Patents

Literature

1265results about How to "Guaranteed fit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

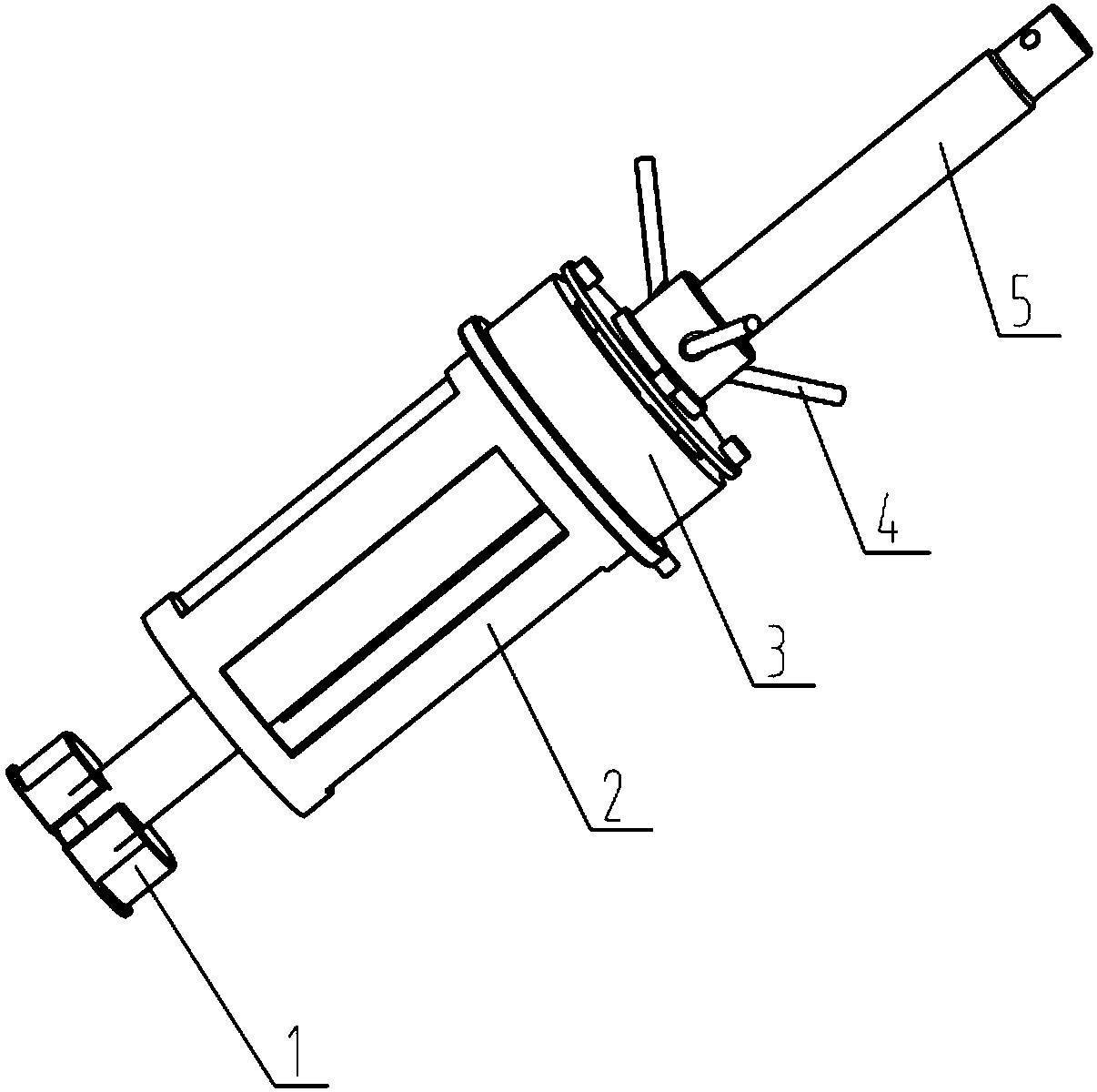

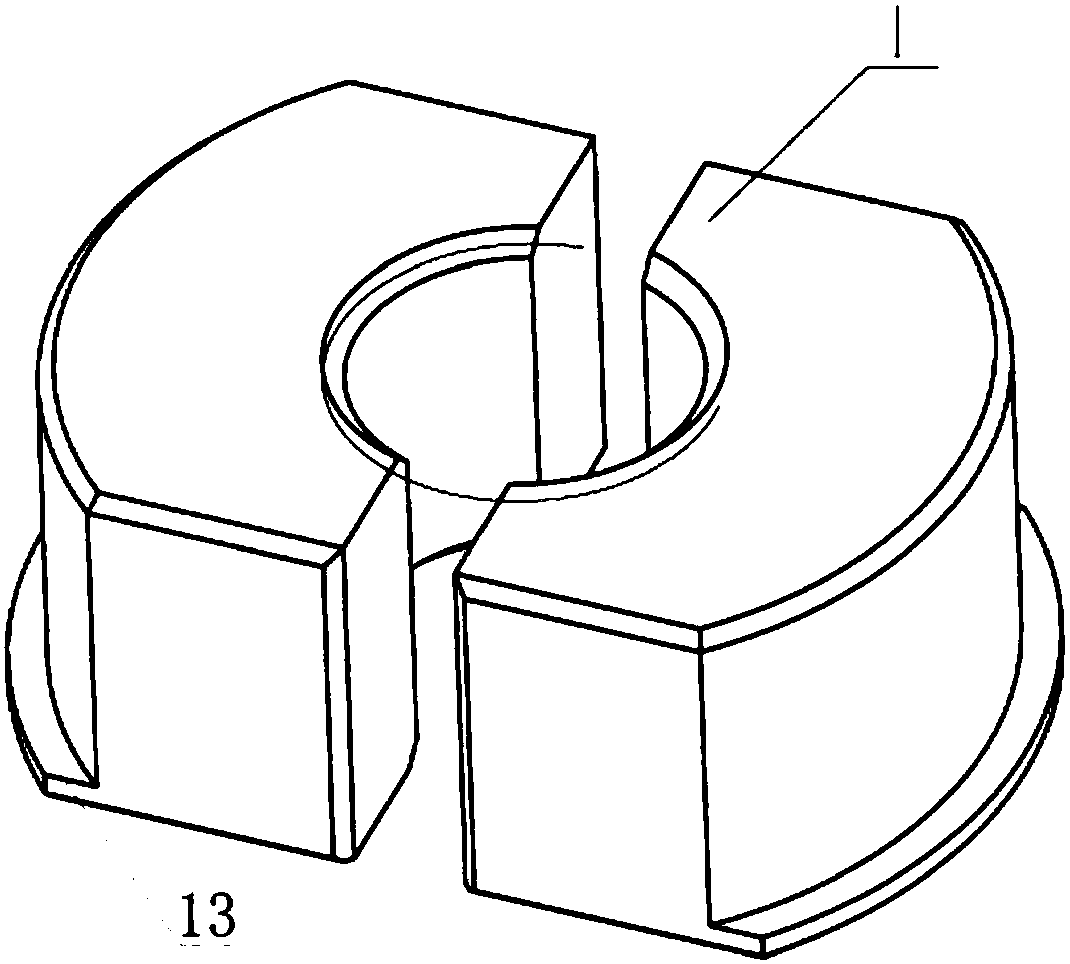

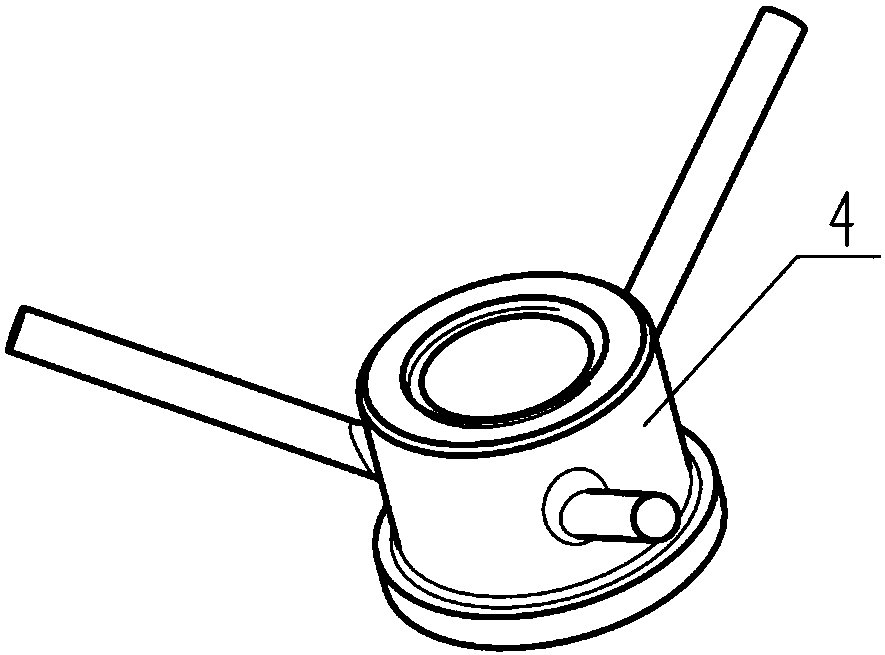

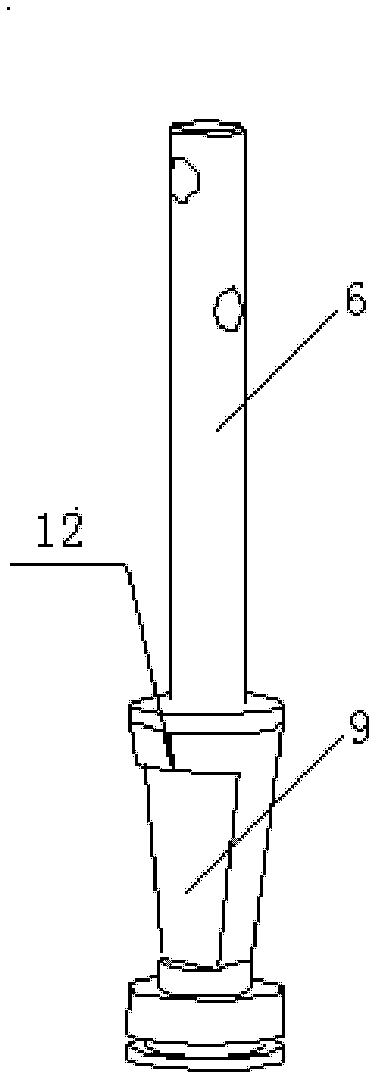

Thin-wall sliding sleeve disassembling fixture

PendingCN108555826AEasy loadingGuaranteed fitMetal-working hand toolsEngineeringMechanical engineering

The invention provides a thin-wall sliding sleeve disassembling fixture. The thin-wall sliding sleeve disassembling fixture comprises a puller nut and a puller screw. The puller screw is in threaded connection with the puller nut. One end of the puller screw is provided with a clamping jaw. The puller screw is in threaded connection with the clamping jaw. A bracket and a hydraulic system are installed between the puller nut and the clamping jaw. The bracket and the hydraulic system are sheathed on the puller screw. The bracket is adjacent to the clamping jaw. The hydraulic system is adjacent to the puller nut. Through controlling the hydraulic system to boost pressure and reduce pressure, the disassembly of a thin-wall sliding sleeve can be realized. The thin-wall sliding sleeve disassembling fixture is small in volume, light in weight, smooth and steady in movement, and safe and convenient in operation, and capable of preventing the deformation of the thin-wall sliding sleeve and thescratching of a hole wall in an disassembling process.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

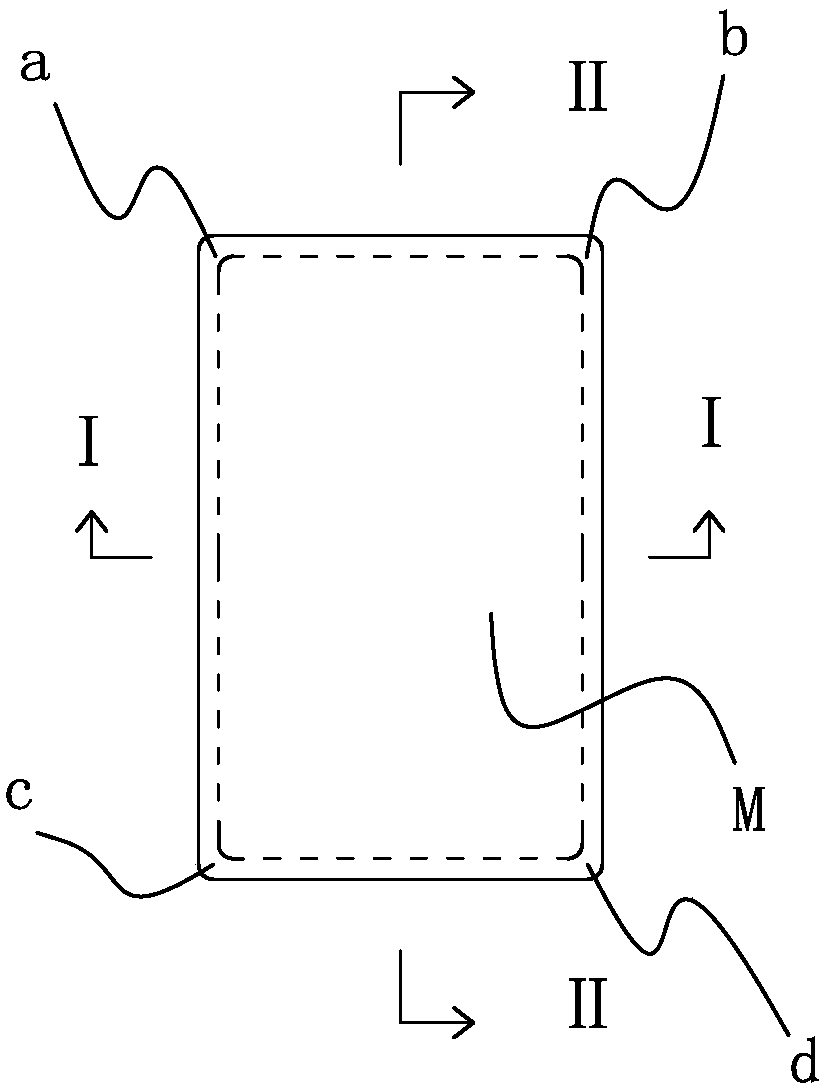

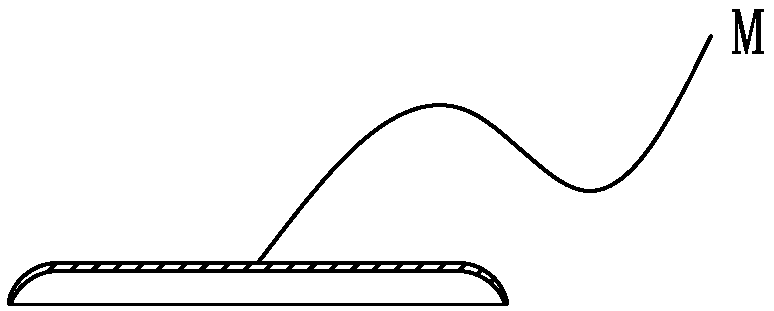

Laminating method of special-shaped curved surface cover plate and flexible screen

The invention relates to a laminating method of a special-shaped curved surface cover plate and a flexible screen. The method comprises the following steps: sticking the back side of the flexible screen onto the surface of a laminating device via a visbreaking film, so that an initial assembly is obtained; sticking a laminating adhesive layer to the front side of the flexible screen or the inner side of the special-shaped curved surface cover plate; translating the initial assembly into the special-shaped curved surface cover plate, and operating the laminating device so that a straight area of the special-shaped curved surface cover plate at least partially fits to the flexible screen; and conducting a visbreaking operation on the visbreaking film, and operating the laminating device to stick rest part of the flexible screen to the inner side of the special-shaped curved surface cover plate. According to the laminating method, the flexible screen is stuck onto the laminating device via the visbreaking film, and the visbreaking operation after the flexible screen is at least partially laminated with the straight area of the special-formed curved surface cover plate, so that the flexible screen can slide relative to the laminating device; therefore, full laminating of the flexible screen, in particular an arc-hook area, is guaranteed, and interference with the arc-hook area is prevented.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

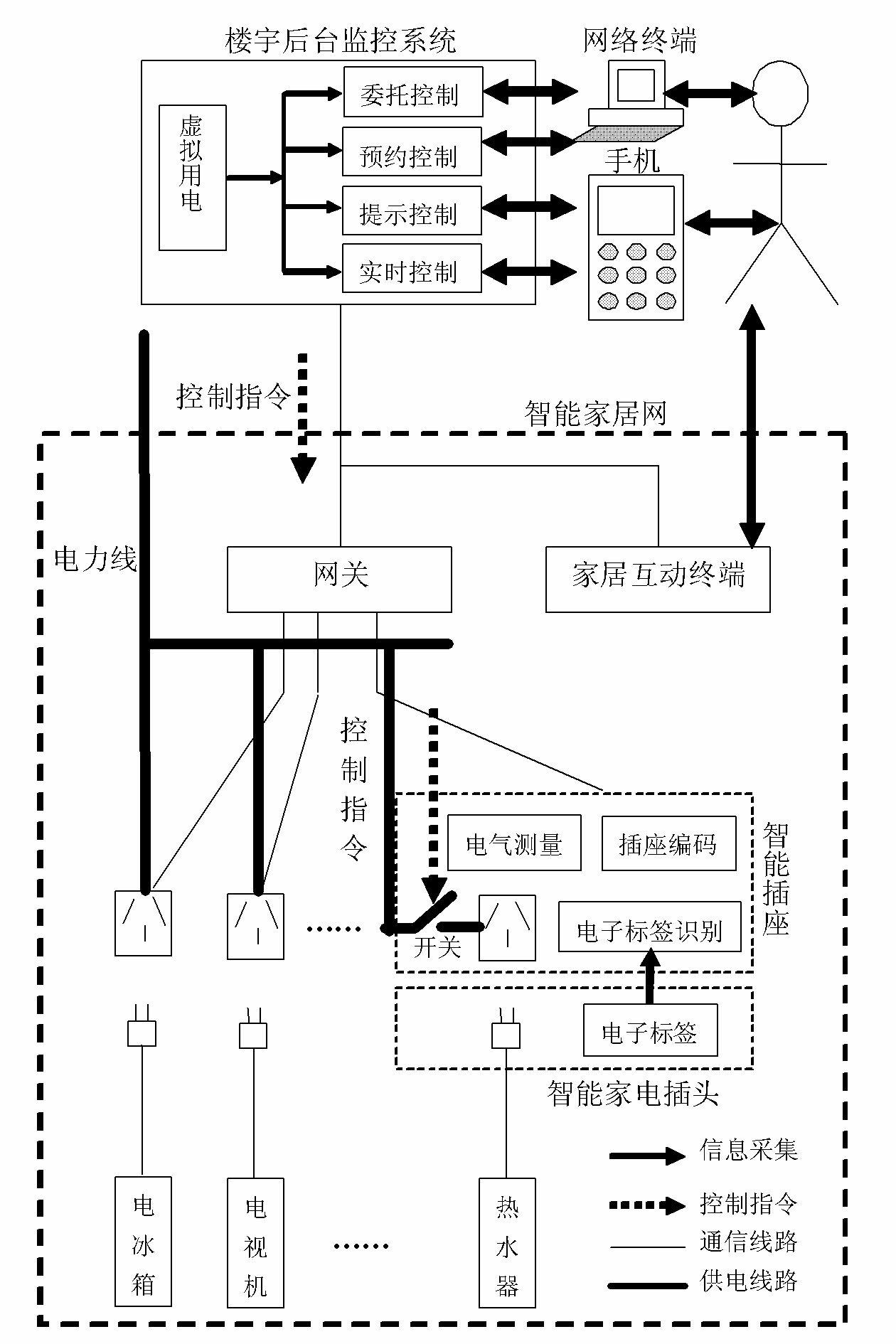

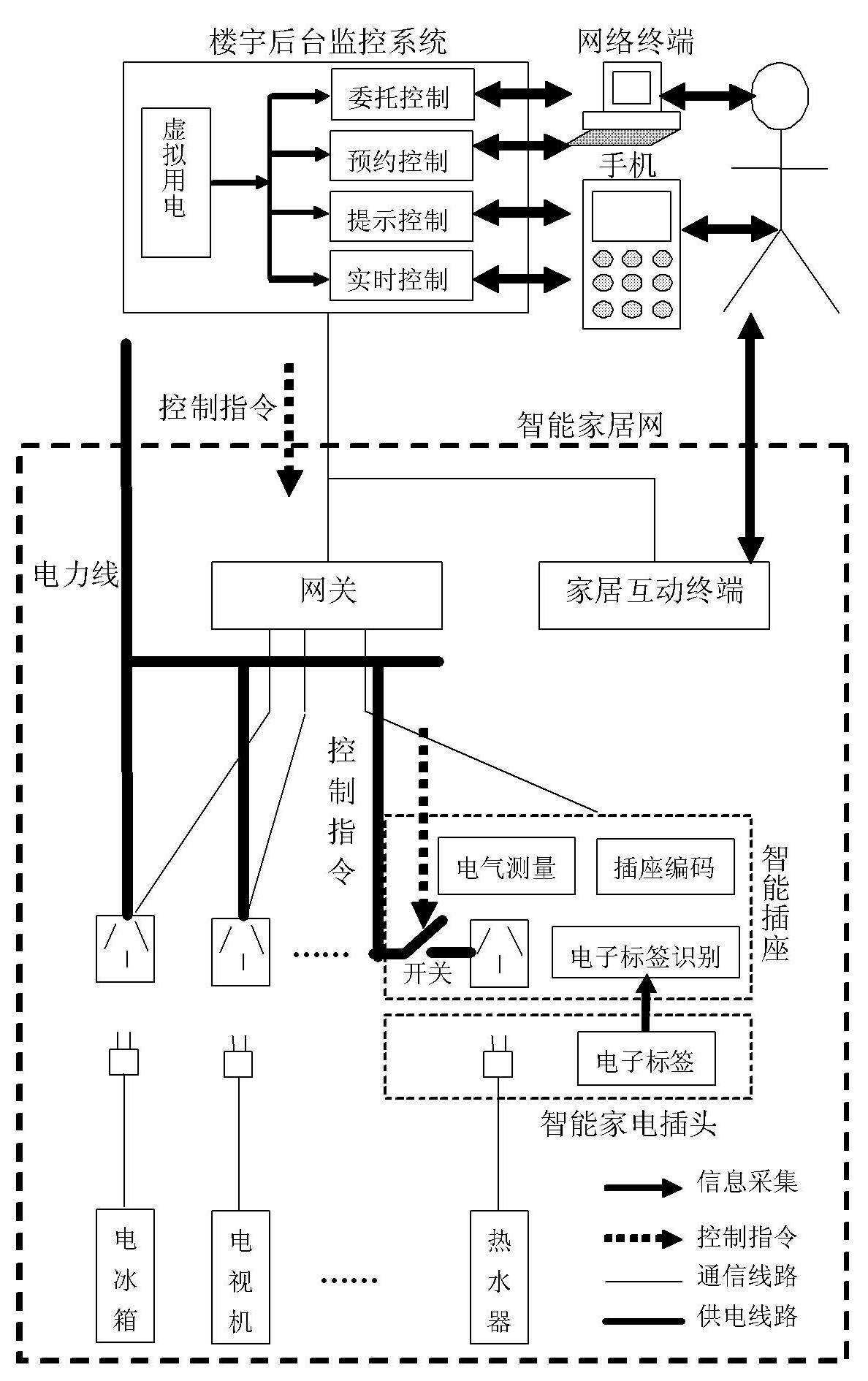

Networked intelligent household electricity optimizing control method

ActiveCN102193550AAvoid unrulyMeet different kinds of control needsProgramme total factory controlAutomatic controlControl mode

The invention relates to a networked intelligent household electricity optimizing control method, and the situation that the user can learn about the panoramic information of household electricity states through a household terminal or in a remote mode implemented through a network terminal and a cell phone is realized, meanwhile, the method has a point-to-point optimizing control capacity. Because a user-defined electricity utilization scheme and a 'virtual electricity utilization' validation method are adopted, the pertinence between the control method and user demands can be ensured, and the occurrence of control actions violating life logics and life habits can be avoided. In addition, through using the combination of a delegate control mode, a scheduled control mode, a prompted control mode and a real-time control mode, a flexible choice is provided for satisfying different control needs of the users, and because of using the flexible combination of the modes, the situation that the full-automatic control mode is hard to master and unable to cope with rigid molds with different needs can be avoided.

Owner:BEIJING XJ ELECTRIC +1

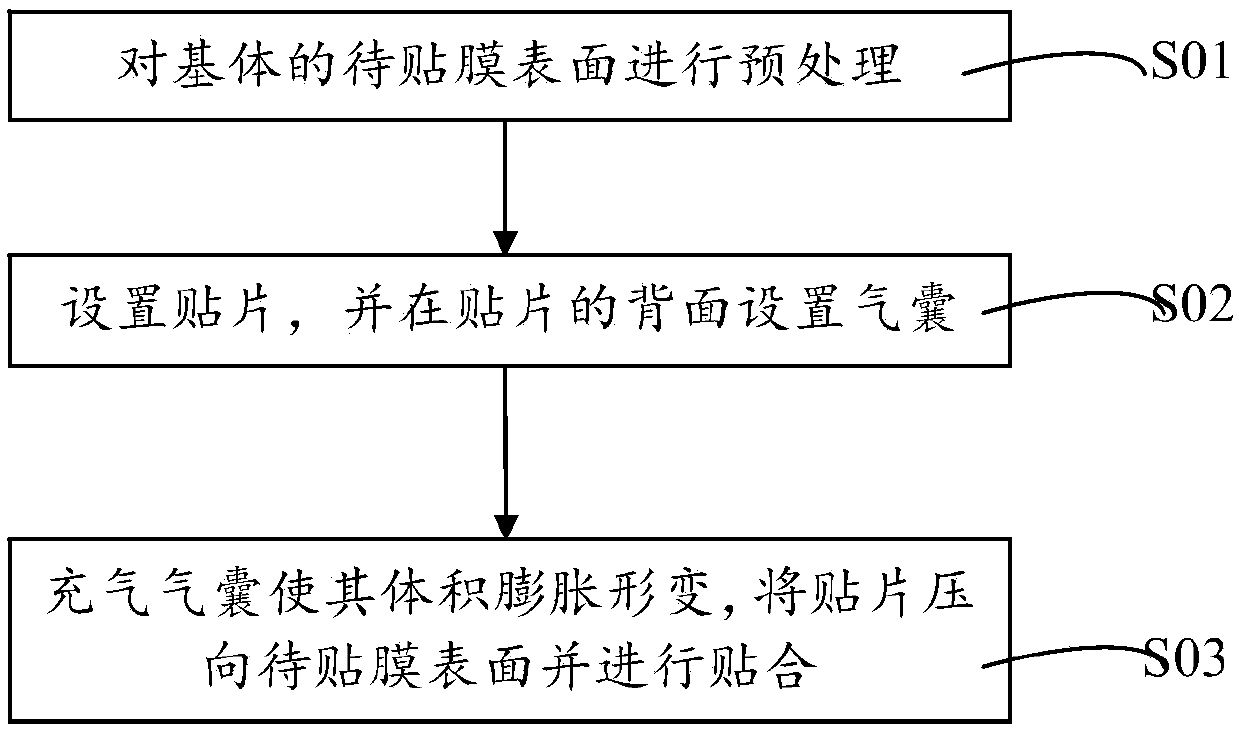

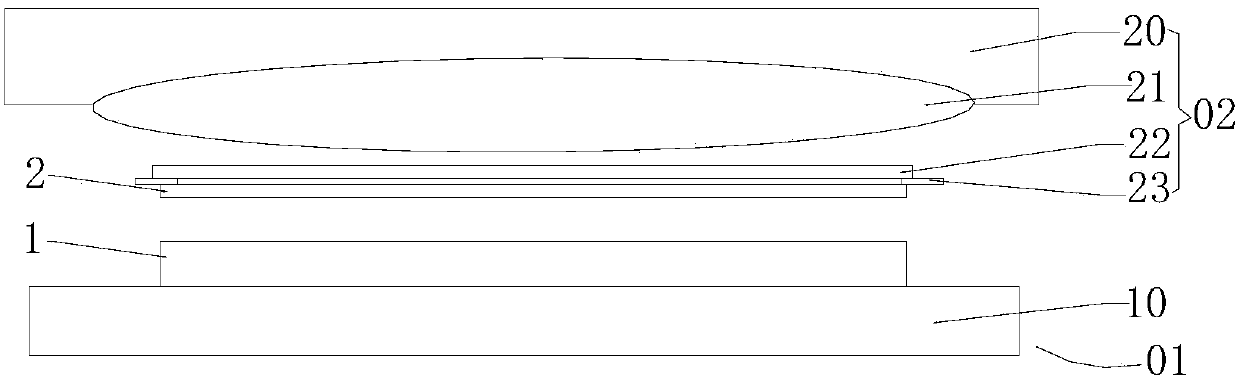

Film sticking method and equipment

ActiveCN107934018AEven by forceEffective fitPackagingVolume expansionElectrical and Electronics engineering

Owner:SHENZHEN WEIHONGKE TECH

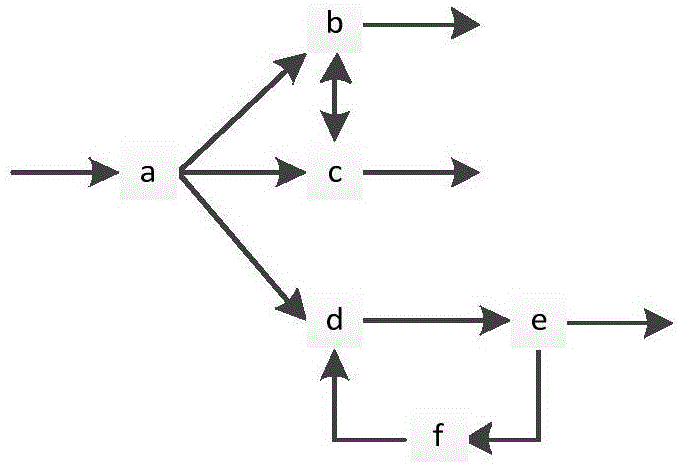

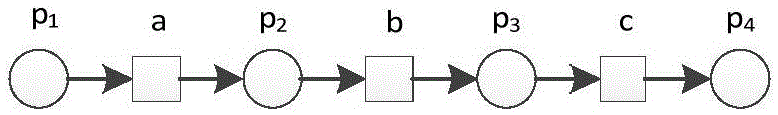

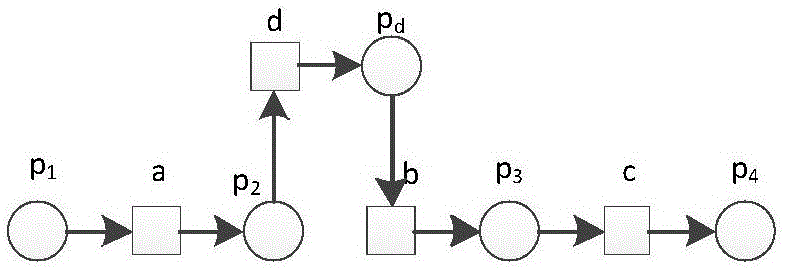

Process model repair method based on Petri net basic structures

ActiveCN105095491AImprove consistencyConducive to simplificationSpecial data processing applicationsOriginal dataPetri net

The invention discloses a process model repair method based on Petri net basic structures. The repair method comprises the steps that processing is conducted on original data to make the original data be an event log which is in compliance with specifications; then an inductive mining algorithm is conducted on the processed data to mine a corresponding process model; calibration is conducted on an extended event log and the process model obtained through mining, and it is discovered that a deviation exists in the process model; finally, repair schemes of the process model under different structures are proposed, and the repair schemes aim at repairing the process model and enhance the consistency of the process model. In a case structure, special repair is conducted on the situation that a log action is adjacent to a model action, a repair algorithm is provided, the degree of fitting and the degree of accuracy are guaranteed, and meanwhile the simplification degree of the process model is increased.

