Concrete polycarboxylate water reducer and preparation method thereof

A technology of polycarboxylic acid and water reducing agent, applied in the field of polycarboxylate water reducing agent for concrete, can solve the problems of poor quality stability of polymer products, complicated synthesis of water reducing agent, etc., and achieve reasonable molecular structure, good slump retention, The effect of high water reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] In the reactor, add 58g of water and 45.4g of monomer A-1 (weight-average molecular weight of 1142), stir and heat to 30°C, then add 2.23g of 25% hydrogen peroxide, and add solution 1 (1.39g white block Mixture with 7.5g water) and Solution 2 (mixture of 7.82g maleic anhydride and 17g water), keep the temperature at 30°C, the dripping time is 2h, the aging time is 1h, after the reaction, the temperature is reduced to room temperature, with a mass concentration of 40 % NaOH aqueous solution adjusts the pH value to neutral, and discharges the material to obtain a high-performance polycarboxylate water-reducer product with a weight average molecular weight of 20,100 according to the present invention.

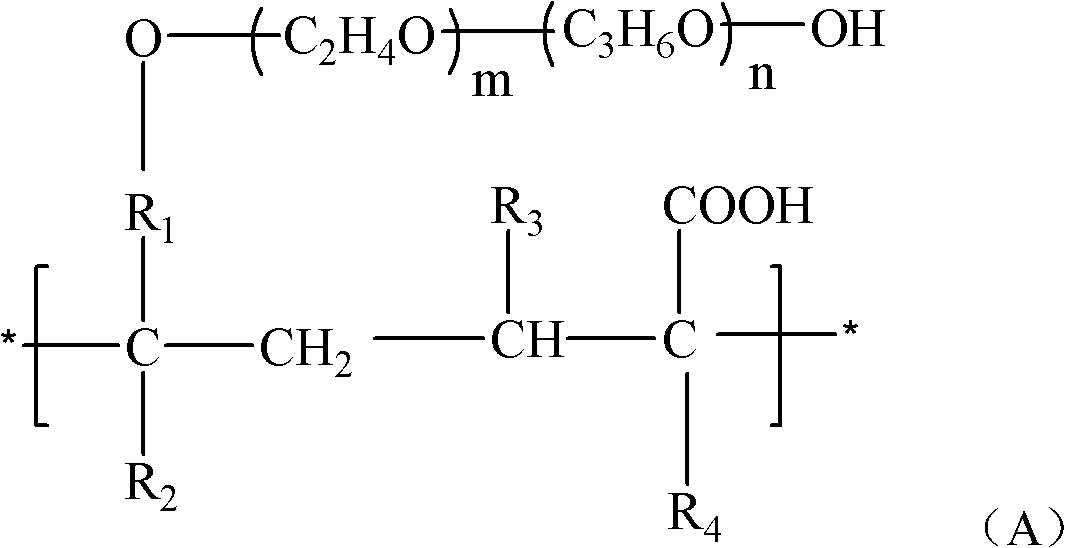

[0031] The structure of monomer A-1 is

[0032]

[0033] The structure of the finally obtained polycarboxylic acid water reducing agent is:

[0034]

example 2

[0036] In the reactor, add 154g water and 124g monomer A-2 (molecular weight 3430), stir and heat to 40℃, then add 2.23g 25% hydrogen peroxide, and add solution 1 (1.27g ascorbic acid and 7.5g water mixture) ) And solution 2 (mixture of 5.2g acrylic acid and 17g water), control the temperature to 40℃, the dripping time is 2h, the aging time is 1h, after the reaction, the temperature is reduced to room temperature, and the pH value is adjusted with the NaOH aqueous solution with a mass concentration of 40% To neutrality and discharging, a high-performance polycarboxylic acid water reducer product with a weight average molecular weight of 24,600 is obtained.

