Patents

Literature

321results about How to "High functionality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porous carbon material composites and their production process, adsorbents, cosmetics, purification agents, and composite photocatalyst materials

InactiveUS20100291167A1Significant valueHigh propertyCosmetic preparationsCarbon compoundsSorbentPorous carbon

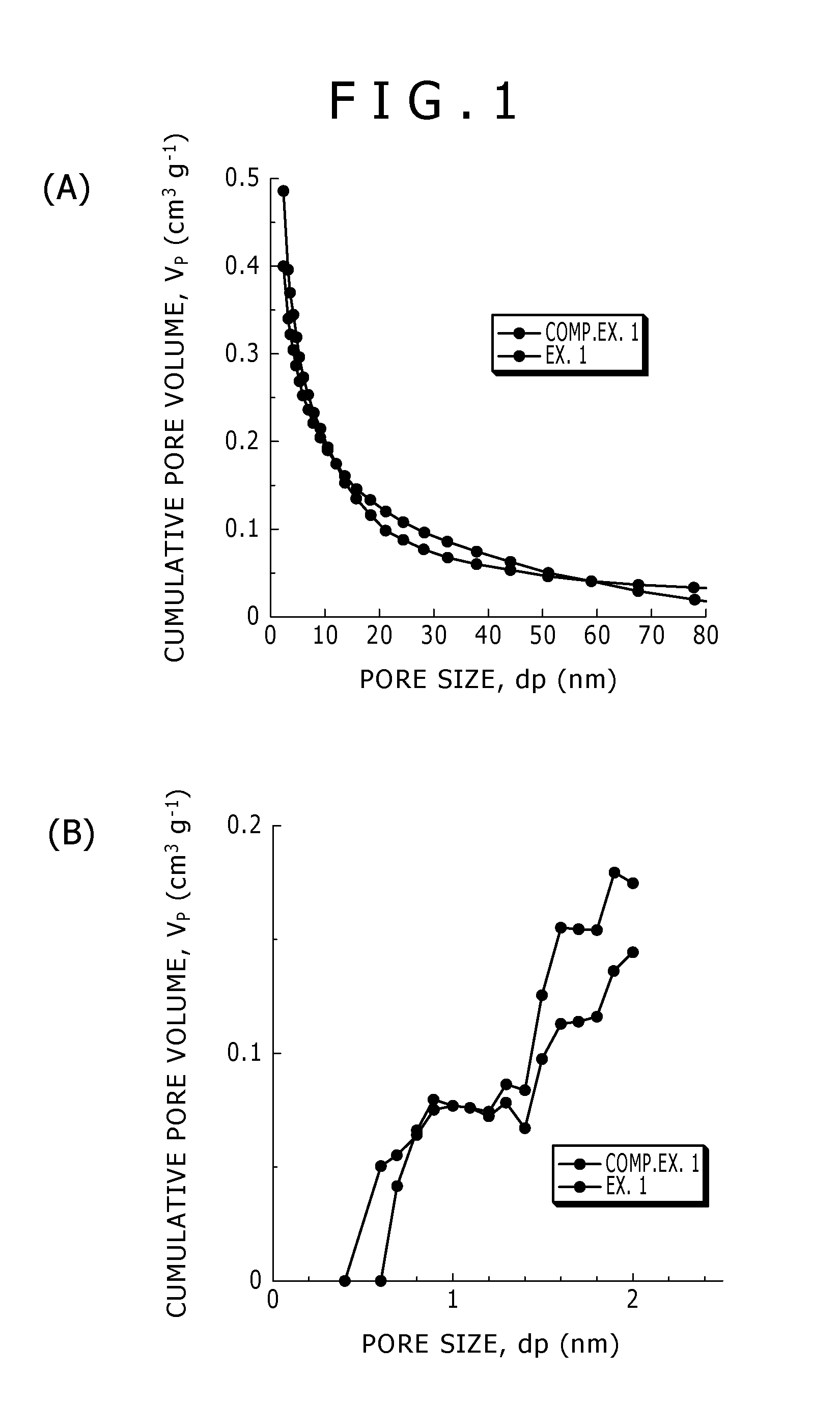

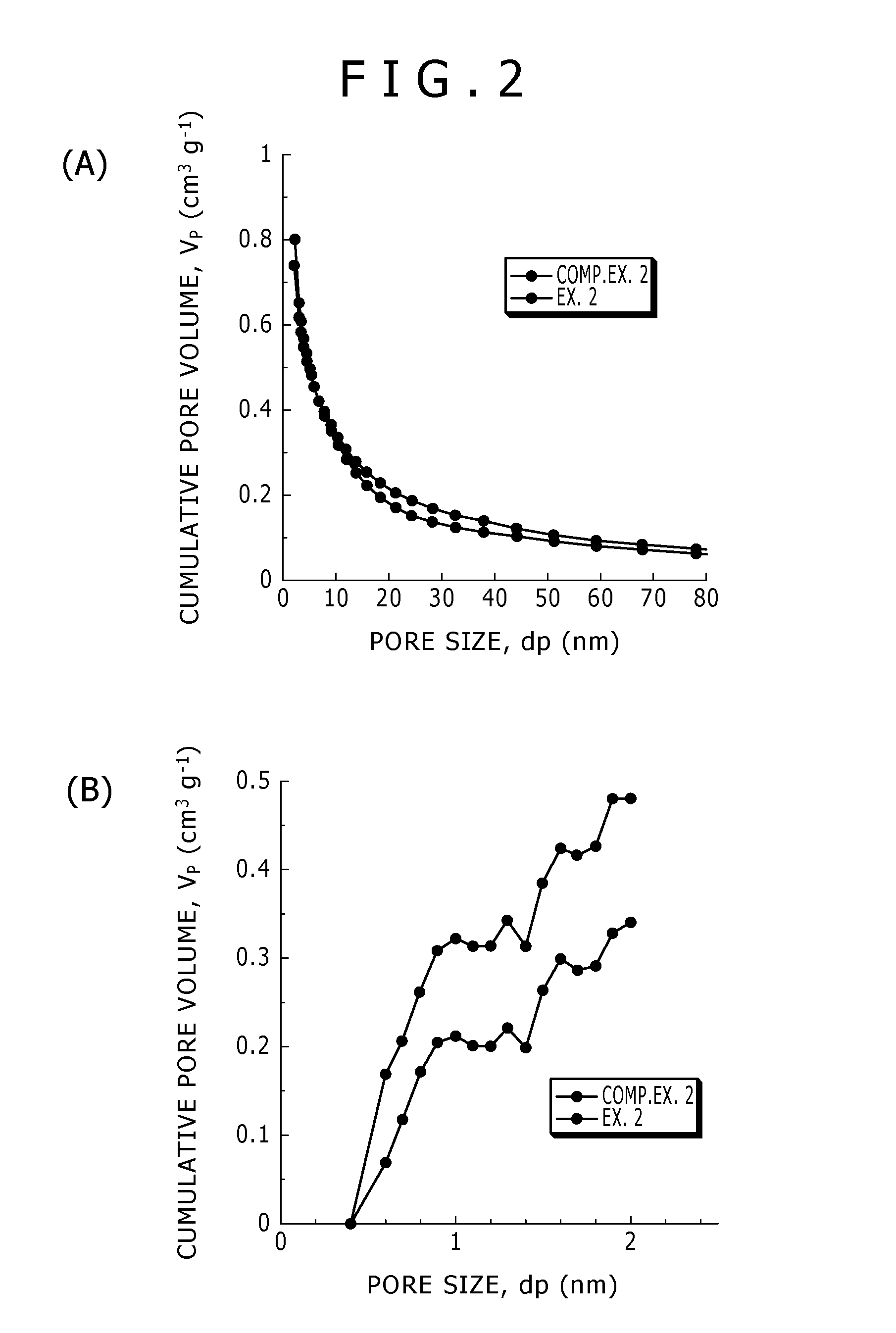

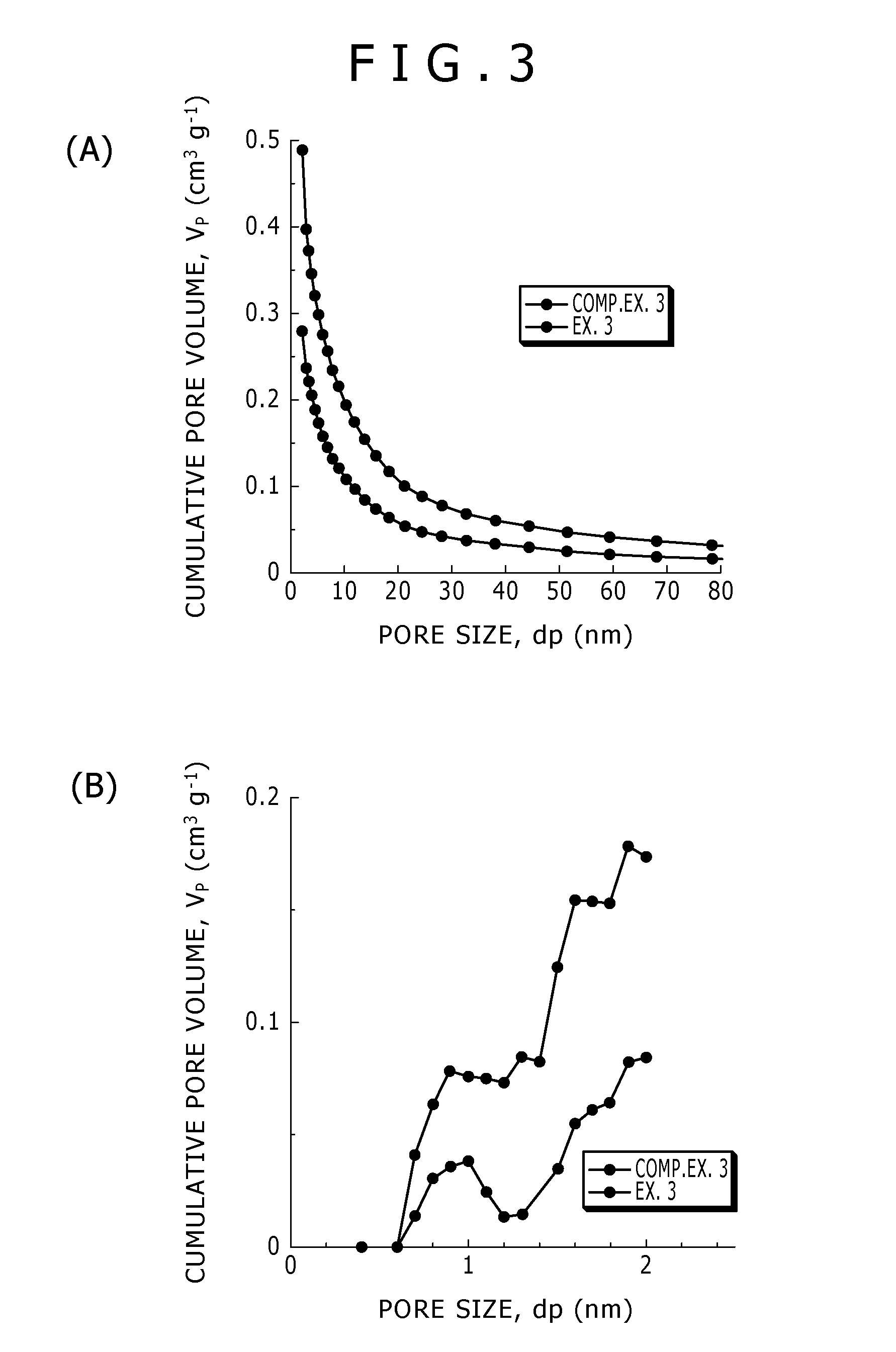

Provided is a porous carbon material composite formed of a porous carbon material and a functional material and equipped with high functionality. A porous carbon material composite is formed of (A) a porous carbon material obtainable from a plant-derived material having a silicon (Si) content of 5 wt % or higher as a raw material, said porous carbon material having a silicon (Si) content of 1 wt % or lower, and (B) a functional material adhered on the porous carbon material, and has a specific surface area of 10 m2 / g or greater as determined by the nitrogen BET method and a pore volume of 0.1 cm3 / g or greater as determined by the BJH method and MP method.

Owner:SONY CORP

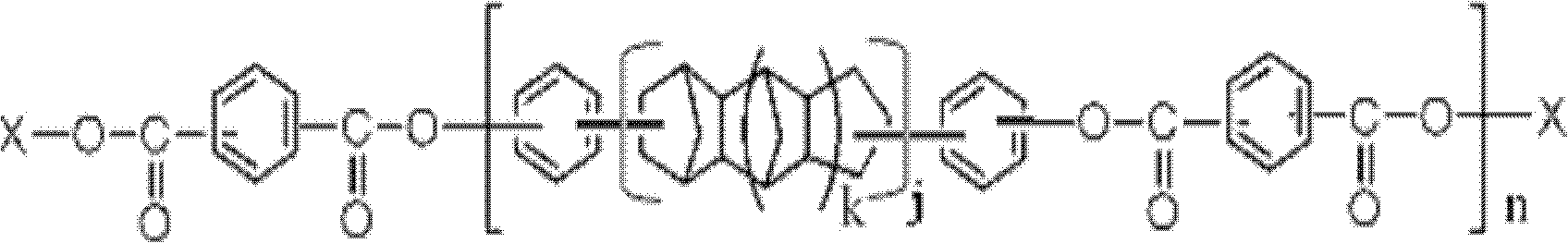

Epoxy resin composition as well as prepreg and copper-foil-clad laminated board prepared by using same

InactiveCN102443138AHigh glass transition temperatureHigh functionalitySynthetic resin layered productsMetal layered productsEpoxyDielectric loss

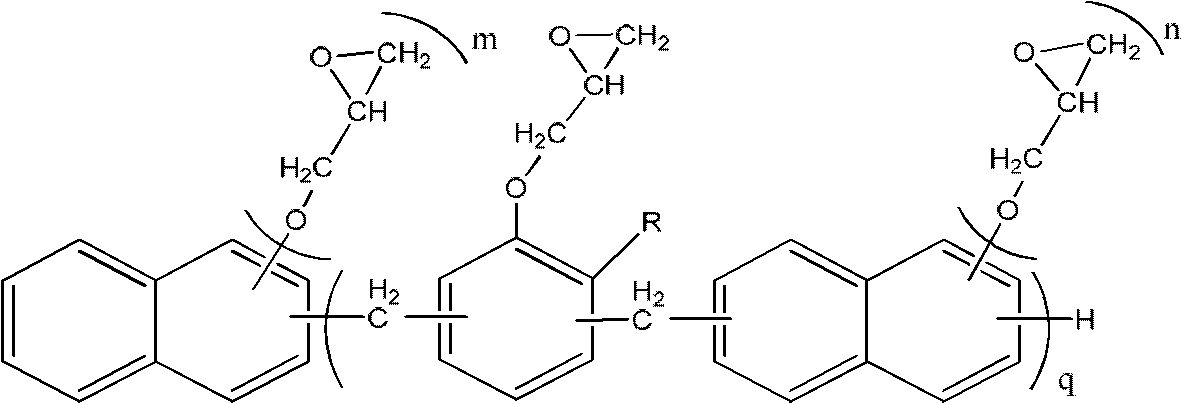

The invention relates to an epoxy resin composition as well as a prepreg and a copper-foil-clad laminated board prepared by using the same. The epoxy resin composition comprises the following essential components: (A) epoxy resin containing a naphthol structure, (B) an active ester serving as a curing agent, and (C) a curing accelerant. Because epoxy resin at least contains the naphthol structure in the molecular structure, the epoxy resin composition provided by the invention has higher functionality degree and high glass transition temperature; at the same time, the naphthol group structure is introduced to the molecular structure, thus the cured product has low water absorptivity and low expansion coefficient; due to the active ester serving as the curing agent, the advantages that the a polar group is not generated during the reaction between the active ester and epoxy, thus the dielectric properties are excellent and moisture and heat resistance are good are fully exerted; and in addition, because of the epoxy resin containing the special naphthol structure, the hydroscopicity of the resin cured product is further reduced and the dielectric loss value of the cured product is lowered. The prepreg and the copper-foil-clad laminated board provided by the invention have excellent dielectric properties, moisture and heat resistance and high glass transition temperature.

