Patents

Literature

1327 results about "Streptococcus thermophilus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Streptococcus thermophilus also known as Streptococcus salivarius subsp. thermophilus is a gram-positive bacterium, and a fermentative facultative anaerobe, of the viridans group. It tests negative for cytochrome, oxidase, and catalase, and positive for alpha-hemolytic activity. It is non-motile and does not form endospores. S. thermophilus is fimbriated.

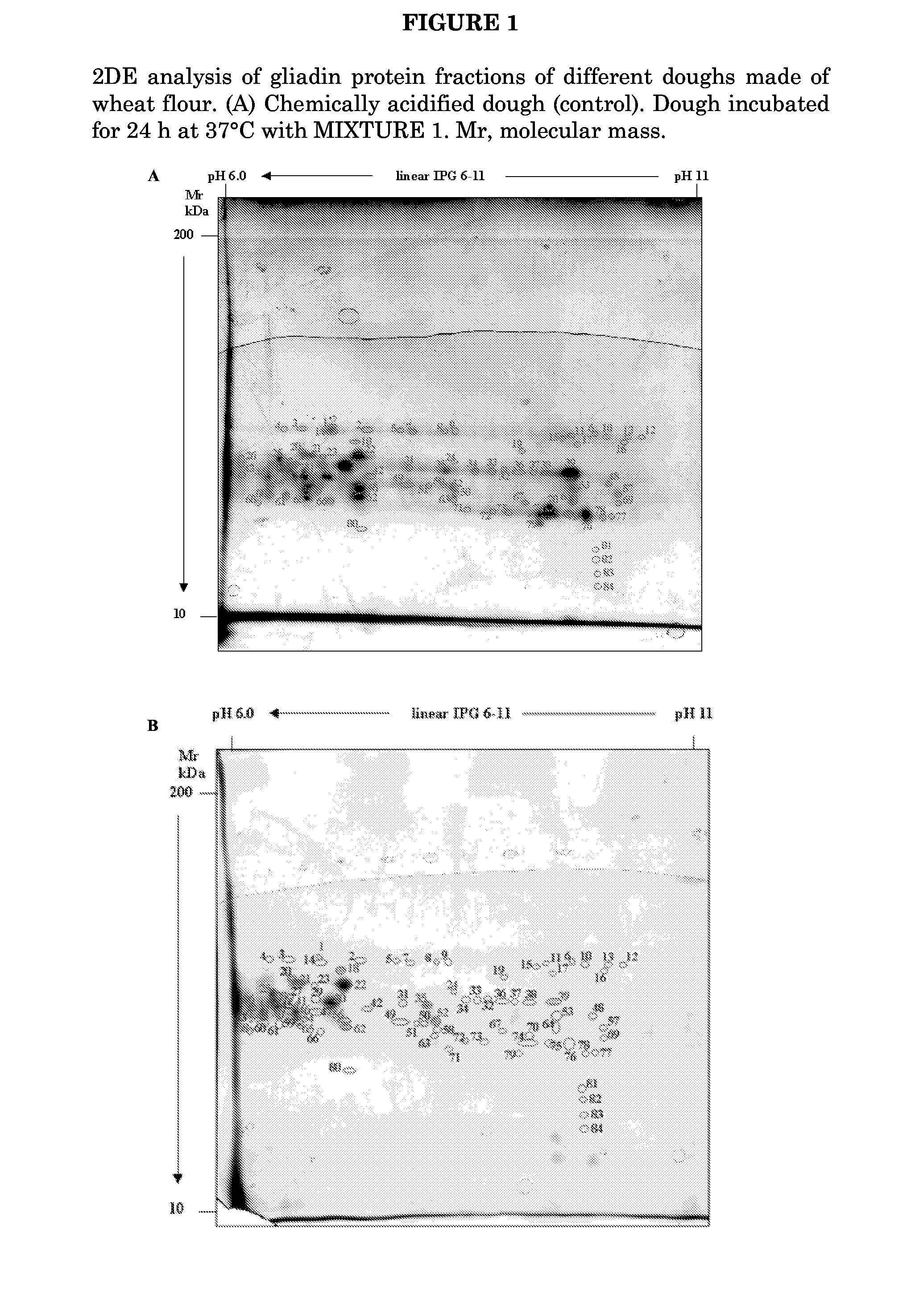

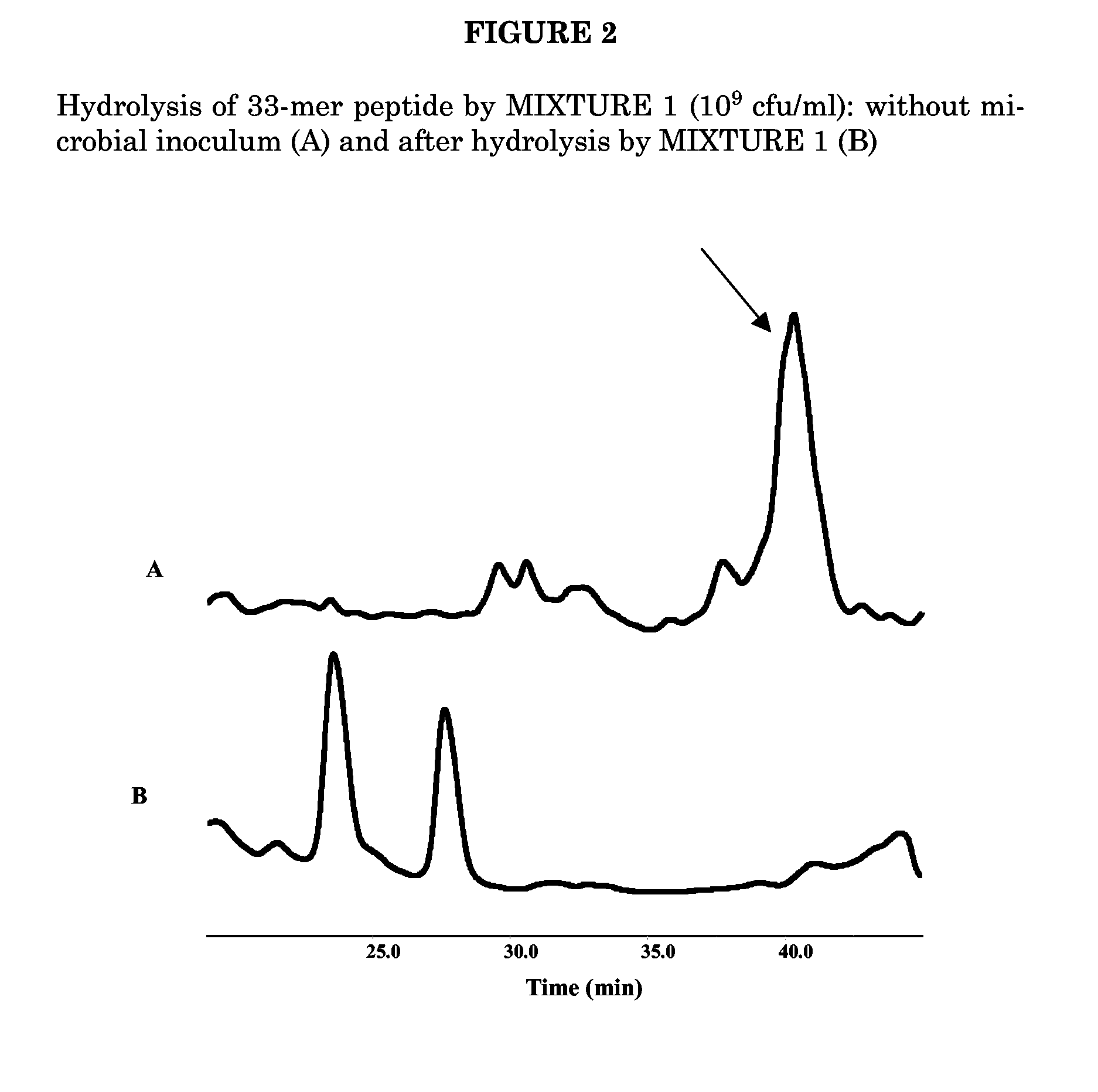

Mixture of at Least 6 Species of Lactic Acid Bacteria and/or Bifidobacteria in the Manufacture of Sourdough

A mixture of at least 6 species of lactic acid bacteria and / or Bifidobacteria is disclosed for use in bakery and medical field. The preferred mixture comprises Streptococcus thermophilus, Bifidobacterium infantis, Bifidobacterium longum, Bifidobacterium breve, Lactobacillus acidophilus, Lactobacillus plantarum, Lactobacillus casei, Lactobacillus delbrueckii subsp. bulgaricus. Said mixture is useful for a sourdough, a leavening composition. Baked goods and other food products obtained therefrom are disclosed. These goods have low or no gluten content and are suitable for the integration of the diet of a subject suffering from celiac disease, for decreasing the risk of allergies due to wheat flour albumins and globulins, for the treatment of schizophrenic symptoms, in the preparation of products for enteric diet.

Owner:VSL PHARMA INC

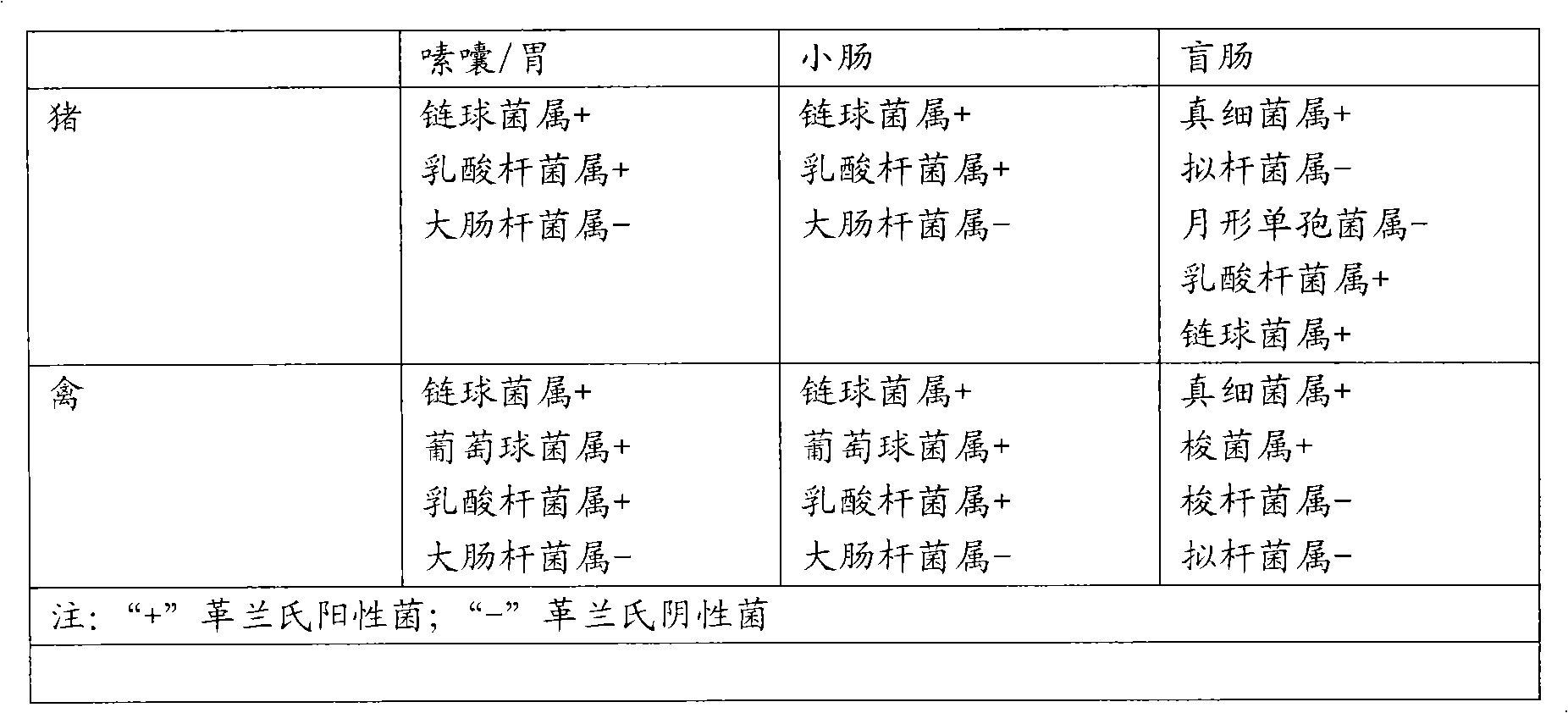

Composite probiotics feed additive containing lactic acid bacteria and preparation method thereof

ActiveCN103652322AImprove adaptabilityThe effect is accurateAnimal feeding stuffCelluloseBiotechnology

The invention relates to a composite probiotics feed additive containing lactic acid bacteria. The composite probiotics feed additive is prepared by spraying, freezing, drying and compounding 40-60% of lactobacillus acidophilus, 15-20% of lactobacillus amylophilus, 5-10% of lactobacillus salivarius, 5-10% of streptococcus thermophilus, 5-10% of bacteroides thetaiotaomicron and 5-10% of glucose. All strains are separated from pig intestines chime. With the consideration of each part of an intestinal canal of animal, the lactic acid bacteria which produce lactic acid of the front section of the intestinal canal are combined with the bacteroides thetaiotaomicron which dissolve cellulose and polysaccharide of the rear section of the intestinal canal, the proportion among the bacteria is similar to the composition of corresponding bacteria in the intestinal canal of a healthy animal, so that the respective advantages can be developed well, the health of the animal is improved further, the feed digestibility is improved, and the production performance of the animal is improved.

