Patents

Literature

2720results about "Pigs/moles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

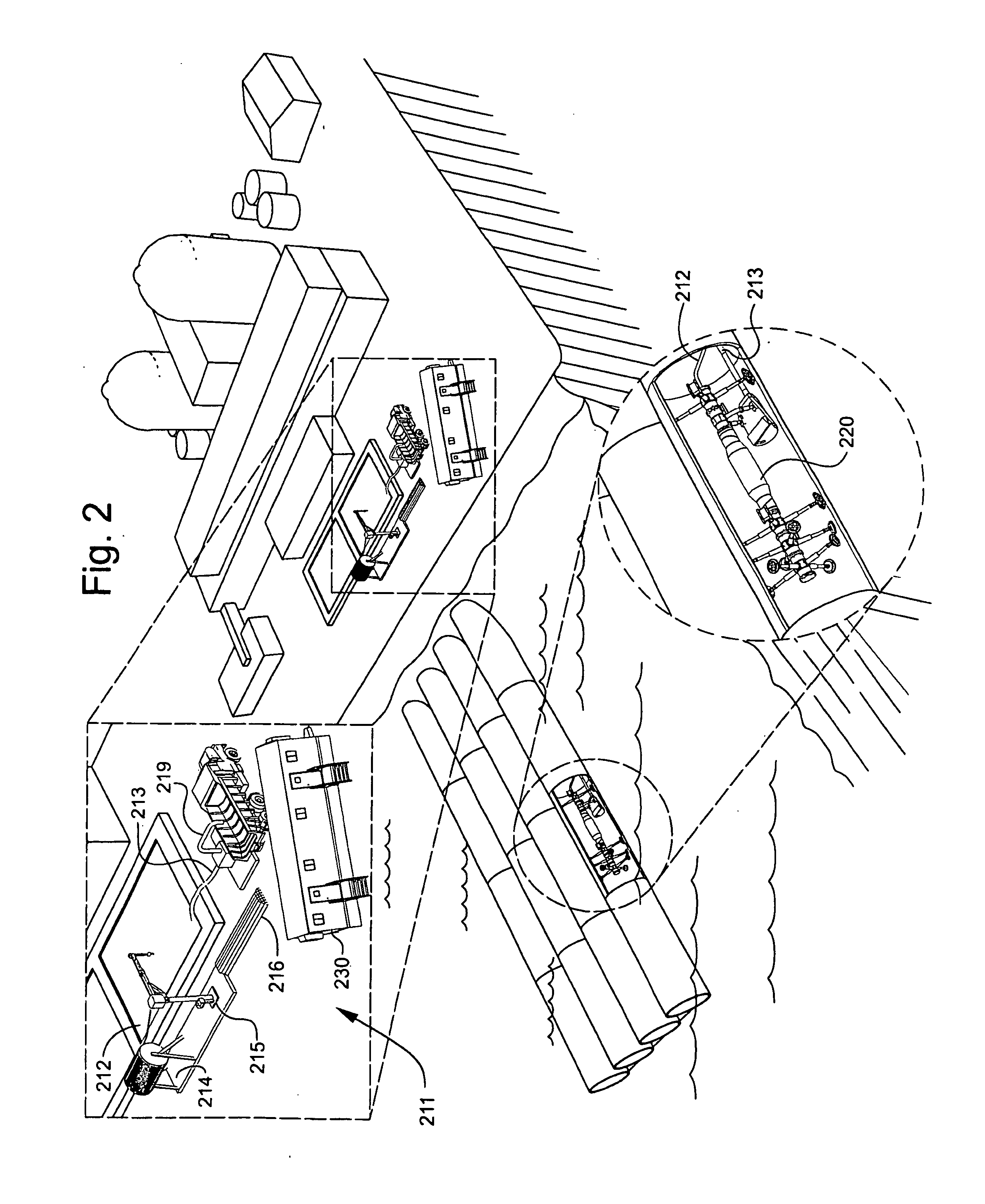

Gas main robotic inspection system

InactiveUS6917176B2Programme-controlled manipulatorMaterial analysis using sonic/ultrasonic/infrasonic wavesComputer moduleComputer terminal

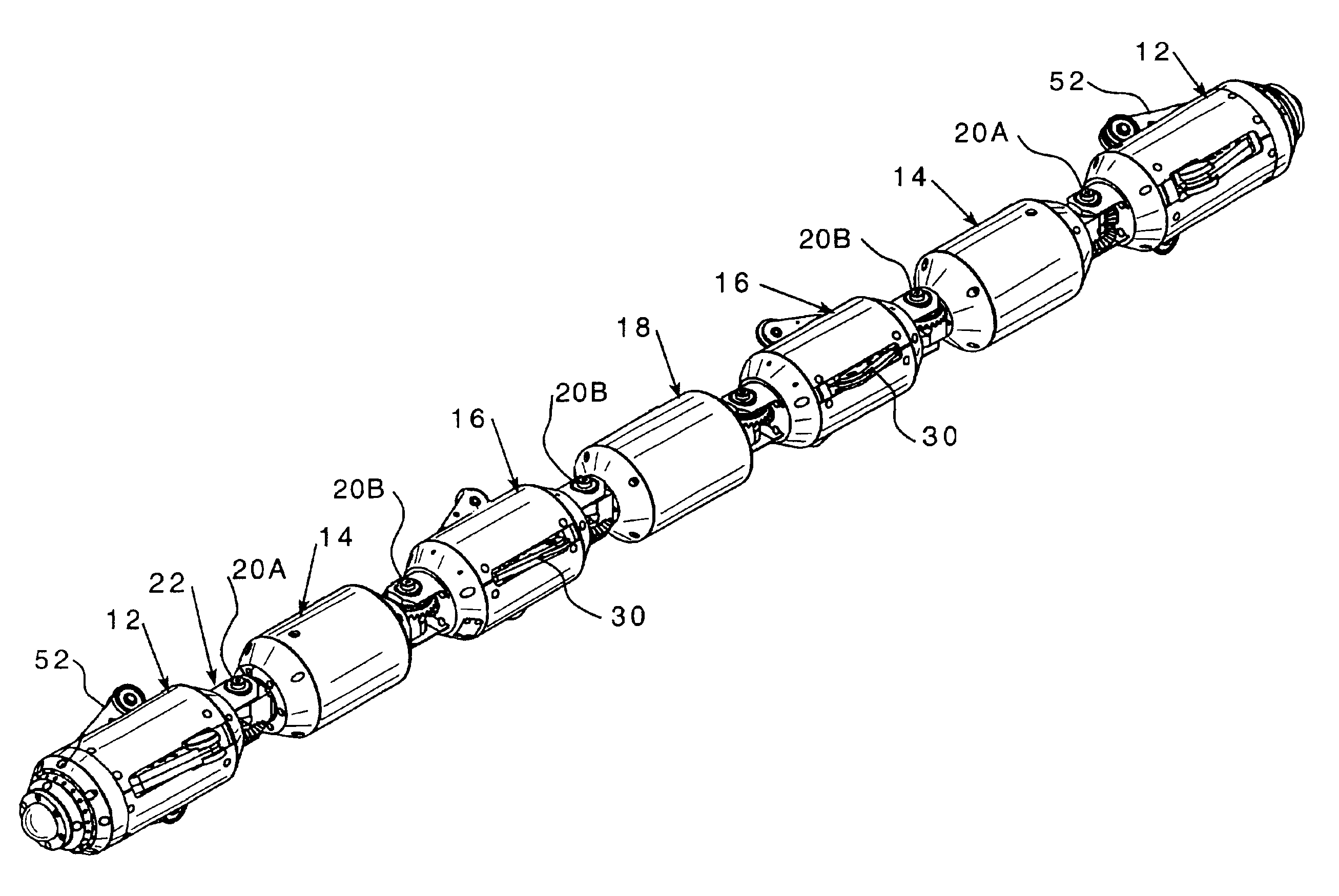

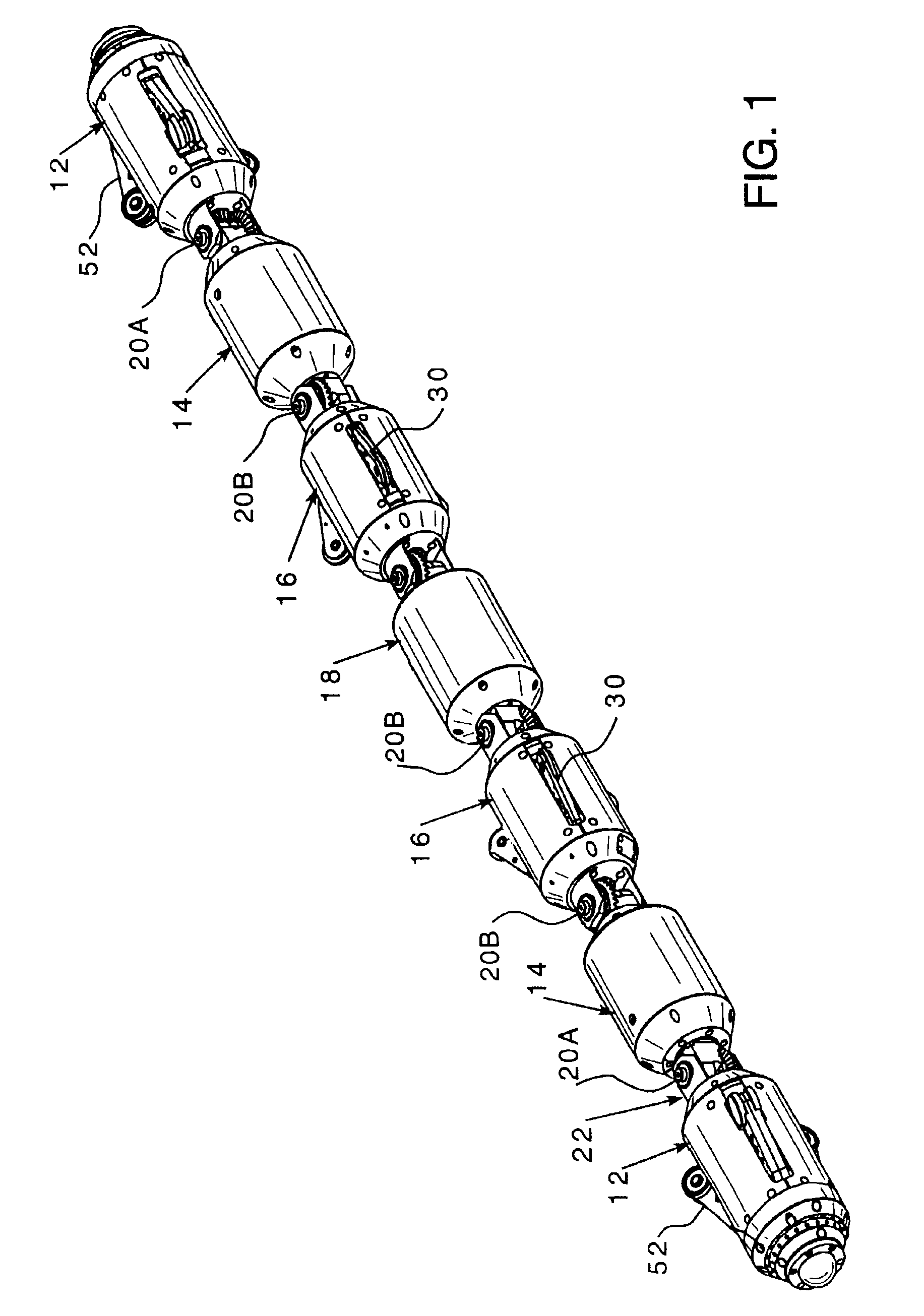

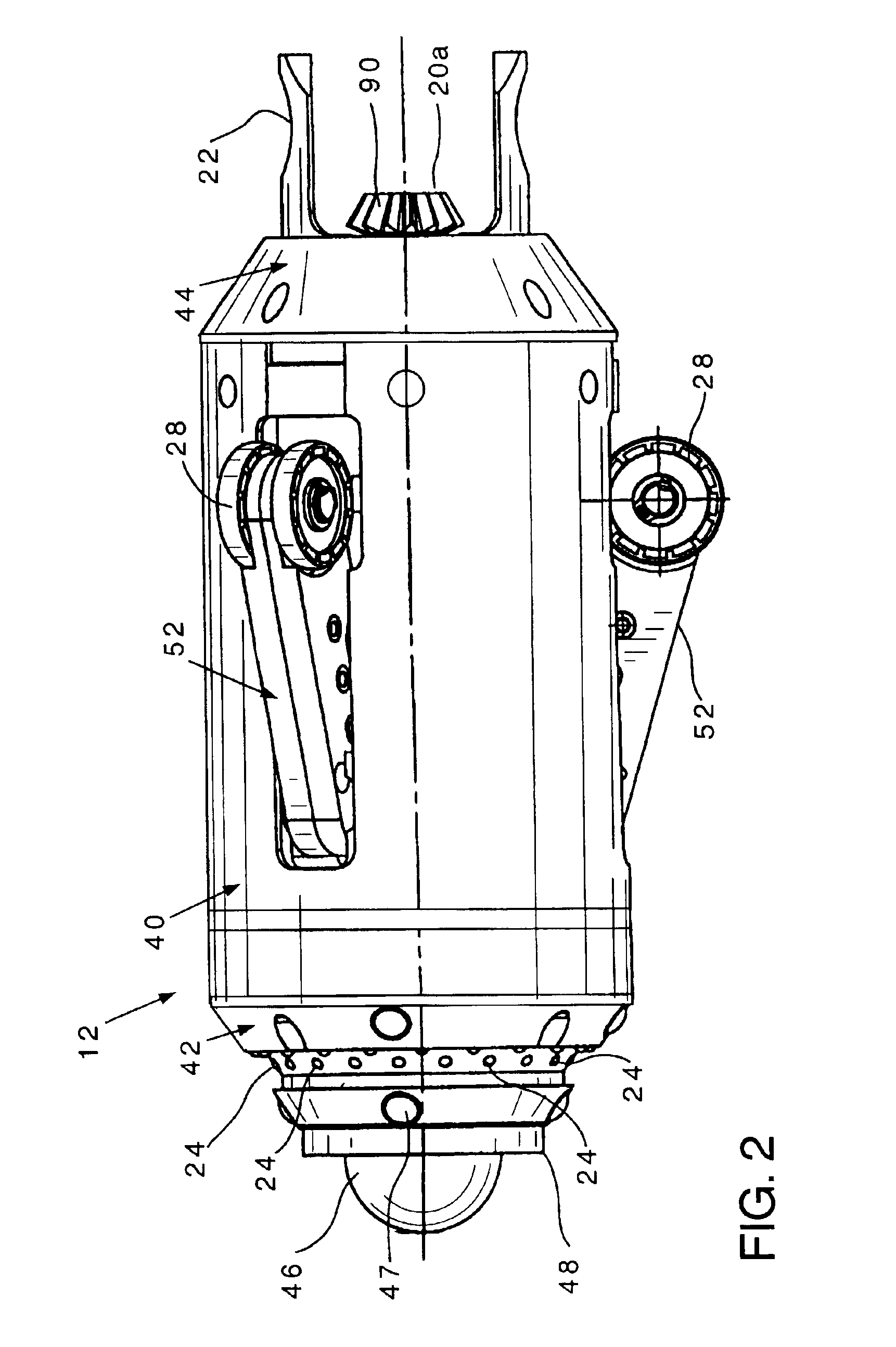

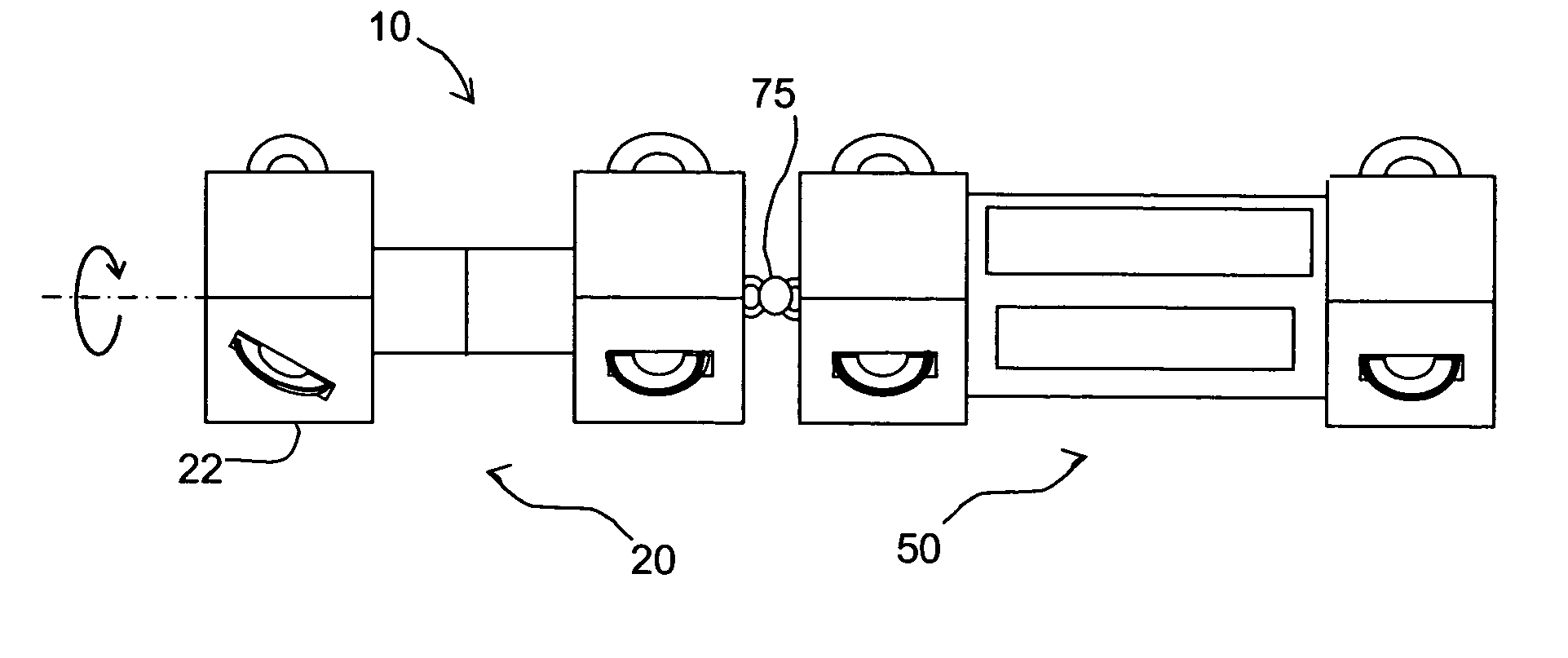

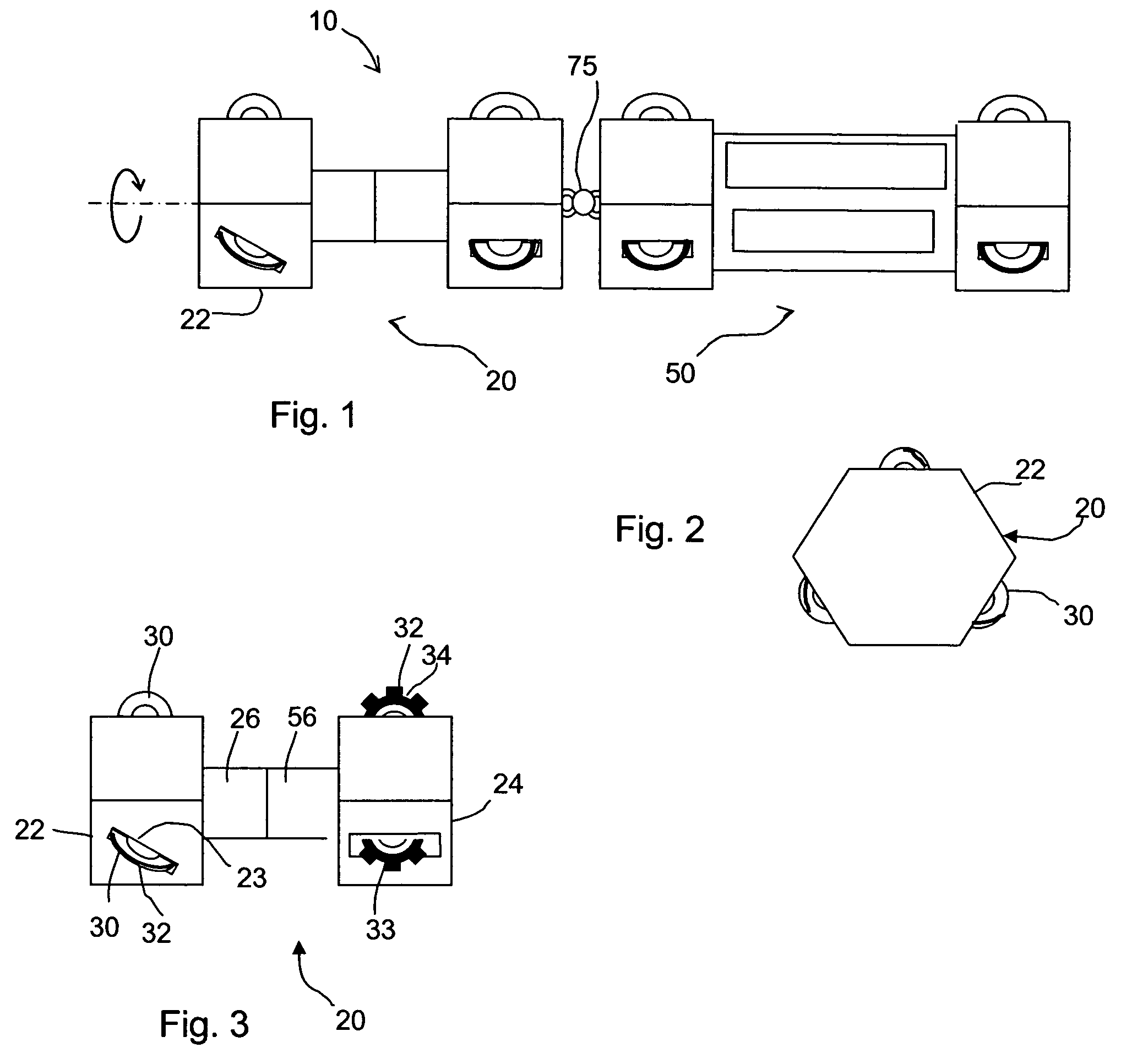

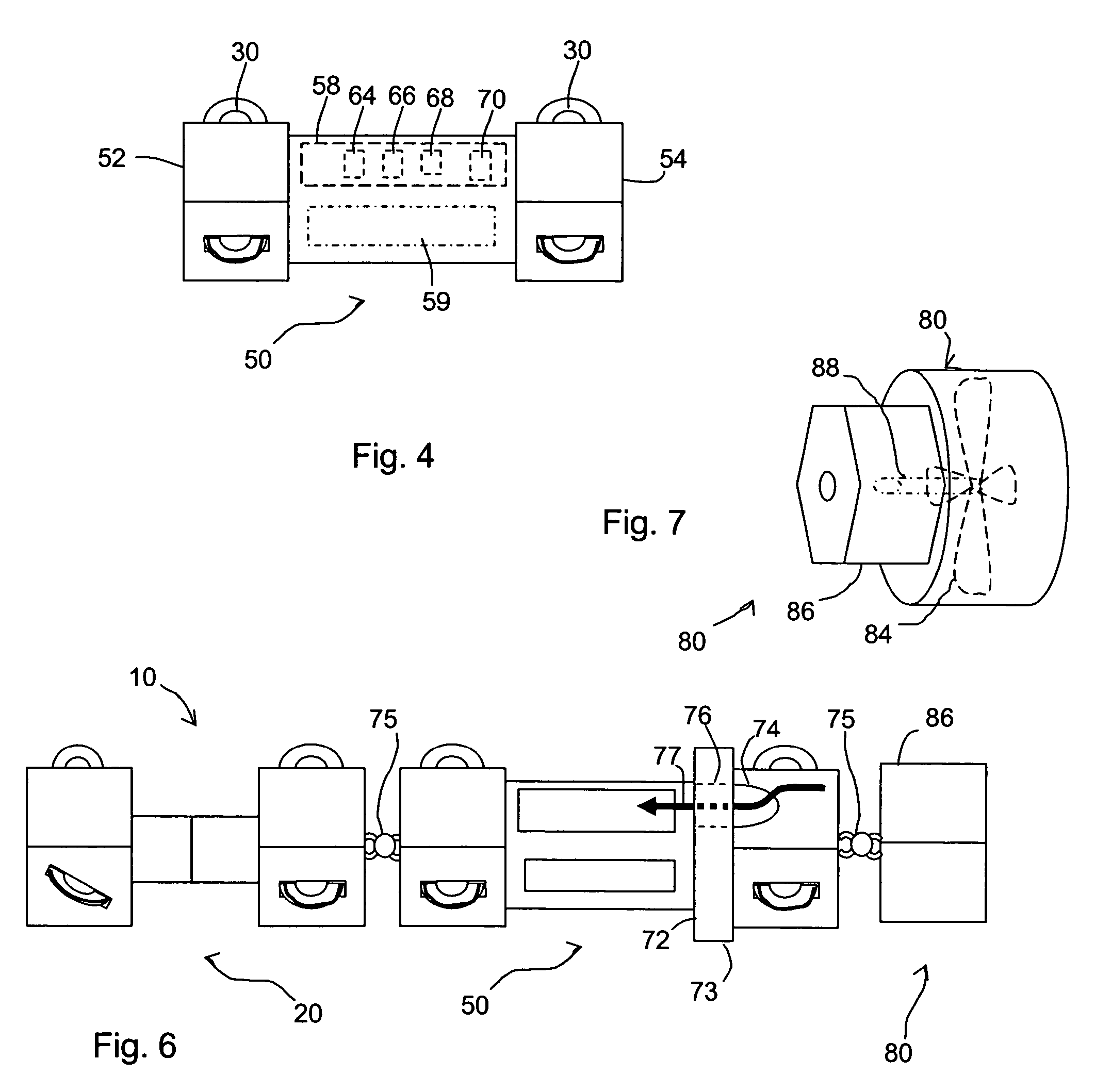

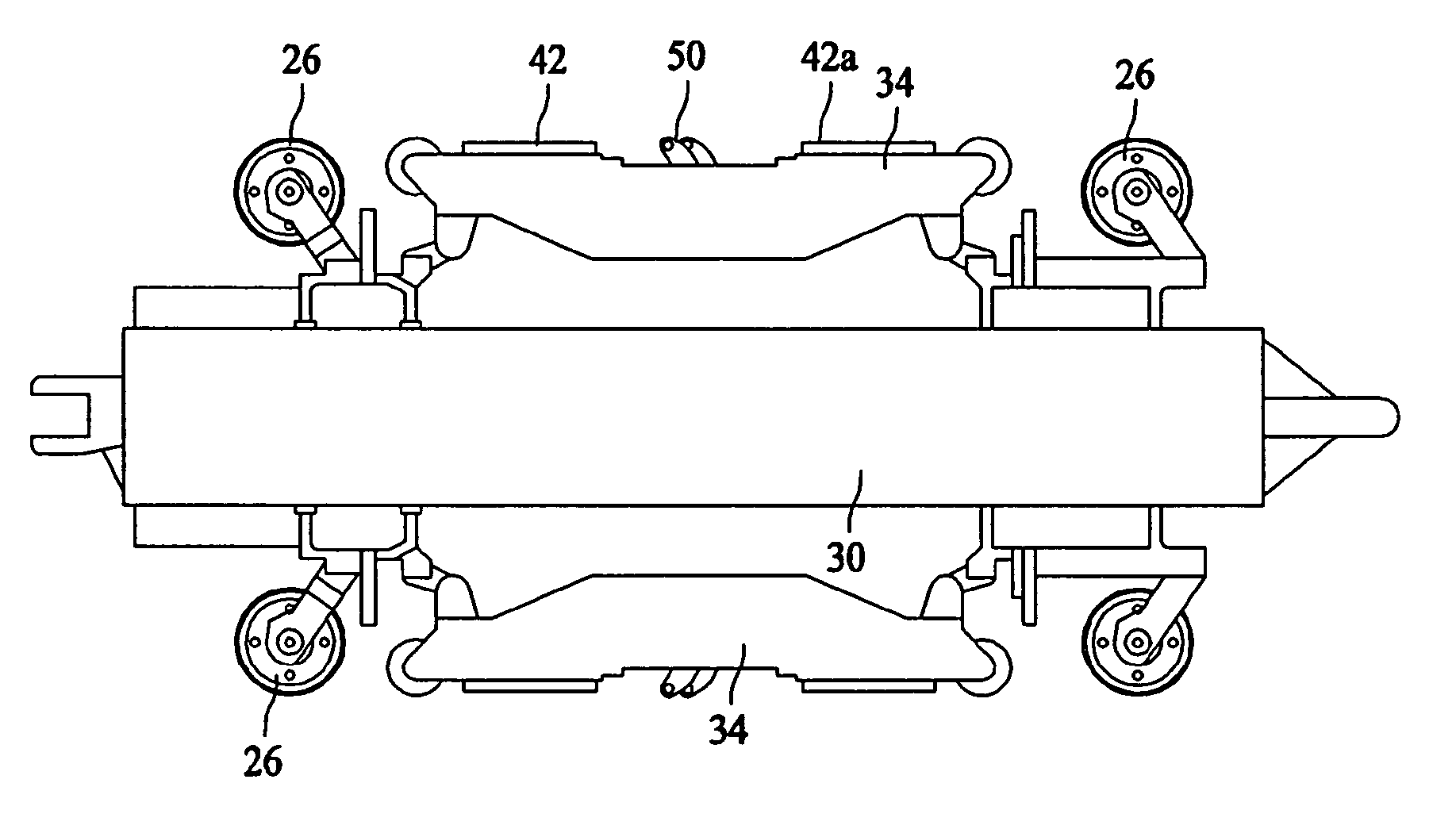

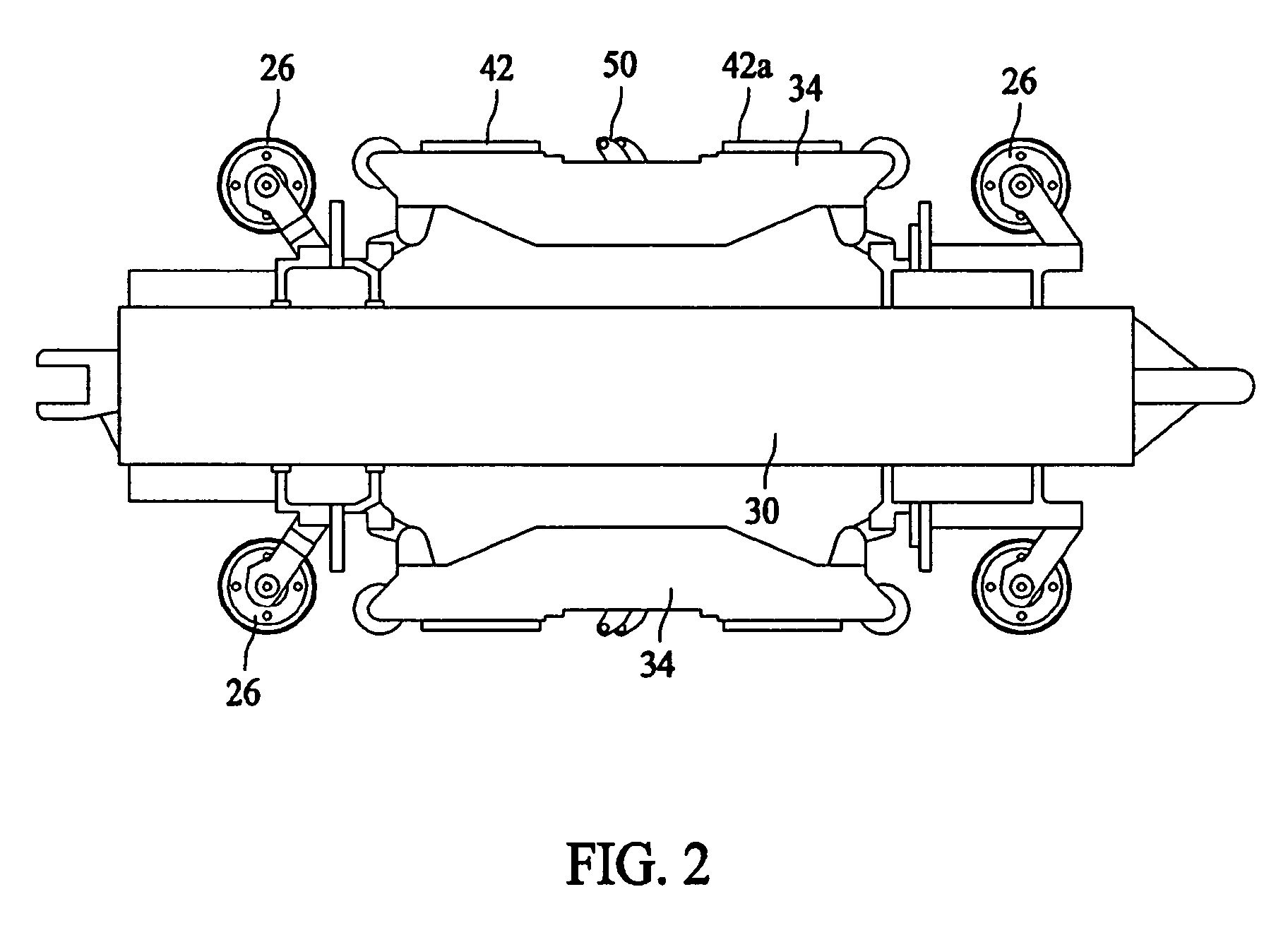

The present invention provides a long-range, untethered, live, in-pipe inspection system that includes a self-propelled train having a plurality of modules; joint members for interconnecting adjacent modules, data collection components, and wireless communication components for transmitting collected data and receiving control messages. The module-train includes, generally, at least one, and preferably two drive modules, at least one power module and an electronics module. The train may additionally include at least one support module, which may be interposed between the power and electronics modules. In one embodiment of the invention, there are two drive modules, one at each terminal end of the train, two power modules, one adjacent to each drive module, two support modules, one adjacent to each power module, and one central electronics and computing module.

