Patents

Literature

68results about How to "Small linear density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antibacterial blended regenerated cotton yarn and preparation method thereof

InactiveCN104911727AGood antibacterial effectHigh strengthFibre treatmentMonocomponent polypropylene artificial filamentYarnAgricultural engineering

The present invention discloses an antibacterial blended regenerated cotton yarn which is characterized by being prepared by the following raw materials by weight: 36-40 parts of waste cotton fabric, 15-17 parts of cotton yarn leftover, 5-8 parts of bamboo fiber, 2-3 parts of graphene oxide, 0.8-1 part of epsilon-polylysine, 9-10 parts of nano-titanium dioxide, 6-8 parts of silica sol, 2-4 parts of waterborne polyurethane, 39-44 parts of polypropylene, 3-5 parts of nano-zinc oxide, 12-14 parts of liquid paraffin, 1.5-2 parts of carboxymethyl cellulose, 1-2 parts of glyceryl stearate and proper amount of water; by mixing of regenerated cotton yarn and modified polypropylene fiber, the characteristics of various fibers can be neutralized, the disadvantages of poor sunscreen property of the cotton yarn and the polypropylene fiber can be made up, the antibacterial property can be enhanced, the antibacterial blended regenerated cotton yarn has high strength, good elasticity, wear resistance, corrosion resistance and thermal resistance, improves product quality, and saves cost.

Owner:SHUNTIAN SPINNING LIMITED

Strength-improvable blended regenerated cotton yarn and preparation method thereof

InactiveCN104911909AHigh strengthGood sun protectionYarnMonocomponent polyolefin artificial filamentYarnStaining

The present invention discloses a strength-improvable blended regenerated cotton yarn which is characterized being prepared from the following raw material by weight: 30-33 parts of waste cotton fabrics, 15-17 parts of cotton yarn leftover material, 2-3 parts of glycerin, 8-10 parts of copper ammonia fibre, 3-4 parts of starch, 3-5 parts of nano-silica, 39-44 parts of polypropylene, 3-5 parts of nano-zinc oxide, 12-14 parts of liquid paraffin, 9-10 parts of nano-titanium dioxide, 1.5-parts of carboxymethyl cellulose, 1-2 parts of glyceryl stearate, and proper amount of water; the starch, the nano-silica and other components are used for prepare processing slurry to process waste cotton fabric renewable fiber, the strength and sunscreen resistance of the fiber are improved, then the waste cotton fabric renewable fiber is mixed with the copper ammonia fiber, and strength and hand feel of the fiber are improved by cotton carding; the strength-improvable blended regenerated cotton yarn is prepared by addition of the nano-titanium dioxide and the nano-zinc oxide-modified polypropylene staple fiber for blending, the strength of the cotton fiber is improved, and the strength-improvable blended regenerated cotton yarn has the characteristics of easy staining and grinding resistance.

Owner:SHUNTIAN SPINNING LIMITED

Blending regeneration cotton yarn with antimould effect and manufacturing method thereof

InactiveCN104947260AGood flexibilityImprove sun protection effectYarnMonocomponent polyolefin artificial filamentYarnEngineering

The invention discloses blending regeneration cotton yarn with the antimould effect. The cotton yarn is characterized by being manufactured by, by weight, 40-43 parts of waste cotton fabrics, 10-12 parts of cotton yarn leftover materials, 5-7 parts of bamboo charcoal fibers, 1-2 of Guran glycine, 0.5-0.7 part of cetyl trimethyl ammonium bromide, 3-4 parts of hydroxypropyl starch, 4-6 parts of hydroxyl silicone oil emulsion, 39-44 parts of polypropylene, 3-5 parts of nano-zinc oxide, 12-14 parts of liquid paraffin, 9-10 parts of nano-titanium dioxide, 1.5-2 parts of carboxymethyl cellulose, 1-2 parts of glyceryl stearate, 0.4-0.6 part of cason and a proper amount of water. The cotton yarn is formed by blending two kinds of fiber, is high in strength, good in toughness and resistant to wear, and makes up the shortcoming of pure-cotton fiber; by means of respective modification, the sunscreen effect is improved, the anti-microbial and antimould effects are good, the storage time is long, the process can be controlled conveniently in an industrial mode, and the product quality is high.

Owner:SHUNTIAN SPINNING LIMITED

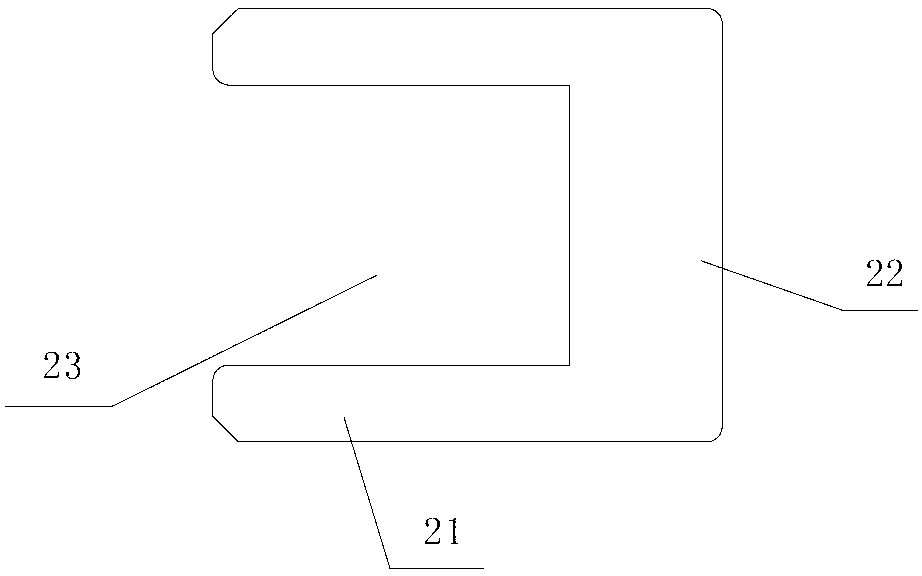

Solar cell module border and solar cell module

InactiveCN102479857AReduced weight and manufacturing costsSmall linear densityPhotovoltaicsPhotovoltaic energy generationLinear densityBackplane

The invention provides a solar cell module border and a solar cell module, wherein the solar cell module comprises a solar module, a U-shaped body and a sealant; the solar module comprises a transparent cover plate, a first sealing adhesive layer, a solar cell plate, a second sealing adhesive layer and a back plate, which are overlapped in sequence; at least one side edge of the solar module is clamped in the U-shaped body by two clamping parts arranged at the opening of the U-shaped body; and the sealant is arranged between the U-shaped body and the solar module. The solar cell module border provided by the invention has extremely low linear density, so that the weight and the manufacturing cost of the solar cell module border can be effectively reduced; furthermore, for the solar cell module, the combination of the solar cell border and the sealant provided by the embodiment of the invention can better prevent water vapor from penetrating in the solar cell module to cause the failure of the solar cell module.