Owner:GUANGDONG SHENGYI SCI TECH

Method for making fermented minced or cubed meat by utilizing fermenting agent

InactiveCN103704765AGood colorAdd flavorMeat/fish preservation using chemicalsFood ingredient for microbe protectionBiotechnologyFlavor

The invention provides a method for making fermented minced or cubed meat by utilizing a fermenting agent. The method comprises the steps of minced or cubed meat raw material pretreatment, preserving, fermenting, storing and the like, the above raw material selects cold meat or fresh meat, and a strain comprises one or more of lactic acid bacteria, Debaryomyces hansenii, Micrococcus Kristinae, Micrococcus varians and Staphylococcus xylosus. A fermented product obtained in the invention has the characteristics of fine texture, elasticity, rich and pure fragrance, possessing of the sour fragrance specially possessed by fermented meat products, good mouthfeel and unique flavor, and also has the advantages of high nutrition value, high safety, eating convenience, easy preservation, probiotic effect and the like.

Owner:胡永金

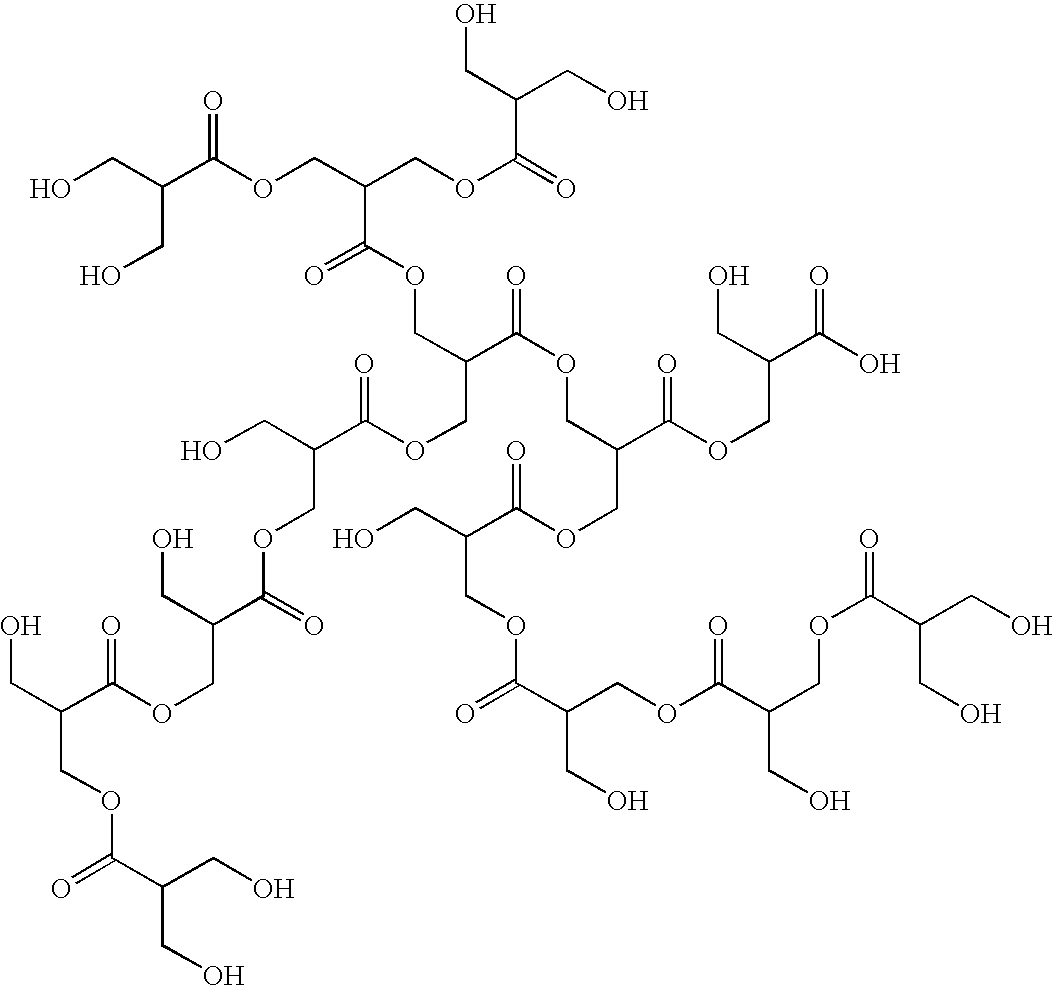

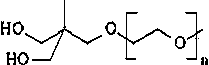

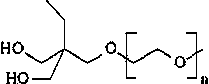

Branched, amorphous, polyester-based macropolyols of narrow molecular weight distribution

ActiveUS7005002B2Function increaseReduce polydispersityRefuge islandsPigmenting treatmentPolyesterPolyol

Branched, amorphous, polyester-based macropolyols having a narrow molecular weight distribution and a process for making the macropolyol.

Owner:EVONIK OPERATIONS GMBH

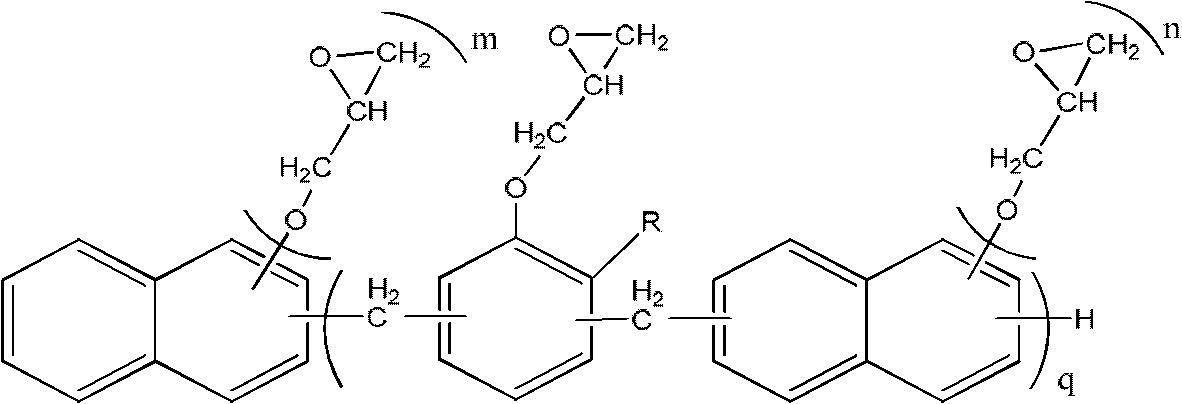

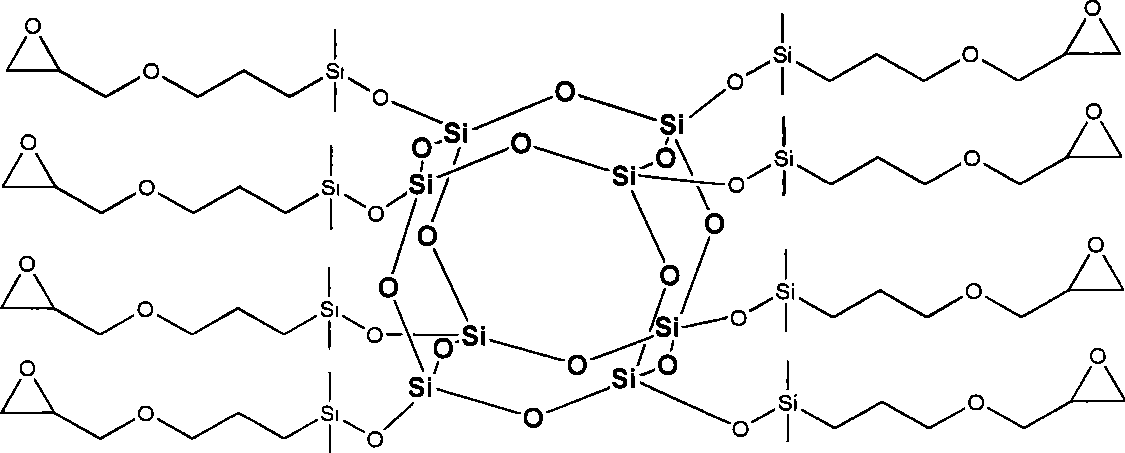

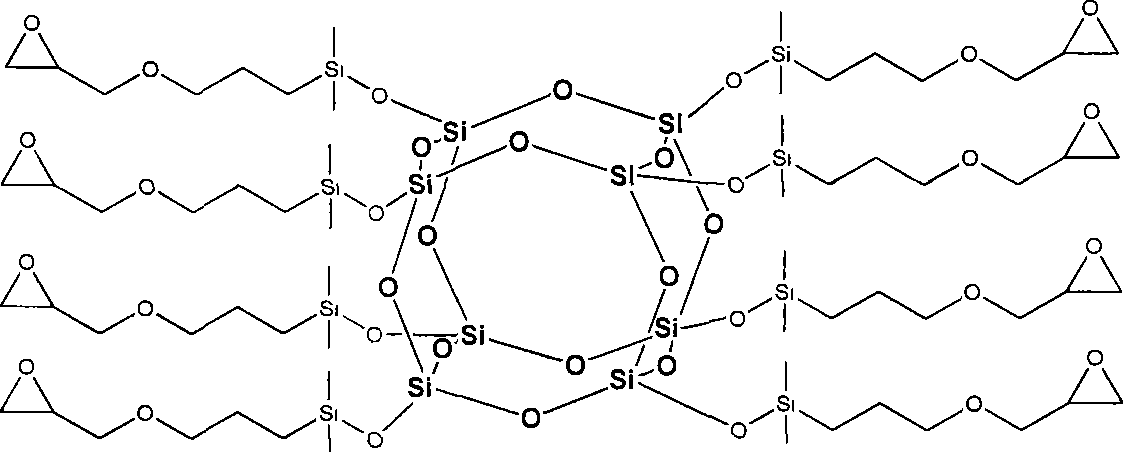

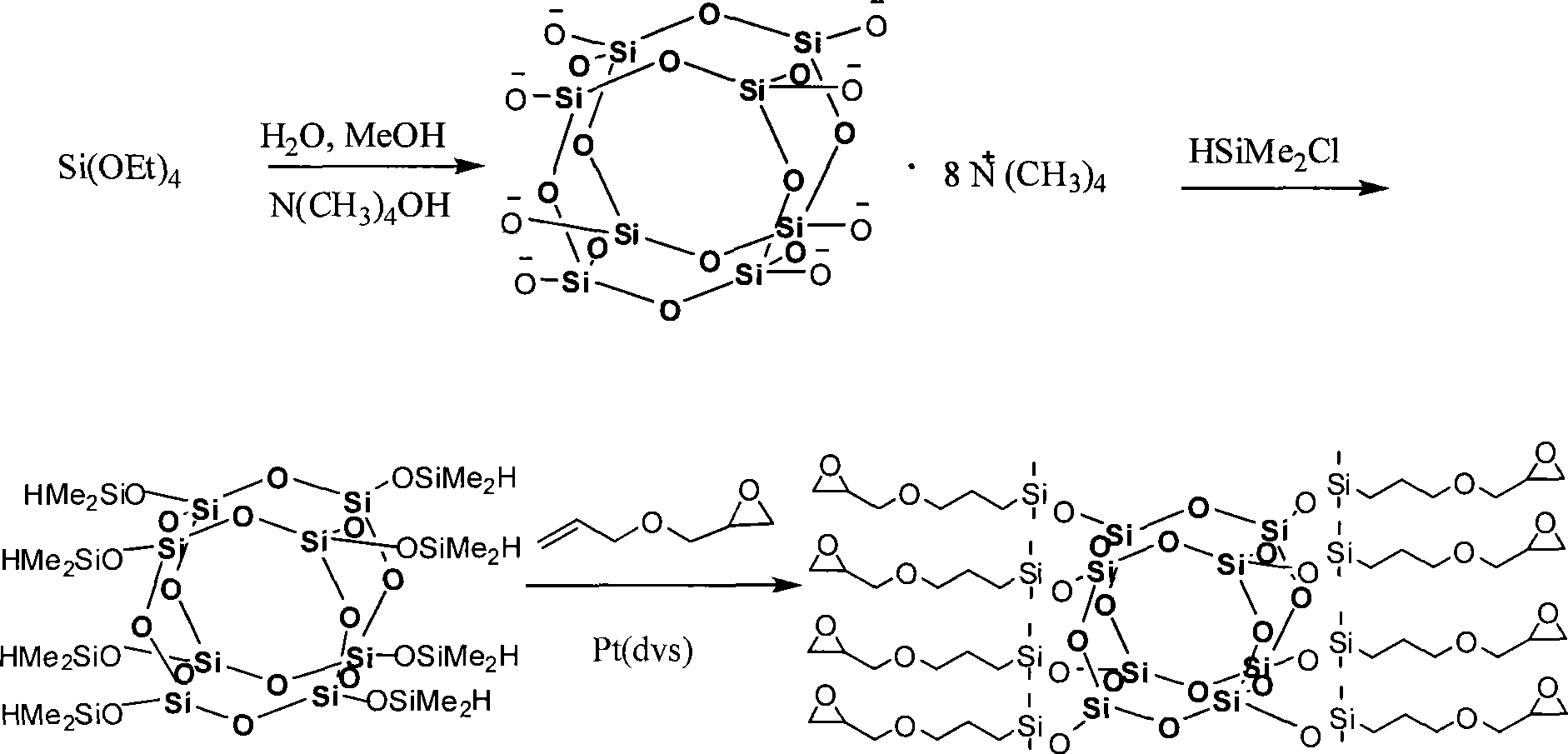

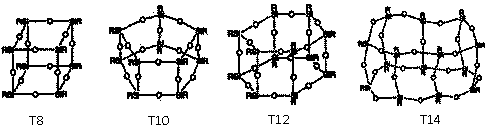

Octa-epoxy cage type sesquialter siloxane and preparation thereof

InactiveCN101503420AHigh reactivityHigh functionalitySilicon organic compoundsTetraethyl orthosilicateChemistry

The invention relates to octa-epoxy group cage-like silsesquioxane and a preparation method thereof. At present, the preparation of the cage-like silsesquioxane is generally not functionalized, and has a plurality of synthesis steps, low yield and too high cost. The cage-like silsesquioxane with epoxy groups is most noticeable with unique performance, but the existing cage-like silsesquioxane prepared by taking vinyl trichlorosilane as a raw material through hydrolytic condensation and oxidation is not completely epoxidized, and most of final products are mixtures. The preparation method takes industrialized tetramethyl orthosilicate or tetraethyl orthosilicate as a primary raw material, firstly synthesizes hydrated octa cage-like silicate through hydrolytic condensation, and then prepares the octa-epoxy group cage-like silsesquioxane with flexible chains through hydrosilation reaction and hydrosilylation reaction. The invention is simple and feasible, has high yield and single product structure, and is suitable for industrialized production; and the octa-epoxy group cage-like silsesquioxane has high reactivity, and is easily modified by being compounded with resins such as epoxy resin, phenolic resin, nylon, and the like so as to prepare composite materials with high performance.

Owner:BEIJING UNIV OF CHEM TECH

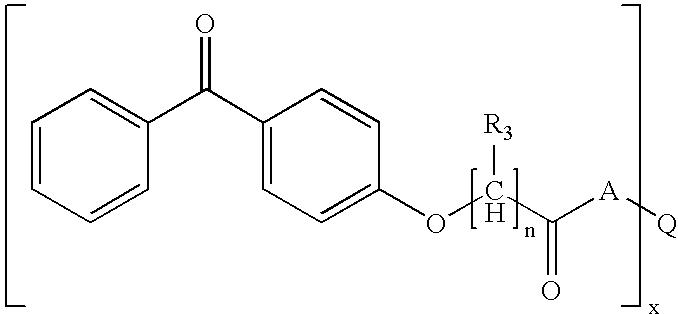

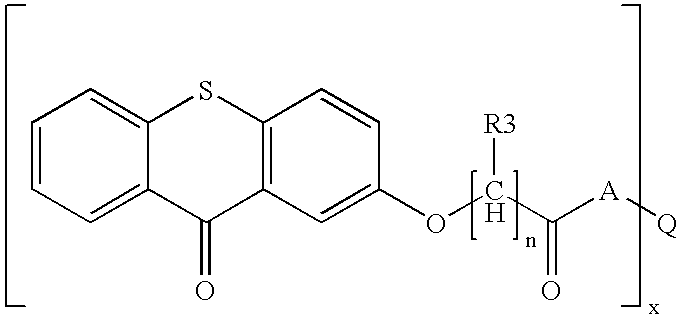

Novel radiation curable compositions

InactiveUS20060014851A1Function increaseInhibition effectDuplicating/marking methodsSynthetic resin layered productsEnd-groupLacquer

A novel polymeric initiator is disclosed comprising a dendritic polymer core with at least one initiating functional group as an end group. The dendritic polymeric core is preferably a hyperbranched polymer. The polymeric initiators are useful in radiation curable compositions such as varnishes, lacquers and printing inks and are especially useful in radiation curable inkjet inks.

