Automatic lateral sponge supporting synchronous operation device

A synchronous operation and automatic technology, applied in the direction of metal processing, etc., can solve the problems of reducing cutting accuracy, affecting cutting accuracy, slippage of sponge and conveyor belt, etc., and achieving the effect of avoiding the reduction of cutting accuracy and having strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

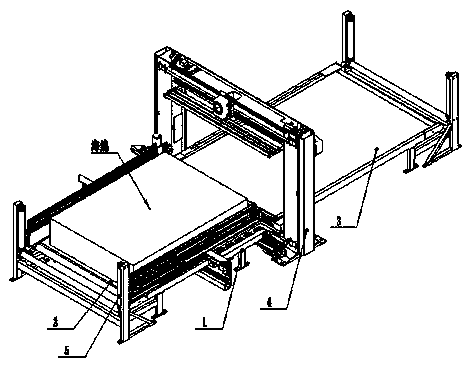

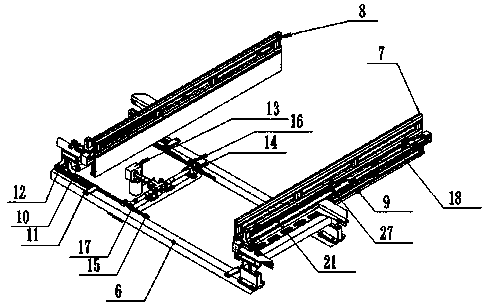

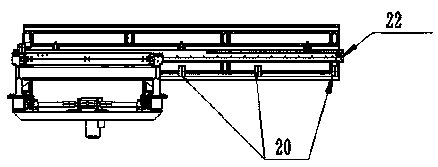

[0023] Such as Figure 1-Figure 5 Shown is an automatic lateral cotton-supporting synchronous operation device, the automatic lateral cotton-supporting synchronous operation device is installed on a sponge cutting machine, and the sponge cutting machine includes a conveying bracket 1, and a feed conveyor belt 2 is installed on the conveying bracket 1 , the discharge conveyor belt 3, and the feed conveyor belt 2 and the discharge conveyor belt 3 are driven by their respective drive motors to work, and the feed conveyor belt 2 and the discharge conveyor belt 3 are located on the conveyor bracket 1 A pair of vertically arranged guide rollers 5 are all set at the outlets of the outlets, and a gantry 4 is also arranged between the feed conveyor belt 2 and the discharge conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com