Owner:BYD CO LTD

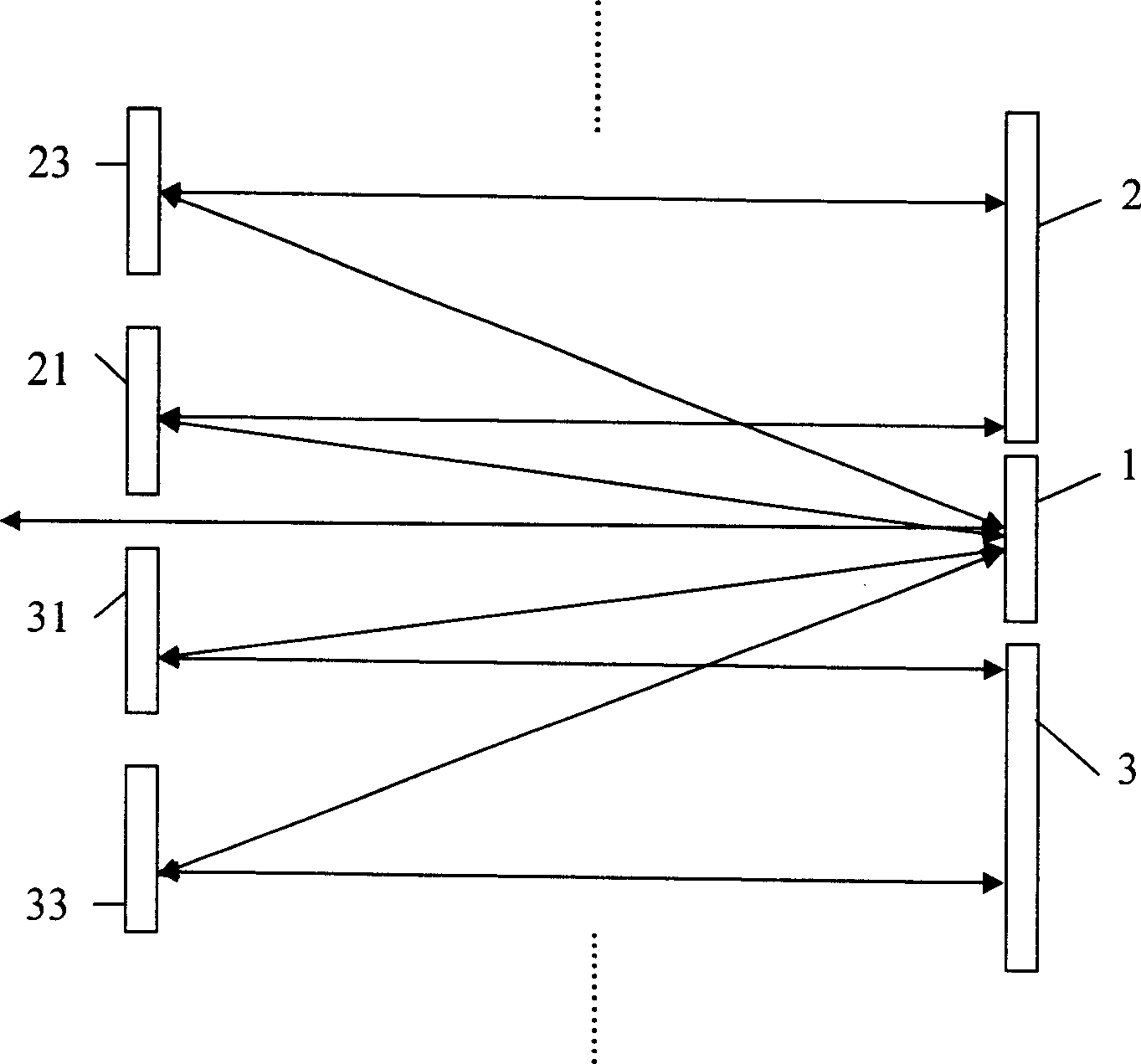

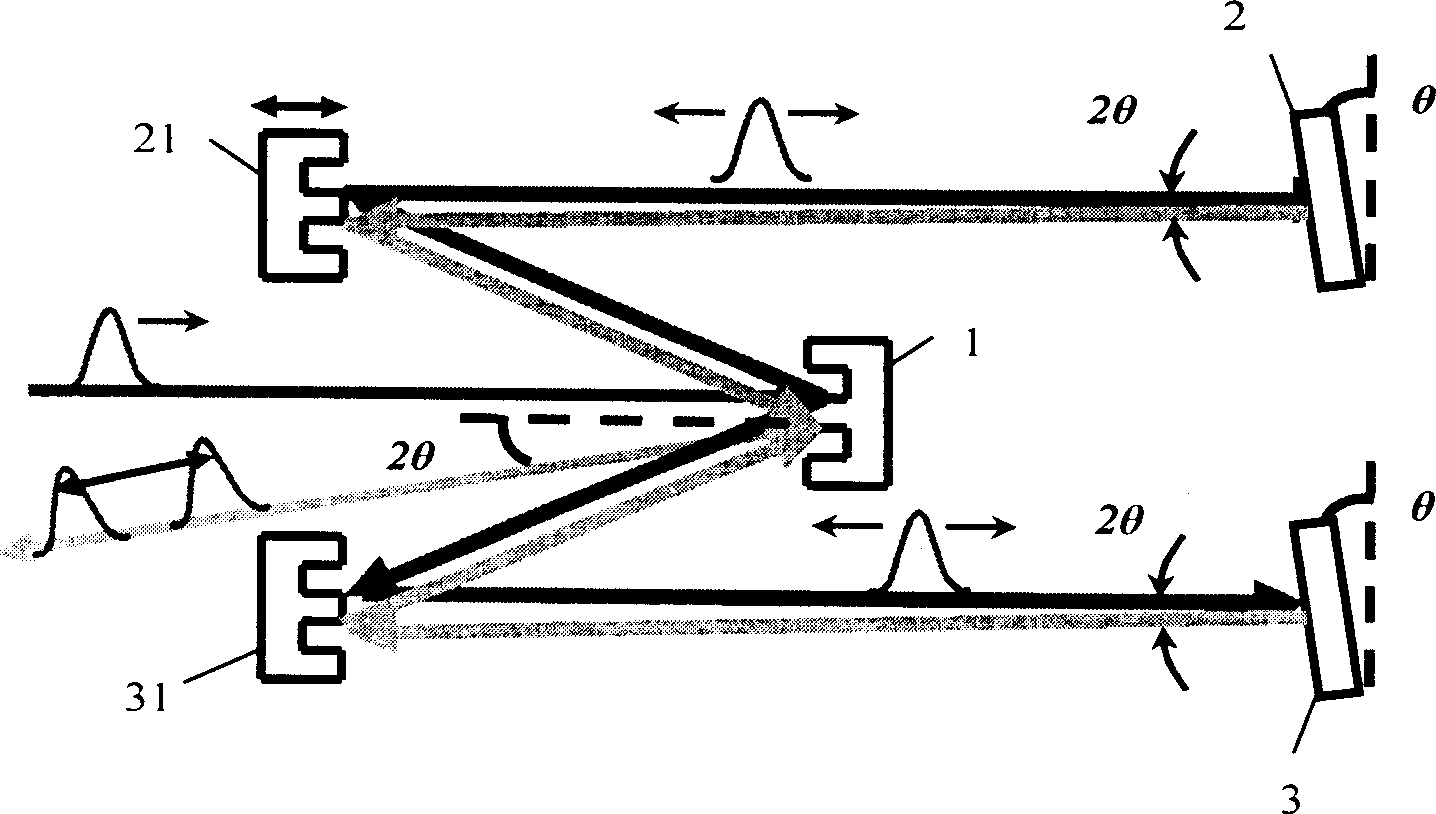

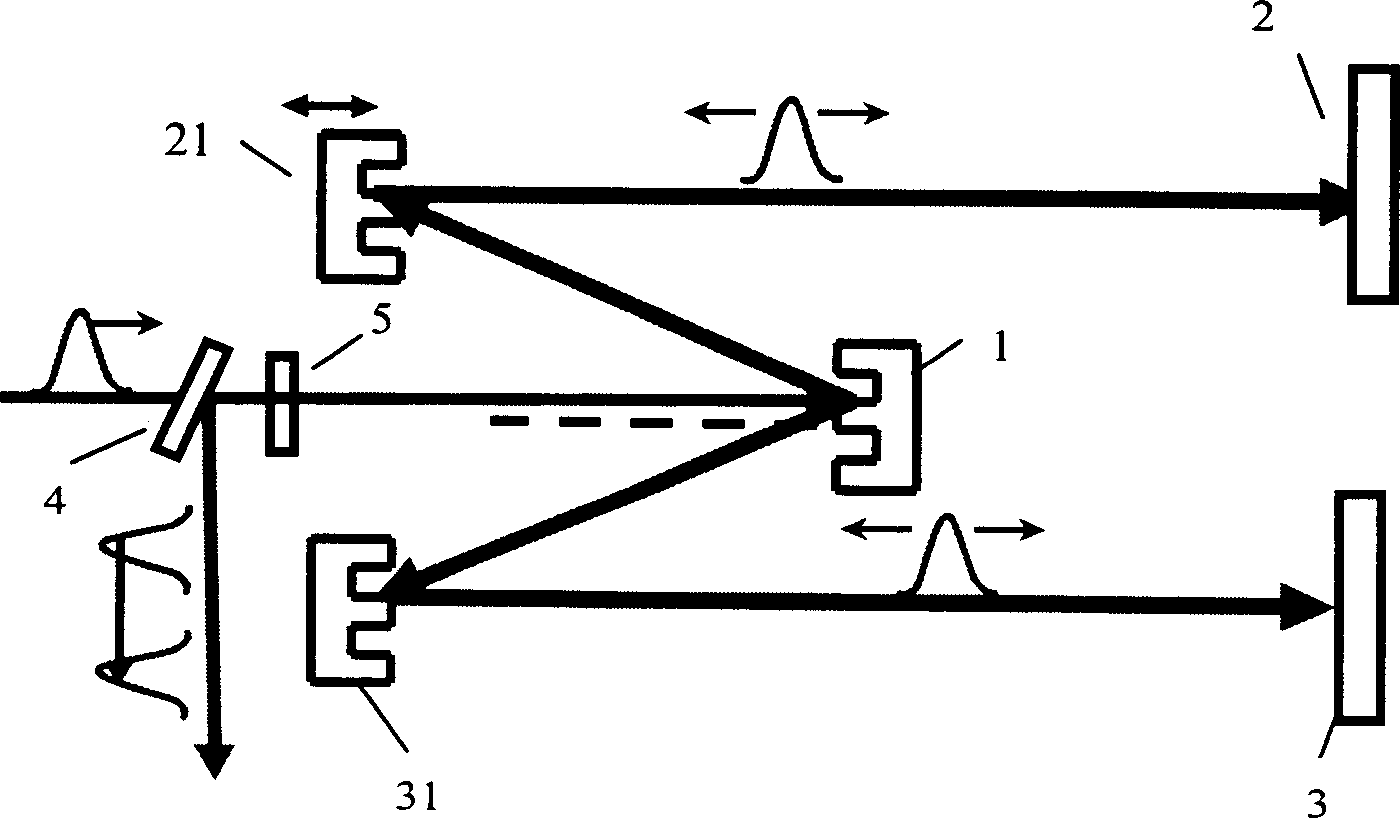

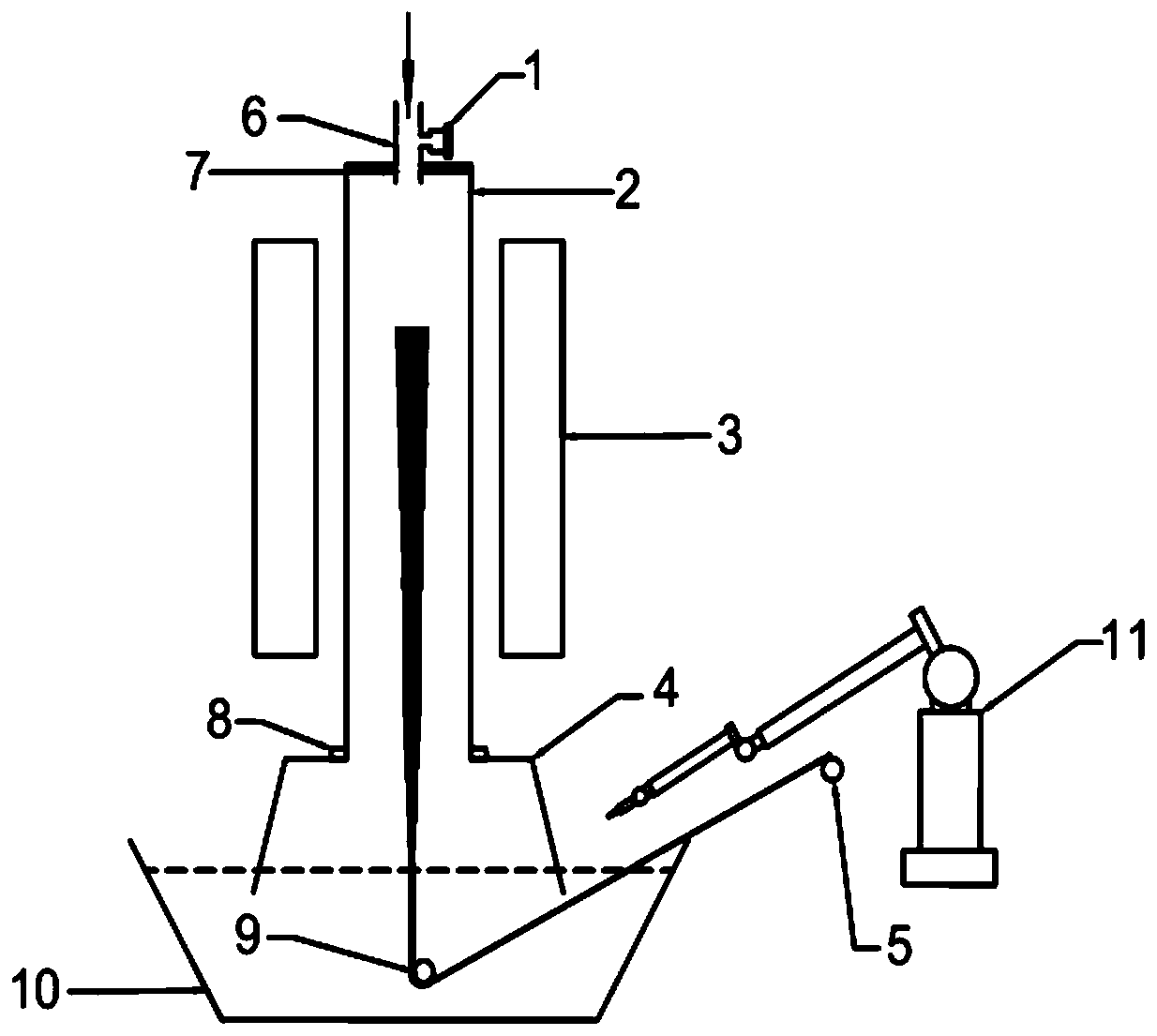

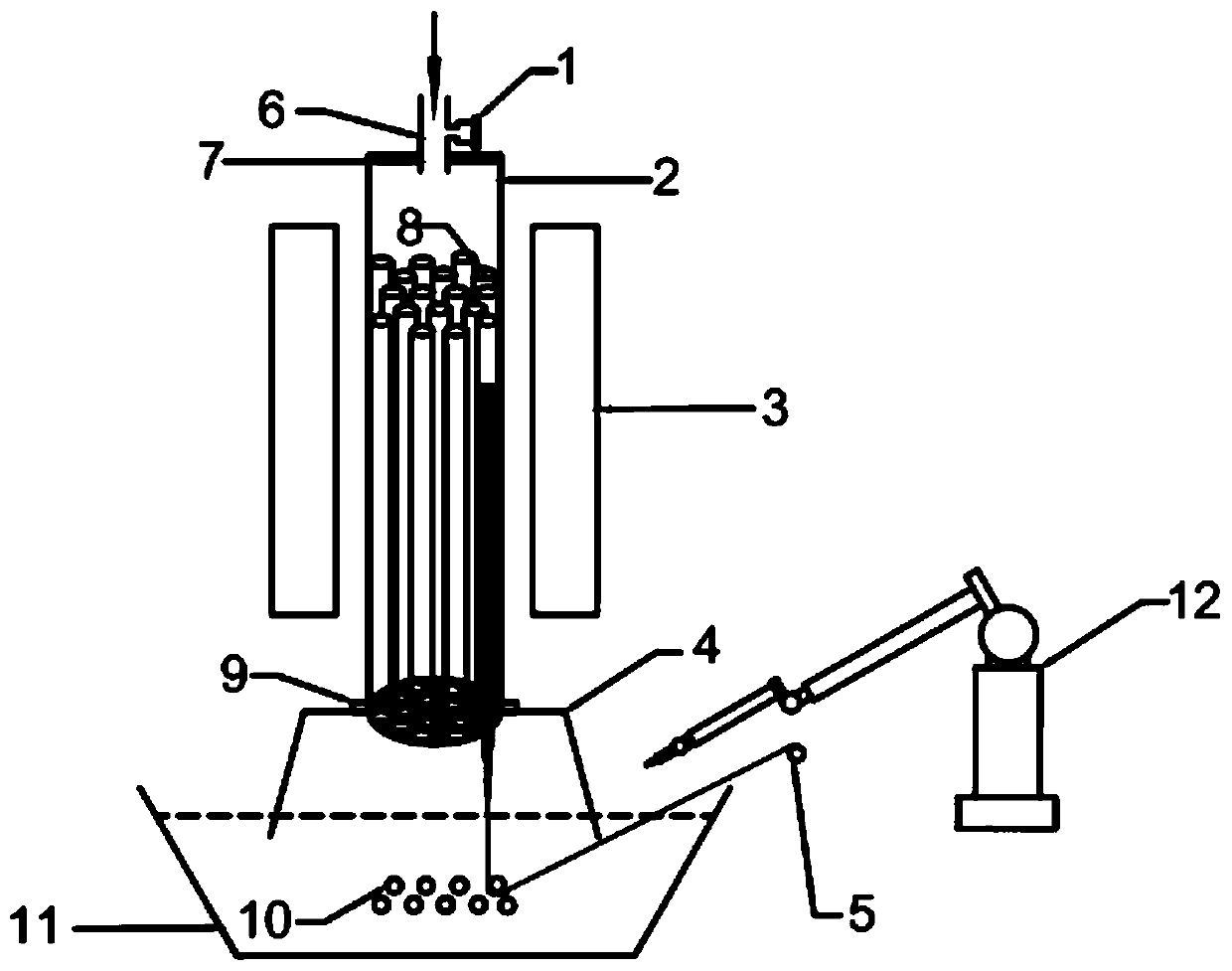

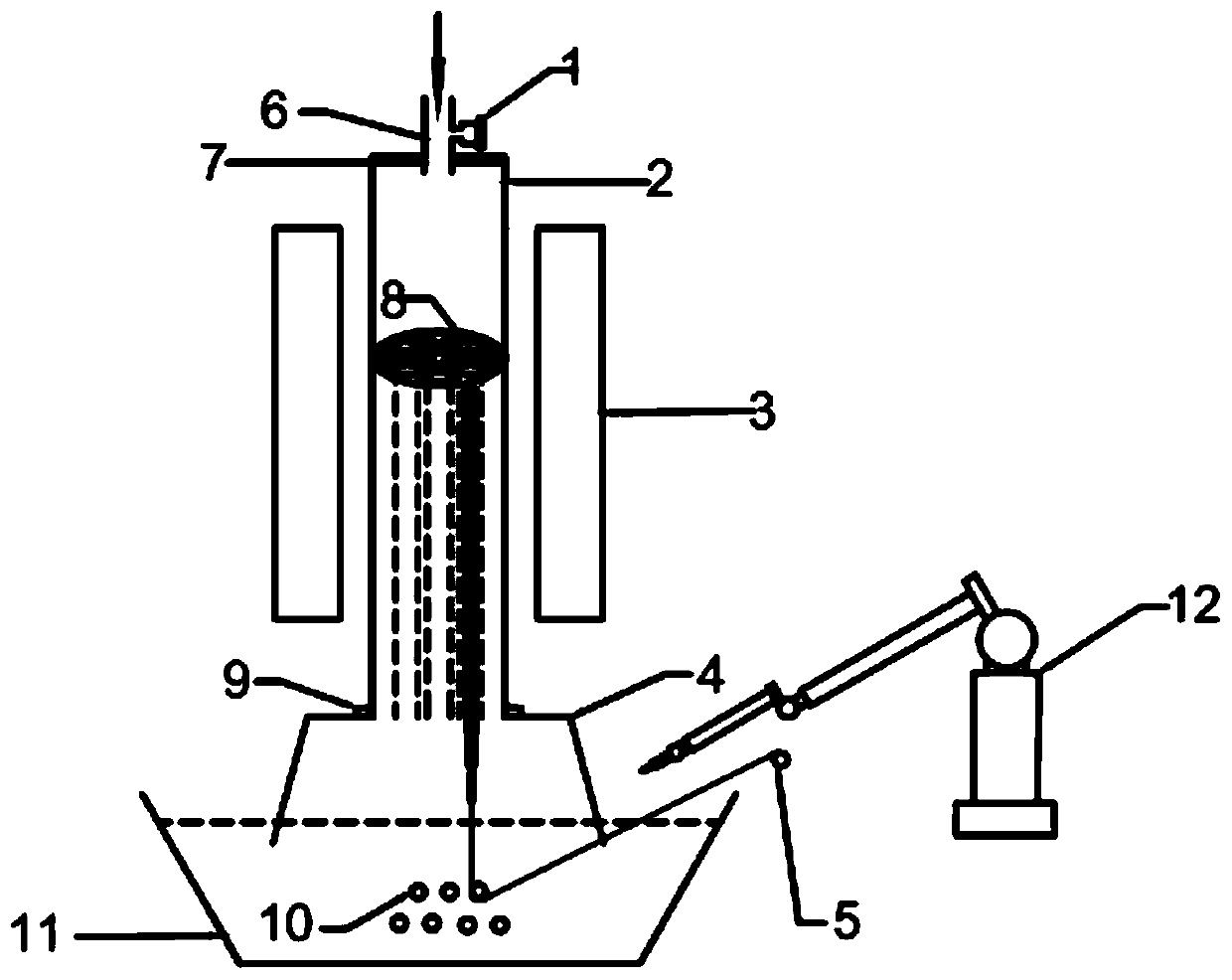

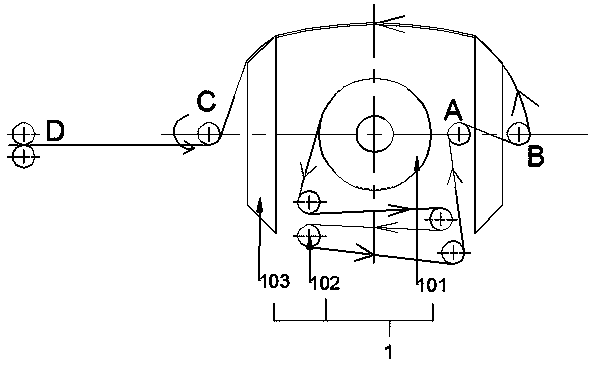

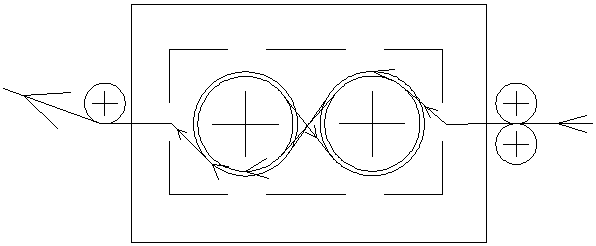

Apparatus for producing multi pulse by Dammann grating pair

The invention relates to producing multi-pulse equipment by Dammann grating set. Its structure includes a main grating. It is 1xn reflection type Dammann grating, n is the positive integer. The n / 2 blocks reflection type compensating grating is set at L distance, two sides of the normal line, and diffracted light direction. Each of them is first grade, third grade, and fifth grade Dammann gratings. The distance between each two Dammann gratings is b. The period of the main grating is d. The third grade is d / 3. The fifth grade is d / 5. The first and second holophotes are set at s distance between main grating two sides to the working surface of the compensating grating. It also includes separating mechanism used to separate output light form input light. The invention can realize compression for positive chatter pulse and form multi-pulse with identical wavelength and adjustable pulse interval.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

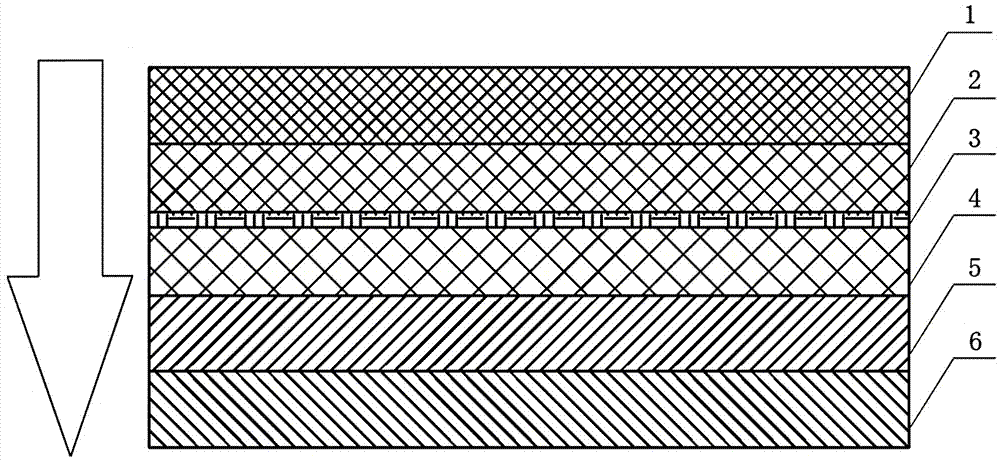

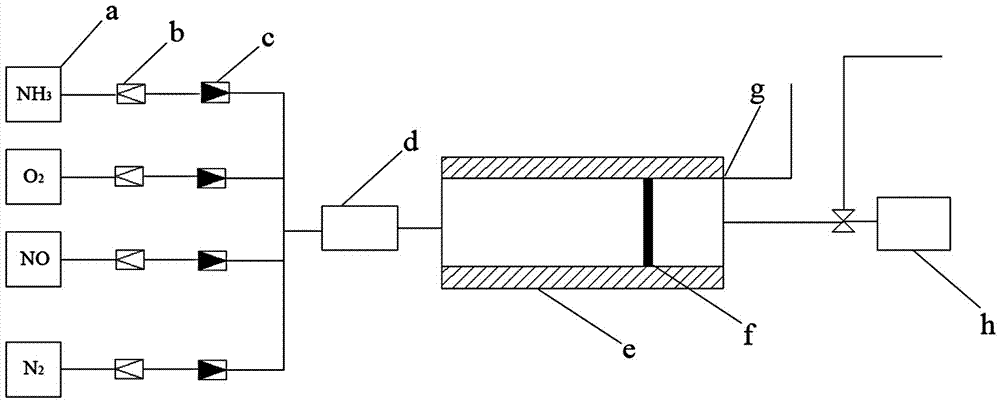

High-temperature-resistant filtering material with ultra-clean filtering and low-temperature catalytic denitration functions, and preparation method thereof

ActiveCN106914064ALarge specific surface areaHigh porosityOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationChemistryFiber layer

The invention discloses a high-temperature-resistant filtering material with ultra-clean filtering and low-temperature catalytic denitration functions, and a preparation method thereof. The filtering material successively comprises, from a dust-facing surface, an island-type or fragment-type extremely superfine fiber layer, a superfine fiber layer, a PTFE sewing-thread base-cloth layer, a fine-denier fiber layer, a high-temperature-resistant adhesive layer and a catalyst coating. The high-temperature-resistant filtering material provided by the invention has the excellent characteristics of a large specific surface area, high porosity and the like, can realize ultralow dust discharge and has superhigh filtration accuracy and good filtering effect; a catalyst is uniform in distribution, firm in loading, high in catalysis efficiency, good in anti-sulfur effect and long in service life; the preparation method for the filtering material is simple in process and easy for realization of industrialization; the catalyst is not prone to poisoning and long in service life; and the high-temperature-resistant filtering material is applicable to flue gas filtering under complex conditions like high working temperature, great dust content and high requirements on filtration accuracy, and can realize low-temperature denitration of nitrogen oxides in flue gas without extra heating while realizing high-precision filtering.

