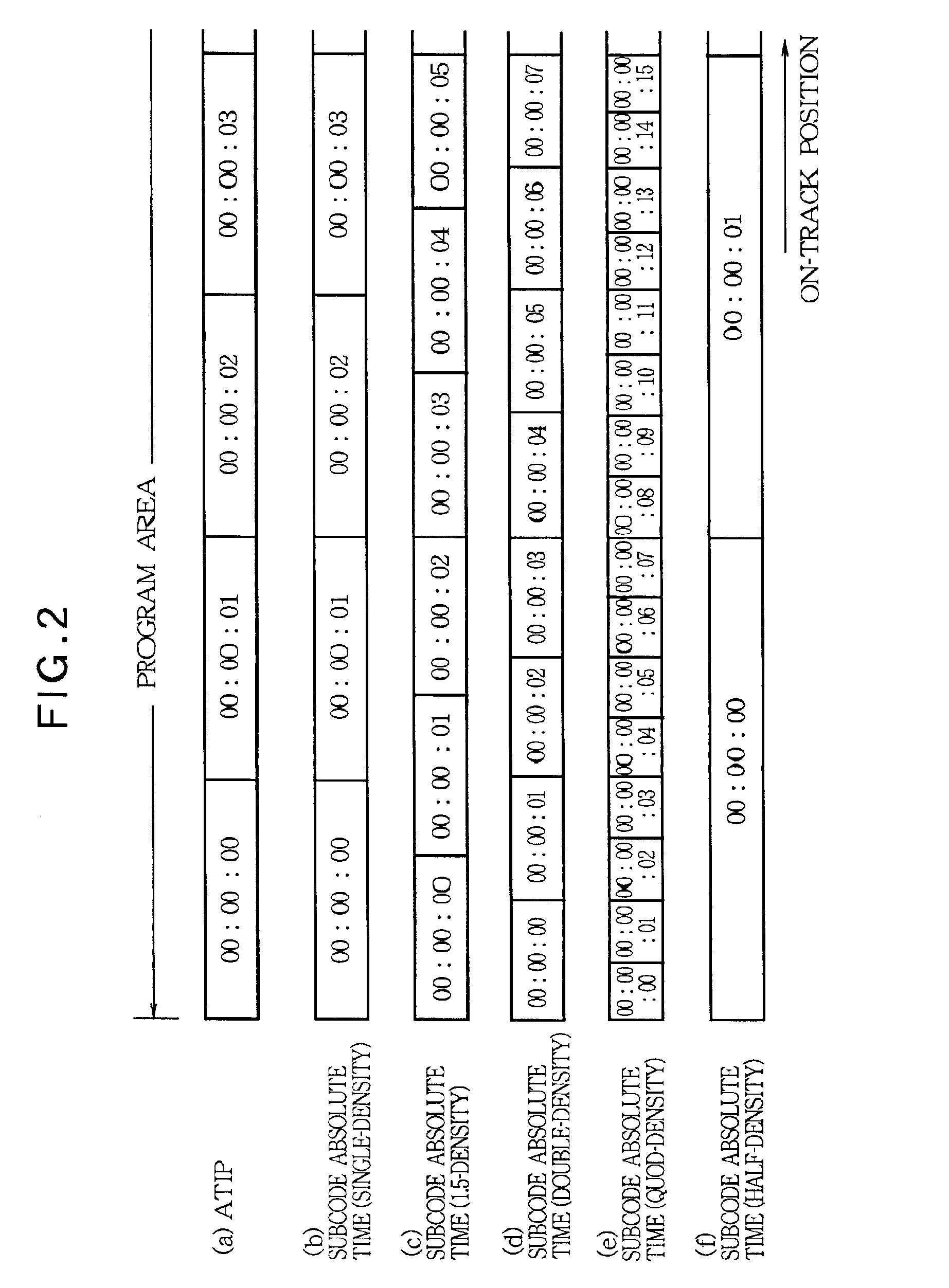

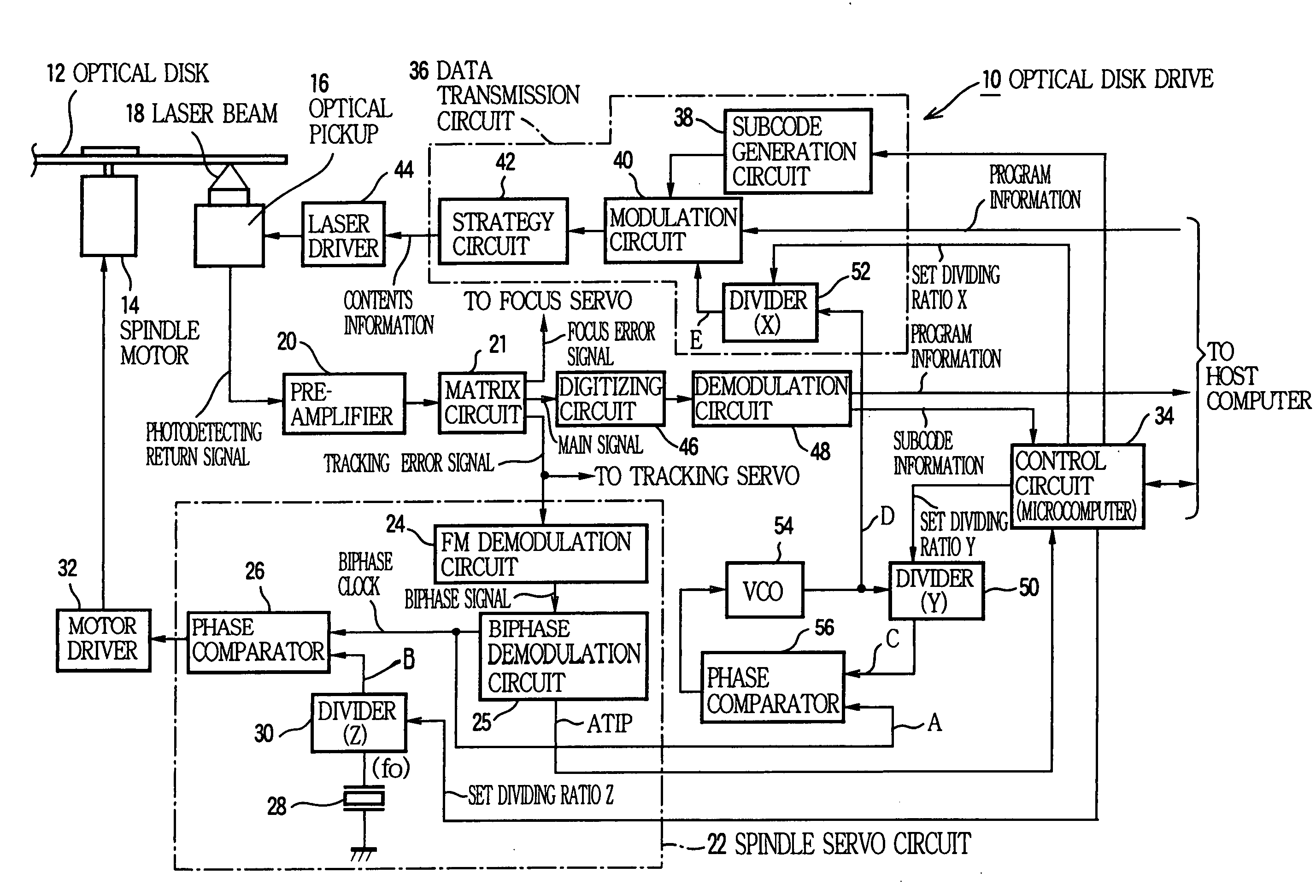

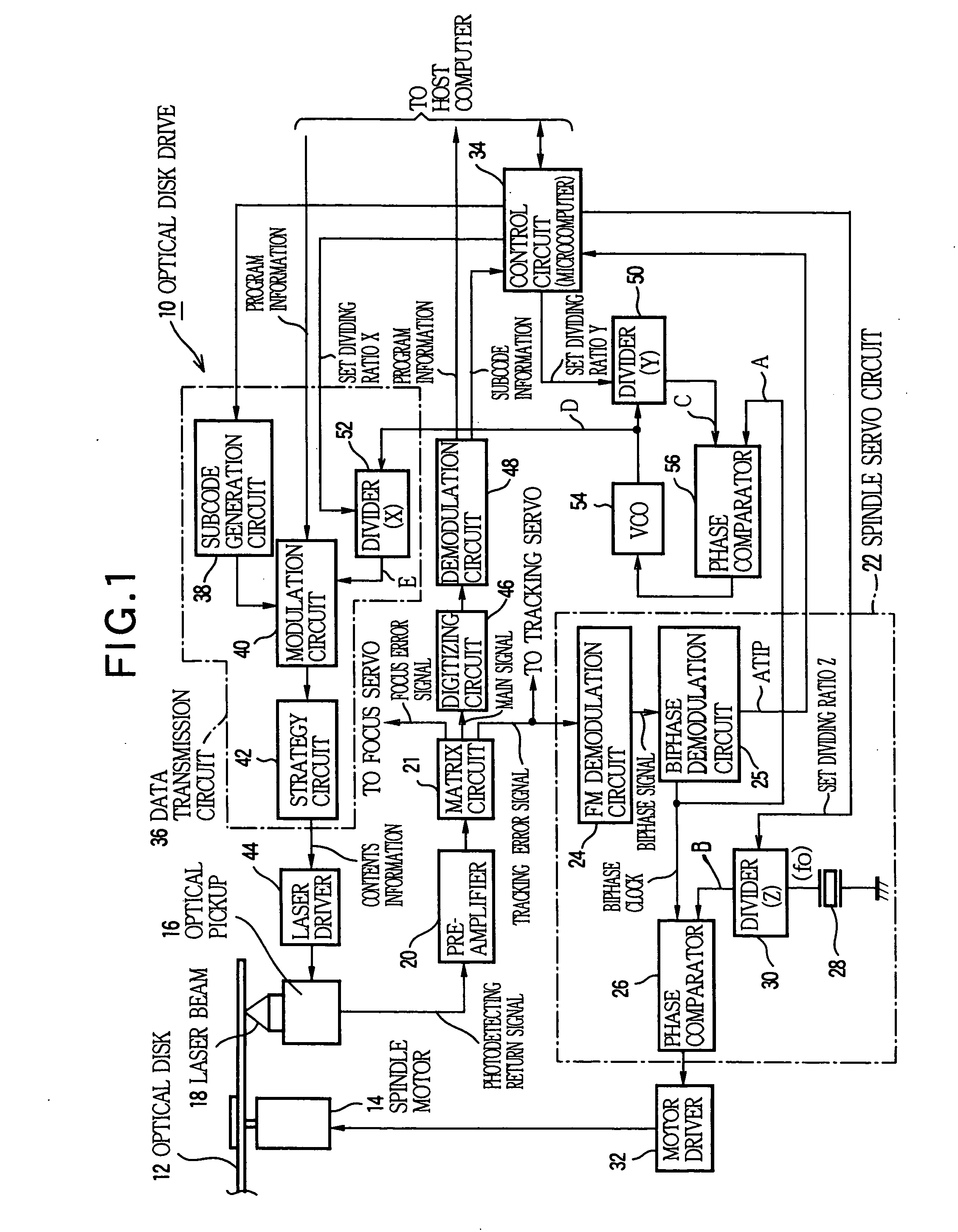

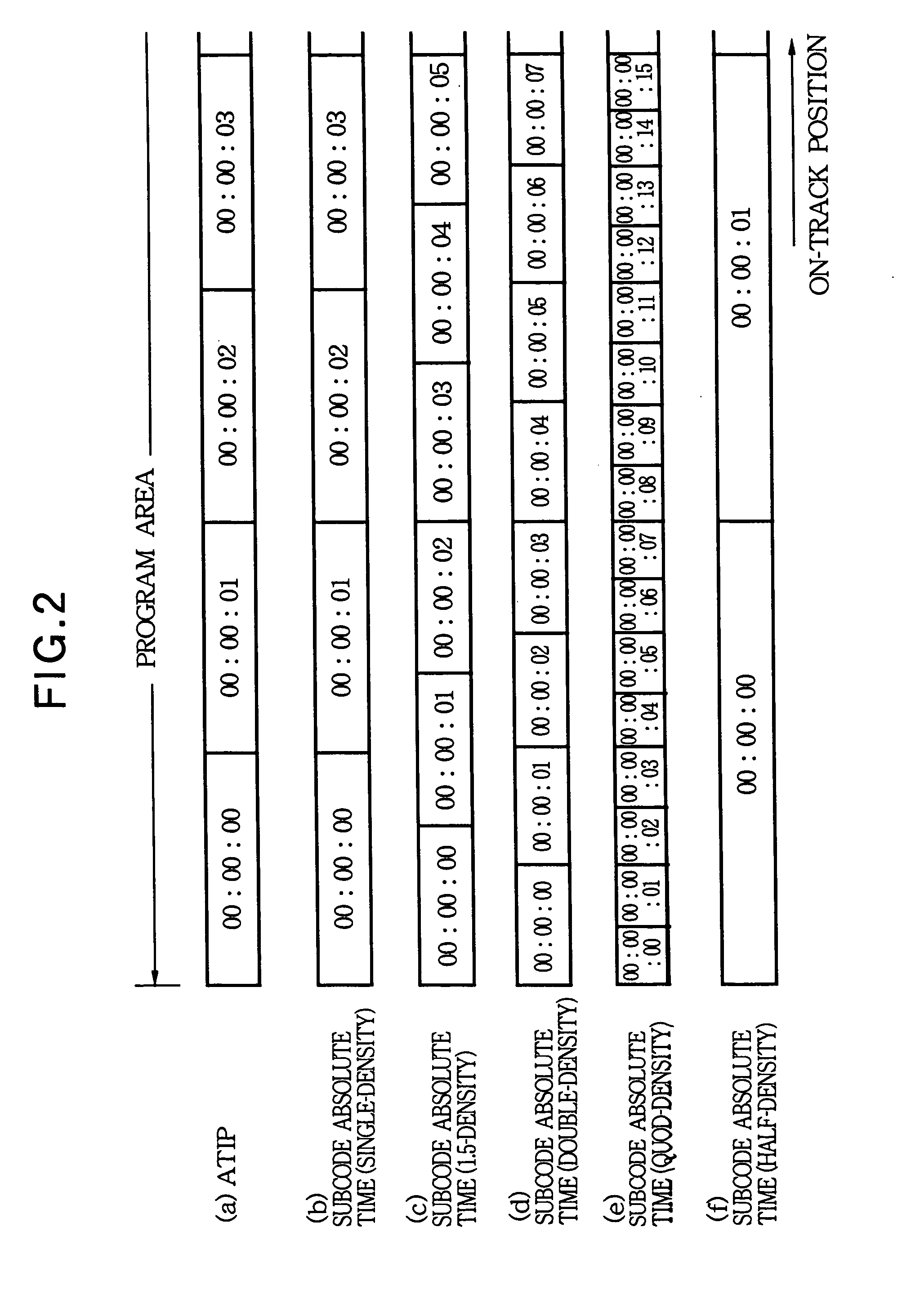

Optical disk recorder for writing data with variable density

InactiveUS6894967B2Reduce recording timeReduce in quantityTelevision system detailsFilamentary/web record carriersConstant linear velocityData recording

An optical disk recording apparatus operates on an optical disk having circular tracks which are provisionally written with an index signal used for securing a constant linear velocity of the optical disk from an innermost circular track to an outermost circular track, and records data along the circular tracks at different linear densities on different annular zones of the optical disk. In the apparatus, a disk drive section rotates the optical disk while synchronizing the index signal successively read from the rotated optical disk with a predetermined reference clock signal to thereby maintain the constant linear velocity of the circular tracks. A clock generating section multiplies or divides the reference clock signal by different rates to generate different writing clock signals