Patents

Literature

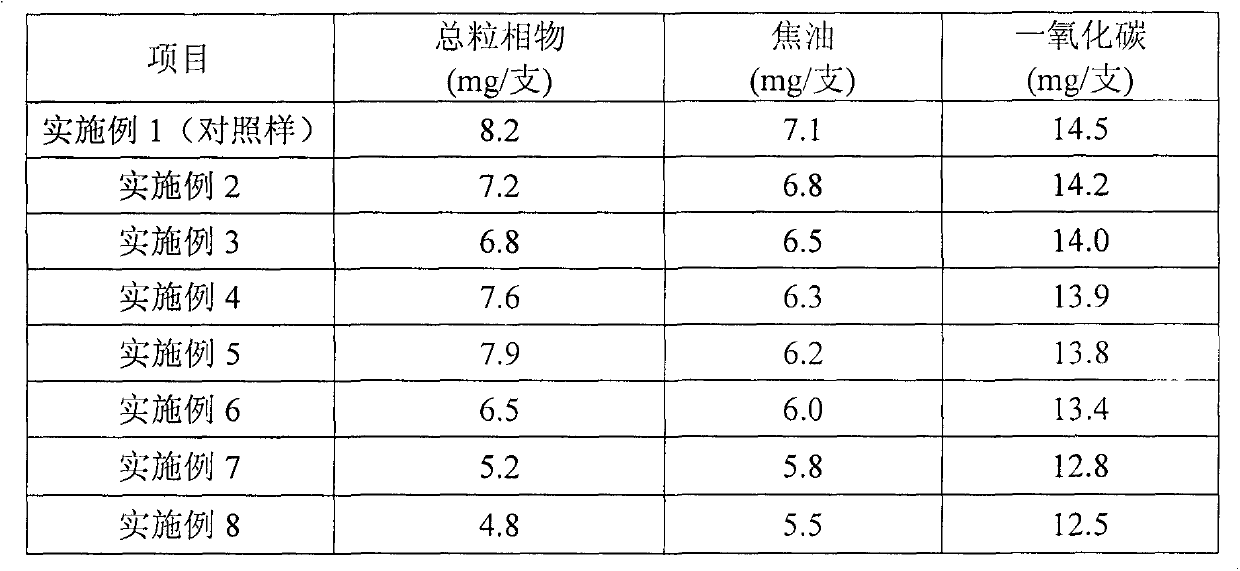

4136results about How to "Reduce stimulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

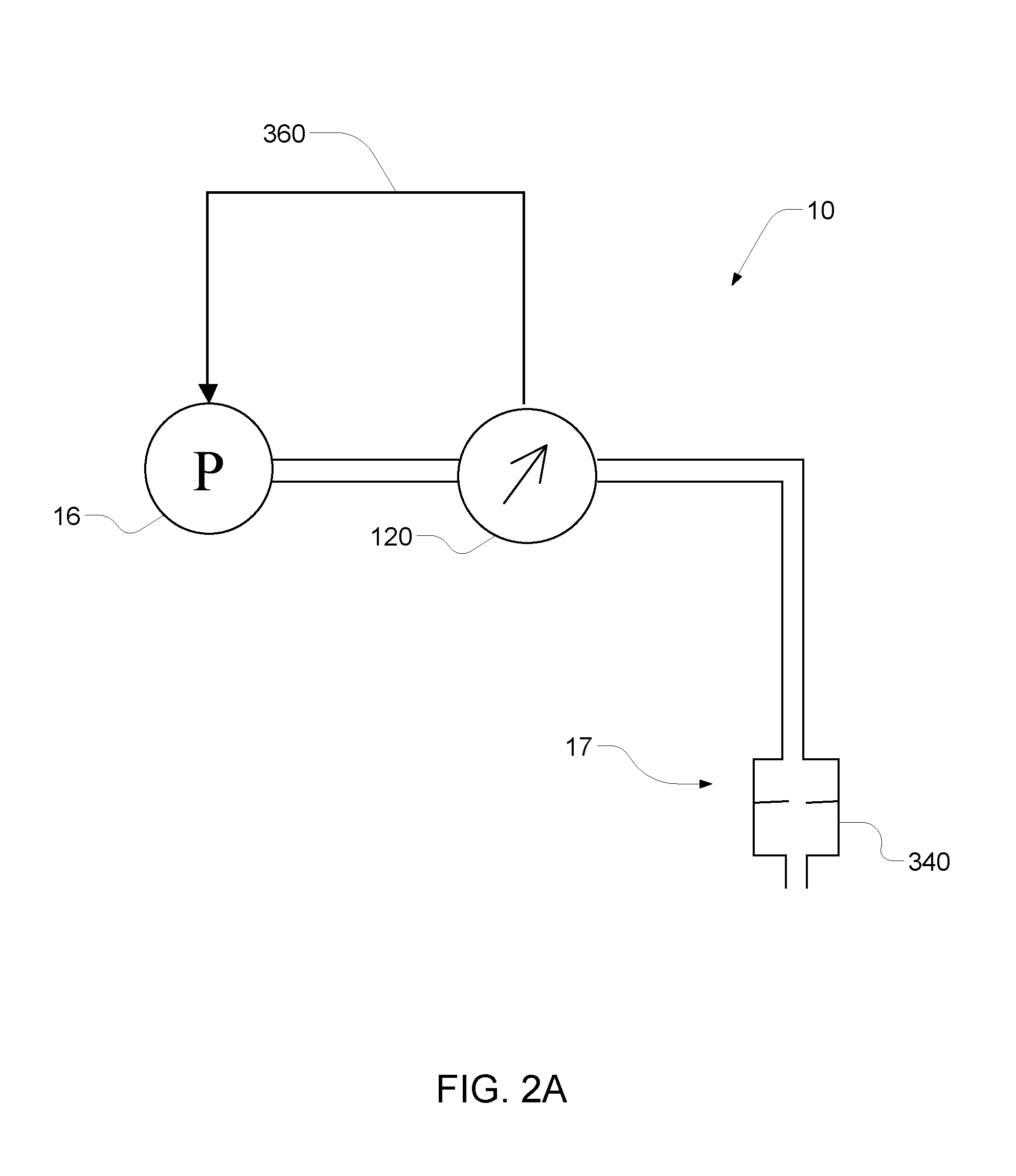

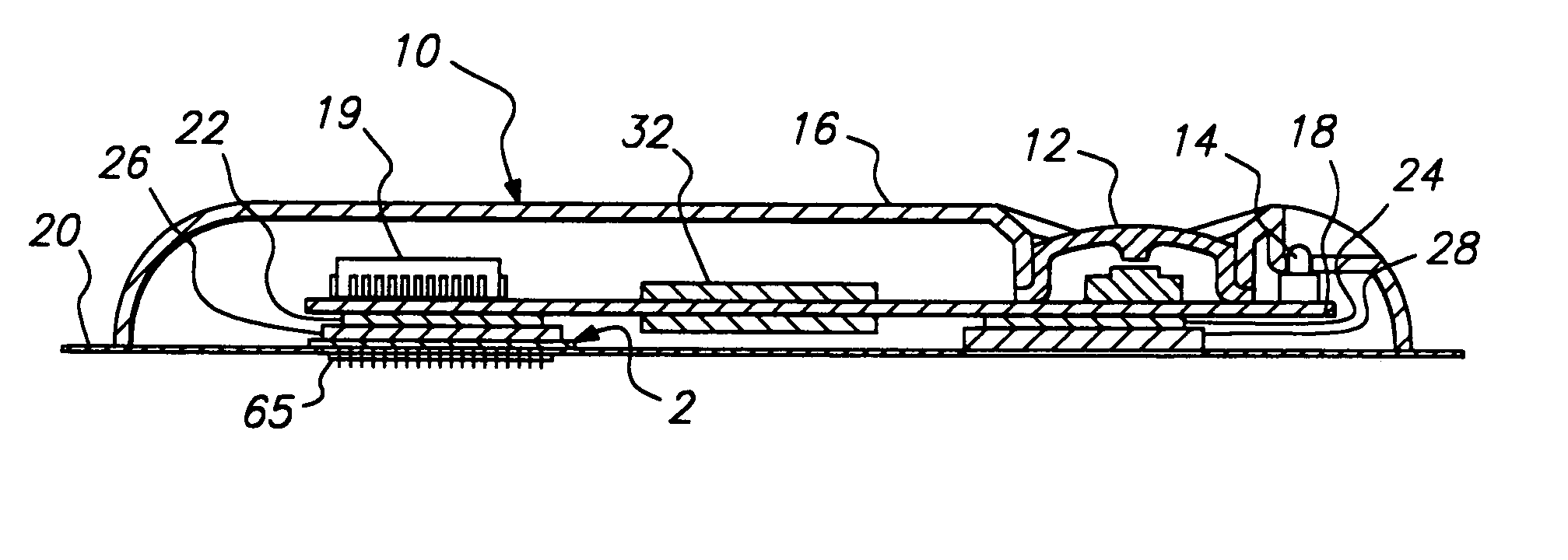

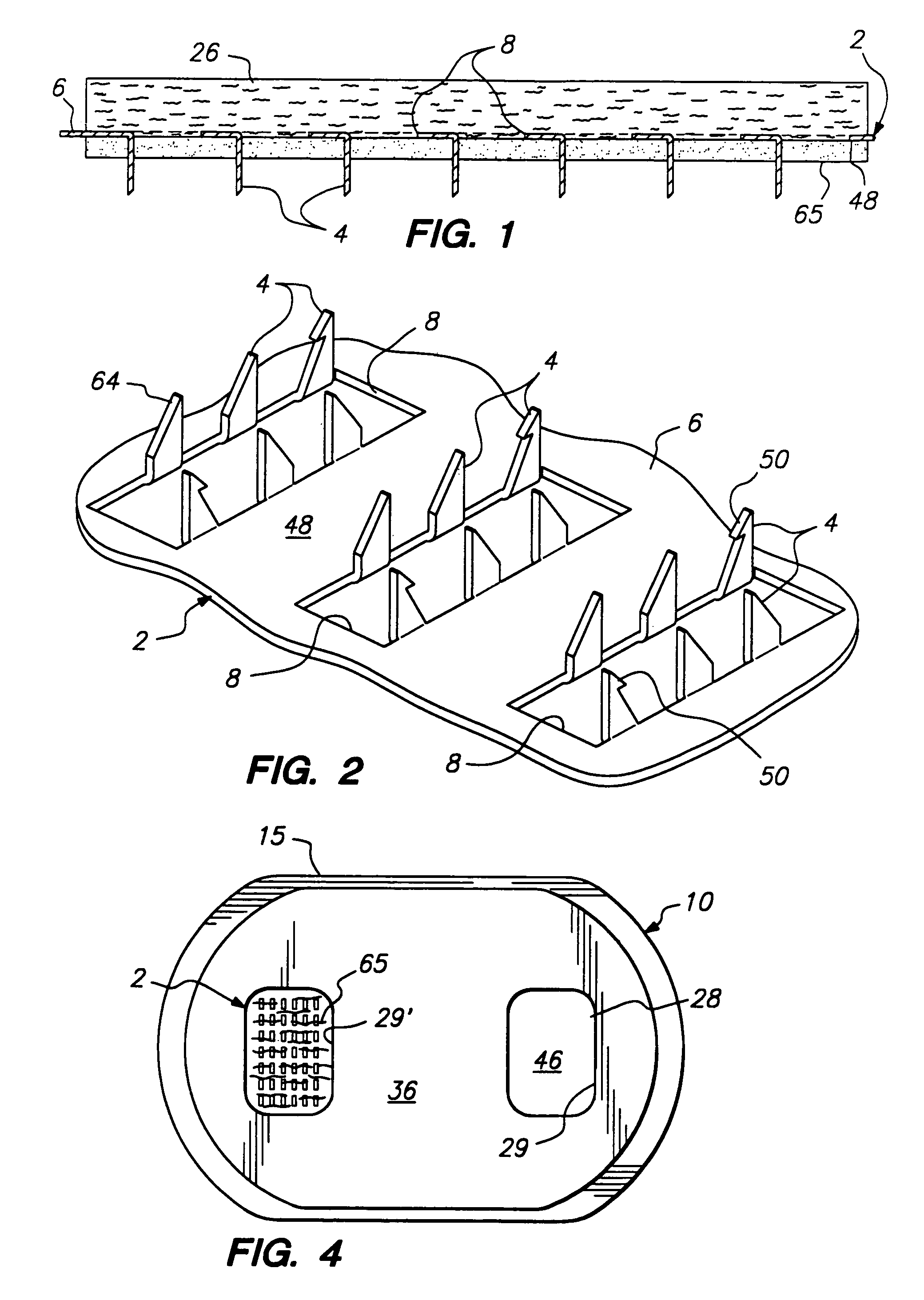

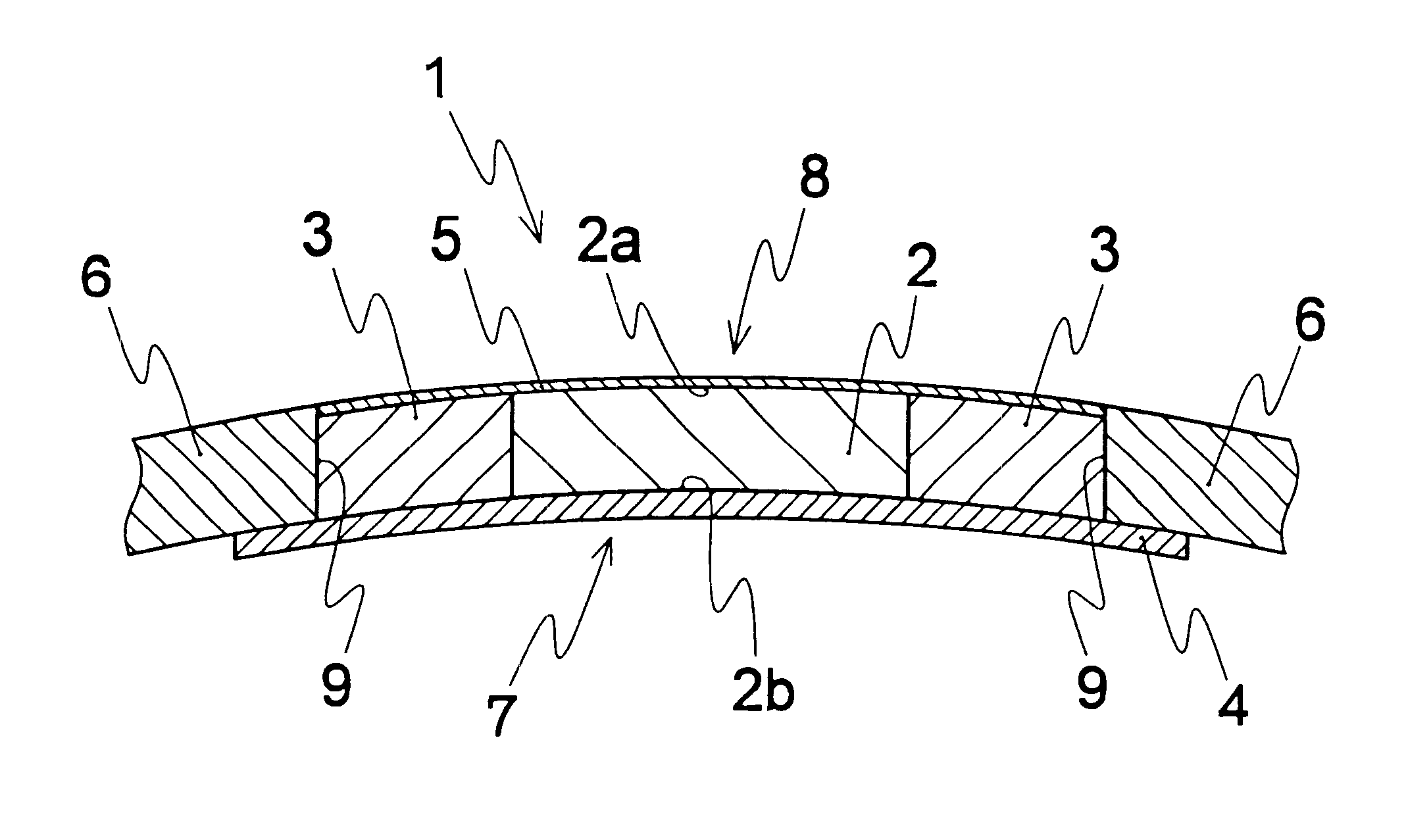

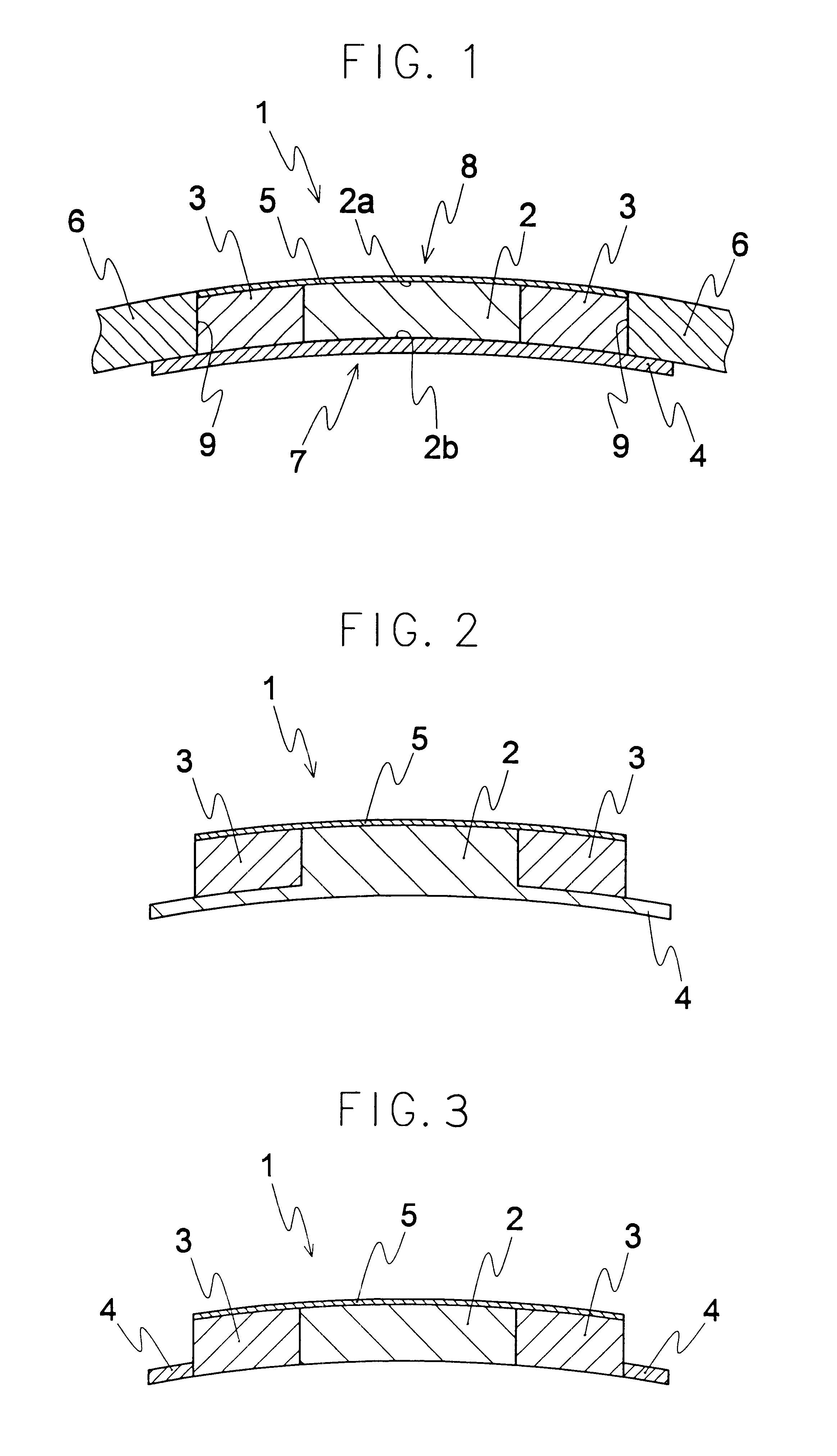

Adhesive and peripheral systems and methods for medical devices

A repeater system may control a pump by using a repeater and a user interface. An adhesive patch system may be used for affixing a pump or other object to a human body. Such an adhesive patch system may include two sets of adhesive members, each member including an adhesive material on at least one side so as to attach to the body. The members of the first set are spaced to allow the members of the second set to attach to the body in spaces provided between the members of the first set, and the members of the second set are spaced to allow members of the first set to detach from the body without detaching the members of the second set. Also, fill stations and base stations are provided for personal pump systems.

Owner:DEKA PROD LLP

Device and method for enhancing transdermal agent flux

InactiveUS6918901B1High volume producableIncreasing transdermal fluxElectrotherapySurgerySkin contactBiomedical engineering

Owner:THEEUWES FELIX +2

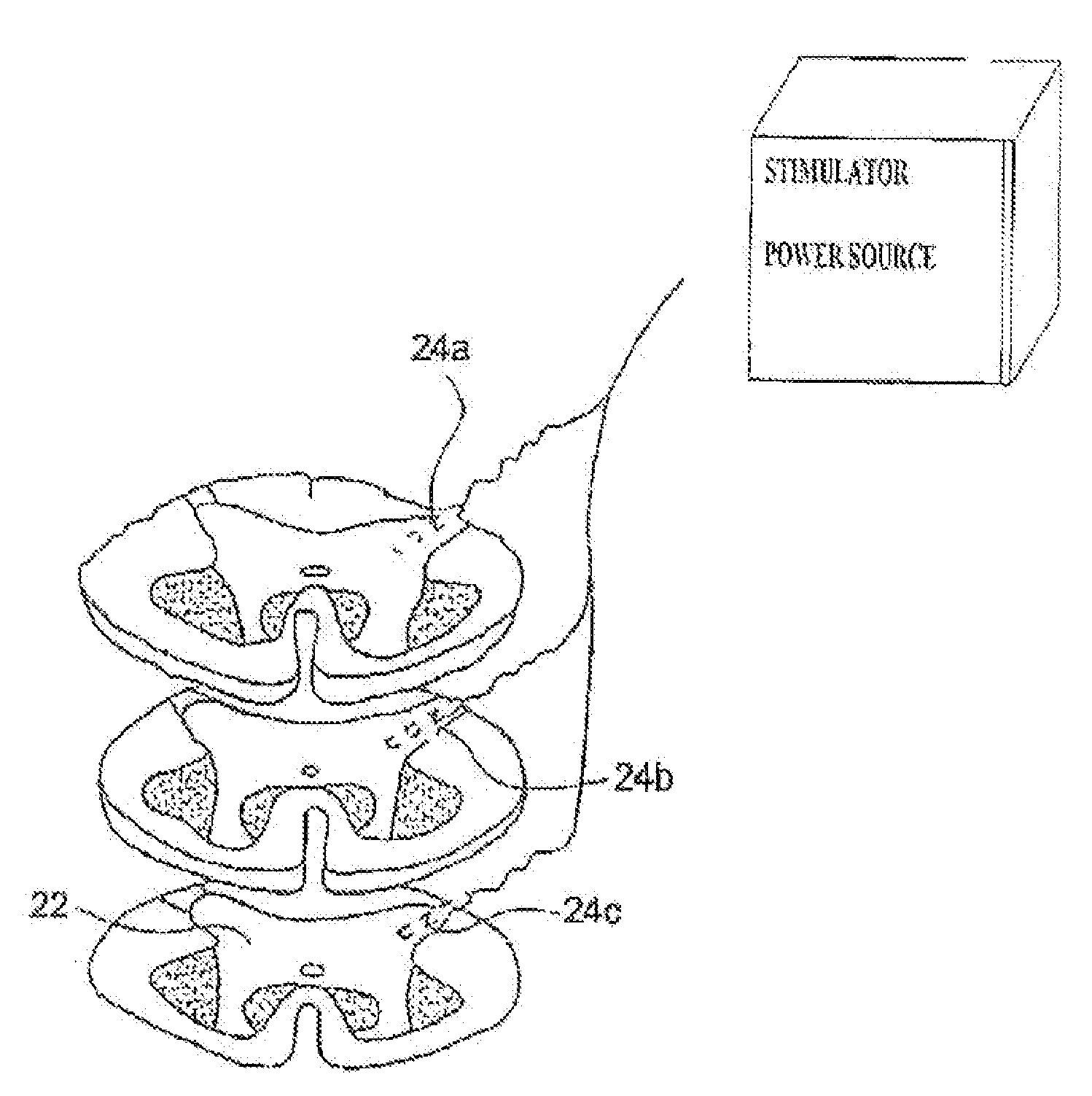

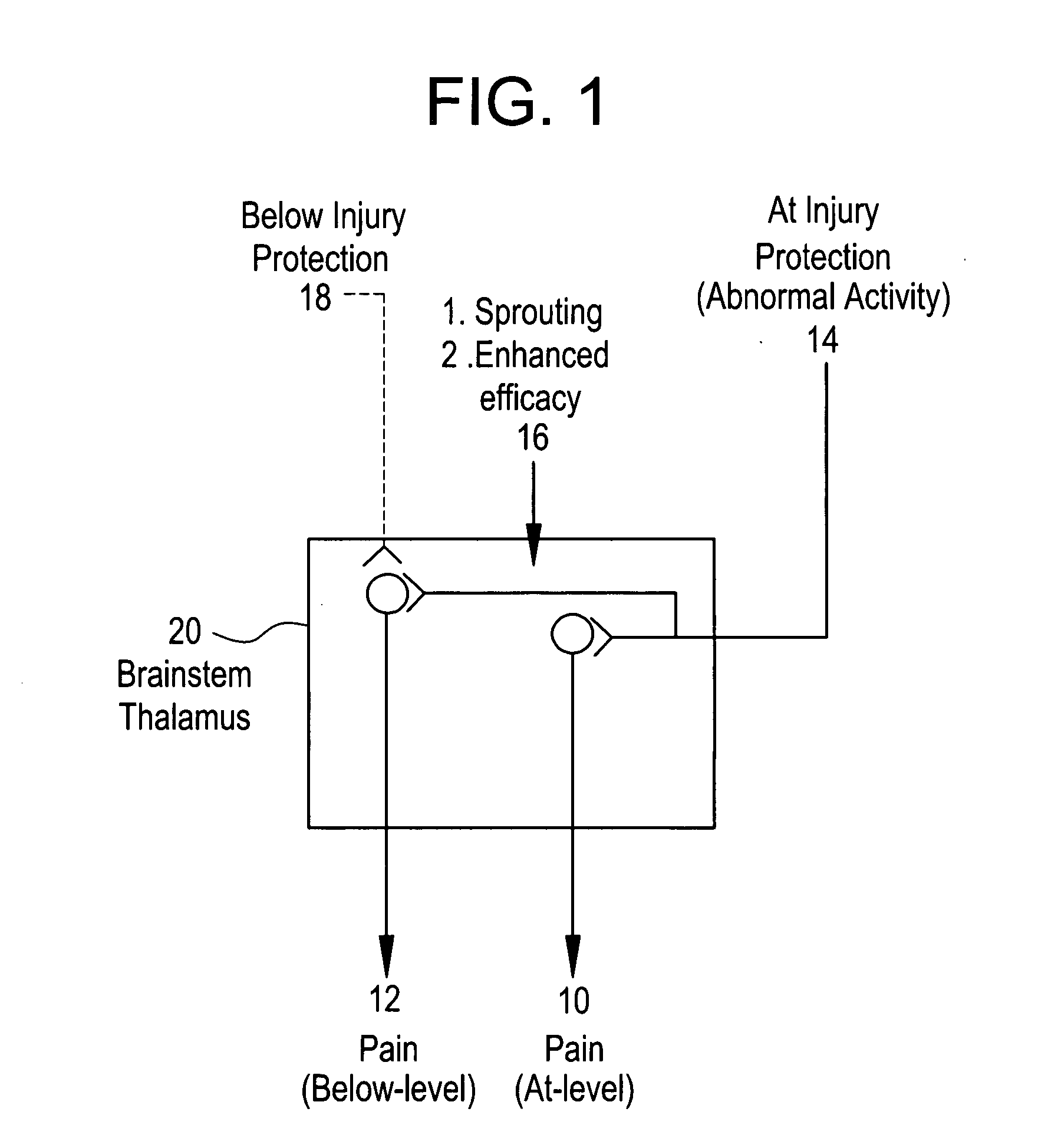

Treatment of pain

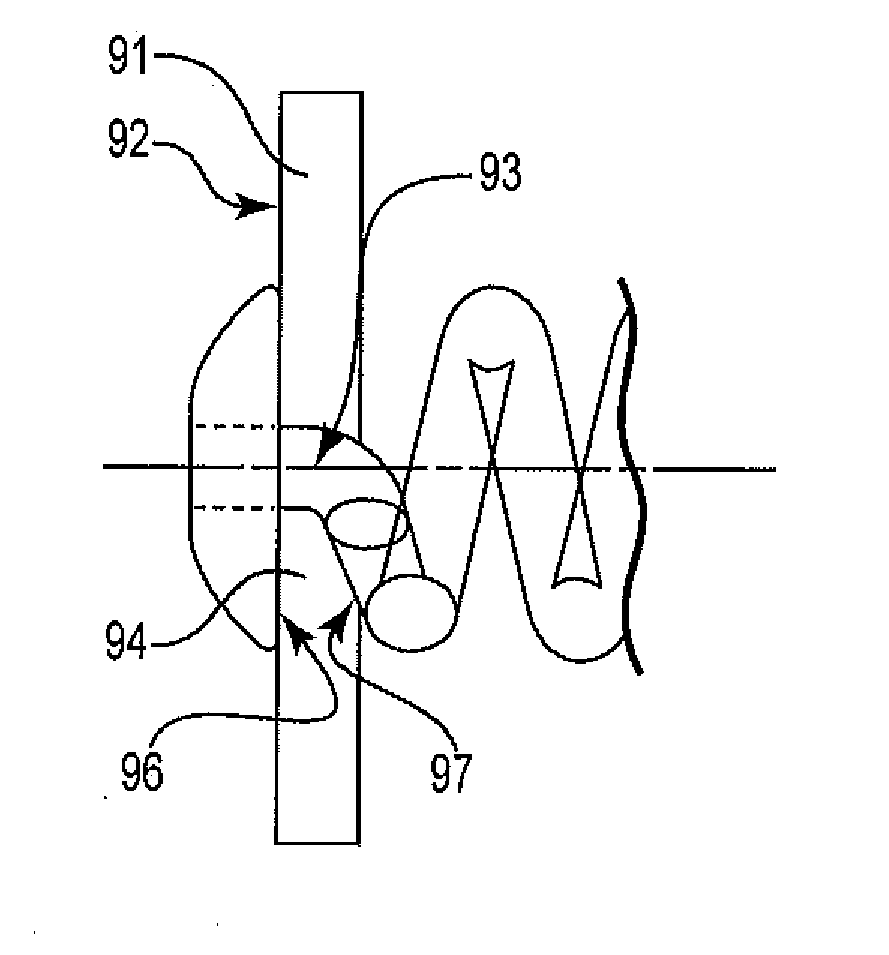

InactiveUS7333857B2Reduce stimulationAvoid signalingSpinal electrodesExternal electrodesAnatomySpinal tracts

The method disclosed herein entails spinal cord stimulation via electrodes placed directly into the dorsal horn, dorsal column, spinothalamic tract, nucleus cuneatus, nucleus gracilis, spinal tract of V, or spinal nucleus of V (nucleus caudalis) depending on the source of pain. This “intramedullary” stimulation “jams” or otherwise prevents the pain signal from being transmitted. The method provides a means to stimulate the targeted area directly, creating a stable means of stimulating the desired area, and decreasing stimulation of other structures.

