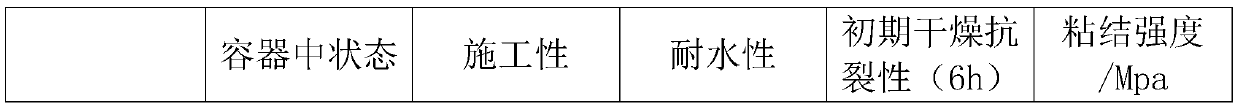

Patents

Literature

135results about How to "Molecular chain length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boilproof alumen-free sheet jellies and processing method thereof

The invention discloses boilproof alumen-free sheet jellies and a processing method thereof. The boilproof alumen-free sheet jellies comprise the raw materials of starch, oxidized starch, sodium alginate, sodium dihydrogen phosphate, disodium hydrogen phosphate, sodium carbonate, salt and water. The boilproof alumen-free sheet jellies have the advantages that: the oxidized modified starch is applied to the process for preparing the sheet jellies for the first time; the paste liquid of the oxidized starch is transparent; the paste strip is short; and gelatinous property and film-forming property are high. The oxidized starch has a coordinated compatible and complementary action with the sodium alginate, the sodium dihydrogen phosphate, the disodium hydrogen phosphate, the sodium carbonate and the salt to form a good network structure. Therefore, the prepared sheet jellies have the characteristics of good mouthfeel, boiling resistance, no turbid soup, no broken strips and high transparency. The used oxidized starch has the advantages of simple preparation, eating safety and low cost.

Owner:黑龙江北大荒斯达奇生物科技有限公司

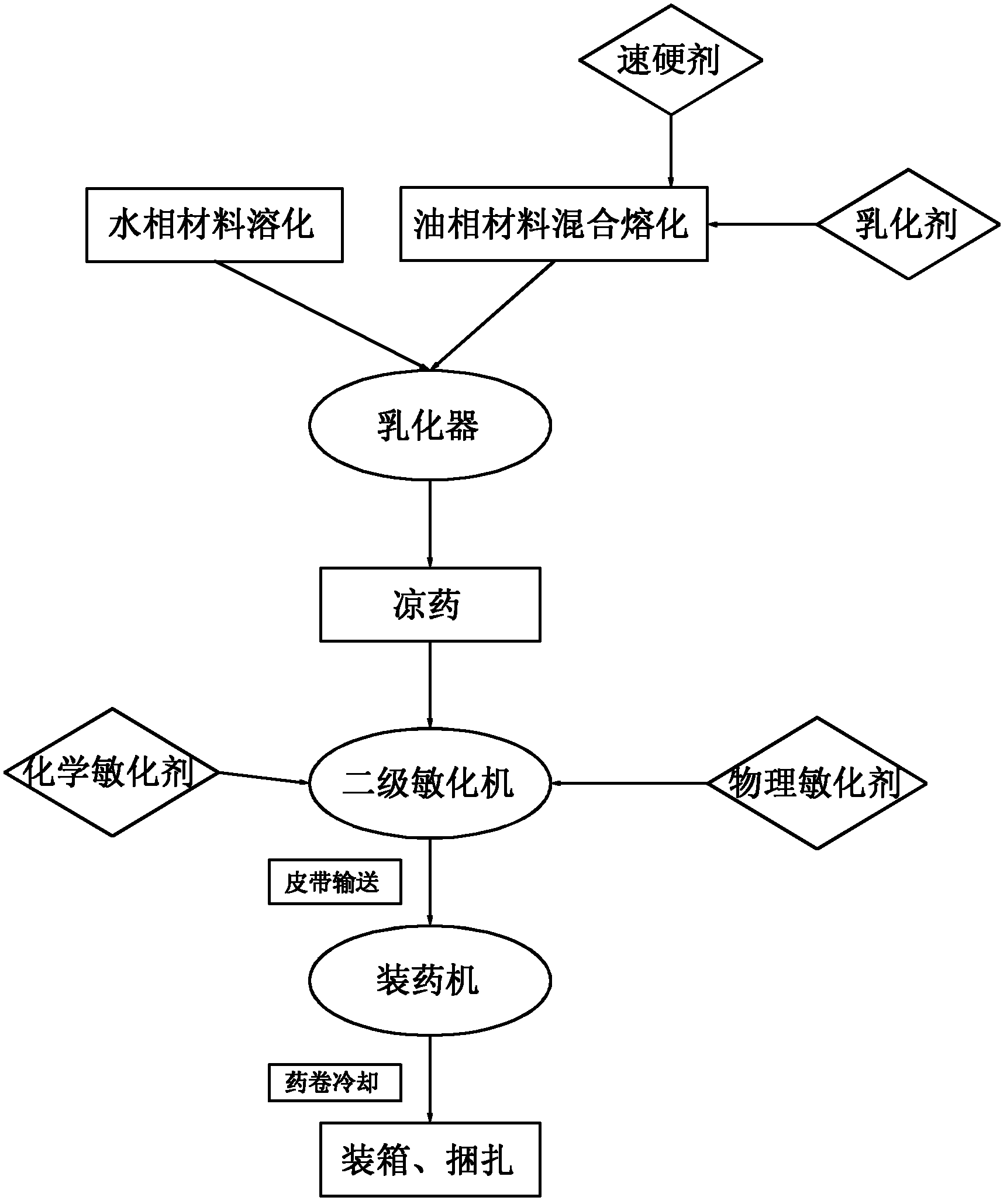

High-temperature acceleratingly-hardened emulsion explosive and preparation method for same

ActiveCN102633580AIncrease the hardness of the outer phaseMolecular chain lengthNon-explosive/non-thermic compositionsEmulsion explosiveHardness

The invention relates to a high-temperature acceleratingly-hardened emulsion explosive, which comprises water-phase materials, oil-phase materials, emulsifier, sensitizer and hardening accelerator, wherein the water-phase materials include wax and / or fatty acid; the sensitizer includes physical sensitizer and chemical sensitizer simultaneously; and the hardening accelerator is selected from silicate and / or alkaline matter. The temperature of the emulsion explosive is higher than 35 DEG C, and the emulsion explosive has a certain hardness and is non-sticky, thereby being applicable to open-air filling operation in hot summer, and being high in explosion performance.

Owner:ANHUI JIANGNAN CHEM IND CO LTD

Composite high polymer flocculant for coking wastewater and preparation method thereof

InactiveCN106335988AReduce secondary pollutionWide variety of sourcesWater/sewage treatment by flocculation/precipitationCoking wastewaterIron(II) chloride

The invention discloses a composite high polymer flocculant for coking wastewater and a preparation method thereof. The composite high polymer flocculant adopts non-ionic modified starch, cationic modified starch, anionic modified starch, and amphoteric modified starch as the raw materials, in the presence of an initiator and under a weak acid condition, the raw materials undergo graft copolymerization with acrylamide, acrylic acid, methacrylic acid, acrylonitrile, acrylic ester, styrene, methylene acrylamide, maleic anhydride and other monomers to obtain a modified starch graft copolymer, and the copolymer is blended with an inorganic flocculant ferric sulfate, ferric silicate, ferric chloride, ferrous sulfate and ferrous chloride to obtain the composite high polymer flocculant. The composite high polymer flocculant has the characteristics of long molecular chain, compact floccules, wide source of raw materials, low price, biodegradability, and little secondary pollution, etc., and is a real efficient and environment-friendly flocculant. During use, the dosage of the composite high polymer flocculant accounts for 0.1-1% of the volume fraction of the treated coking wastewater, the COD removal rate of the treated coking wastewater reaches 85% or more, the decolorization rate is 95% or more, and the removal rate of suspended solids reaches 95% or more.