Owner:SHANDONG UNIV OF SCI & TECH

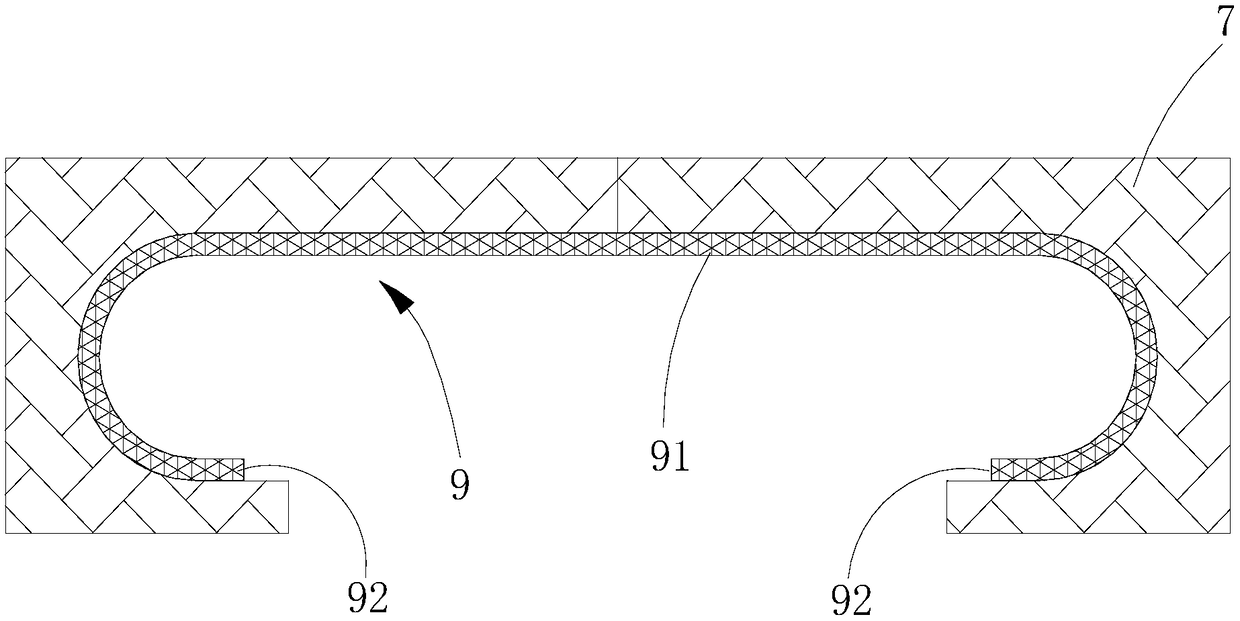

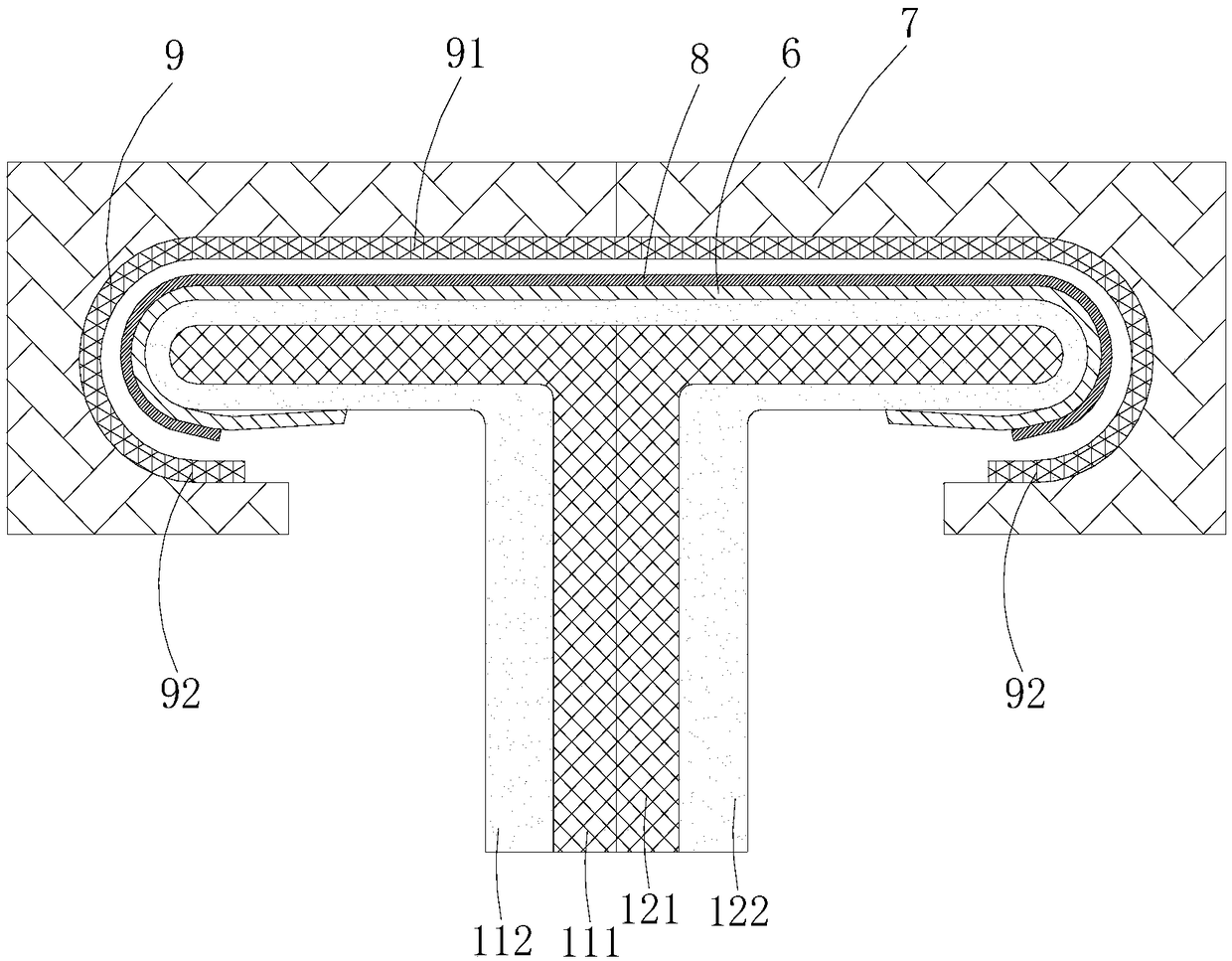

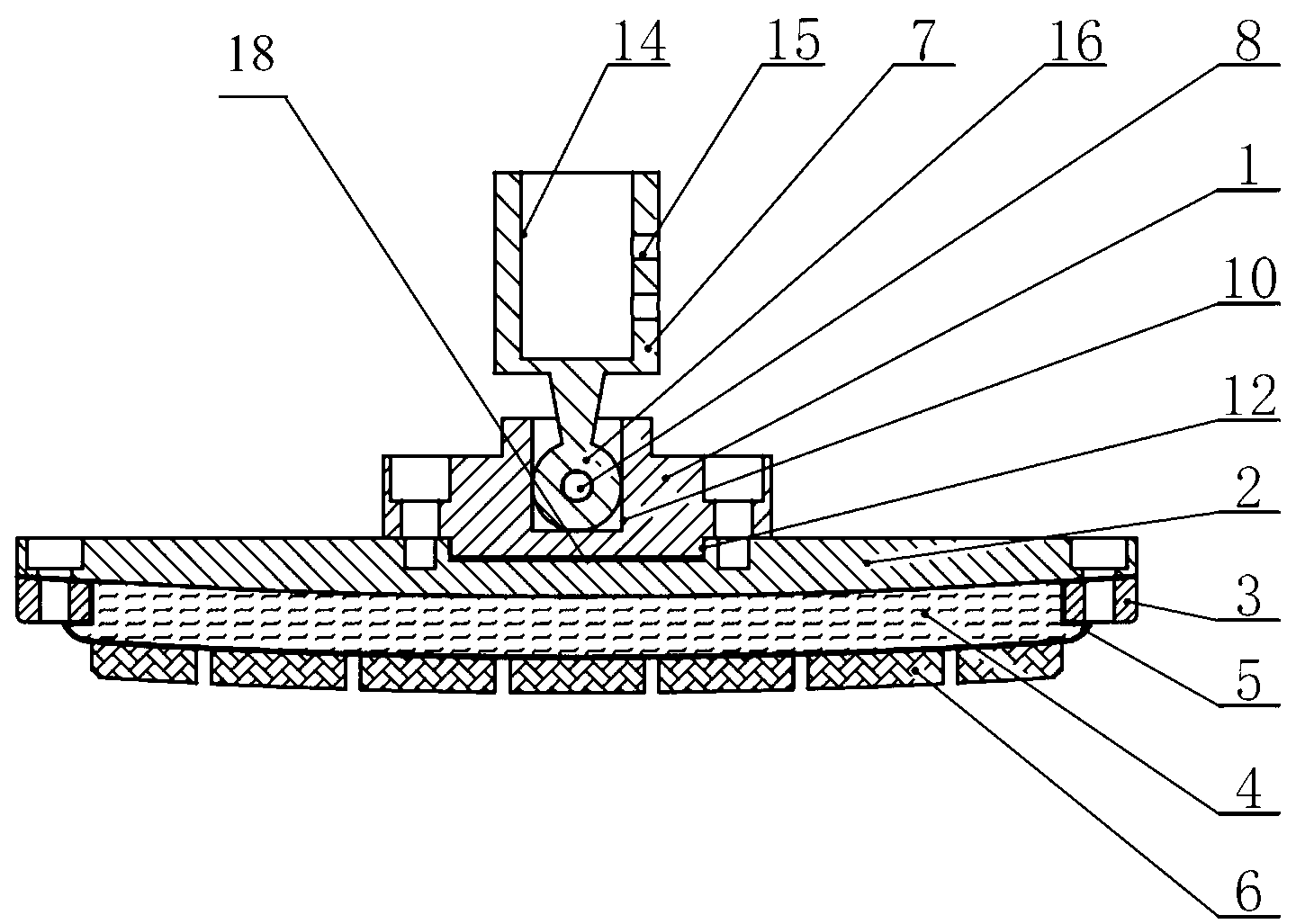

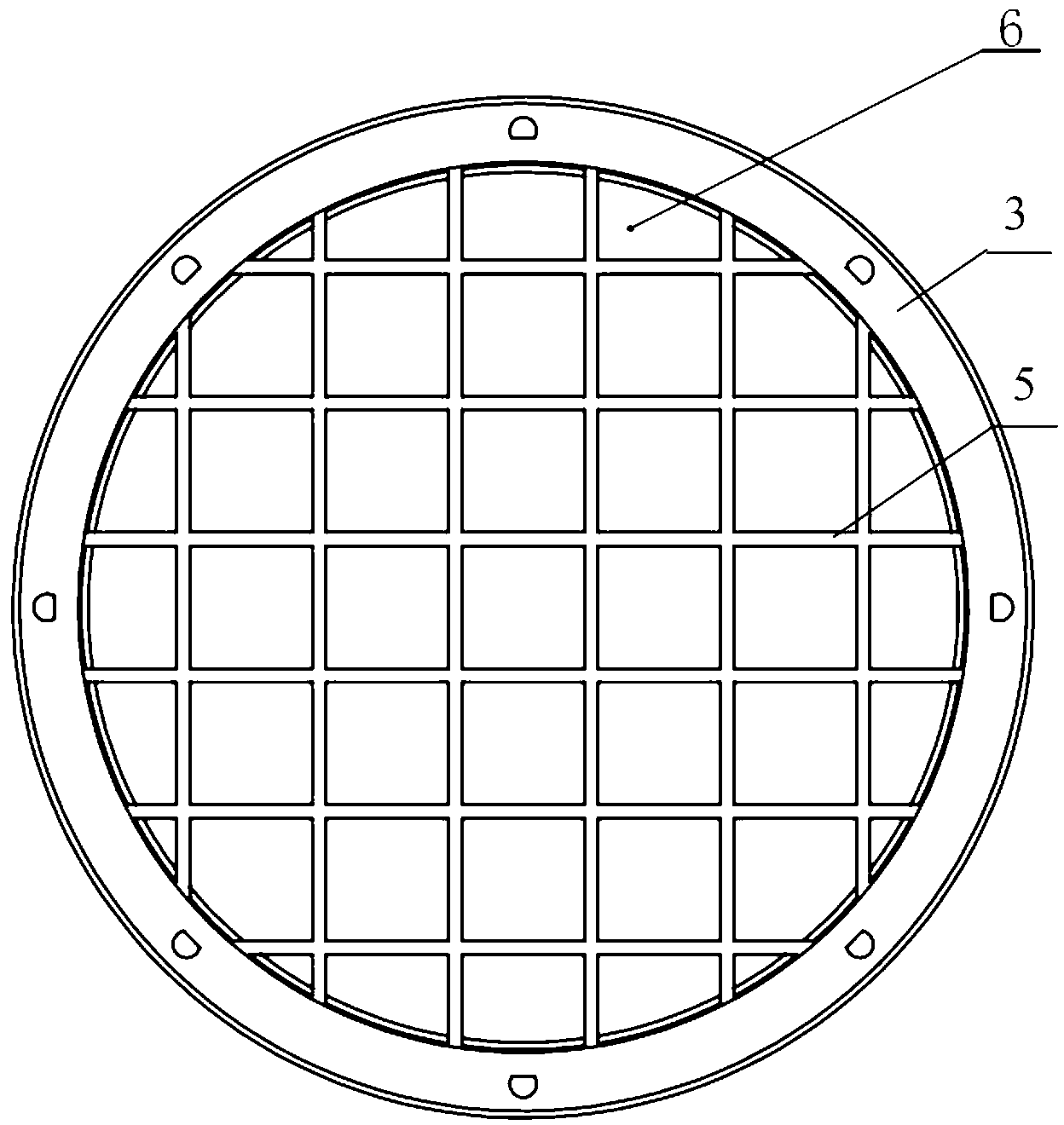

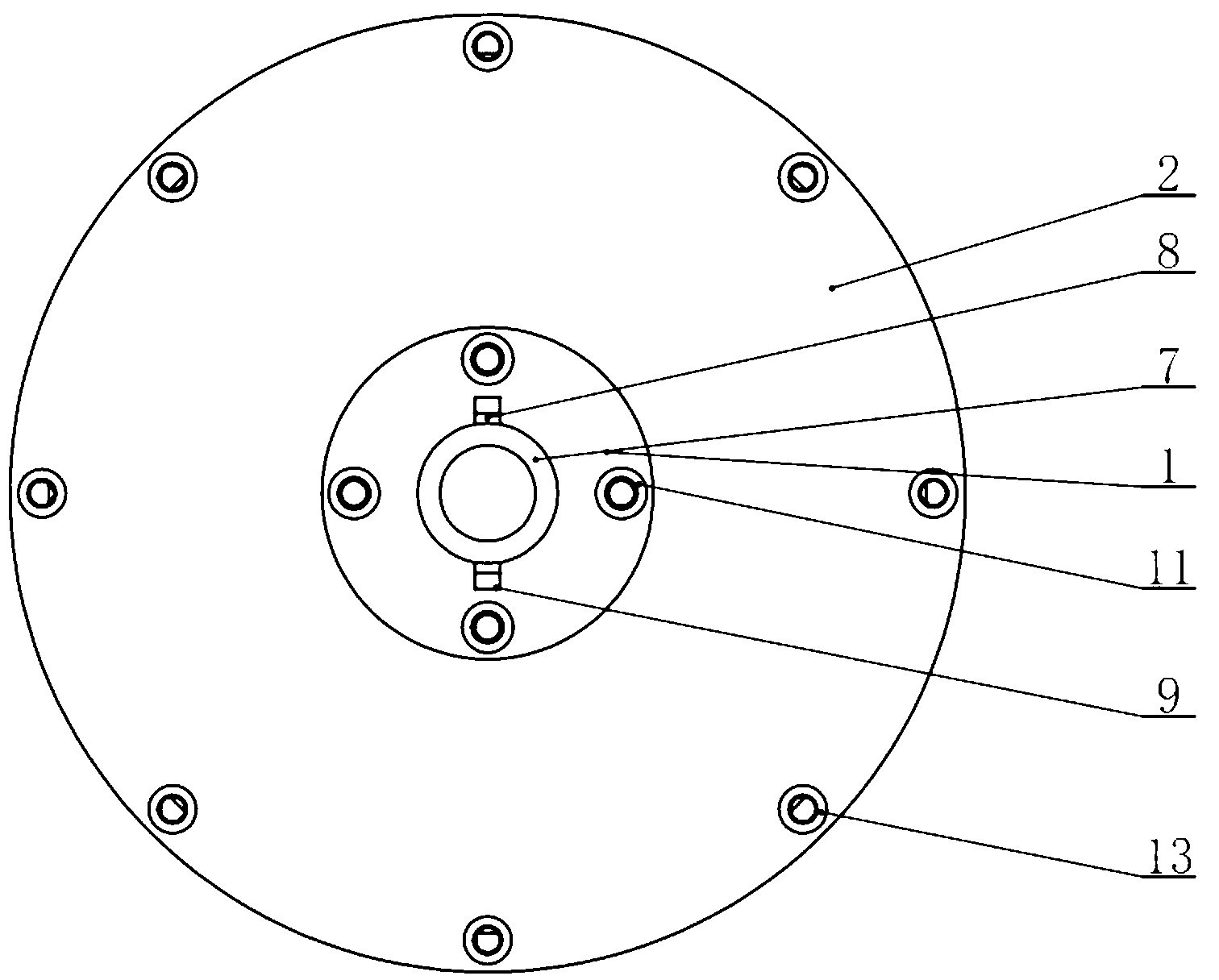

Flexible passive adaptation type fairing disc and flexible sandwich layer thereof and method for operating flexible passive adaptation type fairing discs

ActiveCN102794718AGuaranteed fitControl processing volumeOptical surface grinding machinesFlexible-parts wheelsAdhesiveEngineering

The invention discloses a flexible passive adaptation type fairing disc which comprises a chassis (2) and a polishing adhesive (6), wherein the chassis (2) is fixedly connected with a connecting flange (1), the connecting flange (1) is movably connected with a ball head shaft (7) which can be connected with a machine tool, the downside of the chassis (2) is wrapped with a flexible sandwich layer (4) through an isolating membrane (5), and the polishing adhesive (6) is arranged at the bottom of the isolating membrane (5); and the flexible sandwich layer (4) is mainly prepared through carrying out heating reaction on boric acid and dimethyl silicone oil in a certain proportion at a certain temperature. In the process of operating, the fairing disc is installed firstly, and then an operation of processing is performed according to a certain rotating speed and a certain processing path. The fairing disc disclosed by the invention has the advantages of simple control, low cost, high rotating speed, high fairing efficiency and the like.

Owner:NAT UNIV OF DEFENSE TECH

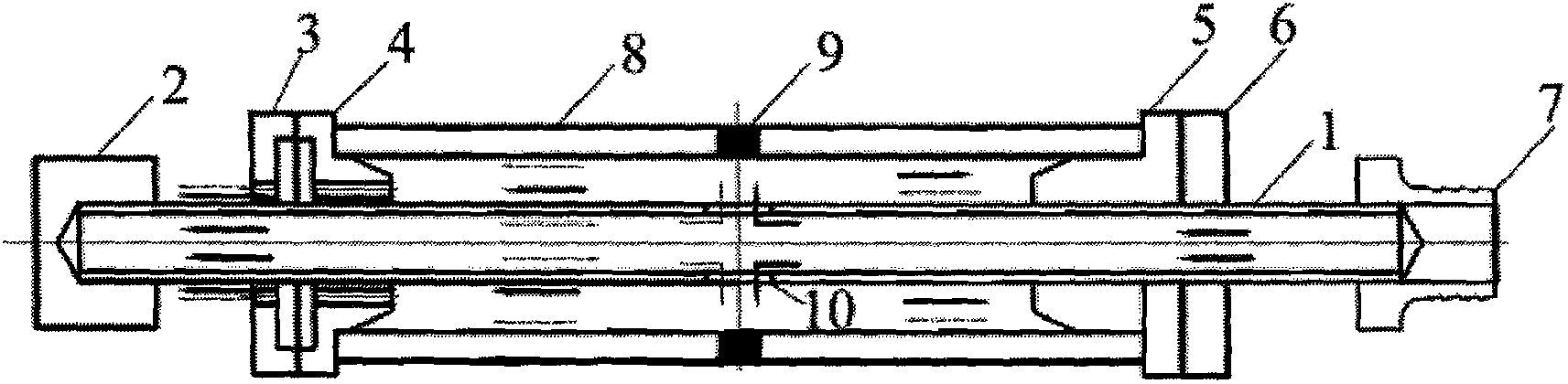

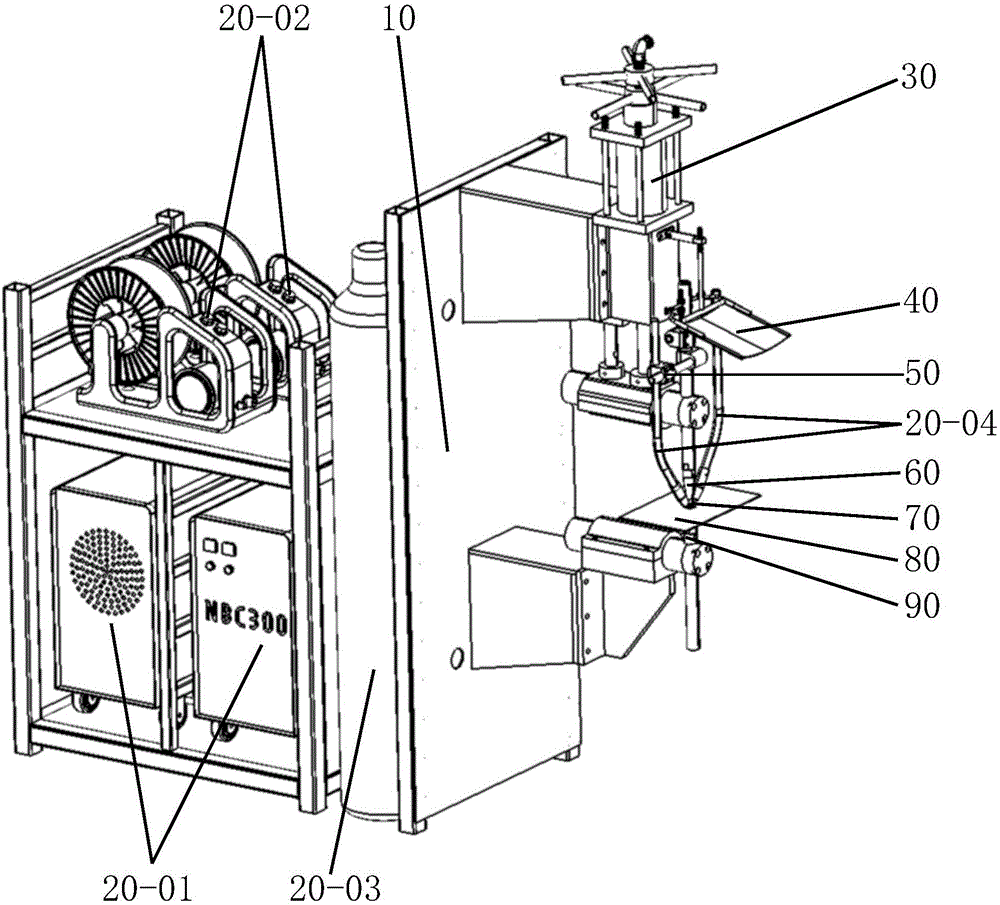

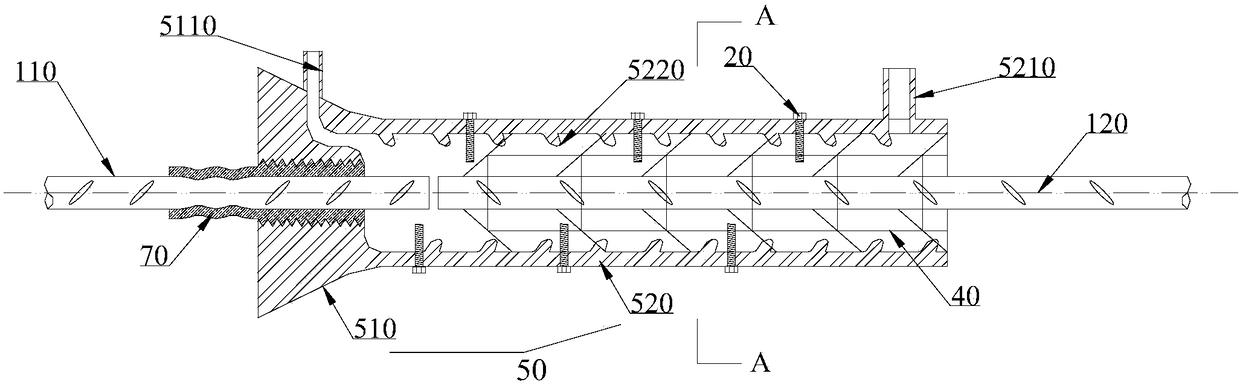

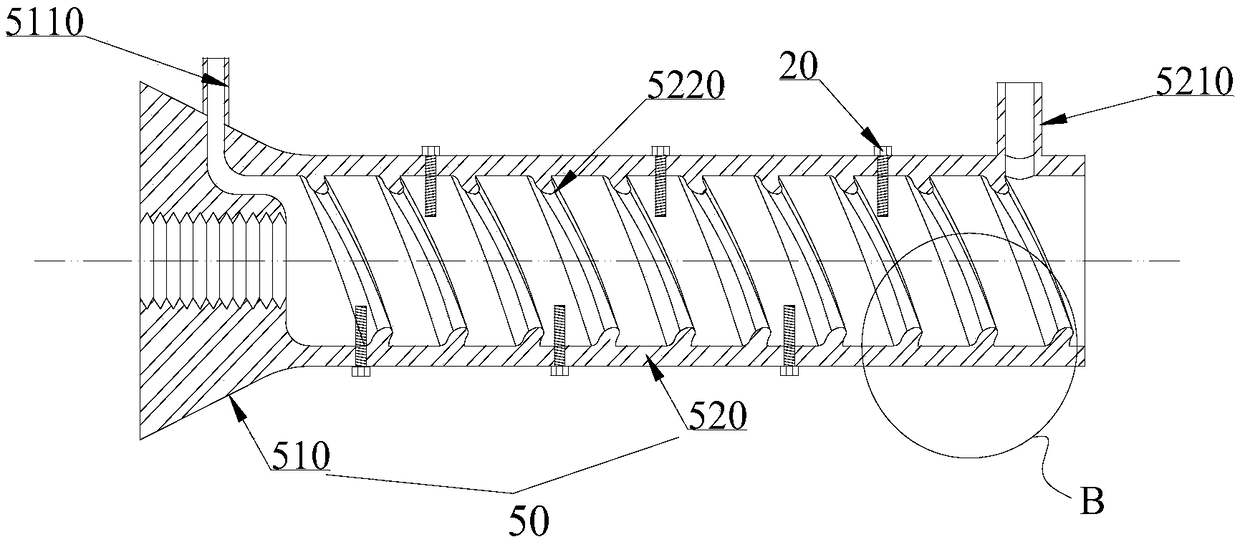

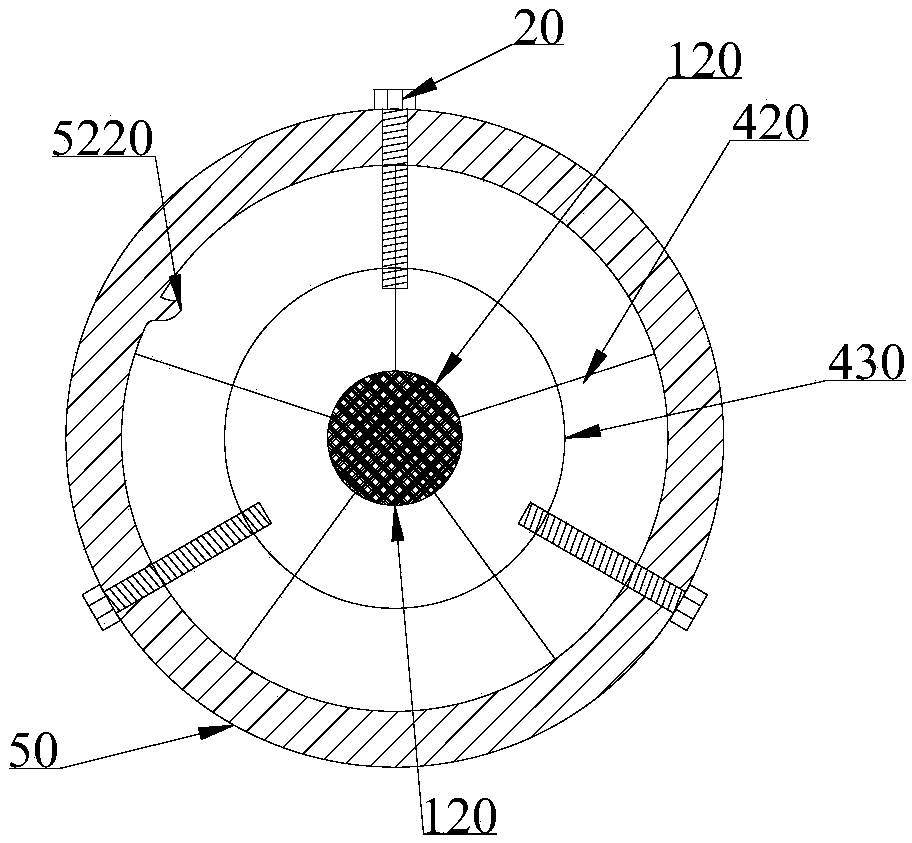

Small-caliber straight pipe butt welding device

ActiveCN103170768AGuaranteed fitGuaranteed final shapeWelding/cutting auxillary devicesAuxillary welding devicesWeld seamFilling materials

