Sunscreen lotion and preparation method thereof

A technology of sunscreen and emulsifier, which is applied in pharmaceutical formulations, cosmetic preparations, dressing preparations, etc. It can solve the problems of thick and sticky skin, easy peeling, skin irritation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

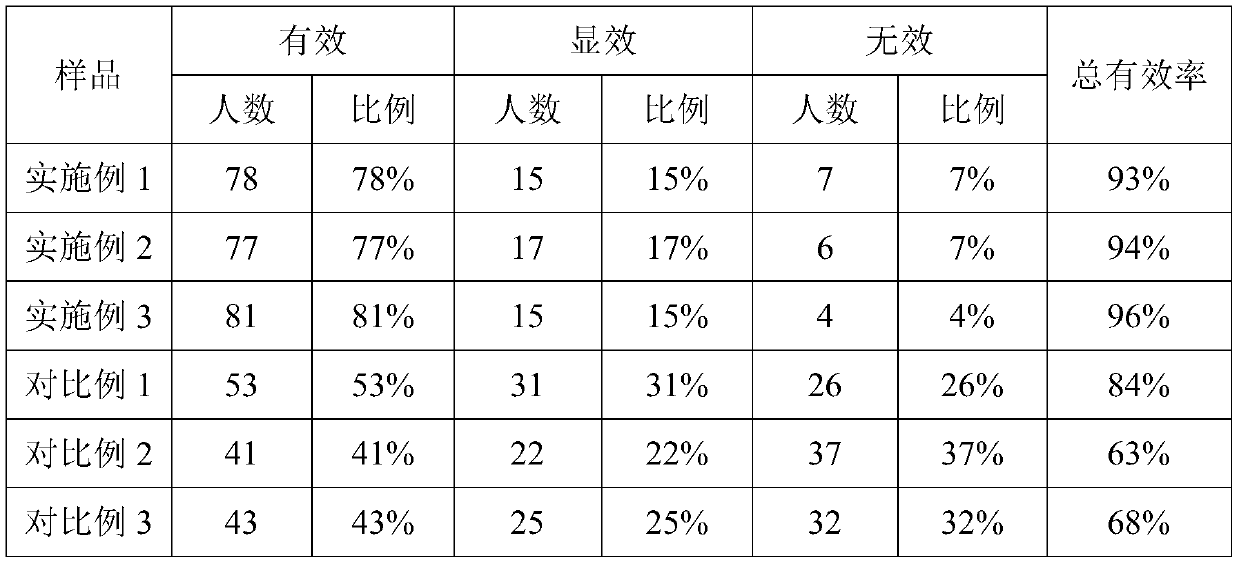

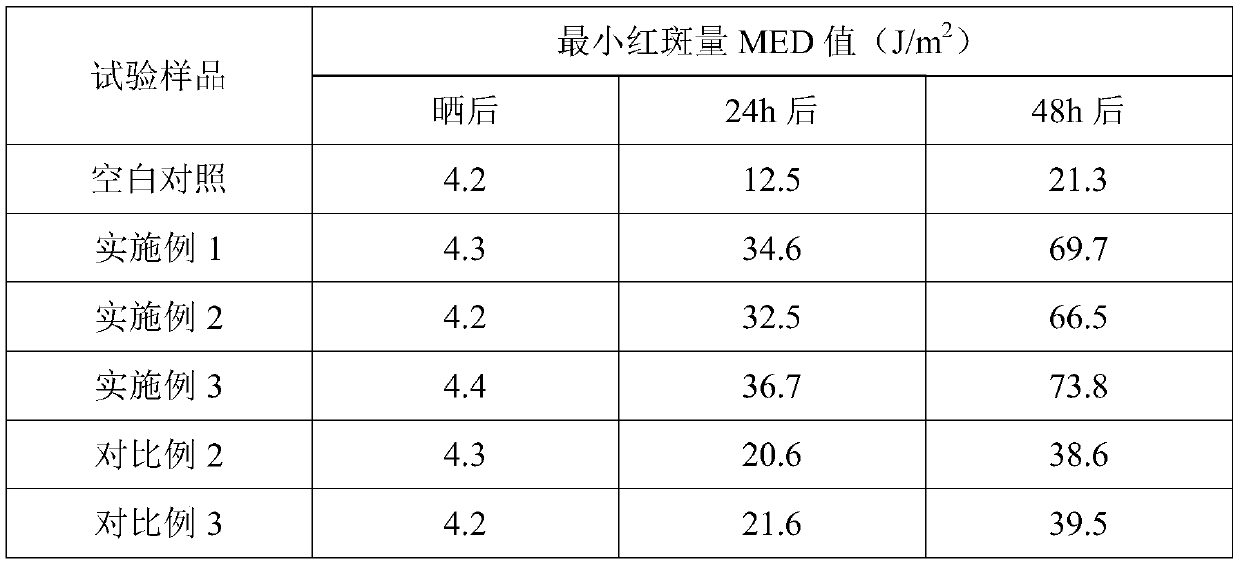

Examples

Embodiment 1

[0051] Embodiment 1 A kind of sunscreen lotion

[0052] The sunscreen consists of the following components and their weight percentages: 10% of nano-zinc oxide treated with alkyl silicon, 1% of oil-dispersed nano-titanium dioxide, 1% of oil-dispersed silicon dioxide, 0.05% of bismuth oxychloride treated with alkyl silicon, Cyclopentasiloxane 20%, Capryl Silicone Oil 1%, Polyhydroxystearic Acid 1%, Disteardimethylammonium Hectorite 0.2%, Iron Red 0.001%, Ethyl Hydroxystearate Hexyl Ester 1%, Ethylhexyl Methoxycinnamate 7%, Polysiloxane-15 0.5%, Diethylaminohydroxybenzoyl Hexyl Benzoate 1%, Sorbitan Isostearate 0.05%, Emulsifier 1%, butanediol 3%, 1,2-hexanediol 0.4%, sodium chloride 0.5%, wild soybean seed extract 0.2%, sandalwood extract 0.3%, lotus leaf extract 0.4%, into Film 0.5%, Dior essence 0.01%, water 49.889%; the emulsifier consists of cetyl polyethylene glycol / polypropylene glycol-10 / 1 dimethylsiloxane and lauryl PEG-9 polydimethylsiloxane Oxyethyl polydimethylsilo...

Embodiment 2

[0057] Embodiment 2 A kind of sunscreen milk