Owner:TIANJIN ZHONGFU ENG TECH

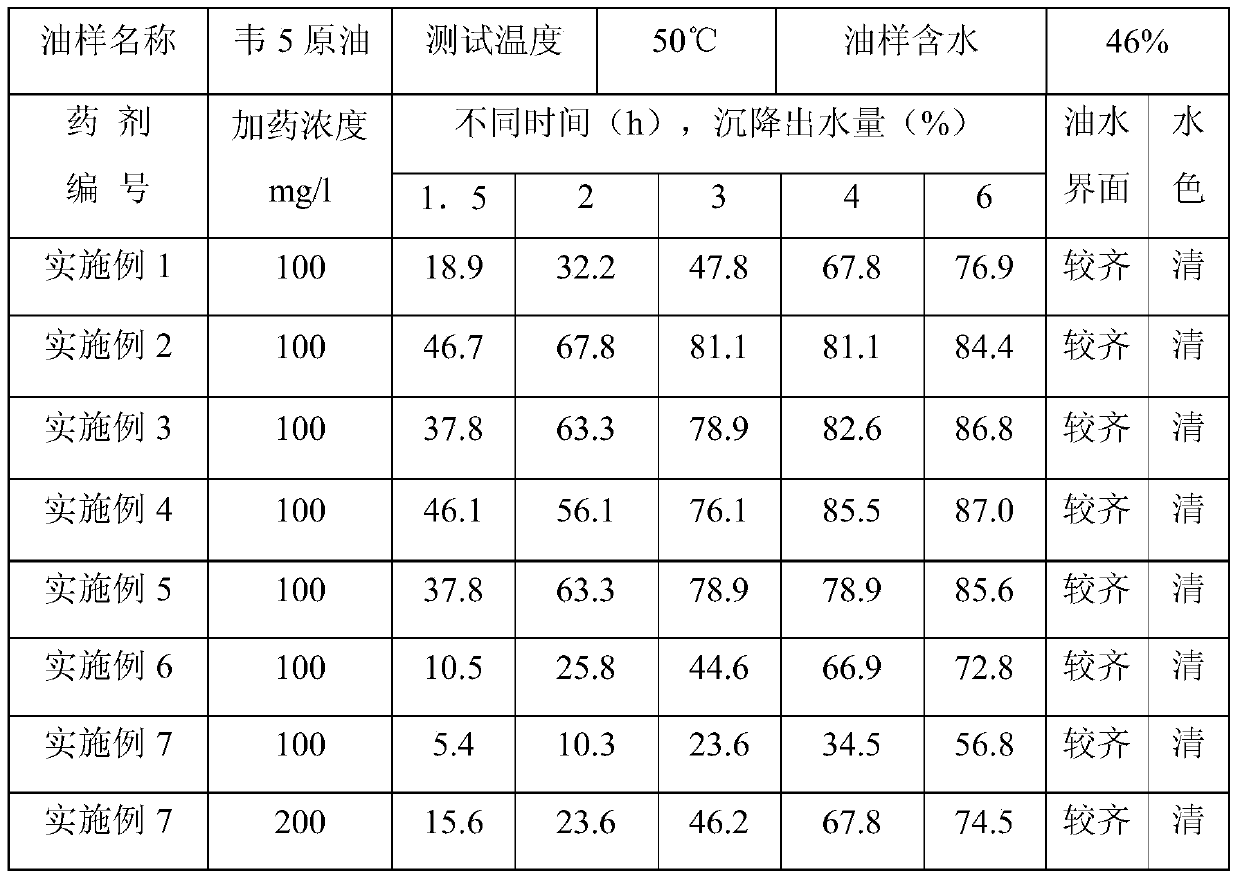

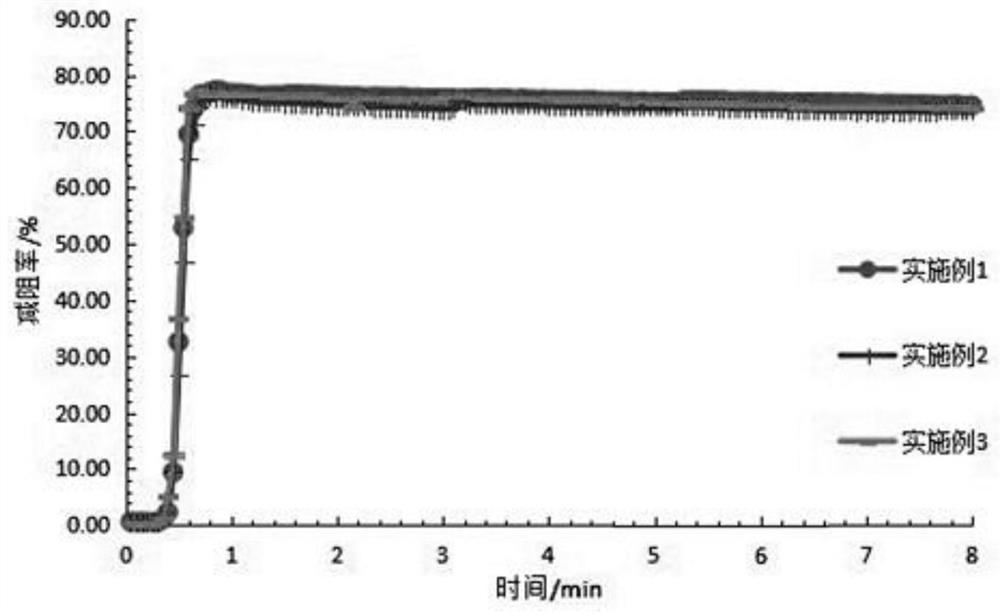

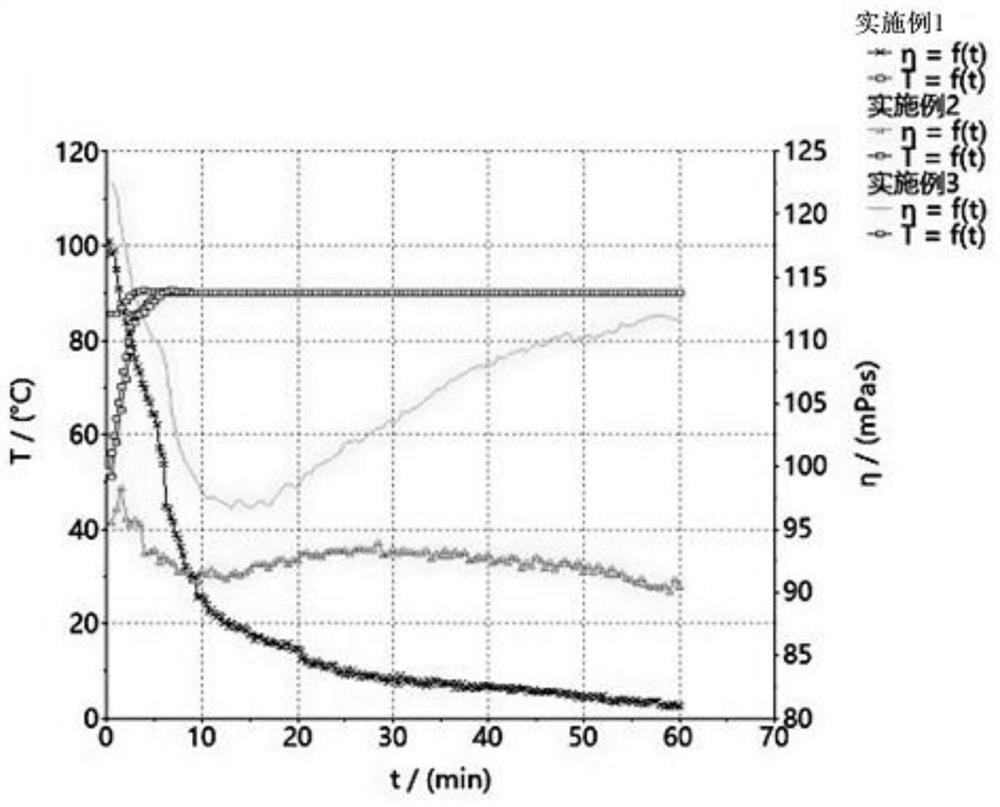

Non-polyether demulsifier and preparation method thereof

ActiveCN105504143AAvoid pollutionMolecular chain lengthDewatering/demulsification with chemical meansHydrophilic monomerCross-link

The invention provides a novel non-polyether demulsifier and its preparation method. The non-polyether demulsifier contains a copolymer prepared by seeded emulsion copolymerization of a hydrophilic monomer, a hydrophobic monomer and an optional cross-linked monomer. The weight ratio of the hydrophilic monomer to the hydrophobic monomer is 3: 97-20: 80. The demulsifier of the invention has advantages as follows: raw materials are easily available; production condition is mild; high temperature and high pressure are not required; operation is convenient; and cost is low. The non-polyether demulsifier of the invention can be used in demulsification of crude oil in an oil field, especially in demulsification of thickened oil. The non-polyether demulsifier has a good demulsification effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Efficient salt-resistant dual-purpose thickening agent, preparation method and application thereof

ActiveCN112521560AHigh viscosityFast dissolutionDrilling compositionFunctional monomerSuspending Agents

The invention discloses an efficient salt-resistant dual-purpose thickening agent, a preparation method and application thereof. The preparation method of the thickening agent comprises the followingsteps of: S1, preparing a water phase; S2, preparing an oil phase; S3, performing emulsifying; S4, conducting polymerization; and S5, carrying out aftertreatment. A hydrophobic monomer, a functional monomer and a salt-resistant monomer are introduced into the thickening agent to form a compact and complex spatial network structure in an aqueous solution, so that the thermal stability and the saltresistance of the thickening agent are improved, and the aqueous solution of the thickening agent can keep relatively high viscosity under a hypersalinity condition. Due to the addition of a chain extender, the molecular chain of the polymer is longer, and the viscosity is greatly improved. A cosolvent is introduced, so that the dissolving speed of a polymer emulsion is further increased, the polymer emulsion can be completely dissolved in 30 seconds, the requirement on water quality is low, and the polymer emulsion can be prepared from oilfield reinjection water and oilfield wastewater. Due to the addition of a suspending agent, the emulsion system is more stable, and the emulsion is not layered within two years. The thickening agent also has the characteristic of dual purposes, and can be used as a fracturing fluid slickwater drag reducer and a fracturing fluid thickening agent.

Owner:西安长庆化工集团有限公司 +1

Polymeric magnesium silicate-sulfate composite flocculant

InactiveCN102259963AImprove adsorption capacityMolecular chain lengthWater/sewage treatment by flocculation/precipitationMagnesium silicateAluminium

The invention discloses a polymeric magnesium silicate-sulfate composite flocculant, and relates to a flocculant for water treatment. The invention aims to solve the problem that the traditional flocculant has a large adding amount, a low ammonia nitrogen removing effect and a narrow water application range. The polymeric magnesium silicate-sulfate composite flocculant is prepared from silicate, magnesium salt, aluminum salt, iron salt, an aid A and an aid B. When the polymeric magnesium silicate-sulfate composite flocculant is used for treating 15DEG C domestic sewage, the suspended matter removing rate is 95-99 percent, the chemical oxygen demand (COD) removing rate is 60-70 percent, the PO4<3->-P removing rate is 95-99 percent and the ammonia nitrogen removing rate is 15-20 percent. Compared with the traditional flocculant, the polymeric magnesium silicate-sulfate composite flocculant has a small dosage and a wide water application range and is applied to the field of water treatment.

Owner:HARBIN INST OF TECH

Low-modulus monocomponent de-ketoxime type room temperature sulfurized silicone sealant and preparation method thereof

InactiveCN106833503AImprove adhesionImprove mechanical propertiesNon-macromolecular adhesive additivesMacromolecular adhesive additivesVulcanizationALUMINUM STEARATES

The invention discloses a low-modulus monocomponent de-ketoxime type room temperature sulfurized silicone sealant and a preparation method thereof. The silicon sealant is prepared from hydroxyl end-blocked dimethylsiloxane, a plasticizer, white mineral oil, gas phase method silica aerogel, a reinforcing filler, aluminum stearate, pigment, a crosslinking agent, a vulcanization accelerator, a silane coupling agent and a catalyst. The preparation method comprises the following steps: 1) uniformly mixing the hydroxyl end-blocked dimethylsiloxane, the plasticizer, the white mineral oil, the gas phase method silica aerogel, the reinforcing filler, the aluminum stearate and the pigment, and drying the mixture fully to obtain a premix compound; 2) performing vacuum full kneading on the premix compound to obtain base; 3) adding the crosslinking agent, the vulcanization accelerator and the silane coupling agent into the base, performing vacuum stirring uniformly;4) adding the catalyst into the base, performing vacuum stirring uniformly, discharging the mixture, and performing filling and sealing. The low-modulus monocomponent de-ketoxime type room temperature sulfurized silicone sealant provided by the invention has the advantages of neutral solidification, strong bonding power, excellent mechanical property, and good heat resistance and oil resistance.

Owner:GUANGDONG RES INSTITITUTE OF PETROCHEM & FINE CHEM ENG

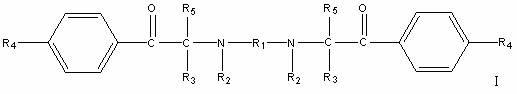

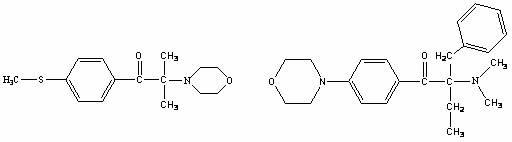

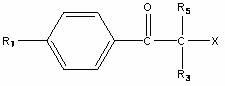

Macromolecular bifunctional amino ketone photoinitiator and preparation method thereof

ActiveCN101974112AImprove performanceInitiation efficiency is highOrganic compound preparationSulfide preparationKetonePhotoinitiator

The invention discloses a macromolecular bifunctional amino ketone photoinitiator and a preparation method thereof. Single amino ketone photoinitiators are combined with one another by using di-secondary amine, so that a molecular weight is doubled and the defects of easy volatilization, easy migration, smell and the like caused by a small molecular weight are overcome; simultaneously, the number of introduced invalid groups is small and the performance of the initiator is not lowered obviously; moreover, a molecular chain is longer and the problem of poor compatibility is solved. The invention also discloses the application of the macromolecular bifunctional amino ketone photoinitiator in a polymerization reaction. The photoinitiator has high initiating efficiency, high performance in various aspects and wide application prospect and can fully replace a micromolecular amino ketone photoinitiator.

Owner:CHANGSHANG NEWSUN CHEM IND

Polysilicate-metals composite flocculant and preparation method thereof

InactiveCN102249387ALarge flocsGood decolorization effectWater/sewage treatment by flocculation/precipitationSodium bicarbonatePhosphate

The invention discloses polysilicate-metals composite flocculant and a preparation method thereof and relates to flocculant for water treatment and the preparation method thereof. The method aims to solve the technical problem that the alkalization degree and polymerization degree of flocculant are increased by externally increasing alkalizer so water treatment cost is increased in the conventional polysilicate-metals composite flocculant. The polysilicate-metals composite flocculant is prepared from silicate, aluminum salt, ferric salt, an assistant agent A and an assistant agent B in a weight ratio, wherein the assistant agent A is one or combination of phosphate, calcium oxide, polyacrylamide, and chitosan; and the assistant agent B is one or combination of sodium hydroxide, potassium hydroxide, sodium carbonate, potassium carbonate, sodium bicarbonate or potassium bicarbonate. The method comprises the following steps of: adjusting pH of the aqueous solution of silicate, stirring and standing to obtain solution of polysilicate, and then adding the aluminum salt, the ferric salt, the assistant agent A and the assistant agent B, and mixing uniformly to obtain the polysilicate-metals composite flocculant. Other agents are not needed to be added, and the polysilicate-metals composite flocculant is low in cost and can be used for the field of water treatment.

