Patents

Literature

193results about How to "Reduce depletion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

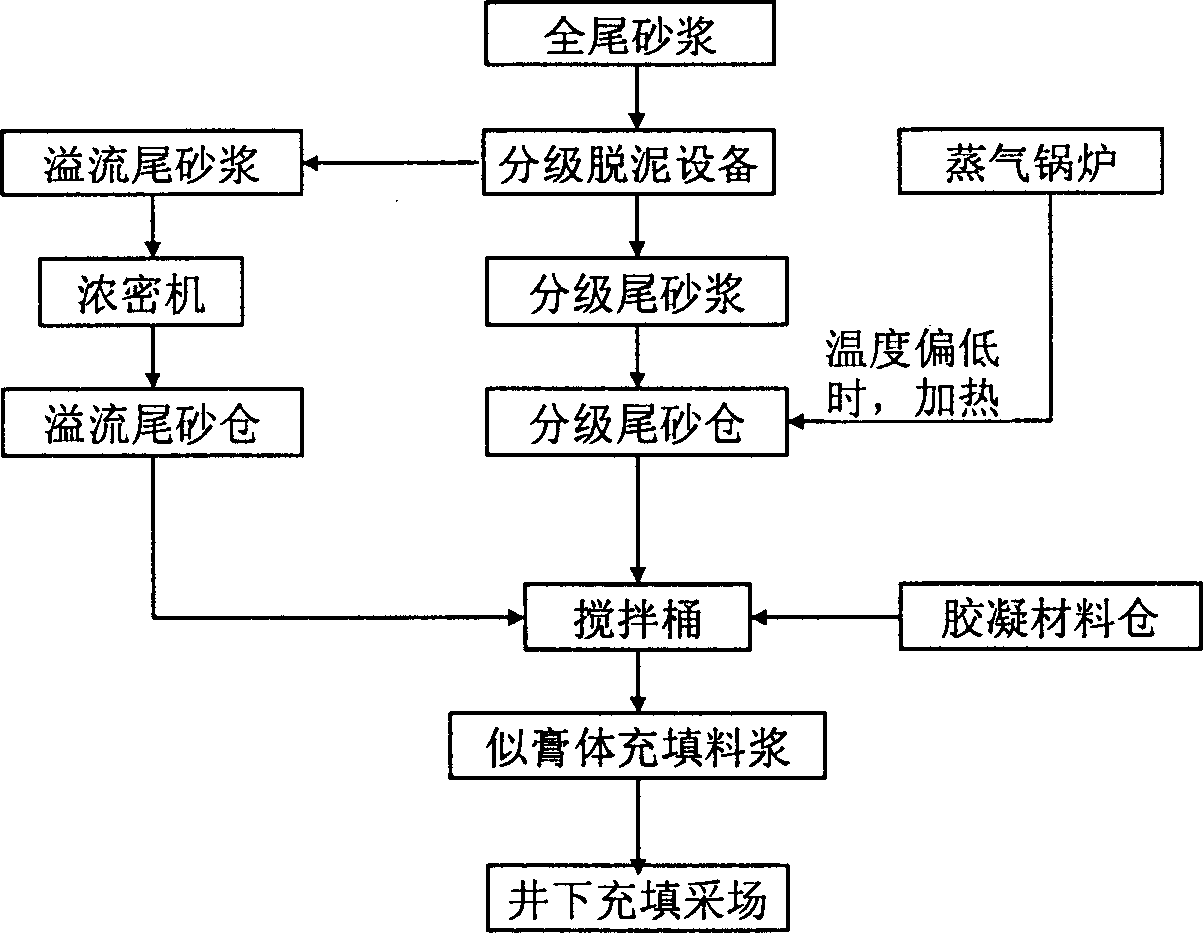

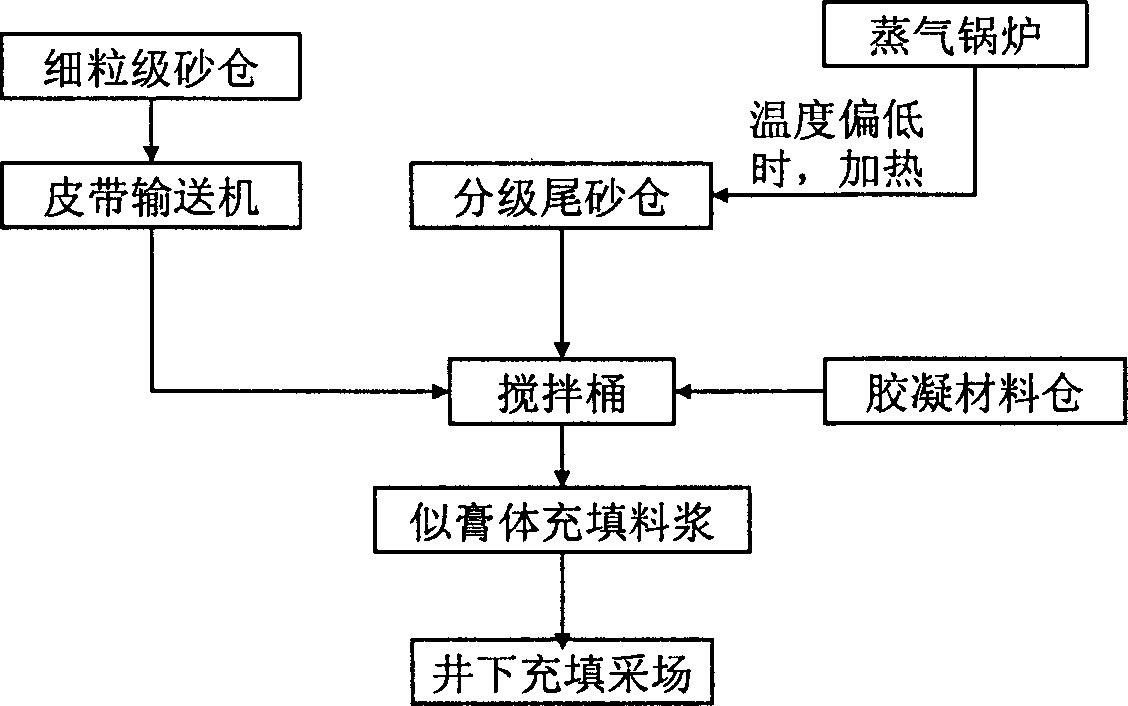

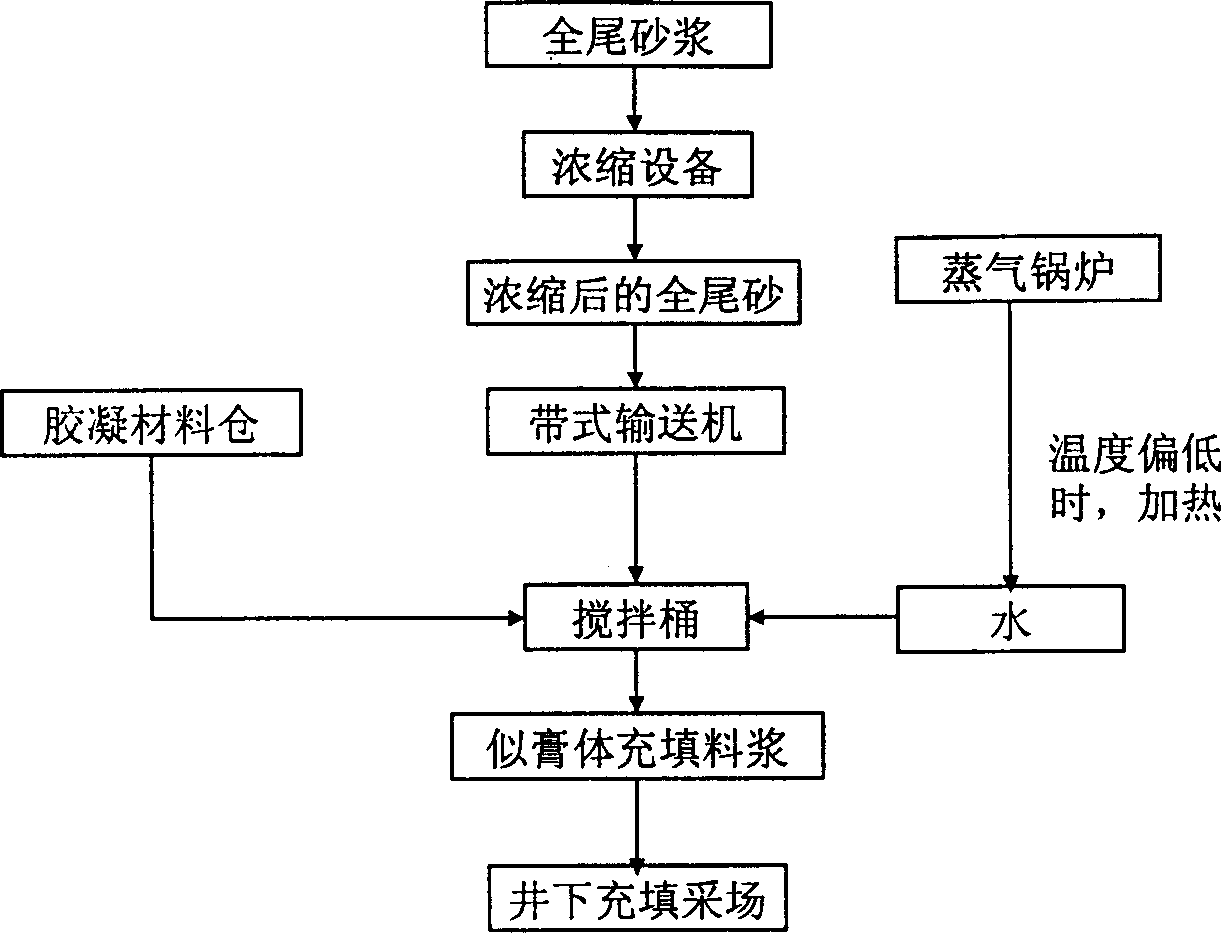

Cementing materials for filling, slurry and preparing and filling processes

InactiveCN1424275AReduce manufacturing costLess investmentSolid waste managementMaterial fill-upSlurrySulfur containing

A gelatining material similar to cream for filling underground working surface is preapred from the Ca-contained non-crystal and microcrystal material, alkali and / or sulfur contained exciting material, active material, aggregate and regulator. A filling slurry is prepared from said gelatining material, filling aggregate, fine particles, regulator and water through heating to at least 18 deg.C and proportional mixing.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

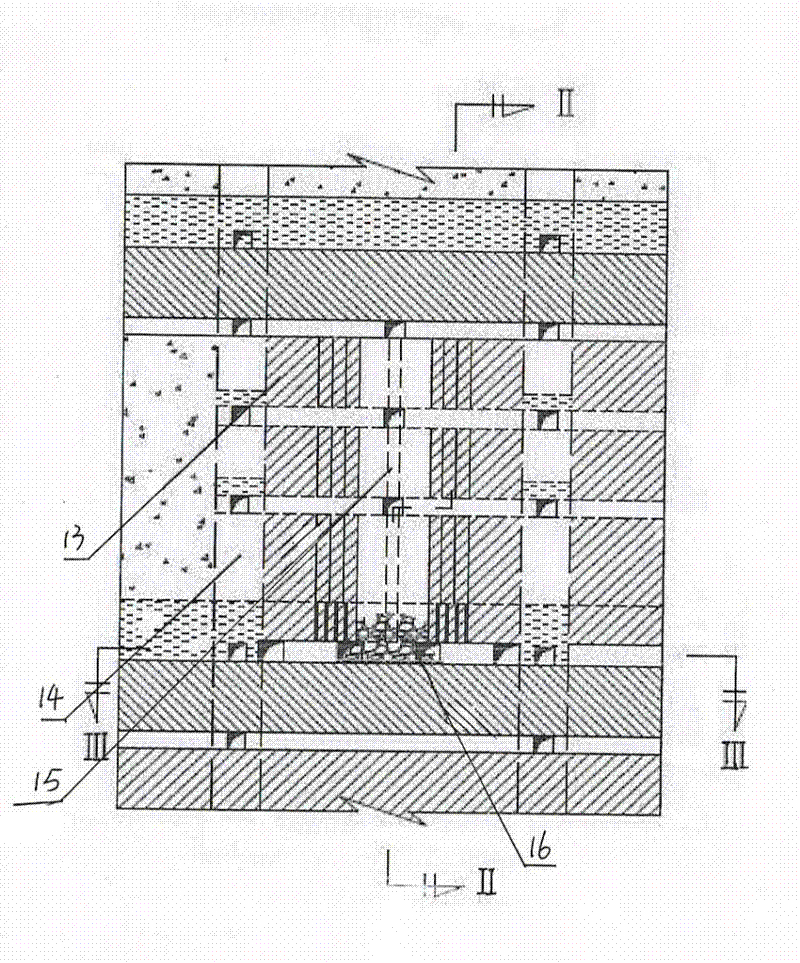

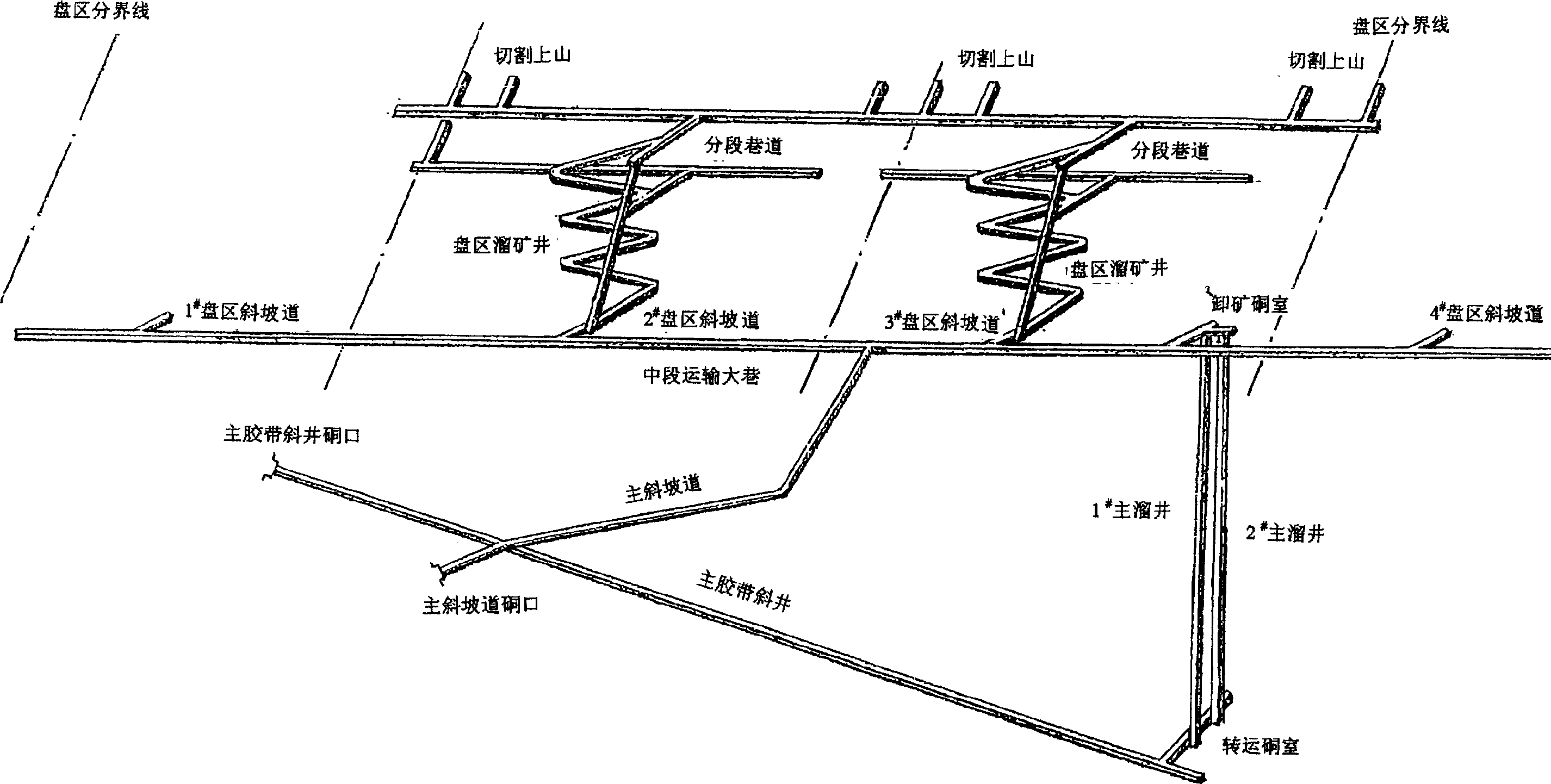

High-sublevel subdivision mining method of moderately thick heavy-pitch waste-rock-containing interlayer phosphate orebody along strike

InactiveCN102418526AAvoid damageIncrease productivityUnderground miningSurface miningMining engineeringSlag

The invention discloses a high-sublevel subdivision mining method of a moderately thick heavy-pitch waste-rock-containing interlayer phosphate orebody along a strike. The high-sublevel subdivision mining method comprises four steps of exploiting, mining preparation, cutting and recovery, wherein a footwall intermediate-section main roadway is respectively arranged on a high sublevel along a top plate and a bottom plate of the orebody, and the intermediate-section main roadways of the top plate and the bottom plate are connected through a communication channel at intervals of 100m, therefore reduced roadway cutting construction, small development rate and simple process are achieved; after overall blasting of a stope is finished, a large amount of concentrated ore drawing is carried out, and the production efficiency is high; tail sand is adhered and filled after space pillars are mined first, then rooms are evacuated, and the rooms are filled with waste rocks or tail sand in a non-adhering way, thus recovery rate is high; and the high-sublevel subdivision mining method has little damage to the environment and capabilities of changing oredressing tail sand and waste rocks generated in open-air production into valuables and reducing geological disaster from happening. Due to the adoption of the high-sublevel subdivision mining method disclosed by the invention, ore recovery rate can be increased, ore dilution rate and emission of mine wastes are reduced, capacity of slag disposal pit is relatively increased, expropriation of land is decreased, and mineral land harmony is promoted.

Owner:WENGFU (GRP) CO LTD

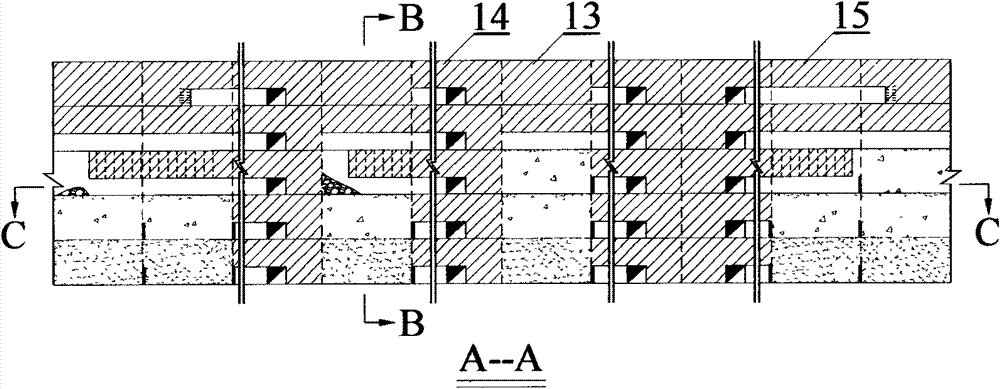

Mining environment reconstructed continuous mining afterwards filling mining method

InactiveCN101105129AHigh recovery rateImprove productivityUnderground miningSurface miningProduction rateMineralogy

The invention discloses a method of continuous mining followed by filling with mining environment reconstruction. The method comprises mining strip ore section in the middle part of the ore body, mining ore section with proper width extending towards two sides of the site that is perpendicular to and has proper distance far away the strip ore section followed by cementation filling to the mined-out area to form a continuous crisscross cementation filling top plate support frame structure. The frame structure meanwhile separates the ore body into several spaced and independent ore sections to reconstruct a new mining environment in the ore body. In such environment, performing spacedly or parallelly second mining with independent ore sections as second mining units followed by non-cementation filling to the mined-out area to realize continuous mining in the overall ore body, performing ore breaking in lateral direction with downward parallel and vertical deep holes, loading ore with double-trench or single-trench as bottom structure along ore blocks direction, landing down to the main gangway in the next stage through stage drop shaft, and transporting out of the mine by downhole locomotive. The invention has the advantages of safe and reliable mining environment, remarkably improved ore recovery rate and productivity, effectively controlled loss, and remarkably reduced production cost.

Owner:CENT SOUTH UNIV

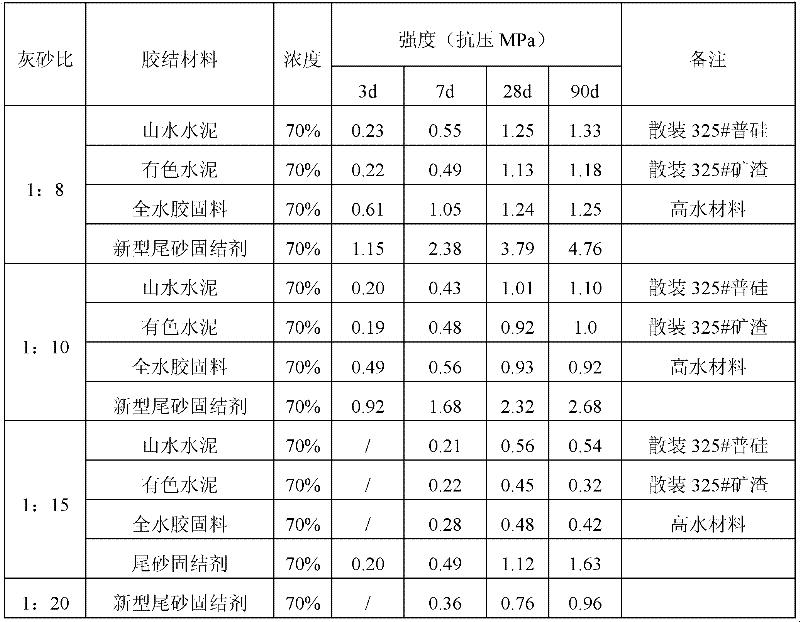

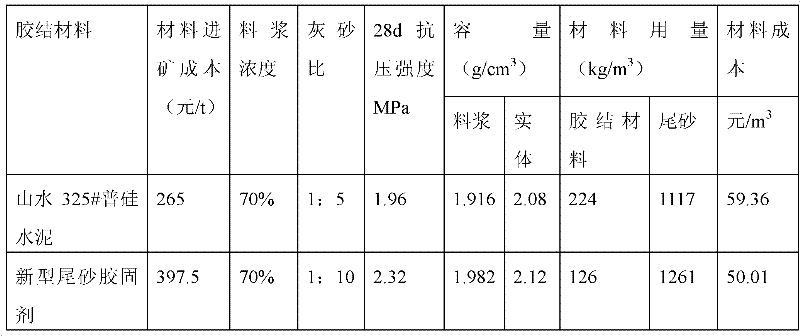

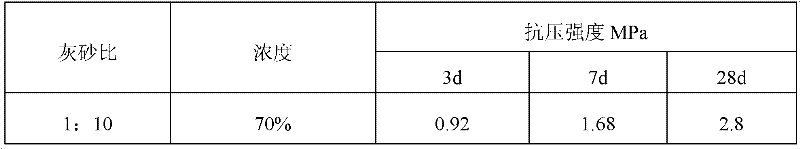

Novel tailing consolidator and preparation method thereof

The invention concretely relates to a novel tailing consolidator which uses fine powder ground from blast furnace water quenching slag as a main raw material and a preparation method of the consolidator. The consolidator is characterized in that the consolidator comprises, by mass concentration, 9 % to 17.54% of portland cement clinker, 10% to 17.54% of anhydrite, 6% to 10% of quicklime, 0.2 to 6 thousandths of Na2SO4, 0.2 to 0.5 thousandths of carboxymethyl cellulose, 5% to 10% of coal ash and 43.65% to 69.96% of the fine powder ground from the blast furnace water quenching slag. Each above component is dried by a dryer, put in a mixer to be evenly stirred, and conveyed to a bowl mill by a belt conveyer to be ground. The blast furnace slag discharged from a smeltery is used as the main raw material in the invention to reduce the cost and solve slag processing, so the consolidator has the advantages of low production cost, simple processing, and agile and convenient usage. A usage amount of the consolidator in the present invention is half or less than the usage amount of common cement under the same conditions with the same backfilling intensity.

