Patents

Literature

1133results about How to "No stratification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

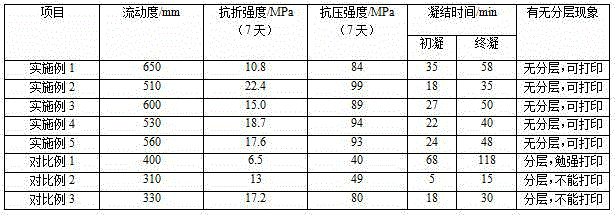

High-performance powder concrete for 3D (three-dimensional) printing

The invention relates to high-performance powder concrete for 3D (three-dimensional) printing. The concrete is prepared from the following raw materials in parts by weight: 500-900 parts of ordinary Portland cement, 250-350 parts of active mineral admixture, 800-1,300 parts of inert filler, 10-20 parts of composite efficient water reducing agent powder, 2-5 parts of thickener, 4-10 parts of self-curing agent, 2-10 parts of fast setting time regulator, 145-230 parts of water, 3 parts of organic fiber and 40-200 parts of copper plated fiber. The concrete material for 3D printing has the characteristics of ultrahigh strength and toughness, good durability, long full life cycle, high curing rate, good flowing property and easiness in pumping and lifting and is suitable for constructing 3D-printed building structural materials in all kinds of engineering.

Owner:黄贺明

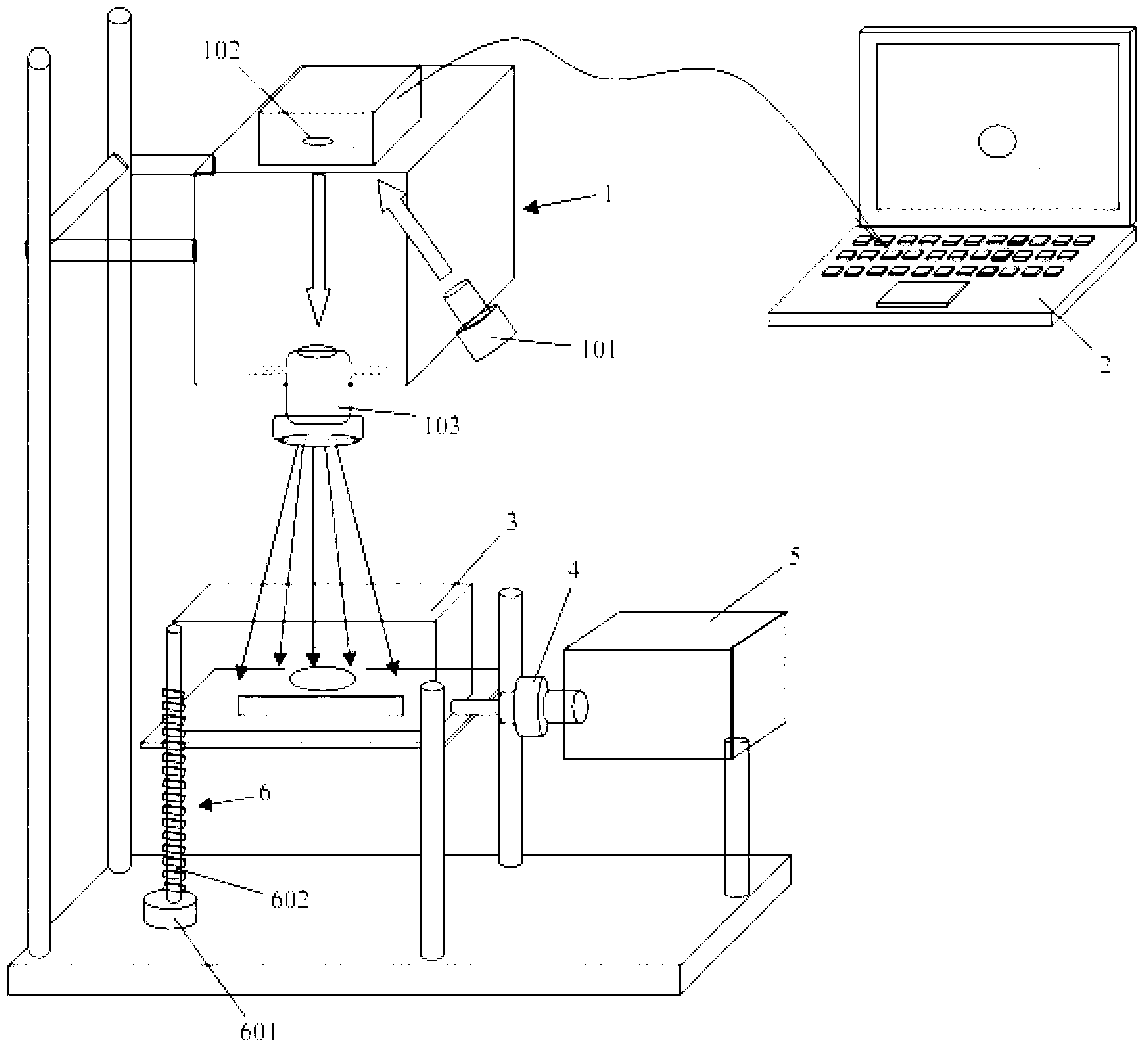

Light-curing three-dimensional printer based on digital light processing (DLP) projection

The invention discloses a light-curing three-dimensional printer based on digital light processing (DLP) projection, which comprises a computer system (2), an automatic control system, a DLP projection system (1), a molding work pool (3), a feeding system (4) and a lifting system. Compared with the three-dimensional printer in the prior art, the light-curing three-dimensional printer has the advantages of high molding speed and high printing precision, and the surface of a molded product is continuous and is not layered; moreover, the DLP projection-based light-curing three-dimensional printer can be applied to performing light curing on light-sensitive materials with various strengths and made from different raw materials.

