Patents

Literature

173results about How to "High epoxy value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

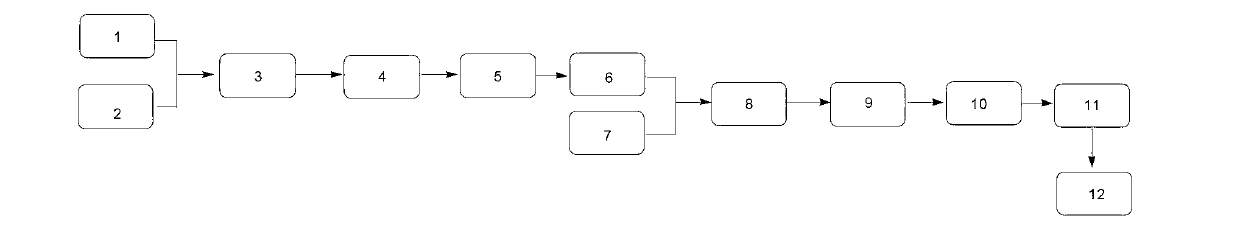

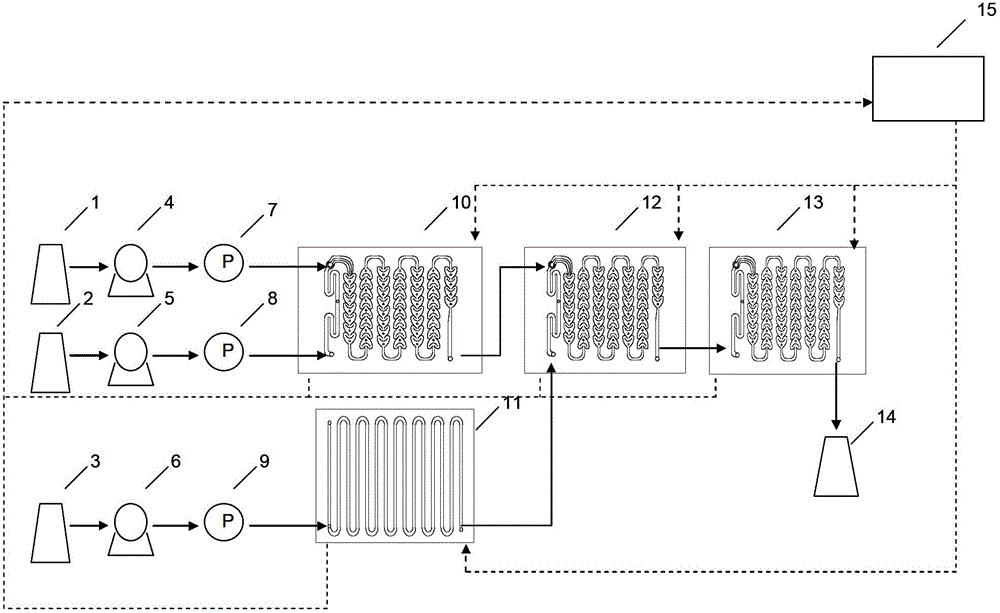

Method for preparing epoxidized fatty acid methyl ester with microreactor one-step method

ActiveCN102993133AImprove product qualityHigh epoxidation yieldOrganic chemistryDouble bondFatty acid methyl ester

The invention discloses a method for preparing epoxidized fatty acid methyl ester with microreactor one-step method, comprising the following steps: injecting oil and fat, low-carbon alcohol and basic catalyst in a first microstructure reactor of a microchannel modularized reaction device, wherein the mole ratio of oil and fat to low-carbon alcohol is 1:11-17, and remaining for 3-10 min at the temperature of 65-85 DEG C; mixing outlet material of the first microstructure reactor with hydrogen peroxide, organic acid, acidic catalyst and stabilizing agent in a second microstructure reactor of the microchannel modularized reaction device, wherein the mole ratio of number of double bonds in organic acid to number of double bonds in oil and fat is 11-17:1, and remaining 1-5 min at the temperature of 65-95 DEG C; guiding the outlet material of the first microstructure reactor in a separator, standing for demixing to remove aqueous solution at lower layer; washing an organic phase at the upper layer with water till the pH is 6.5-7.5; and drying to obtain epoxidized fatty acid methyl ester.

Owner:NANJING UNIV OF TECH

Method for preparing bisphenol-A liquid epoxy resin

The invention relates to a method for preparing bisphenol-A liquid epoxy resin, and belongs to the field of high polymer preparation. The method comprises the following steps: 1) adding a quaternary ammonium salt phase-transfer catalyst, and performing etherification at a temperature of between 70 and 85 DEG C for 45 to 240 minutes; 2) at a constant temperature of between 60 and 70DEG C, droppingalkali by NaOH aqueous solution for 1.5 to 4 hours, keeping epoxy chloropropane refluxing in the alkali dropping period, and discharging water out of a reaction system; and 3) separating unreacted epoxy chloropropane by a rotary evaporator at a temperature of 135DEG C, dissolving a mixture of resin and salt, removing solid salt by a filter, washing the resin for 3 to 5 times by water, separating solvent, and obtaining the final product. The prepared epoxy resin has the epoxy value between 0.55 and 0.56 through titration by hydrochloric acid acetone solution, low viscosity (between 7,000 and 10,000mPas), and the epoxy index between 0.595 and 0.622 through infrared spectroscopic analysis, and comprises 91 to 92 percent of micro molecular epoxy resin.

Owner:CHINA PETROCHEMICAL CORP

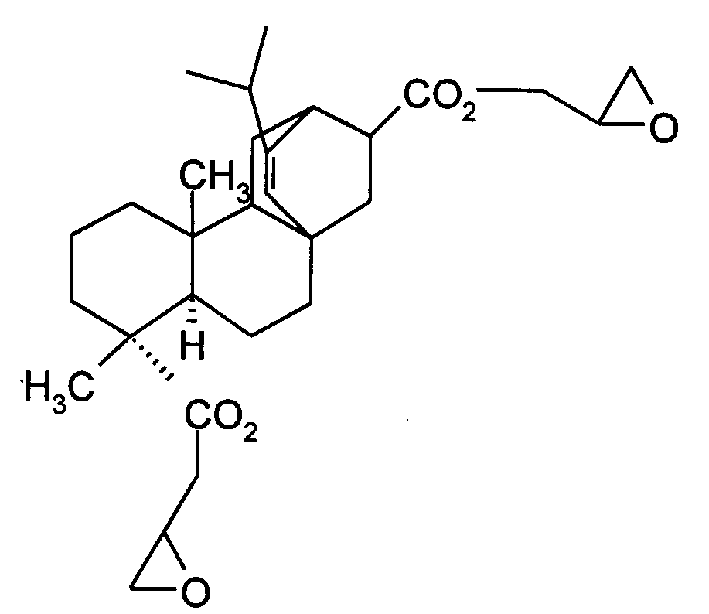

Propylenyl pimaric acid diglycidic ester and its epoxy resin and their preparation

The present invention relates to modified rosin and is propylenyl pimaric acid diglycidic ester and acrylic acid modified rosin epoxy resin containing propylenyl pimaric acid diglycidic ester in 40-100 wt%. The present invention also provides their preparation process. The propylenyl pimaric acid diglycidic ester and acrylic acid modified rosin epoxy resin are prepared with cheap natural material and are new environment friendly adhesive material with high epoxide number. The may be used also as the intermediate for preparing rosin surfactant, and has simple preparation process easy to use in industry.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

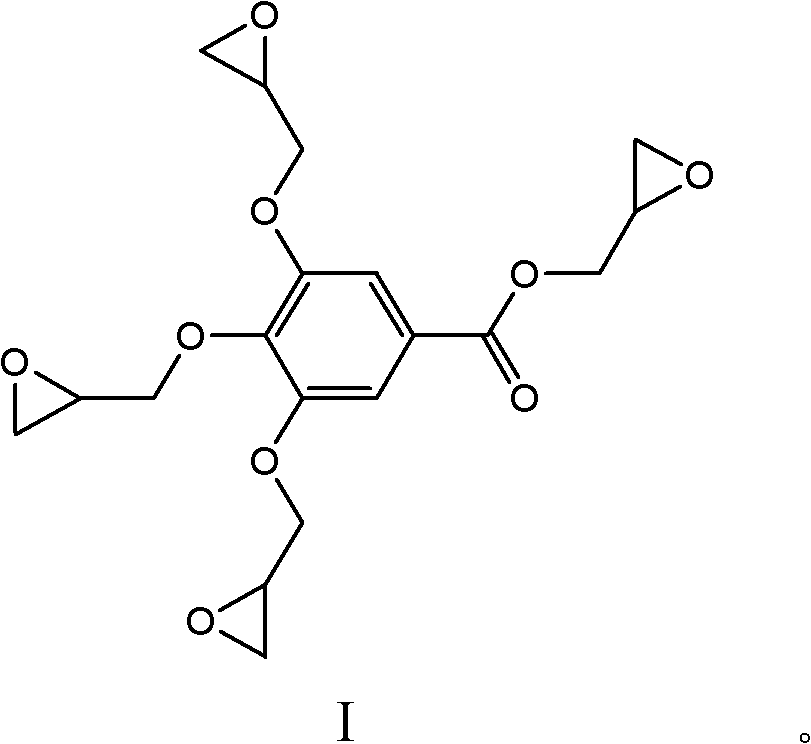

A kind of epoxy resin based on gallic acid and its preparation method and application

