Patents

Literature

226 results about "Open-pit mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Open-pit, open-cast or open cut mining is a surface mining technique of extracting rock or minerals from the earth by their removal from an open pit or borrow. This form of mining differs from extractive methods that require tunnelling into the earth, such as long wall mining. Open-pit mines are used when deposits of commercially useful ore or rocks are found near the surface. It is applied to ore or rocks found at the surface because the overburden is relatively thin or the material of interest is structurally unsuitable for tunnelling (as would be the case for sand, cinder, and gravel). In contrast, minerals that have been found underground but are difficult to retrieve due to hard rock, can be reached using a form of underground mining.

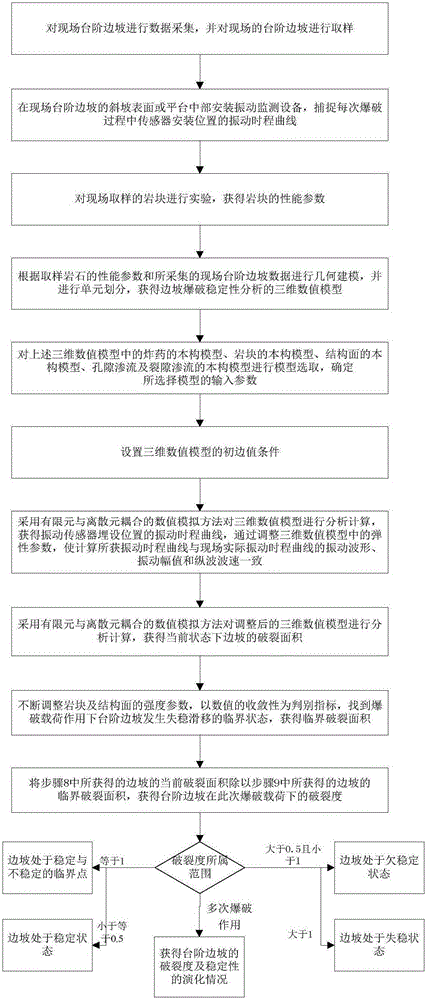

Method for analyzing bench slope stability under blasting effect

ActiveCN105224742ADirectly reflect the damage and ruptureEnter parameters accuratelySpecial data processing applicationsBlast loadOpen-pit mining

The invention provides a method for analyzing bench slope stability under blasting effect, and belongs to the technical field of open-pit mining. Compared with a conventional method, the method combines numerical simulation with vibration monitoring, and uses vibration information of a slop body to correct material parameters of the slop body, and provides more accurate input parameters for numerical simulation. A numerical simulation method coupling finite elements with discrete elements is used to perform mechanical analysis, and progressive failure process of the slope under blast load effect is completely depicted. A calculation result is more accurate. Rupture degree is used to evaluate slope stability, and internal damage and rupture conditions of a slope body can be directly reflected, and an evaluation index is more reasonable.

Owner:ANSTEEL GRP MINING CO LTD

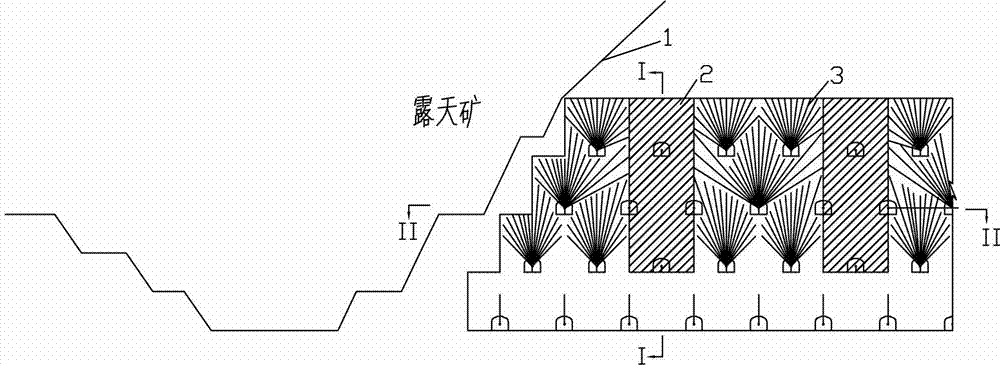

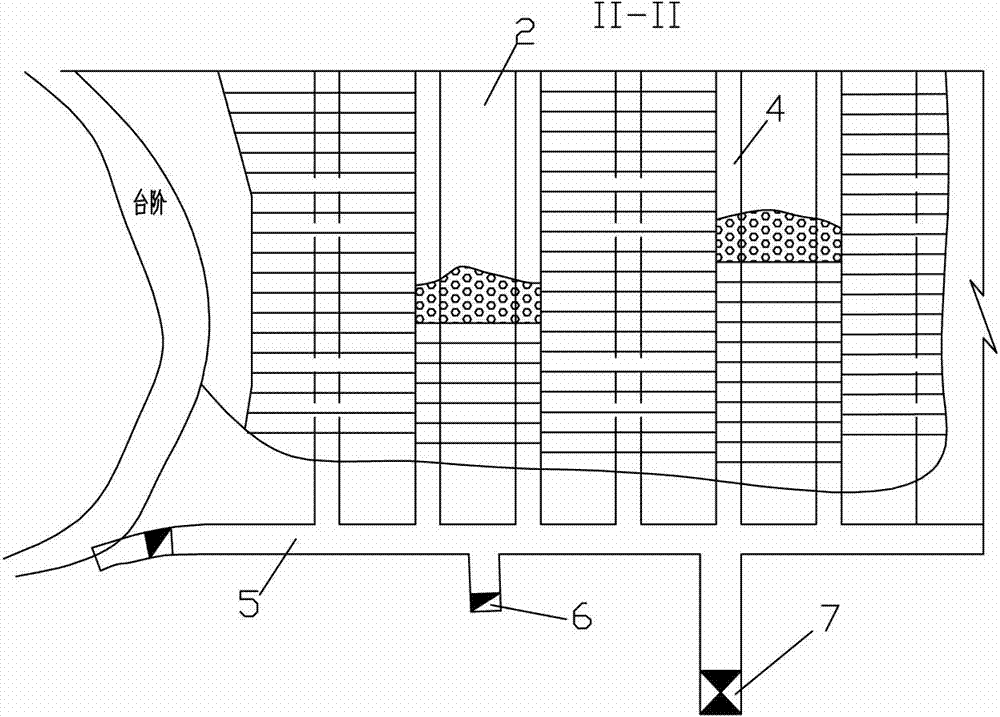

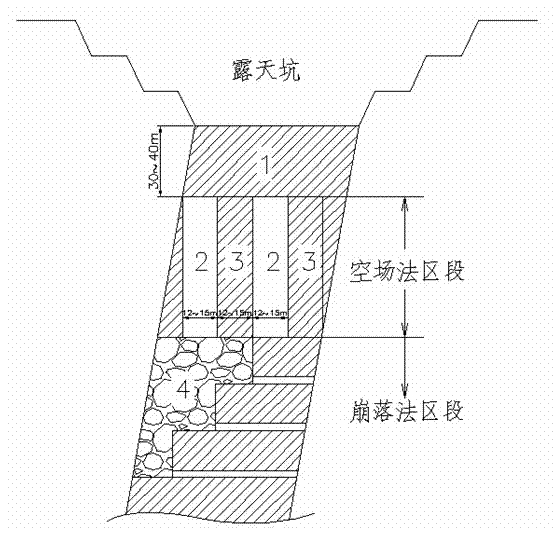

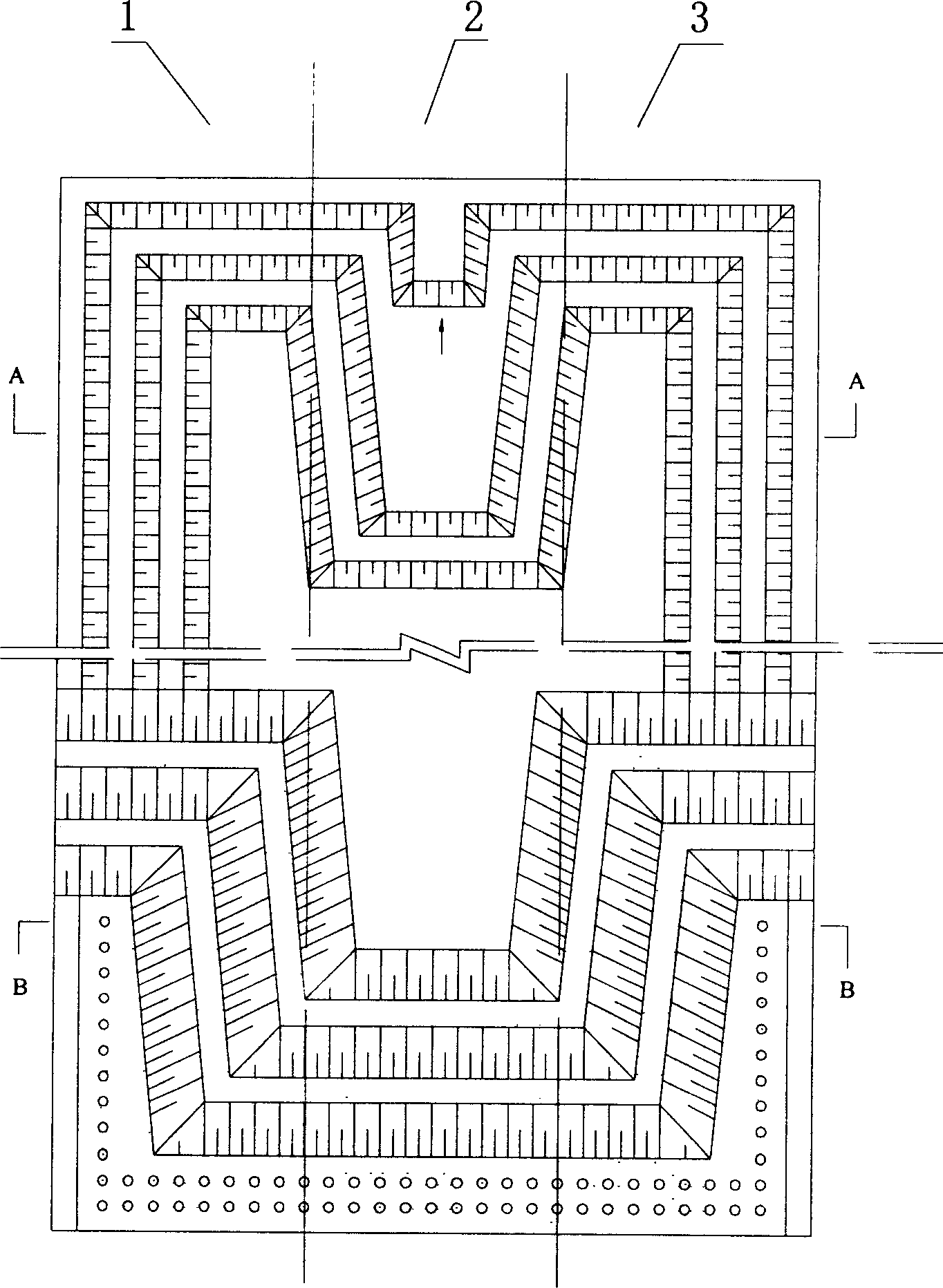

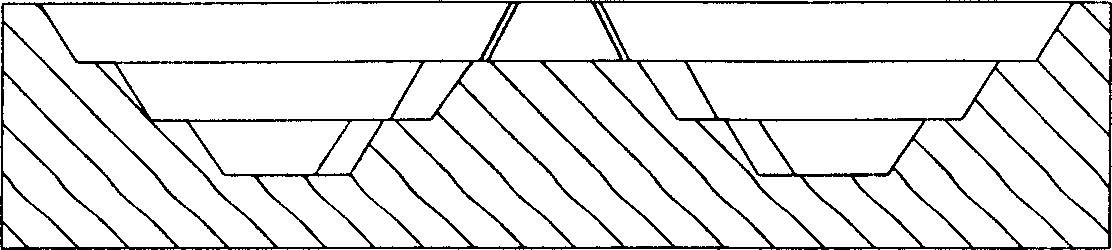

Drift-pillar-free sublevel barnyard caving mining method of open pit transferred underground transitional period

ActiveCN103089266ADecrease the sampling factorReduce the amount of quasi-engineeringUnderground miningBlastingOpen-pit miningRock cutting

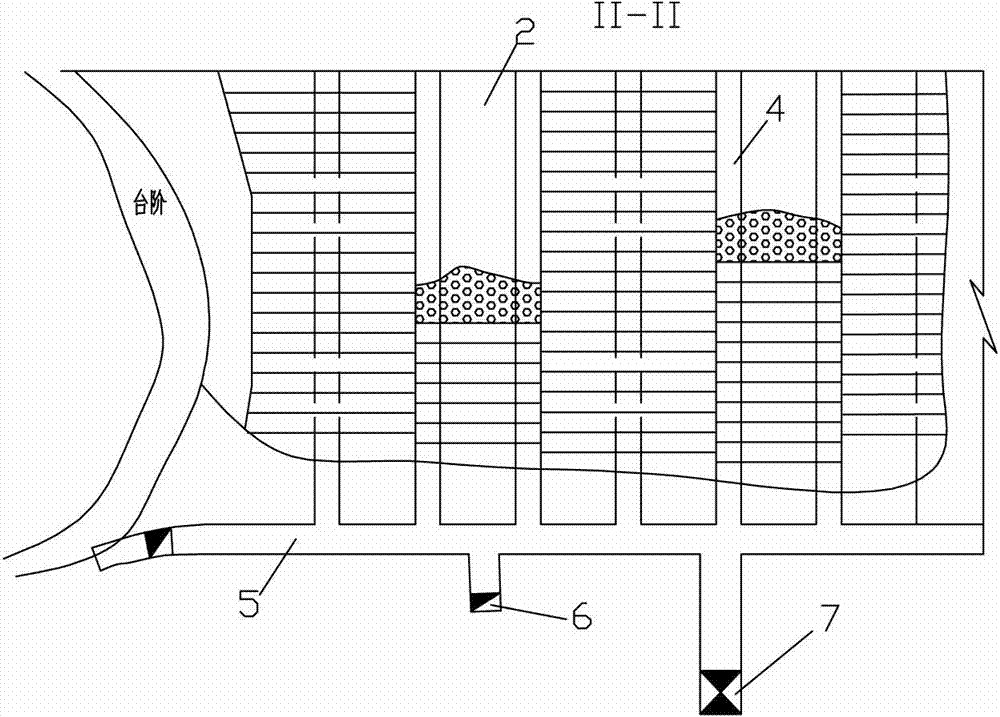

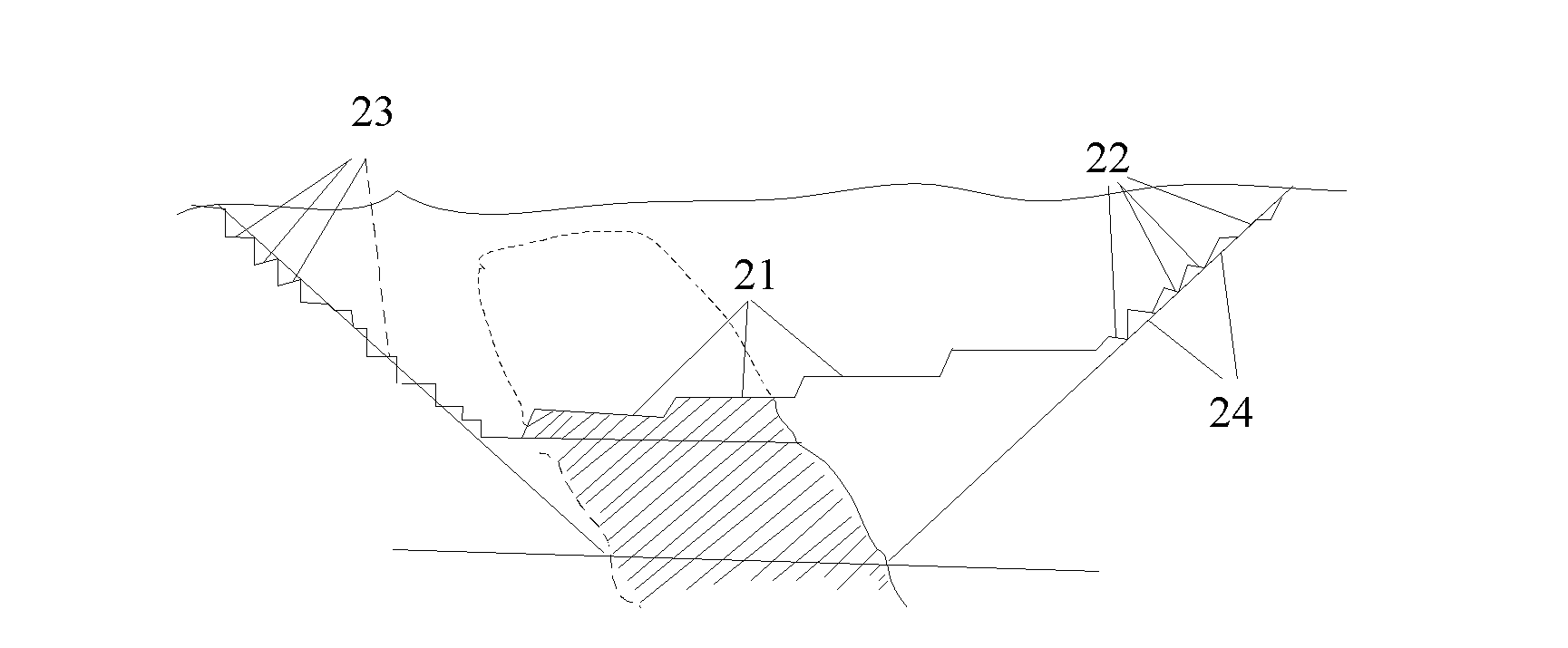

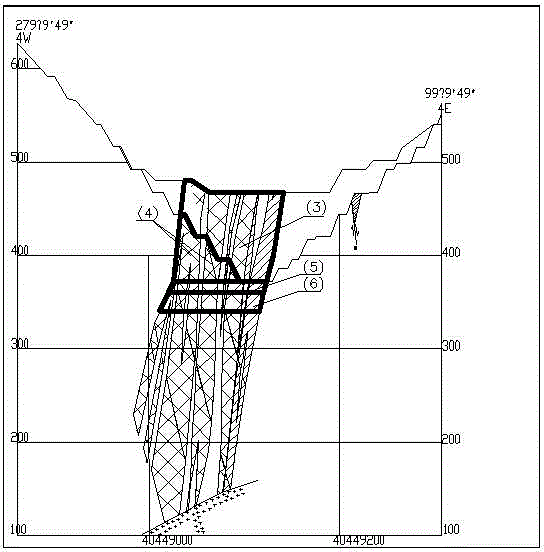

The invention relates to a drift-pillar-free sublevel barnyard caving mining method of an open pit transferred underground transitional period. The drift-pillar-free sublevel caving mining method comprises the following steps of: carrying out sublevel recovering; and finishing rock drilling, blasting and ore removing in a feeding path. The drift-pillar-free sublevel caving mining method is characterized in that at an open pit transferred underground recovering transitional period, open pit mining and underground hanging wall ore recovering are carried out at the same time; a barnyard method and a drift-pillar-free sublevel caving method are combined to recover hanging wall ore; when open pit ore is mined, a drift-pillar-free sublevel barnyard method is used for recovering a hanging wall ore sublevel feeding path; and after the open pit mining is finished, a drift-pillar-free sublevel caving method is used for carrying out large-scale blasting and ore removing on safety pillars, other sublevel ores and barnyard-method residual ores. The drift-pillar-free sublevel barnyard caving mining method disclosed by the invention has the advantages of effectively reducing accurate mining coefficient and saving economic cost. The accurate mining engineering amount is greatly reduced and the accurate mining invest is reduced at the same time; and the extracted ore amount and the production capability of unit accurate mining engineering are increased and the economic benefit is effectively improved.