Owner:CARNEGIE MELLON UNIV

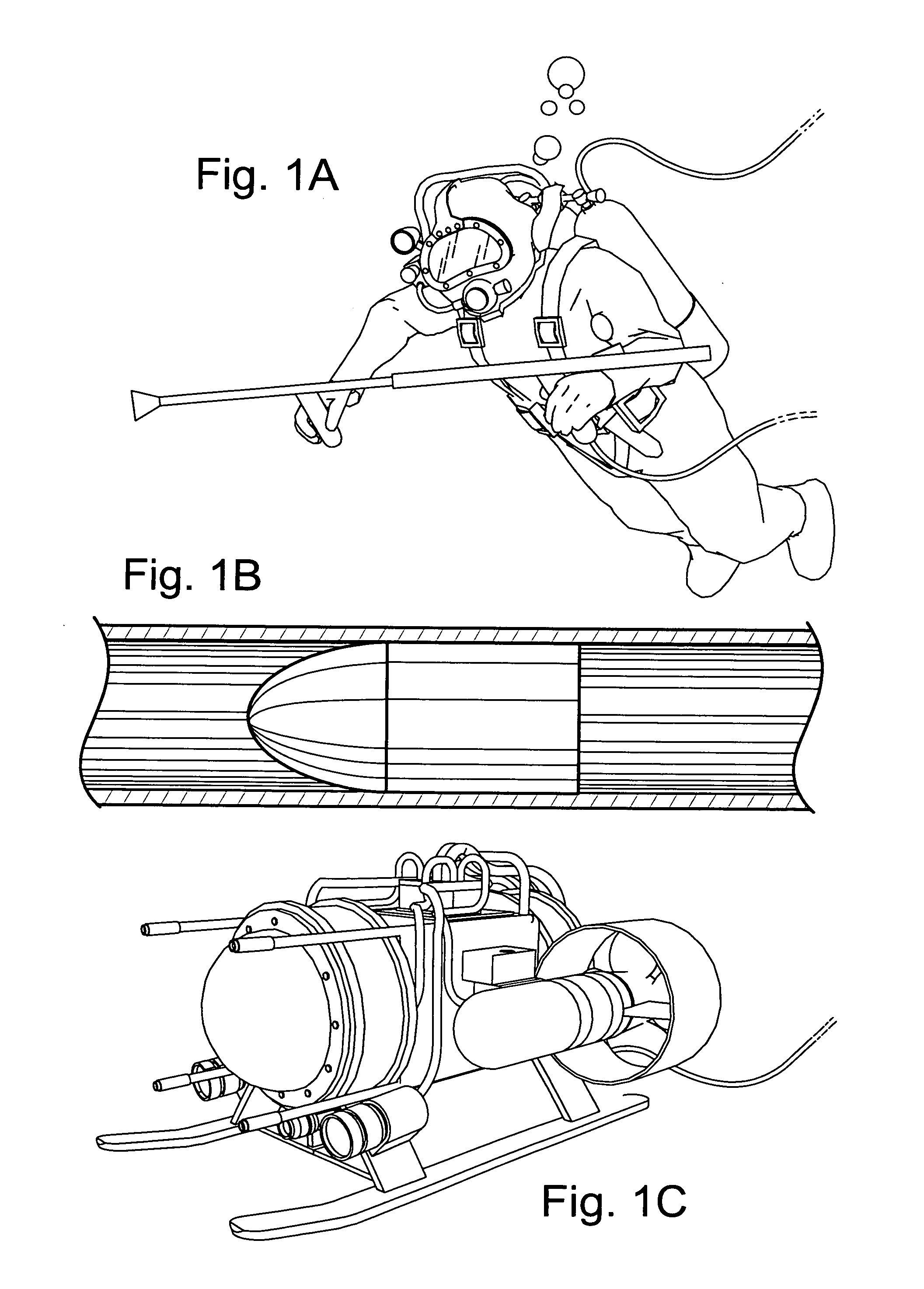

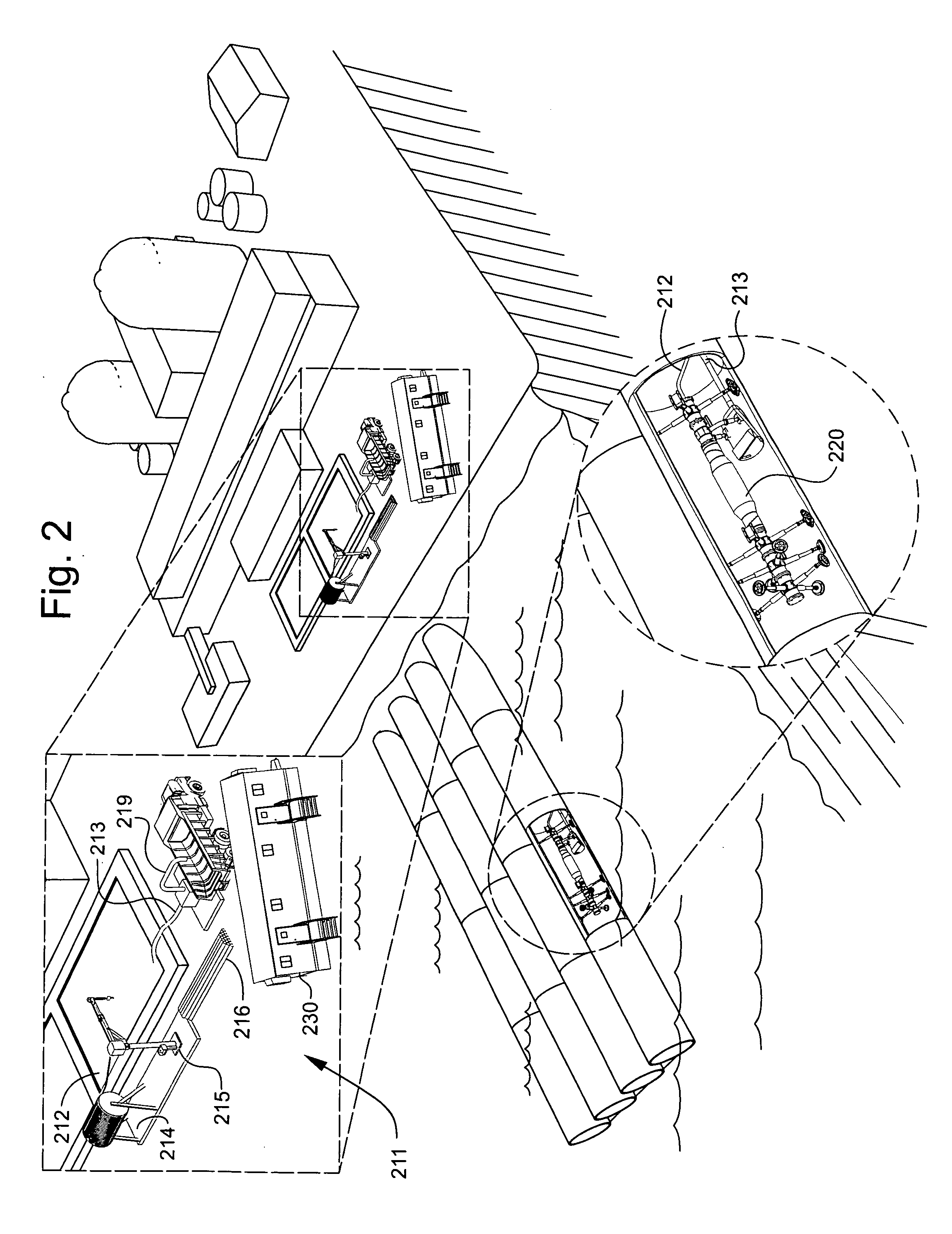

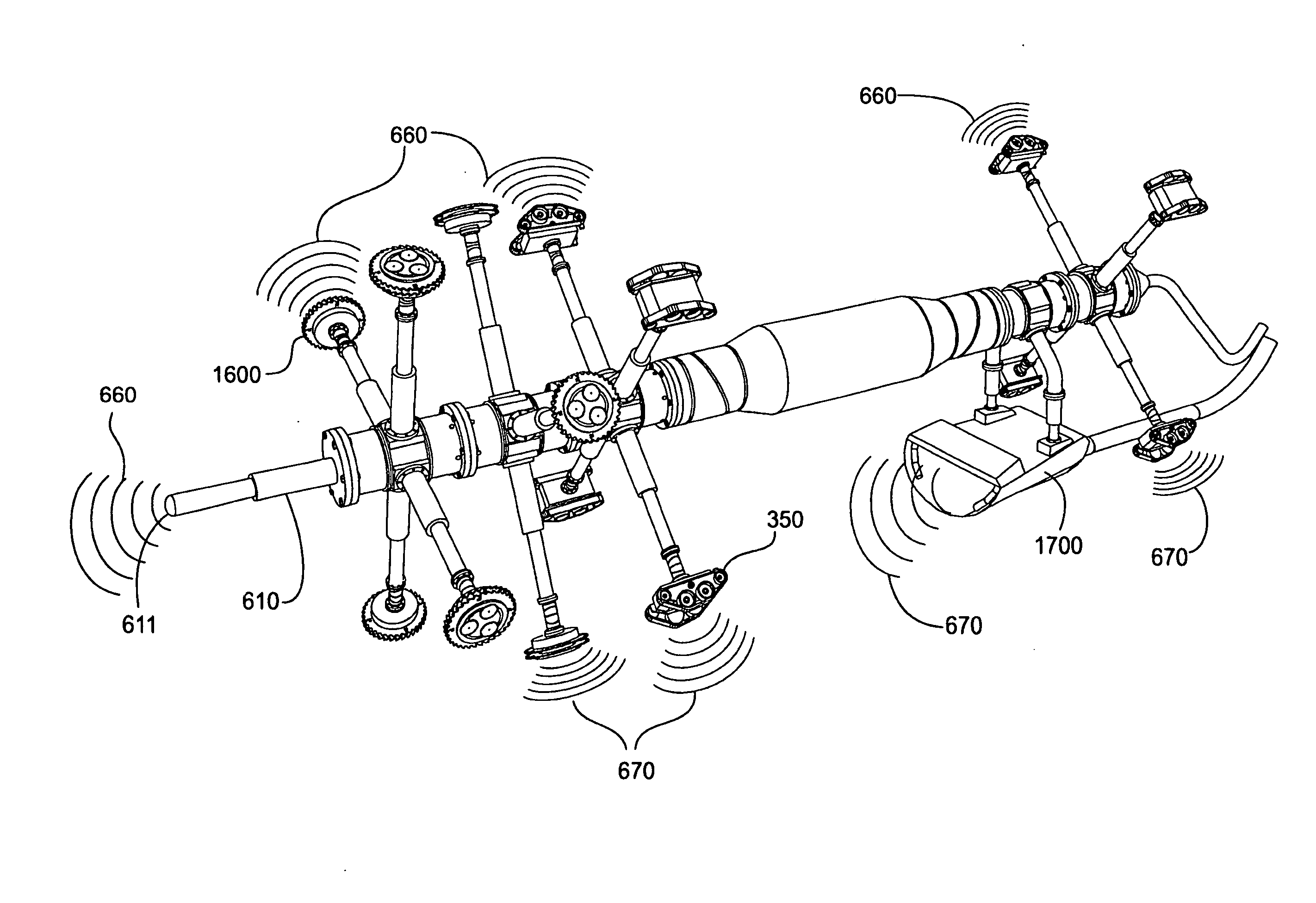

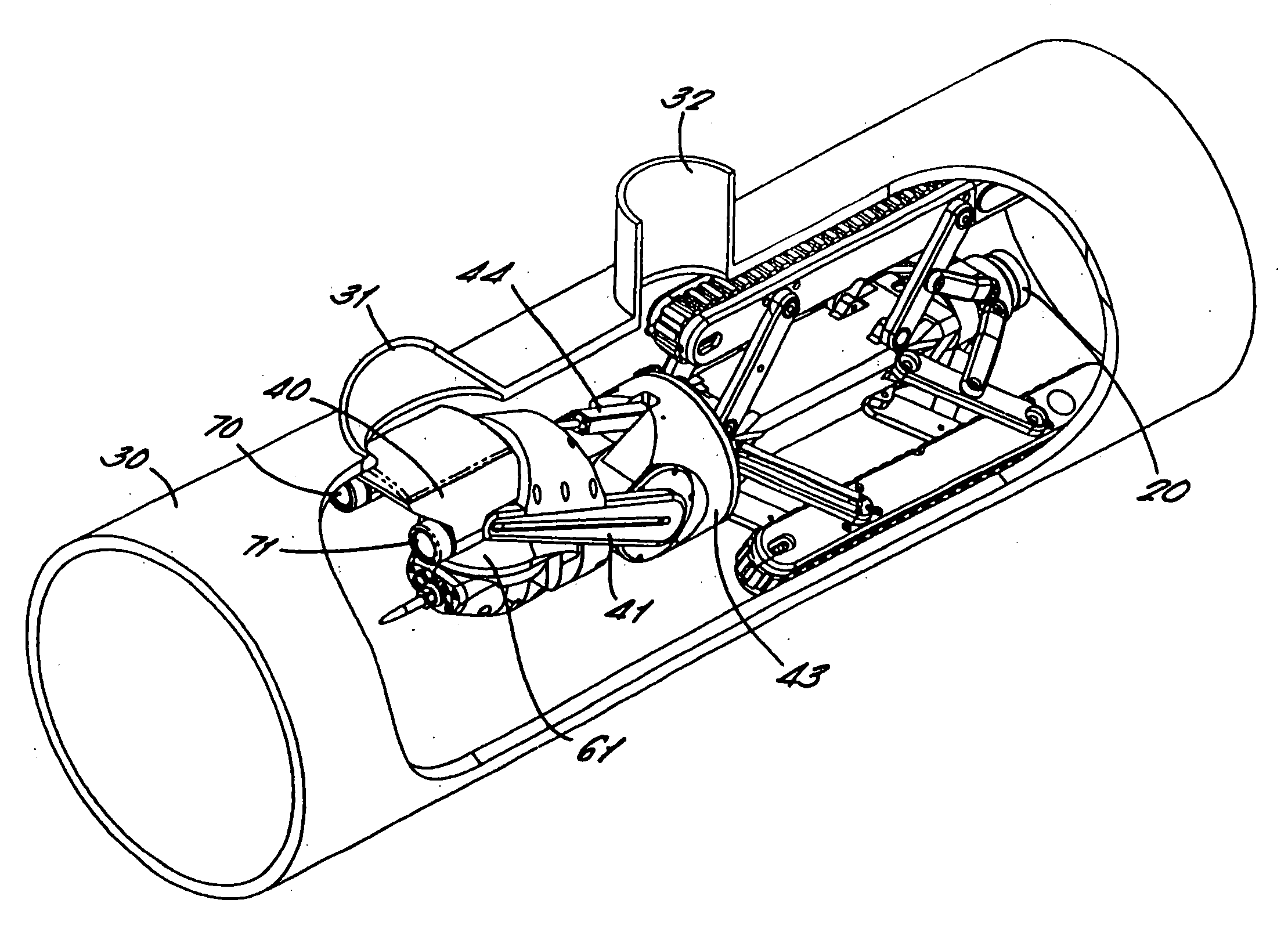

Submersible robotically operable vehicle system for infrastructure maintenance and inspection

InactiveUS20120215348A1Programme-controlled manipulatorDigital data processing detailsElectric powerInstrumentation

A configurable robotic apparatus and system is disclosed that is remotely operable in difficult, hazardous, subterranean, or submerged environs. The apparatus merges diverse disciplines to effect inspecting, cleaning, treating, repairing or otherwise maintaining a wide variety of materials and conditions. Deployment environments include power, municipal water and wastewater plants, surface and submerged infrastructures (pipes, lines, conduits), and like industrial applications. Extensible and articulating modules, configurable through standardized and interchangeable connectors, provide unique flexibility, scalability and versatility to accommodate a wide range of shapes, surfaces, and obstacles. In-module intelligence and instrumentation eliminates the need for constant manual control through autonomous operation capable of simultaneous optimization and synchronization of multiple work processes, but manual override and remote control is provided to overcome unanticipated limitations. Benefits include improved efficiency, cost, and safety over prior art. High-performance, one-pass operation reduces facility downtime while incorporating environmentally responsible debris recovery.

Owner:SKRINDE RICHARD ARTHUR

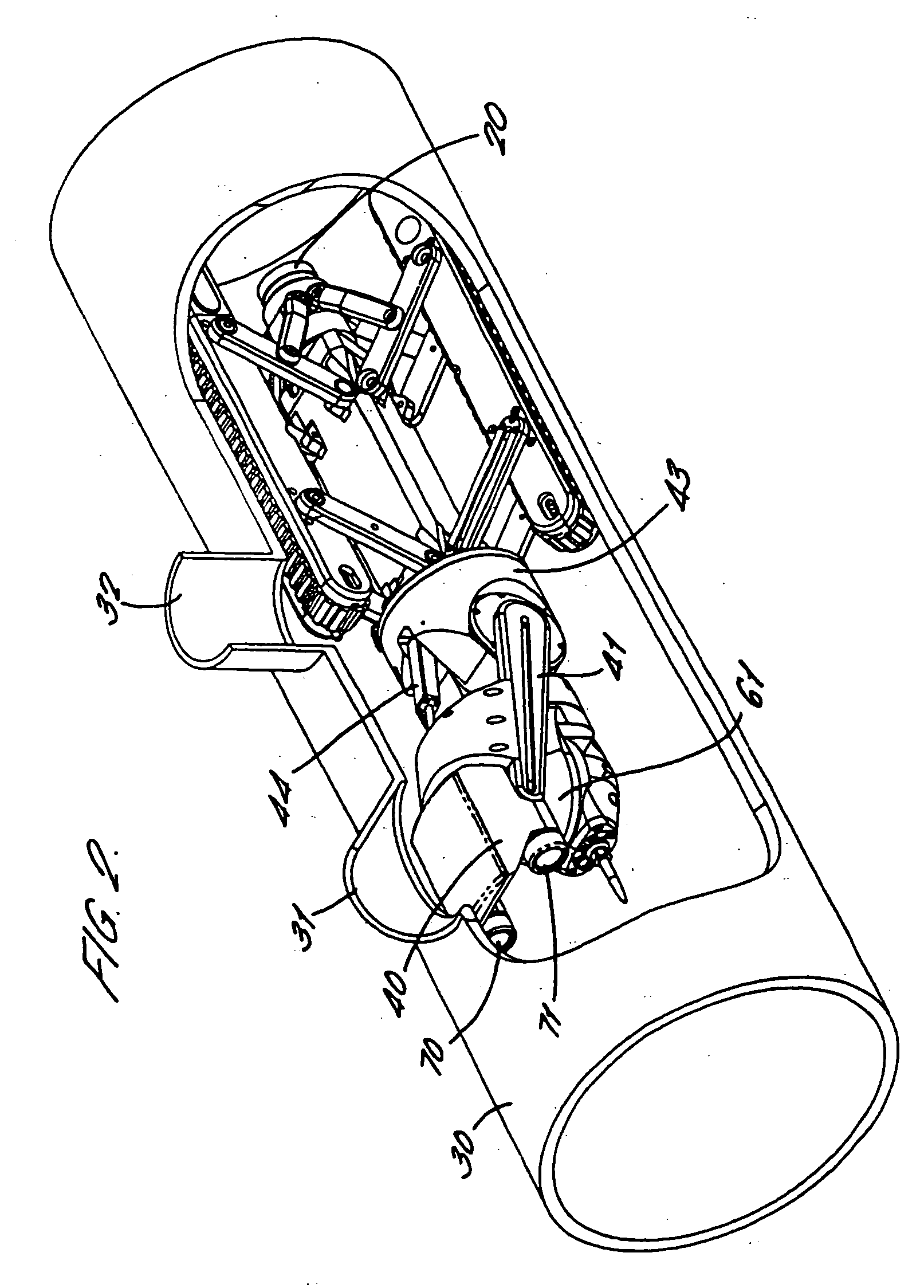

Serpentine robotic crawler

Owner:SARCOS LC

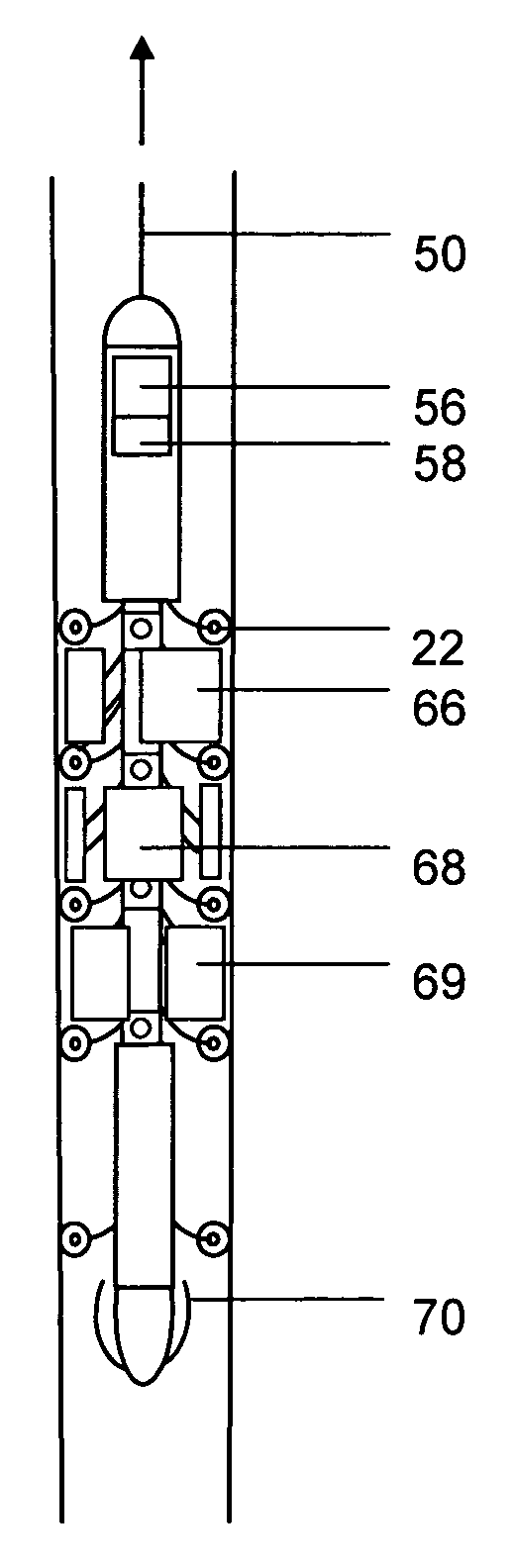

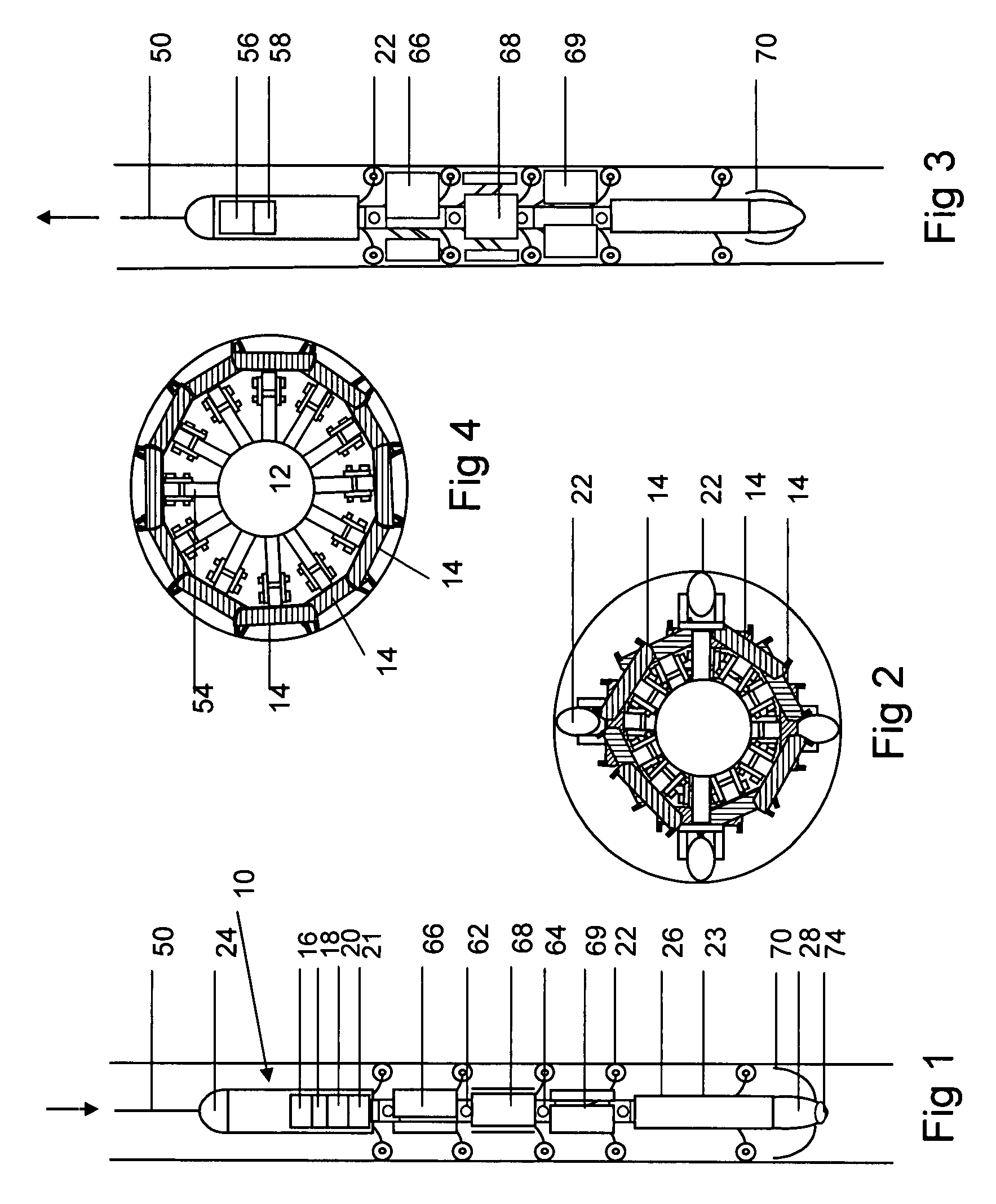

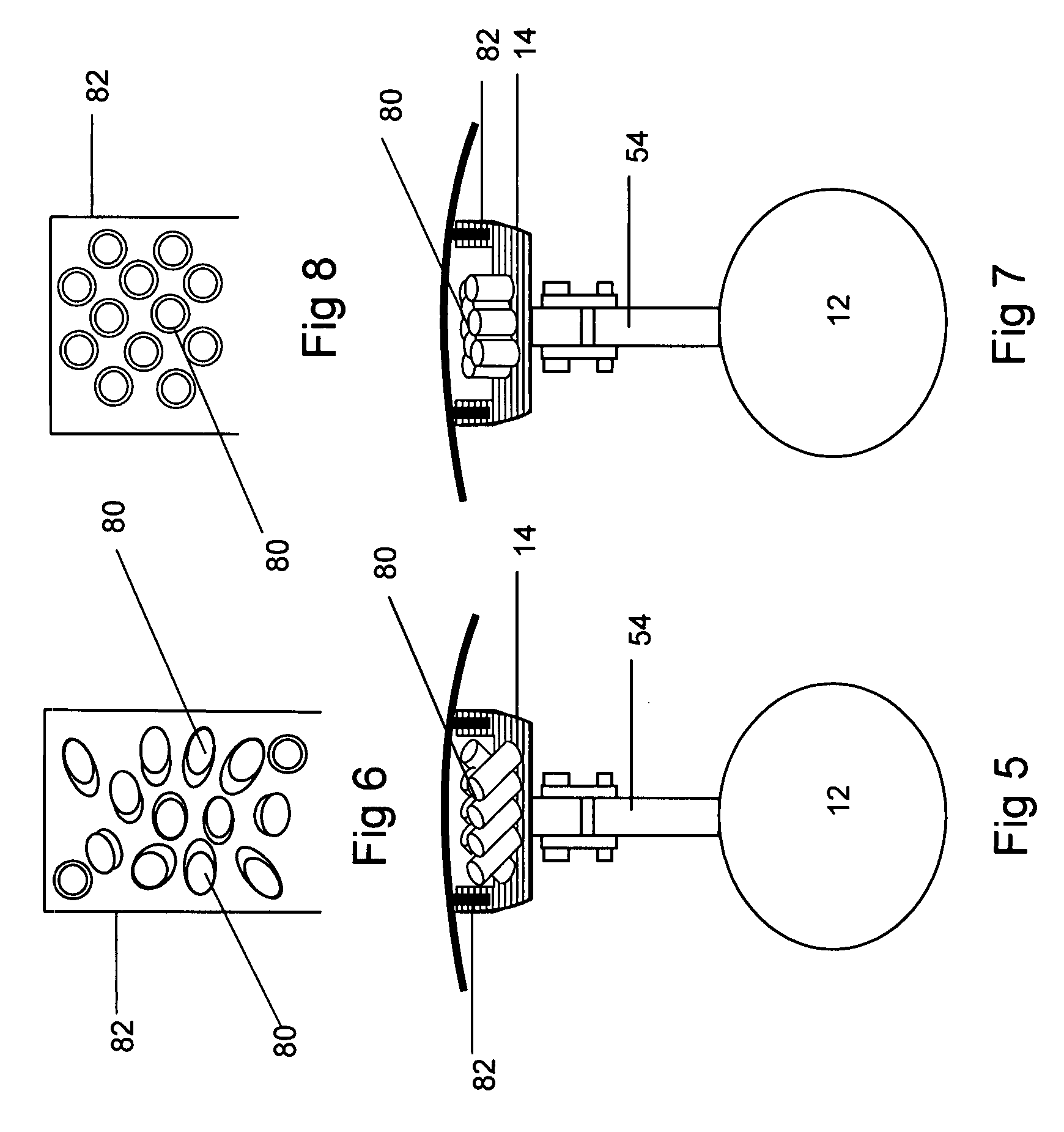

Autonomous robotic crawler for in-pipe inspection

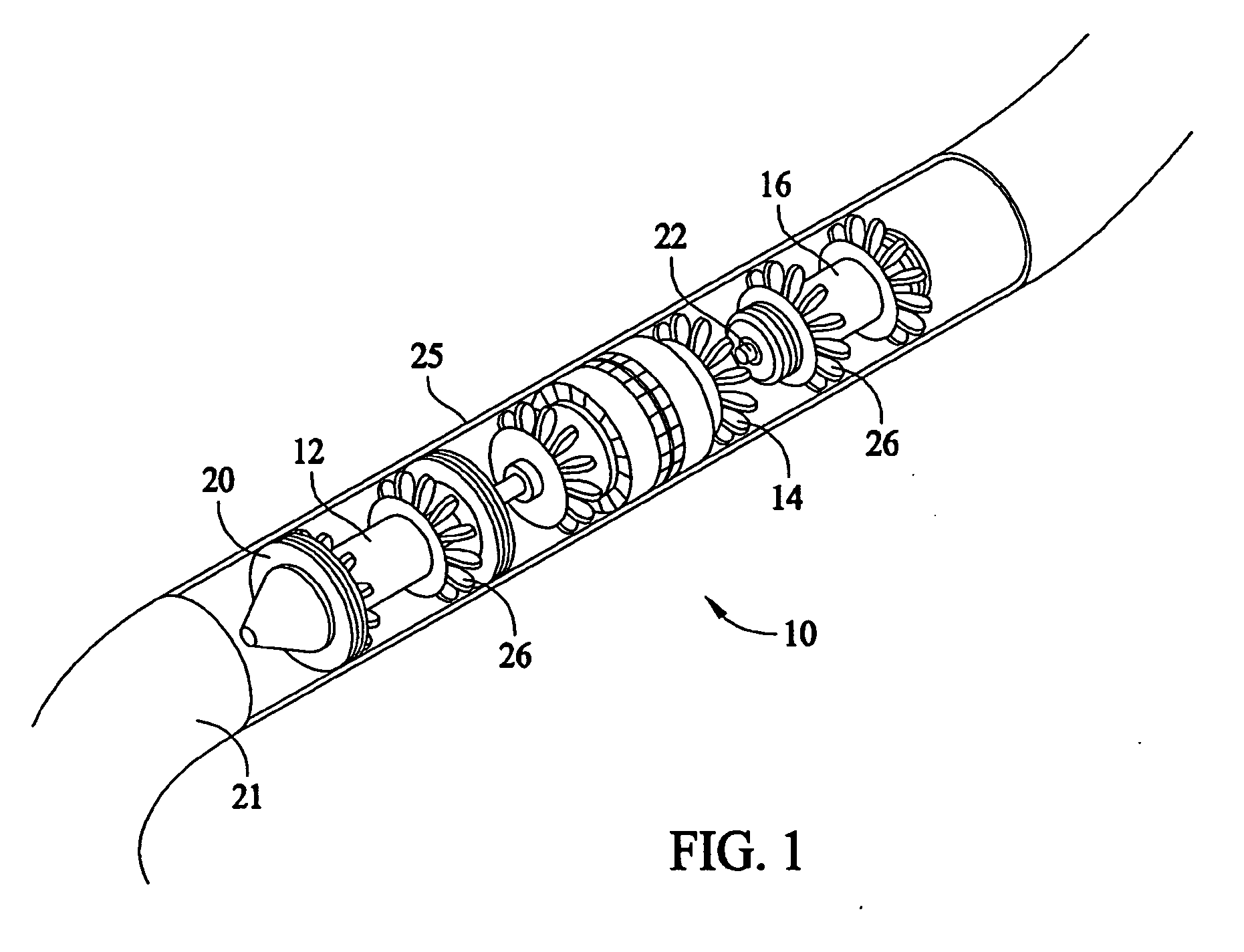

The specification discloses a robot for inspection adapted to travel virtually unlimited distances through small-diameter enclosed spaces such as conduits or ducts, preferably using a fluid-driven screw-drive propulsion system. The robot preferably includes a plurality of wheels inclined at an angle greater than zero degrees and less than ninety degrees to the longitudinal axis of the pipe, a plurality of wheels aligned parallel to the longitudinal axis of the pipe, and a power system for causing relative rotation of the sections bearing the pitched and non-pitched wheels. The robot may include internal fluid flow passages, notched wheels, multiple retractable wheels, and is configured so as to have an operating diameter less than six and preferably less than two inches.

Owner:RICE UNIV +1

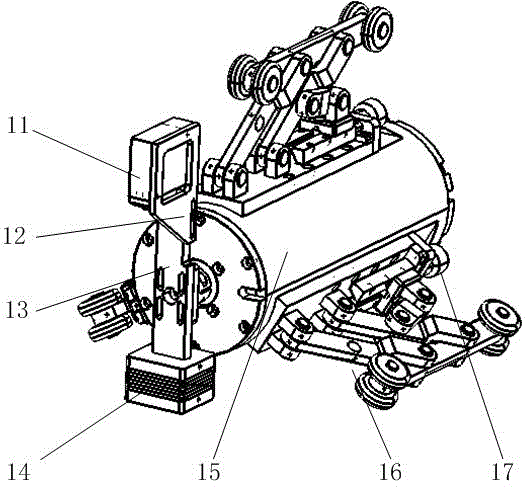

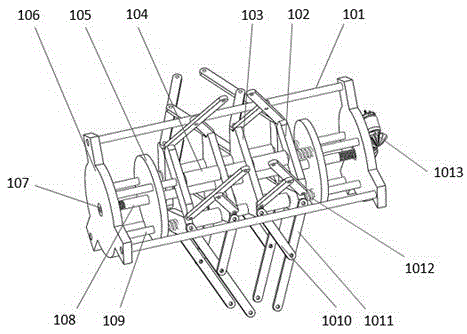

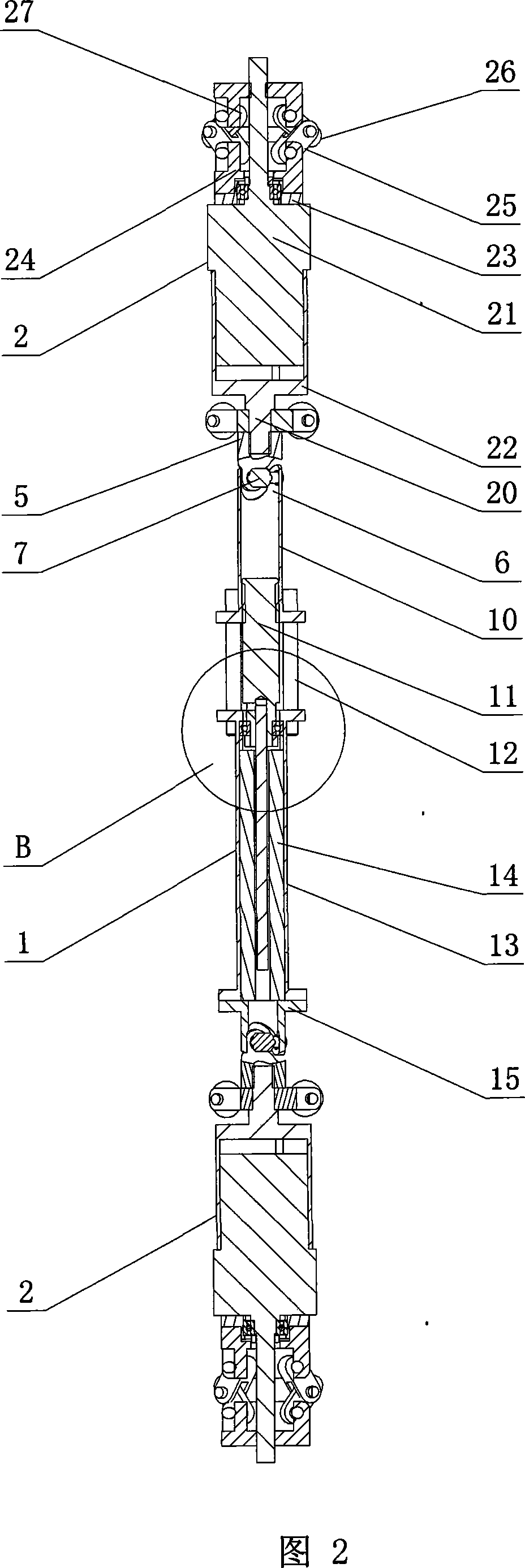

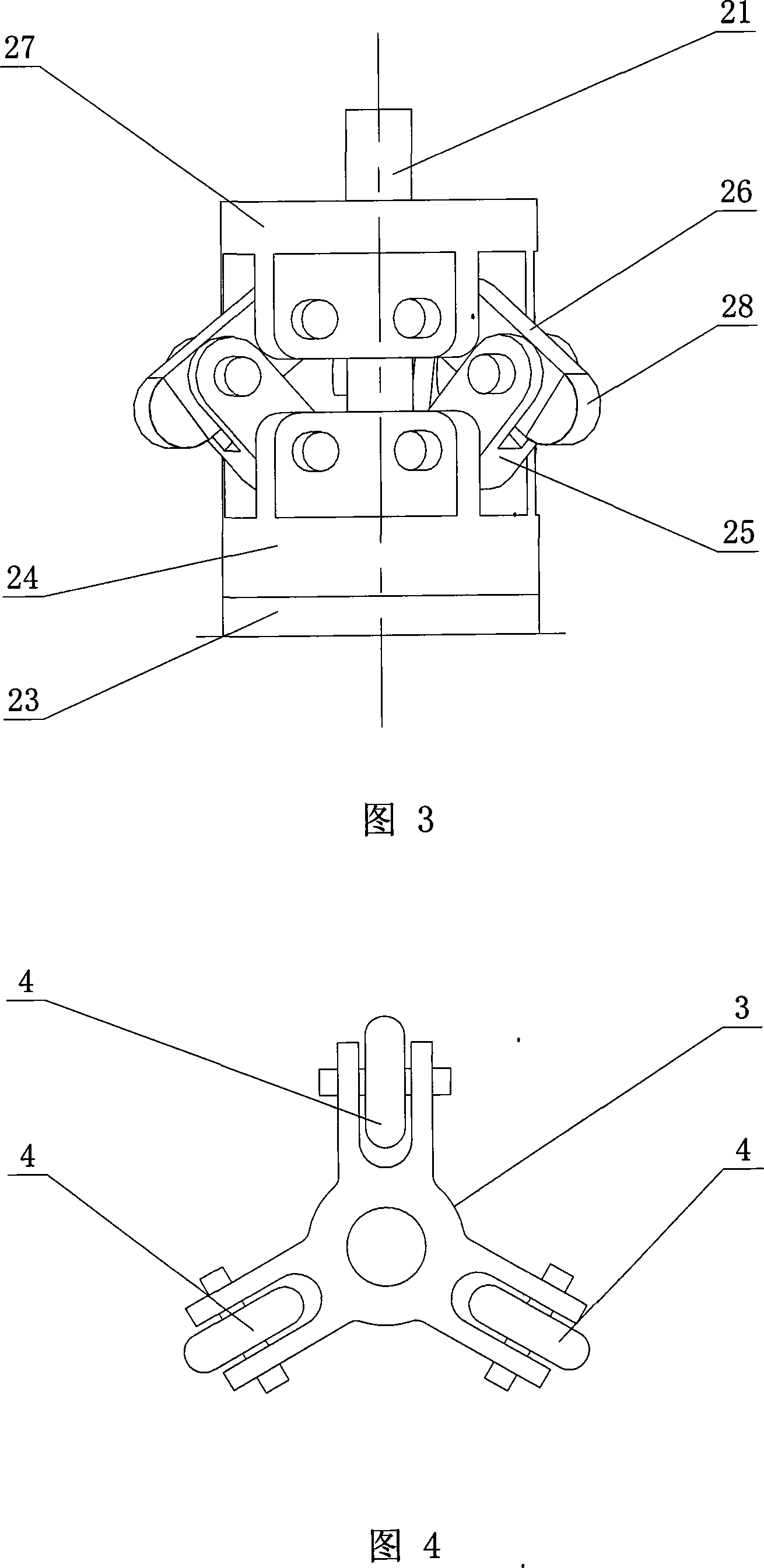

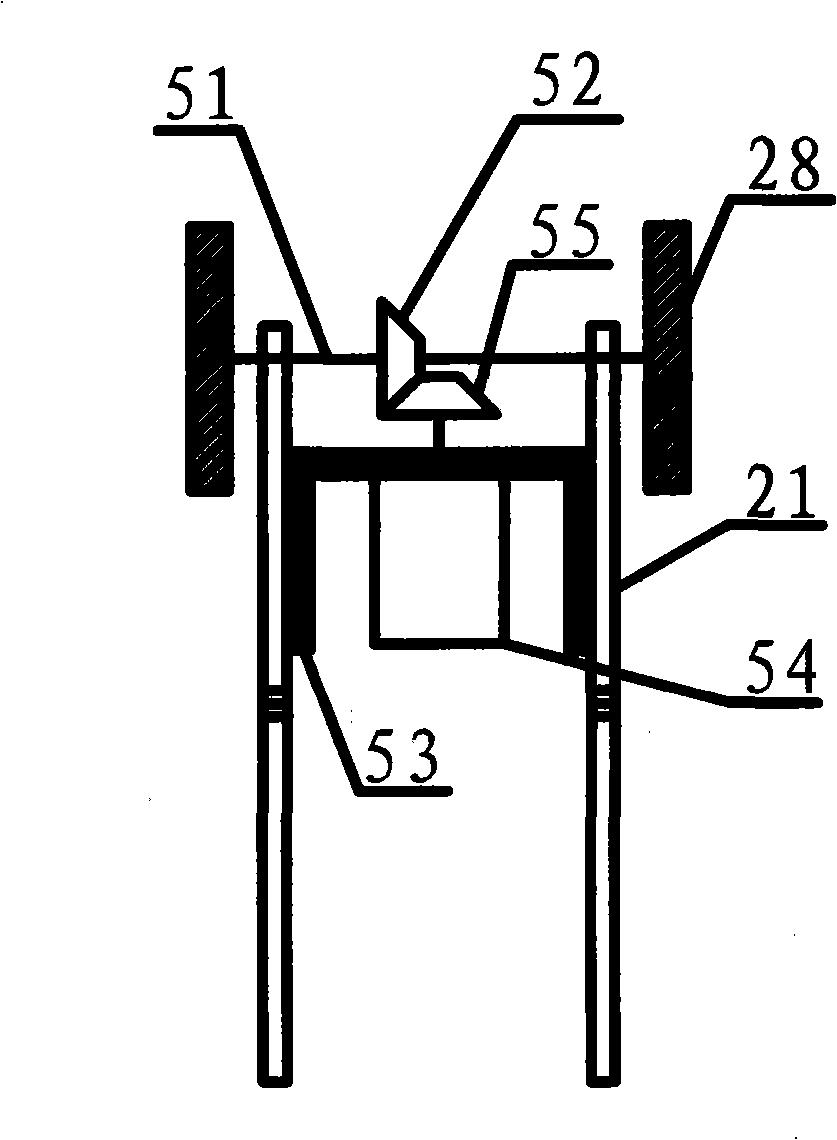

Drive running mechanism of pipeline robot

The invention relates to a drive running mechanism of a pipeline robot, which mainly solves the problems of the existing drive running mechanism of the pipeline robot that the pulling force is smaller, the pipe diameter adaptability is poorer, the ability of surmounting obstacles is insufficient and the like. The invention is characterized in that the drive running mechanism also comprises a wheel leg regulating motor arranged in a body, three running drive units arranged outside the body, three elastic wheel leg support units formed by combining a front support connecting rod, a rear support connecting rod and a regulating connecting rod, and a pipe diameter adaptation adjustment unit; and the body, the front support connecting rod, the rear support connecting rod and running drive units form a parallelogram wheel leg structure; after sensing the pressure from pipe walls, the pipe diameter adaptation adjustment unit regulates the front support connecting rod and the rear support connecting rod so as to adapt to the pipe diameter changes; and each running drive unit is driven by two motors so that larger pulling force can be ensured. The mechanism of the invention has larger pulling force, larger pipe diameter regulating range and better ability of surmounting the obstacles; and compared with the prior art, the mechanism has high transmission efficiency.

