Patents

Literature

330results about How to "Moderate proportion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apple stem cell culture method and apple stem cells cultured by method

InactiveCN104711215AShort cycleHigh yieldDead plant preservationPlant cellsFreeze-dryingStem cell culture

The invention relates to the technical field of plant stem cell culture, particularly an apple stem cell culture method and apple stem cells cultured by the method. The method comprises the following steps: by using an apple new branch as a raw material, inducing to form callus, and carrying out enrichment culture and amplification culture to obtain the apple stem cells. The method provided by the invention has the advantages of shorter period and high yield. The method can obtain abundant apple stem cells within about 48 days. The induction culture medium used in the apple stem cell culture process and the variety of the phytohormones contained in the enrichment culture medium are proper and suitable in proportion, and can ensure fast dedifferentiation and abundant reproduction of apple branch cells. The apple stem cells can be freeze-dried or extracted and used for preparing food, drugs, health products or cosmetics. The apple stem cell extraction method provided by the invention is simple and easy to implement and has higher extraction efficiency. The prepared extract contains abundant flavones and polyphenols.

Owner:GUANGZHOU SALIAI STEMCELL SCI & TECH CO LTD

Glass fiber air filter paper with high dust holding capacity and production process thereof

ActiveCN103541279AGood mechanical strengthStable chemical propertiesWater-repelling agents additionSynthetic cellulose/non-cellulose material pulp/paperCorrosionAdhesive

The invention discloses glass fiber air filter paper with high dust holding capacity, which is prepared from alkali-free glass fiber chopped strands and alkali-free glass fiber cotton in the diameter of 0.3-0.4 mu m, as well as an adhesive, wherein the glass fiber air filter paper comprises 3-8 parts by weight of the alkali-free glass fiber chopped strands and 92-97 parts by weight of the alkali-free glass fiber cotton, and the adhesive is a water repellent containing fluorocarbon. The invention further discloses a production process of the glass fiber air filter paper with the high dust holding capacity, and the production process comprises the following steps: firstly beating and dispersing raw material to obtain pulp, then performing wet process forming on the pulp to obtain wet paper, removing water in the wet paper, then performing two-sided sizing on the dehydrated wet paper, and finally drying to obtain a product, wherein the beating degree during beating is 52-56 degrees SR, suction dehydration is performed in three stages, and drying treatment is performed in four stages. The glass fiber air filter paper disclosed by the invention has the advantages of smooth and uniform surface, large specific surface area and dust holding capacity, high mechanical strength and resistance to acid and alkali corrosion.

Owner:CHONGQING ZAISHENG TECH CORP

Feed stuff for common carp

InactiveCN101077132AMeet actual needsModerate proportionFood processingClimate change adaptationCommon carpFodder

The present invention discloses one kind of carp feed, which consists of soybean dregs 35-50 wt%, cotton seed dregs 15-25 wt%, DDGS 3-8 wt%, fish meal 3-8 wt%, starch 6.2-16.1 wt%, corn dregs 8-12 wt%, calcium dihydrogen phosphate 1.5-1.7 wt%, salt 0.2-0.4 wt%, Chinese medicinal stone 1.5-2.5 wt%, soybean oil 0.5-1.5 wt%, and premixed fish feed material 0.8-1.2 wt%. It has comprehensive balanced nutrients, and can promote the growth of carp and raise its disease resistance.

Owner:侯彦卫

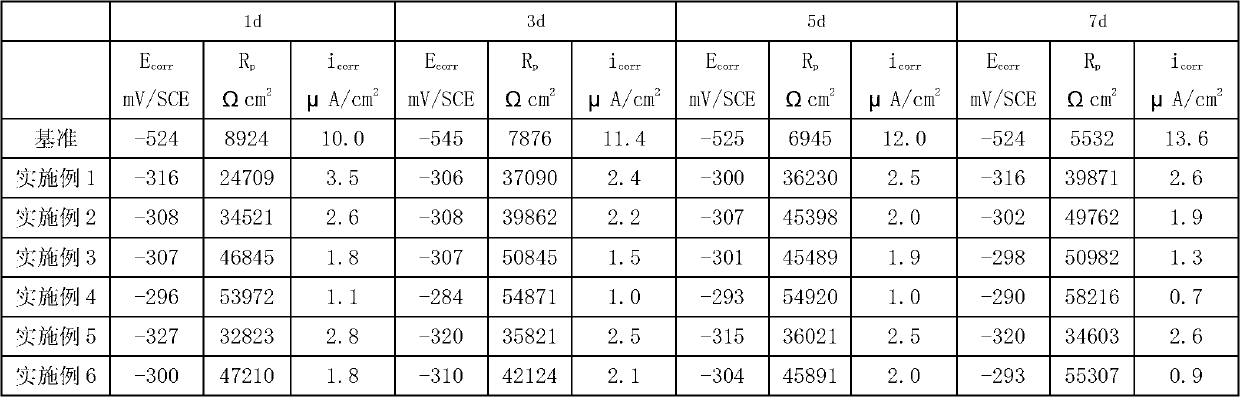

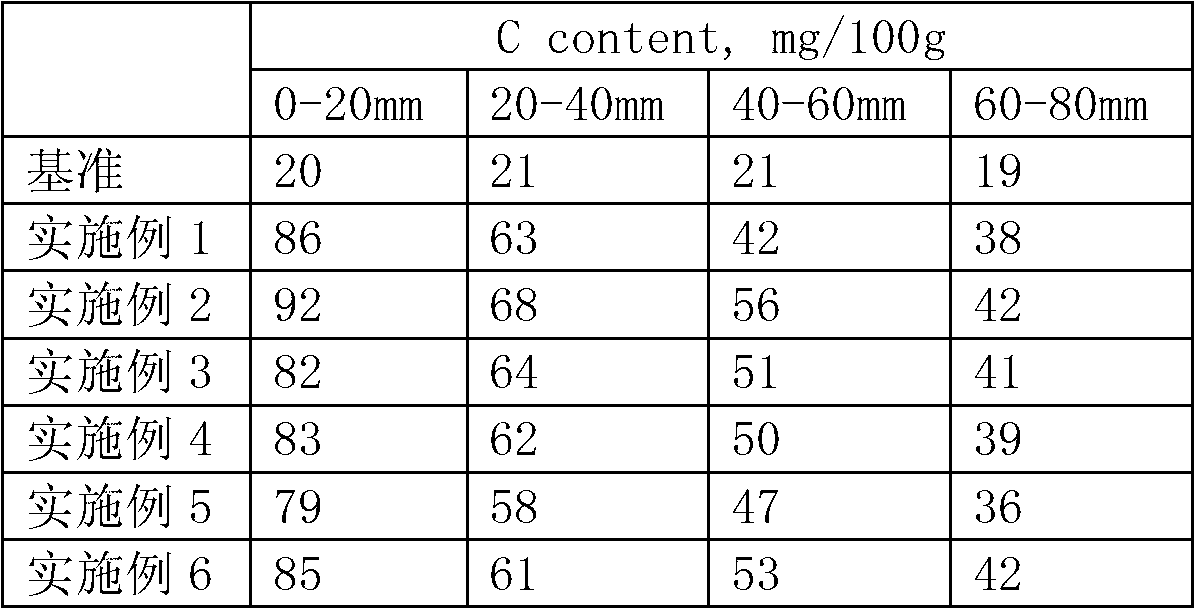

Surface coating type reinforced concrete corrosion inhibitor and preparation method thereof

ActiveCN102757197AModerate proportionPrevent and inhibit corrosionWater insolubleSurface-active agents

The invention relates to a surface coating type reinforced concrete corrosion inhibitor. The surface coating type reinforced concrete corrosion inhibitor comprises the components as follows: 15 to 40 wt% of a non-ionic surface active agent with HLB (Hydrophile Lipophile Balance) value more than 10, 5 to 30 wt% of a cosurfactant, 1 to 20 wt% of water insoluble organic inhibitor, and 20 to 50 wt% of water, wherein the cosurfactant is selected from organic alcohol or organic amine. The preparation method comprises the steps of mixing the non-ionic surface active agent, the cosurfactant and the water insoluble organic inhibitor, and agitating along with heating unit the mixture is completely molten, and then agitating along with water adding until the mixed liquid is turned into a clear state from a muddy state, thus obtaining the product. The preparation method provided by the invention is simple; the prepared product can be applied to surface treatment of the constructed concrete structure; and the prepared product has superior infiltration capacity, can effectively prevent the reinforcement surface from being eroded by chloride salt and sulfate, and has no adverse effect to the performance of the concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