in correspondence to the different annular zones of the optical disk. A data recording section operates in synchronization to the different writing clock signals for recording data along the circular tracks at the different linear densities on the different annular zones.

Owner:YAMAHA CORP

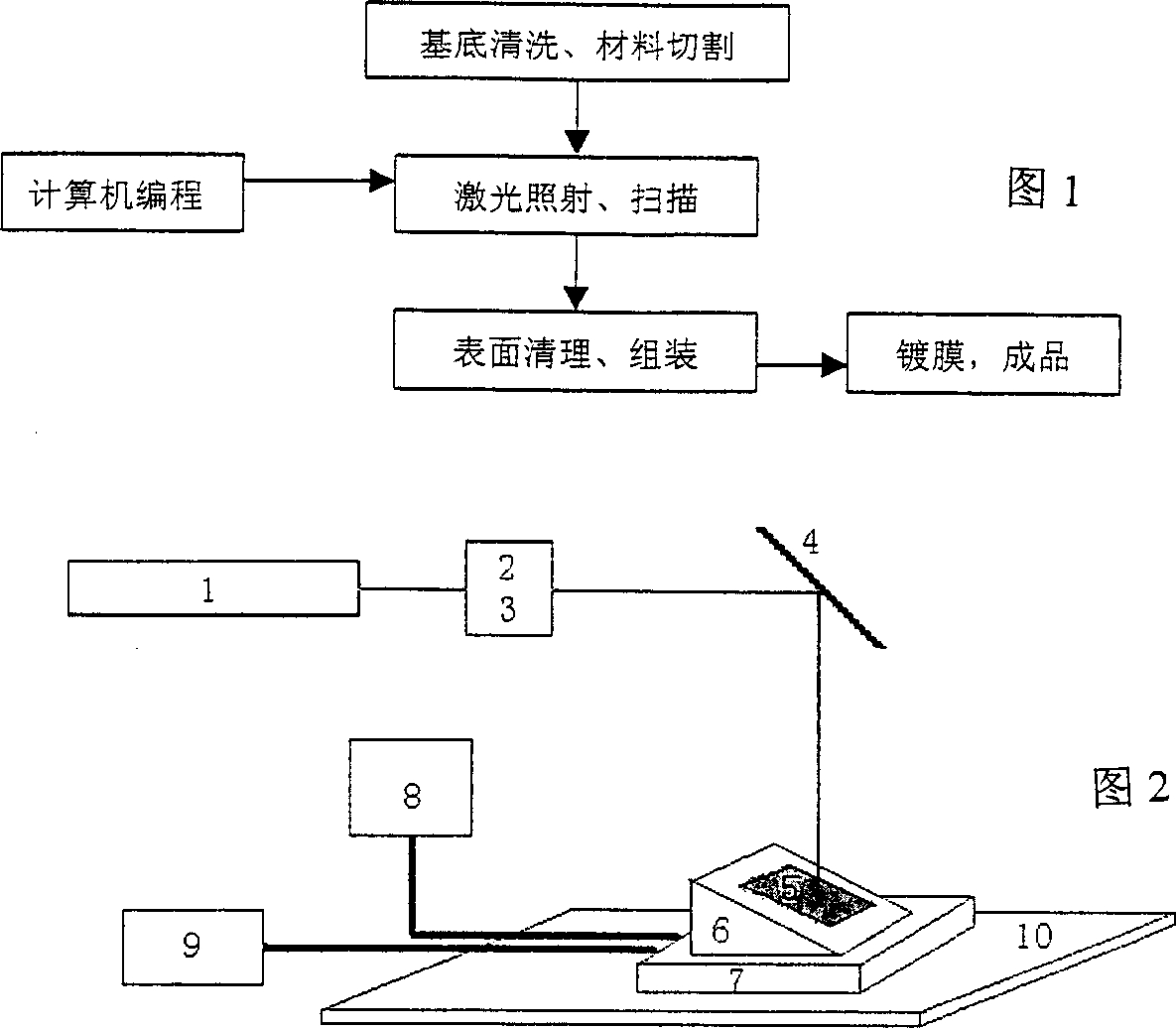

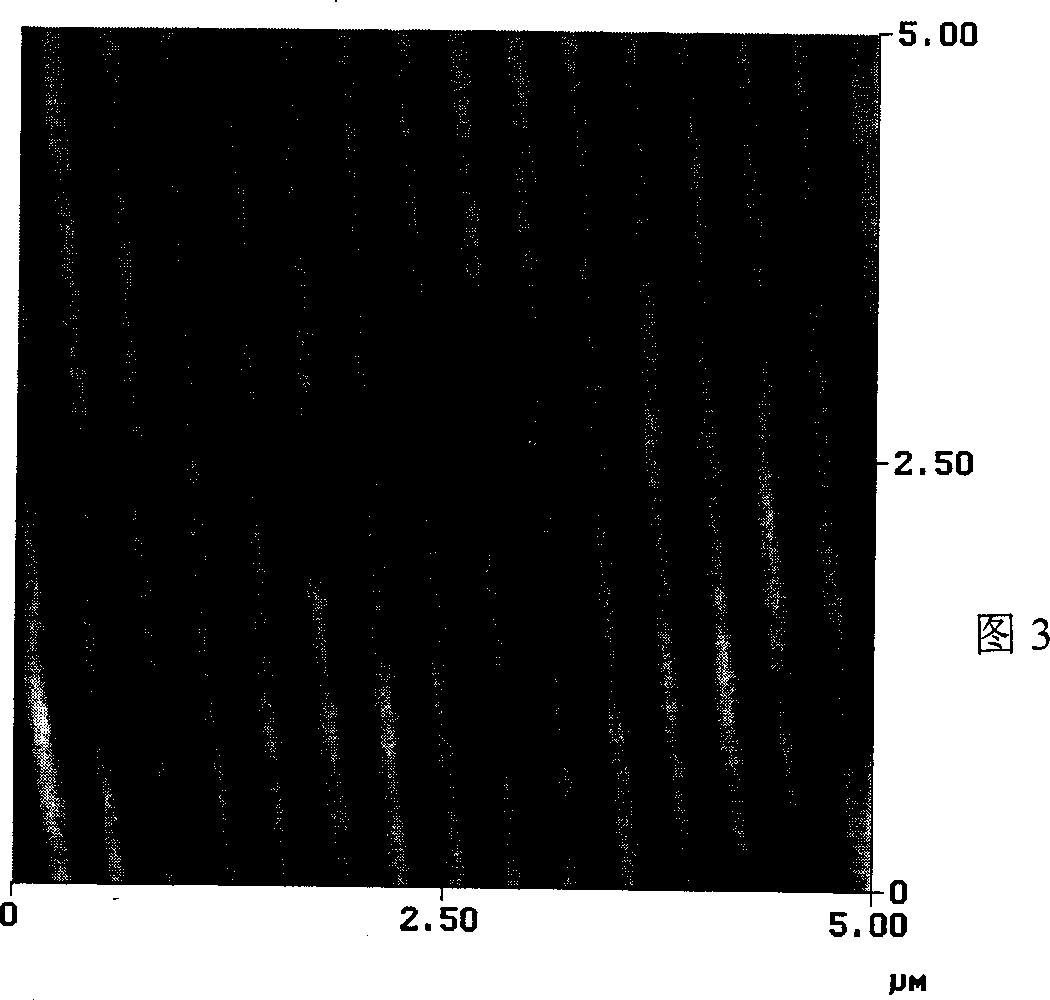

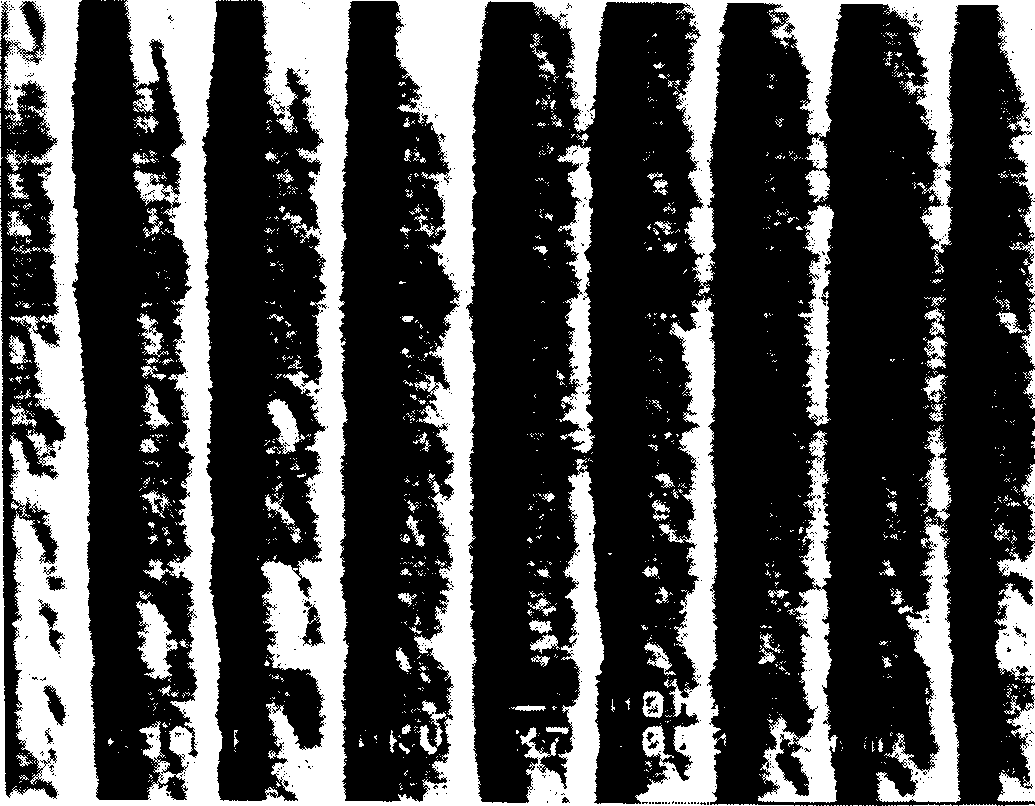

Holographic grating making process

Through laser scanning process and by means of the surface diffusion wave interference of single laser beam on the surface of some material, straight line channel strength is formed on the surface ofthe material and holographic grating in different interval and different depth may be made. After the selected grating material is cleaned and cut, it is placed on computer controlled moving platformand through stepped laser scanning and regulating the technological parameters, including pulse width, frequency, incident angle, power density, etc., regular channel structure is formed on the surface of the material. The present invention has simple process, easy control, wide material selecting range and controlled cost.