Owner:XIAMEN ZHONGCHUANG ENVIRONMENTAL TECH CO LTD

Transparent conductive film and preparation method thereof

InactiveCN108231245AUniform diameterGood dispersionConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersComposite filmCopper wire

The invention relates to a transparent conductive film and a preparation method thereof, and belongs to the technical field of preparation of conductive films. With copper chloride as a copper source,oleic acid and oleylamine as inducers, glucose as a reducing agent and polyvinylpyrrolidone as a stabilizer, copper nanowires with high length-diameter ratio, uniform diameter, good dispersibility and regular morphology are prepared; through formation of a network with smaller linear density, a longer penetration path is provided, internal copper wire nodes are reduced, the resistivity is reduced, and a transparent metal film with low haze, high transparency, high conductivity and excellent mechanical flexibility and strength is achieved; then the copper nanowires are covered with an aqueouspoly(3,4-ethylenedioxythiophene)-polystyrene sulfonic acid solution to prepare a composite film to improve the oxidation resistance of the copper nanowires, so that the energy absorbing ability of themetal film layer during folding deformation is enhanced, the slippage degree of conductive particles is reduced, and thus the resistance change rate of a coating layer is reduced and the flexibilityand the electrical stability of a product are further improved.

Owner:常州市丰瑞电子有限公司

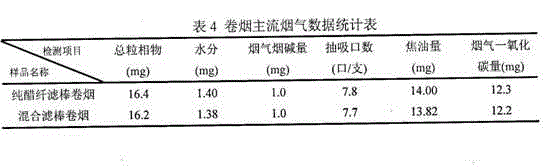

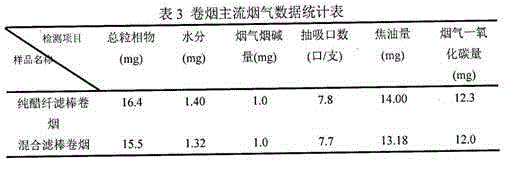

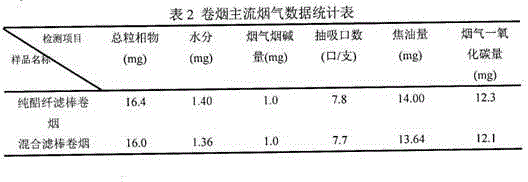

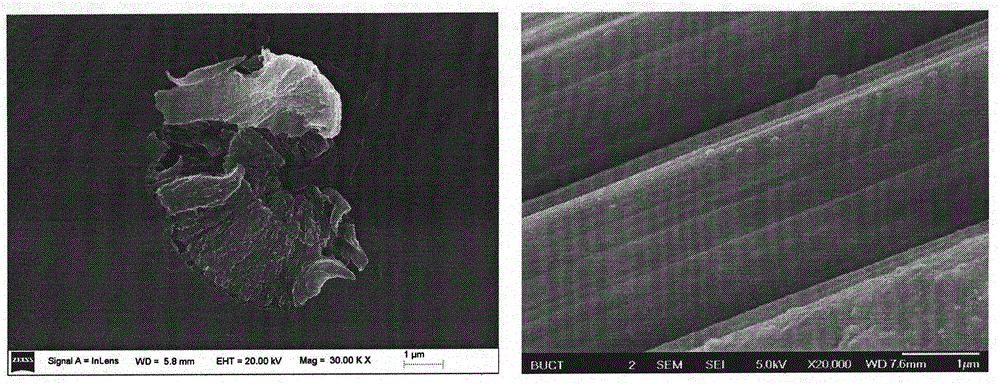

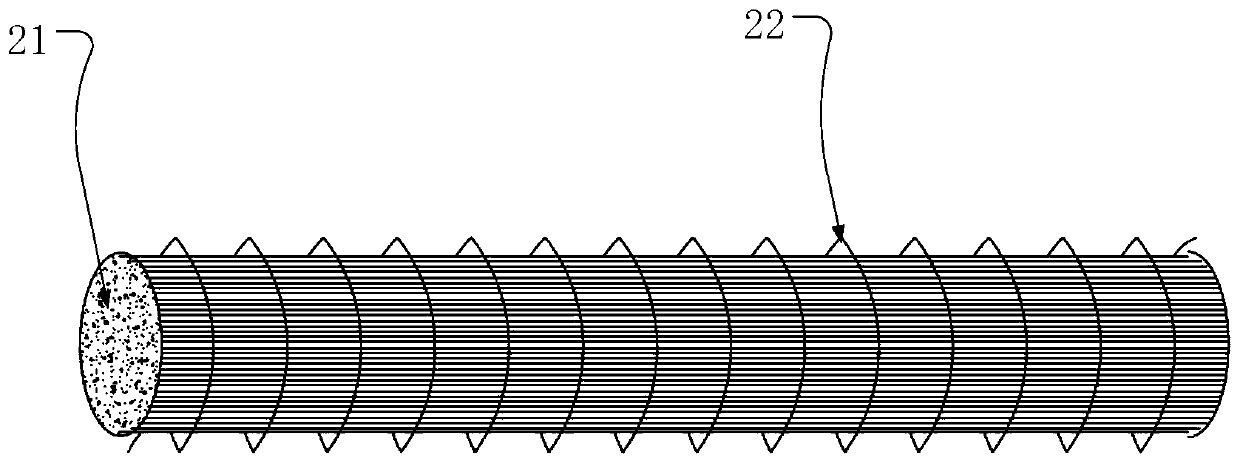

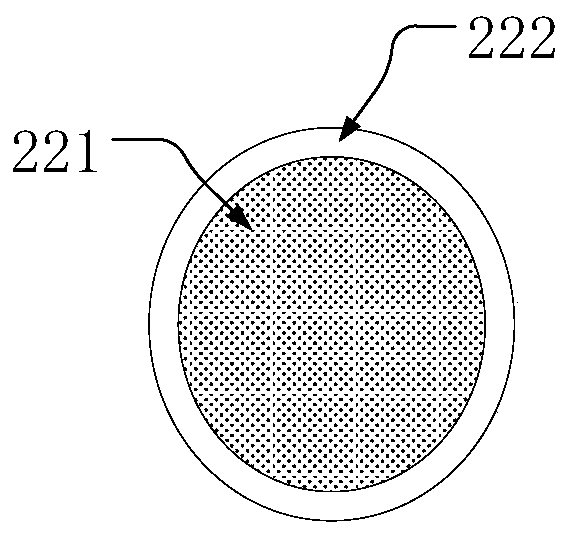

Filament bundle for polylactic acid cigarette with low filament bundle linear density, preparation method thereof and application thereof

ActiveCN102747454ASmall linear densityReduce dosageTobacco smoke filtersMelt spinning methodsCellulose diacetatePolymer chemistry

The invention relates to a filament bundle for a polylactic acid cigarette with a low filament bundle linear density, a preparation method thereof and an application thereof. The filament bundle for the polylactic acid cigarette is prepared through mixing polylactic acid master batches with titanium dioxide brightening master batches, and the filament bundle linear density, the monofilament linear density and the crispation number of the filament bundle are 0.4-1.5ktex, 2-6dtex and 20-30 / 25mm respectively. The filament bundle for the polylactic acid cigarette with a low filament bundle linear density can be mixed with a corresponding filament bundle (an acetate fiber filament bundle) for a cellulose diacetate cigarette to form a filter rod, so the application amount of the acetate fiber filament bundle is reduced, the insufficient situation of the filament bundle for the acetate fiber cigarette is alleviated, the cost is reduced, and the suction taste of the cigarette is maintained without a too large change. In addition, the pollution to the environment is reduced because polylactic acid has a biodegradable characteristic.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +2

Blending reprocessed cotton yarn capable of emitting anions and being good for health, and preparation method thereof.

InactiveCN104988616AImprove light resistanceImprove product qualityMonocomponent polyolefin artificial filamentYarnCelluloseEpoxy

The invention discloses blending reprocessed cotton yarn capable of emitting anions and being good for health and a preparation method thereof. The blending reprocessed cotton yarn is made from the following raw materials, by weight, 40 to 43 parts of waste cotton goods, 15 to 17 parts of cotton yarn scraps, 5 to 7 parts of epoxy resin emulsion, 2 to 3 parts of water soluble cellulose ether, 3 to 4 part of gelatin, 39 to 44 parts of polypropylene, 2 to 3 parts of nano-zinc oxide, 2 to 3 parts of nanometer tourmalinite powder, 12 to 14 parts of liquid paraffin, 9 to 10 parts of nanometer titanium dioxide, 1.5 to 2 parts of carboxymethyl cellulose, 1 to 2 parts of glyceryl stearate, and an appropriate amount of water. The blending reprocessed cotton yarn is blended by reprocessed cotton yarn fiber, and short polypropylene fiber flocks modified by nanometer tourmalinite powder and nanometer titanium dioxide, characteristics of the fibers can be combined, and the The blending reprocessed cotton yarn is good for health. The blending reprocessed cotton yarn is high in light resistance and strength, good in wear resistance, chemical corrosion resistant, high in quality and low in cost.

Owner:SHUNTIAN SPINNING LIMITED

Blended regenerating cotton yarns capable of improving ultraviolet ray resistance, and preparation method thereof

InactiveCN104963021AMake up for the shortcomings of poor sun protectionHigh strengthFibre typesMonocomponent cellulose artificial filamentYarnPhosphoric Acid Esters

The present invention discloses blended regenerating cotton yarns capable of improving ultraviolet ray resistance, wherein the blended regenerating cotton yarns are characterized in that the blended regenerating cotton yarns are prepared from the following raw materials by weight: 40-43 parts of waste cotton fabric, 15-17 parts of cotton yarn leftover, 2-2.5 parts of phosphoric ester starch, 1.5-2 parts of pectin, 6-8 parts of pure acrylic emulsion, 0.5-0.7 part of dodecanol polyoxyethylene ether sodium sulfate, 39-44 parts of polypropylene, 3-5 parts of nanometer zinc oxide, 12-14 parts of liquid paraffin, 9-10 parts of nanometer titanium dioxide, 1.5-2 parts of carboxymethyl cellulose, 1-2 parts of glyceryl stearate, and a proper amount of water. According to the present invention, the waste cotton fabric is used to regenerate the fibers, and the obtained fibers and the surface modified polypropylene short fibers are subjected to drawing and blending to obtain the blended regenerating cotton yarns of the present invention, such that the characteristics of various fibers are neutralized, the disadvantage of poor sunscreen property of the cotton fibers and the polypropylene fibers are overcome, characteristics of strength enhancing, good elasticity, wear resistance, corrosion resistance, good warm keeping and product quality improving are provided, and the waste cotton regeneration is adopted so as to save the cost.