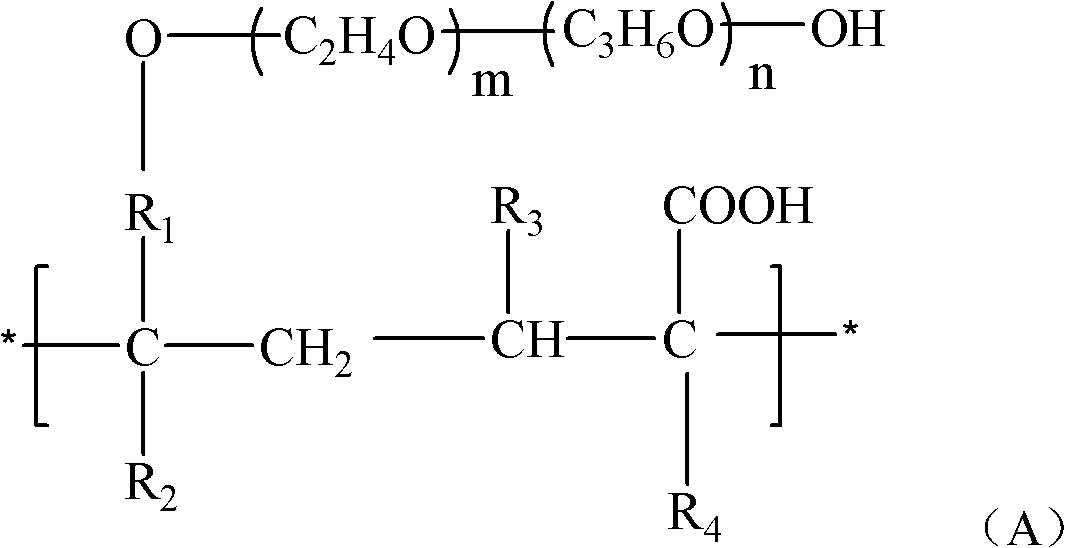

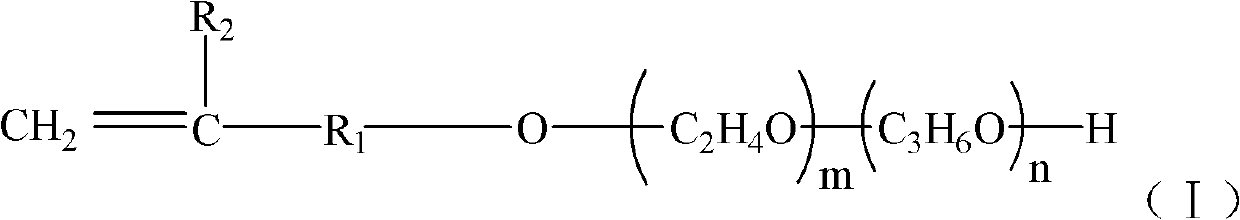

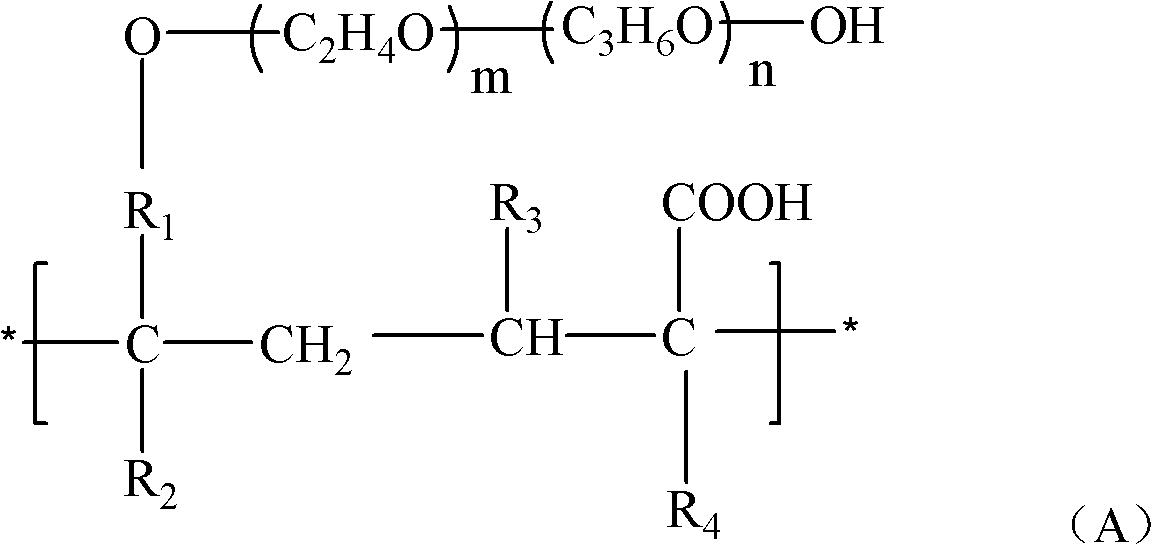

Concrete polycarboxylate water reducer and preparation method thereof

The invention provides a concrete polycarboxylate water reducer, which is shown in the formula (A), wherein R1 is alkyl having 1 to 10 carbon atoms, R2 is alkyl having 1 to 10 hydrogen or carbon atoms, R3 is H or COOH, and R4 is H or CH3. The water reducer has stable performance and high water-reducing rate and slump retention. The invention also provides a preparation method of the water reducer, which has the advantages of simple process, convenience for operation, environmental friendliness, low energy consumption and the like.

Owner:LIAONING OXIRANCHEM INC +3

Eel feed

InactiveCN101874564AModerate proportionDelicious meatAnimal feeding stuffCod liver oilAnimal science

The invention relates to an eel feed. The eel feed consists of the following components in percentage by weight: 30 to 55 percent of mussel powder, 8 to 15 percent of corn protein powder, 2 to 4 percent of milk powder, 7 to 10 percent of chicken blood powder, 1 to 4 percent of duck blood powder, 4 to 7 percent of sorghum protein powder, 10 to 20 percent of cabbage worm powder, 1 to 2 percent of mineral additive, 2 to 5 percent of vinasse, 3 to 7 percent of cod liver oil and 1 to 2 percent of vitamin blending agent. The method for preparing the eel feed comprises the following steps of: pouring the components into a blender in a certain ratio to mix and stir uniformly; adding quantitative grease and water into the mixture; stirring the mixture into a sticky dough shape; and feeding the eel after sieving the mixture by using a 60-mesh sieve.