Owner:浙江启润生物科技有限公司

Method for preparing germinated brown rice milk beverage by compound lactobacillus fermentation

The invention provides a method for preparing germinated brown rice milk beverage by compound lactobacillus fermentation, which comprises the following steps of: preparing four lactobacillus direct-throwing fermentation agents such as lactobacillus rhamnosus, pediococcus acidilactici, streptococcus thermophilus and lactobacillus brevis; then soaking brown rice for 10 hours at 30 DEG C, and germinating for 12 hours at 2 DEG C to prepare germinated brown rice; adding 3 times water into the germinated brown rice, grinding milk by adopting colloid, gelatinizing and saccharifying the milk, adding 150 grams of direct-throwing fermentation agents into each ton of liquid rice milk, and performing standing fermentation for 6 hours at the temperature of between 38 and 40 DEG C; and centrifuging the liquid rice milk at 5,000 revolutions per minute, removing residue, adding xylitol according to the clear liquid volume for blending, filtering the liquid by using a hollow fiber membrane, performing ultrahigh-temperature instantaneous sterilization for 2 seconds at 143 DEG C, and filling the liquid with pillow-type package or tetra package to obtain a finished product.

Owner:黑龙江大荒春酒业有限公司

Powder of fermented milk or of yogurt with a high density of lactic ferments

The present application relates to a fermented milk or yoghurt powder which contains very high contents of S. thermophilus and L. bulgaricus, and which exhibits exceptional storage capacities. In the powder according to the invention, no substantial loss of live S. thermophilus and L. bulgaricus is observed after four months of storage at 20° C. The powder according to the invention has microbiological characteristics such that it itself corresponds to the name yoghurt or fermented milk.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

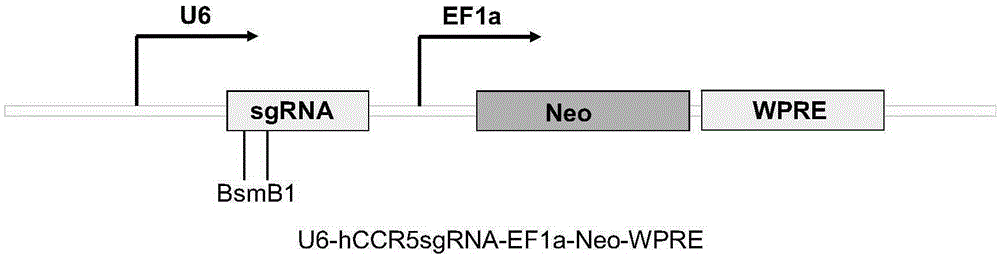

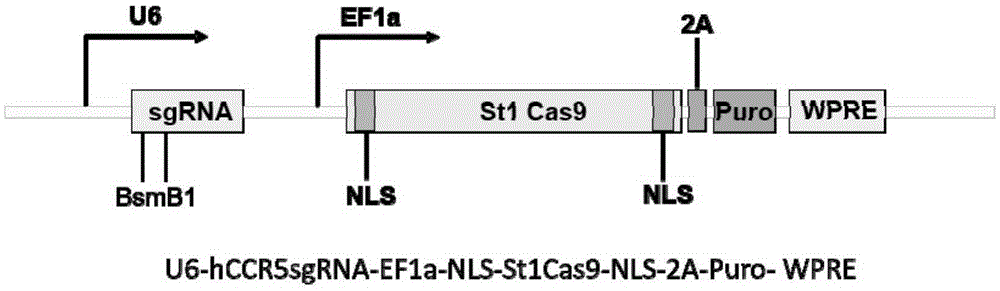

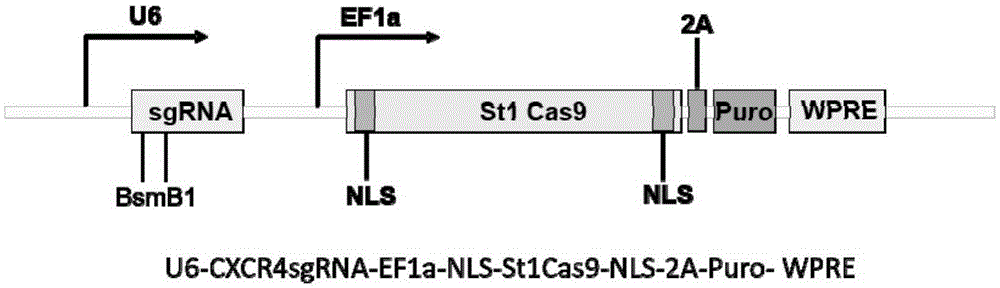

Human CCR5 gene target sequence recognized by streptococcus thermophilus CRISPR (clustered regularly interspaced short palindromic repeat)-Cas9 (CRISPR-associated protein 9) system, sgRNA (single guide ribonucleic acid) and application

InactiveCN105331607AAchieve preventionAchieve therapeutic effectGenetic material ingredientsAntiviralsGene targetsA-DNA

Owner:张竞方

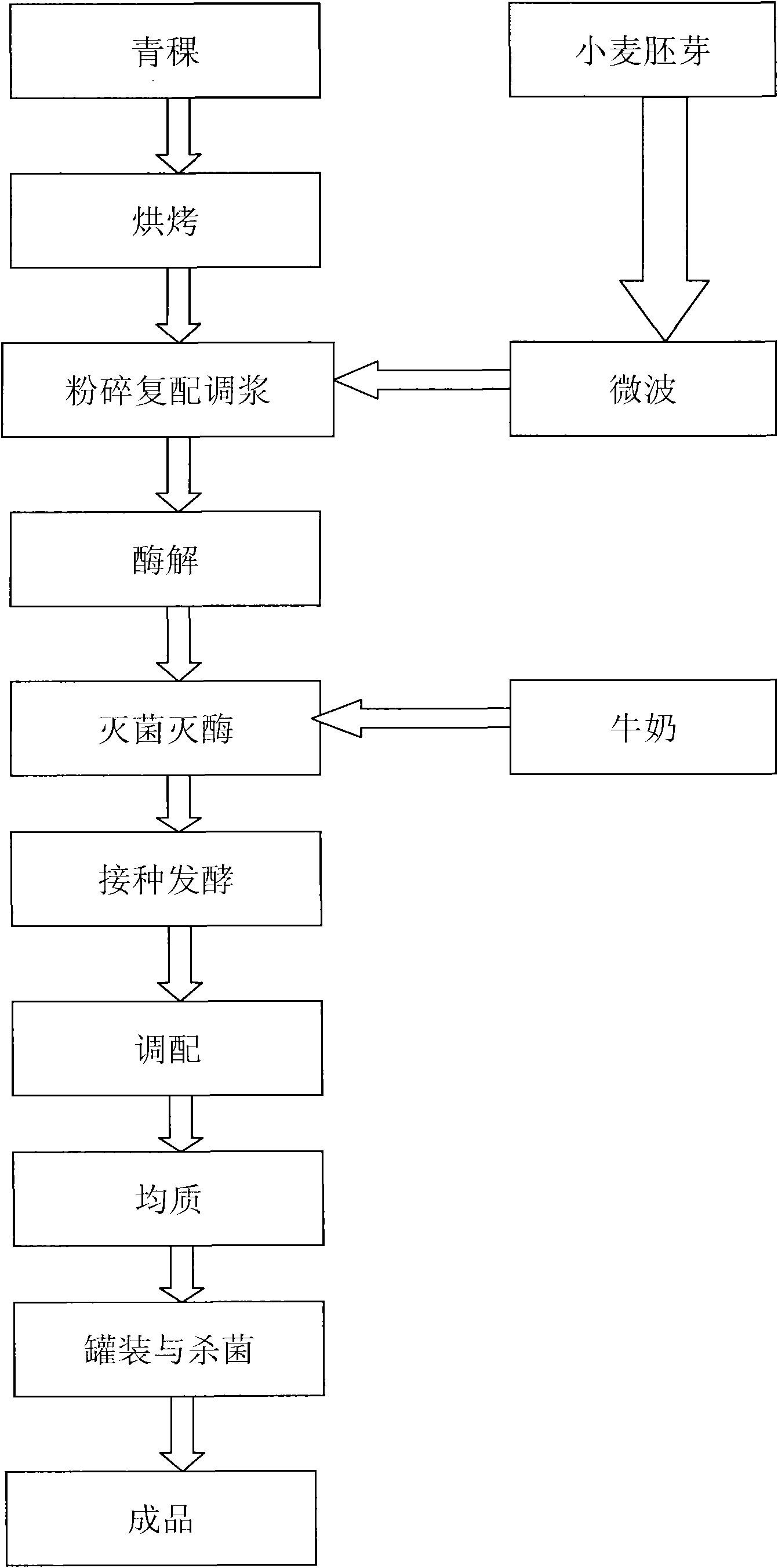

Process for preparing highland barley-wheat germ composite fermented beverage

ActiveCN102028289AOvercome rough tasteOvercome absorbencyFood preparationLactobacillus acidophilusBiology

The invention relates to a method for preparing a highland barley-wheat germ deep processing product, in particular to a process for preparing highland barley-wheat germ biological fermented milk, which solves the problems that the highland barley-wheat germ deep processing product has a single form and that nutrients cannot be absorbed by a human body completely. Lactobacillus bulgaricus, streptococcus thermophilus and lactobacillus acidophilus are inoculated according to a certain ratio, and a beta-glucan functional factor, dietary fibers, trace elements, microorganisms and the like of highland barley, and the nutrients such as high-quality plant proteins, vitamin E and the like of the wheat germ are utilized. The method mainly comprises the steps of: the compounding of the highland barley and the wheat germ, grinding into thick liquid, enzymolysis, the addition of milk and lactic acid fermentation. The prepared highland barley-wheat germ lactobacillus beverage is rich in proteins, lactic acid bacteria, beta-glucan, various trace elements, vitamins and the like.