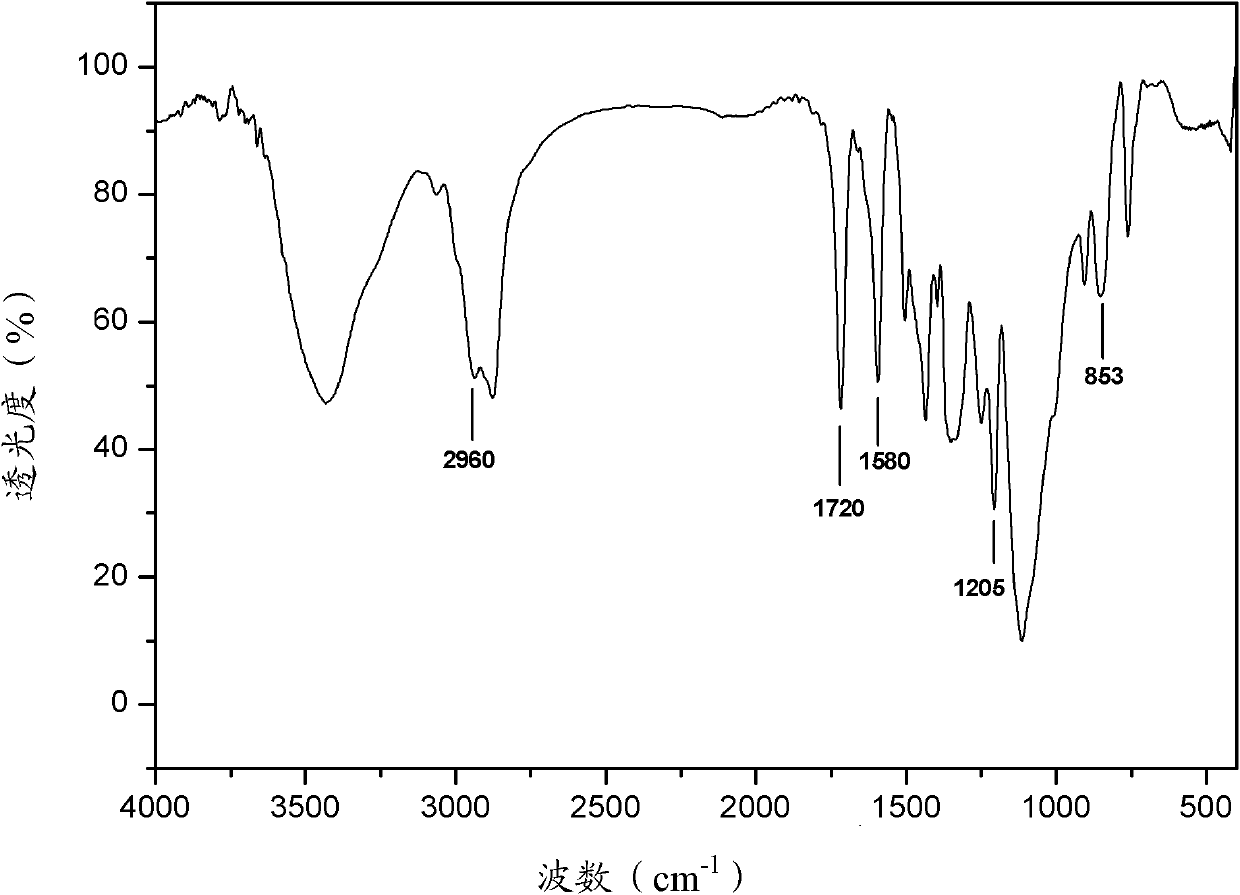

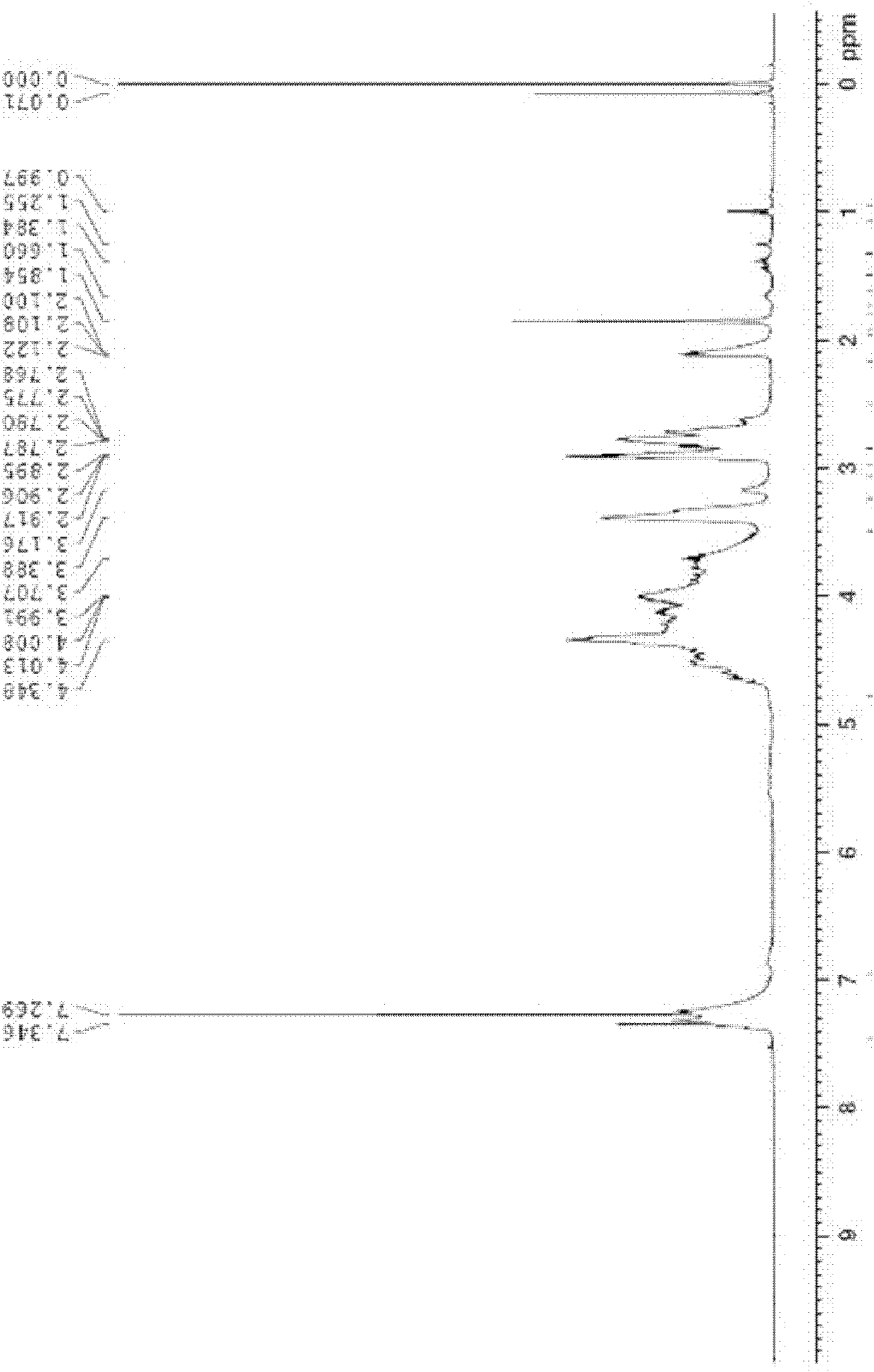

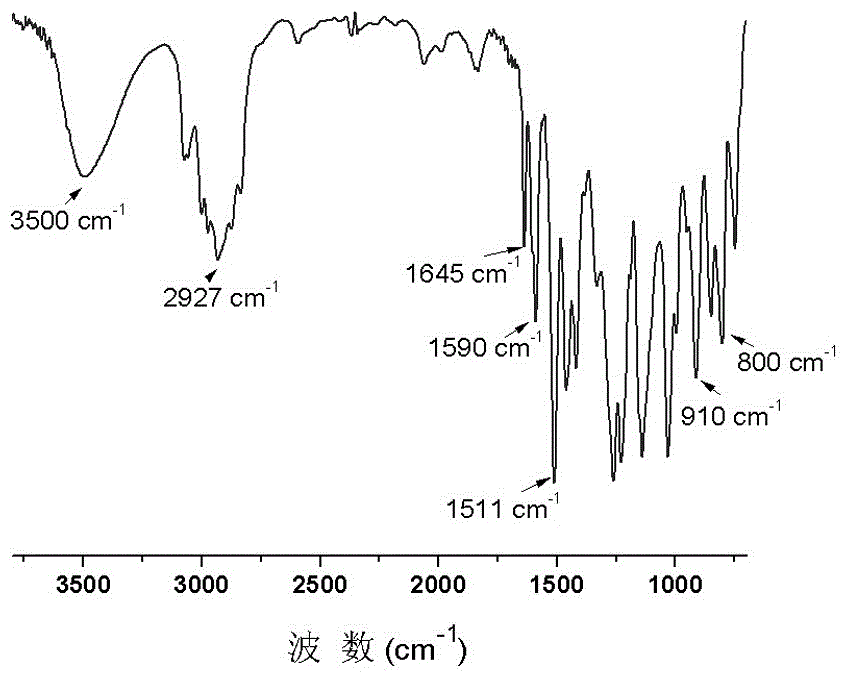

ActiveCN102276788AHigh epoxy valueIncrease crosslink densityEpoxy resin adhesivesEpoxy resin coatingsPolymer scienceGallic acid ester

The invention discloses an epoxy resin based on gallic acids with a structure shown as the formula I, which has high epoxy values and also has higher crosslinking density after being cured, thus having good mechanical property and thermal property. The invention also discloses a preparation method of the epoxy resin based on the gallic acids, comprising the following steps: mixing the gallic acids, epoxy halogenopropane and a catalyst and reacting for 2-5 hours at the temperature of 100-120 DEG C; cooling to 20-40 DEG C; adding alkaline compounds and water and continuing to react for 2-5 hours; and washing, removing a solvent and drying to obtain the epoxy resin based on the gallic acids. The preparation method is simple in process, good in controllability and easy to implement industrially. The invention also provides an application of the epoxy resin based on the gallic acids. The epoxy resin based on the gallic acids is particularly applied to preparing composite materials, epoxy adhesives and coatings.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

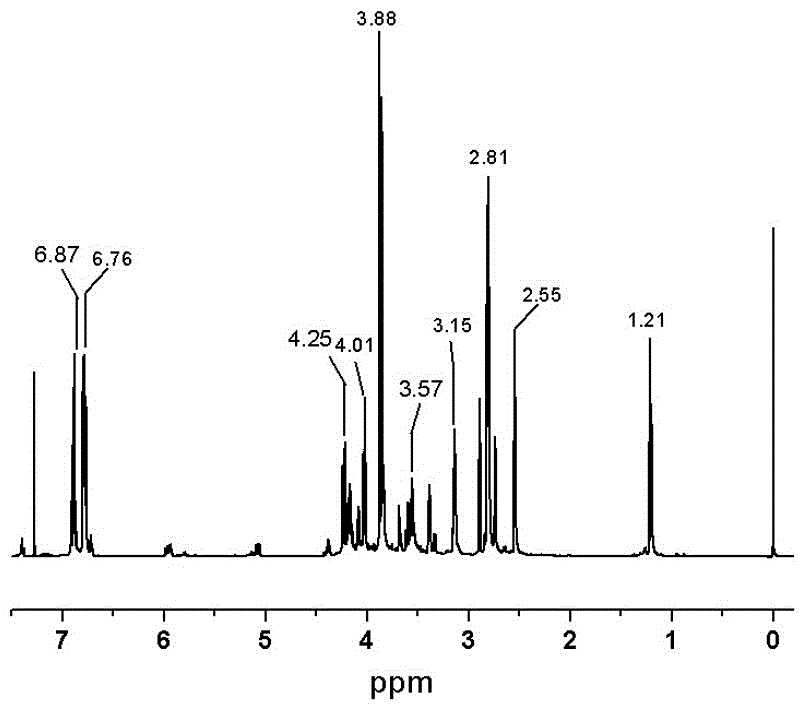

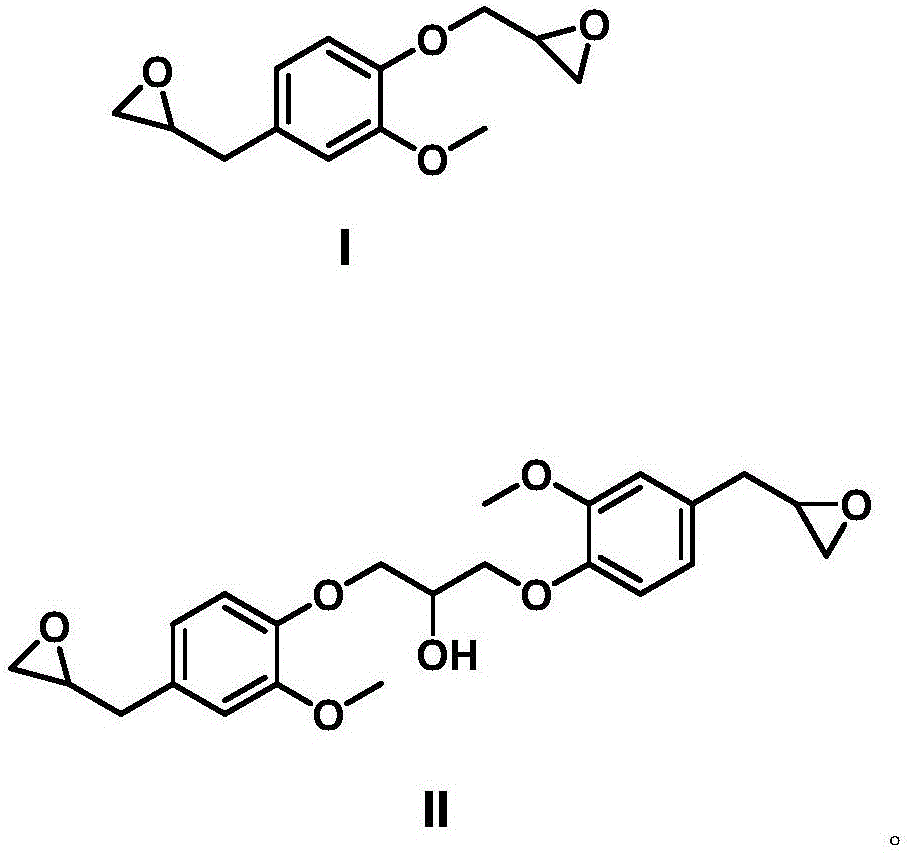

Eugenol epoxy resin and preparing method and application thereof

InactiveCN105924623AHigh epoxy valueReduce dependenceOrganic chemistryEpoxy resin adhesivesEpoxyAdhesive

The invention provides a eugenol epoxy resin and a preparing method and application thereof. The eugenol epoxy resin is prepared from a compound shown in the formula I in the description and / or a compound shown in the formula II in the description. The epoxy resin is free of biotoxicity, the mechanical property of the epoxy resin is similar to that of traditional epoxy resin, and the eugenol epoxy resin can replace traditional petroleum-based epoxy resin. The epoxy resin is liquid at the room temperature, and is beneficial to subsequent processing and application and capable of being used for preparing composites, paint, adhesives and the like.

Owner:HEBEI UNIVERSITY

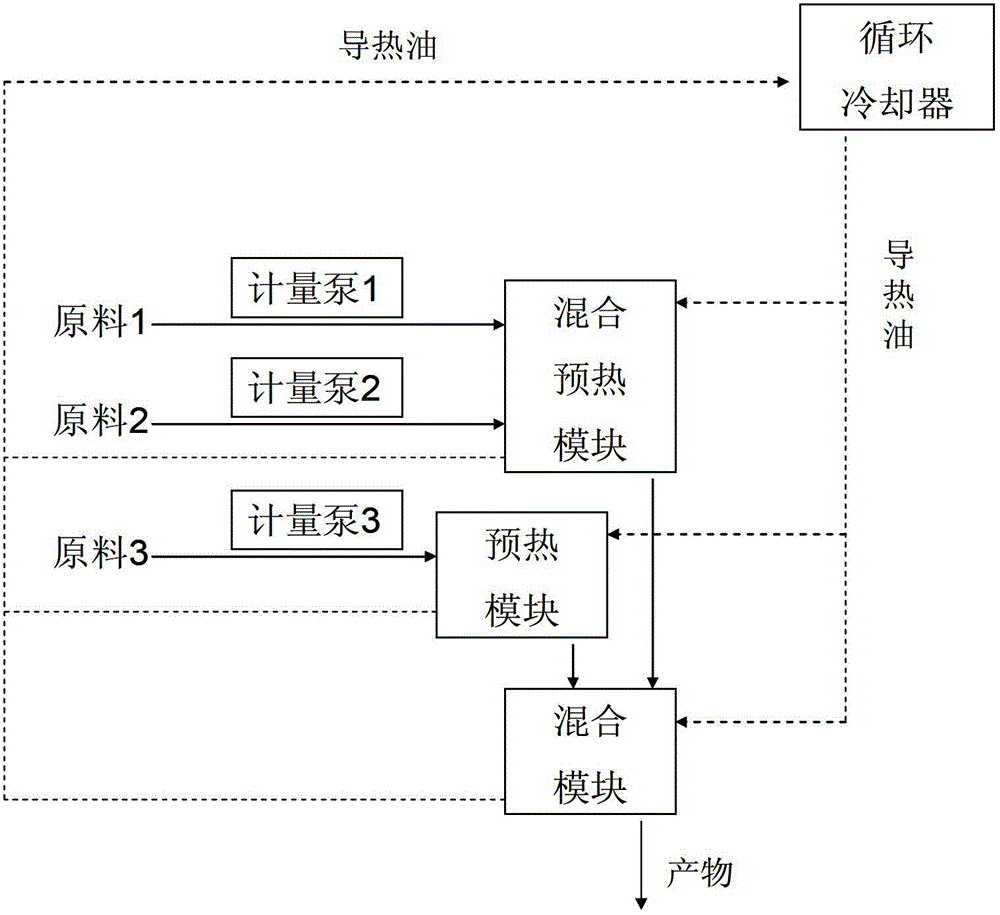

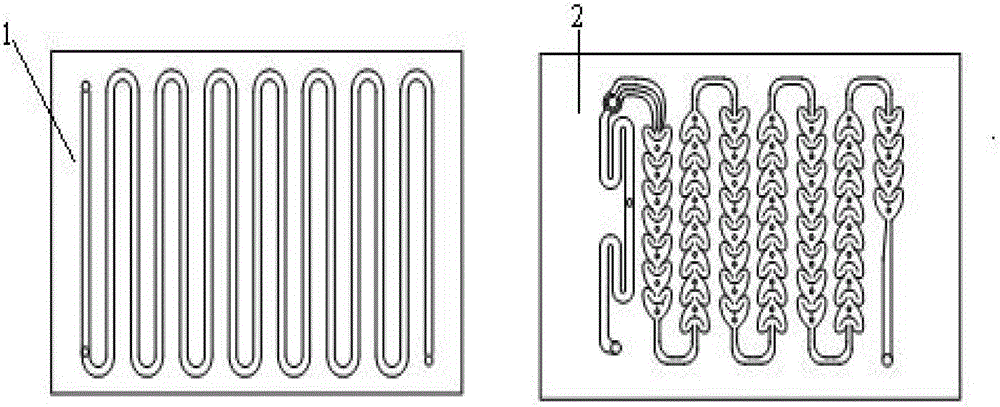

Method for preparing epoxidized fatty acid methyl esters in continuous flow microchannel reactor

The invention relates to a method for preparing epoxidized fatty acid methyl esters by using a microchannel reactor. The method comprises the following specific steps of: preparing catalyst formic acid and concentrated hydrochloric acid in a certain proportion; pumping fatty acid methyl ester, a formic acid catalyst, and hydrogen peroxide into the microchannel reactor by using three metering pumps; and washing reaction products, separating and drying to obtain the final product epoxidized fatty acid methyl esters. The whole process is an exothermic reaction process, and peroxyformic acid and epoxidized fatty acid methyl esters are synthesized simultaneously. When the epoxidized fatty acid methyl esters are produced by the method, the temperature of the reaction process can be controlled effectively, high safety can be guaranteed, a module is good in mixing effect, and a product obtained through reaction is high in quality; and the continuous flow reaction is performed, the process is continuous, and high production efficiency is achieved.

