Shape design method of dip bedded slope of open-pit mine in composite coal seam

A technology for open-pit mines and slopes, which is used in excavation, ground mining, earth-moving drilling and other directions, and can solve problems such as failure to achieve optimal design, affecting the economic benefits of open-pit mines, and threats to safe production in open-pit mines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

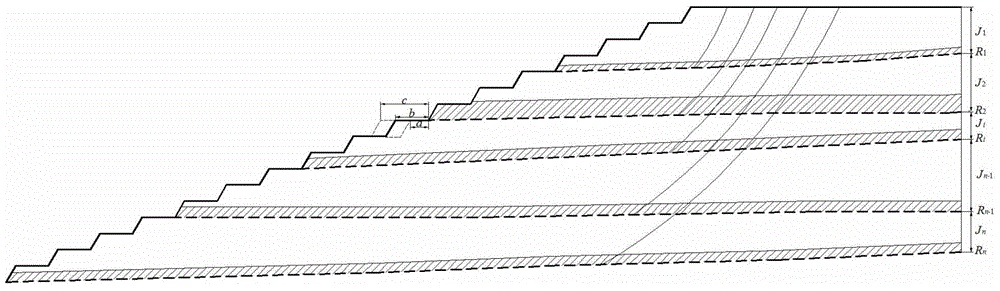

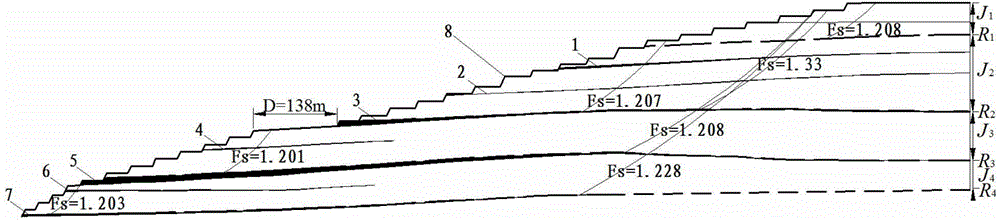

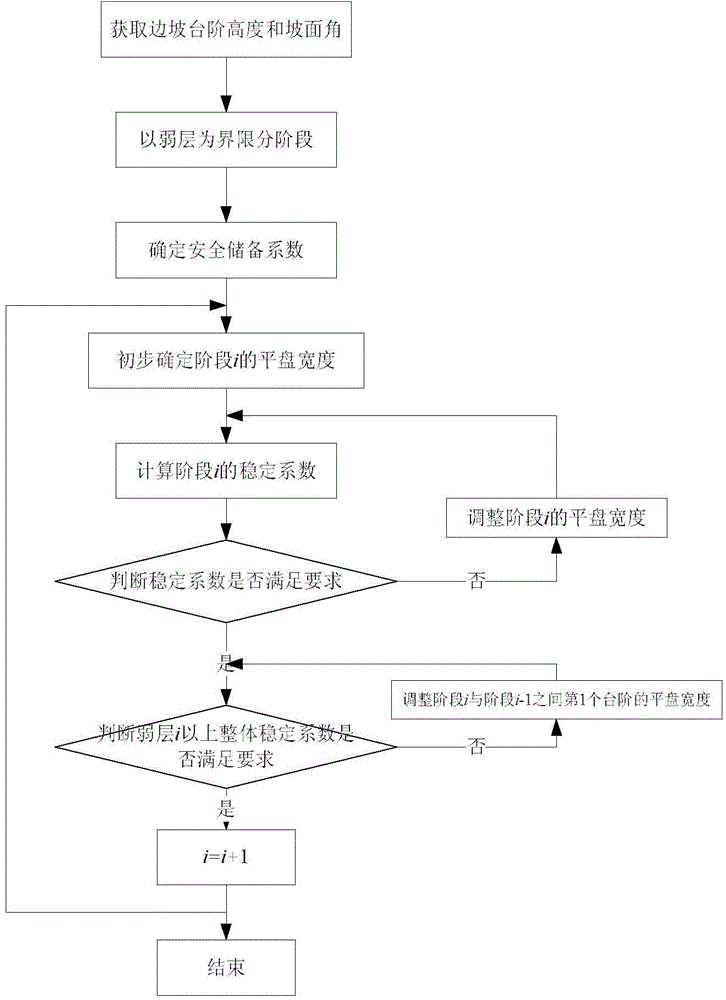

[0017] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. An open-pit mine has a down-dipping layered slope, and its strata are composed of Cretaceous, Tertiary, and Quaternary strata from bottom to top. Among them, the Cretaceous strata are mainly composed of mudstone and argillaceous sandstone, with a layered structure; the Tertiary strata are dominated by red clay, in a semi-consolidated state; the Quaternary strata are dominated by fine sand and medium sand, with a loose structure. Weak interlayers are relatively developed in the slope, and there are clay weak layers on the Tertiary floor. 中下 The coal roof, 3-1 coal roof, and 3-3 coal roof all have weak mudstone layers, and most of the weak layers are down-dipping. The existence of weak interlayers will greatly weaken the mechanical properties and stability of the rock mass. The physical and mechanical indexes of rock mass in each s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com