Patents

Literature

79 results about "Rubber seed oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rubber seed oil is oil extracted from the seeds of rubber trees. In the latex manufacturing process, rubber seeds are not historically collected and commercialized. In Cambodia and other rubber manufacturing areas, rubber seeds are used to feed livestock. Although rubber seed is rich in nutrients, it also contains cyanogenic glycosides which will release prussic acid in the presence of enzymes or in slightly acidic conditions. Oil from the rubber seed is also of commercial importance. Hitherto, rubber seed has largely been allowed to waste with very little used for raising root stock seedlings for propagation purposes. The useful properties of the rubber seed oil make it similar to well-known linseed and soybean oil. Rubber seed oil also could be used for the paint industry as a semidrying oil, in the manufacture of soap, for the production of linoleum and alkyd resin; in medicine as antimalaria oil; and in engineering as core binder for factice preparation, and the cake left after oil extraction is used in fertilizer preparation and as feed for cattle and poultry. The potential of rubber wood as a source of timber is recognized in India, Sri Lanka, Indonesia, and Malaysia, with an increasing volume of sawn rubber wood used for furniture manufacturing and a variety of other applications.

Rubber seed oil polyalcohol and preparation method thereof

ActiveCN101906016AReduce dependenceIncrease added valuePreparation by alcoholysisEpoxyReaction temperature

The invention relates to rubber seed oil polyalcohol and a preparation method thereof. The method comprises the following steps of: mixing rubber seed oil, hydrogen peroxide and a catalyst serving as raw materials in a weight ratio of 1:0.5-1.5:0.01-0.05, putting the mixture into a reaction kettle, stirring the mixture and raising temperature to 50 to 80 DEG C, keeping reaction temperature for 3 to 8 hours, lowering the temperature to 30 DEG C, separating acid water out, washing the mixture with aqueous solution of sodium carbonate until the pH of the mixture is between 5 and 6, washing the mixture to be neutral with saturated sodium chloride and water, and performing pressure reduction and water removal at the temperature of between 50 and 90 DEG C for 2 to 5 hours to obtain epoxy rubberseed oil; and adding the epoxy rubber seed oil, methanol, isopropanol and fluoboric acid into the reaction kettle in a weight ratio of 1:1-5:1-5:0.002-0.01, raising the temperature to 75 to 100 DEG C, performing a reaction for 0.5 to 3 hours, washing the reaction product with the aqueous solution of the sodium carbonate until the pH of the reaction product is between 5 and 6, washing the reaction product to be neutral with water, and performing vacuum pumping at the temperature of between 50 and 120 DEG C for 2 to 5 hours to obtain the rubber seed oil polyalcohol. In the method, the conventional petroleum chemical is replaced by a non-edible plant oil resource, so that the dependence of polyurethane industry on petroleum chemicals is reduced, and the added value of the rubber seed oil is increased.

Owner:SOUTHWEST FORESTRY UNIVERSITY

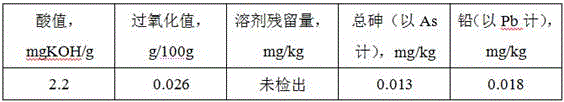

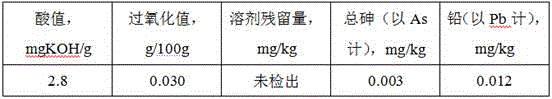

Application of rubber tree seed oil and preparation method of rubber tree seed oil

The invention provides application of rubber tree seed oil and a preparation method of the rubber tree seed oil, and in particular relates to the application of the rubber tree seed oil which is used as base oil in skin care products. The rubber tree seed oil is prepared through the steps of raw material screening, drying, shelling, cold pressing, filtering, water vapor stripping and the like. Utilization of the rubber tree seed oil as the base oil has the advantages of refreshing, easiness in absorption, good stability, obvious skin protection effects, low price, long storage and quality guarantee period and the like. The preparation method of the rubber tree seed oil, provided by the invention, has the advantages that the oil extraction rate is high, the nutritional substances in the oil cannot be damaged, the production cost is low, and no unboiled oil flavor exists. If the rubber tree seed oil is used as the base oil and pure essential oil is also added, various essential oil skin care products which are refreshing, non-greasy and easy to absorb, have specific effects of the pure essential oil, contain no chemical additive and are 100 percent purely natural can also be developed.

Owner:XISHUANGBANNA HUAKUN BIOTECH CO LTD

Technique for producing protein feed by using rubber seed expeller

InactiveCN101194669ASolving difficult-to-feed problemsImprove use valueAnimal feeding stuffAnti nutrientsCircular economy

The invention relates to the technical field of preparing feed protein, in particular to a method using rubber seed oil cake or oil meal to product the feed protein. Using a physical-chemical process of combining detoxification additive and puffing process, poisonous and anti-nutrient substance in the rubber seed oil cake or oil meal are effectively removed, and high quality feed protein is produced. The method not only is capable of preventing human and animal from eating the rubber seed oil cake or oil meal by mistake to poison, but also is capable of providing alternative or complementary new source of protein, simultaneously, the rubber seed oil cake or oil meal is fully used, waste is changed into valuable, and the advantage of circular economy is developed.

Owner:周晓南 +2

Method for producing environment-friendly type regenerated rubber

The invention relates to an environment-friend regeneration rubber production method, which is characterized in composed of a, washing, purifying, breaking, screening via a screen of 45 meshes, taking off the screened material, removing metal and fiber to obtain rubber powder, b, preparing materials as rubber powder of 100 accounts, activator of 0.2-0.5 accounts, pine gum of 1-4 accounts, organic acid salt of 0.3-1.5 accounts, rubber seed oil of 8-12 accounts and water of 5-10 accounts, c, mixing rubber powder, activator, pine gum, organic acid salt, rubber seed oil and water uniformly to be fed into a vulcanizing pot at the temperature of 200-220DEG C and the pressure of 1.5-2.0MPa to dynamically desulfurize for 3-3.5h, using a biological chemical adsorption tower to purify tail gas, d, refining and tabletting to obtain environment-friend regeneration rubber. The invention has reasonable method, simple process, wide material resource, low price, better physical property and chemical stability, high product quality, high yield, low cost, little environment pollution and wide application in rubber product.

Owner:KUNMING PHOENIX RUBBERS

Epoxy plant oil and preparation method thereof

The invention relates to epoxy plant oil and a preparation method thereof. In the preparation method, the epoxy plant oil is synthesized by taking soybean oil, caster oil, rubber seed oil, palm oil, cotton seed oil, rap oil, corn oil and the like as raw materials, using mesoporous titanium-silicon molecular sieve as a catalyst and utilizing hydroperoxides for reaction, wherein the epoxy value of the epoxy plant oil is 3.1-6.3%, the iodine value of the epoxy plant oil is 3.0-18.1% and the acid value of the epoxy plant oil is 0.6-4.3 KOH mg / g. The reaction process is carried out in the presence of no carbosylic acid and no protonic acid, thereby generating no acid waste water and being friendly to environment.

Owner:SOUTHWEST FORESTRY UNIVERSITY

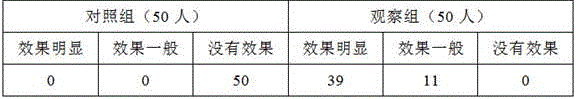

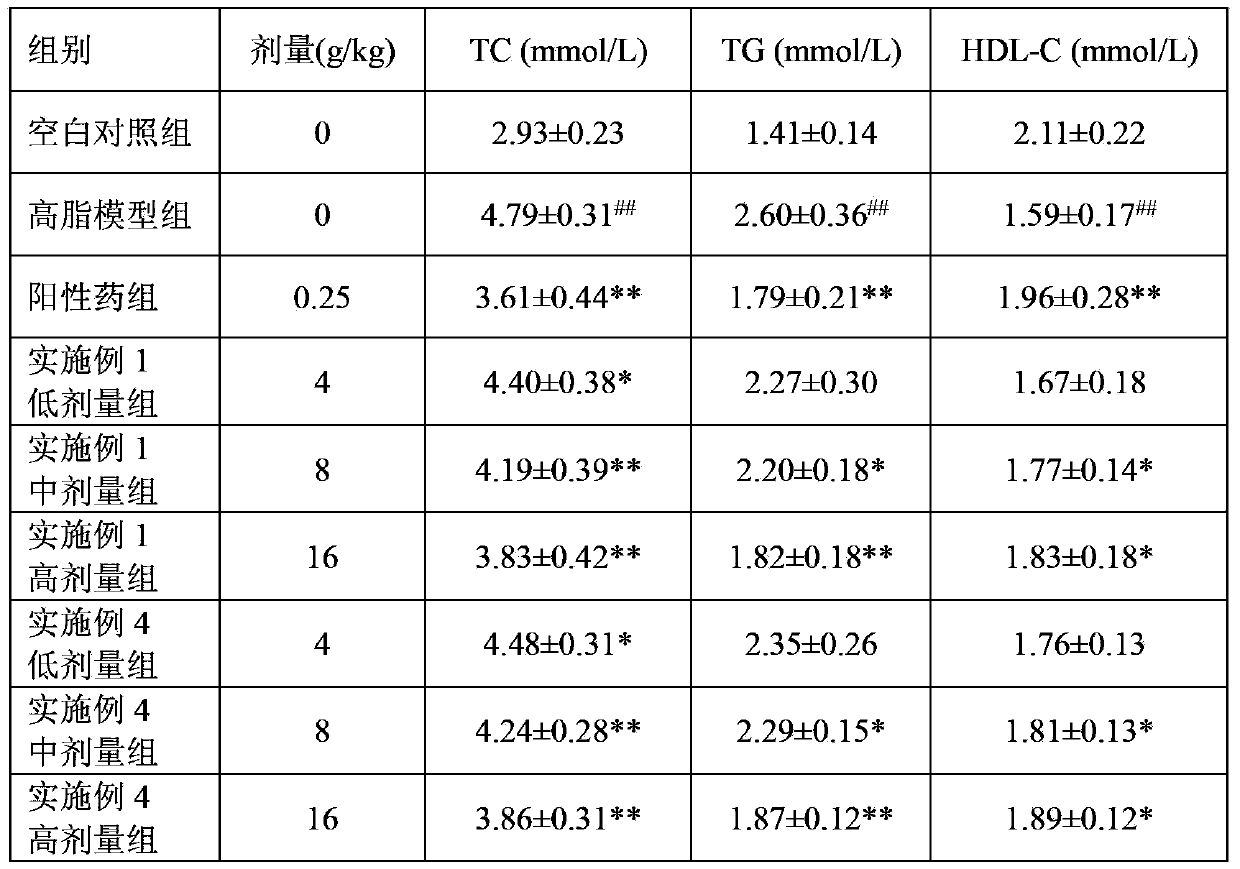

Vegetable oil composition with hypolipidemic effect as well as preparation method and application thereof

The invention discloses a vegetable oil composition with hypolipidemic effect and a preparation method thereof. The vegetable oil composition is prepared from the following raw materials in parts by weight: 5-50 parts of jujube seed oil, 10-80 parts of artemisia seed oil, 5-50 parts of perilla seed oil, 10-80 parts of flax seed oil and 5-50 parts of grape seed oil. The vegetable oil composition with hypolipidemic effect provided by the invention is prepared and screened by a large number of experiments and is prepared by adopting natural and traditional medicine and food dual-purpose vegetable oil with multiple healthcare functions, thereby being free of toxic side effect, healthy and safe; as shown in the experimental results, the vegetable oil composition can safely and effectively regulate the blood fat of human body, prevent arteriosclerosis and soften blood vessels, and is capable of being widely used by hyperlipidemia population resulting from high cholesterol or high triglycerides.