Owner:CHANGZHOU UNIV

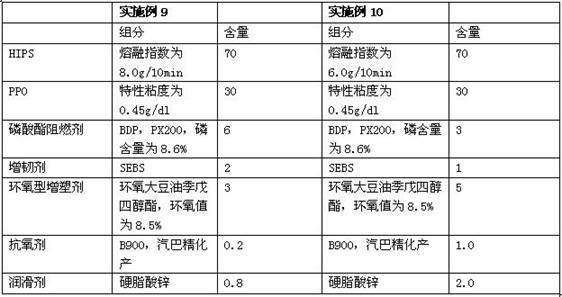

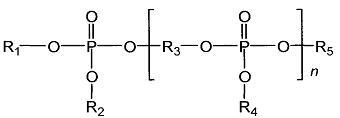

Halogen-free inflaming-retarding high impact polystyrene resin

The invention discloses a halogen-free inflaming-retarding high impact polystyrene resin, comprising the following components based on parts by weight: 70-90 parts of high impact polystyrene resin, 10-30 parts of polyphenyl ether, 3.0-20 parts of phosphate ester fire retardant, 1.0-5.0 parts of flexibilizer, 0.1-5.0 parts of epoxy plasticizer, 0.2-1.0 parts of anti-oxidant and 0.2-2.0 parts of lubricating agent. The invention uses PPO, phosphate ester fire retardant and epoxy plasticizer to form synergistic inflaming retarding system which has high inflaming retarding efficiency and excellentmechanical performance.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

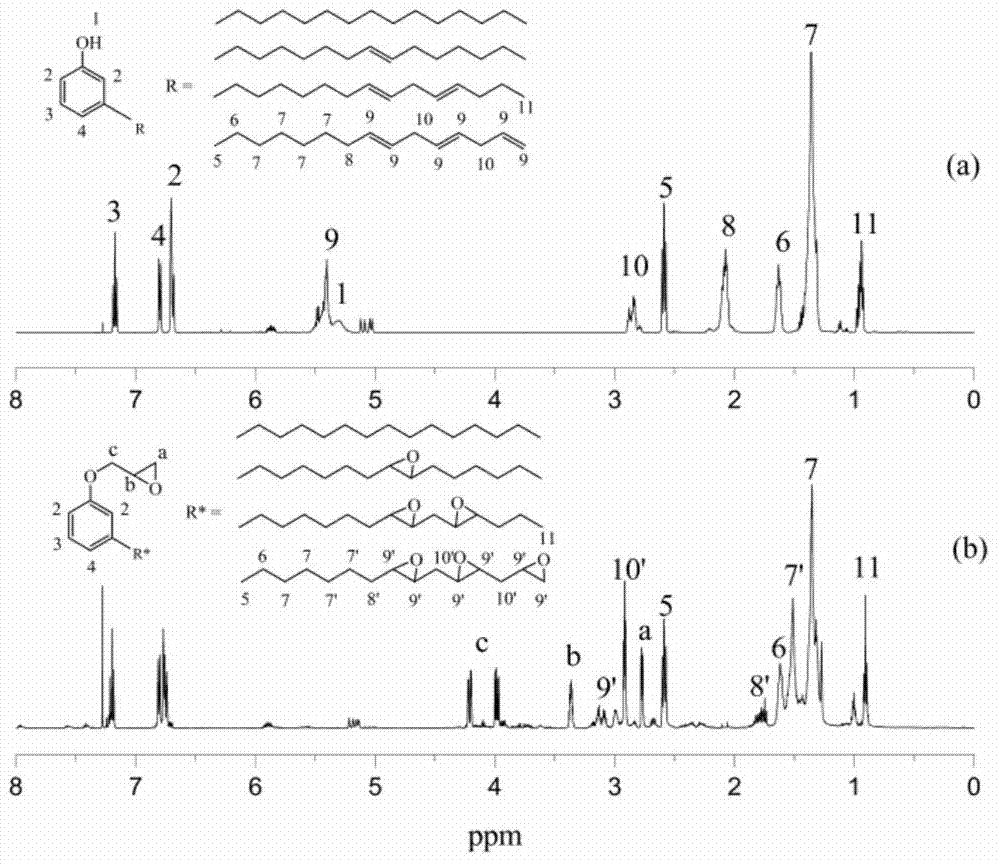

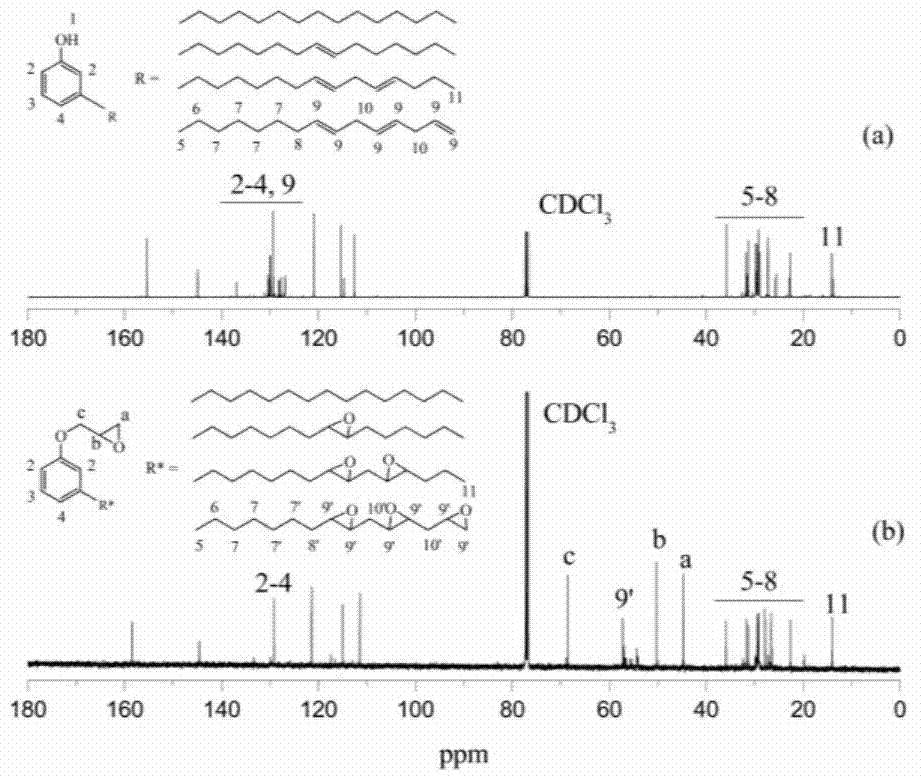

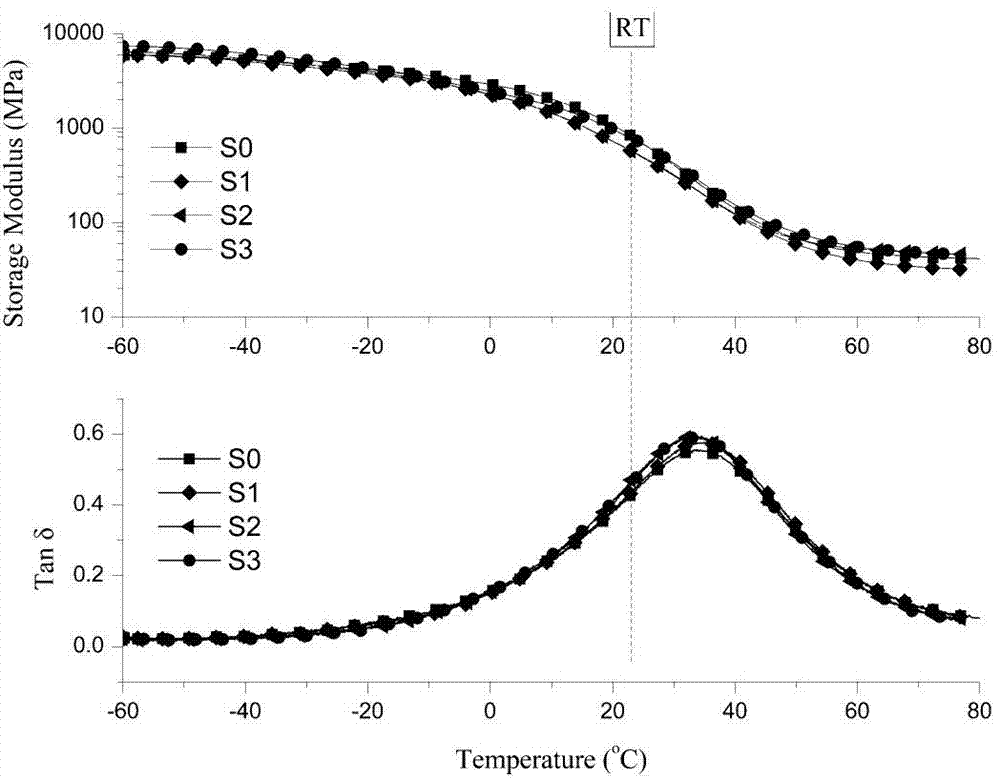

Epoxy cardanol-based glycidyl ether as well as preparation method and application thereof

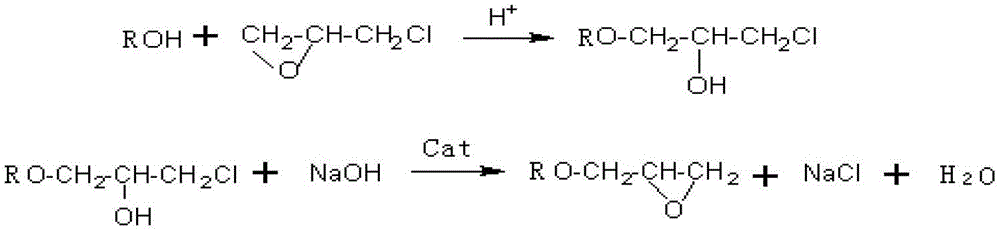

InactiveCN104710388AEmission reductionSimple production processOrganic chemistryOrganic acidGlycidyl ethers

The invention discloses an epoxy cardanol-based glycidyl ether plasticizer as well as a preparation method and application thereof. The preparation method comprises the following steps: taking cardanol and epoxy chloropropane as main raw materials and carrying out ring-opening addition reaction and ring-closure reaction to synthesize an intermediate product cardanol-based glycidyl ether; and further uniformly mixing the intermediate product with organic acid and a catalyst, heating to a certain temperature, dripping a peroxide source to carry out epoxidation reaction to obtain a crude product, leaving the crude product to stand, layering, performing neutralization and dehydration on the crude product after the reaction so as to obtain an epoxy cardanol-based glycidyl ether plasticizer. The plasticizer is non-toxic, has relatively high plasticizing efficiency and can endowing resin products with favorable thermal stability and mechanical property; and moreover, by taking the cardanol which is low in cost and easy to get as raw material, the epoxy cardanol-based glycidyl ether plasticizer integrates the advantages of being environment-friendly and being reproducible, complies with the developing trend of the plastic additive industry and has wide application and favorable application prospect.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