Owner:王健犀

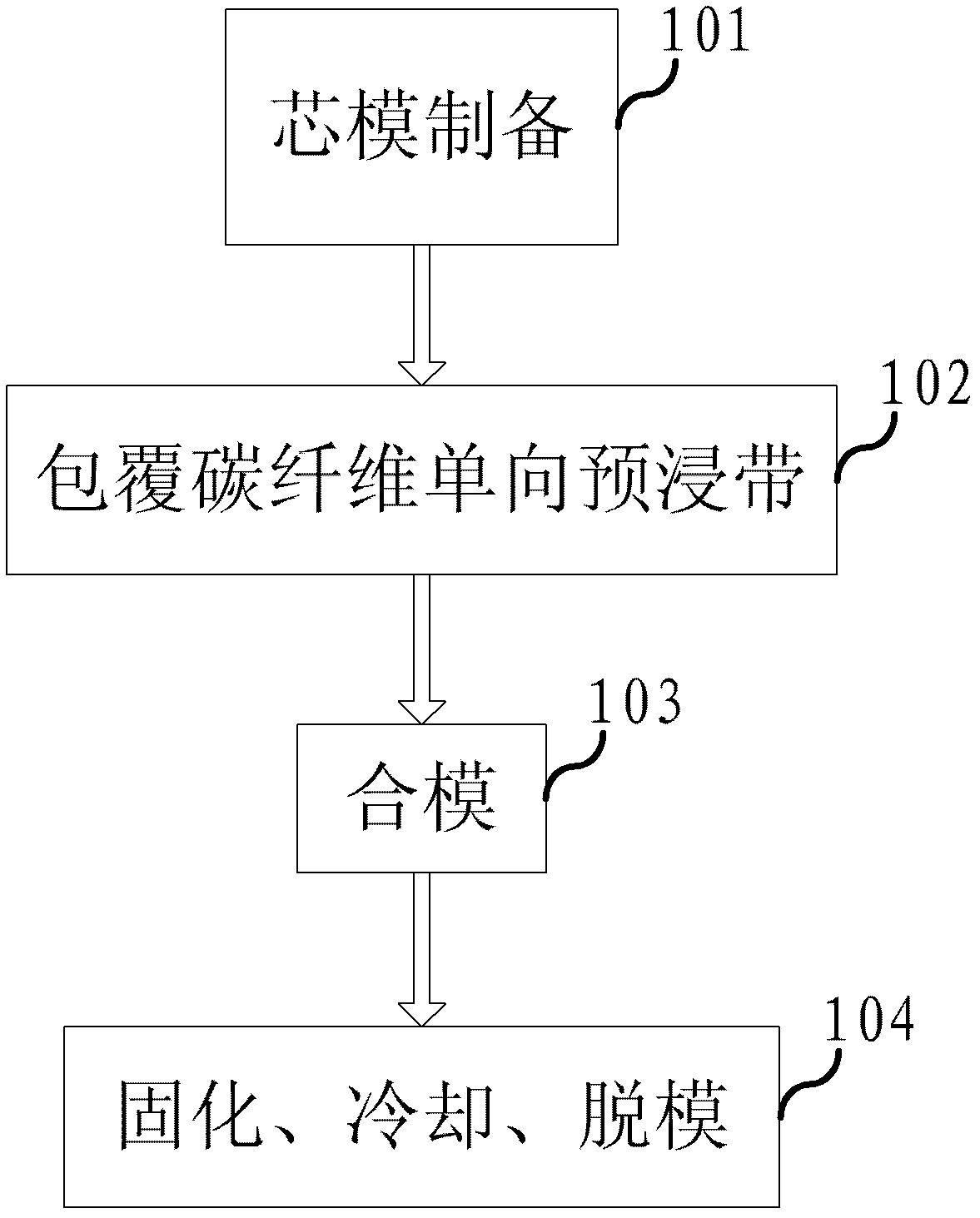

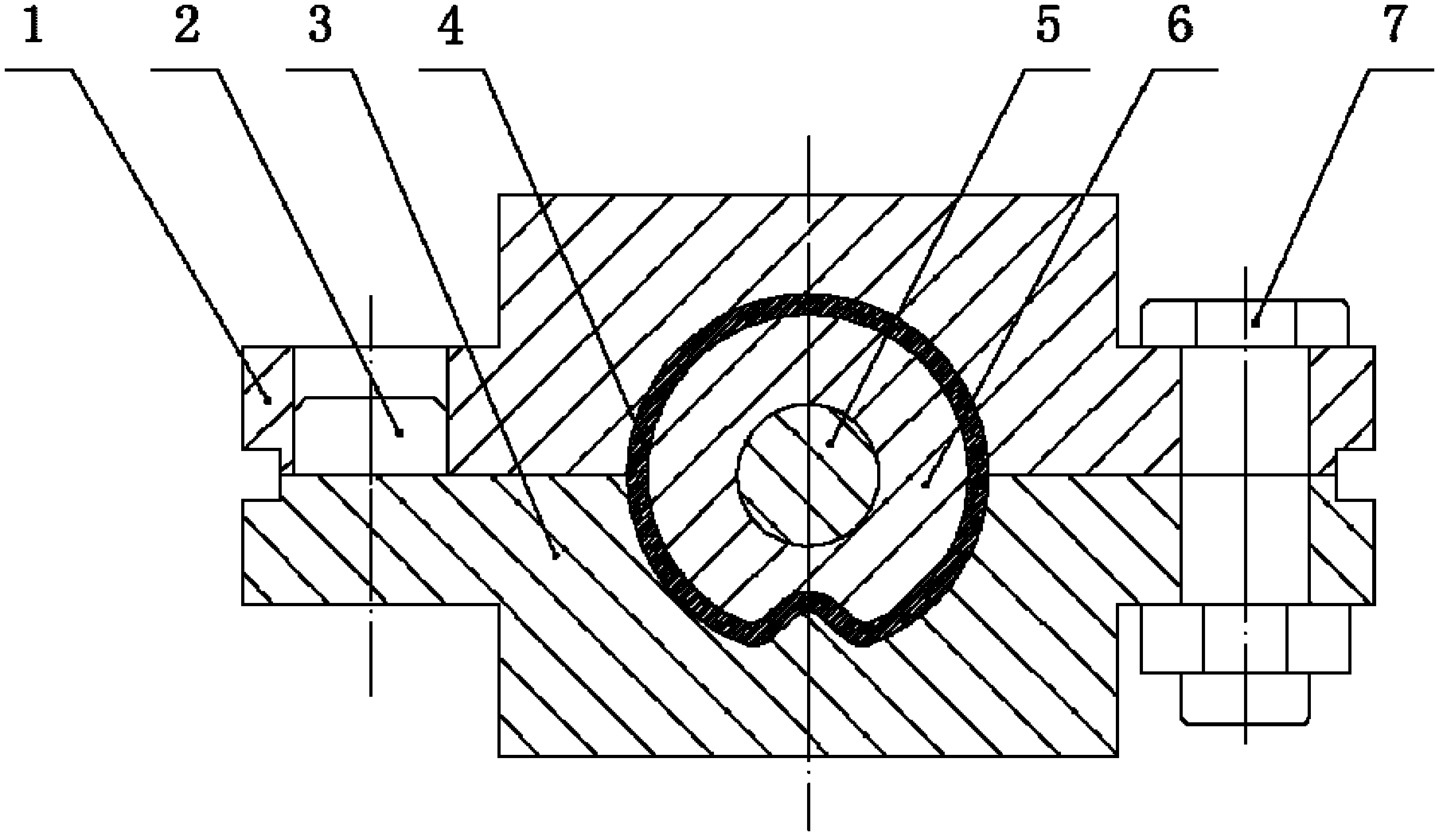

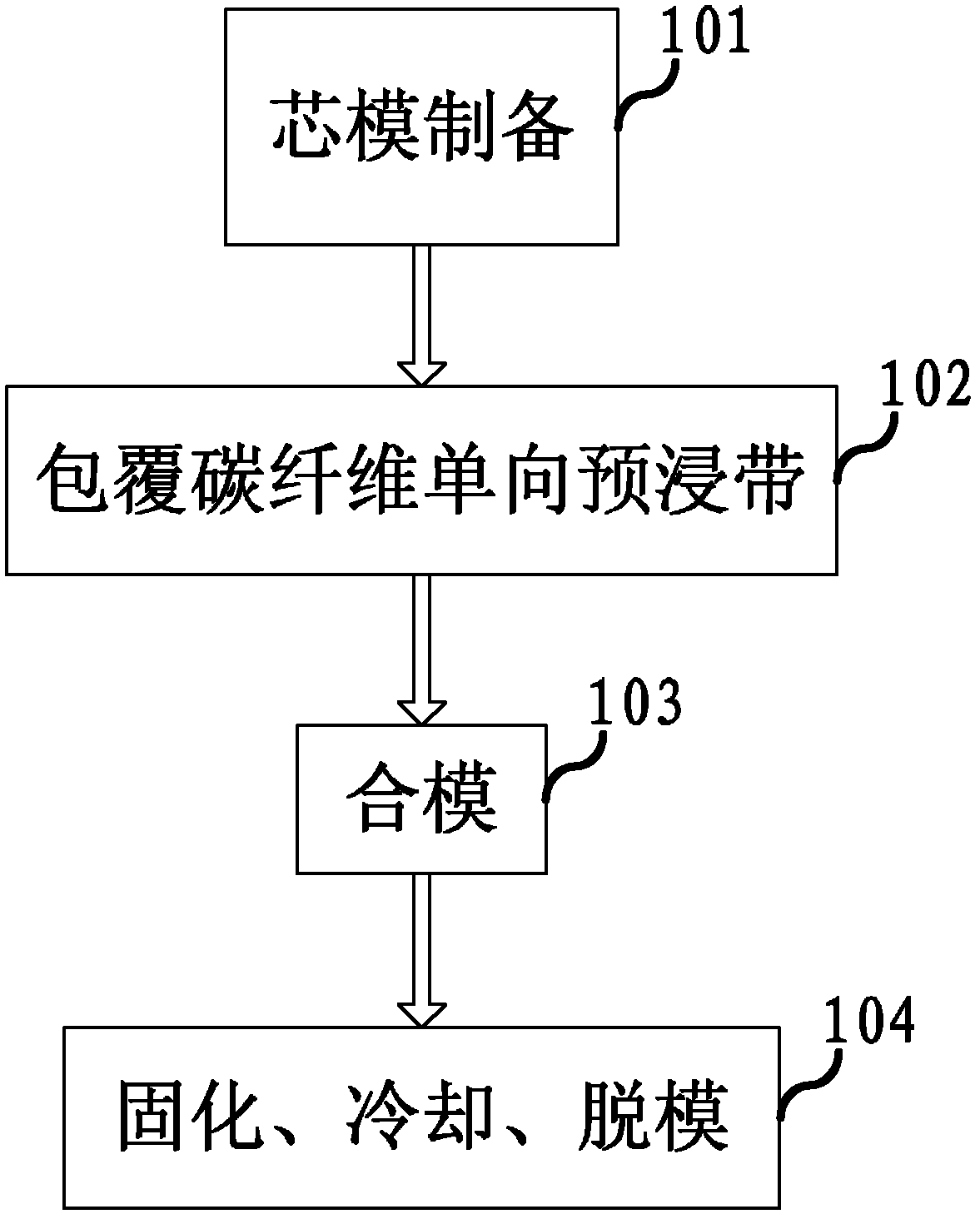

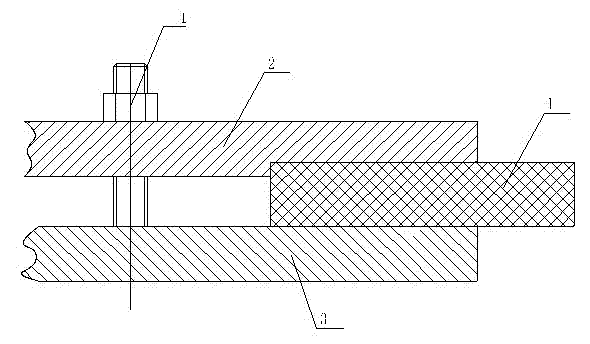

Method for forming carbon fiber pipe and die thereof

The invention discloses the technical field of carbon fiber composite materials, and discloses a method for forming a carbon fiber pipe. The method comprises the following steps of: preparing a core mould, namely preparing the core mould for wrapping carbon fiber one-way preimpregnation belts, wherein the core mould comprises a metal core rod and a rubber material wrapping the metal core rod; paving and coating the carbon fiber one-way preimpregnation belts, namely after coating a release agent on the surface of the core mould, paving and coating a plurality of layers of carbon fiber one-way preimpregnation belts according to different angles; closing the die, namely positioning the core mould in which the carbon fiber one-way preimpregnation belts are paved and coated and putting into a female die, closing the die, and fastening; and curing, cooling and demoulding, namely putting the die which is closed into a drying oven, curing, cooling with a furnace, and demoulding to form the required finished piece. The method for forming the carbon fiber pipe has the advantages of simple process, high production efficiency, low manufacturing cost, uniform wall thickness of the product, high quality and stability and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

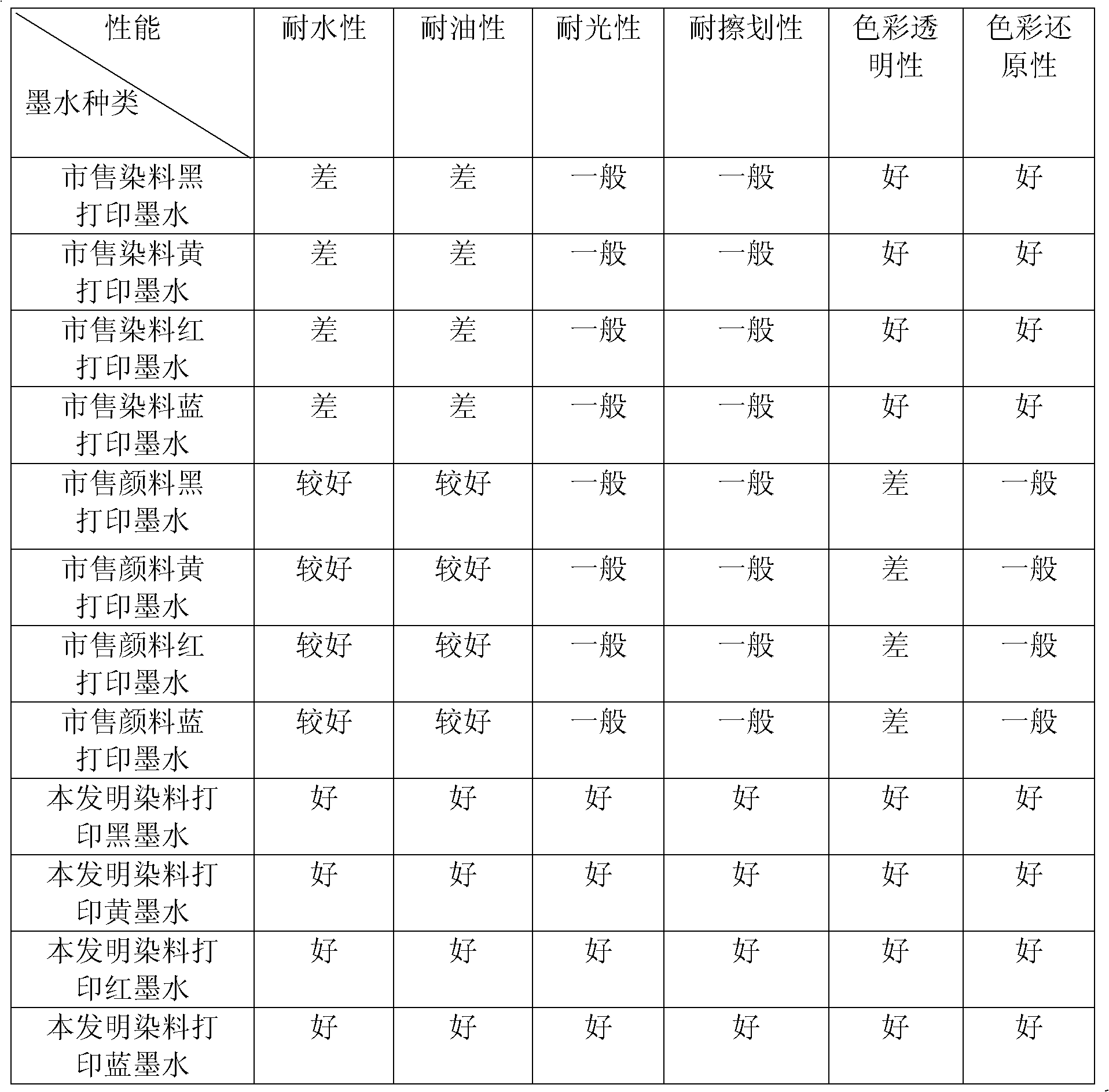

Water-based dye ink and application thereof

InactiveCN101805542AOvercome LightfastnessOvercome fading under lightInksDyeing processTextile printerWater based

The invention discloses a water-based dye ink and an application thereof. The water-based dye ink comprises the following components in percent by weight: 0.2 to 12 percent of water-soluble dye, 55 to 80 percent of modified acrylic resin emulsion, 0.01 to 1 percent of ultraviolet absorbent and balance of water, and different additives can be added. The dye ink can be applicable to the fields such as jet ink, cipher paint ink, textile printing ink, water-type printing ink, fountain pen ink and water ball pen ink, and has the advantages of water resistance, oil resistance, scratch resistance, illumination resistance, high temperature resistance, low temperature resistance, good color reducibility, duration and the like.

