Patents

Literature

35 results about "Automated mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automated mining involves the removal of human labor from the mining process. The mining industry is in the transition towards automation. It can still require a large amount of human capital, particularly in the developing world where labor costs are low so there is less incentive for increasing efficiency. There are two types of automated mining- process and software automation, and the application of robotic technology to mining vehicles and equipment.

Thin coal seam unmanned automated mining mode

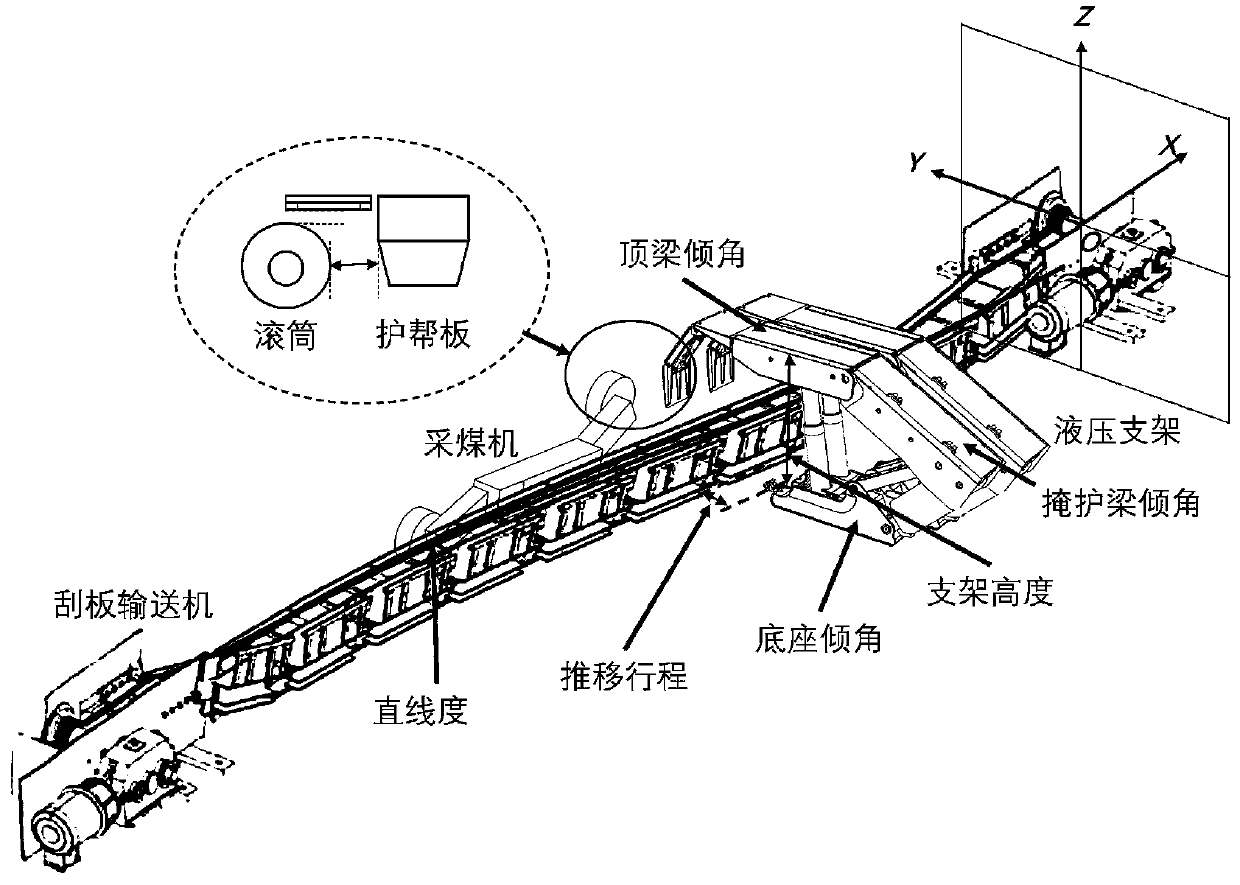

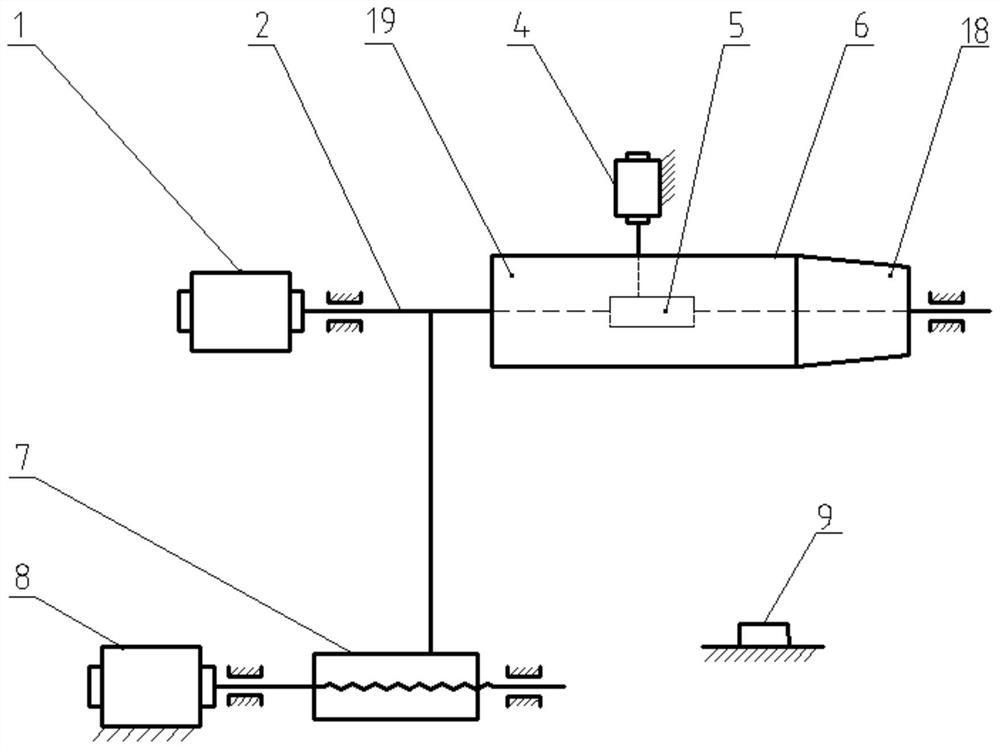

The invention discloses a drum-coal-mining-machine-based thin coal seam unmanned automated mining technology. The technology has the characteristics that: persons do not exist on an operating surface; operators know about conditions of the operating surface through video in a control center far from the operating surface and simultaneously complete various kinds of operation; video signals and control instructions are transmitted through a wireless switch; a coal mining machine has a function of memory cutting and is provided with a position monitoring device and an infrared transmitter at the same time, coal is automatically cut according to a preprogram, and operation parameters such as positions, directions and the like are sent out at any time; a bracket controller receives the parameters, automatically drives an electric hydraulic control valve to do actions of column lowering, frame moving, pushing, column erecting and the like according to the preprogram, and a hydraulic bracket is pushed to move forward along with the coal mining machine, so that the unmanned automated mining on the operating surface is realized; and when the thickness of coal seams, and top and bottom boards are changed, the operators regulate operation programs and the parameters in the control center and perform manual intervention on the coal mining machine and the hydraulic bracket, so that the remote-control unmanned automated mining on the operating surface is realized.

Owner:TIANDI SCI & TECH CO LTD

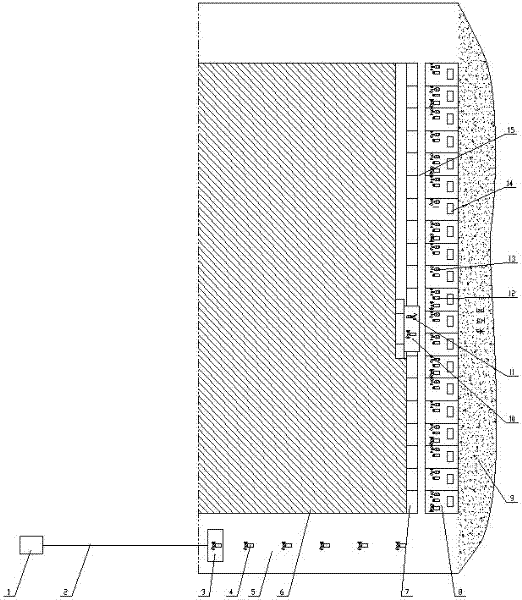

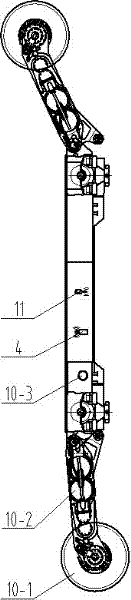

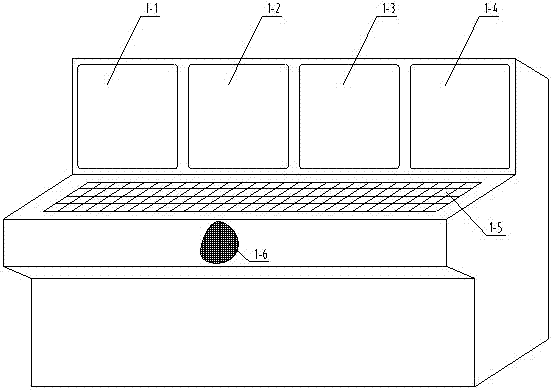

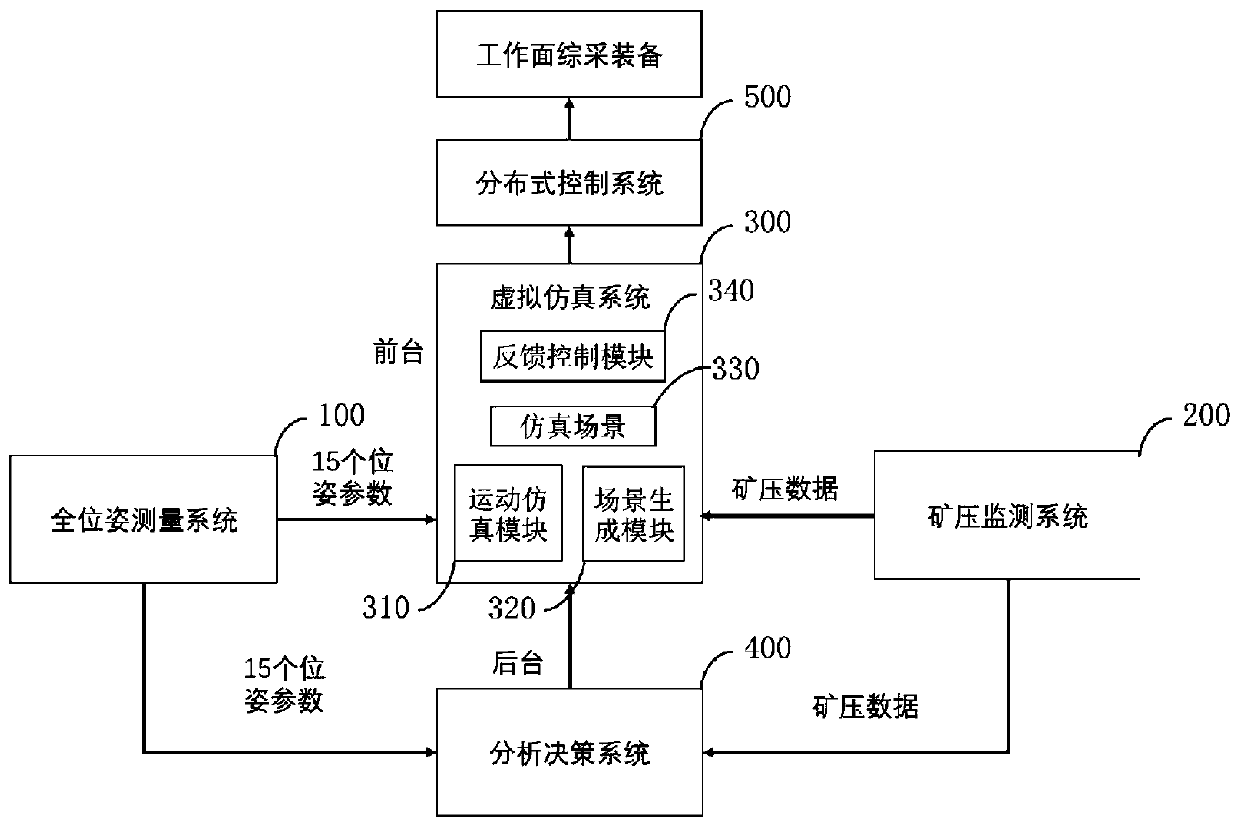

Intelligent control method and system for fully mechanized mining device used for complex condition working face

PendingCN111173510AImprove running qualityGuaranteed fitMining devicesSlitting machinesDecision controlPressure data

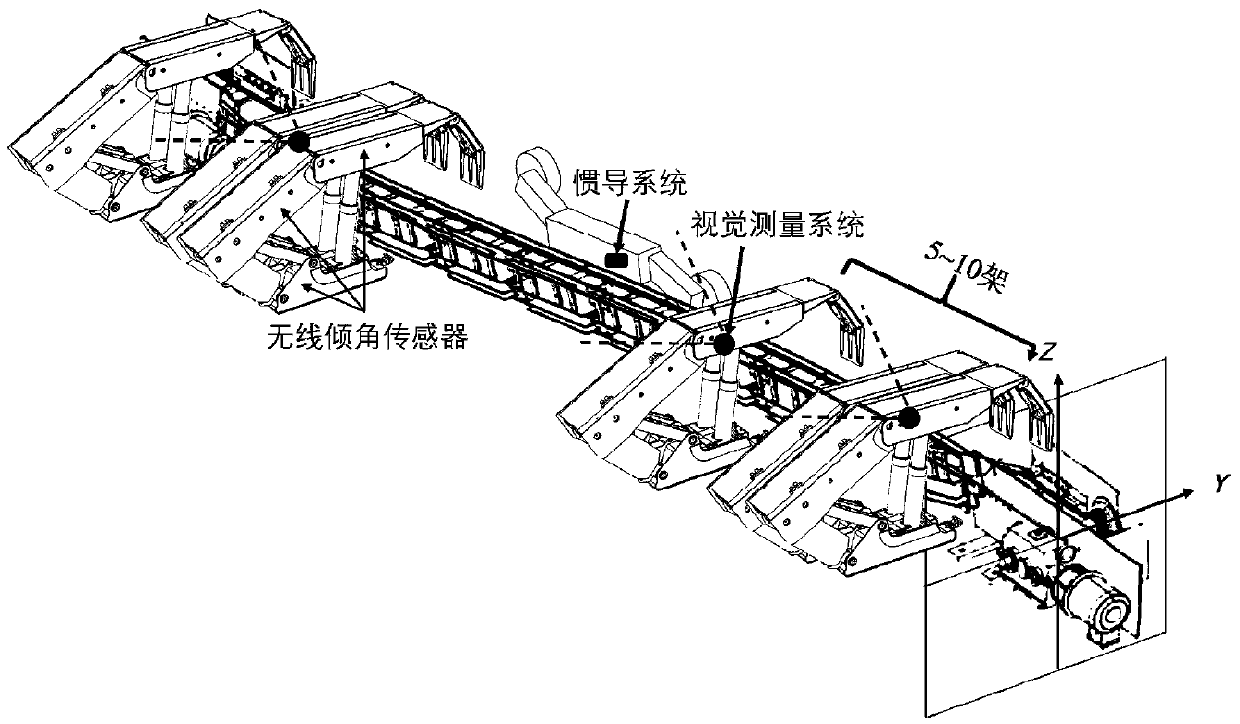

The invention aims to solve the problem of equipment interference, abnormal mechanical conditions and the like due to excessive error accumulation after multiple cycles in a current automated mining system under complex geological conditions, and discloses an intelligent decision control method and system for a fully mechanized mining device used for a complex condition working face. The intelligent decision control system comprises a full posture measurement system for the fully mechanized mining device, a mine pressure monitoring system, a virtual simulation system, an analysis and decisionsystem and a distributed control system. 15 spatial parameters and mine pressure data of the real-time operating state of the device are measured comprehensively, the real mining process is simulatedthrough data superposition, the device abnormalities caused by the complex geological conditions are calculated, the surrounding rock state is predicted, error elimination and surrounding rock controlmethods based on known process methods and historical data learning results are proposed, and subsequent mining control parameters are predicted; and based on real data and virtual simulation results, the optimization and decision-making of underground comprehensive mining device control parameters are completed, so as to ensure that device control under the complex geological conditions can be consistent with actual environmental conditions, and the operation quality of the fully mechanized mining device is greatly improved.

Owner:TIANDI SCI & TECH CO LTD

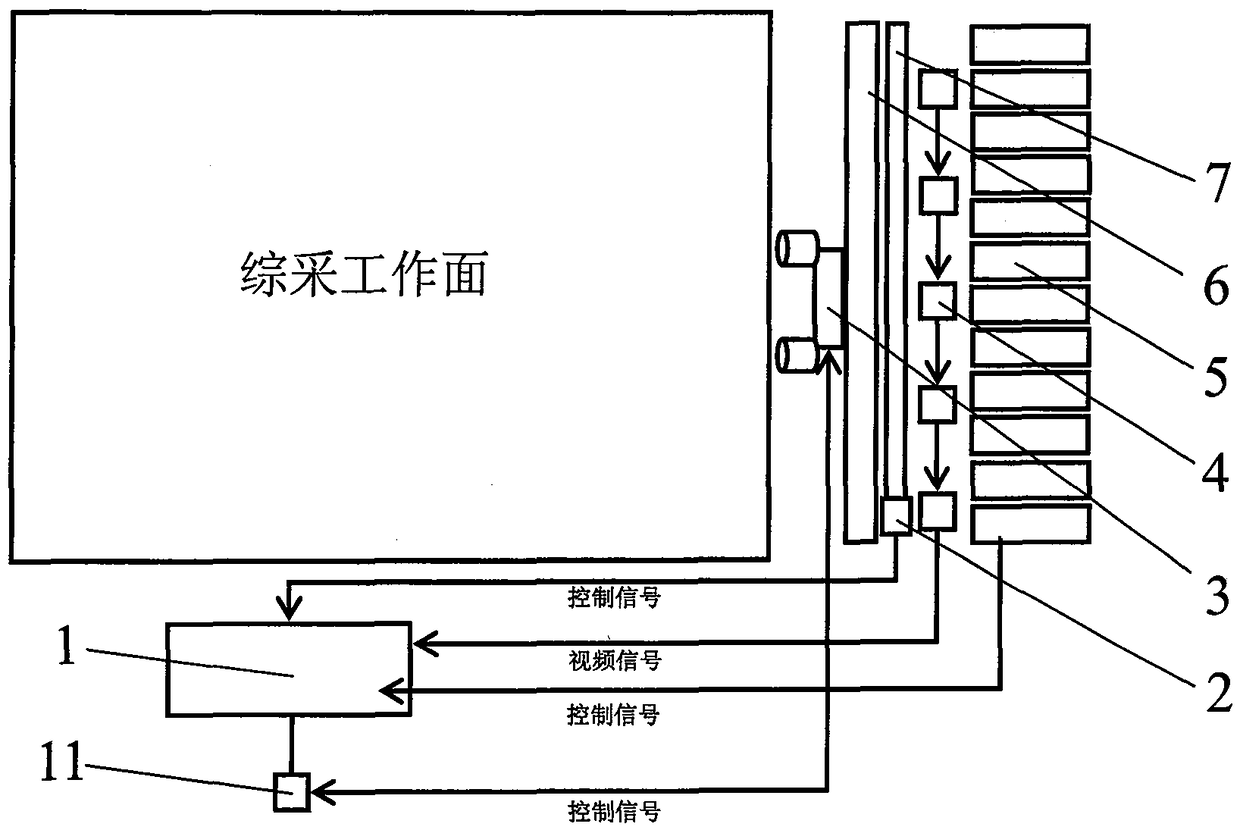

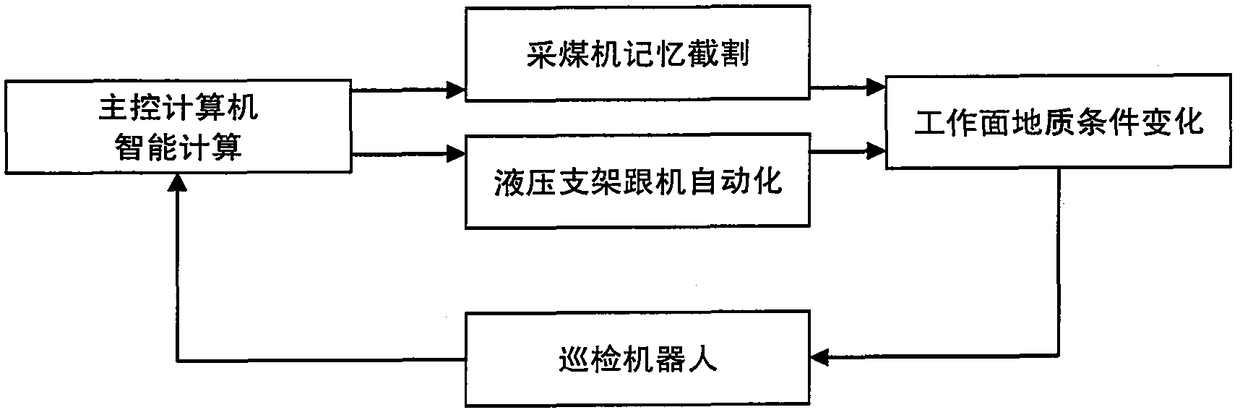

Coal mine unmanned mining system and method

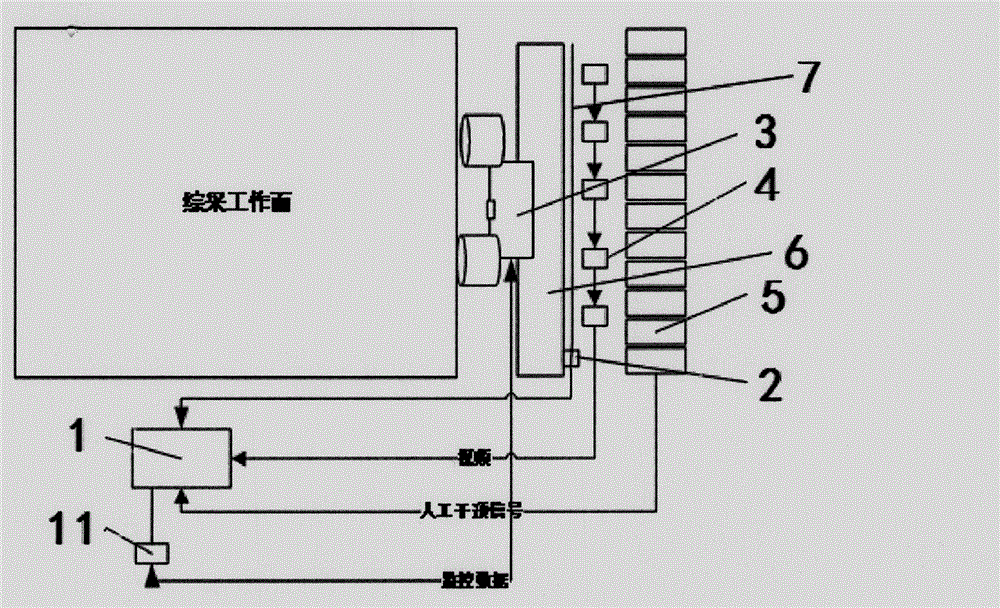

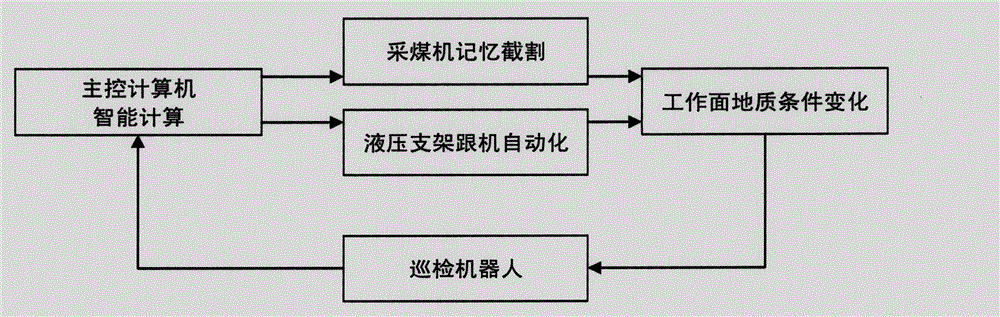

ActiveCN105064997AImprove adaptabilityExisting conditions vary greatlySlitting machinesMine roof supportsRemote controlTele operation