Owner:SHANGHAI JIAO TONG UNIV

High linear density tunnel junction flux guide read head with in-stack longitudinal bias stack (LBS)

InactiveUS20050146812A1Reduce gapAvoid large gapsNanomagnetismElectrical transducersSensor planeLinear density

Several embodiments of a sense current perpendicular to the planes of the sensor (CPP) and flux guide type of read head has a gap between first and second shield layers at an air bearing surface (ABS) where the flux guide is located which is less than a gap between the first and second shield layers at a recessed location where the sensor is located. This reduced gap increases the linear bit density capability of the read head. A longitudinal bias stack (LBS) is located in the sensor stack. Several unique methods of construction are described for forming the magnetic head assemblies.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

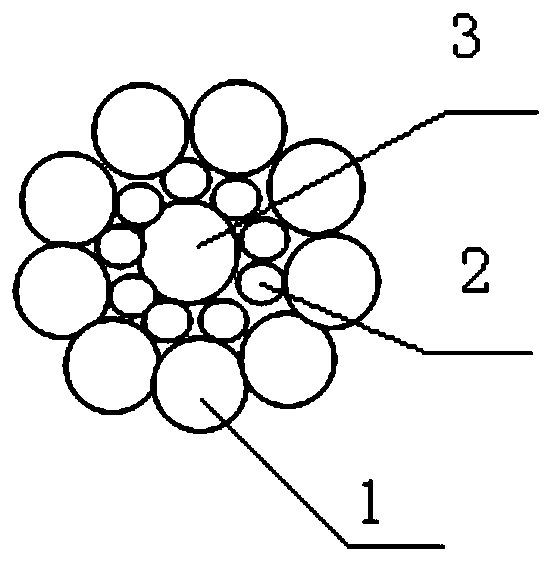

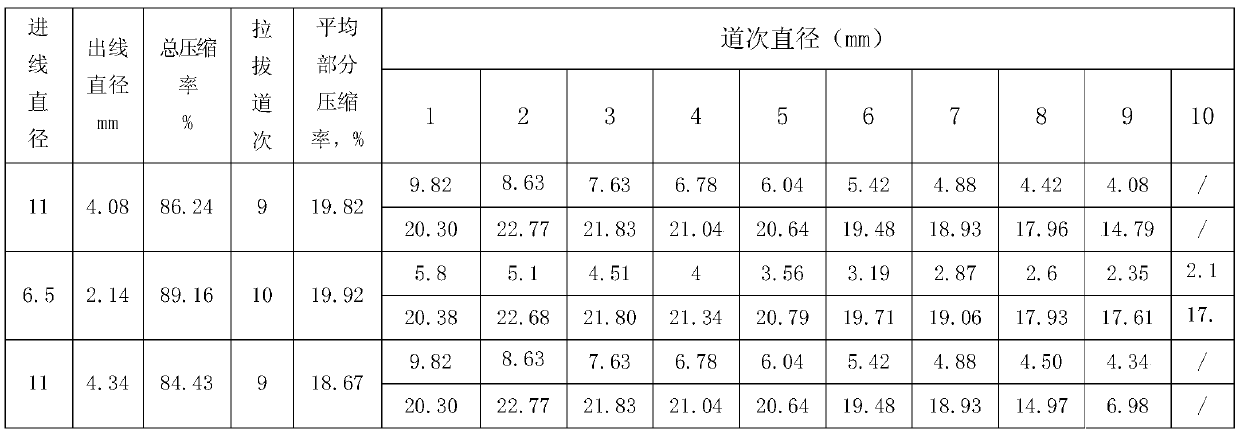

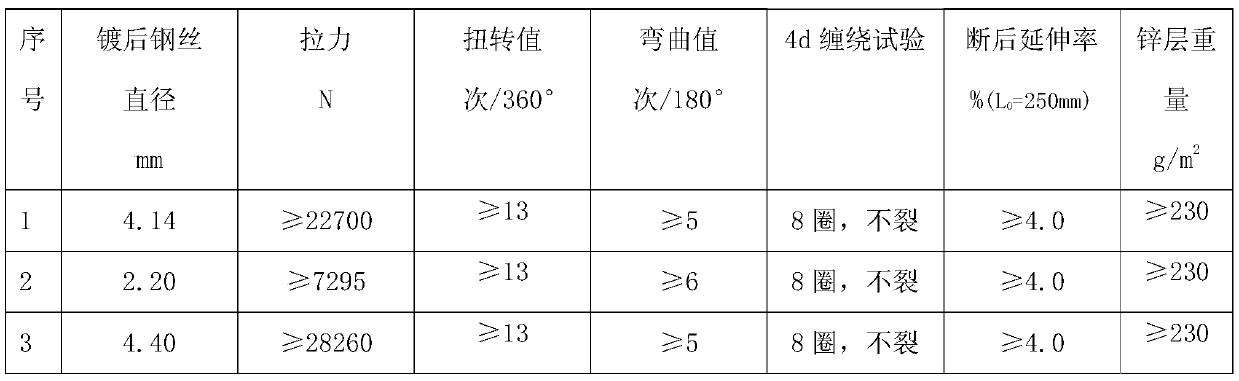

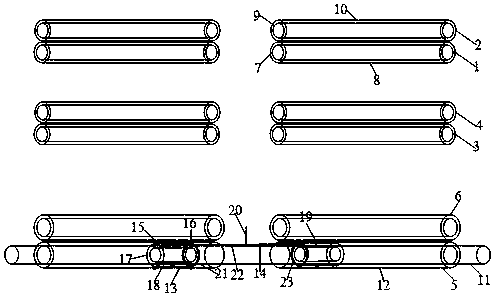

Production technology for HDPE hot-galvanizing-zinc-aluminum-alloy pre-stress steel strand

InactiveCN109853274AIncrease linear densityIncrease the cross-sectional areaHot-dipping/immersion processesRope making machinesCorrosionPre stressing

The invention relates to the technical field of steel strand production, in particular to a production technology for a HDPE hot-galvanizing-zinc-aluminum-alloy pre-stress steel strand. The productiontechnology includes the following steps of steel-wire-rod preparing and detecting; acid pickling parkerizing; wiredrawing; hot galvanizing; finishing; twisting and stabilizing treating; anti-corrosive grease coating; plastic covering; packaging warehousing. According to the production technology for the HDPE hot-galvanizing-zinc-aluminum-alloy pre-stress steel strand, the corrosion resistance andthe flexible performance of the pre-stress steel strand can be improved, particularly, when the pre-stress steel strand is used on a bridge, the bridge building cost can be saved, the service life isprolonged, and construction is convenient.

Owner:天津市新天钢钢线钢缆有限公司

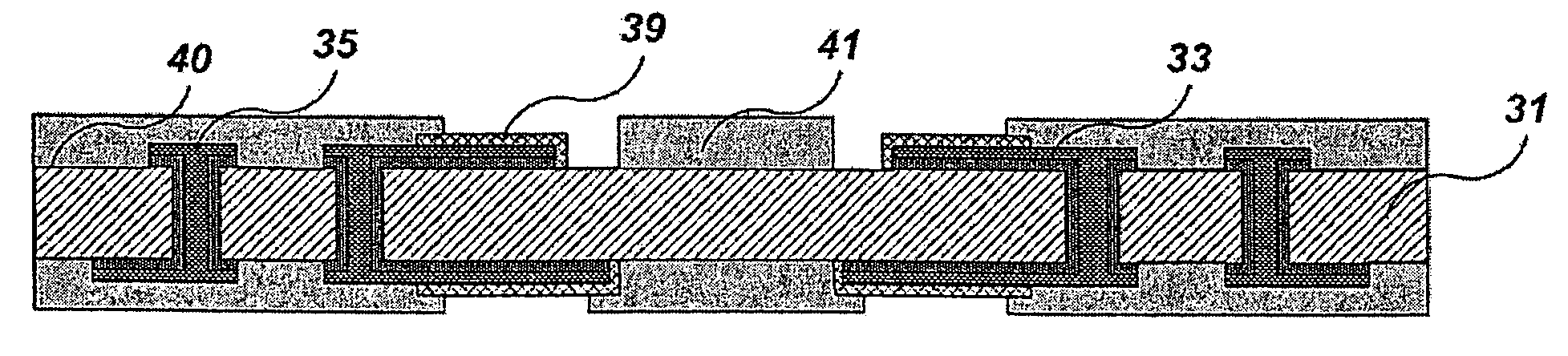

Package substrate manufactured using electrolytic leadless plating process, and method for manufacturing the same

InactiveUS20050095862A1Increase linear densityAvoid noiseSemiconductor/solid-state device detailsPrinted electric component incorporationResistCopper plating

A package substrate manufactured by electrolytically plating Au in a semi-additive manner without using any plating lead line on wire bonding pads and solder ball pads, and a method for manufacturing the package substrate. The method includes the steps of forming a first copper plated layer on a base substrate having through holes and inner surfaces of the through holes, coating a first resist over the first copper plated layer, partially removing the first resist, thereby exposing portions of the first copper plated layer respectively corresponding to regions where circuit patterns are to be plated, forming a second copper plated layer on the exposed portions of the first copper plated layer, stripping the first resist, coating a second resist over the resultant structure, and removing the second resist from regions where wire bonding pads and solder ball pads are to be formed, removing exposed portions of the first copper plated layer, forming the wire bonding pads and the solder ball pads, removing the second resist, removing exposed portions of the first copper plated layer, and coating a solder resist over all surfaces of the resultant structure, and removing portions of the solder resist respectively covering the wire bonding pads and the solder ball pads.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

