Method for density compensation by drop size adaptation

一种尺寸、油墨密度的技术,应用在印刷、打印装置、仪器等方向,能够解决印刷图像重新加网等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

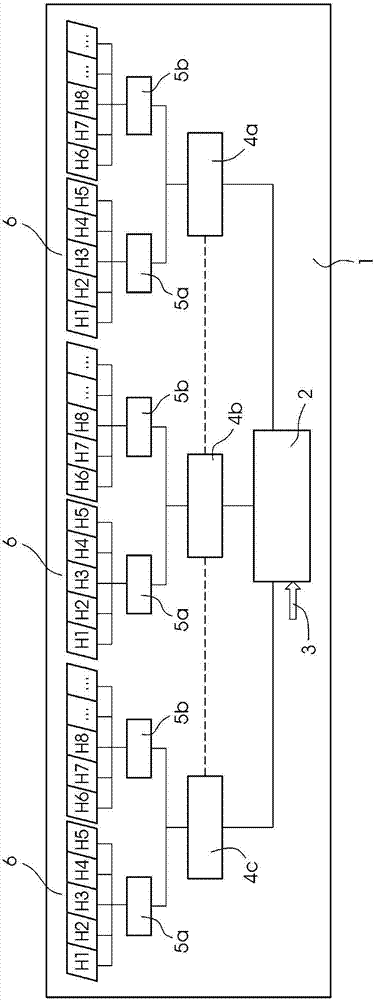

[0017] The drawing shows an inkjet printing machine 1 which operates with page-wide printing swaths. The printing bar here has three printing heads 6 which contain printing nozzles. In the drawing, the printing heads 6 each have ten printing nozzles, where each printing head 6 applies printing ink to the printing material. In this case, each print head 6 is controlled by two print head control electronic cards in the form of inkjet converter cards 5a, 5b. The task of the inkjet converter cards 5 a , 5 b is to convert the temporal activation signals of the individual nozzles into control signals for controlling the printing head 6 . For reasons of computing power, two inkjet converter cards 5 a , 5 b are provided for each printing head 6 in the figure.

[0018]Furthermore, the printing system 1 has digital graphics cards 4 a , 4 b , 4 c , wherein one digital graphics card is responsible for each ink channel. The digital graphics cards 4 a , 4 b , 4 c generate the temporal ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com