Graphene conductive coating and preparation method thereof

A conductive coating and graphene technology, applied in the field of materials, can solve the problems of affecting the gloss and mechanical properties of the coating, affecting the conductivity and light transmission, and easy delamination, so as to achieve easy popularization and large-scale production, and improve dispersion sex, promotes the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

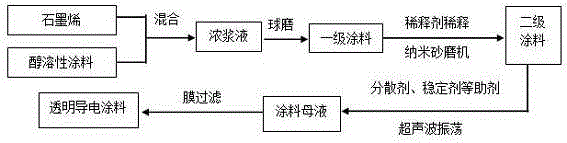

Method used

Image

Examples

Embodiment 1

[0033] 0.5 parts of graphene and 5 parts of alkyd resin alcohol-soluble paint were uniformly mixed, and the uniformly mixed slurry was ground on a ball mill for 15 minutes to obtain a primary dispersion paint. Mix the first-level dispersion paint with 30 parts of ethanol diluent, and process it through a nano sand mill for 10 minutes to obtain a second-level paint; mix the second-level paint with 0.5 parts of octadecyltrimethylammonium bromide dispersant, 0.5 parts Sodium dialkylbenzene sulfonate stabilizer and 0.5 part of polyether modified silicon defoamer were stirred and mixed evenly, ultrasonically oscillated for 10 minutes, and filtered through a membrane until the graphene conductive coating was obtained. The obtained graphene conductive paint is prepared through a coating process to produce a conductive film with excellent conductivity, and the sheet resistance of the film is 405Ω / sq.

Embodiment 2

[0035] 3 parts of graphene and 10 parts of polyvinyl acetate resin alcohol-soluble paint were mixed evenly, and the uniformly mixed slurry was ground on a ball mill for 30 minutes to obtain a primary dispersion paint. Mix the primary dispersion coating with 40 parts of ethanol diluent, and process it through a nano sand mill for 20 minutes to obtain a secondary coating; mix the secondary coating with 1 part of octadecyltrimethylammonium bromide dispersant, 1 part Twelve stabilizers and 0.3 parts of polyether modified silicon defoamer were stirred and mixed evenly, ultrasonically oscillated for 15 minutes, and filtered through a membrane until the graphene conductive coating was obtained. The obtained graphene conductive paint is prepared through a coating process to produce a conductive film with excellent conductivity, and the sheet resistance of the film is 335Ω / sq.

Embodiment 3

[0037]5 parts of graphene and 20 parts of polyvinyl acetate resin alcohol-soluble paint were uniformly mixed, and the uniformly mixed slurry was ground on a ball mill for 30 minutes to obtain a primary dispersion paint. Mix the primary dispersion coating with 50 parts of isopropanol diluent, and process it with a nano sand mill for 30 minutes to obtain a secondary coating; mix the secondary coating with 2 parts of dodecyltrimethylammonium bromide dispersant, 2 parts of dioctyl sodium sulfosuccinate stabilizer and 0.5 part of polyether defoamer were stirred and mixed evenly, ultrasonically oscillated for 30 minutes, and filtered through a membrane until the graphene conductive coating was obtained. The obtained graphene conductive paint is prepared through a coating process to produce a conductive film with excellent conductivity, and the sheet resistance of the film is 375Ω / sq.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com