Patents

Literature

281results about How to "Easy to mine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

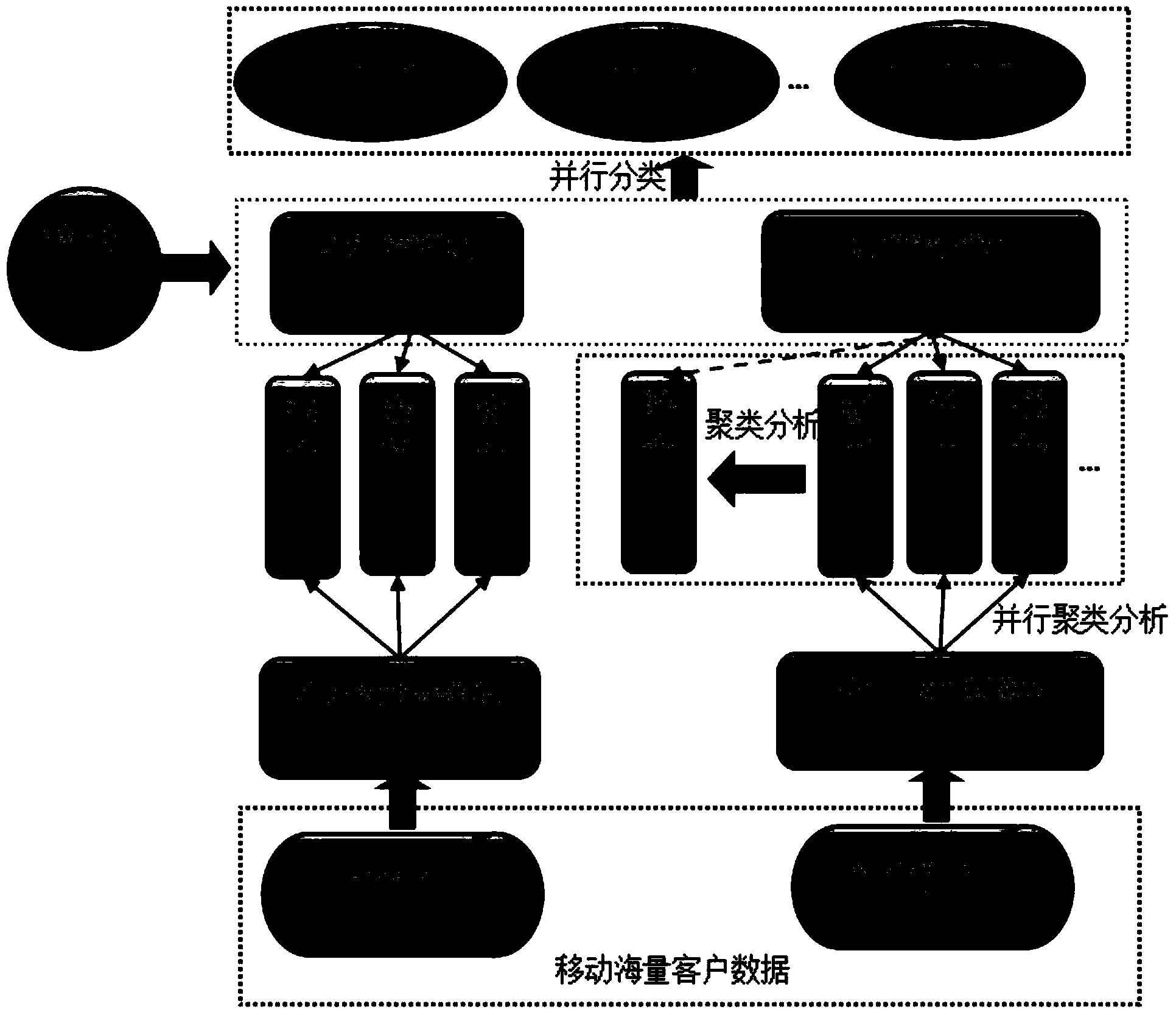

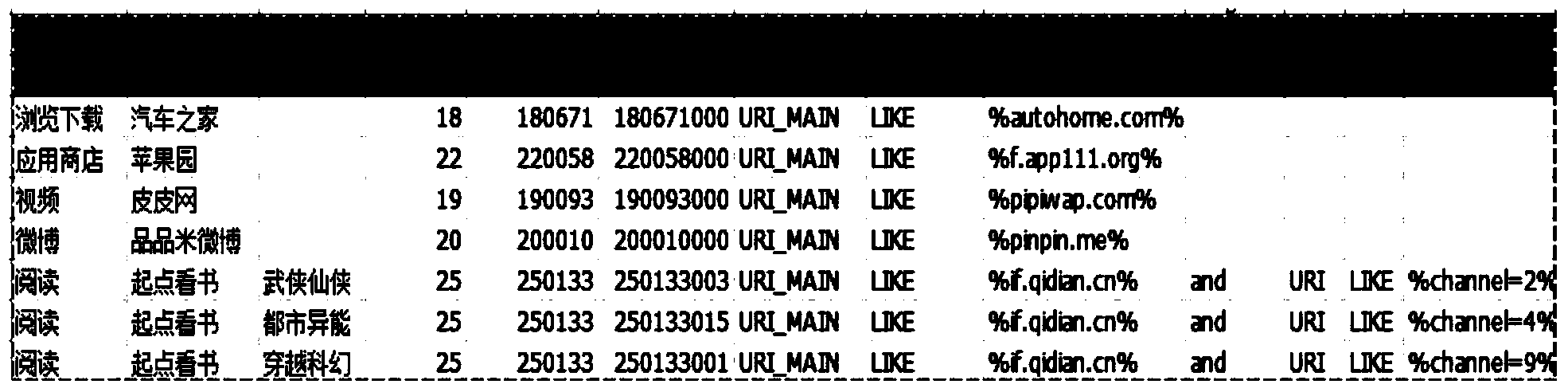

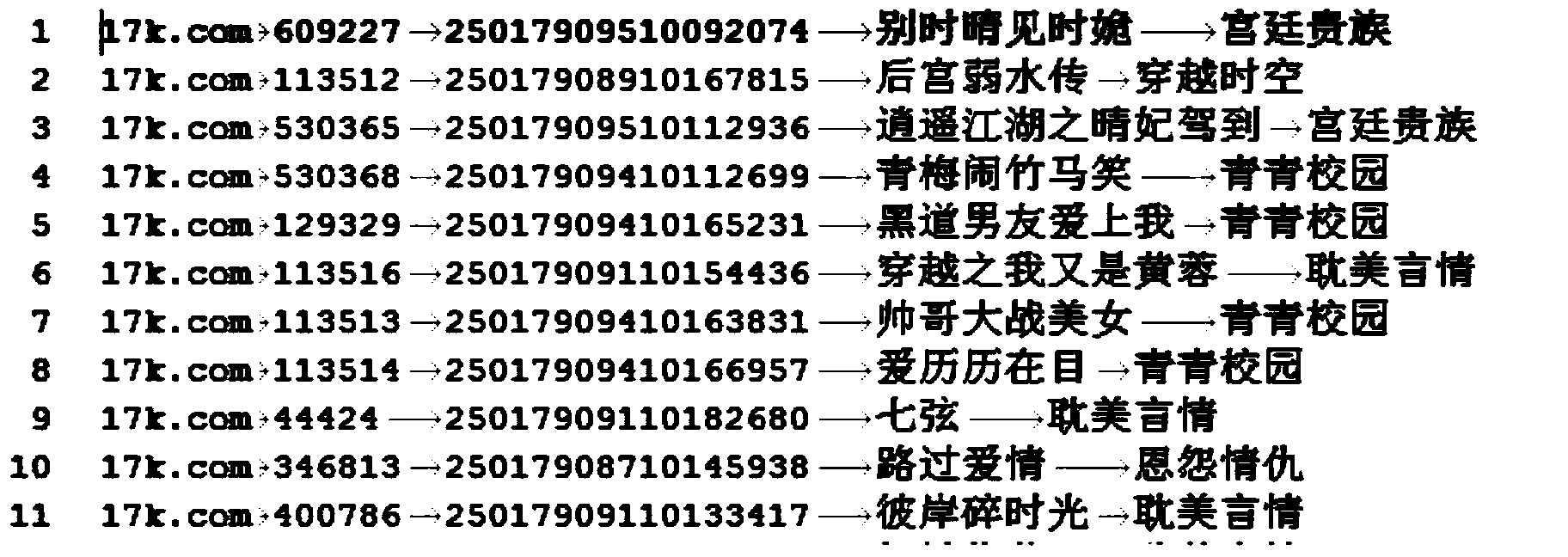

Parallel data mining method for identifying a mass of mobile client bases

ActiveCN103714139AStrong reference valueEfficient data mining analysisMarketingSpecial data processing applicationsThe InternetPurchasing

The invention discloses a parallel data mining method for identifying a mass of mobile client bases. The parallel data mining method includes the steps of building a client value model and a client behavior model, classifying clients according to the client value model and the client behavior model, popularizing assigned preference services to the clients with the high purchasing power and the high potential purchasing inclination, and then achieving accurate marketing. According to the parallel data mining method, the mass of mobile client bases can be identified, the aspects such as Internet surfing time preferences, Internet surfing place preferences and browsed website preferences of the clients can be identified, and the social group classes of the clients can be accurately judged. Clustering and classifying can be rapidly carried out through the adopted parallel clustering algorithm and the adopted parallel classifying algorithm. By means of the parallel data mining method, different strategies can be formulated for the different client bases by an enterprise, and the important guiding function for profit maximization of the enterprise is achieved.

Owner:SOUTH CHINA UNIV OF TECH

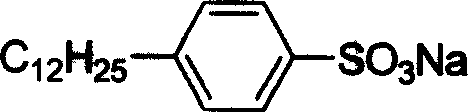

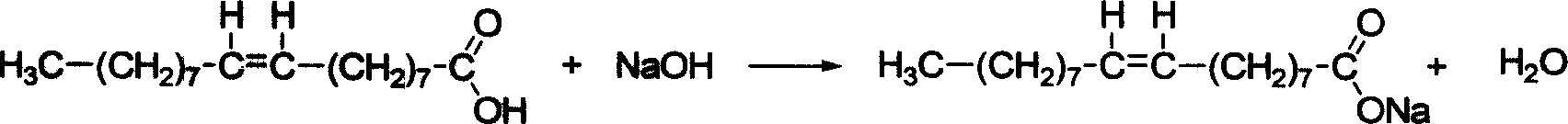

Surface activating agent for oil-field thick-oil well

InactiveCN101024764AGood viscosity reduction effectImprove performanceTransportation and packagingMixingPhenolOleic Acid Triglyceride

The invention discloses a surface activator used in oil field thick oil well that is made up from water 1500kg, sheet alkali 330kg, alcohol 450kg, oleic acid 275kg, alkyl phenol polyoxyethylene (15) ether 200kg, sodium dodecyl benzene sulfonate 150kg. The invention could decrease interface tension, and under the emulsion effecting, the o / w or w / o would form flow state in normal state to be convenient to convey and pump. The invention has low cost and high effect.

