Method for improving coupling efficiency of high-power pulsed laser optical fiber

A high-power pulse and fiber-coupled technology, applied in the laser field, can solve the problems of fiber ablation damage, low space utilization, fiber damage, etc., and achieve uniform laser spatial energy distribution, reduce laser energy density, and reduce end face loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

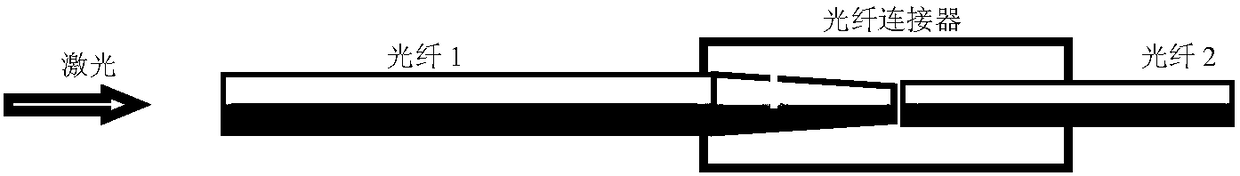

[0020] A method for improving the coupling efficiency of a high-power pulsed laser fiber, comprising the steps of:

[0021] The first step: fiber selection. The parameters of fiber 1 and the requirements for tapering are selected based on fiber 2. It is advisable to control the core diameter of the optical fiber 1 within 2 times of the core diameter of the optical fiber 2, otherwise the taper part will be too long and the processing will be difficult.

[0022] The second step: fiber taper. The diameter of the tail end of the tapered fiber 1 should be smaller than the core diameter of the fiber 2 to prevent energy loss and fiber damage caused by laser energy leakage. It is better to satisfy (r1-r2) / L<0.01 when tapering. Among them, r1 is the diameter of the large end, r2 is the diameter of the small end, L is the length of the tapered part, and the unit is the same.

[0023] The third step: fiber optic connection. Connect optical fiber 1 and optical fiber 2 through a custo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com