Production technique of asparagus wine

A production process and asparagus technology, applied in the field of asparagus wine production technology, can solve problems such as no specific means are given, and achieve the effects of overcoming rough taste, balanced plant aroma and long aftertaste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

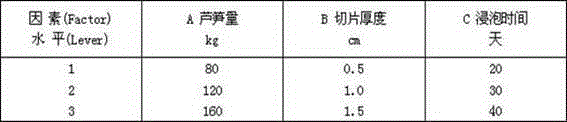

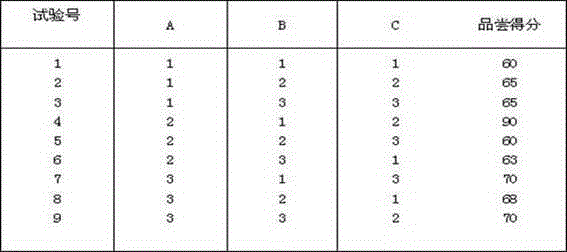

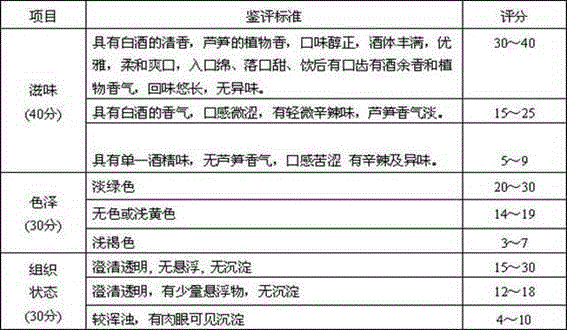

Method used

Image

Examples

Embodiment 1

[0022] A kind of asparagus wine production process, take 850 kilograms of sorghum, 250 kilograms of asparagus, 130 kilograms of distiller's yeast, some water;

[0023] The steps are raw material crushing, sorghum crushing, koji crushing, each grain of sorghum is crushed into 4-8 grains, fine powder does not exceed 20% of the total weight, koji is broken into 3-5 mm particle size,

[0024] Add 480 kg of hot water at 80-90°C to the crushed sorghum, mix well, pile up and cover the surface for 18-20 hours, then steam the material for 60-80 minutes to gelatinize, until it is cooked but not sticky, and there is no raw heart inside; then dry During the drying process, 320 kg of cold water at 18-20°C should be added and stirred to make the sorghum fully absorb the water;

[0025] Asparagus is crushed and dried at 60-80 degrees Celsius to obtain asparagus scraps. The drying standard for the scraps is that the asparagus juice produced during the crushing process stops flowing out. It ta...

Embodiment 2

[0037] Embodiment 2 A kind of asparagus wine production technology, get 900 kilograms of sorghum, 260 kilograms of asparagus, 100 kilograms of distiller's yeast, some water;

[0038] Raw materials are broken, sorghum is broken, koji is broken, each grain of sorghum is broken into 4-8 grains, fine powder does not exceed 20% of the total weight, koji is broken into 3-5 mm particle size,

[0039] Add 450kg of hot water at 80-90℃ to the crushed sorghum, mix well, pile up and cover the surface for 18-20 hours, then steam the material for 60-80 minutes to gelatinize, until it is cooked but not sticky, and there is no heart in it; then let it dry During the drying process, 450 kg of water at 18-20°C should be added and stirred to make the sorghum fully absorb the water;

[0040] Asparagus is crushed and dried at 60-80 degrees Celsius to obtain asparagus scraps. The drying standard for the scraps is that the asparagus juice produced during the crushing process stops flowing out. It ta...

Embodiment 3

[0044] Embodiment 3 A kind of production process of asparagus wine, take 800 kilograms of sorghum, 230 kilograms of asparagus, 100 kilograms of distiller's yeast, some water, soak step, put 115 kilograms of asparagus slices according to every ton of base wine, soak at room temperature for 30 days, the rest Step is with embodiment 1.

[0045] The wine that this embodiment 3 obtains is 86 after tasting panel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com