Owner:鲁继烈

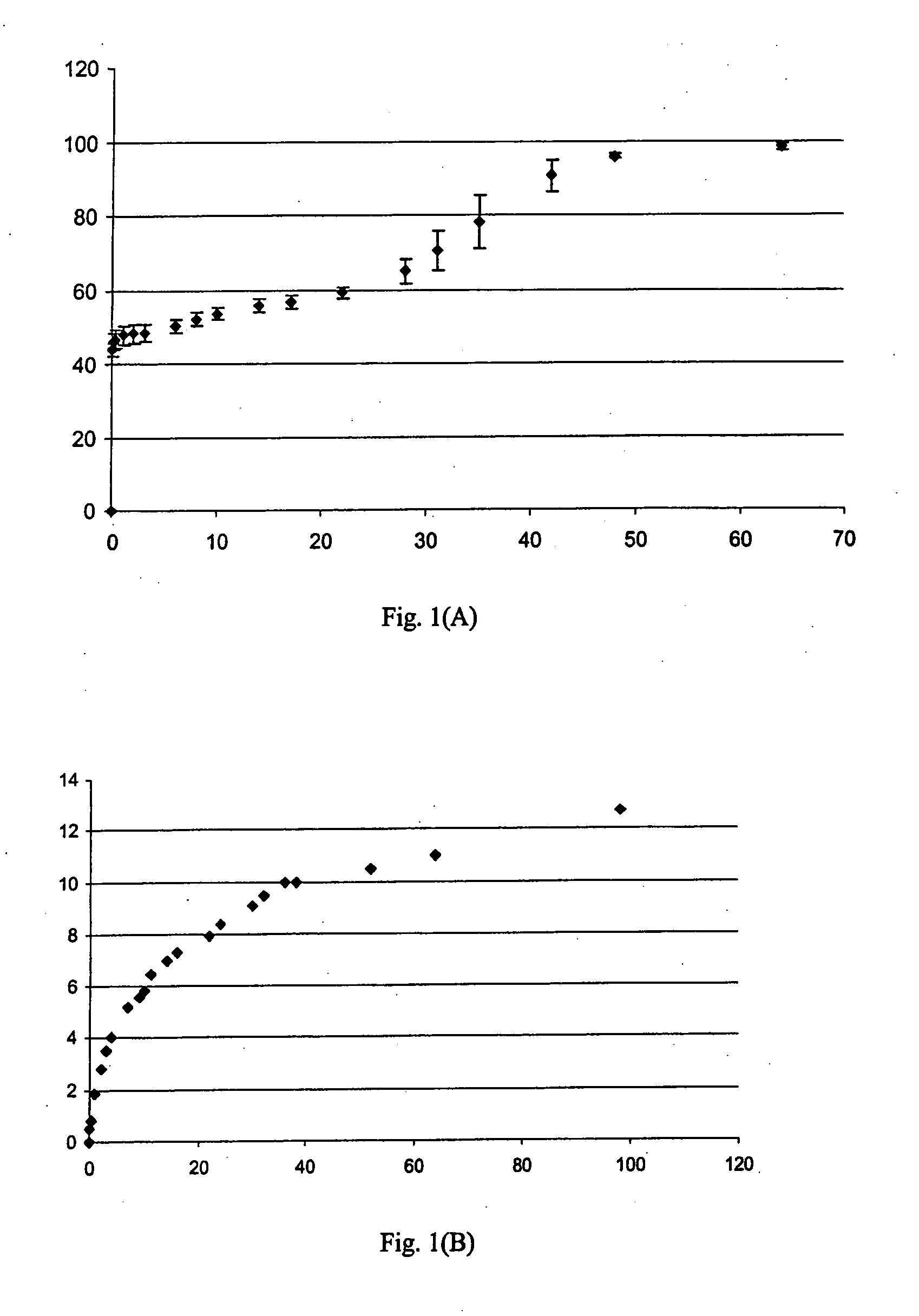

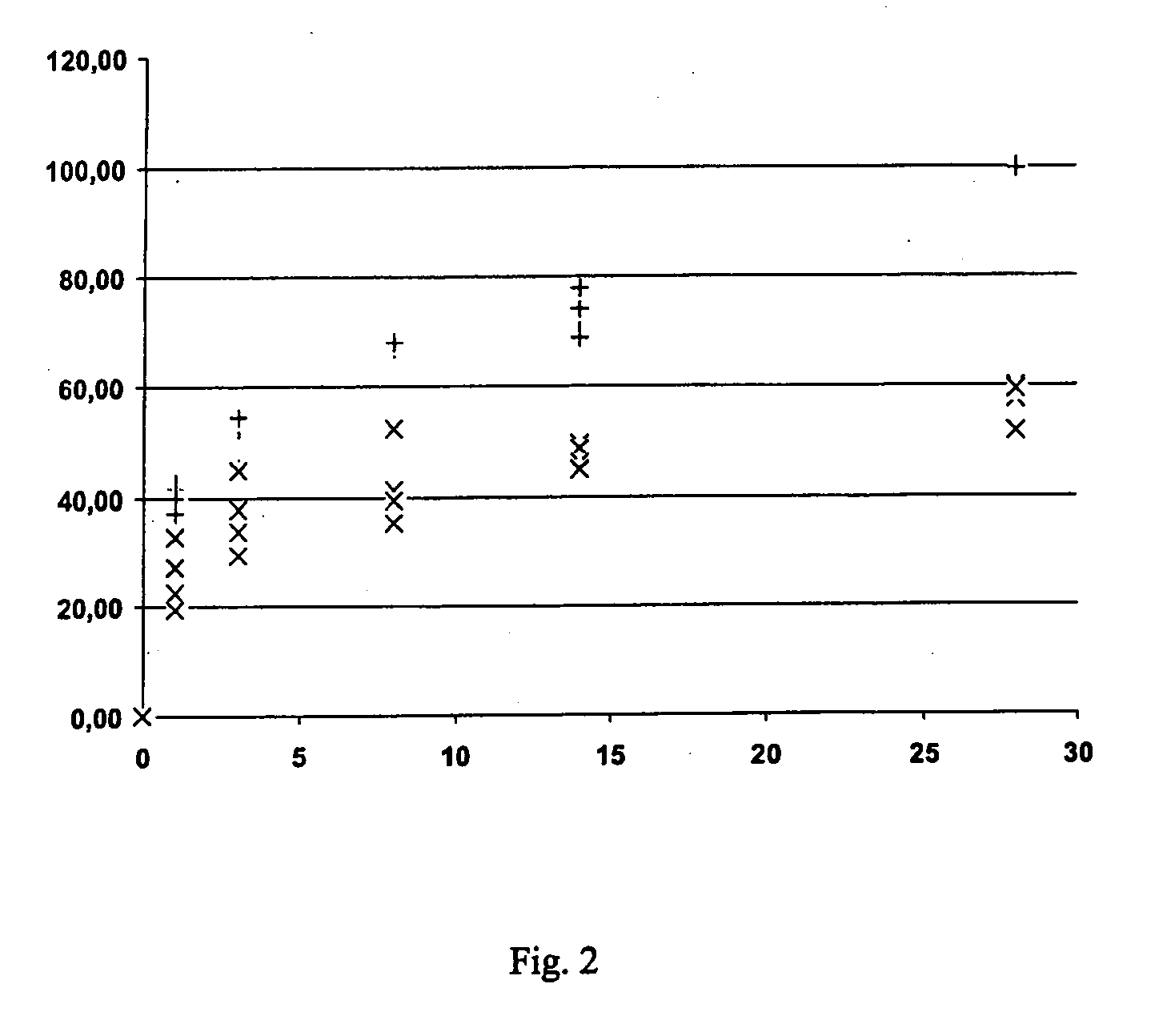

Drug eluting stent with a biodegradable release layer attached with an electro-grafted primer coating

InactiveUS20070288088A1Improve adhesionGood propensity cell migrationStentsSurgeryInsertion stentBiomedical engineering

The present invention provides a drug eluting stent including a metallic stent framework, an electro-grafted primer coating disposed on the stent framework; and a biodegradable polymer coating hosting a drug disposed on the electro-grafted primer coating and a method of manufacturing said biodegradable drug eluting stent.

Owner:ALCHIMEDICS

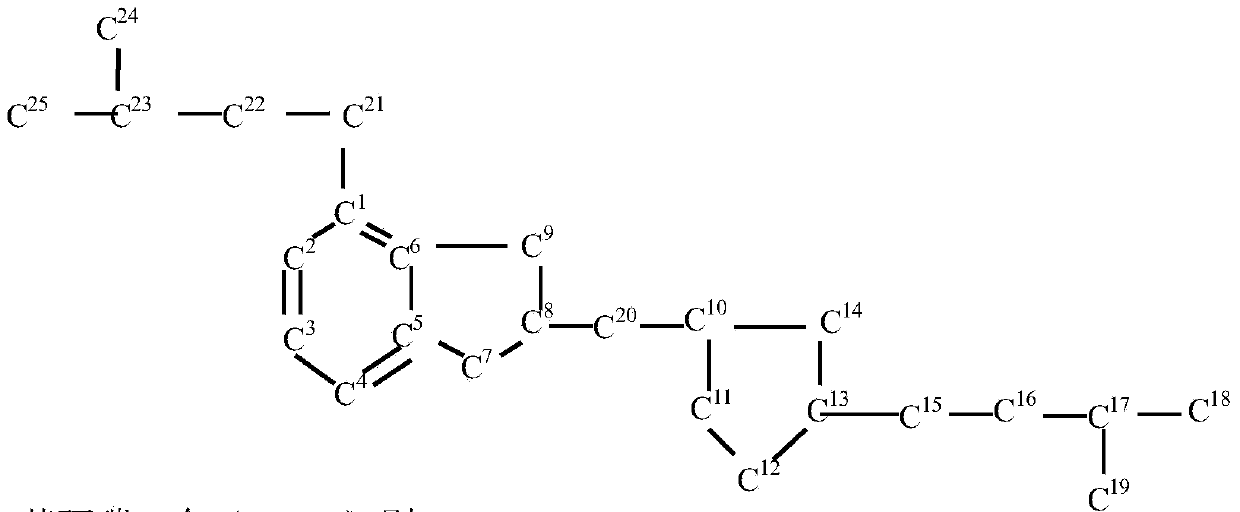

Synthesis of aliphatic alcohol polyoxyethylene sulfonate and complex formulation used for tertiary oil recovery displacement agent

InactiveCN101255127AEnhanced Oil RecoveryReduce interfacial tensionDrilling compositionSulfonic acid preparationSurface-active agentsEther

The invention relates to synthesis of polyoxyethylene fatty alcohol ether sulphonate, and complex formulation for tertiary oil recovery displacement agent, and belongs to chemical displacement agent technic field. The invention discloses a synthesis method of a surface active agent for tertiary oil recovery for a high-temperature, high salinity and high calcium and magnesium ion oil reservoir, and complex formulation for highly effective displacement agents. Polyoxyethylene fatty alcohol ether sulphate is reacted with a sulfonating agent under the action of catalyst to produce polyoxyethylene fatty alcohol ether sulphonate. Polyoxyethylene fatty alcohol ether sulphonate are used as main material which is complex formulated with heavy alkyl benzene sulfonate, water, polymerisate, etc. Compared with existing products, the displacement agent of the invention in the three-high system reduces the oil-water boundary tension ultra-low (10<-3>mN / m), and the boundary tension is not affected by temperature, degree of mineralization and the concentration of calcium and magnesium ions.

Owner:JIANGNAN UNIV

Centrifugal casting radiant tube paint and preparation method thereof

ActiveCN101502868AWide variety of sourcesLow costFoundry mouldsFoundry coresCrack resistanceSodium Bentonite

The invention is a centrifugal casting radiant tube coating and a preparation method thereof, the coating comprises the ingredients (mass percent) of: 25-30% of diatomite of, 5-10% of zircon powder, 1.0-1.2% of titanium powder, 1.5-1.8% of iron powder, 4.5-5.0% of sodium bentonite, 2.0-2.5% of polyvinyl alcohol, 0.8-1.0% of sodium alginate, 3.5-4.0% of silica sol, 0.8-1.0% of sodium dodecylbenzene sulfonate, 0.05-0.08% of silane and 46.82-49.95% of water, wherein, the mass percent of the diatomite and the zircon powder is not less than 35% and not more than 37%, the mass percent of the titanium powder and the iron powder is not less than 2.7% and not more than 2.9%, and the mass percent of the sodium bentonite plus the polyvinyl alcohol plus the sodium alginate is not less than 8.0% and not more than 8.2%. The inventive coating is used for the centrifugal casting radiant tube after dry-blending, mixed grinding and sieving, uniformly distributed bulges (namely pitting surface) can be formed on the outer surface of the radiant tube to improve heat efficiency of the radiant tube. The inventive coating also has excellent adhesive force, high temperature strength and crack resistance, thus reducing defects on the surface of the radiant tube and improving quality of complex tube. Using the inventive coating to cast the radiant tube can result in remarkable economical benefit.