Owner:ARC 1

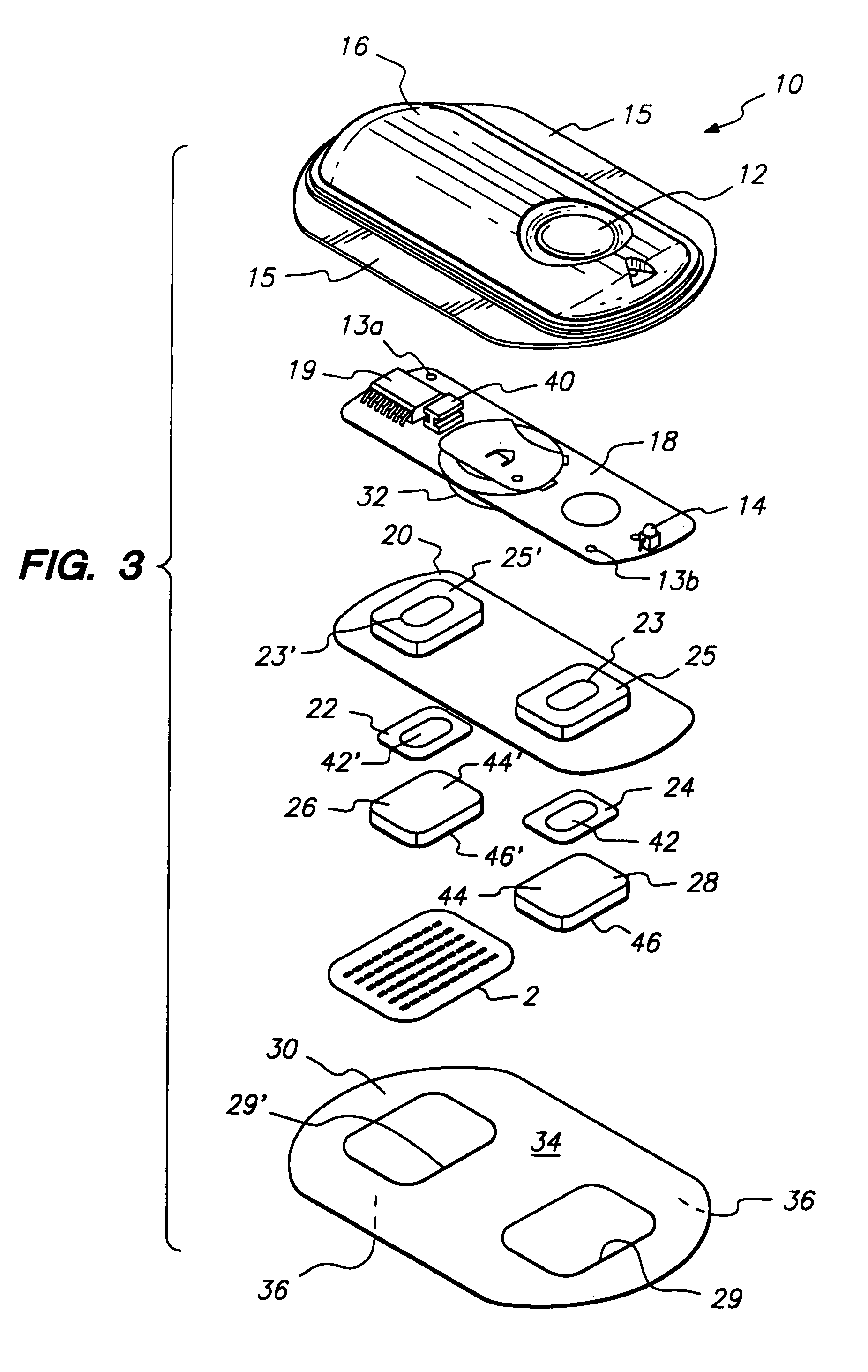

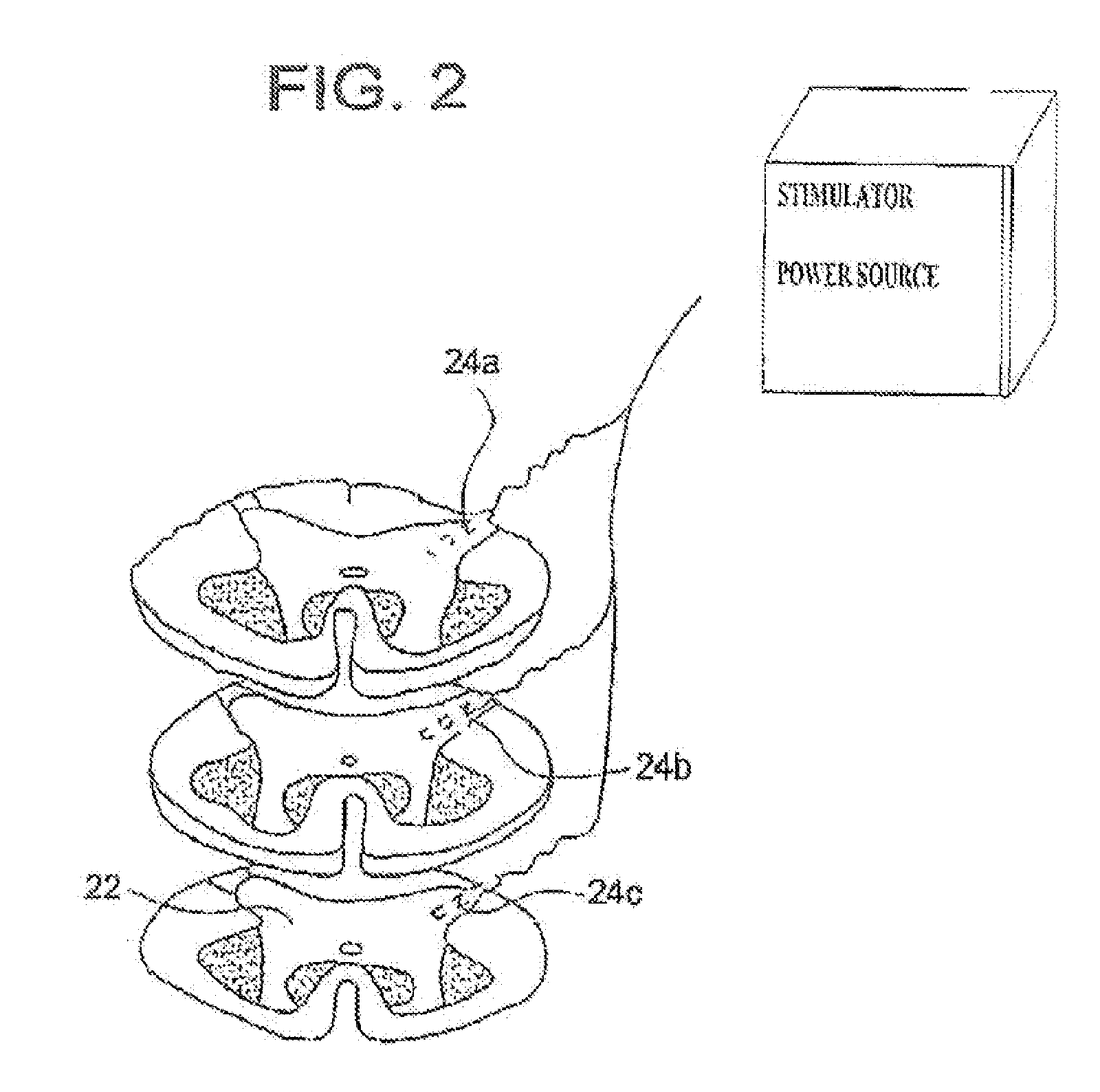

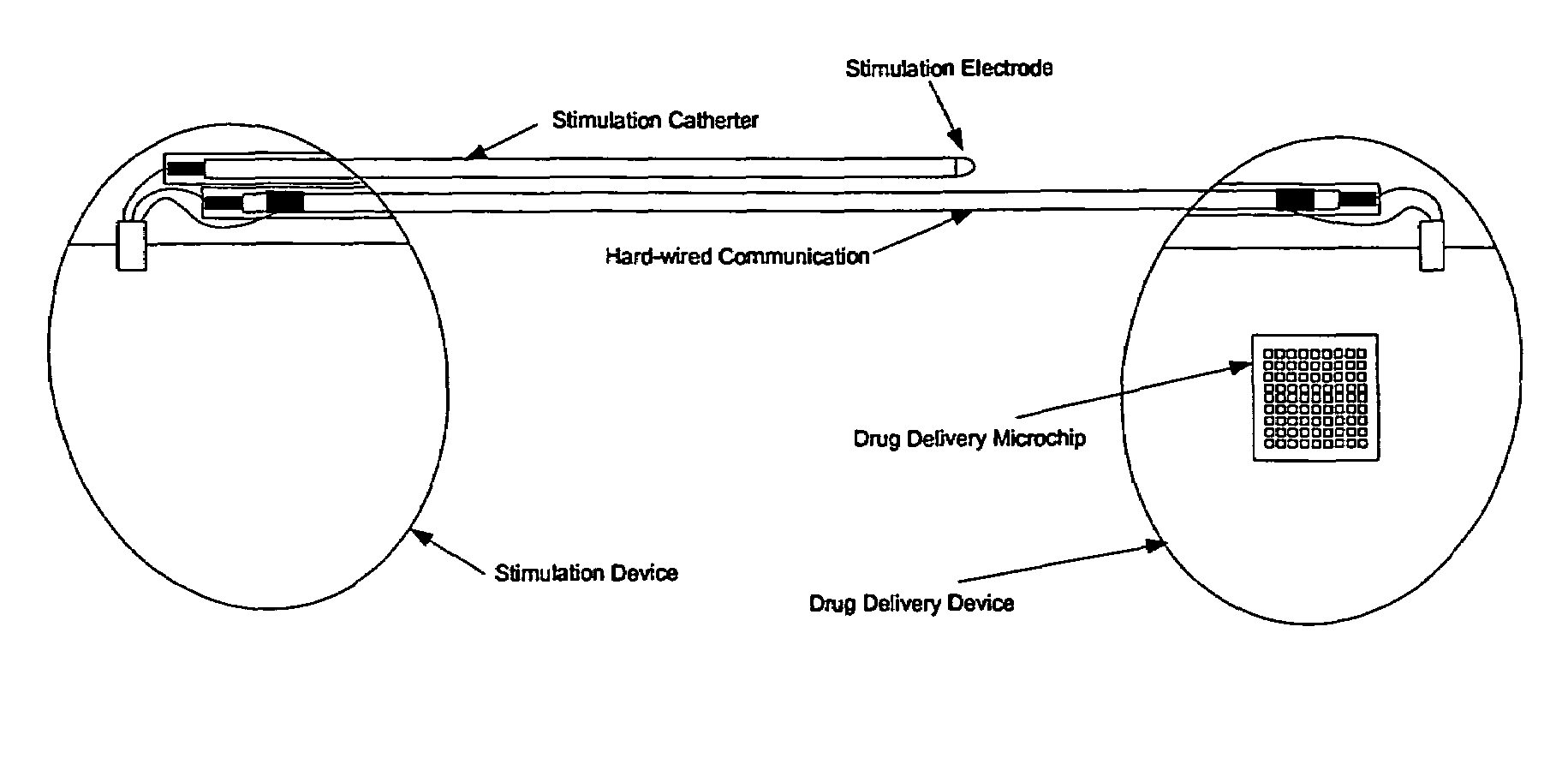

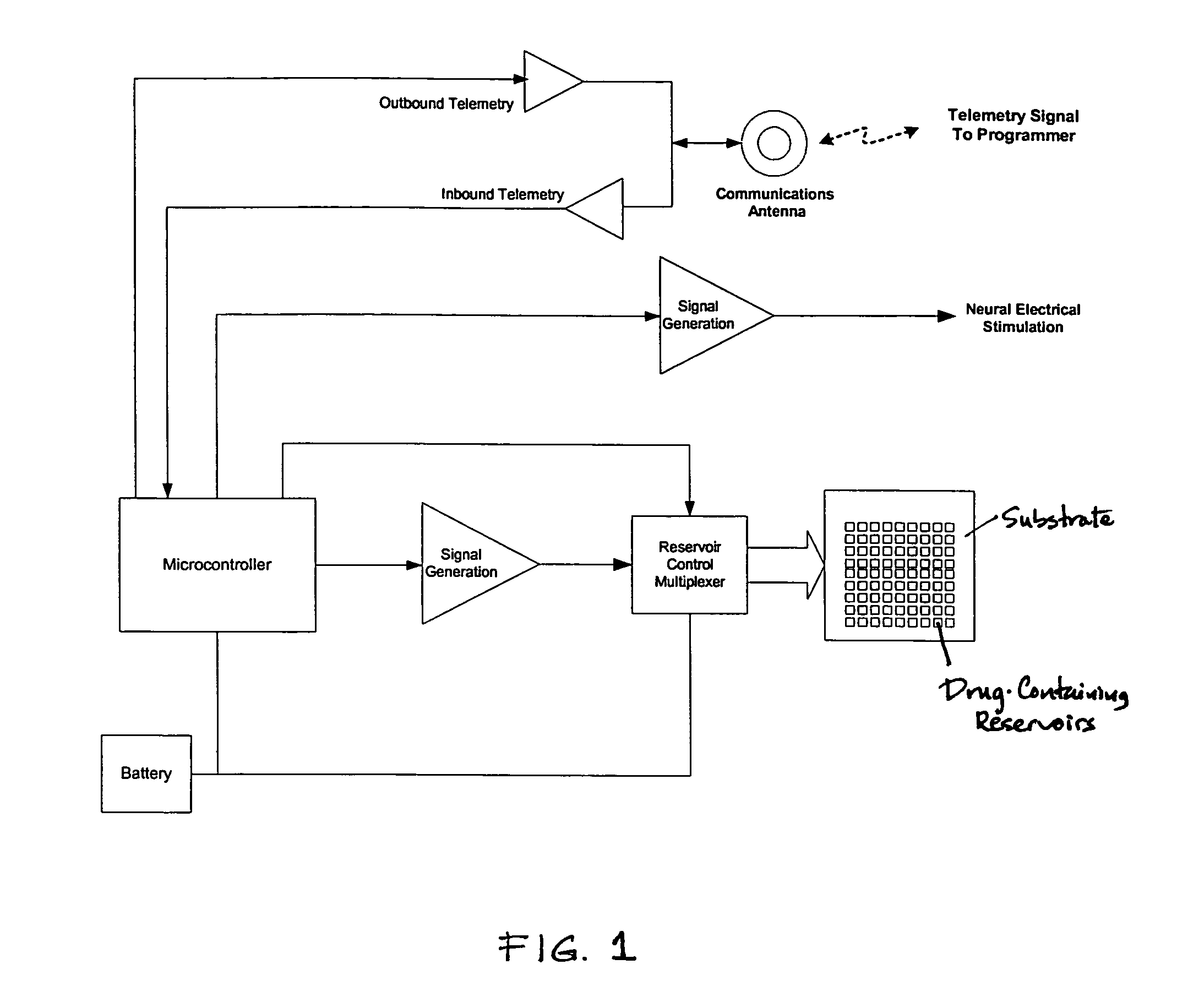

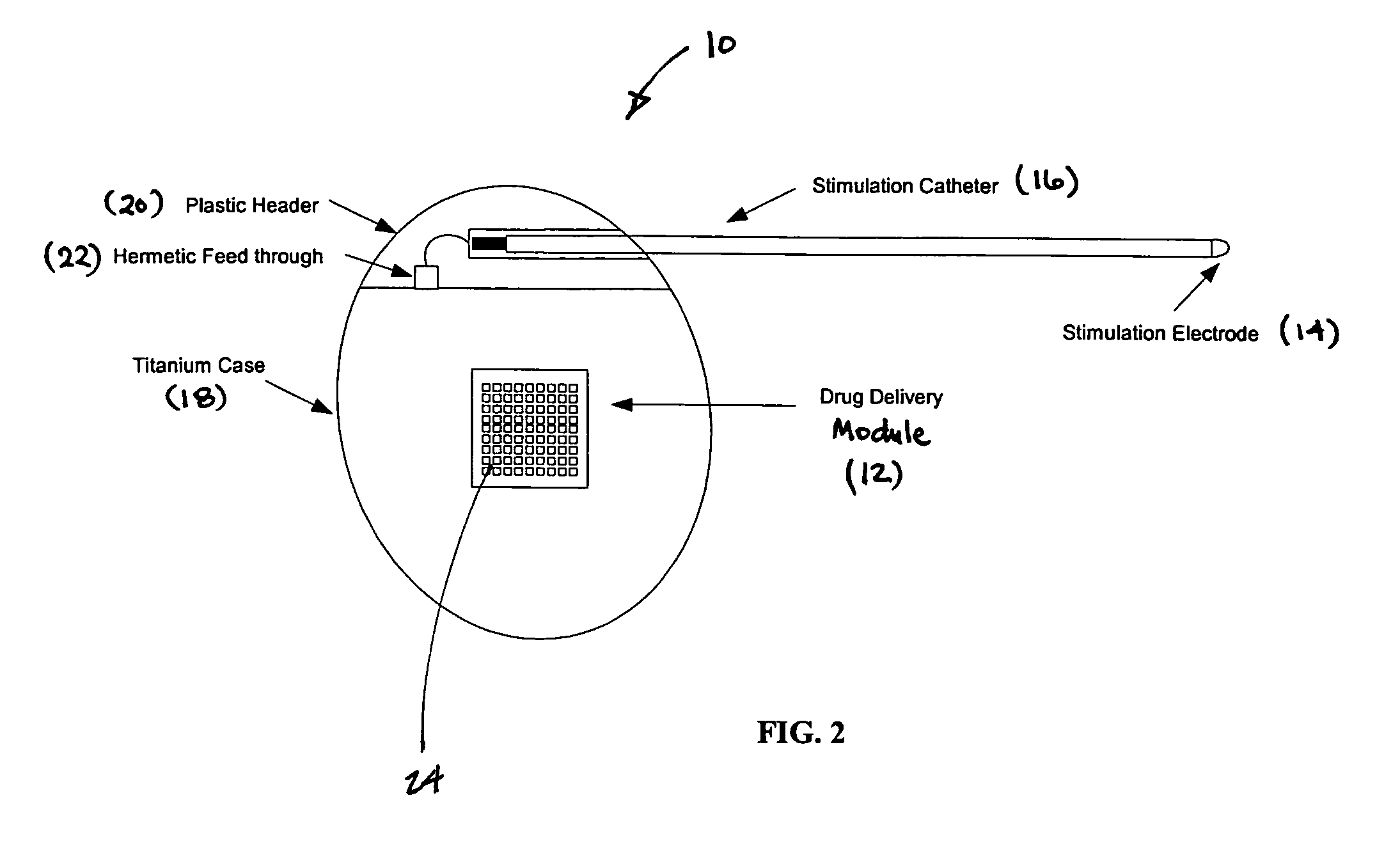

Medical device for neural stimulation and controlled drug delivery

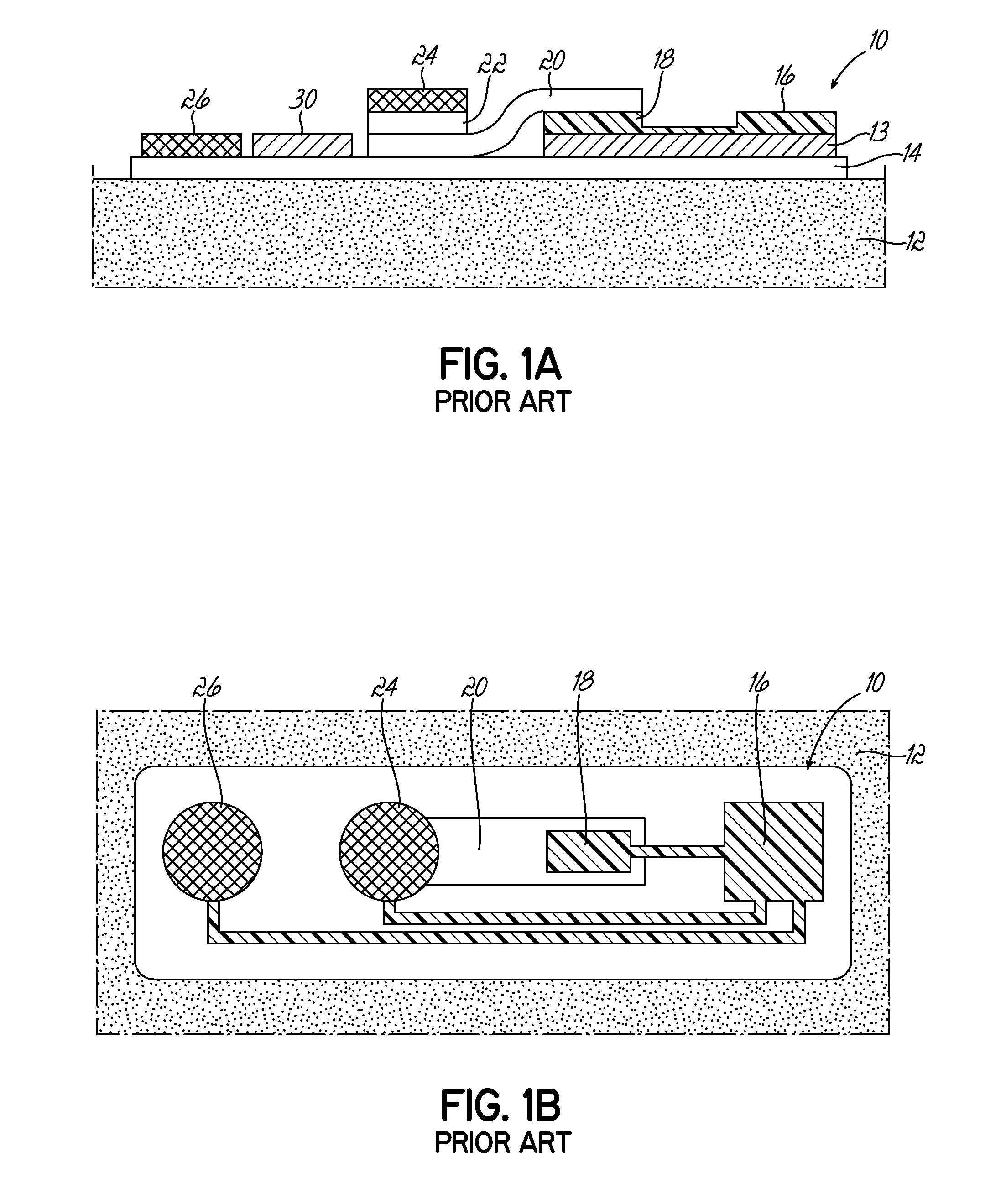

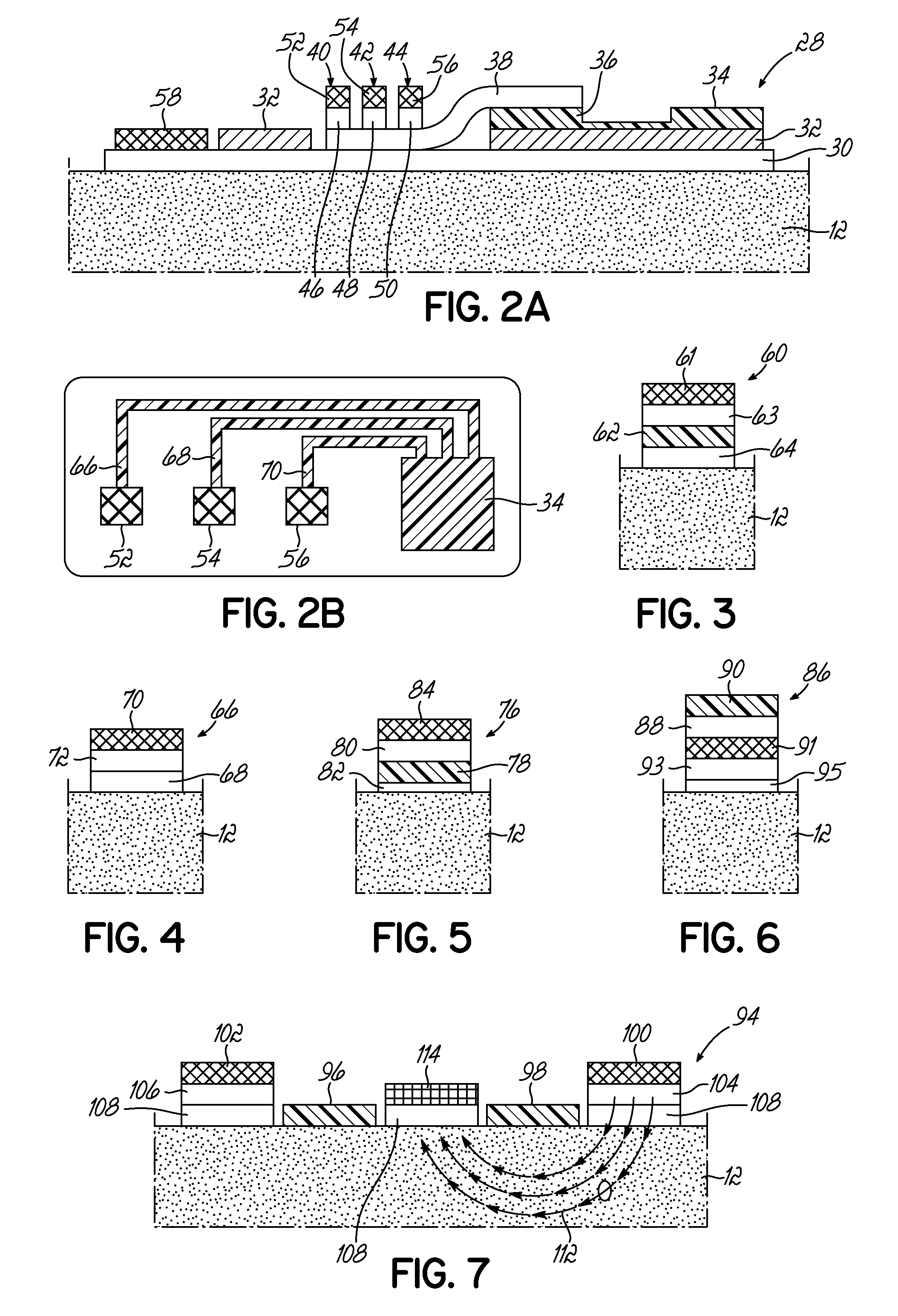

InactiveUS7599737B2Reduce stimulation thresholdReduce stimulationElectrotherapyMicromachined deliveryMicrocontrollerElectrical stimulations

Medical devices and methods are provided for electrical stimulation of neural tissue and controlled drug delivery to a patient. The device includes an implantable drug delivery module which comprises a plurality of reservoirs, a release system comprising at least one drug contained in each of the reservoirs, and control means for selectively releasing a pharmaceutically effective amount of drug from each reservoir; a neural electrical stimulator which comprises a signal generator connected to at least one stimulation electrode for operable engagement with a neural tissue of the patient; and at least one microcontroller for controlling operational interaction of the drug delivery module and the neural electrical stimulator. The microcontroller may control the signal generator and the control means of the drug delivery module. The device may further include a sensor operable to deliver a signal to the microcontroller, for example to indicate when to deliver electrical stimulation, drug, or both.

