Symbiotic functional high-protein Greek yogurt utilizing polymeric whey protein as main thickening agent and preparation method thereof

A technology of polymerizing whey protein and Greek yogurt, which is applied in dairy products, milk preparations, applications, etc., can solve the problems of limited application and poor performance, and achieve the effects of high food safety, simple processing methods, and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

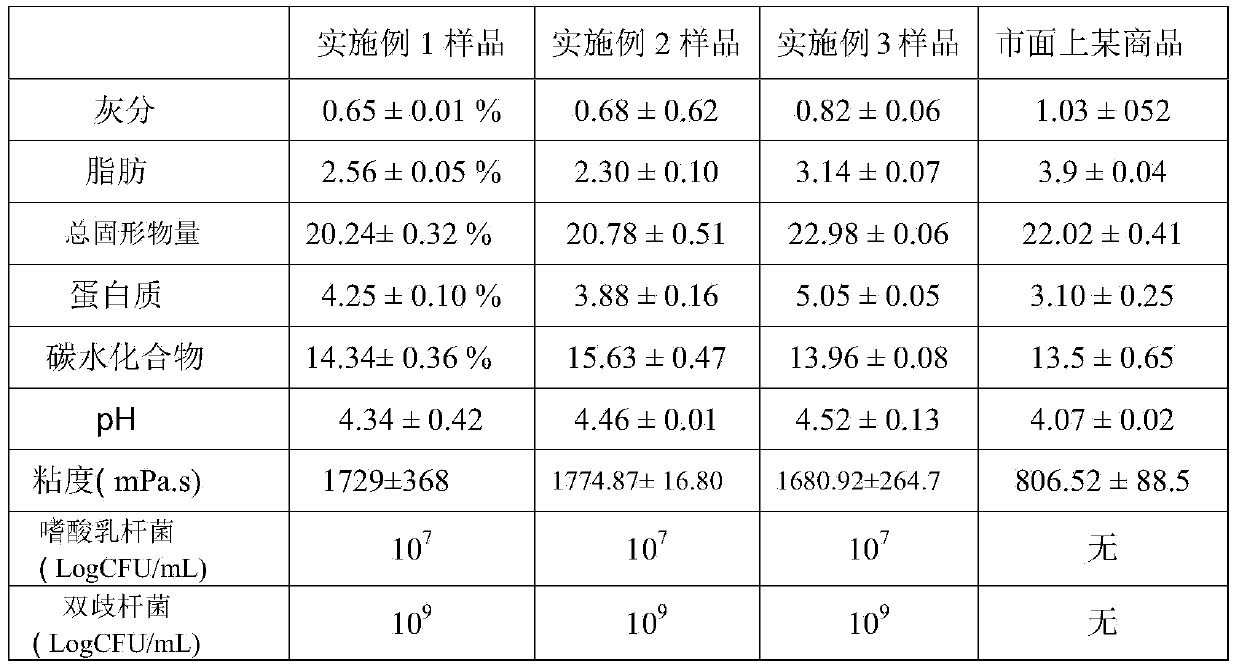

Examples

Embodiment 1

[0031] Symbiotic high-protein Greek yogurt is made by mixing liquid raw milk, sucrose, pectin, inulin, polymerized whey protein, and concentrated whey protein (80% protein content), and then fermenting.

[0032] The polymerized whey protein is prepared through the following steps: 10.8g of whey protein isolate (92% protein content) is dissolved in 100mL of water, magnetically stirred for 60min, placed at 4°C for 8-10h to fully Hydrate. Use 1M sodium hydroxide solution to adjust the whey protein suspension to pH = 7, heat in a water bath at 85°C for 30 minutes, cool in an ice bath, and store at 4°C until use;

[0033] The preparation method of the symbiotic high-protein Greek yogurt of this embodiment is to make according to the following process steps:

[0034] Concentrated whey protein (80% protein content) is added to the liquid raw milk, mixed and stirred to dissolve → hydrate for 8-10 hours → add the pre-mixture → heat → keep warm at 80°C for 10 minutes → cool → add start...

Embodiment 2

[0037] The symbiotic high-protein Greek yogurt is made by mixing liquid raw milk, sucrose, pectin, inulin, polymerized whey protein, and skim milk powder, and then fermenting.

[0038] The polymerized whey protein is prepared through the following steps: 10 parts (10.6g) of whey protein isolate (94% protein content) are dissolved in 100 parts (100mL) of water, magnetically stirred for about 60min, at 4°C Leave it for 8-10 hours to make it fully hydrated. Use 1M sodium hydroxide solution to adjust the whey protein suspension to pH = 7, heat in a water bath at 85°C for 30 minutes, cool in an ice bath, and store at 4°C until use;

[0039] The preparation method of the symbiotic high-protein Greek yogurt of this embodiment is to make according to the following process steps:

[0040] Skim milk powder (34% protein content) is added to the liquid raw milk, mixed and stirred to dissolve → hydrate for 8-10 hours → add the pre-mixture → heat → keep warm at 85°C for 10 minutes → cool →...

Embodiment 3

[0043] The symbiotic high-protein Greek yogurt is made by mixing liquid raw milk, sucrose, pectin, inulin, polymerized whey protein, and whole milk powder, and then fermenting.

[0044] Polymeric whey protein is prepared through the following steps: 10 parts (11.1g) of whey protein isolate (90% protein content) are dissolved in 100 parts (100mL) of water, magnetically stirred for about 30min, at 4°C Leave it for 8-10 hours to make it fully hydrated. Use 1M sodium hydroxide solution to adjust the whey protein suspension to pH = 8, heat in a water bath at 90°C for 30 minutes, cool in an ice bath, and store at 4°C until use;

[0045] The preparation method of the symbiotic high-protein Greek old yoghurt of this embodiment is to make according to the following process steps:

[0046] Add whole milk powder (25% protein content) into liquid raw milk, mix and stir to dissolve → hydrate for 8-10 hours → add pre-mixture → heat → keep warm at 90°C for 10 minutes → cool → add starter an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com