Owner:DAQING GASOLINEEUM INST

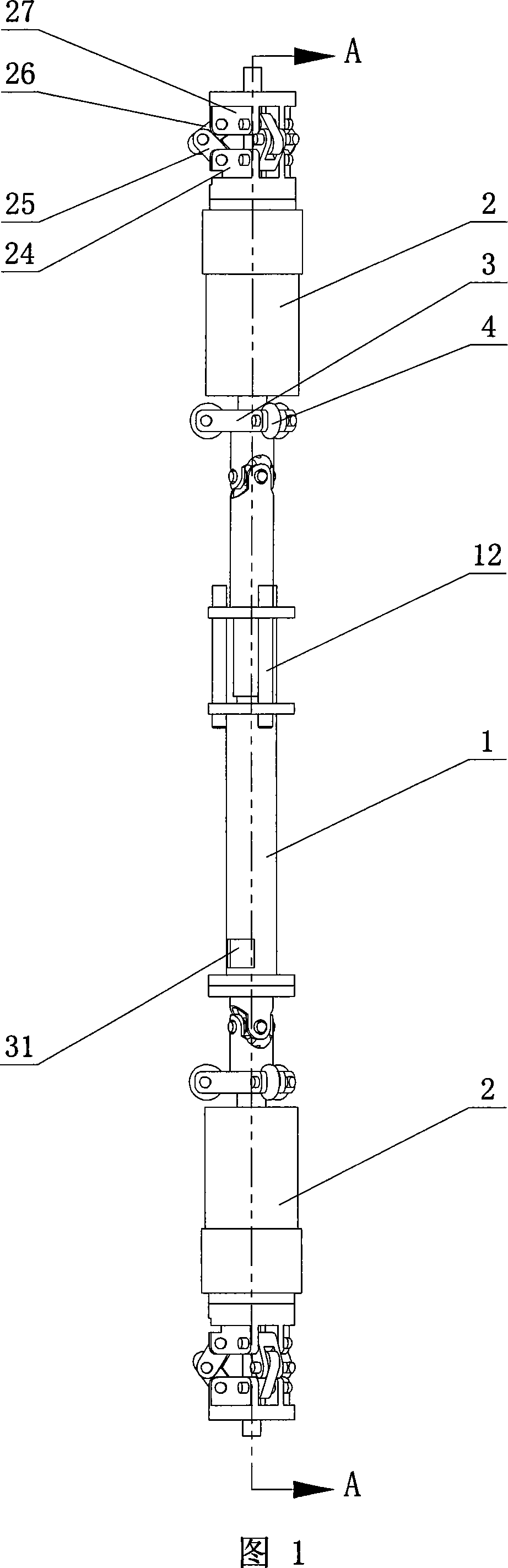

Pipe walking robot and control method thereof

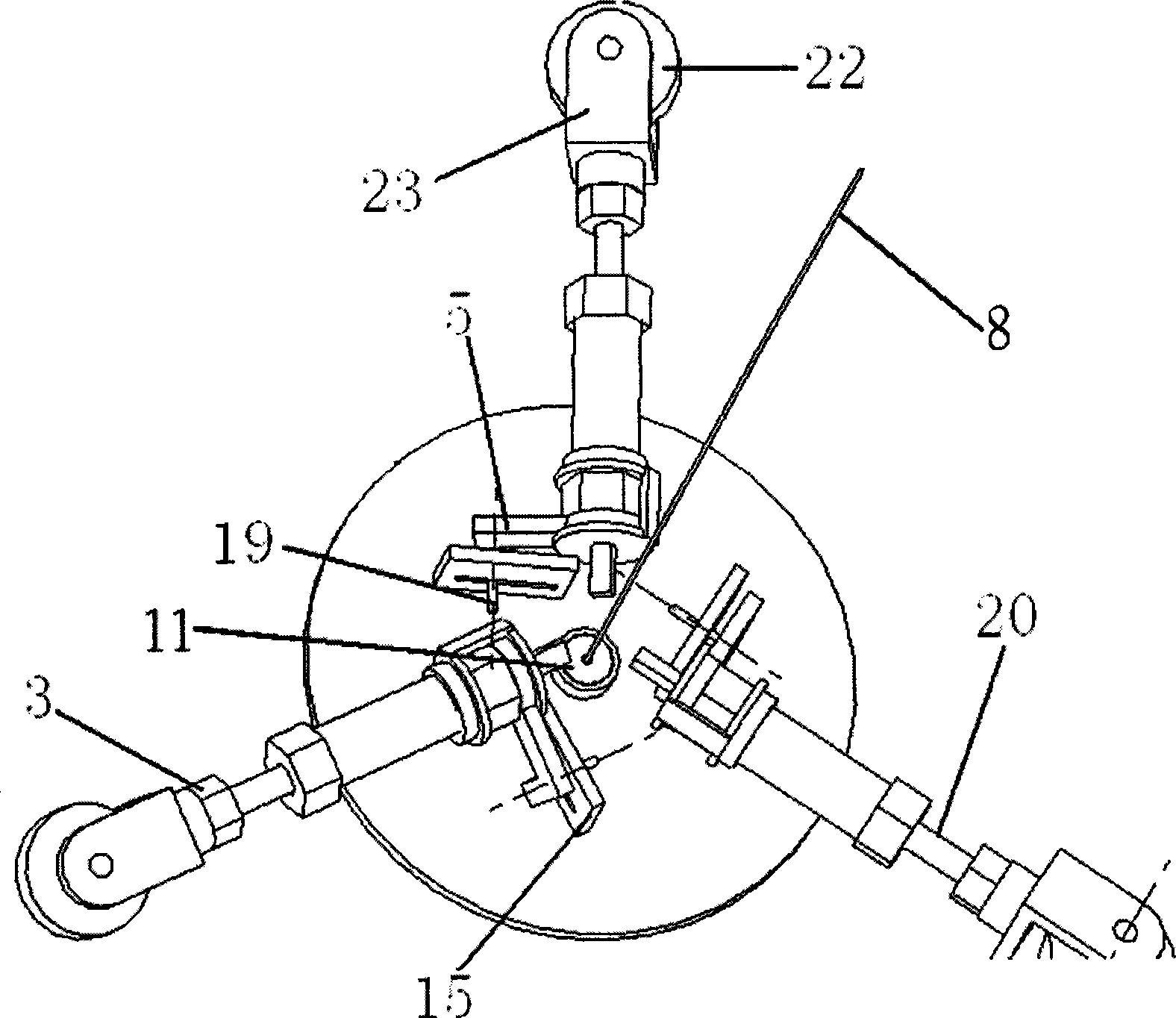

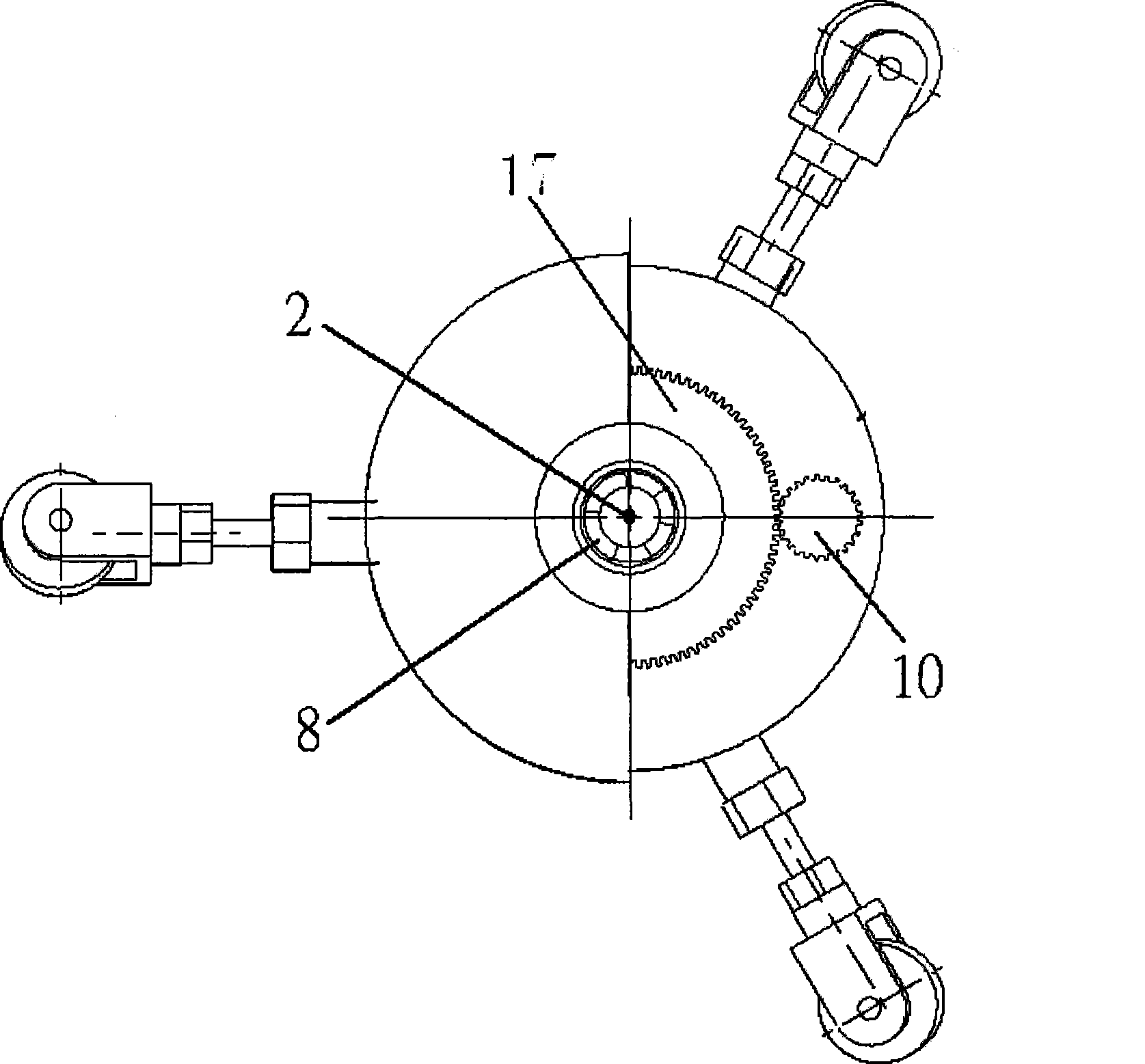

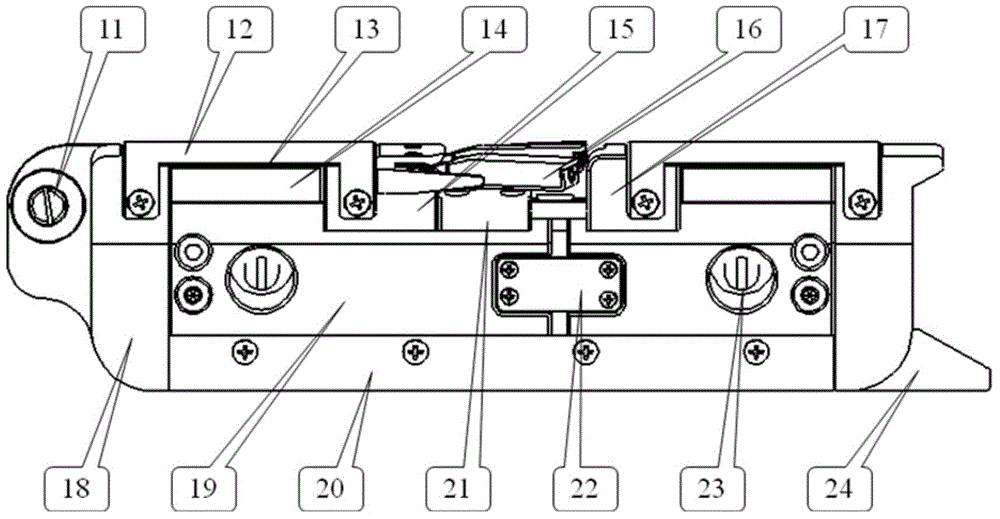

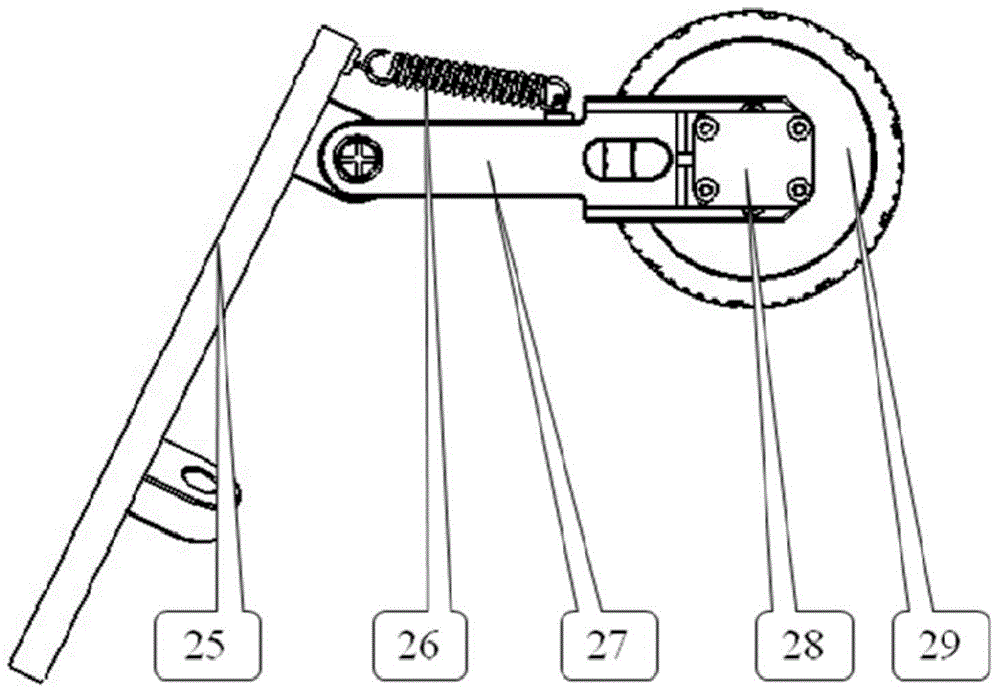

InactiveCN101435522AImprove mechanical efficiencyEasy to operateHollow article cleaningPigs/molesDrive motorEngineering

The invention relates to a pipeline cleaning robot applied to industrial field, and also relates to a method for controlling the walking robot. The robot comprises a connection shaft (2), a supporting leg (3), a drive plate (4), a pusher dog (5), a connection rope (8), a variable pitch motor (9), a drive motor (10), a cleaning device (12) and a roller wheel device (14), wherein the connection rope (8) passes through the drive plate (4), and is connected with variable pitch motor (9); the supporting leg (3) which can retractably rotate is connected with the drive plate (4); the drive motor (10) is connected with another frame shell end part (18) through a gear disc (17) and the connection shaft (2); the supporting leg extends out of a frame shell (13), and is contacted with the inner surface of the pipeline; and the cleaning device (12) is arranged on the frame shell (13). With the scheme, the robot is more efficient, can turn a curve smoothly, can be controlled more easily, has the advantages of simple structure and convenient manufacture, and is applicable to pipelines with different diameters.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

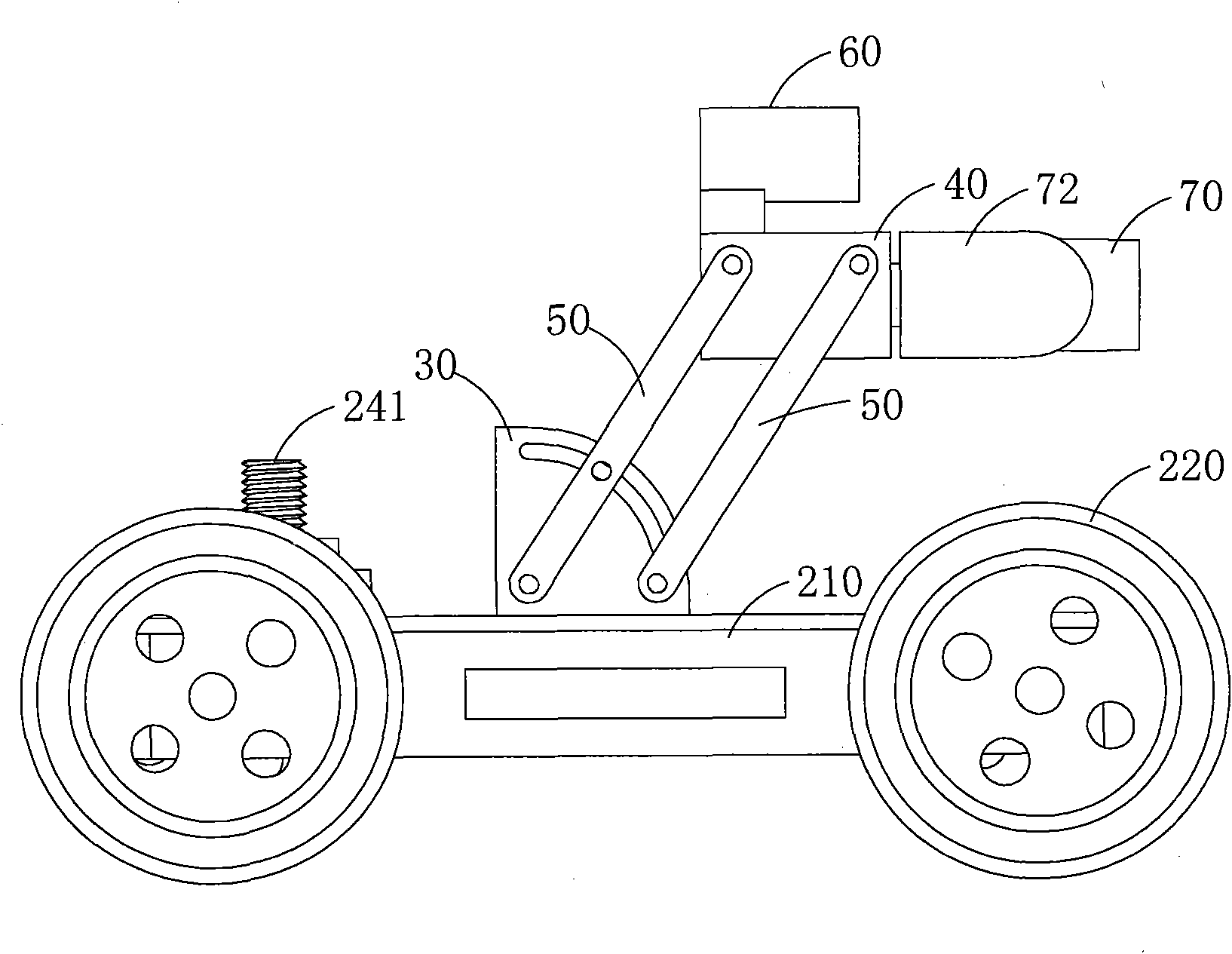

Pipeline robot

The invention relates to a pipeline robot, which comprises a main pipeline robot body. The main pipeline robot body comprises a moving carrier, and the moving carrier comprises a carriage body, wheels, flexible wheel shafts, a rocker and slider mechanism, and also comprises a robot base, a holder, a rod mechanism, a lighting lamp and a camera connected with the holder, wherein the flexible wheel shafts are used for connecting the carriage body and the wheels; the rocker and the slider mechanism is connected with the carriage body and the flexible wheel shafts and used for adjusting included angles between the wheels and the carriage body; the robot base is arranged on the moving carrier; the rod mechanism is used for connecting the holder and the robot base; and the lighting lamp is arranged on the holder. The included angles between the robot wheels and the carriage body are adjustable so as to ensure that when the robot works in pipelines with different diameters, the peripheries of the wheels are still in vertical contact with wall surfaces, therefore, a contact area between the peripheries and the pipeline wall surface is increased, the robot can operate more stably in the pipeline; and moreover, the structure can provide larger driving force. The flexible shafts are adopted for connecting the driving wheels and the carriage body so that the included angles between the wheels and the main pipeline robot body are adjustable and the sufficient driving force can be ensured.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Spiral driving pipeline robot

The invention discloses a spiral driving pipeline robot. The spiral driving pipeline robot comprises a robot body and a remote control box which are connected with each other through an cable, the robot body comprises a driving mechanism, a walking mechanism and a control system, the driving mechanism comprises a driving wheel rack, driving wheels are mounted on the driving wheel rack, the walking mechanism comprises a walking body, and guide wheels are disposed on the walking body. According to the spiral driving pipeline robot, a spiral driving mode is utilized, the robot can specially work in an elongated pipeline that people can not reach so as to perform cleaning, detecting, wiring and the like, an artificial intelligence control technology is applied, and thereby, the walking process of the robot in the pipeline is smooth. Besides, the spiral driving pipeline robot is high in driving force and stable in moving speed, walking speed and angles of the robot can be changed with the change of working environment by the aid of remote control so as to be adapted to changeable conditions in the pipeline, and specific implementation of investigation, cleaning and the like in actual application is facilitated.