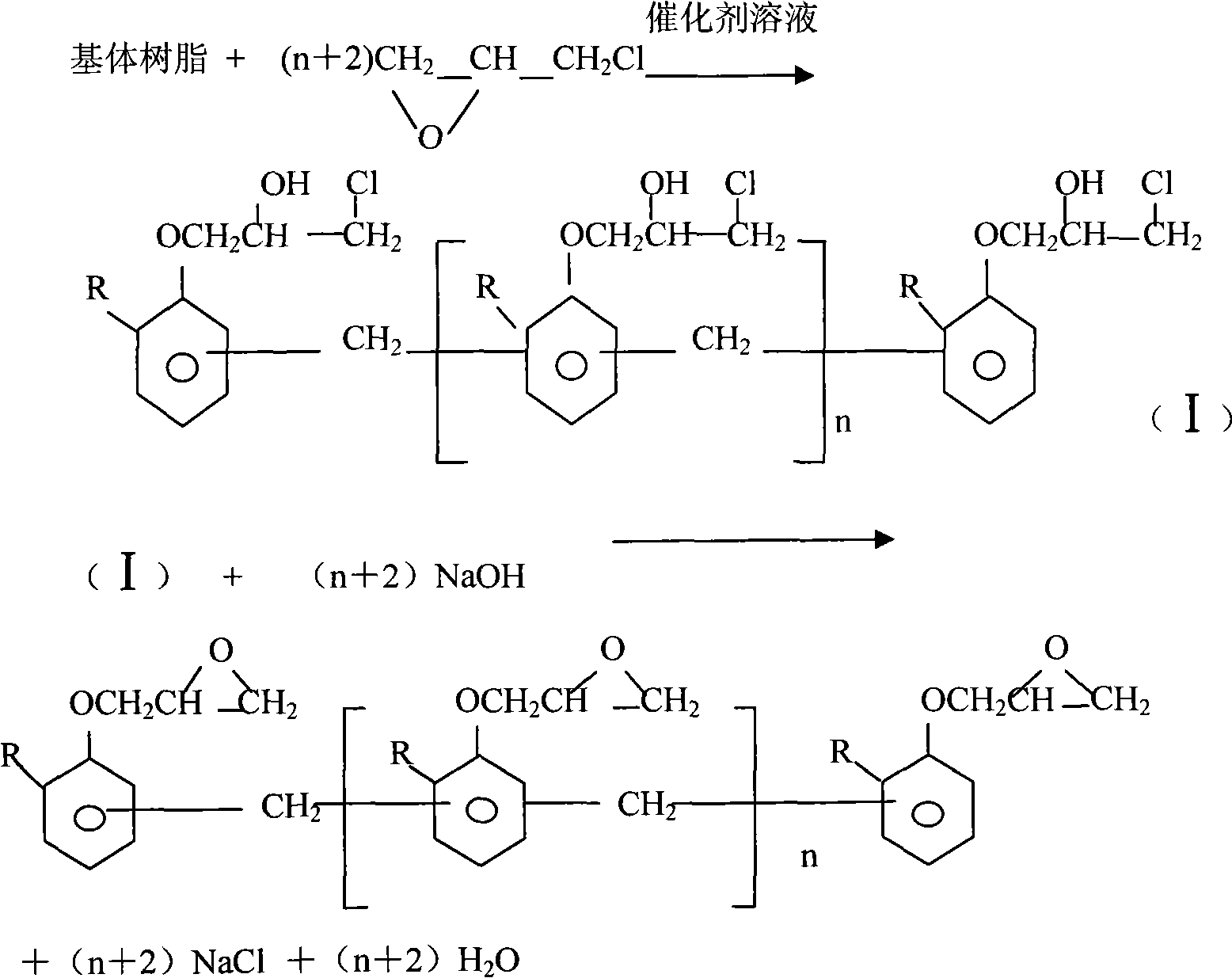

Method for preparing epoxy resins of phenol formaldehyde type

The invention discloses a method for synthesizing phenol formaldehyde epoxy resin with (alkyl)phenolic resin and epoxy chloropropane as raw materials. Base resin and epoxy chloropropane undergo epoxidation reaction under the existence of catalyzer and alkali, and then are refined and processed with post treatment; in this way, phenol formaldehyde epoxy resin can be prepared. The epoxidation technique applied by the invention can effectively reduce the occurrence of side reaction and reduce production of isomerized chlorine and is easy to produce the products with high softening point, high epoxy equivalent weight and low chlorine content and has remarkable effects in improving the stability and heat resistance of the product and in reducing the consumption of the raw materials.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

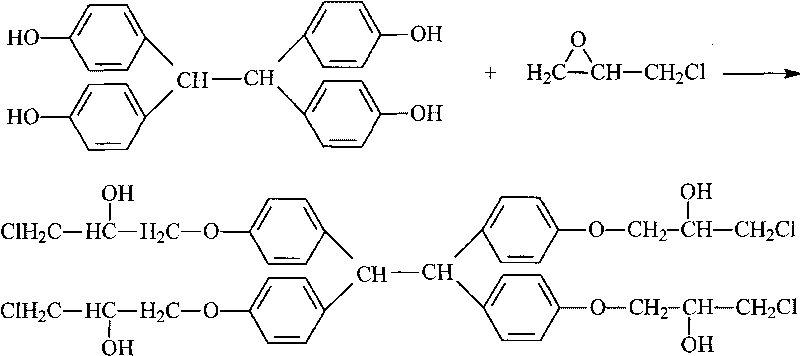

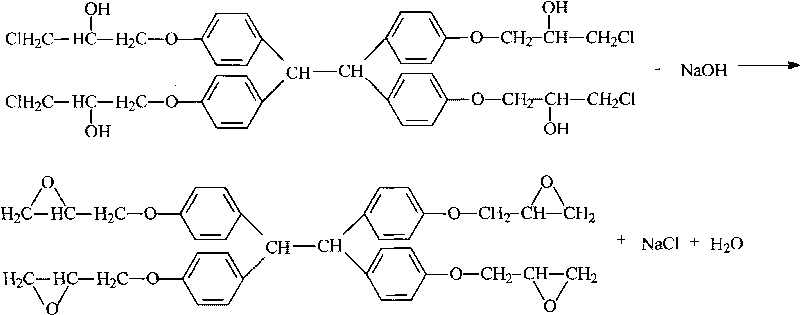

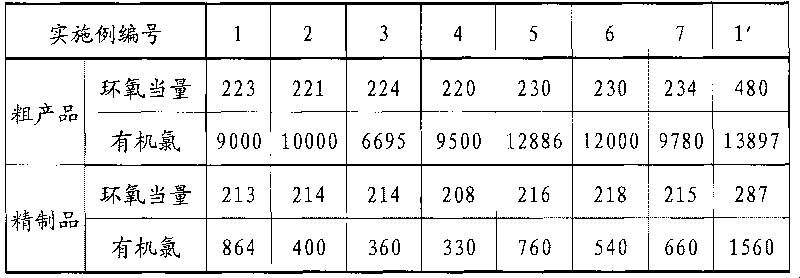

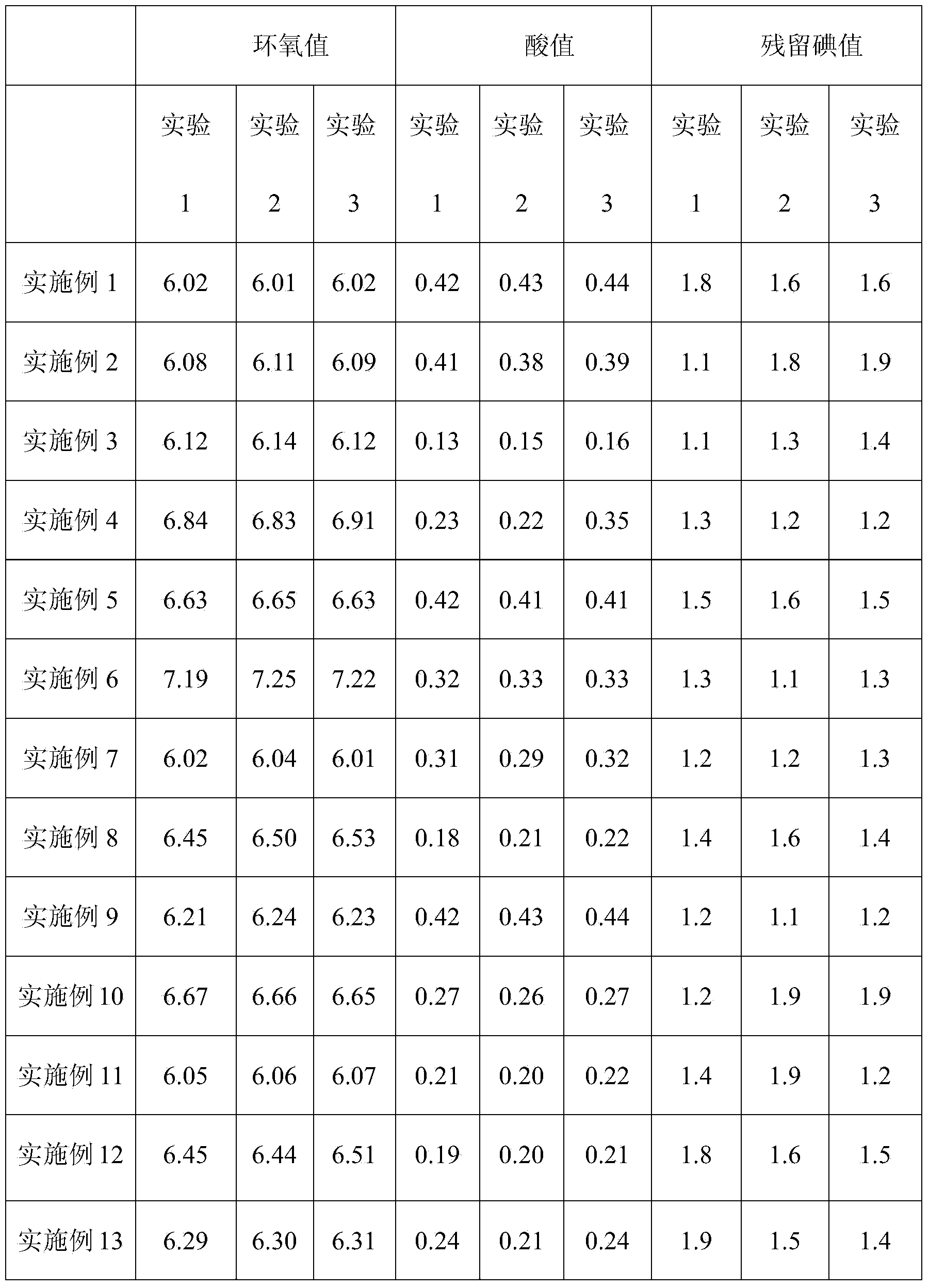

Synthesis method of four-functional group epoxy resin and prepared epoxy resin

The invention discloses a synthesis method of four-functional group epoxy resin. The method comprises the following steps: 1. dissolving tetraphenolichydroxyl phenolic resin with epichlorohydrin, performing an etherification reaction under the existence of a catalyst; 2. adding excessive alkali to complete a ring-closure reaction; 3. blasting acidic gas or adding inorganic acid or adding water-soluble organic acid to neutralize and remove residual alkali, rinsing to remove salt, recycling epichlorohydrin to obtain four-functional group epoxy resin coarse product; and 4. refining the coarse product to obtain four-functional group epoxy resin. The invention also provides the epoxy resin prepared by the synthesis method. Compared with the synthesis method of four-functional group epoxy resin in the prior art, the epoxy value of the four-functional group epoxy resin of the invention is higher, the organochlorine content is low and the demand of the copper-clad plate on epoxy resin can be satisfied; and by using the synthesis method of the invention, the wastewater generated in the synthesis process is greatly reduced.

Owner:建滔覆铜板(深圳)有限公司

Preparation method of microbial oil-based epoxide

ActiveCN104356097AReduce manufacturing costEasy to achieve large-scale industrial productionOrganic chemistryMicrobial oilEpoxy

The invention discloses a preparation method of microbial oil-based epoxide. The preparation method comprises the following steps: adding organic acid and an acidic catalyst into microbial oil, stirring, keeping the reaction temperature at 40-80 DEG C, slowly and dropwise adding peroxide, after the peroxide is added, reacting for 4-8 hours at a constant temperature, washing a crude product by using hot water with the temperature of 50-60 DEG C, performing alkali washing by using a dilute alkali solution with the concentration of 0.1-0.3mol / L, washing by using water until the solution is neutral, and dehydrating the washed product by distilling under reduced pressure to obtain a target product. The microbial oil-based epoxide can replace epoxy soybean oil, can be used as a plasticizer for plastic food and medicine packaging materials, can also be used as a biological and chemical raw material for preparing polyols, lubricants and binders and the like, and has a relatively high industrial value.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

