Patents

Literature

185results about How to "Improve sun protection effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microcapsule wrapping solid sun-screening agent, preparation method and application thereof

ActiveCN103169625AStrong UV Absorbing PropertiesImprove sun protection effectCosmetic preparationsToilet preparationsCelluloseUltraviolet

The invention discloses a microcapsule wrapping a solid sun-screening agent, a preparation method and application thereof. The microcapsule comprises the solid sun-screening agent and a natural polymer. The solid sun-screening agent is wrapped in the microcapsule formed by the natural polymer. The solid sun-screening agent is an inorganic ultraviolet screener, an organic ultraviolet adsorbent or a mixture of the inorganic ultraviolet screener and the organic ultraviolet adsorbent. The natural polymer is agar, agarose, cellulose, chitosan or a derivative thereof. The microcapsule provided by the invention can be used in cosmetic to effectively prevent the solid sun-screening agent from being decomposed, and the sun-screening agent is separated from skin, so that irritation to skin is reduced. Hydrophilic natural polymer can cover color, improve feel and enhance cooperation in cosmetic.

Owner:ETERNAL CHINA INVESTMENT

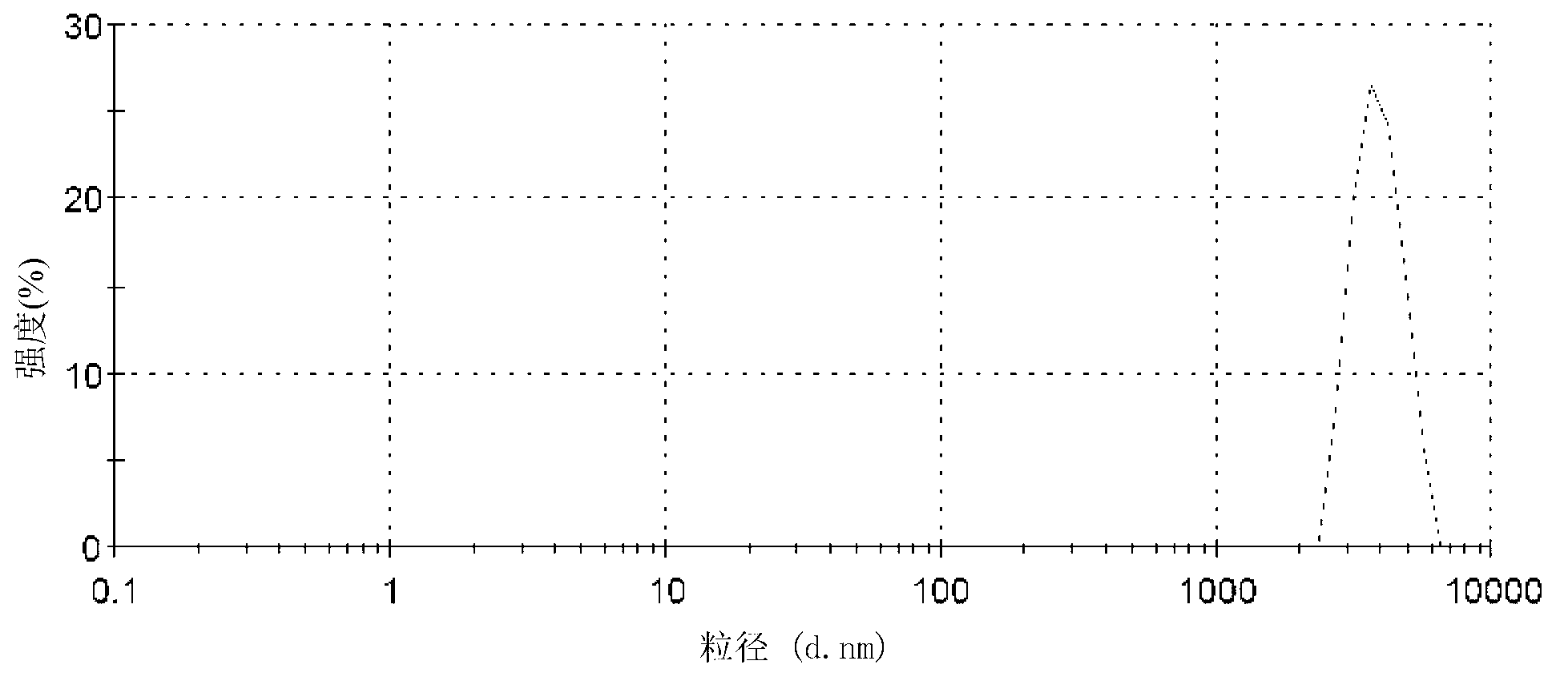

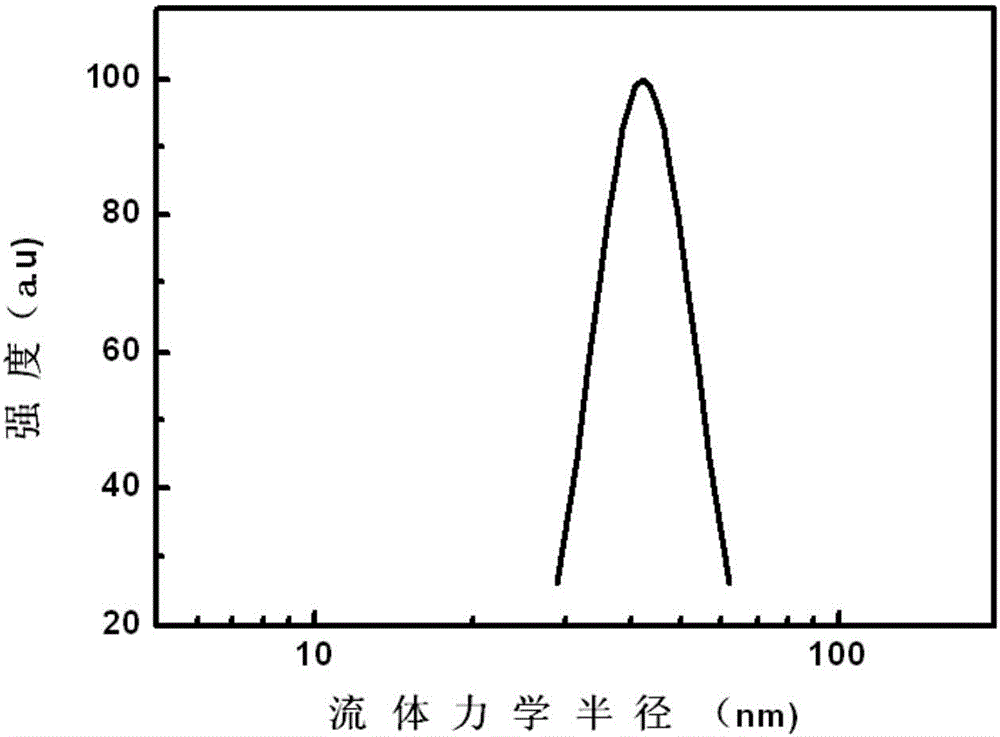

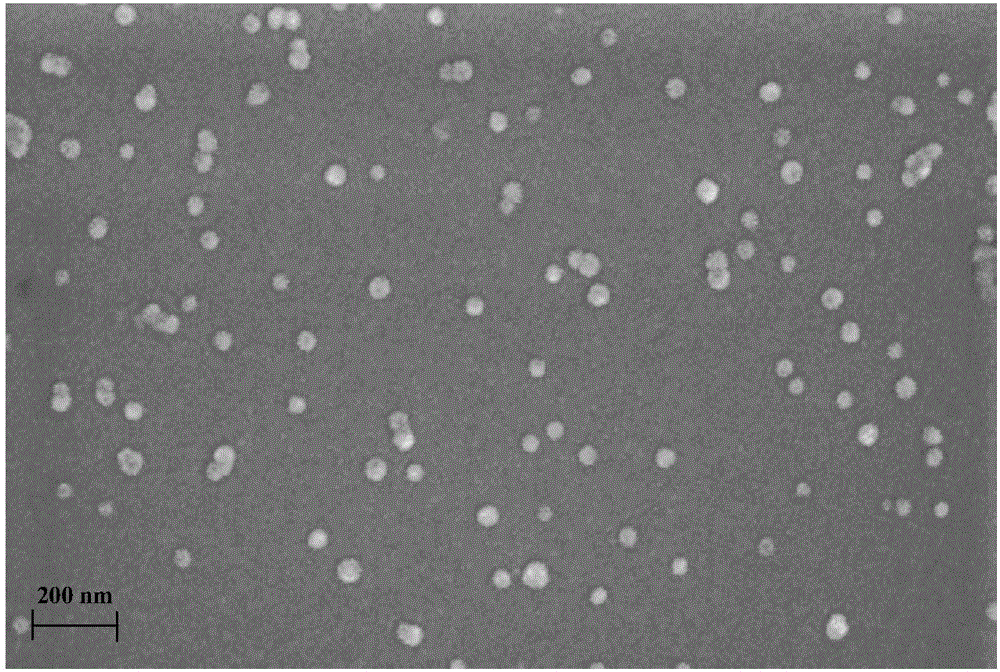

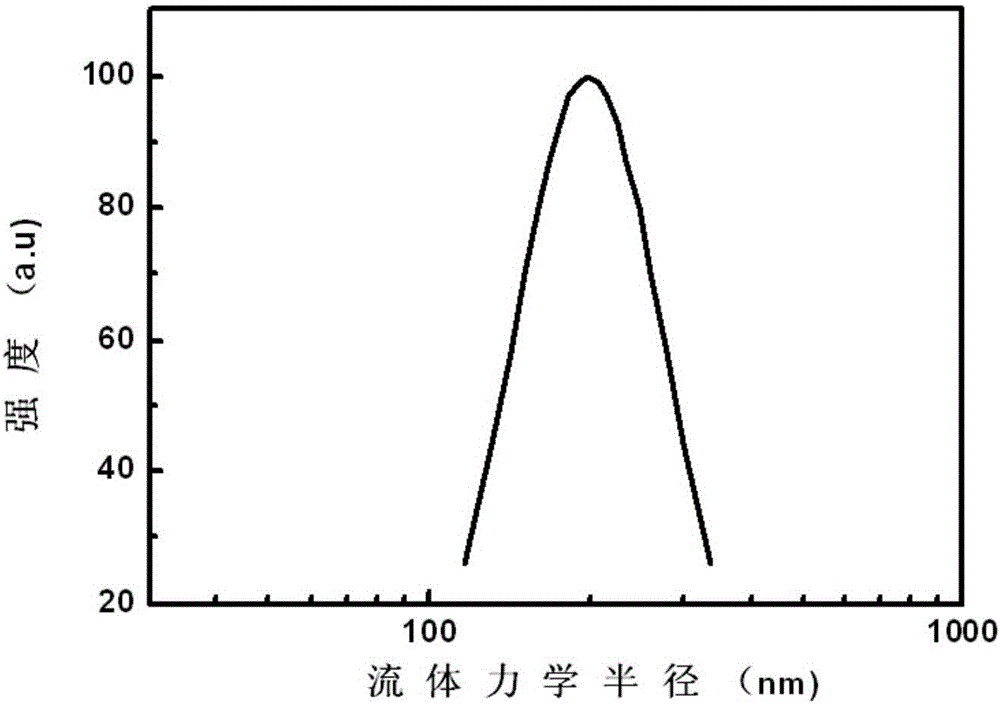

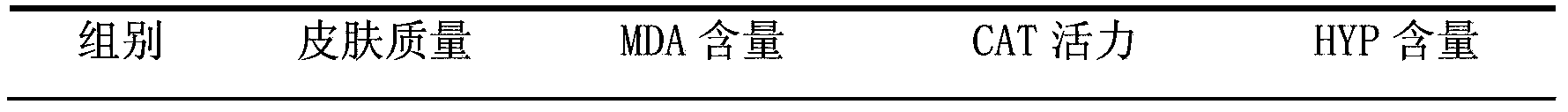

Lignin nano-particles with high ultraviolet protection performance and preparation method of lignin nano-particle

InactiveCN106361591APromote absorptionImprove antioxidant capacityCosmetic preparationsToilet preparationsHydrodynamic radiusChemical products

The invention belongs to the technical field of preparation of nano-materials, and discloses lignin nano-particles with high ultraviolet protection performance and a preparation method and application of the lignin nano-particles. The preparation method comprises the following steps: (1) dissolving 0.1-50 parts by weight of lignin in 1,000-2,000 parts by weight of an acetone / water mixed solvent to obtain a lignin organic solution; and (2) mixing the lignin organic solution in the step (1) with 1,000-4,000 parts by weight of water, and stirring to obtain the lignin nano-particles. The hydrodynamic radius of the lignin nano-particles is 50-300 nm, the lignin nano-particles are solid spherical particles of which hydrophilic groups are positioned externally and hydrophobic groups are positioned internally, the number of phenolic hydroxyl groups distributed on the unit area is large, the ultraviolet protection performance is the best, and the oxidation resistance is the most excellent. The size is controllable, the field of large-scale and high-value application of the lignin is expanded, and particularly, the lignin nano-particles which are used as ultraviolet protecting agents have huge application prospect in the field of high-end daily chemical products such as sun block and skin care.

Owner:SOUTH CHINA UNIV OF TECH

Blending regeneration cotton yarn with antimould effect and manufacturing method thereof

InactiveCN104947260AGood flexibilityImprove sun protection effectYarnMonocomponent polyolefin artificial filamentYarnEngineering

The invention discloses blending regeneration cotton yarn with the antimould effect. The cotton yarn is characterized by being manufactured by, by weight, 40-43 parts of waste cotton fabrics, 10-12 parts of cotton yarn leftover materials, 5-7 parts of bamboo charcoal fibers, 1-2 of Guran glycine, 0.5-0.7 part of cetyl trimethyl ammonium bromide, 3-4 parts of hydroxypropyl starch, 4-6 parts of hydroxyl silicone oil emulsion, 39-44 parts of polypropylene, 3-5 parts of nano-zinc oxide, 12-14 parts of liquid paraffin, 9-10 parts of nano-titanium dioxide, 1.5-2 parts of carboxymethyl cellulose, 1-2 parts of glyceryl stearate, 0.4-0.6 part of cason and a proper amount of water. The cotton yarn is formed by blending two kinds of fiber, is high in strength, good in toughness and resistant to wear, and makes up the shortcoming of pure-cotton fiber; by means of respective modification, the sunscreen effect is improved, the anti-microbial and antimould effects are good, the storage time is long, the process can be controlled conveniently in an industrial mode, and the product quality is high.