Owner:张瀚文

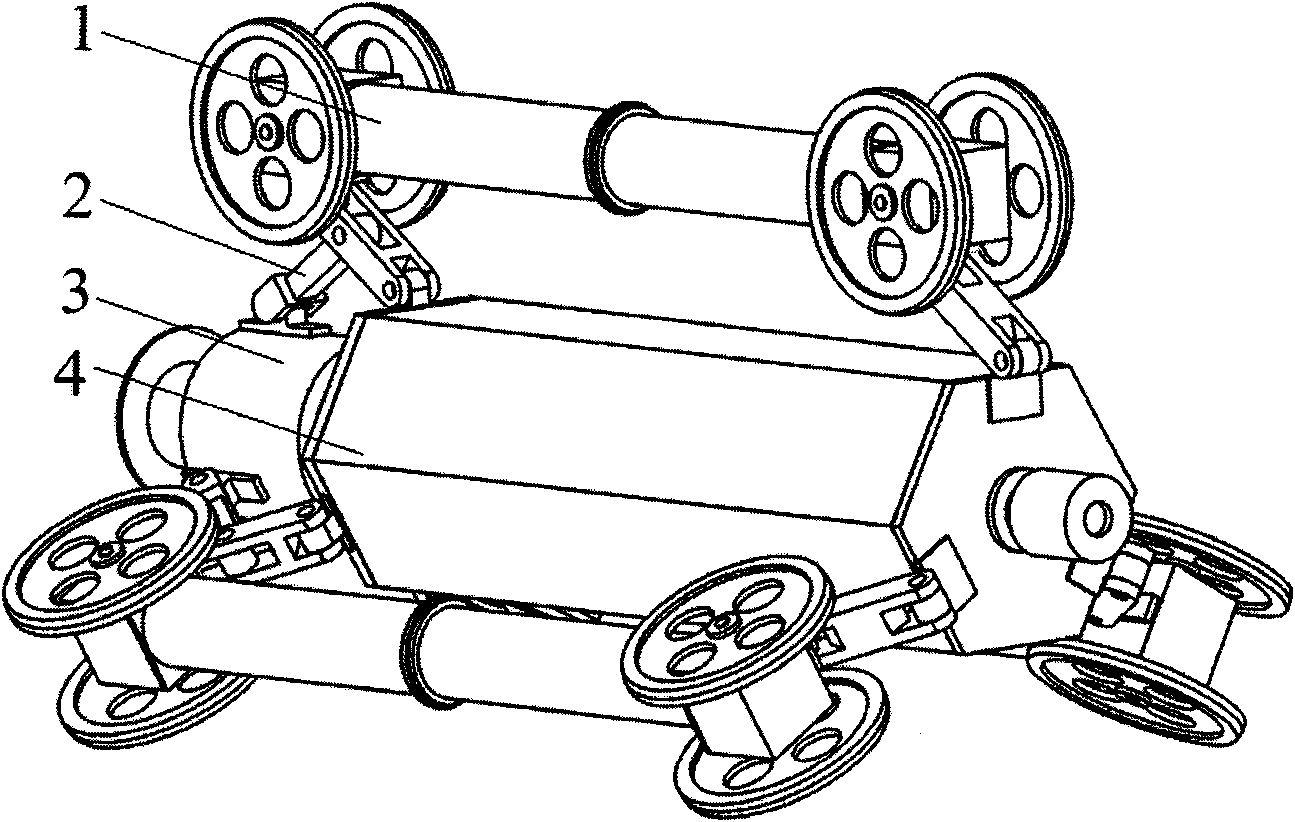

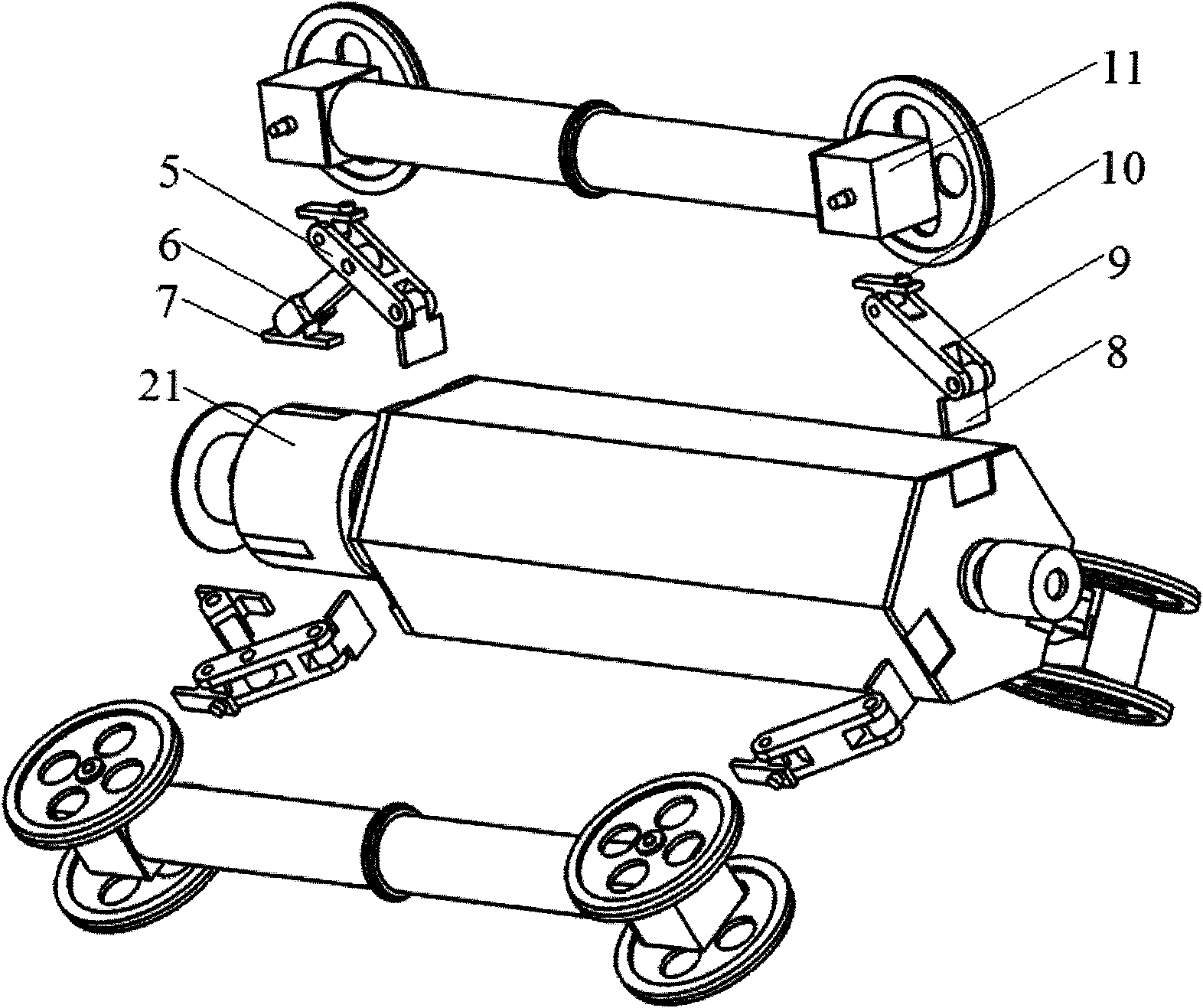

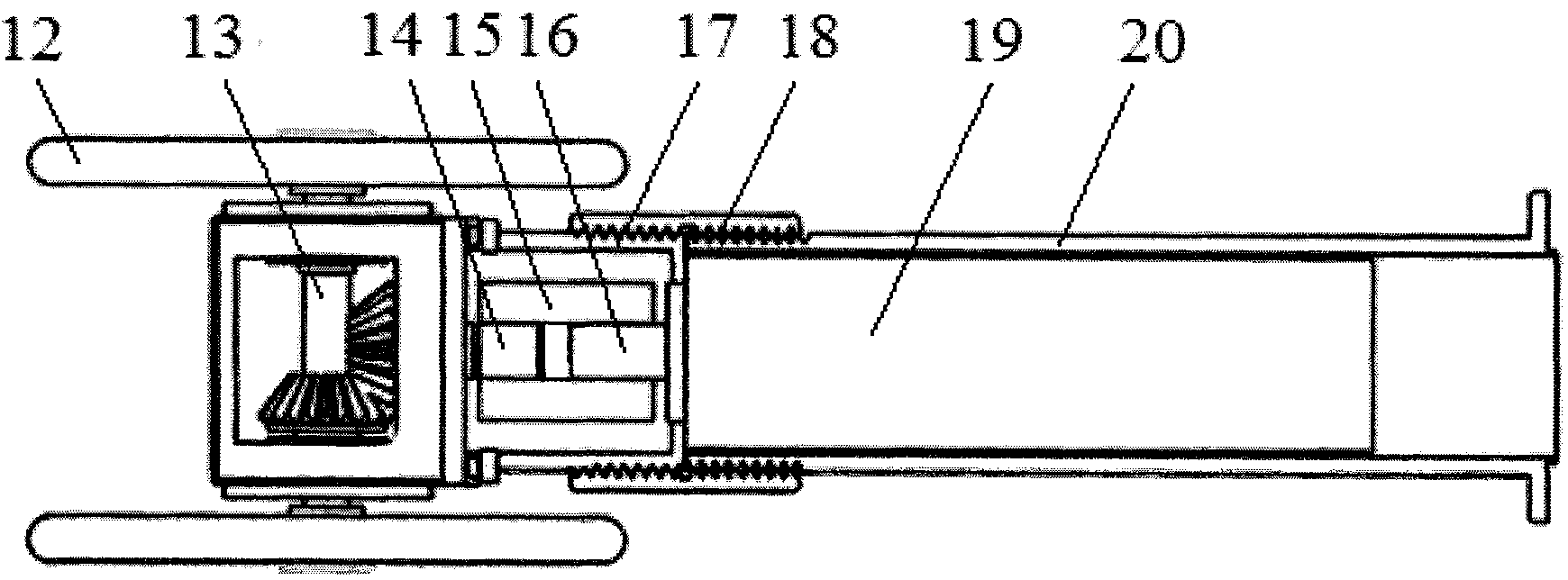

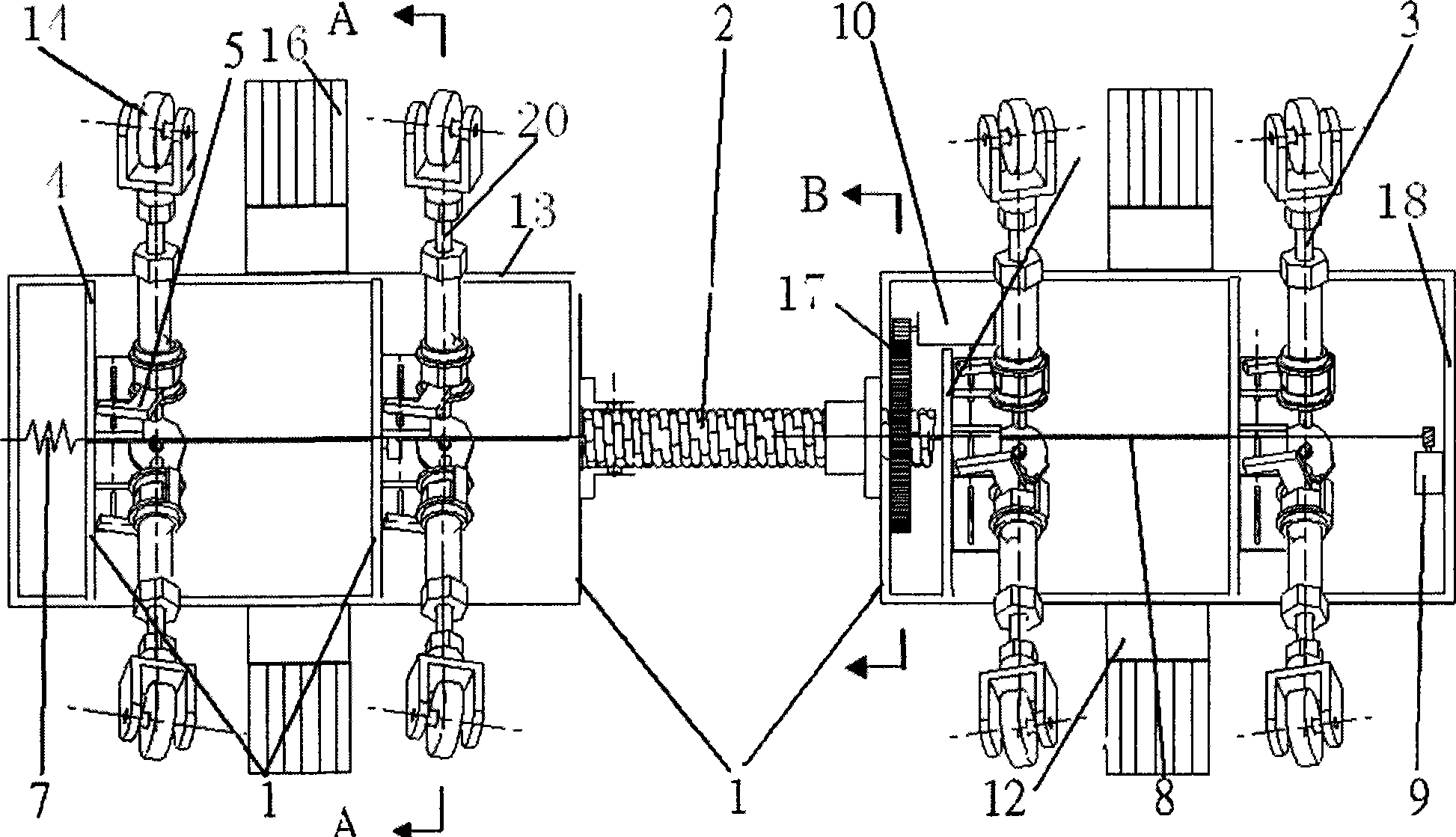

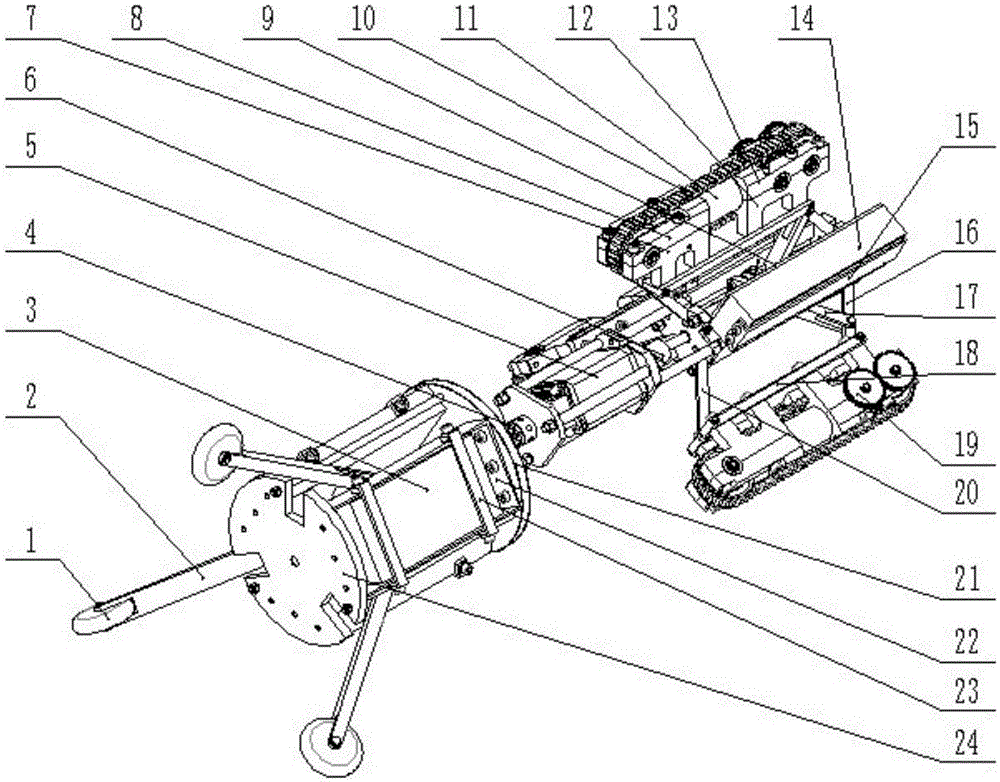

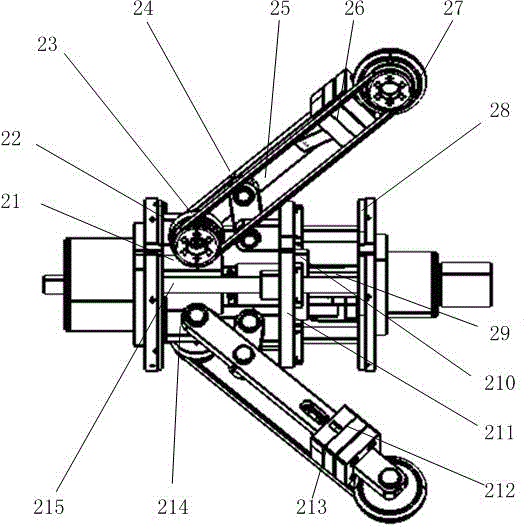

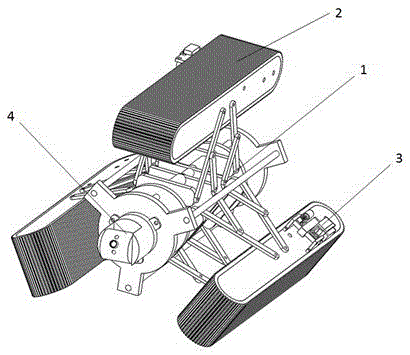

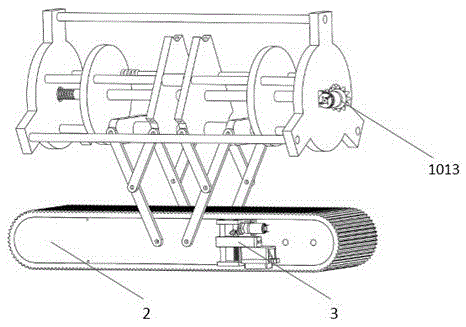

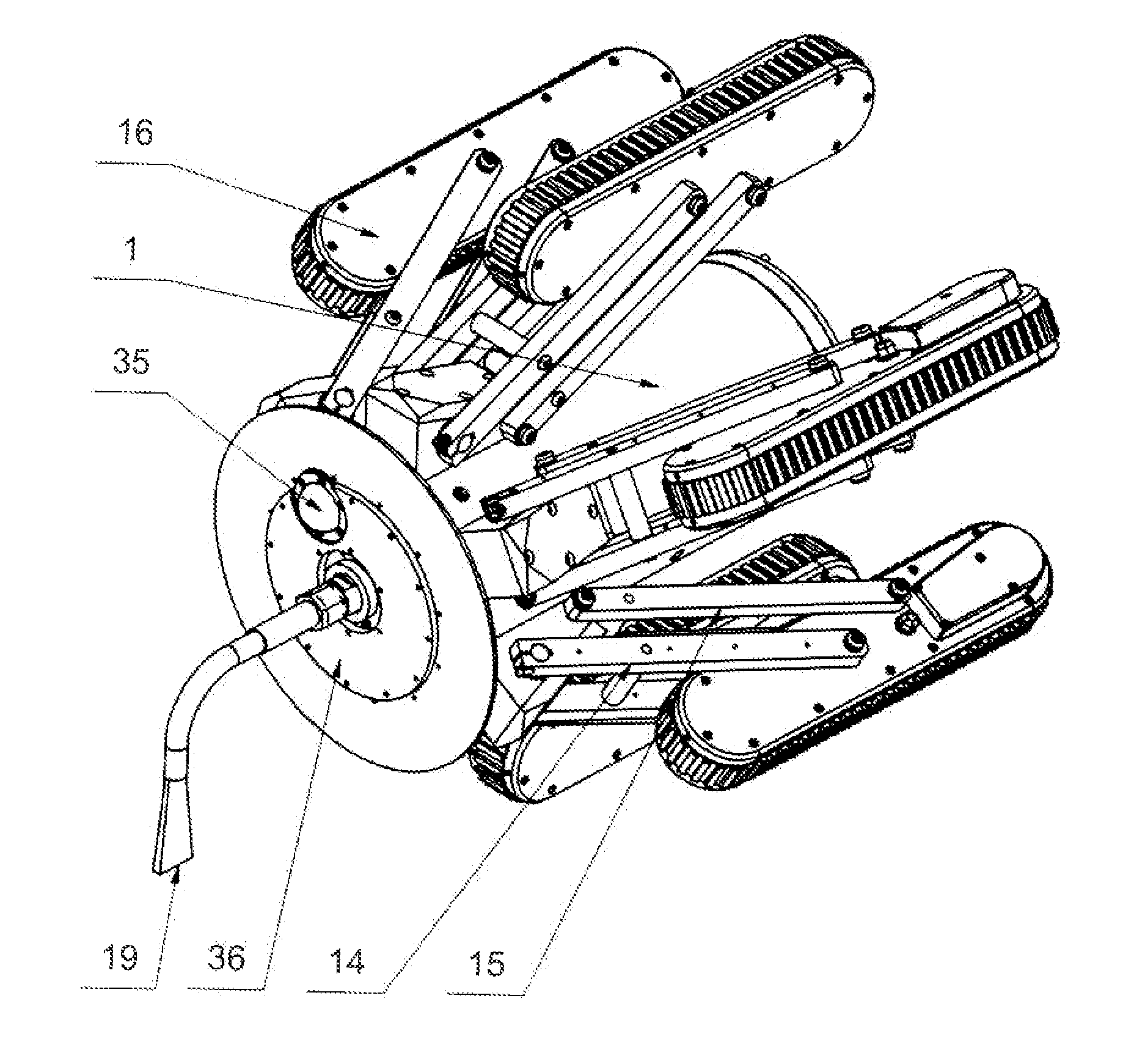

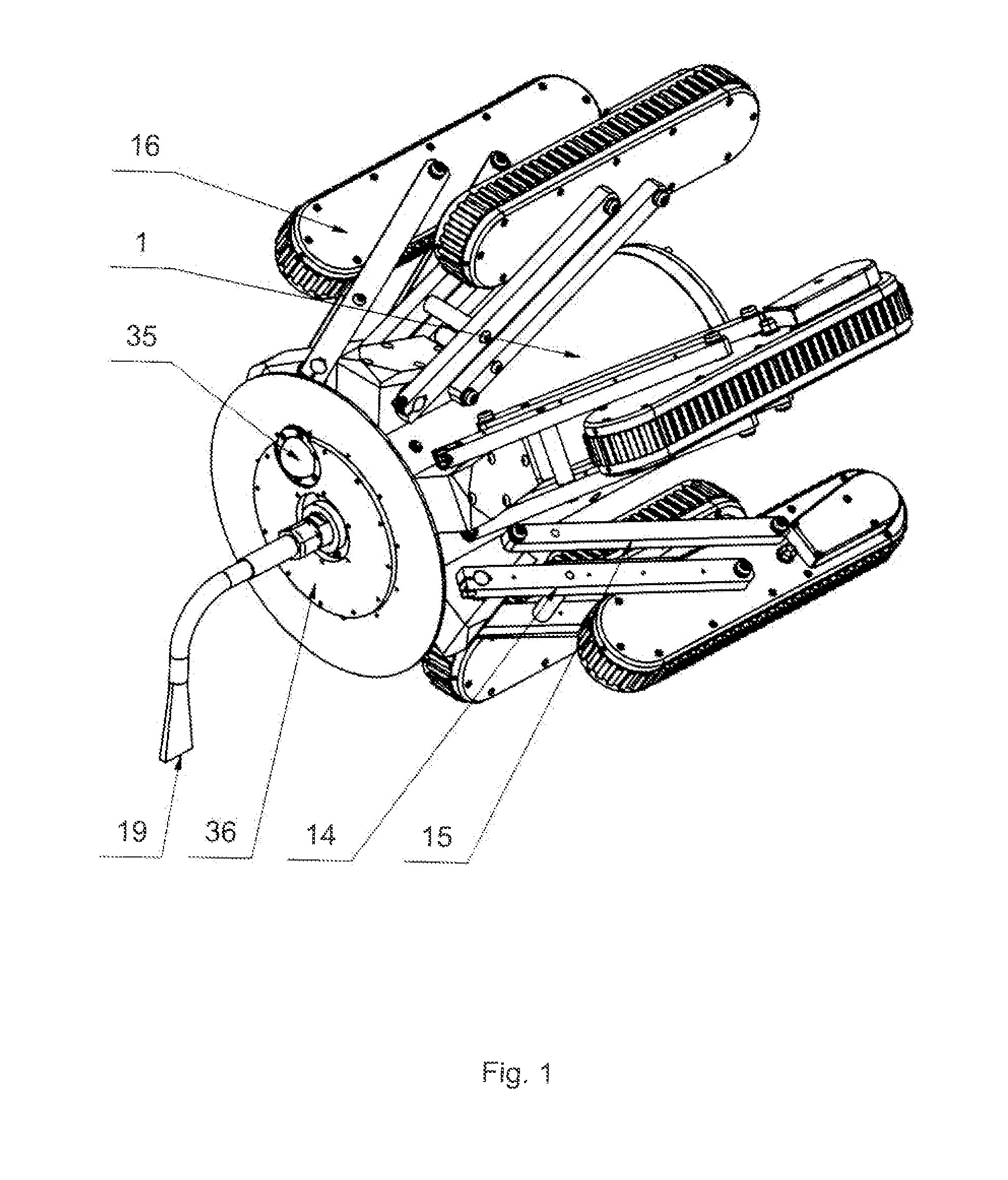

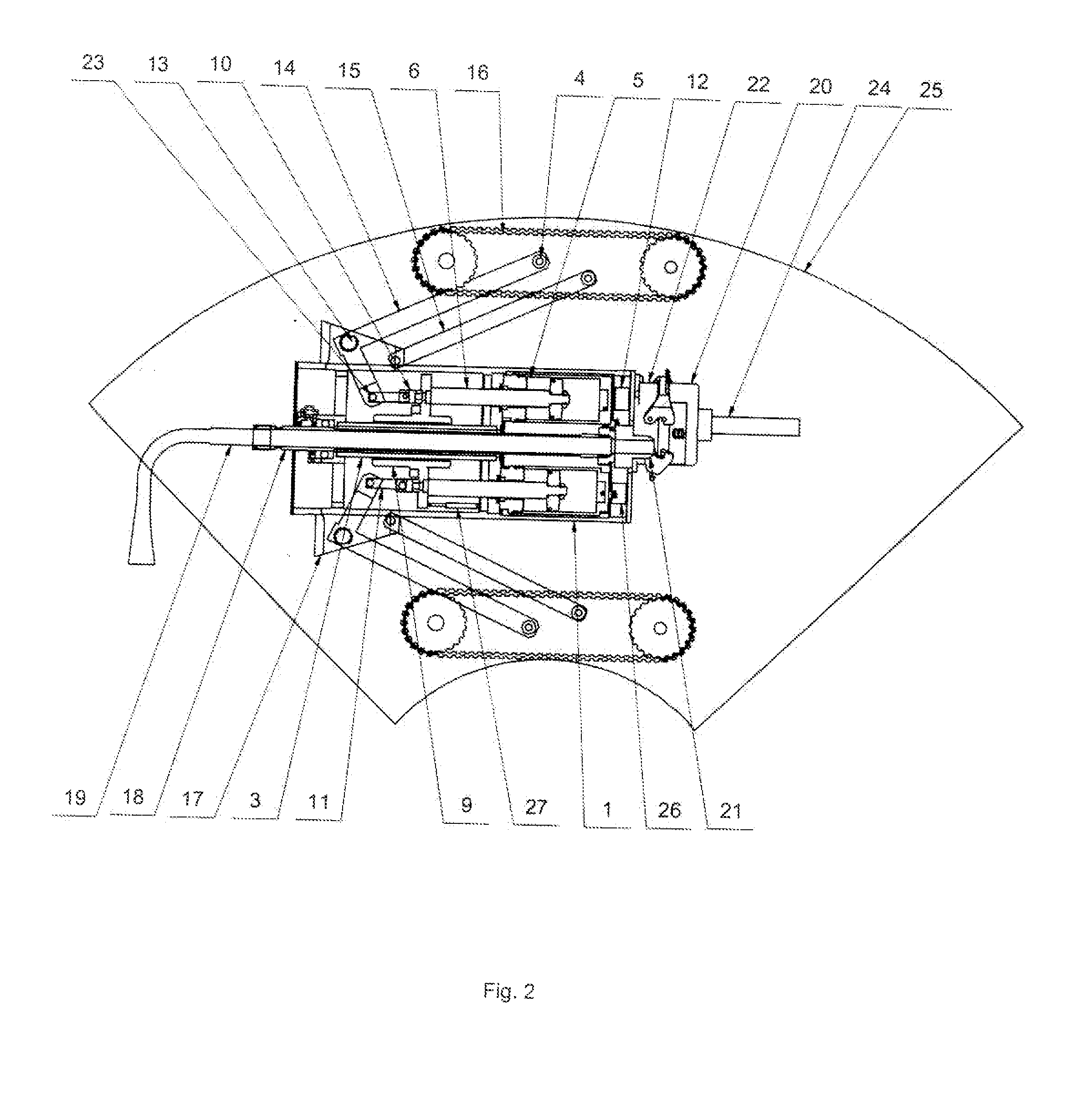

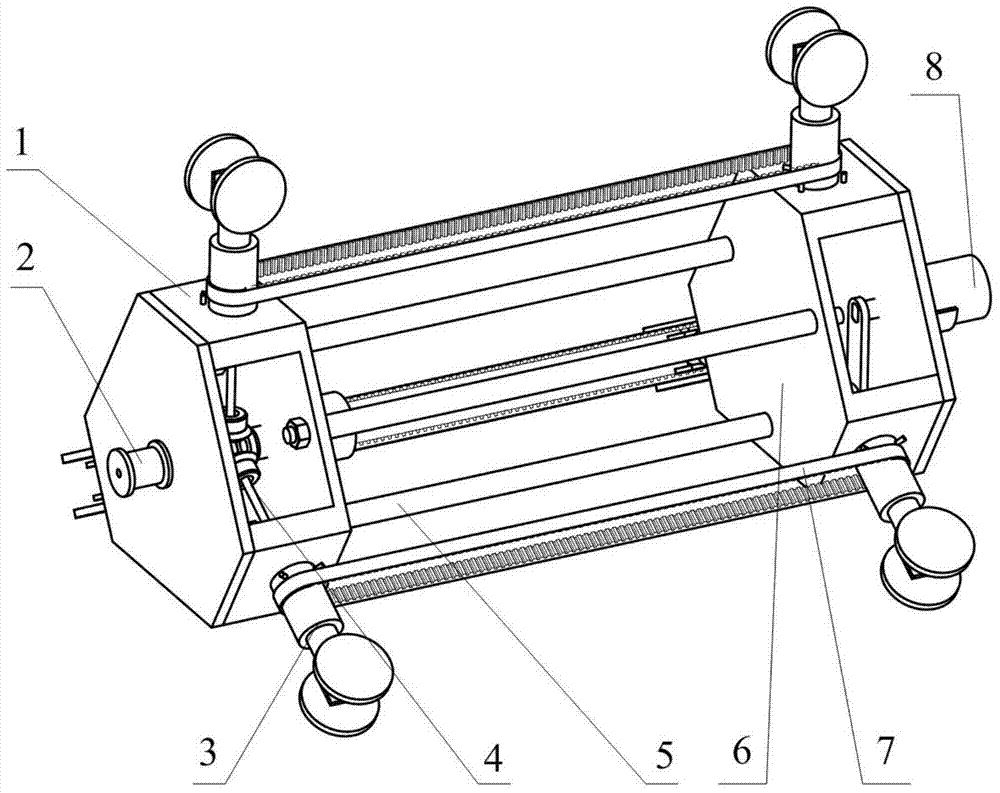

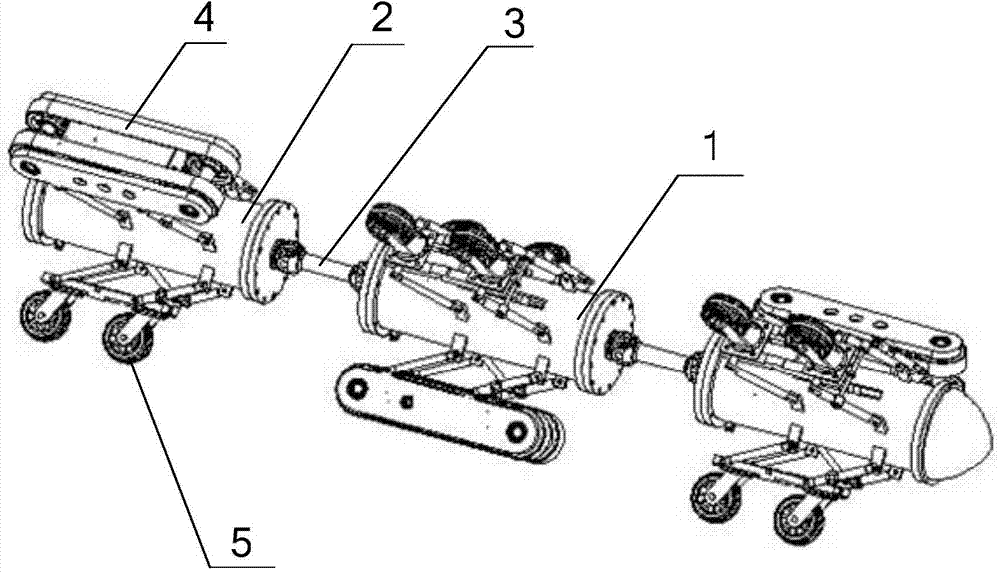

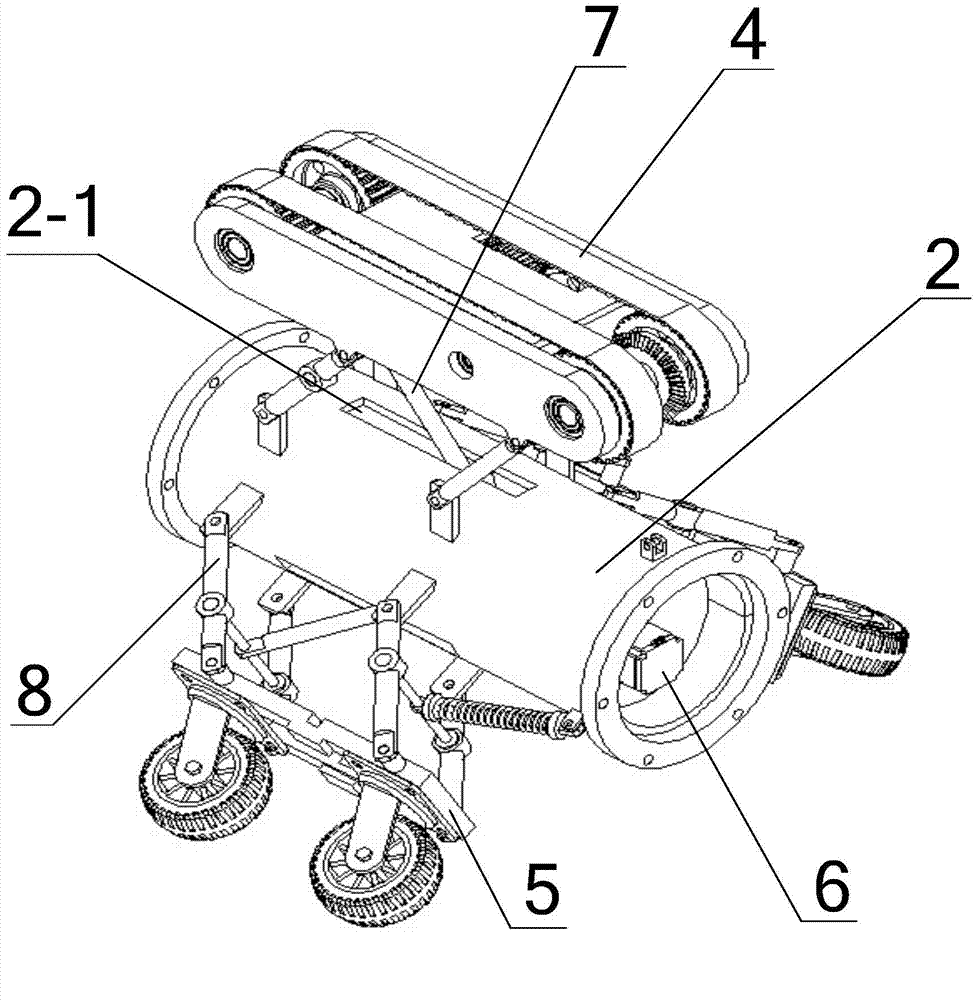

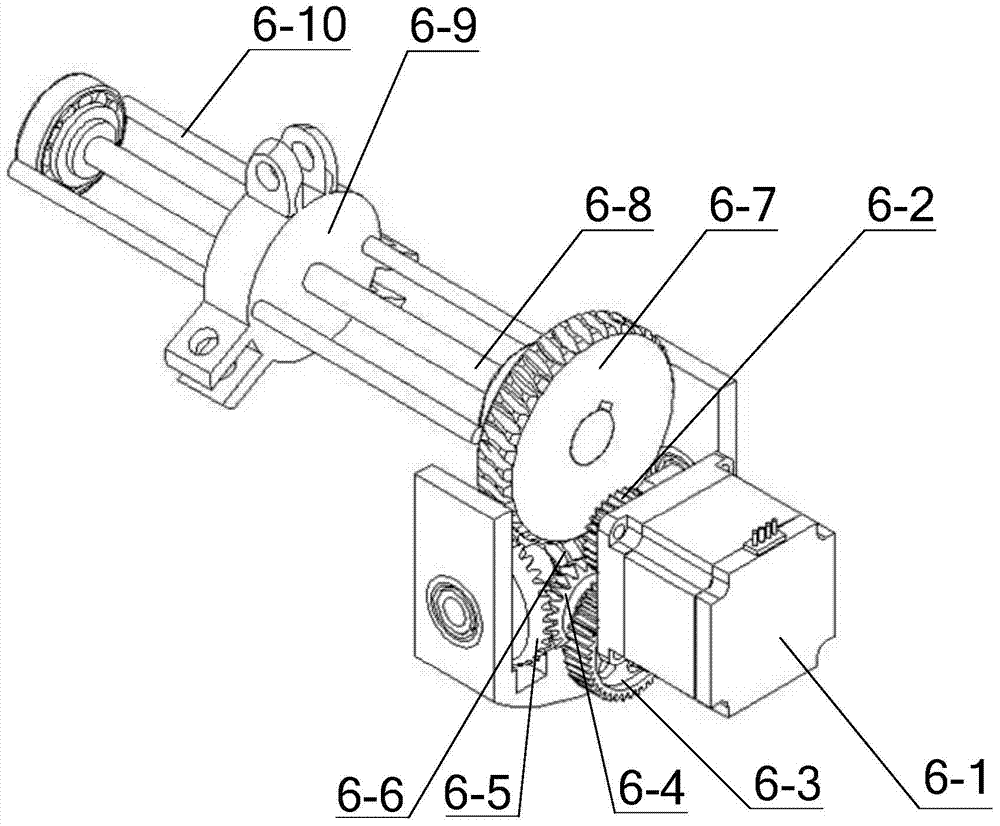

Crawler-type pipeline robot with active adaptation and self-adaptation functions

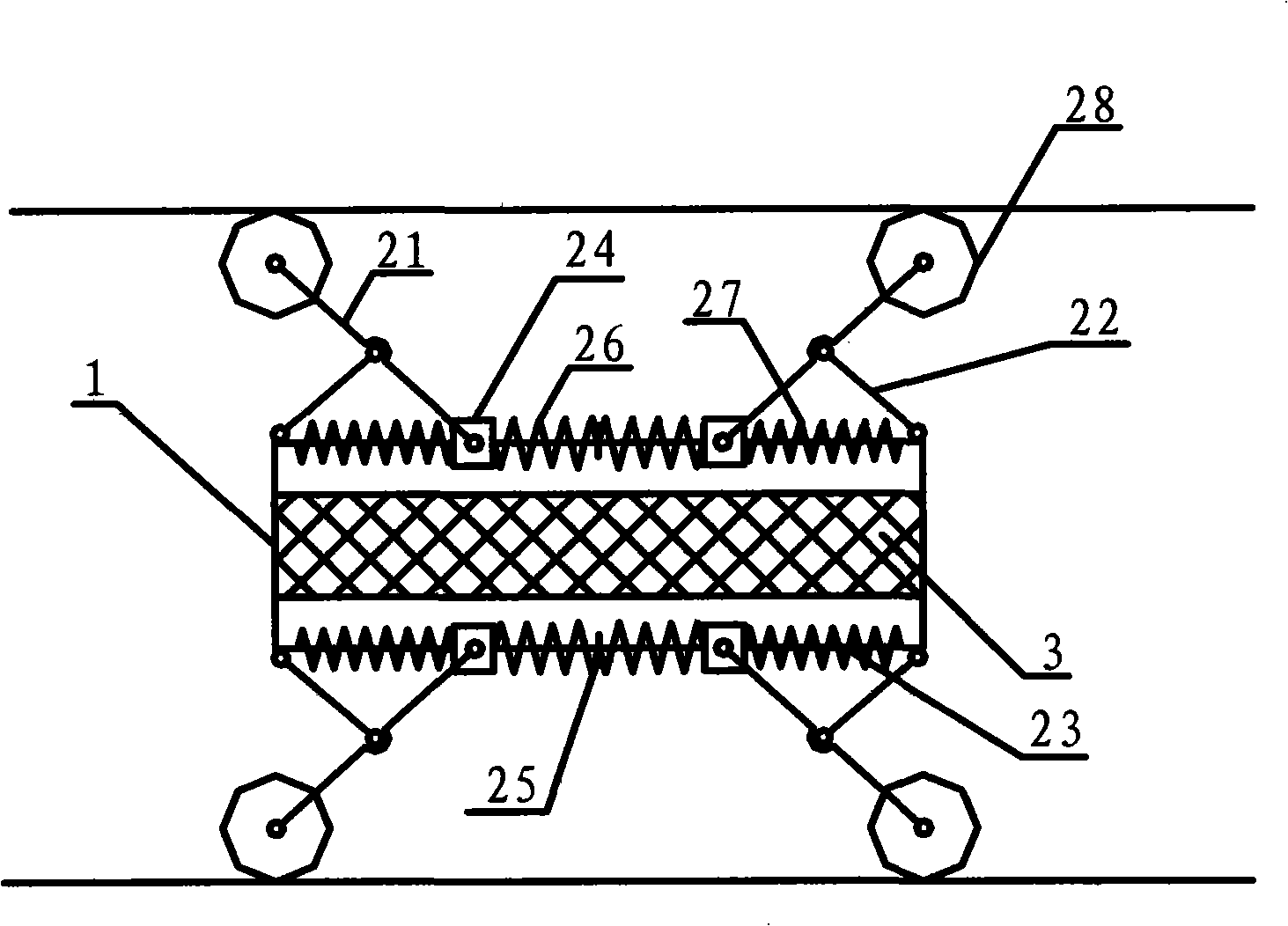

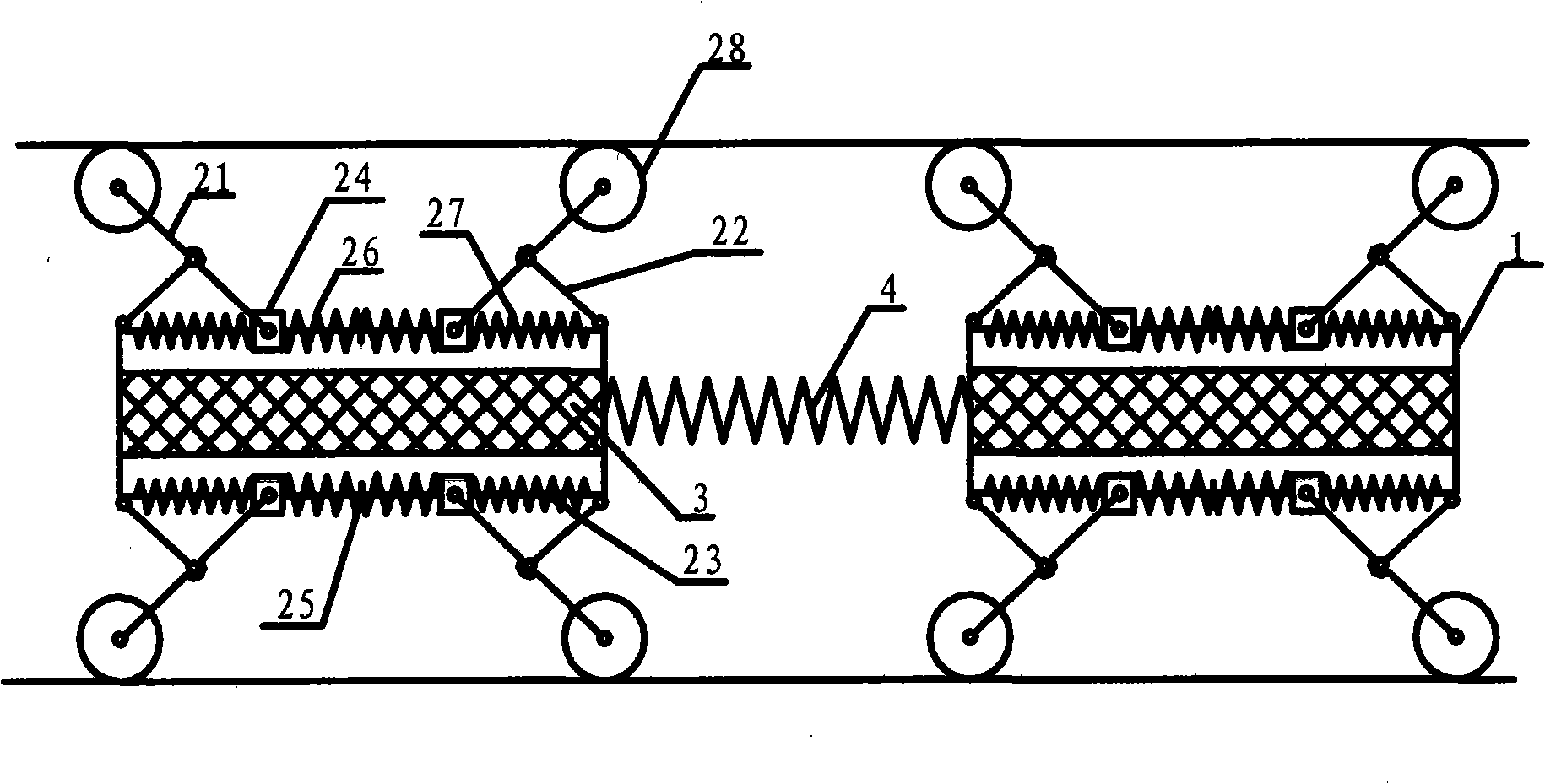

InactiveCN105135151ARealize driving functionRealize active adaptive driving functionPigs/molesSimulationServomotor

The invention belongs to the technical field of robots, and relates to a crawler-type pipeline robot with active adaptation and self-adaptation functions. A series combination mechanism, which is composed of a screw mechanism, a rocker slider mechanism and a parallelogram mechanism and driven by a stepper motor, is utilized to actively adapt to different pipeline diameters and keep a certain pressure between the crawler and pipeline inner wall. A set of butterfly springs arranged between the screw nut and slider are stressed to generate deformation to automatically adapt to the working conditions of pipeline joints, uneven-surface partial obstacles and the like in the pipeline. Three servomotors drive three sets of synchronous belt wheels to rotate through the transmission of a bevel gear and a cylindrical gear, thereby driving the three bifacial synchronous notched belts used as pipeline robot crawlers to move, and implementing the running function of the pipeline robot. The crawler-type pipeline robot has the simple structure, high operation and running safety, high environmental adaptability and wide application range, is convenient to use, and can work in pipelines with different diameters.

Owner:QINGDAO UNIV

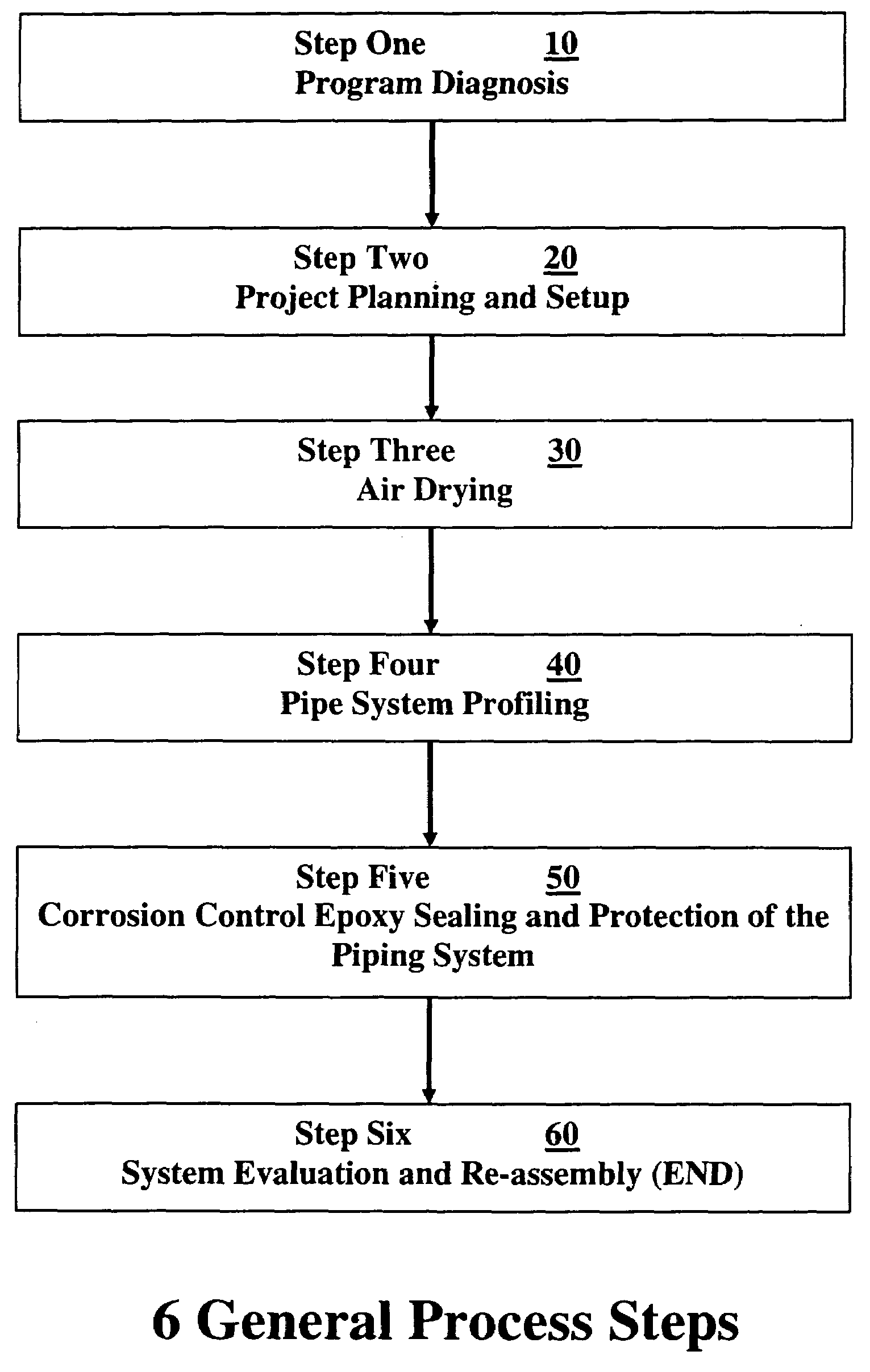

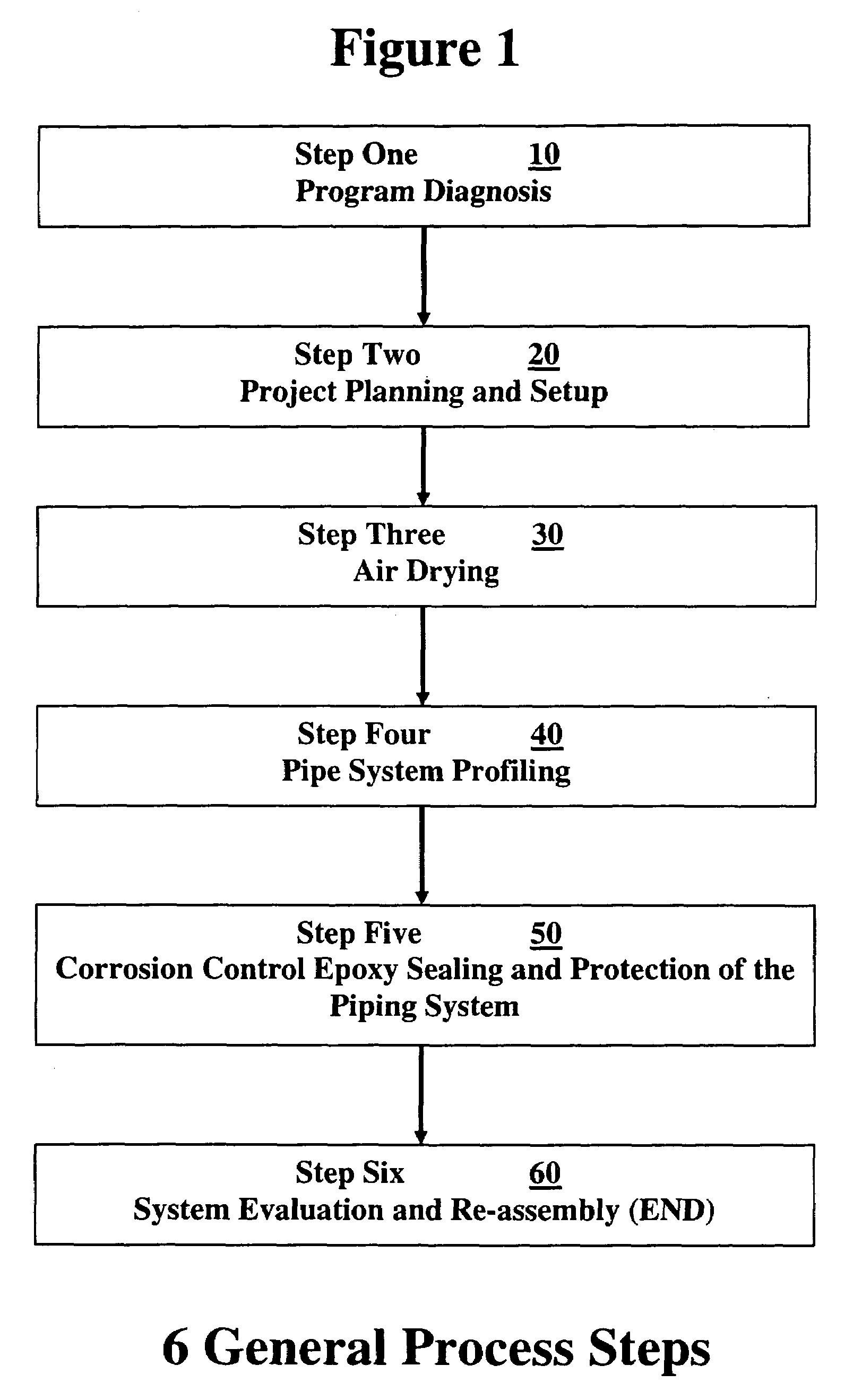

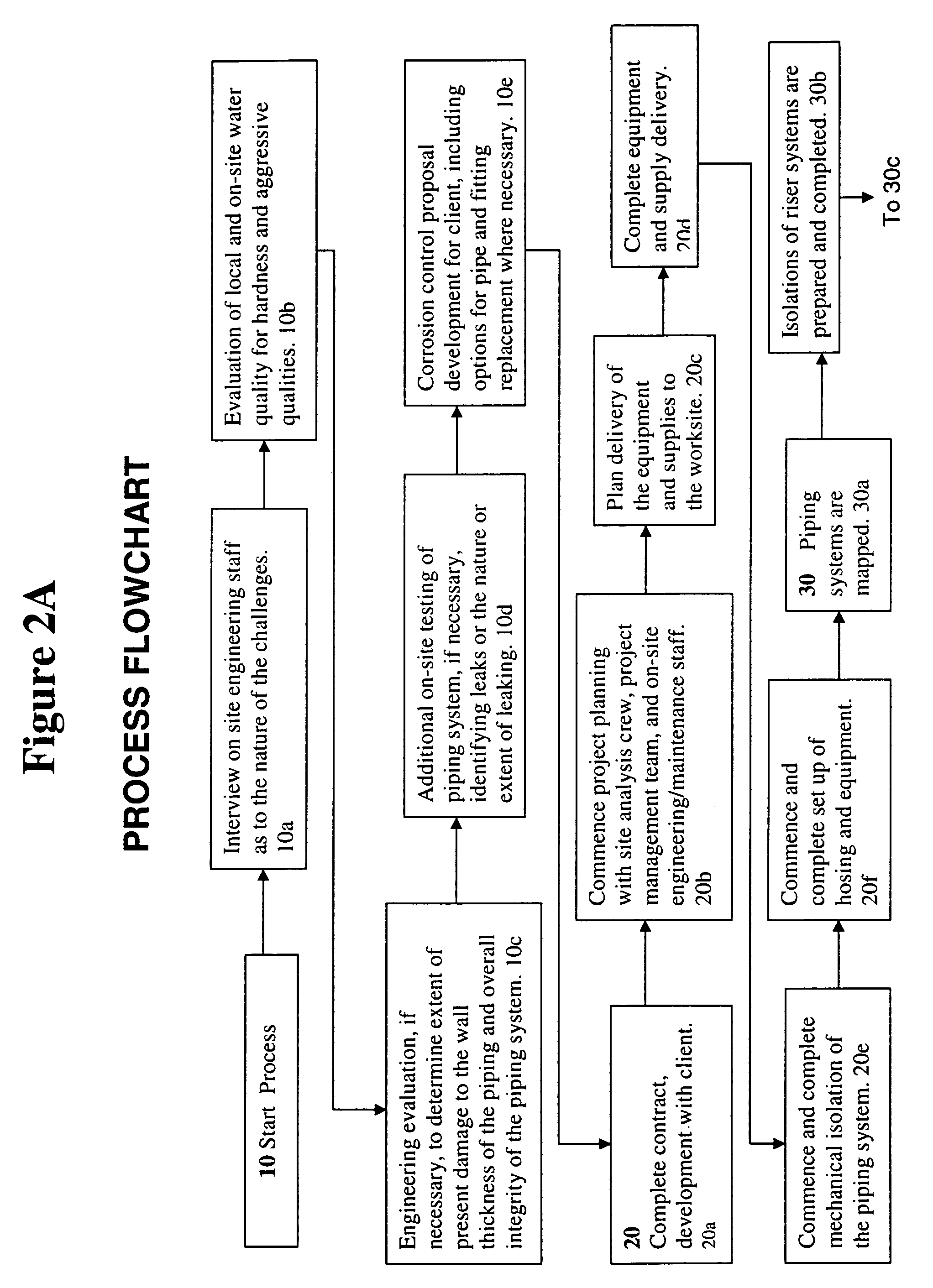

Barrier coating corrosion control methods and systems for interior piping systems

Methods and systems for cleaning and providing barrier coatings to interior walls of piping systems. An entire piping system can be cleaned in one single pass by dry particulates forced by air and the piping system coated in one single pass. Pipes can be protected from water corrosion, erosion and electrolysis. Pipes having diameters of approximately ⅜″ up to approximately 6″ are treatable. Piping systems such as potable water lines, natural gas lines, HVAC, drains, and fire sprinkler systems in homes, apartments, high-rise hotel / resorts, office towers, high-rise apartment and condominiums and schools, can be treated. The coating forms an approximately 4 mils or greater covering inside the pipes. Buildings can return to service within approximately 24 to approximately 96 hours.