Owner:靖江市黎明铸造材料厂

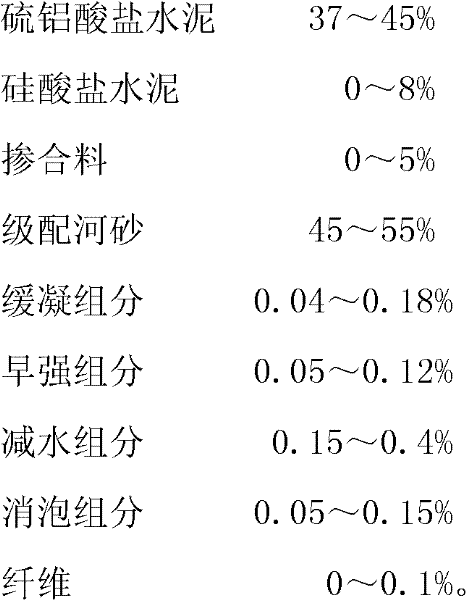

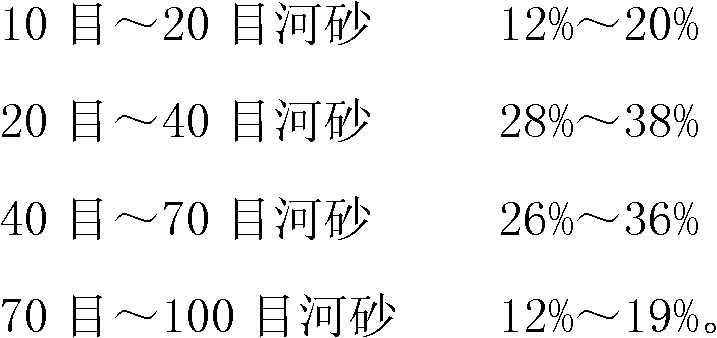

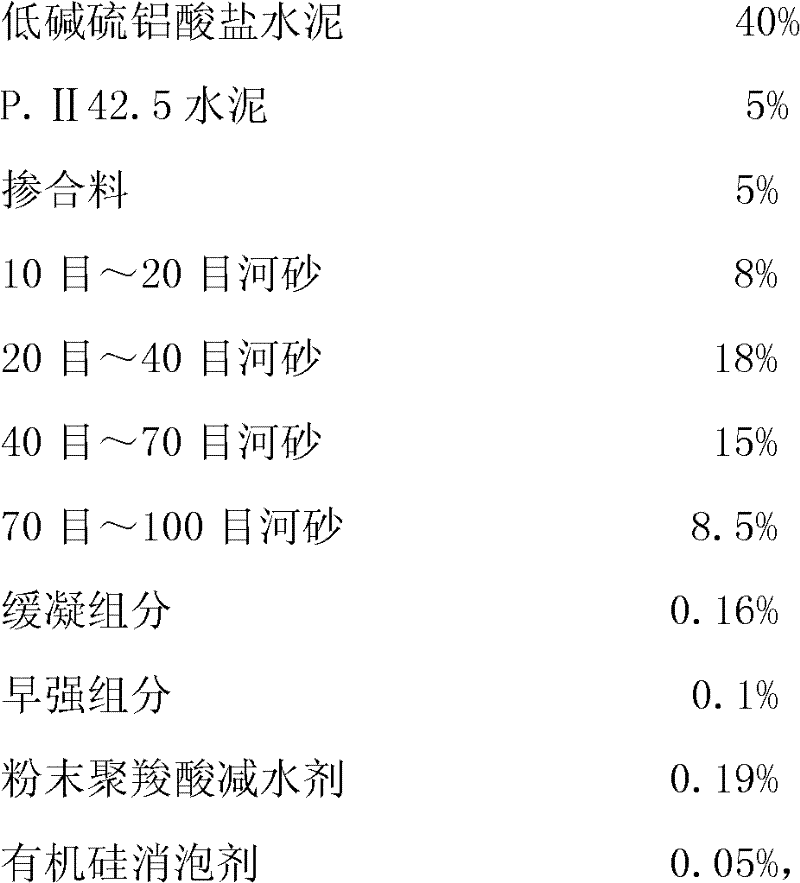

High speed railway bridge bearing anchoring mortar material

The invention discloses a high speed railway bridge bearing anchoring mortar material with is blended from components of, by weight: 37 to 45% of sulphoaluminate cement, 0 to 8% of Portland cement, 0 to 5% of an addition, 45 to 55% of graded river sand, 0.04 to 0.18% of a solidification retarder, 0.05 to 0.12% of an accelerant, 0.15 to 0.4% of a water reducing component, 0.05 to 0.15% of a defrothing component, and 0 to 0.1% of fiber. The material provided by the invention is specially used in anchoring and grouting of high speed railway bridge pot rubber bearings. The material has characteristics of good fluidity, high early strength, good filling properties, no strength reversing in later stage, low cost, convenient application, and the like. The material also can be applied in large equipment installation and pavement rush-repairing.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD

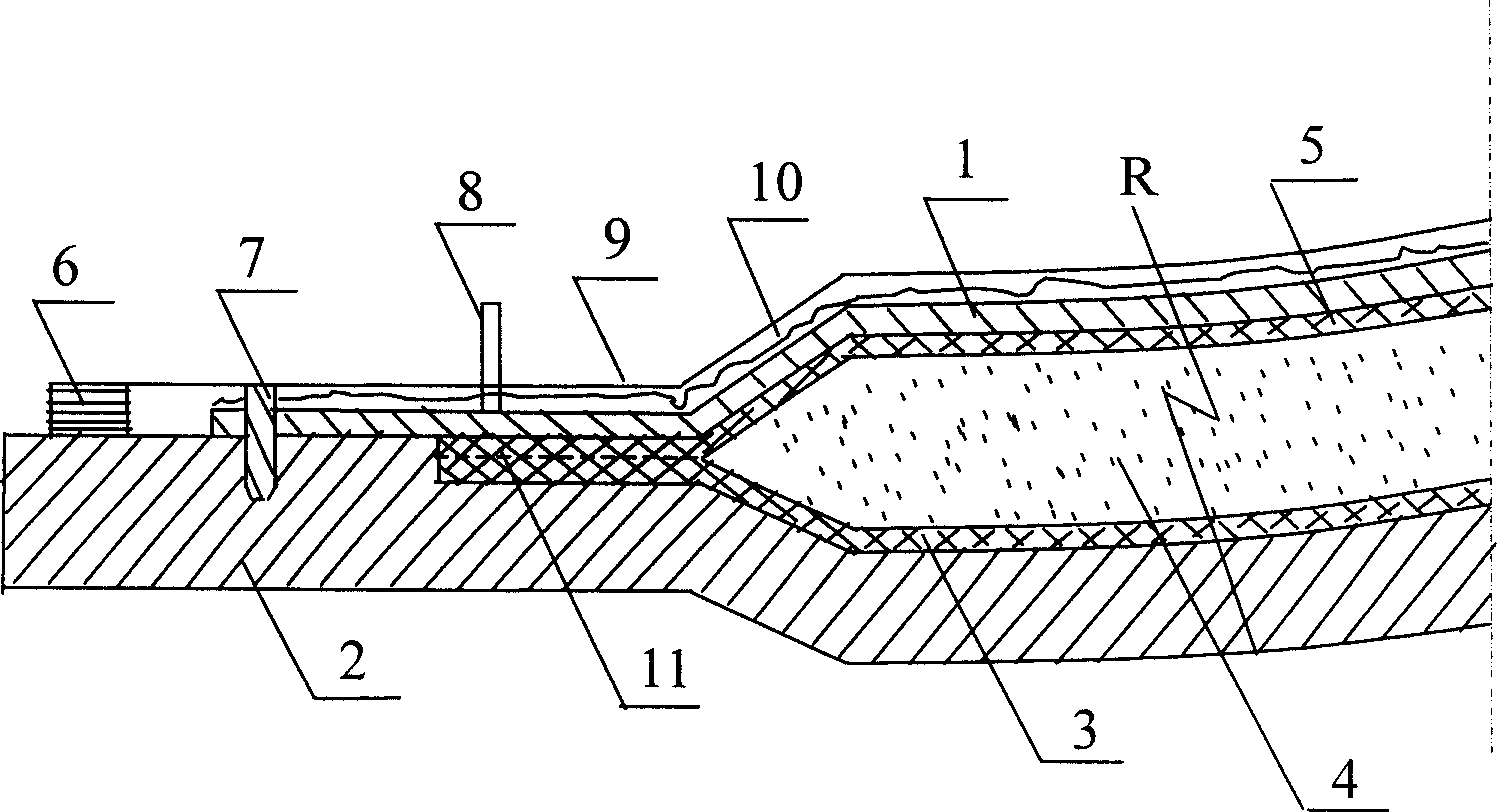

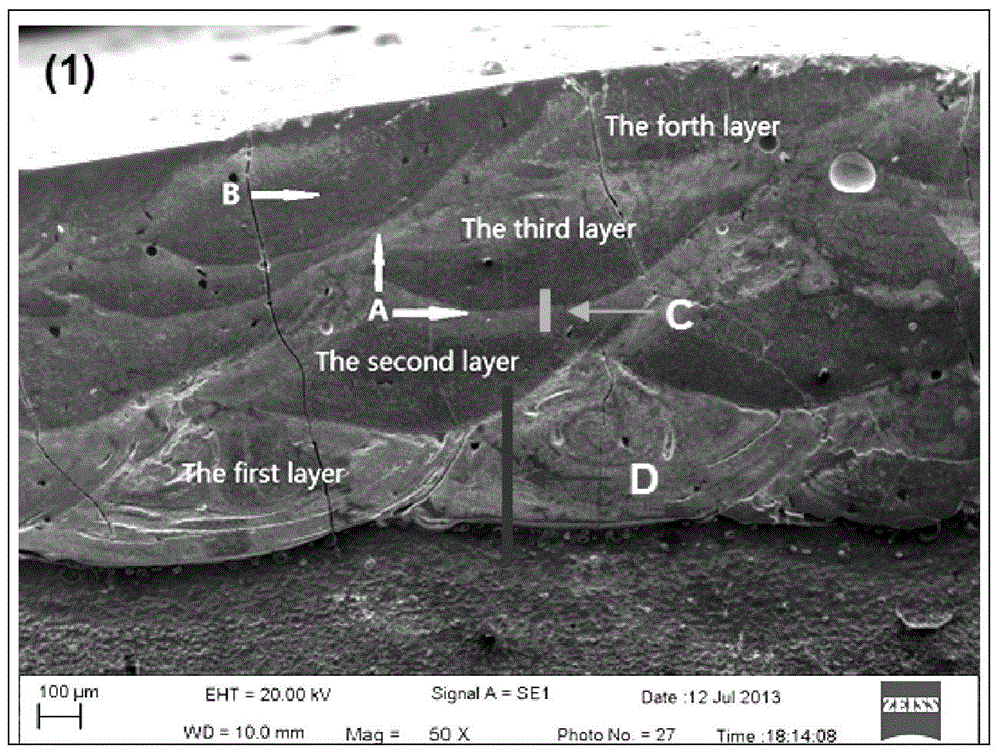

Vacuum forming technique for sandwich structure piece of composite material of fiberglass-reinforced plastics

ActiveCN1915650AFlat surfaceNo stratificationSynthetic resin layered productsGlass fiberOptoelectronics

A composite glass fiber reinforced plastics material with sandwich structure is composed of an external layer made of glass fiber reinforced plastics and coated by water-proof resin, an internal layer made of glass fiber reinforced plastics, and a core layer with cellular structure or made of foam plastics. Its vacuum forming technology includes such steps as respectively preparing mould, external layer, internal layer and core layer, molding, and vacuum solidifying.