Owner:SHUNTIAN SPINNING LIMITED

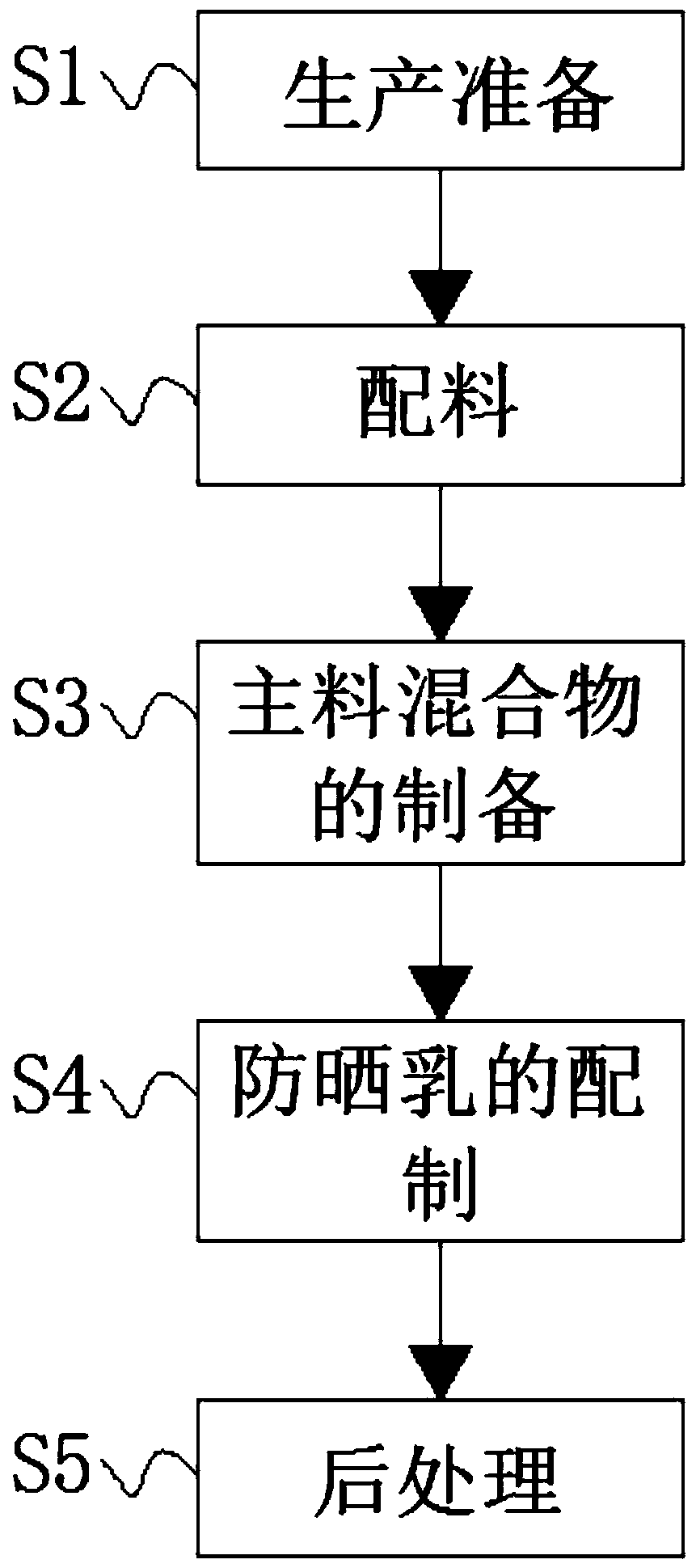

Sun-proof skin care composition and preparation method thereof

InactiveCN103445989AImprove sun protection effectIncrease contentCosmetic preparationsToilet preparationsPROCYANIDOLIC OLIGOMERParaffin wax

The invention provides a sun-proof skin care composition and a preparation method thereof. The composition comprises main raw materials including millet bran oil, oryzanol, procyanidolic oligomer, silicon dioxide, titanium dioxide and the like. The preparation method comprises the following steps: taking liquid paraffin, distill monoglyceride, the millet bran oil and the oryzanol as a phase A; taking the procyanidolic oligomer, polyglycerol fatty acid ester, sucrose fatty acid ester, glycerol and deionized water as a phase B, and the silicon dioxide and the titanium dioxide as a phase C; taking ethylparaben and essence as a phase D; respectively heating and dissolving the phase A and the phase B, so that the temperature achieves 60-75 DEG C; slowly adding the phase B and the phase C to the phase A under a mixing condition respectively; carrying out vacuum nitrogen charge treatment on the system, and adding the phase D when emulsion is cooled to about 45-55 DEG C; and evenly emulsifying and cooling to room temperature. The emulsion prepared from the sun-proof skin care composition can play a role of absorbing or shielding different bands of ultraviolet rays.

Owner:广州市诗盈化妆品科技有限公司

Sunscreen cream with cooling and restoring function

InactiveCN104586692AImprove cooling effectImprove sun protection effectCosmetic preparationsToilet preparationsSunscreen agentsStabilizing Agents

The invention discloses a sunscreen cream with cooling and restoring function. The sunscreen scream comprises the following components in percentage by weight: 17-35% of oils, 20-39% of sunscreen agent, 0.4-0.7% of preservative, 2-7% of stabilizing agent, 2-4% of thickening agent, 7-15% of emulsifying agent, 2-4% of dispersing agent, 0.1% of essence, 0.1% of citric acid, 3-6% of Aloe vera, 0.5-0.8% of allantoin, 1-2% of bisabolol, 1-2% of vitamin E derivatives, 1-2% of menthol and the balance of de-ionized water. The problems existing in the prior art are solved, and the sunscreen cream with cooling and restoring function and good sunscreen effect is provided.

Owner:GUANGZHOU JIUMEI QIANHUI BIOLOGICAL TECH

Oil-control air cushion BB cream and preparation method thereof

InactiveCN107233225APrevent makeupImprove sun protection effectCosmetic preparationsBody powdersScreening effectSilicon dioxide

The invention discloses oil-control air cushion BB cream which comprises, by weight, 2-5 parts of emulsifying agents, 10-30 parts of moisturizing grease, 5-10 parts of sun-screening agents, 0.5-2 parts of trimethylsiloxysilicate, 0.1-2 parts of acrylic acid (ester) / polydimethylsiloxane copolymers, 1-5 parts of spherical silicon dioxide, 0.1-5 parts of polymethylsilsesquioxane, 0.5-5 parts of methyl methacrylate crosslinked polymers, 0.1-1 part of toner, 6-10 parts of titanium dioxide, 0.1-2 parts of thickening agents, 5-15 parts of moisturizing agents, 0.5-1.5 parts of stabilizing agents, 2-5 parts of alpine plant extracts, 0.5-1 part of phenoxyethanol, 0.1-0.5 part of methylparaben, 0.01-0.1 part of essence and 40-50 parts of water. According to the oil-control air cushion BB cream, a hydrophobic permeable film can be formed on surfaces of skins, makeup meltdown caused by sweating in summer and the like can be effectively prevented, and the sun-screening effect of the BB cream can be improved by film forming characteristics of the BB cream.

Owner:DOCTOR PLANT GUANGDONG BIOTECHNOLOGY CO LTD

Soothing anti-allergic cosmetic composition

ActiveCN111494266APrevent and relieve inflammation and symptomsSoothe the skinCosmetic preparationsToilet preparationsSunflower seedChrysanthellum indicum

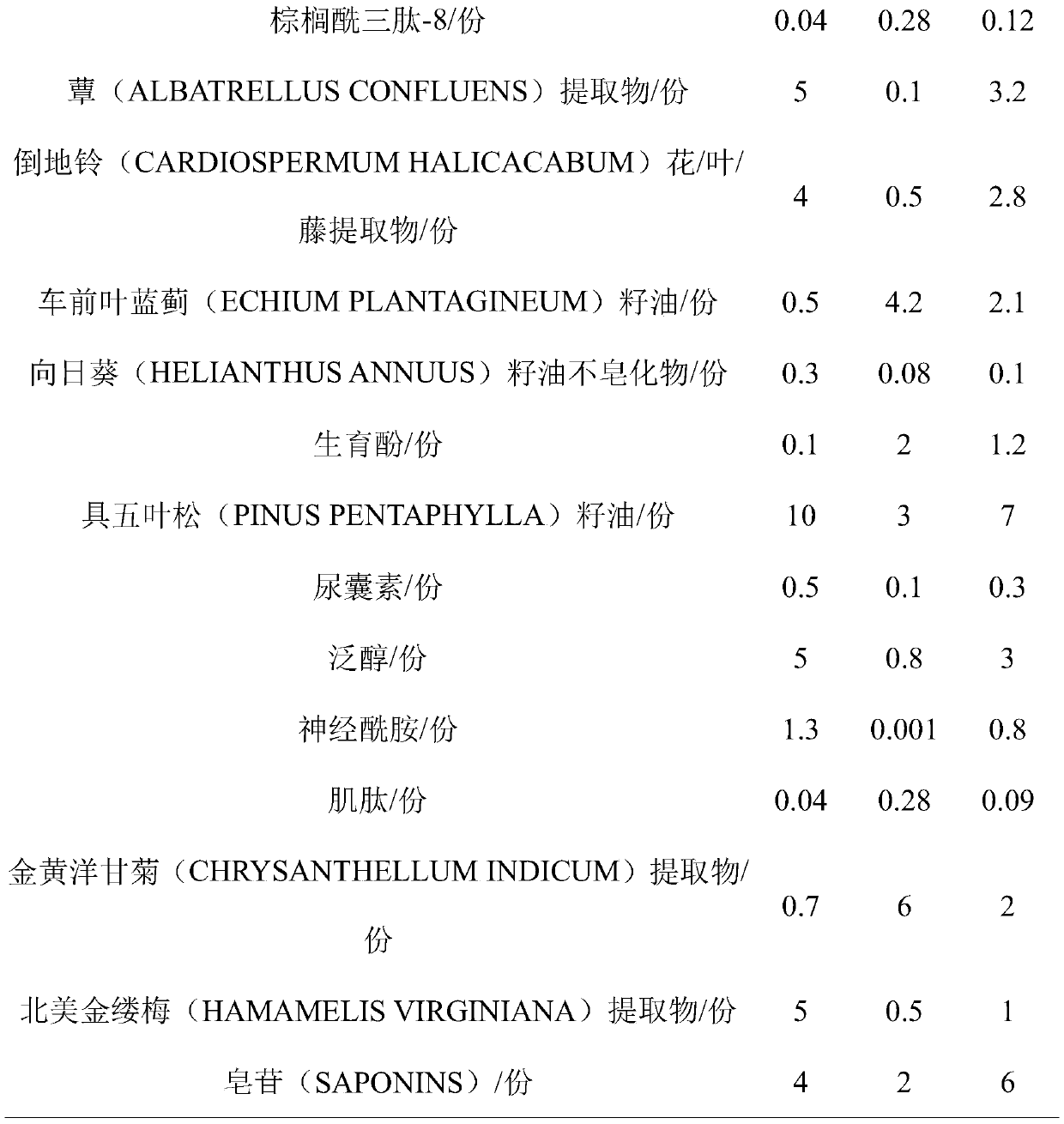

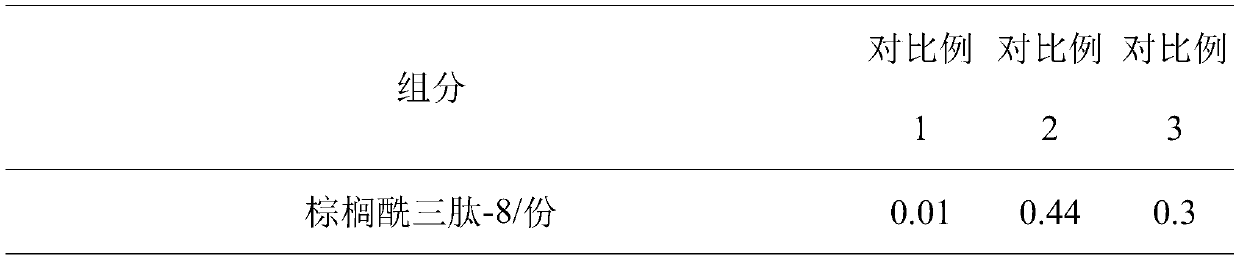

The invention belongs to the technical field of cosmetics, and relates to a soothing anti-allergy cosmetic composition. The composition comprises the following components by weight: 0.04-0.28 part ofpalmitoyl tripeptide-8; 0.1-5 parts of a mushroom extract; 0.5-4 parts of a cardiospermum halicacabum flower / leaf / vine extract; 0.5-4.2 parts of echium plantagineum seed oil; 0.08-0.3 part of sunflower seed oil unsaponifiable matter; 0.1-2 parts of tocopherol; 3-10 parts of pinus pentaphylla seed oil; 0.1-0.5 part of allantoin; 0.8-5 parts of panthenol; 0.001-1.3 parts of ceramide; 0.04-0.28 partof carnosine; 0.7-6 parts of a chrysanthellum indicum extract, 0.5-5 parts of a hamamelis virginiana extract and 2-6 parts of saponin. The soothing anti-allergy cosmetic composition contains differenteffective components in reasonable proportions, all the active components cooperate with one another, sensitive skin can be improved and repaired, stimulation of parts of exogenous factors to the skin can be effectively blocked, and burning heat, stabbing pain, pruritus and taut feeling and other symptoms are not further induced any more.

Owner:广州雅纯化妆品制造有限公司

Sunscreen emulsion containing nanocellulose and preparation method thereof

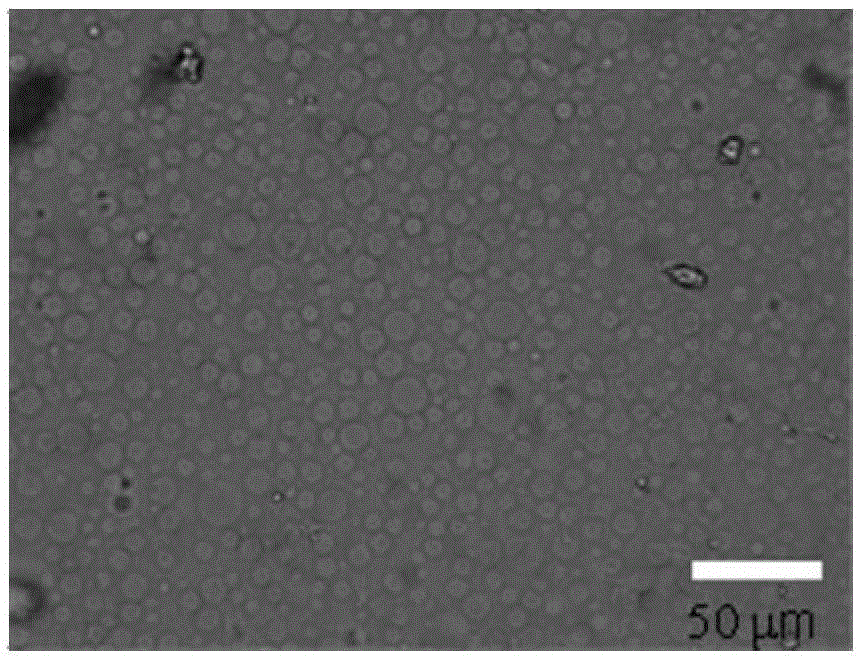

InactiveCN109316367AImprove sun protection effectHigh specific surface areaCosmetic preparationsToilet preparationsEmulsionUltraviolet

The invention belongs to the technical field of preparation of cosmetics, and particularly relates to a sunscreen emulsion containing nanocellulose and a preparation method thereof. The sunscreen emulsion has the characteristics of that by utilizing the nanocellulose, the length-diameter ratio is high, the specific surface area is high, the diameter is smaller than 100 nm and is far smaller than the wavelength of ultraviolet rays, and therefore the sun-screening effect of the sunscreen emulsion is remarkably improved, and the SPF value of the sunscreen emulsion reaches 45-60 nm; the surface ofthe nanocellulose also contains a large amount of hydroxyl groups, the hydroxyl groups and polar components in the emulsion can form hydrogen bonds and can be combined stably in the sunscreen emulsion, and therefore the problem that particles in a traditional physical sunscreen emulsion fall off can be solved; and meanwhile, the nanocellulose is nano-particles prepared by carrying out chemical ormechanical treatment on natural plant fibers, no damage is caused to the skin, the hydroxyl groups on the surface of the cellulose is excellent in hydrophily and water absorbing and moisturizing performance, and therefore, and an obvious hydrating effect is further achieved after the sunscreen emulsion with the nano-cellulose is added.