Owner:SHUNTIAN SPINNING LIMITED

Stretch-proofing mekralon blending reprocessed cotton yarn and preparation method thereof

InactiveCN104988618AHigh tensile strengthImprove sun protection effectYarnMonocomponent polyolefin artificial filamentParaffin waxYarn

The invention discloses stretch-proofing mekralon blending reprocessed cotton yarn and a preparation method thereof. The stretch-proofing mekralon blending reprocessed cotton yarn is made from the following raw materials, by weight, 35 to 40 parts of waste cotton goods, 15 to 17 parts of cotton yarn scraps, 9 to 10 parts of nanometer titanium dioxide, 6 to 8 parts of flax fiber, 2 to 3 parts of polyvinyl alcohol, 0.3 to 0.5 part of polyoxyethylene octyl phenyl ether, 1 to 2 parts of glyceryl stearate, 39 to 44 parts of polypropylene, 3 to 5 parts of nano-zinc oxide, 12 to 14 parts of liquid paraffin, 1.5 to 2 parts of carboxymethyl cellulose and an appropriate amount of water. The stretch-proofing mekralon blending reprocessed cotton yarn is blended by reprocessed cotton yarn fiber and sun proof and modified short polypropylene fiber blended yarn, characteristics of the fibers can be combined, and the defect that the light resistance is poor can be overcome at the same time. The stretch-proofing mekralon blending reprocessed cotton yarn is energy saving, environmental friendly, low in cost, wear resistant, stretch resistant, corrosion resistant, and high in quality.

Owner:SHUNTIAN SPINNING LIMITED

Blending regeneration cotton yarn with ray proof efficacy and preparation method thereof

InactiveCN104963048AMake up for the shortcomings of poor sun protectionIncrease elasticityYarnMonocomponent polyolefin artificial filamentEpoxyYarn

The invention discloses a blending regeneration cotton yarn with ray proof efficacy and a preparation method thereof; the features are that the blending regeneration cotton yarn is formed by the following raw materials by weight parts: 34-40 parts of waste and old cotton goods; 15-17 parts of cotton yarn scraps; 7-9 parts of silver fibers; 9-10 parts of nanometer titanium dioxide; 3-4 parts of diatom mud; 1-2 parts of silicone oil; 1-1.5 parts of monoglyceride stearate; 6-7 parts of epoxy resin emulsion; 39-44 parts of polypropylene; 3-5 parts of nanometer zinc oxide; 12-14 parts of liquid paraffin; 1.5-2 parts of carboxymethyl cellulose; proper water. The method uses regeneration fibers like waste and old cotton goods to mix with the silver fibers, then polypropylene short fiber blended yarn with modified surface is drawn, thus forming the blending regeneration cotton yarn; the blending regeneration cotton yarn neutralizes various fiber features so as to make up disadvantages of the cotton fiber and mekralon are poor in sunscreen property, and intensity can be enhanced, thus providing excellent anti electromagnetic radiation effect; the fabric is good in elasticity, hard to deform, and very suitable for making pregnant woman ray proof clothes.

Owner:SHUNTIAN SPINNING LIMITED

Flame-retardant, antistatic, modified polyester-blended regenerated cotton yarns and preparation method

InactiveCN105297215AImprove antistatic performanceImprove flame retardant performanceConjugated synthetic polymer artificial filamentsYarnYarnPolyester

The invention discloses flame-retardant, antistatic, modified polyester-blended regenerated cotton yarns. A preparation method is characterized by comprising following raw materials: 100-110 parts by weight of polyethylene glycol terephthalate, 10-12 parts by weight of polypropylene, 25-28 parts by weight of polyethylene glycol, 10-12 parts by weight of nano bamboo carbon powder, 6-9 parts by weight of nano-zinc oxide, 3 to 4 parts by weight of antistatic agents P, 3-4 parts by weight of carboxymethylcellulose, a proper amount of water, 90-100 parts by weight of waste cotton yarns, 3 to 5 parts by weight of aluminum hydroxide, 2-3 parts by weight of melamine, 3-5 parts by weight of soluble starch and 3-4 parts by weight of dispersible adhesive powder. The flame-retardant, antistatic, modified polyester-blended regenerated cotton yarns have following beneficial effects: the flame-retardant, antistatic, modified polyester-blended regenerated cotton yarns are fine in abrasion resistance and corrosion resistance and high in strength by adopting modified waste cotton yarns and polyester blended yarns and combining features of fibers; an innovative improvement is made on steps for a conventional process; the process is easily controlled by industry; by utilization of waste cotton yarns, production cost is decreased; product quality for production is stable; and a safety coefficient for fibers is increased.

Owner:SHOUXIAN LIFENG WEAVING

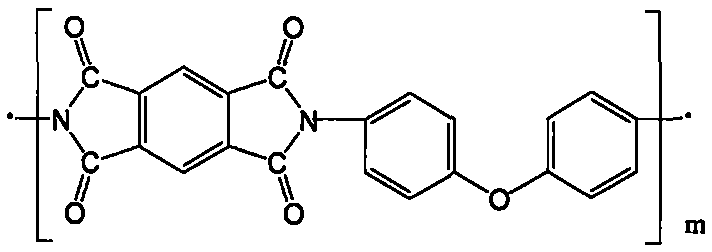

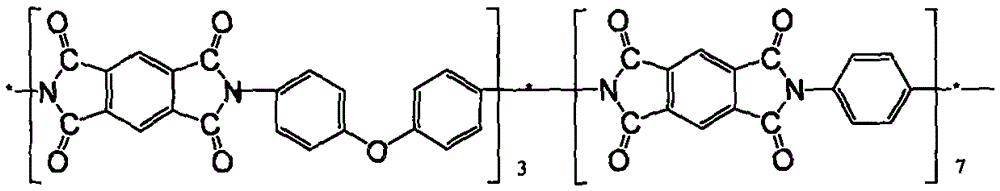

Polyimide superfine fiber and preparation method thereof

ActiveCN105648567ASmall linear densityOvercoming problems such as spinning instabilityMonocomponent synthetic polymer artificial filamentWet spinning methodsFiberNitrogen

The invention discloses a polyimide superfine fiber and a preparation method thereof. The method includes the steps of adding solvent to dissolve diamine under protection of nitrogen, adding dianhydride to make the solid content of the solution be 9-20%, conducting reaction for 3-12 hours at a temperature of 0-50 DEG C to obtain a polyimide spinning solution, conducting spinning through the polyimide spinning solution according to a wet method or dry method spinning process, and conducting imidization on polyamide acid protofilament through the thermal amidation or chemical imidization process. The minimum monofilament density of the prepared polyimide superfine fiber can reach 0.153 dtex, the raw materials are wide in source and low in cost, the spinning process is stable, and industrial production can be achieved.

Owner:JIANGSU XIANNUO NEW MATERIAL TECH

Corrosion resistant antistatic blending cotton yarn with added carbon fiber and preparation method thereof

InactiveCN104963047AHigh strengthImprove toughnessYarnMonocomponent polyolefin artificial filamentYarnCarbon fibers

The invention discloses a corrosion resistant antistatic blending cotton yarn with added carbon fibers; the corrosion resistant antistatic blending cotton yarn is formed by the following raw materials by weight parts: 10-12 parts of carbon fibers; 30-33 parts of waste and old cotton goods; 15-17 parts of cotton yarn scraps; 5-7 parts of pure acrylic emulsion; 2-3 parts of polyoxyethylene glue powder; 3-4 parts of gum acacia; 39-44 parts of polypropylene; 3-5 parts of nanometer zinc oxide; 12-14 parts of liquid paraffin; 9-10 parts of nanometer titanium dioxide; 1.5-2 parts of carboxymethyl cellulose; 1-2 parts of glyceryl stearate; and balance water. The corrosion resistant antistatic blending cotton yarn is blended by age proof modified mekralon and modified regeneration cotton fibers, thus greatly improving blended yarn mechanical properties which exceeding pure cotton yarn; in addition, sunscreen ageing resistance property is enhanced, thus prolonging life and storage time of the product; the corrosion resistant antistatic blending cotton yarn is wear resistant, corrosion resisting, antistatic, good in warmth retention, and high in quality.

Owner:SHUNTIAN SPINNING LIMITED

Antibacterial acarus-killing polypropylene fiber and regenerated cotton blended yarn and preparation method thereof

The invention discloses an antibacterial acarus-killing polypropylene fiber and regenerated cotton blended yarn; the blended yarn is characterized in that the yarn is prepared from the following raw materials in parts by weight: 30 to 33 parts of waste cotton fabrics, 15 to 17 parts of cotton yarn leftover materials, 0.1 to 0.2 parts of antibacterial agent HFXZ-881, 39 to 44 parts of polypropylene, 3 to 5 parts of nano zinc oxide, 12 to 14 parts of liquid paraffin, 9 to 10 parts of nano titanium dioxide, 1.5 to 2 parts of carboxymethyl cellulose, 1 to 2 parts of glyceryl stearate, 3 to 4 parts of zeolite, 10 to 13 parts of apocynum venetum fibers, 10 to 12 parts of softwood pulp, 2 to 3 parts of polyvinyl alcohol and proper water. According to the antibacterial acarus-killing polypropylene fiber and regenerated cotton blended yarn disclosed by the invention, through the scientific and reasonable formula and a convenient control process, the regenerated cotton fibers, the modified polypropylene, the apocynum venetum fibers and the like are blended and the prepared yarn is high in strength, firm, wear resistant, sun resistant and anti-ageing; the fabric made with the yarn is light and soft, and has extremely strong antibacterial and acarus-killing effects and good wear resistance and durability; meanwhile, the application range of the regenerated cotton fibers is expanded, so the antibacterial acarus-killing polypropylene fiber and regenerated cotton blended yarn has wide prospect.

Owner:SHUNTIAN SPINNING LIMITED

New non-hygroscopic wear-resisting anti-bacterial polypropylene fiber and recycled cotton blended yarn and preparation method thereof

InactiveCN104911776AGood moisture absorptionHigh strengthMonocomponent polyolefin artificial filamentYarnYarnSurface water

The invention discloses a new non-hygroscopic wear-resisting anti-bacterial polypropylene fiber and recycled cotton blended yarn, which is characterized by being prepared from the following raw materials in parts by weight: 40 to 43 parts of waste cotton fabrics, 15 to 17 parts of cotton yarn leftover bits and pieces, 1 to 2 parts of carnauba wax, 1 to 2 parts of polyoxyethylene fatty alcohol sodium sulfate, 5 to 7 parts of silicone acrylic emulsion, 3 to 4 parts of pre-gelatinized starch, 39 to 44 parts of polypropylene, 3 to 5 parts of nano-zinc oxide, 12 to 14 parts of liquid paraffin, 9 to 10 parts of nanometer titania, 1.5 to 2 parts of carboxymethylcellulose, 1 to 2 parts of glyceryl stearate and a moderate amount of water. According to the new non-hygroscopic wear-resisting anti-bacterial polypropylene fiber disclosed by the invention, after surface water proofing and sun-screening treatment is performed on recycled cotton fibers prepared from the waste cotton fabrics and the like, the waste cotton fabrics are blended with polypropylene fibers modified through sun-screening to form the yarn, and the prepared blended yarn is firm, wear-resisting, high in strength and light in specific gravity, and does not easily absorb moisture; the blended yarn can be used for manufacturing underwater clothing, such as swimsuits, or netting twines and the like; the quality of the recycled cotton fibers is promoted, and the application range of the recycled cotton is broadened.

Owner:SHUNTIAN SPINNING LIMITED

New sun-proof light-resistant enhanced polypropylene fiber and recycled cotton blended yarn and preparation method thereof

InactiveCN104911775AHigh strengthIncrease elasticityMonocomponent polyolefin artificial filamentYarnYarnUltraviolet

The invention discloses a new sun-proof light-resistant enhanced polypropylene fiber and recycled cotton blended yarn, which is characterized by being prepared from the following raw materials in parts by weight: 40 to 43 parts of waste cotton goods, 15 to 17 parts of cotton yarn leftover bits and pieces, 39 to 44 parts of polypropylene, 3 to 5 parts of nano-zinc oxide, 12 to 14 parts of liquid paraffin, 9 to 10 parts of nanometer titania, 1.5 to 2 parts of carboxymethylcellulose, 1 to 2 parts of glyceryl stearate, 8 to 10 parts of carbonized coffee grounds, 5 to 7 parts of dispersible adhesive powder, 3 to 4 parts of gelatin and a moderate amount of water. According to the new sun-proof light-resistant enhanced polypropylene fiber and recycled cotton blended yarn disclosed by the invention, modified recycled cotton fibers containing the carbonized coffee grounds are added, so that the ultraviolet resistance of the fibers is improved; the blended yarn made by blending the modified recycled cotton fibers with nanometer titania modified polypropylene fibers has the advantages that the strength is higher, the sun-proof light resistance is enhanced, and not only are the cotton goods recycled to protect the environment but also the value of the recycled cotton fibers is improved, and the application range is broadened.