Owner:西藏藏缘青稞科技有限公司

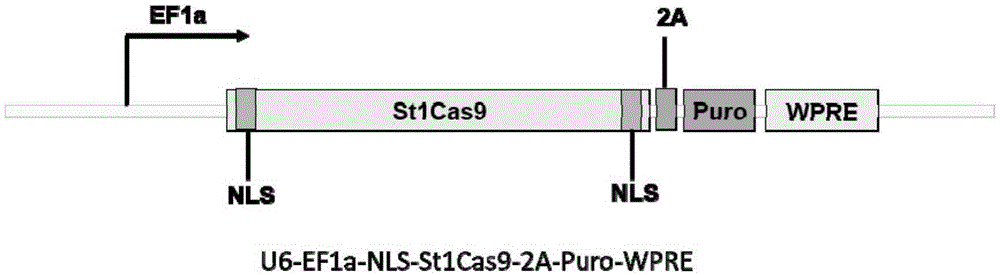

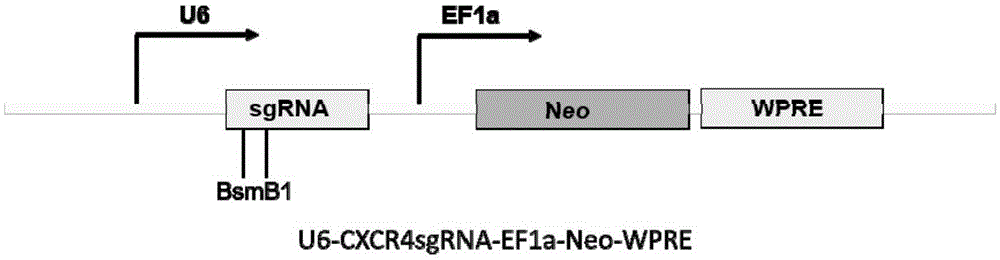

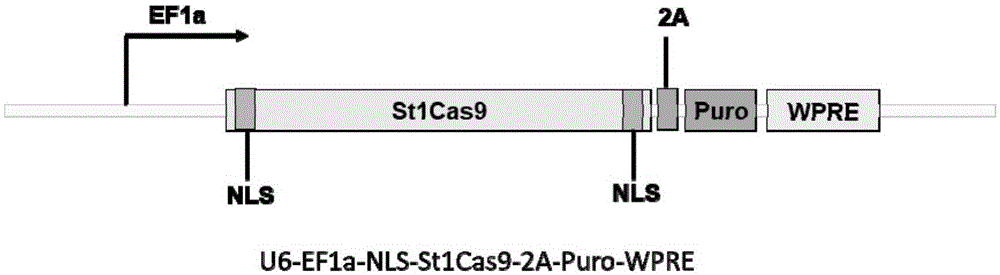

Streptococcus thermophilus derived human CXCR3 gene target sequence recognizable by CRISPR (clustered regularly interspaced short palindromic repeat)-Cas9 (CRISPR associated 9) system and sgRNA (single guide ribonucleic acid) and application thereof

InactiveCN105316324AAchieve preventionAchieve therapeutic effectOrganic active ingredientsHydrolasesProtein recruitmentA-DNA

The invention belongs to the field of genetic engineering, discloses a streptococcus thermophilus derived target sequence recognizable by a CRISPR (clustered regularly interspaced short palindromic repeat)-Cas9 (CRISPR associated 9) system and further discloses a sgRNA (single guide ribonucleic acid) and a coding DNA (deoxyribonucleic acid) molecule thereof. The target sequence is shown as n-20th of any one of SEQ ID NO:1-63, wherein n=1-5. A sequence of the sgRNA is 5'-recognition sequence- Cas9 protein recruitment sequence-3', and a DNA sequence corresponding to the recognition sequence is identical to the target sequence. The invention also discloses the CRISPR-Cas9 system, and the CRISPR-Cas9 system comprises Cas9 proteins and sgRNA and / or comprises carriers carrying a Cas9 protein coding sequence and a sgRNA coding sequence. The invention further discloses application of the CRISPR-Cas9 system to CXCR4 gene editing and preparation of medicines for treating HIV (human immunodeficiency virus) infection. CXCR4 gene editing can be realized to protect cells from HIV infection.

Owner:张竞方

Production of pure soya-bean lactacidase fermenting beverage

InactiveCN1644112AFine tissuePure bean flavorFood preparationMilk substitutesStreptococcus thermophilusBiology

A fermented lactobacillus beverage is prepared from soybean through preparing soybean milk, inoculating thermophilic streptococcus and lactobacillus, fermenting, dispensing, homogenizing and sterilizing. Its advantages are agreeable taste, not containing cholesterine and lactose, and high nutritive value.

Owner:JIANGNAN UNIV

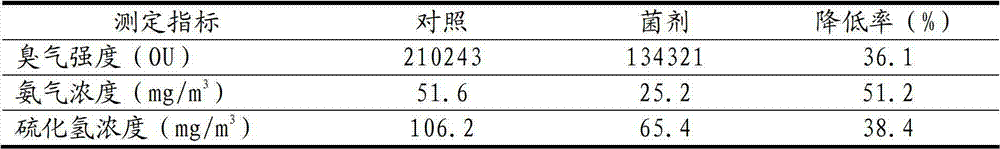

Microbial deodorizing inoculant

InactiveCN104946544AGeneration and solutionSolve the stenchFungiBacteriaBacillus licheniformisBacteroides

The invention discloses a microbial deodorizing inoculant which is used in refuse sites, public toilets and livestock / poultry cultivation farms. The microbial deodorizing inoculant contains Candida utilis of which the collection number is ACCC 20060, Lactobacillus plantarum of which the collection number is ACCC 11016, lactic streptococci of which the collection number is ACCC 10653, cerevisiae fermentum of which the collection number is ACCC 21135, Streptococcus thermophilus of which the collection number is ACCC 10651, Bacillus licheniformis of which the collection number is ACCC 01870, and Bacillus natto of which the collection number is ACCC 19833. The microbial deodorizing inoculant absorbs and degrades generated malodorous gas hydrogen sulfide and ammonia gas, eliminates the malodor of the garbage and garbage leachate, inhibits the putrefaction bacteria from growth, basically prevents the malodorous gas from generation, and forms a disease-spread-free refuse piling environment capable of eliminating the malodor.

Owner:防城港市盛吉科技有限公司

Method for preparing brown rice enzyme yogurt

InactiveCN101703105AShorten fermentation timeImprove biological activityMilk preparationAdditive ingredientFermentation starter

The invention discloses a method for preparing a brown rice enzyme yogurt. The preparation method mainly comprises the steps of pretreatment of raw materials, homogenization, sterilization, cooling, addition of brown rice enzyme and a ferment, fermentation, cooling, filling and refrigeration. The addition of the brown rice enzyme and the ferment is as follows: 3-7 parts by weight of the brown rice enzyme and 4-6 parts by weight of the ferment are added in 100 parts by weight of mixed solution after the treatment for carrying out inoculation; and the ferment is mixed culture solution of streptococcus thermophilus and lactobacillus bulgaricus. The brown rice enzyme is formed by fermenting brown rice, dozens of types of new enzyme can be derived when having the nutrition of the brown rice, and the brown rice enzyme yogurt is further rich in gamma-aminobutyric acid, glutathione, gamma-oryzanol, ceramide, lipopolysaccharides from rice bran, minerals and other nutritional components. The brown rice enzyme yogurt mixes the dual functions of the brown rice enzyme and the yogurt, is easy to be absorbed by human body and can improve the immunity of the human body and activate cells, thereby being the beneficial complement to modern dietary nutrition.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Fermented chenopodium quinoa willd milk, flavored fermented chenopodium quinoa willd milk, chenopodium quinoa willd sour milk beverage and preparation method

InactiveCN106036311AReasonable nutritional compositionImprove digestion and absorption rateLactobacillusStrepto/lacto-coccusLactobacillus acidophilusHydrolysis

The invention relates to fermented chenopodium quinoa willd milk, flavored fermented chenopodium quinoa willd milk, a chenopodium quinoa willd sour milk beverage, and a preparation method of products, and belongs to the technical field of food industry. Chenopodium quinoa willd is used as a raw material for pulping, the protein content is not less than 2.9g / 100g, a yoghourt fermenting agent is inoculated, fermentation is performed until acidity reaches to 70DEG T or above so that the fermented chenopodium quinoa willd milk is obtained. The yoghourt fermenting agent comprises a mixed bacterium agent which is obtained by mixing lactobacillus bulgaricus with streptococcus thermophilus in the mass ratio of the lactobacillus bulgaricus to the streptococcus thermophilus being 1 to 1 and of which the inoculum concentration is 20-25g / T, a mixed bacterium agent in which the mass ratio of lactobacillus acidophilus to bifidobacteria and to lactobacillus casei is 1 to 1 to 1 and of which the inoculum concentration is 12-15g / T, and lactobacillus plantarum of which the preservation number is CGMCC No.11763 and of which the inoculum concentration is 60-80ml / T. The chenopodium quinoa willd is used as the raw material, composite enzyme hydrolysis and composite active probiotic fermentation are used, and active probiotic fermented chenopodium quinoa willd milk and series products are prepared, so that industry blank is filled.

