Patents

Literature

209 results about "Laser power density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aside from energy density, a second important parameter in lasers measurement is a power density. The power density (irradiance) is a ratio of power (P) in Watt (W) to the cross section area (I=W/cm 2). The importance of this will be clarified when we consider the interaction of laser beams with different materials [5].

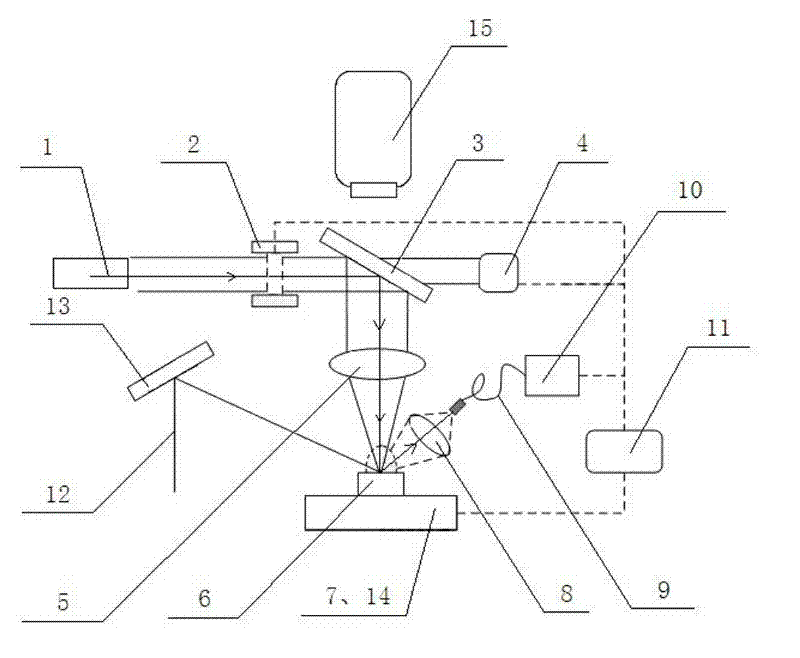

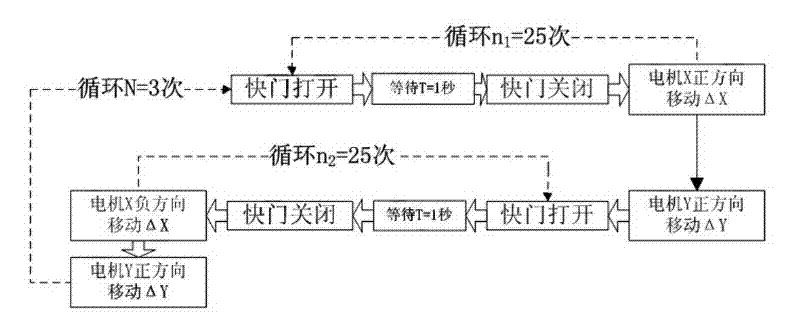

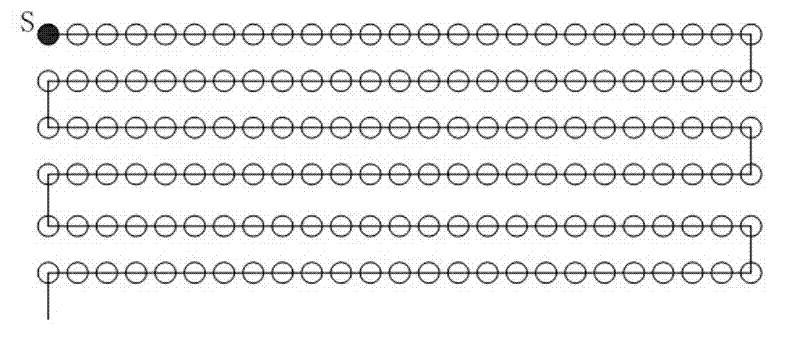

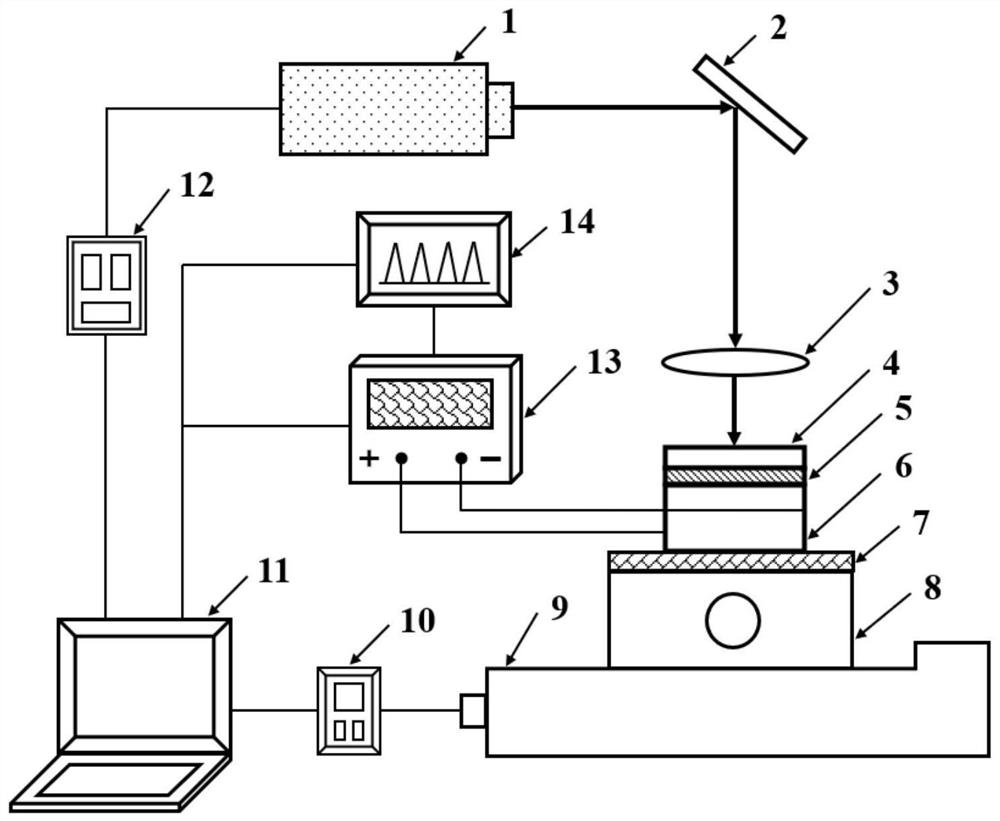

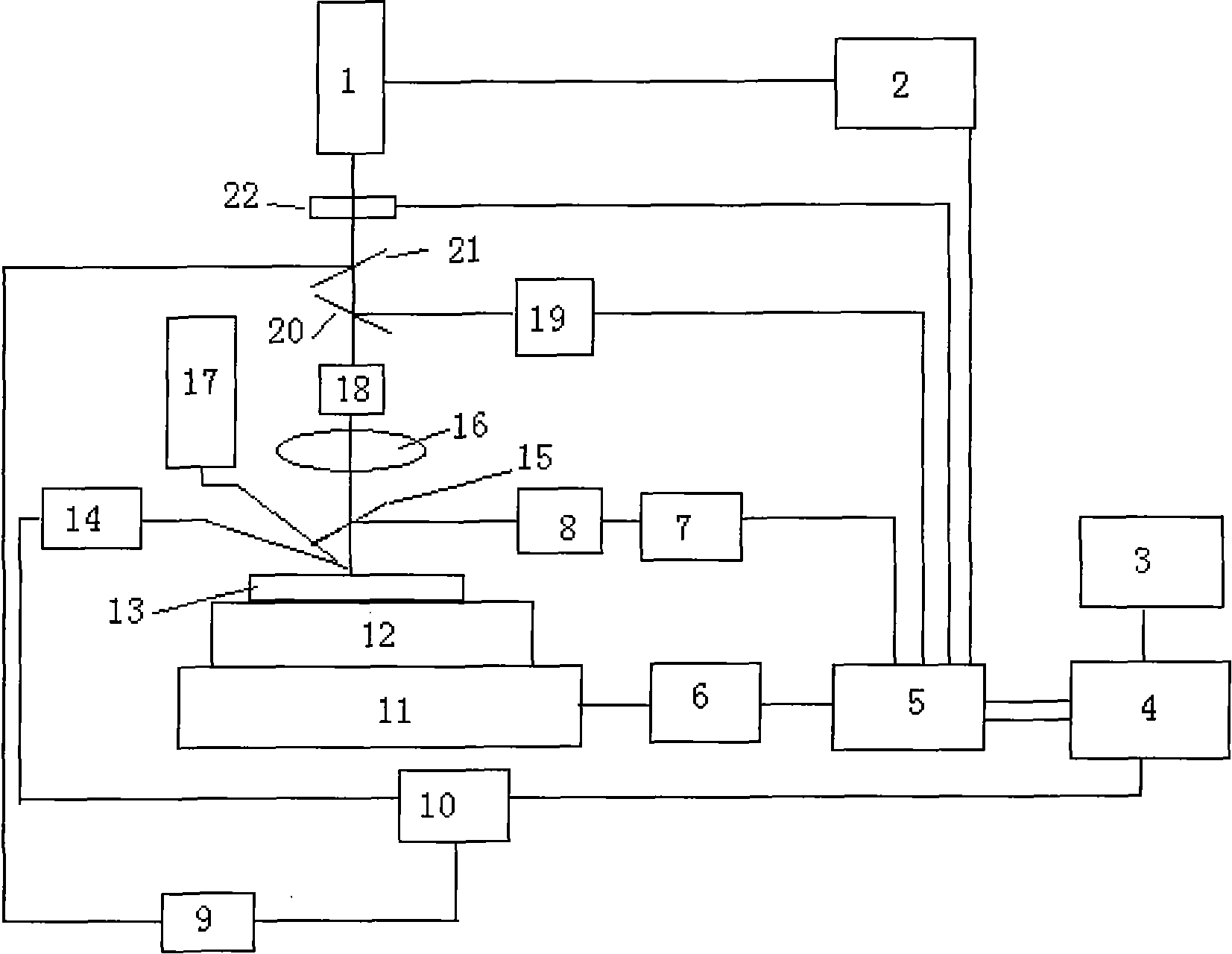

Automatic collection system of laser-induced breakdown spectroscopy

InactiveCN102364329ARealize automatic alignment functionThe degree of focus does not changeSpectrum investigationAnalysis by material excitationConstant powerCollection system

The invention relates to a novel analysis way in the spectrum analysis field, in particular to an automatic collection system of a laser-induced breakdown spectroscopy, which is characterized in that: a sample is moved through a movable platform, the height of the sample is estimated through the precise positioning of the laser, and the data are automatically collected. The automatic collection system has the advantages that: the automation of control and data collection of an experimental device is realized, so the labor investment can be greatly reduced, and the experiment is more convenient to carry out; an automatic aligning function of a laser ablation position can be realized, so a specific position to be ablated by the laser is conveniently known in advance, and the positioning function contributes to measuring a small-size sample; a distance of a focusing lens in the sample is locked, so the focusing degree of the laser can be maintained constant during the experimental process, and further the constant power density of the laser reaching the surface of the sample can be guaranteed; and the real-time monitoring of an optical detection device can substitute the situation that the sample is directly observed by the eyes during the experimental process, so the danger that the laser shoots the eyes can be avoided.

Owner:EAST CHINA NORMAL UNIV

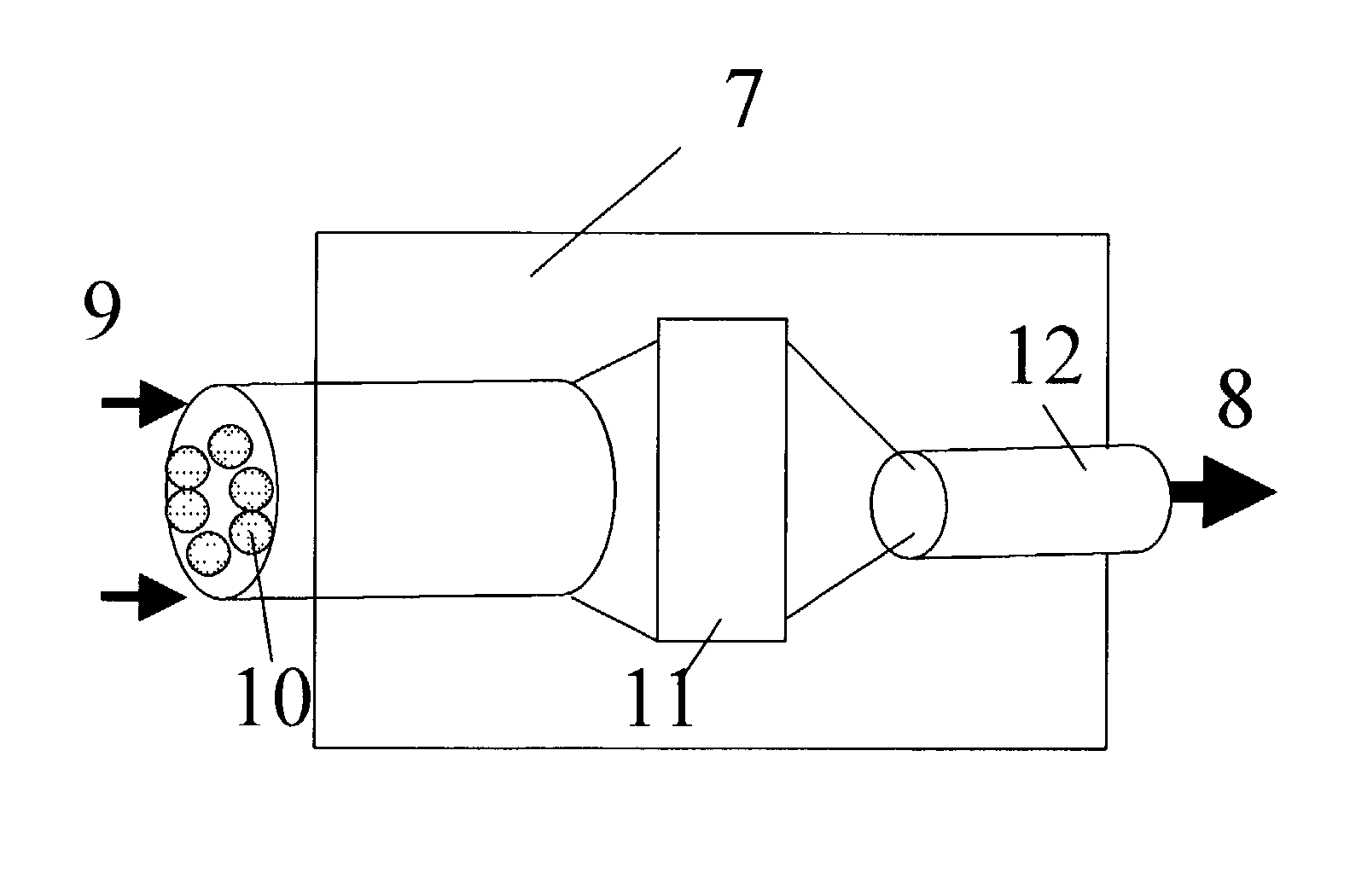

Methods and apparatus for presbyopia treatment using a dual-function laser system

InactiveUS20040078030A1Quicker procedureMinimize damageLaser surgerySurgical instrument detailsOphthalmologyUltraviolet

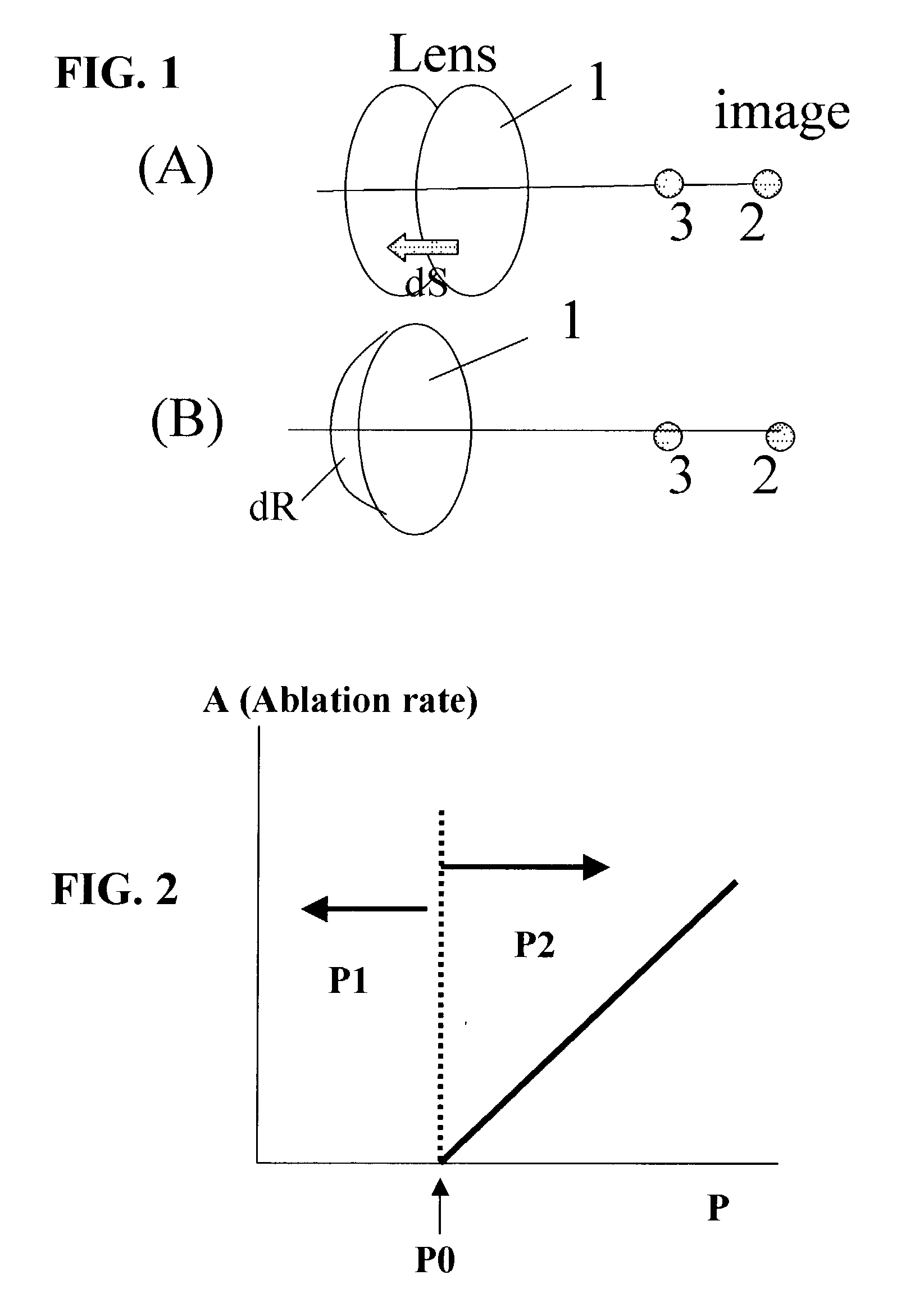

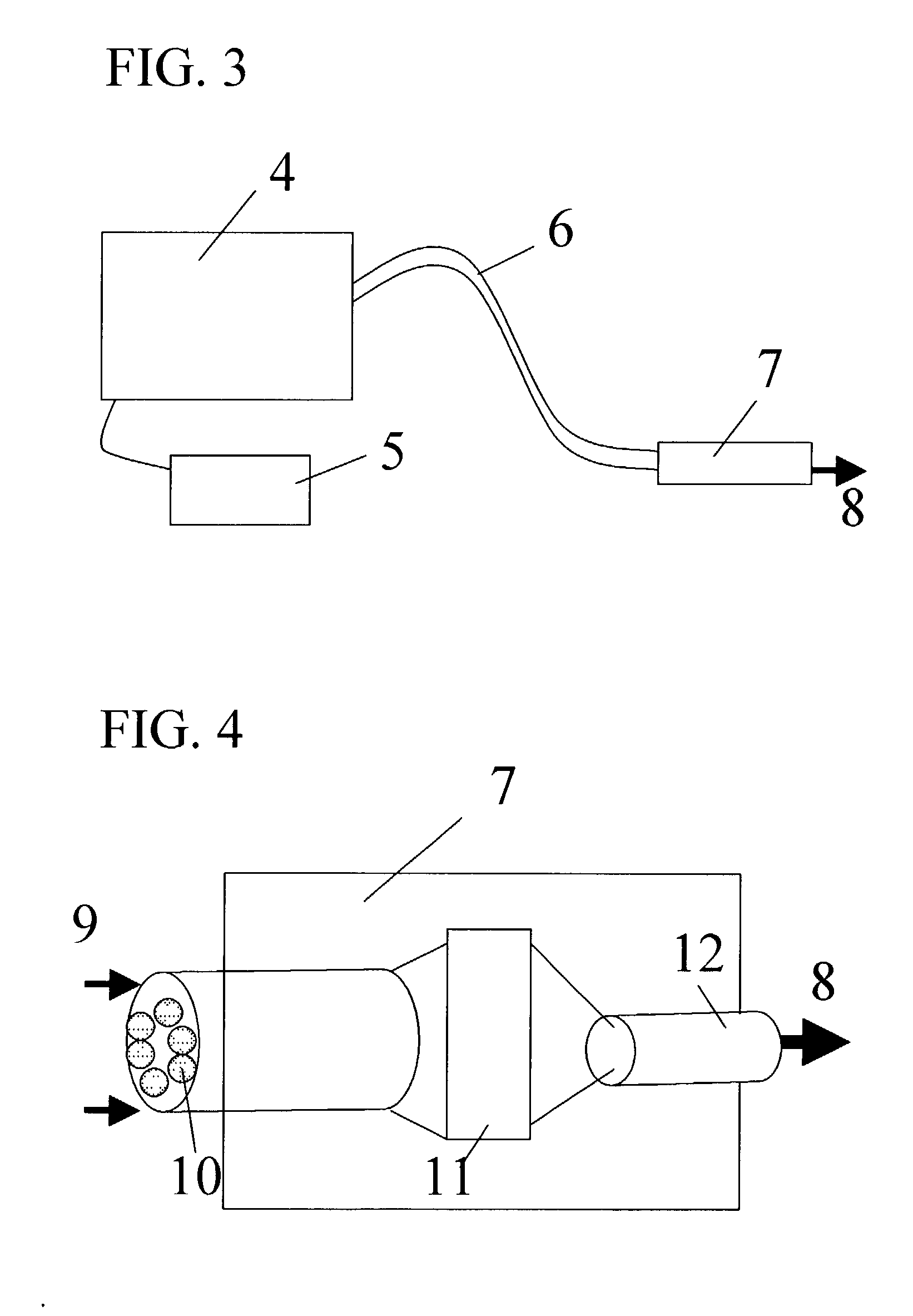

Presbyopia is treated by a method which uses various lasers to remove a portion of the scleral tissue and increase the accommodation of the presbyopic patient's eye By changing the laser power density, fluency or spot size, a single laser device having dual-function of ablation and coagulation is proposed for minimum bleeding. Fiber-bundle coupled to a single fiber is presented to increase the power density of the laser for efficient tissue ablation New mechanisms of lens curvature change and lens anterior shift are proposed for the total accommodation. The preferred laser wavelength ranges from ultraviolet to infrared including (0.15-0.36) microns, (0.9-1.6) microns, (1.8-2.2) microns and (2.8-3.2) microns Both scanning and fiber delivered systems are proposed.

Owner:NEW VISION

Carburization-like overloading tooth component tooth surface laser cladding powder material and repairing method thereof

InactiveCN101100746AImprove repair qualityImprove performanceMetallic material coating processesLaser beam welding apparatusLaser power densityAlloy

A process for laser powder-melting onto the surfaces of the teeth parts that are of heavily loaded cemented steel to be repaired is disclosed herewith. The powder of grains = (-140-+260 mesh) comprises (mass%): C 0.80-1.10, Mn 7.50-9.00, Cr 0.90-1.30, Mo 0.20-0.35, B 2.00-3.50, Si 2.50-3.50, and balanced with Fe with impurities of P not more than 0.06 and S not more than 0.04. Laser power density is equal to 1.0 X 108W-109W / m2 per unit of time. The said powder has good re-melting property, self-enhancing and fatigue-resistance performances, so that it can be used to repair worn gears.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Laser cleaning device

ActiveCN104959349AImprove cleaning efficiencyGuaranteed Power DensityCleaning processes and apparatusPoint lightLight spot

The invention provides a laser cleaning device. The device comprises a laser emitting laser beams, and a light spot generation mechanism used to perform scanning and irradiation on a to-be-cleaned workpiece. The light spot generation mechanism comprises a collimating mirror and a battery of lenses arranged in the emergent optical path of the laser beams in sequence. The battery of lenses comprises a convex cylindrical lens and a concave cylindrical lens. The convex cylindrical lens is between the collimating mirror and the concave cylindrical lens. The convex cylindrical lens and the concave cylindrical lens are arranged in an orthogonal manner. The light spot generation mechanism makes a point light source become linear beam patterns through using an optical lens system, and laser cleaning is changed to line scanning from spot scanning. On the premise of ensuring laser power density, laser cleaning efficiency is greatly improved.