Owner:AGFA NV

UV curing resin, preparation method thereof and application of UV curing resin in UV curing colored paint

ActiveCN103421156ASolve technical problems that are difficult to cureGuaranteed color uniformityInksPolyurea/polyurethane coatingsPolyolFoaming agent

The invention discloses a UV curing resin, a preparation method thereof and the application of the UV curing resin in a UV curing colored paint. The preparation method comprises the following steps: mixing polyalcohol, polyacid and fatty acid at first, adding a reflow solvent to prepare alkyd resin, then mixing an ester compound and isophorone diisocyanate, adding a polymerization inhibitor and a catalyst, reacting to obtain acrylic acid modified polyurethane, reacting the acrylic acid modified polyurethane and the alkyd resin for 2-3 h at the temperature of 60-100 DEG C to obtain the YV curing resin, and performing reaction of the UV curing resin, an acrylic acid alkyl oxidation polyol ester active diluent, a pigment, thermoplastic acrylic resin, a photoinitiator, an alkyd resin drier, a dispersant, a foam agent and a flattening agent to obtain the UV curing colored paint. The invention solves the problems that as a pigment in a conventional ultraviolet light curing colored paint system shields ultraviolet light, the paint system can not be completely cured, and as the UV curing resin can not well moisten the pigment, and the coating adhesive force is poor.

Owner:SOUTH CHINA UNIV OF TECH

Adhesive for soft package compound and preparation method thereof

ActiveCN101544880AReduce contentReduce heat seal strengthPolyureas/polyurethane adhesivesChemical structurePolyester

The present invention discloses a macromolecule adhesive, particularly relates to an adhesive for a flexible package compound film and a preparation method thereof. The adhesive for a compound film includes a hydroxy polyester polymer component (A) and an isocyanate end capping prepolymer component (B), the preparation method is that firstly a polyester is synthesized by using a diatomic alcohol and a dibasic acid, a polyester is then synthesized by using a polyatomic alcohol and a dibasic acid, the polyester molecular mass is adjusted by selection and dosage proportion of the diatomic alcohol, the polyatomic alcohol and the dibasic acid chemical structure, so as to prepare the component (A); the diatomic alcohol reacts with a different isocyanate, and compose a isocyanate end capping prepolymer together with a biuret polymer of the isocyanate so as to prepare the component (B); the component (A) and the component (B) are mixed with each other at a certain proportionality to prepare a polyurethane adhesive for a double-component solvent-free type compound film. When using the adhesive, the coating amount of the adhesive is small, and a compound speed may arrive 300 m / min.

Owner:中山市康和化工有限公司

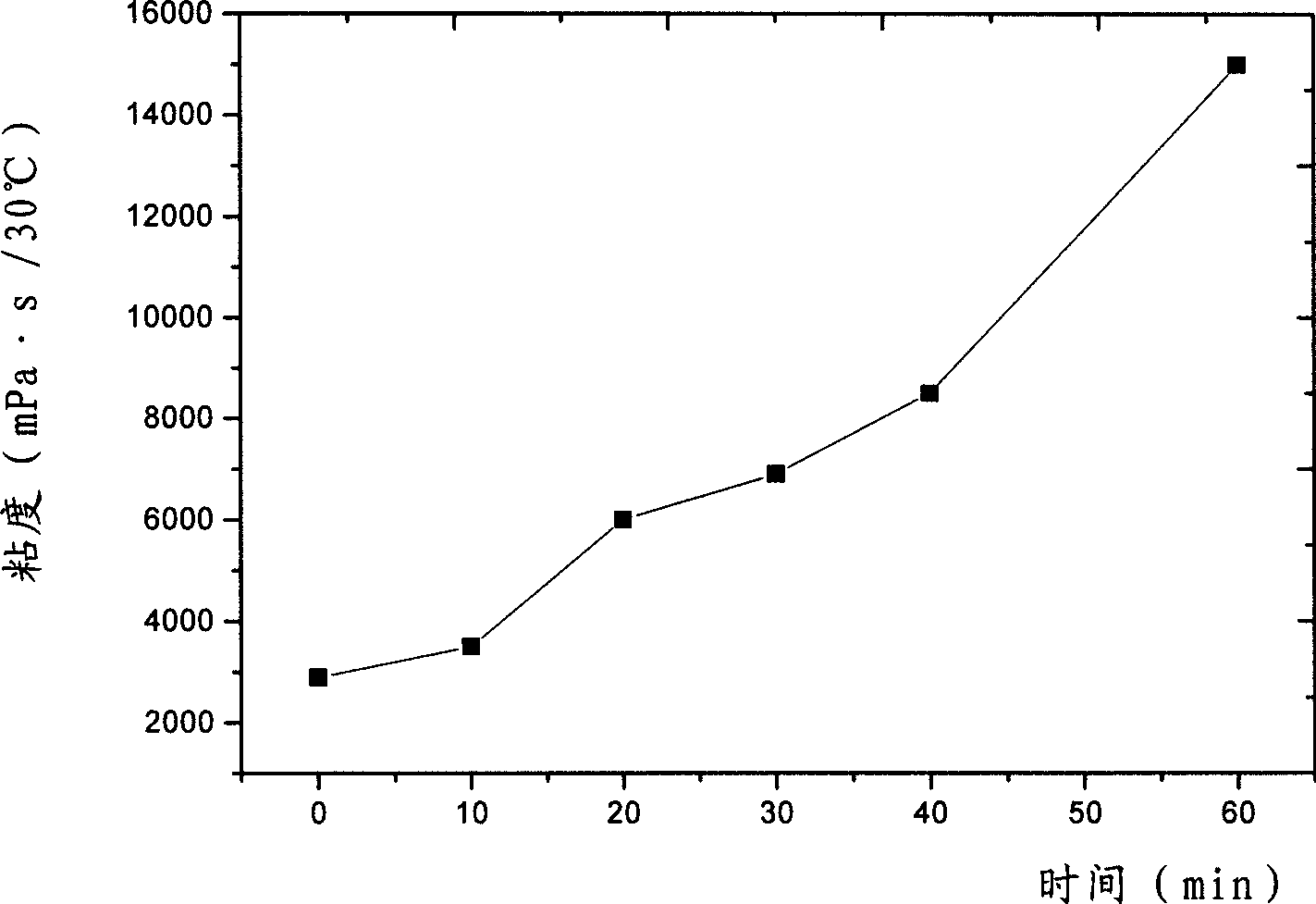

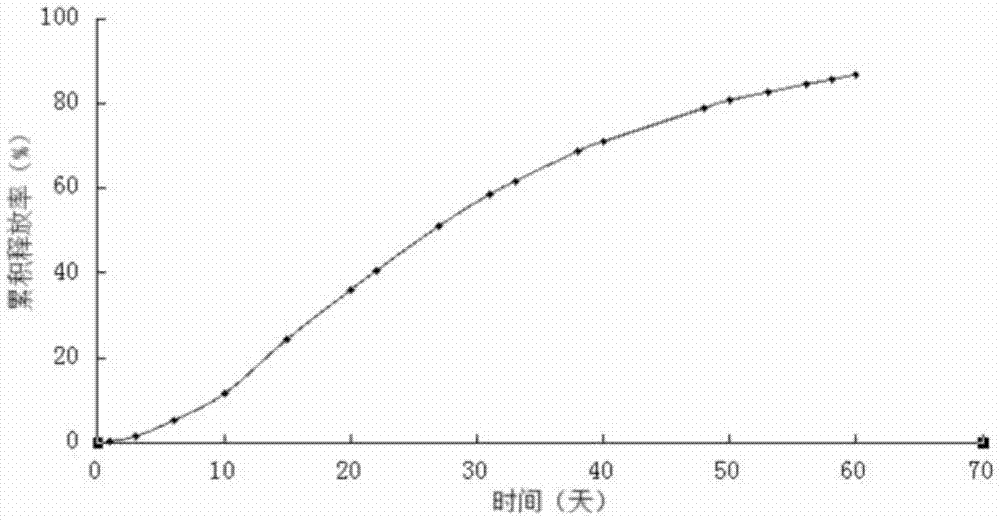

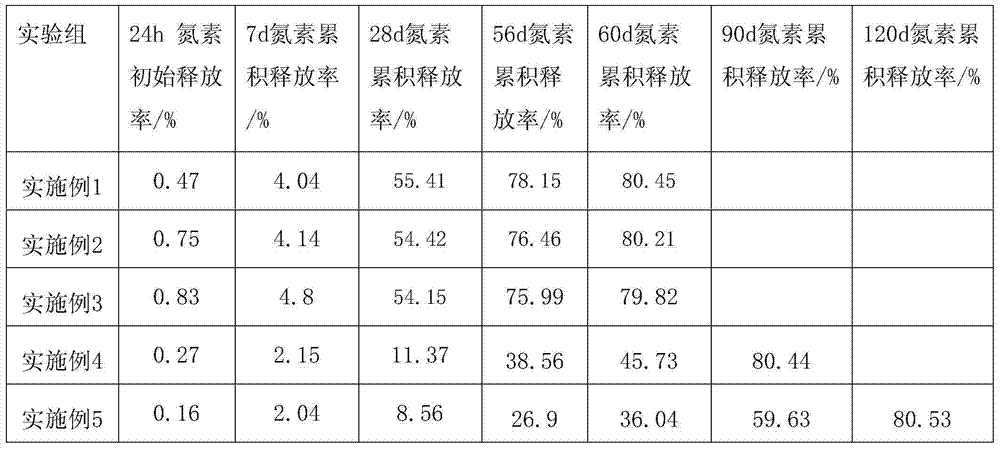

Biodegradation sustained-release fertilizer coating material containing soybean oil polyhydric alcohol and preparation process thereof

ActiveCN103772646AStrong water resistanceImprove biodegradabilityFertilizer mixturesFertilizerSolvent

The invention relates to a biodegradation sustained-release fertilizer coating material containing soybean oil polyhydric alcohol and a preparation process thereof. The coating material is prepared by stirring a material A and a material B for 5s to 15s under the condition of 65 to 75 DEG C, wherein the material A accounts for 50 to 75 percent of the weight of the coating material, and the material B accounts for 25 to 50 percent of the weight of the coating material; the material A is one or combination of soybean oil polyhydric alcohol, polyether polyhydric alcohol and castor oil, and the material B is isocyanate. The soybean polyhydric alcohol prepared from the soybean oil which is low in price and easy to obtain is strong in water resistance, the coating material which is prepared from multiple functional groups and isocyanate is high in strength and biological degradability and environmentally friendly. By adopting the coating technology, no special equipment is needed, so that not only can the equipment investment cost be greatly reduced, but also the waste of solvent in the recycling process can be avoided, and the biodegradation sustained-release fertilizer coating material is free from polluting the soil, plants and the environment after being utilized for a long time.

Owner:MAOSHI AGRI TECH CO LTD

Plant-fiber-base polyether ester polylol, and preparation method and applications thereof

The invention discloses a preparation method of a plant-fiber-base polyether ester polylol, which belongs to the field of high polymer chemistry. The preparation method comprises the following steps:liquefying plant fiber materials and a liquefacient under the catalysis of an acid catalyst to obtain a liquefying product; and carrying out the reaction of the liquefying product and cyclic carboxylic ethers, open-chain hydroxyl carboxylic ethers or estolides, and the like under the catalysis of acids, organic tin compounds or titanic acid esters so as to obtain the polyether ester polylol. The method realizes the high functionality and the high reactive activity of the plant-fiber-base polyether ester polylol. The hydroxyl value and the relative molecular mass of the product can be regulatedby changing the material proportions and the technique conditions to obtain the required product so as to prepare the polylol material required by different polyurethane materials and enhance the performance of the polyurethane materials.

Owner:SOUTH CHINA UNIV OF TECH

Low viscosity solvent-free polyurethane laminating adhesive and preparation method thereof

ActiveCN103215006AIncrease crosslink densityHigh functionalityFilm/foil adhesivesPolyureas/polyurethane adhesivesAdhesiveSolvent based

The invention discloses a low viscosity solvent-free polyurethane laminating adhesive, which includes component A and component B. The component A is an isocyanate terminated compound, and the component B is a hydroxyl terminated compound. The component A and the component B are mixed according to that the isocyanate terminated group and the hydroxyl are in a mole ratio of 1.3-1.75, thus obtaining the bicomponent polyurethane laminating adhesive. The invention also discloses a preparation method of the low viscosity solvent-free polyurethane laminating adhesive. The low viscosity solvent-free polyurethane laminating adhesive prepared by the invention has the advantages of low viscosity, fast curing speed, high peel strength and resistance to 100DEG C cooking.

Owner:SOUTH CHINA UNIV OF TECH +1

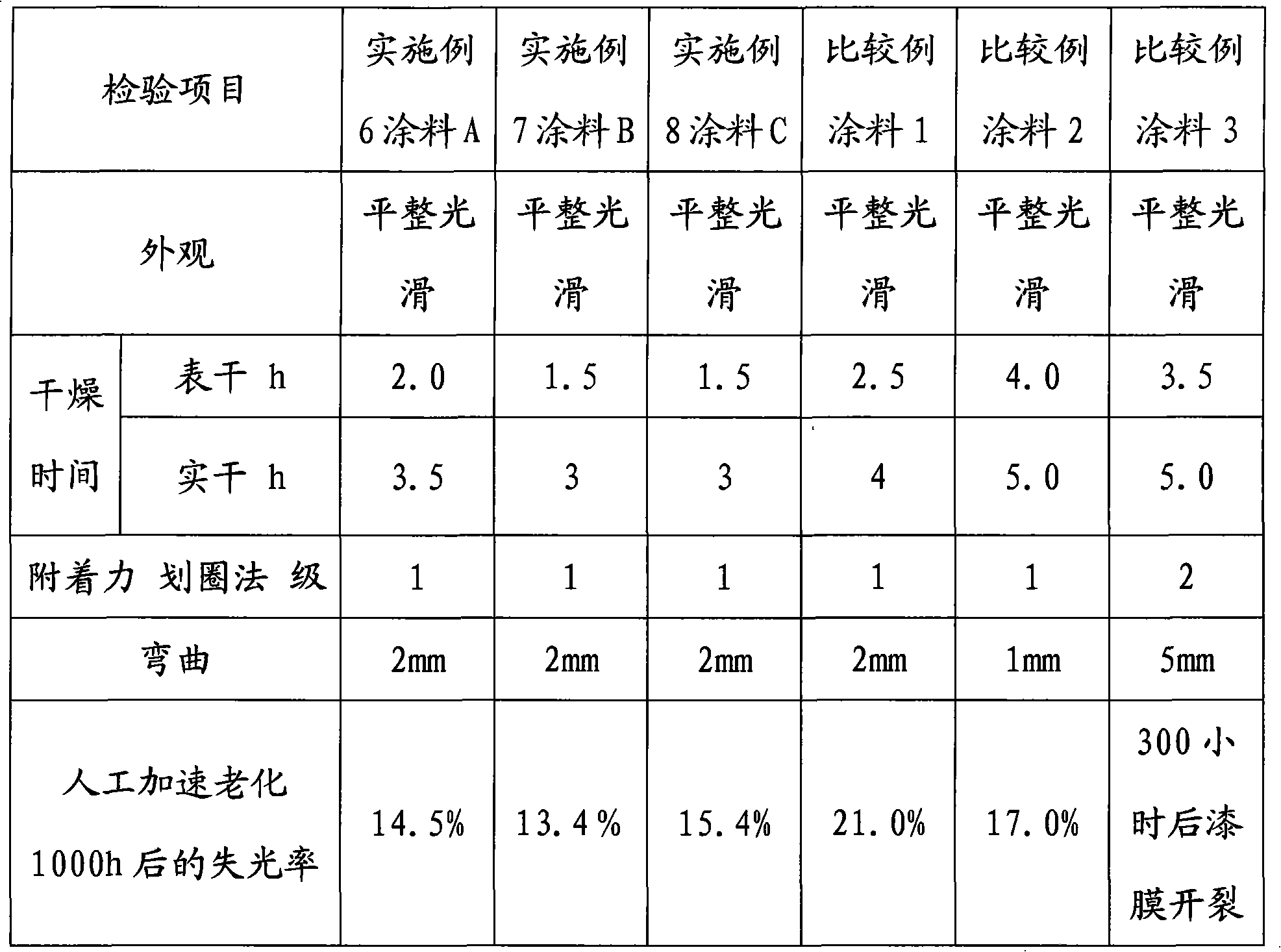

Acroleic acid modified polysiloxane resin and coating thereof

The invention relates to an acrylic modified polysiloxane resin and paint thereof. The acrylic modified polysiloxane resin is a compound resin of an acrylic resin with glycidyl and siloxane prepolymer with the number average molecular weight between 400 and 3,000. On the basis of counting solids, in the compound resin, the weight ratio of the acrylic resin with glycidyl and the siloxane prepolymer is between 10 and 40 to between 60 and 90. The paint containing the acrylic modified polysiloxane resin has a component A and a component B, wherein the weight ratio of the dosages of acrylic modified polysiloxane resin, pigment, filler, solvent and additives of the component A is 100:10-60:5-40:5-20:1-2; the component B is amino alkoxy silane as a curing agent; and when the coating is in use, the component A and the component B are well mixed in the weight ratio of 10 to between 0.8 and 1.5. Compared with the prior acrylic modified polysiloxane coating, the coating is fast in drying rate and excellent in weatherability.

