Patents

Literature

71results about How to "Save tuning time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

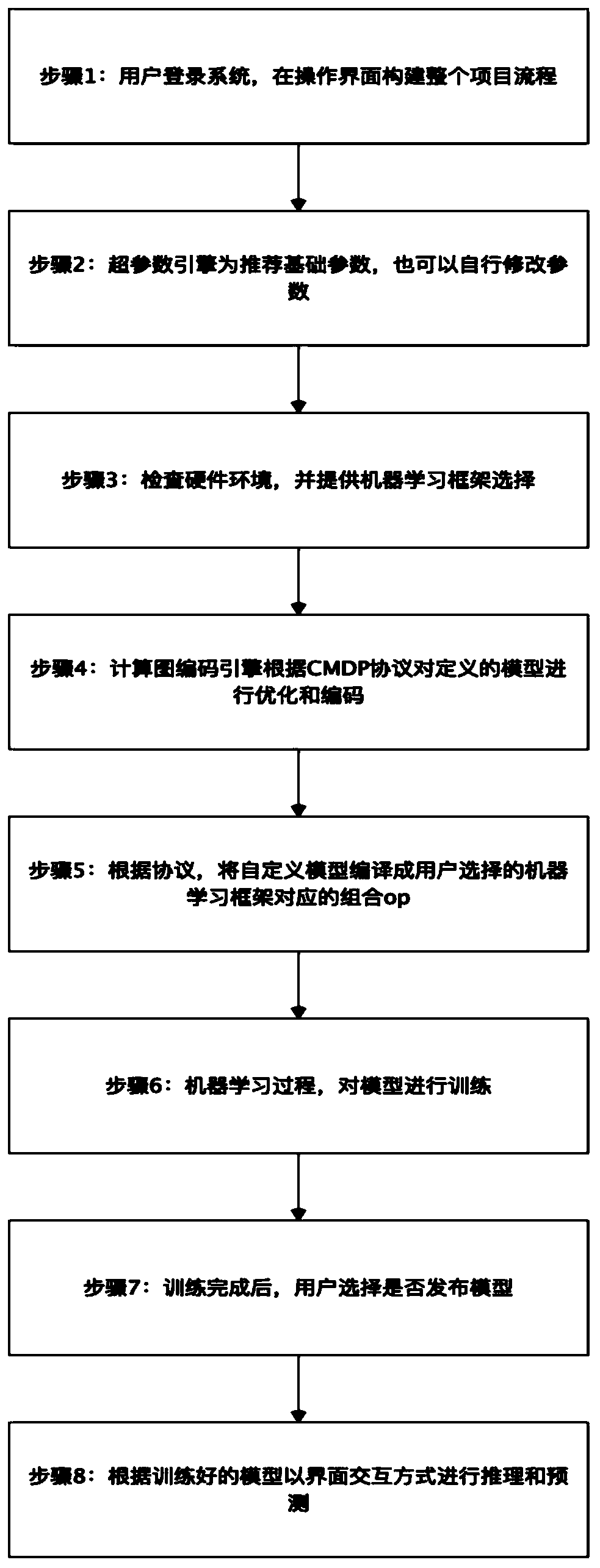

Cross-machine learning platform model definition protocol and adaptation system

ActiveCN110119271ALower learning and maintenance thresholdEasy to useVisual/graphical programmingCode compilationFull life cycleAlgorithm

The invention provides a cross-machine learning platform model definition protocol and configuration system, and relates to the field of artificial intelligence automatic machine learning. The systemcomprises a computational graph construction engine; a computational graph optimization engine; a cross-machine learning platform model definition protocol (Cross-Platforms Model definition Protocol);a computational graph encoding engine; a hyper-parameter recommendation engine; a protocol parsing engine; a model training process control assembly; a hardware information detection and configuration system. The system has the advantages that cross-platform machine learning network construction is achieved, the system is easy to use, and the machine learning maintenance threshold is lowered; machine learning network construction in a dragging mode is achieved, and the latest algorithm network can be iterated rapidly; a large number of algorithm models are provided, and machine learning and deep learning network construction under different scenes are supported; a parameter recommendation function is provided, and a lot of parameter adjustment time is saved; algorithm network constructionfrom data cleaning to model release full life cycle is provided, and the system can be directly put into production and use.

Owner:厦门渊亭信息科技有限公司

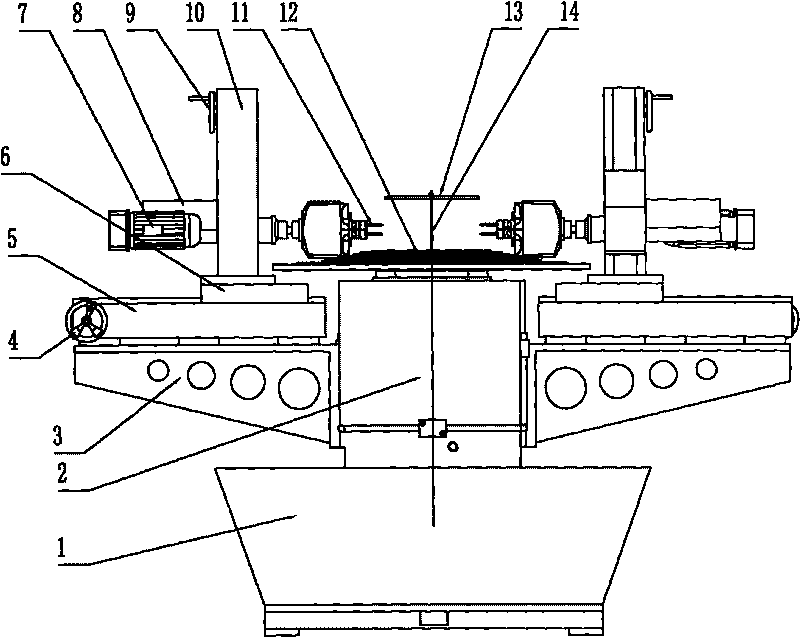

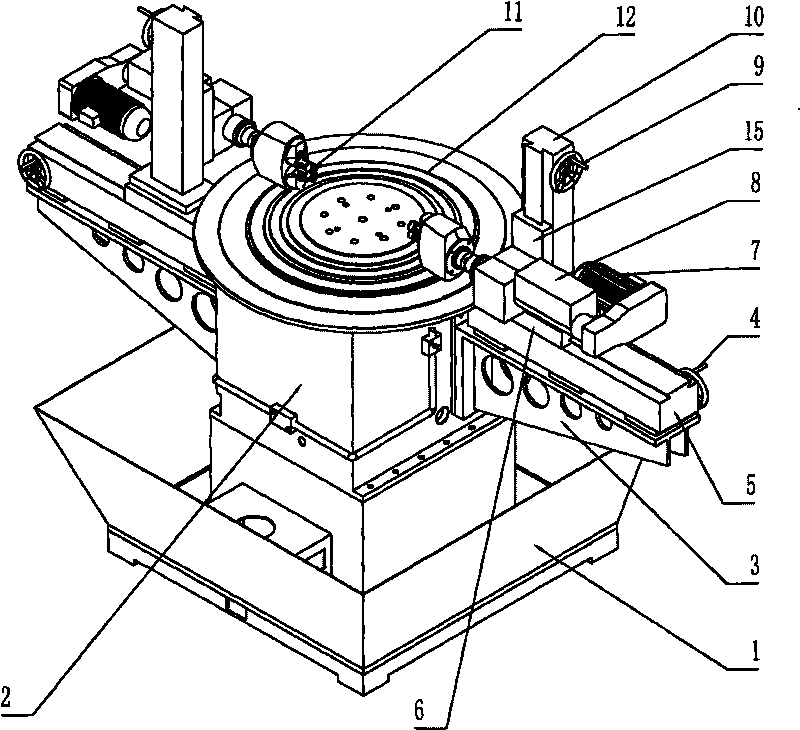

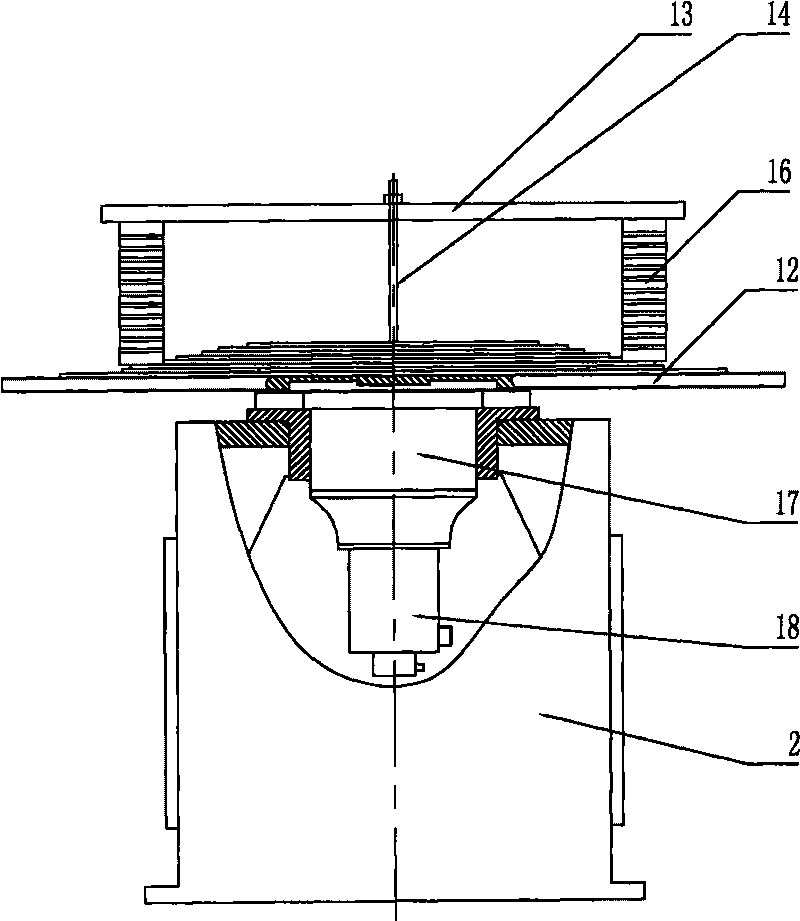

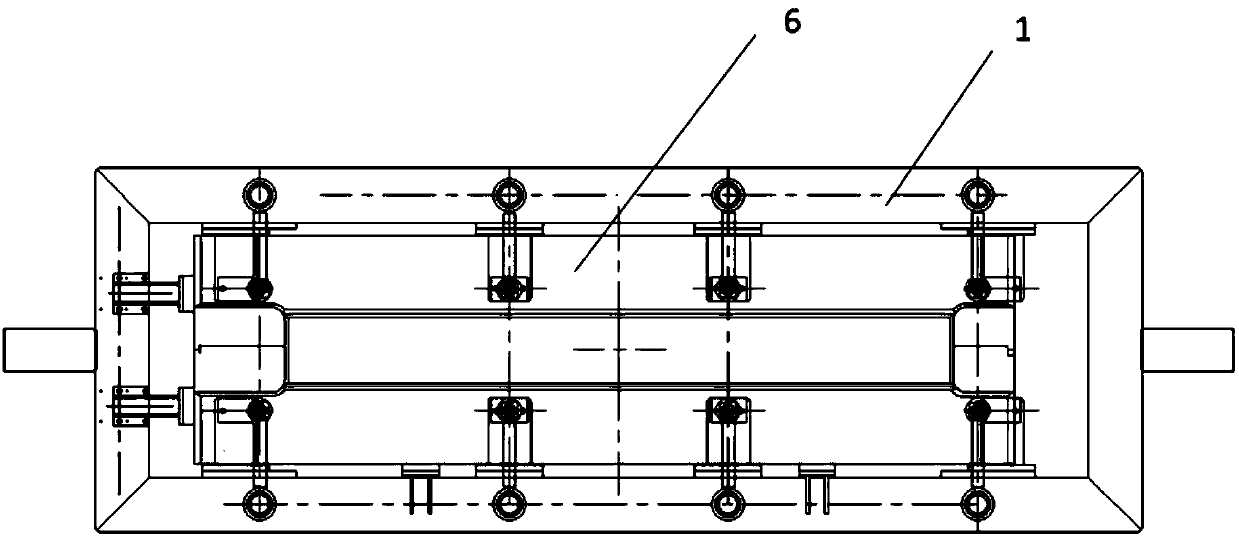

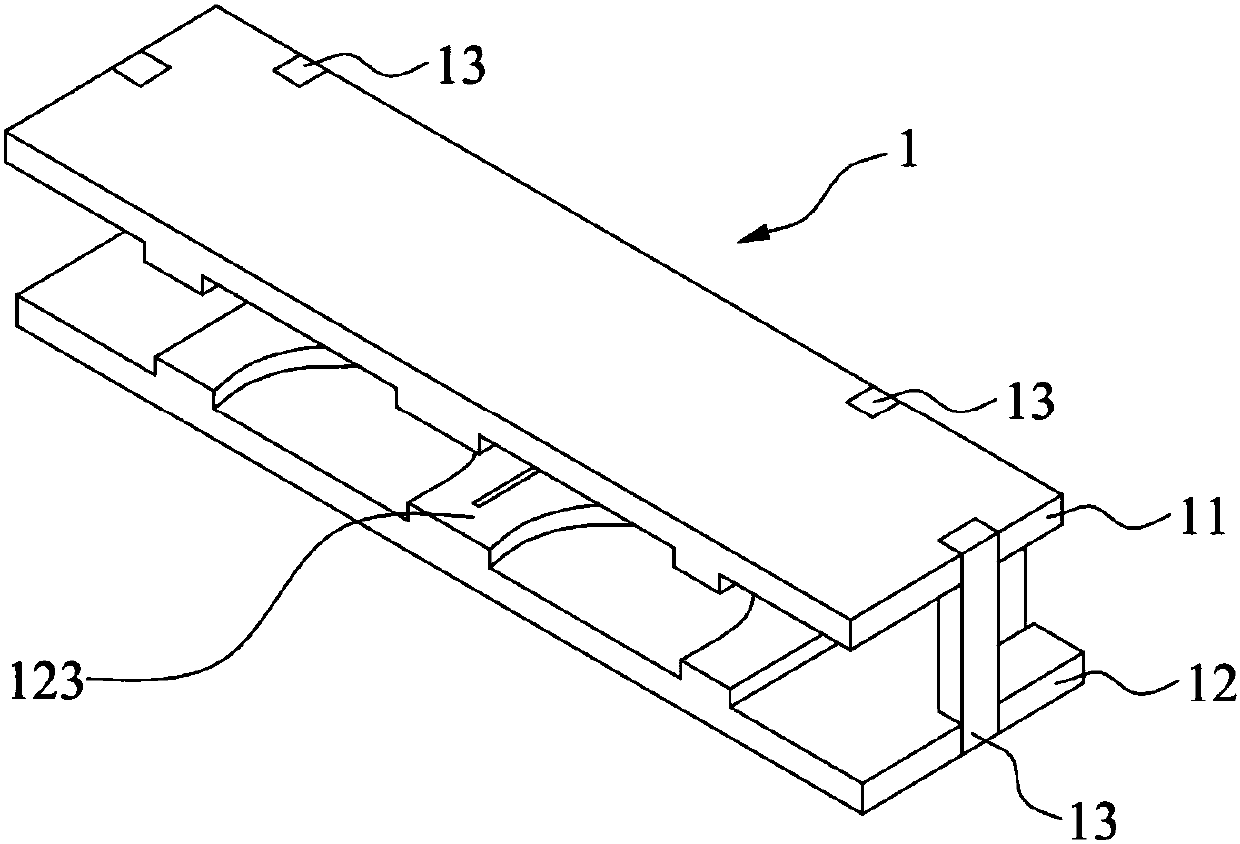

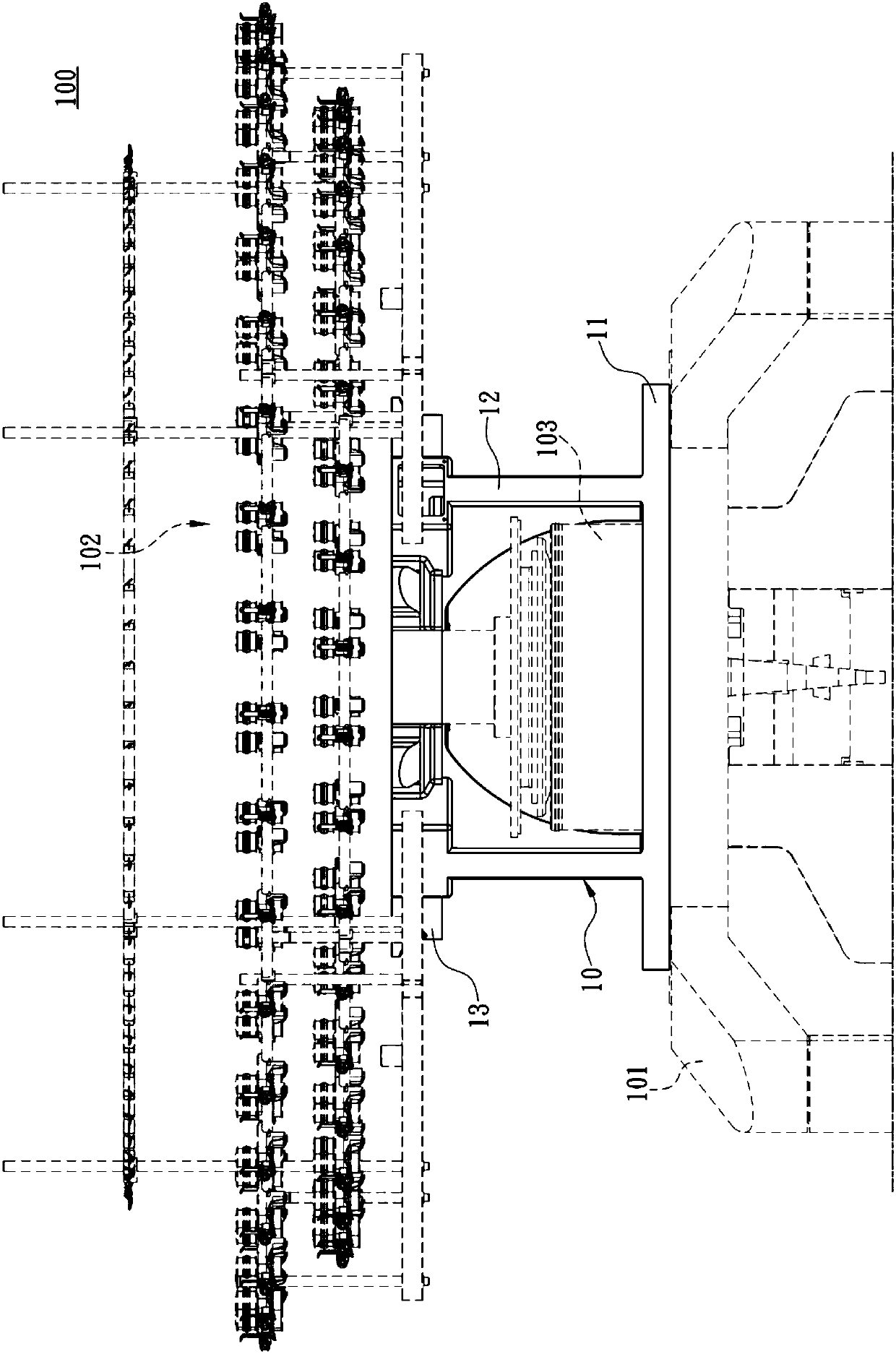

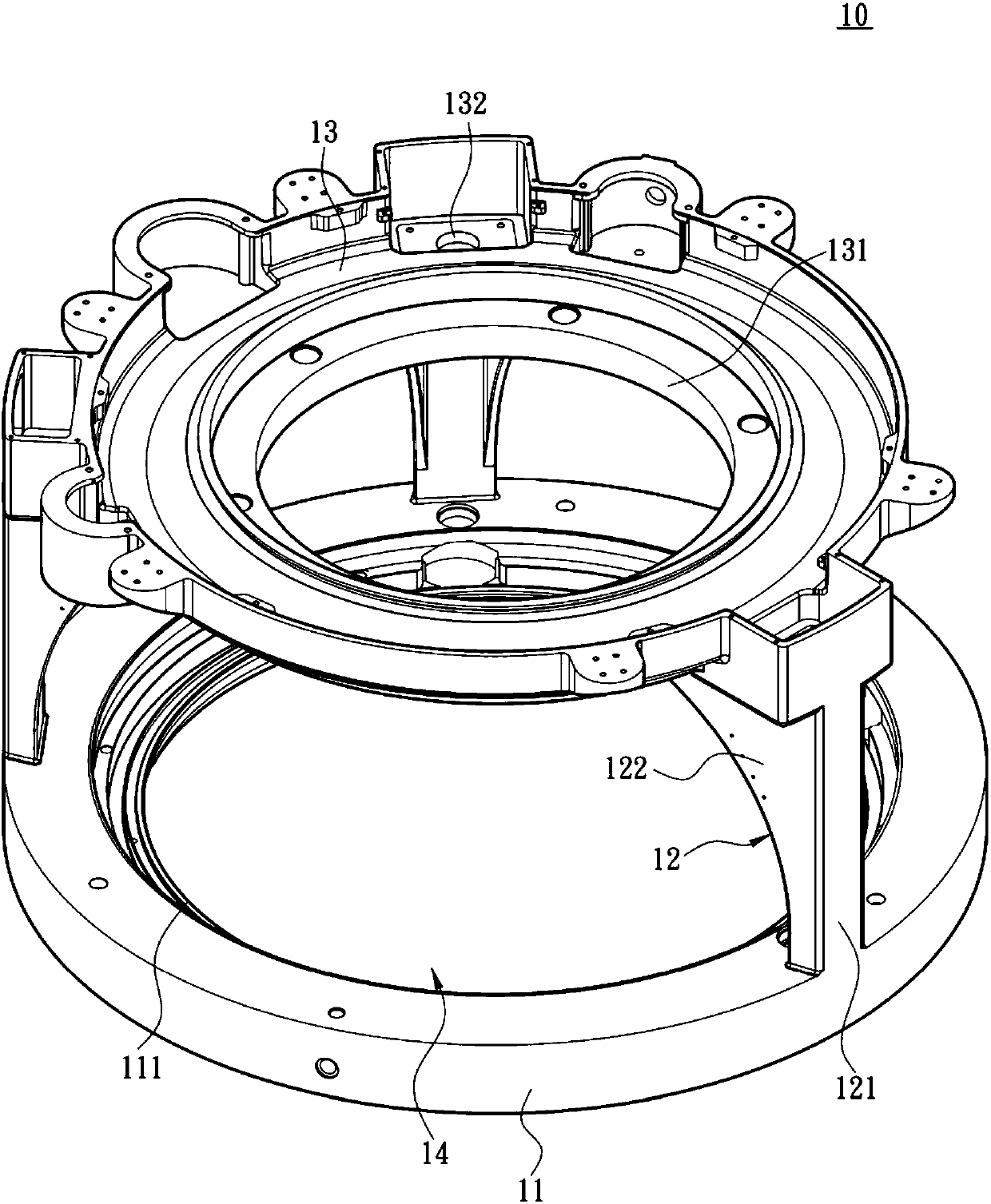

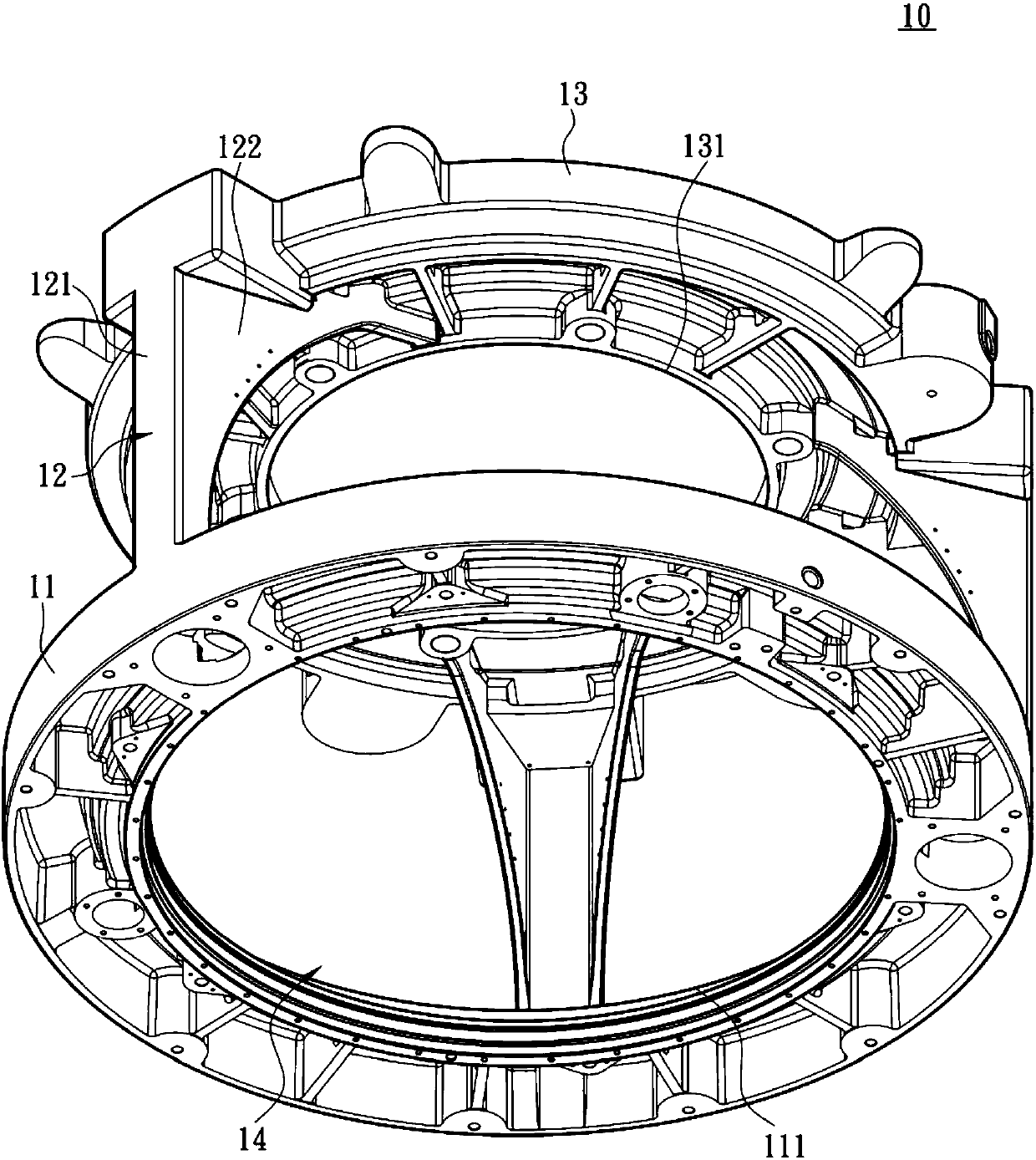

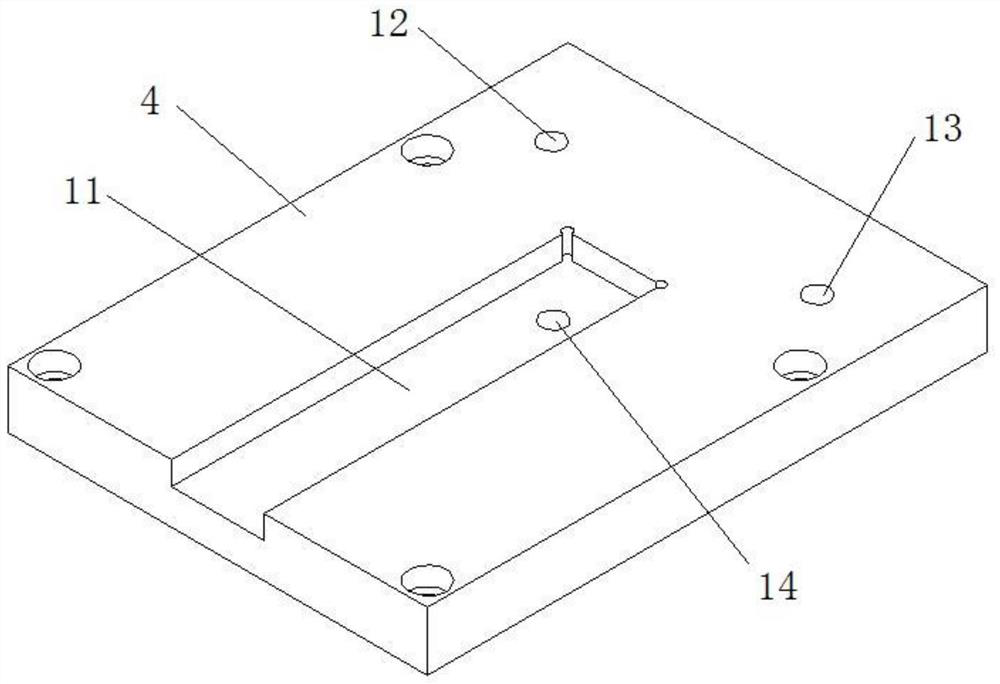

Borehole and counterbore machine for annular mold

InactiveCN101733445AAchieve horizontal movementAchieve positioningBoring/drilling componentsBoring/drilling machinesDrill bitEngineering

The invention discloses a borehole and counterbore machine for an annular mold in the field of bore machining tools, which comprises a main spindle box body. At least one side of the main spindle box body is provided with a supporting beam, a horizontal guide rail is arranged on the supporting beam, and a horizontal slide block is arranged on the horizontal guide rail in a matching mode. The horizontal slide block and the horizontal guide rail are in transmission connection through a lead screw nut pair. A vertical guide rail is fixedly arranged on the horizontal slide block, and a vertical slide block is arranged on the vertical guide rail in a matching mode. The vertical slide block and the vertical guide rail are in transmission connection through another lead screw nut pair. A bit component is fixed on the vertical slide block, and a speed-reducing mechanism is fixed in the main spindle box body. An input shaft of the speed-reducing mechanism is connected with an end of an output shaft of a servo motor. An output shaft of the speed-reducing mechanism extends upwards, an upper end of which is connected with a rotating table. A plurality of rotating steps in step-shaped distribution are arranged on the rotating table, wherein the rotating steps and the rotating table are arranged coaxially. The borehole and counterbore machine for the annular mold has the advantages of accurate positioning of a workpiece and convenient processing, and can be applied to machining the annular mold or radial multi-hole parts.