Owner:苏州市星科四达激光科技有限公司

Method and device for strengthening metal material through pulse current coupled laser peening

The invention discloses a method and device for strengthening a metal material through pulse current coupling laser peening, and belongs to the technical field of metal material strengthening. The method comprises the following steps of (a) pretreating the surface of the metal material; (b) determining optimal electric pulse treatment process parameters of a test sample; (c) testing the test sample by utilizing a Hopkinson pressure bar to obtain the dynamic yield strength of the metal material in the electric pulse treatment process; (d) solving the Hugoniot elastic limit of the metal material, and further obtaining the optimal laser power density of the test sample; and (e) in the electric pulse treatment process, performing laser peening strengthening treatment on the test sample by a Nd:YAG solid laser in the optimal laser power density range at the same time. Through the coupling effect of electroplastic deformation caused by electric pulses and ultrahigh-strain-rate plastic deformation induced by laser peening, the amplitude and depth of residual compressive stress are improved, and more excellent comprehensive mechanical properties are obtained.

Owner:CHANGZHOU UNIV

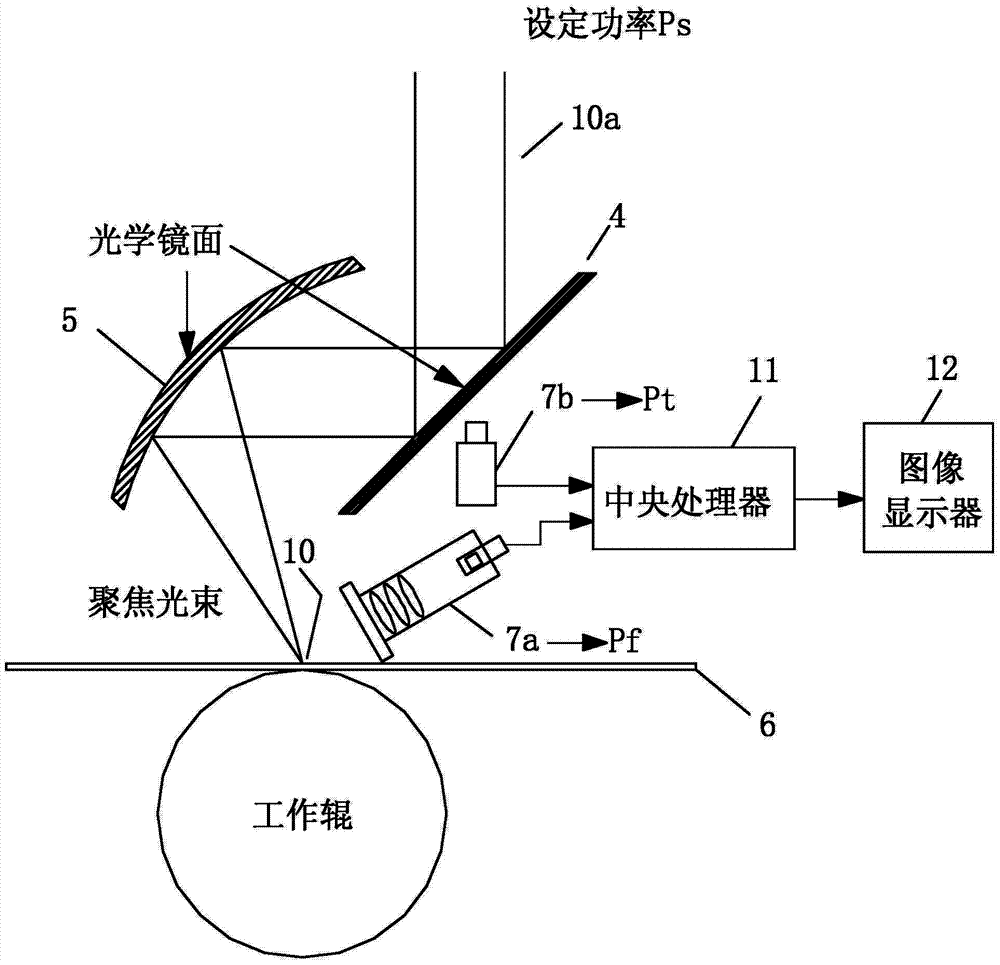

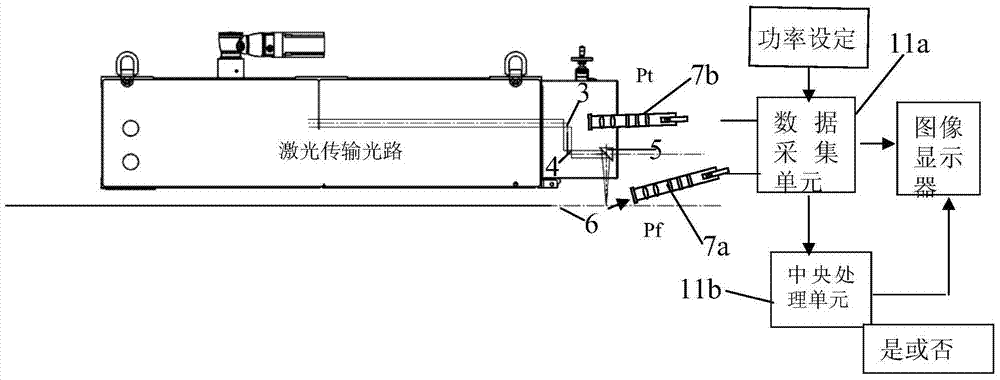

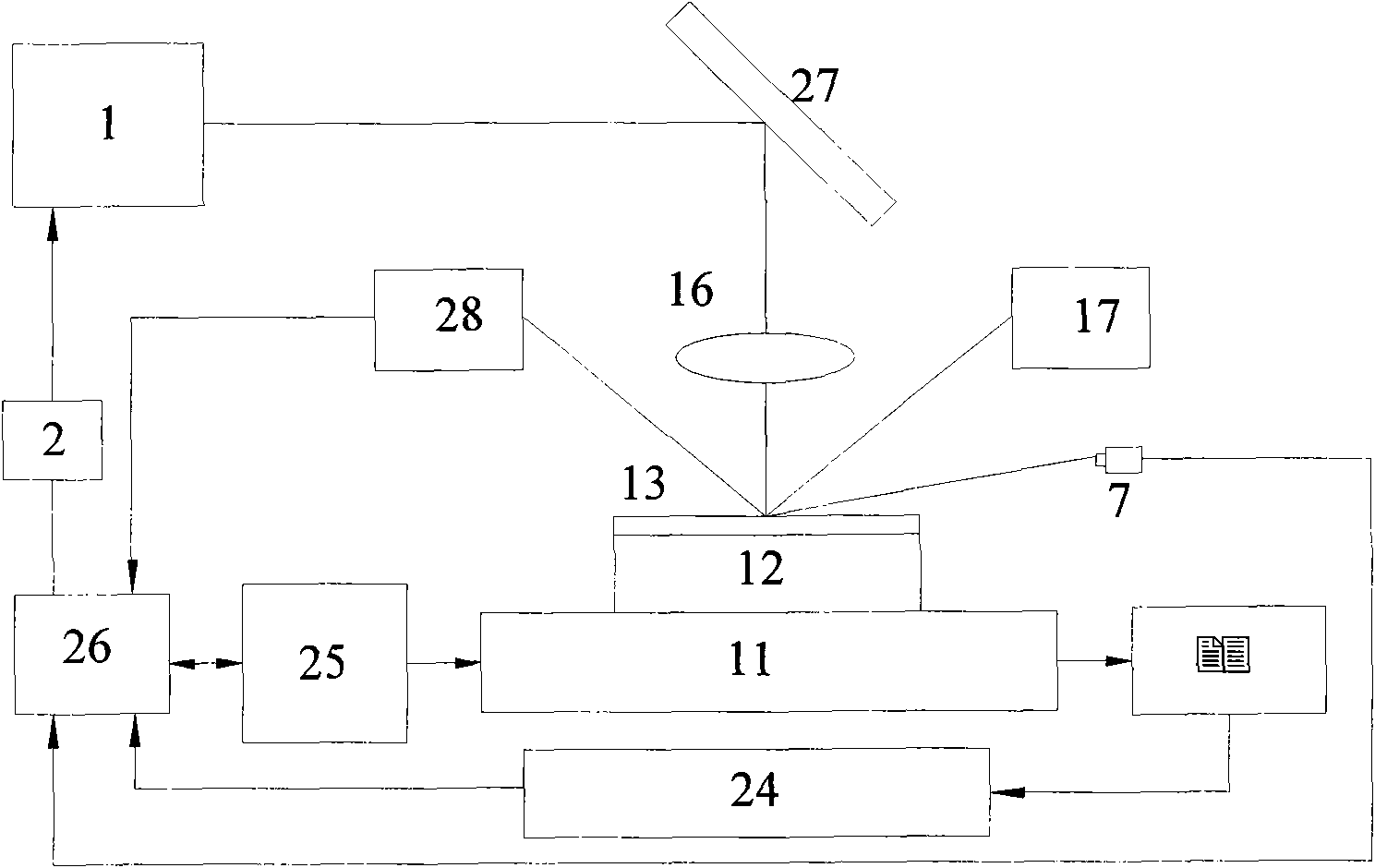

Laser surface treatment quality control method and on-line monitoring system thereof

ActiveCN104772568AInhibit productionGuaranteed reliabilityLaser beam welding apparatusTime informationDisplay device

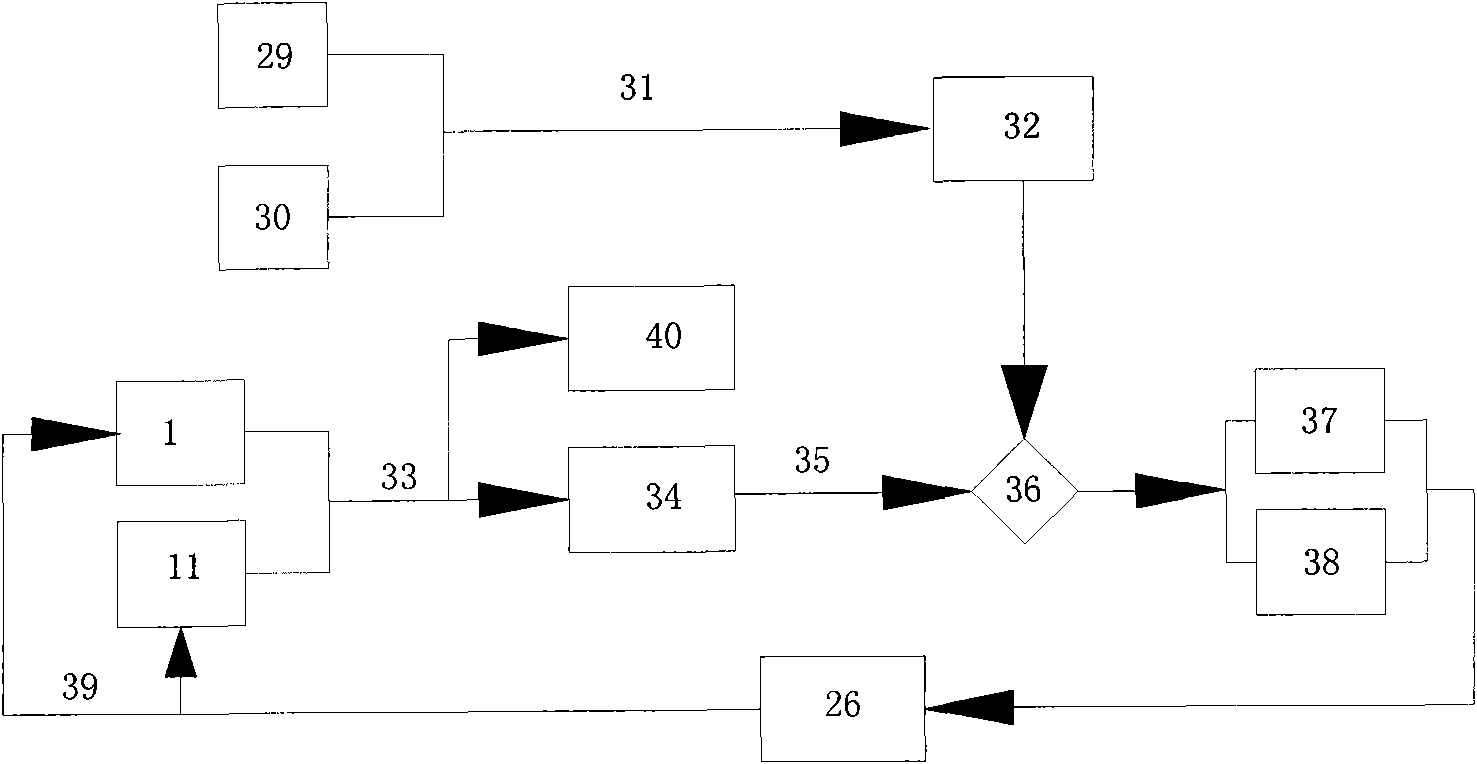

The invention provides a laser surface treatment quality control method and an on-line monitoring system thereof. The laser surface treatment quality control method comprises the steps that incident laser is emitted through a laser, passes through an inner transmission light path, and at last is focused on a workpiece through a focus lens; the light reflected on the surface of the workpiece in practical processing is detected through a first photoelectric sensor; the light is converted to be a reflective power value through photovoltaic conversion; the residual penetration light of the reflective lens surface of a reflective lens in the transmission light path is detected through a second photoelectric sensor to obtain the practical power; parameters, set power, the reflective power value and the practical power are sent to a central processing unit to be subjected to comparison calculation through a data collection unit, and a mass control factor is determined through logic judgment; the mass control real-time information is displayed through an image display device. The invention guarantees the high consistence of laser power density of the laser in the material surface treatment process and the accuracy of the height position of a laser focal point on a material surface.

Owner:BAOSHAN IRON & STEEL CO LTD

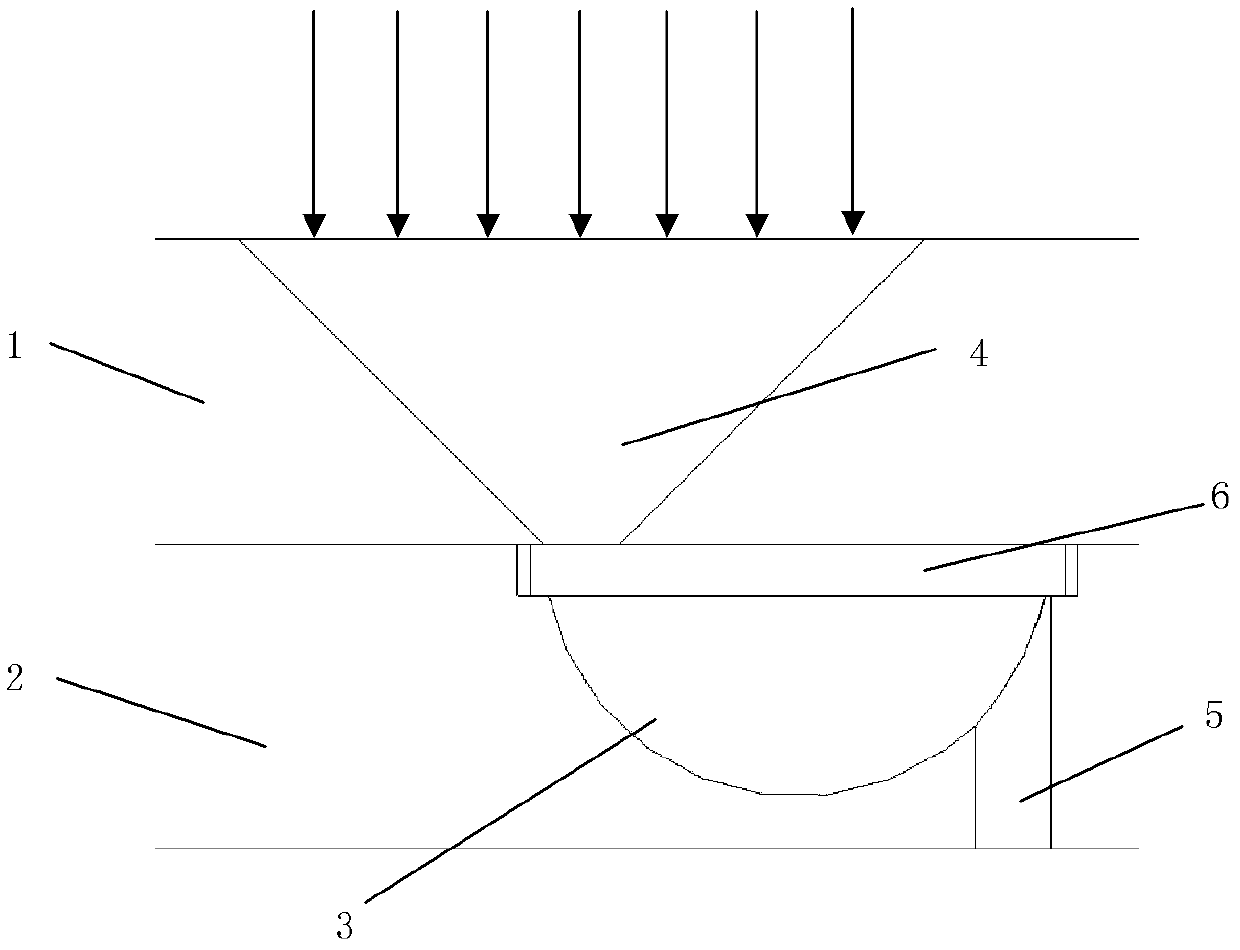

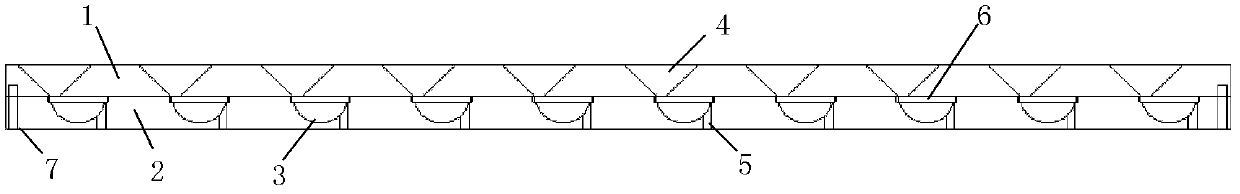

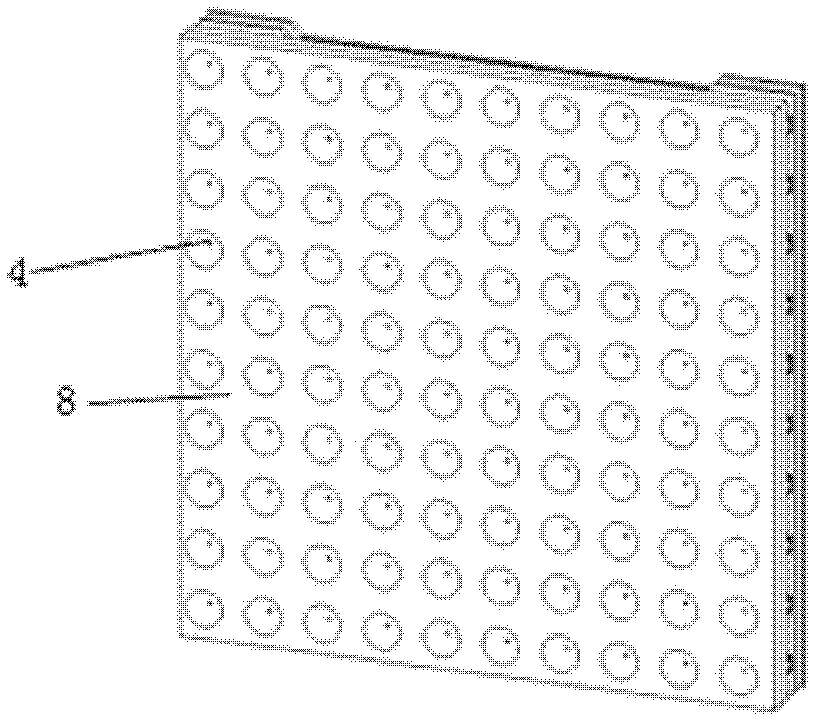

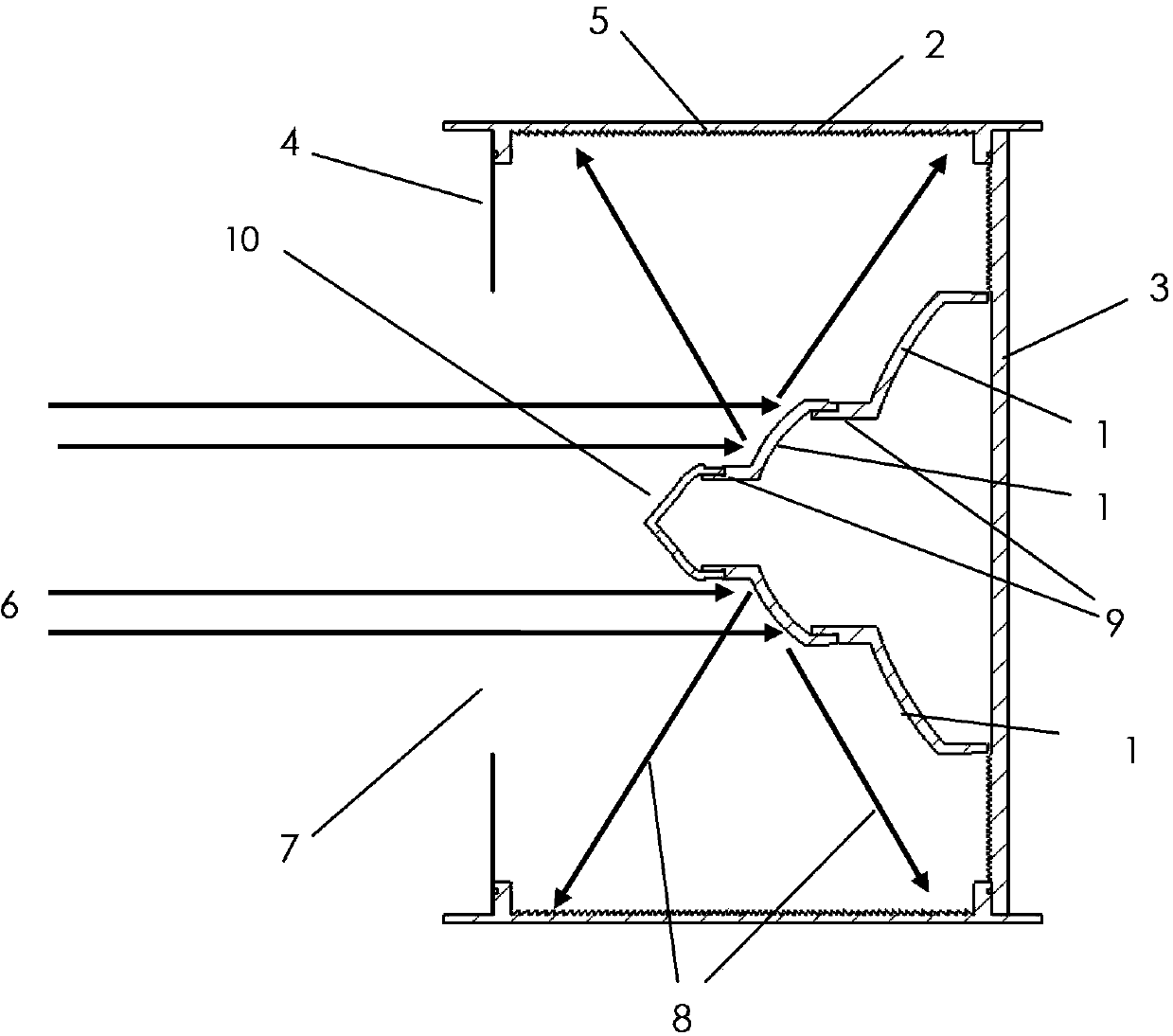

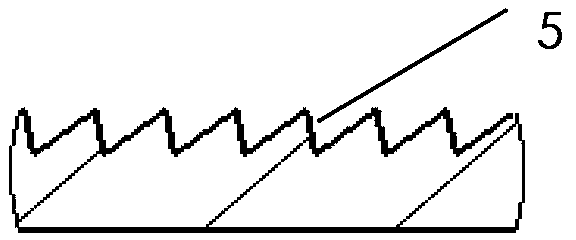

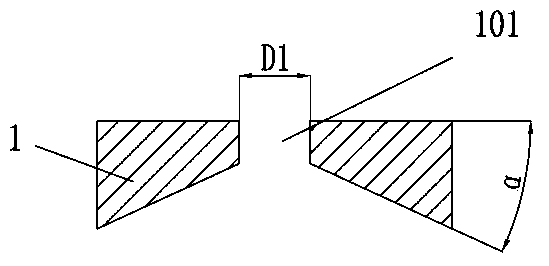

High-energy laser semi-integrating-sphere array attenuator

ActiveCN102384783AReduce laser power densityAttenuation Sampling SatisfiedPhotometryUltrasound attenuationLaser power density

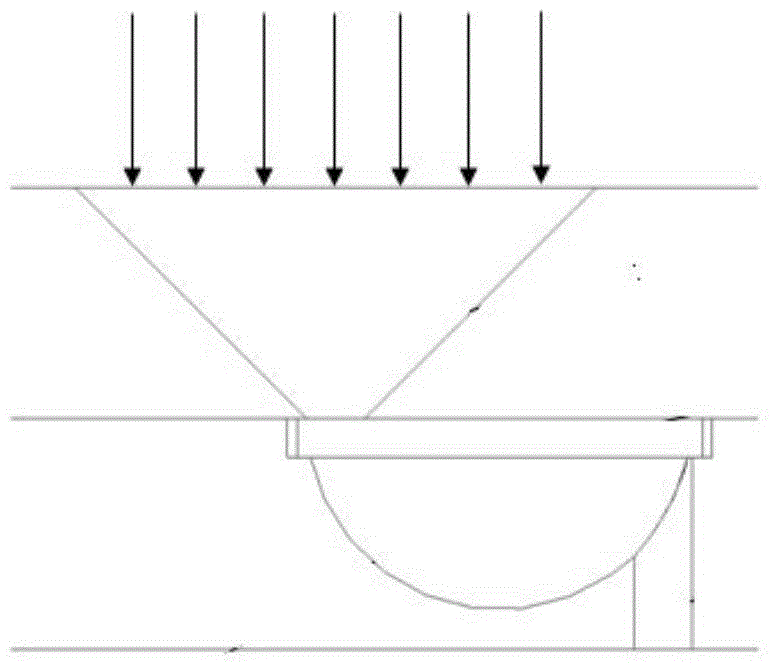

The invention provides a high-energy laser semi-integrating-sphere array attenuator, which comprises a front panel arranged along a laser incident direction, a back panel and a plurality of attenuation units, wherein the attenuation units comprise wide-angle sampling taper holes arranged on the front panel, semi-sphere cavities arranged on the back panel, and laser emergent holes which are arranged on the edges of the semi-sphere cavities and are vertical to the back panel; the positions of the wide-angle sampling taper holes are corresponding to the positions of the semi-sphere cavities one to one; and the wide-angle sampling taper holes and the laser emergent holes are respectively arranged on the two sides of the semi-integrating-sphere cavities. In the attenuator provided by the invention, laser is coupled into the semi-sphere cavities via the wide-angle sampling taper holes, is absorbed and diffuse-reflected by the semi-sphere cavities, and then is ejected from the laser emergentholes, large amplitude attenuation of laser power density is realized, and the requirement of attenuation sampling during oblique incidence of the laser can be satisfied.