The invention provides a small-caliber straight pipe butt welding device comprising a positioning core bar, a fastening nut, an end portion top cover and a protective gas transition pipe nozzle. One end of the positioning core bar or two ends of the positioning core bar are open, the middle of the positioning core bar is hollow, and an air hole is formed in the middle of the positioning core bar. The protective gas transition pipe nozzle is screwed at one opening end of the positioning core bar, and the other end of the positioning core bar is unopened or is selectively connected with a plug nut. The end portion top cover is sleeved on the positioning core bar, and a flange is arranged on the end portion top cover along the center direction of the positioning core bar. The positioning core bar, outside the end portion top cover, is provided with the fastening nut in a sleeved mode. The end portion top cover and the fastening nut are provided with air holes. By means of the small-caliber straight pipe butt welding device, assembly precision of a heat exchange pipe butt-joint connector, a heat exchange pipe and filler materials is controlled, inertia gas protection effectiveness on the inner wall of the connector is improved, and accordingly the fact that ultimate forming of connector welding seams meets manufacture requirements of products is guaranteed, and quality of a welding seam at the root portion of a butt-joint groove of the heat exchange pipe is guaranteed.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

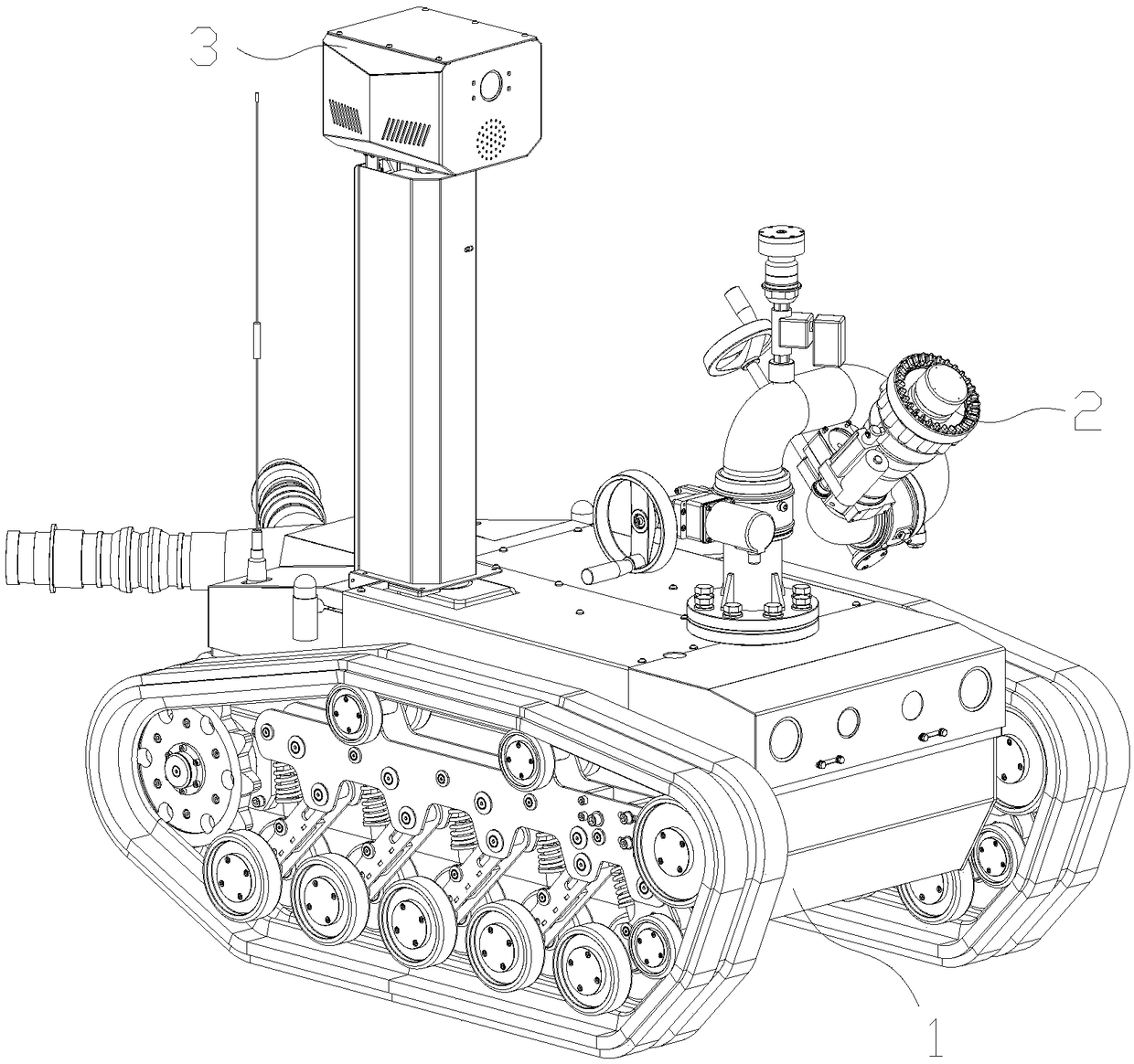

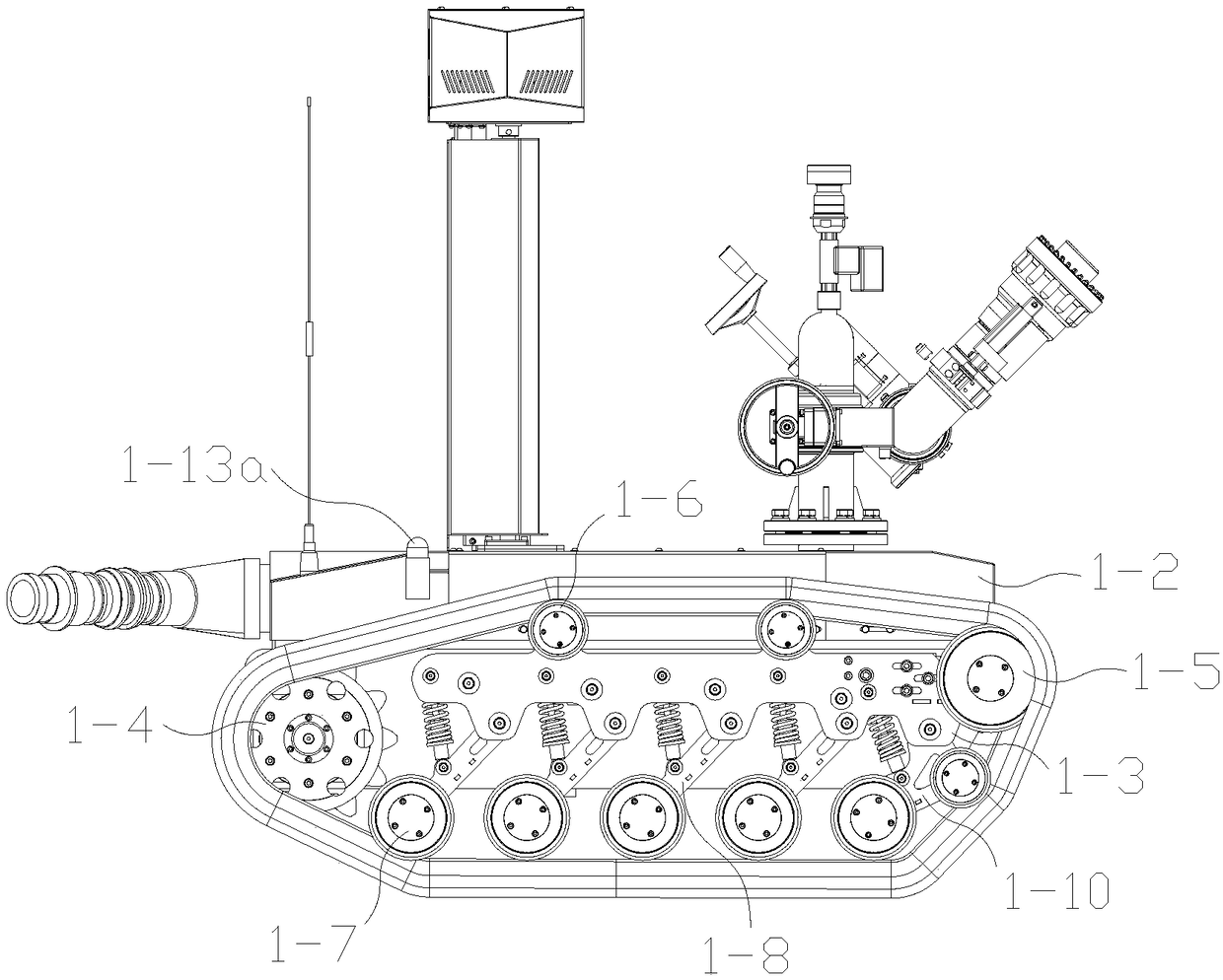

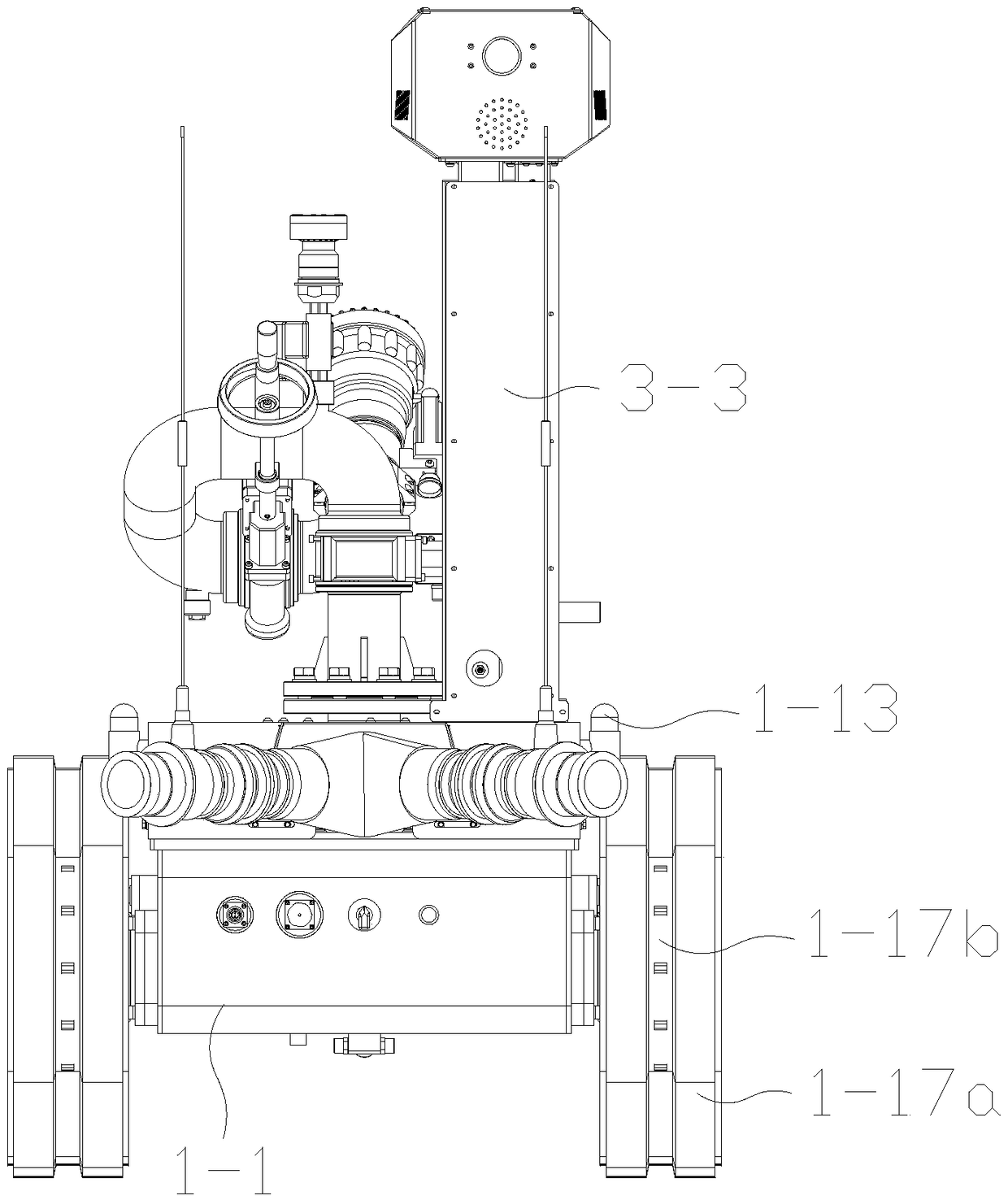

Fire-reconnoitering and fire-extinguishing robot and operation method thereof

ActiveCN109303994ASolve problems such as slipping and falling beltsHigh efficiency transmissionFire rescueObstacle avoidanceSupport belt

The invention discloses a fire-reconnoitering and fire-extinguishing robot. The fire-reconnoitering and fire-extinguishing robot comprises a caterpillar chassis, a fire-extinguishing water cannon anda reconnoitering mechanism, wherein the fire-extinguishing water cannon and the reconnoitering mechanism are arranged on the caterpillar chassis; the caterpillar chassis is composed of a chassis body,a chassis shell, a suspension cross beam, driving wheels, a driven wheel set, support belt wheel sets, bearing wheel sets, damping plate sets, elastic components, an approach wheel set, tensioning mechanisms, an obstacle avoidance assembly, a warning assembly, a driving assembly, a controller, a wireless transmission assembly, caterpillar assemblies, a dustproof cover plate, searchlights and a lithium battery. Through the fire-reconnoitering and fire-extinguishing robot, the problem of slippage and removal between the driving wheels and the caterpillar is solved; the efficient transmission between the driving wheels and the caterpillar is achieved; the adhesion performance between a suspension system with the caterpillar in the obstacle surmounting process is ensured; the stability of therobot when surmounting the obstacles and climbing can be also improved; the function of tensioning the suspension system on the robot is achieved; the safety and the stability of movement of the robot are further improved; the maintenance difficulty and the usage cost of the robot are reduced.

Owner:SHANDONG GUOXING SMARTECH CO LTD +1

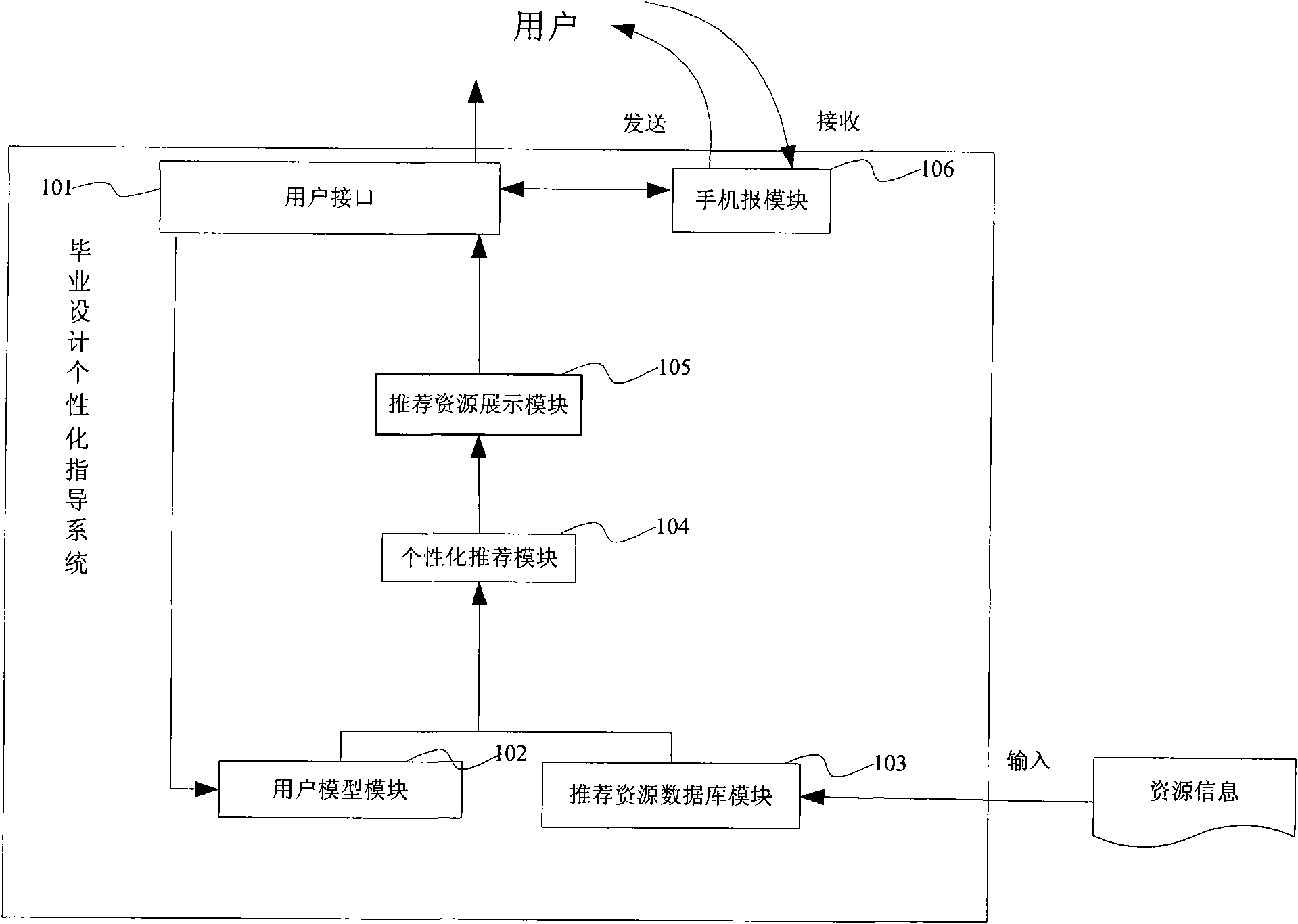

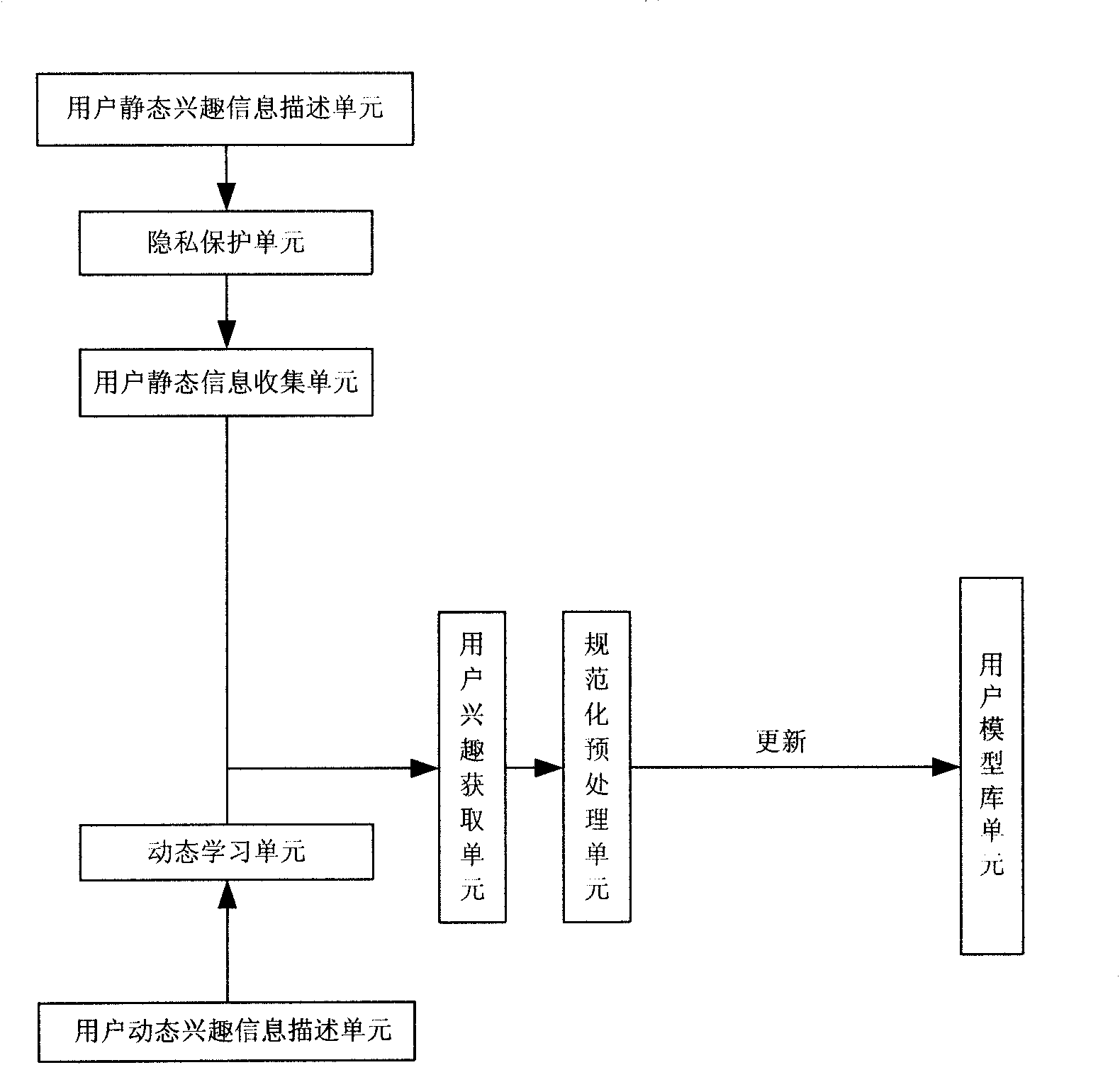

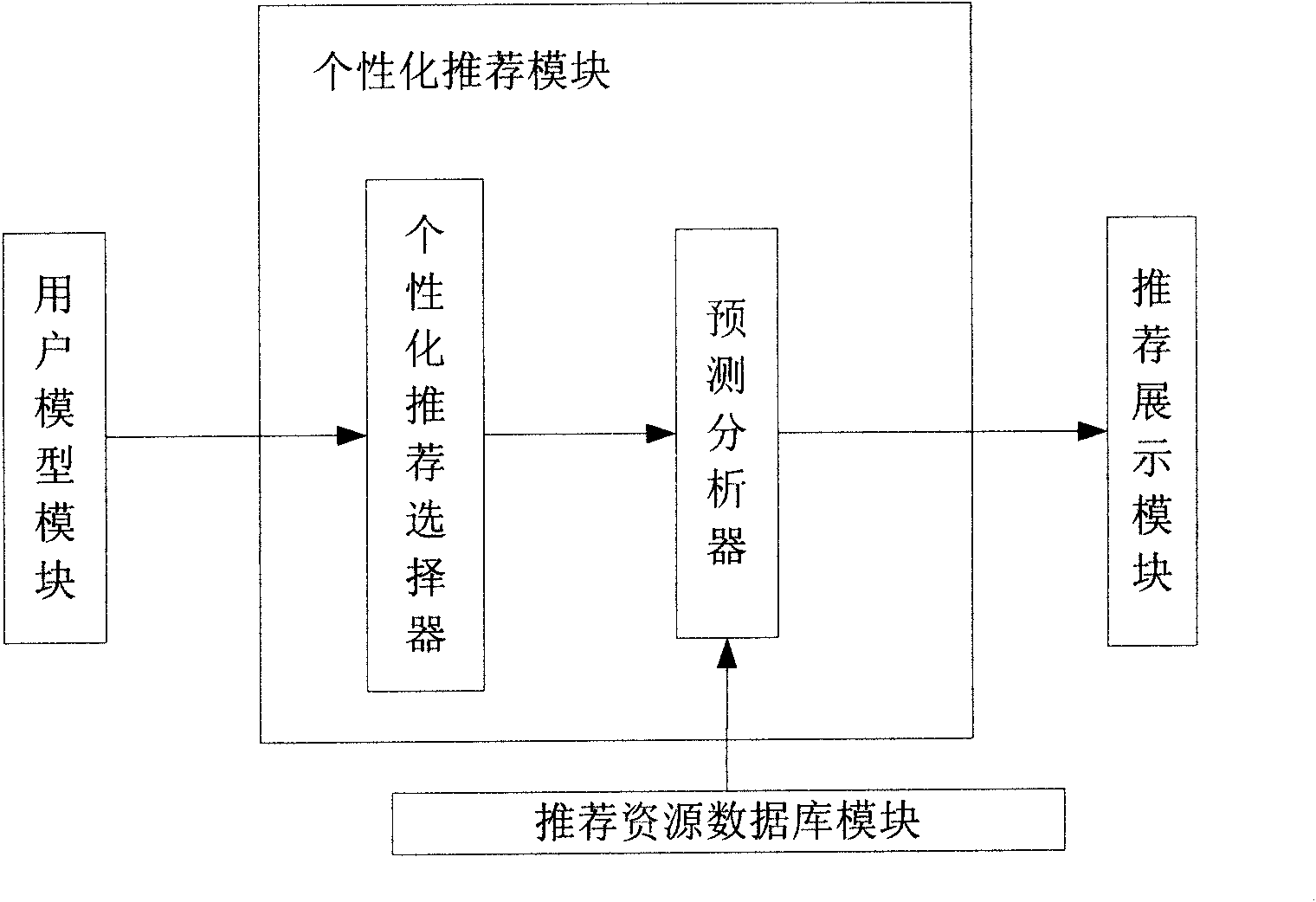

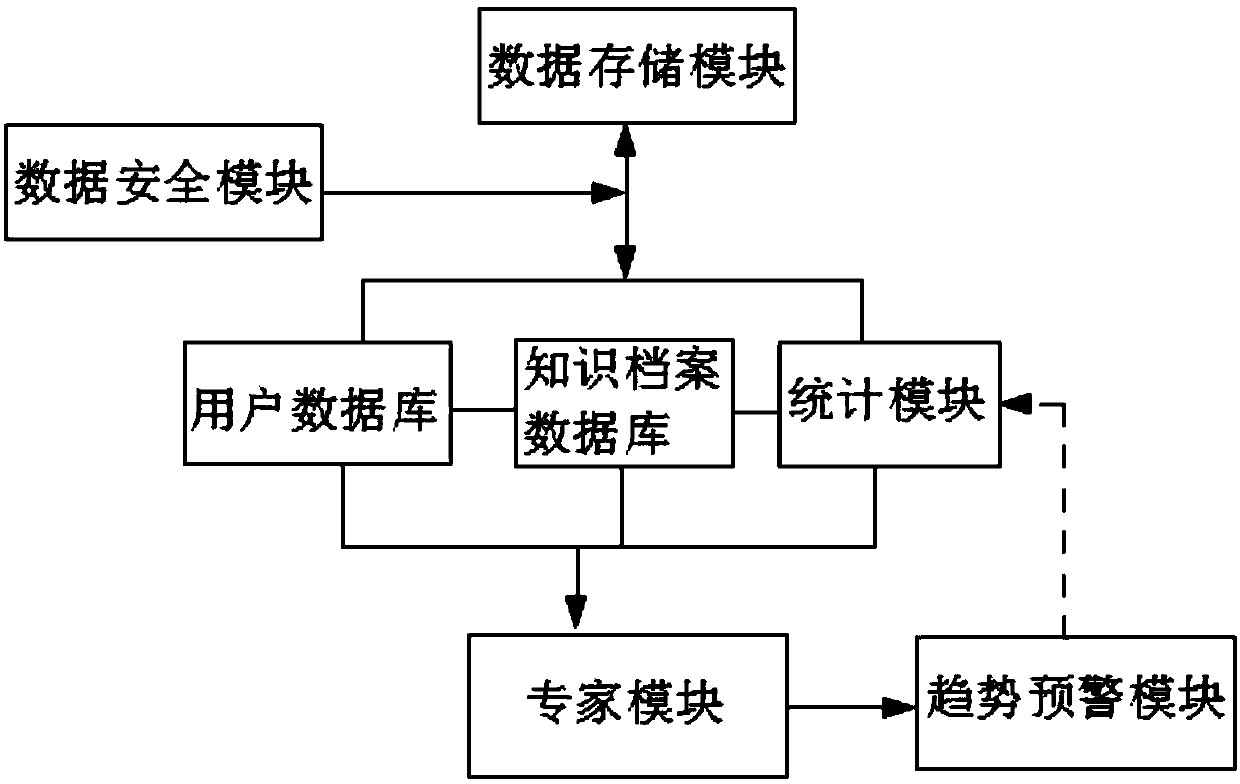

Graduation design personalized guide system

InactiveCN101937524AGuaranteed fitGuaranteed to meet the actual needs of usersData processing applicationsMessaging/mailboxes/announcementsPersonalizationReal-time data

The invention discloses a graduation design personalized guide system, which comprises a user interface, a mobile paper module, a user model module, a personalized recommendation module, a recommendation resource database module and a recommendation resource display module. The user interface serving as a communication port realizes real-time data communication between a user and the graduation design personalized guide system; the mobile paper module is used for forwarding a recommendation resource object to a mobile phone of the user and transmitting the feedback effective information to the user model module through the user interface; the user model module is used for acquiring the effective information of the user and establishing a user interesting model; the recommendation resource database module is used for extracting and storing a static attribute value and a dynamic attribute value of the resource information according to a static attribute and a dynamic attribute preset in a recommendation resource database; the personalized recommendation module is used for predicting and analyzing a recommendation result; and the recommendation resource display module is used for encapsulating the recommendation resource object according to the recommendation result of the personalized recommendation module and transmitting the recommendation resource object to the user interface.