Owner:DARE MB INC

Zinc salt compositions for the prevention of dermal and mucosal irritation

InactiveUS20040102429A1Minimize and prevent irritationReduce transmissionAntibacterial agentsOrganic active ingredientsHigh concentrationFungicide

The addition of low concentrations of combinations of water-soluble organic salts of zinc to gels, creams, lotions or ointments can increase the ability of these products to reduce or prevent exogenous irritants from causing irritation of the underlying substrate. The addition of low concentrations of combinations of water-soluble organic zinc salts to these gels, creams, lotions or ointments also can reduce the irritation of skin or mucous membranes caused by the addition of potentially-irritating substances such as spermicides, microbicides, fungicides or other therapeutic agents to the gel, cream, lotion or ointment. The advantages of this anti-irritant approach over others, which generally employ high concentrations of single zinc salts, are the reduced potential for zinc toxicity, the reduced potential for toxicity related to zinc itself, and the preservation of the desirable biological properties of potentially-irritating therapeutic substances added to the gel, cream, lotion or ointment.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

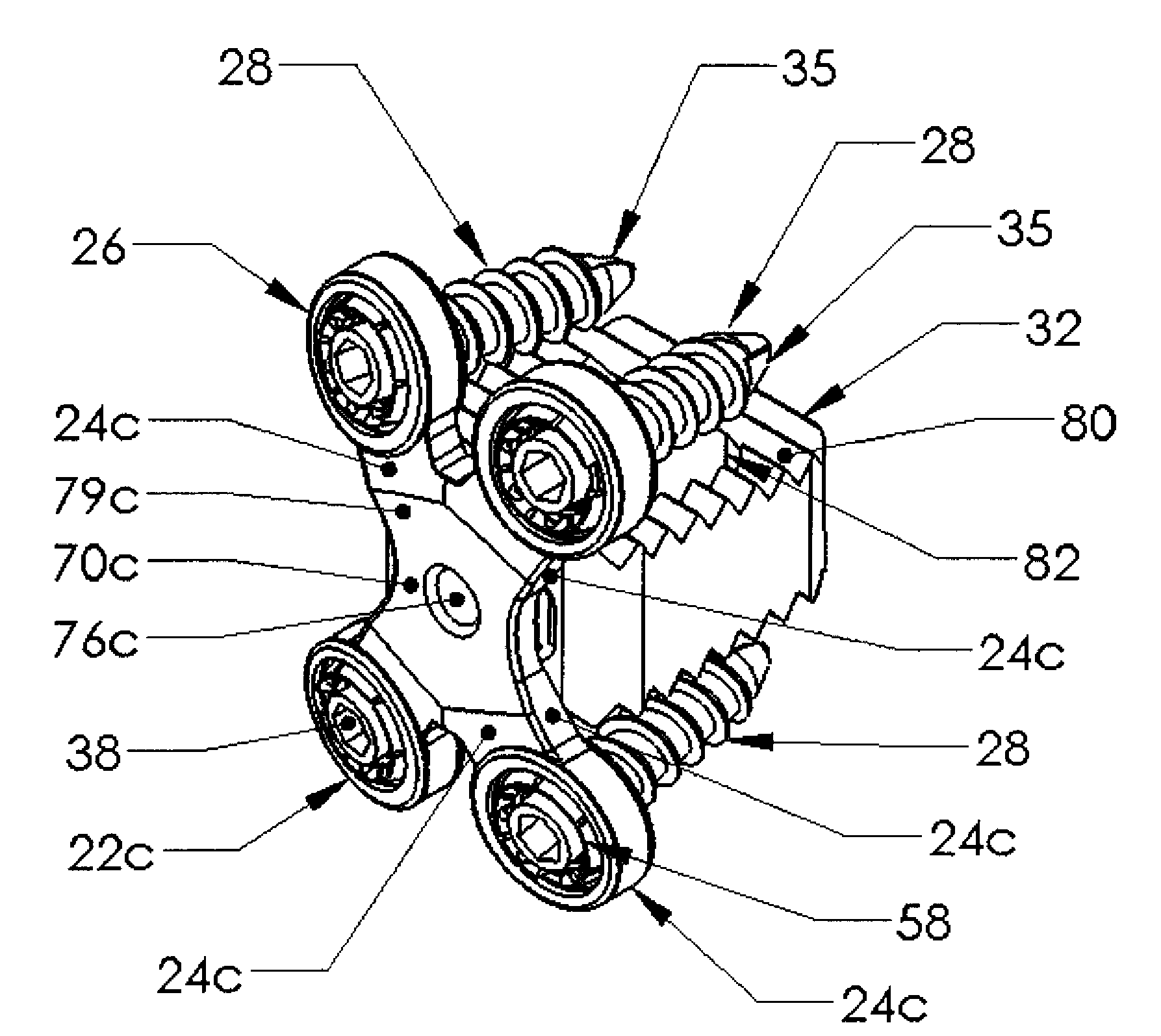

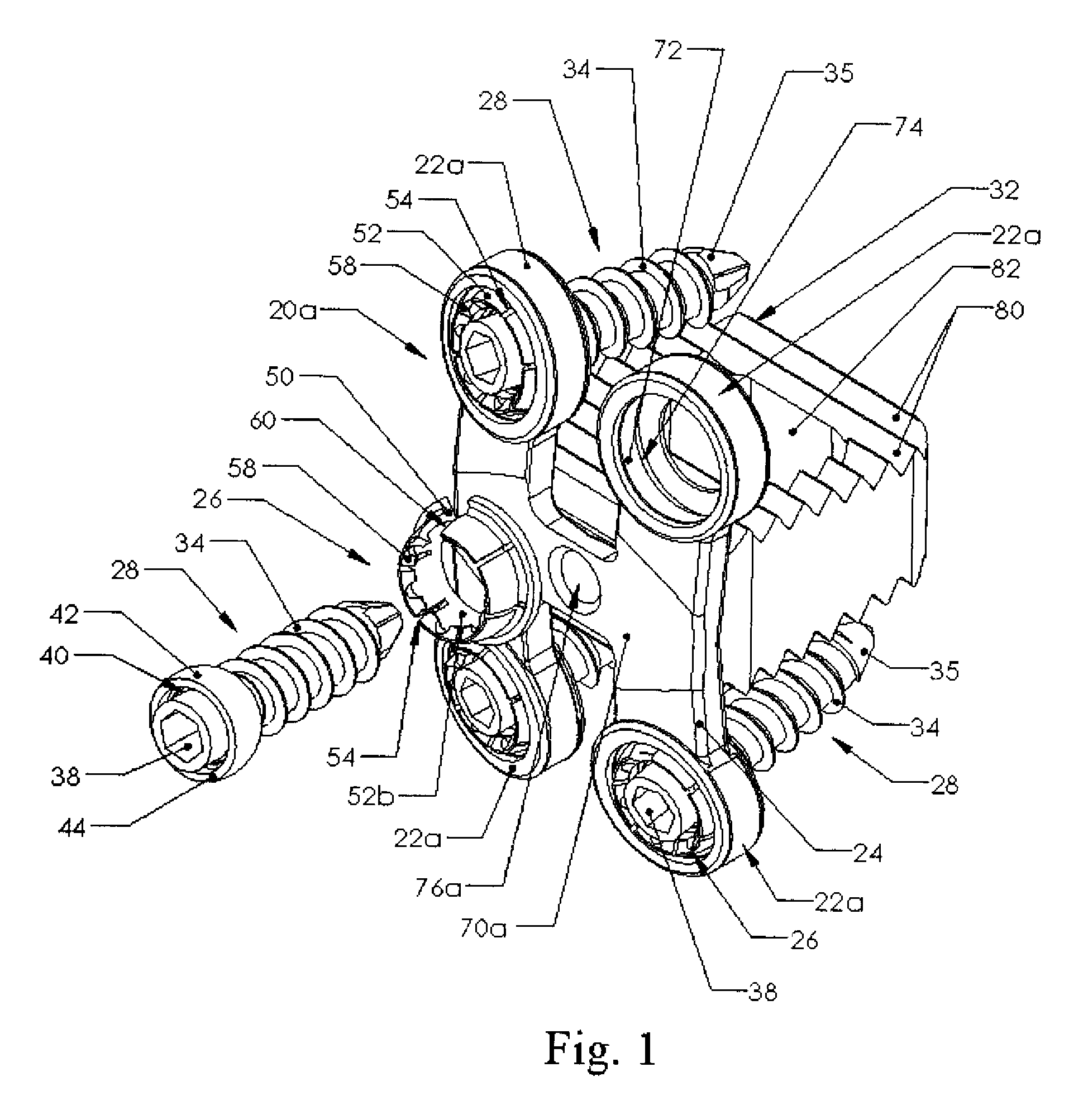

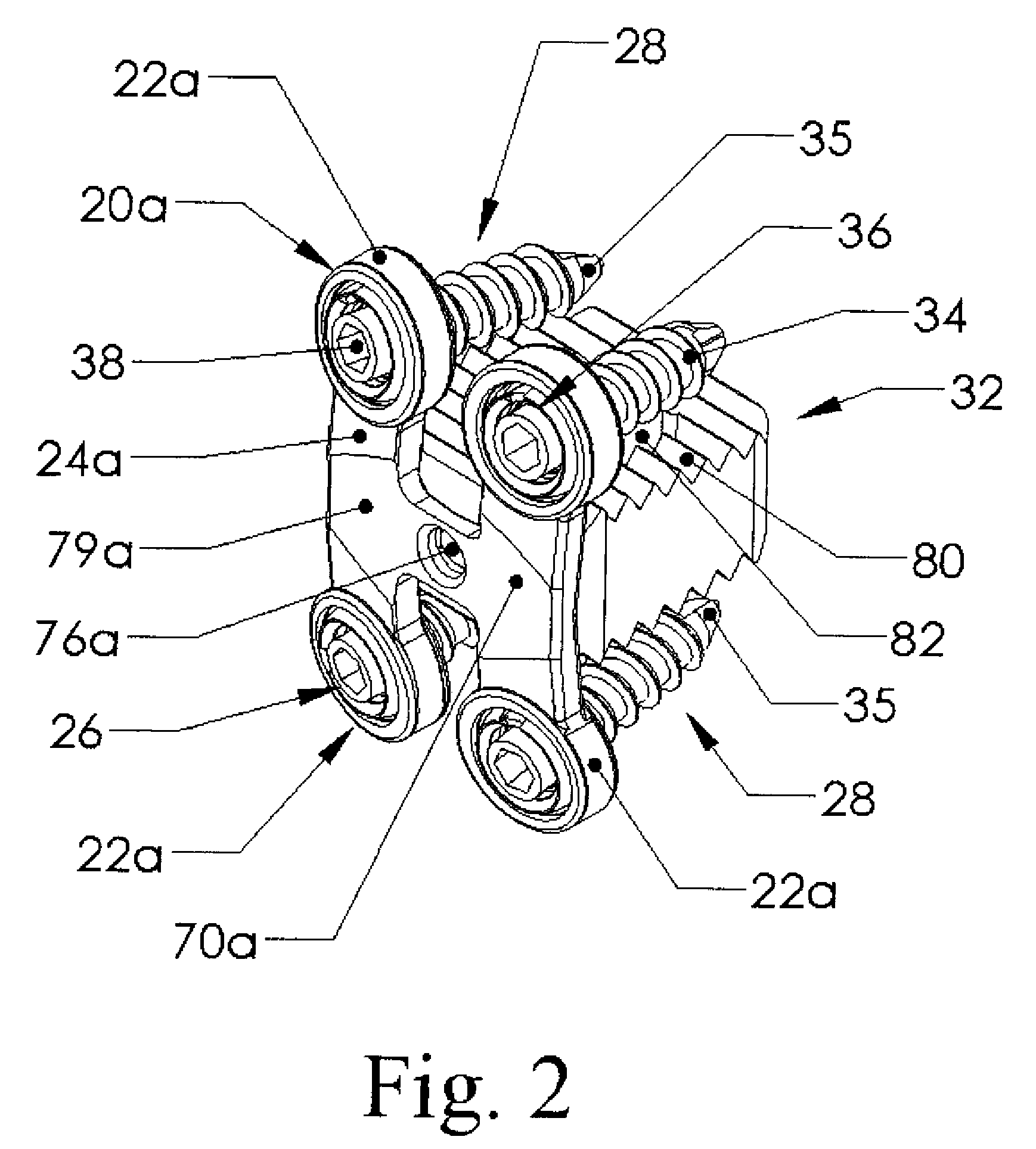

Spinal fixation device

ActiveUS20090326580A1Reduce stimulationAdjustable flexibilitySuture equipmentsInternal osteosythesisIliac screwBiomedical engineering

A spinal fixation assembly has a bone screw with head having a continuously curved spherical outer surface. The curved surface nests in a split annular bushing having a plurality of segments curving around the screw head. The bushing has an outward extending flange that fits into a recess in a socket in a fixation plate. The plate has at least three legs which extend from ends of a cross-member to form one of an H shaped, X shaped or A shaped configuration. Each socket is curved to rotatably receive rotation of the bushing. The socket recess is larger than the bushing flange to allow the bushing to tilt a predetermined amount depending on a thickness of the outward extending flange.

Owner:WESTMARK MEDICAL

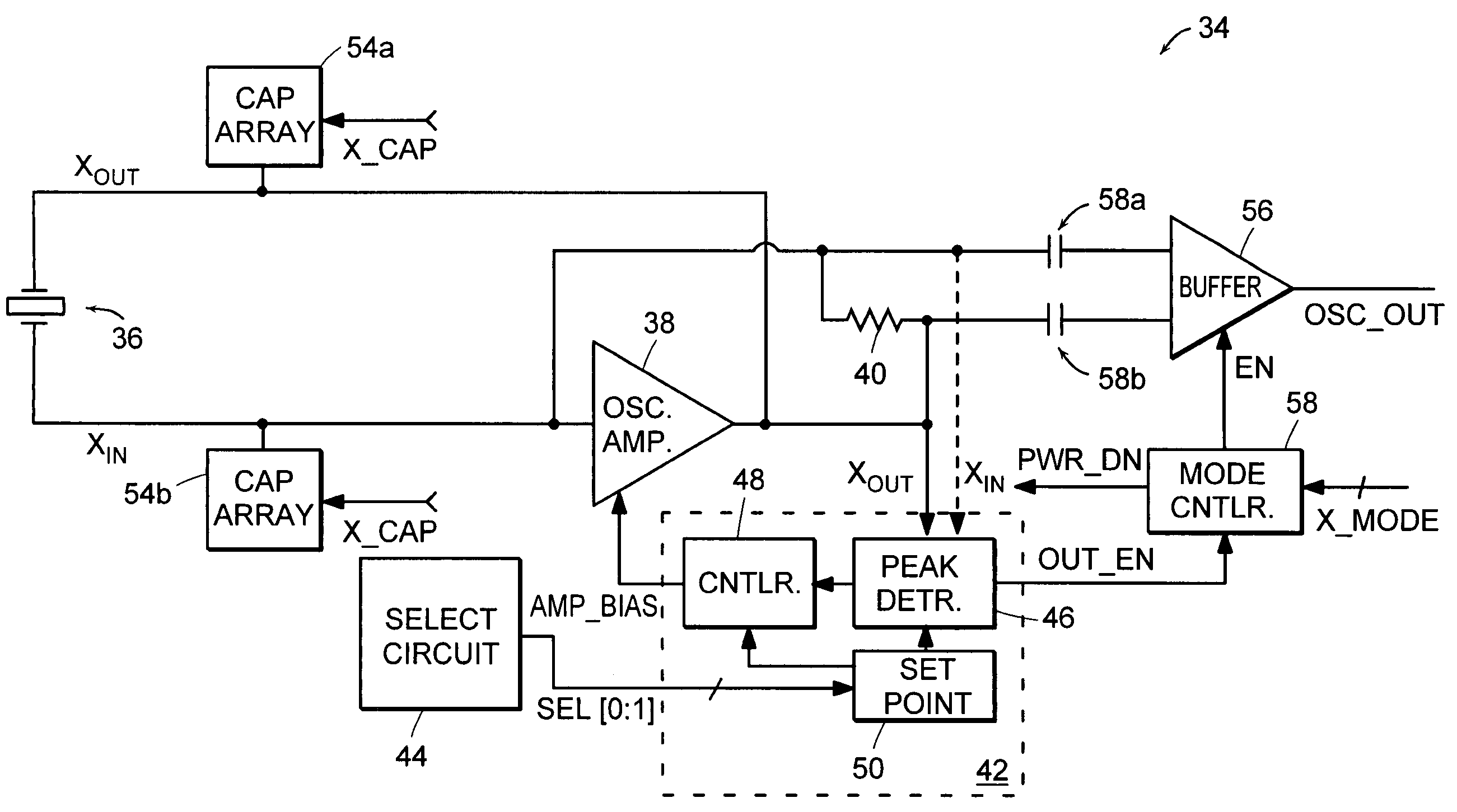

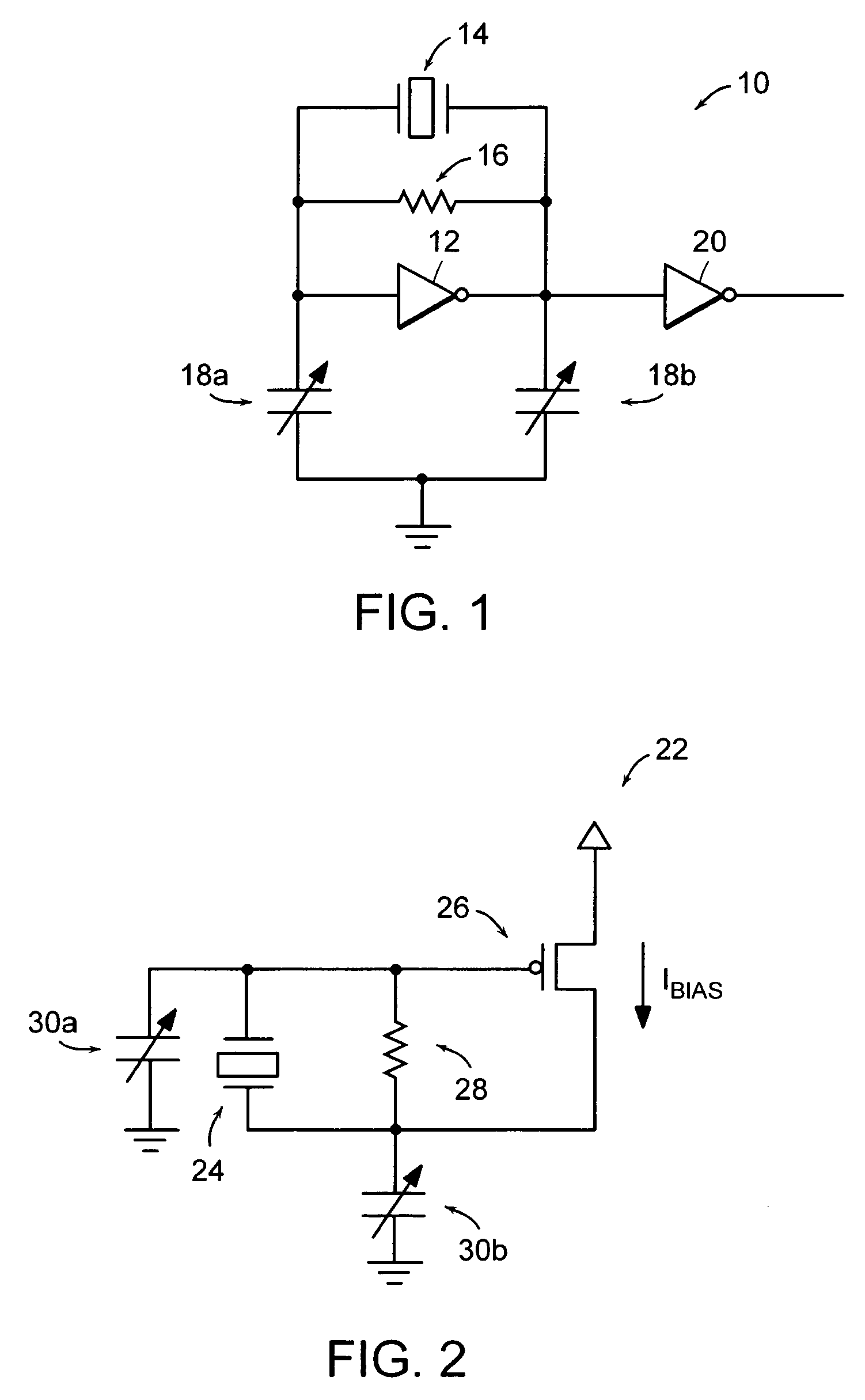

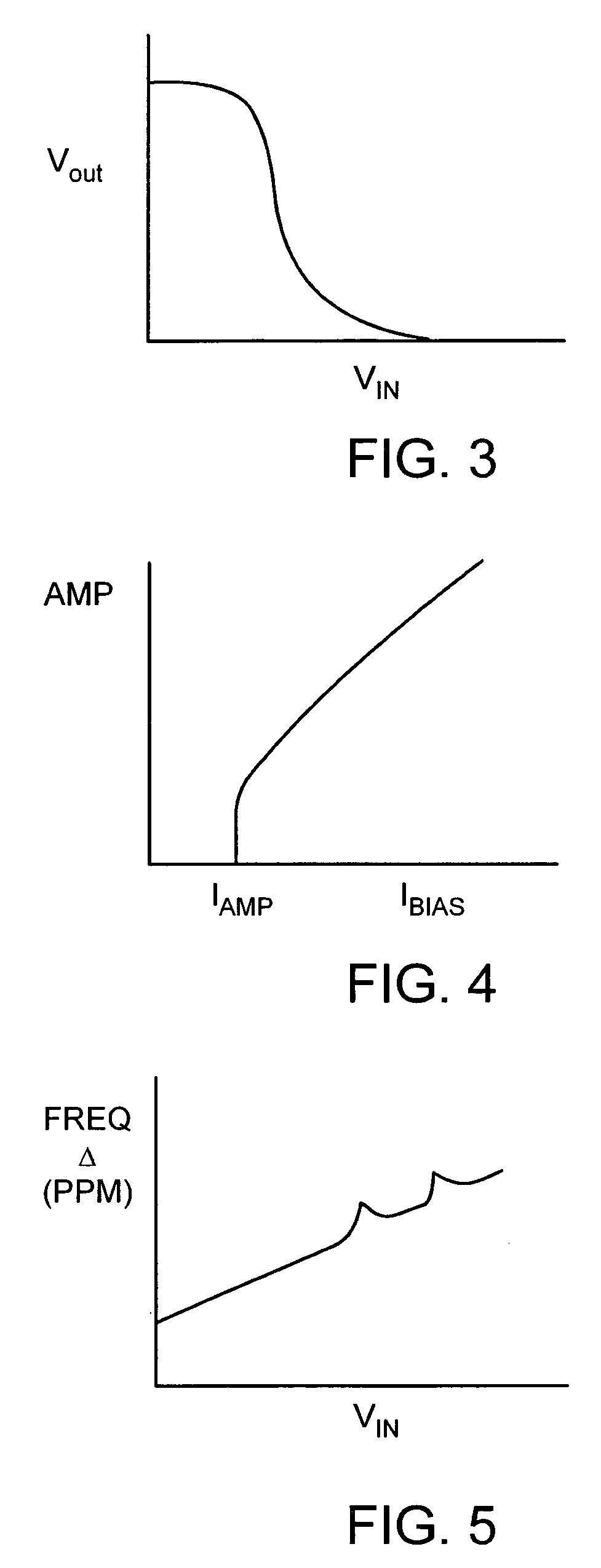

Regulated, symmetrical crystal oscillator circuit and method

ActiveUS7123113B1Reduce stimulationMinimizing stimulationPulse automatic controlGenerator stabilizationAudio power amplifierPeak value

An oscillator circuit is provided that is preferably a crystal oscillator, where voltage placed across the crystal is regulated. The regulated voltage or amplitude of the cyclical signal across the crystal is monitored and maintained through a regulation circuit that measures a peak voltage across the crystal. Once the peak voltage exceeds a predetermined setpoint value, then a controller within the regulation circuit will reduce a biasing current through an amplifying transistor within the amplifier coupled across the crystal input and output nodes. By regulating the biasing current, gain from the amplifier is also regulated so that unwanted non-linearities and harmonic distortion is not induced within the crystal to cause frequency distortion and unwanted modes of oscillation within the crystal. The amplifier is preferably symmetrical in that the amplifier sources and sinks equal current to reduce unwanted peaks at the negative or positive half cycles of the sinusoidal signal.

Owner:MONTEREY RES LLC

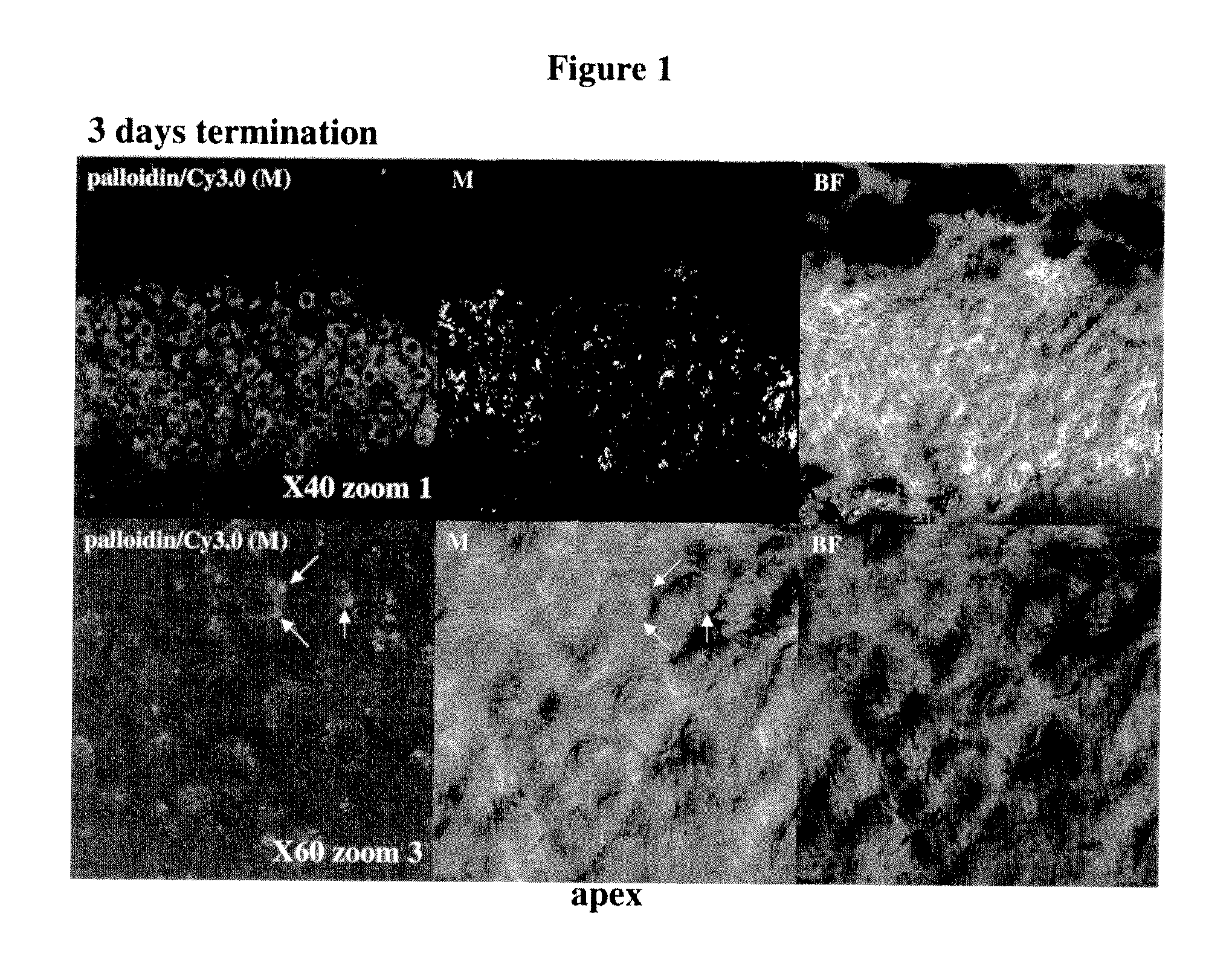

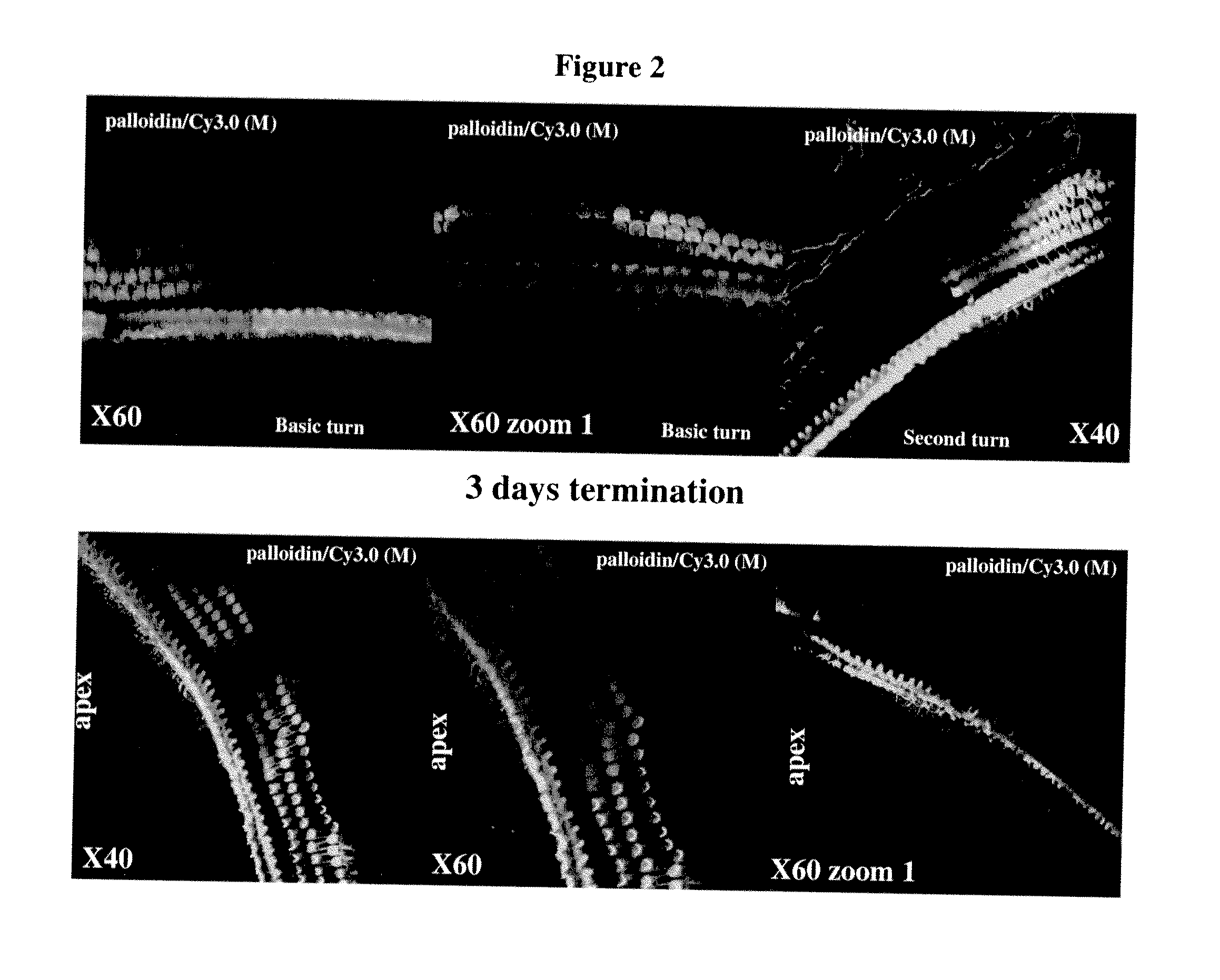

Compositions and methods for treatment of ear disorders

ActiveUS20110142917A1Reduces and inhibits expression of geneReduce expressionHeavy metal active ingredientsOrganic active ingredientsDiseasePresbycusis

The present invention relates to pharmaceutical compositions useful for topical, non-invasive delivery of an oligonucleotide to the ear and to methods for the treatment of an ear disorder, including hearing loss arising from chemical-induced ototoxicity, acoustic trauma and presbycusis; and microbial infections. The method comprises topically administering to the ear of a subject in need thereof a pharmaceutical composition comprising an inhibitory oligonucleotide, a permeability enhancer and a pharmaceutically acceptable carrier, wherein the oligonucleotide reduces or inhibits expression of a gene associated with the ear disorder in the subject.