Owner:NORTHWEST INST OF NUCLEAR TECH

Method for preparing hard particle coating on hard substrate through laser-assisted cold spraying

ActiveCN103469197ALower the preheat temperatureReduce hardnessHeat inorganic powder coatingSand blastingLaser power density

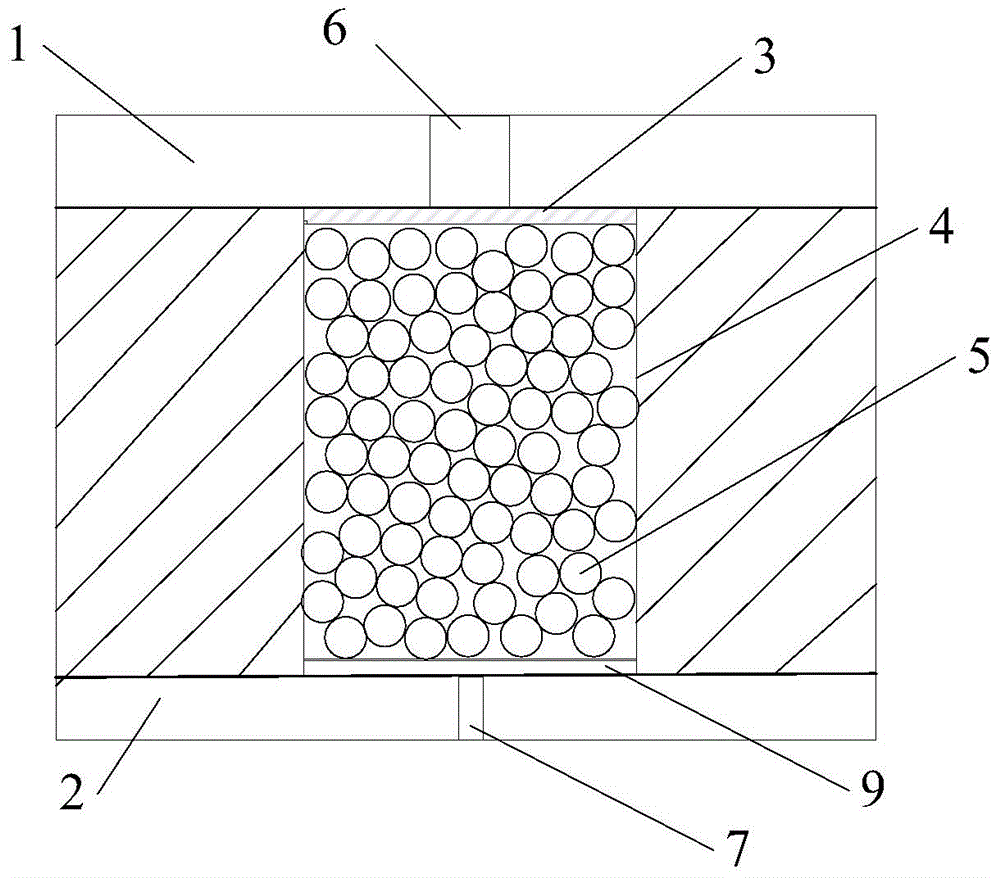

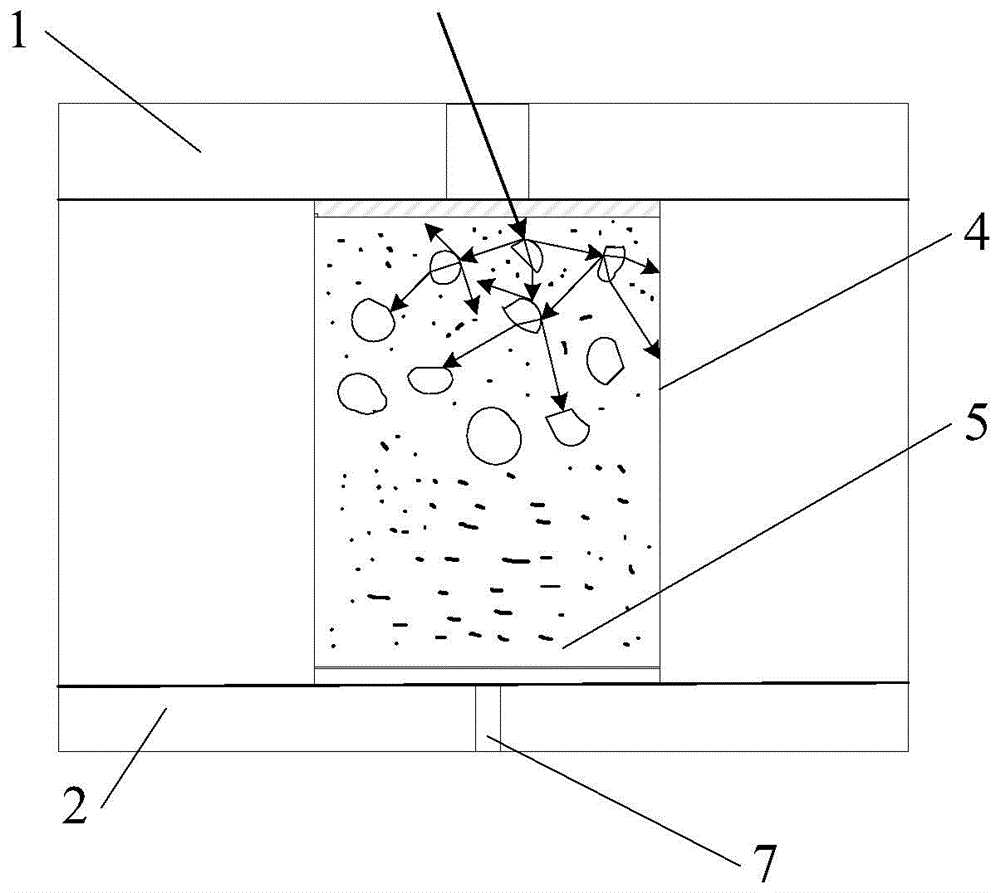

The invention discloses a method for preparing a hard particle coating on a hard substrate through laser-assisted cold spraying. The method comprises the following steps: subjecting the hard substrate to sand blasting, wherein the hardness of the hard substrate is 300 HV; preheating a spherical hard particle with a diameter in a range of 30 to 50 mu m, wherein preheating temperature is 300 to 600 DEG C, and the hard particle is one or more selected from the group consisting of 2Cr13, 17-4PH, Ni45, Ni60 and Inconel718; carrying out spraying on the surface of the hard substrate by using compressed air having a pressure of 1.5 to 3.0 MPa and carrying the preheated hard particle; and starting laser to synchronously heat a spraying area so as to form the hard particle coating on the surface of the hard substrate, wherein laser power density is 3*10<5> to 5*10<5> W / cm<2>, and wavelength is 850 to 1060 nm. The method provided by the invention can substantially improve plastic deformation generated during collision between the hard particle and the substrate, so the binding force of the coating is improved; thus, the coating with higher stability is obtained.

Owner:ZHEJIANG UNIV OF TECH +1

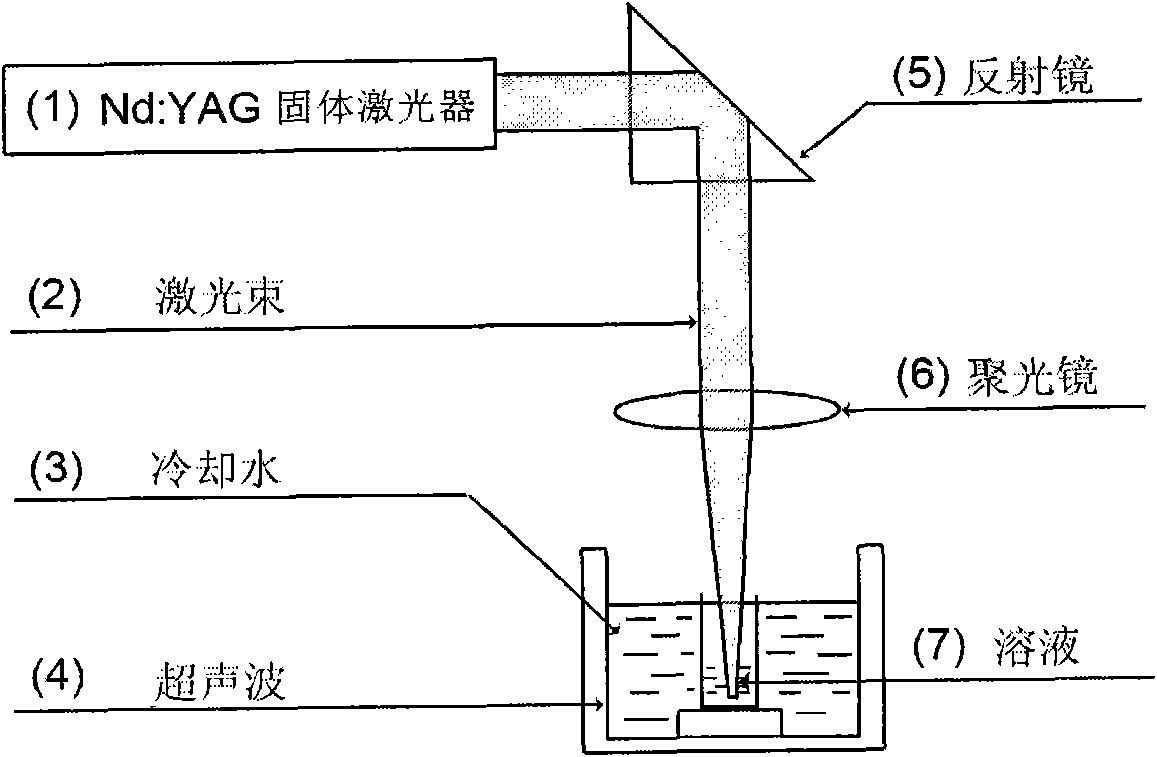

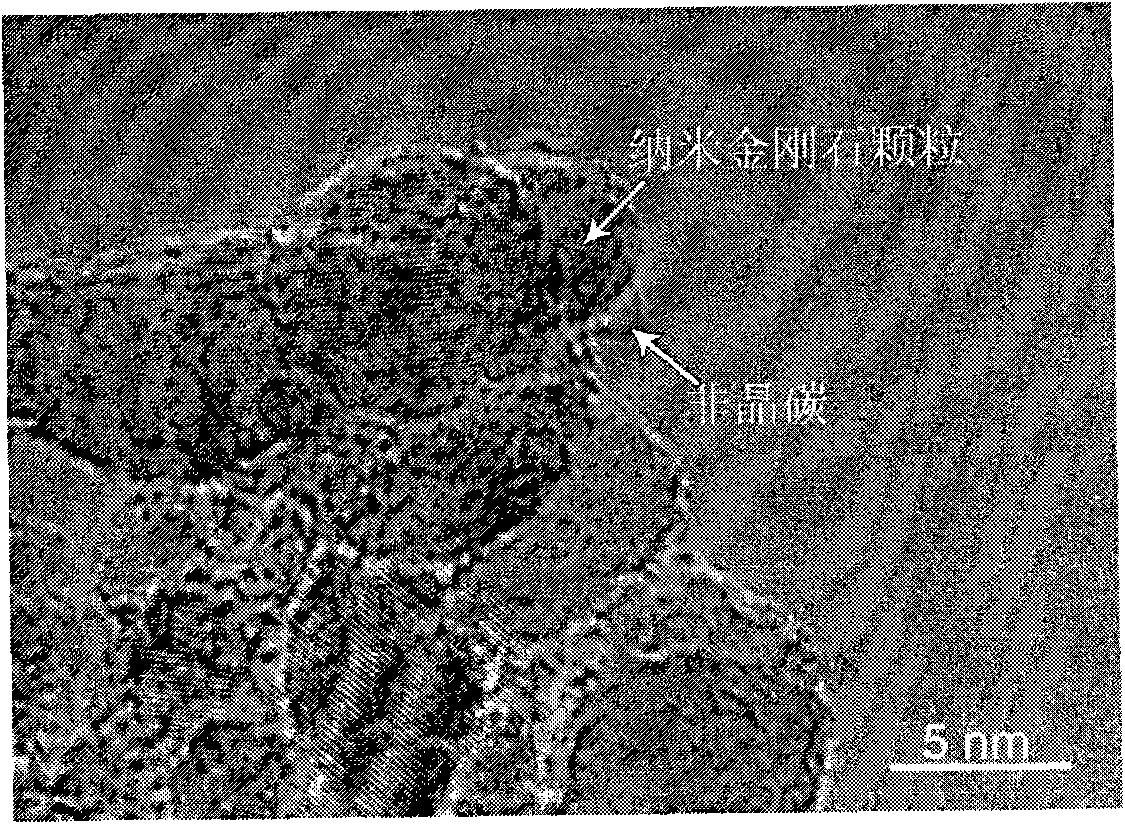

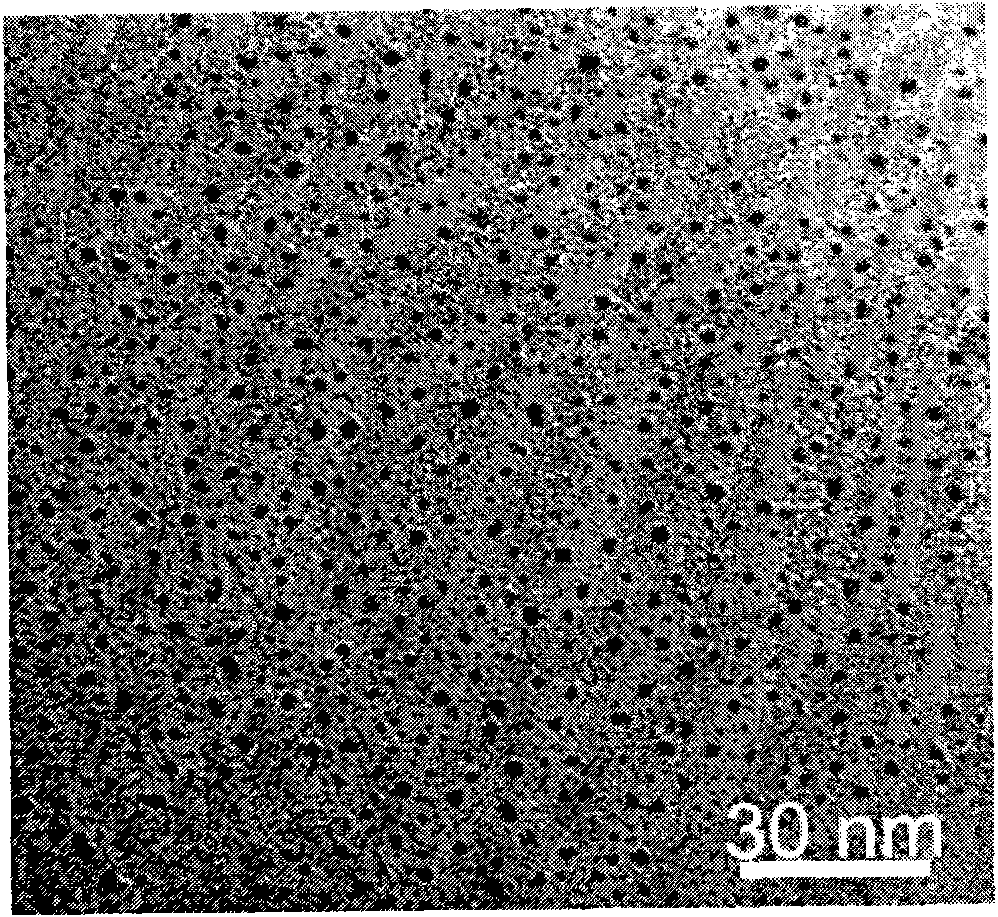

Method for dispersing detonation method nano-diamond in liquid phase

The invention discloses a method for dispersing a detonation method nano-diamond in a liquid phase. The method comprises the following steps of: a, mixing commercial detonation method nano-diamond powder serving as a raw material into a liquid medium for the ultrasonic processing to form a suspension; b, bombarding the suspension by using a pulse laser with a laser power density of 106W / cm<2> in the action area for 1 to 3h to obtain stable suspension with no precipitate; and c, oxidizing the product which is subjected to the laser bombardment by using strong acid. The method has the advantages of overcoming the problem of easy product pollution in the conventional process for dispersing the detonation method nano-diamond, and aggregating the aggregated detonation method nano-diamond in multiple kinds of solution to obtain monodisperse nano-diamond particles, along with simple process and safe and controllable laser action process. The method can be widely used in the fields of paint, polymer composites, lubrication and the like.

Owner:TIANJIN UNIV

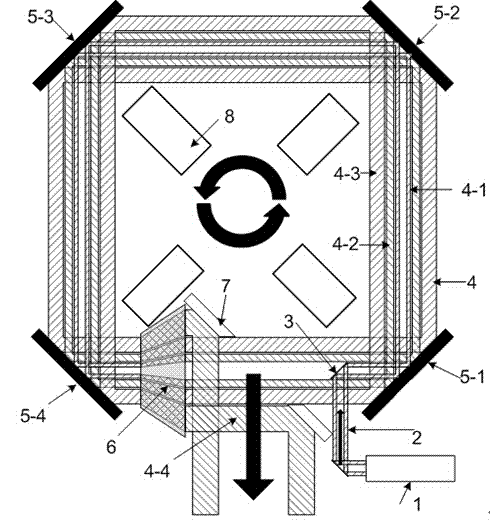

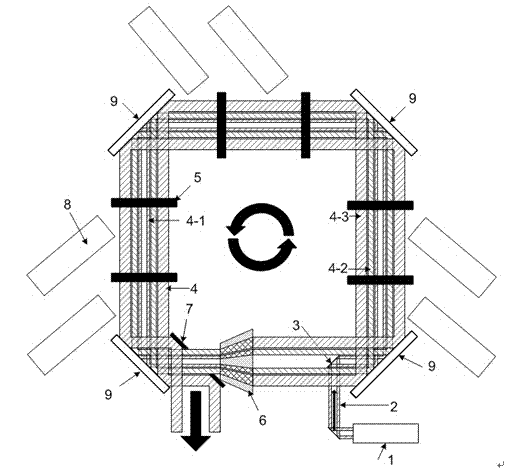

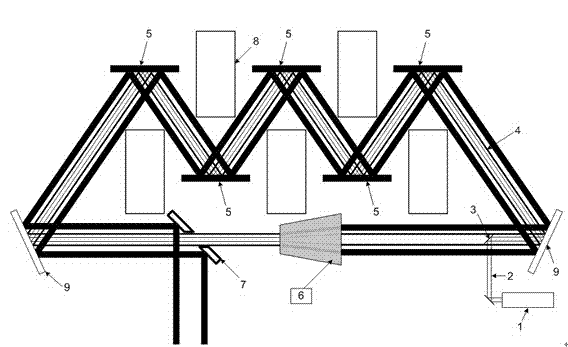

Annular-spot chip amplifier

ActiveCN104242045AIncrease powerIncrease spot sizeActive medium materialLaser power densityLuminous flux

The invention provides an annular-spot chip amplifier. By the annular-spot chip amplifier, annular laser beams, with high beam quality and low power, obtained by the aid of an unstable cavity can pass through different aperture areas of a same chip gain medium or chip gain medium sequence conveniently and repeatedly in different beam sizes, equal-flux laser extraction with high laser power density is realized, ASE (amplified spontaneous emission) is suppressed effectively, high optical to optical conversion efficiency is realized, and temperature gradient and temperature to optical distortion caused by non-uniform radial laser on a chip can be further avoided.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