Owner:南京百草和康医药科技有限公司

Method for extracting oil from rubber seed

ActiveCN101475872AReduce sizeSpeed up dryingFatty-oils/fats productionEdible oils/fatsEngineeringHeat generation

The invention discloses novel technology for squeezing oil from fresh rubber seeds. The technology is characterized in that the fresh rubber seeds are not required to be stacked on a stock dump for a long time but directly crushed, dried, cooked, hardened, tempered and squeezed. The time from incoming of raw materials to obtaining of squeezed rubber seed oil and squeezed rubber seed oil cakes can be shortened to be within 3 hours. The technology can avoid the phenomena of heat generation, germination and mould development caused by the fact that the rubber seed raw materials are stacked on the stock dump for a long time in the prior art, can greatly improve the quality of the obtained rubber seed oil and the obtained rubber seed oil cakes, and can also improve the oil yield and the cake yield.

Owner:XISHUANGBANNA HUAKUN BIOTECH CO LTD

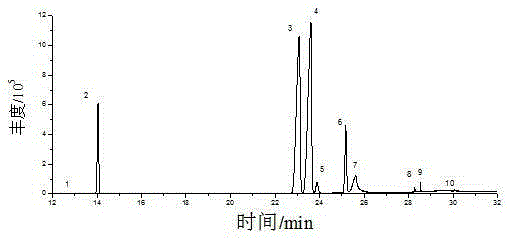

Process for producing conjugated linoleic acid by using rubber seed oil

InactiveCN102086427AImprove securityHigh development valueFatty acid isomerisationFatty acids production/refiningIsomerizationPEG 400

The invention discloses a process for producing conjugated linoleic acid by using rubber seed oil, comprising the following steps of: undergoing an isomerization reaction between the rubber seed oil containing linoleic acid with higher content and a polyethylene glycol 400 solution of alkali under the protection of nitrogen gas, carrying out molecular distillation purification, and adding tertbutylhydroquinone with stronger antioxidation to the product to produce the conjugated linoleic acid. In the invention, the utilized base oil is the rubber seed oil, and the content of the linoleic acid of the rubber seed oil is as high as 32.8%, thus the rubber seed oil is an excellent oil source for preparing the conjugated linoleic acid; and the utilized solvent is a pharmaceutic adjuvant, thus the safety of the products is ensured. The purification process is a molecular distillation technique, thus the conjugated linoleic acid products with higher purification can be obtained. The invention has the advantages of high yield of the reaction, simple process flow and good product quality.

Owner:海南省粮油科学研究所

Method for preparing biological diesel oil from rubber seed oil

InactiveCN101186834ANo pollutionMild reaction conditionsBiofuelsFatty-oils/fats refiningOil and greaseSingle process

Provided is a process for producing biodiesel, belonging to the technical field of grease modification. The process is characterized in that inedible oils with high acid value, such as rubber seed oil is employed, raw bran oil, raw corn oil, and low carbon alcohol accomplish two reactions of esterificationand and alcoholysis in a single process, and the key technology for achieving biodiesel with high efficiency is esterification and alcoholysis of catalysts.

Owner:钱生球

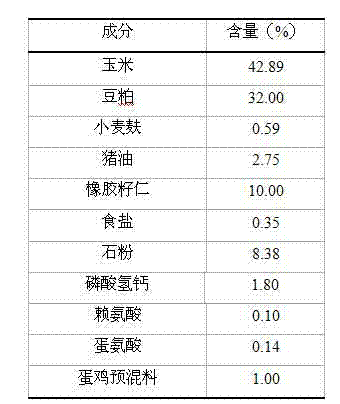

Eggs rich in omega-3 polyunsaturated fatty acids and preparation method

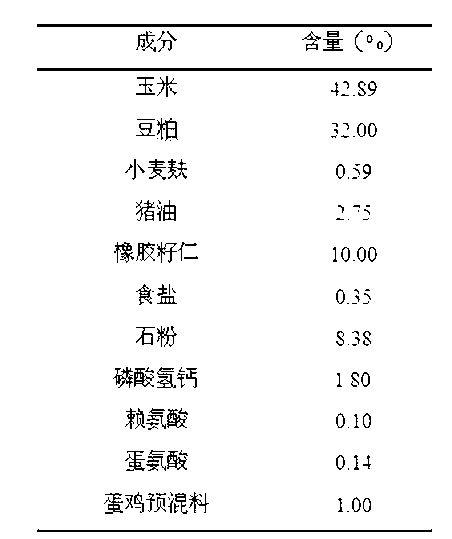

The invention relates to a preparation method for eggs rich in omega-3 polyunsaturated fatty acids. The preparation method comprises the following steps of: (1) adding screened rubber seed kernel or rubber seed oil cake into non-gm feed for laying hens, with the additive amount of the rubber seed kernel being 10-20% of the total weight of the feed for laying hens, and the additive amount of the rubber seed oil cake being 15-25% of the total weight of the feed for laying hens; (2) adjusting ingredients of the feed to enable the feed to comprise the following ingredients: 42.89 of corn, 17-32 of soybean meal, 0.59 of wheat bran, 2-3 of lard, 10-20 of rubber seed kernel or 15-25 of rubber seed oil cake, 0.35 of salt, 8.38 of stone powder, 1.8 of calcium hydrogen phosphate, 0.1 of lysine, 0.14 of methionine, 1 of premix for laying hens, and 5 international units of vitamin E per kg of feed; (3) feeding 130-140-day laying hens by using the feed for laying eggs rich in omega-3 polyunsaturated fatty acids after feeding for 2-4 weeks. The preparation method is low in cost, stable in content of the omega-3 polyunsaturated fatty acids, and safe without peculiar smell, and effectively and sufficiently utilizes rubber seed resources.

