Patents

Literature

65results about How to "Use less raw materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

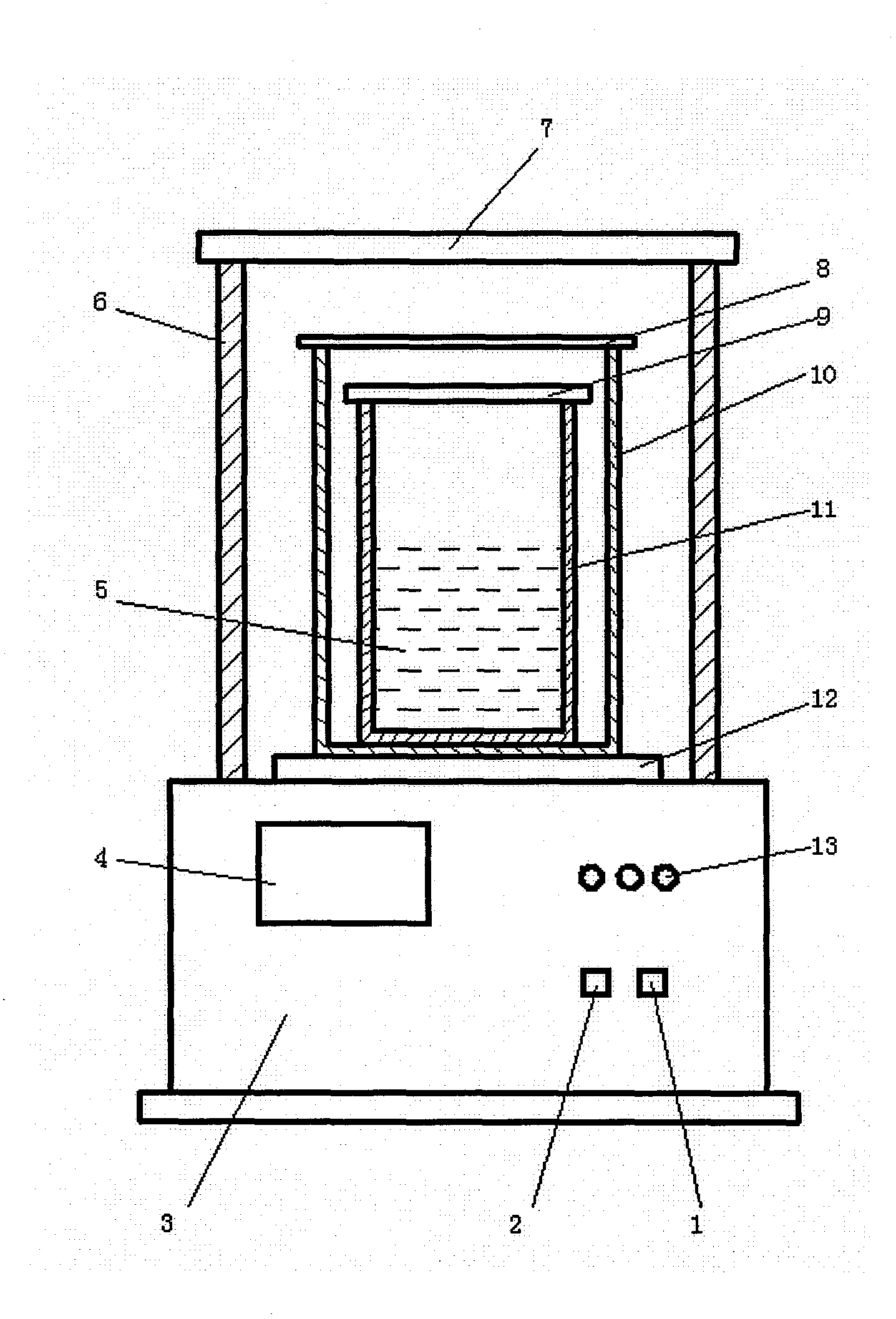

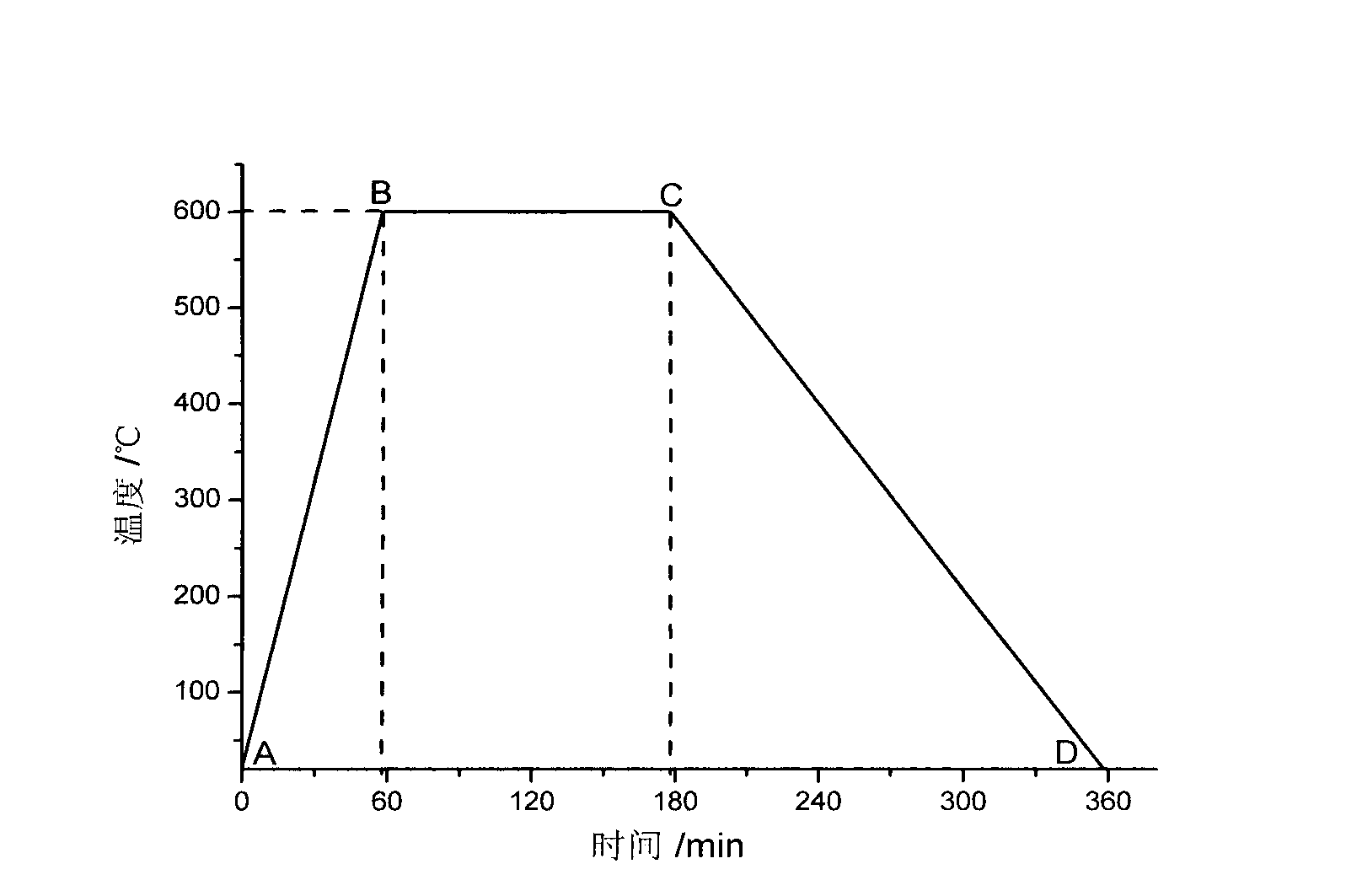

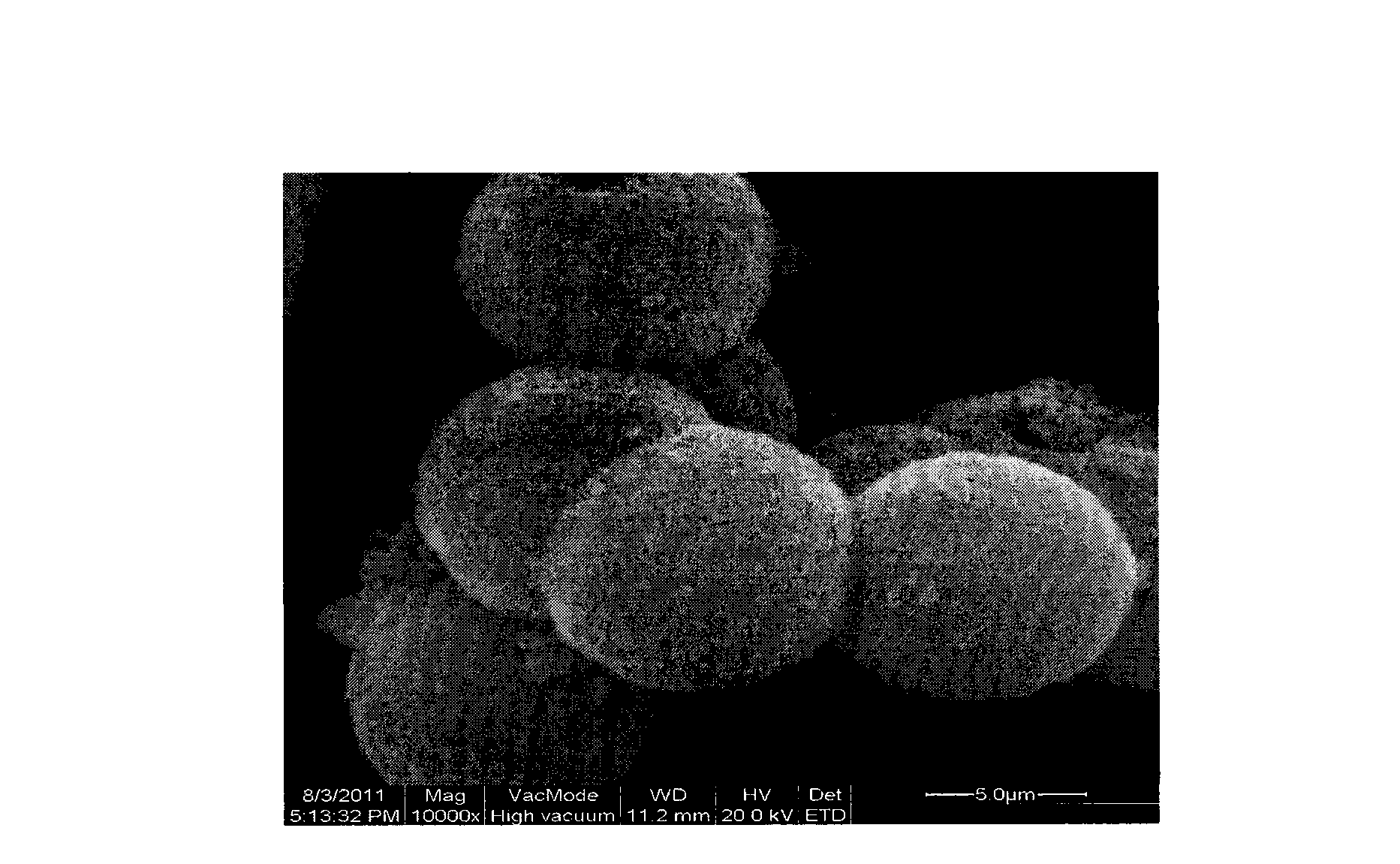

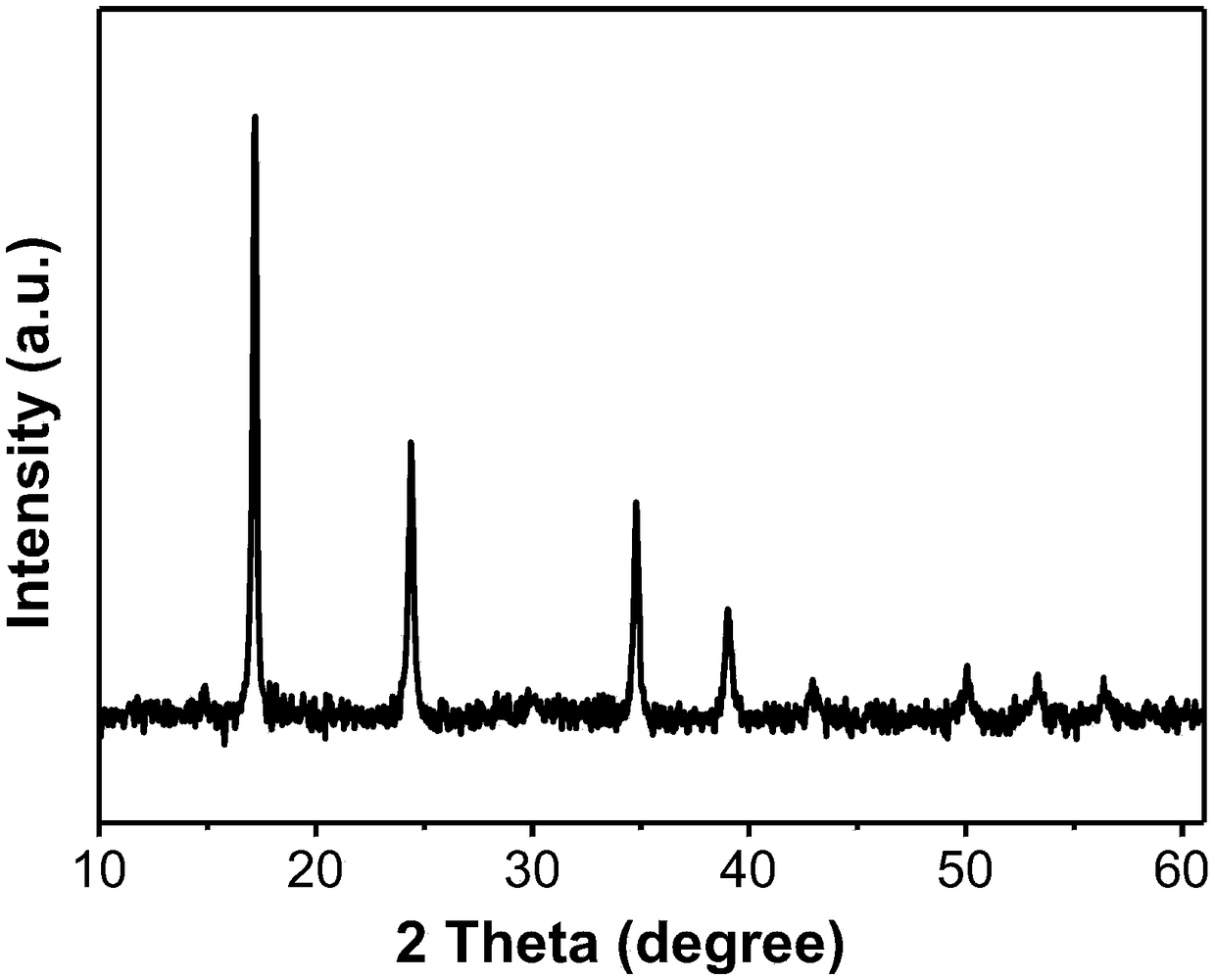

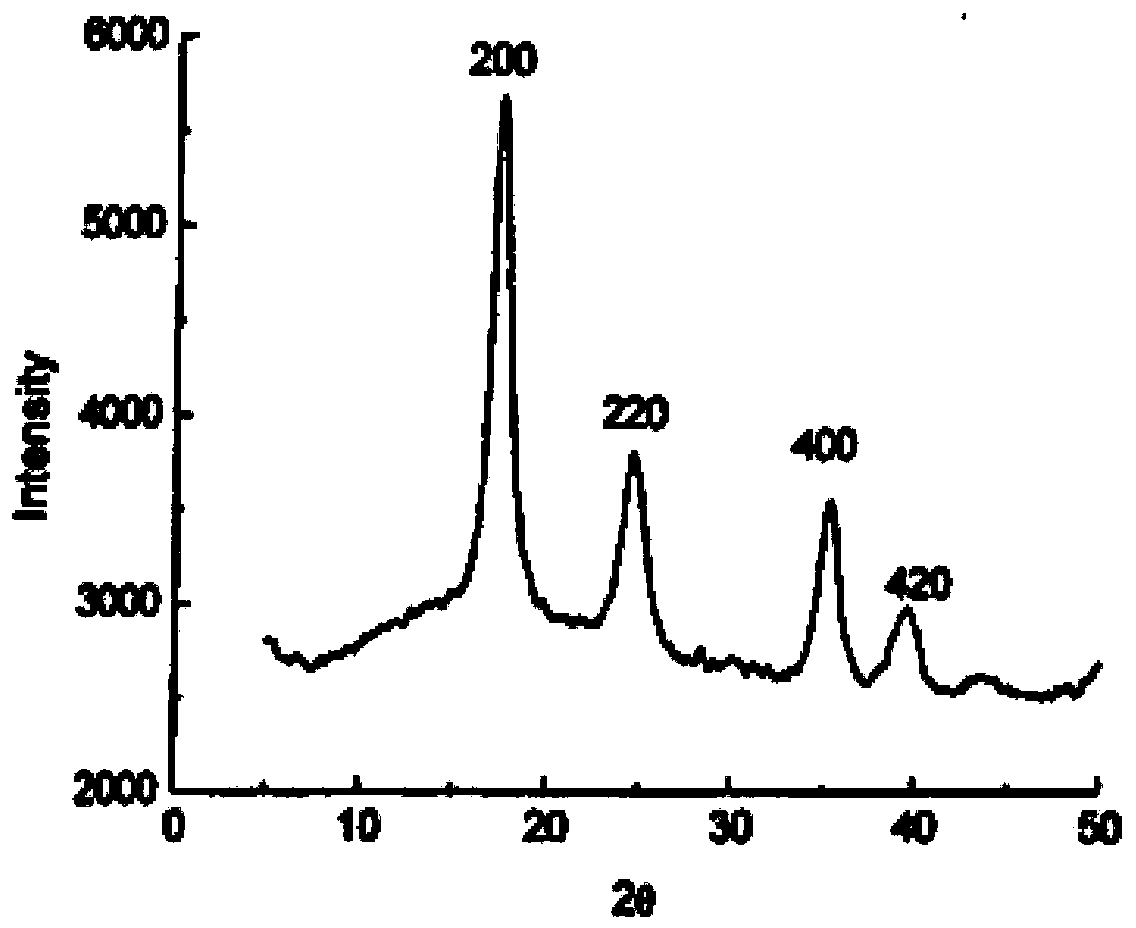

Method for preparing large-specific-surface-area porous nickel oxide microspheres

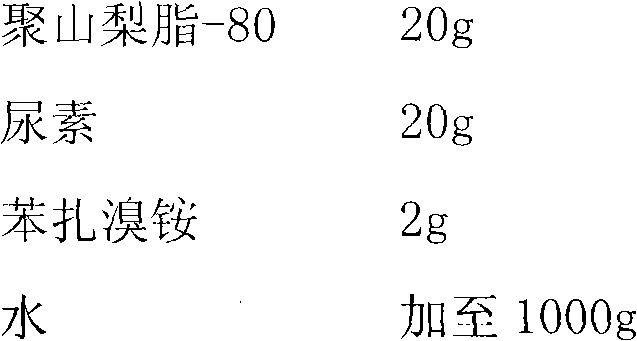

The invention discloses a method for preparing large-specific-surface-area porous nickel oxide microspheres. The method comprises the following steps of: preparing and synthesizing a mixed solution by taking nickel nitrate and urine as raw materials, taking hexadecyl trimethyl ammonium bromide as a surfactant, taking absolute ethanol and deionized water as washing agents and refining raw materials; heating in a reaction kettle for preparing hydrogen nickel carbonate; and washing, performing suction filtration, drying in vacuum, and baking to obtain large-specific-surface-area porous nickel oxide microspheres. The preparation method has the advantages of advanced process, short process flow, small using amount of raw materials, detailed and accurate data, high product yield which can be up to 95 percent and high product purity, which can be up to 98.5 percent; the specific surface area of the product, i.e., nickel oxide microspheres is 748.25m<2> / g, microsphere particles are less than or equal to 10 mum, irregular hexagonal nano-sheets are distributed on the surfaces of the microspheres and are less than or equal to 40 nanometers in diameter, and the microspheres can be matched with a plurality of chemical substances; and the method is very ideal method for preparing large-specific-surface-area porous nickel oxide microspheres.