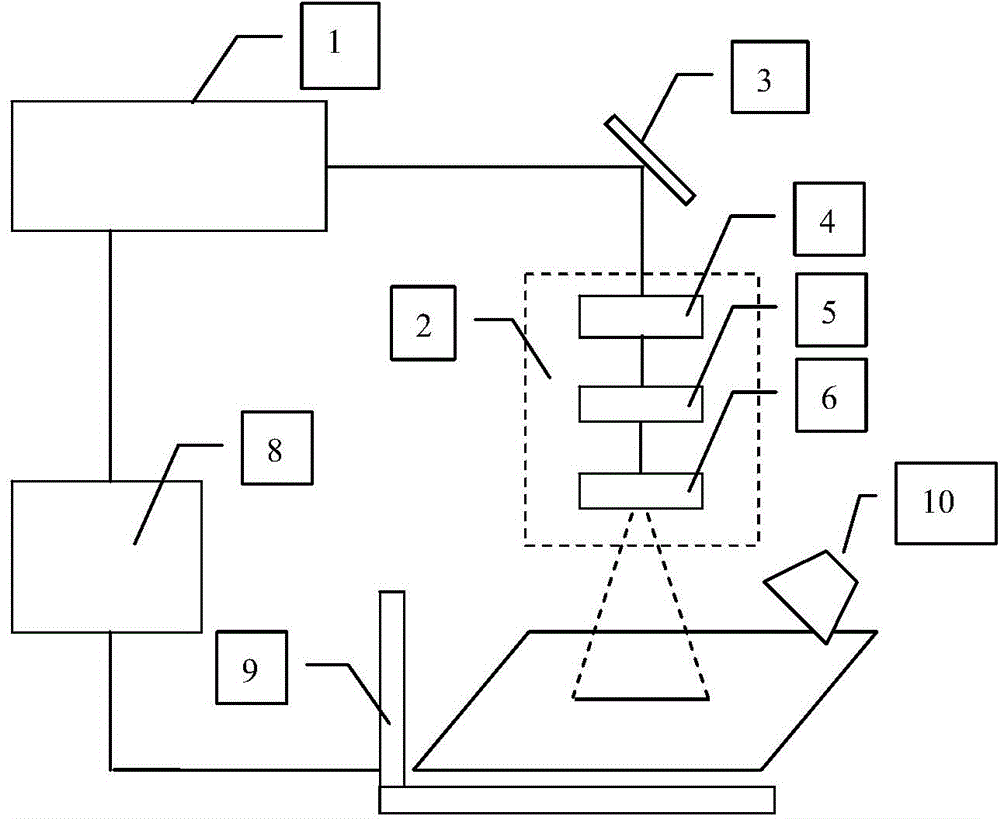

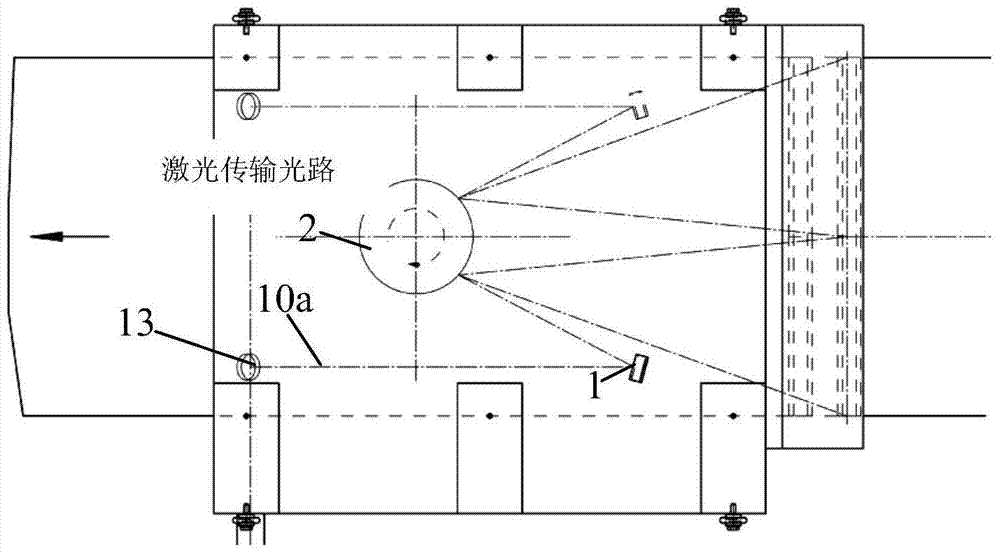

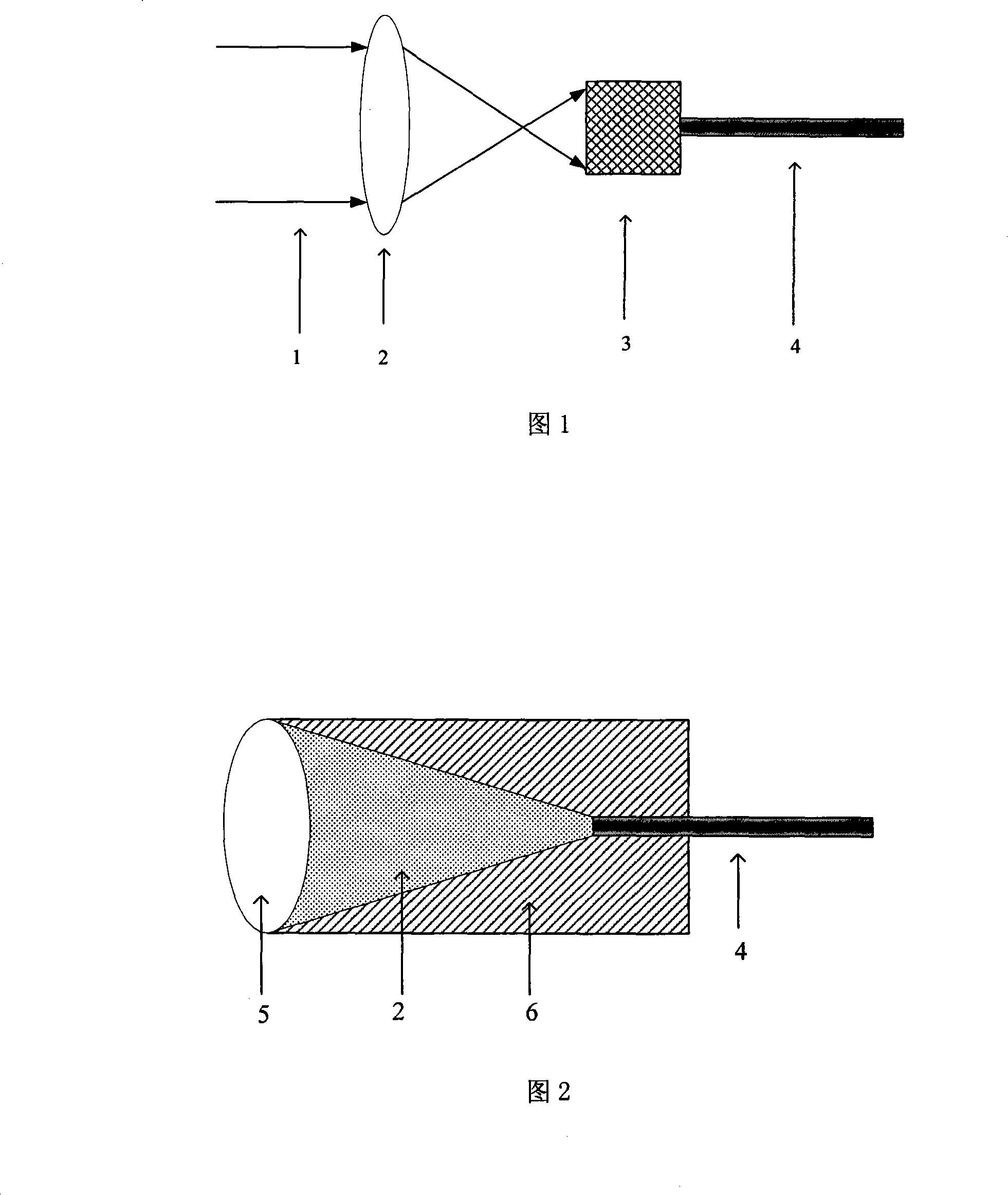

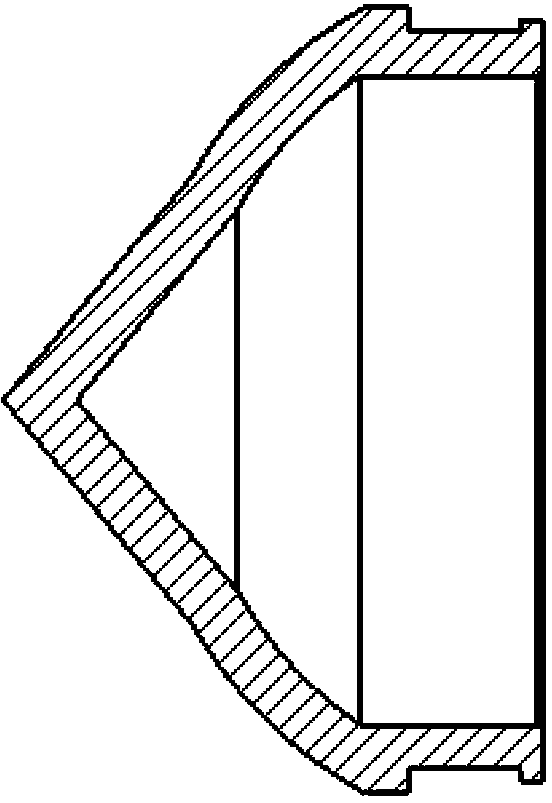

Hollow light guiding cone coupling vacuum transmission laser device

InactiveCN101241209AReduce damage rateReduce nonlinear lossCoupling light guidesLight spotLaser power density

An optical fiber transmission device based on hollow light guiding cone coupling for vacuum-transmitting high-capacity laser is provided. A hollow light guiding cone is connected to the input end of the optical fiber, and small injection light spots are obtained by the hollow light guide cone to implement laser optical fiber coupling transmission. The hollow light guiding cone and the interior of the optical fiber are vacuumed or injected with inert gas to enlarge laser capacity of the optical fiber transmission system and enhance output beam quality. The invented device enlarges the lighted area on the laser input end surface effectively, reduces laser power density of the input end surface, and lowers laser damage probability. Linear and nonlinear wastage is decreased by vacuuming the laser transmission path, and the transmission efficiency of the optical fiber transmission system is increased. The invented device is provided with a simple structure, strong innovation and an evident effect.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

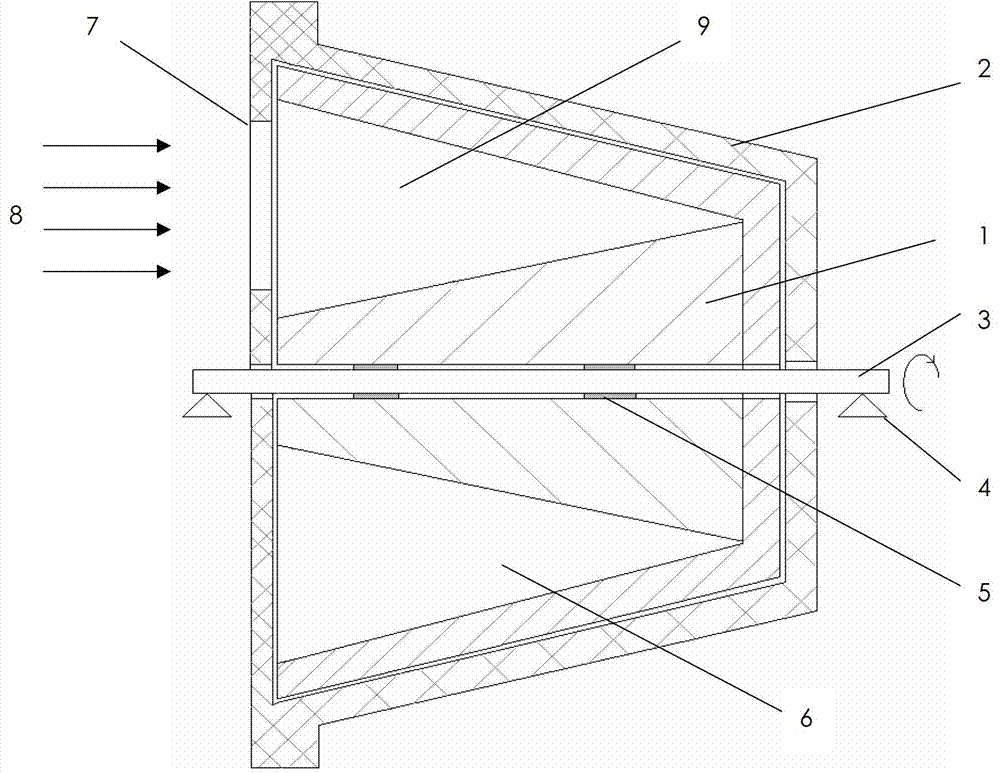

High-energy laser beam expanding and absorbing device

InactiveCN103389157AHigh measurement accuracyAchieve absorptionPhotometry using electric radiation detectorsHigh power lasersLaser power density

The invention discloses a high-energy laser beam expanding and absorbing device which comprises a laser beam expanding cone, an energy absorption cavity, a front panel and a fixing plate, wherein the energy absorption cavity adopts a hollow cylinder; the front panel is arranged at a laser incident end of the energy absorption cavity, and the fixing plate is arranged at the rear end of the energy absorption cavity and used for fixing the laser beam expanding cone; and the laser beam expanding cone comprises a pointed beam expanding cone, at least two spherical beam expanding cones and cylinder transition sections which are arranged in the laser incident direction sequentially, and radii of cylinders of the cylinder transition sections are increased gradually in the laser incident direction. The laser beam expanding cone simultaneously realizes beam expanding of incident laser beams in the length direction and the circumference direction of the absorption cavity, and effectively reduces the power density of laser shot to a heat absorption cylinder by the laser beam expanding cone; and by means of the high-energy laser beam expanding and absorbing device, absorption and conduction of hundred thousand joules to a megajoule of high-power laser energy of continuous waves are realized, the measuring accuracy of an energy meter is improved greatly, and the device has wide applicability.

Owner:NORTHWEST INST OF NUCLEAR TECH

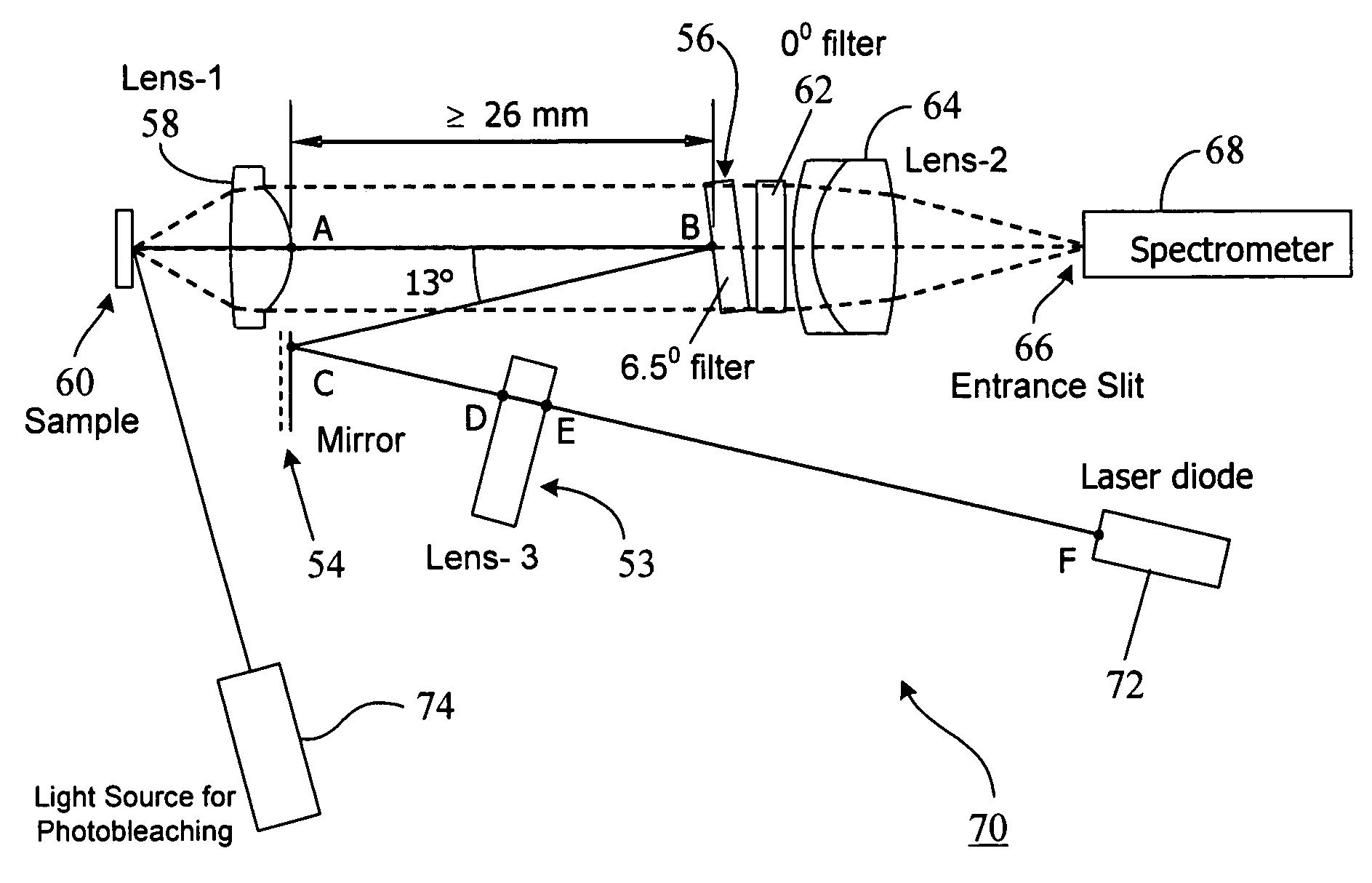

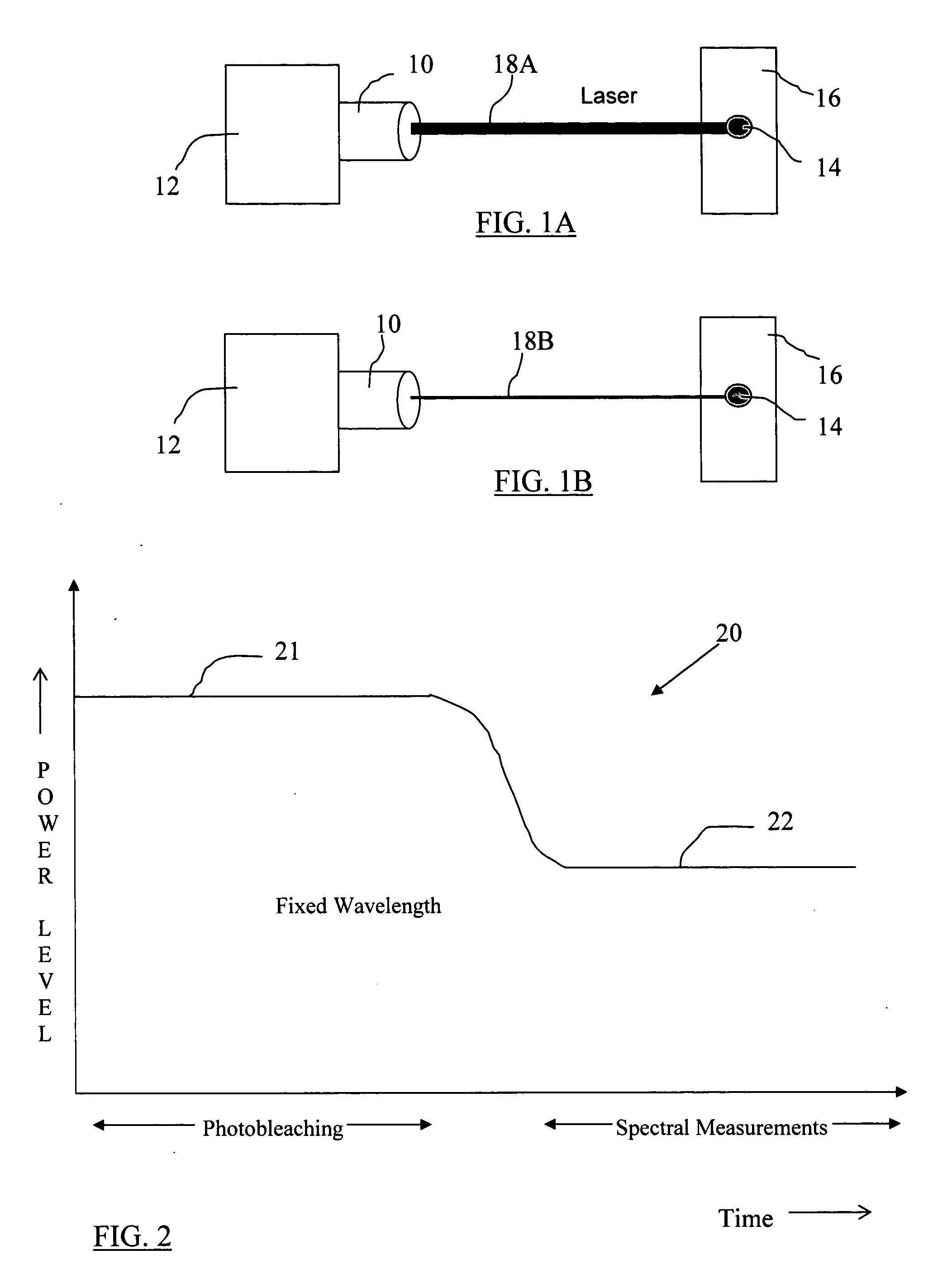

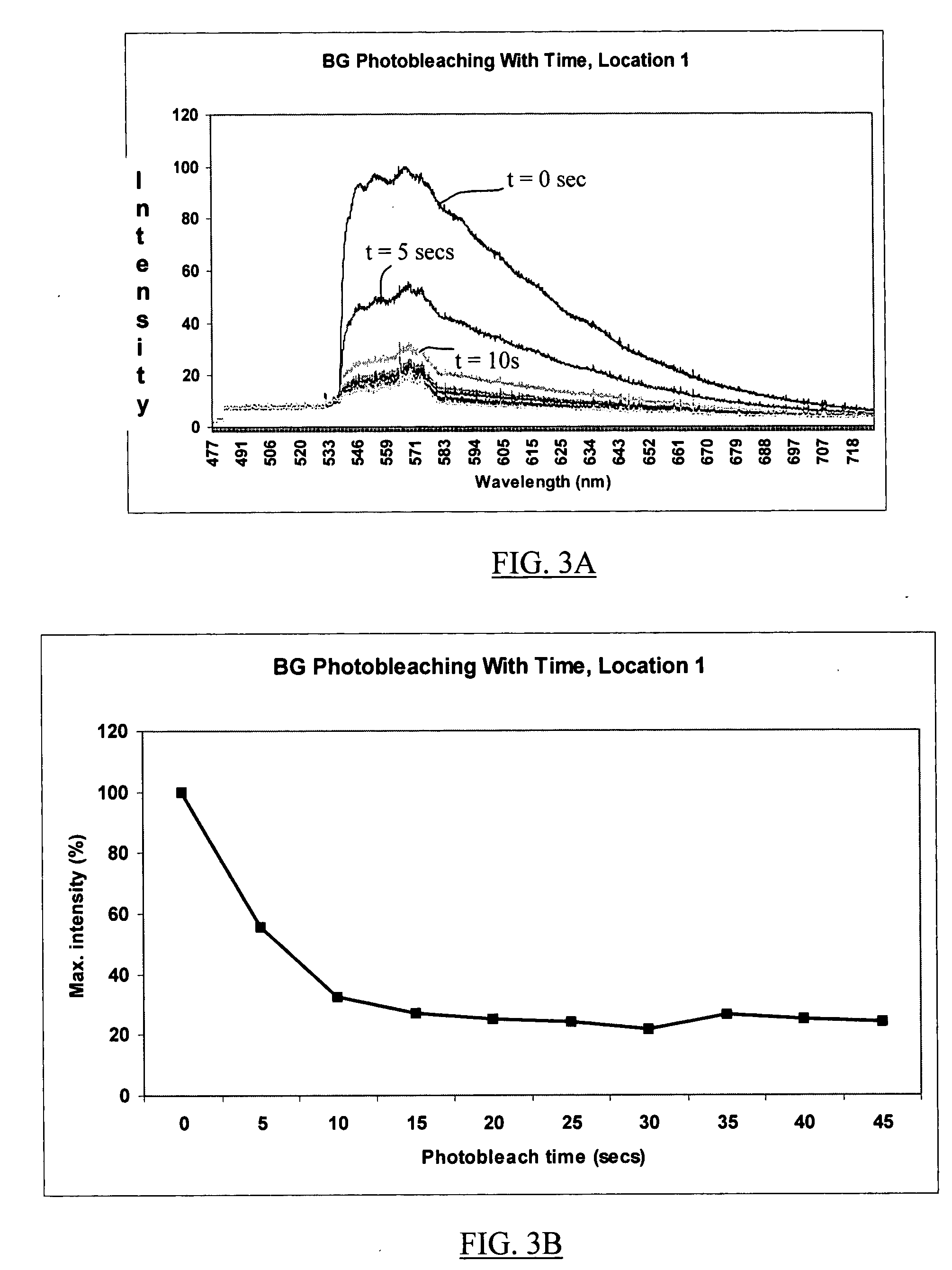

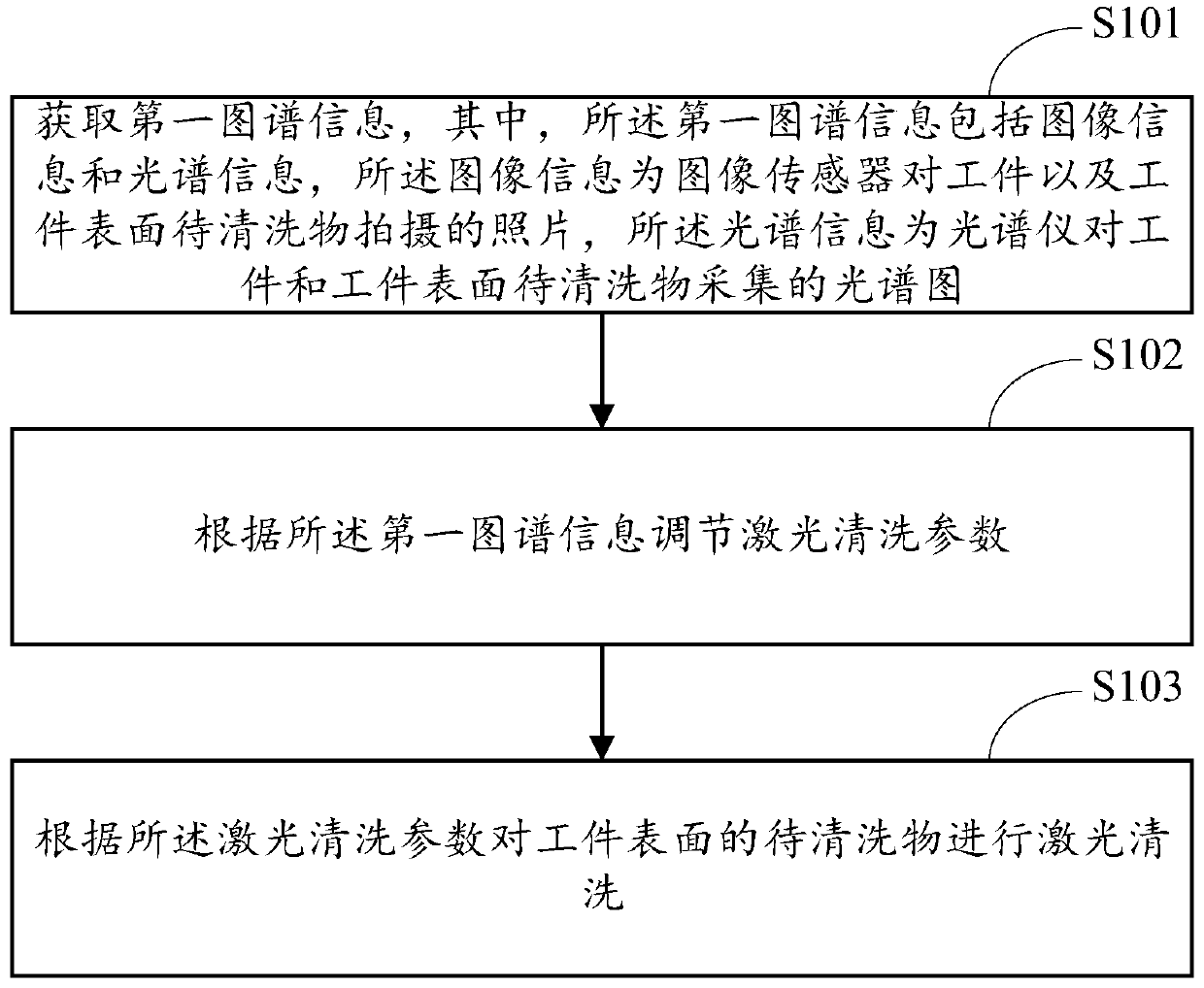

Photobleaching by high power pulses

InactiveUS20080094614A1Reduce laser power densityRadiation pyrometrySamplingSpectroscopyOptical measurements

A pulse photobleaching methodology wherein a monochromatic illumination (e.g., laser illumination) having a higher power intensity (photobleaching power) just below the photodamage threshold of a luminescent sample is initially used to significantly attenuate sample luminescence without photothermally destroying the sample material. Thereafter, the laser power density may be reduced to a significantly lower level (analytical power level) to carry out spectroscopic measurements (e.g., collection of Raman scattered photons) on the sample. In one embodiment, the laser illumination wavelength remains the same despite changes in laser power intensity. Some figures-of-merit may be computed from optical measurements made at the analytical power level to guide the photobleaching process. Sample-dependent combinations of laser power density and short exposure times may be obtained to significantly expedite photobleaching to assist in collection of sample spectral data in the field without a long wait. Portable spectroscopy systems employing pulse photobleaching may be devised for expeditious collection of spectral data from luminescent samples in the field.