The invention discloses a coal mine unmanned mining system and method. The coal mine unmanned mining system comprises a coal mining machine, a main control computer, a patrol robot, a hydraulic support electrohydraulic control system, a remote control console and a coal wall video camera, wherein the main control computer is electrically connected with the patrol robot and the coal wall video camera; the main control computer is electrically connected with the coal mining machine through the remote control console; and the main control computer is electrically connected with the hydraulic support electrohydraulic control system. The coal mine unmanned mining system and method solve the problem that automated mining systems for thin seams are poor in adaptability to coal seams of other thickness; and by applying an inspection robot technology to mining of a fully mechanized coal face, the coal mine unmanned mining system and method also solve the problems that conventional mine automation production fails to adapt to geological condition changes and must be interfered by manpower. The coal mine unmanned mining system and method intelligently correct automatic mining of the fully mechanized coal face through various sensing methods.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD

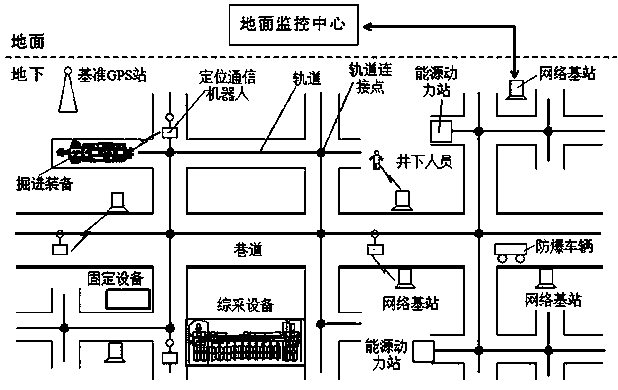

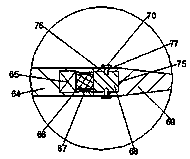

Underground positioning and communication system

PendingCN111093150AEfficient positioning and transmissionLabor savingElectrical testingSurveying instrumentsCommunications systemInformation transmission

The invention relates to an underground positioning and communication system. The underground positioning and communication system comprises a ground monitoring center, an underground GPS reference point, a positioning communication robot, a track, a positioning label, a network base station and an energy station; and a monitoring center is arranged on the ground. Information of underground equipment and personnel is transmitted to a ground monitoring center through the positioning communication robot and a network; and ground personnel inquire operation information and positions of underground equipment, all the underground equipment can be subjected to remote positioning, remote control and information transmission through the positioning communication robots, and task planning is carried out on the multiple positioning communication robots operating underground. The method has the advantages of low cost; positioning information with different precisions can be provided, positioningof various underground equipment and personnel can be efficiently completed, meanwhile, information of underground working equipment is collected and transmitted, an operator can know the running states of all the equipment and personnel through control of a remote control center, and the method is the basis for achieving underground automatic mining.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

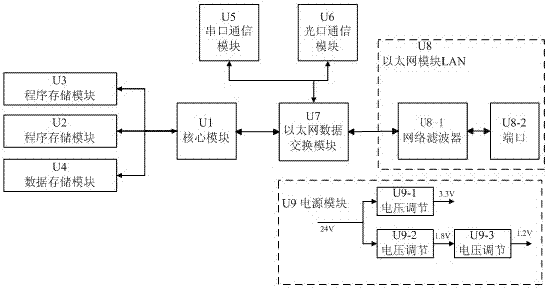

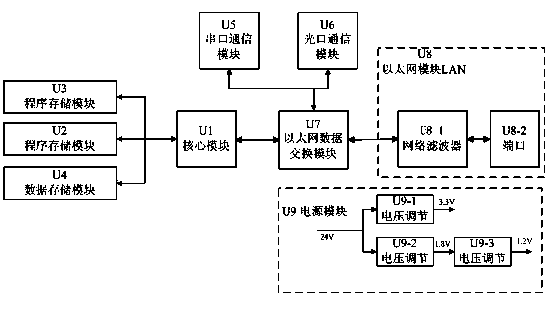

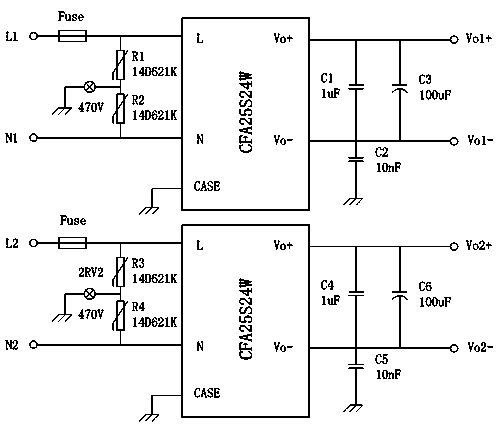

Multi-protocol Ethernet switch for mines

ActiveCN102231706ARedundant switching time is smallImprove reliabilityData switching networksPower conditionerData transformation

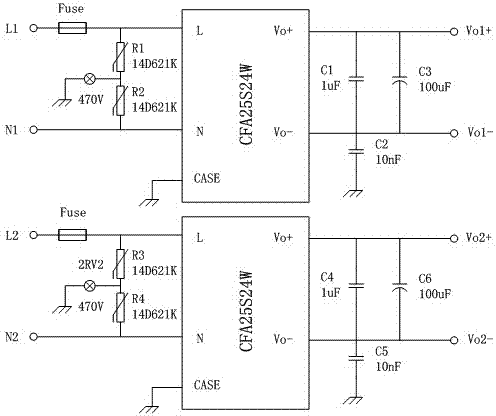

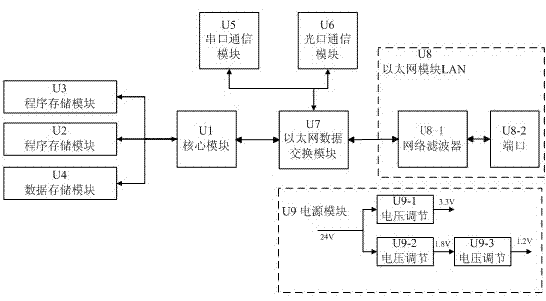

The invention relates to a multi-protocol Ethernet switch for mines and belongs to comprehensive network communication equipment for mines. In the multi-protocol Ethernet switch provided by the invention, a core processing module is simultaneously connected with a first program storage module, a second program storage module, a data storage module and an Ethernet data transformation module, wherein the Ethernet data transformation module is simultaneously connected with a serial port communication module, an optical port communication module and an Ethernet module; the Ethernet module comprises a network filter and a port; the port is connected with the Ethernet data transformation module through the network filter; a power supply module is connected with all the modules and provides energy sources for each module; the power supply module comprises a first power supply regulator, a second power supply regulator and a third power supply regulator; the second power supply regulator is connected with the third power supply regulator in series; and the second power supply regulator and the third power supply regulator which are connected in series are connected with the first power supply regulator in parallel. The multi-protocol Ethernet switch provided by the invention has the advantages that the access of multiple types of equipment is realized; and reliable data sources are provided for the high-efficiency automated mining of coal mines and the remote supervision and fault diagnosis of coal mine equipment.

Owner:CHINA UNIV OF MINING & TECH

Wireless network switch system suitable for underground coal mine or coal mine shaft

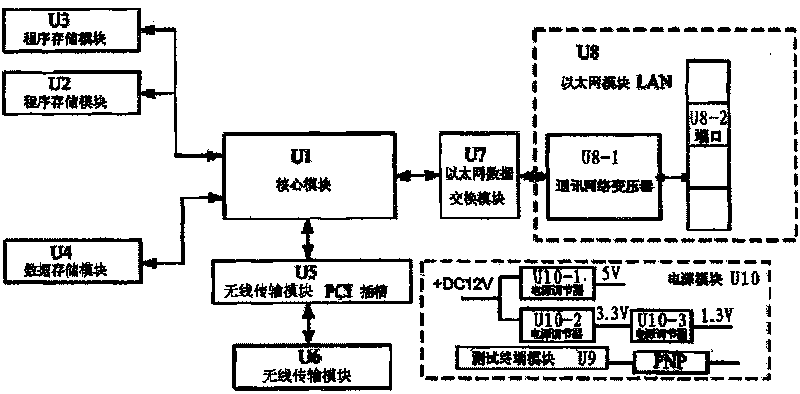

InactiveCN101729263AImprove communication technologyAchieve coverageData switching by path configurationData switching switchboardsIntrinsic safetyLow-power electronics

The invention provides a wireless network switch system which is suitable for underground coal mine or coal mine shaft. The wireless network switch system is characterized by adopting designs based on an explosive gaseous environment electric equipment general requirement GB3836.1-2000 and an intrinsic safety requirement GB3836.4-2000; based on high reliability and security of networking operation, adopting a modularized design and international brand industrial-grade chips, adopting electric control components which are all mature and reliable products and suitable for serious working environment of the coal mine underground, and adopting low power consumption design and an external power supply. The wireless network switch system has the advantages that the underground coal mine or coal mine shaft communication technology is improved, the full coverage of the underground coal mine or coal mine shaft network is realized, the defects of a wired network are remedied, the remote monitoring and control for coal mine integrated excavated working face electromechanical equipment and other underground coal mine or coal mine shaft motion equipment are realized, and reliable data are provided for realizing coal extractor high-efficiency automated mining, remote operation and control and fault diagnosis.

Owner:周双

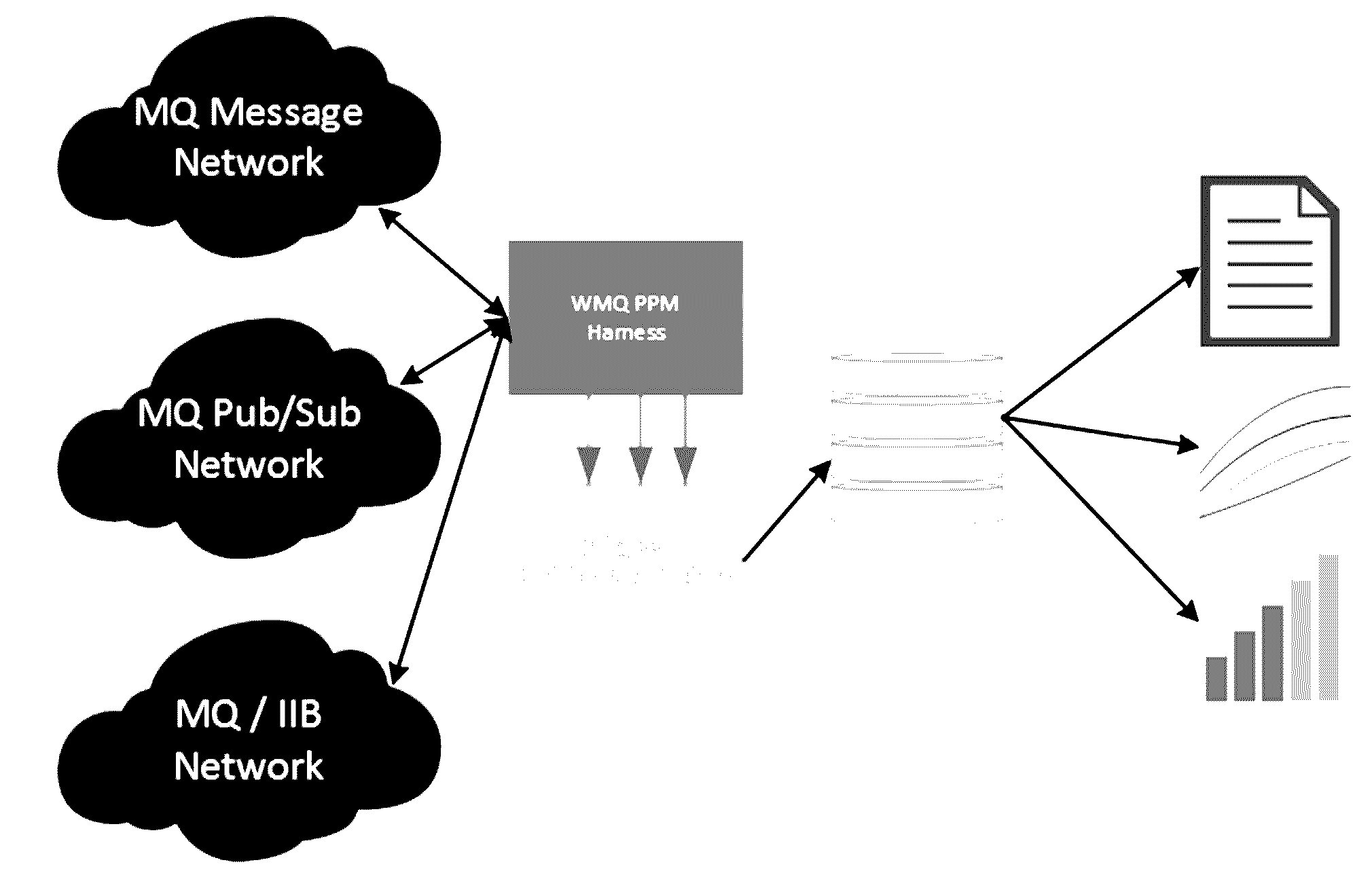

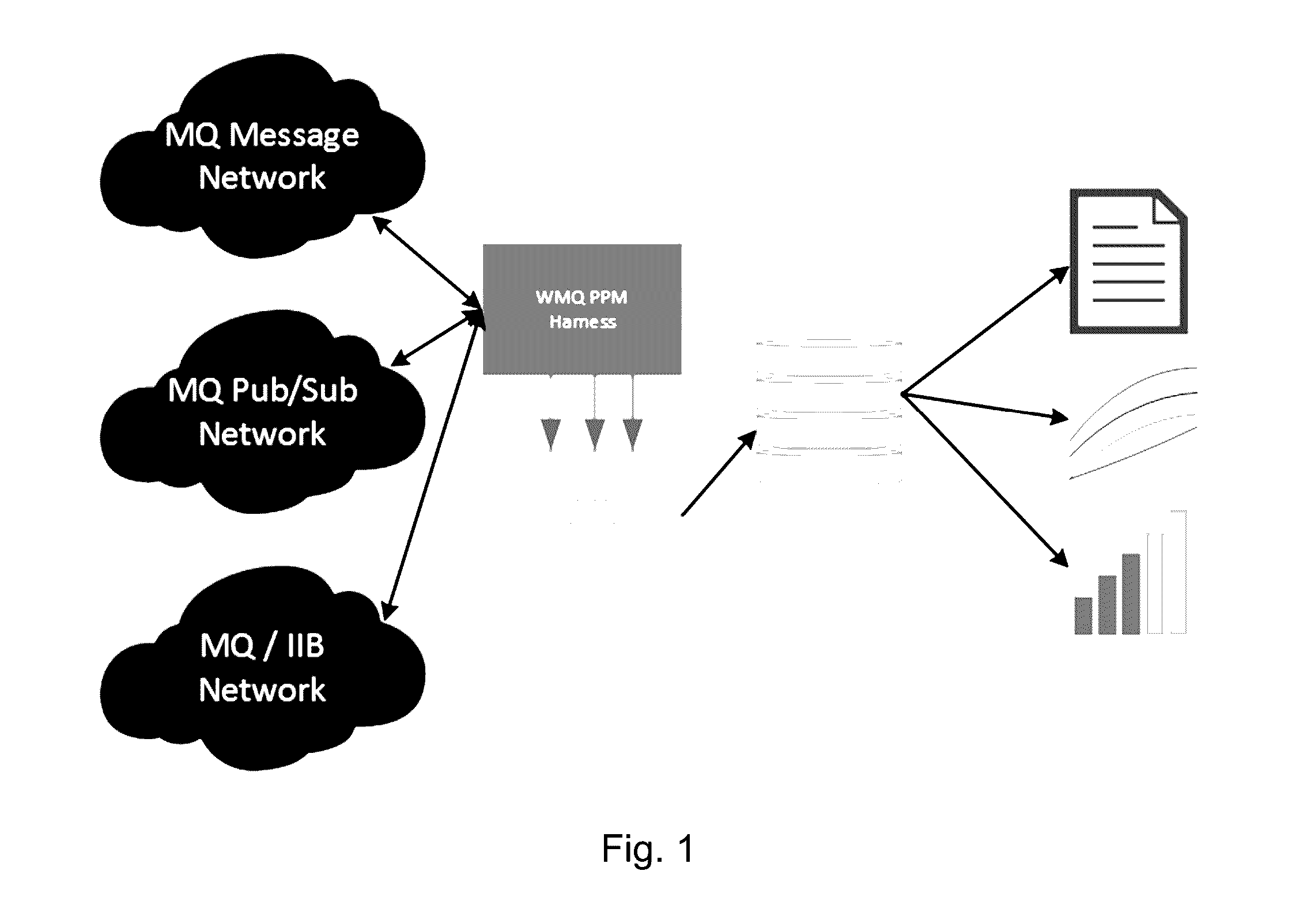

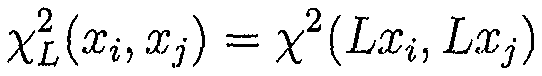

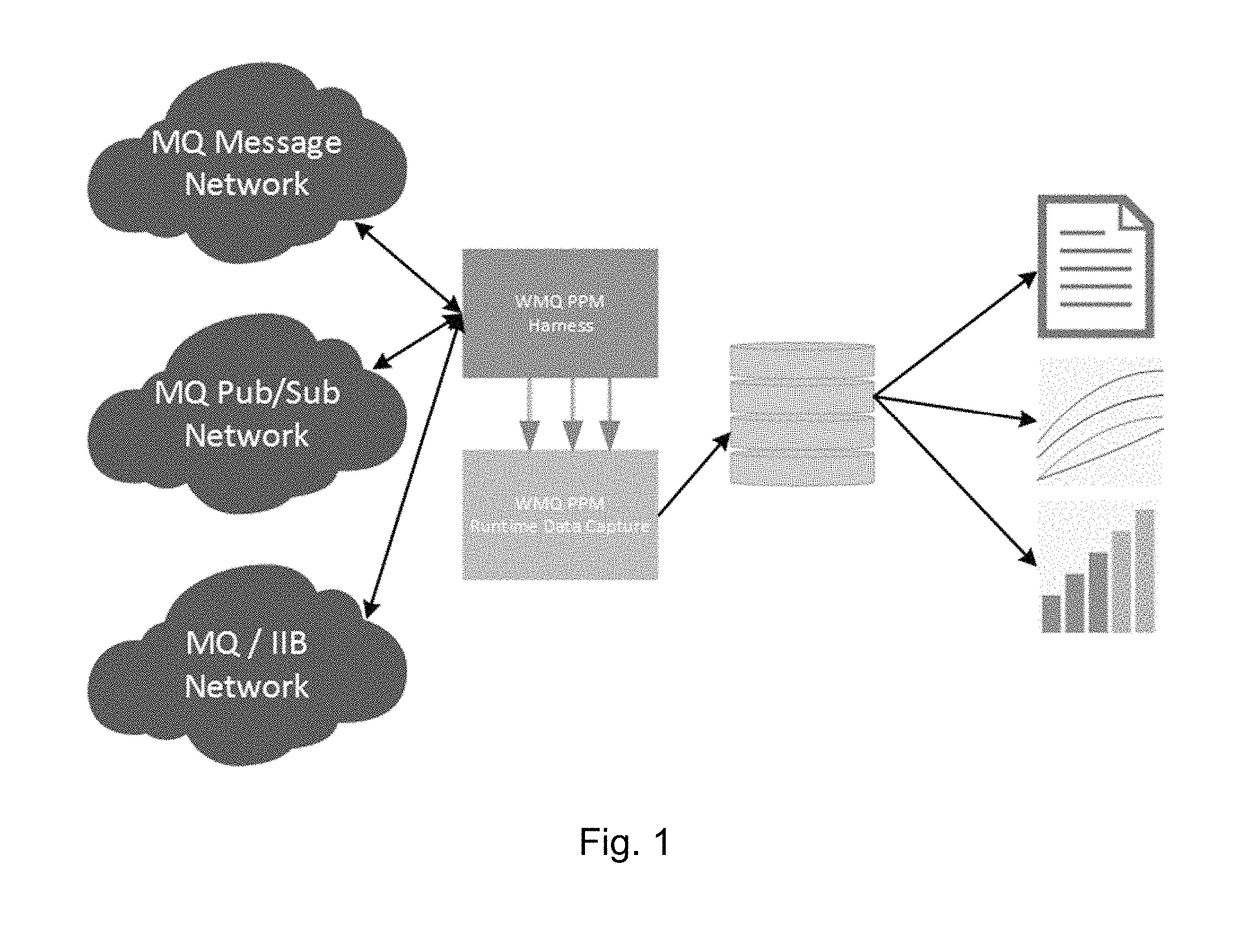

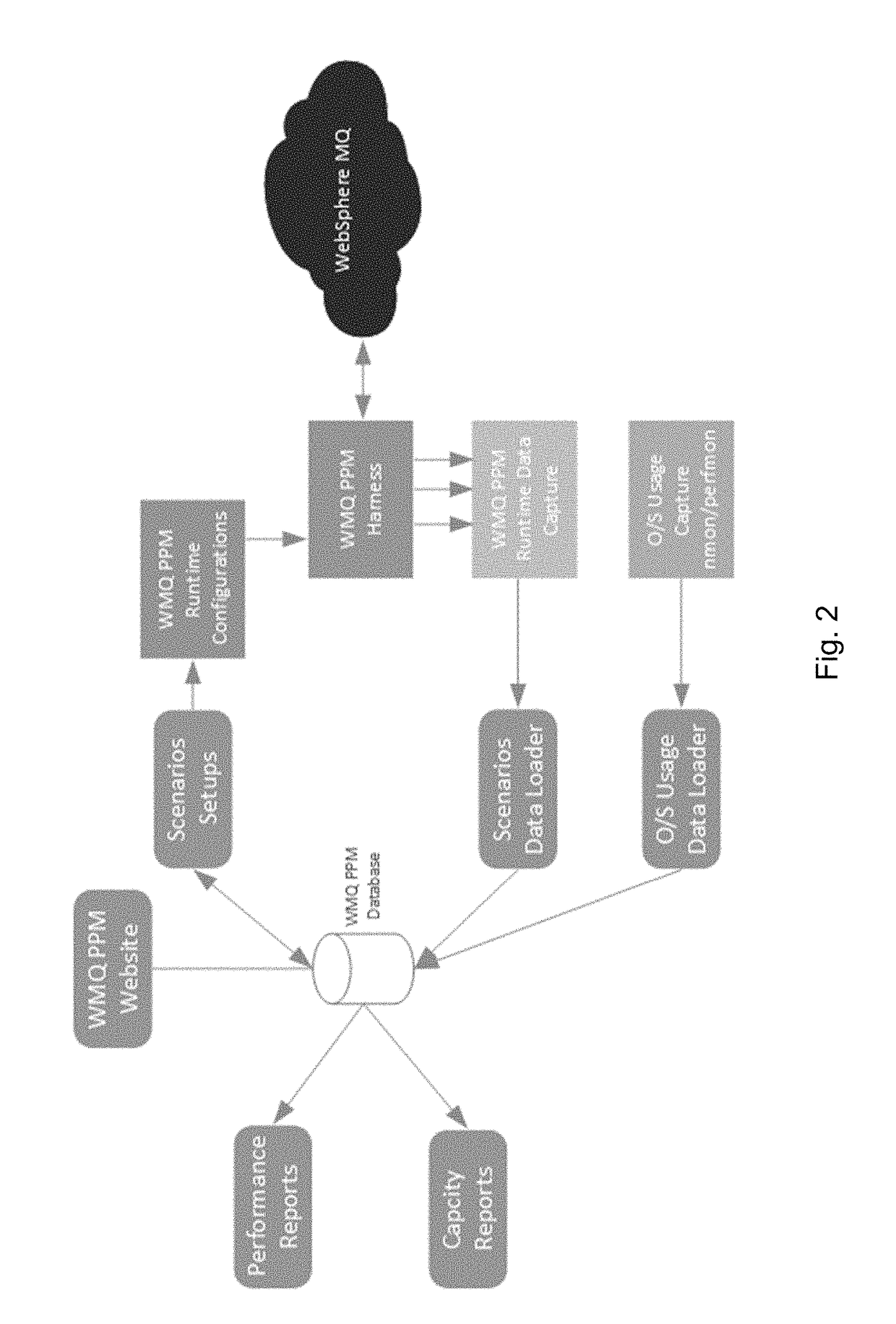

Systems and Methods for WebSphere MQ Performance Metrics Analysis

InactiveUS20170048120A1Facilitate rapid correctionEasy to modifyHardware monitoringData switching networksAutomated miningPerformance tuning

Systems and methods for the computer-automated mining and profiling of server monitoring data and related information are disclosed. Performance monitoring is performed through system commands and queries against particular software components arranged in a particular way that provides comparative information for the management and optimization of server and software resources through the identification of constraints and bottlenecks. Further, the present disclosure relates to the analysis and comparison of a current running profile of a server against previous or archived profiles. The profiles characterize the utilization and usage of server resources, or prior systems performance history for the purpose of performance tuning and resource optimization of the middleware messaging software.