Owner:SOUTH CHINA UNIV OF TECH

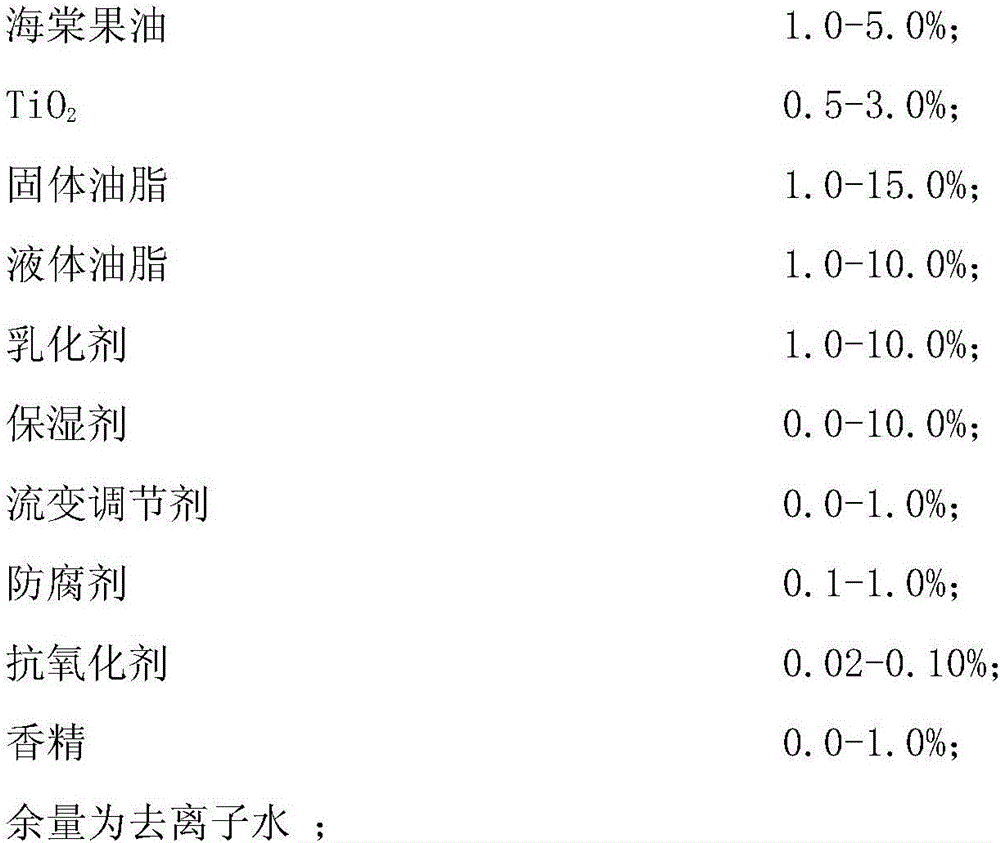

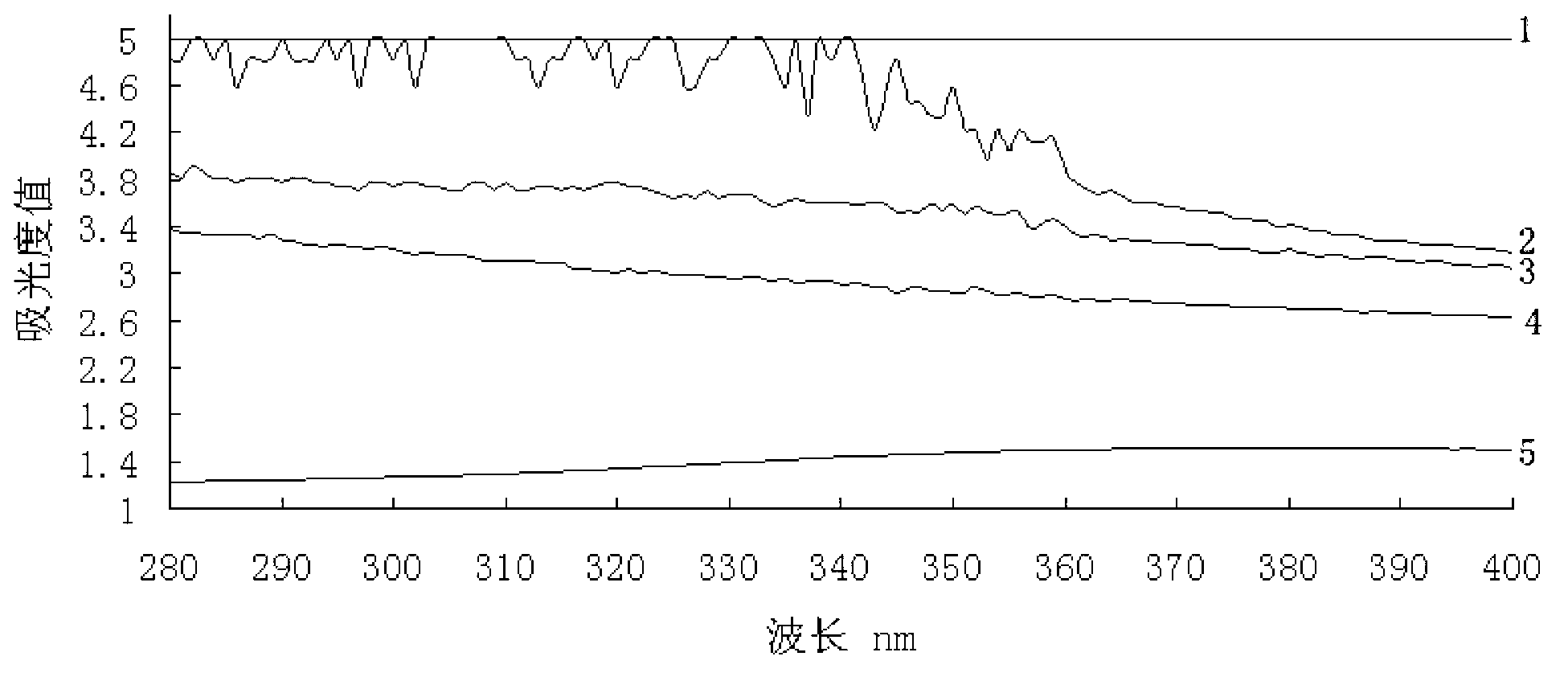

Cosmetic containing calophyllum inophyllum kernel oil and preparation method thereof

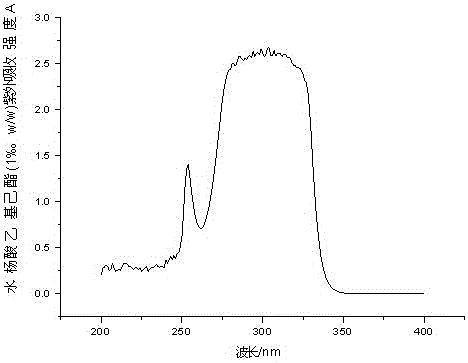

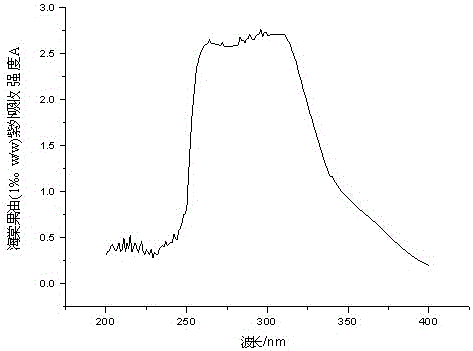

InactiveCN105726365AStrong UV Absorbing PropertiesWide absorption rangeCosmetic preparationsToilet preparationsCalophyllum inophyllumEmulsion

The invention provides a cosmetic containing crabapple oil, wherein the mass percentage of the crabapple oil in the cosmetic is 1-5%, and the skin cosmetic is a skin cream, lotion, or skin care gel. The present invention also provides a preparation method of the above-mentioned cosmetics. The crabapple fruit oil adopted in the invention has strong ultraviolet absorption and wide absorption range, and when used together with the physical sunscreen agent titanium dioxide, it has obvious synergistic effect. Therefore, crabapple fruit oil is used as a sunscreen and skin care agent in skin cosmetics, and the final skin cosmetics obtained are natural and safe. While enhancing the sunscreen effect of skin cosmetics, they also have the characteristics of anti-oxidation and the like.

Owner:SHANGHAI INST OF TECH

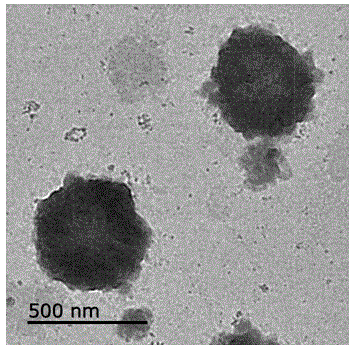

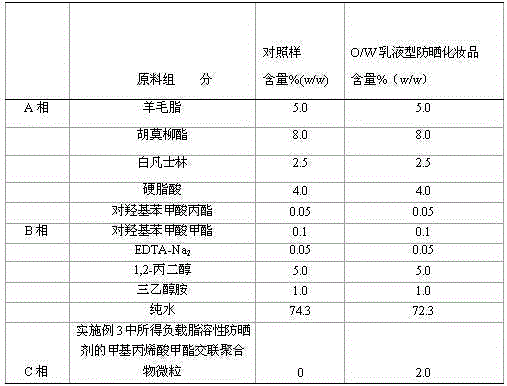

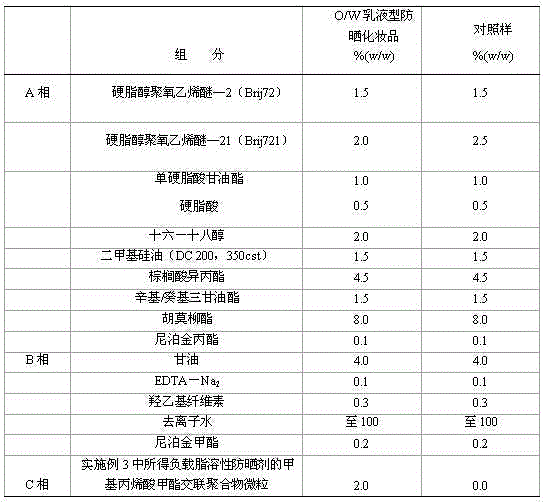

Methyl methacrylate cross-linked polymer microparticle loaded with lipid-soluble sun-screening agent and preparation method of microparticle

InactiveCN104873412AReduce absorptionLess irritatingCosmetic preparationsToilet preparationsPolymer scienceSunscreen agents

The invention discloses a methyl methacrylate cross-linked polymer microparticle loaded with a lipid-soluble sun-screening agent and a preparation method of the microparticle. The methyl methacrylate cross-linked polymer microparticle loaded with the lipid-soluble sun-screening agent is of a core-shell structure, wherein the lipid-soluble sun-screening agent serves as a core and a methyl methacrylate cross-linked polymer functions as a shell; and at 25 DEG C, the microparticle is 178.2-1298nm in granularity and is 10.81-51.96% in embedding rate. The preparation method comprises the following steps: dissolving a surfactant in de-ionized water at room temperature to obtain an aqueous phase; uniformly mixing the lipid-soluble sun-screening agent with methyl methacrylate and divinyl benzene so as to obtain an oily phase; mixing, homogenizing and emulsifying the oil phase and the aqueous phase, then adding an initiator and reacting at 30-75 DEG C for 4-8h so as to obtain a reaction liquid; and demulsifying, filtering, cleaning, suction-filtering and drying the reaction liquid so as to obtain the methyl methacrylate cross-linked polymer microparticle loaded with the lipid-soluble sun-screening agent.

Owner:SHANGHAI INST OF TECH

Waterproof sweat-resisting full-range sunscreen skin-care product

ActiveCN109077974AEliminate the effects ofTo achieve the purpose of full-band broad-spectrum sun protectionCosmetic preparationsToilet preparationsSunscreen agentsUltraviolet

The invention relates to a waterproof sweat-resisting full-range sunscreen skin-care product, comprising: three components A forming a polyol aqueous phase; component B, including 1-10 parts of water,1-5 parts of phenylbenzimidazole sulfonic acid, and 0.5-2.0 parts of aminomethyl propanol; three components C, forming a polyurethane sunscreen core. A composite structure is finally formed to obtainoptimal wetproof effect. The waterproof sweat-resisting full-range sunscreen skin-care product is an oil-in-water cream product, giving skin cool and light feeling, and providing good waterproof andsweat-resisting properties. The waterproof sweat-resisting full-range sunscreen skin-care product has high sunscreen index and PA protection value, can reach SPF50 and PA+++, and can protect skin forlong time. A sunscreen agent herein has good light stability and high safety, can resist ultraviolet, rarely produces free radicals, and causes less burden on skin. The plant anti-allergy and anti-inflammation ingredients and materials to resist visible light and infrared are added, thereby preventing inflammation and photo-aging, preventing red spots and pigmentation, and improving protecting efficiency of the product herein; full-range sun screening is truly achieved.