Owner:QUARK FARMACUITIKALS INC

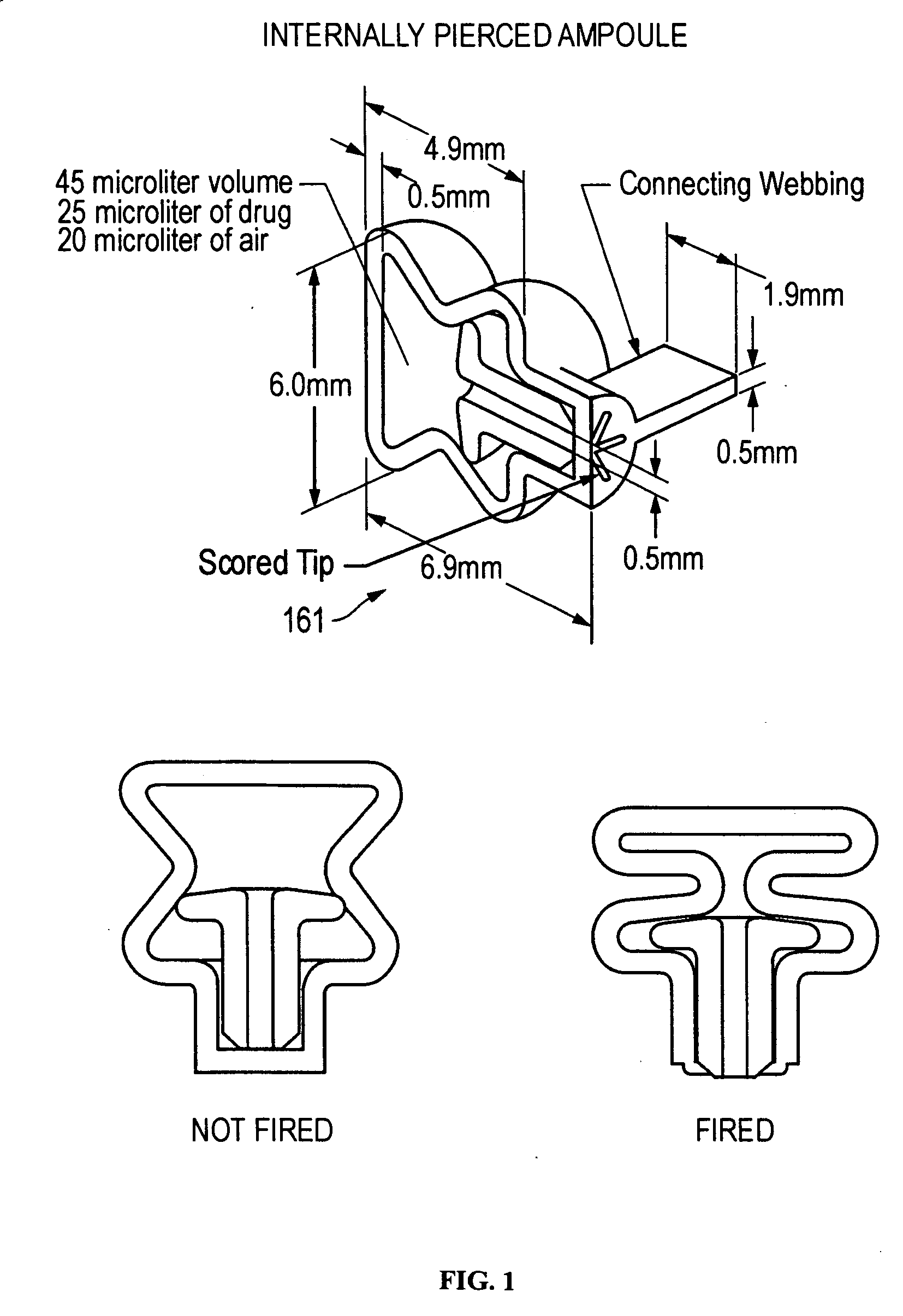

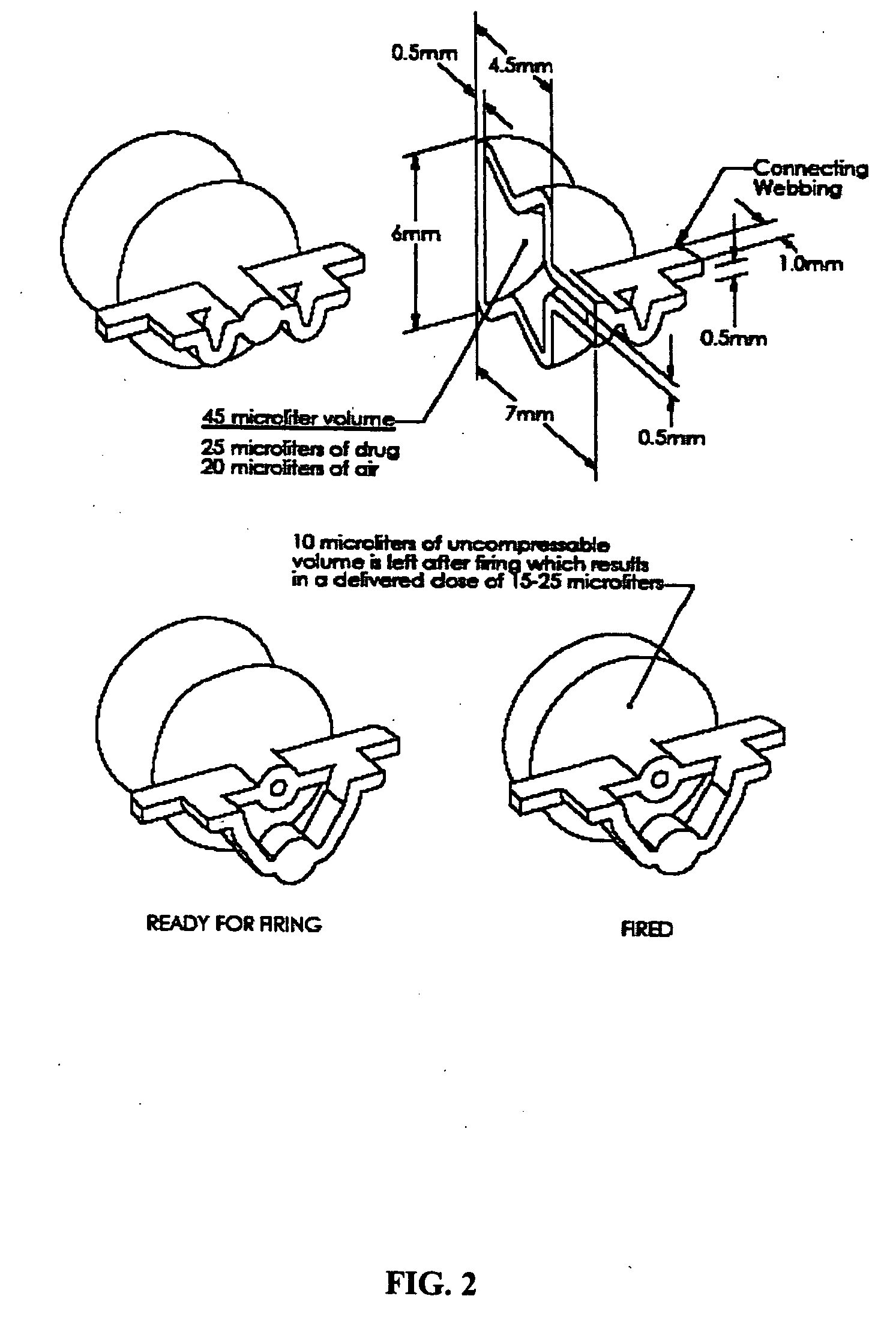

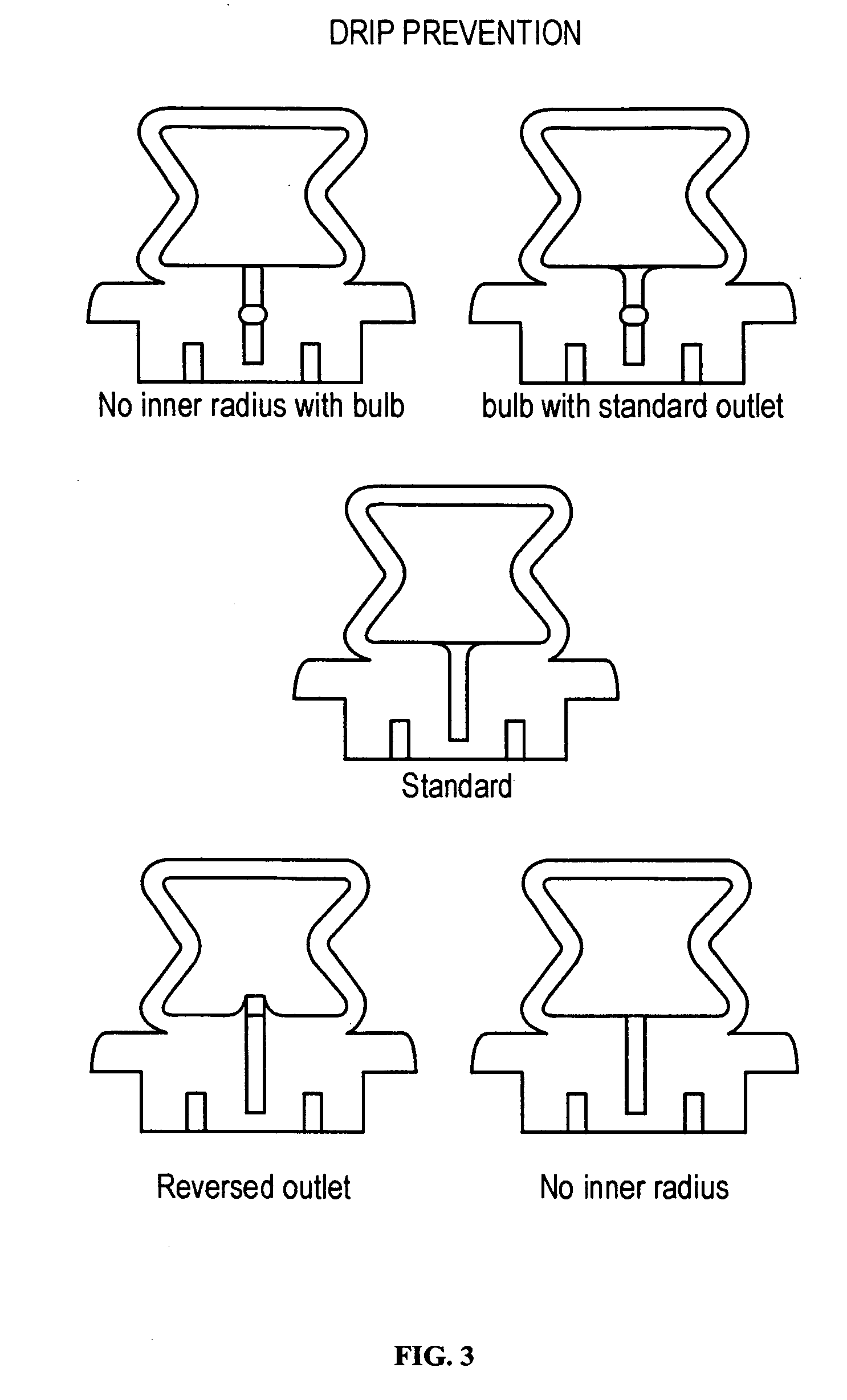

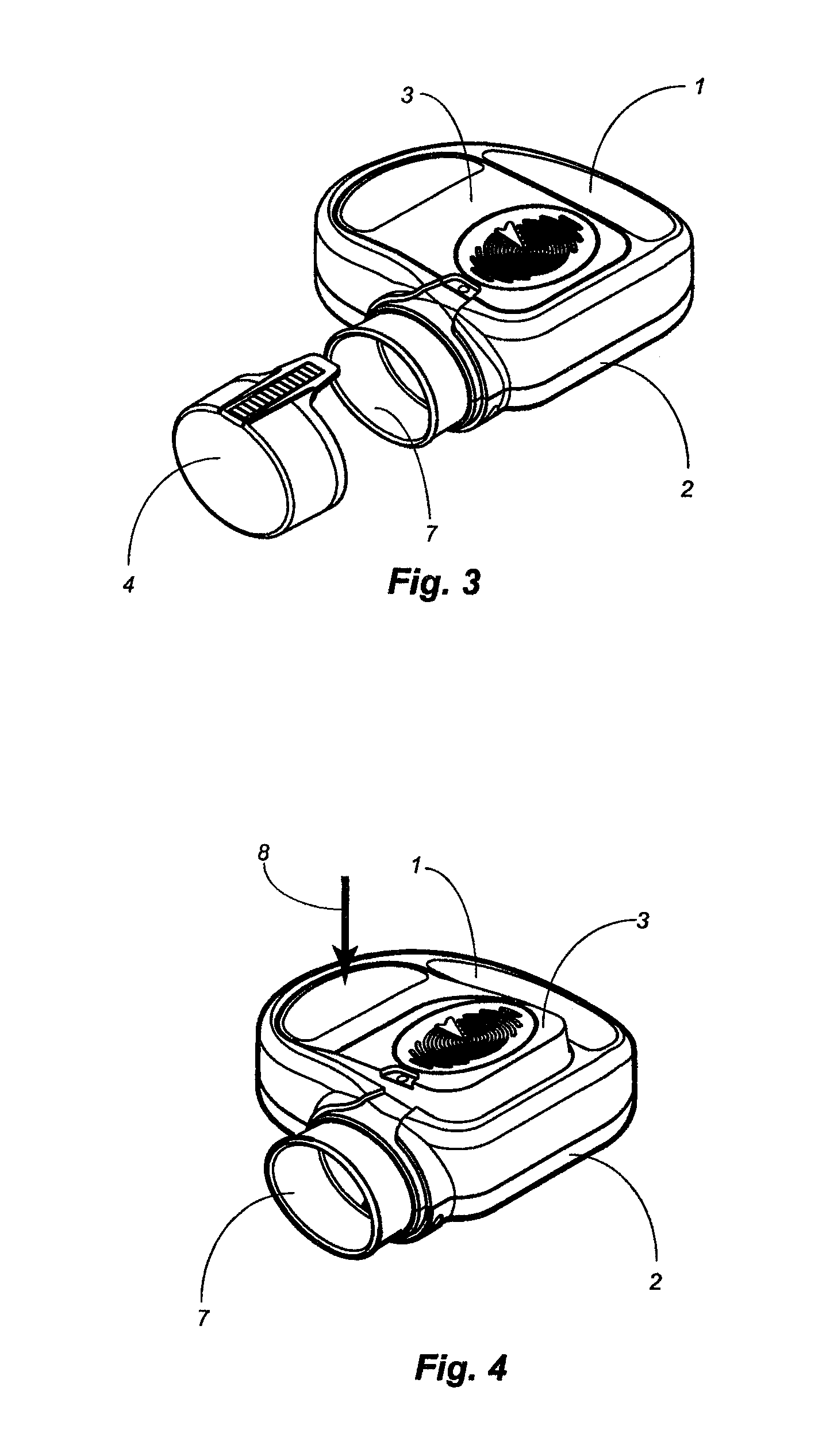

Multiple unit dose drug delivery system

InactiveUS20070051362A1Reduces potentially unpleasant side effectConvenient, fast and safeBiocideMedical devicesOphthalmologyNose

The present disclosure is directed to devices that administer single or multiple doses of one or more substances to the eye, nose, or ear of a user. The precise and repeatable dosing features of the presently disclosed devices overcome many of the disadvantages associated with known methods for dispensing substances to, for example, the eye of a user. The devices administer precise doses of a substance to a precise location from ampoules that may be single-dose or two-dose ampoules, which may be externally or internally pierced.

Owner:MYSTIC PHARMA INC

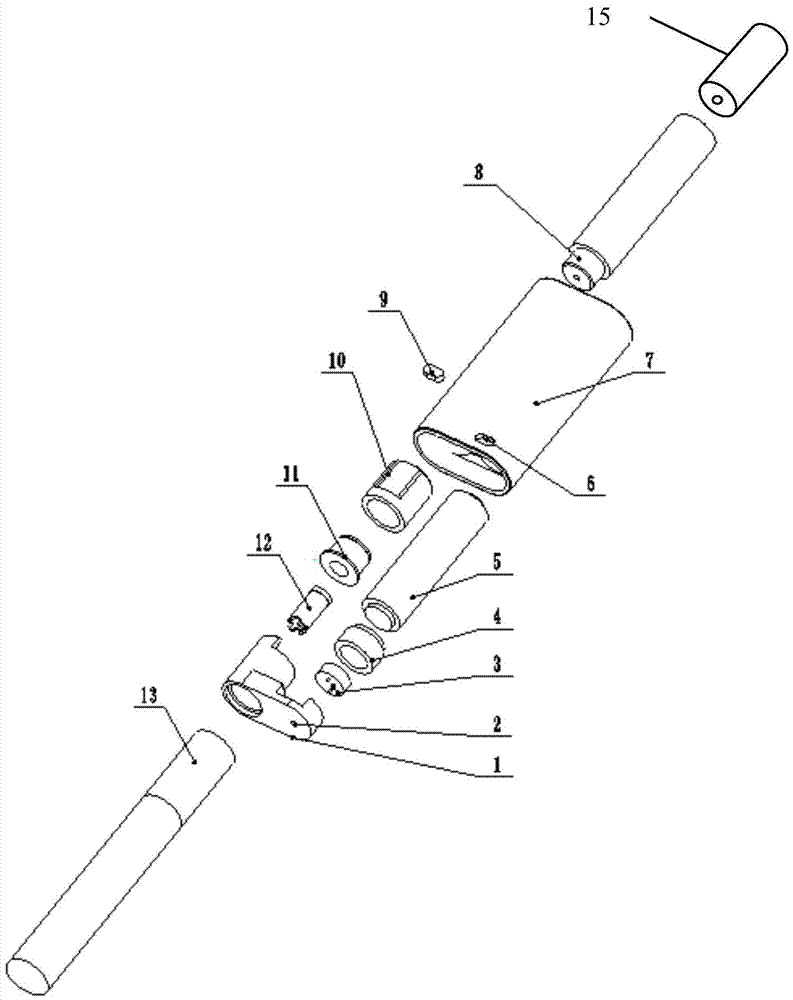

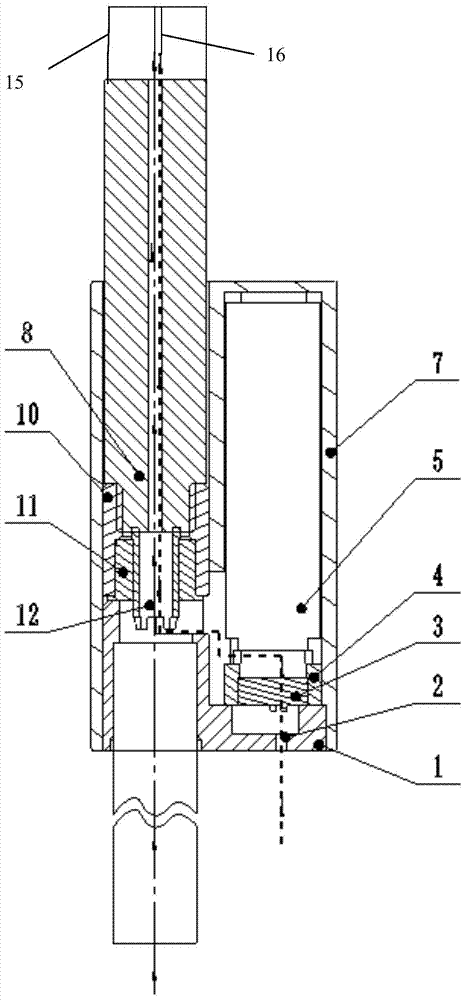

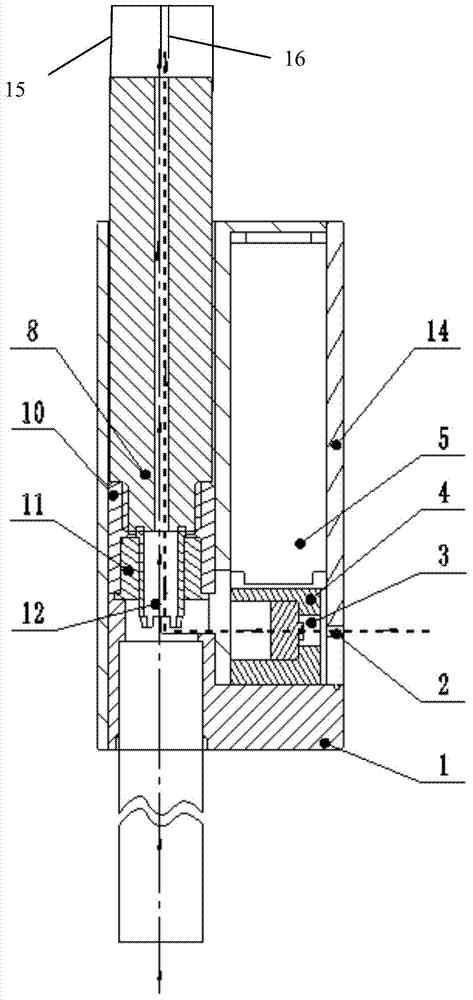

Electric heating type cigarette suction device with electronic cigarette suction function

ActiveCN104770878ASolve the problem of poor fullnessReduce stimulationTobacco treatmentTobacco pipesElectric heatingAirflow

The invention relates to an electric heating type cigarette suction device with an electronic cigarette suction function. The electric heating type cigarette suction device comprises an electric heating type cigarette holder (1), an electronic atomization assembly and a suction nozzle section (15), wherein the electric heating type cigarette holder (1) is provided with an electric heater, the electric heating type cigarette holder (1), the electronic atomization assembly and the suction nozzle section (15) are assembled in a matching manner, and the electric heating type cigarette holder (1) comprises an electric heating type cigarette holding cavity and an optional end cover; the electronic atomization assembly comprises a shell (7), a power supply (5), an airflow induction switch (3) and an electronic cigarette atomizer (8) with a center airflow channel, and the power supply (5), the air induction switch (3) and the electronic cigarette atomizer (8) are positioned in the shell (7); an airflow channel (16) is formed the suction nozzle section (15); the electronic cigarette atomizer (8) and the electric heating type cigarette holder (1) are connected in series or in parallel. The electric heating type cigarette suction device has the effects of being capable of increasing the electric heating type cigarette suction sensory quality and reducing the harmfulness of smoking.

