Acroleic acid modified polysiloxane resin and coating thereof

A technology of polysiloxane resin and acrylic resin, which is applied in the direction of coating, etc., can solve the problems of slow curing speed of coating film, slow surface drying speed of coating film, low grafting reaction rate, etc., and achieve fast curing speed and accelerated reaction Effect of speed, high crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

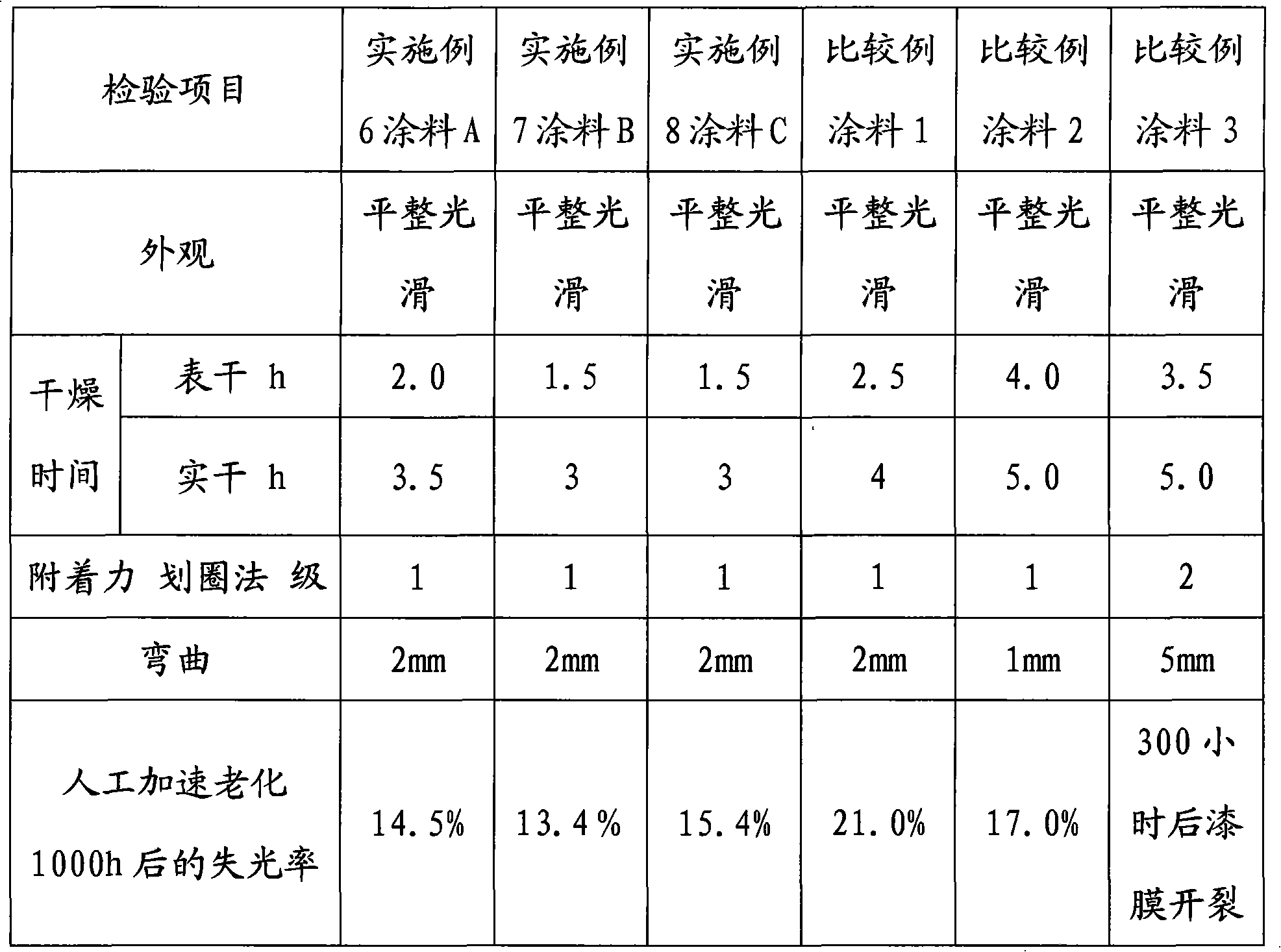

Examples

Embodiment 1

[0023] Embodiment 1 prepares the acrylic resin with glycidyl

[0024] (1) Monomer raw materials and dosage

[0025] Glycidyl acrylate 40Kg;

[0026] Other ethylenic monomers

[0027] n-butyl acrylate (Tg=-54°C) 30Kg;

[0028] 2-ethylhexyl acrylate (Tg=-85°C) 40Kg;

[0029] Methyl methacrylate (Tg=+105°C) 10Kg;

[0030] In the total weight of monomers, glycidyl acrylate accounts for 33.3%;

[0031] Other ethylenic monomers are composed of 87.5% (weight) of other ethylenic monomers with a glass transition temperature Tg of -100°C to -20°C and other ethylenic monomers with a glass transition temperature Tg of -20°C to +110°C Body 12.5% (weight) composition.

[0032] (2) Specific operation

[0033] Add 40Kg of solvent xylene and 40Kg of butanol into a 300L reaction kettle, stir and raise the temperature to 110±2°C, start to drop 40Kg of glycidyl acrylate, 30Kg of n-butyl acrylate, 40Kg of 2-ethylhexyl acrylate, methacrylic acid The mixed solution of 10Kg of methyl ester ...

Embodiment 2

[0034] Embodiment 2 prepares the acrylic resin with glycidyl

[0035] (1) Monomer raw materials and dosage

[0036] Glycidyl methacrylate 24Kg;

[0037] Other ethylenic monomers

[0038] n-butyl acrylate (Tg=-54°C) 40Kg;

[0039] 2-ethylhexyl acrylate (Tg=-85°C) 30Kg;

[0040] Styrene (Tg=+100°C) 26Kg;

[0041] In the total weight of monomers, glycidyl methacrylate accounts for 20%;

[0042] Other olefinic monomers are composed of 72.9% (weight) of other olefinic monomers with a glass transition temperature Tg of -100°C to -20°C and other olefinic monomers with a glass transition temperature Tg of -20°C to +110°C Body 27.1% (weight) composition.

[0043] (2) Specific operation

[0044] The acrylic resin with glycidyl group was obtained by the same method as in Example 1, and its solid content was 60% (by weight).

Embodiment 3

[0045] Embodiment 3 prepares acrylic acid modified polysiloxane resin A

[0046] (1) Resin and dosage

[0047] Have the acrylic resin of glycidyl, solid content 60% (embodiment 1 system) 40Kg;

[0048] Siloxane prepolymer (brand 3074, Dow Corning product) 76Kg;

[0049] Note: The reactive group of siloxane prepolymer 3074 is methoxy group, the methoxy group content is 15-18% (weight) of the total solid weight of siloxane prepolymer, and the number average molecular weight is 1000-1500.

[0050] (2) Specific operation

[0051] Add the above-mentioned siloxane prepolymer and the acrylic resin (made in Example 1) with a glycidyl group in the container, and stir evenly to obtain the acrylic modified polysiloxane resin A of the present invention. In terms of solids, In the acrylic-modified polysiloxane resin A, the weight ratio of the glycidyl-containing acrylic resin to the silicone prepolymer was 24:76.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com