Owner:TIANJIN KANGTING BIOLOGICAL ENG GRP CO LTD

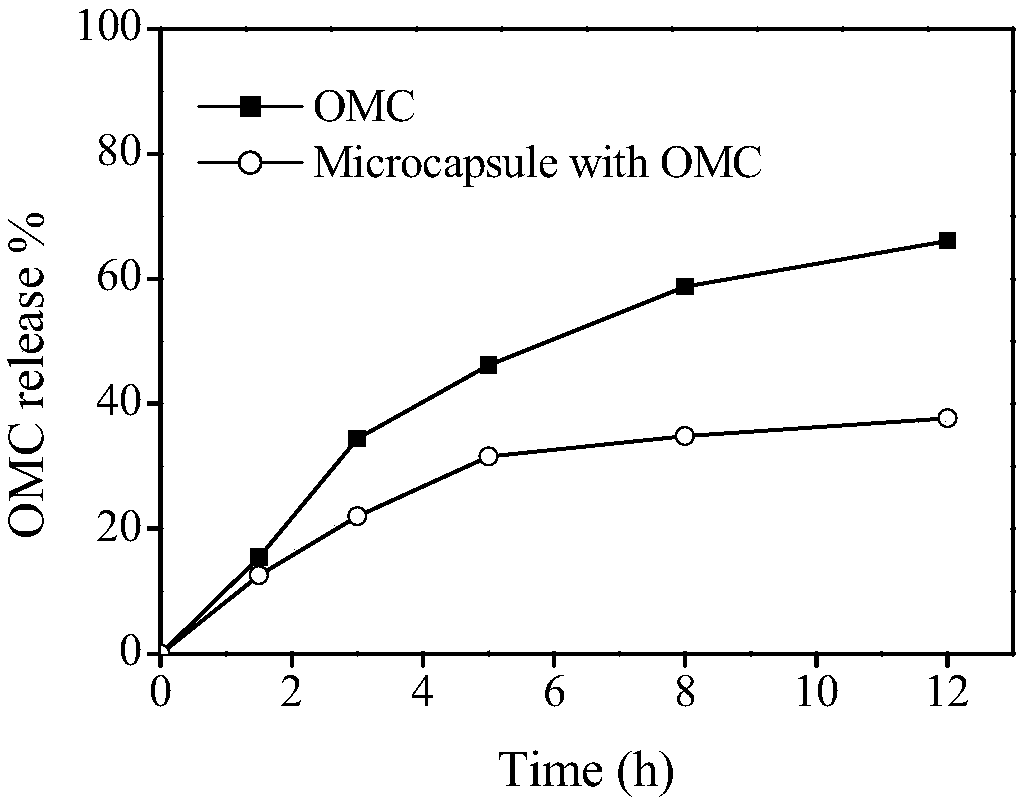

Method for preparing synergistic sunscreen micron capsule by virtue of composite condensation

InactiveCN108969388AImprove sun protection effectLow priceCosmetic preparationsToilet preparationsEmulsionSodium Caseinate

The invention discloses a method for preparing a synergistic sunscreen micron capsule by virtue of composite condensation. The method comprises the following steps: (1) preparing sodium caseinate solution with pH of 6-8; (2) preparing Arabic gum solution with pH of 6-8; (3) adding a core material, the mass ratio of the core material to a wall material being 1:1; (4) shearing with a high-speed shearing machine to form uniform and milk white emulsion; (5) dropwise adding the emulsion in step (4) into the solution in step (2), wherein, pH is 2.3-3.0, and reacting at 30-50DEG C; (6) cooling the solution in step (5) to room temperature; (7) adding a curing agent, and controlling the curing temperature to 10-30DEG C to obtain the sunscreen micro capsule; (8) standing and precipitating the obtained product to separate out supernate; and (9)freezing and drying the precipitate obtained in step (8) to obtain the synergistic sunscreen micron capsule. The wall material selected by the invention isa natural macromolecule compound having an ultraviolet adsorption effect, sodium caseinate is abundant in nature and cheap in price and has good biocompatibility. The sunscreen effect of the synergistic sunscreen micron capsule is higher than that of a sun-screening agent.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

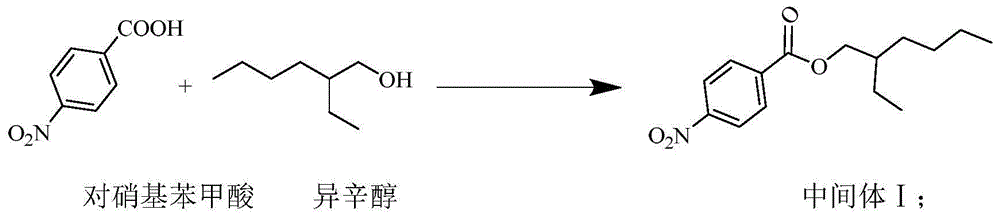

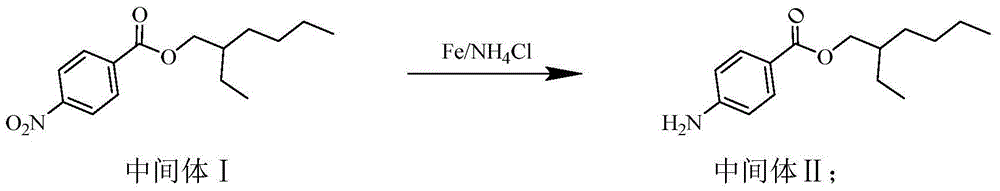

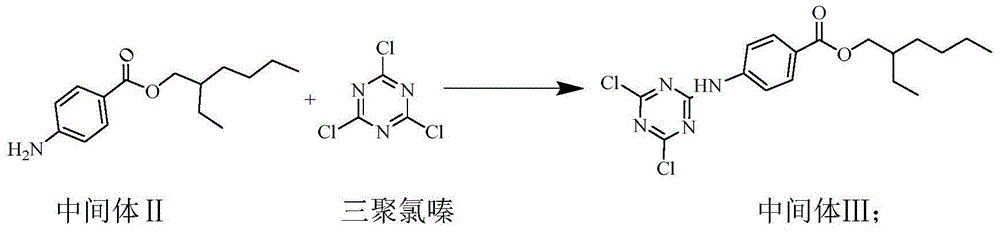

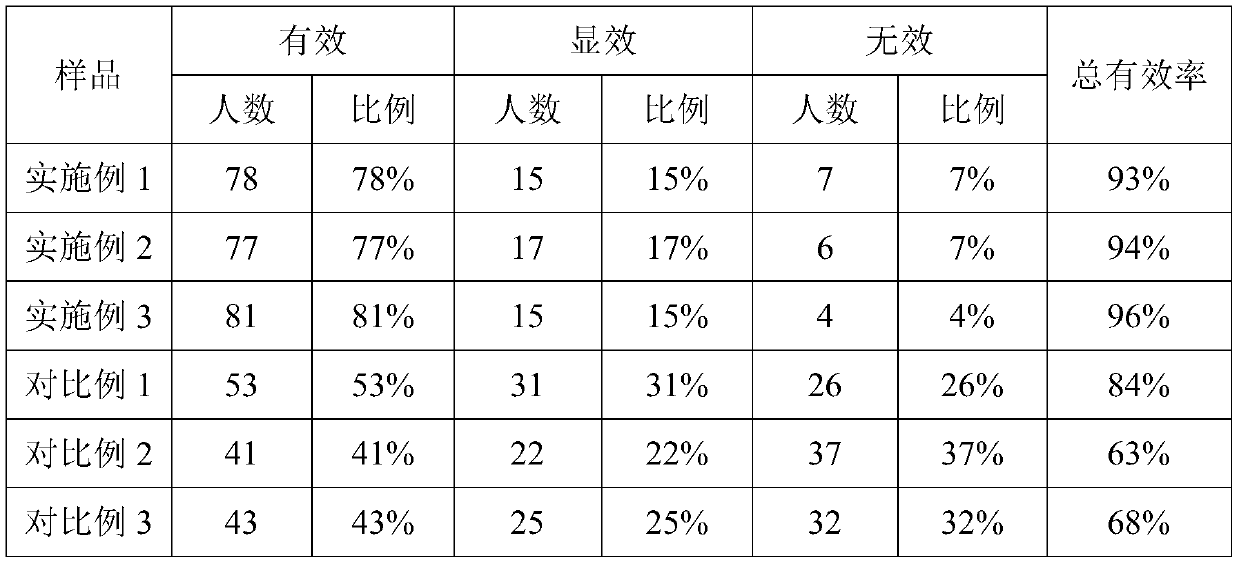

Synthetic method for ultraviolet absorbent--octyl triazone

The invention relates to a synthetic method for an ultraviolet absorbent--octyl triazone. The method comprises the following steps: with sodium bisulfate as a catalyst, reacting p-nitrobenzoic acid with isooctanol under the action of toluene so as to prepare an intermediate I; allowing the intermediate I to be reduced by iron powder and ammonium chloride in a methanol-water solution so as to obtain an intermediate II; subjecting the intermediate II to reaction with melamine in an acetone solution so as to prepare an intermediate III; and subjecting the intermediate II and the intermediate III to reaction in a toluene solution so as to obtain octyl triazone, wherein the purity of liquid phase reaches 99.45%. The synthetic method provided by the invention has the characteristics of usage of easily-available raw materials, mild reaction conditions, short reaction time, low pollution, high yield, etc., and is suitable for industrial production.

Owner:湖北君邦新材料科技有限公司

Sunscreen lotion and preparation method thereof

ActiveCN110559197AReduce dosageImprove securityCosmetic preparationsToilet preparationsIrritationSandalwood extract

The invention belongs to the field of cosmetics, and particularly relates to a sunscreen lotion and a preparation method thereof. The sunscreen lotion provided by the invention belongs to the water-in-oil type sunscreen lotion; meanwhile, a physical sun-screening agent alkyl silicon is used for treating the nano zinc oxide, oil-dispersed nano titanium dioxide, a chemical sun-screening agent ethylhexyl methoxycinnamate, diethylaminohydroxybenzoyl hexyl benzoate, a natural plant sun-screening agent wild soybean seed extract, a sandalwood extract and a lotus leaf extract are mixed and matched, sothat the sunscreen lotion has better safety and stability and small irritation, and the sunscreen performance of the skin is remarkably enhanced. Moreover, due to the addition of the natural plant sun-screening agent, the dosage of the chemical sun-screening agent is reduced, and the natural plant sun-screening agent also has an after-sun repairing effect, has better compatibility with the skin and is good in mildness.

Owner:卡丝生物(广东)科技有限公司

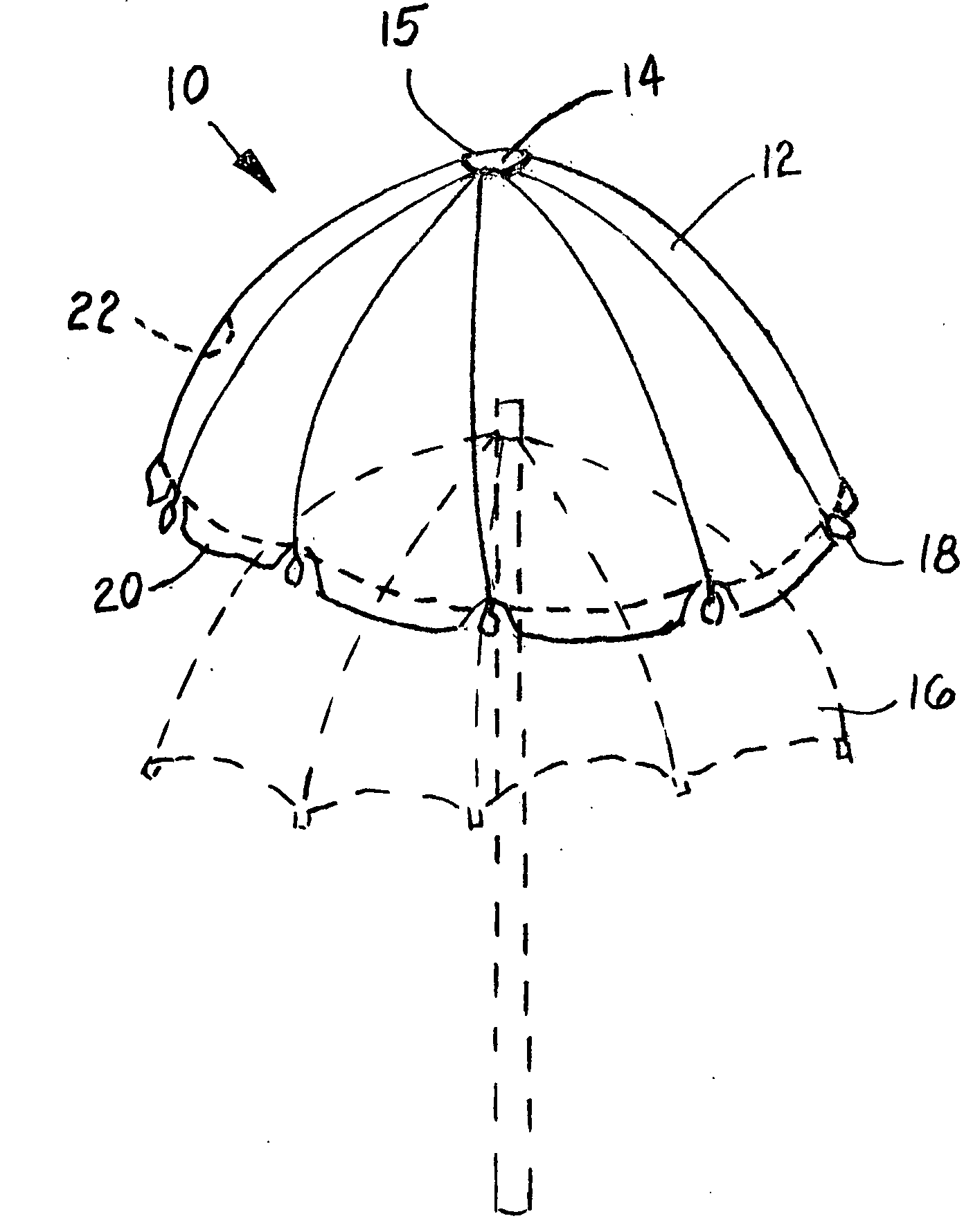

Reflective overlay for shade umbrellas

InactiveUS20080308139A1Improve sun protection effectReduce the temperatureWalking sticksTents/canopiesEngineeringReflective layer

A reflective overlay for shade umbrellas that is both functional and decorative. A substantially circular piece of fabric with a reflective outer surface has a central aperture for positioning on a host umbrella. Built into the periphery are a multiplicity of flaps with gaps between adjacent flaps and at least two attachment means connected to the outer periphery at said gaps for removably attaching the reflective overlay at the periphery of a host umbrella dome.

Owner:KEESLING JERRY M

Sunscreen cream cosmetic composition containing nano crystal cellulose

ActiveCN103230355AAvoid exposureProtect the skinCosmetic preparationsToilet preparationsCelluloseUltraviolet b

The invention discloses a sunscreen cream cosmetic composition containing nano crystal cellulose. The sunscreen cream cosmetic composition comprises the nano crystal cellulose and nano titanium dioxide. The sunscreen cream cosmetic composition is used for a sunscreen cream, is capable of preventing ultraviolet irradiation in a UVA (Ultraviolet A) region being 320-400nm and a UVB (Ultraviolet B) region being 280-320nm, and is high in sunscreen efficiency; and the sun protect factor (SPF) value is more than 15. The sunscreen cream is safe for a human body without toxicity, and can be suitable for being used by various kinds of persons.