Owner:TAIYUAN UNIV OF TECH

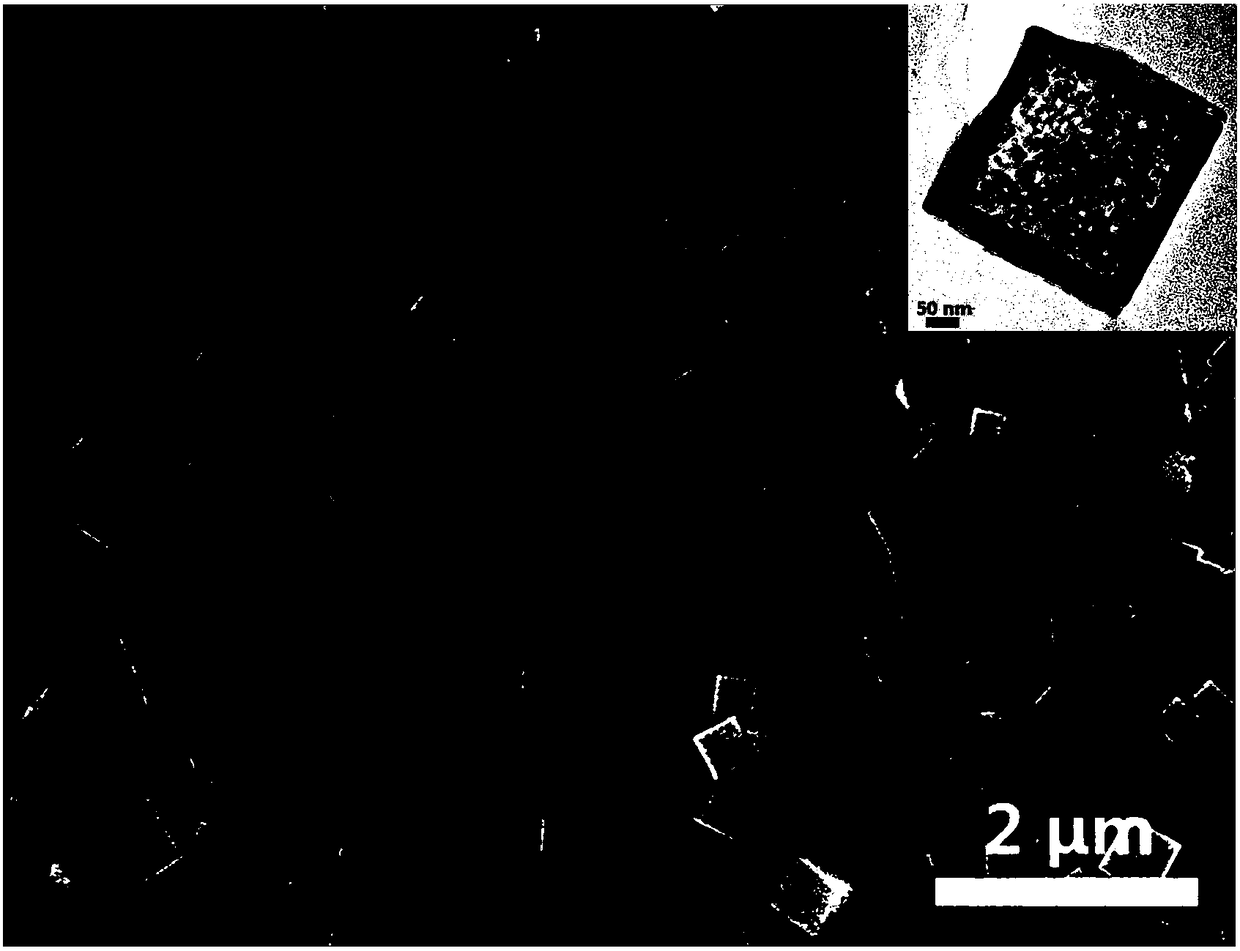

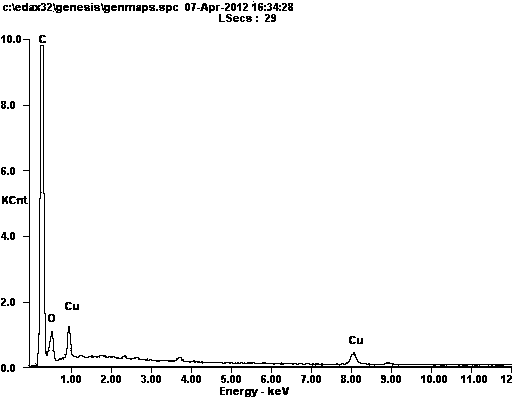

Preparation method of nano hollow structure prussian blue and analogues thereof

InactiveCN108133832AEasy to transportUniform shapeHybrid capacitor electrodesCell electrodesManganeseRoom temperature

The invention relates to a preparation method of nano hollow structure prussian blue and analogues thereof, in particular to a preparation method of nano hollow structure prussian blue and analogues thereof used for an electrochemical energy storage device. According to the method, the nano hollow structure of the prussian blue and the analogues thereof is prepared by adopting a cation exchange method through taking manganese hexacyanoferrate as a sacrificial template in a solution at room temperature. The preparation method is simple in technical operation, mild in reaction condition and cheap in used raw materials, and has universality for preparation of the nano hollow structure prussian blue and the analogues thereof; and obtained products have the characteristics of being uniform in shape, controllable in wall thickness and large in specific surface area. When the nano hollow structure prussian blue and the analogues thereof are used as electrode materials for the electrochemicalenergy storage device, reaction sites are greatly improved through a nanoscale shell and the hollow structure; meanwhile, improvement of ion transportation is facilitated; and an assembled device hasexcellent electrochemical properties.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Catalyst for desorbing nitrogen oxides and carbon monoxide at low temperature and preparation method thereof

InactiveCN103406122ALarge specific surface areaHigh activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonPtru catalyst

The invention relates to a catalyst for desorbing nitrogen oxides and carbon monoxide at a low temperature and a preparation method thereof. The catalyst is composed of an active component and an activated carbon carrier, wherein the active component adopts cupric oxide and / or cuprous oxide, according to cupric oxide, the content of the active component accounts for 1 to 30 percent of the total weight of the catalyst, the catalyst can be used for desorbing nitrogen oxides and carbon monoxide in flue gas independently or simultaneously at a low temperature, and the rate of desorbing nitrogen oxides independently at the temperature of 225 DEG C can reach 97 percent; the rate of desorbing carbon monoxide independently at the temperature of 275 DEG C can reach 93 percent; the rates of desorbing nitrogen oxides and carbon monoxide at the same time at the temperature of 250 DEG C can reach 94 percent and 83 percent respectively. The composition of the catalyst is simple, the cost is low, an industrial emission reduction process is simplified and purifying equipment can be reduced. The invention further comprises the preparation method of the catalyst for desorbing nitrogen oxides and carbon monoxide at the lower temperature, the preparation method of the catalyst is simple, the used raw material is low in cost, the production cost is low, and zero contamination to the environment can be ensured.

Owner:HUNAN NORMAL UNIVERSITY

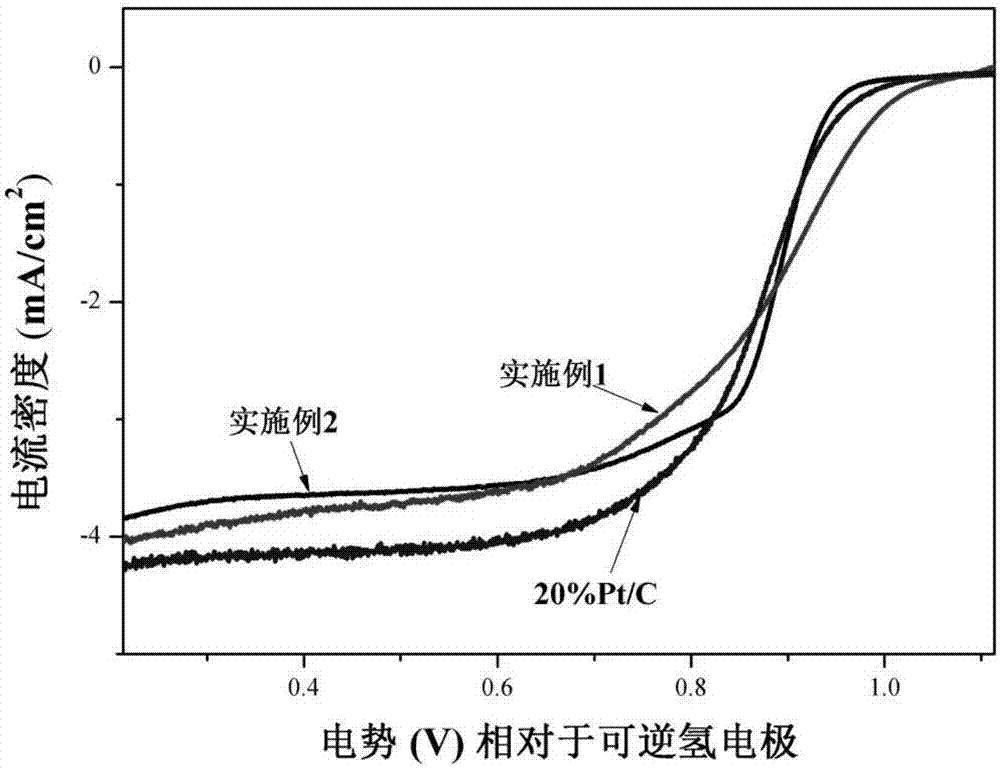

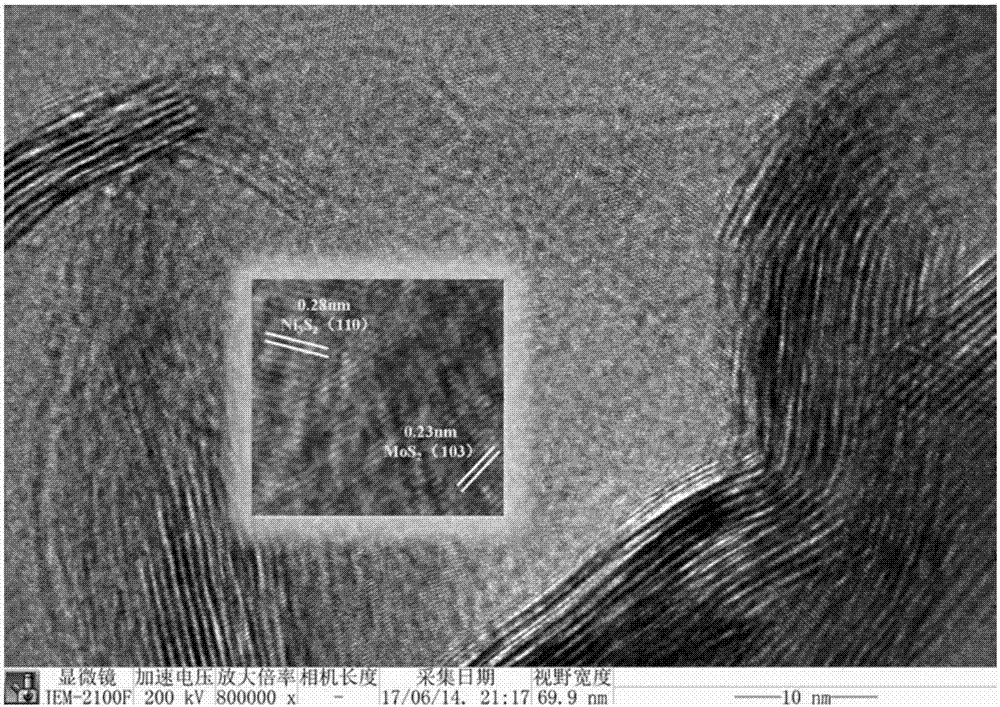

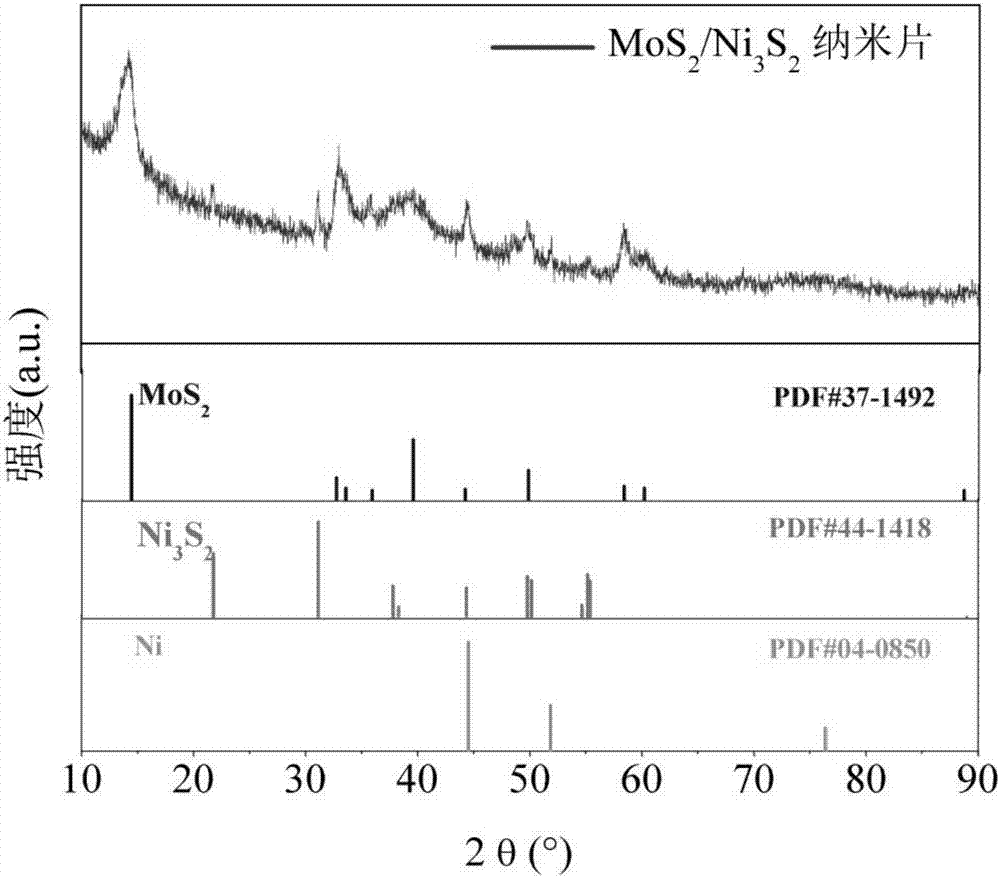

Nano-lamellar structure of Ni3S2/MoS2 composite material and preparation method thereof

InactiveCN107968208ALarge specific surface areaAbundant electrochemical active sitesMaterial nanotechnologyCell electrodesVulcanizationSynthesis methods

The invention relates to a nano-lamellar structure of a Ni3S2 / MoS2 composite material and a preparation method thereof. The nano-lamellar structure is formed from two-dimensional nano-sheets, in a stacking manner, of a composite material formed by uniformly mixing the Ni3S2 and the MoS2. The structure has two metal active centers, so that catalytic synergistic effect is improved through modes of vulcanization and in-situ composition; in addition, due to the lamellar structure, specific surface area of the material is increased greatly. The material has the oxygen reduction reaction catalytic performance equal to commercial 20% Pt / C catalyst. The composite material has simple synthesis method, is less in raw material consumption, is low in raw material cost, and has good industrial prospect.

Owner:JILIN UNIV

Compound material support roller and preparation method thereof

The present invention relates to an idler roller made of composite material and its preparation method. Said preparation method includes the following steps: adding coupling agent, nano material, anti-static agent, fire-resisting agent and flow modification agent in the dried ultrahigh molecular polyethylene, mixing and stirring them, extruding with extruding machine, cooling by water tank, cutting ink into circular cylinder with required length and placing it into the rotating shaft wind bearing so as to form the invented composite material idler roller with the advantages of resisting corrosion, resisting wear, resisting impact, resisting static electricity and long service life.