Owner:CHEMIMAGE TECH

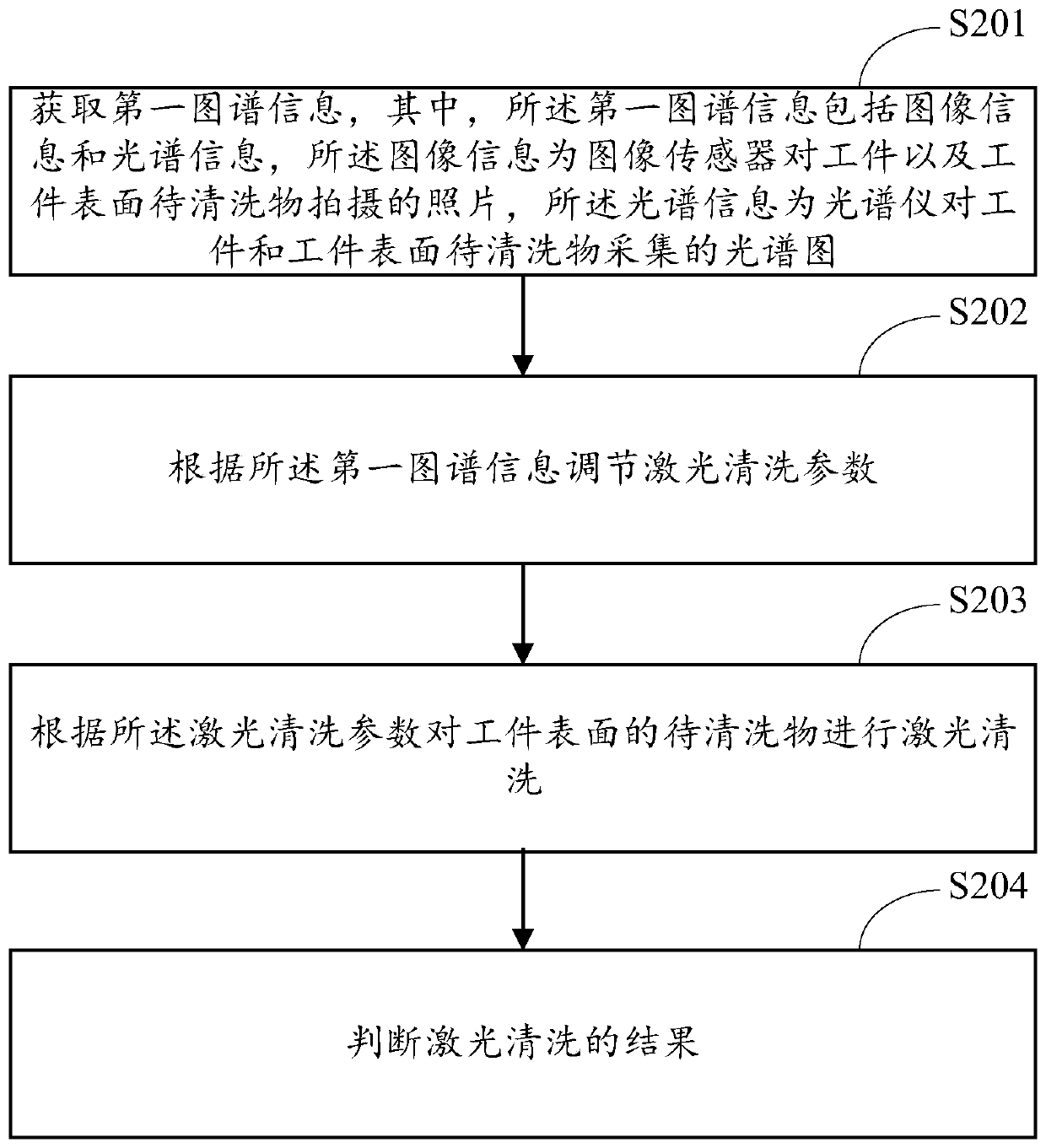

Laser cleaning method, device and system

ActiveCN110153107AAvoid damageImprove cleaning qualityCleaning processes and apparatusSpectrographLaser power density

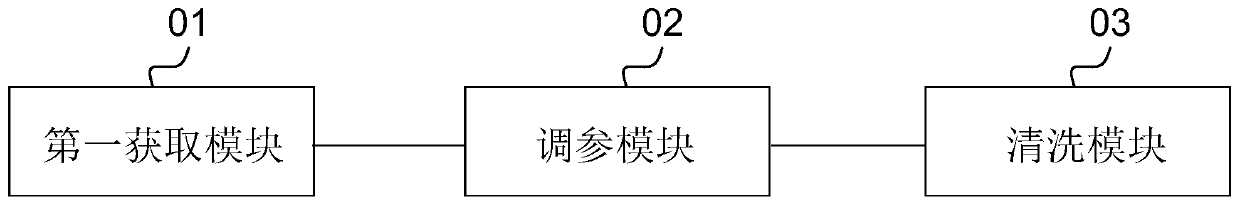

The invention relates to a laser cleaning method, device and system. The laser cleaning method comprises the steps that first image and spectrum information is obtained and comprises image informationand spectrum information, the image information is pictures shot by an image sensor for a workpiece and a to-be-cleaned object on the surface of the workpiece, and the spectrum information is about spectrum charts collected by a spectrograph for the workpiece and the to-be-cleaned object on the surface of the workpiece. Laser cleaning parameters are adjusted according to the first image and spectrum information; and laser cleaning is conducted on the to-be-cleaned object on the surface of the workpiece according to the laser cleaning parameters. Accordingly, the laser power density is largerthan or equal to the cleaning threshold value of the to-be-cleaned object and smaller than the damage threshold value of the workpiece. Thus, the to-be-cleaned object on the surface of the workpiece can be removed, workpiece damage can be avoided, and the effect of the high cleaning quality is achieved.

Owner:HANS LASER TECH IND GRP CO LTD +1

Diffraction color changing laser marking method and apparatus thereof

ActiveCN101135776AHigh-resolutionReduce etch depthLaser detailsDiffraction gratingsLaser power densityImage resolution

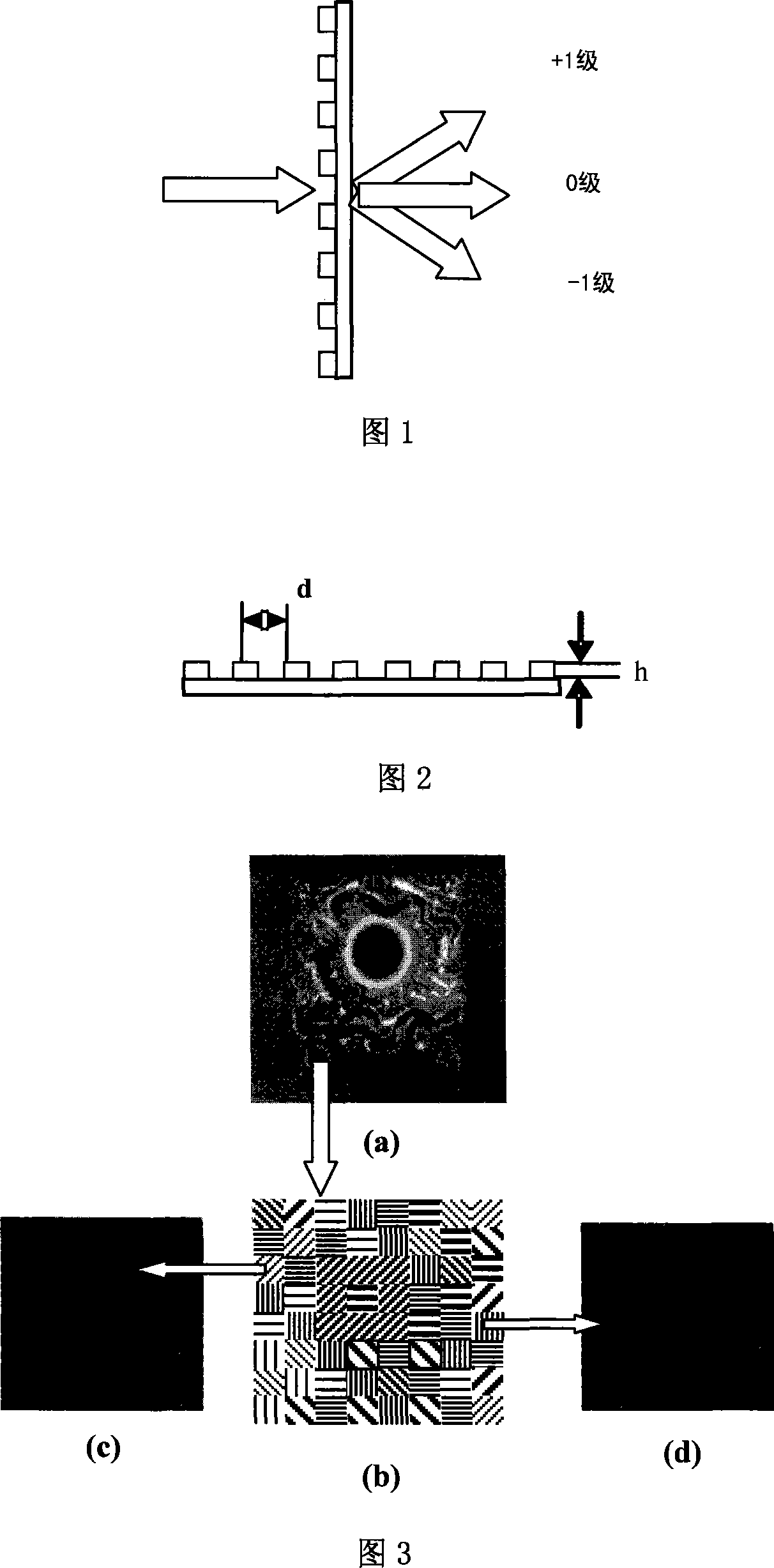

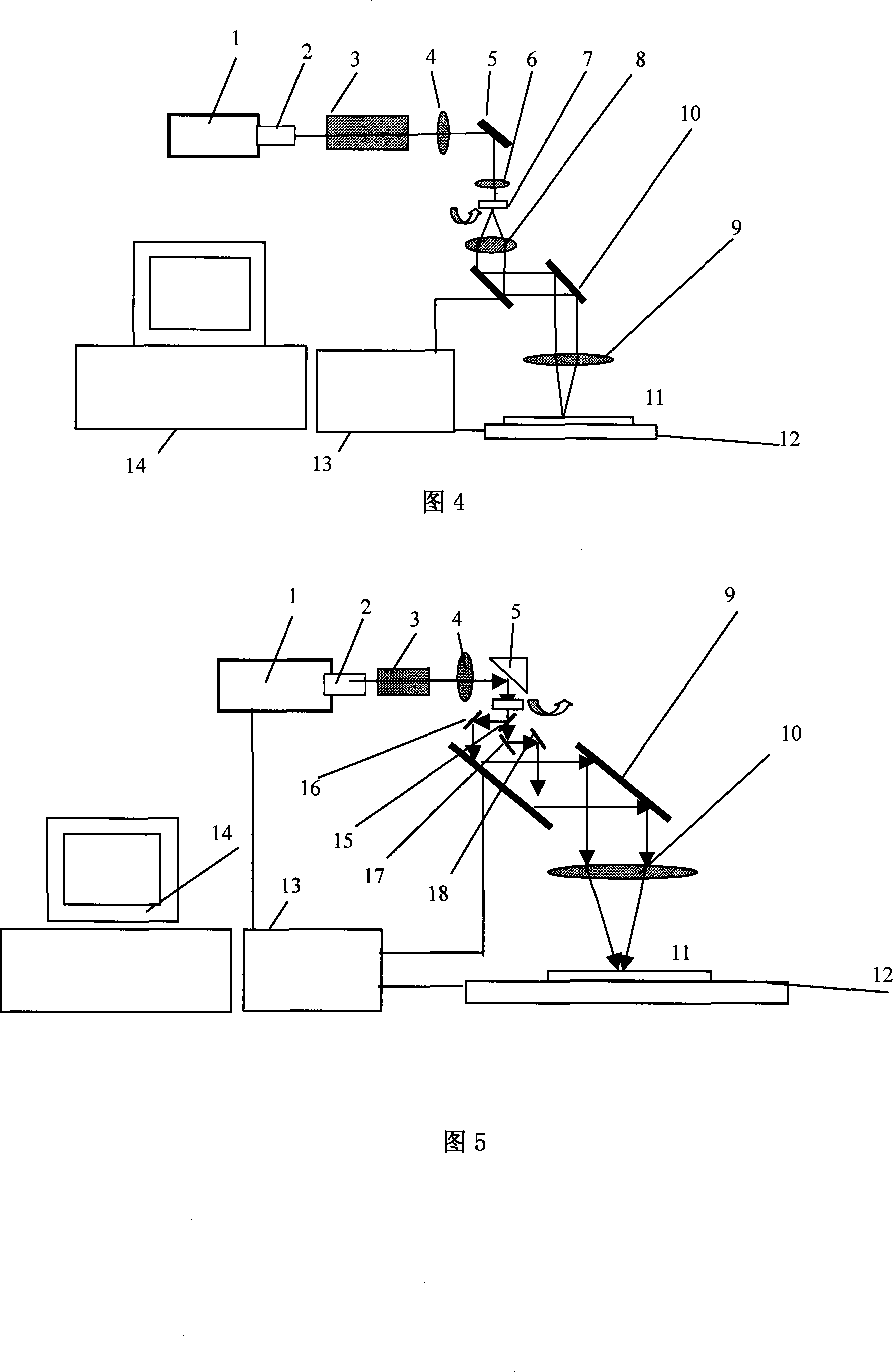

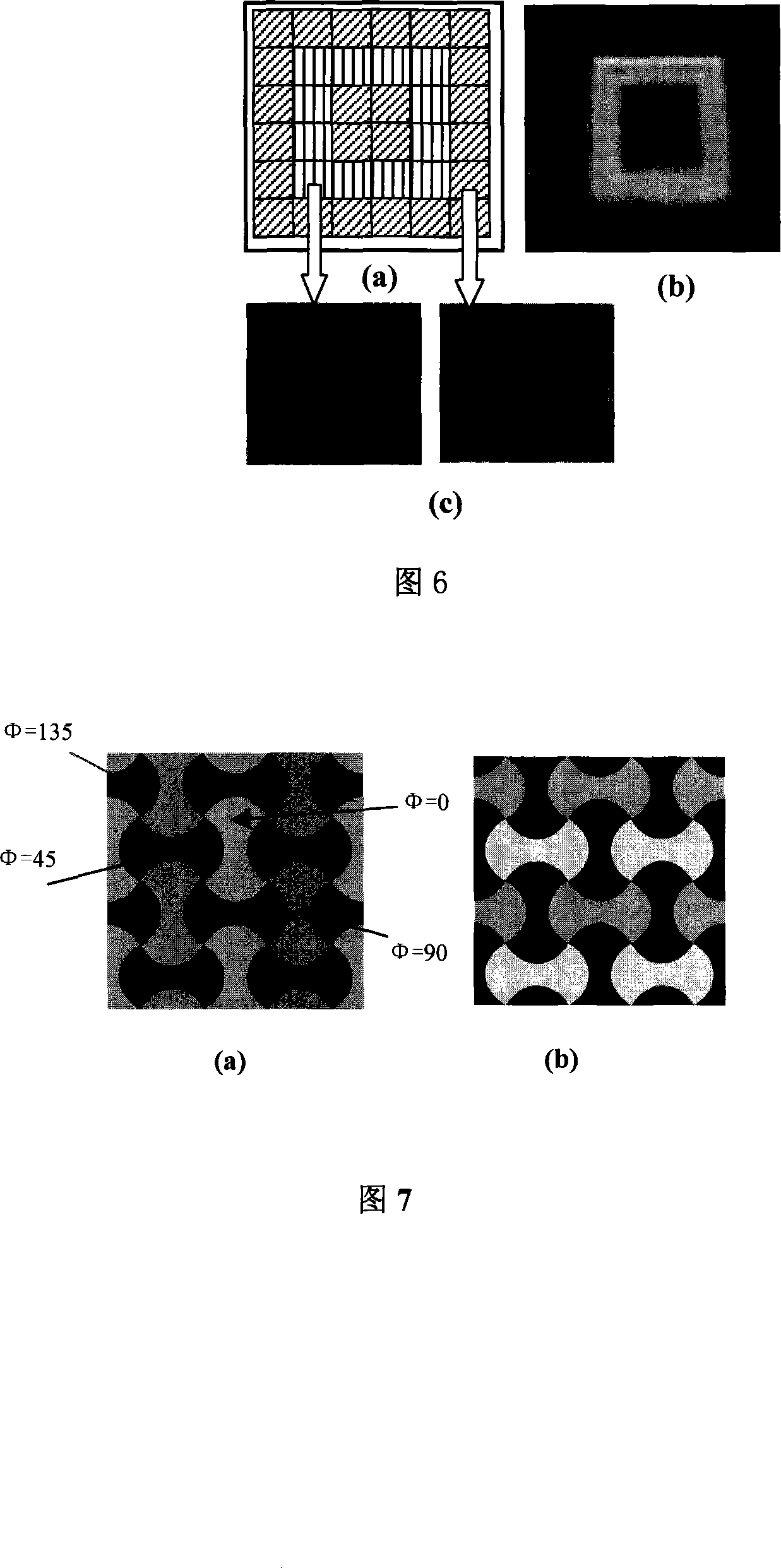

The method thereof comprises: using a high power semiconductor pumping solid state laser as light source; the laser beam satisfies the requirement of interference; using a beam-splitting component to generate a beam-splitting light; using a optical lens group to converge the light spot on the material surface to form an even interference fringe optical field; the laser power density on the surface of the materials is over a damage threshold to form the fringe etch; by controlling the scan, realizing the marking of diffracted light color-changed image.