Owner:淄博乾耀固结材料有限公司

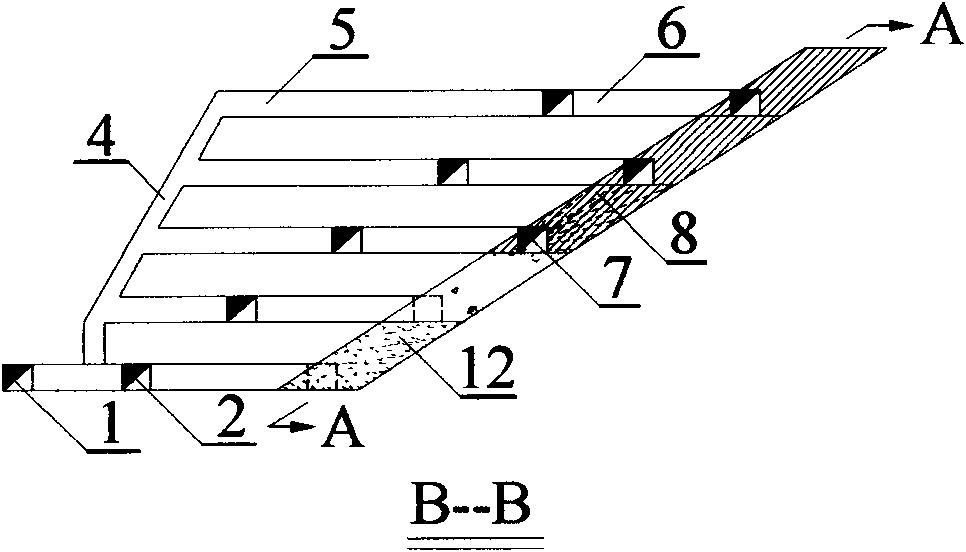

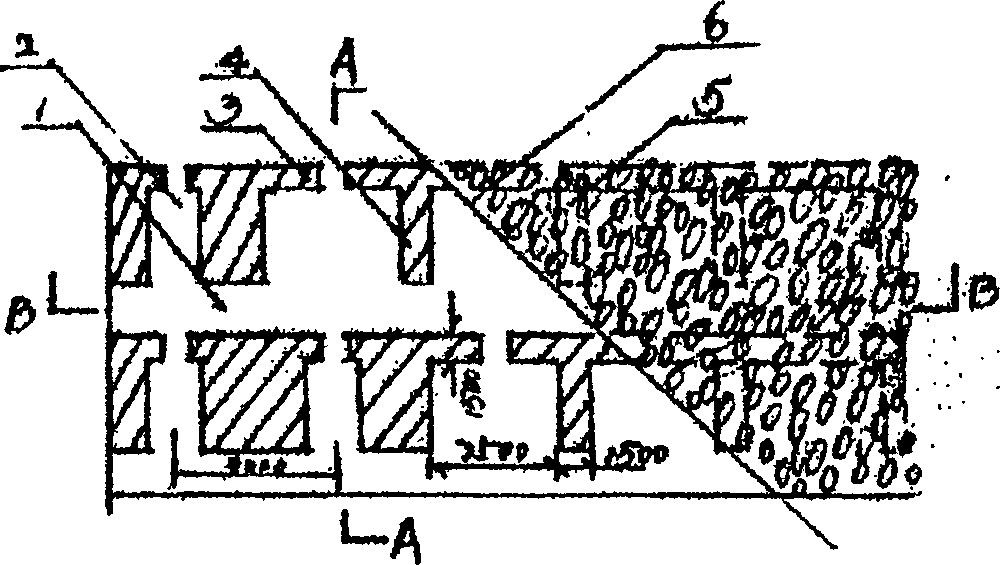

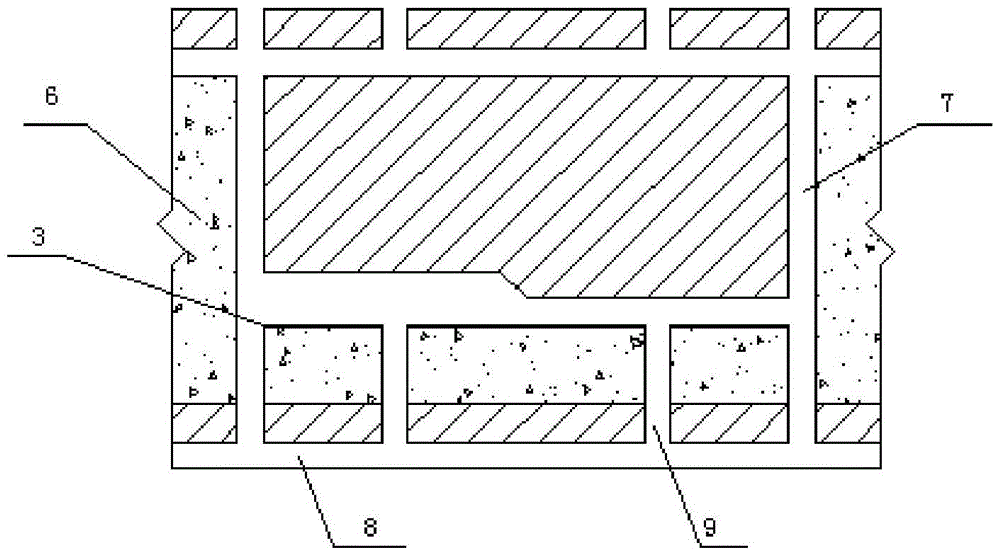

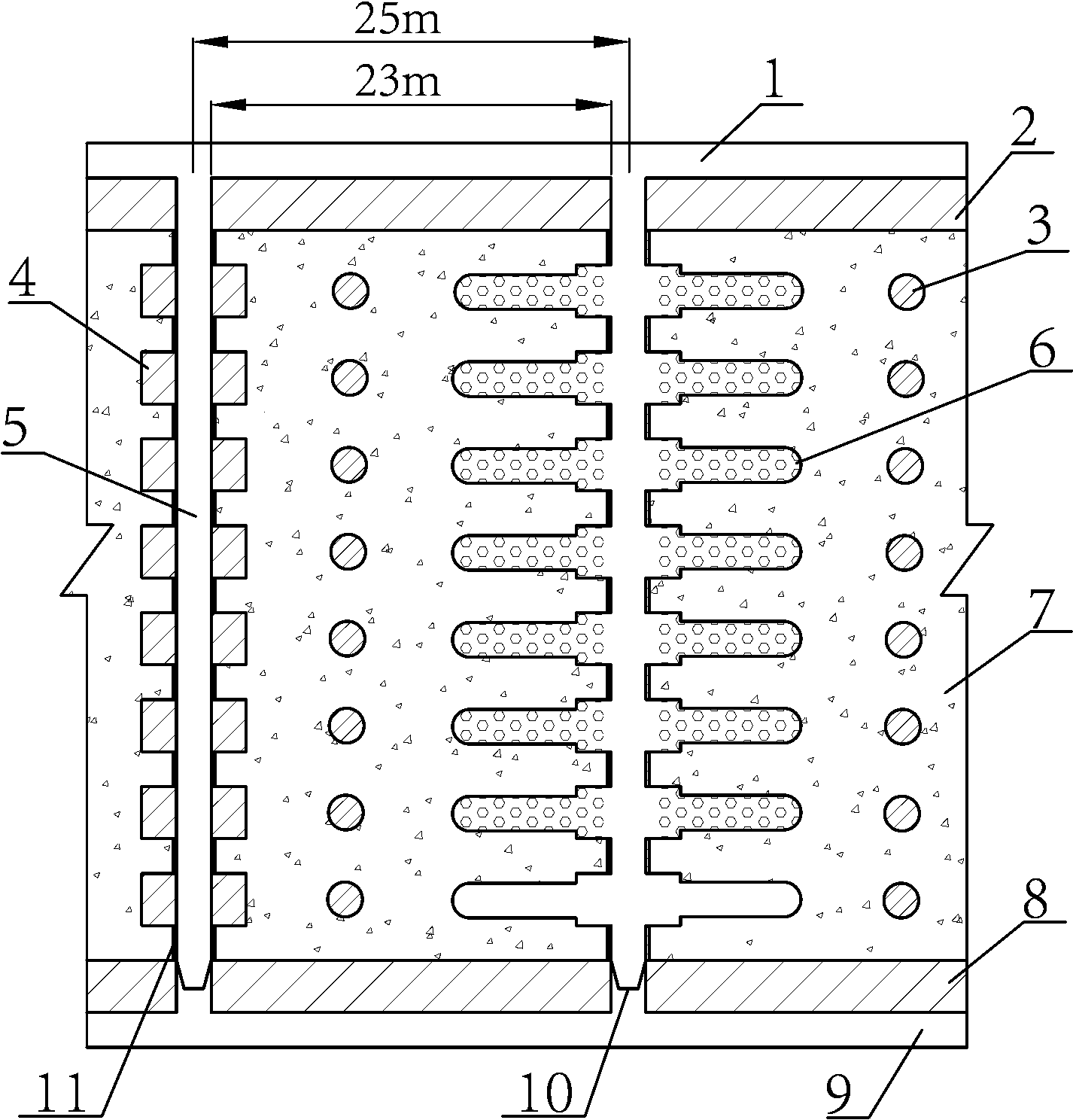

Central outside-vein house pillar type combined crosscut two-end inside-vein continuous segment filling mining method

InactiveCN102953733AHigh degree of mechanizationReduce labor intensityUnderground miningSurface miningVeinEngineering

The invention discloses a central outside-vein house pillar type combined crosscut two-end inside-vein continuous segment filling mining method for medium-thickness inclined crushed phosphorus ores. The method comprises the following steps: dividing an ore into middle segments, dividing each of the middle segments into panels, dividing each of the panels into segments, dividing the center of each of the segments into ore houses and ore pillars, and dividing two ends of each of the segment along an inside-vein drilling ore-removal level non-pillar into recovery units; adopting a hanging side outside-vein trackless mining system which is formed by a panel ramp, a concentrated ore-removal ore-pass, segment levels at the central outside-vein and shifting to inside-vein at two sides, and an connection lane commonly used by the ore houses and the ore pillars; recovering the ore houses in the middle segments, filling close to back, and recovering the ore pillars; and carrying out parallel operations of technologies comprising drilling, exploding, supporting, ore removal, filling and the like of a plurality of the ore houses to realize continuous mining. The method disclosed in the invention has the substantial characteristics of improvement of the recovery safety and the panel productivity, reduction of the resource dilution rate and the mining-cutting ratio, increase of enterprise benefits and the like.

Owner:彭康

Method for recycling ore pillars by middle-deep hole and deep hole united blasting technique

ActiveCN102808622AImprove safety and reliabilityEasy to operateUnderground miningBlastingDetonatorDetonation

The invention discloses a method for recycling ore pillars by a middle-deep hole and deep hole united blasting technique. The method comprises the following steps: arranging middle-deep hole drilling drifts on barrier pillars of a worked-out chamber; arranging a plurality of rows of middle-deep hole blast-hole sets on the walls of the middle-deep hole drilling drifts; arranging a cutting slot gate way in each middle-deep hole drilling drift, and arraying a plurality of groups of blast-hole sets in the cutting slot gate way; excavating a deep hole drilling drifts in top pillars and arranging a plurality of rows of deep hole blast-hole sets on the walls of the deep hole drilling drifts; arranging nonel detonators on the bottoms of the middle-deep hole blast holes and the middle parts of the deep hole blast holes; using a complex network structure to be connected with the blast holes; using non-electric nonel detonators to detonate the main detonating cord for detonation, and detonating branch detonating cords by the main detonating cord; transmitting detonation wave to each non-electric millisecond detonator section by the connected detonators, and controlling each row of blast holes to detonate in sequence to complete ore pillar detonation; and recycling the detonated ore pillars after ventilation. With the adoption of the method, the barrier pillars and top pillars above the bottom pillars can be once detonated, thereby rate of ore dilution is reduced and the recovery rate is improved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

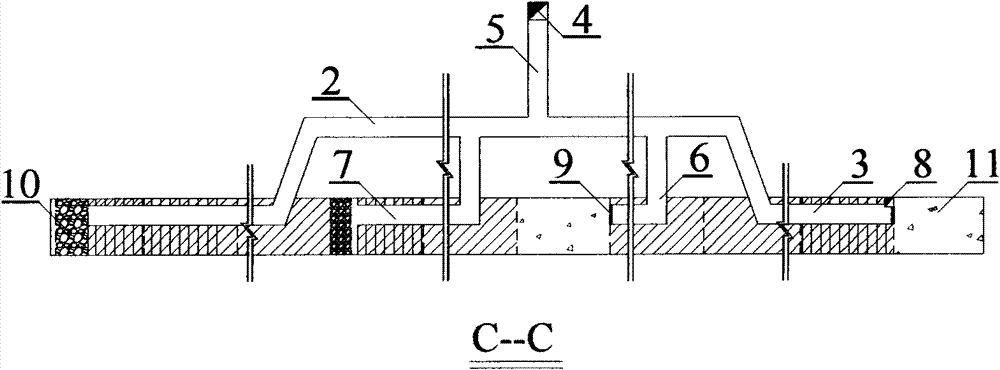

Chamber and overhand cut combined cut-and-filling stoping method in pre-roof-protecting stage

InactiveCN104847352AImprove mining safetyImprove stope production capacityUnderground miningSurface miningEngineeringCut and fill

The invention relates to a chamber and overhand cut combined cut-and-filling stoping method in a pre-roof-protecting stage. The method comprises the following steps: dividing a middle ore body into panels along the trend of the ore body, further dividing the middle section into a plurality of sections in the vertical direction, and mainly adopting a footwall out-out-pulse traceless accurate mining mode; arranging chambers and pillars in the panels at intervals; recovering the chambers first, and adopting a sublevel open stoping method with subsequent backfilling; after recovering the chambers, recovering the pillars and adopting an overhand horizontal cut-and fill method for the pillars, and before recovering the chamber in stages, pre-supporting a long cable in advance for an upper panel in a sublevel upper panel supporting lane; pre-supporting the fore-set by using an anchor rod and a metal net in an air return cross gateway below the fore-set; when the pillars are recovered in layers, stopping mining when the pillar is 3m close to the main crack of the upper panel F1 in horizontal distance and reserving the panel as an upper panel roof-protecting ore of the sub layer, and when the lower layer is recovered, fully recovering the upper panel roof-protecting ore reserved in the previous layer, and meanwhile, reserving the upper panel roof-protecting ore in the lower sub layer; and sequentially circularly recovering and reserving the upper panel roof-protecting ore. By virtue of the method provided by the invention, safe, efficient and low-cost mining can be implemented for thick and large ores which are relatively broken.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

Mining method of thin minor ore body

ActiveCN104847356AAvoid lostImprove recovery rateUnderground miningSurface miningMining engineeringCircular economy

The invention discloses a mining method of a thin minor ore body, which comprises the steps of ore recovery and goaf filling, which are alternatively circularly performed from bottom to top in a horizontal layering manner, propelling is performed along with a work surface, lime, loess, dead rock and the like are adopted and mixed layer by layer to fill a goaf, a filling body supports hanging wall and heading wall surrounding rocks, and serves as a work platform of upper layering recovery and ore removal, the ore is conveyed to an ore chute with a mechanical method, spallation ore removal of each recovery spallation step length and the filling procedure of the goaf are performed alternatively, when the uppermost horizontal layer of a chamber is recovered, mechanical and manual fill tightening are performed. The method solves the problem of discharge of tunneled dead rocks, effectively processes the goaf, prevents surface subsidence, accords with requirements of circular economic development and green ore construction. Compared with a shallow hole shrinkage method, the mining method has the advantages of improving ore recovery rate, reducing ore dilution rate and improving ore removal grade and ore removal efficiency through production practice.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