Owner:PIPE RESTORATION TECH

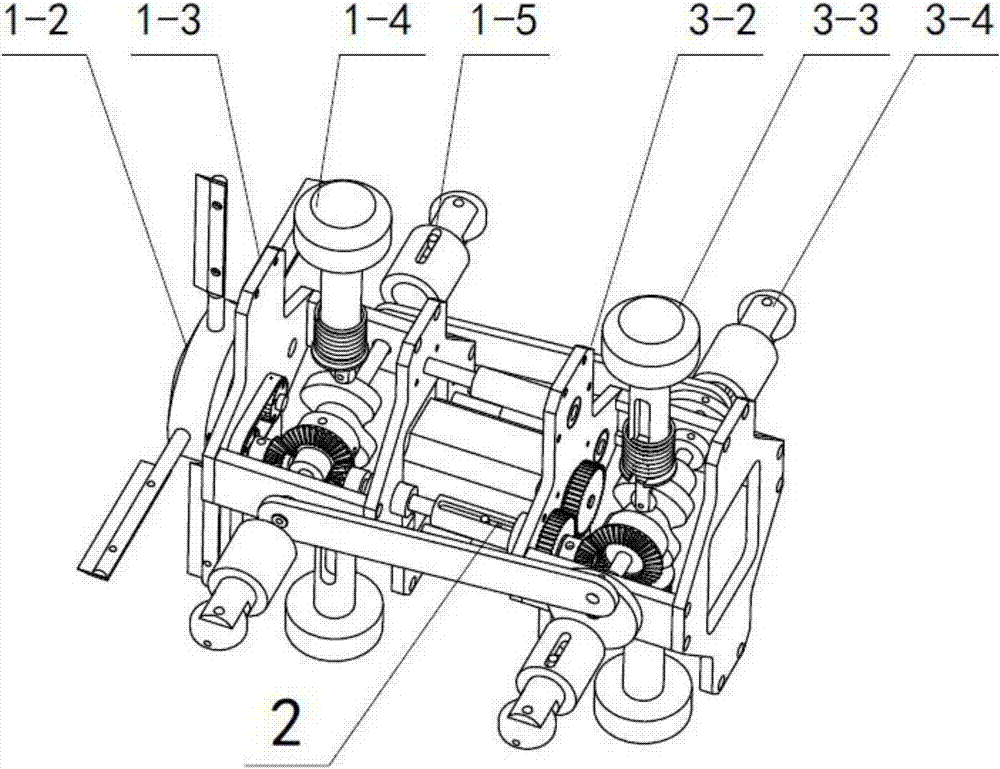

Pipeline detection robot

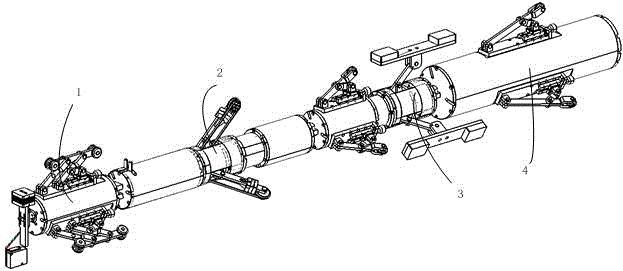

The invention relates to a pipeline detection robot. The pipeline detection robot mainly comprises a laser detection mechanism (1), a traction mechanism (2), an electromagnetic ultrasonic detection mechanism (3) and an electronic cabin (4), all of which are connected through connecting hinge shafts; the traction mechanism (1) adopts a single-motor all-drive mode and is driven by a turbo-worm synchronous belt to supply a walking power to the robot; the laser detection mechanism (2) comprises a laser displacement sensor, a rotating arm, a counterweight, a support body and the like and is used for measuring surface corrosion and deformation of a pipeline; the electromagnetic ultrasonic detection mechanism (3) comprises a support assembly, a probe and a fixing plate and is used for measuring the wall thickness and the crack defect of the pipeline; the electronic cabin (4) is used for carrying auxiliary components, such as a stepping motor controller, a servo motor driver, a power supply and an FPGA (Field Programmable Gate Array) control panel. The pipeline detection robot disclosed by the invention can be used for finding the defects, such as pipeline corrosion, cracks and deformation, carrying out in-service detection on an oil and gas pipeline in a working process, carrying out targeted repair, maintenance and replacement according to a detection result, reducing the maintenance cost and guaranteeing safe and stable operation of the oil and gas pipeline.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

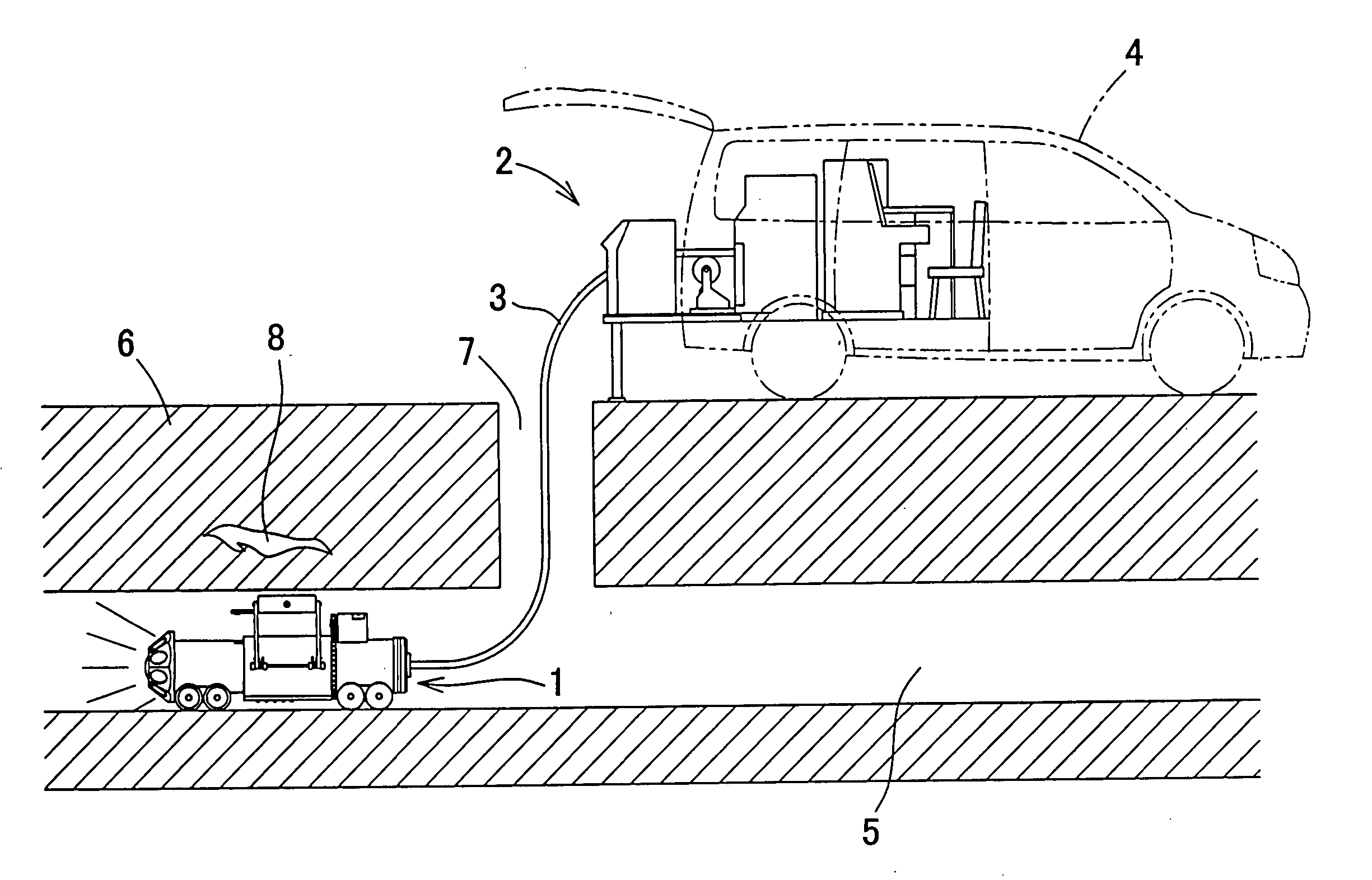

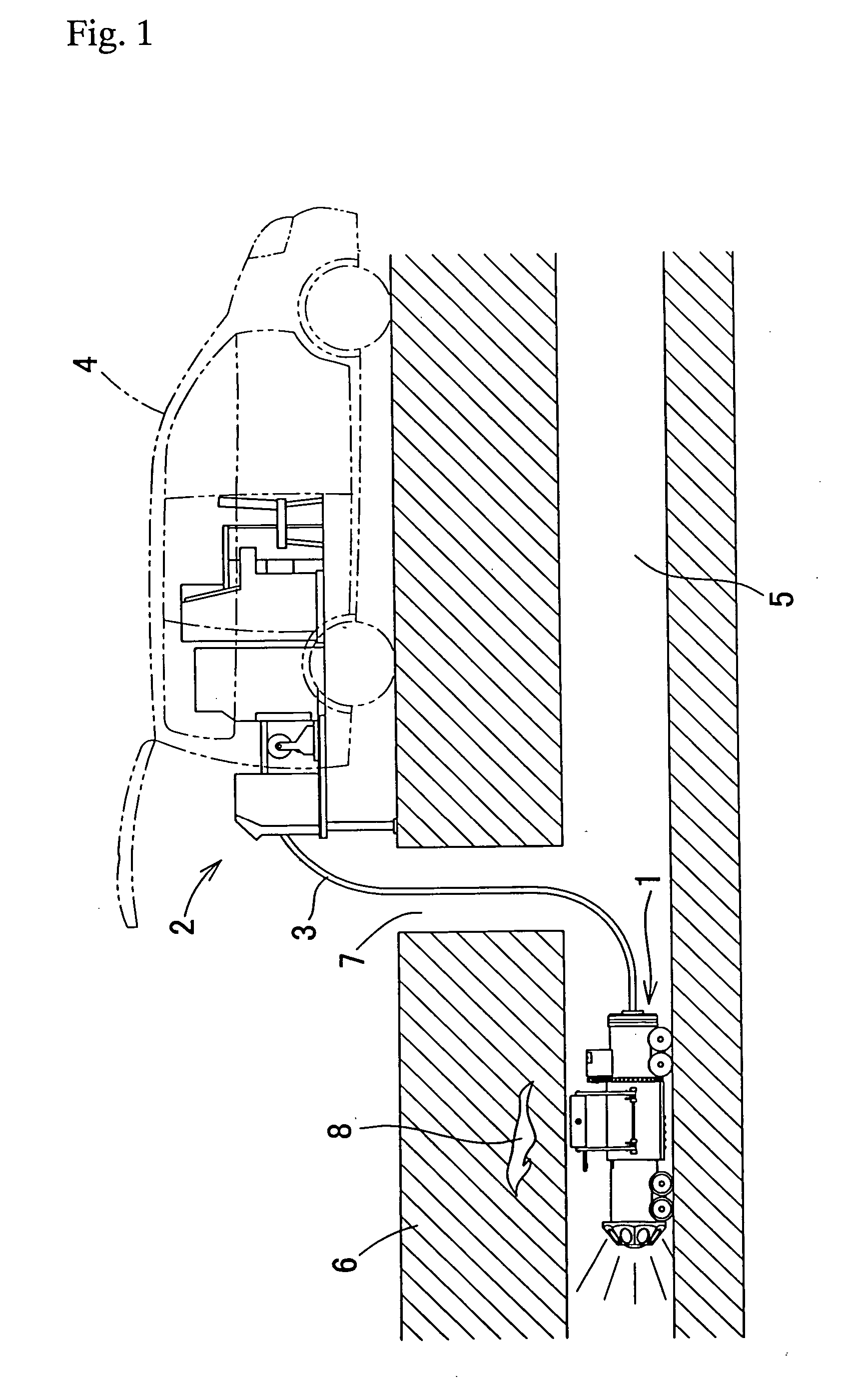

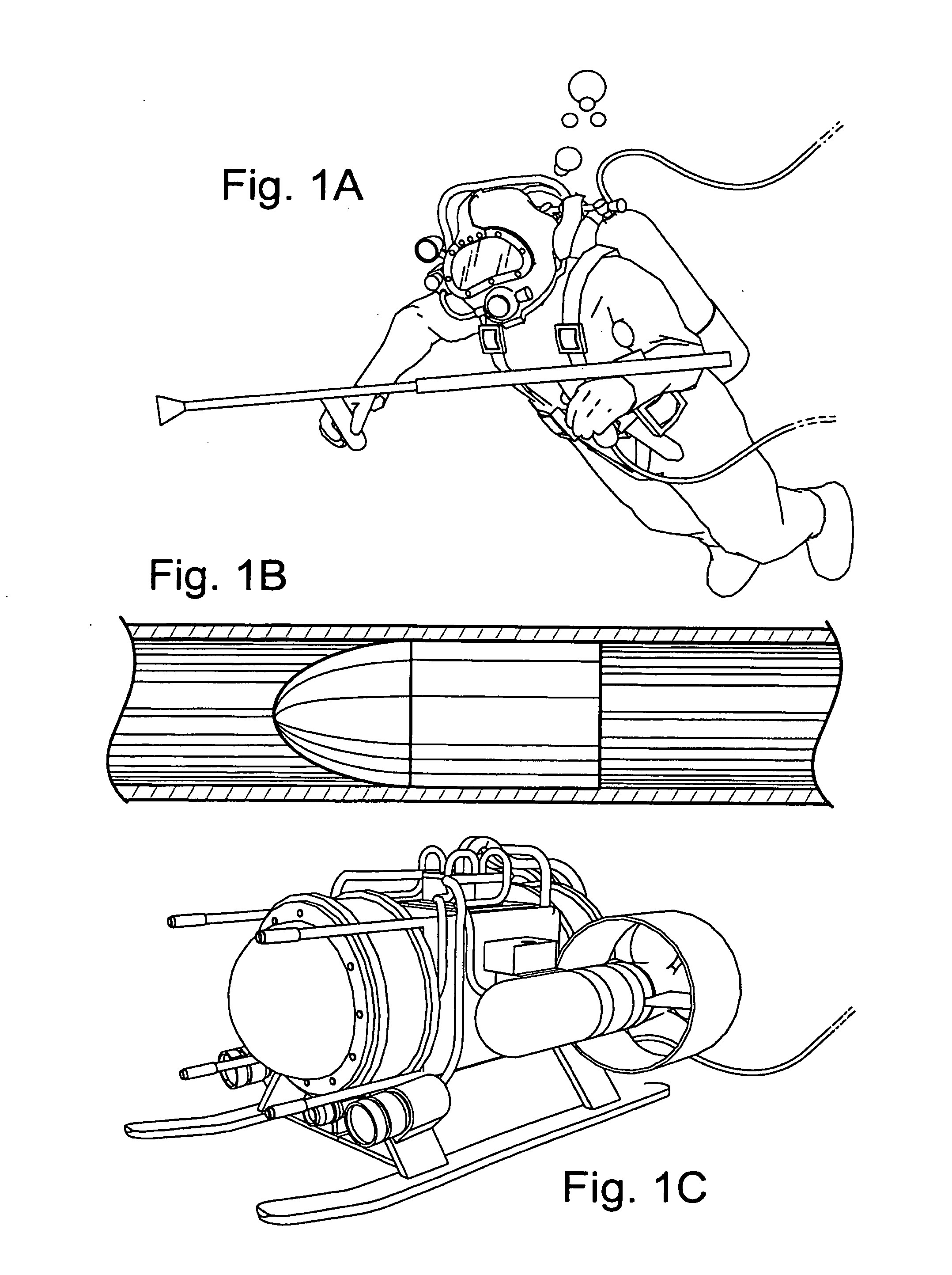

Device and method for inspecting inside of underground pipe line and method of inspecting concrete on inside of underground pipe line for deterioration

InactiveUS20050115337A1Reliably determinedAccurate measurementHollow article cleaningStructural/machines measurementFisheye lensGyroscope

A device for inspecting the inside of an underground pipe line which makes it possible to search for cavities on the outside of the underground pipe over the entire internal peripheral surface of the underground pipe, that is, not only upward of the underground pipe, but also toward both sides and downward thereof, to obtain detailed images of the inner peripheral surface of the pipe line without using a complex mechanism, and to display patterns of cracks and irregularities on the inner peripheral surface of the underground pipe by three-dimensional convergence images. The device comprises a pipe line internal self-propelled vehicle and an on-ground control unit, and the pipe line internal self-propelled vehicle is provided with a radar antenna, a camera equipped with a fisheye lens, a gyro, a laser sensor, and an infrared encoder.

Owner:BURN AM

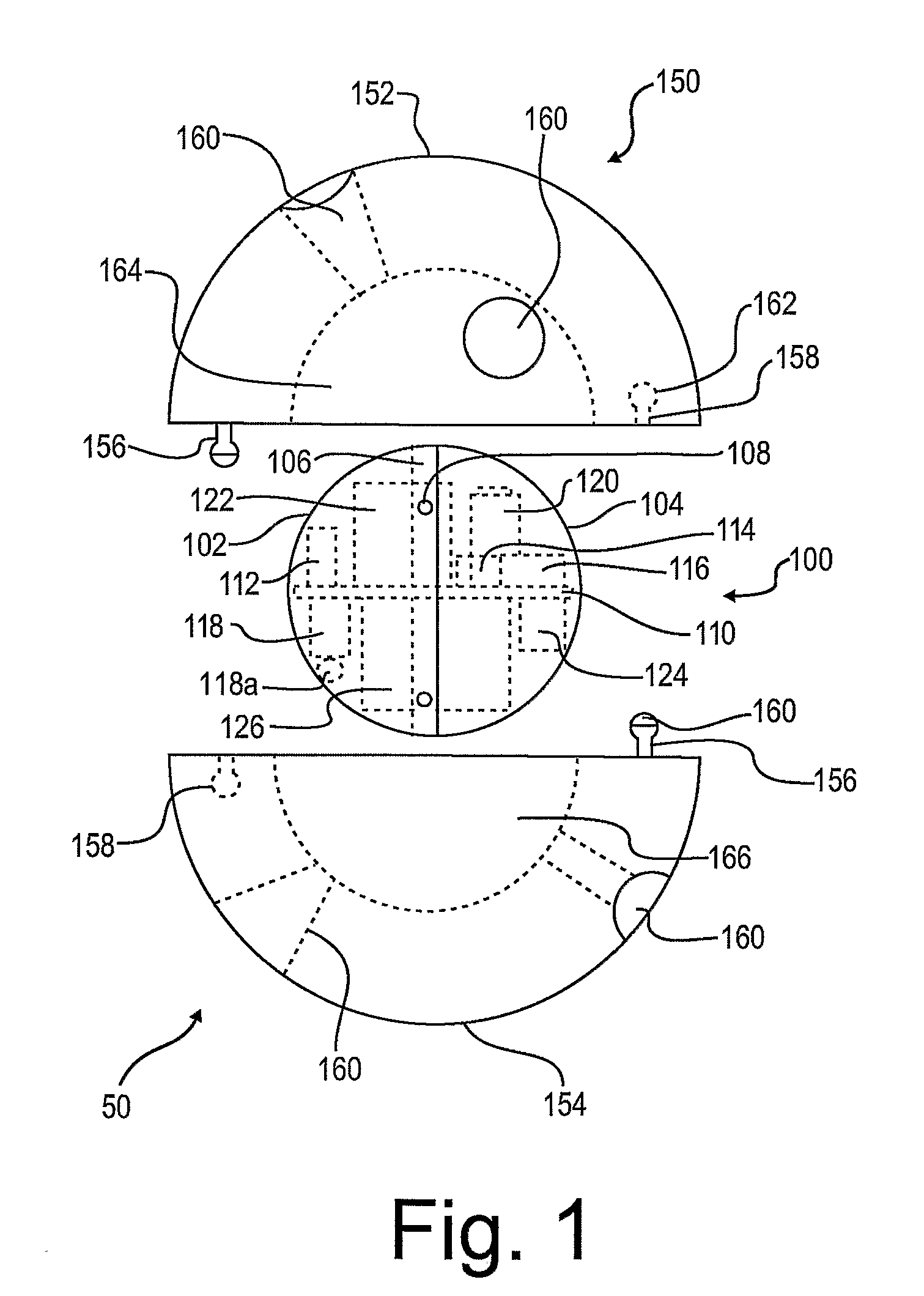

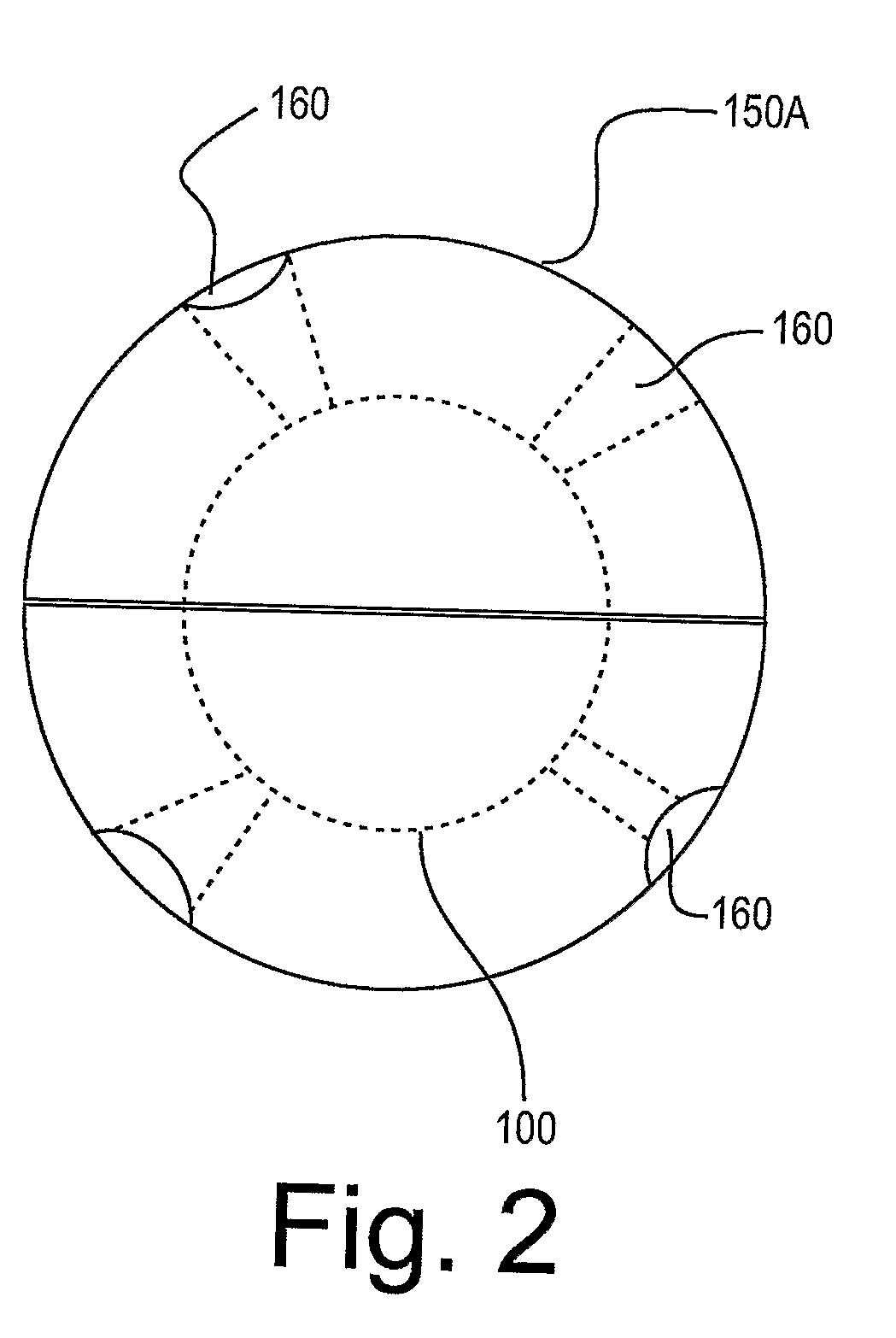

Anomaly detector for pipelines

A sensor unit for use in sensing conditions in a pipeline comprises an untethered a ball-shaped surround adapted to roll along the interior surface of a pipeline, and instrument package within the ball-shaped surround. The package contains at least one magnetometer or accelerometer. Preferably, three magnetometers, arranged orthogonally, are present. Other sensors can also be present as required, such as an acoustic sensor to detect leaks and a temperature or chemical sensor. Recording means record the data acquired by the magnetometer(s) or accelerometer and the sensors, and optionally also record a timing trace.

