High power laser beam expander

A laser beam and high-power technology, applied in the field of beam expanders, can solve the problems of not disclosing the working principle of the internal optical path, the unfavorable miniaturization of the laser emission system, and the poor pointing stability of the laser beam, so as to improve the laser damage threshold, Effect of reducing laser energy density and improving stealth ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

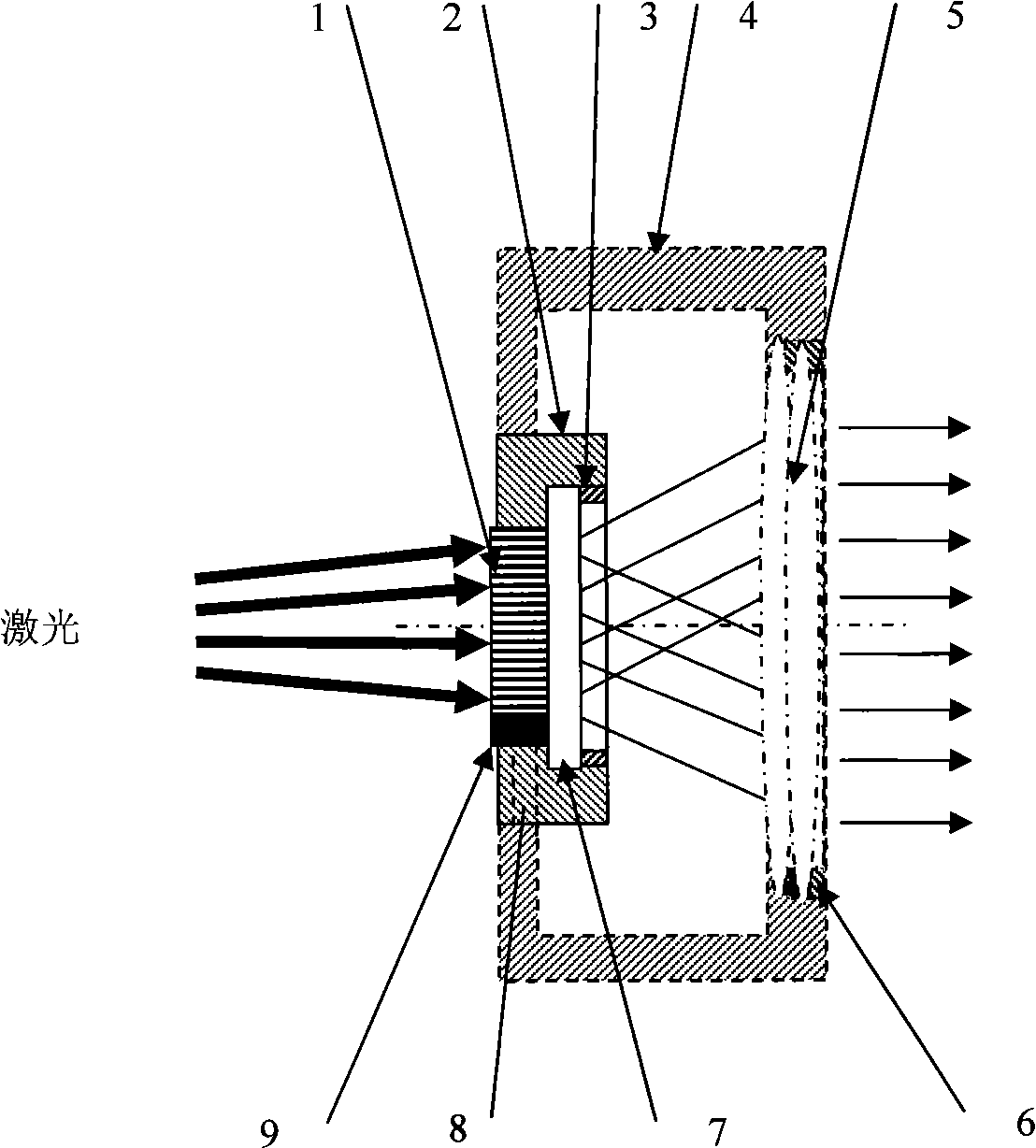

[0022] Embodiment 1 beam expander: according to figure 1As shown, the preferred embodiment of the present invention includes a beam expander 1 , a housing 2 , a mirror tube 4 , and an optical system 5 . The beam expander 1 is formed by a group of short bare single-mode optical fiber rods 11 of equal length closely arranged. The bare optical fiber rods are neatly arranged in the cylindrical shell 2 along the axial direction, and the input / output end faces of the optical fiber rods are strictly aligned. . A commercially available single-mode fiber is used for the fiber rod, and the coating layer of the single-mode fiber is removed, and the bare fiber is cut into small sections with a length of 5 mm with a special cutter. The housing 2 includes protective glasses 7 , a pressure ring 3 , a plurality of pressure pieces 9 and screws 8 . The shell 2 has one or more cylindrical tubes with axial grooves on the inner wall. The inner diameter of the cylindrical tubes is Φ12mm and the l...