[0058]The sunscreen consists of the following components and their weight percentages: 15% of nano-zinc oxide treated with alkyl silicon, 3% of oil-dispersed nano-titanium dioxide, 3% of oil-dispersed silicon dioxide, 0.15% of bismuth oxychloride treated with alkyl silicon, Cyclopentasiloxane 30%, Capryl Silicone Oil 3%, Polyhydroxystearic Acid 2%, Disteardimethylammonium Hectorite 0.4%, Iron Red 0.003%, Ethyl Hydroxystearate Hexyl Ester 3%, Ethylhexyl Methoxycinnamate 8%, Polysiloxane-15 1.5%, Diethylaminohydroxybenzoyl Hexyl Benzoate 3%, Sorbitan Isostearate 0.15%, Emulsifier 3%, Butanediol 5%, 1,2-Hexanediol 0.8%, Sodium Chloride 1.5%, Wild soybean seed extract 0.4%, Sandalwood extract 0.5%, Lotus leaf extract 0.6%, Cheng Film 1.5%, Dior essence 0.05%, water 14.447%; the emulsifier consists of cetyl polyethylene glycol / polypropylene glycol-10 / 1 dimethylsiloxane and lauryl PEG-9 polydimethylsiloxane The composition of oxyethyl...

Embodiment 3

[0063] Embodiment 3 A kind of sunscreen lotion

[0064] The sunscreen is composed of the following components and their percentages by weight: 12% of nano-zinc oxide treated with alkyl silicon, 2% of oil-dispersed nano-titanium dioxide, 2% of oil-dispersed silicon dioxide, 0.10% of bismuth oxychloride treated with alkyl silicon, ring Pentamethicone 25%, Capryl Silicone Oil 2%, Polyhydroxystearic Acid 1.5%, Disteardimethylammonium Hectorite 0.3%, Iron Red 0.002%, Ethylhexyl Hydroxystearate Ester 2%, Ethylhexyl Methoxycinnamate 7.5%, Polysiloxane-15 1.0%, Diethylaminohydroxybenzoyl Hexyl Benzoate 2%, Sorbitan Isostearate 0.10%, emulsified 2%, butanediol 4%, 1,2-hexanediol 0.6%, sodium chloride 1.0%, wild soybean seed extract 0.3%, sandalwood extract 0.4%, lotus leaf extract 0.5%, film-forming agent 1.0%, Dior essence 0.03%, water 32.668%; the emulsifier is composed of cetyl polyethylene glycol / polypropylene glycol-10 / 1 dimethylsiloxane and lauryl PEG-9 dimethicone Ethyl polydi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com