Patents

Literature

222results about How to "Realize synchronized motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

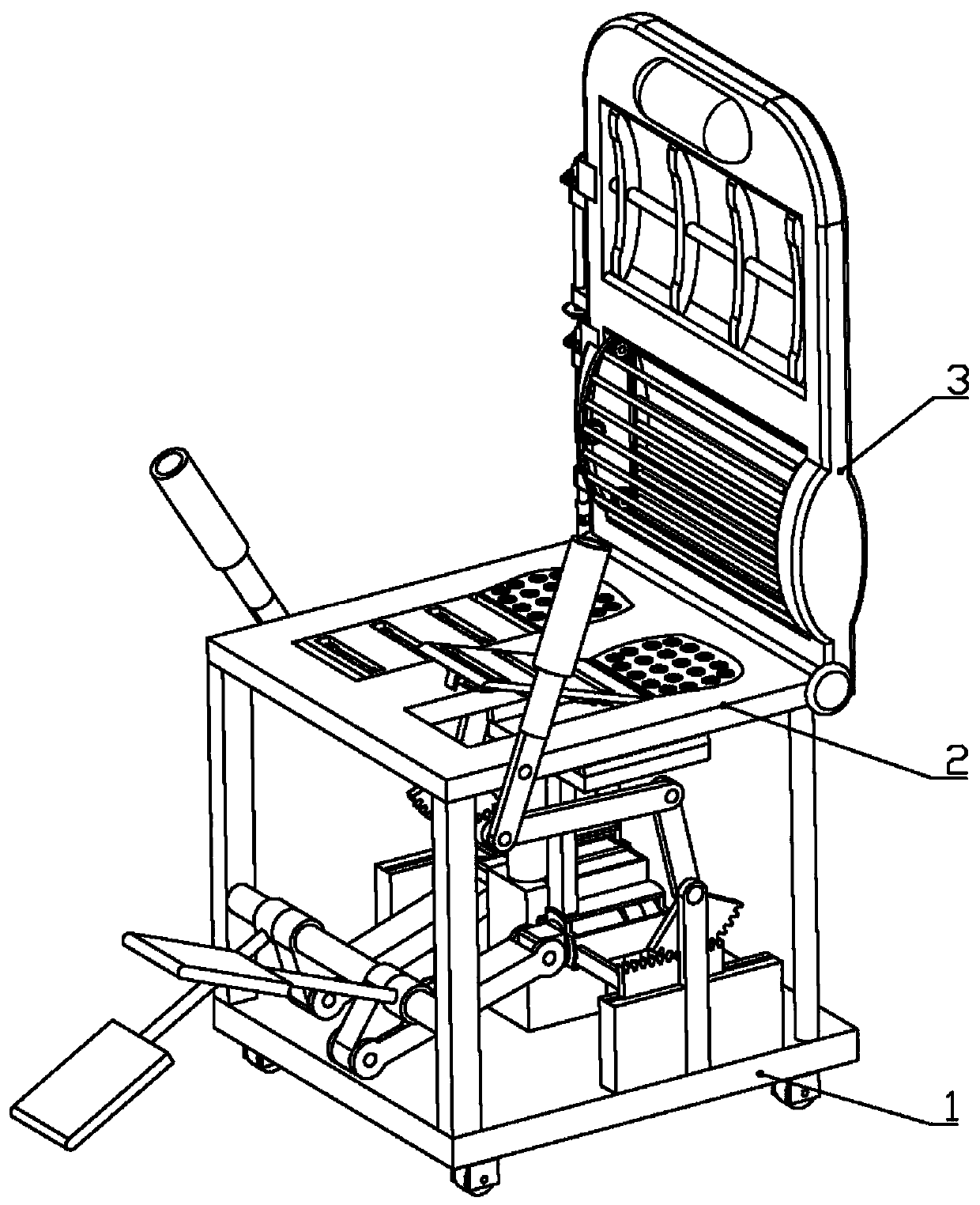

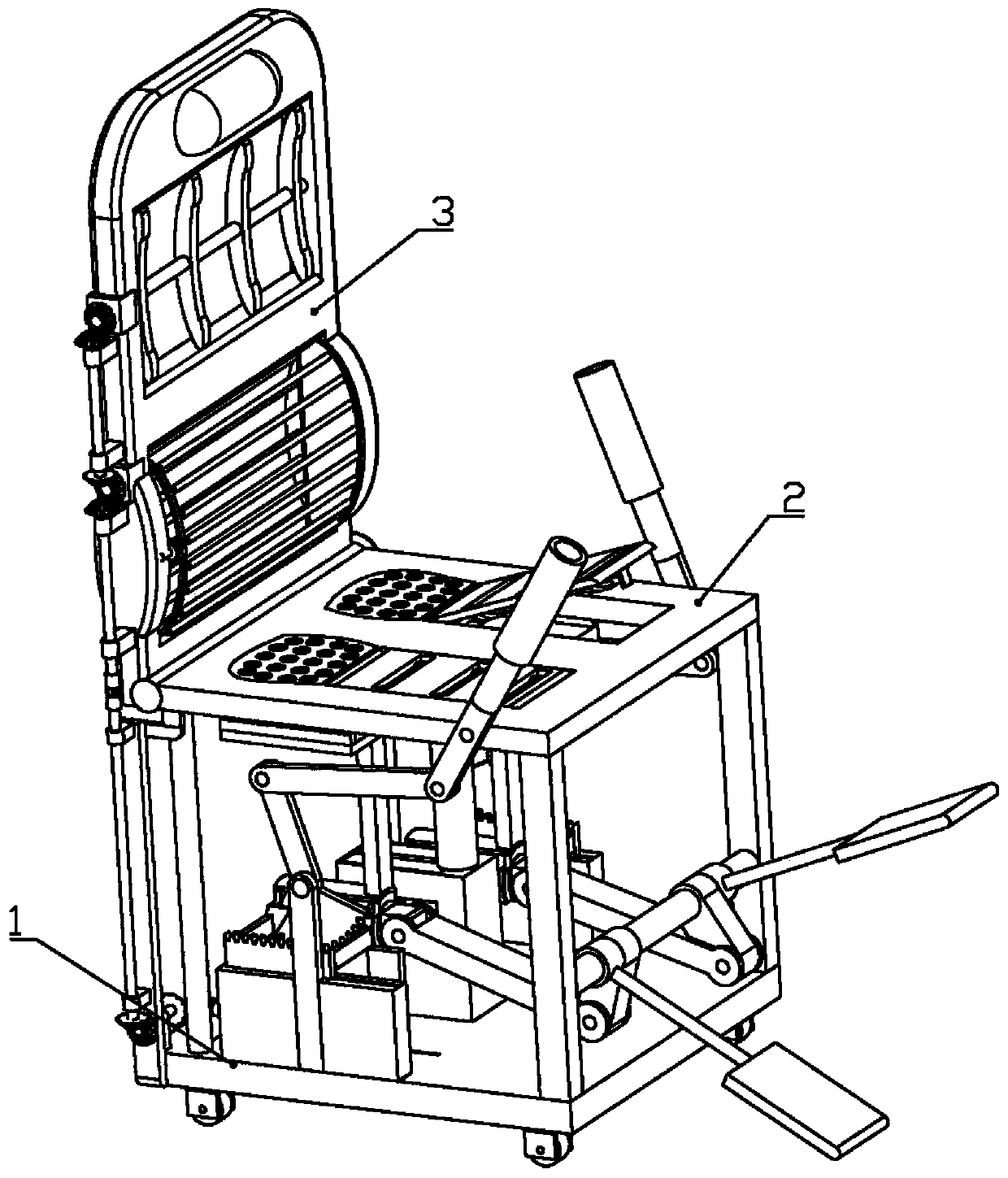

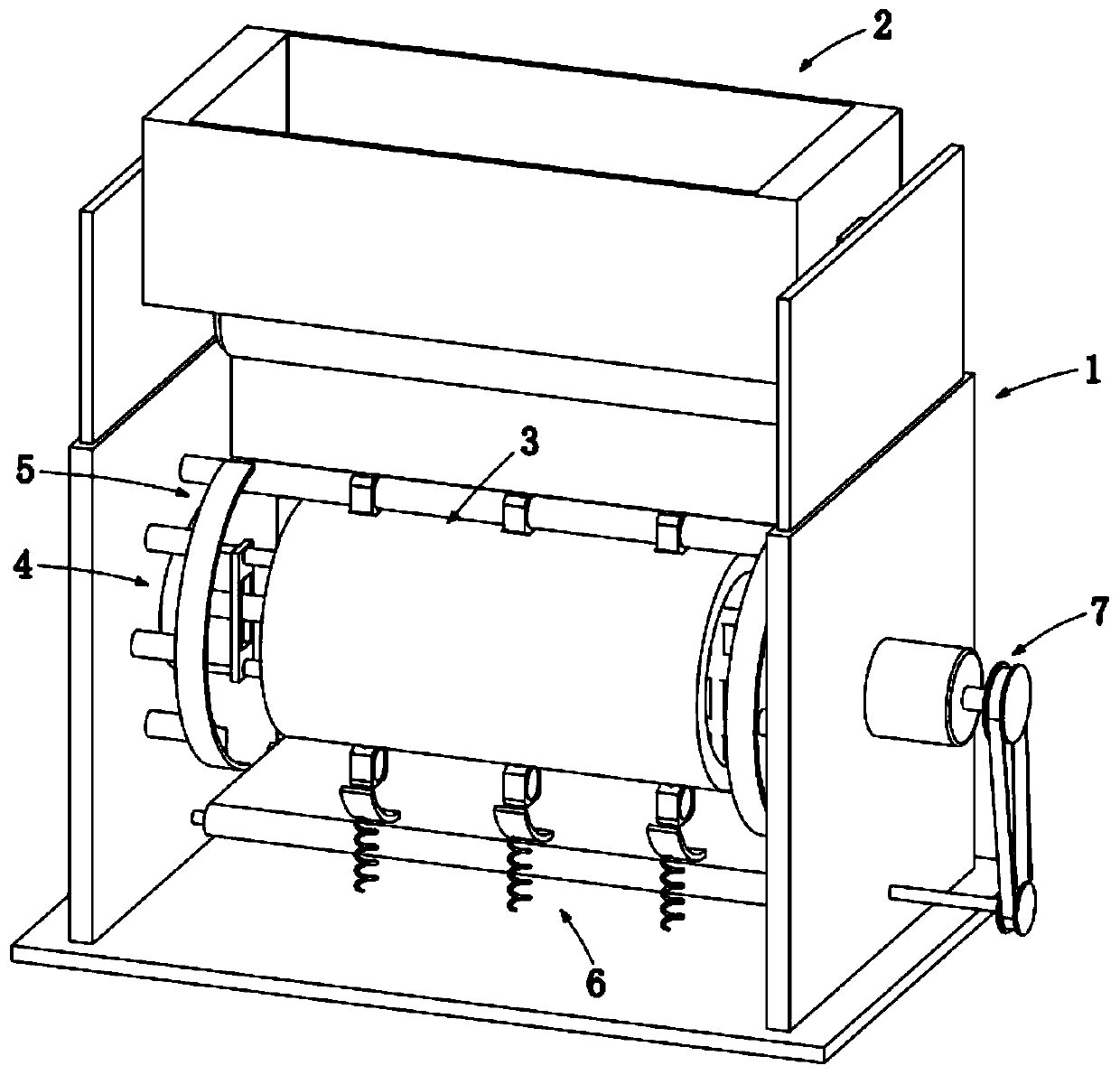

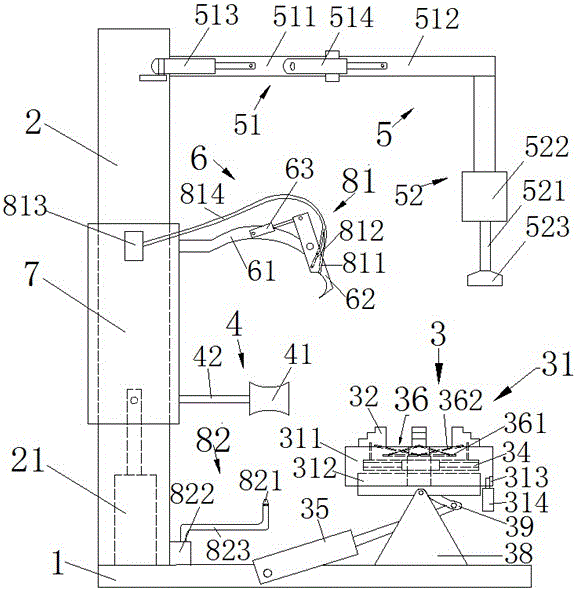

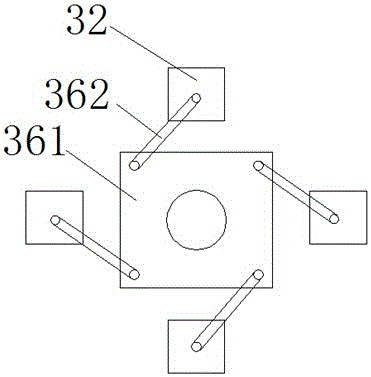

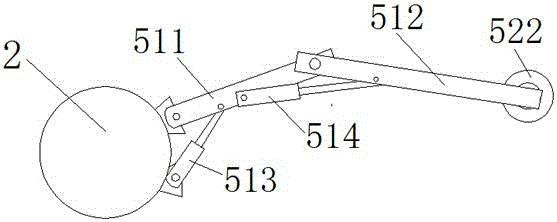

Recovering training device for neural medicine

ActiveCN110037894APromote recoveryImprove recovery effectDevices for pressing relfex pointsChiropractic devicesButtocksArm exercise

The invention belongs to the technical field of medical apparatuses, and particularly relates to a recovering training device for neural medicine. The recovering training device comprises a training bench, wherein the training bench comprises a base mechanism; a chair seat mechanism is arranged on the base mechanism; a chair back mechanism is hinged to the chair seat mechanism; a power structure is arranged on the base mechanism, and comprises a pedal structure and an arm exercising structure which is in simultaneous movement with the pedal structure; the chair seat mechanism comprises a chairseat; a buttock massaging structure is arranged on the chair seat; a leg massaging structure which moves along with legs is hinged to the chair seat; a chair seat transmission structure which cooperates with the buttock massaging structure and the leg massaging structure is connected to the pedal structure; the chair back mechanism comprises a chair back hinged to the chair seat; a waist massaging structure and a back massaging structure are arranged on the chair back; and a chair back transmission structure which cooperates with the waist massaging structure is connected to the pedal structure. Through the adoption of the recovering training device disclosed by the invention, the problem that a conventional training device is poor in training effects is effectively solved.

Owner:NANYANG CITY CENT HOSPITAL

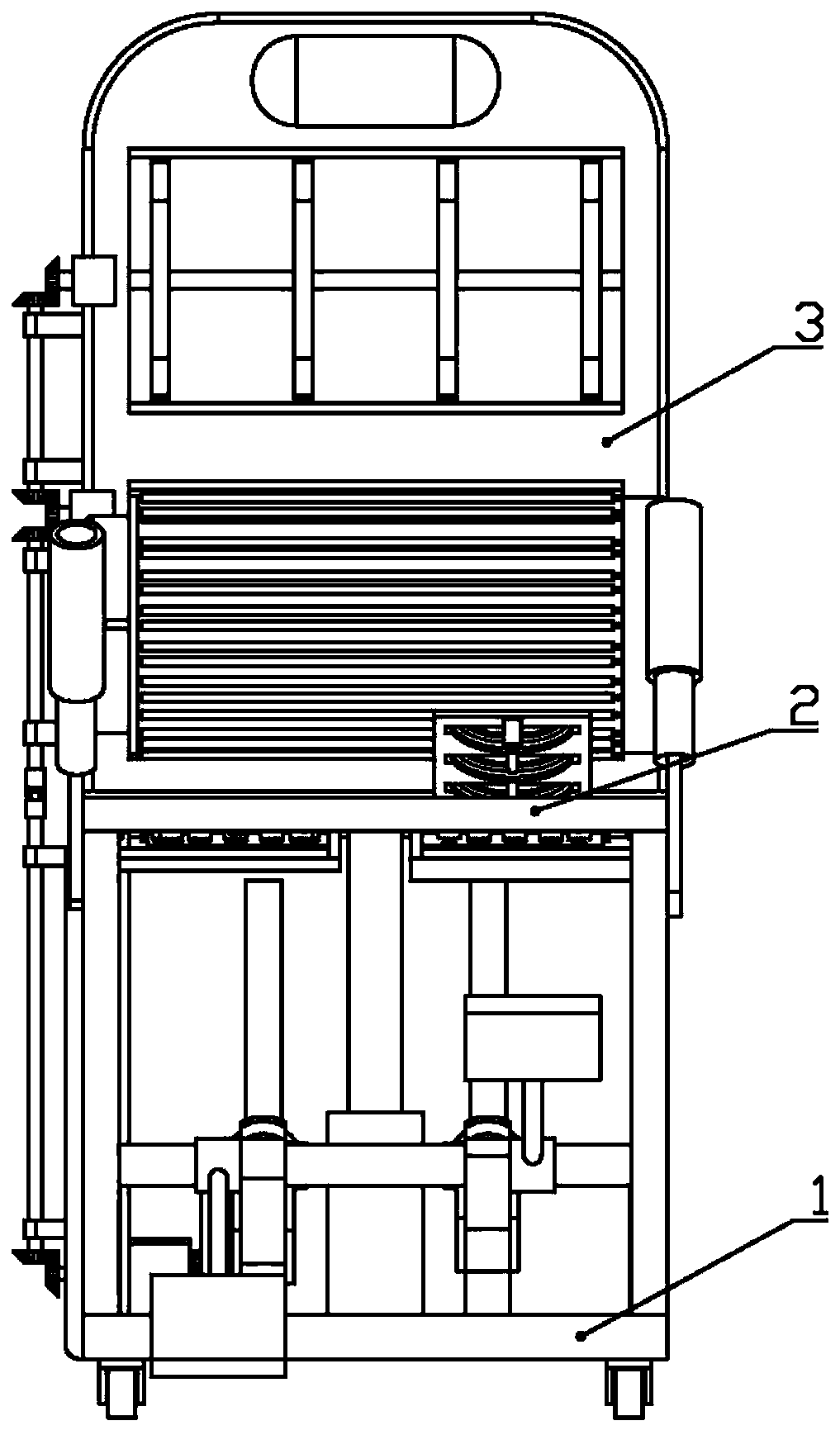

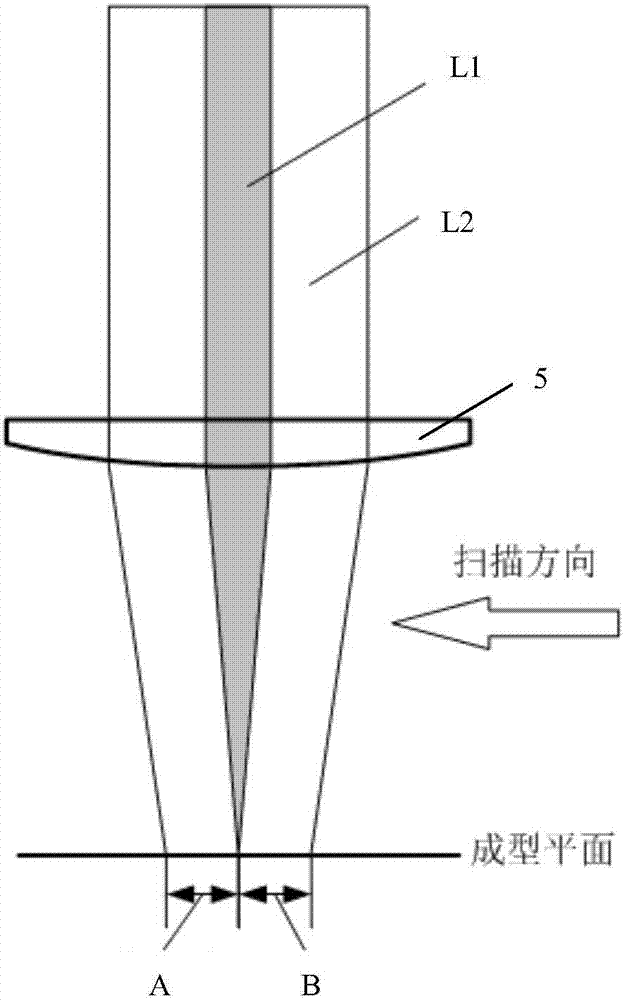

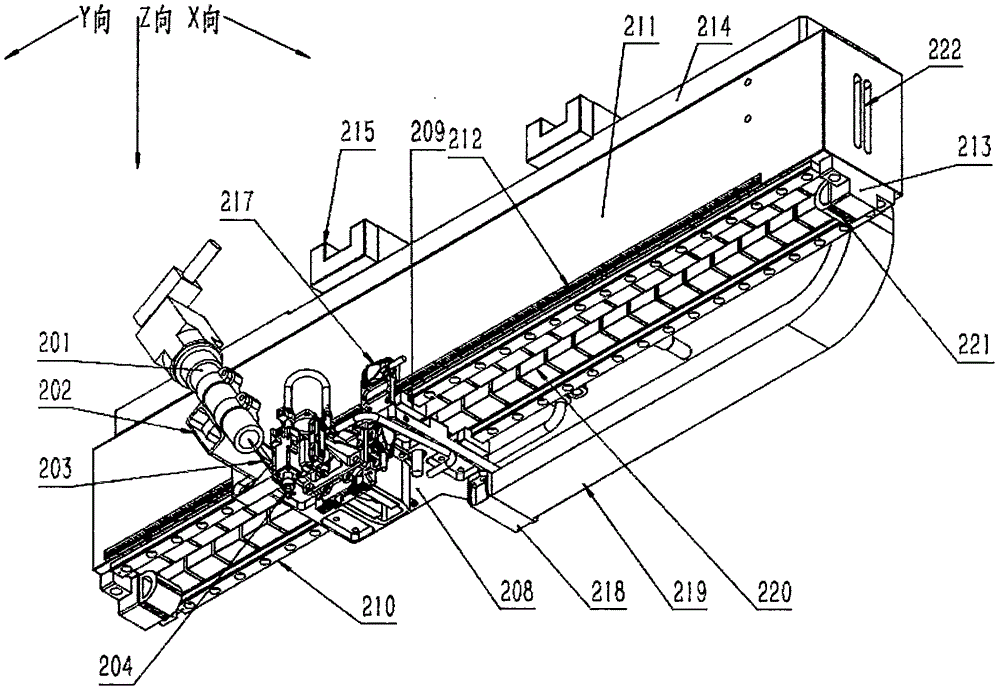

Non-mean-value double-light-beam synchronous scanning laser selective melting device and light path synthesis method thereof

ActiveCN107096920ARealize synchronized motionIncrease energy densityAdditive manufacturing apparatusIncreasing energy efficiencySynthesis methodsLight spot

The invention discloses a non-mean-value double-light-beam synchronous scanning laser selective melting device and a light path synthesis method thereof. The device comprises a large light spot laser beam incidence device body, a small light spot laser beam incidence device body, a laser beam light composition assembly, an X-Y vibration mirror scanning device body and a field mirror, wherein the laser beam light composition assembly is composed of a large light spot reflecting mirror and a small light spot reflecting mirror, and the X-Y vibration mirror scanning device body is composed of an X-axis-direction vibration mirror and a Y-axis-direction vibration mirror. According to the non-mean-value double-light-beam synchronous scanning laser selective melting device and the light path synthesis method thereof, the light composition assembly is additionally arranged in a traditional light path system so that synthesis of two laser beams with different light spot sizes and the process of synchronous scanning can be conveniently and quickly achieved. Through synthesis of the laser beams with different light spots, an annular heat source with the temperature gradient can be generated on a forming plane, metal power firstly passes through a low-temperature preheating area before being heated to be melted, solidified solid metal goes through a transient low-temperature tempering process, and thus the heat stress influence generated in the laser scanning process is effectively lowered.

Owner:SOUTH CHINA UNIV OF TECH

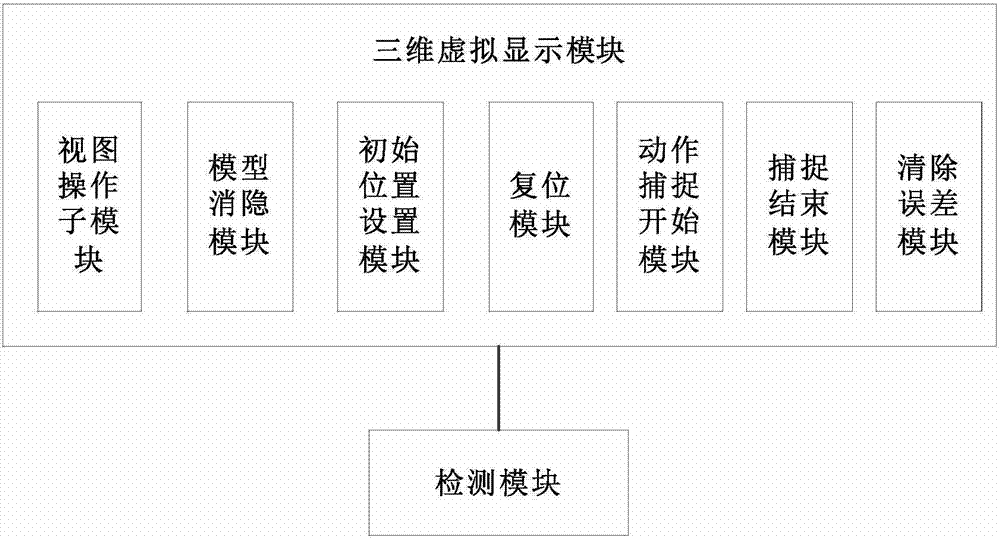

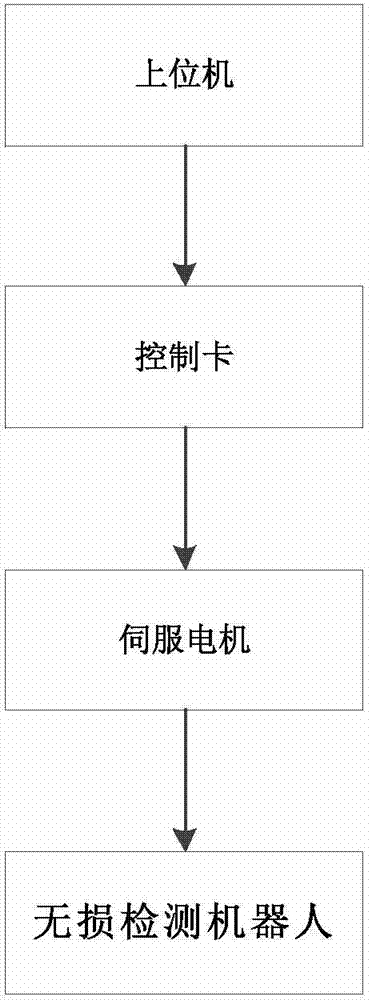

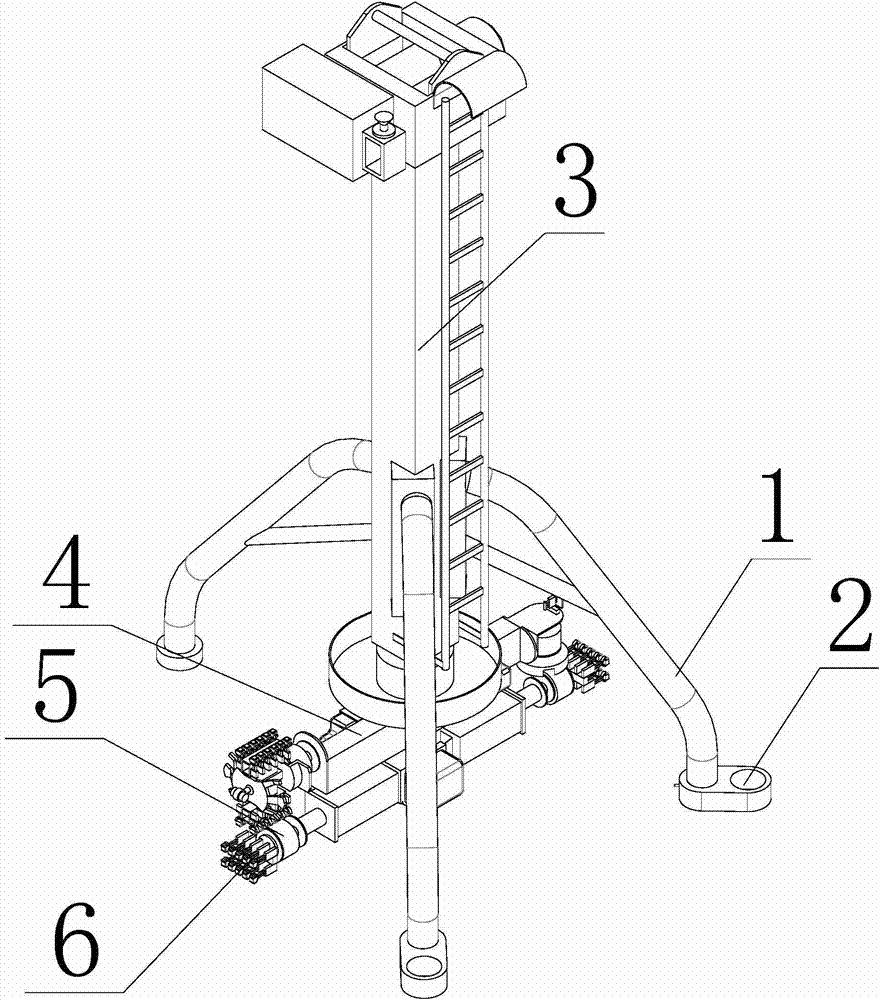

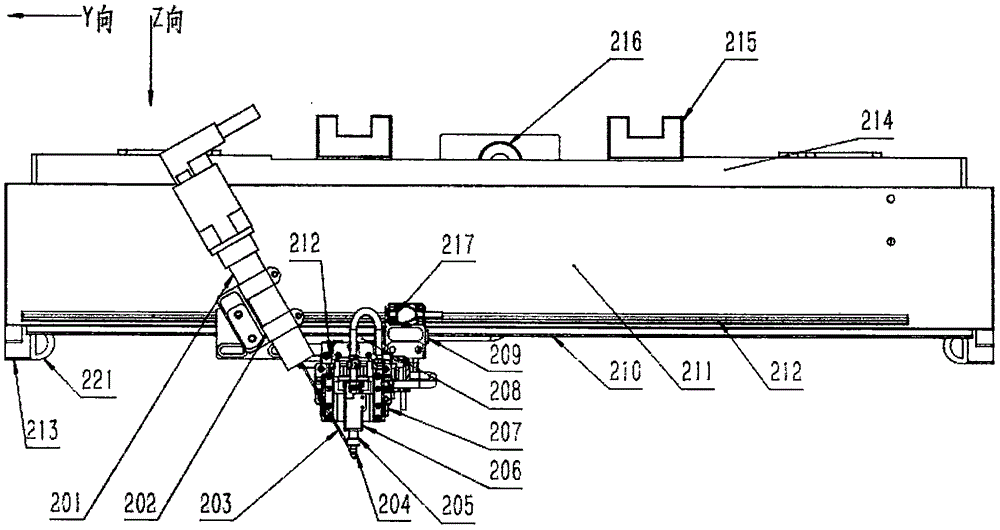

Nondestructive testing robot intelligent testing method based on virtual reality technology

