Raw oil-resistant coating composition

A composition and coating technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of oily sewage corrosion resistance, high temperature resistance, long protection life, etc., to increase crosslinking density and improve flexibility sex, with a reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 prepares A component A1 and A2

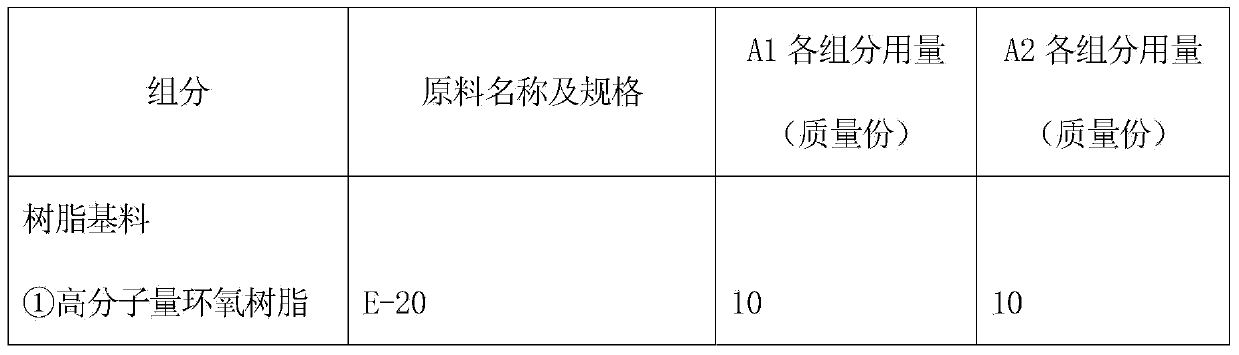

[0023] ① Formula

[0024] In the crude oil resistant coating composition of the present invention, in 100 parts by mass of component A, there are 25-33 parts of resin base material, 50-60 parts of pigment and filler, 1-3 parts of auxiliary agent, and the balance is organic solvent, wherein, The resin base material is a mixture of a high molecular weight epoxy resin and one or more low molecular weight epoxy resins, wherein the mass ratio of the high molecular weight epoxy resin to the low molecular weight epoxy resin is 1:1~3, specifically The formula is shown in Table 1.

[0025] Table 1

[0026]

[0027]

[0028] ②Preparation process

[0029] In the dispersion tank, add resin base material, organic solvent, and dispersant according to the formula in Table 1, stir evenly, add thixotropic agent, stir at high speed for 15 minutes, then add pigment titanium dioxide, filler talc powder, and feldspar powder respectively...

