Low-salt fermented leaf mustard and preparation method thereof

A mustard and salt technology, applied in food preparation, bacteria and bifidobacteria used in food preparation, etc., can solve the problems of increasing the burden on the heart and kidneys, excessive nitrite, and long production cycle, and inhibit the growth of miscellaneous bacteria. , the effect of improving fermentation efficiency and speeding up the formation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

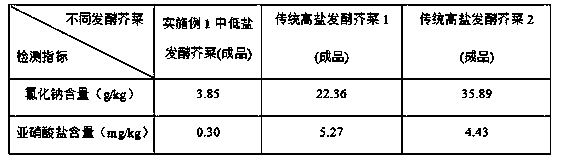

Embodiment 1

[0032] The preparation method of the low-salt fermented mustard provided by the present embodiment is as follows:

[0033] (1) Pretreatment of mustard raw materials

[0034] (1) Select fresh mustard greens with crisp texture, thick flesh, no insects and no trauma, wash them with running water, and place them in a ventilated place to drain the water naturally;

[0035] (2) Cut the above-mentioned drained mustard into strips about 6cm long and 2cm wide to complete the pretreatment of mustard raw materials;

[0036] (2) Preparation of fermentation base liquid

[0037] (1) Wash the fresh ginger and garlic, cut them into even thin slices, and mix them in an equal weight ratio to obtain a ginger and garlic mixture;

[0038] (2) Put the ginger and garlic mixture in a container and add purified water, wherein the weight ratio of the ginger and garlic mixture to the purified water is 1:10, and reflux extraction in a water bath at 70°C for 2 times, each time for 5 hours, and extract ...

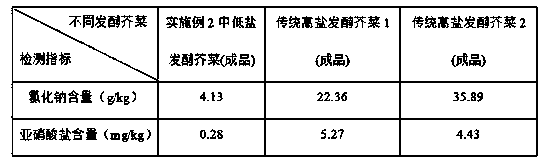

Embodiment 2

[0053] The preparation method of the low-salt fermented mustard provided by the present embodiment is as follows:

[0054] (1) Pretreatment of mustard raw materials

[0055] (1) Select fresh mustard greens with crisp texture, thick flesh, no insects and no trauma, wash them with running water, and place them in a ventilated place to drain the water naturally;

[0056] (2) Cut the above-mentioned drained mustard into strips about 7cm long and 2cm wide to complete the pretreatment of mustard raw materials;

[0057] (2) Preparation of fermentation base liquid

[0058] (1) Wash the fresh ginger and garlic, cut them into even thin slices, and mix them in an equal weight ratio to obtain a ginger and garlic mixture;

[0059] (2) Put the ginger and garlic mixture in a container and add purified water, wherein the weight ratio of the ginger and garlic mixture to the purified water is 1:15, reflux extraction in a water bath at 60°C for 2 times, each time for 5 hours, and extract The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com