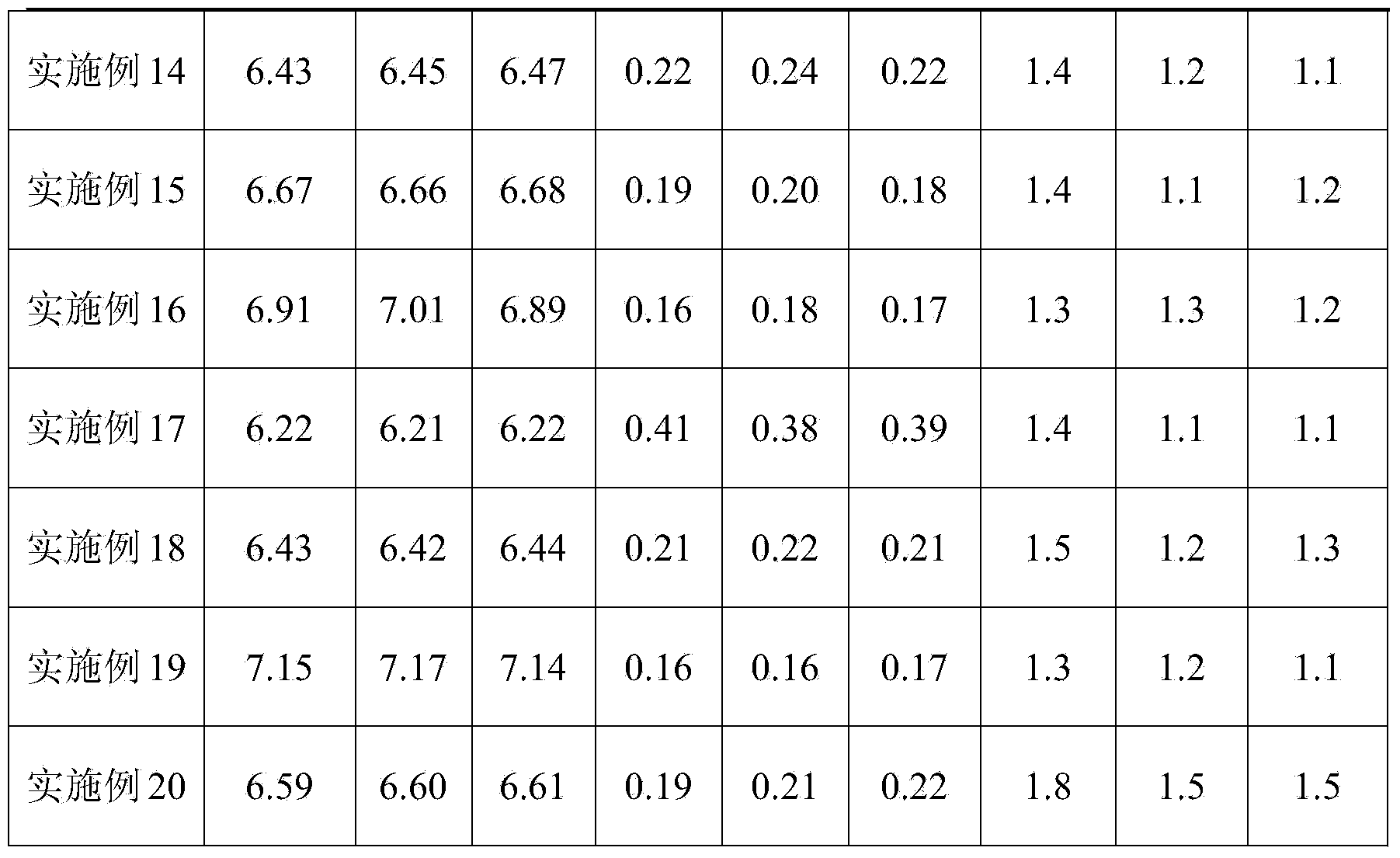

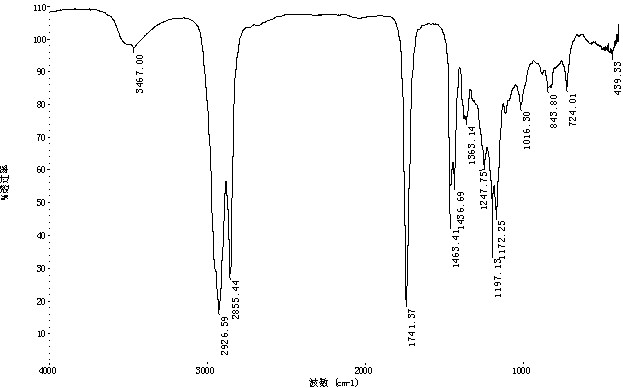

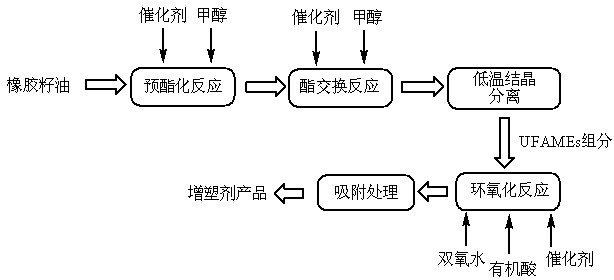

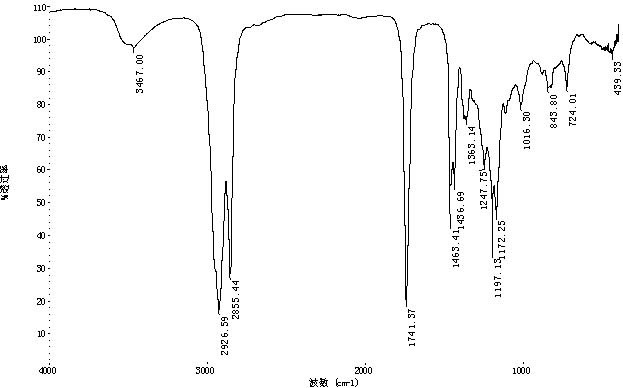

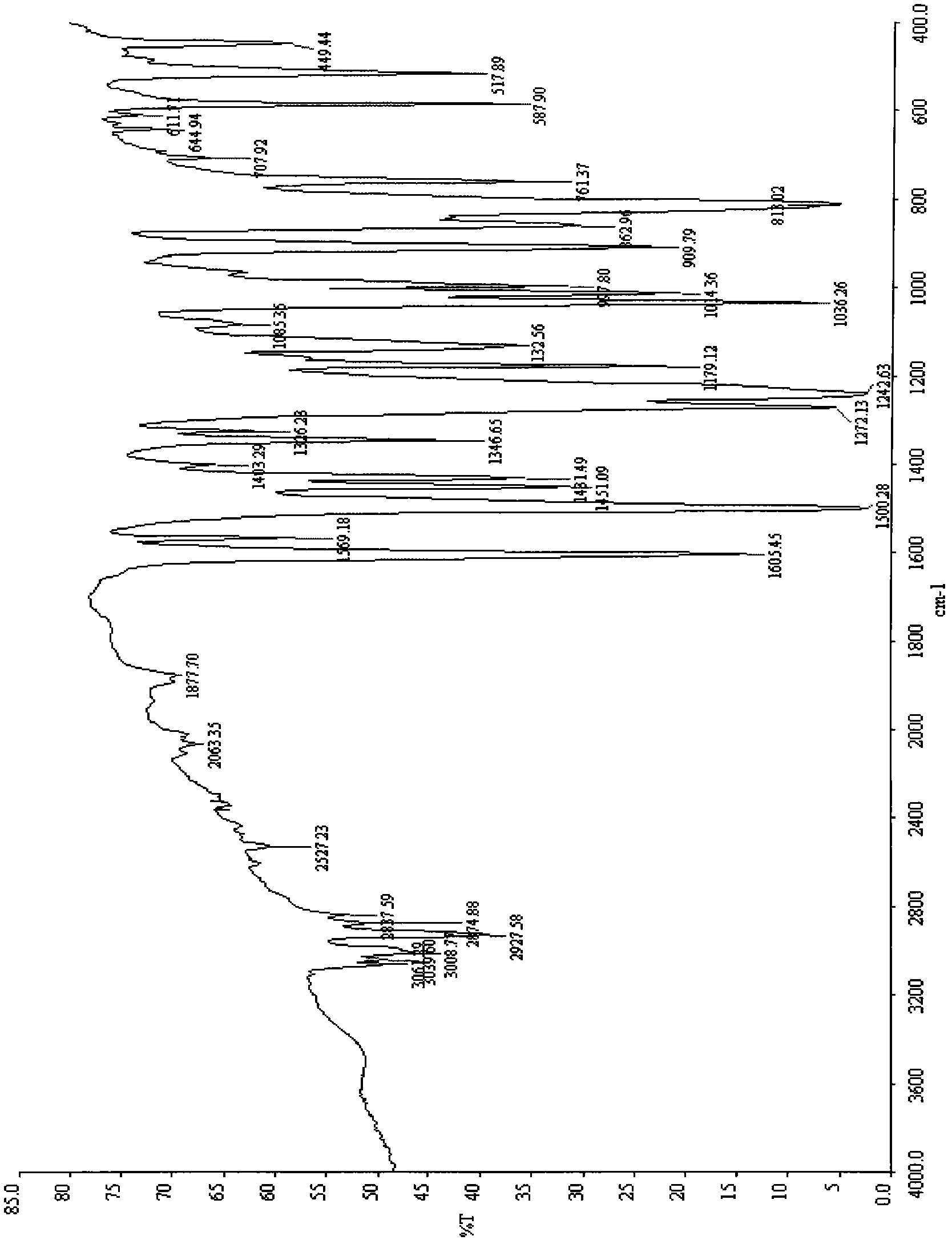

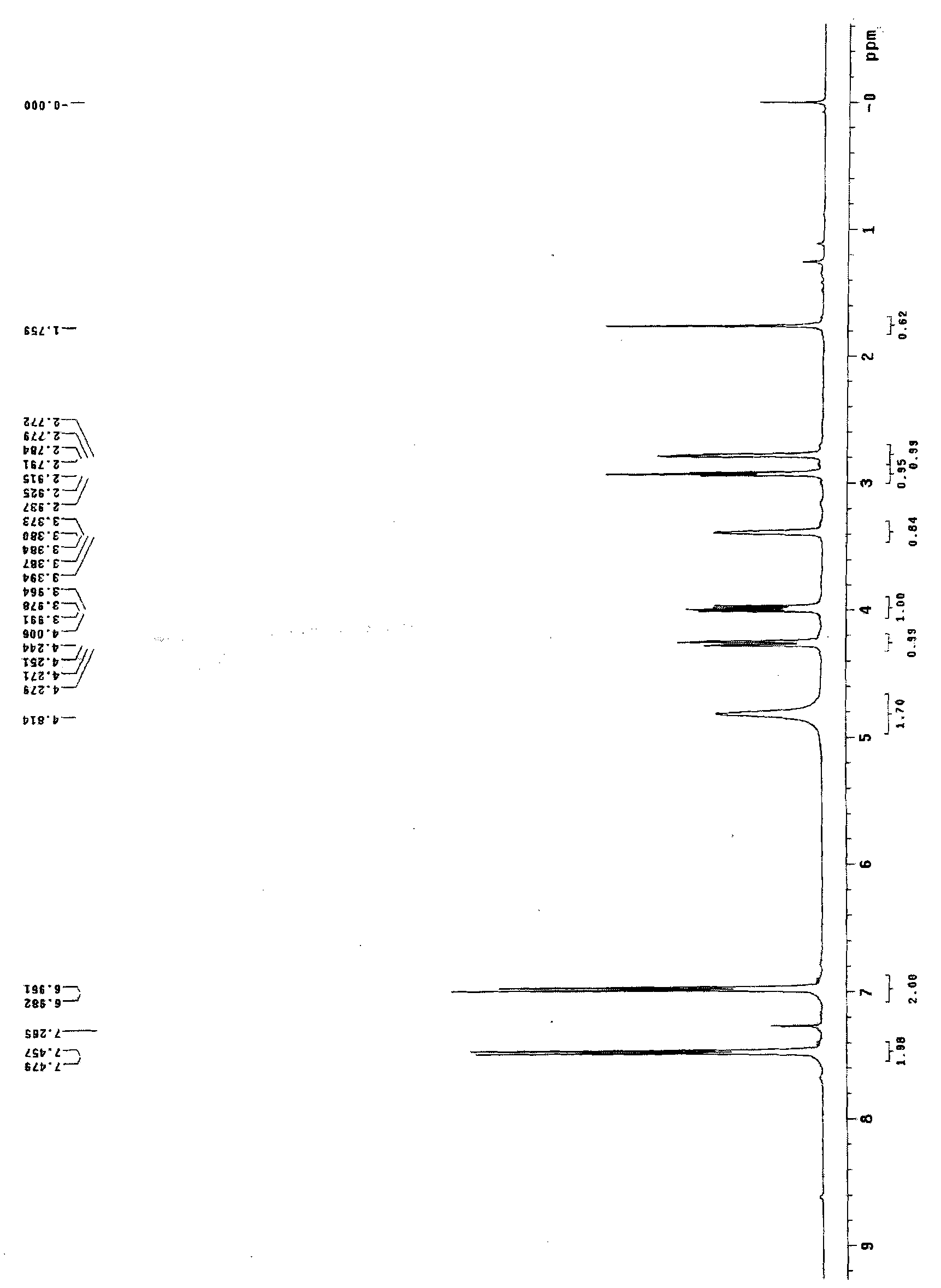

Rubber seed oil-based epoxy fatty acid methyl ester and preparation method and application thereof

InactiveCN102517157ASimple preparation processEnvironmentally friendlyFatty acid esterificationUnsaturated fatty acidRubber seed oil

The invention relates to rubber seed oil-based epoxy fatty acid methyl ester and a preparation method and application thereof. After being degummed, rubber seed oil and methanol are subjected to pre-esterification and ester exchange reaction so that rubber seed oil-based fatty acid methyl ester rough product is obtained, the rubber seed oil-based fatty acid methyl ester rough product is subjected to crystallization and separation at low temperature so that UFAMEs (unsaturated fatty acid methyl esters) rich in polyene is obtained, products from epoxidation can be allowed to stand and delaminate, and finally the rubber seed oil-based epoxy fatty acid methyl ester is obtained after the upper oil phase is neutralized, dehydrated and adsorbed. The epoxide value is equal to or larger than 5.0%, the flash point is equal to or larger than 200 DEG C, the resistivity is equal to or larger than 1.0X109 ohmm, the tincture is smaller than or equal to 180, the acid value ranges from 0.45-0.5mgg-1, and the heating loss is smaller than or equal to 0.5. The raw materials of the rubber seed oil-based epoxy fatty acid methyl ester are easy to obtain so that the cost thereof is low. The rubber seed oil-based epoxy fatty acid methyl ester is high in performance and stable in quality and suitable for industrial production. The preparation method of the rubber seed oil-based epoxy fatty acid methyl ester is simple in process, convenient in operation, short in production cycle, low in energy consumption and low in pollution during production.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method of preparing glycidyl ether epoxy resin through monomer containing alcoholic hydroxyl group and/or phenolic hydroxyl group

The invention discloses a method of preparing glycidyl ether epoxy resin through monomer containing alcoholic hydroxyl group and / or phenolic hydroxyl group, belonging to the technical field of epoxy resin. The method comprises the following steps of: adding the monomer containing alcoholic hydroxyl group and / or phenolic hydroxyl group and epoxy chloropropane into a reactor, and heating the reactor to fully dissolve the ingredients; controlling the reaction temperature to 40-80 DEG C, and adding a quaternary ammonium salt and solid alkali; pumping and filtering to remove the redundant alkali and the generated salt after the reaction is finished for 0.5-5 hours, adding an organic solvent immiscible to water while capable of dissolving the obtained epoxy resin to dilute the product, washing the product through deionized water for multiple times, separating out an organic phase, and decompression distilling. The method provided by the invention has the advantages of high reaction speed, high percent conversion and capable of simultaneously etherifying the alcoholic hydroxyl group and the phenolic hydroxyl group.