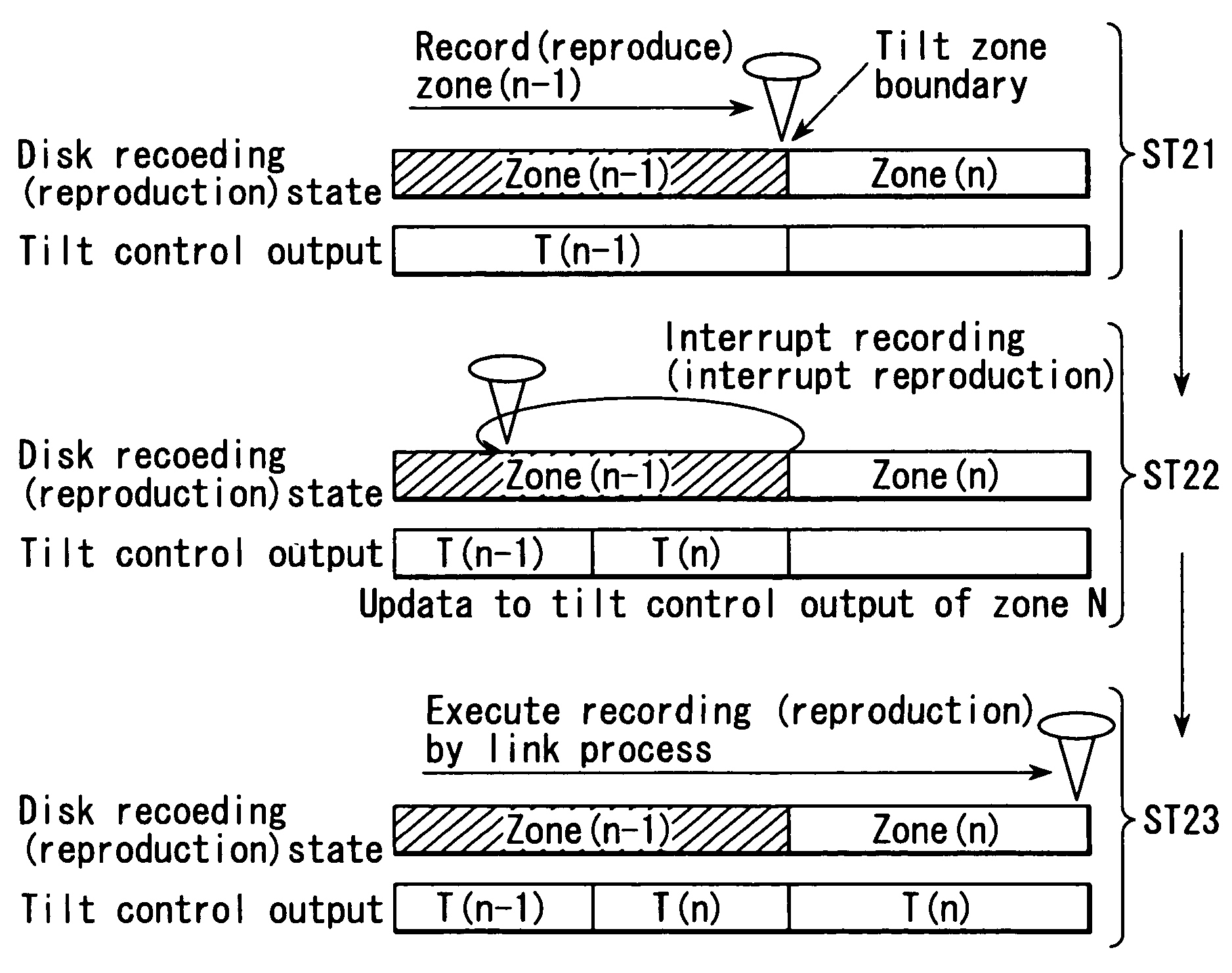

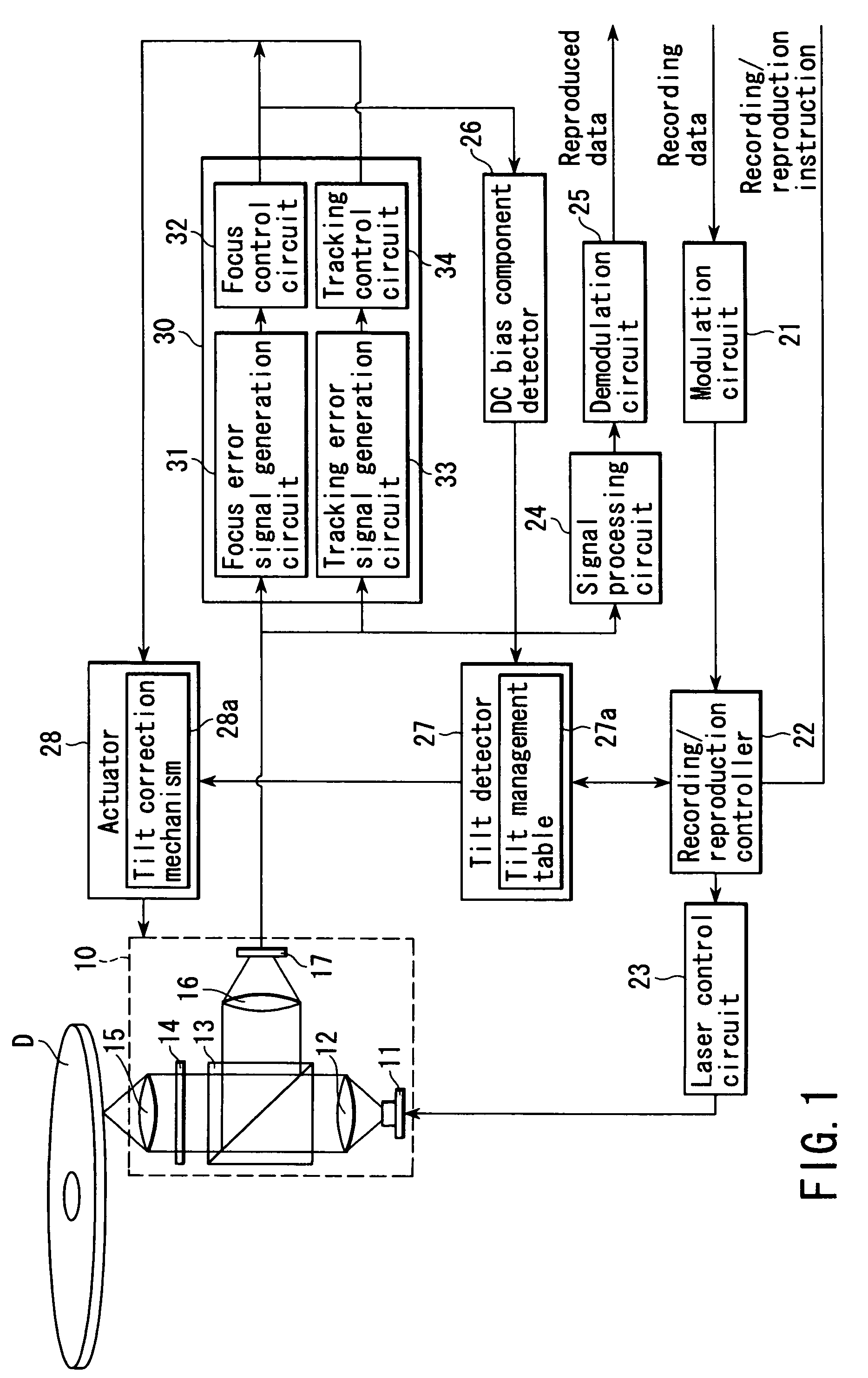

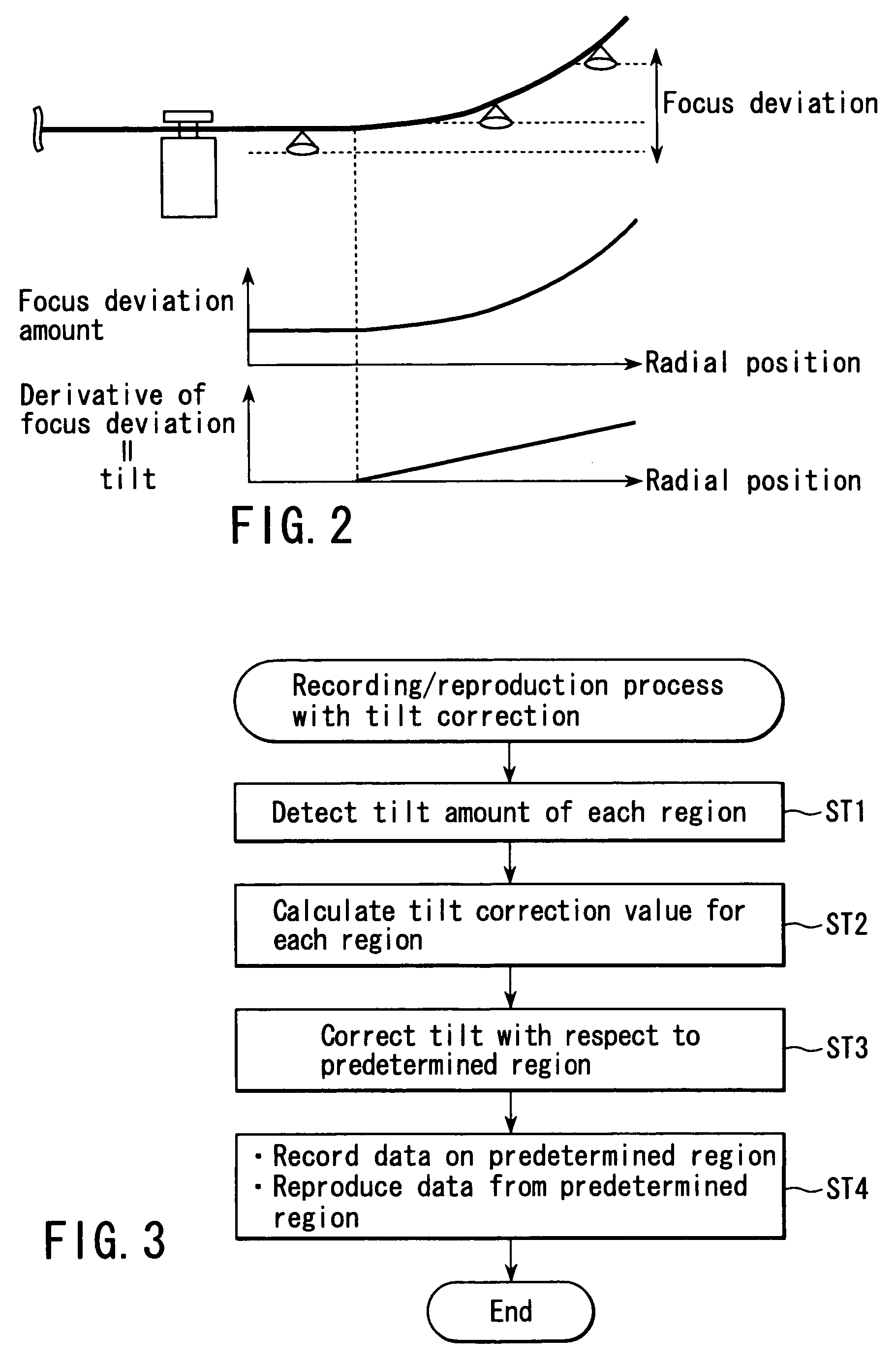

Disk apparatus, data recording method, and data reproduction method for continuous data processing

InactiveUS7218588B2Increase linear densityShorten the trackCombination recordingRecord information storageOptical axisControl signal

A data recording method according to one aspect of this invention comprises specifying a plurality of regions with different radial positions on a disk, and detecting the tilt amounts of the respective regions with respect to the optical axis of a light beam on the basis of a focus control signal used to just-focus the light beam on a recording surface of the disk, calculating tilt correction amounts for the respective regions in accordance with the tilt amounts of the respective regions, correcting a tilt of the optical axis with respect to a predetermined region on the basis of the tilt correction amount corresponding to the predetermined region, and recording data on the predetermined region while the tilt of the optical axis with respect to the predetermined region is corrected.

Owner:KK TOSHIBA

Tilted structures to reduce reflection in laser-assisted TAMR

ActiveUS8923098B2Eliminate the effects ofStable powerArm with optical waveguideRecord information storageOptical radiationMagnetic anisotropy

A TAMR (Thermal Assisted Magnetic Recording) write head uses the energy of optical-laser excited surface plasmons in a plasmon generator to locally heat a magnetic recording medium and reduce its coercivity and magnetic anisotropy. The optical radiation is transmitted to the plasmon generator by means of a waveguide, whose optical axis (centerline) is tilted relative to either or both the backside surface normal and ABS surface normal in order to eliminate back reflections of the optical radiation that can adversely affect the properties and performance of the laser. Variations of the disclosure include tilting the plasmon generator, the waveguide and the laser diode.

Owner:HEADWAY TECH INC

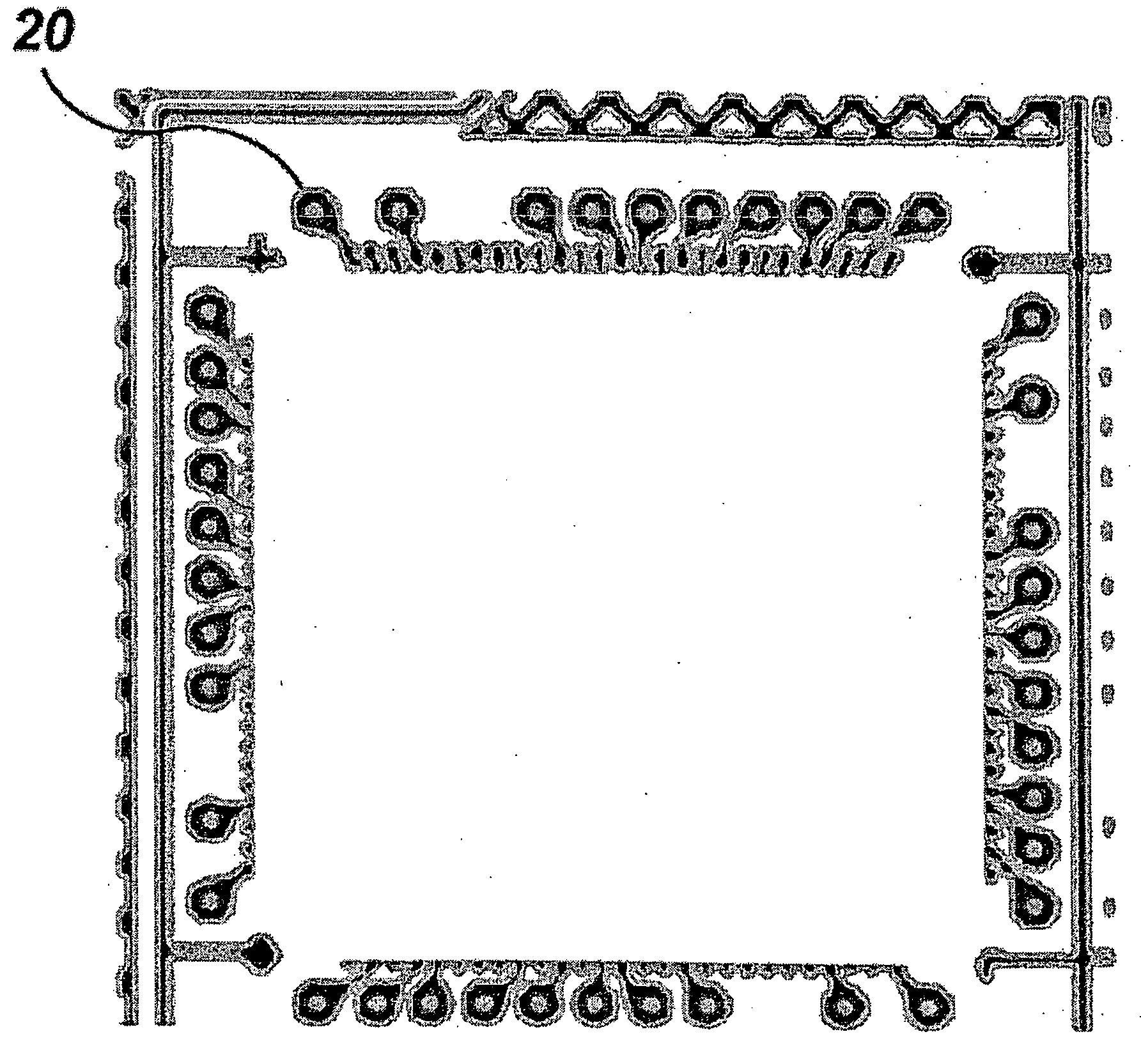

Electro-optical device and electronic apparatus

ActiveUS7567330B2Improve insulation performanceIncrease linear densityPrinted circuit aspectsSolid-state devicesEngineeringElectron

An electro-optical device includes a substrate having a display region; and an extending region extending from the display region. The extending region is provided with wiring lines, and at least some wiring lines, which are disposed to be adjacent to each other, are correspondingly disposed in a plurality of different layers.