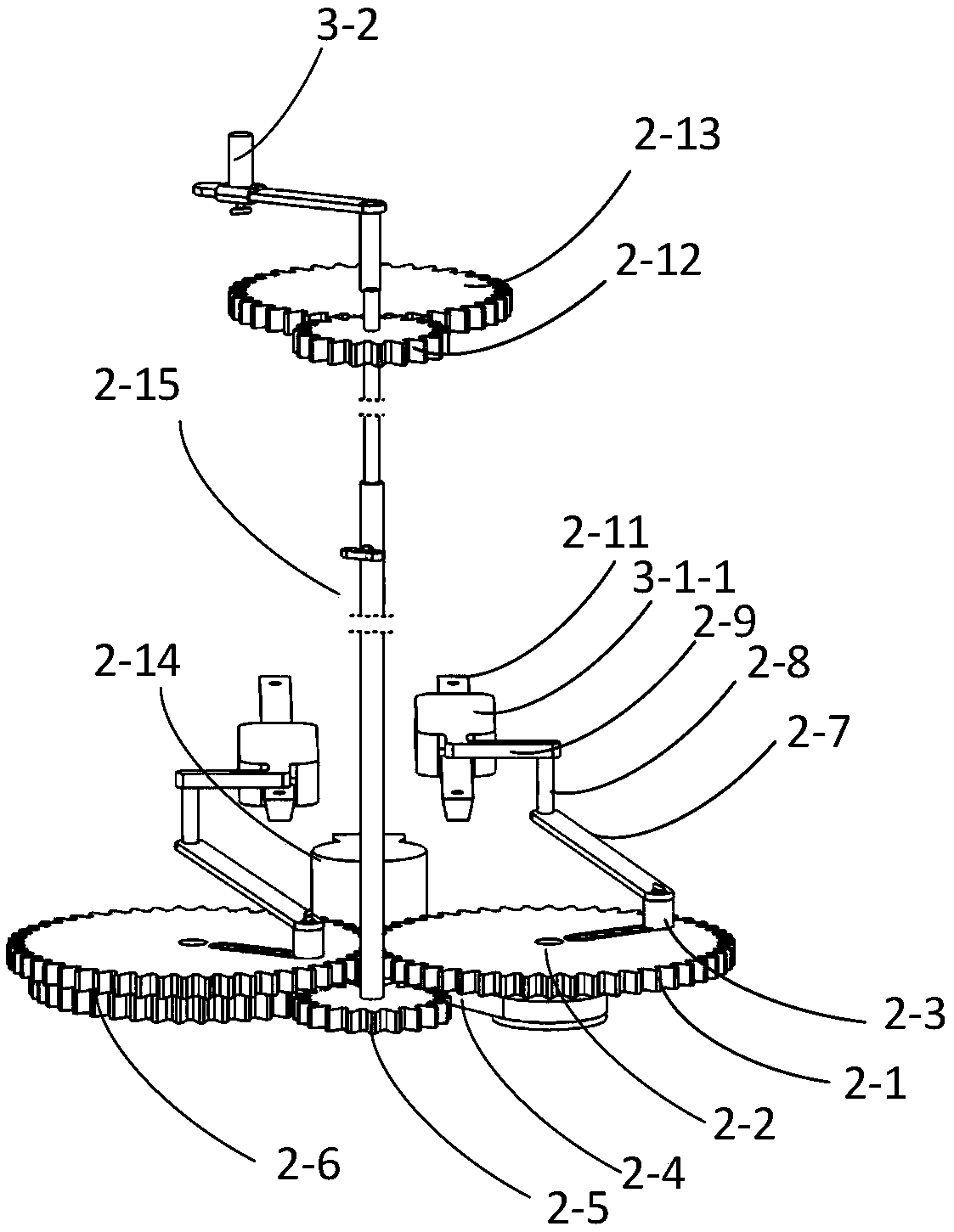

ActiveCN103761996ARealize synchronized motionImprove control efficiencyNuclear energy generationNuclear monitoringReactor pressure vesselSimulation

The invention discloses a nondestructive testing robot intelligent testing method based on a virtual reality technology. The method comprises the following steps: (1) a nondestructive testing robot for nondestructive testing is mounted at a predetermined position in a to-be-tested reactor pressure vessel; (2) freedom degree kinematic axes of the nondestructive testing robot are each restored to an initial state, then the freedom degree kinematic axes are each subjected to position calibration, and a global coordinate system and axis coordinate systems of the freedom degree kinematic axes are constructed; (3) corresponding relationships are established between simulation models and real devices; and (4) the simulation model of the nondestructive testing robot performs position attitude transformation, virtually displays and controls synchronous movement of the nondestructive test robot to perform nondestructive testing in a three-dimensional virtual environment according to real-timely acquired position attitude information feedback values of the freedom degree kinematic axes of the nondestructive testing robot. The method realizes the omni-directional three-dimensional WYSIWYG display control mode, greatly improves the security of on-site project implementation, and improves the project implementation efficiency.