Owner:HENGSHUI HONGQI ROLLER MFG

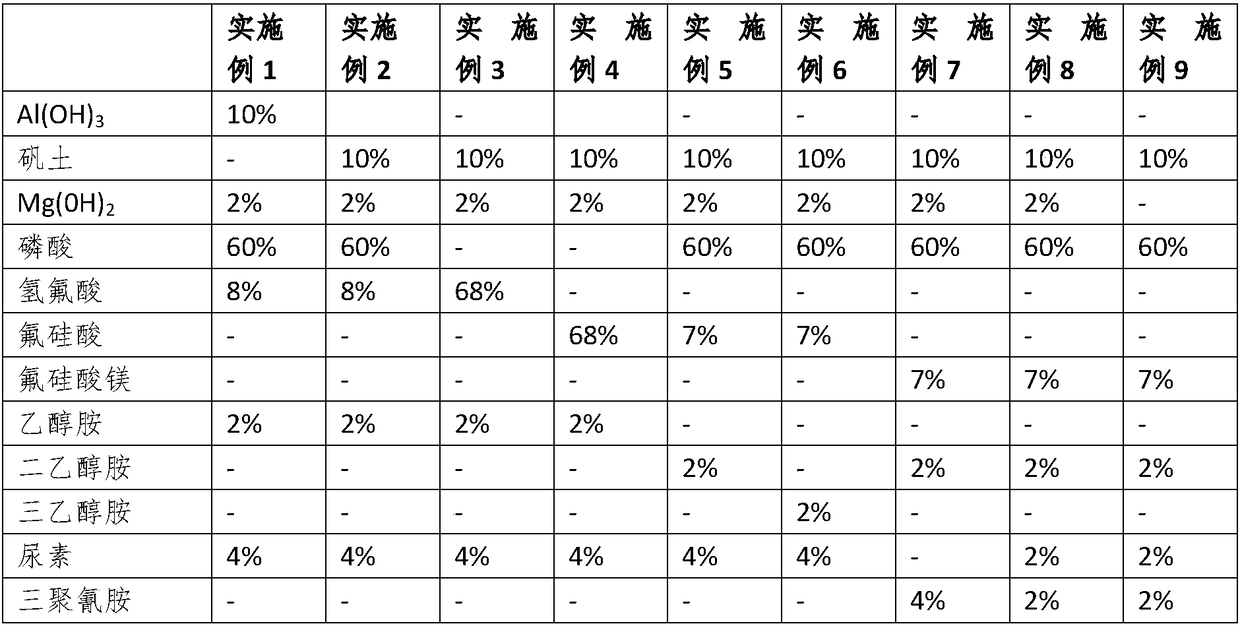

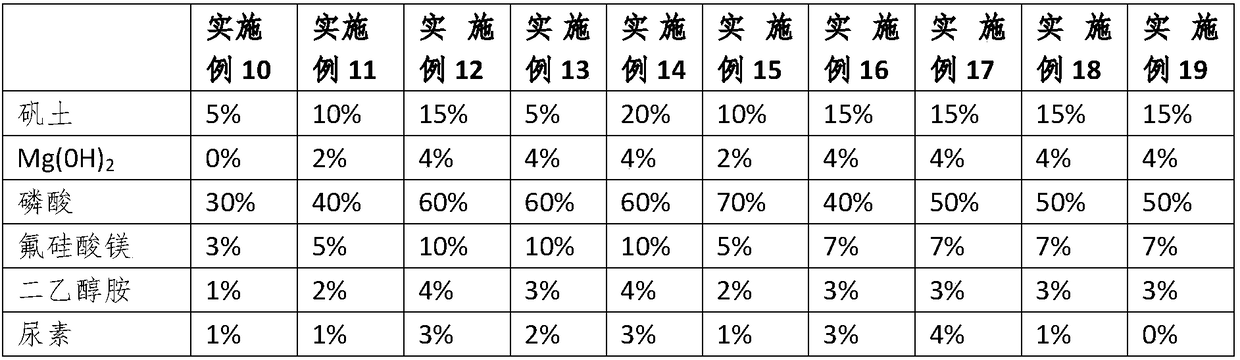

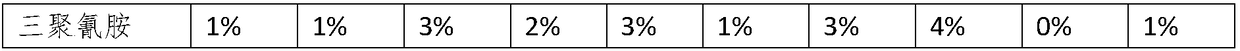

Polyaluminium phosphate-series chlorine-free sulfur-free liquid alkali-free accelerator and preparation method thereof

The invention discloses a polyaluminium phosphate-series chlorine-free sulfur-free liquid alkali-free accelerator and a preparation method thereof and relates to the technical field of alkali-free accelerators. The alkali-free accelerator comprises, by mass, 50-60% of phosphoric acid, 10-15% of alumina, 5-10% of magnesium fluorosilicate, 2-4% of magnesium hydroxide, 2-4% of diethanolamine, 2-6% ofa condensing agent and the balance of water. The accelerator is mainly used in shotcrete, and the use amount of the accelerator is 5 to 7% of that of a gelling material. The accelerator has good stability and does not produce layering and precipitation crystallization and use effect change after being placed at the room temperature and a low temperature (5 DEG C) for 3 months. The accelerator does not contain alkali metal ions, chloride ions and sulfate ions so that the corrosion of the steel bars in the concrete and the alkali aggregate reaction are reduced and the durability of the shotcrete is improved. Through a compatibility of the condensing agent, the compressive strength ratio measured at 28th days is greater than 100% and satisfies the requirement on the one-grade product in JC477-2005.

Owner:贵州天威建材科技有限责任公司

Preparation method of ZnO/graphene photocatalyst

InactiveCN104275175AImprove adsorption capacityEfficient separationMetal/metal-oxides/metal-hydroxide catalystsGrowth promotingGraphene

The invention provides a preparation method of a ZnO / graphene photocatalyst. The preparation method comprises the following steps: (1) preparing growth-promoting liquid; (2) preparing seed crystal liquid; and (3) preparing ZnO / graphene: a, adding a proper amount of graphene oxide into the seed crystal liquid and heating to 80-90 DEG C, then preserving the heat for 30 minutes; washing and filtering, and drying at 120 DEG C for 1-2 hours for later use; b, putting a dried sample into the growth-promoting liquid and heating to 80-90 DEG C, then preserving the heat for one hour, washing and drying to obtain ZnO / graphene oxide; and c, putting the prepared ZnO / graphene oxide into an atmosphere reduction furnace and heating to 1000-1100 DEG C to be reduced for one hour under the protection of carrier gas, thereby finally obtaining the ZnO / graphene photocatalyst. The preparation method of the ZnO / graphene photocatalyst is simple in steps and low in cost; and the catalytic activity and the stability of the obtained ZnO / graphene photocatalyst are greatly improved and the ZnO / graphene photocatalyst is hopeful to be applied to photocatalysis treatment of industrial pollutants.

Owner:湖南元素密码石墨烯高科技有限公司

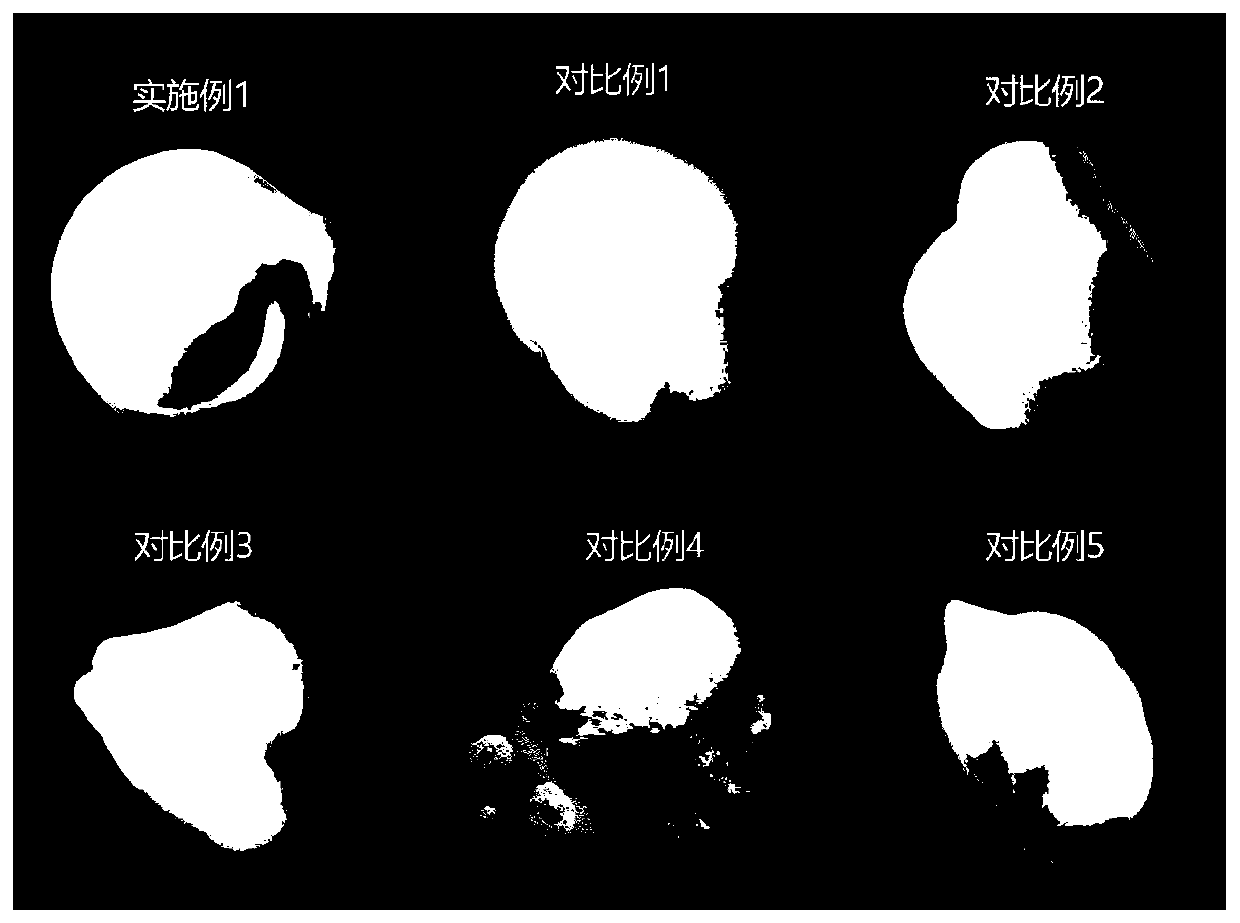

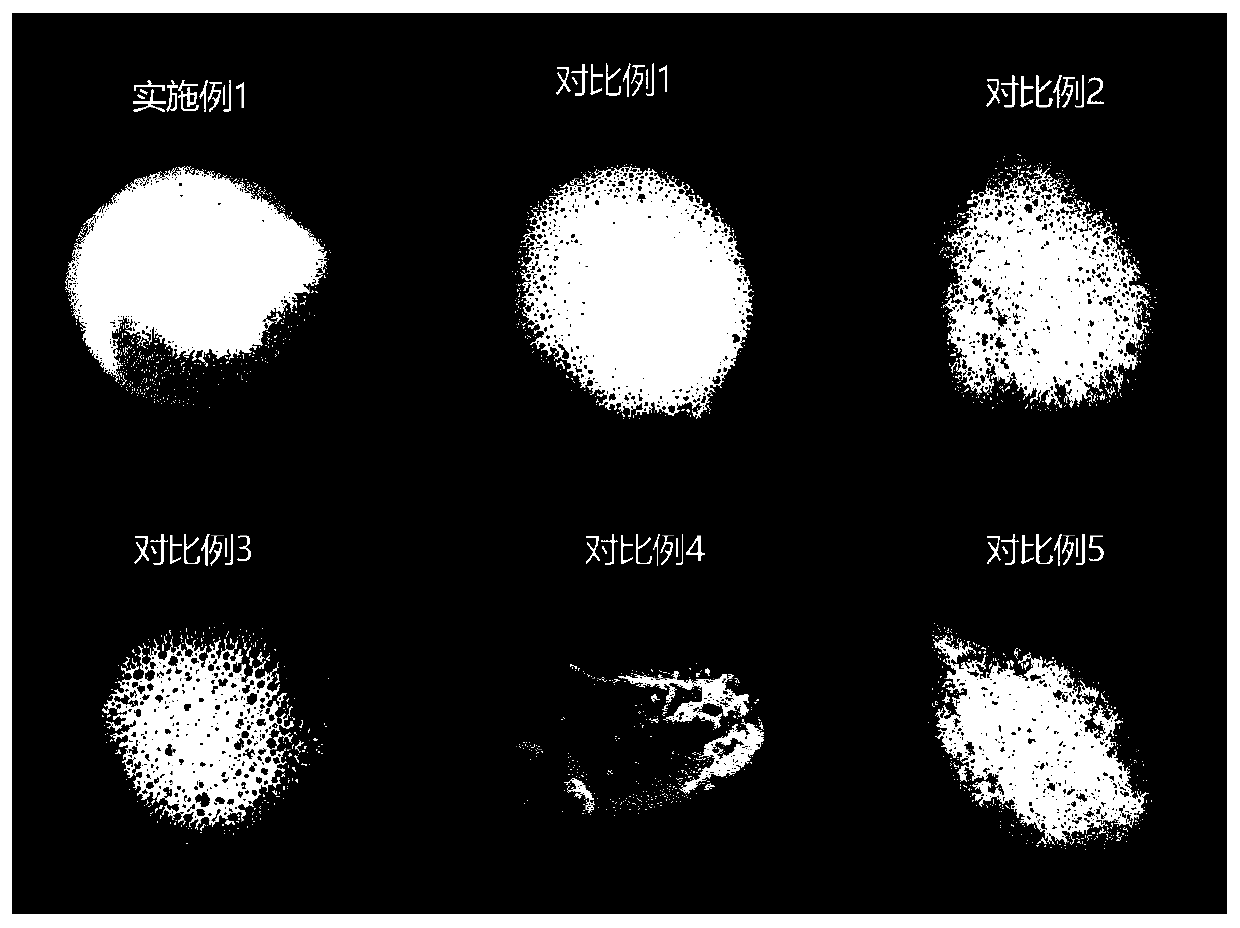

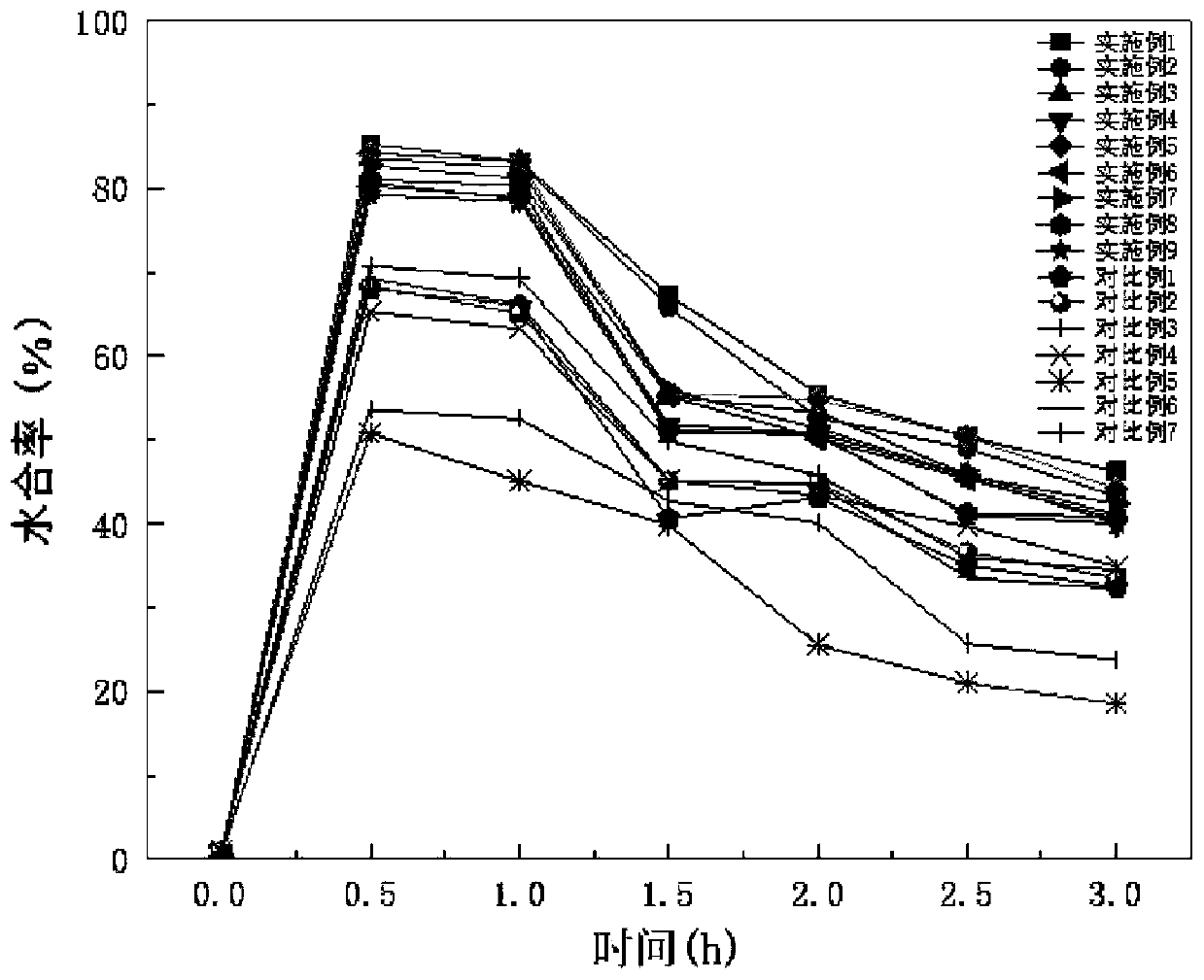

Elastic, dense and soft facial cleanser mousse and preparation method thereof

ActiveCN110327235ALower pHEasy to rinseCosmetic preparationsToilet preparationsCleansers skinMedicine

The invention relates to elastic, dense and soft facial cleanser mousse and a preparation method thereof. The elastic, dense and soft facial cleanser mousse includes the following components: methylglucosamine, fatty acids, surfactants, PEG-75 shea butter glycerine, and water. The components are combined for the first time in the facial cleanser mousse, so that the components interact and synergistically take an effect so as to make the facial cleanser mousse rich and dense in foam; and thus, the facial cleanser mousse can penetrate into deep tiny pores so as to have the pores thoroughly cleaned and make-up residues removed. Moreover, the elastic, dense and soft facial cleanser mousse is very easy to wash off, and has the functions of nourishing the skin. The preparation method of the elastic, dense and soft facial cleanser mousse disclosed by the invention is capable of ensuring uniform mixing of all the components in the facial cleanser mousse so as to form a stable, homogeneous andcontinuous mixture; moreover, the various components make full contact with each other, interact and synergistically take an effect so as to make the prepared facial cleanser mousse rich in foam, highin cleaning capability, mild in property and not liable to cause tightening after face washing. In addition, the preparation method of the elastic, dense and soft facial cleanser mousse disclosed bythe invention is low in raw material consumption, simple in formula, easy to operate, high in production efficiency, and capable of greatly reducing energy consumption in production.

