Self-adapting pipe moving mechanism

A mobile mechanism and self-adaptive technology, which is applied in the direction of special pipes, pipe components, mechanical equipment, etc., can solve problems such as being stuck in the middle of the pipe, the robot cannot overcome obstacles, and rescue work is difficult, achieving the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

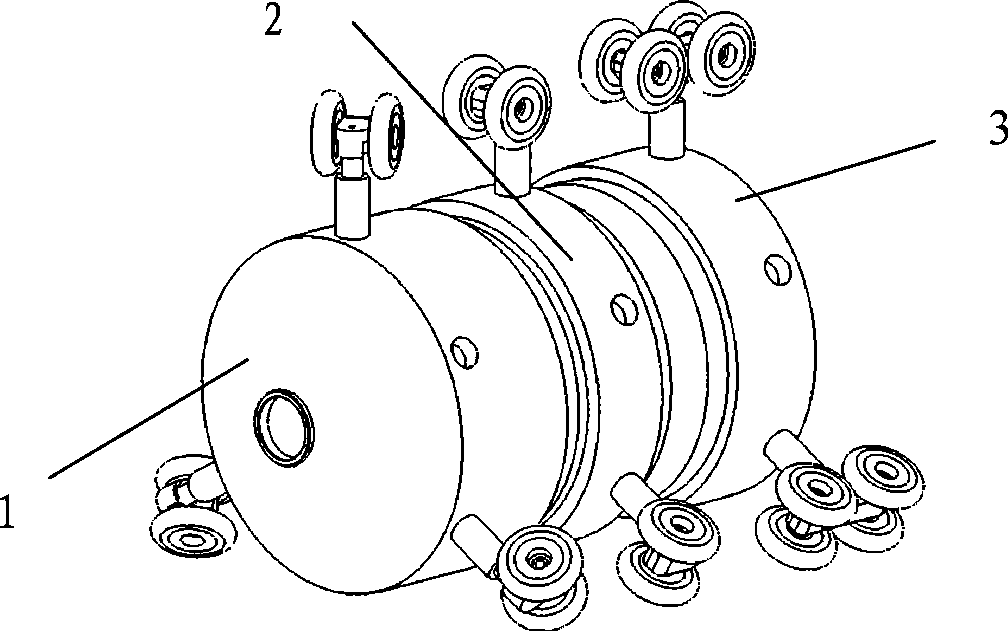

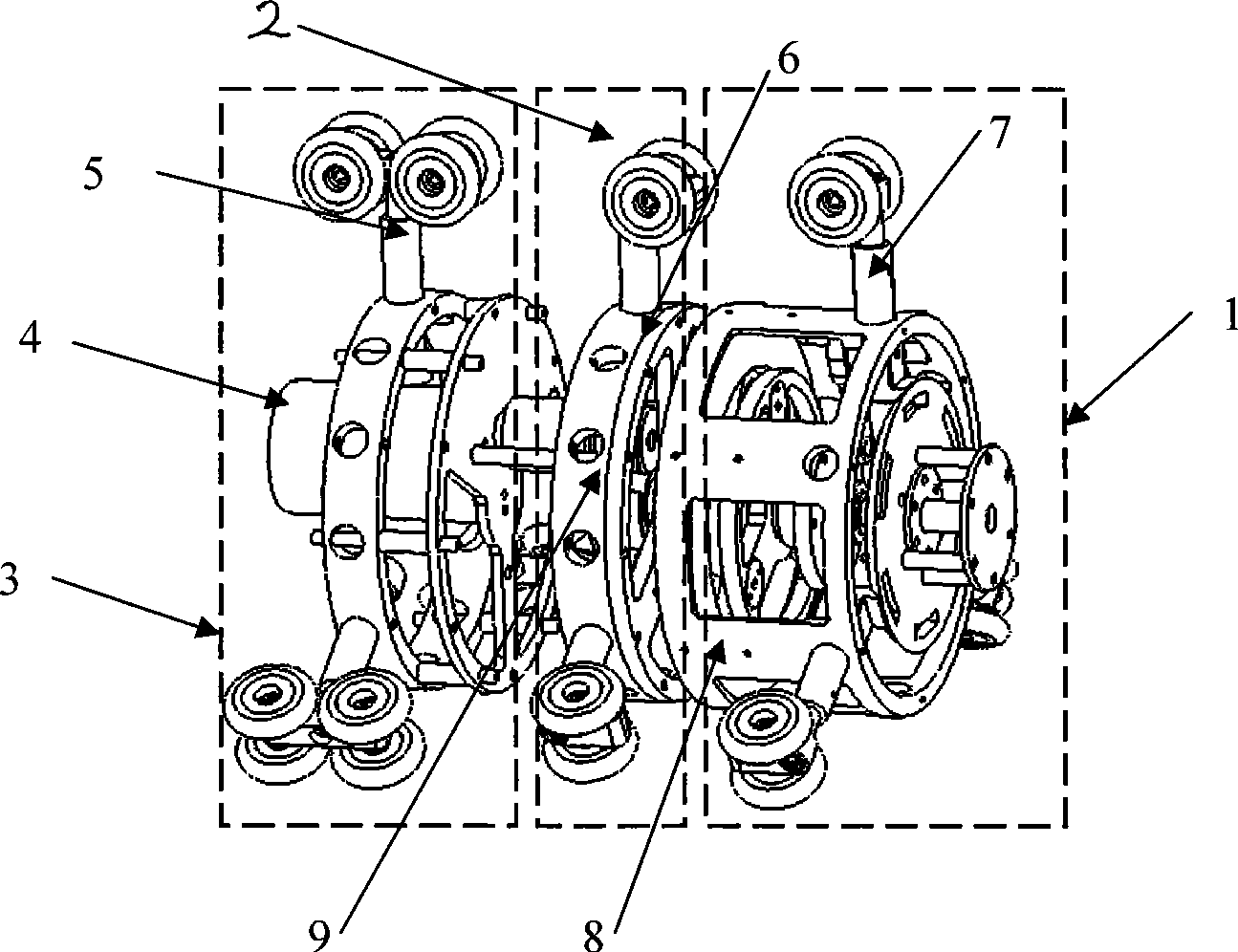

[0015] Embodiment 1: as figure 1 , figure 2 As shown, the structure of the present invention includes three parts: a forward drive mechanism, a reverse drive mechanism and a support mechanism. The forward drive mechanism is connected with the reverse drive mechanism through the first transmission mechanism, and connected with the motor in the support mechanism through the second transmission mechanism. A locking mechanism and a linkage mechanism are also installed between the forward driving mechanism and the first transmission mechanism.