Owner:CGNPC INSPECTION TECH +3

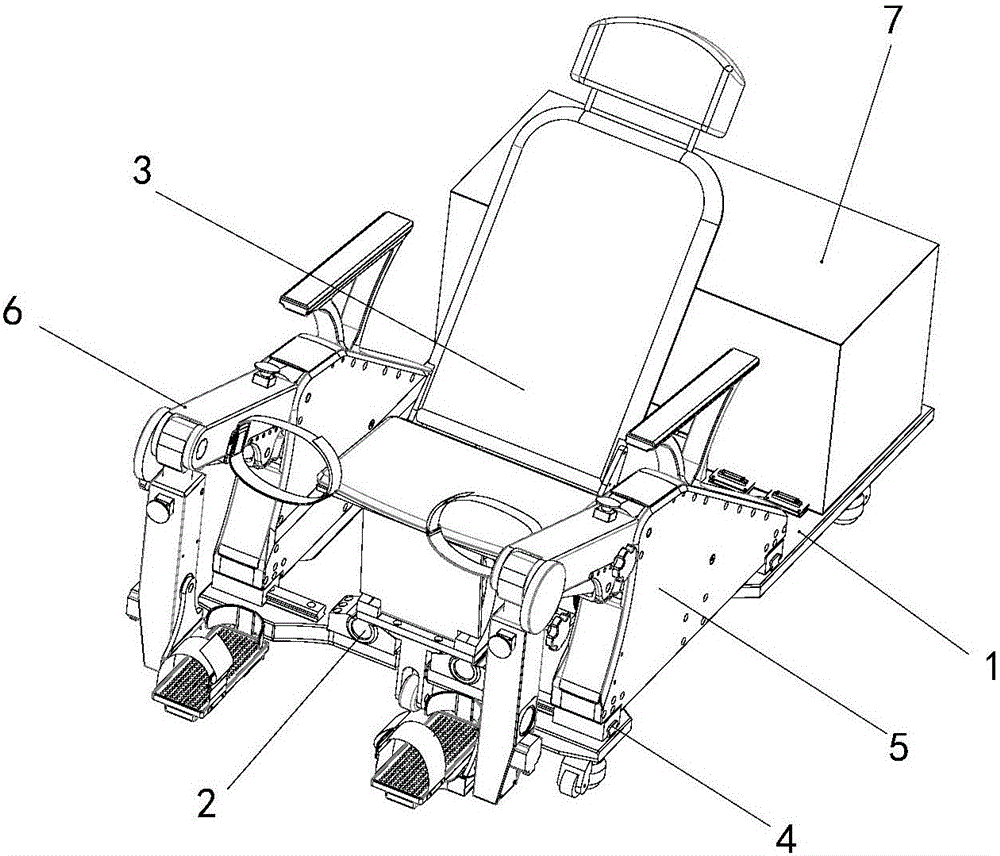

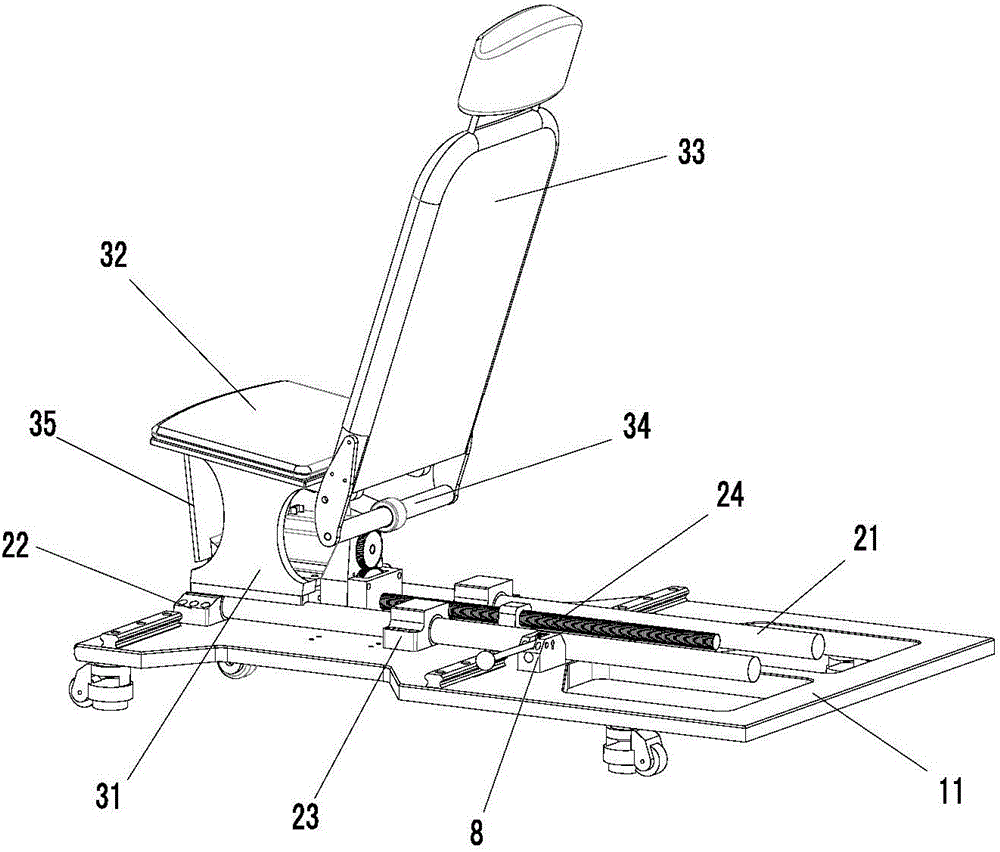

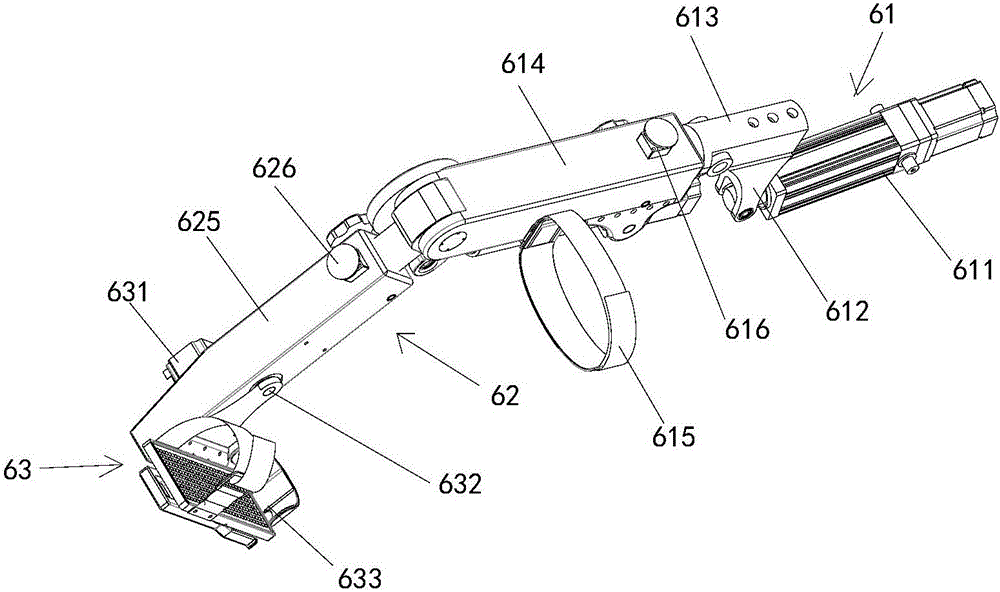

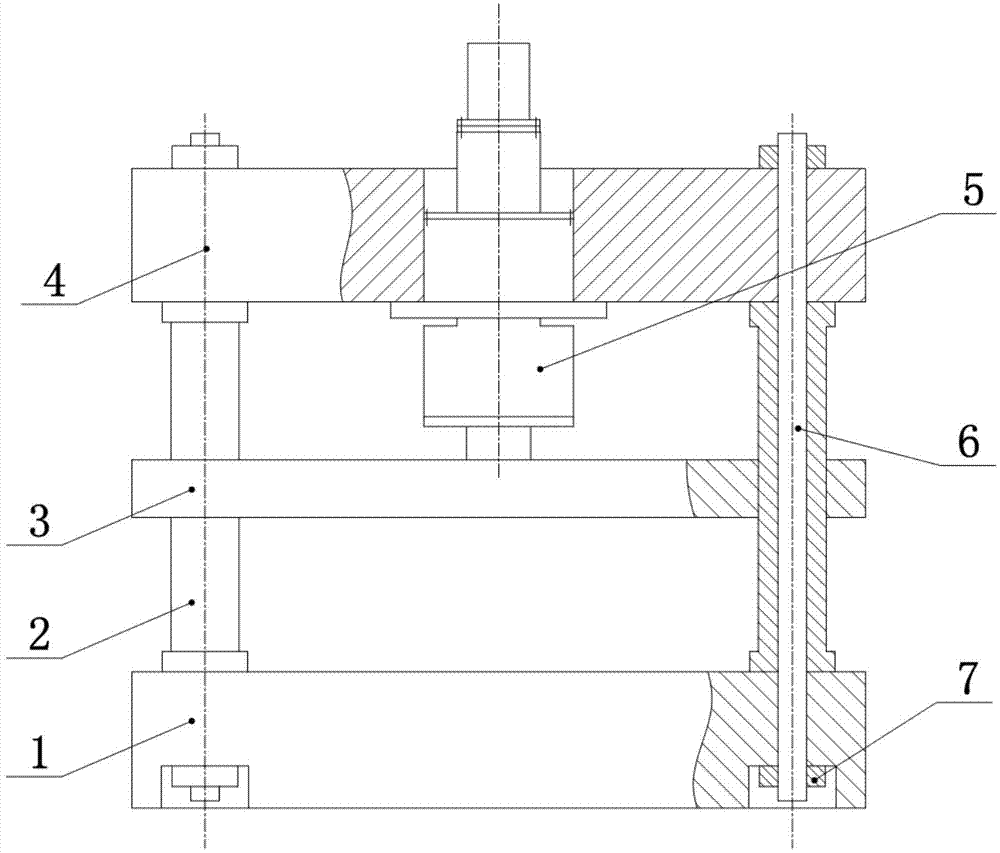

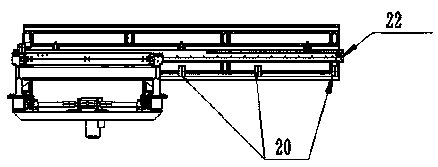

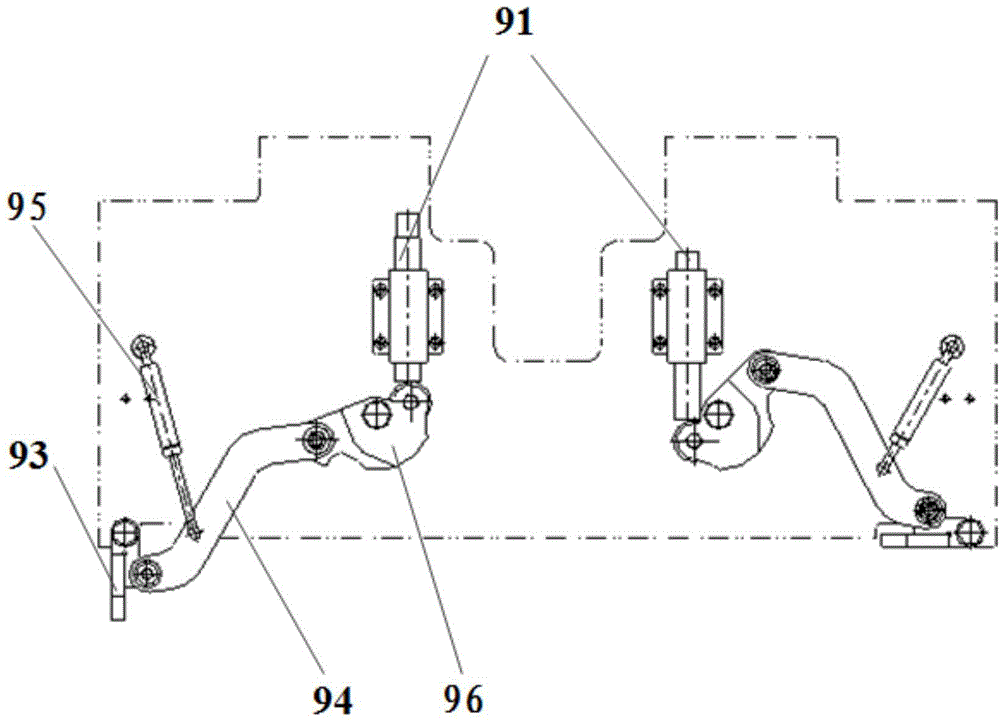

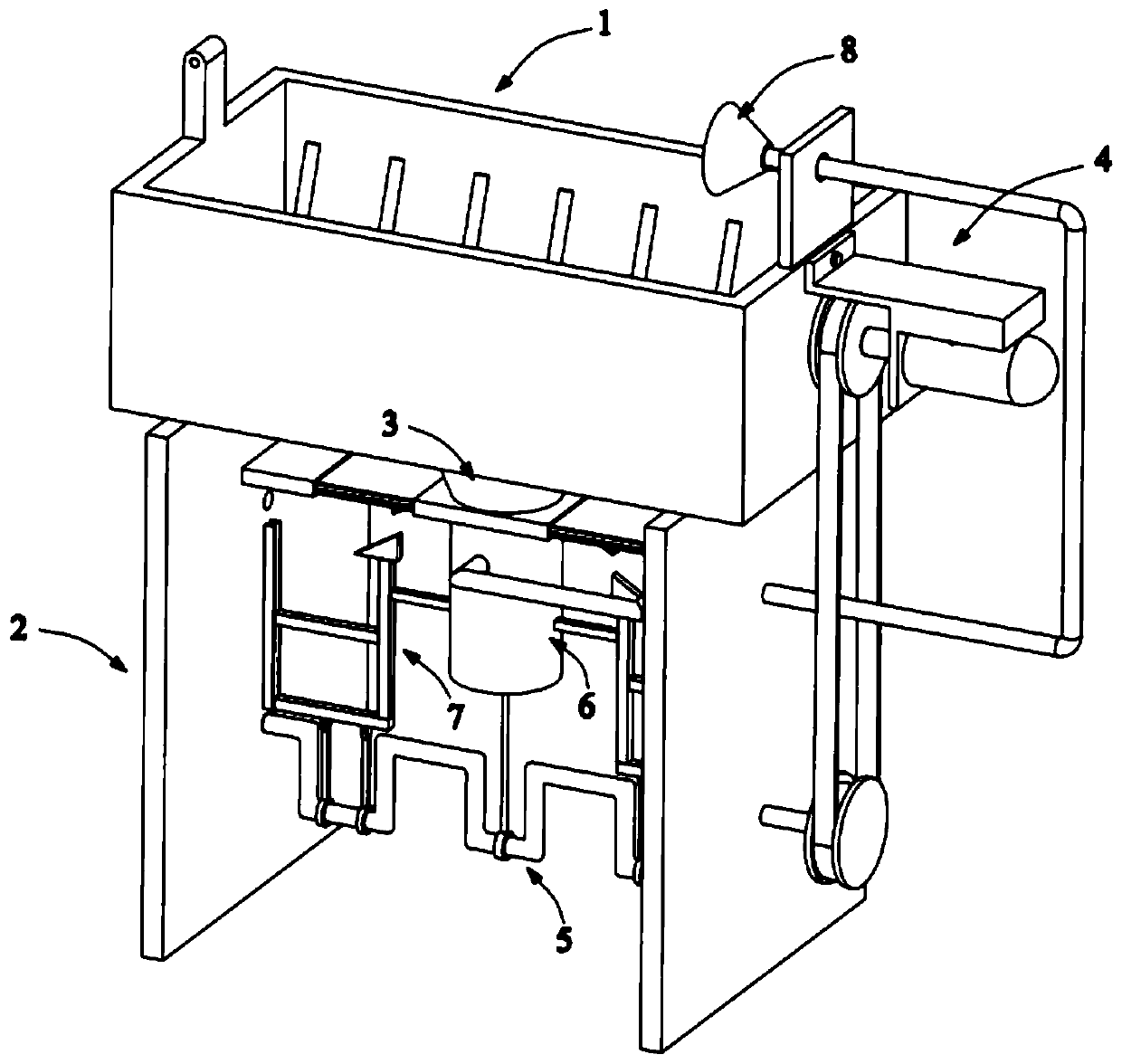

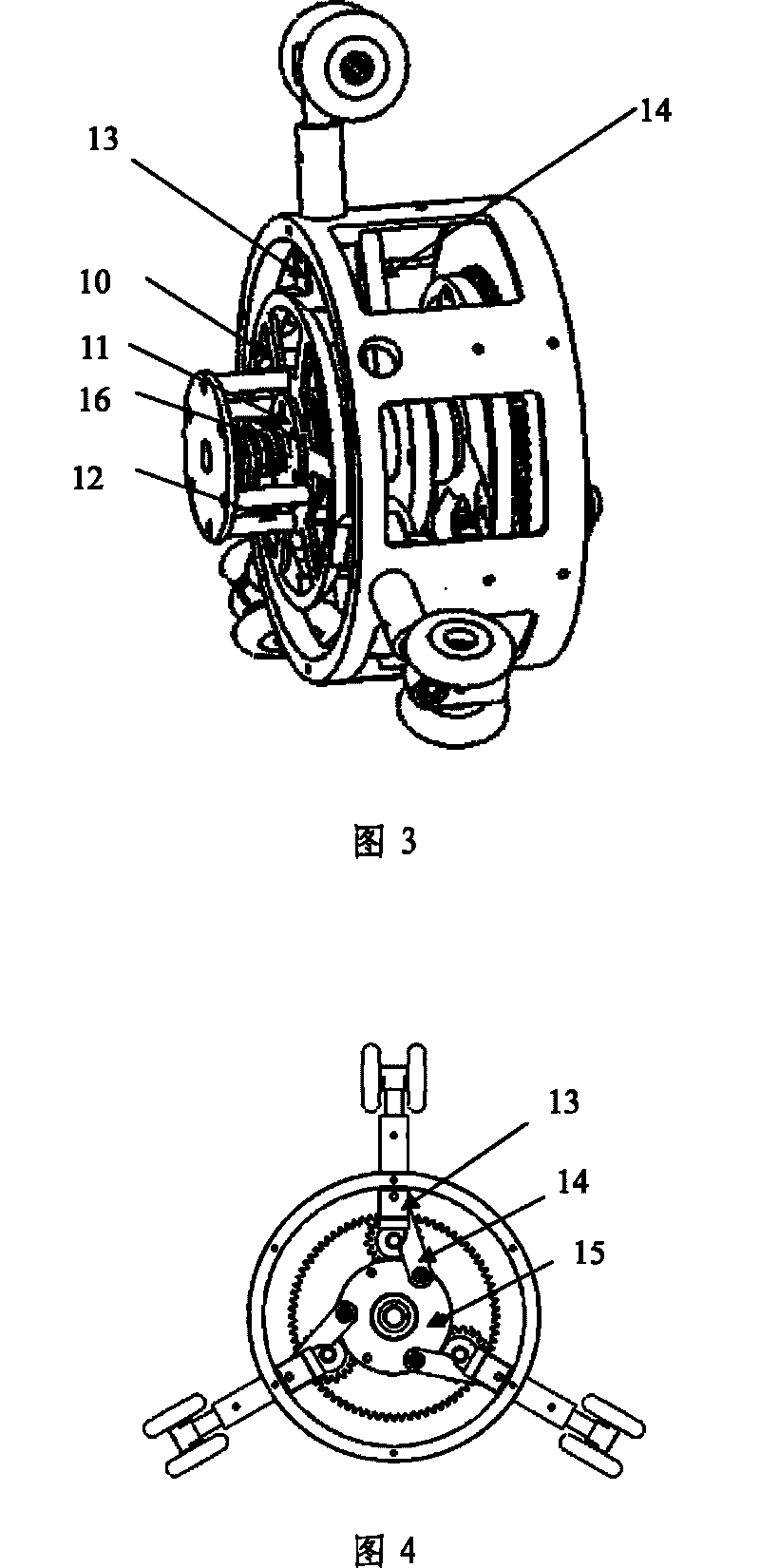

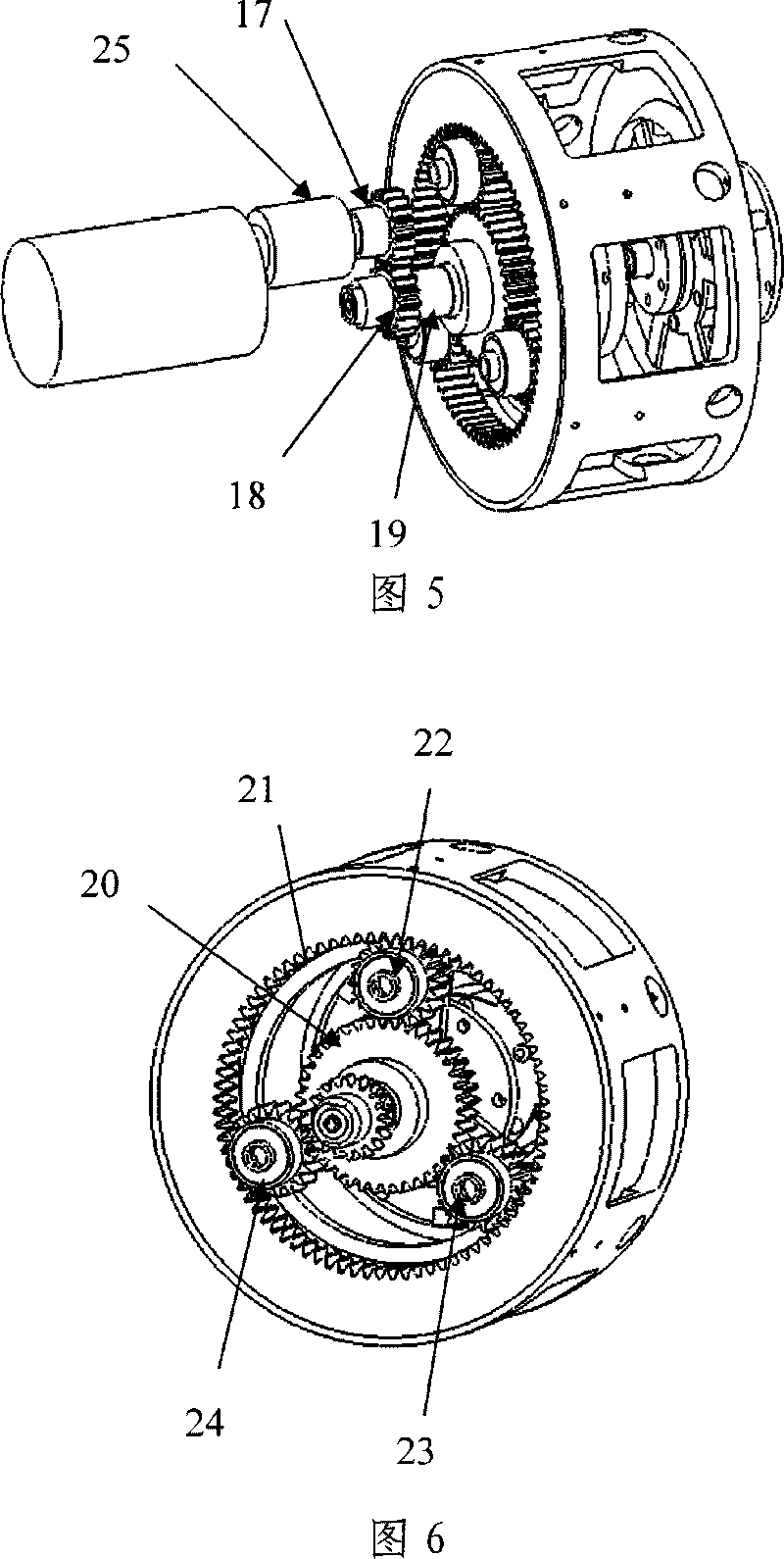

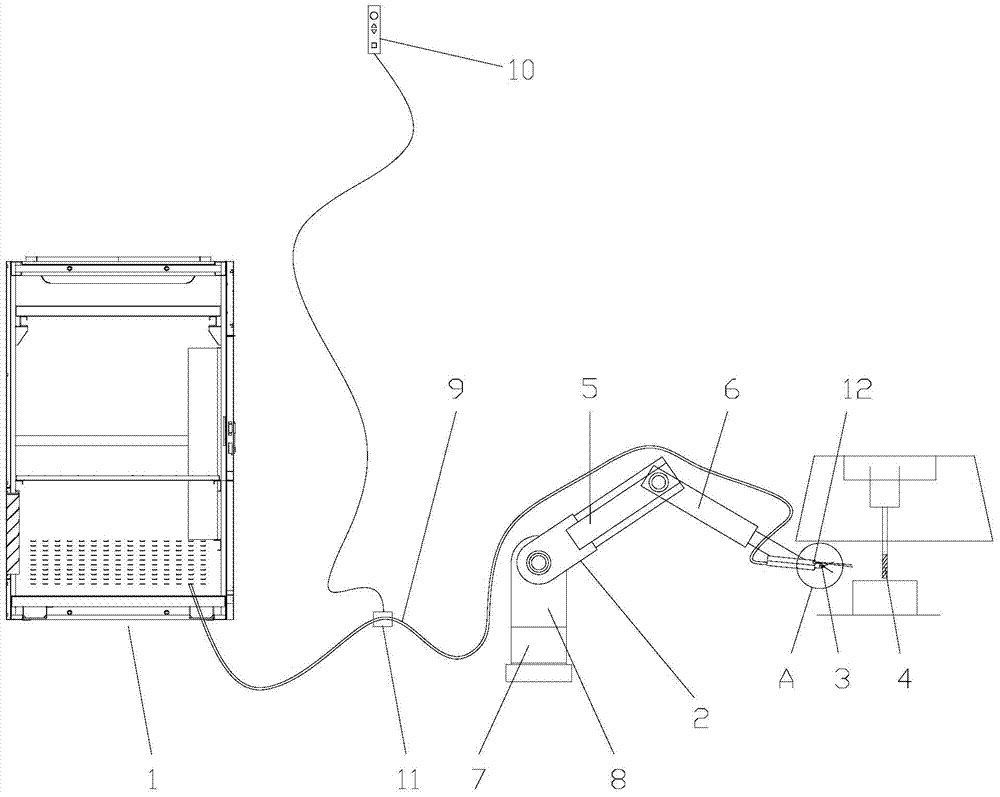

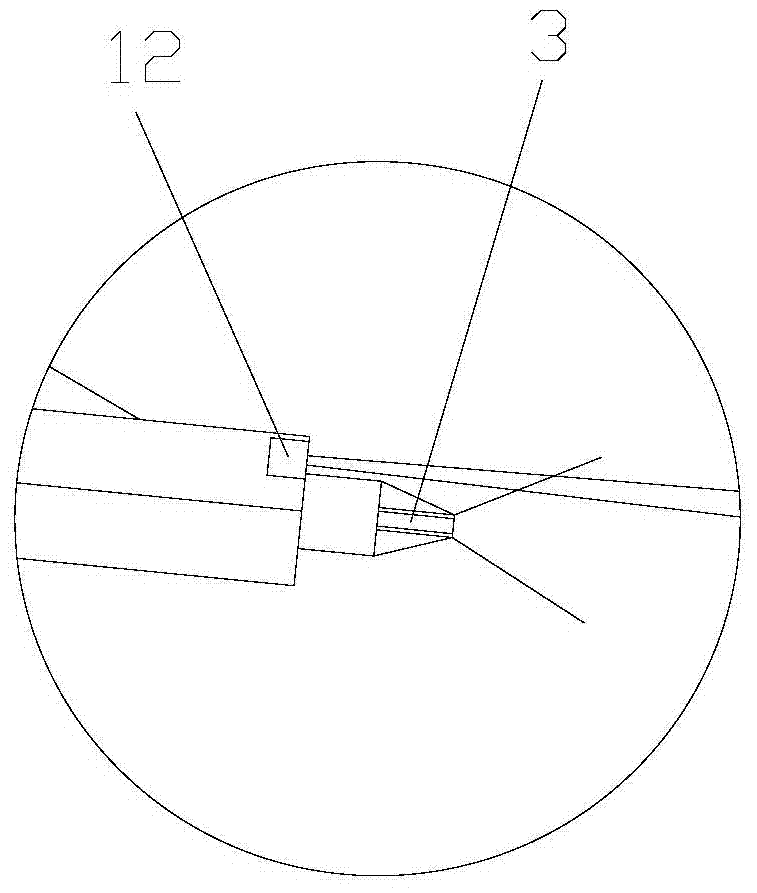

Lower limb exoskeleton rehabilitation training device provided with movable chair

A lower limb exoskeleton rehabilitation training device provided with a movable chair mainly comprises a base, a chair frontward and backward adjustment mechanism, the chair, a mechanical leg leftward and rightward adjustment mechanism, two mechanical leg fixing platforms, two mechanical legs and a counter weight control box. Because the mechanical leg leftward and rightward adjustment mechanism is arranged, the training requirements of training people having different widths between the hip joints can be met in the manner that the width between the two mechanical arms can be adjusted. The lower limb exoskeleton rehabilitation training device is combined with a chair movement and transmission mechanism, before a patient gets on the lower limb exoskeleton rehabilitation training device, the chair is moved to the front end of the base, and therefore the influence generated by the fact that the mechanical legs occupy space when the patient gets on and gets off the lower limb exoskeleton rehabilitation training device is overcome. Because thigh mechanisms, shank mechanisms and ankle joint mechanisms of the two mechanical legs are each provided with a drive mechanism, exercise training and movement range practices of one joint can be achieved, and coordinate exercise training of one leg and the double legs can also be achieved. Through independent hip joint adjusting mechanisms, independent knee joint adjusting mechanisms and independent ankle joint adjusting mechanisms, adjustment of the shanks and the thighs can be achieved, and therefore personalized training is achieved.

Owner:SHANDONG CLASSIC MEDICAL DEVICE TECH CO LTD

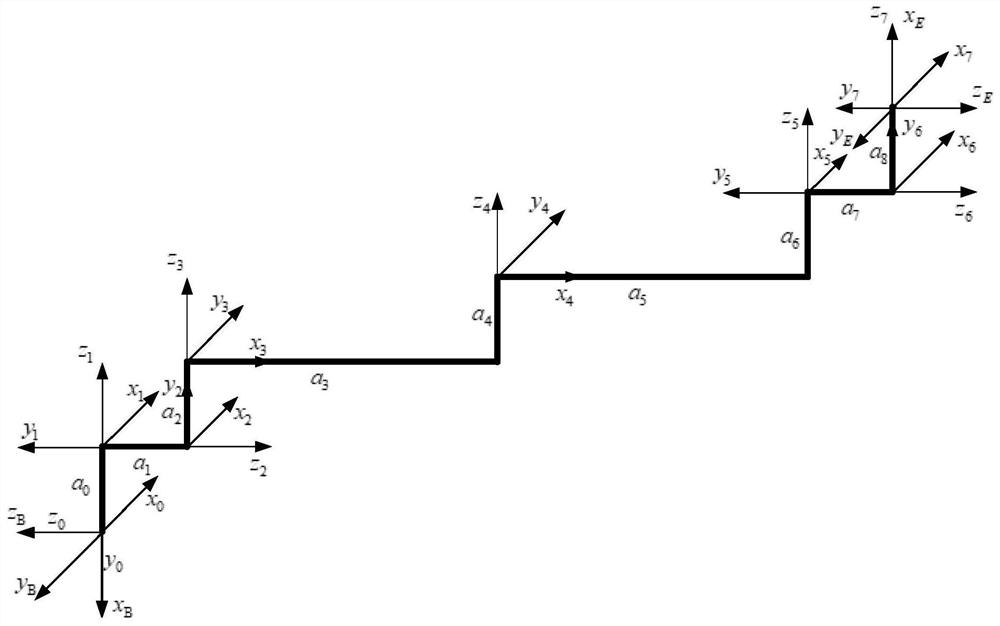

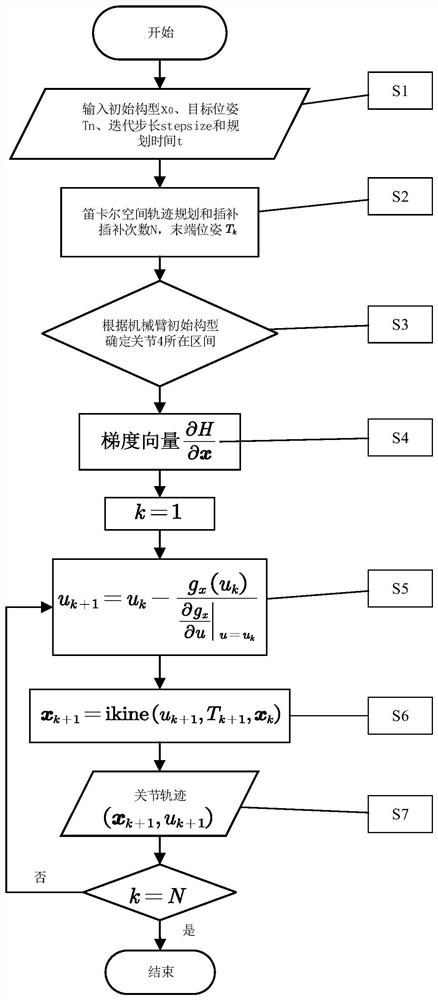

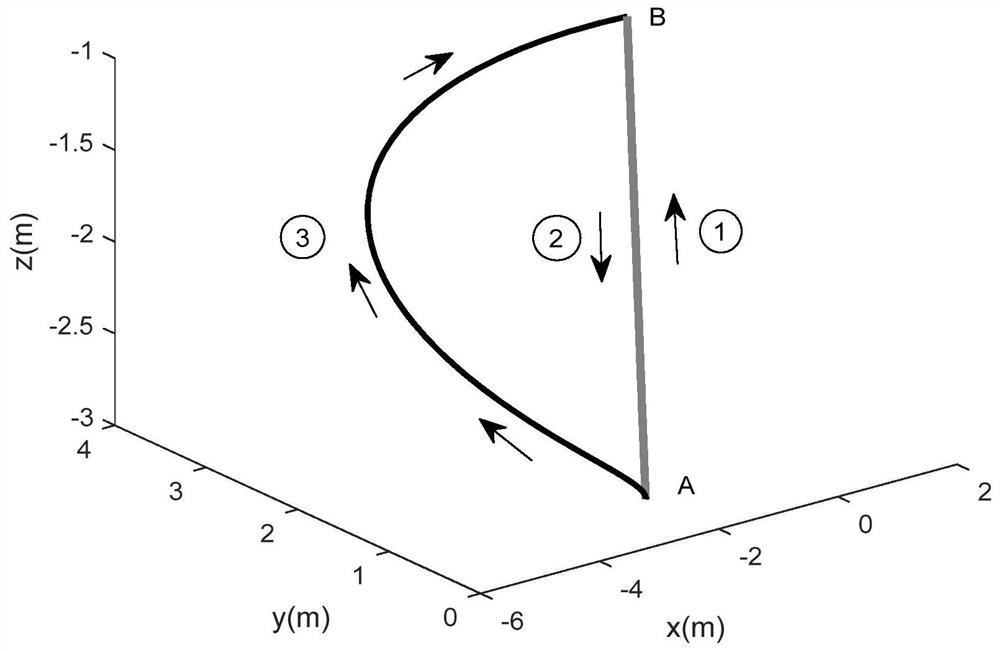

Seven-degree-of-freedom mechanical arm limiting optimization method based on position-level inverse kinematics

ActiveCN112091979ASolving Inverse Solving ProblemsTake advantage of redundancyProgramme-controlled manipulatorOptimal controlIterative method

The invention provides a seven-degree-of-freedom mechanical arm limiting optimization method based on position-level inverse kinematics, and relates to a seven-degree-of-freedom mechanical arm limiting optimization method. The method aims to solve the problems that an existing numerical solution cannot obtain a closed solution, and final-state self-motion exists; and an analytical solution cannotbe used for offset configuration, and motion optimization cannot be realized. The method comprises the steps that firstly, an analytical solution of seven-degree-of-freedom mechanical arm inverse kinematics is obtained based on a parametric solving method for fixing a certain joint angle; then, the fixed joint angle parameter is used as input, joint limiting is used as an optimization index, and an optimal control problem is established; then, a constrained problem is converted into an unconstrained problem based on a Lagrangian multiplier method; and finally, the optimal joint angle parameteris solved based on a Newton iteration method, and seven joint space trajectories considering joint limiting optimization are obtained by giving an initial configuration, an expected tail end pose anda Cartesian path planning. The method is used for limiting optimization of a seven-degree-of-freedom mechanical arm.

Owner:HARBIN INST OF TECH

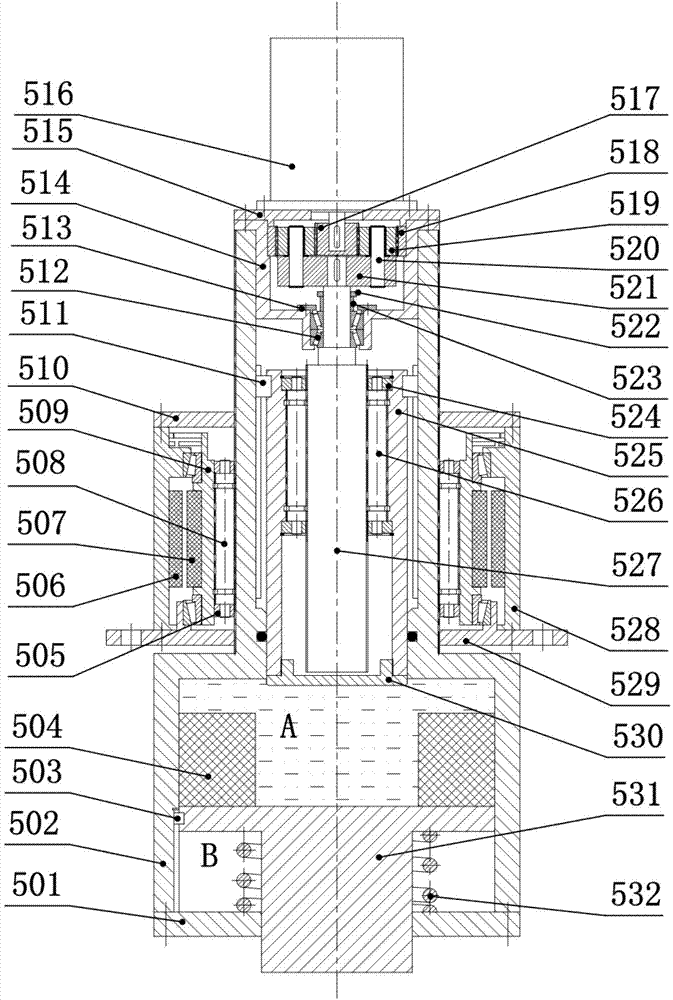

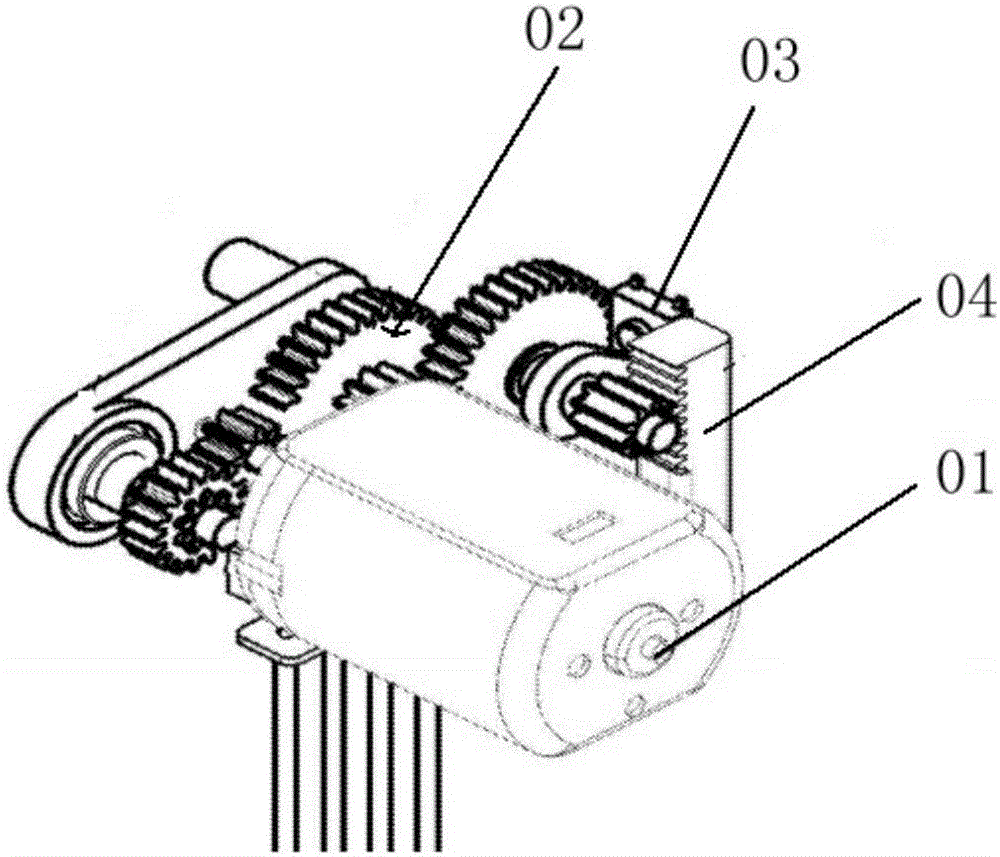

Double-acting servo pressure cylinder for press machine

InactiveCN103939427AImprove running speed and responsivenessCompact designFluid-pressure actuator componentsMachine pressCylinder block

A double-acting servo pressure cylinder for a press machine comprises an idle stroke device and a working stroke device. The idle stroke device is designed inside an outer cylinder body. An idler stroke servo motor rotor and planetary roller lead screw nuts are designed together. The nuts drive an inner cylinder body through rollers to reciprocate mechanically inside an idle stroke motor. The working stroke device is designed inside the inner cylinder body. A planetary reduction gear, a planetary roller lead screw device, a pressure boost cavity and a stroke cavity are sequentially arranged on the inner cylinder body from top to bottom. Both an idle stroke and a working stroke are powered by a servo motor. According to the double-acting servo pressure cylinder for the press machine, the idle stroke and the working stroke are independently controlled, energy consumption is reduced, flexibility and control precision of the press machine are improved, and the design cost of the press machine is reduced.

Owner:XI AN JIAOTONG UNIV

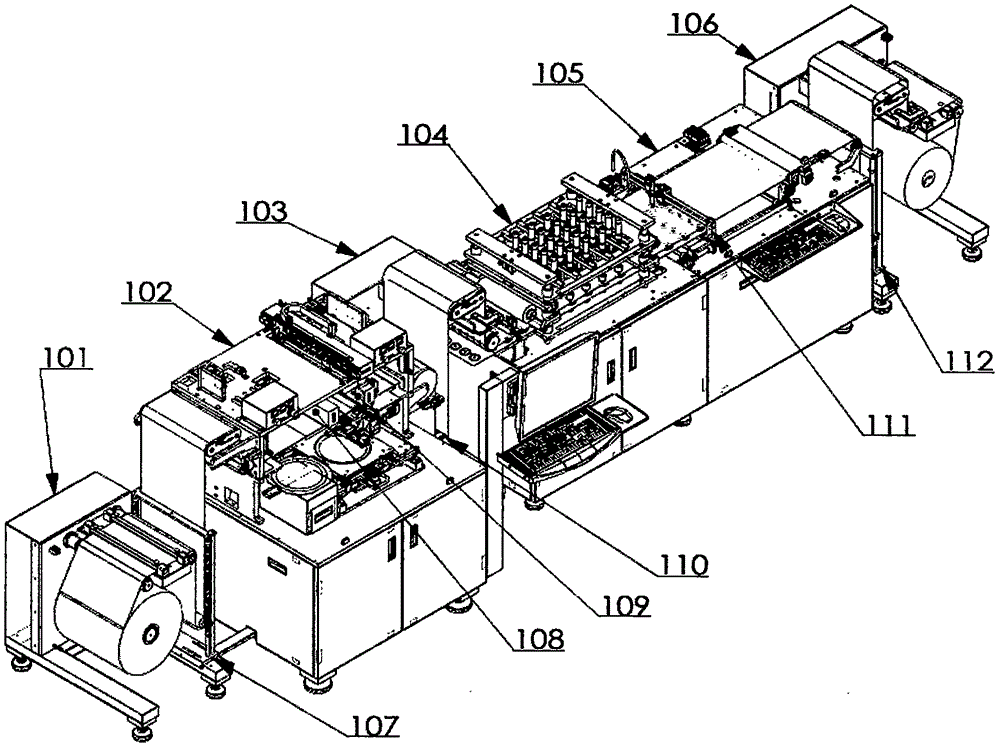

Electronic tag packaging equipment

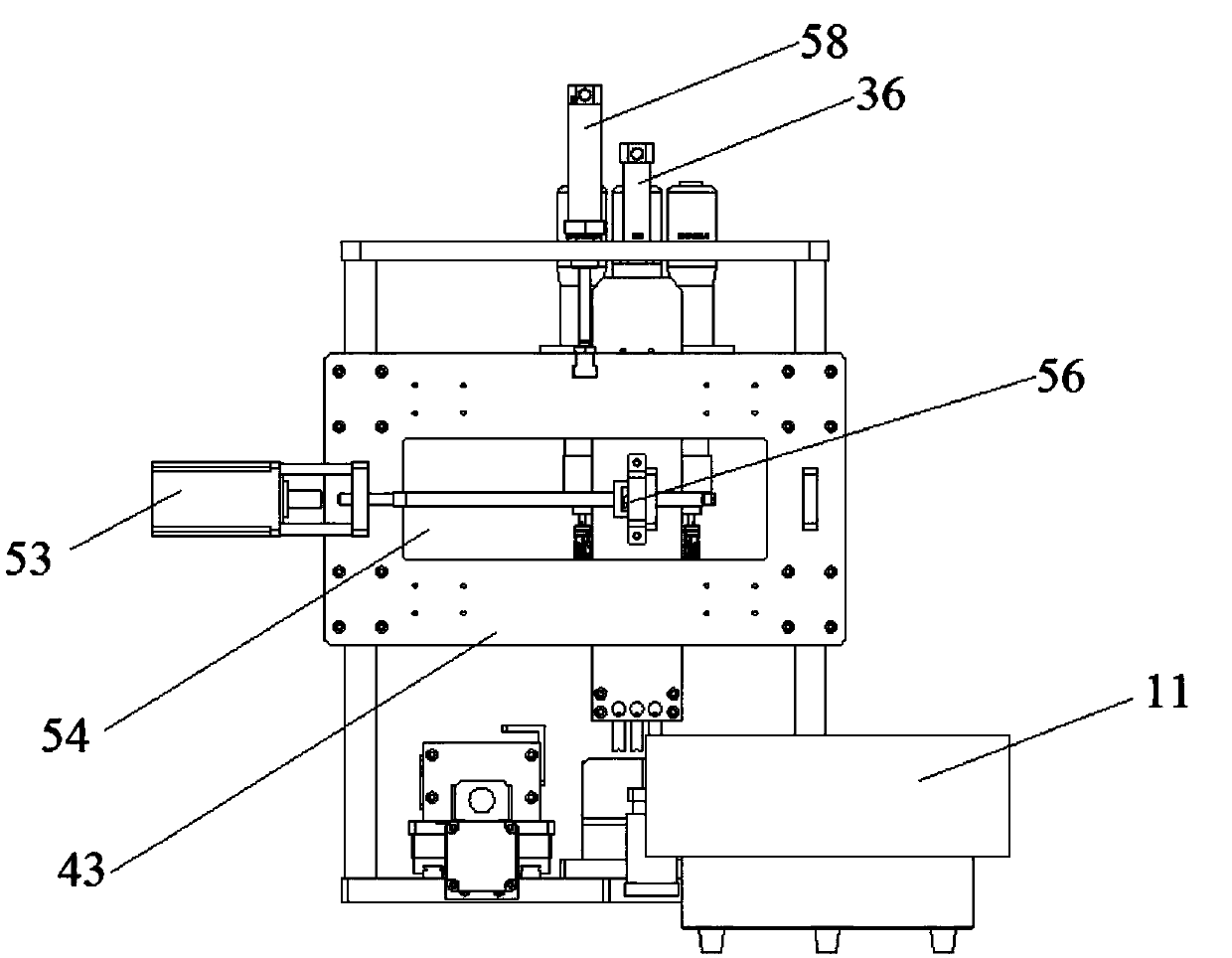

PendingCN105826225ASimple structureImprove system rigiditySemiconductor/solid-state device manufacturingSensing record carriersCamera lensLinear drive

The invention discloses a piece of electronic tag packaging equipment which is used for chip inverted mounting, hot-pressing and production testing of electronic tags. A bonding arm and a dispensing arm are designed into a five-side closed groove structure, and thus a compact and light high-speed bonding arm and dispensing arm structure which is of high rigidity and has a function of flux leakage from the bottom is formed. A bonding head and a corresponding squint-eyed camera lens group are arranged on a linearly-driven carrier, so the antenna photographing task and the bonding or dispensing task are completed in the same position area, and the capacity is improved. By using tension control mechanisms of a linear bearing, a support optical axis, a cylinder and a spring, the friction resistance is reduced, the precision of tension control is improved, and a simple structure and low cost are achieved. A tag test drive mechanism connects a lower detection reading head and an upper marking head through a Y-direction synchronous belt bypassing an antenna film area so as to realize mechanical synchronous movement. The tag test drive mechanism is simplified, and the cost is reduced greatly.