Owner:孙秀美

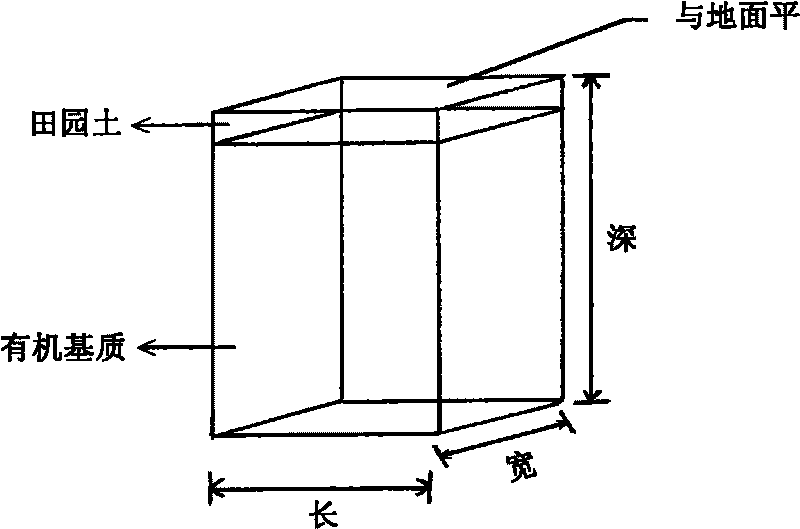

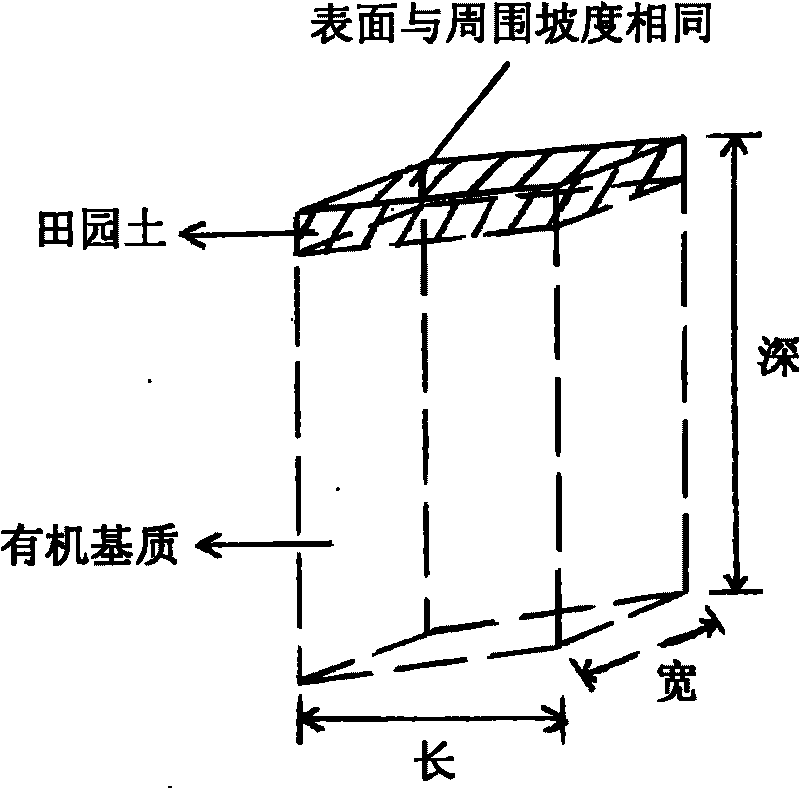

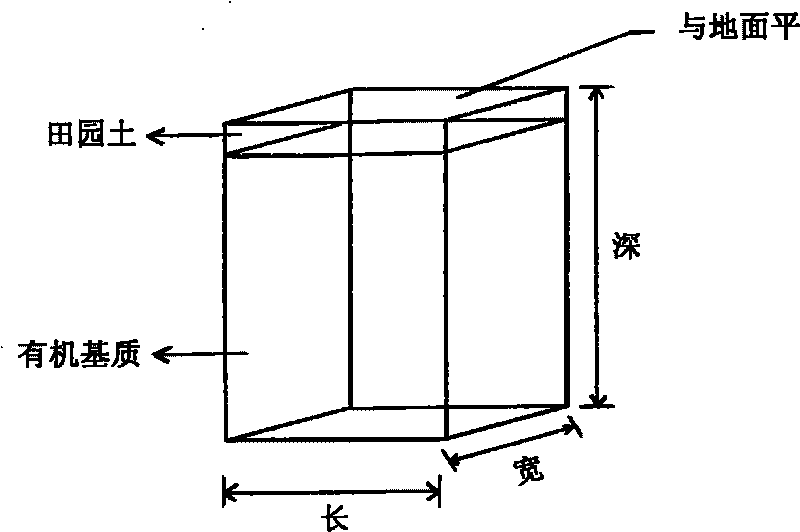

Fertilizer applying method for improving tea garden soil aqueous vapor fertilizer environment

ActiveCN101715681AIncreasing the thicknessImprove water, gas and fertilizer environmentBio-organic fraction processingFertilising methodsEarth surfaceOrganic matter

The invention relates to a tea garden fertilizer applying method and aims to provide a fertilizer applying method for improving the tea garden soil aqueous vapor fertilizer environment. The method comprises the following steps of: (1) digging substrate grooves with the lengths of 30-60cm, the widths of 20-40cm and the depths of 50-80cm in the positions among tea tree lines or plants every 150-200cm and uniformly distributing the substrate grooves between the line and the line alternately; and (2) filling fermented organic substrates into the substrate grooves and then covering garden soil with the thickness of 5-8cm so that the surface of the garden soil is leveled with the ambient earth surface. The invention is beneficial to deepening an effective soil layer and improving the soil fertility and the soil structure; the substrate grooves are earthworm sources and are beneficial to improving the soil fertility and the soil ventilation; organic matters are more intensively applied to one side of a tea tree relatively, and the proportion of an absorbing root system and a transportation root system is proper, thereby being beneficial to improving the yield and the quality of tea; and the invention can improve the water content of the slope tea garden deep soil and the water retaining capacity of the soil and promote the downward growth of the root system.

Owner:ZHEJIANG UNIV

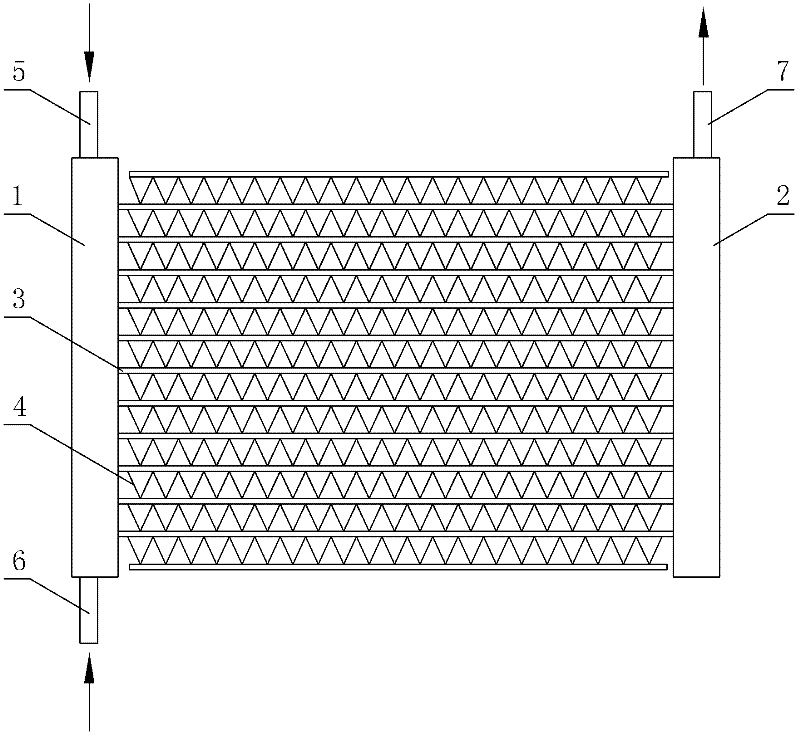

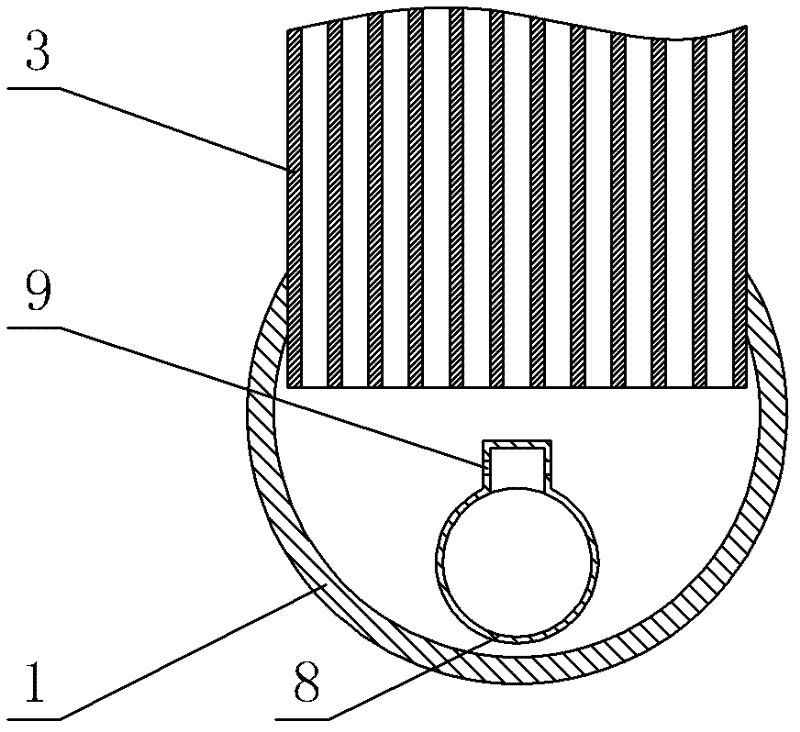

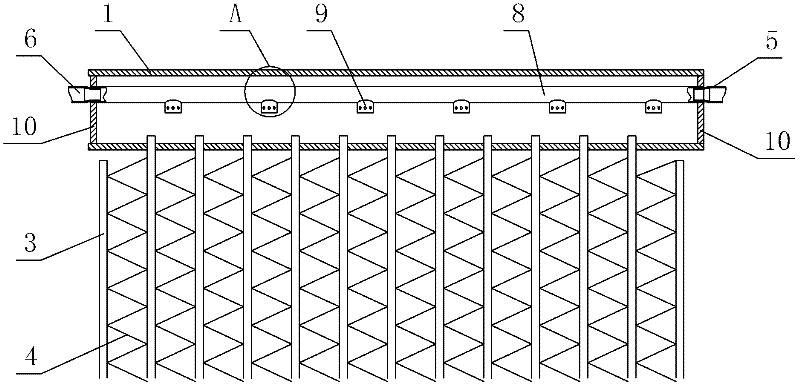

Microchannel parallel-flow heat exchanger

InactiveCN102313400AEvenly distributedReasonable allocationEvaporators/condensersHeat exchanger casingsRefrigerant distributionPlate heat exchanger

The invention discloses a microchannel parallel-flow heat exchanger, which comprises an inlet flow collecting tube, an outlet flow collecting tube and a refrigerant inlet tube, wherein the refrigerant inlet tube is arranged in the inlet flow collecting tube; the end parts of the inlet flow collecting tube and the outlet flow collecting tube are both provided with end covers; more than two porous flat tubes are arranged between the inlet flow collecting tube and the outlet flow collecting tube; two ends of each porous flat tube are respectively inserted into the inlet flow collecting tube and the outlet flow collecting tube; at least one end of the refrigerant inlet tube extends out of the inlet flow collecting tube through refrigerant input tubes; the periphery of the refrigerant inlet tube is provided with more than two connecting tubes; and the connecting tubes are communicated with an inner cavity of the refrigerant inlet tube and an inner cavity of the inlet flow collecting tube. A strip flute-shaped tubular refrigerant distributor is formed in the microchannel parallel-flow heat exchanger provided by the invention; a refrigerant enters the refrigerant inlet tube from the refrigerant input tubes at two ends of the inlet flow collecting tube; and the refrigerant is uniformly distributed in the inlet tube. The refrigerant enters the inlet flow collecting tube through flow distributing hole groups on the connecting tubes on the inlet tube. The microchannel parallel-flow heat exchanger has high integral heat exchange efficiency, and the refrigerant can be uniformly distributed in a plurality of porous flat tubes.

