High-energy laser homogenizing cavity attenuator

A high-energy laser and homogenizing cavity technology, applied in the field of array attenuators, can solve the problems of small size of integrating sphere, limited laser incident angle, etc., achieve large contact thermal resistance, reduce the difficulty of calibration, and reduce the effect of thermal influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

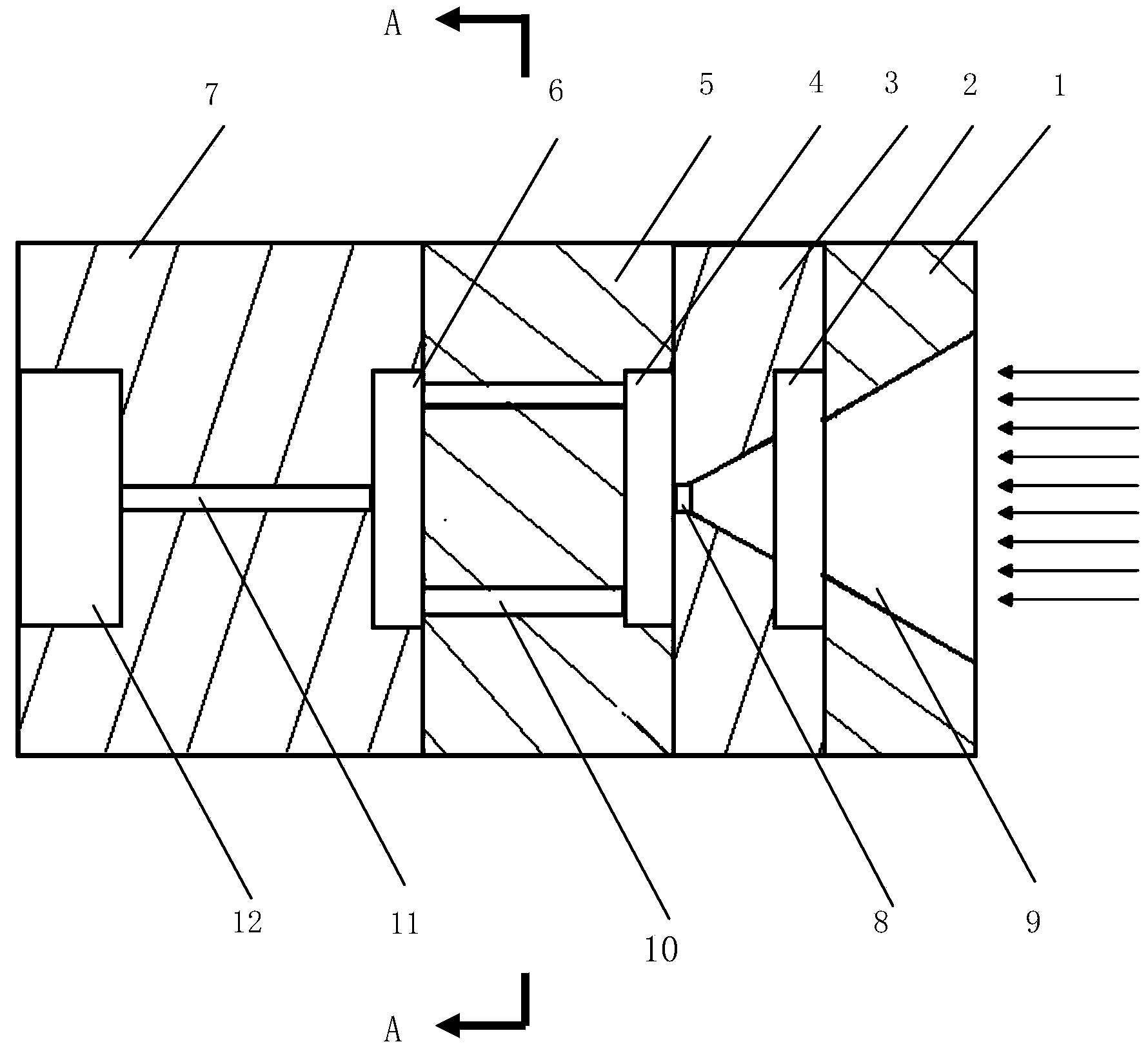

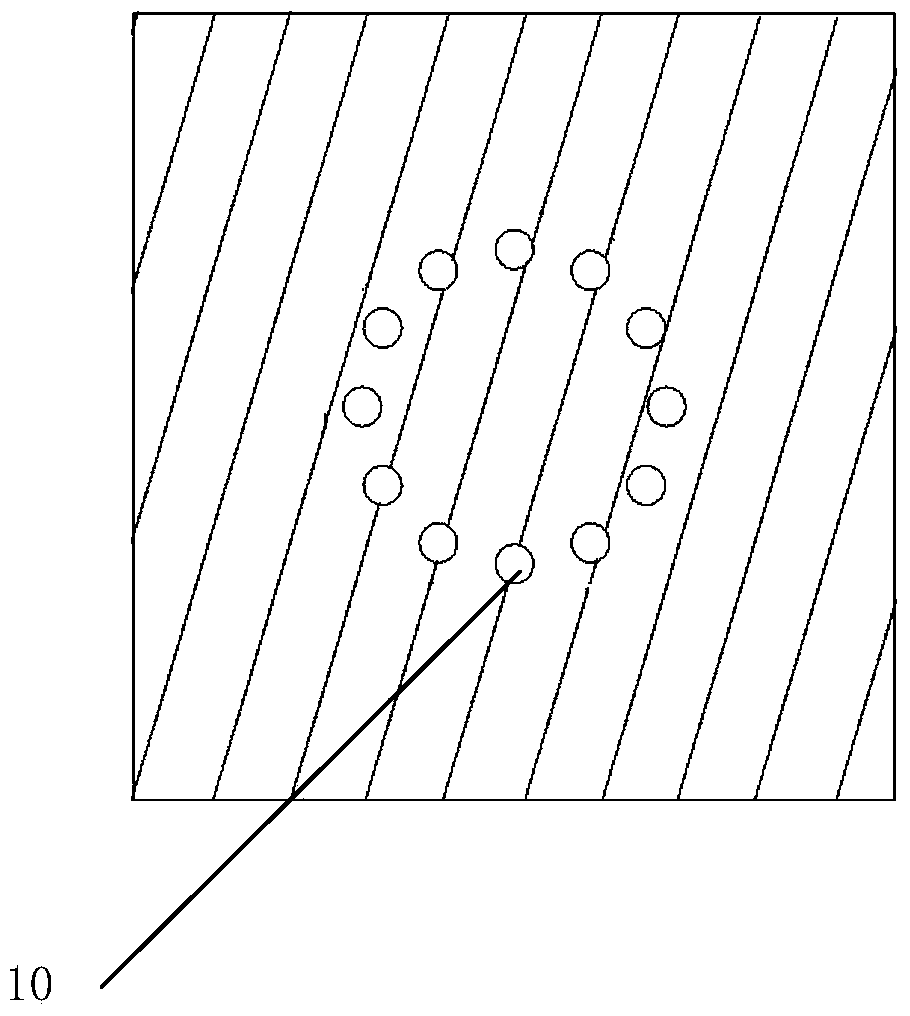

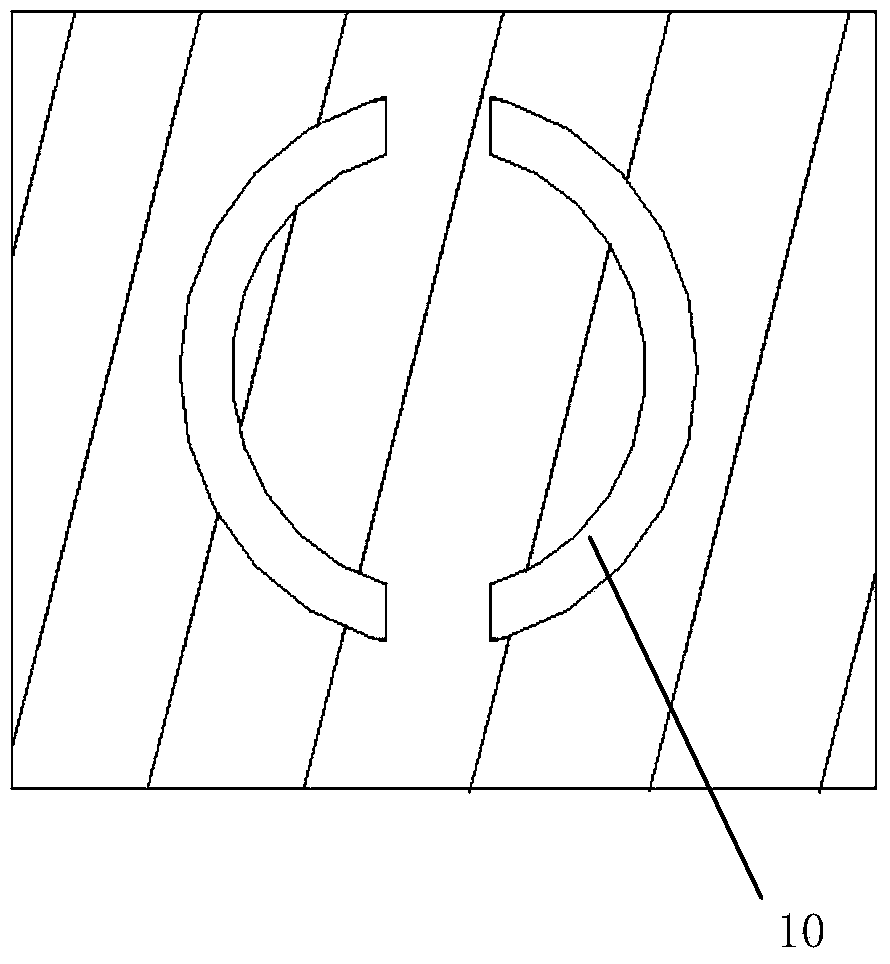

[0033] Such as figure 1 As shown, the high-energy laser homogenization cavity attenuator includes a front panel 1 , a small hole sampling panel 3 , an attenuation panel 5 and an output panel 7 arranged in sequence along the incident laser direction. After the front panel 1 and the small hole sampling plate 3 are laminated, a large-angle sampling cone 9 is processed on it, and the opening end of the large-angle sampling cone 9 is arranged on the front panel 2, facing the laser incident direction, and the tail end Set the inside of the small hole sampling plate 3, and communicate with the light-through straight hole 8 coaxially arranged at the rear end of the small hole sampling plate 3; the front end of the attenuation plate 5 is provided with a homogenization cavity 4, the thickness of the cavity is about 1 mm, and the diameter is about 5 mm. The cavity of the homogenization cavity is processed into a diffuse reflection surface; a light transmission channel 10 is arranged betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com