Modified solid epoxy resin with high glass transition temperature and high tenacity as well as preparation method thereof

A solid epoxy resin, high vitrification technology, used in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problem of reducing the flexibility of anti-corrosion coatings, and achieve strong resistance to high temperature cathodic disbondment performance, high toughness, expansion Application-wide effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

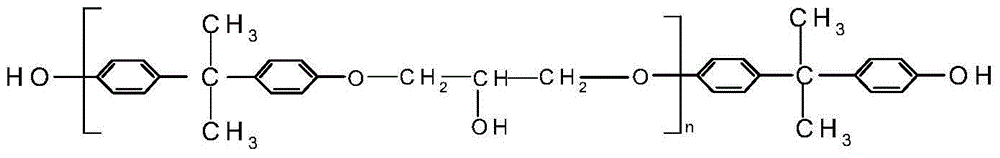

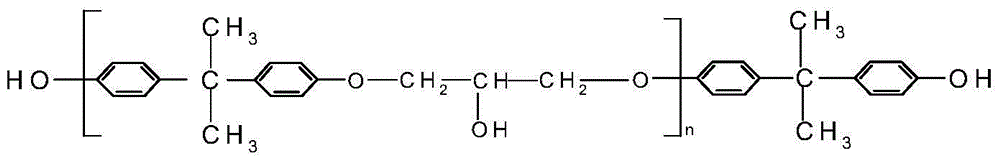

Image

Examples

Embodiment 1

[0026] Mix 100g of epoxy resin E44 with 50g of polyurethane and 0.02g of boron trifluoride ether, raise the temperature to 90°C, react for 4h, then add 0.03g of boron trifluoride ether, raise the temperature to 120°C, react for 10h, and obtain the modified ring oxygen resin. The obtained modified epoxy resin was mixed with 70g of linear bisphenol A type phenolic resin (n=2.5 in the molecular formula), sprayed on a sample plate preheated to 110°C by spraying, cured at 130°C for 24h, and obtained a high Vitrified high toughness modified epoxy resin coating, testing various properties. The glass transition temperature of the coating is 155°C; the cathodic disbondment radius is 9.7mm (1.5V, 95±3°C, 28d); there is no crack after the bending test at -30°C and 3°; the softening point is 105°C; It is 0.255mol / 100g; the functionality is 2.6.

Embodiment 2

[0028] Mix 100g of epoxy resin E44 with 70g of 1,6-hexamethylene diisocyanate and 0.02g of boron trifluoride diethyl ether, raise the temperature to 100°C, and react for 6h, then add 0.03g of triethanolamine, raise the temperature to 150°C, and react for 10h to obtain Modified epoxy resin. The obtained modified epoxy resin was mixed with 70g of linear bisphenol A type phenolic resin (n=1 in the molecular formula), sprayed on a sample plate that had been preheated to 110°C, and cured at 120°C for 24h to obtain high Vitrified high toughness modified epoxy resin coating, testing various properties. The glass transition temperature of the coating is 138°C; the cathodic disbondment radius is 9.2mm (1.5V, 95±3°C, 28d); there is no crack after the bending test at -30°C and 3°; the softening point is 96°C; It is 0.275mol / 100g; the functionality is 2.6.

Embodiment 3

[0030] Mix 100g of epoxy resin E44 with 100g of polysiloxane and 0.02g of boron trifluoride ether, raise the temperature to 120°C, react for 2h, then add 0.03g of boron trifluoride ether, raise the temperature to 150°C, and react for 2h to obtain Modified epoxy resin. The obtained modified epoxy resin was mixed with 70g of linear bisphenol A type phenolic resin (n=4 in the molecular formula), sprayed on a sample plate that had been preheated to 110°C, and cured at 130°C for 24h to obtain high Vitrified high toughness modified epoxy resin coating, testing various properties. The glass transition temperature of the coating is 164°C; the cathodic disbondment radius is 9.5mm (1.5V, 95±3°C, 28d); there is no crack after the bending test at -30°C and 3°; the softening point is 111°C; It is 0.205mol / 100g; the functionality is 2.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com