Owner:BOE TECH GRP CO LTD

Package substrate manufactured using electrolytic leadless plating process, and method for manufacturing the same

InactiveUS20050194696A1Increase linear densitySuppress noiseSemiconductor/solid-state device detailsSolid-state devicesResistSolder ball

A package substrate of, for example, a BGA type or a CSP type, manufactured by carrying out an electrolytic Au plating process without using any plating lead line for formation of bond fingers and solder ball pads, and a method for manufacturing the package substrate. The method includes the steps of laminating first dry films over upper and lower surfaces of a base substrate having via holes while being formed at its upper and lower surfaces with copper foils, and patterning the first dry films to expose predetermined surface portions of the base substrate, removing portions of the copper foils not covered by the first dry films to form circuits, stripping the first dry films, and forming a plated layer over the base substrate, laminating second dry films over the plated surfaces of the base substrate, and patterning the second dry films to expose portions of the plated surfaces of the base substrate corresponding to regions where Au is to be plated, removing the plated layer from the exposed surface portions of the base substrate corresponding to the Au plating regions, plating Au on the exposed surface portions of the base substrate, stripping the second dry films, and removing the remaining plated layer to expose the circuits, and coating a solder resist on the exposed circuits while exposing predetermined portions of the circuits.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Optical disk recorder for writing data with variable density

InactiveUS20050232105A1High-density recordingLow-density high-qualityRecord information storageDigital recordingConstant linear velocityData recording

An optical disk recording apparatus operates on an optical disk having circular tracks which are provisionally written with an index signal used for securing a constant linear velocity of the optical disk from an innermost circular track to an outermost circular track, and records data along the circular tracks at different linear densities on different annular zones of the optical disk. In the apparatus, a disk drive section rotates the optical disk while synchronizing the index signal successively read from the rotated optical disk with a predetermined reference clock signal to thereby maintain the constant linear velocity of the circular tracks. A clock generating section multiples or divides the reference clock signal by different rates to generate different writing clock signals in correspondence to the different annular zones of the optical disk. A data recording section operates in synchronization to the different writing clock signals for recording data along the circular tracks at the different linear densities on the different annular zones.

Owner:YAMAHA CORP

Package substrate manufactured using electrolytic leadless plating process, and method for manufacturing the same

InactiveUS7208349B2Increase linear densitySuppress noiseSemiconductor/solid-state device detailsSolid-state devicesResistCopper plating

