Microchannel parallel-flow heat exchanger

A parallel flow heat exchanger, micro-channel technology, applied in the direction of heat exchanger shell, heat exchange equipment, evaporator/condenser, etc., can solve the problem of poor uniformity of porous flat tubes, affecting the uniformity of refrigerant distribution, The problem of poor uniformity of refrigerant distribution, etc., to achieve the effect of appropriate proportion, uniform distribution, and reasonable distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

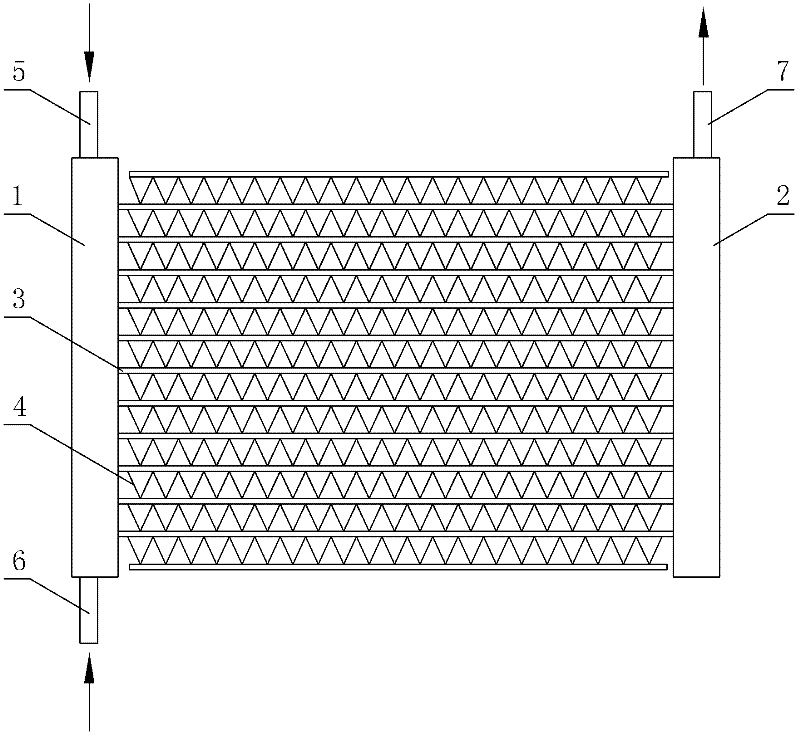

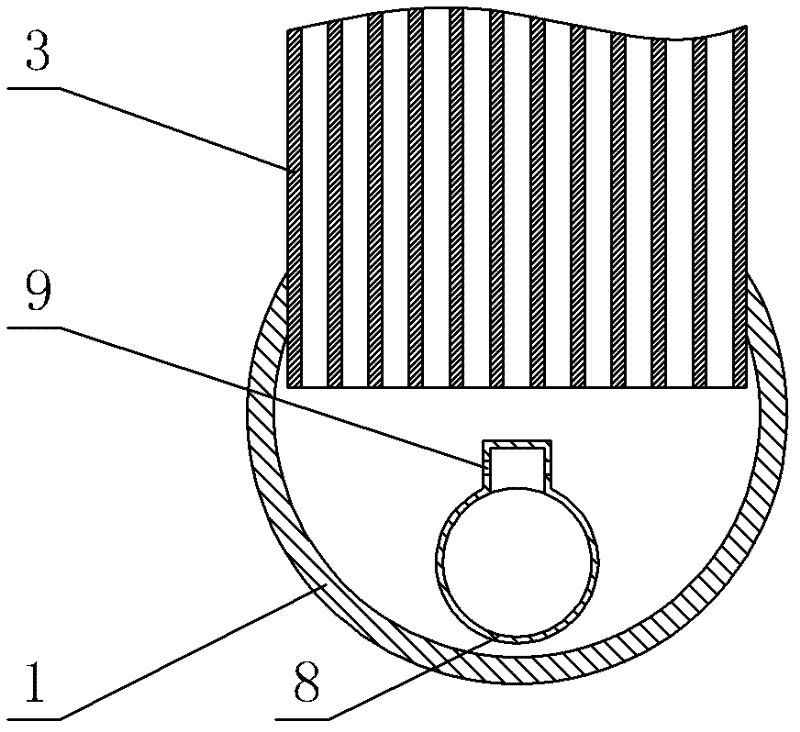

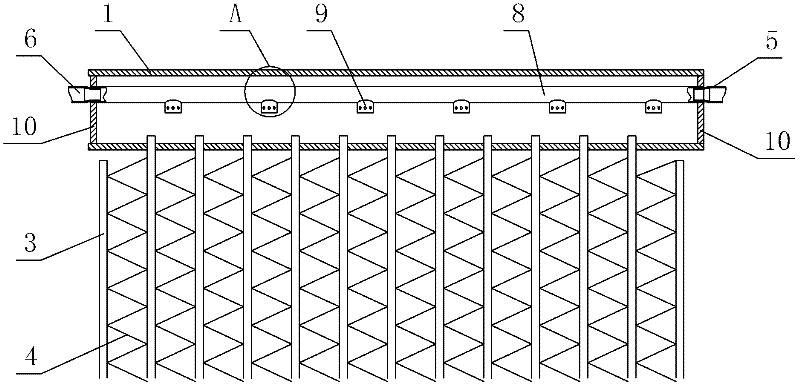

[0036] see Figure 1-Figure 4 , the micro-channel parallel flow heat exchanger includes an inlet header 1, an outlet header 2, and a refrigerant inlet pipe 8 arranged in the inlet header 1; the ends of the inlet and outlet headers are provided with More than two porous flat tubes 3 are arranged between the end cap 10 and the inlet and outlet headers, and the two ends of the porous flat tubes 3 are respectively inserted into the inlet and outlet headers. The outer periphery of the refrigerant inlet pipe 8 is provided with more than two connecting pipes 9 , and the connecting pipes 9 communicate with the inner chamber of the refrigerant inlet pipe 8 and the inner chamber of the inlet header 1 . The connecting pipe 9 is arranged on one side of the outer periphery of the refrigerant inlet pipe 8 and arranged linearly along the axial direction of the refrigerant inlet pipe 8 . The end face of the connecting pipe 9 faces the end face of the porous flat tube 3 .

[0037] The inlet ...

no. 2 example

[0041] see Figure 5 and Figure 6 , the end face of the connecting pipe 9 faces away from the end face of the porous flat tube 3, so as to prevent the refrigerant from spraying out from the split hole on the connecting pipe 9, and directly spray into the porous flat tube 3. Other unmentioned parts are the same as the first embodiment.

no. 3 example

[0043] see Figure 7 and Figure 8 , the connecting pipes 9 are arranged on the left and right sides of the periphery of the refrigerant inlet pipe 8, and more than two connecting pipes 9 on each side are provided to form two rows of connecting pipes 9; each row of connecting pipes 9 is arranged along the axial direction of the refrigerant inlet pipe 8 The directions are arranged in a straight line; wherein, the connecting pipes 9 on the left and right rows are arranged symmetrically. Wherein, the included angle between the axes of the connecting pipes 9 on the left and right sides is 180 degrees; the included angle between the axis of the connecting pipe 9 and the axis of the porous flat tube 3 is 0-90 degrees. The axis of the connecting pipe 9 and the axis of the porous flat tube 4 form an included angle of 90 degrees.

[0044] Refer to Figure 9 , the connecting pipes 9 on the left and right rows are arranged in a staggered manner.

[0045] Other unmentioned parts are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com