Owner:王云

Woody plant blending oil with scientific proportioning

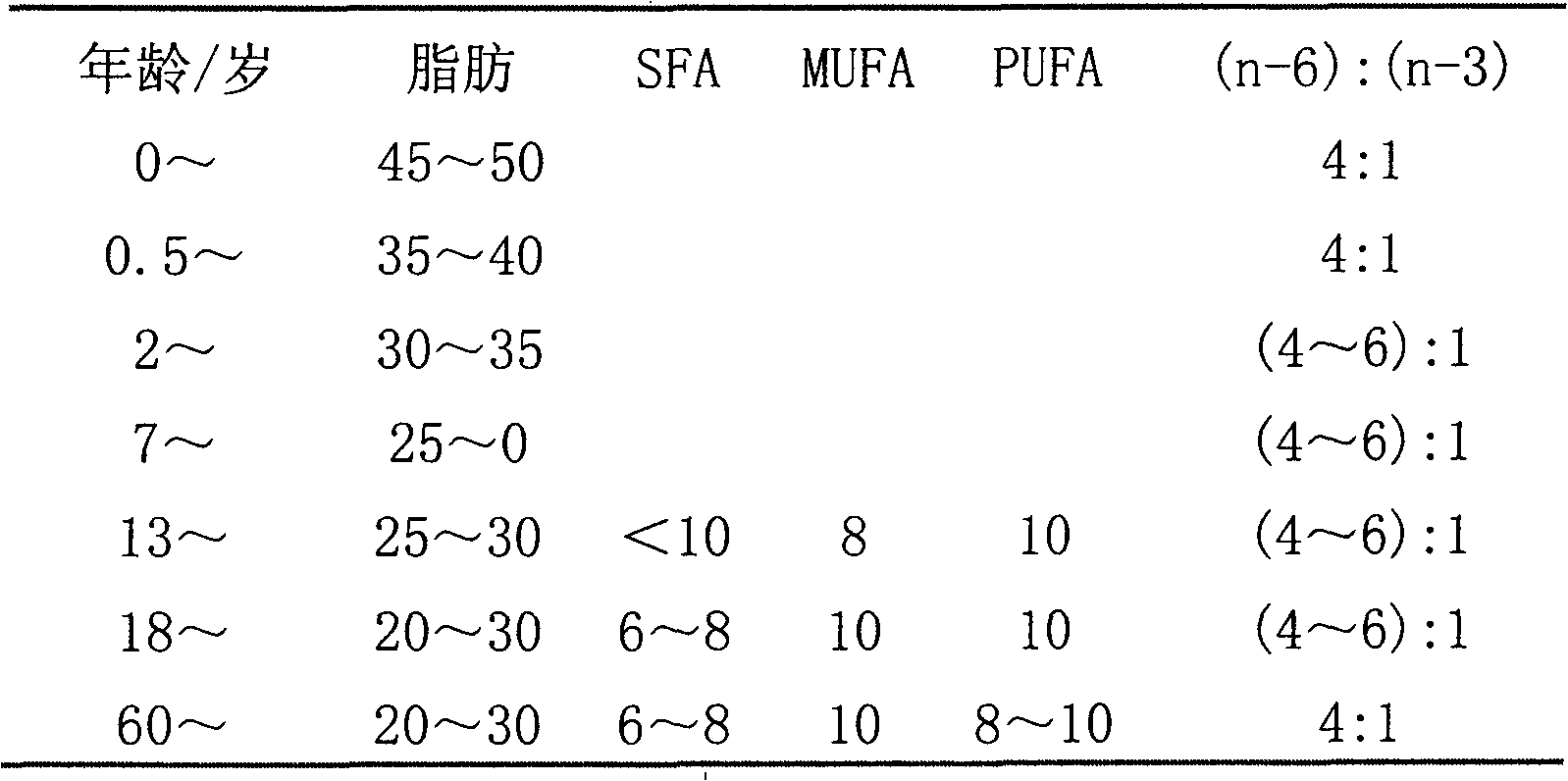

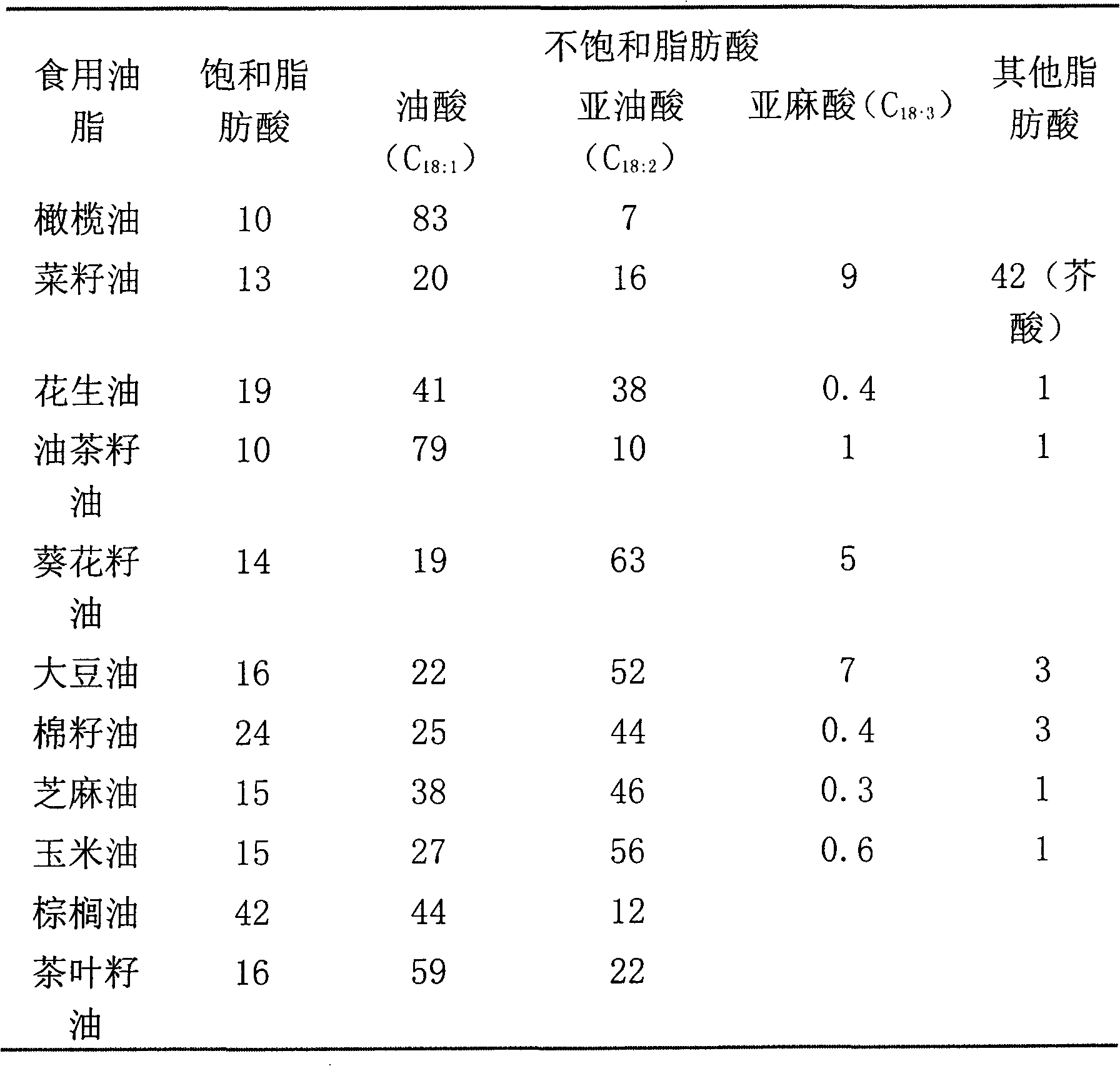

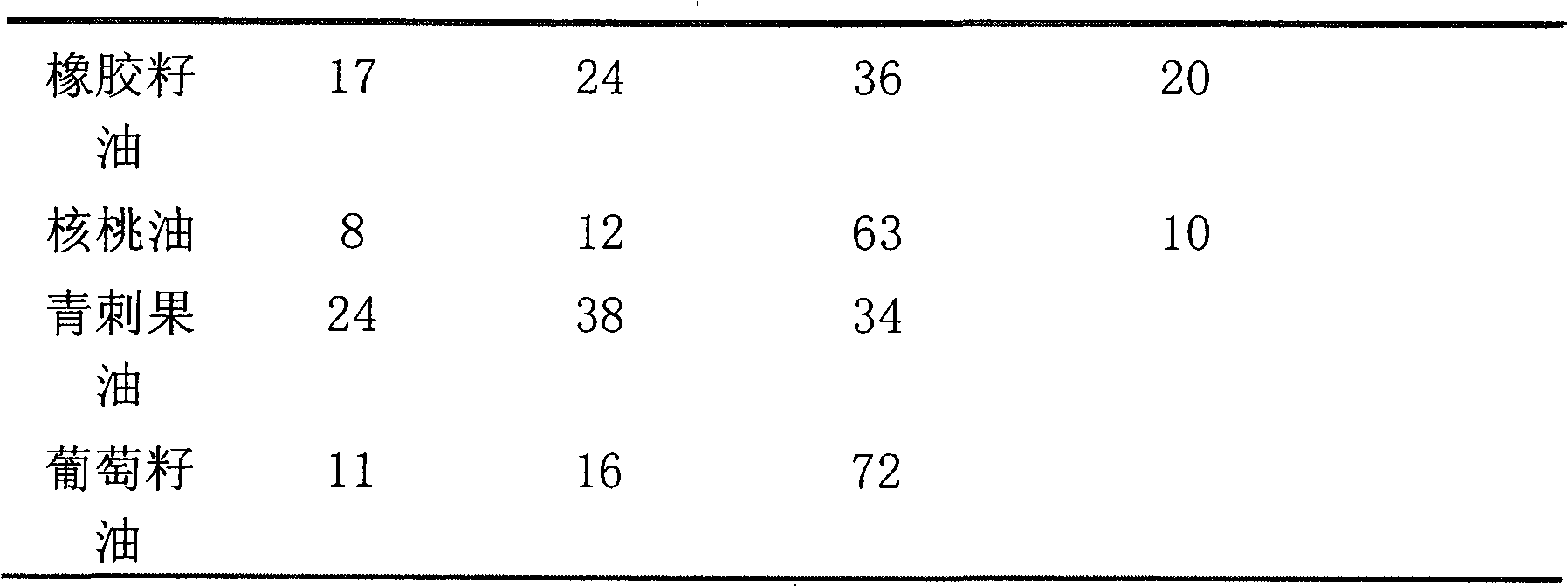

The invention discloses a woody plant blending oil with a scientific proportioning. The woody plant blending oil comprises the following vegetable oil components by weight percent: 40-65% of tea seedoil and / or camellia seed oil, 20-50% of walnut oil and / or grape seed oil and 5-30% of rubber seed oil and / or eucommia ulmoides oliver seed oil. The fat of the woody plant blending oil finished productof the invention is composed of the following fatty acids by weight percent: 12%-20% of saturated fatty acid, 40%-45% of monounsaturated fatty acid, 32%-38% of n-6 polyunsaturated fatty acid and 5%-10% of n-3 polyunsaturated fatty acid. The woody plant blending oil of the invention is prepared according to the scientific proportioning on the basis of the recommended nutrient intake and recommended ratio of fat and fatty which is provided by the Chinese Nutrition Society for Chinese residents so that the blending oil can meet the demand of human body for the nutritive equilibrium of differentfatty acids and reach the aim of eating less oil, eating good oil and eating oil scientifically.

Owner:陈军 +1

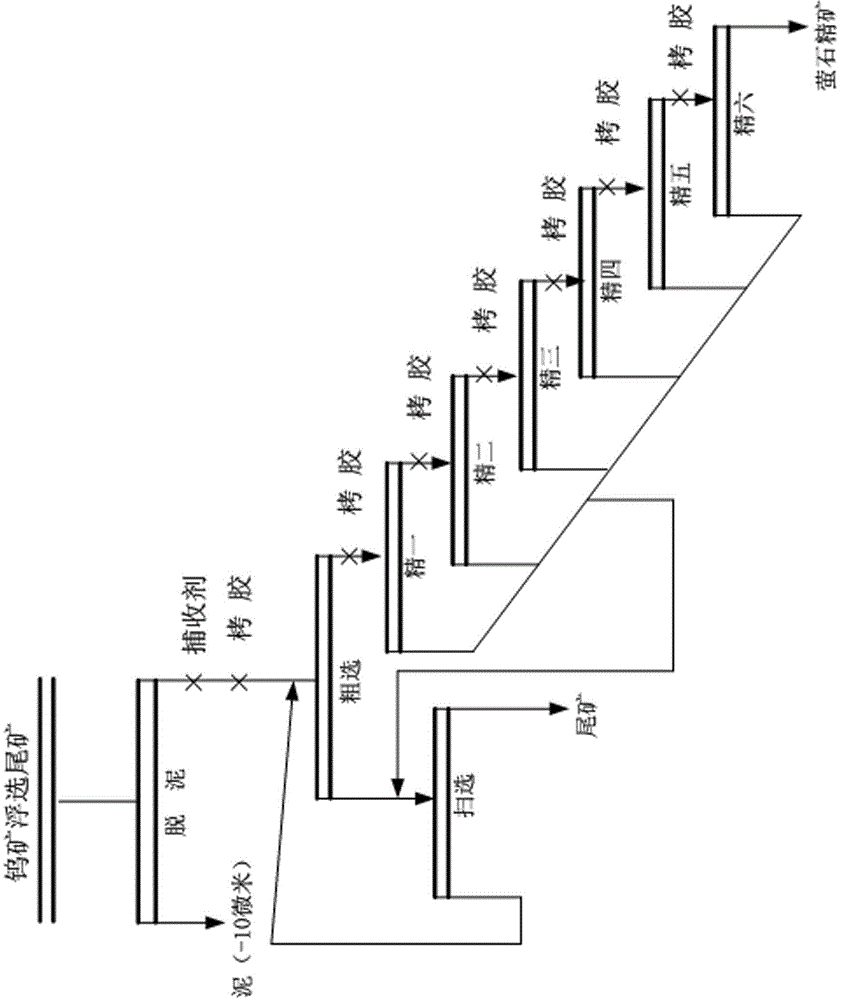

Production method for collecting fluorite-contained tailings from rubber seed oil

The invention discloses a production method for collecting fluorite-contained tailings from rubber seed oil. The method comprises the following steps: (1) the rubber seed oil is prepared to a low-temperature resistant fatty acid saponified matter collecting agent; (2) the desliming classification treatment is performed for fluorite ore-contained flotation tailings; (3) the pulp mass concentration of the deslimed fluorite-contained tailings is controlled within 25-30%; and (4) the fluorite contained ore pulp is mineralized; and a four-six-segment direct flotation separation process is performed to obtain fluorite concentrate products with 90-95% of the fluorite (CaF2) content. The method has the following characteristics: the novel low-temperature resistant fatty acid saponified matter collecting agent prepared by the rubber seed oil has better collecting property on the fluorite in the fluorite-contained tailings; and the fluorite concentrates with 90-95% of the CaF2 grade can obtained through a simple elixir system and a shorter flotation technological process. Meanwhile, the collecting agent also has better collecting property on the fluorite ores under the condition of low temperature.

Owner:YUNNAN CHEM RES INST

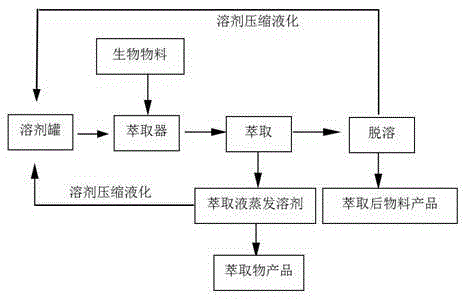

Rubber seed oil extracting process

InactiveCN101020858AAvoid clogging the sieve plateGood removal effectFatty-oils/fats productionSolventWater content

The rubber seed oil extracting process with high oil yield includes the following steps: stoving rubber seed to water content of 5-15 %, crushing and wind selecting to obtain rubber seed kernel with rubber seed hull content of 20-50 %, heating to 30-120 deg.c, squeezing in squeezer to obtain coarse oil and seed cake, refining coarse oil, puffing the seed cake, leaching the puffed seed cake to obtain mixed oil, evaporating the mixed oil to eliminate solvent and obtain rubber seed oil. The present invention combines oil squeezing and oil leaching, and has high oil yield.