Owner:北京农品堂食品有限公司

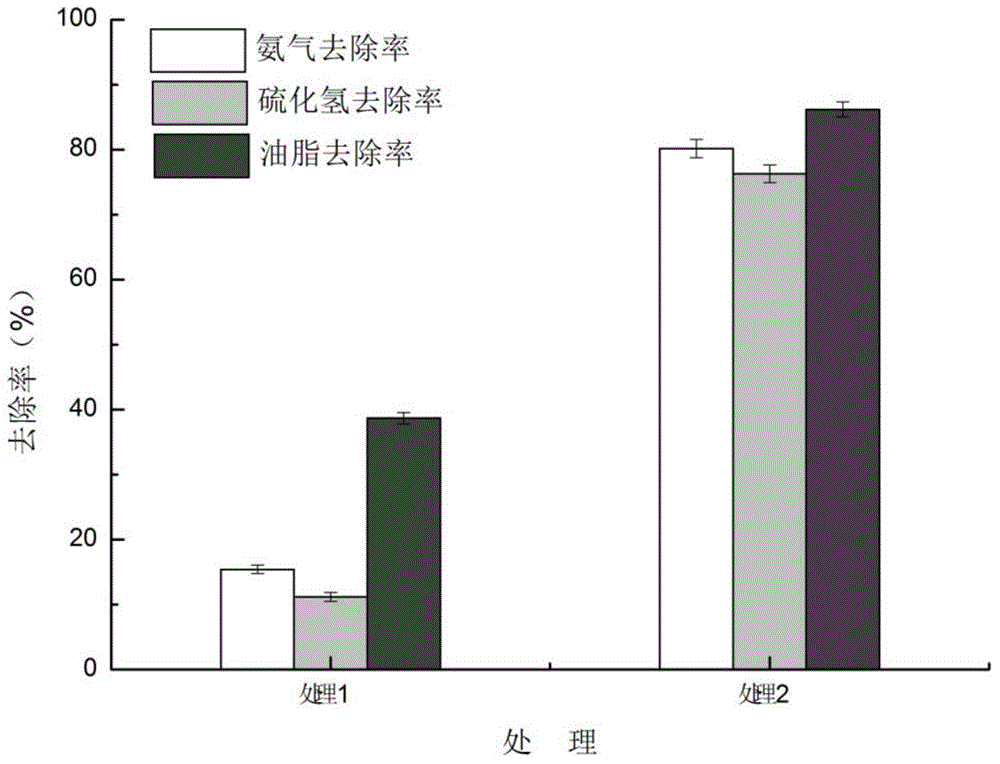

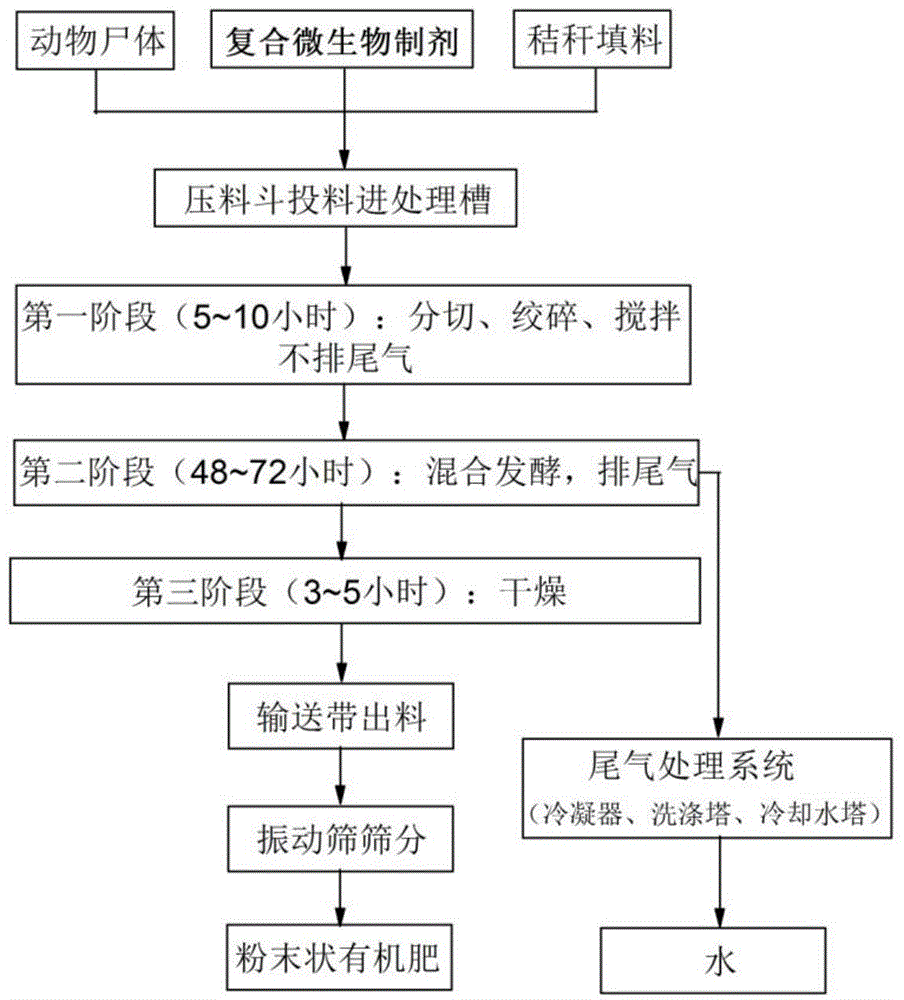

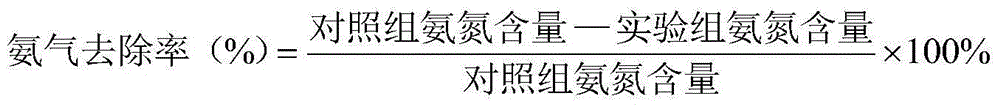

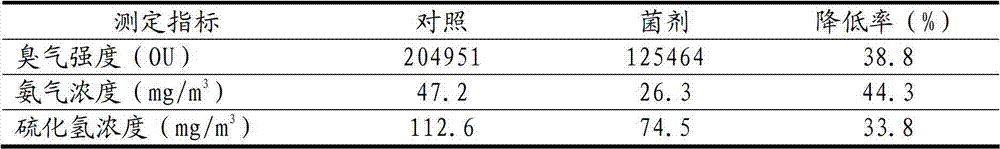

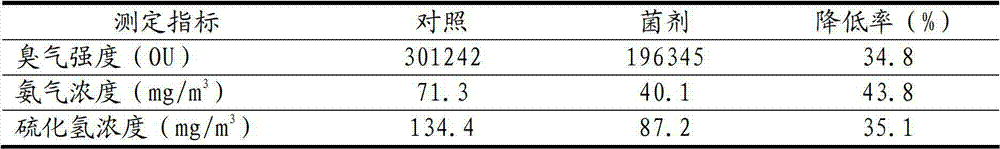

Compound microorganism preparation, preparing method and application of compound microorganism preparation to processing animal carcasses

ActiveCN104894007AEfficient decompositionQuick breakdownBio-organic fraction processingBacteriaBiotechnologyCellulose

The invention discloses a compound microorganism preparation. The compound microorganism preparation comprises thermophilic fat bacillus, pseudomonas aeruginosa, streptococcus thermophilus, bacillus megatherium and bacillus flexus. The invention further discloses a preparing method of the compound microorganism preparation and application of the compound microorganism preparation to processing animal carcasses. Compared with the prior art, the compound microorganism preparation has the beneficial effects that macromolecular compounds, such as fat and celluloses in the animal carcasses and straw auxiliary materials, which are difficult to decompose can be efficiently and rapidly decomposed through the compound microorganism preparation, and the animal carcasses are converted into organic fertilizers with the low fat content; and the compound microorganism preparation further has the efficient deodorization function, the release amount of NH3 and H2S in the processing procedure can be effectively reduced, the stink concentration is reduced, and odorless processing is achieved. Finally, the animal carcasses are efficiently and safely processed into the organic fertilizers in an environmental protection manner, and resource utilization of the animal carcasses is achieved.

Owner:ANHUI QINGMING ENVIRONMENTAL PROTECTION TECH CO LTD

Nutrition for prevention of infections

InactiveUS20110097437A1Decreased bacterial translocationImprove intestinal barrier functionOrganic active ingredientsPeptide/protein ingredientsPhysiologyBacterial translocation

A nutritional composition comprising a combination of non-digestible oligosaccharides and a product obtained by incubating an aqueous substrate by bifidobacteria and optionally a product obtained by incubating an aqueous substrate by S. thermophilus. Said combination reduces bacterial translocation and improves the intestinal barrier function.

Owner:NUTRICIA

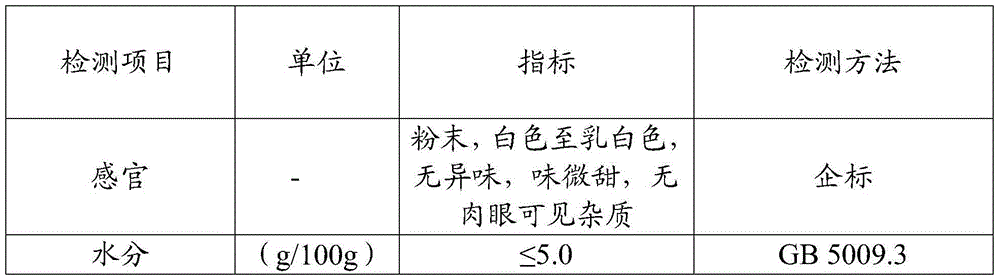

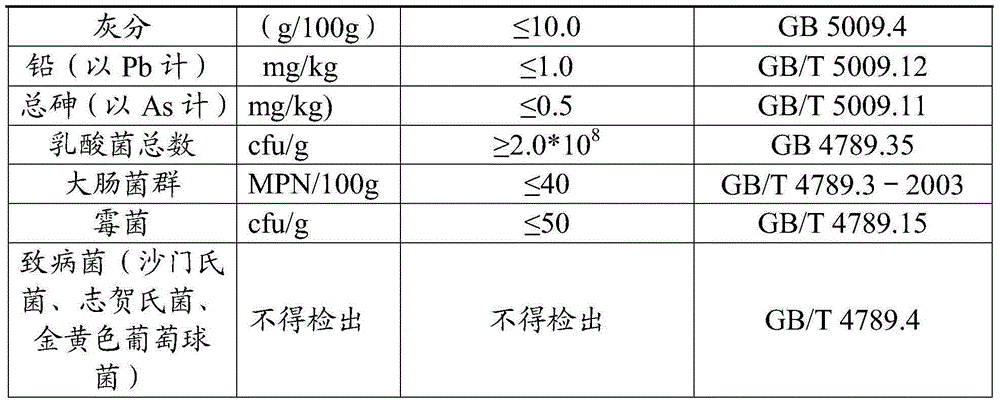

Livestock and poultry excrement microbial deodorizing agent, and preparation method and application thereof

ActiveCN102851210AInhibition of growth and reproductionEasy to controlFungiMicroorganism based processesMicroorganismMicrobiology

The invention relates to a livestock and poultry excrement microbial deodorizing agent, and a preparation method and an application thereof. The invention discloses a composite biological preparation used in public toilet deodorization. The composite biological preparation comprises a lactobacillus strain which is lactobacillus sp with a collection number of CGMCC NO: 5983, a lactobacillus strain which is streptococcus thermophilus with a collection number of CGMCC NO: 5985, and an orange peel extraction liquid. The invention also discloses the preparation method of the composite biological preparation. The method comprises preparation methods of a liquid composite biological preparation and a solid biological preparation. The invention also discloses a purpose of the composite biological preparation.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

Preparation method of R-polysaccharide fermentation liquor and preparation method of composite preservative of R-polysaccharide fermentation liquor

InactiveCN101974601ASimple processNo smellFood preservationMicroorganism based processesBiotechnologyCellulose

The invention discloses to a preparation method of R-polysaccharide fermentation liquor and a preparation method of a composite preservative of the R-polysaccharide fermentation liquor, relating to a preparation of fermentation liquor and a preparation method of a composite preservative of the fermentation liquor, which solves the problems of complex preparation technology of the traditional R-polysaccharide preparation, and high production cost and low yield of the preparation of a preservative of the traditional R-polysaccharide preparation. The preparation method of the R-polysaccharide fermentation liquor comprises the following steps of activating bacillus subtilis, streptococcus thermophilus and brewers' yeast; collecting and washing after being centrifuged; fermenting and cultivating the thalluses after mixing; and purifying the fermentation liquor. The preparation method of the preservative is as follows: mixing nisin, natamycin, propionic acid, antioxidant of bamboo-leaf, chitosan, ethylene diamine tetraacetic acid (EDTA), cellulose, ethanol, sorbitol and oxygen-enriched active water; and mixing the mixed liquor and the R-polysaccharide fermentation liquor to be reacted. The preparation of the R-polysaccharide fermentation liquor has the advantages of simple technology, no three-waste generation, no pollution discharge and no peculiar smell. The R-polysaccharide fermentation liquor is prepared into a composite preservative, the production cost is ** yuan / ton, and the yield is high.

Owner:王心礼

Lactic acid bacteria composition capable of regulating intestinal flora functions and preparation method and application thereof

ActiveCN104824662APromote growthPromote growth and proliferationFood ingredient functionsFood preparationLactobacillus rhamnosusAdditive ingredient

The invention discloses a lactic acid bacteria composition capable of regulating intestinal flora functions and preparation method and application thereof. The active ingredients of the lactic acid bacteria composition capable of regulating intestinal flora functions are prepared from the following raw materials by weight: 20-40 parts of Lactobacillus acidophilus, 40-60 parts of Bifidobacterium longum, 20-60 parts of Lactobacillus rhamnosus, 30-60 parts of Streptococcus thermophilus and 35-75 parts of fructo-oligosaccharide. According to the lactic acid bacteria composition capable of regulating intestinal flora functions, lactic acid bacteria in the composition can reach a certain magnitude, and the raw materials are in reasonable compatibility, and have a good function of regulating intestinal flora. The lactic acid bacteria composition has good stability in a long time, and is suitable for the diabetics to eat.

Owner:SYNSUN HEALTH IND

Probiotic composition and preparation thereof

ActiveCN101897729AAvoid infectionImprove proliferative abilityOrganic active ingredientsBacteria material medical ingredientsBifidobacteriumProbiotic

The invention relates to a probiotic composition and a preparation. The composition consists of three main probiotics, namely lactobacillus, bifidobacteria and streptococcus thermophilus. The composition can be regulated to be suitable for different intestinal canal characteristics of more people and meet the market requirement and has the advantages of safety, reliability and obvious effect.