Owner:ANSTEEL GRP MINING CO LTD

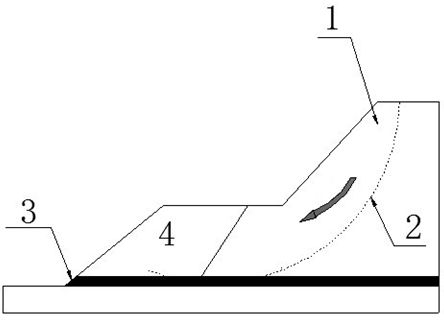

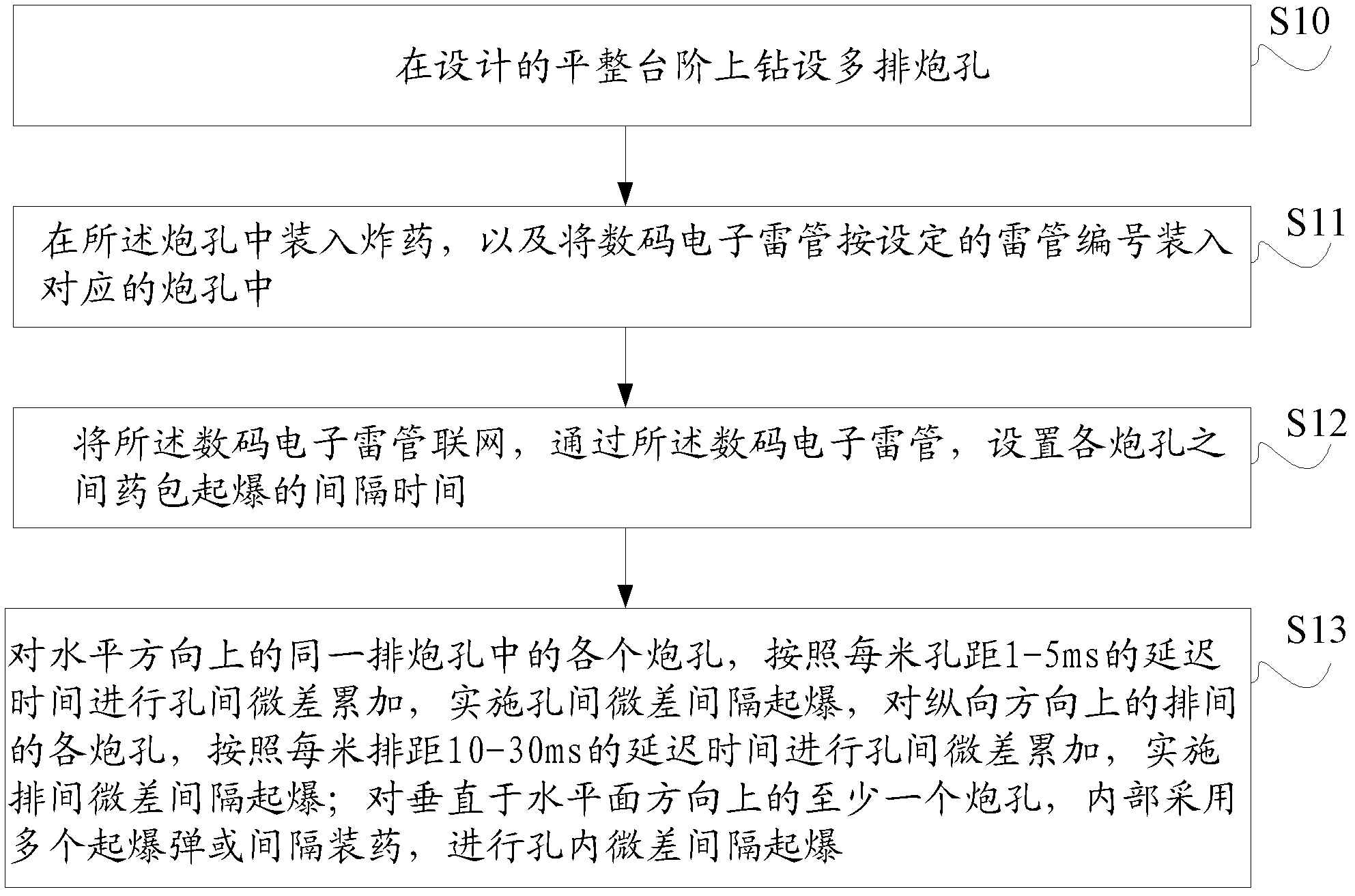

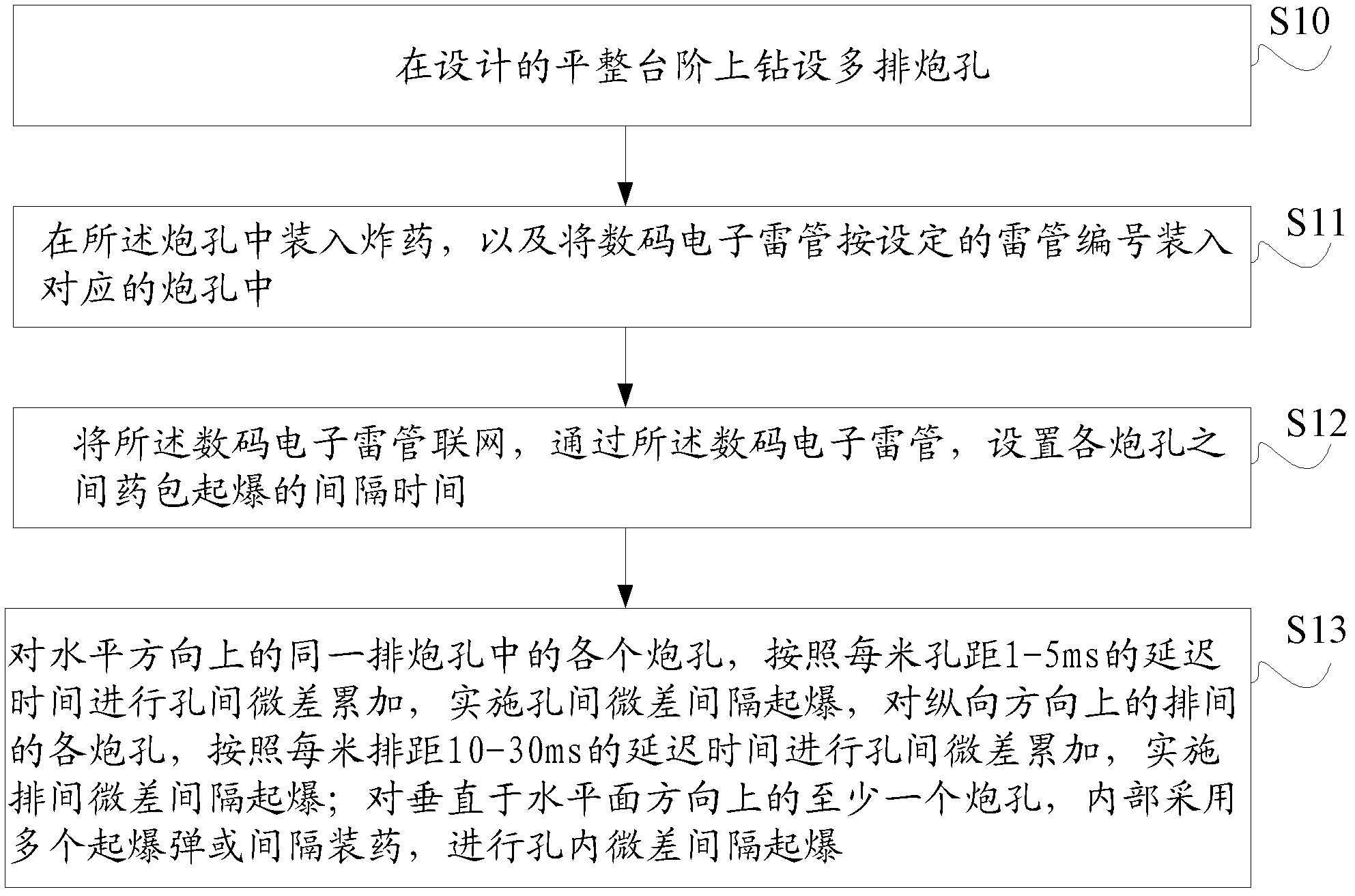

Stable-control blasting method for open-pit mine slopes

An embodiment of the invention discloses a stable-control blasting method for open-pit mine slopes, which relates to the technical field of exploitation of open-pit mines and is invented for solving the problem that damage of the slopes by blast vibration needs to be relieved so that the open-pit mine slopes can be highly stabilized. The method includes: quantity of priming explosive of a largest section in a blasting area close to an open-pit mine slope is limited; and delay time for open bench blast control rows of the blasting area close to the slope and blast holes corresponding to all the control rows are 1-4ms per hole-pitch meter, and delay time for rowed blast holes is 10-30ms per row-spacing meter. The stable-control blasting method is applicable to open-pit mining, and also applicable to hydropower engineering, excavation of large-sized underground workshop chambers, cutting engineering and the like, which need slope maintenance.

Owner:ZHUOLIWEI BEIJING TECH

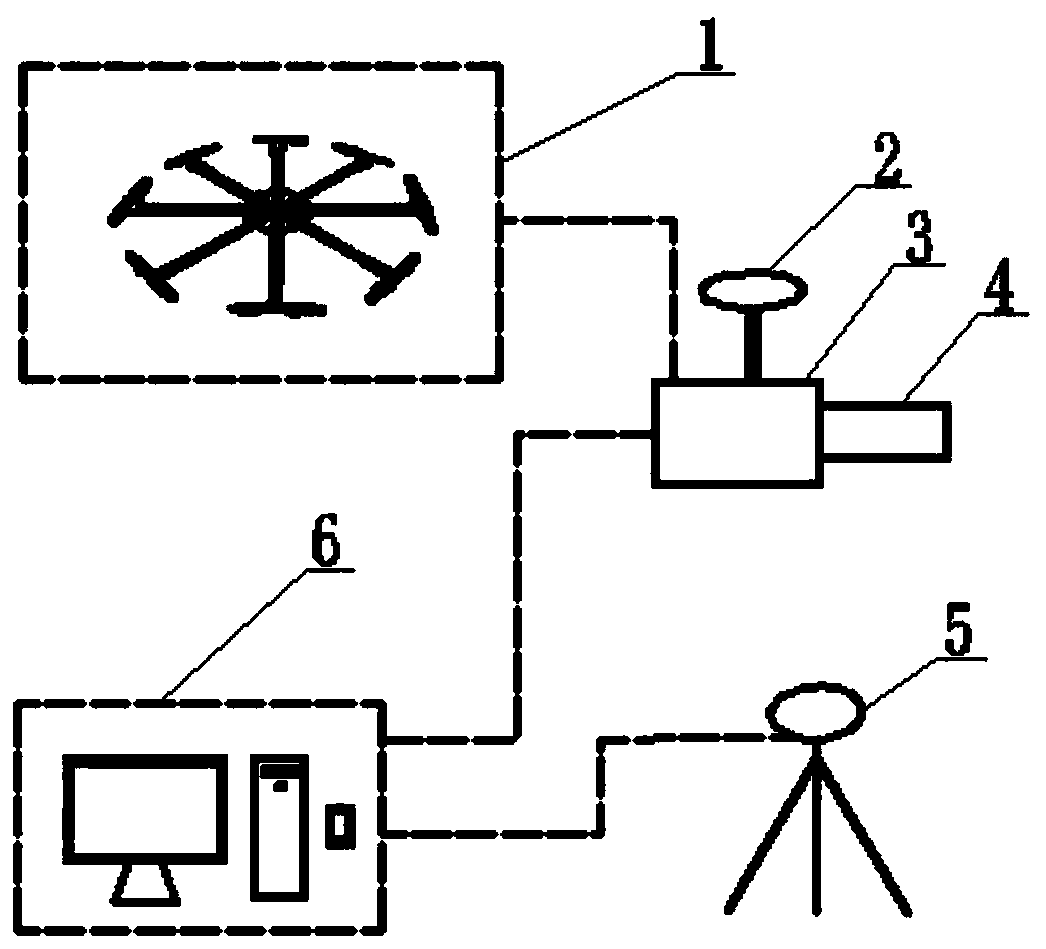

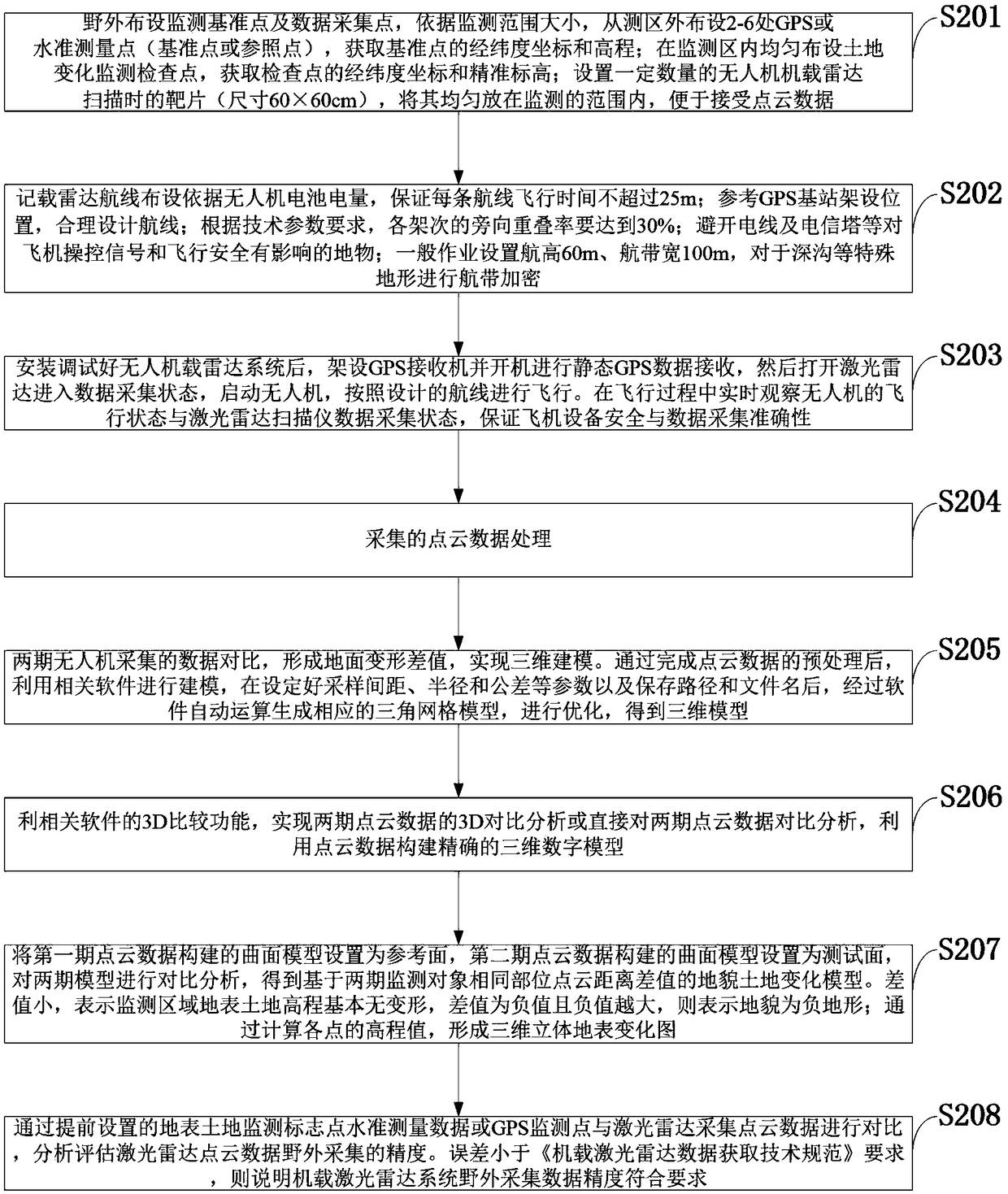

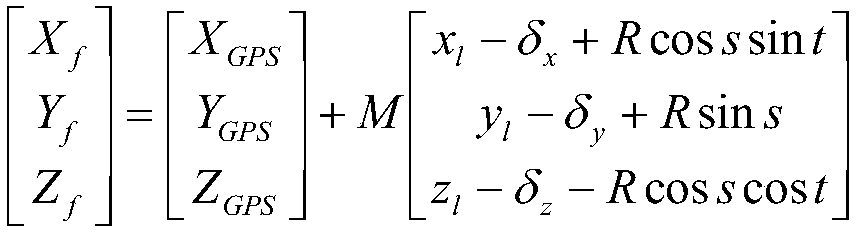

Unmanned aerial vehicle airborne radar mine mining land change monitoring system and method

PendingCN109143257ARealize monitoringScientifically master the law of deformationSatellite radio beaconingElectromagnetic wave reradiationTransceiverSlag

The invention belongs to the technical field of mine geological monitoring, and discloses a non-fixed wing unmanned aerial vehicle airborne radar mine mining land change monitoring system and method.The system comprises a non-fixed wing unmanned aerial vehicle for loading a lidar, a lidar GPS receiver, an inertial navigation system, a laser transceiver, a static GPS receiver and a control and a post-processing system, and comprises inertial navigation control software, LIDAR data acquisition software, trajectory calculation software, point cloud data calculation post-processing software and point cloud post-processing software. Through acquisition of two or more periods of point cloud data of the non-fixed wing unmanned aerial vehicle airborne radar, changes of mine surface geomorphological height differences in different time periods are formed, a new mine mining land area and elevation change monitoring technology is provided, surface elevation changes such as a mine open mining pit, a slag disposing area and mining subsidence are grasped, and scientific basis is provided for mine geological environment control, land reclamation and development, use and planning.

Owner:XIAN CENT OF GEOLOGICAL SURVEY CGS +1

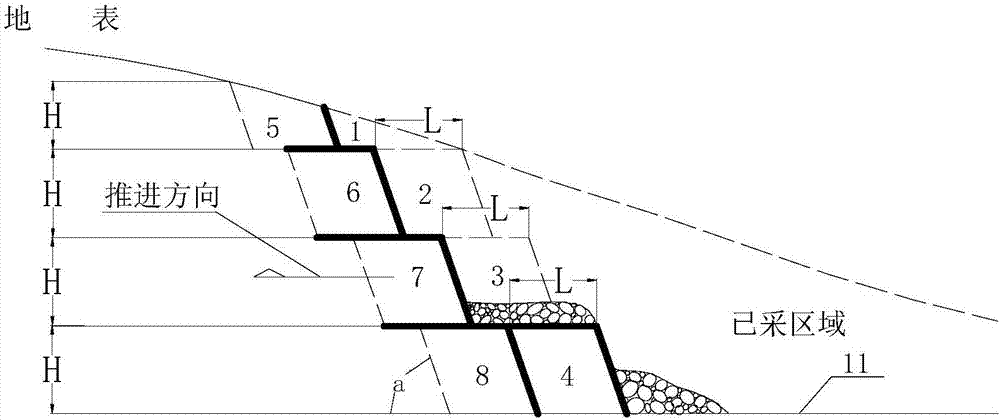

Opencast mine end slope near-slope mining method

ActiveCN103133003AReduce stripping ratioLow application costOpen-pit miningSlope stabilityOpen-pit mining

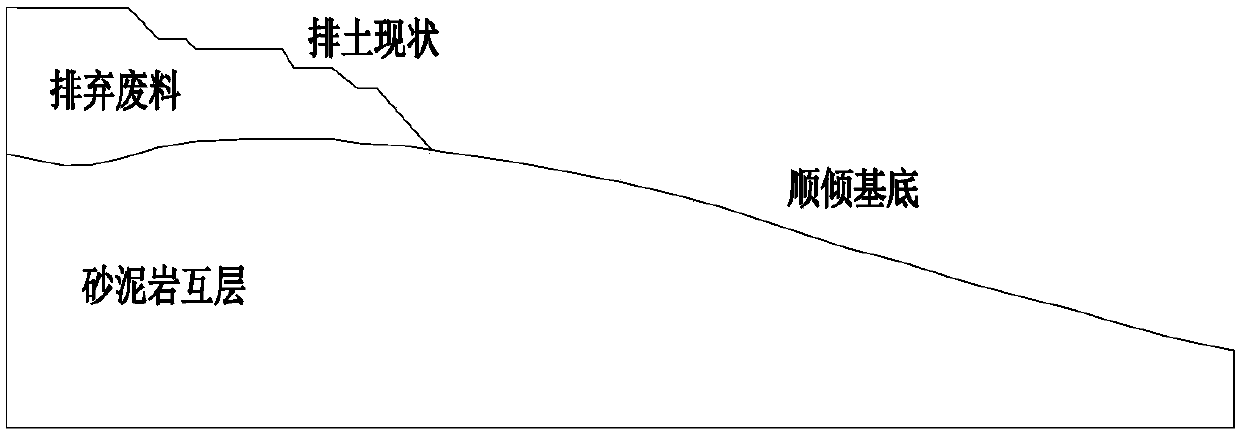

The invention discloses an opencast mine end slope near-slope mining method. During an opencast mining process, for integral side slopes of end slopes on two horizontal sides of a mining field, near-border mining is carried out according to a stable angle alpha as in an initial design; according to a timeliness slope principle, inner dump is followed up in time; a pit bottom distance is shortened to a minimal safety distance Dmin required by mining, and integral height H of the side slope of the end slope is reduced; according to a side slope stable condition, the side slope angle is increased to beta; and near-slope mining is realized. The height of inner dump bottom layer slope-pressing step is 2-3 times that of mining working slope step. Stripped soil and rock are transported to the inner dump bottom layer slope-pressing step through a built soil-discharge bridge. With the method provided by the invention, side slope angle can be increased on a basis that slope end stability is ensured. Therefore, end slope residual coal can be recovered; stripping ratio can be reduced; and transportation cost can be reduced.