Owner:兴储世纪科技股份有限公司

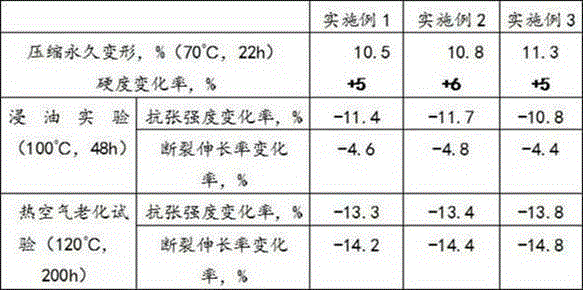

Oil-resistant high-temperature-resistant seal gasket rubber for cylinders and preparation method thereof

InactiveCN104829889AImprove high temperature resistanceGood oil resistanceEngine sealsCalcium silicateTemperature resistance

The invention discloses an oil-resistant high-temperature-resistant seal gasket rubber for cylinders and a preparation method thereof. The oil-resistant high-temperature-resistant seal gasket rubber for cylinders is prepared from the following raw materials in parts by weight: 70-90 parts of nitrile-butadiene rubber, 40-60 parts of fluorosilicone rubber, 5-8 parts of novolac resin, 7-9 parts of methyl hydrogen-containing silicon oil, 13-16 parts of tall oil acetal amide, 12-16 parts of magnesium hydroxide, 4-6 parts of magnesium dimethyl acrylate, 2-4 parts of diisopropyl peroxydicarbonate, 5-7 parts of calcium stearate, 1-3 parts of ammonium persulfate, 20-30 parts of nano calcium silicate, 3-5 parts of nekal, 10-14 parts of hydroxyapatite whisker, 7-9 parts of trimethylolpropane, 6-7 parts of epoxide rubber seed oil, 4-6 parts of N-(beta-aminoethyl)-gamma-aminopropyltrimethoxy silane, 6-9 parts of silica white, 2-4 parts of 3-dimethylaminopropylamine, 6-9 parts of oleic acid epoxy ester and 1-3 parts of sulfur. The seal gasket rubber has the advantages of favorable high temperature resistance, favorable oil resistance, favorable wear resistance, favorable flame retardancy, favorable aging resistance, favorable pressure resistance and the like.

Owner:南京林美鑫电子科技有限公司

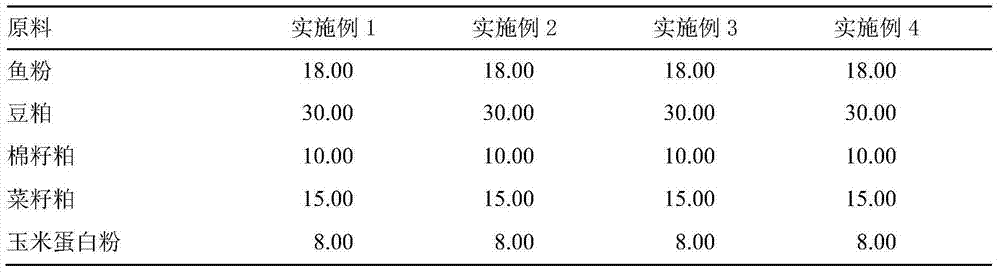

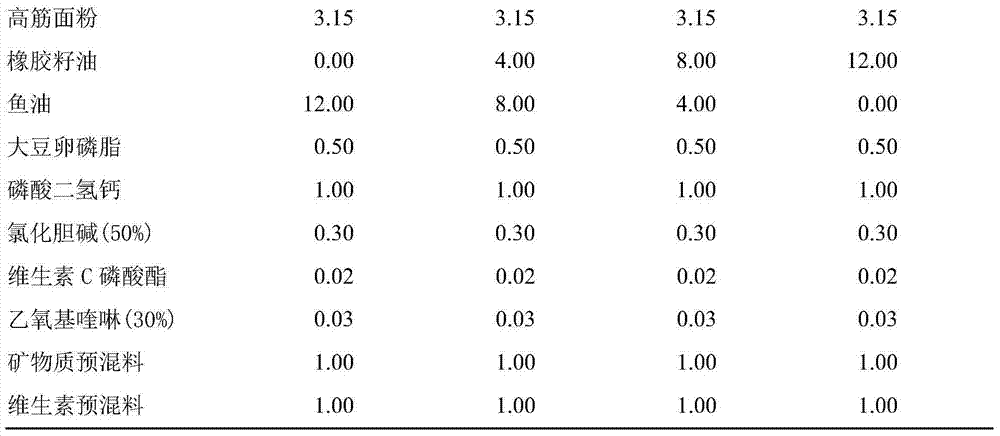

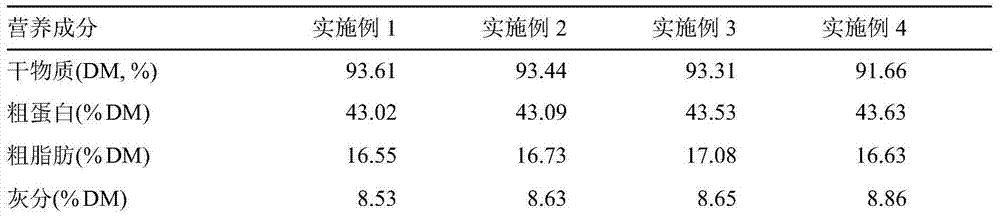

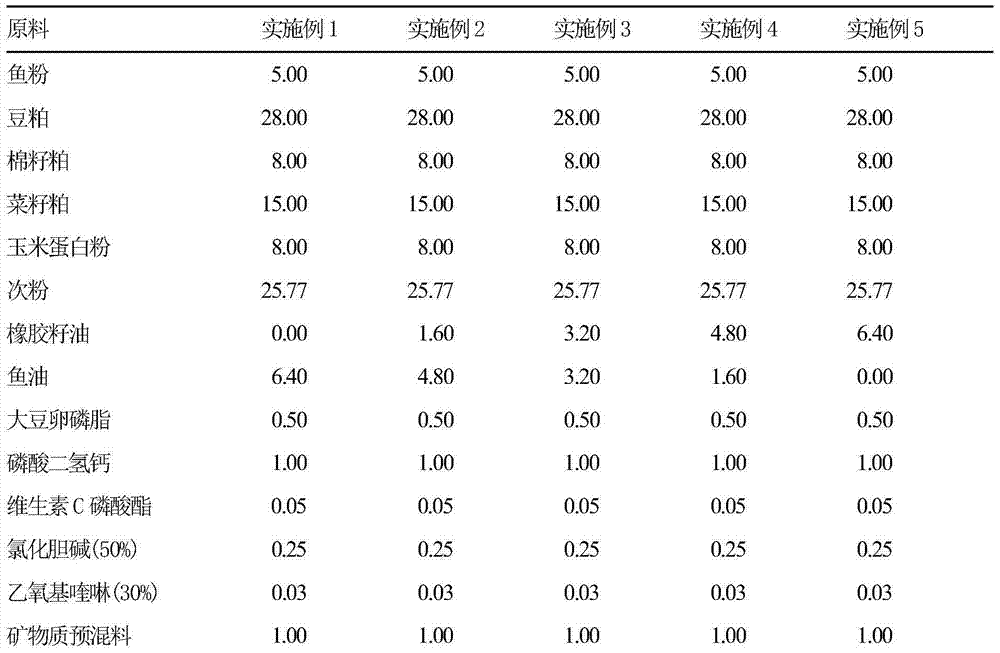

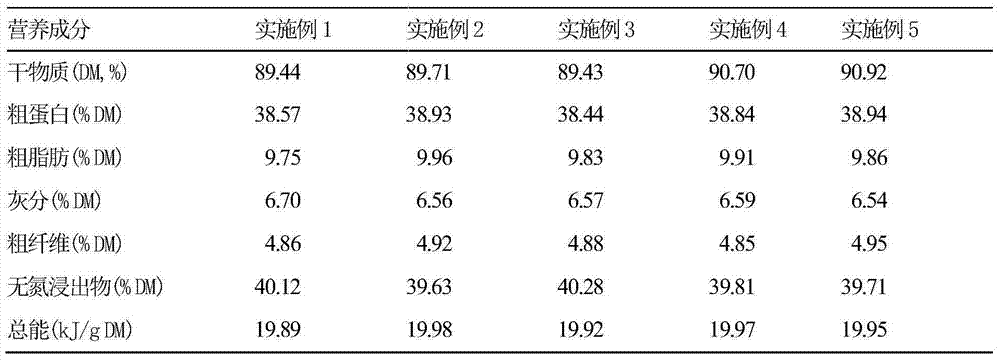

Application of rubber seed oil to rainbow trout compound feed and formula of rubber seed oil

InactiveCN104719679AImprove farming efficiencyNo adverse effect on physiological functionClimate change adaptationAnimal feeding stuffVitamin CFish oil

The invention relates to application of rubber seed oil to rainbow trout compound feed and a formula of the rubber seed oil, and belongs to the technical field of aquaculture. The rubber seed oil is substituted for fish oil partially to be added into the rainbow trout compound feed. The compound feed comprises, by weight, 16-20% of fish meal, 28-32% of bean pulp, 8-12% of cottonseed meal, 13-17% of rapeseed dregs, 6-10% of corn gluten meal, 1-4% of high gluten flour, 4-12% of the rubber seed oil, 0-8% of the fish oil, 0.3-0.5% of soya bean lecithin, 0.7-1.2% of monocalcium phosphate, 0.1-0.3% of choline chloride, 0.02-0.05% of vitamin C phosphate, 0.01-0.03% of ethoxyquin, 0.5-1.0% of mineral substance premix and 0.5-1.0% of vitamin premix. The sum of weight percentages of all raw materials is 100%. The application of the rubber seed oil to the rainbow trout compound feed and the formula of the rubber seed oil have the advantages that the rubber seed oil is fully utilized to serve as a fat source in the rainbow trout compound feed, the fish oil as feed grease in short supply is saved, and the compound feed has no bad influence on rainbow trout; formula cost and feed factors are reduced, high cost performance is achieved, and culture benefit of the rainbow trout is improved.

Owner:YUNNAN AGRICULTURAL UNIVERSITY +1

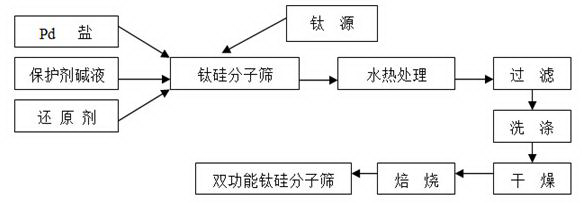

Method for preparing vegetable-oil-based polyalcohol

ActiveCN104003870AEasy to separateNothing producedOrganic compound preparationCarboxylic acid esters preparationBiotechnologyVegetable oil

The invention belongs to the technical field of organic synthesis and relates to a method for preparing vegetable-oil-based polyalcohol, in particular to the method for preparing vegetable-oil-based polyalcohol with soybean oil, castor oil, rubber seed oil, coriander oil, peanut oil, corn oil, colza oil, cottonseed oil, palm oil, sesame oil or sunflower seed oil and other vegetable oil as raw materials. The method for preparing the vegetable-oil-based polyalcohol includes the steps of placing bifunctional titanium silicate molecular sieve catalysts carrying precious metal titanium and palladium, the vegetable oil and a solvent into a reaction kettle to be heated to 40 DEG C to 70 DEG C, replacing air through O2, then feeding H2 and O2 to 0.8 MPa, and then synthesizing the vegetable-oil-based polyalcohol in one step. Through the method, H2O2 is directly synthesized, and then the H2O2 and a downstream product are synthesized and integrated into the same reaction kettle, and consequently the industrialized cost is reduced; meanwhile, the method is simple in preparation method and free of corrosion to equipment, catalysts can be reutilized for many times, no acid wastewater is generated, environmental pollution is avoided, and thus the method has good industrial application prospects.