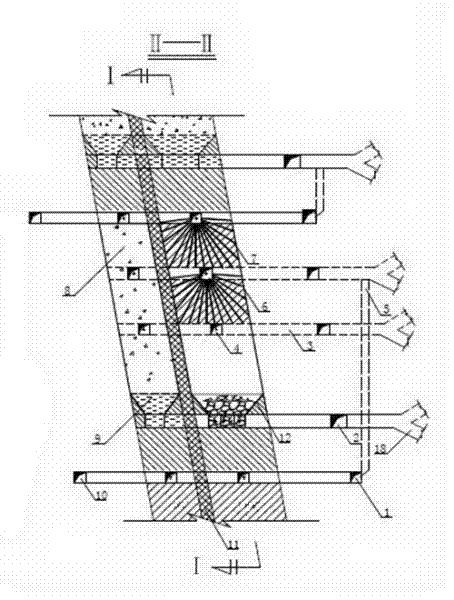

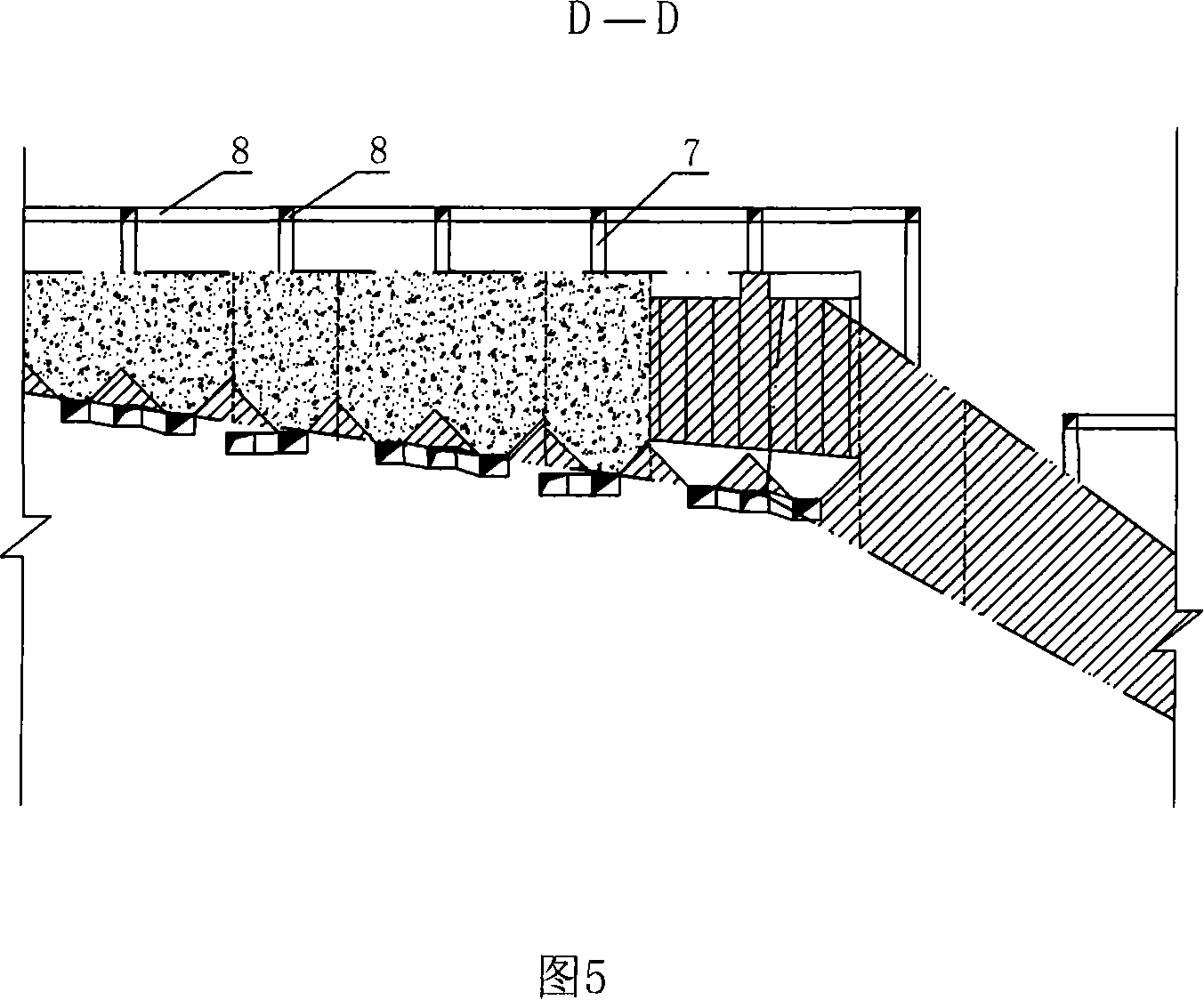

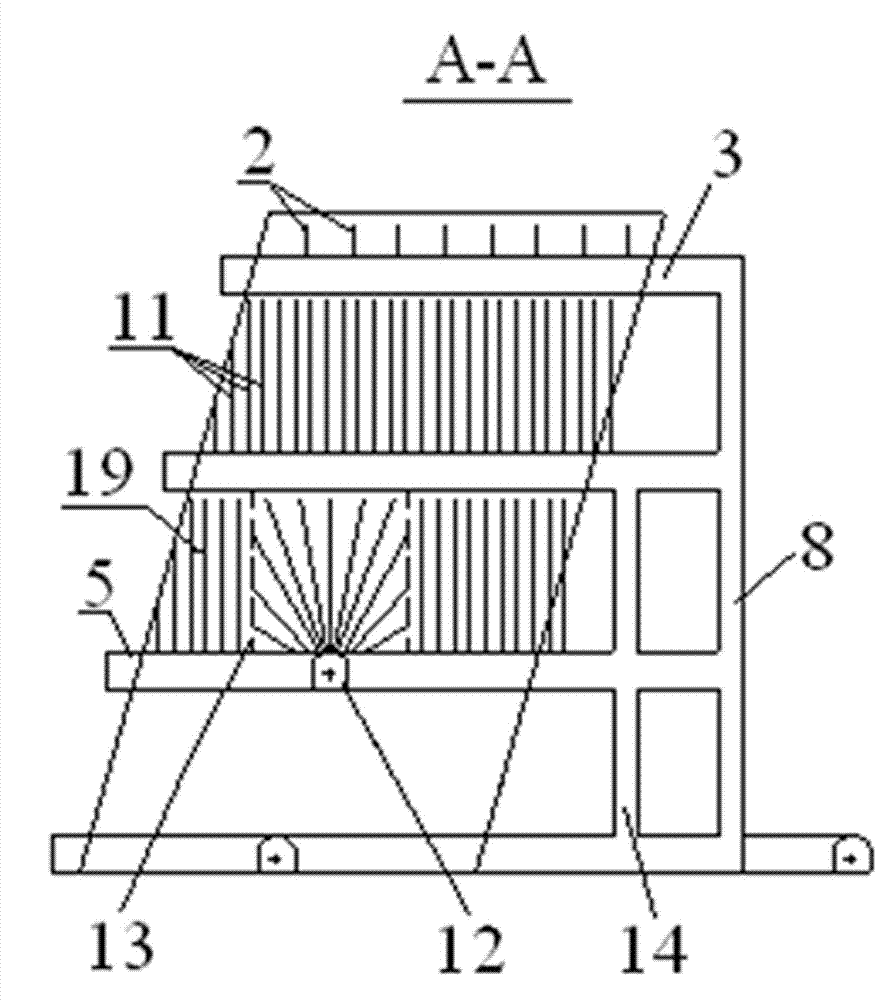

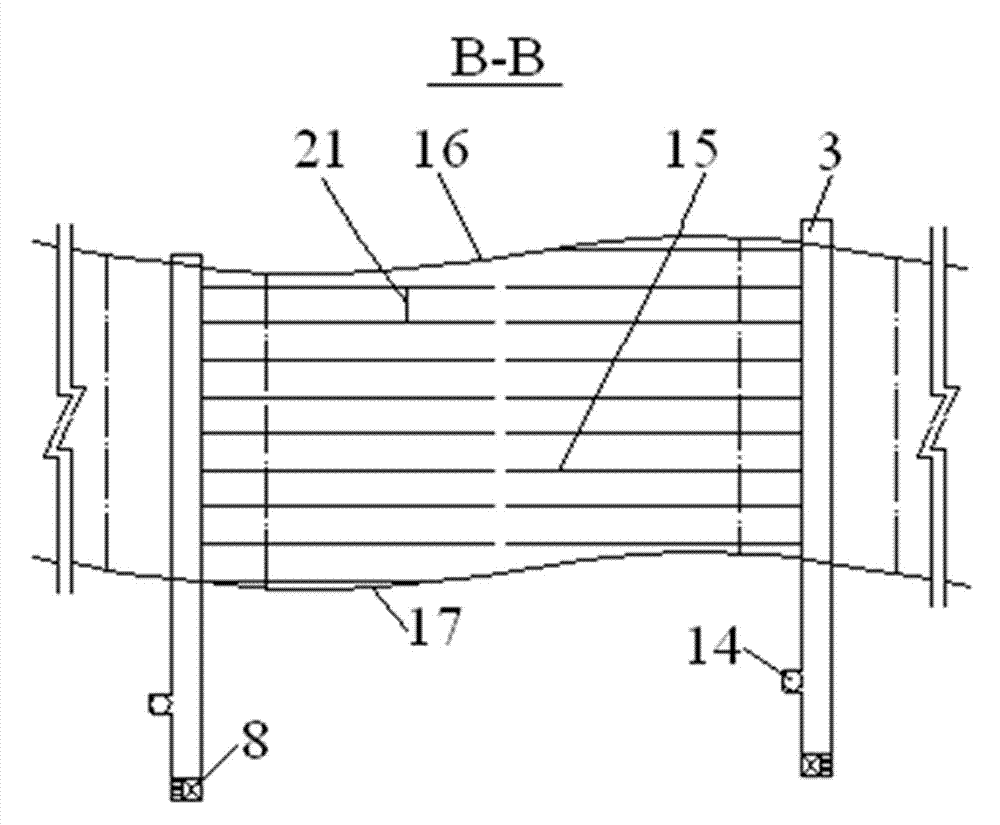

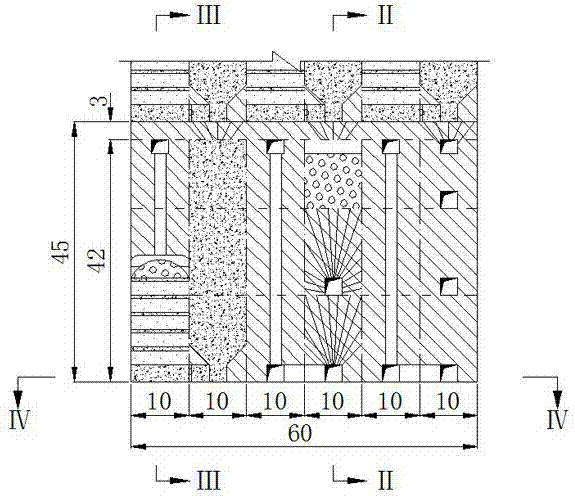

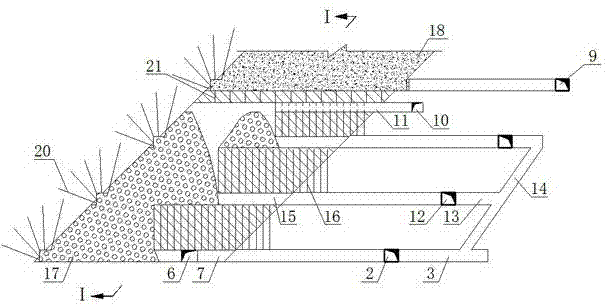

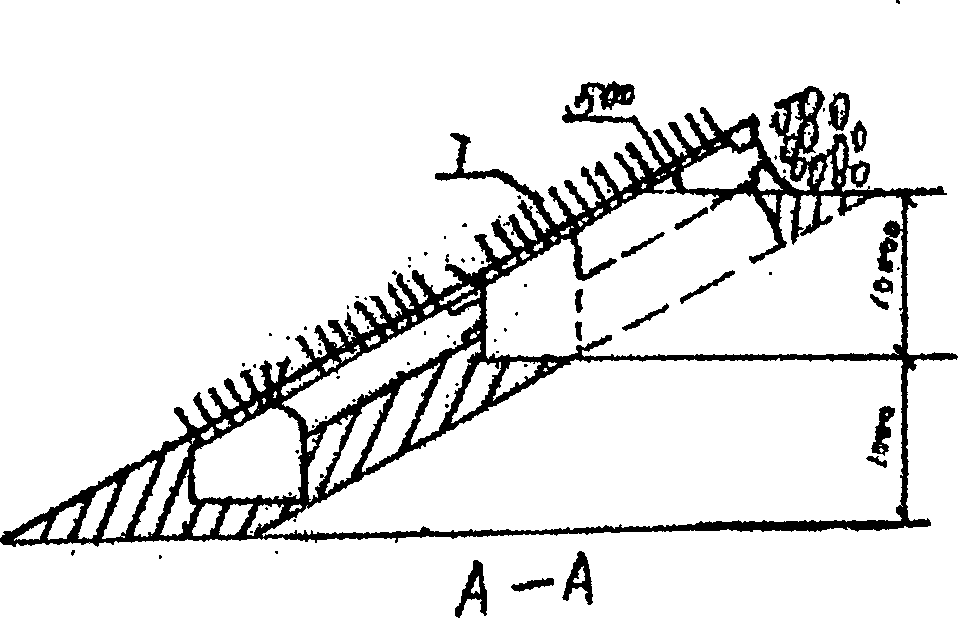

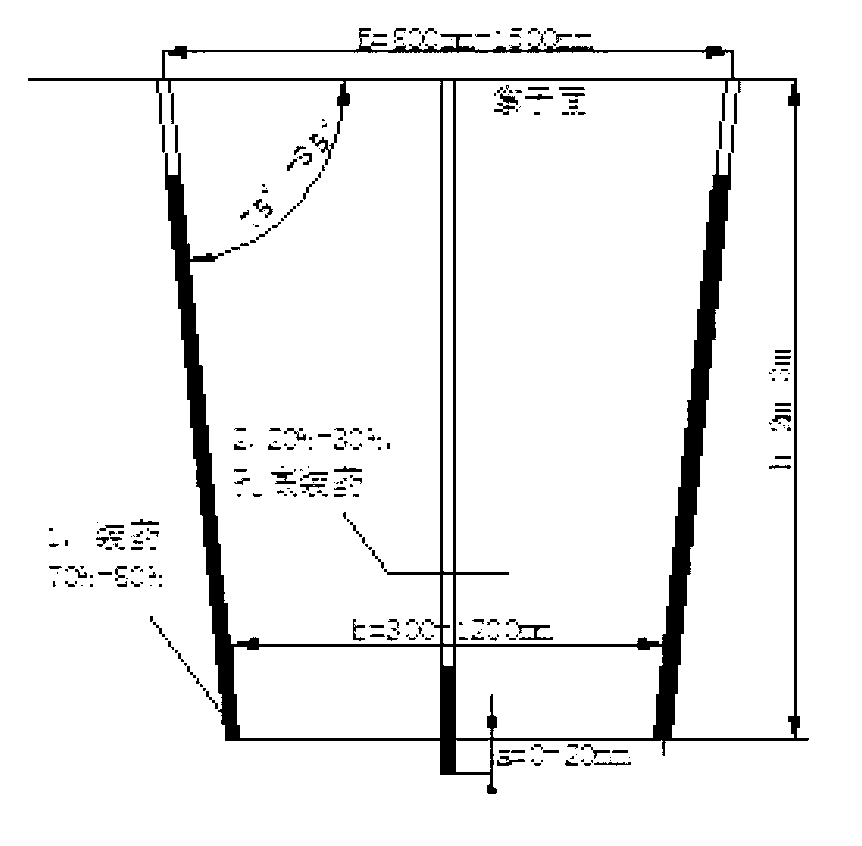

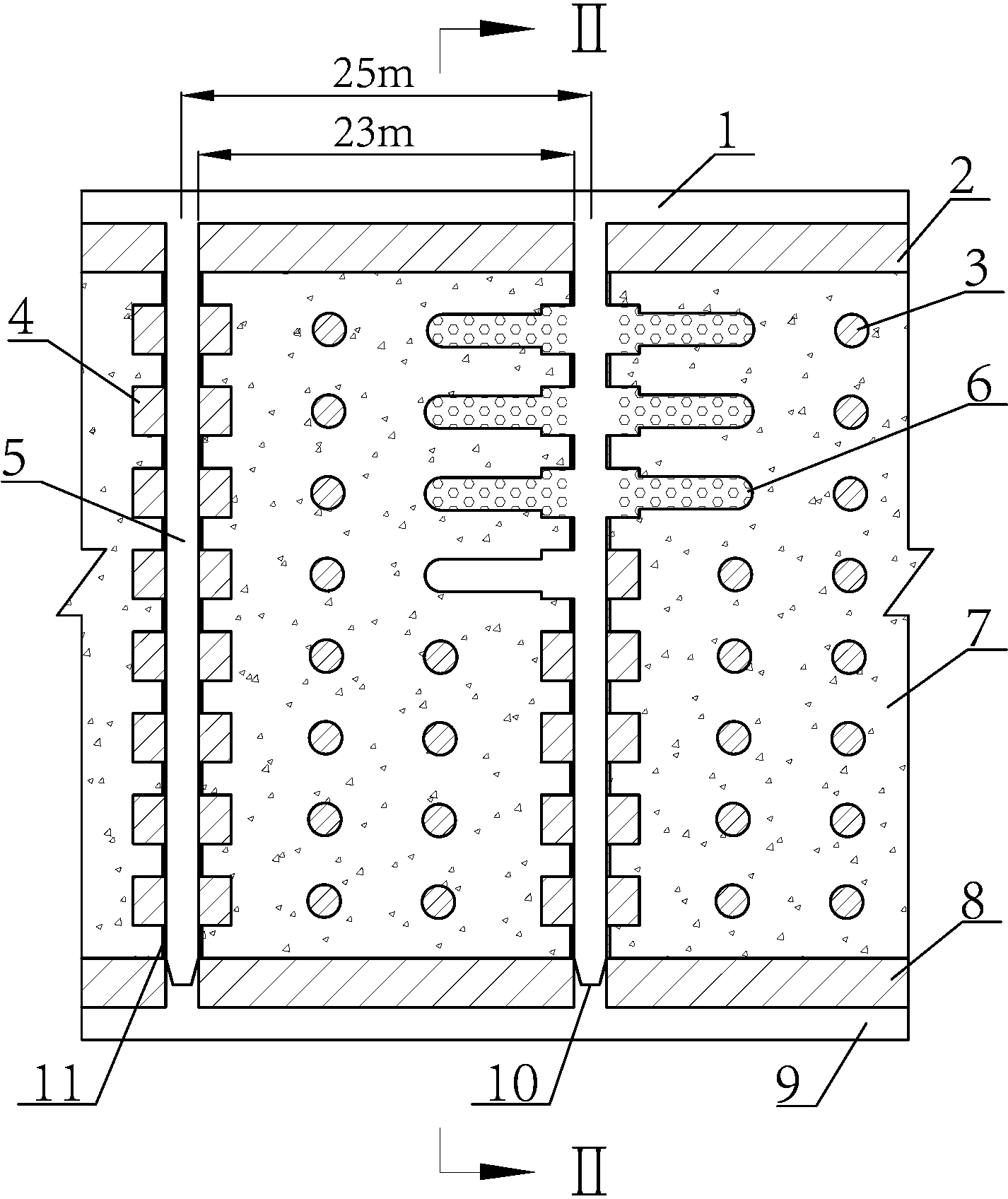

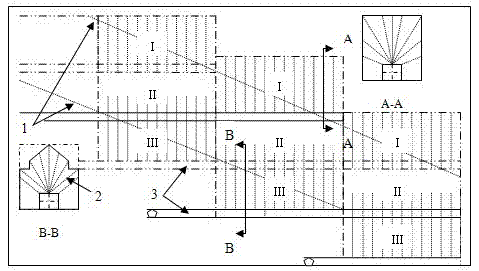

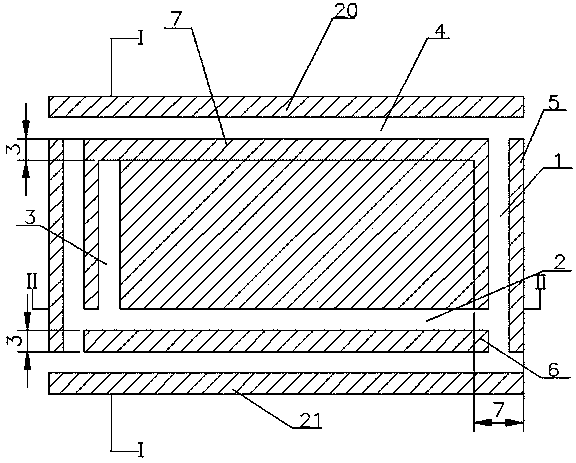

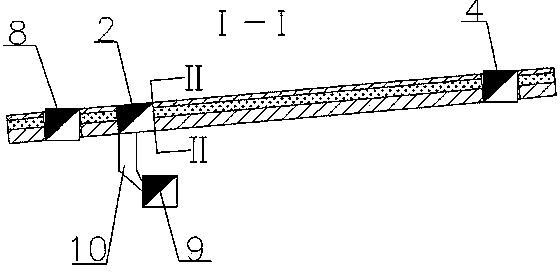

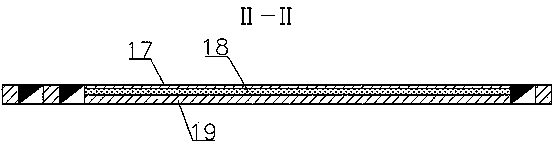

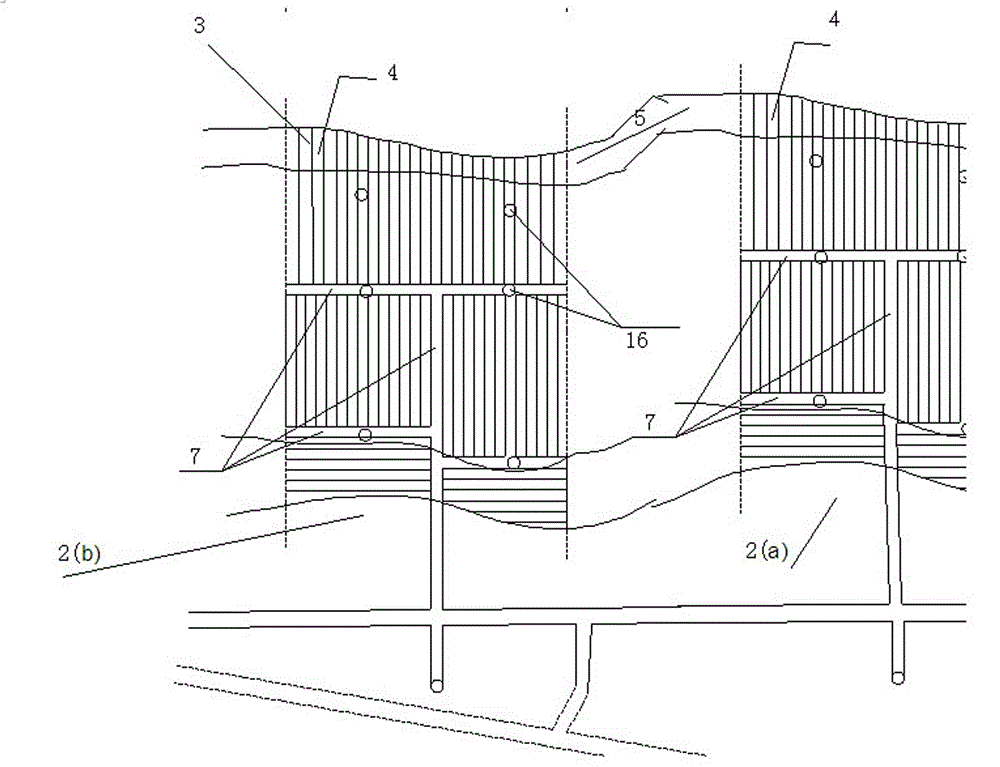

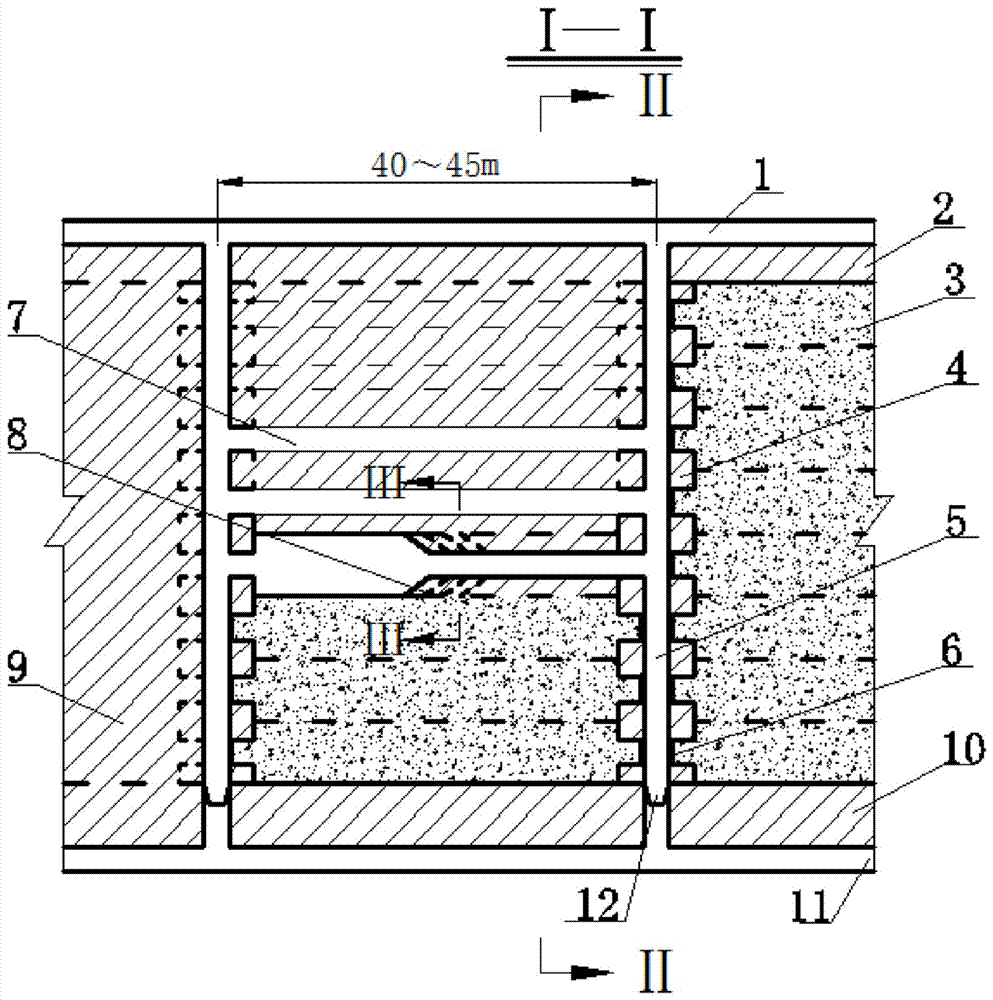

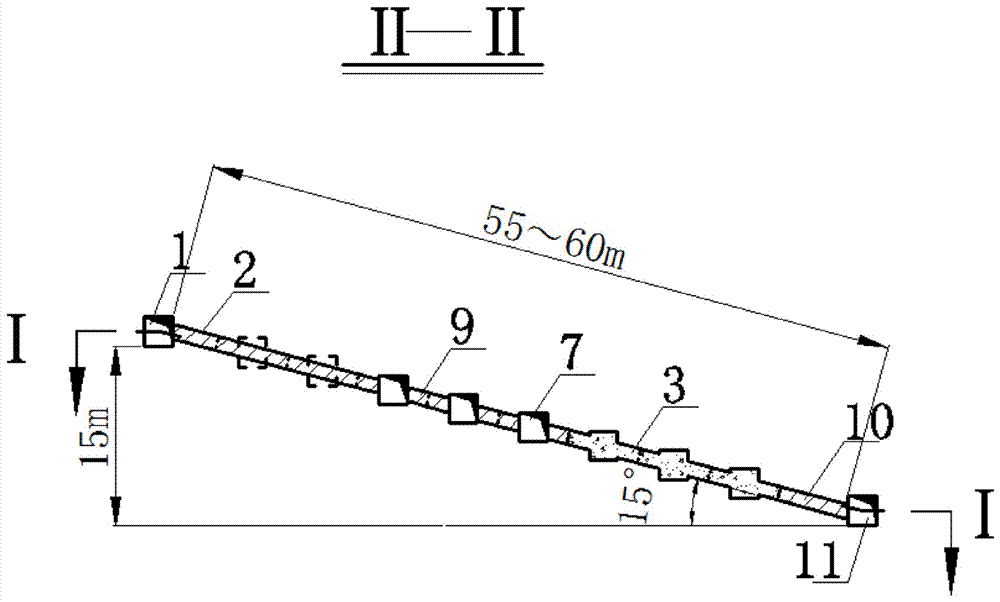

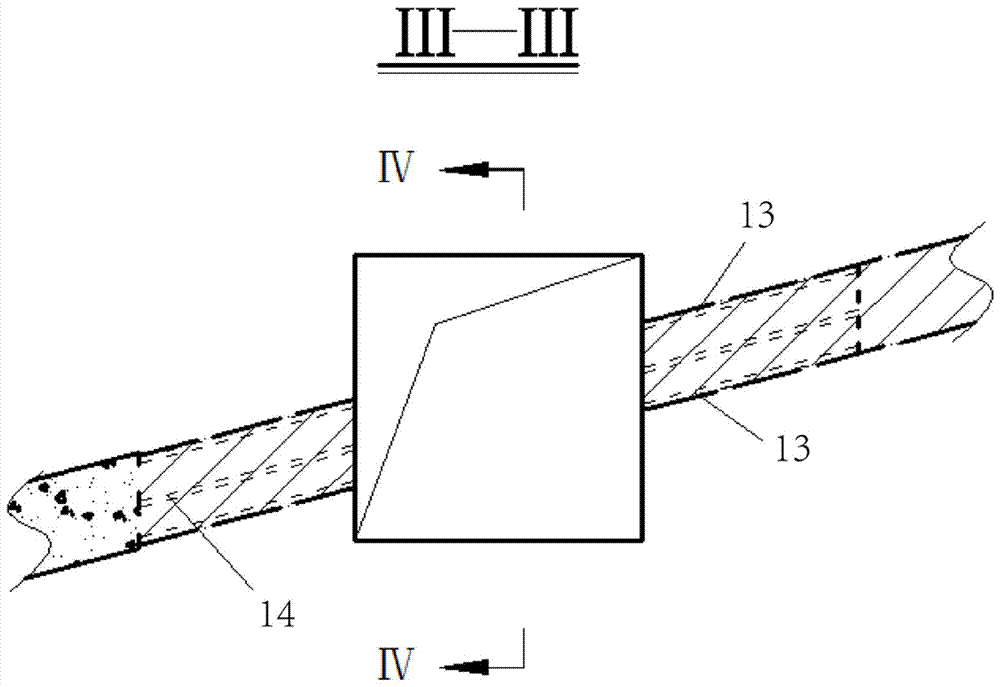

Roof bolt protection and sectioned empty field method for phosphorate rock mining

InactiveCN1458390AImprove stope production capacityReduce depletion rateUnderground miningSurface miningTruckMineralogy

The present invention relates to underground exploitation of phosphorate rock mineral and aims at providing slow inclined middle thick ore body exploiting method. The said exploitation process includes tunneling adit and main inclined tunnel, tunneling middle section main entry, dividing ore body into several panels, tunneling inclined panel slope, dividing the middle section into subsections, dividing subsection ore body into small room via subsection horizontal gallery and cutting raise, supporting roof with anchorage bar and metal net; drilling to bring down with rock drilling machine with cutting raise as free plane; stoping along strike direction; exploding residual ore column to empty area; conveying ore with carry scraper to ore chute and transporting ore with truck. The present invention is suitable for phosphate ore of ore body inclination 0-90 deg and ore body thickness 2-20 m.