Owner:CHINA UNIV OF MINING & TECH

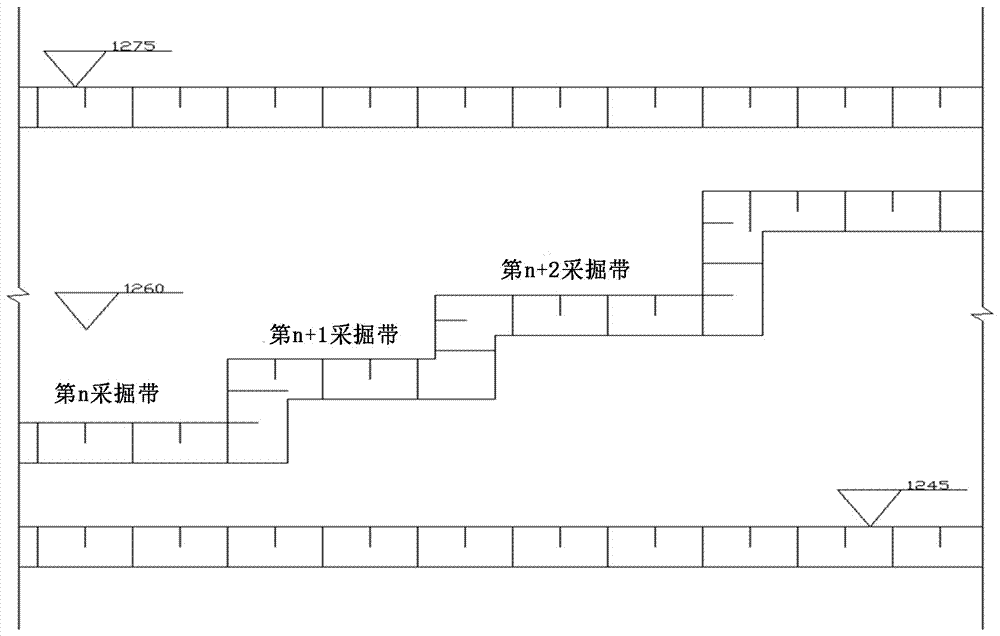

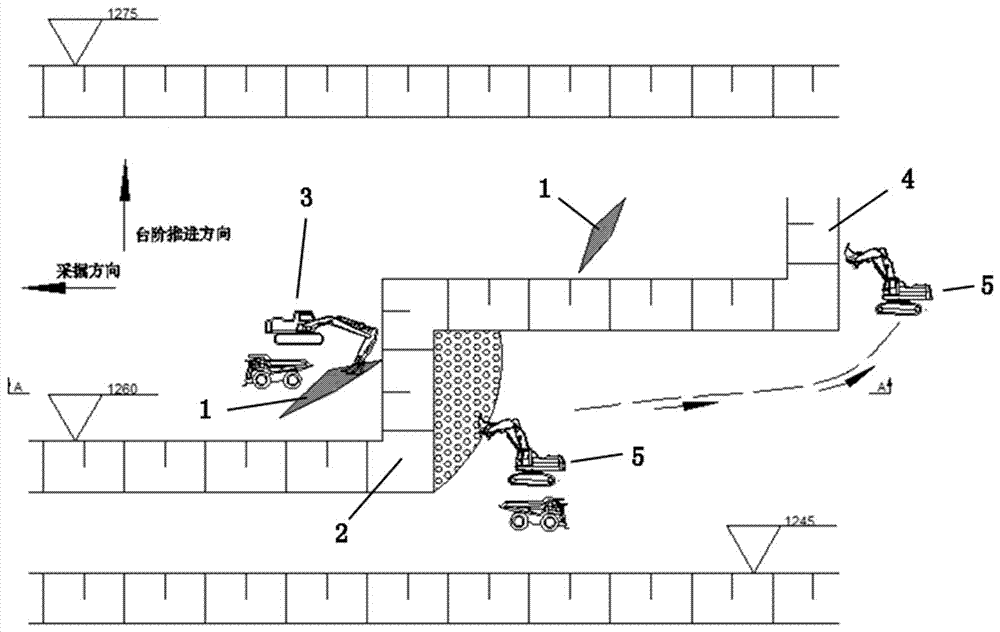

Mining method of nearly horizontal mineral deposit of opencast coal field by casting and internally dumping

InactiveCN103470262AReduce effluxShort distanceUnderground miningSurface miningOpen-pit miningCoal field

The invention relates to a mining method of a nearly horizontal mineral deposit of an opencast coal field by casting and internally dumping and belongs to the mining method of the opencast coal field. The mining method comprises the following steps: (1) dividing a strip mine into a plurality of mining regions, mining overburdened materials of a first strip region, and stacking the overburdened materials outside an opencast mining limit; (2) dividing an overburdening table into one or more tables to be mined; (3) discharging the overburdened materials of a second strip region into a worked-out section of the first strip region after a mineral deposit exposed in the first strip region is mined, and transporting mined mineral products out of a mining field through entering-exiting channel transporting passages arranged on two sides of a channel or the middles of the strip regions. The mining method has the advantages that as the overburdened materials can be discharged and abandoned in the worked-out section, the occupied land of an externally-dumped soil site can be saved; the mining method is environment-friendly and is capable of restoring the land influenced by the mining operation during mining; abandoned and unserviceable lands in barren and mountainous mines can be changed into usable lands.

Owner:CHINA UNIV OF MINING & TECH

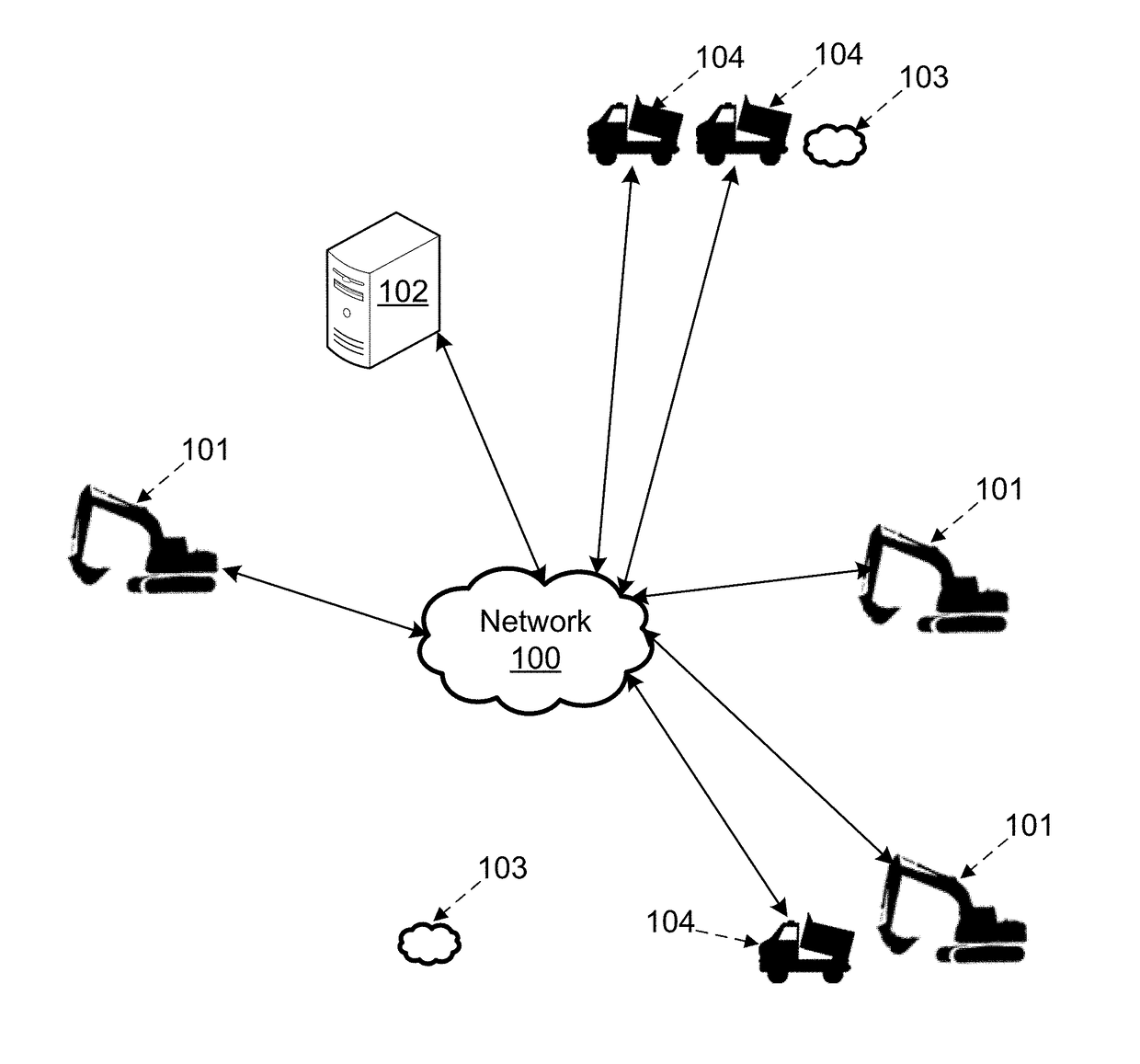

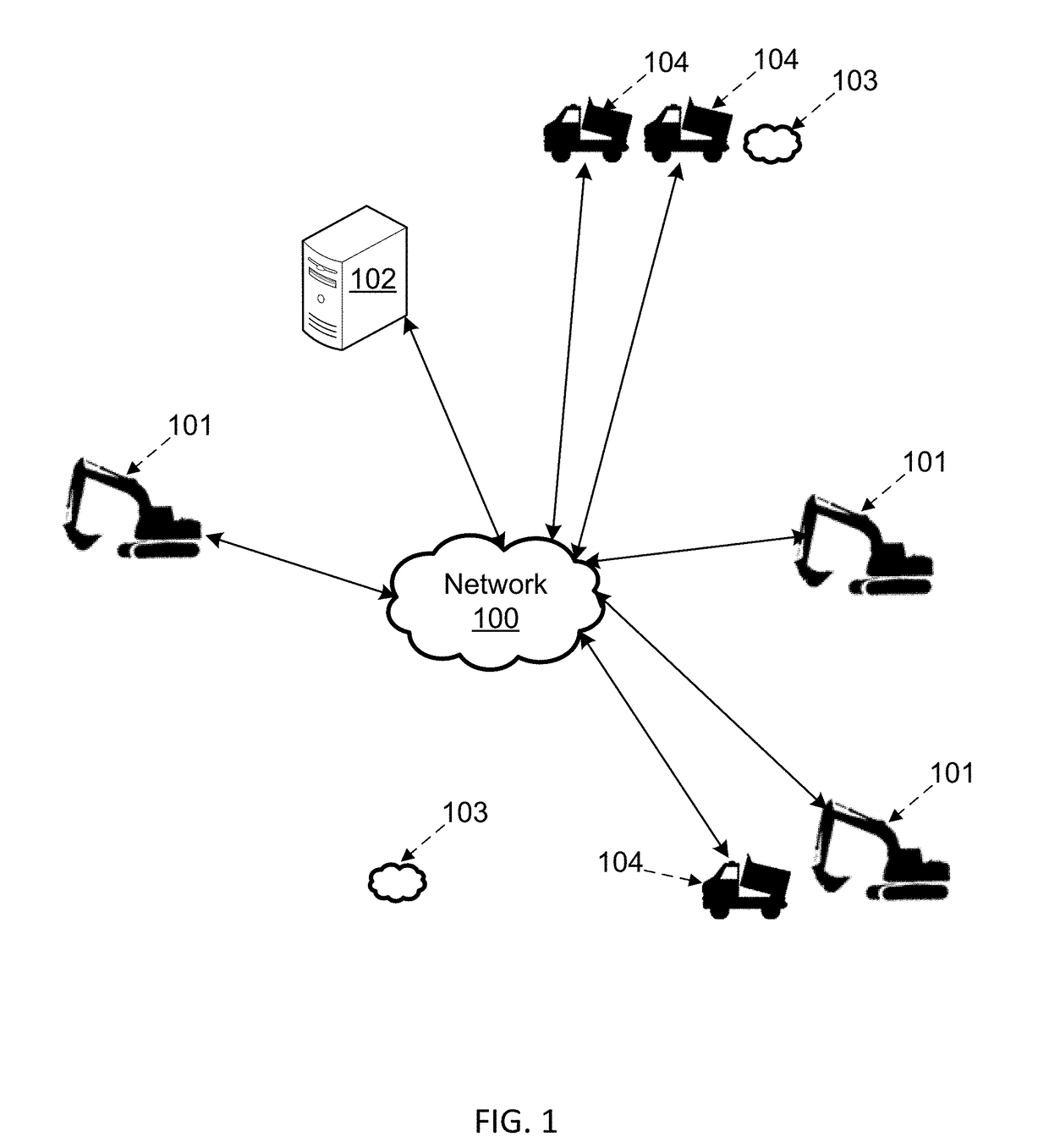

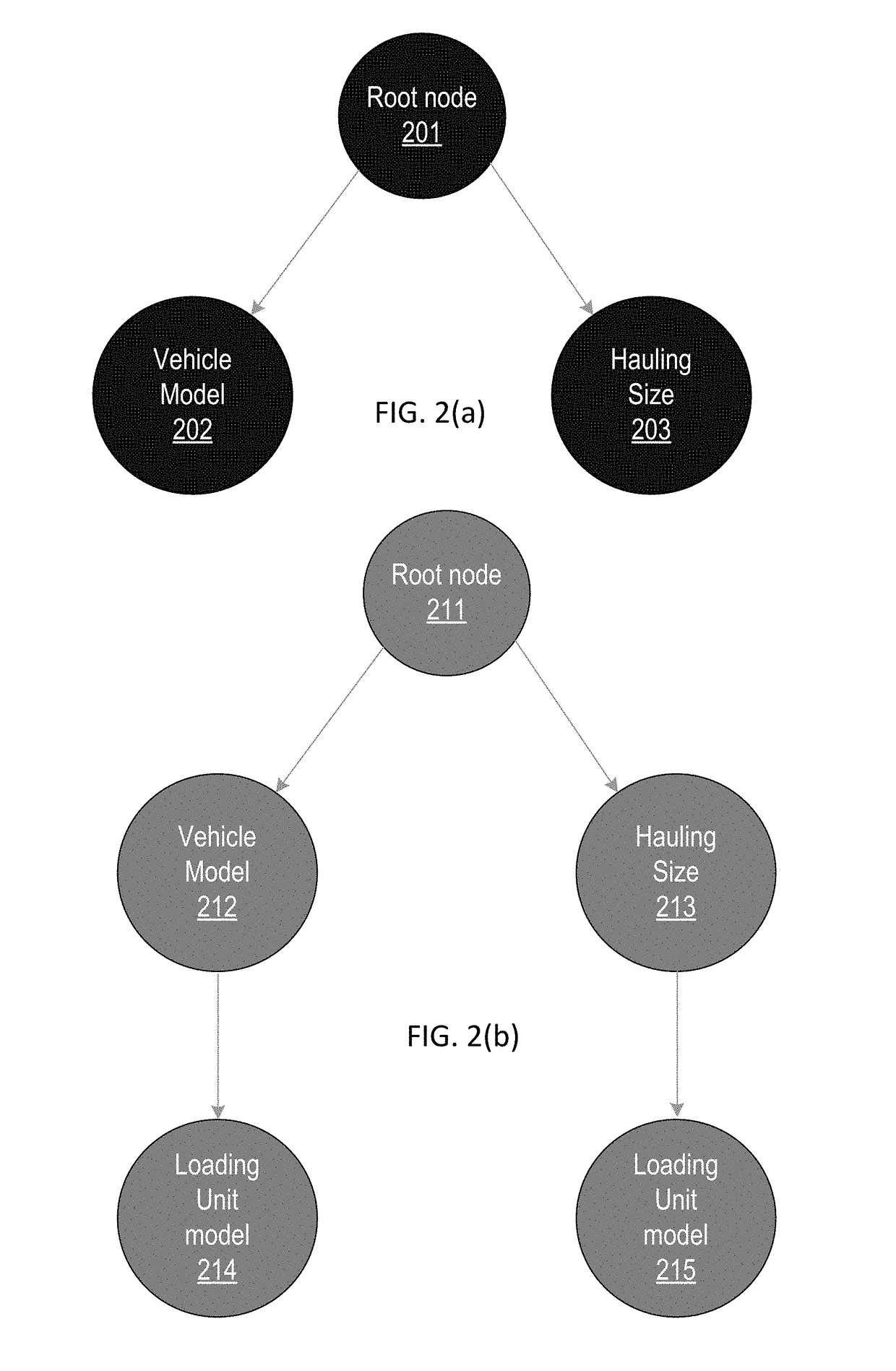

Online hierarchical ensemble of learners for activity time prediction in open pit mining

InactiveUS20180247207A1Low production costReduction in NPTEnsemble learningRegistering/indicating working of vehiclesOpen-pit miningActivity time

Example implementations described herein are directed to vehicle scheduling and management, and in particular for estimation of travel times and other activity times. Example implementations can be used to achieve improved vehicle scheduling and utilization based on the provision of accurate expected activity times. Example implementations are further directed to the integration of predictors to provide an estimation of activity time.

Owner:HITACHI LTD

Method for recovering coal in easily sliding area of strip mine

InactiveCN102606160AReduce stripping ratioLow costUnderground miningSurface miningOpen-pit miningSlope angle

The invention discloses a method for recovering coal in an easily sliding area of strip mine, which is most suitable for recovering coal in a slope of the easily sliding area with a remarkable sliding surface. In a process of strip mining, the sliding surface is existent inside the slope of the easily sliding area; and when the coal in the easily sliding area are mined, the lower part of the sliding surface is located in the mining range. For preventing the exposed length of the sliding surface from being too long, the slope of the easily sliding area is divided into a plurality of mining strips for mining according to the trend, and the width of the mining strip is 2 times the working radius of a used electric shovel. The method comprises the steps of firstly mining the first mining strip, which is perpendicular to the trend of the slope or is pushed in the trend of the slope; timely following by an internal waste dump; after mining the previous mining strip, continuously mining the next mining strip; covering the exposed surface of the previous mining strip after reaching the boundary by the internal waste dump in sequence; and running in cycle until all the mining strips are mined. The method can be used for reducing the exposed length of the sliding surface of the easily sliding area, guaranteeing the slope to be stable, increasing the slope angle, recovering the coal and lowering the stripping ratio.