Owner:GUANGZHOU HUANYA COSMETIC SCI & TECH CO LTD

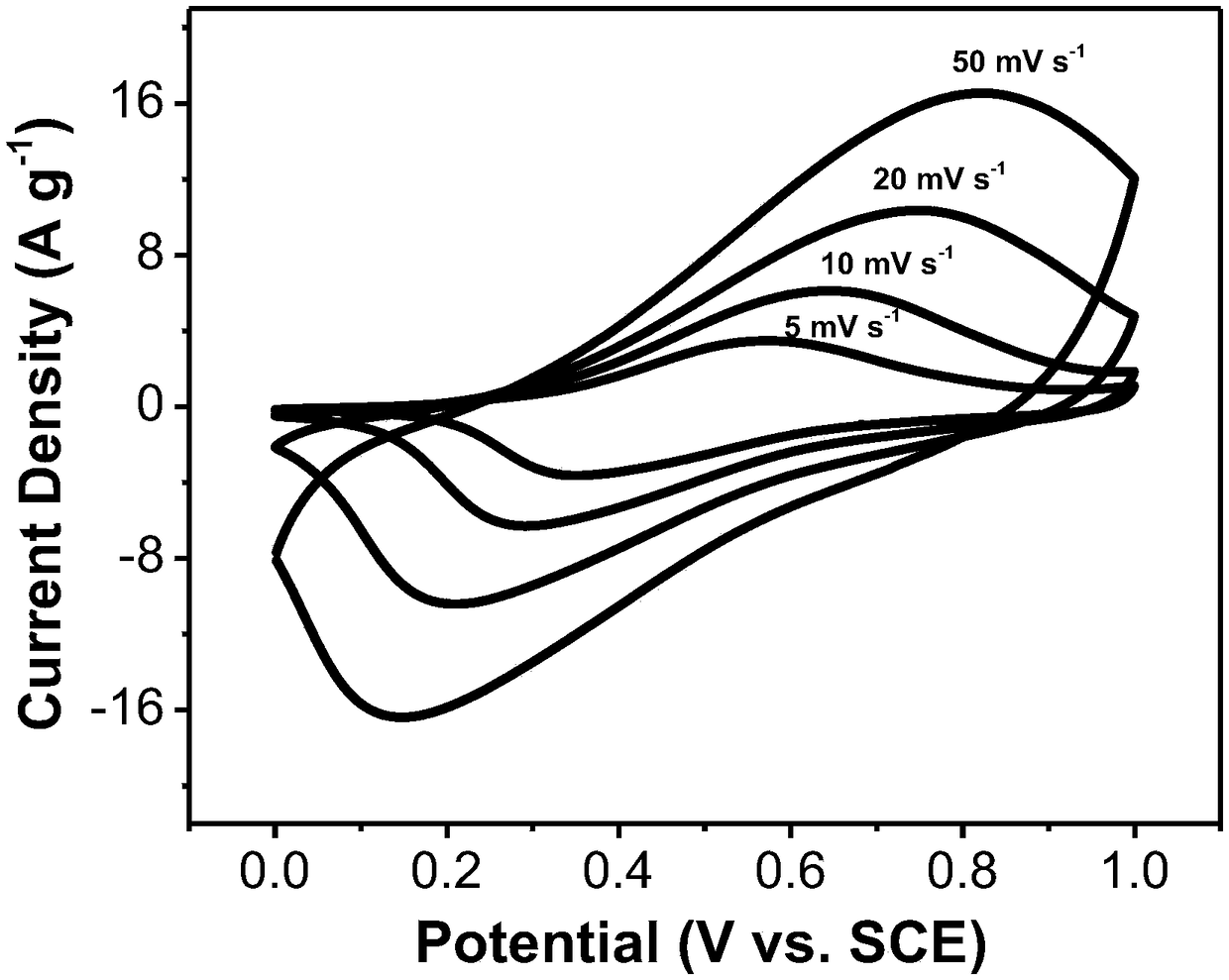

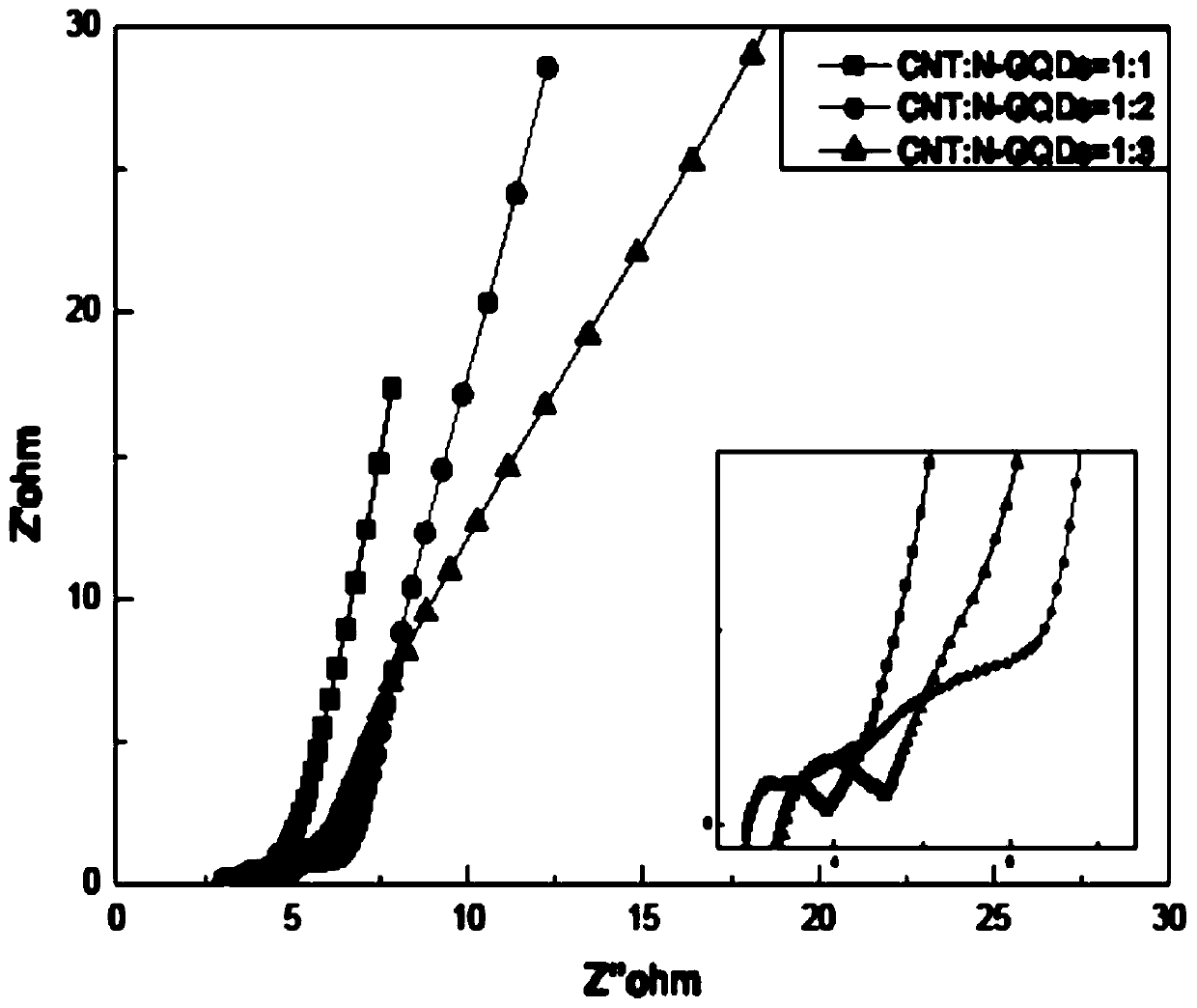

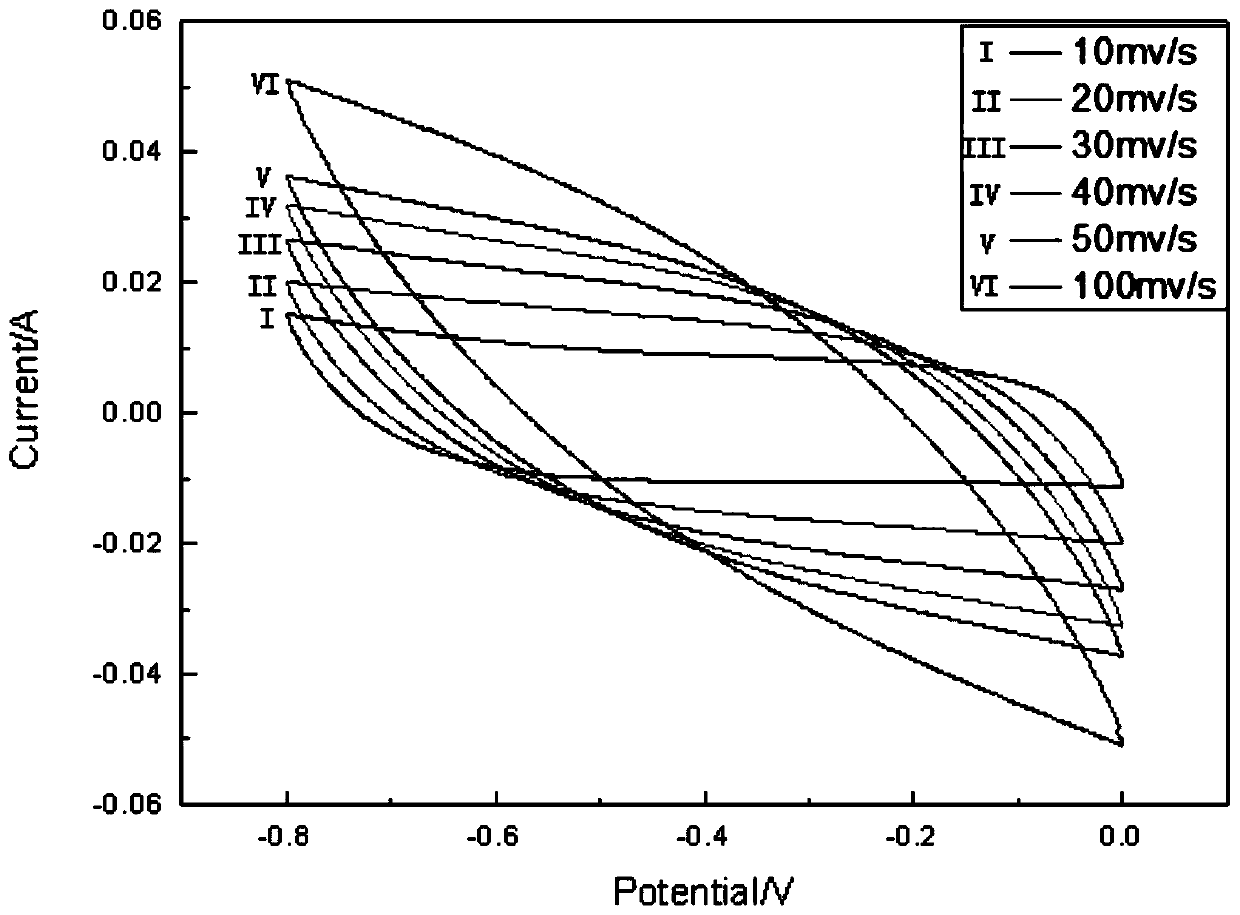

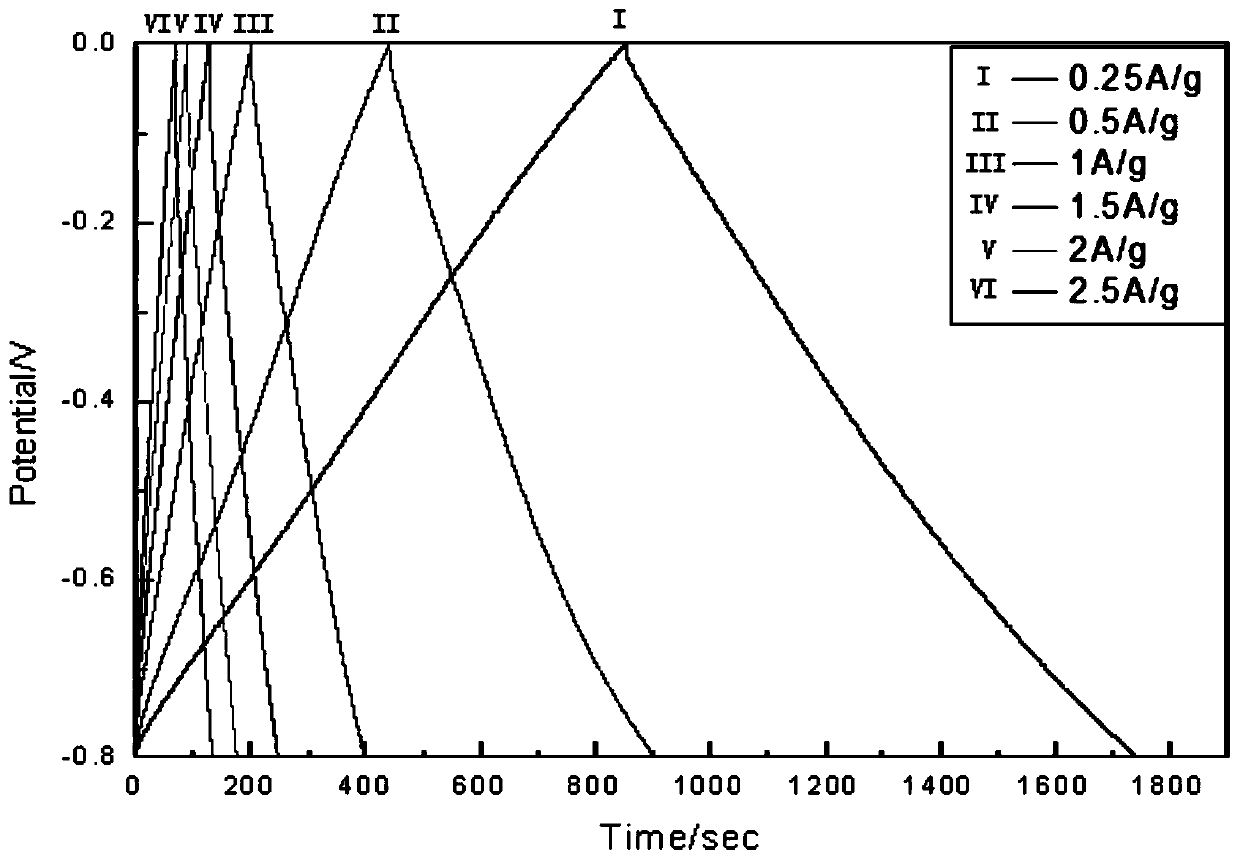

Electrode composite material of flexible supercapacitor and preparation method of electrode composite material

ActiveCN111223682AHigh pseudocapacitanceImprove hydrophilicityHybrid capacitor electrodesHybrid/EDL manufactureDoped grapheneNitrogen doped graphene

The invention provides an electrode composite material of a flexible supercapacitor and a preparation method of the electrode composite material, and belongs to the technical field of energy storage materials. The electrode composite material is a MoS2 / N-GQDs / HCNTs ternary composite material prepared by self-growing molybdenum disulfide nanosheets, nitrogen-doped graphene quantum dots and spiral carbon nanotubes on carbon cloth pretreated by nitric acid by adopting a one-step hydrothermal method, and the energy storage performance of the flexible supercapacitor is improved. The specific preparation method comprises the steps of S1, nitric acid pretreatment of the carbon cloth; S2, nitric acid modification of the carbon nanotubes; S3, preparation of an electrode composite material, specifically, dissolving molybdate and a sulfur source in water, then respectively adding nitrogen-doped graphene quantum dots and spiral carbon nanotubes, adding the carbon cloth pretreated by nitric acid after ultrasonic uniform mixing, reacting at the temperature of 180-220 DEG C for 18-24h to obtain the electrode composite material. The method is convenient to operate, high in efficiency, high in loading rate and cheap in used raw materials.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

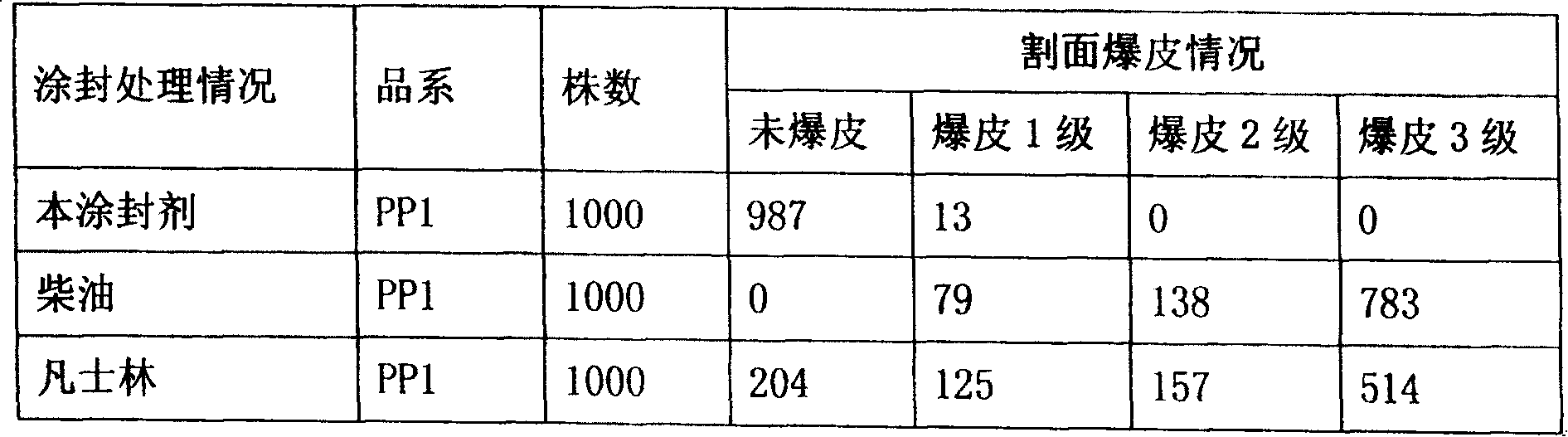

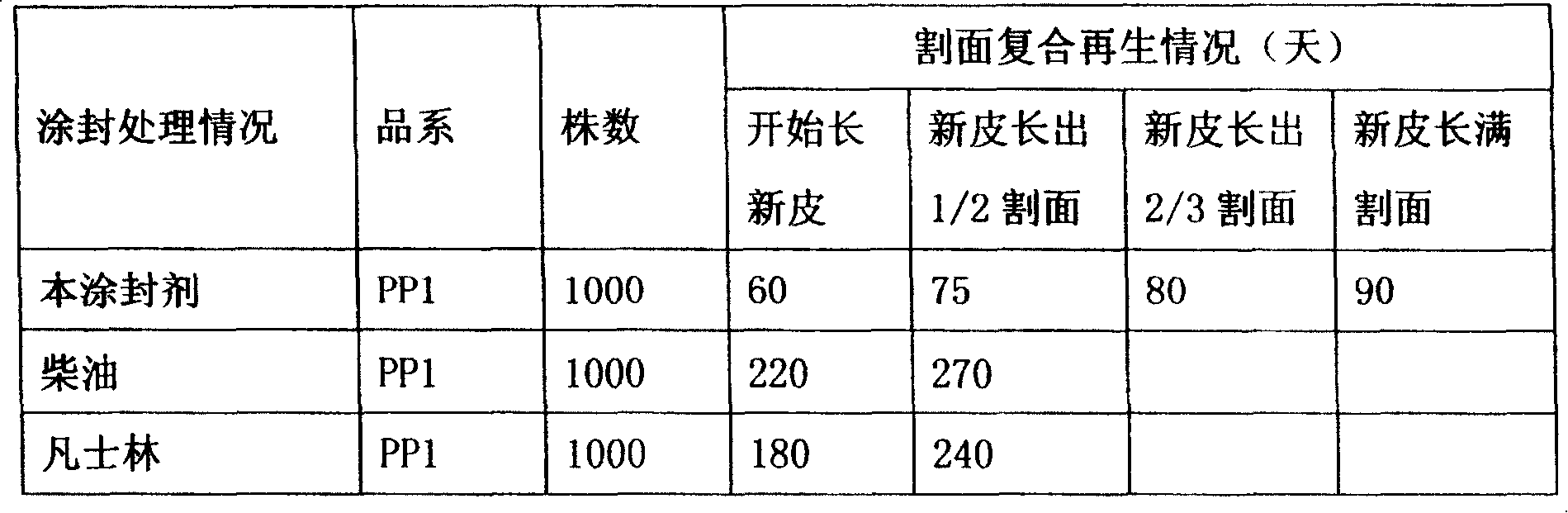

Rubber tree tapping face coldness-proof coating agent and method for producing same

The invention discloses a rubber tree cut cold-proof coating-packing agent and manufacturing method, which consists of 35-50% rubber seed oil and 50-65% vaseline, wherein the vaseline is heated to 45-55 deg.c to add rubber seed oil according to certain proportion, which is cooled to indoor temperature after blending evenly. The invention can coat and pack rubber tree with temperature not less than 10 deg.c, which protects cutting surface from flowing rubber and accelerates bark recombination and regeneration.