Owner:HUAZHONG NORMAL UNIV

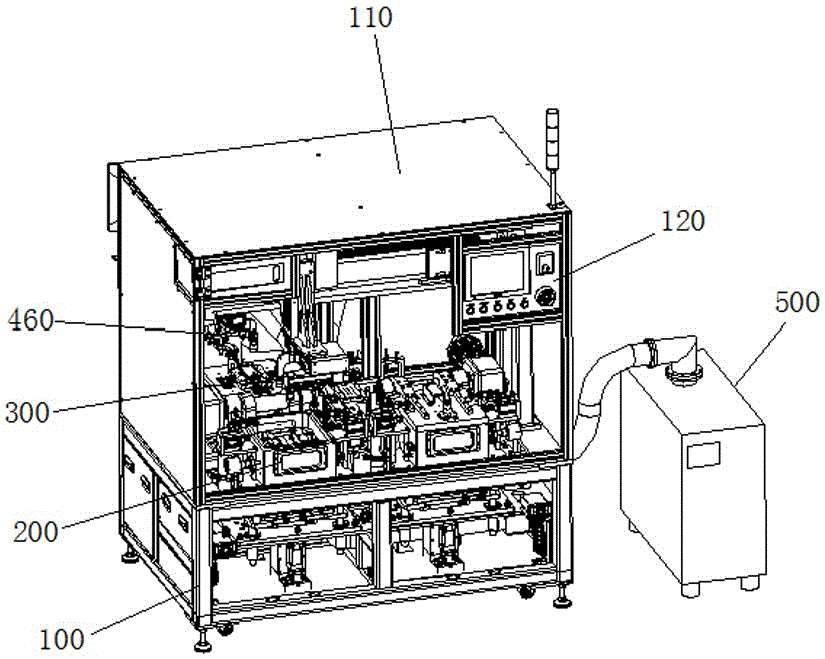

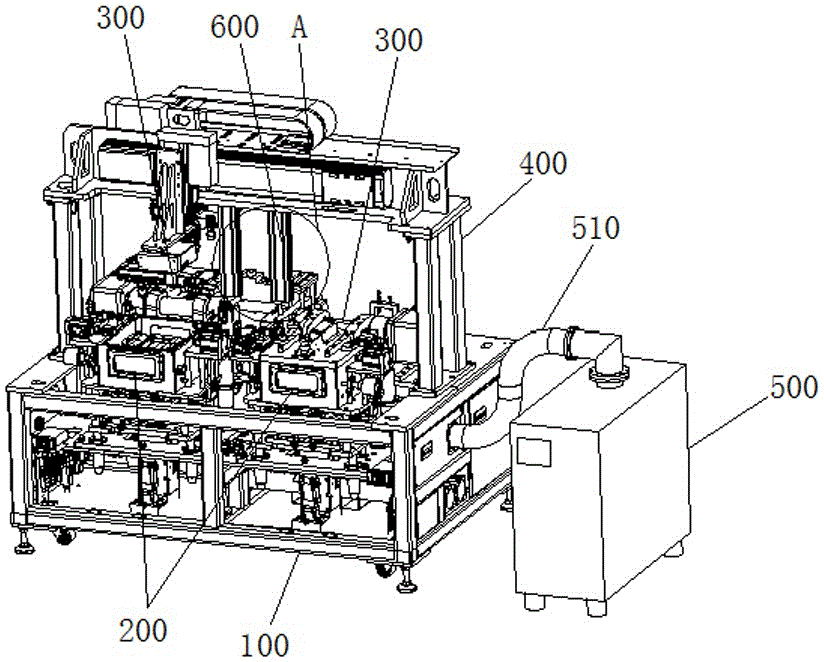

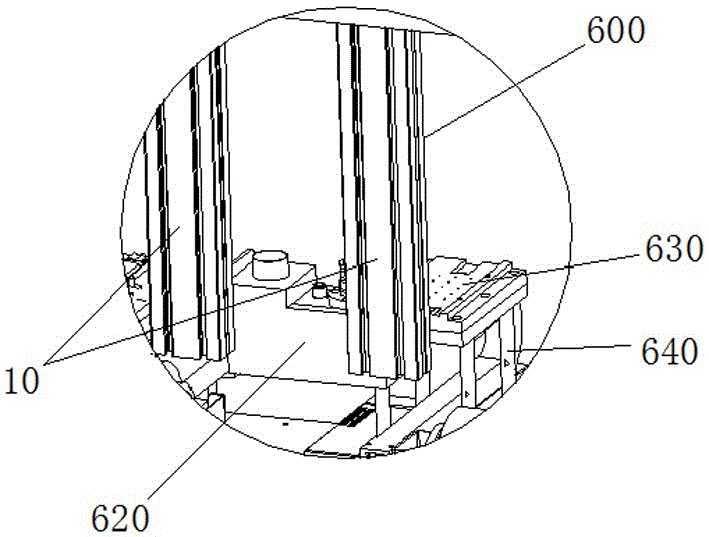

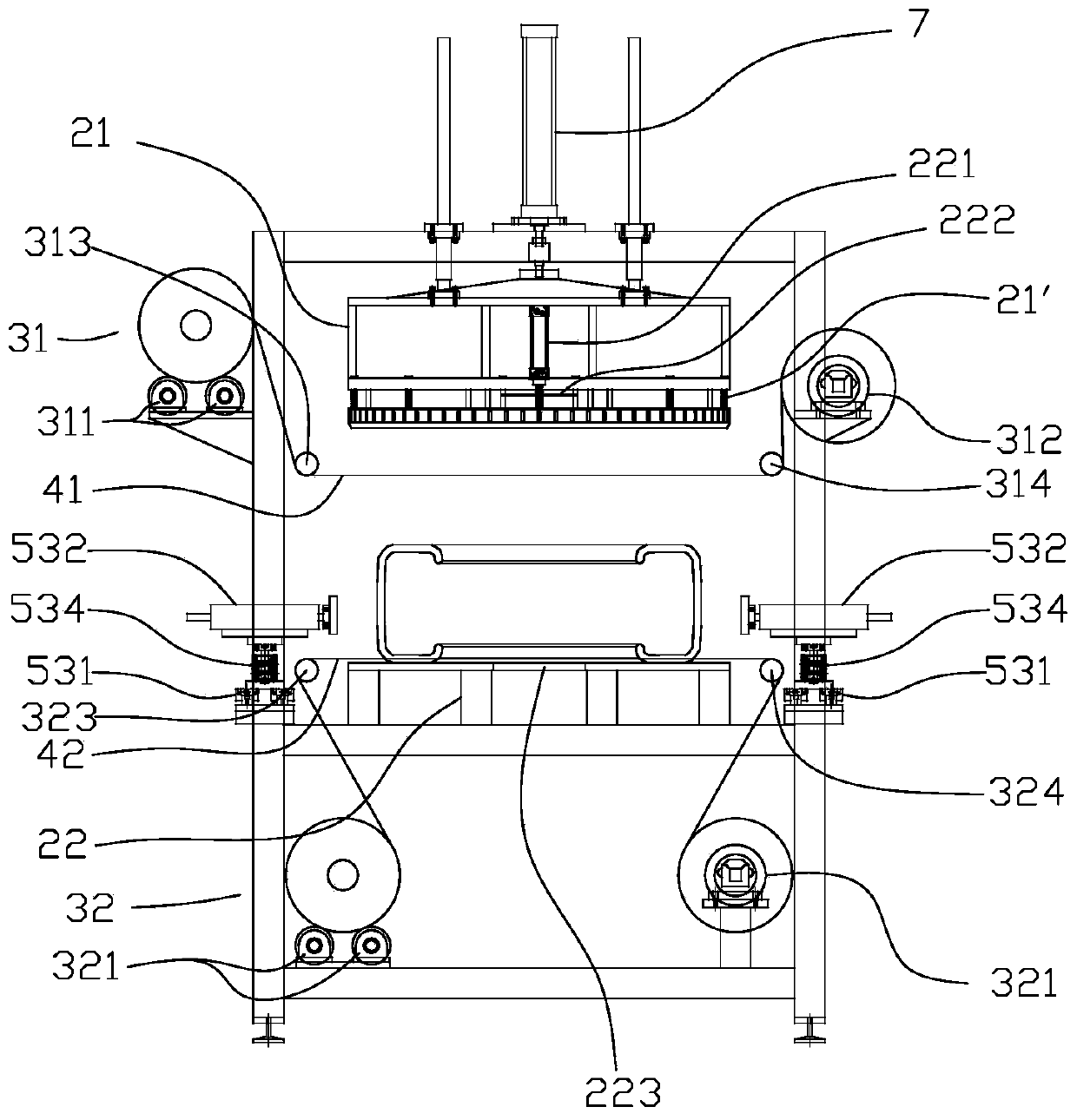

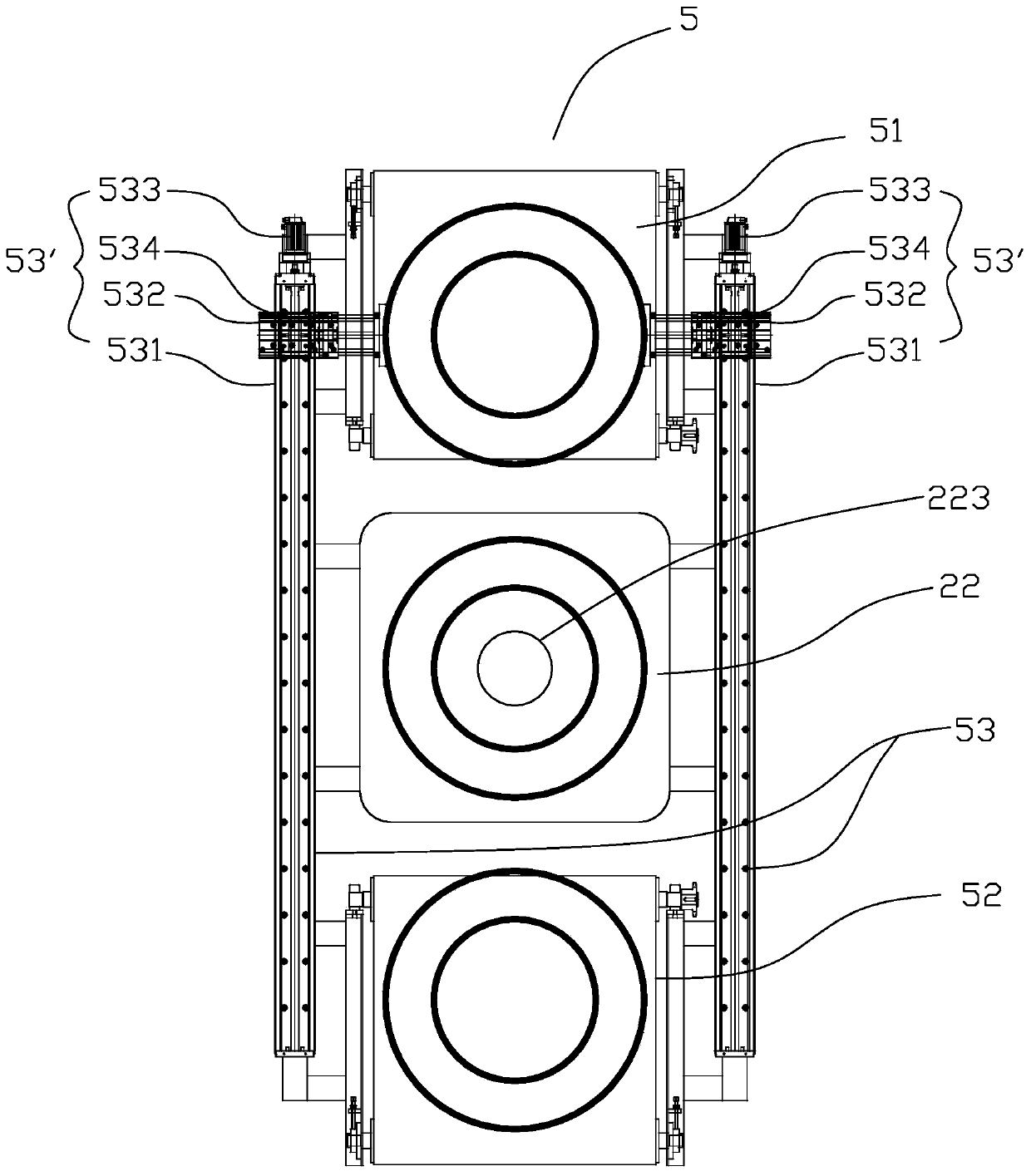

Multipurpose attaching machine for 3D glass curved screens

The invention discloses a multipurpose attaching machine for 3D glass curved screens. The multipurpose attaching machine comprises a rack, and two vacuum cavities, a vacuumizing mechanism, a glass conveying mechanism and two turning mechanisms are arranged in the rack; the vacuum cavities are used for containing Film protection films, and each vacuum cavity comprises a Film protection film positioning mechanism and a Film protection film fine tuning mechanism; the vacuumizing mechanism is used for vacuumizing the vacuum cavities; the glass conveying mechanism is used for automatically conveying 3D glass, and CCD vision inspection units matched with the Film protection film fine tuning mechanisms are arranged at the bottom of the glass conveying mechanism; the turning mechanisms are used for positioning and turning the glass, and each turning mechanism comprises a cavity cover plate, a glass positioning fixture, a pneumatic clamping mechanism and a rotating shaft; after the 3D glass is manually placed in the glass positioning fixtures in parallel to be clamped, driving mechanisms drive the 3D glass to turn along with the cavity cover plates to the position over the Film protection films to complete attaching of the glass and the Film protection films. The multipurpose attaching machine for the 3D glass curved screens has the advantages of being in precise in glass positioning and Film protection film positioning, good in cavity sealing and vacuumizing effect, high in attaching efficiency, good in attaching effect and the like.

Owner:HUIZHOU LONGHAI TECH

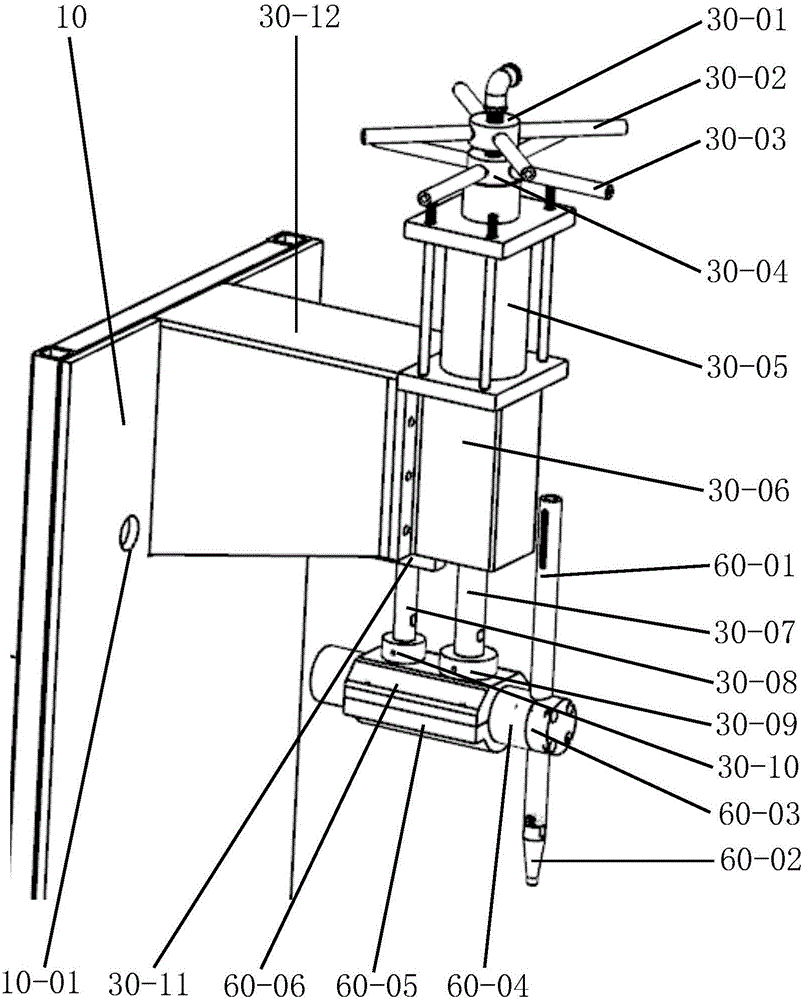

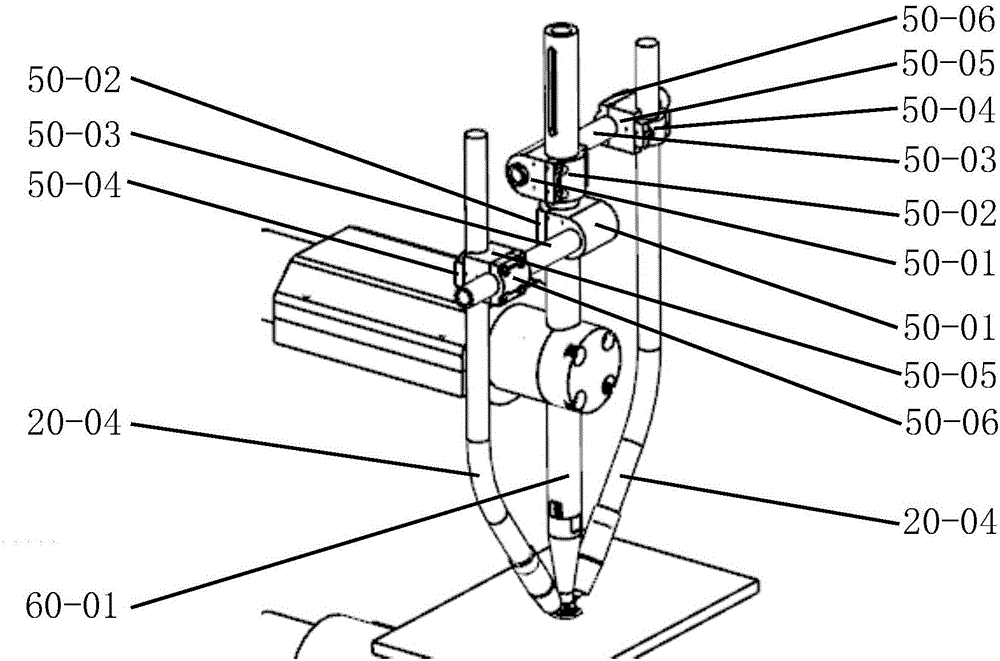

Welding method and equipment for multifunctional threaded fastener

ActiveCN105880895AImprove welding efficiencyImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStud welding

The invention discloses a welding method and equipment for a multifunctional threaded fastener. The welding method comprises MAG welding, TIG welding, MIG welding, stud welding and MIG brazing. The threaded fastener and a workpiece are positioned by a positioning mechanism of the equipment, a welding gun is clamped by a clamping mechanism, a pressing force is transmitted to a pressing mechanism by a power component, the threaded fastener and the workpiece are pressed by the pressing mechanism, the welding gun is driven to move downwards at the same time, and the threaded fastener and the workpiece are welded by a welding mechanism. Compared with existing arc welding equipment for welding the threaded fastener, the method and the equipment have the advantages that the efficiency is improved by 2 to 4 times; moreover, the problems of poor stability of conventional resistance projection welding of the threaded fastener, incapability in welding medium- and high-carbon steel, alloy steel, dissimilar metals and dissimilar materials, incapability of welding on the sidewall of a U-shaped sheet metal part, various hollow and solid pipe fittings and thick plates, incapability of abreast welding of the threaded fastener and the workpiece and the like are solved. In addition, the invention further provides MIG-brazed and flame-brazed fastener and a workpiece used for welding a threaded fastener and positioned by a light beam.

Owner:何强

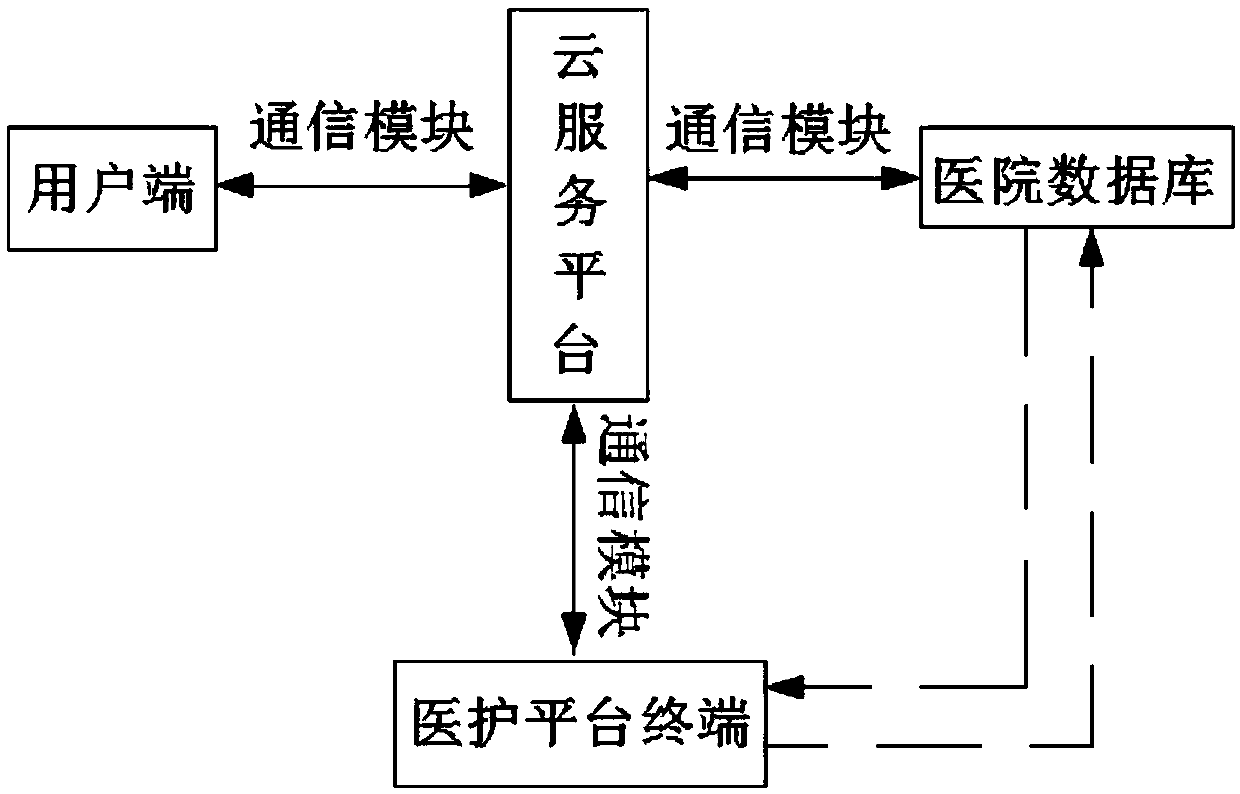

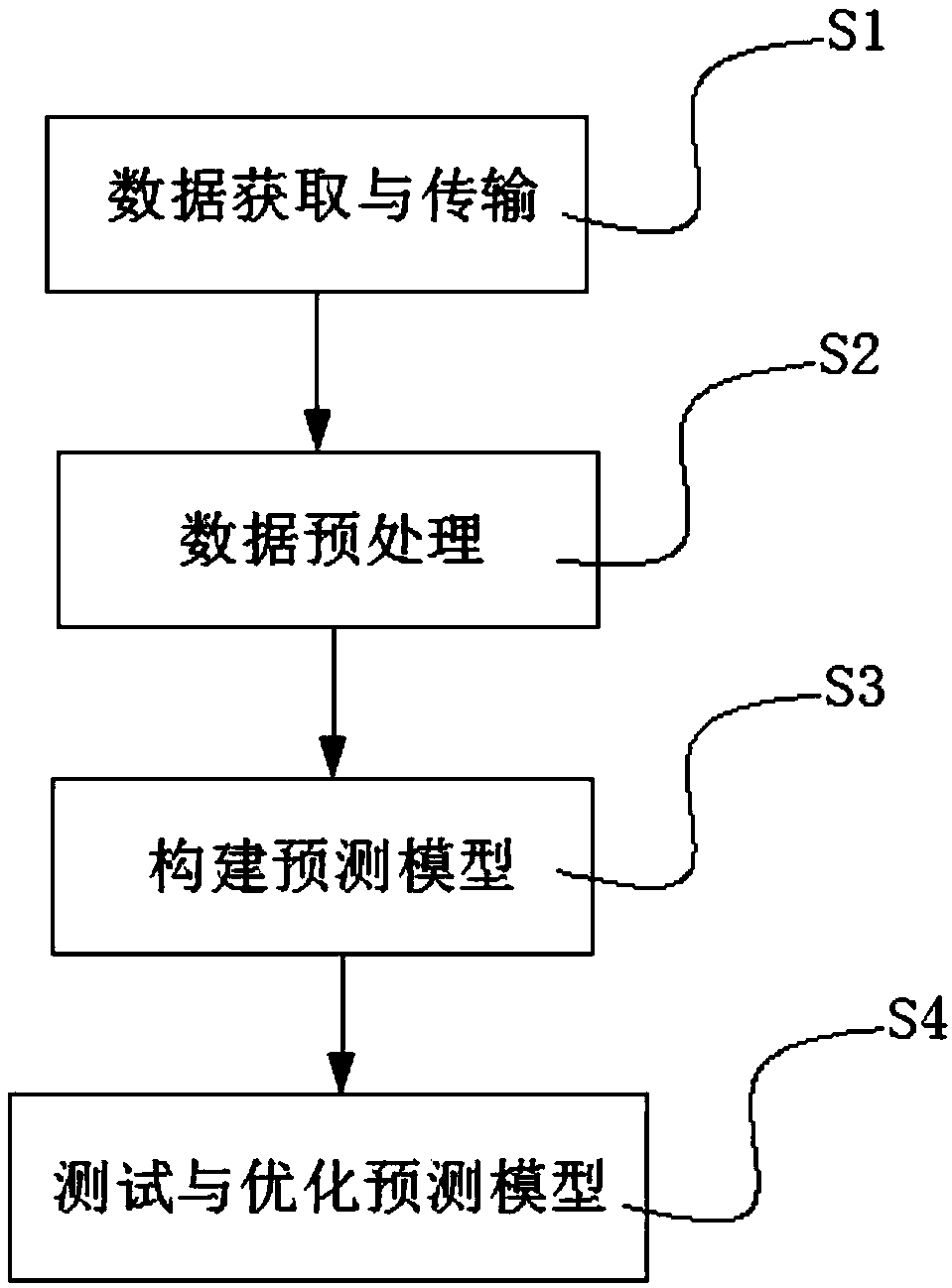

Medical big-data analysis and processing system and method based on IOT (Internet of Things)

PendingCN109545385AExtensive sources of dataEasy way to getMedical data miningNeural architecturesData informationData acquisition

The invention discloses a medical big-data analysis and processing system and method based on the IOT (Internet of Things), and belongs to the technical field of data processing. The big-data analysisand processing system mainly comprises a cloud service platform, a user terminal, a hospital database and a medical platform terminal. The medical big-data analysis and processing method of the invention comprises the steps: data acquisition and transmission, data preprocessing, prediction model constructing, and testing and optimizing of a prediction model. Therefore, the prediction model for indicating the probability of a disease of a predicted object or the probability that the predicted object has a certain disease is obtained, and the IOT transmission of the data information is achievedthrough a communication module. Moreover, the prediction model is obtained based on the convolutional neural network The data source with many correlations and wide influences is inputted, and the data has been preprocessed, which greatly improves the accurate reference value of the prediction results.