Embodiment 2

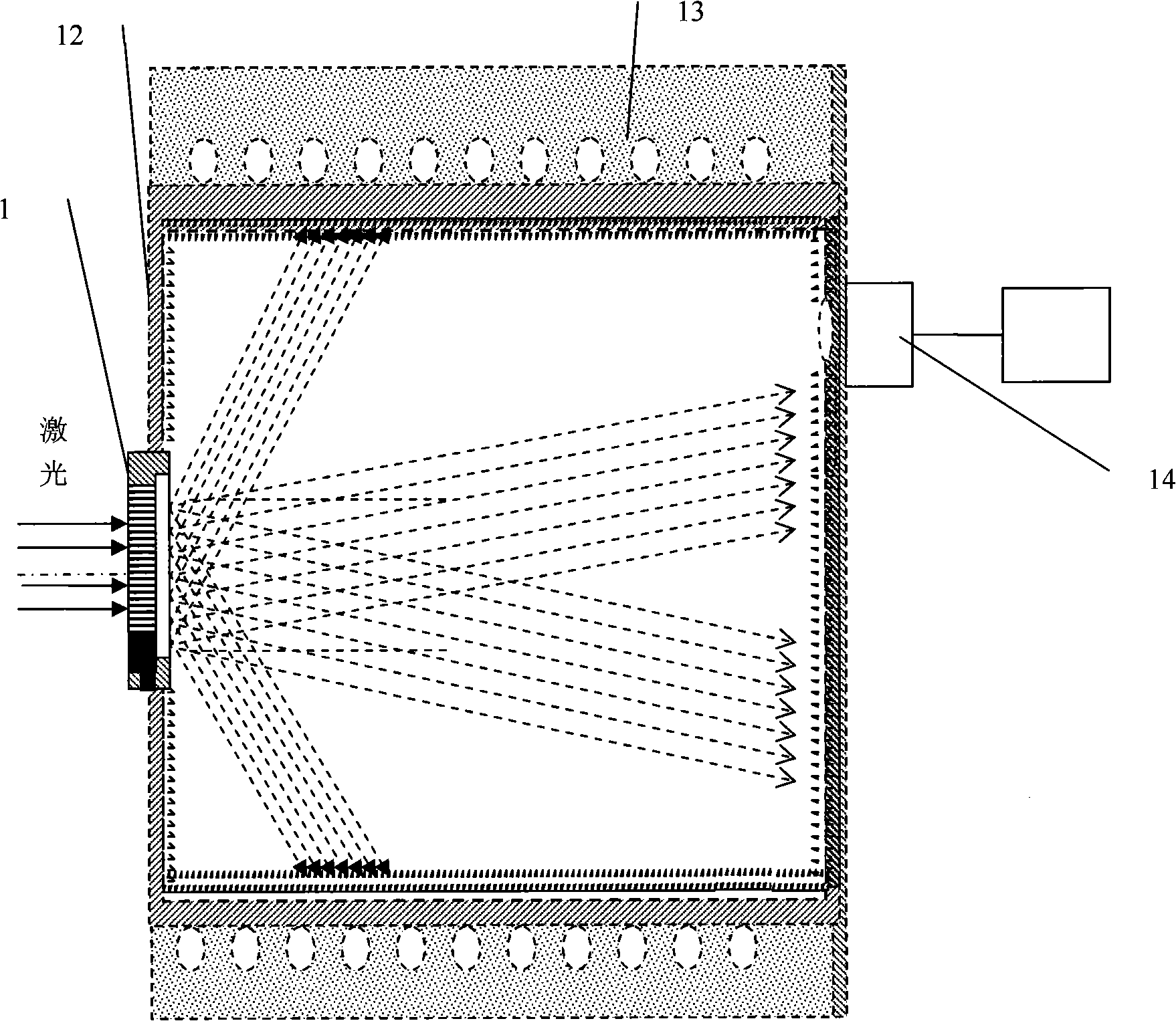

[0023] Embodiment 2 high-power laser parameter measuring device: according to figure 2 As shown, the preferred embodiment of the present invention includes a beam expander 1 , an absorption cavity 12 , a cooling system 13 , and a detection system 14 . The beam expander 1 is the same as the embodiment 1; the absorption cavity 12 is a cylindrical cavity, and the inner wall of the cavity is a zigzag absorption pattern, the beam expander 1 is installed in the center of a bottom surface of the cylindrical cavity, and the optical fiber of the beam expander 1 The direction of the optical axis of the rod is coaxial with the cylindrical cavity. The cooling system 13 is close to the absorption cavity 12, and is used for cooling the absorption cavity 12, so that the temperature of the absorption cavity 12 remains constant after absorbing the laser energy, and at the same time, the deformation of the cavity is reduced. The detection system 14 is composed of an interference filter, a det...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com