Owner:JIANGSU MUYANG GRP CO LTD

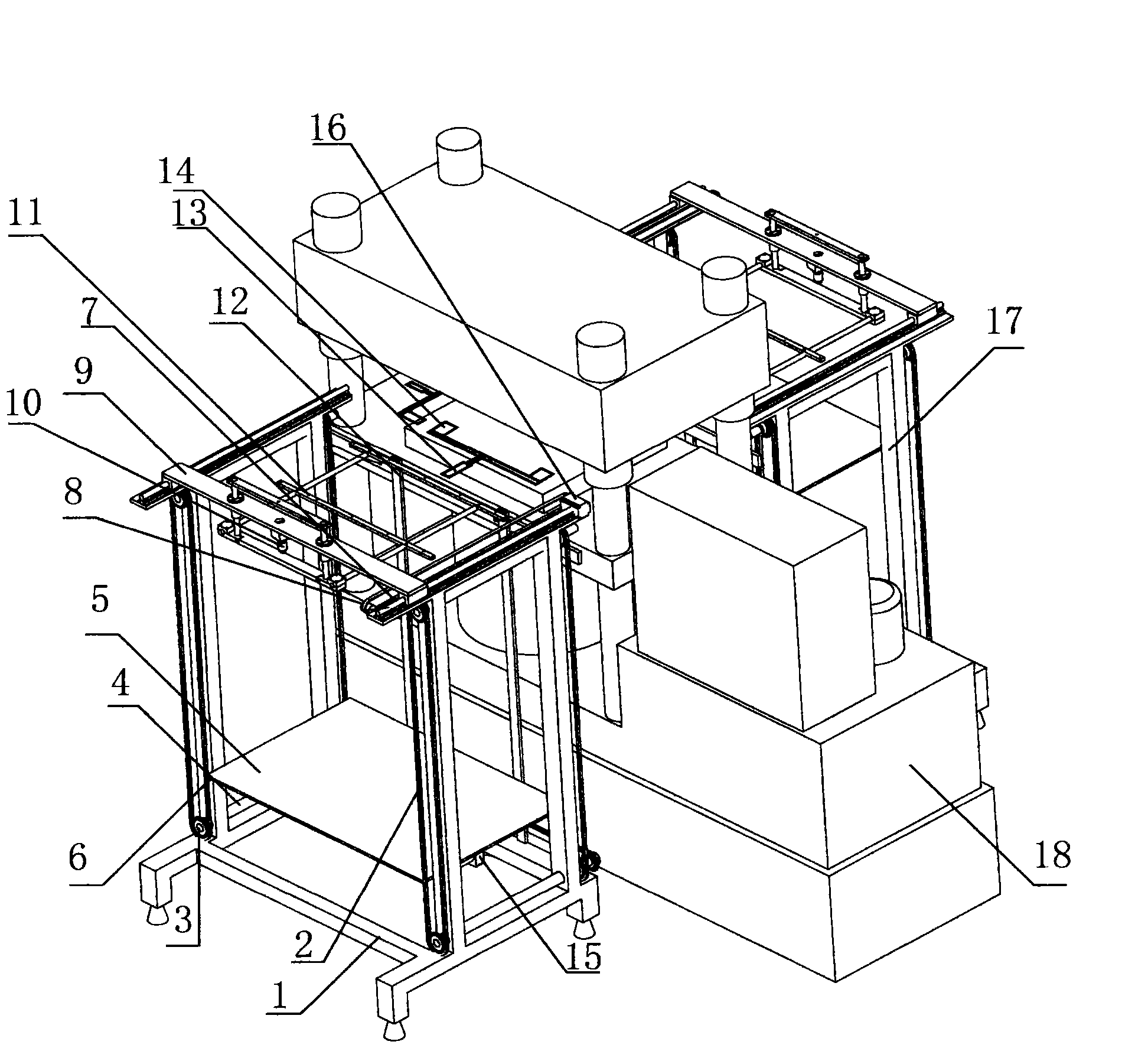

Automatic loading and unloading mechanism of hydraulic machine

The invention relates to an automatic loading and unloading mechanism of a hydraulic machine, wherein a loading stand and an unloading stand are respectively arranged at two sides of the hydraulic machine, an up-down cylinder is arranged at the upper part of the loading stand, a retainer plate is parallel to the middle part of a frame body, and a gear motor is arranged at the lower end of the retainer plate; the upper side of the up-down cylinder is connected with a suction tray frame sliding plate which is connected with a guide rod sliding rail of a frame body at the lateral end in a slidingway and connected with a drag chain in series; and a suction tray is respectively arranged at the rear side of the up-down cylinder and the frame body thereof. In the invention, the material productto be processes just needs to be put on the retainer plate at will and is conveyed into the hydraulic machine under the control of a power switch of a pneumatic motor and an induction switch of a stepping motor by adopting a way of synchronously and translationally loading and unloading by the automatic ascending and descending matching of the retainer plate, and the product to be processed is moved to a specific position by a guiding device, thereby the product can be put in and taken out quickly and accurately; and the invention has the unmatched advantages any conveying machines or mechanical arms can not reach, can effectively avoid potential safety hazards and improves the production efficiency in the packaging process of paper boxes.

Owner:林定亮

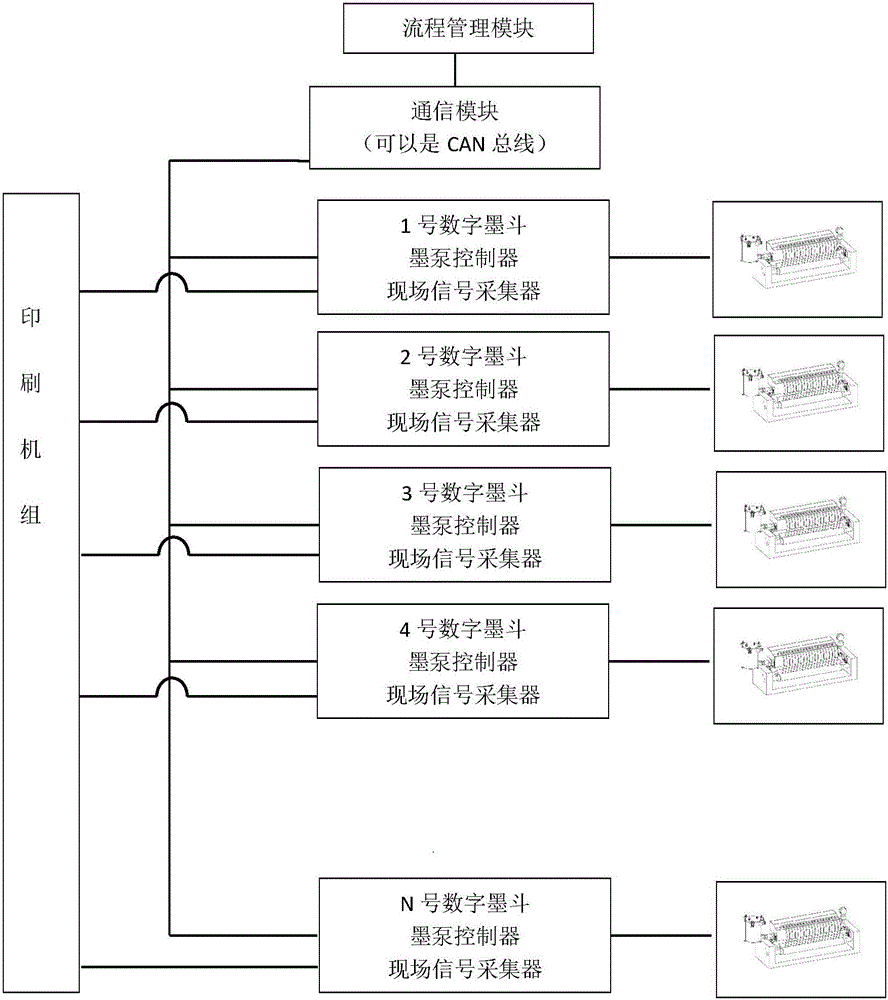

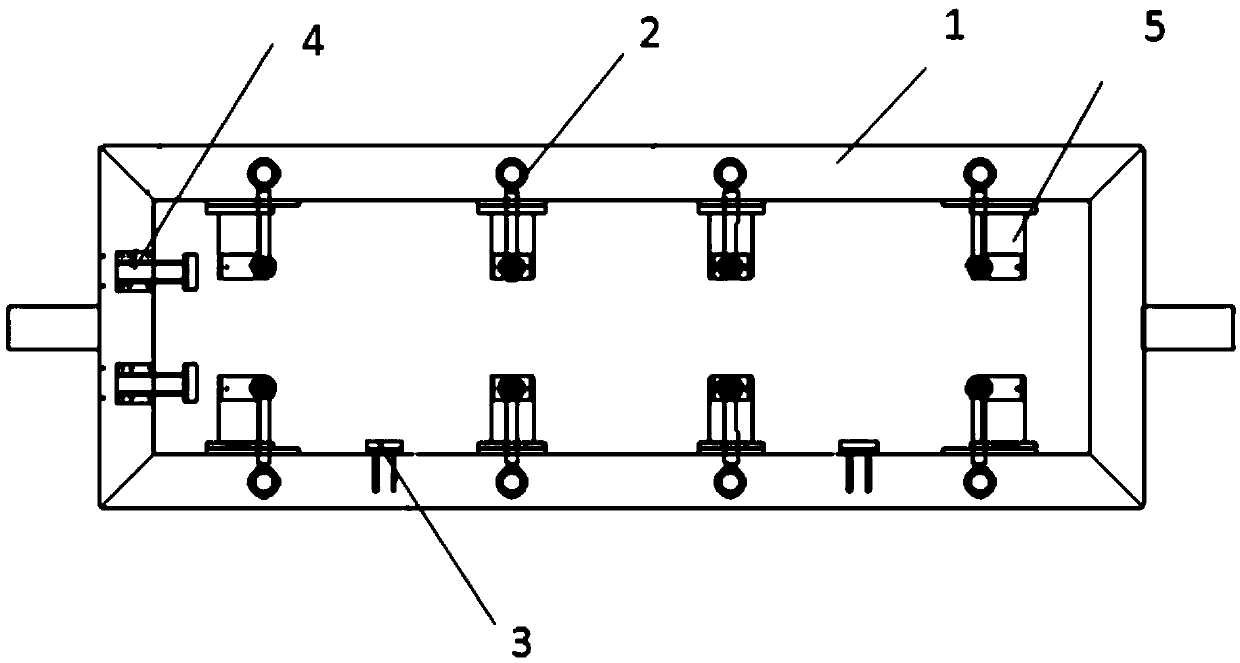

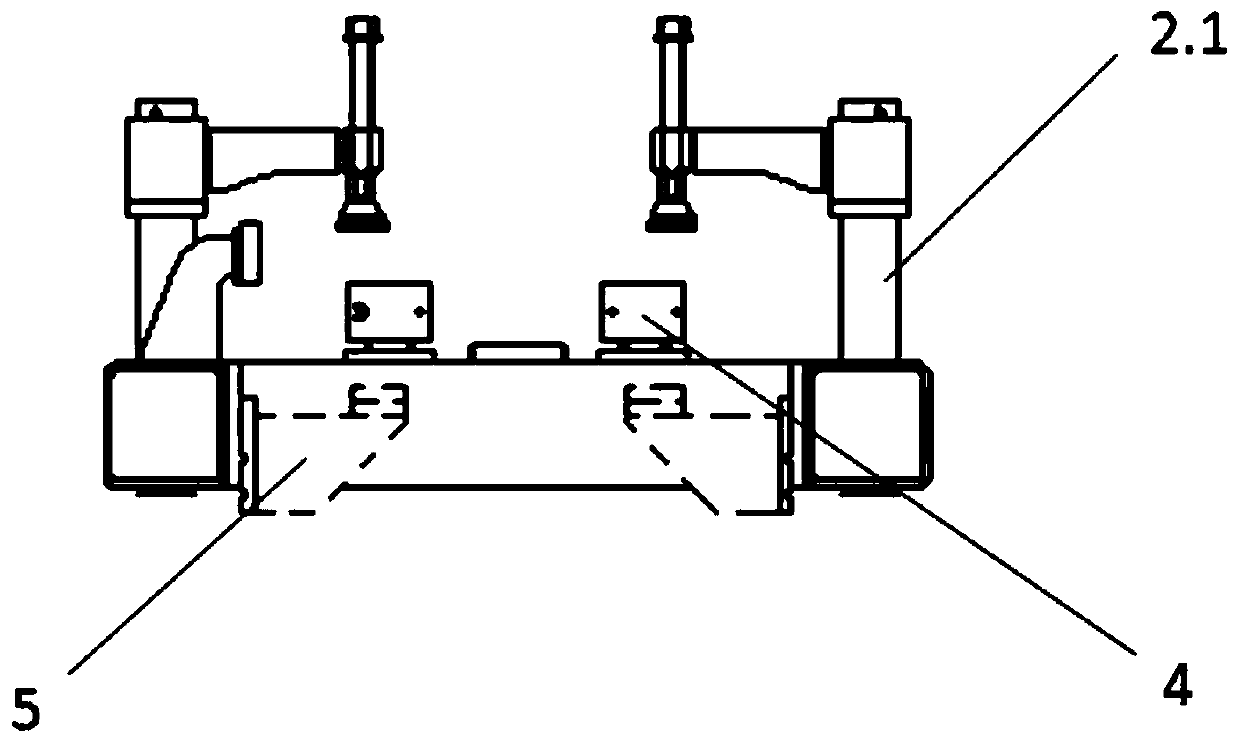

Digitized accurate ink supply method of printing machine

ActiveCN105818533ARealize precise quantitative controlReal-time supplyPrinting press partsEngineeringPrinting ink

The invention discloses a digitized accurate ink supply method of a printing machine. Metering printing ink conveying units replace ink keys on a traditional printing machine; each metering printing ink conveying unit directly conveys printing ink to corresponding ink areas; and the volume or mass serves as metering basis, quantitative supply of the printing ink for each ink area is achieved. In the working state, the ink supply flow speed of each metering printing ink conveying unit is obtained through calculation according to the consumption amount of the printing ink of corresponding color plates and the corresponding ink areas in each printed sheet and the operation speed of the printing machine, and the ink supply flow speed of each metering printing ink conveying unit is calculated and adjusted in real time along with change of the operation speed of the printing machine. By means of the digitized accurate ink supply method of the printing machine, real-time accurate adjustment can be achieved, the automation degree and digitization degree are high, the adjustable range is wide, one-way printing ink conveying is achieved, and printing ink return is avoided.

Owner:杭州科雷智能印刷科技有限责任公司

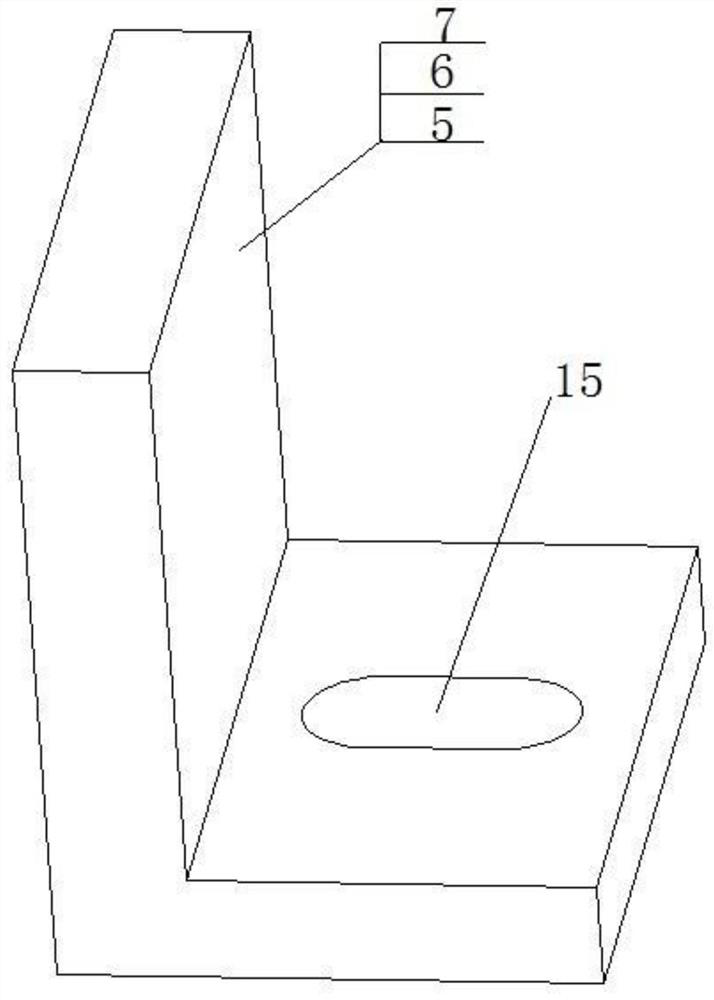

Universal welding tool for sleeper beam of subway rail vehicle and welding method thereof

PendingCN109676299ASave tuning timeImplement anti-morphingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

The invention provides a universal welding tool for a sleeper beam of a subway rail vehicle, comprising a frame, a sleeper beam pressing device, a longitudinal limiting device, a transverse limiting device and a reference adjusting device; the sleeper beam pressing device is arranged on the frame to press the sleeper beam, the longitudinal limiting device is arranged on the frame to limit the sleeper beam in a longitudinal direction, the transverse limiting device is arranged on the frame to limit the sleeper beam in a transverse direction, the reference adjusting device is positioned on the inner side surface of the frame, and the reference adjusting device corresponds to the sleeper beam pressing device one by one to adjust the placing height of the sleeper beam. The invention relates toa welding method for a sleeper beam of a subway rail vehicle, which comprises the following steps of adjusting too before welding, welding and assembling the sleeper beam, and standing after weldingto eliminate stress. The welding tool provided by the invention has a simple structure, novel design, convenient operation and strong universality; double functions of workpiece positioning and welding deformation reduction are simultaneously realized by matching the welding method, and the production efficiency is greatly improved.