Owner:云南神宇新能源有限公司

Application of rubber seed oil to carp compound feed and formula of rubber seed oil

InactiveCN104719678ANo adverse effect on physiological functionImprove farming efficiencyFood processingClimate change adaptationVitamin CFish oil

The invention relates to application of rubber seed oil to carp compound feed and a formula of the rubber seed oil, and belongs to the technical field of aquaculture. The rubber seed oil is substituted for fish oil partially to be added into the carp compound feed. The compound feed comprises, by weight, 3-7% of fish meal, 25-30% of bean pulp, 6-10% of cottonseed meal, 13-17% of rapeseed dregs, 6-10% of corn gluten meal, 20-27% of wheat middlings, 1.6-4.8% of the rubber seed oil, 1.6-4.8% of the fish oil, 0.3-0.5% of soya bean lecithin, 0.7-1.2% of monocalcium phosphate, 0.02-0.05% of vitamin C phosphate, 0.1-0.3% of choline chloride, 0.01-0.03% of ethoxyquin, 0.5-1.0% of mineral substance premix and 0.5-1.0% of vitamin premix. The sum of weight percentages of all raw materials is 100%. The application of the rubber seed oil to the carp compound feed and the formula of the rubber seed oil have the advantages that the rubber seed oil is fully utilized to serve as a fat source in the carp compound feed, the fish oil as feed grease in short supply is saved, and the compound feed has no bad influence on carp; formula cost and feed factors are reduced, high cost performance is achieved, and culture benefit of the carp is improved.

Owner:YUNNAN AGRICULTURAL UNIVERSITY +1

Milk rich in omega-3 fatty acid and conjugated linoleic acid and production method thereof

ActiveCN104872395AIncrease contentIncrease productionMilk preparationAnimal feeding stuffBiotechnologyMilk cow's

The invention relates to milk rich in omega-3 fatty acid and conjugated linoleic acid, a production method thereof, and feedstuffs used in production, which belong to the technical field of rumination animal feedstuffs, and rumination animal milk and milk products. The production method provided by the invention is realized by adding 2-8 percent of rubber seed oil and rubber seed nuts in basic feedstuffs of dairy cows; in the milk obtained by production, the content of the omega-3 fatty acid is larger than 0.6 percent and is more than two times of common milk, the content of the conjugated linoleic acid is larger than 2.0 percent and is more than four times of the common milk, the content of vaccenic acid is larger than 11 percent and is more than six times of the common milk, the content of unsaturated fatty acid in the milk is increased by more than 60 percent compared with the common milk, and the content of saturated fatty acid in the milk is reduced by more than 25 percent compared with the common milk. According to the production method provided by the invention, inedible oil is used, the cost is low, and the feeding and the milk production of the dairy cows cannot be affected.

Owner:XISHUANGBANNA HUAKUN BIOTECH CO LTD

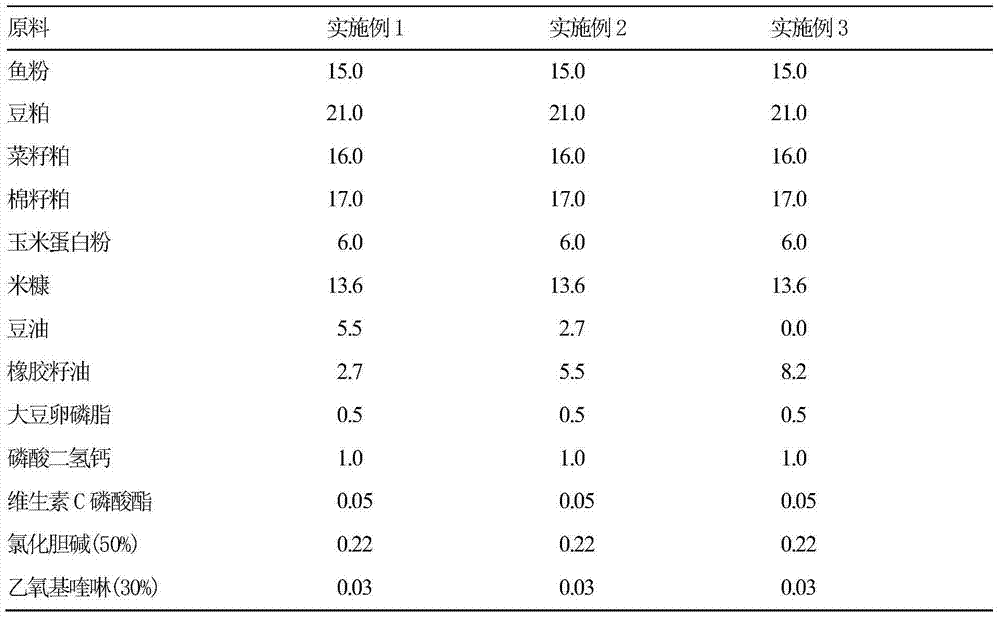

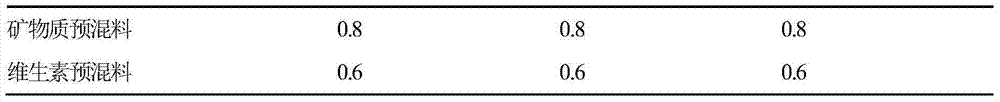

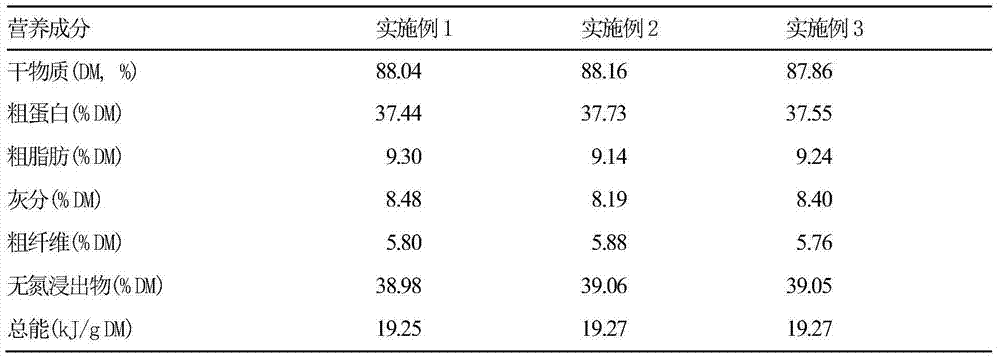

Application of rubber seed oil to sturgeon compound feed and formula of rubber seed oil

ActiveCN104719637ANo adverse effect on physiological functionImprove farming efficiencyFood processingClimate change adaptationOil and greaseVitamin C

The invention relates to application of rubber seed oil to sturgeon compound feed and a formula of the rubber seed oil, and belongs to the technical field of aquaculture. The rubber seed oil is substituted for soybean oil partially to be added into the sturgeon compound feed. The compound feed comprises, by weight, 12-16% of fish meal, 18-22% of bean pulp, 12-17% of rapeseed dregs, 13-18% of cottonseed meal, 5-8% of corn gluten meal, 10-14% of rice bran, 0-5.5% of the soybean oil, 2.7-8.2% of the rubber seed oil, 0.3-0.5% of soya bean lecithin, 0.8-1.2% of monocalcium phosphate, 0.02-0.05% of vitamin C phosphate, 0.1-0.3% of choline chloride ,0.01-0.03% of ethoxyquin, 0.5-1.0% of mineral substance premix and 0.5-1.0% of vitamin premix. The sum of weight percentages of all raw materials is 100%. The application of the rubber seed oil to the sturgeon compound feed and the formula of the rubber seed oil have the advantages that the rubber seed oil is fully utilized to serve as a fat source in the sturgeon compound feed, the soybean oil as feed grease in short supply is saved, and the compound feed has no bad influence on sturgeon; formula cost and feed factors are reduced, high cost performance is achieved, and culture benefit of the sturgeon is improved.

Owner:邯郸市鲟鲵农业科技股份有限公司

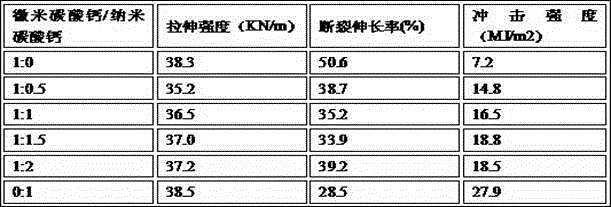

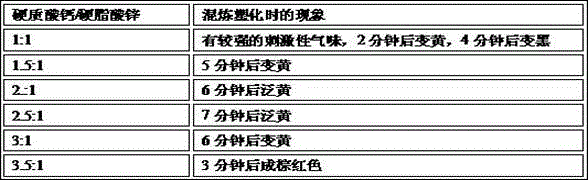

Ca-Zn composite stabilizer for PVC (polyvinyl chloride) cables and preparation method of Ca-Zn composite stabilizer

The invention discloses a Ca-Zn composite stabilizer for PVC (polyvinyl chloride) cables and a preparation method of the Ca-Zn composite stabilizer. The Ca-Zn composite stabilizer is prepared from raw materials in parts by weight as follows: 45-65 parts of calcium stearate, 15-25 parts of zinc stearate, 10-12 parts of dibutyltin maleate, 10-15 parts of hydrotalcite, 5-10 parts of oxidized polyethlene wax, 25-30 parts of compound calcium carbonate, 3-6 parts of pentaerythritol dimer ester and 10-15 parts of epoxy rubber seed oil, wherein compound calcium carbonate comprises micron-calcium carbonate and nano-scale calcium carbonate in the weight ratio of 1:(1-1.5). The invention further discloses the preparation method of the Ca-Zn composite stabilizer. The Ca-Zn composite stabilizer and the preparation method have the following benefits: through regulation of the ratio of the raw materials, the quality of the stabilizer is improved, the quality of the cables is improved, self-degradation of PVC is retarded, the service life of the cables is prolonged, and the maintenance cost is reduced.