Owner:刘宁

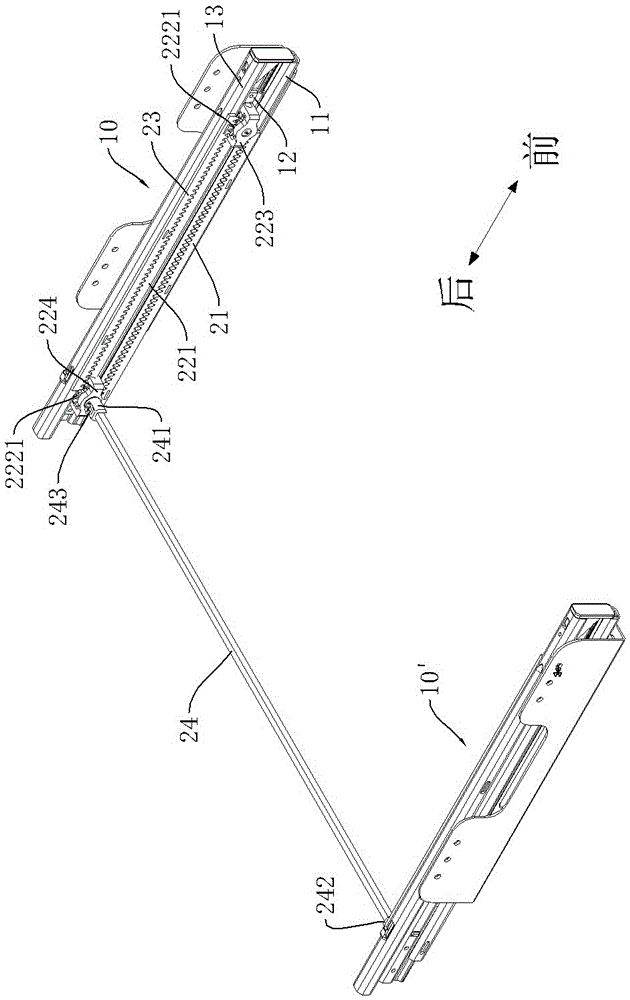

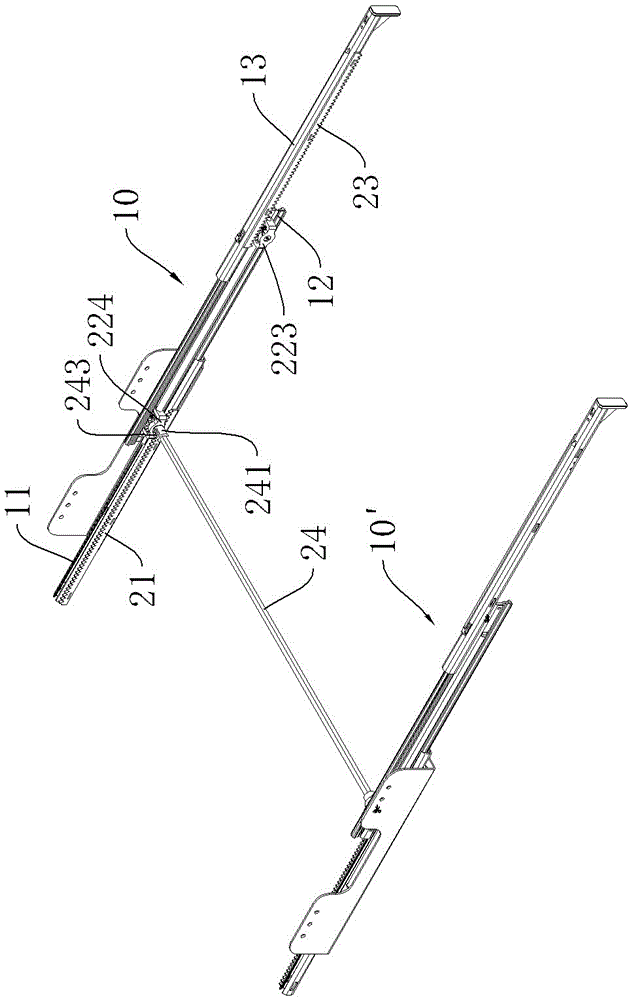

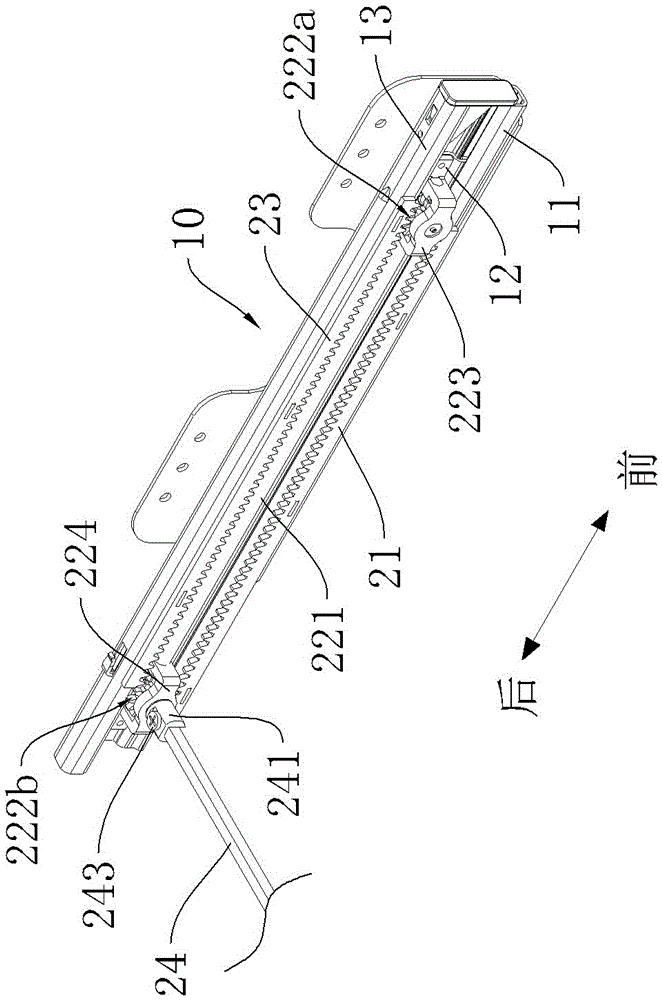

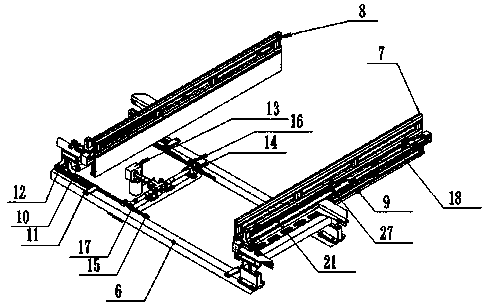

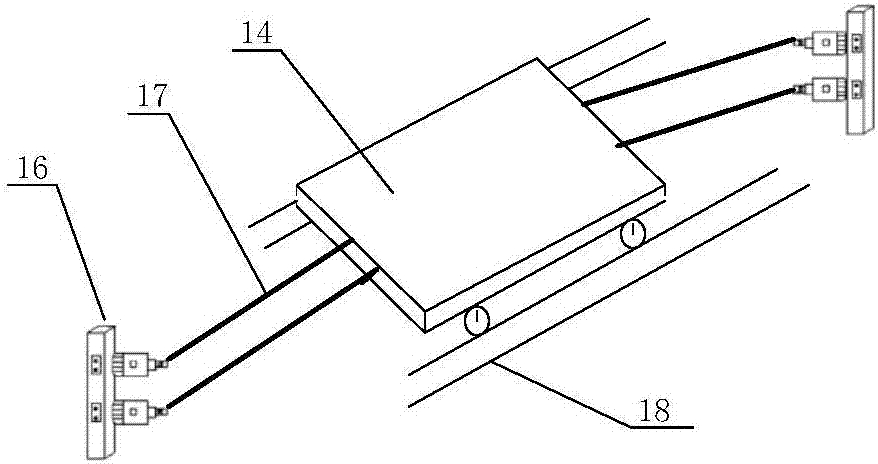

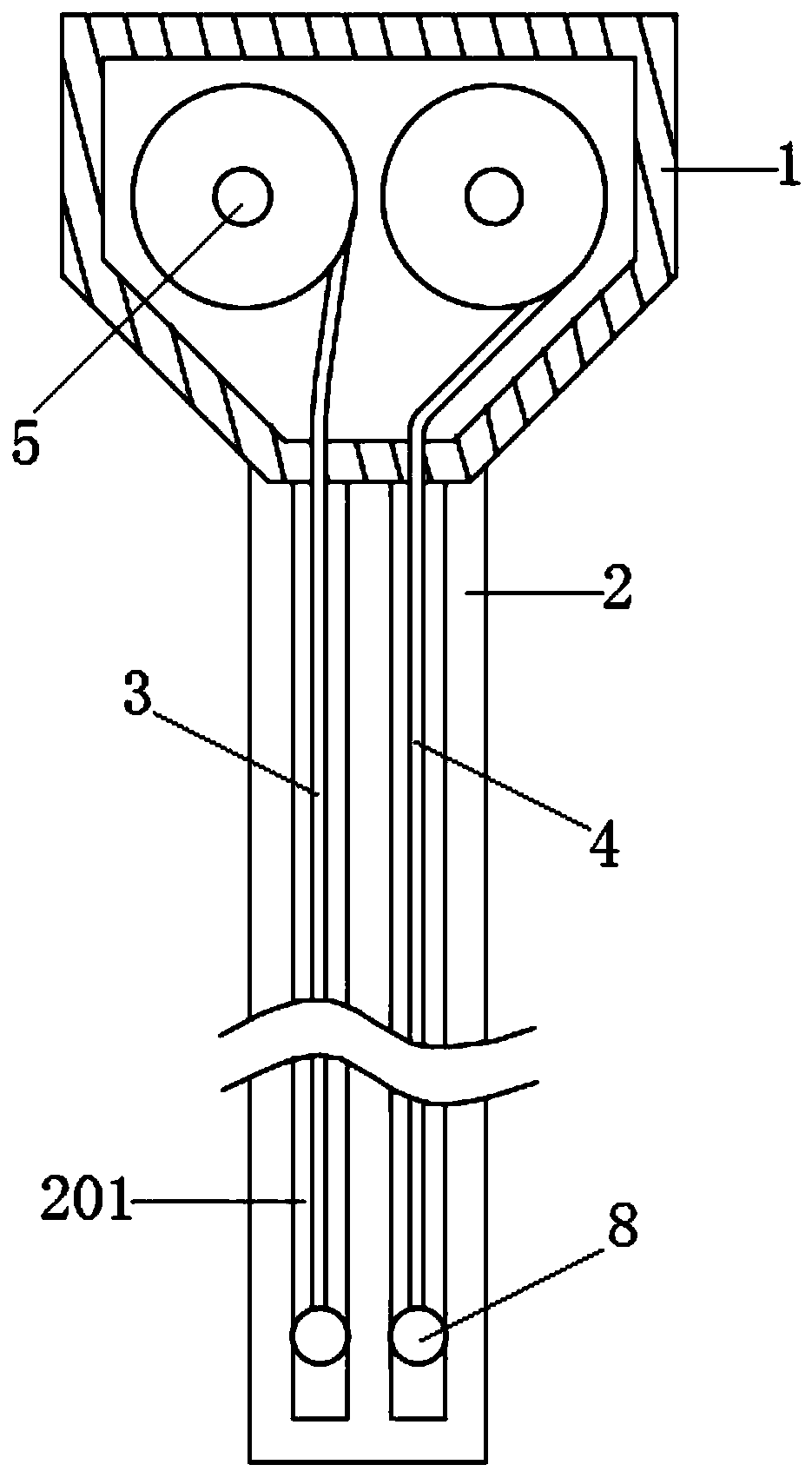

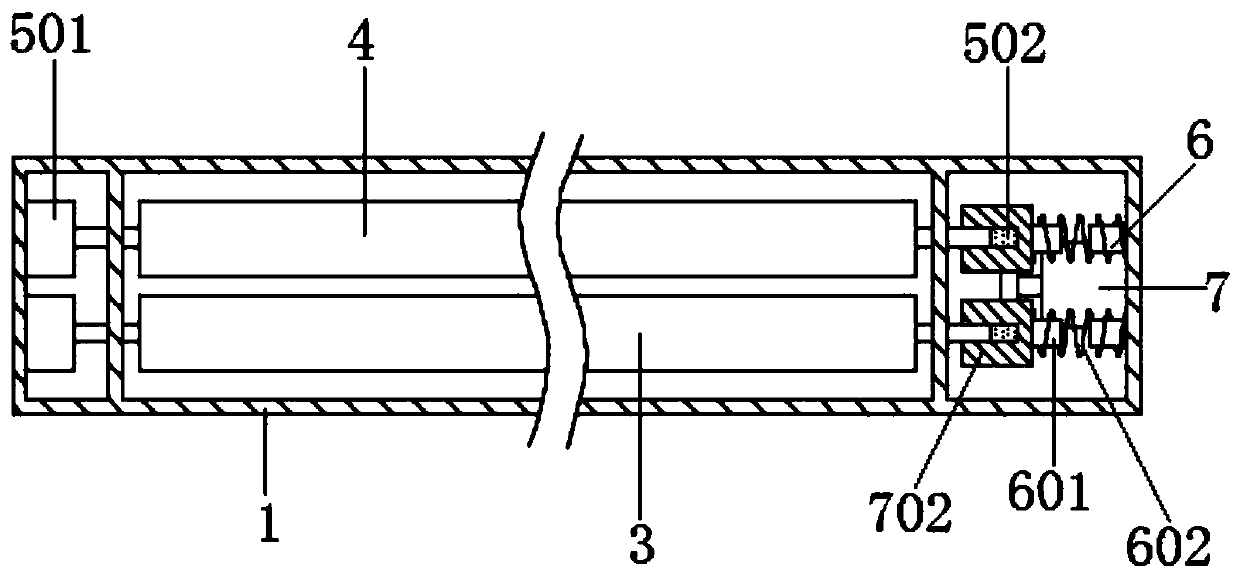

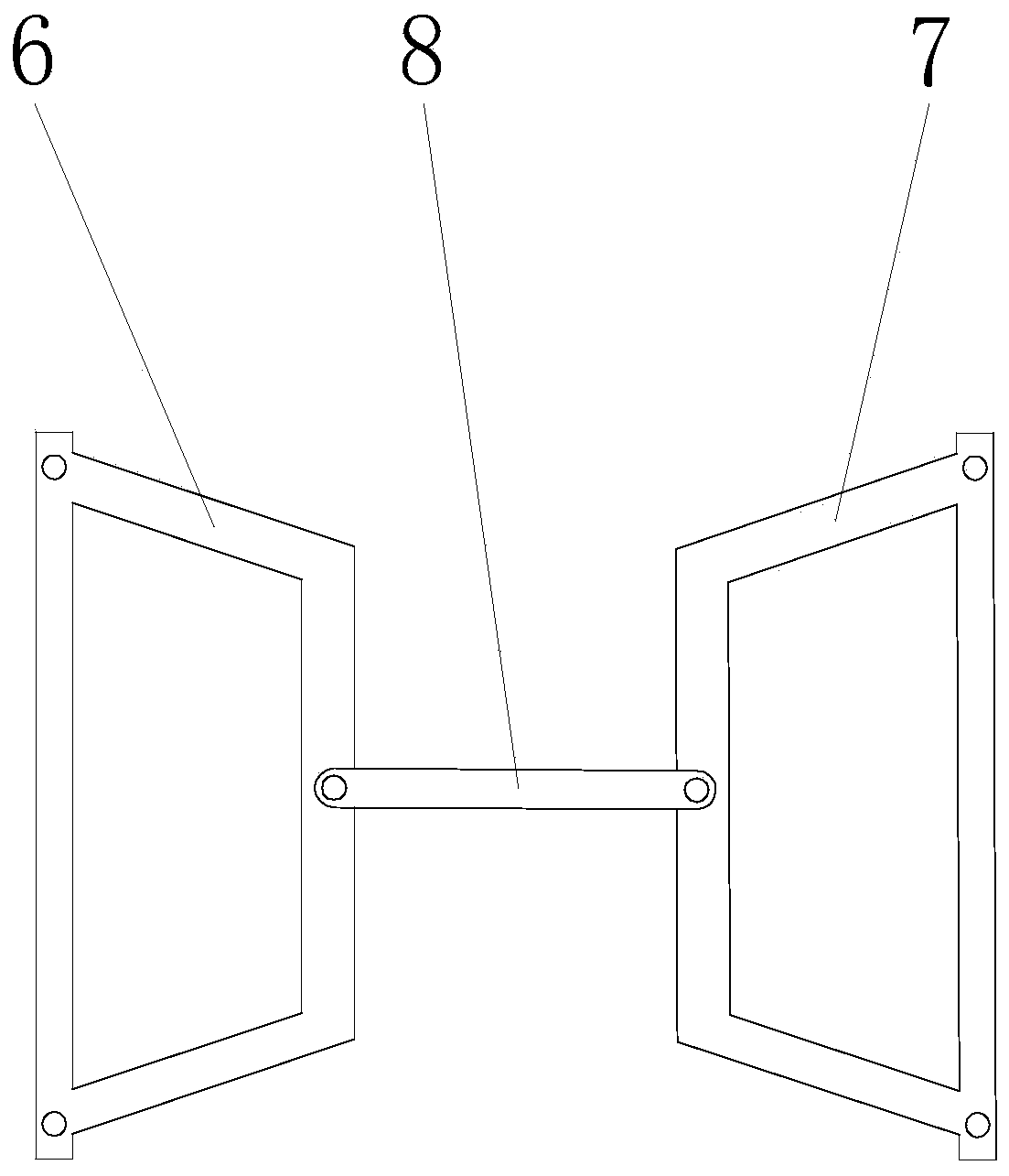

Three-segment synchronous drawer sliding rail

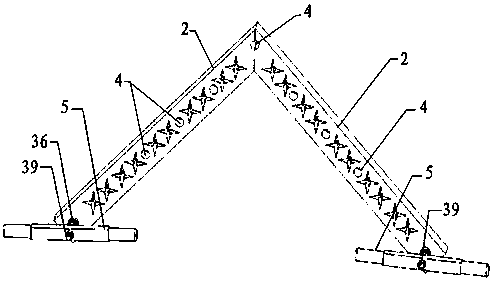

ActiveCN106724189ARealize synchronized motionSimple structureDrawersEngineeringMechanical engineering

The invention provides a three-segment synchronous drawer sliding rail which can solve the problems that an existing three-segment synchronous drawer sliding rail is complex in synchronous structure and unreliable in synchronous driving. The three-segment synchronous drawer sliding rail comprises two sliding rail assemblies, the two sliding rail assemblies are installed at the left side and the right side of a drawer respectively and each provided with a synchronous assembly, and each sliding rail assembly comprises a fixed rail fixedly installed on the inner side wall of a cabinet body through a fixed rail support, a movable rail fixed to the outer side wall of the drawer and a middle rail slidably connected with the fixed rail and the movable rail separately; each synchronous assembly comprises a fixed rail rack, a transmission mechanism and a movable rail rack, wherein the fixed rail rack, the transmission mechanism and the movable rail rack are installed on the inner side face of the corresponding fixed rail, the inner side face of the corresponding middle rail and the inner side face of the corresponding movable rail respectively, teeth of the fixed rail rack and teeth of the movable rail rack are oppositely arranged, the transmission mechanism is in transmission connection with the fixed rail rack and the movable rail rack separately, and the transmission mechanisms of the two synchronous assemblies are synchronously connected through a connecting rod.

Owner:WUXI HAIDAER PRECISION SLIDES CO LTD

Automatic deburring equipment for steel pipe port outer circle

ActiveCN110814911AQuality improvementPolished completely and evenlyEdge grinding machinesRevolution surface grinding machinesFriction forceSteel tube

The invention relates to automatic deburring equipment for a steel pipe port outer circle. The automatic deburring equipment comprises a rack, a feeding assembly, a clamping rotating part, a limitingassembly, a grinding assembly, a discharging assembly and a driving assembly. The grinding assembly comprises a fixing block, a port grinding plate and an outer circle grinding plate. The driving assembly provides power for driving, a steel pipe conveyed by the feeding assembly is clamped and driven to rotate through the clamping rotating part and the limiting assembly arranged on the inner wall of the rack in a matched manner, burrs at a steel pipe port are ground through the port grinding plate in the rotating process, the positions of the two ends of the steel pipe are limited through the port grinding plate, the outer circle of the steel pipe port is ground through the outer circle grinding plate perpendicularly arranged on the outer ring of the port grinding plate in the rotating process, the steel pipe relatively rotates in a clamping block through friction force generated by contact of the outer circle grinding plate and the steel pipe port outer circle, and the steel pipe portand the port outer circle are ground more sufficiently and evenly.