Owner:上海之合玻璃钢有限公司

Methanol gasoline and its preparation method

InactiveCN102260548AEasy to prepareExcellent performanceLiquid carbonaceous fuelsFuel additivesTruckSolvent

The invention discloses a methanol gasoline and a preparation method thereof, relating to the field of new energy. The methanol gasoline comprises 15-30wt% of methanol, 67-83wt% of gasoline and 2-3wt% of additive. The preparation method comprises the following steps: pouring solubilizer, energy increasing and consumption reducing agent, anti-oxidant, metal corrosion inhibitor, rubber swelling inhibitor into a reaction vessel according to a required proportion with stirring, mixing uniformly to obtain an additive; mixing the additive with methanol according to a required proportion to obtain modified methanol; and mixing the modified methanol with gasoline according to a required proportion to obtain the methanol gasoline. The methanol gasoline disclosed in the invention has the advantagesof simple preparation and good performance, can be used mixed with a national standard gasoline in any proportion with similar energy consumption with the national standard gasoline and emission indexes that conforms to requirements of environmental protection, and can be widely used for various petrol-engined motor vehicles, such as car, carriage, fork truck, power-assisted vehicle, farm vehicle, motorcycle, load wagon and forklift.

Owner:永州锦溁新能源开发有限公司

Preparation method of water-in-water cation polyacrylamide

InactiveCN101735388AImprove solubilityImprove stabilityWater/sewage treatment by flocculation/precipitationWater bathsPolyethylene glycol

The invention relates to a method for synthesizing water-in-water cation polyacrylamide. The method takes an inorganic salt water solution as a reaction medium, adopts a mixed dispersion stabilizing agent containing polyethylene glycol PEG series, polyvinylpyrrolidone and polyvinyl alcohol (the mass ratio of the polyethylene glycol PEG series to the polyvinylpyrrolidone to the polyvinyl alcohol is 1:1:1) and enables acrylamide and a quaternary ammonium organic compound with double bonds to generate a free radical copolymerization reaction so as to generate water-in-water cation polyacrylamide emulsion. The preparation method of the water-in-water cation polyacrylamide comprises the following steps: (A) adding acrylamide, a cationic monomer, inorganic salt, a dispersant, a screening agent and deionized water into a four-neck flask, dissolving evenly, putting into water bath of 50 DEG C, introducing nitrogen, deoxidizing and stirring at the speed of 1000rpm; (B) when reacting for 0.5 hour and 1.5 hours respectively, adding a certain amount of initiator; and (C) after adding the initiator for the second time, reacting for 3-4 hours continuously so as to obtain a product. The emulsion has the characteristics of high dissolving speed, good stability and convenient use and transportation and can not cause secondary pollution to the environment.

Owner:TONGJI UNIV

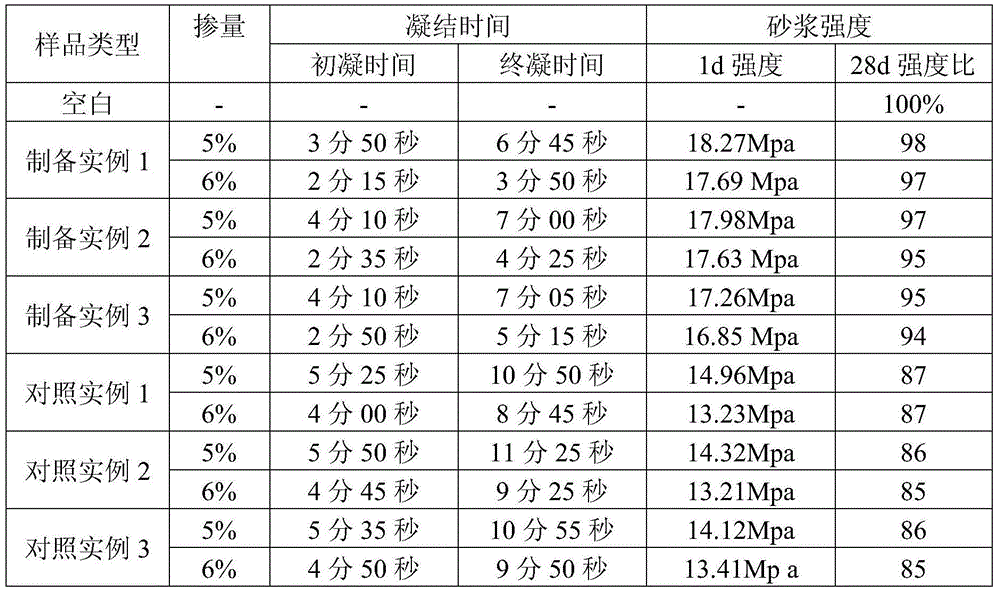

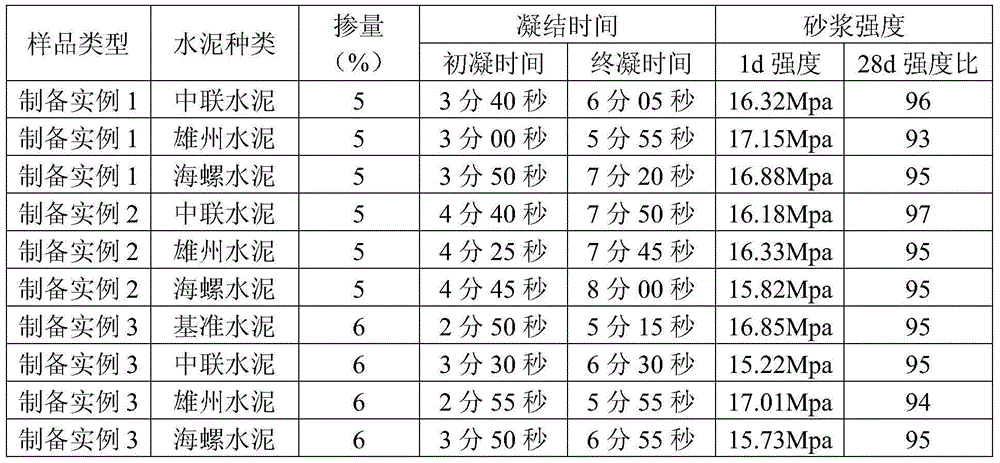

Durable alkali-free liquid setting accelerator and preparation method thereof

The invention discloses a durable alkali-free liquid setting accelerator and a preparation method thereof. The durable alkali-free liquid setting accelerator is prepared from the following components in percentage by mass: 20%-28% of aluminum hydroxide sol, 10%-16% of modified silica sol, 5%-9% of modified alcohol amine, 4%-6% of cellulose fiber, 1%-3% of a stabilizer and 40%-60% of water. The preparation method comprises the following specific steps: (1) preparing the aluminum hydroxide sol; (2) preparing the modified silica sol; (3) preparing modified alcohol amine; and (4) adding reinforced fiber, the stabilizer and water, and stirring for 4-6 hours at 75-85 DEG C to obtain the finished product. The liquid setting accelerator is free of sulfate ions, alkali metal ions, chloride ions and other corrosive substances, a stable solution system is prepared and no phenomenon of layering is caused after the liquid setting accelerator is stored for above 6 months at normal temperature, the cost is low and the long-term strength has almost no loss and when applied in construction of shotcrete, the liquid setting accelerator plays a positive role to improve the durability of concrete.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

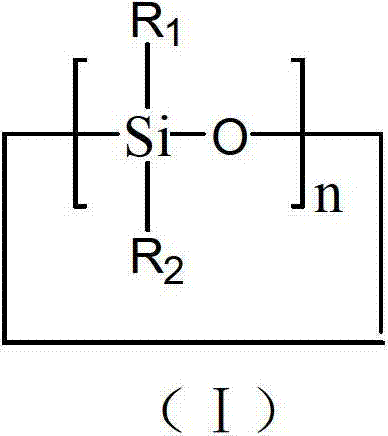

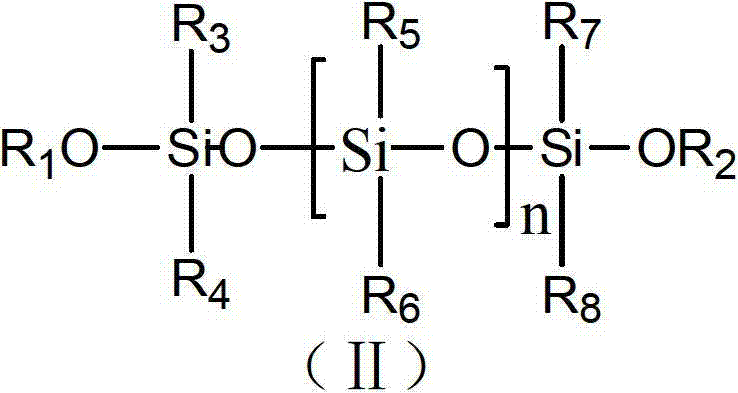

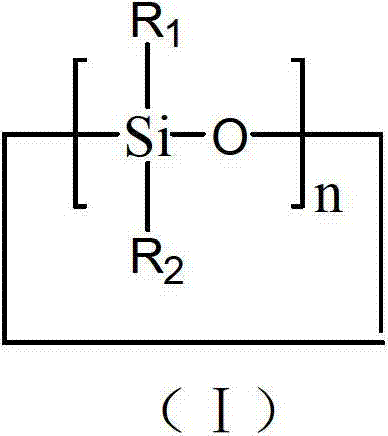

Film-forming polysiloxane emulsion and preparation method thereof

The invention discloses film-forming polysiloxane emulsion and a preparation method thereof. The preparation method of the film-forming polysiloxane emulsion comprises the following steps of: dissolving 0.02-20 parts by weight of composite surfactant to 100 parts of water; adding 10-60 parts by weight of organo-silicone monomers, shearing the organo-silicone monomers by a shearing and emulsifying stirrer, and homogenizing the organo-silicone monomers under 20Mpa-60Mpa to obtain organo-silicone monomer emulsion; raising the temperature of the organo-silicone monomer emulsion to 70 DEG C to 90 DEG C, adding 0.01-10 parts of catalyst for reacting for 4-6 hours, cooling the reaction liquid to 40 DEG C to 60 DEG C, adding 0.5-5 parts of a cationic surfactant and 0.05-20 parts of a cross-linking agent for reacting for 1-3 hours cooling the reaction liquid to 20 DEG C to 30 DEG C and adding acetic acid to neutralize the emulsion to be neutral so as to obtain the film-forming polysiloxane emulsion. The method for preparing the film-forming polysiloxane emulsion is less in steps, simple to operate, low in cost and high in conversion rate. The obtained film-forming polysiloxane emulsion can be placed for more than three months at normal temperature without layering or emulsion-breaking.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Coenzyme Q10 oral emulsion and preparing process thereof

InactiveCN101015524AImprove stabilityEasy to takeOrganic active ingredientsAntinoxious agentsPurified waterAnti oxidant

The invention relates to a coenzyme Q10 oral emulsion and its preparation method, wherein the constituents include coenzyme Q10 0.1-80%, medicinal oil 1-95%, emulsifying agent 0.5-30%, auxiliary emulsifying agent 0-10%, anti-oxidant 0.001-15%, and balancing purified water. The emulsion can be prepared through inversion phase emulsification method, PIT emulsification method, alternative liquid feeding emulsification method, or continuous emulsification method.