Owner:ZHUCHENG POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +2

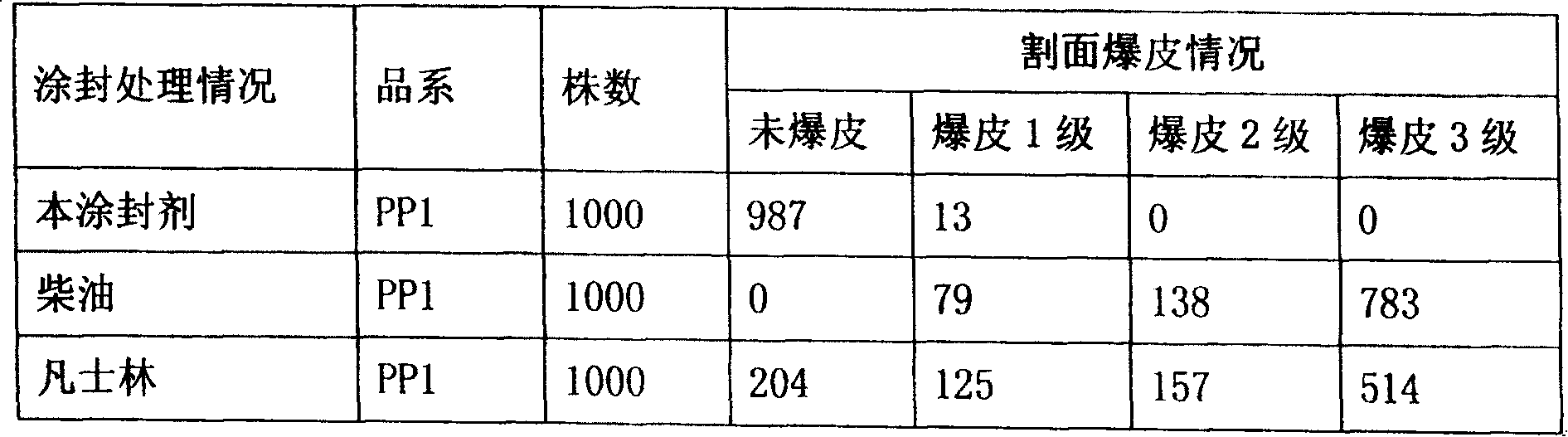

Rubber tree tapping face coldness-proof coating agent and method for producing same

The invention discloses a rubber tree cut cold-proof coating-packing agent and manufacturing method, which consists of 35-50% rubber seed oil and 50-65% vaseline, wherein the vaseline is heated to 45-55 deg.c to add rubber seed oil according to certain proportion, which is cooled to indoor temperature after blending evenly. The invention can coat and pack rubber tree with temperature not less than 10 deg.c, which protects cutting surface from flowing rubber and accelerates bark recombination and regeneration.

Owner:肖余保

Rubber seed shell-based wood-plastic composite material and preparation method thereof

The invention discloses a preparation method of a rubber seed shell-based wood-plastic composite material and belongs to the technical field of processing of polymer materials. The rubber seed shell-based wood-plastic composite material is mainly processed from the raw materials including rubber seed shells, recycled plastics, coupling agent, lubricating agent, antioxidant and the like by steps of high-temperature mixing, pelletizing, extrusion molding, cooling, cutting and the like. The rubber seed shell-based wood-plastic composite material disclosed by the invention has good mechanical performances, a low water absorption and aging resistance, so that performance requirements of international wood-plastic floors and international wood-plastic decorative sheets are reached, and therefore, the rubber seed shell-based wood-plastic composite material can be applied to the fields such as outdoor flooring, landscape wood, furniture and packaging. Moreover, the main materials of the rubber seed shell-based wood-plastic composite material are residues of rubber seed oil and recycled plastics, and therefore, the preparation method belongs to comprehensive utilization of waste resources.

Owner:XISHUANGBANNA HUAKUN BIOTECH CO LTD

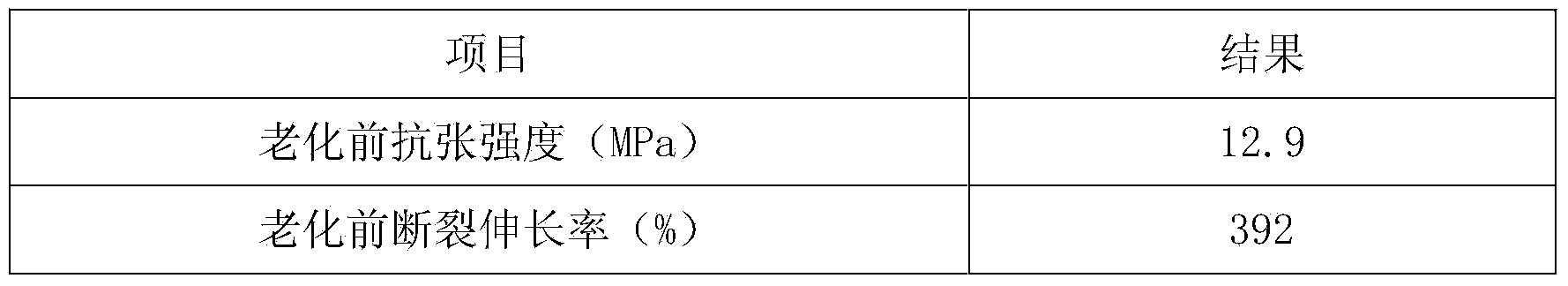

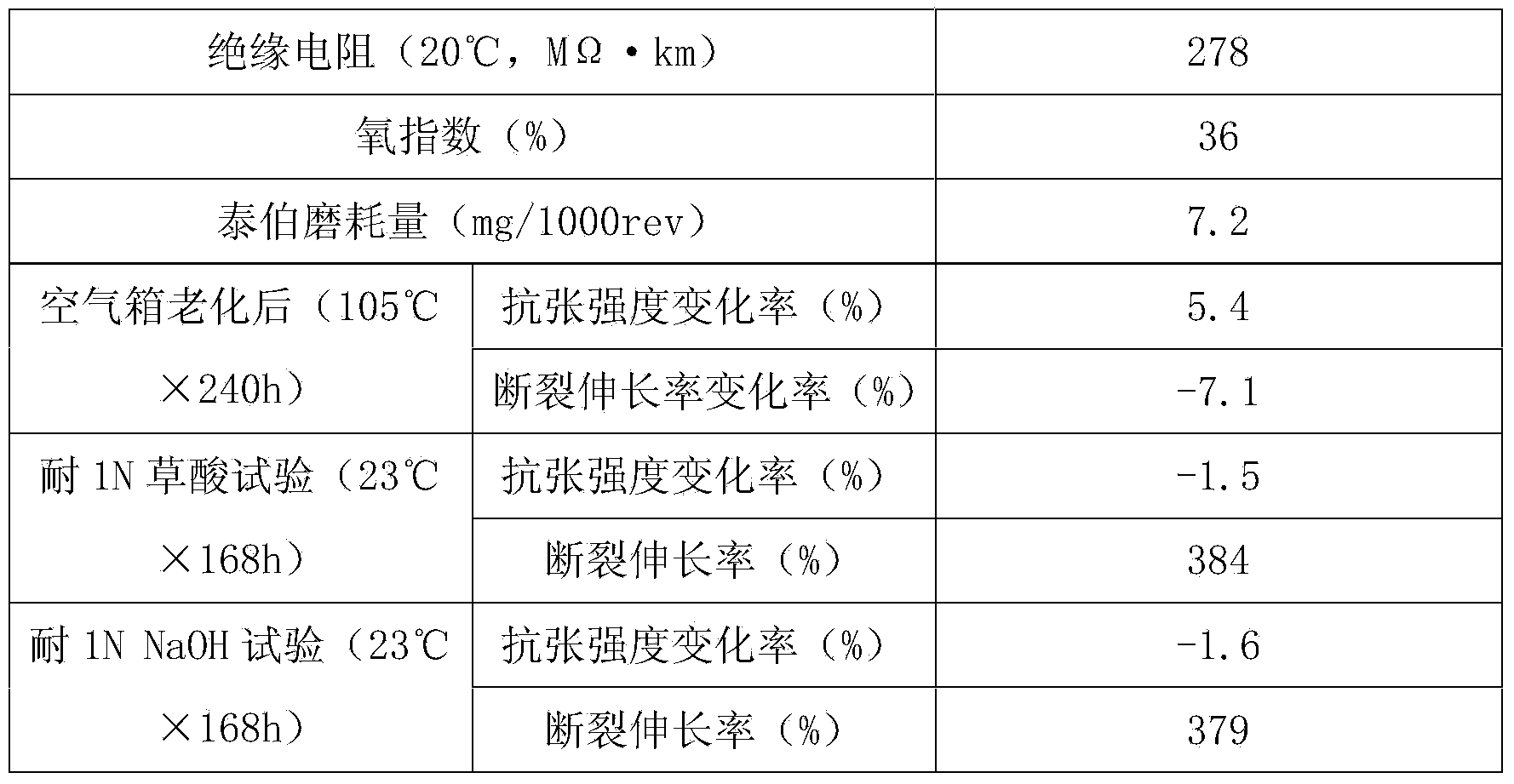

Thermoplastic polyurethane sheath material for automobile cables and preparation method thereof

InactiveCN104017350AImprove wear resistanceImprove heat resistancePlastic/resin/waxes insulatorsCrack resistanceGas phase

The invention discloses a thermoplastic polyurethane sheath material for automobile cables and a preparation method thereof. The sheath material is prepared from the following raw materials in parts by weight: 60-80 parts of thermoplastic polyurethane, 20-30 parts of chlorosulfonated polyethylene, 15-25 parts of poly(butylene succinate), 10-15 parts of aluminum diethylphosphinate, 5-10 parts of tripropyl borate, 3-6 parts of zinc tripolyphosphate, 4-8 parts of polytetrahydrofuran, 5-10 parts of rubber seed oil, 1-2 parts of calcium stearate, 1-2 parts of zinc stearate, 4-6 parts of chlorinated paraffin, 2-3 parts of di-n-butylbis(dodecylthio)tin, 1.5-2.5 parts of isopropyl dioleic(dioctylphosphate) titanate, 2-3 parts of 4-nitrosophenol, 2.5-4.5 parts of tolylene-2,4-diisocyanate, 10-15 parts of n-butyryl tri-n-hexyl citrate, 8-12 parts of asbestos powder, 15-20 parts of gas-phase white carbon black, 10-15 parts of magnesia, 2-3 parts of indoxacarb and 10-15 parts of modified stone flour. The cable material has excellent wear resistance, thermal aging resistance and impact toughness, and relatively good physical mechanical performances, oil resistance, flame retardance, chemicals corrosion resistance, environment stress cracking resistance and the like.

Owner:ANHUI KANGLIYA CO LTD

Rubber tree tapping face coldness-proof coating agent and method for producing same

The invention discloses a rubber tree cut cold-proof coating-packing agent and manufacturing method, which consists of 35-50% rubber seed oil and 50-65% vaseline, wherein the vaseline is heated to 45-55 deg.c to add rubber seed oil according to certain proportion, which is cooled to indoor temperature after blending evenly. The invention can coat and pack rubber tree with temperature not less than 10 deg.c, which protects cutting surface from flowing rubber and accelerates bark recombination and regeneration.