Owner:肖余保

Rubber tree tapping face coldness-proof coating agent and method for producing same

The invention discloses a rubber tree cut cold-proof coating-packing agent and manufacturing method, which consists of 35-50% rubber seed oil and 50-65% vaseline, wherein the vaseline is heated to 45-55 deg.c to add rubber seed oil according to certain proportion, which is cooled to indoor temperature after blending evenly. The invention can coat and pack rubber tree with temperature not less than 10 deg.c, which protects cutting surface from flowing rubber and accelerates bark recombination and regeneration.

Owner:肖余保

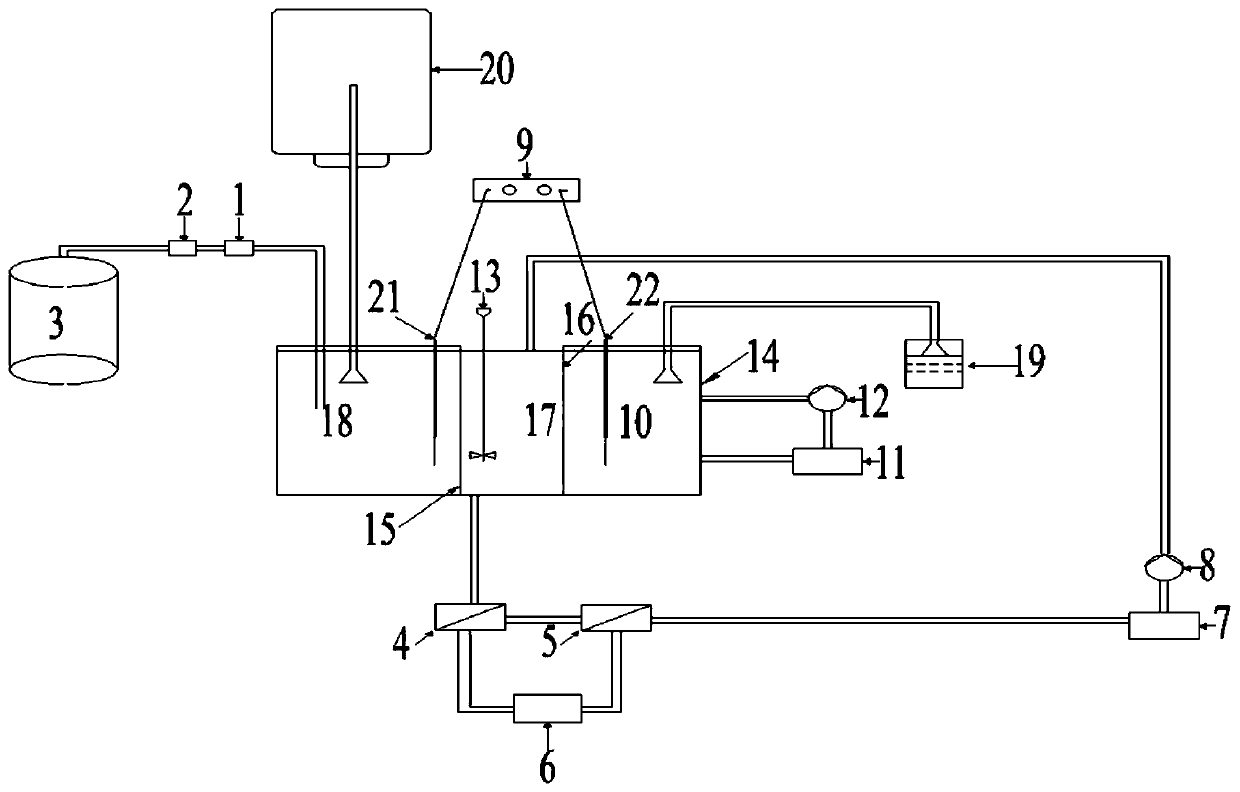

Method for directly preparing basic cobalt carbonate by membrane electrolysis method

The invention provides a method for directly preparing basic cobalt carbonate through a membrane electrolysis method. The method comprises the following steps: (1) using an electrolytic cell system, placing a cobalt chloride solution in an anode chamber, and placing electrolyte in a cathode chamber and a middle chamber; (2) turning on a power supply, and controlling the current density of the anode plate to be 200-800A / m < 2 >; (3) introducing carbon dioxide into the cathode chamber, and mixing the carbon dioxide with the electrolyte to generate carbonic acid; (4) enabling Co < 2 + > in the anode chamber to enter the middle chamber through a cation exchange membrane, and enabling CO3 < 2-> and OH <-> in the cathode chamber to enter the middle chamber through an anion exchange membrane to generate basic cobalt carbonate precipitate; and (5) discharging and filtering materials in the middle chamber, and drying a filter cake to prepare the basic cobalt carbonate. The method is simple in process operation, short in flow and high in automation degree, and the obtained product is high in purity and clean in energy.

Owner:NORTHEASTERN UNIV

Thermal stimulus response type medicine releasing nano-carrier based on hollow prussian blue and preparing method of nano-carrier

InactiveCN110215439AUniversalEasy to operateInorganic non-active ingredientsMicrocapsulesManganeseDrug release

The invention discloses a thermal stimulus response type medicine releasing nano-carrier based on hollow prussian blue and a preparing method of the nano-carrier. The preparing method includes the following steps of dissolving manganese salt to form manganese hexacyanoferrate suspension liquid, adding a transition ferric salt solution to the manganese hexacyanoferrate suspension liquid to obtain the prussian blue of a nanometer hollow structure, dissolving a thermo-sensitive material and a medicine in an organic solvent to obtain a mixed solution, dispersing prussian blue particles of the nanometer hollow structure in the same organic solvent to obtain nanoparticle resuspending liquid, injecting the organic solvent in which the thermo-sensitive material and the medicine are dissolved intohollow parts of the prussian blue particles of the nanometer hollow structure, and solidifying the thermo-sensitive material in the medicine-carrying nano-carrier. The thermal stimulus response type medicine releasing nano-carrier based on hollow prussian blue and prepared through the method has the advantages of being simple in operation, mild in reaction condition and low in applied raw materialprice and has universality to preparing the prussian blue of the nanometer hollow structure, and the adopted raw materials are safe, free of toxin and suitable for the field of food medicines.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

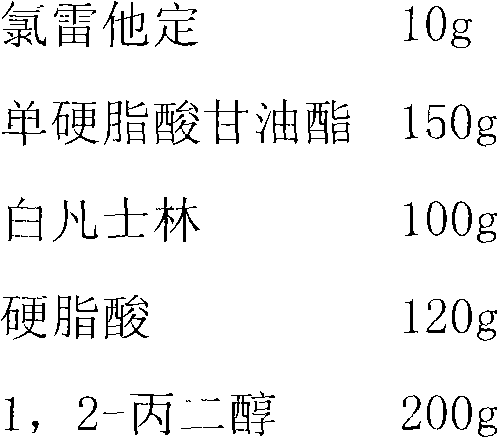

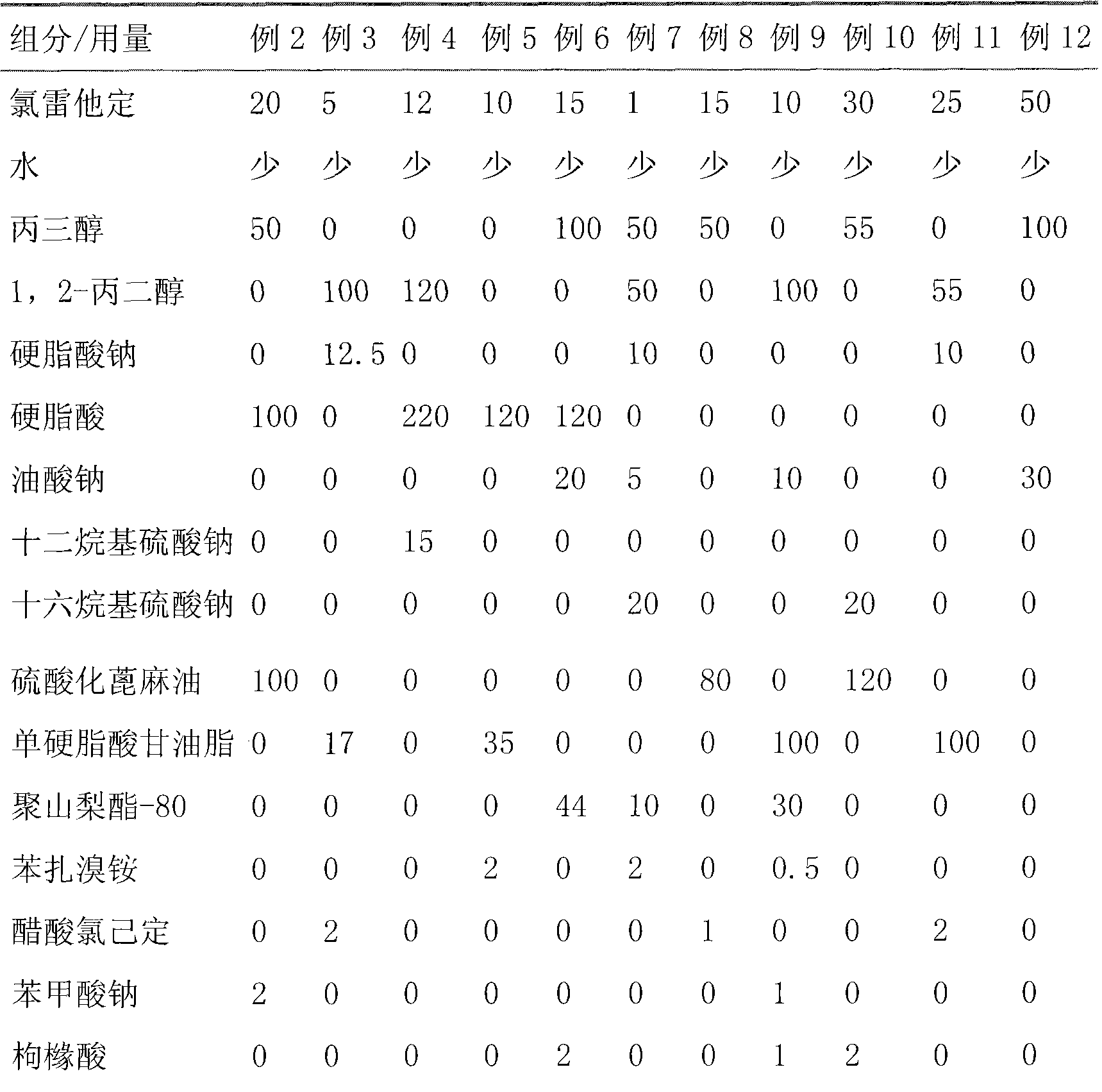

Loratadine cream and application thereof

ActiveCN102048682APromote transdermal absorptionSignificant anti-allergic effectOrganic active ingredientsAerosol deliveryIrritationMedicine

The invention relates to a loratadine cream and application thereof for preparing a medicine for treating inflammation and pruritus caused by mosquito bite, belonging to the technical field of medicines. The loratadine cream has the characteristics of small irritation on skink, high transdermal adsorption speed, inflammation resistance, strong itching activity, obvious curative effect, no adverse reaction and simple preparation process, is prepared from a small quantity of raw materials, and is suitable for industrial production.