Owner:HUNAN LIANCHENG TRACK EQUIP CO LTD

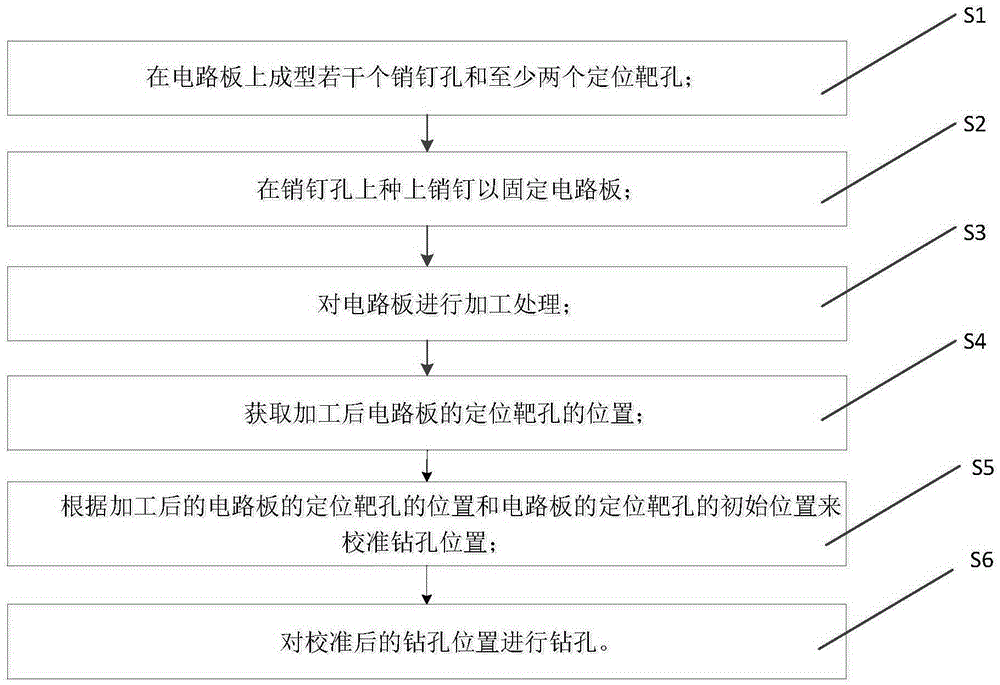

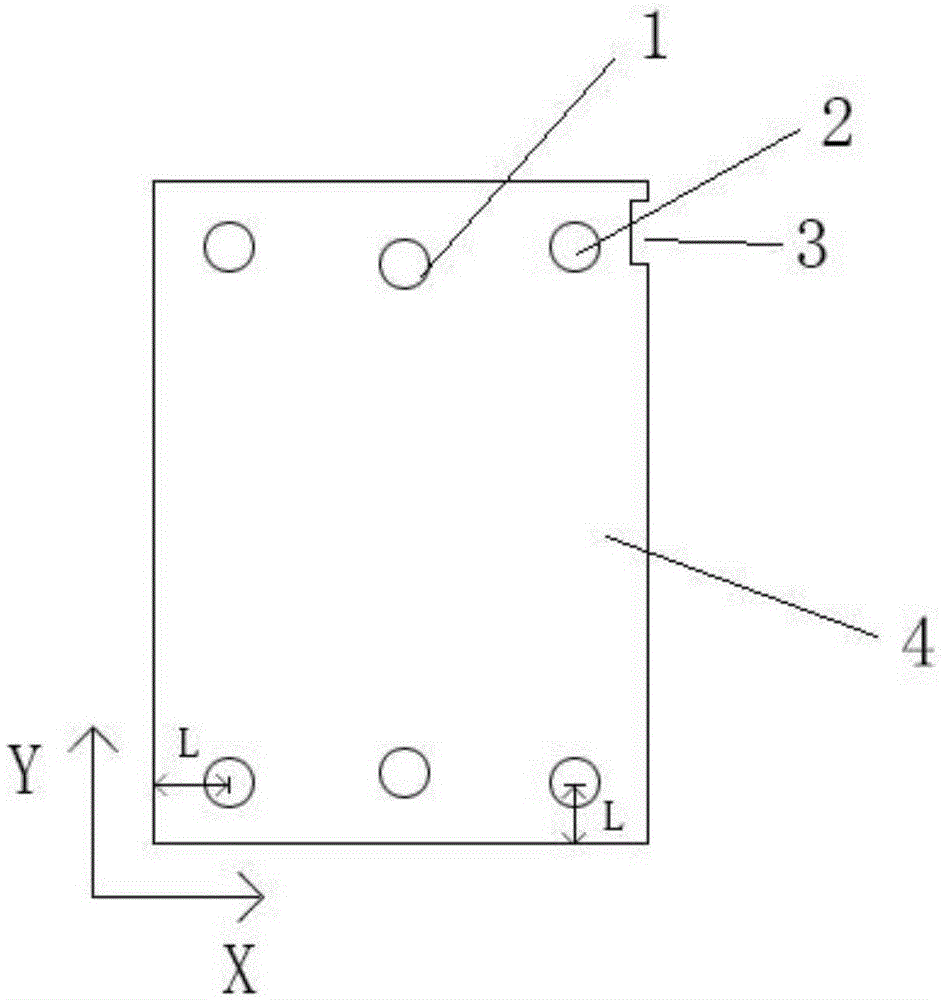

Circuit board hole drilling method

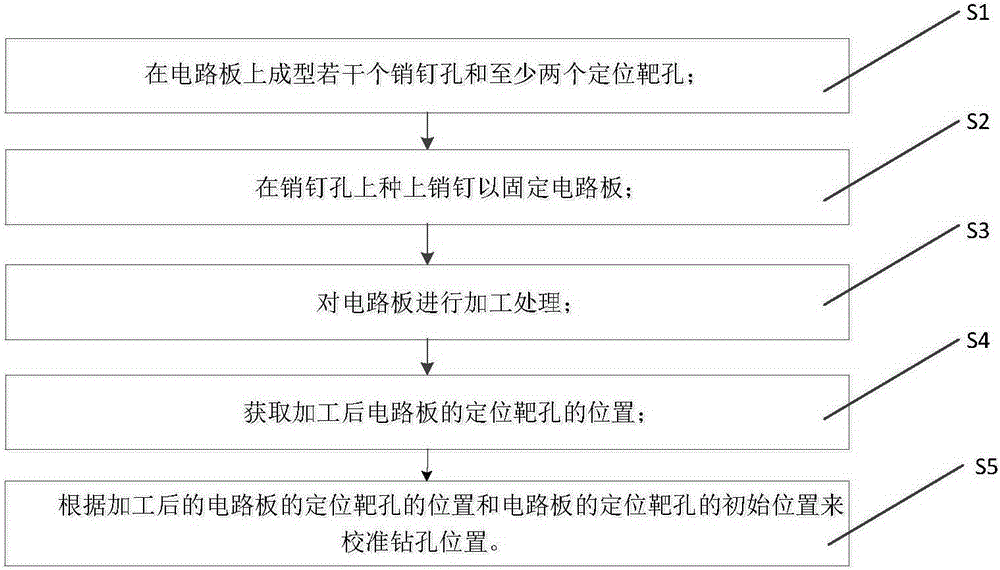

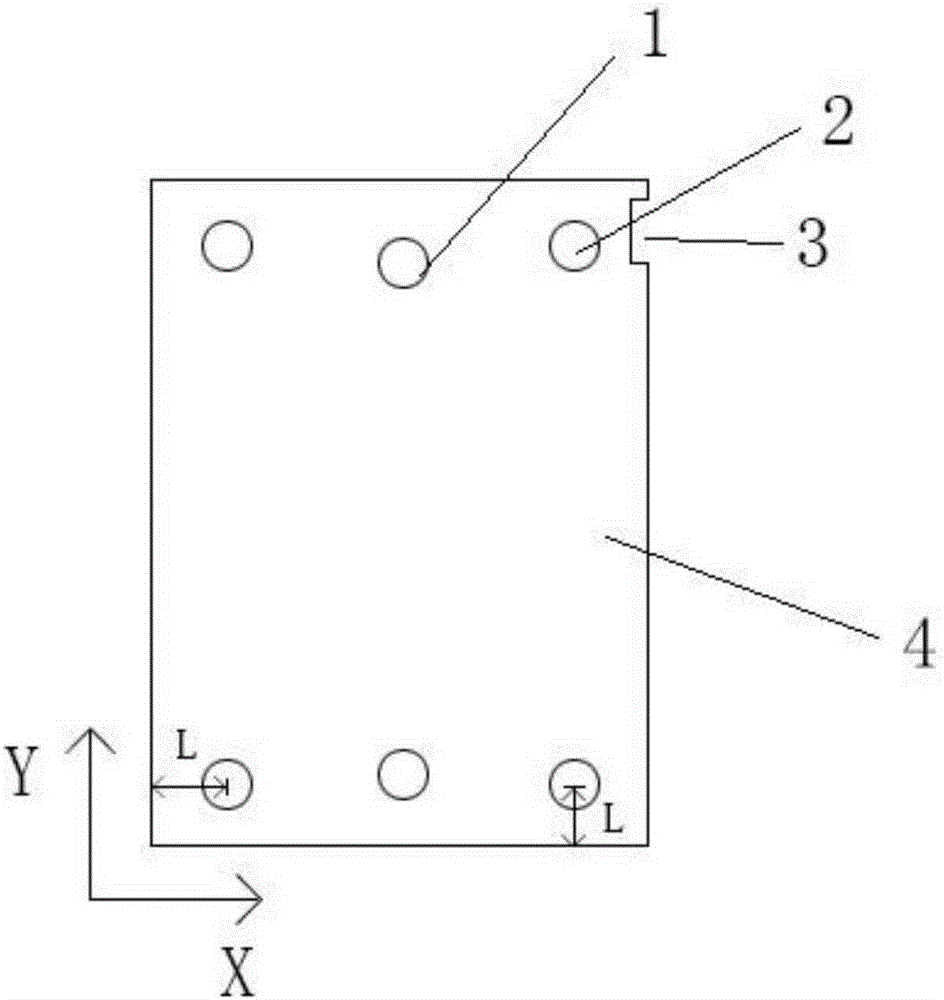

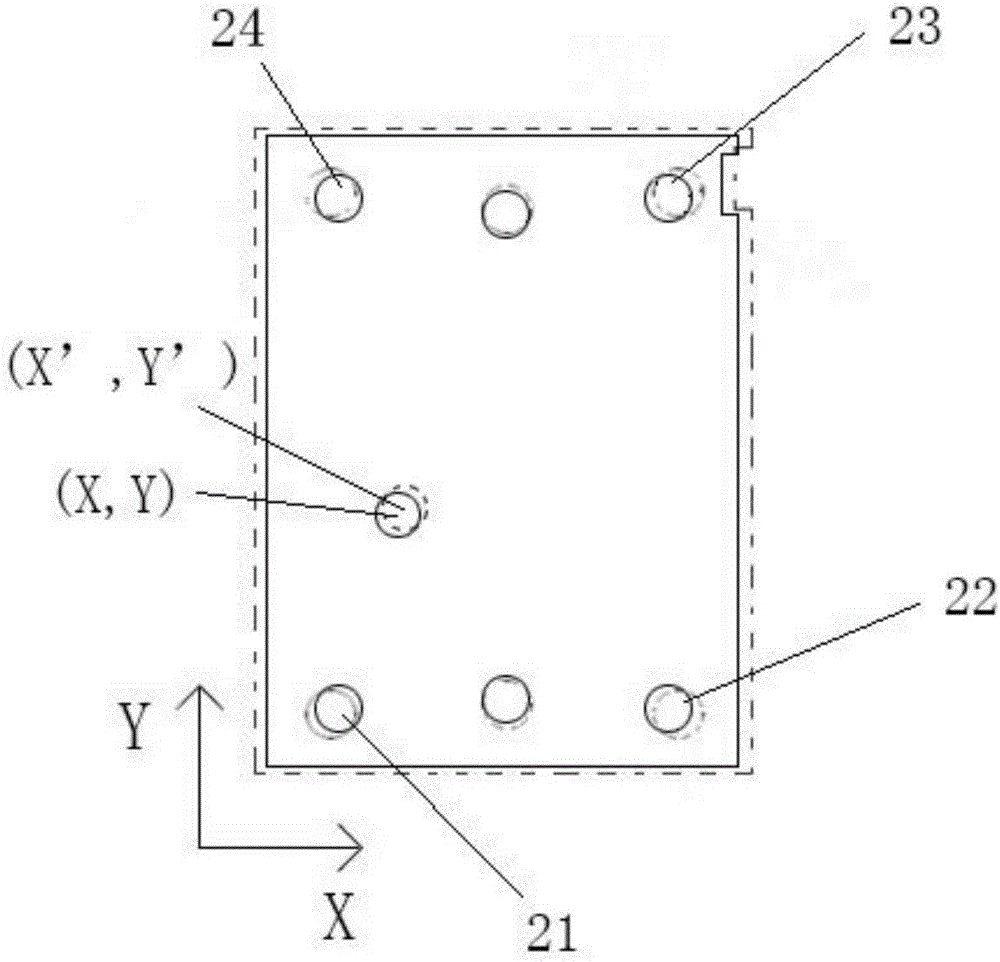

InactiveCN105407640AAchieve precise positioningImprove utilizationPrinted circuit manufactureHole drilling methodDrilling machines

The invention provides a circuit board hole drilling method and relates to the technical field of circuit board production. Through forming a pin hole in the circuit board, the circuit board is fixed through the pin; position data of a positioning target hole in the same board surface as a prefabricated drilling hole after the circuit board is deformed are acquired; according to the position data of the positioning target hole after the circuit board is deformed and position data of the positioning target hole before the circuit board is deformed, a drilling hole position is calibrated; the drilling hole position is accurately positioned, the device for fixing the pin does not need to be adjusted accurately, the adjustment time is reduced, the operation ratio of the drilling machine is improved, and the production efficiency is improved.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

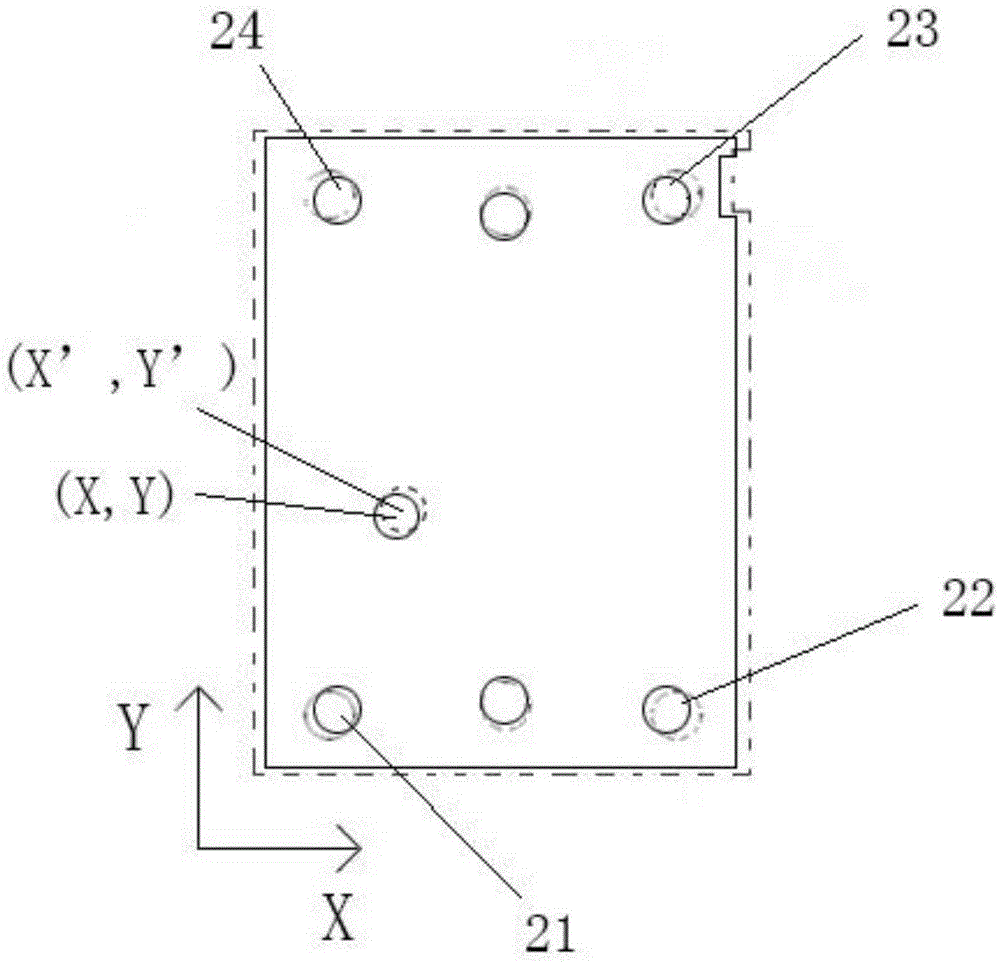

Method for calibrating drill hole of circuit board

ActiveCN105216054AAchieve precise positioningImprove utilizationMetal working apparatusEngineeringDrilling machines

The invention provides a method for calibrating a drill hole of a circuit board, belonging to the technical field of circuit board production. The method comprises the following steps: molding pin holes in the circuit board, and fixing the circuit board through pins; obtaining the position data of a positioning target hole, positioned in the same board surface with a pre-drilled hole, after the circuit board is deformed; according to the position data of the positioning target hole after the circuit board is deformed and the position data of the positioning target hole before the circuit board is deformed, calibrating the position of the drill hole. The accurate positioning for the position of the drill hole is realized. A device for fixing the pins does not need to be finely adjusted, the adjustment time is shortened, therefore the working ratio of a drilling machine is increased, and the production efficiency is improved.

Owner:NEW FOUNDER HLDG DEV LLC +1

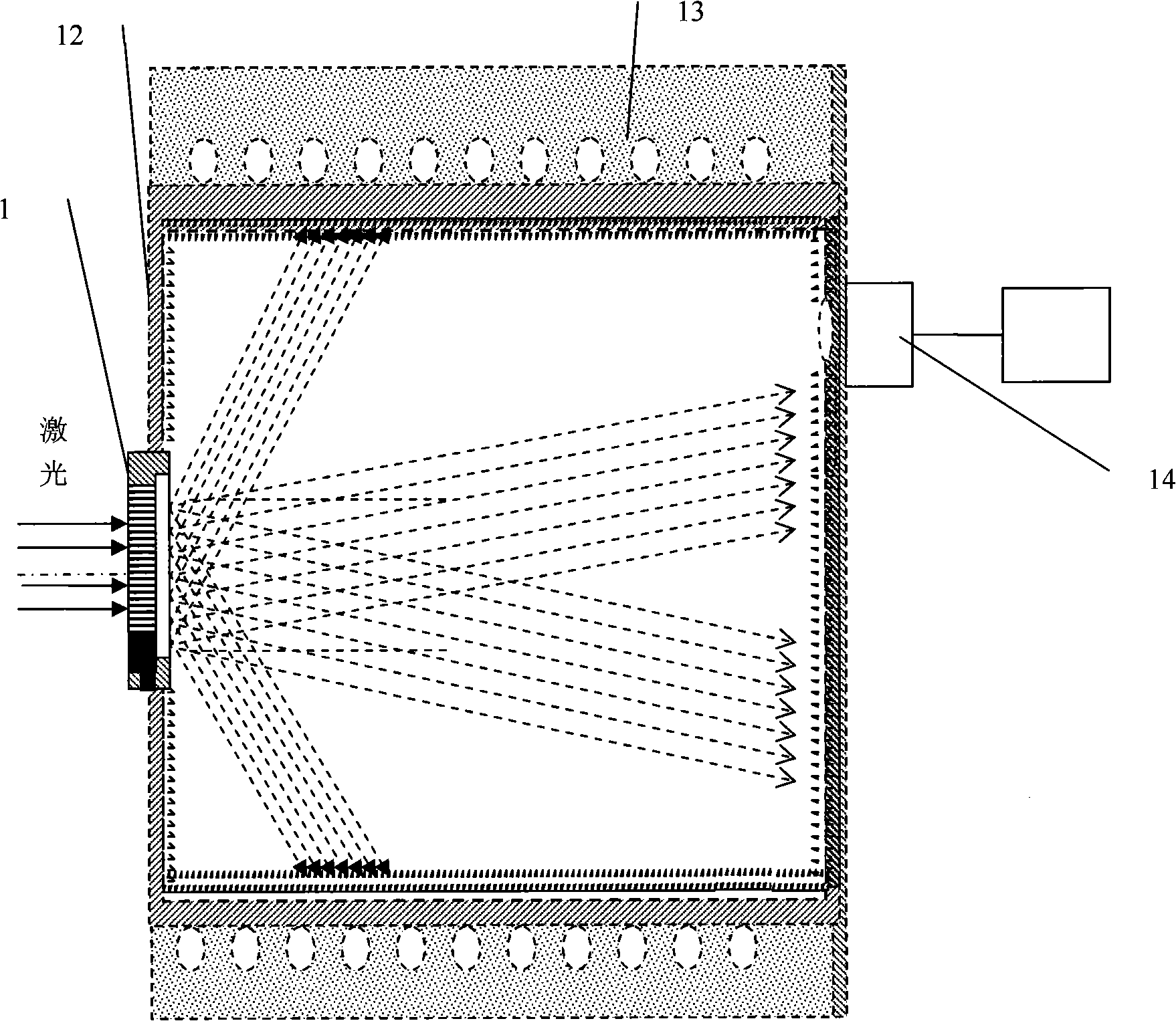

High power laser beam expander

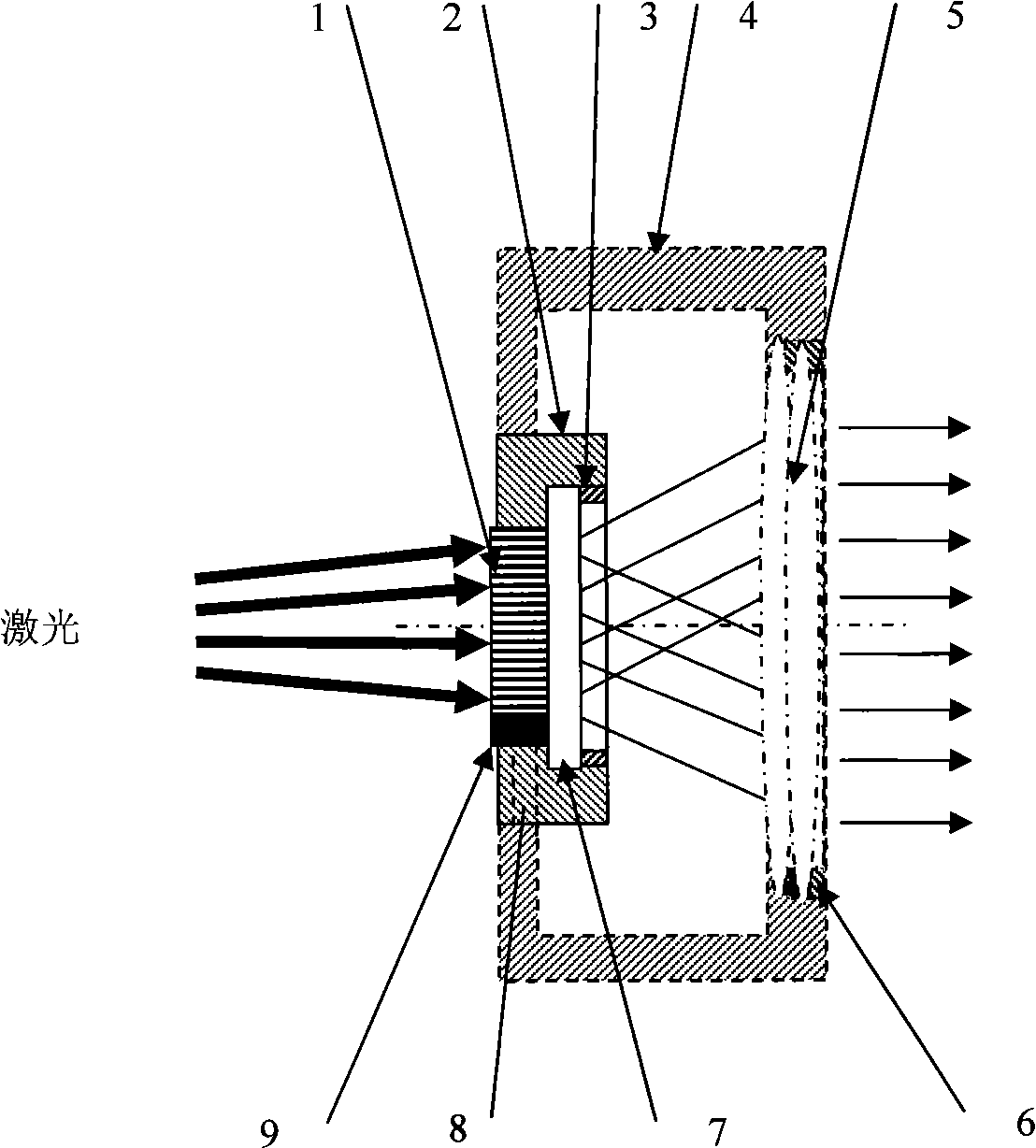

InactiveCN101320132AReduce laser energy densityIncreased Laser Damage ThresholdCoupling light guidesHigh power lasersSingle-mode optical fiber

The invention discloses a extender lens for expanding high power laser beams, which has the main technical characteristics that a plurality of optical fiber rods with equal lengths are all tightly arranged in the cavity body of a housing and the end surfaces of the optical fiber rods respectively form input faces and output faces; the optical fiber rods are bare optical fibers and can adopt optical fibers the core diameter of which is smaller than that of single mode fiber. The invention can expand the laser beans as well as shape and stabilize the direction of the laser beans, and has the advantages of high laser induced damage threshold, simple structure and great reduction of the volume and the weight of a laser shot system.

Owner:南瑶

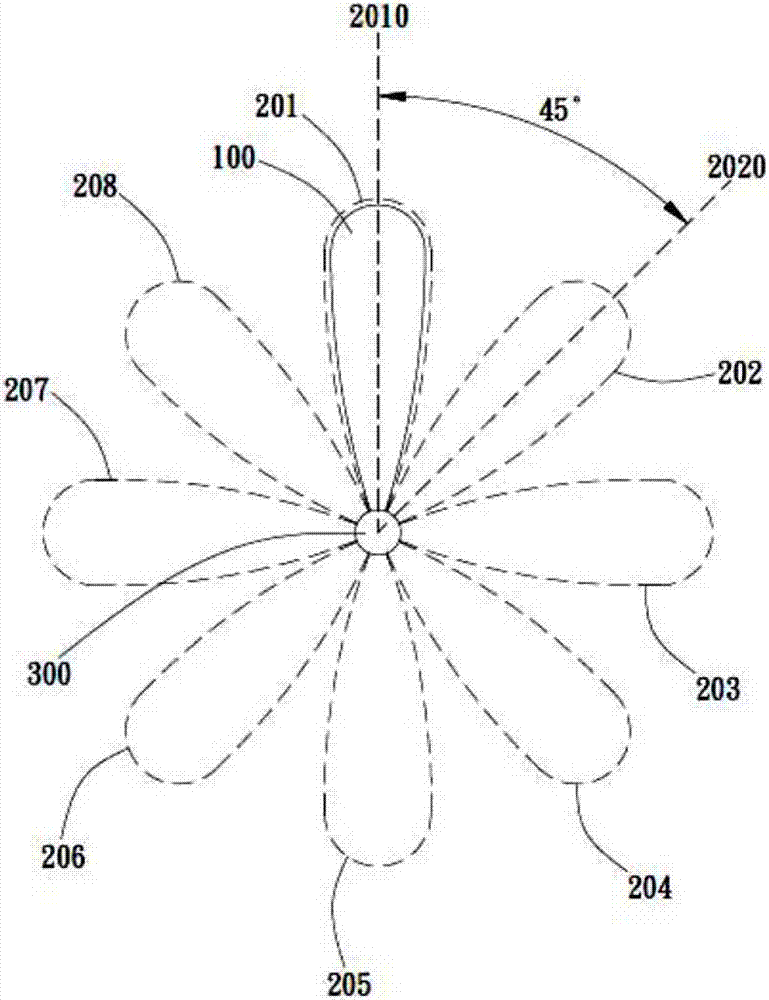

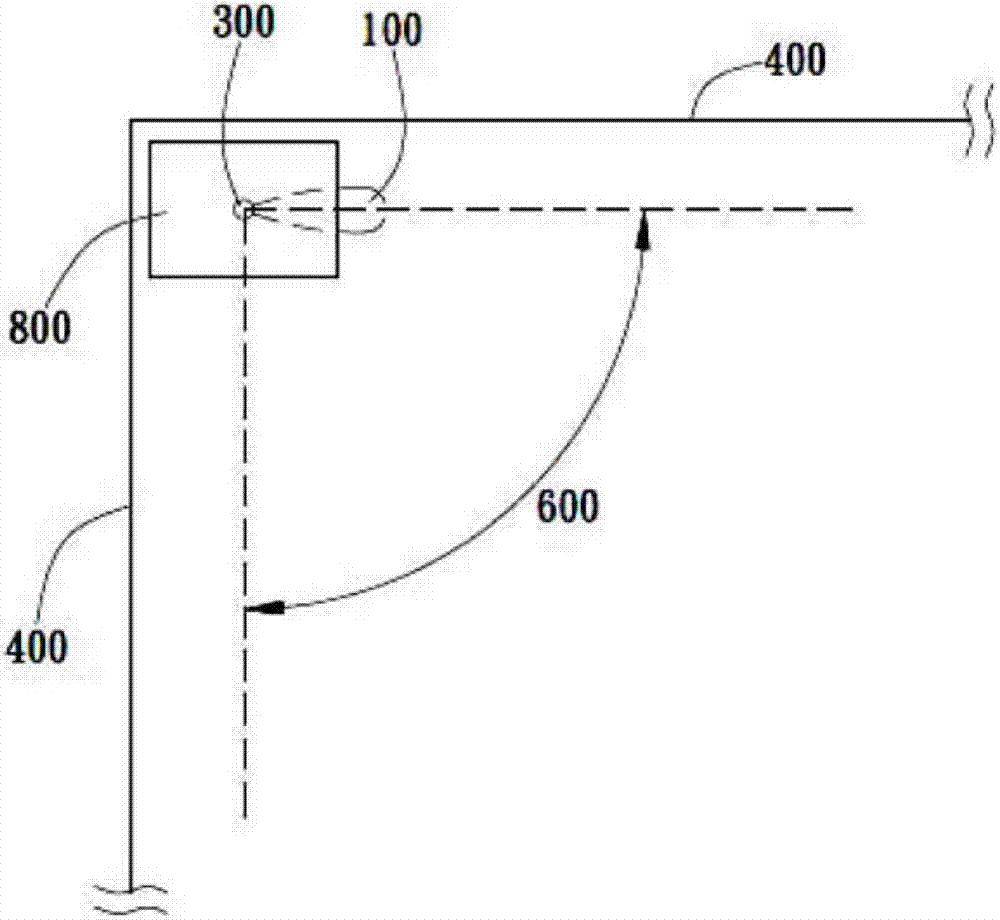

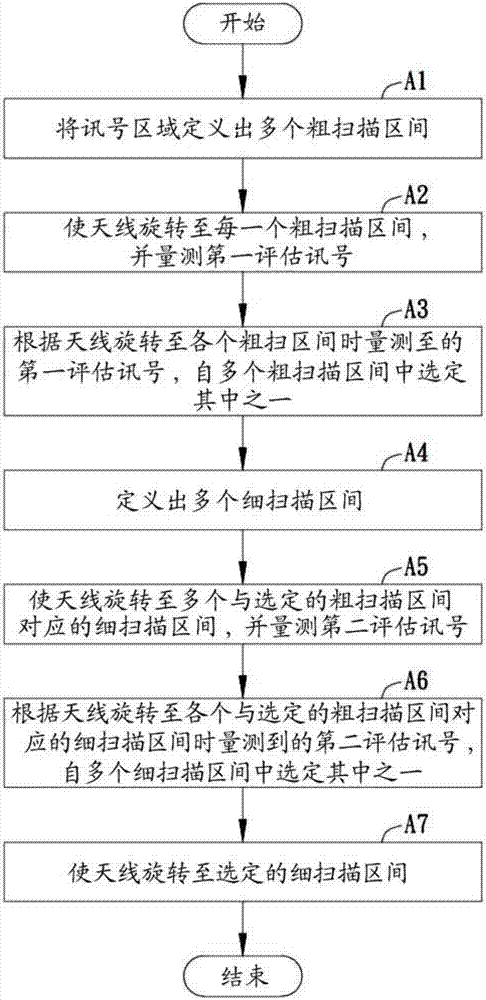

Antenna control method and antenna apparatus using the same

ActiveCN103715506AImprove signal sending and receiving effectShorten the timeControl using feedbackAntennasEngineeringElectrical and Electronics engineering

The invention relates to an antenna control method and an antenna apparatus using the same. The method comprises the following steps: (A1), defining a signal zone to obtain a plurality of coarse scanning intervals; (A2), enabling an antenna to rotate to each coarse scanning interval and measuring a first evaluation signal; (A3), according to the first evaluation signal that is measured during antenna rotation to all the coarse scanning intervals, selecting one coarse scanning interval from the plurality of coarse scanning intervals; (A4), obtaining a plurality of fine scanning intervals by defining; (A5), enabling the antenna to rotate to the plurality of fine scanning intervals corresponding to the selected coarse scanning interval and measuring a second evaluation signal; (A6), according to the second evaluation signal that is measured during the antenna rotation to all the fine scanning intervals corresponding to the selected coarse scanning intervals, selecting one fine scanning interval from the plurality of fine scanning intervals; and (A7), enabling the antenna to rotate to the selected fine scanning interval.