Owner:浙江力创箱包配件有限公司

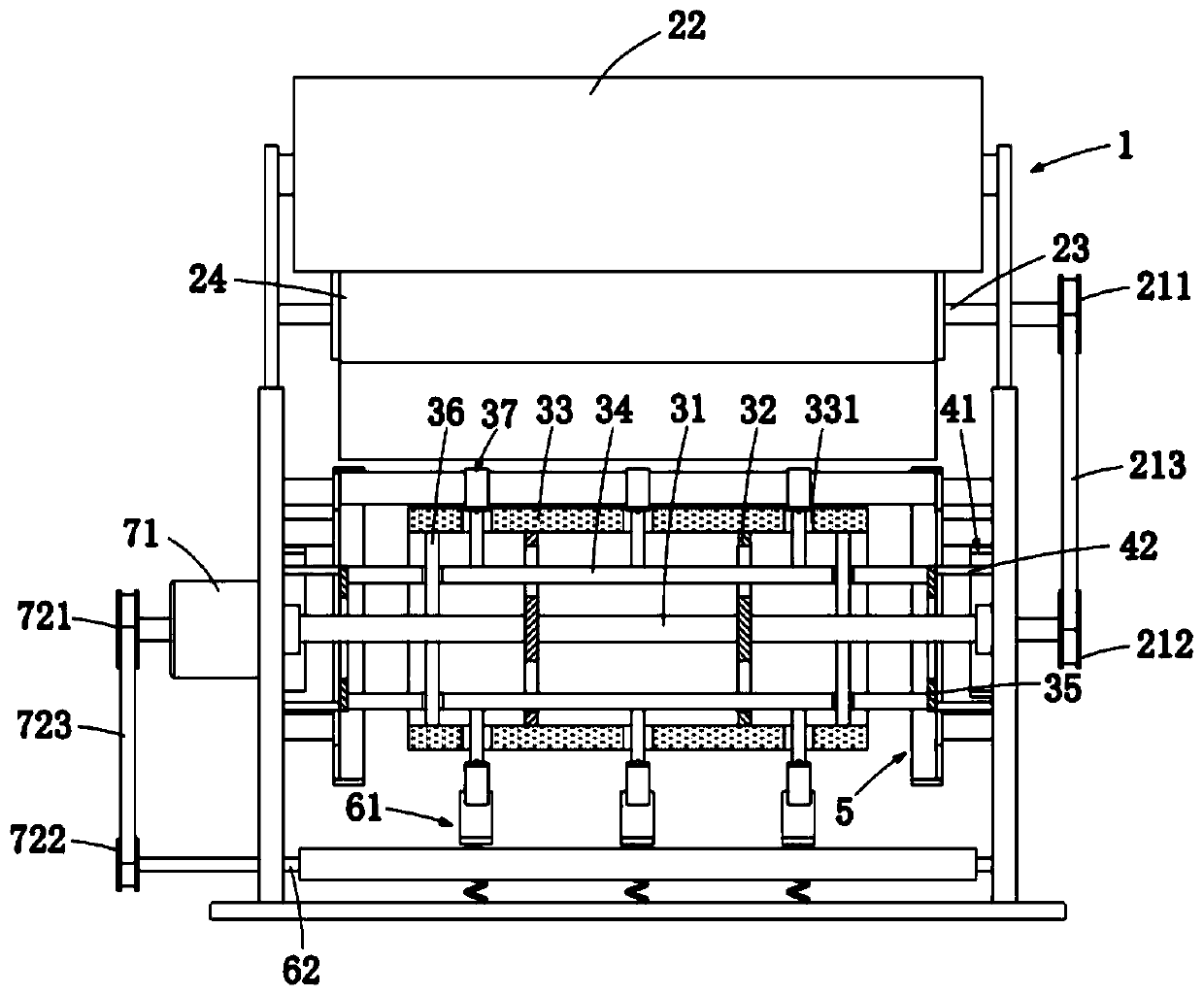

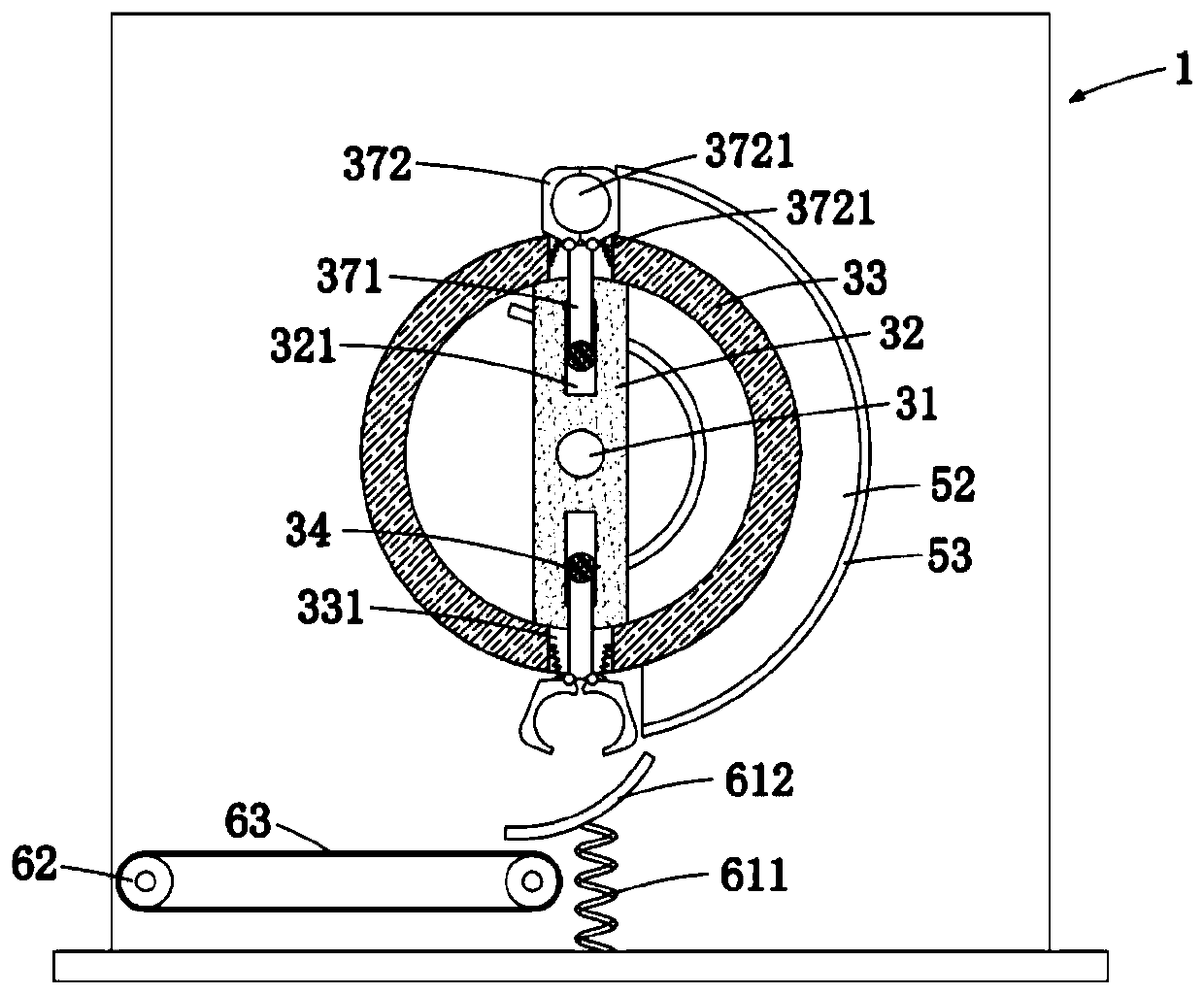

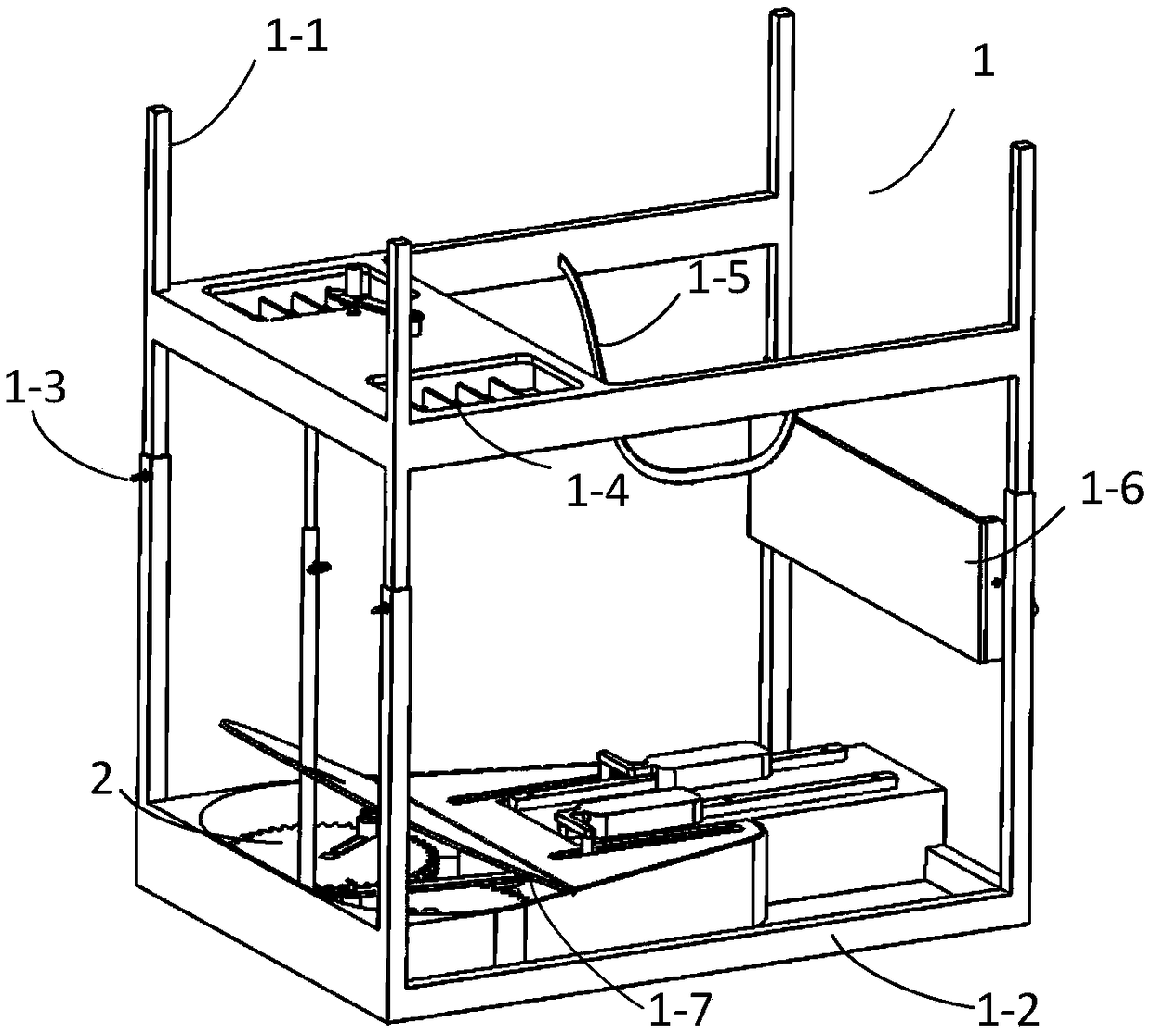

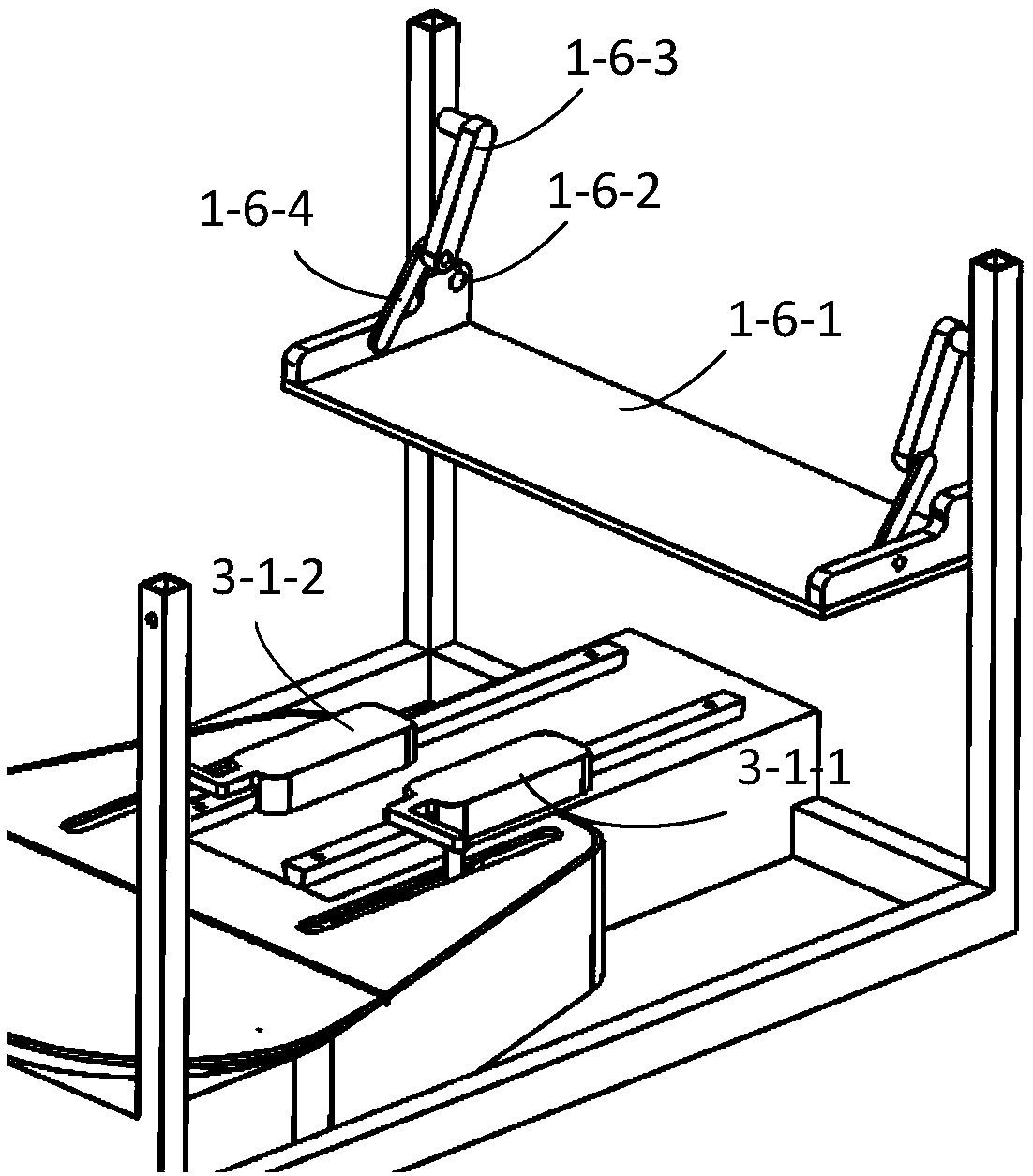

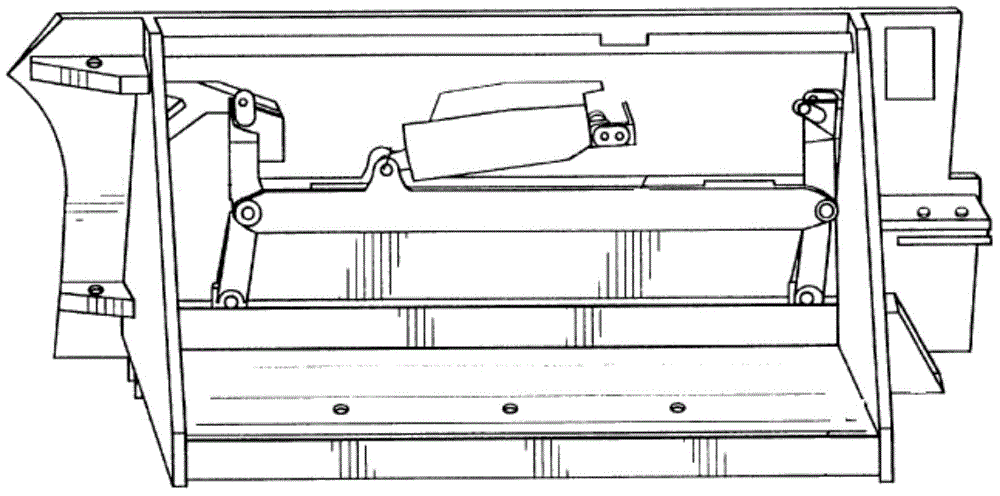

Limb assisted rehabilitation system for patients with stroke sequelae

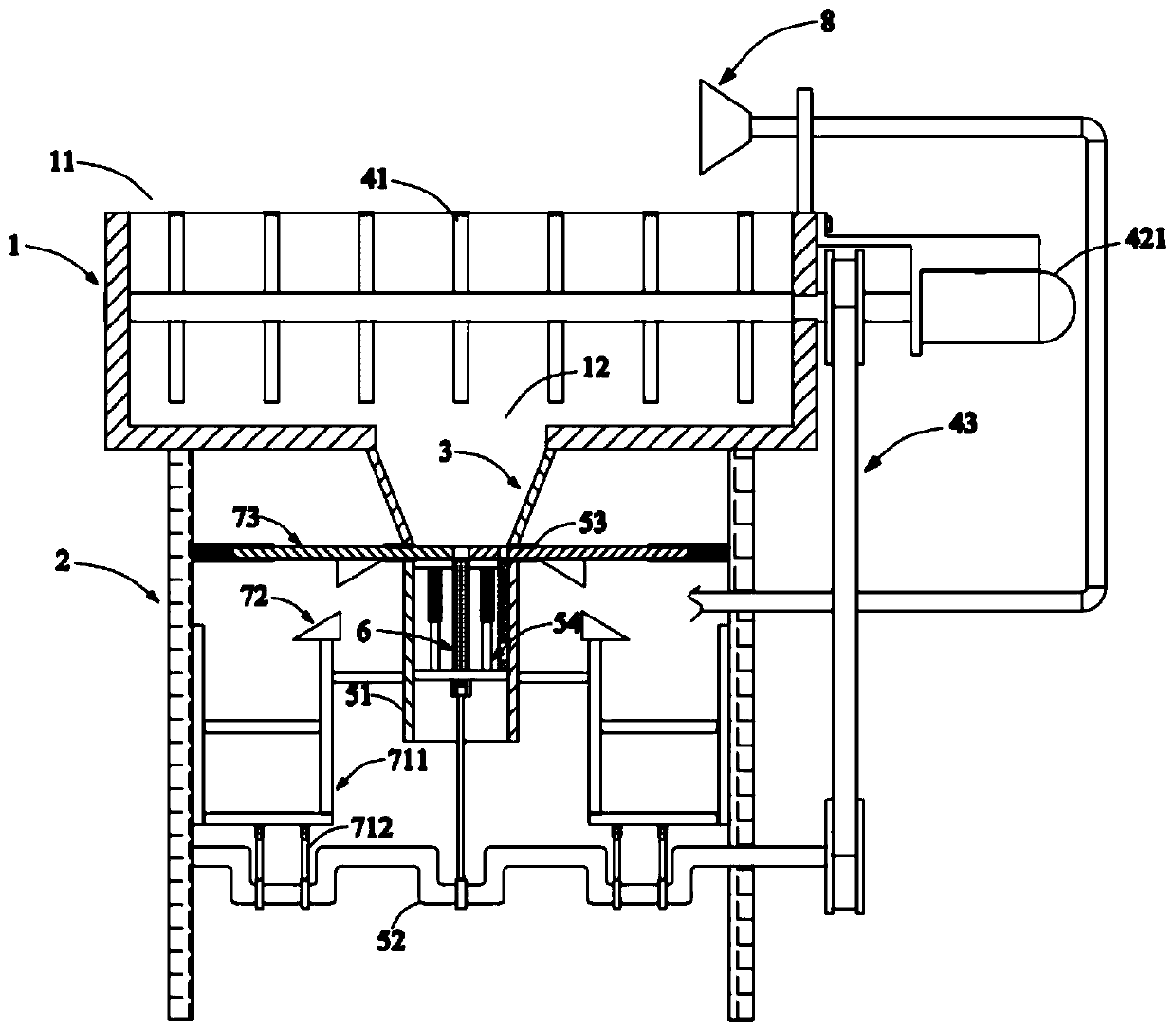

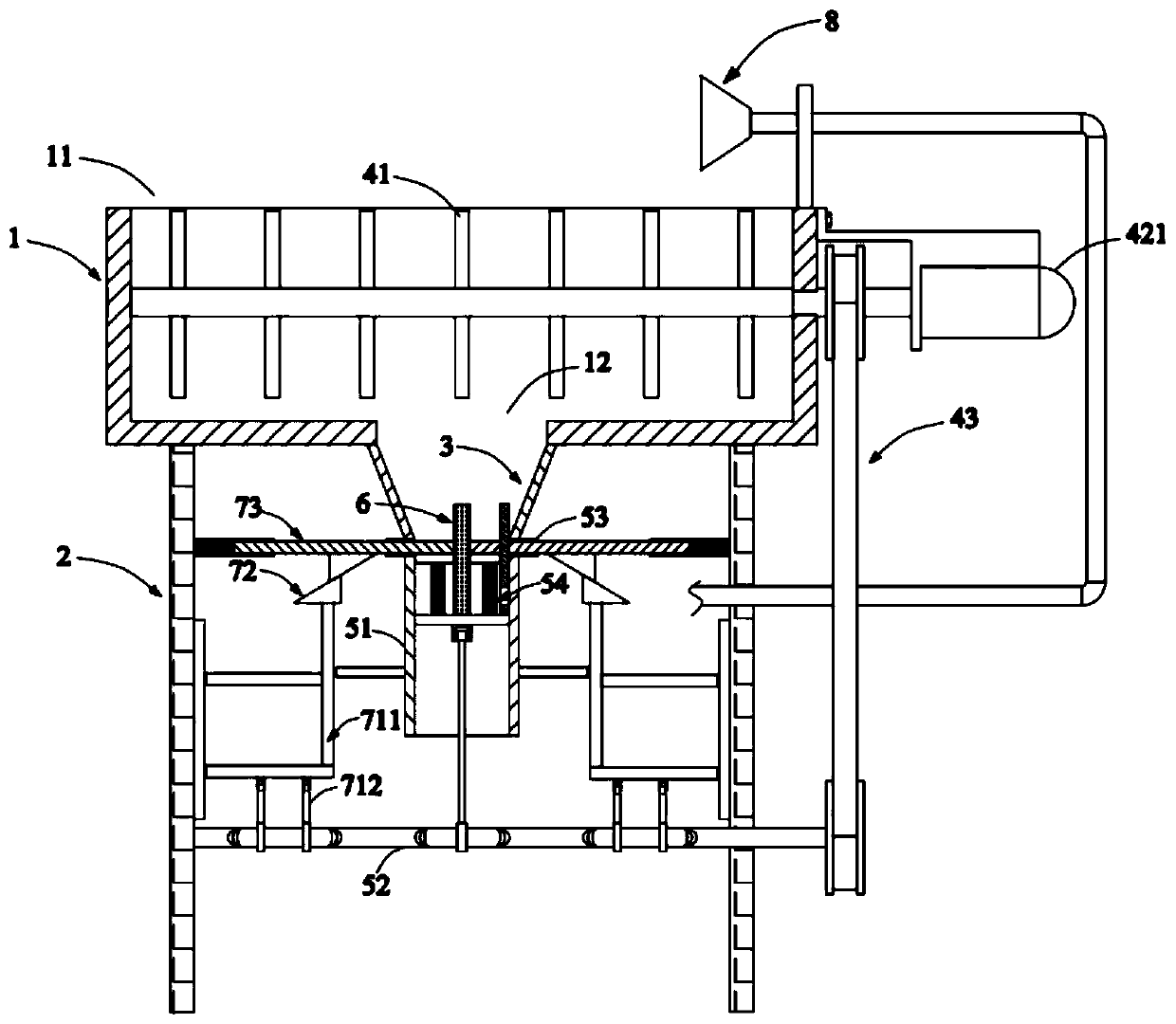

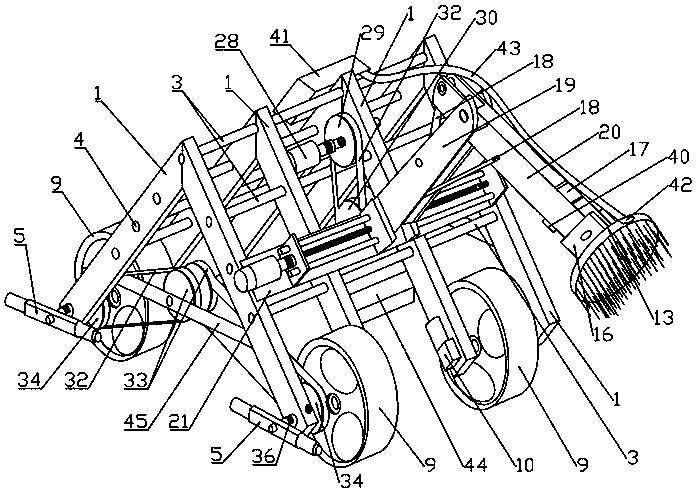

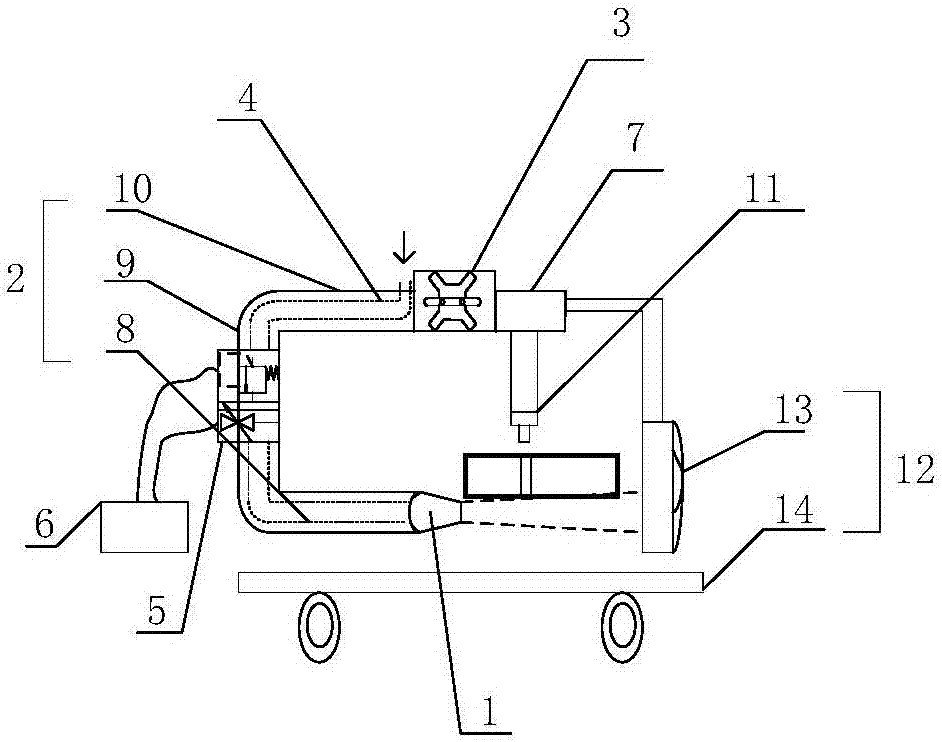

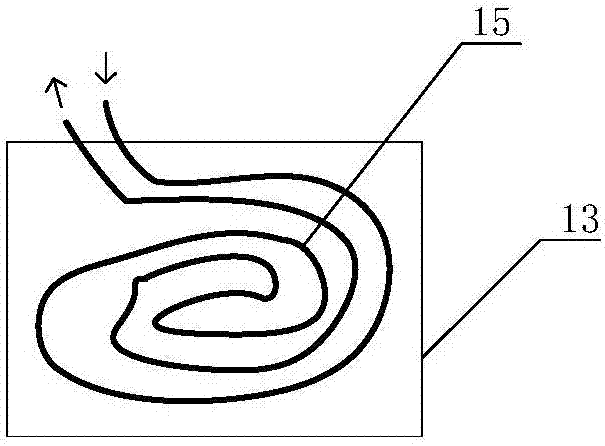

PendingCN109316315AEliminate jerky movementsStepless frequency adjustmentChiropractic devicesReciprocating motionDrive motor

The invention discloses a limb assisted rehabilitation system for patients with stroke sequelae. The system is mainly composed of a main frame, a motion generating mechanism and a motion executing device. Through the motion generating mechanism and initial position planning, the reciprocating movement of two pedals of lower limbs in opposite phases and the synchronous movement of an upper limb rotating rocker arm can be achieved only by the continuous motion of one driving motor. The system has a variety of rehabilitation training modes, and cooperates with a lifting device and a multi-functional seat back, and a patient can passively perform lower limb gait rehabilitation training and upper limb rehabilitation training in standing and sitting postures, and can perform infinitely variablecontrol on training amplitudes and frequencies according to physical conditions. The system also adopts a biasing rod between the pedals and the end of a connecting rod to achieve the movement characteristics of a standard centroid sliding bloc mechanism and eliminate the rapid return of the pedal motion.

Owner:陈浩 +1

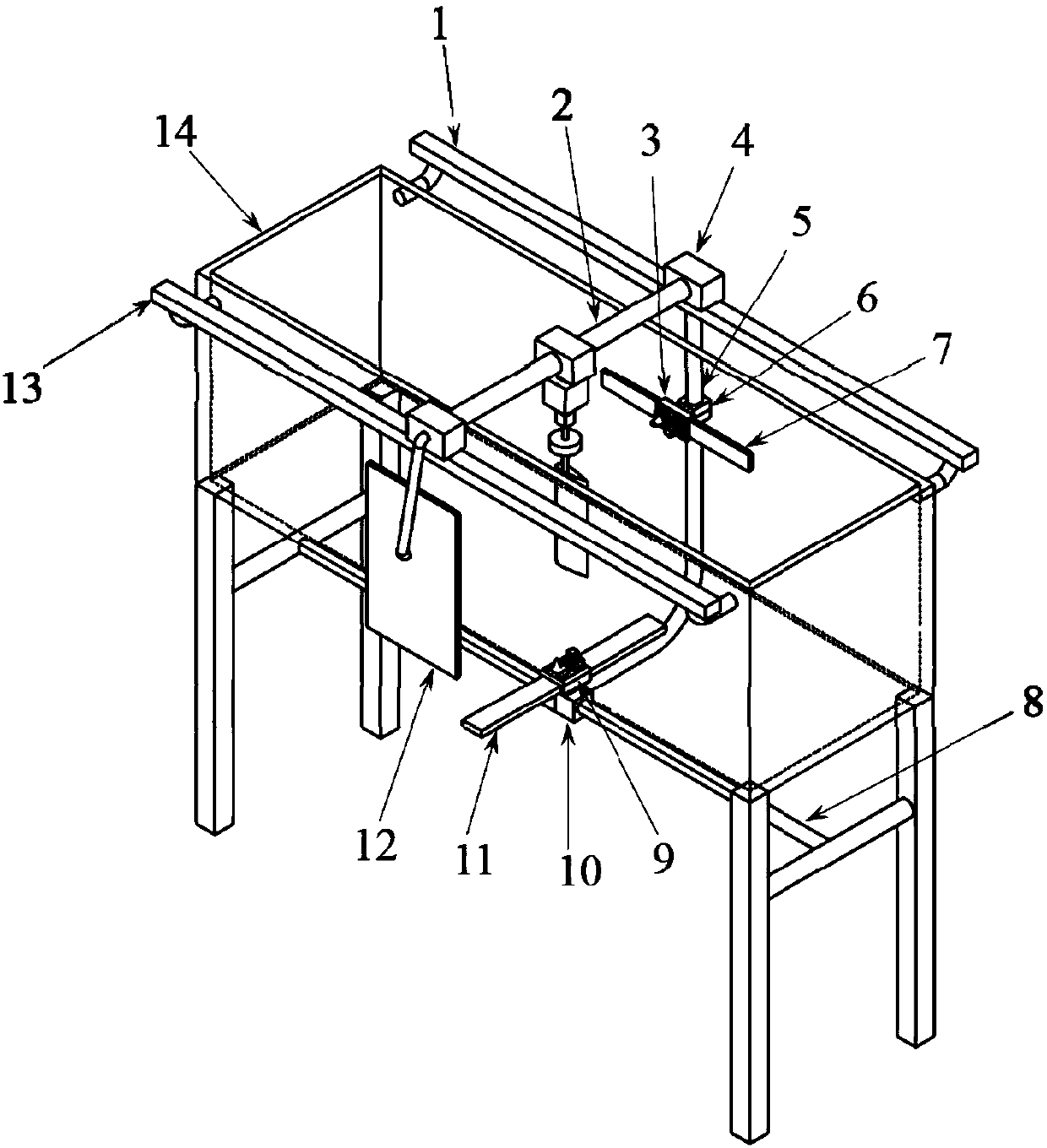

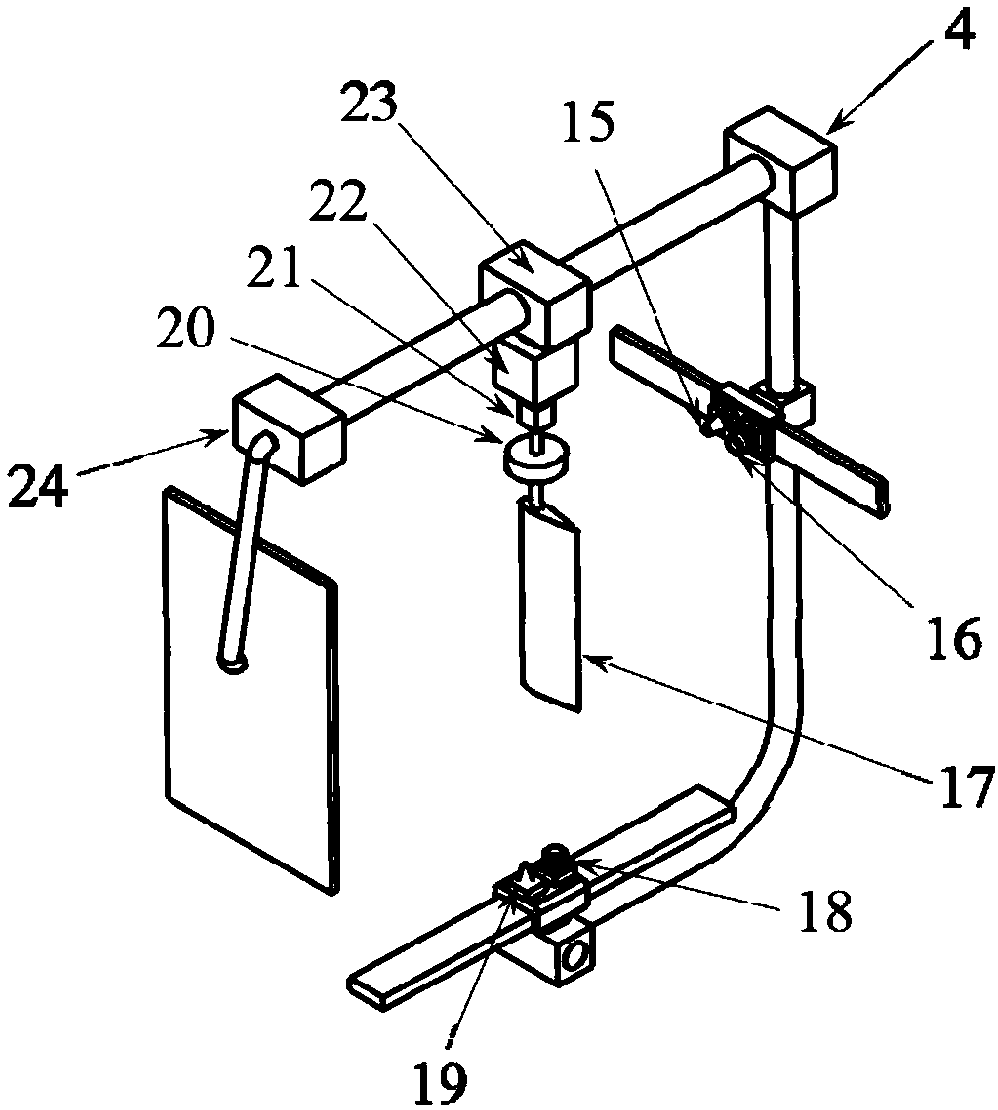

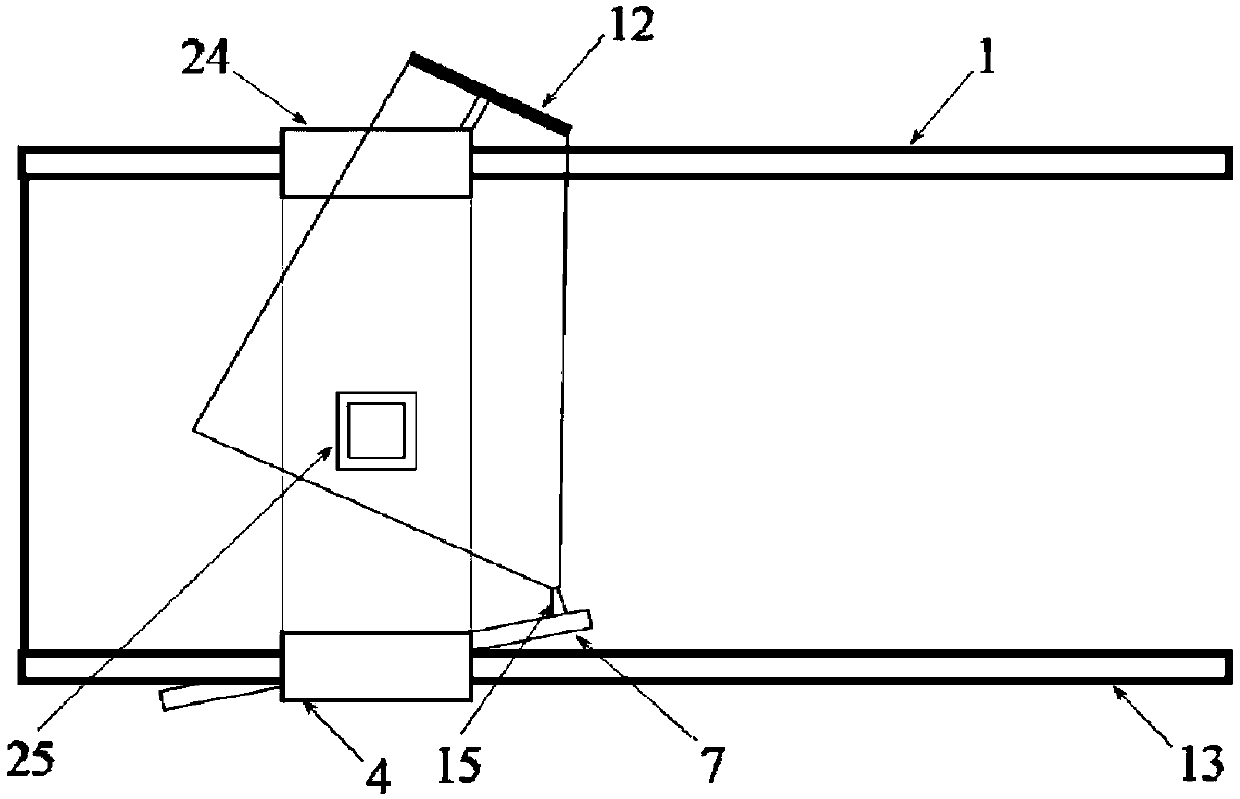

Flow field measurement system and measurement method under model pitching movement

ActiveCN107870079ARealize dynamic pitch motionRealize synchronized motionHydrodynamic testingFluid speed measurementModel dynamicsEngineering

The invention provides a flow field measurement system and measurement method under model pitching movement. A first upper guide rail and a second upper guide rail are arranged on a water tank, lowerguide rails are arranged on a support, two trailers are arranged on the two upper guide rails, lateral connecting rods are arranged on a first trailer, first sliders are arranged on the lateral connecting rods, a second trailer is connected with reflectors through connecting rods, second sliders are arranged on the lower guide rails, sliding vanes are arranged on the first sliders and the second sliders, bases are arranged on the two sliding vanes, a laser device and a camera are arranged on each base, a horizontal connecting rod is arranged between the first trailer and the second trailer, athird slider is arranged on the horizontal connecting rod, a stepping motor and an encoder are arranged at the lower end of the third slider, the lower end of the encoder is connected with a force balance, and the lower end of the force balance is connected with a wing profile to be detected. The system and the method are low in cost, high in measurement efficiency, applicable to measurement of model dynamic pitching movement and also applicable to flow field measurement of a model in other specific dynamic movement modes.