Owner:SHUNTIAN SPINNING LIMITED

Single yarn, single yarn product, and preparation method therefor

InactiveUS20160145775A1Improves Structural IntegrityReduce processing costsYarnFilament/thread formingYarnFiber

The invention relates to a single yarn, a single yarn product and a preparation method thereof, wherein the preparation method of the single yarn comprises: converging or converging and twisting an ultra high molecular weight polyethylene thin film or strip to obtain the single yarn. The single yarn product comprises at least a body prepared from the above-mentioned single yarn. The single yarn obtained by converging or converging and twisting the ultra high molecular weight polyethylene thin films or strips in the invention replaces traditional ultra high molecular weight polyethylene fibers to develop and prepare various products. In addition to the advantages of wear resistance, impact resistance, corrosion resistance, UV resistance and the like which are similar to those of the ultra high molecular weight polyethylene fibers, the single yarn also has the unique advantages of good structural integrity, high strength, high strength utilization ratio, high production efficiency, low processing cost, light weight, small linear density and the like, and therefore the single yarn can replace the traditional ultra high molecular weight polyethylene fibers in the preparation of various products and has a very wide application range.

Owner:ZHENGZHOU ZHONGYUAN DEFENSE MATERIAL

Multi-fiber added antibacterial warming regenerated blended cotton yarn and preparation method thereof

InactiveCN104911897AHigh strengthIncrease elasticityYarnMonocomponent polyolefin artificial filamentYarnHigh fracture

The present invention discloses a multi-fiber added antibacterial warming regenerated blended cotton yarn characterized by being prepared from the following raw materials in parts by weight: 5-7 parts of seaweed carbon fiber, 3-5 parts of soybean protein fiber, 30-33 parts of waste cotton fabrics, 15-17 parts of cotton yarn scrap, 39-44 parts of polypropylene, 3-5 parts of nano-zinc oxide, 12-14 parts of liquid paraffin, 9-10 parts of nano-titanium dioxide, 1.5-2 parts of carboxymethyl cellulose, 1-2 parts of glyceryl stearate, 0.7-0.9 parts of silane coupling agent kh-550, 5-7 parts of pure acrylic emulsion, and proper amount of water; by combination of the two steps, the treated recycled cotton fibers and modified polypropylene fiber are blended into yarn which is capable of emitting far infrared and negative ions, has good antibacterial effect, the produced product has good warming property, high strength, high fracture strength, lower production cost, safety and environmental friendliness, and the quality of the regenerated cotton yarn is improved.