Owner:GUANGDONG MIDEA ELECTRIC APPLIANCES CO LTD

Preparation method of broiler chicken feed

InactiveCN101569363ARich in proteinRich in multivitaminsFood processingAnimal feeding stuffBroiler chickFodder

The invention relates to a preparation method of broiler chicken feed which comprises the following components according to the weight percent: 50-65 of corn, 3-6 of wheat bran, 20-30 of bean pulp, 0.5-1.5 of stone powder, 2-5 of fish meal, 5-8 of rice bran, 0.1-0.5 of salt, 0.6-1 of premix additive and 0.8-1 of calcium hydrophosphate. The preparation method comprises the following steps: taking the corn, the wheat bran, the bean pulp, the stone powder, the fish meal, the rice bran, the salt, the premix additive and the calcium hydrophosphate according to a certain proportion; pouring into a feed mixing machine to mix for 30min; placing into a grinder to be ground into grains after taking out; and then pouring into a multifunctional chicken feed cycle pattern granulation machine to be heated and produced into hard granular feed, sieving by a 80 mesh sieve, and packaging and sealing.

Owner:王广清

Mandarin fish feed

The invention discloses mandarin fish feed. The mandarin fish feed consists of the following substances in percentage by weight: 15 to 35 percent of shrimp powder, 10 to 25 percent of red worm powder, 18 to 38 percent of bran, 7 to 15 percent of rape seed cake powder, 5 to 10 percent of broomcorn powder, 2 to 4 percent of cod-liver oil, 5 to 8 percent of bone powder, 0.5 to 1 percent of salt, 0.5 to 1 percent of multiple vitamins and 1 percent of premix additive. The mandarin fish feed is prepared by the following steps of: pouring the substances into a fish feed stirrer in a ratio and stirring the substances for 60 minutes, then pouring the mixture into a loop-mode granulator, heating the mixture to produce hard granular feed, and screening the hard granular feed with an 80-mesh sieve, wherein the weight of each granule of feed is 0.2 gram.

Owner:李光华

Preparation method of loach fodder

InactiveCN101579049AModerate proportionEasy feedingFood processingClimate change adaptationInorganic saltsAnimal science

The invention relates to a preparation method of loach fodder. The loach fodder comprises the following materials by weight percentage: 10 to 20 of fish meal, 20 to 35 of bean cake powder, 15 to 18 of wheat flour, 8 to 15 of vegetable cake powder, 5 to 8 of rice bran powder, 5 to 8 of shrimp meal, 2 to 4 of chicken intestine powder, 1 to 1.4 of fish auxin, 5 to 8 of blood meal, 4 to 7 of silkworm pupa meal and 0.1 to 0.5 of inorganic salt. The preparation method of the loach fodder comprises the following steps: pouring the materials into a container to uniformly stir; using a circular mould type soft granulator to produce soft granulated fodder; and using a screen of 40 meshes to screen the fodder so that each granule has the weight of 0.1g.

Owner:孙秀美

Special double-layer carbon-free tundish covering agent for silicon steel and use method thereof

ActiveCN102000794AStrong adsorption and inclusion capacityComplete Coverage GuaranteedChemical compositionGranularity

The invention discloses a special double-layer carbon-free tundish covering agent for silicon steel and a use method thereof. The production process of the special double-layer carbon-free tundish covering agent for the silicon steel is simpler and more convenient, and a production process of an the upper layer of covering agent comprises the following steps of: crushing a mixture prepared from all component with qualified chemical components; grinding the mixture to fine granules with the granularity of 0-0.21 mm; uniformly stirring and drying until the water content is less than 0.5 percent; and packaging. A production process of a lower layer of covering agent comprises the following steps of: crushing a mixture prepared from all component with qualified chemical components; grinding the mixture to fine granules with the granularity of 0-0.15mm; uniformly stirring and drying until the water content is less than 0.5 percent; and packaging. The special double-layer carbon-free tundish covering agent for the silicon steel with good fusion performance and spreadability produced by the invention can ensure that the fluctuation of the components C, N, S, P and Al of the molten steel in the tundish is within 10PPm (the fluctuation of the casting in 5PPM is up to more than 80 percent) during the smelting process of the silicon steel, thereby ensuring the smooth operation of continuous casting process.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Preparation method of feed for brocarded carps

InactiveCN101606599APhysically fitColorfulClimate change adaptationAnimal feeding stuffAnimal scienceHouttuynia

The invention relates to a preparation method of feed for brocarded carps. The feed is prepared by the following raw materials in percentage by weight: 22-26 white fish meal, 8-10 trash fish meal, 3-5 green worm meal, 8-12 freshwater shrimp meal, 6-8 pork powder, 3-5 milk powder, 4-6 vegetable protein powder, 4-6 animal protein powder, 3-9 bone meal, 2-5 nutgrass flatsedge powder, 1-3 malt meal, 2-5 phellodendron bark powder, 1-3 honeysuckle flower powder, 2-5 cassia seed powder, 1-3 cordate houttuynia meal, 4-6 expanded powder and 3-6 soybean protein powder; and the powders are taken according to a certain proportion and all put in an agitator to be stirred for 180 min, the mixture is taken out and then put in a crusher to be crushed into 0 mesh of powder, then the powder is taken out and then put in a direr for drying, then put in the agitator to be stirred and then taken out and put in a bulking machine for bulking at the temperature of 80-85 DEG C for 2-3h, the dryness of the bulked powder is controlled between 90 percent and 95 percent and the bulked powder can be packaged according to the specific gravity after being taken out to cool.

Owner:丁全畦

Preparation method of herring feed

InactiveCN101584383AModerate proportionFast growthFood processingClimate change adaptationAnimal scienceBran

The invention relates to a preparation method of herring feed which comprises the following components according to the weight percent: 5-15 percent of fish meal, 15-34 percent of bean cake, 3-9 percent of barley, 10-16 percent of rape-seed cake, 3-8 percent of bran, 18-20 percent of corn, 3-8 percent of bone meal, 5-9 percent of silkworm pupa, 1-2 percent of salt, 1-3 percent of premix additive, 2-4 percent of multiplex vitamin and 2-4 percent of mineral composition additive. The preparation method comprises the following steps: pouring the materials into a container, uniformly mixing, producing settled hard granulated feed by a loop mode hard granulation machine, and sieving by a 40-mesh sieve, wherein the weight of each grain is 0.1g.

Owner:李荣帮

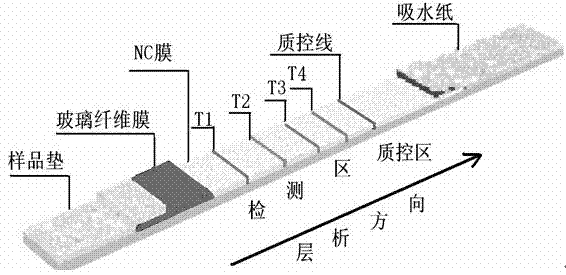

Method for preparing fast detecting test paper of illegal cooking oil

InactiveCN102928600AExtended shelf lifeReduce storage conditionsMaterial analysisGutter oilNitrocellulose

The invention provides a method for preparing fast detecting test paper of illegal cooling oil. The method includes the following steps of sequentially preparing immune colored latex microspheres, an immune colored latex reaction pad and a nitrocellulose (NC) membrane and assembling a colored latex test strip. By means of the detecting test paper of the illegal cooking oil, detection sensitivity is high, a plurality of indexes can be simultaneously detected, a comprehensive and systematic detection method is provided for detecting the illegal cooking oil, and detection costs are relatively reduced; the quality of the detecting test paper can be guaranteed for two years at normal temperatures, the quality guarantee period is effectively prolonged, and preservation conditions are reduced; non-professional persons can use the detecting test paper to accomplish whole detection, so that the operation is simple, and popularization of the method is facilitated; and the whole detection process can be accomplished in 10 minutes at the soonest, and the detecting test paper is suitable for fast field screening.

Owner:深圳市宝凯仑科技有限公司

Preparation method of rainbow trout feed

InactiveCN101569374AModerate proportionDelicious meatClimate change adaptationAnimal feeding stuffVegetable oilBran

The invention relates to a preparation method of a rainbow trout feed comprising following components in percentage by weight : 18-30 of fish meal, 15-25 of blood meal, 8-18 of bean cake meal, 4-10 of bran, 3-7 of wheaten flour, 4-10 of cornmeal, 6-9 of fish liver and glandular meal, 7-15 of vegetables, 1-3 of feed mineral supplement, 1-3 of vegetable oil and 1-2 of various vitamins. The components are poured into a fish feed stirring mill to be stirred for 20 min in proportion, the mixture is taken out and is poured into a multi-purpose ring model type soft pelleter to be heated and processed into soft particle feed and is then screened by a 40-mesh filter screen, and the weight of each particle is 0.1 g.