Owner:SVG TECH GRP CO LTD +1

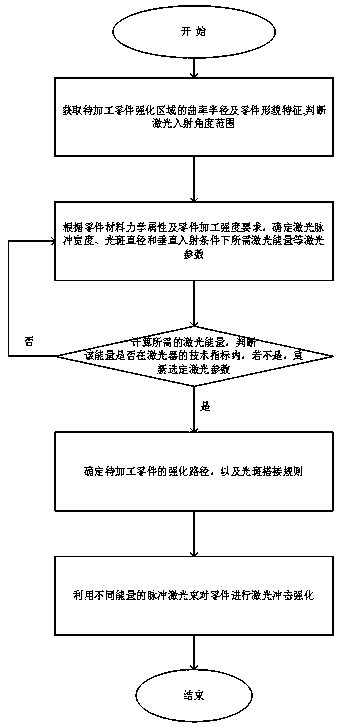

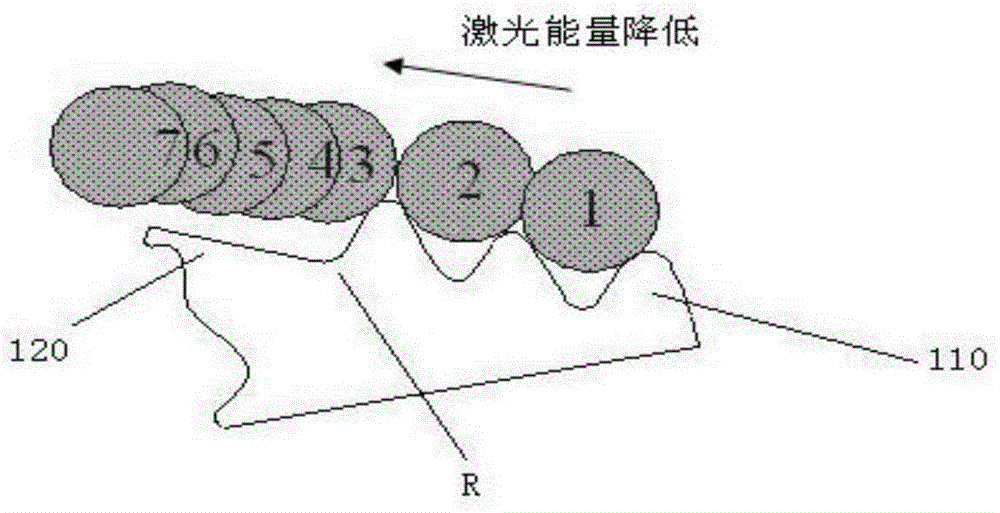

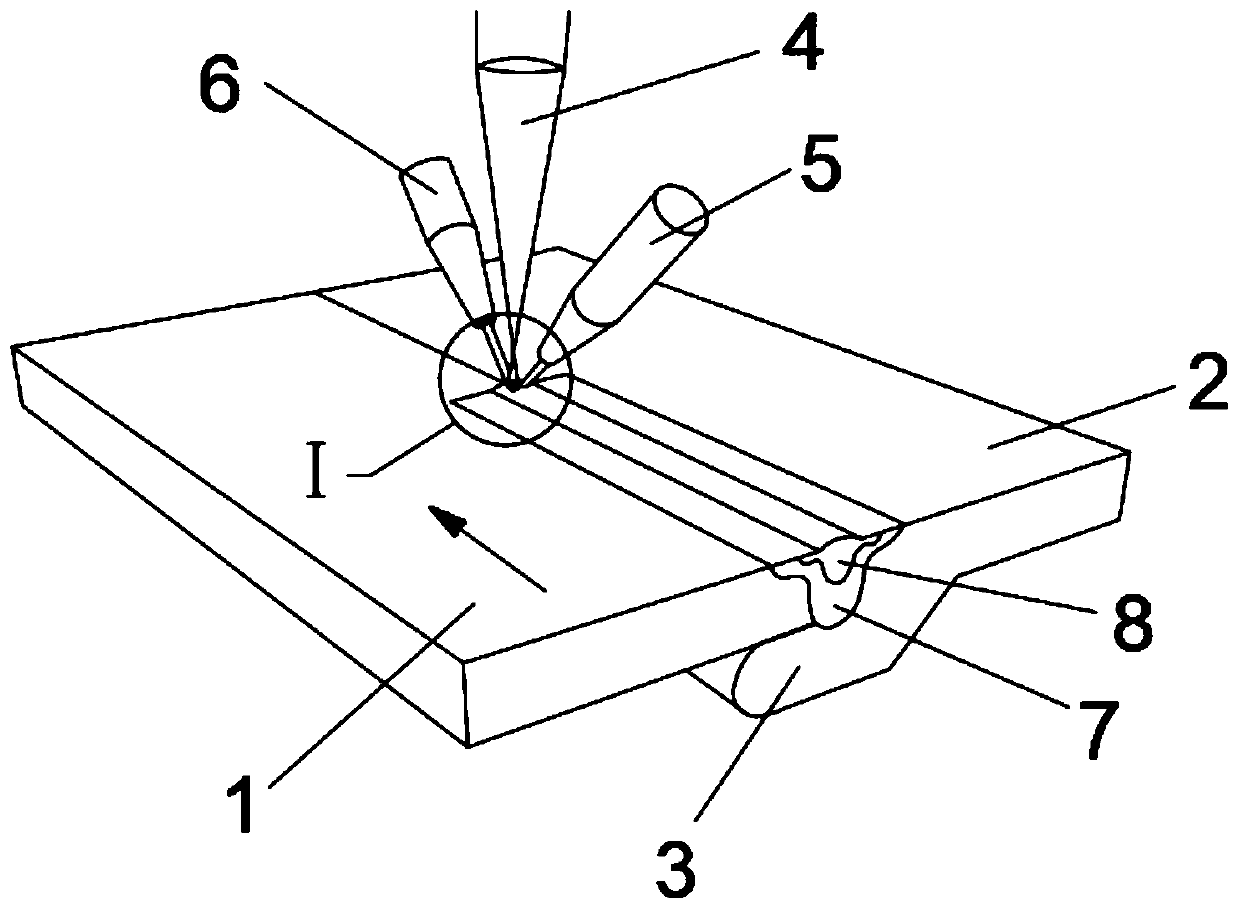

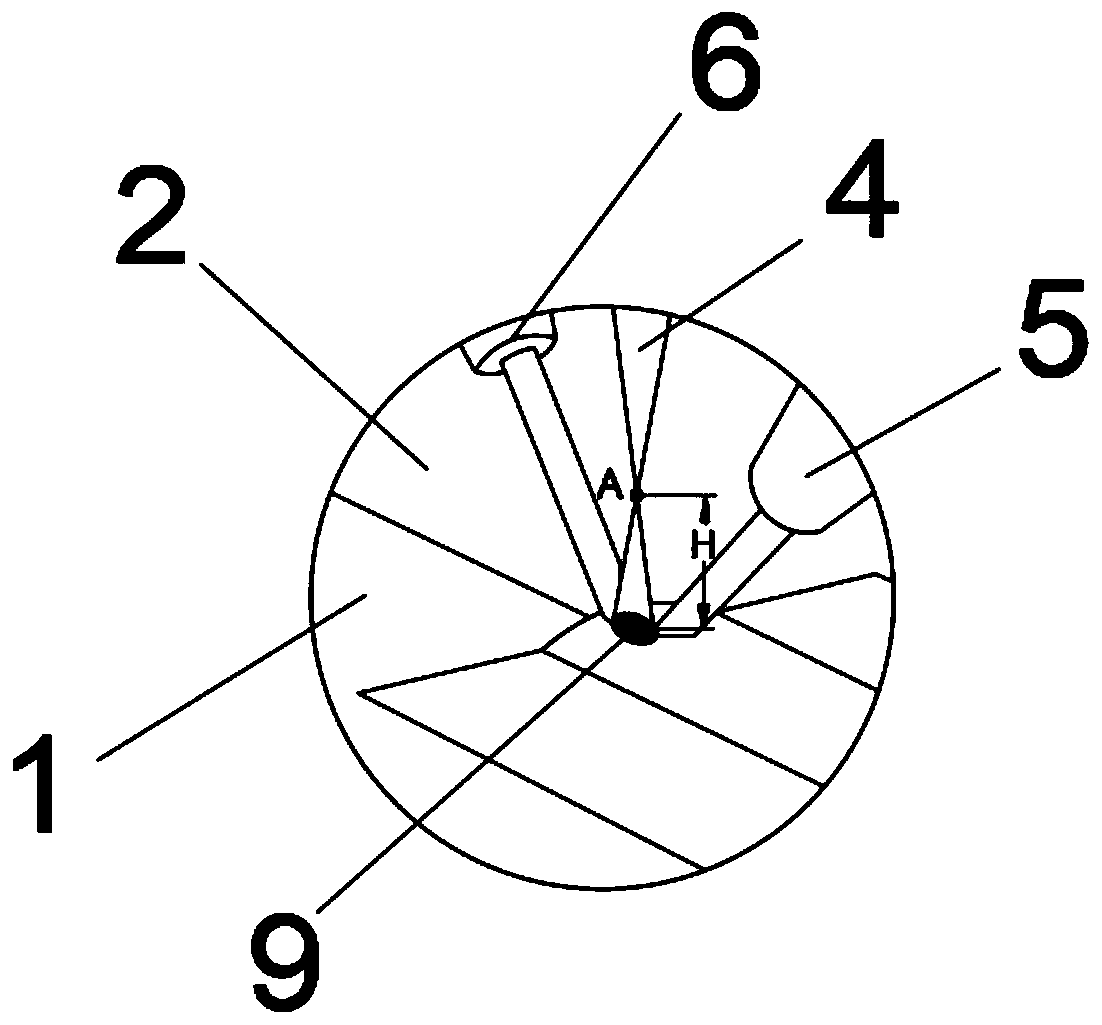

Energy compensation constant power density laser oblique impact method

ActiveCN108517400AImprove distribution uniformityReduce roughnessLaser beam welding apparatusConstant powerLaser power density

The invention relates to the technical field of material surface strengthening treatment, and concretely relates to an energy compensation constant power density laser oblique impact method. The method comprises the following steps: obtaining the curvature radius of the strengthening area of a part to be processed, and judging the incident angle range of laser; determining the pulse width, the light spot diameter, laser energy required by a vertical incidence condition, and other parameters of the laser; calculating the required laser energy at a minimum incidence angle, and judging whether the energy is within the technical indexes of a laser device or not; and performing laser impact strengthening on the part by using pulsed laser beams of different energies. The laser power or energy iscompensated according to the change of the incident angle and the curvature radius of the part to be processed to avoid the uneven strengthening effect caused by the change of the shape and the areaof the projection surface, of the laser beam, on the surface of the part, so constant strength enhancement is achieved, the constant value of the laser power density in the same area or on the same track is ensured, the uniformity of the impact effect is improved, and the roughness of the laser impact treated surface is reduced.

Owner:GUANGDONG UNIV OF TECH

Method for measuring thermal conductivity of single semiconductor nanowire material

ActiveCN102053101AAvoid damageReduce processing stepsMaterial heat developmentMicro nanoSemiconductor materials

The invention relates to a method for measuring the thermal conductivity of a single semiconductor nanowire material. The method comprises the following steps of: suspending a semiconductor nanowire material to be measured on a substrate etched with a groove; confirming the diameter D1 of the semiconductor nanowire to be measured and the length L of the suspended part of the semiconductor nanowire sample suspended on the groove through an SEM (Scanning Electron Microscope); selecting an excitation light source, observing the remarkable red shift of the peak position of a band-edge fluorescence transmitter peak of the nanowire when laser is focused in the center of the suspended part of the nanowire and the laser strength is changed, measuring the variance relation of the nanowire fluorescence spectrum with temperatures and estimating the local temperature of the suspended nanowire part under the laser illumination so as to acquire the temperature grads of the nanowire under a certain laser power density. According to the calculation of a heat conduction equation of a one-dimensional nanowire sample: K=x*(2L / pai*D12)(beta*lambda / beta*pa)-1, the thermal conductivity of a single nanowire is derived. The method for deriving the local temperature and the thermal conductivity by utilizing the photoluminescent property of the semiconductor material is practically applied to the aspect of non-contact micro-nano thermal property measurement.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

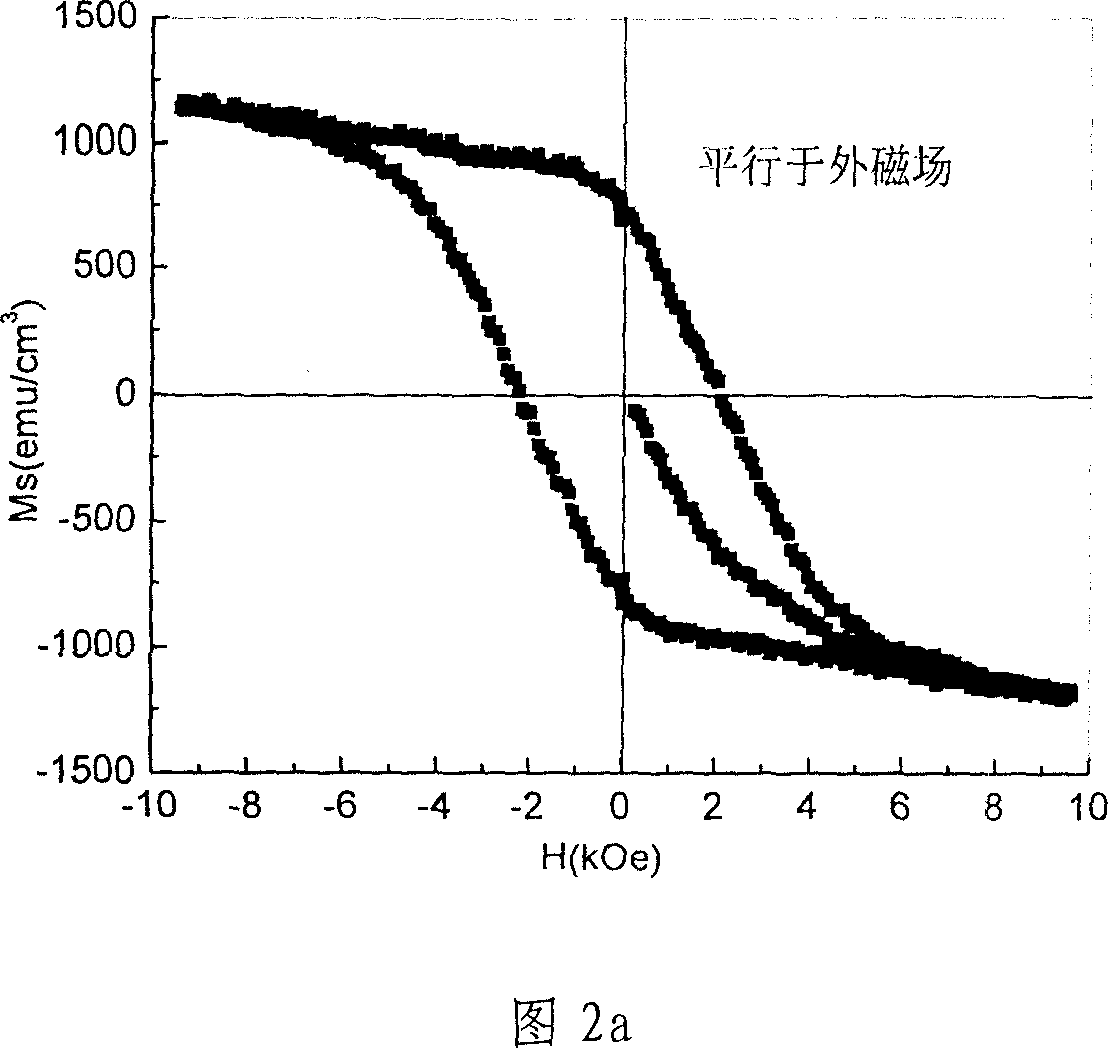

Method for preparing L10 ordered alloy film

InactiveCN1958839AReduce the interaction forceAvoid growing upVacuum evaporation coatingMechanical record carriersAlloy thin filmLaser power density

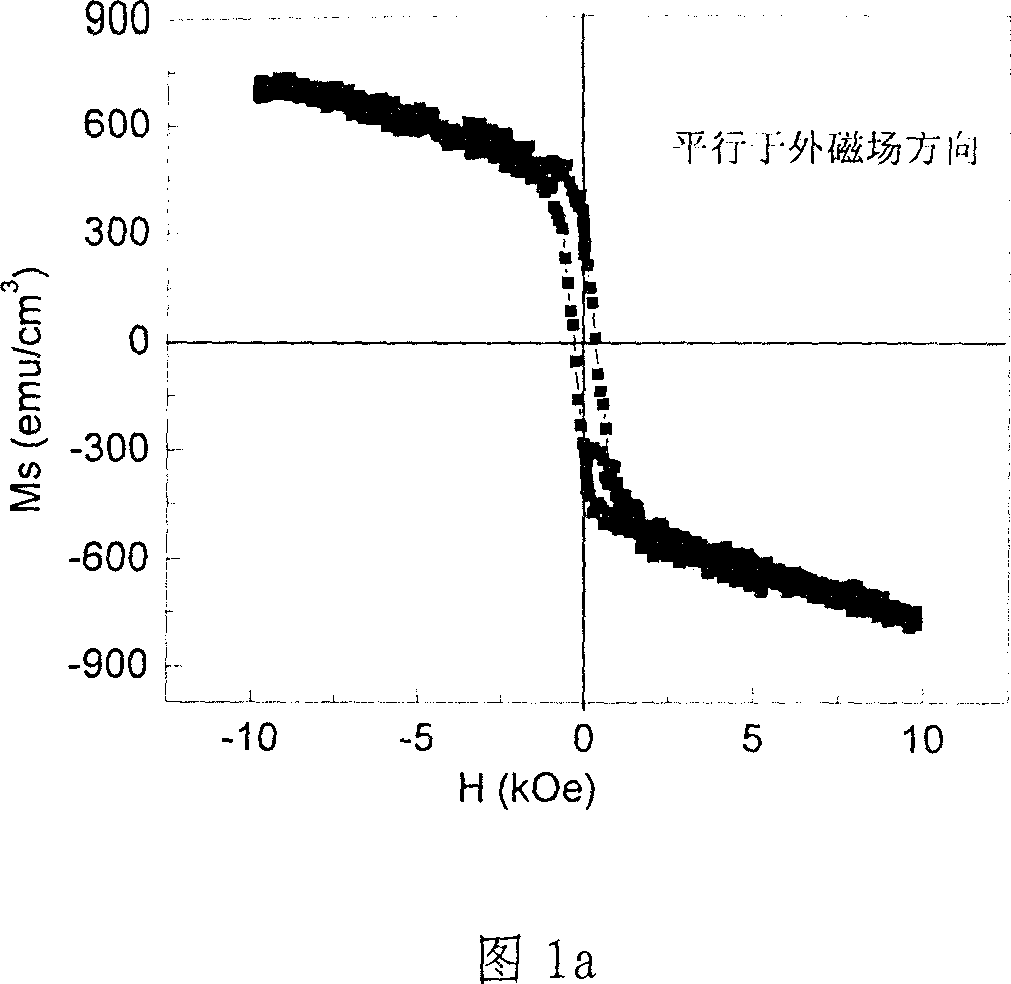

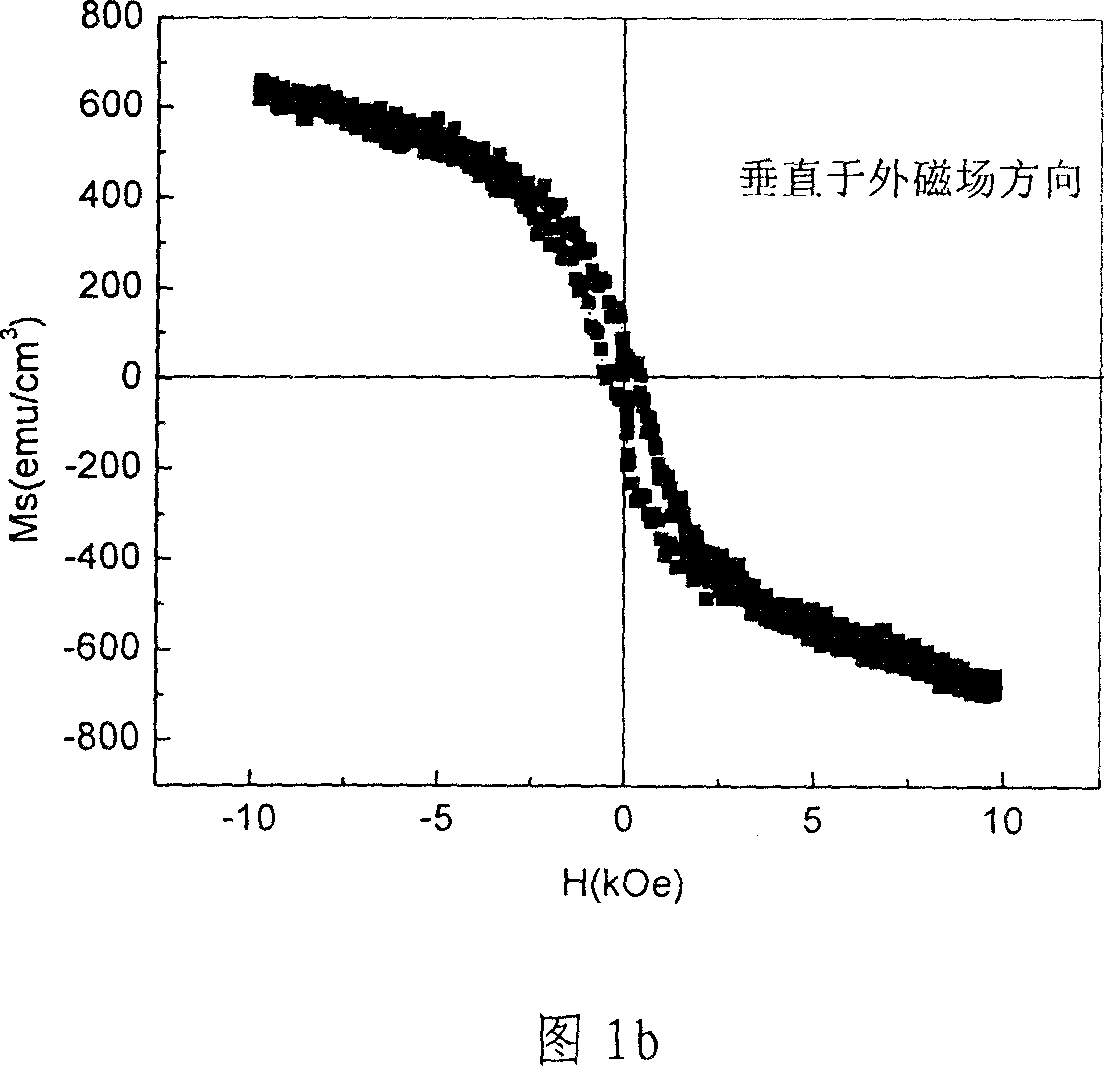

This invention discloses a method for preparing ordered L10 alloy thin film. The order-disorder transition of the thin film is realized by laser annealing. The laser is CO2 laser, Ar+ laser, Nd: YAG laser or excimer laser. The power intensity of the laser applied on the surface of the alloy thin film is 10-100 W / mm2. The alloy thin film is placed on a platform that can be adjusted in three dimensions and can move freely, and the scanning rate of rapid scanning is 1-10 mm / s. By this method, the alloy thin film can maintain small grain sizes and decrease interaction forces among grains while forming fct ordered structure. Compared with traditional thermal annealing method, the method has simple process, and is suitable for industrial production of ordered L10 alloy thin film.

Owner:SHANGHAI INST OF TECH

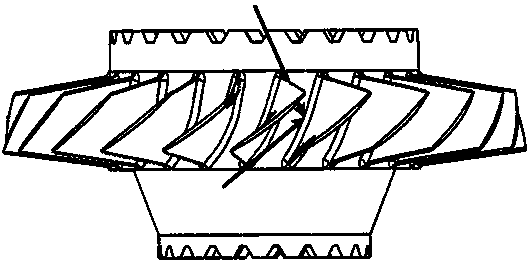

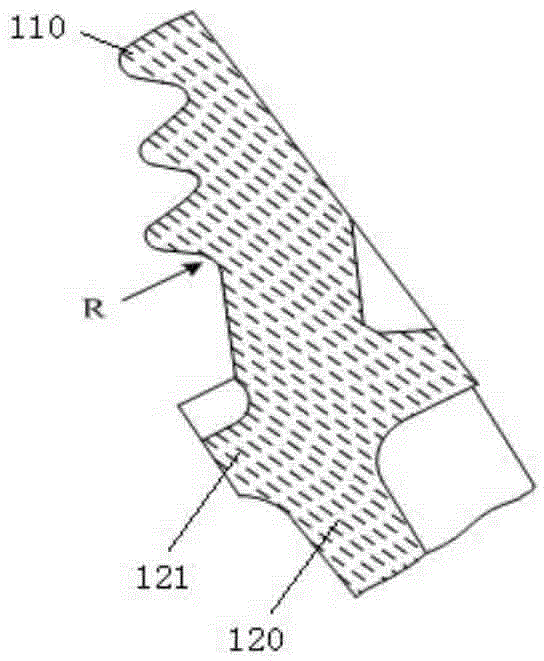

Turbine rotor blade tenon tooth laser shock processing method

The invention provides a turbine rotor blade tenon tooth laser shock processing method. A turbine rotor blade comprises a blade portion and a cylinder portion connected to the bottom of the blade portion, one side of the cylinder portion is provided with a tenon tooth portion, the connection of the tenon tooth portion and the cylinder portion is an R area, laser shock processing is carried out on the R area and the tenon tooth portion close to the R area, and laser shock processing conditions comprise a laser power density of 3.3-7.96GW / cm<2> and an overlapping rate of 65-100%. The method allows the roughness, hardness, residual stress and the microstructure of the surface of a processed member to be optimized through adjusting the laser shock processing method, the laser power density and the overlapping rate, effectively improves the fatigue performance of the blade at 530DEG C, prolongs the service life, and avoids the frequent generation of fatigue fracture.

Owner:CHINA HANGFA SOUTH IND CO LTD

Laser phase change reinforcing method to reinforce gradient structure

InactiveCN1403598AIncreased incident laser power densityHigh hardnessDesign phaseLaser power density

The present invention relates to laser heat treatment technology. The laser phase change reinforcing method to control phase change and reinforce gradient structure includes the steps of: designing phase change reinforcing gradient structure of workpiece; performing proper heat treatment, usually tempering, of the workpiece; coating nano absorbing oxide paint; selecting proper laser power density and scanning speed; and performing laser phase change reinforcing treatment. Thus treated workpiece has high hardness, high load capacity and excellent wear resisting performance.

Owner:SHANGHAI UNIV OF ENG SCI

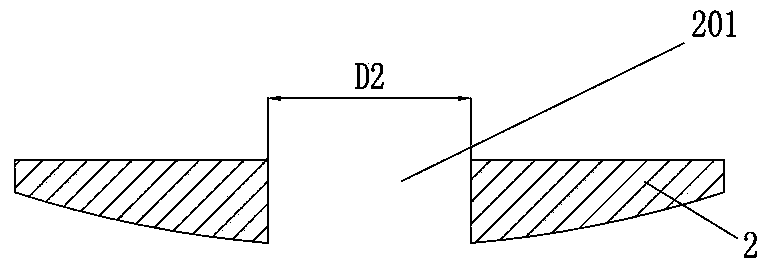

High-energy laser homogenizing cavity attenuator

ActiveCN103644967AImproved angular incidence characteristicsRealize light intensity attenuationPhotometryUltrasound attenuationScattering attenuation

The invention discloses a high-energy laser homogenizing cavity attenuator which comprises a front panel, a small-hole sample plate, an attenuation plate, an output panel and a plurality of scattering attenuation units. Each attenuation unit includes a large-angle sampling taper hole arranged on the small-hole sample plate, a homogenizing cavity and a light transmission channel which are arranged on the attenuation plate, and a homogenizing cavity and a laser output hole which are arranged on the output panel, wherein the light transmission channel is of a circular symmetric structure, which enables the angle characteristic of the attenuator to have circular symmetry. The attenuator has a multi-layer plate structure, which can effectively reduce the influence of high temperature generated due to long-time irradiation of high-energy laser on the front panel to a subsequent measurement unit. According to the attenuator of the invention, laser is output from the output hole after being homogenized for multiple times, substantial attenuation of the laser power density is achieved, and the attenuator has better attenuation angle characteristics.