Owner:珠海市红旌发展有限公司

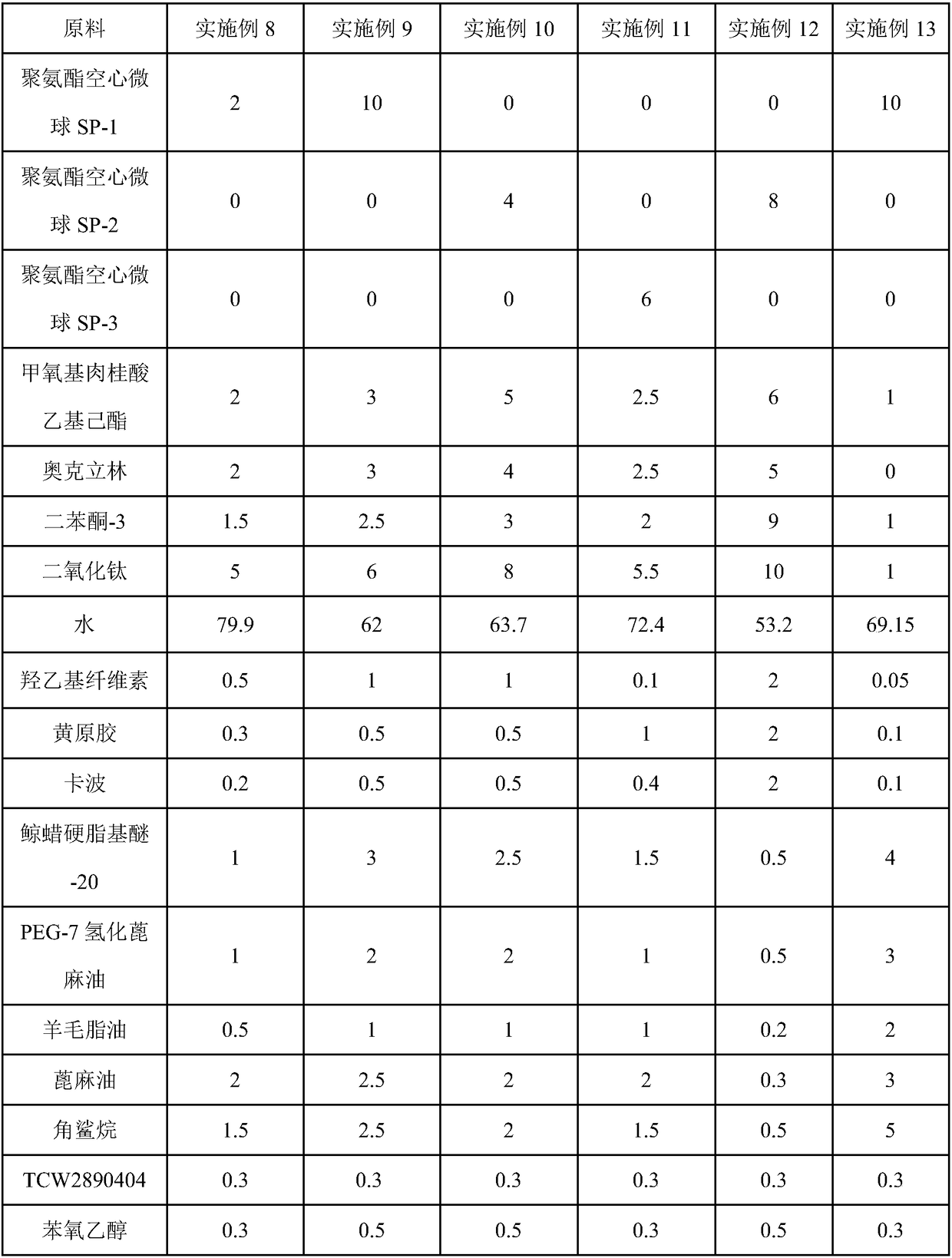

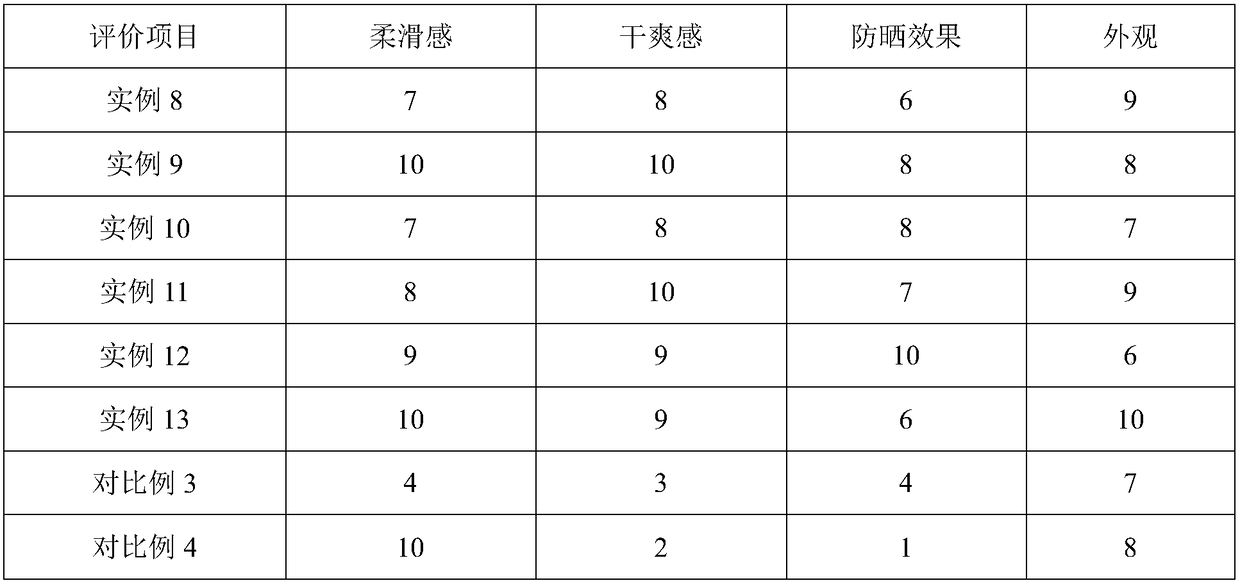

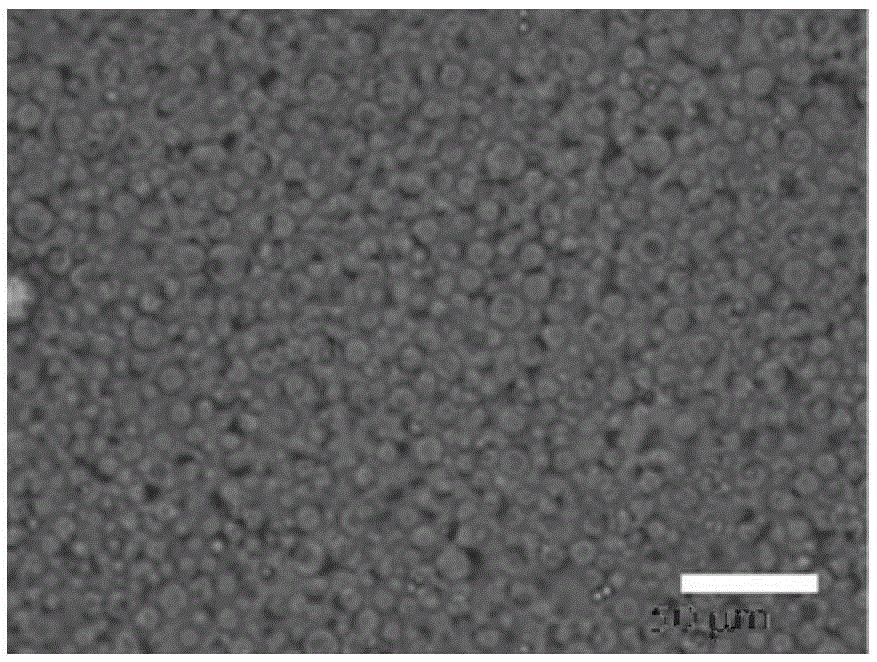

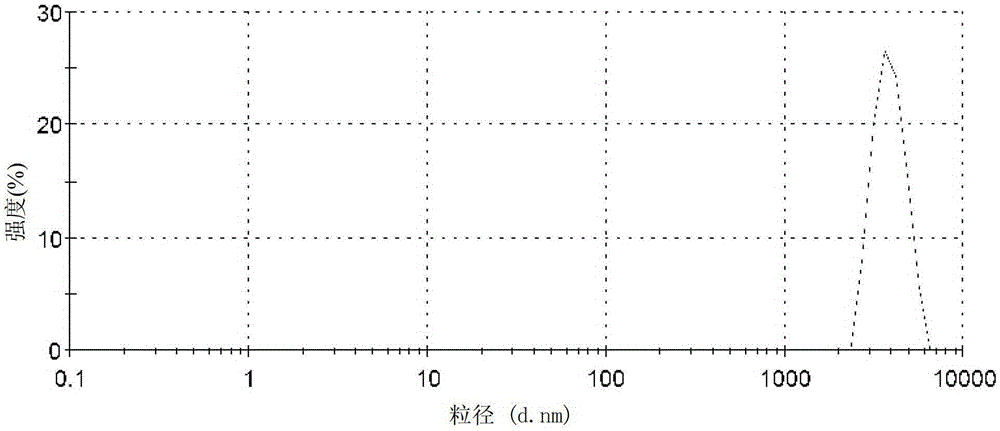

Preparation method of hollow polyurethane microspheres and photo-protection cosmetic composition containing hollow polyurethane microspheres

ActiveCN108175716ASoft skinSmooth and non-greasy skinCosmetic preparationsToilet preparationsHollow coreElastic skin

The invention relates to photo-protection cosmetic composition containing hollow polyurethane microspheres and a preparation method of the hollow polyurethane microspheres. Specifically, the composition has unique effects in aspects of high smooth and refreshing skin feelings while protecting skin against visible sunlight radiation. The hollow polyurethane microspheres are shells with specific optical performance and specific soft and elastic skin feelings, can bring smooth and refreshing skin feelings and the like to the photo-protection cosmetic composition and can effectively increase the SPF (sun protection factor) value of sun cream.

Owner:WANHUA CHEM GRP CO LTD +1

Sunscreen mist spray and preparation method thereof

InactiveCN108158852AProlong the action timeUniform adhesionCosmetic preparationsToilet preparationsSunscreen agentsIrritation

The invention provides a sunscreen mist spray which comprises the following raw materials: methoxy-cinnamic acid ethylhexyl acrylate, octocrilene, bi-ethyl hexyloxyphenol methoxyphenyl triazine, butylmethoxy-dibenzoyl methane, natural phospholipid, absolute ethyl alcohol, titanium dioxide, zinc oxide, polydimethylsiloxane, polydimethylsiloxane, an emulsifier, 1,2-pentanediol, disodium hydrogen phosphate, sodium alginate, mannitol, sodium hyaluronate and water. A preparation method comprises the following steps: firstly, preparing lipidosome from chemical sunscreen agents, and together with physical sunscreen agents, preparing the sunscreen mist spray. By adopting the sunscreen mist spray, on one hand, irritation of the chemical sunscreen agents to skin can be reduced, on the other hand, the sunscreen agents can be uniformly clung to the surface of skin, the action time of the chemical sunscreen agents is prolonged, the overall sunscreen effect of the mist spray is greatly improved, and the use amount of the mist spray can be reduced.

Owner:QINGDAO BAIRUIJI BIOTECH

New non-hygroscopic wear-resisting anti-bacterial polypropylene fiber and recycled cotton blended yarn and preparation method thereof

InactiveCN104911776AGood moisture absorptionHigh strengthMonocomponent polyolefin artificial filamentYarnYarnSurface water

The invention discloses a new non-hygroscopic wear-resisting anti-bacterial polypropylene fiber and recycled cotton blended yarn, which is characterized by being prepared from the following raw materials in parts by weight: 40 to 43 parts of waste cotton fabrics, 15 to 17 parts of cotton yarn leftover bits and pieces, 1 to 2 parts of carnauba wax, 1 to 2 parts of polyoxyethylene fatty alcohol sodium sulfate, 5 to 7 parts of silicone acrylic emulsion, 3 to 4 parts of pre-gelatinized starch, 39 to 44 parts of polypropylene, 3 to 5 parts of nano-zinc oxide, 12 to 14 parts of liquid paraffin, 9 to 10 parts of nanometer titania, 1.5 to 2 parts of carboxymethylcellulose, 1 to 2 parts of glyceryl stearate and a moderate amount of water. According to the new non-hygroscopic wear-resisting anti-bacterial polypropylene fiber disclosed by the invention, after surface water proofing and sun-screening treatment is performed on recycled cotton fibers prepared from the waste cotton fabrics and the like, the waste cotton fabrics are blended with polypropylene fibers modified through sun-screening to form the yarn, and the prepared blended yarn is firm, wear-resisting, high in strength and light in specific gravity, and does not easily absorb moisture; the blended yarn can be used for manufacturing underwater clothing, such as swimsuits, or netting twines and the like; the quality of the recycled cotton fibers is promoted, and the application range of the recycled cotton is broadened.

Owner:SHUNTIAN SPINNING LIMITED

Multi-fiber added antibacterial warming regenerated blended cotton yarn and preparation method thereof

InactiveCN104911897AHigh strengthIncrease elasticityYarnMonocomponent polyolefin artificial filamentYarnHigh fracture

The present invention discloses a multi-fiber added antibacterial warming regenerated blended cotton yarn characterized by being prepared from the following raw materials in parts by weight: 5-7 parts of seaweed carbon fiber, 3-5 parts of soybean protein fiber, 30-33 parts of waste cotton fabrics, 15-17 parts of cotton yarn scrap, 39-44 parts of polypropylene, 3-5 parts of nano-zinc oxide, 12-14 parts of liquid paraffin, 9-10 parts of nano-titanium dioxide, 1.5-2 parts of carboxymethyl cellulose, 1-2 parts of glyceryl stearate, 0.7-0.9 parts of silane coupling agent kh-550, 5-7 parts of pure acrylic emulsion, and proper amount of water; by combination of the two steps, the treated recycled cotton fibers and modified polypropylene fiber are blended into yarn which is capable of emitting far infrared and negative ions, has good antibacterial effect, the produced product has good warming property, high strength, high fracture strength, lower production cost, safety and environmental friendliness, and the quality of the regenerated cotton yarn is improved.