Embodiment 2

[0030] Embodiment 2 prepares modified amine 1 and modified amine 2

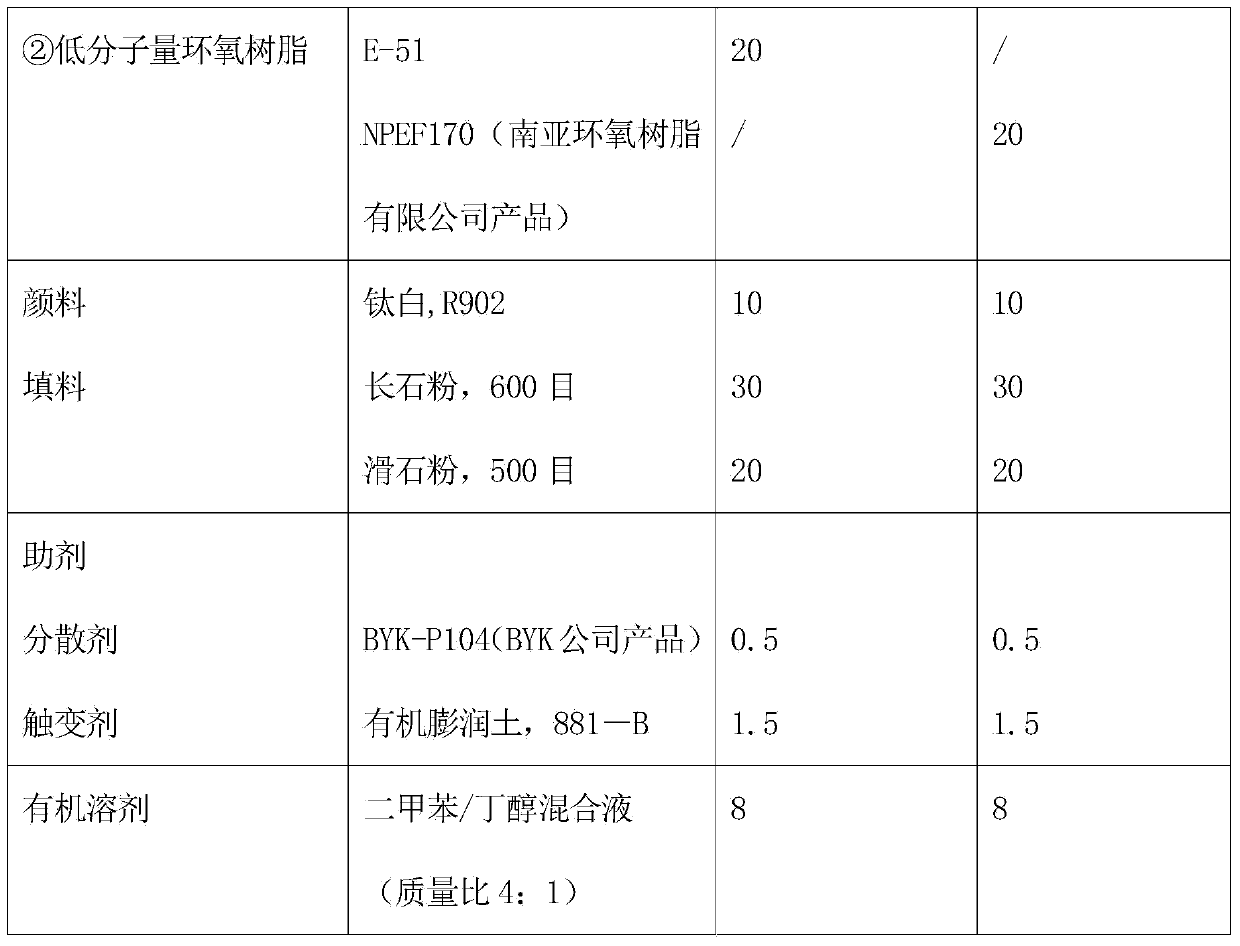

[0031] ① Formula

[0032] The modified amine of the present invention is obtained by modifying an organic amine with a monofunctional epoxy resin containing a benzene ring. When modifying, in 100 parts by mass of raw materials used, 35 to 55 parts of the organic amine contain a benzene ring 10-25 parts of monofunctional epoxy resin, and the balance is a mixed solvent. The specific formula is shown in Table 2.

[0033] Table 2

[0034]

[0035]

[0036] ②Preparation process

[0037] In the reaction kettle equipped with a water separator, add organic amine and mixed solvent according to the formula in Table 2, stir evenly, heat up to 40°C, add dropwise a monofunctional epoxy resin solution containing a benzene ring, add dropwise After completion, raise the temperature to 80°C and keep it warm for 1 hour, fill the water separator with mixed solvent, raise the temperature to 110°C-120°C for reflux dehydr...

Embodiment 3

[0038] Embodiment 3 prepares B component B1 and B2

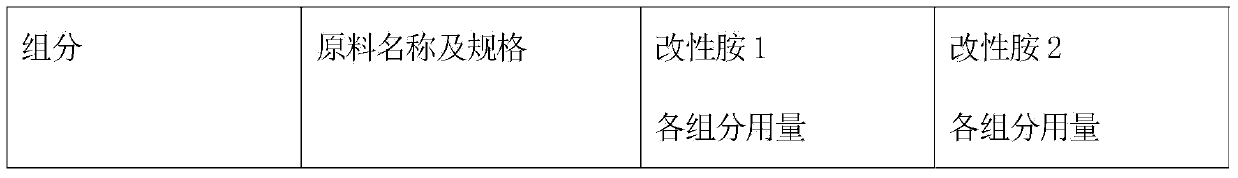

[0039] ① Formula

[0040]In the crude oil resistant coating composition of the present invention, in 100 parts by mass of component B, there are 35 to 45 parts of polyamide, 40 to 55 parts of modified amine, 0.1 to 1.5 parts of coupling agent, 0.1 to 1.5 parts of catalyst, and the balance It is a mixed solvent, and the specific formula is shown in Table 3.

[0041] table 3

[0042]

[0043]

[0044] ②Preparation process

[0045] According to the formula in Table 3, add polyamide into the reaction bottle, then add modified amine, coupling agent, catalyst and mixed solvent, stir evenly, filter and pack, obtain B components B1 and B2 respectively, pack and store for future use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com