Owner:CHINA UNIV OF MINING & TECH

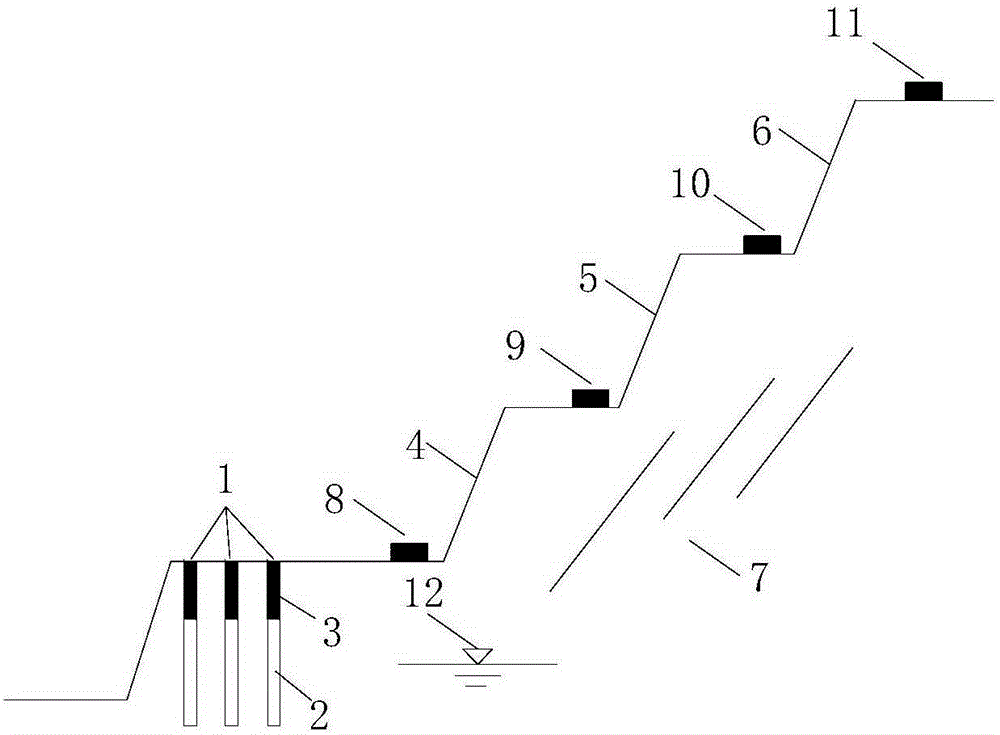

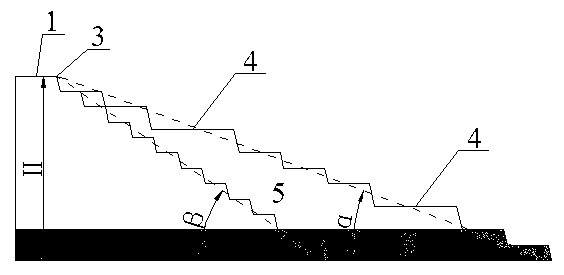

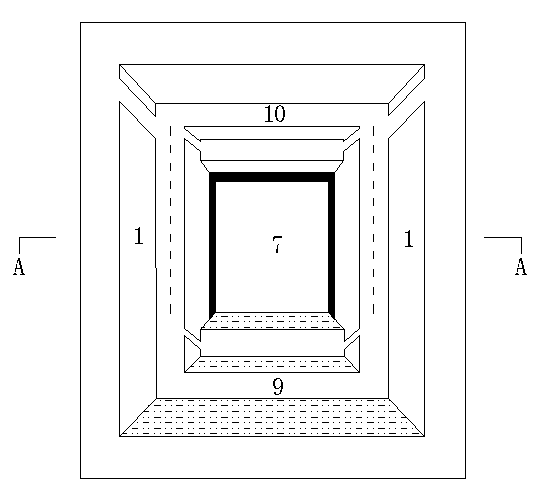

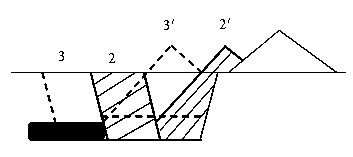

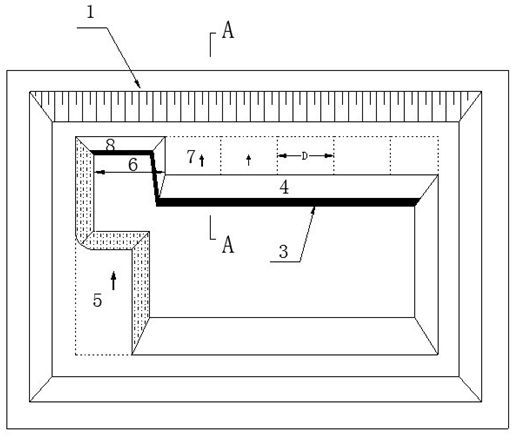

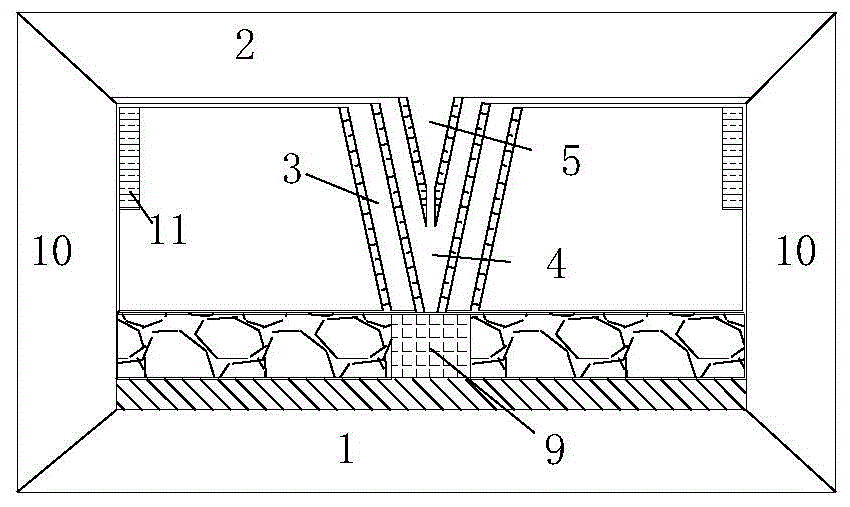

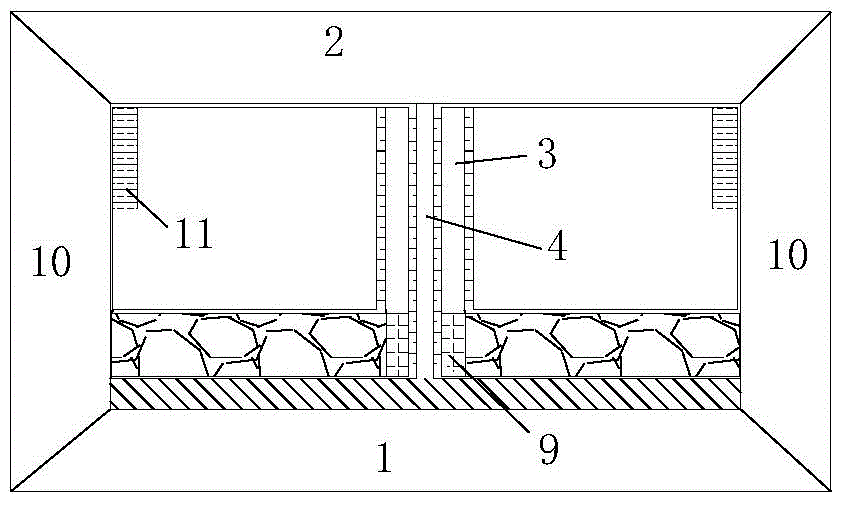

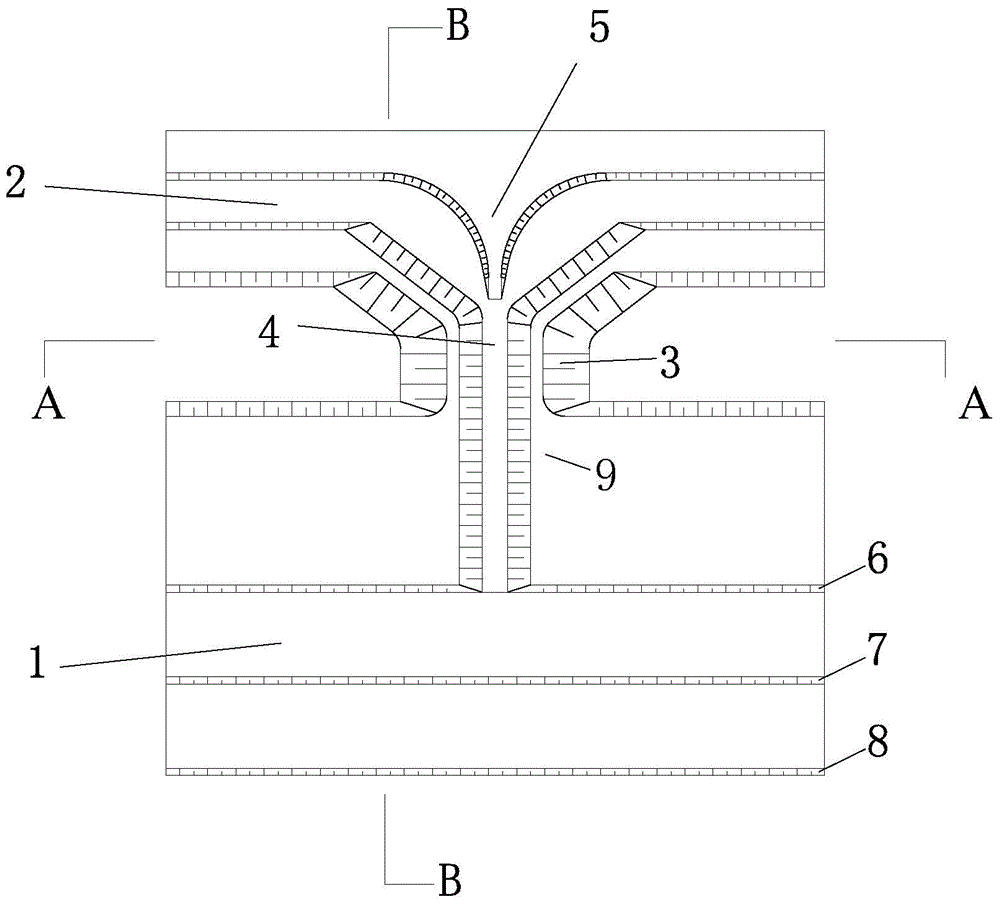

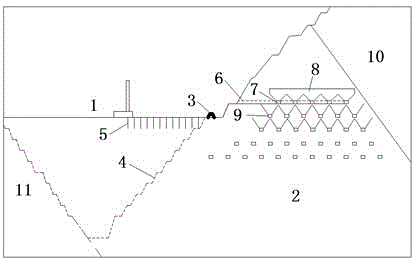

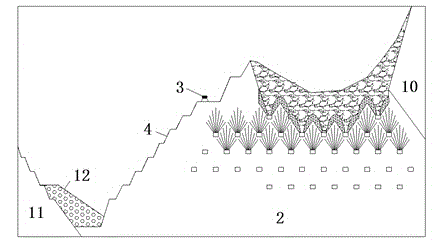

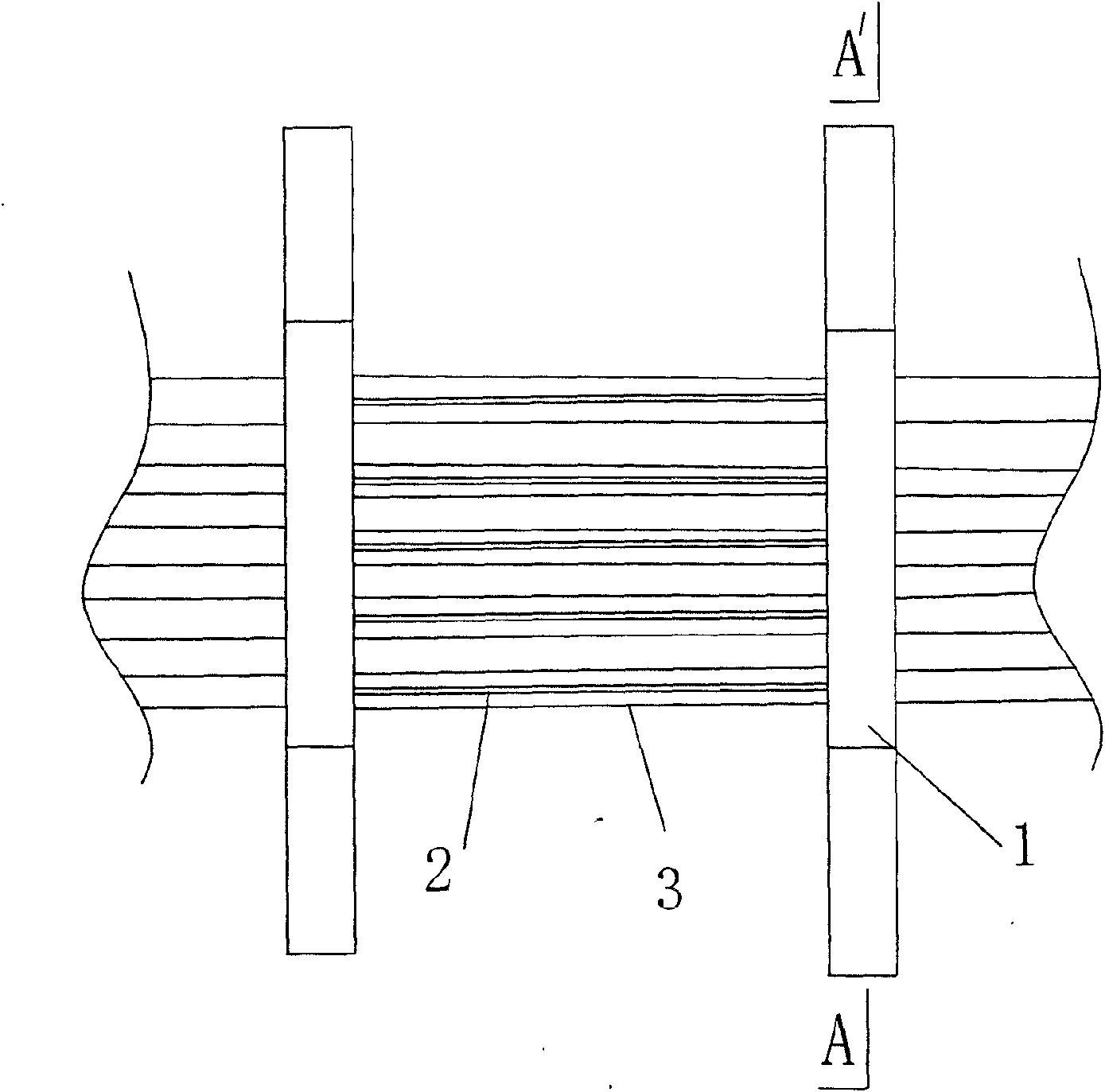

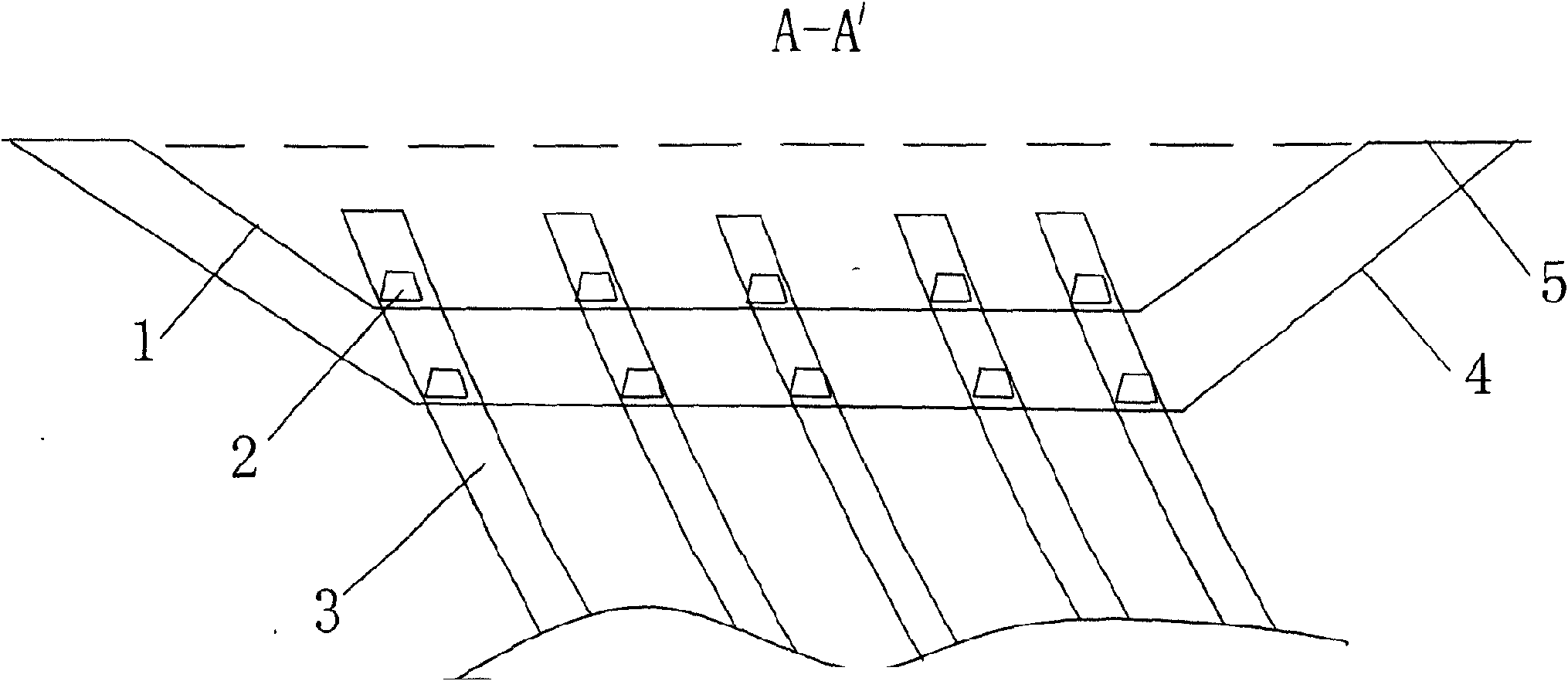

Jamb recovery and cushion layer formation integrated technology in process of mining from outdoors into underground

ActiveCN103114855AImprove securityReduce depletion rateUnderground miningSurface miningOpen-pit miningCushion

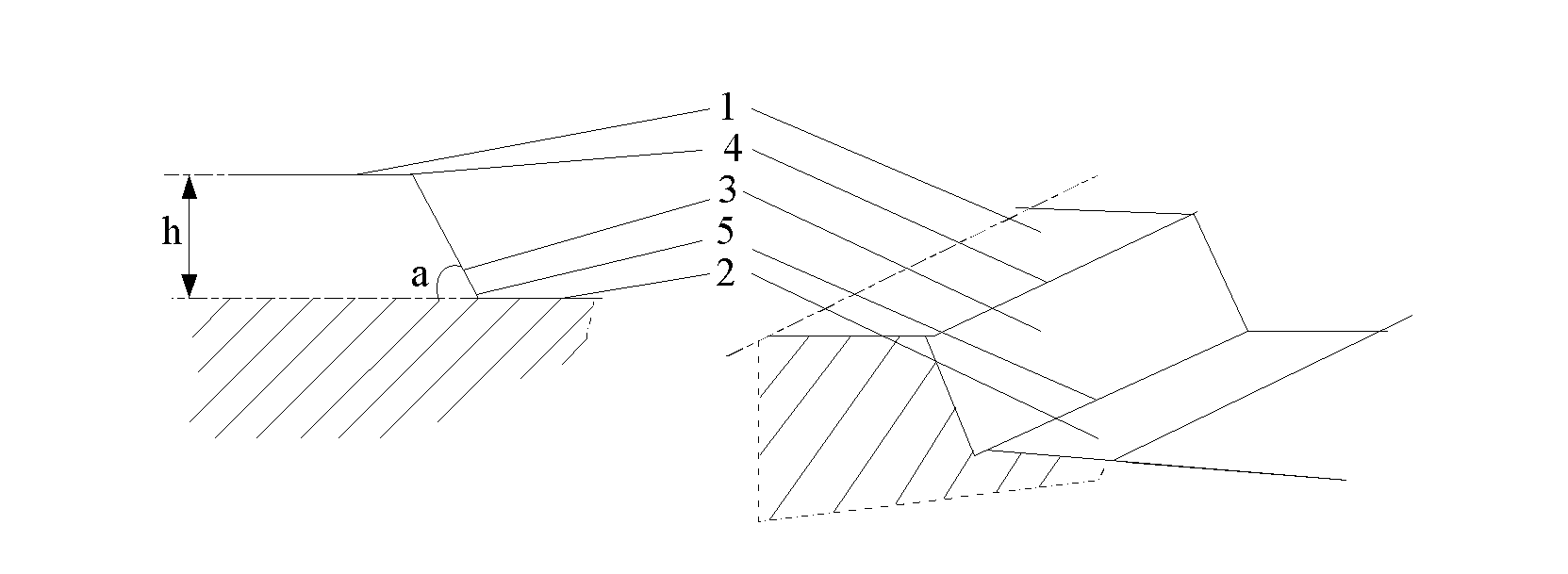

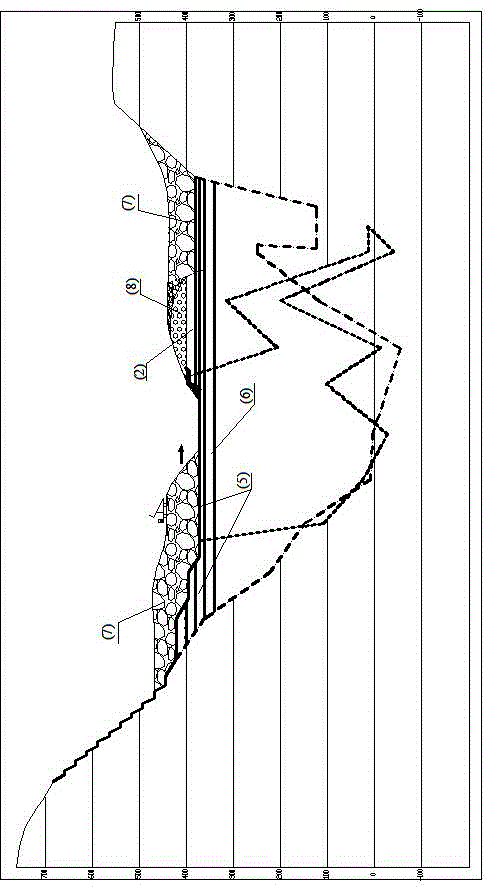

The invention discloses a jamb recovery and cushion layer formation integrated technology in the process of mining from outdoors into underground. The technology comprises the following steps of: in the later stage of opencast mining, reserving a boundary pillar (1) at the bottom of an open pit, and carrying out underground mining on a first middle section in the process of underground mining by a large-parameter studding open-stope method; when the opencast mining and the open-stope method zone mining are ended, distributing blasted holes in the boundary pillar (1), distributing blasted holes in a jamb (3), charging powder at the same time and detonating in a segmented way, firstly detonating the blasted holes in the jamb (3), detonating the blasted holes in the boundary pillar (1) at the bottom of the open pit, and enabling fallen ores formed in a detonating way to form a cushion layer (4); and mining at a later-medium section in the process of underground mining by a caving method, and recovering the cores of the cushion layer (4) in the process of mining at a zone adopting a caving method. According to the technology, the open work and the underground work are carried out at the same time, the transition is stable, the safety in the process of open mining and underground mining can be improved, a mass of ores are recovered, a covering cushion layer for mining adopting the caving method can be solved, and the dilution ratio caused by the caving method can be greatly reduced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

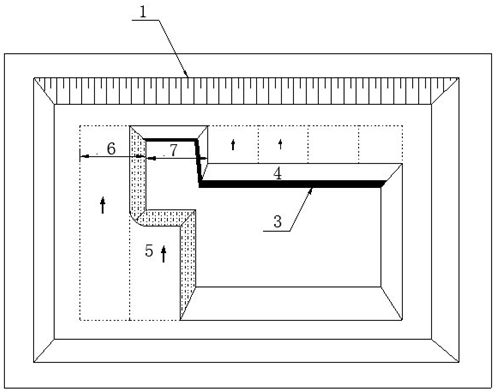

Open pit and underground space-time synchronous mining method for multiple-ore body