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

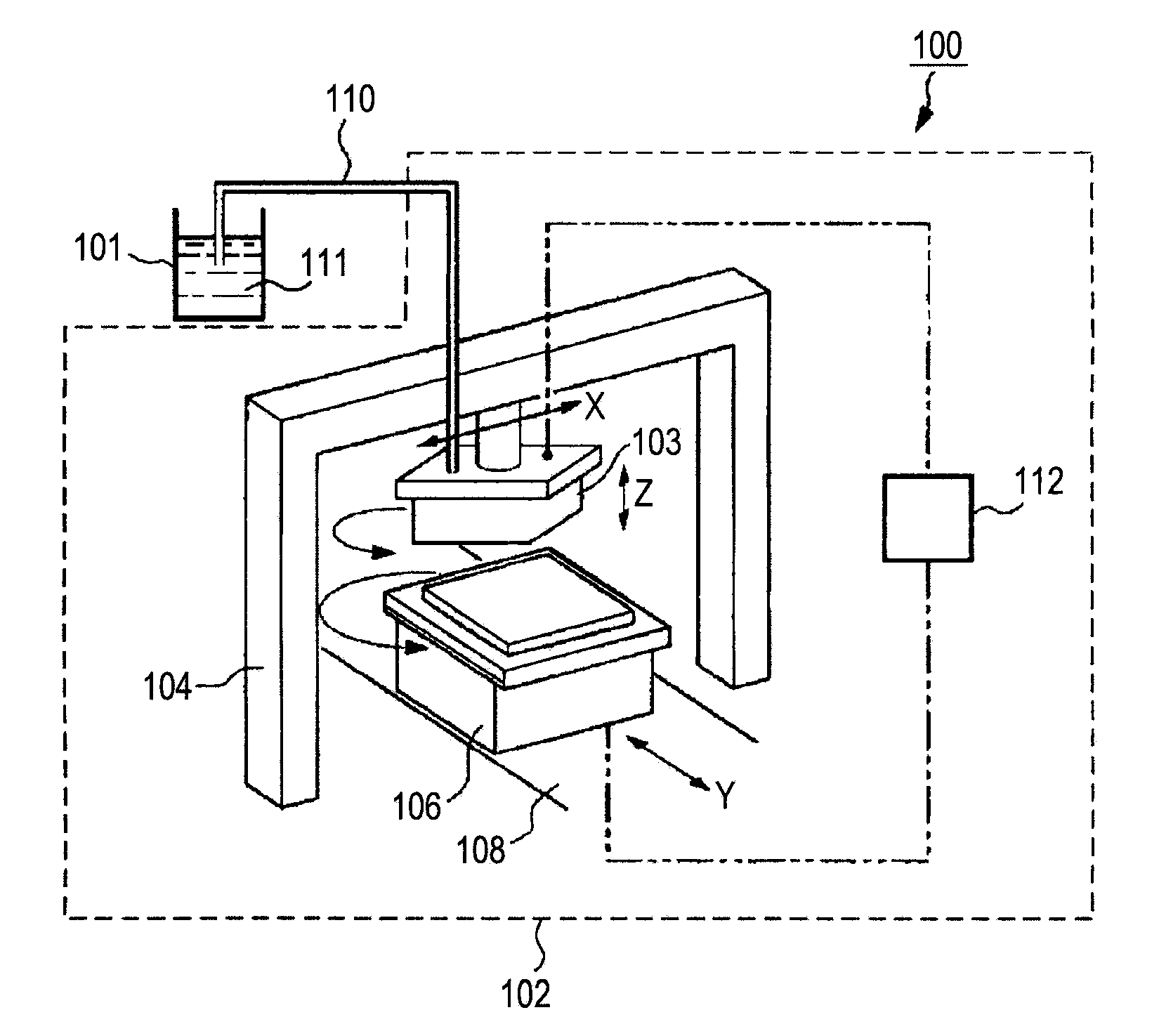

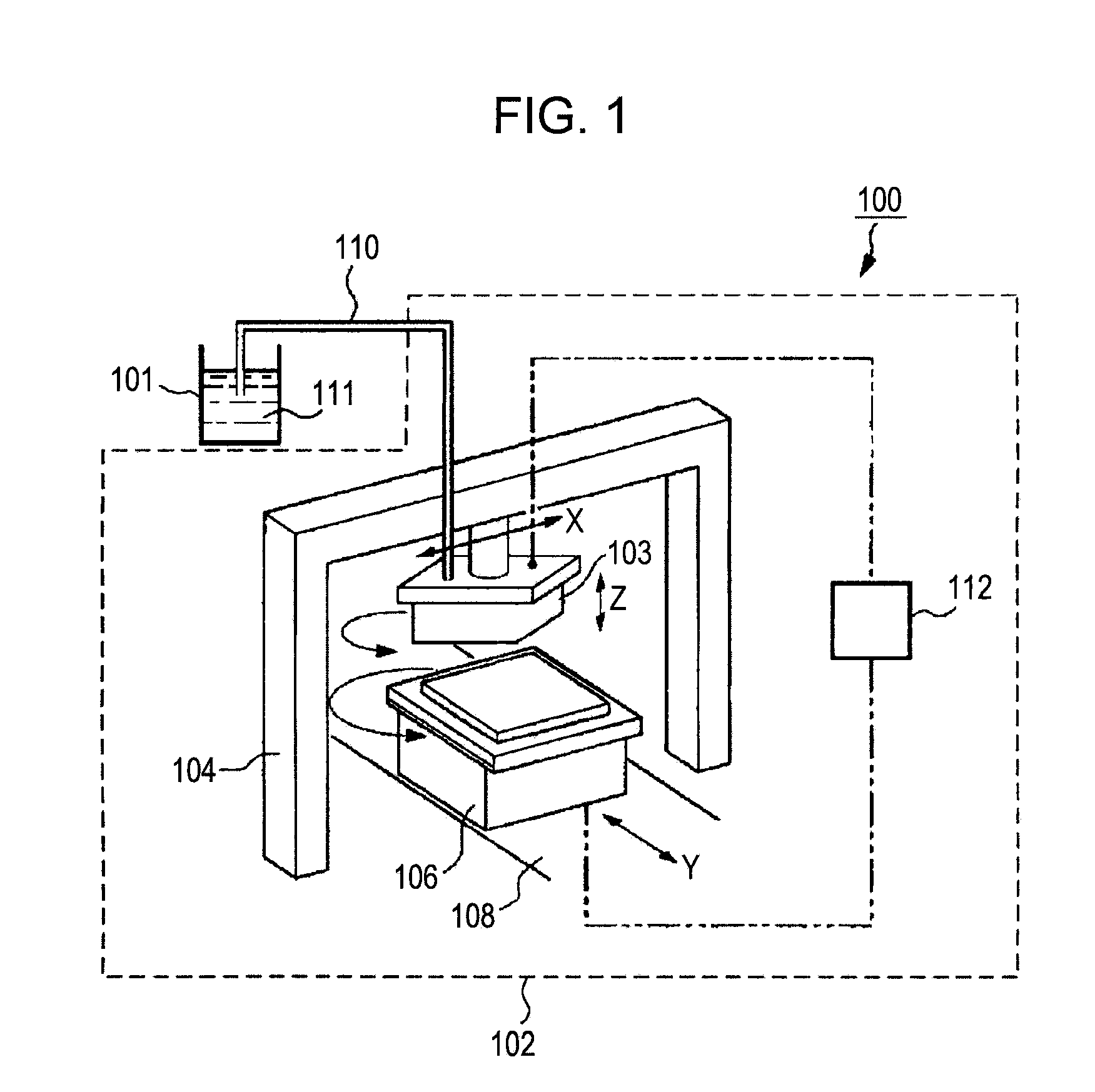

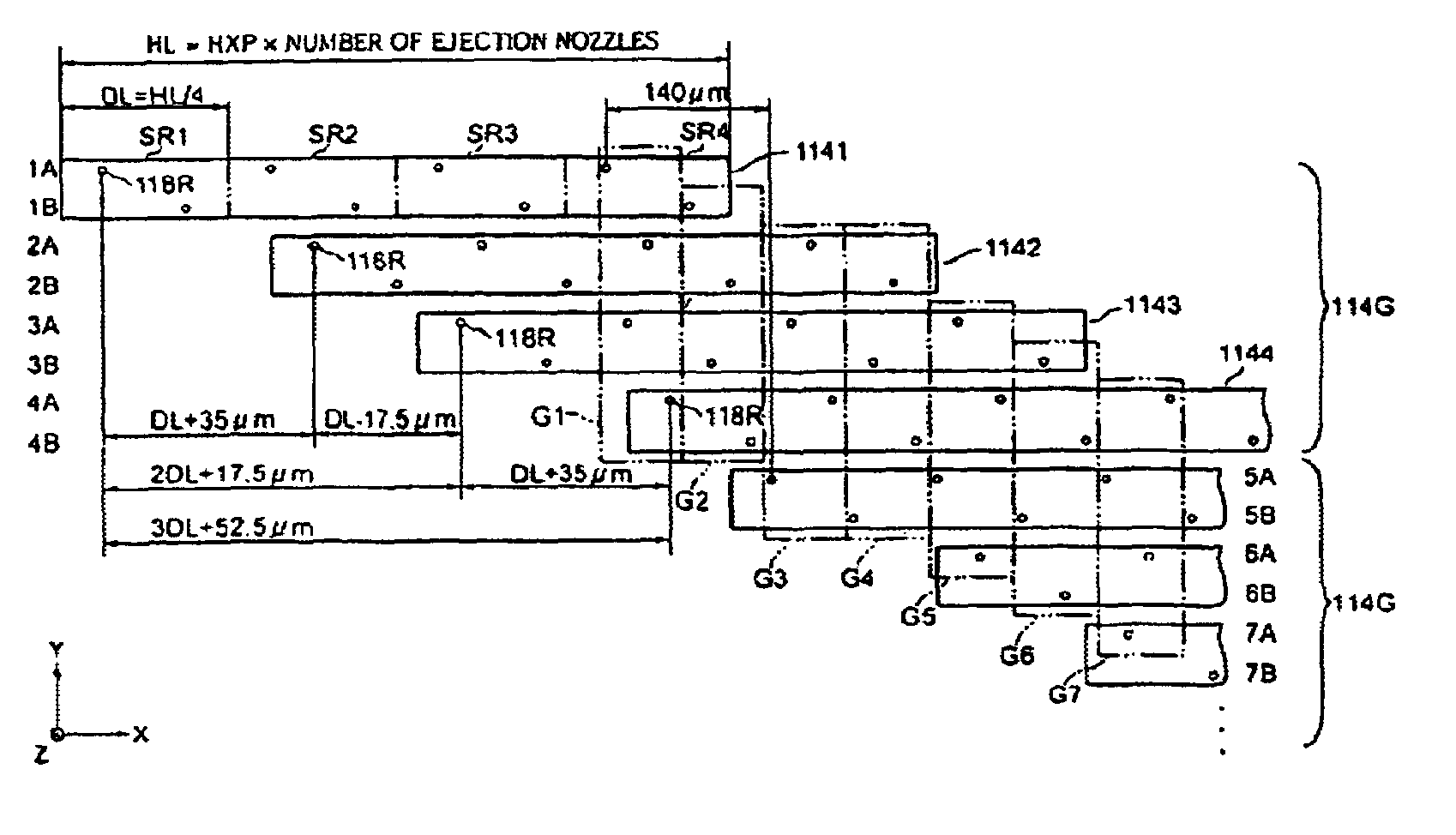

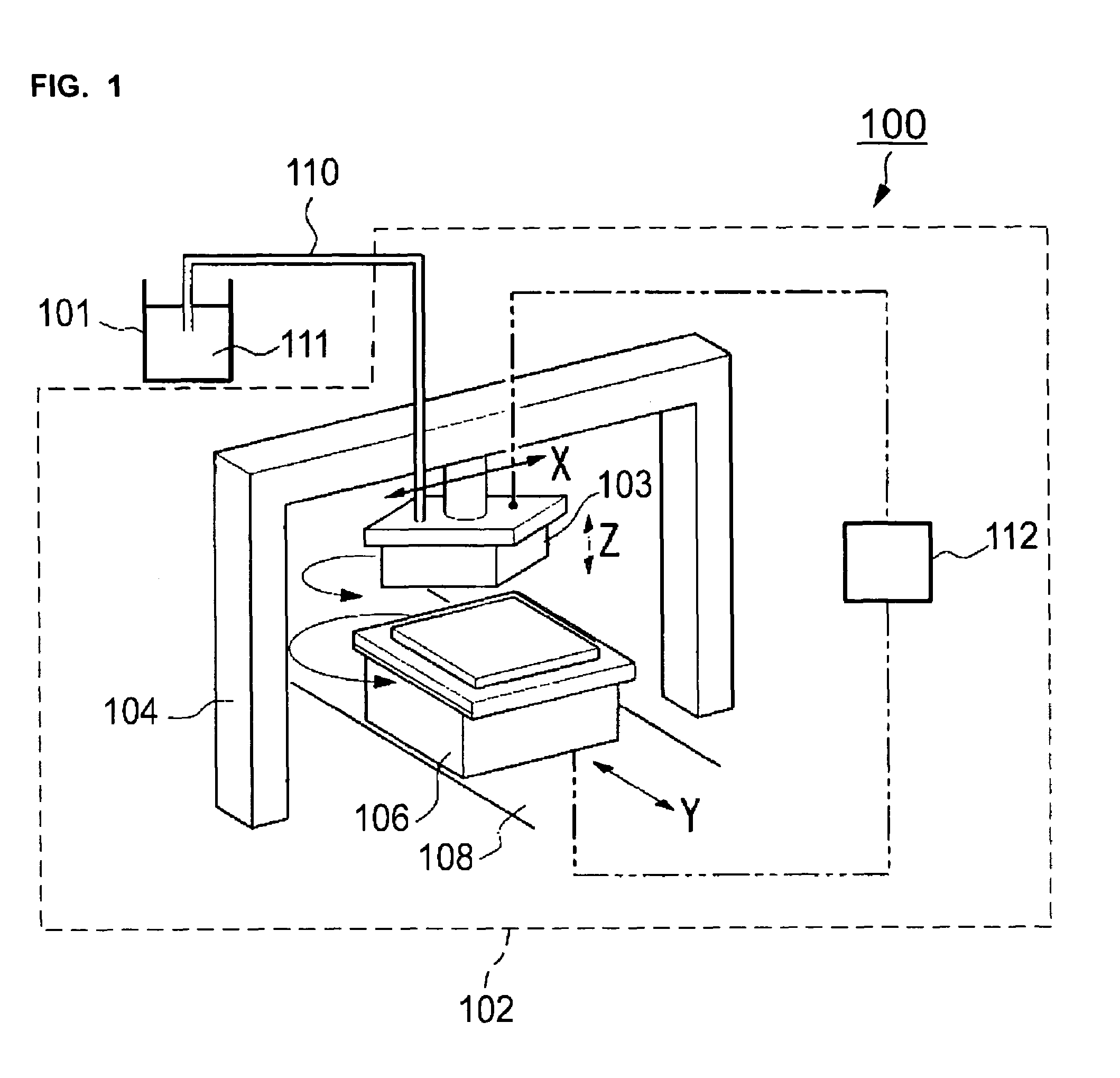

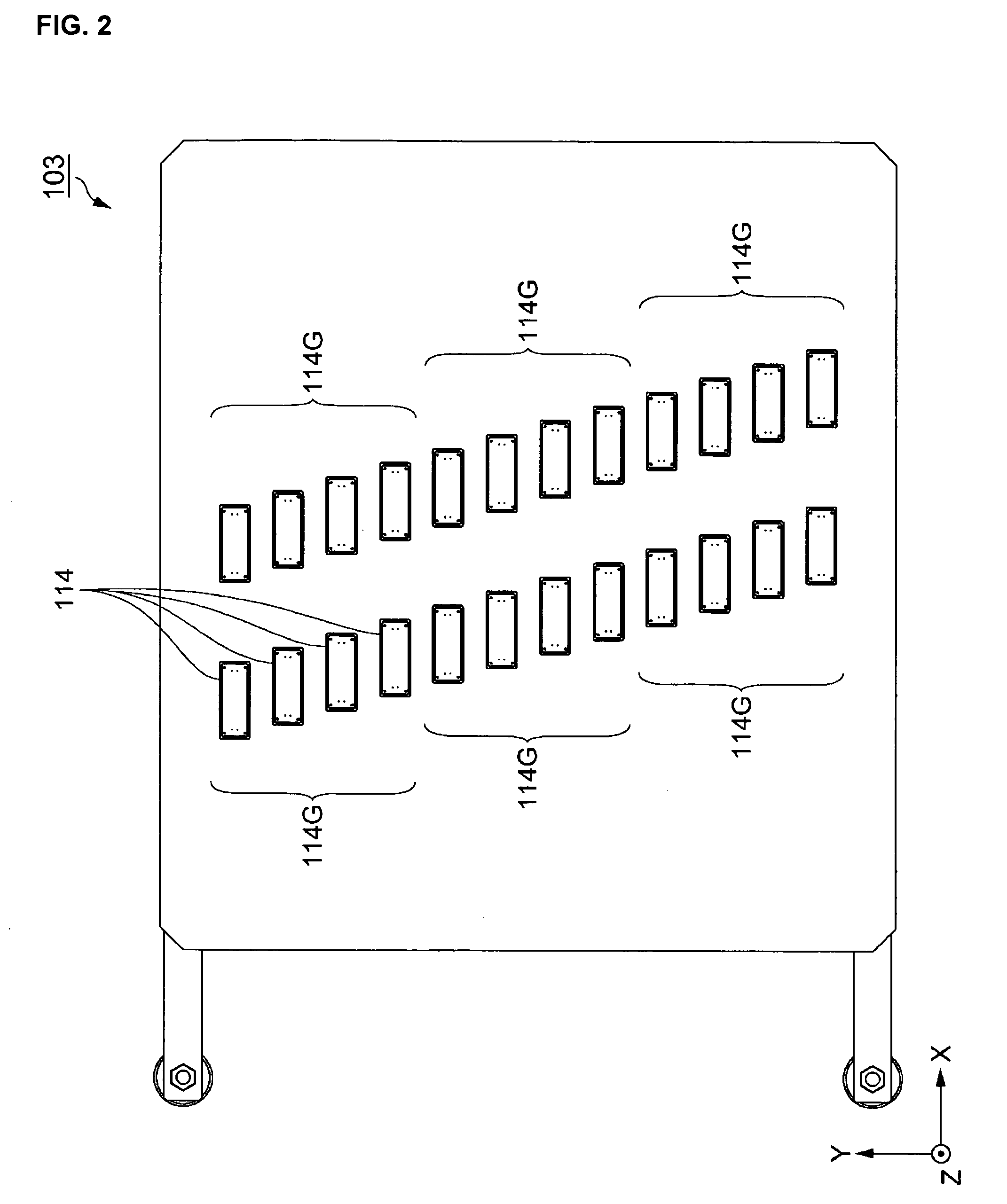

Droplet-discharging apparatus, electrooptic device, electronic apparatus, and method for electrooptic device

InactiveUS20100283810A1Easy to adjustImprove accuracyInking apparatusLiquid surface applicatorsEngineeringPosition control

A droplet-discharging apparatus for discharging a droplet onto a base through the nozzle of a head, the apparatus including: a platform retaining the base; a plurality of transportation units, each including a head group having at least one head with a nozzle line and each being moved in the sub-scanning direction on an axis or on a plurality of axes disposed parallel to each other; and a position-controlling unit for adjusting relative position of the adjacent head groups arranged in the main scanning direction or in the sub-scanning direction to adjust the nozzle pitch by independently driving the plurality of transportation units, wherein the droplet is discharged onto predetermined portions on the base from the head group while the transportation units are relatively moved for the platform in the main scanning direction.