Owner:图们市科兴石化技术开发有限公司

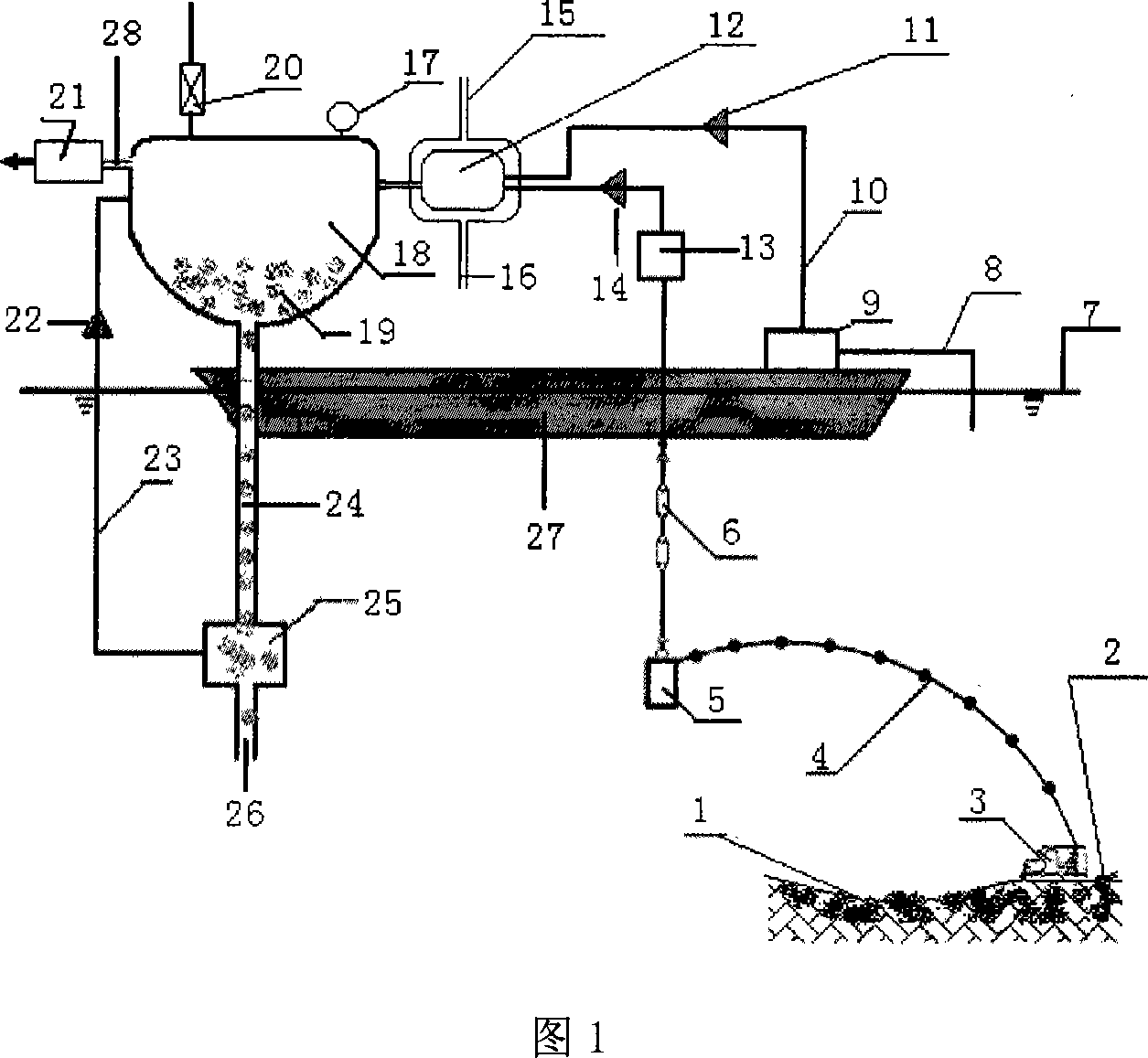

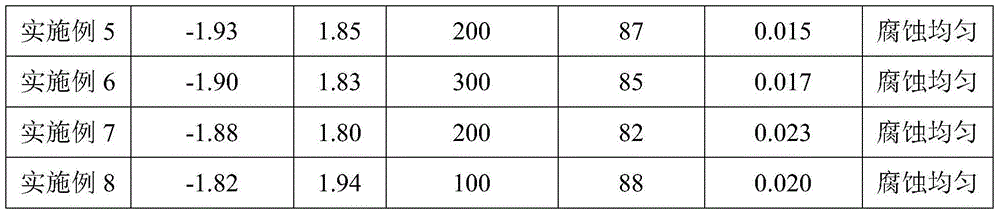

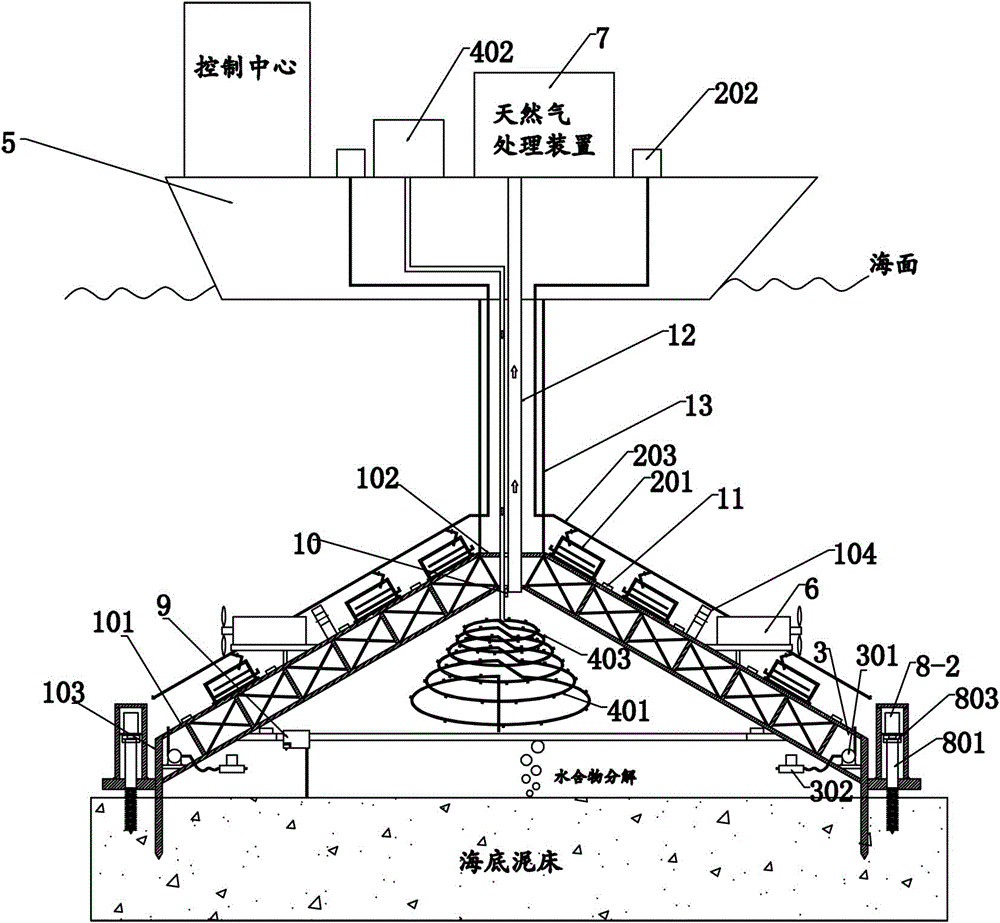

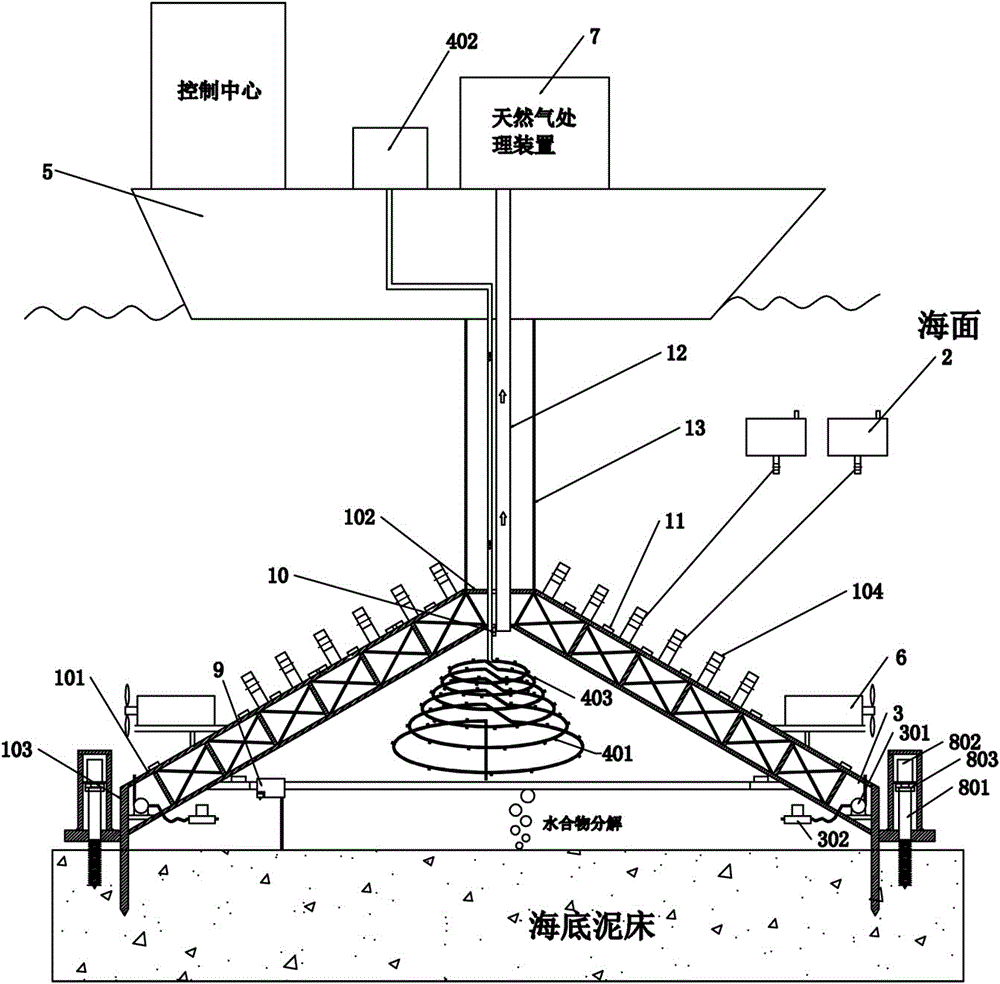

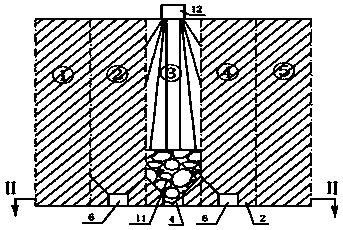

Seabed gas hydrate mining methods and device

The present invention provides a method and a device for exploiting the submarine natural gas hydrate. The present invention transfers the natural gas hydrate on the submarine surface to a dredge and then to a large-volume container after being ground; a water pump is used to add sea water appropriately into the large-volume container. As the temperature of the sea water keeps about 20 DEG C, the temperature of the sea water makes the mixture of ground hydrate and sandstone fully decomposed in the large-volume container so as to separate the natural gas, water and sandstone. The separated natural gas is drained and then directly connected with a user terminal. The present invention with convenient operation and simple device can conveniently, economically and effectively achieve the exploitation of the submarine natural gas hydrate.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

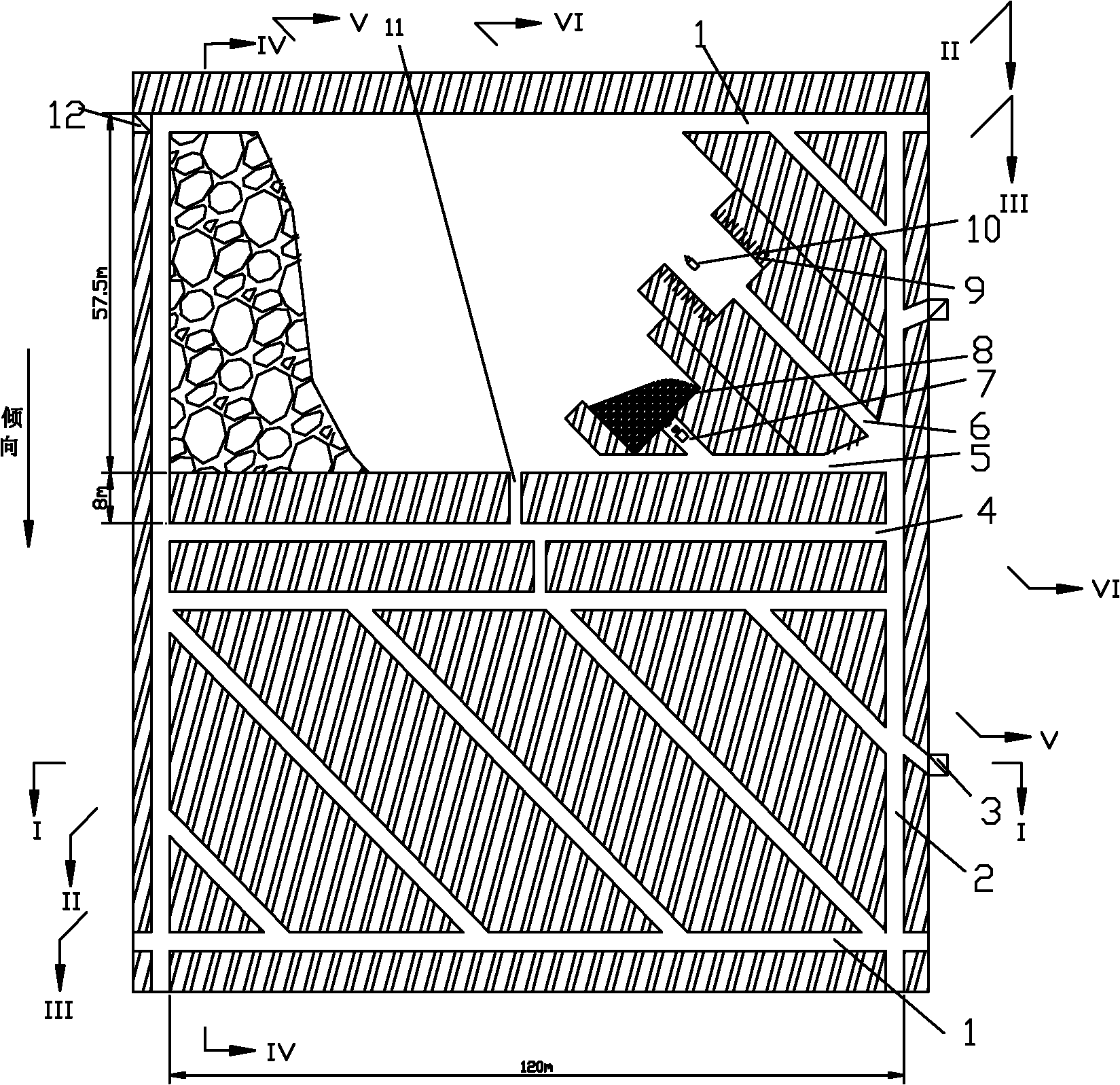

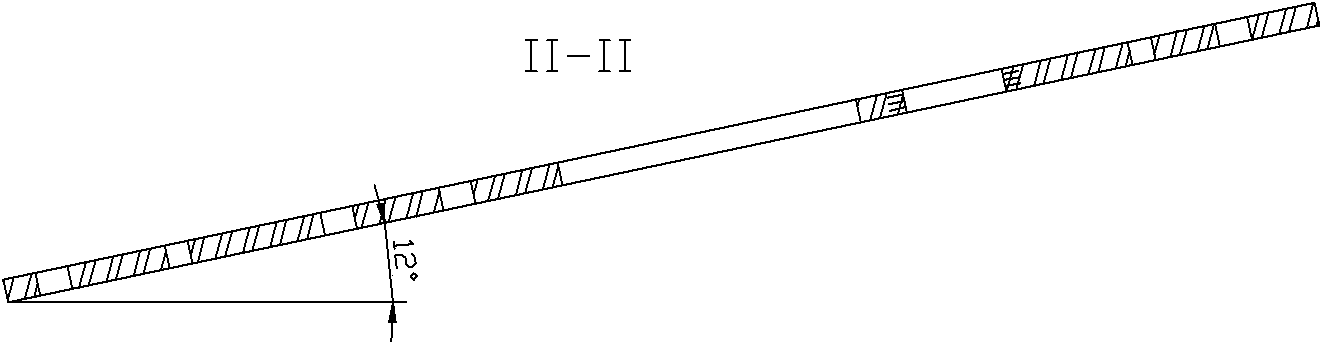

Mechanical continuous mining method for gently inclined thin ore body

ActiveCN101975064ASolve the mining disasterResolutionUnderground miningSurface miningEngineeringDrill

The invention discloses a mechanical continuous mining method for a gently inclined thin ore body. Based on the principle of lengthening the slope distance to reduce the angle, ore blocks are arranged in an inclined way, so that an angle smaller than the original inclination angle can be formed between a working plane and the horizontal plane, thus creating an operating space for a drill jumbo and a scraper; a return air shaft is arranged at the corner of one ore room so as to be communicated with an upper horizontal return airway; each ore room is provided with an orepass used for the transmission of ores in the ore room; and a tunnel is respectively excavated along the strike direction above and below each ore room, the upper tunnel is used for ventilation connection, and the lower tunnel is used for ore removal connection. The invention is especially applicable to the mining of the gently inclined thin ore body of an underground mine, mining preparation has no requirements for undercutting projects, and the drill jumbos and scrapers are used for the operation, thereby achieving the characteristics of high degree of mechanization, high production efficiency, full-thickness continuous mining and low ore loss rate.

Owner:CENT SOUTH UNIV

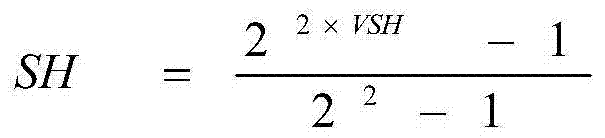

Shale gas physical geography quick evaluation method

InactiveCN104500049AEasy to mineSolve the very inconvenient problem of miningInformaticsInstrumentsKerogenWell logging

The invention discloses a shale gas physical geography quick evaluation method. The geologic factors of production of shale gas are as follow: clay, kerogen, porosity, water saturation and permeability, and according to the above geologic factors, evaluation calculation with different models is performed: in the conventional well logging interpretation, the content of clay is calculated by a uranium-free gamma ray curve; the formation of kerogen is mostly in the reduction environment with relatively high content of the radioactive element U, so that a peak appears in the natural gamma ray curve, and as the density of kerogen is relatively low, TOC is integrally calculated with several methods; the value of porosity is calculated by a neutron-density crossplot, and the amount of minerals in rock can also be calculated through correction of the crossplot; the water saturation is calculated by the Archie's formula; and the permeability is calculated according to regression of porosity, and only the shale segment reservoir bed is subjected to regression. The shale gas physical geography production factors can be quickly and accurately calculated, and the results are accurate.