Owner:TXMQ INC

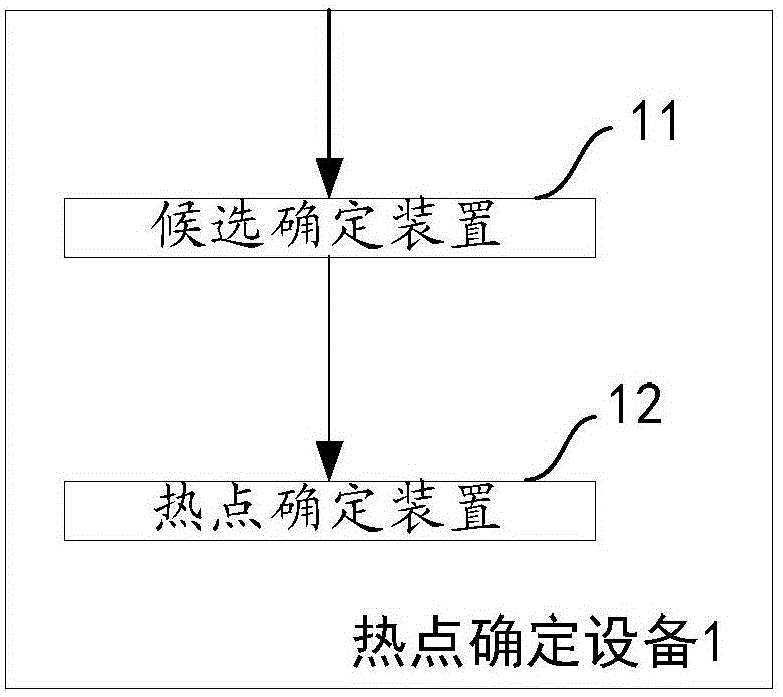

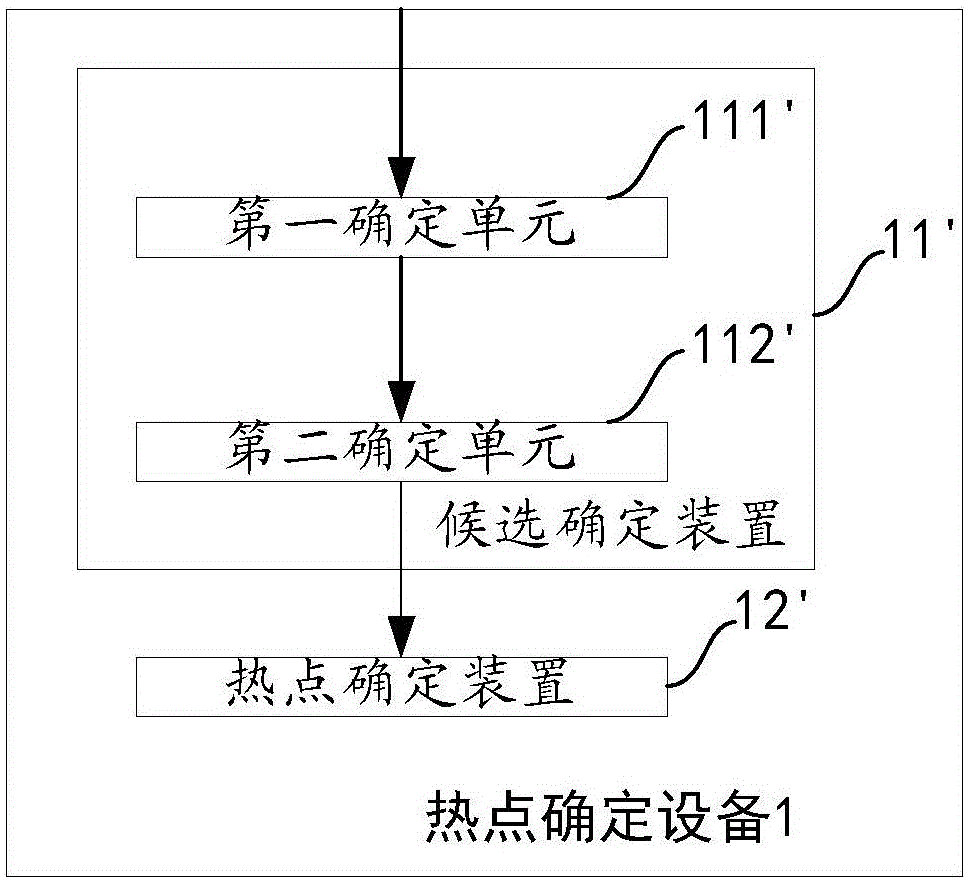

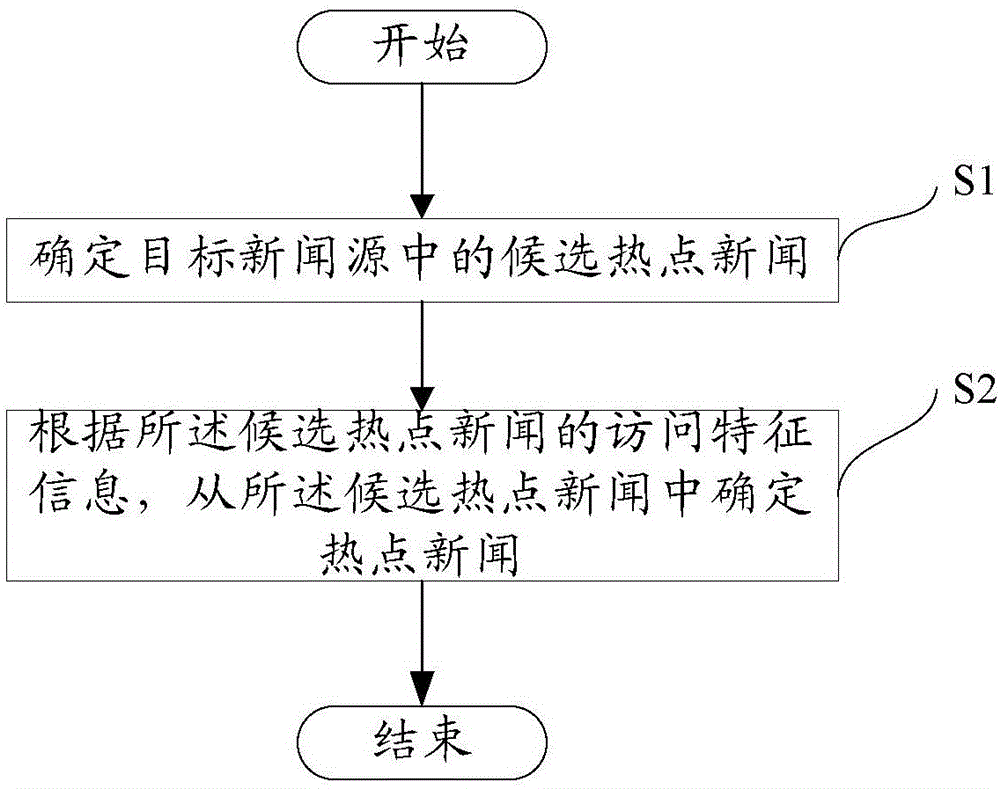

Method and device for determining hot news in target news source

InactiveCN105045890AAutomate miningImprove recognition rateWeb data indexingSpecial data processing applicationsAutomated miningEngineering

The invention aims to provide a method and a device for determining hot news in a target news source. Particularly, candidate hot news in the target news source is determined, wherein the candidate hot news is positioned in a hot news block of the target news source; and according to access characteristic information of the candidate hot news, the hot news in the candidate hot news is determined. Compared to the prior art, the candidate hot news in the target news source is determined, wherein the candidate hot news is positioned in the hot news block of the target news source; and according to the access characteristic information of the candidate hot news, the hot news in the candidate hot news is determined, so that automated mining of the hot news is realized, the identification rate of the hot news is increased, the identification cost is reduced, the efficiency for obtaining the hot news by users is improved, and the user experience is enhanced.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

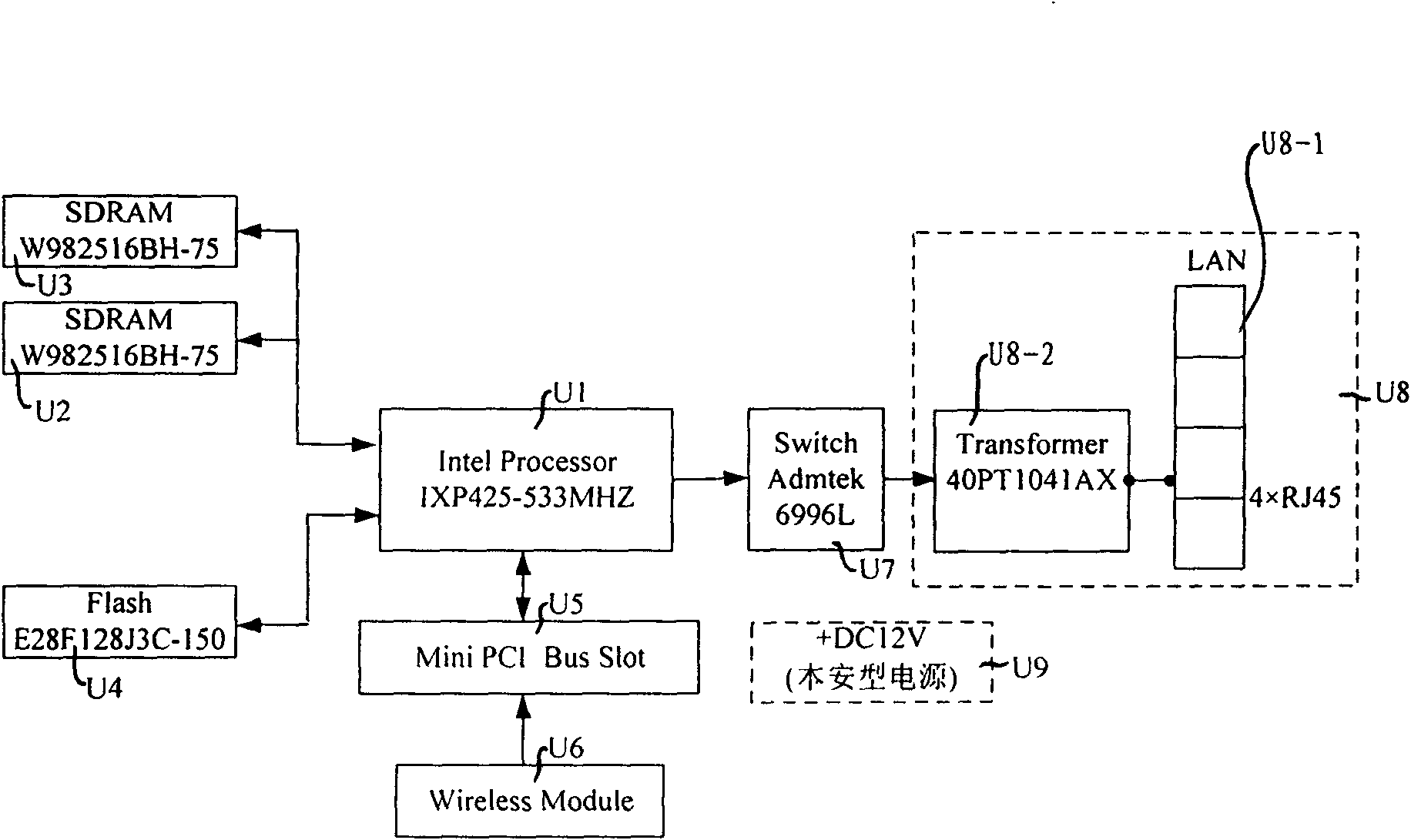

Intrinsic safety type wireless switch

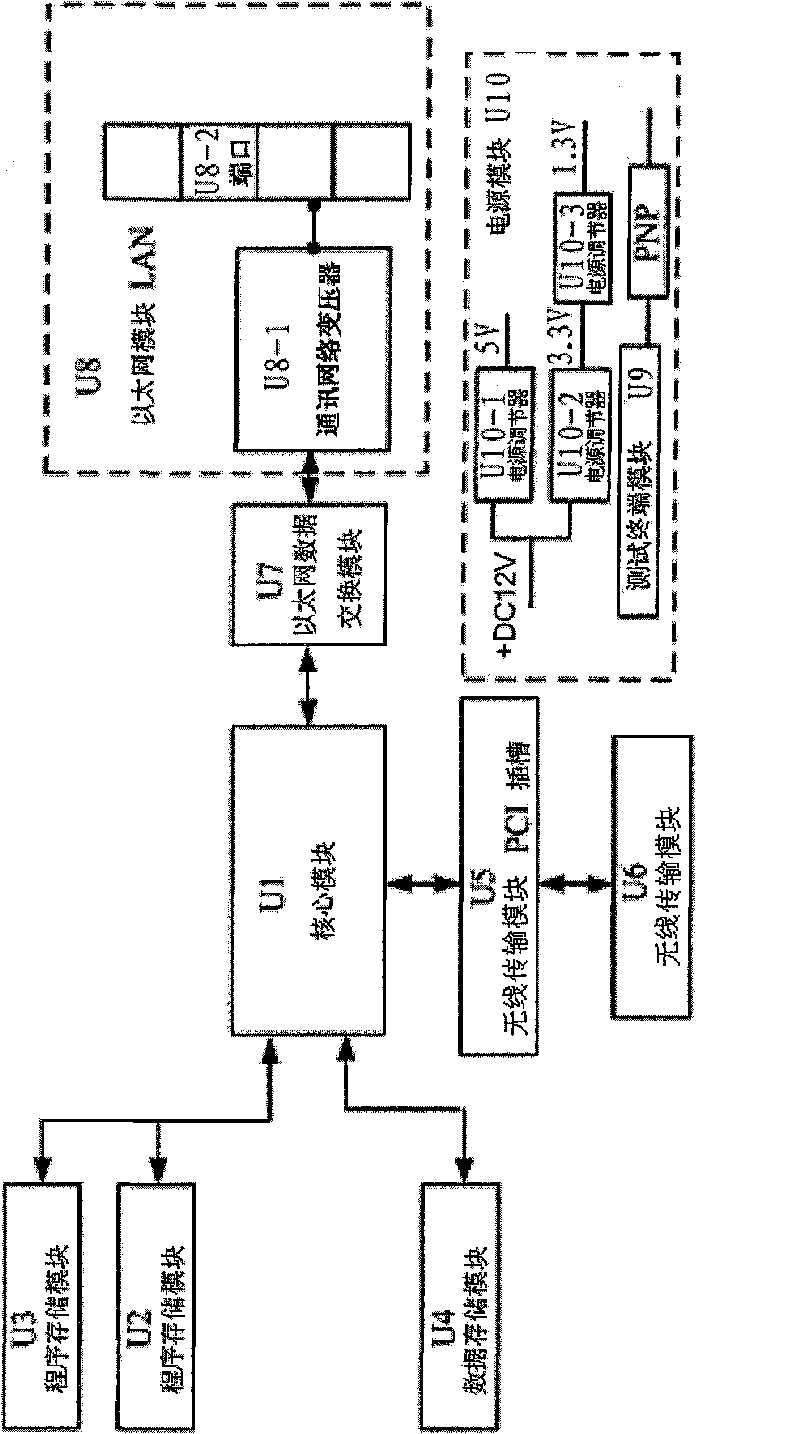

InactiveCN101631393AAchieve coverageImprove reliabilityNetwork topologiesIntrinsic safetyWireless transmission

The invention relates to an intrinsic safety type wireless switch which is characterized by comprising a core processing module, a program storage module, a data storage module, a PCI bus slot, a wireless transmission module, an Ethernet data switching module, an Ethernet module and a power supply module. The invention has the advantages of improving down-hole communication technology of coal mines, realizing the overall coverage of down-hole networks of the coal mines, making up the defects of wired networks and realizing the remote monitoring and control of electrometrical equipment on comprehensive faces of the coal mines and other down-hole moving equipment of the coal mines, thereby providing reliable data for high-efficiency automated mining, remote manipulating and fault diagnosis of coal mining machines.

Owner:SUZHOU FREED BOREAL TECH DEV

Steeply pitching seam mining method

PendingCN110566205AGuaranteed normal operationEnsure U-shaped ventilationUnderground miningSlitting machinesAutomated miningMineralogy

The invention relates to the technical field of steeply pitching coal seam mining, and discloses a steeply pitching coal seam mining method. The steeply pitching coal seam method includes the following steps that step 1, an air return way is horizontally formed along the trend of the seam on the upper part of a section, and a transportation way is horizontally formed along the trend of the coal seam on the lower part of the section to the boundary of a mining area; and step 2, open-off cuts are obliquely arranged along the trend of the coal seam, and the angle range between the open-off cuts and the transport way is 8 degrees to 40 degrees. According to the steeply pitching coal seam mining method, a main system of the mining area, the air return way, the transportation way and a working face roadway are enabled to form complete U-shaped ventilation, meanwhile, the main system of the mining area, the air return way, the transportation way, the working face roadway and a mining system jointly form a high-efficiency, high-yield and safe long-wall mechanized mining working face based on the coal mining process, non-minable coal seam becomes mineable coal seam again, a ventilation system cannot be damaged with the mining of the coal seam, the mining efficiency of the coal seam is greatly improved, the safety is improved, and the level of automated mining is improved.