Owner:HARBIN INST OF TECH

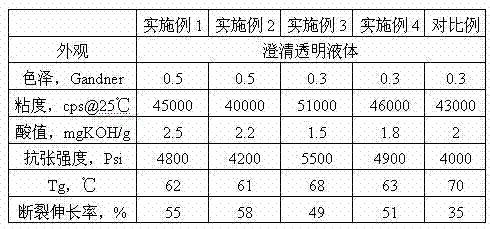

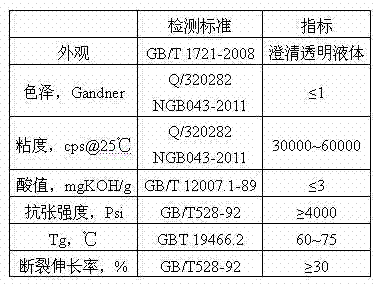

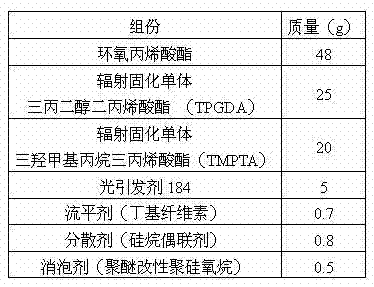

Method for preparing modified epoxy acrylate

ActiveCN102504198AResponse to the whole process is smoothStrong exothermic reactionEpoxy resin coatingsEpoxyOrganic acid

The invention discloses a method for preparing modified epoxy acrylate. The method comprises the following steps of: (1) synthesizing an intermediate: adding anhydride, hydroxyl acrylate monomers, an anti-oxidant 1 and a polymerization inhibitor 1 in turn into a reaction kettle in turn, uniformly stirring, heating to the temperature of between 80 and 120DEG C, reacting for 2 to 3 hours, and discharging a material (marked as A) for later use; (2) expanding chain of organic acid: adding epoxy resin, organic diacid and a catalyst 1 into the reaction kettle in a formula ratio, uniformly stirring,slowly heating to the temperature of between 90 and 120DEG C, reacting for 2 to 3 hours, and after the acid value is less than or equal to 1mgKOH / g, starting cooling water to cool to the temperature of between 50 and 70DEG C; (3) heating for esterification: adding the material A, a catalyst 2, a polymerization inhibitor 2 and an anti-oxidant 2 into the reaction kettle in a formula ratio in turn, heating and keeping temperature; (4) cooling and diluting; and (5) performing central control inspection. The molecular weight can be properly increased, flexible groups can be increased, and the glass-transition temperature of the product is reduced.

Owner:江苏三木化工股份有限公司

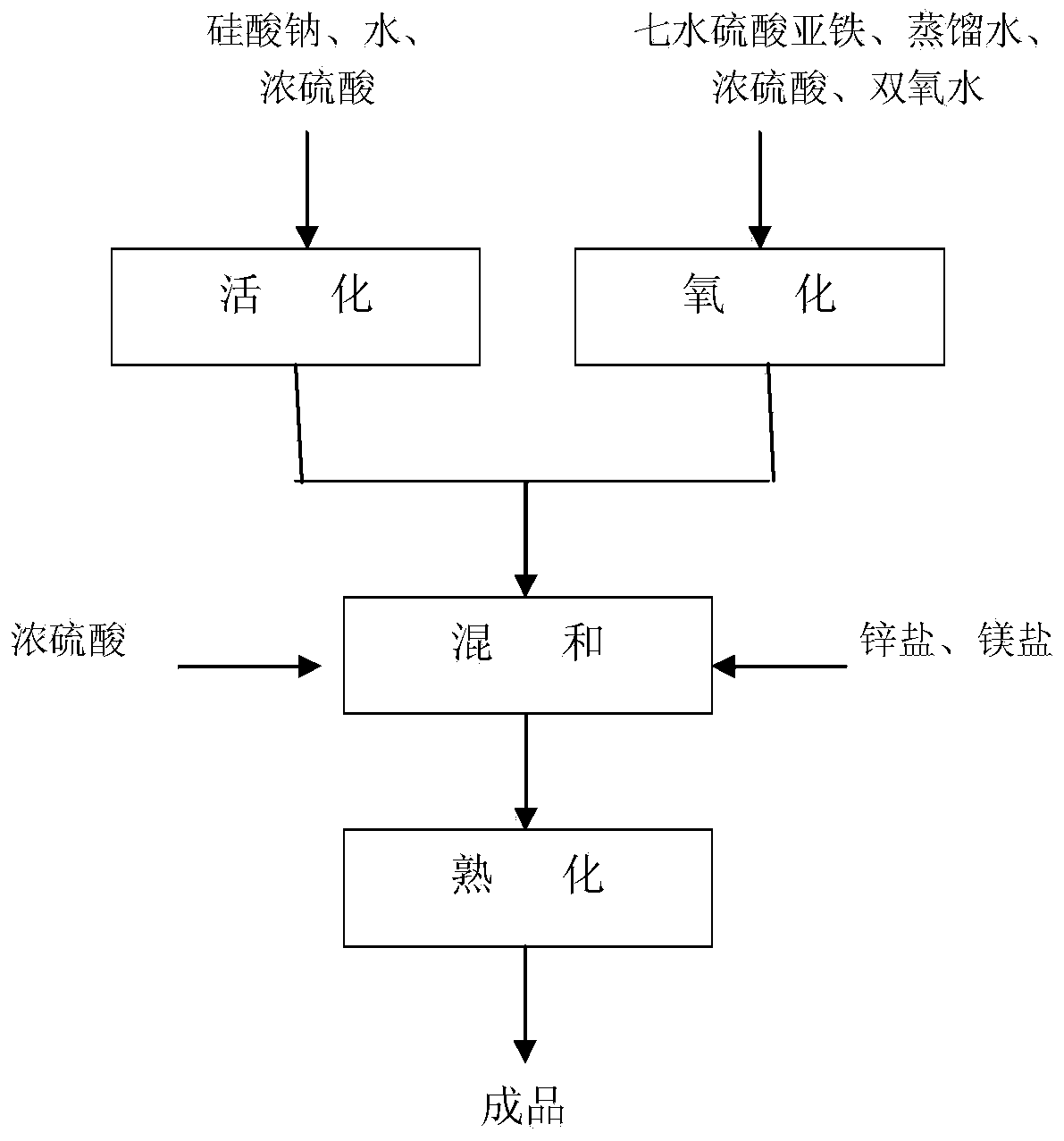

Compound type water treatment flocculating agent and preparation method thereof

InactiveCN103964555AStrengthen the ability of bonding and aggregationMolecular chain lengthWater/sewage treatment by flocculation/precipitationMagnesium saltWater treatment

The invention discloses a compound type water treatment flocculating agent and a preparation method thereof and belongs to the field of waste water treatment. The flocculating agent is prepared from ferrous sulfate, sodium silicate, zinc salt, magnesium salt, hydrogen peroxide, concentrated sulfuric acid, and distilled water and the preparation method comprises the steps of activating, oxidation, mixing, curing and the like. The compound type water treatment flocculating agent disclosed by the invention has the benefits of simple preparation technology, low cost, high convenience in product application and good stability, is suitable for flocculation treatment of sewage and has good effects on sewage in COD reduction, phosphorous removal and de-coloration.

Owner:QINGDAO SHIZHILI CHINESE HERBAL MEDICINE INST

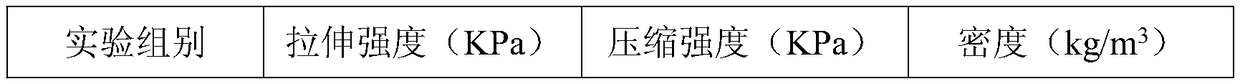

High-strength mattress material and preparation method thereof

The invention discloses a high-strength mattress material and a preparation method thereof, and belongs to the technical field of mattress materials. The high-strength mattress material comprises thefollowing raw materials: toluene diisocyanate, polyolefin, a chain extender, carbon fibers, a foaming agent, a foam stabilizer, a catalyst, a surfactant, triethylenediamine, grafted polyether, silicaaerogel, graphene and sodium bicarbonate, wherein grafted polyether, the silica aerogel and graphene are in a dose ratio of (4-6):(2-4):(1-3); the mattress material is prepared through steps of mixing, stirring, heating, drying and cooling. With the adoption of a reinforcing system formed by grafted polyether, the silica aerogel and graphene, tensile strength and compressive strength of the mattress material are improved, and density of the mattress material is reduced.

Owner:CHANGSHA XIAORU INFORMATION TECH CO LTD

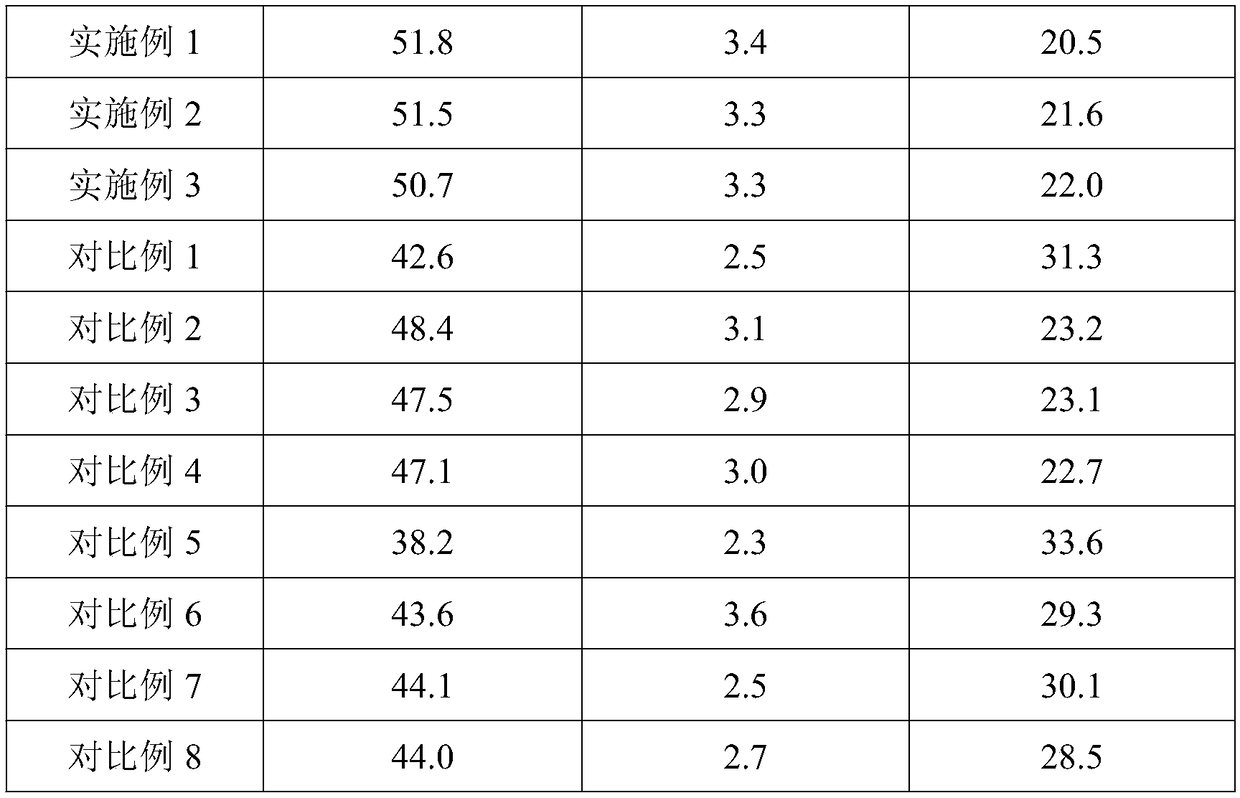

Polyamic acid composition and preparation method and application thereof

ActiveCN106589368AMolecular chain lengthMonocomponent synthetic polymer artificial filamentOrganic solventCarboxylic acid

The invention relates to a polyamic acid composition and a preparation method and application thereof, and mainly solves the problems that a polyamic acid solution is not stable in viscosity control in the preparation process and polymer molecule chains are difficult to further grow in a subsequent imidization process in the prior art. The preparation method of the polyamic acid composition comprises the following steps: a) a tetracid and diamine composition solution is prepared by evenly stirring a tetracarboxylic acid and a diamine in an organic solvent at low temperature of-10 to 40 DEG C; b) the main part of a tetracarboxylic dianhydride is added into the tetracid and diamine composition solution for stirring for reaction at the low temperature of-10 to 40 DEG C to obtain a low viscosity polyamic acid composition solution; and c) the rest part of the tetracarboxylic dianhydride is added into the low viscosity polyamic acid composition solution to obtain the polyamic acid composition. The polyamic acid composition well solves the problems that the polyamic acid solution is not stable in viscosity control in the preparation process and the polymer molecule chains are difficult to further grow in the subsequent imidization process, and can be used in industrial production of a polyimide material.