Owner:WISTRON NEWEB

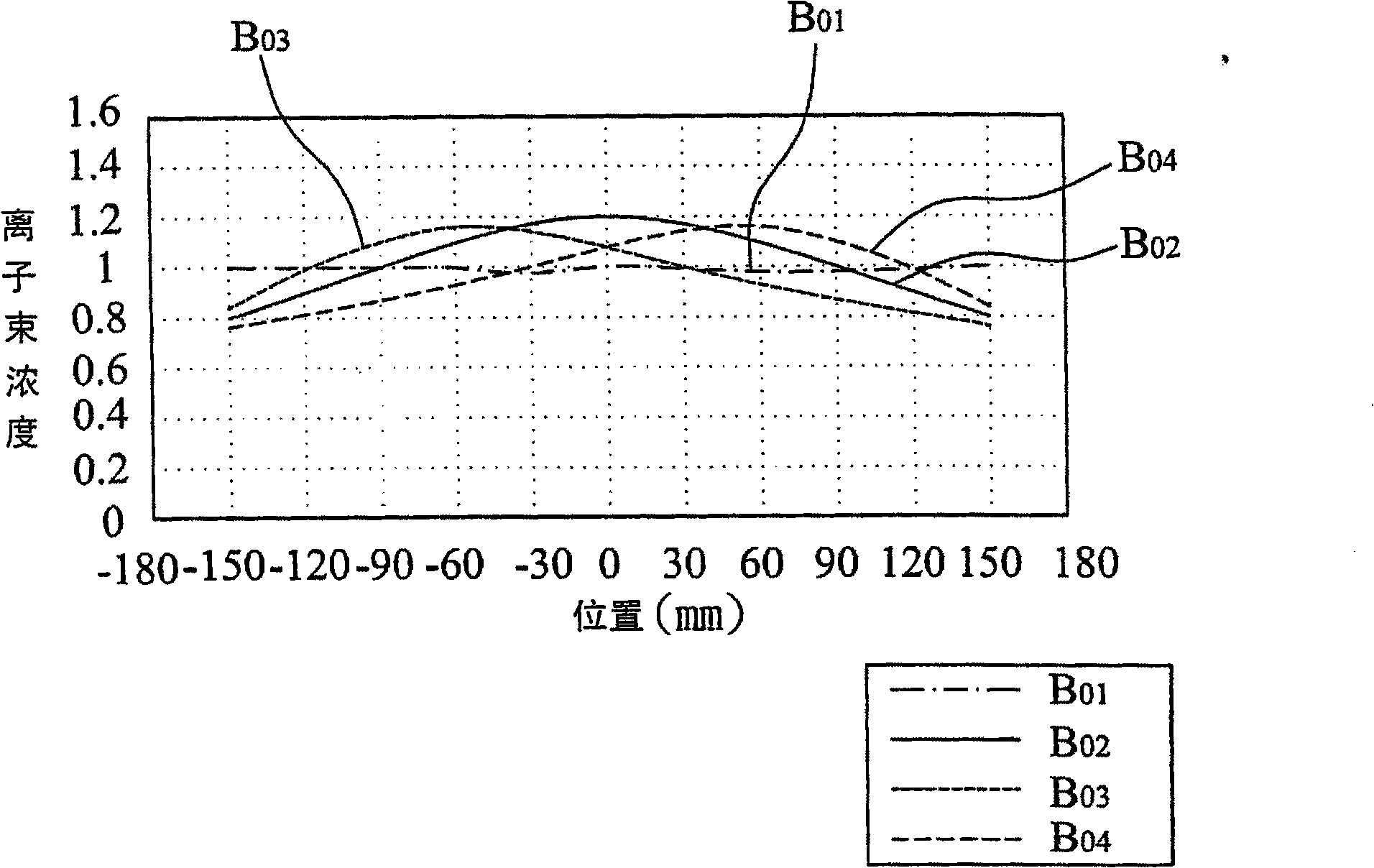

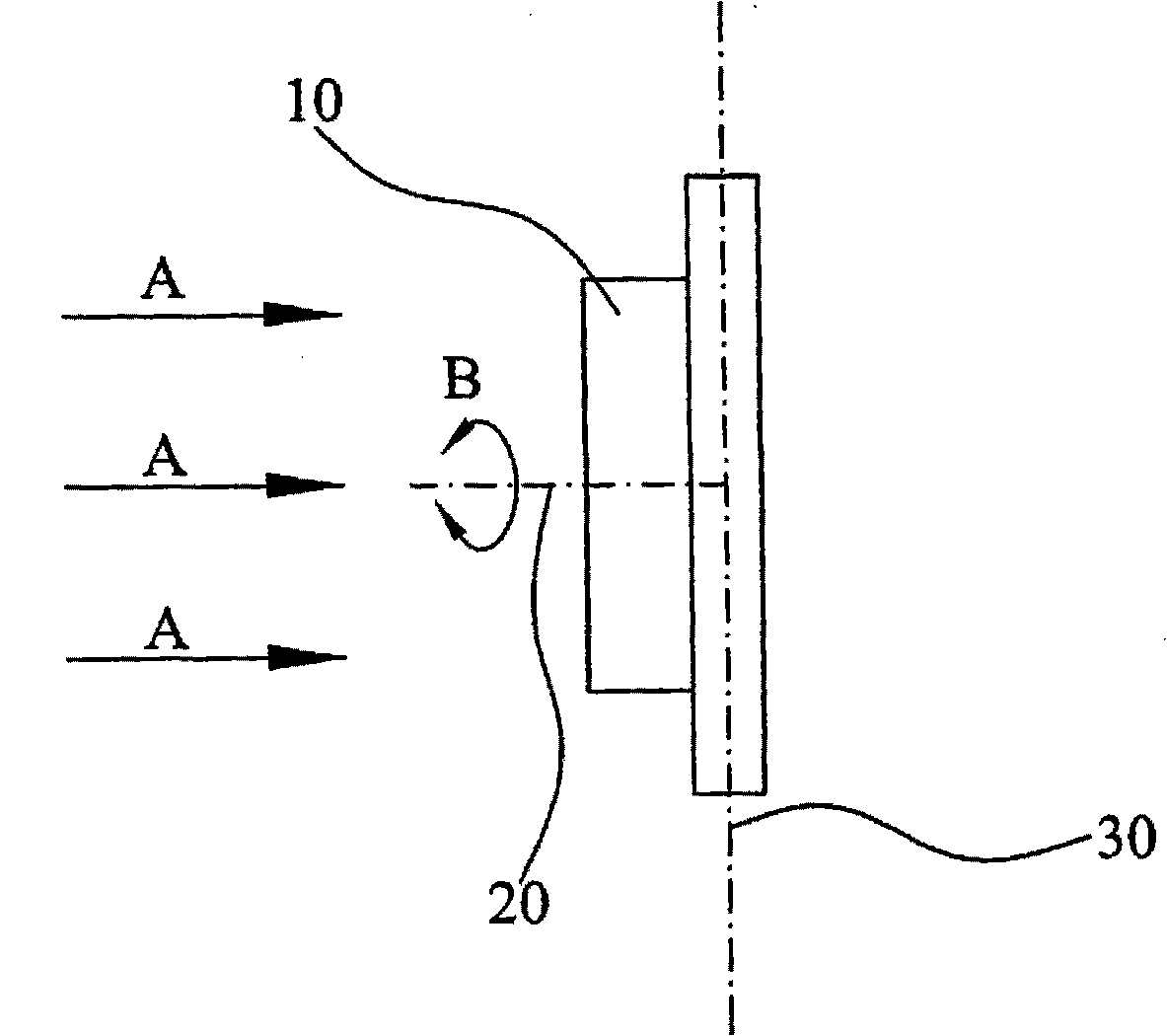

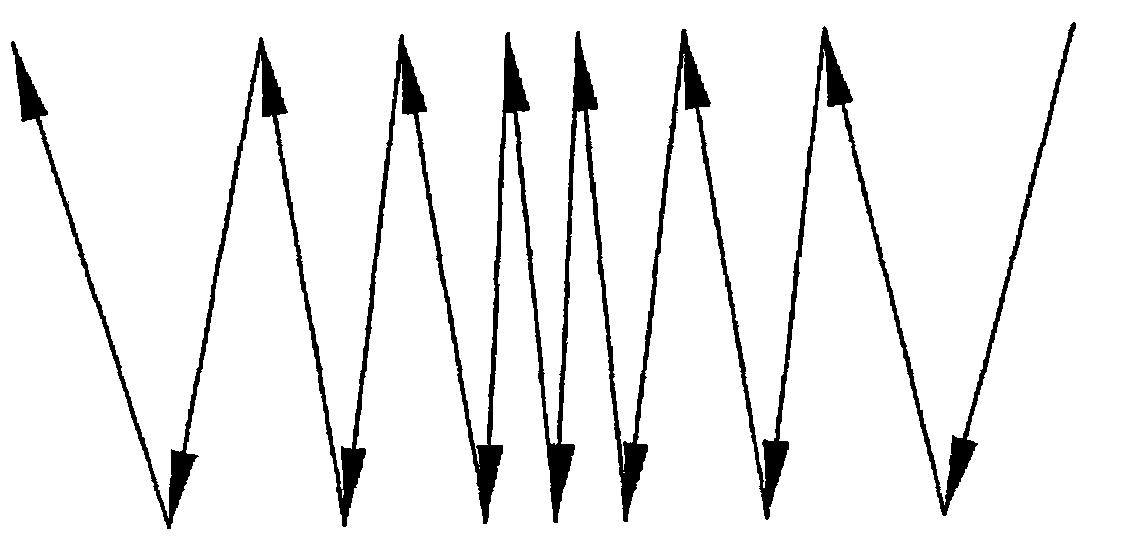

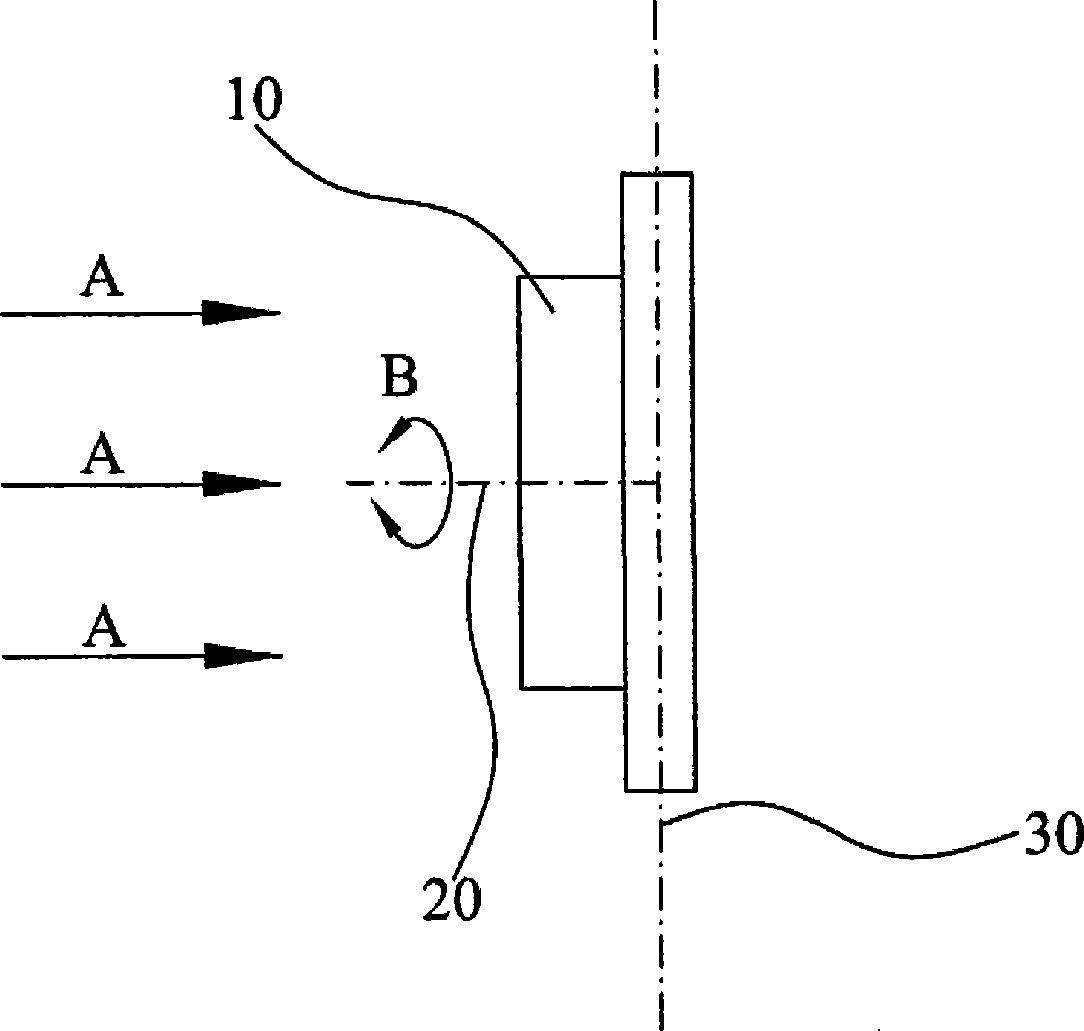

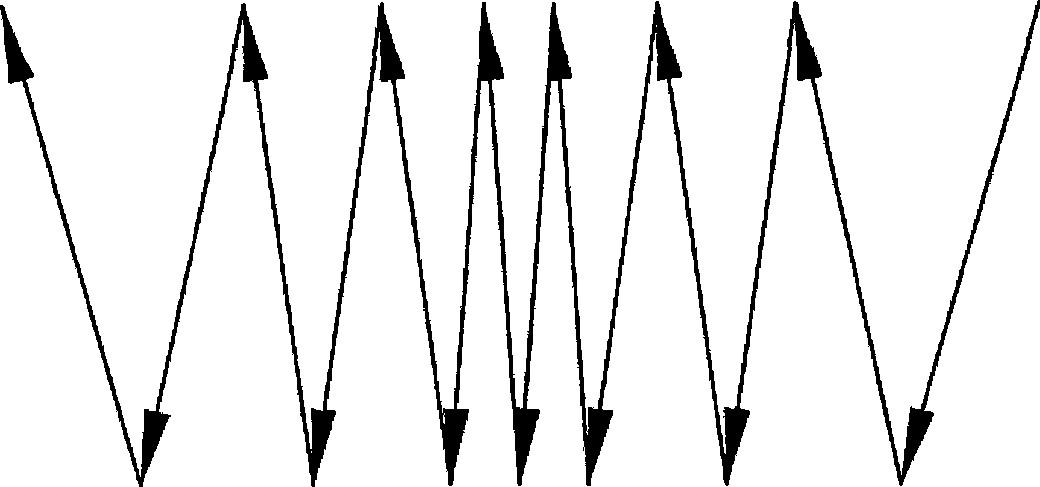

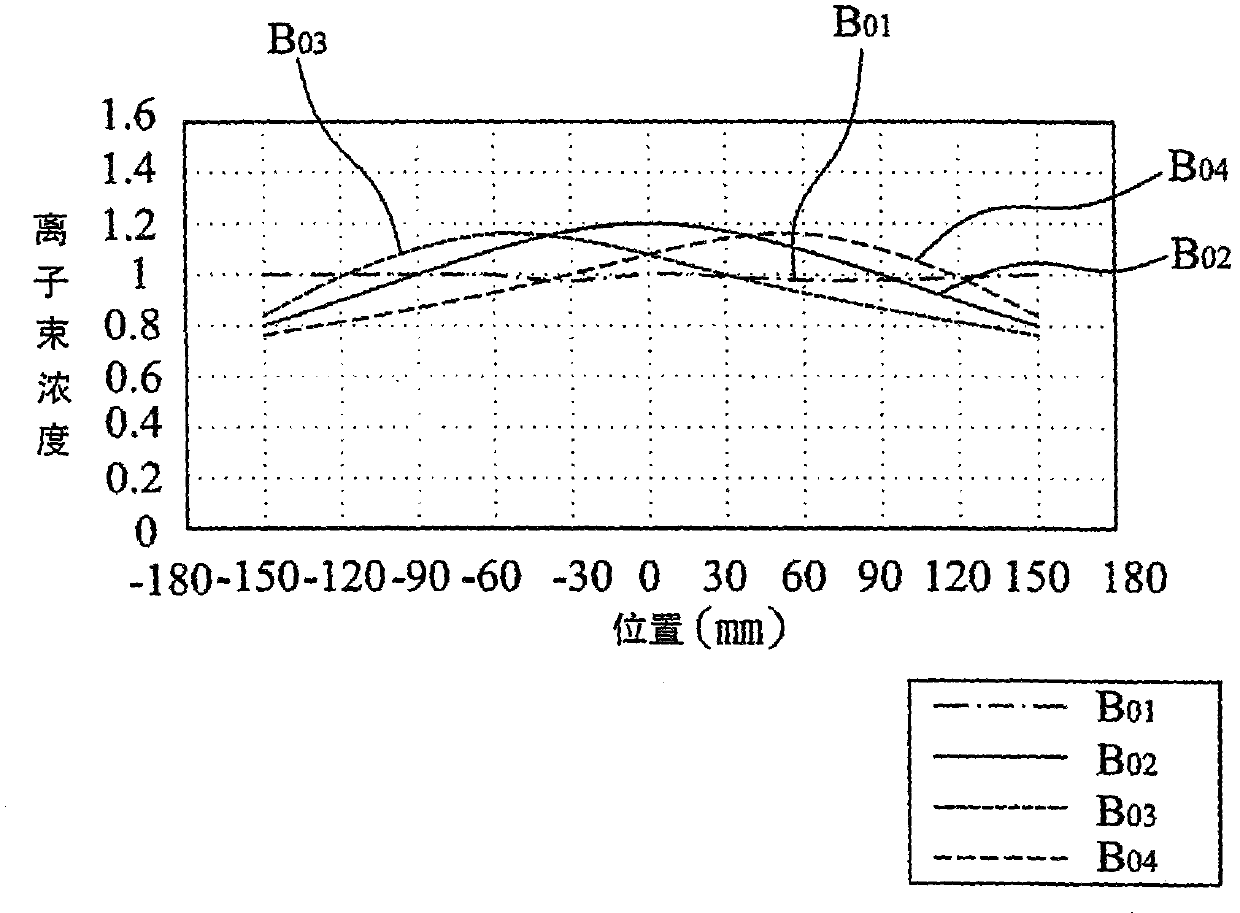

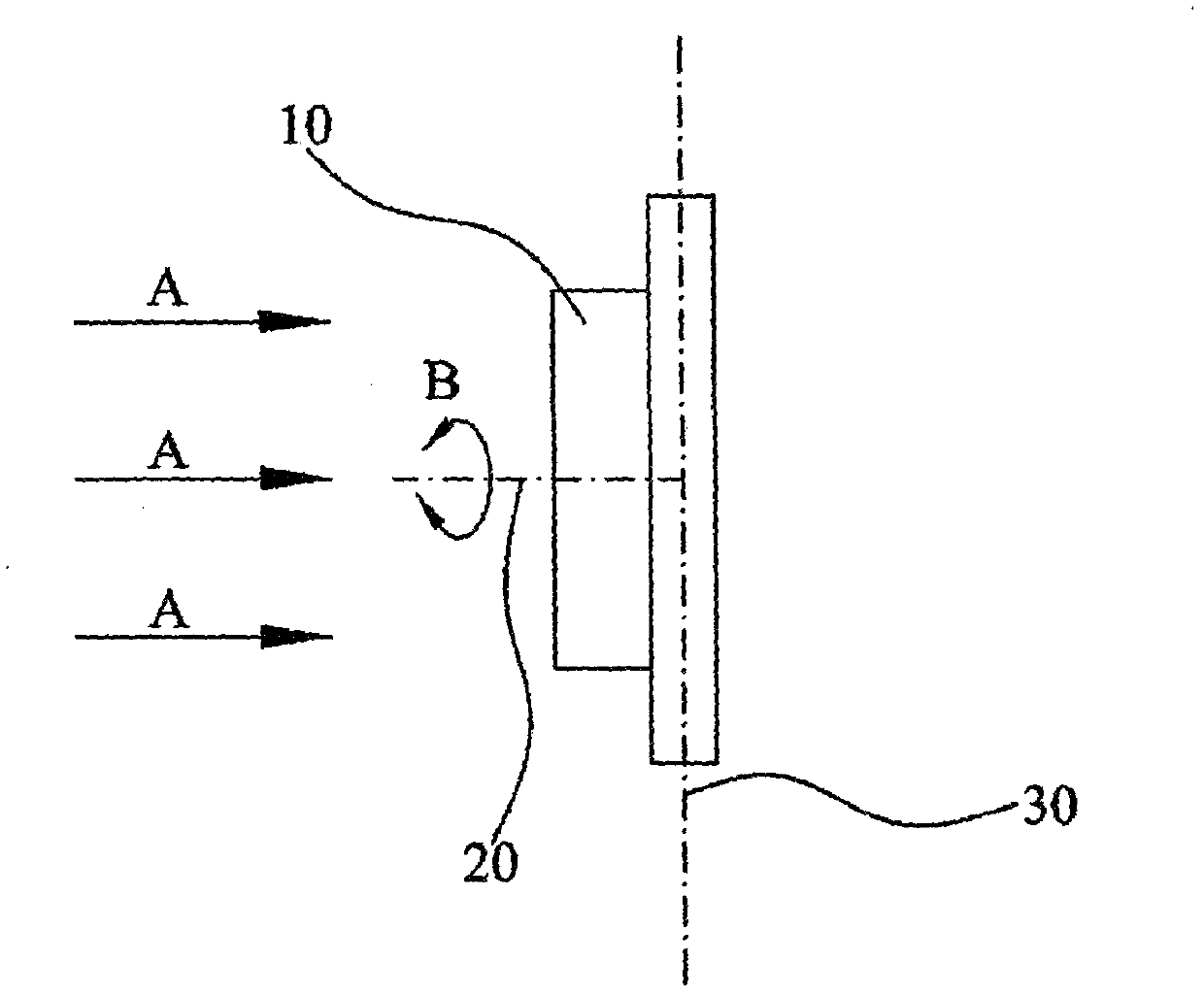

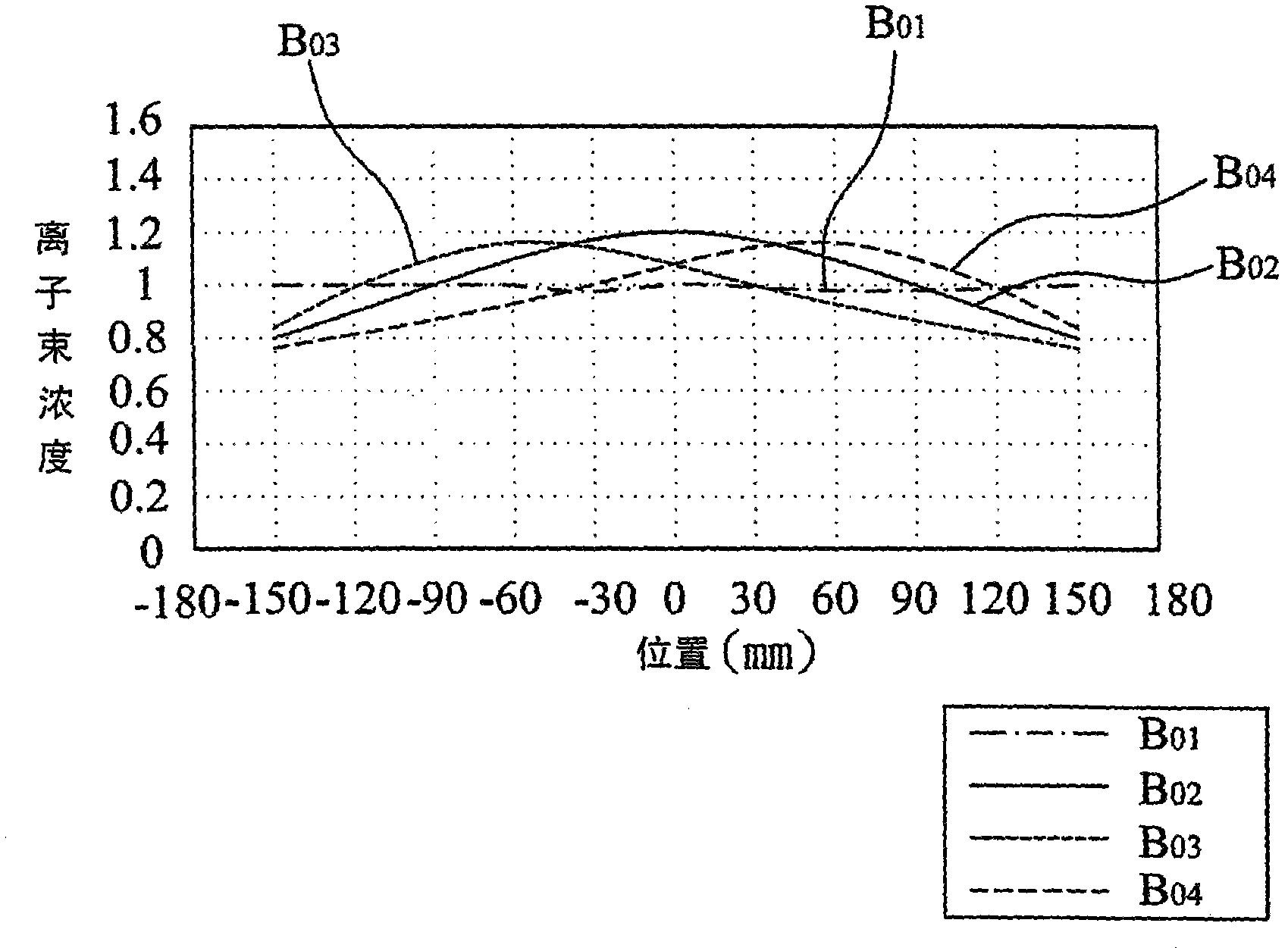

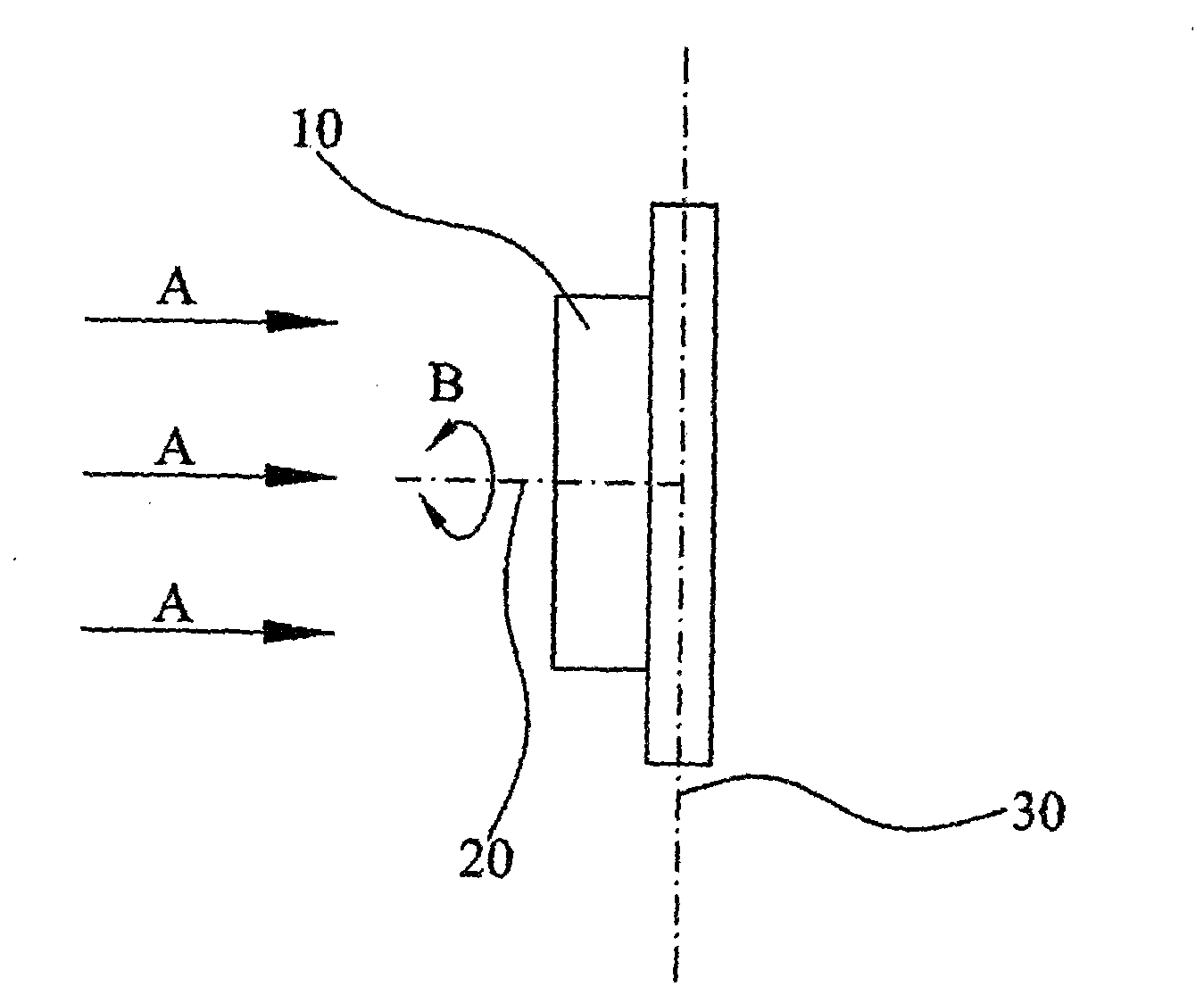

Ion implantation method

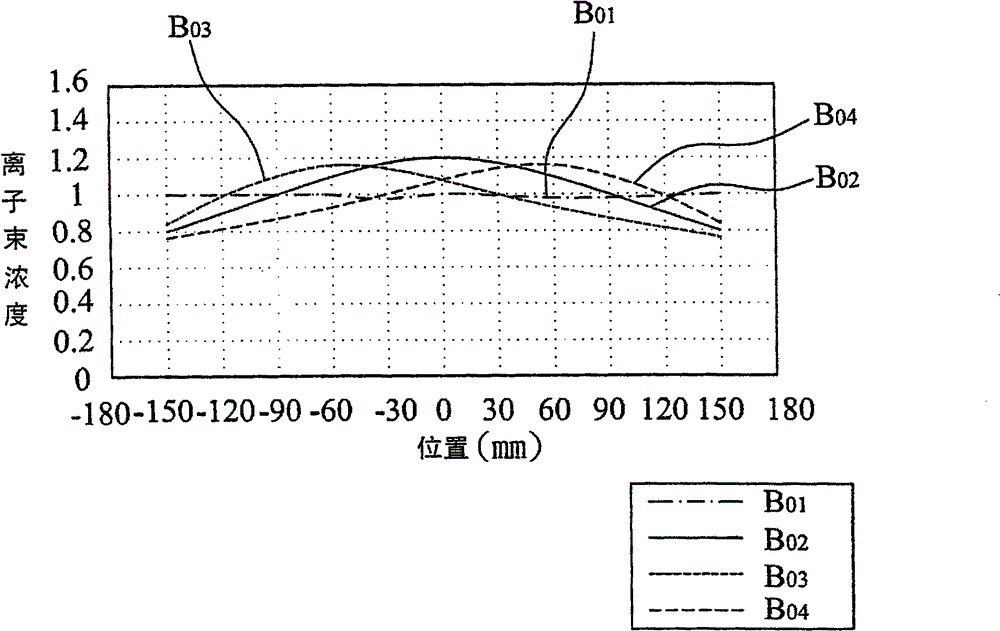

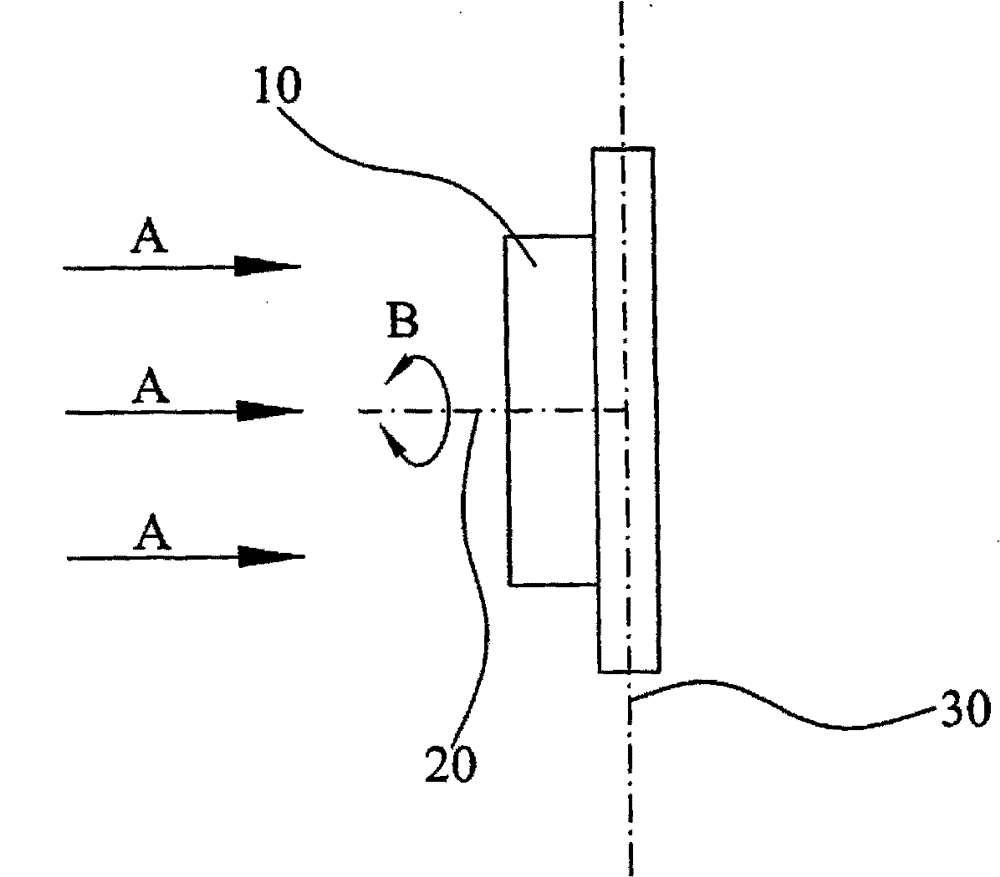

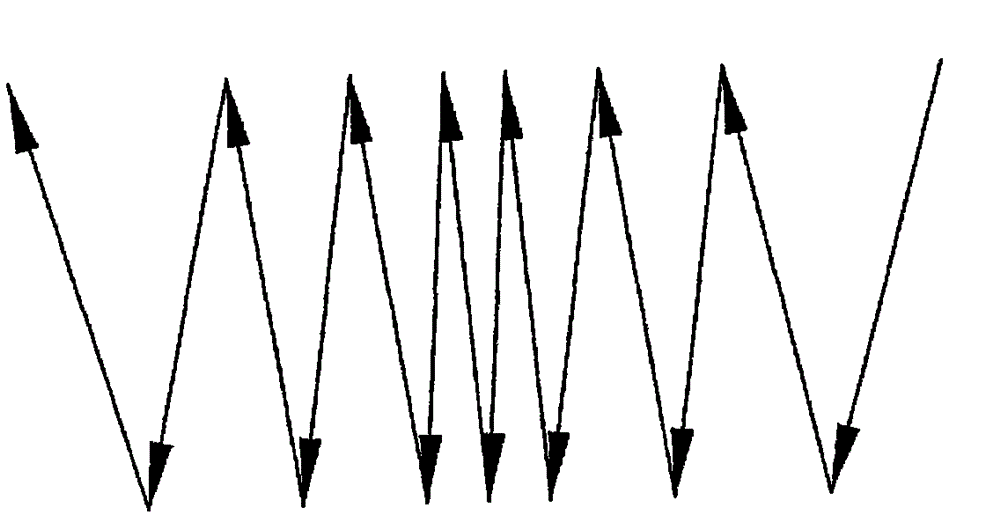

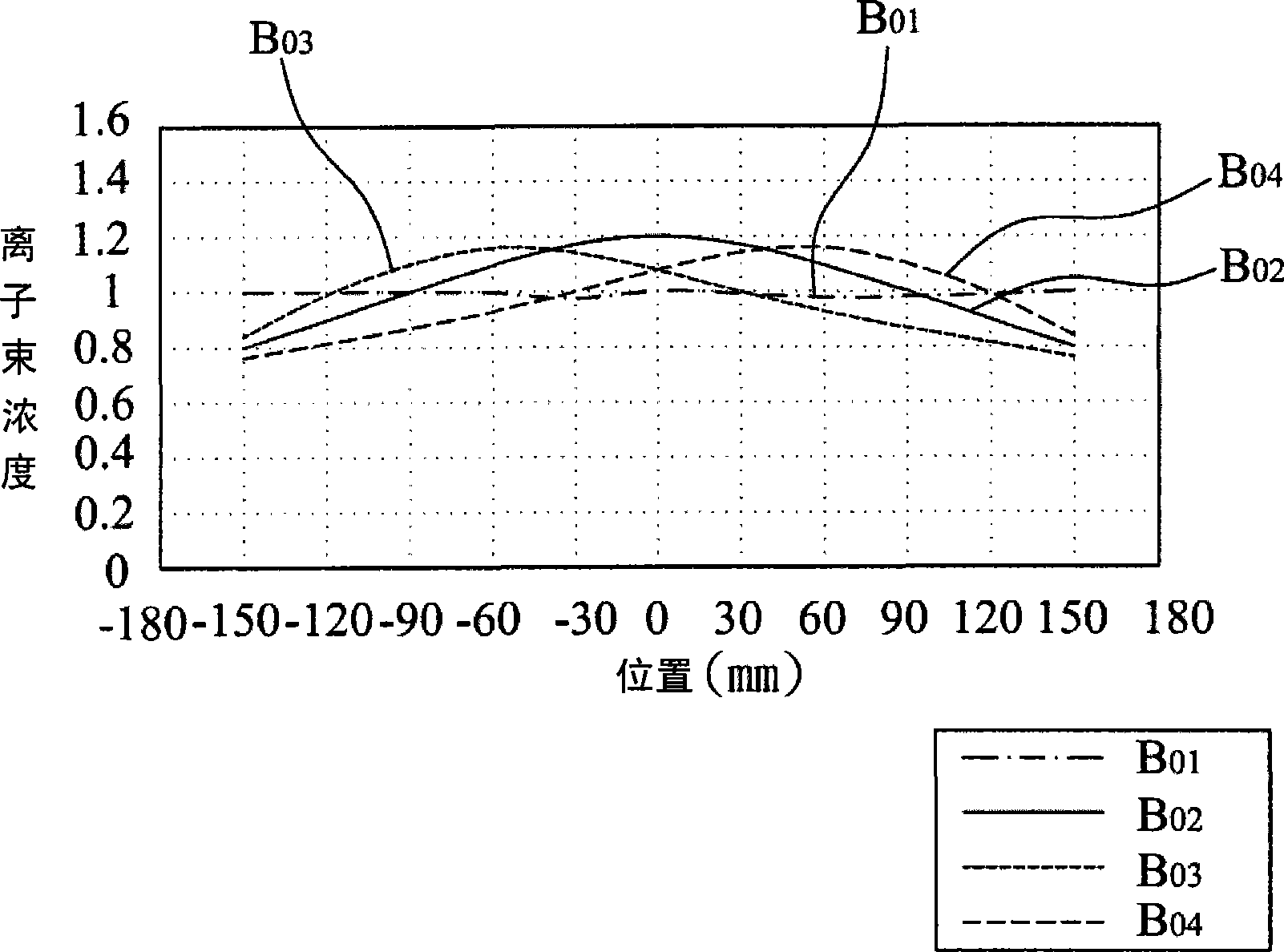

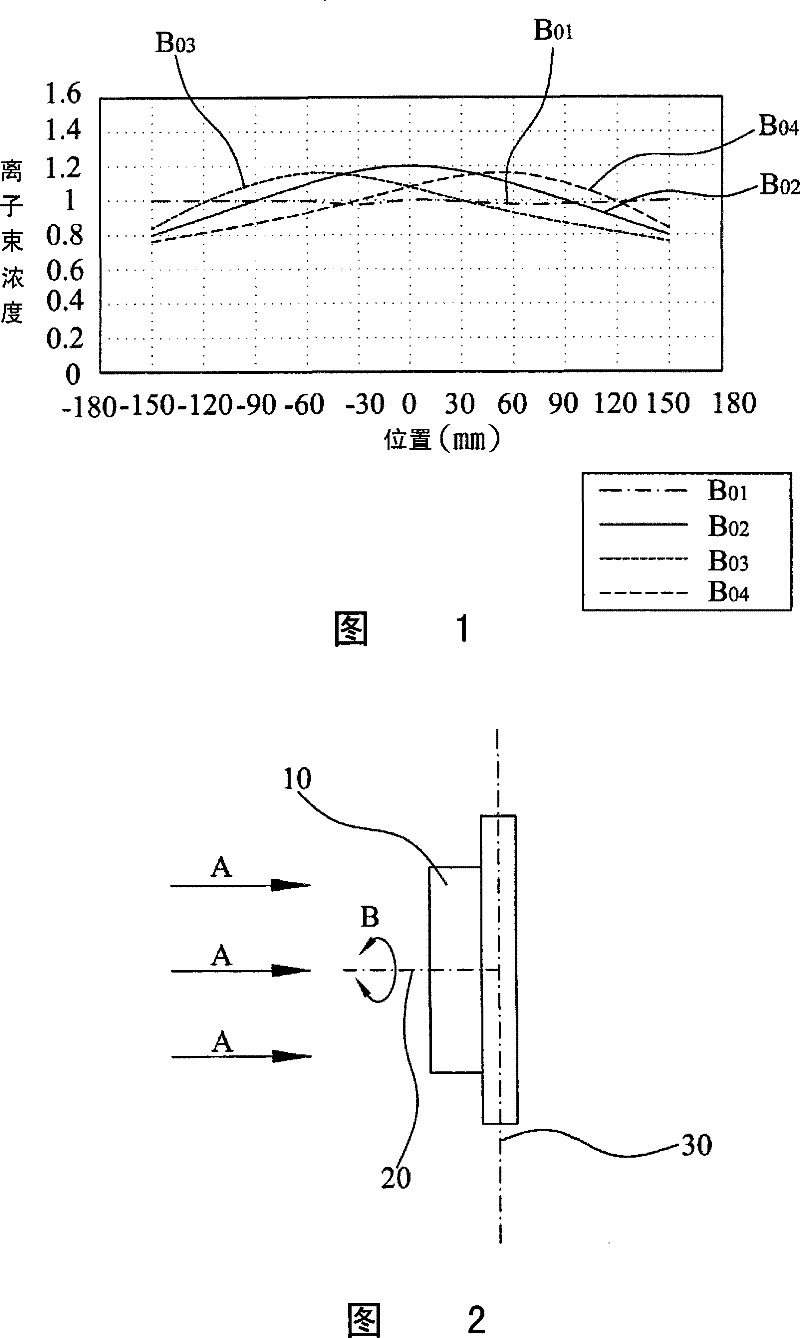

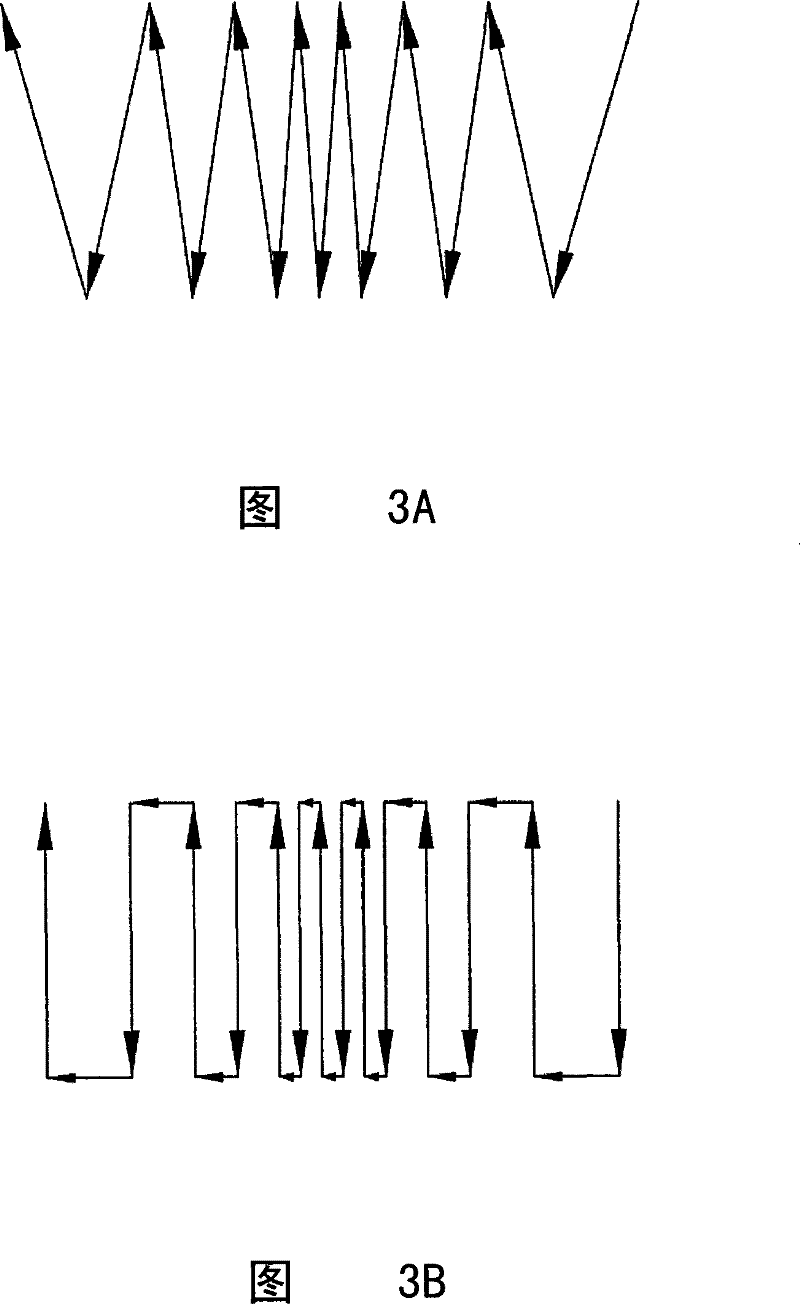

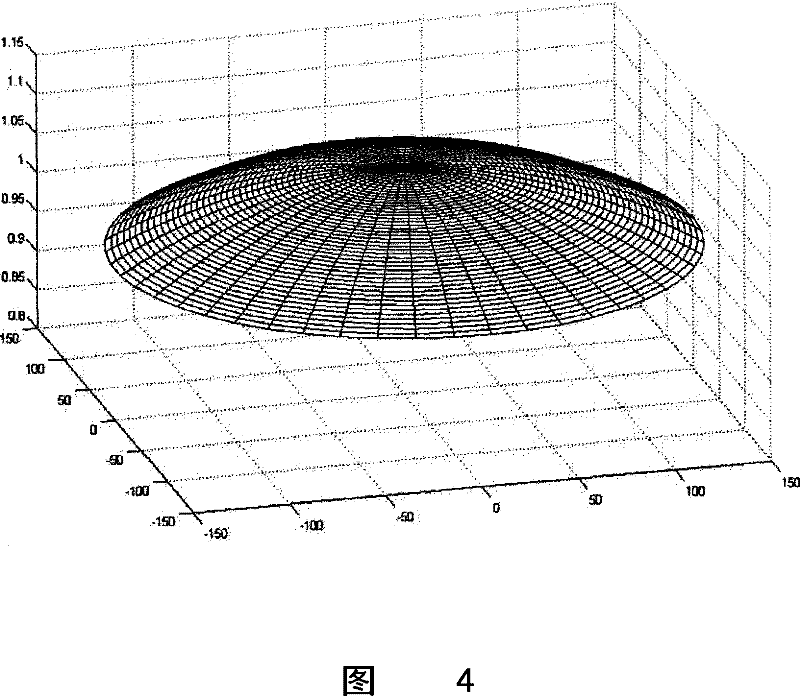

ActiveCN102324383ATo achieve the effect of ion distributionSave tuning timeElectric discharge tubesSemiconductor/solid-state device manufacturingIon beamIon implantation

The invention provides an ion implantation method used for implanting ions into a target. The ion implantation method comprises the step of implanting multiple ions into the target by using a rotating target during constant speed scanning; or implanting the multiple ions into the target by using a variable speed under the premise that the target is not rotated. Ion