Owner:CHINA NAT OFFSHORE OIL CORP +1

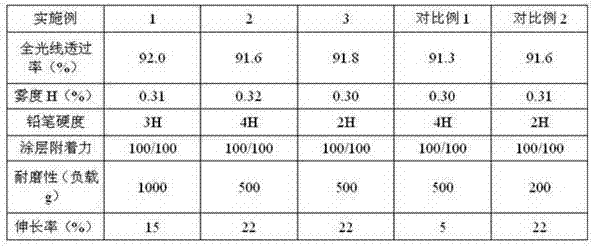

Transparent hardened film for in-mold decoration

ActiveCN102786874AHigh surface hardnessIncrease crosslink densitySynthetic resin layered productsPolyurea/polyurethane coatingsPolyethylene glycolUltraviolet

The invention provides a transparent hardened film for in-mold decoration. The transparent hardened film comprises a base film and a hardened coating layer coated thereon. The base film is a PET (polyethylene glycol terephthalate) film, and the thickness of the hardened coating layer ranges from 3 micrometers to 5 micrometers. The hardened coating layer comprises, by weight, 15-30 parts of high-functionality polyurethane acrylate prepolymer, 5-20 parts of low-functionality polyurethane acrylate prepolymer, 5-10 parts of organic-inorganic hybrid materials, 5-10 parts of photoinitiators, 0.01-0.1 part of flattening agents and 30-64 parts of organic solvent which are subjects to ultraviolet curing. The transparent hardened film has the advantages of high hardness, excellent stretch forming performance, good wear resistance, high transparency and low haze.

Owner:NINGBO HUGHSTAR ADVANCED MATERIAL TECH

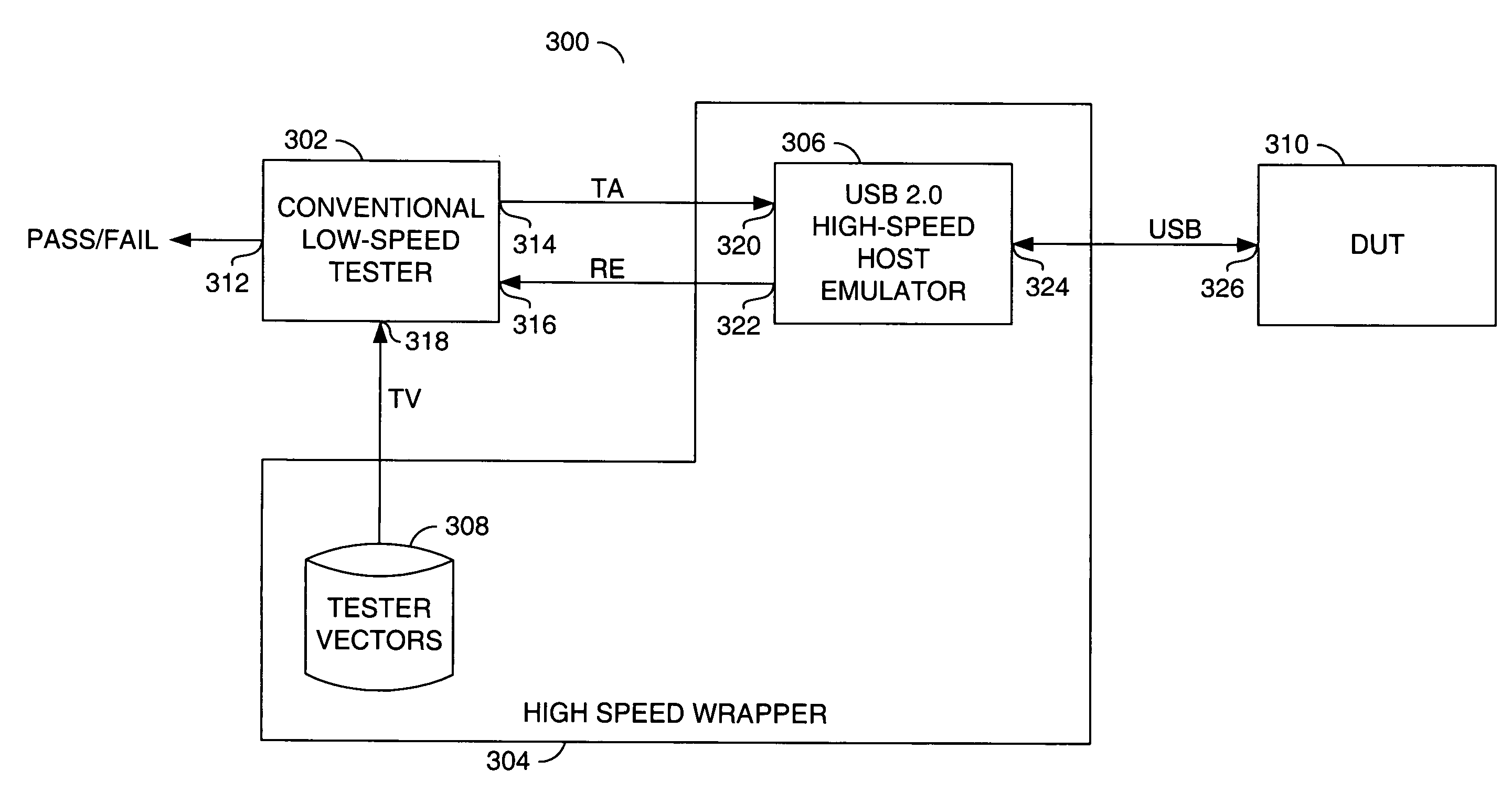

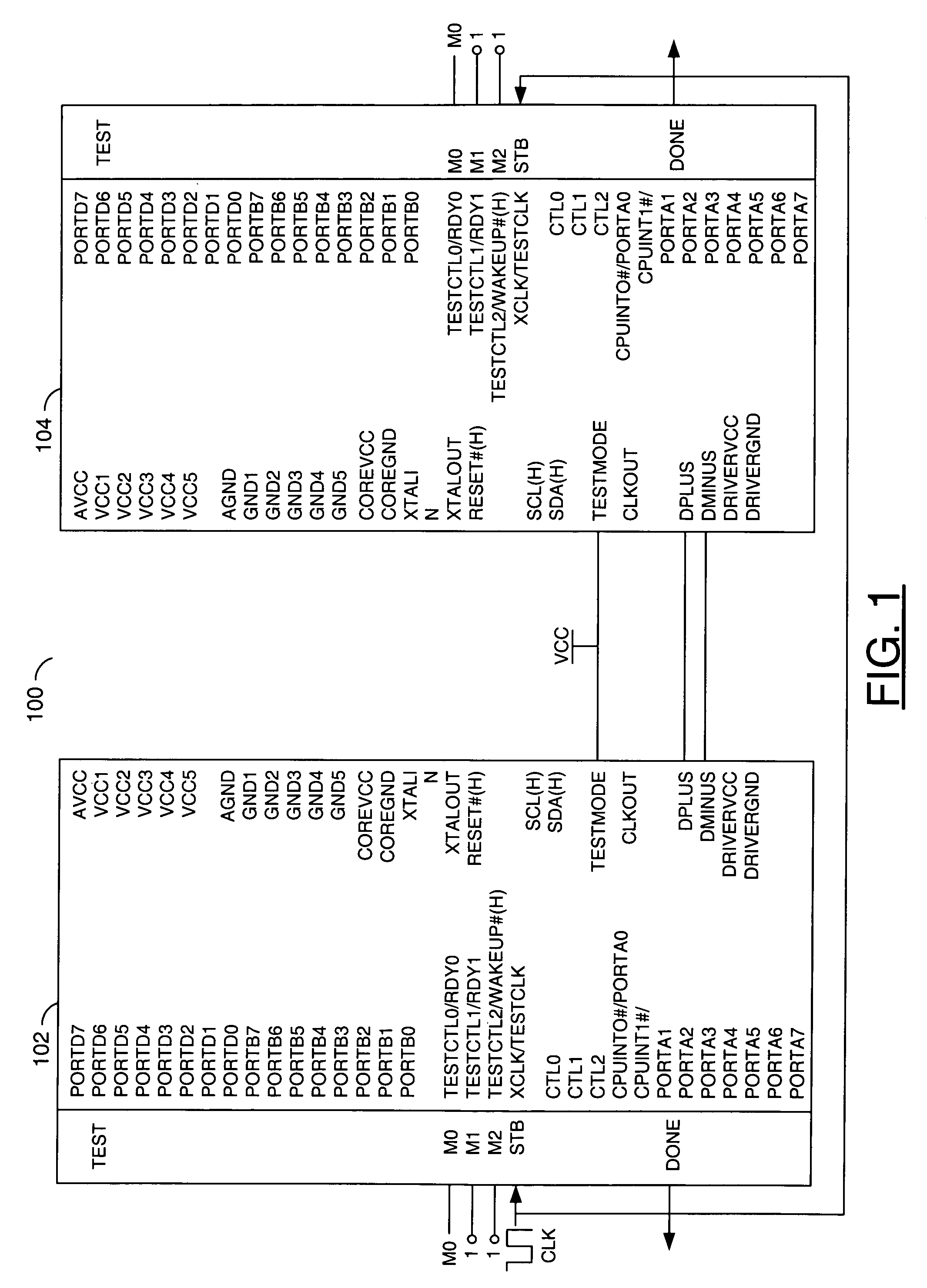

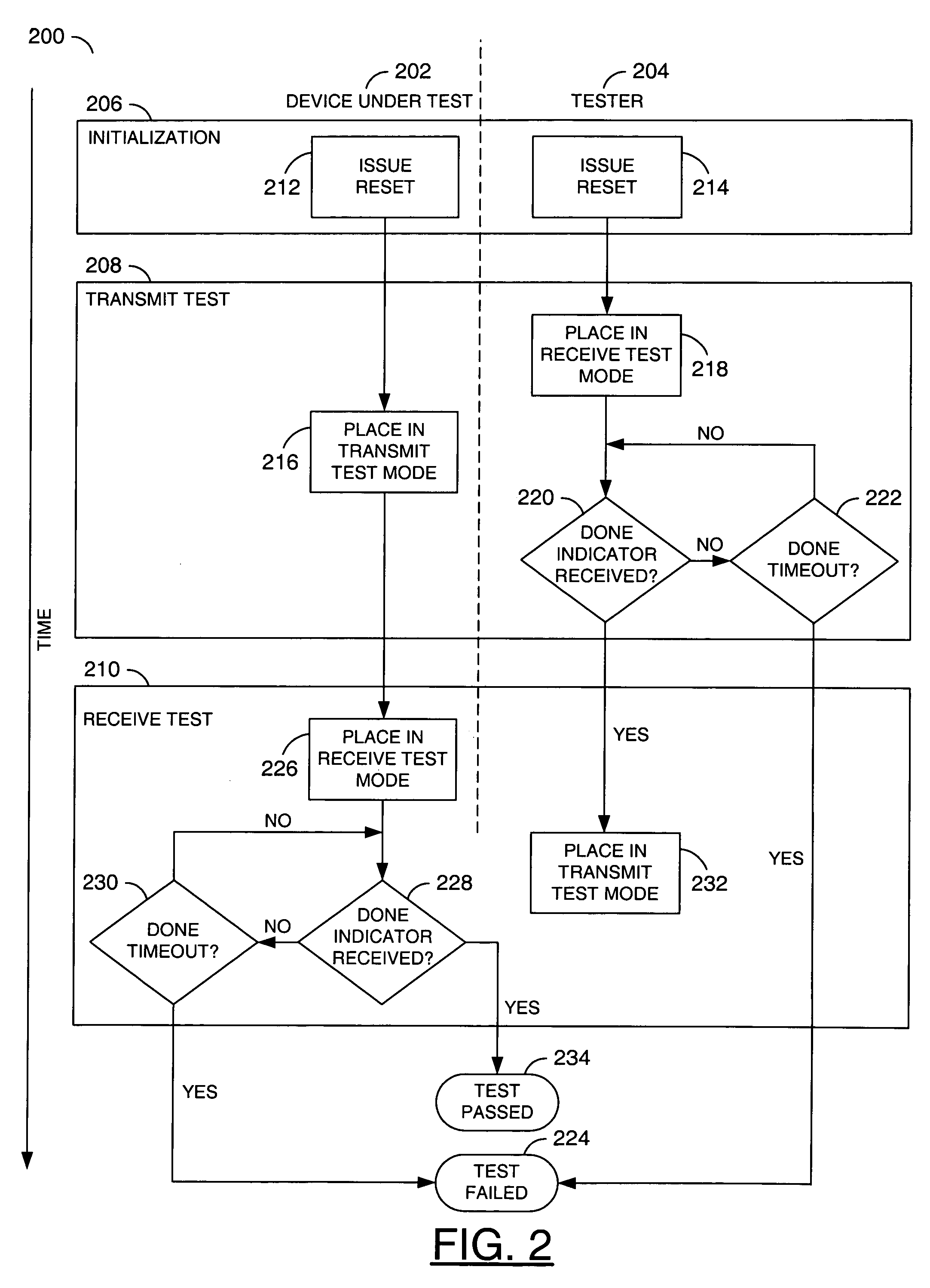

Apparatus and method to test high speed devices with a low speed tester

InactiveUS6959257B1Low costHigh functionalityResistance/reactance/impedenceNuclear monitoringEngineeringFast speed