ActiveCN103590830ASafe miningGuaranteed thicknessUnderground miningSurface miningOpen-pit miningTime space

The invention discloses an open pit and underground space-time synchronous mining method for a multiple-ore body. According to the technical scheme, the method comprises the following steps: marking the demarcation line of the ore bodies at the shallow and deep positions so as to divide the multiple-ore body into a shallow-position ore body and a deep-position ore body according to an economical and reasonable stripping ratio; delineating the demarcation line of an open-pit mining protection zone according to a moveable angle (7) determined by underground mining by taking the largest demarcation ring of the open-pit mining as a protection line, wherein the deep-position ore body in the protection zone is a filling-process mining zone section (9) and the deep-position ore body outside the protection zone is a caving-process mining zone section (10); filling the waste stone stripped in open pit back to a waste stone back filled region (14) in a rubber belt conveying manner and carrying out cemented filling on the dead zone of the filling-process mining zone section (9) with tailings so as to form a tailings cemented filling region (11). According to the method, the technological characteristics of different mining manners such as open-pit mining, filling-process milling and caving-process mining are organically combined, so that the open-pit, underground space-time synchronous, environment-friendly and efficient mining of the multiple-ore body can be realized.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

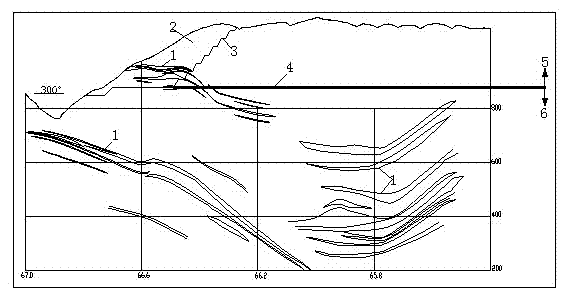

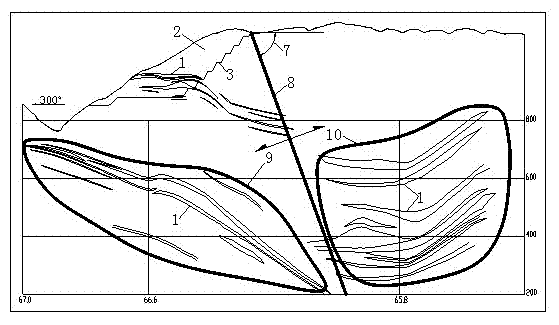

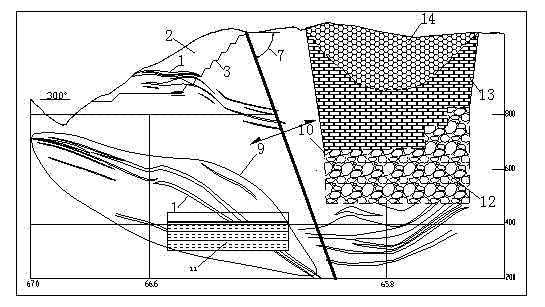

Mining method for recycling long-thick ore body hanging wall ore and transforming strip mine to underground mine

InactiveCN104314570AFormed in timeControl particle compositionUnderground miningSurface miningOpen-pit miningMineral Sources

The invention relates to a mining technique for recycling hanging wall ore body and transforming a strip mine to an underground mine, in particular to a mining method for recycling long-thick ore body hanging wall ore and transforming the strip mine to the underground mine. The method comprises the following steps: dividing the hanging wall ore on the other end of a mining pit into a transitional-period underground mining area, a transitional-period strip mining area and an isolation ore pillar at the later period of the strip mining; simultaneously mining the ore in the transitional-period strip mining area and the transitional-period underground mining area, and backstoping an upper side of hanging wall ore after being disclosed by adopting a open-stope method; and sequentially forming a cover layer along the trend of the ore body from the end of the pit without the hanging wall ore by utilizing a method for backfilling a dead zone with waste stone, breaking the ore pillar reserved when the upper side of hanging wall ore is mined in the area with the cover layer reaching the thickness requirement after the backstoping of the upper side of hanging wall ore is ended by adopting the fragmental open-stope method, improving the mining intensity after the cover layer is formed, and gradually carrying out the mining, cut and backstoping work of a second section of deep ore. By adopting the method, the transition from the strip mining to the underground mining is realized, the reserved hanging wall ore reserved in the strip mining can be recycled, and the waste of mineral resource can be avoided.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Experimental device and method for flowing water sand carrying under effect of simulated seepage-vibration

PendingCN106768840AExperimental conditions close toAchieve recyclingHydrodynamic testingPermeability/surface area analysisOpen-pit miningMechanism of action

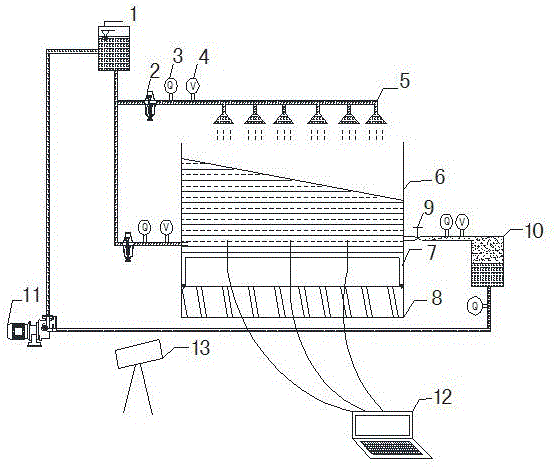

The invention belongs to the technical field of open pit mining of a coal mine, and particularly relates to an experimental device and method for flowing water sand carrying under the effect of simulated seepage-vibration. A flowing water sand carrying process in a water-containing sand bed under the water injection conditions of change of groundwater level, rainfall penetration and the like under the effects of high water head difference and vibration is simulated in a laboratory, related anisotropic flowing water sand carrying parameters and a saturation line distribution law under different water injection conditions are acquired, inner structural features in the sand bed and a dynamic evolution and water-sand two-phase flow integral migration trend of a seepage path are observed, and therefore, mutual relations and mechanisms of action of the inner structural features of the water-containing sand bed, flowing water sand carrying parameters and a water-sand two-phase flow migration law in a hole are disclosed.

Owner:SHENYANG UNIV

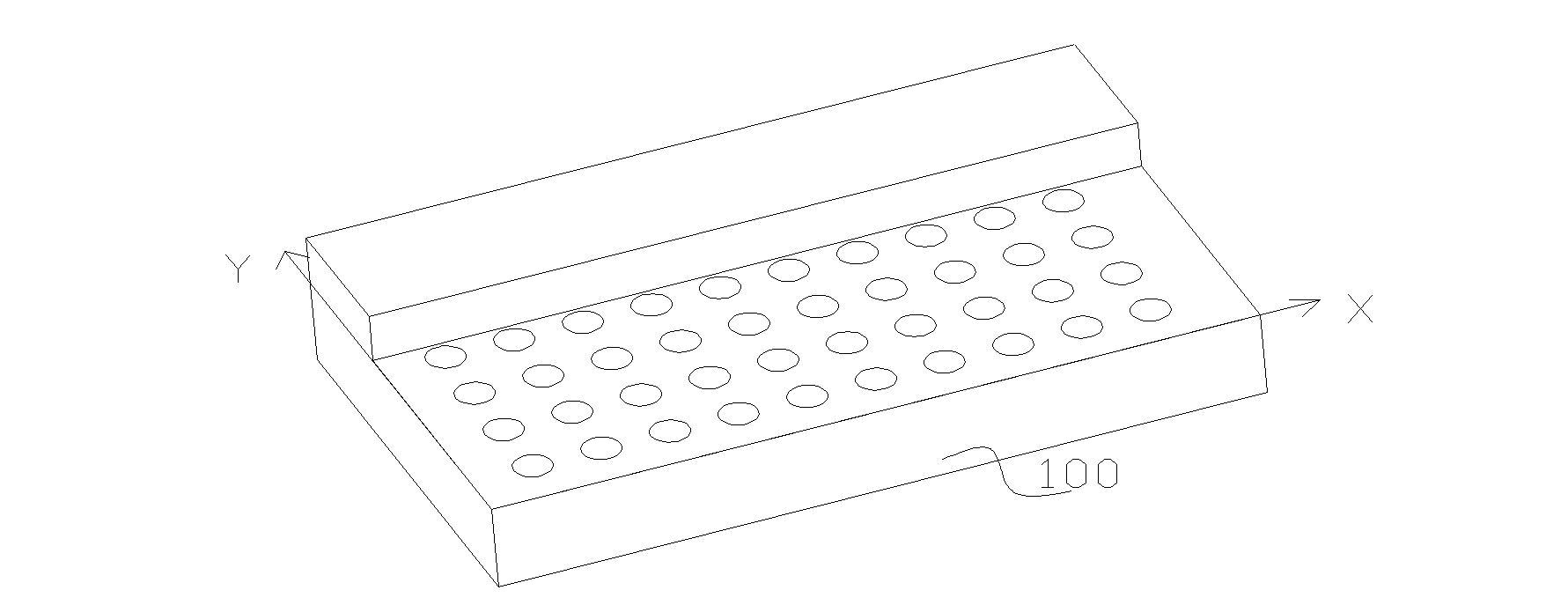

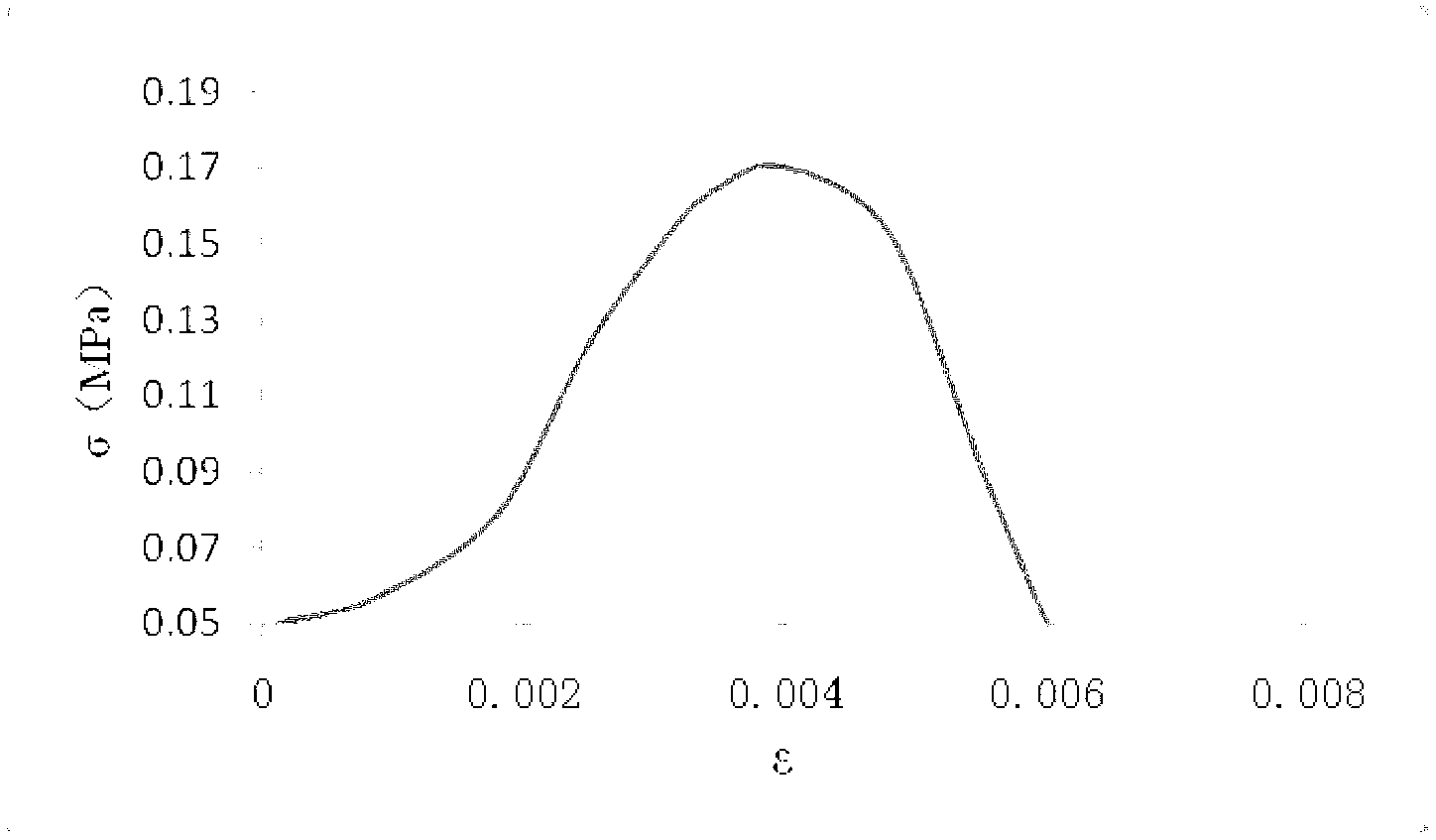

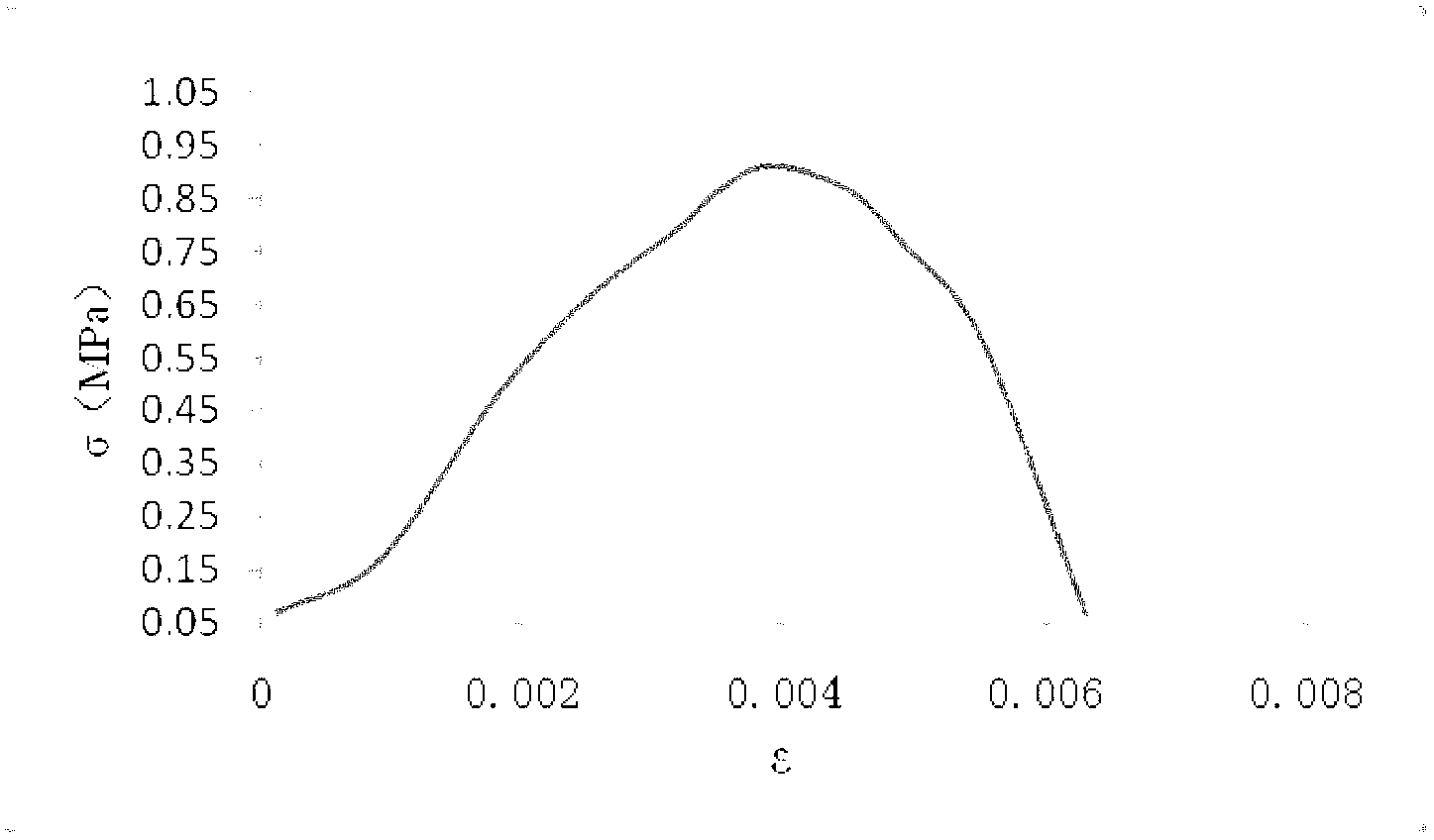

Ore rock similar material for model test for transferring open pit mining into underground mining

InactiveCN102701696AEffective simulationEffective simulation of self-gravity stress fieldGypsumOpen-pit mining

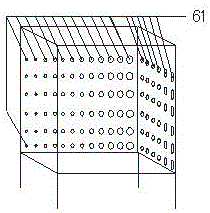

The invention provides an ore rock similar material for a model test for transferring open pit mining into underground mining. The ore rock similar material at least comprises an ore body and upper and lower bottom wall surrounding rock body similar material and a fault simulation material, wherein the ore body and upper and lower bottom wall surrounding rock body similar material is formed by mixing and curing main aggregate, a cementing agent and additive; the main aggregate comprises barite powder and quartz sand and one of iron ore powder and reduced iron powder; the cementing agent is unsaturation resin and gypsum; the additive at least comprises glycerol and water; and the fault simulation material is a polypropylene film and is adhered to the ore body and upper and lower bottom wall surrounding rock body similar material. According to the similar material, the defects in the prior art are overcome; the ore rock similar material is low in preparation cost, stable in performance,easy to prepare, and short in curing period; the raw materials are wide in source and low in price and does not have any toxic or side effect; and scientific basis is provided for research on the relative scientific technology for realizing safe working of a mode of transferring open pit mining into underground mining.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

A high-efficiency, safe and environmentally-friendly mining method for irregular strip-shaped distribution of poor and shallow buried seams

InactiveCN102278115AIncrease production capacityEasy to manageMaterial fill-upOpen-pit miningEcological environmentLand resources

The invention discloses a high-efficiency, safe and environment-friendly mining method for irregular strip-shaped thin and shallow buried mine seams. The mining method adopts the method of arranging mining pits along the direction of the mine seam, and Stripping and mining by step-by-step open-air step blasting in sequence, drilling, blasting and transportation are arranged in steps. The drilling, blasting, and transportation operations have high production efficiency and are safer than other mining methods. The stripped waste rock is backfilled to the first mining area. The mined-out area of the section saves land resources, protects the natural environment, saves transportation costs, reduces comprehensive mining costs, reduces energy consumption, and reduces waste rock discharge. The invention solves the problems of backward mining planning, low production efficiency, unsafe production, valuable land occupied by dumps, environmental pollution by dumps, high transportation energy consumption, high mining costs and living environment caused by mining in traditional open-pit mining projects. and environmental pollution and other technical issues.