Owner:张道君

Method for preparing soft-shelled turtle feed

InactiveCN101574123AModerate proportionImprove palatabilityFood processingClimate change adaptationInorganic saltsAnimal science

The invention relates to a method for preparing a soft-shelled turtle feed. The soft-shelled turtle feed comprises the following materials in percentage by weight: 30 to 55 percent of white fish meal, 10 to 30 percent of red fish meal, 5 to 8 percent of starch, 16 to 23 percent of bean pulp, 2 to 4 percent of cuttlefish meal, 2 to 4 percent of liver meal, 1 to 3 percent of inorganic salt, 1 to 3 percent of bonding agent, and 1 to 2 percent of various vitamins. The method comprises the following steps: pouring the white fish meal, the red fish meal, the starch, the bean pulp, the cuttlefish meal, the liver meal, the inorganic salt, the bonding agent and the vitamins into a crusher in proportion and crushing the materials into powder; and pouring the powder into a fish feed granulator, and heating and processing the powder into a powder feed, wherein the feed is fed by adding quantitive water into the feed and stirring the mixture evenly when the feed is fed to soft-shelled turtles.

Owner:丁大奎

Feed for black carp

The invention provides feed for black carp, which comprises the following components in percentage by weight: 5 to 15 percent of freshwater shrimp meal, 15 to 34 percent of sorghum meal, 3 to 9 percent of soybean meal, 10 to 16 percent of sweet potato meal, 3 to 8 percent of loach meal, 18 to 20 percent of corn protein powder, 3 to 8 percent of clamworm meal, 5 to 9 percent of tenebrio molitor meal, 1 to 2 percent of table salt, 1 to 3 percent of premix additive, 2 to 4 percent of edible adhesive, and 2 to 4 percent of animal protein meal. The components are mixed and stirred uniformly in a vessel in the ratio, and the precipitate rigid particular feed is produced by using a ring die type rigid granulator unit, and is sieved with a 60-mesh screen, wherein each particle is 0.2 gram.

Owner:李荣帮

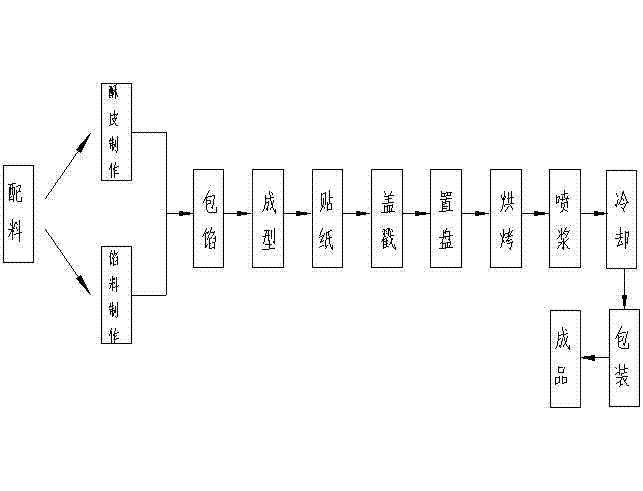

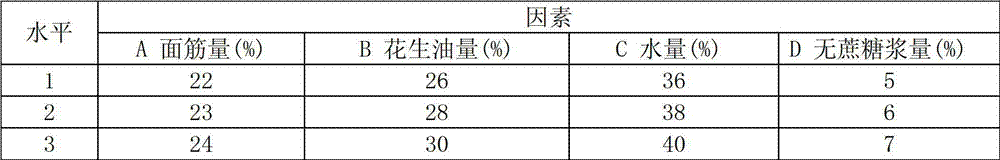

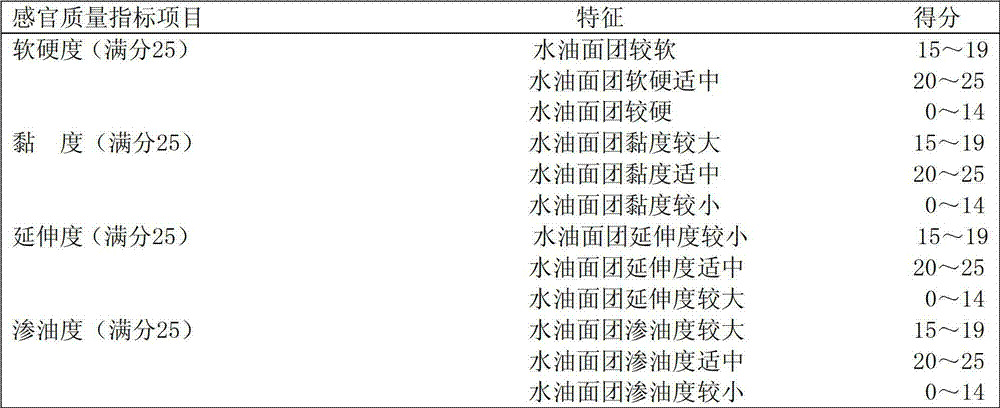

Suzhou-style mooncake with good cake crust sensation quality and production technology of mooncake

InactiveCN102919332AImprove qualityConducive to processBakery productsClear LayerAdditive ingredient

The invention relates to a production technology of a Suzhou-style mooncake with good cake crust sensation quality. The production technology of the Suzhou-style mooncake with good cake crust sensation quality comprises the following steps of: (1) preparing ingredients; (2) making crisp crust and fillings, wherein the crisp crust making comprises the following step of preparing water and oil doughs, oil crisp doughs and crisp crust doughs; (3) wrapping the fillings and forming; (4) baking; and (5) cooling. According to the production technology, the cake crust formulation is adjusted appropriately; the cake crust of the prepared Suzhou-style mooncake has favorable comprehensive sensory quality, and the Suzhou-style mooncake with good cake crust sensation quality has the advantages of low sweetness, clear layers, crisp taste, complete cake crust and nutrition and health.

Owner:苏州稻香村食品工业有限公司

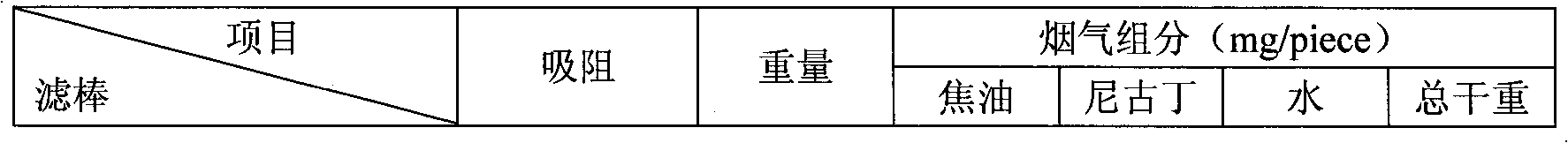

Method for preparing tows for modified cigarettes

ActiveCN102134758ALight weightSimple spinning processArtificial filament physical treatmentMelt spinning methodsFiberPolymer science

The invention relates to a method for preparing tows for blended modified polylactic acid cigarettes. Fiber grade polypropylene particles, functional master batches and polylactic acid particles are uniformly mixed according to a certain ratio, and the tows for polylactic acid cigarettes are prepared through the working procedures of spinning, oiling, drafting, wrapping and drying. The method has a simple process and high speed to form, the produced product can reduce the specific weight of polylactic acid fiber, the operational performance is increased, the surface area of the fiber is increased, grain phase particles in smoke can be effectively absorbed, and a good filtering effect is generated.

Owner:JIANGSU DAYA CIGARETTE FILTER MATERIAL CO LTD

Pine nut shell gas-phase adsorption active carbon and preparation method thereof

InactiveCN103566901AHard textureModerate proportionOther chemical processesDispersed particle separationGas phaseOxygen

The invention relates to pine nut shell gas-phase adsorption active carbon, which is prepared from the following raw materials in parts by weight: 150 to 160 parts of pine nut shell, 3 to 4 parts of graphene, 10 to 15 parts of attapulgite, 8 to 10 parts of ferric trichloride, 8 to 10 parts of sodium perborate, 10 to 15 parts of citric acid, 4 to 5 parts of modified diatomite and an appropriate amount of water. The pine nut shell is adopted as a raw material to produce the active carbon. The pine nut shell has hard texture and moderate specific gravity and is likely to form a fine pore structure after being carbonized at a high temperature, the weaknesses of a traditional method can be overcome and the active carbon is suitable for the gas adsorption; by adopting the attapulgite, a sterilizing, deodorizing, moisture absorbing and mildew preventing functions can be achieved and organisms can be catalyzed and decomposed; by utilizing the ferric trichloride, oxidization and desulphurization can be realized; due to addition of the sodium perborate, the oxidization decoloring function be realized and ecological oxygen can be realized; and the pine nut shell gas-phase adsorption active carbon is safe, healthy, low in cost and particularly suitable for purifying the air of a living environment.

