Methyl methacrylate cross-linked polymer microparticle loaded with lipid-soluble sun-screening agent and preparation method of microparticle

A technology of methyl methacrylate and cross-linked polymers, which is applied in the field of preparation of microparticles, can solve the problems of reducing product safety, increasing product cost, and skin irritation, and achieves improved sun protection performance, small temperature influence, and good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

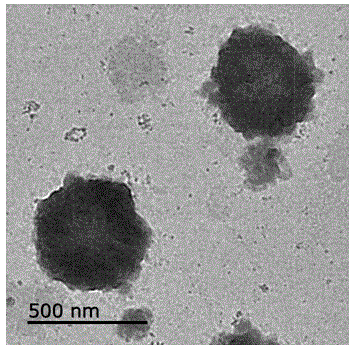

Image

Examples

Embodiment 1

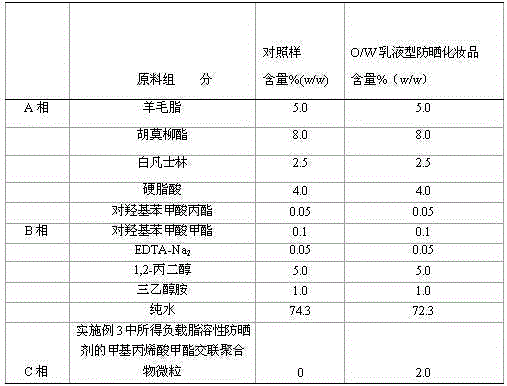

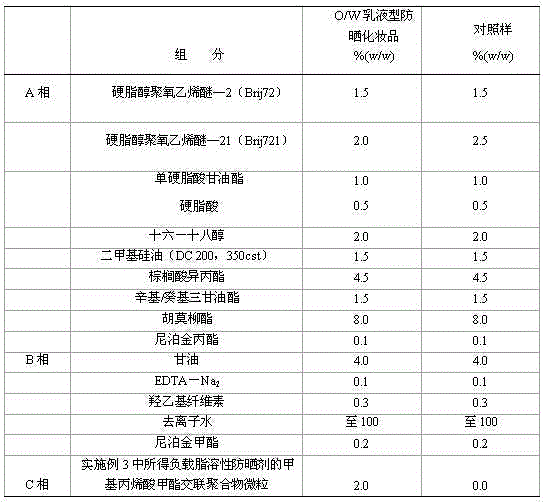

[0032] A kind of methyl methacrylate cross-linked polymer particles loaded with fat-soluble sunscreen, the raw materials used in the preparation process are calculated in parts by weight, and the composition and content of the raw materials are as follows:

[0033] Surfactant 12 parts

[0034] 76 parts of deionized water

[0035] Fat-soluble sunscreen 4.5 parts

[0036] 4.5 parts of methyl methacrylate

[0037] 0.6 parts of divinylbenzene

[0038] Initiator 1 part

[0039] Described tensio-active agent is anionic surfactant sodium lauryl sulfate;

[0040] Described fat-soluble sunscreen is ethylhexyl salicylate;

[0041] The initiator is a water-soluble initiator, and the water-soluble initiator is a redox initiation system mixed with potassium persulfate and sodium bisulfite, calculated by mass ratio, wherein potassium persulfate: hydrogen sulfite Sodium is 4:3;

[0042] The concrete steps of its preparation process are as follows:

[0043] (1) First, dissolve 12g of ...

Embodiment 2

[0049] A kind of methyl methacrylate cross-linked polymer particles loaded with fat-soluble sunscreen, the raw materials used in the preparation process are calculated in parts by weight, and the composition and content of the raw materials are as follows:

[0050] Surfactant 21 parts

[0051] 76 parts of deionized water

[0052] Fat-soluble sunscreen 4.5 parts

[0053] 4.5 parts of methyl methacrylate

[0054] 0.6 parts of divinylbenzene

[0055] Initiator 1 part

[0056] Described tensio-active agent is anionic surfactant sodium lauryl sulfate;

[0057] Described fat-soluble sunscreen is ethylhexyl salicylate;

[0058] The initiator is a water-soluble initiator, and the water-soluble initiator is a redox initiation system mixed with potassium persulfate and sodium bisulfite, calculated by mass ratio, wherein potassium persulfate: hydrogen sulfite Sodium is 4:3;

[0059] The concrete steps of its preparation process are as follows:

[0060] (1) First, dissolve 21g of ...

Embodiment 3

[0066] A methyl methacrylate cross-linked polymer particle loaded with a fat-soluble sunscreen has a core-shell structure, the core is a fat-soluble sunscreen, and the shell is a methyl methacrylate cross-linked polymer. The raw materials used in the preparation process are as follows: The parts by weight are calculated, and its raw material composition and content are as follows:

[0067] Surfactant 15 parts

[0068] 76 parts of deionized water

[0069] Fat-soluble sunscreen 4.5 parts

[0070] 4.5 parts of methyl methacrylate

[0071] 0.6 parts of divinylbenzene

[0072] Initiator 1 part

[0073] Described tensio-active agent is anionic surfactant sodium lauryl sulfate;

[0074] Described fat-soluble sunscreen is ethylhexyl salicylate;

[0075] The initiator is a water-soluble initiator, and the water-soluble initiator is a redox initiation system mixed with potassium persulfate and sodium bisulfite, calculated by mass ratio, wherein potassium persulfate: hydrogen sulfi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| spf | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com