Owner:HARBIN ENG UNIV

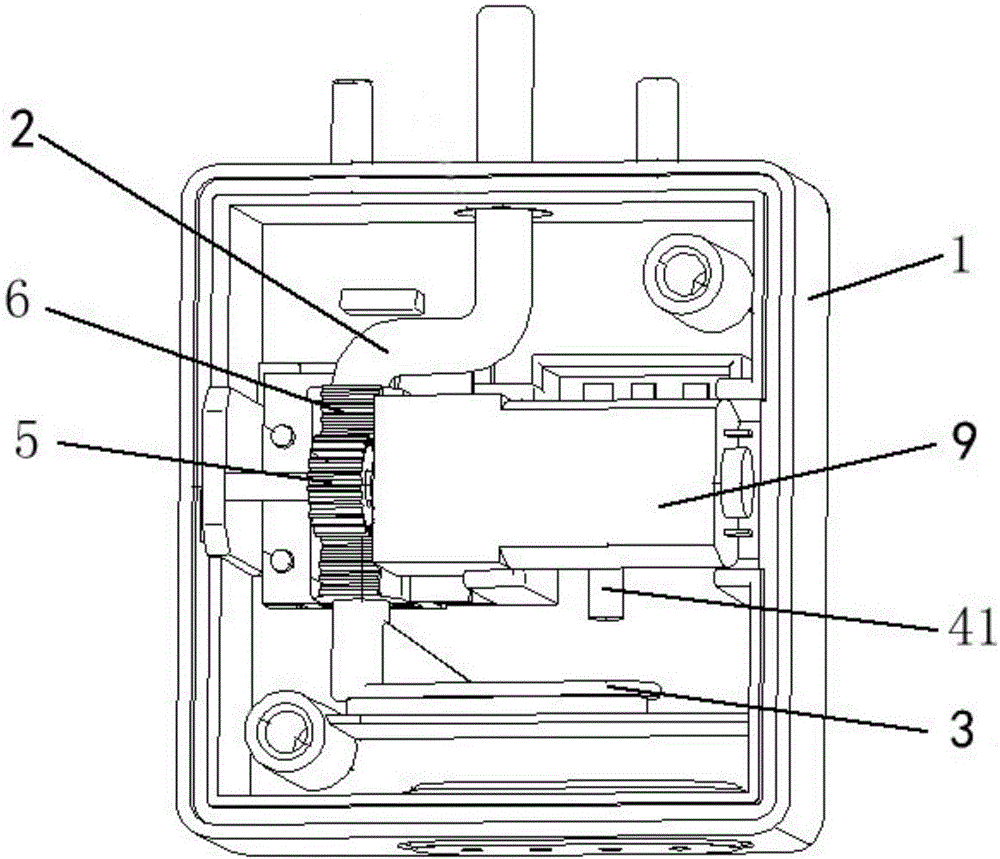

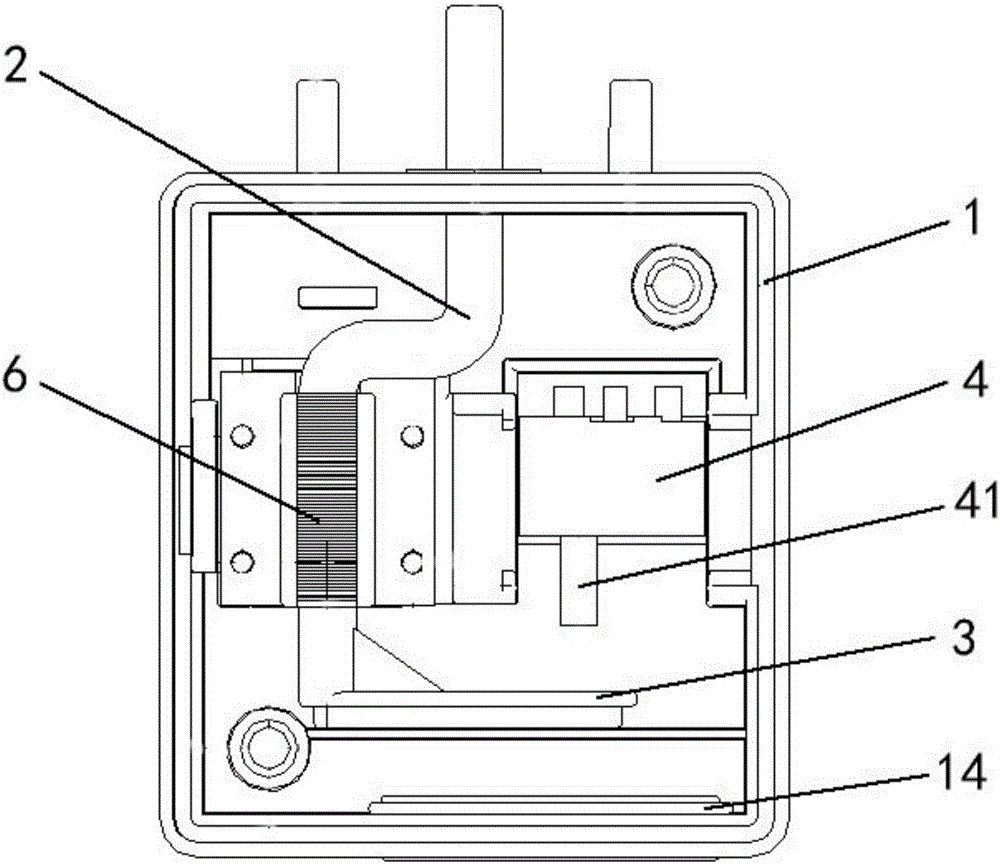

Electronic lock

ActiveCN107524349ACompact structureReduce volumeNon-mechanical controlsElectric vehicle charging technologyReciprocating motionTime to trigger

The invention discloses an electronic lock. The electronic lock comprises a housing, as well as a driving device, a signal triggering device, a locking structure and a triggering structure which are arranged in the housing, wherein the signal triggering device is provided with a triggering button; the locking structure has a first state and a second state which can enable the electronic lock to be locked or unlocked; and the reciprocating direction of the triggering structure is consistent with that of the pressed or bounced triggering button. By adoption of the structural arrangement, the triggering structure can be in contact with and press the triggering button when the locking structure is in the first state, and can be separated from the triggering button when the locking structure is in the second state. According to the technical scheme, the electronic lock is simple and compact in structure, small in size and reliable in matched transmission, ensures the consistency and the synchronicity between the instantaneous triggering time of the signal triggering device and the corresponding locking / unlocking time of the electronic lock, is high in control accuracy and is safe and reliable, and the service performance of the electronic lock is improved.

Owner:浙江致威电子科技有限公司

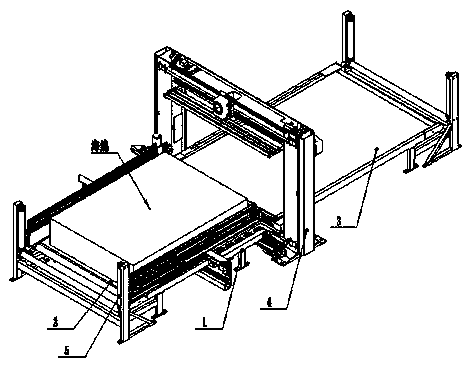

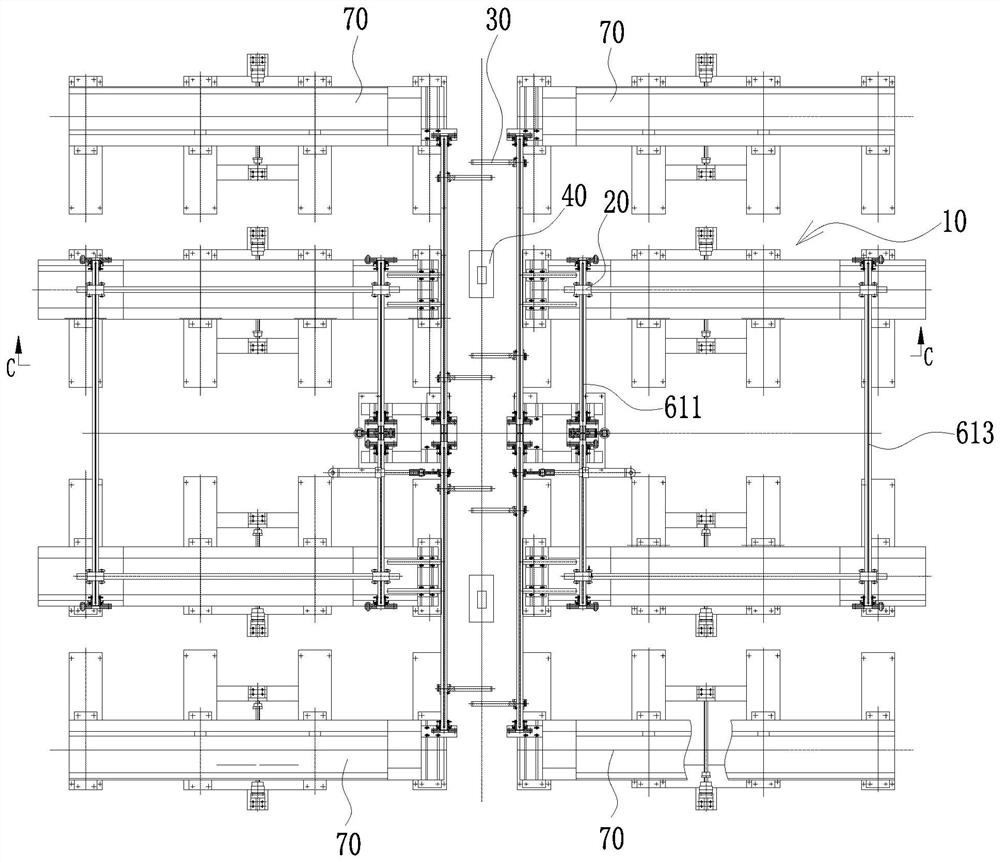

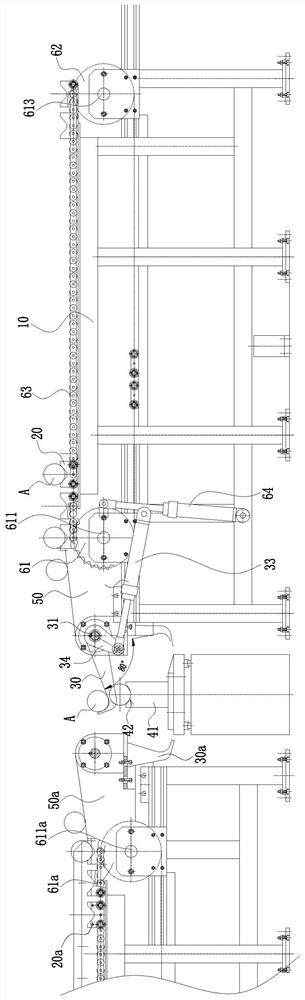

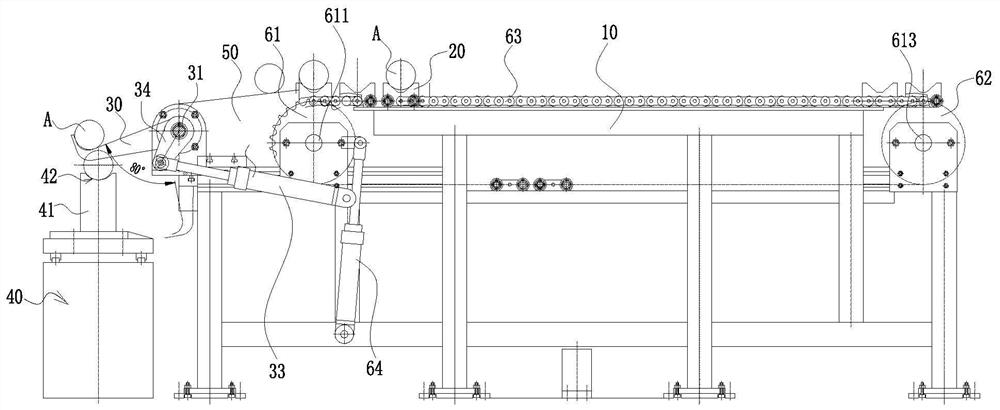

Automatic lateral sponge supporting synchronous operation device

The invention relates to an automatic lateral sponge supporting synchronous operation device. The automatic lateral sponge supporting synchronous operation device comprises a pair of sponge supportingplates arranged on the two sides of a conveying support, the two sponge supporting plates are jointly matched to achieve clamping of a sponge, and the two sponge supporting plates are driven by a transverse moving mechanism to do reciprocated moving between a feeding conveying belt and a discharging conveying belt. The device has the advantages that the two sponge supporting plates are matched jointly to achieve clamping of the two sides of the sponge, through cooperation of the transverse moving mechanism, the sponge supporting plates can synchronously move in the conveying process of the feeding conveying belt, it is ensured that in the cutting whole process, sponge clamping is achieved, the phenomenon that due to slippage between the sponge and the conveying belts, the cutting precision is reduced is avoided, in addition, it is ensured that the cut side sponge is not separated from the sponge body, and the cutting precision of the side sponge is affected.

Owner:南通恒康数控机械股份有限公司

Aerial operation car pit protection mechanism and aerial operation car

ActiveCN106315471AMove preciselyImproved ability to resist horizontal lateral forcesSafety devices for lifting equipmentsVehicle fittings for liftingProtection mechanismState switching

The invention discloses an aerial operation car pit protection mechanism and an aerial operation car, relates to the technical field of engineering machinery, and solves the technical problem that a protection plate is difficult to accurately move to a horizontal state and a vertical state in the prior art. The aerial operation car pit protection mechanism comprises a lifting device linkage part, a transmission mechanism and a protection plate; the lifting device linkage part can drive the transmission mechanism to move in the falling process, and the transmission mechanism drives the protection plate to move to the horizontal state for keeping; in the vertical state, the driving device is connected with the transmission mechanism; and when a lifting device of the aerial operation car is ascended, the vertical-state driving device can drive the transmission mechanism to drive the protection plate to move to the vertical state for locking at least in the horizontal direction. The aerial operation car includes the aerial operation car pit protection mechanism. The aerial operation car pit protection mechanism is used for improving the protection plate state switching accuracy and reliability.

Owner:XCMG CONSTR MACHINERY

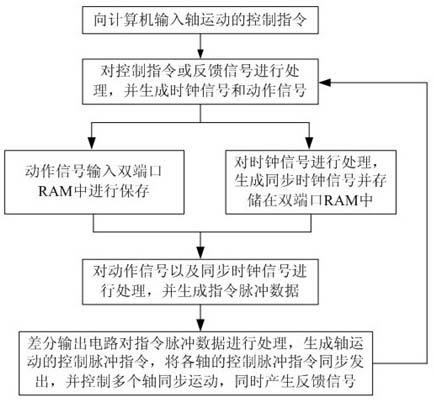

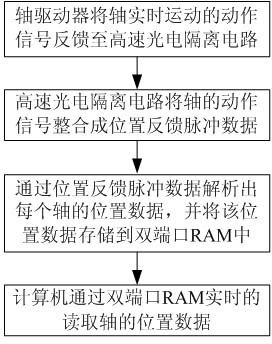

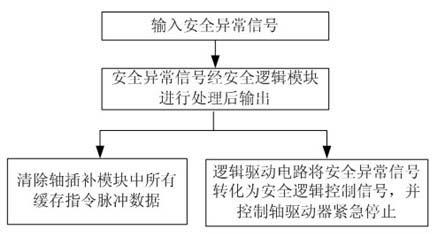

Multi-axis movement control method of industrial robot

ActiveCN102615647AControl Synchronized MotionRealize synchronized motionProgramme-controlled manipulatorEngineeringMovement control

The invention discloses a multi-axis movement control method of an industrial robot, and the method is characterized by comprising the following steps of: (1) obtaining current data of each axis of the industrial robot by a computer and utilizing the current data to generate a clock signal and a movement signal for controlling the next step of the movement of each axis of the industrial robot; (2) utilizing a clock managing unit to treat the clock signal to generate a synchronous clock signal for controlling synchronous movement of each axis; (3) processing the synchronous clock signal and the movement signal through an interpolation module to generate a control pulse instruction for controlling the movement of each axis of the industrial robot; and (4) synchronously sending the control pulse instruction to a driver of each axis of the industrial robot to realize the synchronous movement of all the axes. According to the multi-axis movement control method disclosed by the invention, a plurality of axes of the industrial robot can be controlled for synchronous movement and instruction data for controlling the axial movement is corrected, so that the precision of the multi-axis synchronous movement can be better guaranteed; and therefore, the multi-axis movement control method is applicable to popularization and application.

Owner:CHENGDU CRP ROBOT TECH CO LTD

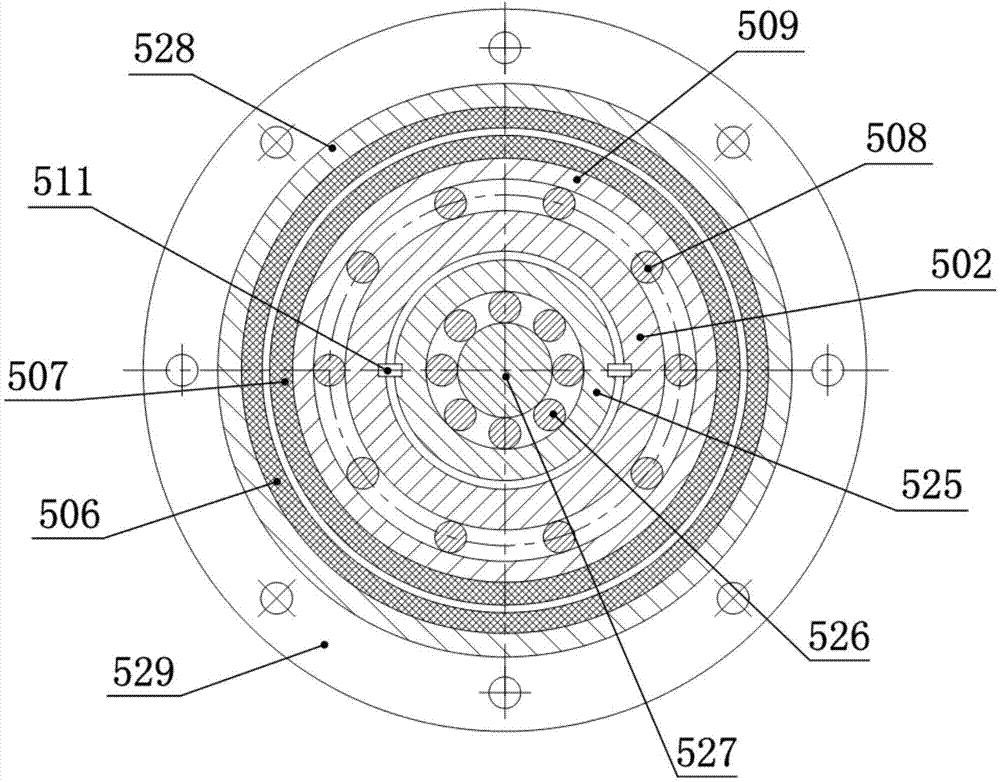

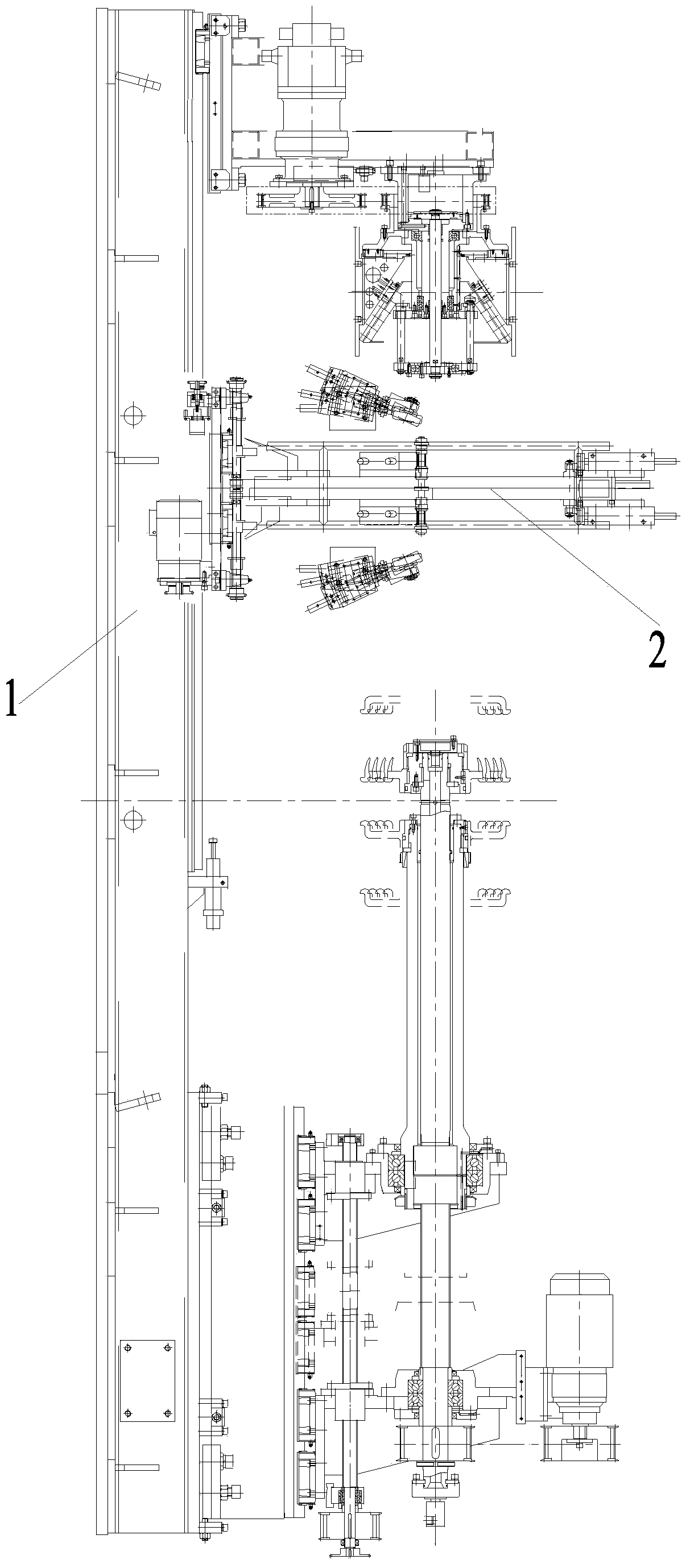

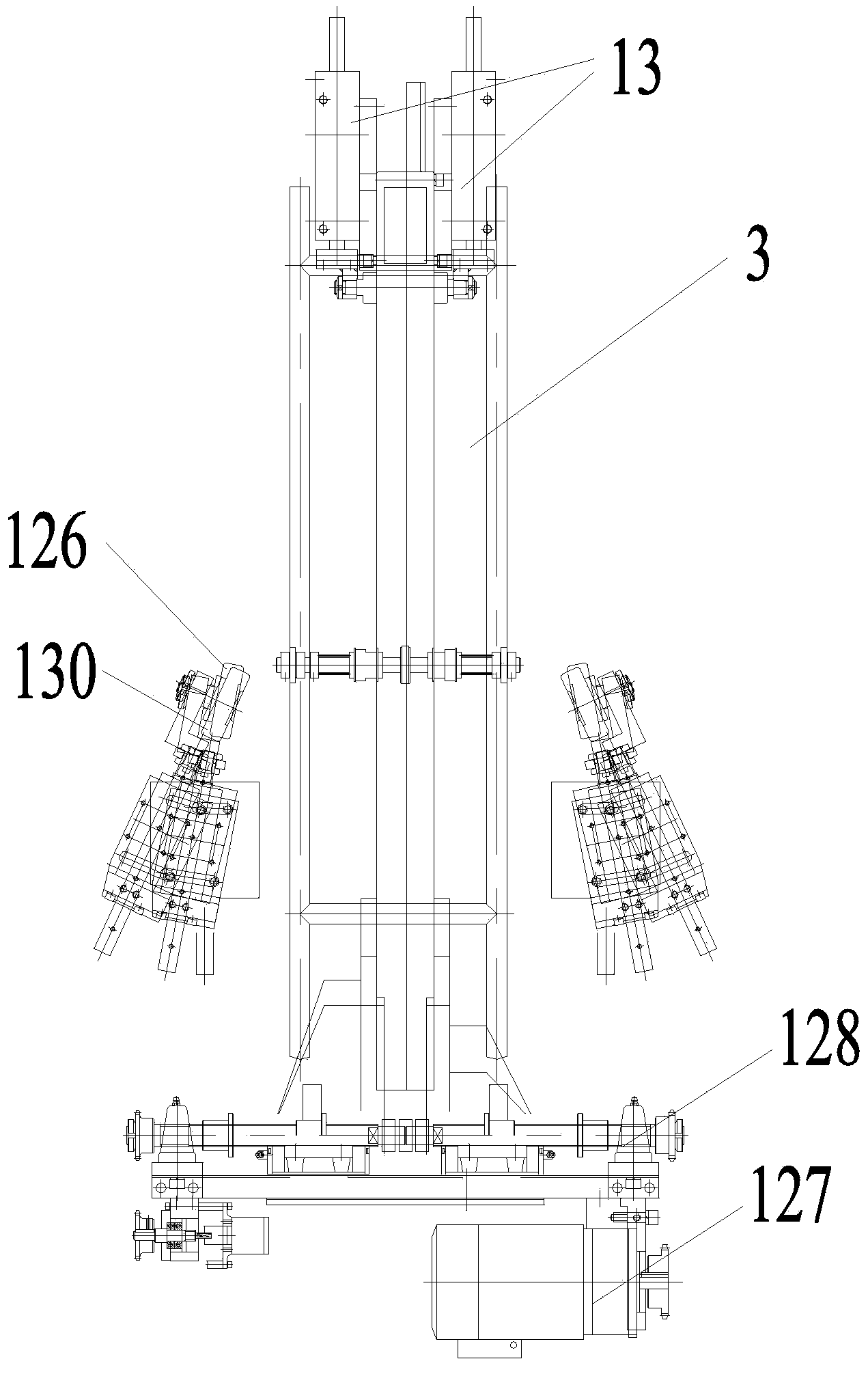

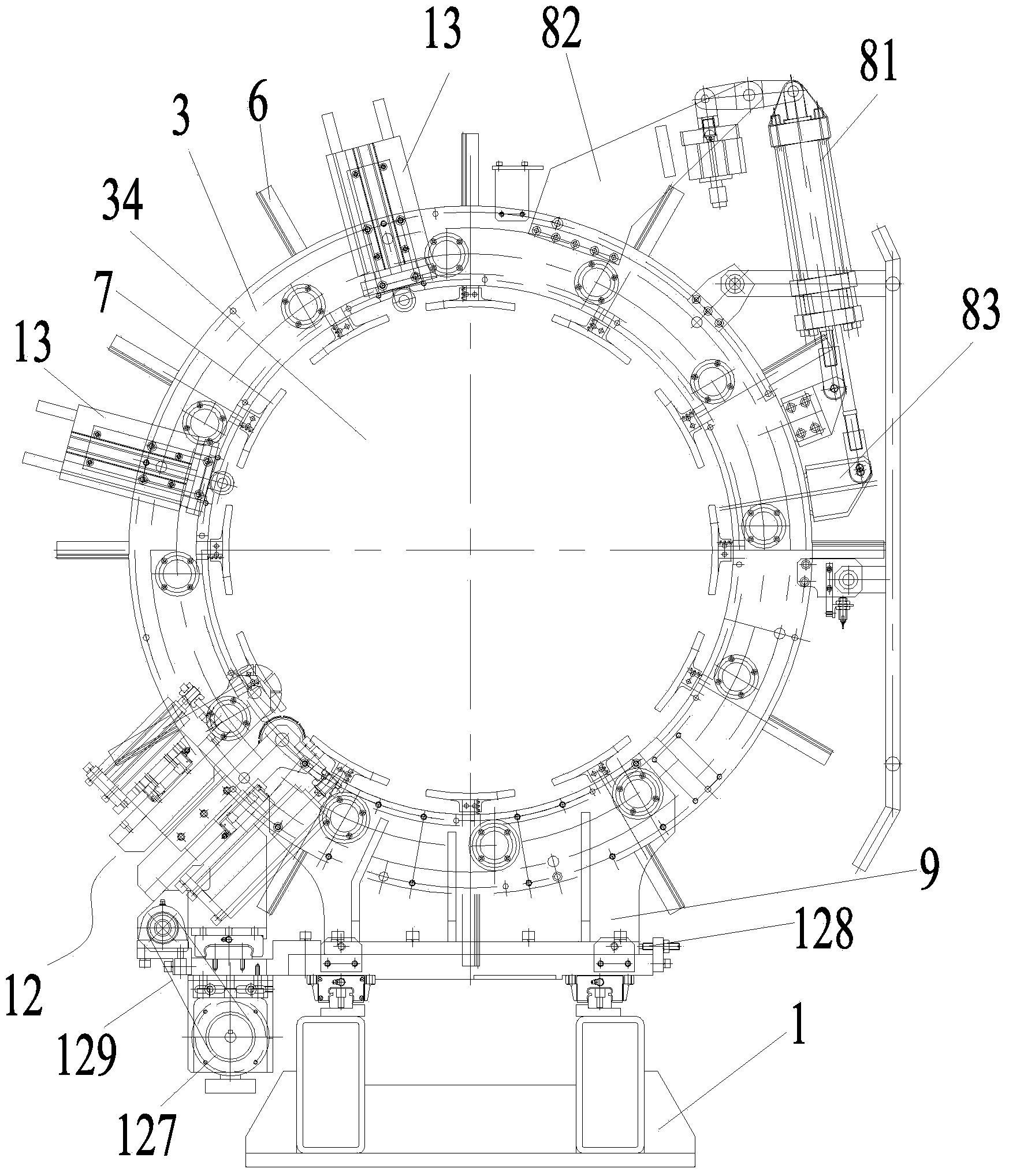

High-precision passenger tire molding machine adopting two-time method

The invention discloses a high-precision passenger tire molding machine adopting a two-time method. The molding machine comprises a first section molding machine and a second section molding machine, wherein the second section molding machine comprises a second section base and a transferring ring; the transferring ring comprises a transferring base, a ring body and a clamping mechanism; a centre hole is formed in the centre of the ring body; the clamping mechanism comprises a plurality of clamping blocks; a rotary ring-shaped gear coaxial with the centre hole is arranged on the ring body, and is connected with the clamping blocks through a gear rack mechanism. According to the molding machine of the passenger tire, as the ring-shaped gear is arranged and is connected with the clamping blocks through the gear rack mechanism, and the gear rack mechanism converts rotary motion input by the ring-shaped gear into linear motion of the clamping blocks, synchronous motion of the clamping blocks can be realized to clamp and release a crown; the transferring ring adopting the structure is excellent in centering performance and repeatability; the position of the crown transferred each time can be ensured to be uniform and good in coaxiality of a tire blank. Therefore, the quality of the tire blank can be improved.