Owner:SHUNTIAN SPINNING LIMITED

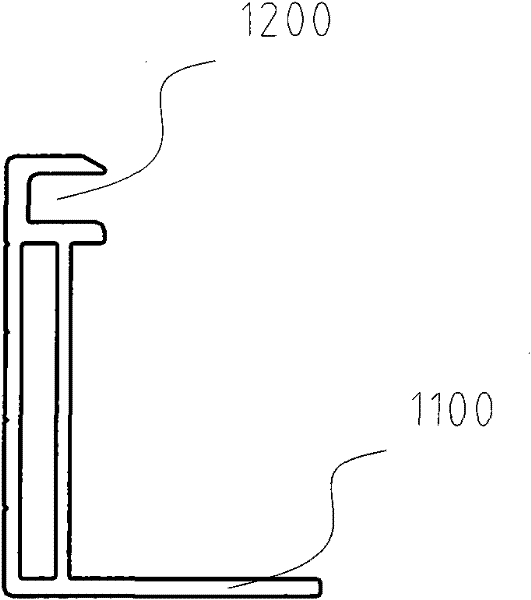

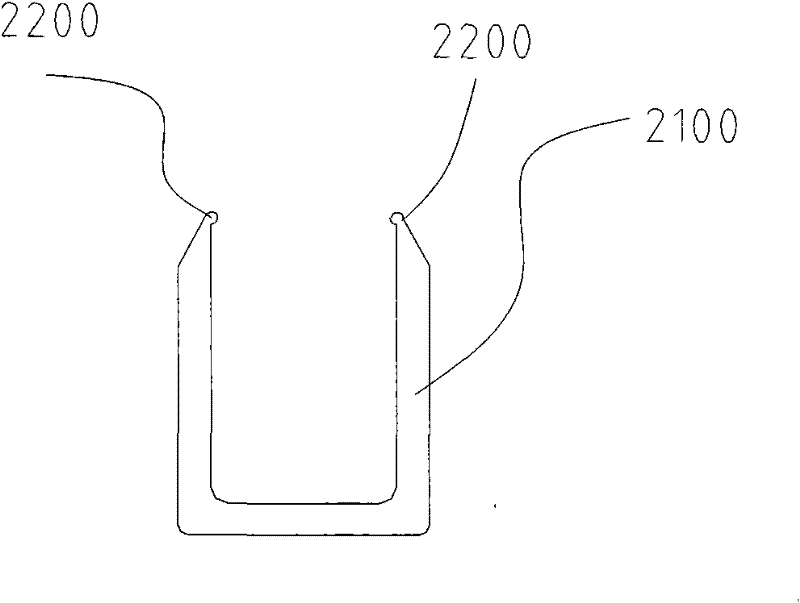

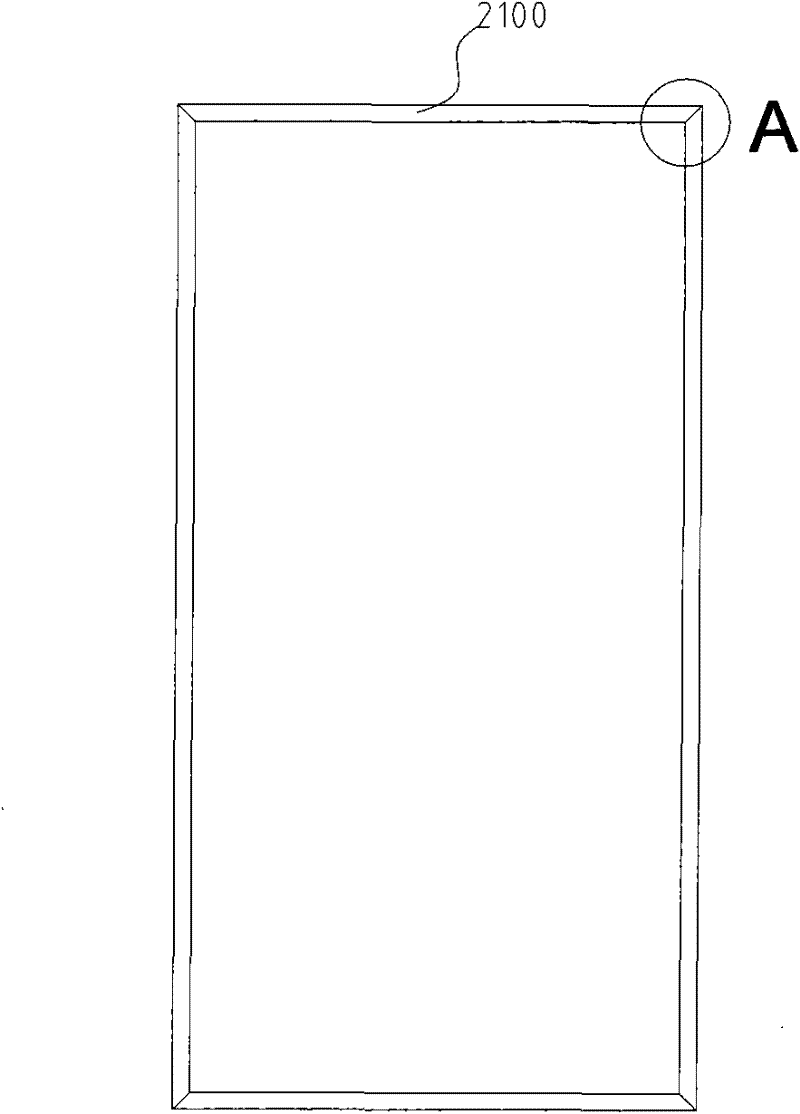

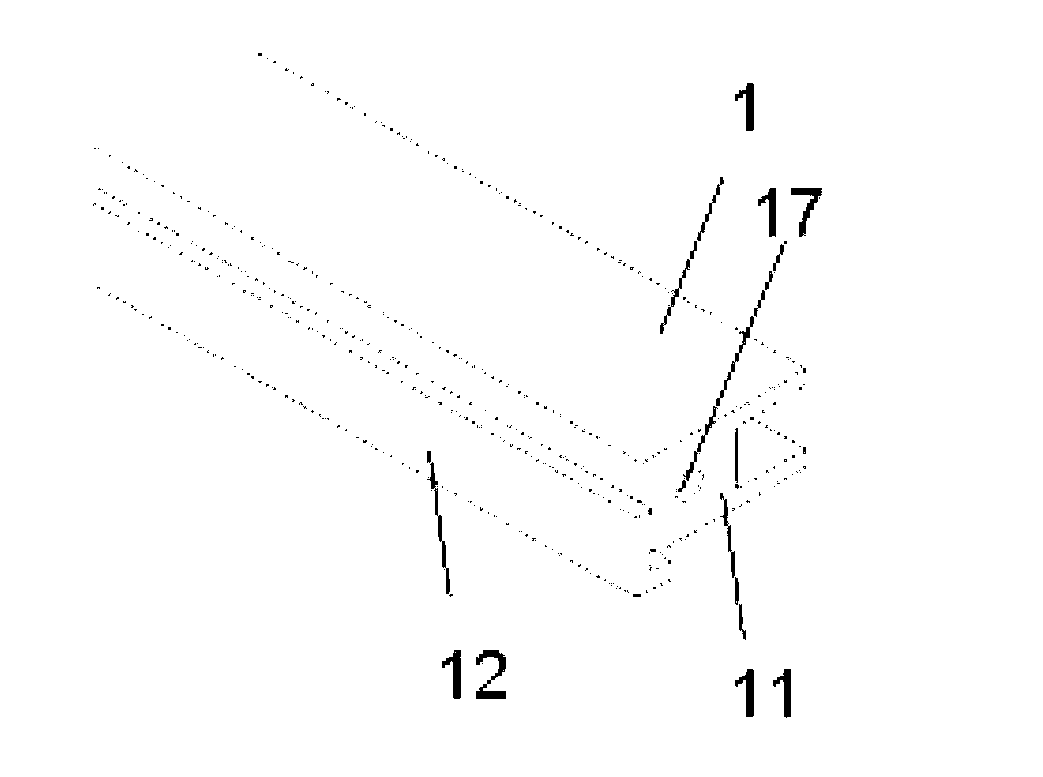

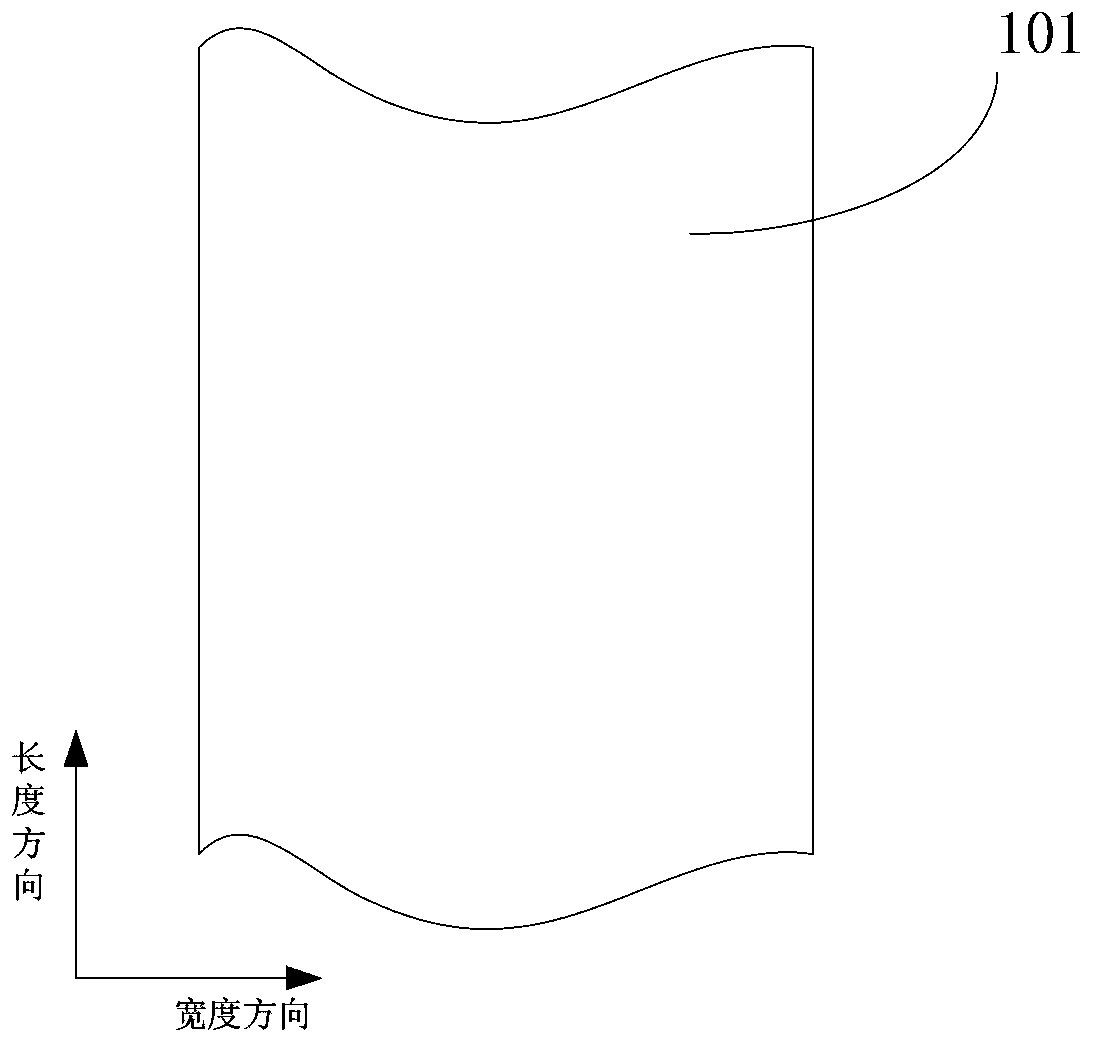

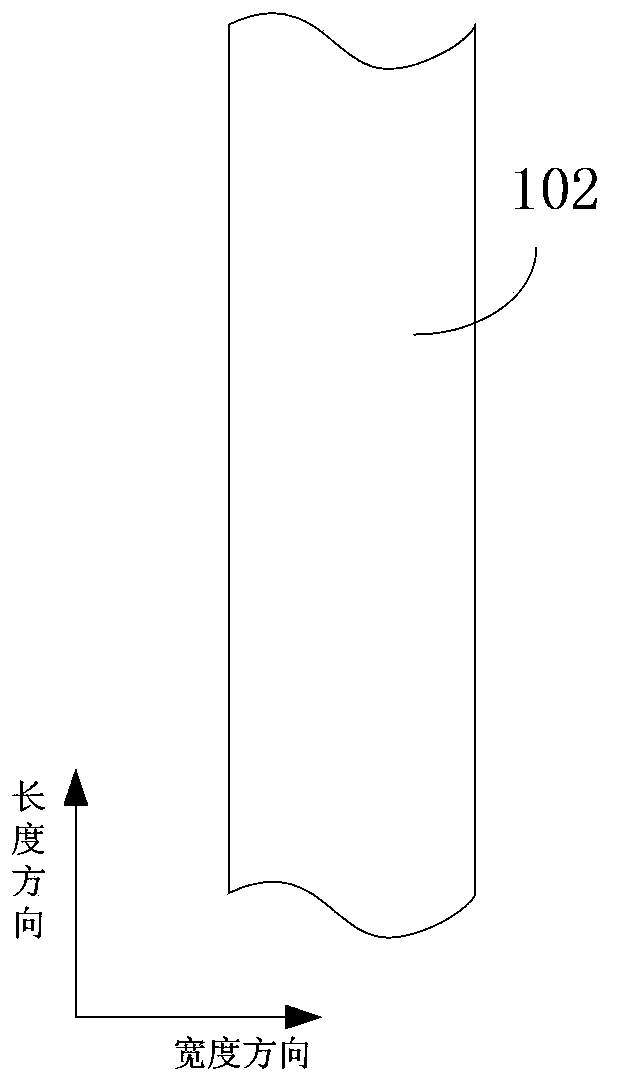

Peripheral sealing framework of photovoltaic module

InactiveCN103296113AHighly corporatedSmall linear densityPhotovoltaic energy generationSemiconductor devicesEngineeringMechanical engineering

The invention discloses a peripheral sealing framework of a photovoltaic module. The peripheral sealing framework of the photovoltaic module is composed of short frames or long frames, each short frame comprises a first U-shaped section bar and an L-shaped section bar, a groove is formed in one side of the short frame, the other side of the short frame is connected with the short edge of the L-shaped section bar and forms a U-shaped groove with the long edge of the L-shaped section bar, the bottom of the first U-shaped section bar and the bottom of the L-shaped section bar are on the same horizontal plane, the bottom of the L-shaped section bar exceeds the bottom of the first U-shaped section bar for a certain distance in the length direction, and a first screw hole is formed in one side of the groove which is formed in the first U-shaped section bar. Each long frame comprises a second U-shaped section bar and a rectangular section bar, a groove is formed in one side of the long frame, the other side of the long frame extends outwards in the length direction and forms the rectangular section bar, and a second screw hole corresponding to the first screw hole is formed in the rectangular section bar. The peripheral sealing framework of the photovoltaic module has the advantages of being capable of meeting the basic sealing and protecting requirements, low in cost, convenient to machine and mount, wide in application range, strong in universality and the like.

Owner:JIANGSU SHENGMEI IND TECH GRP +2

Method for batch production of carbon nanotube fibers

The invention belongs to the technical field of nanofiber preparation, and particularly relates to a method for batch production of carbon nanotube fibers. A large quartz tube with a honeycomb structure inside, or the large quartz tube with small quartz tubes nested inside is used as a reaction chamber; a mixed solution of a carbon source, a catalyst, a promoter and water is introduced into a carrier gas stream through a micro-injection pump or an atomizer; the mixed solution enters the quartz tube under driving of the stream, and is vaporized and then cracked into atoms; the cracked atoms enter honeycomb cells of the quartz tube / the small quartz tubes under the driving of the stream; carbon nanotube aerogel in cylindrical structure is formed inside each honeycomb cell / small quartz tube; the gel with the cylindrical structure is pulled out of the quartz tube by mechanical tangling and is hydrated to obtain the continuous carbon nanotube fibers. The fibers prepared by the invention aresmaller in diameter and lower in linear density; the fiber quality is increased, and the yield is increased; the strength is higher, and the performance is better; the method is suitable for mass production of carbon nanotube fibers.

Owner:CHANGZHOU UNIV

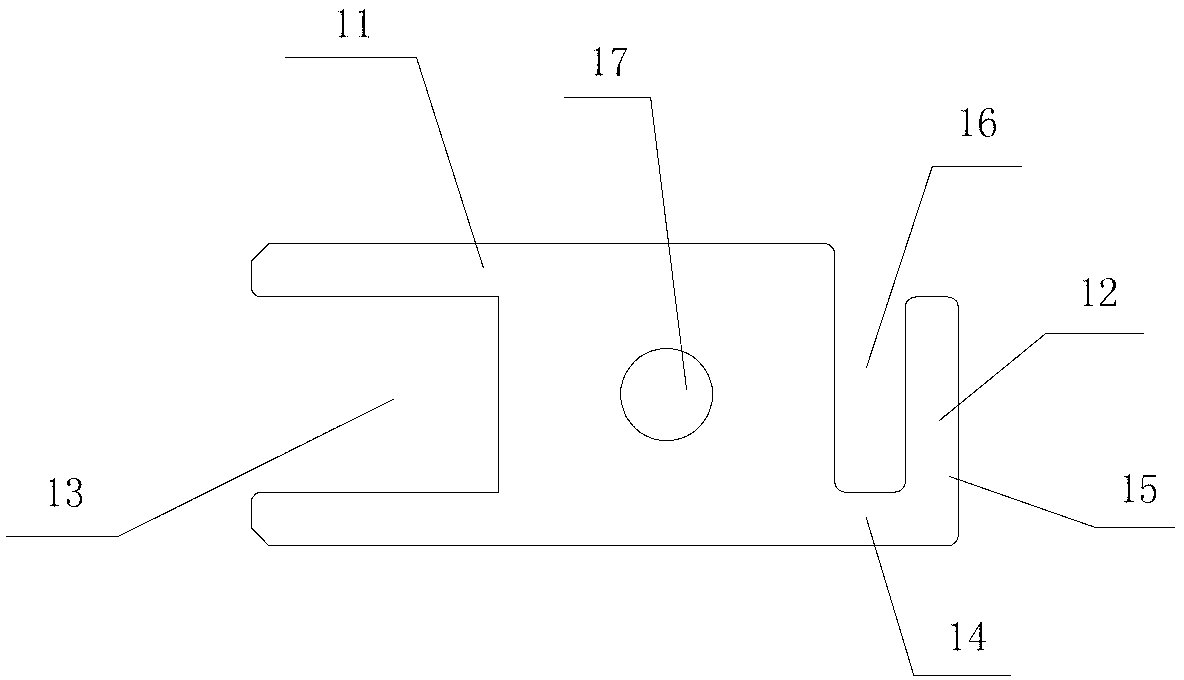

Folding thread weaving method and system for preparing plastic basketwork and production

InactiveCN1990924AHigh tensile strengthSmall linear densityOrnamental textile articlesFilament/thread formingWeft yarnEngineering

The invention discloses a knitting method for folding silk, comprising silking process that one or more than one plastic silk is obtained by silking equipment; folding process that each plastic silk is folded two or more than two times on the wide direction by folding equipment; rolling process that each plastic silk after folding is rolled together to form a folding silk, which can be used as an integration, by rolling equipment; and knitting process that above mentioned silk, as one kind of warp yarn and weft yarn at least is knitted by knitting equipment.

Owner:FSPG HI TECH

Easily-dyed modified polypropylene fiber blended regenerating cotton yarn and preparation method thereof

InactiveCN104911728AEasy to dyeQuality improvementFibre typesMonocomponent cellulose artificial filamentYarnAgricultural engineering

The present invention discloses an easily-dyed modified polypropylene fiber blended regenerating cotton yarn, which is characterized in that the easily-dyed modified polypropylene fiber blended regenerating cotton yarn is prepared from the following raw materials by weight: 40-43 parts of waste cotton fabric, 15-17 parts of cotton yarn leftover material, 5-7 parts of an aqueous polyurethane emulsion, 2-3 parts of dextrin, 39-44 parts of polypropylene, 2-4 parts of vinyl pyridine, 0.3-0.5 part of a titanic acid ester coupling agent TC-F, 3-5 parts of kaolin, 12-14 parts of liquid paraffin, 9-10 parts of nanometer titanium dioxide, 1.5-2 parts of carboxymethyl cellulose, and a proper amount of water. According to the present invention, the waste cotton fabric is used to modify to prepare the regenerating cotton fibers so as to reduce the production cost, then the polypropylene is molten and then is mixed with vinyl pyridine and other components, and spinning is performed to prepare the fibers having the active group, such that the dyeing is easy to perform, and the shortcomings of polypropylene fibers are improved; and the regenerating cotton fibers are blended with the modified polypropylene fibers, such that the prepared product has characteristics of easy coloring, high strength, wear resistance and corrosion resistance, and the quality of the regenerating cotton yarn is improved.