Owner:周立广

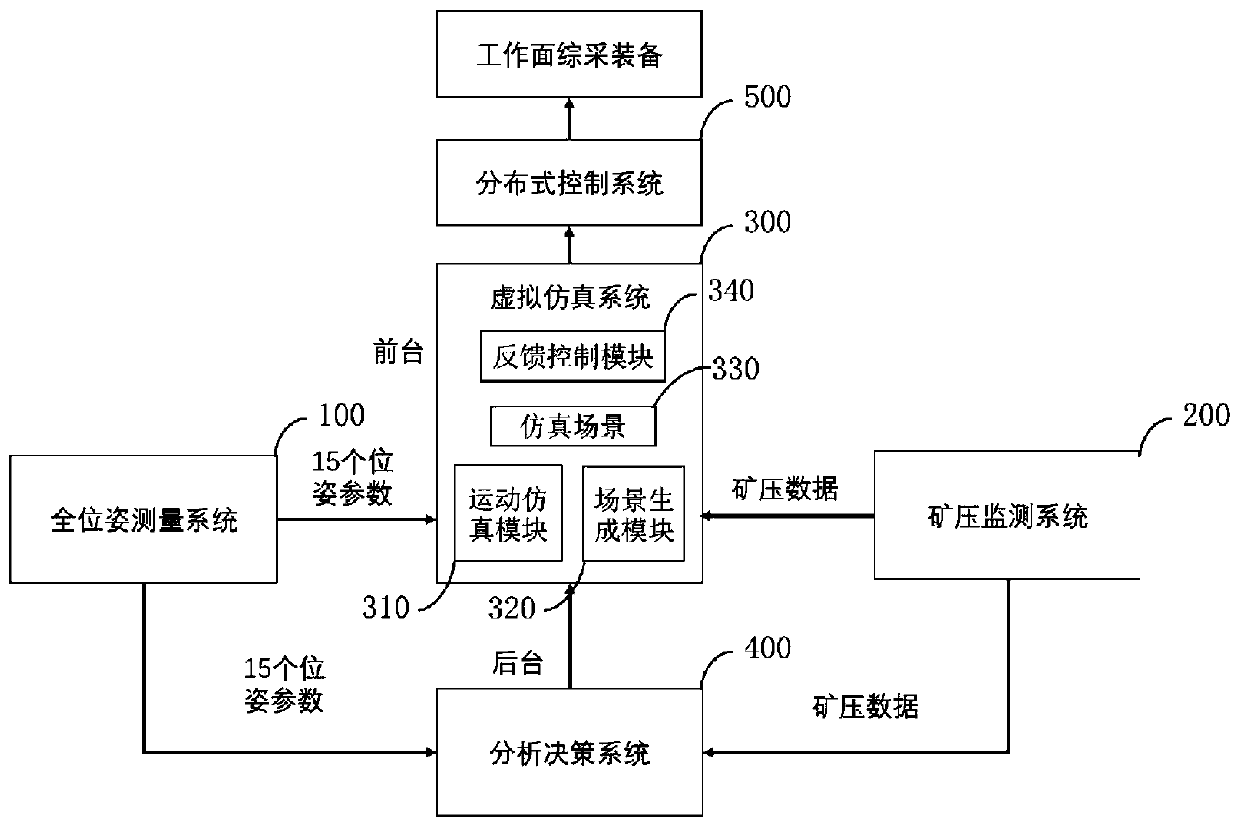

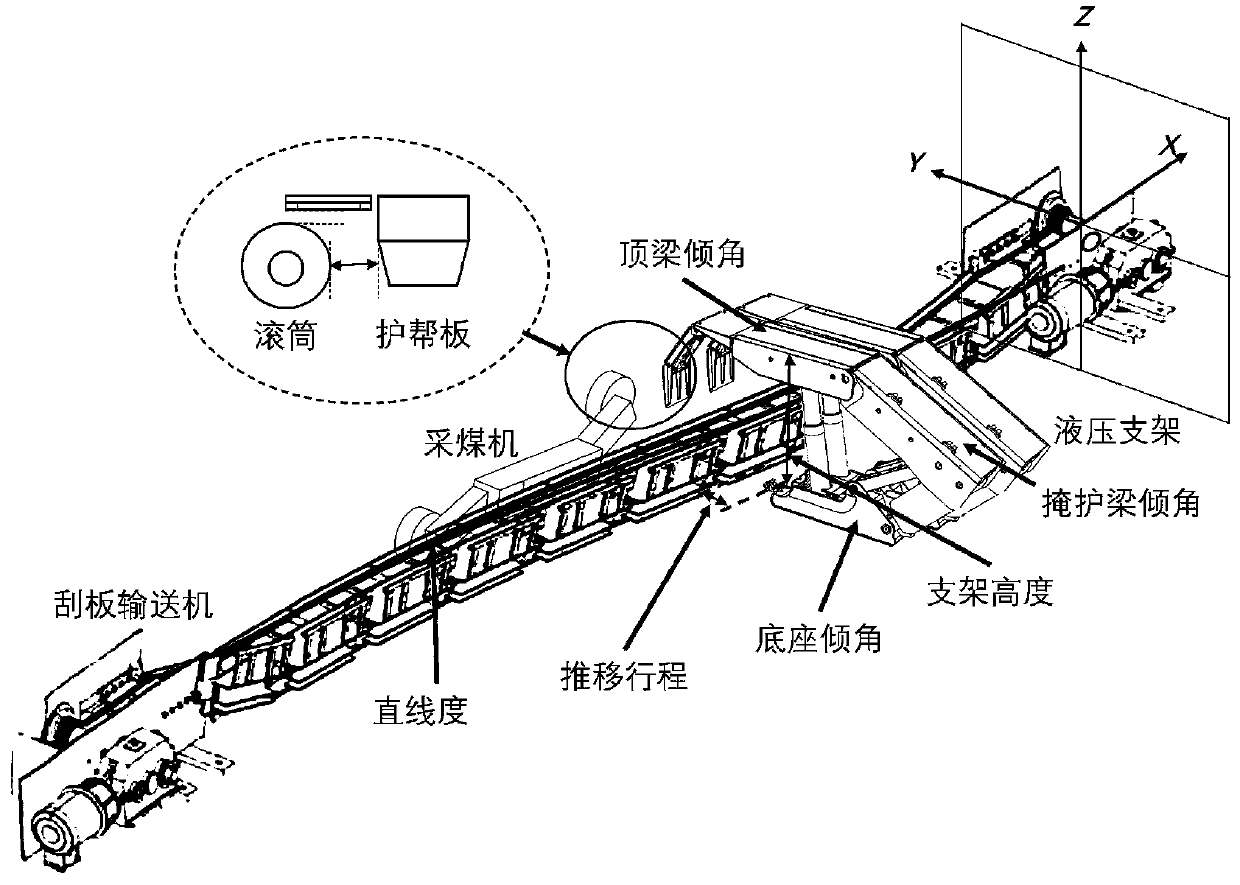

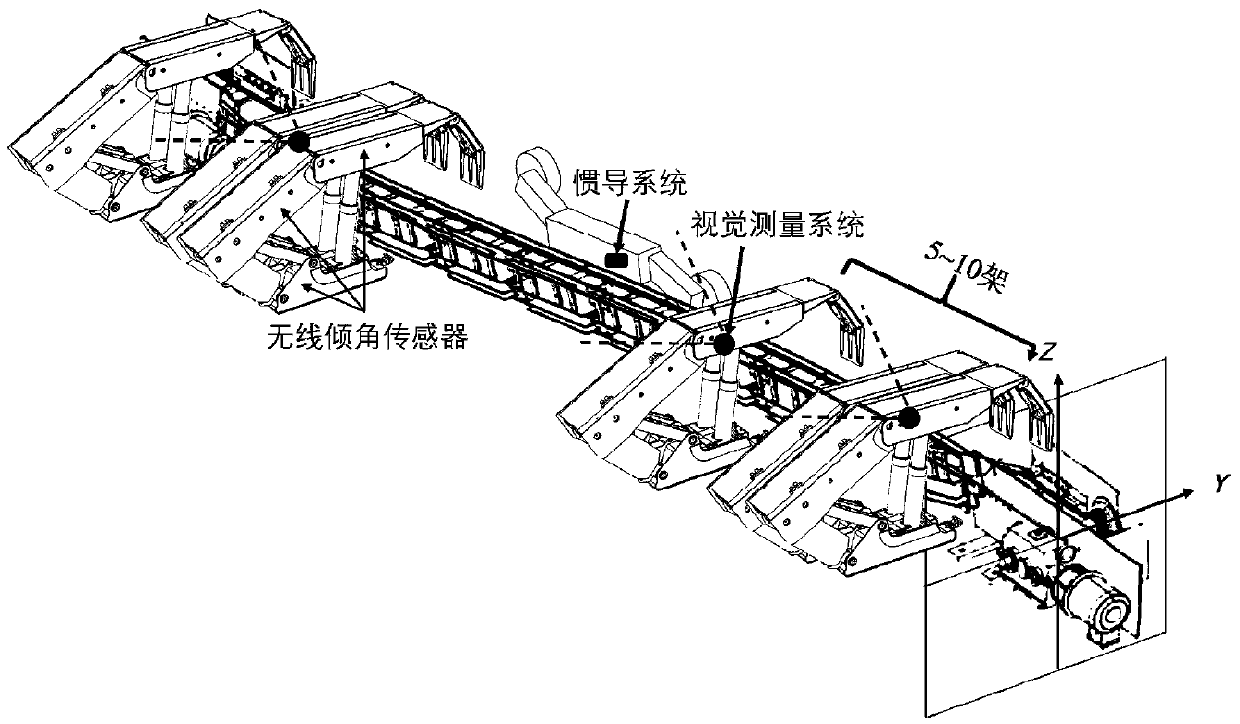

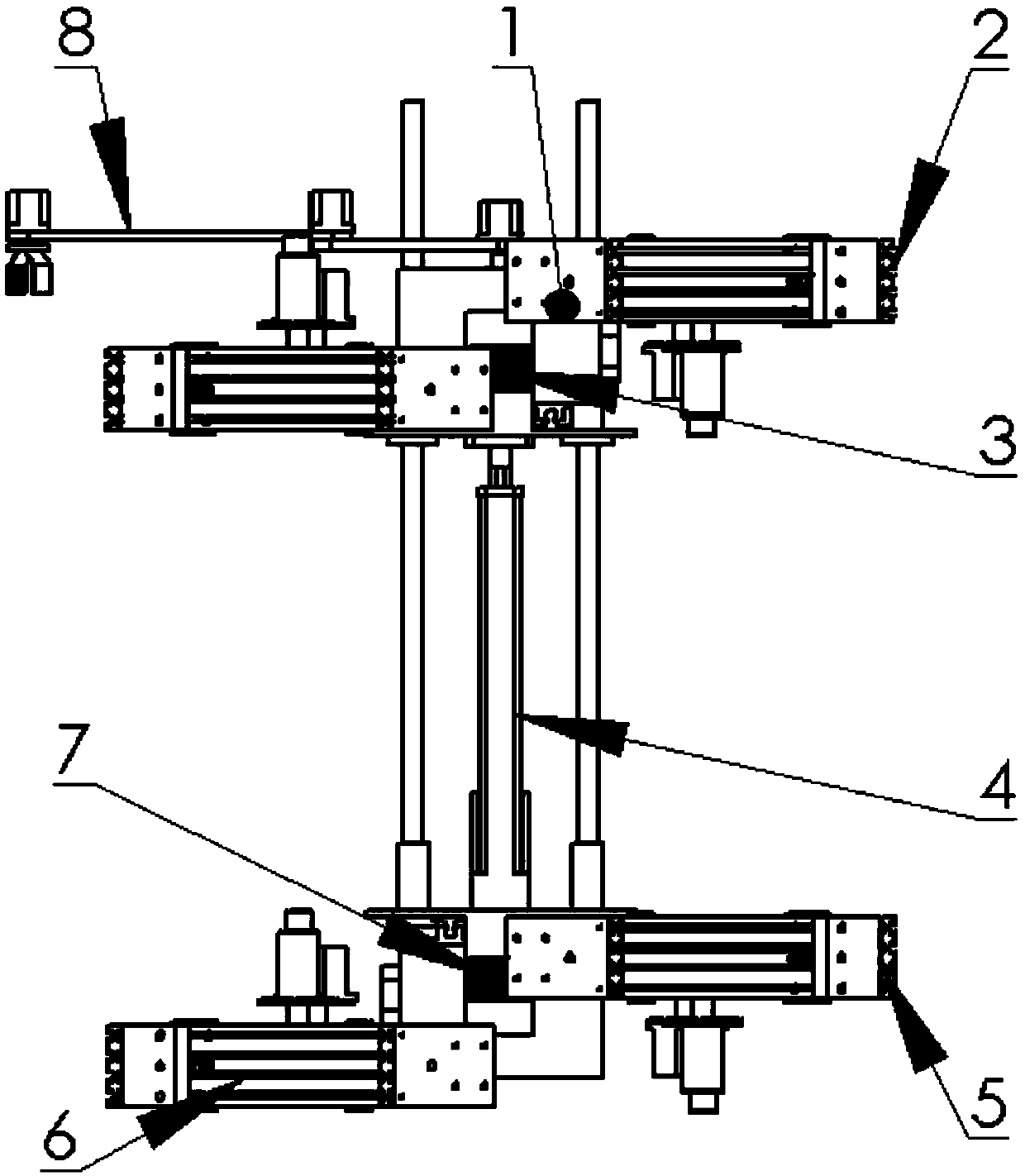

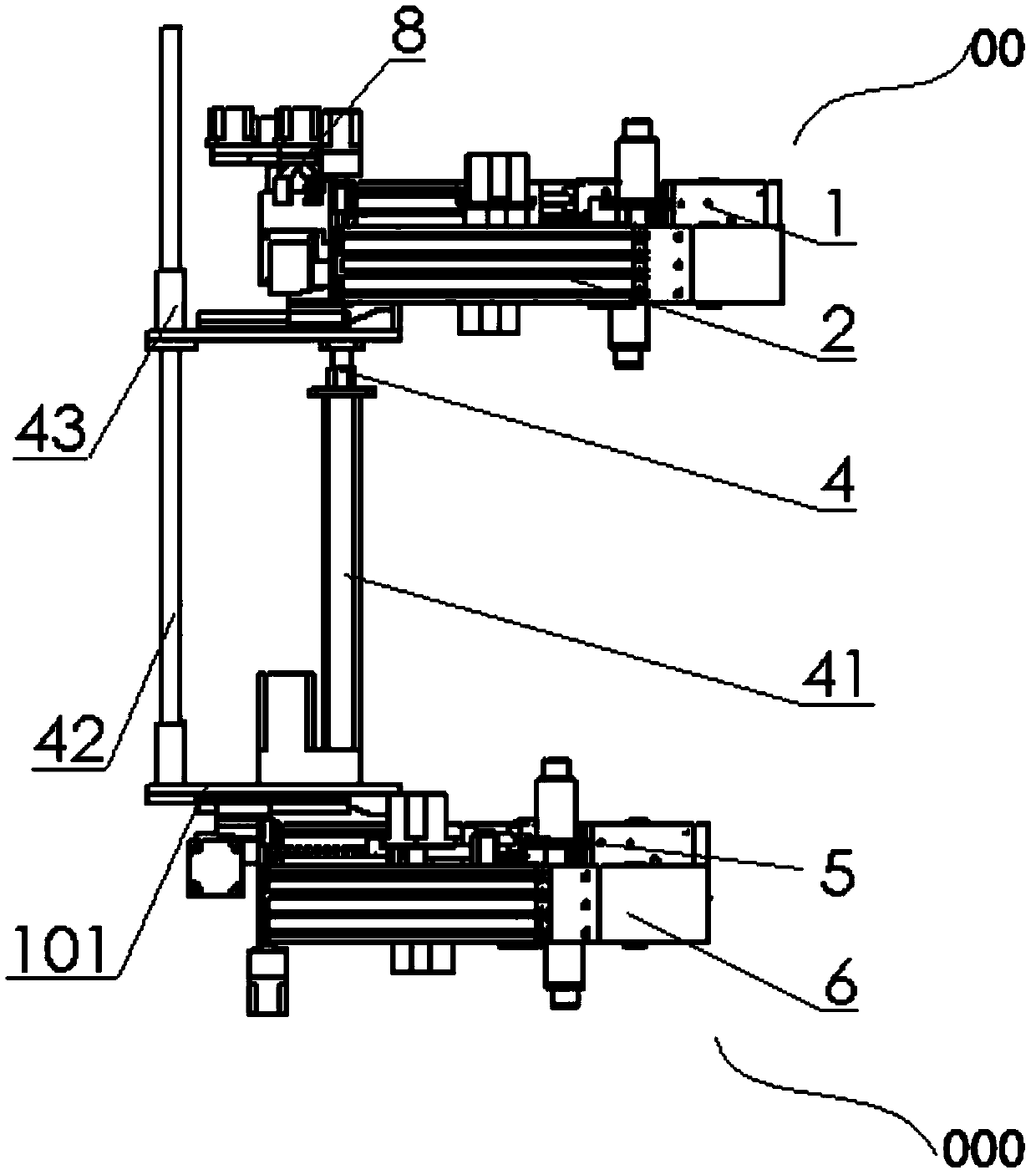

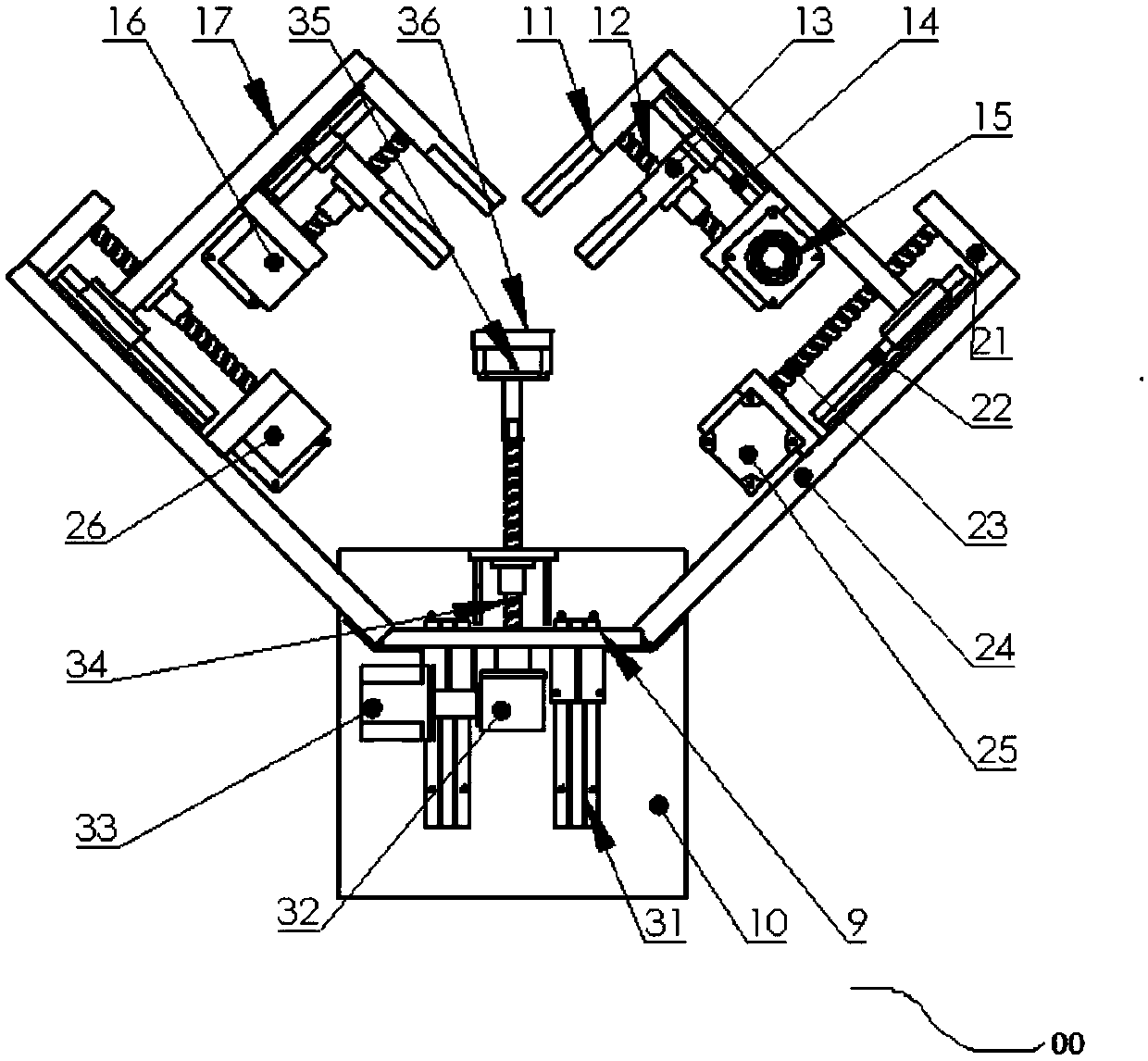

Intelligent control method and system for fully mechanized mining device used for complex condition working face

PendingCN111173510AImprove running qualityGuaranteed fitMining devicesSlitting machinesDecision controlPressure data

The invention aims to solve the problem of equipment interference, abnormal mechanical conditions and the like due to excessive error accumulation after multiple cycles in a current automated mining system under complex geological conditions, and discloses an intelligent decision control method and system for a fully mechanized mining device used for a complex condition working face. The intelligent decision control system comprises a full posture measurement system for the fully mechanized mining device, a mine pressure monitoring system, a virtual simulation system, an analysis and decisionsystem and a distributed control system. 15 spatial parameters and mine pressure data of the real-time operating state of the device are measured comprehensively, the real mining process is simulatedthrough data superposition, the device abnormalities caused by the complex geological conditions are calculated, the surrounding rock state is predicted, error elimination and surrounding rock controlmethods based on known process methods and historical data learning results are proposed, and subsequent mining control parameters are predicted; and based on real data and virtual simulation results, the optimization and decision-making of underground comprehensive mining device control parameters are completed, so as to ensure that device control under the complex geological conditions can be consistent with actual environmental conditions, and the operation quality of the fully mechanized mining device is greatly improved.

Owner:TIANDI SCI & TECH CO LTD

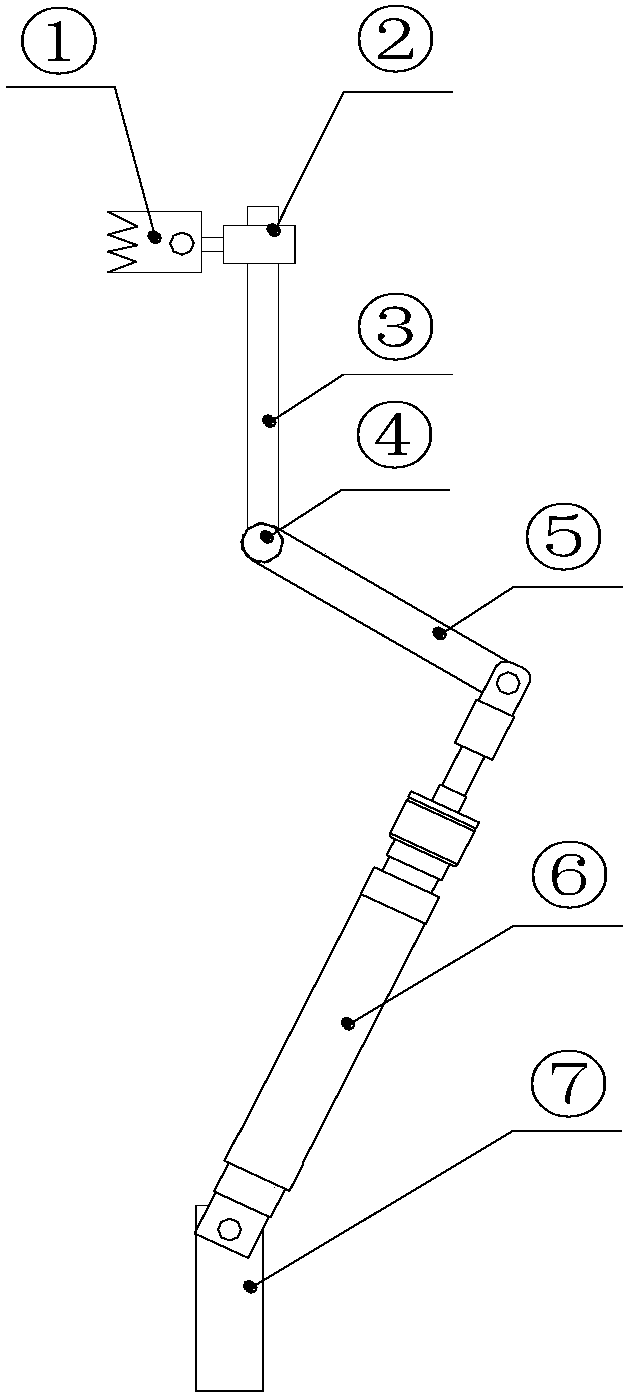

Clamping mechanisms of robot used for transmission tower and climbing robot

ActiveCN109572849ACompact structureIncrease clamping forceApparatus for overhead lines/cablesVehiclesTransmission towerReciprocating motion

The invention discloses clamping mechanisms of a robot used for a transmission tower and the climbing robot. The clamping mechanisms of the robot used for the transmission tower and the climbing robotsolve the problem in the prior art of high safety risk in the process of manually climbing the transmission tower, and have the beneficial effects of allowing the robot to climb the transmission tower, and providing a safety guarantee for climbing workers during follow-up operations. According to the technical solution, the robot used for the transmission tower consists of the clamping mechanisms, a lifting mechanism and a mechanical arm, wherein the clamping mechanisms comprise clamping components; the clamping components comprise clamping blocking plates and clamping plates; the clamping plates move back and forth relative to the clamping blocking plates through second telescopic units so as to clamp one side of the transmission tower through the clamping blocking plates and the clamping plates; extension components are provided with first telescopic units; the first telescopic units are connected to the clamping components so as to drive the clamping components to approach or get away from the side of the transmission tower; the top end and the bottom end of the lifting mechanism are separately connected to an upper clamping mechanism and a lower clamping mechanism; and the movement of the robot along a linear guideway is realized through the extension and retraction of the lifting mechanism.

Owner:SHANDONG JIANZHU UNIV

Assembly structure of assembly-type concrete member

The invention provides an assembly structure of an assembly-type concrete member. A sleeve comprises a non-grouting connection section and a grouting connection section. A steel skeleton comprises inner barbs and outer barbs, the diameter of a passage defined by the multiple inner barbs is smaller than that of a second to-be-connected steel bar, and the outline diameter defined by the outer barbsis larger than the diameter of an inner cavity of the grouting connection section. An alignment device comprises lower supports and upper supports which are both electromagnets, the same magnetic poles of the upper supports and the lower supports are opposite, and the upper supports and the lower supports are connected in the same circuit in series. All parts of the grouting sleeve are machined and manufactured correspondingly and then assembled, mass production is achieved, and the quality of all the parts is easy to control; connection of the grouting sleeve and a steel pipe transition section is operated by machines in a factory, the threaded connection quality is easy to control, the self-locking type steel skeleton is adopted, thus the purpose of pulling preventing is achieved, and shock resistance is improved; through the principle of magnetic levitation, fast and accurate centering of the steel bars of upper and lower concrete member bodies is achieved, so that the time and labor are saved; and through the series-connection circuit, the same magnetic forces of a plurality of supporting mechanisms can be achieved, and stable supporting is guaranteed.

Owner:HEFEI CONSTR ENG GRP

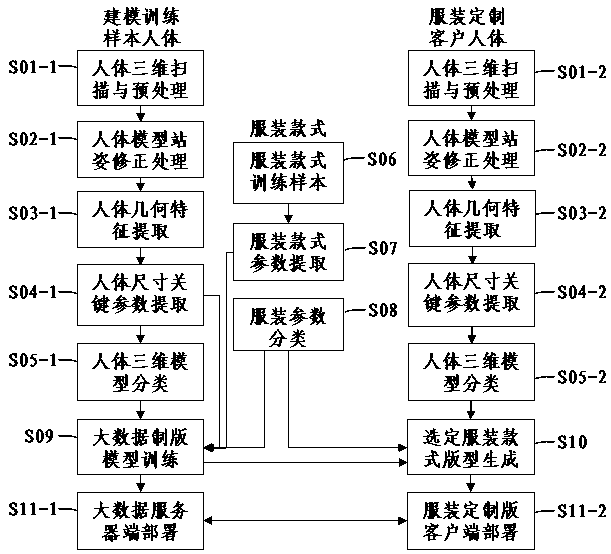

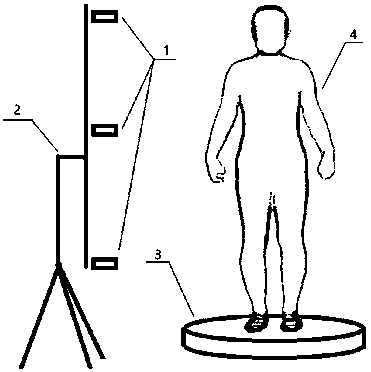

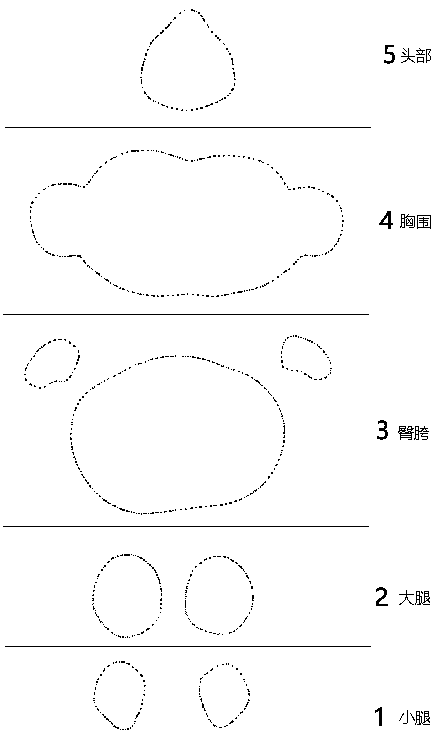

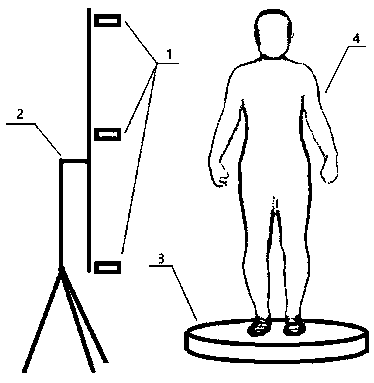

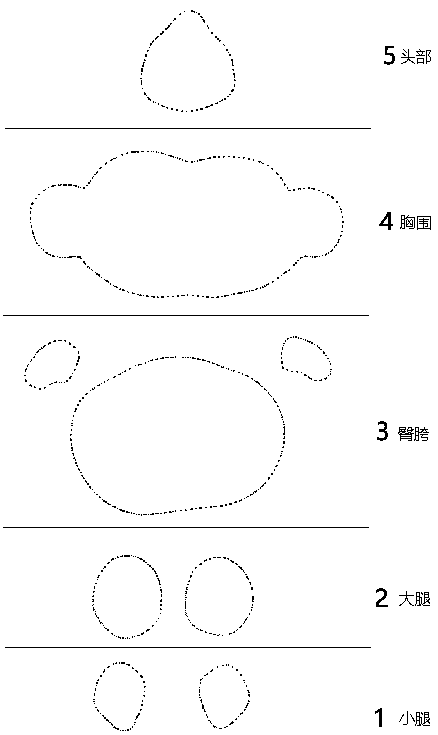

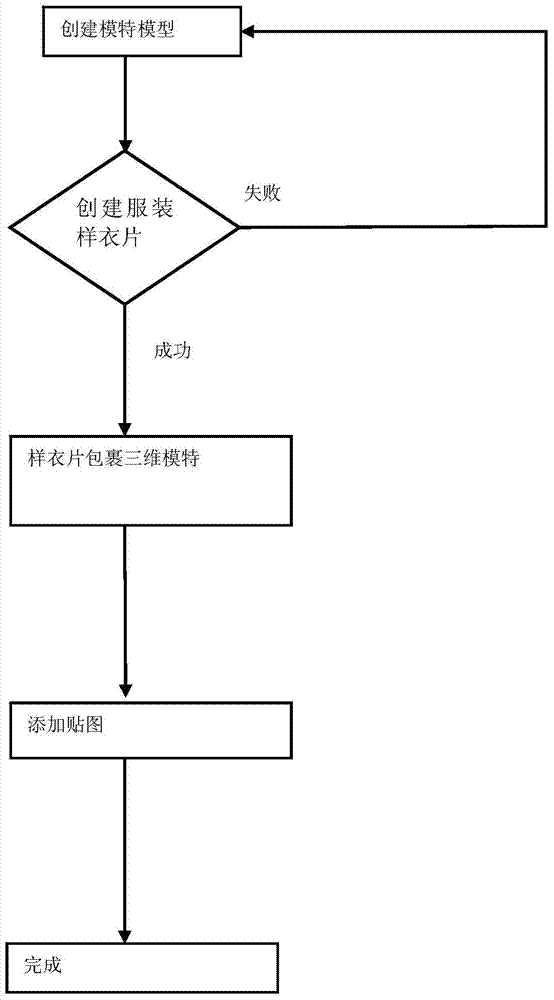

Garment plate making method based on human body big data

ActiveCN110264310AFast automatic plate makingAccurate automatic plate makingBuying/selling/leasing transactions3D modellingPersonalizationHuman body

The invention provides a garment plate making method based on human body big data. The invention, and relates to the technical field of human body three-dimensional measurement and garment plate making. The problem of rapid, accurate and automatic plate making under the condition of irregularly scanning a human body model is solved. The method comprises the following steps of human body three-dimensional scanning and preprocessing, human body model standing posture correction and symmetry, human body geometric feature extraction, human body size key parameter extraction, human body three-dimensional model classification and body shape feature space construction. ; mManufacturing of the model of the garment style training sample according to the garment style; garment style parameter extraction, clothes parameter classification and clothes feature space construction; . according to the method, Tthe model of the big data platemaking neural network is trained, the pattern of the garment style is generated according to the human body model of a client, online service is deployed, rapid, accurate and automatic platemaking of the garment customization pattern based on the big data of the human body is achieved, and the big data model learns the platemaking experience of a platemaker, so that an intelligent technical solution is provided for large-scale personalized garment customization.