Owner:WUHU DERY ENG

Pulping system for improving slurry concentration uniformity

InactiveCN110449053ARealize on and offStir wellFlow mixersRotary stirring mixersHigh concentrationSlurry

The invention relates to a pulping system for improving the slurry concentration uniformity. The system includes a pulping barrel, a stirring component, a slurry return component, a filter component and a control part. The top and bottom of the pulping barrel are respectively provided with a feed inlet and a drain port. The stirring component is provided with a driving device to drive stirring blades to stir the slurry in the pulping barrel. The slurry return component includes a slurry return barrel, a transmission shaft, a connecting plate, and a piston component cooperatively installed in the slurry return barrel. The filter component includes a filter pipe and a limit plate. The control part includes a lifting mechanism, a displacement component and a control component. The slurry return component, the filter component and the control part work cooperatively to filter a high concentration slurry deposited at the bottom of the pulping barrel, then the filtered slurry is transportedto the feed inlet of the pulping barrel for mixing with a low concentration slurry, and the substances are stirred to enable more uniform concentration distribution of the slurry in the pulping barrel, so that the stirred slurry can be more uniform. The pulping system provided by the invention has the advantages of simple mechanism, convenient operation, low energy consumption and high work efficiency.

Owner:长兴东锦纺织品有限公司

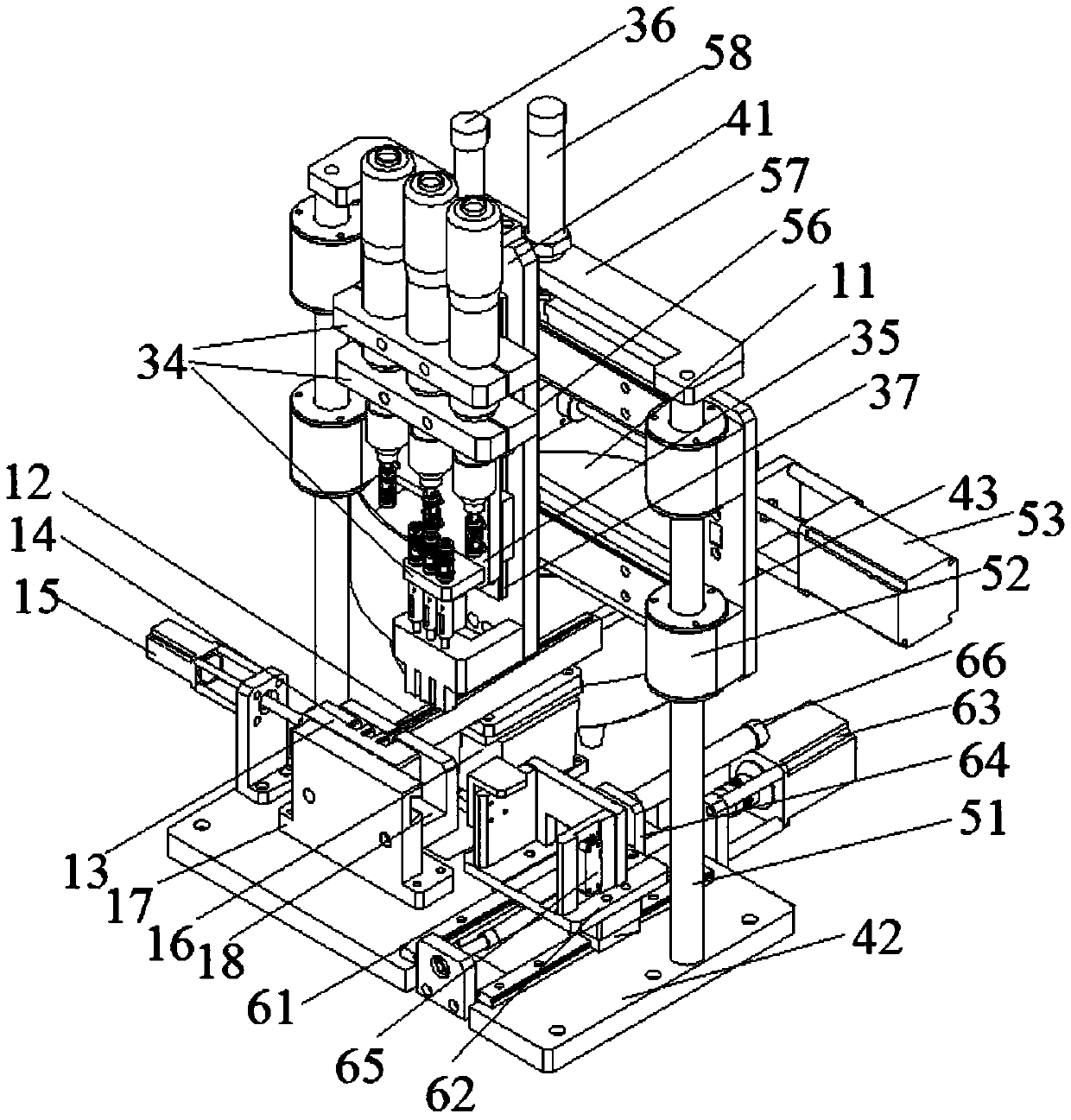

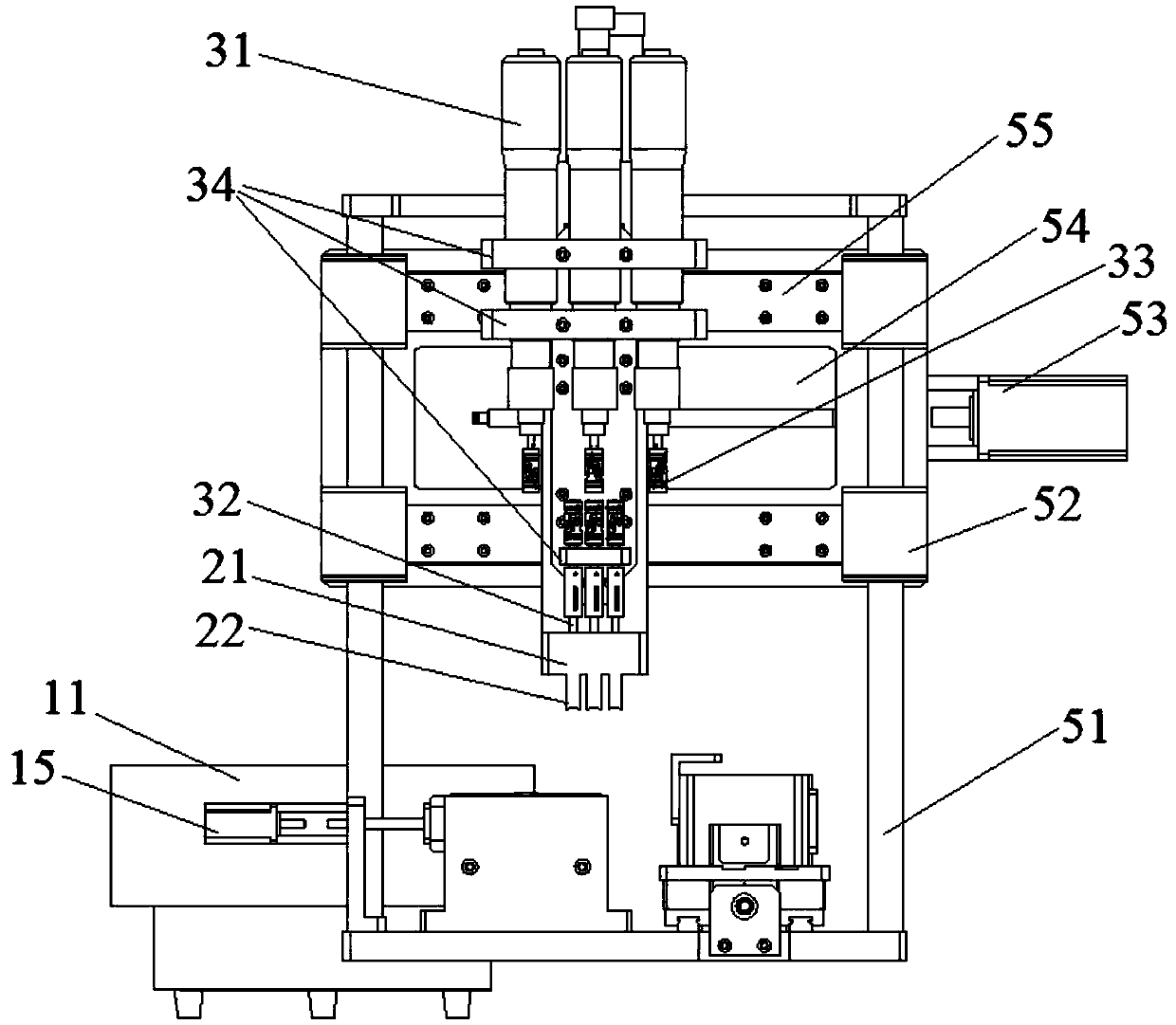

Automatic screw assembling device and method

PendingCN107855766ASave dispensing timeReduce total timeMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic screw assembling device. The automatic screw assembling device comprises a distributing mechanism and an assembling mechanism and further comprises a moving mechanism, wherein the distributing mechanism outputs screws regularly; the assembling mechanism comprises at least one execution unit which assemblies the screws onto a workpiece, the assembling mechanismfurther comprises a fetching unit which is connected with the execution units, and the fetching unit corresponds to the discharging end of the distributing mechanism; and the moving mechanism is connected with the assembling mechanism and drives the assembling mechanism to move between the fetching position and the assembling positions. According to the automatic screw assembling device of the structure, the fetching unit corresponds to the distributing mechanism and can fetch a plurality of screws at the same time, and the screws are hit into the assembling positions through the multiple execution units; and the fetching unit is arranged and can move under driving of the moving mechanism, so that the problem that the distributing mechanism and the assembling positions are not located in the same position is solved.

Owner:ZHEJIANG TENGEN ELECTRIC

Full-automatic cleaning type mopping machine for stairs

The invention relates to a full-automatic cleaning type mopping machine for stairs. The mopping machine comprises a vehicle body frame, a stairs climbing mechanism, a flat ground advancing mechanism and a cleaning mechanism, wherein the stairs climbing mechanism comprises four stairs climbing rods and a transmission device, the transmission device is used for synchronously driving the four stairsclimbing rods, and the four stairs climbing rods are arranged on four outer sides of the lower end of the vehicle body frame; the flat ground advancing mechanism comprises four walking wheels and twoflat ground advancing motors for driving two of the walking wheels; and the cleaning mechanism comprises a mechanical arm, a cleaning brushing head and two electric push rods, the two electric push rods are used for driving the mechanical arm to work, one end of the mechanical arm is mounted on the vehicle body frame, and the cleaning brushing head is mounted at the other end of the mechanical arm. The full-automatic cleaning type mopping machine simultaneously has a flat ground cleaning function and stairs climbing and cleaning functions, is suitable for the cleaning work of various corridorsand stairs, and a large quantity of manpower, material resources and financial resources are saved in the working process; and the mopping machine has good practical significance and promotional values.

Owner:LUOYANG INST OF SCI & TECH

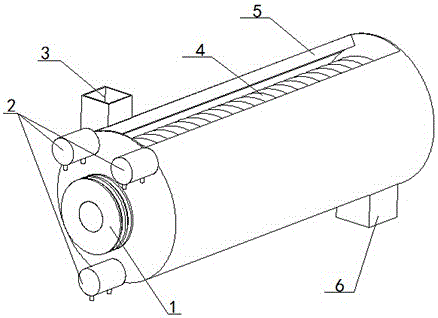

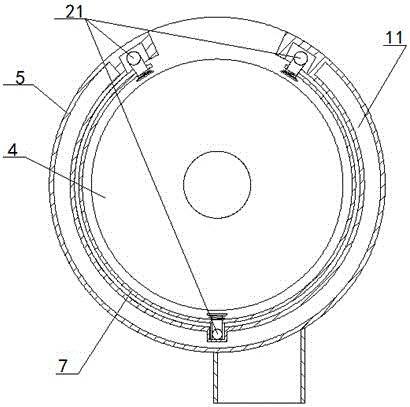

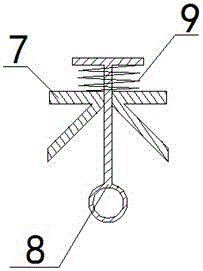

Novel fish meal dryer

InactiveCN105953565AEfficient removalAffect qualityDrying solid materialsHeating arrangementLinear motionHydraulic motor

The invention discloses a novel fish meal dryer and belongs to the field of machines. The novel fish meal dryer comprises a barrel, hydraulic motors, lead screws, loop bars and a scraper. According to the operating principle, steam is introduced into a barrel interlayer and a blade interlayer to dry fish meal. The scraper is in a circular arc shape in the positive direction and is closely attached to the inner wall of the barrel. The loop bars are used for connecting the scraper with the lead screws. The lead screws are driven by the hydraulic motors to rotate. The scraper does back and forth linear motion on the lead screws to achieve the function of automatically removing fish meal adhering to an inner barrel body. The novel fish meal dryer has the beneficial effects that the scraper can effectively remove fish meal adhering to the inner barrel body to prevent the fish meal left on the barrel from going smelly or moldy and affecting the quality and drying effect of subsequent products; and meanwhile, the novel fish meal dryer can play a role in assisting in stirring fish meal to increase the drying speed.

Owner:NANNING FUJIU INFORMATION TECH

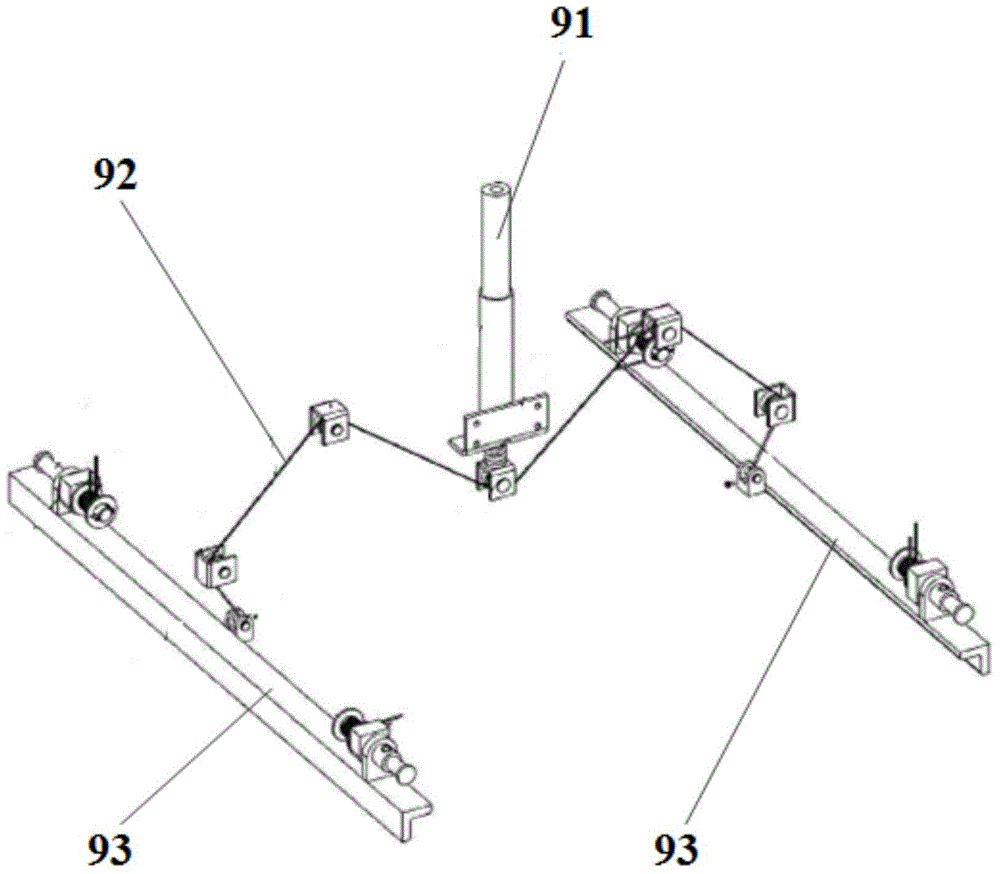

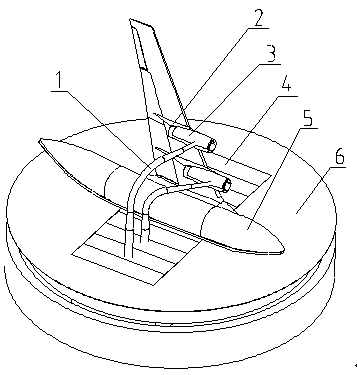

Separated half-mode injection type nacelle dynamic influence test method

InactiveCN110907125AReduce application difficultyAvoid layoutAerodynamic testingFlight vehicleNacelle

The invention discloses a separated half-mold injection type nacelle power influence test method. A semi-model of an aircraft is arranged on a tunnel wall turntable of a wind tunnel, an injection typenacelle is arranged at a nacelle hanger of a semi-model wing, the injection type nacelle is not in contact with the semi-model wing, and a gap between the injection type nacelle and the nacelle hanger is filled with a soft material; the injection type nacelle is arranged on the tunnel wall turntable through a support, the semi-model and the injection type nacelle are driven to rotate synchronously under rotation of the tunnel wall turntable, and the interference acting force of intake and exhaust of the injection type nacelle on an airplane is obtained. According to the scheme, the injectiontype nacelle and the air supply system thereof are separated and independent from the model; the injection type nacelle does not make contact with the model to transmit force, static thrust measurement of the injection type nacelle does not need to be conducted, the injection type nacelle and the semi-model are supported on the wind tunnel test section turntable together through the special movable supporting device, synchronous movement of the nacelle and the semi-model is achieved, and a complex movement and control mechanism does not need to be designed for the nacelle.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

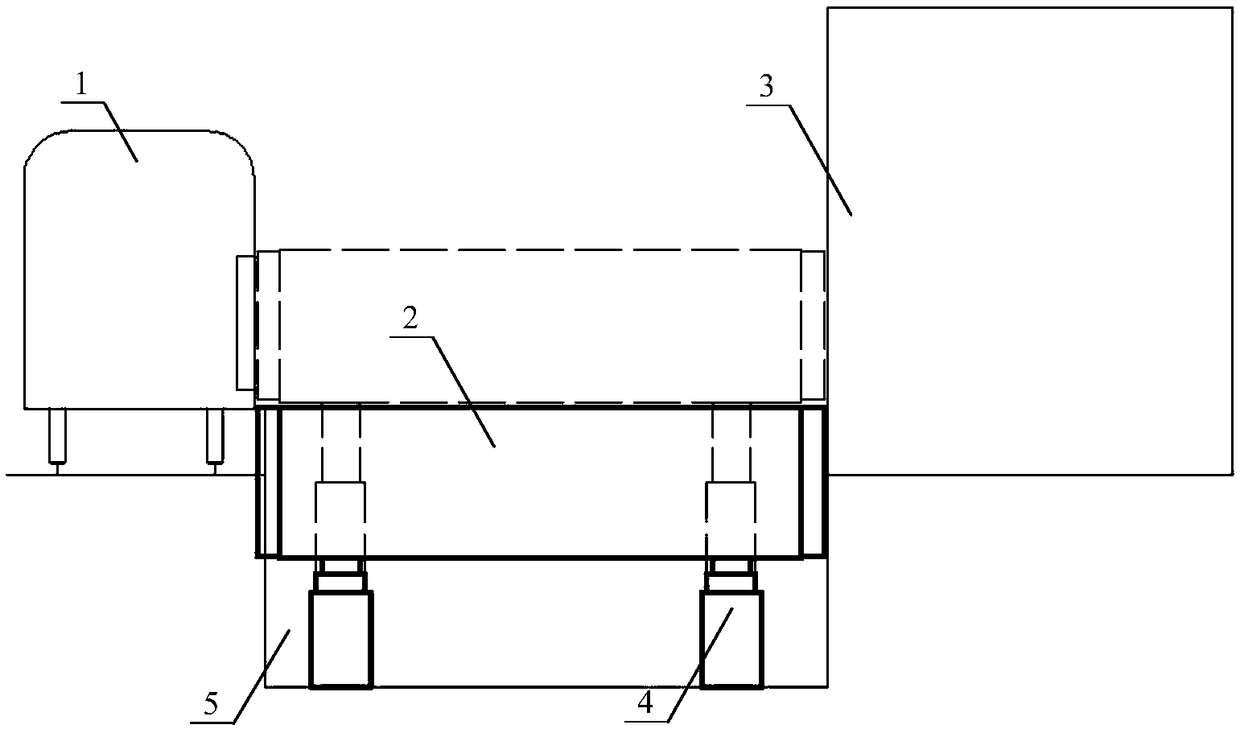

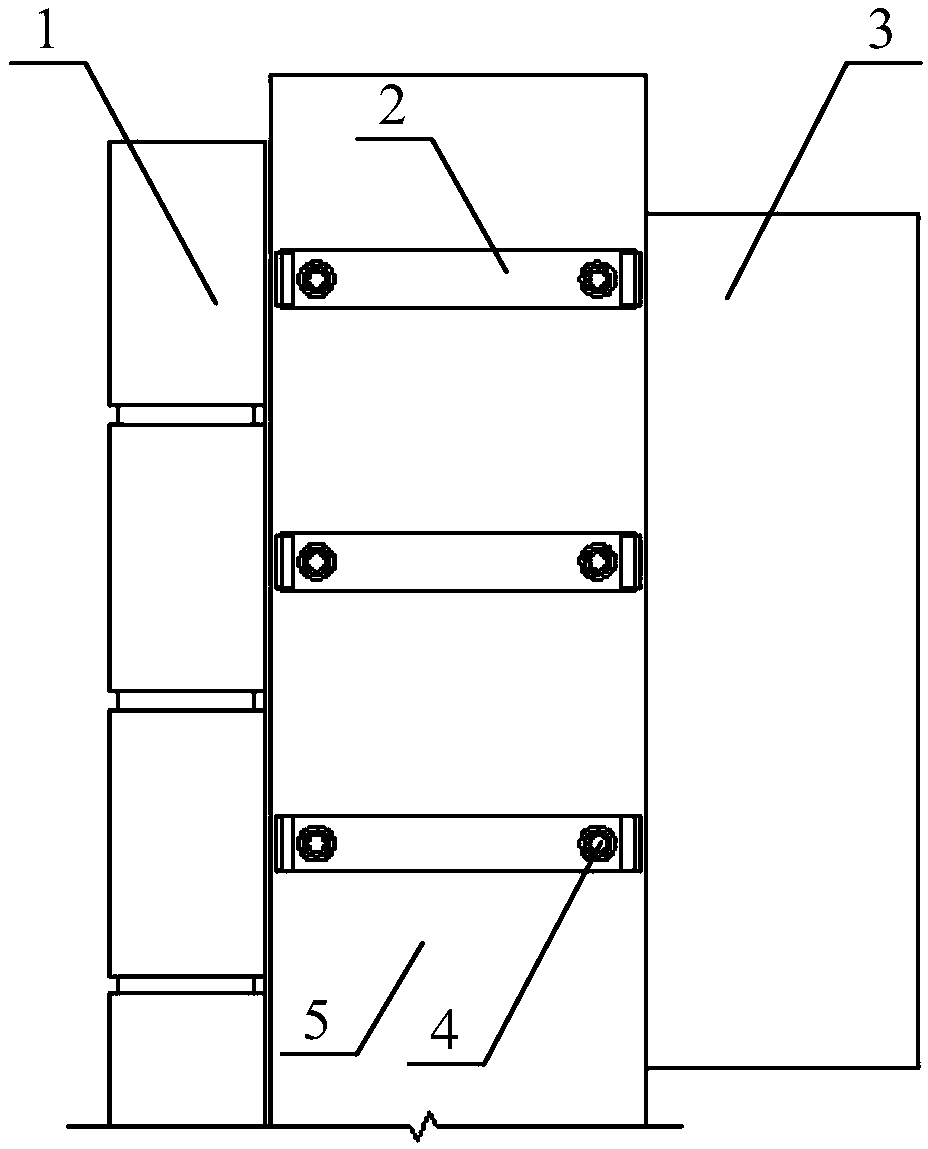

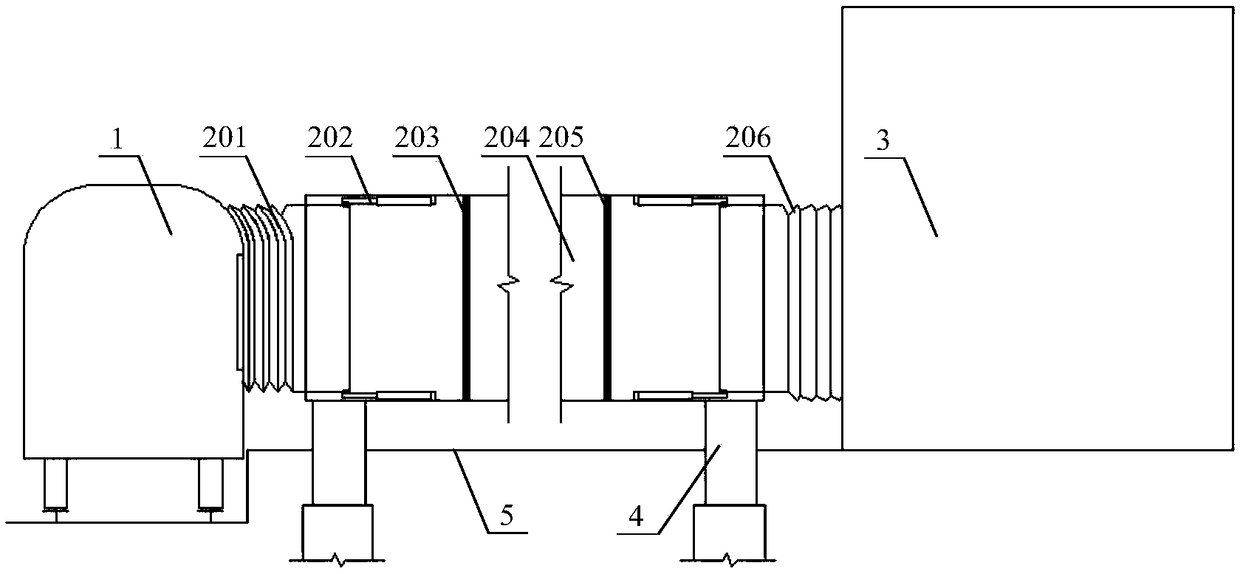

Railway platform cold chain lifting and docking system and method with heat preservation function

ActiveCN108891944AEasy to useSolve the problem of not being able to keep warmLoading/unloadingStorage devicesCold chainShortest distance

The invention discloses a railway platform cold chain lifting and lowering docking system with heat preservation function, comprises an arc-type elastic sealing ring, a hydraulic push rod, a first isolation door, an integral incubator, a second isolation door and a flat-type elastic sealing ring. The arc-type elastic sealing ring comprises an arc-type elastic sealing ring, a hydraulic push rod, afirst isolation door, an integral incubator, a second isolation door and a lifting support. The arc-shaped elastic sealing ring (201) is butted with the train (1), and the plane-shaped elastic sealingring (206) is butted with the refrigerator (3); an integral incubator (204) is formed between the first isolation door (203) and the second isolation door (205). The invention also discloses a railway platform cold chain lifting and lowering butt joint heat preservation method. The railway platform cold chain lifting and lowering docking system with heat preservation function of the invention establishes a sealed heat preservation channel between the train and the cold storage, and carries out heat preservation transportation on the goods before entering the storage or after leaving the storage, and solves the problem that the goods cannot carry out heat preservation in the short-distance transportation process.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