Owner:汉通控股集团有限公司

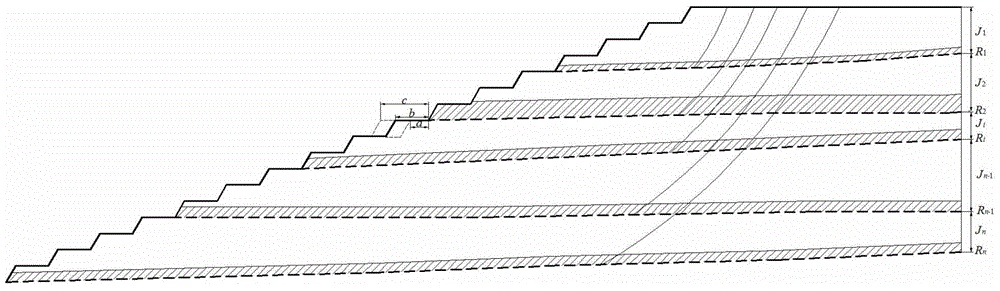

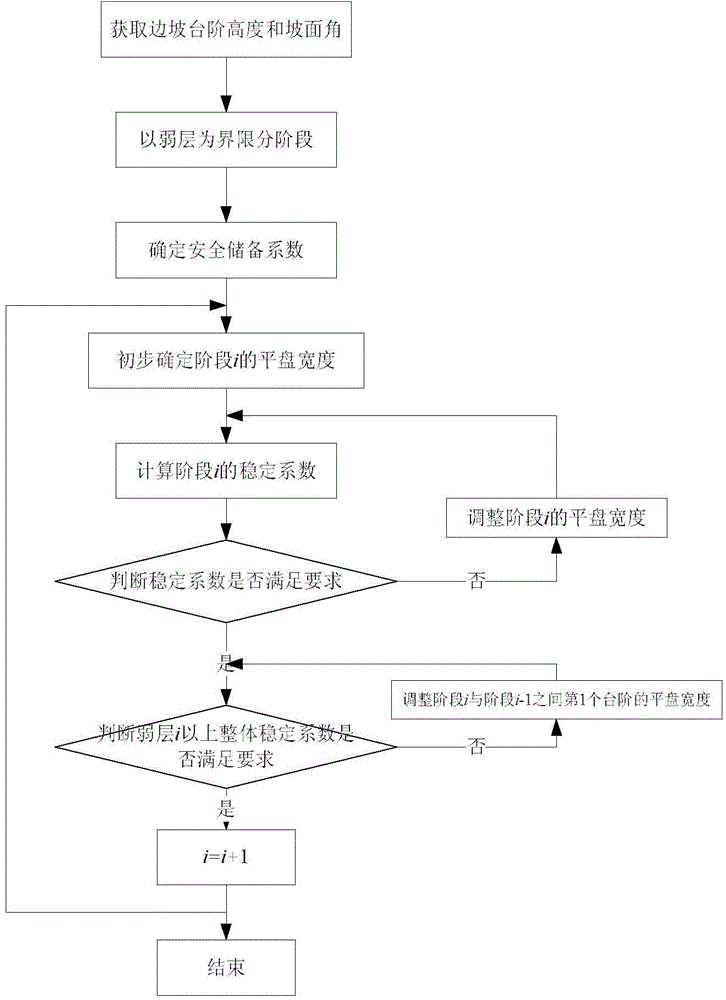

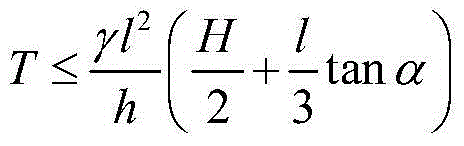

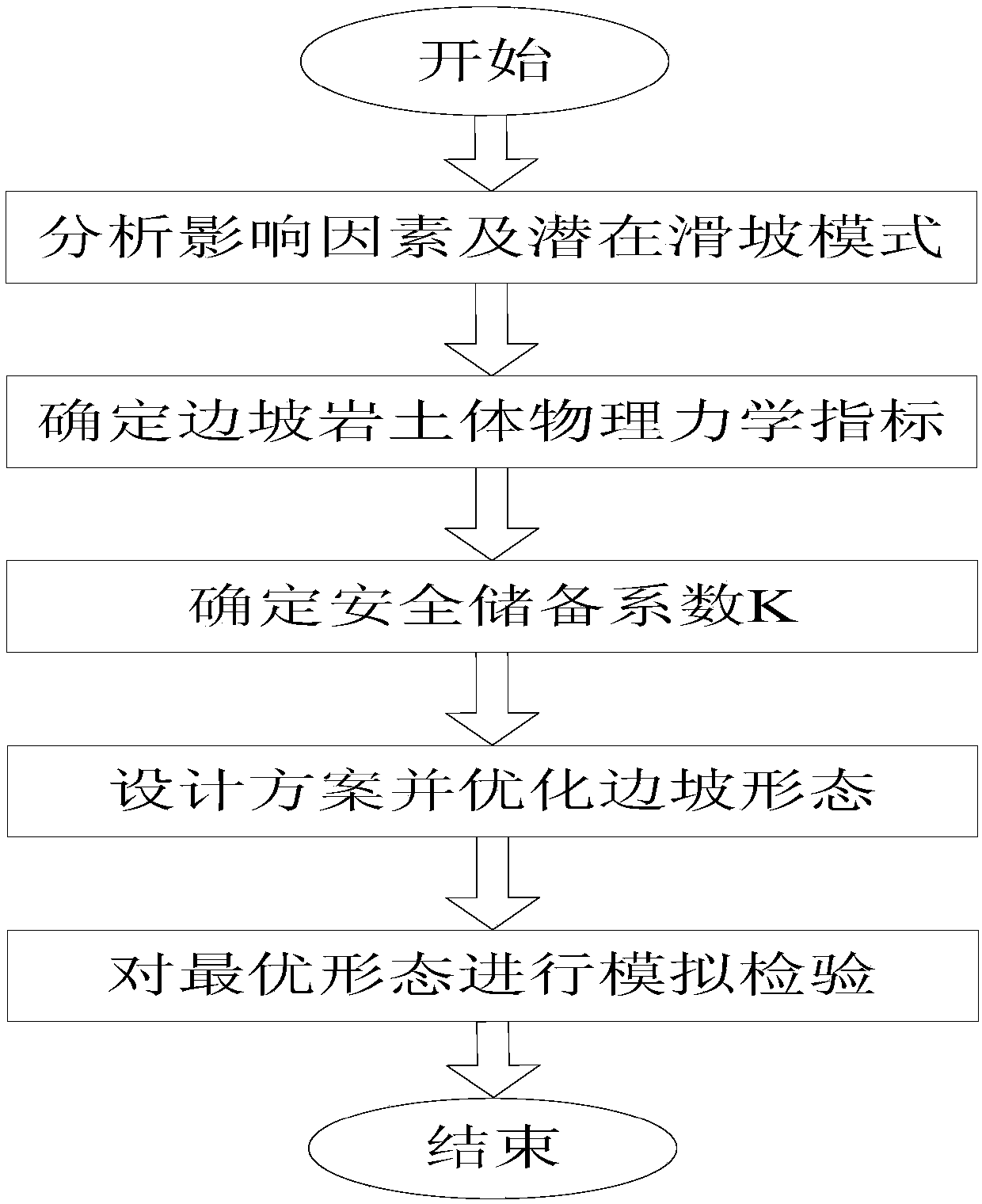

Shape design method of dip bedded slope of open-pit mine in composite coal seam

InactiveCN105178964AGuaranteed recyclingPrevent landslidesUnderground miningSurface miningOpen-pit miningLandslide

The invention belongs to the field of open-pit mining and relates to a shape design method of a dip bedded slope of an open-pit mine in a composite coal seam. The method includes: first, acquiring step height and face angle of the dip bedded slope of the open-pit mine in the composite coal seam; second, numbering from top to bottom a plurality of weak beds in the dip bedded slope of the open-pit mine in the composite coal seam, and dividing the slope into a plurality of segments from top to bottom by using the weak beds as boundaries; third, determining a safety reserve coefficient K of the slope; fourth, determining flat plate width of the slope segment by segment from top to bottom, thereby allowing an absolute value of a difference between a slope stability coefficient of each segment and the safety reserve coefficient to be not greater than 0.01 and be satisfactory to checking calculation conditions, and meanwhile using flat plate widths of the corresponding segments as slope shape design results. The slope shape designed by the method is capable of effectively preventing landslide, ensuring maximum recycling of resources and maximizing economic benefit.

Owner:LIAONING TECHNICAL UNIVERSITY

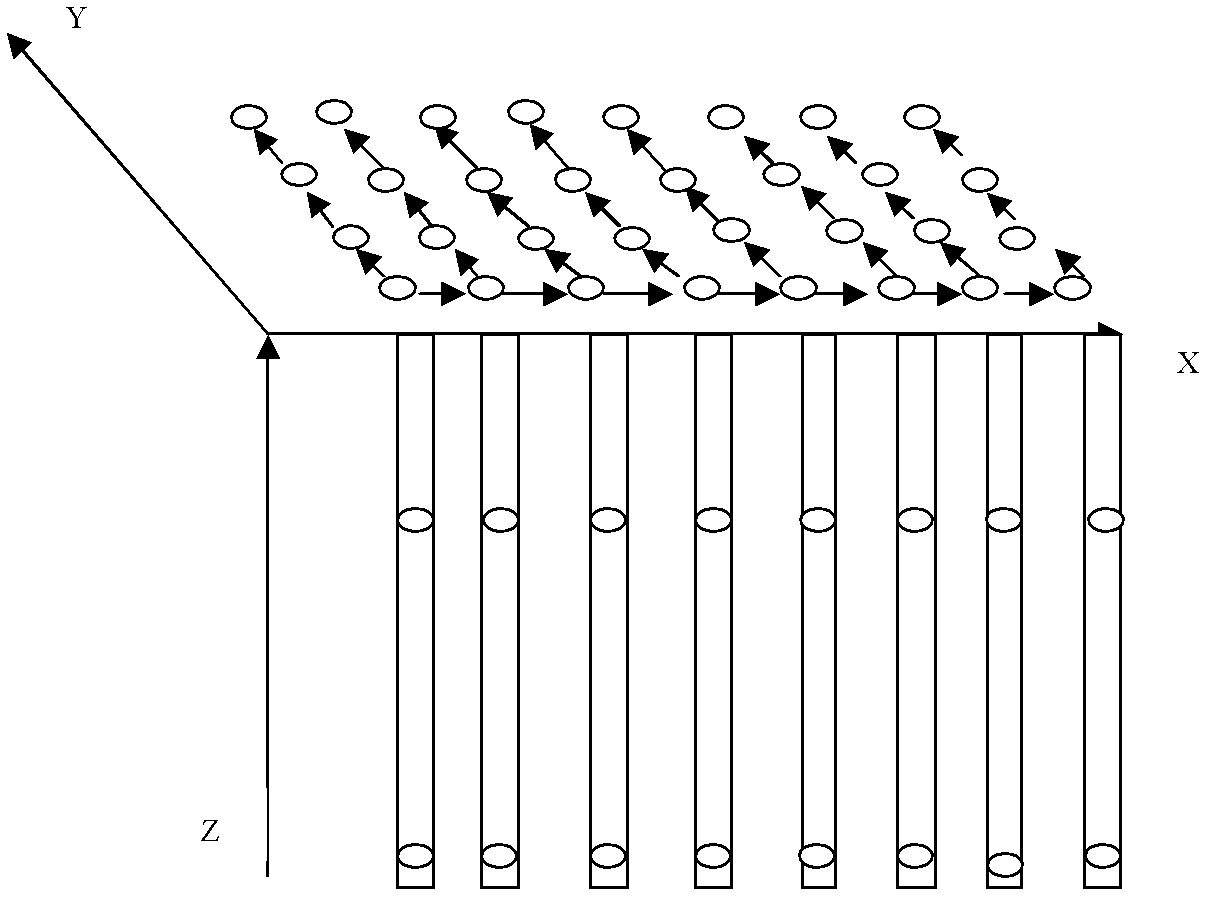

Open bench inter-hole differential control blasting method

ActiveCN102607353AImprove energy utilizationAvoid vibration peaksBlastingOpen-pit miningDelayed time

An embodiment of the invention discloses an open bench inter-hole differential control blasting method, which relates to the technical field of mining and is invented for solving the problems that resulting fragmentation degree needs to be better, blast vibration damage needs to be reduced, and large-scale blasting needs to be implemented effectively. The method includes: subjecting blast holes in a same row to inter-hole differential accumulation according to delay time of 1-5ms per hole-pitch meter, and performing inter-hole differential interval blasting; subjecting the blast holes in all rows to inter-hole differential accumulation according to the delay time of 10-30ms per row-spacing meter, and performing inter-row differential interval blasting; and filling at least one of the blast holes with a plurality of priming bombs or spaced charged explosive, and performing intra-hole differential interval blasting. The method is applicable to open-pit mining, and also applicable to large-scale earth-rock excavation engineering, large-scale hydropower engineering, large-scale civil engineering, large-scale underground workshop excavation and the like.

Owner:ZHUOLIWEI BEIJING TECH

Outdoor underground three-period mining method of inclined, thick and large mineral deposit

InactiveCN102606161AIn line with the actual situationReduce duplication of investmentUnderground miningSurface miningOpen-pit miningComprehensive planning

The invention discloses an outdoor underground three-period mining method of an inclined, thick and large mineral deposit. The outdoor underground three-period mining method comprises the steps of dividing a life cycle of the mining the mineral deposit into an outdoor mining period, an mining transition period shifting from outdoor mining to underground and an underground mining period by the following two steps: creating an outdoor underground mining boundary division formula, according to a relationship between a limit stripping ratio function and an economic stripping ratio function, determining an outdoor underground mining boundary, and distinguishing the dividing of the life cycle of the mine; and on the basis of outdoor underground mining boundary division, determining a mining opportunity in each of three mining periods. According to the outdoor underground three-period mining method, three mining periods are subjected to unified comprehensive planning and designing, so that when the outdoor mining period is designed, a development system is considered to be utilized in the subsequent underground mining period, and when the mining operation transitions from outdoor mining period to the underground mining period, favorable factors such as related engineering and facilities and the like in the outdoor mining period are utilized as far as possible in the underground mining period at the same time. Therefore, repeated investment of the mine development system in construction can be effectively reduced. The outdoor underground three-period mining method can be widely applied to the mining of medium and thick or thick and large inclined or steep mineral deposits in the industries of black metal, nonferrous metal, coal, chemical and the like.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

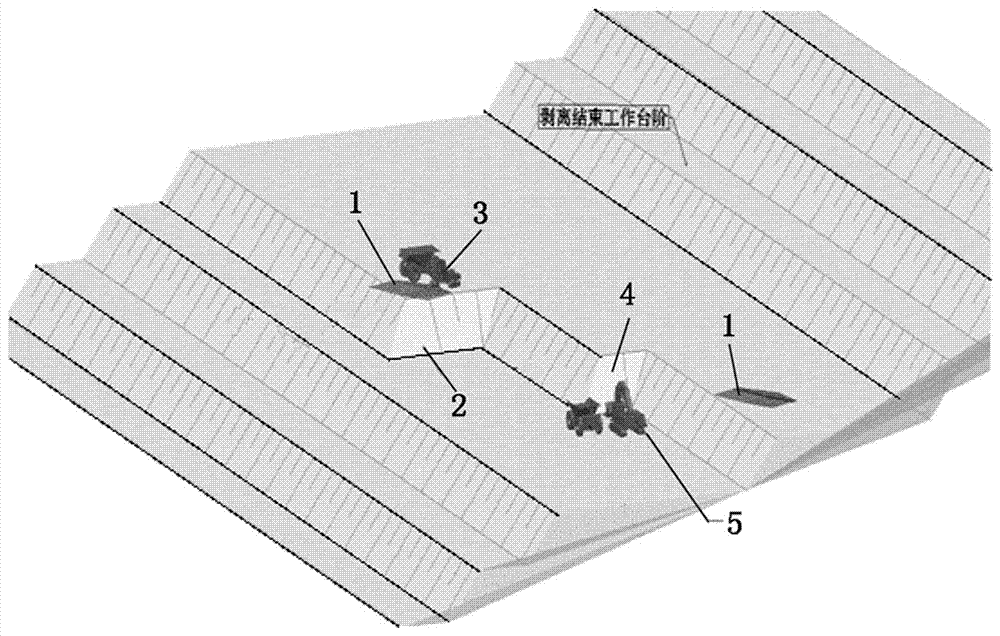

Open-pit refined mining method for gently dipping-thin ore body

ActiveCN106988746AAvoid mine downtimeReduce loss rateUnderground miningSurface miningOpen-pit miningMineralogy

The invention relates to the field of open-pit mining methods, in particular to an open-pit refined mining method for a gently dipping-thin ore body. The open-pit refined mining method comprises four steps of cut dividing, explosion arranging, hanging wall layered mine rock shovel mucking and heading wall sequential stripping advancing. The open-pit refined mining method solves the contradictory problem of loss ratio and dilution ratio reducing and large shovel mucking equipment production efficiency improving when a traditional mining method is used for stoping the gently dipping-thin ore body and ensures that a user can stope the gently dipping-thin ore body economically and efficiently.

Owner:YUNNAN HUALIAN ZINC & INDIUM

Fast spoil disposal slope protection and ecological recovery open-pit mining technology

The present invention relates to an open-pit mine excavation process, in particular, it relates to an open-pit mining process capable of quickly discharging earth to protect bank and making ecological restoration. It is characterized by that in one end of open-pit mine or its middle said invention adopts a conventional method, if the stripping and mining operation of initial stripping working face is completed, on the deposit mining direction the mining working face can be divided into left side zone, medium zone and right side zone, then they are further divided into several smaller subsections, every subsection can be used as an unit, on every subsection the processes of stripping, mining, backfilling and banking, cultivating-greening or covering with concrete are progressively adopted so as to implement the invented open-pit mining process.

Owner:WUHAN UNIV OF TECH

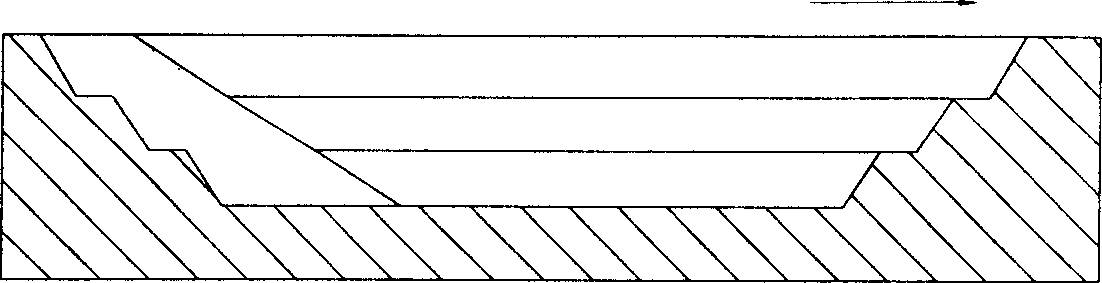

Transport method of building longitudinal composite bridge in middle of strip mine stope

InactiveCN104806247AGuarantee normal productionShort distanceOpen-pit miningOpen-pit miningEconomic benefits

The invention discloses a transport method of a lower stripping material of a strip mine, and particularly relates to a transport method of building a longitudinal composite bridge in the middle of a strip mine stope. Bridging manners of the longitudinal composite bridge include linear bridge stacking and fan-shaped bridge stacking. In a strip mining process, an operating line is long and a material stripping haul distance is large, so that building of a middle bridge perpendicular to the operating line in the gravity center of a stripping material in the stope can reduce a perpendicular haul distance of material handling on a bridge body. Building of sub-bridges based on the single bridge can increase service stripping steps of the bridge body. The transport method of building the longitudinal composite bridge in the middle of the strip mine stope is applicable to internal dumping strip mines adopting single-bucket excavator and truck mining technologies in a horizontal or subhorizontal strip coal mine, can reduce an automobile haul distance of the lower stripping material, can lower the transport cost, can increase an economic benefit, and has wide practicability.