Owner:CHENGDU CHUANGYUAN OIL & GAS TECH DEV

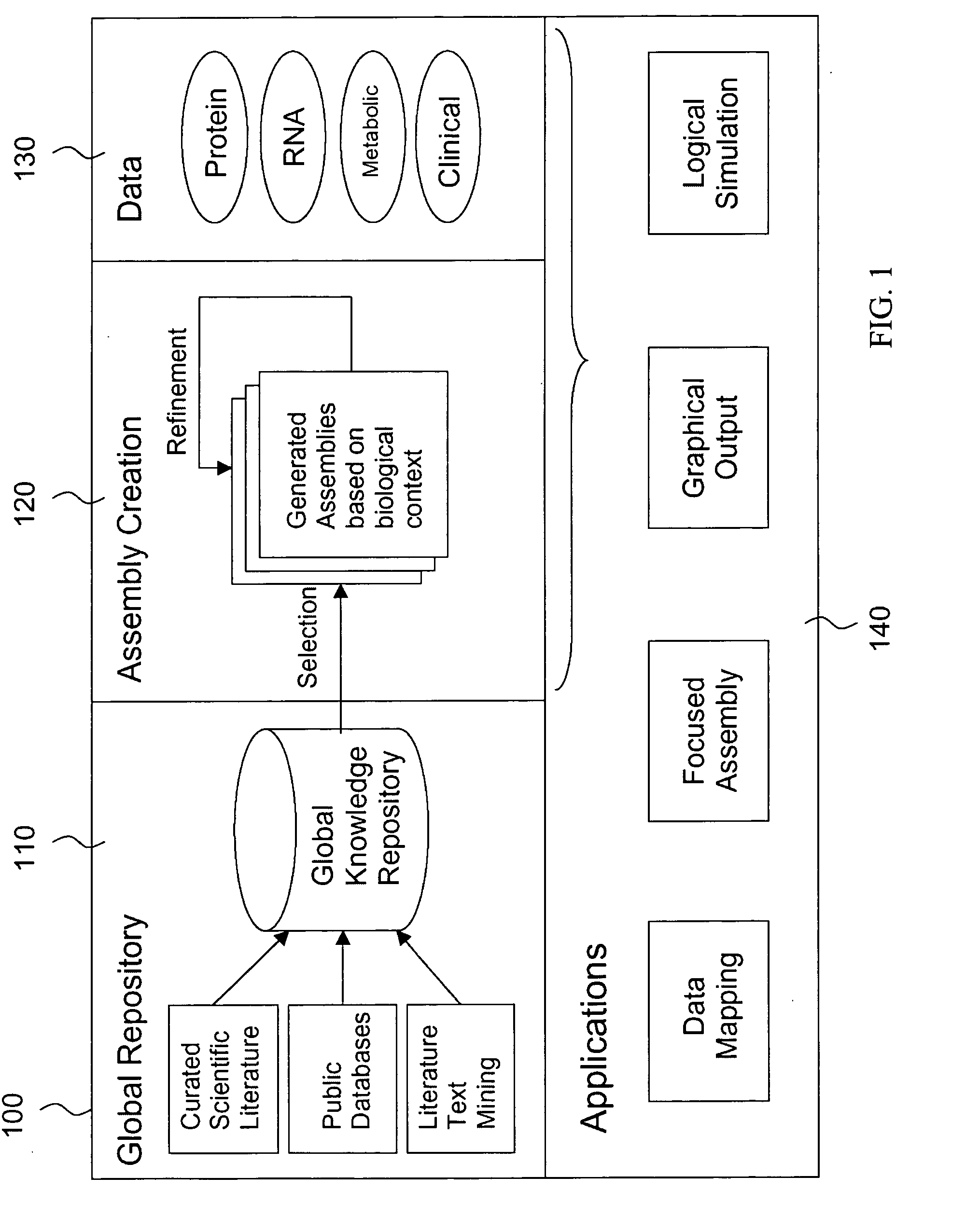

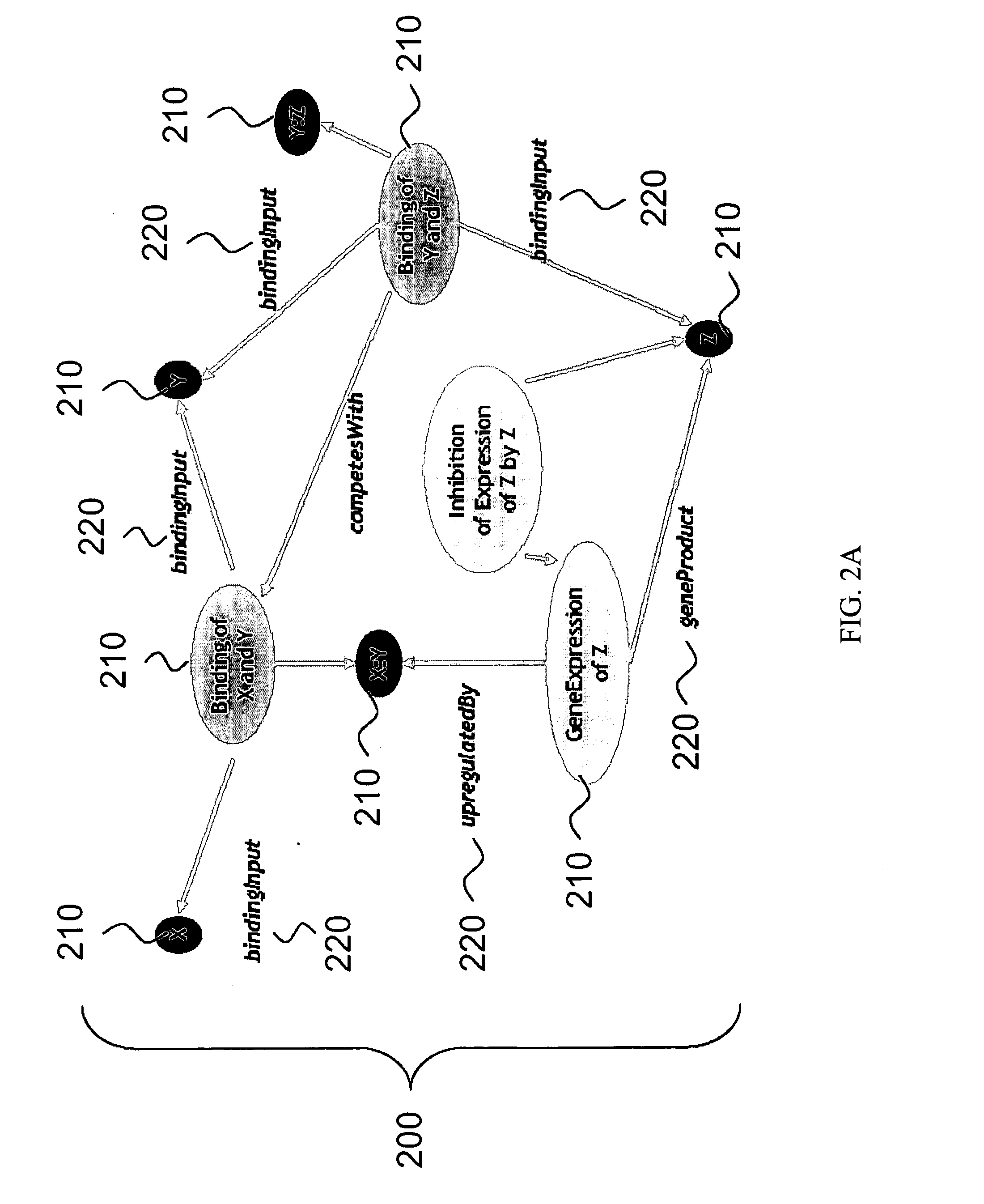

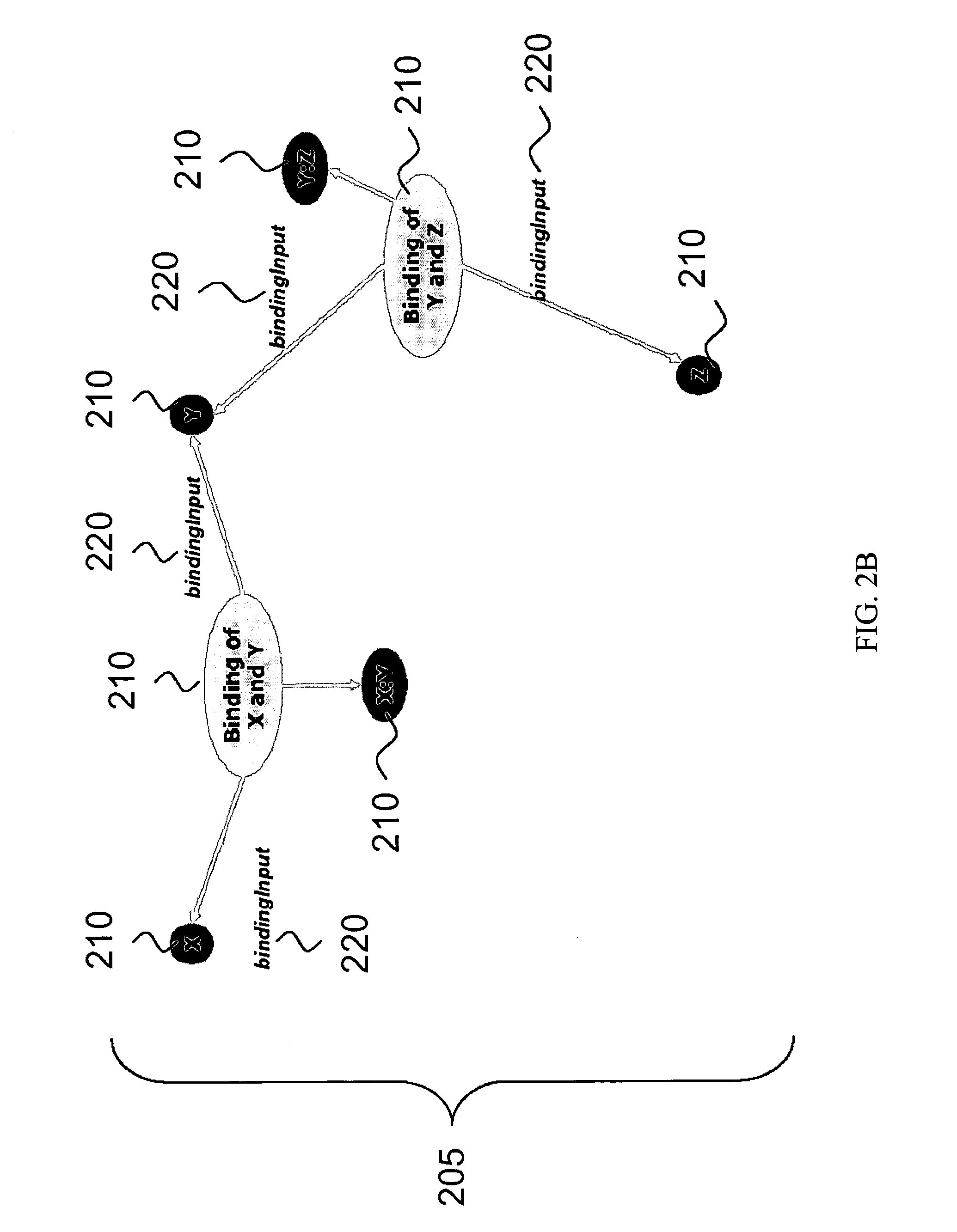

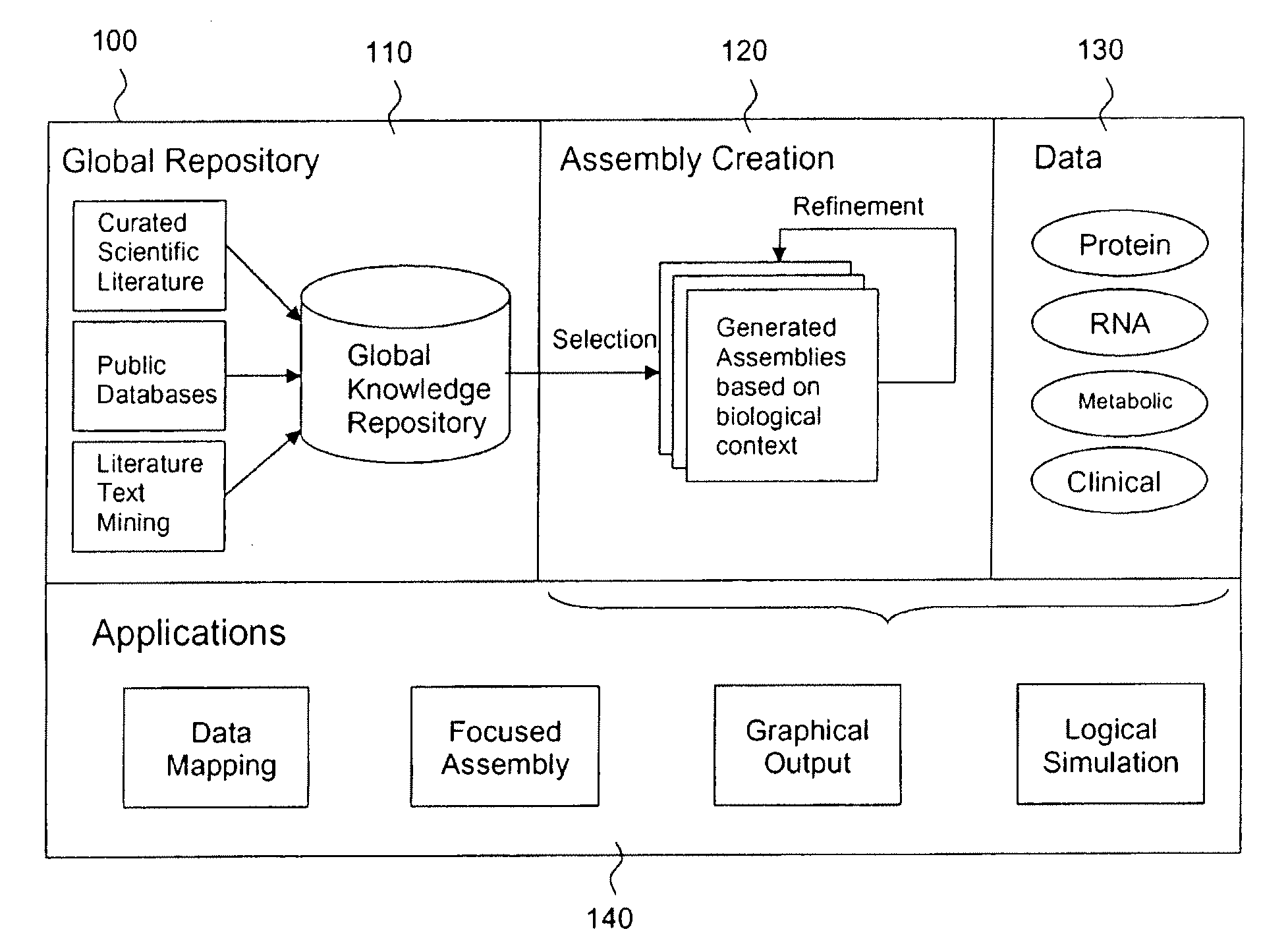

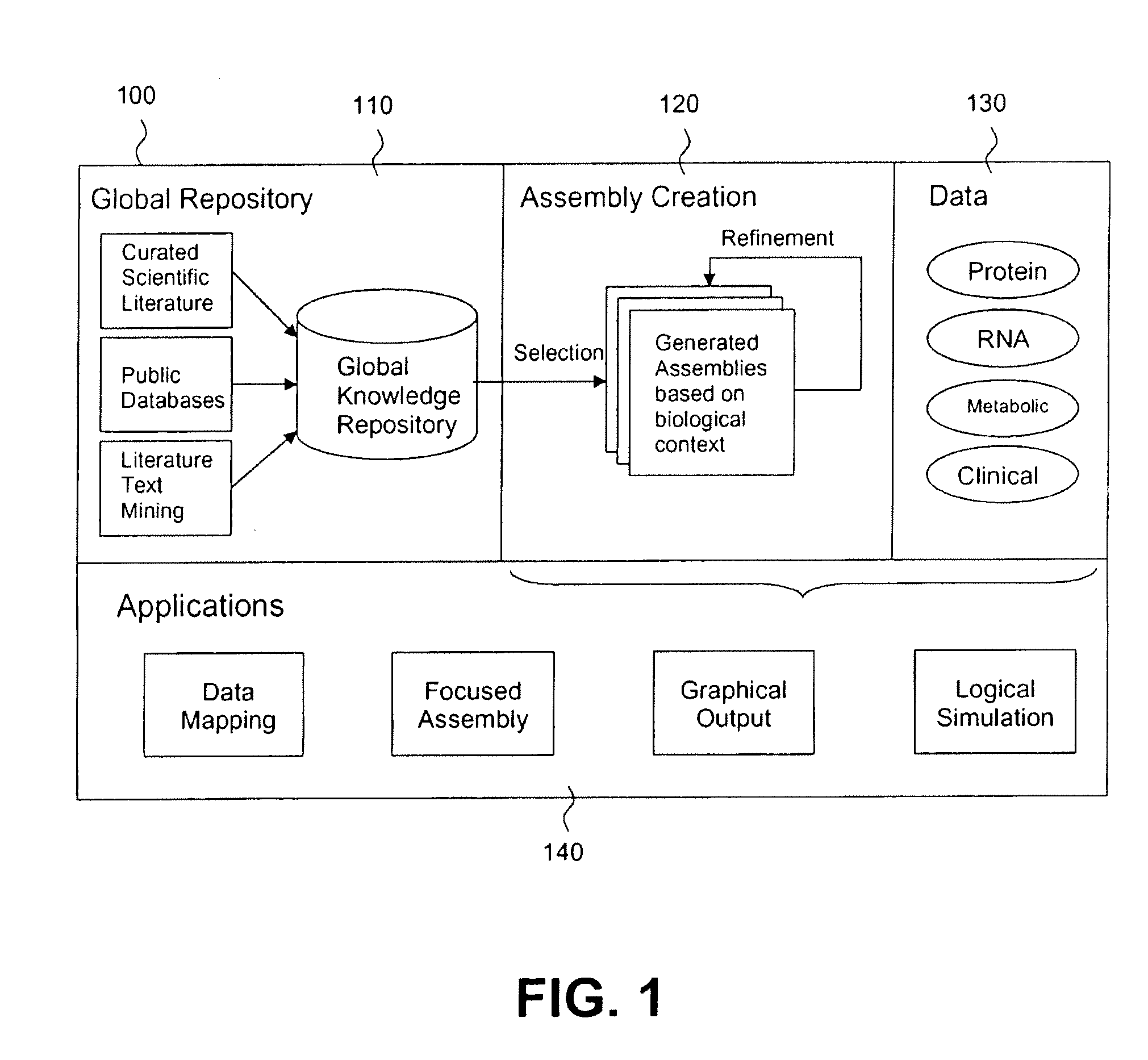

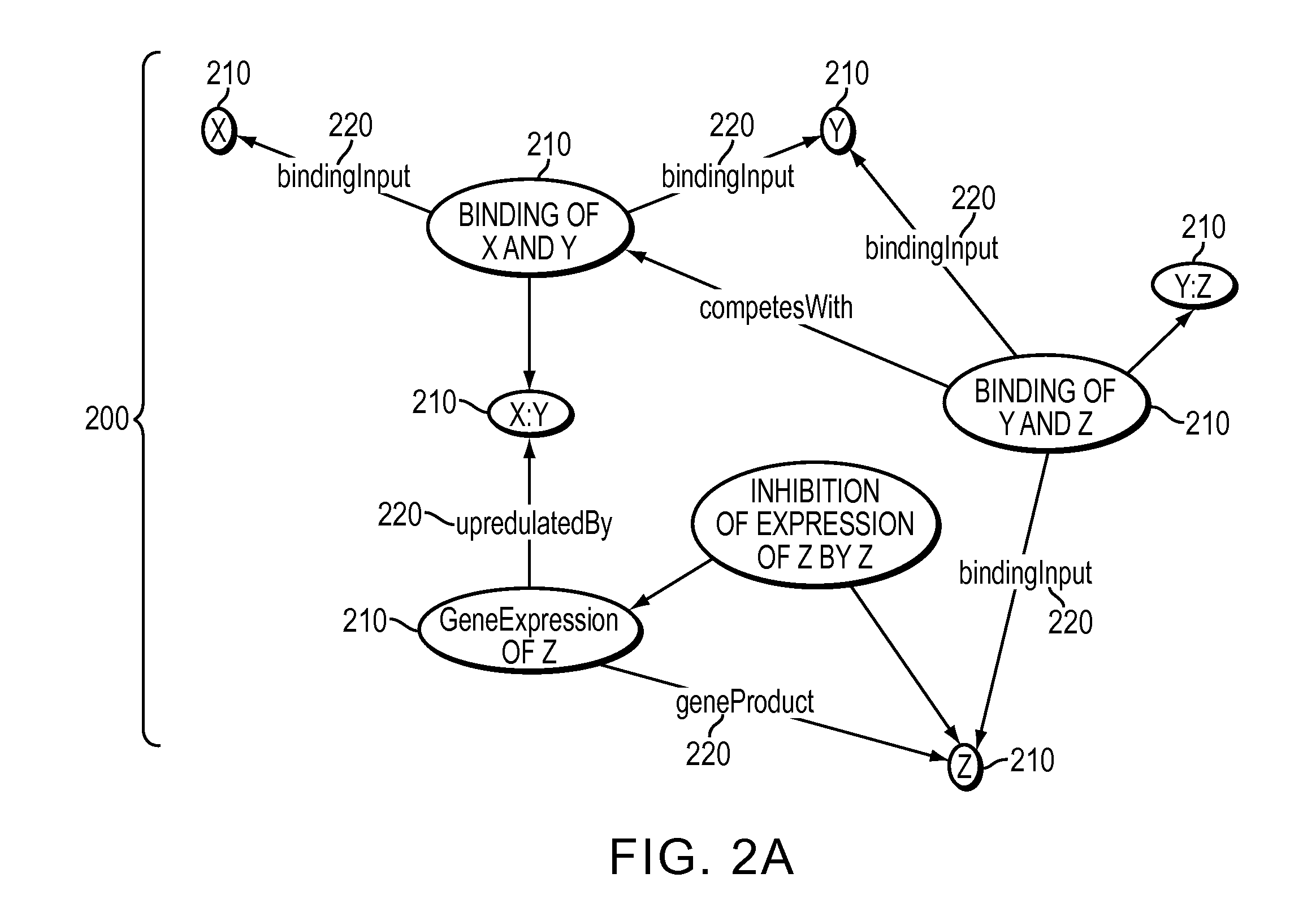

Method, system and apparatus for assembling and using biological knowledge

InactiveUS20050154535A1Efficient modelingEasy to understandBiological testingSystems biologyProduction rateComputer science

Disclosed are methods, systems and apparatus for constructing assemblies of biological knowledge constituting a biological knowledge base, and for subsetting and transforming life sciences-related data and information into biological models to facilitate computation and electronic reasoning on biological information. A subset of data is extracted from a global knowledge base or repository to reconstruct a more specialized sub-knowledge base or assembly designed specifically for the purpose at hand. Assemblies generated by the invention permit selection and rational organization of seemingly diverse data into a model of any selected biological system, as defined by any desired biological criteria. These assemblies can be mined easily and can be logically reasoned with great productivity and efficiency.