Owner:CHINA PETROLEUM & CHEM CORP +1

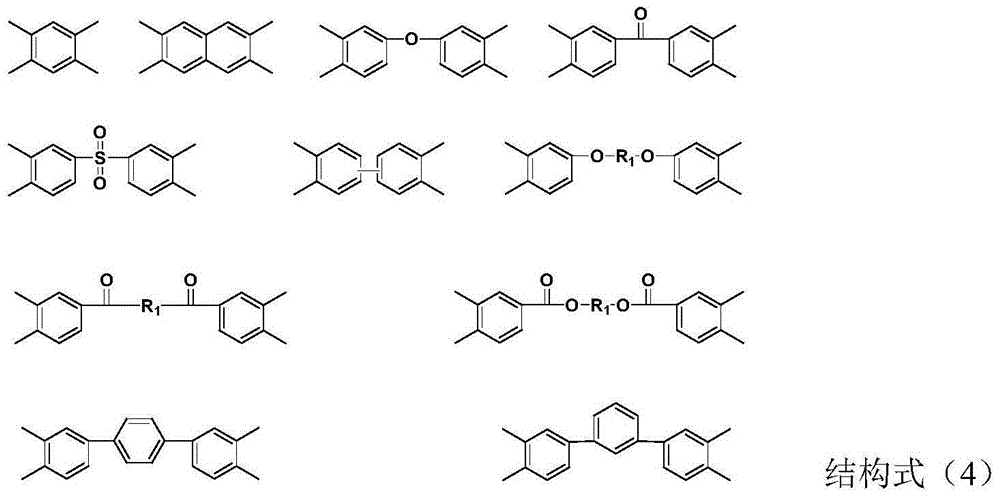

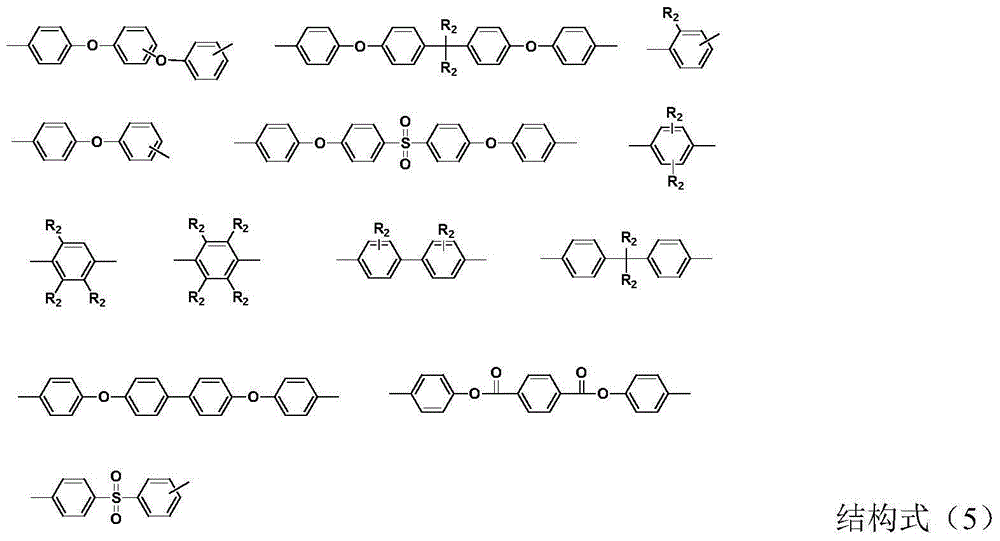

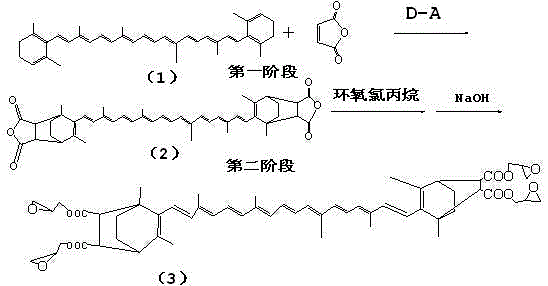

Epoxy chain extender and preparation method thereof

The invention discloses an epoxy chain extender and a preparation method thereof. The method includes following steps: on the basis of weight part, adding 22-27 parts of [gamma]-carotene and 9-11 parts of cis-butadiene anhydride to an organic solvent with a material liquid ratio being 31:60-38:60 g / ml; performing a mixing process fully and uniformly; carrying out a D-A reaction at 130-170 DEG C for 3-5 hours with protection of nitrogen; adding 90-95 parts of epichlorohydrin and 0.6-0.8 parts of ammonium bromide to a mixture after the reaction; performing a heating reflux process for 5-7 hours; performing a cooling process to 65-75 DEG C; and adding excessive amounts of sodium hydroxide to obtain a finished product. The epoxy chain extender can be applied in recycle of polyester-type and polyamide-type engineering plastics and performance improvement of biodegradable polymer materials. The method is wide in sources of raw materials and reagents, is low in cost, is mild in reaction conditions, is simple in separation and purification and is especially suitable for large-scale industrial production. By means of the method, the chain extender, which is high in purity, long in molecular chain, large in molecular weight and multiple in epoxy functional groups, can be prepared in high efficiency and yield. The epoxy chain extender is large in molecular weight, is high in molecular chain length, is rich in epoxy functional groups, is easy to subject to a chain-extension reaction, is not reacted with water and is environment-friendly.

Owner:贵州一当科技有限公司

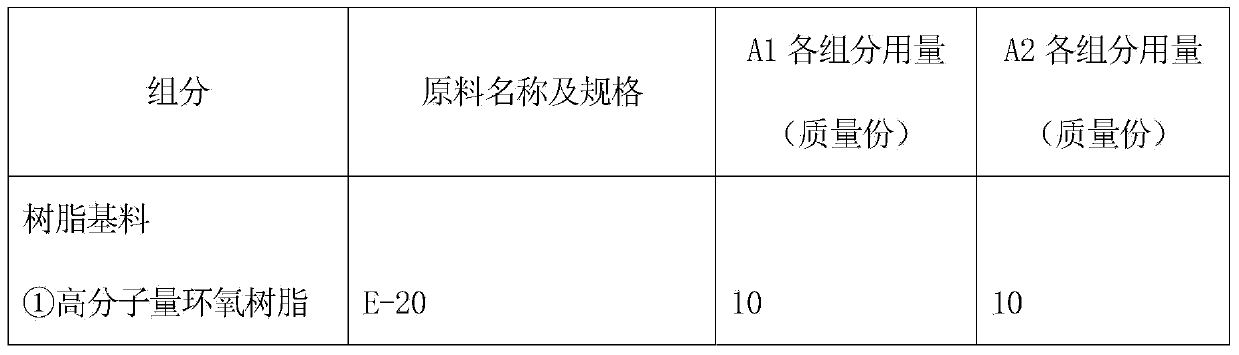

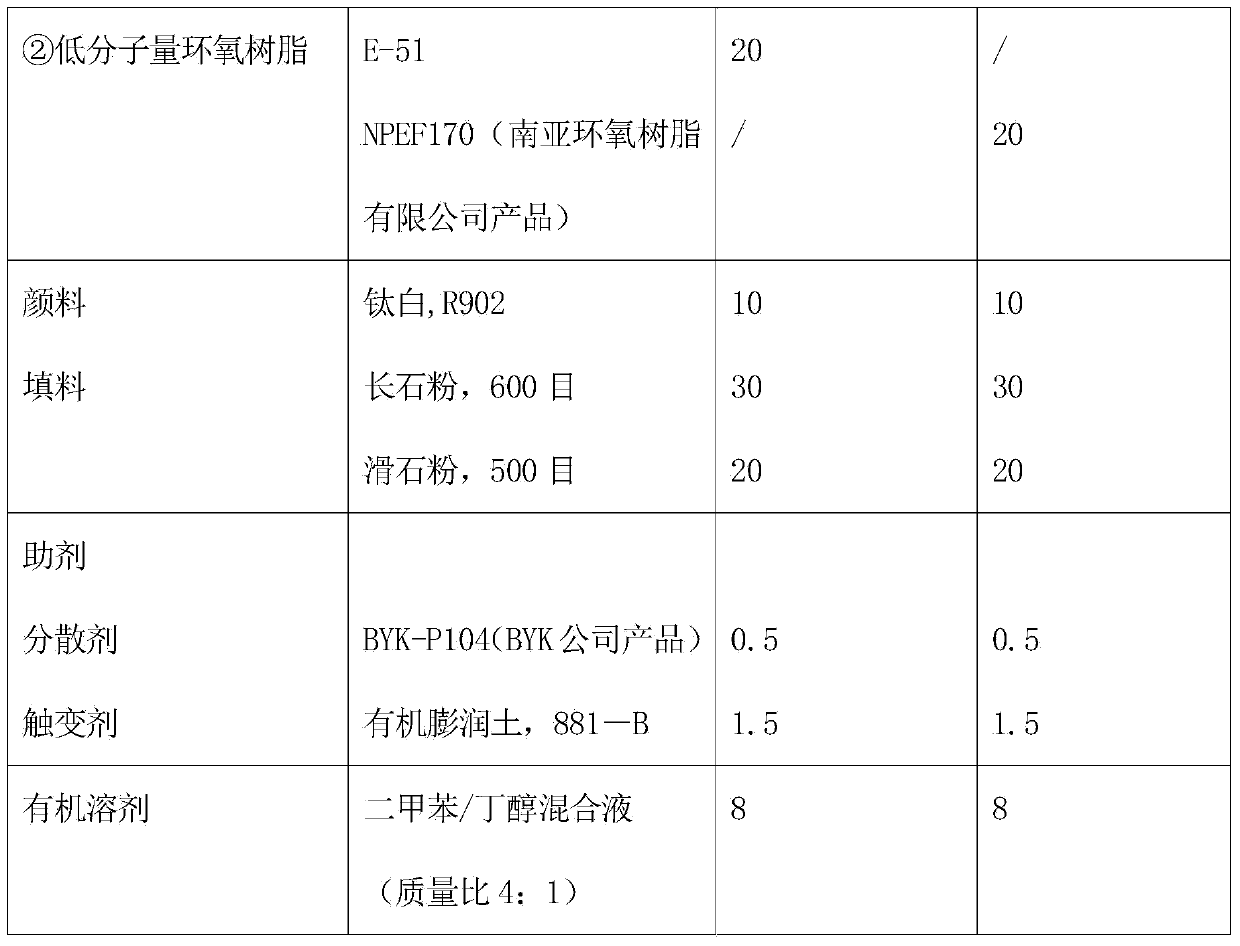

Raw oil-resistant coating composition

ActiveCN103725164AHigh molecular weightModerate proportionAnti-corrosive paintsEpoxy resin coatingsEpoxyOrganic solvent

The invention relates to a raw oil-resistant coating composition. The raw oil-resistant coating composition is a bi-component epoxy coating composed of a component A and a component B. 100 parts of component A by weight comprises the following components in parts by weight: 25-33 parts of resin binder, 50-60 parts of paint and a filling material, 1-3 parts of an additive and the balance of an organic solvent, wherein the resin binder is a compound of a high molecular weight epoxy resin and one or multiple low molecular weight epoxy resin; 100 parts of component B by weight comprises the following components in parts by weight: 35-45 parts of polyamide, 40-55 parts of modified amine, 0.1-1.5 parts of a coupling agent, 0.1-1.5 parts of a catalyst and the balance of a component solvent, wherein the modified amine is prepared by using a monofunctional epoxy resin containing benzene ring to modify organic amine; 100 parts of a used raw material by weight comprises the following components in parts by weight: 35-55 parts of organic amine, 10-25 parts of monofunctional epoxy resin containing benzene ring and the balance of the component solvent. According to the invention, the coating performance can reach performance standards of a protective coating for an oil cargo tank of a raw oil cargo, and the coating composition is suitable for being used as a protective coating for raw oil storage and transportation equipment and facilities.

Owner:CHINA NAT OFFSHORE OIL CORP +3

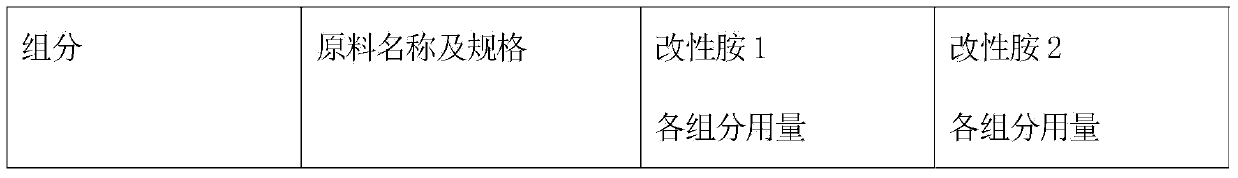

Textile printing and dyeing wastewater decolorizing flocculant and preparation method thereof

InactiveCN110902789AAdaptableHigh molecular weightWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationTextile printerDyeing wastewater

Relating to the technical field of sewage treatment, the invention provides a textile printing and dyeing wastewater decolorizing flocculant and a preparation method thereof. The preparation method ofthe decolorizing flocculant includes: sequentially adding a plurality of inorganic components into deionized water; performing stirring to form a homogeneous solution, adjusting the pH value of the system by citric acid, then adding an organic component, graft modified chitosan, modified zeolite powder and polyacrylamide, performing stirring for a period of time, then adding hydrogen peroxide dropwise, and conducting standing sealing curing. The decolorizing flocculant disclosed by the invention has good adsorption decolorizing performance on different reactive dyes, has a decolorizing rate up to 90% or above, and can be used for decolorizing treatment on textile printing and dyeing wastewater.