Owner:新疆矿源重工科技有限公司

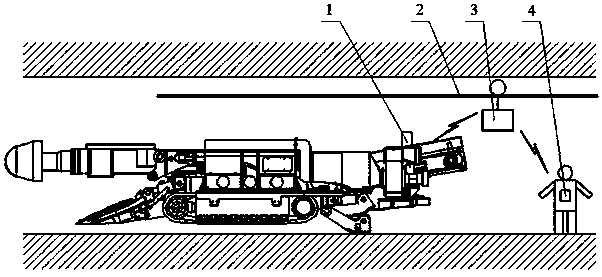

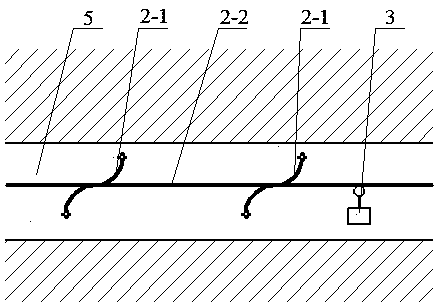

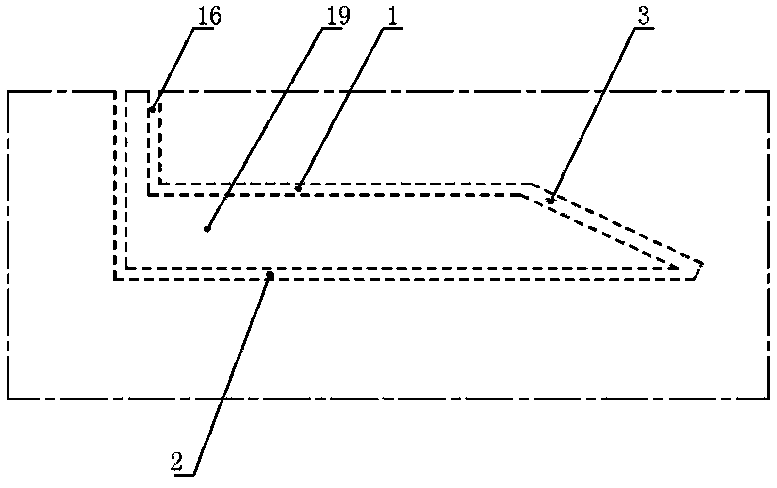

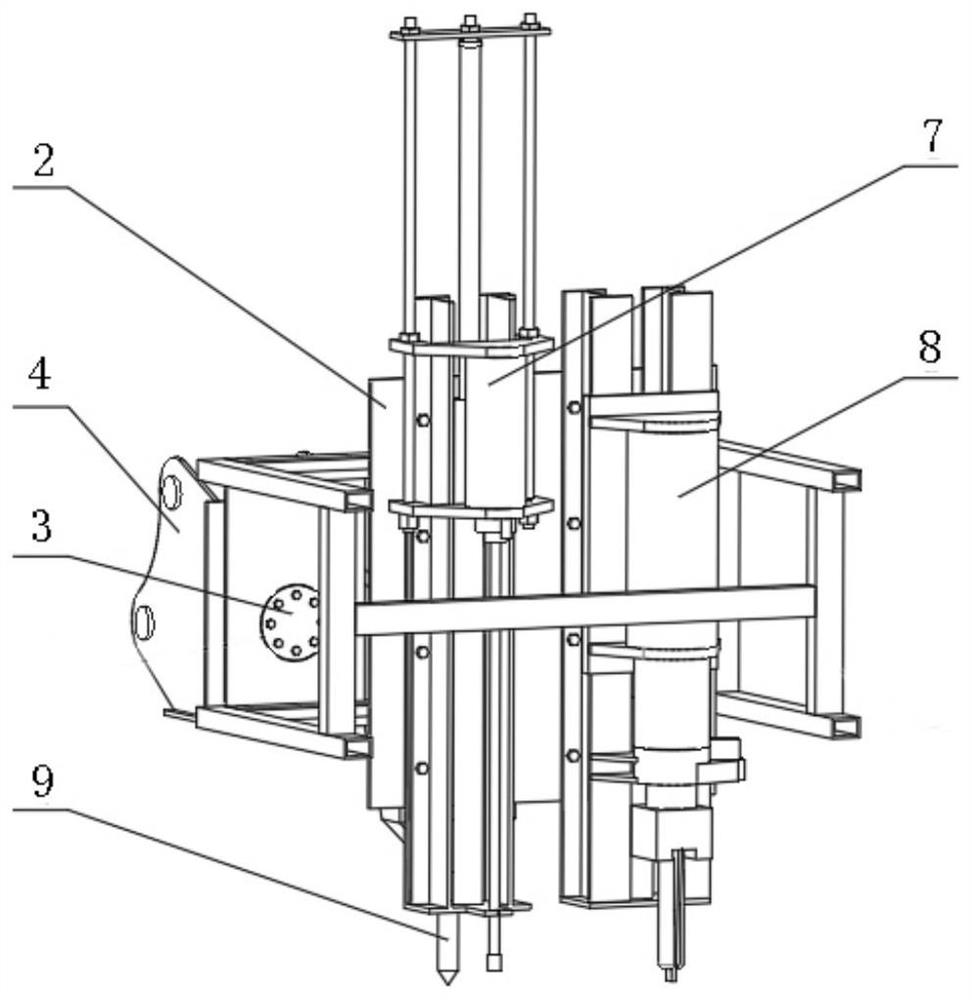

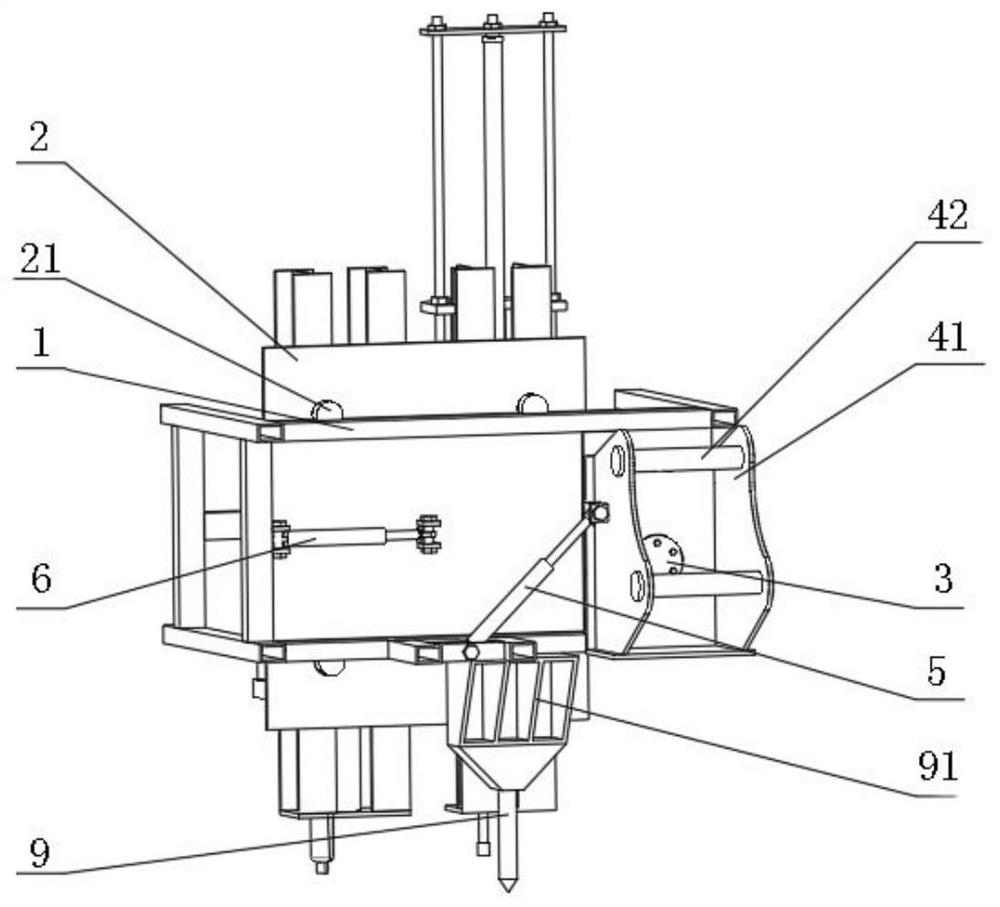

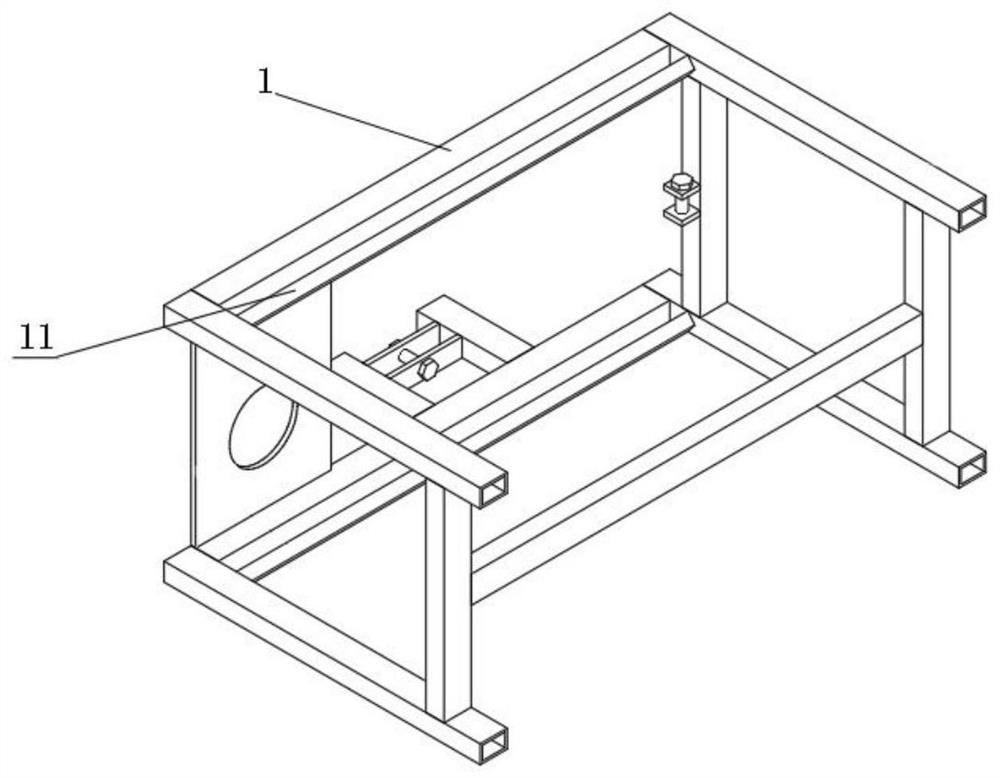

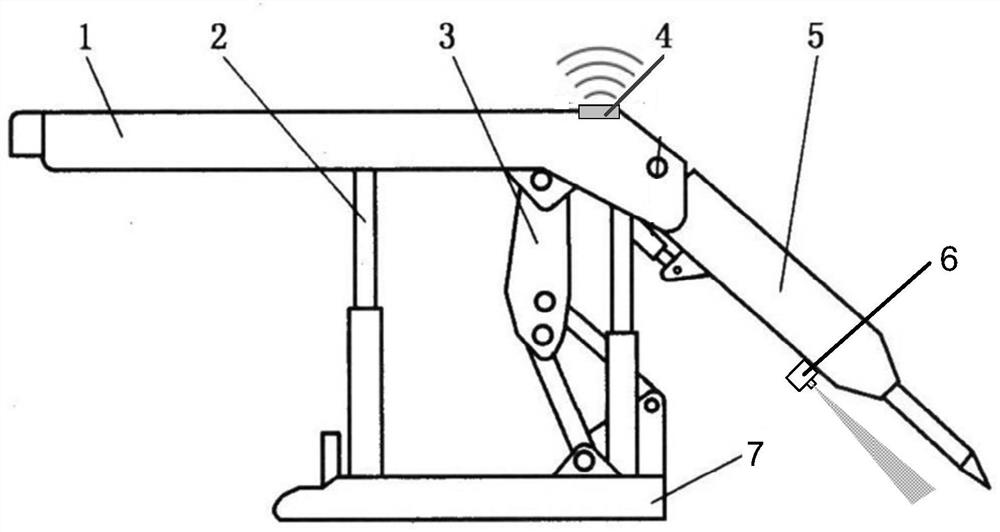

Airborne drilling and splitting combined machine

PendingCN113445914AEasy to manufactureLow failure rateConstructionsDisloding machinesAutomated miningControl engineering

The invention discloses an airborne drilling and splitting combined machine. The airborne drilling and splitting combined machine comprises a mounting frame and a transposition plate, wherein the mounting frame is provided with a slewing bearing; the slewing bearing is connected with a hanging lug; a rotation degree control device is arranged between the hanging lug and the mounting frame; the rotation degree control device is linked with the slewing bearing; rails are oppositely arranged at the upper end and the lower end of the mounting frame; each rail is provided with at least two rail wheels; wheel shafts of the rail wheels are relatively fixed with the transposition plate; a distance control device is arranged between the transposition plate and the mounting frame; the transposition plate is fixedly provided with a drilling module and a splitting module, and the working directions of the drilling module and the splitting module are vertical to the rails; and the mounting frame is provided with a positioning rod, and the working direction of the positioning rod is vertical to the rails. The transposition plate, the rotation degree control device and the distance control device are arranged so that the drilling module and the splitting module can realize controllable selection of angles and distances, and furthermore, the technical effect of efficiently and automatically mining stones with different inclination degrees on the surfaces can be realized.

Owner:JIANGSU ZHONGJI MINE EQUIP

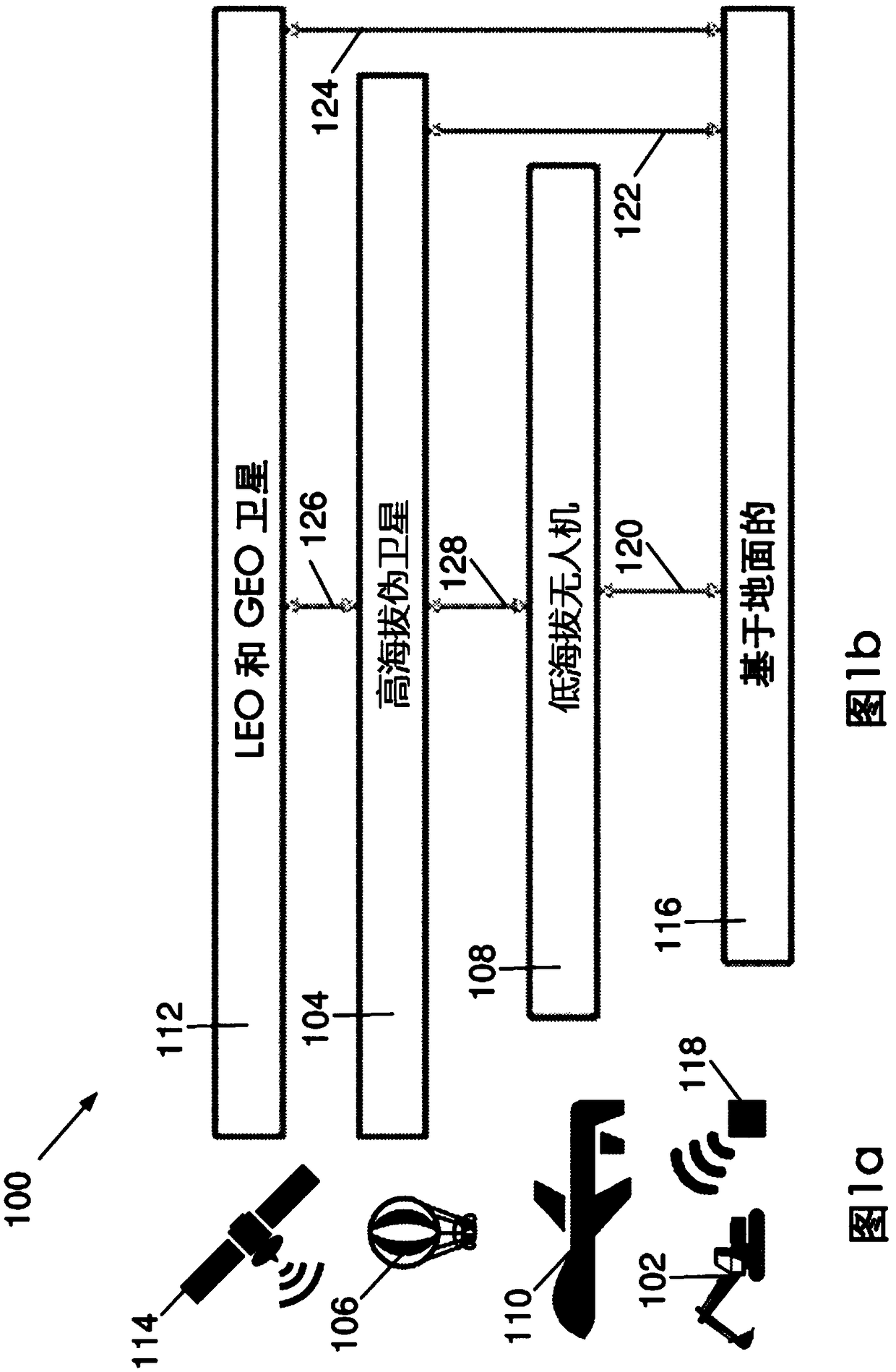

A wireless communication system

InactiveCN108885457AUnderground miningRemote controlled aircraftCommunications systemAutomated mining