Owner:GENSTRUCT

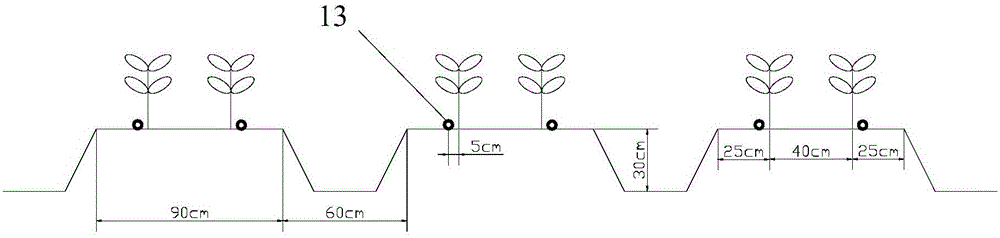

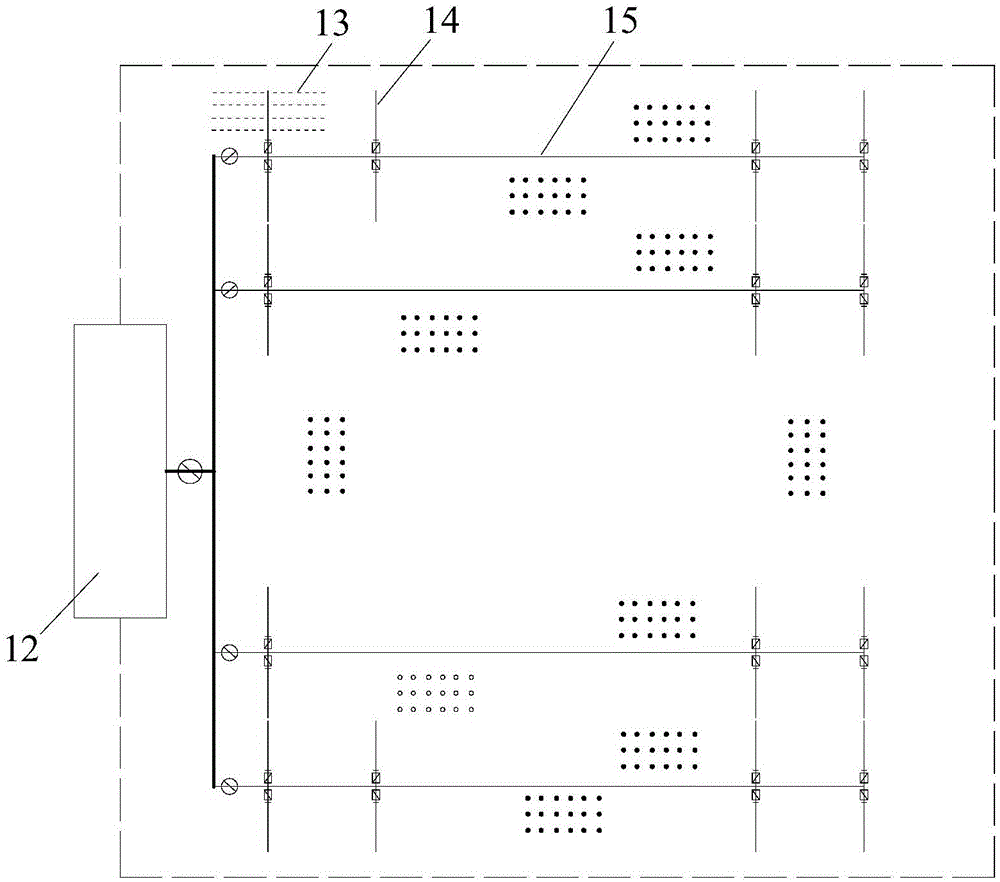

Saline-alkali soil brackish water film mulching drip irrigation processing tomato planting method

ActiveCN105103857AEasy to mineReduce evaporationClimate change adaptationWatering devicesAridAlkali soil

The invention provides a saline-alkali soil brackish water film mulching drip irrigation processing tomato planting method, which comprises the following steps: (1) planting processed tomatoes: planting the processed tomatoes by adopting a manner of wide rows and high ridges, and mulching a white film above plants; (2) laying out a drip irrigation system, wherein an interval b between the drip irrigation systems is 48 to 52 cm; an interval a between drip emitters is 0.25 to 0.35 m; (3) carrying out high-frequency and small fixed amount water irrigation in a growing period of the processed tomatoes: alternatively irrigating brackish water and fresh water, and adopting the fresh water for irrigation in a seedling stage, and no irrigation in a red-mature period. The invention puts forward a cultivation method taking the brackish water and saline-alkali soil as targets in combination with the realities of shortage of fresh water resources, abundant underground brackish water resources and serious soil salinization in an arid region and a semi-arid region, and not only moisture is enabled to be held up within a field microcirculation of soil-and-film, deep seepage losses of the moisture are greatly reduced, but also under-film soil evaporation is remarkably lowered, sources of soil secondary salinization are cut off and the surface accumulation of salt is eliminated.

Owner:CHINA AGRI UNIV

Method, system and apparatus for assembling and using biological knowledge

InactiveUS20090313189A1Efficient modelingFacilitate understanding and revelationDigital computer detailsBiological testingProduction rateBiological modeling

Disclosed are methods, systems and apparatus for constructing assemblies of biological knowledge constituting a biological knowledge base, and for subsetting and transforming life sciences-related data and information into biological models to facilitate computation and electronic reasoning on biological information. A subset of data is extracted from a global knowledge base or repository to reconstruct a more specialized sub-knowledge base or assembly designed specifically for the purpose at hand. Assemblies generated by the invention permit selection and rational organization of seemingly diverse data into a model of any selected biological system, as defined by any desired biological criteria. These assemblies can be mined easily and can be logically reasoned with great productivity and efficiency.

Owner:GENSTRUCT

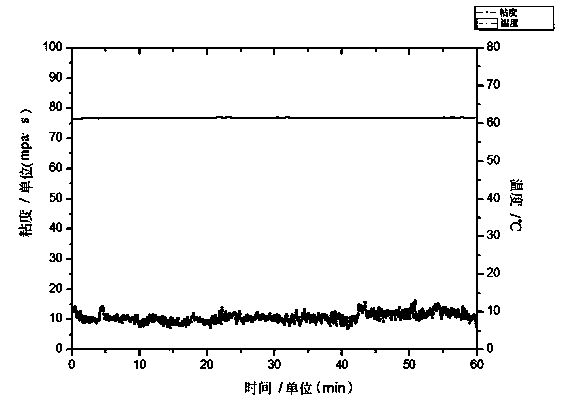

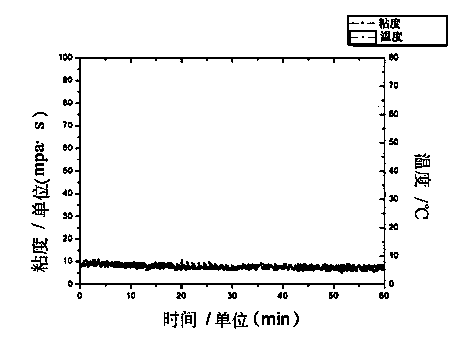

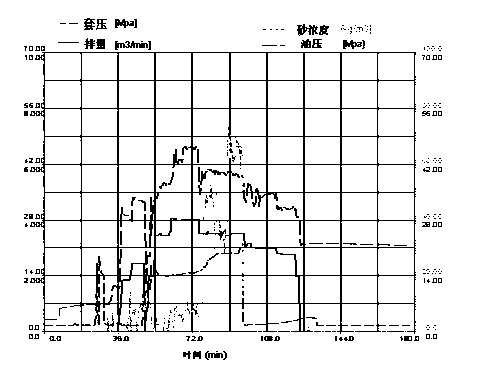

Supercritical carbon dioxide based fracturing liquid system and application thereof

ActiveCN103540308AViscosity value adjustableGood sand carryingFluid removalDrilling compositionEnvironmental resistanceAdhesive

The invention relates to a supercritical carbon dioxide based fracturing liquid system and application thereof. The fracturing liquid system comprises the following components: 0.1%-5% of adhesive, 0.3%-6.5% of conditioner and the rest of supercritical carbon dioxide. The supercritical carbon dioxide based fracturing liquid system provided by the invention can be used for oil field fracturing. In an application field, all components are mixed in certain mass percentage, and a propping agent is pumped into a stratum together with the mixture. The fracturing liquid system provided by the invention has the characteristics of good sand-carrying properties, easy backflow, no residues and no water phase, completely eliminates water-lock and water-sensitive damages, effectively reduces the viscosity of crude oil, inhibits clay swelling, improves the reservoir permeability, greatly saves water resources and can reach the purpose of efficient, environment-friendly and green construction.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

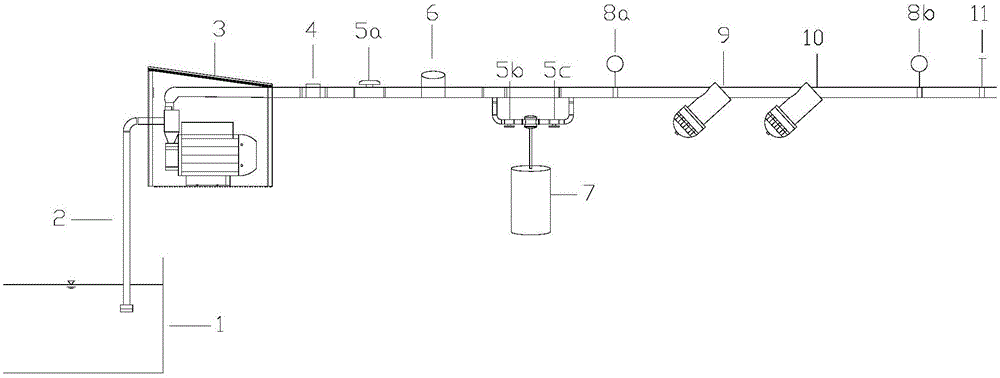

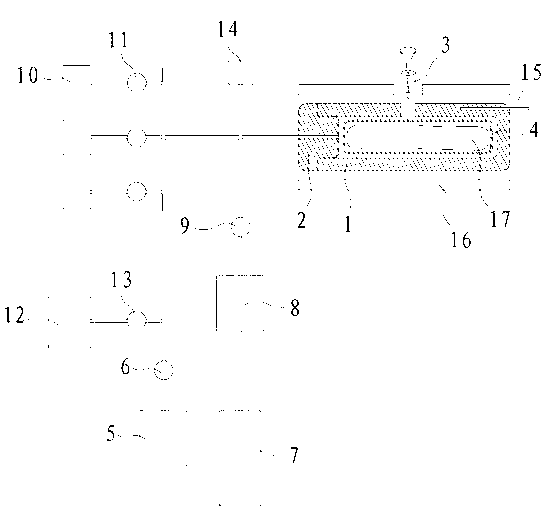

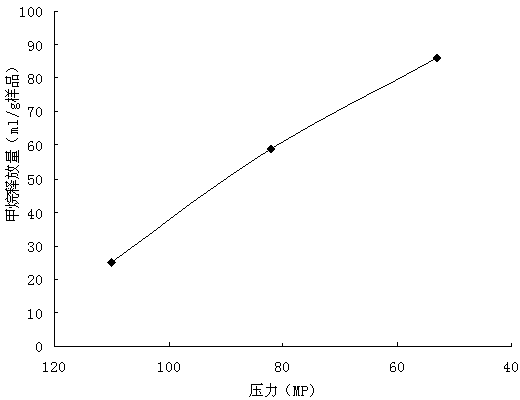

On-line measuring device for measuring generating amount and discharging amount of shale gas

InactiveCN103323366AEasy to mineAccurate and reliable measurement resultsComponent separationShale gasNeedle valve

The invention relates to an on-line measuring device for measuring generating amount and discharging amount of shale gas. The device comprises a heating tube; a rotary needle valve, which can screw into the inner cavity body of the heating tube and is arranged on the heating tube; a shale packaging tube, which is arranged in the inner cavity body of the heating tube; a vacuuming system, which is connected with the inner cavity body of the heating tube; an inert gas providing system, which is connected with the inner cavity body of the heating gas, a gas collecting system, which is connected to the inner cavity body of the heating tube; a gas analysis gas chromatography, which is connected to the gas collecting system; and a pressure sensor used for detecting the air pressure of the inner cavity body of the heating tube. The online measuring device has the advantages that processes of shale hydrocarbon generating and shale hydrocarbon discharging are truly simulated under geological conditions, and the measure results are precise and reliable.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

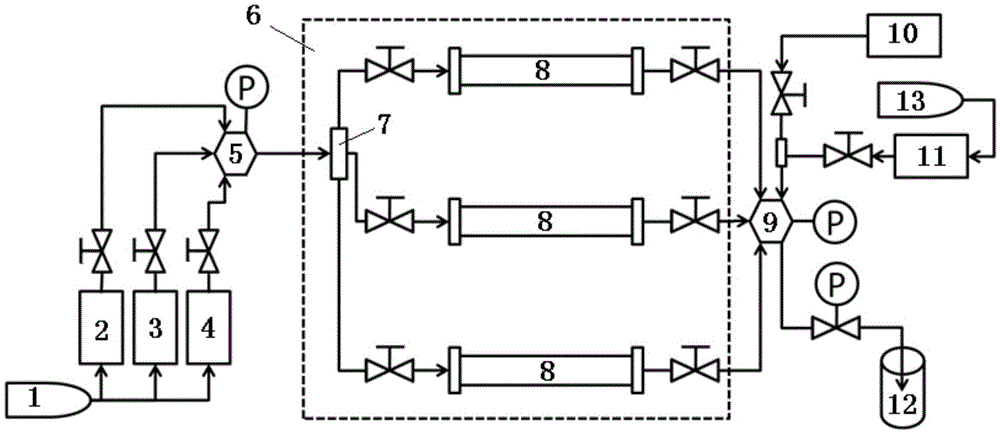

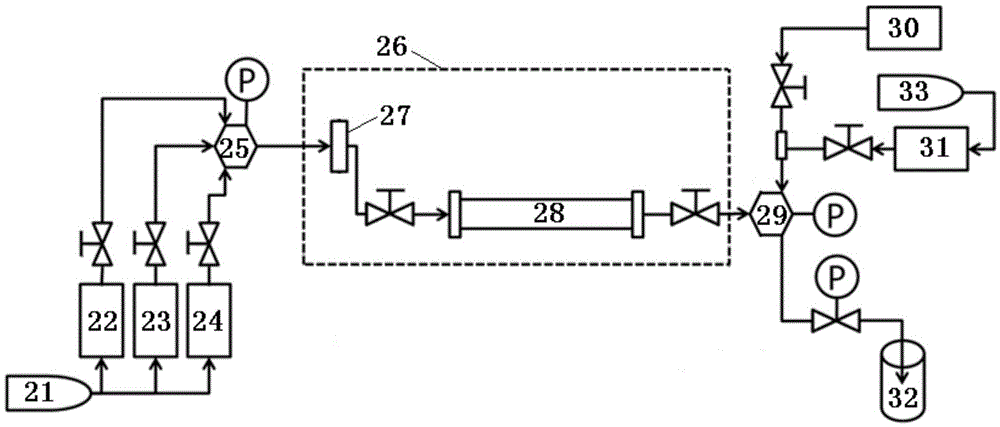

Physical simulation huff-puff production experimental method and device

The invention relates to a physical simulation huff-puff production experimental method and device. The method is characterized by comprising the steps that 1, a core model for an experiment is vacuumized; 2, simulation formation water is sucked into the core model till the core model absorbs water to reach saturation; 3, crude oil is injected into the core model till no simulation formation water is drained out of the core model; 4, according to the solution gas-oil ratio data of a target oil field to be measured and core model output simulation formation water volume, the volume of gas needing to be injected into the core model is worked out; 5, the gas is injected into the core model; 6, huff-puff fluid is injected into the core model, the core model is closed, and a soaking process is simulated; 7, after experiment time is up, the core model is opened for huff-puff fluid and crude oil spurt, and one-time physical simulation huff-puff production experiment is completed. Experiments in different huff-pull ways can be carried out, influence effects of different injection parameters or parameter quantized comparison effect data, and a reliable evaluation platform is provided for thickened oil field exploitation in different huff-puff ways.

Owner:CHINA NAT OFFSHORE OIL CORP +1

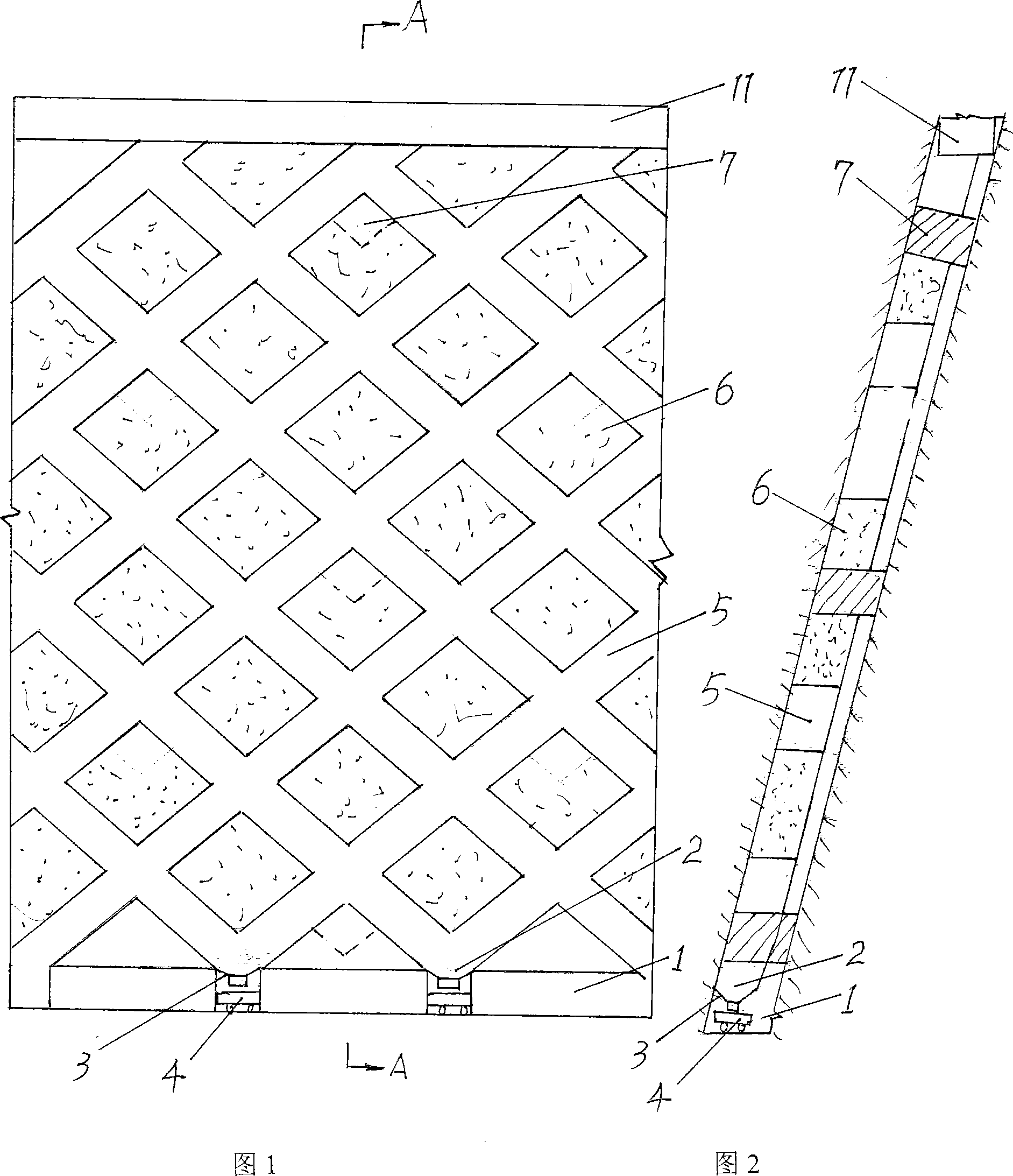

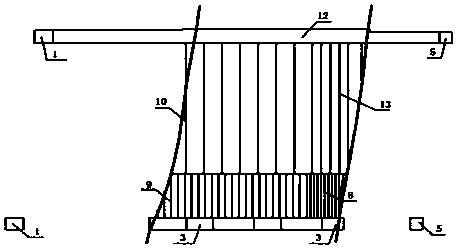

High-dipping ore block house column mining method

InactiveCN101509377AEasy to mineReduce depletion rateUnderground miningSurface miningRoom and pillar miningEngineering

The invention provides a steeply inclined ore body room-and-pillar mining method, comprising the following steps: a traveling roadway is tunneled along the trend of the ore body; broken-ore troughs are tunneled in the traveling roadway at interval with the broken-ore troughs as junctions, two inclined shafts are tunneled toward the uphill direction to the top of a quarry; a rhombic ore block formed between the inclined shafts is mined from top to bottom in sequence; ore pillars are left in the rhombic ore block at interval; ores mined in the process of tunneling slip into the broken-ore troughs along the inclined shafts depending on self weight and then put into a mine car in the traveling roadway from the broken-ore troughs to be delivered; the tunneled inclined shafts in networked cross distribution can serve as a passage and an ore chute for the miners to go up and down and as a ventilation shaft and a workplace for rock drilling, ore breaking and blasting avoiding. The method is good in ventilation effect, safe, reliable, low in cost, simple in construction operation, high in ore recovery ratio and low in dilution ratio.