implantation result with special dose distribution can be obtained without need of providing ion beams with uniform concentration distribution; the process time can be reduced; and the process yield can be increased.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

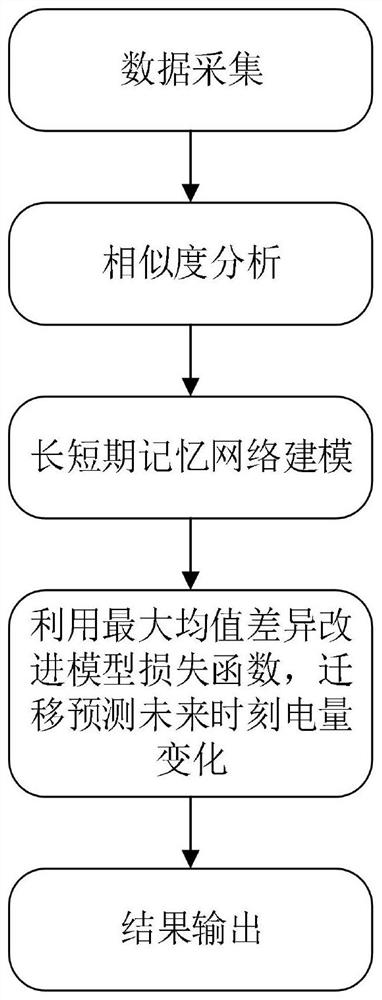

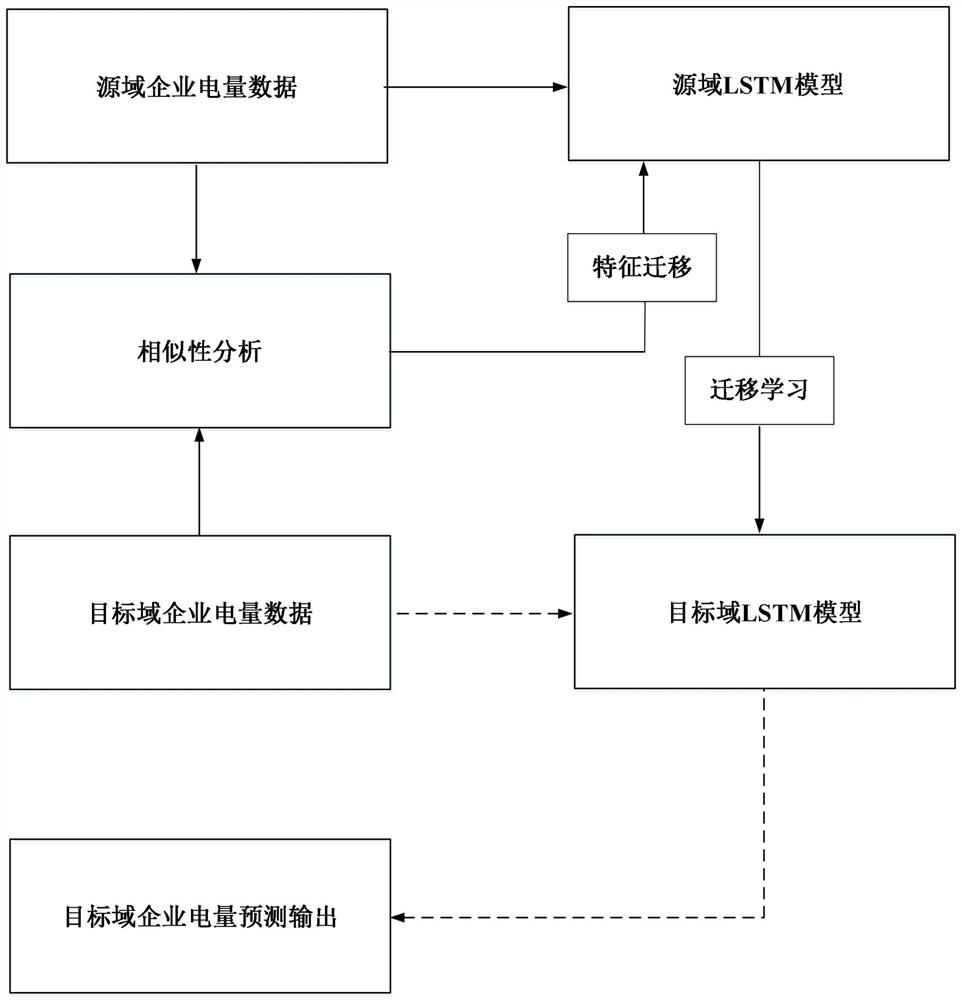

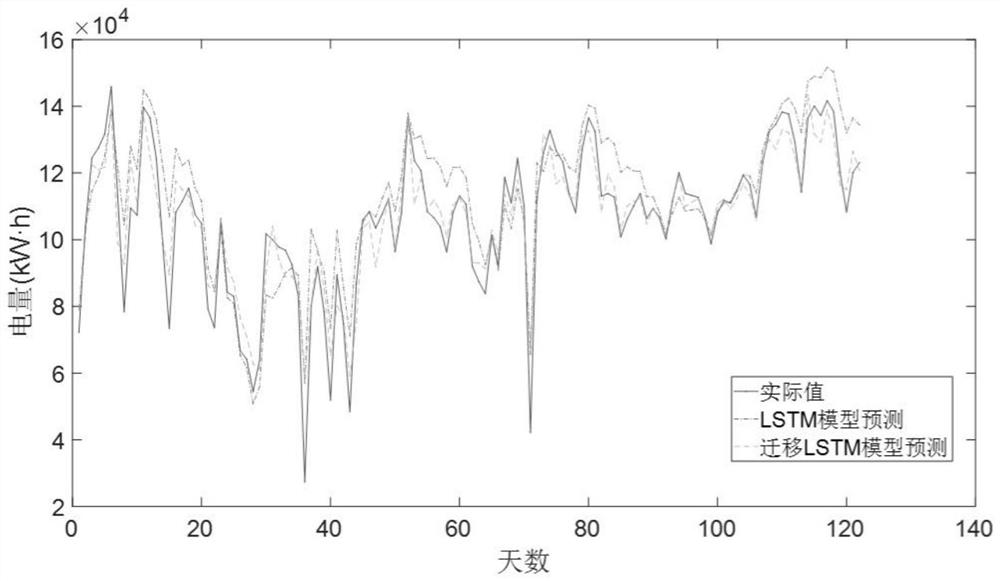

Enterprise electricity consumption prediction method

InactiveCN114169639AReduce training timeImprove forecast accuracyForecastingNeural architecturesData acquisitionElectric consumption

The invention discloses an enterprise electricity consumption prediction method. The method comprises the following steps: 1) data acquisition; 2) introducing the maximum mean value difference, and carrying out similarity analysis; 3) modeling a long short-term memory network of transfer learning; and 4) electric quantity prediction: predicting the electric quantity of the target domain enterprise at the future moment by using the improved model in the step 3). The problem of insufficient data volume during electric quantity prediction is effectively solved, the model training time is saved, and the electric quantity prediction precision is improved.