Owner:CHINA TOBACCO YUNNAN IND

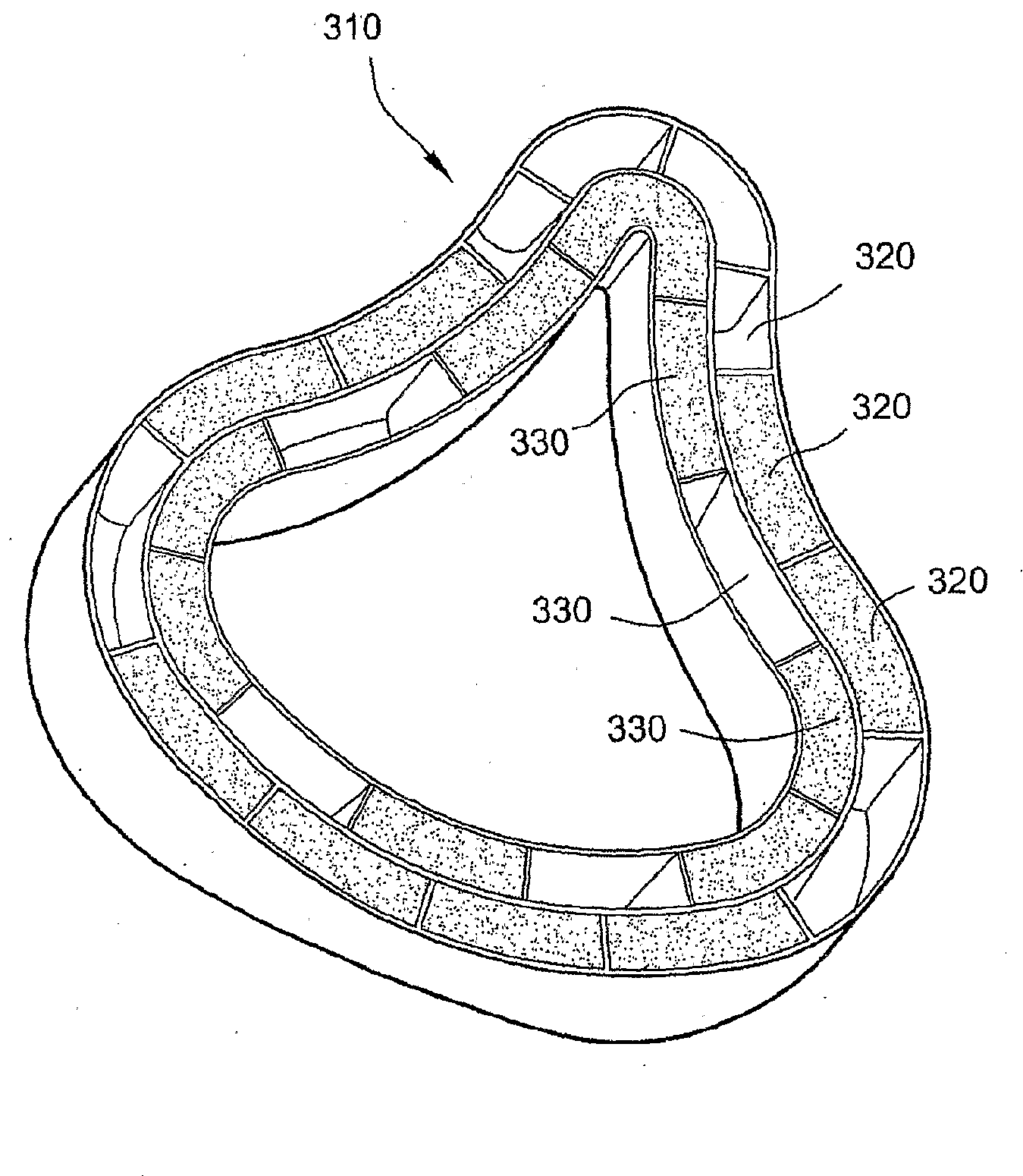

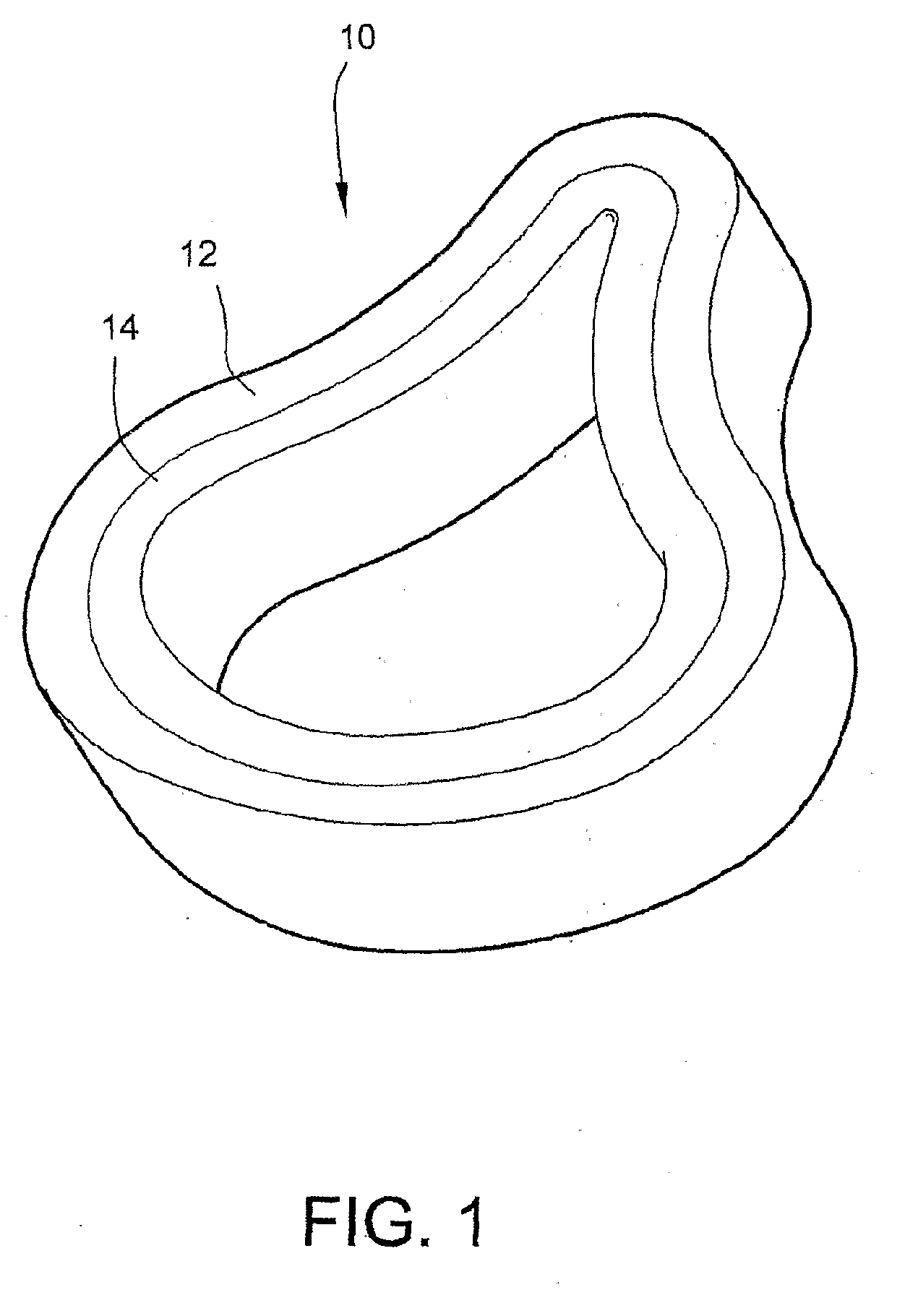

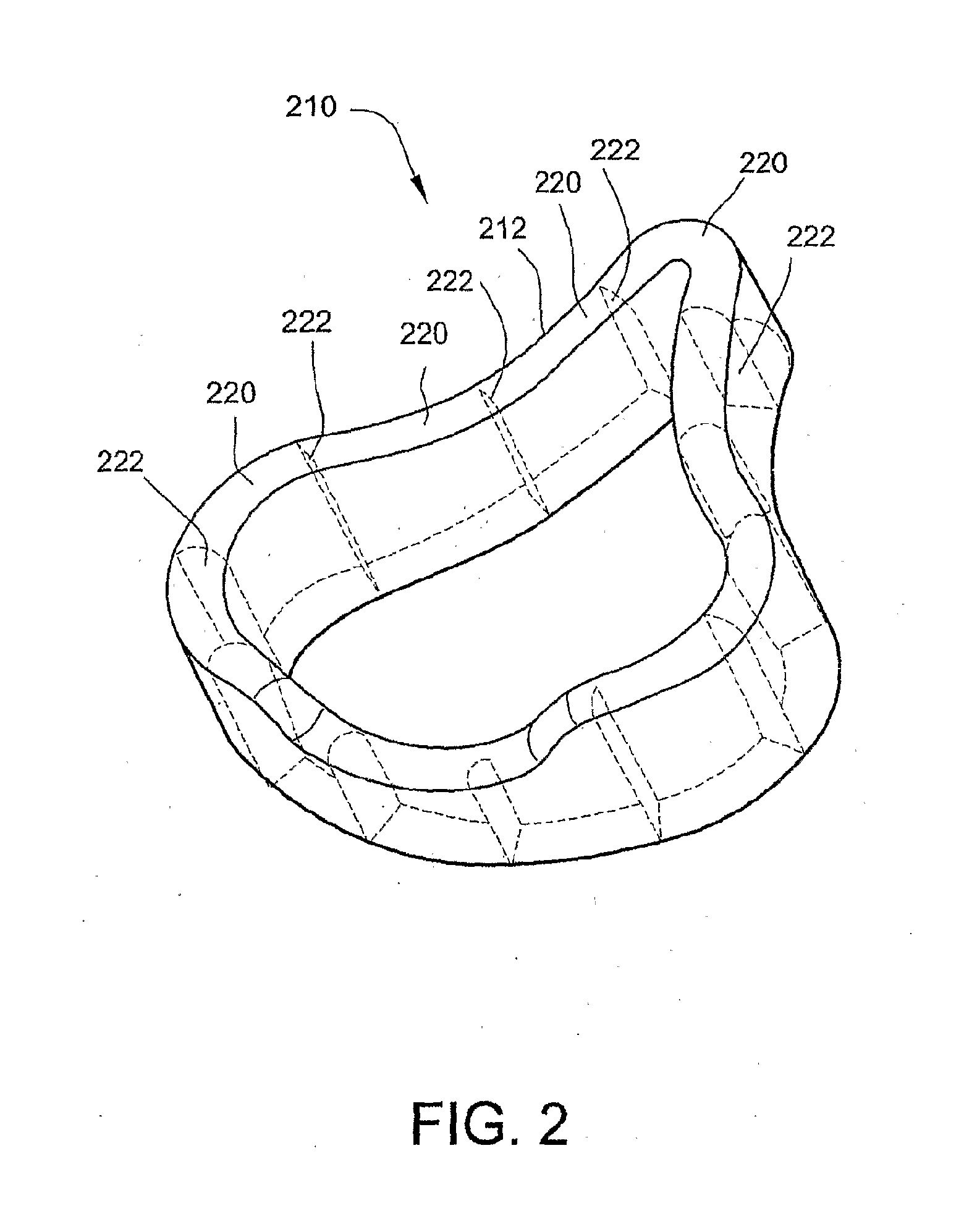

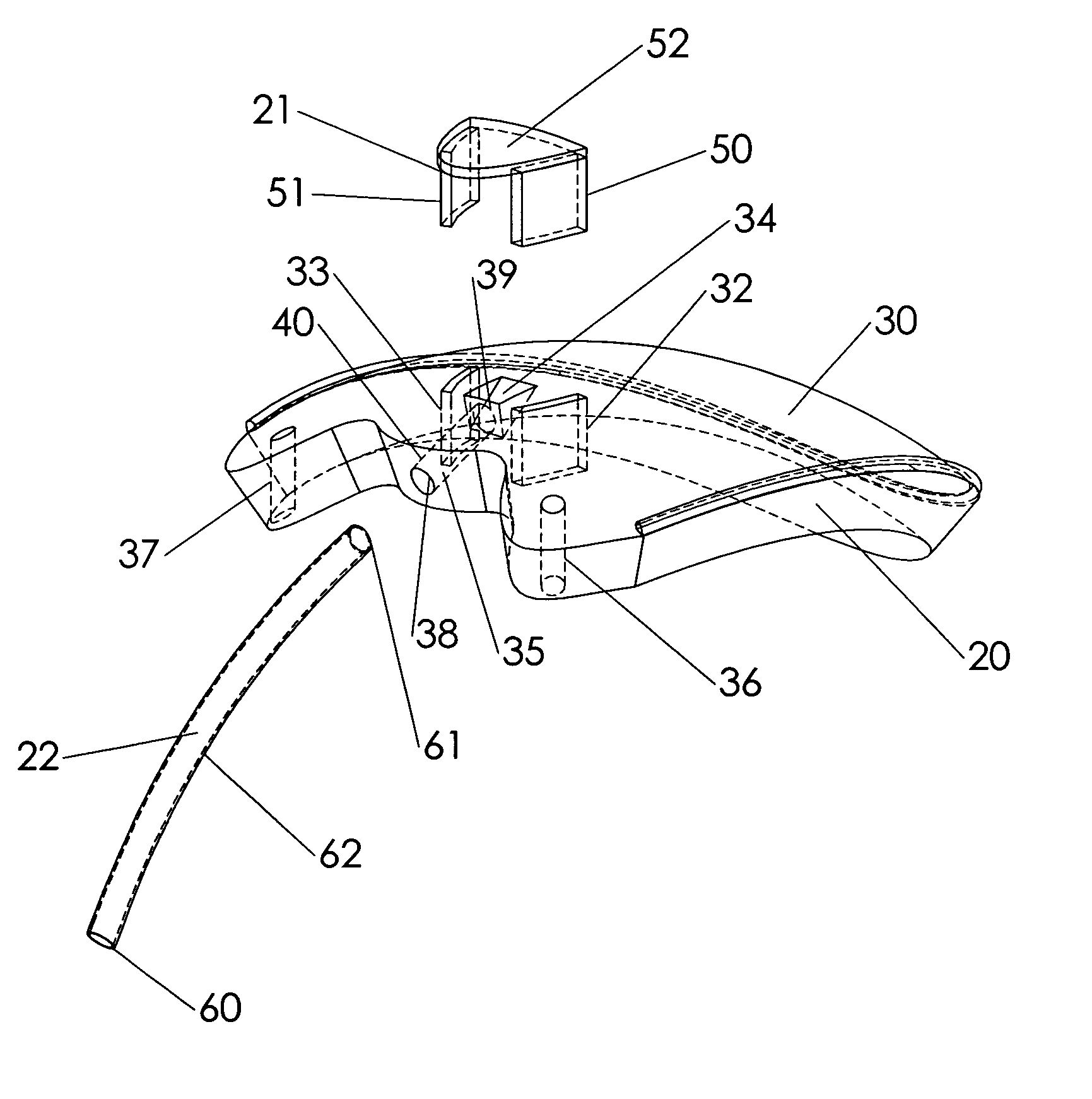

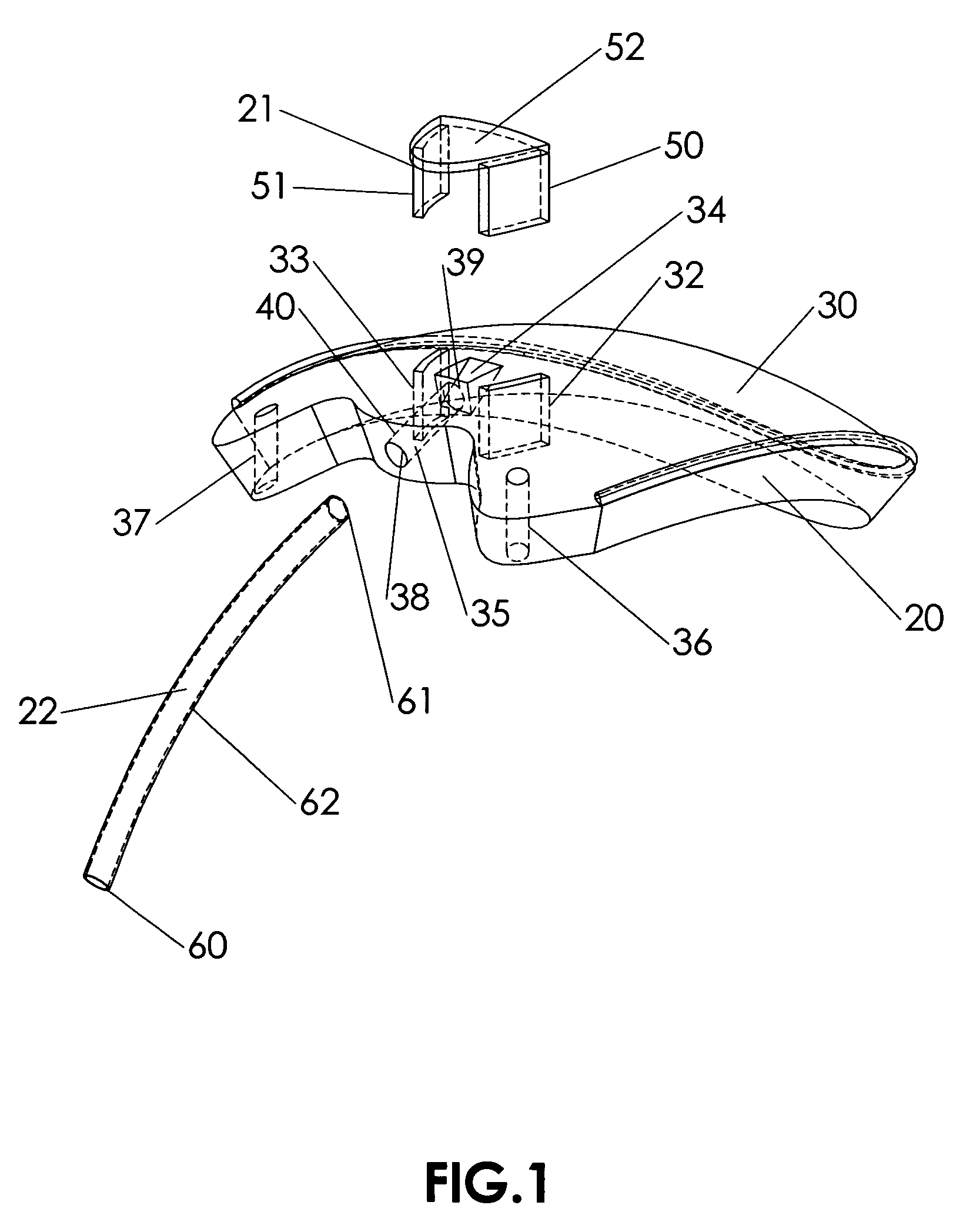

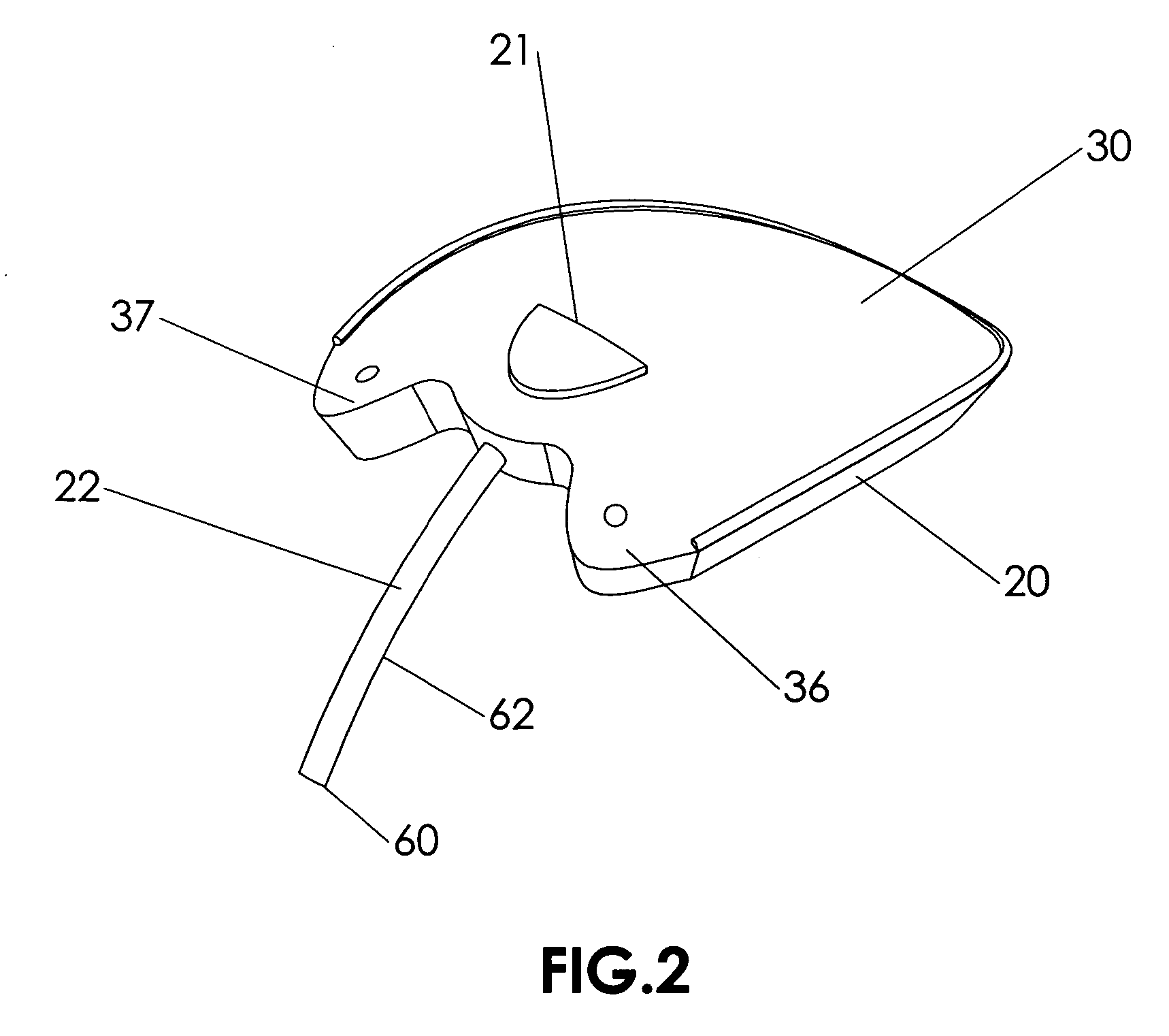

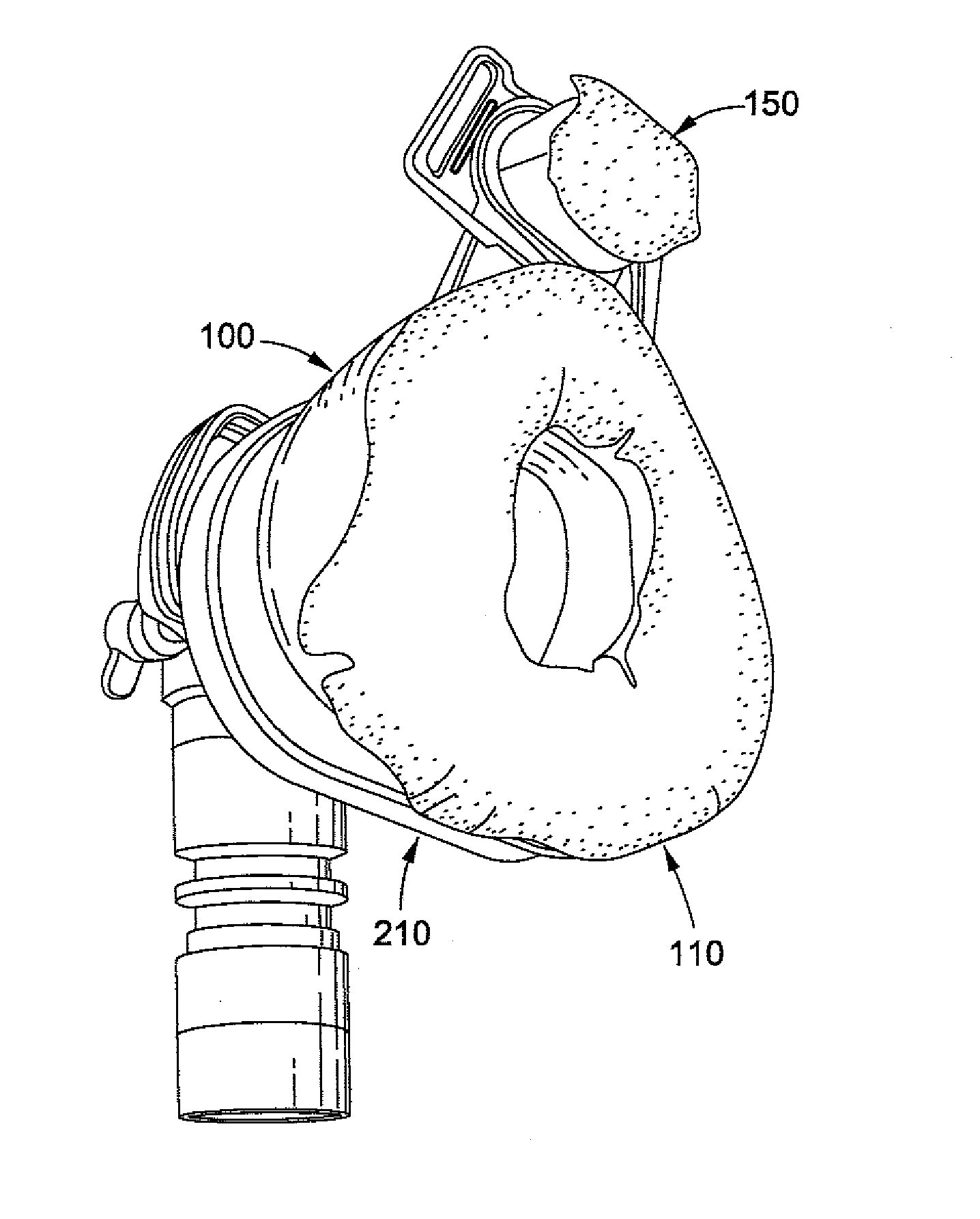

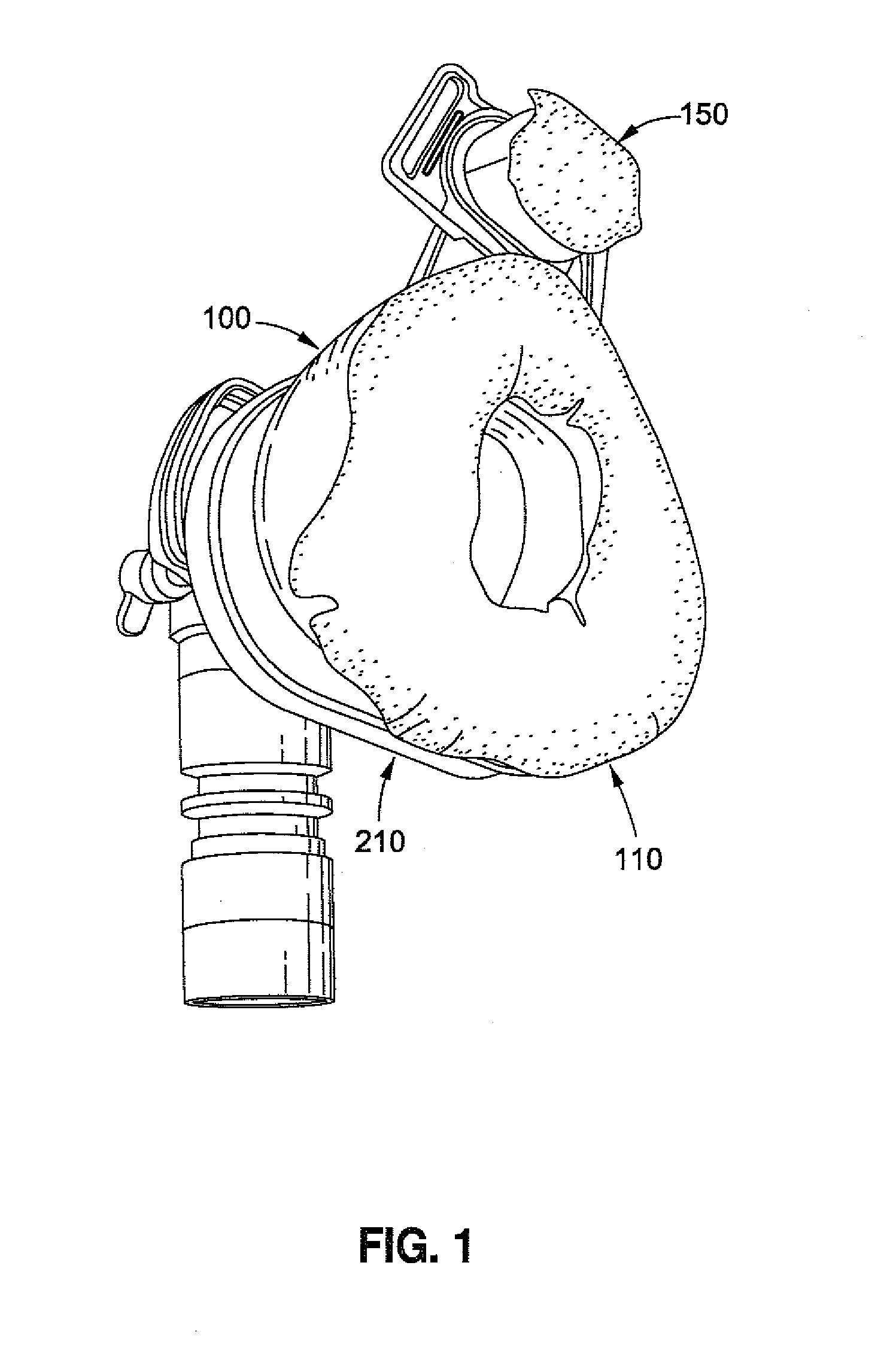

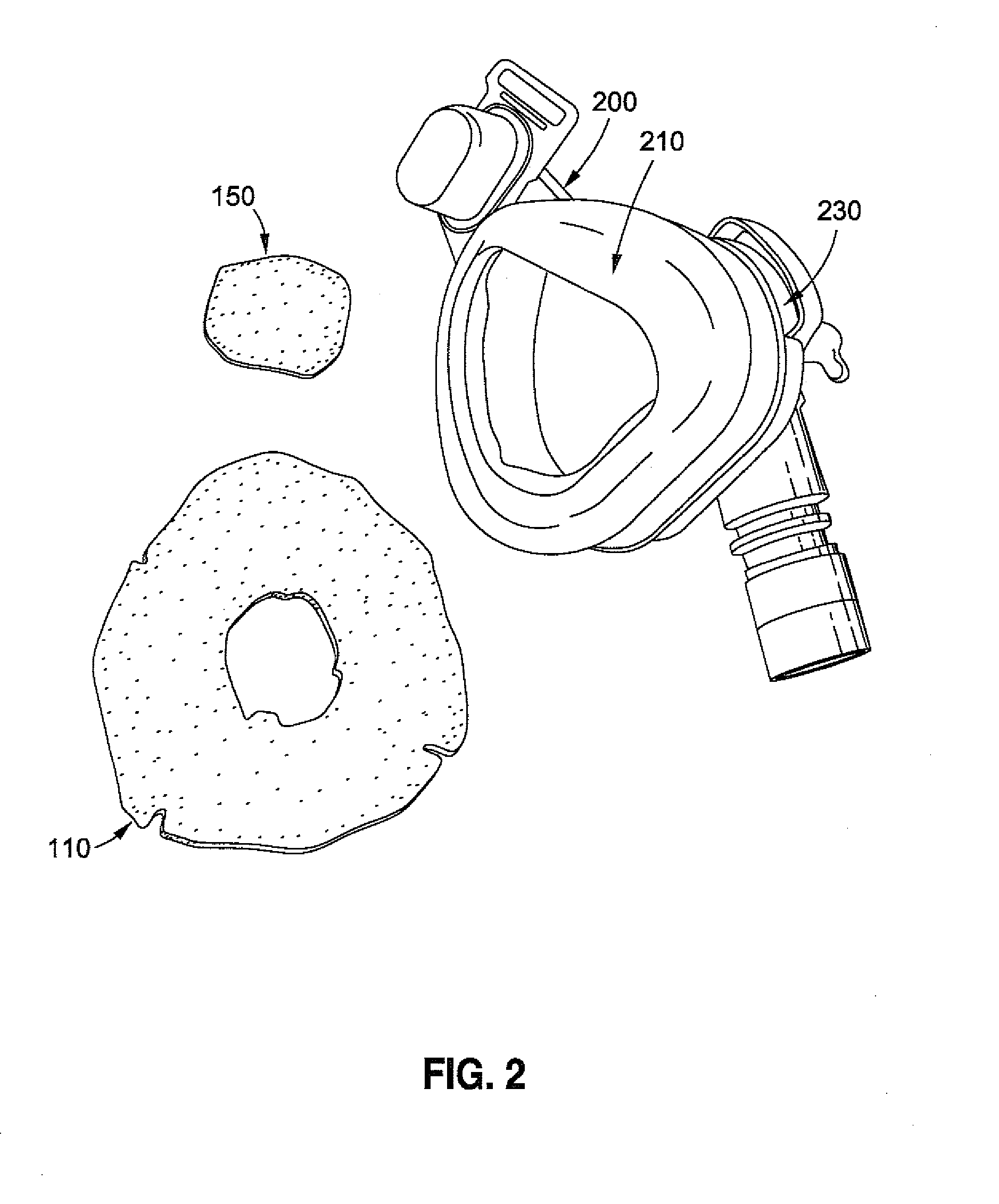

Bladder Cushion, Forehead Cushion, Headgear Straps, Headgear Cap and/or Chinstrap

A cushion for a patient interface includes two or more bladders arranged in concentric relation. Each of the bladders includes a face-contacting portion adapted to engage the patient's face, and each of the bladders is adapted to be pressurized independently from one another. At least one of the bladders is an active bladder that is pressurized to at least a sealing pressure to form a continuous seal with the patient's face in use.

Owner:RESMED LTD

Zinc salt compositions for the prevention of dermal and mucosal irritation

InactiveUS20050281762A1Minimize and prevent irritationReduce transmissionBiocideCosmetic preparationsMedicineIrritation

The present invention relates to methods and compositions which employ low concentrations of combinations of zinc salts to prevent the irritation of skin or mucous membranes that may be caused by therapeutic agents, by personal hygiene products, or by various physical, chemical, mechanical, or biological irritants, including infectious agents.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

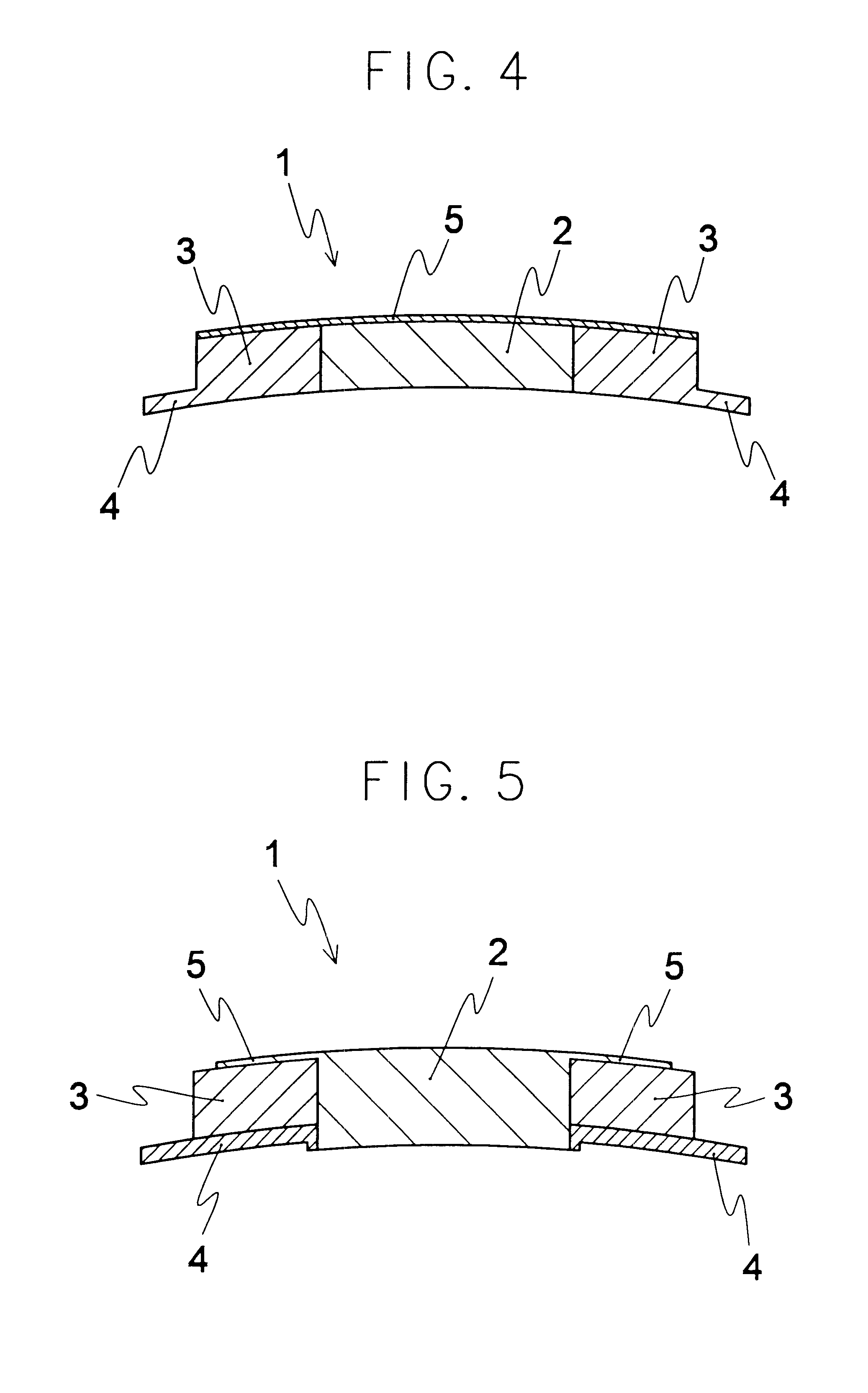

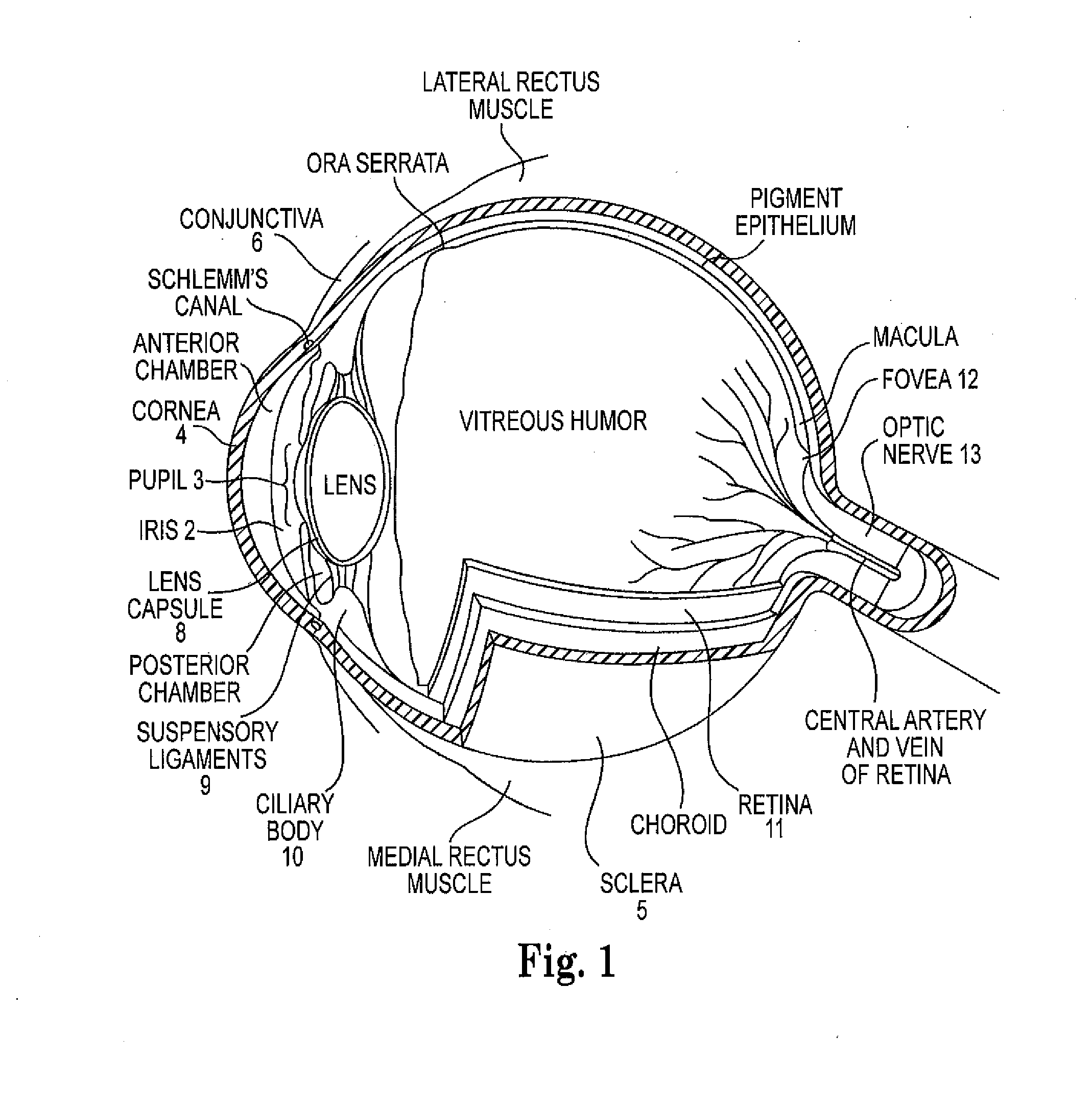

Artificial cornea

An artificial cornea comprising an optical element made of an optically transparent material, having a front surface and a posterior surface, and a skirt provided so as to support with surrounding at least a part of the optical element, characterized in that the skirt is provided with a flange on its side facing the interior of eyes during implantation of the artificial cornea and the flange radially protrudes outward from the skirt. The artificial cornea can be well compatible with ocular tissue, prevent leakage of intraocular aqueous humor and intraocular invasion of bacteria, reduce stimulation on palpebral conjunctiva and further, inhibit progression of the down growth, and which has no possibility of reduction in transparency of the optical element due to the down growth as well as detachment and extrusion from the implanted state.