Owner:BHP BILLITON INNOVATION PTY LTD

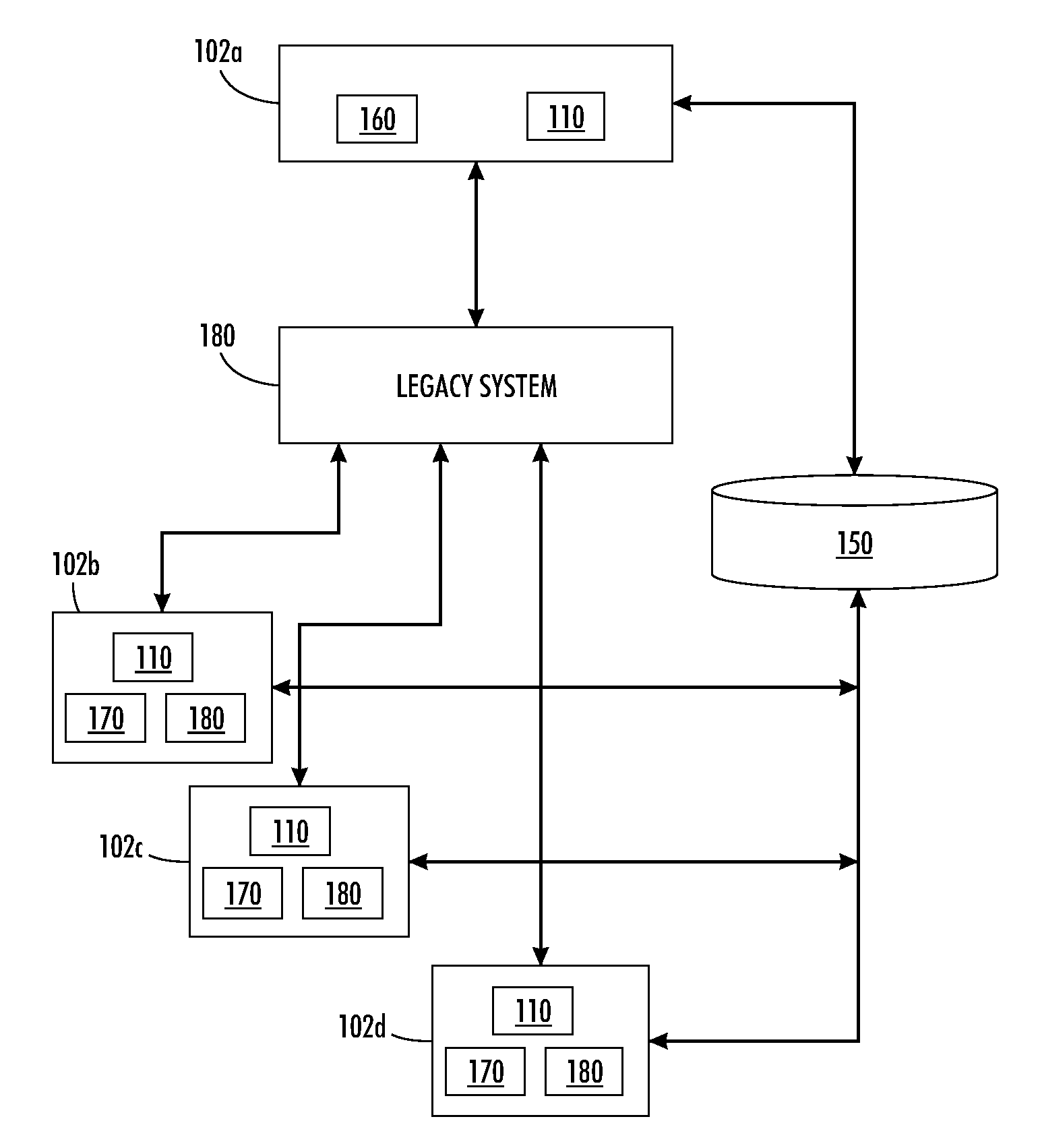

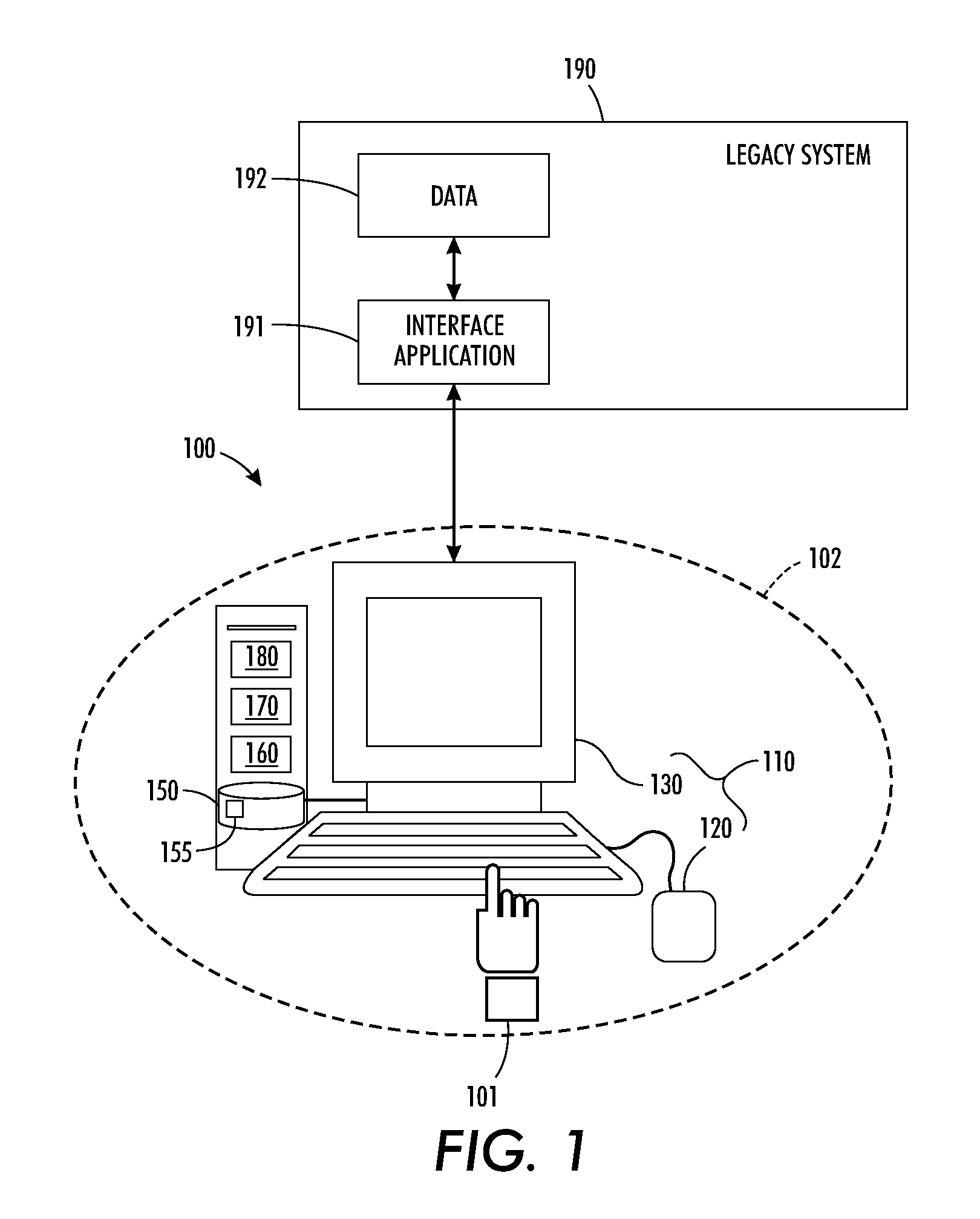

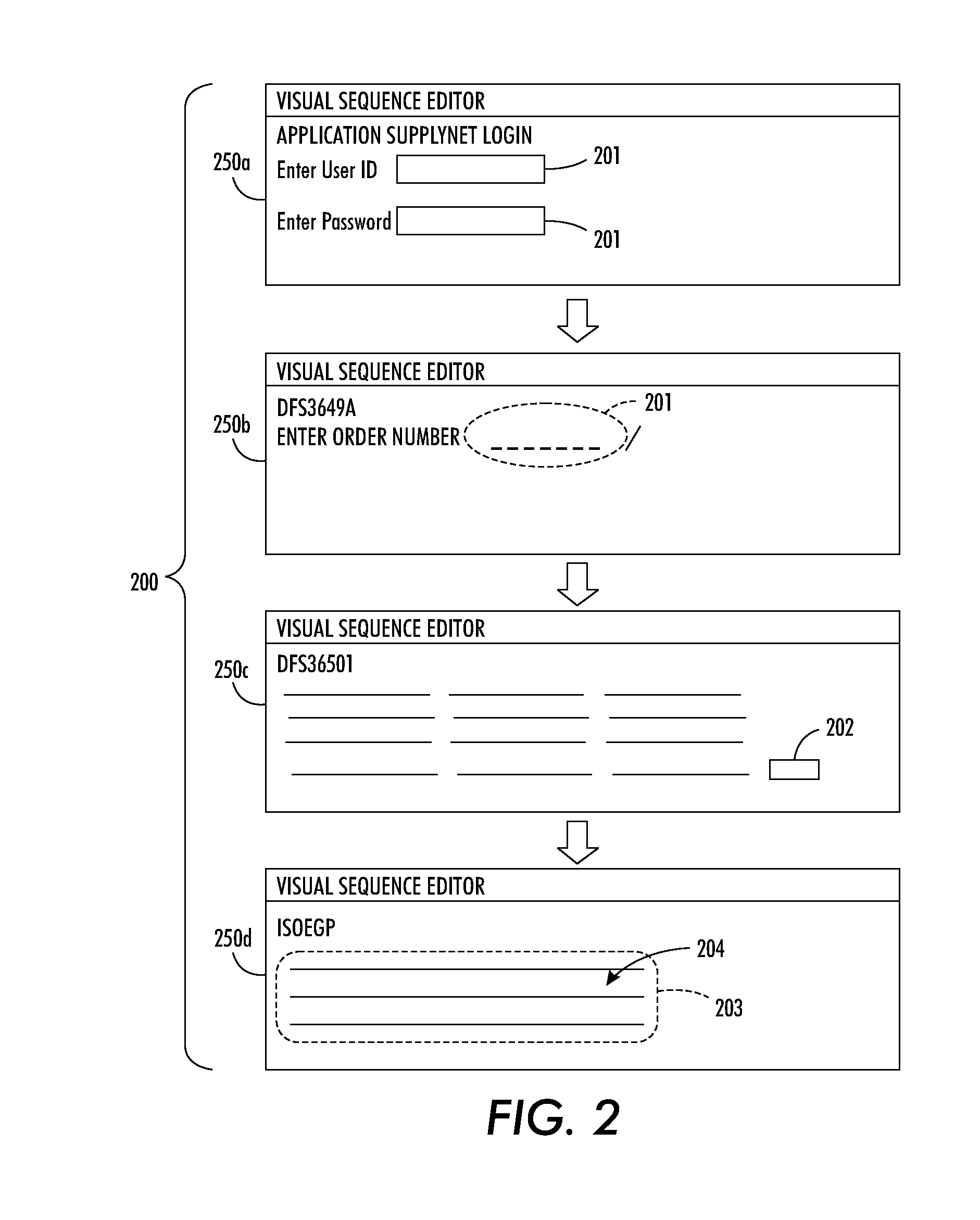

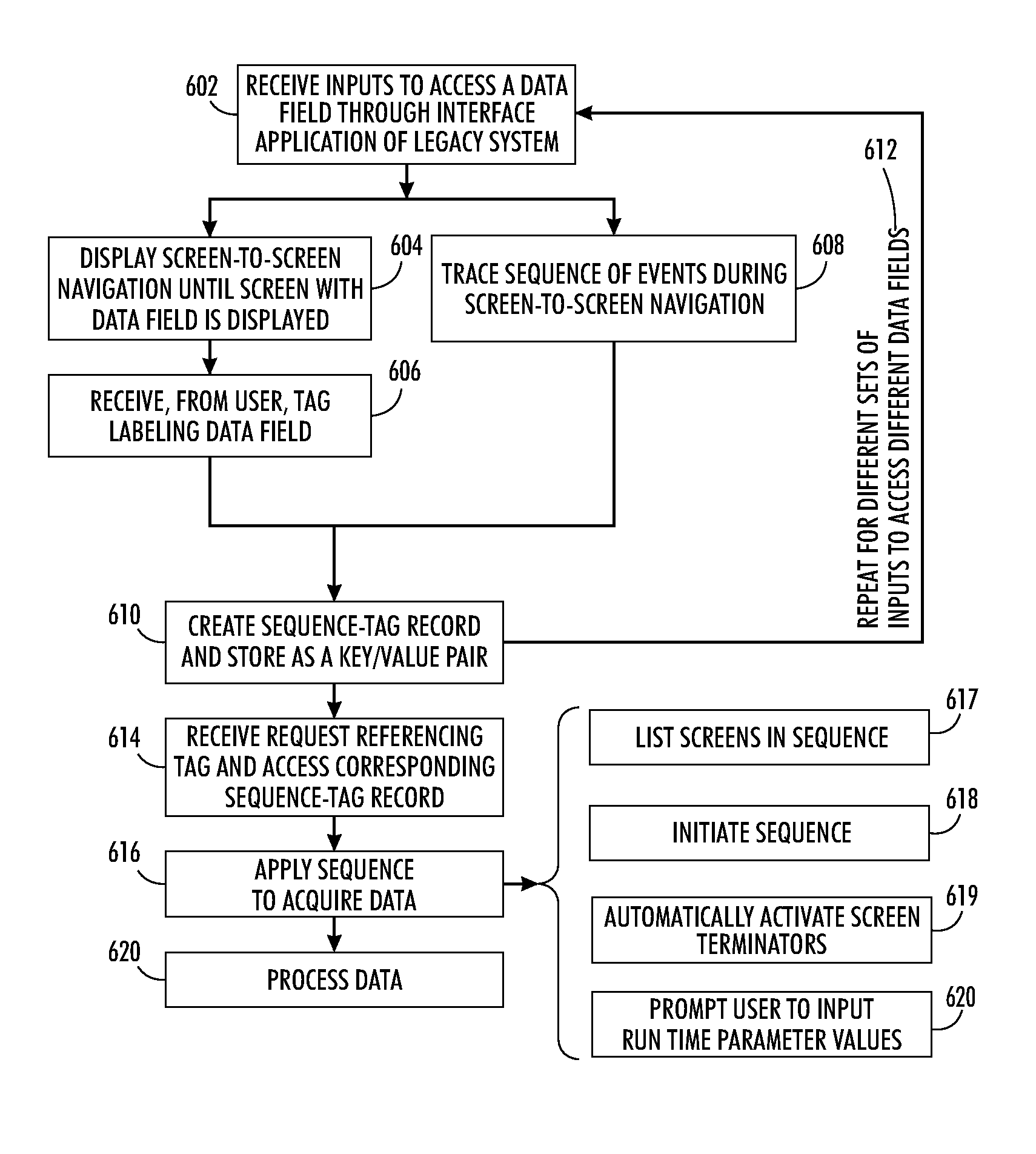

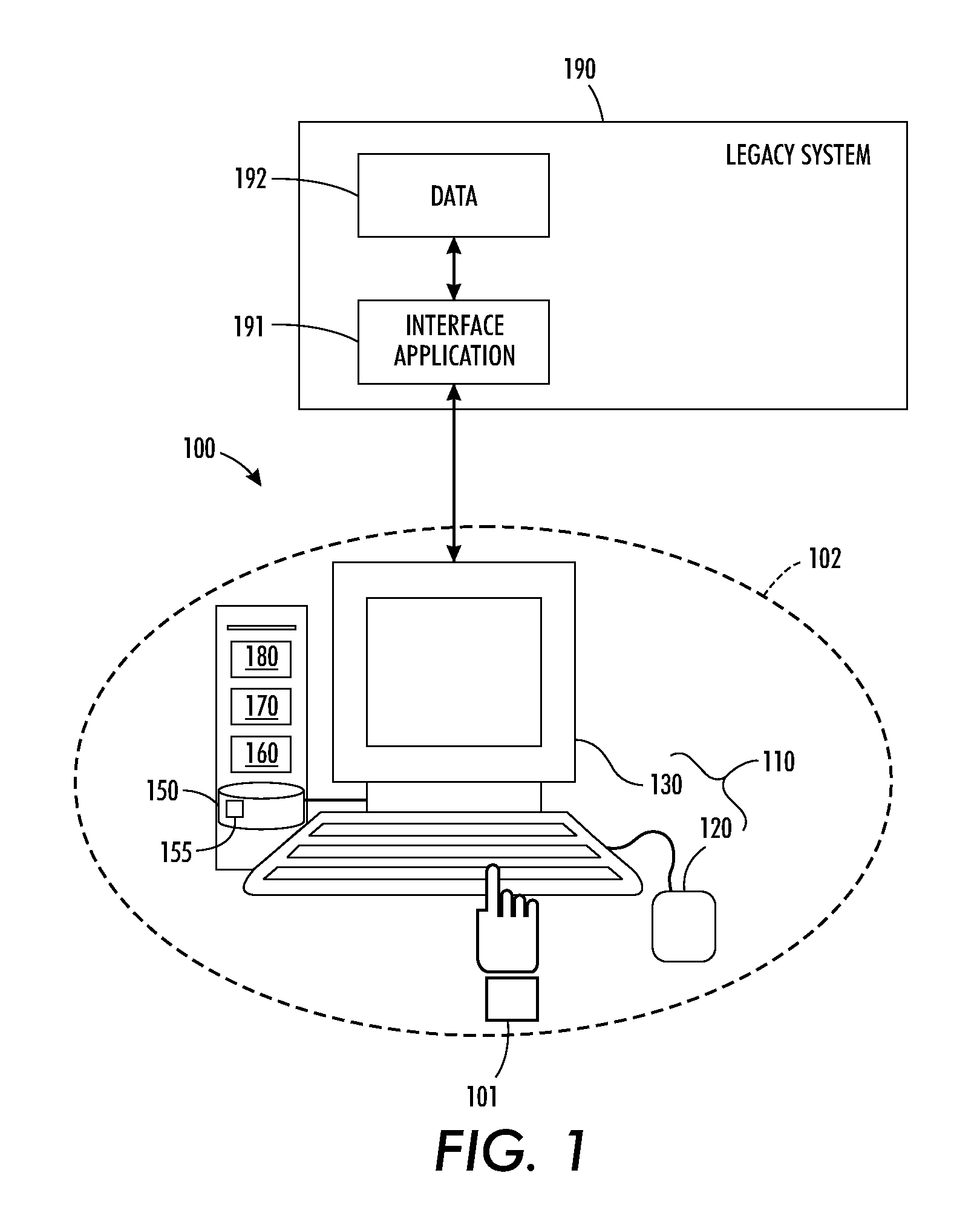

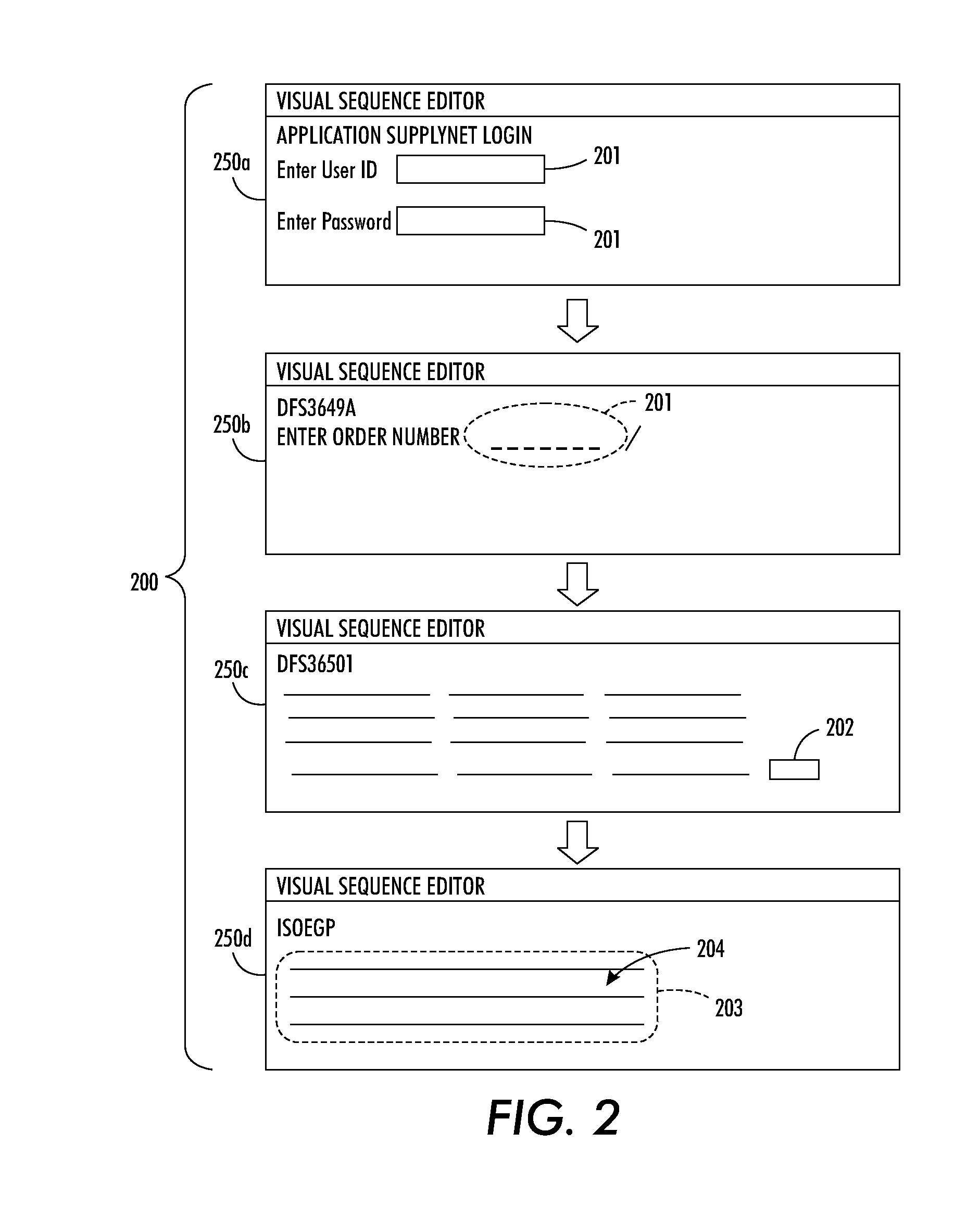

Interface structures and associated method for automated mining of legacy systems using visual configuration tools

InactiveUS20100293506A1Digital data information retrievalOffice automationAutomated miningData field

Disclosed are embodiments of an interface structure and a method for automated data mining of a legacy system. A GUI is employed to navigate through the legacy system interface application and access a data field. Once the data field is displayed, the GUI can receive a tag from the user labeling the data field. Additionally, a screen tracing device can trace the sequence of events that ultimately results in the data field being displayed. The traced sequence and its corresponding tag are then stored in a data storage device. These processes can be repeated for multiple different data fields. Subsequently, a sequence applying device can retrieve one or more previously stored sequences in response to a request referencing the corresponding tag(s) and can apply the sequence(s) in order to access, for processing, data from the corresponding data field(s).

Owner:XEROX CORP

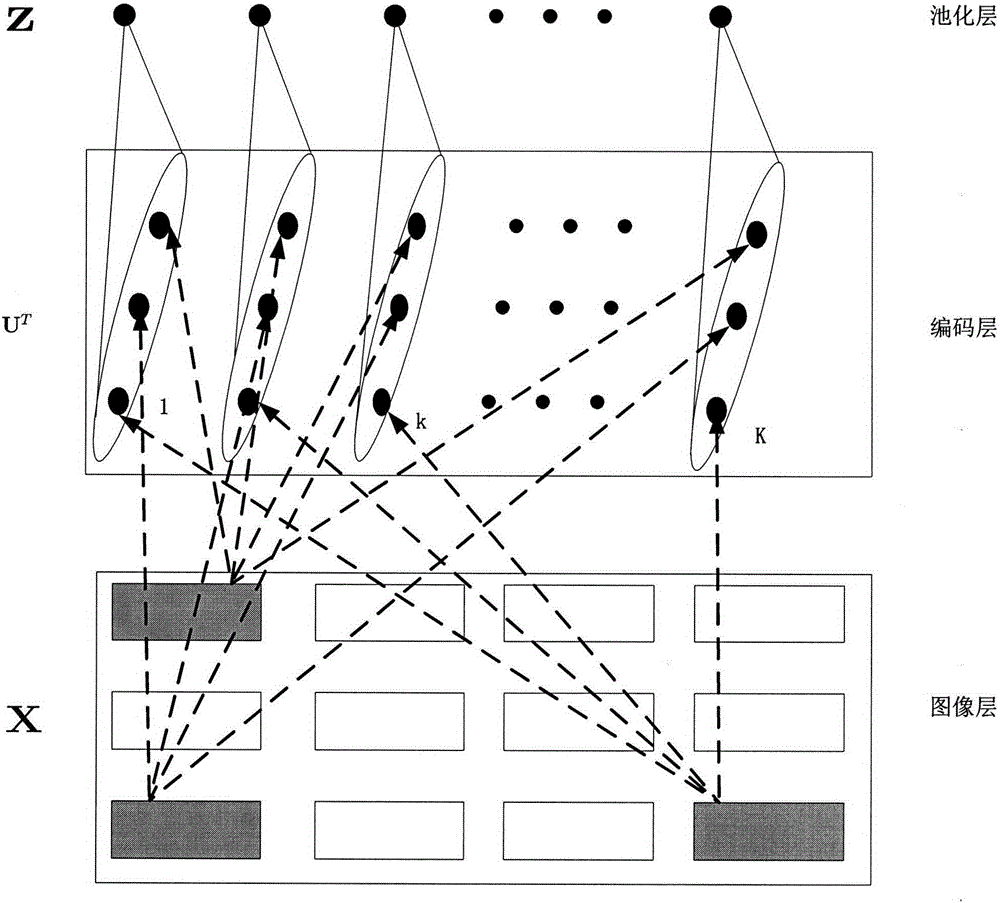

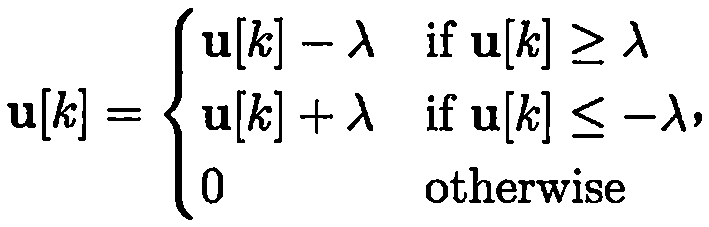

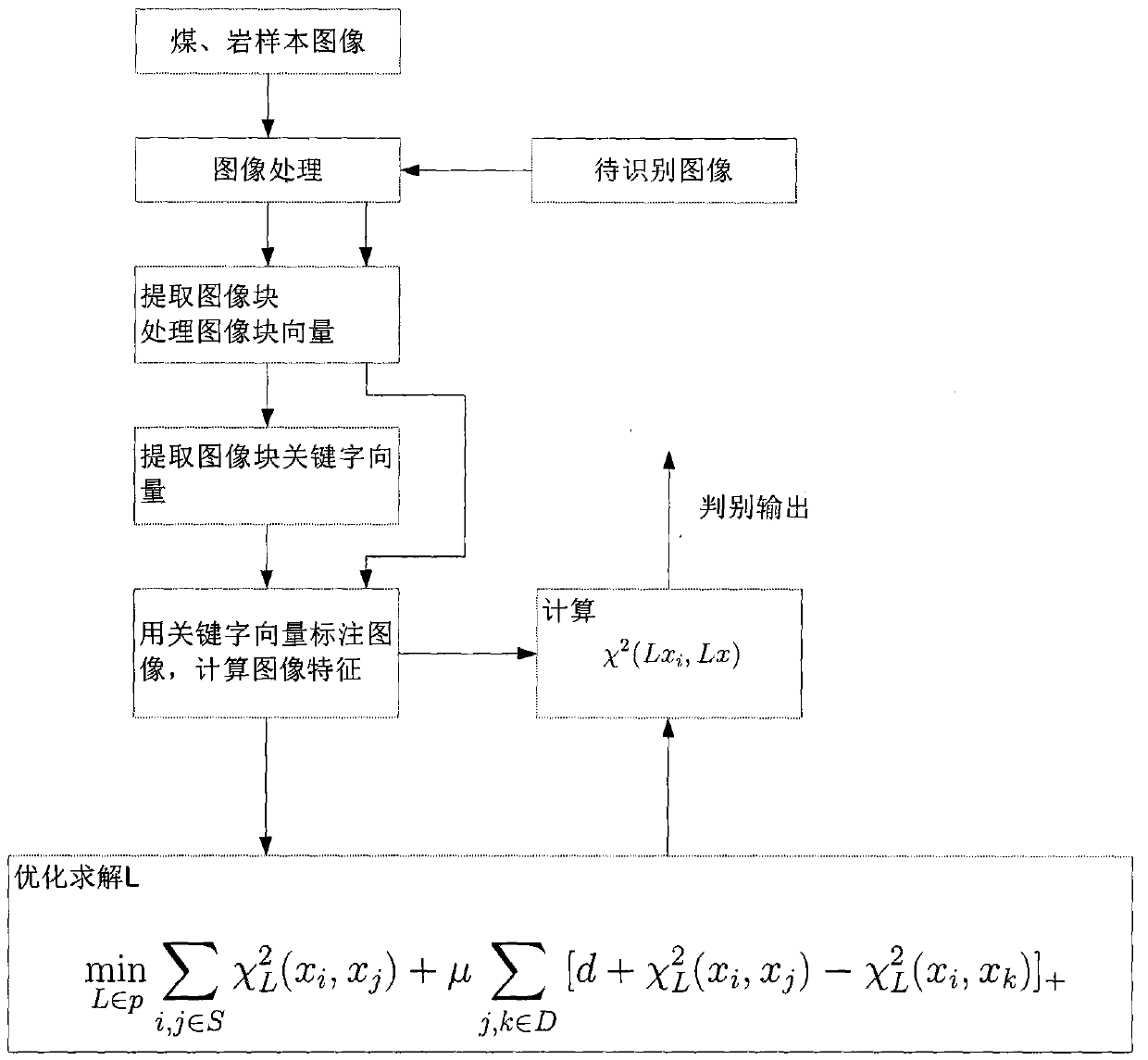

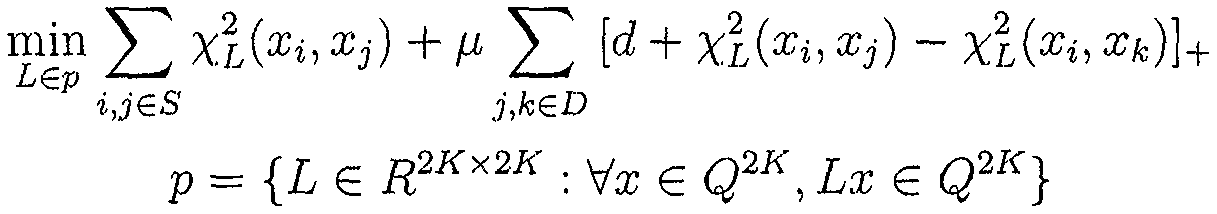

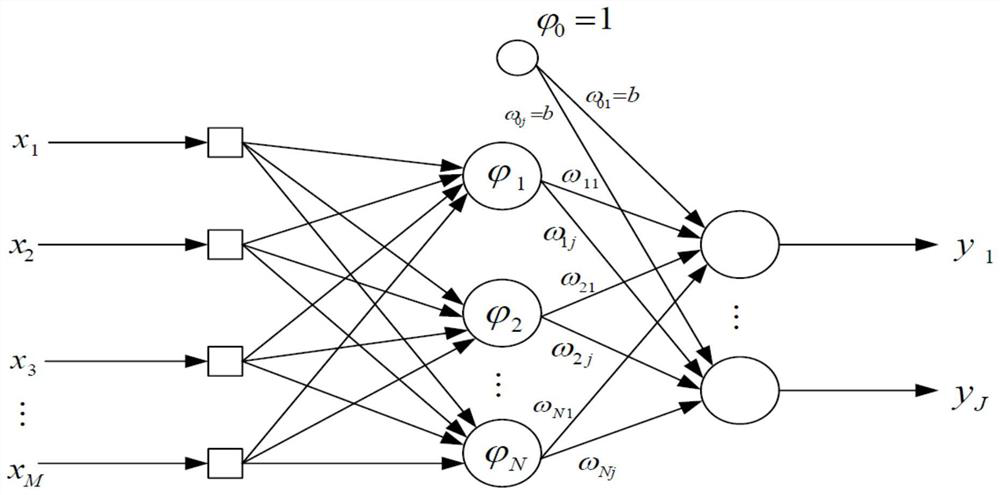

Structured sparse coding based coal rock identification method

InactiveCN105354596AImprove robustnessStrong discriminationCharacter and pattern recognitionSpatial structureAutomated mining

The invention discloses a structured sparse coding based coal rock identification method. According to the method, spatial structure features of coal rocks are captured, so that the method has very good discrimination capability and robustness to imaging environment change. Therefore, the method has very high identification stability and identification correctness and can provide reliable coal rock identification information for production processes of automated mining, automated coal discharge, automated waste rock selection and the like.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

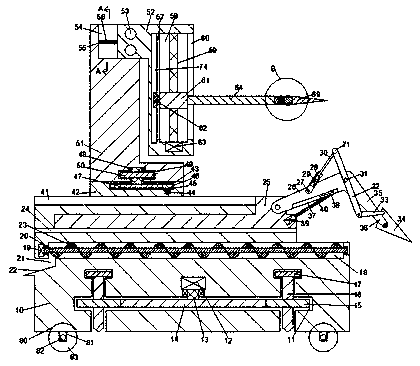

Complex difficult mining deposit large-scale automated mining device

The invention discloses a complex difficult mining deposit large-scale automated mining device which comprises a base. A first transmission cavity is formed in the base, and a first motor is fixedly arranged in the first transmission cavity. A first rotary shaft is fixedly connected to an output shaft of the first motor, and a first gear is fixedly arranged on the lower end face of the first rotary shaft. Four second gears are evenly arranged on the periphery of the first gear in an engaged mode, and a fastening stud is arranged in the middle of each second gear in a penetrating mode. The fastening studs are engaged with the interiors of the second gears. During working of the complex difficult mining deposit large-scale automated mining device, the device is simple in structure, easy to operate, small in occupied area, small in region limitation, and suitable for difficult mining deposit mining; and accurate punching positioning is conducted in a four-dimensional mode, mined mineral aggregate is transported to the rear side of the mining device by a digger through a conveying cavity, the time and manpower used for traditional shut down for mineral aggregate clearing are reduced, adrill bit can be replaced directly, and the mining efficiency is improved.

