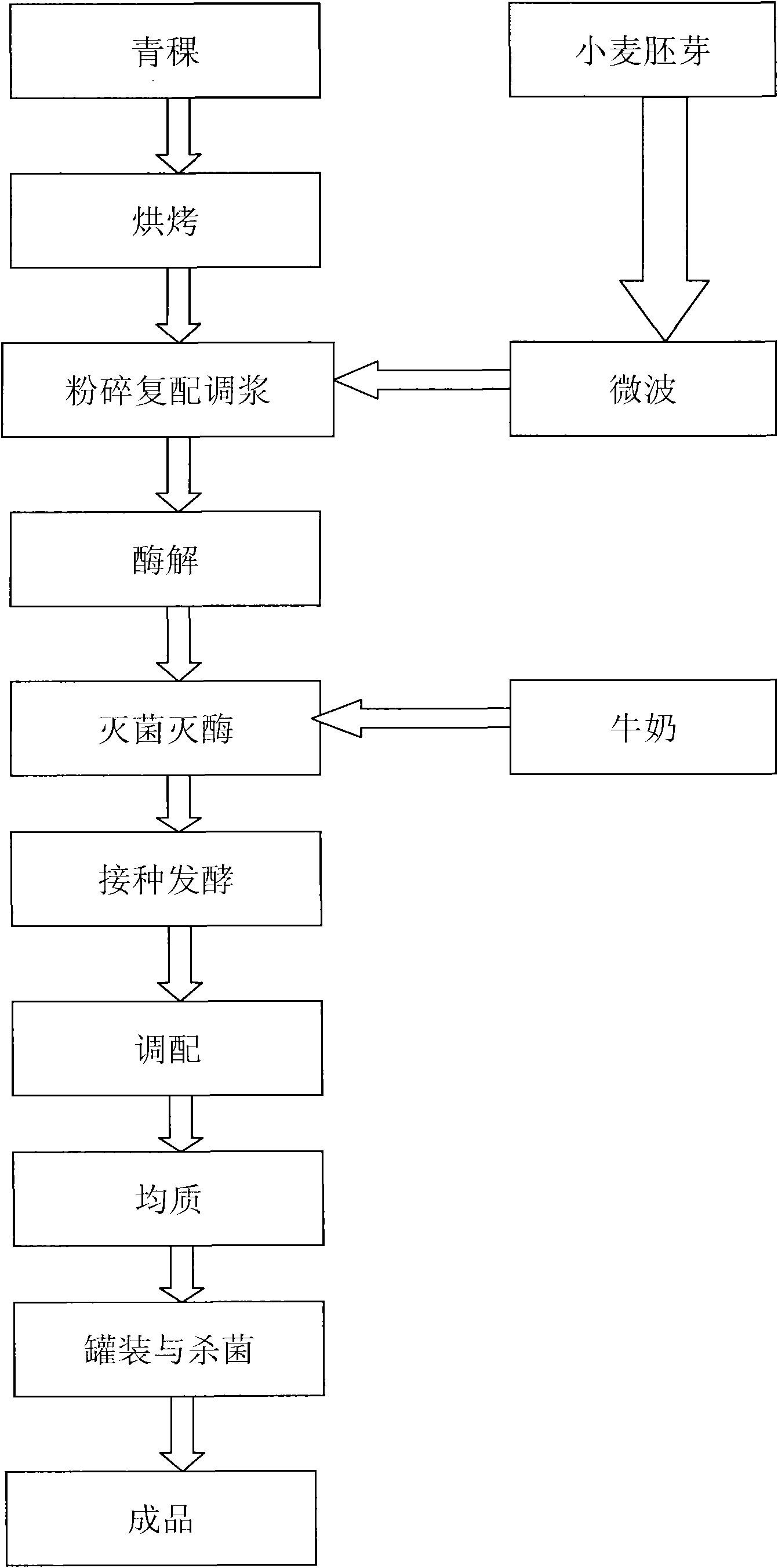

Process for preparing highland barley-wheat germ composite fermented beverage

A compound fermentation and preparation technology, which is applied in the field of grain deep processing, can solve the problems of single form and insufficient nutrition conversion, and achieve the effect of scientific and reasonable process design, easy absorption and utilization, and overcoming rough taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Take 100 g of highland barley and 20 g of wheat germ, and use 500W power and 60s microwave treatment for fresh wheat germ; bake the highland barley raw material at 120°C for 30 minutes; Mesh screen; mixed with water at a weight ratio of 1:10 to obtain a mixed slurry heated to 65°C, first enzymatically hydrolyzed with a medium-temperature α-amylase, pH 7.0, for 30 minutes, and the enzyme dosage was 60U / g, and then used glucoamylase Hydrolysis, temperature 55°C, pH 4.0, time 60min, enzyme dosage 50U / g; centrifuge the mixed feed liquid at 3000r / min for 30 min, separate and discard the sediment; add 6% total volume of milk to the separated supernatant feed liquid , sterilized at 95°C for 3 minutes, cooled to 30°C, poured into the fermenter, and added 3% of the total volume of mixed lactic acid bacteria (Lactobacillus bulgaricus: Streptococcus thermophilus: Lactobacillus acidophilus = 1:1:1) to ferment 24 hour; the temperature of the fermented liquid is cooled to ...

Embodiment 2

[0018] Example 2: Take 100 g of highland barley and 50 g of wheat germ, and the fresh wheat germ is treated with 600W power and 80s of microwave; the raw material of highland barley is baked at 130°C for 25min; Mesh sieve; mixed with water at a weight ratio of 1:15 to obtain a mixed slurry heated to 60°C, first enzymatically hydrolyzed with a medium-temperature α-amylase, pH 6.5, for 40 minutes, and an enzyme dosage of 70U / g, and then with glucoamylase Hydrolysis, temperature 60°C, pH 4.5, time 30min, enzyme use 45U / g; centrifuge the mixed feed solution at 3000r / min for 35min, separate and discard the sediment; add 4% total volume of milk to the separated supernatant feed liquid , sterilized at 93°C for 5 minutes, cooled to 40°C, poured into the fermenter, and added 4% of the total volume of mixed lactic acid bacteria (Lactobacillus bulgaricus: Streptococcus thermophilus: Lactobacillus acidophilus=3:3:1) to ferment 12 hour; the fermented liquid temperature is cooled to below 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com