Rubber seed oil-based epoxy fatty acid methyl ester and preparation method and application thereof

A technology of oil-based epoxy fatty acid methyl ester and fatty acid methyl ester, which is applied in the field of preparation of bio-based plasticizers, can solve problems such as insufficient effective utilization, achieve high-value development and utilization, simple preparation process, and environmentally friendly friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

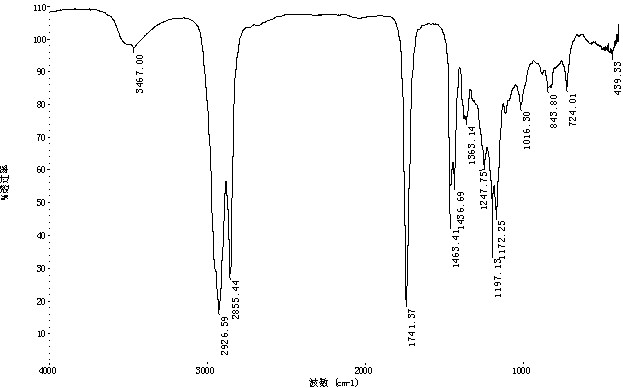

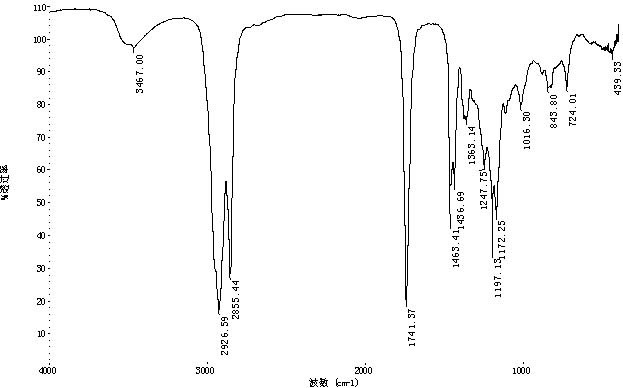

Image

Examples

preparation example Construction

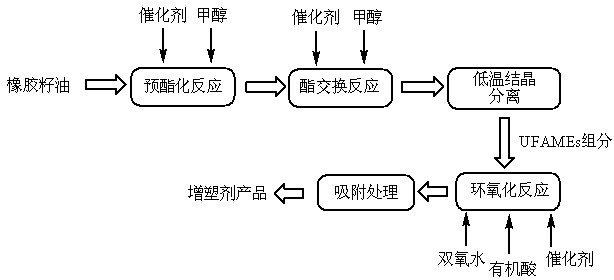

[0027] The technical solution preparation method that the present invention specifically adopts comprises the following steps:

[0028] The rubber seed oil fatty acid methyl ester was prepared by a two-step method. Take 100g of rubber seed oil after degumming treatment, mix it with 20-40g of methanol and 0.8-1.2g of catalyst, carry out esterification reaction at a constant temperature of 60-80°C, and stop the reaction after the acid value drops below 2mg KOH / g , when a solid catalyst is used, the catalyst is removed, and the excess methanol and the water generated by the esterification reaction are removed by distillation under reduced pressure at 90°C. If a liquid catalyst is used, it is removed together with methanol, etc.; the resulting oil phase product is then added with 10- 30g of methanol and 0.8-1.2g of catalyst, carry out transesterification reaction at 55-65°C for 2 hours at a constant temperature, cool down properly, then distill under reduced pressure to 90°C, l...

Embodiment 1

[0042] The rubber seed oil fatty acid methyl ester was prepared by a two-step method. Take 100g of rubber seed oil after degumming treatment, mix it with 20-40g of methanol and 0.8-1.2g of catalyst cation exchange resin catalyst, carry out esterification reaction at a constant temperature of 60-80°C, and wait for the acid value to drop to 2mg KOH / g Stop the reaction after the following, remove the catalyst, and distill under reduced pressure at 90°C to remove excess methanol and water generated by the esterification reaction; add 10-30g of methanol and 0.8-1.2g of catalyst to the obtained oil phase product, and dissolve it at 55-65 The transesterification reaction was carried out at a constant temperature of ℃ for 2 hours, cooled properly, and then distilled under reduced pressure to 90 ℃, allowed to stand and separated, recovered the glycerin in the lower layer, and took the crude fatty acid methyl ester in the upper layer for later use.

[0043] 100 g of crude fatty ac...

Embodiment 2

[0047] The rubber seed oil fatty acid methyl ester was prepared by a two-step method. Take 100g of rubber seed oil after degumming treatment, mix it with 20-40g of methanol and 0.8-1.2g of catalyst p-toluenesulfonic acid, and carry out esterification reaction at a constant temperature of 60-80°C until the acid value drops to 2mg KOH / g Stop the reaction after the following, and distill under reduced pressure at 90°C to remove excess methanol, p-toluenesulfonic acid and the water generated by the esterification reaction; add 10-30g of methanol and 0.8-1.2g of catalyst to the obtained oil phase product, and dissolve it at 55- The transesterification reaction was carried out at a constant temperature of 65°C for 2 hours, cooled properly, and then distilled under reduced pressure to 90°C, allowed to stand and separate layers, recovered the glycerol in the lower layer, and took the crude fatty acid methyl ester in the upper layer for later use.

[0048] Take 100g of crude fatt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com