Owner:毛建锋

Automatic mining dust removal apparatus

InactiveCN108144395ARealize lifting functionRealize automatic cleaning functionCombination devicesDirt cleaningAutomated miningUltimate tensile strength

The invention discloses an automatic mining dust removal apparatus. The automatic mining dust removal apparatus comprises a support and a cleaning apparatus, wherein a dust removal tank is arranged inside the support, one side of the dust removal tank is provided with the cleaning apparatus, the other side of the dust removal tank is provided with an intake pipe, the cleaning apparatus comprises adriving rod, a lifting motor, a coupler, an installation plate and a brush, one side of the lifting motor is provided with the driving rod, one side, away from the lifting motor, of the driving rod is provided with the installation plate, and one side, away from the driving rod, of the installation plate is provided with the brush. By virtue of the lifting motor structure, the lifting function ofa connecting rod is realized; by virtue of the connecting rod and the brush, a dust collection plate can be automatically cleaned; and the structure is simple, the operation is convenient, the problem that partial dust is accumulated inside the dust collection plate is avoided, the dust collection plate is unnecessary to replace frequently, the labor intensity of the working personnel is alleviated, and the operation cost of the enterprise is reduced.

Owner:成都伍加玖网络科技有限公司

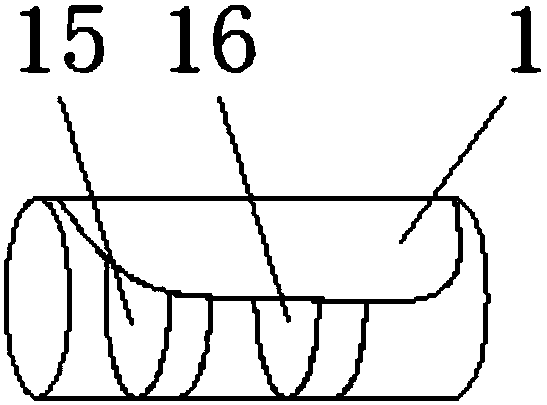

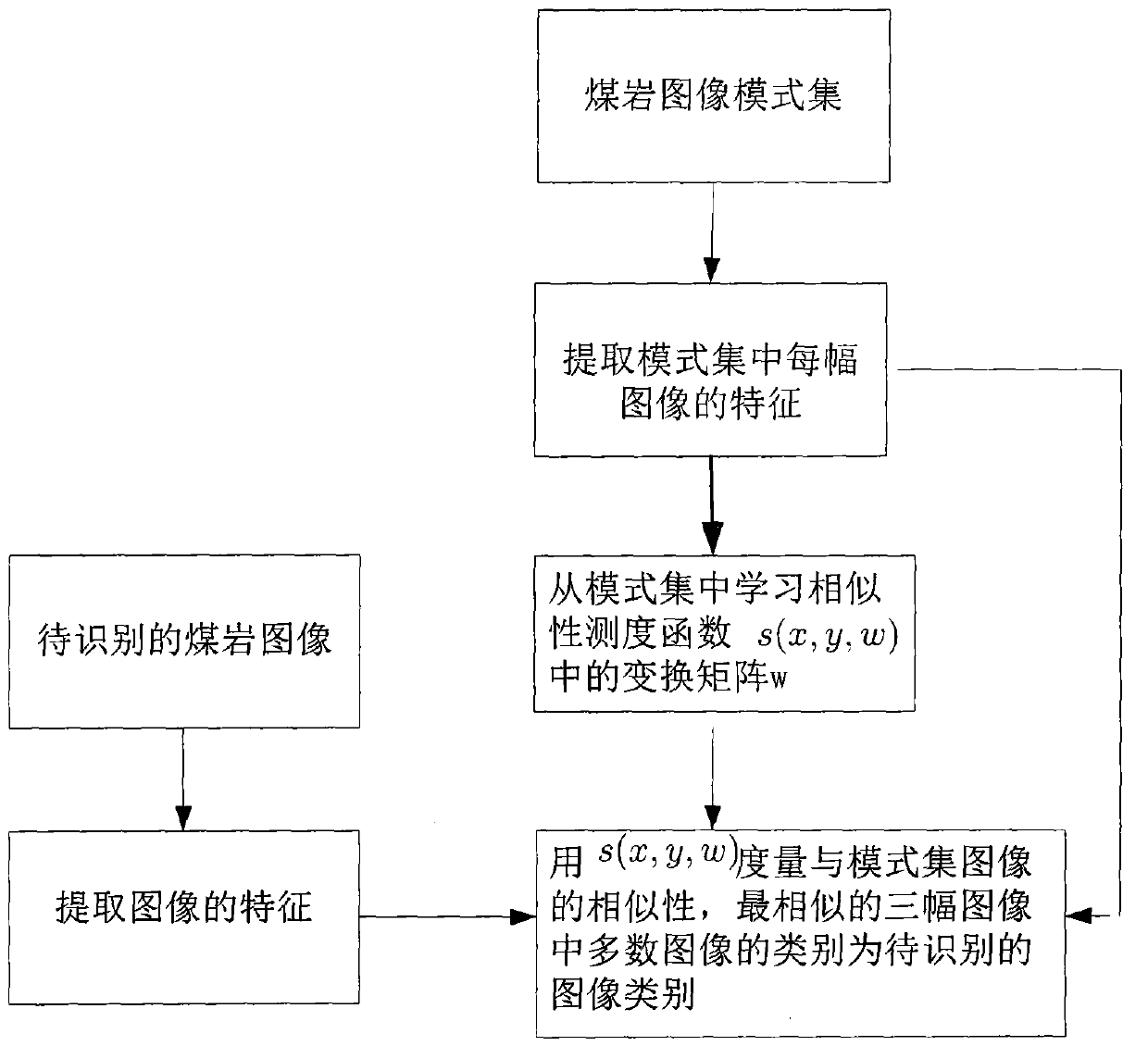

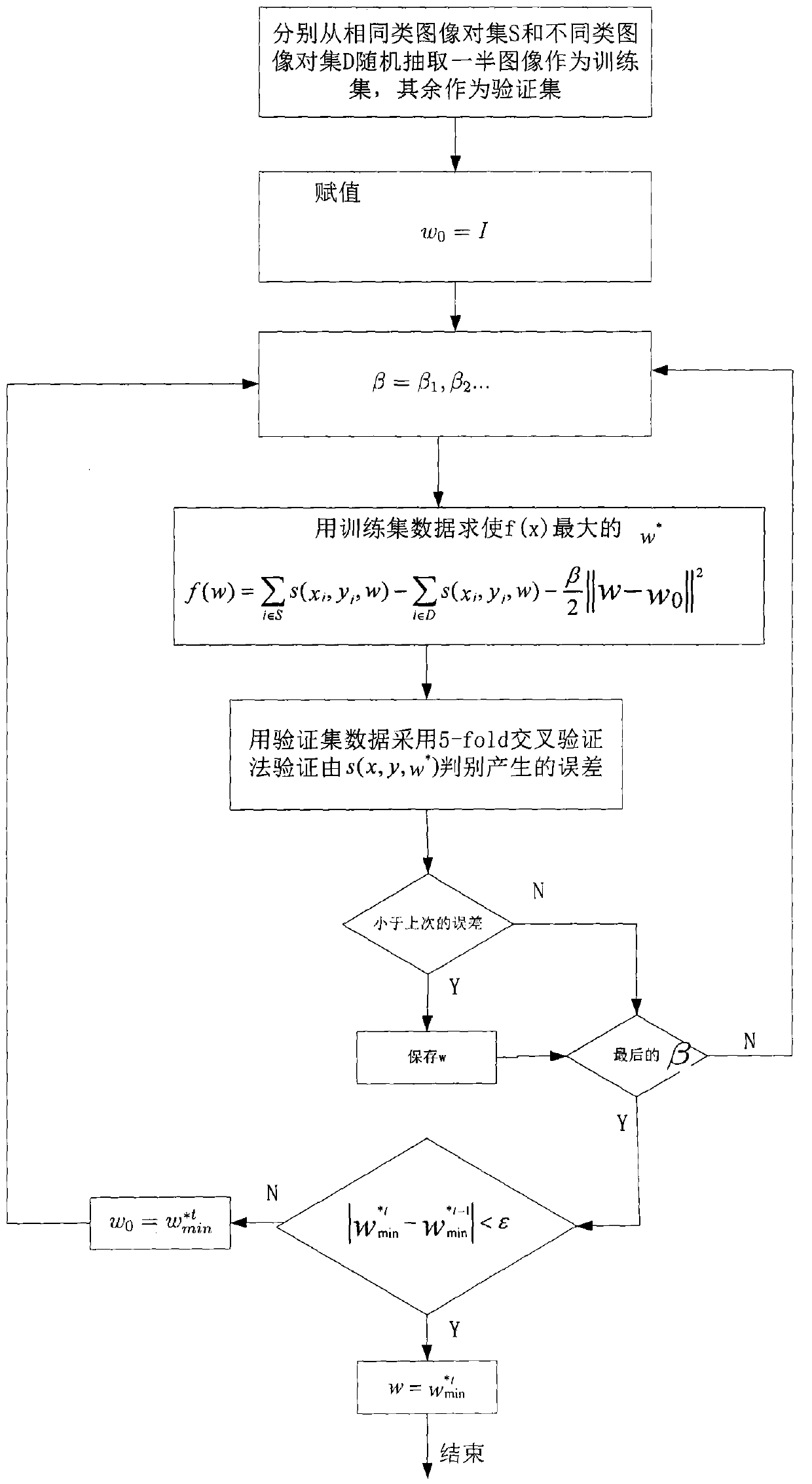

Coal and Rock Recognition Method Based on Similarity Measure Learning

InactiveCN104778461BImprove stabilityEasy to identifyCharacter and pattern recognitionAutomated miningSimilarity measure

The invention discloses a coal-rock identification method based on similarity measurement learning. The method is directly oriented to the coal-rock identification task, and learns a measurement function capable of distinguishing the essential similarity of coal-rock from coal-rock data by supervising the correct rate of coal-rock identification. , has the ability to adapt to changes in coal and rock image data, so that the method has high recognition stability and recognition accuracy, and provides reliable coal and rock identification information for production processes such as automatic mining, automatic coal discharge, and automatic gangue selection.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

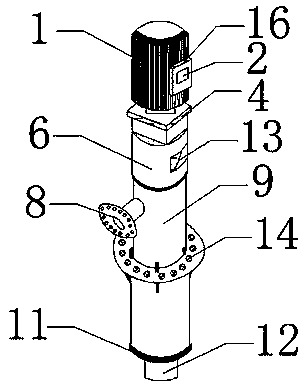

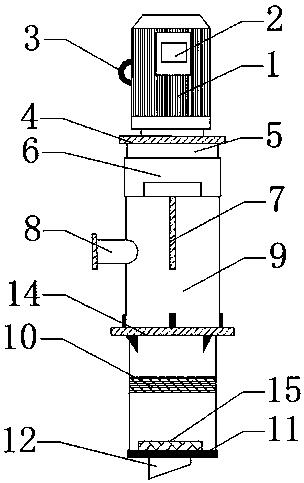

Coal mine closed roadway unsealing dangerous gas source monitoring device based on automatic mining

PendingCN114215603AImpact observationAffects observation of downhole conditionsMining devicesMining engineeringAutomated mining

The invention discloses a coal mine closed roadway unsealing dangerous gas source monitoring device based on automatic mining, and relates to the technical field of coal mine internal gas intelligent monitoring equipment.The coal mine closed roadway unsealing dangerous gas source monitoring device comprises a base and a bearing plate, the bearing plate is located above the base, and a sliding groove plate is welded to the top of the base; a hinge rod is slidably connected to the inner wall of the sliding groove plate, the top of the hinge rod is slidably connected with the left side of the base, and the bearing plate is movably connected with the base through the hinge rod. The electric hydraulic rod is arranged between the base and the bearing plate for combination, the height of the camera recorder can be adjusted according to the underground condition, rotation between the first rotating rod and the second rotating rod is matched, the underground condition can be conveniently recorded in all directions, and the gas detection device, the alarm lamp and the buzzer are arranged in a combined mode, so that the detection efficiency is improved. When the underground gas concentration is detected to reach a certain value, the alarm lamp can be used for reminding.

Owner:山东能源集团鲁西矿业有限公司

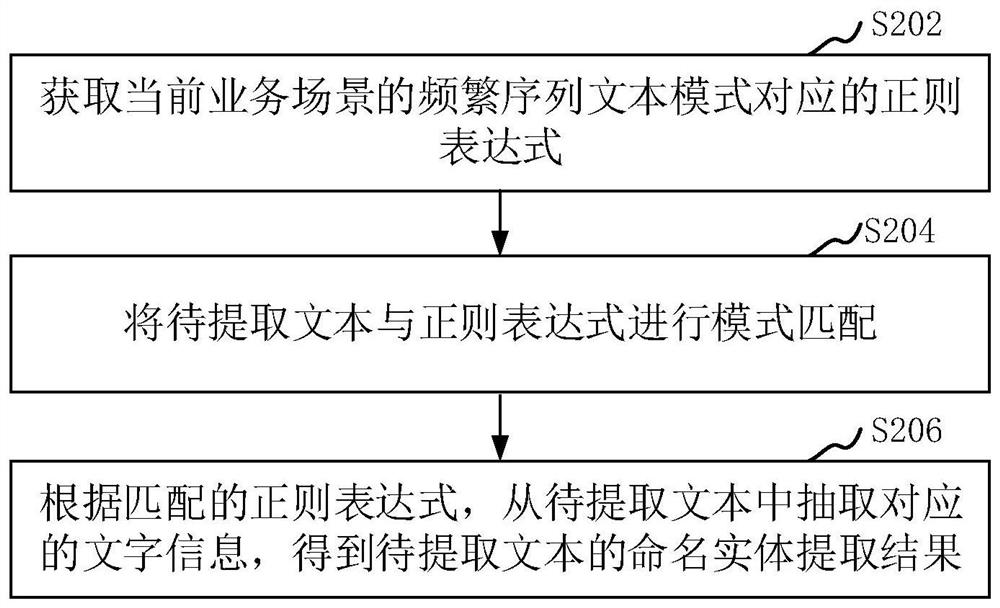

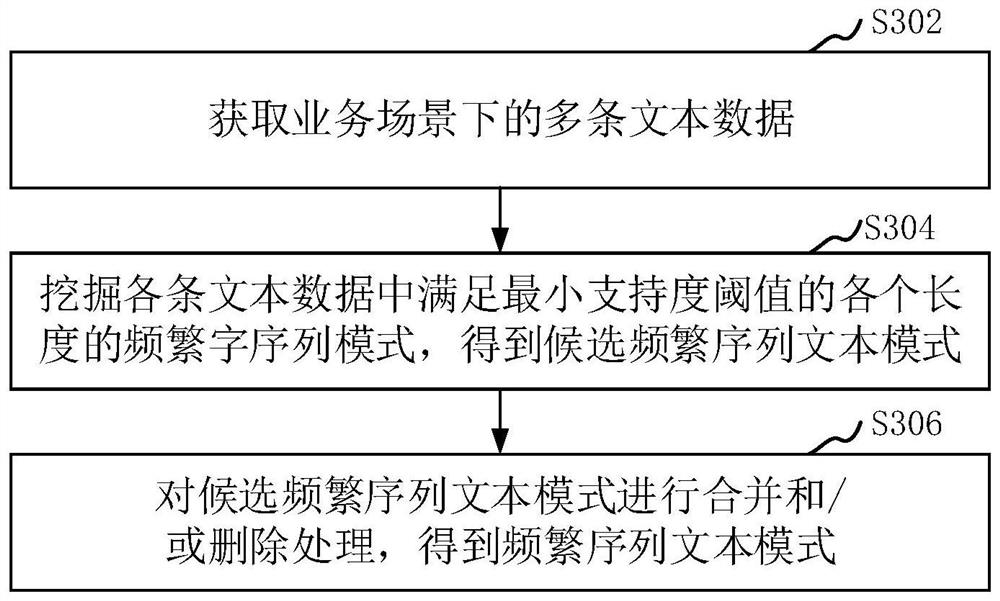

Named entity recognition method, device and computer equipment

ActiveCN109858040BSave tuning timeImprove the efficiency of named entity recognitionNatural language data processingNamed-entity recognitionPattern matching

The present application relates to a named entity recognition method, device, computer-readable storage medium and computer equipment. The method includes: obtaining the regular expression corresponding to the frequent sequence text pattern of the current business scene, and combining the text to be extracted with the regular expression Perform pattern matching, extract corresponding text information from the text to be extracted according to the matched regular expression, and obtain a named entity extraction result of the text to be extracted. This method automatically mines entity recognition patterns based on the frequent sequence pattern mining algorithm, extracts recognition rules from limited patterns to obtain frequent sequence text patterns, and converts them into regular expressions for extraction without parameter adjustment, which saves parameter adjustment time and further improves improved the efficiency of named entity recognition.

Owner:TENCENT TECH (SHENZHEN) CO LTD

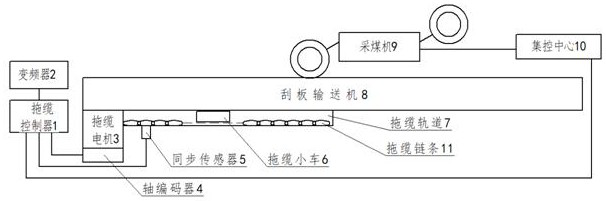

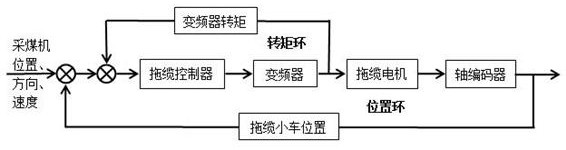

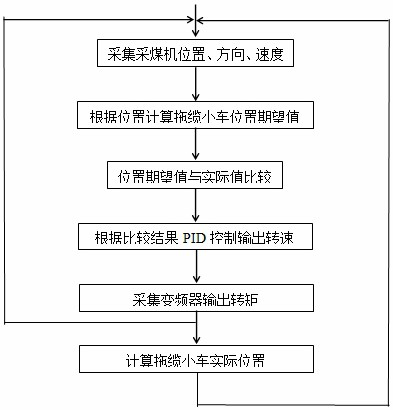

Coal cutter cable automatic dragging control method based on double closed-loop control

PendingCN114167714AGuaranteed uptimeReasonable designSlitting machinesControllers with particular characteristicsLoop controlAutomated mining

The invention relates to the technical field of coal mining, in particular to a coal cutter cable automatic dragging control method based on double closed-loop control. According to an existing method, a cable towing wheel is controlled to follow a coal mining machine to run at a half speed in the same direction, although a cable towing system can be controlled to run, the control precision and the real-time performance are greatly insufficient, and the risk that a cable of the coal mining machine is snapped exists. Operation information such as the position, the speed, the current and the torque of the cable towing wheel is collected in real time, and the position and the speed of the coal mining machine are combined to form a double-closed-loop control method based on the position and the torque to control operation of the cable towing wheel. The control method has the advantages that the designed control method is scientific and reasonable, the cable towing wheel is accurately controlled in real time, the safety and stability of an automatic cable towing system of the coal mining machine are ensured, and powerful support is provided for automatic mining of thin coal seams.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