Owner:LUNAN PHARMA GROUP CORPORATION

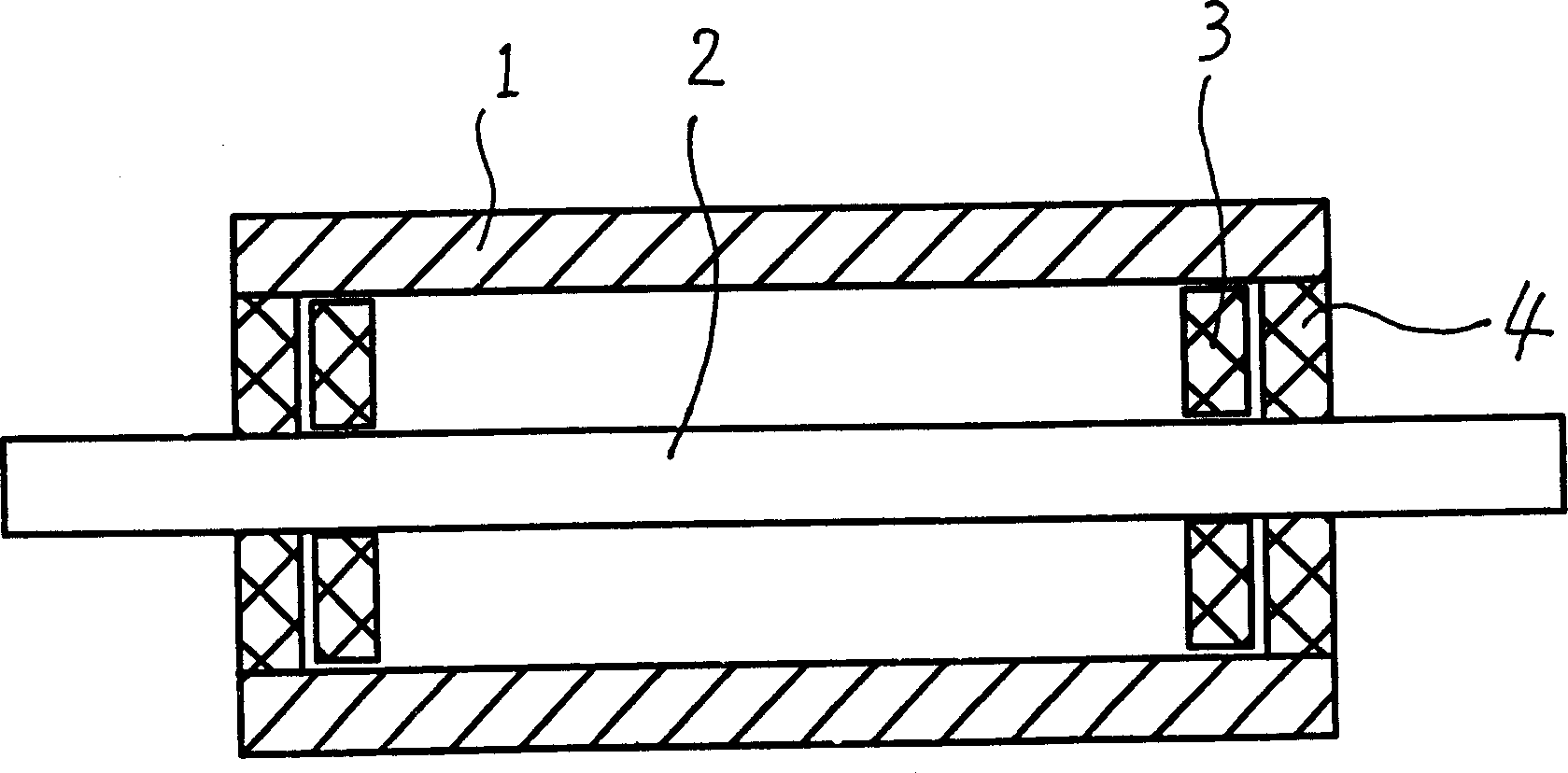

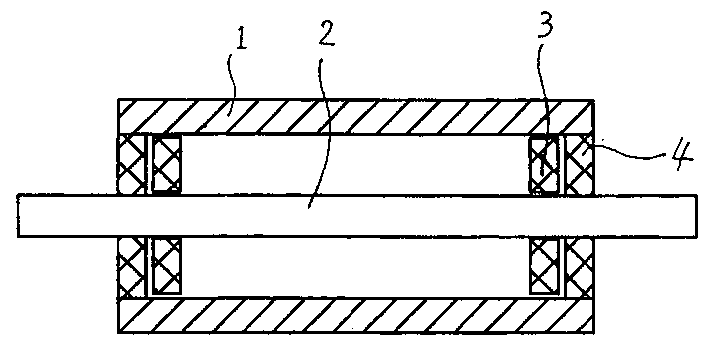

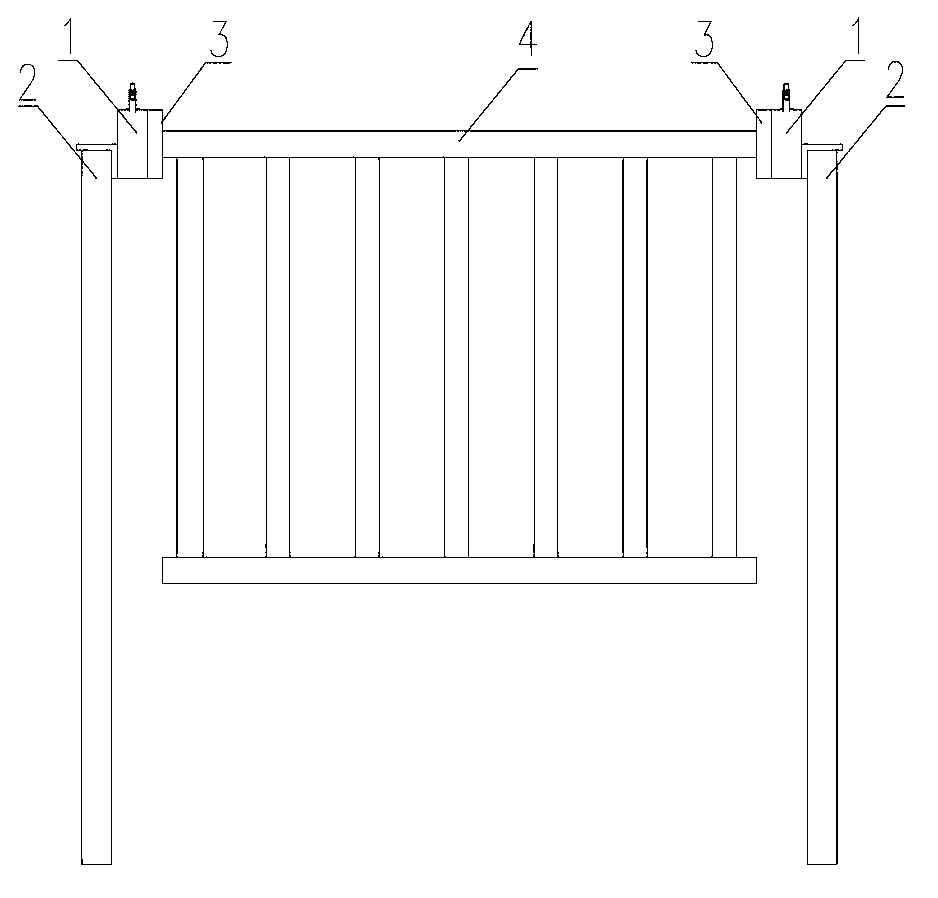

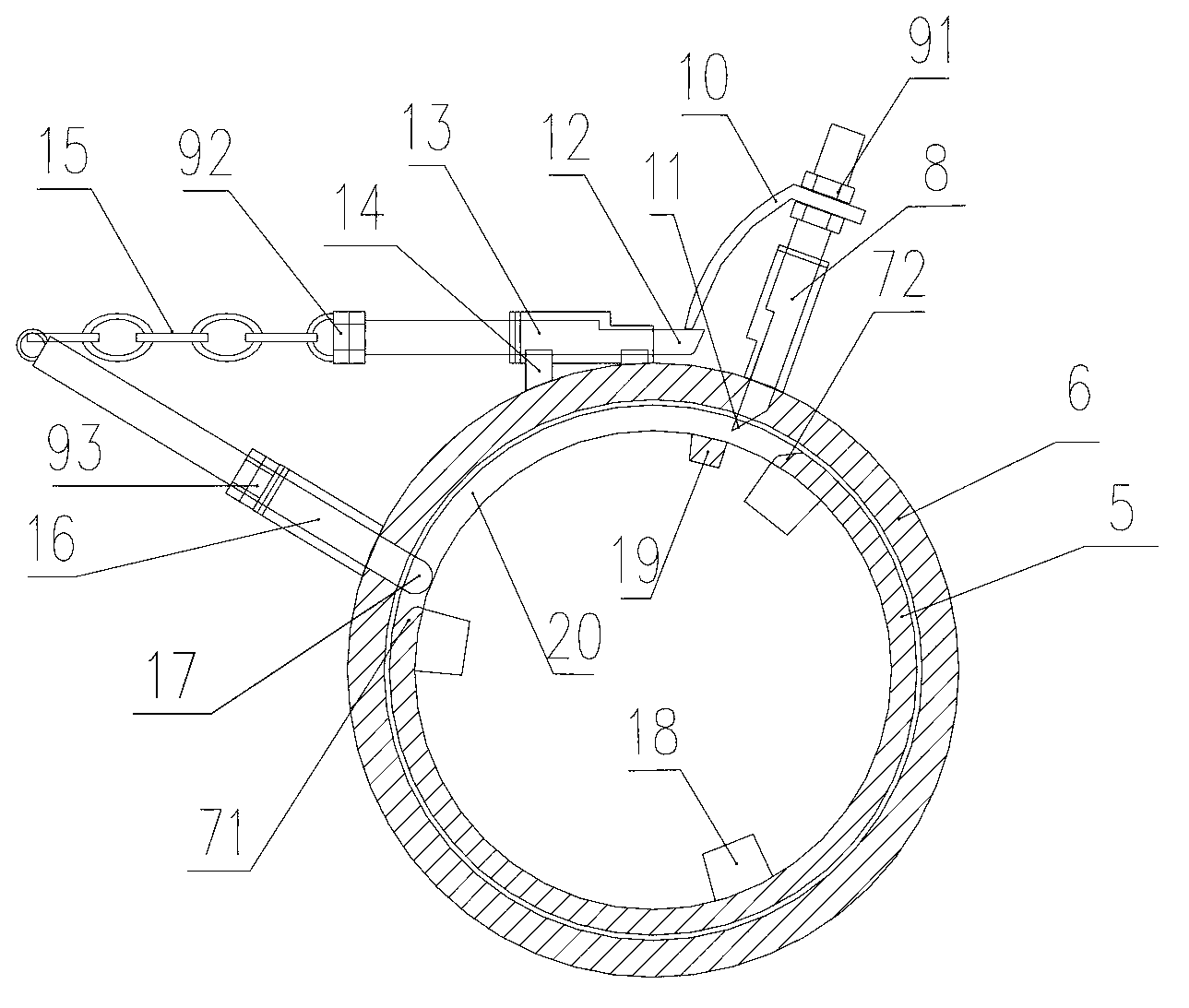

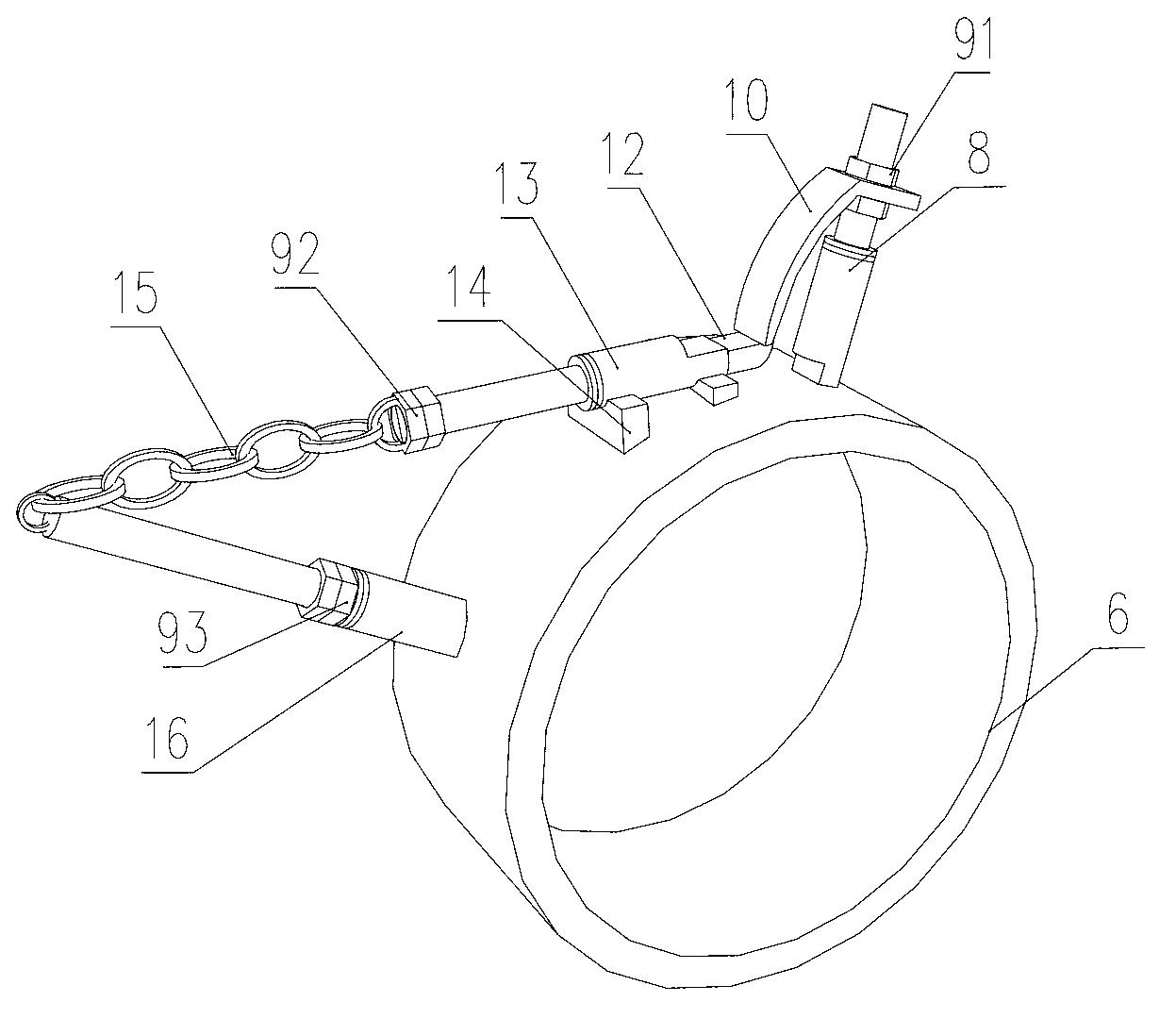

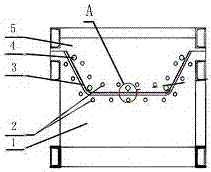

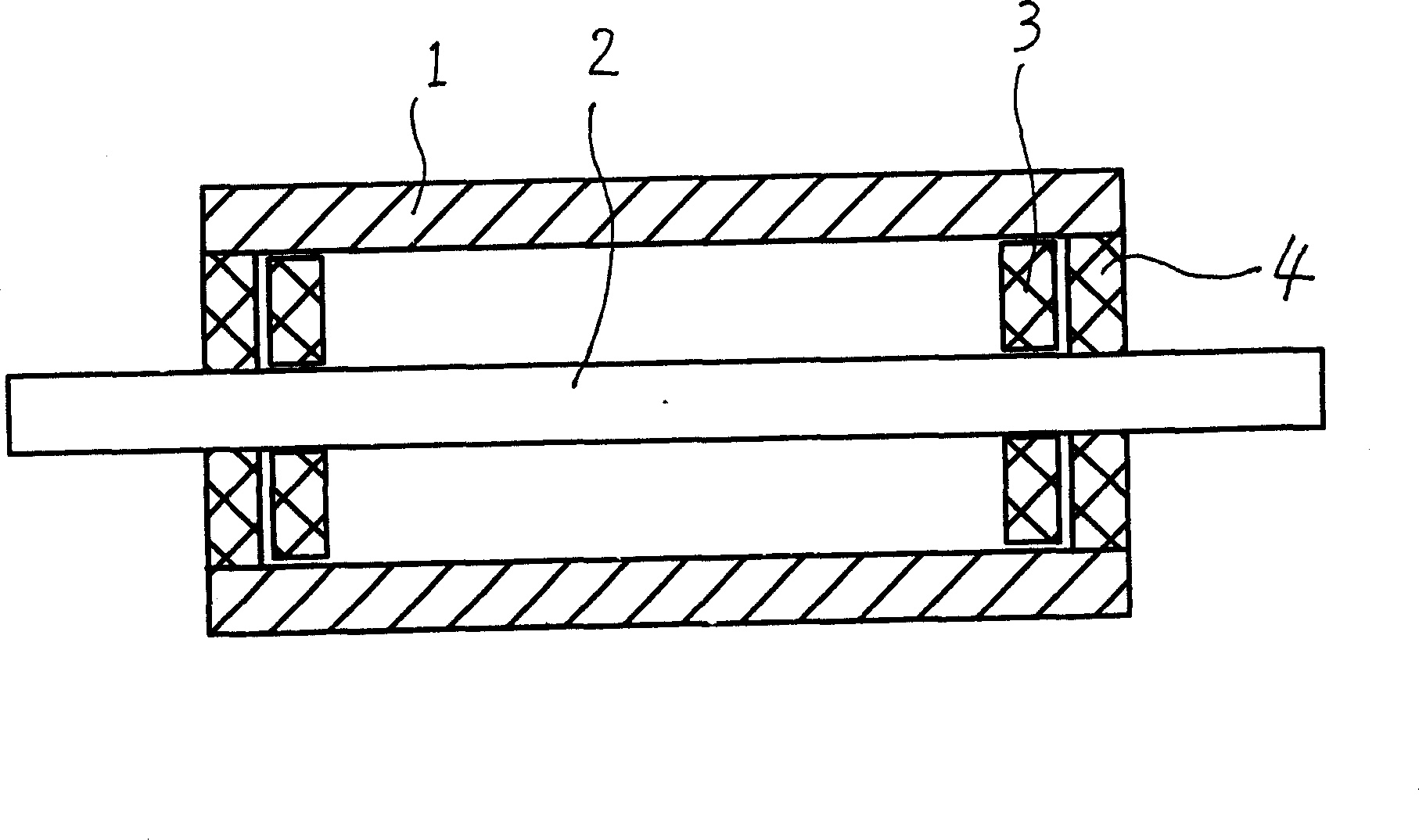

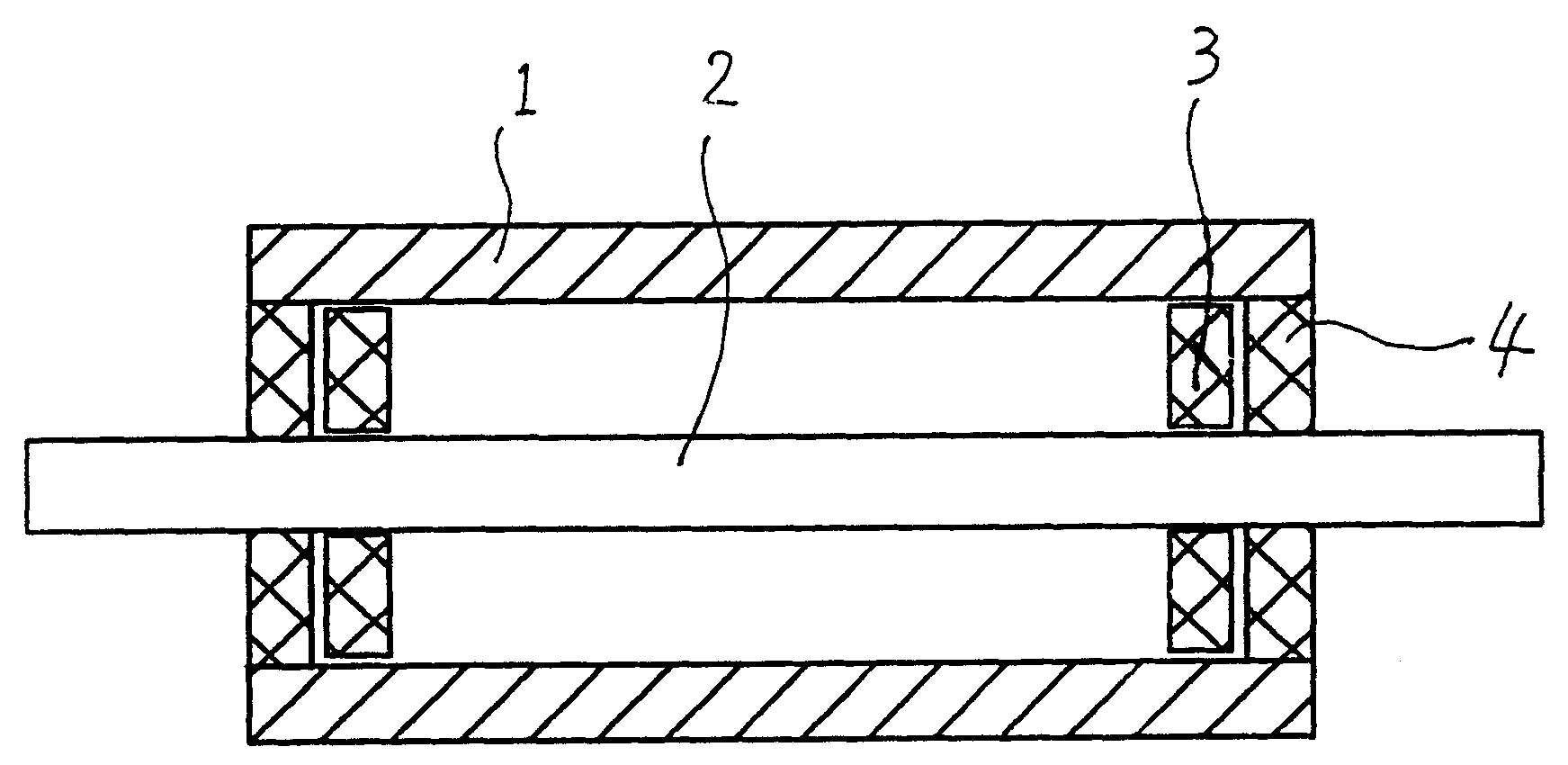

Free entry and exit door capable of automatically locked for individual isolation of domestic animals

The invention belongs to a domestic animal raising facility and particularly relates to a group-breeding domestic animal semi-limiting raising rail, comprising a door frame (2) and a door (4), wherein rotary shafts (3) are respectively inserted at the two ends of the upper part of the door (4); the rotary shafts (3) are connected to a linked switch (1); the linked switch (1) is provided with a fixing ring (6); a rotary ring (5) is arranged inside or outside the fixing ring (6); a plurality of switches with switch pins are fixedly arranged on the fixing ring (6); a hole is formed in the middle of the fixing ring (6); the rotary ring (5) is provided with a groove (20); the groove (20) is internally provided with a transverse rod (19); and baffles (71, 72) are respectively arranged at the two ends of the groove (20). According to the group-breeding domestic animal semi-limiting raising rail, domestic animals are prevented from being interfered by the other domestic animals in a feeding or resting process; and meanwhile, the group-breeding domestic animal semi-limiting raising rail has the advantages of simple design, material conservation and strong practical applicability.

Owner:CHINA AGRI UNIV

Hard polyvinyl chloride (PVC) pipe for feeding water and production method of hard PVC pipe

The invention discloses a hard polyvinyl chloride (PVC) pipe for feeding water and a production method of the hard PVC pipe. The production method comprises the following steps of (1) weighting all raw materials in parts by weight: 80-120 parts of PVC, 0.3-0.8 part of calcium stearate, 0.8-2.0 parts of basic lead sulfate, 0.4-1.0 part of stearic acid, 0.6-1.0 part of dibasic lead phosphite, 0.2-1.2 parts of carbon black and 0.2-0.6 part of lead stearate; (2) after kneading the raw materials in the step (1), carrying out double-roller mixing, smashing and extrusion molding as well as cooling shaping under the conditions that the temperature is 160-180 DEG C, the compression ratio is 2-4, and the length to diameter ratio is 20-25; (3) cutting a cooled product treated in the step (2) to obtain the hard PVC pipe for feeding water. Compared with the prior art, the hard PVC pipe has the following advantages of low price, relatively few raw materials, simple production process, relatively high strength, relatively stable physical property even if at relatively high water pressure, environment friendliness, no pollution and relative safety when used as a water pipe.