Owner:SHENYANG PHARMA UNIVERSITY

Novel modified emulsifying olefin concrete curing agent

The invention relates to a novel modified emulsified paraffin concrete curing agent. Aiming at overcoming the defects that the existing concrete curing agent cannot reach the industrial standard on building material in terms of the water retention property and is unfavorable for environmental protection, the price is high and the decoration at later stage is also affected, the following technical proposal is provided: the curing agent is mixed with the following materials and water: 10-20% of vinyl acetate-ethene high molecular polymer emulsion, 0-5% of silicone resin modified acrylic polymer emulsion, 50-75% of paraffin emulsion, 0.1-0.5% of colloidal dispersing agent of the emulsified paraffin for stabilizing the emulsion state and 0.05-0.02% of special defoamer for emulsion. The invention has the beneficial effects that: the chemical curing method which is adopted for retaining water is an innovation for the traditional curing method; compared with the prior art, the method is labor-saving, time-saving and water-saving and is convenient to operate, can improve the film formation ability and the sealing ability of the emulsified paraffin emulsion, and can improve the bonding and absorbing capacity of the emulsified paraffin emulsion on the concrete surface, which leads the effective water retention rate of the coating film to reach more than 90%.

Owner:LIAONING BUILDING SCI RES INST

Water-permeable agent for water-permeable bricks or water permeable concrete and application of water-permeable agent

The invention discloses a water-permeable agent for water-permeable bricks or water permeable concrete and application of the water-permeable agent. The water-permeable agent comprises, by weight, 75-110 parts of water reducing agent, 150-300 parts of retarder, 100-150 parts of binder, 55-70 parts of air entraining agent and 55-100 parts of water. The water-permeable agent has the advantages that the water-permeable agent can increase the workability of a water-permeable layer, increase water permeability and increase the durability and later strength of the water-permeable bricks and is low in adding amount and low in cost. The water-permeable bricks have the advatnages that the bricks use haycite and regenerated porous coarse aggregate as the aggregate of the water-permeable layer and use the water-permeable agent, the features of porosity, good water absorption performance and high strength of the aggregate and the good performance of the water-permeable agent are utilized to increase the strength and water permeability of the water-permeable bricks, and the bricks are lightweight and convenient to carry.

Owner:SHANDONG JINYI GARDEN SHARES CO LTD

Production of pure soya-bean lactacidase fermenting beverage

InactiveCN1644112AFine tissuePure bean flavorFood preparationMilk substitutesStreptococcus thermophilusBiology

A fermented lactobacillus beverage is prepared from soybean through preparing soybean milk, inoculating thermophilic streptococcus and lactobacillus, fermenting, dispensing, homogenizing and sterilizing. Its advantages are agreeable taste, not containing cholesterine and lactose, and high nutritive value.

Owner:JIANGNAN UNIV

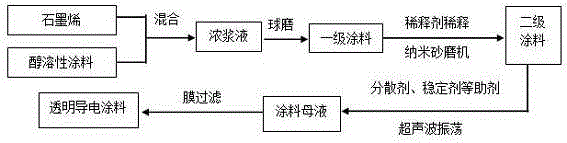

Graphene conductive coating and preparation method thereof

InactiveCN104449377AGood dispersionLow viscosityNatural resin coatingsElectrically-conductive paintsDispersityFiltration

The invention relates to a graphene conductive coating and a preparation method thereof. The graphene conductive coating comprises the following components in parts by weight: 0.01-10 parts of graphene, 1-30 parts of an alcohol-soluble coating, 20-50 parts of a diluent, 0.5-5 parts of a dispersing agent, 0.5-5 parts of a stabilizer and 0.1-1 part of a defoaming agent. The preparation method comprises the following steps: by taking the graphene as a conductive component and taking the alcohol-soluble coating as a film forming matter, adding other aids, grinding, performing ultrasonic oscillation, and performing film filtration, thereby obtaining a conductive coating in a uniform system. The alcohol diluent has an effect of diluting the coating, dispersion of the graphene is promoted, the dispersity of the graphene is effectively improved, and the graphene can stably exist for a long time. The types and amount of the diluent, dispersing agent and other aids are adjusted, so that the viscosity of the coating is controlled, the subsequent spraying, brushing and coating process is conveniently implemented, large-scale production is easily realized, and the graphene conductive coating is expected to be applied to the fields such as mobile phones, flat-panel displays, solar cells, transparent electromagnetic wave shielding and automotive window heat-conducting glass.

Owner:HUBEI UNIV OF TECH

Fermented milk beverage containing peanut, lotus root and pawpaw and production method thereof

The invention relates to the field of liquid milk, in particular relating to a fermented milk beverage containing peanut, lotus root and pawpaw and a production method thereof. On the basis of 100 parts of fermented milk beverage by weight, the fermented milk beverage containing peanut, lotus root and pawpaw comprises: 30-80 parts of liquid milk by weight, 0.004-0.007 part of leaven by weight, 3.5-8.0 parts of sweet substance by weight, 0.2-0.7 part of acidity regulator by weight, 0.1-1.5 parts of stabilizing agent by weight, 1-30 parts of peanut paste by weight, 1-10 parts of lotus root powder by weight, 1-5 parts of pawpaw primary paste by weight and the balance water, wherein the stabilizing agent is composed of thickening agent and / or emulsifier, and the thickening agent contains 0.1-0.25 part of high acyl pectin and propylene glycol alginate. The product of the invention has refreshing and smooth taste when being drunk and contains special fragrance of peanut, lotus root and pawpaw products. Tests prove that the product has no layering phenomenon or severe fat flotation in the storage and placement process within the 6-month quality guarantee period. Thus, the product of theinvention has favorable stability.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

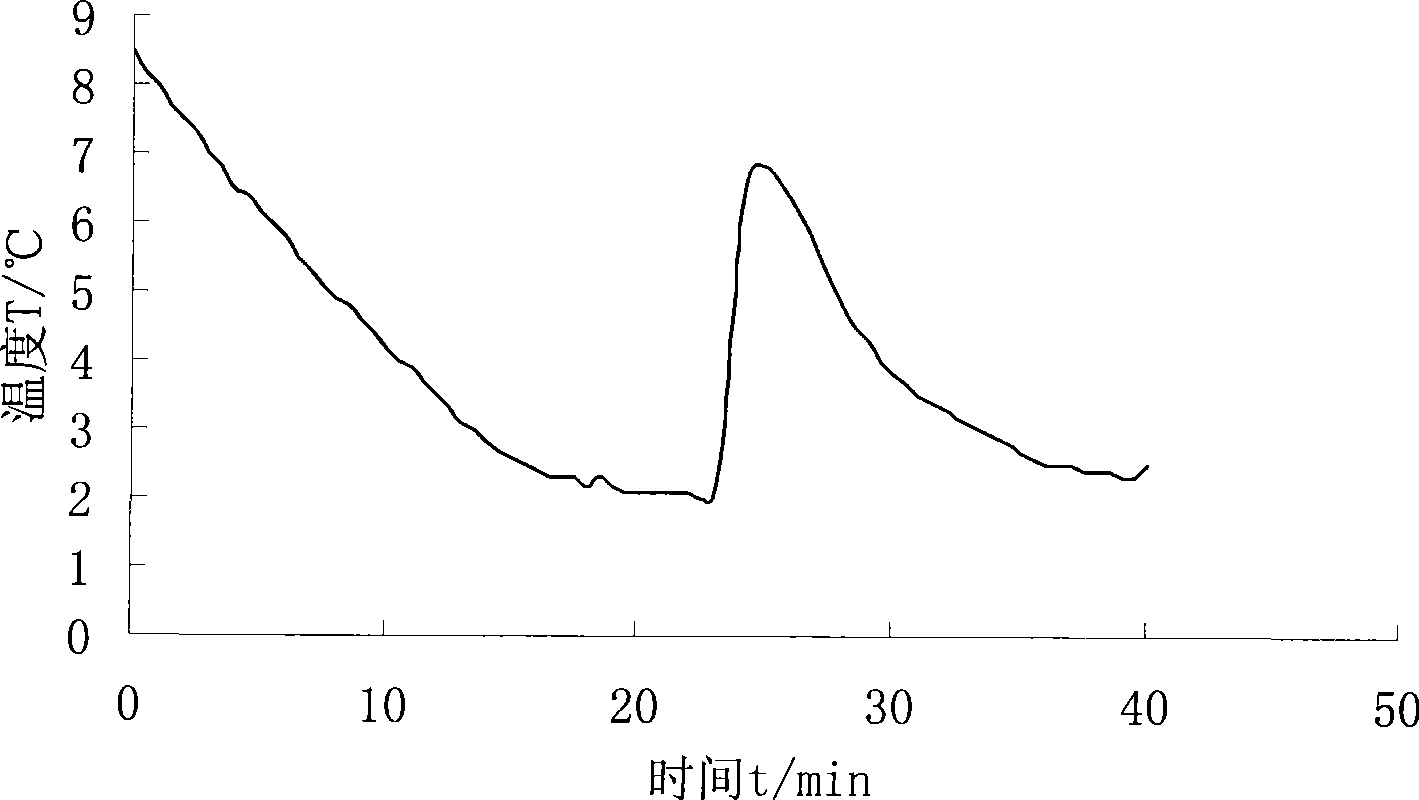

Nano refrigerant hydrate phase change cold-storage working substance and preparation thereof

InactiveCN101434833AEasy to passReduce running power consumptionHeat-exchange elementsSolubilityTurbidity

The invention provides a nano-refrigerant hydrate phase change cool-storage refrigerant and a preparation method thereof; surfactant is dissolved in water to prepare the water solution of the surfactant; subsequently, the refrigerant is dripped into the water solution of the surfactant and mixed till that the solution is changed from turbidity to brightness. According to the solubility of the surfactant in water and in the refrigerant, the surfactant can be dissolved in the water and can also be dissolved in the refrigerant. Under static state, the water phase and the refrigerant phase are uniformly mixed in microscopic scale to augment the two-phase diffusion interface, thus promoting the growth of the hydrate crystal. The system can lead the water phase and the refrigerant phase to be mixed uniformly without applying mixing, disturbing and external field; the refrigerant phase is dispersed in water in the form of micelle or (and) microemulsion; and alternatively, the water phase is dispersed in the refrigerant phase in the form of micelle or (and) microemulsion; the dripping size of the dispersing phase is 100nm or less. The hydrate phase change cool-storage refrigerant does not delaminate after being placed for a long time, is single-dispersion system with stable thermal-mechanics performance and has the appearance of transparent or semi-transparent solution.

Owner:XI AN JIAOTONG UNIV

ITO-Ag-ITO etching liquid for AM-OLED display screen and preparation method

ActiveCN105176533AAdjust densityConsistent etch rateSurface treatment compositionsAcetic acidO-Phosphoric Acid

The invention discloses ITO-Ag-ITO etching liquid for an AM-OLED display screen and a preparation method. The etching liquid is prepared from phosphoric acid, acetic acid, nitric acid, additives, surfactants and pure water. The preparation method of the etching liquid comprises the steps that the rotating speed of a stirrer of a dosing tank is kept at normal temperature and pressure, the pure water, the phosphoric acid, the acetic acid, the nitric acid, the additives, the surfactants and the balance pure water are sequentially added into the dosing tank, and after full stirring is conducted, the ITO-Ag-ITO etching liquid is prepared by introducing a fully-stirred mixture into a filter for filtration. According to the ITO-Ag-ITO etching liquid for the AM-OLED display screen and the preparation method, the ITO-Ag-ITO etching liquid is small in particle size and high in purity, the etching rate to different metal is basically the same, and reaction is stable; the etching rate can be controlled by adjusting the concentrations of the phosphoric acid and the nitric acid, the surface of a substrate etched through the etching liquid is clean and tidy, residues do not exist, the intermetallic layering phenomenon does not exist, remaining lines are flat and smooth, and the etching angle is kept between 70 degrees to 90 degrees.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