Owner:BENGBU HUAFANG FILTER

Method of continuously synthesizing large diameter single wall carbon nano-tube

InactiveCN1948145AControl shapeQuality improvementNanostructure manufactureShielding gasCarbon nanotube

The present invention relates to a method for continuously synthesizing large-diameter single-wall carbon nano tube, belonging to the field of nano material preparation technology. Said method is characterized by that it includes the following steps: using transition metal organics ferrocene as catalyst, using thiophene as accelerating agent, using methyl alcohol or ethyl alcohol as carbon source and solent, using inert gas as protection gas and carrier gas, introducing the carbon source and catalyst into high-temperature zone, in the high-temperature zone making the metal iron atoms decomposed out from metal organics ferrocene be agglomerated and formed into nano iron particles, under the catalytic action of high-temperature and transition metal iron particles making the carbon decomposed out from methyl alcohol or ethyl alcohol be formed into large-diameter single-wall carbon nano tube, at the same time continuously supplying alcohol and metal organics ferrocene, collecting formed single-wall carbon nano tubes in collector so as to implement continuous synthesis of large-diameter single-wall carbon nano tube.

Owner:SHANGHAI JIAO TONG UNIV

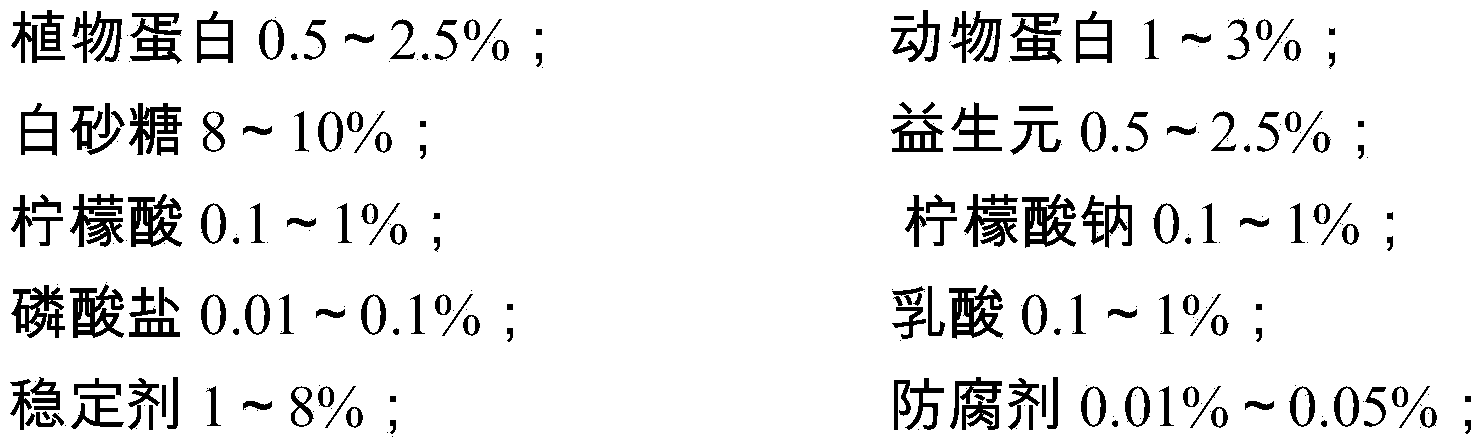

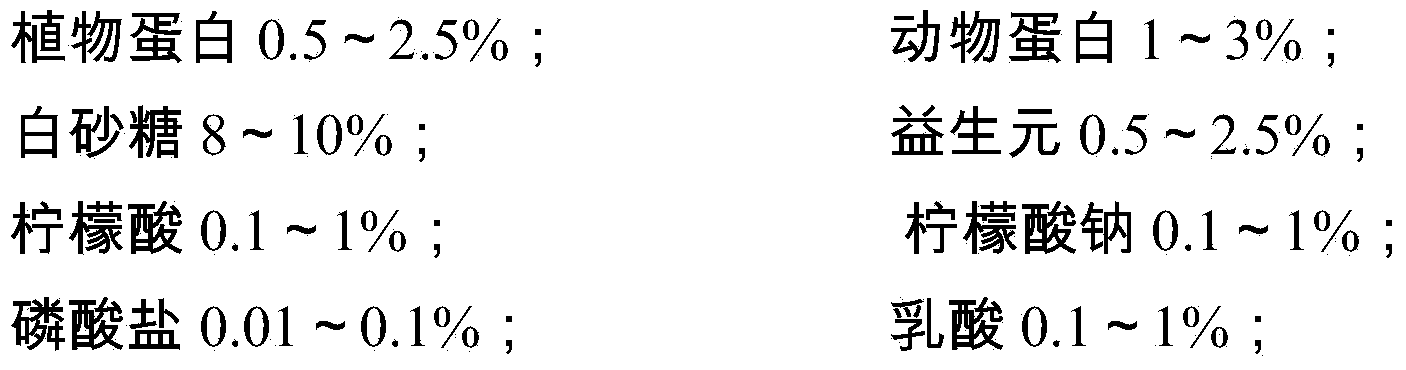

Inactive double-protein lactobacillus beverage and preparation method thereof

The invention discloses an inactive double-protein lactobacillus beverage and a preparation method of the beverage. The inactive double-protein lactobacillus beverage comprises the following components by weight percent: 0.5-2.5% of vegetable protein, 1-3% of animal protein, 8-10% of white granulated sugar, 0.5-2.5% of prebiotics, 0.1-1% of citric acid, 0.1-1% of sodium citrate, 0.01-0.1% of phosphate, 0.1-1% of lactic acid, 1-8% of stabilizing agent, 0.01-0.05% of preservative, 0.02-0.1% of lactobacillus, 0.01-0.05% of edible essence and the balance of water. The inactive double-protein lactobacillus beverage is high in protein content, and the protein content reaches up to 1.5%; the proportion between animal protein and plant protein is proper, so that the nutrition is more balanced; furthermore, the product is stable in shelf life and does not have the phenomenon of protein precipitation.

Owner:SHANDONG YUWANG ECOLOGY FOOD IND

Pelteobagrus fulvdraco feed

The invention relates to a pelteobagrus fulvdraco feed, which is prepared with the following components by weight percentage: 6-10 percent of shrimp meal, 20-40 percent of bran, 10-15 percent of bone meal, 25-35 percent of soybean meal, 5-10 percent of sweet corn gluten meal, 8-10 percent of rice bran powder, 0.4-1 percent of chicken blood powder, 0.1-0.5 percent of salt, 0.5-2 percent of inorganic salt and 0.5-1 percent of mineral additive. The pelteobagrus fulvdraco feed is prepared through the following steps: mixing all the components according to the proportion, crushing the mixture with a multi-purpose fish feed crusher, heating with an annular die type hard particle machine to produce sediment hard-particle feed, and screening the hard-particle feed with a 60-mesh sieve, thereby obtaining the pelteobagrus fulvdraco feed. The weight of each piece of pelteobagrus fulvdraco feed is 0.2g.

Owner:杨保磊

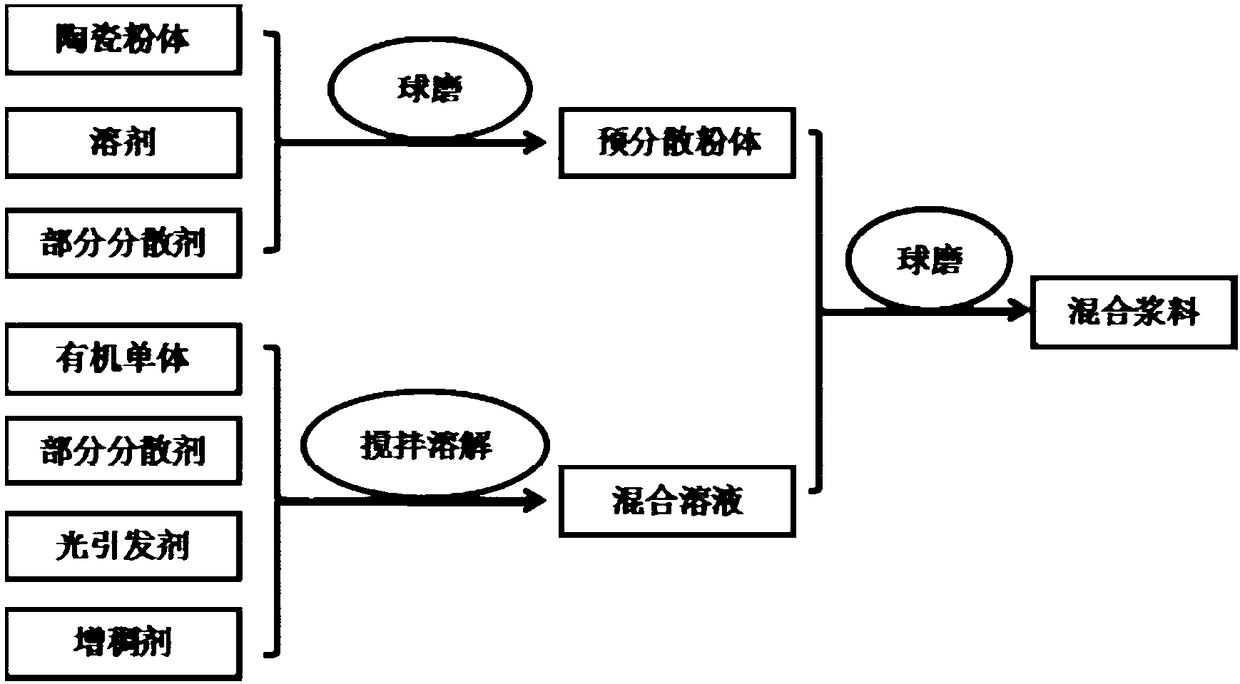

Ceramic material for photocuring 3D printing and ceramic member, and preparation methods thereof