Owner:SHUNTIAN SPINNING LIMITED

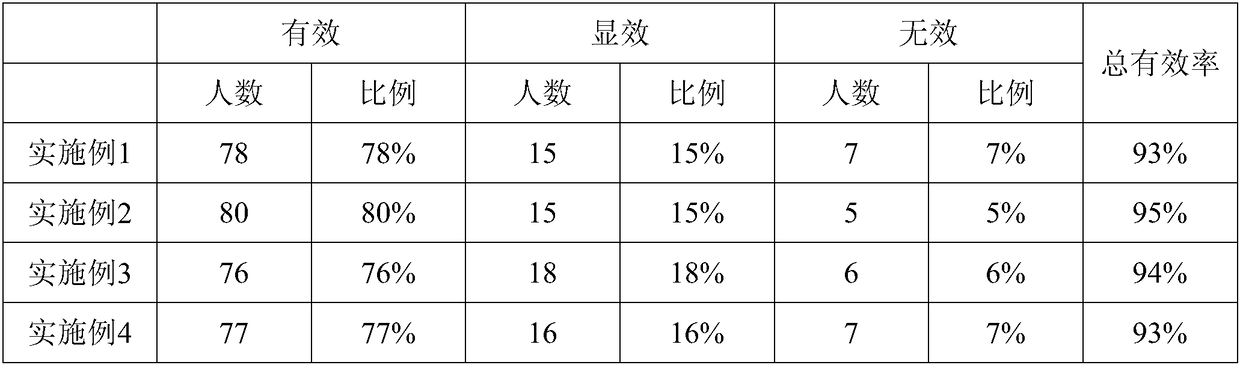

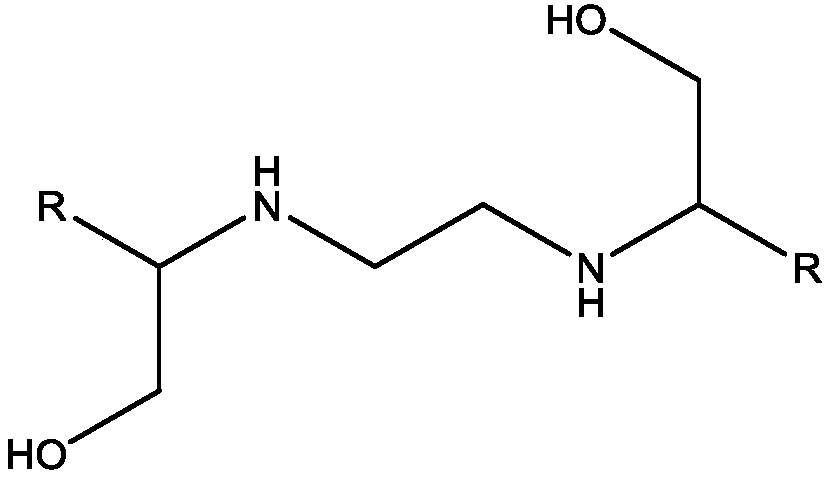

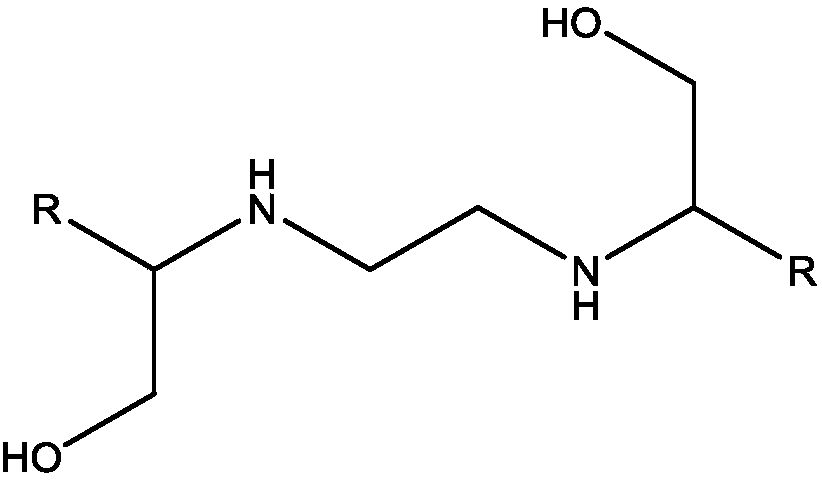

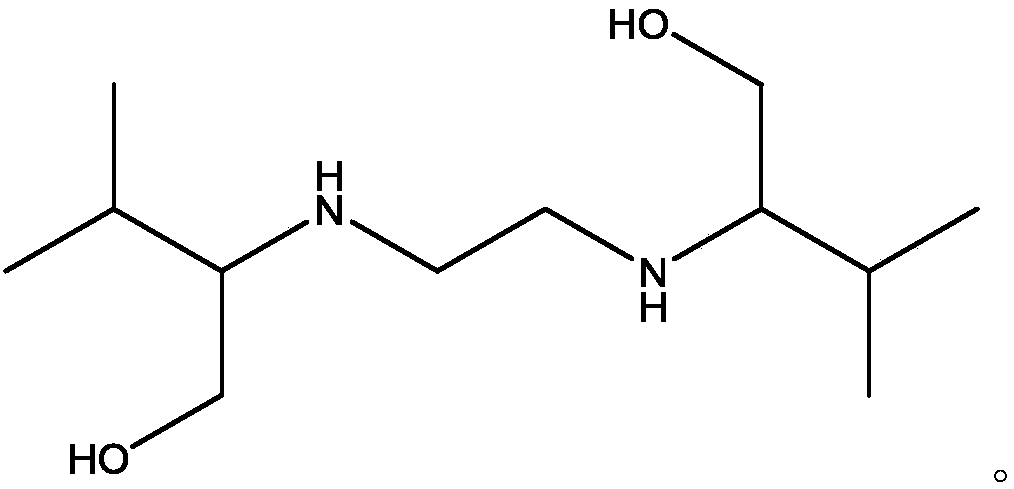

Waterborne polyurethane dispersion, preparation method thereof and sunscreen cosmetic composition

ActiveCN110613633AImprove adhesionMolecular chain lengthCosmetic preparationsToilet preparationsPolyurethane dispersionMoisture

The invention discloses a waterborne polyurethane dispersion, a preparation method thereof and a sunscreen cosmetic composition. According to the waterborne polyurethane dispersion, a diamine chain extender containing two hydroxyl groups is used for preparing the sunscreen cosmetic composition, so that the waterborne polyurethane dispersion resin has relatively good waterproof performance, good adhesive force on the surface of human skin and a moisture-permeable effect; the sunscreen index (SPF value) can be increased; and the skin feeling can be improved.

Owner:WANHUA CHEM GRP CO LTD +2

Microcapsule for wrapping solid sunscreen, preparation method and application thereof

ActiveCN103169625BStrong UV Absorbing PropertiesImprove sun protection effectCosmetic preparationsToilet preparationsCelluloseIrritation

The invention discloses a microcapsule wrapping a solid sun-screening agent, a preparation method and application thereof. The microcapsule comprises the solid sun-screening agent and a natural polymer. The solid sun-screening agent is wrapped in the microcapsule formed by the natural polymer. The solid sun-screening agent is an inorganic ultraviolet screener, an organic ultraviolet adsorbent or a mixture of the inorganic ultraviolet screener and the organic ultraviolet adsorbent. The natural polymer is agar, agarose, cellulose, chitosan or a derivative thereof. The microcapsule provided by the invention can be used in cosmetic to effectively prevent the solid sun-screening agent from being decomposed, and the sun-screening agent is separated from skin, so that irritation to skin is reduced. Hydrophilic natural polymer can cover color, improve feel and enhance cooperation in cosmetic.

Owner:ETERNAL CHINA INVESTMENT

High-sun-blocking automobile window based on electrochromism device and manufacturing method thereof

InactiveCN105204263AImprove performanceImprove photoelectric energy conversion efficiencyWindowsWindscreensElectricityManufacturing technology

The invention discloses a novel-electrochromism-device-based automobile window with the high sun blocking performance and a manufacturing method thereof. According to the automobile window and the manufacturing method, the structure and the manufacturing technology of the electrochromism device are both improved, the electrochromism device has the self energy supplying characteristic accordingly, and therefore the novel service-life-prolonged automobile window which is high in sun blocking performance, free of a film pasting procedure and good in freezing resistance is manufactured; in addition, the method is simple and easy to operate, and industrial production is facilitated.