Owner:安徽子延科技有限公司

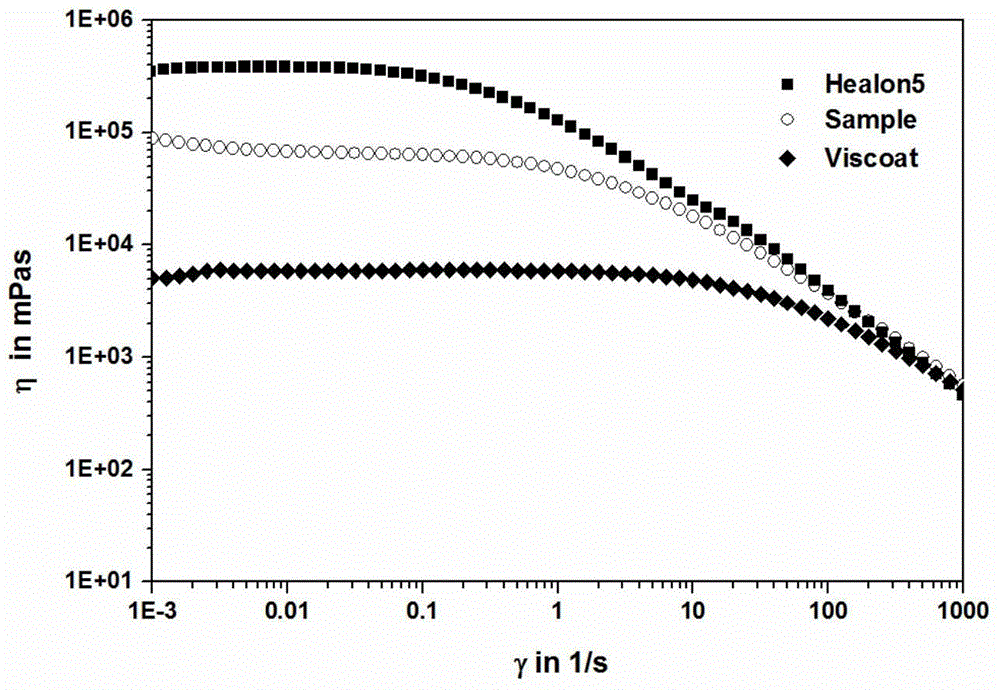

Preparation method of viscoelastic agent with cohesiveness and dispersivity

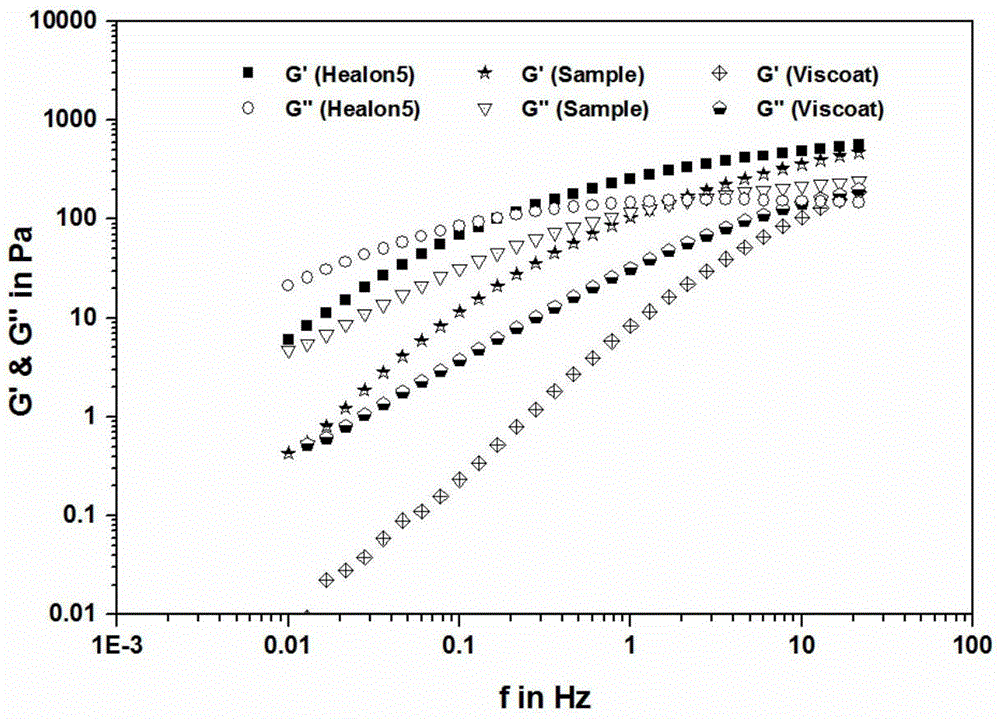

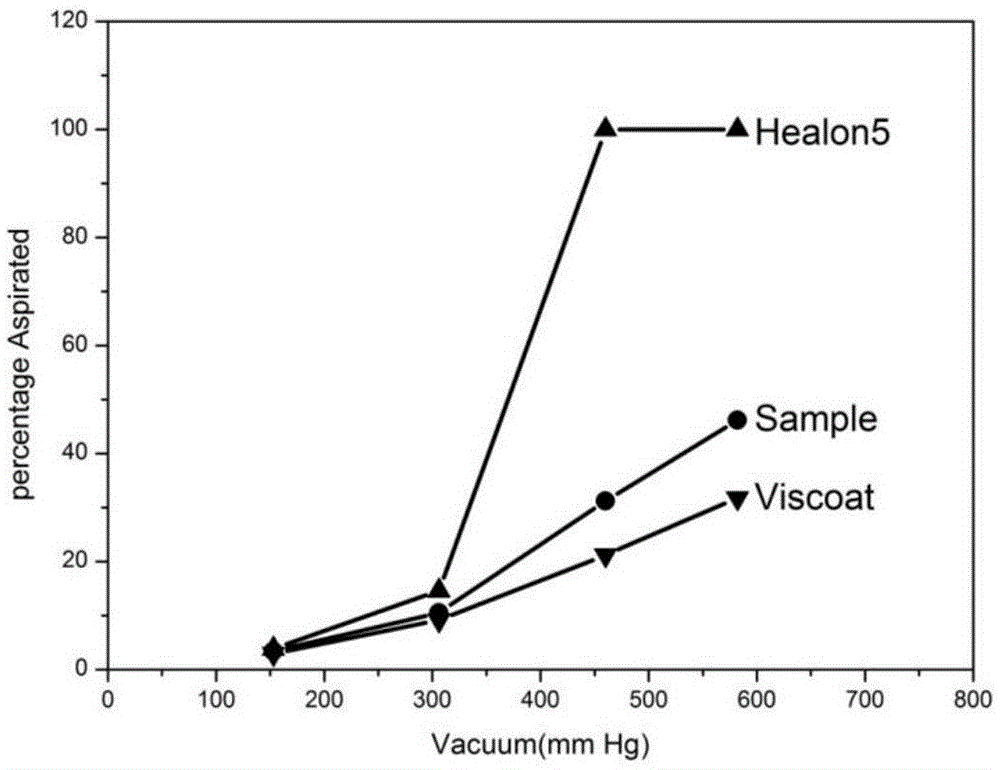

InactiveCN105903087AGood molecular weightSmall molecular weightSurgeryThermal instabilitySodium hyaluronate

Single cohesiveness or dispersivity cannot simultaneously satisfy different needs in the whole cataract surgery. Chitosan and sodium hyaluronate respectively belong to natural polycation and polyanion polysaccharides. Through charge interaction between chitosan and sodium hyaluronate, a polyelectrolyte complex is formed and the polyelectrolyte complex is processed to form the viscoelastic agent with cohesiveness and dispersivity. Medical chitosan gel has thermolability and after moist heat sterilization, the molecular weight of the chitosan gel is reduced and dispersivity is improved so that the chitosan gel can prevent corneal tissue mechanical damage. After positive and negative charge interaction, ionic crosslinked compound gel still has good cohesiveness, still has typical non-Newton rheological behavior and can be removed easily and reduce residual in eyes. Cohesiveness and dispersivity guarantees that a single product can satisfy demands in different stages in the whole cataract surgery and has a wide clinical application prospect.

Owner:SHANGHAI QISHENG BIOLOGICAL PREPARATION CO LTD

House roof indoor decoration method

The invention relates to the field of building decoration, in particular to a house roof indoor decoration method. The house roof indoor decoration method comprises the following steps that S1, wall surface treatment is carried out, specifically, dust, oil pollution and ash slag on the wall surface are cleaned, local concave and convex parts of the wall surface are filled and compacted by using gypsum, and flattening and polishing with sandpaper are carried out after drying; S2, the wall surface is coated with clean water first to moisturize the wall surface, and then an interface agent is evenly brushed on the wall surface; S3, after the interface agent on the wall surface is dried, glue is evenly sprayed and brushed on the wall surface; S4, putty is prepared; S5, the putty is batch scraped, transverse batch scraping is carried out during the first batch scraping putty, a scraping board is tightly connected to a scraping board, rafts are not left at joints, and a putty layer is polished with the sandpaper after drying the putty for the first time; the putty is batch scraped vertically when the putty is batch scraped the second time, and the putty layer is polished with the sandpaper after drying the second time; S6, primer paint is evenly brushed; S7, the first time of finishing coat is uniformed, and after an interval of 3-5 hours, the finishing coat is brushed for the secondtime. The house roof indoor decoration method has the advantage of good anti-cracking effect of the putty layer.