Owner:KUNMING IRON & STEEL GRP CO LTD

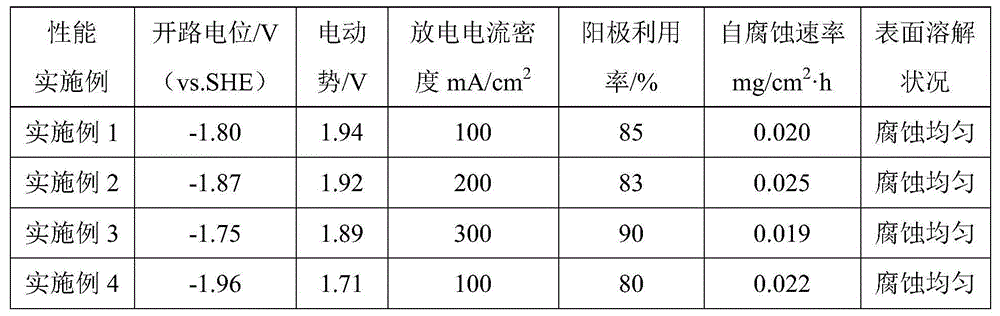

Rare earth-containing amorphous/nanocrystal aluminum anode composite material, preparation method and aluminum air battery

InactiveCN104372206AImprove electrochemical performanceAbundant resourcesFuel and primary cellsCell electrodesRare-earth elementDissolution

The present invention discloses a rare earth-containing amorphous / nanocrystal aluminum anode composite material, a preparation method and an aluminum air battery, and belongs to the techncial field of air batteries. The aluminum anode composite material comprises, by weight, 0.5-5% of Mg, 0.02-2% of Sn, 0.02-2% of Ga, 0.1-5% of La or Ce, and the balance of Al. According to the present invention, aluminum with the purity of more than or equal to 99.8% is adopted as the base, the trae amounts of Mg, Sn, Ga and the rare earth element La or Ce are added so as to reduce the self-corrosion rate and improve the electrochemical property and the surface dissolution uniformity of the alloy, especially the trae amount of the rare earth element is added to the aluminum alloy, and the addition of the rare earth element to the aluminum has effects of oxygen removing, hydrogen removing, desulfuration, melting rate accelerating, metal burning loss reducing, change of species distribution and refinement modification of iron and other harmful impurities, and the like so as to slow down the self-corrosion of the aluminum alloy, such that the anode utilization rate is improved.

Owner:HENAN UNIV OF SCI & TECH

Seabed natural gas hydrate collecting device

ActiveCN105781497AConnect warmUniform temperatureConstructionsFluid removalDecompositionElectric heating

The invention discloses a seabed natural gas collecting device for suspension buoyancy tank electric heating, and belongs to the technical field of natural gas collection. The device comprises a mother ship and a hollowed natural gas collecting cover; a natural gas storage device is arranged on the mother ship, and is connected to the top of the natural gas collecting cover through a gas extracting pipeline; the natural gas collecting cover is connected to the bottom of the mother ship through a water separation pipe; the gas extracting pipeline is arranged in the water separation pipe; anchoring systems are arranged around the bottom of the natural gas collecting cover; a pressure adjusting system is arranged at the bottom of the natural gas collecting cover; a propelling system is arranged on the outer wall of the natural gas collecting cover; a density adjusting system is arranged on the natural gas collecting cover; and a temperature adjusting system and a stirring system are arranged in the natural gas collecting cover. The device mainly solves the problem of incapability of forming emission and leakage of natural gas in the decomposition, collection and extraction process of natural gas hydrates on a seabed mud bed.

Owner:SOUTHWEST PETROLEUM UNIV

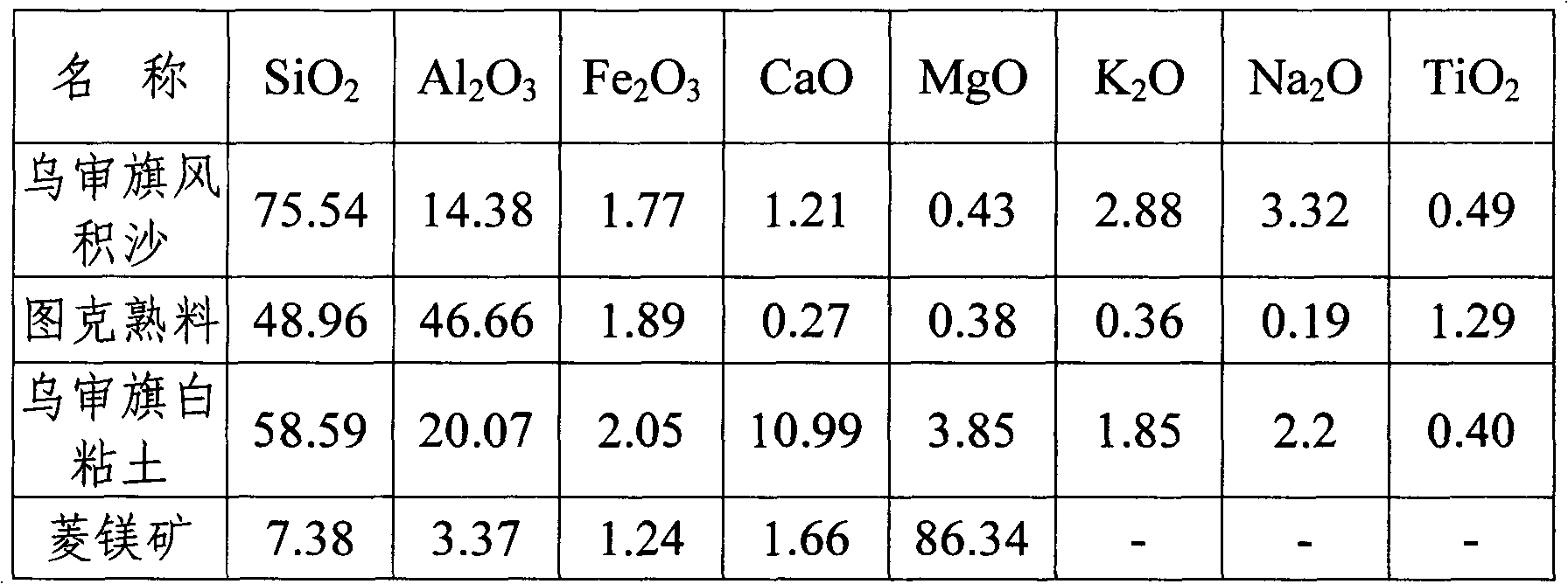

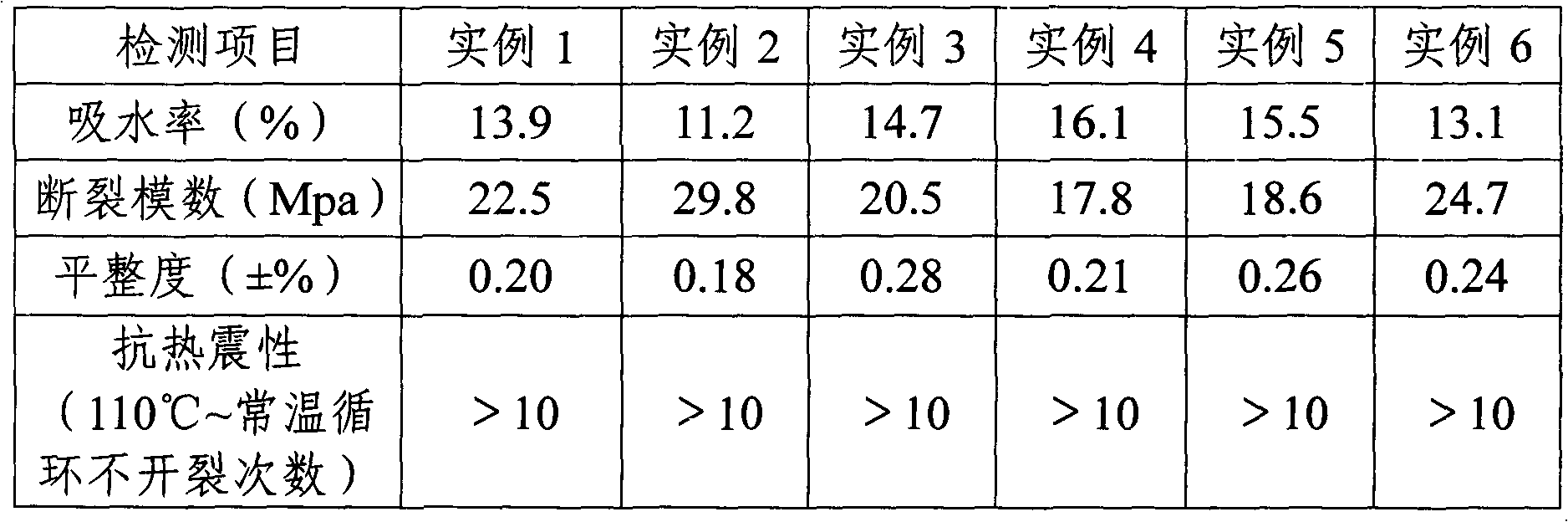

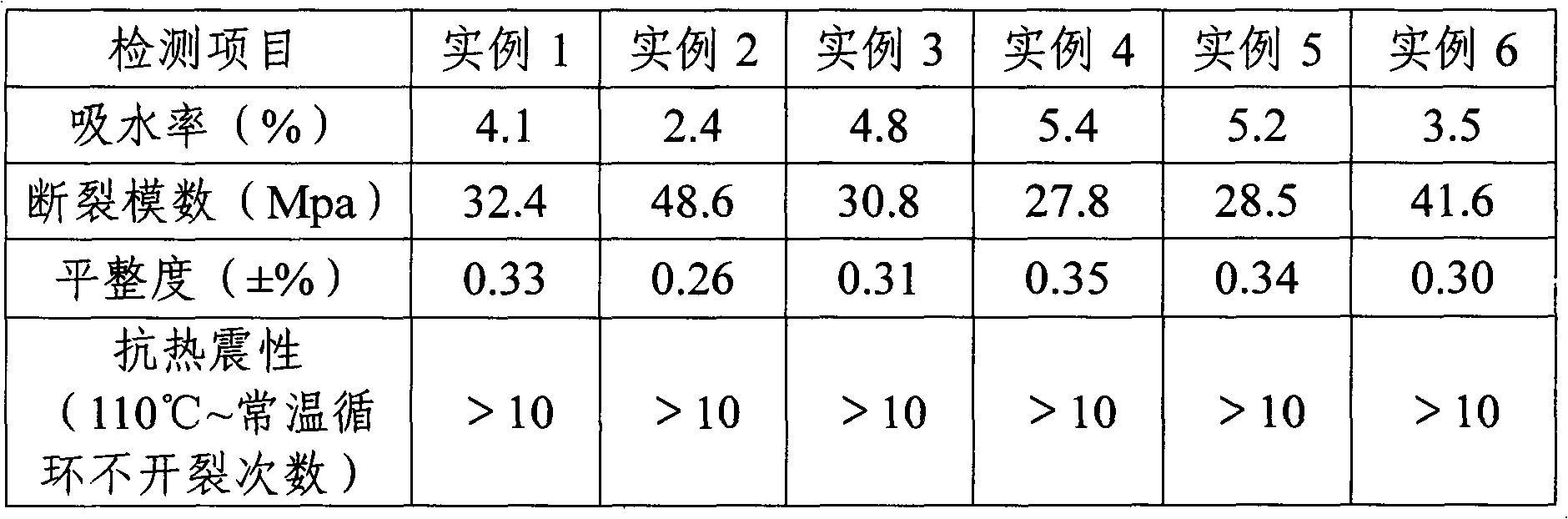

Ceramic brick prepared from aeolian sand

The invention relates to a ceramic brick prepared from aeolian sand. The ceramic brick comprises the following raw materials by weight percent: 50-60% of Uxen aeolian sand. 20-28% of Tuke clinker, 12-20% of Uxen white clay and 2-8% of magnesite. The ceramic product is prepared by the steps of ball milling, smashing, sieving, deironing, forming and firing at the temperature of 1080-1220 DGE C. According to the invention, the aeolian sand enriched in Inner Mongolia is used as a main ceramic-making material, which is beneficial to low-cost desert control and leads the production cost of the ceramic product to be greatly reduced; and the prepared ceramic product has the advantages of excellent quality, small size difference, low water absorption and high strength, and relative indexes reach the requirement of national detection standards.