Owner:NINGGUO DONGXING IND

Oil resistant gasket

The invention discloses an oil resistant gasket characterized by comprising the following raw materials by weight: 80-120 parts of high acrylonitrile NBR, 3-7 parts of zinc oxide, 0.5-1.5 parts of stearic acid, 0.1-0.3 part of sulfur, 10-30 parts of semi reinforcing furnace black, 25-45 parts of active calcium carbonate, 5-15 parts of plasticizer DOS, 3-7 parts of plasticizer TP-90B, 1-3 parts of promoter CZ and 1-3 parts of promoter TMTD. Compared with the prior art, the oil resistant gasket has the following advantages: (1) the product of the oil resistant gasket has the advantages of low price, less use of raw materials and simple production process; (2) the oil resistant gasket has the advantages of being safe, environmentally friendly, good in oil resistance, heat resistance and aging resistance and other a series of advantages; and (3) by simultaneous use of the NBR and PVC, the manufactured oil resistant gasket has excellent resistance to bending, and high fatigue resistance and sealing performance.

Owner:宁国天运橡塑制品有限公司

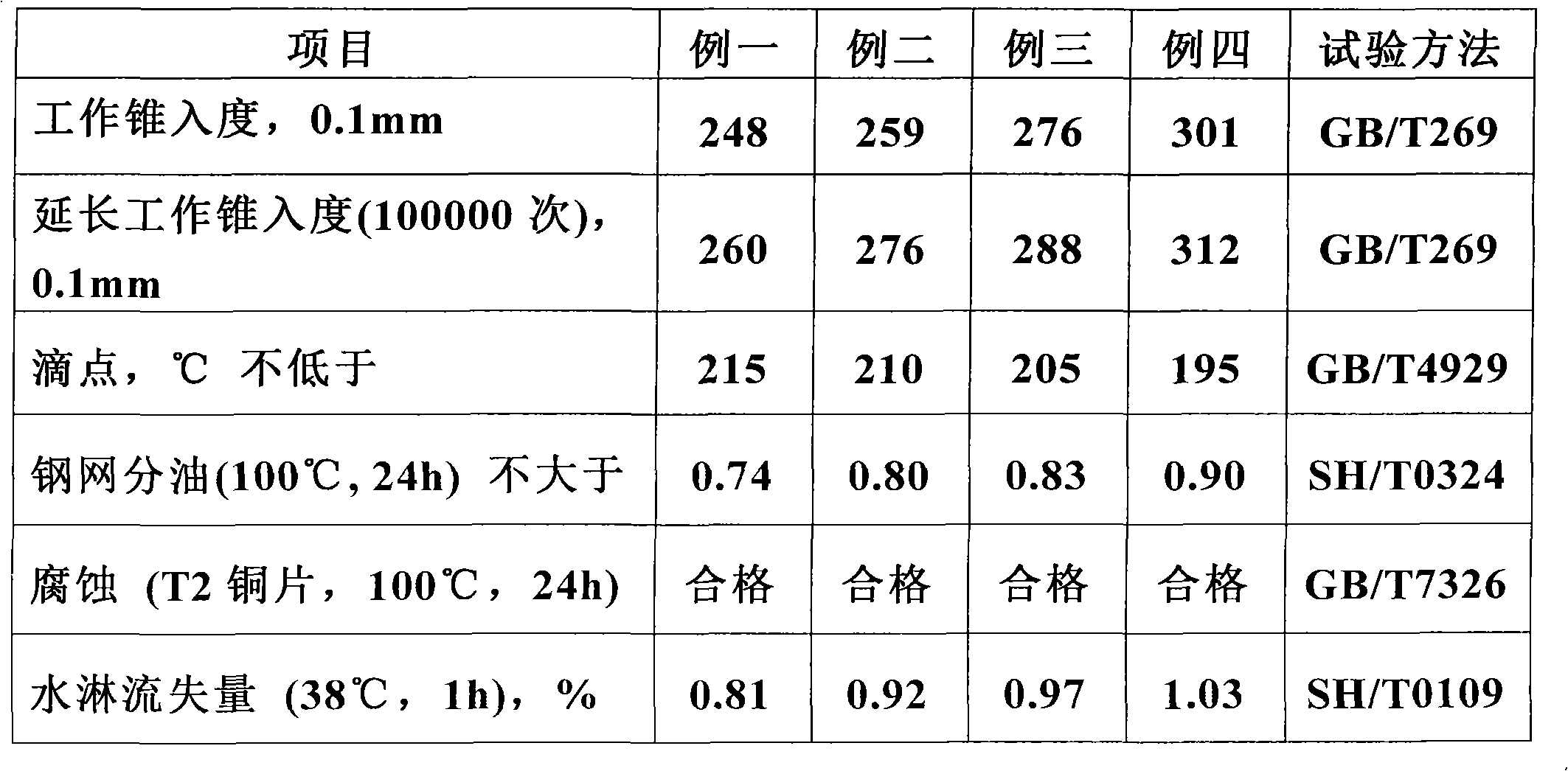

Complex calcium sulfonate grease and method for preparing same

The invention discloses a complex calcium sulfonate grease and a method for preparing the complex calcium sulfonate grease. The complex calcium sulfonate grease comprises the following components: 30-50% of mineral oil, 20-40% of plant oil, 8-30% of concentrated sulfuric acid, 1-15% of calcium hydroxide, 0.1-5% of organic acid and 0.1-5% of transformation accelerator. The mixture of the mineral oil and the plant oil is used as a base oil. The prepared complex calcium sulfonate grease has the advantages of low energy consumption, low cost, excellent performance, is easy to prepare, has high drop point, good water resistance and other excellent physical and chemical properties and also has a certain biodegradability.

Owner:XINJIANG MODERN PETROCHEM IND

Cement prefabricated member, cement cementing material, and production method thereof

InactiveCN109020395AImprove the problem of poor flexural performanceLow costGrapheneUltimate tensile strength

A cement prefabricated member, a cement cementing material, and a production method thereof belong to the field of cement. The cement cementing material includes a cement base material, a graphene material and a polycarboxylate water reducer, wherein the graphene material accounting for 0.02-0.04 mass% of the cement base material. The cement base material includes an aggregate, Portland cement andBelite cement. By introducing the graphene, the cement cementing material is improved in rupture strength.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Environment-friendly tread base rubber for umbrella stroller

The invention discloses environment-friendly tread base rubber for an umbrella stroller. The rubber is characterized by containing the following raw materials in parts by weight: 50-90 parts of natural rubber (NR), 30-50 parts of oil-filled cis-butadiene rubber, 4-6 parts of zinc oxide, 2-4 parts of stearic acid, 2-4 parts of anti-aging agent 4020, 60-80 parts of carbon black N339, 10-20 parts of dioctyl phthalate, 10-20 parts of aromatic hydrocarbon oil, 0.8-1.6 parts of accelerant NOBS and 1-3 parts of sulfur. Compared with the prior art, the rubber has the following advantages that products produced from the rubber are cheap, lower in raw material consumption and simple in production process; the rubber has a series of advantages of safety, environment-friendliness, excellent toughness, wear resistance and the like; the rubber adopts NR as a basis material, and the prepared tire tread rubber is high in skid resistance and good in wear resistance.

Owner:ANHUI HAPPYANG CHILDRENS ARTICLES

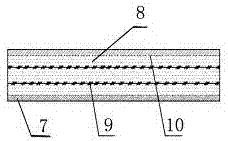

Method for manufacturing halogen-free flame-retardant glass fabric laminates

InactiveCN101811388AImprove thermal performanceUse less raw materialsLaminationLamination apparatusAlkali freeEngineering

The invention provides a method for manufacturing halogen-free flame-retardant glass fabric laminates to overcome the defects that the electric property of electronic products in the using process is reduced and the like because the vitrification of copper-clad laminates has low mechanical strength and poor thermal stability at high temperature due to adding great amount of flame retardant and flame-retardant auxiliary materials in the conventional production of flame-retardant glass fabric laminates. The manufacturing method comprises the following steps of: uniformly mixing benzoxazine resin, phenolic resin and diphenylene ether resin; coating the mixture onto alkali-free glass cloth to prepare gray cloth; performing hot pressing to prepare a flame-retardant glass fabric laminate; and deburring and polishing to obtain a finished product.

Owner:河南许绝电工绝缘材料有限公司

Modified polypropylene (PP) spray irrigation tube

The invention discloses a modified polypropylene (PP) spray irrigation tube which is characterized by comprising the following raw materials in parts by weight: 80-120 parts of PP, 0.2-0.8 part of antioxidant 1246, 10-20 parts of LDPE (low-density polyethylene), 0.2-0.8 part of high-pigment carbon black, 10-20 parts of high cis-1,4-polybutadiene rubber, 0.2-0.8 part of sodium benzoate and 0.2-0.4 part of UV-327.Compared with the prior art, the modified PP spray irrigation tube has the advantages of low product price, low raw material consumption, simple production technique, high strength, favorable low-temperature resistance, favorable aging resistance and the like.

Owner:NINGGUO DONGXING IND

High-toughness tube for explosion and production method thereof

A disclosed high-toughness tube for explosion is characterized by comprising the following raw materials in parts by weight: 80-120 parts of PVC resin, 0.2-0.4 part of a liquid stannum stabilizing agent, 0.6-1.0 part of calcium stearate, 1.0-1.4 part of paraffin, 0.5-1.0 part of an acrylic acid processing auxiliary agent, 2.0-5.0 parts of calcium carbonate, 10.0-15.0 parts of a plastic impact-resistant agent and 2.0-3.0 parts of rutile titanium dioxide. Compared with the prior art, the technical scheme has the following advantages: (1) the produced product is low in price, the employed raw materials is less, and the production technology is simple; and (2) the high-toughness tube has relatively high toughness, the toughness is destroyed without generating too much fragments when explosion is performed.

Owner:ANHUI NINGGUO MINGHAO PACKAGING MATERIALS

Polyurethane closed-cell foam product and manufacturing technology thereof

InactiveCN107089045AReduce usageGuaranteed Mechanical IndexSynthetic resin layered productsVehicle componentsPolyesterGlass fiber

The invention discloses a polyurethane closed-cell foam product which comprises a leather layer and a PU foam material layer, wherein the foam material layer is arranged on the leather layer, glass fiber gridding cloth is arranged in the foam material layer, and a polyester toughened breathable layer is arranged on the foam material layer. A foam product manufacturing technology comprises the steps: 1, preparing a mould and heating the mould; 2, rolling a gridding glass fiber cloth layer and a toughened breathable composite material according to stipulated area, size and layer number for standby application; 3, flatly laying leather into a lower mould body; 4, laying the glass fiber gridding cloth on the leather and injecting a PU material into the mould; 5, covering the PU material by the toughened breathable composite material; 6, closing the mould, maintaining pressure and foaming. Before being laid, glass fibers are woven into nets and cloth; thus, use amounts of the glass fibers and the PU foam material are reduced, a product density is reduced to 395 to 392 kg / m<3> from 500kg / m<3>, a weight is reduced by about 20%, mechanical property of the product is improved, composite cost is reduced by about 25%, and good economical benefits are achieved.

Owner:湖南亚太实业有限公司

Preparation method for sauced and spiced pepper

InactiveCN104256473AEasy to prepareUse less raw materialsFood preparationMonosodium glutamateCapsicum annuum

The invention discloses a preparation method for sauced and spiced pepper. The sauced and spiced pepper adopts peppers as a main material and is added with auxiliary materials, namely ginger, garlic, sauce, salt, distilled spirit, monosodium glutamate, white sugar, spiced powder and peanut oil. The preparation method comprises the steps of cleaning the peppers, the ginger and the garlic, drying to remove water, heating the peanut oil to be 100 DEG C according to the proportion, adding the sauce, the salt, the distilled spirit, the monosodium glutamate, the white sugar and the spiced powder in sequence, cooling completely, and adding the peppers, the ginger and the garlic. The sauced and spiced pepper has the characteristics of delicious taste, fragrance, crispiness, high nutritional value, and simple preparation method.

Owner:董春年

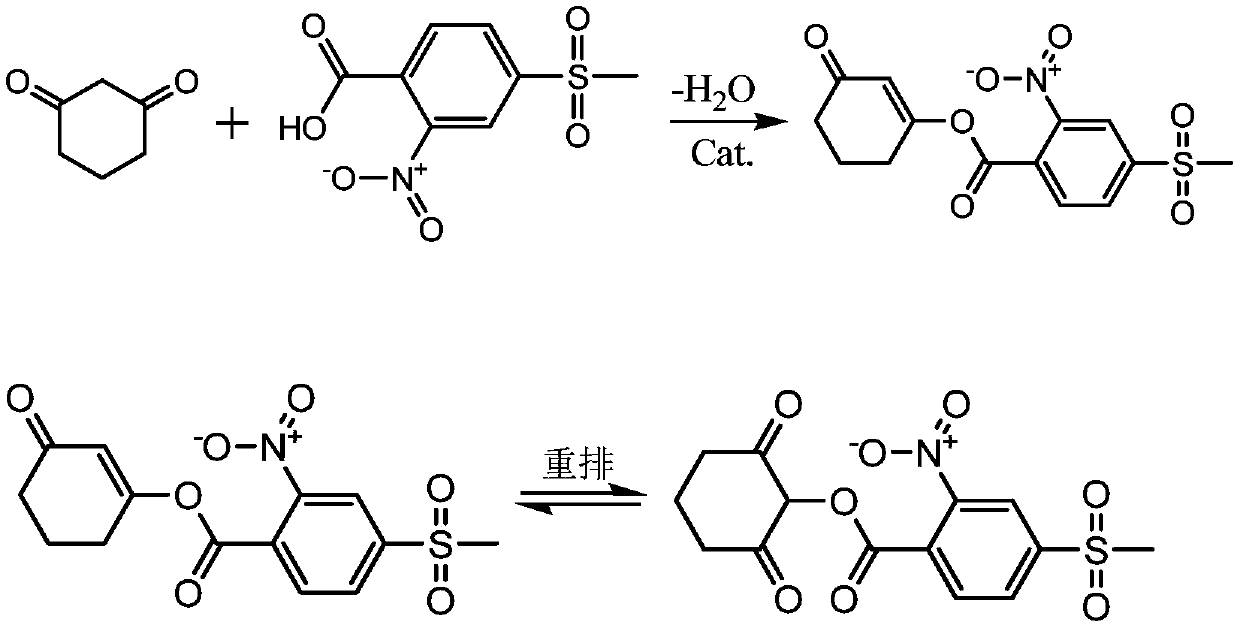

Synthetic process of methyl sulcotrione

InactiveCN109810032ASimple and efficient operationFew reaction stepsOrganic chemistryOrganic compound preparationSolventExhaust gas

The invention discloses a synthetic process of methyl sulcotrione. 2-nitro-4-methylsulfony benzoic acid and 1,3-cyclohexanedione are added into a solvent, then, a catalyst and an addition agent are added, temperature is raised to 140-150 DEG C under stirring, and condensation reaction is directly carried out; and then, rearrangement is carried out to obtain the methyl sulcotrione. According to thesynthetic process of the methyl sulcotrione, the catalyst and the addition agent are added for dehydration, so that the condensation reaction is directly carried out on the 2-nitro-4-methylsulfony benzoic acid and the 1,3-cyclohexanedione; and then, the rearrangement is carried out to obtain a methyl sulcotrione product. Due to no adding of thionyl chloride or phosgene for chlorination, reactionsteps are reduced, and meanwhile, tail gas treatment or production safety is further avoided; and in addition, acid-binding agents are not added, and later wastewater treatment is reduced. Therefore,used raw materials are less, and greenness, environmental protection and no pollution are achieved.