Owner:GUANGZHOU NO 4 DECORATION CO LTD

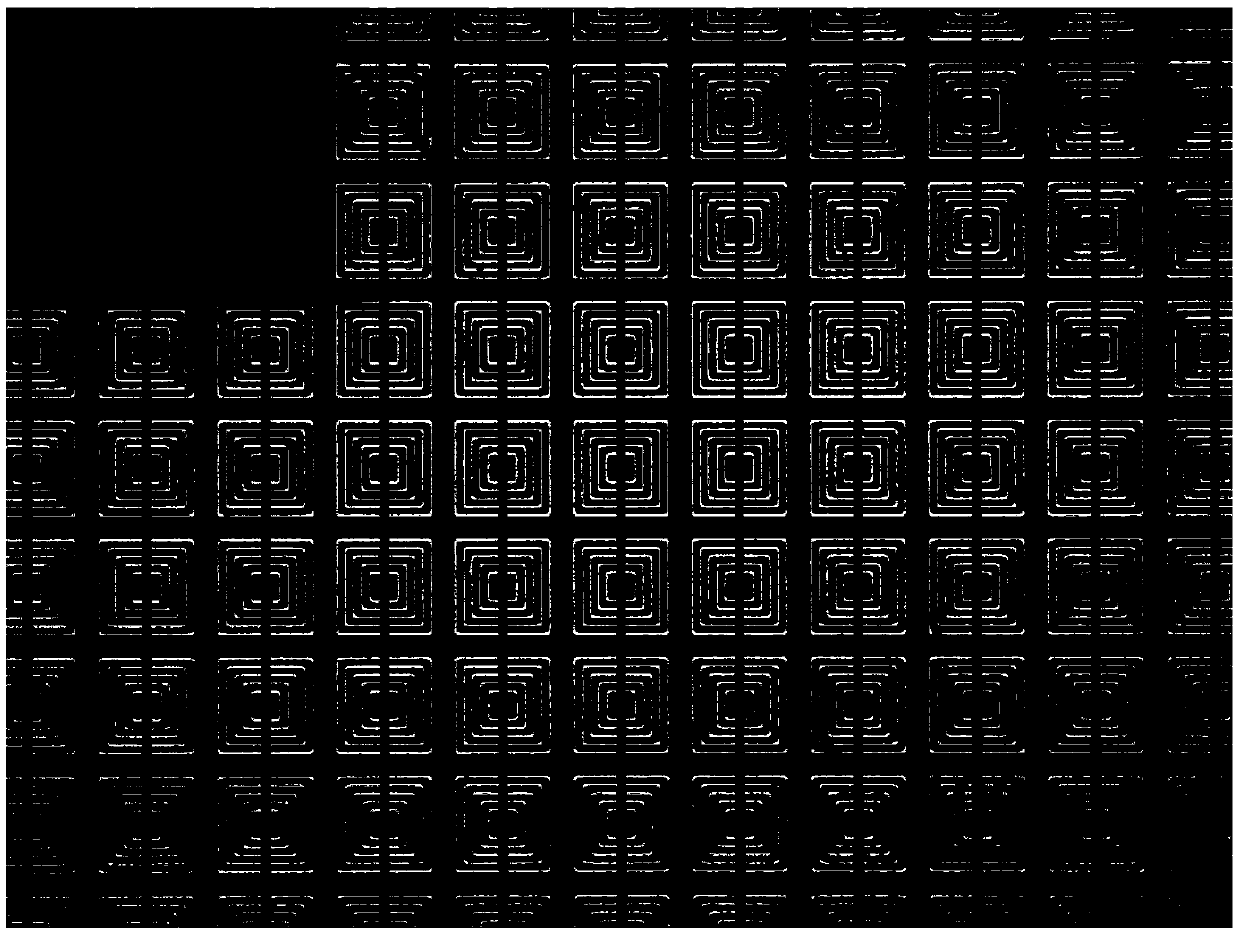

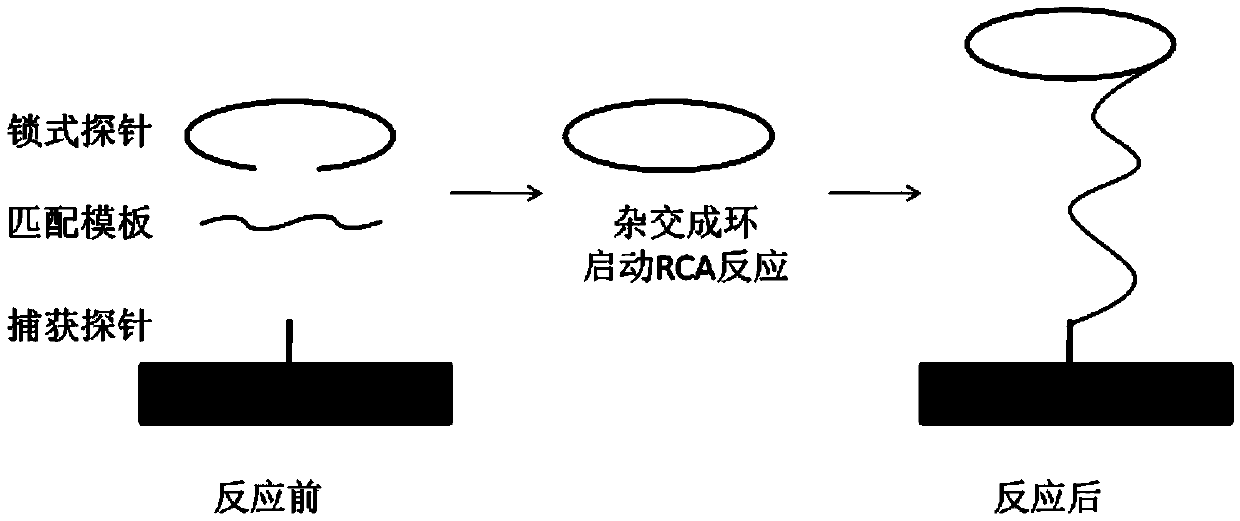

RCA (rolling circle amplification)-terahertz metamaterial biosensor for parallel detection of multiple pathogenic bacteria, and detection method of biosensor

ActiveCN105505759AIn situ replication amplificationAchieving Parallel DetectionBioreactor/fermenter combinationsBiological substance pretreatmentsTerahertz metamaterialsPolystyrene

The invention discloses an RCA (rolling circle amplification)-terahertz metamaterial biosensor for parallel detection of multiple pathogenic bacteria, and a detection method of the biosensor. The biosensor comprises a terahertz metamaterial, capturing probes used for recognizing different pathogenic bacteria and coated with reaction zones made of the terahertz metamaterial, and a polystyrene slide; the upper layer of the terahertz metamaterial is covered with the polystyrene slide and forms a liquid film cavity used for liquid phase amplified reaction; the coated capturing probes of the RCA-terahertz metamaterial biosensor are hybridized with RCA annular templates to realize in-situ replication amplification. A stable and reliable result can be obtained with the method, and the parallel detection of six clinical common pathogenic bacteria can be performed within 3 hours.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

Method for preparing modified aliphatic series water reducing agent

The invention discloses a method for preparing a modified aliphatic series water reducing agent. The method comprises the following steps: (1) adding 25-45 parts of sodium hydrogen sulfite,120-150 parts of formaldehyde and 70 parts of water into a first reaction kettle, stirring to dissolve for 0.5-1 hour, adding 30-70 parts of waste acetone and 10-25 parts of pure acetone into the reaction kettle at one time when the temperature is controlled to be less than 30 DEG C, continuously reacting for 0.5-1 hour, and further adding 1-5 parts of a stabilizing agent, thereby obtaining a first mixed liquid; (2) adding 20-35 parts of sulfite and 100 parts of water into a second reaction kettle, stirring to dissolve, adding liquid caustic soda to adjust the pH value to be 11-12, controlling the reaction temperature to be 40-55 DEG C, dripping the first mixed liquid within 2 hours at a uniform speed, and controlling the temperature to be no greater than 90 DEG C; and (3) after the first mixed liquid is dripped, adding 30-50 parts of CLT waste acid and 2-3 parts of formaldehyde into the second reaction kettle, carrying out heat preservation for 2-3 hours, and cooling to be the room temperature, thereby obtaining the modified aliphatic series water reducing agent. By adopting the method disclosed by the invention, the production cost is greatly lowered while the property of the water reducing agent is not degraded, so that the competitiveness of the product is improved.

Owner:科之杰新材料集团河南有限公司 +1

Method for preparing group A meningococcal capsular polysaccharide conjugate vaccine

InactiveCN105056228AAvoid steric hindranceMolecular chain lengthAntibacterial agentsCarrier-bound antigen/hapten ingredientsTetanus toxoidsCarrier protein

The invention relates to a method for preparing group A meningococcal capsular polysaccharide conjugate vaccine. The method includes the following steps that group A meningococcal capsular polysaccharide is diluted, activated and coupled into a group A meningococcal polysaccharide-sebacic dihydrazide derivative together with sebacic dihydrazide; then the group A meningococcal polysaccharide-sebacic dihydrazide derivative and a tetanus toxoid solution are subjected to a catalytic reaction through carbodiimide, so that group A meningococcal capsular polysaccharide and carrier protein conjugate is obtained. According to the method, the sebacic dihydrazide is used as a coupling agent in the preparation process of the group A meningococcal conjugate vaccine; compared with adipic dihydrazide, the sebacic dihydrazide has two more methylenes on carbon chains, molecular chains are longer, the steric hindrance of biomacromolecules can be better resisted, and the conjugation yield is increased.

Owner:CHENGDU OLYMVAX BIOPHARM

Method of plugging leak of medium-depth well via cross-linked polymer gel plugging agent

ActiveCN105114032AAvoid stickingEnsure anaerobicDrilling compositionSealing/packingCross-linkCeric sulfate

The invention relates to a method of plugging a leak of a medium-depth well via cross-linked polymer gel plugging agent. Raw materials include, by weight, 120 parts of refined cotton sodium salt solution, 75-85 parts of acrylamide, 13-17 parts of ammonium persulfate, 2-5 parts of ceric sulfate, 4 parts of beta-D-mannuronic acid (M), 1-1.5 parts of ammonium dihydrogen phosphate, 100 parts of composite Portland cement mortar, 150-200 parts of mixed microfiber. A water-cement ratio of the composite Portland cement mortar is 0.44. The plugging agent is obtained by adding the acrylamide, ammonium persulfate granules, ceric sulfate granules, the beta-D-mannuronic acid (M), the composite Portland cement mortar, the mixed microfiber and the ammonium dihydrogen phosphate in order into the refined cotton sodium salt solution and mixing them well; the plugging agent is delivered to a leak layer; a pressure test is run after mud replacement is performed in a drill pipe; if bottom hole pressure rises, borehole mud replacement is performed after standing and pressure holding; after standing and pressure holding for 12 hours, a leak plugging pressure-bearing test is run; if pump pressure is normal, drilling is continued. The method allows reliable leak plugging and resistance to high temperature and pressure.