Owner:贵州开磷设计研究院有限责任公司

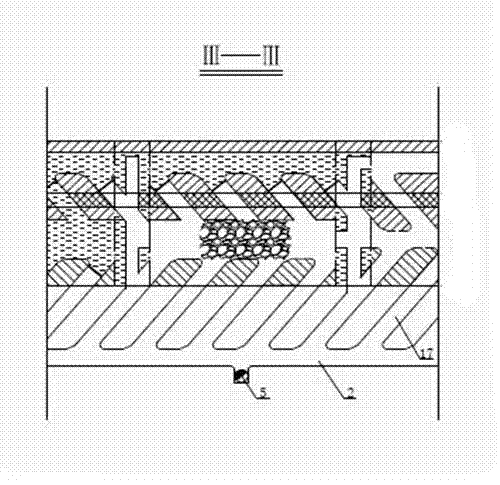

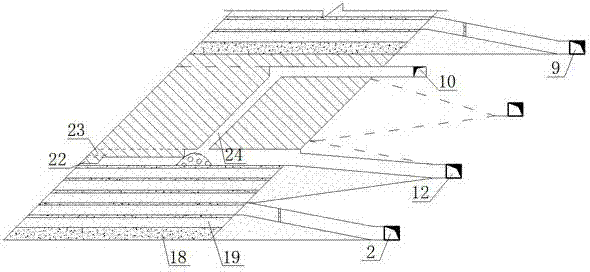

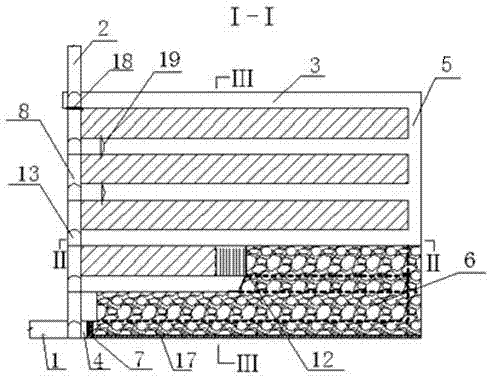

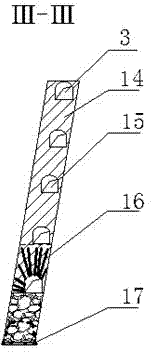

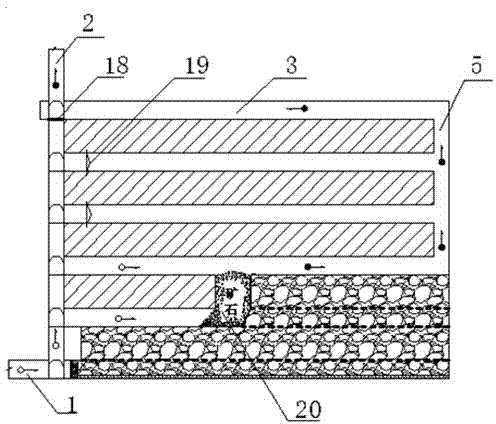

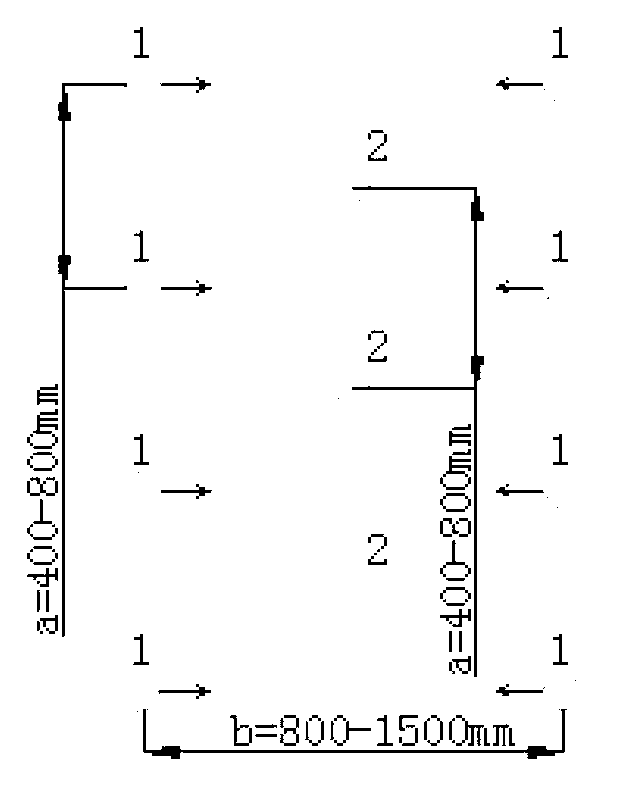

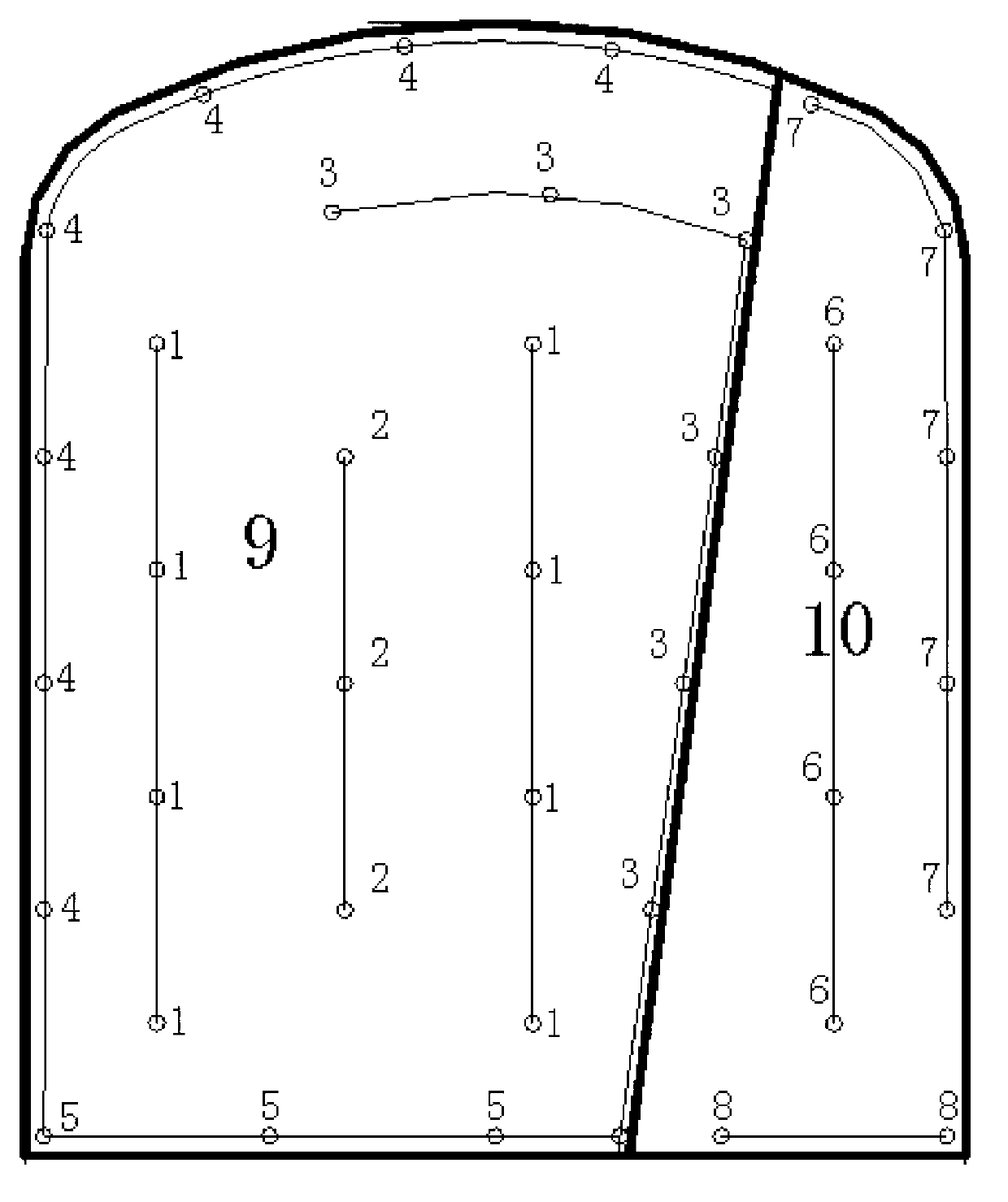

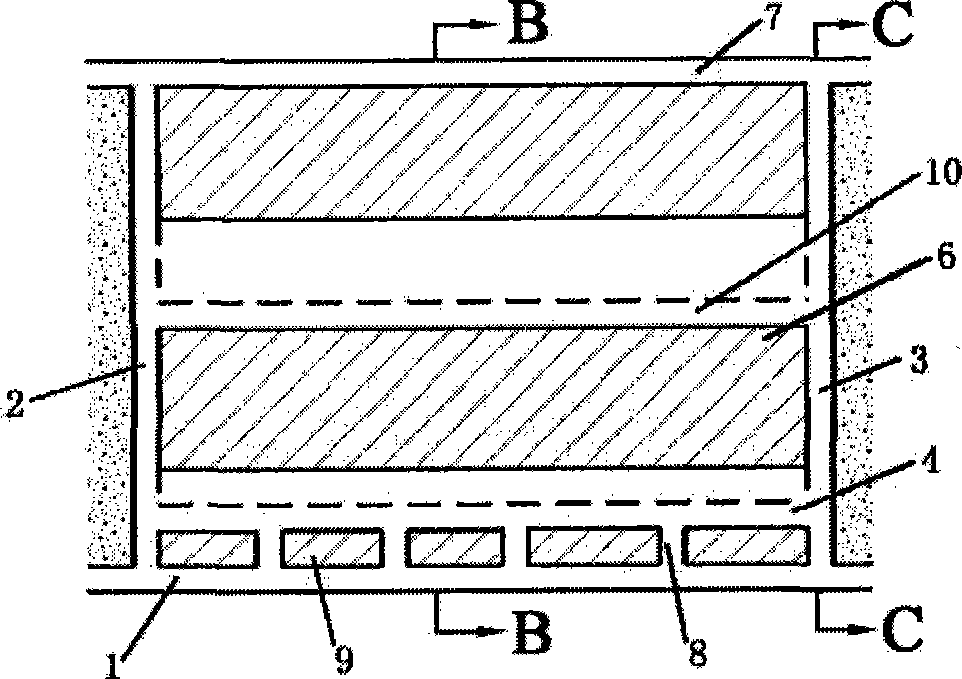

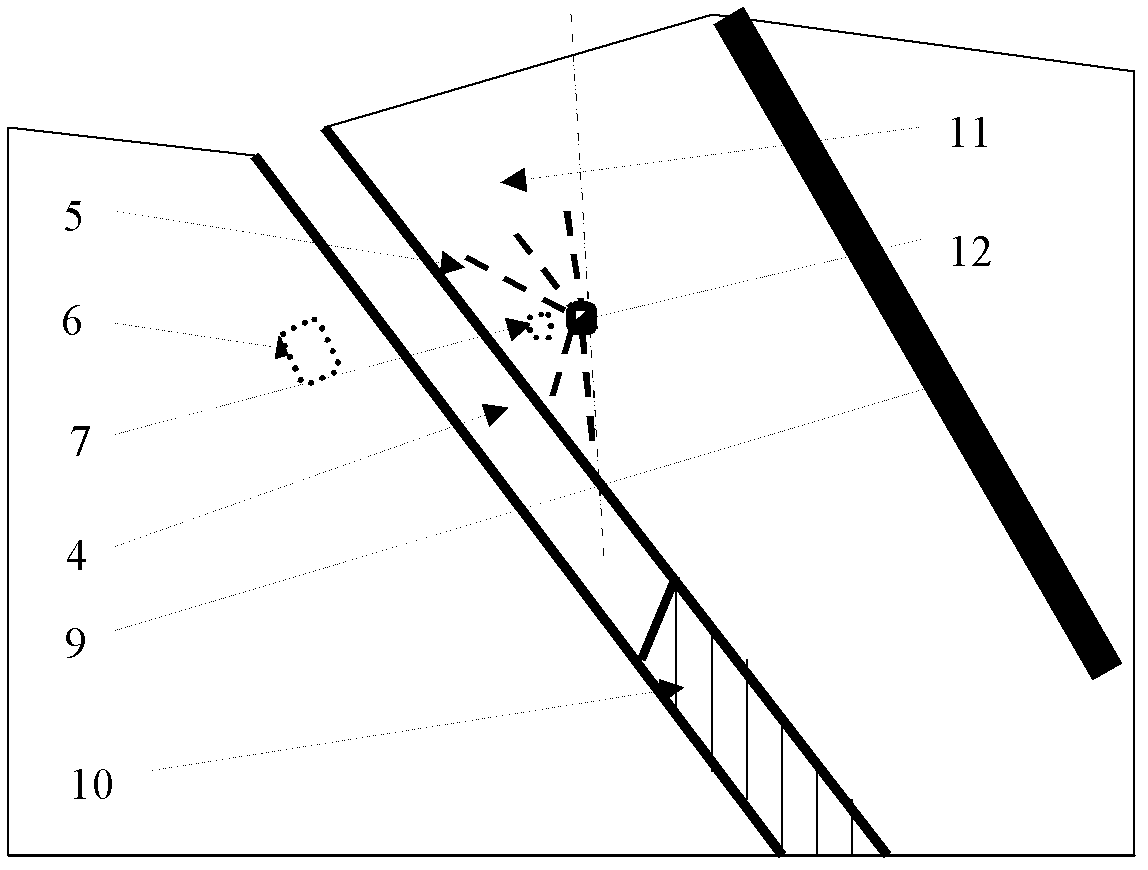

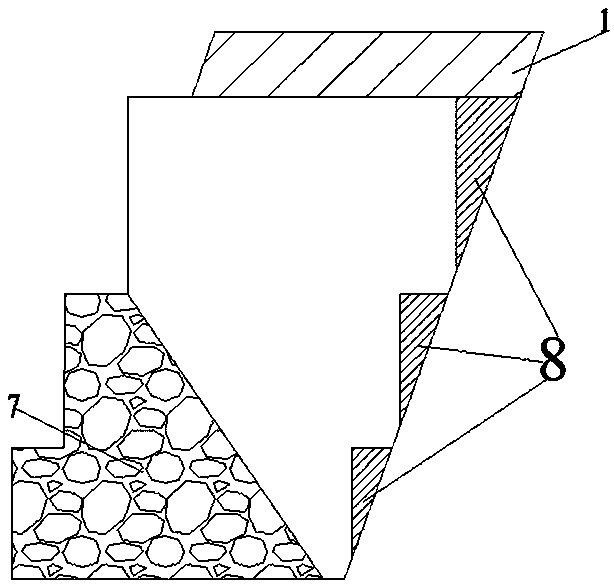

Method for blasting inclined thin ore body by dividing ores and rocks in area in drift driving

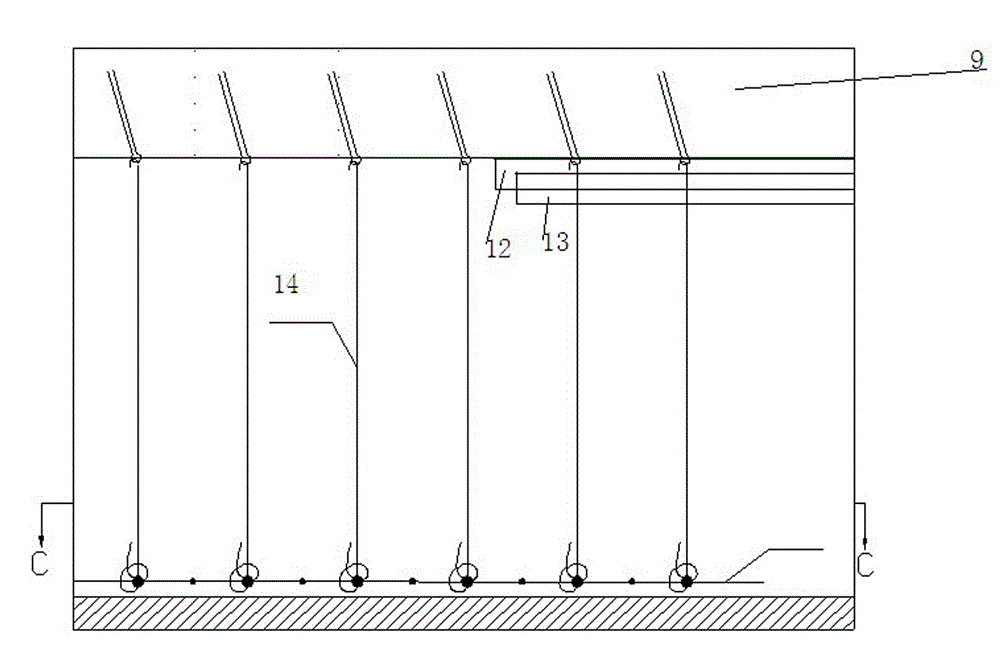

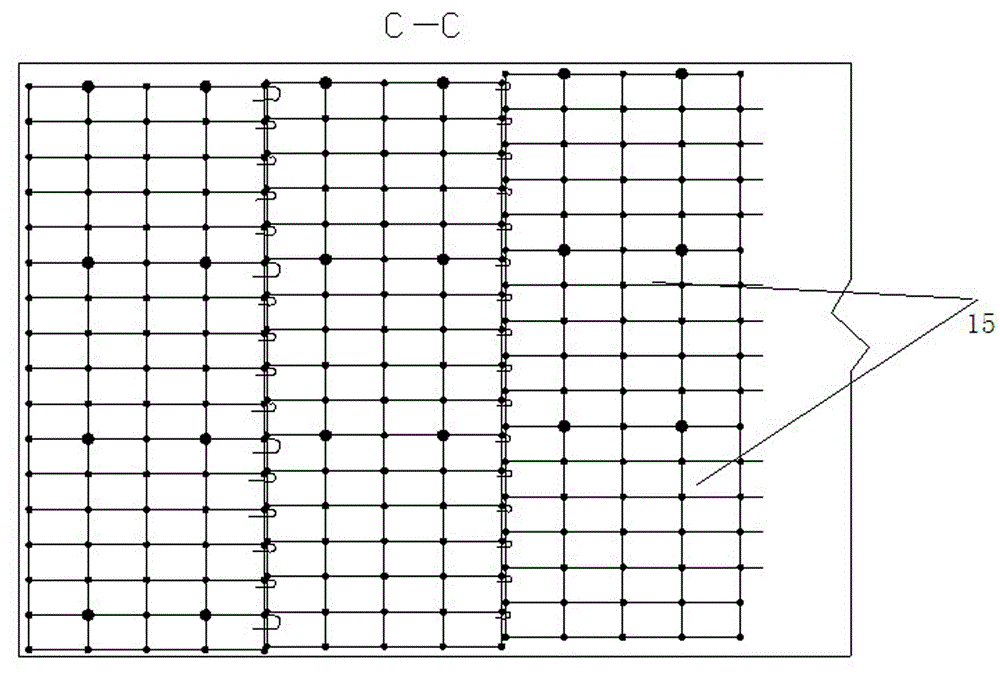

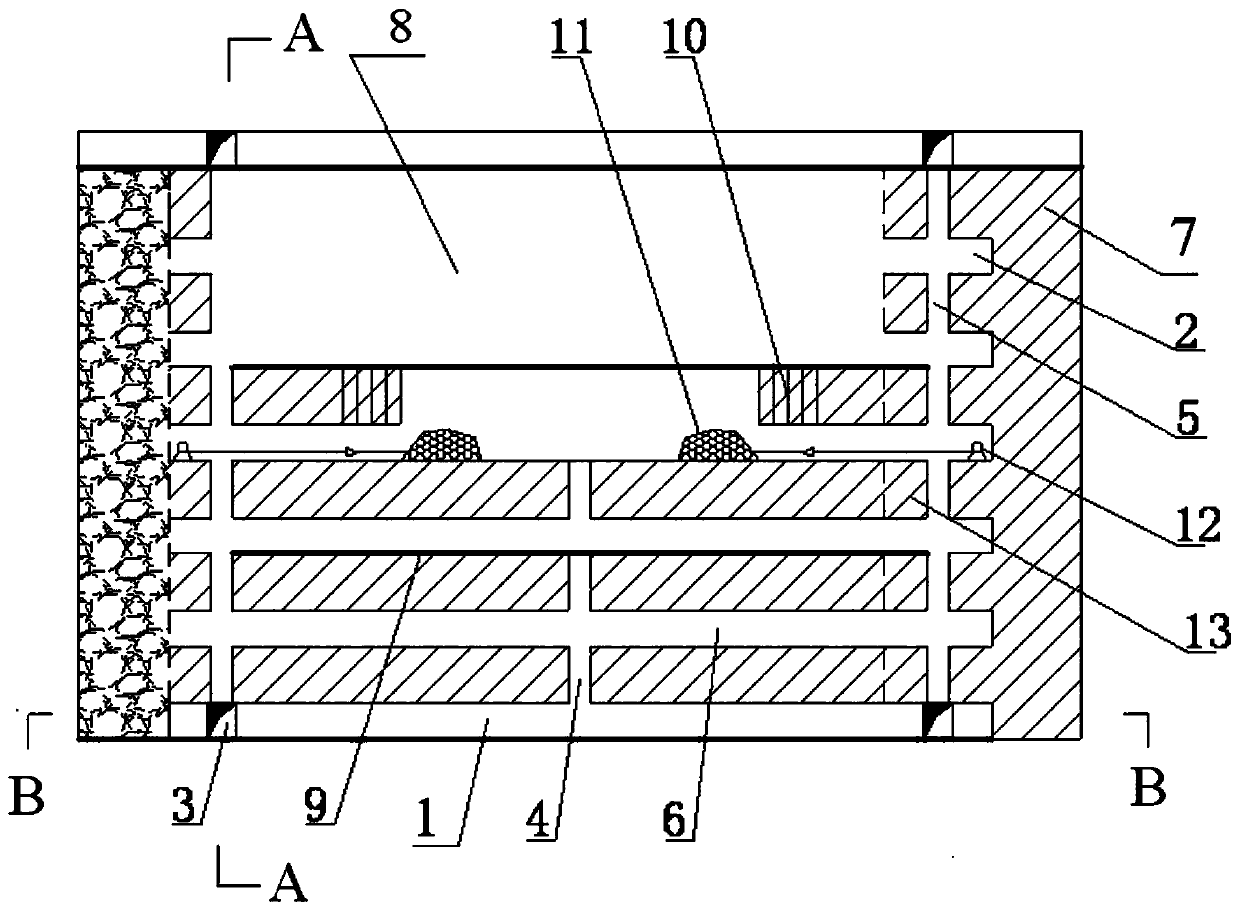

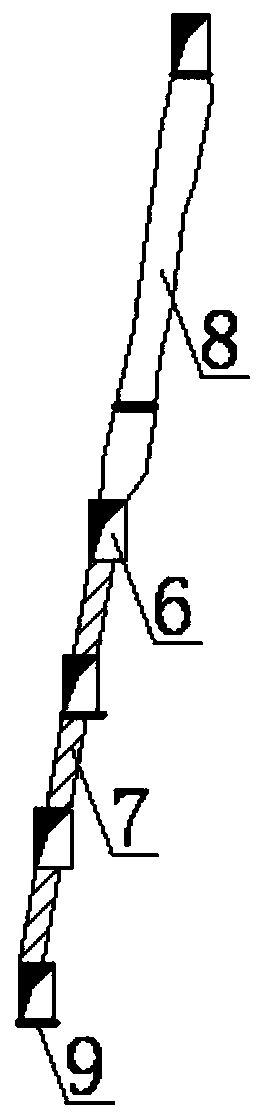

The invention provides a technology for blasting an inclined thin ore body by dividing ores and rocks in area in drift driving, belonging to the field of mining engineering. A design process comprises the steps of: 1, dividing a waste rock area (9) and an ore area (10) according to an ore body and a rock distribution condition of a tunnel cross section; 2, arranging a main easer (1) and a secondary easer (2) at the lower part in the waste rock area; 3, arranging an auxiliary hole (3) in the waste rock area according to the size of the cross section; 4, arranging a breaking hole (6) in the ore area according to an inclination angle of the ore body and the size of the cross section; 5, arranging rim holes (4 and 7) and bottom holes (5 and 8) in the circumference edge and the bottom edge of a tunnel; 6, charging each blast hole; 7, sequentially initiating the blast holes; and 8, clearing slag after blasting, and respectively transporting the ores and the waste rocks. With the adoption of the technology provided by the invention, the quantity of the blast holes can be reduced, the use ratio of the blast holes can be improved, a blast effect can be enhanced, the driving efficiency and the ore and rock transportation efficiency can be improved, the dilution rate of the byproduct ores and the engineering cost can be reduced, and the economical benefits of a mine can be improved.