Owner:肖余保

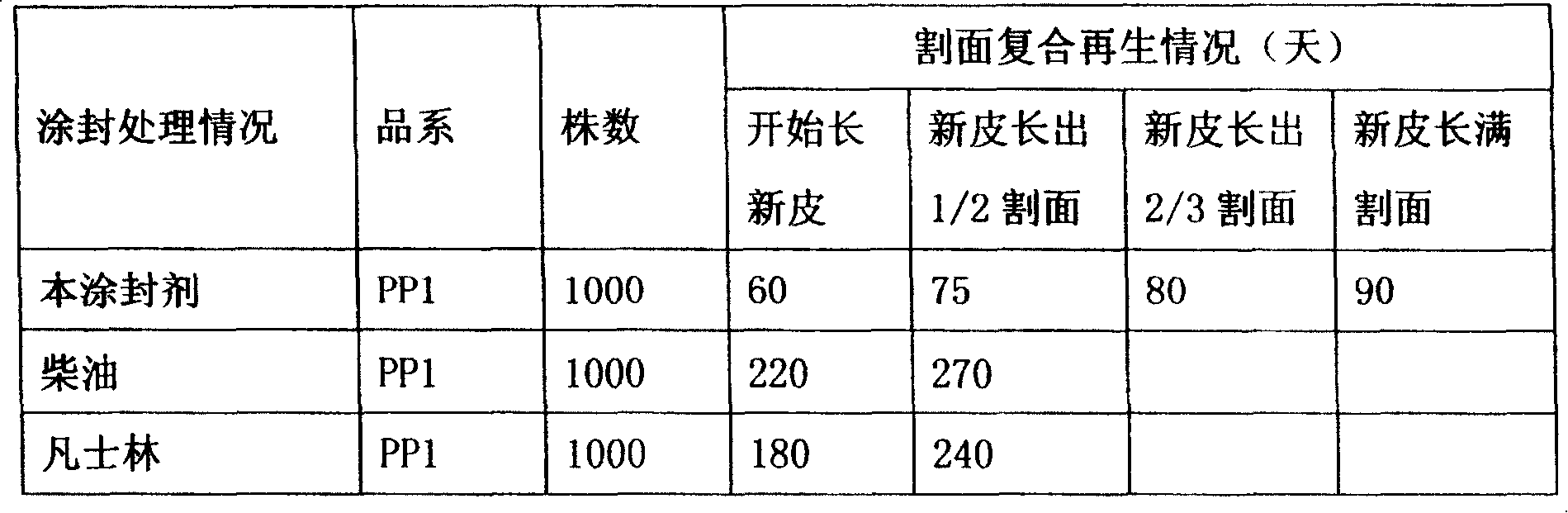

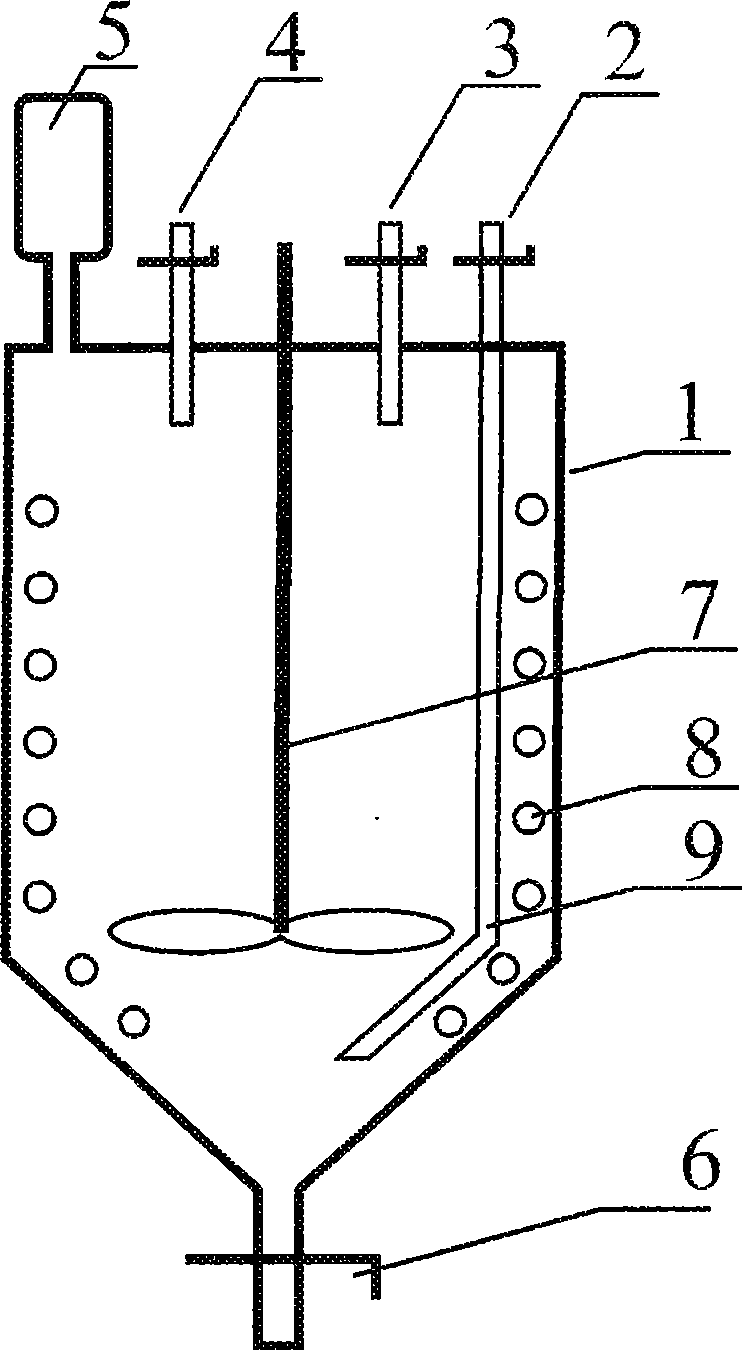

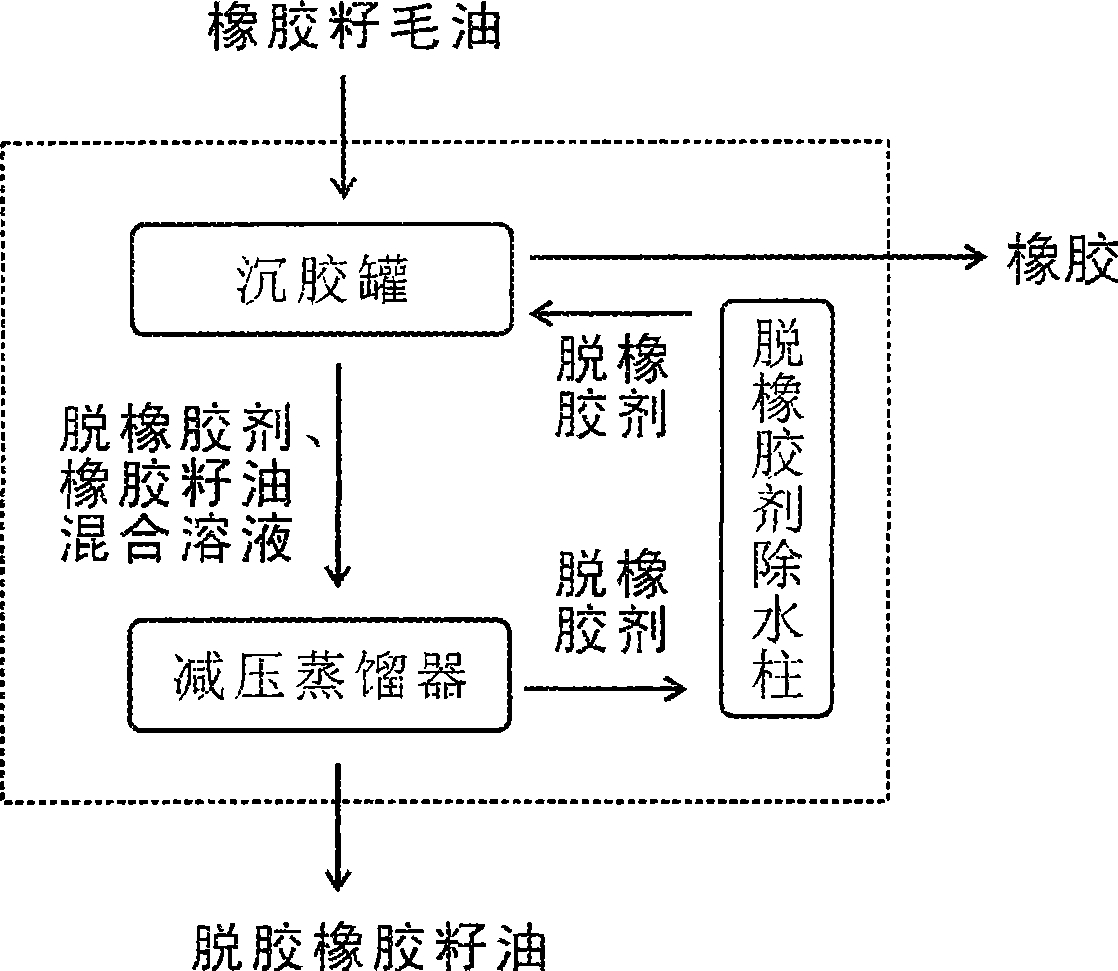

Method and apparatus for removing rubber from rubber seed oil

The invention discloses a method and a device for removing rubber from rubber seed oil. The method comprises: firstly, adding a rubber removing agent and the rubber seed oil into a rubber precipitation tank according to the proportion of 1:1-1:1.5, heating the rubber precipitation tank to be between 50 and 60 DEG C, mildly stirring for 5 minutes, standing for 40 to 60 minutes, and separating out, agglutinating and precipitating the rubber; secondly, pumping a mixed solution of the rubber seed oil and the rubber removing agent out of the rubber precipitation tank, recovering the rubber removing agent through reduced pressure distillation, and obtaining rubber seed oil after removal of the rubber; and thirdly, heating a tank body to be between 140 and 260 DEG C after rubber paste in the rubber precipitation tank is accumulated to certain quantity, softening the rubber, and exhausting the rubber from a rubber outlet at the bottom of the rubber precipitation tank. The rubber removing agent comprises 90 to 100 percent of acetone and 0 to 10 percent of water. The method is complete to remove the rubber, and the rubber removing agent can be recycled.

Owner:云南三环生物技术有限公司

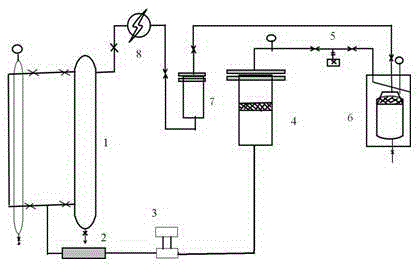

Method for preparing rubber seed oil through subcritical extraction

InactiveCN105385501ALow boiling pointResidue reductionFatty-oils/fats refiningFatty-oils/fats productionNutritive valuesOil and grease

The invention discloses a method for preparing rubber seed oil through subcritical extraction. In the method, the rubber seed oil is obtained through subcritical fluid butane extraction. According to the method, the extraction efficiency of the rubber seed oil is high, the recovery rate of an extraction solvent is high, the solvent residual in materials and the oil is low, and no cyanide remains in the oil; the relative content of unsaturated fatty acid in the obtained oil can reach up to 84.32%, the content of saturated fatty acid is 15.68%, and the oil is high in nutritive value, low in industrial cost and suitable for large-scale production.