Owner:SEIKO EPSON CORP

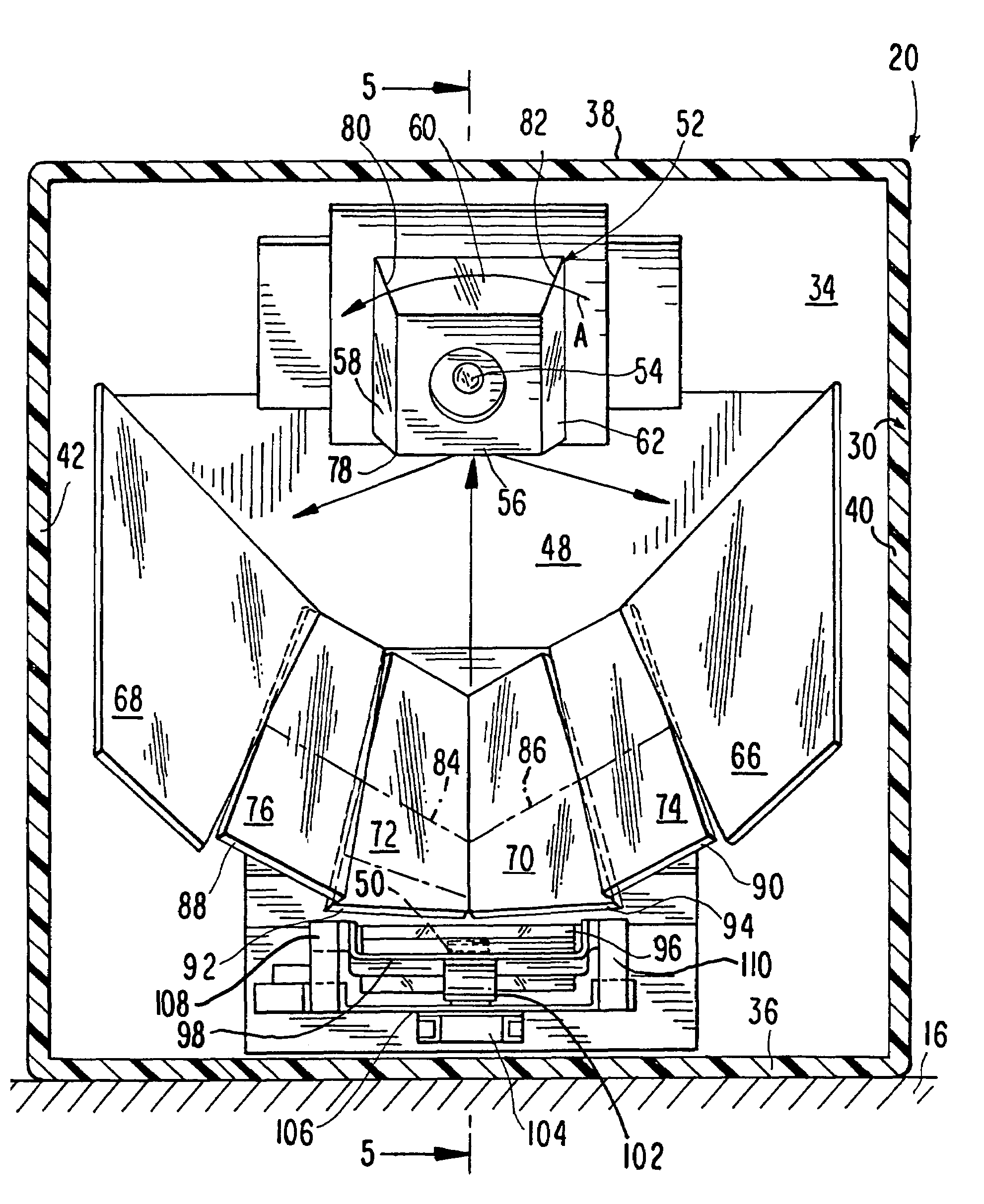

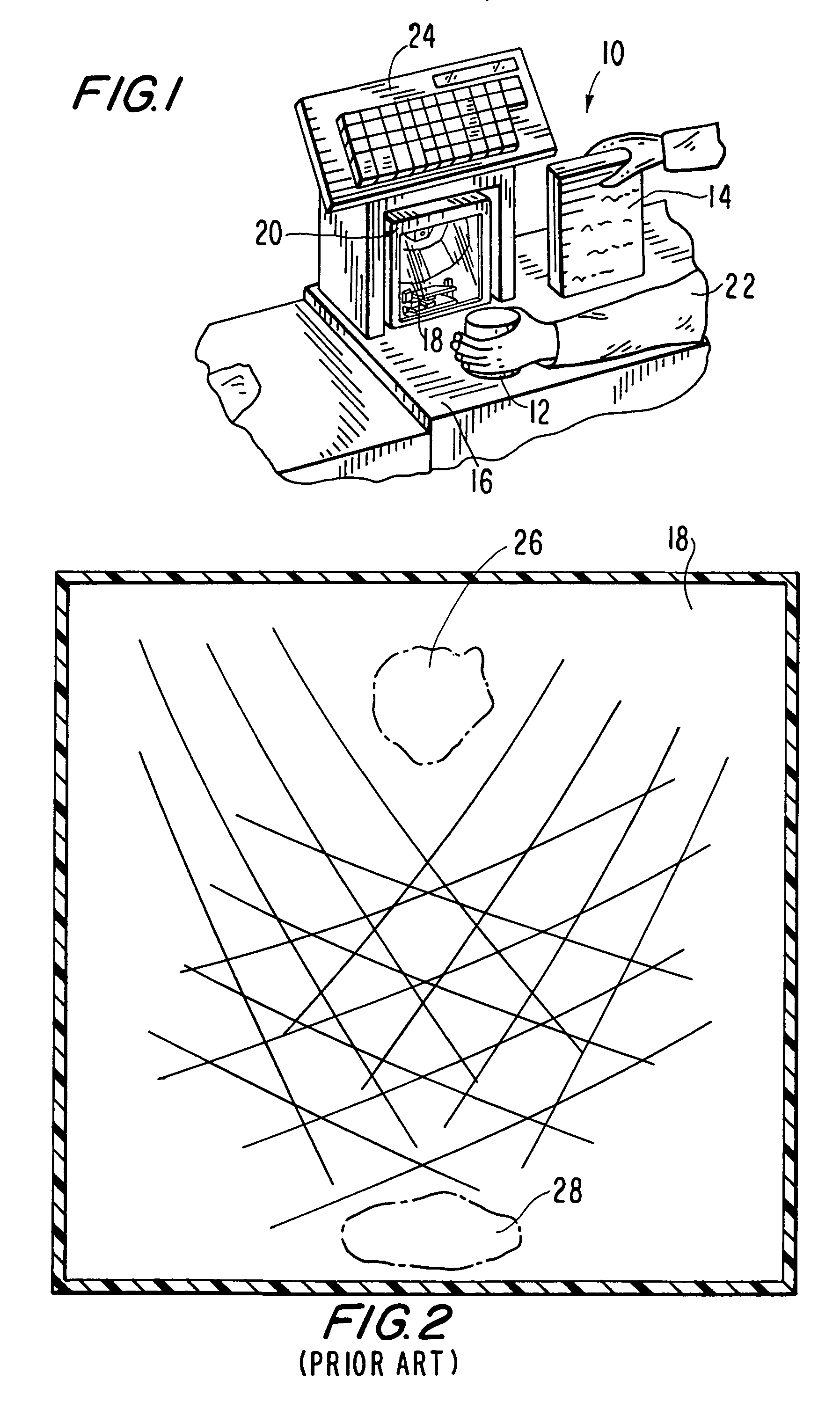

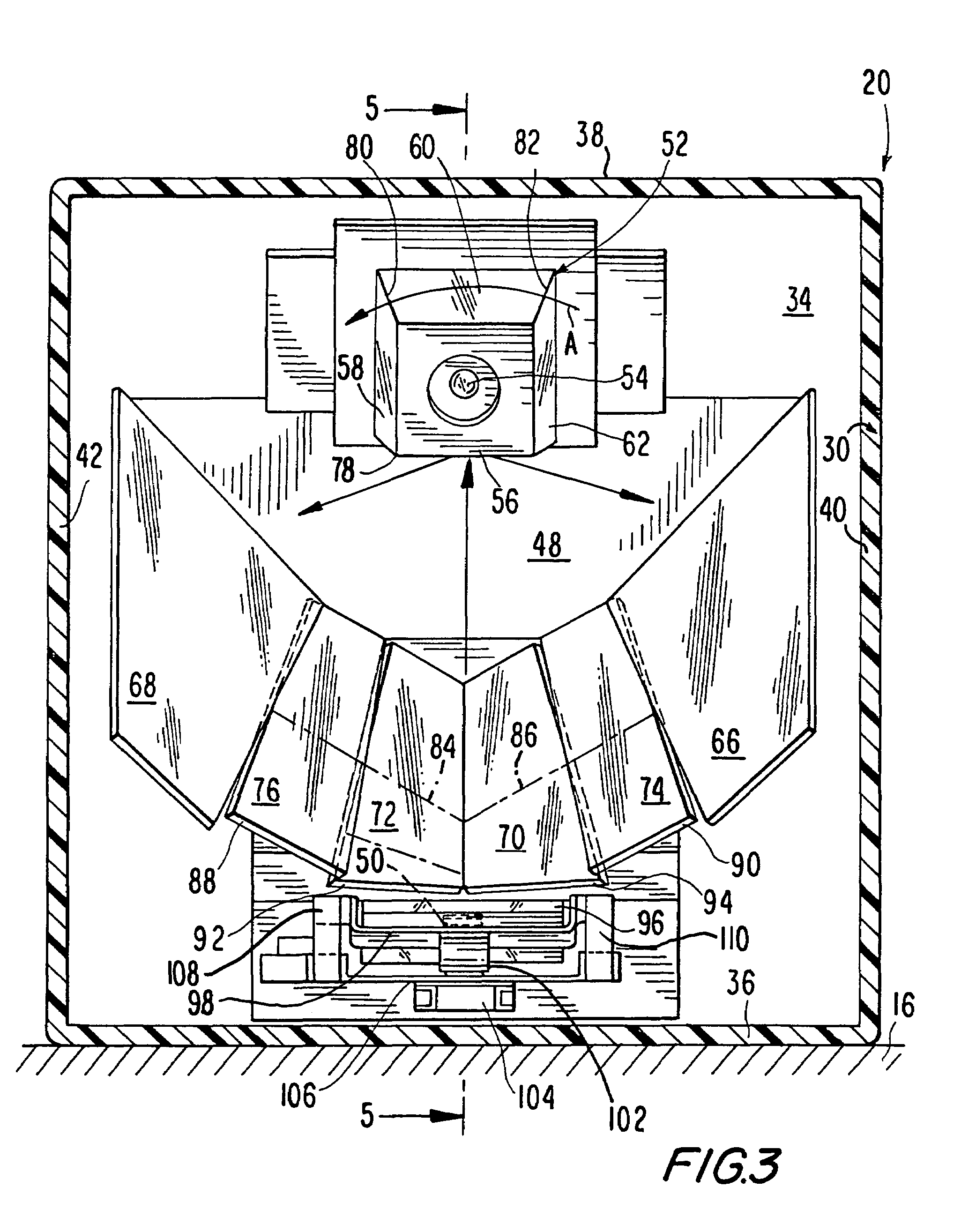

Reader for electro-optically reading indicia through vertical window at which full coverage, omni-directional scan pattern is generated

InactiveUS7007844B2Raise the possibilityIncrease linear densityCharacter and pattern recognitionCash registersProduction ratePattern recognition

A vertical slot scanner generates a full coverage scan pattern for reading symbols presented or moved past a vertical window. Scan lines are generated in upper and lower central regions of the window to improve scanner productivity.

Owner:SYMBOL TECH LLC

Ejection device, manufacturing device of color filter substrate, manufacturing device of electro-luminescent display device, manufacturing device of plasma display device, and ejection method

ActiveUS6948795B2Reduce nozzle pitchIncrease linear densityVacuum evaporation coatingSputtering coatingDisplay deviceEngineering

Owner:KATEEVA

Digital signal processing method, data recording and reproducing apparatus, and data recording medium that are resistant to burst errors

InactiveUS7154835B2Convenient lengthIncrease redundancyTelevision system detailsCode conversionDigital signal processingData recording

With two consecutive product-coded ECC blocks, EB1 and EB2, as a set, the rth row of first ECB block EB1 is followed by the rth row of second ECC block EB2 in such a way that the first row of first ECC block EB1 is followed by the first row of second ECB block EB2, which is followed by the second row of first ECC block ECB1, which is followed by the second row of second ECC block EB2, and so on, to interleave data on a row basis. That is, data of two ECC blocks, EB1 and EB2, is allocated alternately on a row basis. This allocation method allows an error to be distributed after reproduction even when a serious burst error extending 18 rows occurs in an ECC block.

Owner:JVC KENWOOD CORP A CORP OF JAPAN

Single-spindle controllable condensed spinning device and condensing method

InactiveCN110129929ASmall linear densityReduce the interaction forceDrafting machinesYarnMotor drive

The invention provides a single-spindle controllable condensed spinning device and a condensing method. A hollow structure large roller is adopted as a front roller, a circular closed hollow air suction insert is arranged between the hollow structure of the roller and a roller shaft, the air suction insert is embedded in an inner wall slide of the hollow structure of the roller by a roller drivenby a motor, an air suction groove is formed in the circular surface, adjacent to the inner wall of the hollow structure of the roller, of the air suction insert, the left side surface or the right side surface of the air suction insert is connected with a branch pipe through a closed bearing in a communication manner, and the branch pipes of two adjacent spindles are connected with a middle pipe in a communication manner. During use, the motor drives the air suction insert to rotate around the inner wall of the hollow structure of the roller, so that relative rotation between the air suction groove and the roller is realized, the time when the air suction groove is located right below the inner wall of the hollow structure of the roller and the relative position are controllable, controllable condensing of single spindle is realized, and random controllability of style characteristics of yarn surfaces under different condensing actions is realized.

Owner:合肥经新科技有限公司

Silver halide emulsion and silver halide photographic material

InactiveUS20050191587A1Enhancement of dislocation line densitySuperior performance in latent image stabilityPhotoprinting processesMulticolor photographic processingIodideDislocation

A silver halide emulsion is disclose, containing silver halide grains, in which at least 50% by number of the silver halide grains is accounted for by (1) cubic grains (2) having a chloride content of not less than 90 mol %, (3) an iodide content of from 0 to 2 mol % and (4) a bromide content of from 0.1 to 10 mol %, and (5) containing dislocation lines in the peripheral region and (6) having rounded corners.