Owner:NORTHWEST INST OF NUCLEAR TECH

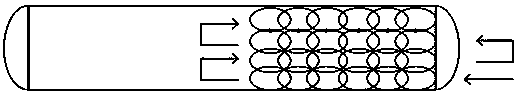

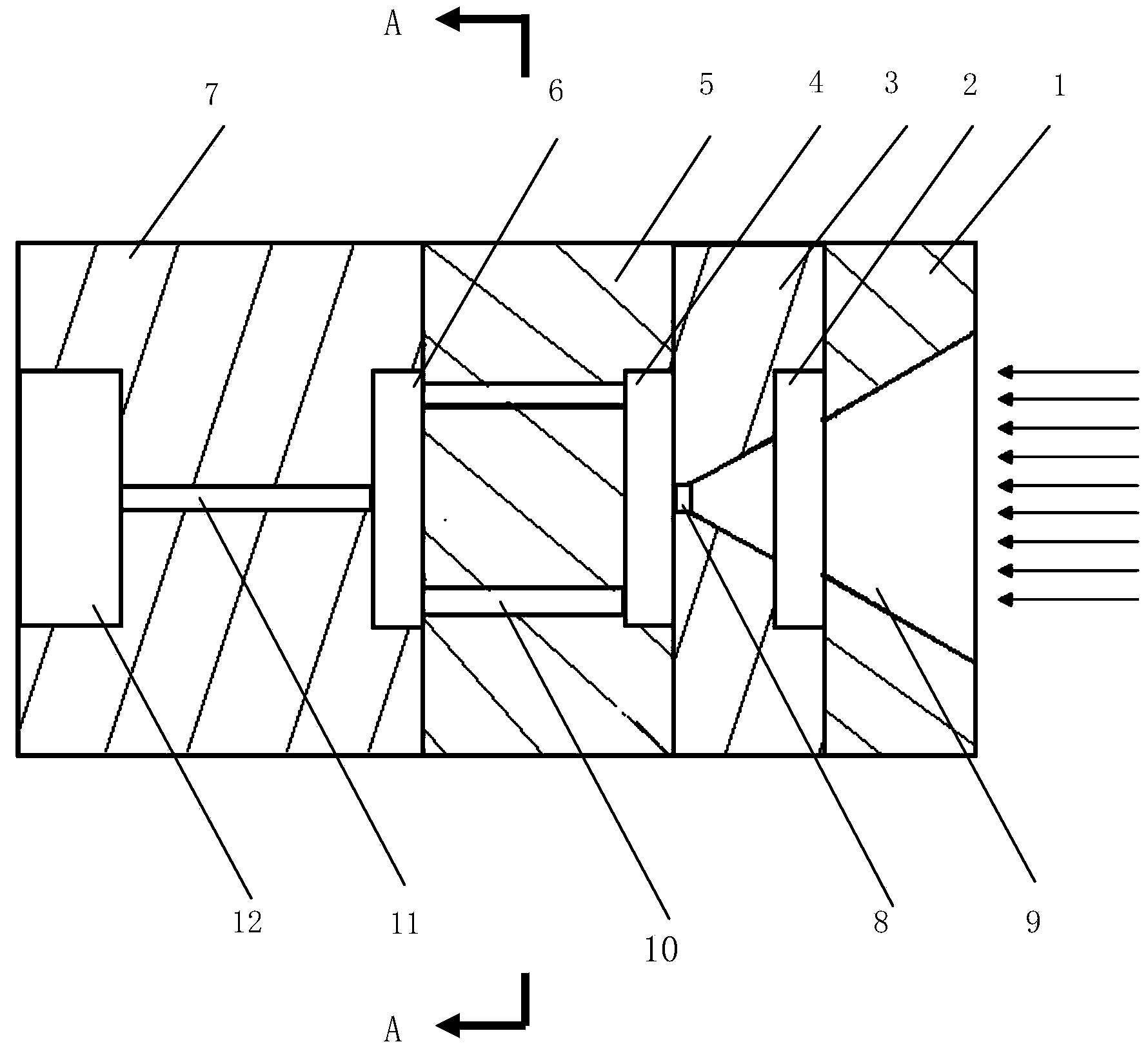

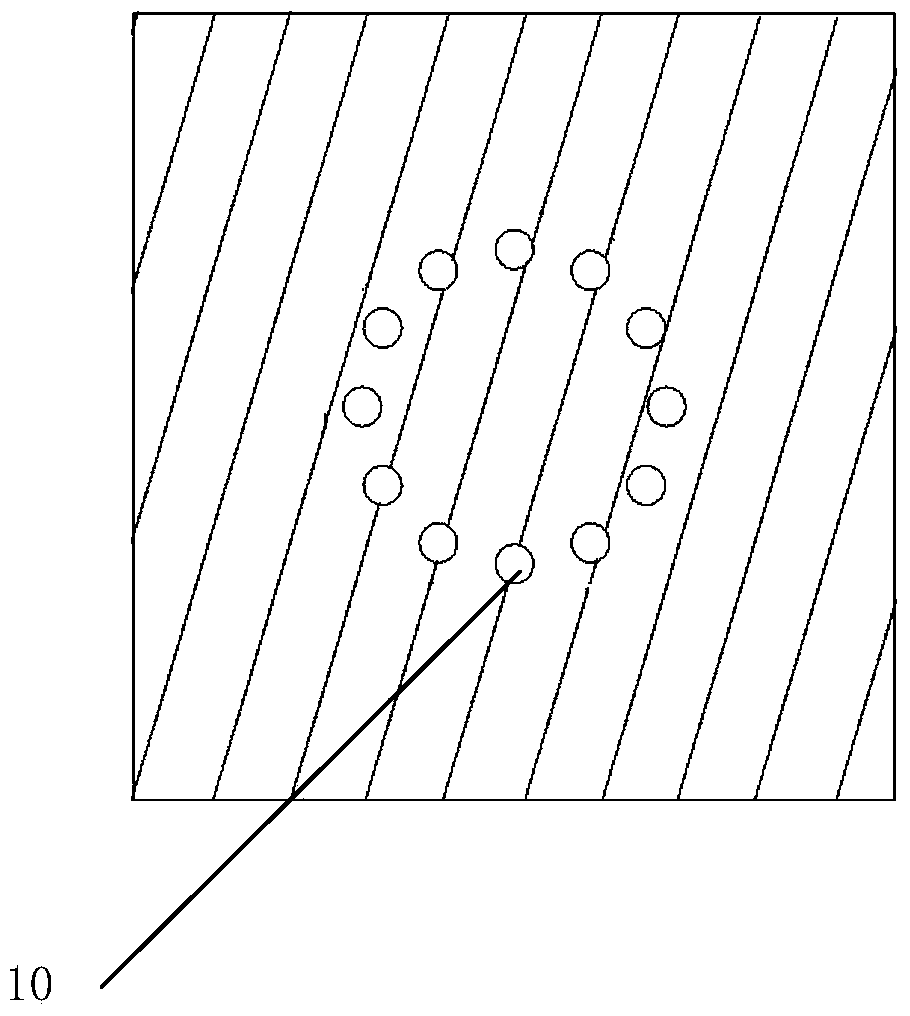

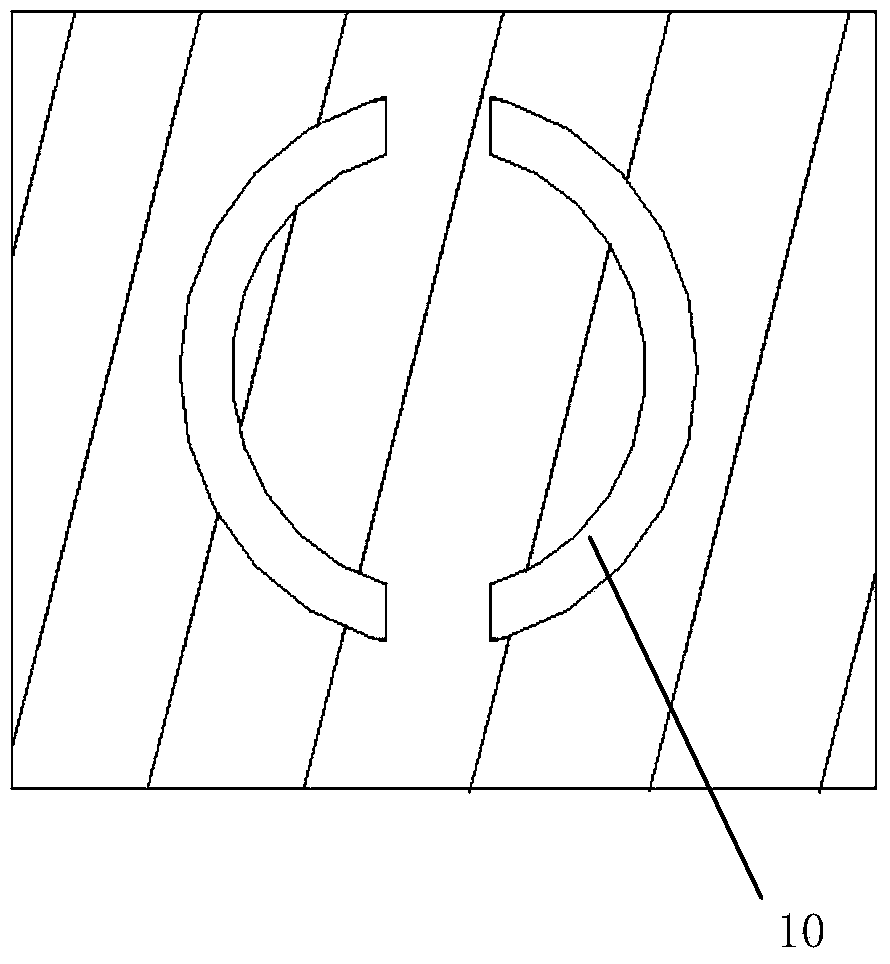

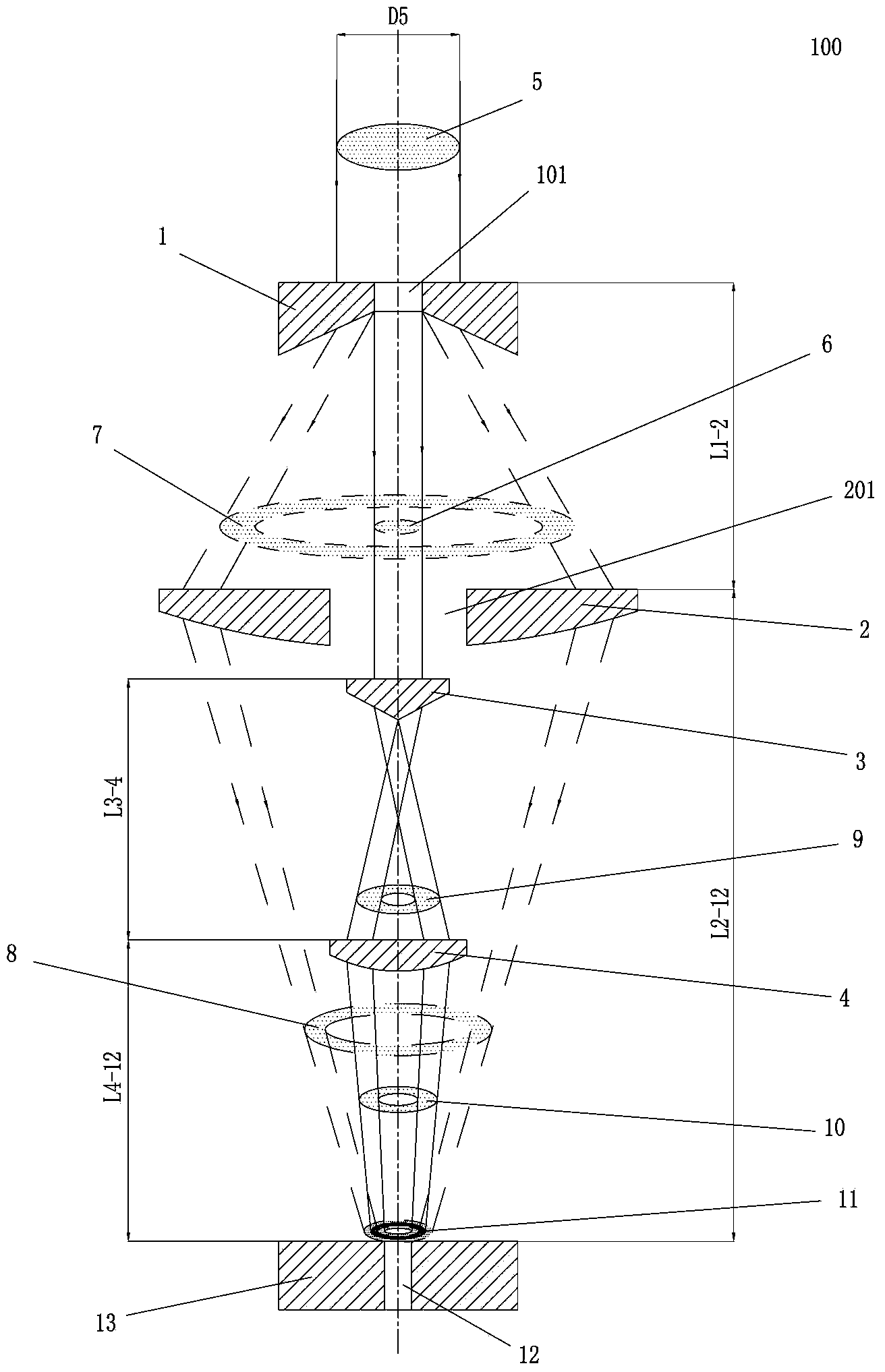

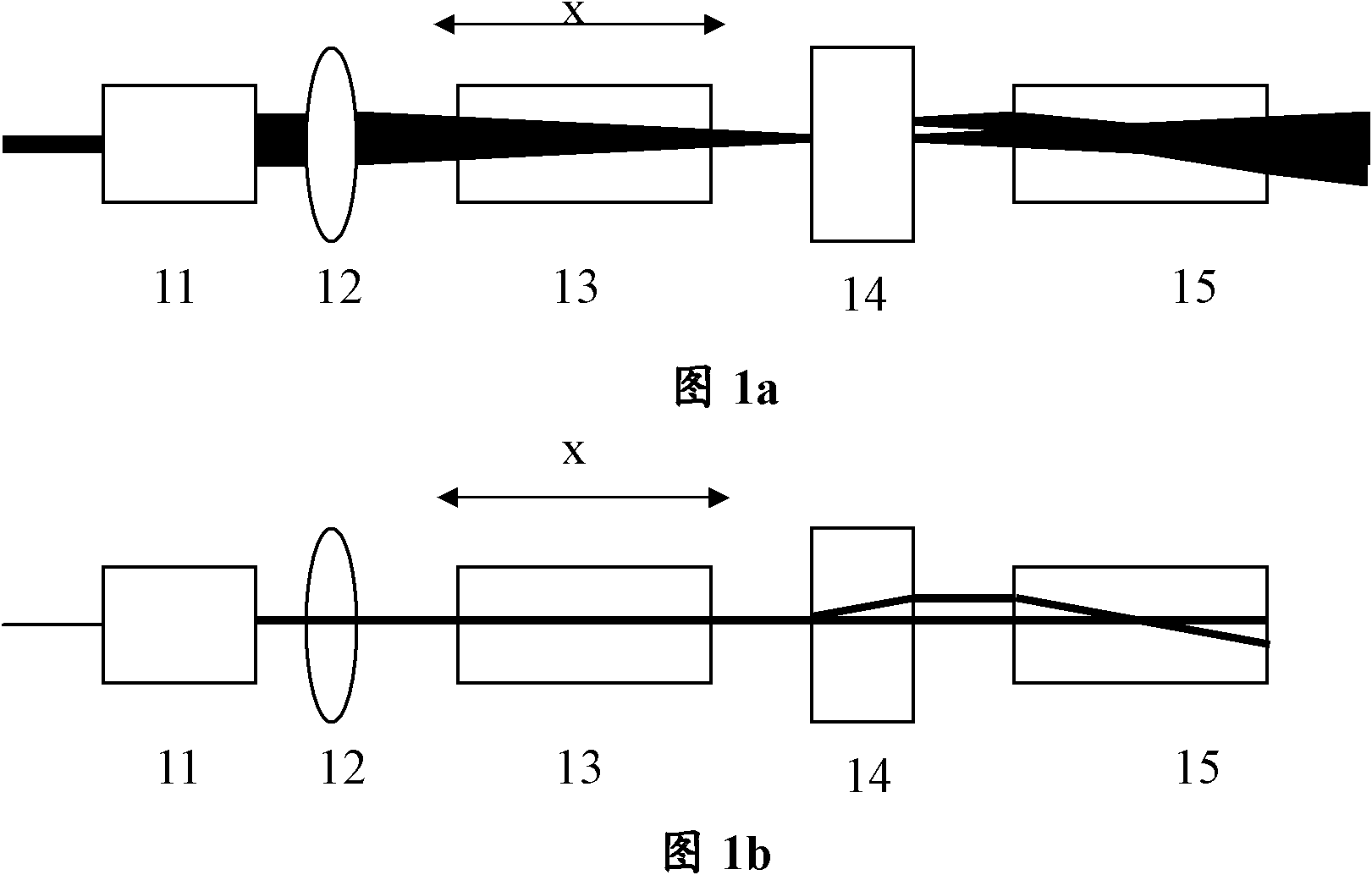

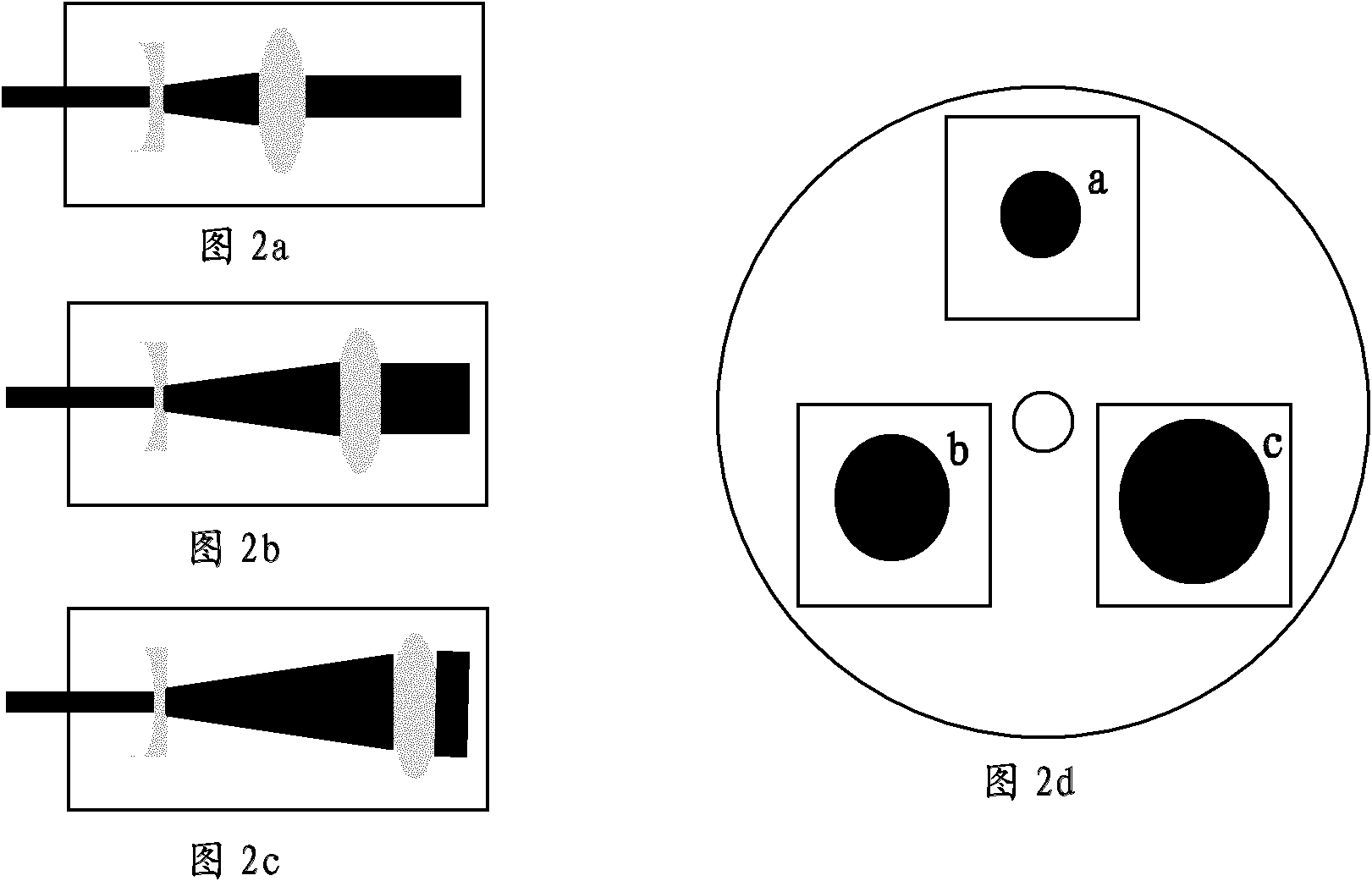

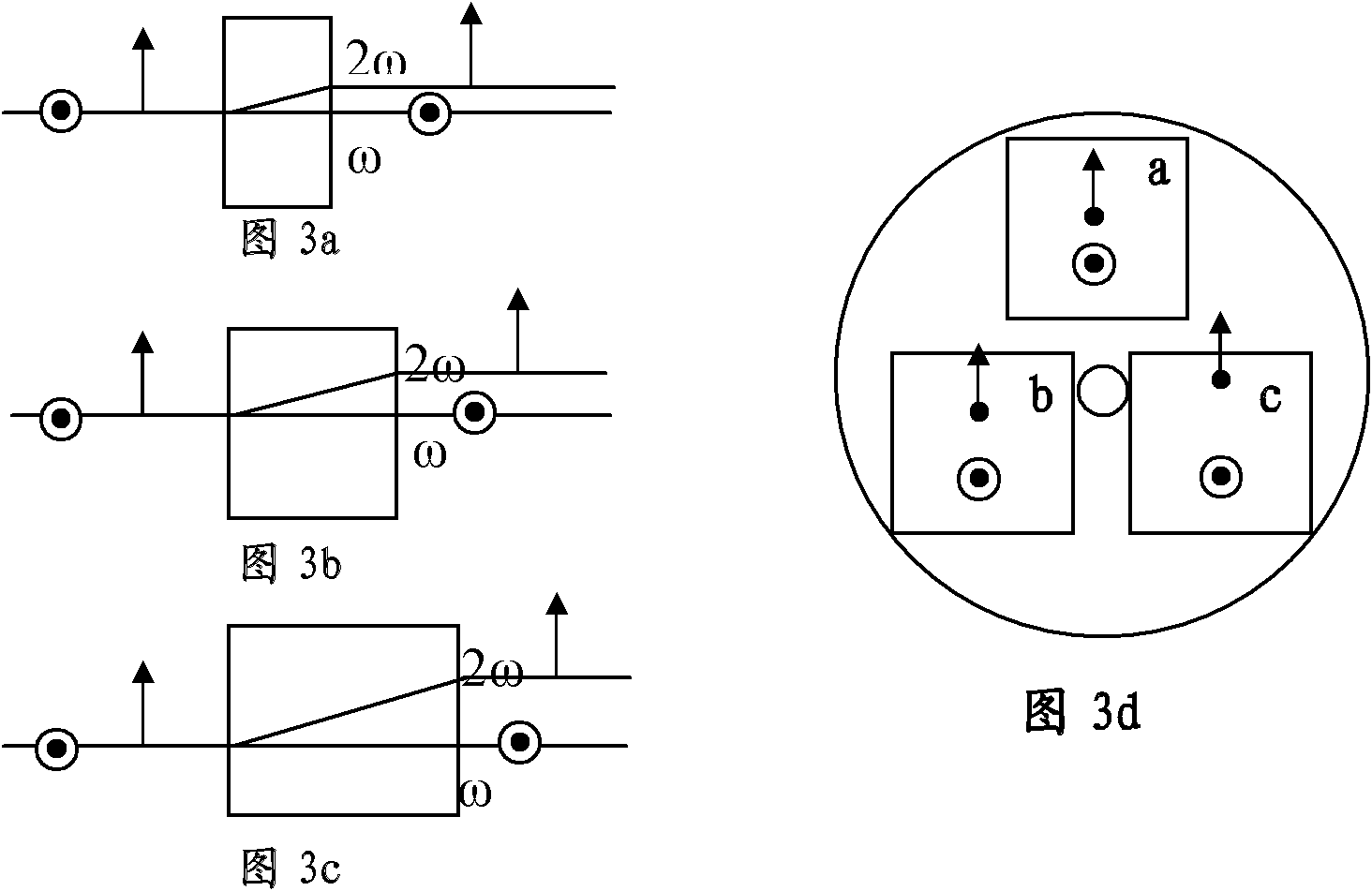

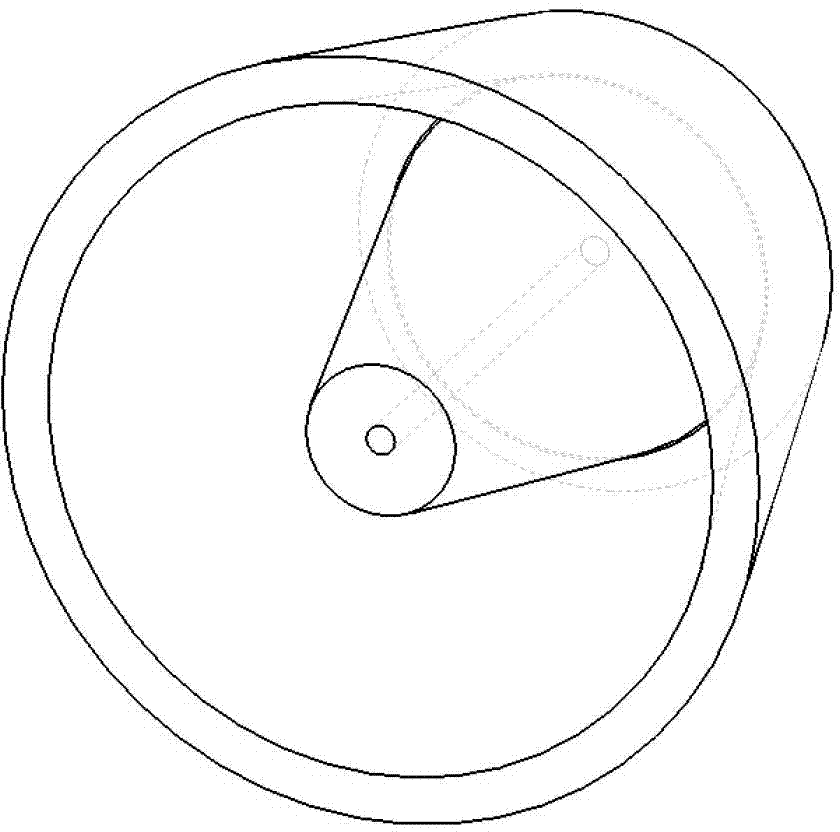

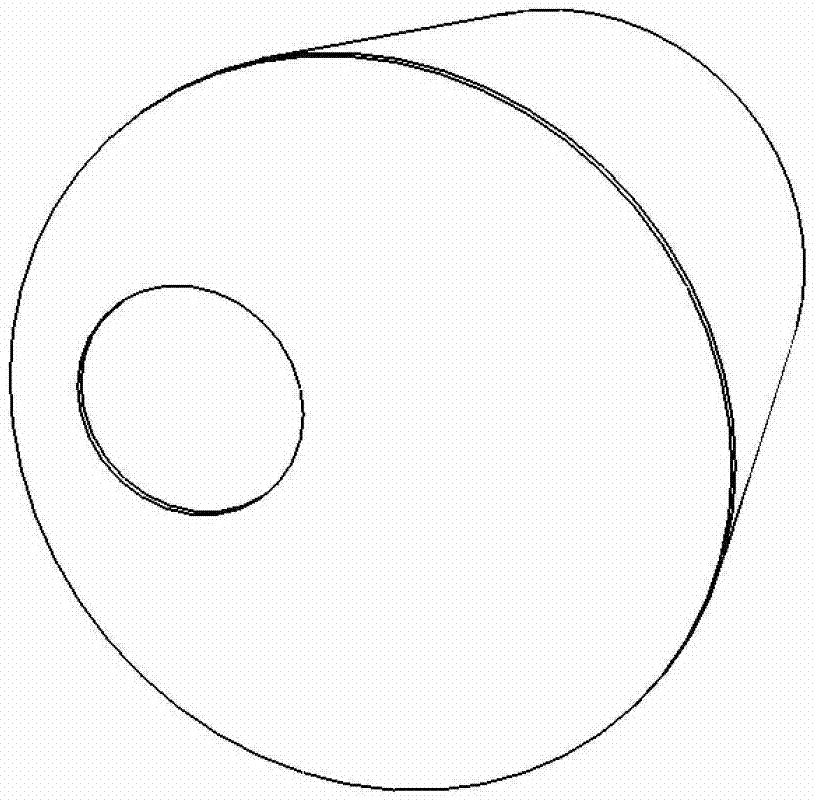

Device and method for impacting and strengthening fastening hole through ring laser

The invention discloses a device and method for impacting and strengthening a fastening hole through ring laser. The device is arranged above a laser impacting and strengthening object provided with a fastening hole and comprises an inner concave cone lens provide with a center hole, a focusing lens provide with a center hole, an outer convex cone lens and a focusing lens, which are sequentially and coaxially arranged from top to bottom; the lenses are arranged on an optical lens adjusting frame; the lenses are coaxially arranged with the fastening hole; a ring laser beam with diameter larger than the aperture of the center hole of the inner concave cone lens is axially incident from the upper side of the inner concave cone lens. The device disclosed by the invention can spatially separate the ring laser beam, couple the separated ring laser beams into a new ring laser beam and regulate the spatial energy distribution of the new ring laser beam to improve the bearable laser power density, and the ring laser beam is used for impacting, strengthening, regulating and controlling the residual stress distribution on the surrounding of the fastening hole end so as to further improve the fatigue performance of the fastening hole. The device disclosed by the invention is capable of increasing the utilization rate of laser pulse energy, simple to operate and convenient to promote and use.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

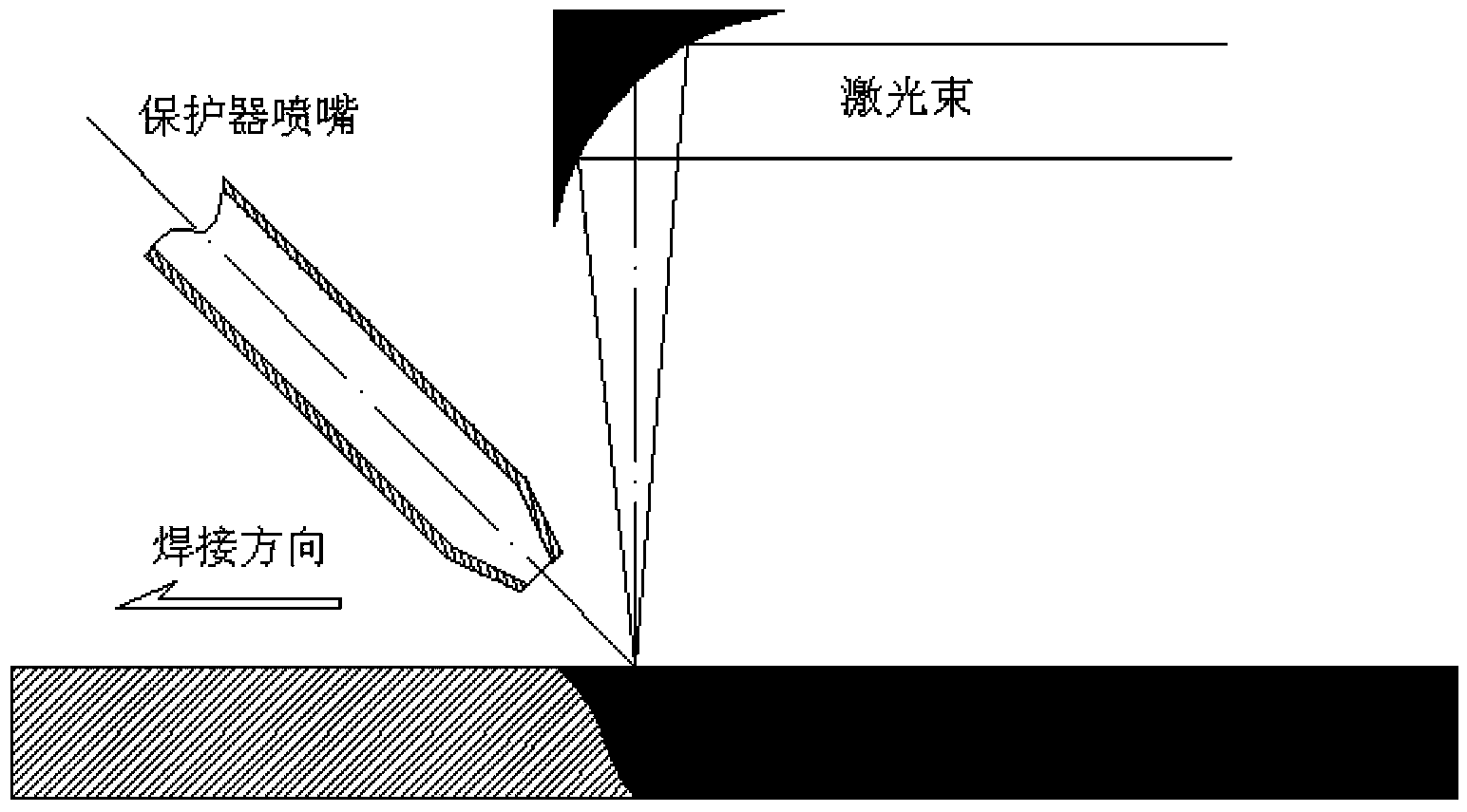

IC10 alloy connecting and repairing method for controlling dendrite growth direction through laser

The invention discloses an IC10 alloy connecting and repairing method for controlling a dendrite growth direction through lasers and belongs to the field of laser material processing. Firstly, in the process of welding, the welding direction needs to be kept parallel to the dendrite growth direction of IC10 directional solidification alloy. Secondly, the range of laser welding parameters is that laser power density is 1.41*106-3.01*106W / cm<2>, the defocusing amount is zero, scanning speed is 0.5-2.5m / min, and the thickness of an IC alloy plate is 0.5-1.7mm. In the process of welding, Ar gas serves as protective gas, gas flows are 10-30L / min, the direction of the protective gas input to a welding zone is contrary to the welding direction, and namely is over against the direction of laser scanning. A laser device is adopted for scanning welding seam positions of the IC10 alloy or positions needing to be repaired, corresponding positions of components and parts of the IC10 alloy are melted to form a liquid state molten pool under the action of the lasers, and the liquid metal is again solidified to form welding seams due to reduction of temperature after the lasers leave the scanning positions. The method is high in stability, simple in technology and small in deformation and has practical engineering significance.

Owner:BEIJING UNIV OF TECH

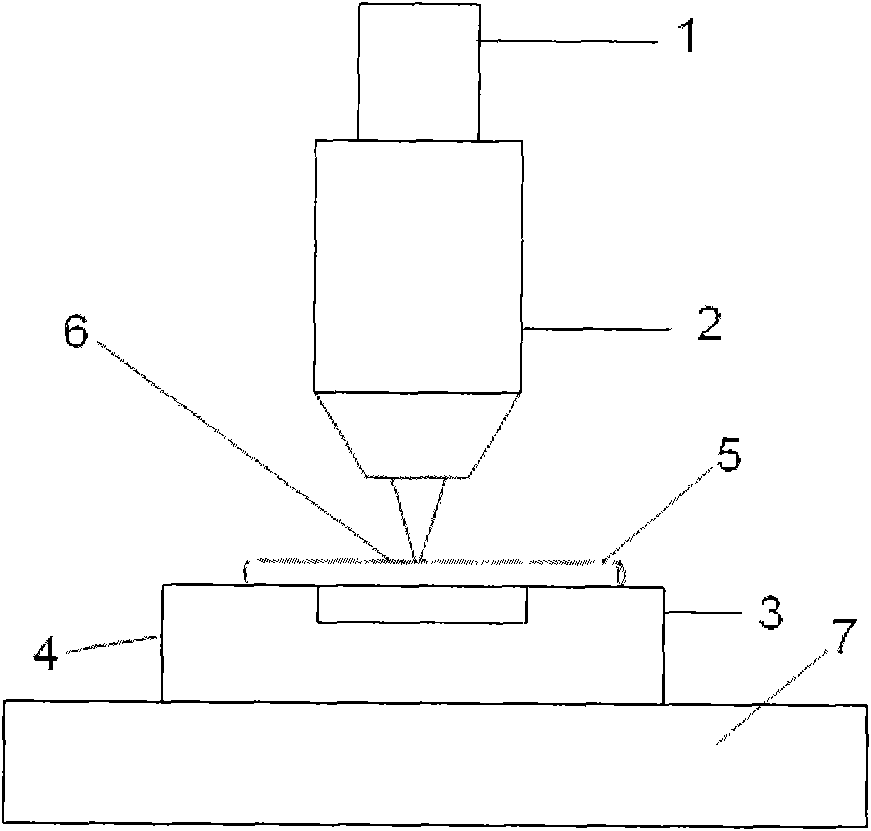

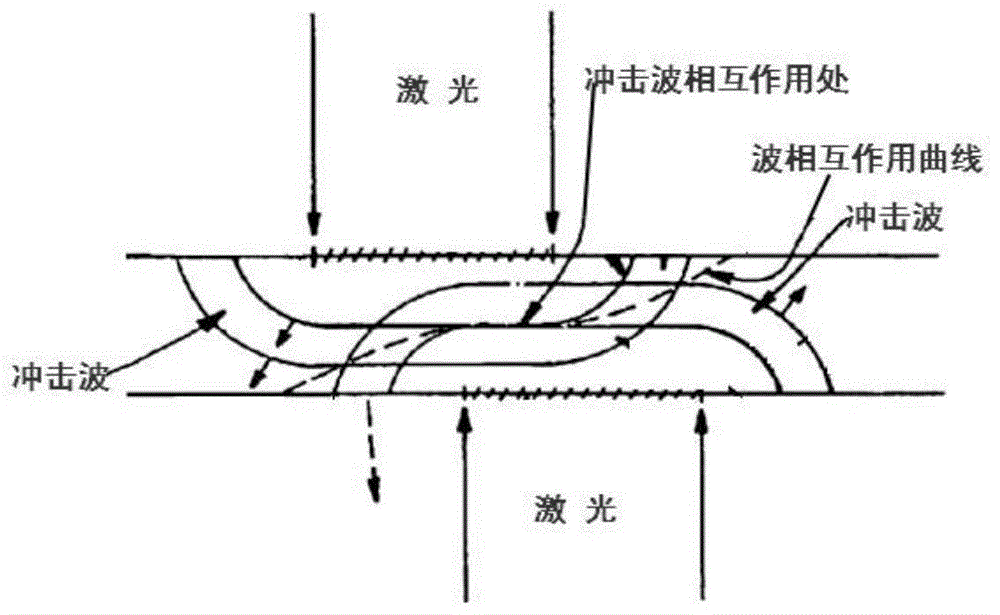

Impeller high-inclination-angle laser oblique impact laser beam space energy distribution compensation method

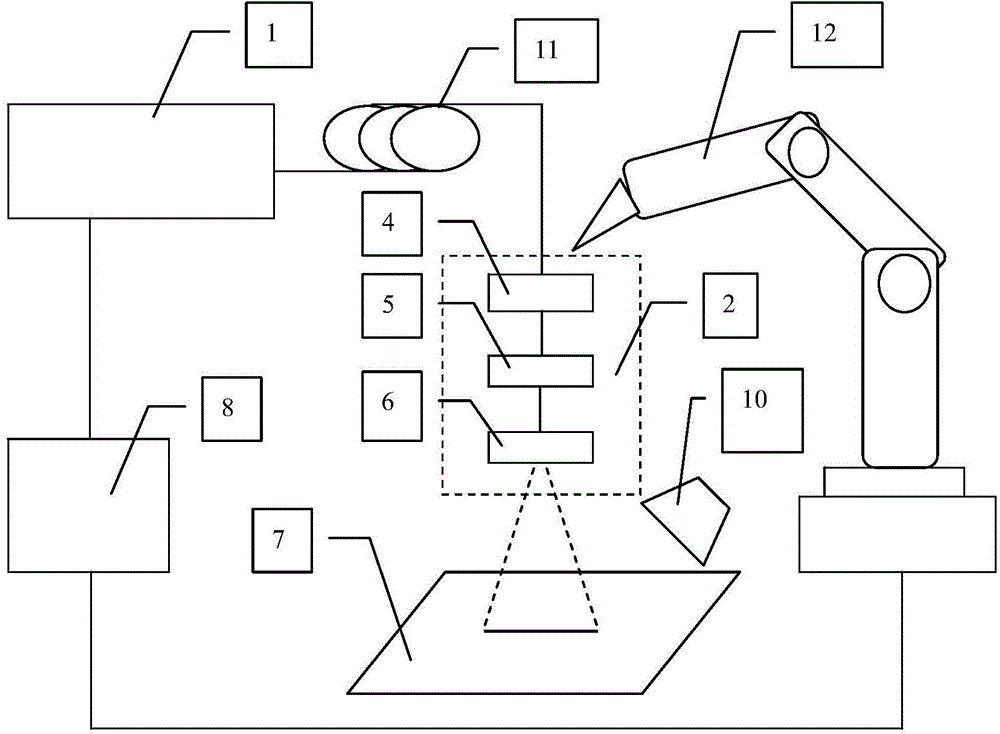

ActiveCN109504849AAvoid interferenceGuaranteed reachableDesign optimisation/simulationSpecial data processing applicationsRobotic systemsImpeller

The invention discloses an impeller high-inclination-angle laser oblique impact laser beam space energy distribution compensation method, and belongs to the field of laser impact enhancement. The method comprises following steps that a part model and a clamp model are guided into robot simulation software, the robot simulation software is used for adopting the discrete point off-line programming manner for writing the motion track of a clamping robot during laser impact enhancement; c, according to the track parameters, differences of overlap rates of different portions and space coordinates of a laser beam on each point in the offline programming, the laser power density parameter of each point is determined through the vector formula; d, the track parameter of the clamping robot and theimpact enhancement parameter of a laser device can be continuously modified; e, the motion track program of the clamping robot in the simulation software is guided into the robot system, and accordingto the preset state in the simulation software, the actual part is subjected to laser impact enhancement treatment. The problem about interference between blades of a small-space large-inclination-angle impeller and the laser beam can be solved.

Owner:GUANGDONG LASER PEENING TECH CO LTD

Laser reinforcing process of the intake side of turbine vane

InactiveCN1740350ARealize integrated manufacturingEasy to operateHeat treatment process controlSolution treatmentLaser power density

The laser reinforcing process is for treating the intake side of turbine vane made of super high strength stainless steel. The laser reinforcing process includes the following steps: cleaning the surface of the intake side to be treated; painting light absorbing alloy material; laser solid solution treatment of the selected area with proper laser beam after the alloy layer dries, with the laser solid solution treatment parameters including laser power density of 500-1200 w / sq cm, layer moving speed of 50-300 mm / min and solid solution treatment temperature of 1150-1600 deg.c; cooling while laser solid solution treatment; and final ageing treatment at temperature of 400-570 deg.c for 2.0-5.0 hr.

Owner:ZHEJIANG UNIV OF TECH

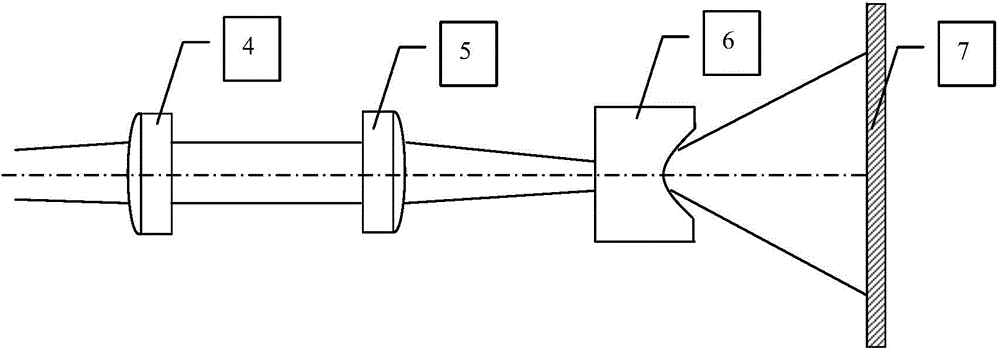

Laser triple frequency system

InactiveCN101986484AEasy to findImprove laser conversion efficiencyLaser detailsNonlinear opticsBirefringent crystal