Owner:中石化石油工程技术服务有限公司 +1

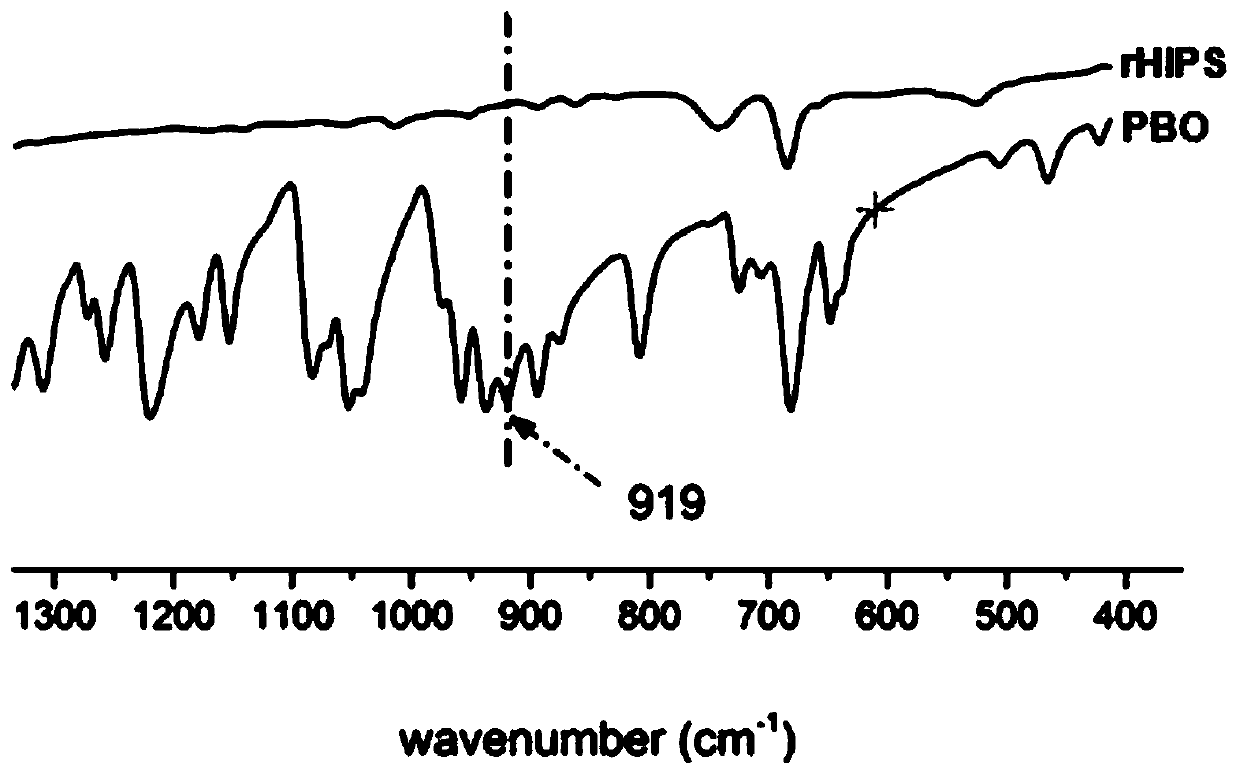

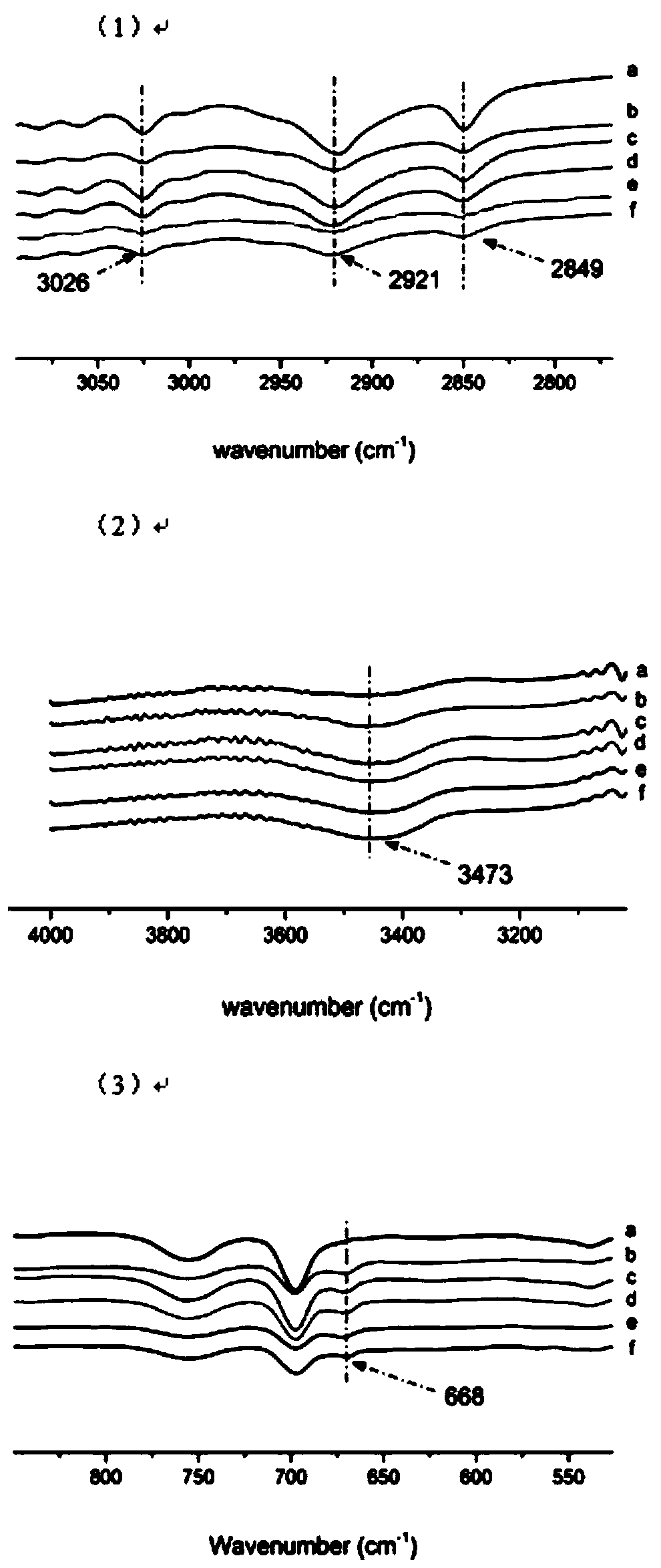

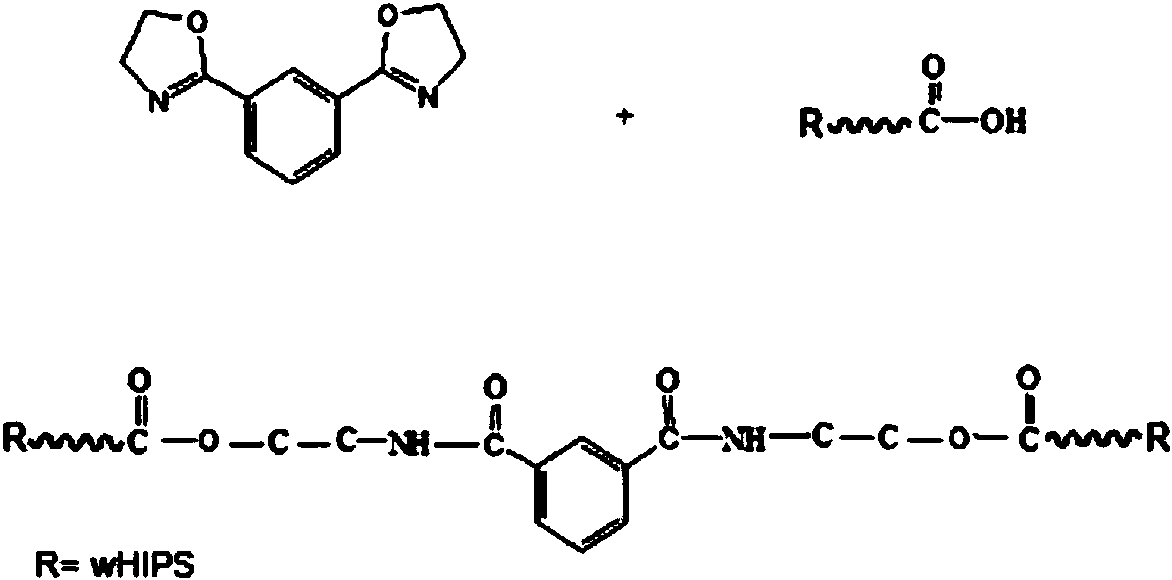

Recycling method of waste HIPS

PendingCN111187446AGeneric Full RestorationSimple processPlastic recyclingChemical reactionEnd-group

According to the invention, a novel recycling method is sought from a wHIPS degradation mechanism; and a terminal group with reaction activity, which is produced after wHIPS aging, is utilized and subjected to melting and blending with an active chain extender. The method specifically comprises the following steps: uniformly mixing the chain extender and waste HIPS in a mass ratio of (1-1.6): 100,carrying out heating until the materials are in a molten state, controlling a temperature to be 180-250 DEG C, and allowing the chain extender and carboxyl functional groups on the molecular chains of the waste HIPS to undergo an in-situ chain extension reaction in the process of continuous mixing so as to realize regeneration of the waste HIPS, wherein the chain extender is 1,3-bisdihydrooxazolylbenzene. Molecular chains broken due to aging are connected through a chemical reaction between the chain extender and aging molecules of the waste, so material performance recovery is realized, andrecycled HIPS (namely rHIPS) with excellent comprehensive performance is prepared.

Owner:广东华越环保科技有限公司 +1

Preparation method of modified organosilicone dephenolized membrane

InactiveCN104258746AInnovativeStrong application prospectDistillationSeparation factorPolymer science

The invention belongs to the technical field of pervaporation membrane separation and in particular relates to a preparation method of a modified organosilicone dephenolized membrane. The preparation method of the modified organosilicone dephenolized membrane comprises the following steps: firstly, mechanically stirring room temperature vulcanization liquid silicone rubber with a solvent until the room temperature vulcanization liquid silicone rubber is dissolved and a transparent solution is formed; then, adding a crosslinking agent and a catalyst, and mechanically stirring for 5-20 minutes, wherein the mass ratio of the room temperature vulcanization liquid silicone rubber to the solvent to the crosslinking agent to the catalyst is 33:60:5:2; then adding oleic alcohol the mass of which is 1%-5% of that of the room temperature vulcanization liquid silicone rubber, mechanically stirring for 2-10 minutes, and uniformly mixing; and finally, casting the obtained solution on a supporting basement membrane to form a membrane, standing at room temperature for 4-5 hours, and then drying the membrane in a vacuum drying oven at the temperature of 60-80 DEG C for 8-12 hours. A preparation process of the modified membrane is simple and easy, and the obtained membrane has good comprehensive performance of separating phenol from water when being used for separating a phenol / water mixture; permeation flux of the membrane can be 526g.m<-2>.h<-1>, and a separation factor of the membrane can be 8.63; great potential in industrialized application is shown.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Two-component polyurethane resin adhesive for flexible packaging film of polymer lithium ion battery and preparation method thereof

InactiveCN109181621AHigh heat sealing strengthImprove liquidityPolyureas/polyurethane adhesivesUreaChemistry

The invention discloses a two-component polyurethane resin adhesive for a flexible packaging film of a polymer lithium ion battery and a preparation method thereof. The technical scheme essentially includes that the two-component polyurethane resin adhesive includes an adhesive A and an adhesive B with the weight ratio of (3-5):1. The adhesive A includes the following components in parts by weight: 16-24 parts of castor oil, 55-75 parts of ethylene glycol, 12-18 parts of polyester polyol, 14-18 parts of carbamyl urea, 8-12 parts of 2,2-dimethylolpropionic acid, 1-2 parts of a chain extender, 1-2 parts of a flame retardant, and 1-2 parts of a thixotropic agent; the adhesive B includes the following components in parts by weight: 24-32 parts of diphenylmethane diisocyanate, and 3-6 parts ofan activator. The castor oil and polyester polyol with high viscosity and good fluidity can guide ethylene glycol to undergo a condensation reaction and be combined with the chain extender to form OH-terminated polyester polyol with longer molecular chain and larger molecular weight, so that heat resistance and strength are significantly improved; the flame retardant can play a role in enhancing the flame retardancy of the OH-terminated polyester polyol; the thixotropic agent can play a role in enhancing the consistency of the OH-terminated polyester polyol.

Owner:浙江奔富新能源股份有限公司

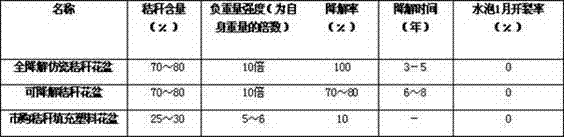

Fully degradable ceramic-imitated straw flowerpot and manufacture method thereof

The invention discloses a fully degradable ceramic-imitated straw flowerpot and a manufacture method of the flowerpot. The manufacture method comprises the following steps: using crushed straw powder as materials, adding a gelatin adhesive, wherein the weight ratio of the straw powder to the gelatin adhesive is 1 to 0.5-0.8; mixing the materials, and then thermo-forming to obtain the fully degradable ceramic-imitated straw flowerpot. The industrial gelatin adopted in the invention is modified in a cross-linking manner by silane coupling agent Kh-550, zinc chloride and a borax composite modifier; the advantages of the silane coupling agent Kh-550, zinc chloride and the borax composite modifier are used for achieving a good effect. Hydroxide radical in the gelatin protein is closed to reduce the water solubility of the gelatin; a peptide chain of the gelatin protein is lengthened to generate part coordination compound, so that the flexibility of the gelatin is reinforced, and the degradation characteristic of the glue solution is kept. The fully degradable ceramic-imitated straw flowerpot product is applied to domestic urban landscaping, landscape modeling and beautifying, ecological tourism, holiday villages, families, units, public places, catering industry, wine shops, hotels, conference rooms, offices, schools, clubs, hospitals, villages, and the like.

Owner:漳浦中龙红麻籽贸易有限公司

Absorptivity hemostatic micropowder of hydroxyethyl modified cotton fiber and preparation method thereof

InactiveCN101716365AIncrease the speed of wound hemostasisFast hemostasisAbsorbent padsBandagesFiberSide effect

The invention provides an absorptivity hemostatic micropowder of hydroxyethyl modified cotton fiber and a preparation method thereof, mainly solving the problem that the present hemostatic materials can not effectively stanch the wound caused by minimally invasive surgery. The particle size of the absorptivity hemostatic micropowder of hydroxyethyl modified cotton fiber is between 50mu m and 100mu m. The preparation method of the absorptivity hemostatic micropowder of hydroxyethyl modified cotton fiber comprises the main steps of alkalization treatment of cotton fiber, modification treatment of cotton fiber, supermicro grinding, crosslink sterilization and the like. The hemostatic micropowder made from hydroxyethyl modified cotton fiber can be directly applied to the wound of minimally invasive surgery in human body, and can be directly absorbed by human body without toxic or side effect, thus improving wound stanching speed and avoiding the problem of easy agglomeration in the process of micropowder storage.