Owner:MENICON CO LTD

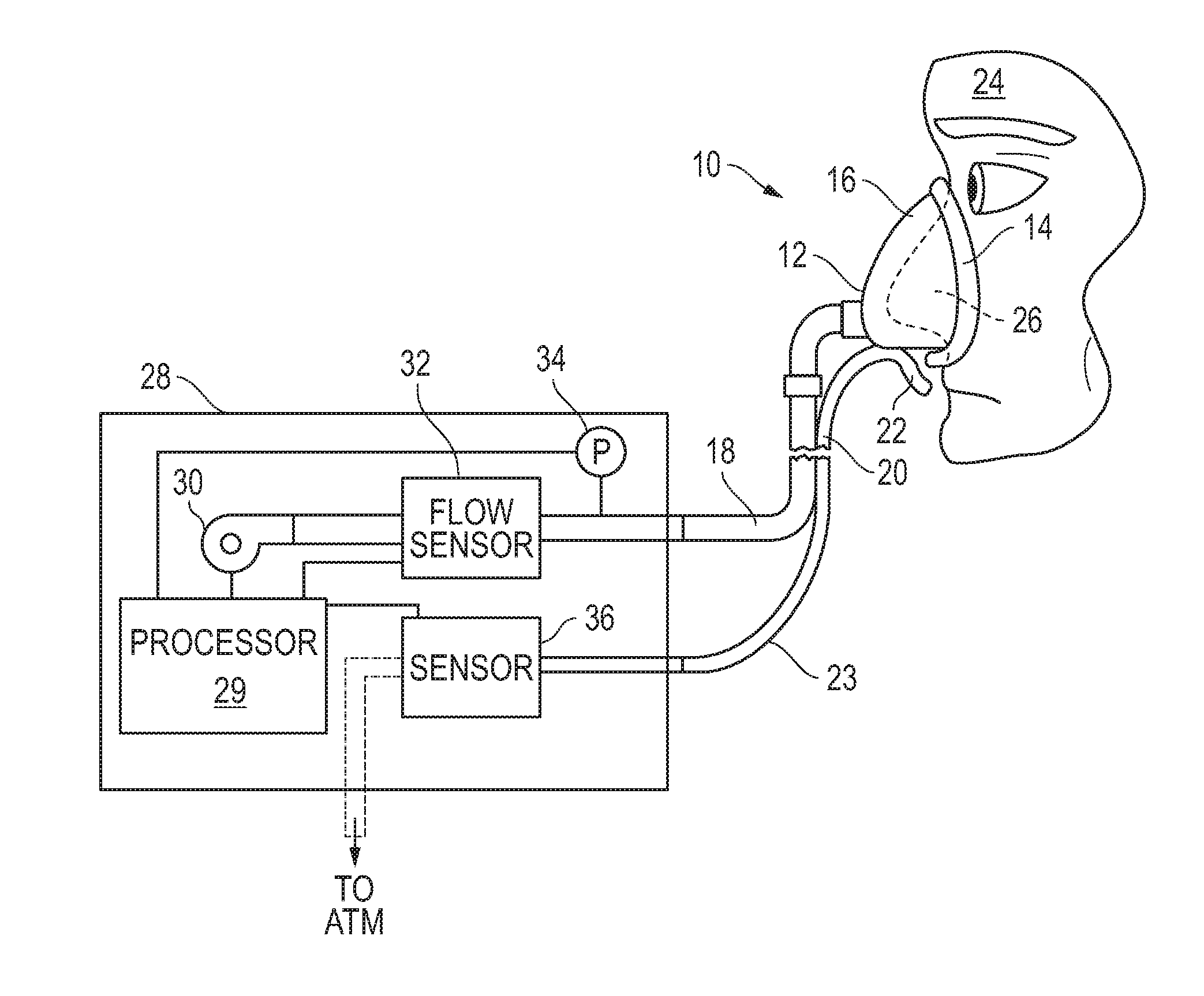

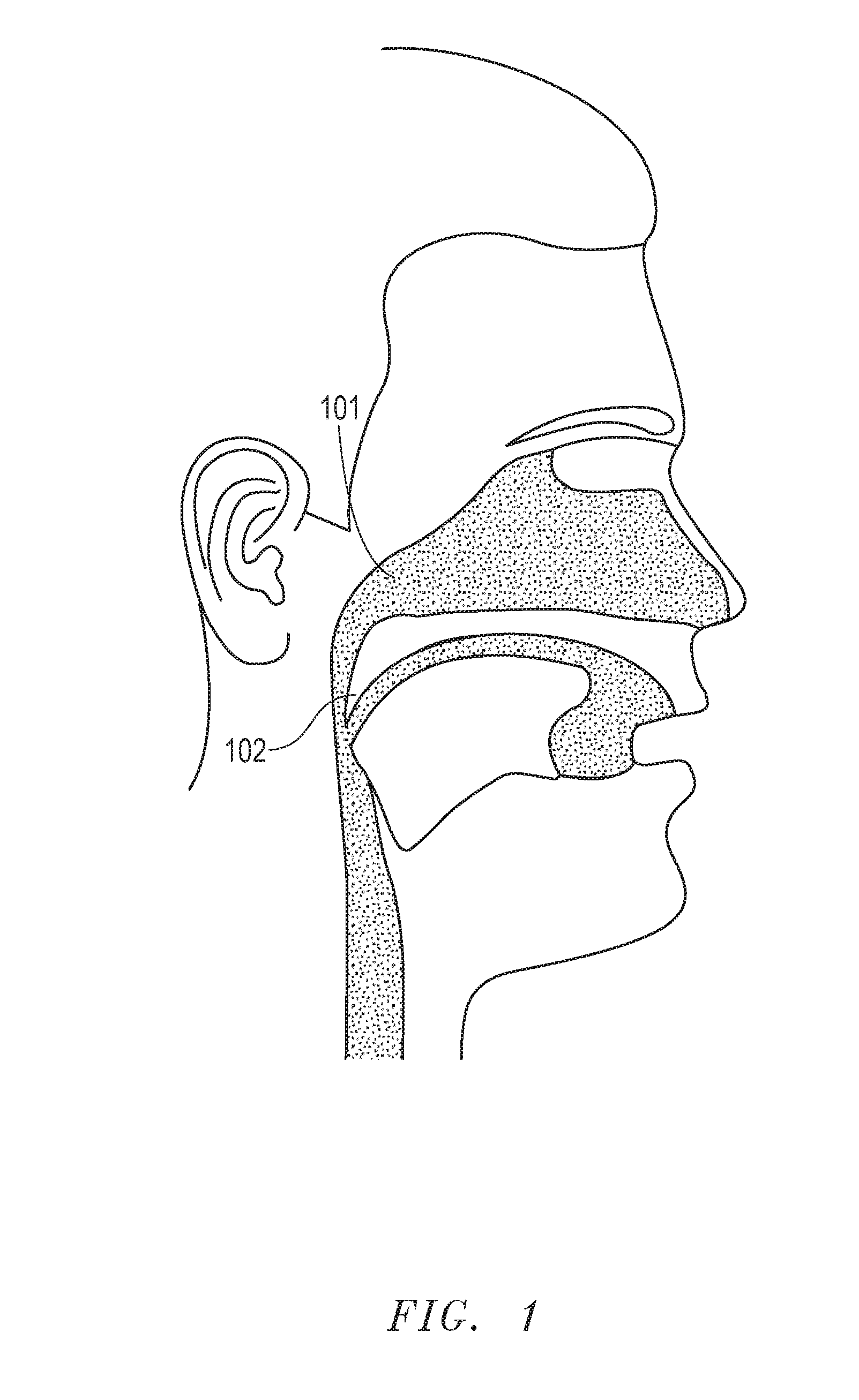

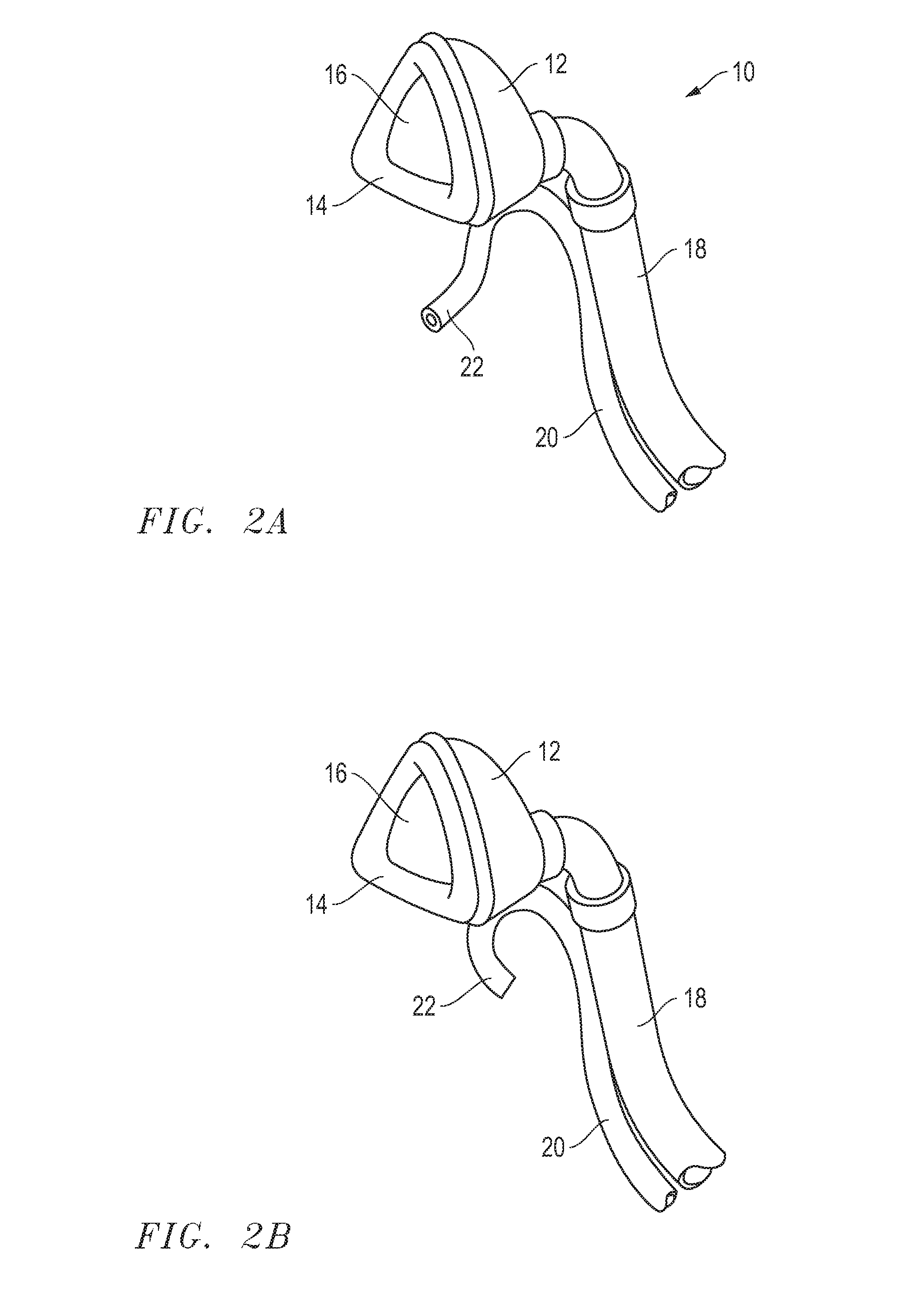

Method and System for Detecting Mouth Leak During Application of Positive Airway Pressure

InactiveUS20100186741A1Facilitates dilationImprove upper airway patencyOperating means/releasing devices for valvesRespiratory masksIrritationPositive airway pressure

A method and system for providing therapeutic gas to a patient during positive airway pressure ventilation and, more particularly, detecting the presence of a mouth leak during ventilation and, upon the detection of a mouth leak, reducing the applied pressure so as to reduce irritation and discomfort experienced by the patient. Respiratory air flow from a patient is measured in a waveform as a function of time. An approximate value of the root mean square voltage of the waveform is established during a period in which the patient is experiencing a mouth leak and a root mean square voltage of the waveform is established during a period in which the patient is experiencing an apneic event. The waveform is subsequently monitored and the rate of respiratory airflow is decreased when there is an indication of a mouth leak provided there is no indication of an apneic event.

Owner:3 INVENTING GUYS

Aqueous drainage and flow regulating implant

InactiveUS20050267397A1Relieve pressureReduces post-operative irritationEye surgeryCatheterDrainage tubesBiomedical engineering

For use in controlling the release of aqueous from anterior chamber of the eye, a surgically implantable flow regulating implant is provided which is assembled in parts from a molded elastomeric plate, a flow regulating member and drainage tube. The elastomeric plate contains a pocket, a circular passageway and slots. The flow regulating member includes tabs and a resilient membrane, said tabs are securely attached to the plate inside the slots to support the membrane. The membrane being generally arch-shaped completely covers the pocket forming a releasable seal between the said pocket and outer surface of the said plate.

Owner:BHALLA AJAY

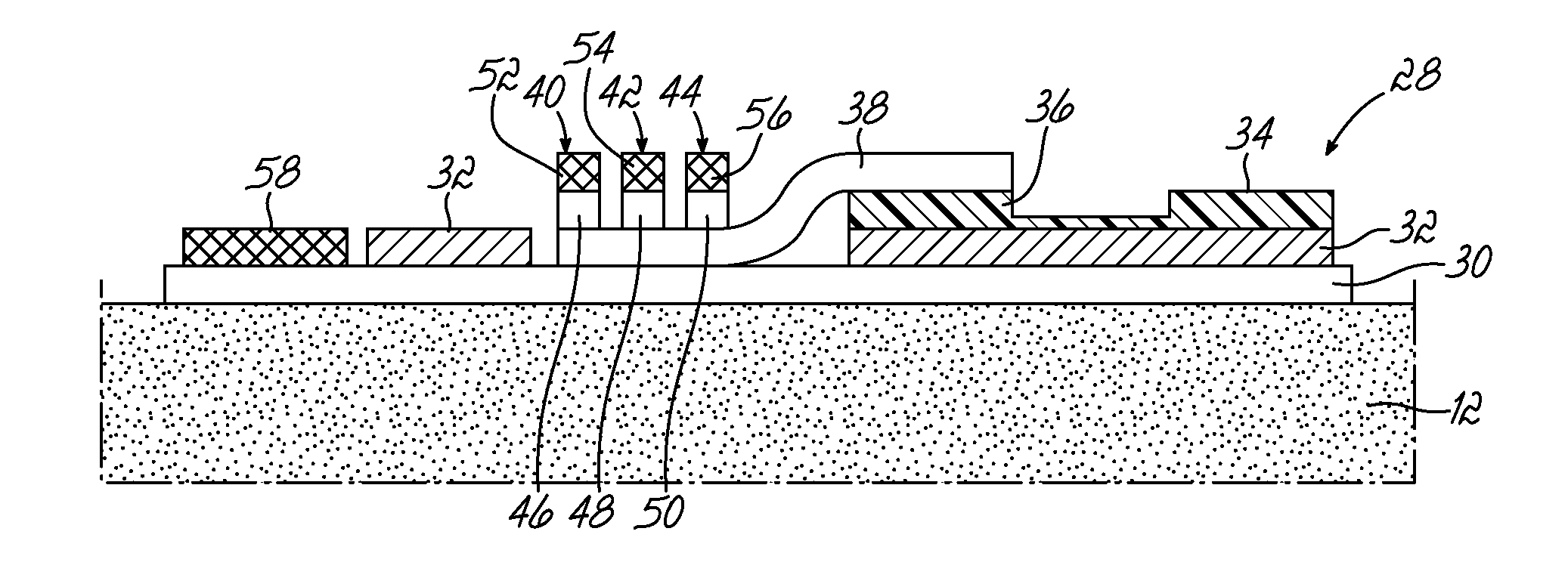

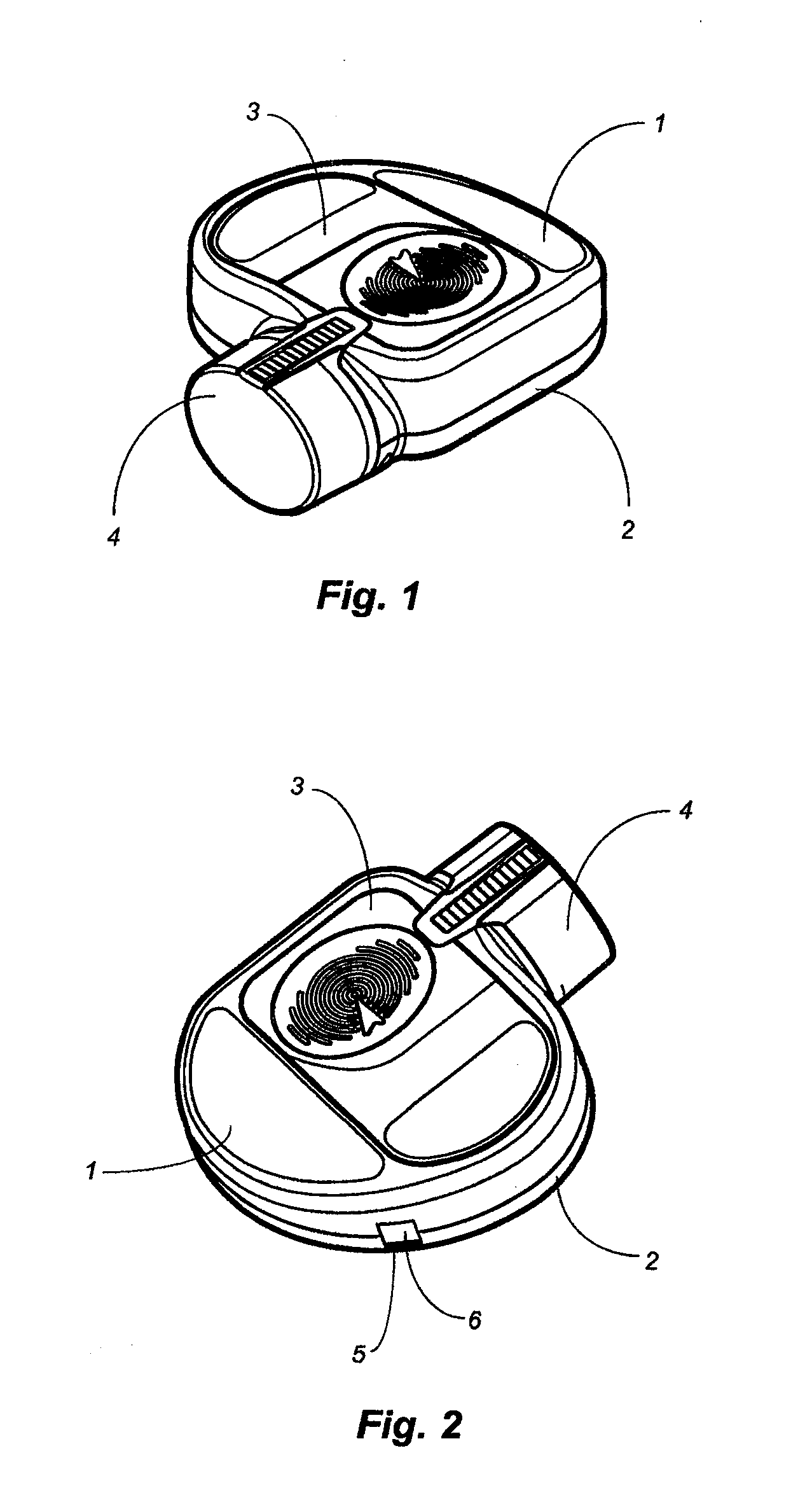

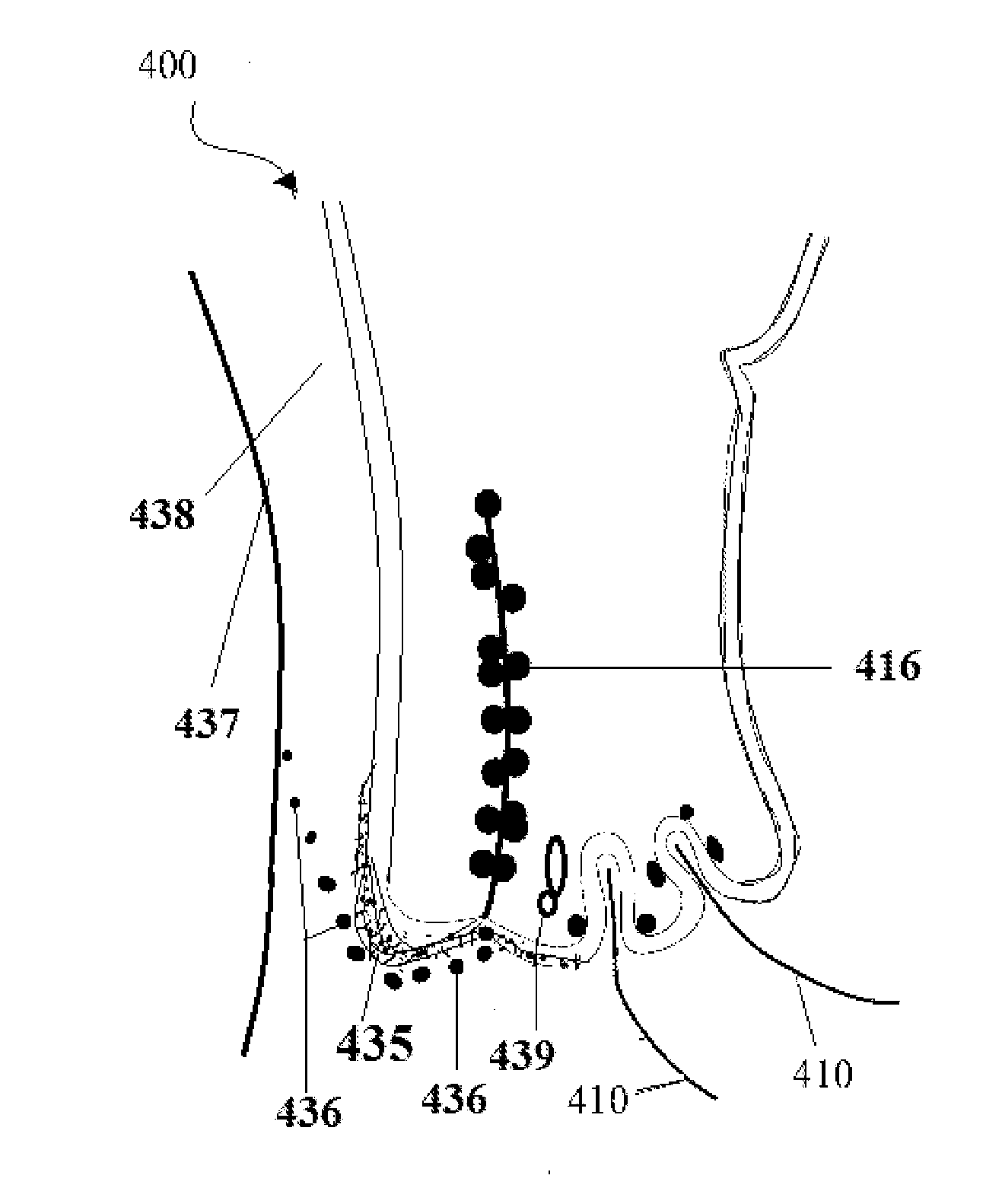

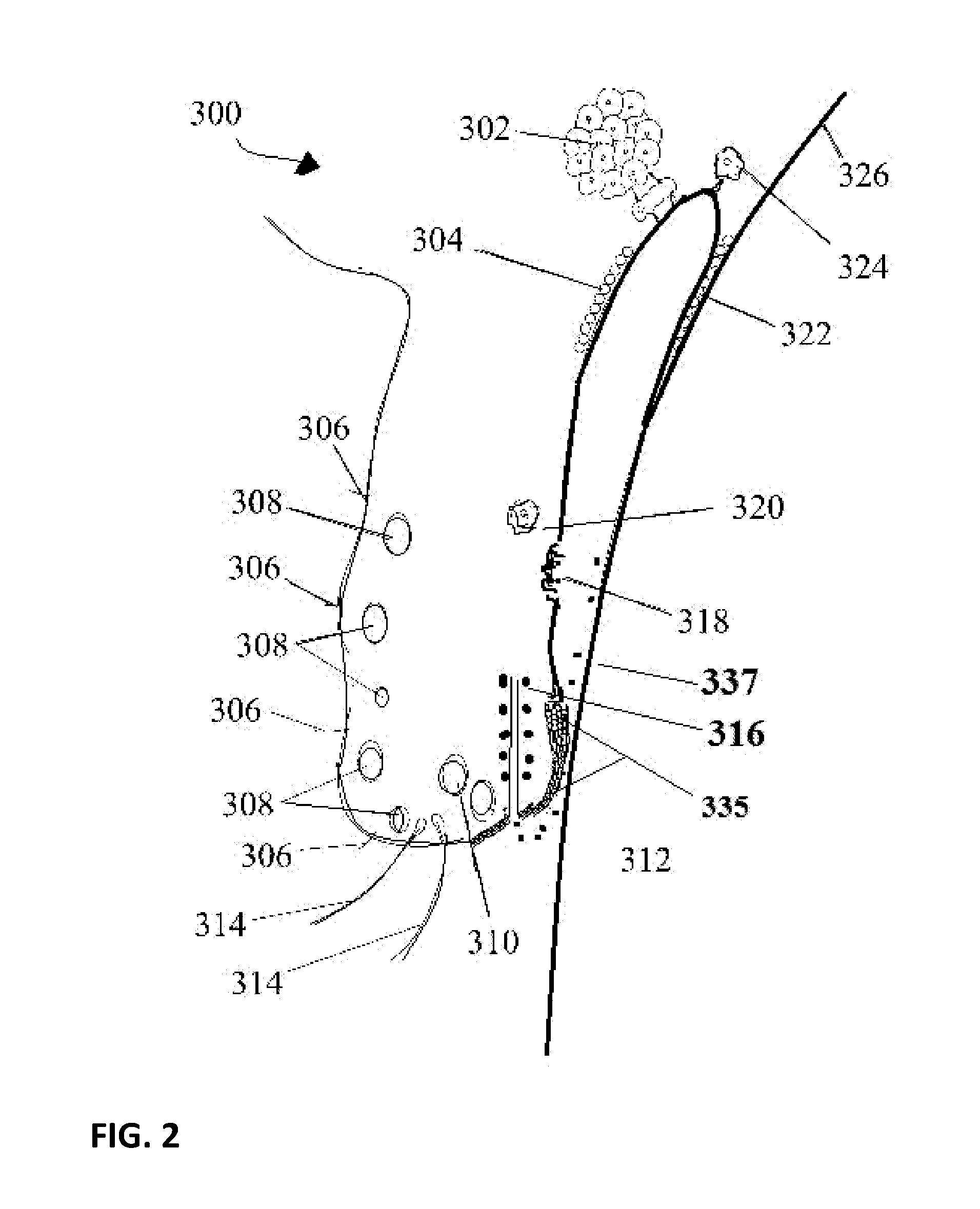

Devices for integrated, repeated, prolonged, and/or reliable sweat stimulation and biosensing

ActiveUS20150112164A1Effective simulationMitigate interference of stimulatingElectrotherapySurgerySkin surfaceIrritation

A sweat sensing device includes a plurality of sweat collection pads communicating with a sensor. Each of the pads is activated by a timing circuit which allows one or more of the pads to be activated at a selected time and subsequent deactivated after a defined period of time. This allows for selective collection of sweat from a plurality of pads over a prolonged period of time. An impedance measuring circuit can be employed to determine if one or more of the pads becomes disconnected, in order to avoid irritation. Further, the devices can use a common microfluidic device which both transports sweat activating substance, such as pilocarpine, to the surface of the skin and directs sweat away from the skin to a sensing device.

Owner:UNIVERSITY OF CINCINNATI

Unit Dose Drug Delivery Platform

ActiveUS20100331765A1Increase ease of administrationAdequate doseMedical devicesMedical applicatorsNoseDosing drugs

The delivery systems of the present disclosure are configurable to administer either single-dose or multiple-doses of one or more substances to a user, for example to the eye, nose, mouth, ear or rectum of the user. The precise and repeatable dosing features of the presently disclosed delivery systems overcome many of the disadvantages associated with known methods for dispensing substances to, for example, the eye of a user. The delivery systems administer precise doses of a substance to a precise location from unit dosage forms that may be single-dose or multiple-dose unit dosage forms, which may be externally or internally pierced.