Owner:BEIJING UNIV OF CHEM TECH

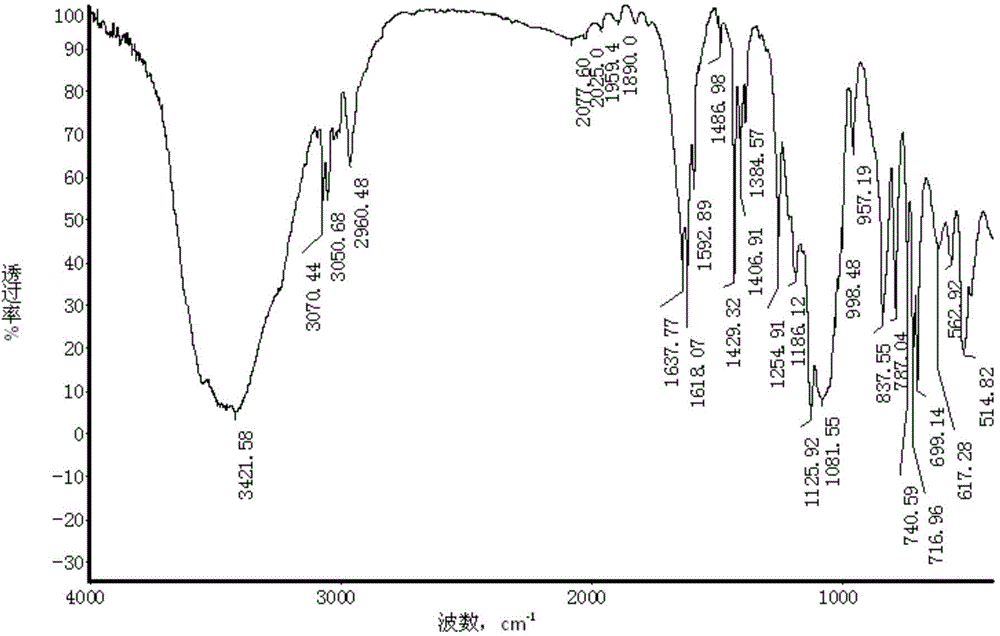

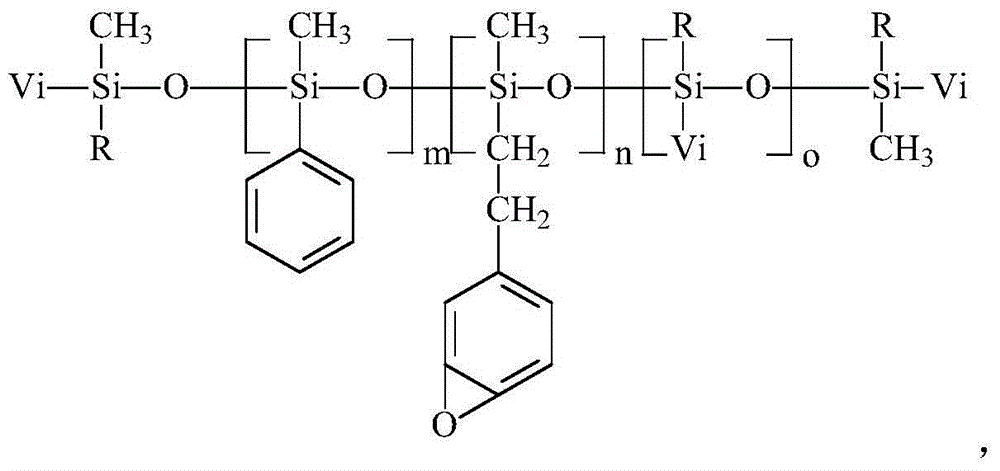

Vinyl phenyl silicon resin with side chain containing epoxy group and preparation method of vinyl phenyl silicon resin

The invention relates to vinyl phenyl silicon resin with a side chain containing an epoxy group, and the structural formula is as shown in the specification. The invention also discloses a preparation method of the vinyl phenyl silicon resin. The preparation method comprises the following steps: under nitrogen condition, adding 1,3,5,7-tetramethyl cyclotetrasiloxane and 4-vinyl cyclohexene oxide to a reaction container according to a proportion, adding a solvent, a catalyst and a polymerization inhibitor in parts by weight, increasing temperature to react, carrying out reduced pressure distillation to obtain a cyclotetrasiloxane containing cyclohexene oxide group, then adding cyclotetrasiloxane containing cyclohexene oxide group, vinyl cyclosiloxane, methyl phenyl cyclosiloxane and an end-capping reagent to the other reaction container according to a proportion, increasing temperature to react, and carrying out reduced pressure distillation to obtain vinyl phenyl silicon resin with a side chain containing an epoxy group. The preparation method is simple, flexible, moderate in reaction condition and suitable for industrial production.

Owner:SHANGHAI INST OF TECH

Method for preparing environment-friendly type plasticizer from low-quality animal and vegetable oil through modification and deep epoxidation

Owner:SICHUAN UNIV

Preparation method of epoxy aliphatic ester biological lubricant base oil

ActiveCN103145651AImprove catalytic performanceUse lessOrganic chemistryFatty acid chemical modificationEpoxyBase oil

The invention relates to a preparation method of epoxy aliphatic ester biological lubricant base oil. Metal ion supported cation exchange resin is used for a catalyst to prepare the epoxy aliphatic ester biological lubricant base oil. The preparation method of the epoxy aliphatic ester biological lubricant base oil is mild in reaction condition, high in catalyst activity, capable of reducing dosage of the catalyst, shortening reaction time, reducing addition quantity of formic acid, and reducing influence on the catalytic performance of other metal ions and the water content in a reaction system, and environment-friendly in production process. In addition, the prepared epoxy aliphatic ester is high in epoxide value, and the largest epoxide value can be over 4.6.

Owner:JIANGSU ZHONGSHENG GAOKE ENVIRONMENTAL CO LTD

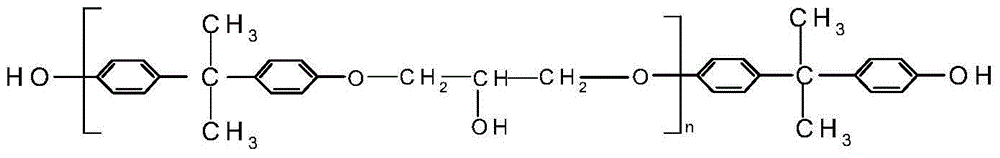

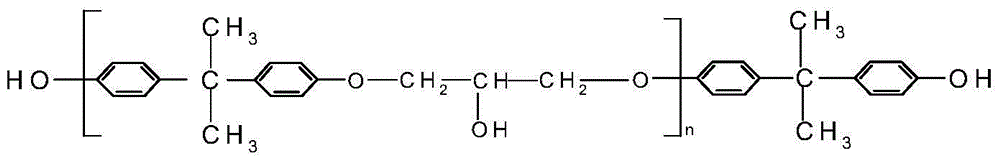

Modified solid epoxy resin with high glass transition temperature and high tenacity as well as preparation method thereof

ActiveCN104788648AImprove heat resistanceImprove toughnessAnti-corrosive paintsEpoxy resin coatingsEpoxyVitrification

The invention relates to modified solid epoxy resin with high glass transition temperature and high tenacity. The modified solid epoxy resin is prepared from the following components in parts by weight: 100 parts of epoxy resin, 50-120 parts of a modifier, 0.05-5 parts of a catalyst, and 25-100 parts of a curing agent. The invention further provides a preparation method of the modified solid epoxy resin with high glass transition temperature and high tenacity. The modified solid epoxy resin has the excellent properties that the glass transition temperature is 128-178 DEG C, the cathodic cathodic disbonding radius is smaller than or equal to 10 mm (1.5 V, 92-98 DEG C, 28d), the modified solid epoxy resin can pass a bend test of 3 degrees at minus 30 DEG C as no crack generates, the softening point is 96-115 DEG C, the epoxide number is 0.19-0.275 mol / 100g, and the functionality degree is 2.6, so that the modified solid epoxy resin can be applied to the fields of petroleum and gas long-distance pipelines, urbane groundwater, gas pipe network pipelines, transportation industry (automobiles and ships), oceanographic engineering, corrosion prevention in bridges and construction reinforcing steel bar, and the like in which the use temperature is higher than 95 DEG C.

Owner:大庆庆鲁朗润科技有限公司

Method for preparing epoxy fatty acid methyl ester

The invention relates to an improved method for preparing epoxy fatty acid methyl ester, which is characterized in that a solid catalyst or a sodium bisulfate solid catalyst obtained by mixing 30-90 parts of sodium bisulfate, 10-50 parts of ferric sulfate and 0-20 parts of calcium sulfate is adopted in an epoxidation reaction. By using the solid catalyst, when catalytic activity of the solid catalyst corresponds to that of sulfuric acid, the reaction condition is temperate; the production safety is good; the obtained product has high epoxy value which can reach more than 3.5; the epoxidation temperature is reduced to a certain degree, for example, the reaction temperature can be reduced by about 10 DEG C; and because too high temperature is needless, the fatty acid eater is not easy to be carbonized; the obtained product has light and bright color and luster and can be directly used for a light-color product without a decolorization process; the yield is also enhanced; and particularly the corrosivity to equipment is greatly reduced, thereby reducing equipment investment, maintainance and replacement. Meanwhile, the solid catalyst is simpler than a liquid catalyst in use and recovery aspects and is friendly to environment.

Owner:JIANGSU ZHONGSHENG GAOKE ENVIRONMENTAL CO LTD

Catalyst, preparation method thereof and method for preparing aliphatic glycidyl ether by using catalyst

InactiveCN103191761AGood choiceHigh epoxy valueOrganic chemistryPhysical/chemical process catalystsActivated carbonBoron trifluoride

The invention discloses a catalyst which comprises an activated carbon body, wherein boron trifluoride is fixedly loaded on the outer surface of the activated carbon body. The solid-phase catalyst formed by fixedly loading boron trifluoride on the activated carbon is good in selectivity on the main reaction in the ring-opening reaction process that aliphatic glycidyl ether is prepared, and a final product is high in epoxy value, low in organic chloride content and good in quality; and in addition, the solid-phase catalyst is low in equipment corrosion, easy to be separated from a reaction product after the ring-opening reaction is accomplished, and can be recycled and reused after being separated.

Owner:NANJING FORESTRY UNIV +2

High epoxide number environment-friendly plasticizer production process

InactiveCN102503912AHigh epoxy valueProcess raw materials are easy to getFatty acid esterificationSulfonic acid esters preparationSodium methoxideMethyl oleate

The invention discloses a high epoxide number environment-friendly plasticizer production process. The production process comprises the following steps of: adding cottonseed oil, methanol and sodium methoxide into an ester exchange reactor for reaction to obtain mixed fatty acid methyl ester; adding into a rectifying tower for separation, and performing epoxidation, neutralization, washing and dehydration on methyl oleate obtained from the tower bottom to obtain a high epoxide number environment-friendly plasticizer; and performing sulfonation reaction on palmitic acid methyl ester obtained from the tower top and sulfur trioxide, and ageing, esterifying, neutralizing and drying to obtain an environment-friendly surfactant MES. By the production process, the raw materials are readily available, the process is advanced, equipment is simple, the high epoxide number plasticizer can be prepared, and the byproduct, namely the palmitic acid methyl ester can be used for producing the environment-friendly surfactant.

Owner:扬州市双全塑胶材料厂

Preparation method of 4,4'-biphenol diglycidyl ether

ActiveCN102030726AReduce hydrolysis side reactionsHigh yieldOrganic chemistryTwo stepEpichlorohydrin

The invention discloses a preparation method of 4,4'-biphenol diglycidyl ether. In the preparation method provided by the invention, 4,4'-biphenol and epichlorohydrin are used as raw materials to be synthesized by a two-step method under the effect of a heterogeneous catalyst. The preparation method comprises the following steps: firstly, carrying out a ring-opening etherifying reaction, then carrying out a ring-closing reaction, and in the alkalizing process, separating out water generated in the reaction by a water-separating technique, so that the reaction shifts to the right at equilibrium, and various hydrolysis secondary reactions in the system can be controlled. The product obtained by the technique has high epoxide equivalent and high yield, the technique has simple reaction steps and is convenient for posttreatment, and experimental results show that the epoxide number is 0.65-0.67, and the melting range is 159.1-160.4 DEG C.