Owner:MONTEREY RES LLC

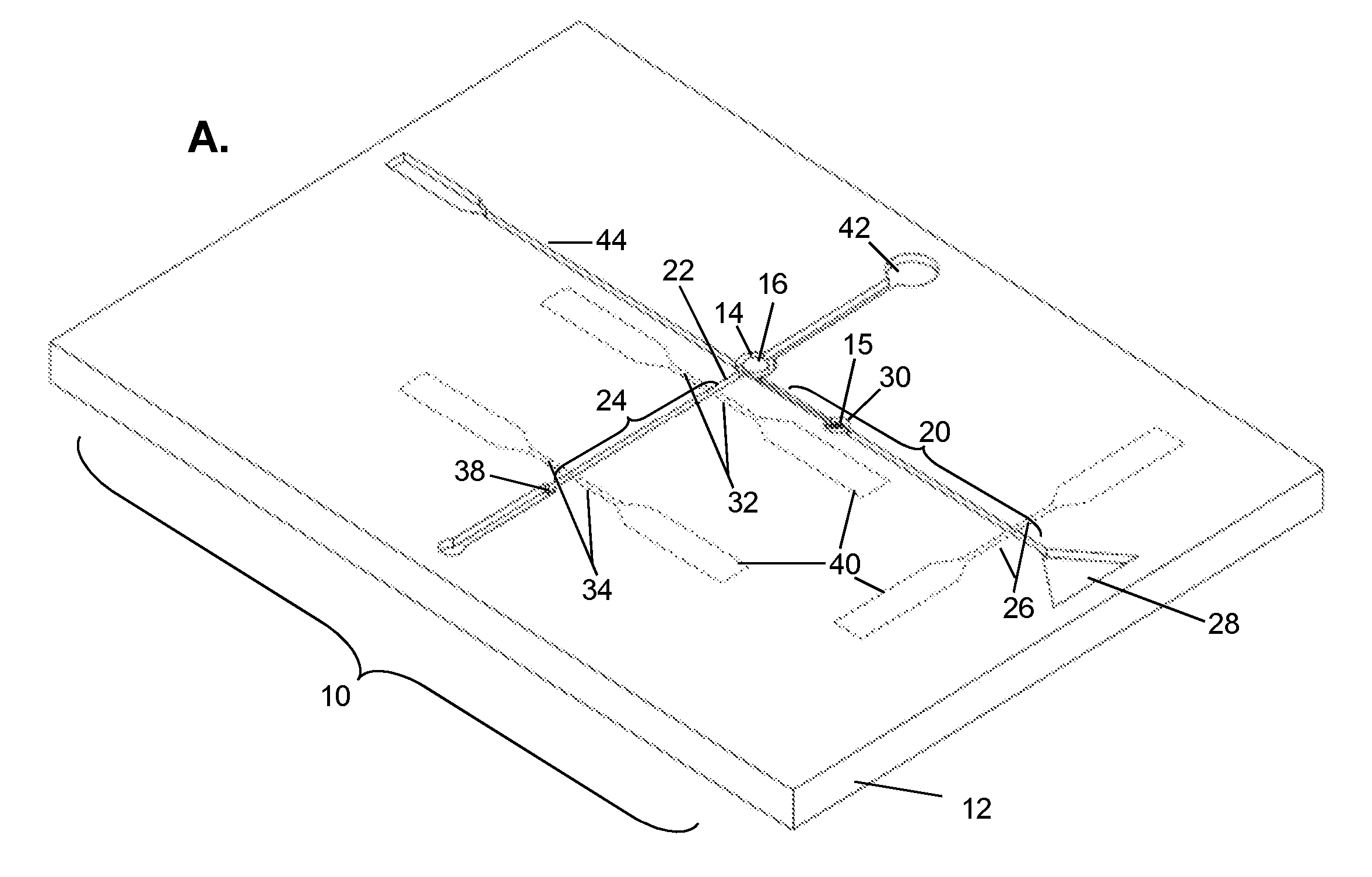

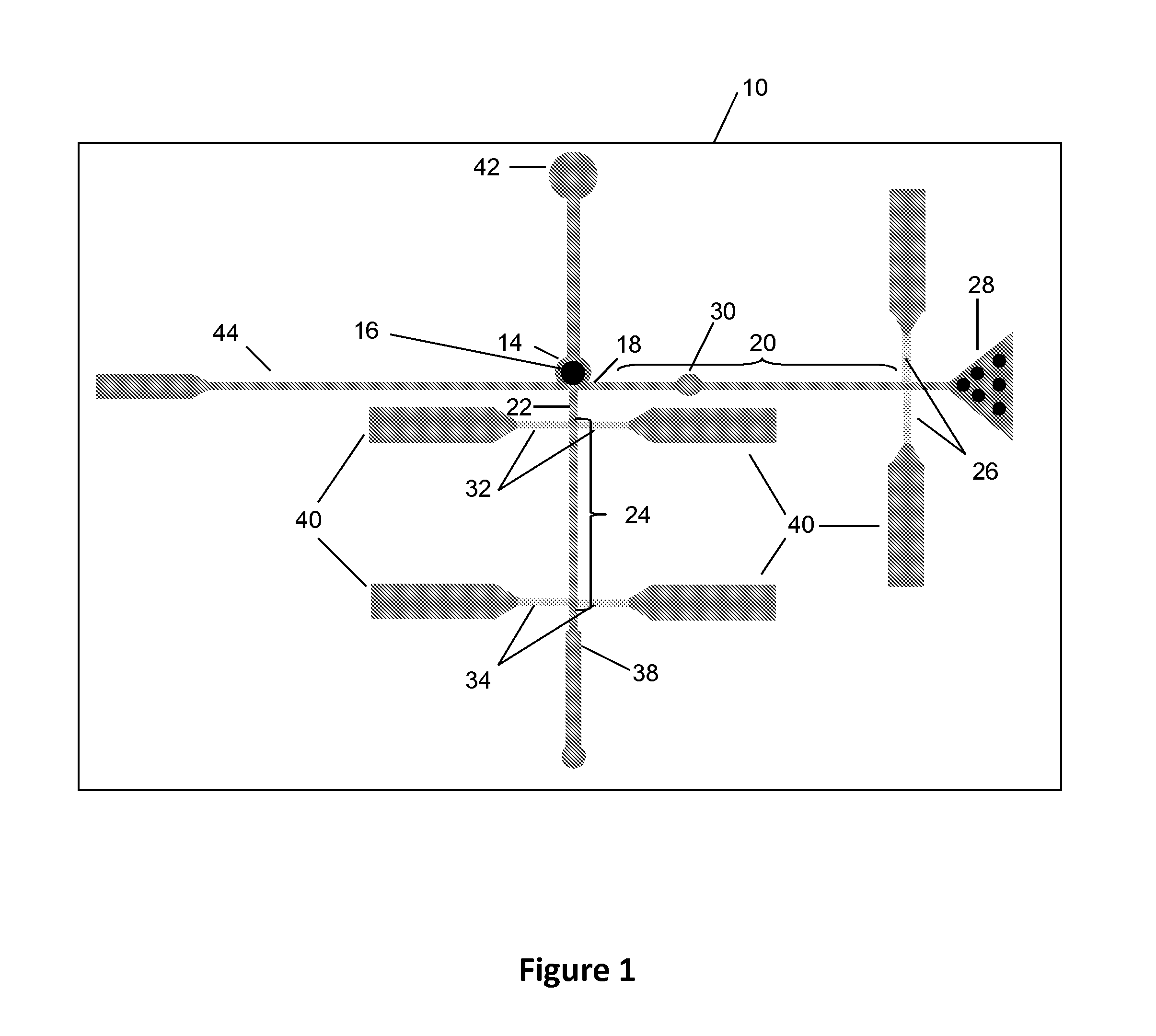

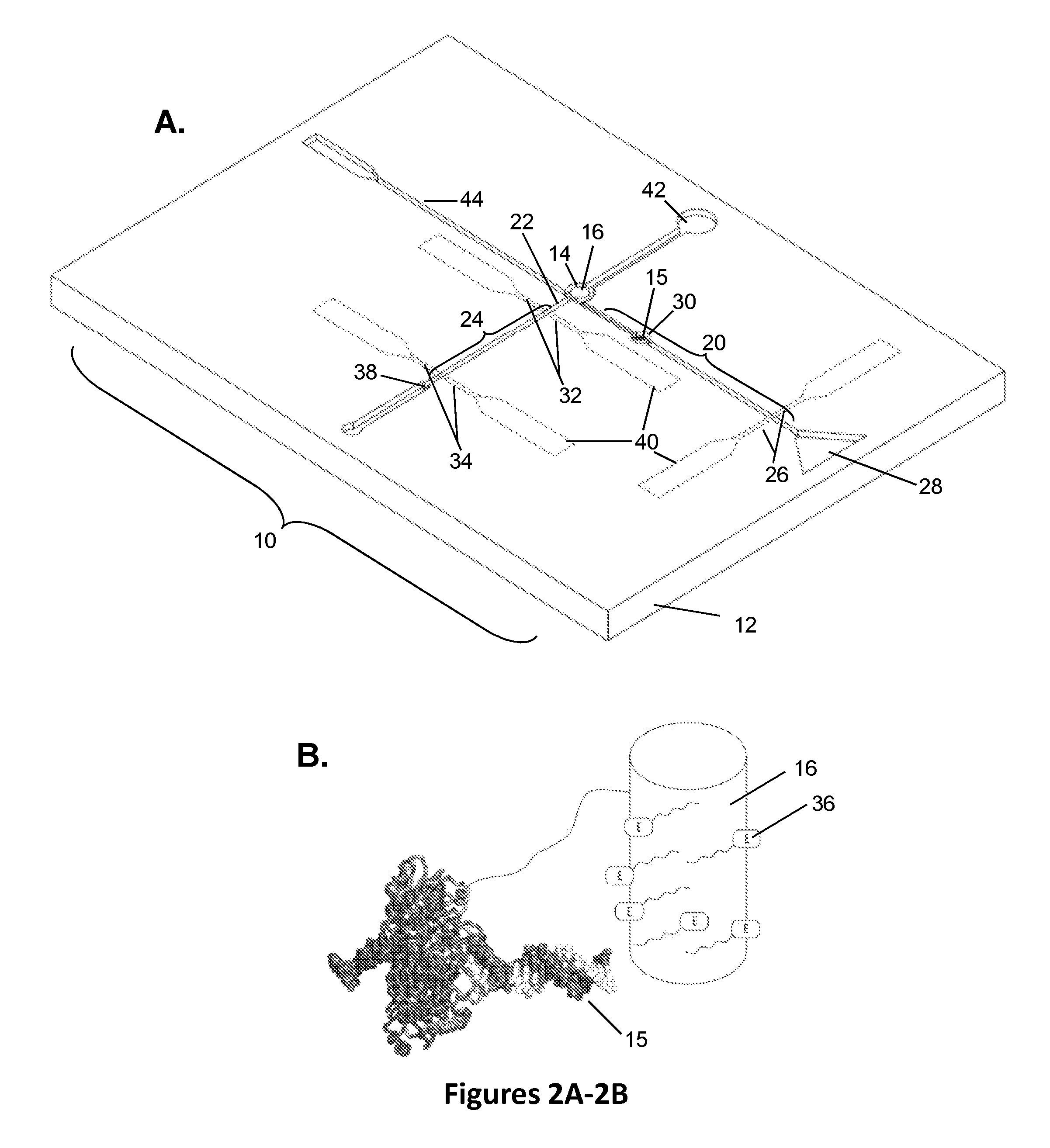

Biomolecular processing platform and uses thereof

ActiveUS20150361489A1Low costReduce laborParticle separator tubesMicrobiological testing/measurementProximateBiopolymer

The present invention relates to a device comprising a biomolecular processor. Each biomolecular processor has one or more bioreactor chambers defined by a solid substrate; a support structure within each bioreactor; a cleaving enzyme immobilized to the support structure and operatively positioned within the bioreactor chamber to cleave monomer or multimer units of a biopolymer molecule operatively engaged by the cleaving enzyme; and one or more time-of-flight channels formed in the solid substrate and fluidically coupled to said one or more bioreactor chambers. Each of the time-of-flight channels have two or more sensors including at least (i) a first sensor contacting the time-of-flight channel proximate to the input end of the channel and (ii) a second sensor contacting the time-of-flight channel proximate to the output end of channel. The present invention further relates to methods of sequencing and identifying biopolymer molecules using the device.

Owner:CORNELL UNIVERSITY +3

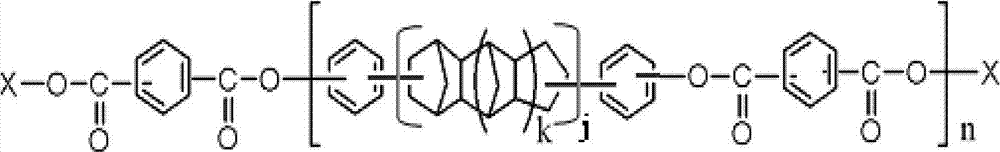

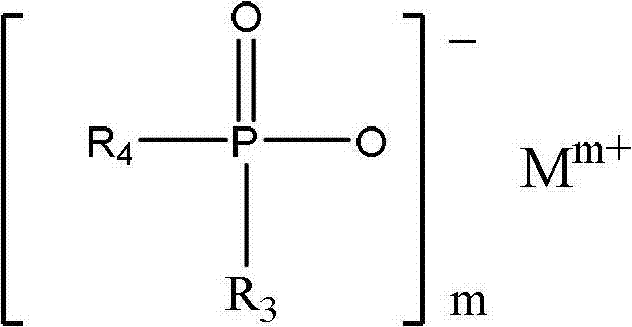

Epoxy resin composition, and prepreg and copper foil-clad laminated sheet prepared by using epoxy resin composition

ActiveCN102850722AHigh functionalityLow water absorptionSynthetic resin layered productsPrinted circuit aspectsPolymer scienceFirming agent

The present invention relates to an epoxy resin composition, and a prepreg and a copper foil-clad laminated sheet prepared by using the epoxy resin composition. The epoxy resin composition comprises the following components: (A) an epoxy resin containing two or more than two epoxy groups, (B) an active ester curing agent, and (C) a phosphate compound. According to the epoxy resin composition of the present invention, the epoxy resin having a specific molecular structure is adopted, and functionality is high, such that the resulting cured product has characteristics of high glass transition temperature and low moisture absorption; the active ester is adopted as a curing agent, such that the advantage of the active ester is completely provided, wherein the advantage comprises that no polar group is produced when the active ester reacts with the epoxy resin so as to provide excellent dielectric property and good moisture heat resistance; with application of the active ester as the curing agent, water absorption of the phosphorous-containing component can be further improved, a water absorption rate and a dielectric loss value of the cured resin material can be reduced, and purposes of no halogen, fire retardation and good moisture heat resistance can be concurrently achieved; and the prepreg and the copper foil-clad laminated sheet in the present invention have characteristics of no halogen, fire retardation, excellent dielectric property and excellent moisture heat resistance.

