Laser damage testing device for optical thin film

A technology for laser damage and testing devices, which is used in measurement devices, scientific instruments, weather resistance/light resistance/corrosion resistance, etc. Measurement accuracy, convenient optical path layout and parameter adjustment, and the effect of reducing protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

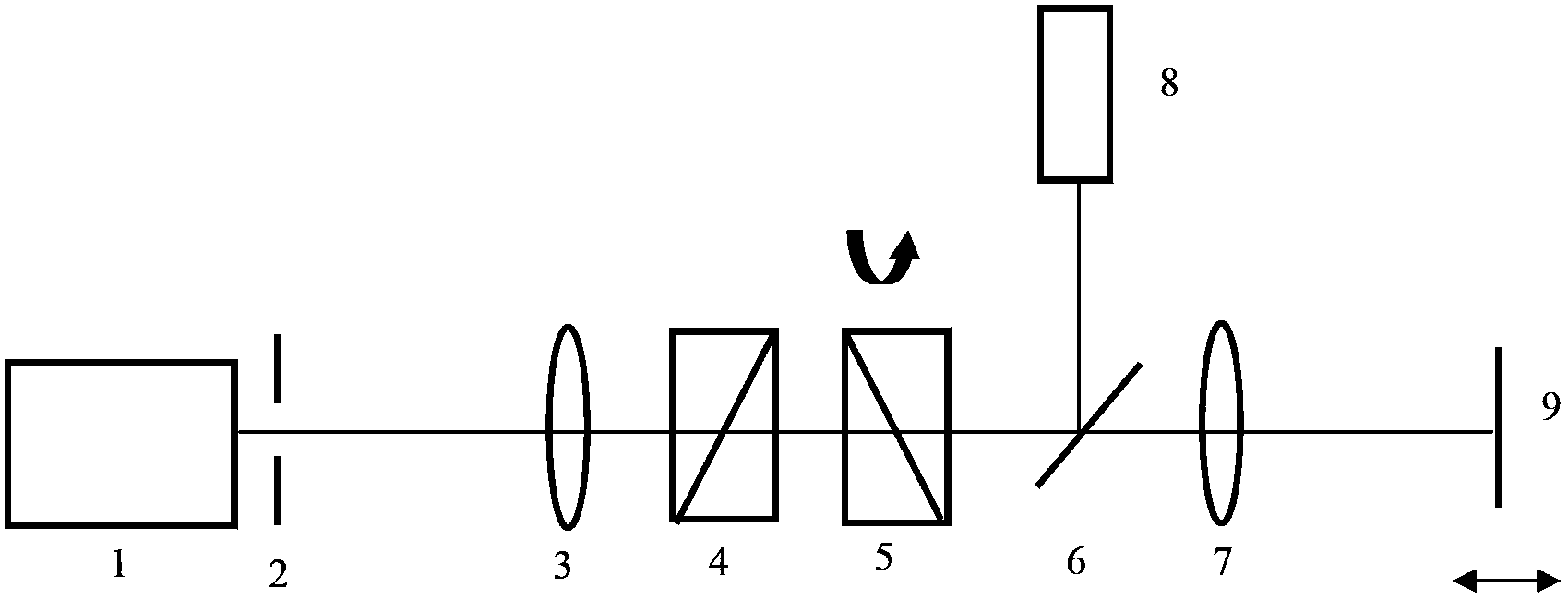

[0028] Such as figure 1 As shown, the optical thin film laser damage testing device of the present invention includes an optical power energy measuring instrument 8 and an aperture stop 2, a first lens 3, and an optical attenuator 4 / 5 arranged sequentially between the laser 1 and the coated lens 9 to be tested. , sampling beam splitter 6 and focusing lens 7; wherein aperture 2 is arranged on the front focal plane of the first lens 3, and the coating lens 9 to be measured is arranged on the back focal plane of focusing lens 7, selects the near aperture 2 place The object plane in the central uniform area of the field beam is imaged to the coated mirror surface to be measured through the first lens 3 and the focusing lens 7 through the infinite distance microscopic imaging method, and the object plane and the coated mirror surface to be measured are respectively ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com