Owner:ALLTECH CO LTD

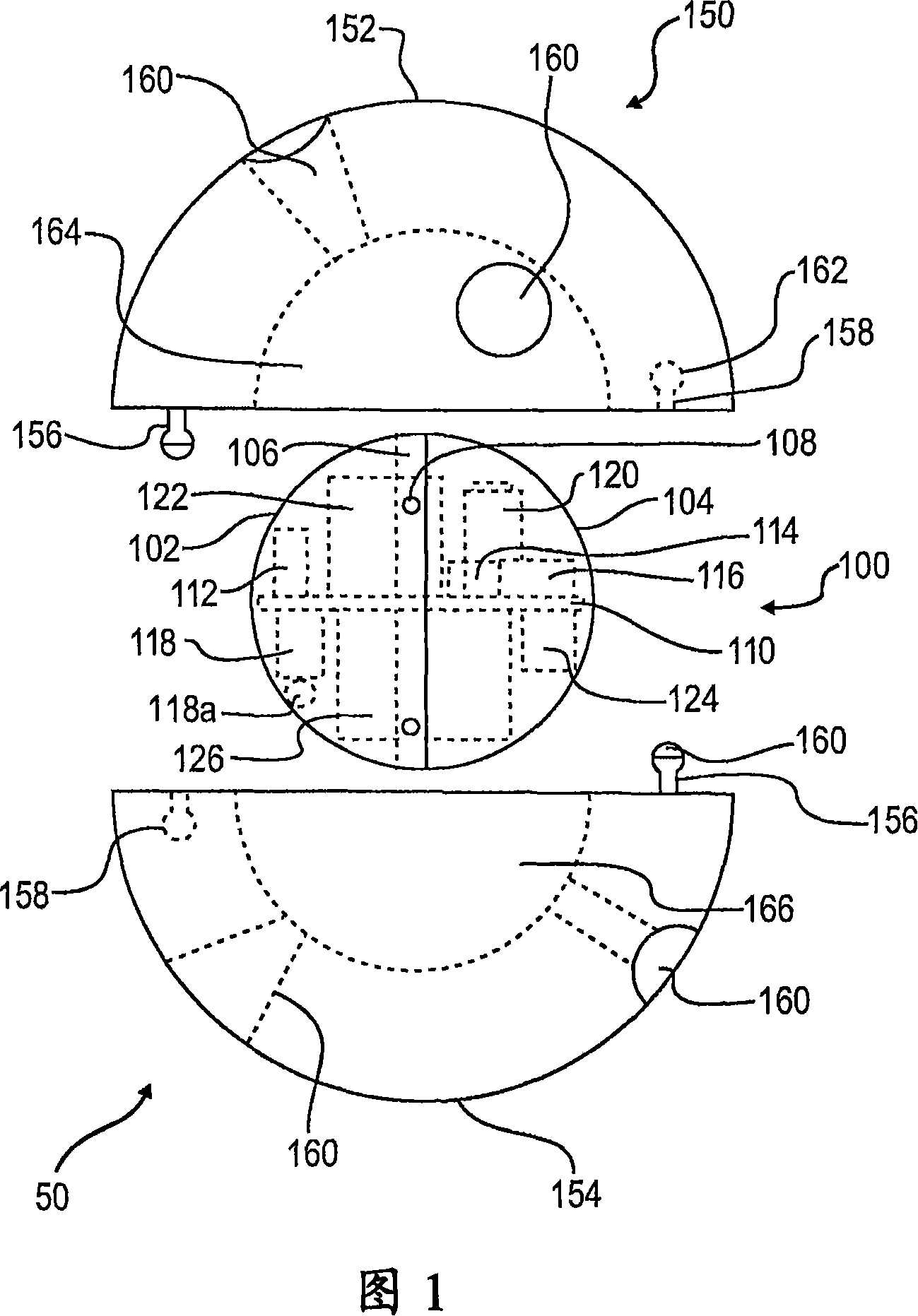

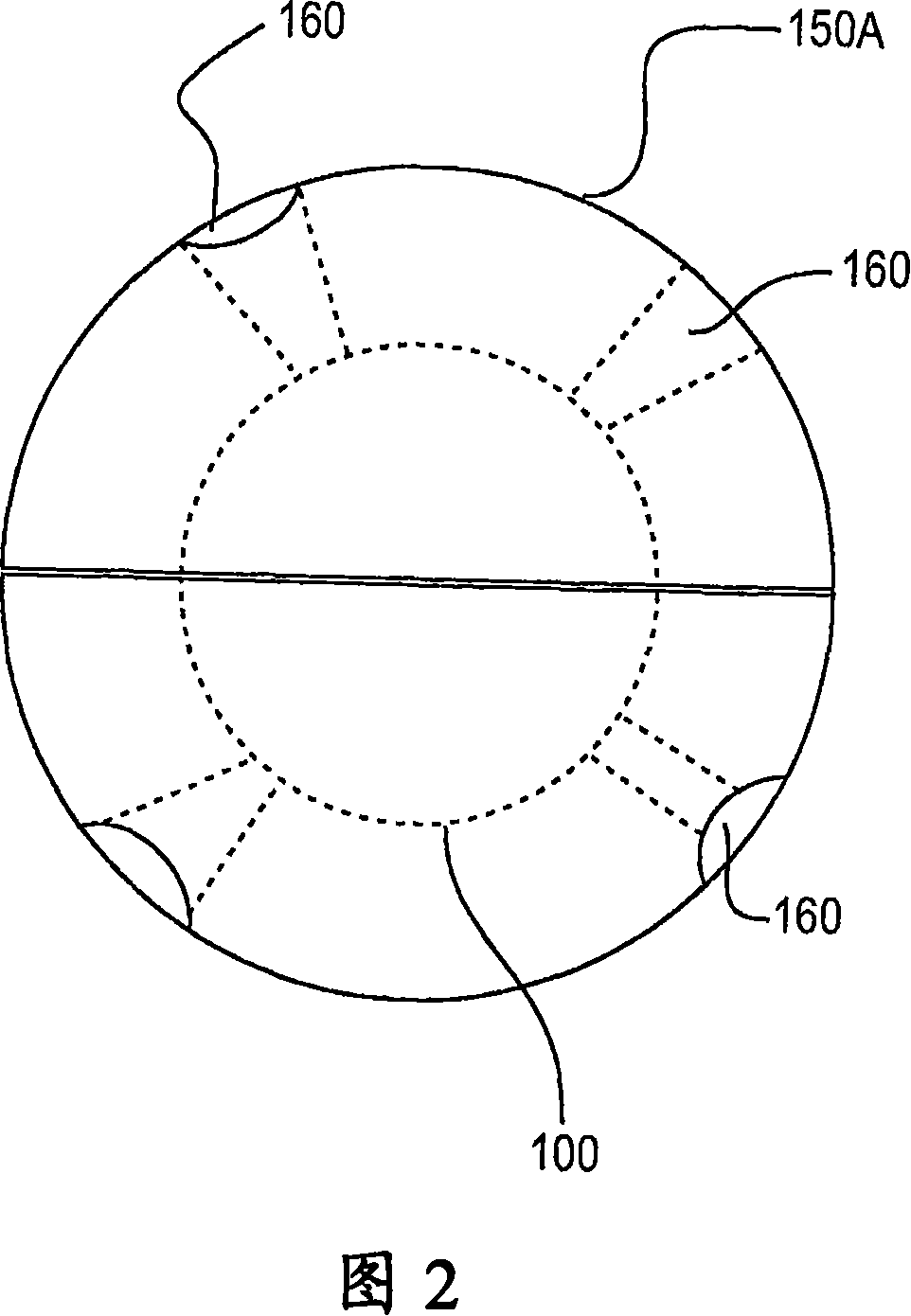

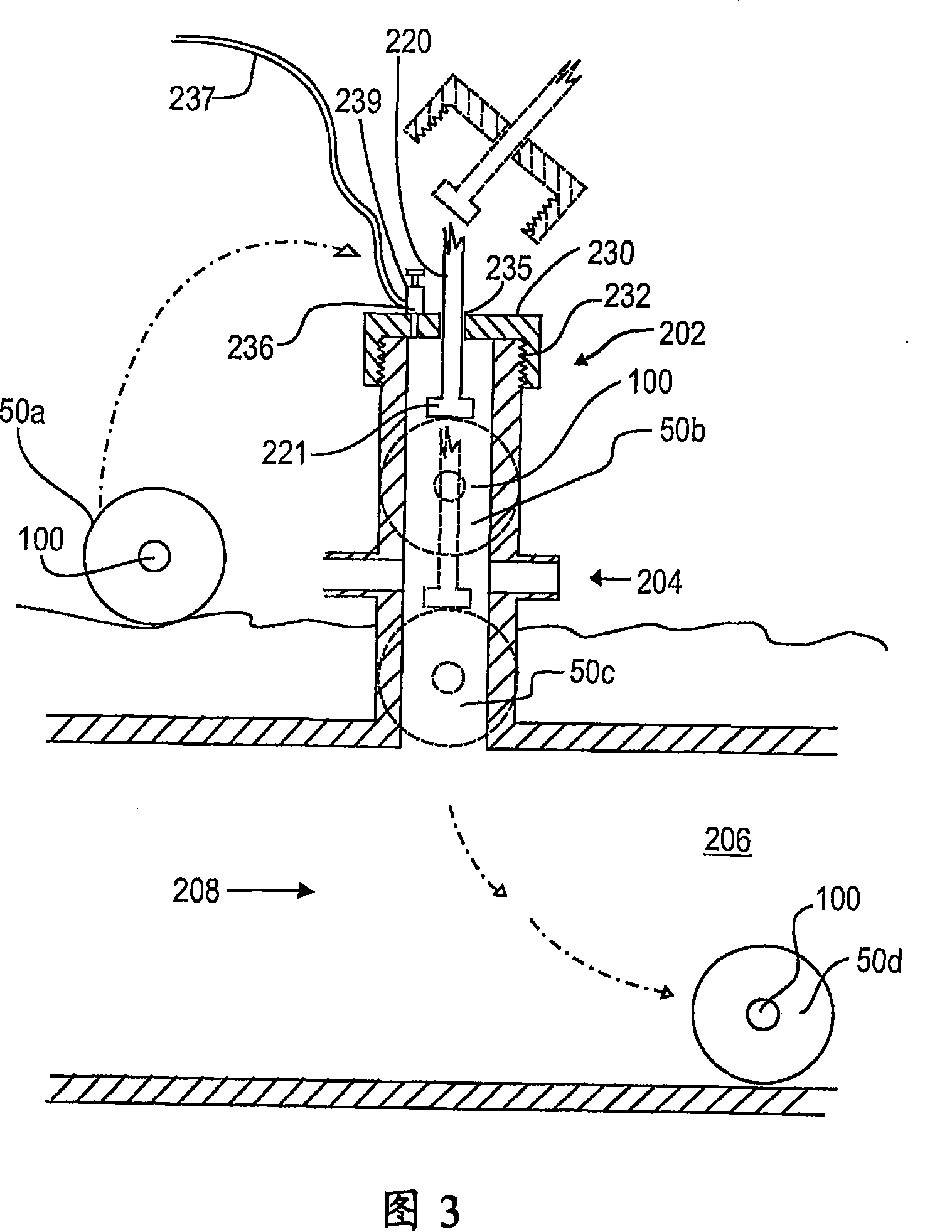

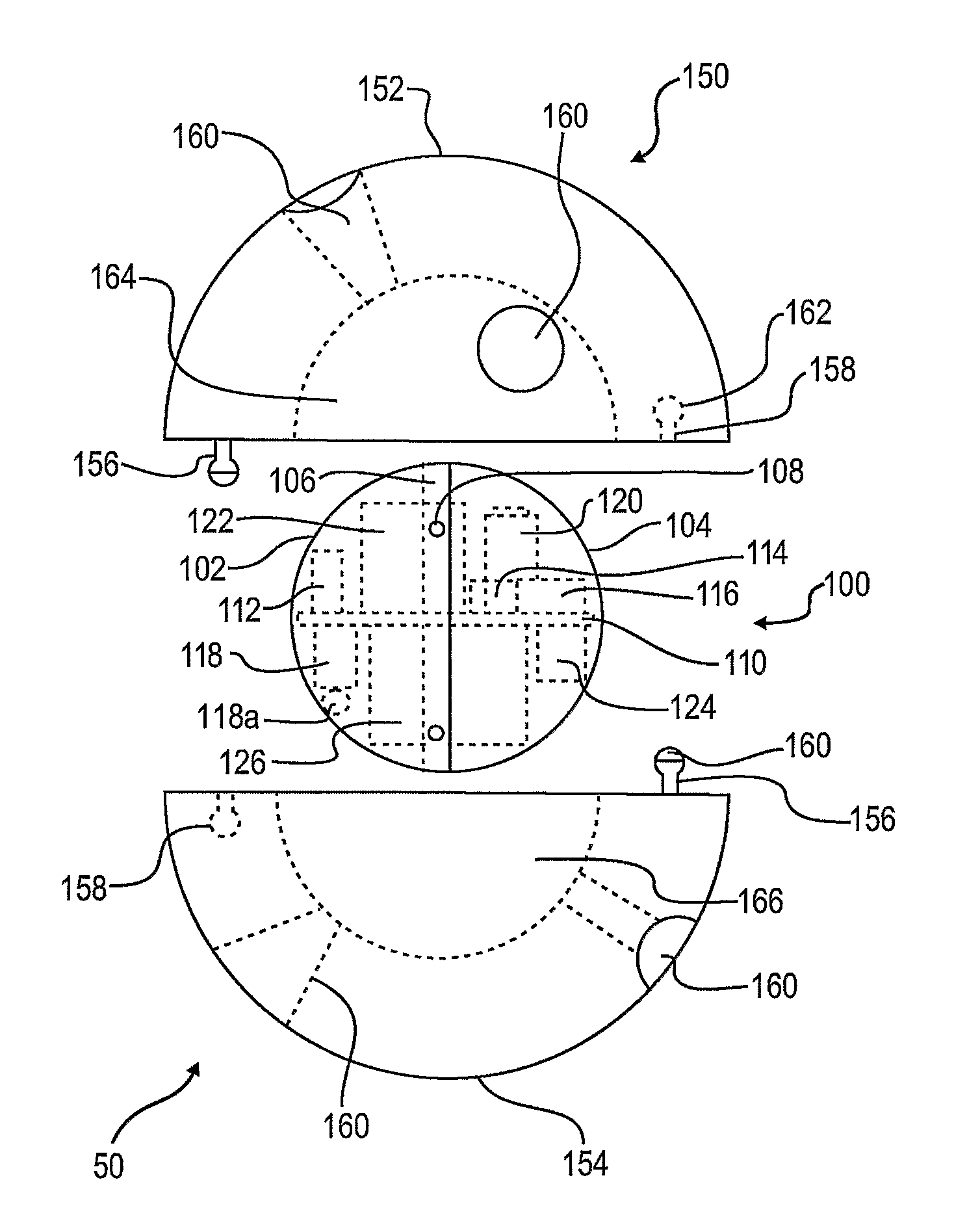

Anomaly Detector for Pipelines

ActiveUS20080204008A1Maximum water resistanceEasy for to push it up inclineMaterial analysis using sonic/ultrasonic/infrasonic wavesVibration measurement in fluidAccelerometerEngineering

A sensor unit for use in sensing conditions in a pipeline comprises an untethered a ball-shaped surround adapted to roll along the interior surface of a pipeline, and instrument package within the ball-shaped surround. The package contains at least one magnetometer or accelerometer. Preferably, three magnetometers, arranged orthogonally, are present. Other sensors can also be present as required, such as an acoustic sensor to detect leaks and a temperature or chemical sensor. Recording means record the data acquired by the magnetometer(s) or accelerometer and the sensors, and optionally also record a timing trace.

Owner:PURETECH VENTURES

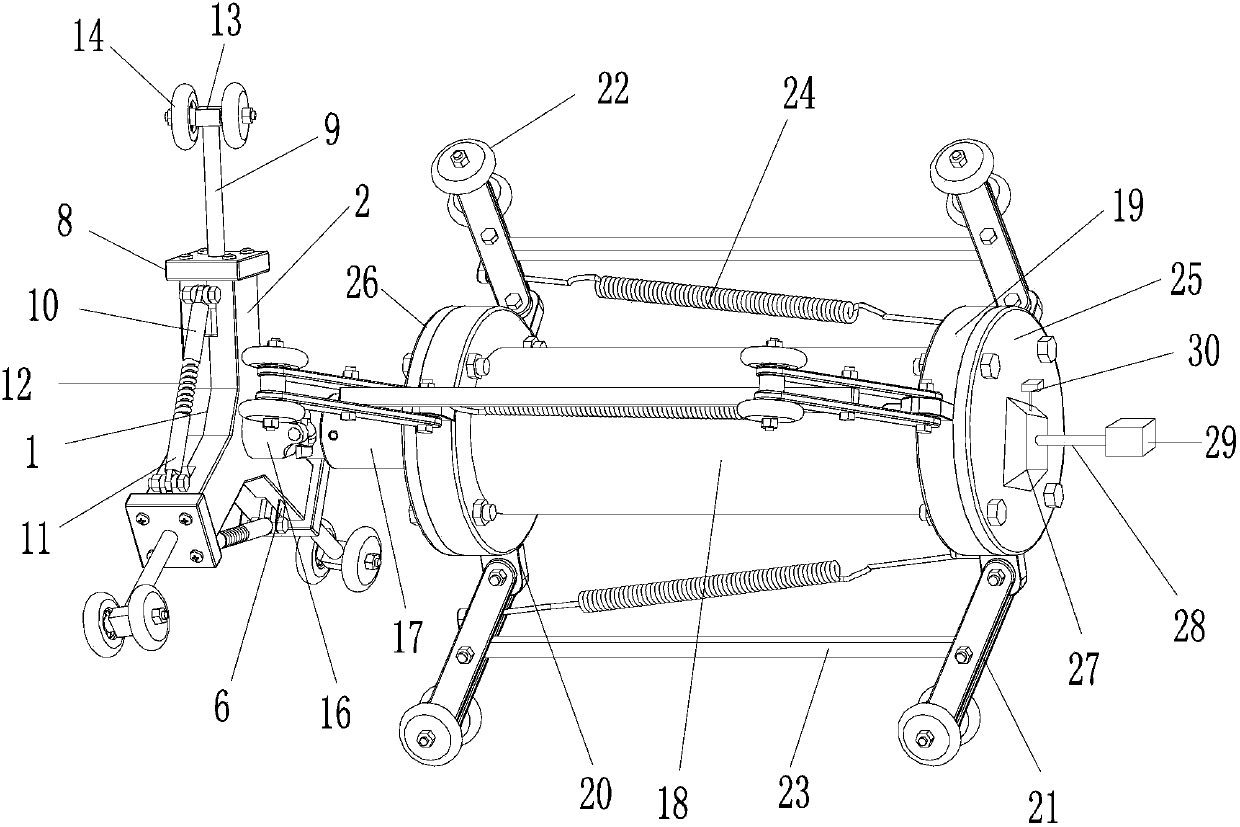

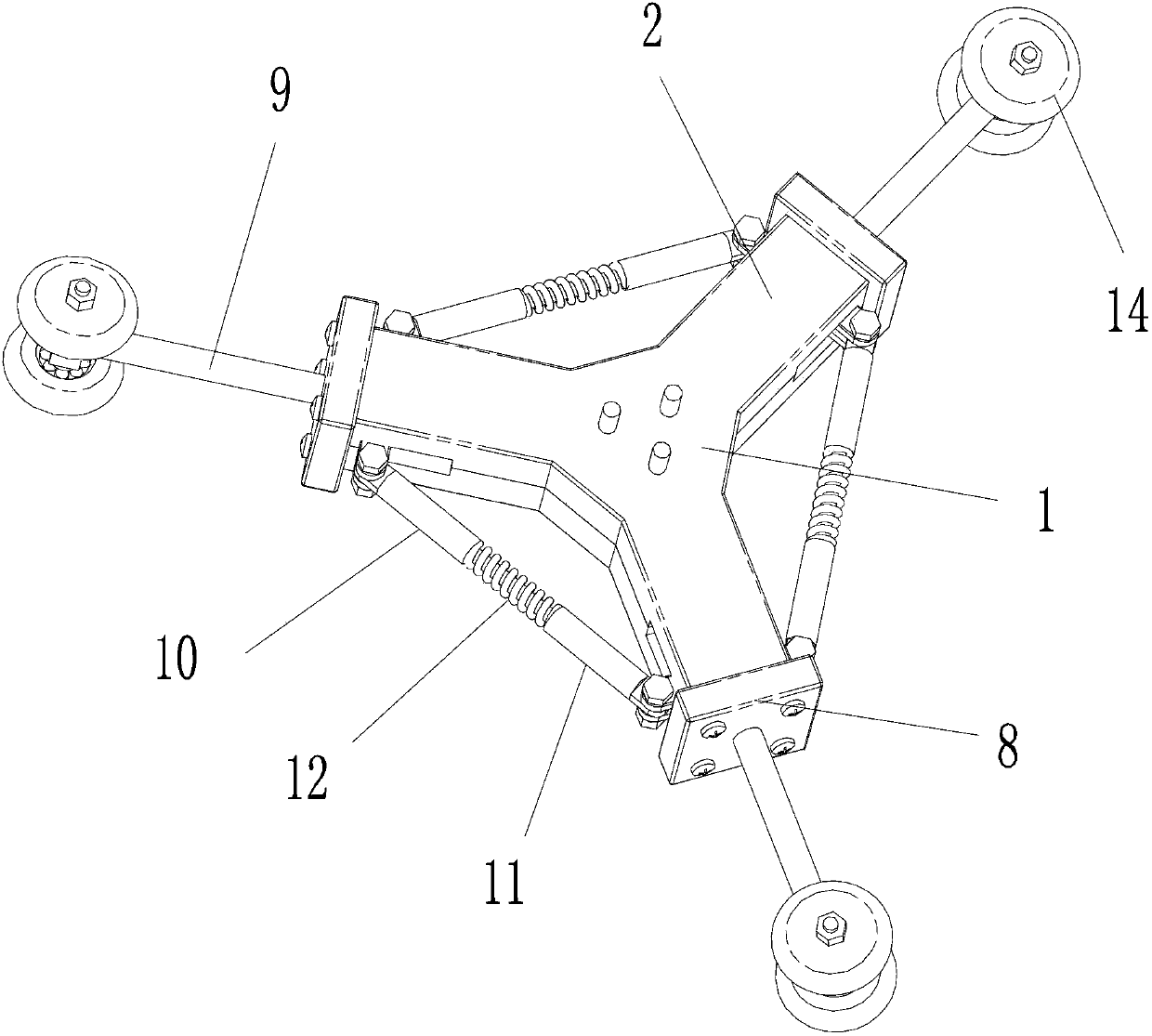

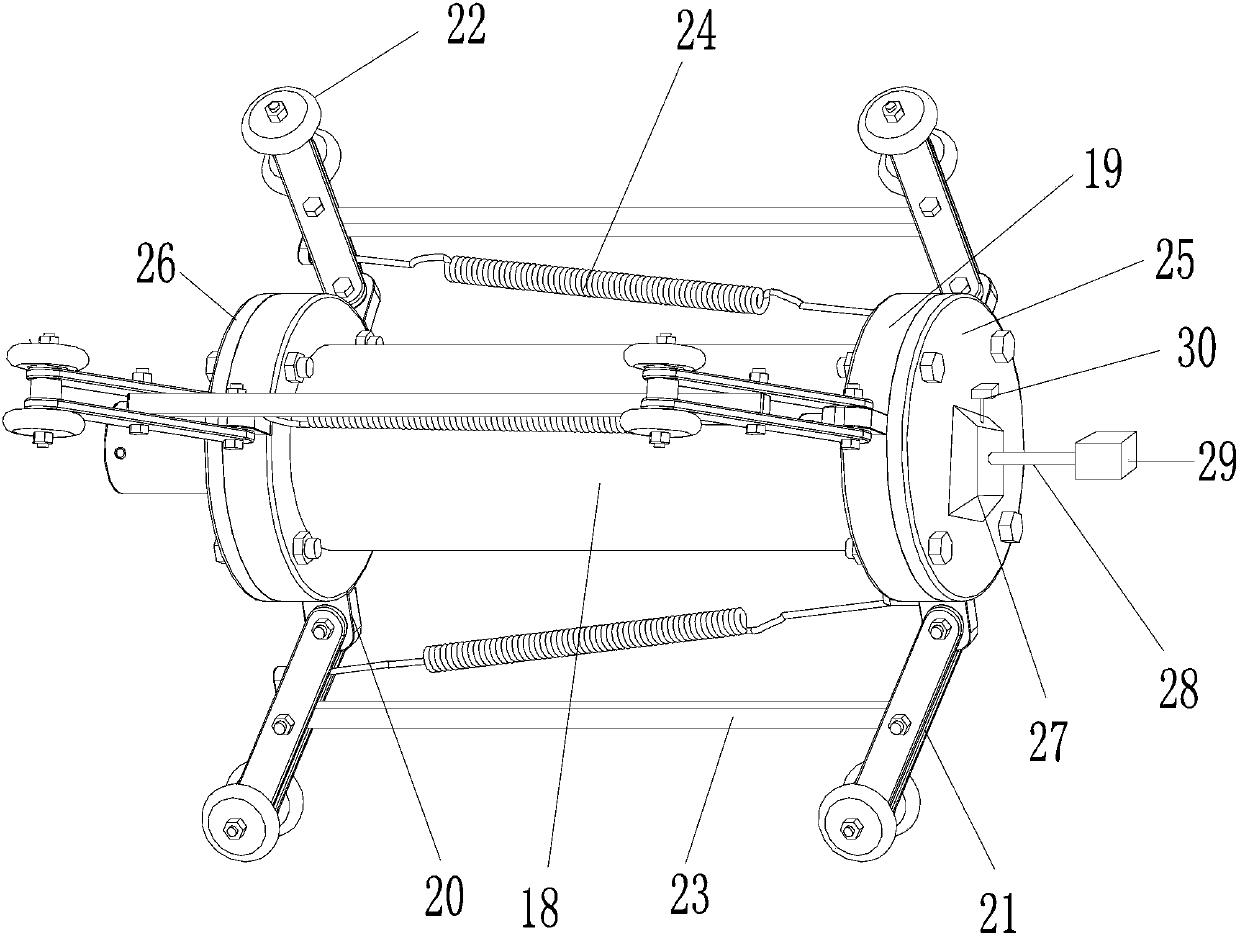

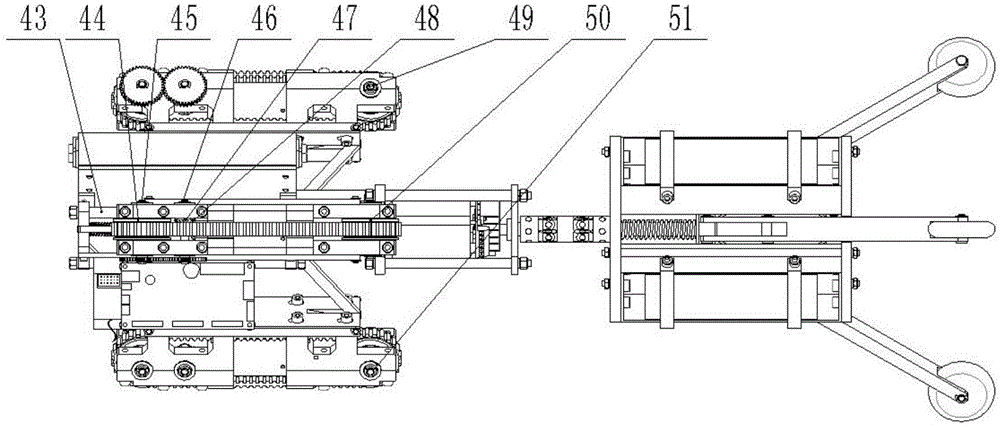

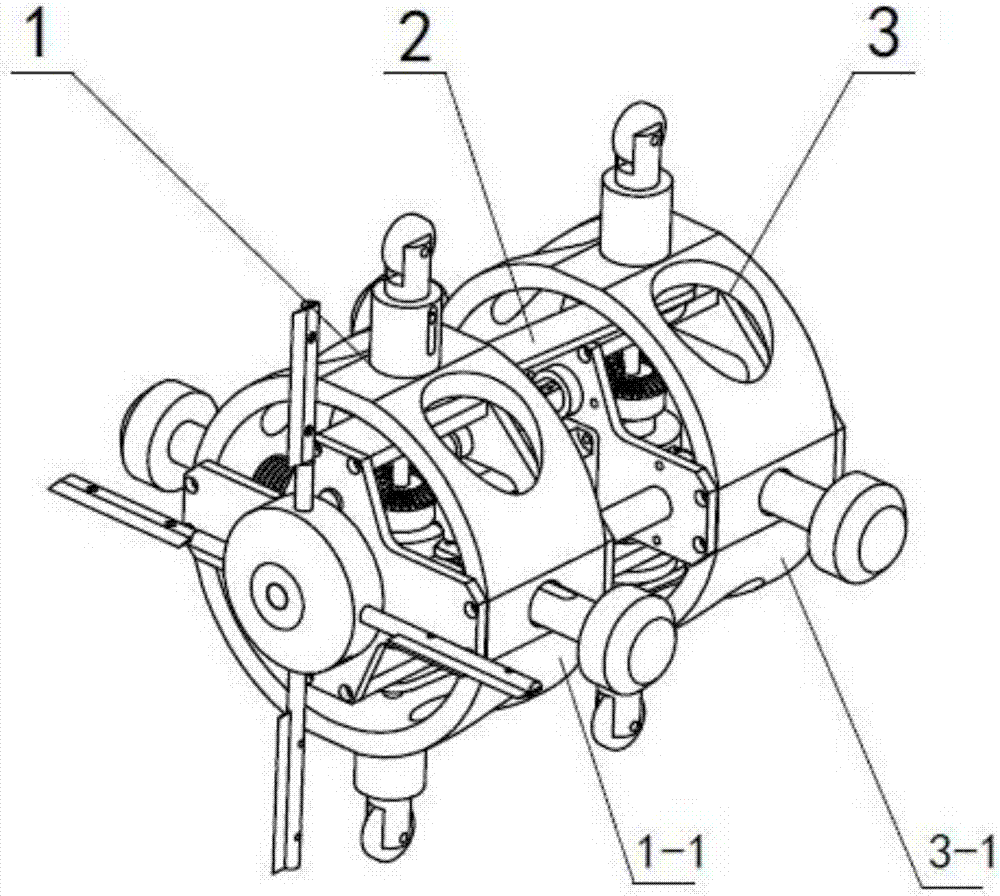

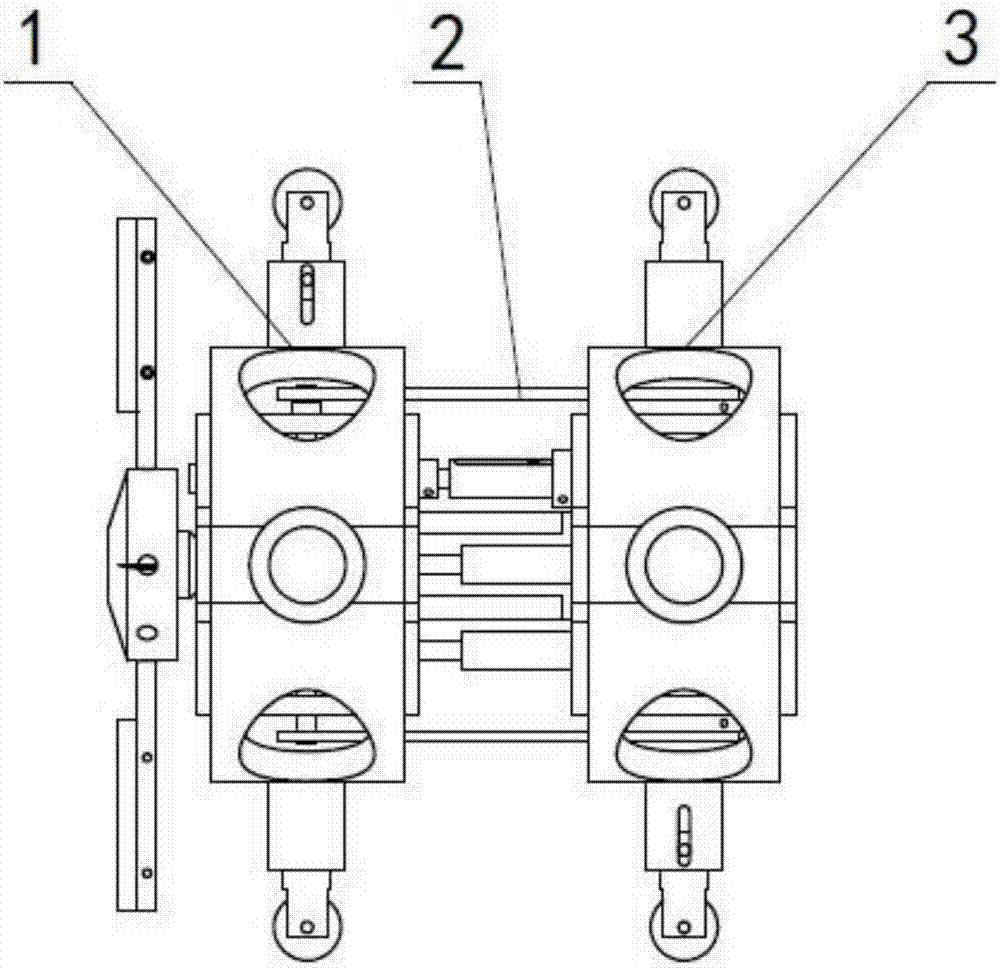

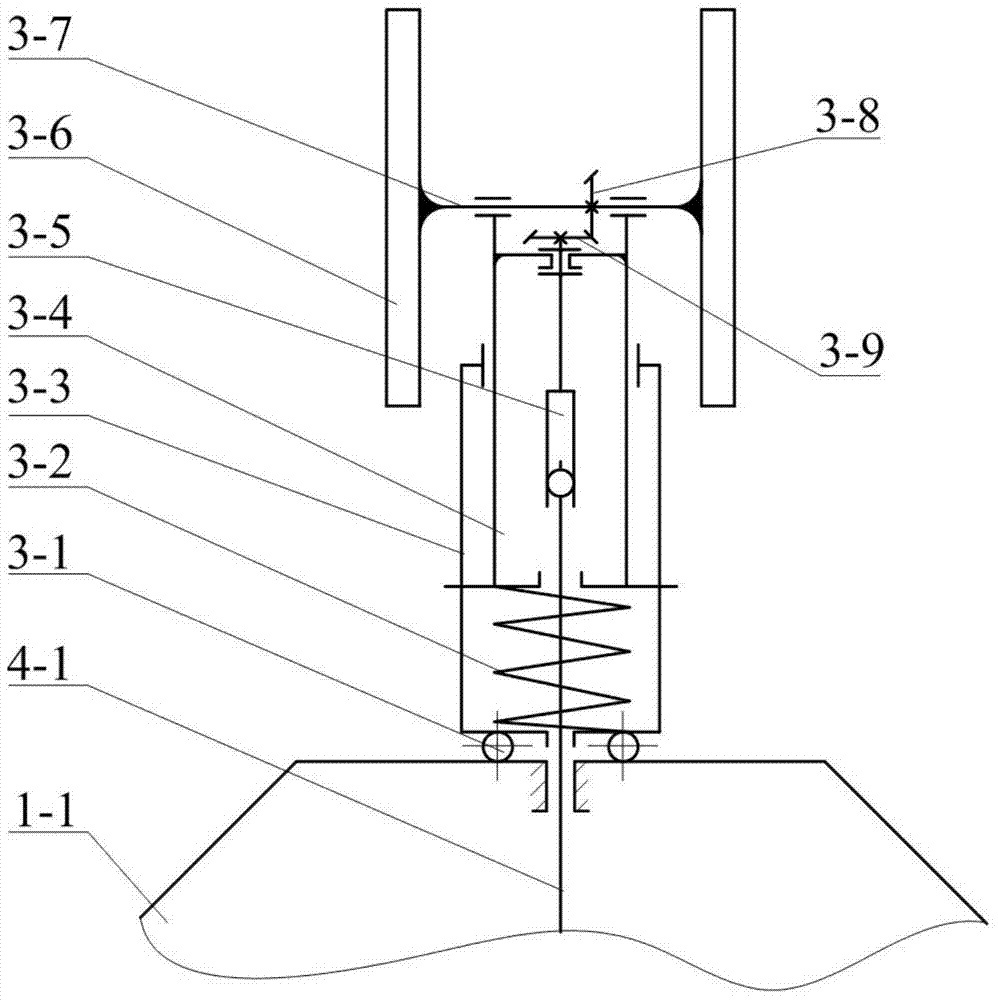

Supporting type pipeline inside detection robot with flexibility self-adapting function

The invention discloses a supporting type pipeline inside detection robot with the flexibility self-adapting function. The supporting type pipeline inside detection robot comprises a flexibility self-adapting supporting mechanism, a driving mechanism, a detection mechanism and a camera shooting mechanism. The camera shooting mechanism is installed at the front end of the flexibility self-adapting supporting mechanism. The flexibility self-adapting supporting mechanism is connected with the driving mechanism and used for guaranteeing that the robot has the capacity of automatically adapting to a reducer pipe or obstacles or bent pipes when the robot moves in a pipeline. The detection mechanism is installed on the driving mechanism, and when the robot conducts detection work in the pipeline, a probe part in the detection mechanism completely makes contact with the inner wall of the pipeline. Flexibility self-adapting of the robot to the pipeline and modularization of the supporting type pipeline inside robot are achieved, the walking capacity of the robot in the pipeline is enhanced, and overhauls of the robot are also facilitated. Meanwhile, the purpose that nondestructive testing equipment is carried on the pipeline inside detection robot is achieved, and therefore the detection capacity for the fault pipeline is improved.

Owner:WUHAN UNIV

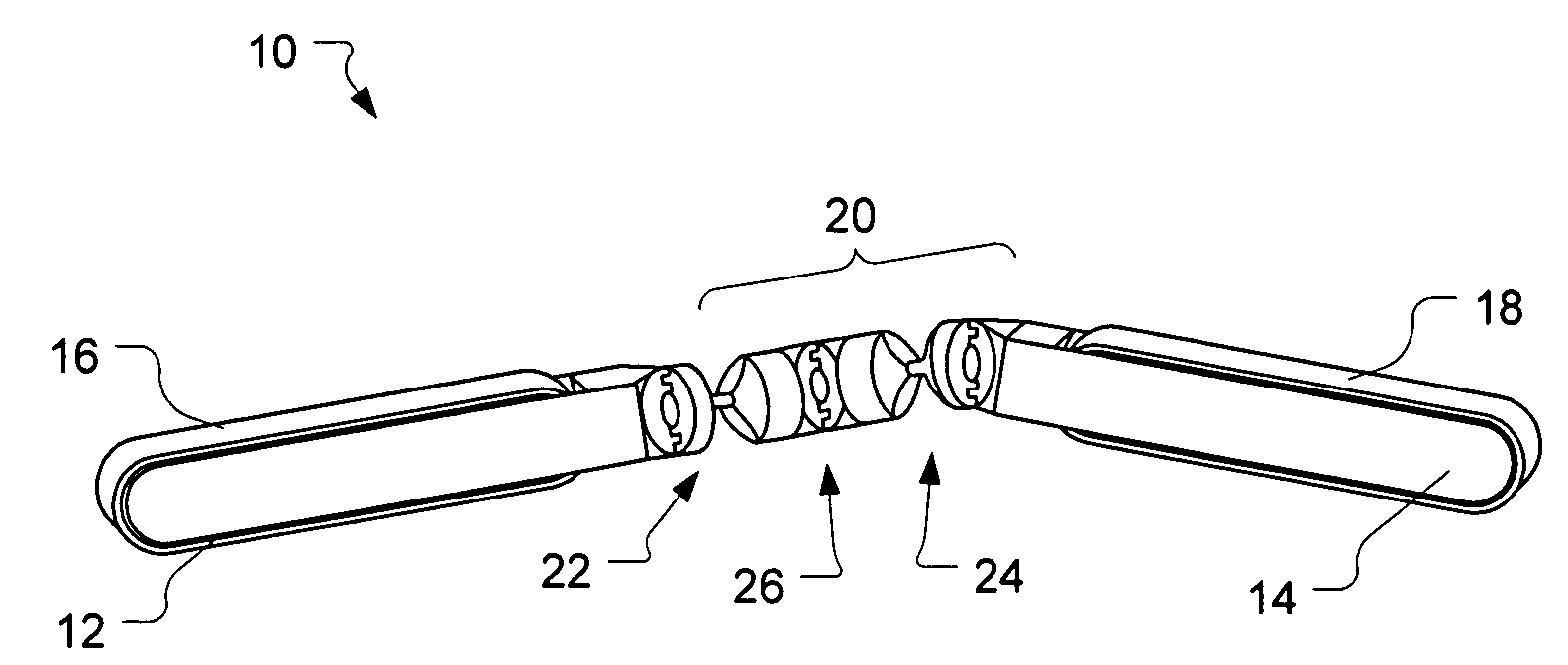

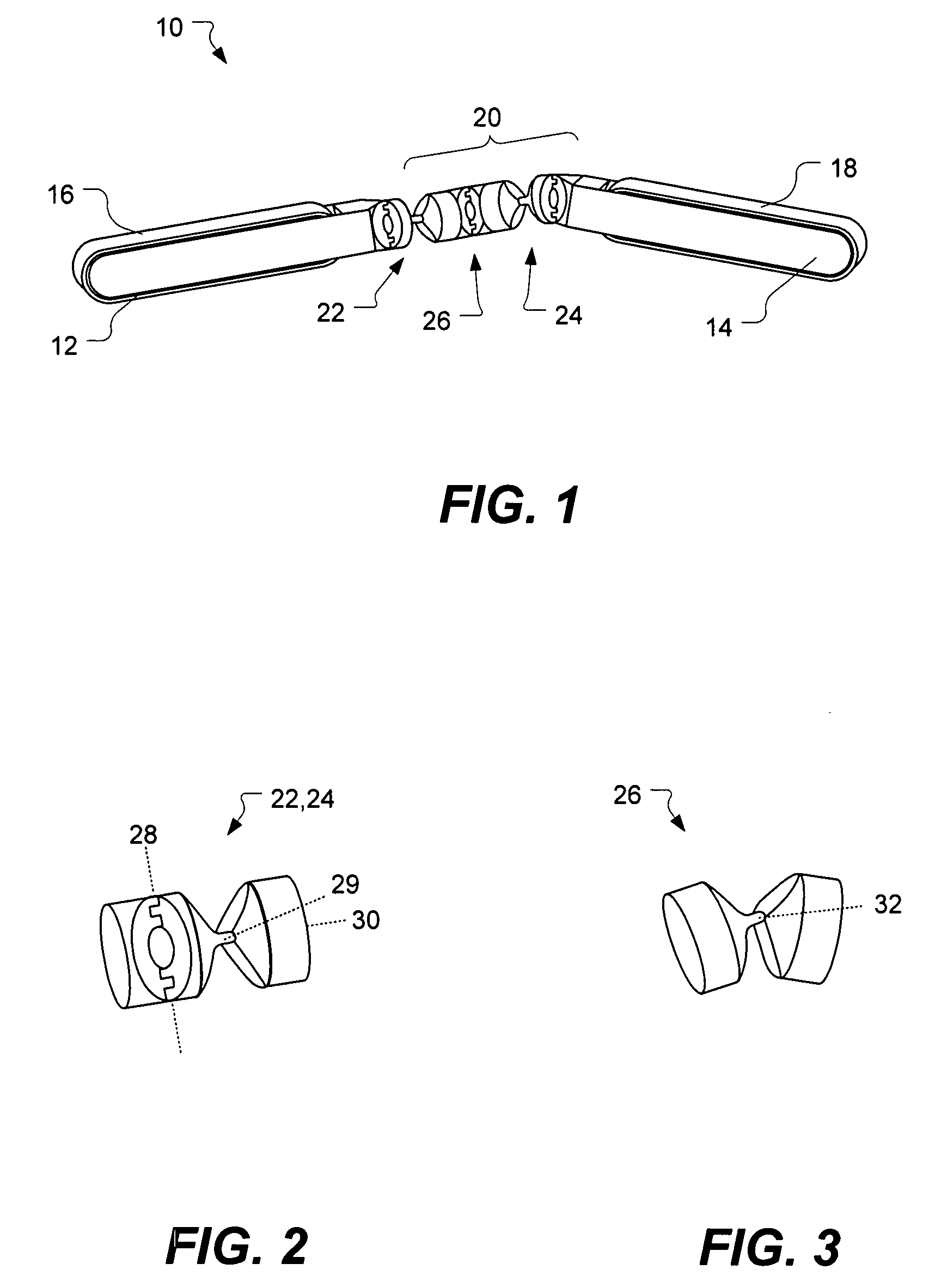

Apparatus and method for enabling rapid configuration and reconfiguration of a robotic assemblage

InactiveUS20140350722A1Reduce riskMore cost-effectiveProgramme-controlled manipulatorHollow article cleaningModularityComputer module

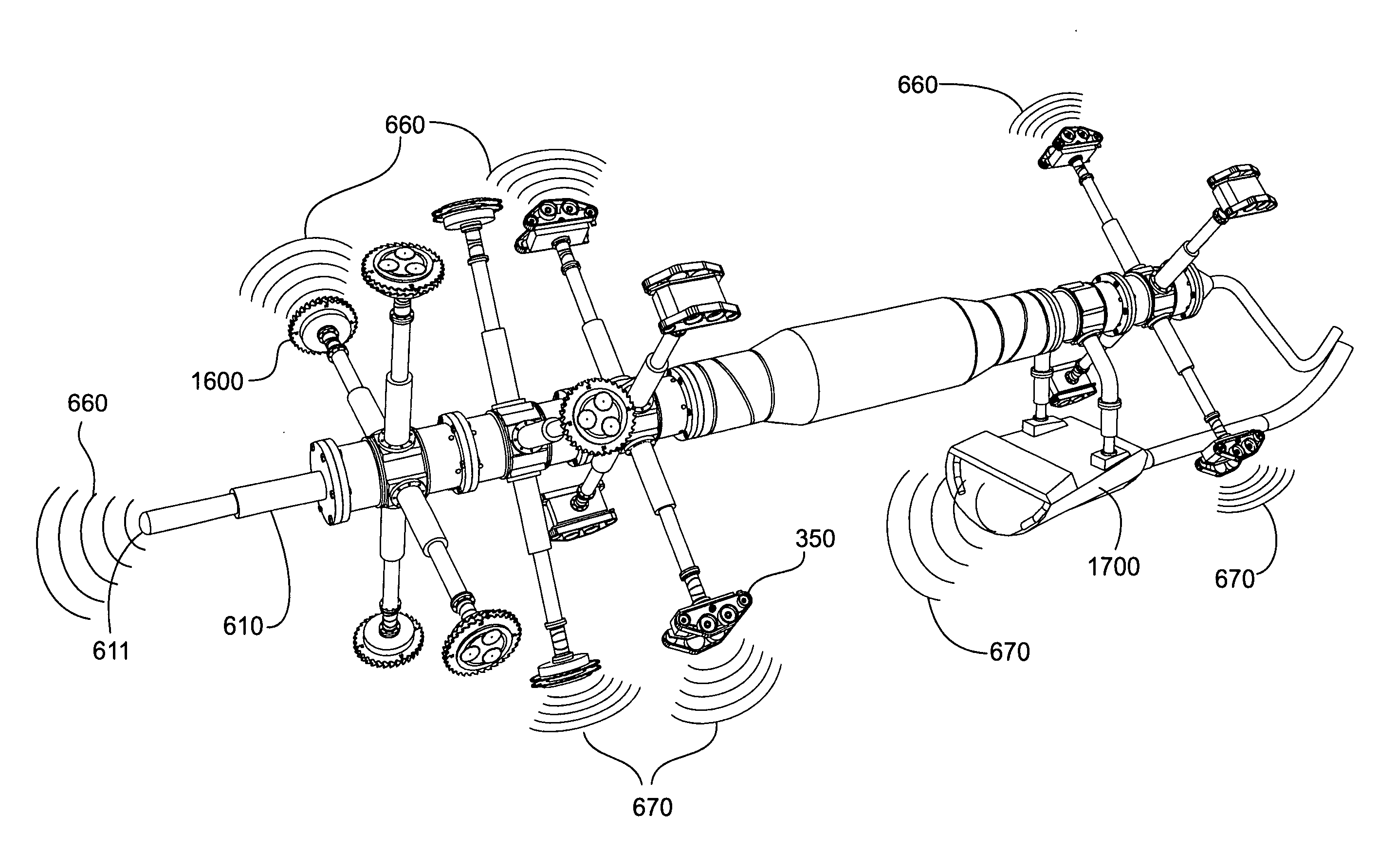

Modular components form a robotic assembly. the mod-components include modules and tools, each have a set of functions and capabilities, are rapidly configured-reconfigured to function cooperatively, creating a configurable robotic assemblage. Each mod-component incorporates a standardized connector mating with any other standardized connector in an interchangeable manner providing mechanical stability, power, and signals therebetween. Each mod-component incorporates a processor, data storage for mod-component identity, status, and programmable functionality, and for responding to commands. Storage is reprogrammed while the robot is operational, altering both commands and responses. After interconnection, inter-module power and communication are established and each modular component identifies itself and its functionality, thereby providing “plug and play” configuration.