Owner:GUANGDONG SHENGYI SCI TECH

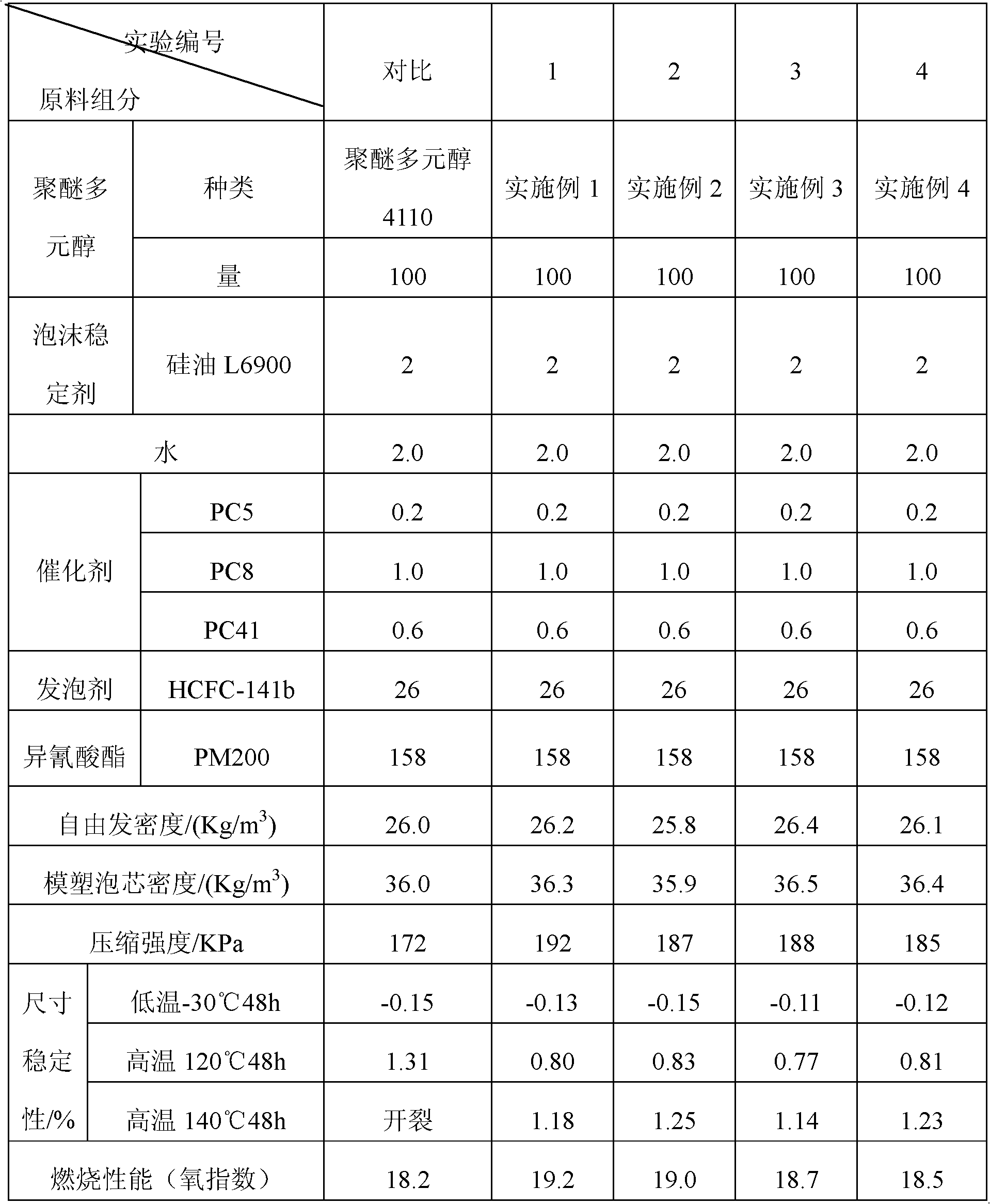

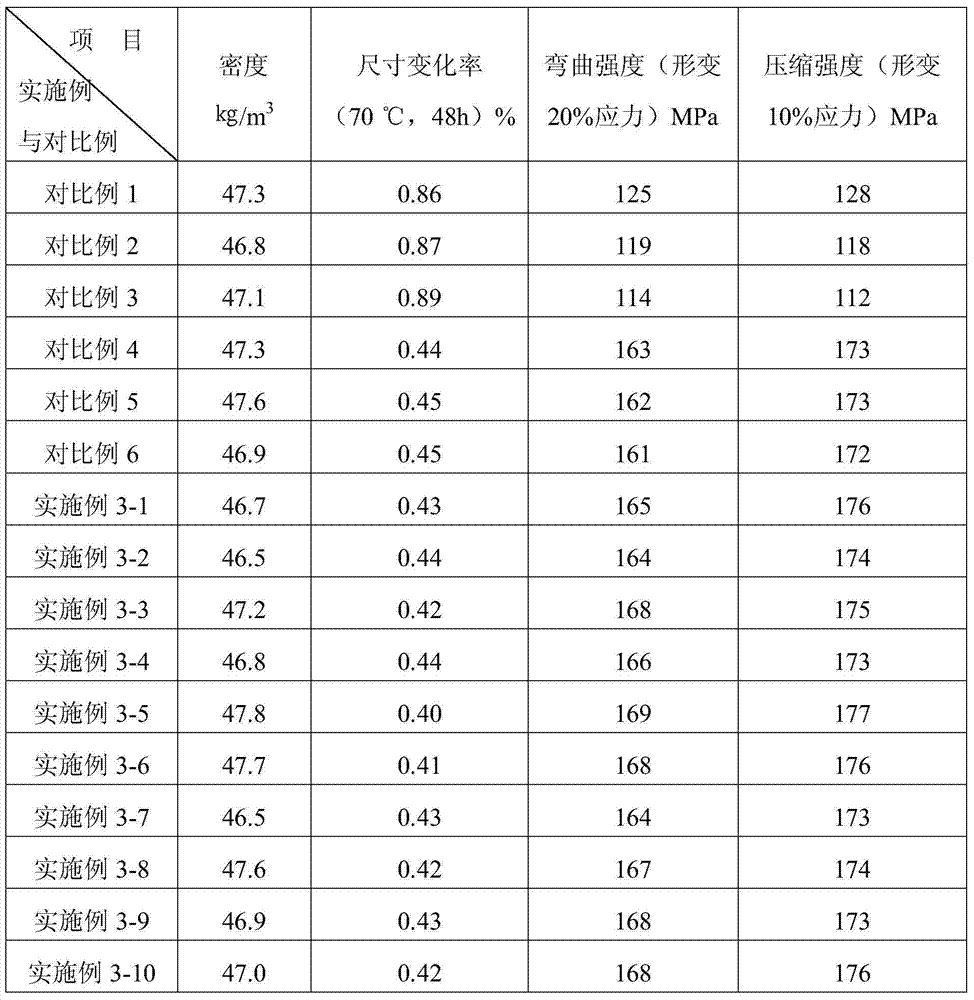

Polyether glycol, polyurethane rigid foamed plastic and preparation methods thereof

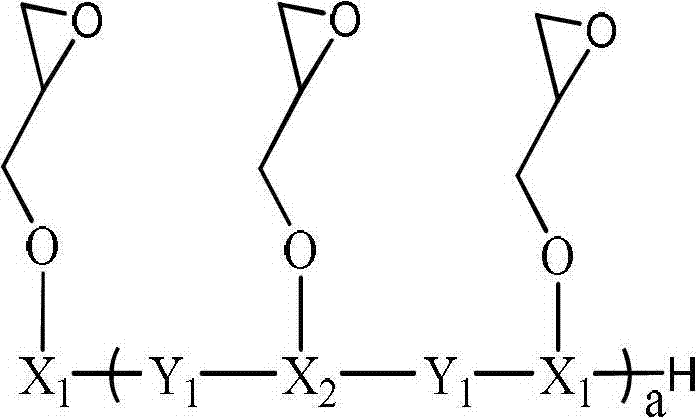

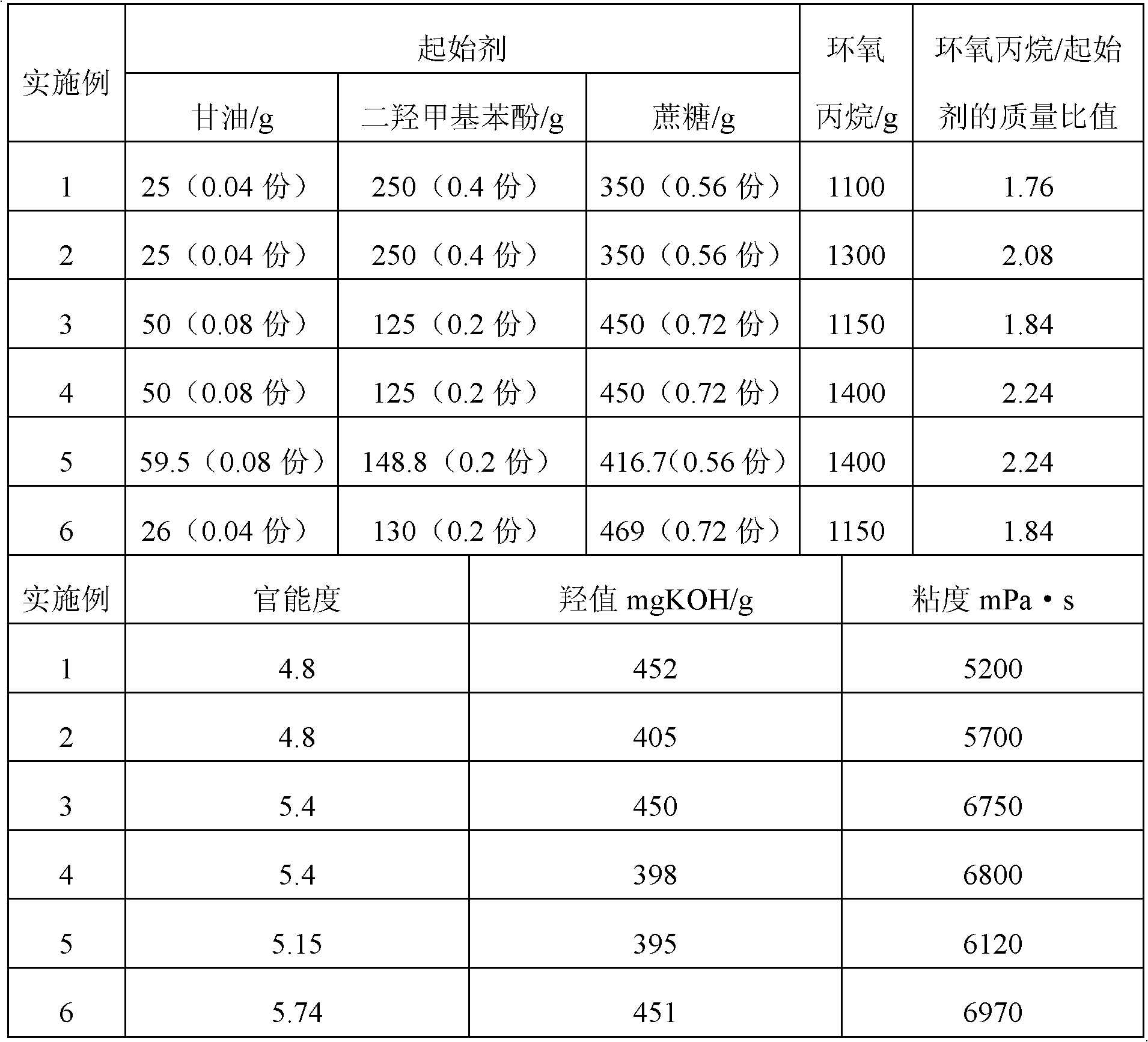

InactiveCN102050945ALow viscosityHigh functionalitySugar derivativesEther preparation from oxiranesPolymer scienceSucrose

The invention discloses a preparation method of polyether glycol. The method comprises the following step: preparing the polyether glycol from compound initiator, polyether glycol synthetic catalyst and propylene oxide by using a conventional polyether glycol synthesis method, wherein the compound initiator comprises the following components in parts by weight: 0.04-0.08 part of glycerol, 0.2-0.4 part of dihydroxymethylphenol and 0.56-0.72 part of sucrose; and the mass ratio of the propylene oxide to the compound initiator is 1.7-2.3. The invention also discloses polyether glycol prepared by using the method, a method for preparing polyurethane rigid foamed plastic from the polyether glycol, and polyurethane rigid foamed plastic. The polyether glycol disclosed by the invention has the advantages of low viscosity and high functionality, and has favorable processing properties when being used as a raw material. The polyurethane rigid foamed plastic prepared from the polyether glycol has the advantages of excellent high-temperature resistance, high flame resistance and high compression strength.

Owner:SHANGHAI DONGDA POLYURETHANE

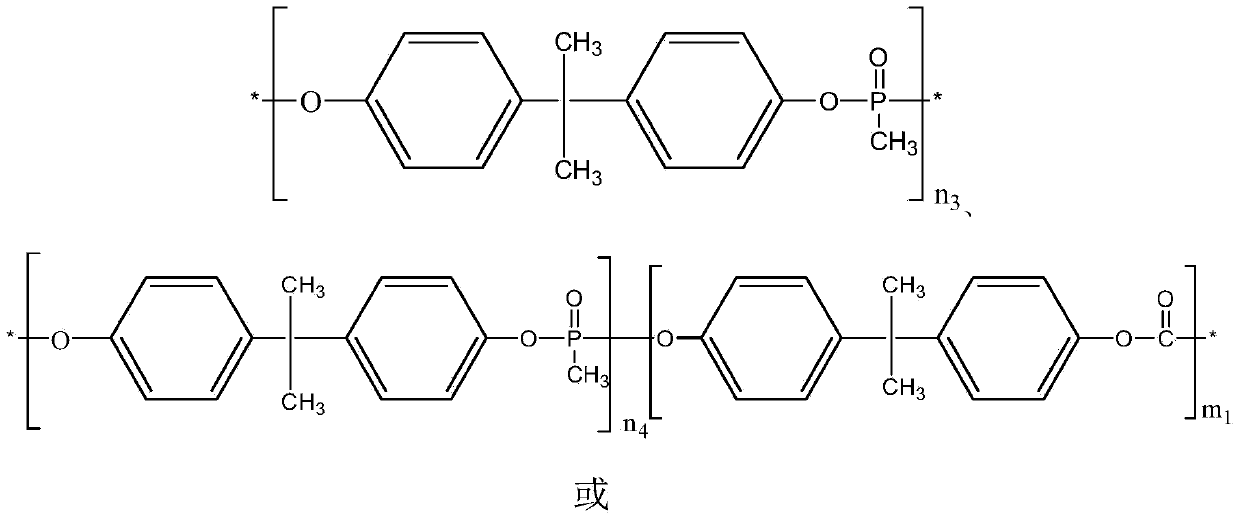

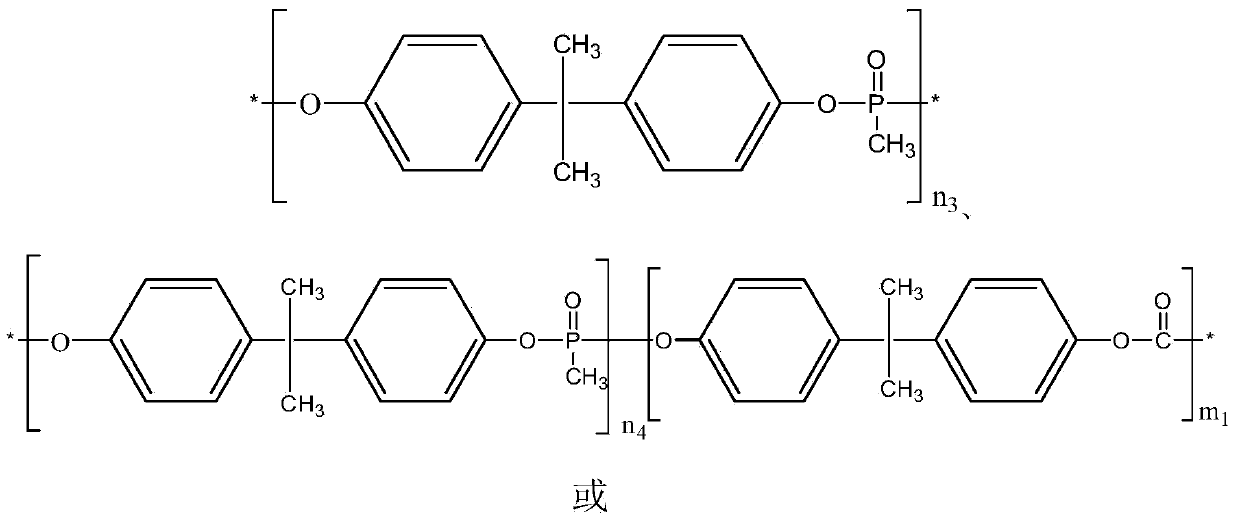

Thermosetting epoxy resin composition and use thereof

ActiveCN103756257AExcellent dielectric propertiesExcellent heat and humidity resistancePrinted circuit aspectsConductive materialDielectricEpoxy

The invention relates to a thermosetting epoxy resin composition which comprises epoxy resin, an active ester curing agent, and polyphosphonate or / and phosphonate-carbonate copolymer. The prepreg prepared by the epoxy resin composition and a copper foil coated laminated board have excellent dielectric property and heat and humidity resistance, and the flame retardance can reach level UL94V-0.