Owner:CHONGQING TECH & BUSINESS UNIV

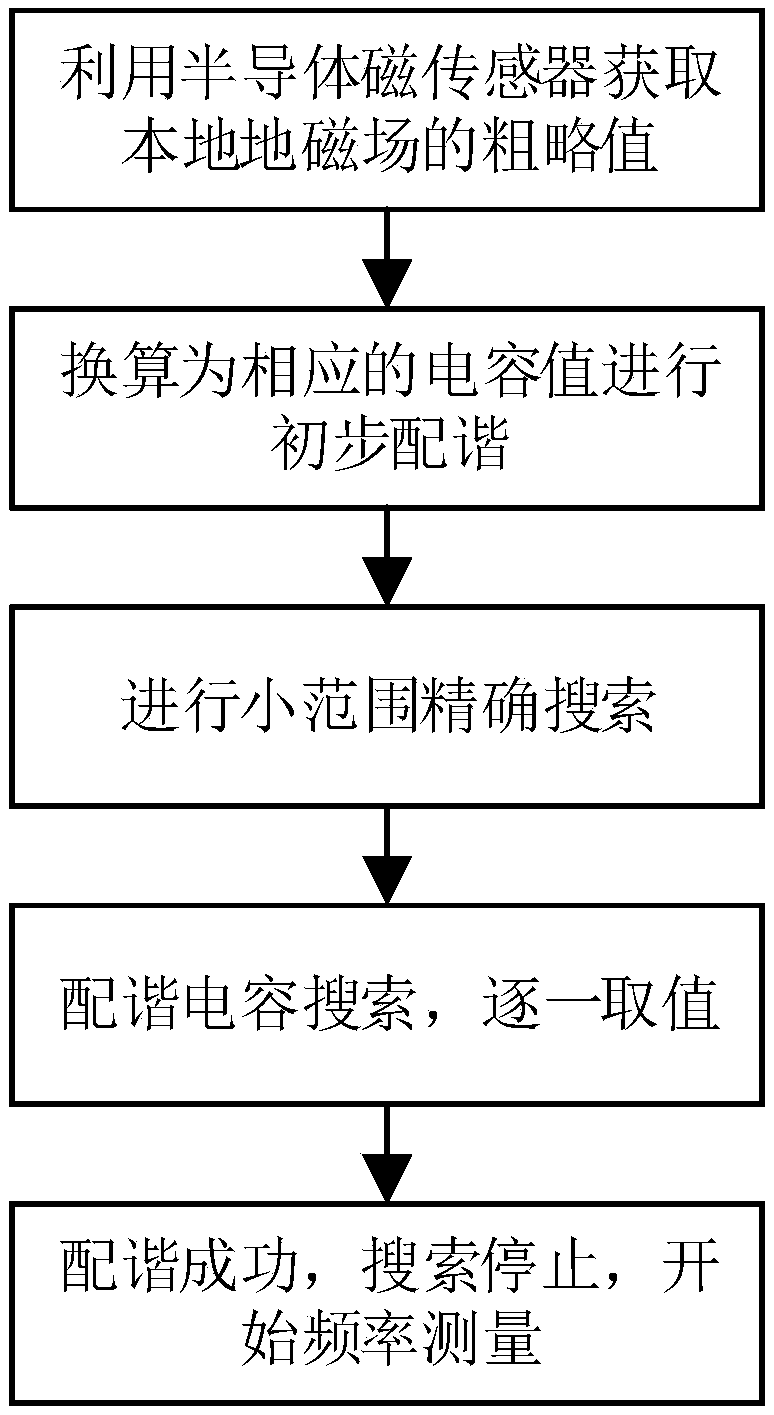

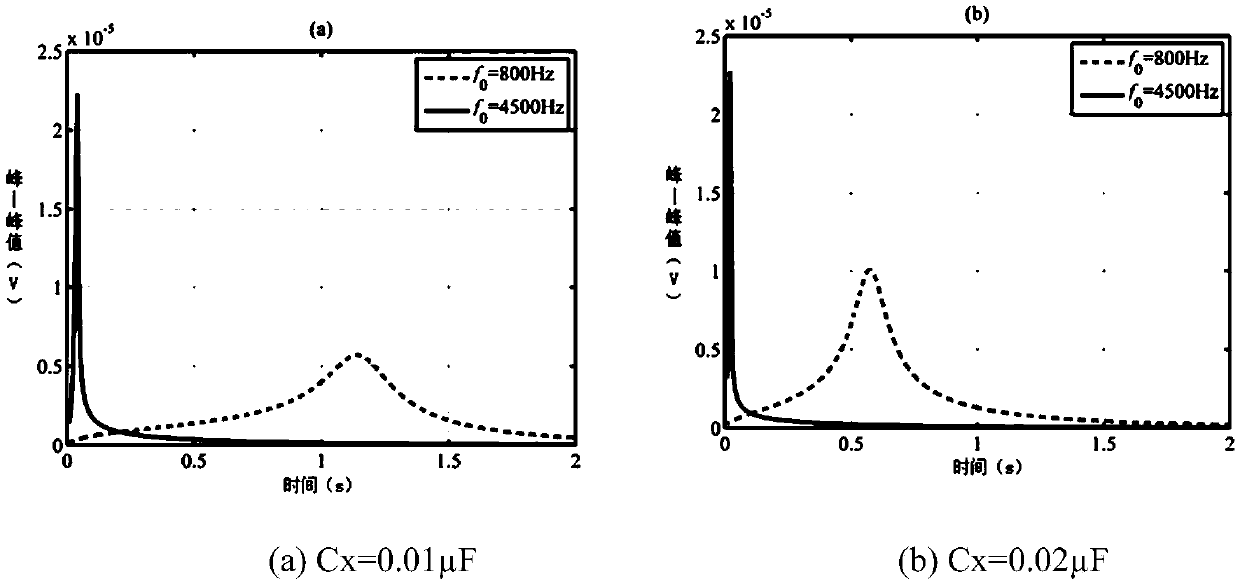

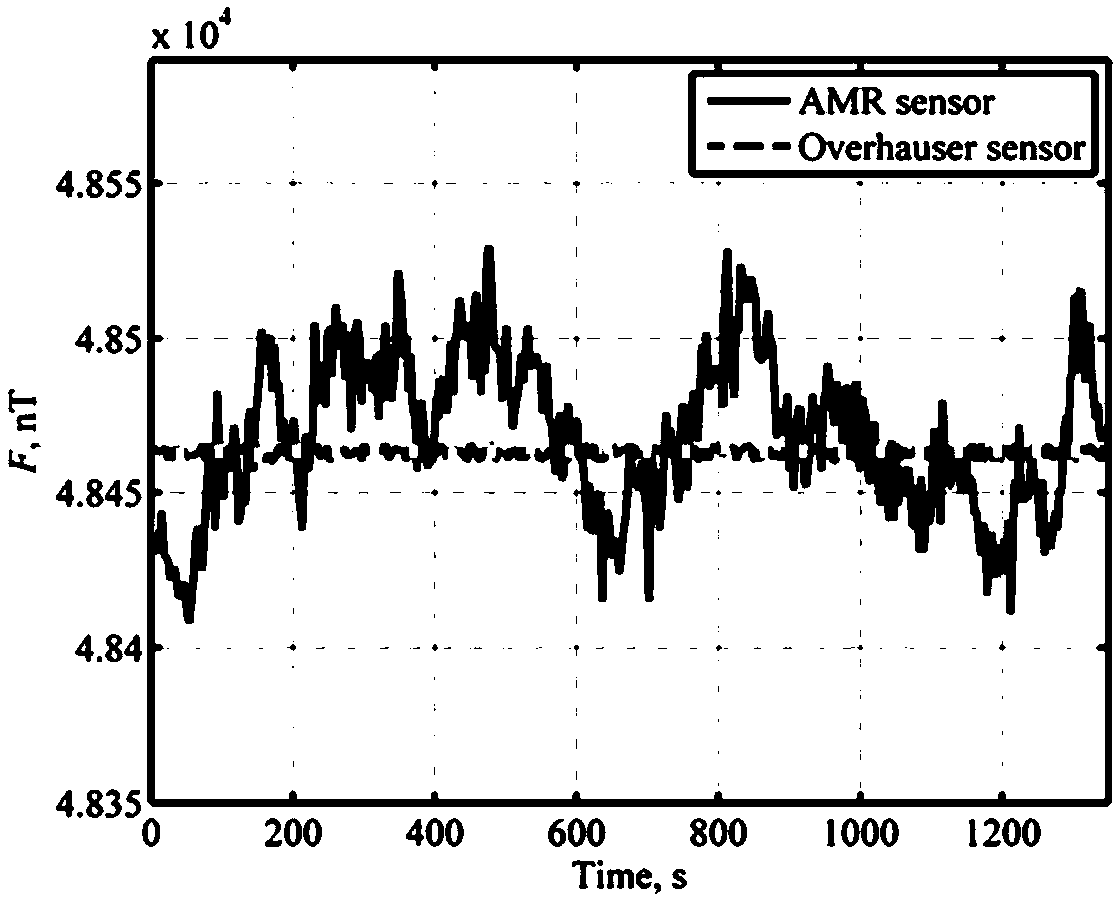

Semiconductor magnetic sensor-based rapid tracking and tuning method for Overhauser magnetometer

ActiveCN109597137AFast Track TuningGood signal to noise ratioElectric/magnetic detectionAcoustic wave reradiationOptimal tuningCapacitance

The invention provides a semiconductor magnetic sensor-based rapid tracking and tuning method for an Overhauser magnetometer. The method comprises the following steps of acquiring a rough value F of ageomagnetic field by utilizing the semiconductor magnetic sensor, and determining a value of f0 according to a relation between the geomagnetic field F and a frequency f0 of an FID signal; preliminarily determining a capacitance value C of a tuning capacitor of the Overhauser magnetometer according to the f0; and according to the obtained capacitance value C of the tuning capacitor, preliminarilydetermining an actual tuning capacitor value Cm of a tuning circuit, adjusting the actual tuning value Cm up and down, searching for an optimal tuning value C0, detecting a peak value of the FID signal according to a peak detector, and when the peak value is maximum, indicating that the circuit is in a resonance state, at the moment, determining that the tuning is successful, stopping the search,and then starting frequency measurement.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for correcting gun barrel of 25mm self-propelled antiaircraft gun using tilt angle sensor

The invention provides a method for correcting a gun barrel of a 25mm self-propelled antiaircraft gun using a tilt angle sensor. The method comprises the step of putting a measuring carrier with the tilt angle sensor into the gun barrel to measure the angle of the gun barrel. The method essentially comprises the following steps of: shooting all the gun barrels at the horizontal position; measuring the high low angle of a base gun barrel with the measuring carrier; marking the horizontal position of the measuring carrier at the inner side of the base gun barrel to be corrected; adjusting the high low angle of the gun barrel to be corrected to be accordance with the base gun barrel; adjusting all the gun barrels at the vertical direction; measuring the tilt angle of the base gun barrel by the measuring carrier; putting the measuring carrier into the gun barrel to be corrected to measure the tilt angle of the gun barrel to be corrected; and adjusting the tilt angle of the gun barrel to be corrected to be in accordance with the tilt angle of the base gun barrel.

Owner:中国人民解放军济南军区军械雷达修理所

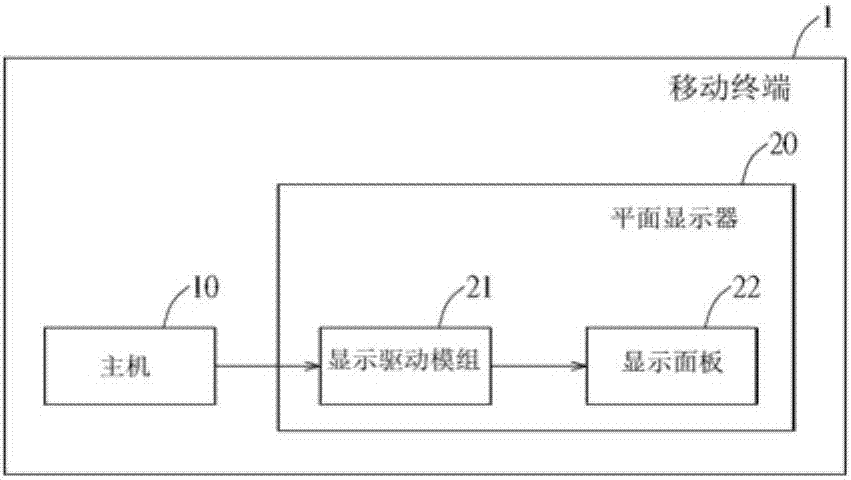

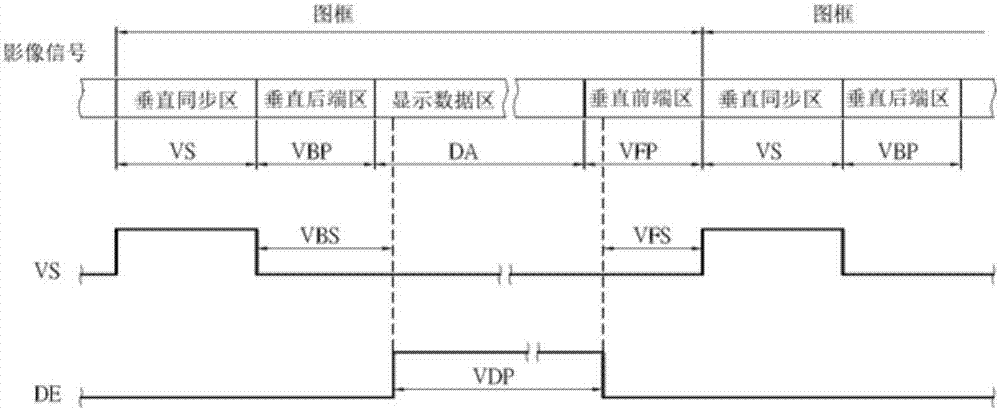

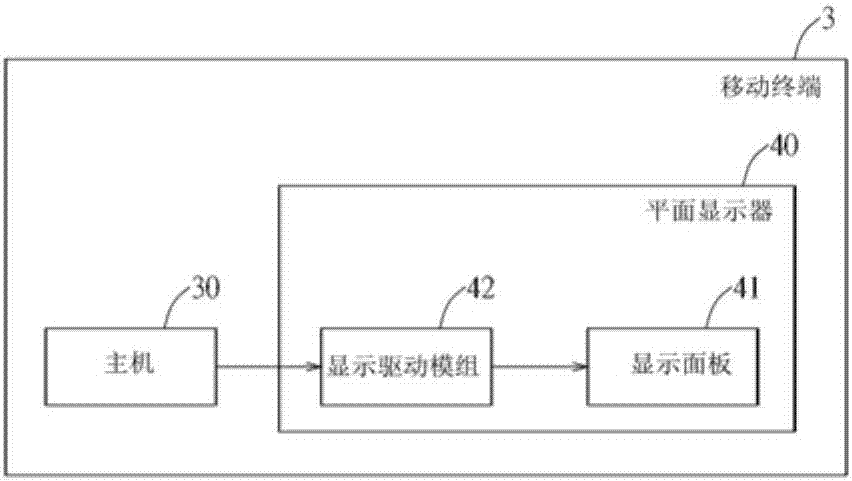

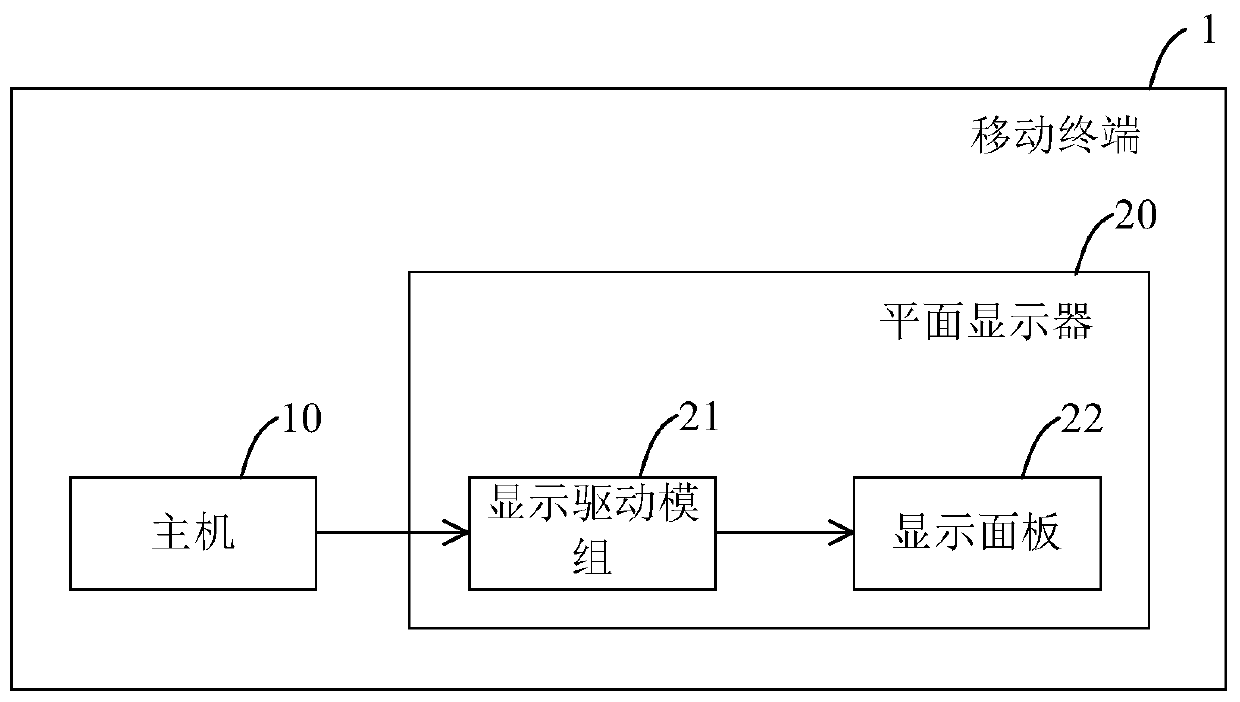

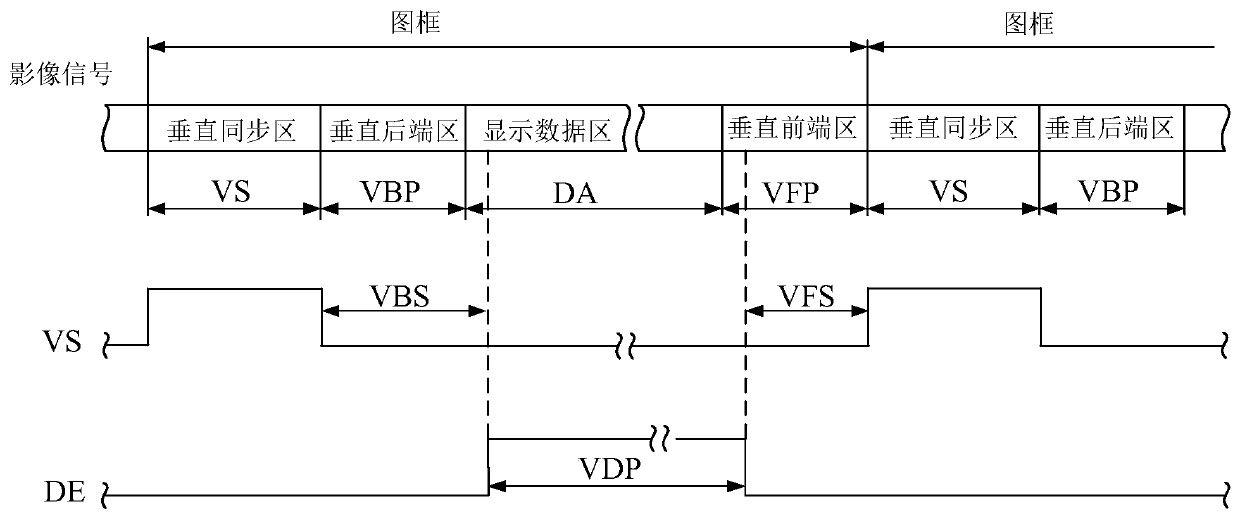

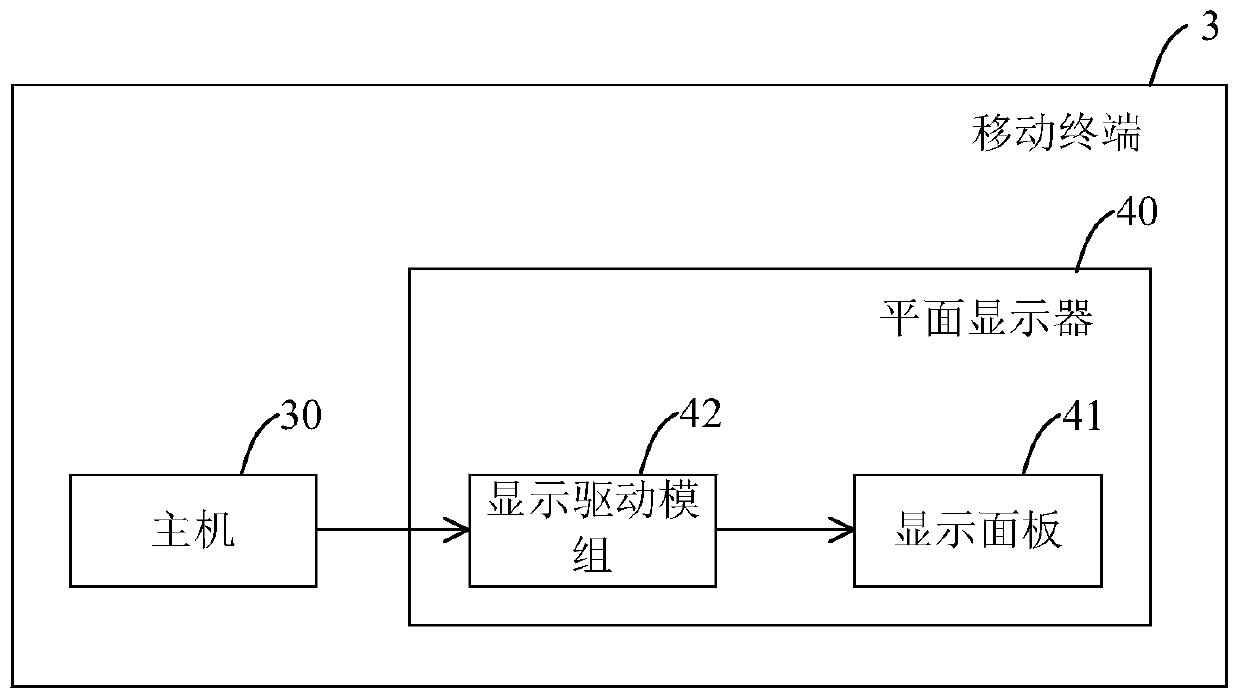

Display driving method and planar display

ActiveCN107424550ASave tuning timeReduce labor costsStatic indicating devicesDisplay deviceComputer module

The invention discloses a display driving method. The method includes the following steps: a display driving module detecting front N picture frames (N is an integer and N is greater than or equal to 2) in an image signal which is transmitted by a DSI interface of the MIPI of a main computer, computing a first time length of a vertical rear end region and a second time length of a vertical front end region of each of the front N picture frames, and if it is determined that the first time lengths are of the same length and are different from a preset vertical rear end value, and the second time lengths are of the same length and are different from a preset vertical front end value, updating the vertical rear end value with the first time lengths and updating the vertical front end value with the second time lengths, and based on a vertical synchronous signal, a vertical rear end set value and a vertical front end set value, outputting the display data of each picture frame to a display panel.

Owner:CHIPONE TECH BEIJINGCO LTD

Method for correcting gun barrel of 25mm self-propelled antiaircraft gun using tilt angle sensor

The invention provides a method for correcting a gun barrel of a 25mm self-propelled antiaircraft gun using a tilt angle sensor. The method comprises the step of putting a measuring carrier with the tilt angle sensor into the gun barrel to measure the angle of the gun barrel. The method essentially comprises the following steps of: shooting all the gun barrels at the horizontal position; measuring the high low angle of a base gun barrel with the measuring carrier; marking the horizontal position of the measuring carrier at the inner side of the base gun barrel to be corrected; adjusting the high low angle of the gun barrel to be corrected to be accordance with the base gun barrel; adjusting all the gun barrels at the vertical direction; measuring the tilt angle of the base gun barrel by the measuring carrier; putting the measuring carrier into the gun barrel to be corrected to measure the tilt angle of the gun barrel to be corrected; and adjusting the tilt angle of the gun barrel to be corrected to be in accordance with the tilt angle of the base gun barrel.