Owner:马东升

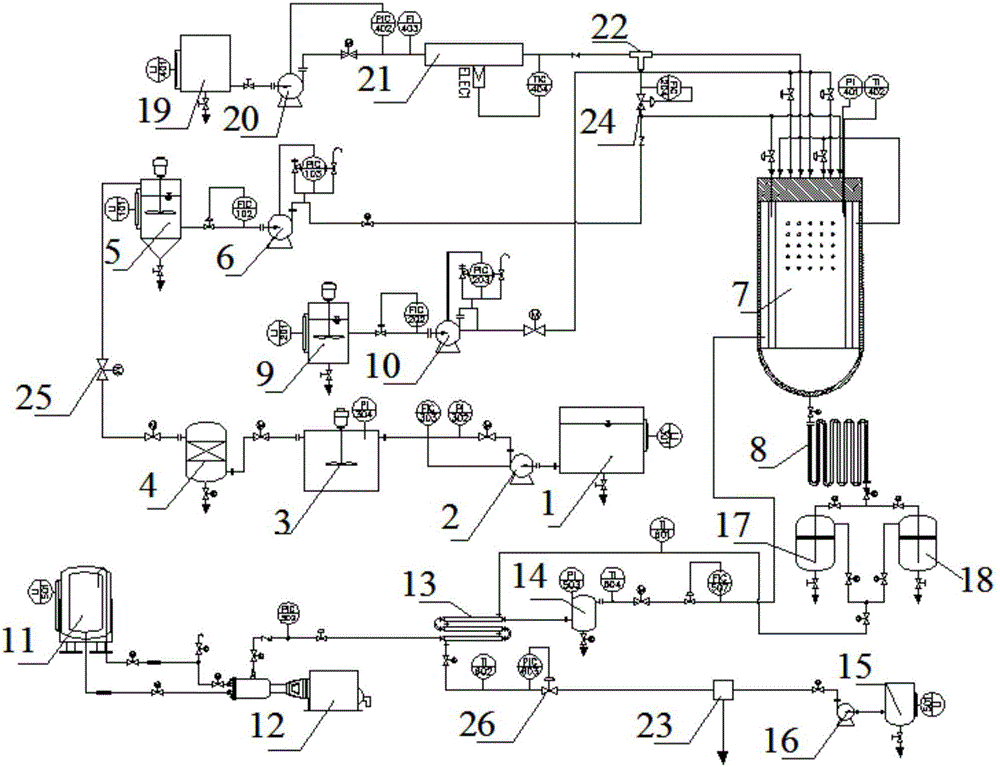

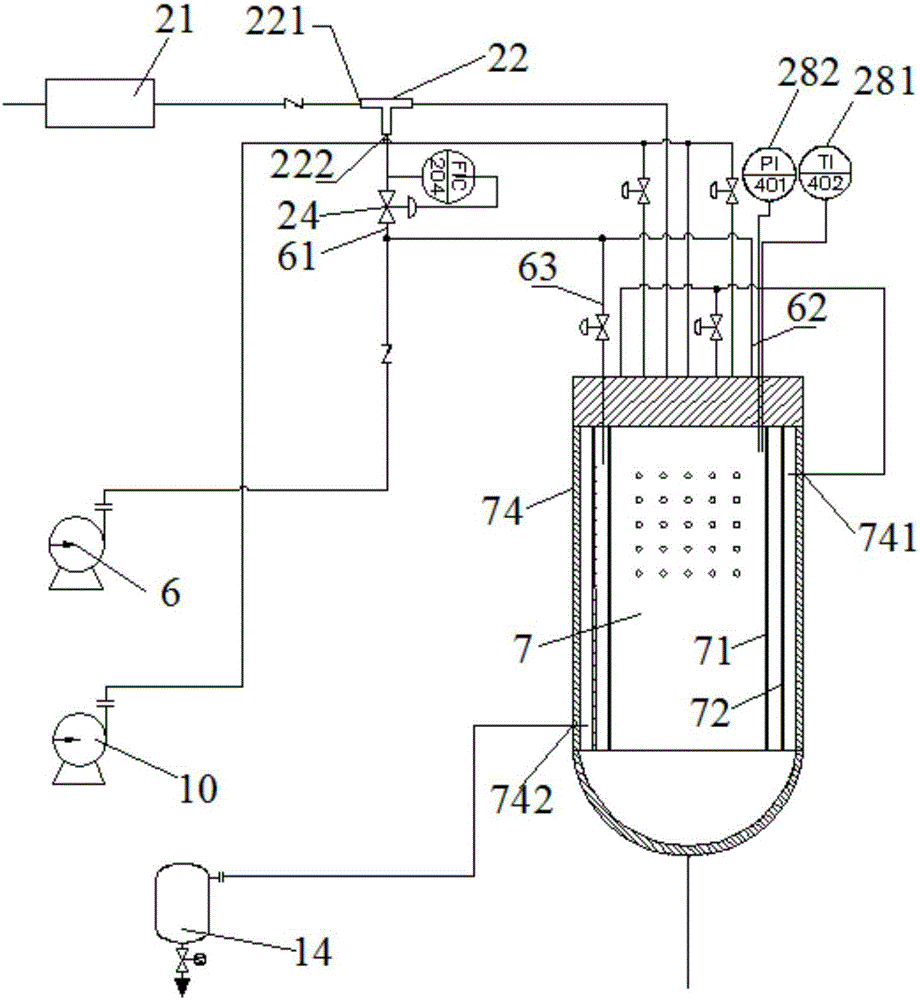

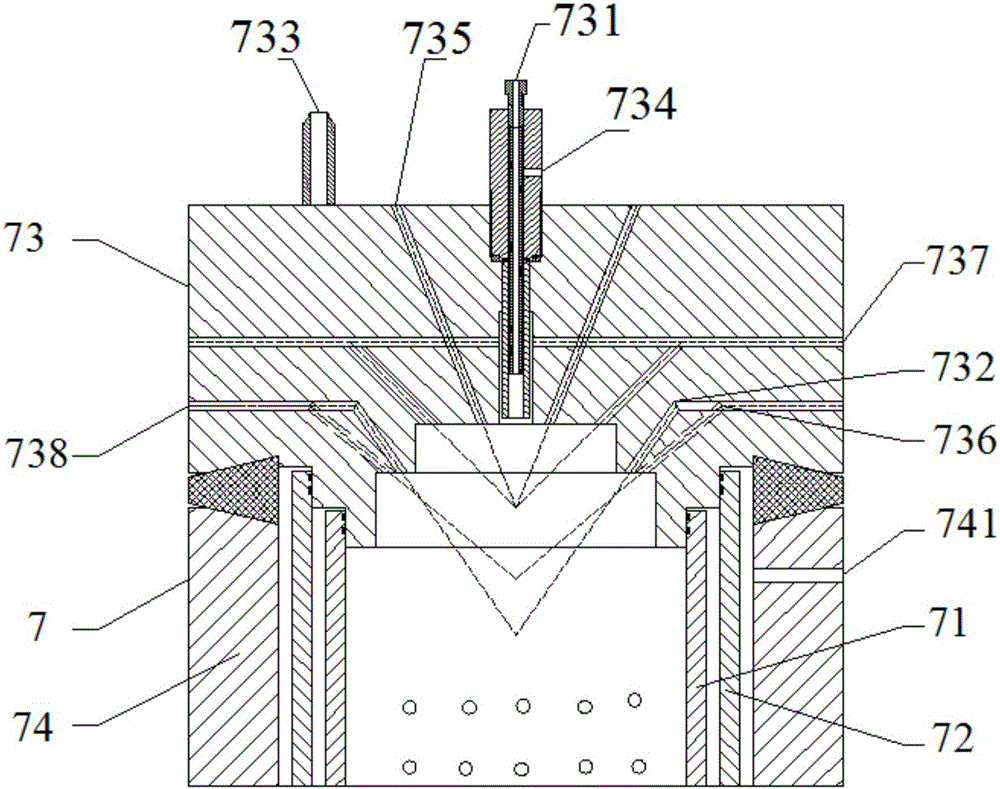

Supercritical hydrothermal combustion treatment and steam injection system for oil extraction waste liquid

ActiveCN106630287AReduce consumptionSmall footprintWaste water treatment from quariesTreatment involving filtrationCombustionPre treatment

The invention discloses a supercritical hydrothermal combustion treatment and steam injection system for oil extraction waste liquid. The supercritical hydrothermal combustion treatment and steam injection system for the oil extraction waste liquid comprises a coagulation pretreatment unit; the coagulation pretreatment unit is connected with a material transporting unit; the material transporting unit is connected with a supercritical hydrothermal combustion unit; the supercritical hydrothermal combustion unit is connected with an initiating preheating unit; the supercritical hydrothermal combustion unit is connected with a supercritical water treatment oxidization unit; the supercritical water treatment oxidization unit is connected with a steam post-treatment unit; the oil extraction waste liquid can be treated harmlessly, meanwhile, an effective steam injection medium can be provided, and heavy oil recovery efficiency is improved.

Owner:XIAN UNIV OF TECH

Novel high-efficiency composite viscosity reducer for super heavy oil

ActiveCN102604621AReduce dosageEasy to minePipeline systemsDrilling compositionWater qualityOil phase

The invention relates to an oil-soluble and water-soluble composite temperature-resistant and salt-resistant viscosity reducer for super heavy oil in the field of petroleum exploitation. The composite viscosity reducer contains oil-soluble viscosity reducer A and water-soluble viscosity reducer B, and mass ratio of the oil-soluble viscosity reducer A to water-soluble viscosity reducer B is 1:(4-9). The viscosity reducer provided by the invention has the following advantages: the viscosity reducer has temperature resistance (up to 140 DEG C), salt resistance (up to 22*10<4>mg / L), and combines the advantages of both oil-soluble viscosity reducers and water-soluble viscosity reducers; the viscosity reducing effect is obviously superior to the effect of single use of oil-soluble viscosity reducer and water-soluble viscosity reducer; the application range is wide; the viscosity of the oil phase can be reduce after demulsification; and demulsification is not affected and water quality is not influenced. The viscosity reducer provided by the invention can greatly saves consumption of thin oil and exploitation cost when being used for well casing viscosity reduction; and can effectively improve exploitation and delivery performance of heavy oil / super heavy crude oil and greatly increase well yield when being used for heavy oil viscosity reduction.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

CO2 mineralizing process

InactiveCN101020577ARich reservesEasy to mineCalcium/strontium/barium carbonatesMagnesium carbonatesSodium bicarbonateReaction temperature

The CO2 mineralizing process includes the steps of: grinding silicate mineral of natural calcium and magnesium into powder, mixing with the mixed solution of sodium bicarbonate and sodium chloride or distilled water in a reaction kettle, filling CO2 gas to the reaction kettle to 3-12 MPa and reaction at 100-250 deg.c via stirring for 30-90 min to produce carbonate and realize the permanent storage of CO2. The present invention adopts rich natural silicate and can realize large scale CO2 treatment.

Owner:HUAZHONG UNIV OF SCI & TECH

Selenium-rich ceramic appliance and preparation technology thereof

The invention relates to a selenium-rich ceramic appliance. A ceramic appliance body is fired from raw materials in parts by mass as follows: 30-50 parts of selenium-rich soil, 35-45 parts of petalite, 5-15 parts of spodumene, 1-15 parts of quartz, 10-15 parts of kaolin, 5-8 parts of microcrystalline ceramic powder, 1-3 parts of halloysite nanotubes, 0.5-1 part of nano tungsten carbide powder, 0.5-1 part of nano technetium oxide powder and 0.3-0.5 parts of polyacrylamide. The inner wall of the ceramic appliance body is coated with a selenium-containing coating. The selenium-rich ceramic appliance is prepared from main materials including cheaper petalite and selenium-rich soil, is coated with the selenium-rich coating, has good thermal shock resistance, crack resistance, wear resistance and heat conductivity and can separate out trace selenium element to supplement the human body with selenium.

Owner:JIANGXI JINGSHANG IND CO LTD

Petalite heat-resistant ceramic wok and preparation process thereof

ActiveCN108101525AIncrease productionImprove control effectCooking-vessel materialsCrack resistanceTalc

The invention relates to a petalite heat-resistant ceramic wok. The petalite heat-resistant ceramic wok is prepared by firing the following raw materials in parts by weight: 45 to 65 parts of petalite, 15 to 40 parts of spodumene, 12 to 20 parts of quartz, 15 to 20 parts of kaolin, 6 to 9 parts of talc, 5 to 8 parts of microcrystalline ceramic powder, 1 to 3 parts of halloysite nanotubes, 0.5 to 1part of nanometer tungsten carbide powder, 0.5 to 1 part of nanometer technetium oxide powder, 0.3 to 0.5 part of polyacrylamide. The petalite heat-resistant ceramic wok utilizes the cheaper petaliteas a main raw material, and the prepared petalite heat-resistant ceramic wok has good thermal shock resistance, good crack resistance, good wear resistance and good thermal conductivity.

Owner:JIANGXI JINGSHANG IND CO LTD

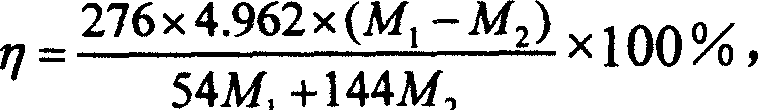

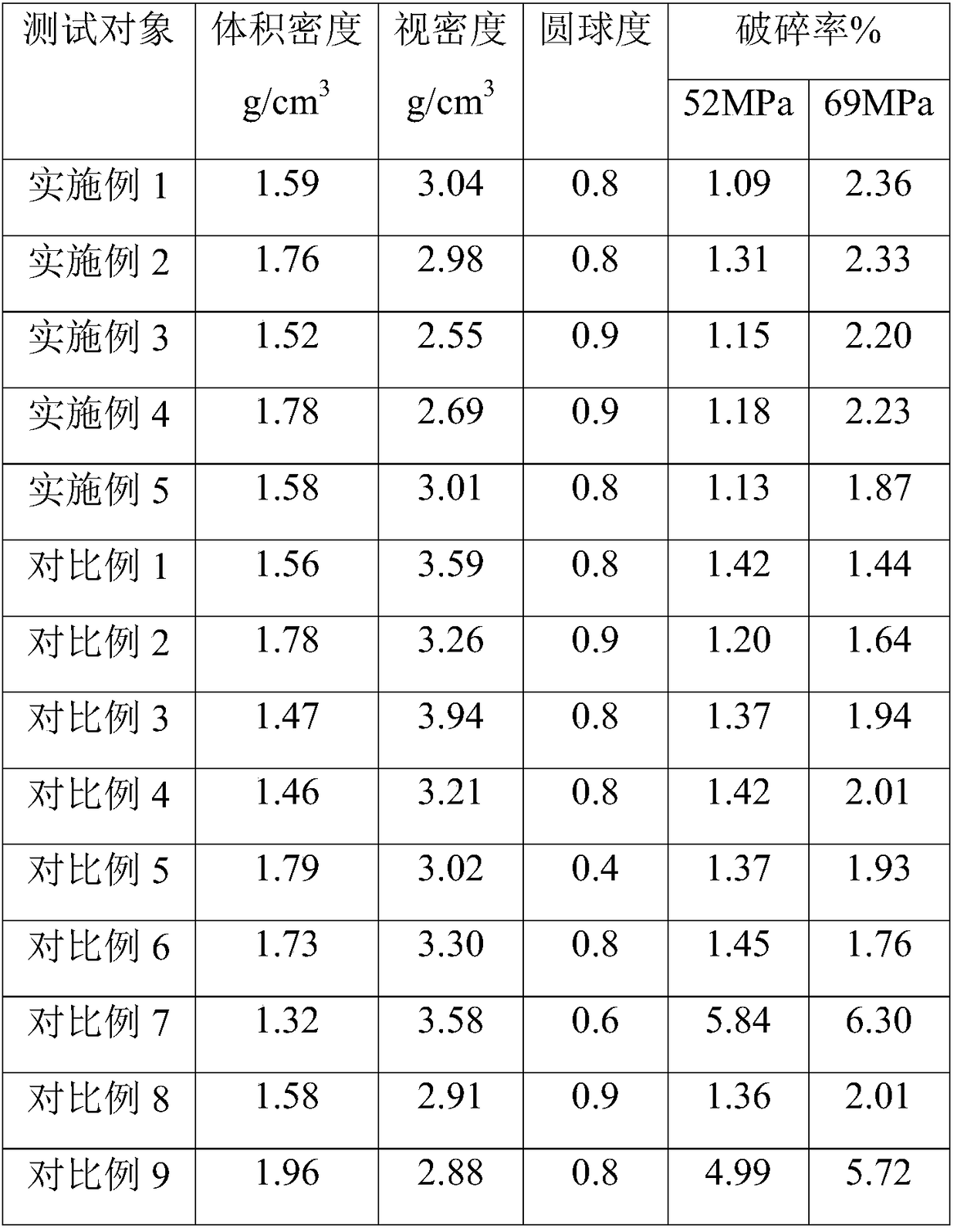

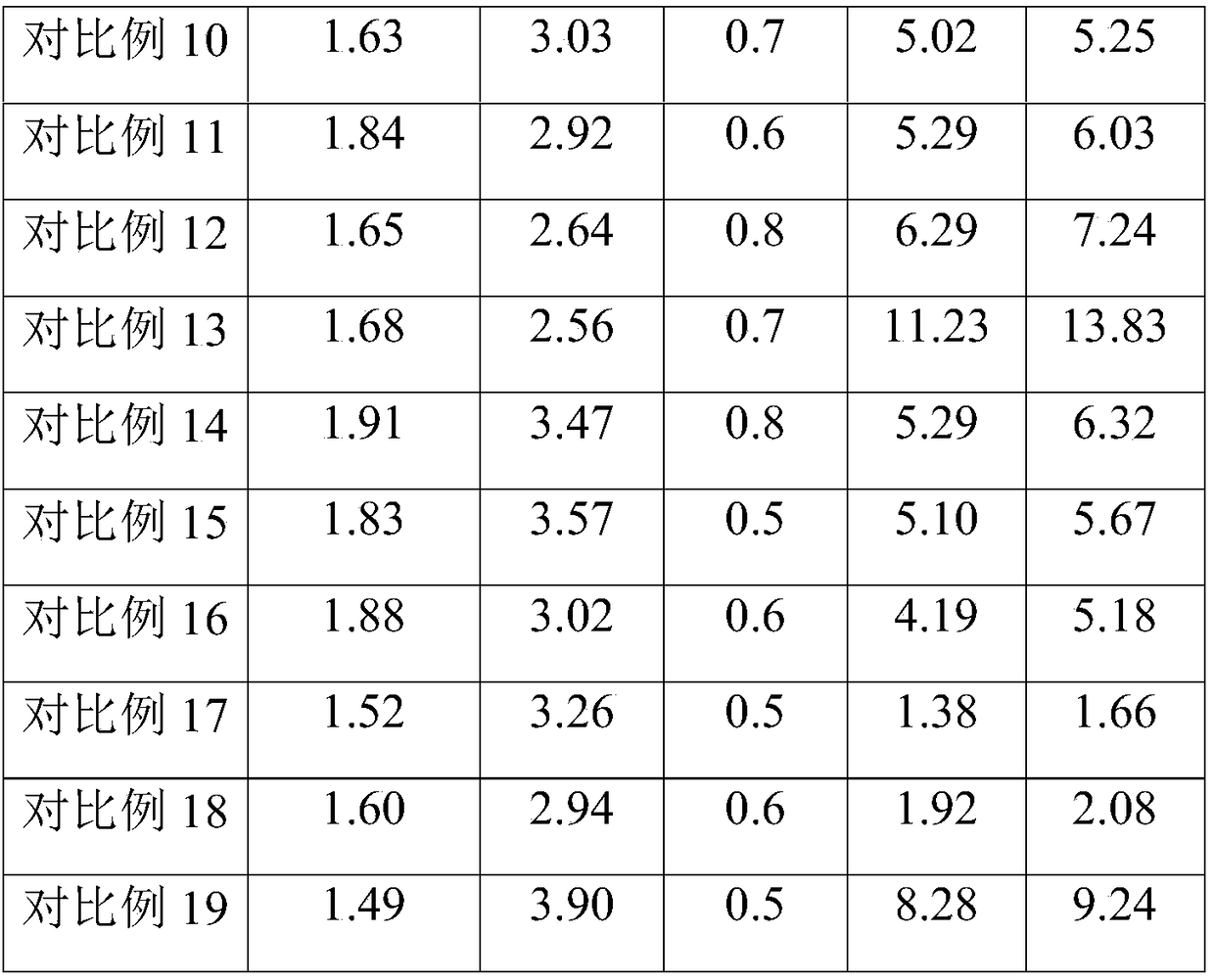

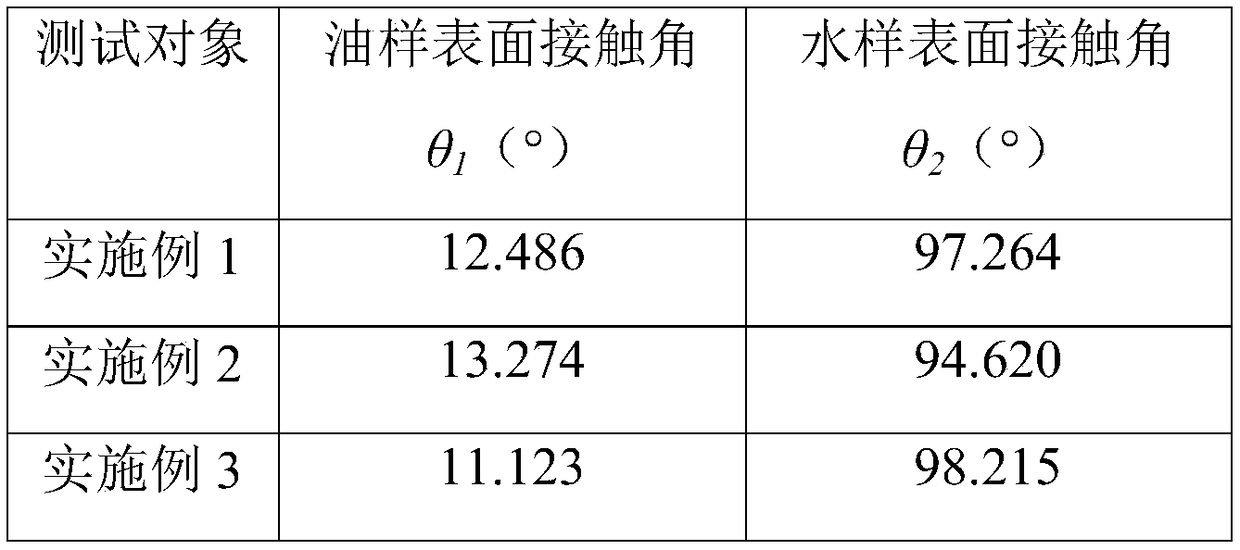

Hydrophobic membrane laminating propping agent as well as preparation method and application thereof

ActiveCN108976366AImprove antioxidant capacityImprove the diversion effectFluid removalDrilling compositionEnvironmental resistanceOil production

The invention discloses a hydrophobic membrane laminating propping agent as well as a preparation method and application thereof. The hydrophobic membrane laminating propping agent can be used for sticking bubbles and has excellent flow guide capability and transporting capability, and good hydrophobic property, lipophilic property and oil-penetration and water-resisting properties; the oil production amount of crude oil is improved and petroleum is easy to exploit; the method is simple and easy to popularize, and is suitable for industrialization; the cost is low, the damage level to a stratum is relatively low and environment protection and sustainable development are facilitated.