Owner:CHINA UNIV OF MINING & TECH

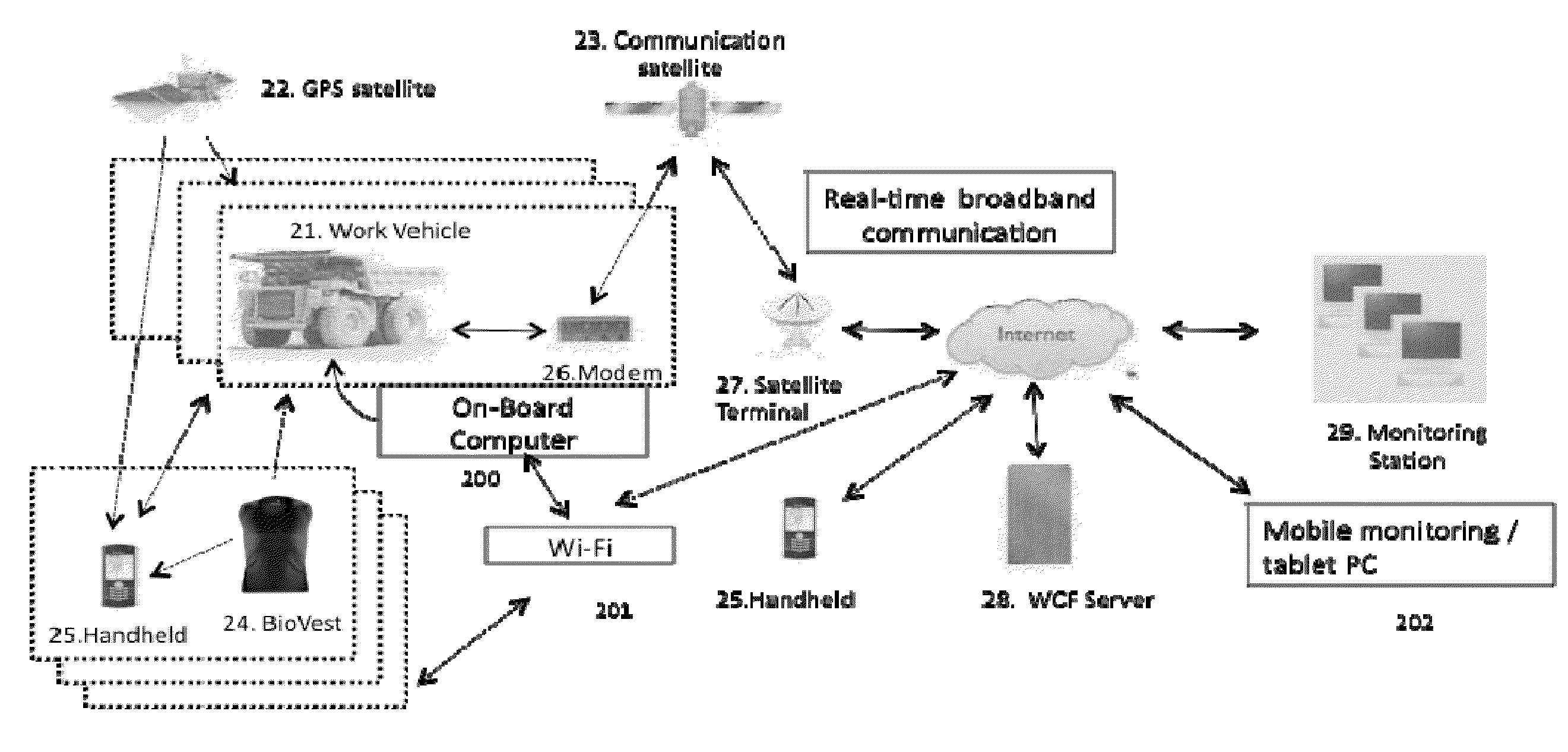

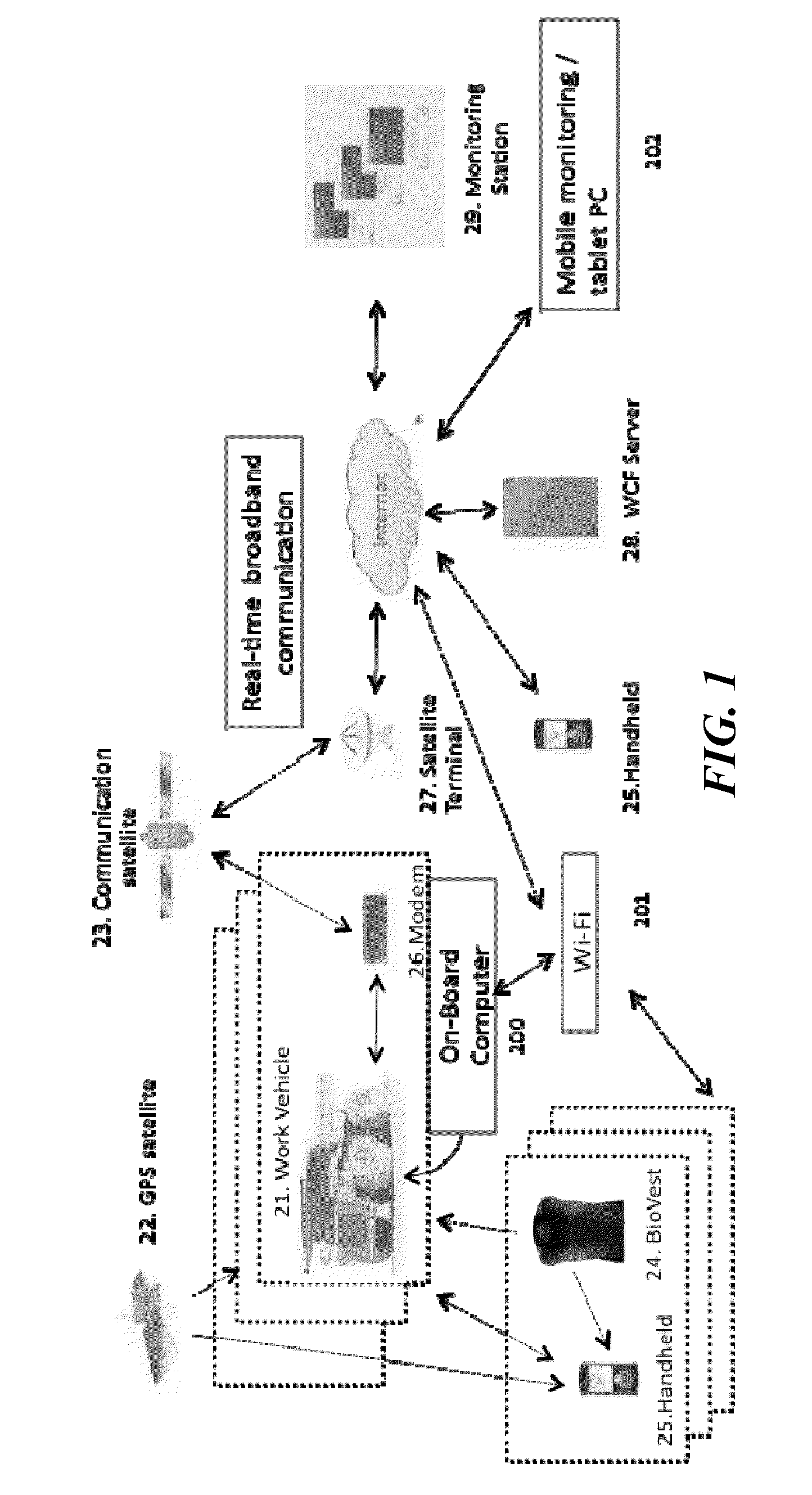

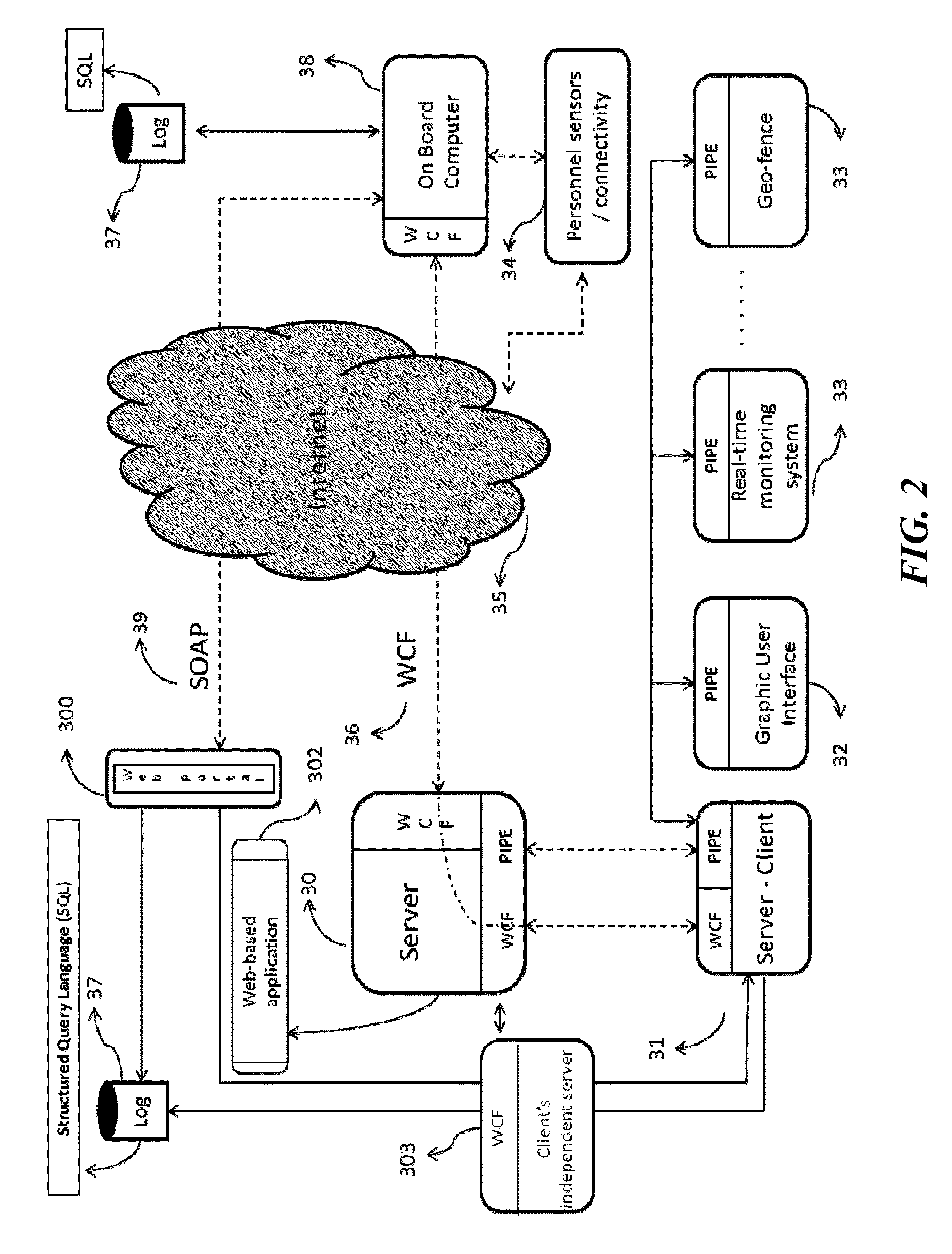

Apparatus, method, and platform for real-time mobile broadband communication data

ActiveUS20100256862A1Improve reliabilityVehicle testingAnalogue computers for trafficOn boardData access

A real-time mobile communication platform comprising a remote unmanned apparatus, an earth station associated with a data receiver, status monitoring sensors, a plurality of biometric sensors, a microprocessor, a warning device, a plurality of broadband wireless communication devices, a plurality of broadband wireless communication devices, and a control room. The present disclosure teaches Real-time mobile broadband data access via satellite to mobile heavy equipment and personnel, focusing on health and safety solutions to open-pit mining operations in remote areas of the world. The system consists of a platform which allows for the integration of health and safety solutions, status monitoring systems, and transmitting broadband information in Real-time from these systems to anywhere in the world. The present disclosure's teaches: 1) Gathering information from the sensors on work vehicles and personnel; 2) Transmitting Real-time broadband data packets over a wireless appliance; 3) Translating and processing information obtained through an intelligent diagnostic application which is placed on board heavy mobile vehicles and personnel and then transmitting it via a wireless network; 4) Displaying the information collected in Real-time anywhere in the world via host computers or on a web page.

Owner:ESTRELLASAT

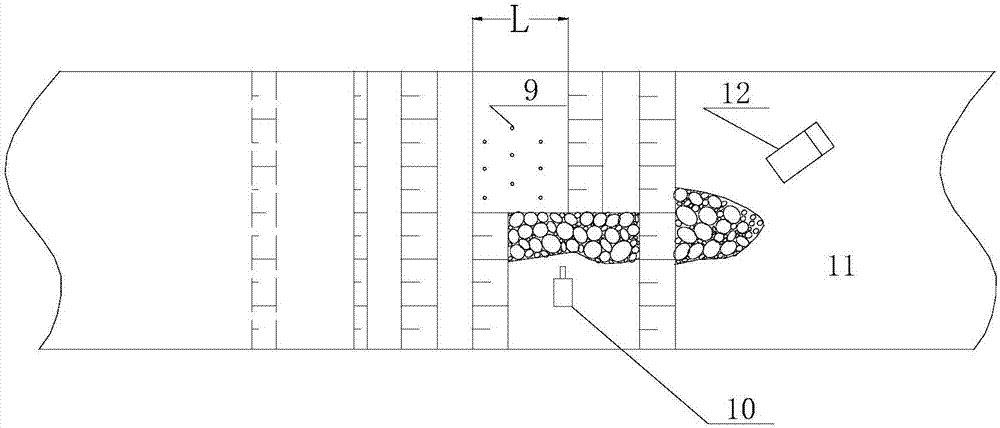

Novel open-pit mining method suitable for steep slope topography

InactiveCN106869936ASimple processSolve difficult construction problemsOpen-pit miningOpen-pit miningSteep slope

The invention discloses a new open-pit mining method suitable for steep slope terrain. The steep slope terrain is divided into 2 to 4 steps, the stripping operation surface is arranged along the strike, and a vertical strip L is divided every 14 to 16m in the vertical strike direction. , the step height H is not greater than 1.5 times the maximum excavation height of the hydraulic excavator (10), and the width of the bottom loading platform (11) is greater than 18m, so as to meet the operation requirements of the mine transport vehicle (12), implement single-step operation, blasting operation Finally, the hydraulic excavator (10) is used for mining from top to bottom, from outside to inside, and gradually advances to the final side. The ore is unloaded to the bottom by the hydraulic excavator (10) from top to bottom, from inside to outside The loading platform (11) is transported out through the mining transport vehicle (12). The invention has the advantages of simple process, easy-to-obtain equipment, safety and feasibility, and effectively solves the problems of large steep slope terrain, impossibility to build transportation roads, and difficult construction when conventional step mining is adopted.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

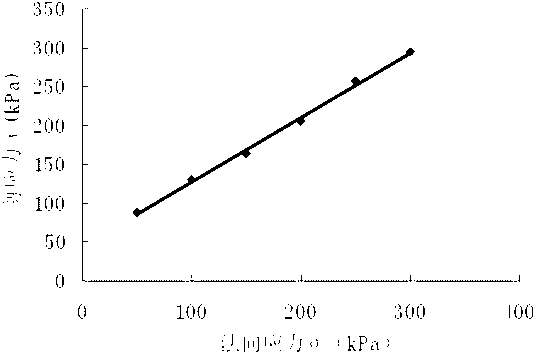

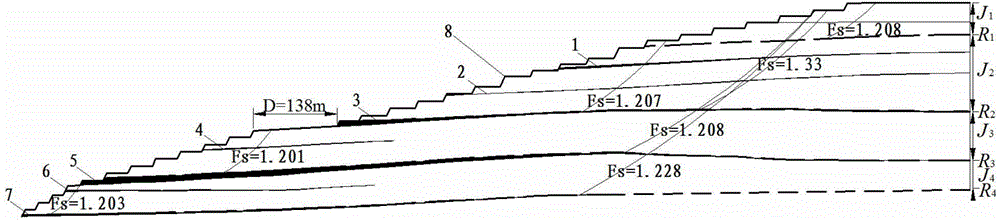

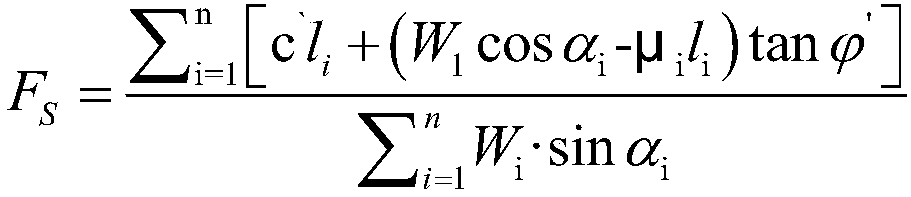

Optimization method for slope shape of end wall of open-pit mine

The invention discloses an optimization method for the slope shape of the end wall of an open-pit mine, and belongs to the field of open-pit mining. The method includes the steps of combining specificconditions of the slope of the end wall of an open-pit mine, qualitatively analyzing stability influencing factors and a potential landslide mode; conducting a mechanical experiment on the rock massof the slope of the end wall of the open-pit mine to obtain physical and mechanical indexes; determining a safety reserve coefficient K of the slope of the end wall of the open-pit mine; dividing theslope of the end wall of the open-pit mine into n stages; adjusting the width of a flat plate at each stage, and when a stability coefficient Fs satisfies |FS-K|< / =0.01, completing the slope shape optimization of each stage; and combining a strength reduction theory algorithm, using FLAC3D finite difference numerical simulation software for simulation test on the optimal slope shape scheme obtained above, and further verifying the feasibility of the optimal slope shape. The method ensures the maximum recovery of the compressed coal under the end wall, provides a basis for the design of the slope shape, and also creates a large number of economic benefits for the open-pit mine.

Owner:LIAONING TECHNICAL UNIVERSITY

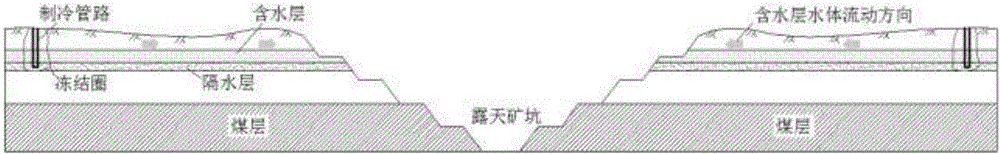

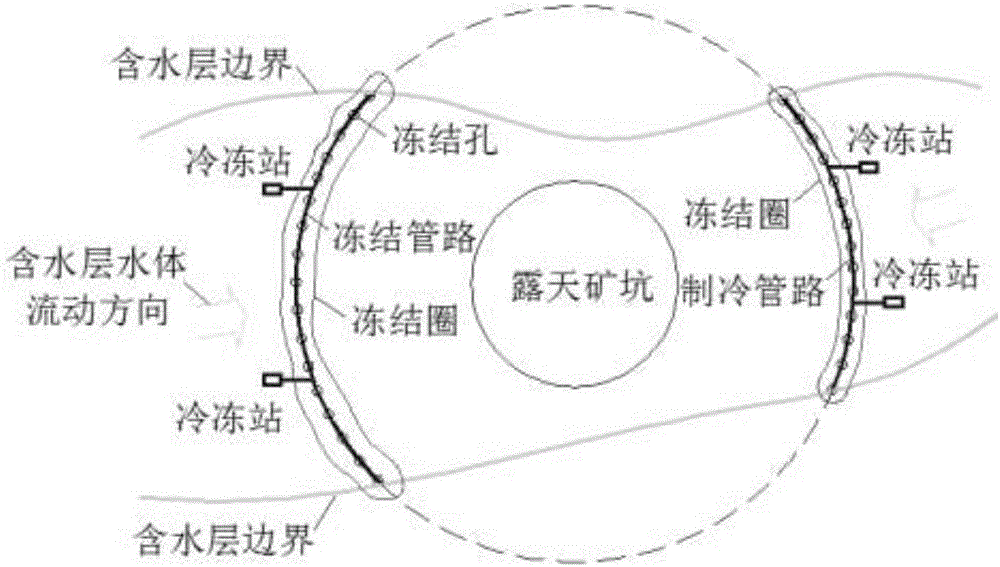

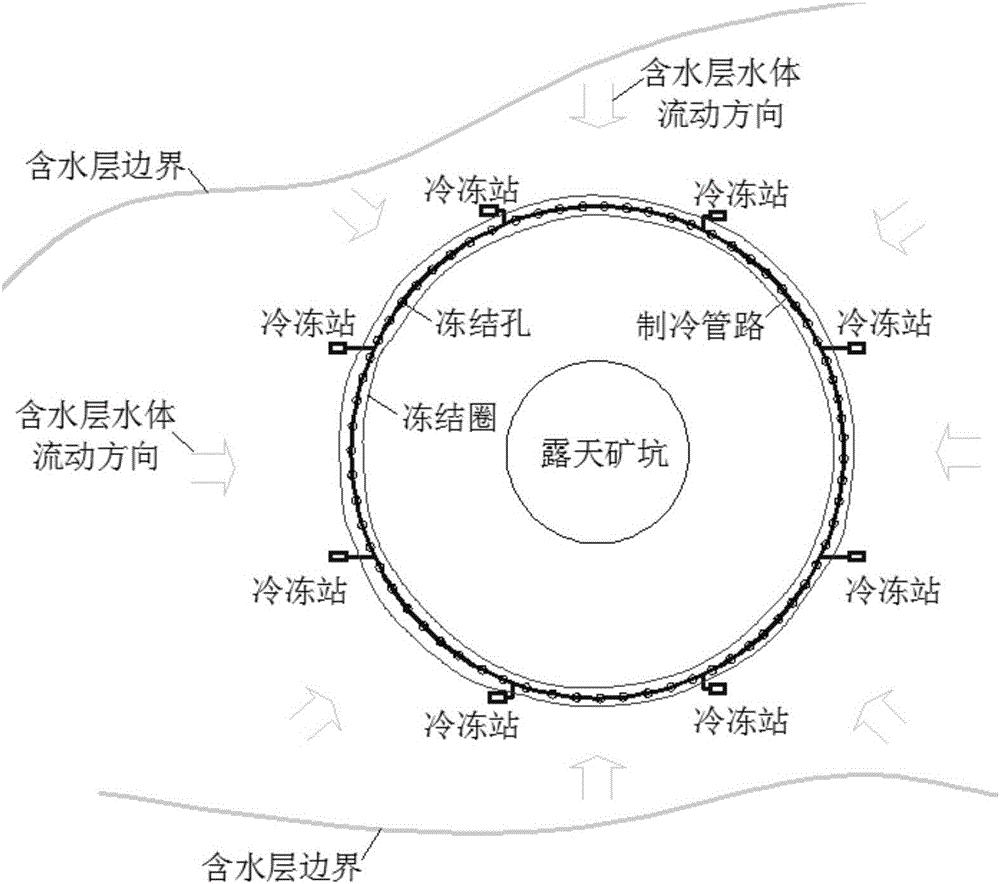

Water retention method of open coal mining frozen water-bearing stratum

InactiveCN106759245ABarrier excretionProtect environmentUnderground miningSurface miningEcological environmentOpen-pit mining

The invention discloses a water retention method of open coal mining frozen water-bearing stratum, which is applicable to the technical field of coal mining and environmental protection. The method includes steps of exploring distribution content of underground water-bearing stratum of a zone through hydrogeology drilling; practicing a freezing circle interception on the underground water-bearing stratum in a well field scale by an artificial cooling method, and preventing the underground water out of the well field mining scale from discharging to an open mine pit. The water retention method cannot disturb normal production activity, and can effectively prevent underground water body at periphery of the well field from discharging towards the open mine pit, maintain the underground water level at the peripheral zone, and effectively protect the ecological environment at surrounding of the mine zone; particularly, the method is applicable to the water retention and mining in the severely cold opencast working zone in the west part; the local climate condition can be fully utilized to reasonably reduce the energy consumption from practicing the embodiment; the method is economic and environment-friendly, and has very high reliability and practicability.