Owner:KONICA MINOLTA PHOTO IMAGING

Production method of colored polyester yarn

The invention provides a production method of a colored polyester yarn. The production method adopting three raw yarns including white polyester pre-oriented yarns, cation fuel dyeable polyester and black polyester pre-oriented yarns as materials comprises the following steps of: enabling the materials to pass through a yarn guide, a first roller, a first hot box, a twister, a second roller, a mesh spray nozzle, a third roller and an oil applying roller in sequence; and stretching, rolling and forming the materials, wherein the weight ratio of the white polyester pre-oriented yarns to the cation fuel dyeable polyester to the black polyester pre-oriented yarns is 2:2:3. The production method of the colored polyester yarn provided by the invention has the following technical effects that the produced colored polyester yarn is good in performance, stable in quality, provided with three mixed colors, high in product linear density and strength and good in rolling performance and stability, so that the fabric is rich in elasticity and good in hand feeling.

Owner:HAIAN HENGYE SILK

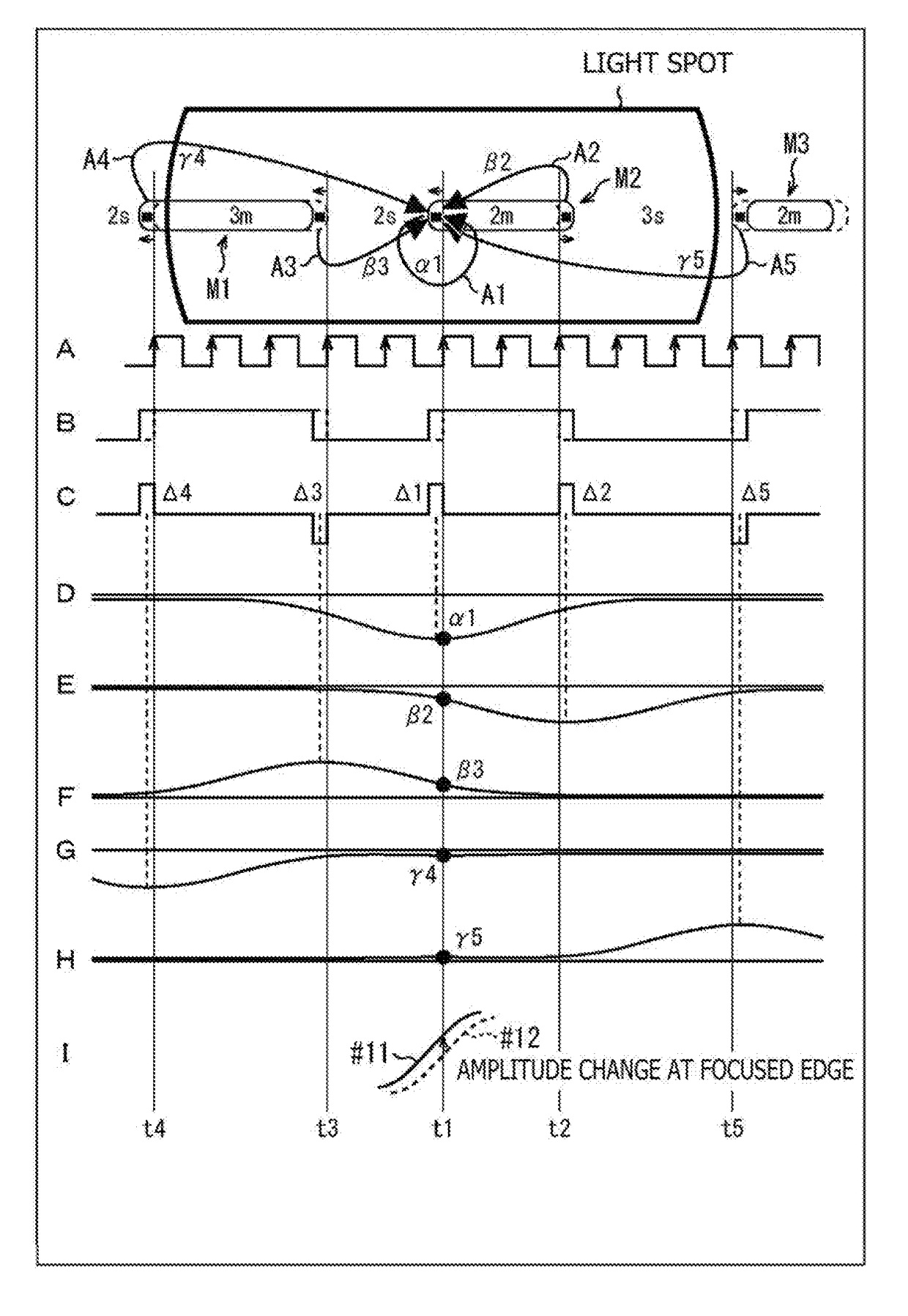

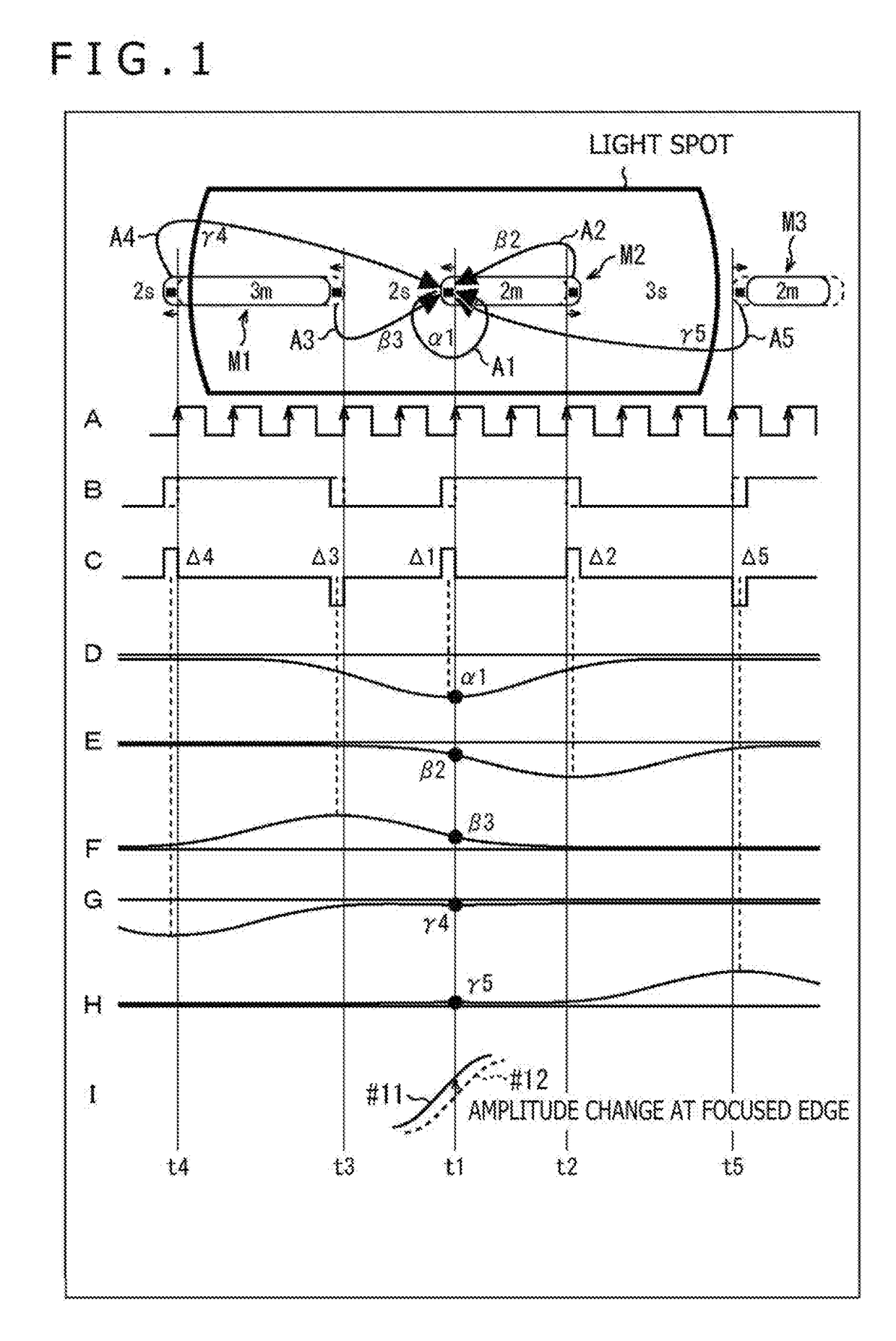

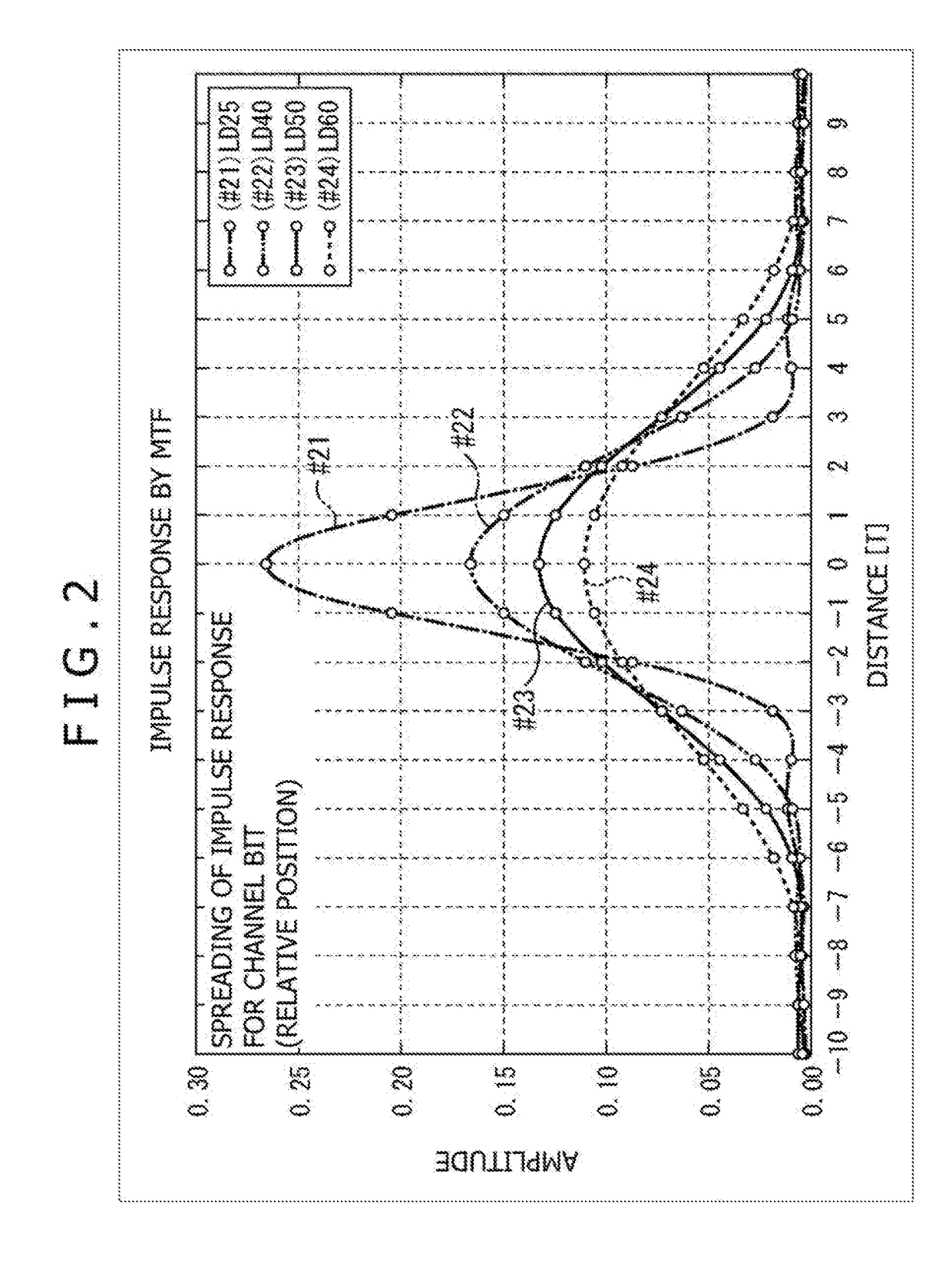

Recording adjustment device, recording adjustment method, and program

ActiveUS20180330752A1Increase linear densityRecording strategiesRecord information storageComputer hardwareLinear density

There is provided a recording adjustment device, a recording adjustment method, and a program of which enables recording compensation for an optical disc for a high-linear density to be realized. The recording adjustment device according to an embodiment of the present technique executes filter processing on the basis of a regenerative signal obtained by reproducing data recorded in a recording medium, and a recording pattern of marks and spaces of the data, identifies an impulse response of a system, calculates a difference in amplitude between an output from the filter processing after the identification of the impulse response and the regenerative signal every edge type, and detects a slope of a step response in the vicinity of an edge position.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com