Owner:河南祥盛陶粒有限公司

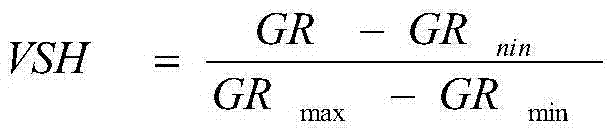

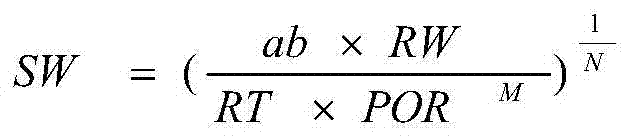

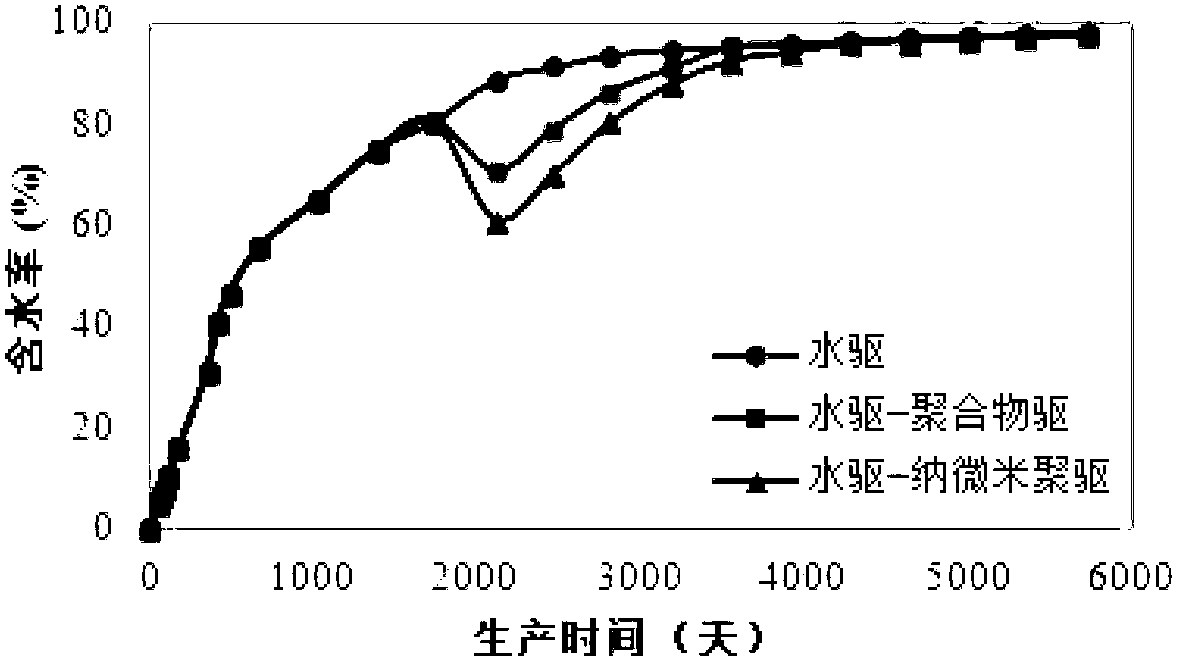

Method for exploiting residual crude oil in low-permeability oilfield by using polymer micro/nanoparticle

ActiveCN102797443AStrong expansion and volume effectStrong oil washing abilityFluid removalDrilling compositionEnhanced oil recoveryLow permeability

The invention relates to a method for exploiting residual crude oil in a low-permeability oilfield by using a polymer micro / nanoparticle, comprising the following steps of: (1) carrying out prior period water drive on the low-permeability oilfield; (2) measuring the average throat radius of the low-permeability oilfield to determine the particle size r of the polymer micro / nanoparticle, wherein the particle size r of the polymer micro / nanoparticle meets a formula shown as the specification; (3) carrying out copolymerization by using a distillation-precipitation method according to the determined particle size r of the polymer micro / nanoparticle to obtain the polymer micro / nanoparticle; and (4) injecting the polymer micro / nanoparticle obtained in the step (3) into an oil layer, and carrying out the following water drive on the low-permeability oilfield. The method has the advantages that the used polymer micro / nanoparticle injection system can selectively enter large, medium and small ducts, a stronger wave and volume expanding function and an oil washing capacity are achieved, the residual oil on a low-permeability layer is better exploited, the crude oil exploiting yield is increased, and the economic benefit is increased.

Owner:UNIV OF SCI & TECH BEIJING

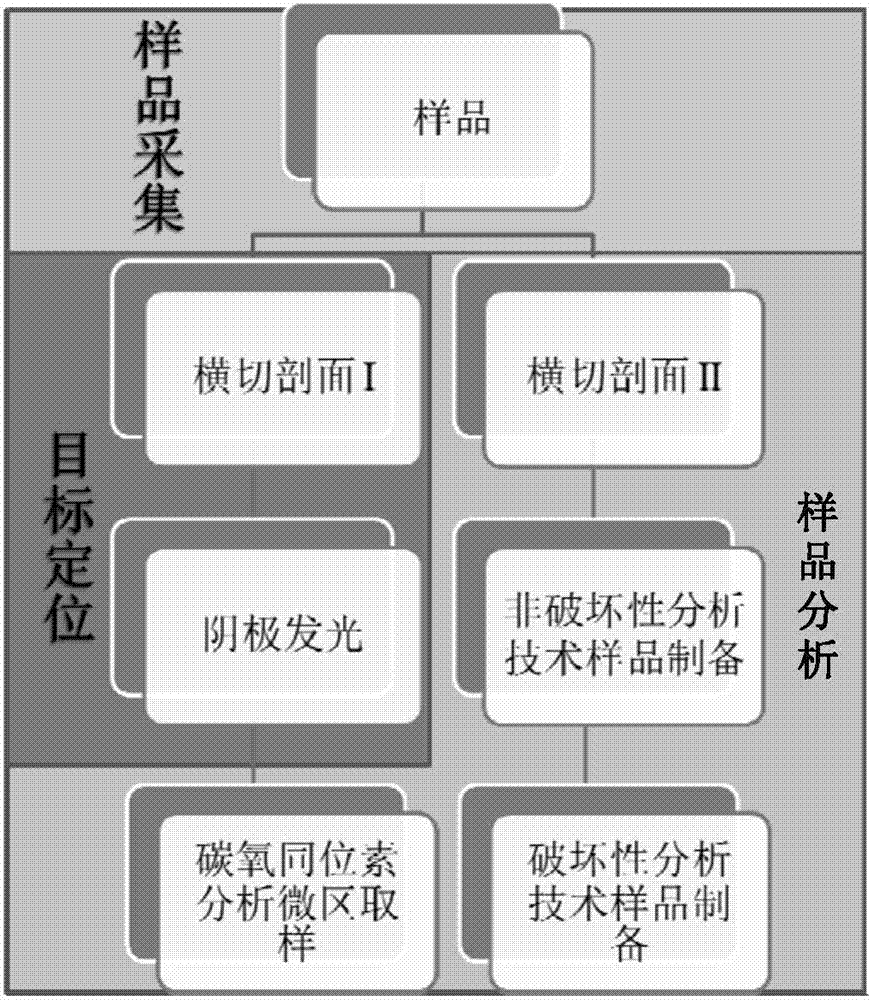

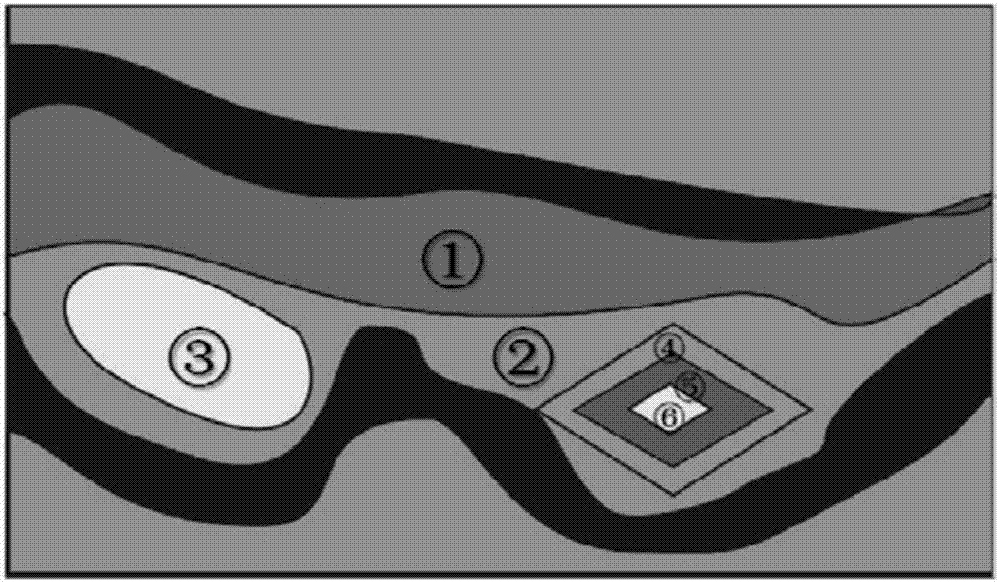

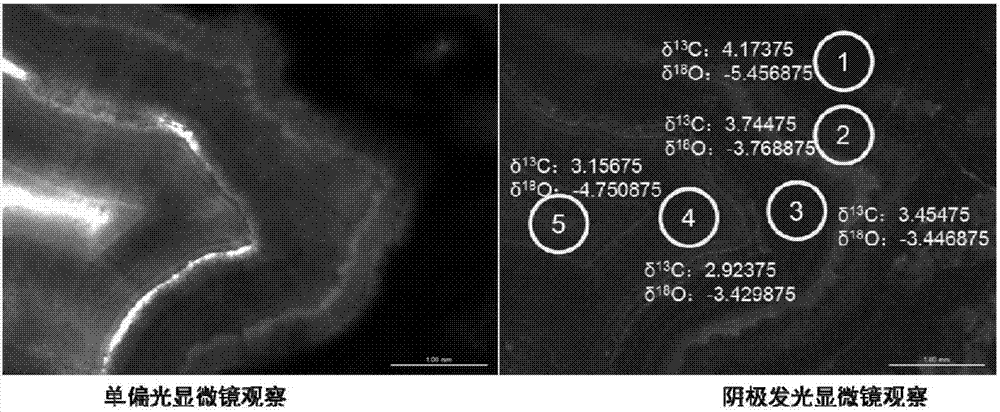

Sample treatment method for in-situ micro-area combination analysis

ActiveCN107490503AEasy to minePreparing sample for investigationEarth material testingNon destructiveTest analysis

The invention provides a sample treatment method for combining multiple in-situ micro-area test analysis. The sample treatment method mainly comprises three steps such as sample collection, target positioning, and sample preparation. According to the present invention, by macroscopically and microscopically observing and positioning the target area, and reasonably setting and coordinating the sample treatment process and the method, the in-situ micro-area test analysis in the structure, the component, the isotope and other fields are performed on the same part of the same sample to the greatest extent, the destructive and non-destructive in-situ micro-area analysis methods of a variety of samples are combined, and the possibility is provided for the fine description and analysis of the reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

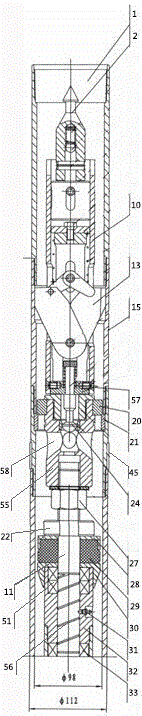

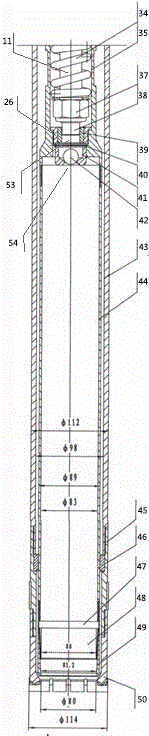

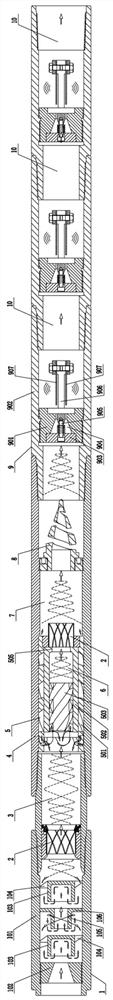

A wireline core drilling tool

ActiveCN104481439BImprove connection strengthIncreased drilling depthCore removalRubber ringMechanical engineering

The invention discloses a wire core drilling tool which comprises an inner pipe assembly and an outer pipe assembly. A blockage notifying mechanism comprises a pull rod and an alarming rubber ring fixed on the pull rod, a conical pad and a sliding sleeve connected on the pull rod in a sleeved manner are arranged at the lower end of the alarming rubber ring, the conical pad comprises an annular extrusion portion and a conical portion, the upper end of the annular extrusion portion is matched with the alarming rubber ring for extrusion, the conical portion is arranged at the lower end to protect the sliding sleeve, the upper end of the sliding sleeve and the conical pad are rotatably connected through a bearing, a clamping block is arranged on the lower portion of the pull rod, a buffering spring is connected between the clamping block and the sliding sleeve in a clamped manner and connected on the pull rod in a sleeved manner, a buffering spring sleeve is arranged outside the buffering spring, and the lower end of the buffering spring sleeve is connected with an inner pipe. The blockage notifying mechanism of the drilling tool is simplified, so that structure of the drilling tool is simplified greatly, and the drilling tool is enabled to be convenient to maintain, reliable to use and high in practicability.

Owner:无锡锡钻地质装备有限公司

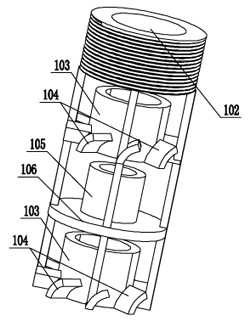

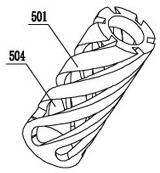

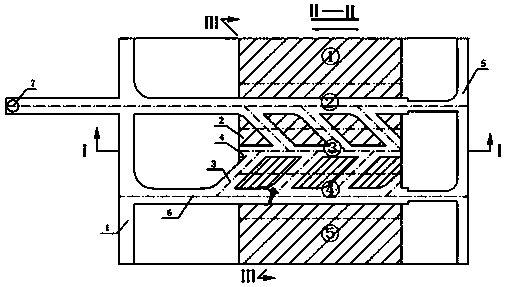

Multi-stage composite rotational flow and turbulent flow sound wave super-strong viscosity reduction, paraffin control and oil increasing device

ActiveCN112096346ASolve the problem of easy blockageImprove liquidityCleaning apparatusFluid removalAtomizer nozzleEngineering

The invention provides a multi-stage composite rotational flow and turbulent flow sound wave super-strong viscosity reduction, paraffin control and oil increasing device. The multi-stage composite rotational flow and turbulent flow sound wave super-strong viscosity reduction, paraffin control and oil increasing device comprises a pipe shell; an oil inlet is formed in the front end of the pipe shell; an oil outlet is formed in the rear end of the pipe shell; a layered rotational flow mechanism is mounted in the position, located behind the oil inlet, in the pipe shell and comprises an outer-layer rotational flow sleeve mounted on the inner wall of the pipe shell; a middle spacer sleeve is fixedly arranged on the inner wall of the outer-layer rotational flow sleeve; an inner-layer rotationalflow column core is arranged in the middle spacer sleeve; the middle spacer sleeve is used for separating an inner-layer oil passage from outer outer-layer oil passage; an atomizing nozzle is arranged in the position, located on the inner side of the oil outlet, in the pipe shell; a multi-stage turbulent flow mechanism is arranged at the outer end of the oil inlet in the pipe shell; a first-stageturbulent flow chamber is formed between the multi-stage turbulent flow mechanism and the layered rotational flow mechanism; a second-stage turbulent flow chamber is formed between the rear end of the middle spacer sleeve and the end part of the inner-layer rotational flow column core; and a third-stage turbulent flow chamber is formed between the layered rotational flow mechanism and the atomizing nozzle. According to the multi-stage composite rotational flow and turbulent flow sound wave super-strong viscosity reduction, paraffin control and oil increasing device, the paraffin control and viscosity reduction effects are greatly improved, the efficiency of an oil well pump is improved, an oil pipe almost cannot be blocked, and the yield of an oil well is increased.