Owner:兰州精细化工有限责任公司

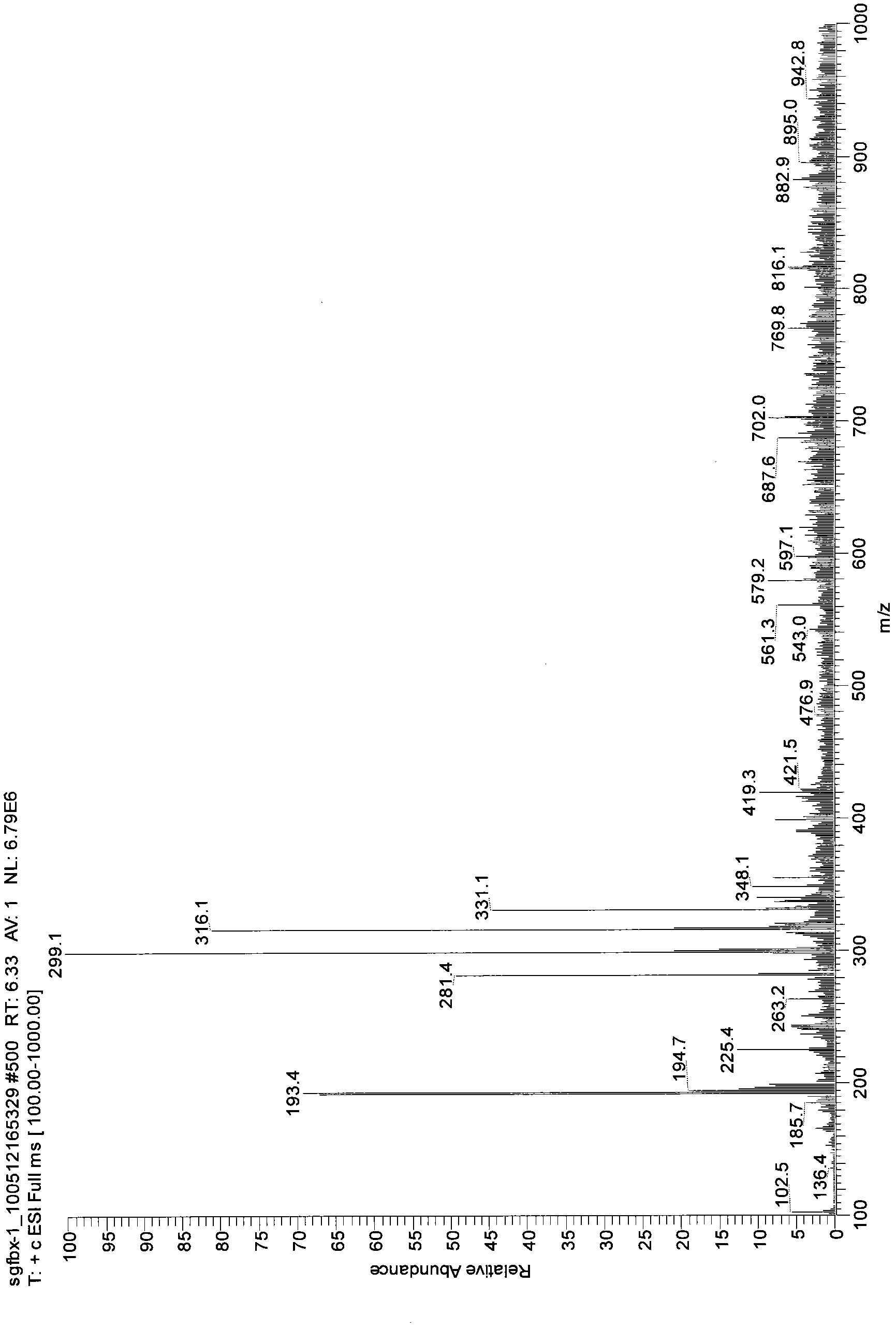

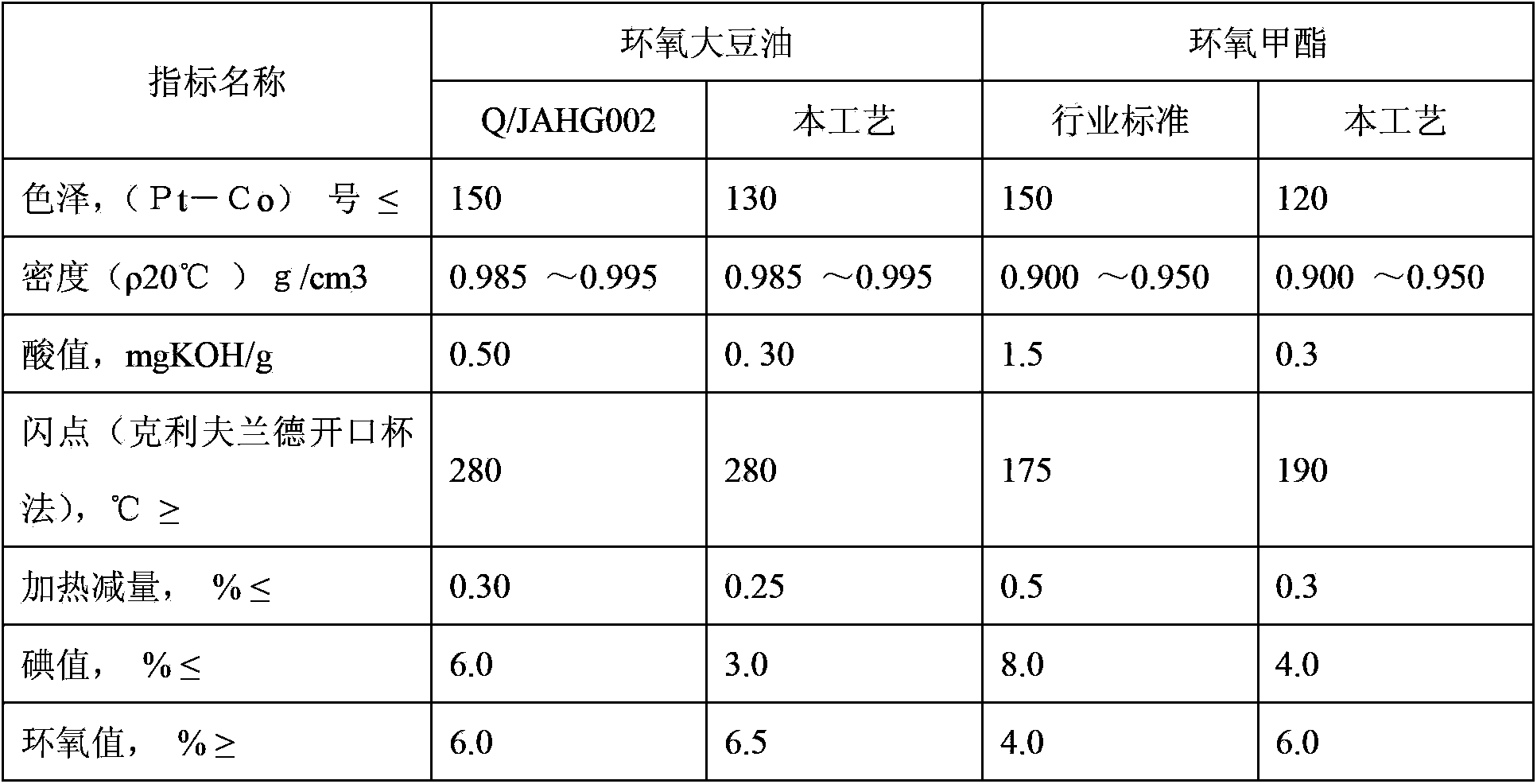

Production method of epoxidized fatty acid methyl ester/epoxidized soybean oil

InactiveCN103382415AIncrease the epoxy value of methyl esterHigh epoxy valueFatty acid chemical modificationHigh concentrationReaction speed

The invention relates to a production method of epoxidized fatty acid methyl ester / epoxidized soybean oil. The production method concretely comprises the following technological steps: (1) taking one of soybean oil and fatty acid methyl ester, formic acid and hydrogen peroxide and preheating them to 90+ / -2 DEG C; and (2) adding preheated soybean oil, formic acid and hydrogen peroxide into a pipeline reactor to react until the end of the reaction. According to the invention, by the utilization of the pipeline reactor, the technical bias that a high concentration of hydrogen peroxide cannot be used in a traditional epoxidized soybean oil production technology is overcome; by the use of 70% high concentration of hydrogen peroxide in the production process, the reaction time is greatly shortened, and the yield is substantially raised. In addition, by the use of a high concentration of hydrogen peroxide and a high proportion of formic acid, the reaction speed is fast, side reaction is less, epoxy value of the produced epoxidized soybean oil / epoxidized fatty acid methyl ester is remarkably raised, color is obviously improved, and transparency is better.

Owner:江苏悦达卡特新能源有限公司

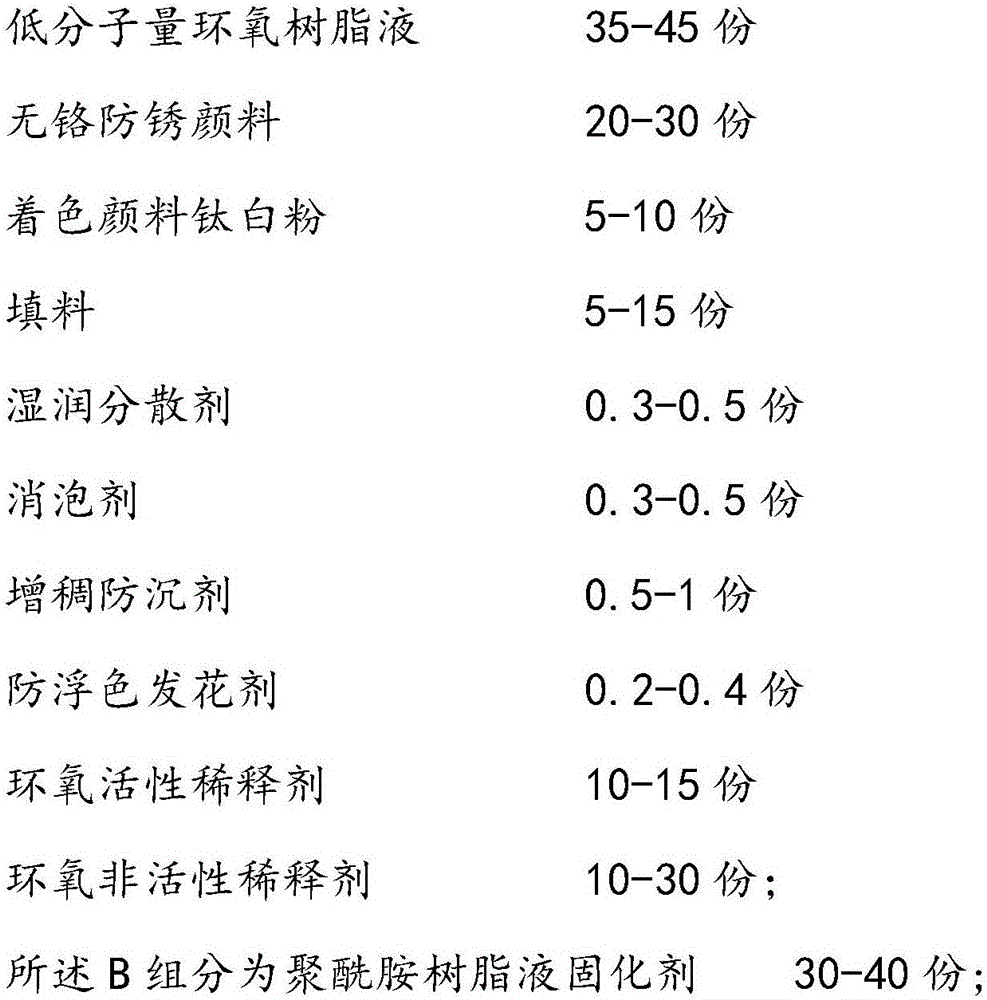

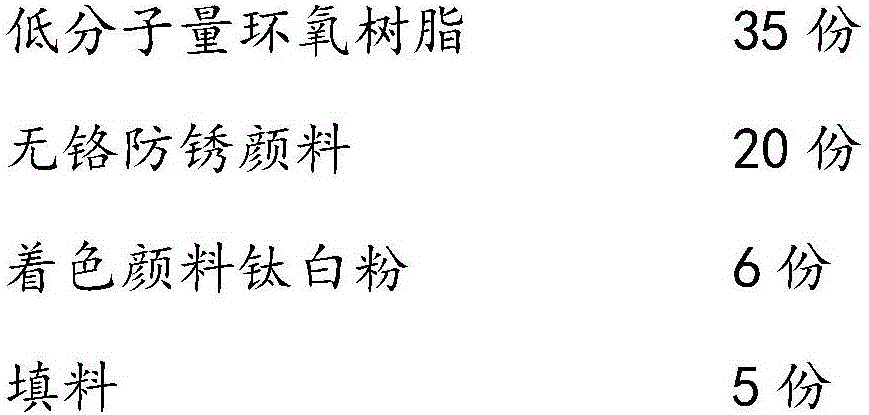

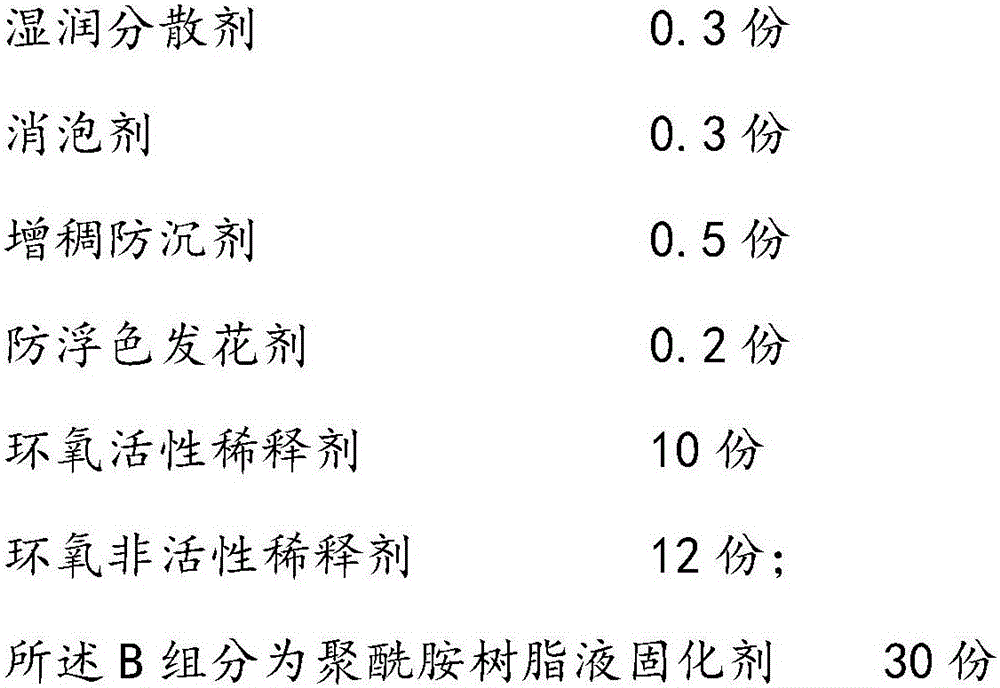

Chromium-free high-solid-content double-component epoxy primer and preparation method thereof

ActiveCN106800861AGood resistance to salt sprayExcellent resistance to filiform corrosionFireproof paintsAnti-corrosive paintsChromium freeEpoxy

The invention provides a chromium-free high-solid-content double-component epoxy primer and a preparation method thereof. The chromium-free high-solid-content double-component epoxy primer is composed of a component A and a component B in a weight ratio of 100:(30-40). The chromium-free high-solid-content double-component epoxy primer is mainly used for the surfaces of steel, iron, aluminum and other substrates, and aircrafts and equipment components with harsh requirements for environment friendliness and corrosion resistance in military and civil industries, and has the advantages of excellent salt spray resistance, excellent filiform corrosion resistance, excellent water resistance, excellent machine oil resistance and excellent adhesive force. The preparation method is simple, and is suitable for the demands of large-scale industrial production.