Owner:MYSTIC PHARMA INC

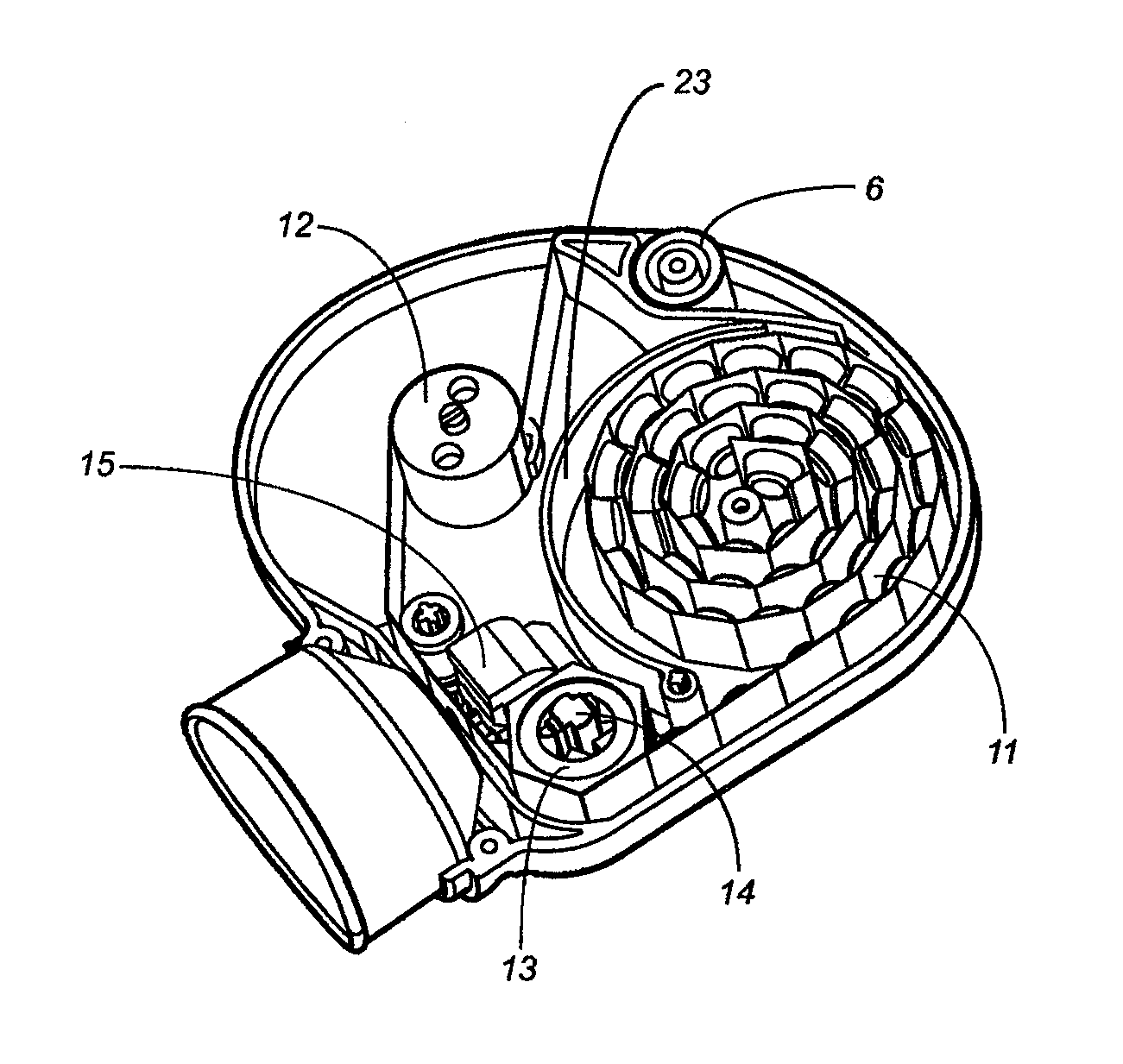

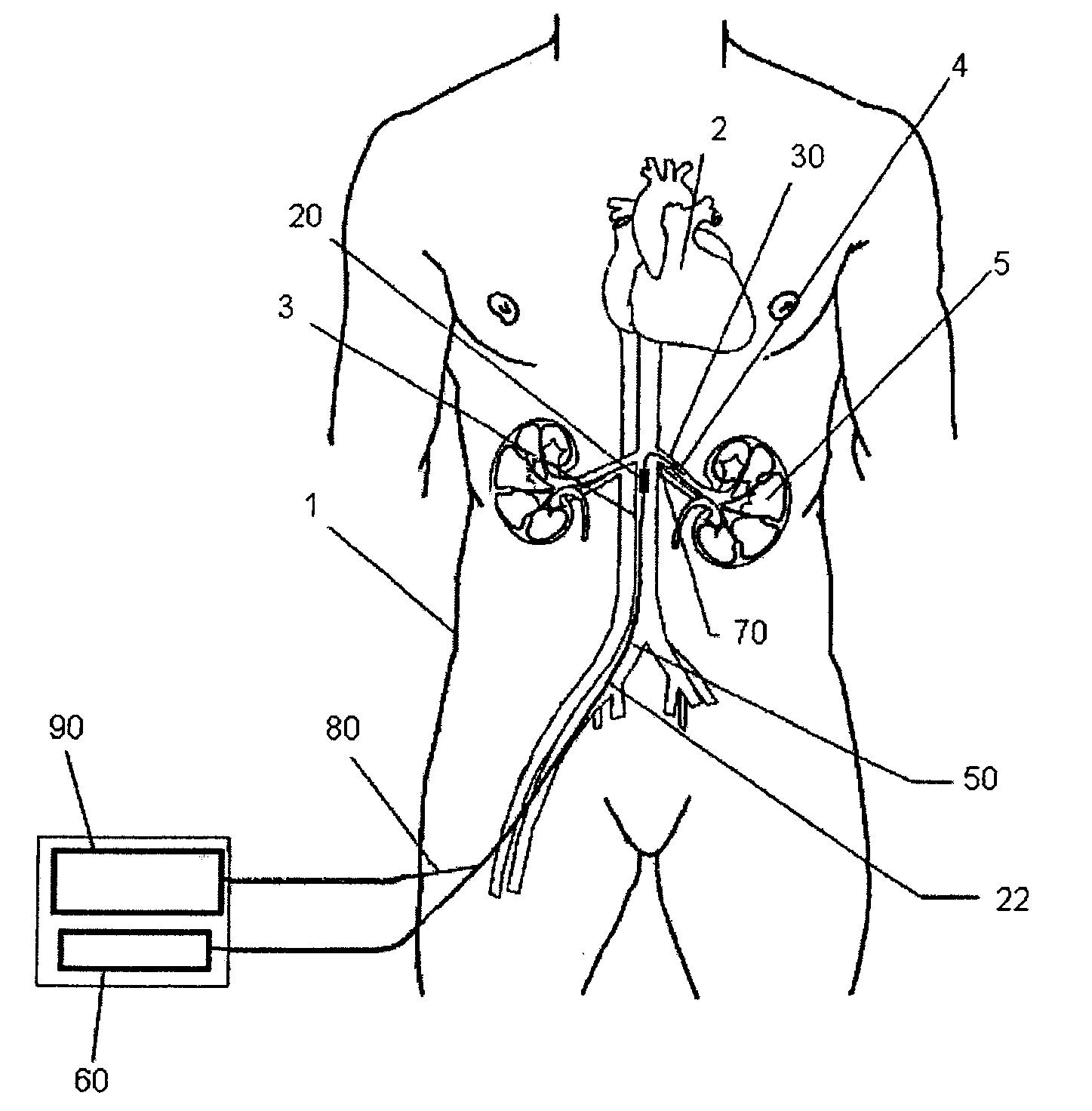

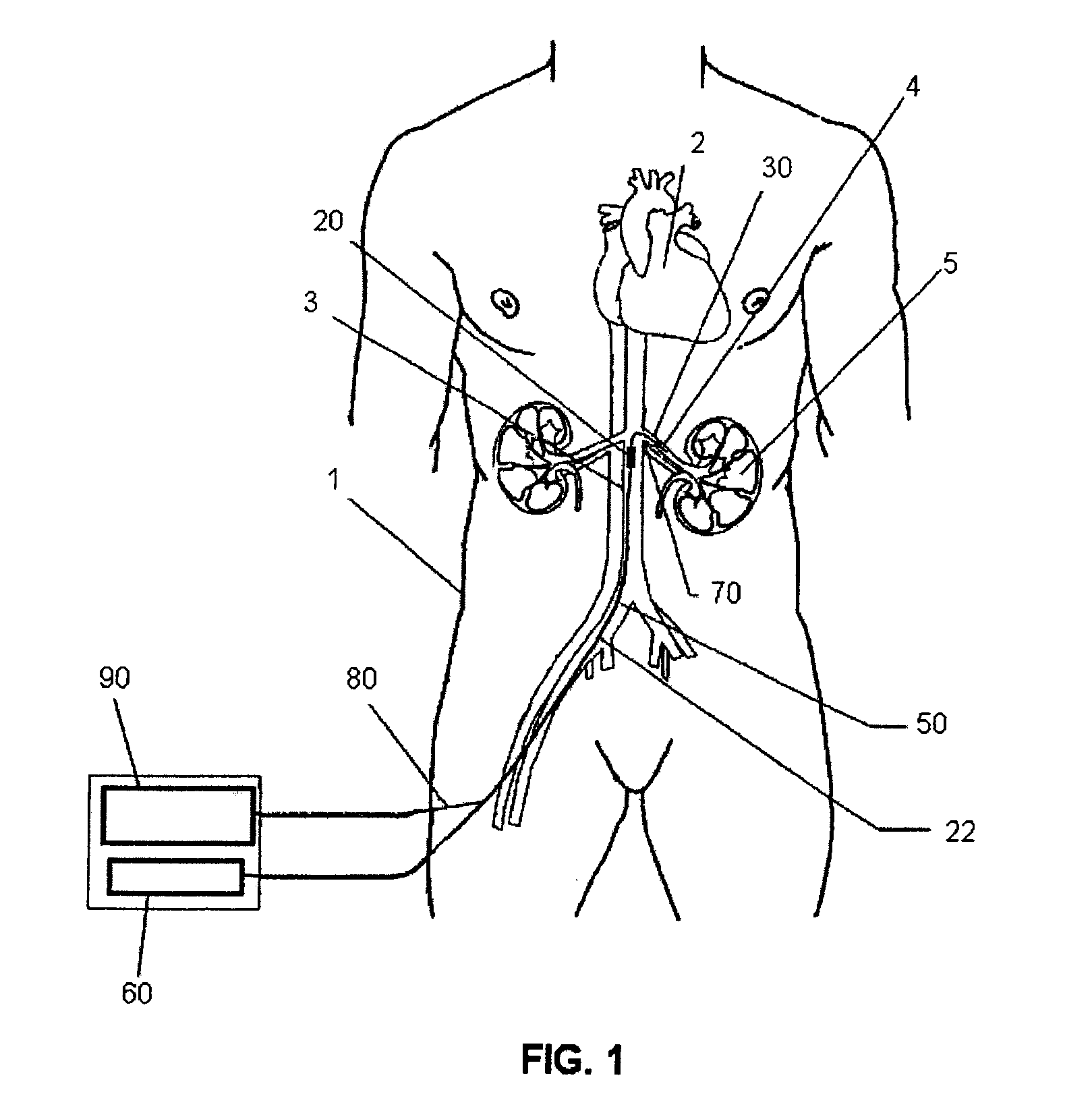

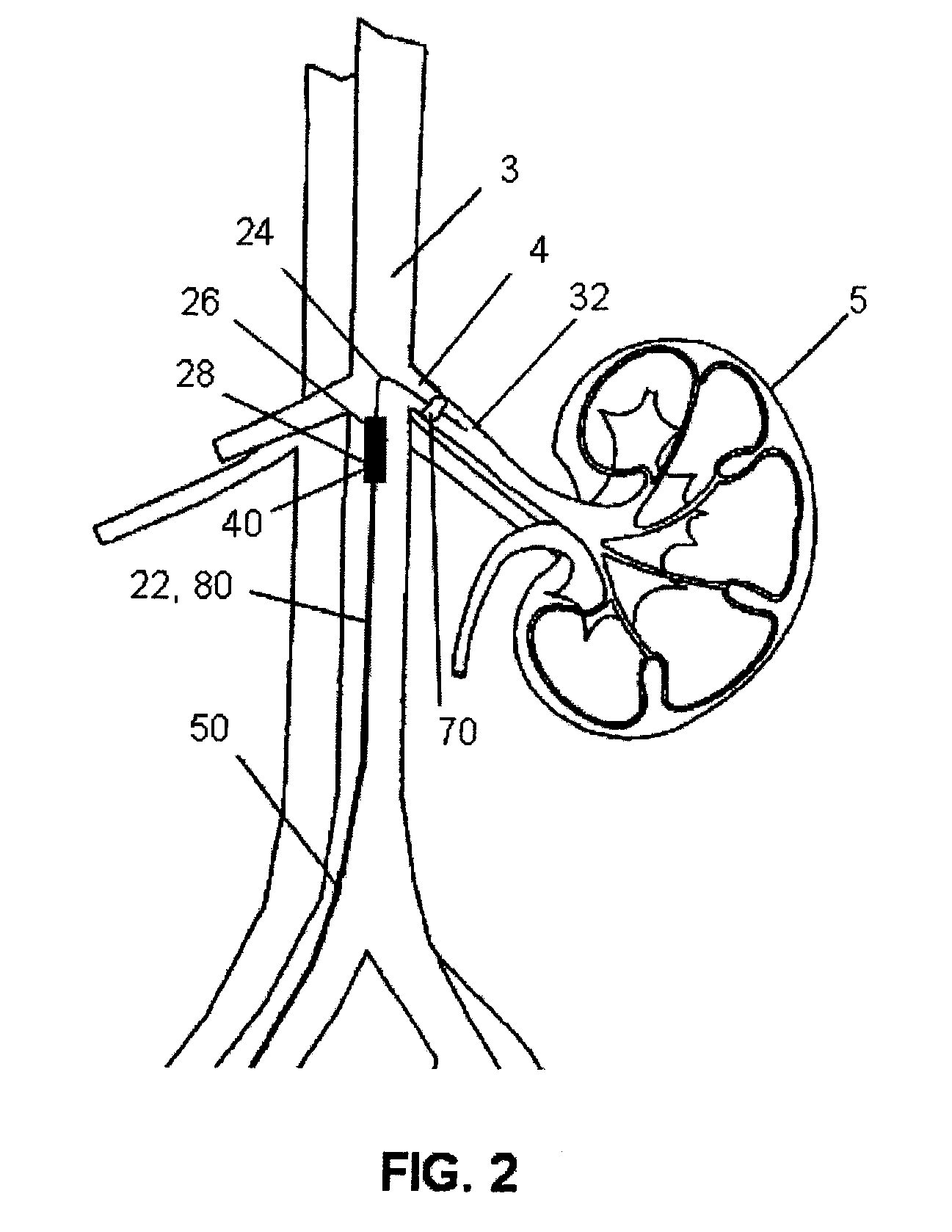

Method and Apparatus for Treatment of Congestive Heart Disease

ActiveUS20070208291A1Increase blood flowImprove kidney functionControl devicesBlood pumpsRenin–angiotensin systemPerfuse kidney

In one aspect, the present invention is directed to an apparatus and method for treating congestive heart failure that restores kidney renal functions by artificial perfusion of at least one kidney. In one aspect, a catheter inserted into the aorta of the patient has an outlet port that supplies the patient's blood obtained from a patient's aorta into an adjoining renal artery of the patient to perfuse the kidney. The catheter comprises a rotor housed inside a portion of the catheter to supply the blood to the kidney at a desired pressure. The restoration of kidney function assists the heart by removing excess fluid, urine and toxin from the patient, and by normalizing the patient's renin-angiotensin system and other neurohormonal substances.

Owner:PATEL VINOD

Essential oil of tobaccos as well as preparation method and application thereof to cigarettes

InactiveCN102559388ANo residueImprove extraction yieldTobacco treatmentEssential-oils/perfumesOrganic solventWater vapor

The invention relates to the essential oil of tobaccos as well as a preparation method and application thereof to cigarettes. The essential oil of the tobaccos is prepared by the following method of: taking discarded / defective tobacco wastes, extracting by an organic solvent, taking the crude extract of the essential oil, introducing water vapor, condensing and separating oil and water so as to obtain the essential oil of the tobaccos. By adding the essential oil of the tobaccos, which is disclosed by the invention and is used as a flavoring agent, into the tobacco shreds of cigarettes, the self fragrance of the tobaccos can be increased, the quality of the fragrance of the cigarettes is enhanced, the excitation and the miscellaneous gas of the tobaccos are reduced, and smoke is softened. The essential oil of the tobaccos as well as the preparation method and the application thereof to the cigarettes have the advantages that the advantage of higher extracting yield of a solvent extracting method and the characteristic of refinement of a water-vapor distillation extracting method are combined, the yield of the essential oil of the tobaccos is obviously higher than that of a traditional water-vapor distillation method, and extracting equipment and a solvent are simple and convenient and are easy to obtain; and moreover, no solvent residue exists in a final product of the essential oil of the tobaccos, and the safety of the product is high.

Owner:CHINA TOBACCO ZHEJIANG IND

Polypeptide-polysiloxane copolymers

InactiveUS6358501B1Simple processWithout usingCosmetic preparationsHair cosmeticsOrganic chemistryCopolymer

The present invention relates to polypeptide-polysiloxane copolymers, to their preparation by thermal copolymerization of amino acids with organofunctional polysiloxanes, and to their use as interface-active substances. The polypeptide-polysiloxane copolymers consist of at least one polysiloxane unitand of at least one polypeptide unit

Owner:GOLDSCHMIDT GMBH

Methods related to the treatment of mucosal associated conditions

InactiveUS20060216333A1Reduce stimulationReduce riskAntibacterial agentsBiocideIrritationTreatment level

Using interrupted delivery of IRMs by intermittently applying an IRM to a mucosal surface it is possible to achieve therapeutic levels and durations of cytokine induction, while substantially reducing irritation side effects.

Owner:3M INNOVATIVE PROPERTIES CO

Blue ray radiation preventing and achromatism spectacle lens, and method of producing the same

InactiveCN101216611AEffectively filter outReduce harmVacuum evaporation coatingSputtering coatingUltravioletTitanium oxide

The invention relates to a spectacle lens capable of preventing blue light radiation and eliminating the chromatic aberration and a manufacture method thereof, which belongs to the technical field of spectacles and the manufacture method thereof. The spectacle lens is characterized in that a substrate is prepared from an organic polymer, a blue light absorbent and a UV absorbent by mixing; and a coated film layer includes a TiO2 layer, an Al2O3 layer, an ITO layer, a noble metal layer, an MgF2 layer and a SiO2 layer. The manufacture method of the spectacle lens comprises following steps of: preparing materials, mixing, stirring, curing, cleaning the substrate, reinforcing and coating film on the substrate. The spectacle lens capable of preventing blue light radiation and eliminating the chromatic aberration can effectively filter most of UV light and a portion of blue light to reduce the damage to human retina and the irritation of shortwave glare, thus reducing chromatic aberration and improving resolution of human eyes. Accordingly, persons wearing the spectacle lens can view objects clearly in weaker or stronger light environment.

Owner:曾琪 +1

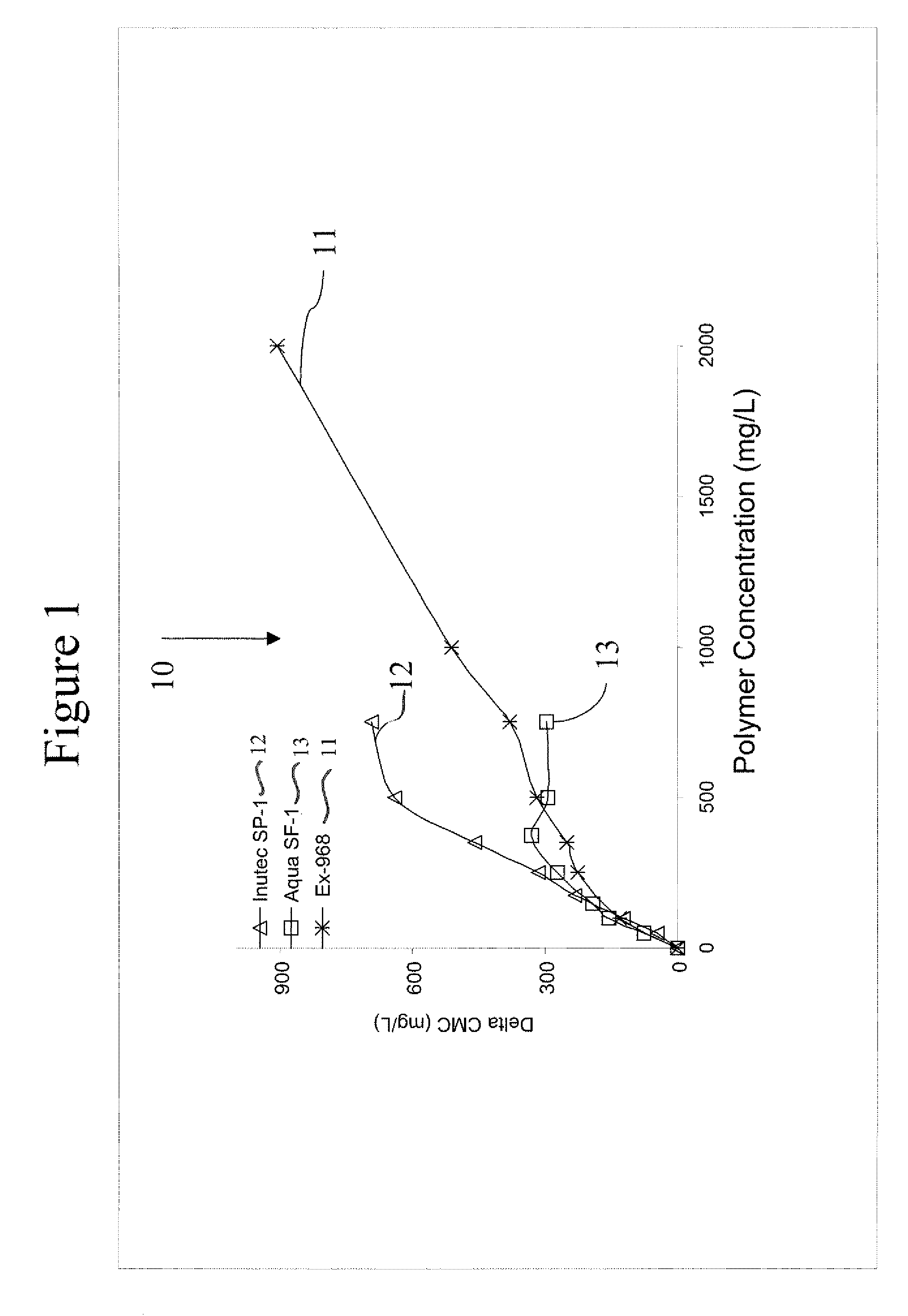

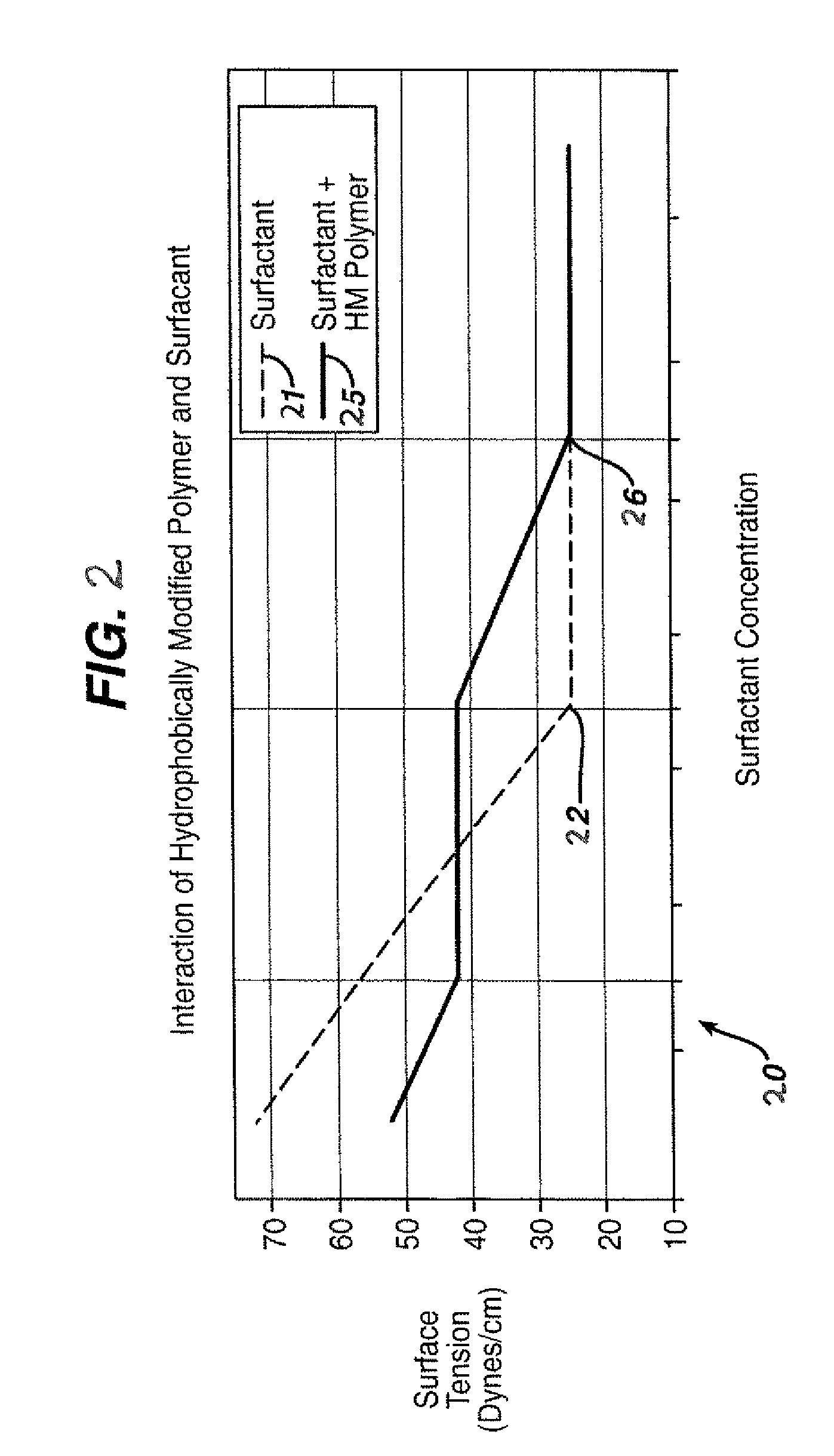

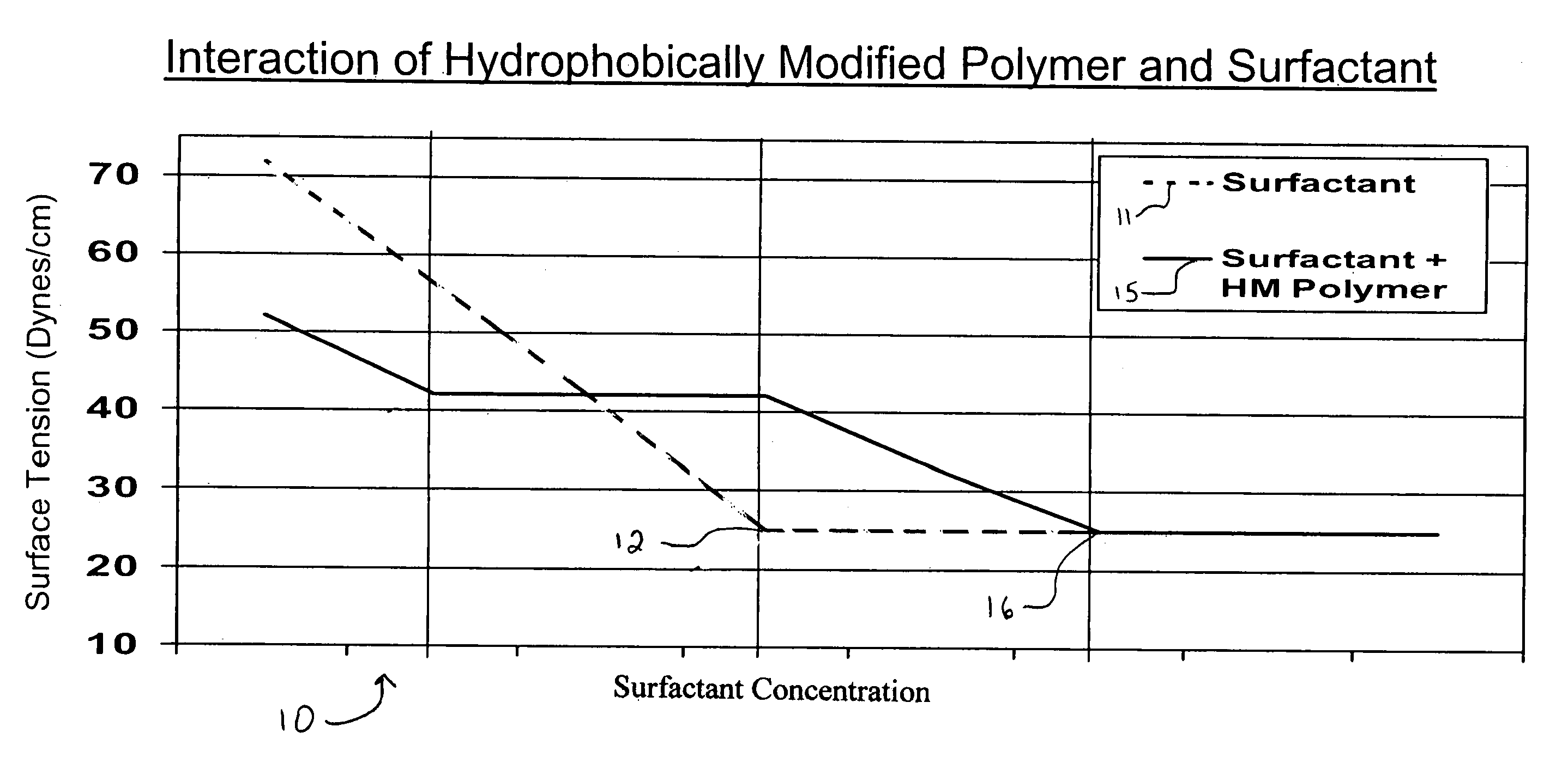

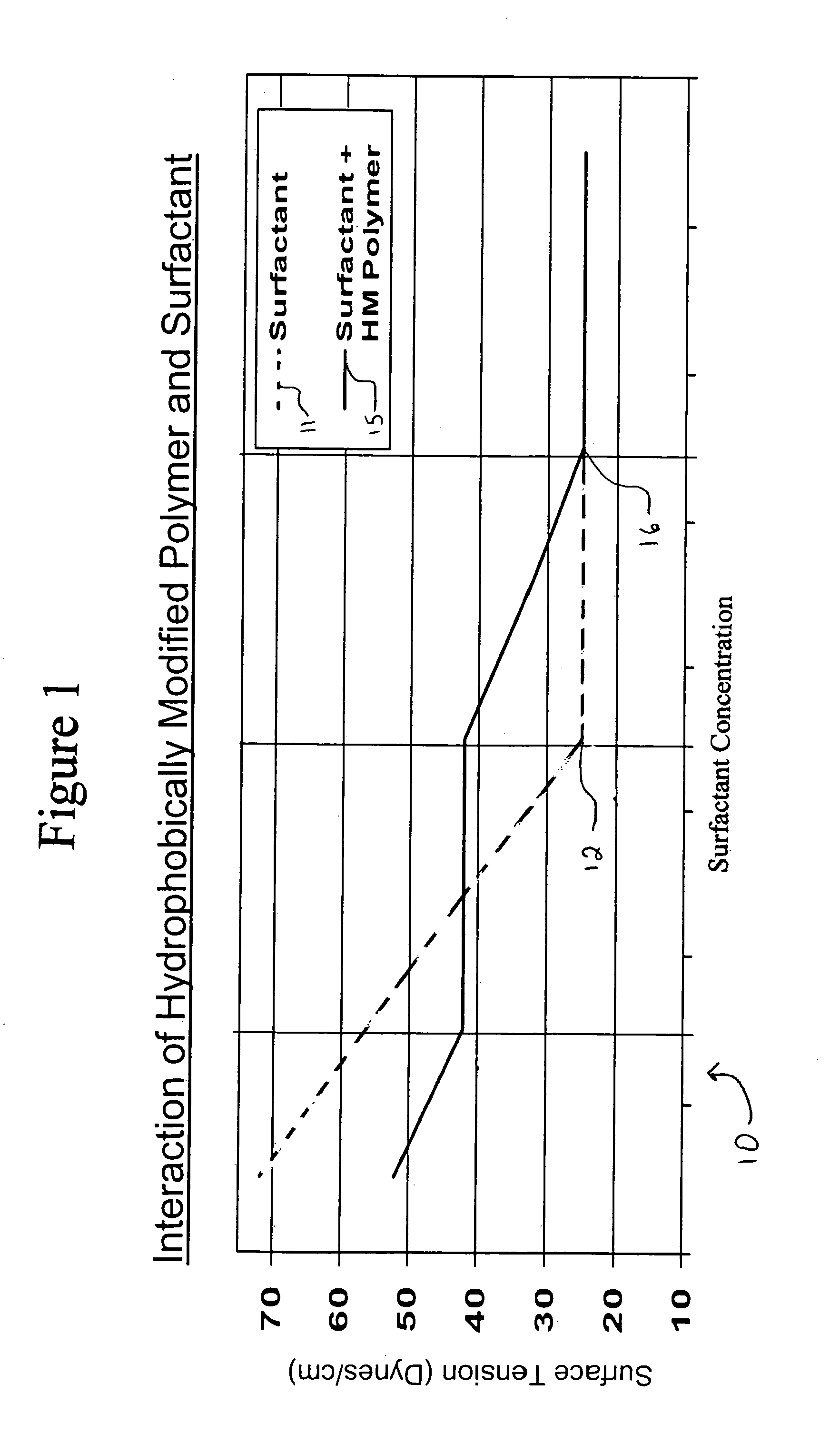

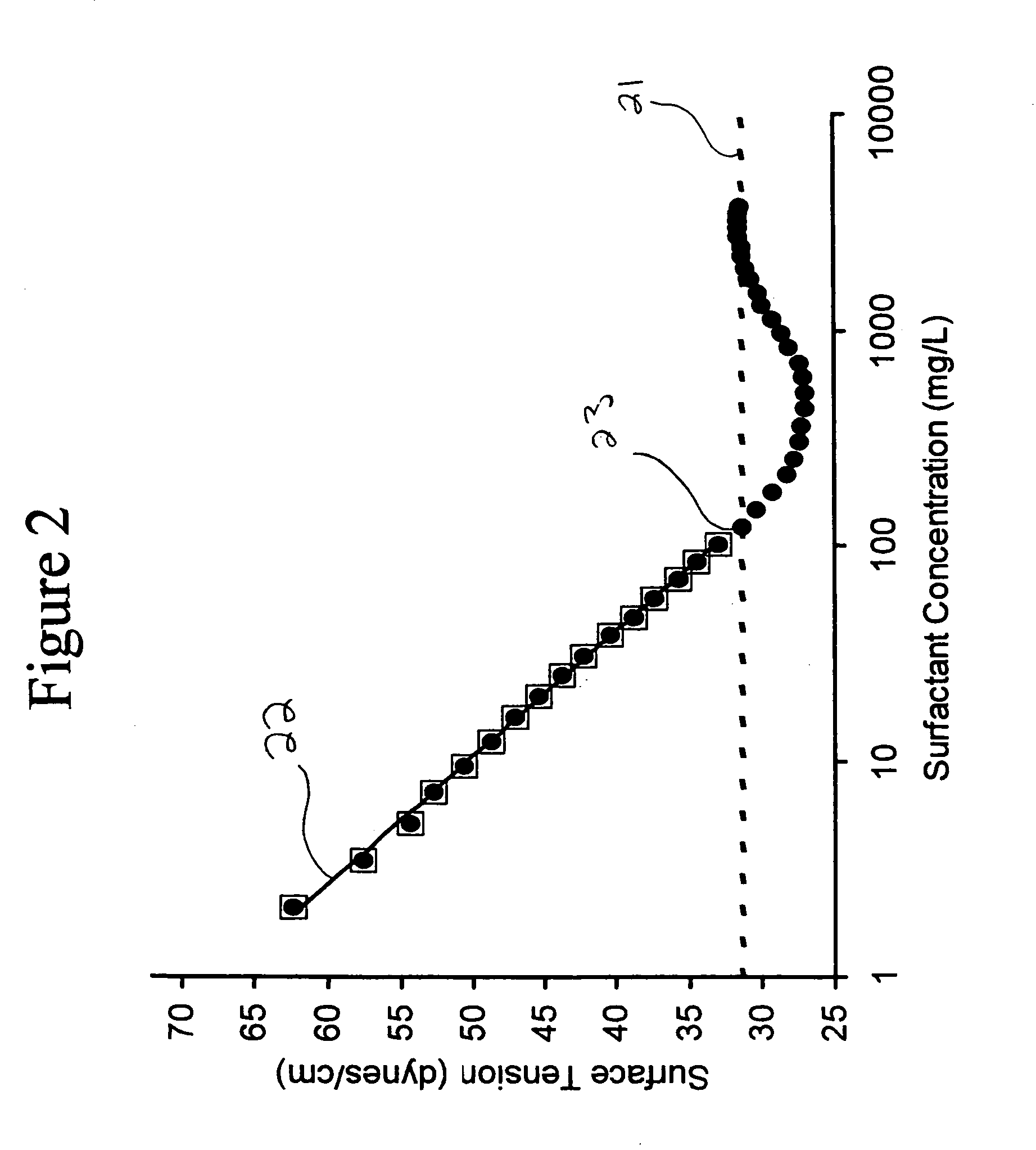

Low-irritation compositions and methods of making the same

ActiveUS7803403B2Reduce stimulationLess irritatingPowder deliveryCosmetic preparationsIrritationSURFACTANT BLEND