Owner:林杨

Camellia oil sunscreen skin care product and preparation method thereof

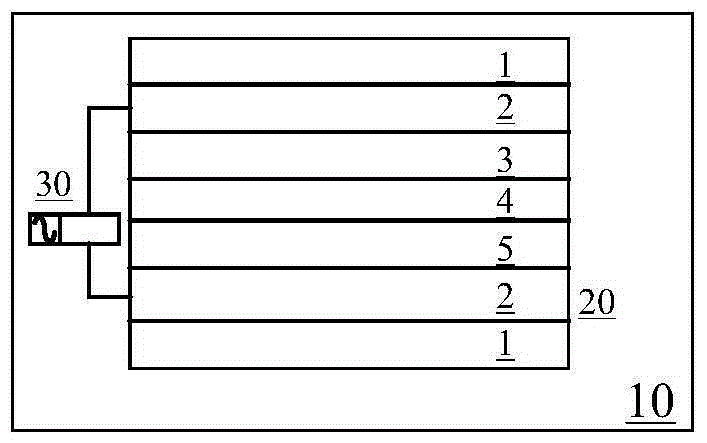

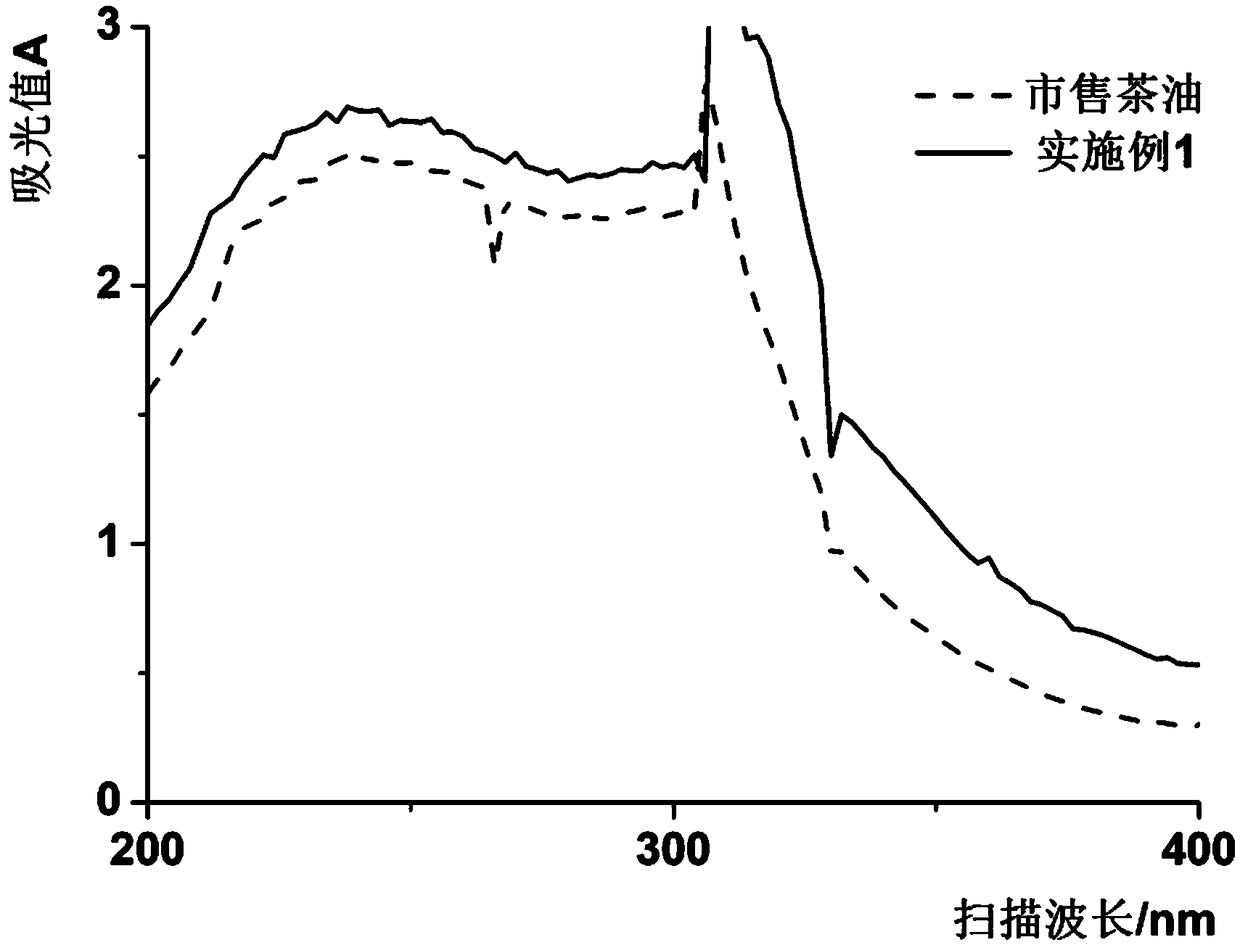

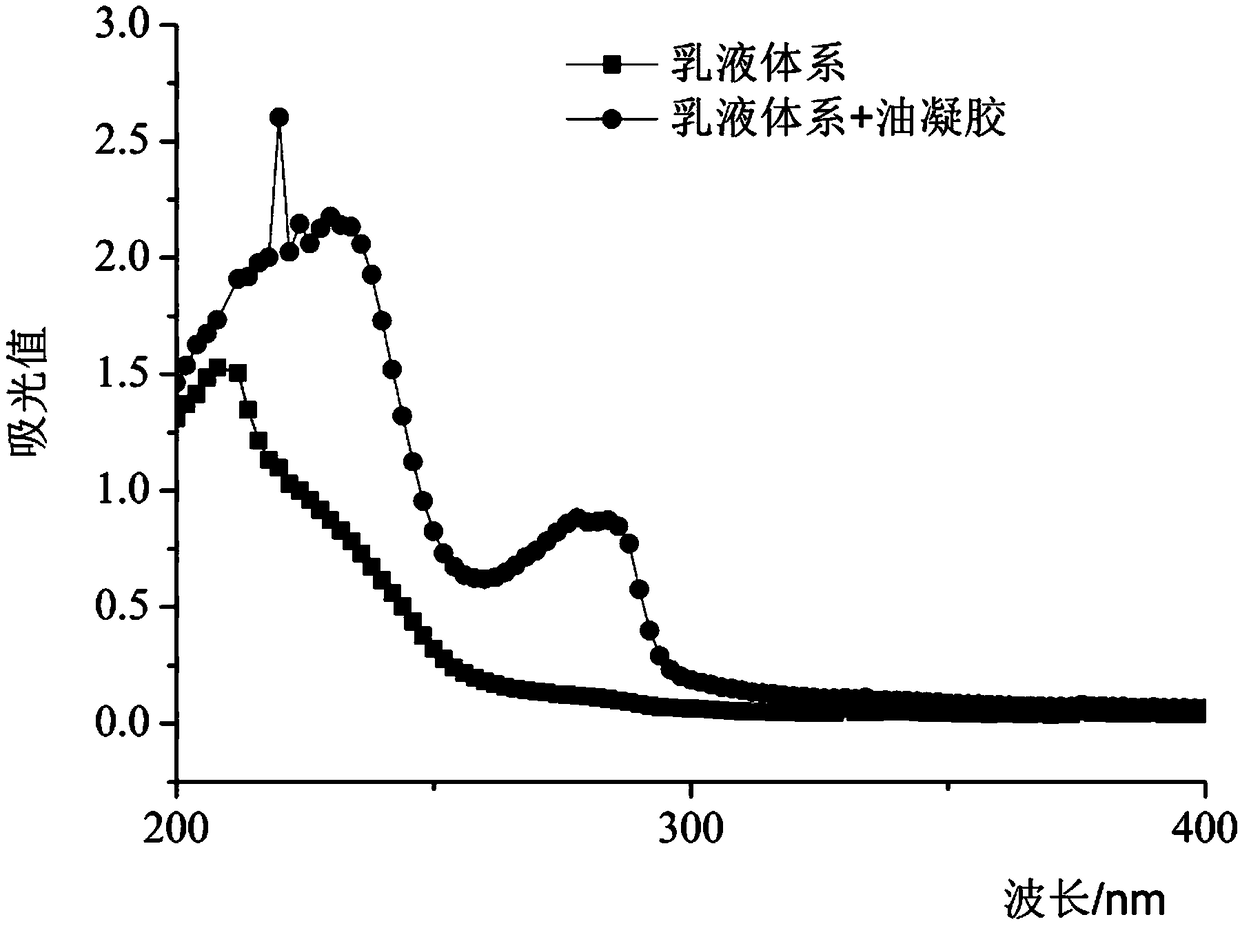

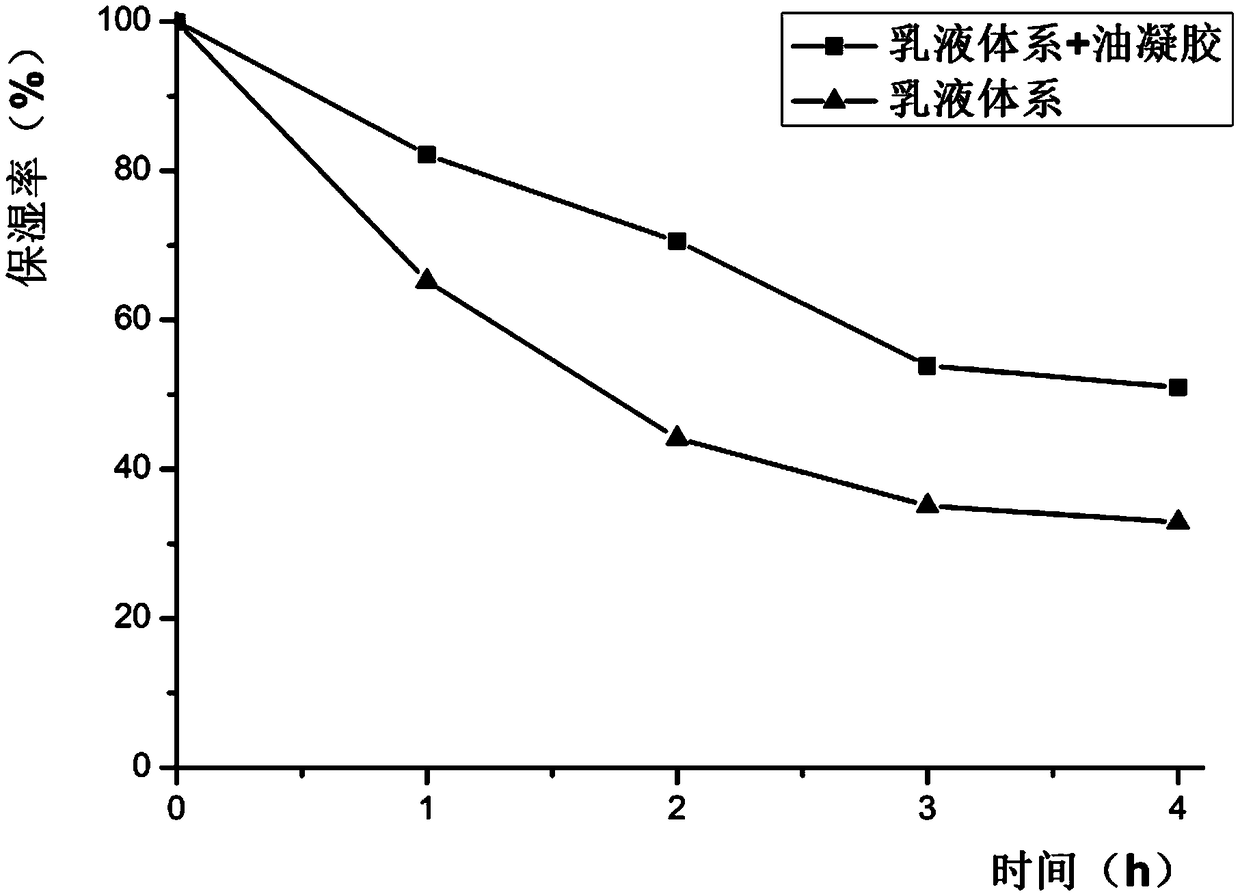

InactiveCN109260062AReduce aggregation or flocculationGood stabilityCosmetic preparationsToilet preparationsChemistrySpreadability

The invention provides a camellia oil sunscreen skin care product and a preparation method thereof. The oil-tea seed oil sunscreen skin care product comprises an oil phase substrate, an aqueous phasesubstrate and an oil gel. The oil gel is organically combined with an emulsion system of a traditional cosmetic matrix to change the mechanical properties of the oil phase so as to transform the oil phase into a more complex aqueous phase. Gel biphasic system; as the droplets are difficult to move easily through the three-dimensional network of the gel, aggregation or flocculation is reduced, so that the product of the invention has better stability, emulsion spreadability, smoothness, sunscreen performance and sensory performance are greatly improved, and better moisturizing effect and more moisturizing skin feeling are obtained. The invention also provides a preparation method of the camellia oil sunscreen skin care product, which is simple in operation, suitable for industrialization and popularization, and has wide application prospect.

Owner:SOUTH CHINA AGRI UNIV

Sunscreen cosmetic composition and application thereof

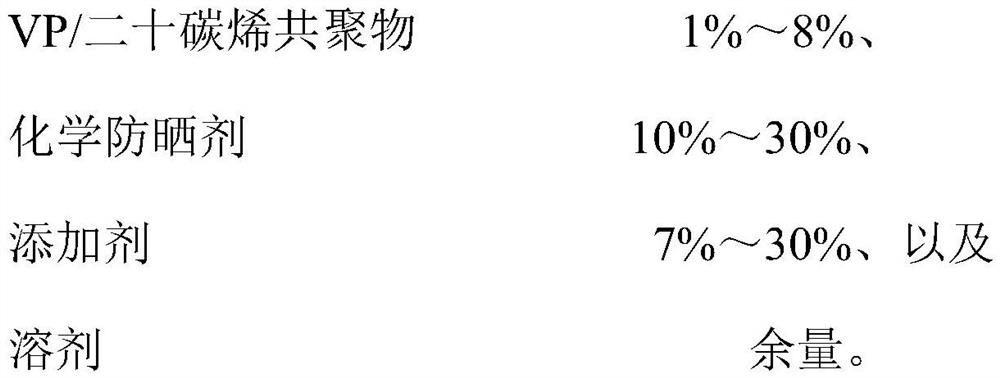

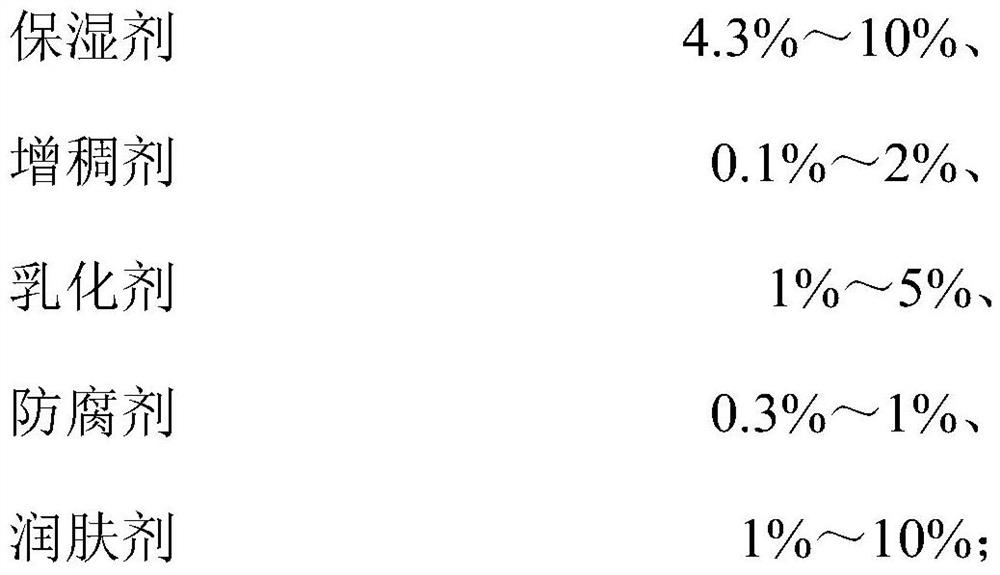

PendingCN112807244AExcellent resistance to water film formationGood dispersionCosmetic preparationsToilet preparationsPolymer chemistrySunscreen agents

The invention relates to a sunscreen cosmetic composition. The sunscreen cosmetic composition comprises the following components in percentage by mass: 1-8% of a VP / eicosene copolymer, 10-30% of a chemical sunscreen agent and the balance additives. The VP / eicosene copolymer is used in a sunscreen formula, so that the skin is endowed with lasting wear resistance and flexibility and good adhesivity and water resistance, the sunscreen index of the sunscreen cosmetic is effectively improved, the stability of the sunscreen formula is enhanced, the irritation of the product is relieved, and the skin feeling experience of the sunscreen cosmetic can be effectively improved under the condition that a skin feeling improver is not added; and under the condition that the ratio of the chemical sunscreen agent is reduced, the 1-8% of the VP / eicosene copolymer is added, so that the obvious synergistic effect on the SPF sunscreen value and the PA sunscreen value is achieved, and the irritation of the product is effectively relieved.

Owner:广州汇朗生物科技有限公司

Water body sunshade ball capable of reducing production cost

InactiveCN105113454AImprove sun protection effectReduce evaporationStream regulationEvaporationEngineering

The invention discloses a water body sunshade ball capable of reducing production cost. The sunshade ball comprises a hollow ball body, and the sunshade ball is mainly characterized in that the hollow ball body is designed to be a hollow oblate ball body, and a layer of reflection film is composited on the spherical surface of the hollow ball body; various knurling and embossing patterns are arranged on the surface of the reflection film. The sunshade balls are distributed on a water body in an even and dense mode, sunlight illumination is shielded, meanwhile, the effect of sun block of the water body can be remarkably improved, water evaporation is reduced, and the production cost can be reduced. The sunshade ball is applicable to water body sunscreen of a reservoir, a lake surface and a pond.