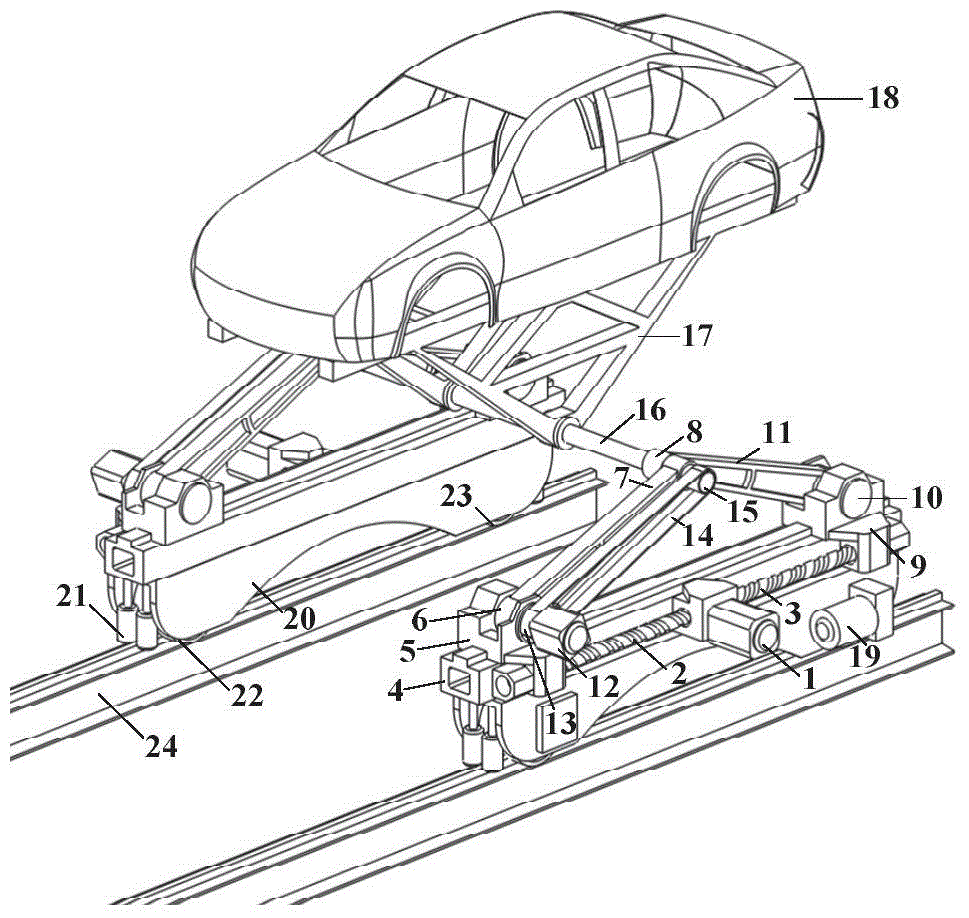

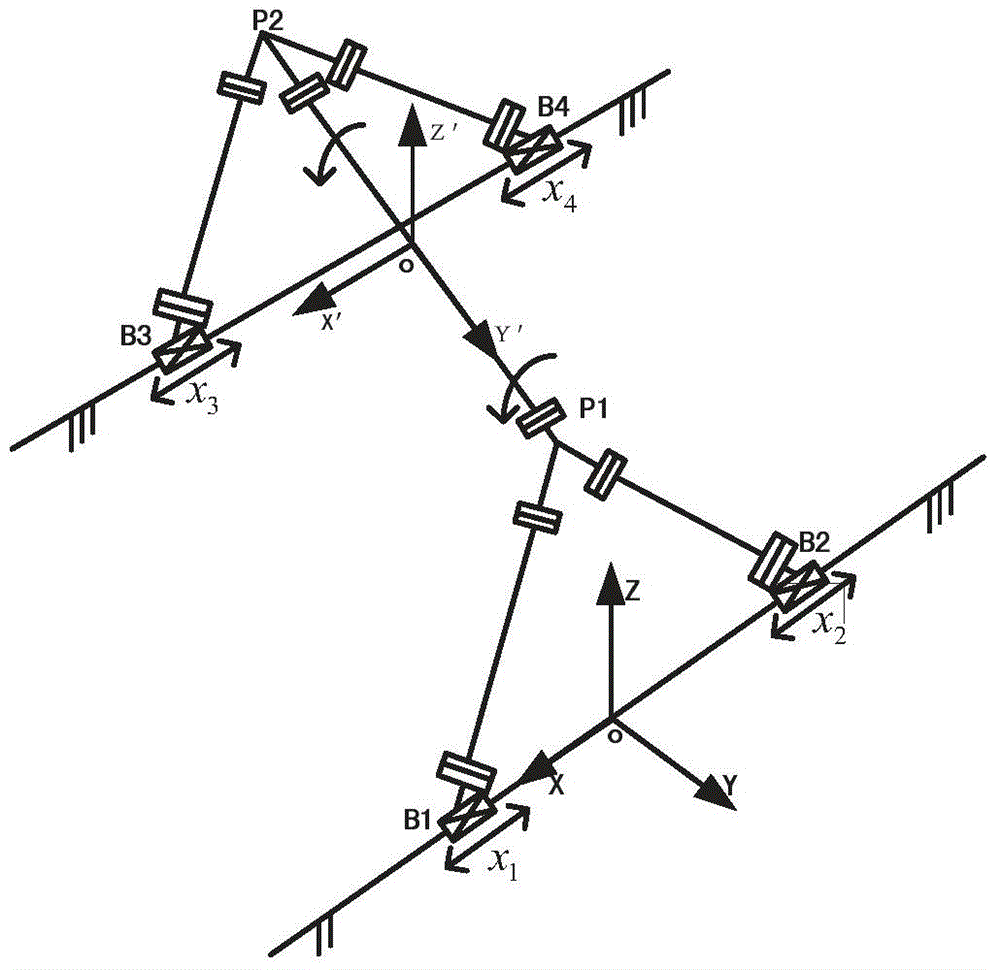

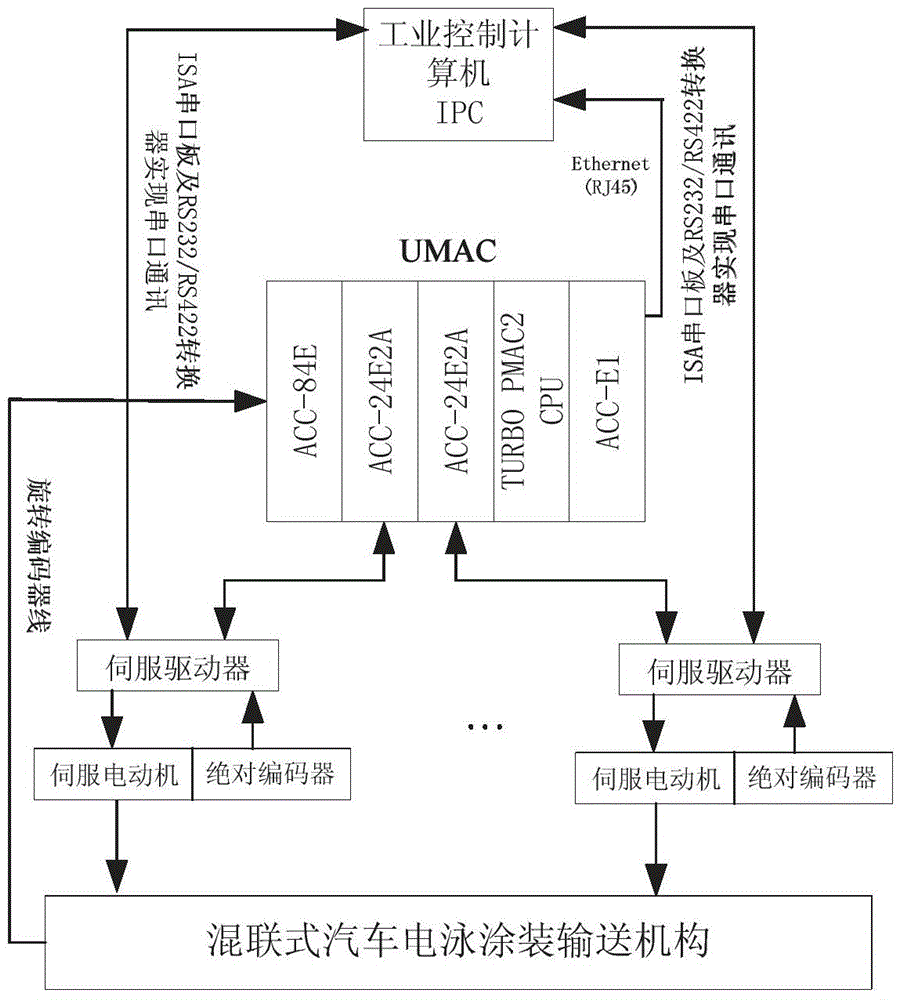

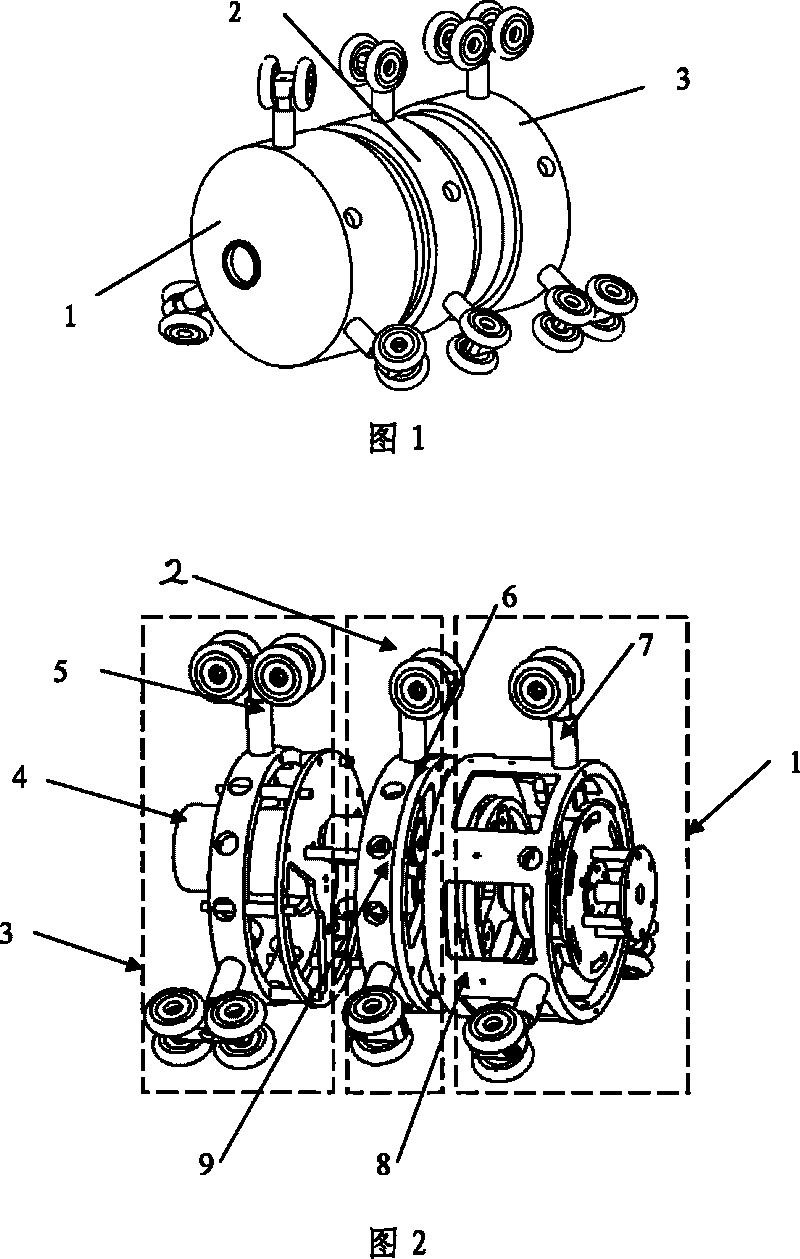

Synchronous coordinated control method of series-parallel automobile electrophoretic painting conveying mechanism

InactiveCN104651909AAchieving Synchronized Coordinated Motion ControlFully consider the dynamic characteristicsElectrophoretic coatingsSliding mode controlMovement control

The invention discloses a synchronous coordinated control method of a series-parallel automobile electrophoretic painting conveying mechanism. The method comprises the following steps: taking the series-parallel automobile electrophoretic painting conveying mechanism as a controlled object, building a kinetic model of the conveying mechanism in a cartesian space, adopting a distributed structure to build a synchronous coordinated control hardware system of the conveying mechanism according to a control requirement of the conveying mechanism, and providing a novel synchronous error according to the structure characteristic and movement characteristic of the lifting turnover mechanism of the conveying mechanism, combining the novel synchronous error with a sliding-mode control, further designing a kinetic synchronous coordinated control rule based on the sliding-mode control, and finally performing software programming through VC++ to realize the synchronous coordinated control of the series-parallel automobile electrophoretic painting conveying mechanism. By adopting the synchronous coordinated control method, the system is high in tracking accuracy and high in response speed; the synchronization of each joint and two side mechanisms can be realized so that the synchronous coordinated motion control performance of the conveying mechanism is improved.

Owner:JIANGSU UNIV

Self-adapting pipe moving mechanism

The invention provides a self-adaptive pipeline moving mechanism, which belongs to the technical field of pipeline robot engineering. The structure of the mechanism comprises a supporting mechanism, a forward drive mechanism and a backward drive mechanism, wherein the forward drive mechanism is connected with the backward drive mechanism through a first transmission mechanism, and is connected with a motor in the supporting mechanism through a second transmission mechanism; the first transmission mechanism is arranged in the forward drive mechanism; and a link mechanism and a locking mechanism are arranged between the forward drive mechanism and the first transmission mechanism. The mechanism can automatically regulate forward and backward in the pipeline without external control. In the invention, when a forward drive arm is contracted because of a barrier, other forward drive arms are also contracted to the center through linkage of the link mechanism, thereby realizing synchronous motion of the drive arms. Meanwhile, the locking mechanism restricts the rotation of the forward drive arms, at this time the route of power output is converted, and backward drive arms rotate and generate backward driving force, namely a robot moves towards an opposite direction. The moving mechanism has strong adaptability.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

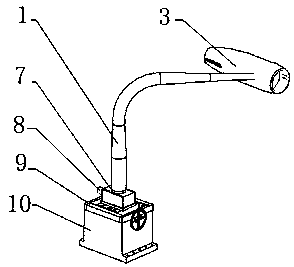

Automatic following control system for machine tool

ActiveCN104708489ARealize synchronized motionGuaranteed cooling effectMeasurement/indication equipmentsMetal working apparatusCold airRobotic arm

The invention discloses an automatic following control system for a machine tool. The system comprises a cooling device, a mechanical arm, a controller and a detecting device for detecting the position of a machining tool, wherein a cold air spray head of the cooling device is fixed to the mechanical arm, the detecting device comprises a camera, the signal output end of the camera is connected to the controller, and the controller is connected to the mechanical arm to be used for image recognition and controlling the mechanical arm to enable the relative positions of the cold air spray head and the machining tool to be unchanged. According to the system, the position of the cold air spray head can be controlled according to the position of the machining tool, synchronous movement of the spray head and the machining tool is achieved, and cooling effect is guaranteed.

Owner:CHONGQING JIAOTONG UNIVERSITY

Slag cleaning plant for flame cutting machine

InactiveCN107309525ARealize synchronized motionSimple structureGas flame welding apparatusPipetteSlag

The invention specifically relates to a slag cleaning device for a flame cutting machine, comprising a slag blowing gun head connected to a cutting torch head guide rail of a flame cutting machine through a fixed bracket, the slag blowing torch head can move synchronously with the cutting torch head, The purge surface of the slag blowing torch head is perpendicular to the cutting surface of the cutting torch head, and the slag blowing torch head is supplied by the air inlet pipe passing through the torch head bracket to blow the slag away from the surface of the cutting material, including The slag collection device can collect the slag blown away from the cutting surface. In the slag cleaning device of the flame cutting machine of the present invention, the slag blowing gun head is connected with the cutting torch head guide rail of the flame cutting machine through a fixed bracket, thereby realizing the synchronous movement of the slag blowing torch head and the cutting torch head; The slag blowing gun head is designed with a separate moving mechanism, which simplifies the structure and ensures the accurate position of the blowing slag. A slag collection device specially designed to collect slag avoids slag splashing and burns the operator, which is safer.

Owner:西安珀尔电子科技有限公司

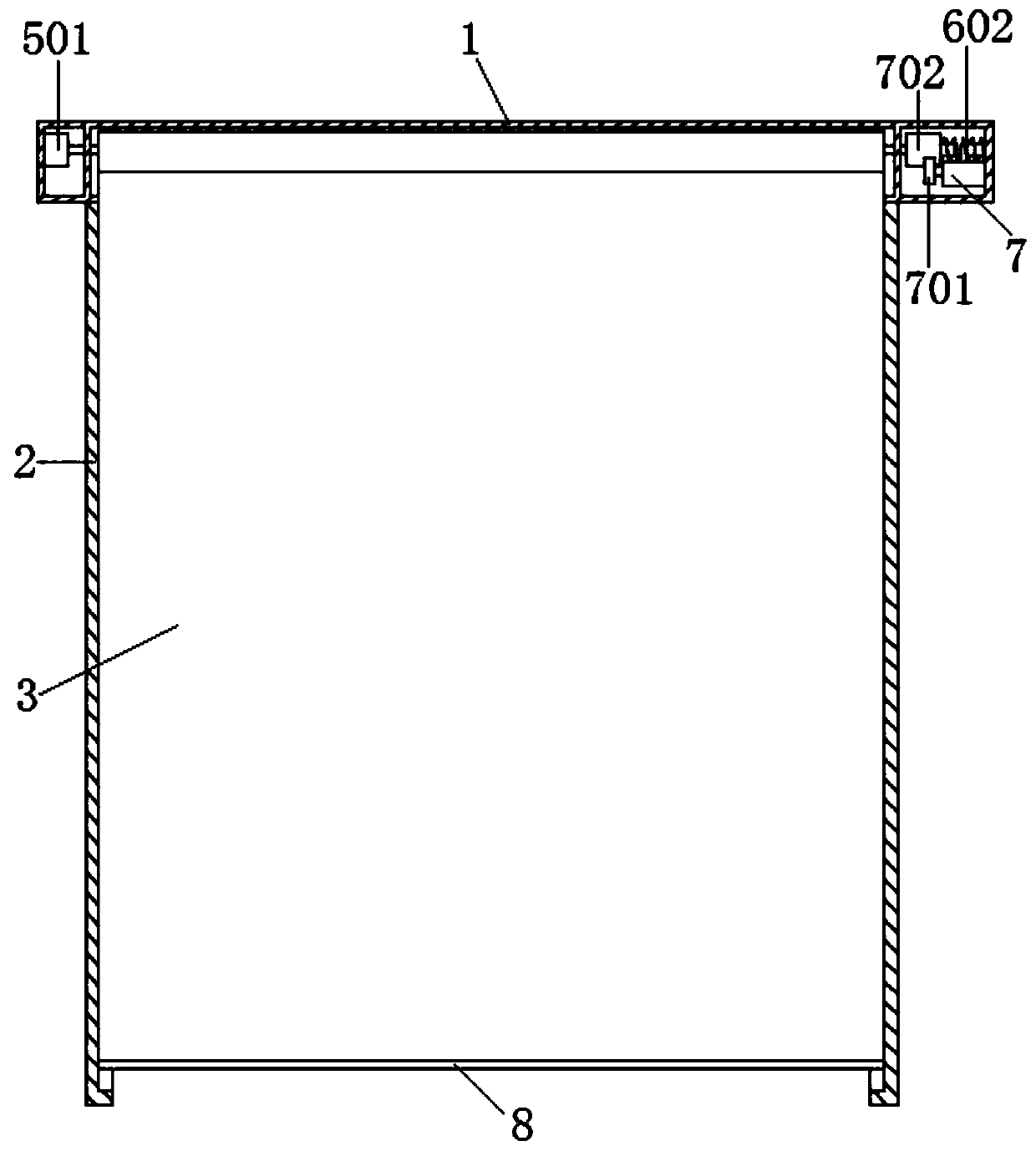

Door and window roller shutter structure for smart home of security engineering

InactiveCN109882058AMeet the needs of useEasy to useLight protection screensSecurity engineeringEngineering

The invention discloses a door and window roller shutter structure for smart home of security engineering, and relates to the technical field of home doors and windows. The door and window roller shutter structure comprises a roller shutter top box, a pair of roller shutter side frames, a sunshade curtain cloth and a shading curtain cloth; a first separating board and a second separating board arearranged in the roller shutter top box in parallel; the interior of the roller shutter top box is separated into a first cavity, a second cavity and a third cavity by the first separating board and the second separating board; a pair of roller shutter feeding and discharging ports are formed in the surface of the second cavity in parallel; a pair of roller shutter rotating shafts are arranged inthe second cavity in parallel; the two roller shutter side frames are symmetrically fixed to the surface of the lower part of the roller shutter top box correspondingly; and the two roller shutter rotating shafts is wound with the sunshade curtain cloth and the shading curtain cloth on separately and correspondingly, and one side edge of the sunshade curtain cloth and one side edge of the shadingcurtain cloth penetrate through the two roller shutter feeding and discharging ports in sequence separately and correspondingly. According to the door and window roller shutter structure for the smarthome of security engineering, the sunshade curtain cloth and the shading curtain cloth are arranged in a matched mode, a shading or sunshade effect can be realized, use requirements of current usersare met, and high market population value is achieved.

Owner:JIESHOU XUNLIDA ELEVATOR CO LTD

Material transportation and transferring structure

PendingCN111994612AFully automatedReduce security risksConveyorsConveyor partsMechanical engineeringIndustrial engineering

The invention belongs to the technical field of transportation machinery, and particularly relates to a material transportation and transferring structure for shaft type materials or column type materials. The structure comprises a rack; a first transportation unit which is used for delivering the shaft type materials is arranged on the rack; a material delivering trolley is arranged on the firsttransportation unit and moves synchronously with the first transportation unit; a transferring unit is arranged at the downstream end of the first transportation unit; the transferring unit comprisesa transferring falcula; the transferring falcula sways under the action of a falcula driving unit and is positioned at a material receiving station in an upper position status or at a material fallingstation in a lower position status; a swaying end of the transferring falcula is in a hook shape and is used for restraining the shaft type materials; the transferring unit further comprises a material falling platform which is used for placing the shaft type materials; and the material falling platform is positioned at the material falling station of the transferring falcula and the height of amaterial receiving position of the material falling platform is higher than the height of the material falling station of the transferring falcular. Automatic transportation and transferring of the shaft type materials are realized, the safety risk is lowered, and the production efficiency is improved at the same time.

Owner:灵璧久工精密钢管制造有限公司

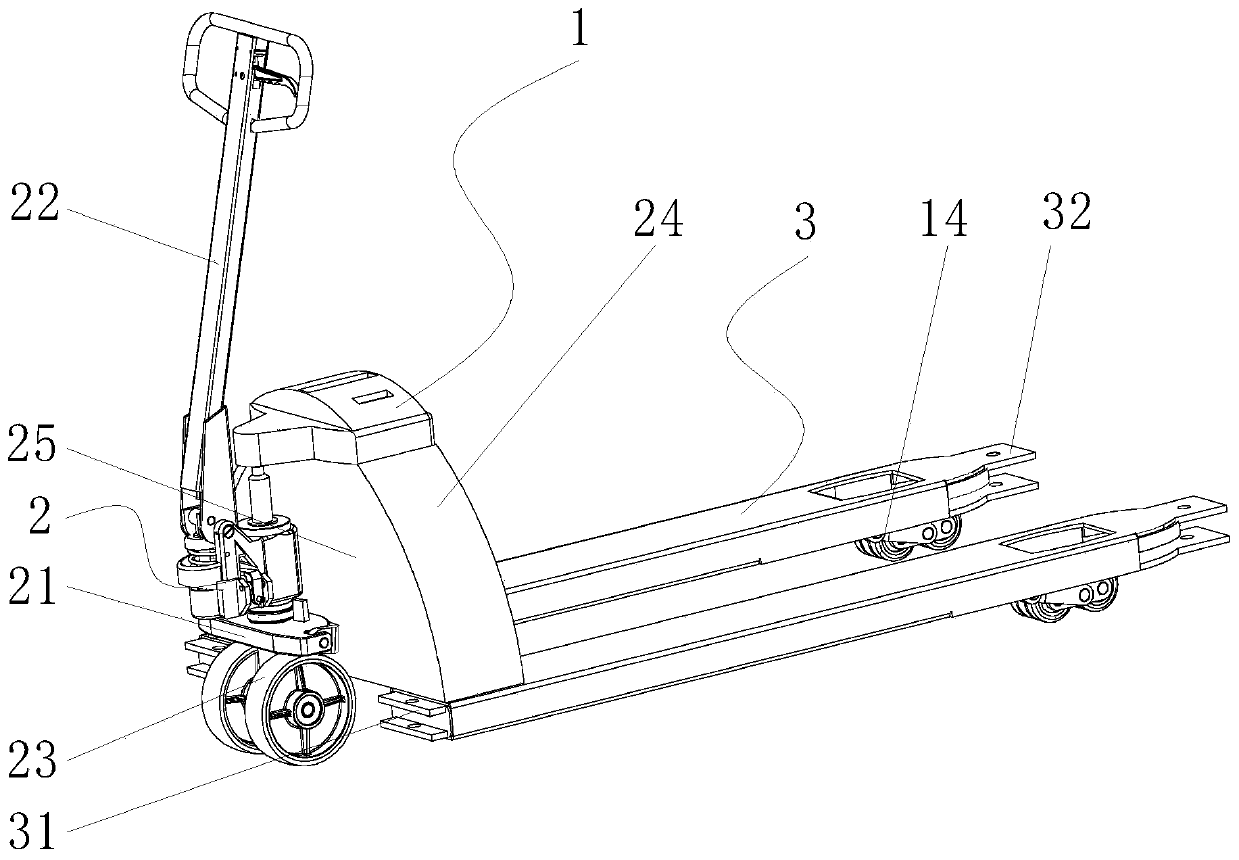

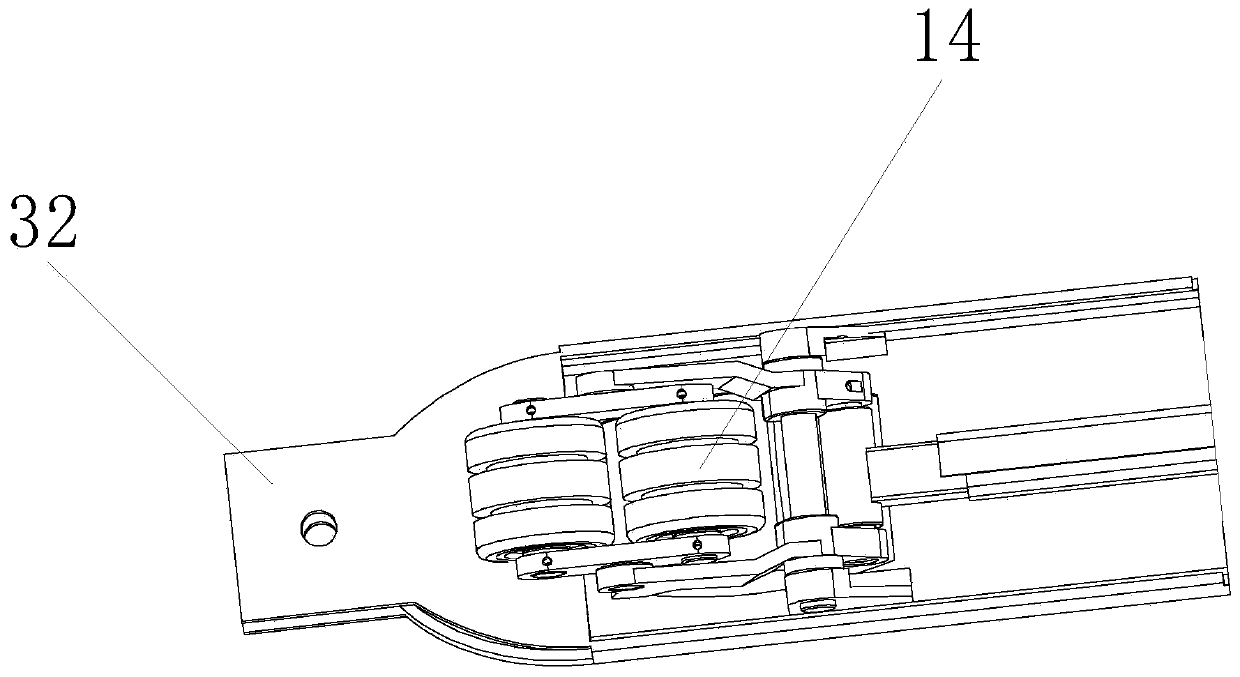

Hybrid electric tray forklift and movement method thereof

In order to solve the problem that different types of forklifts need to be frequently replaced for carrying cargoes with different sizes and different weights in the prior art, the invention providesa hybrid electric tray forklift and a movement method thereof, and belongs to the technical field of electric tray forklifts. The hybrid electric tray forklift comprises multiple electric tray forklift bodies connected mutually, wherein each electric tray forklift body comprises a frame and a fork; the frames comprise bearing bridges, handle mechanisms rotatably connected onto the bearing bridgesthrough rotary shafts, drive wheels controlled through the handle mechanisms so as to steer, forklift backs fixedly connected onto the frames and electric drive devices fixedly arranged in the forklift backs; and the forks comprise fork tail parts fixedly connected with the forklift backs and fork head parts provided with driven wheels. The hybrid electric tray forklift has the advantages that theequipment cost is greatly reduced, the labor intensity is reduced, the carrying efficiency is further improved at the same time, each forklift body can move independently, the forklift flexibility isensured, and the carrying and loading capacities are further improved.

Owner:JINHUA WINNER MECHANICAL&ELECTRICAL CO LTD ZHEJIANG

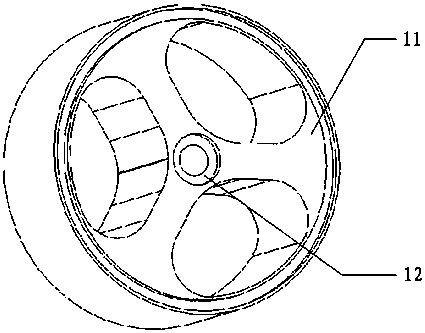

Tire dismounting machine

The invention relates to a tire dismounting machine. The tire dismounting machine comprises a base, a rack which is vertically fixed on the base, an auxiliary tire pressing device arranged at the upper end of the rack, a slide frame which slidingly sleeves the rack, a tire fixing device which is arranged on the base, and a tire pressing device and a tire dismounting device which are arranged on the slide frame in sequence from bottom to top, wherein the tire fixing device comprises a rotary table and tire fixing claws arranged on the upper end face of the rotary table; the tire fixing device is further provided with a fixing claw synchronizer; the fixing claw synchronizer comprises a synchronizing disc arranged in the middle of the rotary table and a plurality of linkage rods; one end of each of the plurality of linkage rods is hinged to the corresponding tire fixing claw and the other end of each of the plurality of linkage rods is hinged to the synchronizing disc at interval; and each linkage rod and the corresponding tire fixing claw are inclined to form a certain angle in the retracting direction of the tire fixing claw.

Owner:浙江科炬源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com