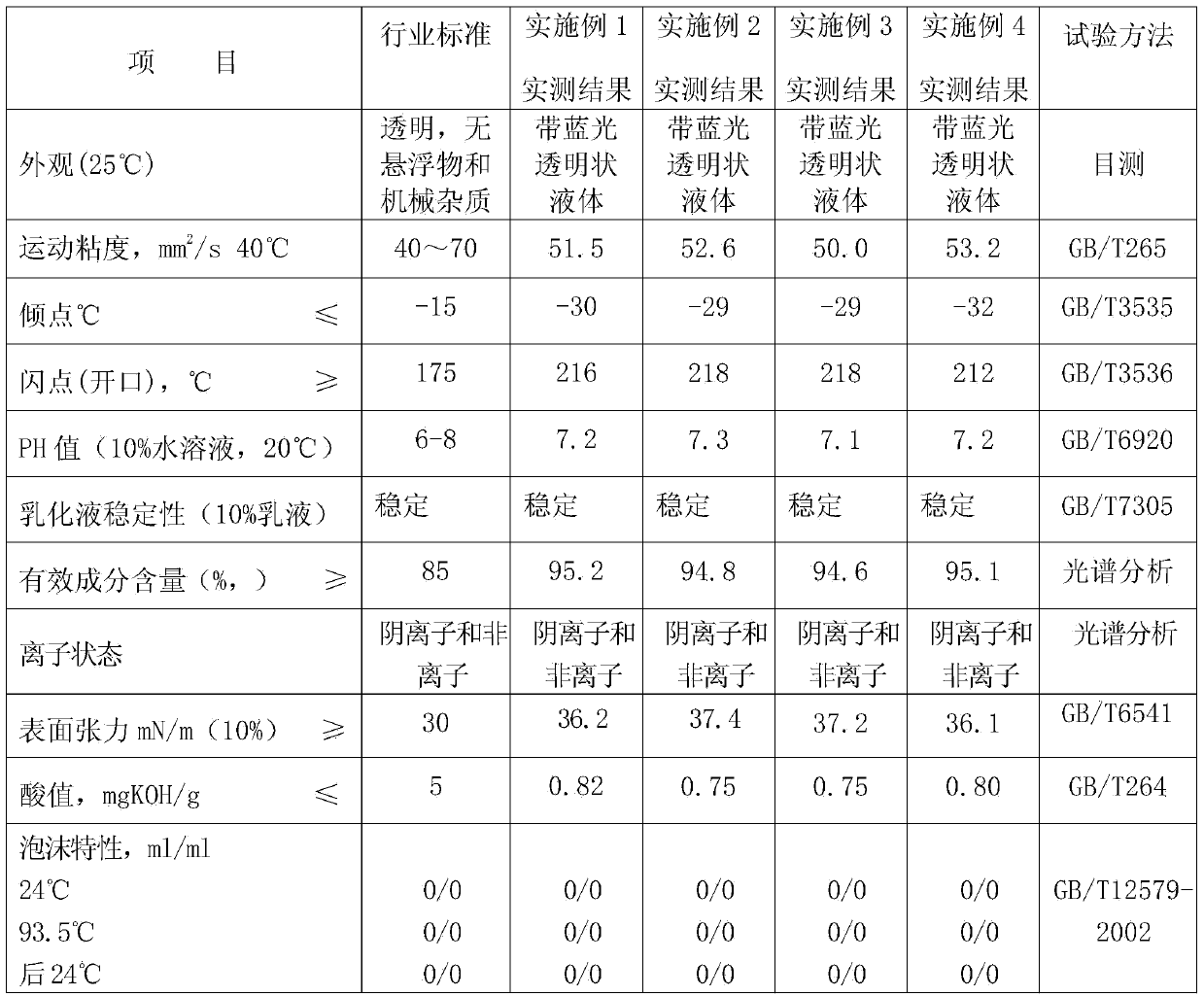

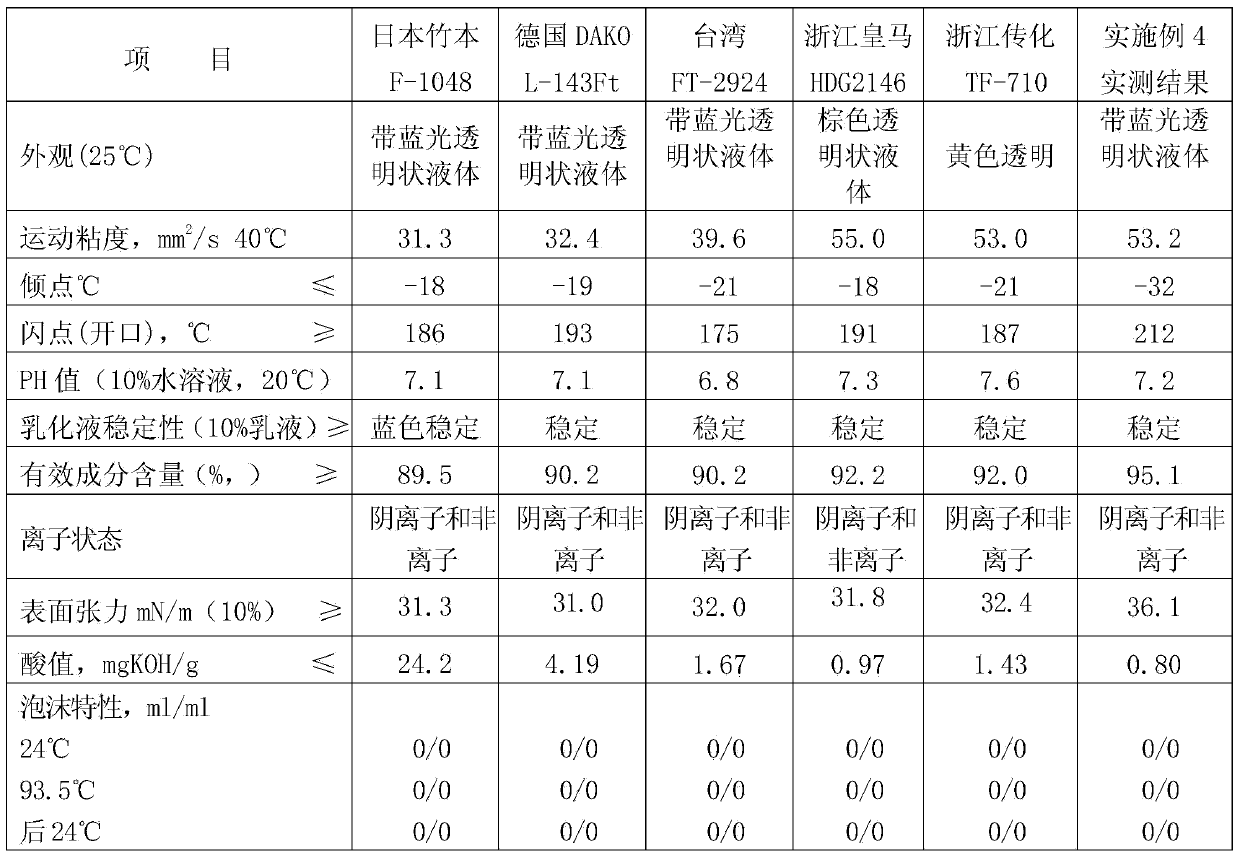

Fiber fully drawn yarn (FDY) spinning oil and preparation method thereof

The invention relates to a fiber fully drawn yarn (FDY) spinning oil which comprises a high-temperature smoothing agent, a composite antistatic agent, a bundling agent, a phenolic group antioxidant, a phenylamino group antioxidant, an olefine acid antioxidant, a high-temperature dispersant, a softening agent, an environment-friendly emulsifying agent, a defoaming agent, a preservative and an environment-friendly penetrating agent, wherein the high-temperature smoothing agent comprises hydrogenation paraffin-based oil and hydrogenation naphthenic oil. The invention also provides a preparation method of the fiber FDY spinning oil. The fiber FDY spinning oil is stable in emulsion and free from stratification and odor, and is not easily rotted; the fiber is easily not yellowed by dyeing, and the fiber FDY spinning oil is easy to rinse; the production process is stable, and the fiber FDY spinning oil has few broken ends, is good in heat resistance, does not have smoke formation, is not coked on a hot roller, has the excellent anti-static performance under the different humidity conditions, and thus the fiber FDY spinning oil can meet the requirements of high-speed spinning technologies of various specifications of fiber including thick fibers and thin fibers; after the fiber FDY spinning oil is used, the fiber can smoothly pass through the after the spinning of various equipment, so that the yield and the good rate of fiber spinning can be effectively increased.

Owner:上海中孚油品集团有限公司

Method for machining slotted holes on carbon fiber laminated boards

The invention discloses a method for machining slotted holes on carbon fiber laminated boards, which belongs to a machining method for nonmetallic materials, solves the problem that by the existing milling and drilling methods, carbon fiber laminated boards are easy to laminate, split and burn, and aims at improving the machining precision of carbon fiber composite products and reducing the surface roughness of carbon fiber composite products. The method disclosed by the invention comprises a clamping step, a machining step and a post-processing step, wherein the machining step is one or two of a milling machining step and a drilling machining step. According to the invention, in the machining process, a non-deformed clamping mode is used, and through selecting reasonable cutting tool materials, geometric parameters of cutting tools, and milling and drilling machining parameters, the appearance allowances in machining are reasonably arranged, thereby solving the quality problems of laminating, splitting and burning and the like existing in the process of opening or drilling carbon fiber thin-wall revolution bodies and carbon fiber laminated boards by using the traditional methods, so that the qualified rate of carbon fiber parts is increased from 50% to more than 99%.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Liquid dairy product containing honey and bee pollen and production method thereof

ActiveCN101623033ANo floatSmooth and smooth tasteMilk preparationFood preparationSweetnessLiquid milk

The invention provides a liquid dairy product containing honey and bee pollen. The dairy product comprises the following raw material compositions in every 100 weight portions: 30 to 90 portions of liquid milk, 3.5 to 20.0 portions of sweet substance, 0.1 to 5.0 portions of stabilizer, 1 to 20 portions of honey and 1 to 30 portions of bee pollen; the liquid dairy product can also contain seabuckthorn inspissated juice; the invention also provides a method for preparing the liquid dairy product, can prepare the dairy product with perfect combination of mouthfeel, nutrition and health care and is suitable for industrialized production.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Environment-friendly high-strength permeable brick

The invention discloses an environment-friendly high-strength permeable brick which comprises permeable abrasion-resistant layers and permeable layers. The permeable abrasion-resistant layers comprise cement, quartz sand, porous fine aggregate, silica fume, water, reinforcing agents and pigment; the permeable layers comprise carbide slurry, fly ash, mineral powder, cement, ceramsite, porous coarse aggregate, permeable agents and water. The environment-friendly high-strength permeable brick has the advantages that permeable gaps and holes can be prevented from being blocked by dust or slurry owing to closed holes and the water absorption of the porous fine aggregate, the porous coarse aggregate and the ceramsite, and accordingly the pollution resistance and the permeability of the environment-friendly high-strength permeable brick can be enhanced; the compressive strength of the environment-friendly high-strength permeable brick is higher than or equal to 40.0 Mpa, the lengths of abrasion pits are shorter than or equal to 28 mm, the water retention of the environment-friendly high-strength permeable brick is higher than 0.8 g / cm<3>, the permeability coefficient of the environment-friendly high-strength permeable brick (at the temperature of 15 DEG C) is larger than 7.2*10<-2> cm / s, and decrease of the permeability of the environment-friendly high-strength permeable brick is lower than or equal to 20% after the environment-friendly high-strength permeable brick is used for 3 years.