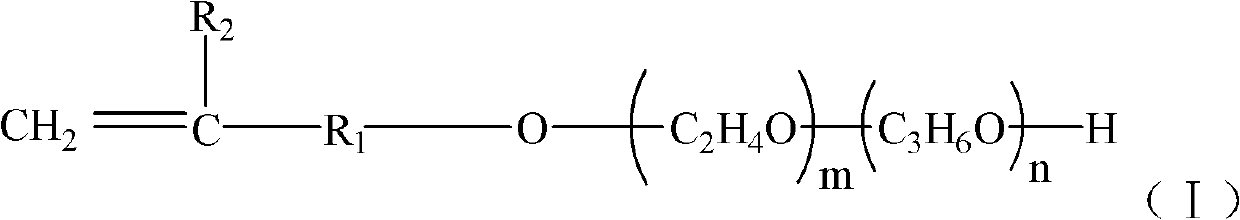

[0037] The structure of monomer A-2 is

[0038]

[0039] The final structure of the polycarboxylic acid water reducing agent is:

[0040]

example 3

[0042] In the reactor, add 133g water and 124g monomer A-3 (molecular weight 3436), stir and heat to 50℃, then add 3.15g ammonium persulfate, and add solution 1 (1.08g sodium bisulfite and 7.5g Water mixture) and solution 2 (a mixture of 9.3g methacrylic acid and 17g water), the temperature is controlled at 50℃, the dropping time is 2.5h, the aging time is 1h, after the reaction, the temperature is reduced to room temperature, and the mass concentration is 40% The pH value of the NaOH aqueous solution is adjusted to neutral, and the material is discharged to obtain a high-performance polycarboxylic acid water reducing agent product with a weight average molecular weight of 27960 according to the present invention.

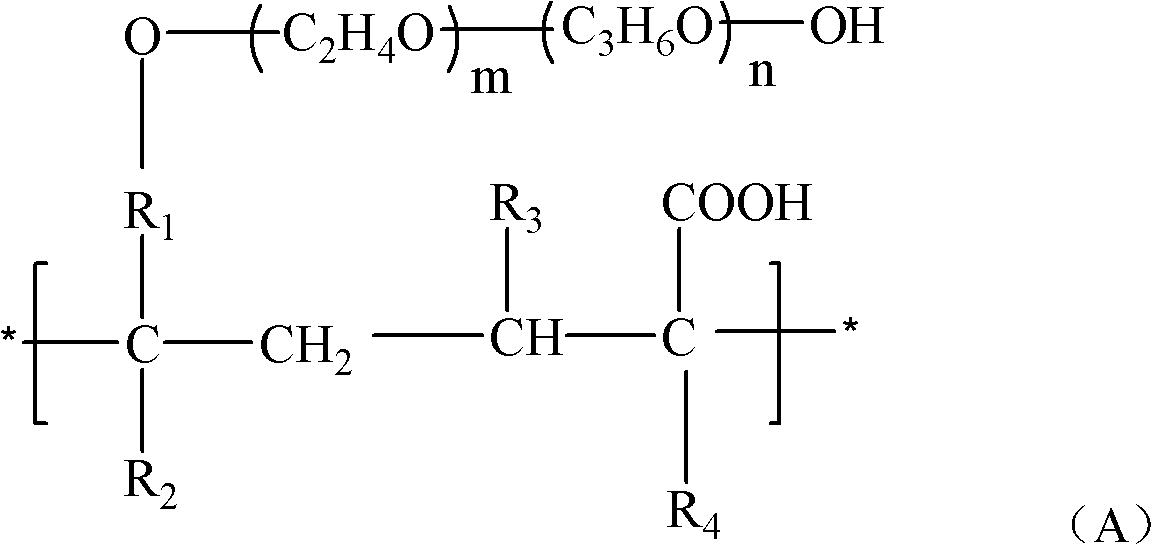

[0043] The structure of monomer A-3 is

[0044]

[0045] The structure of the finally obtained polycarboxylic acid water reducing agent is:

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com