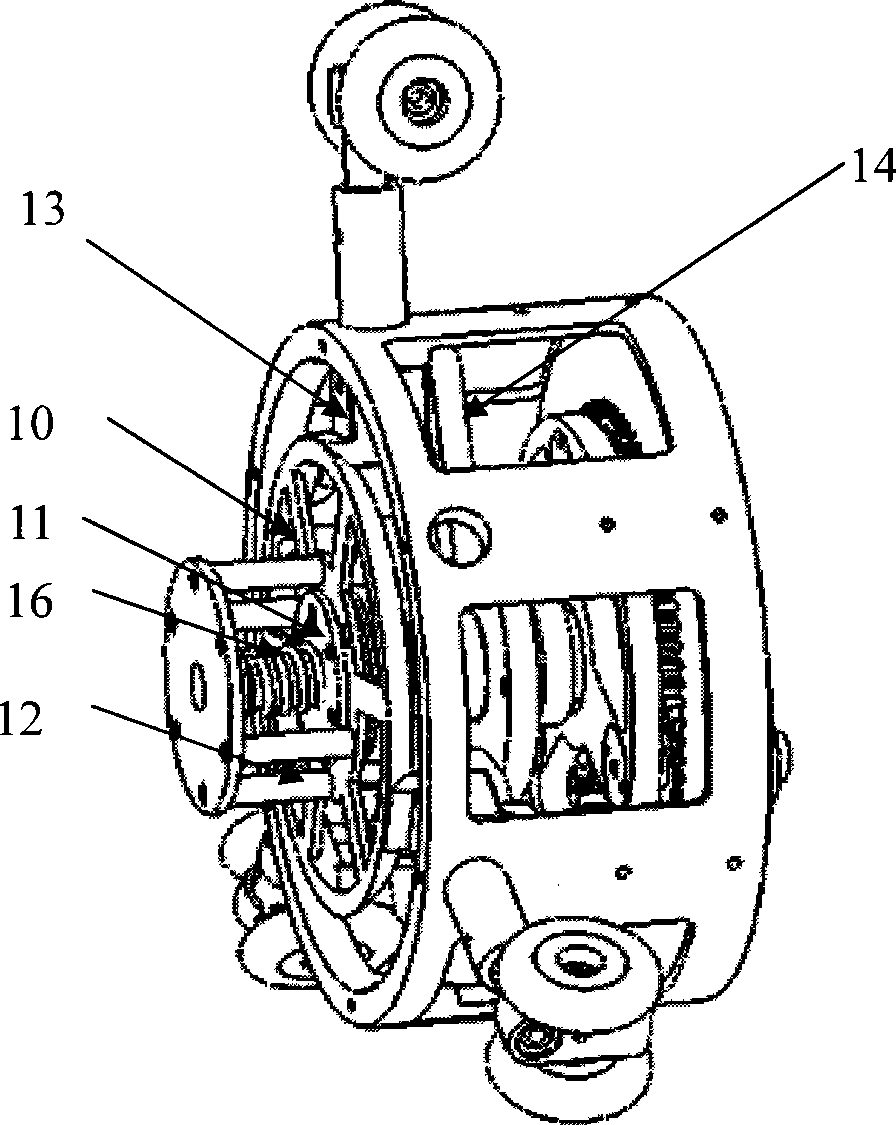

[0016] Such as figure 2 As shown, wherein said forward drive mechanism 1 comprises a front wheel frame 8, three forward drive arms 7 uniformly distributed along its circumference, 2 driven wheels installed on each forward drive arm, the rolling of said driven wheels The axis and the pipe section form an angle of 0 to 45 degrees. The backward driving mechanism 2 includes a rear wheel frame 9, three backward driving arms 6 uniformly dist...

Embodiment 2

[0020] Embodiment 2: the moving mechanism of this example is identical in structure with embodiment 1, and the difference is: in the forward driving mechanism 1, the forward driving arm 7 is evenly distributed along the circumference of the front wheel frame 8, and the driven wheels on each forward driving arm 7 are 1 piece; 5 backward driving arms 6 are evenly distributed along the circumference of the rear wheel frame in the backward driving mechanism 2, and there are 2 driven wheels for each backward driving arm 6; in the supporting mechanism 3, the supporting arms 5 are evenly distributed along the outer frame circumference of the supporting mechanism 6, the support wheels of each support arm 5 are 2.

Embodiment 3

[0021] Embodiment 3: the moving mechanism of this example is identical in structure with embodiment 1, and the difference is: in the forward driving mechanism 1, the forward drive arm 7 is evenly distributed along the circumference of the front wheel frame 8, and the driven wheels on each forward drive arm 7 are 2 pieces; in the backward driving mechanism 2, six backward driving arms 6 are evenly distributed along the circumference of the rear wheel frame, and each driven wheel of the backward driving arm 6 is 2; in the supporting mechanism 3, the supporting arms 5 are evenly distributed along the outer frame circumference of the supporting mechanism 6, the support wheels of each support arm 5 are 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com