Owner:QINGHAI SHANJIN MINING

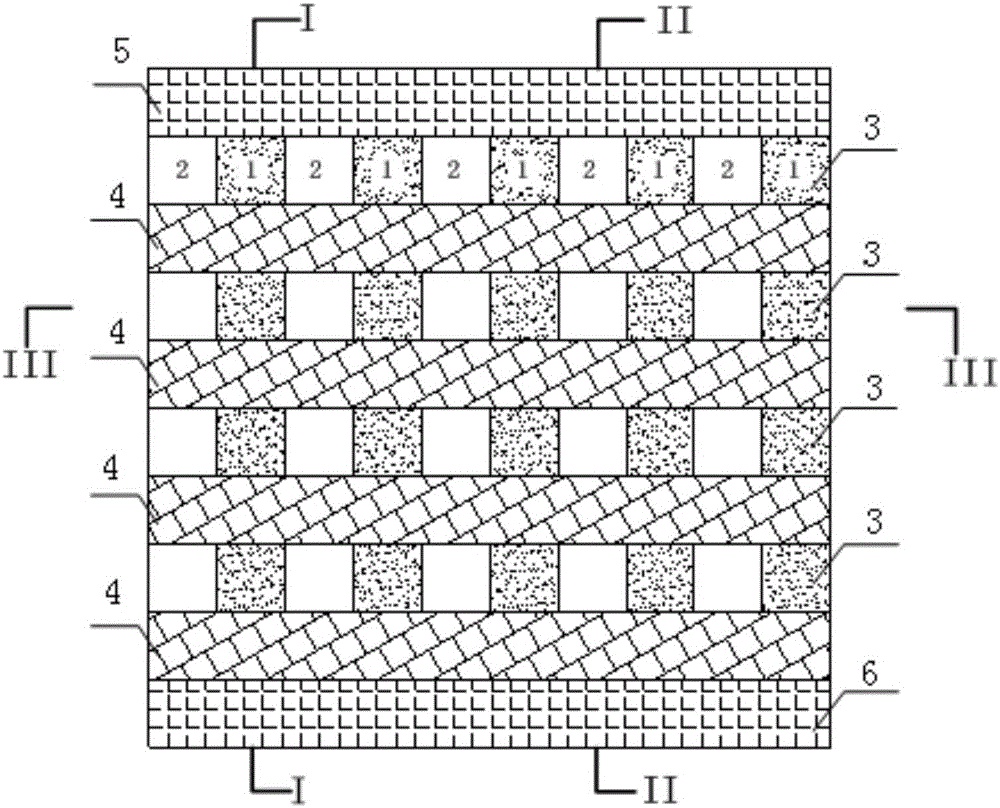

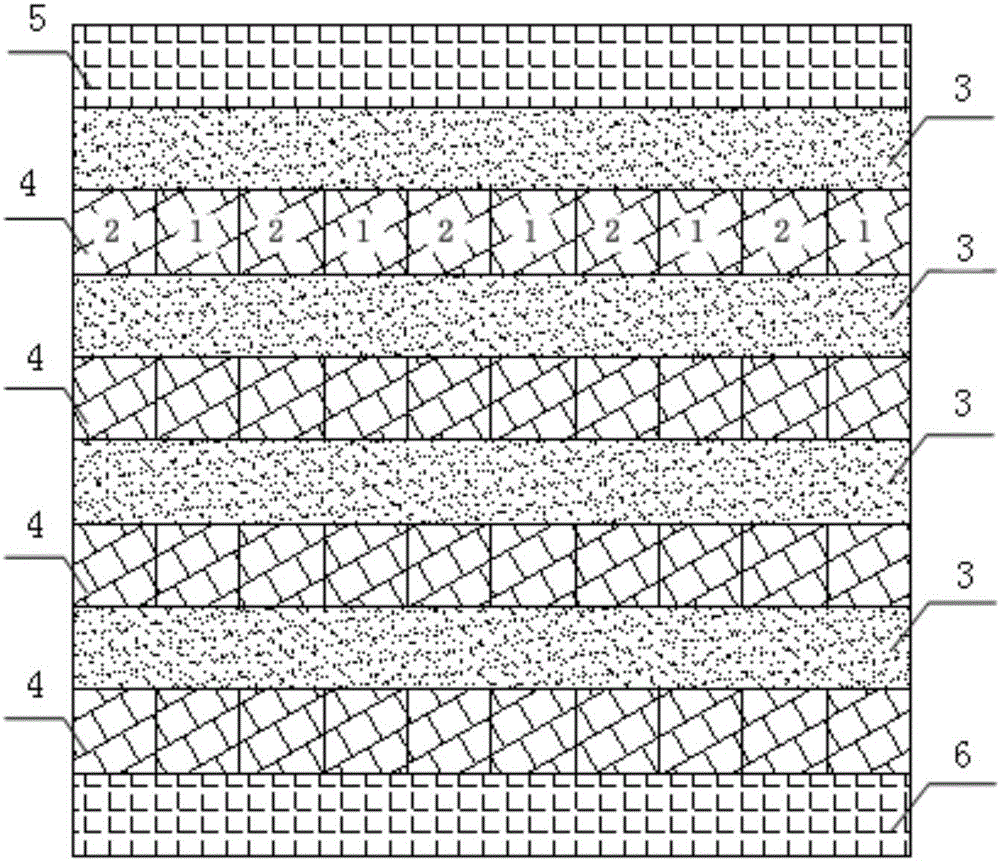

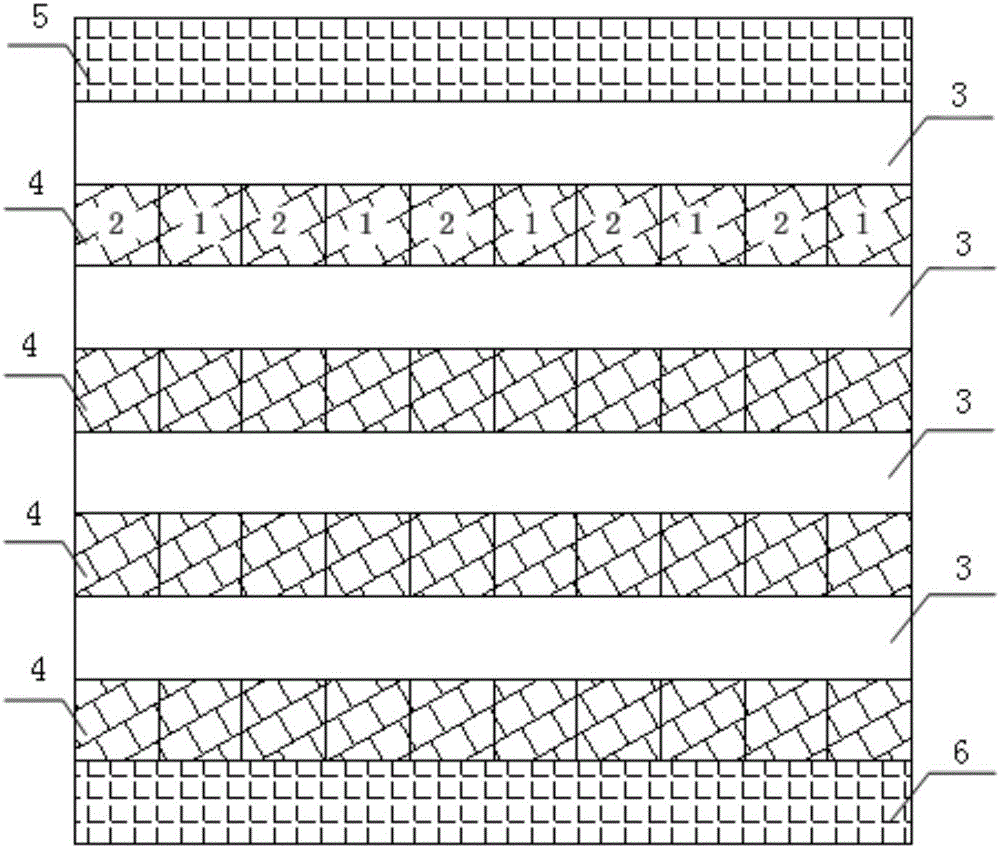

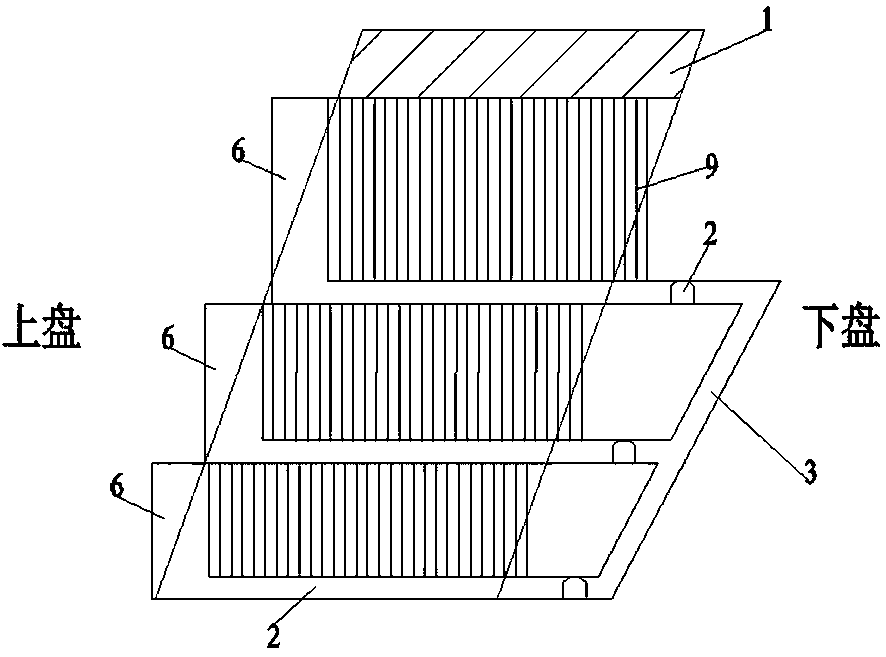

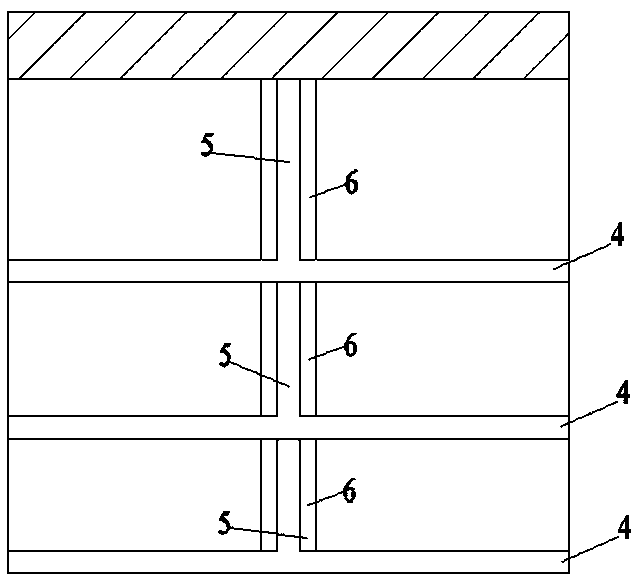

Filling mining method for downward access part

InactiveCN106014410AReduce usageReduce mining costsUnderground miningSurface miningFilling materialsPlacer mining

The invention discloses a filling mining method for a downward access part. In the ore body mining process, a mining area is divided into spaced filling layers (3) and full filling layers (4) which are alternatively distributed in the vertical direction; the spaced filling layers (3) and the full filling layers (4) are each divided into a plurality of first strip blocks (1) and second strip blocks (2) which are alternatively distributed; downward access layer-by-layer mining is conducted in the ore body mining process. According to the filling mining method for the downward access part, the purposes of reducing the filling material usage amount in the mining process and reducing the mining cost are achieved on the premise that the stability of a mining field is guaranteed, layered strip block mining is conducted on an ore body, the filling ratio is decreased by reasonably arranging the mining sequence, and then the filling cost is reduced.