Owner:天津金士力健康用品有限公司

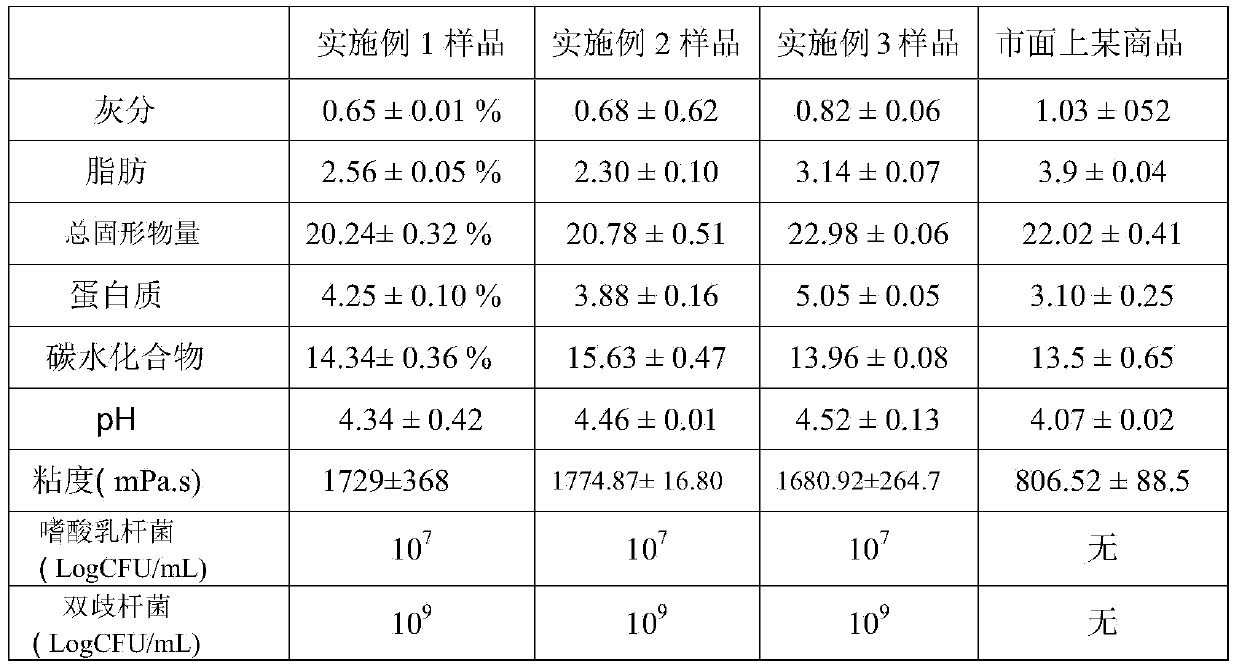

Symbiotic functional high-protein Greek yogurt utilizing polymeric whey protein as main thickening agent and preparation method thereof

InactiveCN103583692AHigh in proteinImprove metabolic efficiencyMilk preparationNutritive valuesGreek yogurt

The invention discloses symbiotic functional high-protein Greek yogurt utilizing polymeric whey protein as a main thickening agent and a preparation method thereof, and belongs to the field of functional health-care foods. The symbiotic functional high-protein Greek yogurt mainly comprises liquid raw material milk, sugar, inulin, polymeric whey protein, pectin and a protein increasing material. The preparation method comprises polymeric whey protein preparation and Greek yogurt preparation. A probiotic fermentation agent used in the preparation method comprises two basic bacteria such as lactobacillus bulgaricus and streptococcus thermophilus and also comprises two probiotics such as bifidobacteria and lactobacillus acidophilus. The symbiotic functional high-protein Greek yogurt has the characteristics of high nutritive value, high protein content, low fat content, fine texture, uniform structure and good taste. The symbiotic functional high-protein Greek yogurt contains the probiotics and dietary fibers and improves intestinal digestive system health. The preparation method can be operated easily, has a low production cost, saves energy, does not produce environmental pollution and has a high yield.

Owner:JILIN UNIV

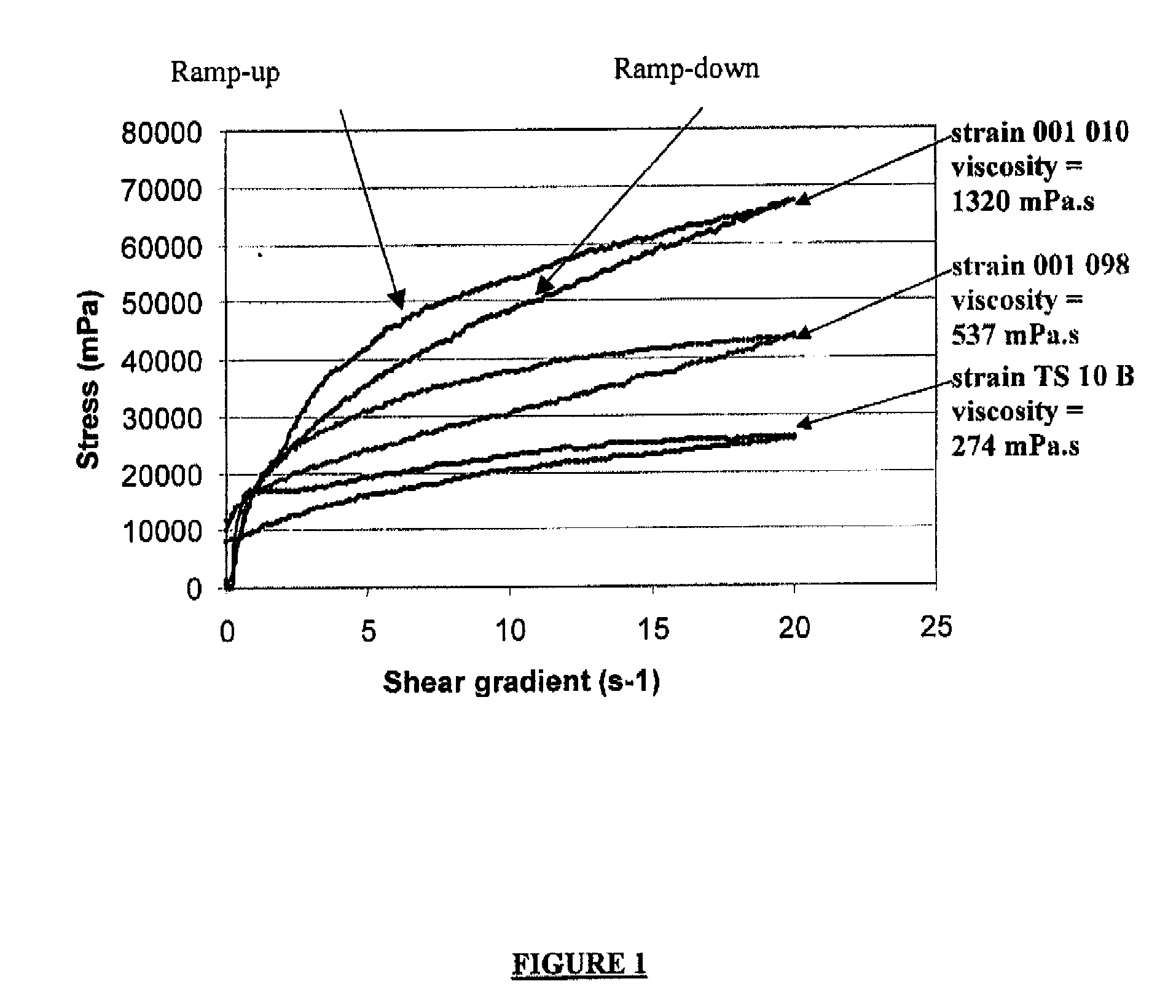

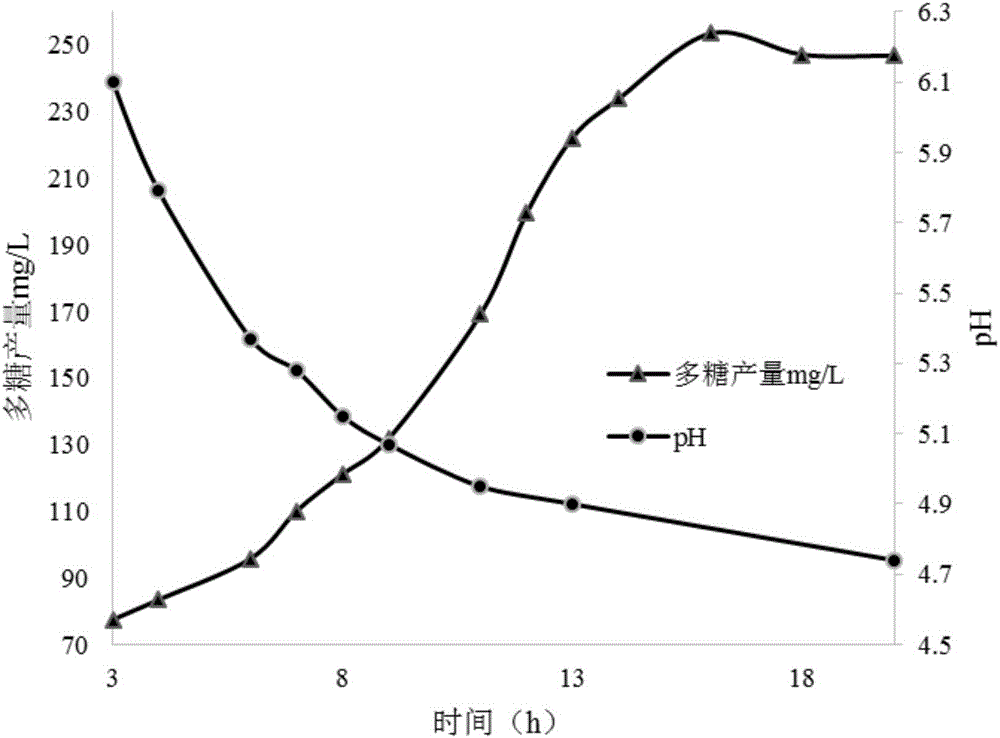

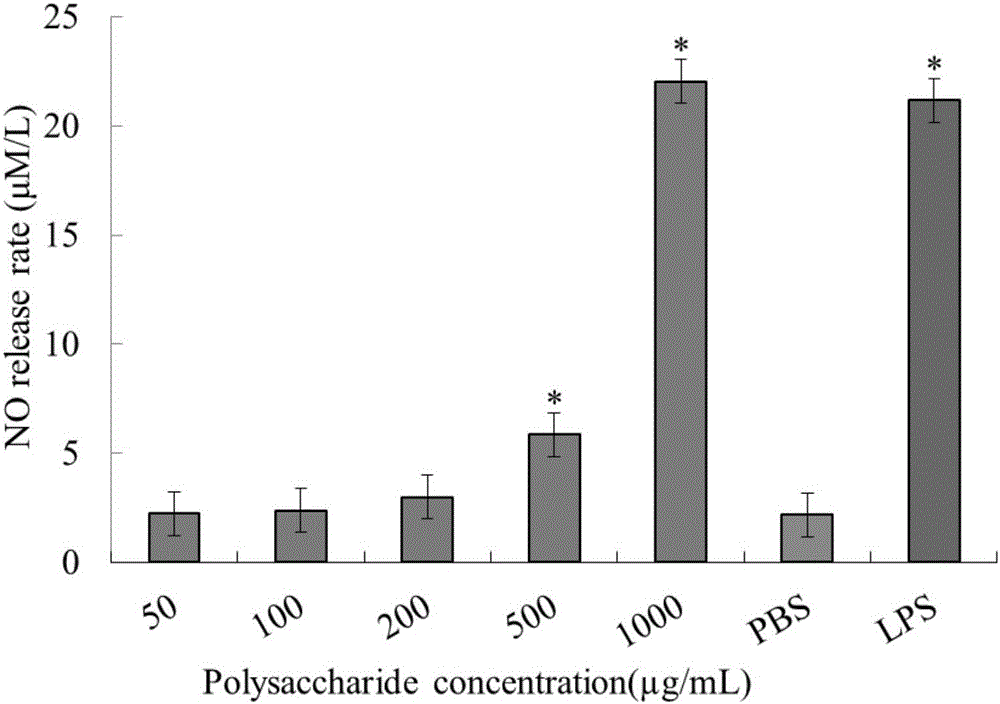

Streptococcus thermophilus and application thereof

InactiveCN105886434AWell organizedImprove textural properties such as tissue stateMilk preparationBacteriaFlavorImmunologic Competence

The invention provides a streptococcus thermophilus AR-333 strain and application thereof. The streptococcus thermophilus AR-333 strain is obtained through being separated from naturally fermented milk, and the collection number of the strain is CGMCC 10262. The streptococcus thermophilus AR-333 is fermented for 16h under the condition of 40 DEG C by skimmed milk; the yield of extracellular mucopolysaccharide reaches 256.97 mg / L; meanwhile, the streptococcus thermophilus is used as a yoghourt fermenting agent; the viscosity of yoghourt can be obviously improved; the tissue state of the yoghourt can be improved; good flavor is realized; the generated extracellular mucopolysaccharide has an immunologic competence regulating function; macrophages RAW264.7 can be simulated to release NO.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Method for making tofu coagulant from lactic acid bacteria fermented yellow slurry water

InactiveCN102258085AImprove qualityRich sourcesCheese manufactureFood scienceLactic acid bacteriumSucrose

The invention discloses a method for making tofu coagulant by lactic acid bacteria fermenting yellow jelly water. After activating Streptococcus thermophilus and Lactobacillus bulgaricus, they are inserted into the yellow jelly water, and the inoculum amount is 0.8-3.5% of the weight of the yellow jelly water. The sucrose with 8-10% of the weight of yellow pulp water is fermented at 37-43 DEG C for 4-8 hours, and when the pH of the fermented liquid is 3.0-4.5, the liquid bean curd coagulant is obtained. The invention recycles yellow pulp water as waste, and obtains a novel natural bean curd coagulant through fermentation of lactic acid bacteria. The method has the advantages of simple process and convenient operation, and is beneficial to maintaining the activity of bacteria. In addition, waste utilization is economical and environmentally friendly, and it is an environmentally friendly technology. The method has the advantages of low cost, no pollution, simple process, simple operation, continuous production, high production efficiency, good biological activity and stability of the product, and the like.