Owner:天津灯塔涂料工业发展有限公司

Synthetic method of butyl glycidyl ether

ActiveCN103145647AHigh epoxy valueThe ring-closing reaction facilitatesOrganic chemistryBoron trifluorideEther

The invention discloses a synthetic method of butyl glycidyl ether. The method comprises the following steps of performing ring-opening reaction on butanol and epoxy chloropropane to prepare a butyl chlorhydrin ether intermediate and performing ring-closing reaction on the butyl chlorhydrin ether intermediate and sodium hydroxide to prepare butyl glycidyl ether. The catalyst used in the ring-opening reaction is an active carbon immobilized boron trifluoride catalyst, wherein the immobilized amount of boron trifluoride is 5-20%. Through using the active carbon immobilized boron trifluoride catalyst to catalyze the ring-opening reaction of butanol and epoxy chloropropane, the selectivity for main reaction of the ring-opening reaction is high, and side reactions are reduced, so that the epoxide number of the obtained butyl glycidyl ether is high, the content of organochlorine is low and the quality is good. In addition, the solid phase catalyst has low corrosion to devices, can be easily separated from reaction products after ring-opening reaction, and can be recycled after being separated, and therefore, the environmental pollution is avoided.

Owner:ANHUI XINYUAN CHEM

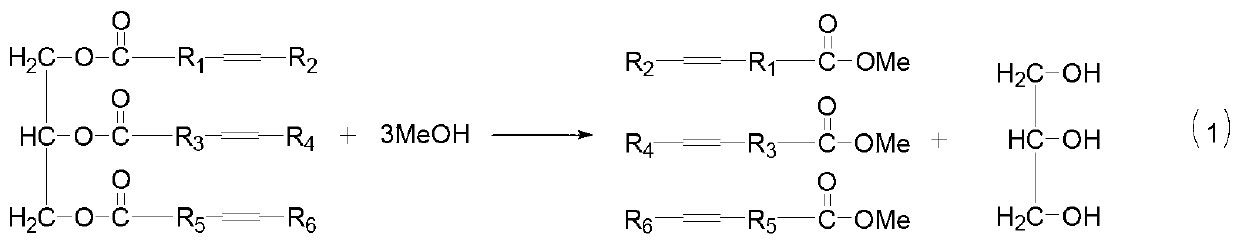

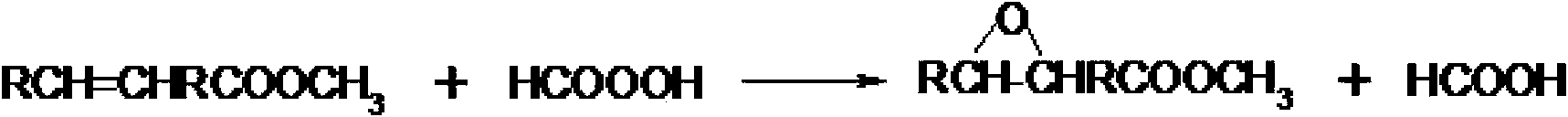

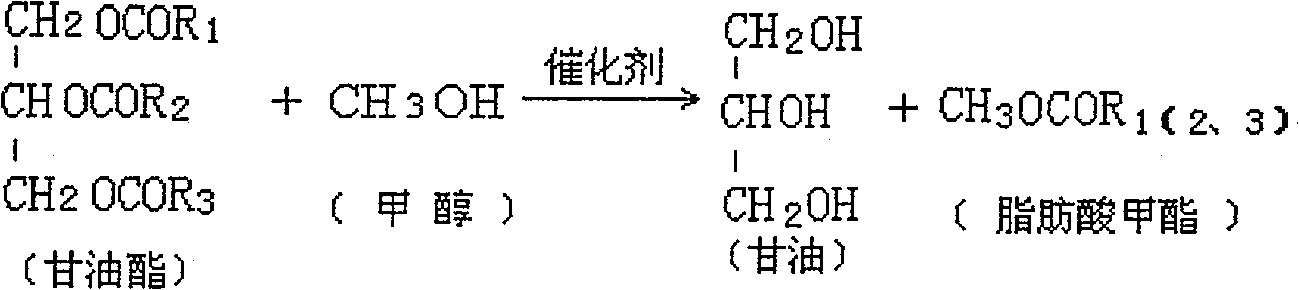

Method for producing epoxy plasticizer using waste grease

InactiveCN100590188CHarm reductionReduce dosageFatty oils/acids recovery from wasteFatty acid esterificationEpoxyOrganic acid

This invention relates to one kind of method to use abandoned grease to produce epoxy plasticizer, its characteristic lies in: Use the abandoned grease as raw materials, by pretreatment, the obtainedglycerin ester to ester exchange respond with the methyl alcohol under alkali catalysis, then get fatty acidmethyl ester, then again with the peroxide organic acid, which is the reaction products ofhydrogen peroxide and organic acid, to directly epoxy respond, get the raw epoxy fatty acid methyl ester, then wash off the acid by water, and obtain the epoxy fatty acid methyl ester by distillationand dehydration product. The raw material cost of this invention is low, originates broadly, conforms to the green environmental protection requirement, and the craft is simple, does not pollute environment, so it is the good substitute of petroleum product.

Owner:江苏向阳科技有限公司

Preparing method for epoxy resin active diluent of low organic chlorine content

The process of preparing active epoxy resin diluent with low organochlorine content includes the following steps: mixing alcohol or phenol, benzene solvent and catalyst, dropping chloroepoxy propane into the mixture at 10-55 deg.c for 4-12 hr, and stilling at 20-60 deg.c for 2-4 hr; adding quaternary ammonium salt as the phase transfer catalyst, dropping water solution of sodium hydroxide of 30-50 wt% concentration at 20-55 deg.c for 2-4 hr, raising the temperature by 5-15 deg.c, and maintaining for 1-5 hr; and extracting, neutralizing or water washing to eliminate sodium chloride, and eliminating benzene solvent to obtain active epoxy resin diluent with low organochlorine content. During the ring-closing reaction, phase transfer catalyst, rather than alkali metal hydroxide, is added to result in even high organochlorine eliminating effect.

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL

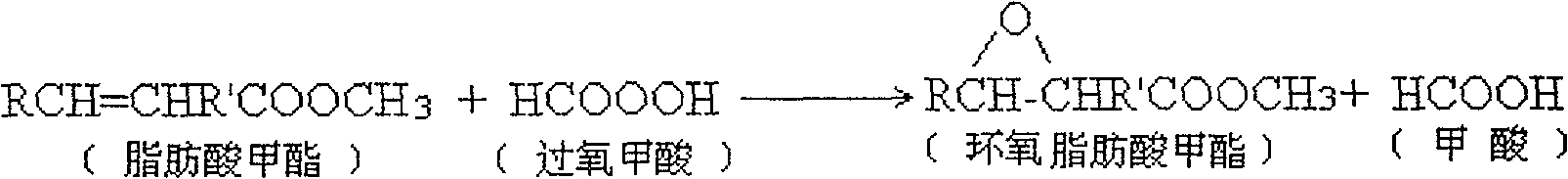

Synthesis process of epoxy resin with anionic catalyst

The synthesis process of epoxy resin with anionic catalyst includes the following steps: the etherification of diphenol propane and epoxy chloropropane in the presence of quaternary ammonium salt at 75-125 deg.c for 1-8 hr to produce etherate; the ring closing reaction of treated alkaline anionic exchange resin and the etherate at 35-65 deg.c for 1-6; filtering the resultant to obtain filtrate and vacuum distilling the filtrate to obtain the epoxy resin product. The synthesis process has no waste water and sodium chloride and is environment friendly, and the multiple times of catalysis with alkaline anionic exchange resin promote the ring closing reaction and results in raised epoxy resin yield.

Owner:蓝星安迪苏股份有限公司

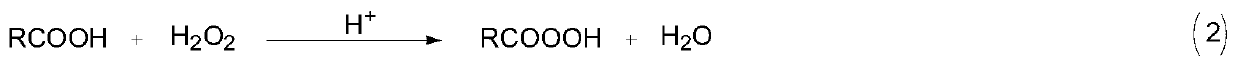

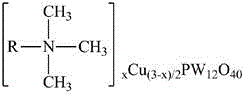

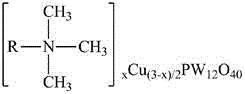

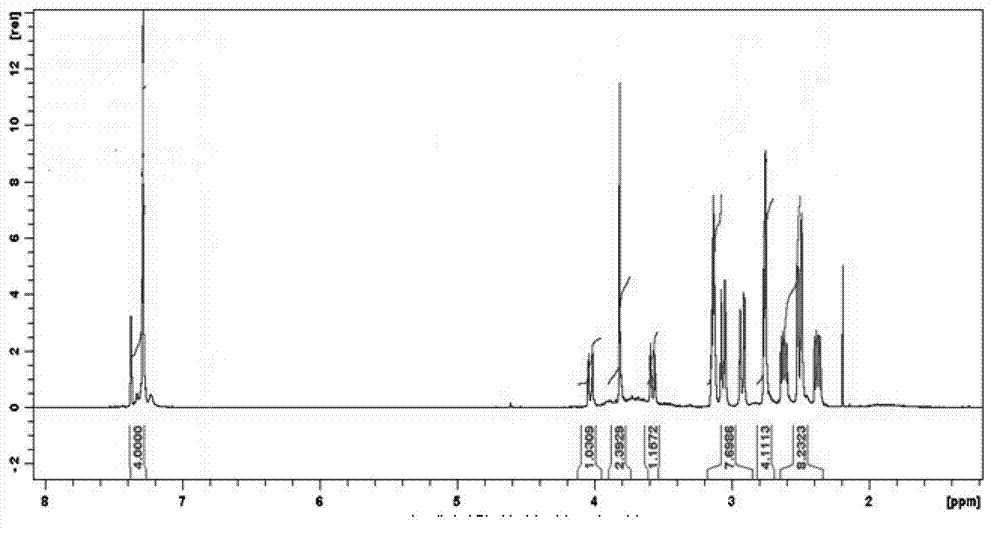

Method for catalytic synthesis of epoxidized soybean oil under carboxylic acid-free condition

InactiveCN106831655AGood synergyImprove catalytic performanceOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsCarboxylic acidStructural formula

The invention relates to a method for catalytic synthesis of epoxidized soybean oil under the carboxylic acid-free condition. By using composite doped phosphotungstate as a catalyst and using hydrogen peroxide as an oxidizing agent and under the carboxylic acid-free condition, soybean oil is epoxidized to prepare the epoxidized soybean oil. The structural formula of the composite doped phosphotungstate is as shown in the specification, wherein R= -C16H33 or -C18H37 and x=1-2. The invention has the following advantages: the composite doped phosphotungstate has excellent catalytic performance on the epoxidation reaction of soybean oil; as the epoxidation reaction is carried out under the carboxylic acid-free condition, the reaction process is clean and efficient and epoxy value of the product is high.

Owner:SHAOYANG UNIV

Method for preparing epoxidized oil under ultrasound condition

InactiveCN101613639AAccelerates the epoxidation reactionHigh epoxy valueFatty acid chemical modificationUltrasound deviceAcetic acid

The invention relates to a method for preparing epoxidized oil under the ultrasound condition, comprising the following steps: a. taking and placing a certain amount of plant oil into a reaction container, placing the reaction container into an ultrasound device, stirring while adding the mixed liquid of formic acid (glacial acetic acid or the mixture of formic acid and glacial acetic acid) and catalyst, adjusting temperature of the system, adding hydrogen peroxide drop by drop slowly as well as starting ultrasound, controlling frequency and power of the ultrasound, adjusting the temperature of the system after the adding of hydrogen peroxide is finished, carrying out ultrasound in a certain reaction frequency, certain reaction power and reaction time, lowering the temperature to room temperature after the reaction, removing the lower layer after stewing, and obtaining crude epoxidized plant oil; b. transferring the crude epoxidized plant oil obtained in step a to water washing equipment for washing, and removing the water layer after stewing; and c. transferring the liquid obtained in step b to a vacuum distillation unit (VDU) for vacuum distillation to remove moisture and obtaining the epoxidized plant oil product.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Preparation method of tetraglycidyl m-xylene diamine epoxy resin

The invention discloses a preparation method of tetraglycidyl m-xylene diamine epoxy resin, which comprises the following steps: (1) adding epichlorohydrin and deionized water into a reaction device, dropwisely adding m-xylene diamine for a ring-opening reaction; (2) adding an aqueous alkali into the material obtained in step (1) for a ring-closure reaction, wherein the molar ratio of the alkali in the aqueous alkali to the m-xylene diamine is 4:1; (3) after the reaction, recovering epichlorohydrin, adding an inert solvent and deionized water, performing extraction layering, removing the water layer; (4) refining the organic layer with the aqueous alkali, wherein the molar ratio of the alkali in the aqueous alkali to the m-xylene diamine is 1:1-2.5:1; (5) washing the refined material with water, removing the solvent to obtain the tetraglycidyl m-xylene diamine epoxy resin. The method of the invention is simple in process, easy to implement, and low in cost, and the prepared tetraglycidyl m-xylene diamine epoxy resin has low viscosity, low organic chloride content, and a high epoxy value.

Owner:CHANGZHOU SUNCHEM HIGH FORMANCE POLYMER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com