Owner:CENT SOUTH UNIV

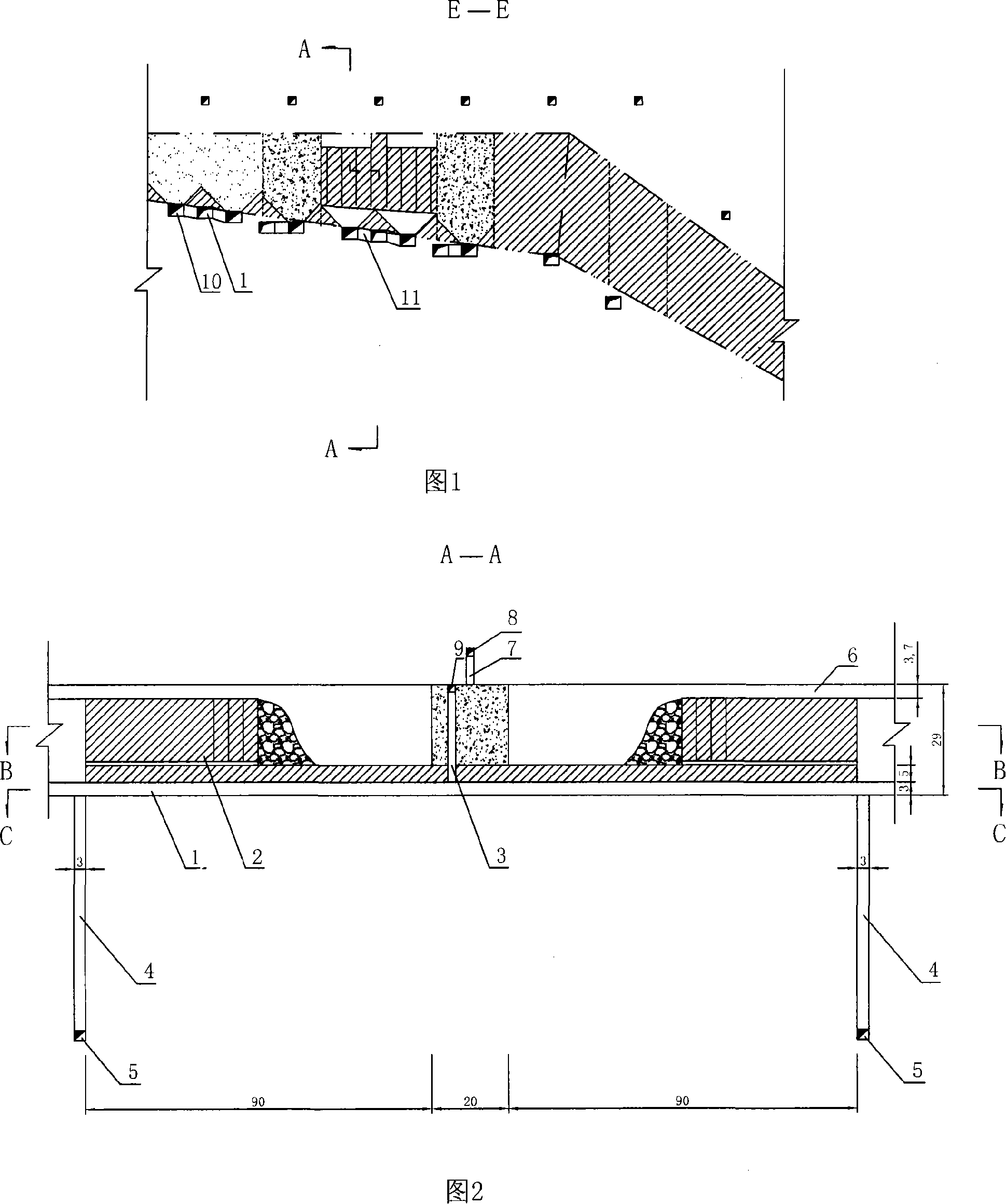

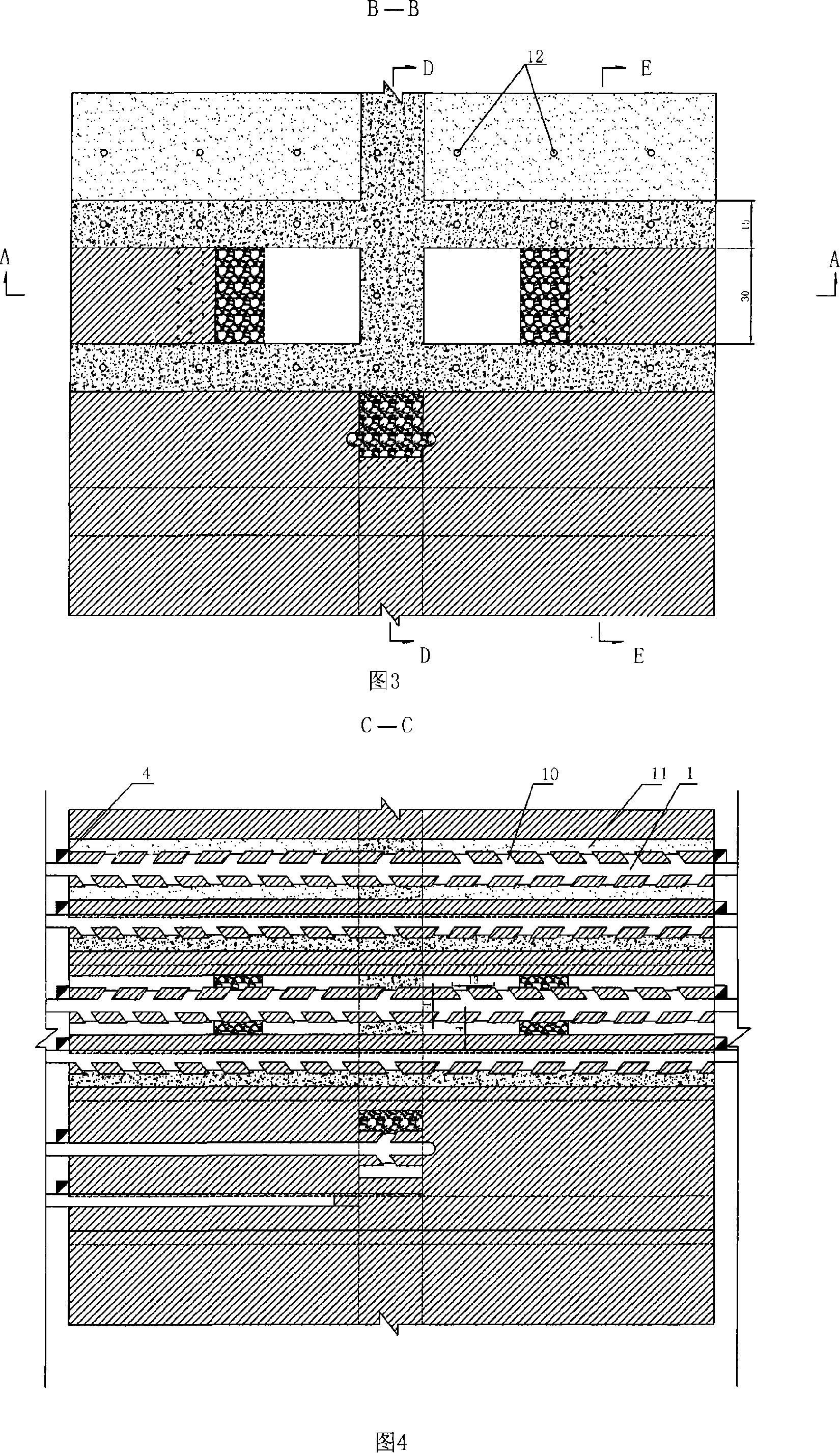

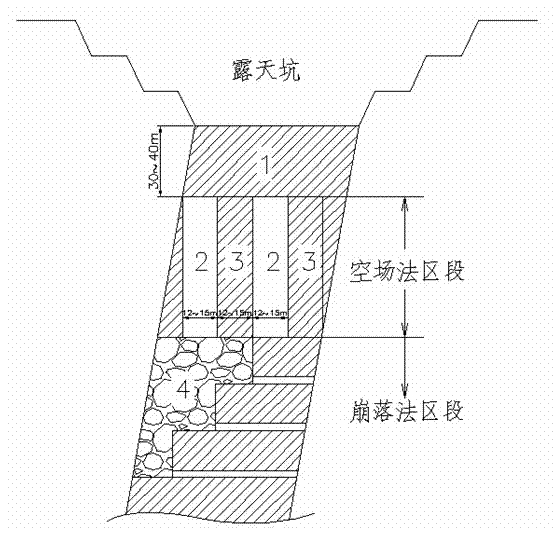

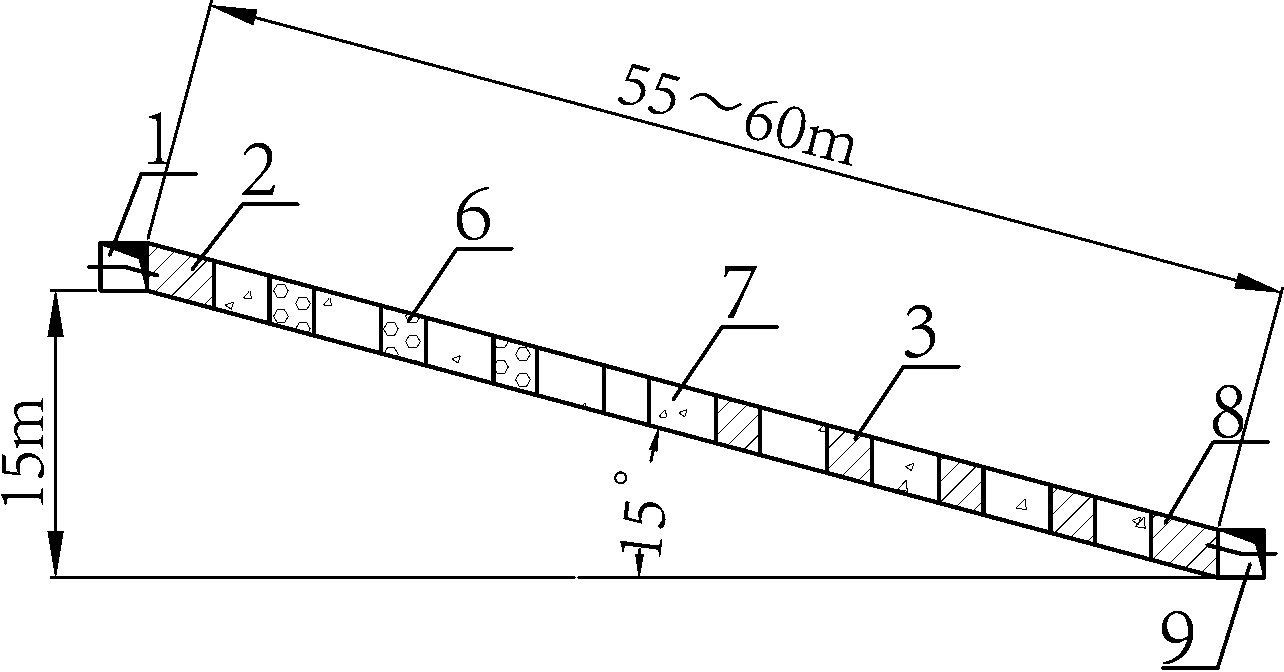

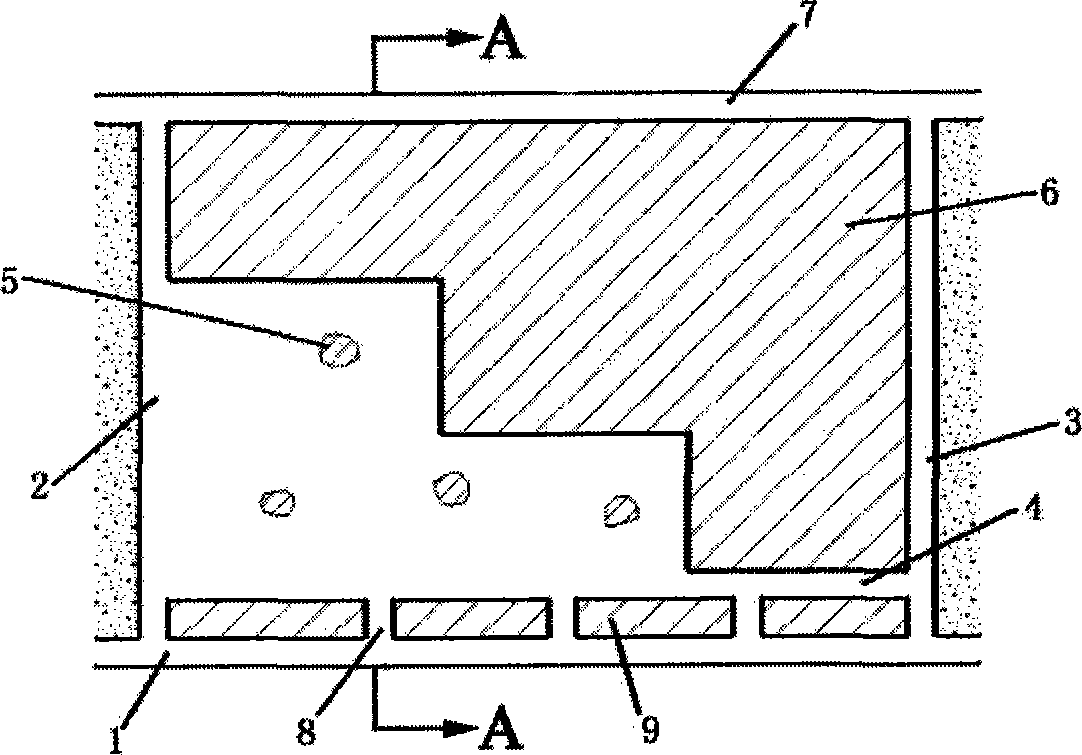

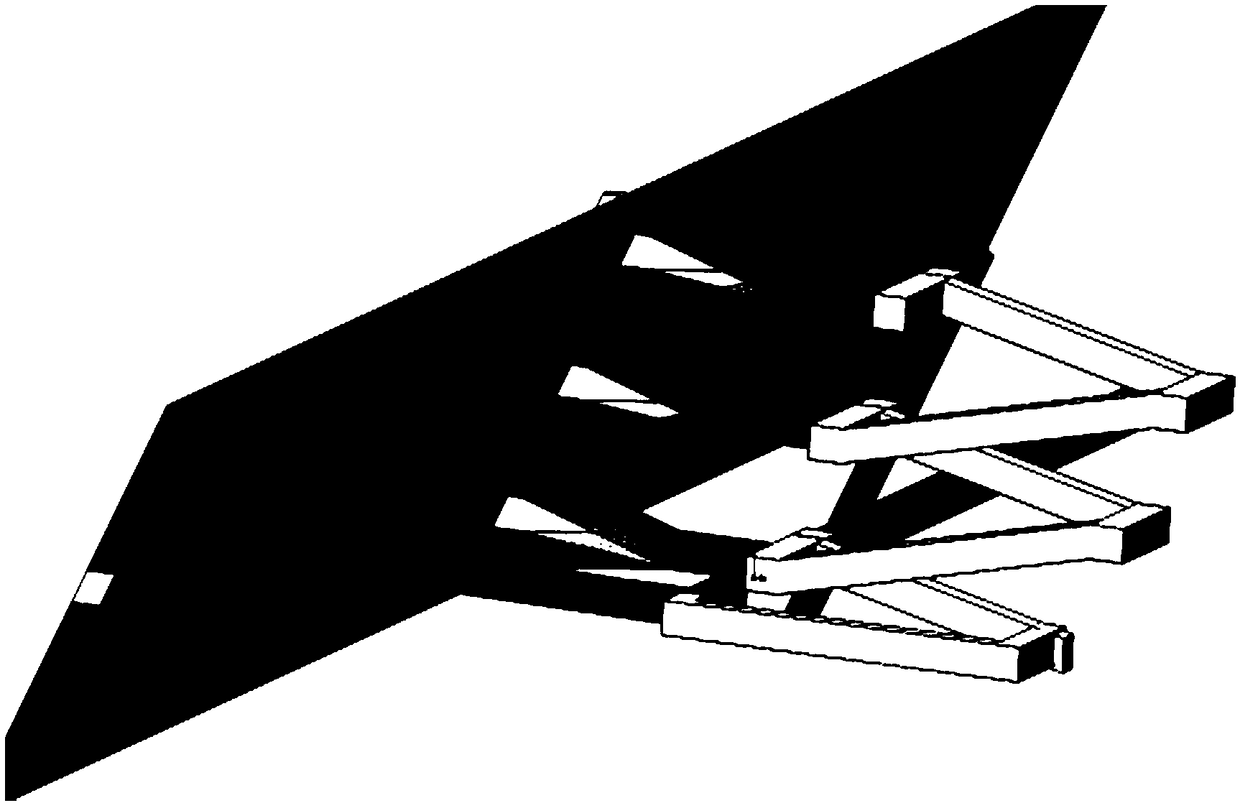

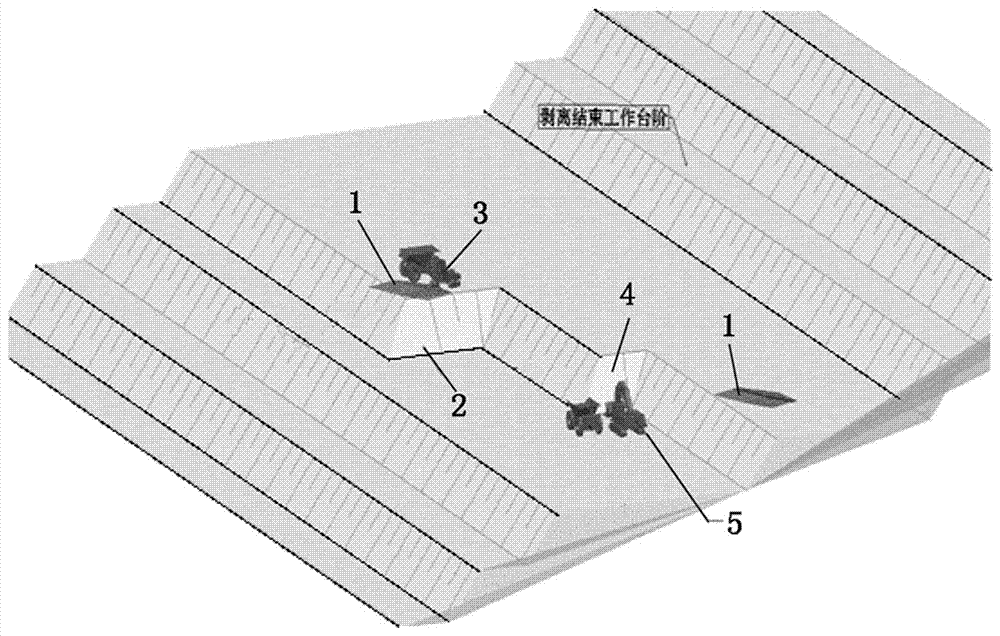

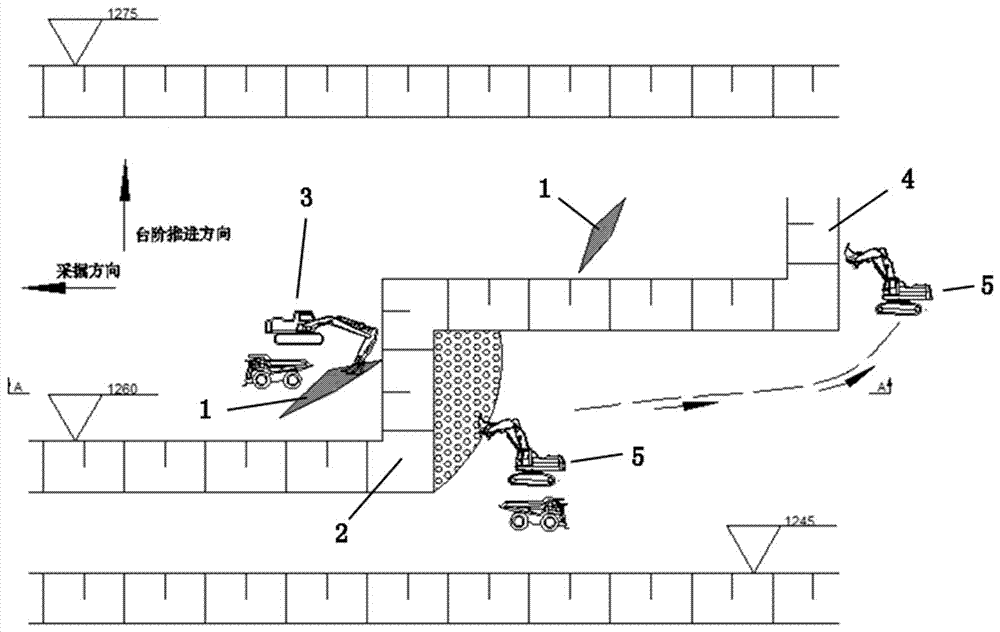

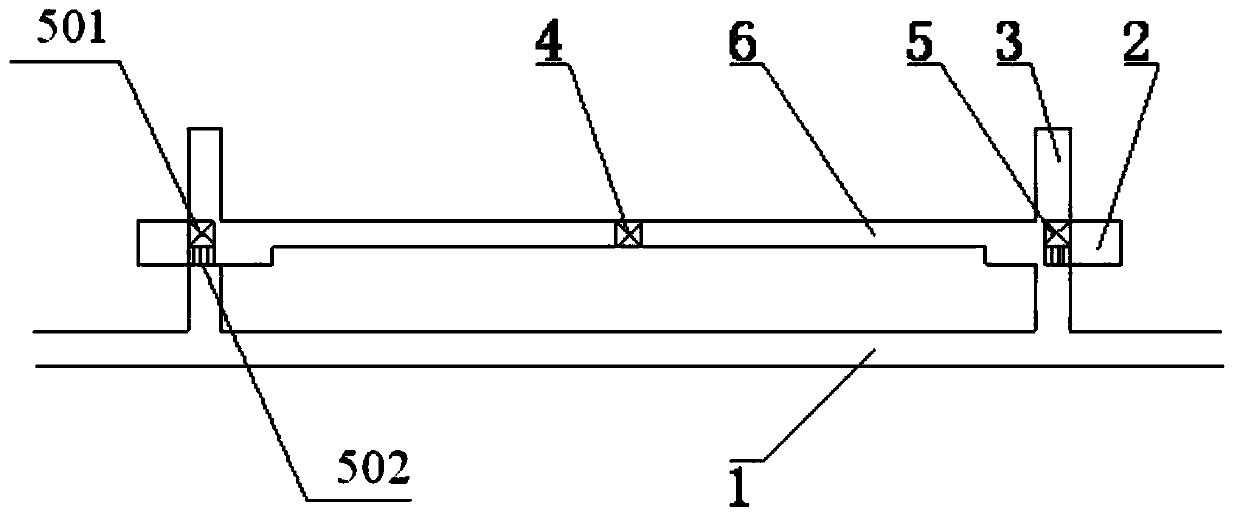

Jamb recovery and cushion layer formation integrated technology in process of mining from outdoors into underground

ActiveCN103114855AImprove securityReduce depletion rateUnderground miningSurface miningOpen-pit miningCushion

The invention discloses a jamb recovery and cushion layer formation integrated technology in the process of mining from outdoors into underground. The technology comprises the following steps of: in the later stage of opencast mining, reserving a boundary pillar (1) at the bottom of an open pit, and carrying out underground mining on a first middle section in the process of underground mining by a large-parameter studding open-stope method; when the opencast mining and the open-stope method zone mining are ended, distributing blasted holes in the boundary pillar (1), distributing blasted holes in a jamb (3), charging powder at the same time and detonating in a segmented way, firstly detonating the blasted holes in the jamb (3), detonating the blasted holes in the boundary pillar (1) at the bottom of the open pit, and enabling fallen ores formed in a detonating way to form a cushion layer (4); and mining at a later-medium section in the process of underground mining by a caving method, and recovering the cores of the cushion layer (4) in the process of mining at a zone adopting a caving method. According to the technology, the open work and the underground work are carried out at the same time, the transition is stable, the safety in the process of open mining and underground mining can be improved, a mass of ores are recovered, a covering cushion layer for mining adopting the caving method can be solved, and the dilution ratio caused by the caving method can be greatly reduced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

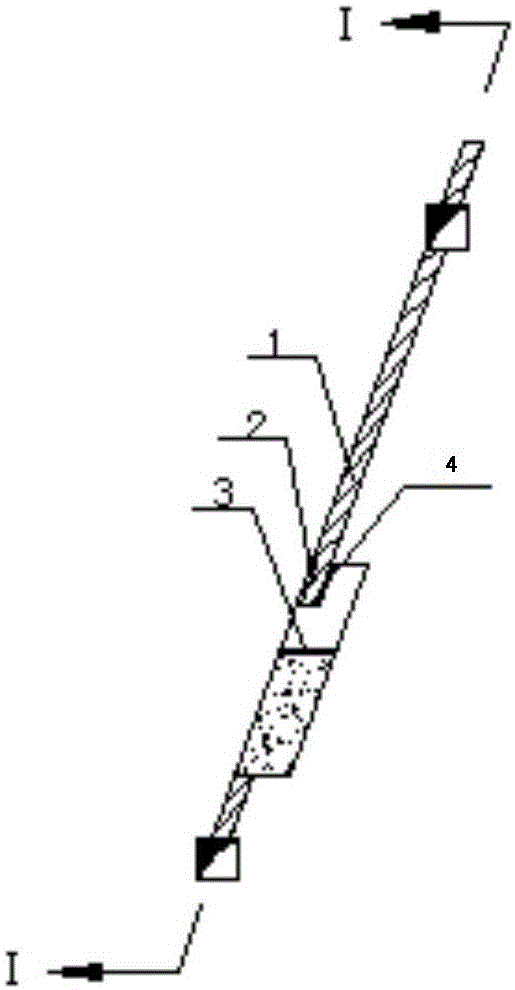

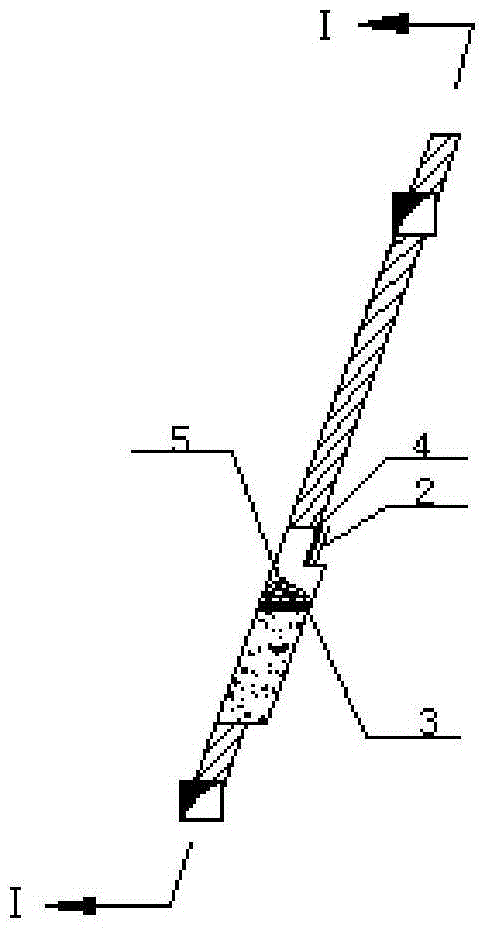

Presplitting type wall cutting and filling stoping method for thin ore vein

InactiveCN105735996AReduce mining dilution rateReduce stacking pressureUnderground miningBlastingSocial benefitsEconomic benefits

The invention discloses a presplitting type wall cutting and filling stoping method for a thin ore vein. The presplitting type wall cutting and filling stoping method for the thin ore vein comprises the steps that a presplitting hole is drilled in the interface of the thin ore vein and surrounding rock on the hanging side or heading side of the wall to be cut, presplitting blasting is conducted, the ore vein and the surrounding rock of the cut wall are blasted at different times, and ore drawing or filling is conducted independently; and all the steps are circulated till a whole ore block is extracted. Simultaneous millisecond blasting is conducted on the presplitting hole and an ore body blasted in the early stage or the surrounding rock of the cut wall, namely the presplitting hole is blasted firstly and then the ore body or the surrounding rock of the cut wall is blasted. After ore drawing (under the condition that mining is conducted firstly) or filling (under the condition that wall cutting is conducted firstly), secondary blasting of the surrounding rock is conducted for on-site filling or the ore body is blasted for ore drawing. All the steps are circulated till the whole ore block is extracted. According to the presplitting type wall cutting and filling stoping method for the thin ore vein, by introducing the presplitting blasting technique into the wall cutting and filling method, separate stoping of ore and wall rock of the thin ore vein is achieved in the true sense, the dilution rate of extraction of the thin ore vein is greatly decreased, and the probability of breakage and cost increase which are caused by excessive dilution of ore is lowered; in addition, the mineral separation technological index can be improved easily, the tailing stacking pressure is relieved, and high economic benefits and social benefits are achieved.

Owner:CENT SOUTH UNIV +1

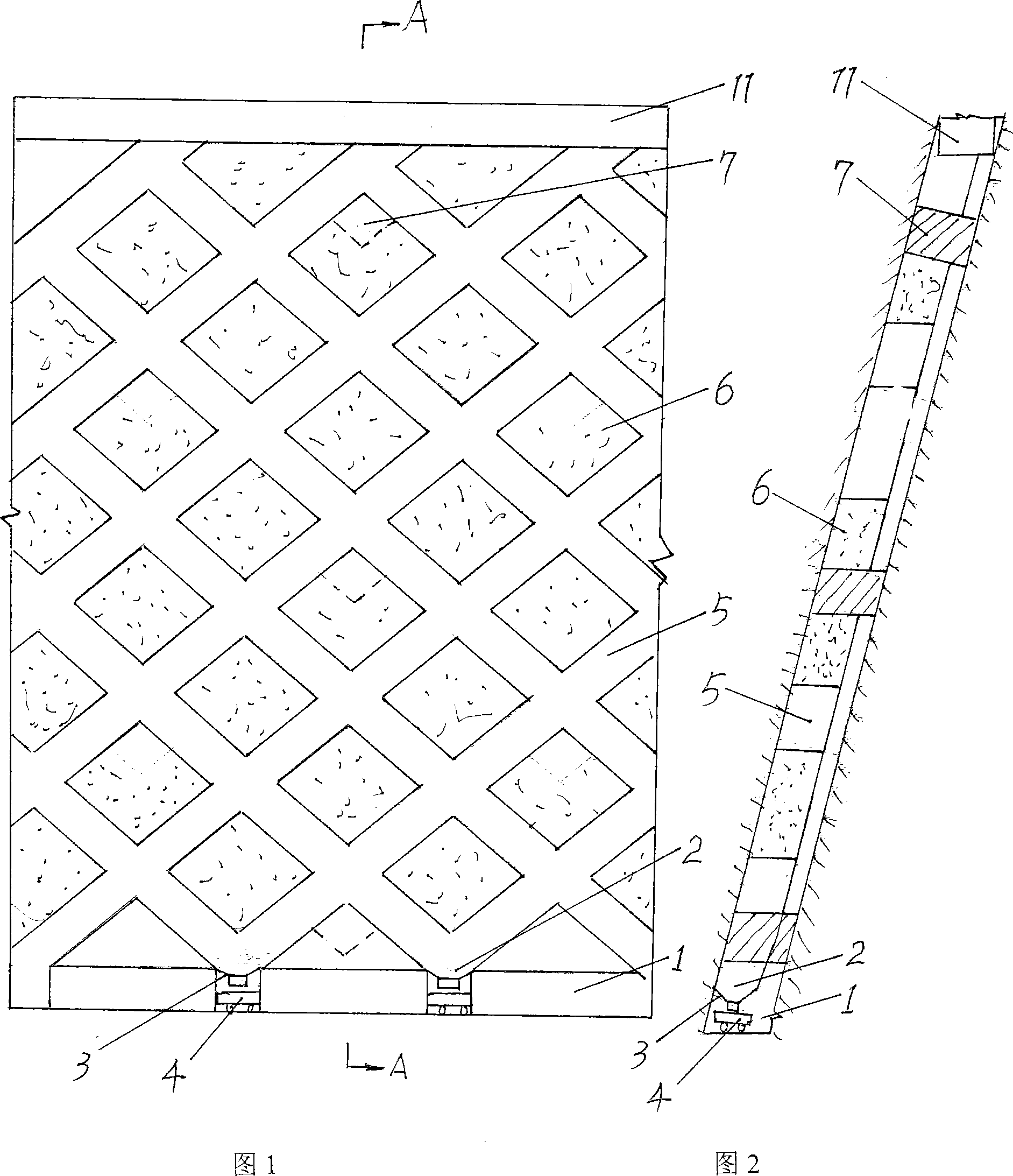

High-dipping ore block house column mining method

InactiveCN101509377AEasy to mineReduce depletion rateUnderground miningSurface miningRoom and pillar miningEngineering

The invention provides a steeply inclined ore body room-and-pillar mining method, comprising the following steps: a traveling roadway is tunneled along the trend of the ore body; broken-ore troughs are tunneled in the traveling roadway at interval with the broken-ore troughs as junctions, two inclined shafts are tunneled toward the uphill direction to the top of a quarry; a rhombic ore block formed between the inclined shafts is mined from top to bottom in sequence; ore pillars are left in the rhombic ore block at interval; ores mined in the process of tunneling slip into the broken-ore troughs along the inclined shafts depending on self weight and then put into a mine car in the traveling roadway from the broken-ore troughs to be delivered; the tunneled inclined shafts in networked cross distribution can serve as a passage and an ore chute for the miners to go up and down and as a ventilation shaft and a workplace for rock drilling, ore breaking and blasting avoiding. The method is good in ventilation effect, safe, reliable, low in cost, simple in construction operation, high in ore recovery ratio and low in dilution ratio.

