Polyaluminium phosphate-series chlorine-free sulfur-free liquid alkali-free accelerator and preparation method thereof

A technology of polyaluminum phosphate and accelerator, applied in the field of non-alkali accelerator, which can solve the problems of poor homogeneity, low early strength, large dosage, etc., achieve good stability, improve early strength, and have no change in use effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

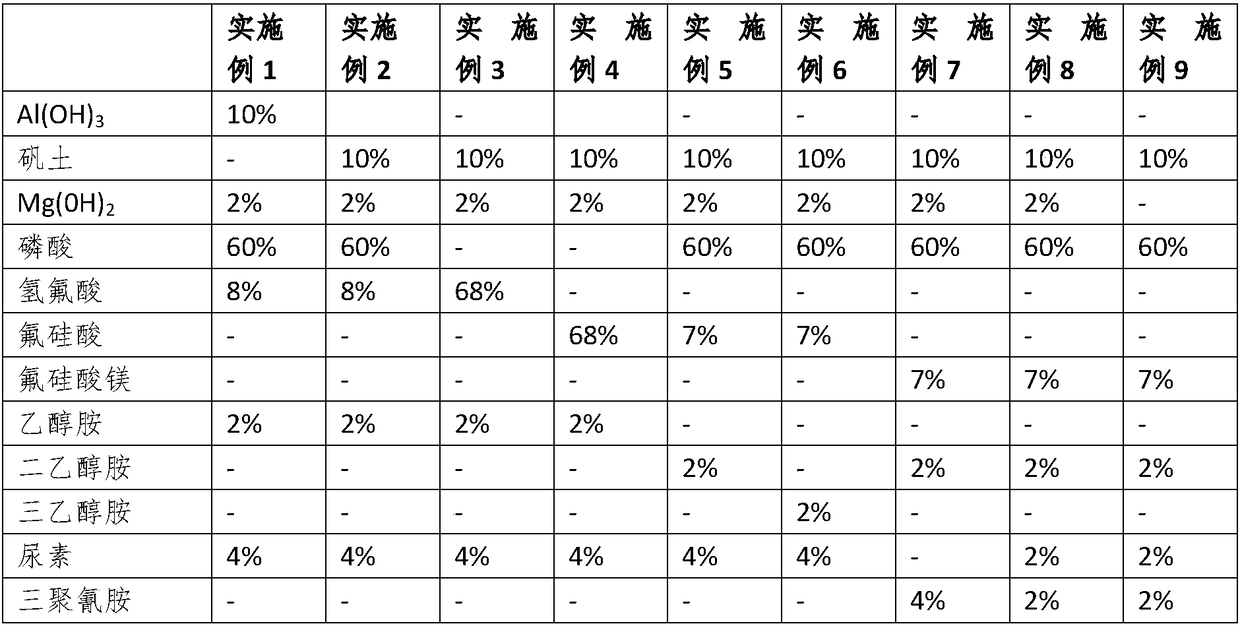

[0042] Embodiment 1-9 formula screening test

[0043] By comparing the different components of the accelerator, screen the following substances in different combination formulas: Al(OH) 3 、Al 2 o 3 , Mg(0H) 2 , phosphoric acid, hydrofluoric acid, fluorosilicic acid, magnesium fluorosilicate, ethanolamine, diethanolamine, triethanolamine, urea, melamine, draw the test group of 9 different formulas, the formula composition of 9 groups of embodiments is shown in Table 1, all the other water Fill to 100%.

[0044] The formula table of table 1 embodiment 1-9 accelerator

[0045]

[0046] The quick-setting agent prepared by the above-mentioned 9 groups of formulas is based on the weight of cement, and the dosage is 5-7%. The product of group embodiment carries out the test of cement slurry setting time and cement mortar compressive strength, and the result shows that the homogeneity of embodiment 7 and embodiment 8, setting time, 1 day strength and the intensity ratio of 28 da...

Embodiment 10~19

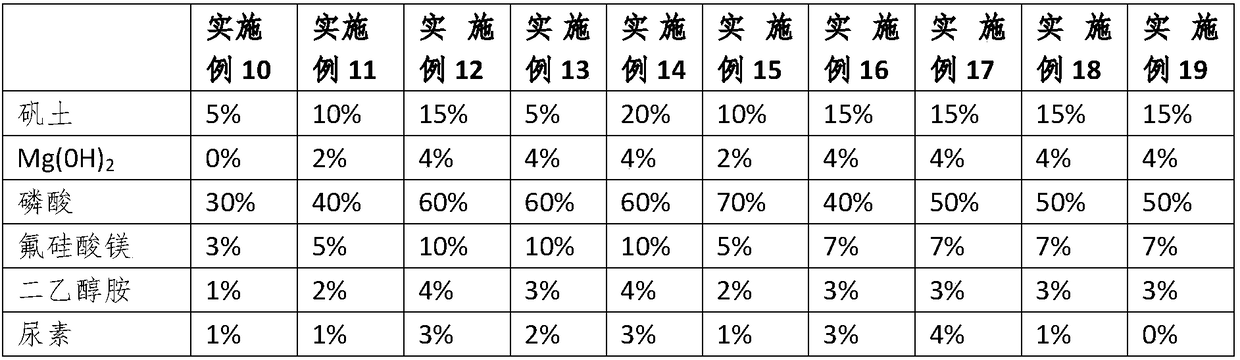

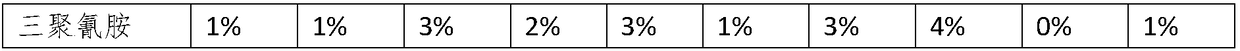

[0047] Embodiment 10~19 formula proportioning screening of the present invention

[0048] Below will further carry out proportioning screening to optimal formula, formula proportioning situation is shown in Table 2, and the rest is made up to 100% with water.

[0049] Table 2 Proportion table of the present invention

[0050]

[0051]

[0052] Prepare quick-setting agent according to the formula (10 groups in total) shown in Examples 10-19, take the weight of cement as the basis, and the dosage is 5-7%, according to the Chinese building materials industry standard JC477-2005 "accelerator for shotcrete" The requirements of above-mentioned 10 groups of embodiment products are carried out the test of cement slurry setting time and cement mortar compressive strength, the result shows the homogeneity of embodiment 11 and embodiment 12, setting time, 1-day strength and 28-day strength The ratio is better than other examples. From the amount of screening in Table 2, it can be ...

Embodiment 20~31

[0054] Since the non-alkali liquid quick-setting agent of the present invention has no strong acid radicals and alkali metal ions, it has no erosion effect, but how to solve the problems of homogeneity, dosage and strength of the non-alkali quick-setting liquid quick-setting agent is also the research point of the present invention One, the present invention increases the aluminum content by adding condensing agent and quick-setting agent, and reacts with polyaluminum monohydrogen phosphate, so that the aluminum content of the alkali-free quick-setting agent of the present invention is much higher than that of conventional alkali-free quick-setting 8.6% of the aluminum content in aluminum sulfate octadecahydrate, a commonly used raw material for the agent, and the non-alkali accelerator of the present invention is not easy to combine with water to flocculate, so the content of aluminum, the main coagulation accelerator in the accelerator, can be significantly increased, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com