Owner:CHINA UNIV OF MINING & TECH

Wedge transferring transition method for transferring from open-pit mining to underground mining

ActiveCN104806243AExpand production scaleAchieving gradual handover transitionsUnderground miningSurface miningOpen-pit miningSteep slope

The invention discloses a wedge transferring transition method for transferring from open-pit mining to underground mining. The method comprises open-pit deepening mining of footwall side ore bodies, underground mining of hanging wall side wall-connected ore bodies with an induced caving method and wedge transferring from open-pit mining areas to underground mining areas; wedge surface angles are required to meet the open-pit safe mining requirement and not higher than rock movement controllable angles in induced caving areas; steep slope mining of footwall side ore bodies in the open-pit mining areas is performed, and deepening mining is performed on the last 2-3 steps with a cross-mining and in-pit dumping method; the production scale is quickly formed by the aid of open-pit digging measure engineering in stopes adopting the underground induced caving method; induced caving engineering adopts a from-far-to-near stoping sequence, and heights of gobs are determined according to the requirement that collapse pits on through ground surfaces can accommodate the slope rock movement bulk solid amount. The method fundamentally solves problems of poor safety production conditions and difficulty in yield linking in transitional periods of large iron mines and lays a foundation for stability of transferring from open-pit mining to underground mining or yield increase.

Owner:NORTHEASTERN UNIV +1

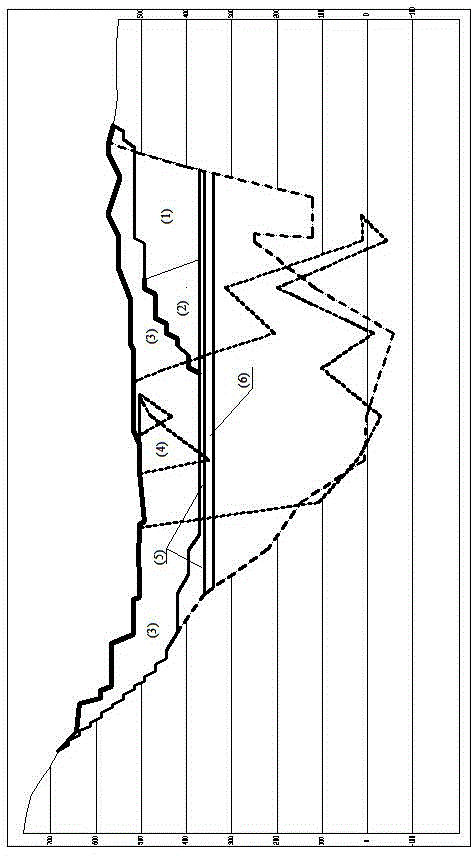

Analysis method for stability of strip mine side slope exploding process

The invention discloses an analysis method for stability of a strip mine side slope exploding process and belongs to the field of coal strip mining engineering. The analysis method for the stability of the strip mine side slope exploding process comprises the following steps of (1) constructing a slide slope model; (2) setting exploding parameters; (3) constructing an exploding model; (4) performing slide slope stability analysis on above explosions. A result shows that the upper layer sandstone is stable after the above explosions, namely the slope top is stable, the lower layer sand stone and the sandy mudstone are damaged in a certain degree, landslides in large areas are not occurred, and the landslides are within a controlled range. The analysis method for the stability of the strip mine side slope exploding process shows that the upper layer sandstone is stable after the above explosions, namely the slope top is stable, the lower layer sand stone and the sandy mudstone are damaged in a certain degree, landslides in large areas are not occurred, and the landslides are within a controlled range.

Owner:内蒙古白音华蒙东露天煤业有限公司

Opencast combined mining method of steeply inclined coal seam groups

InactiveCN101555796ALow costImprove resource recoveryUnderground miningSurface miningSocial benefitsOpen-pit mining

The invention provides an opencast and underground combined mining method of steeply inclined coal seam groups; the detailed implementation method comprises the following steps: opencast construction is carried out downwards in a certain angle along the inclined direction of the steeply inclined coal seam group, the construction is conducted to reach a certain distance deeper than that when the first coal seam appears, then horizontal construction is conducted until all of the steeply inclined coal seam groups are penetrated, and then the construction is continued back to the surface of the earth at a certain angle; at the location with a certain distance below the coal seam, another construction gallery is dug and penetrated through along the trend of the coal seams; transportation equipments are arranged in a laneway, the laneway is used for placing top coal or other coal mining methods are adopted, the coals mined are carried into the construction gallery by the laneway transportation equipment, and then are transported to a mine coal plant. The opencast and underground combined mining method of the steeply inclined coal seam groups solves a plurality of problems such as high mining cost and low resource recovery rate and the like in the opencast of the steeply inclined coal seam groups, simultaneously solves the problems such as low safety, high labor intensity, low efficiency and high cost and the like during the underground mining of the steeply inclined coal seam groups, causes the opencast mining to become underground mining and the underground mining to become opencast and ensures the complementation of the strengths and weaknesses, thus being a safe and highly efficient coal mining method of the steeply inclined coal seam groups and having good social benefit and economic benefit.

Owner:赵刚

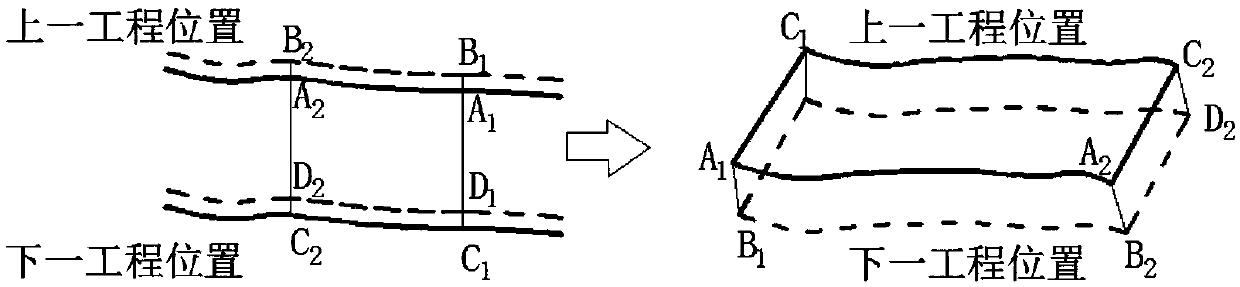

Optimization method for slant-basement inner-dumping-site side slope shapes

ActiveCN107609299AEnsure stabilitySave on surface mining costsSpecial data processing applicationsBasementOpen-pit mining

The invention discloses an optimization method for slant-basement inner-dumping-site side slope shapes, and belongs to the field of opencast working. The optimization method includes the steps that (1) influence factors of the stability of slant-basement inner-dumping-site side slopes and potential landslide modes are qualitatively analyzed; (2) inner-dumping-site side slope rock-soil bodies are subjected to mechanics experimenting, and physical mechanical indexes of the side slope rock-soil bodies are obtained; (3) the safety reserve coefficient K of the slant-basement inner-dumping-site sideslopes is determined; (4) the slant-basement inner-dumping-site side slope shapes with different discharging heights and different flat plate widths are designed, and the optimal side-slope stabilitycoefficient and the maximal discharging space are designed; (5) the obtained optimal side-slope-shape scheme is simulated and checked through FLAC<3D> finite difference numerical simulation softwarewith the strength reduction theory algorithm, and the feasibility of the optimal side-slope shape is further verified. According to the optimization method, the inner-dumping-site stability and continuous development of inner dumping space are guaranteed, a basis is provided for designing of the side slope shapes, and meanwhile a large amount of opencast working cost is saved.

Owner:HUOLINHE OPENCUT COAL IND CORP LTD OF INNER MOGOLIA

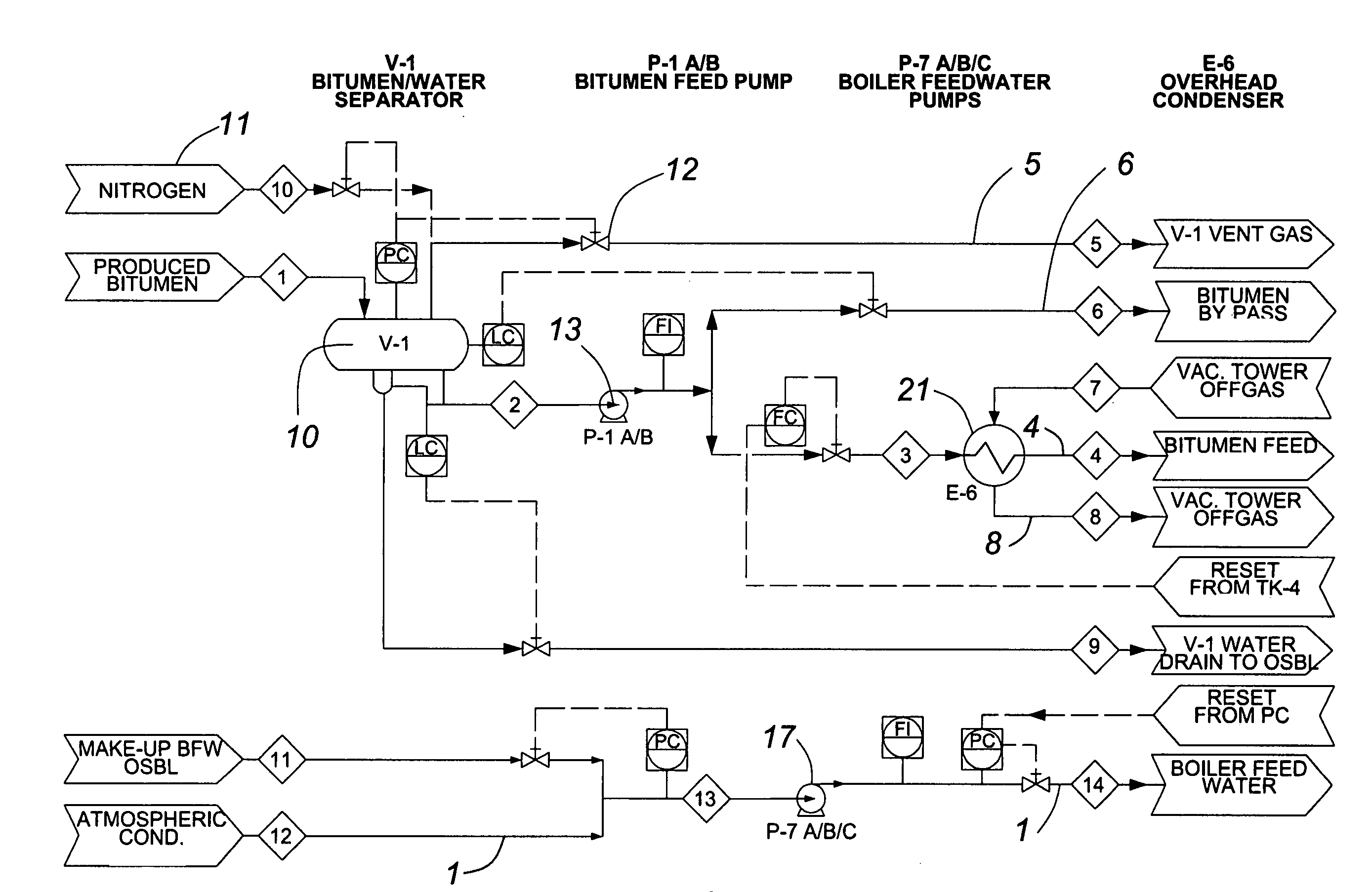

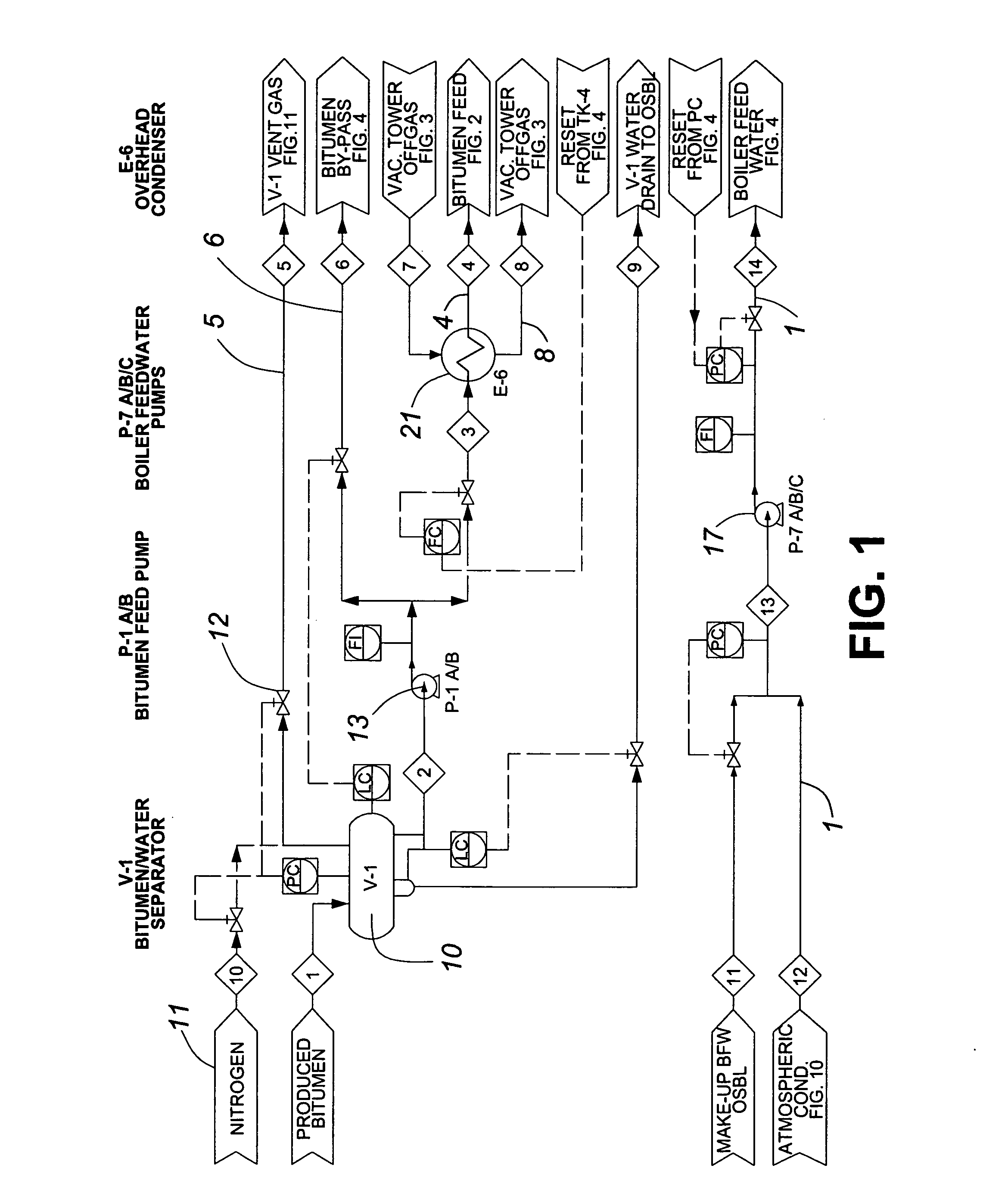

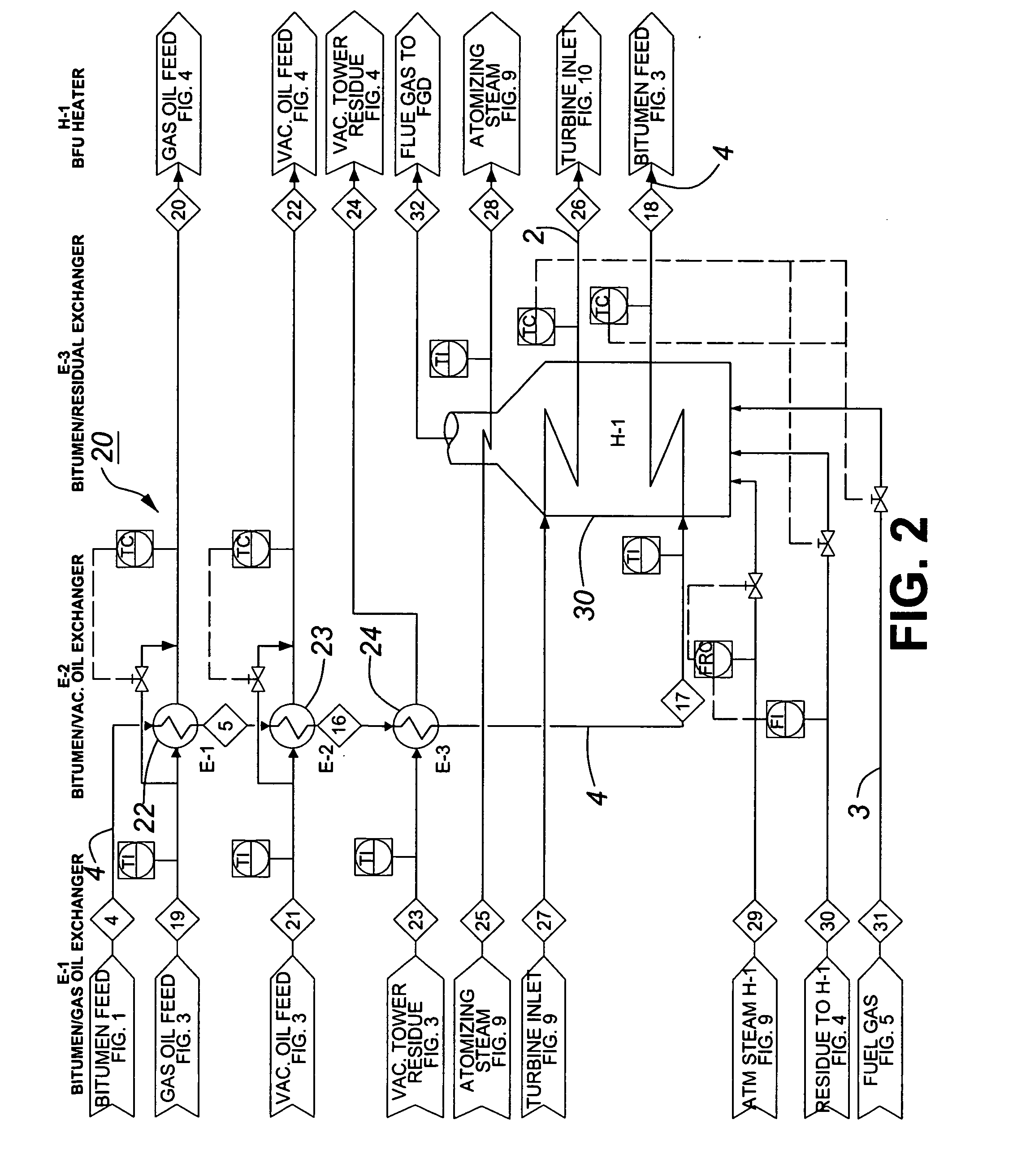

Steam generation apparatus and method

InactiveUS20080093264A1Low viscosityImprove efficiencyWorking-up pitch/asphalt/bitumen by distillationRefining with oxygen compoundsOpen-pit miningAPI gravity

The present invention provides for steam generation replacing natural gas with a selected refined product of a feedstock of bitumen, asphaltines or heavy oil using locally produced surplus bitumen, asphaltine or heavy oil, separating the asphaltines and other components of the feedstock for use in providing a liquid fuel for steam generation. The lighter products from the separation equipment not used for liquid fuel may be blended into the produced bitumen, asphaltines or heavy oil, to increase its API gravity and reduce the diluent required for transportation. This technology may be employed in open pit mining operations for the generation of steam and power. The refined components of the feedstock used to provide liquid fuel are selected to optimize energy output balancing planned energy demand against the value of the components of the feedstock used.

Owner:ACS ENG TECH

Slope greening matrix and preparing method and application thereof

InactiveCN109287433ARealize resource utilizationHigh organic contentGrowth substratesCulture mediaEcological environmentDry weight

The invention relates to the field of mine ecological environment management, in particular to a slope greening matrix and a preparing method and application thereof. The slope greening matrix is prepared from, by dry weight, 800-1,200 parts of open-pit-mining coal mine efflux soil, 10-30 parts of livestock excrement, 0.5-1 part of biomass charcoal, 0.25-0.75 part of microbial fermentation fungicide, 1-3.5 parts of a water-retaining agent and 0.05-0.25 part of a binding agent. The preparing method of the slope greening matrix includes the steps that the biomass charcoal, the livestock excrement and the microbial fermentation fungicide are mixed and fermented; fermentation products and the other raw materials are mixed, and the slope greening matrix is obtained. The open-pit-mining coal mine efflux soil is locally used as a main raw material of the greening matrix, resource utilization of the efflux soil is achieved, the slope greening matrix can effectively provide rich nutrients and moisture for slope vegetation growth, growth of plants is promoted, and the survival rate is increased.

Owner:INNER MONGOLIA M GRASS ECOLOGY & ENVIROMENT GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com