Provided are compositions comprising a low molecular weight, non-crosslinked, linear acrylic copolymer and at least one surfactant selected from the group consisting of anionic surfactants, amphoteric surfactants, and combinations of two or more thereof, and methods of using such compositions.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

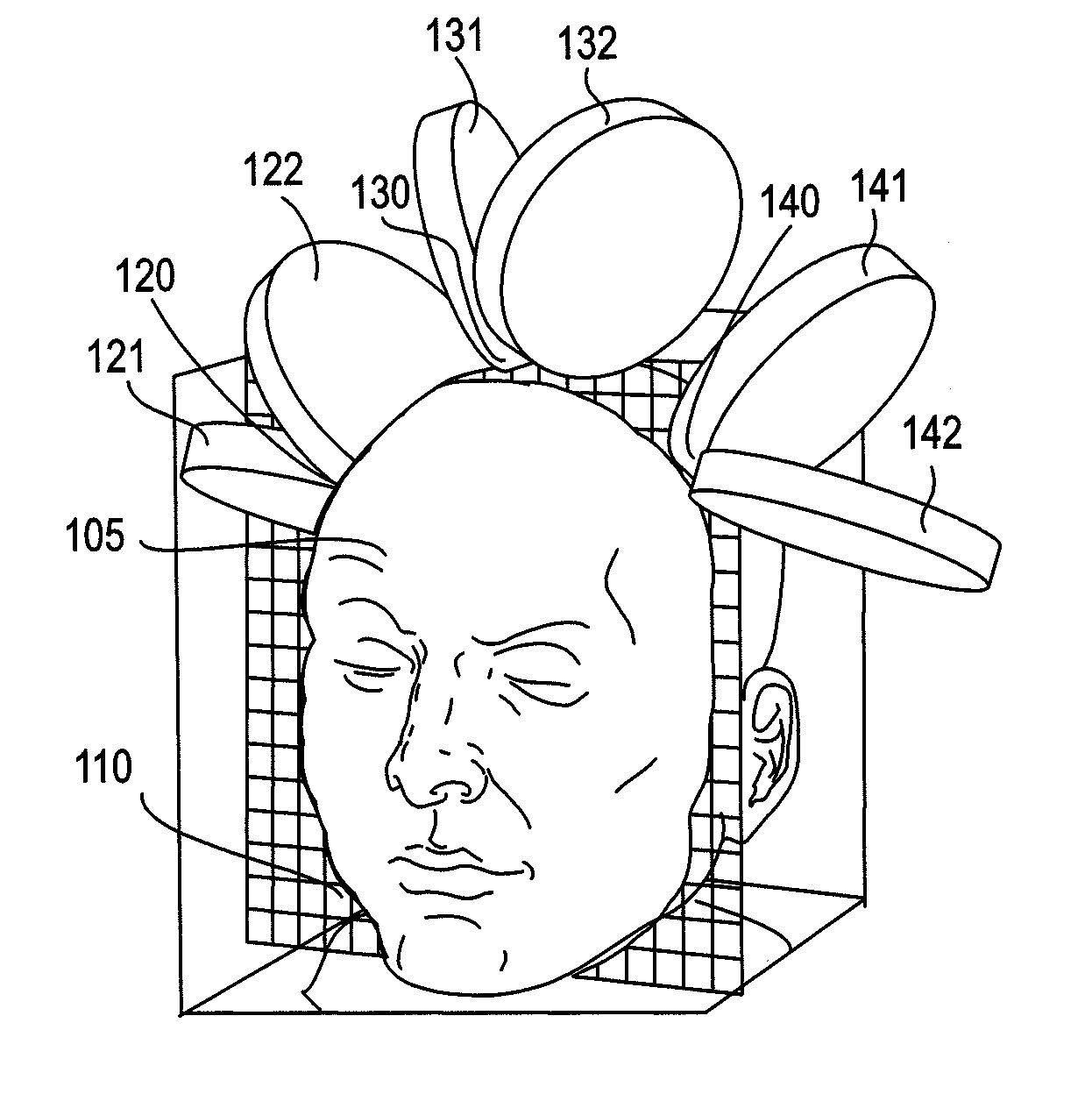

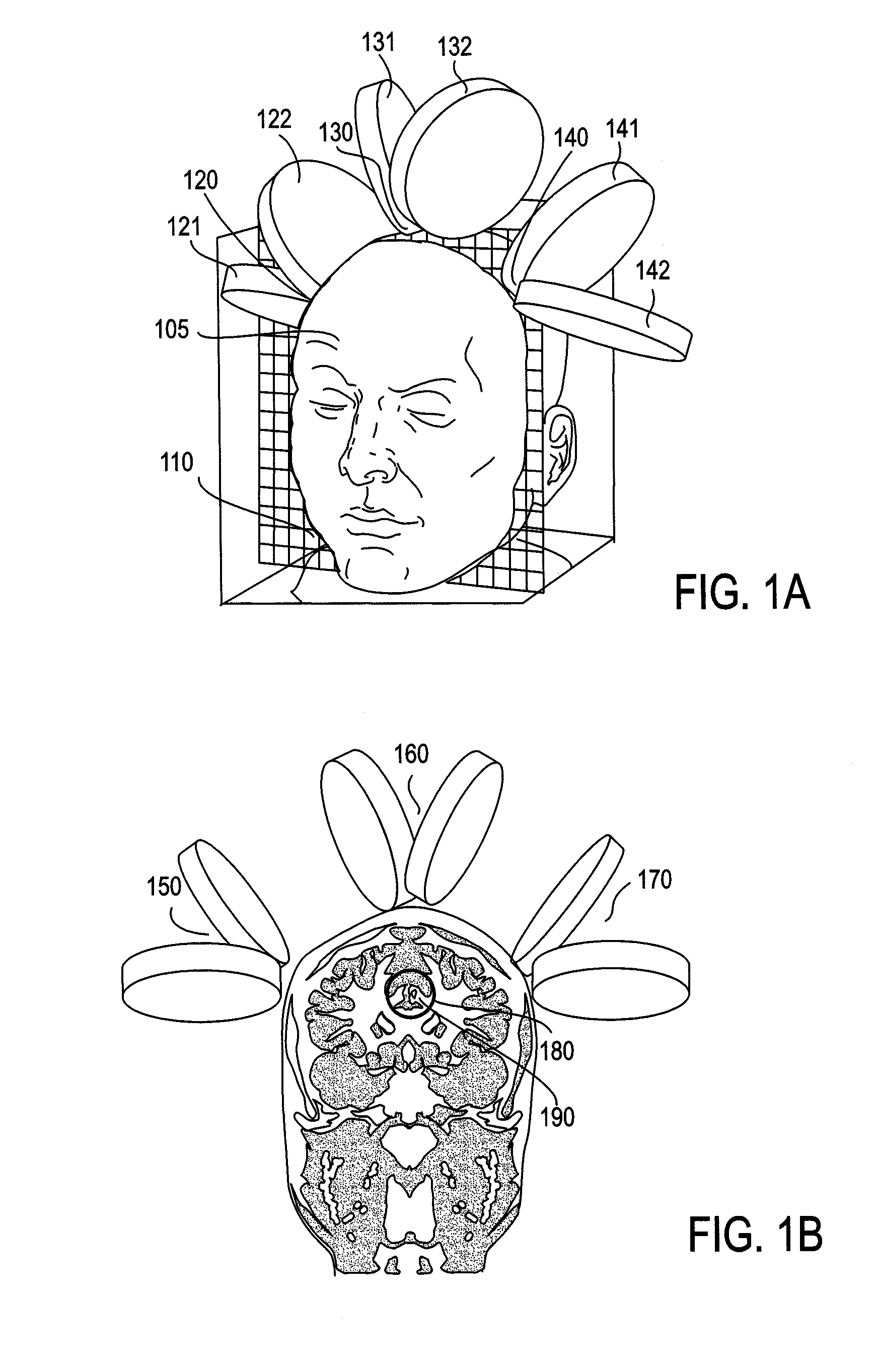

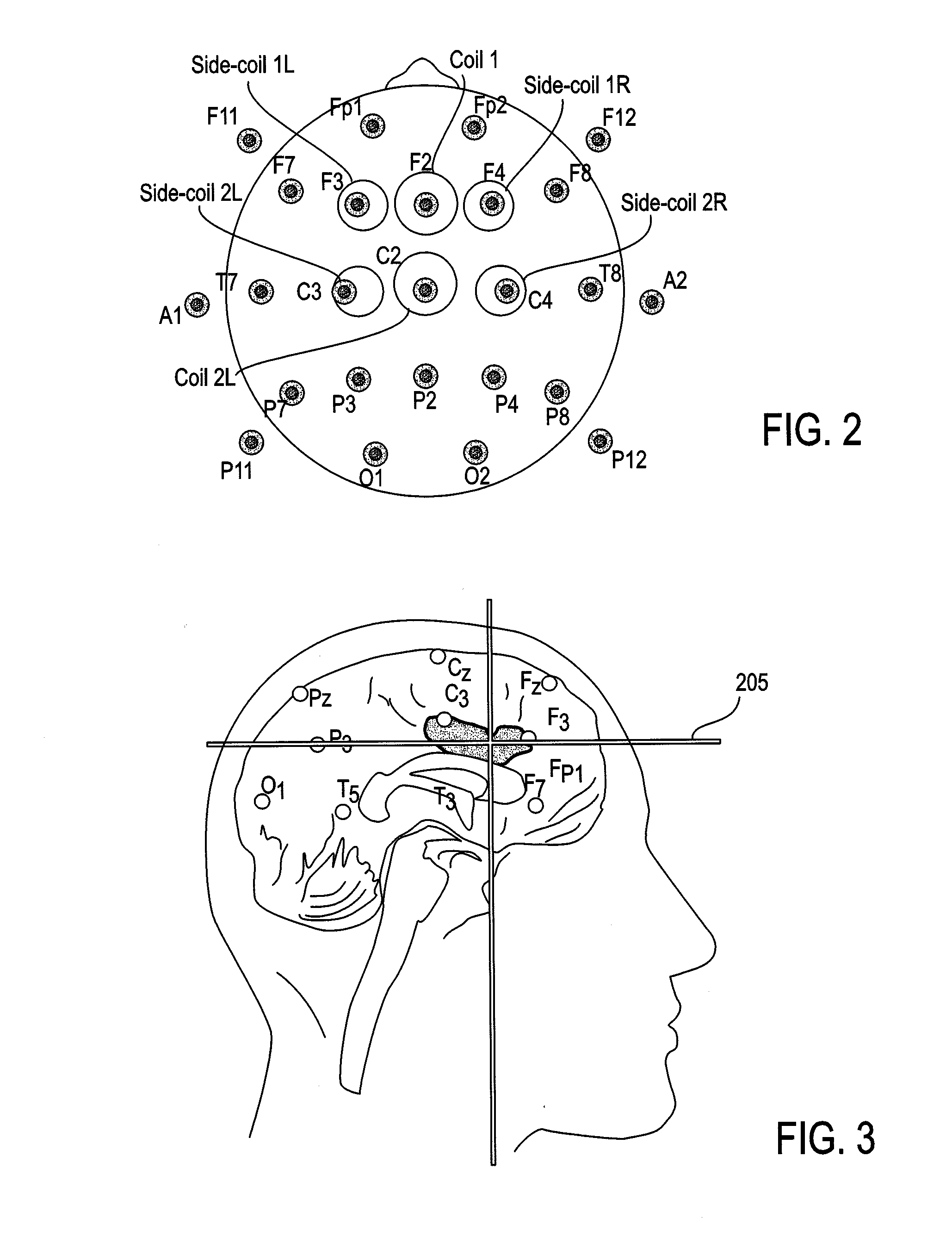

Transcranial magnetic stimulation field shaping

ActiveUS20100286470A1Improve concentrationReduce and prevent painElectrotherapyMagnetotherapy using coils/electromagnetsElectrical polarityEngineering

Described herein are Transcranial Magnetic Simulation (TMS) systems and methods of using them for emitting focused, or shaped, magnetic fields for TMS. In particular, described herein are arrays of TMS electromagnets comprising at least one primary (e.g., central) TMS electromagnet and a plurality of secondary (e.g., lateral or surrounding) TMS electromagnets. The secondary TMS electromagnets are arranged around the primary TMS electromagnet(s), and are typically configured to be synchronously fired with the primary TMS electromagnets. Secondary TMS electromagnets may be fired at a fraction of the power used to energize the primary TMS electromagnet to shape the resulting magnetic field. The secondary TMS electromagnets may be stimulated at opposite polarity to the primary TMS electromagnet(s). Focusing in this manner may prevent or reduce stimulation of adjacent non-target brain regions.

Owner:BRAINSWAY

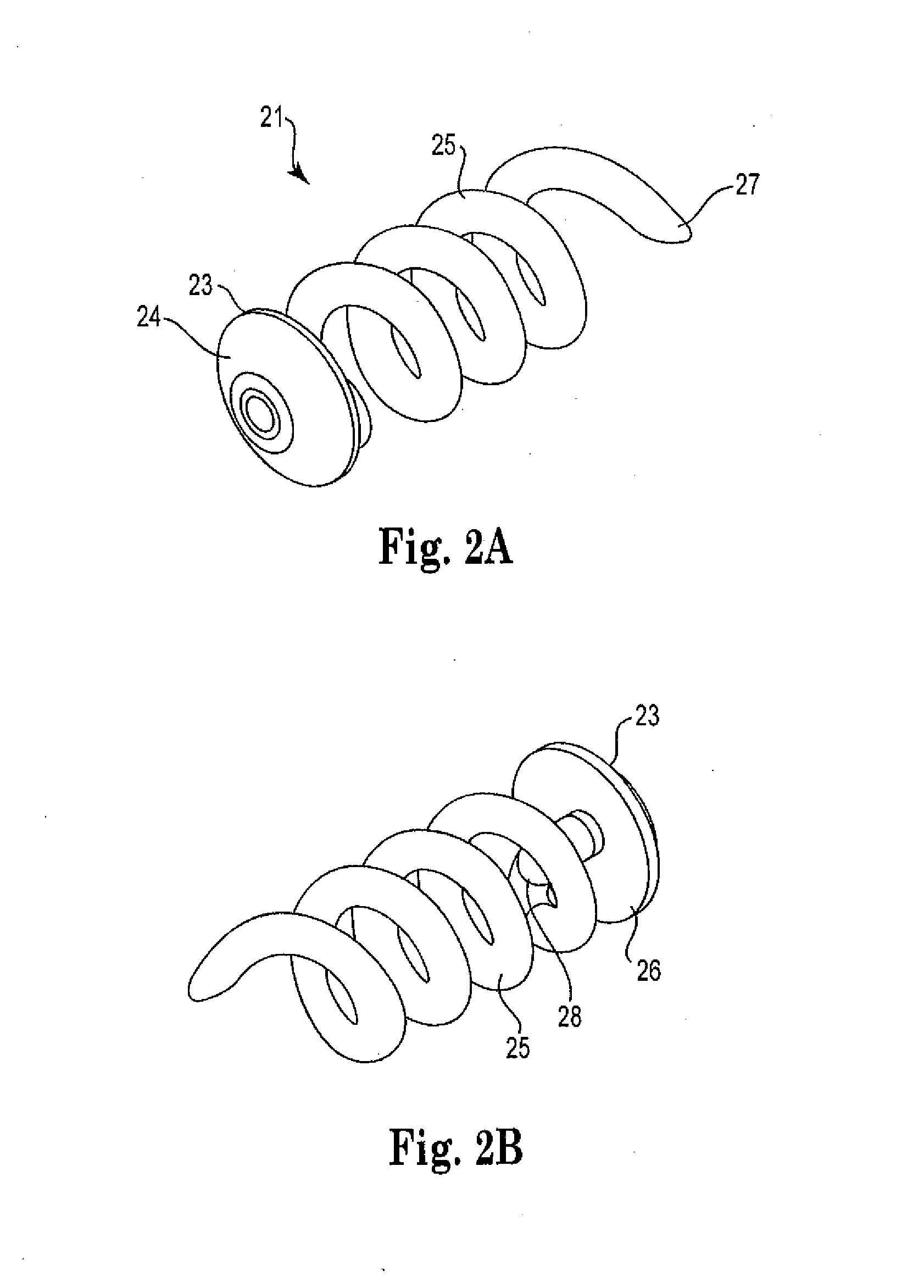

Implantable ocular drug delivery device and methods

InactiveUS20100189765A1Improve stabilityMinimize movementOrganic active ingredientsBiocideDistal portionMedical device

The present invention provides implantable ocular drug delivery devices. Generally, the devices have a distal portion with a coil shaped body member and a proximal portion which contacts the sclera. In one aspect, the coil-shaped body member includes a unique configuration including two coiled portions with different pitches, which improves insertion of the device into the eye. In another aspect, the device has a proximal portion that includes a unique cap configuration having a concave distal face that improves stabilization of the device in the eye. In another aspect, the device includes a transitional portion between the cap and the coil-shaped body member that also improves stabilization of the device in the eye. The invention also provides methods for inserting the medical device into the eye, and methods for the treatment of an ocular condition.

Owner:SURMODICS INC

New methods of treating dry eye syndrome

The invention relates to a method of insulin eye drops for treating dry eye syndrome due to any and all etiological factors (Keratoconjunctivitis sicca), including Sjogren's syndrome, Meibomian gland dysfunction (MGD) and other glandular malfunction in the eye lids, lacrimal glands, cornea, conjunctiva, and exposed scleral surface of the eye. It is treated with Insulin and / or IGF-I with or without known anti-dry eye syndrome therapeutic, pharmaceutical, biochemical and biological agents or compounds.

Owner:SHANTHA TOTADA R +2

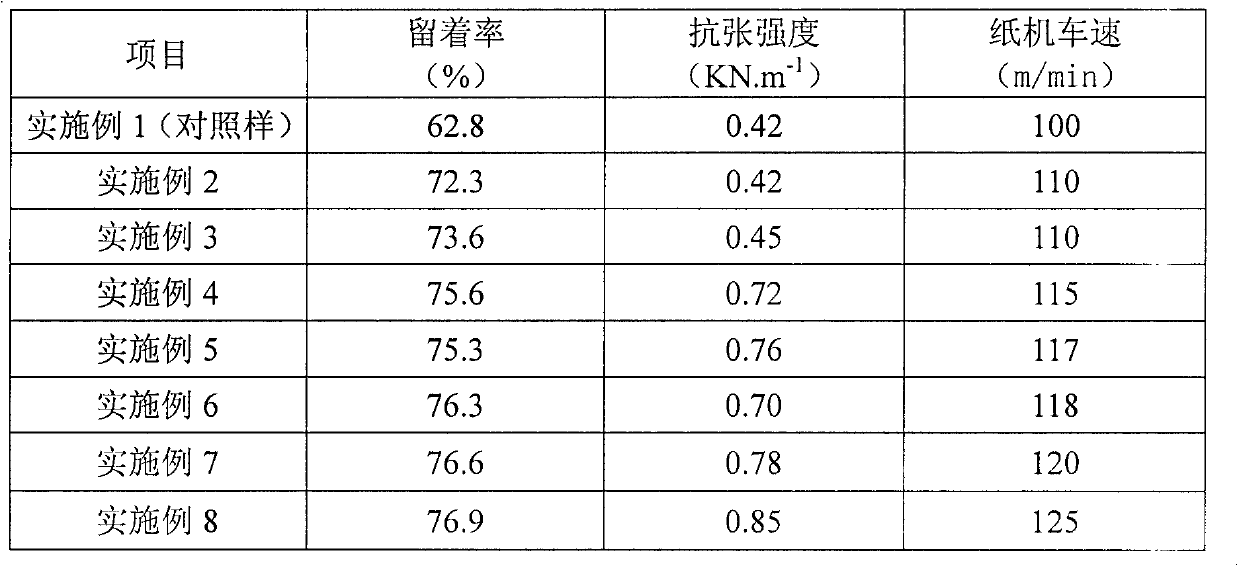

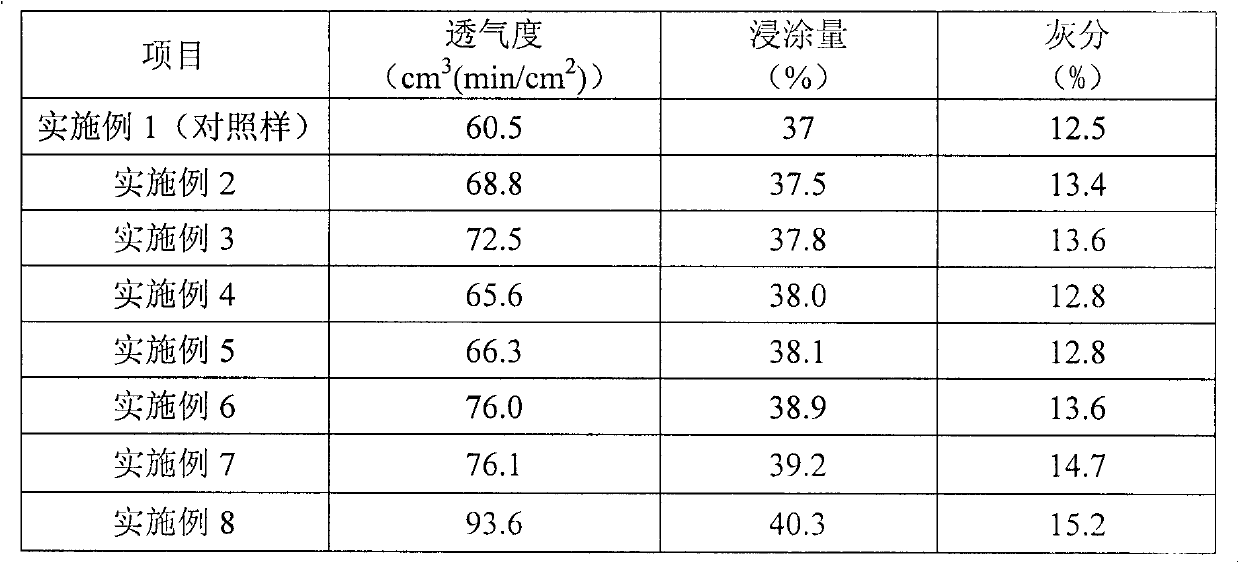

Preparation method for paper-making process tobacco sheet and finished product of paper-making process tobacco sheet

ActiveCN103141928AImprove single layer retentionImprove breathabilityTobacco preparationPlant fibrePaper based

The invention belongs to the field of tobacco industry and relates to a preparation method for a functional harm-reduction and tar-reduction paper-making process tobacco sheet and a finished product of the paper-making process tobacco sheet. The preparation method for the paper-making process tobacco sheet comprises the following steps of extracting and concentrating effective components of tobacco; mixing formulas; pulping and blending fibers; manufacturing paper with pulp; dipping, drying and tearing and shaping. The blending process comprises the following steps of: adding non-tobacco plant fiber pulp of which the beating concentration is 3-4 percent and the Schopper-Riegler (SR) beating degree is 18-28 to tobacco mixed fiber pulp, adding filling to a machine chest, regulating the pulping concentration to 2-3 percent by water, and evenly mixing. By the use or the combine use of the filling and the non-tobacco plant fiber pulp, the combustion state of the sheet can be improved while physical properties, such as the air permeability, the retention and the tensile strength of a paper base, are improved, i.e., harmful ingredients of smoke, such as tar and carbon monoxide of the paper-making process tobacco sheet, can be effectively reduced, and hazard indexes of cigarettes are reduced. Meanwhile, technical-economic indicators, such as the speed and the input- output efficiency of a paper machine, also can be improved.

Owner:杭州利群环保纸业有限公司

Comfort liner for pressure face masks and nasal masks

InactiveUS20090139525A1Large lifetime improvementReducing air leaks around the faceRespiratory masksBreathing masksMedicineBreathing gas

Disclosed is a device and method for improving the facial comfort and sealing ability of a full-face mask comprising a liner of soft material, preferably made from moleskin or the like. The disclosed face mask liner provides a superior feel to the user's face compared with standard face masks with air-filled cushion or silicone gasket cuffs, while providing a more comfortable user experience and a superior seal to prevent loss of breathing gas. Also disclosed is a similar device and method for improving the facial comfort of a nasal mask, providing a mask that is more comfortable to the user.

Owner:SCHIRM LOUIS

Methods of reducing irritation in personal care compositions

InactiveUS7157414B2Less irritatingReduce stimulationPowder deliveryCosmetic preparationsPersonal careMedicine

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

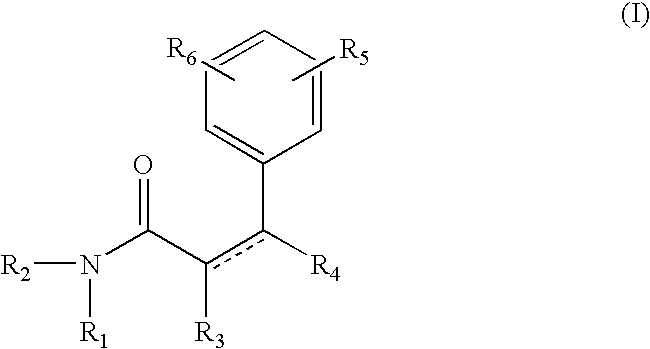

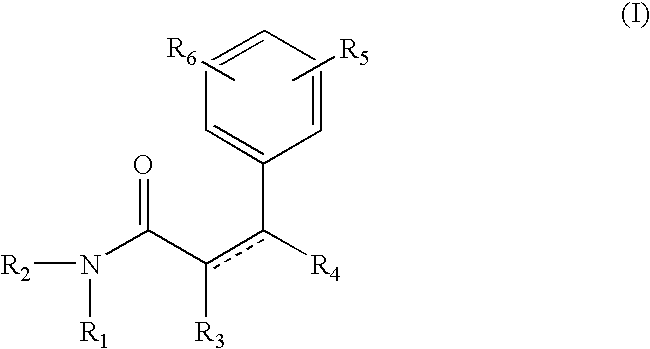

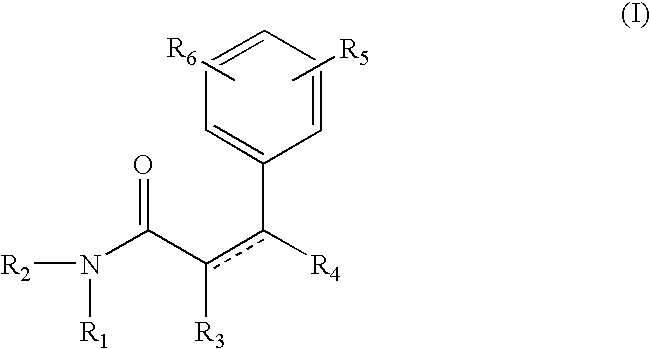

Skin lightening agents, compositions and methods

InactiveUS6852310B2Effective skin lightening propertyLess irritatingCosmetic preparationsHair cosmeticsHydrogen atomAlkoxy group

Cosmetic methods of skin lightening using coumarin derivatives of formula I as skin lightening agents alone or in combination with other skin benefit agents and together with a cosmetic vehicle: Where each or both R1 and / or R2 represents hydrogen; linear or branched C1-C18 alkyl, alkenyl, cycloalkyl, cycloalkenyl, hydroxyalkyl, hydroxyalkenyl, acyl, cycloacyl, or alkoxy groups;Each or both R3 and / or R4, which may be connected by a single or double carbon-carbon bond (shown as a dotted line), represents hydrogen; linear or branched C1-C18 alkyl, alkenyl, alkoxy, cycloalkyl, or cycloalkenyl group; andEach or both R5 and / or R6 represents a hydrogen atom, OH, C1-C4 acyl group, C1-C4 alkyl group, O—CO—R7, O—COO—R8 group, mesyl group or tosyl group, where each or both R7 and / or R8 represents hydrogen; linear or branched C1-C18 alkyl, alkenyl, hydroxyalkyl, hydroxyalkenyl, acyl, cycloacyl, or alkoxy groups.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com