Owner:GUANGDONG SHENGYI SCI TECH

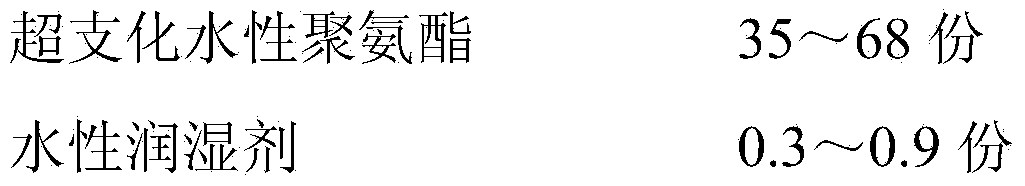

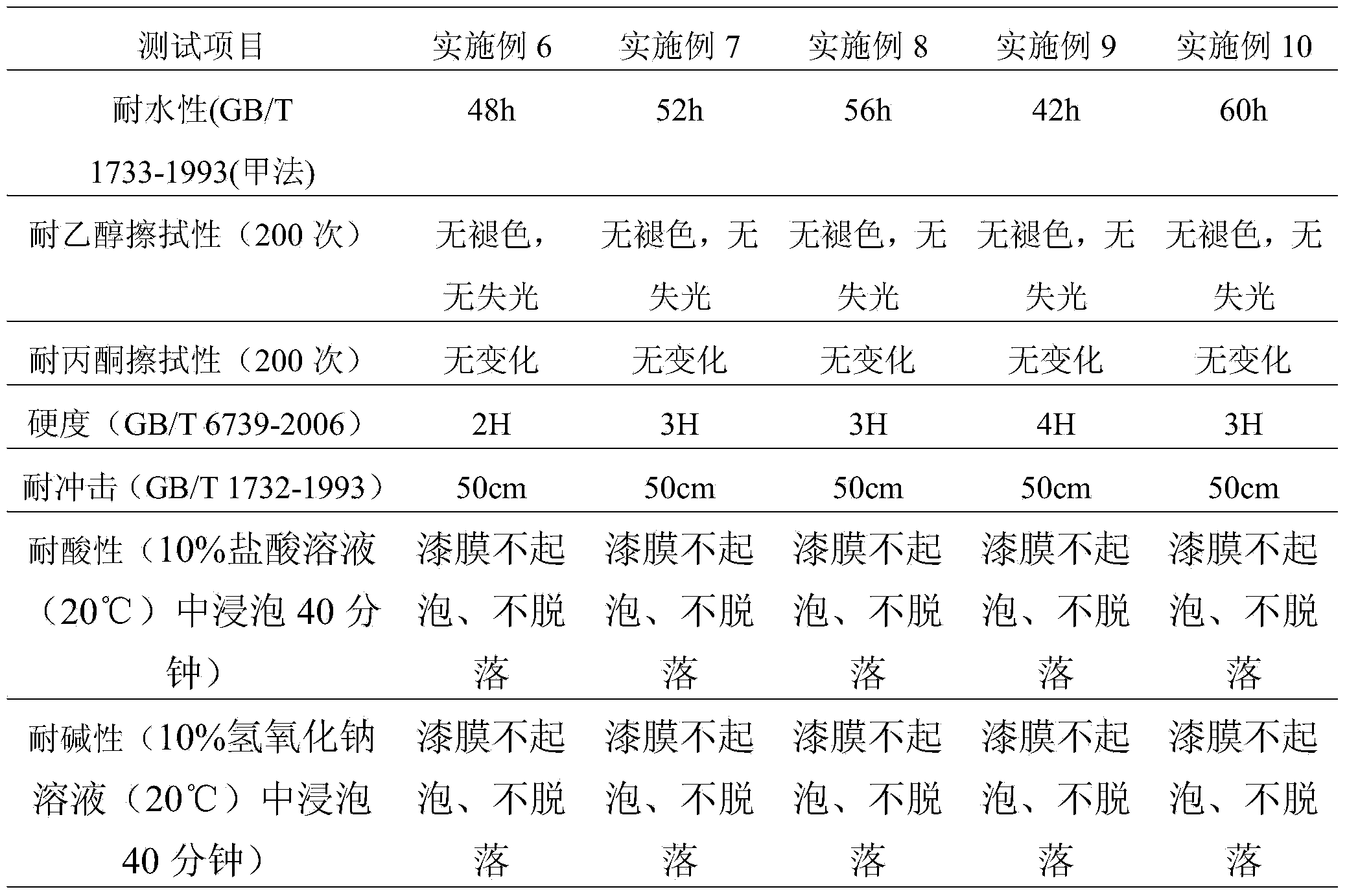

Hyperbranched water-based polyurethane coating and preparation method thereof

ActiveCN103450792AGood storage stabilityHigh functionalityPolyurea/polyurethane coatingsWater basedHyperbranched polyester

The invention provides a hyperbranched water-based polyurethane coating and a preparation method thereof, belongs to the field of water-based coating, and is used for solving the problem that the existing hyperbranched water-based polyurethane is poor in waterproofness, solvent resistance and weather fastness. The coating comprises 35-68 parts of hyperbranched water-based polyurethane, 0.3-0.9 part of water-based wetting agent, 0.2-0.7 part of water-based flatting agent, 0.5-1.1 parts of water-based deformaer, 8-12 parts of water-based cosolvent and 2.5-4.3 parts of curing agent. The hyperbranched water-based polyurethane is prepared with hyperbranched polyester BoltornTMH40 as a soft segment and diaminosulfonate as a hydrophilic chain extender. A film formed by the cured hyperbranched water-based polyurethane coating provided by the invention has no phenomena of blushing, bubbling and falling even after being soaked in normal-temperature water for 60 hours, and also has no phenomena of blushing, facing and dulling even after being wiped 200 times by using ethanol and acetone.

Owner:CHANGCHUN SANHUA IND

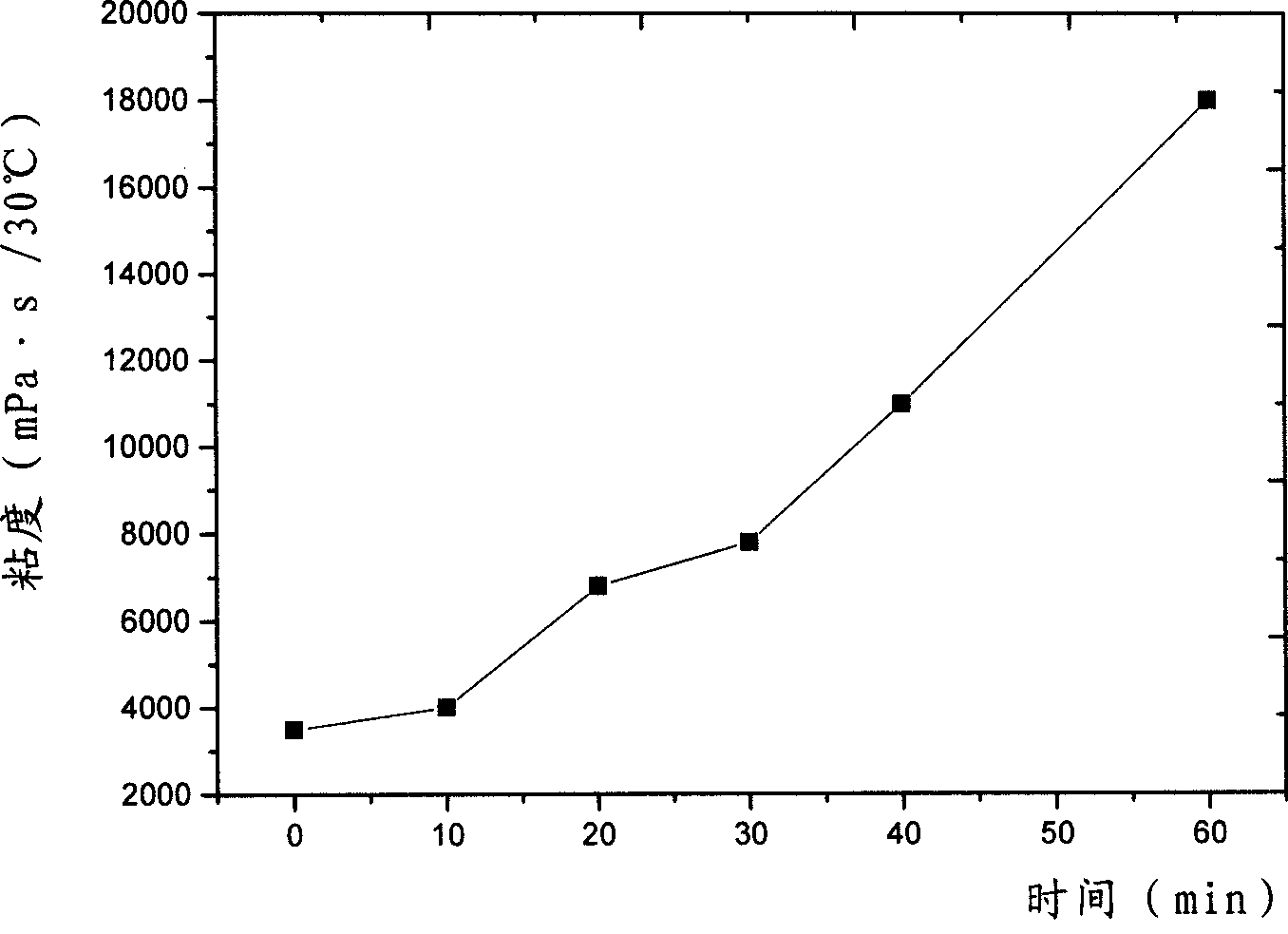

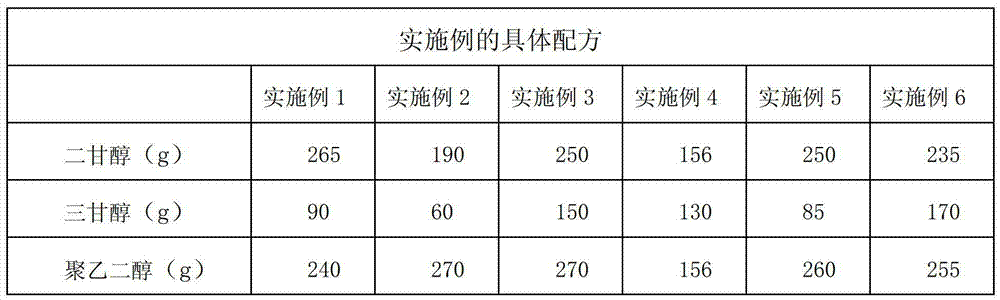

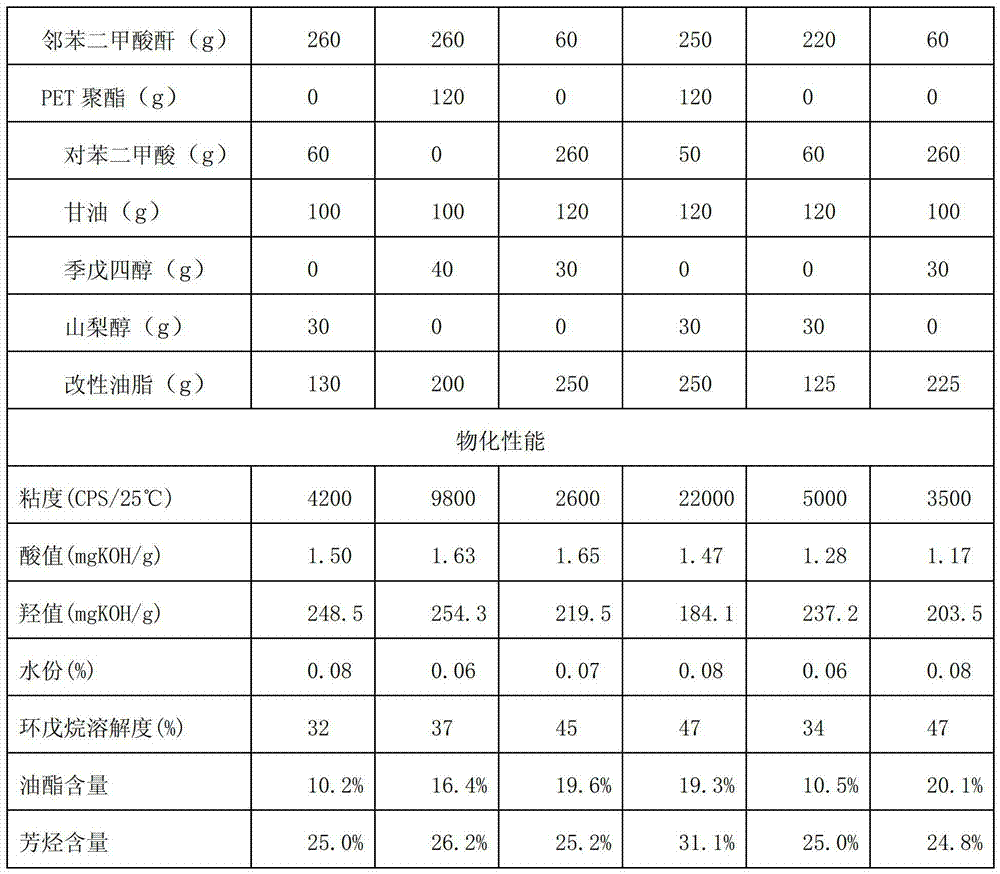

High-functionality degree polyester polyol and preparation method thereof

ActiveCN104262596AReduce usageLow viscosityOrganic-compounds/hydrides/coordination-complexes catalystsPlastic recyclingPolyesterPolyurethane adhesive

The invention discloses high-functionality degree polyester polyol and a preparation method thereof. The high-functionality degree polyester polyol comprises the following components in parts by mass: 900-1200 parts of polyester alcoholysis liquid, 900 parts of phthalic anhydride, 400-600 parts of aliphatic dibasic acid, 800-1000 parts of dihydric alcohol, 550-900 parts of polyhydric alcohols, 0.3-0.5 part of esterification catalyst. The preparation method comprises the following steps: carrying out an esterification reaction, removing the moisture, performing condensation polymerization, thereby obtaining the product. According to the high-functionality degree polyester polyol, the average functionality degree is 2.4-2.5, the viscosity is less than or equal to 10000mPa.S at the temperature of 25 DEG C, the hydroxyl value is 300-350mgKOH / g, the acid value is less than or equal to 1mgKOH / g, and the polyester polyol is non-crystallizable after being stored for three months under the condition of 2 DEG C. The polyester polyol disclosed by the invention can be widely applied to the fields of rigid polyurethane foam plates, polyurethane elastomers and polyurethane adhesives.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Polyester resin used for TGIC curing high-toughness thermal transfer printing powder paints, and preparation method thereof

ActiveCN105367765AHigh glass transition temperatureImprove toughnessPowdery paintsPolyester coatingsVitrificationPolyol

The invention relates to a polyester resin used for TGIC curing high-toughness thermal transfer printing powder paints, and a preparation method thereof. The glass-transition temperature of the polyester resin is relatively high, so that prepared powder paint coating possesses high toughness at normal temperature and -15 DEG C. According to the preparation method, the polyester resin is obtained via melt polycondensation of following raw materials: a polyol, a polyacid, an acidolysis agent, an esterification catalyst, an antioxidant, and a curing accelerator. The preparation method comprises following steps: 1) the polyol is delivered into a reaction kettle at a needed ratio, rapid heating esterification is carried out, water is generated, and is removed via distillation; 2) temperature is increased gradually, and an obtained material is maintained to be clear; 3) sample examination is carried out; 4) one half of the antioxidant is added, and negative pressure polycondensation is carried out; and 5) cooling is carried out, one half of the antioxidant and the curing accelerator are added, stirring dispersing is carried out, and an obtained product is cooled, and is collected.

Owner:ZHEJIANG CHUANHUA TIANSONG NEW MATERIAL CO LTD

Cashew nut shell oil-modified phenolic resin and preparation method for cashew nut shell oil polyether polyol prepared from same

ActiveCN103073689AReduce viscosityHigh functionalityPolyurea/polyurethane coatingsPolymer sciencePolyol

The invention discloses cashew nut shell oil-modified phenolic resin and a preparation method for cashew nut shell oil polyether polyol prepared from the cashew nut shell oil-modified phenolic resin. The method for preparing the cashew nut shell oil-modified phenolic resin comprises the following steps: adding cashew nut shell oil and an acidic catalyst in a reactor; then adding a coupling agent by stirring to enable the coupling agent to be completely dissolved; and raising the temperature, reacting and dehydrating to obtain a product. The method for preparing the cashew nut shell oil polyether polyol comprises the following steps: adding a basic catalyst and an epoxy compound into the product; and rising the temperature, reacting, cooling and filtering to obtain the cashew nut shell oil polyether polyol. The polyether polyol prepared by the preparation method disclosed by the invention has the advantages of low viscosity, moderate functionality degree, no toxicity, regeneration and the like. The phenolic resin disclosed by the invention is used as intermediate resin. The cashew nut shell oil polyether polyol disclosed by the invention is applied to polyurethane coating and is used as hydroxyl-containing resin to be matched with an isocyanatec component to form a polyurethane coating system. The cashew nut shell oil polyether polyol has the characteristics of favorable corrosion resistance, in particular to alkali resistance, excellent mechanical performance and the like.

