Preparation method for nano stannic oxide by metallic tin oxidation

A nano-tin dioxide, metal tin technology, applied in tin oxide, nanotechnology and other directions, can solve the problems of high gasification temperature, high equipment requirements, easy agglomeration of particles, etc., and achieves simple process, low preparation cost, and dispersibility. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

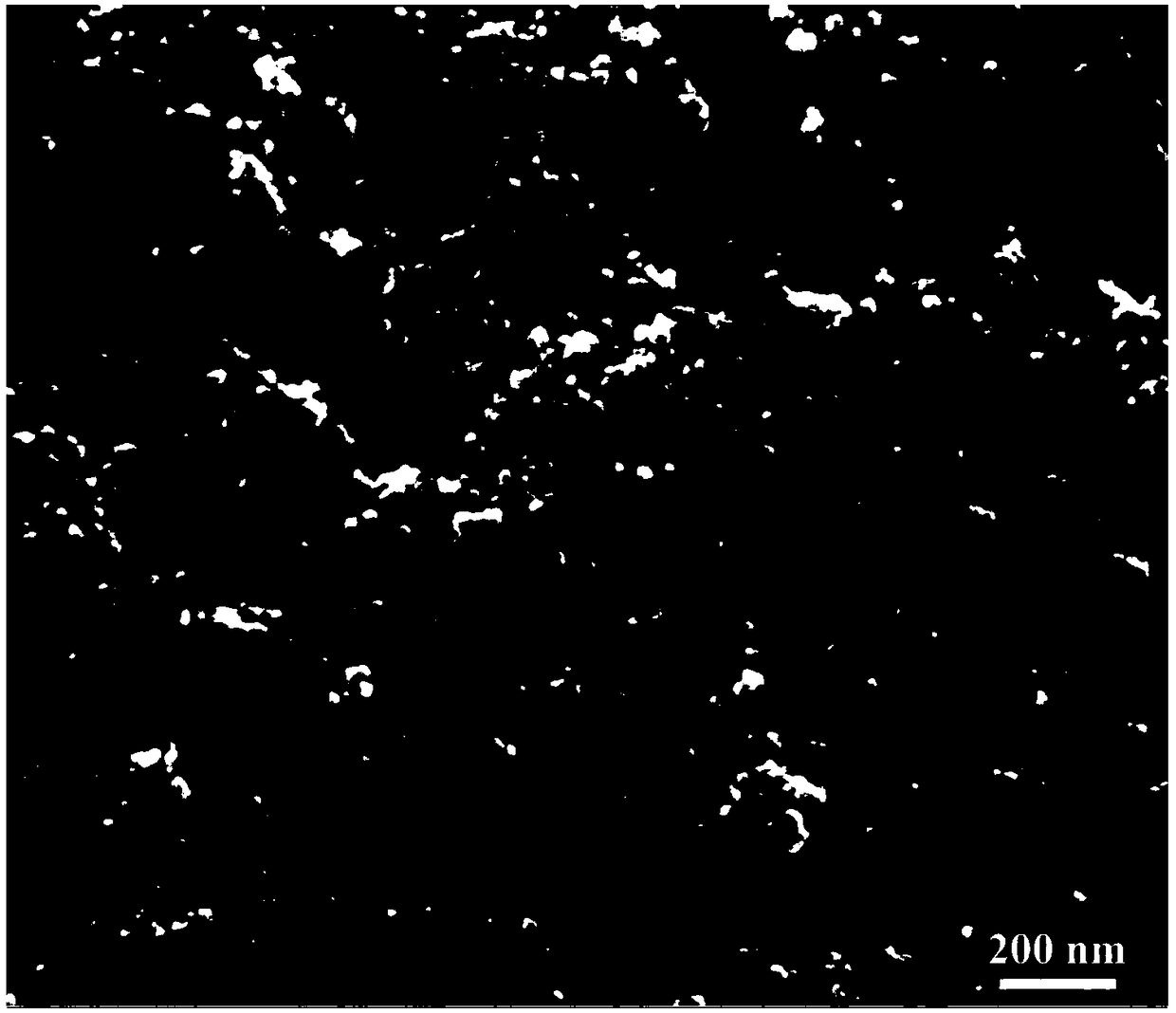

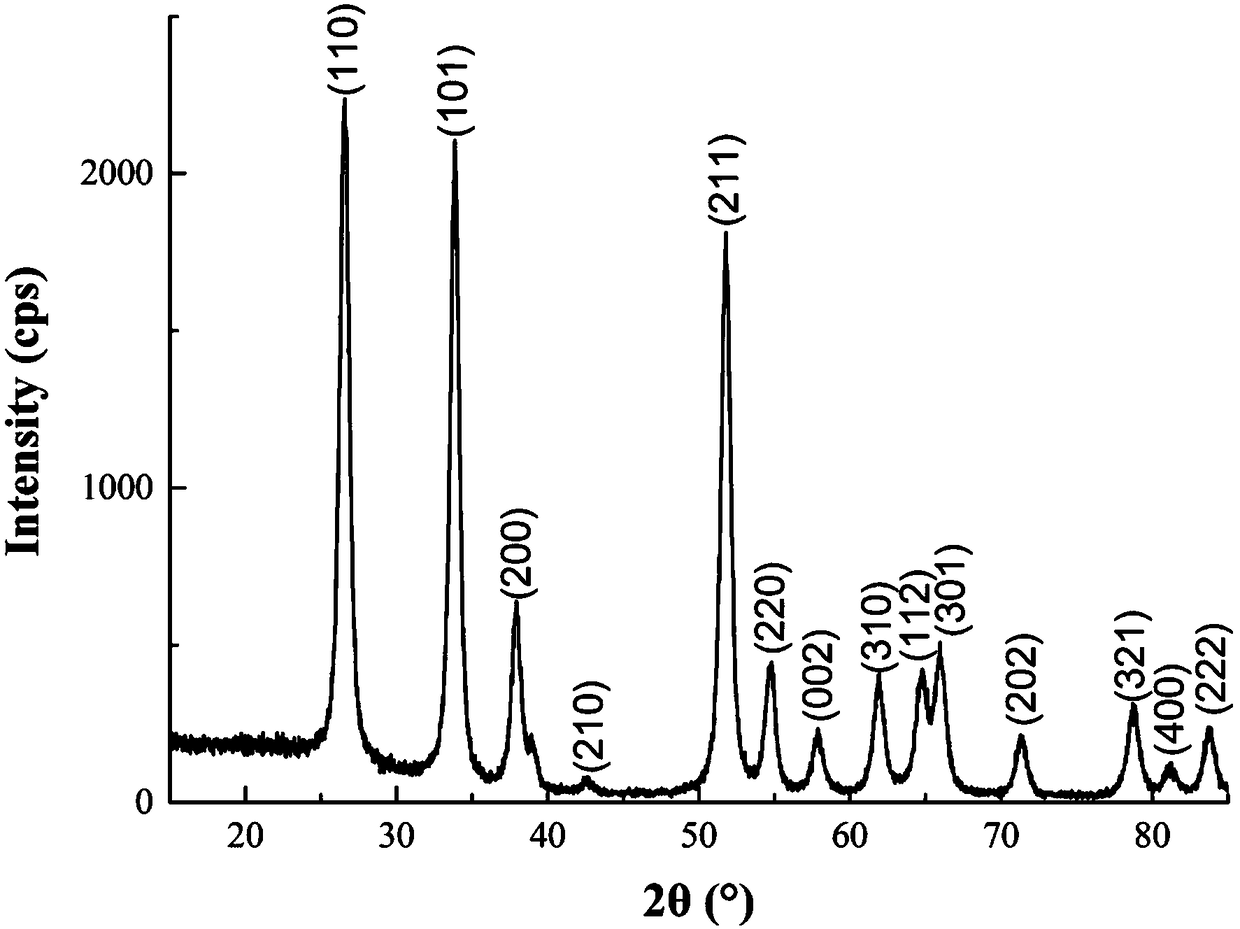

Image

Examples

Embodiment 1

[0036]The method that the metal tin oxidation disclosed in this embodiment 1 prepares nano-tin dioxide comprises:

[0037] S1, react metal tin with nitric acid solution to obtain a slurry containing stannic acid; specifically, select granular metal tin, dissolve the tin particles with a nitric acid solution with a concentration of 33%, and apply stirring during the dissolution process to make the prepared nitric acid solution It is more uniform; the amount of nitric acid to be applied is calculated according to the metering ratio of the tin to be dissolved and the nitric acid. The tin precipitation slurry was left to cool, and deionized water with an amount 3 times the volume of the solution was added and heated and stirred for 3 hours. The heating temperature was 70°C, fully dissolved, and then left to stand, and the supernatant was poured out. This process was repeated 3 times. Obtain a slurry containing stannic acid;

[0038] S2, the slurry containing stannic acid is subje...

Embodiment 2

[0043] The method for preparing nano-tin dioxide by oxidation of metal tin provided in Example 2 of the present invention comprises the following steps:

[0044] S1, react metal tin with nitric acid solution to obtain a slurry containing stannic acid; specifically, select granular metal tin, dissolve the tin particles with a nitric acid solution with a concentration of 44%, and apply stirring during the dissolution process to make the dissolution process more efficient Uniform and sufficient; the amount of nitric acid to be applied is calculated according to the metering ratio of tin to be dissolved and nitric acid. The precipitated slurry was left to cool, and deionized water 4 times the volume of the solution was added and heated and stirred for 2 hours. The heating temperature was 80°C, fully dissolved, then left to stand, and the supernatant was poured off. This process was repeated twice to obtain Stannic acid slurry;

[0045] S2, the slurry containing stannic acid is su...

Embodiment 3

[0050] The method for preparing nano-tin dioxide by oxidation of metal tin provided in Example 3 of the present invention comprises the following steps:

[0051] S1, react metal tin with nitric acid solution to obtain a slurry containing stannic acid; specifically, select granular metal tin, dissolve the tin particles with a nitric acid solution with a concentration of 66%, and apply stirring during the dissolution process to make the dissolution process more efficient Uniform and sufficient; the amount of nitric acid to be applied is calculated according to the metering ratio of tin to be dissolved and nitric acid. The precipitated slurry was left to cool, added deionized water 5 times the volume of the solution and heated and stirred for 3 hours, heated at 65°C, fully dissolved, then left to stand, and the supernatant was poured off. This process was repeated 3 times to obtain Stannic acid slurry;

[0052] S2, the slurry containing stannic acid is subjected to hydrothermal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com