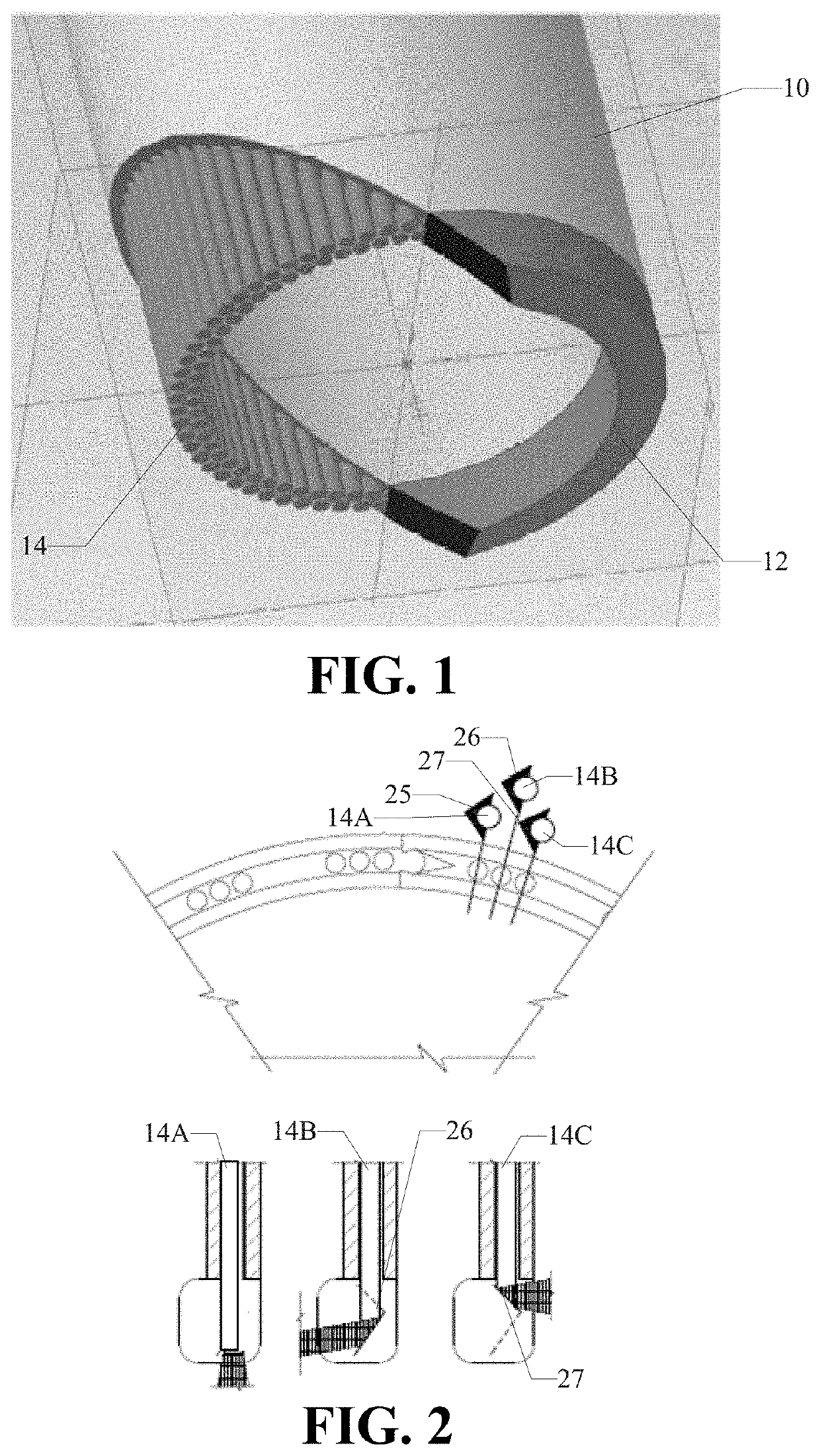

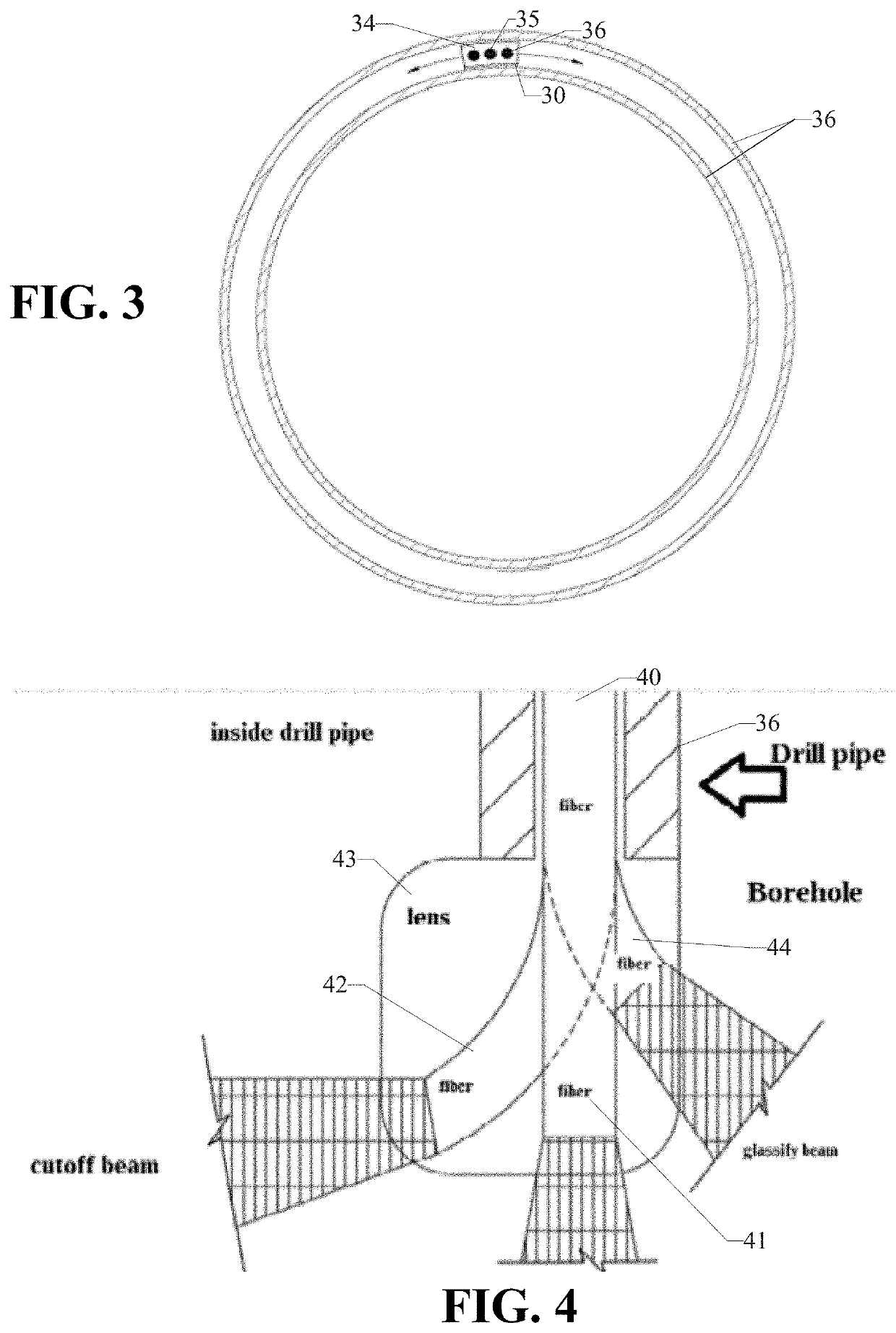

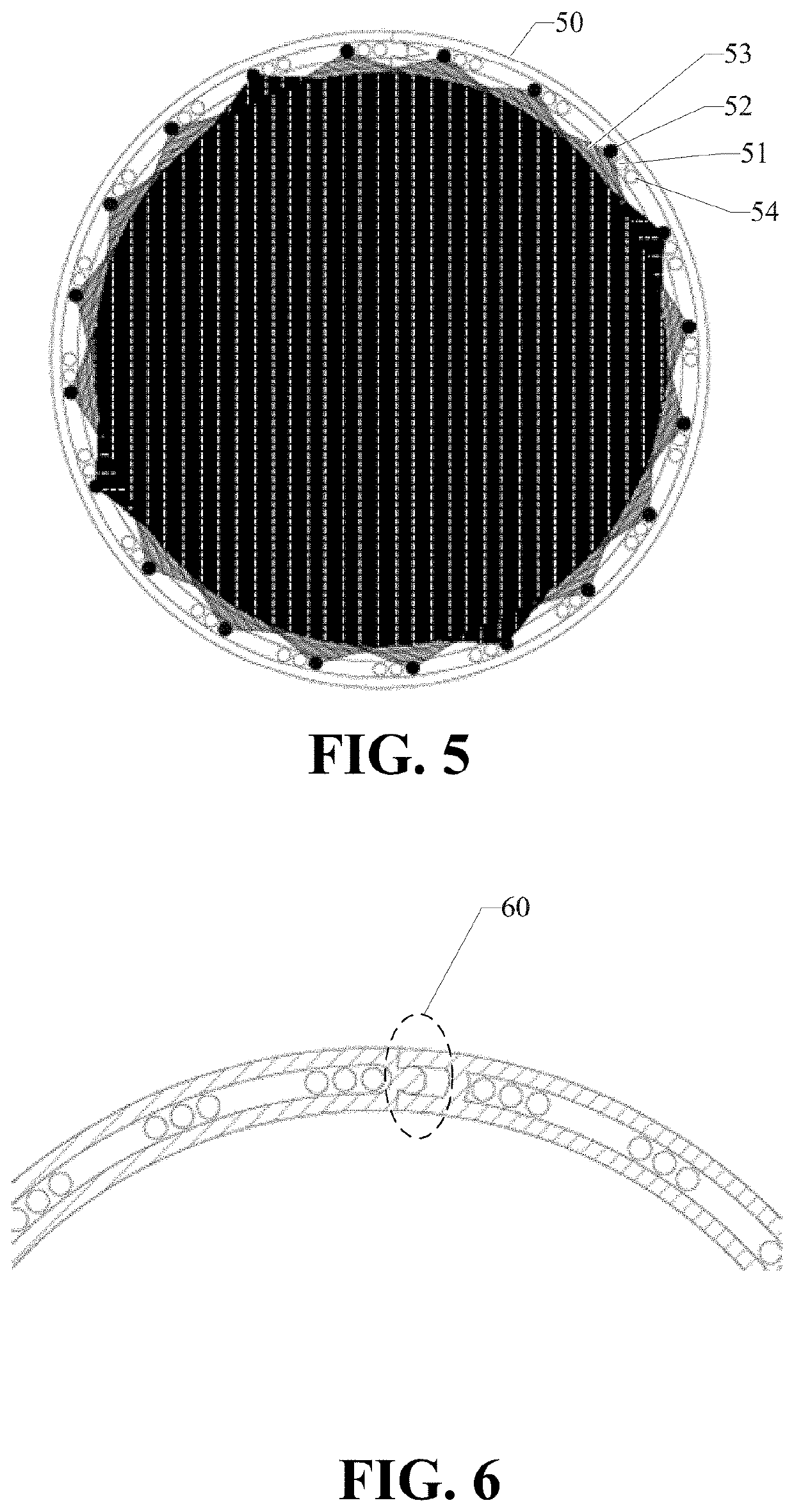

Method and apparatus for concentrated energy drilling, core drilling, automated mining and tunneling

InactiveUS20210381315A1Reduce materialLower energy requirementsThermal drillingCore removalHigh energyLaser beams

A system, method, and apparatus for creating core samples, including a core bit; and a high-energy source disposed at a perimeter of the cutting head. That system, method, and apparatus allows removing much less material using much less energy than the current state of the art. A reason for this is that prior attempts tried to accomplish this via drilling just from the surface with a very large device or to send down hole a very large device. This invention makes it feasible to send high energy down hole is a relatively tiny device such as an optical fiber with a laser beam to cut the peripheral part of the hole to remove an intact center core or to bore a very small hole without a center core. With this invention it is feasible to drill a very small hole such as 0.25 inches diameter hundreds of feet through rock, or a 4 inch hole with less than 0.5 inch outer part of the hole being destroyed leaving a core in the center than can be removed. This invention has many more capabilities beyond these.

Owner:ALLEN DANA R

Automatic digging device for young corn embryos

ActiveCN111183901BRealize automatic miningHorticulture methodsPlant tissue cultureAgricultural scienceElectric machine

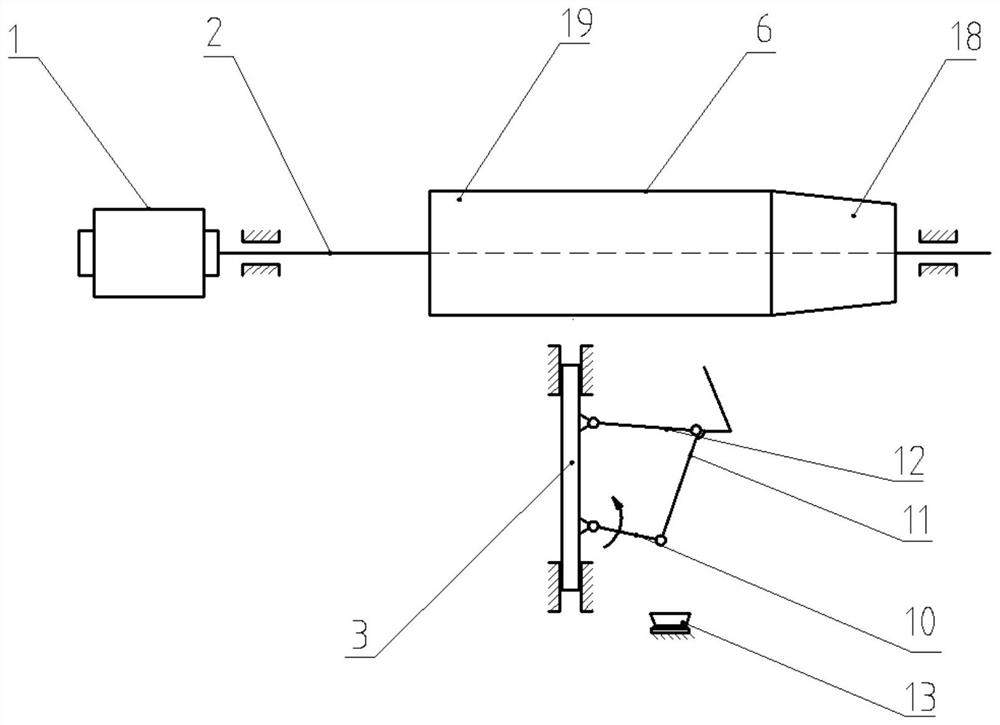

The present invention relates to an automatic digging device for immature corn embryos, which belongs to the technical field of agricultural machinery automation, and in particular to a device for automatically digging young embryos of corn with four linkages. The automatic excavation device for young corn embryos includes: corn ears Rotary motor, corn ear rotating shaft, digging mechanism radial moving platform, digging motor, digging mechanism, corn ear, corn ear axial moving platform, axial moving motor, central processing unit, among which the digging mechanism is a plane four-connected Rod mechanism, including crank, connecting rod, rocker. It solves the problems of low efficiency and high intensity of manual extraction of immature corn embryos, realizes the adjustment of the connecting rod movement track and the position of the end of the connecting rod according to different varieties of corn, to replace the artificial embryo extraction method, and improves the adaptability of corn embryo extraction and flexibility, which improves the efficiency of extracting young corn embryos and reduces the work intensity of embryo extraction.