Owner:KUNMING UNIV OF SCI & TECH

Eggs rich in omega-3 polyunsaturated fatty acids and preparation method

The invention relates to a preparation method for eggs rich in omega-3 polyunsaturated fatty acids. The preparation method comprises the following steps of: (1) adding screened rubber seed kernel or rubber seed oil cake into non-gm feed for laying hens, with the additive amount of the rubber seed kernel being 10-20% of the total weight of the feed for laying hens, and the additive amount of the rubber seed oil cake being 15-25% of the total weight of the feed for laying hens; (2) adjusting ingredients of the feed to enable the feed to comprise the following ingredients: 42.89 of corn, 17-32 of soybean meal, 0.59 of wheat bran, 2-3 of lard, 10-20 of rubber seed kernel or 15-25 of rubber seed oil cake, 0.35 of salt, 8.38 of stone powder, 1.8 of calcium hydrogen phosphate, 0.1 of lysine, 0.14 of methionine, 1 of premix for laying hens, and 5 international units of vitamin E per kg of feed; (3) feeding 130-140-day laying hens by using the feed for laying eggs rich in omega-3 polyunsaturated fatty acids after feeding for 2-4 weeks. The preparation method is low in cost, stable in content of the omega-3 polyunsaturated fatty acids, and safe without peculiar smell, and effectively and sufficiently utilizes rubber seed resources.

Owner:王云

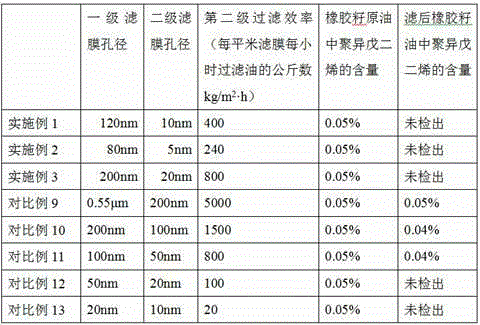

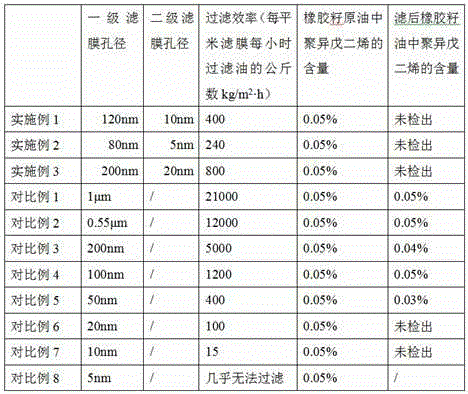

Method for filtering and removing rubber from rubber seed oil by utilizing high-efficiency membrane

InactiveCN104560386AImprove membrane efficiencyImprove filtration efficiencyFatty-oils/fats refiningOil and greaseFiltration membrane

The invention discloses a method for filtering and removing rubber from rubber seed oil by utilizing a high-efficiency membrane. The method comprises the following steps: heating rubber seed crude oil, applying pressure, enabling the heated rubber seed crude oil to pass through a ceramic filtration membrane with the aperture of 80-200 nm, heating the filtered rubber seed crude oil, applying the pressure, and enabling the heated rubber seed crude oil to pass through a ceramic filtration membrane with the aperture of 5-30 nm to obtain the filtered rubber seed oil which removes polyisoprene. According to the method for filtering and removing the rubber from the rubber seed oil by utilizing the high-efficiency membrane, a membrane filtering method for removing trace polyisoprene molecules in the rubber seed oil is pioneering and is a pure physical method which is completely different from the existing chemical method; two-stage filtering is utilized, so that the membrane efficiency is largely improved. The conventional idea that membrane filtration is hard to be applied to vegetable oil from the skilled persons in the art is broken; besides, by limiting two special apertures, the purposes of completely removing the polyisoprene and obtaining high filter efficiency are achieved, and the problems that chemical agents are necessarily imported and other beneficial trace elements are easy to remove in the prior art are solved.

Owner:XISHUANGBANNA HUAKUN BIOTECH CO LTD

High-performance strong-stability biosynthetic diesel oil and preparation method thereof

InactiveCN107245379AHigh oil contentGuaranteed performance qualityFatty acid esterificationBiofuelsDistillationGlyceryl monostearate

The invention discloses high-performance strong-stability biosynthetic diesel oil. The biosynthetic diesel oil is prepared from the following raw materials in parts by weight: 25 to 35 parts of fructus xanthii oil, 30 to 40 parts of rubber seed oil, 10 to 20 parts of rubber oil subjected to distillation and cooling, 4 to 8 parts of methanol, 4 to 8 parts of ethanol, 1 to 3 parts of glyceryl monostearate, 0.5 to 2 parts of naphthenic acid, 1 to 2 parts of fatty acid for soap, 1 to 3 parts of zinc acetate, 1 to 2 parts of sodium hydroxide, 0.05 to 0.1 part of ionic liquid, 0.2 to 0.4 part of stabilizing agent, 0.8 to 1 part of power potion and 0.02 to 0.03 part of cetane value additive. According to the biosynthetic diesel oil disclosed by the invention, the biosynthetic diesel oil has the advantages that flashing points are high, the safety performance is good, the combustion rate is higher, the diesel oil is easy to light, black smoke is avoided, the storage time is long, layering and deterioration are avoided, the chemical stability is stronger, the diesel oil and common diesel oil can be mutually dissolved, and harmful gas emission of automobile tail gas is effectively reduced.

Owner:合肥市老海新材料有限公司

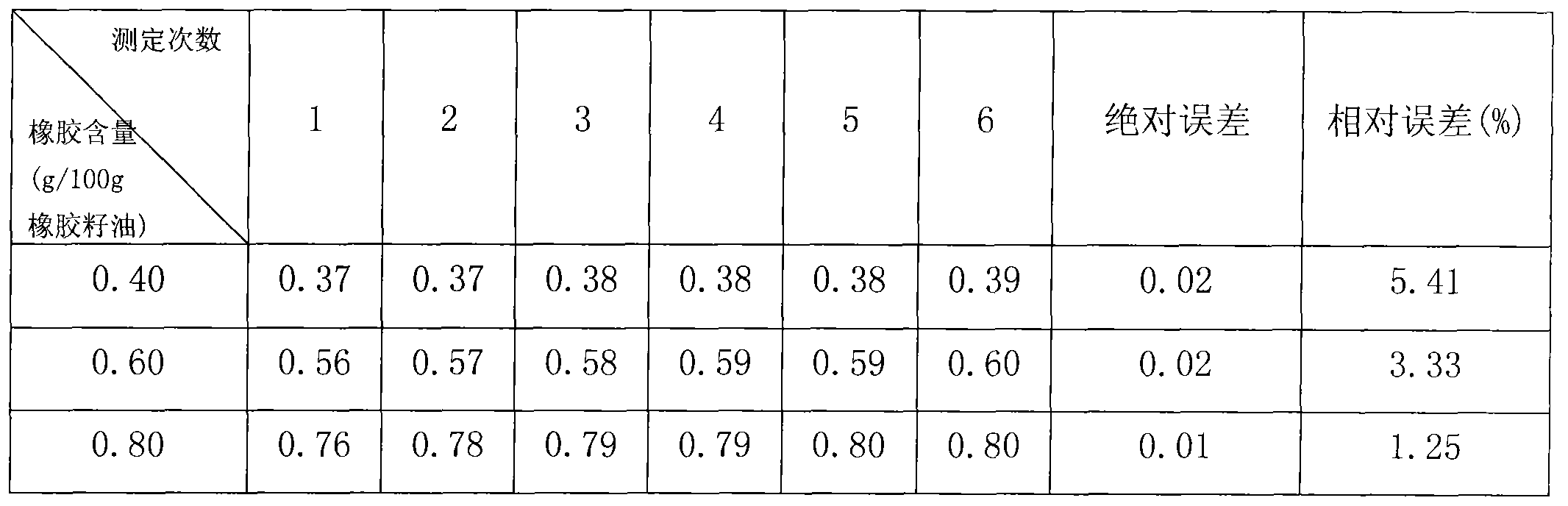

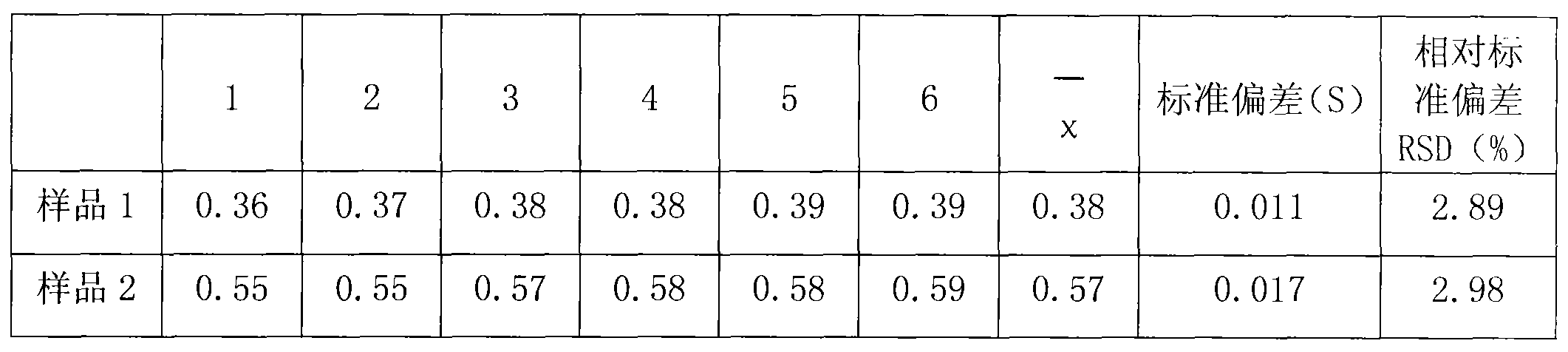

Method for determining content of natural rubber in rubber seed oil

InactiveCN101650288ASimple equipmentSimple and fast operationWeighing by removing componentMaterial testing goodsWater bathsReflux

The invention provides a method for determining the content of natural rubber in rubber seed oil. The determination method has the advantages of simple instrument and equipment, simple, convenient andquick operation, low detection cost and high accuracy and precision. The method for determining the content of the natural rubber in the rubber seed oil by adopting a saponification method is characterized by comprising the following steps: firstly, precisely weighing 100 to 200 grams of rubber seed oil sample and putting the rubber seed oil sample in a flask, adding potassium hydroxide into theflask to form 400 to 800 milliliters of alcohol solution, shaking up the solution and then connecting the solution to a reflux condensing tube, boiling the solution for about 1 to 2 hours in a water bath kettle, taking down the condensing tube, filtering the saponified solution to another flask while the solution is hot, crushing up rubber grains on a piece of filter cloth, washing the rubber grains till no alkali or soap is contained, finally kneading the rubber to form a slice, baking the slice with a vacuum oven (at the temperature of 80 DEG C) to constant weight and then weighing the slice, and calculating the content of the rubber. The rubber seed oil can be saponified in the alkali alcohol solution, the natural rubber belongs to a hydrocarbon substance and does not produce saponification effect, and the natural rubber is coagulated into the rubber grains to be separated out during the saponification of the rubber seed oil so as to determine the content of the natural rubber.

Owner:海南省粮油科学研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com