Owner:中国人民解放军济南军区军械雷达修理所

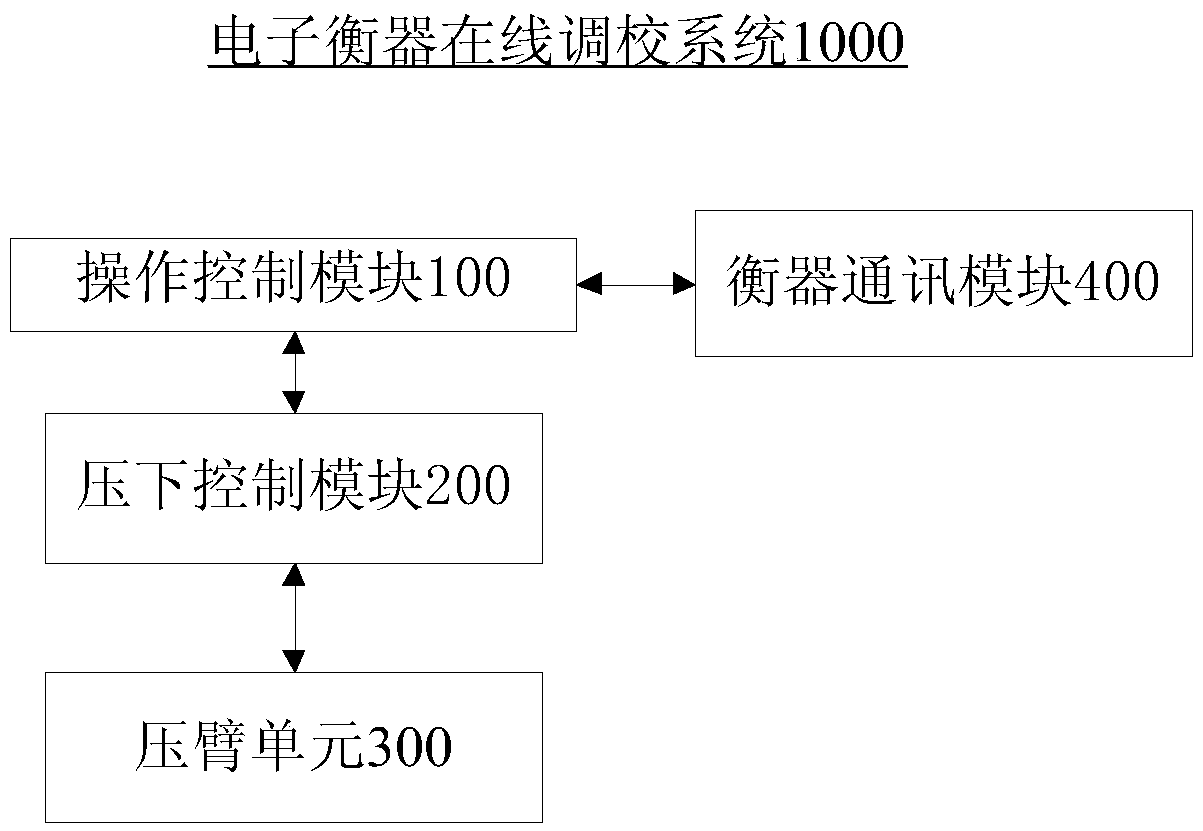

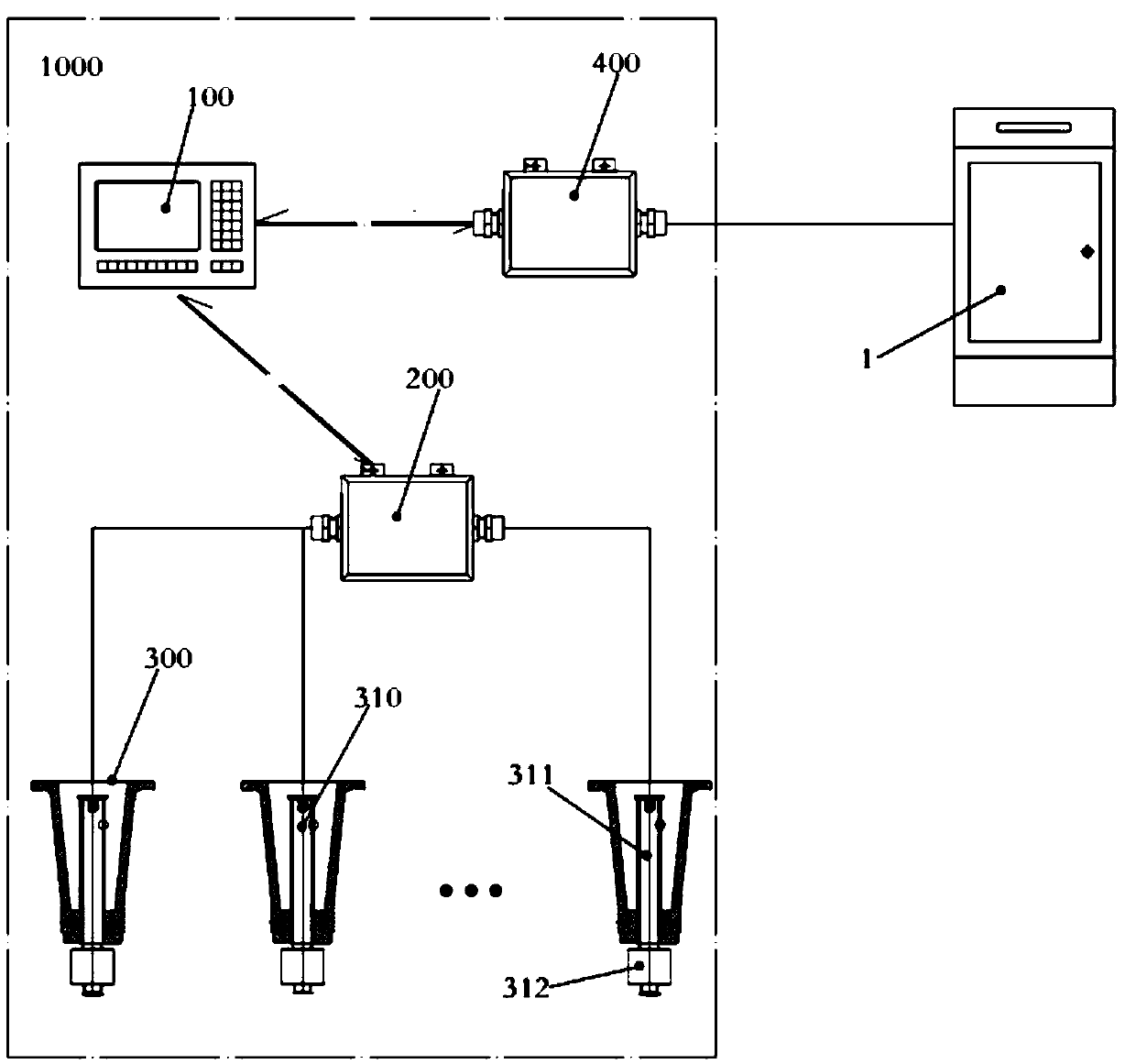

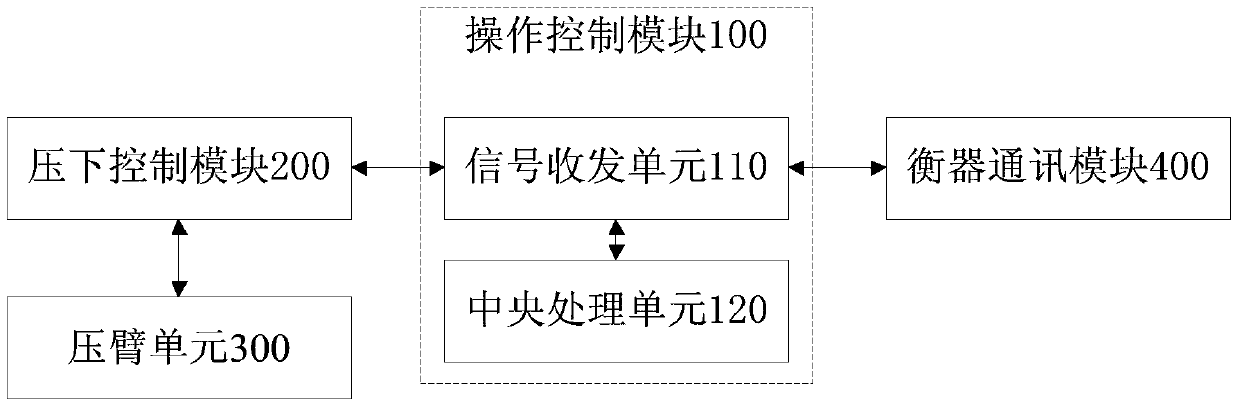

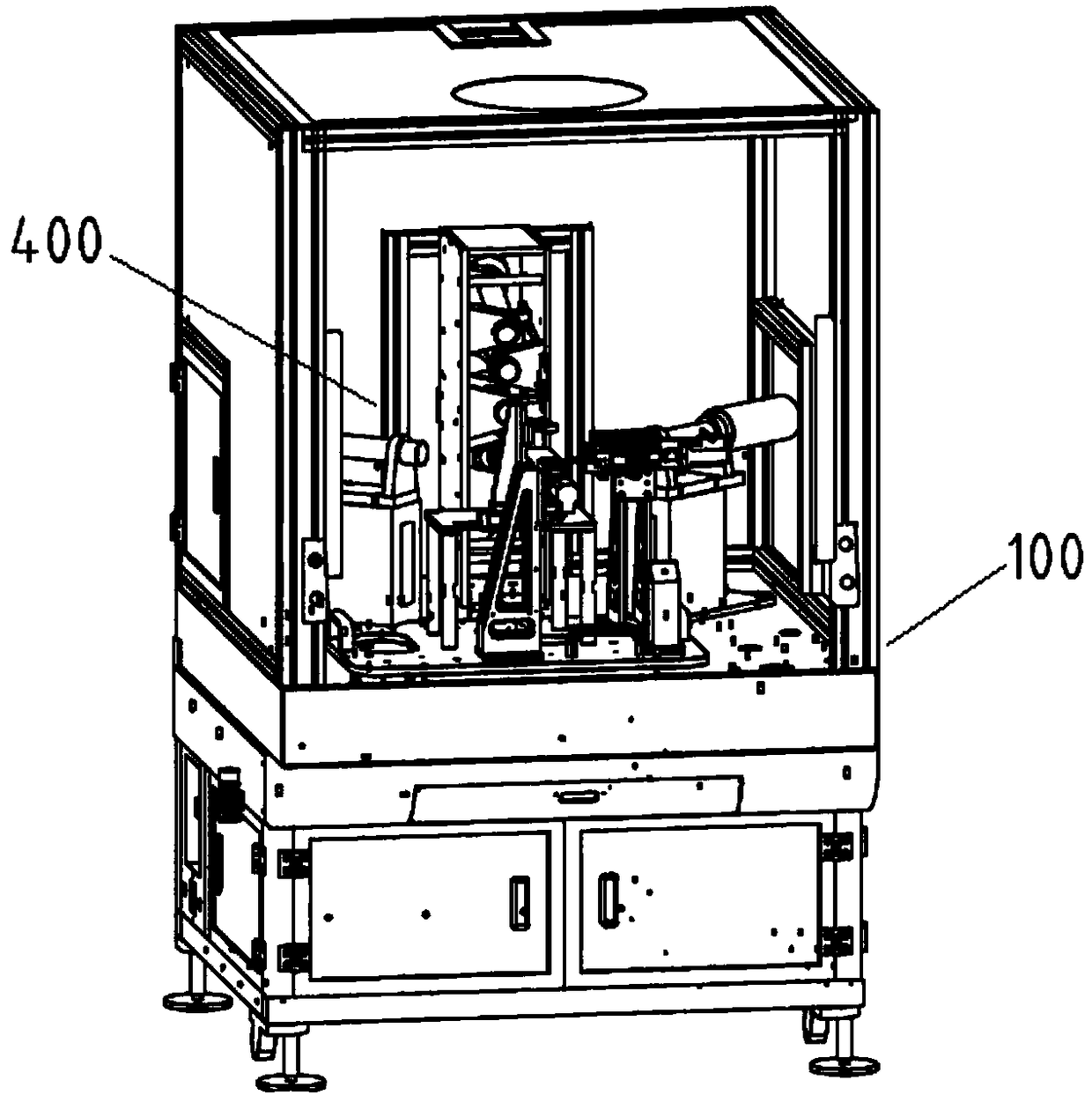

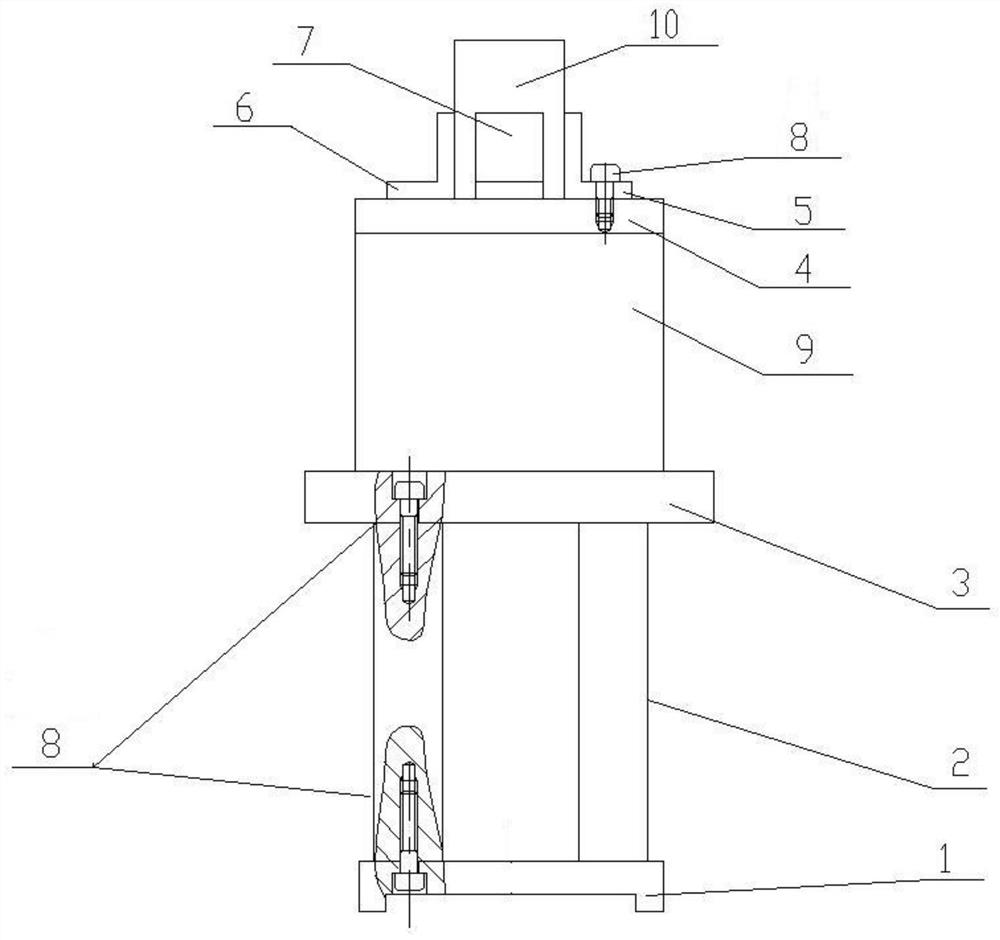

Electronic weighing instrument on-line adjustment and calibration system and adjustment and calibration method

ActiveCN105571706AEasy to installEasy to operateWeighing apparatus testing/calibrationComputer moduleElectric control

The invention provides an electronic weighing instrument on-line adjustment and calibration system, comprising an operation control module, a pressing control module and a pressing arm unit. The operation control module is in wireless connection with a weighing instrument electric control cabinet to generate a weighing instrument zero comparison order and is used for obtaining an address number of the pressing head of the weighing instrument and a pressure value, configuring that the load of the pressing arm is transmitted to the pressing control module, and obtaining the pressure-bearing values of various weighing instrument heads corresponding to various loads from the pressing module so as to determine the correction angular difference coefficient and returning the feedback of the correction result to the weighing instrument control cabinet; the pressing control module is used for performing telescopic control on the pressing arms of the pressing arm unit, and when the load of the pressing arm is equal to the downward pressure of the measurement pressing arm of the pressing arm unit, the pressing arm stops telescopic movement; the pressing arm unit comprises at least one pressing arm and a pressure sensor and a gravity sensor which are installed on the pressing arm, the pressure sensor is used for measuring the applied force on the pressing arm and the gravity sensor is used for measuring the included angle alpha between a downward pressing direction and a gravity direction and the downward pressure of the pressing arm is the product of the applied pressure and the cos alpha.

Owner:WISDRI ENG & RES INC LTD

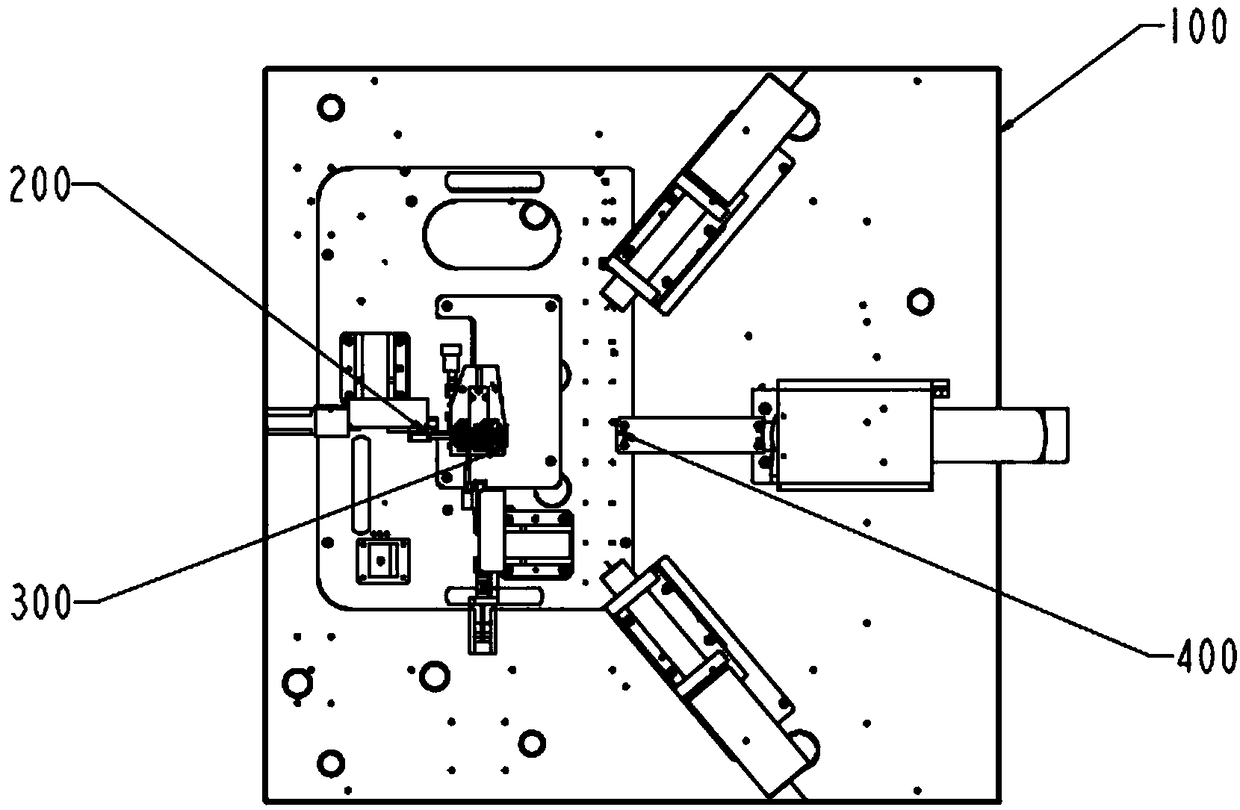

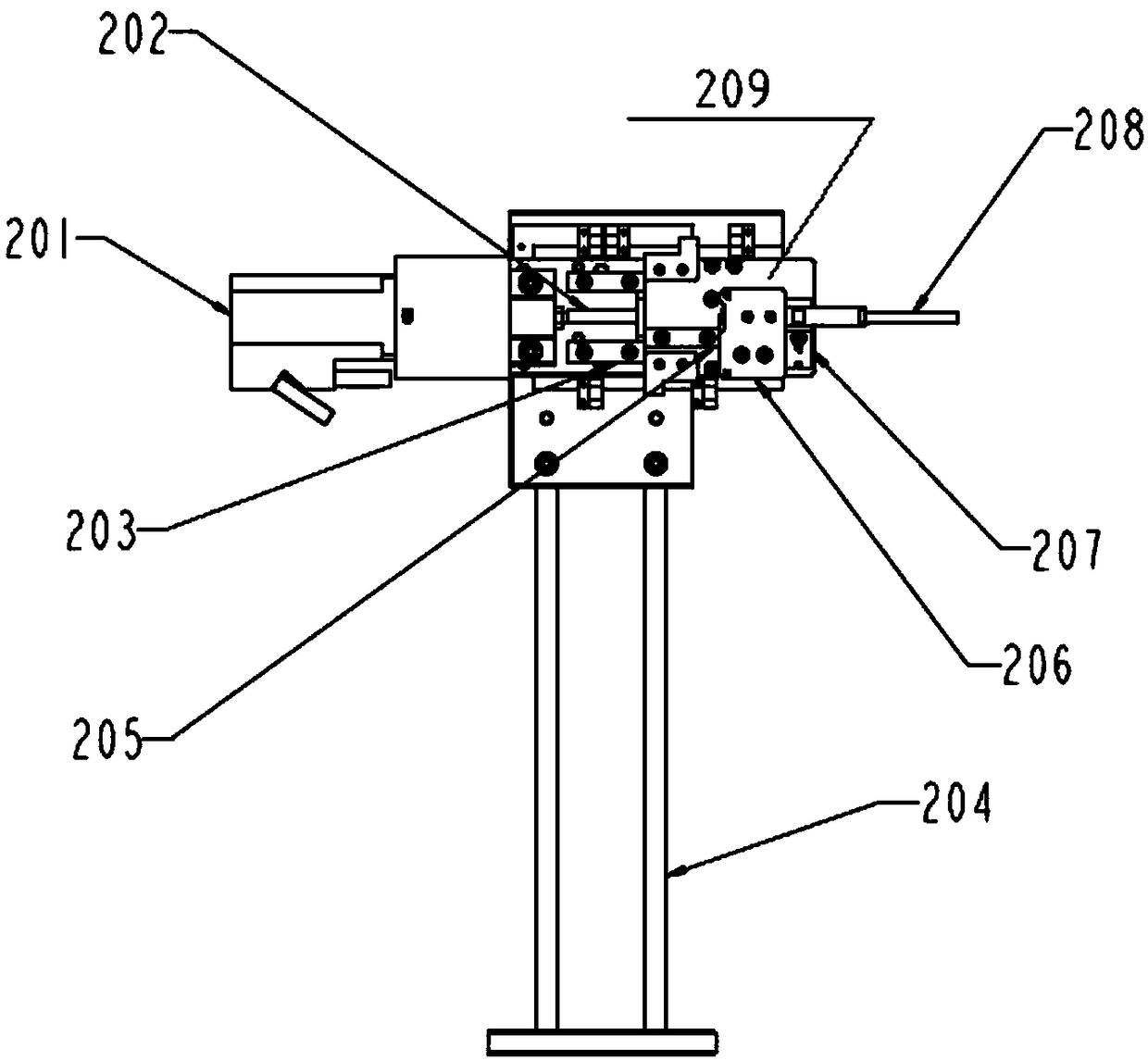

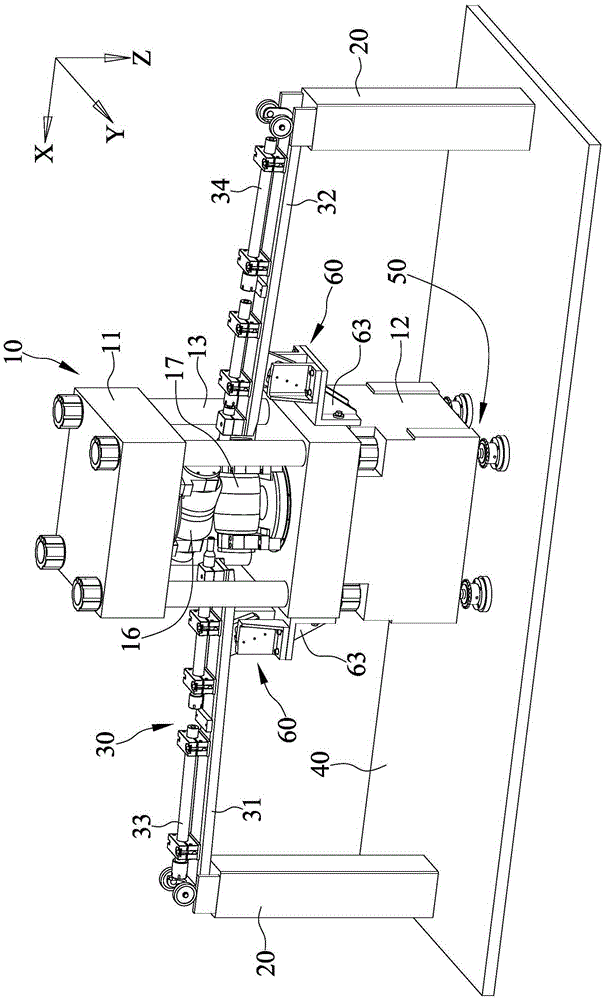

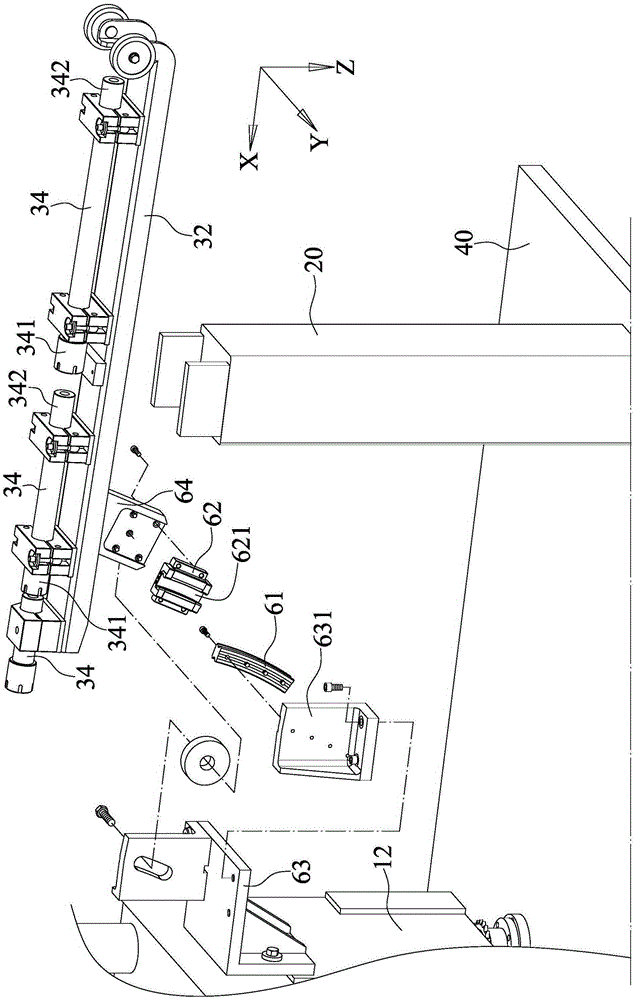

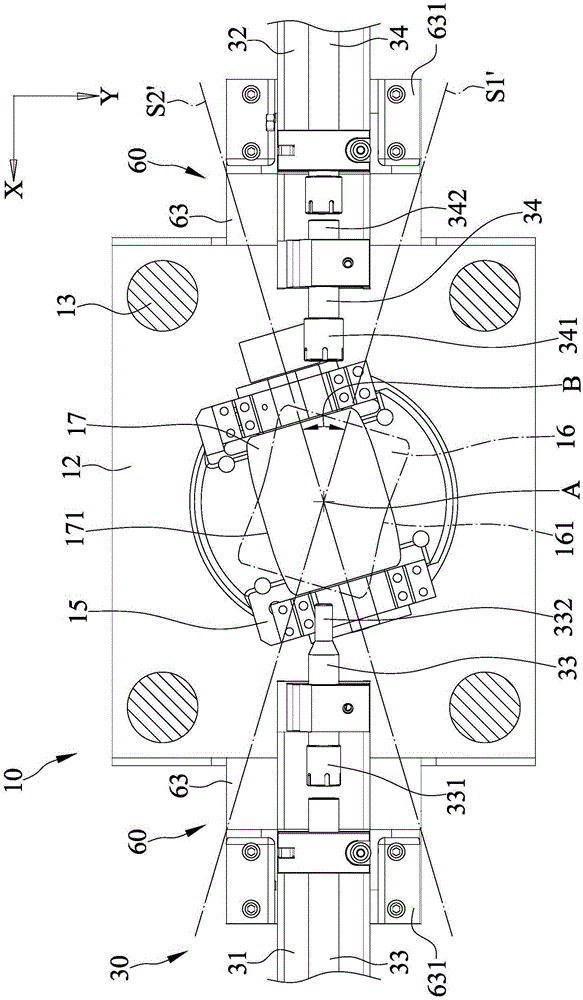

Alignment machine for laser level meter

The invention discloses an alignment machine for a laser level meter. The alignment machine comprises a stander, a clamp positioning and clamping mechanism, a measuring system and a two-axis alignmentmechanism, wherein the clamp positioning and clamping mechanism, the measuring system and the two-axis alignment mechanism are arranged on the stander; the two-axis alignment mechanism comprises an X-axis alignment structure and a Y-axis alignment structure, the X-axis alignment structure is arranged on the stander and is located on a second side of the clamp positioning and clamping mechanism, and the Y-axis alignment structure is arranged on the stander and is located on a third side of the clamp positioning and clamping mechanism; and the X-axis alignment structure and the Y-axis alignmentstructure comprise fixed frames, first linear guide rails, ball screws, servo motors, moving blocks and hollow top absorbing columns, the first linear guide rails are arranged on the fixed frames, the ball screws penetrate through the slide blocks of the first linear guide rails, the servo motors are arranged on the fixed frames and are far from one end of the clamp positioning and clamping mechanism together with the ball screws, the moving blocks are arranged on the slide blocks and can move towards and away from the clamp positioning and clamping mechanism, and the hollow top absorbing columns are arranged at one ends, facing to the clamp positioning and clamping mechanism, on the moving blocks.

Owner:深圳市弗莱博自动化设备有限公司

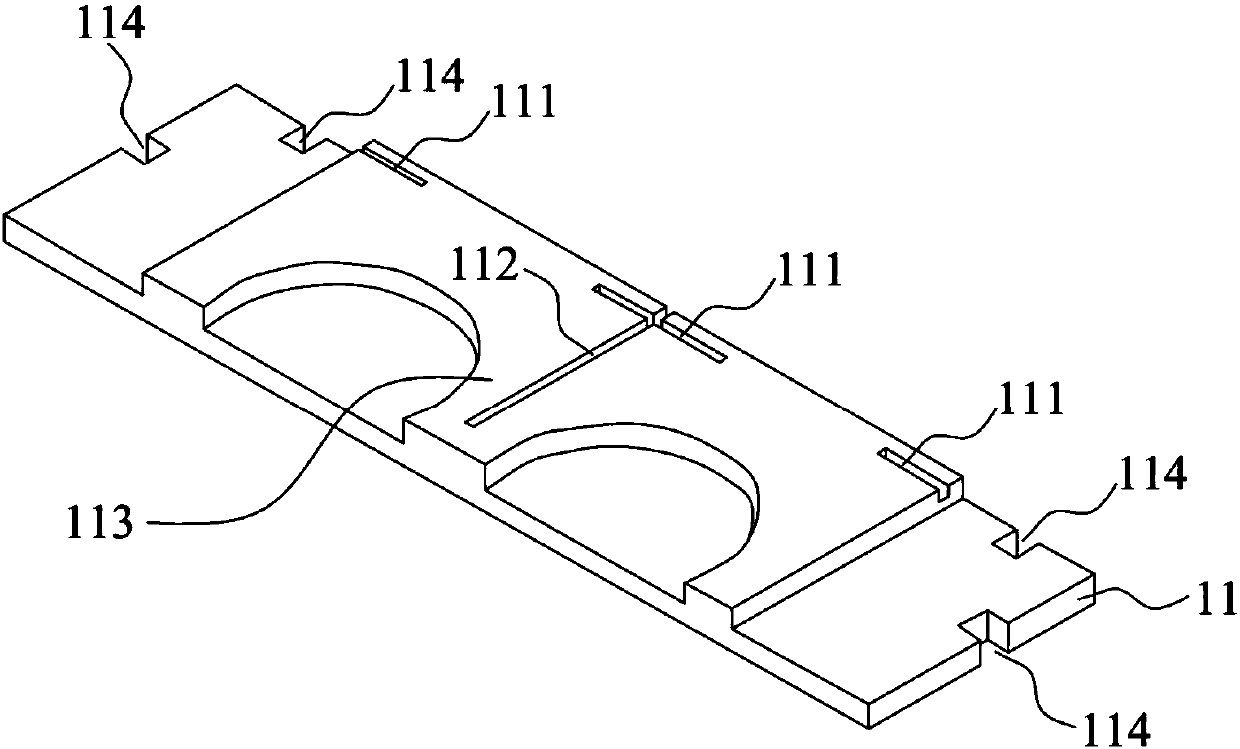

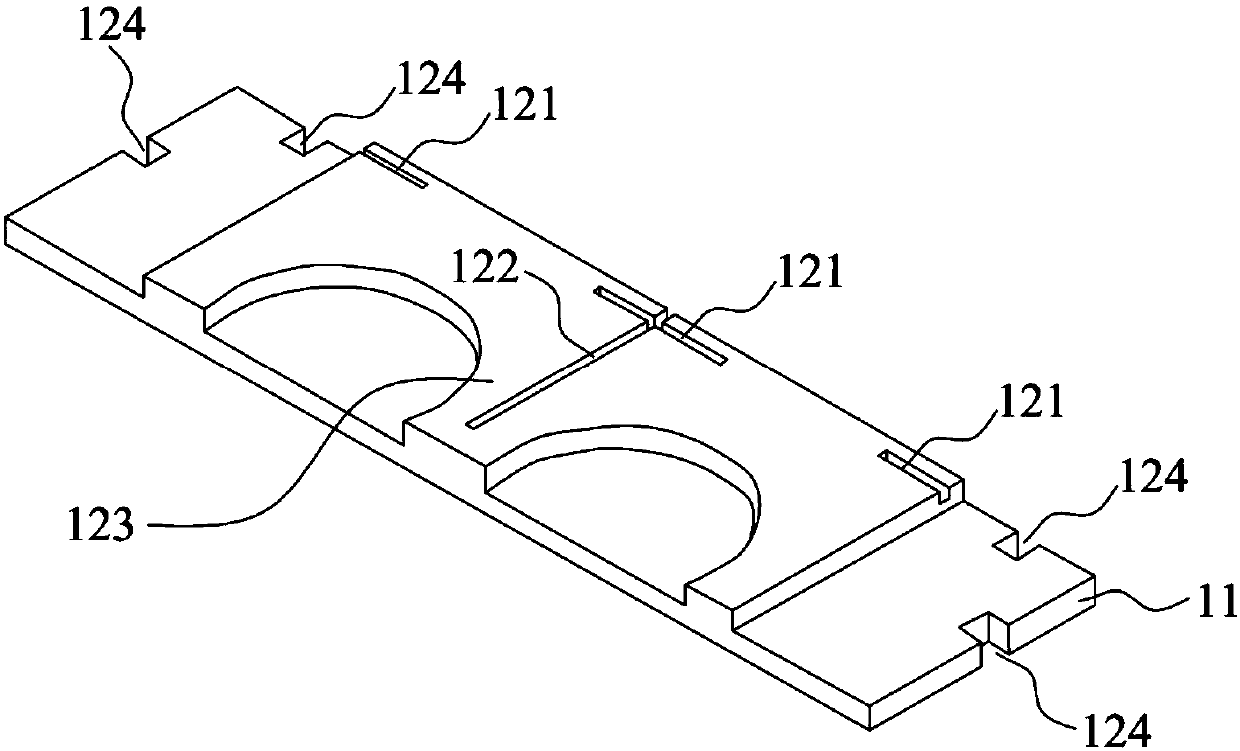

Heat-sealing cutter, heat-sealing device and using method of heat-sealing device

ActiveCN107814008AQuickly determine the heat seal positionAccurately determineFinal product manufactureWrapper twisting/gatheringThin membraneEngineering

The invention belongs to the field of package equipment and discloses a heat-sealing cutter, a heat-sealing device and a using method of the heat-sealing device. The heat-sealing cutter comprises an upper heat-sealing cutter body, a lower heat-sealing cutter body and a positioning device. The lower heat-sealing cutter body and the upper heat-sealing cutter body are arranged oppositely. The upper heat-sealing cutter body and the lower heat-sealing cutter body are used for heat-sealing of a thin film. The positioning device is arranged on the upper heat-sealing cutter body and / or the lower heat-sealing cutter body and used for positioning the thin film. The heat-sealing device comprises the heat-sealing cutter. The using method of the heat-sealing device comprises the steps that the thin film is placed between the upper heat-sealing cutter body and the lower heat-sealing cutter body, upper positioning grooves and lower positioning grooves are aligned with mark patterns on the thin film,and the upper heat-sealing cutter body and the lower heat-sealing cutter body conduct heat-sealing on the thin film. The thin film is positioned through the positioning device so that the heat-sealingposition can be determined rapidly and accurately, and the problems that in the prior art, the heal-sealing position of a heat-sealing cutter needs to be debugged with plenty of time manually, accordingly, a large number of debugging products are wasted, it cannot be ensured that the debugged heat-sealing position is accurate, and the product quality is likely to fluctuate are solved.