Owner:CHINA AGRI UNIV

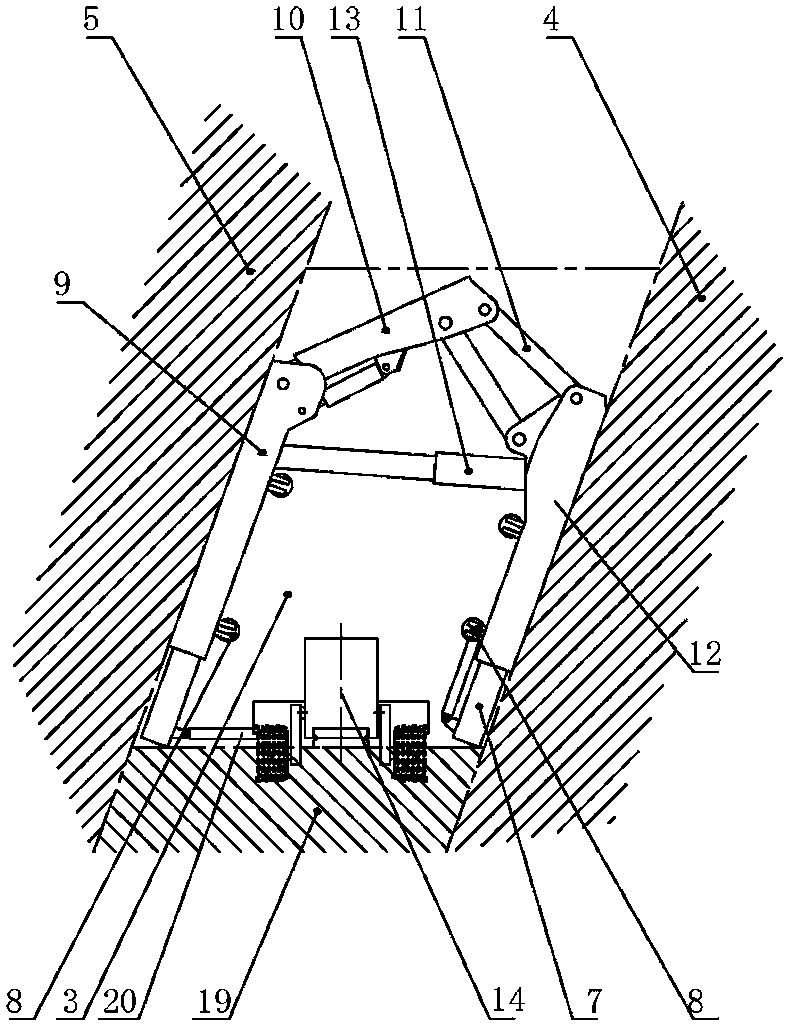

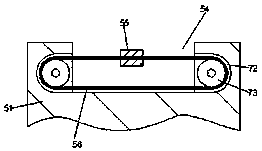

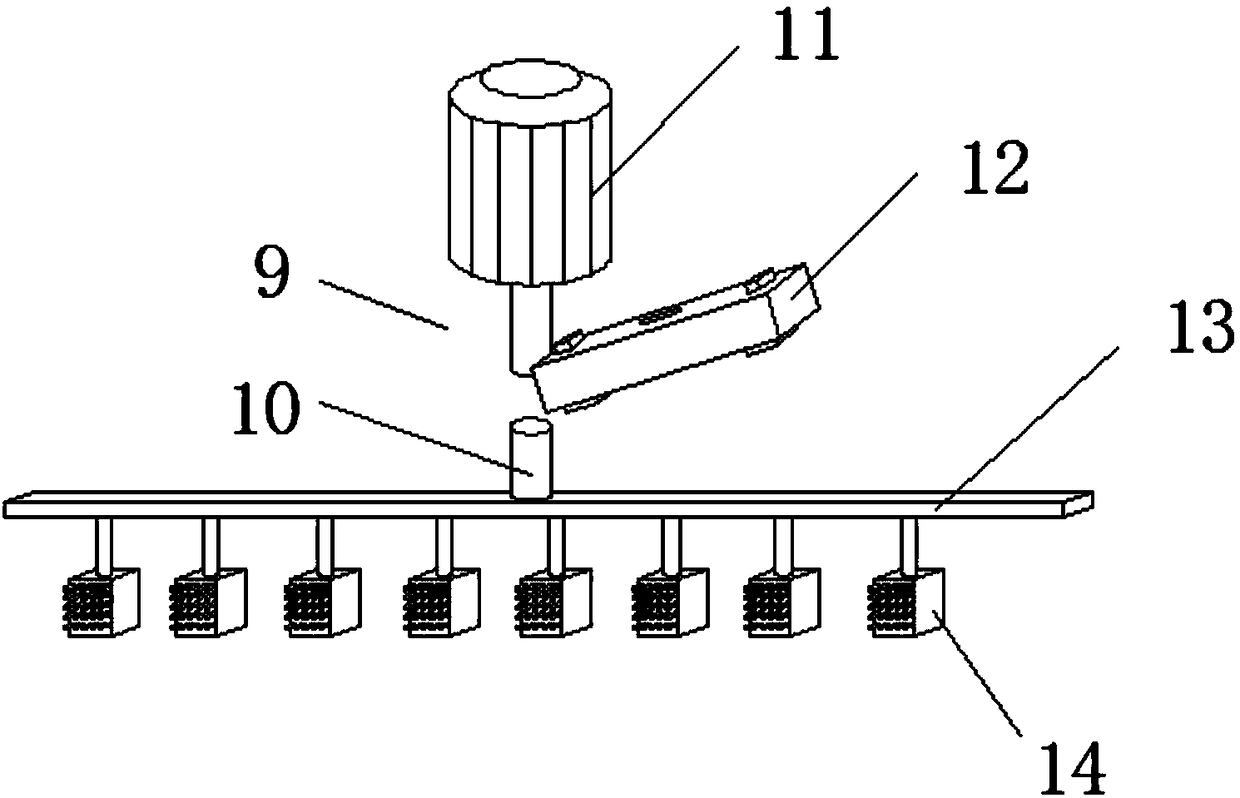

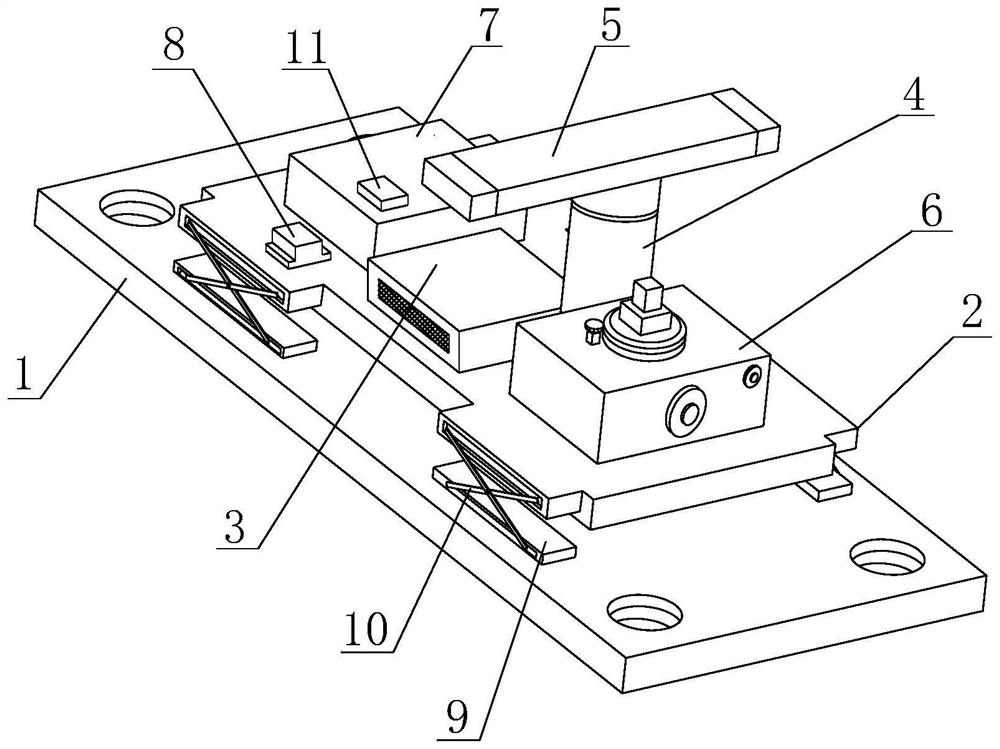

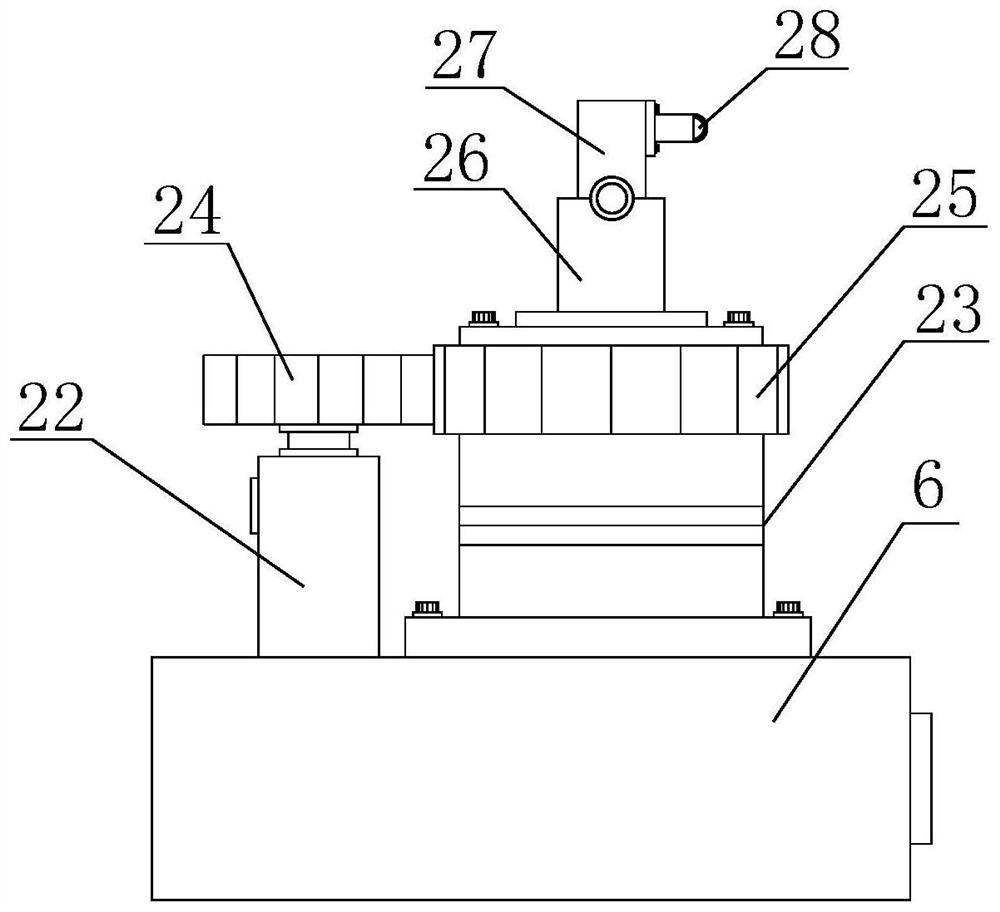

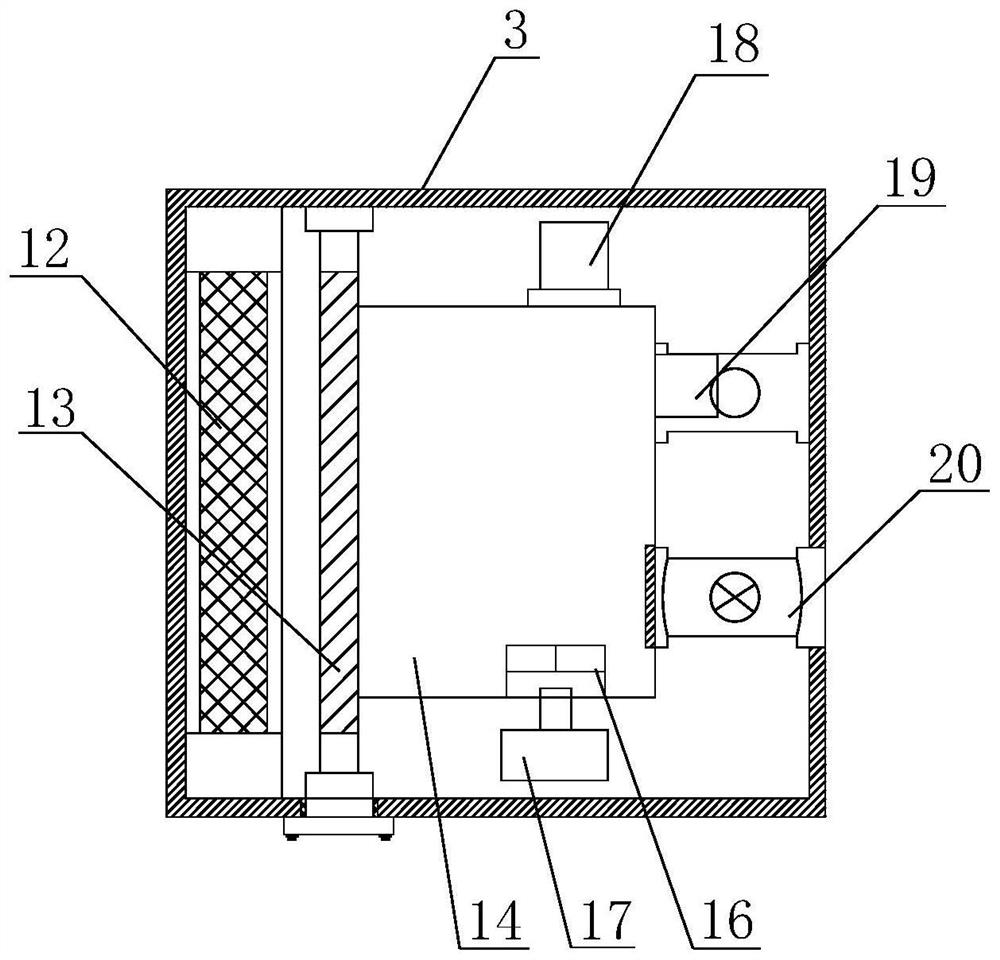

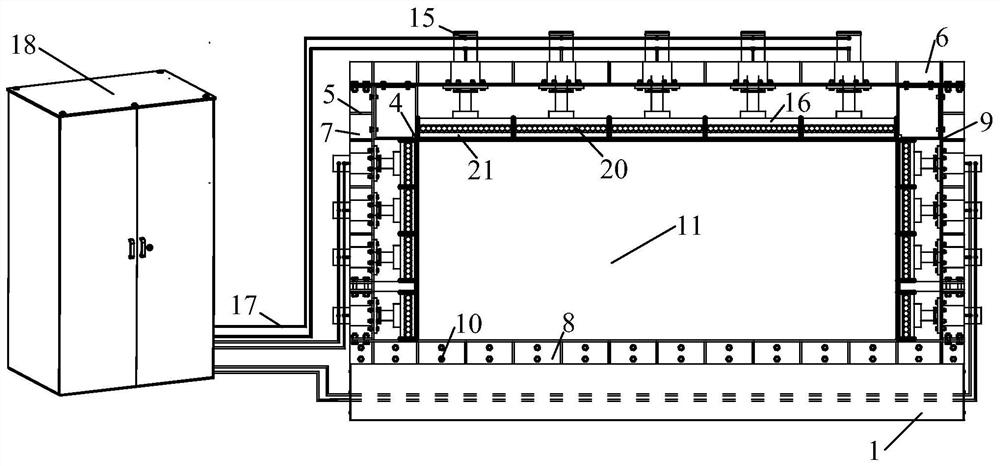

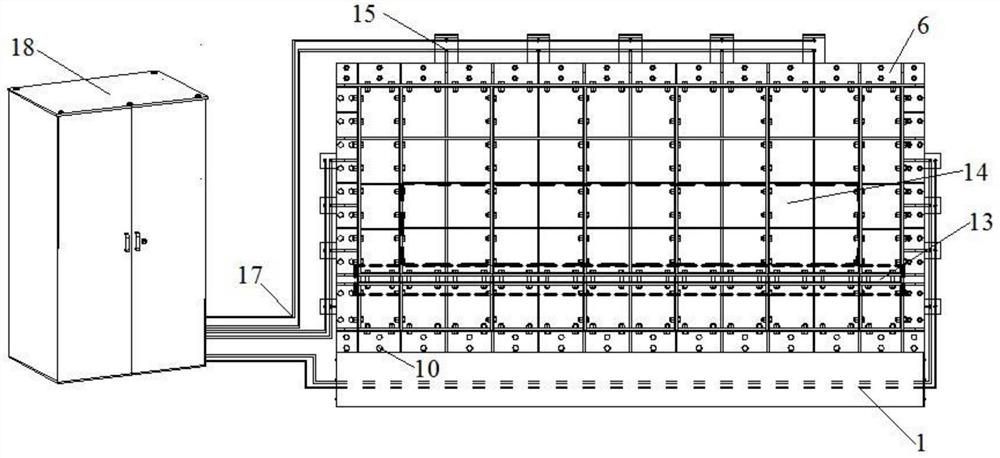

Automatic mining model test device and method for self-formed roadway without coal pillar

ActiveCN111239366BAvoid out-of-sync phenomenon of tangential deformationAvoiding issues that make it impossible to continue test miningMaterial analysis using acoustic emission techniquesEarth material testingAutomated miningMachine

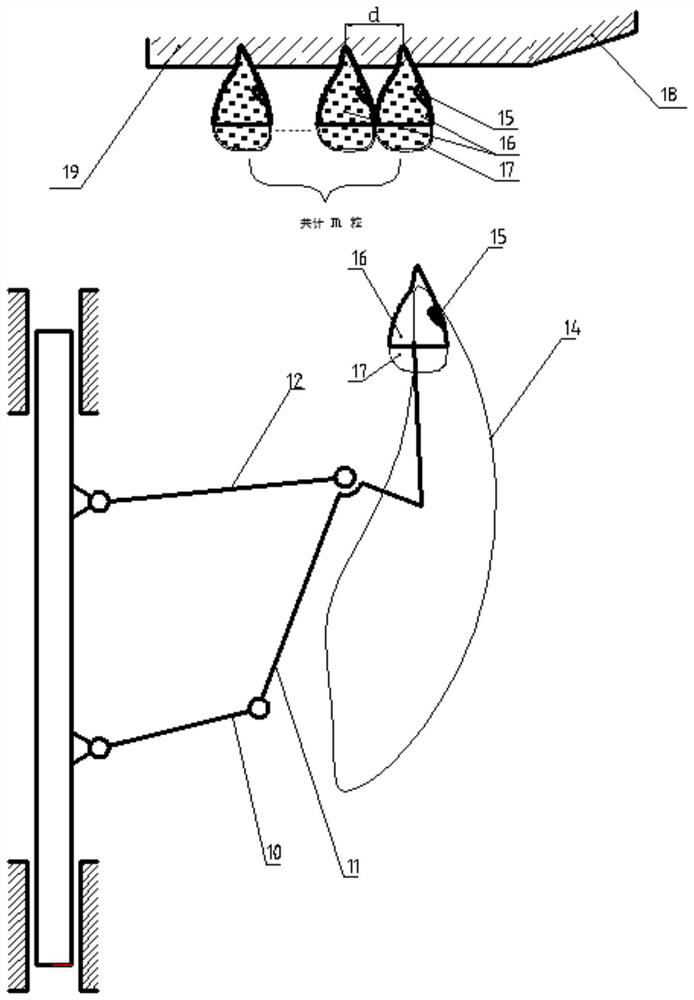

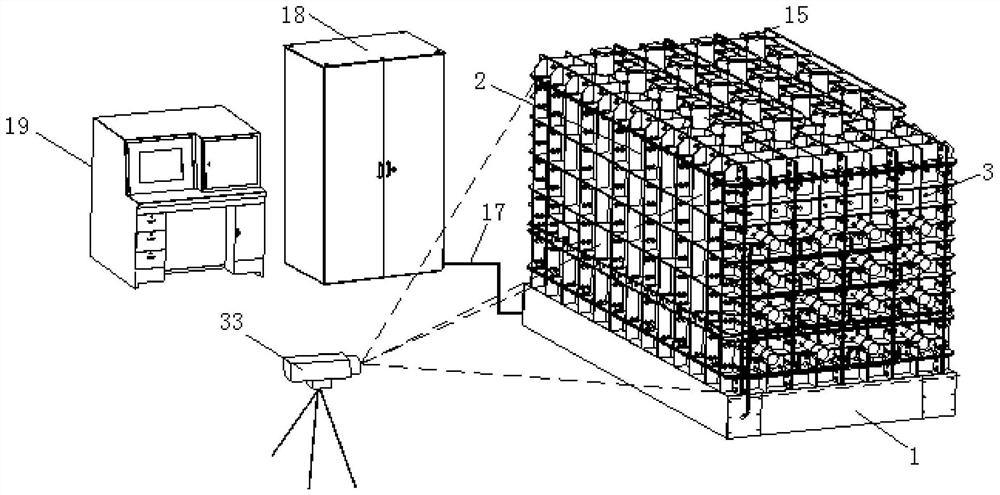

The invention discloses an automatic mining model test device and method for self-forming roadway without coal pillars, which solves the problems of low accuracy and difficulty in simulating the core process of mining self-formed roadway without coal pillars in the prior art, can simulate mining conditions, and realize a The machine is multi-purpose. Its technical solution is: including combined reaction force device, flexible loading device, automatic mining roadway forming device, monitoring device and intelligent control center. The intelligent control center controls the flexible loading device and automatic mining roadway forming device and can receive and process the The data obtained by the monitoring device; the flexible loading device includes a loading cylinder, the loading cylinder is connected to the loading plate, and an adjustment layer and a force transmission layer are arranged at the end of the loading plate; the automatic mining roadway forming device includes a mining simulation device and a slit simulation device, and the mining simulation device can Simulate roadway excavation and working face mining; the cutting simulation device can cut the model body; the monitoring device is used to collect and store the images and data during the test.

Owner:王琦

Multi-protocol Ethernet switch for mines

ActiveCN102231706BDirect conversionImprove operational reliabilityData switching networksPower conditionerData transformation

The invention relates to a multi-protocol Ethernet switch for mines and belongs to comprehensive network communication equipment for mines. In the multi-protocol Ethernet switch provided by the invention, a core processing module is simultaneously connected with a first program storage module, a second program storage module, a data storage module and an Ethernet data transformation module, wherein the Ethernet data transformation module is simultaneously connected with a serial port communication module, an optical port communication module and an Ethernet module; the Ethernet module comprises a network filter and a port; the port is connected with the Ethernet data transformation module through the network filter; a power supply module is connected with all the modules and provides energy sources for each module; the power supply module comprises a first power supply regulator, a second power supply regulator and a third power supply regulator; the second power supply regulator is connected with the third power supply regulator in series; and the second power supply regulator and the third power supply regulator which are connected in series are connected with the first power supply regulator in parallel. The multi-protocol Ethernet switch provided by the invention has the advantages that the access of multiple types of equipment is realized; and reliable data sources are provided for the high-efficiency automated mining of coal mines and the remote supervision and fault diagnosis of coal mine equipment.

Owner:CHINA UNIV OF MINING & TECH

A system and method for unmanned mining of coal mines

ActiveCN105064997BImprove adaptabilityExisting conditions vary greatlySlitting machinesMine roof supportsAutomated miningRemote control

The invention discloses a coal mine unmanned mining system and method. The coal mine unmanned mining system comprises a coal mining machine, a main control computer, a patrol robot, a hydraulic support electrohydraulic control system, a remote control console and a coal wall video camera, wherein the main control computer is electrically connected with the patrol robot and the coal wall video camera; the main control computer is electrically connected with the coal mining machine through the remote control console; and the main control computer is electrically connected with the hydraulic support electrohydraulic control system. The coal mine unmanned mining system and method solve the problem that automated mining systems for thin seams are poor in adaptability to coal seams of other thickness; and by applying an inspection robot technology to mining of a fully mechanized coal face, the coal mine unmanned mining system and method also solve the problems that conventional mine automation production fails to adapt to geological condition changes and must be interfered by manpower. The coal mine unmanned mining system and method intelligently correct automatic mining of the fully mechanized coal face through various sensing methods.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD

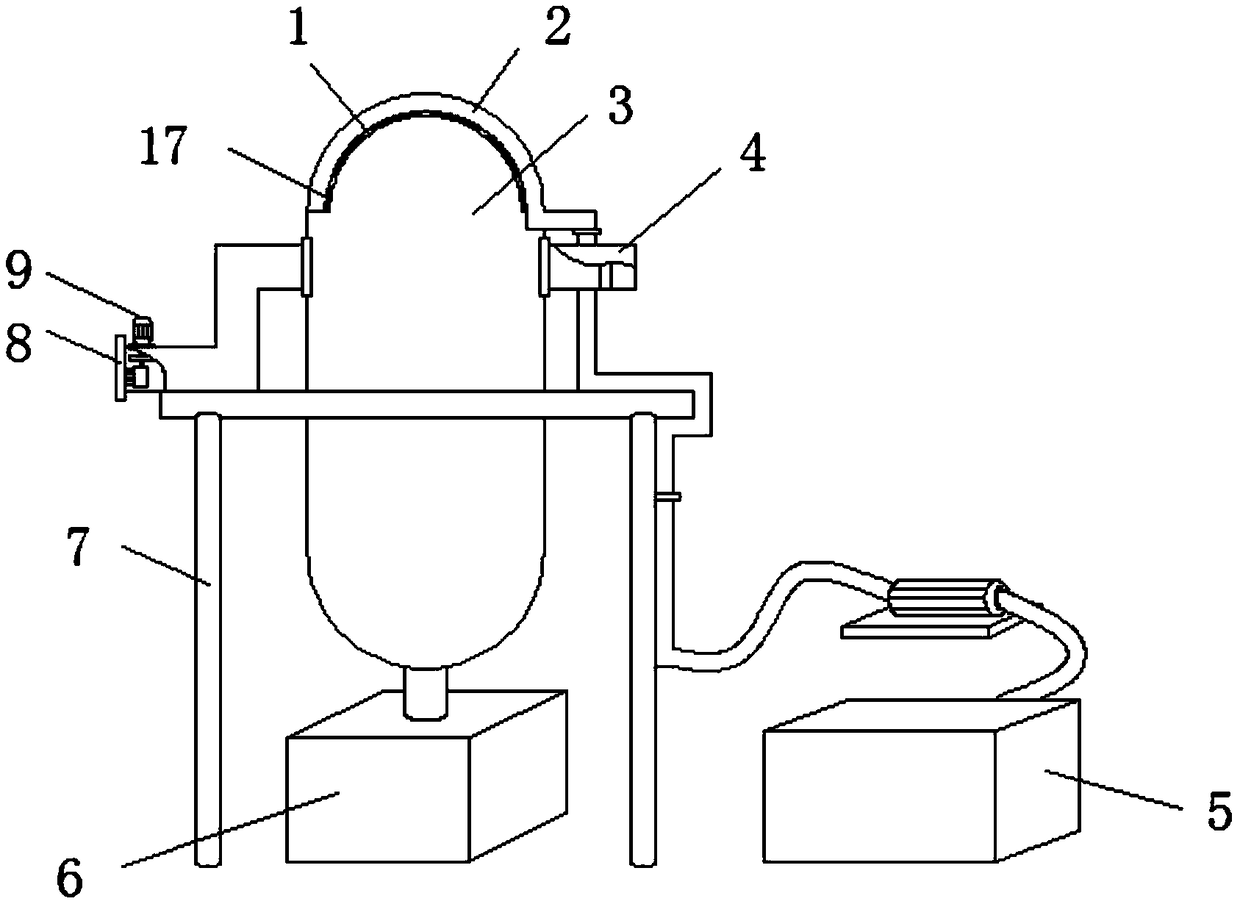

Automatic oil extraction pump

InactiveCN107781233ABeautiful designCompact structurePressure pumpsMachines/enginesLiquid-crystal displayAutomatic control

The invention discloses an automatic oil extraction pump, which comprises a motor, a telescopic tube and a controller. The outer side of the motor is fixedly connected with the controller, and a liquid crystal display is arranged on the outer side of the controller. The right side of the motor is welded to a handle. The lower part of the motor is fixedly connected with the fixed frame by screws, and the lower part of the fixed frame is movably connected with the connecting pipe. A fan chamber is arranged under the connecting pipe, and an air outlet is opened on the outside of the fan chamber. Shaft, the lower part of the connecting pipe is fixedly connected with the cavity by screws, the left side of the cavity is welded to the oil outlet, the lower part of the cavity is fixedly connected with the fixed plate by screws, and a telescopic tube is arranged under the fixed plate. The lower part of the telescopic tube is flexibly connected with the sealing ring. The automatic oil production pump has a beautiful design and a compact structure, and realizes the purpose of intelligent automatic control by using a controller to control equipment and a liquid crystal display.

Owner:黄建辉

Coal and rock identification method based on distance constraint similarity

InactiveCN104751193BImprove stabilityEasy to identifyCharacter and pattern recognitionAutomated miningDistance constraints

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Systems and methods for WebSphere MQ performance metrics analysis

InactiveUS10116534B2Facilitate rapid correction and modificationUse minimizedDigital computer detailsHardware monitoringRelevant informationAutomated mining

Systems and methods for the computer-automated mining and profiling of server monitoring data and related information are disclosed. Performance monitoring is performed through system commands and queries against particular software components arranged in a particular way that provides comparative information for the management and optimization of server and software resources through the identification of constraints and bottlenecks. Further, the present disclosure relates to the analysis and comparison of a current running profile of a server against previous or archived profiles. The profiles characterize the utilization and usage of server resources, or prior systems performance history for the purpose of performance tuning and resource optimization of the middleware messaging software.

Owner:TXMQ INC

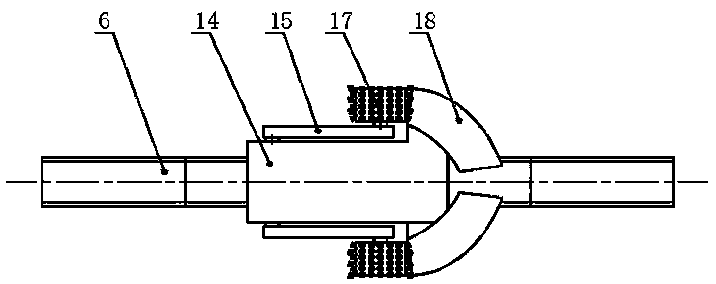

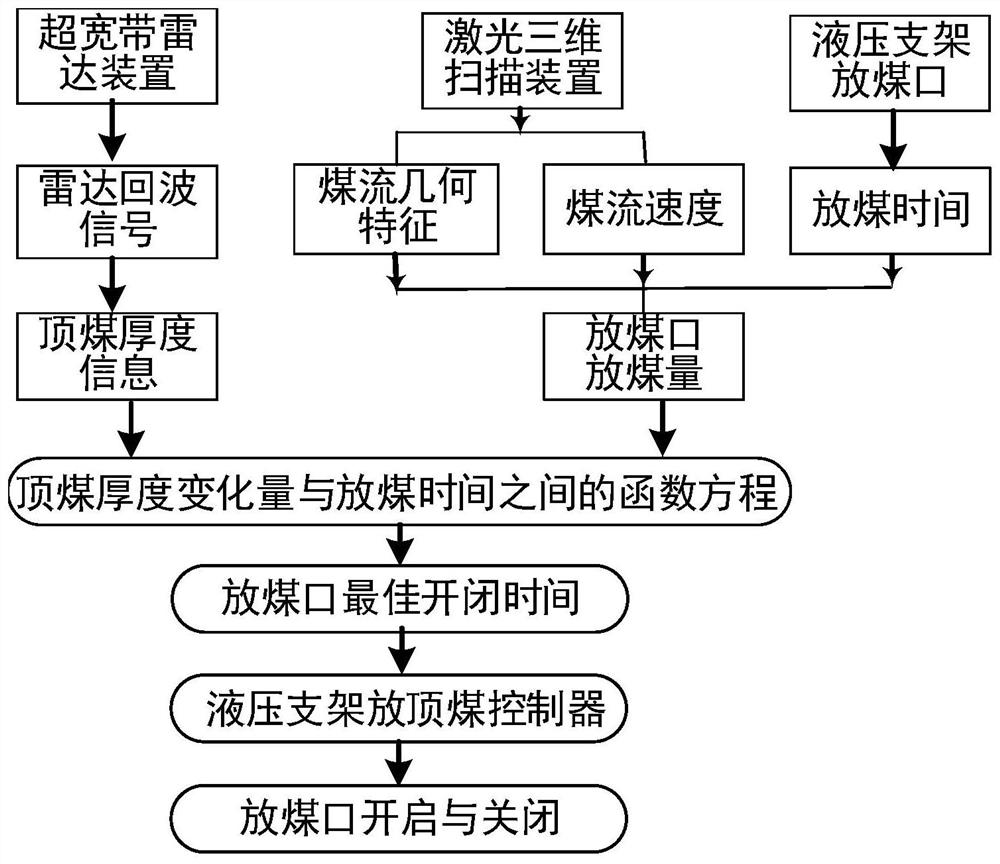

An intelligent coal discharge method based on real-time monitoring of top-coal thickness variation

ActiveCN109856631BOpening and closing time controlAdaptableUnderground miningVolume/mass flow measurementUltra-widebandWideband radar

A smart coal caving method based on real time monitoring of variation in top coal thickness, using ultrawide-band radar and laser 3D scanning technology to monitor top coal thickness information in real time and automatically regulate the opening and closing of a coal caving opening, and comprising the following steps: (I) an ultrawide-band radar apparatus (4) calculates a variation in top coal thickness on the basis of a radar echo signal; (II) a laser 3D scanning apparatus (6) calculates a coal caving amount on the basis of a scanned coal flow geometric feature, coal flow speed, and coal caving time at the coal caving opening; (III) a function equation between the top coal thickness variation and the coal caving time is established, and optimal open and close times of the coal caving opening for different coal caving stages are calculated; and (IV) open and close instructions are sent to the coal caving opening by means of a top coal caving controller, thus achieving smart coal caving in a fully-mechanized caving workface. The present method allows for accurate control and strong adaptability in the entire coal caving process, without the need for manual interference, effectively raising coal caving efficiency, and reducing labor intensity.

Owner:CHINA UNIV OF MINING & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com