Method for determining content of natural rubber in rubber seed oil

A technology for rubber seed oil and natural rubber, applied in the direction of removing certain components, weighing, material inspection, etc., can solve the problems affecting the processing and utilization of rubber seed oil and human harm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Accurately weigh 100 grams of the mixed rubber seed oil sample in a flask, add 400 milliliters of 5% potassium hydroxide ethanol solution, shake well, connect a countercurrent condenser, and boil in a water bath for 1 hour. Take off the condensing tube, filter the saponification solution while hot in another flask with an insulating funnel covered with a piece of 100 mesh filter cloth in advance, wash the saponification flask with 20 milliliters of water, and pour it into the filter. After filtering, the rubber is obtained on the filter cloth. Part of the rubber sticks to the wall of the saponification flask. Wrap the cloth with one end of an iron wire, scrape off all the rubber, wash it with water and put it on the filter cloth. Rinse carefully with water, knead the rubber particles into a ball, and knead and wash repeatedly until there is no alkali and no soap. Finally, knead the rubber into a thin sheet and dry it in a vacuum oven (80°C) to a constant weight, then wei...

Embodiment 2

[0014] Weigh 150 grams of the mixed rubber seed oil sample in a flask, add 600 milliliters of 10% potassium hydroxide ethanol solution, shake well, connect a countercurrent condenser, and boil in a water bath for 1.5 hours. Take off the condensing tube, and filter the saponified solution while it is hot in another flask with an insulating funnel covered with a piece of 100 mesh filter cloth in advance, wash the saponified flask with 30 milliliters of water, and pour it into the filter. After filtering, the rubber is obtained on the filter cloth. Part of the rubber sticks to the wall of the saponification flask. Wrap the cloth with one end of an iron wire, scrape off all the rubber, wash it with water and put it on the filter cloth. Knead the rubber particles into a ball, rinse with water until there is no alkali and no soap, and finally knead the rubber into a thin sheet, dry it in a vacuum oven (80°C) to a constant weight, and weigh it.

Embodiment 3

[0016] Carry out according to the method described in Example 1 basically, but adopt following parameter to reach better measurement result:

[0017] 200 grams of rubber seed oil sample;

[0018] 800 ml of 20% potassium hydroxide ethanol solution;

[0019] Boil for 2 hours on a water bath.

[0020] (2) Statistical evaluation of the detection result of the present invention

[0021] 1. The accuracy of the determination method:

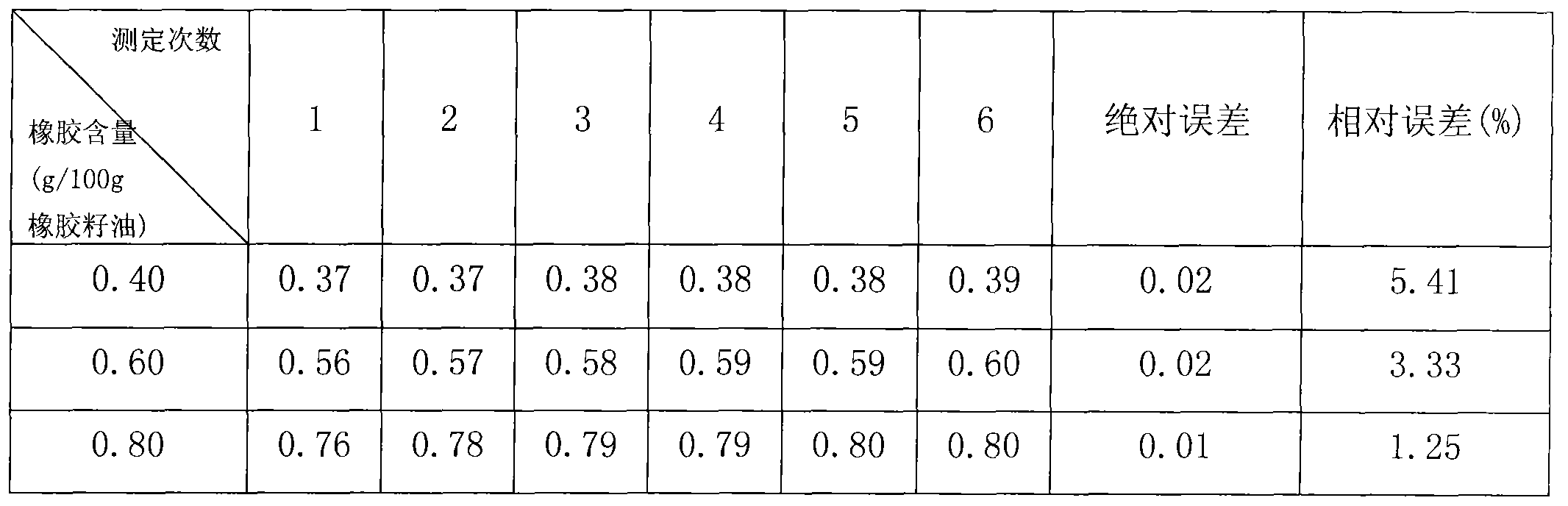

[0022] The recovery rate test was carried out by adding standard natural rubber to peanut oil without natural rubber. The amount of standard rubber added per 100 g of peanut oil was 0.20 g, 0.40 g, and 0.80 g, respectively. Each sample was tested 6 times. The results are shown in Table 1.

[0023] Table 1 measures the data of natural rubber content accuracy

[0024]

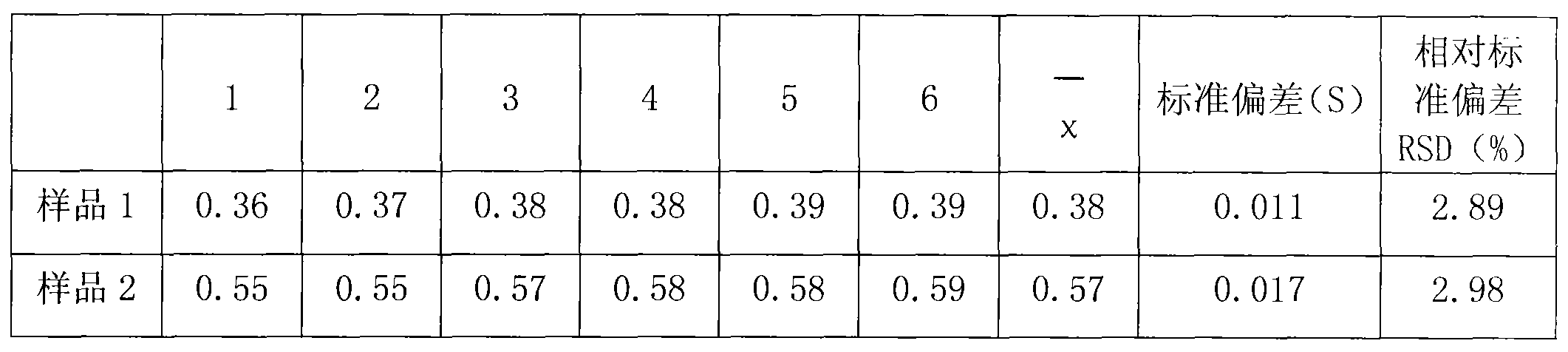

[0025] 2. The precision of the determination method:

[0026] Two parts of rubber seed oil were taken to measure the natural rubber content, and the results of 6 measured values ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com