Owner:上海紫江彩印包装有限公司

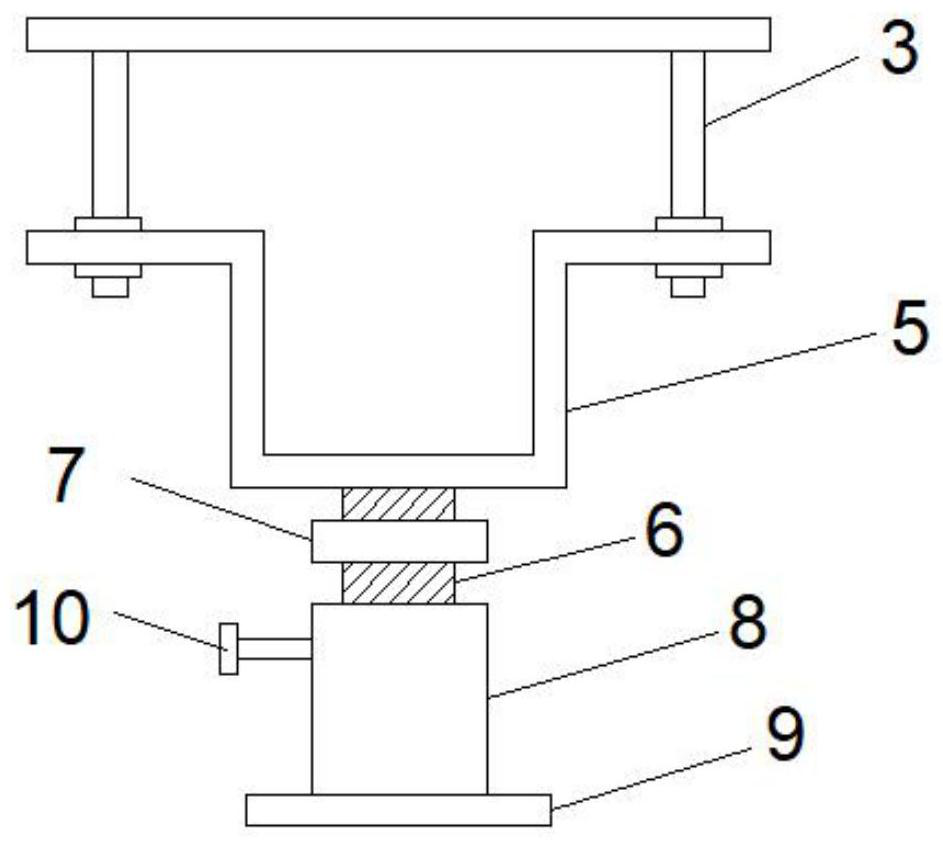

A straightening machine

ActiveCN106270015ASave tuning timeEasy to adjustMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention provides a straightening machine comprising a straightening device, a rail set, a lifting set and two slide devices. The straightening device comprises a first roller, a second roller and a center point; the center point is located between the first roller and the second roller; the straightening device is located between two supporting bodies. The rail set comprises a first rail and a second rail; the first rail is arranged on one of the two supporting bodies in a slideable manner and the second rail is arranged on the other supporting body in a slideable manner; the straightening device is located between the first rail and the second rail. The lifting set is arranged on the straightening device. One of the slide devices is connected with the straightening device and a first rail and the other slide device is connected with the straightening device and the second rail; each of the slide devices comprises a first slide member and a second slide member; each first slide member is connected with the straightening device; one of the second slide members is connected with the first rail and the other second slide member is connected with the second rail.

Owner:何荣机械股份有限公司

Ion implantation method and method for adjusting ion beam scanning rate

ActiveCN102324383BTo achieve the effect of ion distributionSave tuning timeElectric discharge tubesSemiconductor/solid-state device manufacturingChemical physicsIon beam

The invention provides an ion implantation method used for implanting ions into a target. The ion implantation method comprises the step of implanting multiple ions into the target by using a rotating target during constant speed scanning; or implanting the multiple ions into the target by using a variable speed under the premise that the target is not rotated. Ion implantation result with special dose distribution can be obtained without need of providing ion beams with uniform concentration distribution; the process time can be reduced; and the process yield can be increased.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

Ion implantation method

ActiveCN101399147ATo achieve the effect of ion distributionSave tuning timeElectric discharge tubesSemiconductor/solid-state device manufacturingIon beamIon implantation

An iron implantation method is used for implanting iron into target material; by adopting the iron implantation method, the target material is rotated and matched with constant-velocity scanning to implant a plurality of irons into the target material; or the variable-velocity scanning can be adopted to match the target material which is not rotated to implant a plurality of irons into the target material. The iron implantation result with special dosage distribution can be achieved without providing iron beam with even consistency distribution; the time of production process can be reduced and yield rate of the production process can be improved.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

Ion implantation method

ActiveCN102290341BTo achieve the effect of ion distributionSave tuning timeSemiconductor/solid-state device manufacturingIon beamIon implantation

The invention relates to an ion implantation method which is used for implanting ions into a target material; and the ion implantation method comprises the following steps of: implanting a plurality of ions into the target material by rotating the target material through the cooperation of constant ratio scanning; or, implanting the plurality of ions into the target material at a variable rate under the condition that the target material is not rotated. An implantation result of the ions with specific dose distribution can be obtained without providing ion beams with uniform-distributed concentration, thereby the time of manufacturing procedure can be reduced and the yield of manufacturing procedure can be increased.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

ion implantation method

ActiveCN102290341ATo achieve the effect of ion distributionSave tuning timeSemiconductor/solid-state device manufacturingIon beamIon implantation

The invention relates to an ion implantation method which is used for implanting ions into a target material; and the ion implantation method comprises the following steps of: implanting a plurality of ions into the target material by rotating the target material through the cooperation of constant ratio scanning; or, implanting the plurality of ions into the target material at a variable rate under the condition that the target material is not rotated. An implantation result of the ions with specific dose distribution can be obtained without providing ion beams with uniform-distributed concentration, thereby the time of manufacturing procedure can be reduced and the yield of manufacturing procedure can be increased.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

Ion implantation method

ActiveCN101399147BTo achieve the effect of ion distributionSave tuning timeElectric discharge tubesSemiconductor/solid-state device manufacturingIon beamIon implantation

Owner:ADVANCED ION BEAM TECHNOLOGY INC

Big dial of circular knitting machine for double-faced fabric knitting

ActiveCN109943965AShorten development timeImprove machining accuracyWeft knittingEngineeringMechanical engineering

The invention provides a big dial of a circular knitting machine for double-faced fabric knitting. The big dial comprises a big dial base, three feed ring supporting parts, a feed ring part and an installation space. The big dial base is hollow and is provided with a first opening, and the three feed ring supporting parts extend in a same direction and are perpendicular to the big dial base. The feed ring parts are arranged on the big dial base at intervals, the feed ring parts are connected to the three feed ring supporting parts and are horizontal relative to the big dial base, the feed ringpart is hollow and is provided with a second opening, wherein the second opening and the first opening are located at a same axis, and the installation space is between the big dial base and the feedring part and is used for placing a knitting needle group of the circular knitting machine. The big dial base, the three feed ring supporting parts and the feed ring part are integrally formed.

Owner:佰龙(湖北)精密机械有限公司

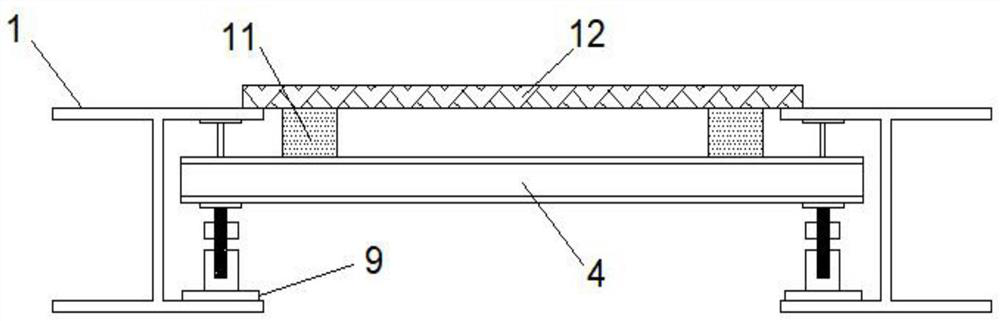

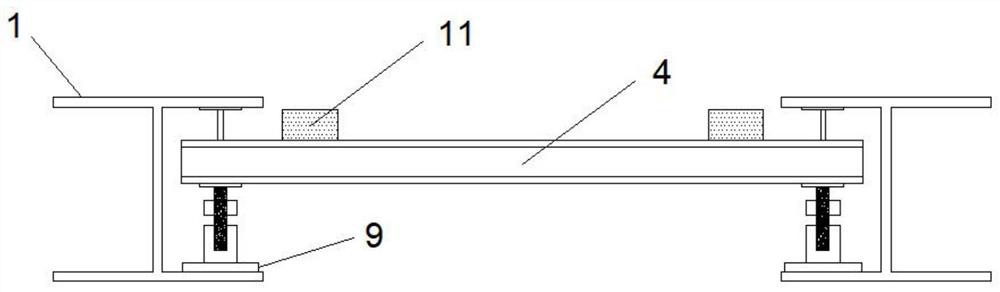

Assembled floorslab suspended adjustable supporting structure and construction method

InactiveCN113565346AImprove assembly efficiencyImprove construction efficiencyBuilding material handlingShoresFloor slabButt joint

The invention discloses an assembled floorslab suspended adjustable supporting structure and a construction method thereof. The assembled floorslab suspended adjustable supporting structure comprises a frame beam, a simple supporting structure and a screw structure, wherein a fixed top plate is mounted at the inner end of the frame beam; a first adjusting bolt is mounted on the inner side of the fixed top plate in a penetrating manner; the lower end of the first adjusting bolt is in threaded butt joint with a butt joint supporting seat; meanwhile, I-shaped steel is mounted at the upper end of the butt joint supporting seat in a nested manner; an upper screw is arranged at the lower end of the butt joint supporting seat; a butt joint nut sleeves the outer side of the upper screw; meanwhile, the upper part of the upper screw is connected with the butt joint supporting seat; and the adjustable fixed top plate is arranged at the upper end of the butt joint supporting seat. According to the assembled floorslab suspended adjustable supporting structure, a supporting frame device is simple and safe in structure, workers can conveniently erect the supporting structure, time and labor are saved, the assembling and construction efficiency of stacked floorslabs can be effectively improved, the supporting structure can be recycled, and the cost is reduced.

Owner:山东天元建设机械有限公司

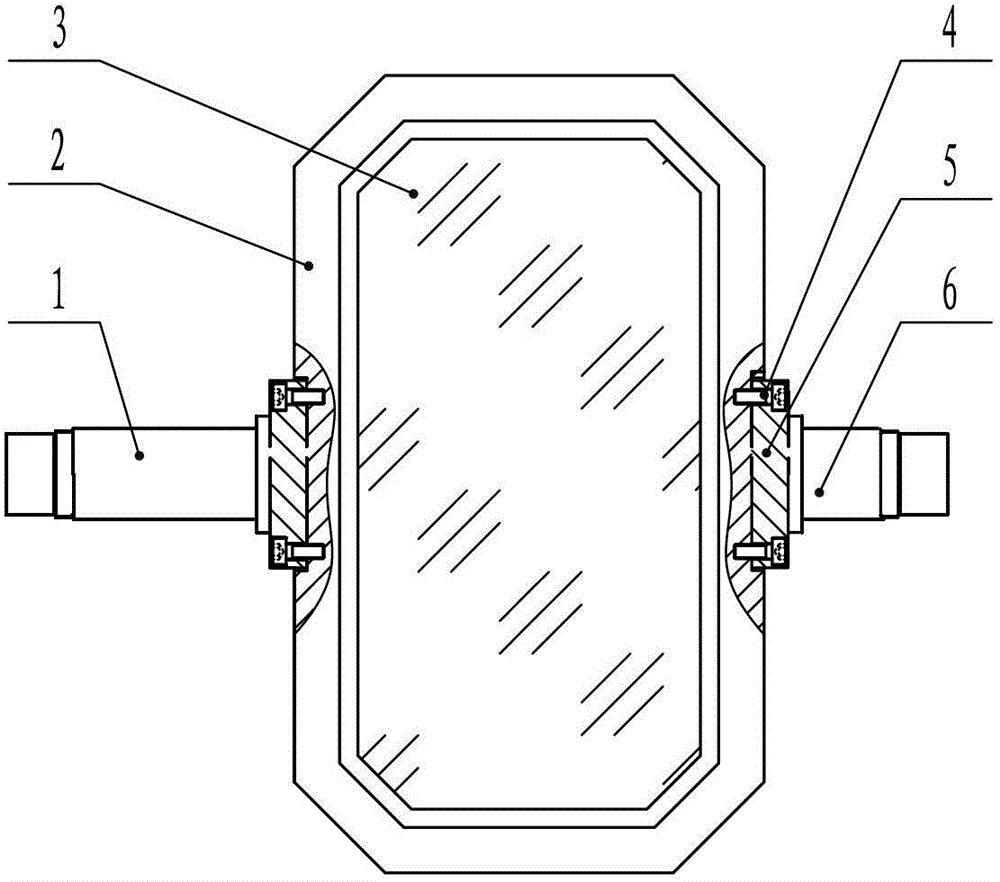

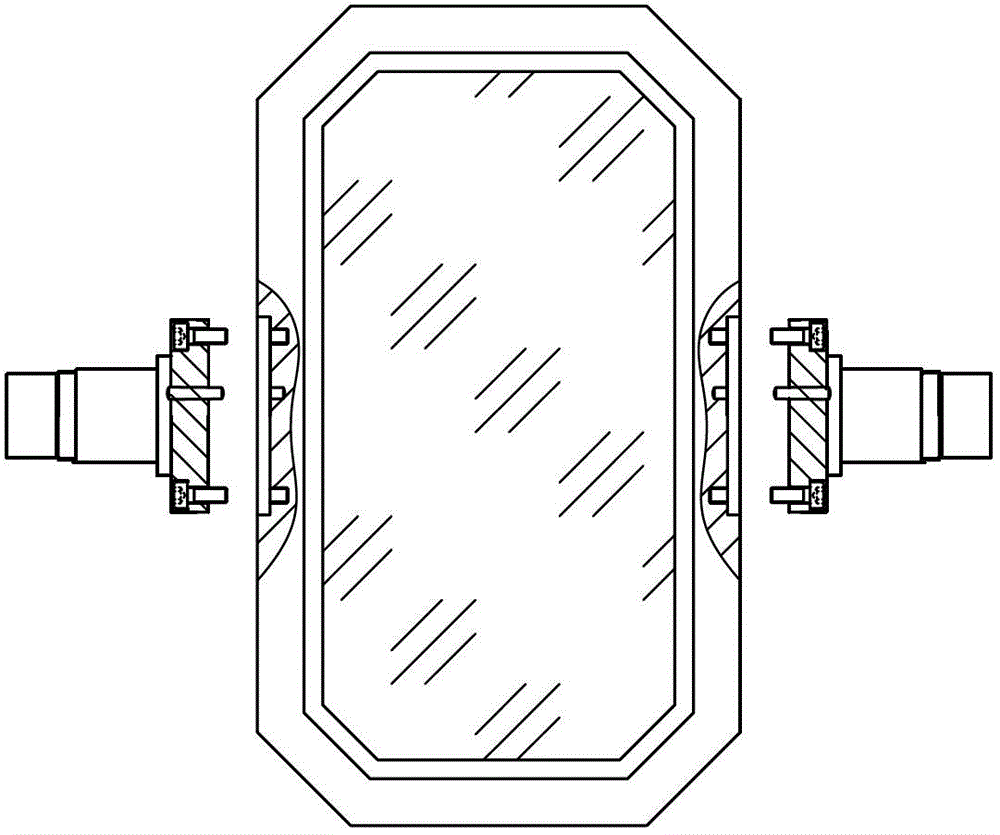

Assembling and adjusting method for high-precision swing mirror shafting component

The invention provides an assembling and adjusting method for a high-precision swing mirror shafting component. The assembling and adjusting method includes the steps: (1) roughly machining each part; (2) subjecting each part to semi-finish machining; (3) assembling all the parts to form a swing mirror component to be accurately machined; (4) respectively accurately machining a left shaft and a right shaft to enable the sizes, cylindricity, end face verticality and coaxiality of the left shaft and the right shaft to meet design requirements, and then accurately machining a swing mirror placing groove of a swing mirror seat according to a left-right shaft rotary center line determined by the left shaft and the right shaft of the swing mirror component at the moment to enable the swing mirror mounting face position and the left-right shaft rotary center line to meet the design requirements on parallelism and perpendicular distance; and (5) drilling and reaming positioning pin holes on the left and on the right of a swing mirror, and performing trial assembly of shaft positioning dowels. By the assembling and adjusting method for the high-precision swing mirror shafting component, an adjusting operation process is simplified, adjusting operation difficulty can be further lowered with adjusting precision improved, and adjusting efficiency is improved.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Adjustment and calibration tool and adjustment and calibration method for imaging detector

PendingCN113834511ASolve the problem of calibration accuracyGuaranteed accuracyInstrumentsEngineeringFocal surface

The invention relates to the technical field of sensor adjustment and calibration, in particular to an adjustment and calibration tool and method for an imaging detector, and solves the problem of adjustment and calibration precision of the imaging detector and an optical lens in an important component image sensor assembly of a certain product. The parallelism of the focused imaging detector and the optical lens is ensured by adopting an adjustment mode of clamping the mobile platform and the pressing plate, a mode of manually lifting the imaging detector for focusing is replaced, and errors caused by judgment of inclined focusing surfaces when the imaging detector is manually lifted are avoided. According to the adjusting and calibration method and the adjusting and calibration tool, the image sensor assembly is adjusted and calibrated, the imaging focal plane can be accurately determined, the link of manually rechecking the thickness of a gasket is omitted, the adjusting time is saved, operation is simple, the procedure process which can be completed in a original manner that one operator is needed for lifting, and an another increaes and decreases the gasket can be completed by one operator And the procedure process of increasing and decreasing the gaskets by another operator can be finished by one operator at present.

Owner:XIAN NORTH ELECTRO OPTIC TECH DEFENSE

Display driving method and flat panel display

ActiveCN107424550BSave tuning timeReduce labor costsStatic indicating devicesComputer hardwareComputer graphics (images)

The invention discloses a display driving method. The method includes the following steps: a display driving module detecting front N picture frames (N is an integer and N is greater than or equal to 2) in an image signal which is transmitted by a DSI interface of the MIPI of a main computer, computing a first time length of a vertical rear end region and a second time length of a vertical front end region of each of the front N picture frames, and if it is determined that the first time lengths are of the same length and are different from a preset vertical rear end value, and the second time lengths are of the same length and are different from a preset vertical front end value, updating the vertical rear end value with the first time lengths and updating the vertical front end value with the second time lengths, and based on a vertical synchronous signal, a vertical rear end set value and a vertical front end set value, outputting the display data of each picture frame to a display panel.

Owner:CHIPONE TECH BEIJINGCO LTD

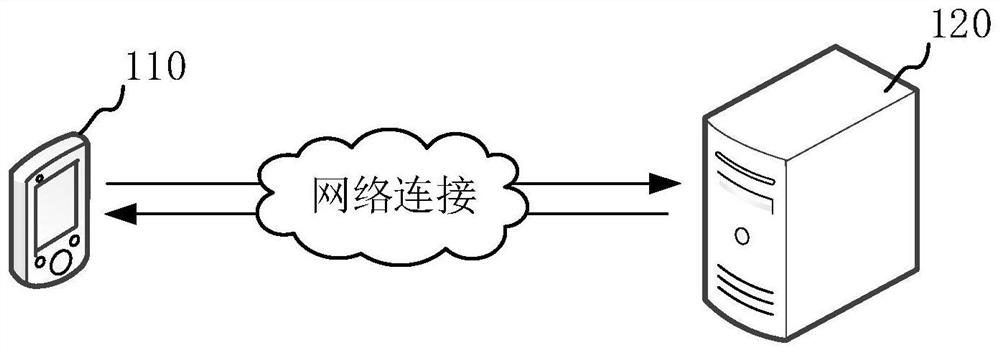

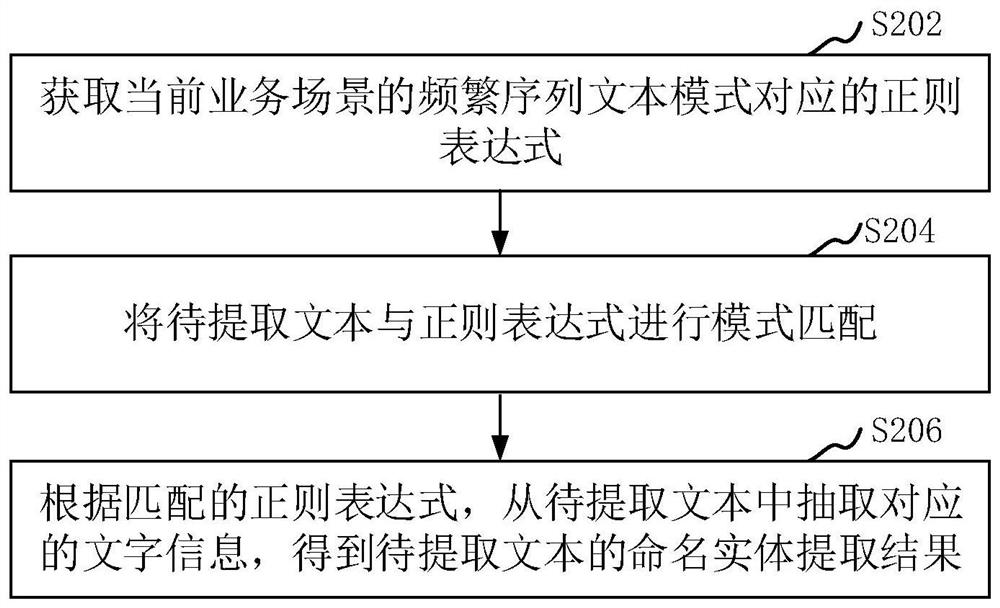

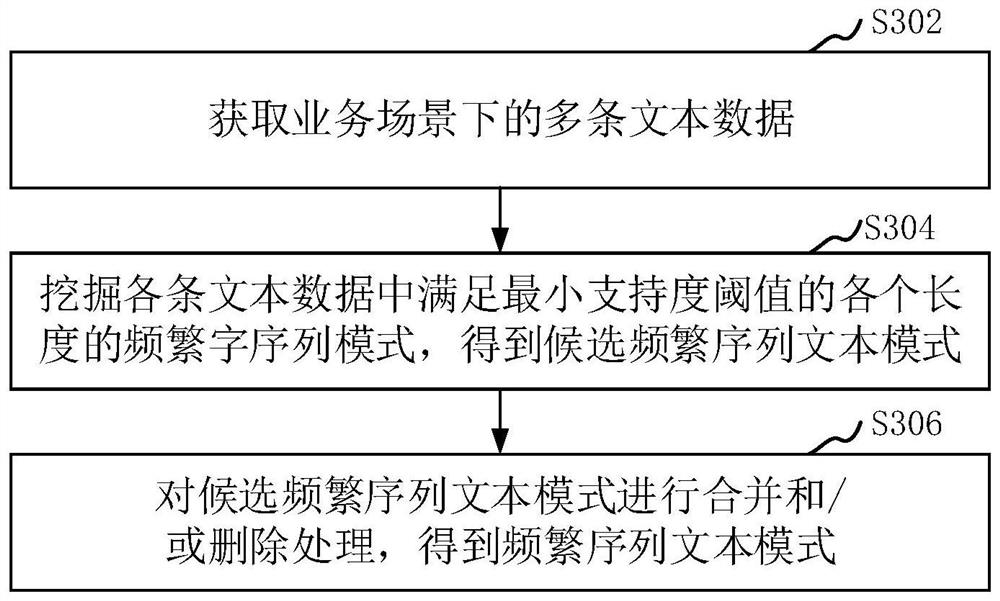

Named entity recognition method, device and computer equipment

ActiveCN109858040BSave tuning timeImprove the efficiency of named entity recognitionNatural language data processingNamed-entity recognitionPattern matching

The present application relates to a named entity recognition method, device, computer-readable storage medium and computer equipment. The method includes: obtaining the regular expression corresponding to the frequent sequence text pattern of the current business scene, and combining the text to be extracted with the regular expression Perform pattern matching, extract corresponding text information from the text to be extracted according to the matched regular expression, and obtain a named entity extraction result of the text to be extracted. This method automatically mines entity recognition patterns based on the frequent sequence pattern mining algorithm, extracts recognition rules from limited patterns to obtain frequent sequence text patterns, and converts them into regular expressions for extraction without parameter adjustment, which saves parameter adjustment time and further improves improved the efficiency of named entity recognition.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com