Owner:肖伯祥

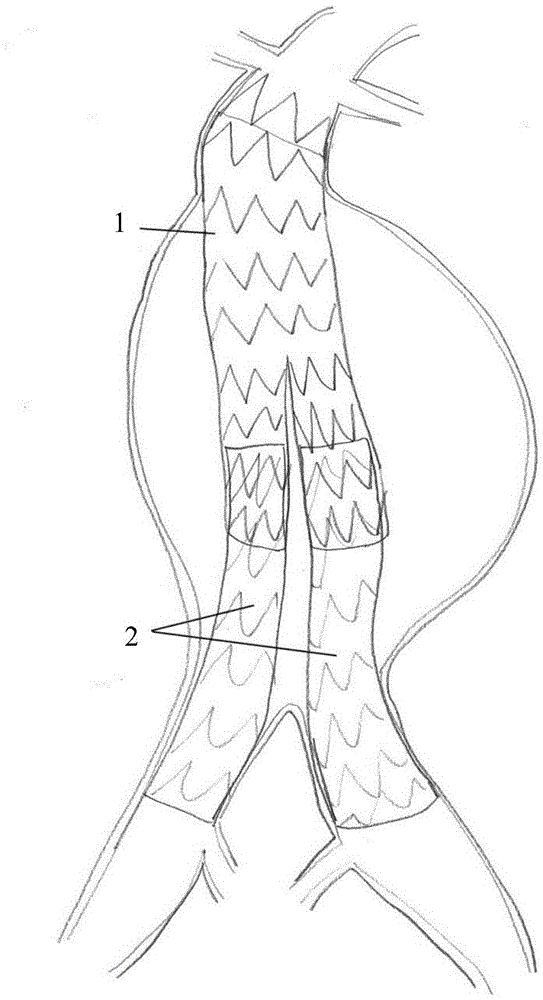

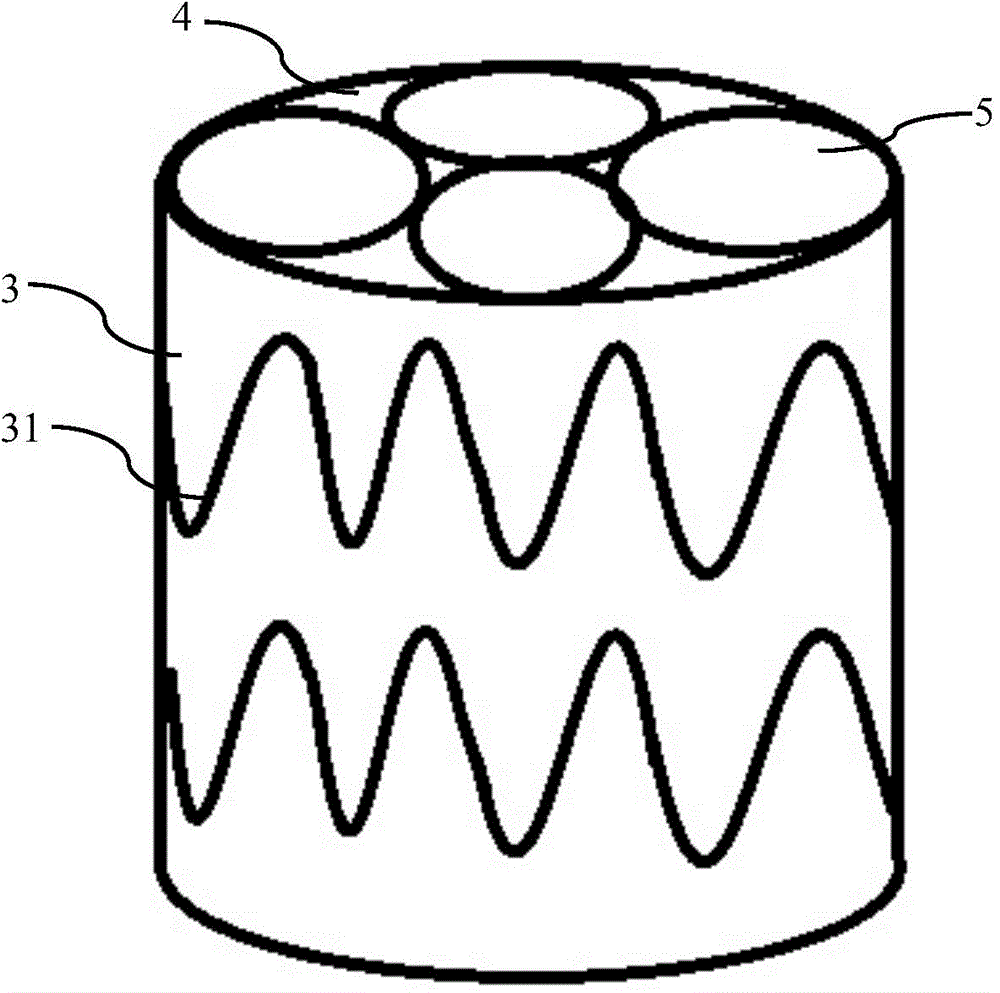

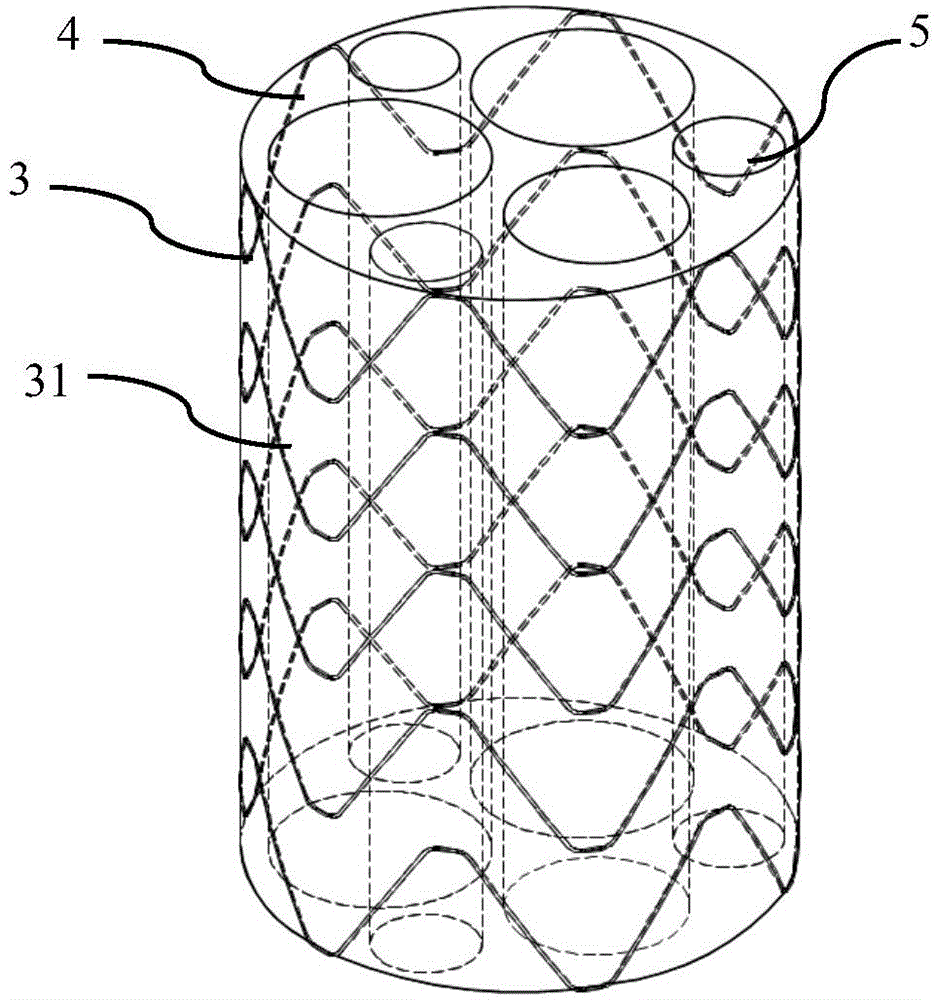

Artificial aneurysm neck and production method thereof

InactiveCN105213076AEliminate risk of ruptureAvoid postoperative complicationsStentsAnterior Cerebral Artery AneurysmIliac Aneurysm

The invention discloses an artificial aneurysm neck and a production method thereof. The artificial aneurysm neck comprises a tubular outer wall and a tubular inner passage arranged in the outer wall, the inner passage is of a hollow structure, and two ends of the inner passage are hermetically connected with the outer wall. The outer wall or / and the inner passage is composed of a tubular tectorial membrane and a metal support arranged on the surface of the tubular tectorial membrane. The artificial aneurysm neck is guided to a normal aorta at the near end of a lesion position and then released during operation, the metal support supports the tectorial membrane on the wall of a normal blood vessel, and fitting between the artificial aneurysm and the normal blood vessel is guaranteed; a tectorial membrane support is enabled to isolate aneurysm from blood flow in a blood vessel cavity, and a blood flow passage of the aorta and branched blood vessels is built; due to using of the artificial aneurysm neck, requirements on structure of the tectorial membrane support are lowered, the artificial aneurysm neck can be realized through a straight-tube tectorial membrane support, requirements on length of the aneurysm neck are low, the artificial aneurysm neck is suitable for cases with extremely short aneurysm necks, production process is simplified obviously, processing cost can be lowered, and production efficiency can be improved.

Owner:SHANGHAI MICROPORT ENDOVASCULAR MEDTECH (GRP) CO LTD

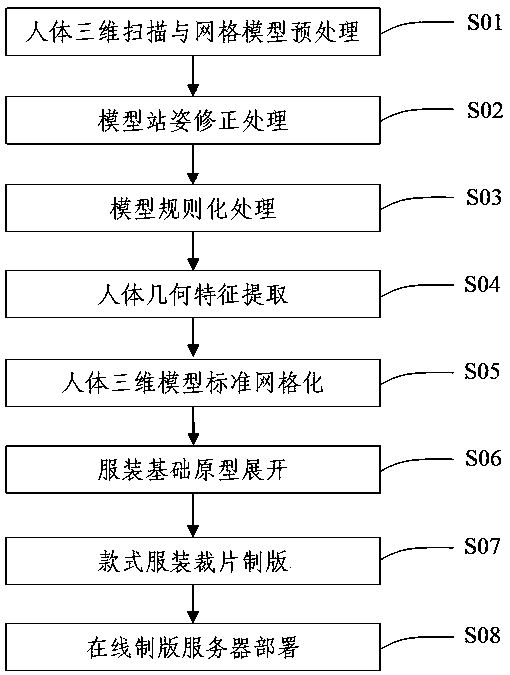

Personalized garment customization plate making method

ActiveCN110163728AFast automatic plate makingAccurate automatic plate makingBuying/selling/leasing transactions3D modellingPersonalizationFeature extraction

The invention provides a personalized garment customization plate making method, relates to the field of automatic plate making in the large-scale personalized garment customization process, and mainly solves the problem of rapid, accurate and automatic plate making under the condition of irregularly scanning a human body model. The method comprises the following steps: carrying out three-dimensional scanning of the human body and preprocessing of the mesh model; correcting the standing posture of the model; performing model regularization processing; extracting human body geometrical characteristics; performing standard meshing on the human body three-dimensional model; unfolding the basic clothes prototype; making a pattern garment cut piece plate; and carrying out online plate making server deployment. According to the method, rapid, accurate and automatic plate making of the garment customization model based on the three-dimensional human body scanning model can be achieved, manualintervention is not needed in the plate making process, and a technical solution is provided for large-scale personalized garment customization.

Owner:肖伯祥

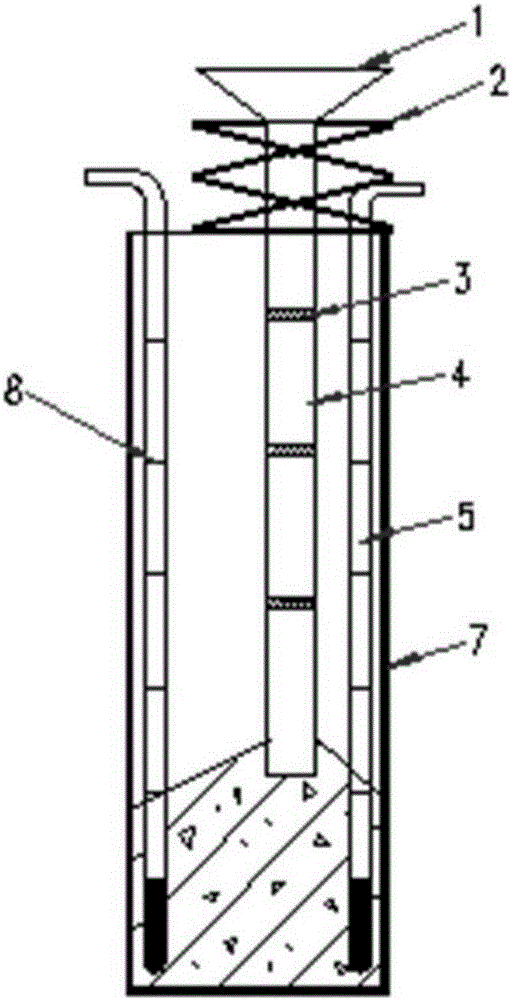

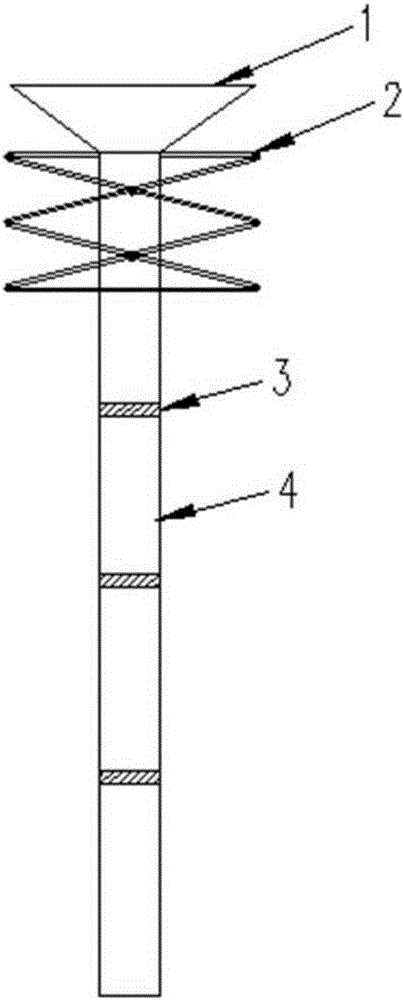

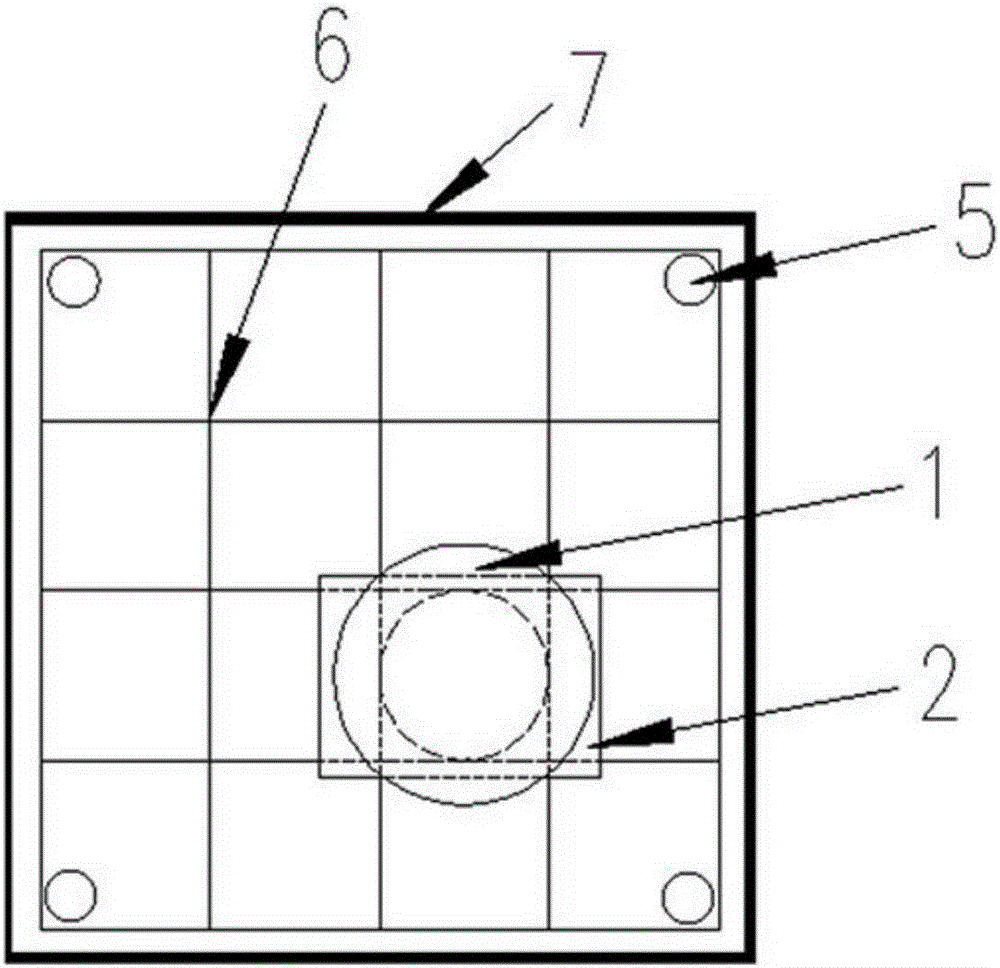

Device and method for one-time pouring molding of ultra-high concrete column

InactiveCN105350777AEnsure structural safetyGuaranteed structural qualityBuilding material handlingReinforced concreteHoneycomb

The invention discloses a device and method for one-time pouring molding of an ultra-high concrete column. The device comprises a guiding device arranged in an ultra-high concrete column formwork. The guiding device comprises a collecting hopper, a scissor fork lifting mechanism, guiding pipe connecting mechanisms and a guiding pipe. The collecting hopper is arranged on the top of the guiding pipe, the guiding pipe is divided into multiple sections with the equal length, the sections are connected through the guiding pipe connecting mechanisms, the lower portion of the collecting hopper is sleeved with the scissor fork type lifting mechanism for lifting the guiding pipe, multiple vibrating rods for vibrating and densifying concrete are arranged between hoops on the edges of the formwork, multiple sections of scale marks are arranged on the vibrating rods, and the length of each section of scale mark is equal to that of each section of guiding pipe. Coincidence and integrity with the concrete are guaranteed, the honeycomb and scale phenomenon caused by the fact that vibration is not in place is avoided, the structural safety and appearance quality of one-time molding of the ultra-high reinforced concrete structure column are guaranteed accordingly, appearance attractiveness is improved, and the construction period is shortened.

Owner:CHINA FIRST METALLURGICAL GROUP

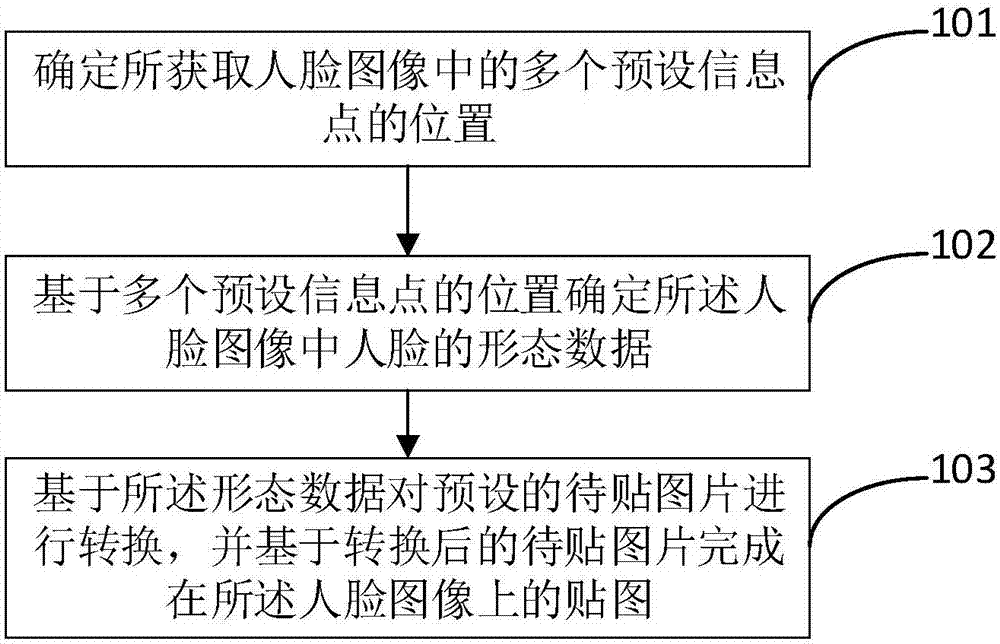

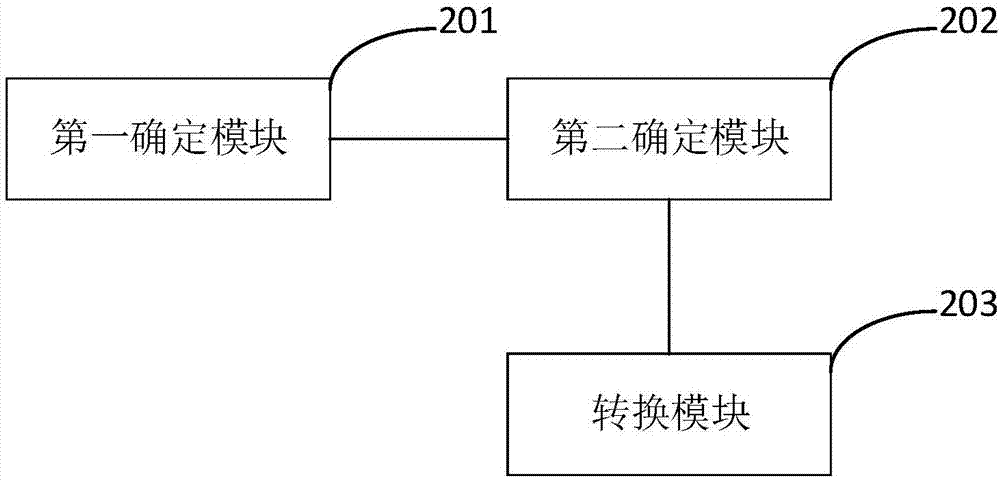

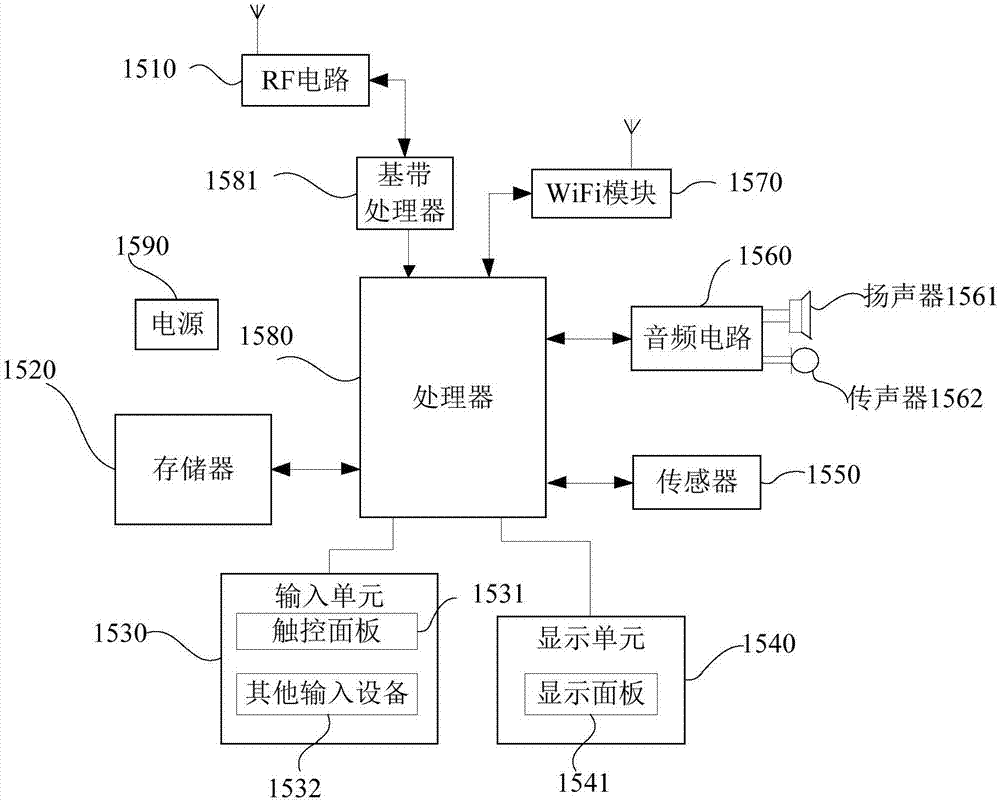

Picture pasting method, device and mobile terminal and computer storage medium

ActiveCN107506732AGuaranteed fitIncrease authenticityTelevision system detailsGeometric image transformationComputer graphics (images)Computer terminal

The invention proposes a picture pasting method, device and mobile terminal and a computer storage medium. The method is used for the mobile terminal and comprises the steps: determining the positions of a plurality of preset information points in an obtained human face image; determining the shape data of a human face in the human face image based on the positions of the plurality of preset information points; carrying out the conversion of a preset to-be-pasted picture based on the shape data, and completing the pasting of a picture on the human face image based on the to-be-pasted picture after conversion. In addition, the method achieves the targeted conversion of the to-be-pasted picture based on the shape of the human face image of a user, so the method can guarantee the fitting degree of the pasted picture with the human face, enables the pasted picture to be attached to the human face more closely, and improves the authenticity of the display effect.

Owner:QIKU INTERNET TECH SHENZHEN CO LTD

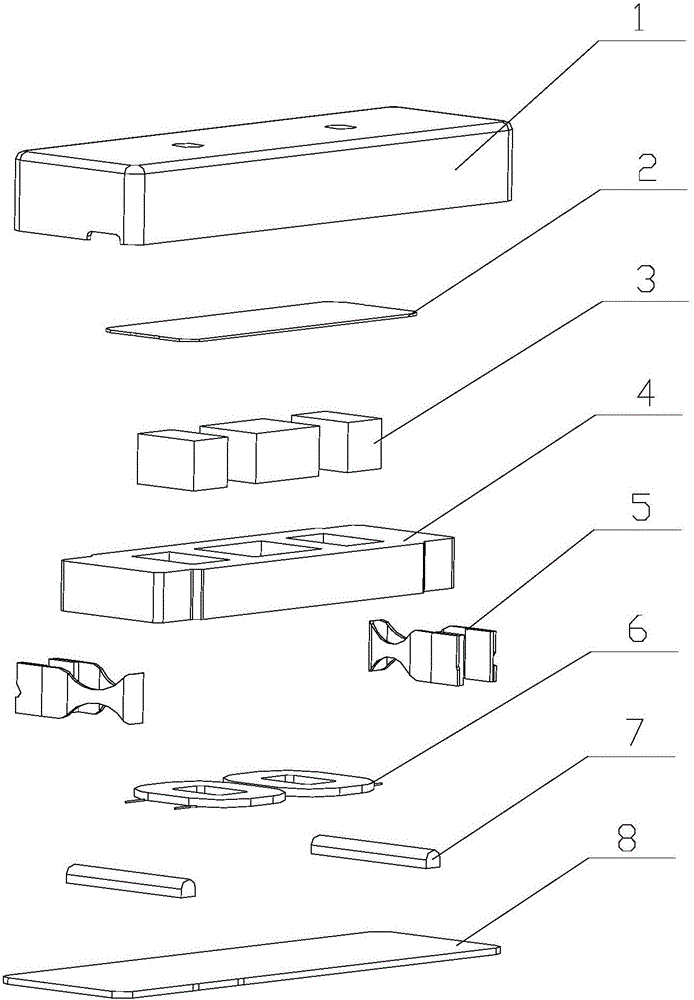

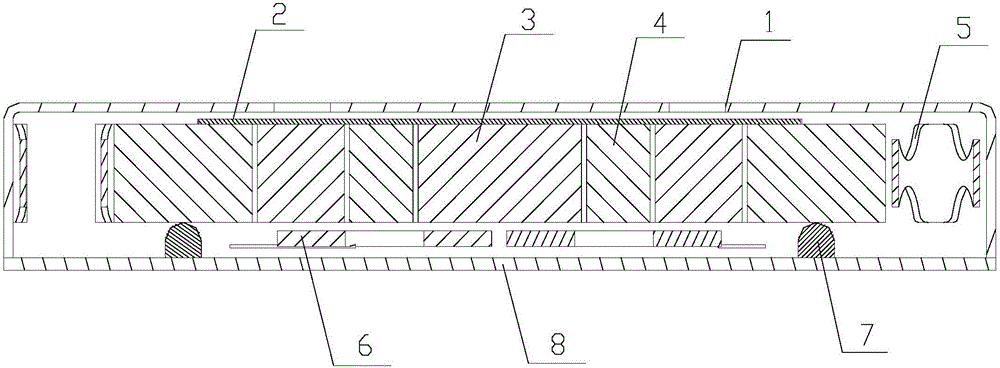

Linear vibration motor

The invention provides a linear vibration motor, which comprises an upper shell, a lower shell, a vibration system, a stator and a spring piece, wherein the upper shell and the lower shell are in fit connection; the vibration system is suspended in the upper shell and the lower shell; the stator is arranged corresponding to the vibration system; the spring piece supports the vibration system and provides an elastic recovery force for the vibration system; the vibration system comprises a mass block and a permanent magnet combined in the middle position of the mass block; a magnetic material is punched to form the lower shell; an elastic support piece is arranged between the mass block and the lower shell; and the elastic support piece is fixed on the mass block / lower shell and performs sliding friction with the lower shell / mass block when the mass block moves. Thus, the frequency band width of the linear vibration motor can be expanded, and collision and noise are reduced.