Owner:KUNMING IRON & STEEL GRP CO LTD

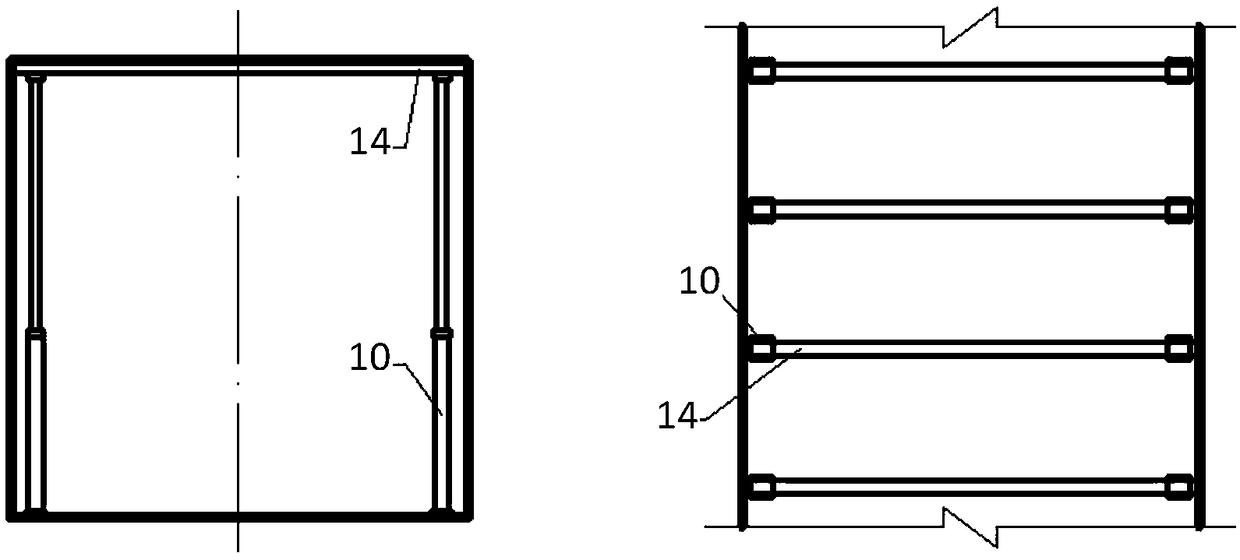

Pillar mining method for gentle dip thin ores

ActiveCN103967493AImprove filling efficiencyReduce filling cyclesUnderground miningSurface miningRoom and pillar miningComputer science

The invention discloses a pillar mining method for gentle dip thin ores. The method comprises the following steps: A, filling the goaf (except upward roadways on the studding side) among top pillars, bottom pillars and studding in an open-stope room-and-pillar method stope (in which stoping is finished) with cementing tailings to form a cemented filling mass; B, firstly stoping pillars in the goaf; then moving tailings and waste stone (dug in the process of stoping the first row of pillars) out of the stope and backfilling the goaf for stoping adjacent upper rows of pillars with tailings and waste stone (dug in the process of stoping other pillars); C, after pillars in the goaf are all stoped, filling the upper roadways and the goaf of pillars by one-time operation; D, after pillars and middle pillars in the whole middle section of the goaf are all stoped, remaining essential airways; for the sake of safety, transporting roadway frontals from the middle section, then going back for stoping top pillars and bottom pills according to a method of drift stroping with backfill, and carrying out alternative stoping and tightened filling. By virtue of the method disclosed by the invention, pillars reserved in the open-stope room-and-pillar method can be stoped safely and efficiently at low cost.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

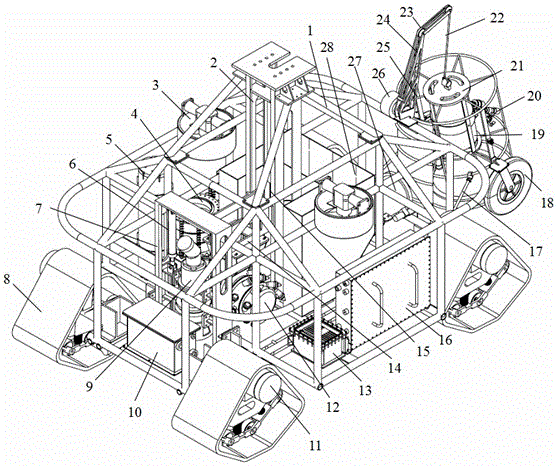

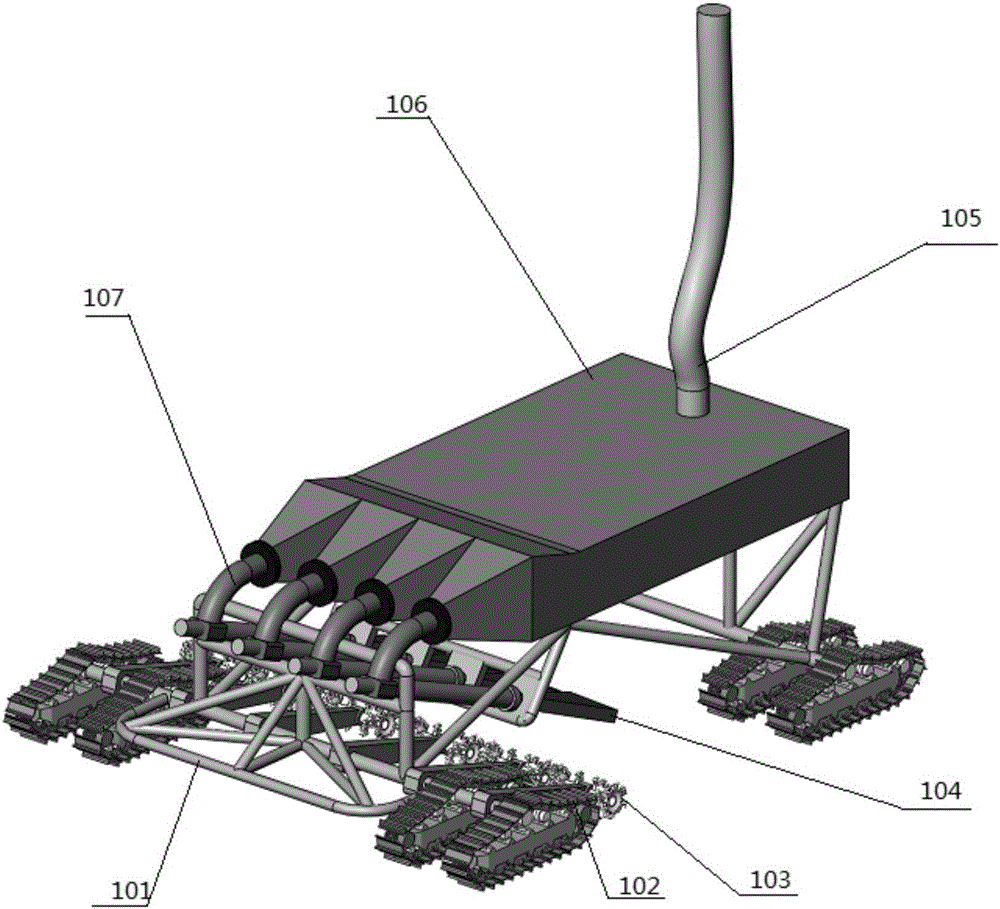

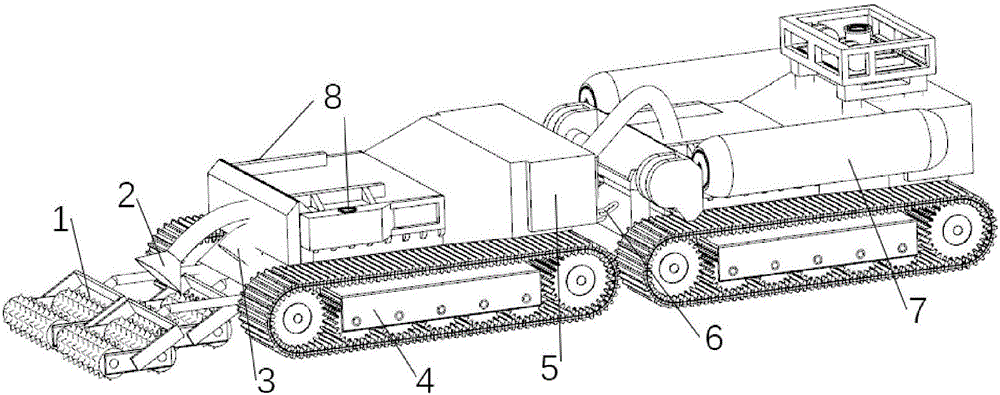

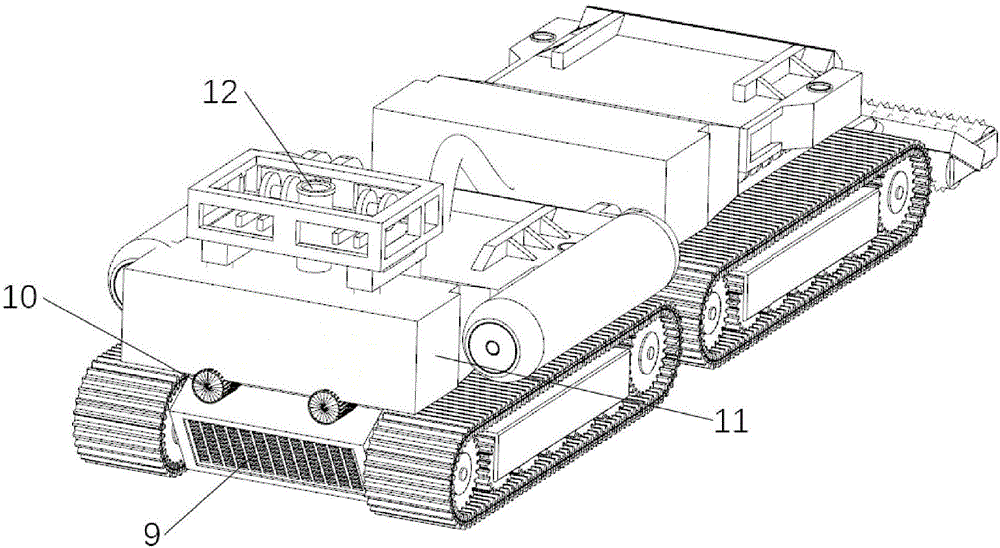

Mining experimental vehicle for cobalt-rich crust mining area on seabed

ActiveCN105673017AImprove work efficiencyReduce depletion rateAmphibious vehiclesMineral miningOcean bottomHydraulic motor

A mining experimental vehicle for a cobalt-rich crust mining area on a seabed comprises a continuous track frame, a central post, propellers, a pressure compensator, an electronic bin, ore absorbing head propelling oil cylinders, an ore absorbing head fixing rack, track wheels, a hydraulic pump ore absorbing head, an underwater inverter, track wheel hydraulic motors, a milling digging head, an underwater battery, a milling digging head slide framework, a milling digging head propelling oil cylinder, a valve box, an acoustic thickness measurement probe, an underwater camera, an acoustic probe bracket, a steel cable, a pulley block, a mechanical arm, an arm folding oil cylinder, a hydraulic motor, an underwater power station and bins. According to the mining experimental vehicle, distribution characteristics of a cobalt-rich crust ore body can be tested on line in real time, the thickness of the tested ore body is acquired, the cutting and breaking depth of a mining head is adjusted, the working efficiency is increased, and the dilution ratio is reduced.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Novel technique of slight-pitch ore body overall mining method

ActiveCN101368482AImprove handling efficiencyImprove recovery rateUnderground miningSurface miningComputer sciencePedestrian

The invention belongs to gently inclined orebody mining field and in particular discloses a new gently inclined orebody overall mining method, including the following steps: digging a pedestrian rise entry and an incision rise entry which are communicated with the upper middle section in the orebody disclosed in a drift at the lower middle section; constructing an undercutting drift at the mouth of the incision rise entry; digging ore passes at a bottom pillar; constructing two layers of incision drifts at the incision rise entry; starting the stopping process after mining and incising processes are finished; increasing the rise entry gradient Alpha between the mouth of the incision rise entry and the two layers of incision drifts to Beta 40-90 degrees by bottom-chopping engineering. Compared with prior art, the new gently inclined orebody overall mining method increases incision drifts and extracts almost all the ores, thus improving stopping rate. With a plurality of working faces operate at the same time, the new mining method increases ore-drawing capacity, reduces reserved natural ore pillars and reduces ore loss ratio and ore dilution ratio. Through bottom-chopping engineering, the new mining method increases the riser entry gradient between the mouth of the incision riser entry and the two layers of incision drifts, thus greatly increasing ore transportation efficiency and increasing ore-drawing capacity.

Owner:LINGBAO CITY JINYUAN MINING

Mechanized mining method through downward or upward cemented filling for steeply-inclined orebody with extremely-crushed ore rock

ActiveCN108756885AReduce blast damageReduce lossesUnderground miningSurface miningShaped beamMineralogy

The invention provides a mechanized mining method through downward or upward cemented filling for a steeply-inclined orebody with extremely-crushed ore rock. The mechanized mining method comprises thesteps that layering drift stoping from top to bottom or from bottom to top is conducted; after a layering contact channel is tunneled, a machine enters the orebody along the layering contact channel,a cantilever tunneling machine is applied to replace ore breaking by blasting, as for each layer of a thin orebody is subjected to ore breaking in the advancing direction, or a large and thick orebody is subjected to ore breaking along a drift in the vertical direction at intervals or in sequence, the drift is arranged in a full-height mode, and ore removal through a forklift is conducted; and after the whole layer is subjected to single-step or two-step advancing stoping and back filling, the next layer is stoped, downward stoping is conducted on the lower portion of a top plate of a fillingbody, or upward stoping is conducted on a bottom plate of the filling body, and thus integrated innovation of a downward (upward) cemented filling mining method and ore breaking through a roadheaderis achieved. According to the method, damage to surrounding rock is reduced through mechanical ore breaking; in addition, a single-body hydraulic prop, a pi-shaped beam and a paved plastic mesh guarda top and a slope during mining, prop pulling is conducted during filling, the effects of high efficiency, safety, low ore loss and dilution rate, flexible stope arrangement are achieved, and exploration and mining combination is easy to achieve.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

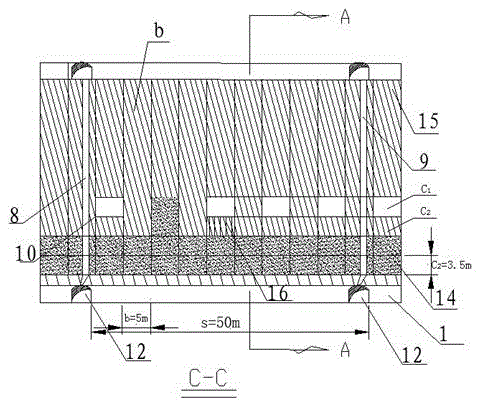

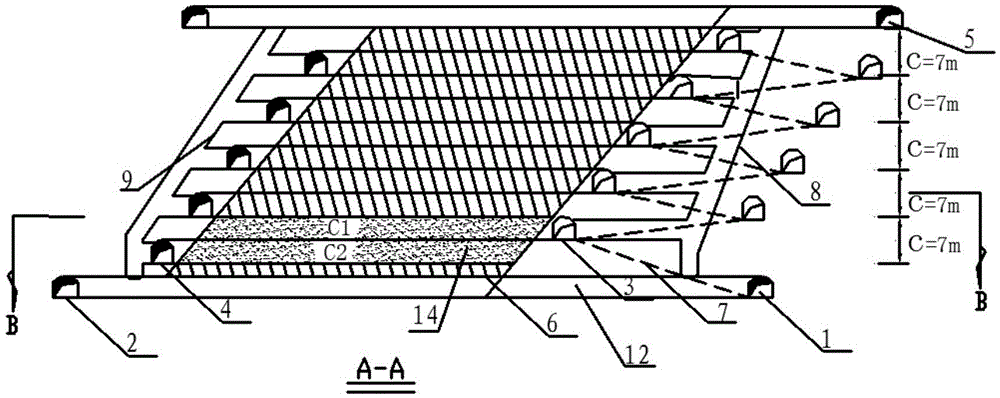

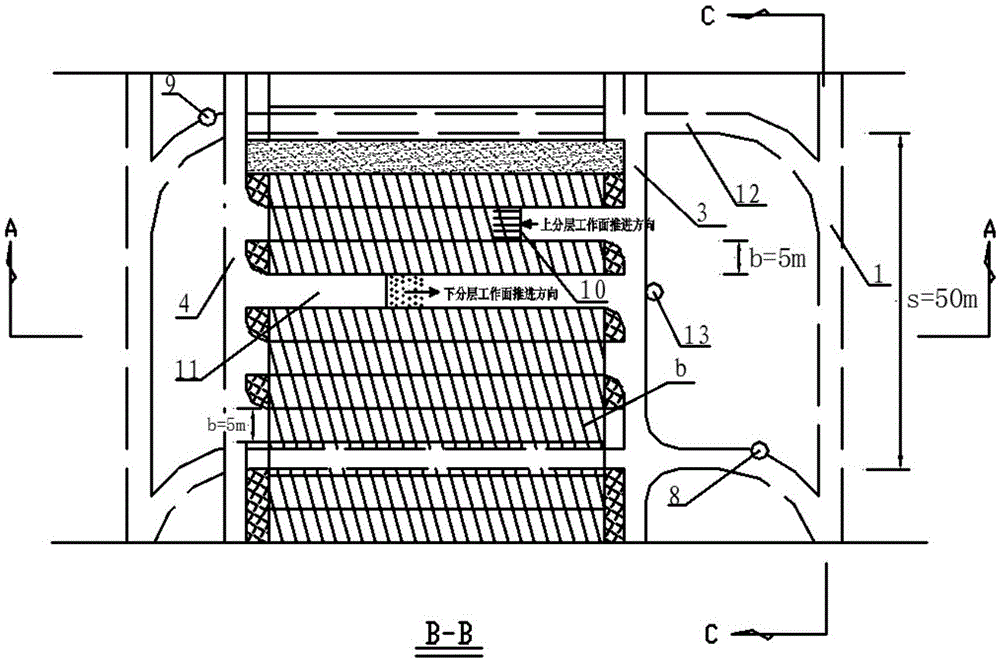

Efficient upward drift slicing and filling mining method suitable for unstable rock stratum

ActiveCN106761912ASimplify mining processes in minesReduce stope support engineering volume and mining quasi-engineering volumeMaterial fill-upMineralogyUltimate tensile strength

The invention discloses an efficient upward drift slicing and filling mining method suitable for an unstable rock stratum. The efficient upward drift upward drift slicing and filling mining method comprises the steps that each section (c) is divided into an upper slice (c1) and a lower slice (c2), and the upper slices (c1) and the lower slices (c2) are combined into the sections (c) for carrying out mining, wherein the upper slices (c1) are firstly mined, and after drift stoping on the upper slices (c1) is completed, drift ore bodies of the lower slices (c2) are mined; and stoping is conducted on the same panel in the horizontal direction in a mode that one slice is mined every other slice or one slice is mined every other two slices, and after stope rooms of the upper slices (c1) and stope rooms of the lower slices (c2) in the first step are stoped, cemented filling is conducted, and stope rooms adjacent to the stope rooms in the first step are immediately stoped after a filling body meets the requirements of the curing strength. By adoption of the efficient upward drift slicing and filling mining method, continuous mining is achieved, and after one section is completely stoped, uniform lifting is conducted for drift stoping of the upper slices, the preparation project amount of second-step ore pillar stoping is decreased, primary roof supporting is reduced, the sectional height of primary filling is increased, the ore stoping and filling efficiency are improved, and the mining cost is lowered.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

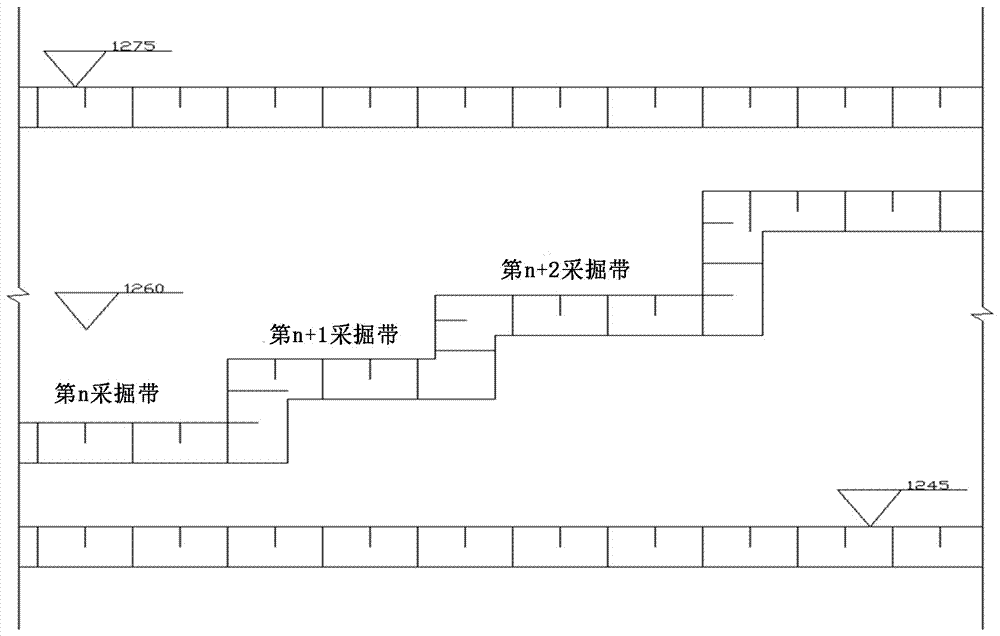

Open-pit refined mining method for gently dipping-thin ore body

ActiveCN106988746AAvoid mine downtimeReduce loss rateUnderground miningSurface miningOpen-pit miningMineralogy

The invention relates to the field of open-pit mining methods, in particular to an open-pit refined mining method for a gently dipping-thin ore body. The open-pit refined mining method comprises four steps of cut dividing, explosion arranging, hanging wall layered mine rock shovel mucking and heading wall sequential stripping advancing. The open-pit refined mining method solves the contradictory problem of loss ratio and dilution ratio reducing and large shovel mucking equipment production efficiency improving when a traditional mining method is used for stoping the gently dipping-thin ore body and ensures that a user can stope the gently dipping-thin ore body economically and efficiently.

Owner:YUNNAN HUALIAN ZINC & INDIUM

Chamber and deep hole blasting method of gob

The invention discloses a chamber and deep hole blasting method of a gob. The method of the invention comprises the steps of: firstly extracting a rib pillar and support pillars or bottom support pillars on the two sides of the rib pillar from the top down, and then, performing deep hole blasting on the hanging side of the worked out section along the ore body direction after extracting the ore pillars at each 2-3 middle segments, filling the barren rocks generated in deep hole blasting and a horizontal construction tunnel of deep hole drilling in the worked out section on the lower part of the construction tunnel formed by extraction in situ, namely, filling the worked out section on the lower part to certain thickness after extracting the ore pillars, cutting a part of triangular prism loads moved downward of the hanging side and avoiding the excessive damage of the surrounding rock of the reserved hanging side so as to limit the hanging side and the reserved rib pillar from generating excessive rock mass movement or damage toward the worked out section; and if the barren rocks generated in the deep hole blasting and the construction tunnel cannot meet the filling thickness and filling demand of the worked out section on the lower part, performin auxiliary chamber blasting along the hanging side direction can be conducted, and the gob is treated to limit the hanging side from generating excessive rock mass movement or damage so as to protect the integrity of the upper layer ore body lagging behind in the extraction operation.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

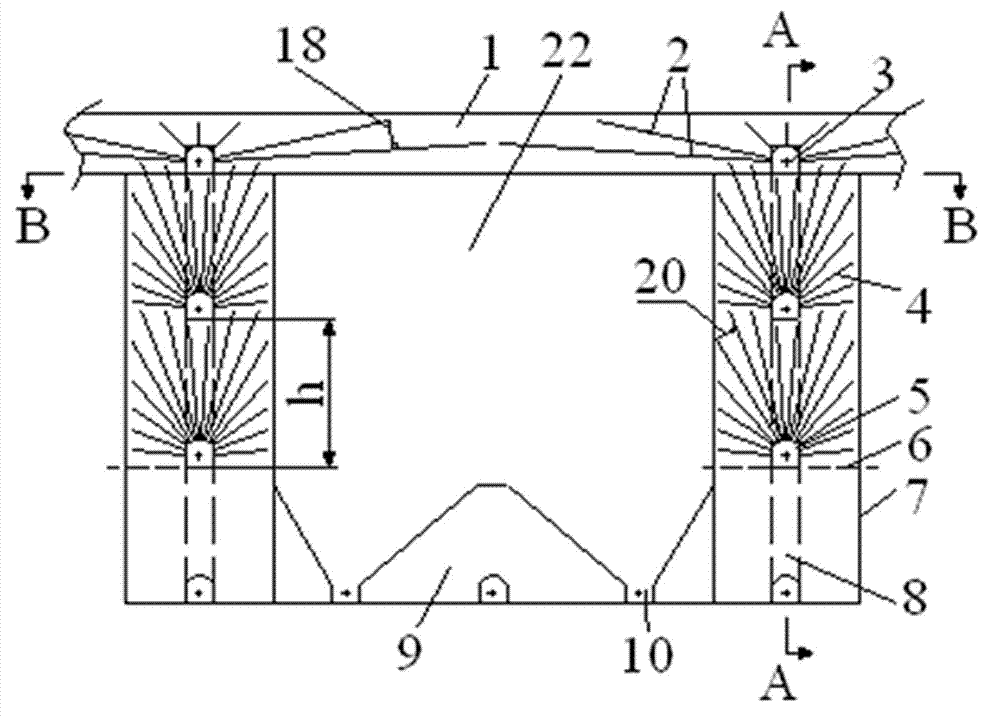

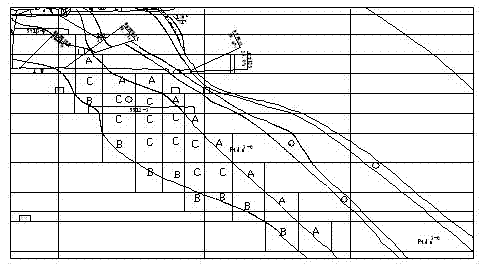

Pillarless sublevel caving method based vertical partitioning and combined ore drawing extraction technology of gently inclined ore bodies

InactiveCN102444403ATop in timeReduce depletionUnderground miningSurface miningMining engineeringMechanical engineering

The invention discloses a pillarless sublevel caving method based extraction technology used under the condition of gently inclined ore bodies. A series of problems of the pillarless sublevel caving method under the condition of gently inclined ore bodies such as efficient extraction of sublevel hanging wall and footwall triangle ore bodies, sublevel transition ore quantity, efficient recovery of footwall residual ores, timely supplementing and caving realization and the like are solved by the technical measures such as vertical partitioning, combined ore drawing, timely supplementing and caving, footwall residue full covering and the like. By designing the new pillarless sublevel caving method based vertical partitioning and combined ore drawing extraction scheme suitable for the condition of gently inclined ore bodies, the loss and dilution indexes when the pillarless sublevel caving method is applied under the condition of gently inclined ore bodies can be substantially reduced and the technical and economic benefits of mining can be increased.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

Mining method for multilayer fragile gently-inclined extra-narrow ore vein

The invention discloses a mining method for a multilayer fragile gently-inclined extra-narrow ore vein. According to the method, mining areas are divided along the ore body trend; mining area columns (5) are reserved among the mining areas; a mine slope (1) is arranged in each mining area column (5); one vein following combined roadway is arranged in the inclination direction every 20m to 40m; vein following cutting roadways (2) and cutting mine slopes (3) are excavated at the end part of a chamber in the trend direction and the inclination direction; and a first layered ore vein, a rock sandwich layer and a second layered ore vein are totally excavated in one step along the vein following cutting roadways (2) and the cutting mine slopes (3). In the backstopping process, different drilling and blasting parameters are adopted at the first layered ore vein, the rock sandwich layer and the second layered ore vein, rocks among the ore veins can be removed; the problem of ore mixing into the rocks is solved; and the ore dilution is reduced. The method provided by the invention is particularly applicable to the mining of the underground metal mine multilayer fragile gently-inclined extra-narrow ore vein and the ore vein easy to crush due to blasting disturbance; the simultaneous recovery of the multilayer ore vein is realized; and the problem of personnel operation and equipment operation space limitation is solved through full thickness mining.