Owner:CARDOLITE CHEM ZHUHAI

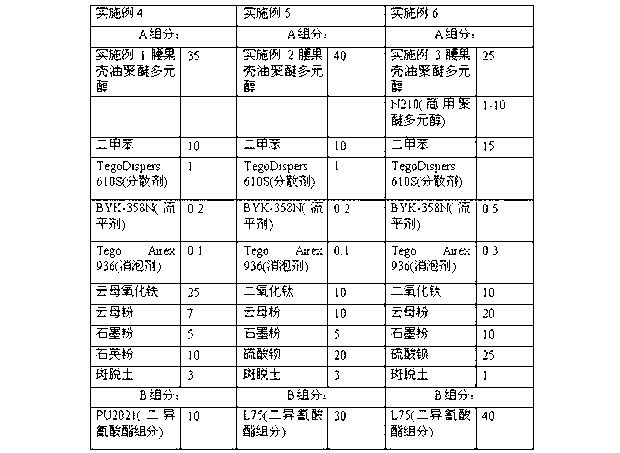

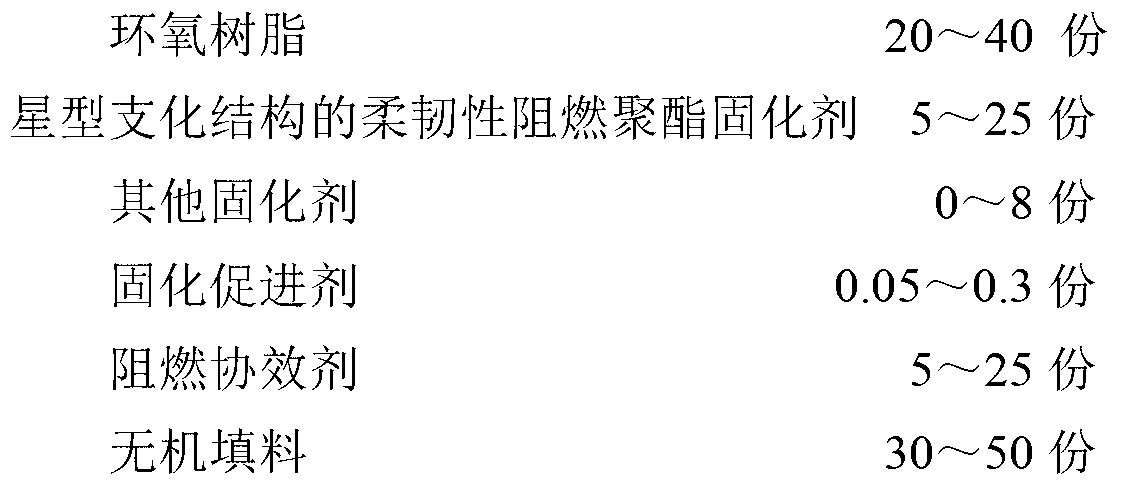

Epoxy resin composition with excellent flexibility and flame retardance, and preparation method thereof

The invention relates to an epoxy resin composition with excellent flexibility and flame retardance, and a preparation method thereof. The epoxy resin composition is powered and comprises the following ingredients in parts by mass: 20-40 parts of epoxy resin 5-25 parts of flexible flame-retardant polyester curing agent with a star-like branched structure, 0-8 parts of other curing agent, 0.05-0.3 parts of curing accelerant, 5-25 parts of flame-retardant synergist, and 30-50 parts of inorganic filler. The epoxy resin composition relating in the invention does not contain halogen and antimonous oxide, has excellent flexibility and flame retardance, not only can realize the halogen-free flame retardance of an electronic packaging material, but also can endow the electronic packaging material with excellent flexibility after being used for the field of the electronic packaging materials, so that the cold and hot impact resistance of the electronic packaging material can be improved greatly.

Owner:天津凯华绝缘材料股份有限公司

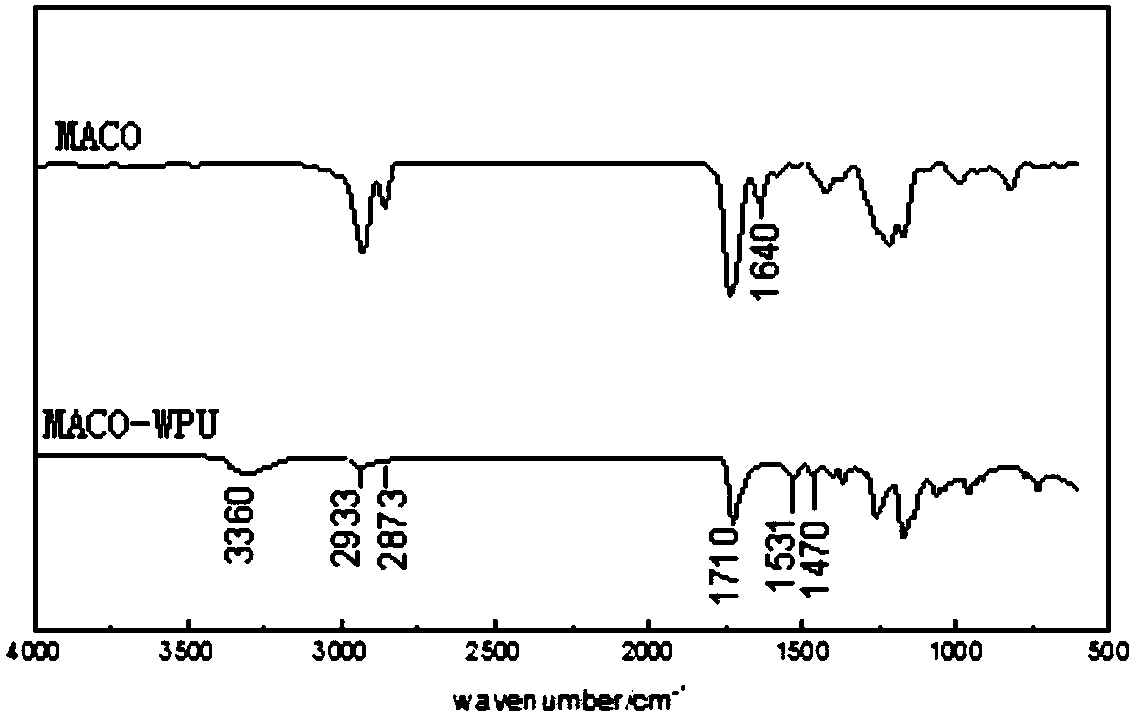

Production method of polyester polyol

The invention discloses a production method of polyester polyol. According to the method, natural oil is modified by maleic anhydride and then reacts with small-molecule polyol, dicarboxylic acid or carboxylic ester to obtain a polyester polyol product with high cyclopentane solubility. According to the invention, the modified oil can be led into a polyester body relatively completely so as to improve the functionality of the whole product; the cost of the adopted raw materials is low, and the technology is easy to operate; and particularly in the process of producing low-density polyurethane foam, the solubility of the adopted cyclopentane in polyester polyol can be improved at least to 25%.

Owner:ZHANGJIAGANG NANGUANG CHEM

Water dispersible hyperbranched polyisocyanate and preparation method thereof

The invention discloses water dispersible hyperbranched polyisocyanate and a preparation method thereof. The preparation method comprises that hyperbranched polyester with different generation quantities is synthesized while polyalcohol is taken as a core molecule, dimethylolpropionic acid is taken as a monomer and dimethylbenzene is taken as a solvent, end group modification is carried out on the hyperbranched polyester, a high reactivity isocyanate group is introduced for synthesizing hyperbranched polyisocyanate, and then waterborne treatment is carried out on the hyperbranched polyisocyanate, so that the water dispersible hyperbranched polyisocyanate is obtained. The preparation method is low in production cost and simple in technological equipment, and the prepared water dispersible hyperbranched polyisocyanate has high functionality degree, high reactivity and low viscosity, can be dispersed in water and can be used for improving the physical and chemical properties of a coating when being applied to a waterborne alkyd paint, a waterborne polyurethane coating and a waterborne acrylic coating as a curing agent.

Owner:武汉仕全兴聚氨酯科技有限公司 +1

Cross-linking waterborne polyurethane and preparation method thereof

The invention discloses a preparation method for cross-linking waterborne polyurethane. The preparation method comprises the following steps that 1, polyester polyol and diisocyanate are mixed, then acatalyst of dibutyltin dilaurate is dropwise added, nitrogen is introduced, and reaction is carried out; 2, a hydrophilic chain extender is added for reaction, then a end-capping chain extender is added for reaction, and after a neutralizer is added for reaction, water is added for dispersing so as to obtain a waterborne polyurethane emulsion; and 3, a multi-double-bond castor oil solution is added into the waterborne polyurethane emulsion, an initiator is dropwise added, reaction is carried out, and after the reaction is finished, a solvent is removed so as to obtain the cross-linking waterborne polyurethane. According to the method, the waterborne polyurethane emulsion is firstly synthesized, then free radical copolymerization reaction is carried out on multi-double-bond castor oil andthe waterborne polyurethane, the multi-double-bond castor oil is connected into a waterborne polyurethane structure so as to form the cross-linking waterborne polyurethane with a spatial network structure, and therefore the mechanical performance of the cross-linking waterborne polyurethane is improved; and the spatial density inside a polymer is increased, so that the space is shrunk, water molecules are difficult to enter, and therefore the water resistance is improved.

Owner:SHAANXI UNIV OF SCI & TECH

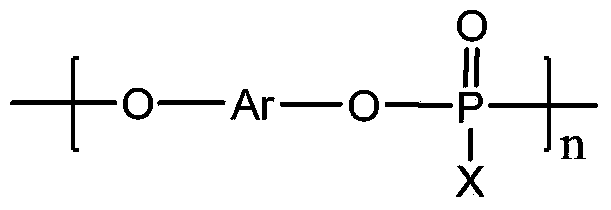

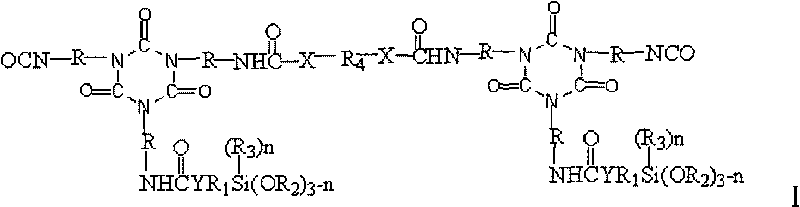

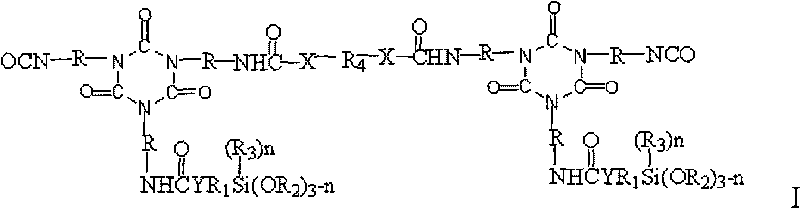

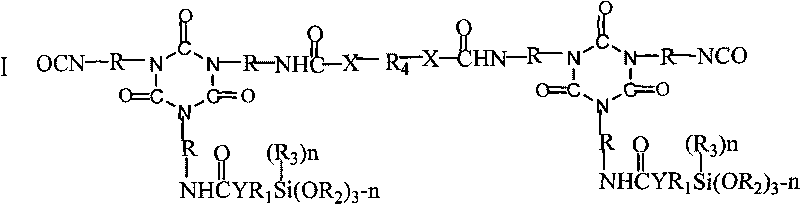

Polyisocyanates containing diphenyl-methane-group diisocyanate, and preparation method

InactiveCN101691380AActs as an adhesion promoterHigh functionalityGroup 4/14 element organic compoundsPolyurea/polyurethane coatingsOrganosiliconIsocyanate compound

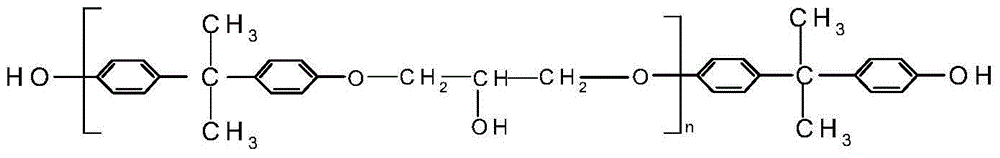

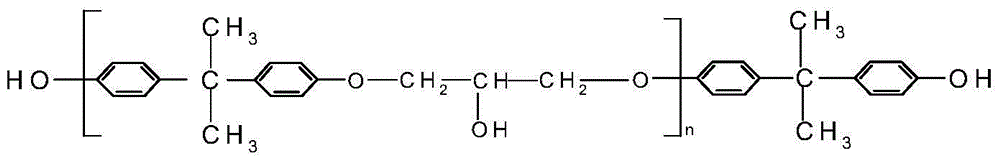

The invention provides polyisocyanates containing diphenyl-methane-group diisocyanate, and a preparation method. The polyisocyanate has a structure ad follows. The preparation method comprises: taking diphenyl-methane-group diisocyanate monomers and trimer products thereof as main isocyanate raw materials; allowing the main isocyanate raw materials to react with functional organic silicon compounds; and obtaining a series of polyisocyanates. The polyisocyanates can be used as paint, ink and curing agents of adhesive, and have low viscosity, quick-drying property, high hardness, good adhesive force and other excellent performances.

Owner:武汉壁千韧硅涂料有限公司

Preparation method of waterborne polyurethane with excellent freeze-thawing stability

The invention discloses a preparation method of waterborne polyurethane with excellent freeze-thawing stability. The preparation method specifically comprises the steps of: at 20-80 DEG C, adding amino type polyhedral oligomeric silsesquioxane into acetone of excessive isocyanate monomer, reacting to be clear, setting the temperature to be 60 DEG C, adding ethyoxyl-terminated polymer glycol, diol and polyol, and catalyst di-n-butyl tin dilaurate, reacting for one to two hours, and controlling the R value to be 1.50-3.00 in the prepolymerization reaction; then increasing the temperature to be 70-90 DEG C, continuously reacting for one to two hours, then cooling to room temperature, adding water for dispersion, adding a chain extender at 30-50 DEG C to conduct chain extension reaction for two to four hours, and cooling to room temperature to obtain waterborne polyurethane. Through tests, the waterborne polyurethane has favorable wear resistance property and bonding strength, as well as excellent freeze-thawing stability.

Owner:JIANGSU HUAXIA PAINT MAKING

Modified solid epoxy resin with high glass transition temperature and high tenacity as well as preparation method thereof

ActiveCN104788648AImprove heat resistanceImprove toughnessAnti-corrosive paintsEpoxy resin coatingsEpoxyVitrification

The invention relates to modified solid epoxy resin with high glass transition temperature and high tenacity. The modified solid epoxy resin is prepared from the following components in parts by weight: 100 parts of epoxy resin, 50-120 parts of a modifier, 0.05-5 parts of a catalyst, and 25-100 parts of a curing agent. The invention further provides a preparation method of the modified solid epoxy resin with high glass transition temperature and high tenacity. The modified solid epoxy resin has the excellent properties that the glass transition temperature is 128-178 DEG C, the cathodic cathodic disbonding radius is smaller than or equal to 10 mm (1.5 V, 92-98 DEG C, 28d), the modified solid epoxy resin can pass a bend test of 3 degrees at minus 30 DEG C as no crack generates, the softening point is 96-115 DEG C, the epoxide number is 0.19-0.275 mol / 100g, and the functionality degree is 2.6, so that the modified solid epoxy resin can be applied to the fields of petroleum and gas long-distance pipelines, urbane groundwater, gas pipe network pipelines, transportation industry (automobiles and ships), oceanographic engineering, corrosion prevention in bridges and construction reinforcing steel bar, and the like in which the use temperature is higher than 95 DEG C.

Owner:大庆庆鲁朗润科技有限公司

High-temperature-resistant polyether polyol and preparation method thereof

The invention belongs to the field of chemical synthesis, and particularly relates to high-temperature-resistant polyether polyol and a preparation method thereof. The high-temperature-resistant polyether polyol is characterized by being prepared from the following components in parts by weight: 600-1,000 parts of sorbierite, 300-600 parts of cane sugar, 3,300-3,800 parts of epoxy propane, 10-18 parts of potassium hydroxide, 20-36 parts of phosphoric acid and 140-200 parts of water. The method has the advantages: the prepared high-temperature-resistant polyether polyol is catalyzed by using potassium hydroxide; sorbierite is an ideal starting agent for preparing temperature-resistant polyether; and the polyether polyol synthesized by adopting sorbierite and cane sugar with high functionality has high functionality and low hydroxyl value. Hard urethane foam plastic prepared from polyether polyol has high heat resistance, high size stability, thermal oxidation resistance, oil resistance, bonding property and high size stability.

Owner:ZIBO DEXIN LIANBANG CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com