Owner:GOERTEK INC

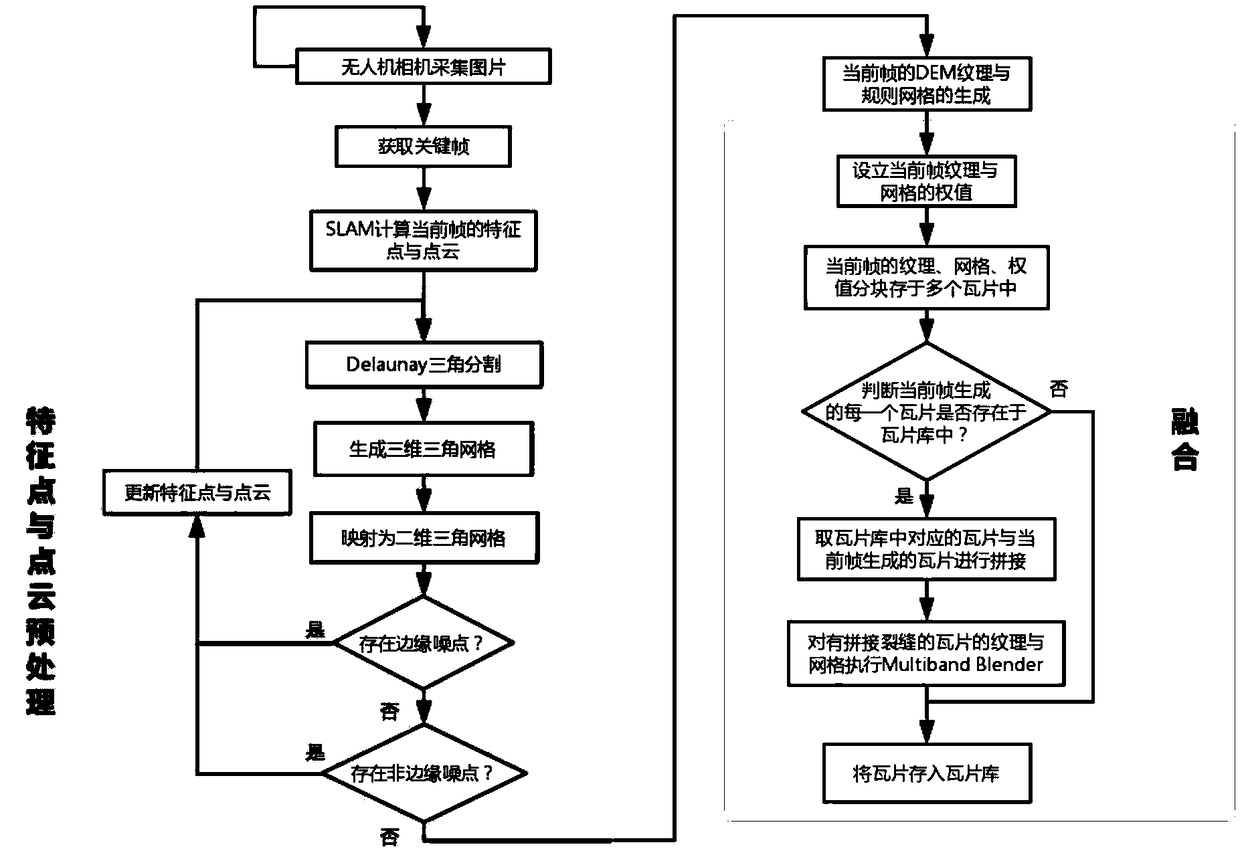

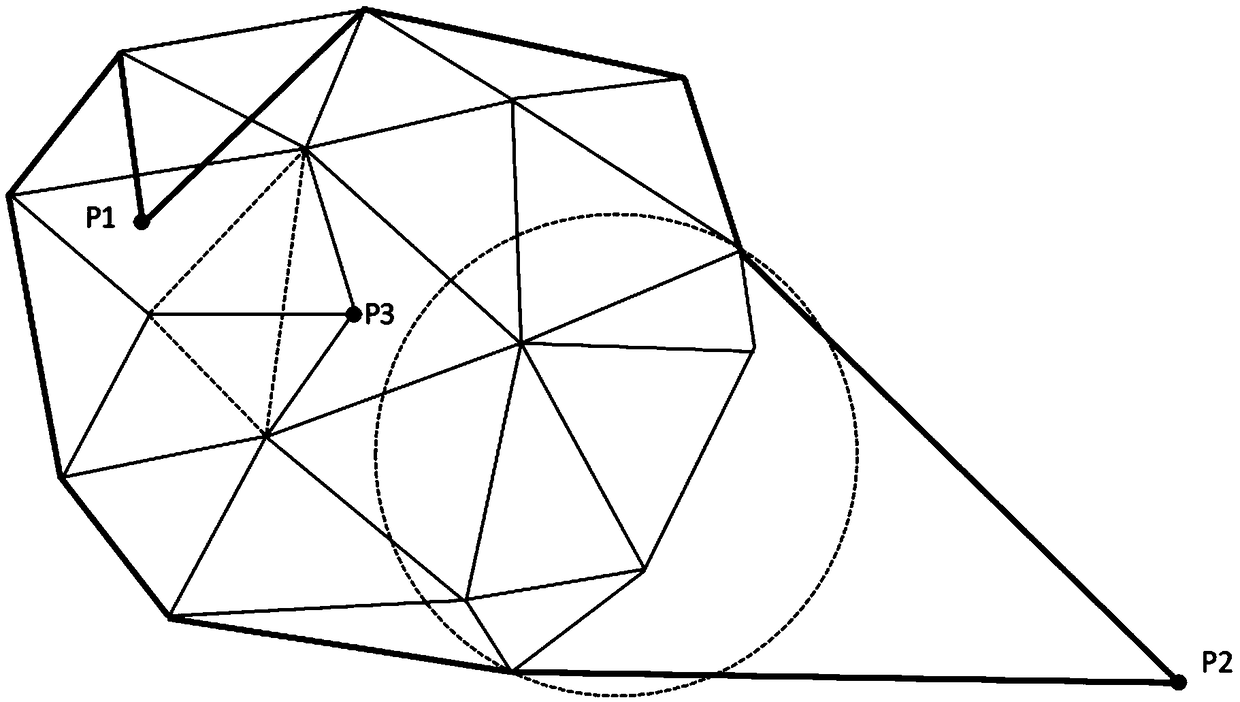

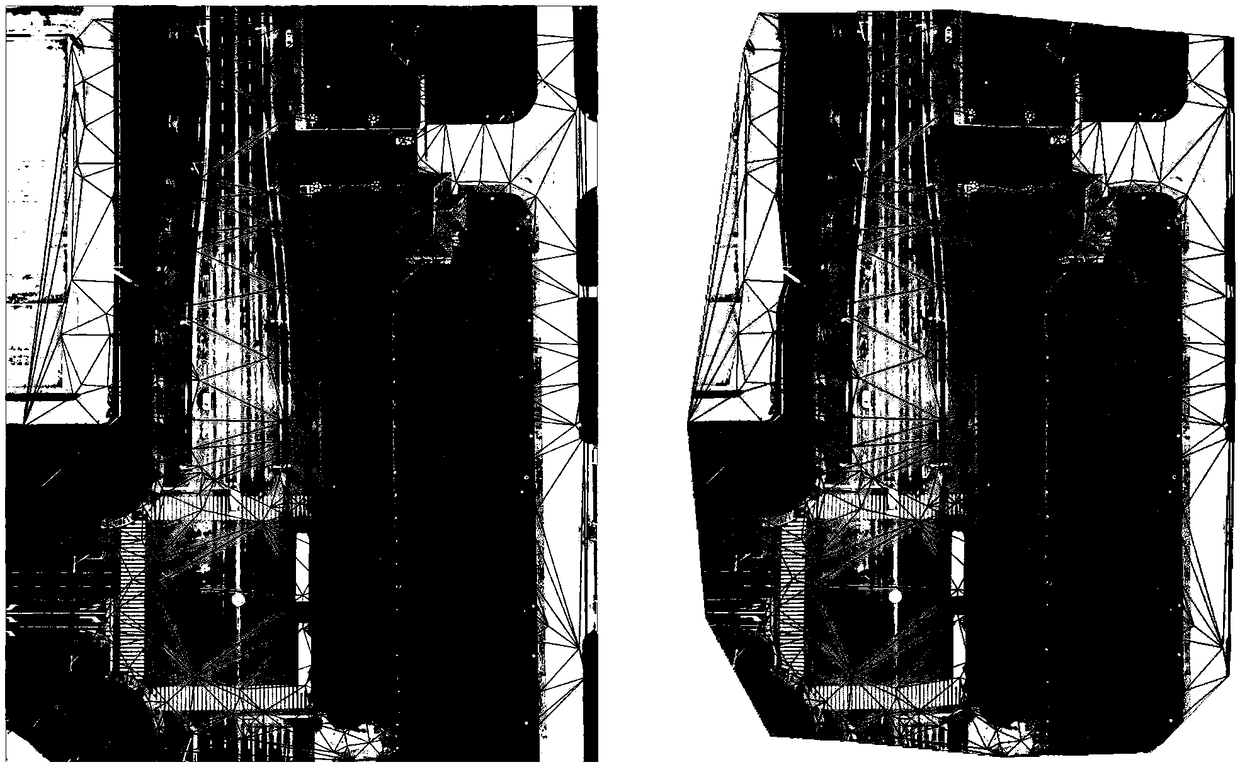

A real-time digital surface model generation method

ActiveCN109242862ASmall time complexityGenerate fastImage analysisGeometric image transformationRegular gridPoint cloud

The invention provides a real-time digital surface model generation method, which takes the current frame image taken by a camera carried by an unmanned aerial vehicle and the current frame feature points and point clouds outputted by the SLAM as input data, and generates a DSM in real-time. Firstly, the airborne camera captures the real-time surface image and processes it with real-time SLAM to obtain the feature points of the current frame and the constructed map point cloud; and the feature points of the current frame and the map point cloud are pretreated in advance; Secondly, the DSM texture and regular mesh of the current frame are generated. Finally, DSM texture and regular mesh fusion are carried out respectively. The invention can meet the real-time requirement, has the advantages of fast generation speed, small time complexity, low memory consumption, high robustness and precision, and good splicing effect.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

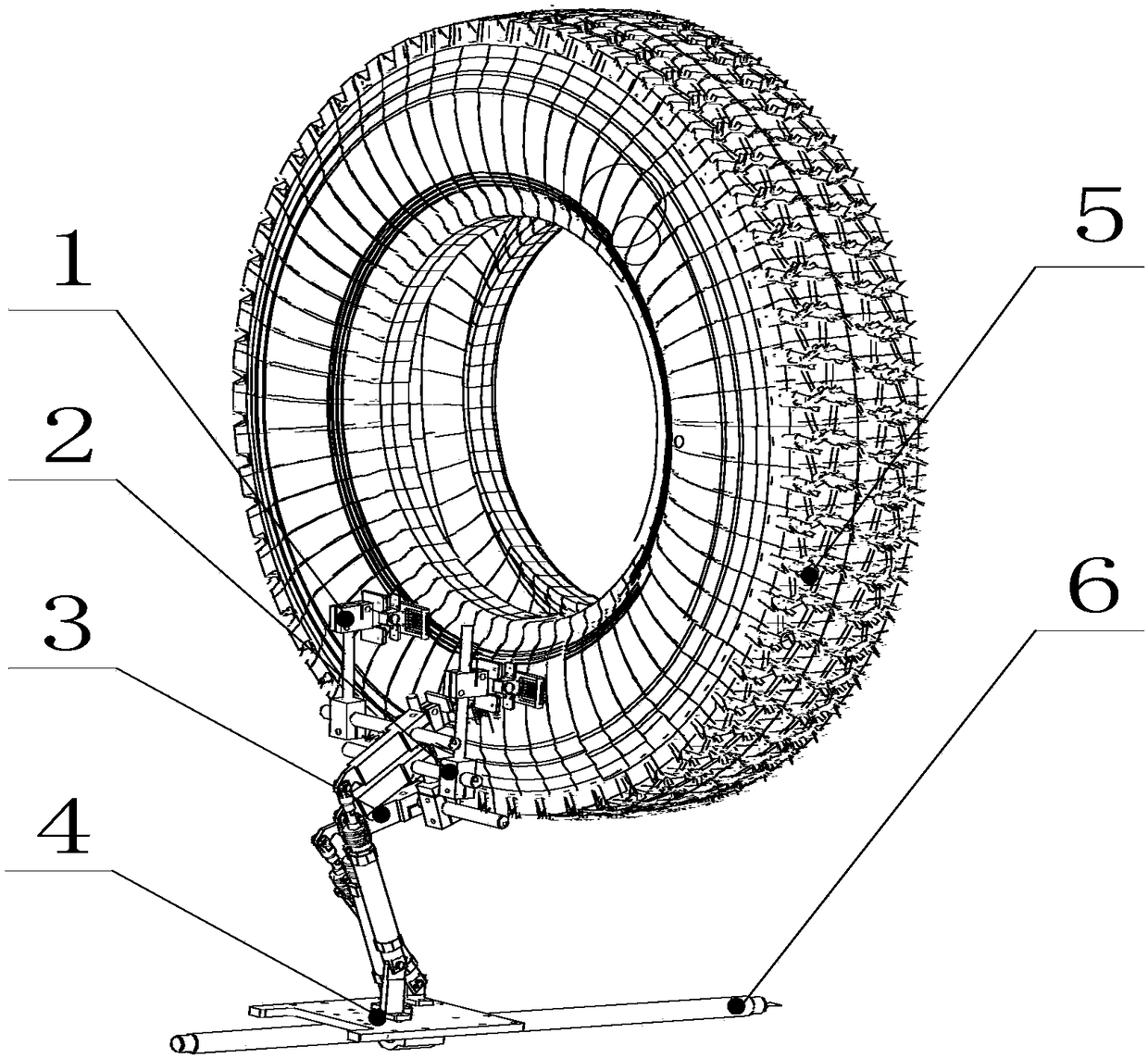

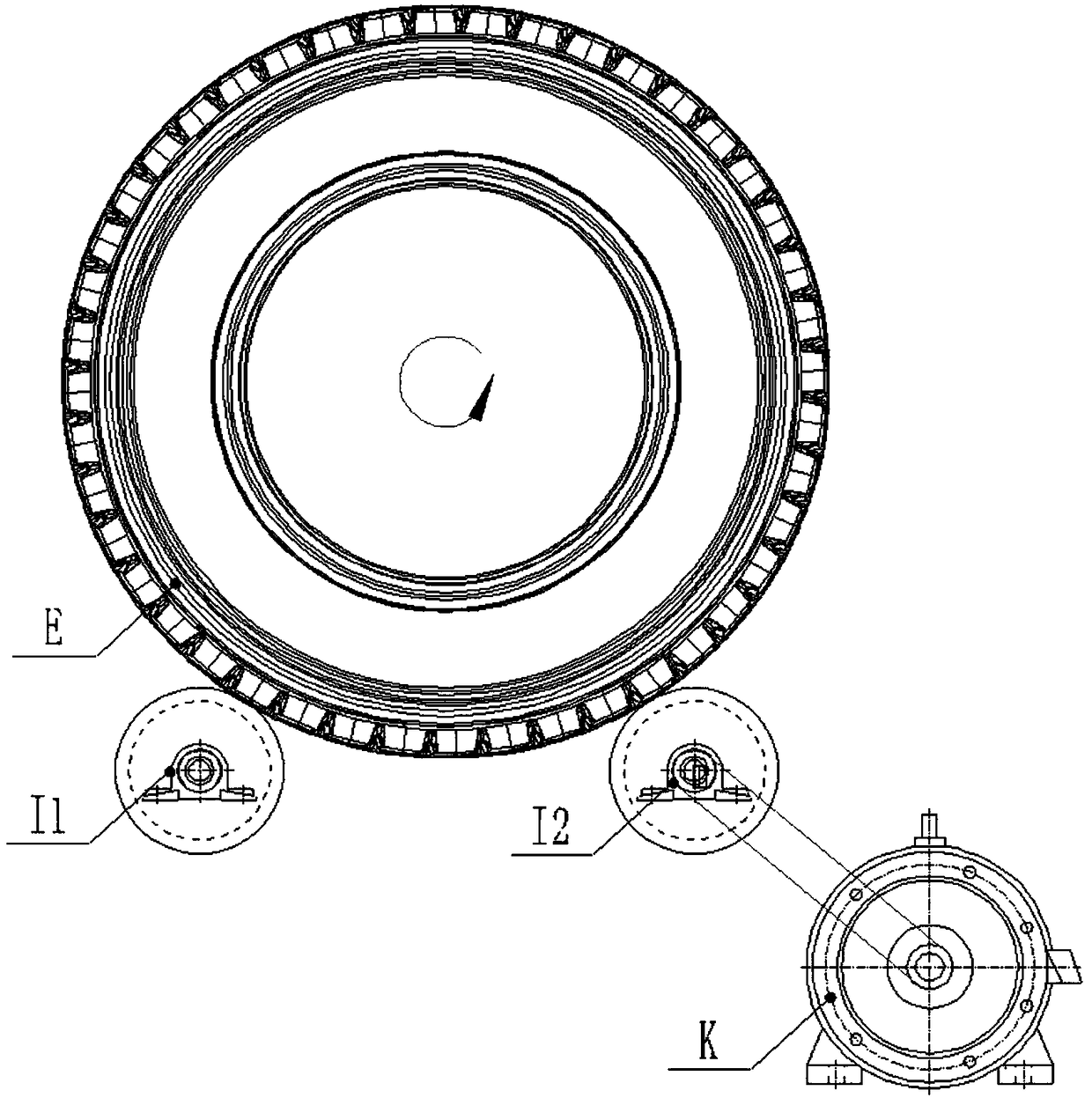

Deburring device for TB tyre side surface

The invention relates to the field of tyre manufacture and particularly relates to a deburring device for a TB tyre side surface. The device includes two sets of cutting tool assemblies that are symmetrical left and right, a rack translation assembly, a tyre and a ball screw. The two sets of cutting tool assemblies are installed on the rack translation assembly and are disposed at both sides of the tyre; opening and closing motion driven by the ball screw is performed on the rack translation assembly to control the distance from the tyre side surface; the tyre is driven by a clamping rotationdevice to perform uniform speed rotary motion, and when the motion is smooth, the cutting tool assemblies are driven by the ball screw to move the tire at a uniform speed on the rack translation assembly, and stop when the cutting tool assemblies move to a suitable distance; at this time, cylinders of cutting tool mechanisms in the cutting tool assemblies perform air inlet work, and cutting toolsare pushed out on a to-be-trimmed tire, and then the cutting assemblies move downward as a whole, and when cutting blades complete trimming deflashing on a tyre surface, the cylinders work at this time, and the cutting tools are recovered; and the cutting tool assemblies are driven by the ball screw to move away from the tyre at the uniform speed until an entire trimming deflashing process is completed.

Owner:JIANGSU UNIV

Mobile phone cover plate attachment mold and process

The invention provides a mobile phone cover plate attachment mold. The mobile phone cover plate attachment mold is used for enabling a glass cover plate to be attached to a protection film so as to form a mobile phone cover plate. The mobile phone cover plate attachment mold comprises an upper mold, a pad film and a lower mold. A groove is formed in the upper mold. The lower mold comprises a substrate, a bearing part and elastic parts. The substrate comprises a bottom plate and a side plate, and containing space is formed between the bottom plate and the side plate. The pad film is located between the upper mold and the lower mold and comprises a bearing portion. The upper surface of the bearing portion faces the upper mold and is used for containing the to-be-attached protection film. Thelower surface of the bearing portion is borne on the bearing part and the side plate of the substrate of the lower mold. The bearing part gives first supporting to the middle area of the bearing portion, and the side plate gives second supporting to the corner areas of the periphery of the bearing portion. When the upper mold and the lower mold are compounded, second supporting pressure providedfor the corners of the periphery of the bearing portion is larger than first supporting pressure of the middle area of the bearing portion. The invention further provides an attachment process for carrying out attachment of the glass cover plate and the protection film through the attachment mold. The protection film and the glass cover plate are attached closely, and the effect is better.

Owner:DONGGUAN GUANHE OPTICAL GLASS CO LTD

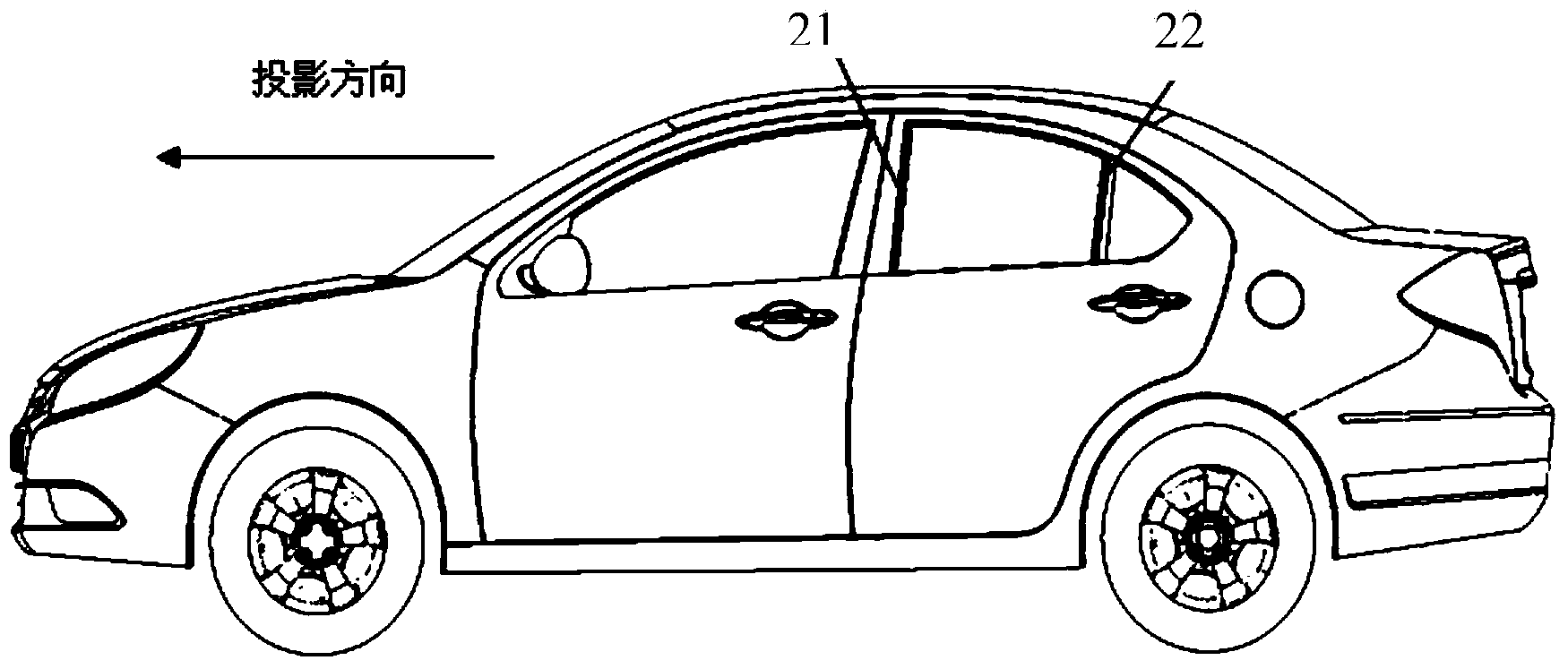

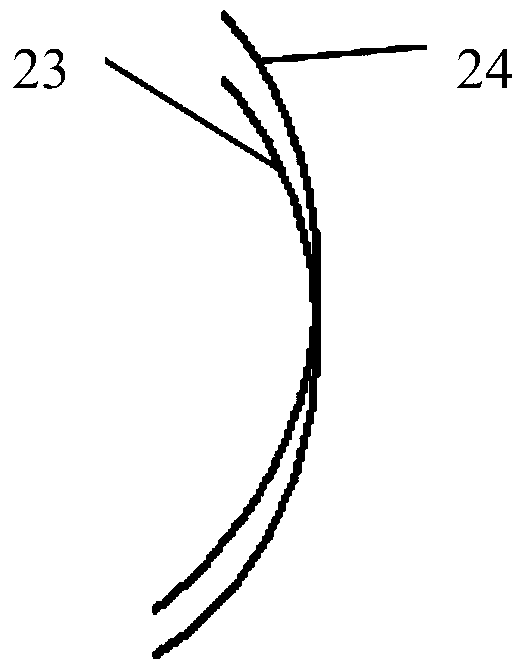

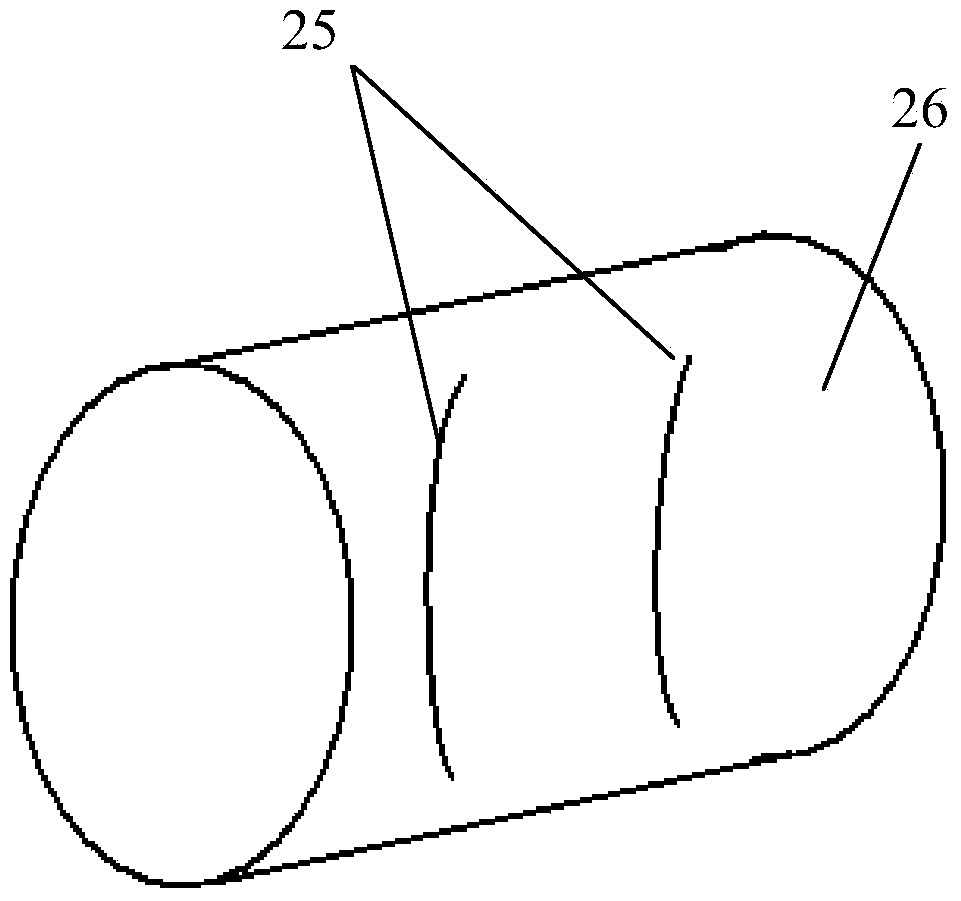

Manufacturing method for lifting guide rail of side window glass of automobile

ActiveCN103696645APurposefulMeet the design requirementsWing arrangementsWing suspension devicesLift lineEngineering

The invention relates to a manufacturing method for a lifting guide rail of a piece of side window glass of an automobile. The method comprises the following steps: selecting a midpoint connected with any point on the glass to be applied for serving as a tangent plane of the glass; extracting the characteristic line of a column B; connecting the characteristic line into a straight line by taking the midpoint in the tangent plane as an original point, and forming a normal plane of the straight line on the midpoint; projecting the characteristic line on the normal plane to obtain a projection line, forming a circle by selecting any three points from the projection line, and forming a cylindrical face; changing included angles between the midpoint of the tangent plant and the straight line of the characteristic line as well as between the midpoint of the tangent plant and the characteristic line to make intersecting lines fit the characteristic line of a boundary virtual guide rail, which is opposite to the column B, of the glass, and forming a spiral line fitting the characteristic line of the column B; forming a spiral line of the same thread pitch on another boundary according to the previous spiral line, wherein the two spiral lines are taken as lifting lines of the glass; manufacturing the glass lifting guide rail according to the lifting lines.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