ActiveCN108275979AIncrease contentImprove flexural strengthAdditive manufacturing apparatusHigh densityOrganic solvent

The invention discloses a ceramic material for photocuring 3D printing and a ceramic member, and preparation methods thereof. The preparation method for the ceramic material comprises the following steps: S0, weighing a certain amount of ceramic powder with an average particle size of 1 to 10 [mu]m, organic monomers with a viscosity of 100 cps or below and a copolymer dispersant containing acidicgroups, and dividing the dispersant into two parts; S1, pouring ceramic powder and an organic solvent in a volume ratio of 1: 1 to 1: 2 into a ball milling tank, adding the first part of the dispersant and successively carrying out sufficient ball milling, filtering and drying so as to obtain pre-dispersed powder; S2, pouring the organic monomers into a container, carrying out mechanical stirring,adding a free radical type photoinitiator, a thickening agent and the second part of the dispersant and carrying out stirring for dissolving so as to obtain a mixed solution; and S3, adding the powder into the mixed solution in multiple times to prepare mixed slurry, carrying out uniform mixing under stirring, transferring the obtained mixture into the ball milling tank and carrying out thoroughball milling so as to prepare the ceramic material. The ceramic material prepared in the invention has good stability; and the prepared ceramic member is reduced in size and has high density and bending strength.

Owner:SHENZHEN SUNSHINE LASER & ELECTRONICS TECH CO LTD

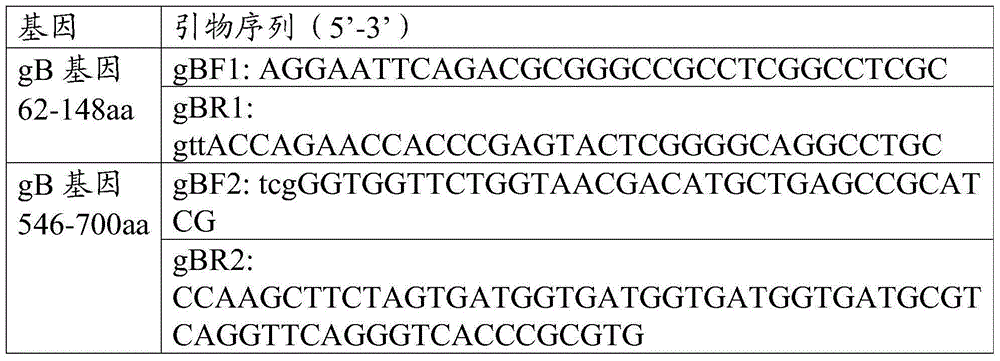

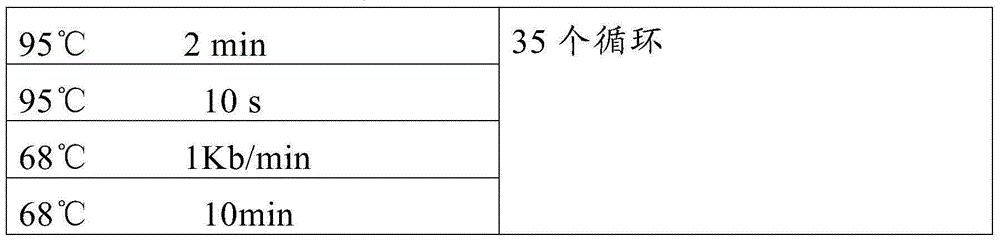

Preparing method of porcine pseudorabies virus subunit vaccine, vaccine composition and application

ActiveCN106267182AEasy to prepareShort timeAntiviralsAntibody medical ingredientsImmune effectsAdjuvant

The invention relates to a preparing method of porcine pseudorabies virus subunit vaccine composition. The preparing method includes the steps that 1, a gB protein fragment gene and a gD protein gene are cloned and amplified respectively; 2, the amplified gB protein fragment gene and the amplified gD protein gene are used for constructing plasmid of tandem expression gB protein and gD protein; 3, gB+gD recombinant protein is expressed through the obtained plasmid of tandem expression gB protein and gD protein and purified, adjuvant is added, and emulsification is carried out. The preparing method is simple, porcine pseudorabies virus gB and gD protein can be prepared in quantity, shorter time is spent, the expression amount is large, the production cost is greatly reduced, which is beneficial for large-scale production. The virus subunit vaccine containing the prepared gB and gD protein is good in immune effect and small in immune amount and capable of effectively preventing diseases related to the porcine pseudorabies virus and related infectious diseases caused by the porcine pseudorabies virus.