Owner:SKRINDE RICHARD ARTHUR

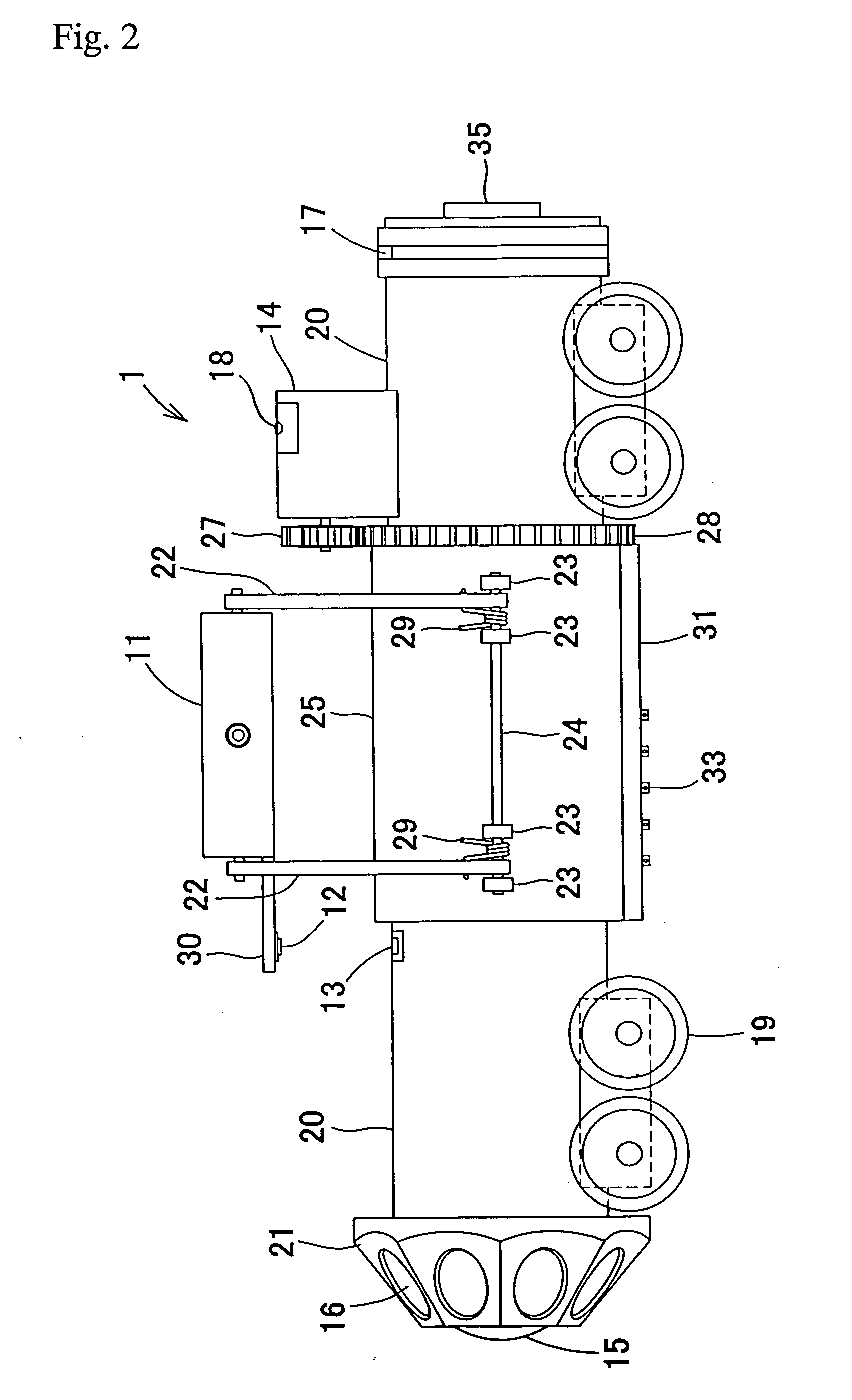

Robot for cleaning and inspection of conduits and its control unit

ActiveUS20120197440A1Small diameterEasy to controlProgramme controlComputer controlEngineeringControl theory

A robot for cleaning and inspecting conduits has a synchronizing mechanism, which extends all driving units simultaneously and with a constant normal force applied to the conduit wall. The robot may be equipped with adapters for conduits with rectangular cross section, and with extension bars for conduits with large diameters. Further, the robot may be equipped with sensors monitoring the robot status, these include a sensor of the synchronizing mechanism position, inclinometer and gyroscope. Data from these sensors may be displayed on a monitor. The movement of the robot inside the conduit and therefore the speed of individual tracks is controlled by the operator by three control elements: direction of turning, diameter of bend and speed of motion. The robot is also able to travel backwards inside the conduit automatically based on stored information about forward movement.

Owner:JETTYROBOT SRO +1

Crawling type micro pipeline robot

The invention discloses a creeping motion type mini pipeline robot, which comprises a middle stretching part and two supporting parts being able to be supported in the mini pipeline. The two supporting parts are respectively connected with the both ends of the middle stretching part, the supporting parts comprise nut supporting frames and driving devices driving the nut supporting frames to move backward and forward, rear supporting legs are hinged on the driving devices, front supporting legs are hinged on the nut supporting frames, and the rear supporting legs are hinged with the front supporting legs. The creeping motion type mini pipeline robot with enough driving traction force can freely move frontward and rearward in the mini pipeline with an arbitrary slope angle, can also creep in an upright pipeline, and can be embarked an extended function module, to realize the examining, the detecting and the maintenance of the condition in the mini pipeline.

Owner:NAT UNIV OF DEFENSE TECH

Vehicle for inspecting a pipe

The present invention provides a vehicle for inspecting a pipe including a chassis; propulsion means for driving the chassis along the pipe; and sensor means which when located adjacent an interior surface of the pipe provide a signal indicative of the presence of lateral openings in the pipe; the sensor means comprising a capacitive sensor.

Owner:RADIODETECTION

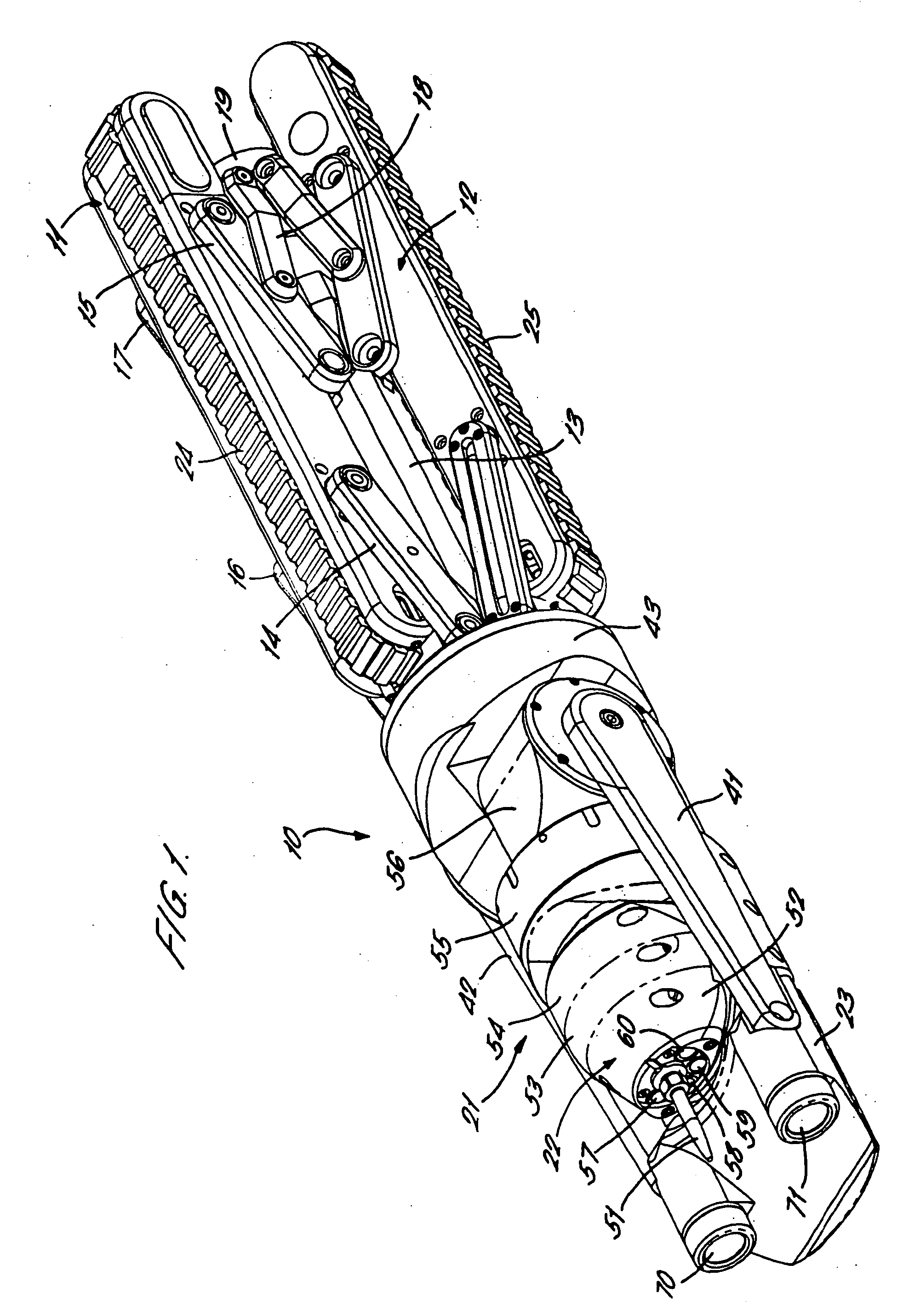

Method and apparatus for detecting defects in oilfield tubulars

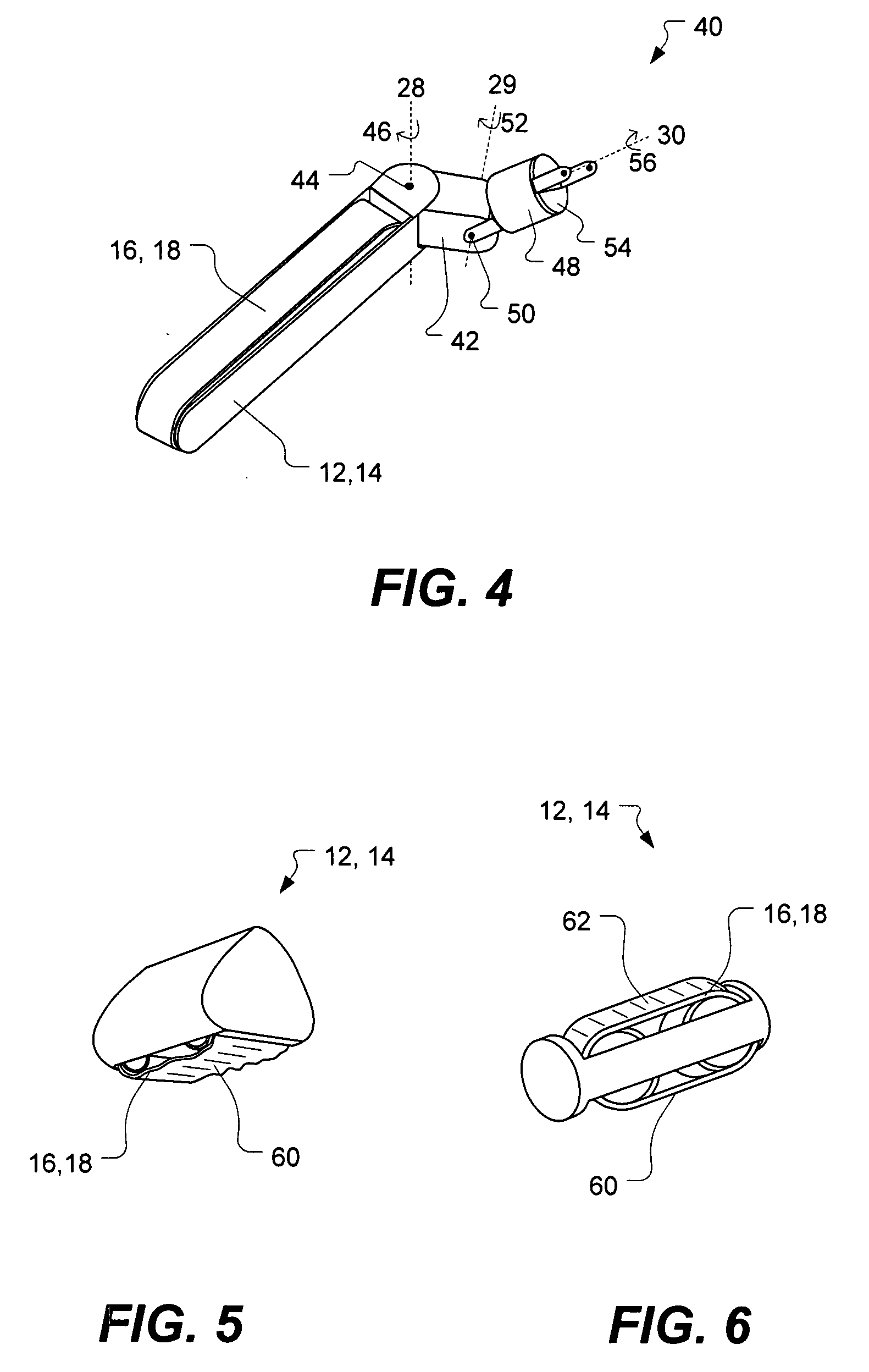

A sensor system for detecting defects in a tubular string while positioned in the well includes a sensor tool (10) comprising a plurality of circumferentially spaced sensors (40) arranged in two or more axially spaced rows. A plurality of sensors are positioned in each row, with each sensor positioned on one of a plurality of sensor support pads. Sensors within a row may include sensors with axes inclined at different angles, and each of the plurality of sensor pads may move from a radially retracted run-in position to a radially extended sensing position. A flexible line (50) may be used for lowering a sensor tool in the well and retrieving the sensor tool from the well.

Owner:NEIDHARDT DEITMAR J

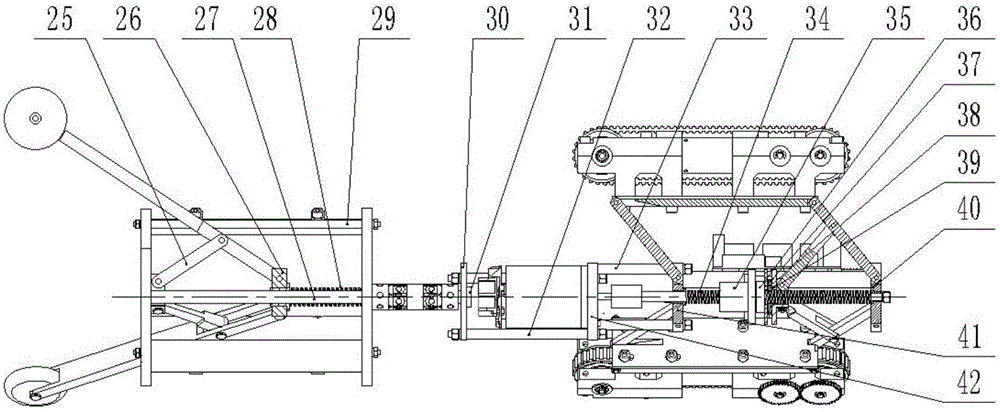

Single-driving double-directional crawling-type pipeline cleaning robot

ActiveCN106903120AImprove mobilityImprove battery lifeSewer cleaningHollow article cleaningGear wheelEngineering

The invention discloses a single-driving double-directional crawling-type pipeline cleaning robot. The single-driving double-directional crawling-type pipeline cleaning robot comprises a front machine body assembly, a transmission assembly and a rear machine body assembly. Through the condition that the transmission assembly is driven by a power assembly and through the transmission effect of a link mechanism, a gear mechanism and an equal-interval cam mechanism, alternant contracting and supporting of the front machine body assembly and the rear machine body assembly in the radial direction are achieved, stretching out and drawing back of the front machine body assembly and the rear machine body assembly in the axial direction are achieved, and meanwhile synchronous rotation of a dredging knife flywheel is achieved, so that crawling-type travelling of the robot in the positive and negative directions of a pipeline and pipeline cleaning operation are achieved. The single-driving double-directional crawling-type pipeline cleaning robot is stable, reliable, compact and practicable, achieves single-driving double-directional crawling-type travelling and pipeline cleaning in the pipeline with large pipe diameter changing, effectively improves the obstacle crossing property and pipe diameter changing adaptability of the pipeline robot, improves the cruising ability of the pipeline robot and has a practical engineering significance on cleaning of the horizontal pipeline with large pipe diameter changing.

Owner:CHINA UNIV OF MINING & TECH

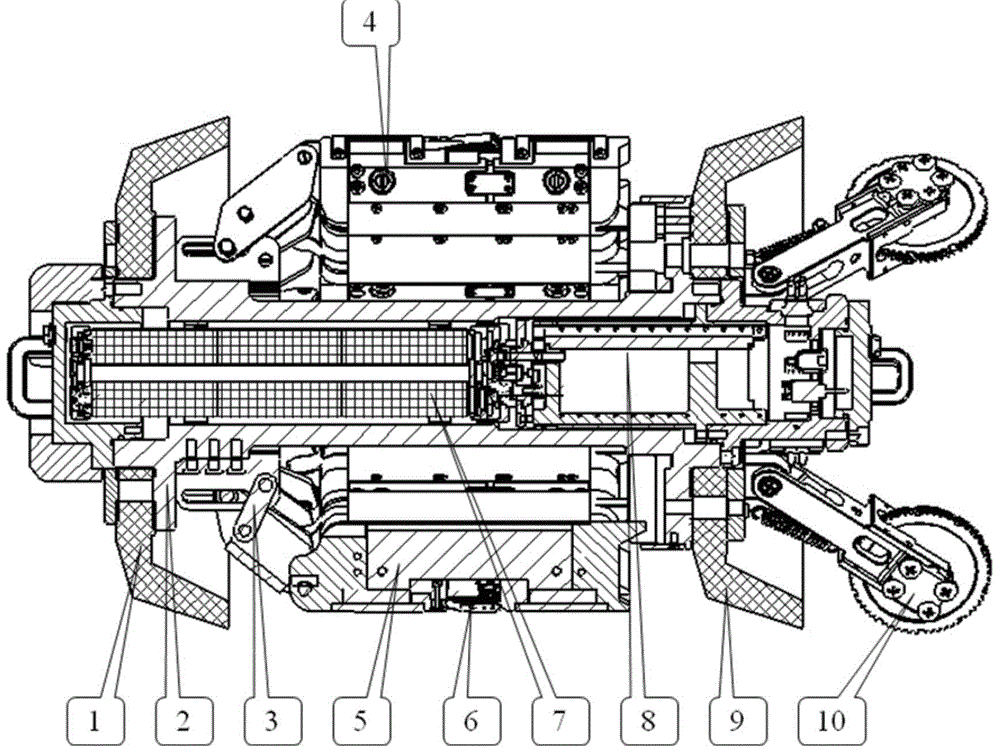

High-precision inner detecting device for seabed oil and gas pipeline flaws

A high-precision inner detecting device for seabed oil and gas pipeline flaws is characterized in that an anti-collision head and a front power packing cup are connected to the front end of a body support shaft, the rear of the front power packing cup is connected with a floating magnetization detecting block through a hinge mechanism, and a lateral jacking spring is disposed on each of the front side and the rear side of the floating magnetization detecting block to form a floating magnetization circuit and a magnetic flux leakage detecting block unit. A finger probe is disposed on the floating magnetization detecting block. A guide groove and a limit ring are arranged at the rear end of the body support shaft. A rear power packing cup is disposed at the rear of the guide groove. The front packing cup and the rear packing cup jointly form a power drive system. A battery pack unit and an electronic recorder are respectively disposed at the front and the rear of a seal cabin in the body support shaft in an opposite insertion manner. A detector odometer wheel unit is mounted at the tail of the body support shaft. By the floating magnetization detecting structure, online inner detection of oil and gas pipeline flaws under complex working conditions can be well achieved.

Owner:TSINGHUA UNIV

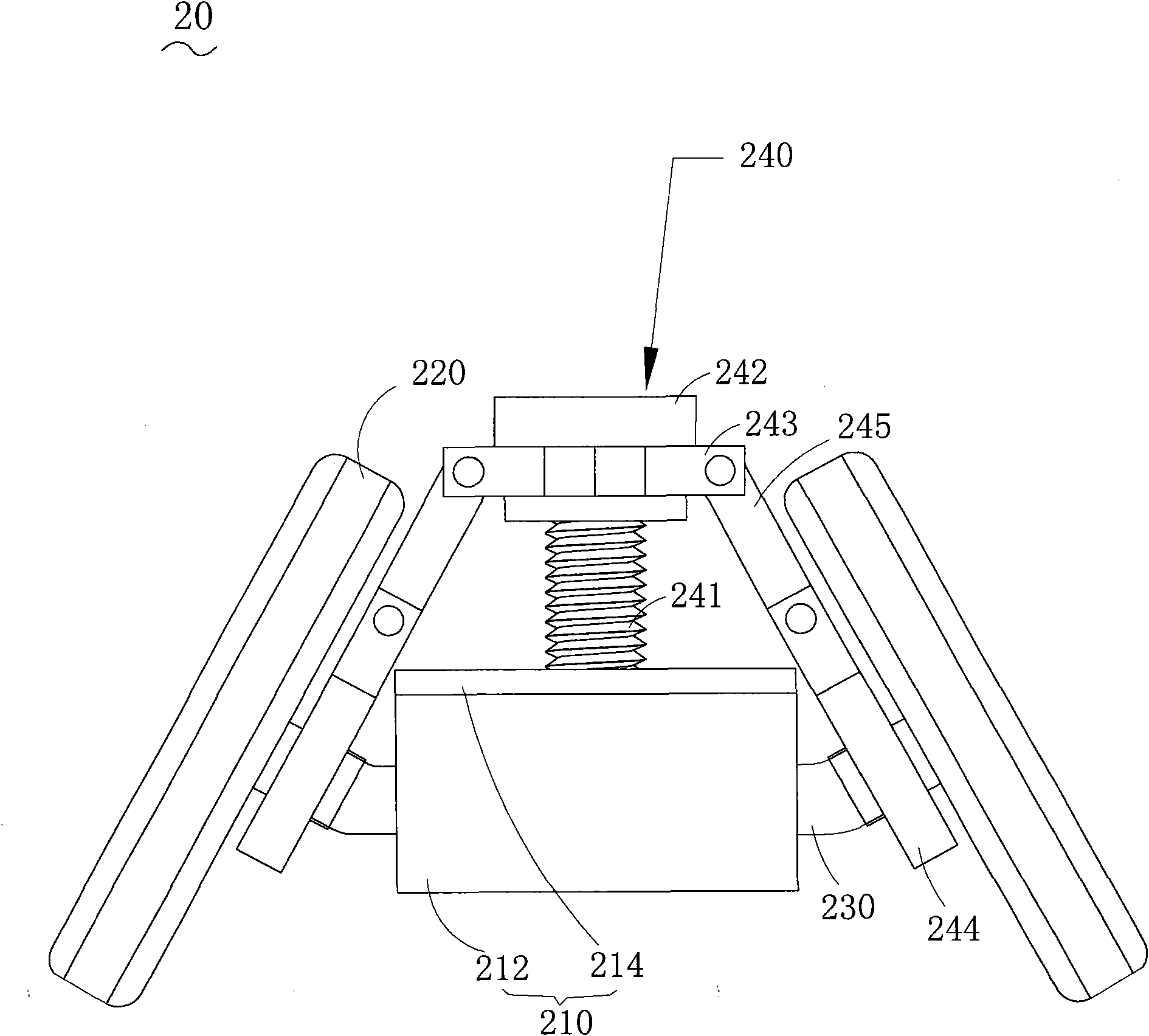

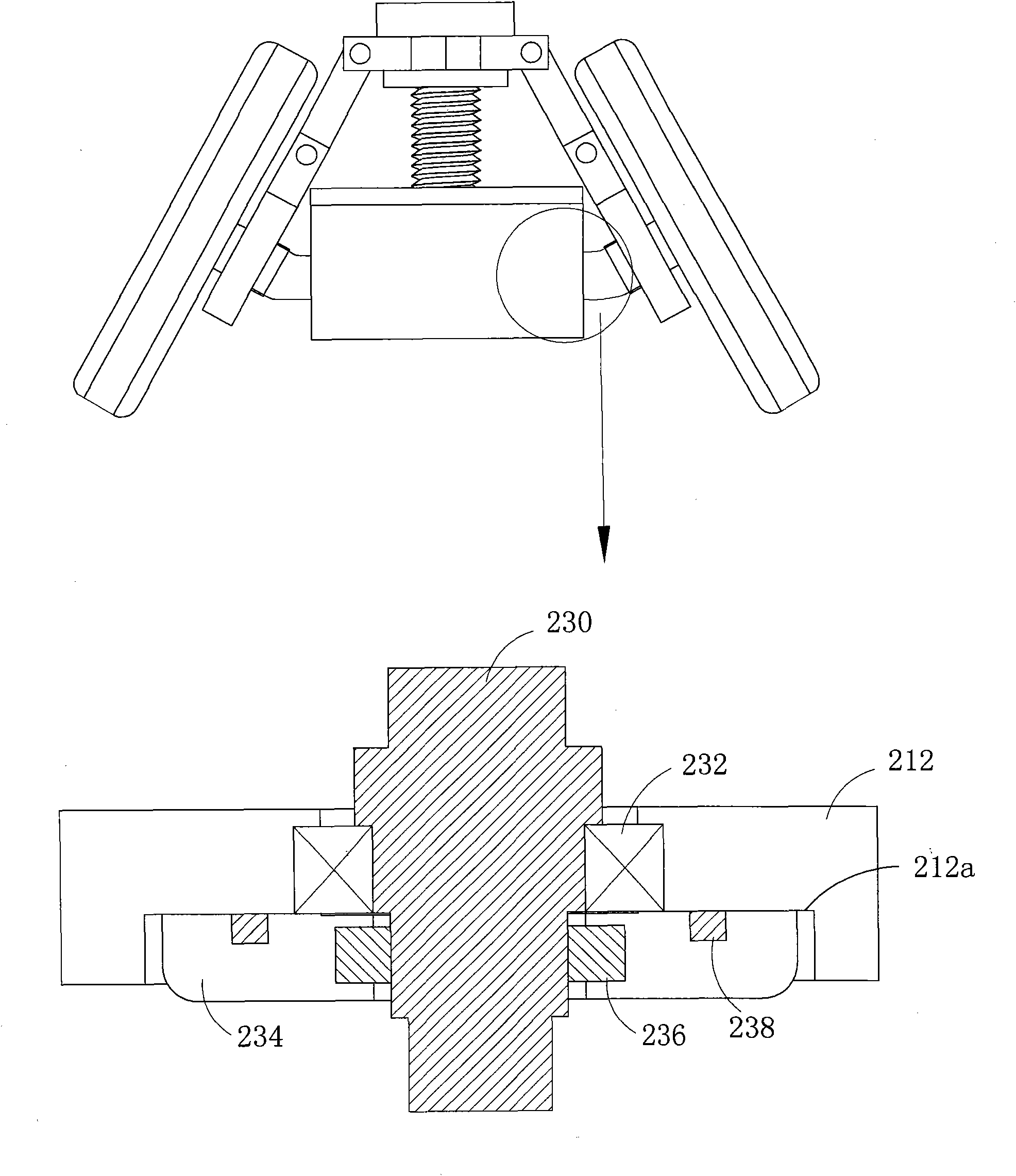

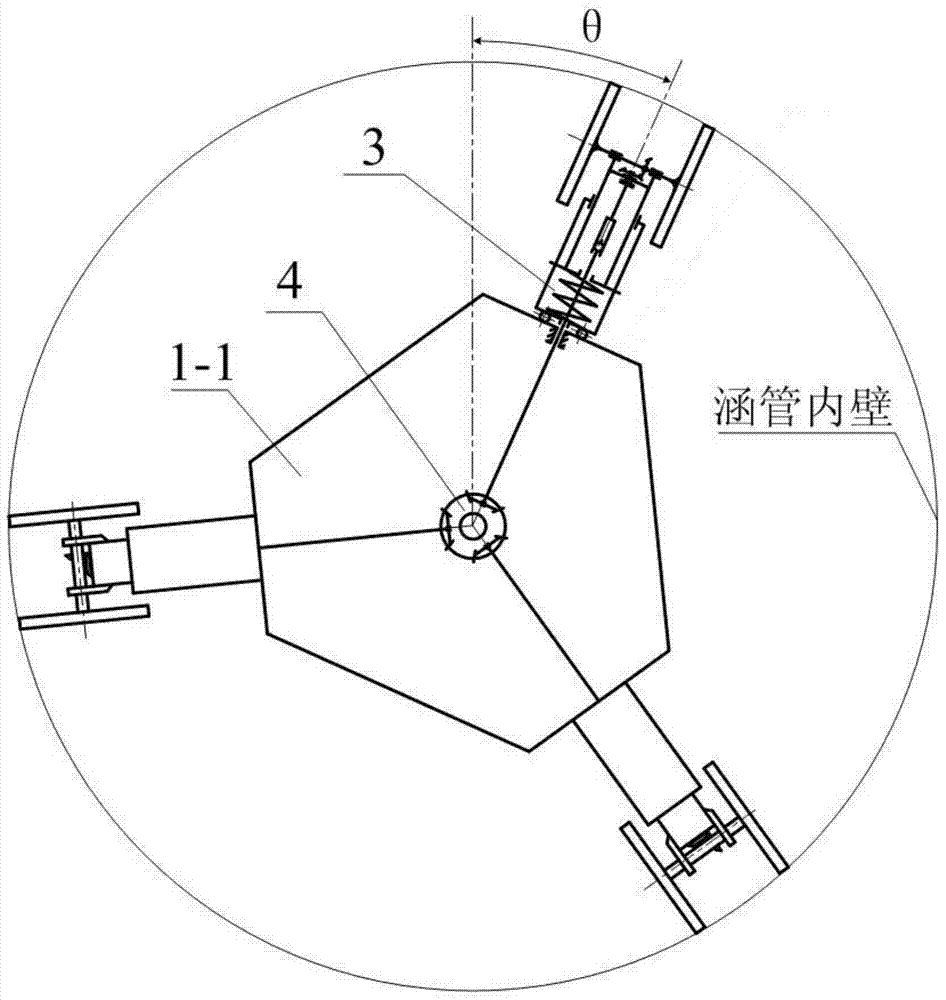

Self-adapting pipe robot

InactiveCN101319747AImprove carrying capacityCapable of stretchingPigs/molesEngineeringSelf adaptive

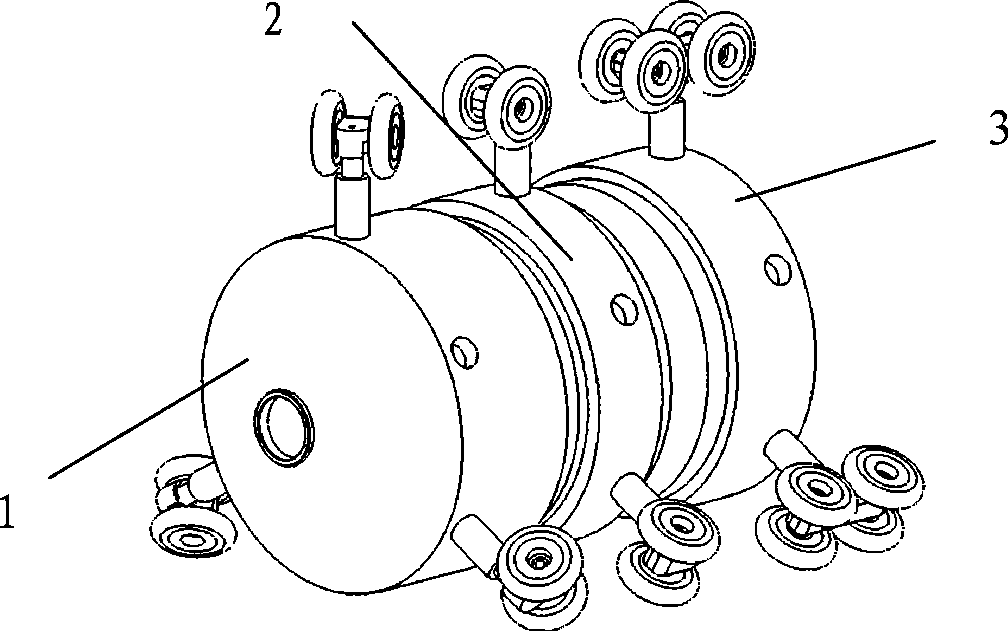

The invention discloses a self-adaptive conduit robot, relating to the field of robot technology, particularly relating to the field of technology about a robot used to test, clean and maintain conduits. The invention comprises a machine body. At least three sets of drive units are evenly arranged along the periphery of the machine body; a slide shaft is arranged on the periphery of the machine body, and both ends of the slide shaft are connected with the machine body respectively; a securing fitting is welded at the middle part of the slide shaft; two slide blocks are coated on the slide shafts on both sides of the securing fitting respectively. Two pressure springs are coated on the periphery of the slide shaft arranged between the securing fitting and the slide block; two reset springs are coated on the periphery of the slide shaft arranged at the outer side of the securing fitting. Both ends of each first connecting rod are connected with a slide block and a roller respectively, and both ends of a second connecting rod are connected with the end part of the slide shaft and the first connecting rod respectively. A power control device is arranged on each group of machine bodies. The invention has sound bearing capacity, and is applicable to conduit work under various environments; and high use value and easy assembly and disassembly are achieved.