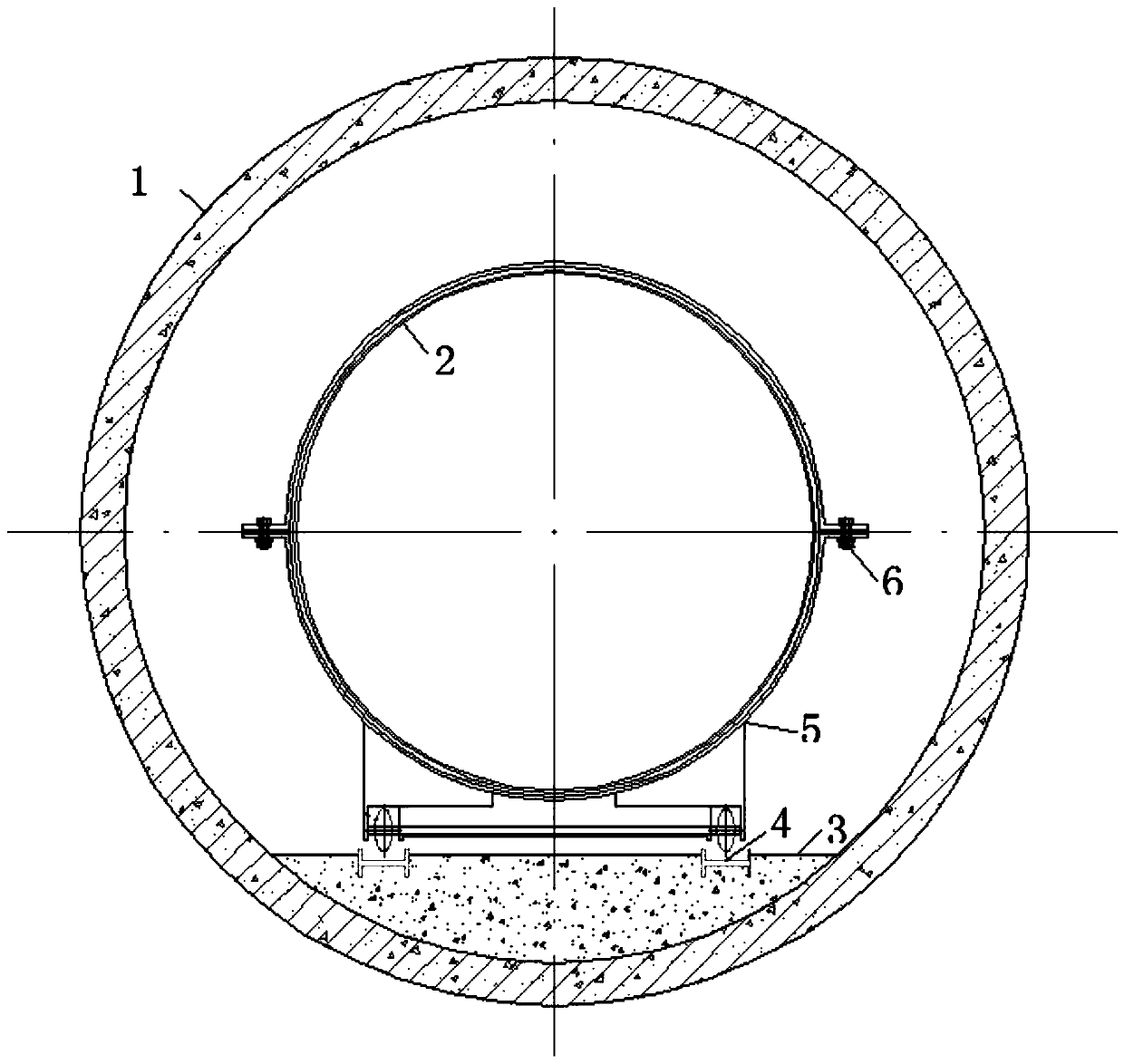

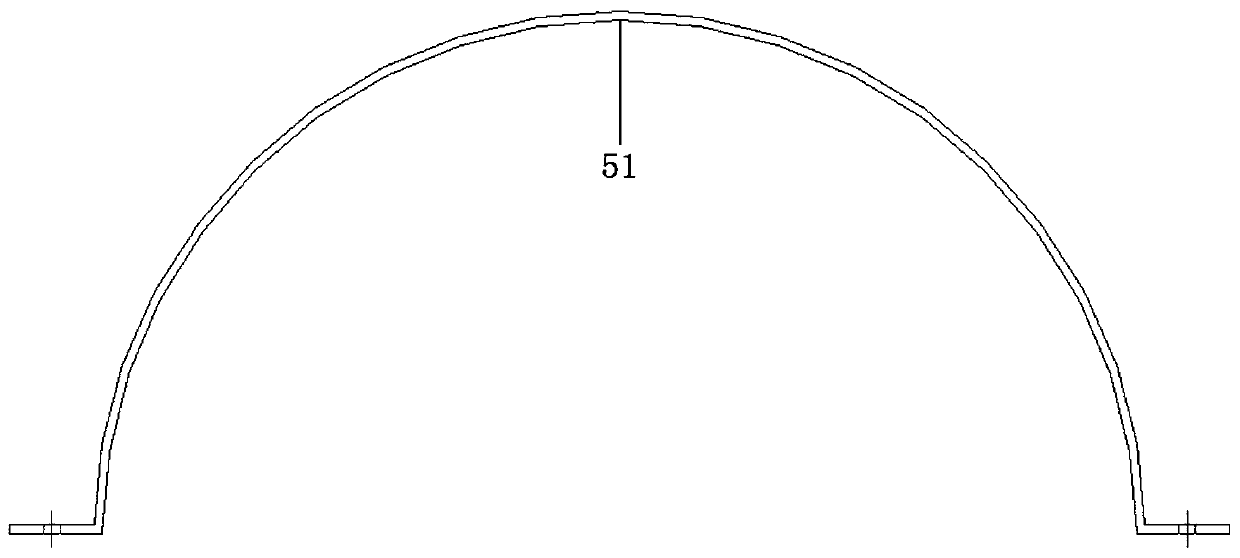

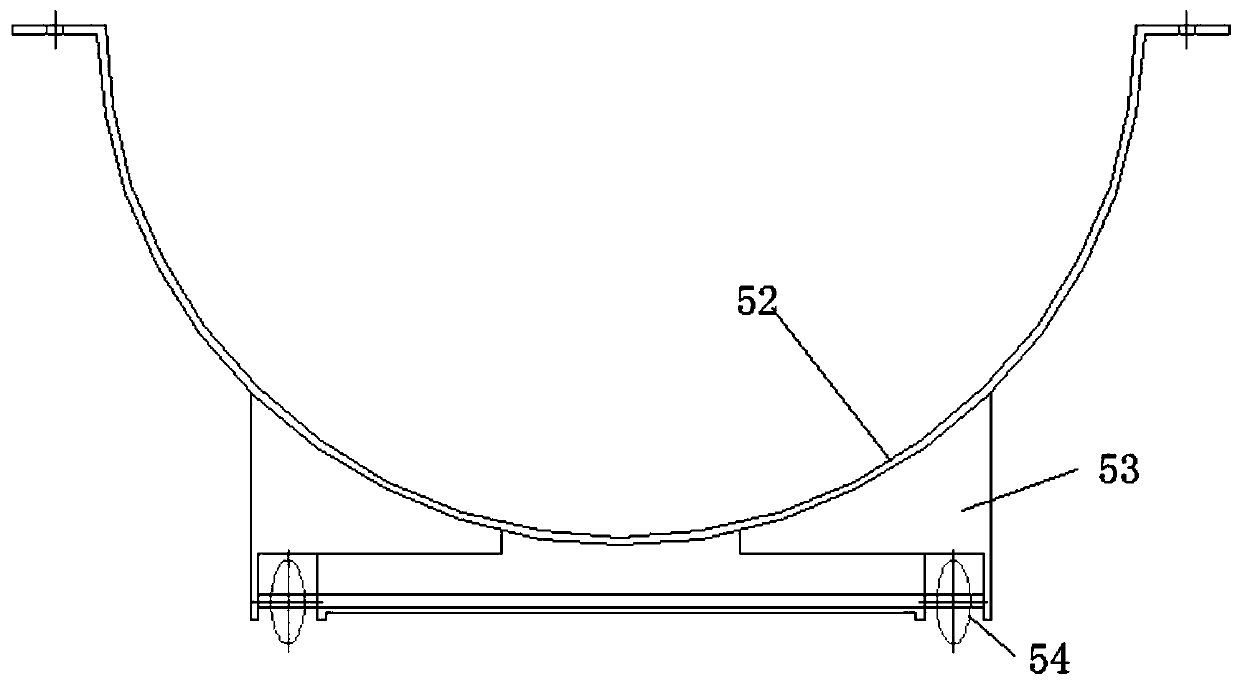

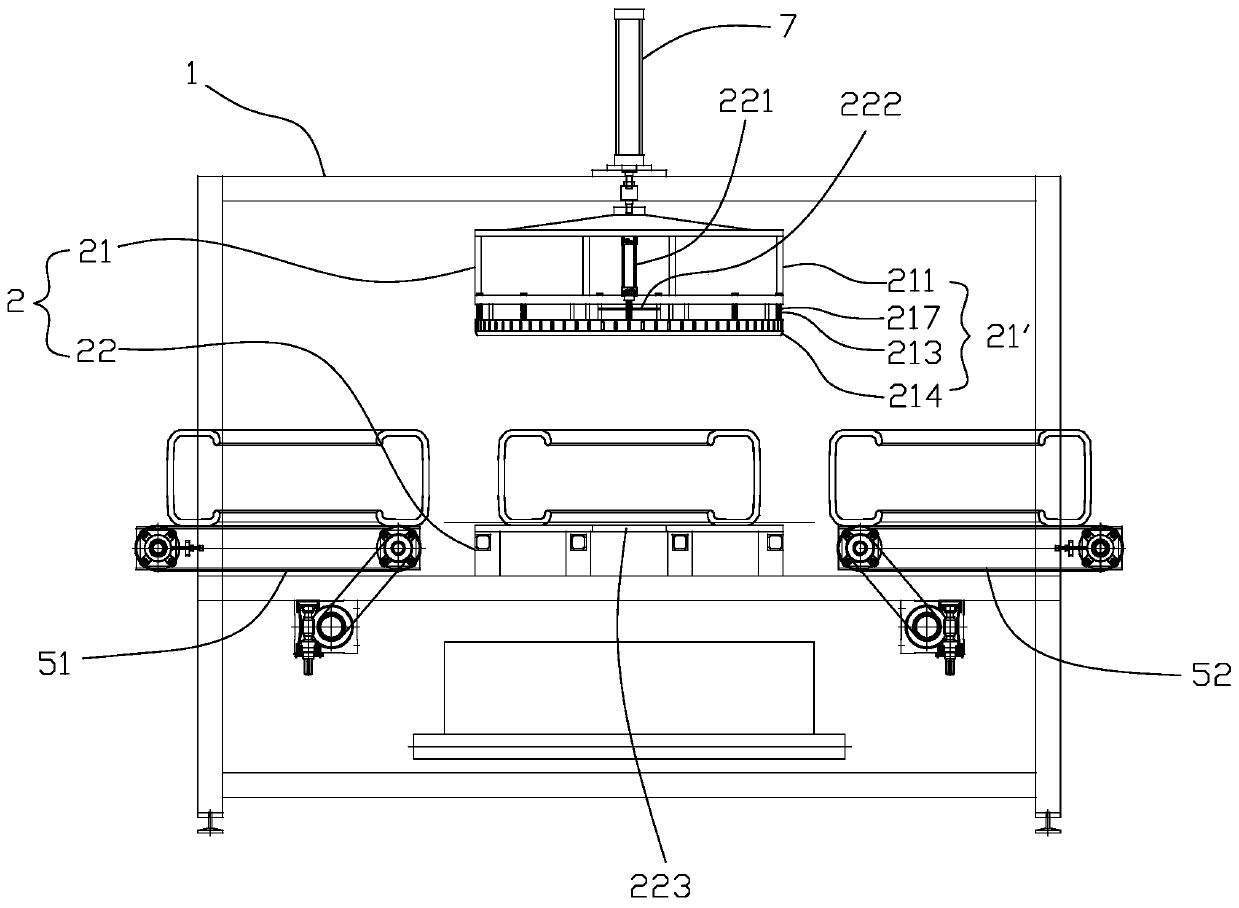

Pipe laying construction method and system inside sleeve pipe based on wheel-rail type pipe hoop

The invention relates to a pipe laying construction method and system inside a sleeve pipe based on a wheel-rail type pipe hoop. The method comprises the following steps that the sleeve pipe is constructed; after constructing of the sleeve pipe is completed, a concrete cushion layer is constructed inside the sleeve pipe; after constructing of the concrete cushion layer is completed, sliding railsare symmetrically arranged on set positions of the two sides of the central axis of the concrete cushion layer; the two ends of a steel pipe are correspondingly and fixedly provided with pre-machinedpipe hoops with pulleys; and the steel pipe is lifted to an inlet of one end of the sleeve pipe so as to be laid, the pulleys of the pipe hoops are connected to the sliding rails on the concrete cushion layer in a sliding mode, the sliding rails are used for providing a fixed advancing route for the pipe hoops, and therefore the steel pipe penetrates into the sleeve pipe. According to the method,aiming at the problems that the advancing track of the pulleys of a traditional steel pulley bracket method is difficult to be unified, and the matching degree and the stability of the steel pipe on the bracket are poor, the pipe laying construction method inside the sleeve pipe based on the wheel-rail type pipe hoop is provided, the sliding rails are utilized for providing the fixed advancing route for the pulleys, and it is ensured that the advancing tracks of the pulleys for conveying all the steel pipes are kept consistent, the steel pipes are free of dislocation, and the directions of thesteel pipes are free of deviation.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Tire film laminating packaging machine

PendingCN110040291AHigh speedSimple structureWrapping material feeding apparatusWrappingEngineeringPackaging machine

The invention discloses a tire film laminating packaging machine which comprises a film sealing unit and a film sending unit which are installed on a rack. The film sealing unit comprises an upper dieand a lower die. The film sending unit comprises an upper film sending device and a lower film sending device. The upper film sending device comprises an upper conveying roller and an upper collection roller, wherein the upper conveying roller and the upper collection roller are located on the two sides of the film sealing unit correspondingly. The lower film sending device comprises a lower conveying roller and a lower collection roller, and the lower conveying roller and the lower collection roller are located on the two sides of the film sealing unit correspondingly. The upper die is provided with laminating parts which are used for pressing an upper film and a lower film on the lower die to conduct hot sealing, and the two laminating parts are in a cylinder shape and are coaxially arranged. By means of the tire film laminating packaging machine, due to laminating of the upper die and the lower die, the upper film and the lower film can be subjected to hot bonding and wrap a tire,the structure of the equipment is simple, in addition, running steps are few, the film laminating packaging speed is high, and the packaging work efficiency is high.

Owner:青岛科力达机械制造有限公司

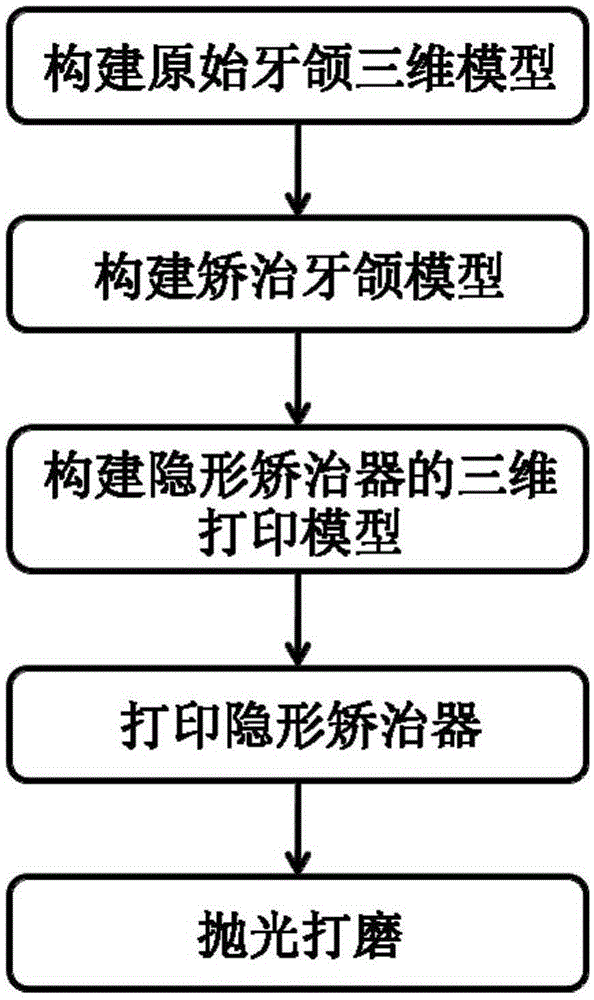

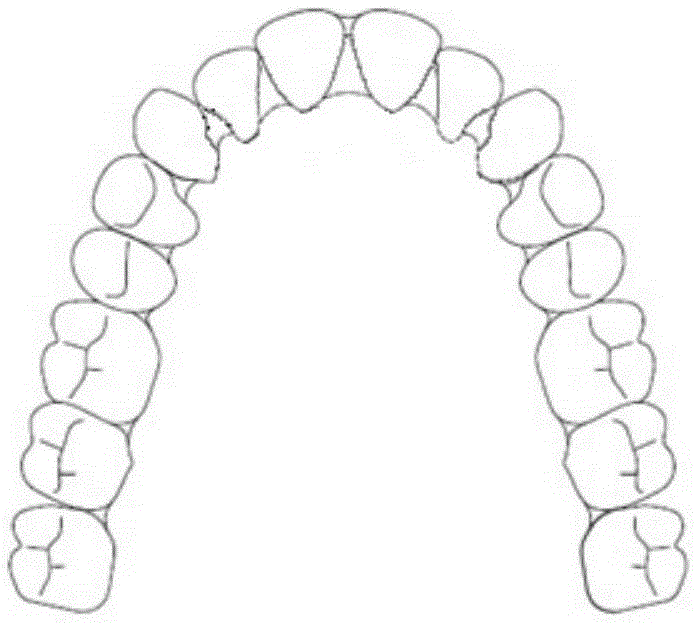

Manufacturing method of invisible tooth correcting treatment devices

InactiveCN105266906AReduce model materialSimplify production stepsOthrodontics3 dimensional printingObjective model

The invention discloses a manufacturing method of invisible tooth correcting treatment devices. According to the method, firstly, an original odonto-maxillary three-dimensional model of a patient is built through a correcting treatment objective and an original odonto-maxillary three-dimensional model; secondly, correcting treatment odonto-maxillary models in different stages of the correcting treatment process are built; then, corresponding three-dimensional printing models are built; corresponding invisible tooth correcting treatment devices are respectively printed out by medial polyethylene according to the three-dimensional printing models; and finally, the invisible tooth correcting treatment devices are polished and ground and are delivered to the patient to be used. By using the method, the invisible tooth correcting treatment devices are directly manufactured without using a solid body objective model, so that the consumption of a great number of light-cured resin materials is avoided; and the problems of high cost and complicated production process of the invisible tooth correcting treatment devices are solved.

Owner:肖然 +1

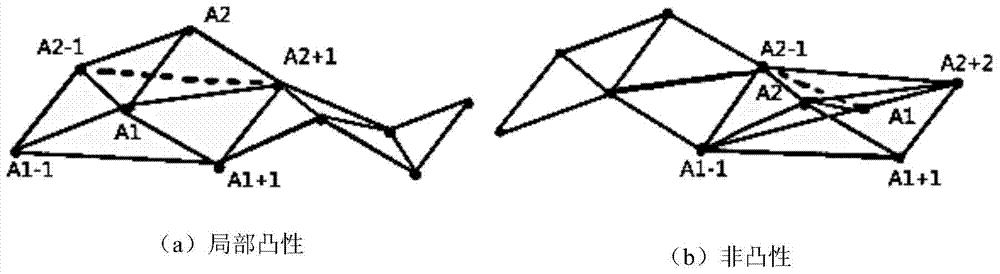

3D virtual garment automatic generation method and system

InactiveCN104268927AGuaranteed fitEasy to integrateDetails involving 3D image data3D-image renderingHuman bodyEngineering

The invention provides a 3D virtual garment automatic generation method. The method comprises the first step of establishing a 3D standard figure model, wherein the 3D standard figure model is a triangulated grid curved-surface human body model, the second step of controlling a two-dimensional garment piece paper pattern and adjusting garment piece parameters to make garment pieces adapt to the 3D standard figure model, the third step of sewing the garment pieces into a 3D garment, and the fourth step of attaching a chartlet to the 3D garment and adjusting clothing material quality. The invention further provides a 3D virtual garment automatic generation system. According to the 3D virtual garment automatic generation method and system, each flattened two-dimensional garment piece is in a regular triangle shape and can be integrated with a traditional pattern making technology conveniently; moreover, the parameters of the garment pieces are set according to the degree of wrap of the garment pieces on a human body, so the basic loose quantity and the fit degree of the garment can be guaranteed.

Owner:上海明穆电子科技有限公司

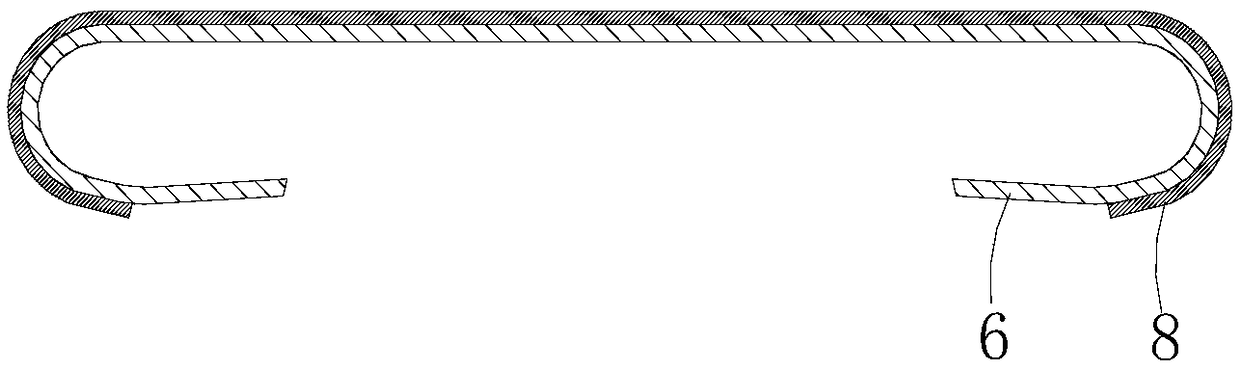

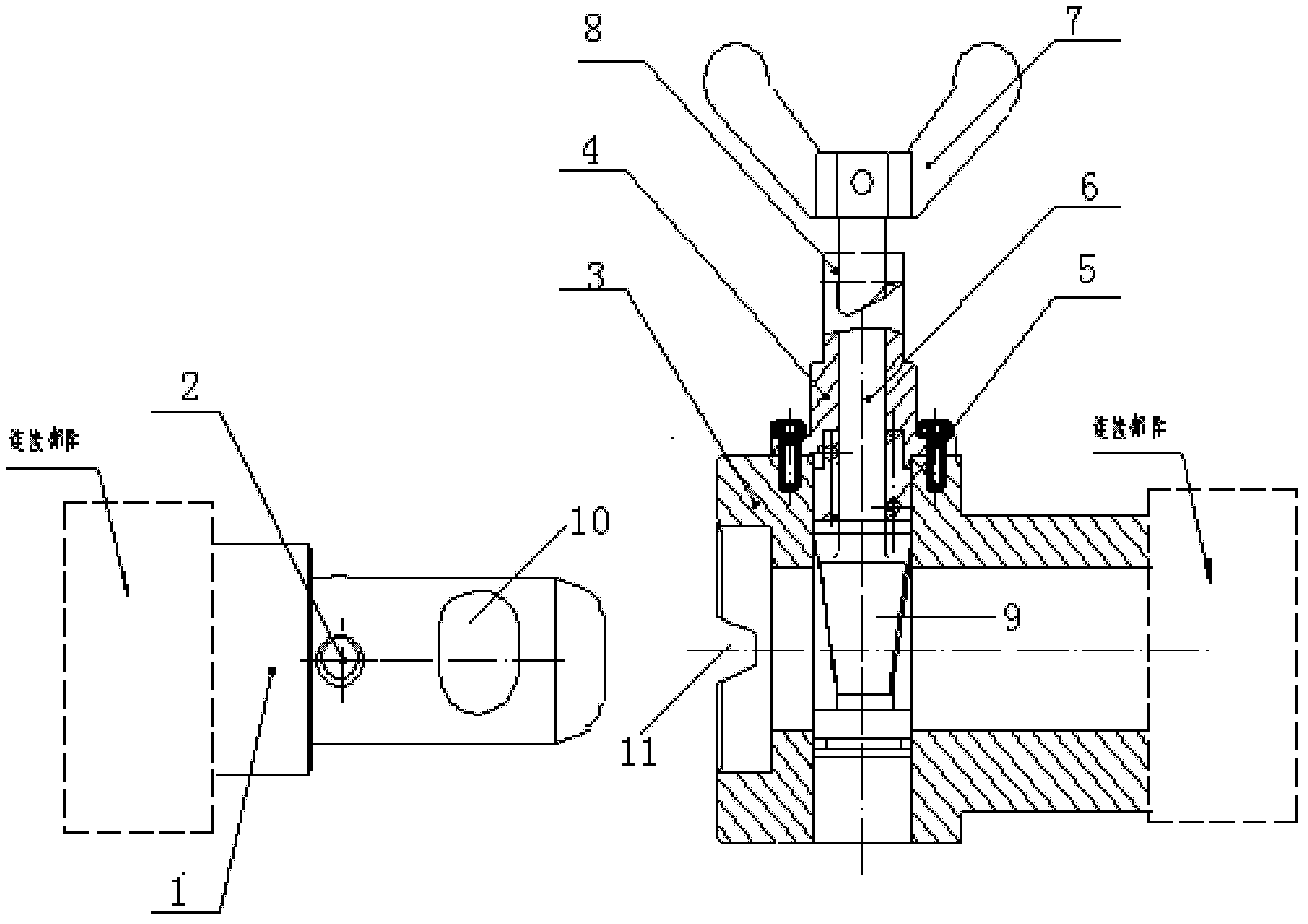

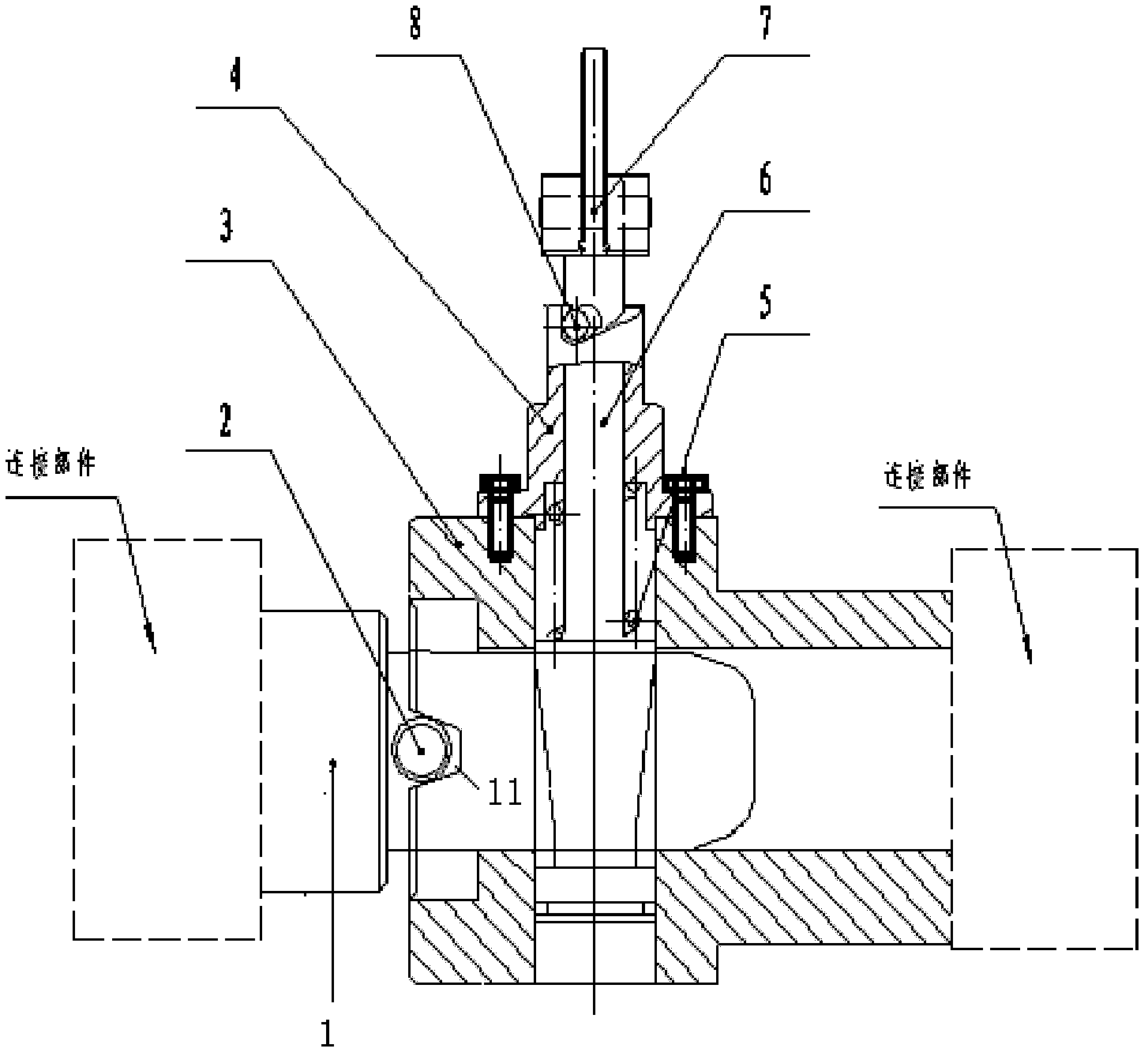

Detachable axial-butting and quick-locking mechanism

The invention provides a detachable axial-butting and quick-locking mechanism, which comprises a connecting shaft (1) and a connecting base (3), wherein one end of the connecting shaft (1) is provided with a positioning pin (2), the connecting base (3) is matched with connecting shaft to connect parts together, the column surface of the connecting base is provided with a lock latch (6) which is vertical to the central axis, penetrates into an upper locking base (4) and is radially communicated with the barrel hole of the connecting base (3), and a lock latch which is used for coaxially locking the connecting shaft, a truncated cone rotating body (12) is machined on the lower end of the lock latch, a connecting shaft penetration contact unlocking surface is machined on the truncated cone rotating body (12) so as to lock and unlock the axial inner-concave ladder-shaped section cutting surface of the truncated cone rotating body (12), and the lock latch always downwards acts on the connecting penetration locking contact surface (10) through a locking spring (5) connected on the step of the upper end of the truncated cone rotating body. According to the invention, quick locking and disassembly between two parts can be realized, the structure is compact and convenient, no calibration and adjustment are needed, and the maintainability, the reliability and the suitably-assembled property are good.

Owner:CHENGDU LINGCHUAN SPECIAL IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com