Owner:PU LIKE BIO ENG

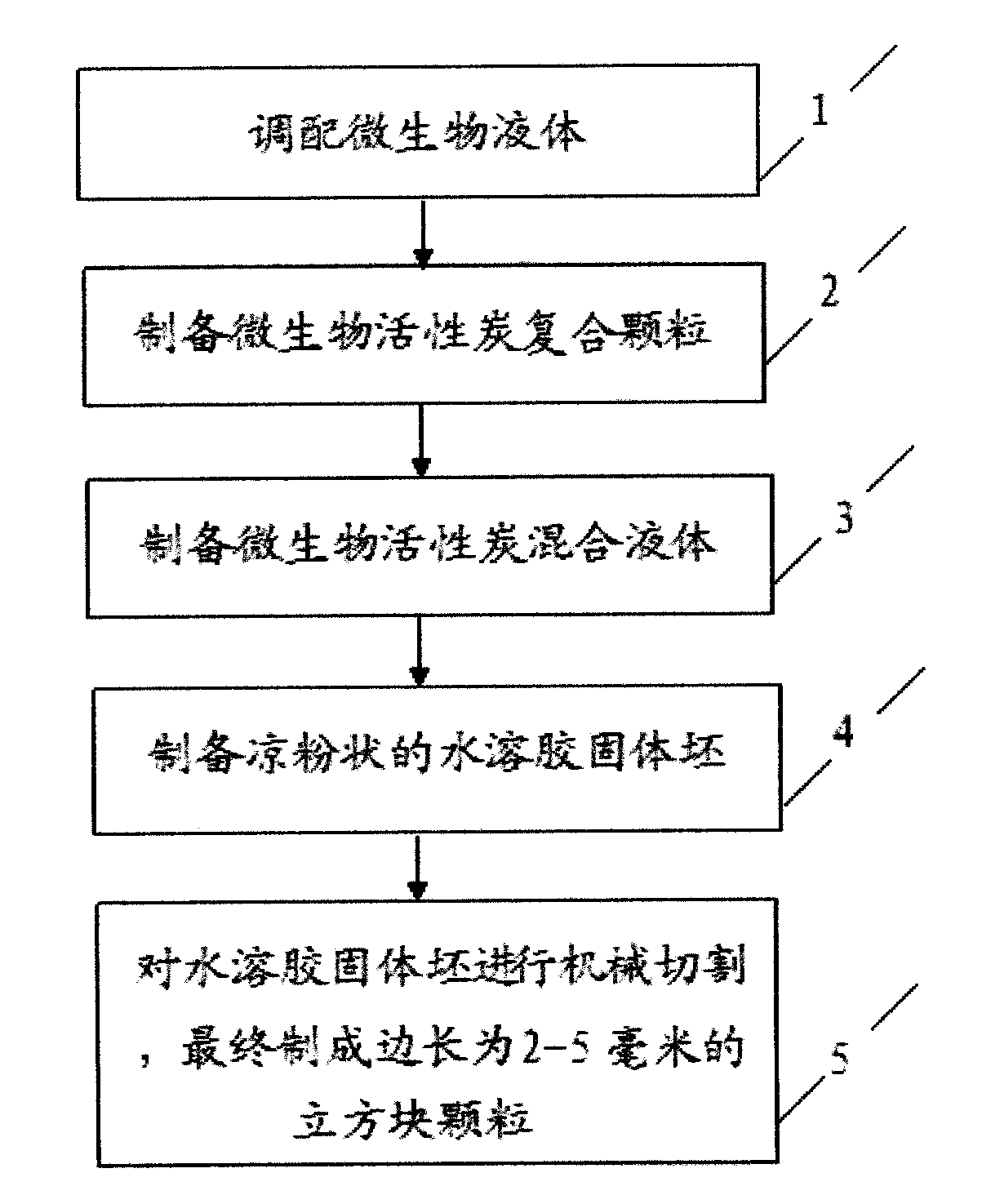

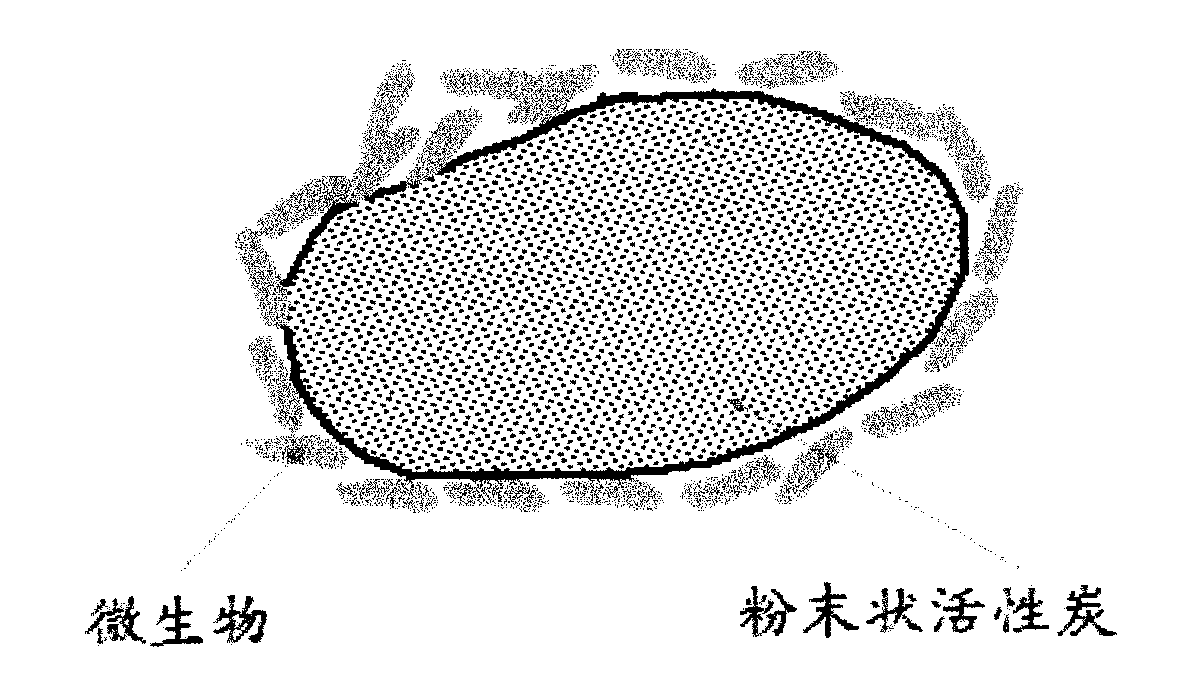

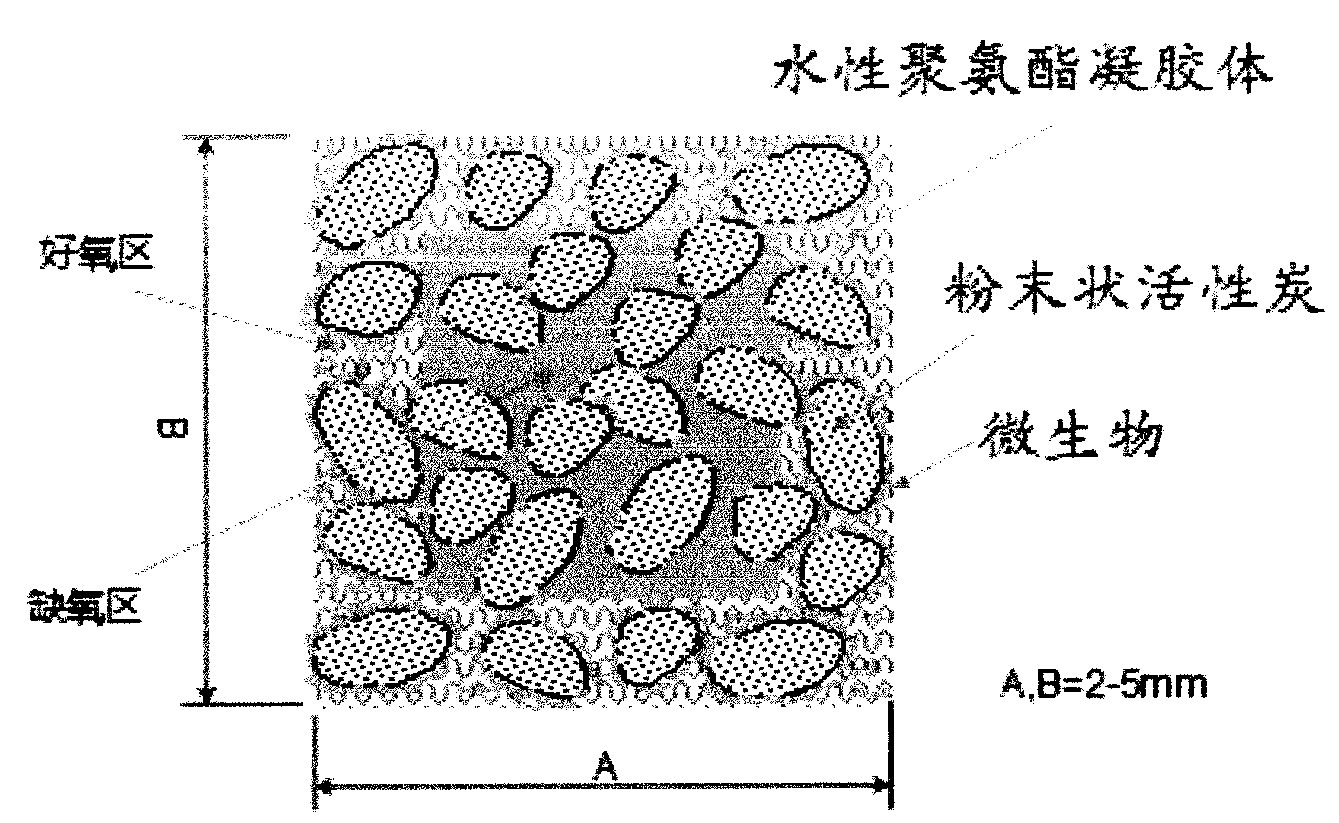

Suspension biological activated carbon particle vector and preparation method thereof

InactiveCN102874922AMedium specific gravityModerate proportionTreatment with aerobic and anaerobic processesBiological activated carbonPhysical chemistry

The invention discloses a suspension biological activated carbon particle vector which is a cube particle with side length of 2-5 mm and specific gravity of 1.02-1.08. The cube particle comprises microbial thallus, bamboo powdery activated carbon and a waterborne polyurethane gel, wherein the quantity of the microbial thallus is 2000-3000 mg / L measured by MLVSS concentration; the concentration of the bamboo powdery activated carbon is 1-8% that of the mass percentage of the cube particle; the concentration of the prepolymer of the waterborne polyurethane gel is 6-12% that of the mass percentage of the cube particle. The suspension biological activated carbon particle vector can reach good effect for removing ammonia nitrogen-oriented pollutants from water.

Owner:苏州康瑞环境科技有限公司

Crataegus pinnatifida bunge yoghourt

InactiveCN104186660AModerate proportionReasonable nutritionMilk preparationBiologyAdditive ingredient

The invention discloses crataegus pinnatifida bunge yoghourt. Crataegus pinnatifida bunge raw pulp is added into yoghourt. The yoghourt keeps all nutritional ingredients of crataegus pinnatifida bunge, particularly anthocyanin; meanwhile, sediment is not generated in the yoghourt and the ratio of the yoghourt to the crataegus pinnatifida bunge raw pulp is suitable; and the yoghourt is sour and sweet, and tasty, is reasonable in nutrition match and has the effects of improving the gastrointestinal function by crataegus pinnatifida bunge and the yoghourt.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Mutton sheep fattening fermented total mixed ration based on high-moisture residual forage feed

The invention provides mutton sheep fattening fermented total mixed ration; after high-moisture residual forage feed and other mutton sheep feed components are mixed, the anaerobic fermentation is performed on the mixture to prepare the mutton sheep fattening fermented total mixed ration, wherein the matching ratio of the residual forage feed and the other feed ensures that the overall water content of the mixed mixture is 40-50%. The used residual forage feed needs no any treatment, and is directly mixed with the other feed to perform the anaerobic fermentation to prepare the mutton sheep fattening fermented total mixed ration which has balanced nutrition and can be preserved for a long time, so that the operation is simple, the processing cost is low, the large-batch production is achieved, the preservation problem of the high-moisture residual forage feed is effectively solved, the local feed resources are preferably used, and the feed cost is reduced. The residual forage feed and coarse fodder are used as main raw materials; concentrated feed is properly matched; the digestion physiological characteristic of mutton sheep is satisfied; the ratio of the coarse fodder and the concentrated feed is proper; the nutrition is balanced; the nutrition metabolism diseases of the mutton sheep can be obviously decreased; the weight gain of the mutton sheep and the utilization efficiency of the feed are improved.

Owner:QINGDAO AGRI UNIV

Equalizing nutrient effervescent tablet and its preparing method

InactiveCN1408363AAvoid reciprocal reactionsImprove absorption rateOrganic active ingredientsMetabolism disorderEffervescent tabletNutrition supplementation

The equalizing nutrient effervescent tablet is prepared with nutrient matters containing vitamins and trace elements and capable of providing human body with essential nutrient matters. It has its acid and alkali nutrient matters separately embedded. It has the advantages of long guarantee period, good taste, easy absorption and capacity of providing equalized nutrients.

Owner:北京劲得健康科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com