Owner:HUANGSHI BOHUI TECH CO LTD

Mining method of efficient big collapse area ore mining

ActiveCN108798672AEasy to mineSolve rock drilling problemsUnderground miningBlastingCement pasteEncryption

The invention discloses a mining method of efficient big collapse area ore mining. Fine tailings are used for filling the collapse area in a cemented mode, and concentration is 50%, and therefore scattered particles can be bonded into an integrated part and mining is convenient. Construction method of downward middle section is used, a mined stope cemented filling body is used as a top plate for the next middle section stope. Grouting is carried out on medium gun hole area which is difficult to construct to solve the problem of rock drilling in medium gun holes. Cement paste pouring is carriedout in large holes which are difficult to construct, when the cement paste seeps down and solidifies, rock drilling construction is carried out to solve the problem of large hole rock drilling. Wellcutting and groove cutting are not carried out at the bottom of the stope. Cutting grooves are formed by squeeze blasting in a medium gun hole encryption area. Drilling chamber construction is not carried out on the upper portion of the stope. Sector-shaped large diameter gun holes are constructed in roadways. Downward sector-shaped hole blasting mining is adopted, and therefore rock drilling construction is convenient.

Owner:安徽大昌矿业集团有限公司

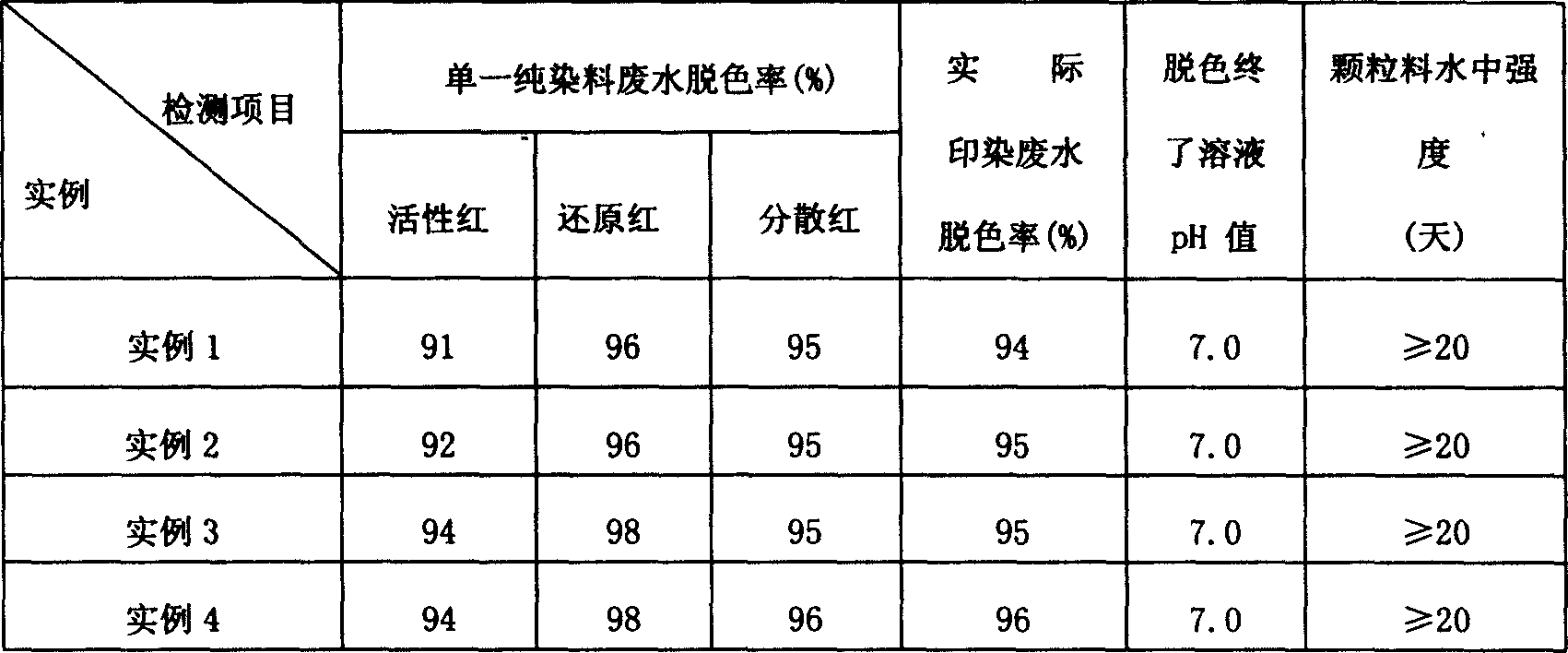

Method for producing decoloring material of printing and dyeing waste water

InactiveCN1858006AReduce manufacturing costRealize rational utilizationWater/sewage treatment by ion-exchangeWater/sewage treatment by flocculation/precipitationPollutant emissionsWastewater

The present invention relates to production process of decolorizing material for printing and dyeing waste water, and features that Hangjin clay No. 2 as main material is prepared into the decolorizing material through crushing to 40-80 mesh, activating with 1.0-2.5 mol / L concentration H2SO4 solution in the quantity of 2-3 times at 80-95 deg.c for 1-2 hr, neutralizing with 3-6 mol / L concentration alkali solution to pH 7-8, solid-liquid separating, pelletizing, stoving at 90-100 deg.c and calcining at 750 deg.c for 2-4 hr. The produced filtrate may be evaporated and concentrated to obtain side product Na2SO4 .10H2O or (NH4)2SO4. The decolorizing material has decolorizing rate on printing and dyeing waste water higher than 94 %. The production process is simple and low in cost, and has no pollutant exhaust.

Owner:SICHUAN UNIV

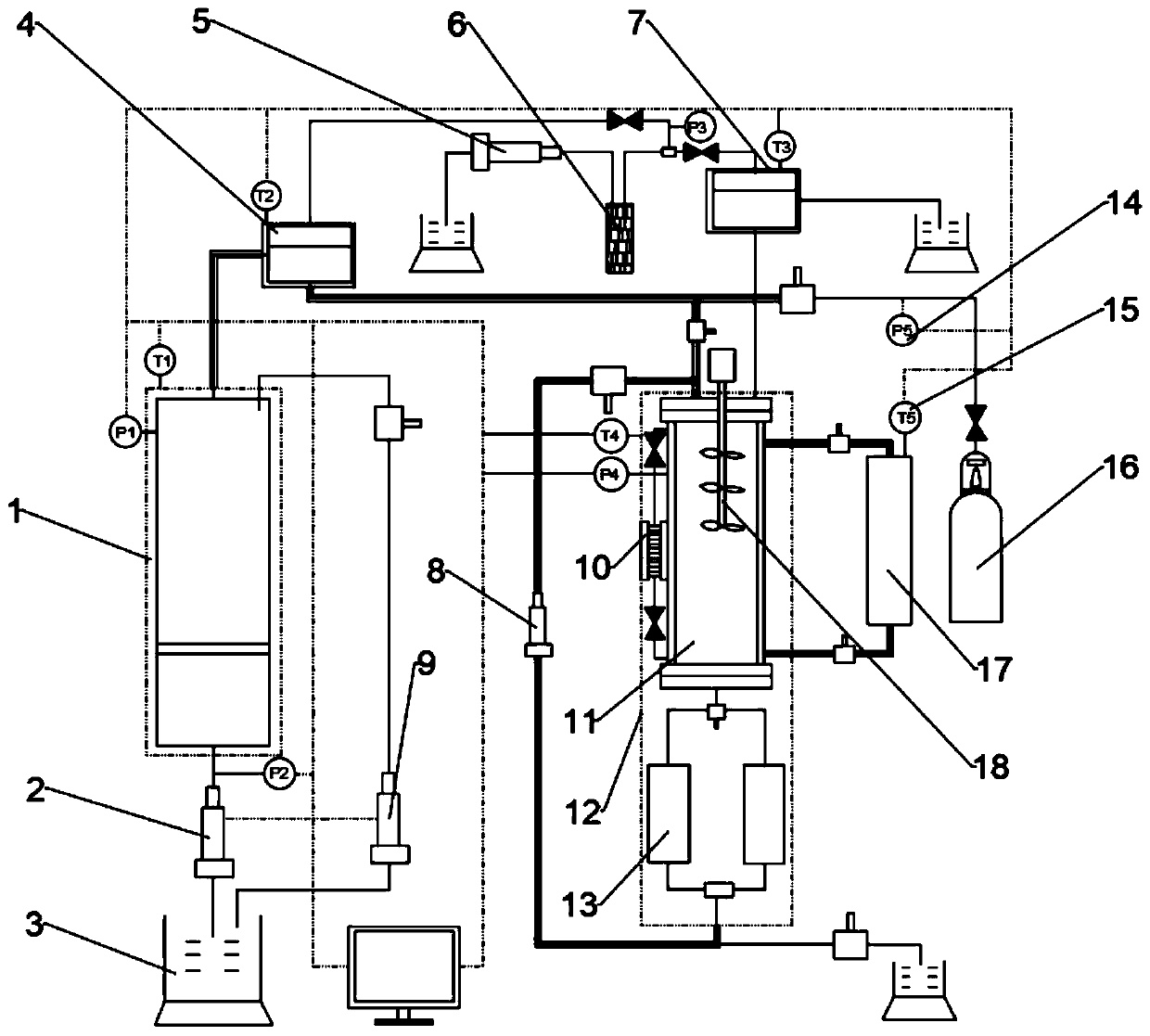

High-temperature high-pressure fluid solid-phase deposition simulation device

PendingCN111189736ACompact structureEasy to install and disassembleMaterial analysis by optical meansEarth material testingSolid phasesChemistry

The invention provides a high-temperature high-pressure fluid solid-phase deposition simulation device, which comprises a sample injection system for configuring and outputting a fluid sample; a solidphase deposition system communicated with the sample injection system and used for carrying out solid phase deposition on the fluid sample output by the sample injection system; and a back pressure system communicated with the sample injection system and the solid phase deposition system and used for controlling the pressure of the solid phase deposition system. The sample injection system is used for preparing the fluid sample and inputting the fluid sample into the solid phase deposition system, solid phase deposition is carried out on the fluid sample, the pressure of the solid phase deposition system is controlled through the back pressure system, and magnitude detection is carried out on the solid phase deposit by adopting a weighing method. The device has the beneficial effects thatthe problem of solid phase deposition in deep gas reservoir, condensate gas reservoir and gas injection miscible flooding oil reservoir exploitation is solved, a scientific research means and a prediction evaluation technology are provided, reservoir damage blockage and wellbore are avoided, and oil reservoir exploitation is facilitated.

Owner:CNOOC ENERGY TECH & SERVICES

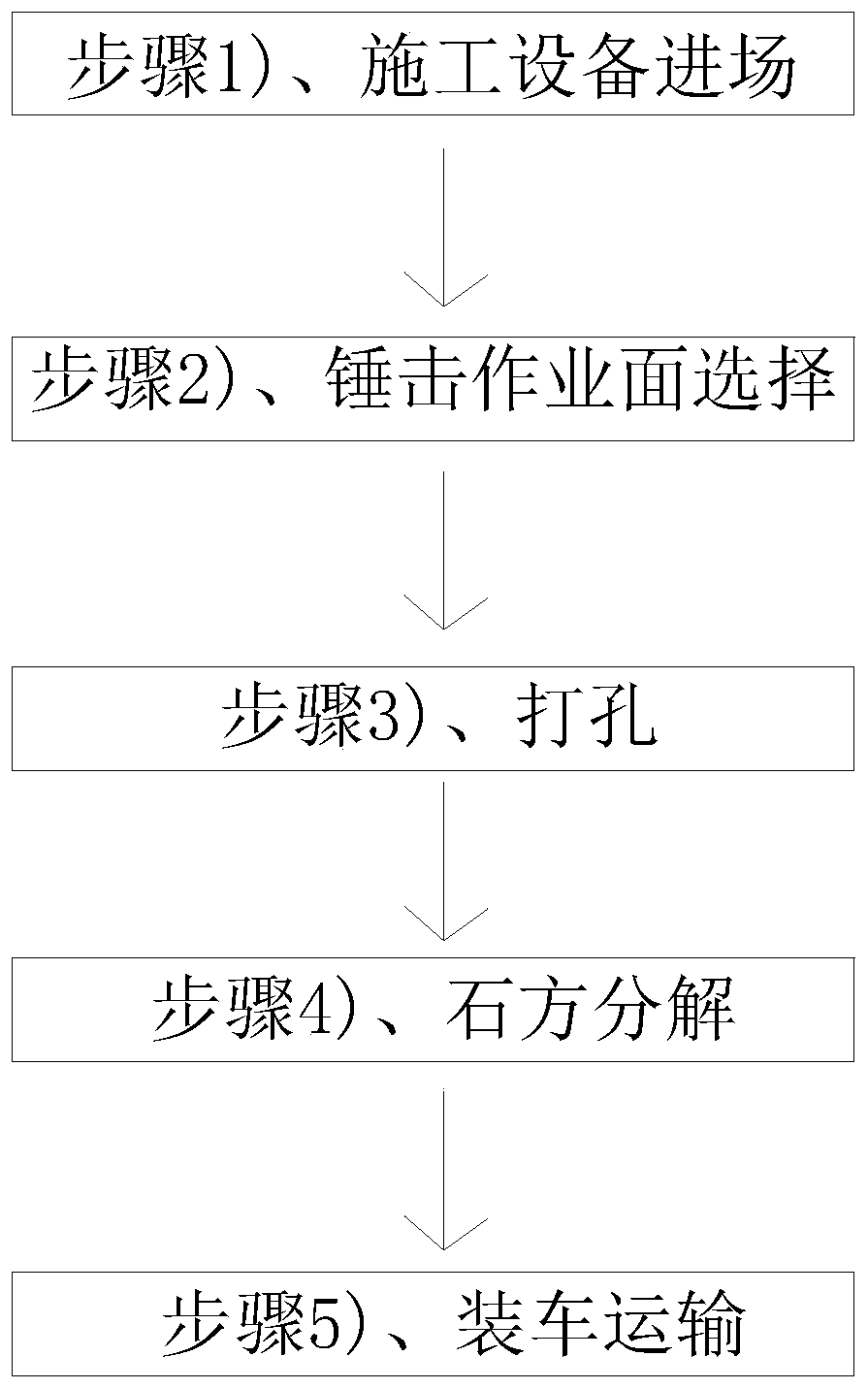

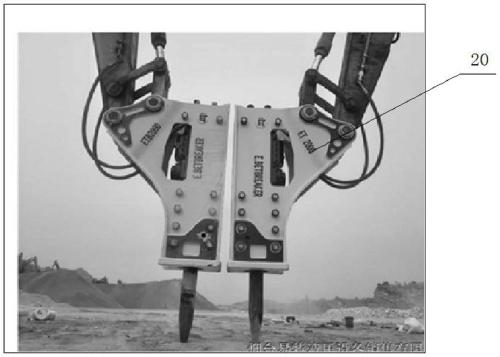

Stone excavation method based on mine hammer

ActiveCN111322070AAvoid influenceAvoid explosion damageSlitting machinesPunchingArchitectural engineering

The invention discloses a stone excavation method based on a mine hammer. The method comprises the following steps of enabling construction equipment to enter a site, wherein the construction equipment is moved to the construction site where stone is to be excavated; selecting a hammering working face, wherein the construction hammering working face is selected on the stone to be excavated, a fallface is arranged on one side of the hammering working face, the height of the fall face ranges from 1 m to 5 m, and the distance between the hammering working face and the fall face ranges from 0.5 mto 3 m; performing punching, wherein the mine hammer is used for hammering a plurality of operation holes in the hammering working face; and performing stone decomposing, wherein the stone which is held open from the hammering working face is dug out and secondarily crushed through a crushing hammer and / or a rock arm, and the stone is crushed into dimension stone which is easy to load and transport; and performing truck loading and transportation. According to the method, stone excavation is conducted through the mine hammer in a non-blasting mode, explosion damage is avoided, combined line production is adopted through the mine hammer and other devices, the method can adapt to various terrains, the construction speed is high, and the construction efficiency is high.

Owner:GUANGDONG LIYUAN HYDRAULIC MACHINERY

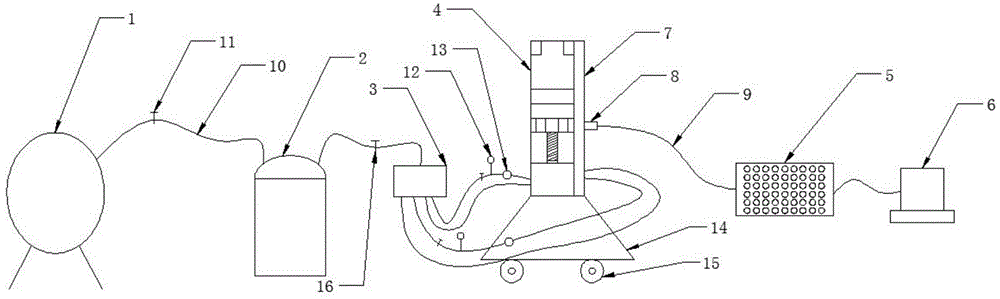

Analog simulation experiment device and method for solid gas coupling of upper protective layer mining

The invention discloses an analog simulation experiment device and method for solid gas coupling of upper protective layer mining. The device comprises an experiment box and a permeability testing system. The experiment box is arranged in a sealed mode, an organic glass plate and a steel plate on the experiment box are provided with a gas inlet hole and a testing hole corresponding to the gas inlet hole respectively, and a stress sensor of the experiment box is sequentially connected with a data collecting instrument and a computer. The permeability testing system is composed of an air compressor, a gas storage tank, a high-pressure rubber pipe, a branching unit, a check valve, a pressure gauge and an electronic flow meter. An inflation system is connected to an inflation hole in the experiment box, and the permeability testing system is connected to the testing hole of the experiment box. The experiment method includes the steps that firstly, a model is laid; secondly, an air impermeability test is conducted; thirdly, an experiment is conducted, and data are recorded. According to the analog simulation experiment device and method for solid gas coupling of upper protective layer mining, the change rule and the distribution characteristics of stress, deformation and permeability in mining underlying coal and rock masses can be measured, the operation process is simple, effects are clear and visual, the testing period is short, and convenience is provided for studying protective layer mining.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com