Owner:SHUNTIAN SPINNING LIMITED

Blended and regenerated cotton yarn with body odor and bromidrosis removing function and manufacturing method thereof

InactiveCN104975390AMake up for the shortcomings of poor sun protectionFast deliveryYarnMonocomponent polyolefin artificial filamentYarnSodium Bentonite

The invention discloses a blended and regenerated cotton yarn with a body odor and bromidrosis removing function. The blended and regenerated cotton yarn with the body odor and bromidrosis removing function is characterized by being composed of, by weight, 40-43 parts of waste cotton fabrics, 15-17 parts of cotton yarn leftover materials, 3-5 parts of bentonite, 3-5 parts of bamboo fibers, 5-7 parts of EVA emulsion, 3-4 parts of carboxymethyl chitosan, 39-44 parts of polypropylene, 1-2 parts of anti-aging agent AW, 3-5 parts of nano-zinc oxide, 12-14 parts of liquid paraffin, 9-10 parts of nanometer titania, 1.5-2 parts of carboxymethylcellulose, 1-2 parts of glyceryl stearate and a proper amount of water. According to the blended and regenerated cotton yarn with the body odor and bromidrosis removing function, the defect of poor sunscreen performance is overcome; meanwhile, the strength is improved, the wear resistance is high, the quality of products is improved, and cost is saved; the cotton yarn contains carboxymethyl chitosan, and thus a good anti-bacterial effect is achieved; in addition, the prepared blended and regenerated cotton yarn has the advantages of polypropylene fibers that the superficial area is large, sweat can be transferred more rapidly and the skin can be kept comfortable; the cotton yarn can remove odor and bromidrosis and is suitable for people having serious bromidrosis and body odor.

Owner:SHUNTIAN SPINNING LIMITED

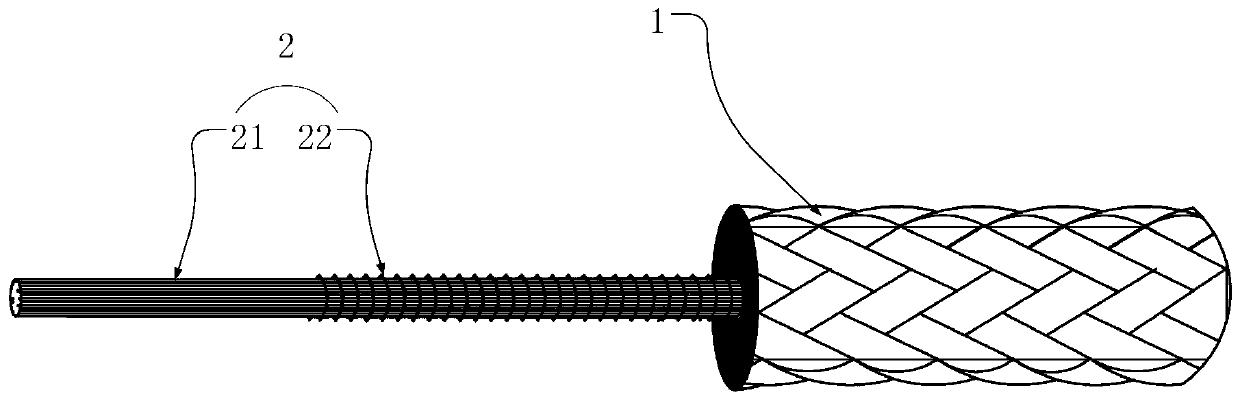

Production equipment and production method of steel cords

ActiveCN110373922ASmall linear densityImprove adhesionRope making machinesEngineeringMethods of production

The invention discloses production equipment of steel cords. The production equipment comprises multiple prefabrication devices, wherein each prefabrication device comprises a pay-off spool with tension control, a tension adjusting device and a pair of auxiliary flywheel discs, multiple first over-twisting devices are arranged on one side of the prefabrication device, each first over-twisting device comprises a front cord passing wheel, a back cord passing wheel and an over-twisting assembly with two over-twisting wheels, a cord collecting device is arranged on the other side of the first over-twisting device and comprises a distributing plate with a cord passing wheel, a cord collecting nozzle, and a main machine is arranged on the other side of the cord collecting device and comprises apair of main flywheel disc, a traction device, a second over-twisting device, a straightener assembly and a take-up device with a cord arranging function. Compared with the prior art, the equipment structure is simplified, the floor area is reduced, noise is reduced, and production efficiency is improved.

Owner:DONGTAI LEIDA STEEL CORD

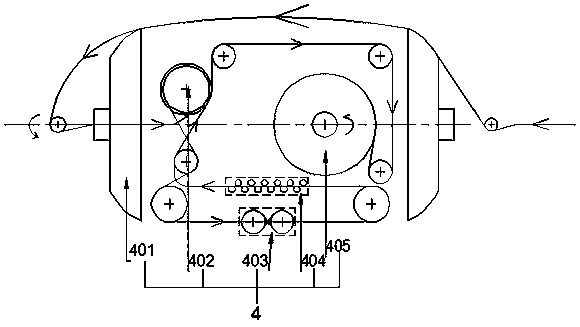

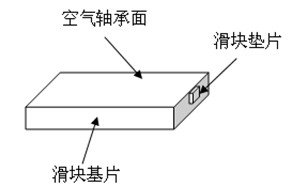

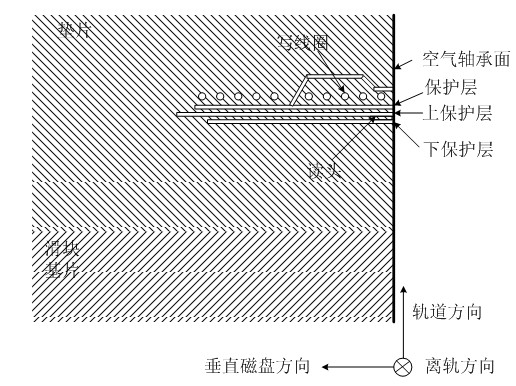

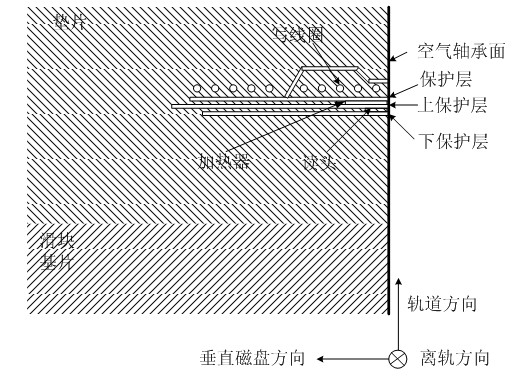

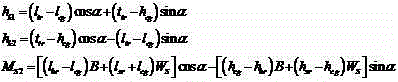

A thermal fly height control slider for hard drives

InactiveCN102280112AFlying lowHigh speedFluid-dynamic spacing of headsSupport for headsHard disc driveFlying height

The invention provides a thermal flying-height control slider for a hard disk drive. In the thermal flying-height control slider, according to a principle that the read-write magnetic head area of the slider can be subjected to thermal expansion so as to further reduce flying height by electrifying a write coil in a magnetic head write process, a microheater is additionally arranged at a selected middle position of a read-write magnetic head on the hard disk slider, and a unique and efficient W-shaped microheater structure is designed. By means of the structure, the magnetic reading head can obviously move downwards in a read operation process, the flying height of the hard disk magnetic head in the read operation process is decreased, and the precision and the efficiency of data read are increased.

Owner:HUAZHONG UNIV OF SCI & TECH

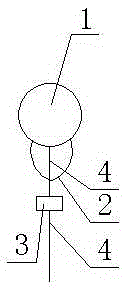

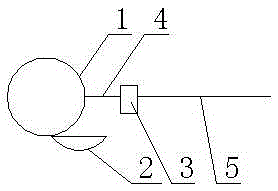

Compact type tethered balloon

InactiveCN106335623AOptimized aerodynamic shape designReduce weightBalloon aircraftsGas-bag arrangementsMarine engineeringSafety valve

The invention discloses a compact type tethered balloon which comprises an air bag (1), a wind direction sail (2), an inflating and deflating valve, a safety valve, a working platform (3), a tethered (4), a tethered hinge (5) and task equipment, wherein the air bag (1) is spheroidal; the wind direction sail (2) is mounted on the air bag (1); the inflating and deflating valve and the safety valve are mounted at an inflating opening of the air bag (1); the task equipment is arranged on the working platform (3); one end of the tethered (4) and one end of the tethered hinge (5) are respectively connected with the working platform (3); the other end of the tethered (4) is connected with the air bag (1). The compact type tethered balloon disclosed by the invention has the advantages that the quickly arranged compact type tethered balloon system optimizes the design of a pneumatic appearance, cancels pressure adjustment equipment, simplifies system mooring equipment, reduces the weight of the tethered and the number of transportation units, so that the compact type tethered balloon has the advantages of being convenient and quick in arrangement, low in design and production cost and the like.

Owner:CHINA SPECIAL TYPE FLIER RES INST

Single yarn, manufacturing method of single yarn, single yarn products and manufacturing method of single yarn product

The invention relates to a single yarn, a manufacturing method of the single yarn, single yarn products and a manufacturing method of the single yarn products. The manufacturing method of the single yarn includes bundling or bundling and twisting ultra-high molecular weight polyethylene films or strips to obtain the single yarn. The single yarn product at least comprises a body made with the single yarn. The single yarn made by bundling or bundling and twisting the ultra-high molecular weight polyethylene films or strips replaces traditional ultra-high molecular weight polyethylene fibers in developing and manufacturing various products. The single yarn has the advantages, such as wear resistance, impact resistance, corrosion resistance and ultraviolet resistance, similar to those of the ultra-high molecular weight polyethylene fibers; the single yarn further has the unique advantages, such as good structural integrity, high strength, high utilization rate of strength, high productivity, low manufacturing cost, light weight and low linear density. Therefore, the single yarn can replace the traditional ultra-high molecular weight polyethylene fibers in manufacturing the various products and is widely applicable.

Owner:ZHENGZHOU ZHONGYUAN DEFENSE MATERIAL

Ocean observation float mooring system and mixed cable for same

ActiveCN110761095ASmall linear densityHigh breaking strengthWaterborne vesselsBuoysMooring systemOcean observations

The invention discloses an ocean observation float mooring system and a mixed cable for the same. The mixed cable comprises a metal fiber mixed cable core and fiber cable skin, the metal fiber mixed cable core comprises a metal spiral spring and a fiber supporting core arranged inside the metal spiral spring, the fiber cable skin is formed by twisting and weaving multiple fiber cable strands, andmass content of the metal fiber mixed cable core is not greater than 20% of mass of the mixed cable while that of the fiber cable skin is not smaller than 80% of the mass of the mixed cable. The mixedcable is small in linear density and high in breaking strength, can serve as a data transmission channel between an underwater sensor and a water surface receiver, has the advantages of softness, light weight and easiness in laying that fiber mooring cables have and has good application prospect in the ocean observation float mooring system.

Owner:SHANDONG ROPE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com