The invention discloses a laser triple frequency system, which belongs to the field of nonlinear optics. The system mainly comprises a focusing system, a frequency doubling system, a frequency summing system, a base frequency light power density adjusting device and a deviation compensating device, wherein base frequency laser enters the frequency doubling system after being focused by the focusing system so as to generate double frequency light in the frequency doubling system; the double frequency light and the remaining base frequency light enter the frequency summing system together so as to generate triple frequency light; the base frequency light power density adjusting device is arranged in front of the focusing system and can continuously adjust the power density of the base frequency light; and the deviation compensating device is arranged between the frequency doubling system and the frequency summing system and can continuously adjust a deviation compensating value. The laser power density and deviation compensation dosage are optimized, so that a higher triple frequency conversion efficiency is obtained; simultaneously, a doubly refracting crystal or dispersion glass is taken as the deviation compensating device, so that the cost of the triple frequency system can be lowered greatly.

Owner:DAHENG NEW EPOCH TECH

Rotary absorber-based high-energy laser energy measuring device

InactiveCN103398785AIncreased resistance to laser damage thresholdReduce the average laser power densityRadiation pyrometryElectricityLight beam

The invention discloses a rotary absorber-based high-energy laser energy measuring device. The rotary absorber-based high-energy laser energy measuring device comprises a heat absorber, a temperature sensor and a temperature acquisition and processing unit, wherein the temperature sensor is embedded in the heat absorber and is electrically connected with the temperature acquisition and processing unit; a rotating shaft is arranged in the center of the heat absorber, so that the heat absorber and the temperature acquisition and processing unit can rotate around the rotating shaft; an incident surface of the heat absorber is provided with an annular V-shaped groove; the inner surface of the annular V-shaped groove is a diffuse reflection surface; the annular V-shaped groove has a sectional shape of two V-shaped groove structures along the rotating shaft; openings of the V-shaped groove structures face the high-energy laser incidence direction; and the aperture of the high-energy laser beam is less than the size of the openings of the V-shaped groove structures. According to the rotary absorber-based high-energy laser energy measuring device, a partial surface of the absorber is prevented from being irradiated by strong laser continuously by a mode of cyclic scanning of the laser beam to the surface of the heat absorber, the average laser power density irradiated to the surface of the heat absorber is reduced, and the anti-laser-damage threshold value of the measuring system is improved.

Owner:NORTHWEST INST OF NUCLEAR TECH

Optimization process-based method for rapidly detecting bonding state of coating interface

The invention discloses an optimization process-based method for rapidly detecting the bonding state of a coating interface and relates to the technical field of laser detection and material performance detection. The method comprises the following steps of: rapidly obtaining the failed laser density range of a coating by an optimization process; loading the coating point by point respectively by using pulse laser in the range to form dot discrete scratches of which the depths increase gradually; detecting the intensity change of reflected light on laser loading points of the discrete scratches through a power meter; when three continuous inflection points occur in a first recess on the powder density map of a detection point for the first time, considering that the recess is the failure threshold point P1 of the coating; and determining the failure critical point (failure threshold) of the coating by judging the length of a relatively short scratch. The method has the advantages of improving scratch efficiency and reducing damage to the coating through the rapid approach of the failed laser power density range of the coating by the optimization process and through the acquisition of the failure threshold by using a coating failure critical point judging process.

Owner:JIANGSU UNIV

Attenuation sampling device used for large-angle high-energy laser incidence

ActiveCN104019891AGood angle characteristicsImprove the ability to resist laser radiationPhotometryUltrasound attenuationHigh spatial resolution

The invention discloses an attenuation sampling device used for large-angle high-energy laser incidence. The device comprises a front panel, an attenuation unit and a rear panel, wherein a straight laser incidence sampling hole is formed in the front panel, a laser exiting hole is formed in the rear panel, the attenuation unit comprises a front transmission window, a rear transmission window and a cylindrical cavity, the cylindrical cavity is arranged coaxial with the straight sampling hole and the laser exiting hole, and the cylindrical cavity is filled with granular optical volume scattering materials. After being coupled into the attenuation unit through the sampling hole, absorbed through inner walls and the materials, and subjected to volume scattering, lasers are emitted out through the laser exiting hole, laser beam energy can be redistributed in a space within a wide range, and the homogenization effect is achieved; meanwhile, large-angle attenuation sampling can be achieved in the laser oblique incidence, the requirement for substantial attenuation of laser power density can be met, and the device can be used for high-spatial-resolution light intensity detection.

Owner:NORTHWEST INST OF NUCLEAR TECH

Hybrid welding continuous welding method and device, welding finished product and vehicle body

ActiveCN110000475AIncreased defocusReduce power densityLaser beam welding apparatusHydrogenWeld seam

The invention relates to the technical field of laser electrical arc welding, in particular to a hybrid welding continuous welding method and device, a welding finished product and a vehicle body. Thehybrid welding continuous welding method comprises carrying out hybrid welding on the groove of a weldment through laser and polarity-changing electric arc coupling, wherein the defocusing amount oflaser is less than the rayleigh range of laser. With adoption of the hybrid welding continuous welding method, the laser power density on the surface of the weldment is effectively reduced, the depth-to-width ratio of a welding seam is reduced, the diameter of a welding molten hole is increased, the hole of the welding molten hole caused by the small hole collapse phenomenon is effectively reducedto solve the problem in the prior art that the welding bubble is difficult to escape, generation of a hydrogen hole is reduced, the welding stability and reliability are effectively reduced, and themechanical property of the welding seam is improved.

Owner:CRRC QINGDAO SIFANG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com