Owner:HENAN AGRICULTURAL UNIVERSITY

Probiotic and prebiotic composition for forming lean body mass and application thereof

ActiveCN110151796AEffective regulationImprove immunityOrganic active ingredientsMetabolism disorderDiseaseBody shape

The invention discloses a probiotic and prebiotic composition for forming lean body mass and application thereof, and relates to the field of biomedicine. The composition comprises probiotics such asbifidobacterium lactis, bifidobacterium longum, lactobacillus reuteri, lactobacillus rhamnosus, lactobacillus acidophilus, streptococcus thermophilus, bacillus coagulans and clostridium butyricum, anda prebiotic mixture is also added. By reasonably matching the components of the composition, the intestinal flora is effectively regulated, and the obesity is more efficiently and healthily relieved;for people with normal weight, the weight reduction effect is not obvious, but the body shape is more beautiful; meanwhile, the composition can effectively prevent hyperglycemia, hyperlipidemia and other diseases and improve the body immunity, is suitable for a wider range of people, and can be applied to food, pharmacy and healthy or natural product production.

Owner:ZHONGKE YIKANG BEIJING BIOTECH CO LTD

Jerusalem artichoke-soybean fermentation beverage and preparation method thereof

The invention discloses a jerusalem artichoke-soybean fermentation beverage and a preparation method thereof. The beverage contains a jerusalem artichoke-soybean fermentation solution as a main component. The preparation method of the jerusalem artichoke-soybean fermentation solution comprises the following steps of: mixing jerusalem artichoke pulp and soya-bean pulp in a volume ratio of (3-5):1, heating and sterilizing, wherein the obtained mixture is used as a fermentation base material; and then inoculating mixture bacterium of lactobacillus bulgaricus, streptococcus thermophilus, monascus and beer yeast into the fermentation base material according to an inoculating amount of 3-5%, fermenting for 12-20hours at a temperature of 28-32 DEG C, filtering after finishing fermentation and then adding aroma enhancement yeast into the fermentation base material according to an inoculating amount of 1-2%, then fermenting for 48-60 hours again at the same temperature, and filtering a fermentation solution after finishing fermentation to obtain a jerusalem artichoke-soybean fermentation solution. The mass ratio of lactobacillus bulgaricus to streptococcus thermophilus to monascus to beer yeast is 2:2:4:2. The preparation method disclosed by the invention is unique; the obtained beverage has good mouth feel, good appearance and rich nutrition; and the immunity can be improved after drinking the beverage for a long time.

Owner:SHANDONG JIANZHU UNIV

Method for preparing yoghourt rich in gamma-aminobutyric acid (GABA)

ActiveCN102550670AHas nutritional valueImprove securityMilk preparationNutritive valuesBiotechnology

A method for preparing yoghourt rich in gamma-aminobutyric acid (GABA) relates to a method for preparing yoghourt and comprises the steps of resuscitating, purifying and activating lactobacillus plantarum NDC75017, lactobacillus bulgaricus 11057 and streptococcus thermophilus CICC 20379, respectively enlarging culture solutions and then mixing to obtain a leavening agent, and inoculating the leavening agent to sterilized milk to ferment. The GABA content in the yoghourt rich in GABA is 151.51mg / 100g. High-yield GABA bacterial strains and existing commonly-used bacterial strains are compoundedand then fermented to prepare the yoghourt rich in GABA, all the bacterial strains are food-grade lactic acid bacteria, and the safety is high. In addition, products have double effects, and the yoghourt rich in GABA integrates physiological efficacy of the GABA and health-care effect of yoghourt, namely the yoghourt rich in GABA is provided with special physiological efficacy of the GABA and thehealth-care effect of the yoghourt and is novel health-care yoghourt.

Owner:湖北均瑶大健康饮品股份有限公司

Preparation method of probiotics fermented pumpkin and carrot vegetable powder

InactiveCN102318806ABacteriaMicroorganism based processesStaphylococcus lactisLactobacillus rhamnosus

The invention provides a preparation method of probiotics fermented pumpkin and carrot vegetable powder. The four probiotics, Lactobacillus rhamnosus, lactobacillus paracasei subsp. paracasei, streptococcus thermophilus, and lactococcus lactis subsp. Cremoris are adopted as the starting strains, which are then subjected to enlargement culture, preparation of lyophilized powder strains, compounding of lyophilized powder, thus obtaining composite probiotic lyophilized powder. The preparation method comprises the steps of: employing cleaned and seed removed pumpkins and cleaned carrots in a weight ratio of 3:1, adding drinking water of the same weight to the mixed material into a colloid mill for slurry refining, matching the slurry with 5% white sugar, after disinfection and cooling, inoculating the composite probiotic lyophilized powder with 0.01% of the slurry, carrying out fermentation for 48h, and then conducting centrifugal dehydration, wall material embedding with sodium alginate and a flaxseed gum, as well as freeze drying, thus obtaining the probiotics fermented pumpkin and carrot vegetable powder.