Owner:郑明义

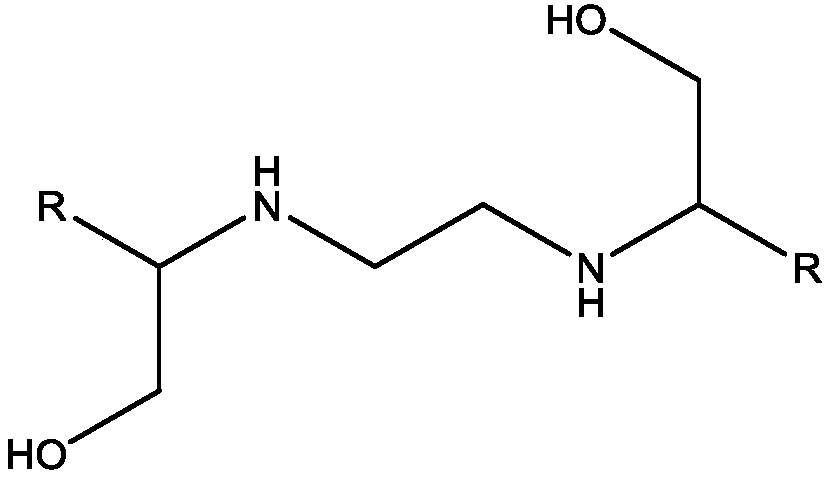

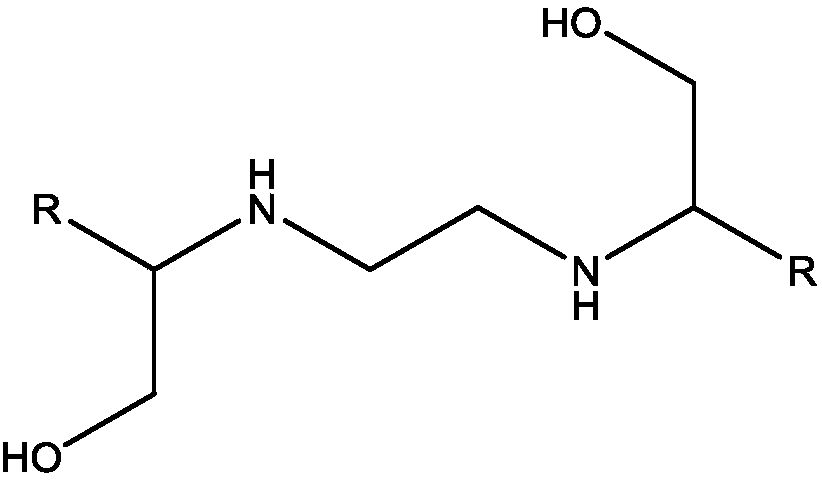

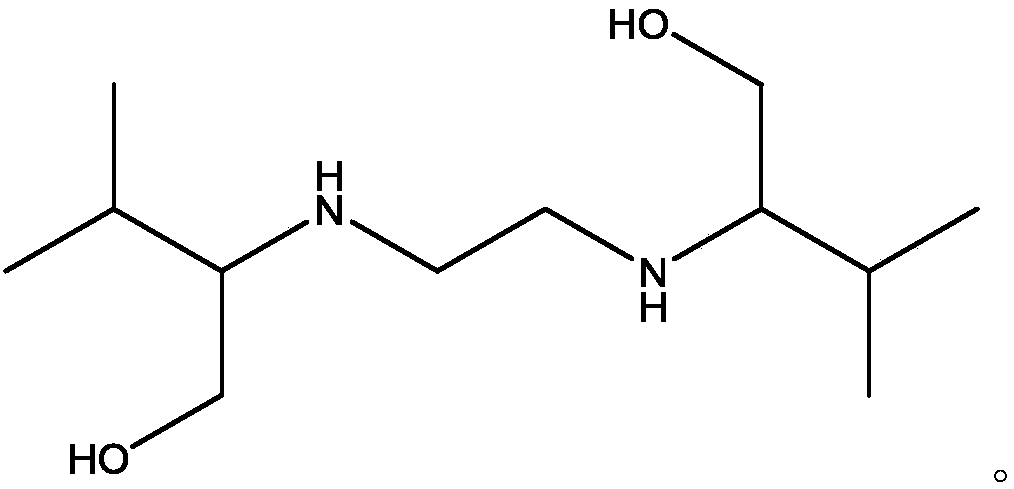

Waterborne polyurethane dispersion, preparation method thereof and sunscreen cosmetic composition

ActiveCN110613633AImprove adhesionMolecular chain lengthCosmetic preparationsToilet preparationsPolyurethane dispersionMoisture

The invention discloses a waterborne polyurethane dispersion, a preparation method thereof and a sunscreen cosmetic composition. According to the waterborne polyurethane dispersion, a diamine chain extender containing two hydroxyl groups is used for preparing the sunscreen cosmetic composition, so that the waterborne polyurethane dispersion resin has relatively good waterproof performance, good adhesive force on the surface of human skin and a moisture-permeable effect; the sunscreen index (SPF value) can be increased; and the skin feeling can be improved.

Owner:WANHUA CHEM GRP CO LTD +2

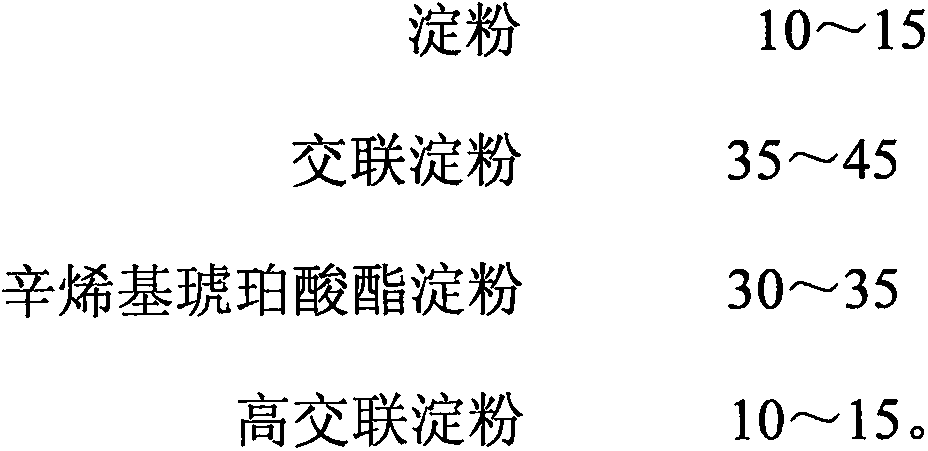

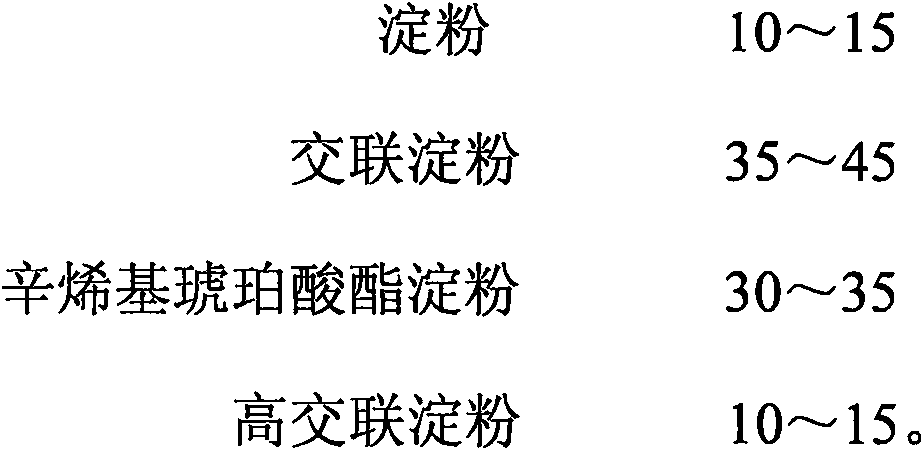

Method for preparing alum-free vermicelli based on modified starch

The invention discloses a method for preparing alum-free vermicelli based on modified starch. The method comprises the following steps of: (1) preparing starch milk by taking starch as the raw material, and then, preparing cross-linked starch by taking phosphorus oxychloride as a cross-linking agent; (2) preparing starch milk by taking starch as the raw material, and then, preparing octenyl succinic acid modified starch by taking octenyl succinic anhydride as an esterifying agent; (3) preparing starch milk by taking starch as the raw material, and then, preparing high cross-linked starch by taking phosphorus oxychloride as a cross-linking agent; and (4) adding starch with a certain mass into water to prepare starch milk, rapidly pouring boiling water into the starch milk to prepare starchy sauce paste, adding the cross-linked starch, the octenyl succinic acid modified starch and the high cross-linked starch in a certain proportion, mixing and uniformly stirring the cross-linked starch, the octenyl succinic acid modified starch and the high cross-linked starch, placing the mixture into a vermicelli machine for extrusion forming, cooking the vermicelli for several seconds, then, rapidly placing the cooked vermicelli into cold water to cool and retrograde for several minutes, and drying to obtain a finished product of the vermicelli. Compared with the traditional vermicelli preparation method, the method has the advantages that no alum is used, the property of the vermicelli is improved, and the prepared vermicelli has favorable boiling fastness, favorable toughness and favorable retrogradation resistance.

Owner:甘肃圣大方舟马铃薯变性淀粉有限公司

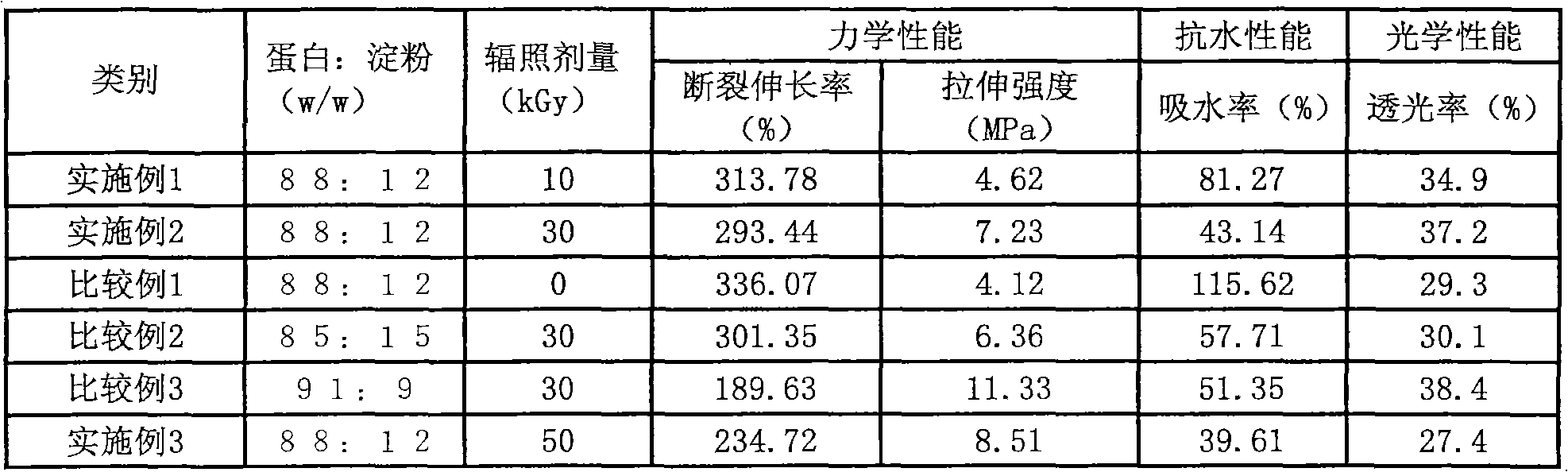

Radiation modified soybean isolated protein/starch plastic and preparation method thereof

The invention claims a radiation modified soybean isolated protein / starch biodegradable plastic and a preparation method thereof, wherein the radiation modified soybean isolated protein / starch plastic is prepared by taking soybean isolated protein and starch as main materials and modifying the materials by ray radiation; when the biodegradable plastic is prepared, each material is mixed according to the following parts by weight: 85-95 parts of modified soybean isolated protein, 5-15 parts of modified starch, 1-3 parts of caprolactam, 10-20 parts of water and 10-25 parts of glycerol. The invention has the following advantages: the soybean isolated protein is modified by proper methanol or ethanol, so hydrophilic group in the protein is reduced and water resistance of the plastic is improved. Proper starch is taken as the filler, so that flexibility of the plastic is enhanced and cost is reduced to be suitable for industrial production. Meanwhile, by regulating content of the starch and irradiation dose, materials with different mechanical properties can be obtained, thereby obtaining high technology content and innovation. The preparation technology adopts a common plastic device and a method thereof, so the process is simple, and easy to operate. Furthermore, the radiation modified soybean isolated protein / starch plastic is formed by the modified soybean isolated protein and a plasticiser by hot pressing, so that the radiation modified soybean isolated protein / starch plastic, after being discarded, is very easy to decompose into carbon dioxide and water by microbe without environmental pollution. The soybean protein is an inexhaustible renewable resource.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com