Owner:河南发恩德矿业有限公司

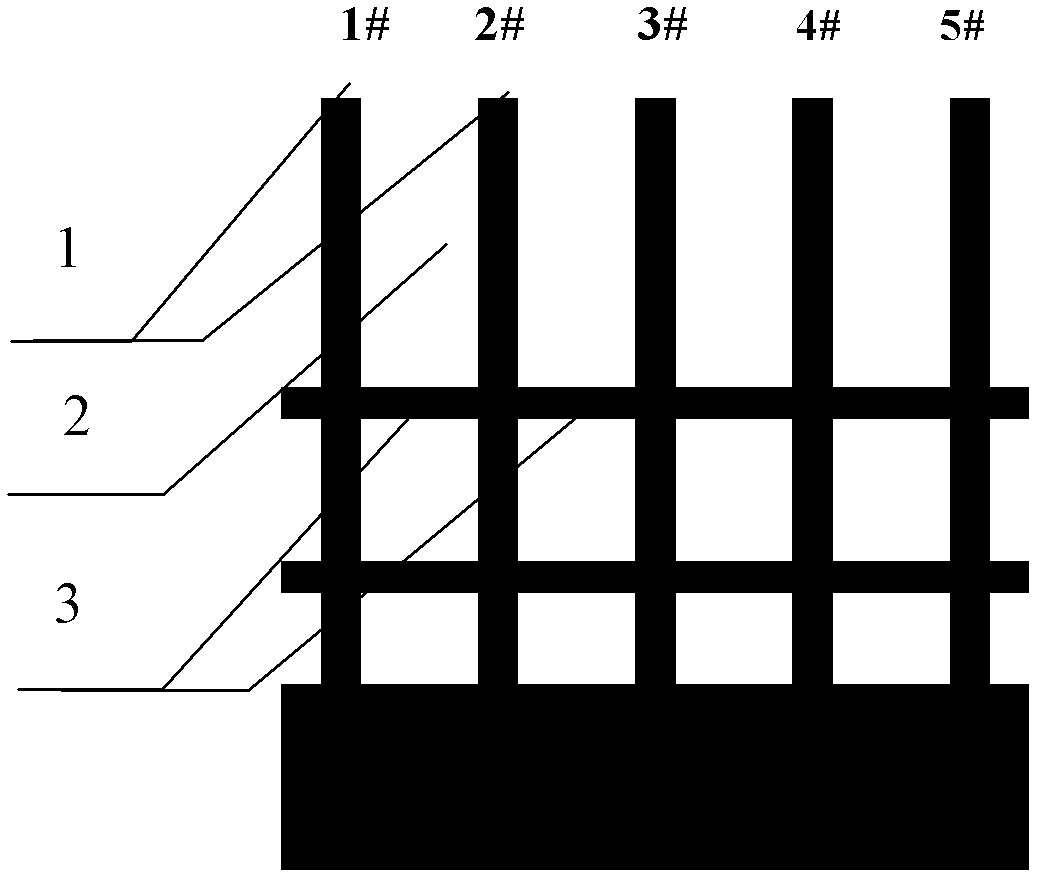

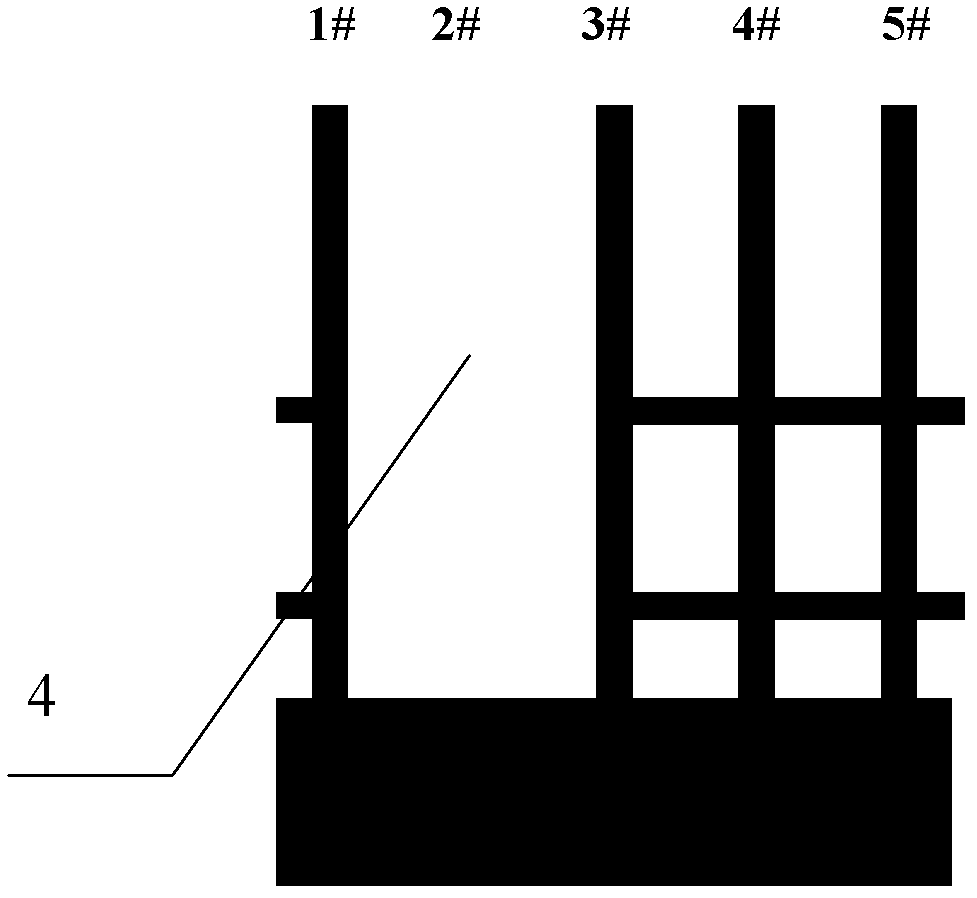

Large-scale horizontal jamb mining method under existence of bottom caving group occurrence

InactiveCN103147760ASafe and effective recyclingImprove recovery rateUnderground miningSurface miningMining engineeringResource recovery

The invention discloses a large-scale horizontal jamb mining method under the existence of a bottom caving group occurrence. The large-scale horizontal jamb mining method comprises the following steps of: planning a caving group occurrence horizontal jamb by adopting a stepped forward mining scheme as well as a mining organization, firstly dividing the horizontal jamb into a plurality of sub-layers according to the height of 4.8m, dividing each layer into a plurality of disc areas, marking the single-number disc areas and the double-number disc areas in sequence according to the direction of an ore body, dividing each disc area into 5m-wide*4.8m-high admission passages, calling the admission passages firstly mined in each disc area as ore chambers, calling the admission passages mined later as ore jambs, firstly mining the ore chambers in the double-number disc areas and then mining the ore jambs in the single-number disc areas, and vice versa. By adopting the method, precious rare metal ores with large ground pressure, broken ore rocks and complicated geological conditions can be safely and effectively recovered; and the method has the advantages of high recovery rate and low dilution ratio, and can meet the demands of the horizontal jamb on safe recovery and resource recovery.

Owner:JINCHUAN GROUP LIMITED

Mining method for steep-dip thin ore body

InactiveCN111456729AReduce mixControl mixinUnderground miningSurface miningMining engineeringRock cutting

The invention relates to a mining method for a steep-drip thin ore body, which belongs to the technical field of mine underground mining. The mining method comprises the following steps: dividing theore body into ore blocks, and tunneling a vein-penetrating roadway in a direction perpendicular to the ore body from an outside-vein transportation roadway at the two ends of each ore block; tunnelinga pedestrian mine slide open yard at a vein of the vein-penetrating roadway, and simultaneously tunneling an in-vein scraper chamber and a sub-section drilling roadway; after tunneling of the sub-section drilling roadway is accomplished, tunneling a center advanced open yard; and recovering the ore blocks from top to bottom, and recovering the next sub section after the last sub section recoveryis ended by adopting a sub-section ore removal way for ore removal. The mining method has the advantage of sub-section ore removal, reduces operation time of each sub section at a working site, effectively controls mixing of surrounding rocks, reduces a rate of dilution, constructs a concrete cushion layer every 1-2 sub sections, can effectively control geopressure show at the working site, improves stability of the working site, reduces the rate of dilution of the ores, improves production efficiency of the working site, and guarantees safety of production operation.

Owner:CHANGCHUN GOLD RES INST

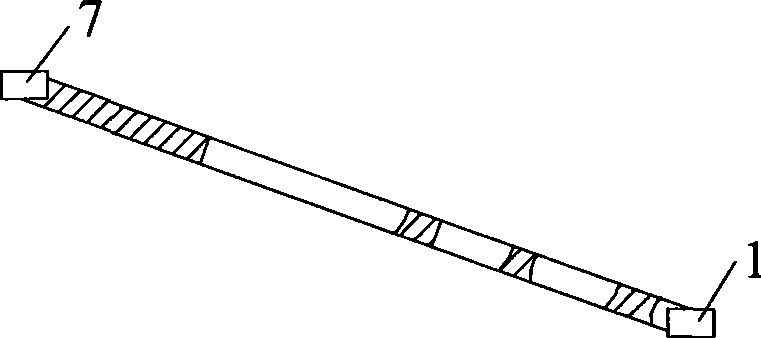

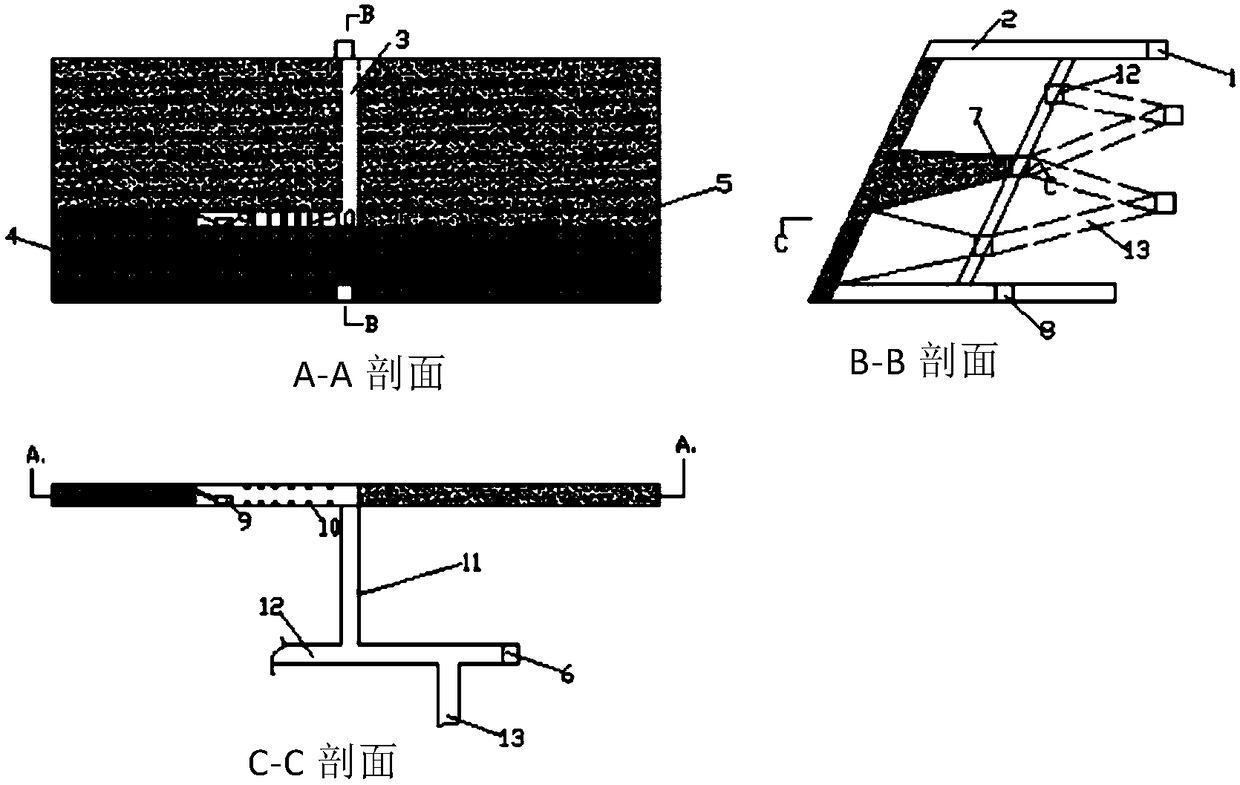

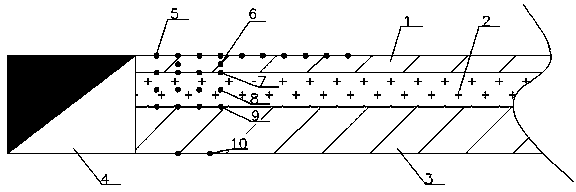

Multilayer gently-inclined extremely-narrow vein stoping blasting technology

The invention discloses a multilayer gently-inclined extremely-narrow vein stoping blasting technology. In the technology, a top-to-bottom layer-by-layer blasting and layered stoping method is employed. An intensive blasthole (5) are dug in a first layered vein (1) and an upper rock layer boundary. First layered vein middle blasthole (6) are dug in the middle of the first layered vein (1). A vein and intercalated rock layer boundary blasthole (7) is dug in the boundary between the first layered vein (1) and an intercalated rock layer (2). An intercalated rock layer and vein boundary blasthole (9) is dug in the boundary between the intercalated rock layer (2) and a second layered vein (3). An intercalated rock layer middle blasthole (8) is dug in the middle of the intercalated rock layer (2). A vein and lower surrounding rock boundary blasthole (10) is dug in the boundary between the second layered vein (3) and the lower surrounding rock boundary. The technology can achieve synchronic recycle of multilayer veins. A buffer seam can weaken an effect of a blasting shock wave on surrounding rock during a stoping process and meanwhile intercalated rock can be directly removed so that a difficult problem that the intercalated rock is mixed with ores and an ore dilution rate is reduced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

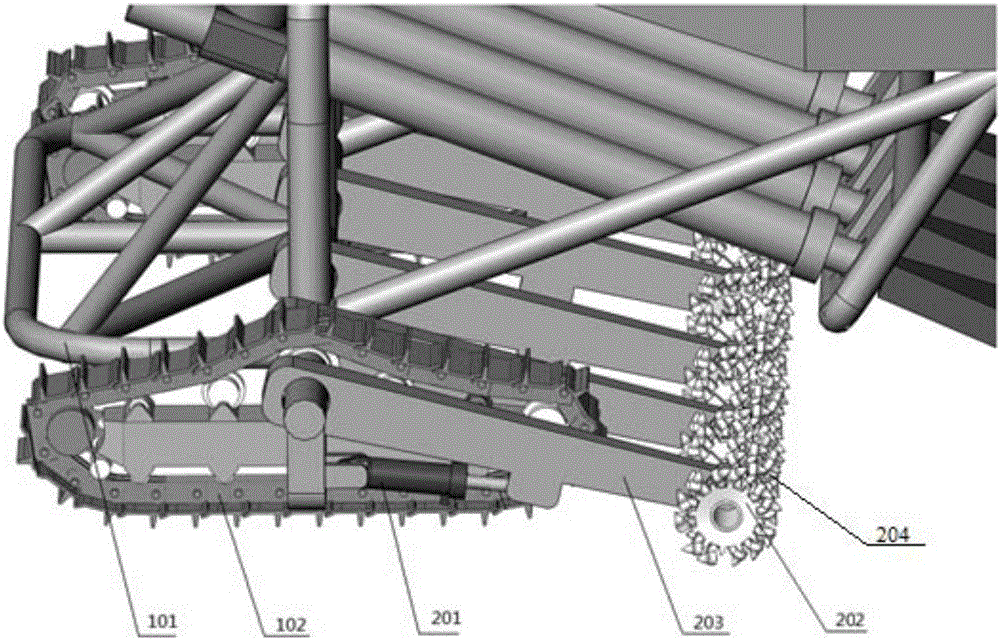

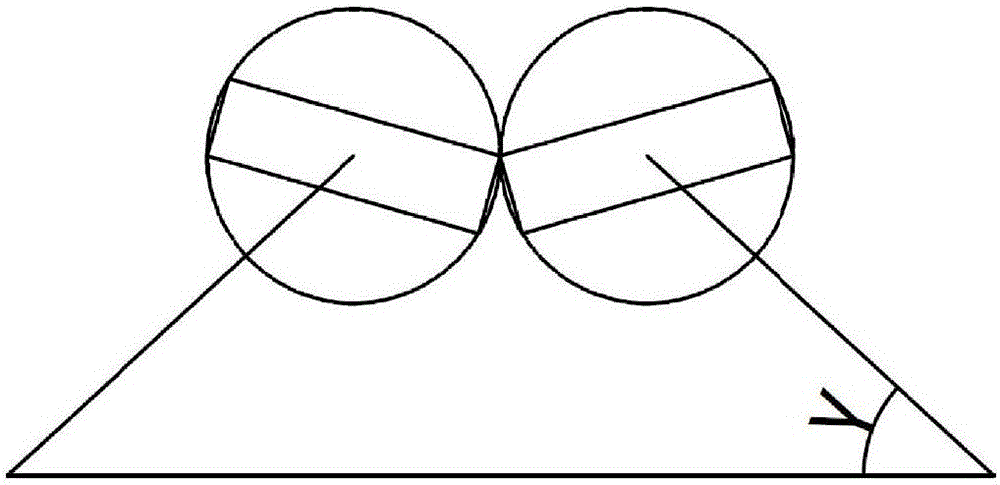

Seabed cobalt-rich crust mining vehicle

InactiveCN106014417AReduce depletion rateRealize joint operation functionMineral miningTerrainRock cutting

The invention discloses a seabed cobalt-rich crust mining vehicle. The seabed cobalt-rich crust mining vehicle comprises a base, a walking device, mining heads, collecting heads and a collecting device, wherein the base is fixed to the walking device, the mining heads are fixed to a support and make contact with the ground to broke cobalt-rich crusts, the collecting heads are fixed to the base and are arranged on the mining heads in the advancing direction of the mining vehicle, and the collecting device is fixed to the base and connected with the collecting heads and provides negative pressure for the collecting heads to suck cobalt-rich crust pulp generated after the mining heads broke the cobalt-rich crusts. The seabed cobalt-rich crust mining vehicle has the advantages that in the walking operation process of the mining vehicle, caterpillar bands can adapt complex and changeable terrain in the cobalt-rich crust mine lot; in the collection operation work, a hydraulic oil cylinder controls a mechanical arm to move up and down to adjust the work height, away from the ground, of the cutting and broking mining heads, bed rock cutting is reduced as much as possible or is avoided, the purpose of broking cobalt-rich crusts as many as possible the achieved, and the dilution rate is reduced.

Owner:CENT SOUTH UNIV

Oblique throwing blasting mining method for gently-inclined thin ore body

InactiveCN107165635AReduce depletion rateReduce mining costsUnderground miningBlastingUnit structureMineralogy

The invention provides an oblique throwing blasting mining method for a gently-inclined thin ore body. The oblique throwing blasting mining method for the gently-inclined thin ore body comprises the following steps that structure parameters of an ore block stoping unit are determined, a stope is arranged in the direction of the ore body, two mining preparation upward-inclining roadways communicating the upper, middle and lower sections are arranged in the stope, and the upward-inclining roadways are arranged in spacer pillars; cutting roadways are sequentially constructed between the two upward-inclining roadways from a bottom pillar to a top pillar of the stope; the oblique distance between the center line of the first cutting roadway and the bottom pillar is 2.5 m, and the oblique distances between the center lines of the subsequent cutting roadways and the bottom pillar are 5 m; stoping starts from the first cutting roadway, backward stoping is adopted, and two controlled blasting methods including oblique pre-splitting blasting and throwing blasting are adopted in order to reduce dilution and loss; after stoping of the first cutting roadway is completed, wooden walls are erected on two sides of the spacer pillars and cementing filling is conducted; after a filling curing period is finished, the second cutting roadway is stoped upwards, and the same stoping process is adopted; and stoping is sequentially recycled until stoping of a mining room is finished. The oblique throwing blasting mining method for the gently-inclined thin ore body is safe, efficient and low in loss, and the loss of mineral resources is reduced.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

Deep-sea cobalt crust mining truck

The invention relates to a deep-sea cobalt crust mining truck, which comprises a double-truck body frame type truck body and a cutting device and a connecting and suction device which are arranged at the front of the truck body, a separation bin, an ore storage bin and a drive mechanism which are sequentially arranged on the truck body, wherein the collecting and suction device is positioned above the cutting device. When the deep-sea cobalt crust mining truck provided by the invention operates, the cobalt crust in a mining area is crushed and collected, mineral particles and mud are separated in the separation bin after being transported by a hose, and collected and stored in the ore storage bin, and then finally transported to a surface mother ship through an absorption pipe, and recycled by a cable and an absorption pipe after the operation is finished; and the deep-sea cobalt crust mining truck has the characteristics of high universality, low dilution rate, high terrain adaptability, safety and reliability, relatively low cost and the like.

Owner:SHANGHAI JIAO TONG UNIV

Sublevel open stoping method ground pressure control method of inclined large and thick ore bodies

ActiveCN109162715AReduce exposure timeReduce loading pressureUnderground miningSurface miningEngineeringGround pressure

The invention belongs to the field of mining and relates to a sublevel open stoping method ground pressure control method of inclined large and thick ore bodies. Chamber is divided into three sublevels in the vertical direction, and a roof pillar is reserved above; an along-vein roadway, a rock drilling roadway, a cutting level and a cutting raise are arranged at each sublevel; medium-length holeblasting is adopted to form cutting grooves; during stoping of the chamber, sublevel centralized blasting is adopted, centralized blasting is performed on the whole chamber four times in total. The method has the benefits as follows: a mining preparation arrangement manner combining going along with and penetrating through veins outside of footwalls is adopted, and the mining preparation work amount is reduced; the sublevel centralized blasting technology is adopted, the stoping cycle of a stope is shortened, and the exposure time of a vacant stope is shortened; sublevel centralized ore removal is adopted, and the hanging wall pressure, transferred by falling ore, applied to footwall rock is reduced; a triangular ore pile is reserved on a chamber hanging wall, mixing of hanging wall wastestone during stoping is avoided, and the dilution rate is decreased.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com