Owner:HEILONGJIANG SHUNKANG VEGETABLES PROCESSING

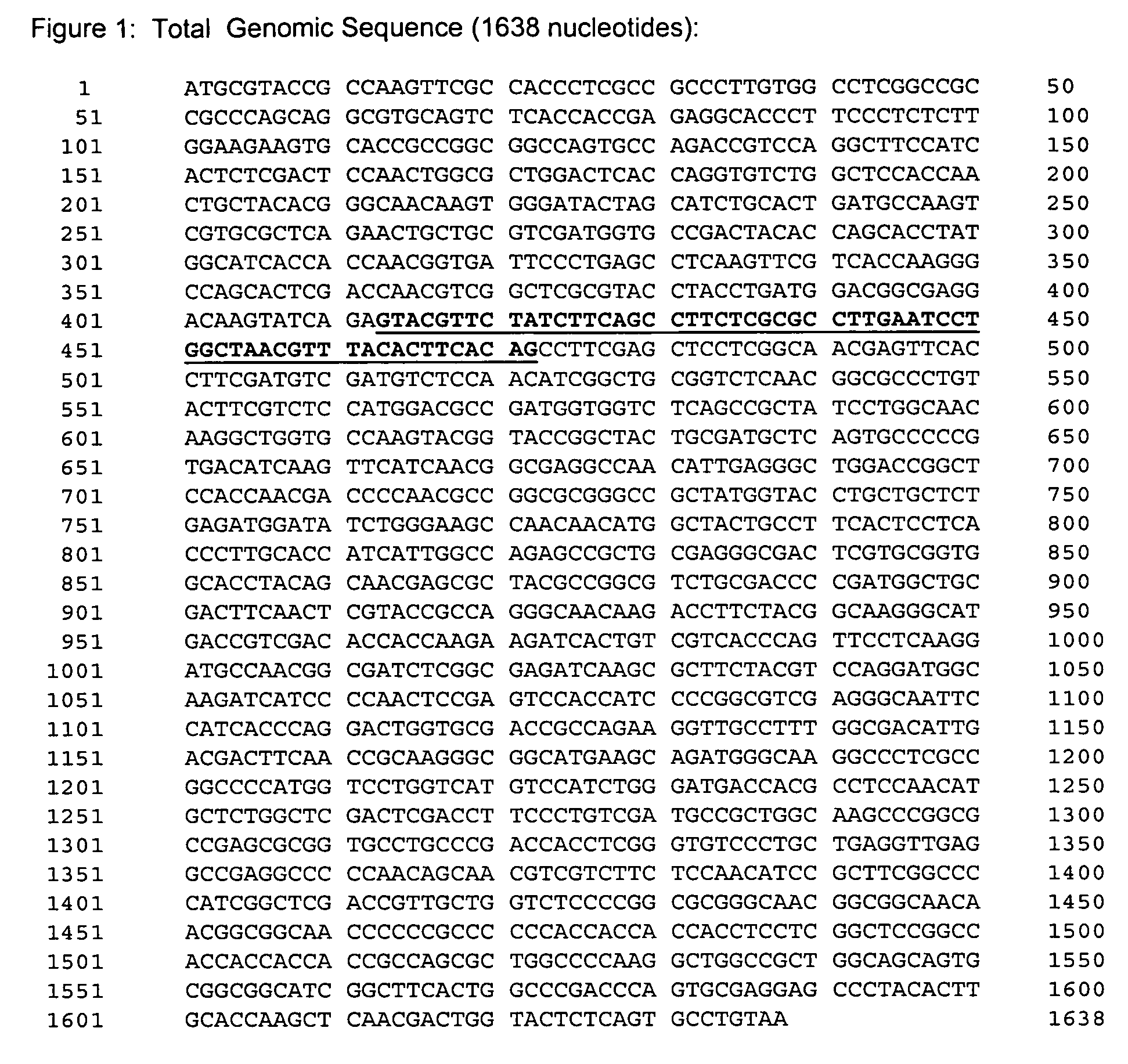

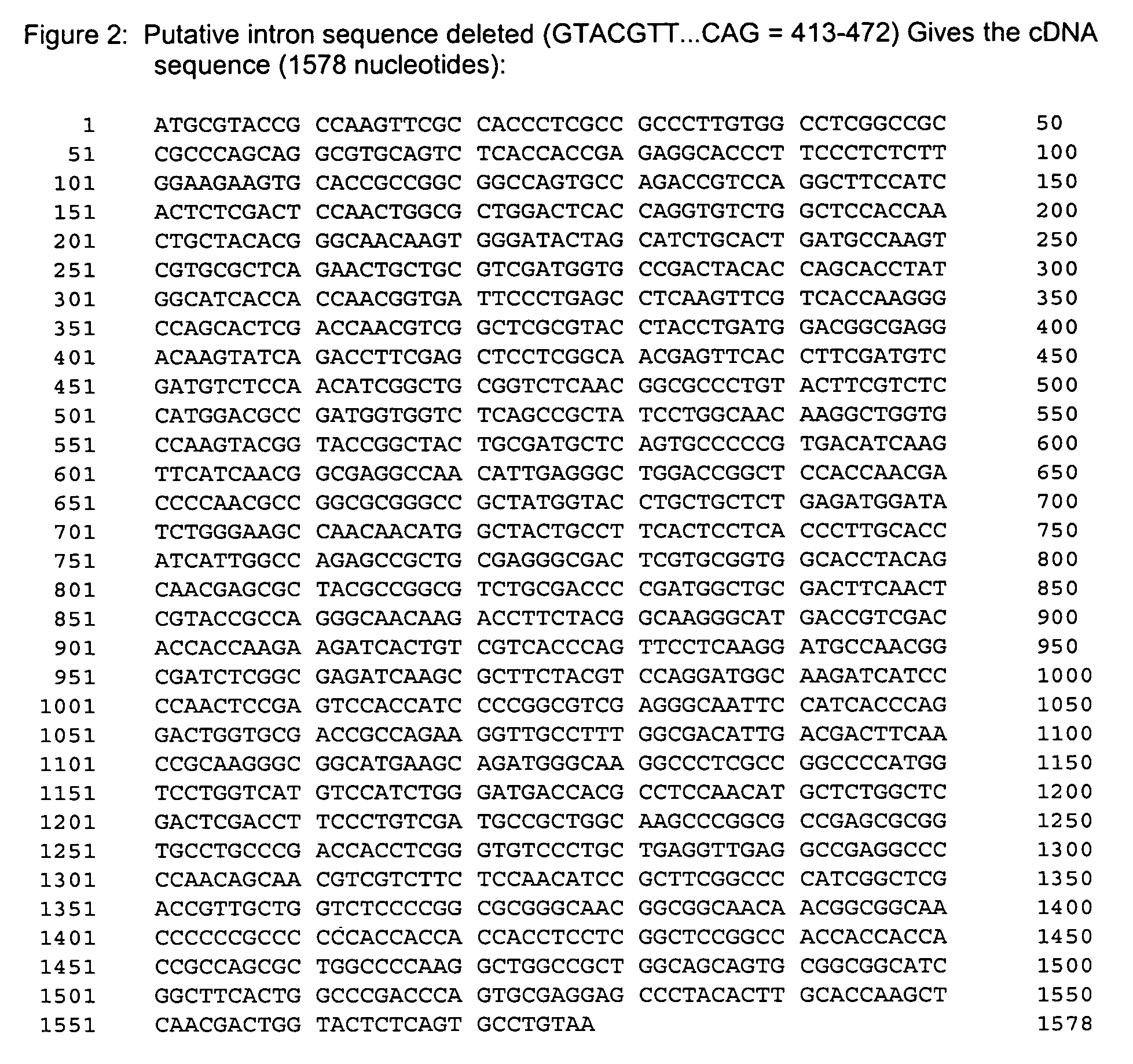

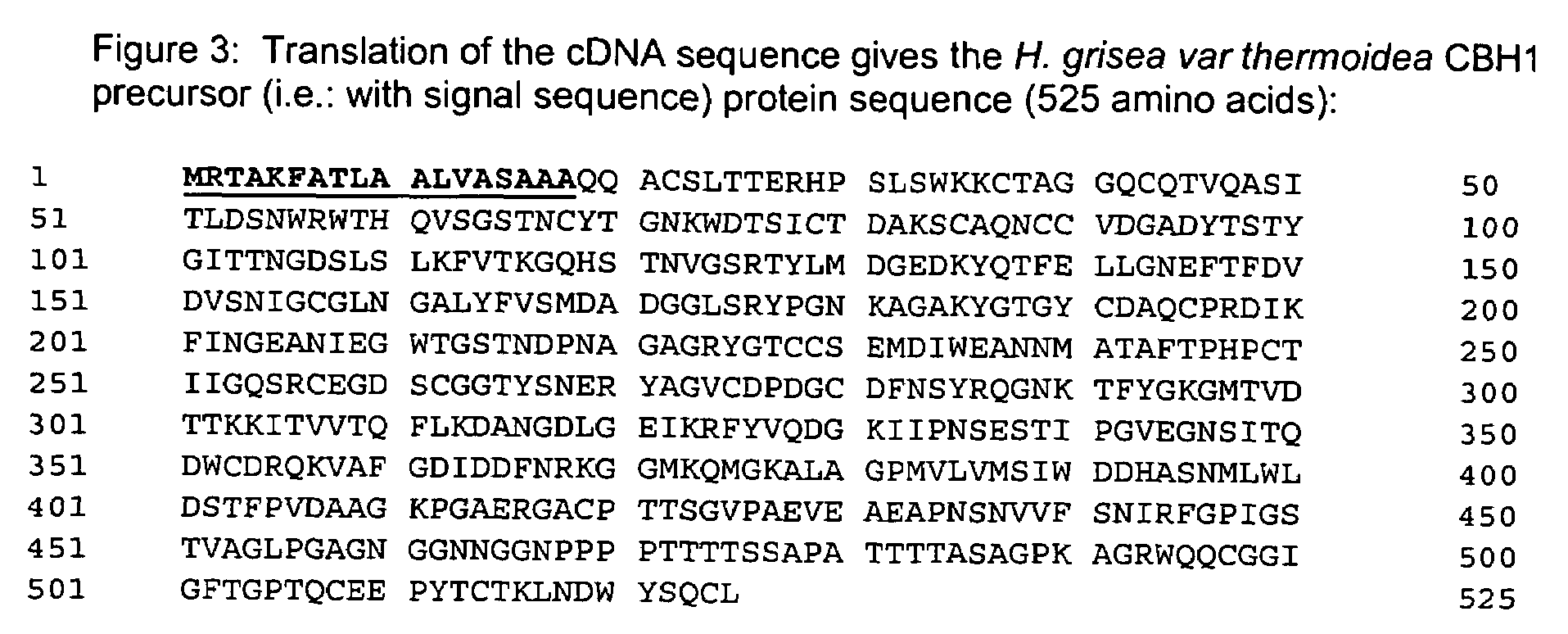

Variant Humicola grisea CBH1.1

Disclosed are variants of Humicola grisea Cel7A (CBH1.1), H. jecorina CBH1 variant or S. thermophilium CBH1, nucleic acids encoding the same and methods for producing the same. The variant cellulases have the amino acid sequence of a glycosyl hydrolase of family 7A wherein one or more amino acid residues are substituted.

Owner:DANISCO US INC

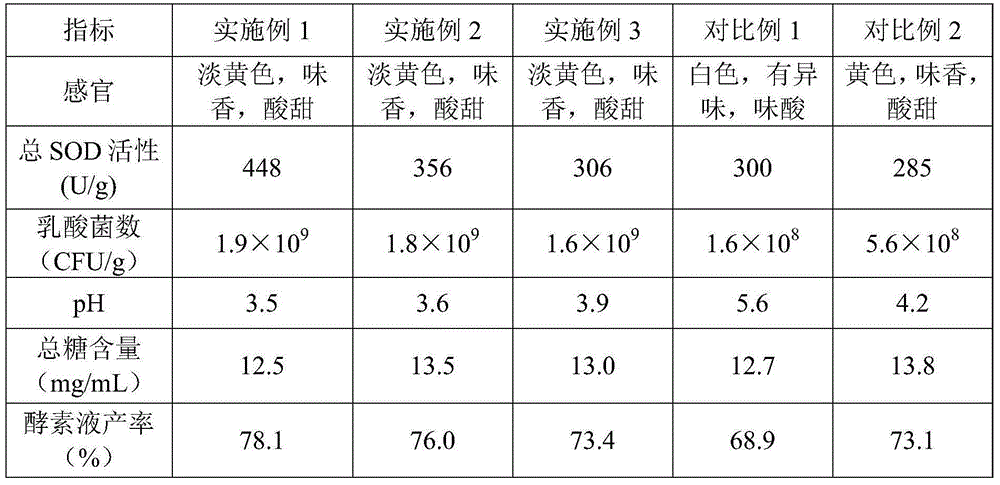

Preparation method of high-SOD-activity fruit and vegetable enzyme solution and fruit and vegetable enzyme powder

ActiveCN105054054ACover up the smellImprove coordinationFood ingredient functionsFood preparationFlavorHansenula anomala

The present invention discloses a preparation method of high-SOD-activity fruit and vegetable enzyme powder. The enzyme powder is prepared by squeezing Chinese watermelon flesh and apple flesh into pulp, respectively fermenting filtrate using saccharomyces cerevisiae and hansenula anomala and streptococcus thermophilus and lactobacillus plantarum, fermenting filter residues with rhizopus oryzae suspension, mixing the three fermentation liquor, conducting secondary fermentation on the mixture, and finally spray-drying the mixture. The prepared enzyme powder is good in mouthfeel and flavor, high in SOD activity and high in lactic acid bacteria content.