Owner:SOUTHEAST UNIV

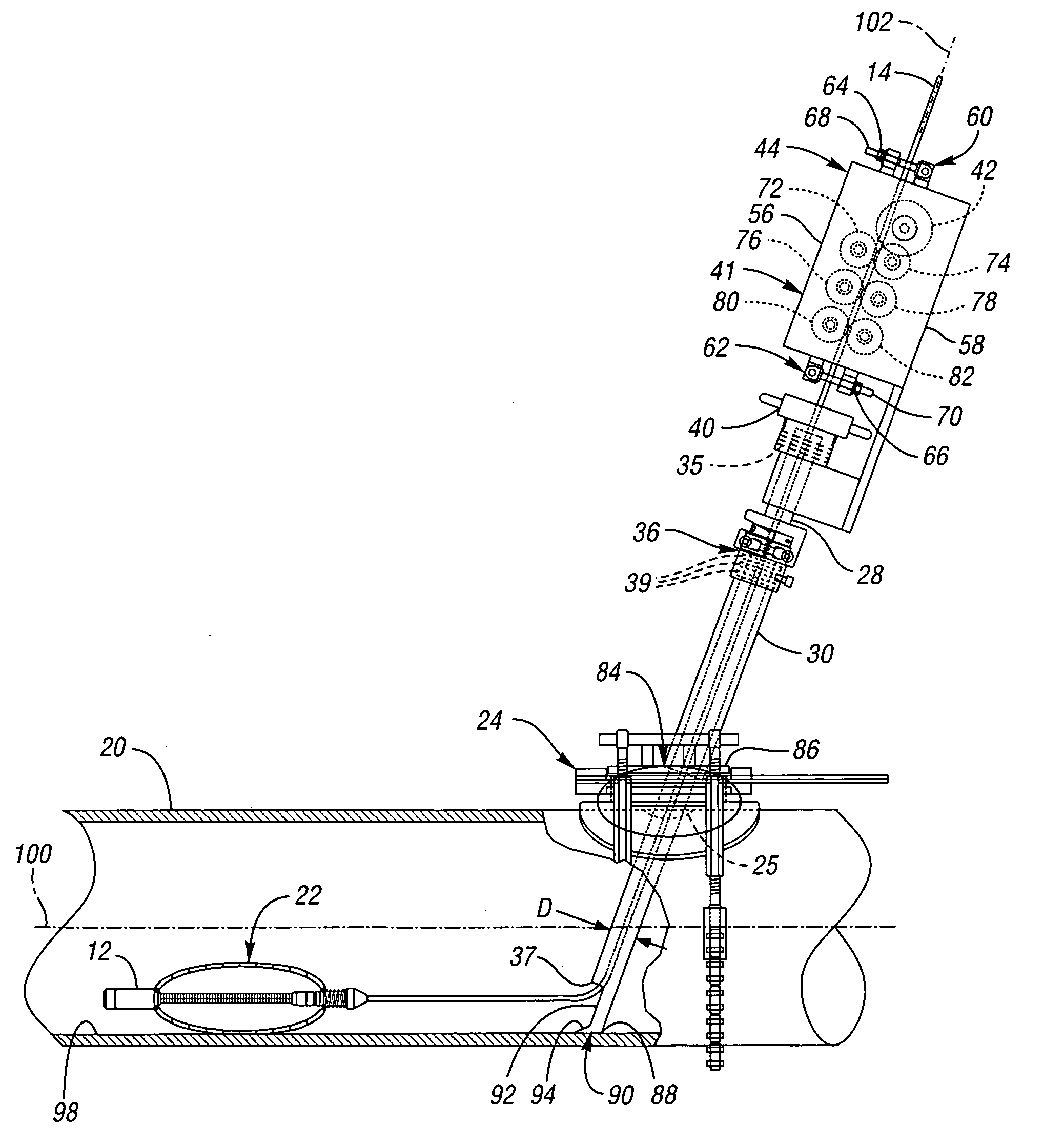

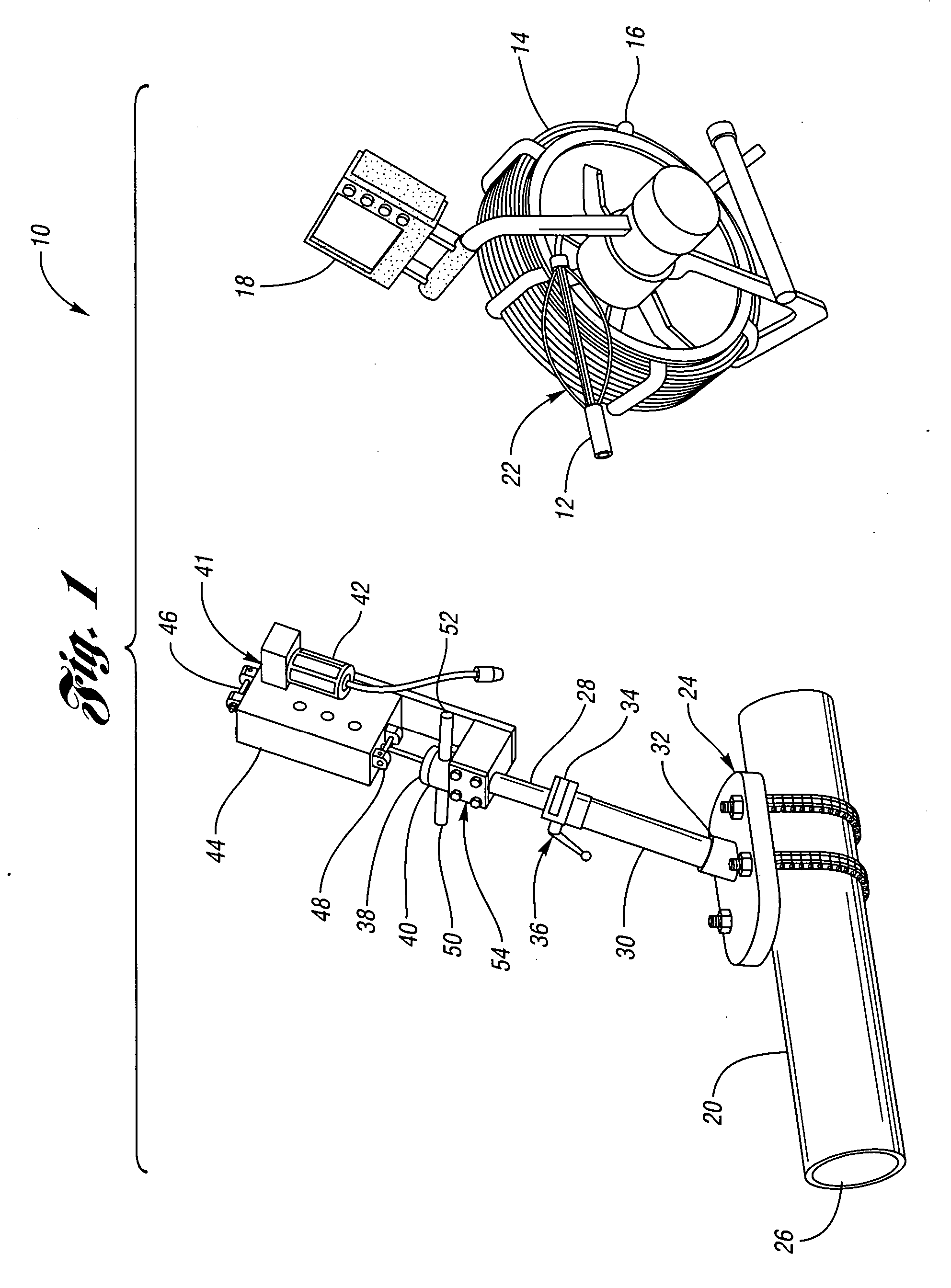

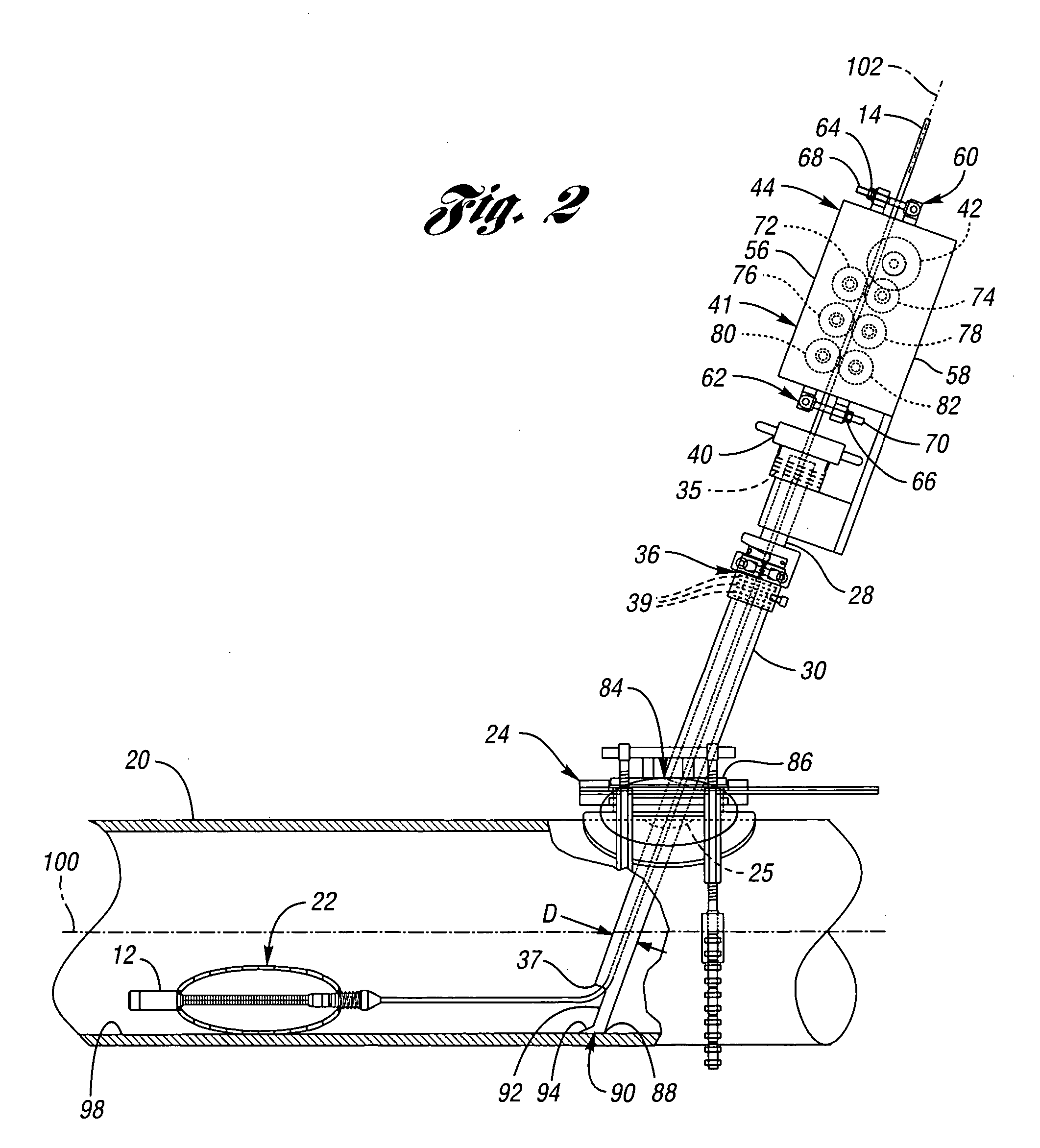

Pipeline inspection system

ActiveUS20070051192A1Facilitate entryPrevent escapeDiaphragm valvesEngine diaphragmsEngineeringPositioning system

An inspection system configured for “no-blow” use in a pressurized gas pipeline includes a push rod wound around a spool for convenient deployment and portability. A camera disposed on one end of the push rod is configured to relay images back to a monitor. A motor is configured for remote actuation by an operator, and provides for self-propelled movement of the camera in the pipeline. An entry tube is configured for sealed entry into the pipeline to facilitate entry of the camera and push rod. A guide shoe at the end of the entry tube provides a smooth transition-for the camera and push rod as it leaves the entry tube and enters the pipeline. An automatically deployable and retractable positioning system is used to keep the camera away from an interior surface of the pipeline, and in the case of smaller pipelines, centers the camera within the pipeline.

Owner:ULC TECH LLC

ID-OD discrimination sensor

InactiveUS20070022830A1Structural/machines measurementHysteresis curve measurementsMicrocontrollerWear resistant

A sensor body for use in a pig for determining characteristics of a pipeline wall though which the pig passes includes a circuit board and a single coil wrapped around the circuit board. A microcontroller is mounted to the circuit board and connected to the single coil and configured to induce a waveform on the coil to thereby create an eddy current in the pipeline wall adjacent the sensor body. The microcontroller is also configured to measure changes in a characteristic of the induced waveform on the single coil that correspond to the presence of anomalies on an inside diameter of the pipeline wall. The sensor body also includes a sensor body cover molded about the circuit board, the microcontroller and the single coil. The sensor body cover consists essentially of a wear resistant, non-conductive material that includes a polymer material.

Owner:GENERAL ELECTRIC CO

Self-adapting pipe moving mechanism

The invention provides a self-adaptive pipeline moving mechanism, which belongs to the technical field of pipeline robot engineering. The structure of the mechanism comprises a supporting mechanism, a forward drive mechanism and a backward drive mechanism, wherein the forward drive mechanism is connected with the backward drive mechanism through a first transmission mechanism, and is connected with a motor in the supporting mechanism through a second transmission mechanism; the first transmission mechanism is arranged in the forward drive mechanism; and a link mechanism and a locking mechanism are arranged between the forward drive mechanism and the first transmission mechanism. The mechanism can automatically regulate forward and backward in the pipeline without external control. In the invention, when a forward drive arm is contracted because of a barrier, other forward drive arms are also contracted to the center through linkage of the link mechanism, thereby realizing synchronous motion of the drive arms. Meanwhile, the locking mechanism restricts the rotation of the forward drive arms, at this time the route of power output is converted, and backward drive arms rotate and generate backward driving force, namely a robot moves towards an opposite direction. The moving mechanism has strong adaptability.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

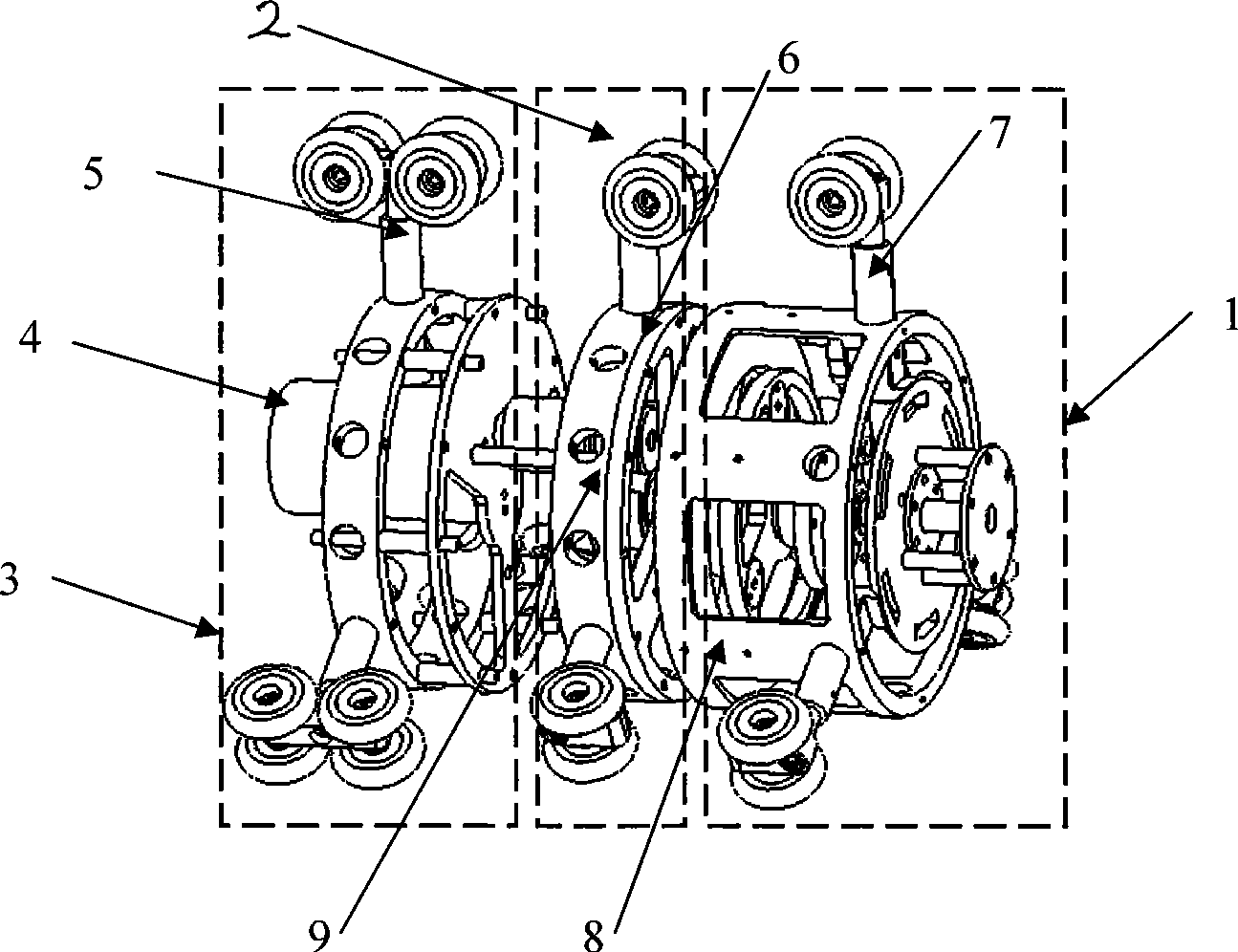

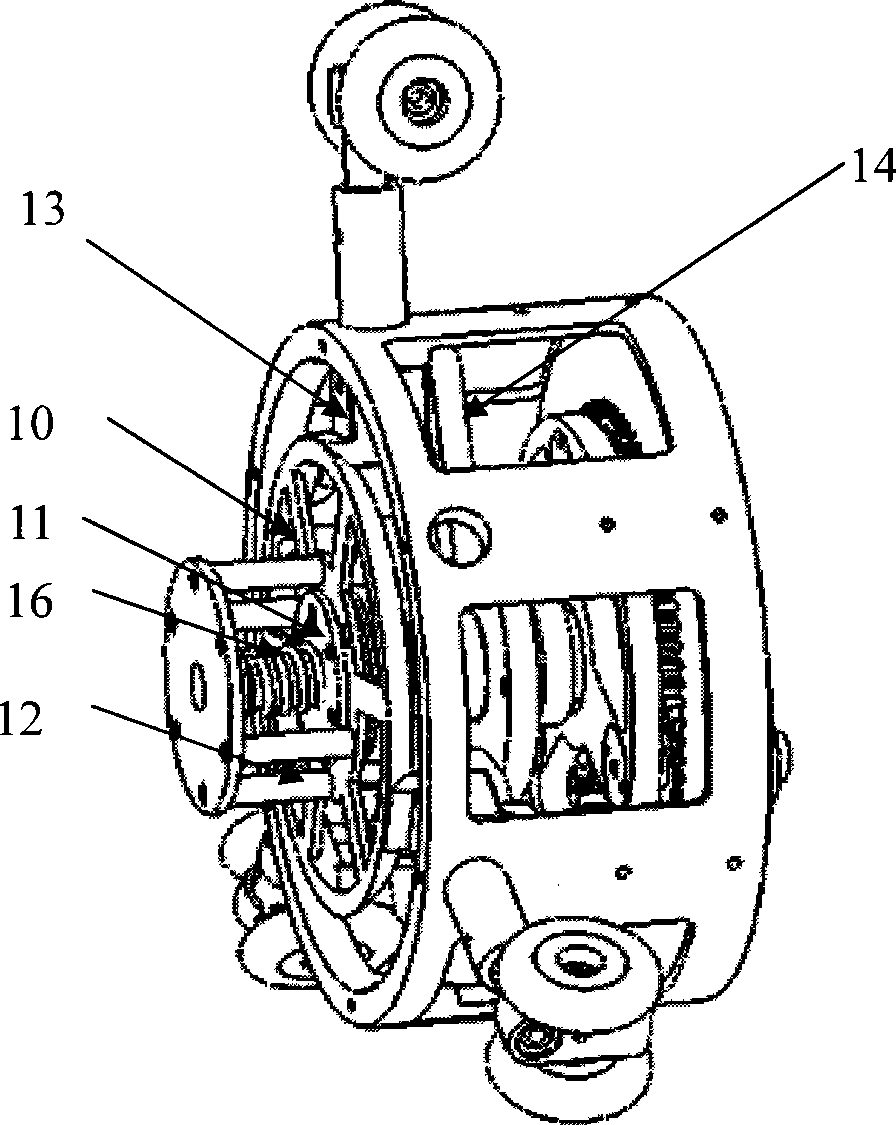

Reservoir culvert detection robot

The invention discloses a reservoir culvert detection robot. A special pipeline robot aiming at the reservoir culvert detection work is not designed in the prior art. The reservoir culvert detection robot comprises a driving wheel group, a steering system, a connecting mechanism, a driven wheel group and a control system, wherein the driving wheel group and the driven wheel group are connected through the connecting mechanism, the steering system controls the steering of the driving wheel group, the driving wheel group comprises wheel leg mechanisms and a transfer system, the three wheel leg mechanisms are uniformly distributed and arranged on the side wall of a first main installing plate, the transfer system is arranged in the center part of the first main installing plate, and drives the three wheel leg mechanisms, and the steering system comprises a rope, a steering rope roller, a steering motor, a steering reset spring, an initial position stop pin, a pull arm and a terminal position stop pin. The reservoir culvert detection robot is suitable for the work environment of a reservoir culvert, and can do autoroatation around the pipeline center in situ in the pipeline for avoiding obstacles; two rows of wheel groups including the front row and the back row and a telescopic diameter change mechanism are adopted, the telescopic quantity of each wheel leg is respectively independent, and the pipeline diameter change adapting capability is high.

Owner:广东智慧水云科技有限责任公司

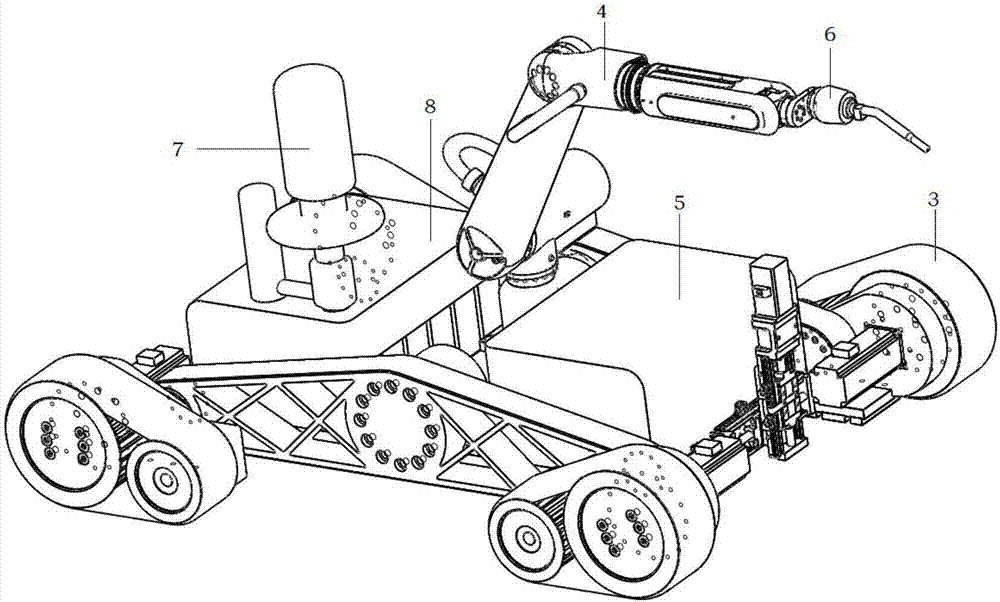

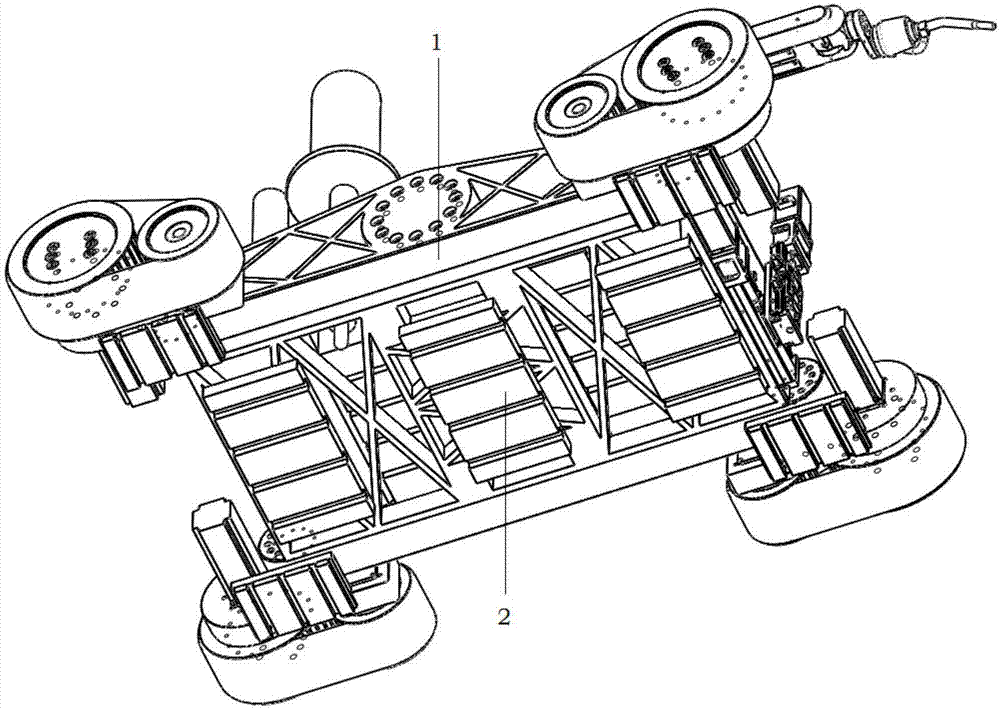

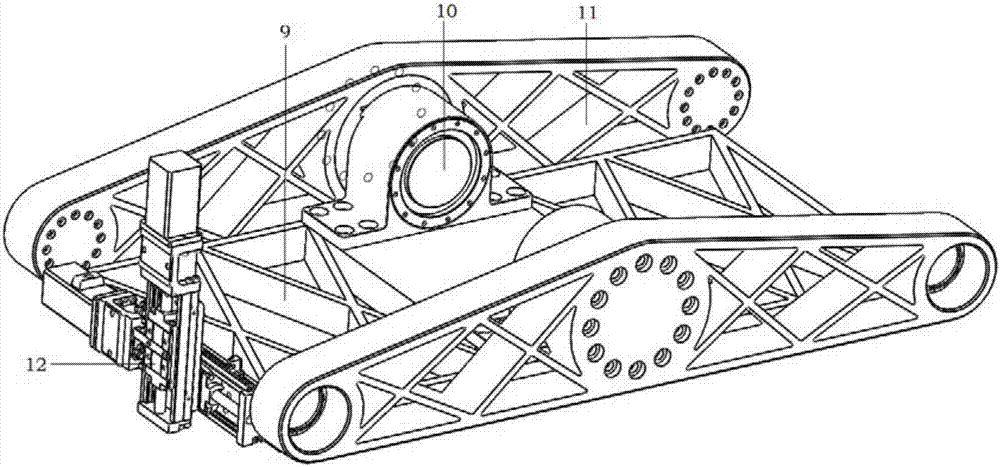

Non-contact type magnetic adsorption wall-climbing robot adaptive to complex wall surface operations

The invention provides a non-contact type magnetic adsorption wall-climbing robot adaptive to complex wall surface operations. The wall-climbing robot comprises a vehicle body, an adsorption device, moving modules, a mechanical arm, a nondestructive inspection module, a polishing and welding module, a paint spraying module and a control sensing module. In the operation process of the wall-climbing robot, crawler belts of the moving modules can be attached to the inner wall of a steel pipe in a self-adaptive mode; and meanwhile, a frame of the vehicle body is provided with the moving modules, the adsorption device, the mechanical arm and the control sensing module, and hence the nondestructive inspection module, the polishing and welding module and the paint spraying module can be replaced according to different functions of the wall-climbing operation of the robot. The non-contact type magnetic adsorption wall-climbing robot has the characteristics that modular design is adopted, various detection and maintenance operations can be executed, loads are large, and no power source is required in the adsorption device; and the functions of pressure steel pipe wall climbing, welded joint nondestructive inspection, welded joint repair and welded joint surface coating corrosion resistance can be provided.

Owner:SHANGHAI JIAO TONG UNIV

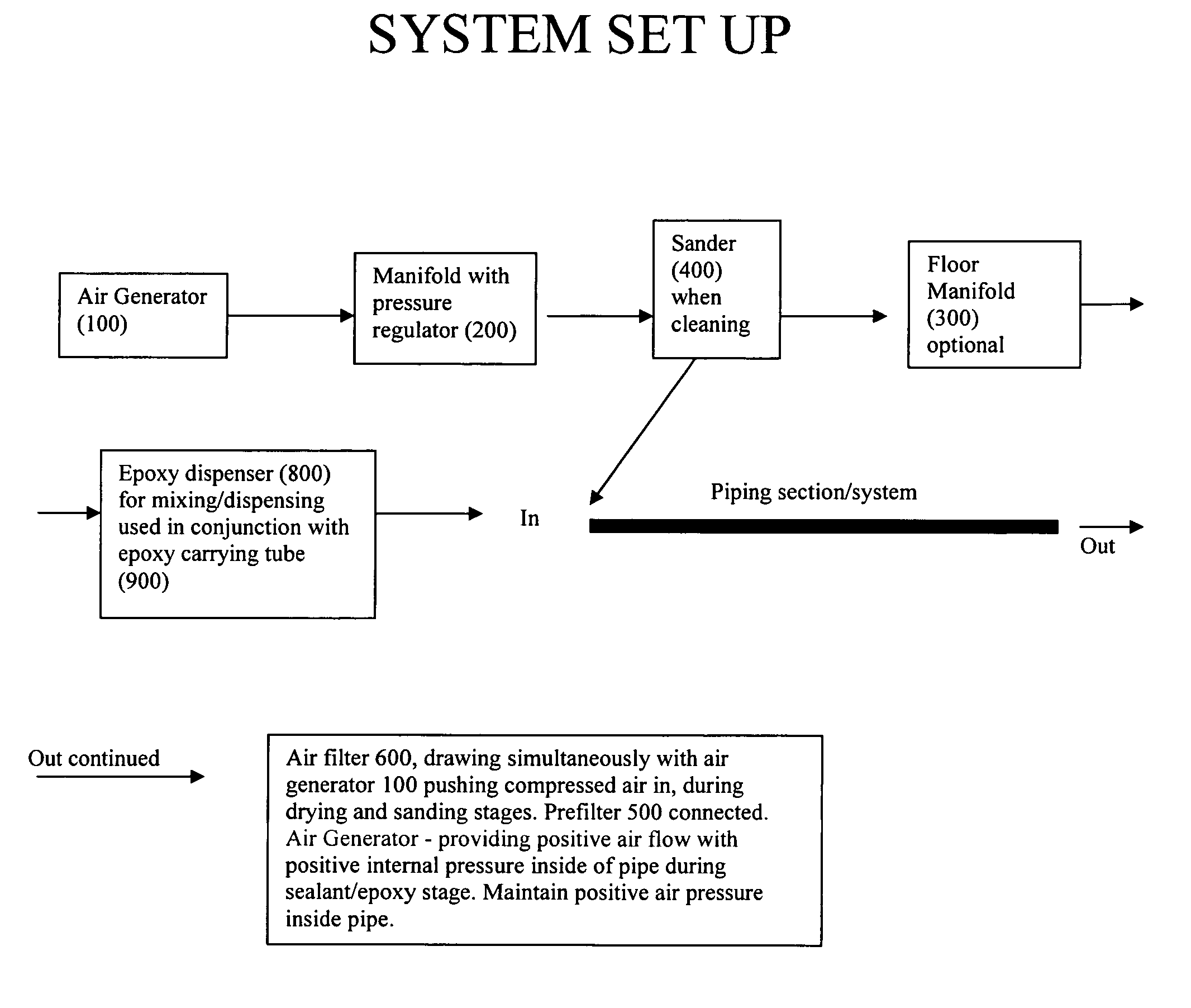

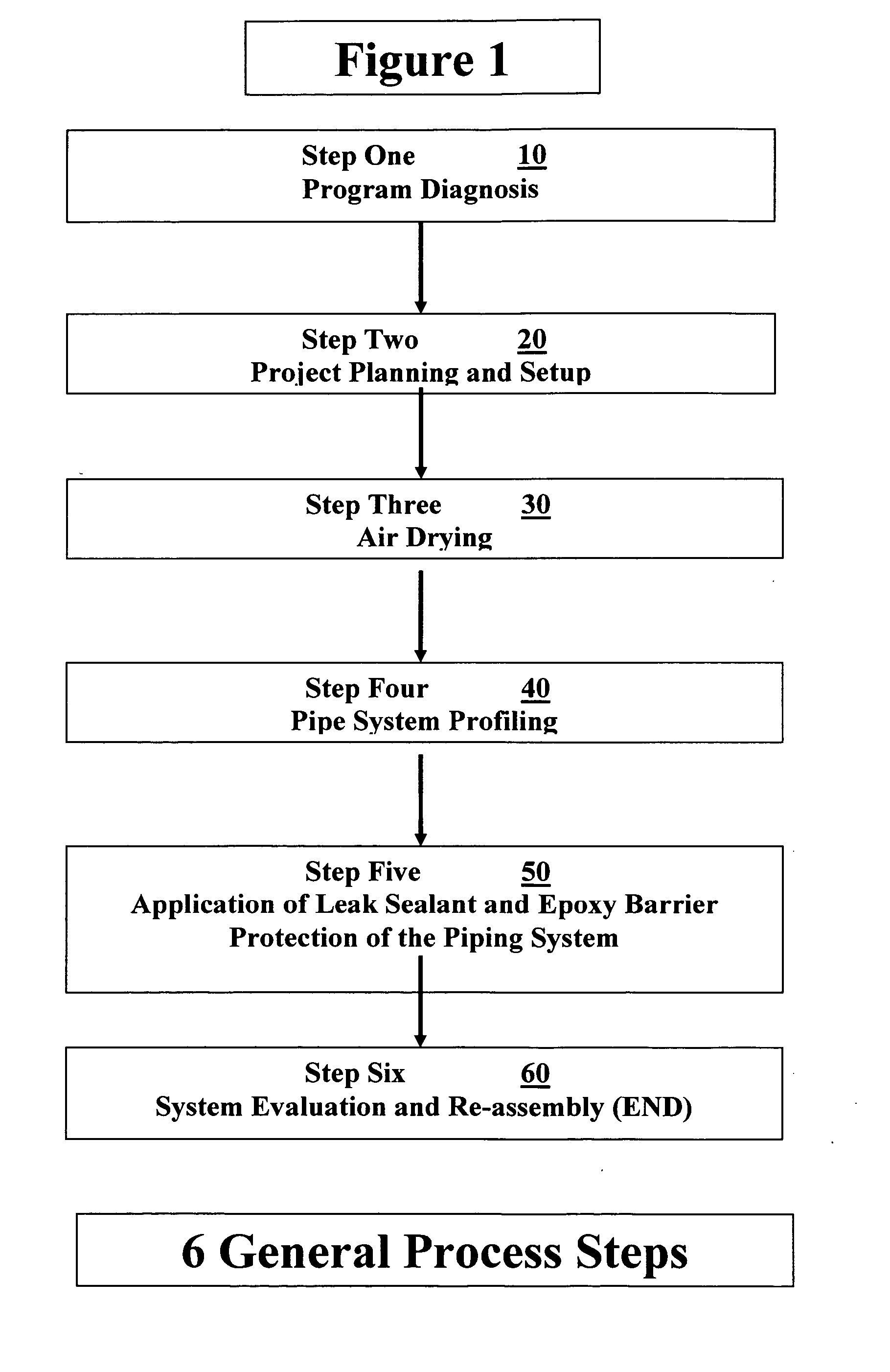

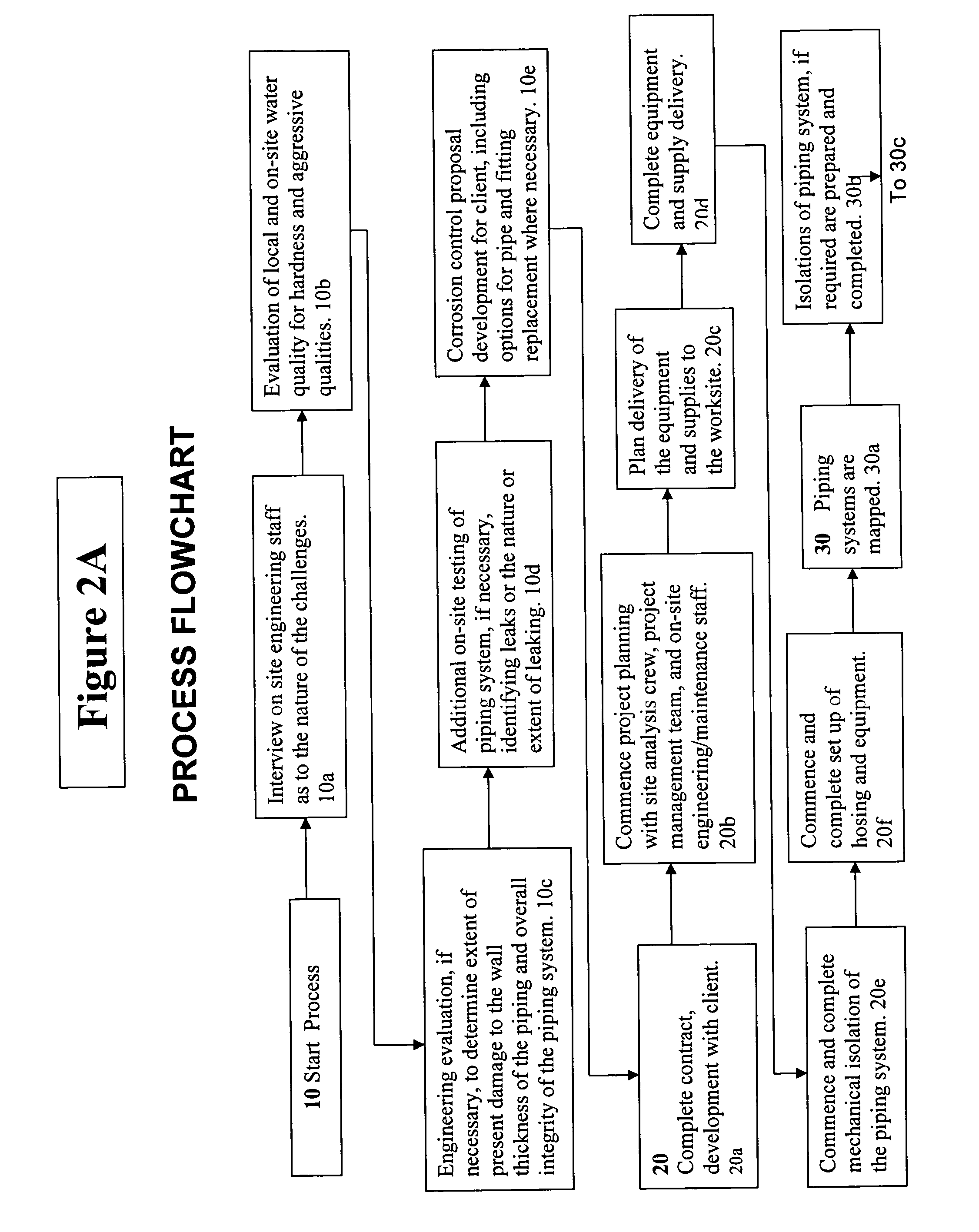

Methods and systems for coating and sealing inside piping systems

Methods and systems for cleaning, coating and sealing leaks in existing pipes, in a single operation. A piping system can be cleaned in one pass by dry particulates forced and pulled by air throughout the piping system by a generator and a vacuum. Pipes can be protected from water corrosion, erosion and electrolysis, extending the life of pipes such as copper, steel, lead, brass, cast iron piping and composite materials. Coatings can be applied to pipes having diameters up to approximately 6″. Leak sealants of at least approximately 4 mils thick can cover insides of pipes, and can include novel mixtures of fillers and epoxy materials, and viscosity levels. A positive pressure can be maintained within the pipes during applications. Piping systems can be returned to service within approximately 96 hours.

Owner:PIPE RESTORATION TECH

Wheel and crawler compounding radial adjustable pipeline robot

The invention discloses a wheel and crawler compounding radial adjustable pipeline robot. A bionic type pipeline robot has low moving speed and great fluctuation, the structure of a crawler type pipeline robot is complicated, and a vehicle type pipeline robot cannot enter a vertical pipeline. The wheel and crawler compound radial adjustable pipeline robot comprises a plurality of wheel and crawler compounding mechanisms, wherein each wheel and crawler compounding mechanism comprises a main casing, a radial adjusting mechanism, a crawler driving walking mechanism and a wheel type support mechanism, two installing side plates are connected through a driving belt wheel installing shaft and a driven belt wheel installing shaft, a driving belt wheel is fixedly arranged on the driving belt wheel installing shaft, a driven belt wheel is fixedly arranged on the driven belt wheel installing shaft, the driving belt wheel is connected with the driven belt wheel through a crawler, the installing side plates are hinged to the main casing through a driven swinging rod, each wheel type support mechanism comprises a bottom plate and a pulley, two ends of the bottom plate are respectively hinged to the main casing through the driven swinging rod, and the driven swinging rod arranged at one end is hinged to the other end of a driving swinging rod. The wheel and crawler compounding radial adjustable pipeline robot has good moving stability and is applicable to various complicated pipelines.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com