Owner:SHANDONG JINYI GARDEN SHARES CO LTD

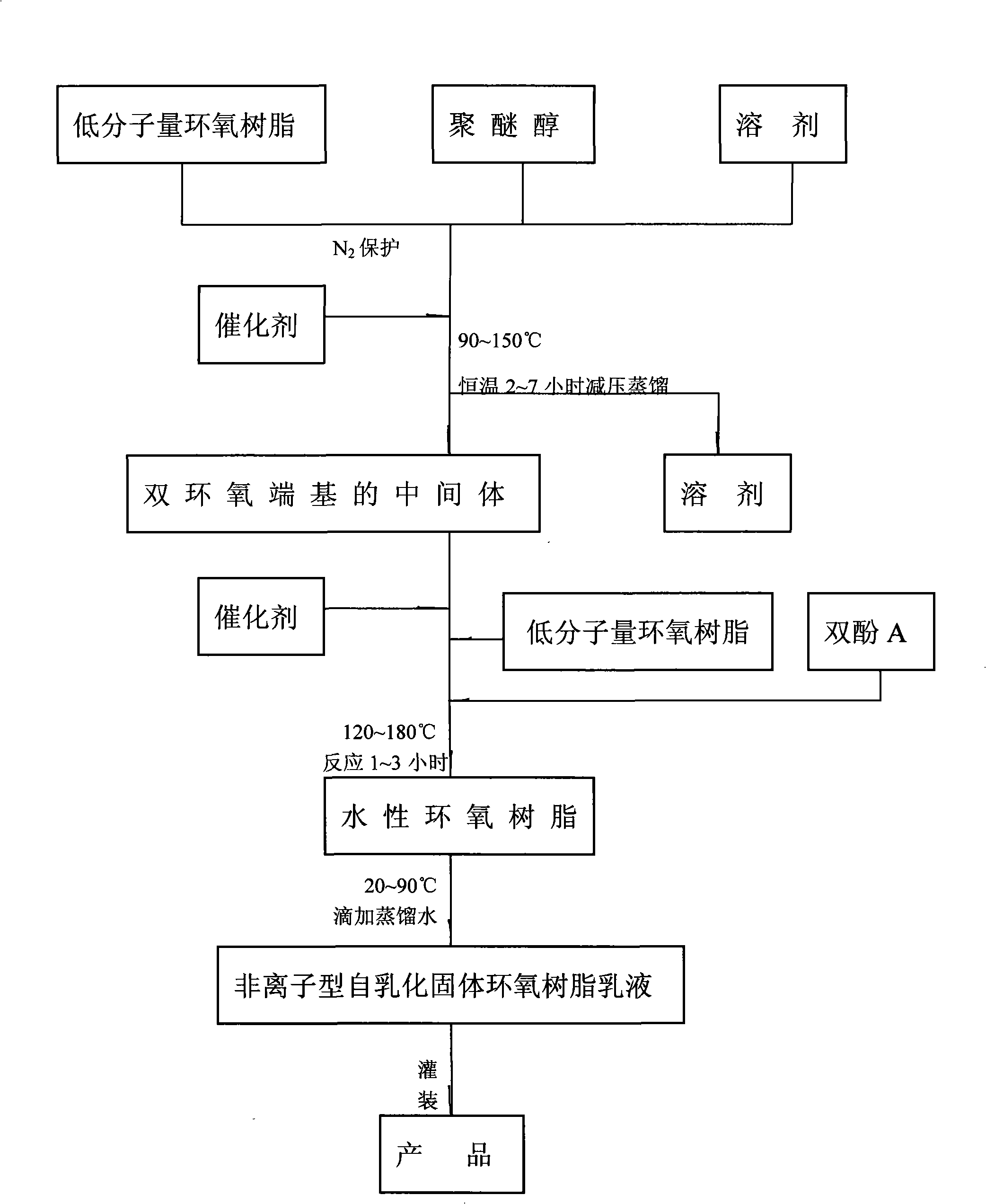

Non-ionic self-emulsification solid epoxy resin and preparation method for emulsion thereof

The invention relates to a non-ionic self-emulsifying solid epoxy resin and a preparation method of the emulsion of the resin, belonging to the coating material chemical manufacturing industry. The preparation method adopts a 'two-step method' principle during preparation: step one: under the protection of nitrogen, the reaction of 5 to 25 percent of low-molecular weight epoxy resin, 40 to 70 percent of polyether alcohol, 1 to 10 percent of solvent and 0.01 to 0.1 percent of catalyst is carried out at 90 to 150 DEG C, and then a constant temperature is kept for 2 to 7 hours before intermediate is obtained through the vacuum distillation of the solvent; step two: 10 to 25 percent of intermediate, 40 to 70 percent of low-molecular weight epoxy resin, 5 to 25 percent of bisphenol A and 0.02 to 0.1 percent of catalyst are heated up to 120 to 180 DEG C, and then a constant temperature is kept for 1 to 3 hours before non-ionic self-emulsifying solid epoxy resin with medium molecular weight and high molecular weight is obtained; and finally, at the temperature of 20 to 90 DEG C, distilled water is dripped in to dilute the solution to a degree with solid content ranging between 30 and 80 percent of through violent stirring, thereby obtaining non-ionic self-emulsifying solid epoxy resin emulsion. The preparation method has convenient operation, stable manufacturing technique, energy conservation and moderate preparation process. Moreover, the water-based epoxy emulsion is exquisite and has uniform particle diameter and high product quality.

Owner:中山大桥化工集团有限公司

Terylene FDY nano spinning finish and its preparing process

The invention relates to polyester FDY nanometer spinning oil solution and a method for preparing the polyester FDY nanometer spinning oil solution, wherein the polyester FDY nanometer spinning oil solution takes the oil solution total weight as benchmark and comprises: smoothing agent 46-48%, emulsifier 28-32%, anstatic agent 9-10%, balance adjuster 5-7% and inorganic nanometer additive 5-7%. Each component of the oil solution is rationally mixed and mutually coordinated, and the oil solution has good comprehensive property. The method for preparing the polyester FDY nanometer spinning oil solution comprises: preparing inorganic nanometer additive, adding the smoothing agent, the emulsifier and the anstatic agent into a reactor, heating and stirring until the mixture becomes even, cooling the mixture which is evenly stirred, filtering, and obtaining the oil solution products. The method for preparing is simple and easy to operate.

Owner:吴江市良燕纺织助剂厂

High-filler paper and production method thereof

InactiveCN102433796AHigh whitenessIncrease the addition ratioInorganic compound additionPulp material addition processesCalcium silicatePlant fibre

The invention discloses high-filler paper and a production method thereof. The high-filler paper contains 30 to 60 mass percent of filler, and the filler is active calcium silicate; in the step of adding the filler, after the active calcium silicate in an amount which is 40 to 70 percent of the total mass of the active calcium silicate and the pulp is fully stirred and dissolved to form emulsion,the emulsion is guided into a covered pulp storage tank or a pre-making pulp storage tank and fully stirred and mixed with plant fibers; the filler adding proportion of the high-filler paper is improved, so that the consumption of the plant fibers is greatly reduced at the same time of improving the performance of the paper; and according to the production method for the high-filler paper, the adding process of the papermaking filler is simplified, the filler and the plant fibers can be fully mixed uniformly, and the internal bonding force is increased, so that the performance of the paper isimproved.

Owner:GUONENG PAPER IND

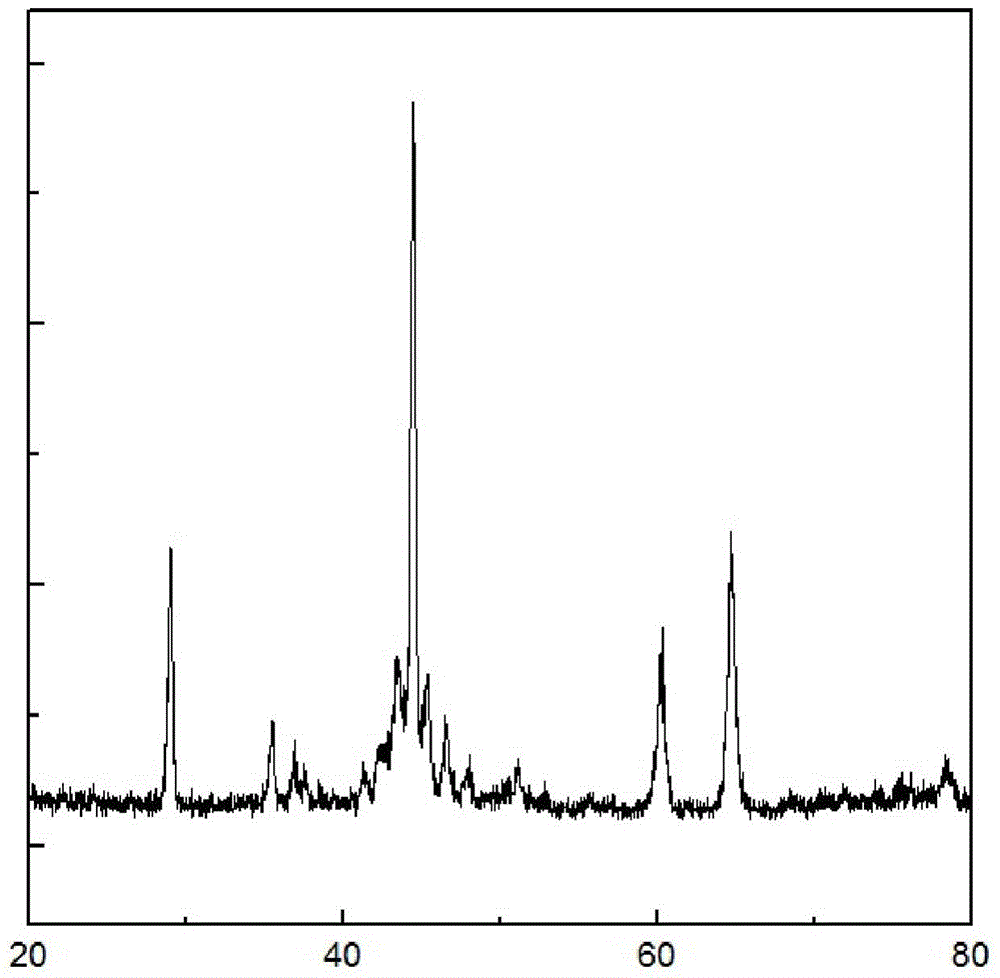

Iron-based nanocrystalline composite coating for protecting boiler tail heating surface and laser-cladding forming process of iron-based nanocrystalline composite coating

ActiveCN104357748AImprove wear and corrosion resistanceReduce corrosion wearMetallic material coating processesRare-earth elementAlloy

The invention discloses an iron-based nanocrystalline composite coating for protecting a boiler tail heating surface and a laser-cladding forming process of the iron-based nanocrystalline composite coating. The iron-based nanocrystalline composite coating comprises the following components in percentage by weight: 49.9-62.8% of Fe, 14.2-20.4% of Cr, 9.0-16.3% of Mo, 2.9-4.1% of B, 0.6-1.3% of C, 1.0-2.4% of Mn, 3.4-8.0% of W, 1.0-1.9% of Si and 0-3.9% of RE, wherein RE is a rare earth element. The forming process comprises the following steps: preparing alloy powder of the iron-based nanocrystalline composite coating; treating the surface of the boiler tail heating surface; preparing the iron-based nanocrystalline composite coating through a simultaneous powder feeding method and a laser-cladding method, wherein the laser cladding is performed for multiple times. The formed iron-based nanocrystalline composite coating is 1 mm above in thickness. The iron-based nanocrystalline composite coating can obviously enhance the wear resistance and corrosion resistance of the boiler tail heating surface, and reduce maintenance costs of worn and corroded parts and consumption of raw materials of a power plant.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Technique for producing sheet-type electronic component paper carrying base paper by using waste paper pulp

InactiveCN101100830AReduce consumptionImprove protectionPure paperDryer sectionHigh concentrationPulp and paper industry

The invention relates to paper technology used waste pulp to produce sheet electronic component paper characteristic carried band base paper. It includes the following steps: mixing 50-80% broadleaf pulp, 0-35% need pulp, 0-15% mechanism ground pulp and sending them into high concentration pulping machine to pump to 40-48 degree SR; adding 0.8-1wt% starch and 0.5-1wt% sizing agent to form cover pulp; de-inking, de-sanding, de-dusting for the waste pulp; sending them into the pulping machine; putting into core pulp storing pool; adding 0.8-1wt% starch and 0.5-1wt% sizing agent to form core pulp; distributing the cover and core pulp into cover net and core net by splitting box to form many paper sheet; spraying a layer of starch on them; folding them to form base paper; rolling; drying; dehydrating; surface sizing; cooling; balancing moisture; coiling up. The invention has the advantages of reasonable technology, convenient production, stable quality, practicality, and environmental protection.

Owner:方隽云

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com