Owner:HUAZHONG AGRI UNIV

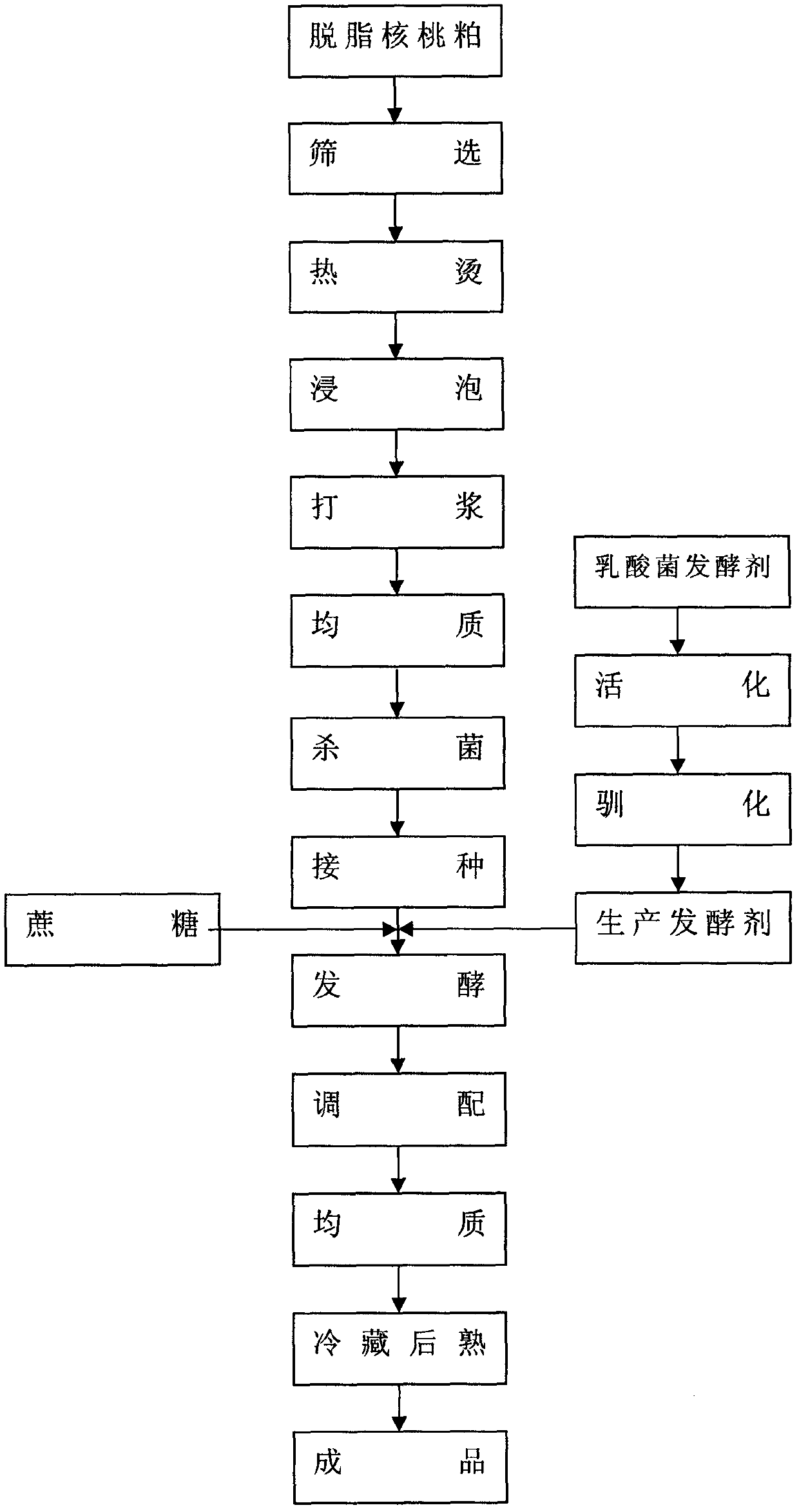

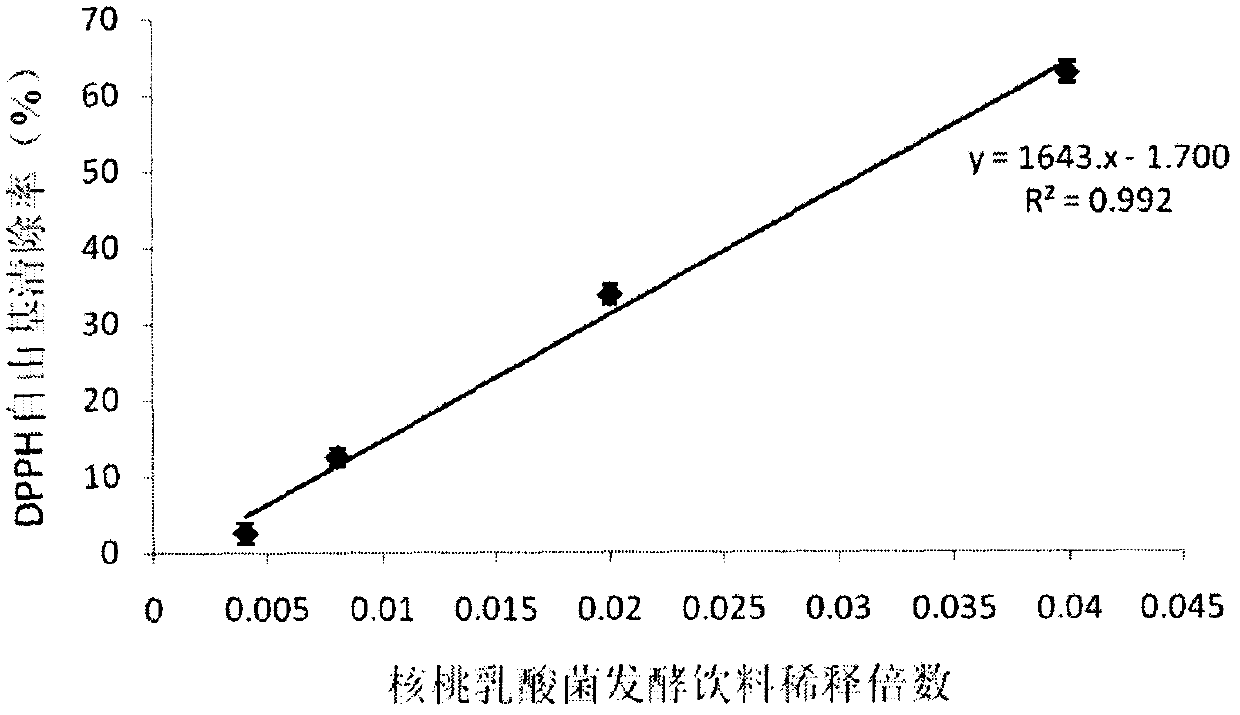

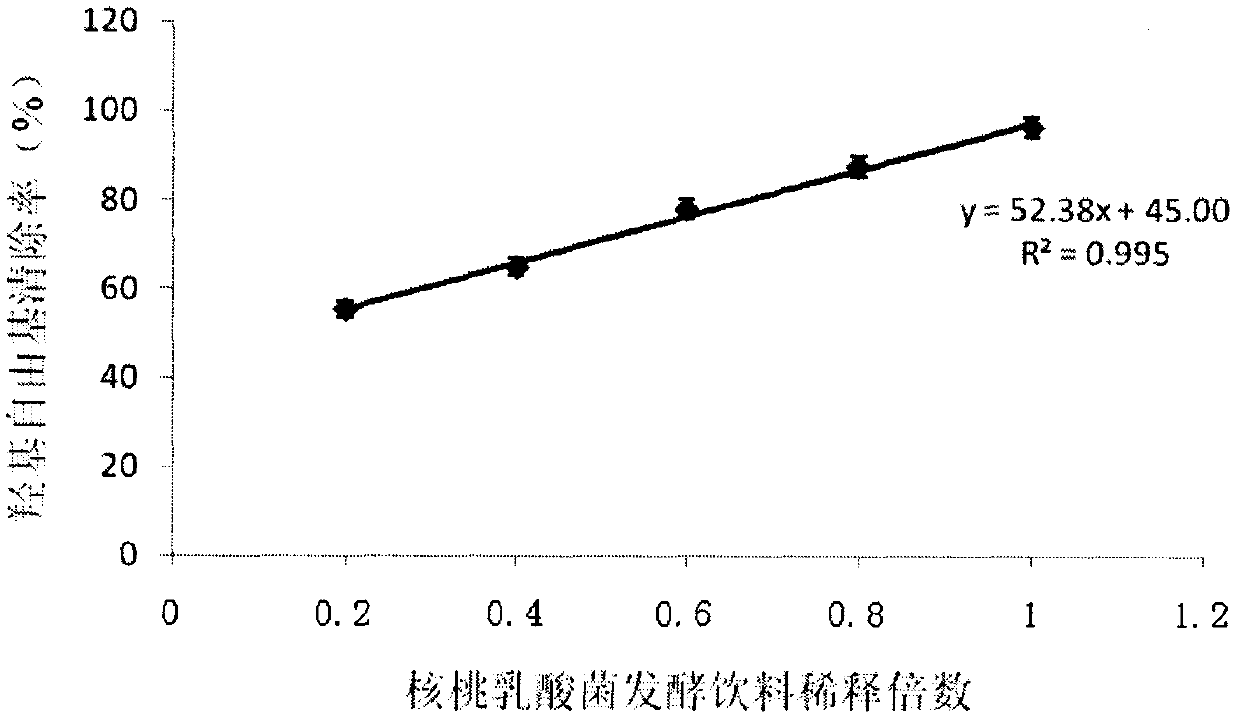

Walnut lactic acid bacteria fermented beverage and preparation method thereof

ActiveCN102630999AIncrease added valueImproves antioxidant activityMilk preparationVegetable proteins working-upBiotechnologyFunctional food

The invention discloses walnut lactic acid bacteria fermented beverage and a preparation method of the walnut lactic acid bacteria fermented beverage. The fermented drink is prepared by taking walnut protein as a raw material, and fermenting the walnut protein through lactic acid bacteria. The specific process procedure comprises the following steps: pulping defatted walnut into walnut milk, performing homogeneity, sterilization and cooling, then mixing the walnut milk with lactic acid bacteria for fermentation, wherein the strain adopted by the fermentation is a mixed strain of lactobacillusbulgaricus and streptococcus thermophilus, and is suitable for a pure walnut milk fermentation system through multi-time domestication. The beverage disclosed by the invention is rich in plant protein and lactic acid bacteria, has higher antioxidant activity, is fermented natural protein beverage with the advantages of walnut and lactic acid bacteria fermented food, and can be applied to the field of functional food or nutritional health-care products.

Owner:HEBEI GOLDEN DRAGON EDIBLE OIL

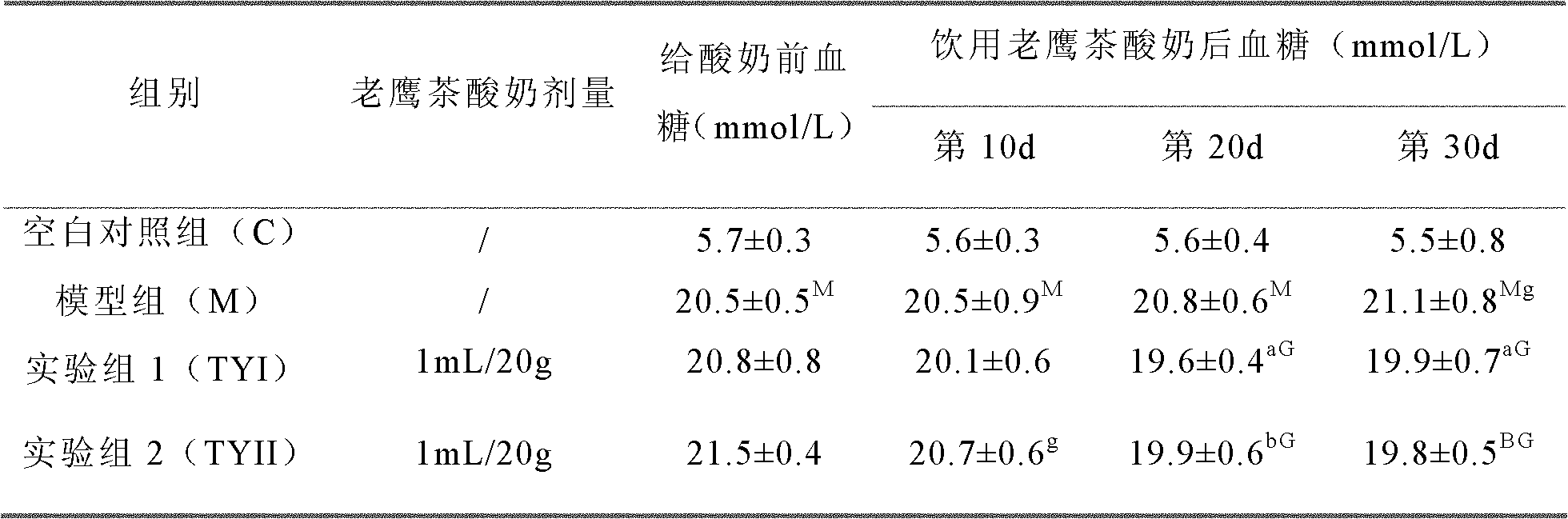

Litsea coreana yoghourt and preparation method and application thereof

The invention discloses Litsea coreana yoghourt, a preparation method and application thereof. The Litsea coreana yoghourt is prepared from the following raw materials: fresh milk or reconstituted milk, isomaltose hypgather, fructooligosaccharide, soybean oligosaccharide, sodium caseinate, Litsea coreana, Lactobacillus delbrueckii and Streptococcus thermophilus. The preparation method for the Litsea coreana yoghourt comprises the following steps of: adding the Litsea coreana serving as a functional factor into the fresh milk or the reconstituted milk, and inoculating lactic acid bacteria for fermentation. The Litsea coreana yoghourt can reduce blood sugar and improve immunity, improves the healthcare function value of yoghourt, and enriches the variety of the yoghourt.

Owner:HEFEI UNIV OF TECH

Preparation method and product of multiple lactic acid bacteria fermentation agent for fermented milk

The invention discloses a multiple lactic acid bacteria fermentation agent for a fermented milk and a preparation method of the multiple lactic acid bacteria fermentation agent. The multiple lactic acid bacteria fermentation agent comprises lactobacillus bulgaricus, streptococcus thermophilus and probiotics. The preparation method of the multiple lactic acid bacteria fermentation agent comprises the following steps: (1) propagating the needed strains for two to three times; (2) carrying out centrifugal precipitation to the strains; (3) washing the strains with sterile water, and resuspending;(4) mixing the suspension of the strains with a sterile skim milk containing a cryoprotectant uniformly; and (5) freezing and drying in vacuum to obtain the multiple lactic acid bacteria fermentationagent. The multiple lactic acid bacteria fermentation agent prepared by adopting the method can realize the compounding of the probiotics and the conventional strains such as the lactobacillus bulgaricus and the streptococcus thermophilus for the fermented milk. Compared with the fermentation agent prepared by adopting the traditional method, the product is convenient to use, and the products of different batches are more stable. In addition, the homogenization of the fermentation agent can be avoided, and the competitiveness can be improved.

Owner:BRIGHT DAIRY & FOOD

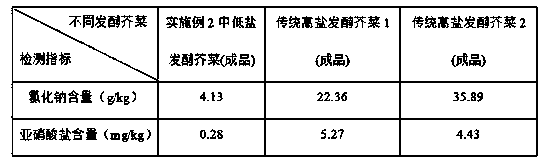

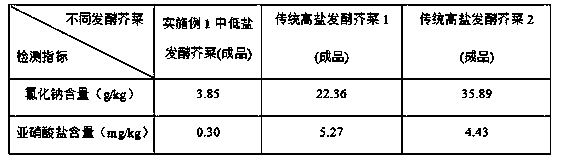

Low-salt fermented leaf mustard and preparation method thereof

ActiveCN103719788AReduce salt contentReduce salt concentrationNatural extract food ingredientsFood preparationBiotechnologyFructose

The invention discloses low-salt fermented leaf mustard. The salt content in the low-salt fermented leaf mustard is lower than 5g / kg and the nitrite content in the low-salt fermented leaf mustard is lower than 4mg / kg. The low-salt fermented leaf mustard has low salt content and nitrite content and is beneficial to health of human bodies. The invention also discloses a preparation method of the low-salt fermented leaf mustard, which comprises the following steps: (1) preparing fermentation base feed liquid, firstly, preparing water extract of ginger and garlic to obtain a extracting solution of a natural flavoring agent, adding salt, isomaltose hypgather and fructo-oligosaccharide into the extracting solution of the natural flavoring agent and uniformly mixing to obtain the fermentation base feed liquid; (2) selecting leaf mustard, preprocessing the leaf mustard, placing the preprocessed leaf mustard into a fermentation container, adding the fermentation base feed liquid, adding a concentrated streptococcus thermophilus solution and a concentrated lactobacillus bulgaricus solution, then sealing the fermentation container and fermenting at room temperature; (3) after fermenting for one day, opening the fermentation container, inoculating a concentrated bifidobacterium adolescentis solution into the fermentation container, then sealing up the fermentation container, and continuously fermenting for 4 to 6 days at room temperature so as to obtain the low-salt fermented leaf mustard.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com