Owner:罗丽秀

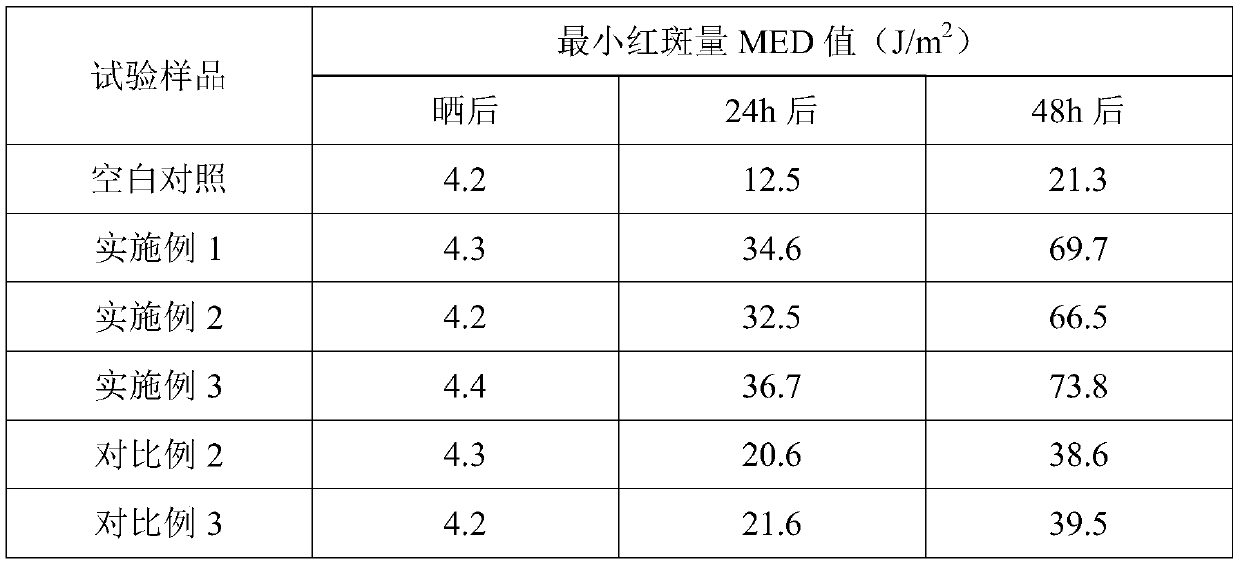

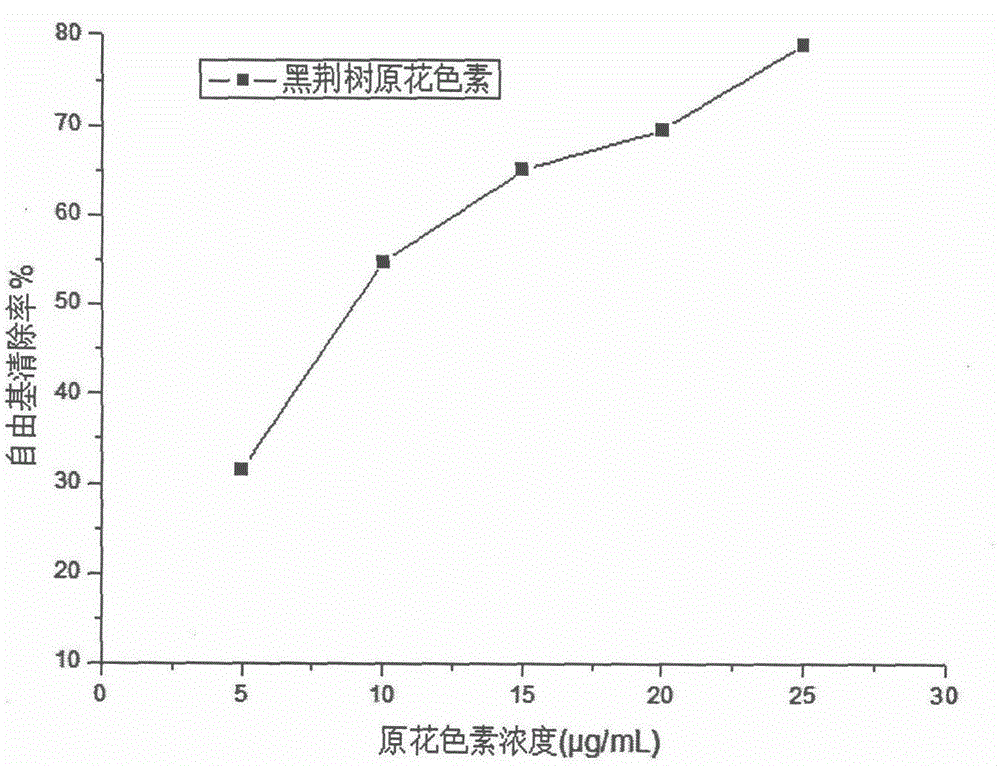

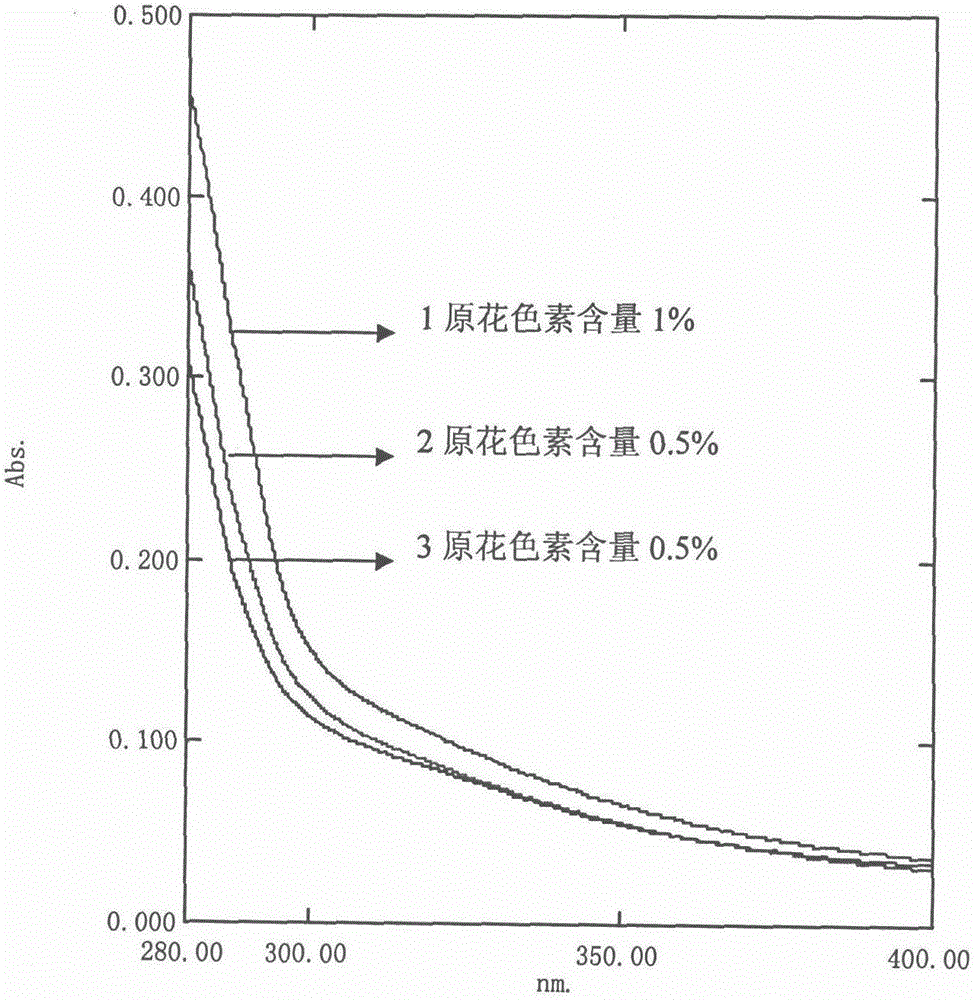

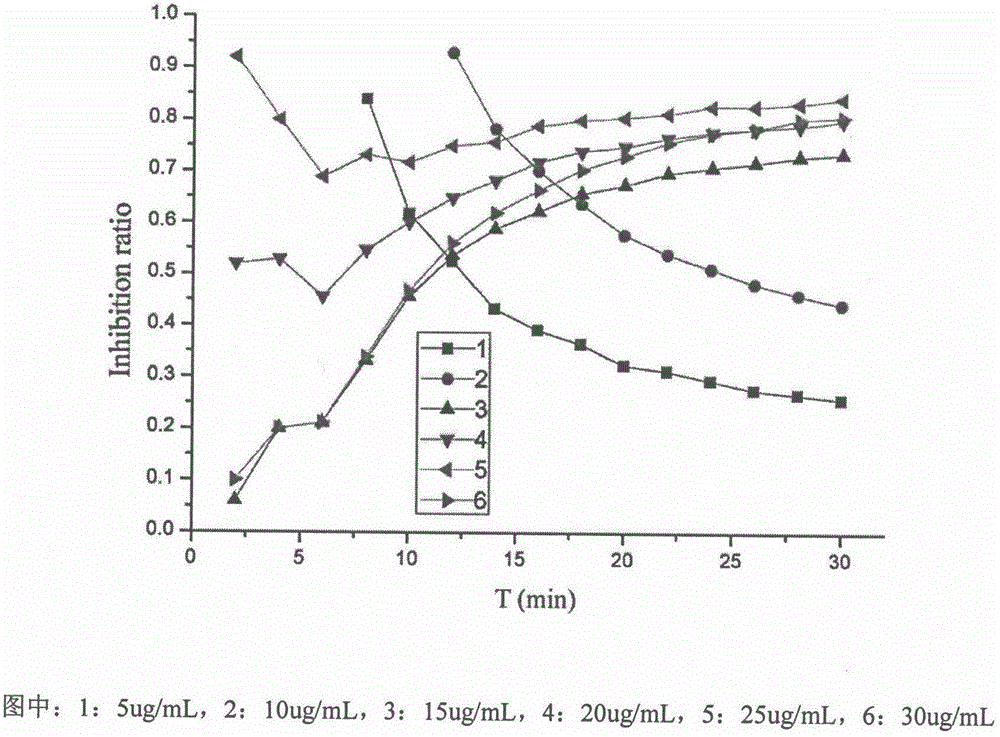

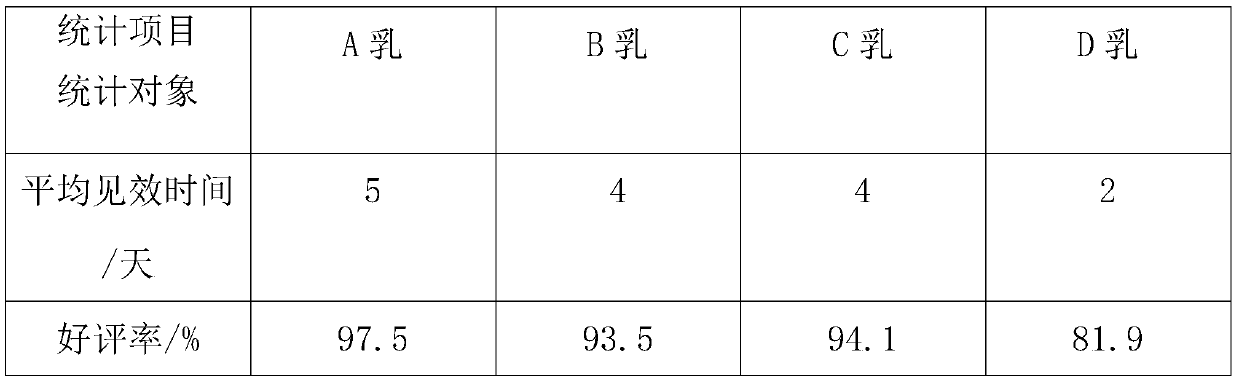

Method for preparing proanthocyanidin whitening sunscreen cream

ActiveCN105106039AImprove whiteningImprove sun protection effectCosmetic preparationsToilet preparationsAdditive ingredientGlycerol

The invention discloses a method for preparing proanthocyanidin whitening sunscreen cream, and belongs to the technical field of skin care products. A scientific formula for proanthocyanidin whitening sunscreen cream and a reasonable and high-utilization-rate sunscreen cream preparation method are provided. The proanthocyanidin whitening sunscreen cream is formed in the way that an aqueous phase and an oil phase are slowly mixed according to certain parts by weight for heat preservation and then stirring is conducted. The oil phase is prepared from oligomerization proanthocyanidin, stearic acid, hexadecanol, isopropyl palmitate, wool fat, olive oil, glycerin monostearate, methylparaben, propylparaben and water. The aqueous phase is prepared from glycerol, triethanolamine, lauryl sodium sulfate, water and azone. The effective component of the whitening sunscreen cream prepared through the method is the oligomerization proanthocyanidin which is a natural polyphenol substance, the oligomerization proanthocyanidin is obtained by purifying and extracting the proanthocyanidin through a macroporous resin isolation technology, and a good whitening sunscreen effect is achieved.

Owner:NANJING FORESTRY UNIV

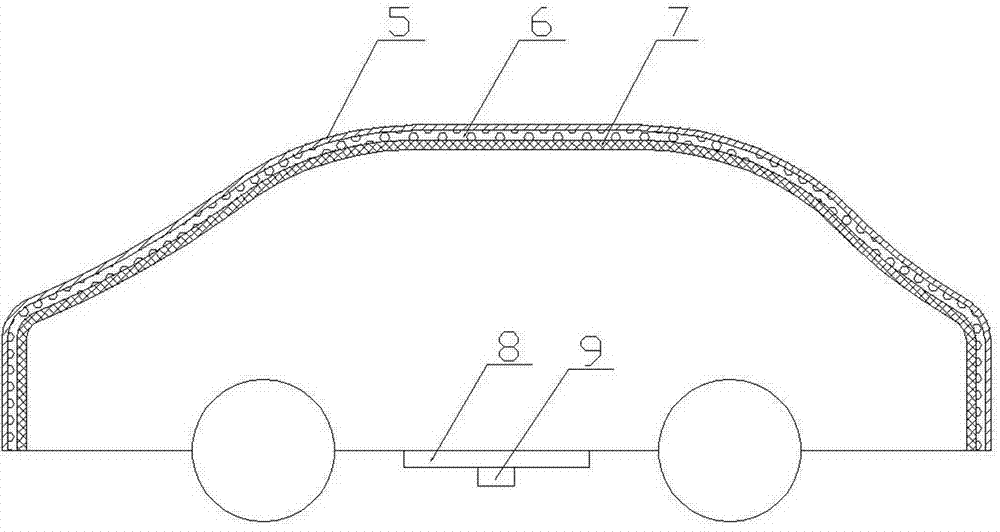

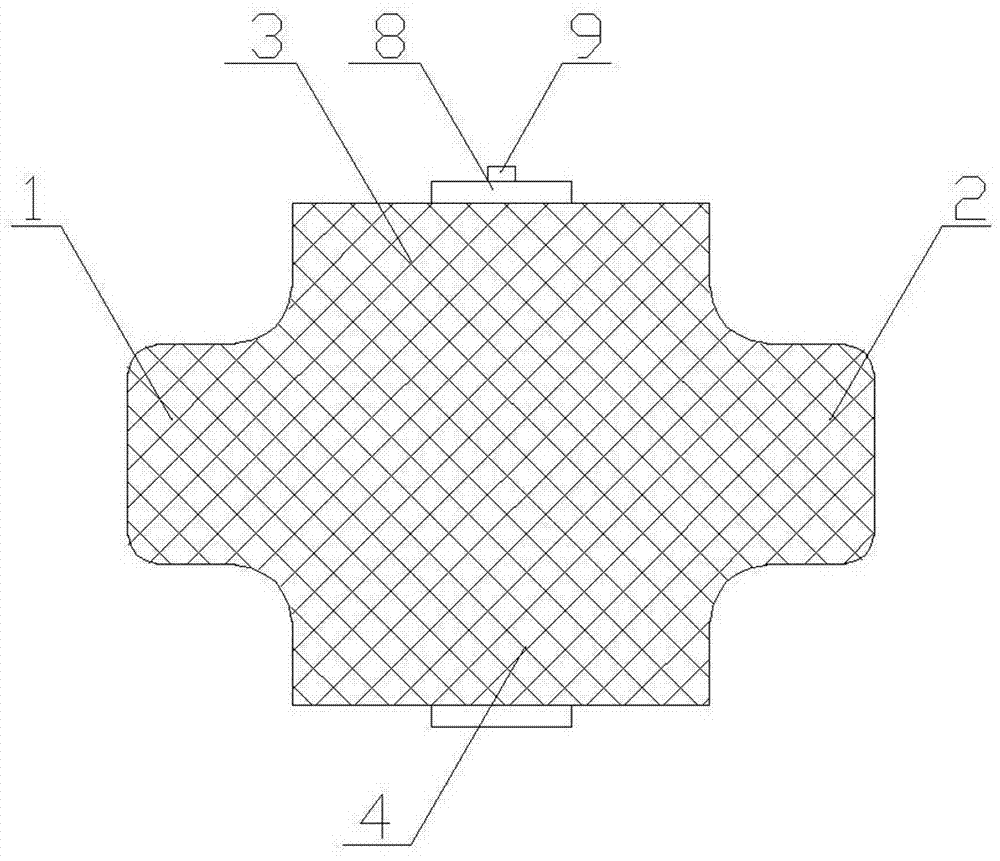

Automobile sunscreen hood

InactiveCN103935221AImprove sun protection effectEasy to useRemovable external protective coveringsLight reflectionEngineering

The invention discloses an automobile sunscreen hood which comprises a hood body. The hood body is a car-shaped hood body formed by connecting a front sunscreen hood (1), a rear sunscreen hood (2), a left sunscreen hood (3) and a right sunscreen hood (4) through a top sunscreen hood. The automobile sunscreen hood is characterized in that the hood body comprises a light reflection layer (5), an inflation layer (6) and a filling layer (7), the inflation layer (6) comprises an air chamber separation layer which forms a sealed inflation chamber, the inflation chamber is provided with an inflation hole, the filling layer (7) comprises a filling separation layer which forms a filling chamber, and the filling chamber is provided with a filling opening. The hood body comprises three sunscreen layers with different sunscreen effects, the sunscreen effect is effectively enhanced, and the automobile sunscreen hood is simple and convenient to use and easy to store.

Owner:娄孟兴

Whitening and sun-screening sunscreen lotion containing natural plant sunscreen components and preparation method thereof

PendingCN111467289AImprove sun protection effectClear and mild waterCosmetic preparationsToilet preparationsETHYLHEXYL SALICYLATETriethanolamine

The invention discloses a whitening and sun-screening sunscreen lotion containing natural plant sunscreen components and a preparation method thereof. The whitening and sun-screening sunscreen lotionis prepared from the following raw materials in parts by weight: 3-5 parts of ethylhexyl methoxycinnamate, 3-5 parts of ethylhexyl salicylate, 3-5 parts of bis-ethylhexyloxyphenol methoxyphenyl triazine, 10-20 parts of octocrilene, 10-20 parts of plant extract, 3-5 parts of ethylhexyl triazinone, 3-5 parts of ultraviolet light absorber, 3-5 parts of humectant, 5-10 parts of whitening agent, 3-5 parts of phenoxyethanol, 3-5 parts of triethanolamine, 1-3 parts of thickener and 3-5 parts of water. The invention relates to the technical field of skin care products. According to the whitening and sun-screening sunscreen lotion containing natural plant sunscreen components and the preparation method thereof, the sunscreen effect of the sunscreen lotion can be greatly improved by taking the natural plant sunscreen components as main components and matching with the whitening and sun-screening components, the sunscreen effect of the sunscreen lotion is greatly improved, and the sunscreen lotion can continuously screen sun for a long time; and meanwhile, the sunscreen lotion is clear and mild in water feeling and is not greasy, so that a user feels comfortable when using the sunscreen lotion.

Owner:广州协和生物医药科技有限公司

Antibacterial and mildew-proof pillow towel fabric

InactiveCN108842468AHair conditionerImprove sleep qualityBiochemical fibre treatmentVegetal fibresPolyesterTextile technology

The invention mainly relates to the technical field of textile, and discloses an antibacterial and mildew-proof pillow towel fabric. The fabric is prepared from the following raw materials: cotton fiber, polyester fiber, bamboo fiber, mulberry fiber, aloe fiber, soybean fiber, bamboo charcoal fiber and polycrystalline alumina fiber. The fabric is high in stiffness, easy to clean, heat-insulating,antibacterial and mildew-proof. The polyester fiber, the bamboo charcoal fiber and the polycrystalline alumina fiber are blended, stiffness and adsorption performance of pillow towels are increased, and mould breeding is avoided; meanwhile, by addition of the polycrystalline alumina fiber, sunscreen capability of the pillow towels can be enhanced, aging of the pillow towels is delayed, cleaning capability of the pillow towels is enhanced, and the pillow towels are easy to clean, loose and comfortable; strength of the pillow towels is improved, pilling and aging caused by washing and solarization are delayed, and the service life of the pillow towels is prolonged.

Owner:安徽玉然经编科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com