Owner:ANHUI FENGLE AGROCHEM

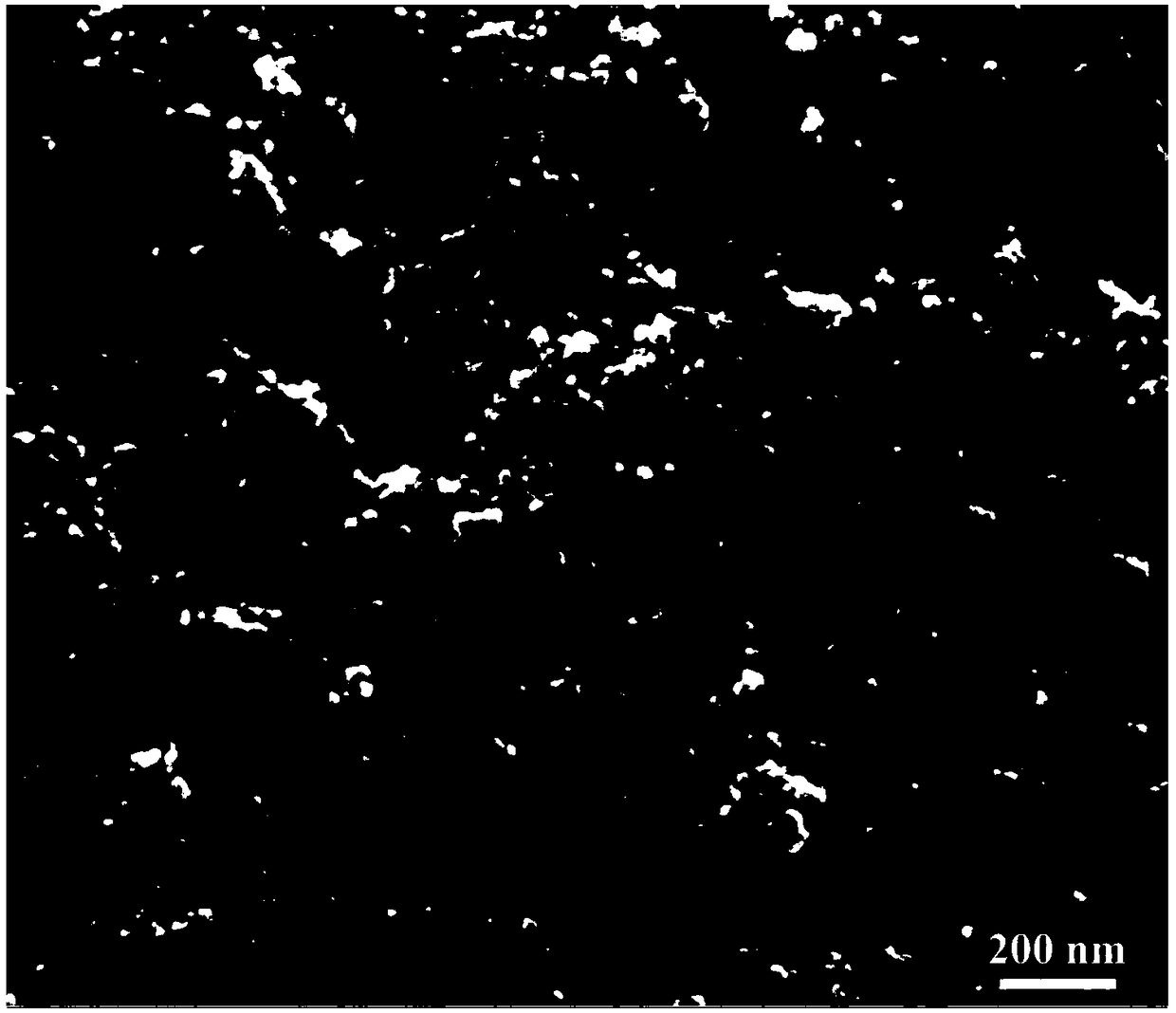

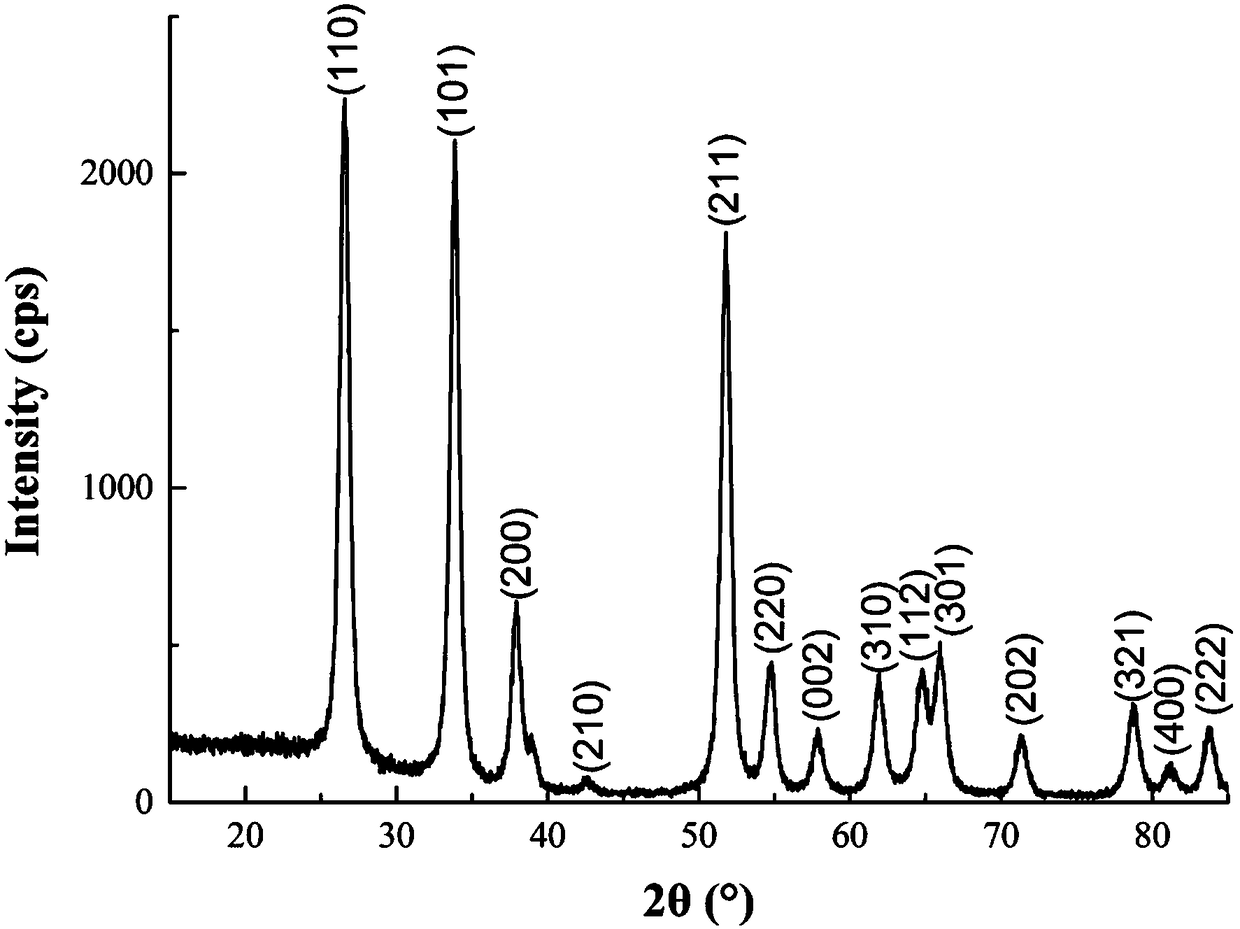

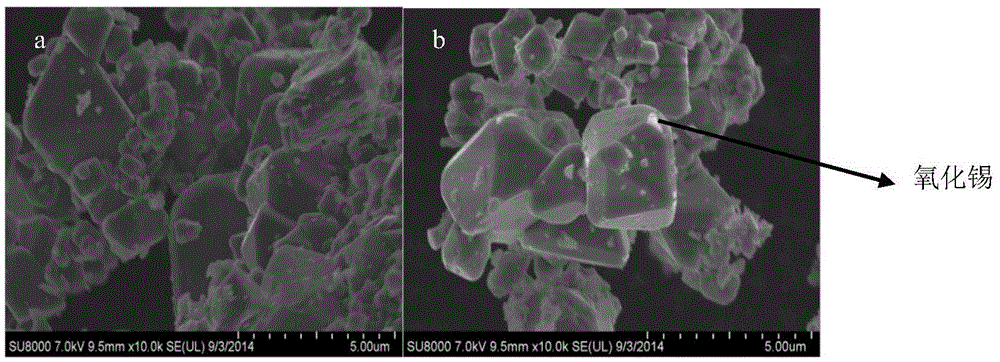

Preparation method for nano stannic oxide by metallic tin oxidation

The invention provides a preparation method for compounding nano stannic oxide by metallic tin oxidation. The method comprises the specific steps that the metallic tin is reacted with salpeter solution, and sizing agent containing stannic acid is obtained; the sizing agent containing the stannic acid experiences hydro-thermal treatment, and the obtained sizing agent is washed; finally, the obtained sizing agent experiences drying and calcining, and the nano stannic oxide is obtained. The preparation method for the nano stannic oxide by the metallic tin oxidation is simple in process, safe, andreliable, the use of material is less, the brought heteroion is less, the obtained product has high pureness, the dispersity is good, and the degree of crystallinity is high.

Owner:ZHENGZHOU UNIV

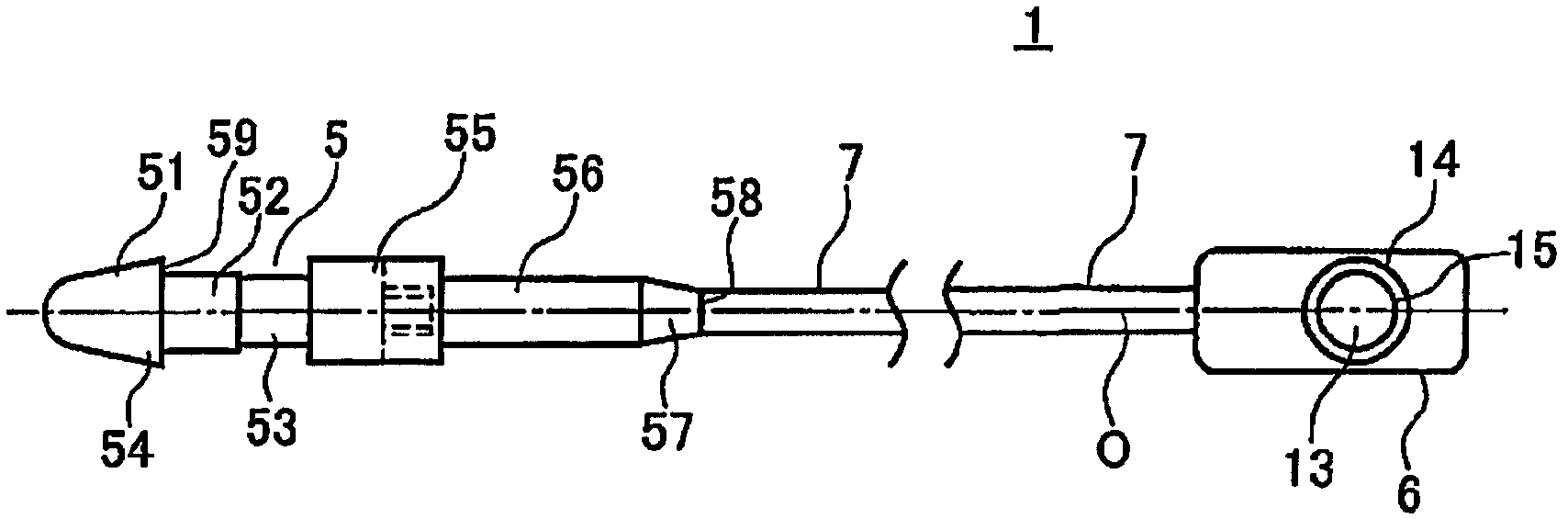

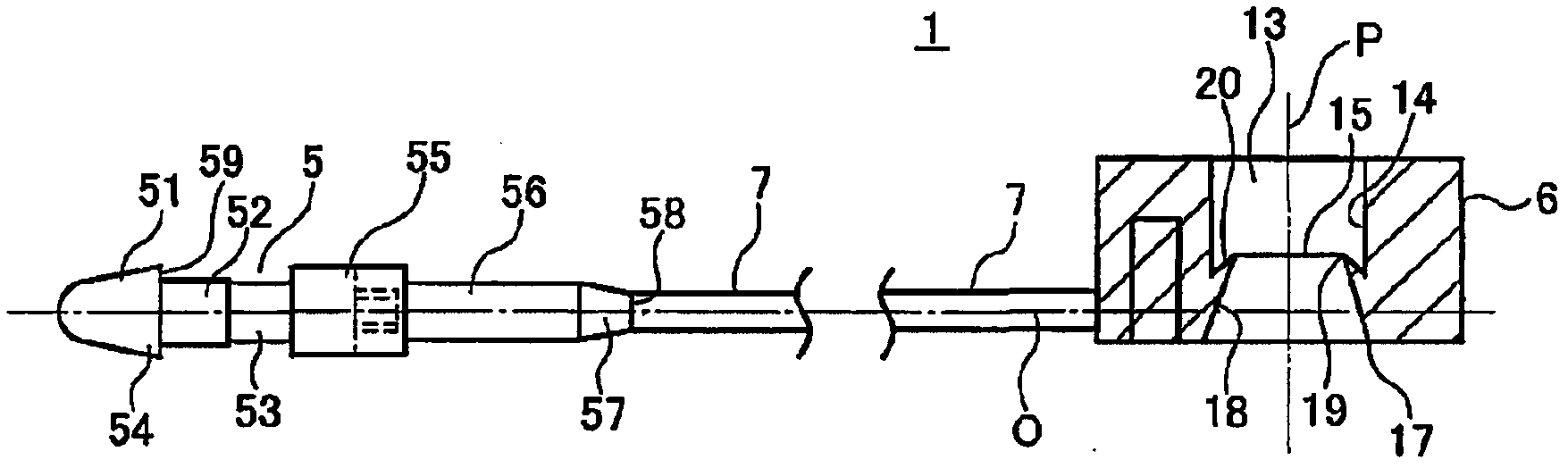

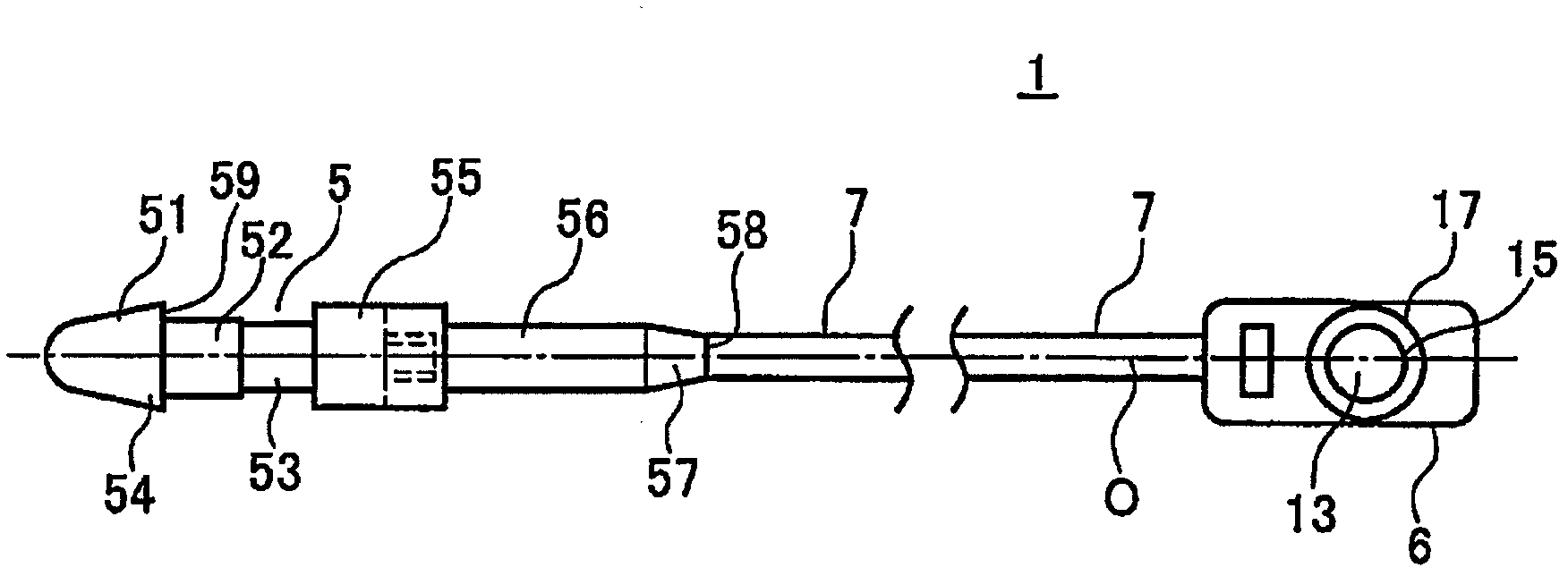

Loop pin

Disclosed is a loop pin that uses a polypropylene-based synthetic resin, is environmentally friendly, and allows decreased manufacturing costs and increased production efficiency. A loop pin (1) is constituted such that an insertion head section (5) comprises a first thin section (52) having a diameter smaller than the greatest diameter of a head section (51), and a second thin section (53) having a diameter smaller than that of the first thin section (52); the through hole (13) of a socket section (6) is provided with an annular step section (15). The step section (15) comprises a first inclined section (18) and a second inclined section (20) that are formed contiguously at prescribed angles.

Owner:M I T INT

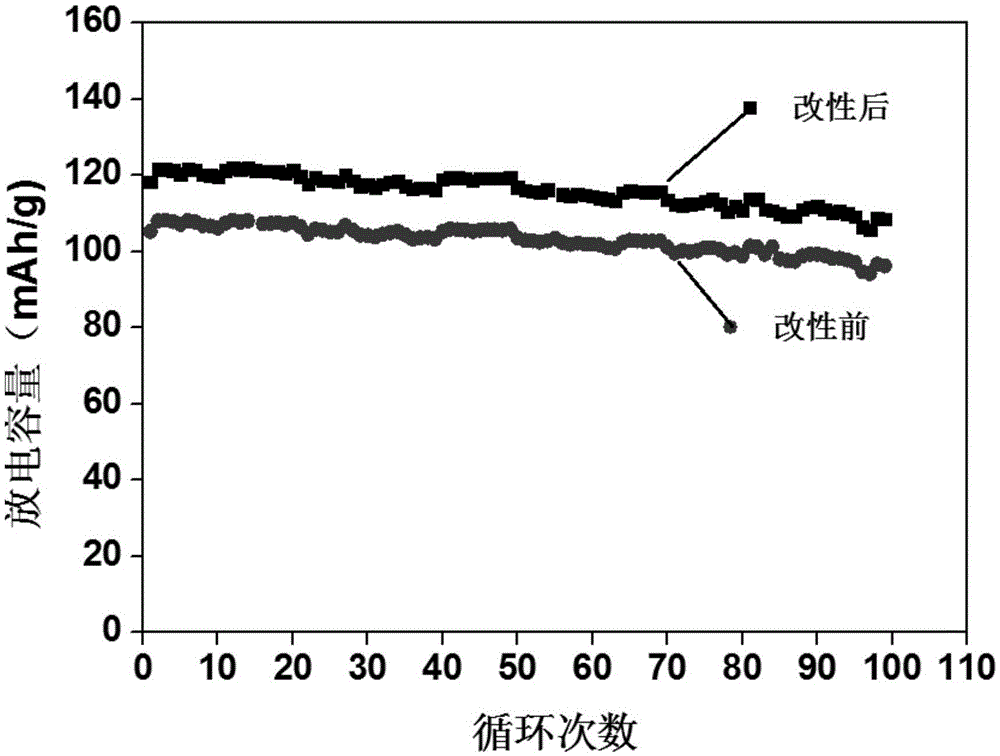

Clean and simple preparation method of tin oxide surface modified lithium manganite and modified lithium manganite positive electrode material prepared by clean and simple preparation method

ActiveCN105576201AImprove cycle performanceReduce solubilityCell electrodesSecondary cellsPhysical chemistryManganese

The invention relates to a positive electrode material of a lithium ion battery and particularly relates to a clean and simple preparation method of tin oxide surface modified lithium manganite and a modified lithium manganite positive electrode material prepared by the clean and simple preparation method. The clean and simple preparation method of the tin oxide surface modified lithium manganite comprises the following steps: (1) uniformly dispersing tin salt by adopting a dispersion medium; (2) uniformly dispersing the lithium manganite by adopting a dispersion medium; (3) mixing the dispersed tin salt and lithium manganite, and reacting by stirring in the air; and (4) separating and drying the mixture obtained by the step (3) to obtain the modified lithium manganite positive electrode material. The lithium manganite positive electrode material is produced through hydrolyzing a tin source and oxidizing in the air; and the clean and simple preparation method has the advantages of simple procedures, low cost, environmental friendliness and no environmental pollution and easiness of realizing large-scale production.

Owner:CHAOWEI POWER CO LTD

Compound material support roller and preparation method thereof

The present invention relates to an idler roller made of composite material and its preparation method. Said preparation method includes the following steps: adding coupling agent, nano material, anti-static agent, fire-resisting agent and flow modification agent in the dried ultrahigh molecular polyethylene, mixing and stirring them, extruding with extruding machine, cooling by water tank, cutting ink into circular cylinder with required length and placing it into the rotating shaft wind bearing so as to form the invented composite material idler roller with the advantages of resisting corrosion, resisting wear, resisting impact, resisting static electricity and long service life.

Owner:HENGSHUI HONGQI ROLLER MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com