Jamb recovery and cushion layer formation integrated technology in process of mining from outdoors into underground

A technology for converting from open-pit to underground and ore pillars, which is applied in underground mining, surface mining, special mining, etc., can solve the problem of not revealing the ore pillar cushion, etc., and achieves the goal of reducing the dilution rate, smooth transition, and improving safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

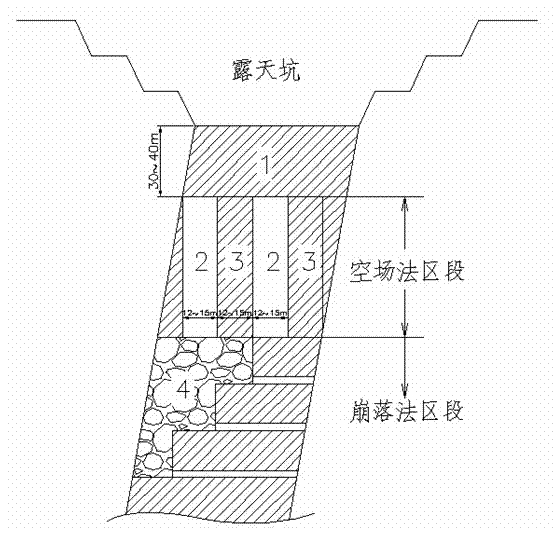

[0017] The integrated technology of pillar recovery and cushion formation in the open-pit to underground mining of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] Depend on figure 1 It can be seen from the schematic diagram of the formation process of the integrated technology of pillar recovery and cushion formation that the present invention adds an underground open-field method section in the process of converting from the open pit to the underground caving method. After the open-pit mining and open-pit mining are all completed, it is really converted to caving mining.

[0019] In order to achieve a smooth transition from open-pit to underground mines, in the later stage of open-pit mining, open-pit and underground production are performed at the same time, and a 30-40m boundary pillar 1 is left between the open-pit mining section and the underground mining section. In the section of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com