Sun-proof skin care composition and preparation method thereof

The technology of a skin care composition and millet bran oil is applied in the directions of skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., and can solve problems such as unreported sunscreen skin care beauty research, and achieves improved skin care sunscreen effect, enhanced ultraviolet absorption effect, Reduce irritating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

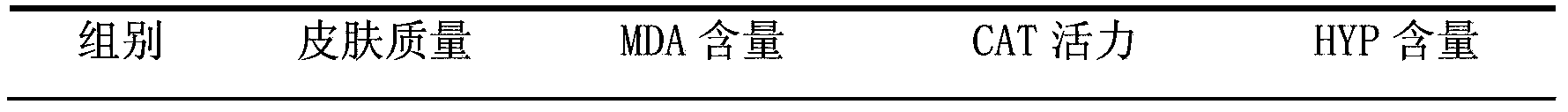

Embodiment 1

[0015] Composition ratio: liquid paraffin 1g, millet bran oil 9g, oryzanol 2g, oligomeric proanthocyanidins 0.2g, molecularly distilled monoglyceride 1g, polyglycerol fatty acid ester 1.5g, sucrose fatty acid ester 1.8g, glycerol 8g, Silicon dioxide 0.4g, titanium dioxide 0.8g, ethylparaben 0.1g, essence 0.8g, deionized water 73.4g.

[0016] Composition preparation:

[0017] Mix liquid paraffin, molecularly distilled monoglyceride, millet bran oil and oryzanol to obtain phase A; mix oligomeric proanthocyanidins, polyglycerol fatty acid ester, sucrose fatty acid ester, glycerol and deionized water to obtain phase B; silicon dioxide Mix with titanium dioxide as phase C; ethylparaben and essence as phase D; heat and dissolve phases A and B separately to make the temperature reach 65°C; slowly add phase B and phase C to the In Phase A: Vacuumize the emulsification system and fill it with nitrogen when the vacuum degree is 0.08MPa. After 3 times of vacuum-nitrogen filling cycle, s...

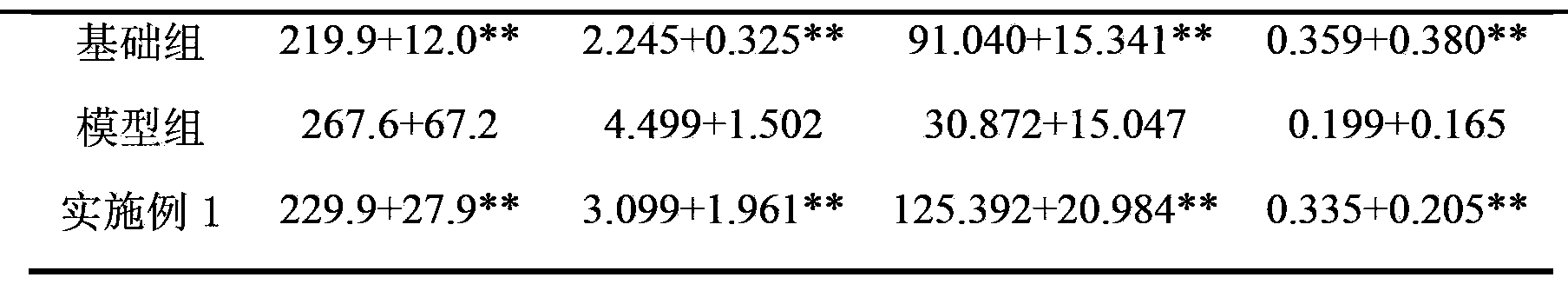

Embodiment 2

[0024] Composition ratio: 2g liquid paraffin, 4g millet bran oil, 1g oryzanol, 0.1g oligomeric proanthocyanidins, 0.5g molecularly distilled monoglyceride, 0.8g polyglycerol fatty acid ester, 1.1g sucrose fatty acid ester, 5g glycerin , 0.5g of silicon dioxide, 0.6g of titanium dioxide, 0.05g of ethylparaben, 0.4g of essence, and 83.95g of deionized water.

[0025] Composition preparation:

[0026] Mix liquid paraffin, molecularly distilled monoglyceride, millet bran oil and oryzanol to obtain phase A; mix oligomeric proanthocyanidins, polyglycerol fatty acid ester, sucrose fatty acid ester, glycerol and deionized water to obtain phase B; silicon dioxide Mix with titanium dioxide as phase C; ethylparaben and essence as phase D; heat and dissolve phases A and B separately to reach a temperature of 60°C; slowly add phase B and phase C to phase A under stirring conditions In the phase; vacuumize the emulsification system, and carry out nitrogen filling treatment when the vacuum ...

Embodiment 3

[0032] Composition ratio: 1.5g liquid paraffin, 6g millet bran oil, 1.5g oryzanol, 0.15g oligomeric proanthocyanidins, 0.8g molecularly distilled monoglyceride, 1.2g polyglycerol fatty acid ester, 1.3g sucrose fatty acid ester, glycerin Alcohol 3g, silicon dioxide 0.3g, titanium dioxide 0.7g, ethylparaben 0.08g, essence 0.6g, deionized water 82.87g.

[0033] Composition preparation:

[0034] Mix liquid paraffin, molecularly distilled monoglyceride, millet bran oil and oryzanol to obtain phase A; mix oligomeric proanthocyanidins, polyglycerol fatty acid ester, sucrose fatty acid ester, glycerol and deionized water to obtain phase B; silicon dioxide Mix with titanium dioxide as phase C; ethylparaben and essence as phase D; heat and dissolve phases A and B separately to reach a temperature of 70°C; slowly add phase B and phase C to phase A under stirring conditions In the phase; the emulsification system is vacuumed, and the nitrogen filling treatment is carried out when the vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com